Dry quenching laying method

A dry quenching and masonry technology, which is applied in coke oven bricklaying operations, coke oven, coke cooling, etc., can solve unreasonable, complicated and unscientific construction processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

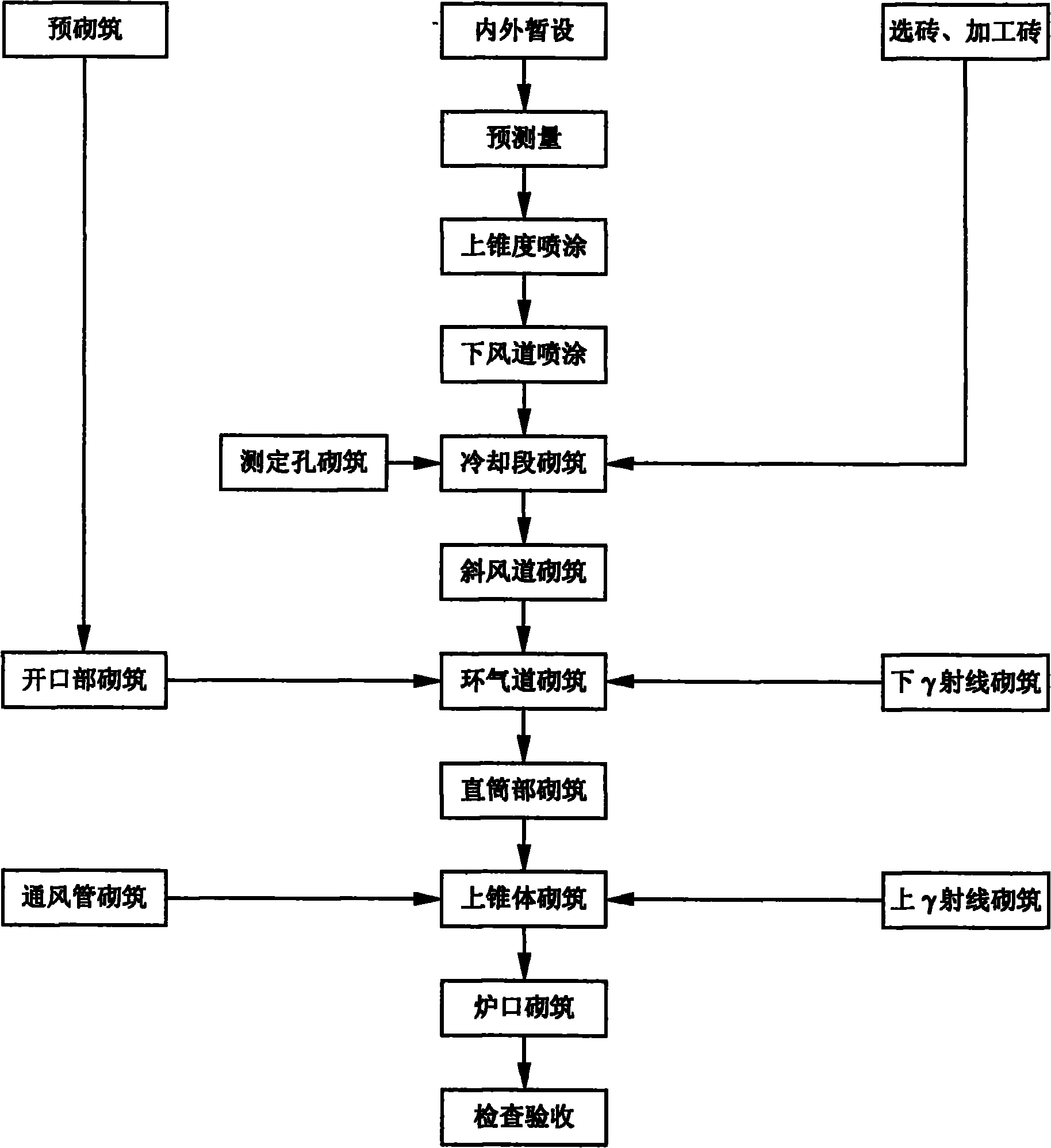

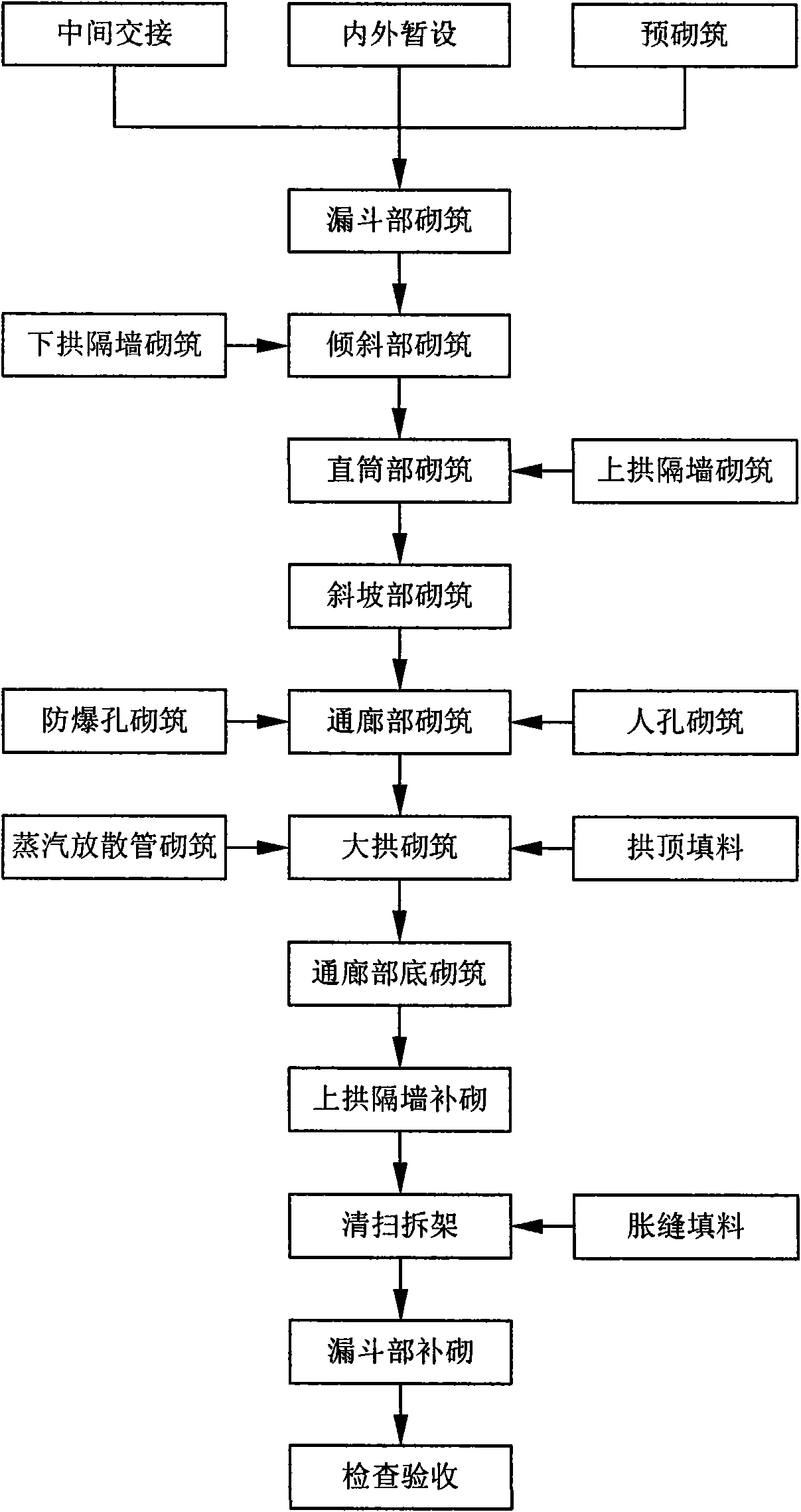

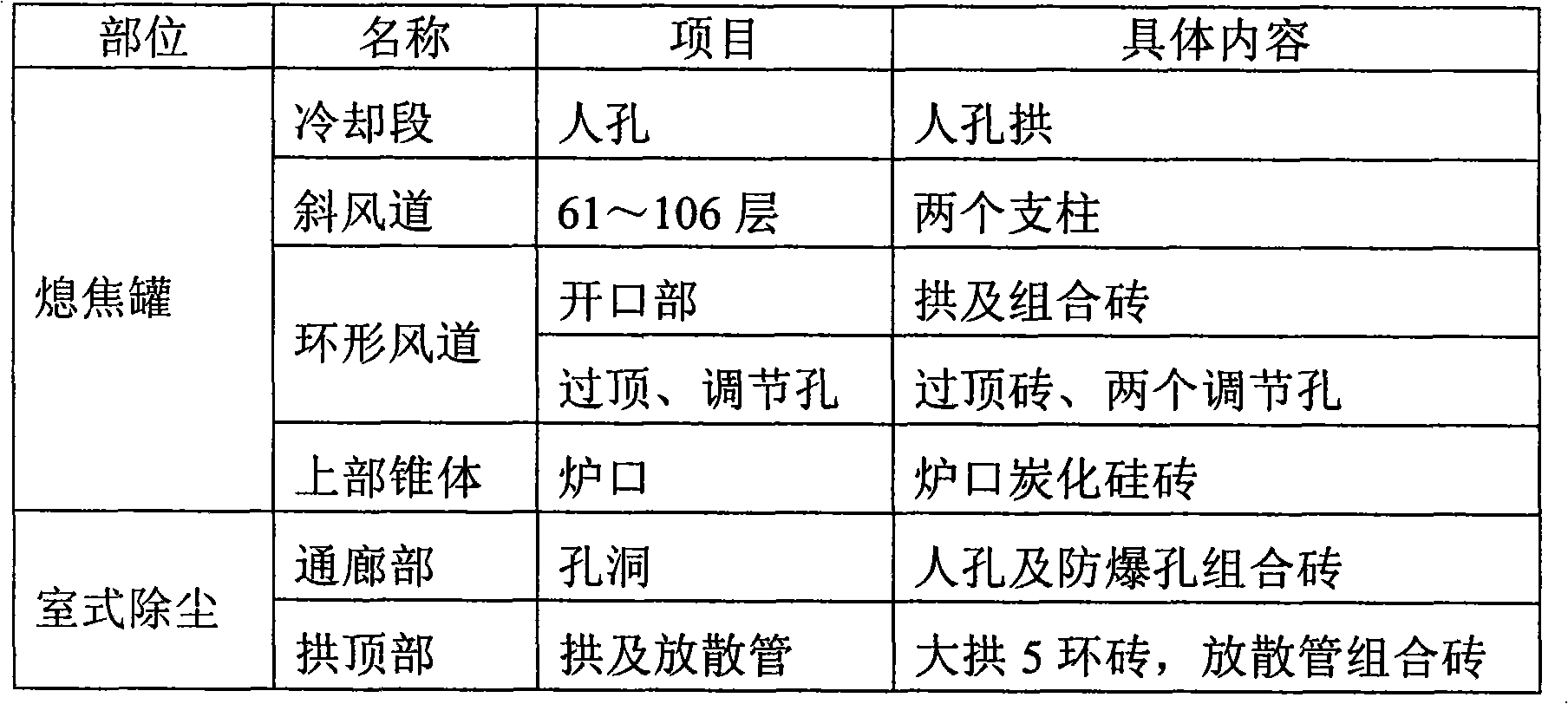

[0034] A coke dry quenching masonry method, comprising pre-constructing a coke quenching tank, pre-constructing a primary dust collector, construction of a coke quenching tank furnace and primary dust collector furnace construction, the coke quenching tank furnace construction is carried out in sequence as follows: ① Construction of the cooling section on the 1st to 54th floors, ② Construction of the inclined air ducts on the 55th to 81st floors, ③ Construction of the inclined air ducts on the 82nd to 114th floors, ④ Construction of the pre-storage section on the 115th to 179th floors. The steps are carried out in sequence: ①Setting out, ②Construction of the inclined part, ③Construction of the straight barrel part, ④Construction of the corridor part, ⑤Vault construction, ⑥Expander construction,

[0035] Main features of CDQ masonry project: A CDQ system consists of a coke quenching chamber, a primary dust collector, a waste heat boiler and two cyclone dust collectors. The hot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com