Device and method for cooling coke

The technology of a cooling device and a cooling method is applied in the cooling of coke, coke oven, petroleum industry, etc., which can solve the problems of high equipment cost, complicated device structure, waste of resources, etc. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in detail below with examples, so that those skilled in the art can realize it, and at the same time, this specific implementation mode can also achieve the effects described in the present invention.

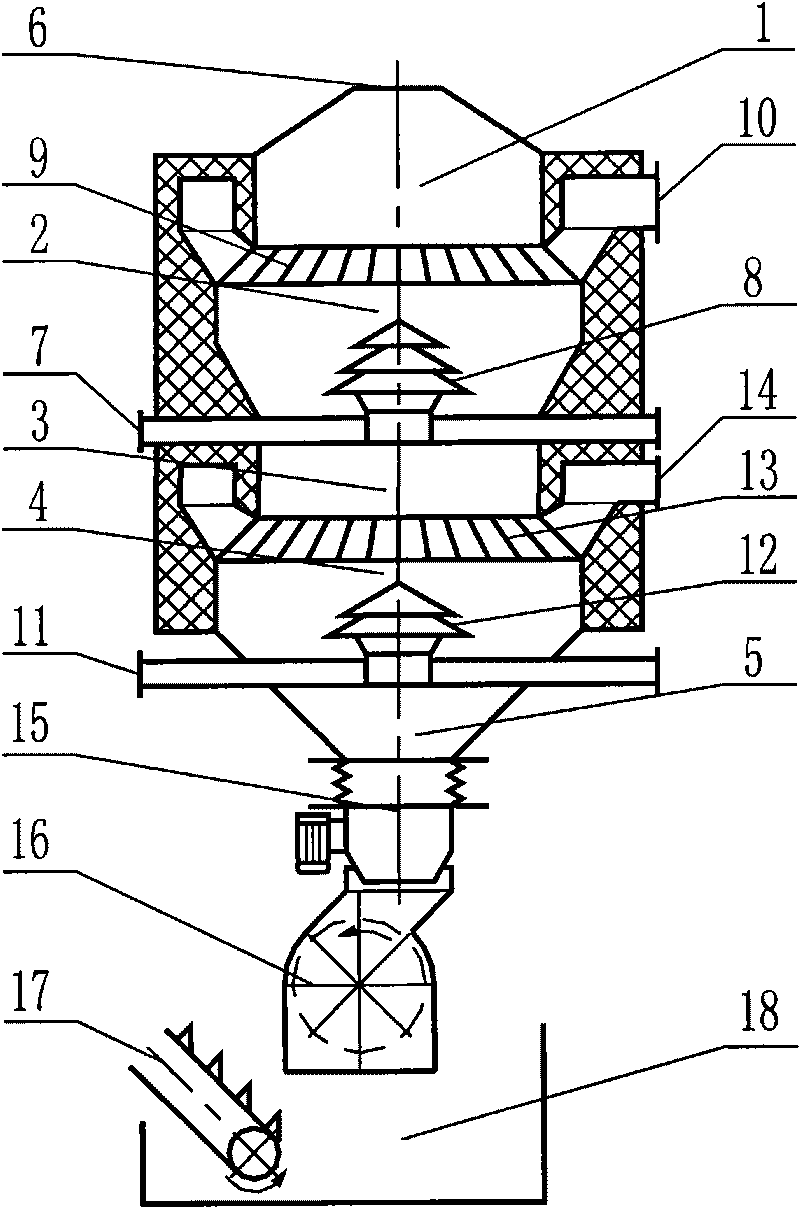

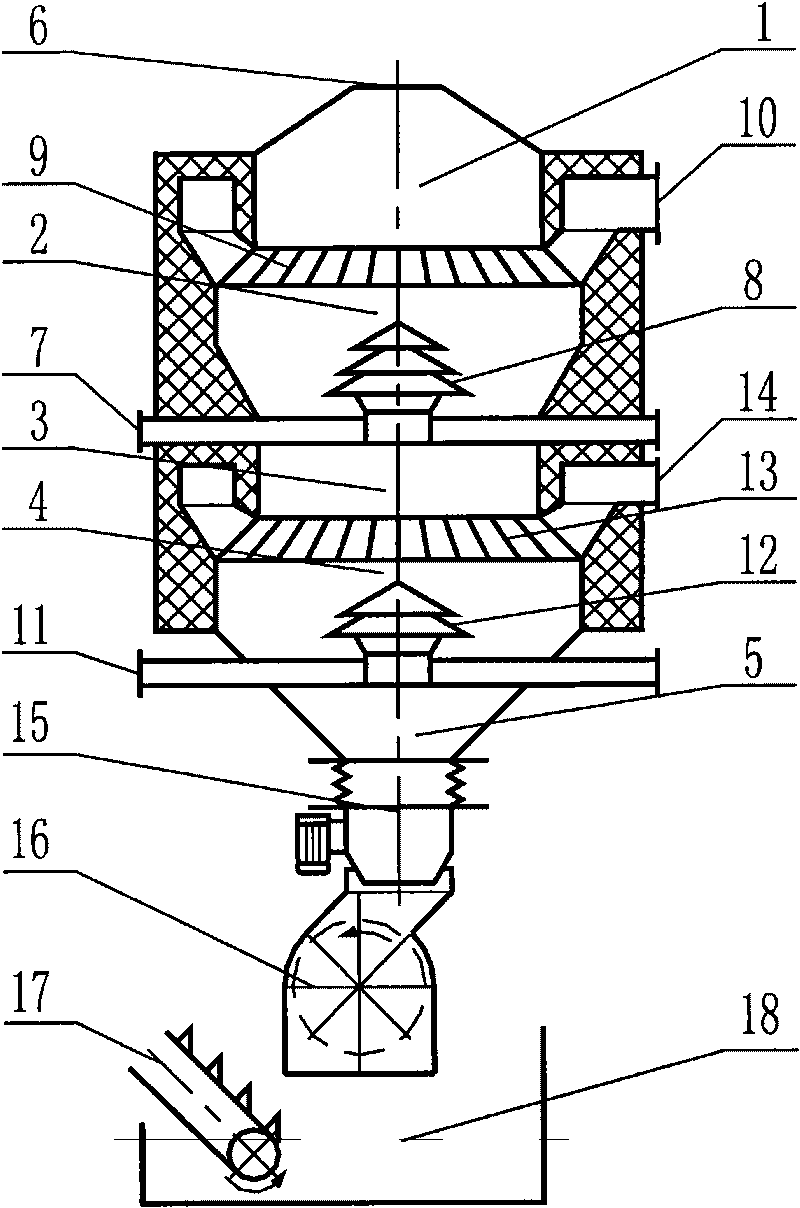

[0017] Coke cooling device of the present invention such as figure 2 As shown, the device is divided into five sections, from top to bottom are pre-storage section 1, gasification cooling section 2, transition section 3, physical cooling section 4 and discharge section 5. The upper pre-storage section 1 and the next gasification cooling section 2 are connected by a gasification gas collection channel 9, and the middle transition section 3 and the next physical cooling section 4 are connected by a high-temperature coolant collection channel 13 . The gasification cooling section 2 is composed of the cooling gasification agent inlet 7 in the upper middle of the device, the cooling gasification agent distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com