Patents

Literature

90results about How to "To achieve the purpose of desulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for cooling coke

InactiveCN101705101AQuality improvementIncrease productionCoke quenchingCombustible gas productionWater vaporEngineering

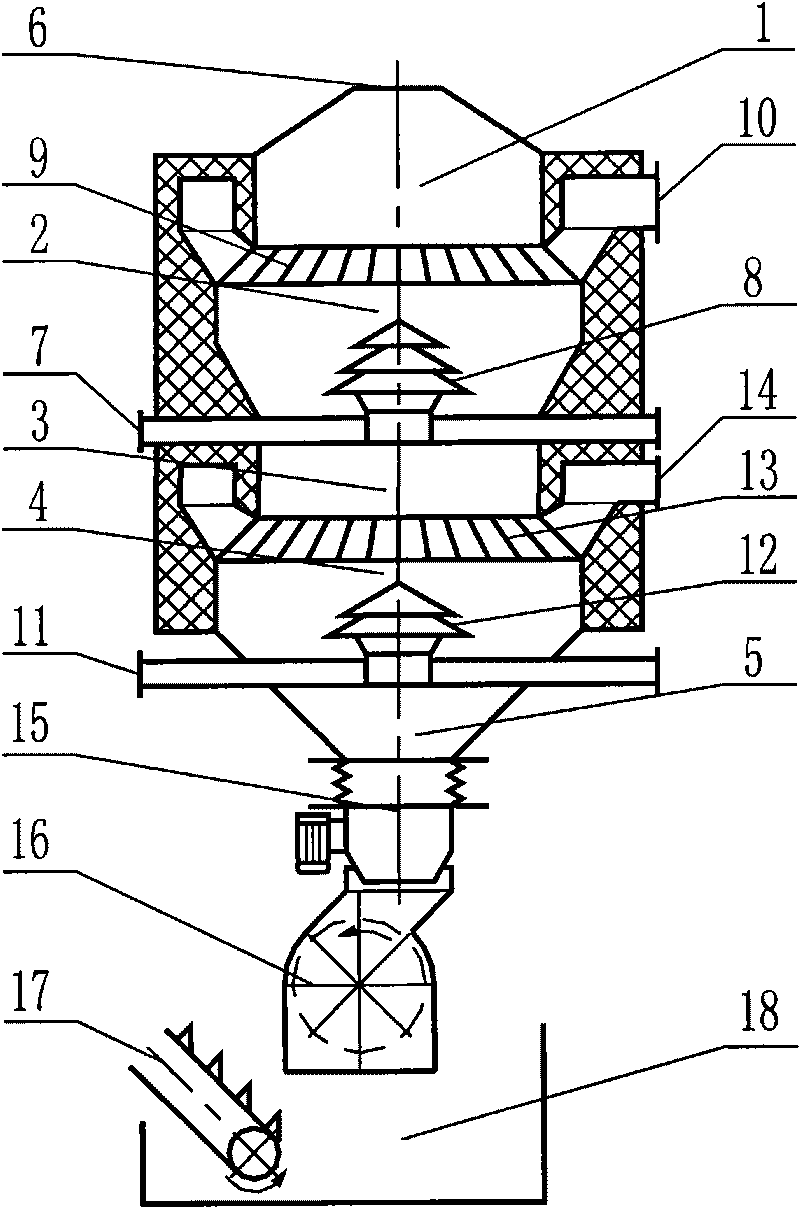

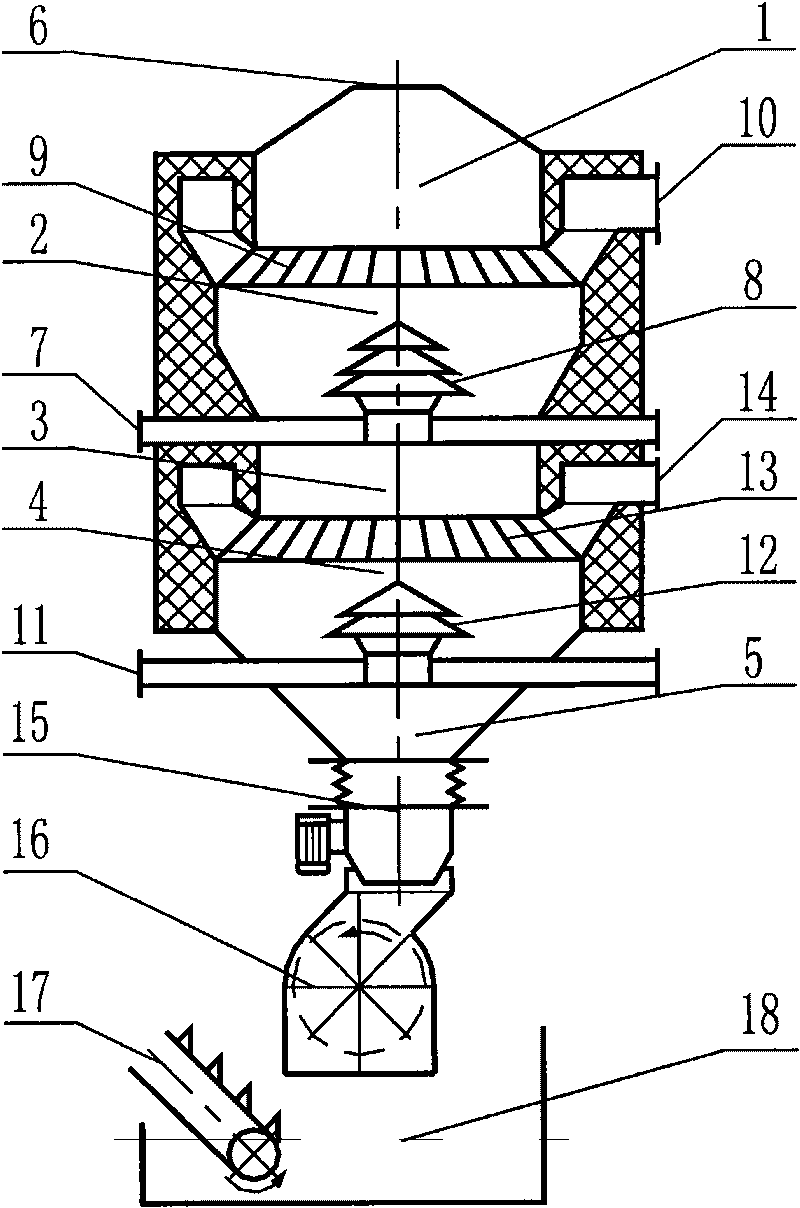

The invention discloses a device and a method for cooling coke. The device consists of a prestorage section, a vapor cooling section, a transitional section, a physically cooling section and a discharge section, wherein the upper prestorage section and the vapor cooling section are communicated by a vaporization gas collection channel; the middle transitional section and the physically cooling section are communicated by high-temperature coolant collection channel; a rotary discharge valve of the discharge second is immersed in liquid-sealed coke quenching tank; and a coke conveying device is arranged in the liquid-sealed coke quenching tank or a belt conveyor is arranged at the outlet of the discharge valve to convey the coke to the outside. The method for cooling the coke by vapor and coke oven gases comprises: introducing the vapor into the vapor cooling section; performing vaporization and generating synthesis gases; and introducing the coke oven gases into the physically cooling section to allow the coke oven gases to absorb the sensible heat of the coke and perform physical heat exchange with the coke. The device and the method have the advantages of reducing circulating gas volume, recovering the sensible heat of high-temperature coke, generating water gas and fully utilizing resources.

Owner:TAIYUAN UNIV OF TECH

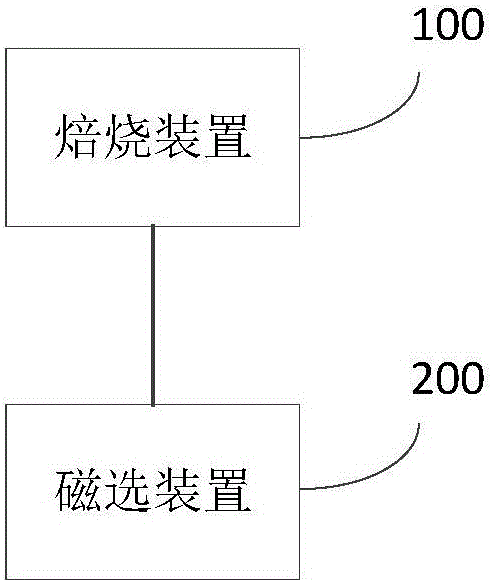

Method and system for treating sodium jarosite residue

InactiveCN106048209AEfficient recyclingHigh nickel gradeProcess efficiency improvementChemistryJarosite

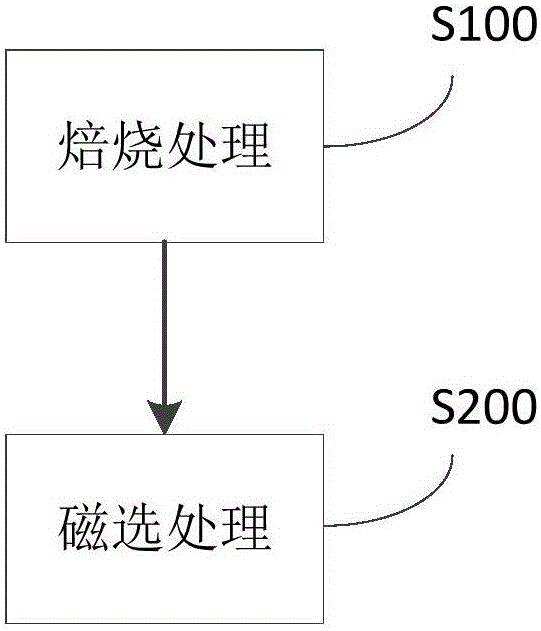

The invention discloses a method and a system for treating sodium jarosite residue. The method comprises the following steps: (1) calcining a mixture containing the sodium jarosite residue, a reducing agent and a desulfurizing agent to obtain a calcined product; and (2) conducting magnetic separation on the calcined product to separate out ferronickel particles. The system comprises a calcination device suitable for calcining the mixture containing the sodium jarosite residue, the reducing agent and the desulfurizing agent, and a magnetic separation device connected with the calcination device and suitable for magnetic separation of the calcined product. The method and the system disclosed by the invention can effectively recover the ferronickel particles in the sodium jarosite residue, and achieve the purpose of desulfurization, wherein the nickel grade of the ferronickel particles is relatively high.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Desulphurization and denitration catalyst and preparation method thereof

InactiveCN101518736AWide variety of sourcesEasy accessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParaffin waxCopper nitrate

The invention discloses a desulphurization and denitration catalyst. The catalyst comprises the following components by mass percentage: 4 to 18 percent of CuO, 80 to 95 percent of gamma-Al2O3, and 1 to 2 percent of promoter. A method for preparing the catalyst comprises the following steps: (1) adding aluminum isopropoxide into distilled water, stirring the mixture, adding a nitric acid solution into the mixture dropwise, and carrying out the evaporation in the air to obtain a boehmite sol; (2) adding the promoter into a copper nitrate solution, then adding the mixture into the boehmite sol, then adding the nitric acid solution dropwise, stirring the mixed solution for ageing, and aggregating the mixed solution into a semi-gel; and (3) adding the semi-gel dropwise into a gel pool containing ammonia water and liquid paraffin through a dropper, and obtaining the catalyst after ageing, drying and baking. The prepared catalyst can be used for synchronous desulphurization and denitration, and can be regenerated and used cyclically with low raw material cost. As the byproducts can be reutilized, the catalyst brings about no secondary pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

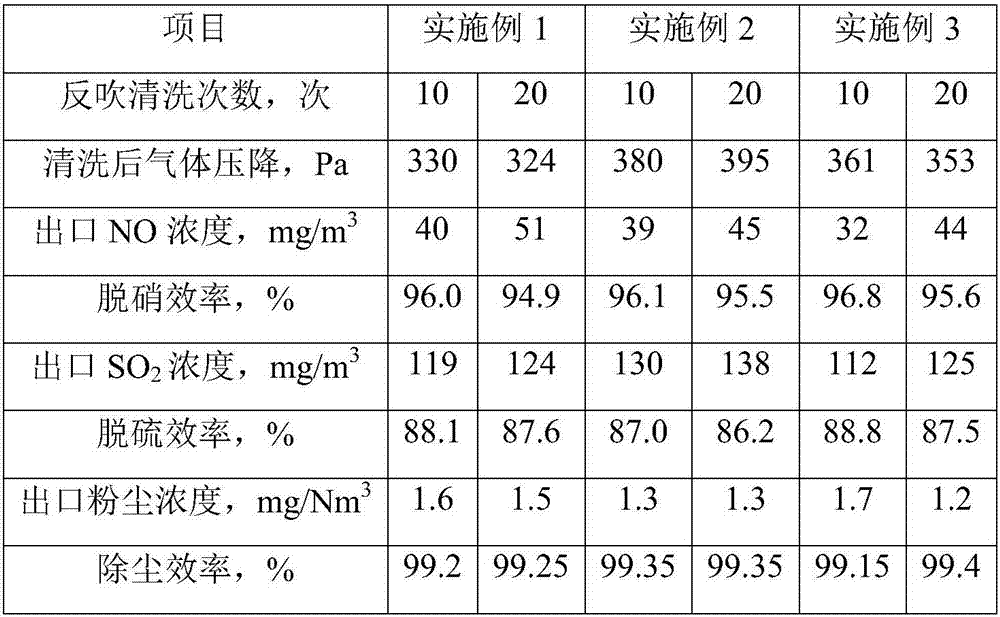

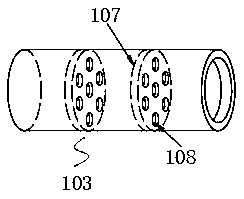

Ceramic catalytic filter element for flue gas purification and flue gas desulfurization and denitrification integrated dust removal method

ActiveCN107876043AExtended service lifeReduce loadDispersed particle filtrationTransportation and packagingActive matrixFlue gas

The invention relates to a ceramic catalytic filter element for flue gas purification and a flue gas desulfurization and denitrification integrated dust removal method. The ceramic catalytic filter element is prepared from the following steps that a microporous alumina ceramic filter tube with a pore diameter of 40-80 microns is taken as a matrix; the matrix is immersed in a mixed sol made of zincacetate, and after the matrix is impregnated under a negative pressure, the matrix is roasted to obtain a modified matrix modified by zinc oxide; an equal volume impregnation method is adopted, and the modified matrix is impregnated with an mixed oxalic acid solution containing ammonium metavanadate and ammonium metatungstate, so that total loading mass of V2O5 and WO3 in pores of the matrix reaches 4.0%-6.0% to obtain an active matrix; the active matrix is immersed in a mixed sol made of Al2O3-SiO2-TiO2, the active matrix is dried and roasted after the active matrix is taken out, and a densefilm with a thickness of 0.2-0.6 millimeter and a pore diameter of 1-10 microns is formed on the outer surface of the active matrix to obtain the ceramic catalytic filter element. A denitrification catalyst of the ceramic catalytic filter element has the advantages of being strong in load, high in denitrification efficiency, long in service life and applicable to popularizing and using.

Owner:济南玉泉生物发电有限公司

Desulphurization method of cracked C5 fraction

ActiveCN105112093AGood desulfurization effectLow processing costTreatment with plural serial refining stagesChemistryBenzene

The invention relates to a desulphurization method of cracked C5 fraction. The desulphurization method of cracked C5 fraction comprises the following steps: firstly adding a desulfurizer into a cracked C5 fraction raw material, and carrying out a reaction at a certain pressure and a certain temperature for a while; separating a cracked C5 fraction which is free of sulfur from the top of a tower by a filtering and a distillation method; after reaction, obtaining a sulfur compound in a column bottom; the desulfurizer comprises the following components: 3-8% of triethanolamine, 3-8% of acetonitrile, 3-8% of toluene, 3-8% of acetone, 8-12% of benzene, 25-35% of saturated ammoniacal liquor, 8-12% of butyronityile, 8-12% of cyclohexane, 10-20% of aniline, and 3-8% of diethyltoluenediamine. According to the method, a proper amount of desulfurizer is added into the cracked C5 fraction raw material, and the purpose for desulphurization of cracked C5 fraction is realized by the methods of filtering and distillation. The method provided by the invention has a good desulphurization effect, by-products are not introduced into the desulphurized product, and the composition of the cracked C5 fraction is not changed; the desulfurizer has little toxicity and is not volatile and inflammable.

Owner:濮阳市联众兴业化工有限公司

Desulfuration and denitration catalyst and preparation method thereof

InactiveCN101797505AWide variety of sourcesEasy accessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAdhesiveRaschig ring

The invention discloses a desulfuration and denitration catalyst, which comprises the following components in percentage by weight: 5-15% of CuO, 80-90% of gamma-Al2O3 and 2-5% of catalyst promoter (Na2O, NiO or ZnO). The preparation method of the catalyst comprises the following steps: (1) mixing main catalyst CuO, catalyst promoter, carrier Al2O3, kieselguhr adhesive and wood-dust pore forming agent, adding water, and completely stirring into paste; (2) molding into cylindrical bodies, spherical bodies or Raschig ring bodies; and (3) drying, calcining, and activating to prepare into the catalyst. The prepared catalyst can realize the desulfuration and the denitration simultaneously, is low in the material cost, and can be recycled. Besides, the byproducts can be recycled, thereby being free of the secondary pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

Montmorillonite as natural gas desulfurizing agent

InactiveCN101053735ASimple processHigh sulfur capacityDispersed particle separationChemical reactionSulfide

The invention discloses a montmorillonite natural gas desulfurizer, and the main points of the technical proposal are that the montmorillonite natural gas desulfurizer is composed of montmorillonite, attapulgite clay, alumina, zinc oxide and sodiumhydroxide. The preparing method is that the burden materials of the montmorillonite natural gas desulfurizer are input into a steeping cistern and then are steeped with water after mixed together to do sodium treatment, extrusion drying, separating by breaking and sieving, baking and packaging to be a finished product. The montmorillonite natural gas desulfurizer is a columniform strip granule, which generates chemical reaction after fully contacting with the nature gas to adsorb the sulfured and cyanide in the nature gas into the columniform strip granules to greatly reduce the content of sulfured in the nature gas and adsorb free water in the nature gas. The montmorillonite natural gas desulfurizer has a simple production process, a low cost and a great economic benefit and social benefit, and is acceptable for the desulfurizing process of nature gas, coal gas and marsh gas.

Owner:许庆华

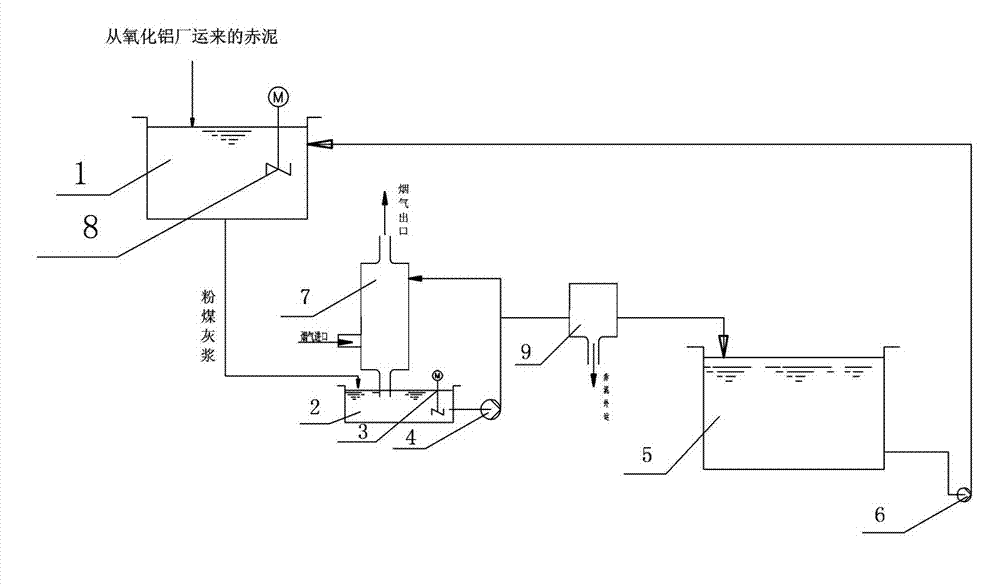

Method for desulfurization of flue gas in boiler by using red mud

ActiveCN103028324ALow costTo achieve the purpose of desulfurizationDispersed particle separationAluminium industryFlue gas

The invention discloses a method for desulfurization of flue gas in a boiler by using red mud. The red mud adopted by the method is the red mud which is prepared by adding water in pollutant waste residue-red mud discharged when aluminum oxide is extracted in the aluminum making industry. The method comprises the following steps: injecting the red mud into a red mud pool and continuously stirring the red mud; conveying the red mud to a desulfurization tower through a desulfurization circulating pump; carrying out desulfurization reaction on the red mud and the flue gas introduced to the middle lower part of the desulfurization tower; discharging desulfurized flue gas from the top of the desulfurization tower; discharging mud products containing sulfate generated by desulfurization from the bottom of the desulfurization tower; conveying the mud products containing sulfate discharged to a mud-water separation device; separating out the red mud and water after desulfurization; pumping separated clean water to a red mud preparation tank for recycling; and conveying separated desulfurized red mud. The flue gas generated by the boiler is desulfurated, so that the method is simple to operate and low in cost. Wastes are treated by wastes to the benefit of environmental protection, so that the method has remarkable economic and social benefits.

Owner:安阳化学工业集团有限责任公司

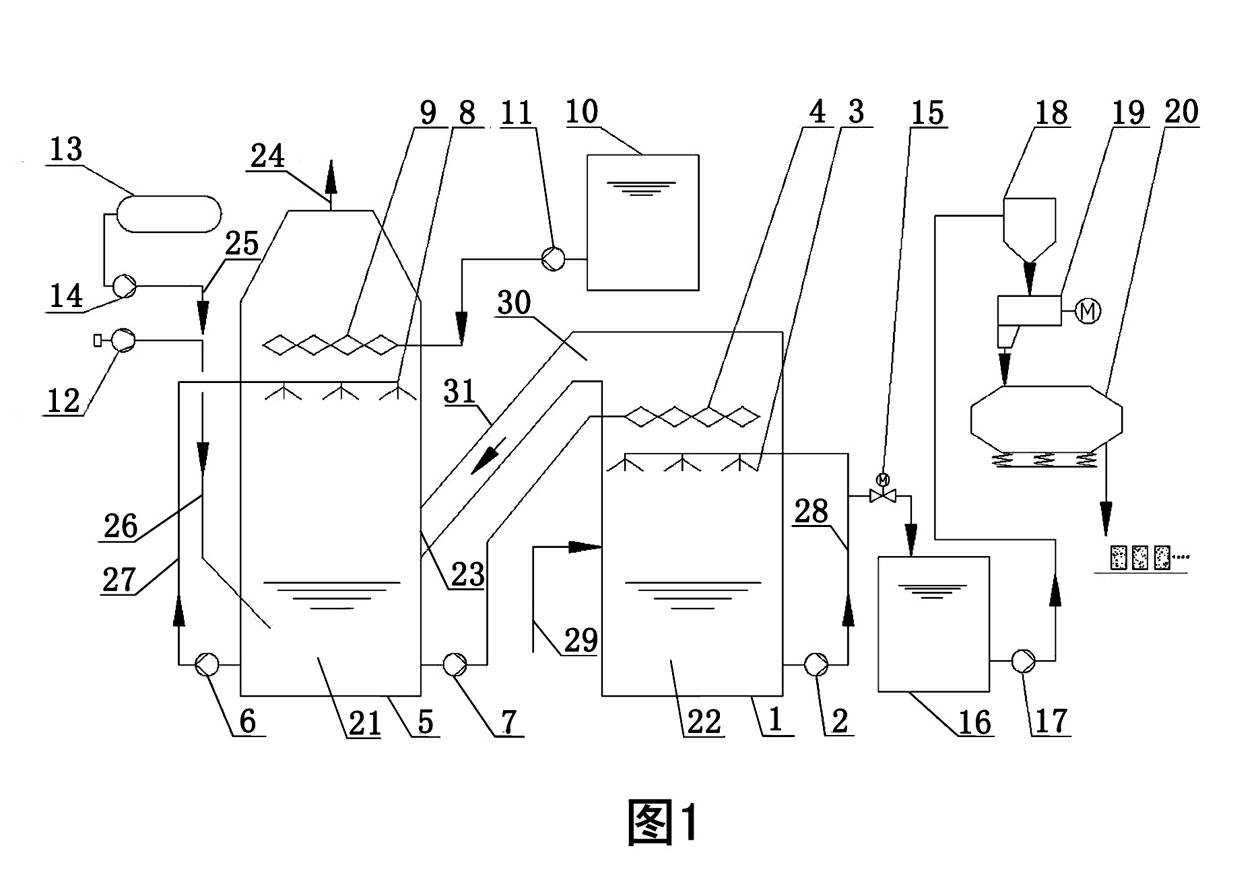

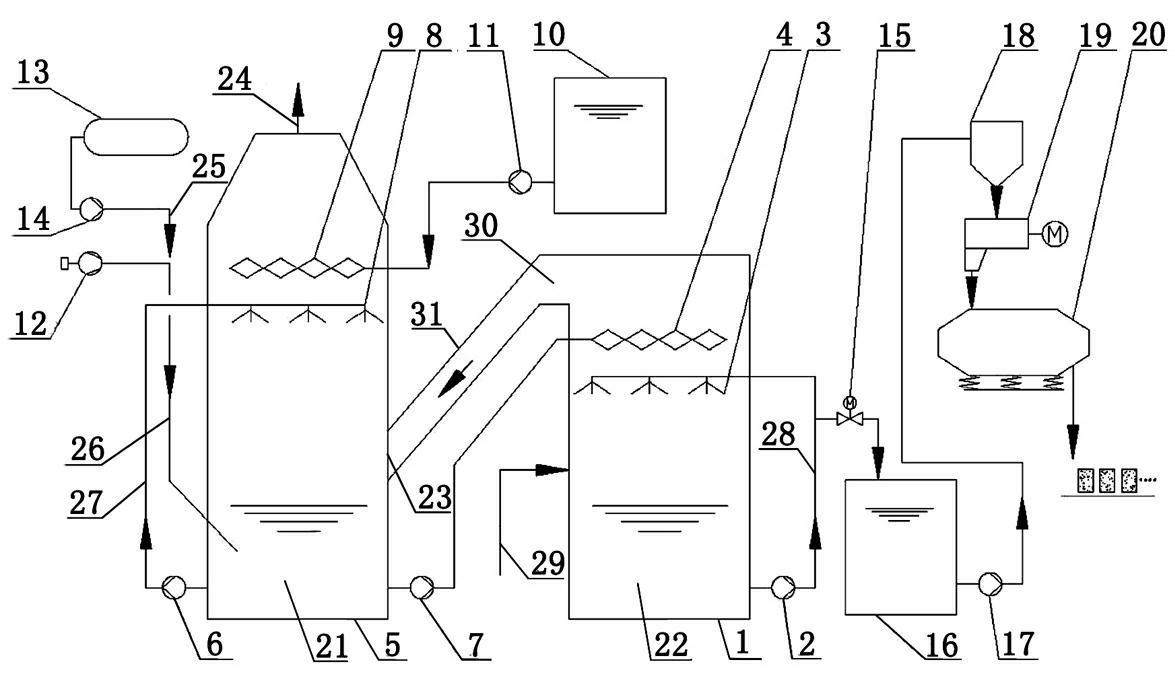

Two-tower ammonia method desulfurization device and method

ActiveCN102151475AImprove purification effectEmission reductionDispersed particle separationAmmonia compoundsEconomic benefitsCircular economy

The invention discloses a two-tower ammonia method desulfurization device and method. A smoke purifying part of the device comprises a desulfurization tower and a pre-scrubbing tower, the lower section inside the desulfurization tower is provided with a desulfurization tower slurry pool, the upper section inside the desulfurization tower is provided with a desulfurization tower spraying layer and a desulfurization tower mist eliminator, the lower section inside the pre-scrubbing tower is provided with a pre-scrubbing tower slurry pool, and the upper section inside the pre-scrubbing tower is provided with a pre-scrubbing tower spraying layer and a pre-scrubbing tower mist eliminator; an absorbing agent supply part comprises a liquid ammonia storage tank, an ammonia supply device and an oxidization fan; and an ammonium sulfate dewatering part comprises an ammonium sulfate slurry discharge valve, a neutralization tank, an ammonium sulfate slurry pump, a swirler, a centrifugal machine and a drying bed. The ammonia method desulfurization device comprises the two towers, system heat source can be effectively utilized through the pre-scrubbing tower, slurry is heated through high-temperature raw smoke so that the purpose of concentration is achieved, and smoke can be primarily purified through circulation of the slurry in the two towers, the emission of aerosol is further reduced, side products with considerable economic benefit can be produced while desulfurization efficiency is ensured, and wastes are changed into valuable, and requirements on circular economy is met.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

Coal economizing agent

InactiveCN106753681AImprove combustion efficiencyImprove efficiencySolid fuelsFuel additivesCombustionNon compliance

The invention belongs to the technical field of coal combustion additives, and in particular relates to a coal economizing agent. The invention solves the problems of unobvious coal economizing effect, high addition level, pollution of the environment and non-compliance of Green blackness of the existing coal economizing agents. The coal economizing agent is prepared from the components in parts by weight: 22-26 parts of a combustion adjuvant, 28-41 parts of a mixed type strong oxidizer, 18-26 parts of a dispersing agent, 2-5 parts of a catalyst and 15-25 parts of a compound sulfur-fixing agent. The coal economizing agent disclosed by the invention can improve the combustion conditions of a furnace body and increase the air permeability of a coal layer, thus enabling sufficient combustion of coal, improving the coal-burning heat efficiency, reducing discharge amount of smoke, improving the thermal conduction efficiency, fixing sulfur to reduce smoke, reducing emission of CO, SO2 and the like, reducing environmental pollution, and achieving the purposes of combustion supporting, sulfur fixing, energy saving and desulfurization.

Owner:GUANGZHOU AUSPICIOUS CHEM

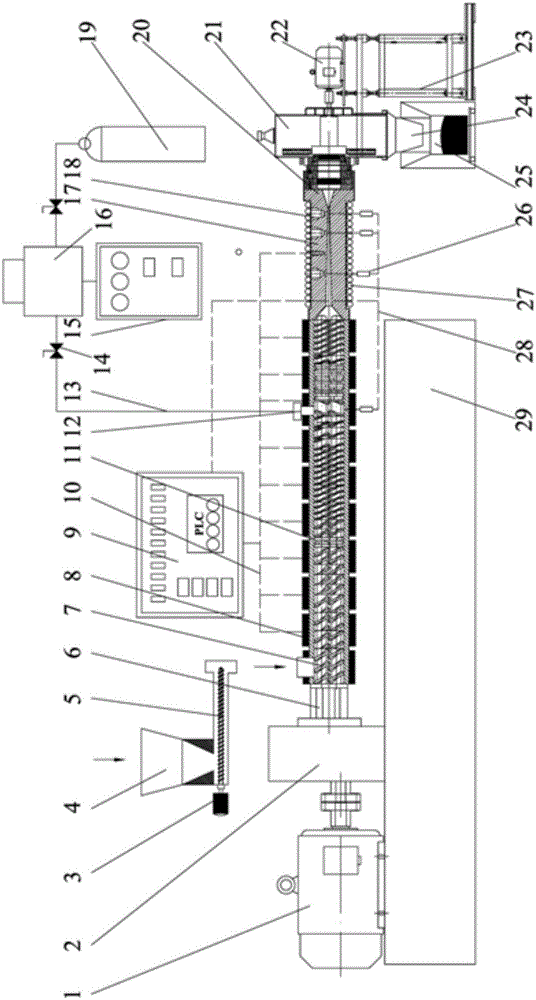

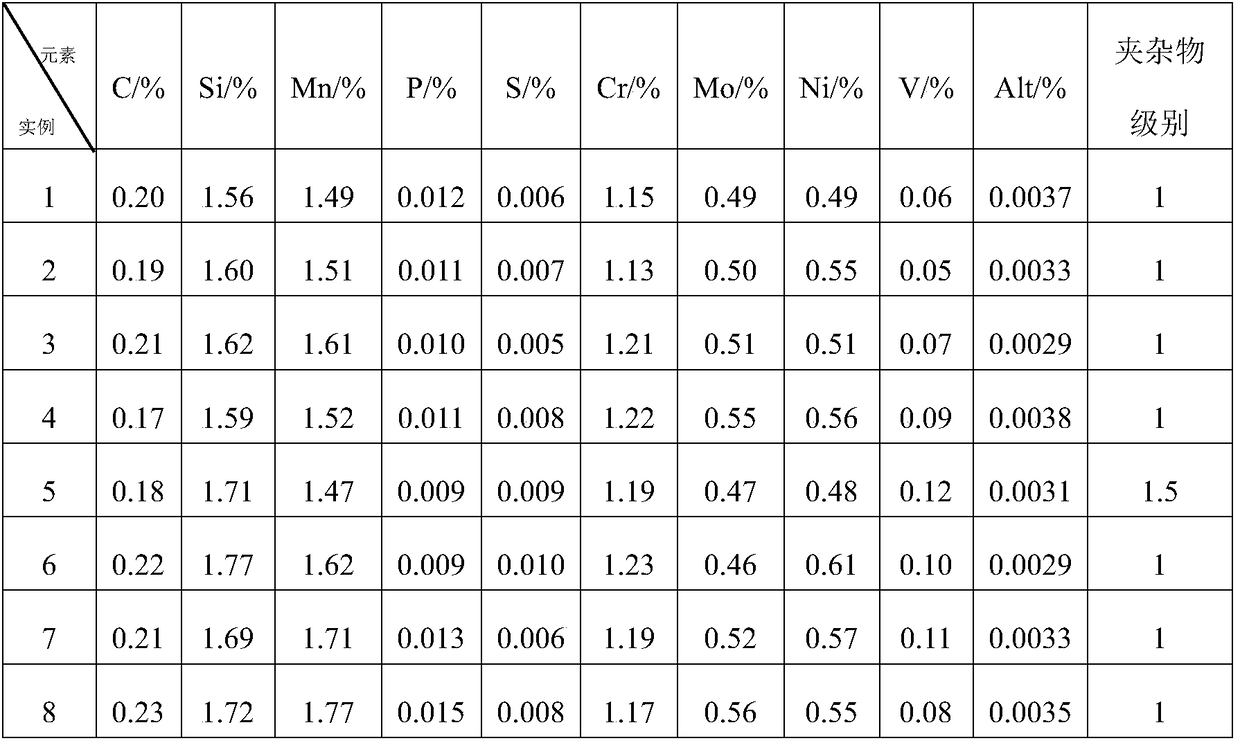

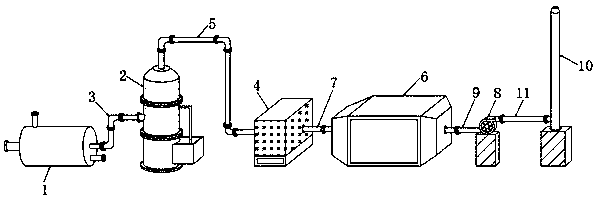

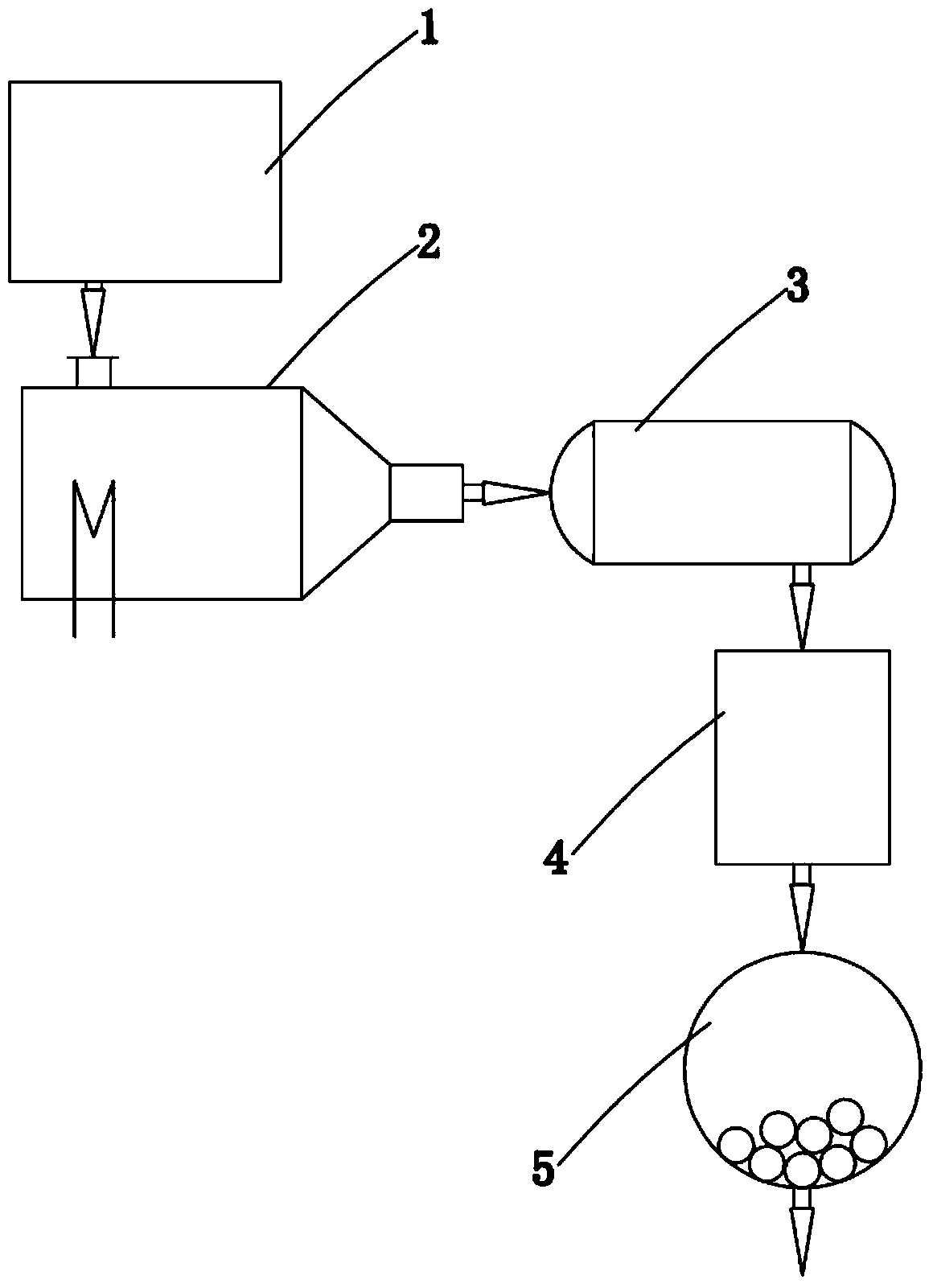

Green devulcanizing and reclaiming apparatus with supercritical CO2 and microwave assisted multi-segment twin-screw extrusion

The invention discloses a green devulcanizing and reclaiming apparatus with supercritical CO2 and microwave assisted multi-segment twin-screw extrusion, comprising a horizontal barrel; a twin-screw is rotationally mounted in the barrel; the barrel is provided with a feed port at the left upper end of the twin-screw, and the upper end of the barrel is fitted ith a microwave heating device; the middle of the barrel is provided with a gas injection end for supplying supercritical CO2; the rear end of the barrel is provided with a cooling extruder, the tail end of the cooling extruder is fitted with a dicing device, and a discharge port of the dicing device is provided with a product packaging device. The apparatus of the invention has simple structure, uses small floor area, is full-automatically controllable, low in production process energy consumption and green, and the defect that traditional reclaimed rubber production process has high contamination, high energy consumption, intermittence, high labor intensity and unstable product properties is effectively solved.

Owner:ANHUI GVG NEW MATERIAL CO LTD

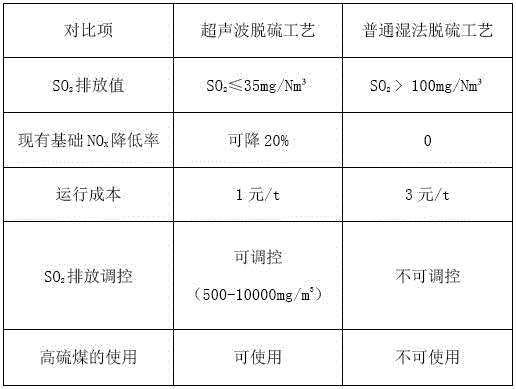

Ultrasonic desulfuration, denitration and dust removal method

InactiveCN105833696ATo achieve the purpose of desulfurizationComplete desulfurizationCombination devicesGas treatmentUltrasound deviceNitrogen oxide

The invention discloses an ultrasonic desulfuration, denitration and dust removal method .The method includes the steps that smoke enters an ultrasonic device; an ultrasonic generator in the ultrasonic device generates ultrasonic waves to atomize desulfuration liquid entering the ultrasonic device, SO2 in the smoke is catalyzed and oxidized by the atomized desulfuration liquid at high speed to generate SO3, and SO3 and a desulfuration medium in the desulfuration liquid react; the smoke processed by the ultrasonic device is sucked in under the action of an air draft fan and is conveyed back into a smoke exhaust pipeline .Desulfuration efficiency can reach 95% or above, the denitration effect is achieved, and nitrogen oxides are reduced by 20% or above.

Owner:陈佐会

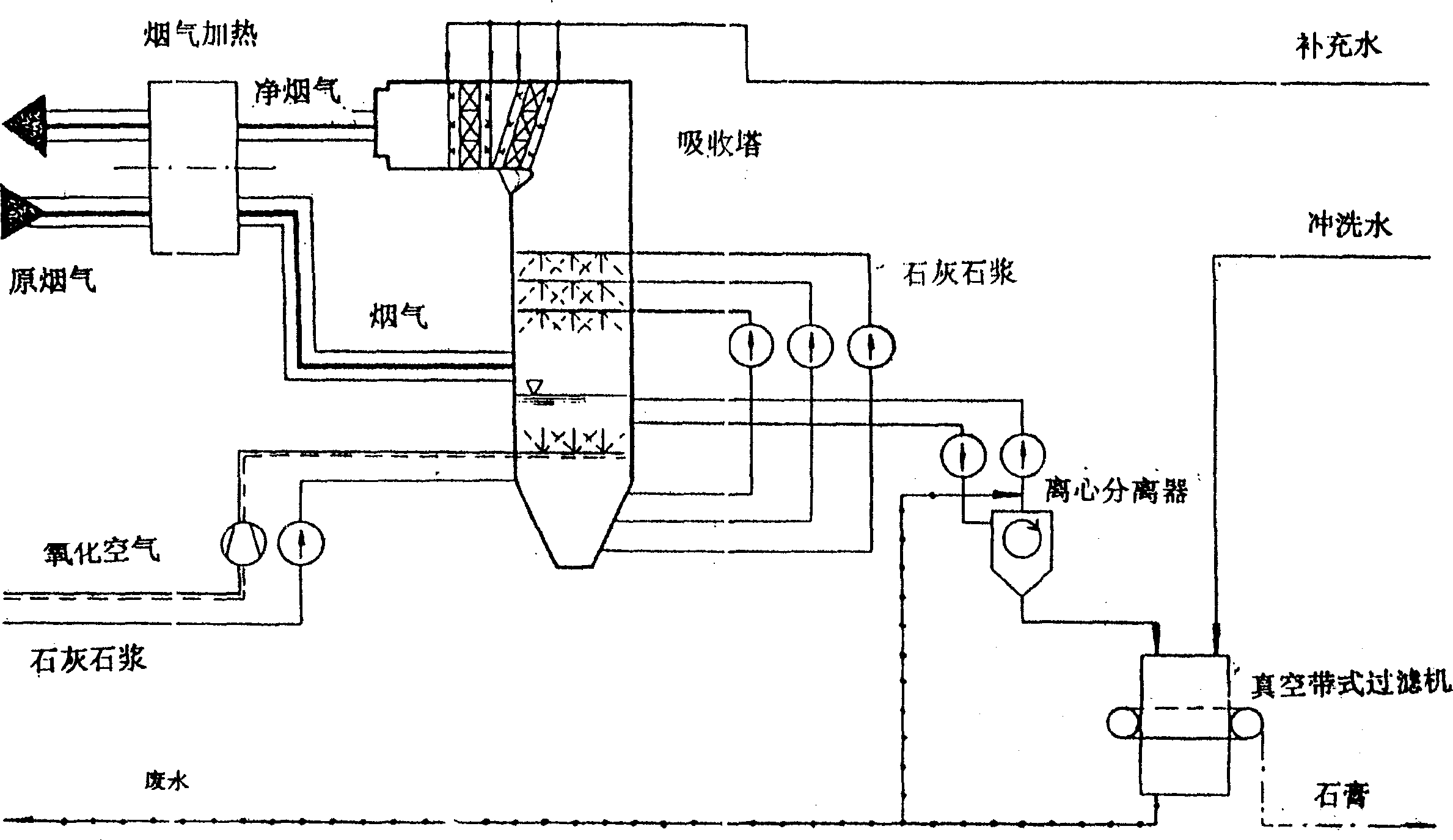

Wetting smoke dust-proof desulfurizing method

InactiveCN1712112ACompact processTo achieve the purpose of desulfurizationDispersed particle separationEngineeringTower

A process for desulfurizing and dusting the fume by wet method includes such steps as introducing the fume to the bottom of absorption tower, cooling it by water evaporating, mixing with washing liquid in counterflow mode, liquid drops separating at the top of reaction tower, and exhausting clean fume.

Owner:王站魁 +1

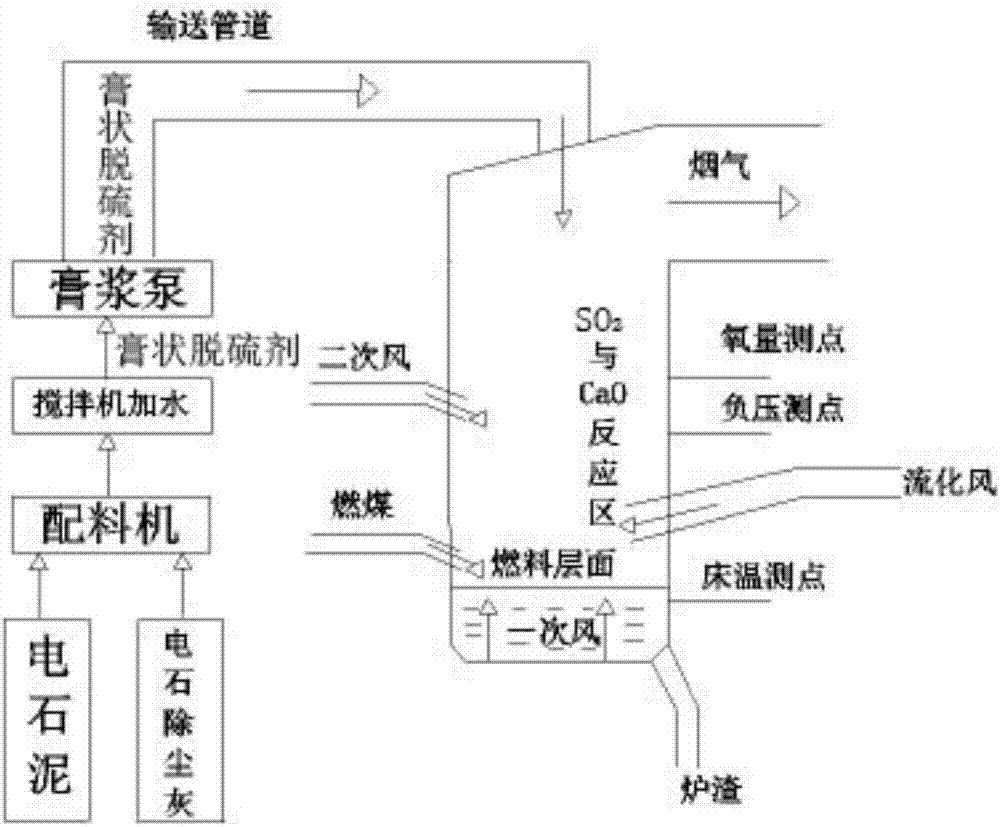

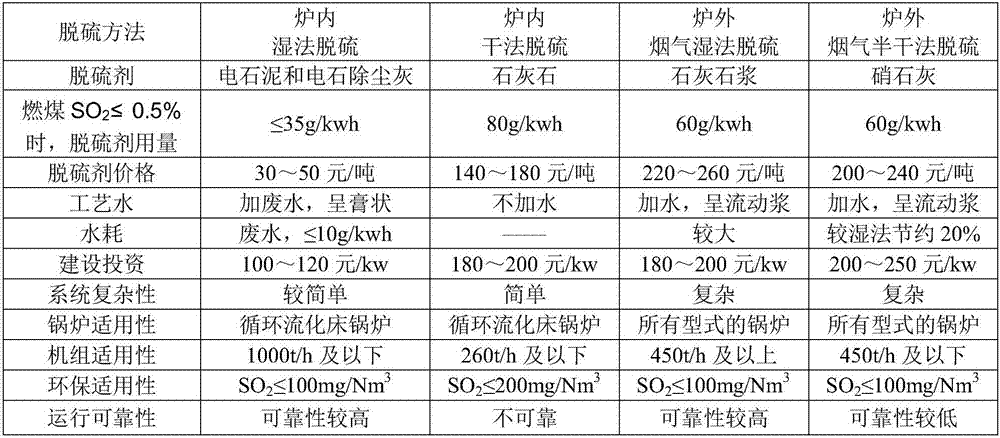

Method for wet desulphurization in CFB boiler

InactiveCN106925106AExtended stayImprove efficiencyDispersed particle separationCombustionEconomic benefits

The invention discloses a method for wet desulphurization in a CFB boiler, especially relates to a wet desulphurization method suitable inside a CFB boiler of 1000t / h level and below in a 350MW power plant, and belongs to the technical field of environmental protection. According to the method for wet desulphurization in a CFB boiler, industrial waste calcium carbide slurry and / or calcium carbide dedusting ash are / is used as a desulfurizer, and water is added to prepare a paste desulfurizer; through conveying equipment, the paste desulfurizer is injected into the CFB boiler; and combustion inside the CFB boiler is regulated so as to finish the desulphurization process. The invention has characteristics of less investment in equipment, simple operation, high desulphurization efficiency, reliable operation, etc. By the method, secondary pollution of a desulfurizer or desulphurization sewage to the environment can be reduced. The method is a brand-new circulating fluidized bed boiler flue gas desulfurization method, provides a brand-new approach to desulphurization for a circulating fluidized bed boiler of 1000t / h level and below, and has good social and economic benefits.

Owner:孙宽

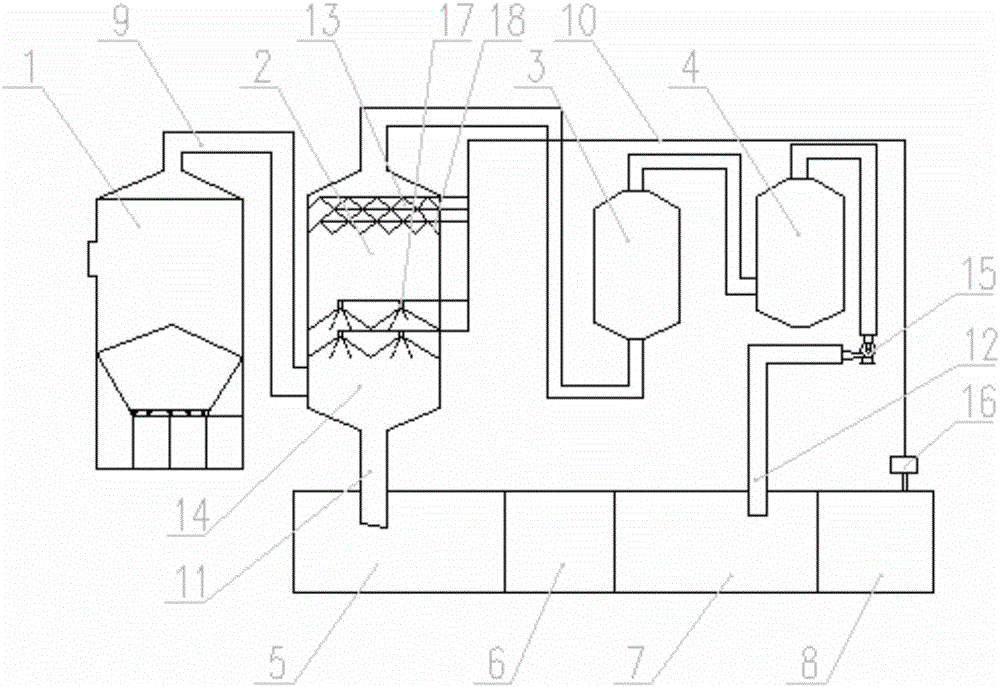

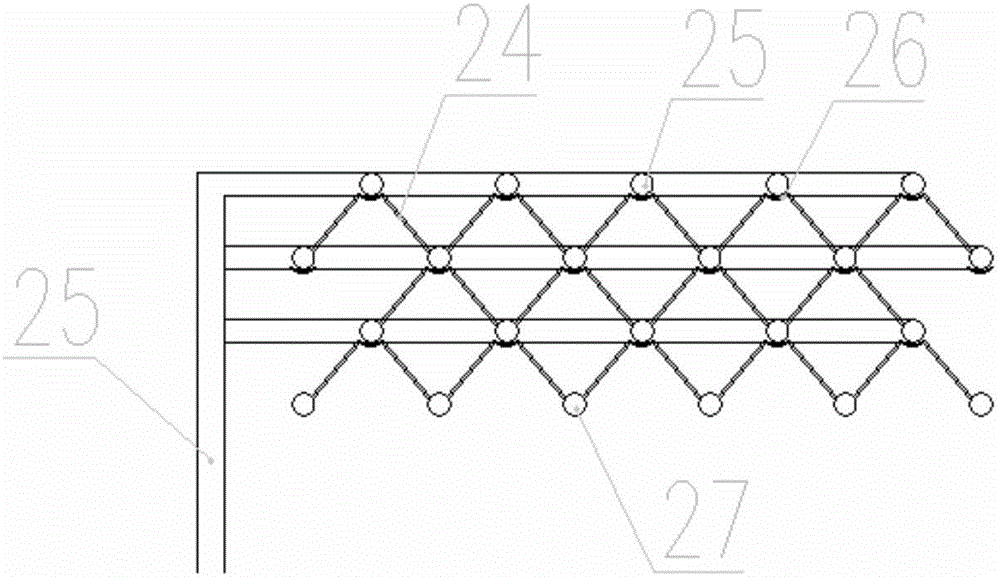

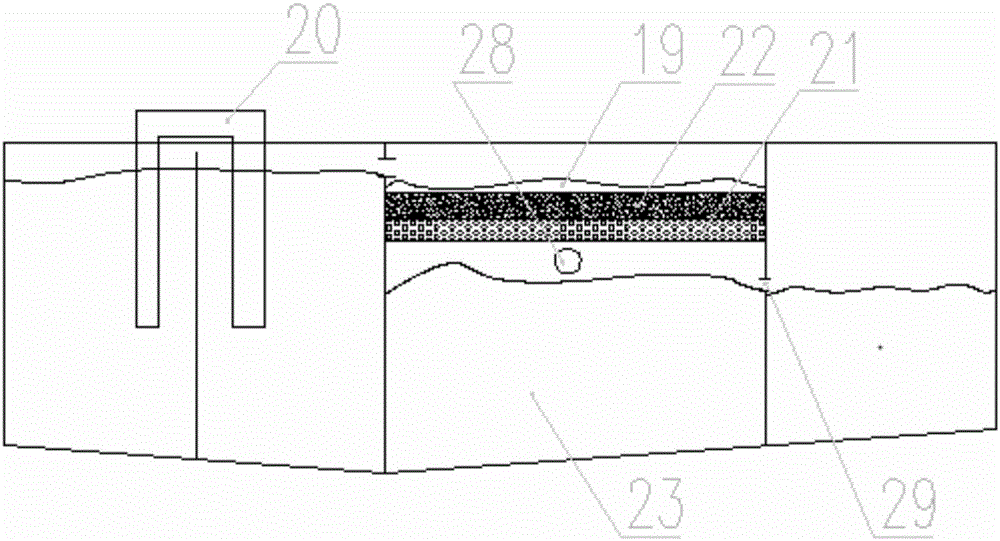

Waste incineration flue gas treatment system

The invention discloses a waste incineration flue gas treatment system which comprises an incinerator, a desulfurization / dedusting integrated device, an adsorption device, a deodorization device, a sewage tank, a sedimentation tank, a sand filtering tank and an alkaline liquid tank, wherein a gas outlet of the desulfurization / dedusting integrated device of the waste incineration flue gas treatment system is connected with a gas inlet of the adsorption device, a gas inlet of the desulfurization / dedusting integrated device is communicated with an exhaust port of the incinerator through a flue, and a sewage outlet is communicated with the sewage tank; a flue gas outlet of the adsorption device is connected with a flue gas inlet of the deodorization device; and a flue gas outlet of the deodorization device is arranged below a filtering layer of the sand filtering tank through a fan and an exhaust pipe. In the invention, the spray levels of a desulfurizing tower are effectively reduced to achieve an aim of lowering the height of the desulfurizing tower; and moreover, the dedusting effect can be effectively improved.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

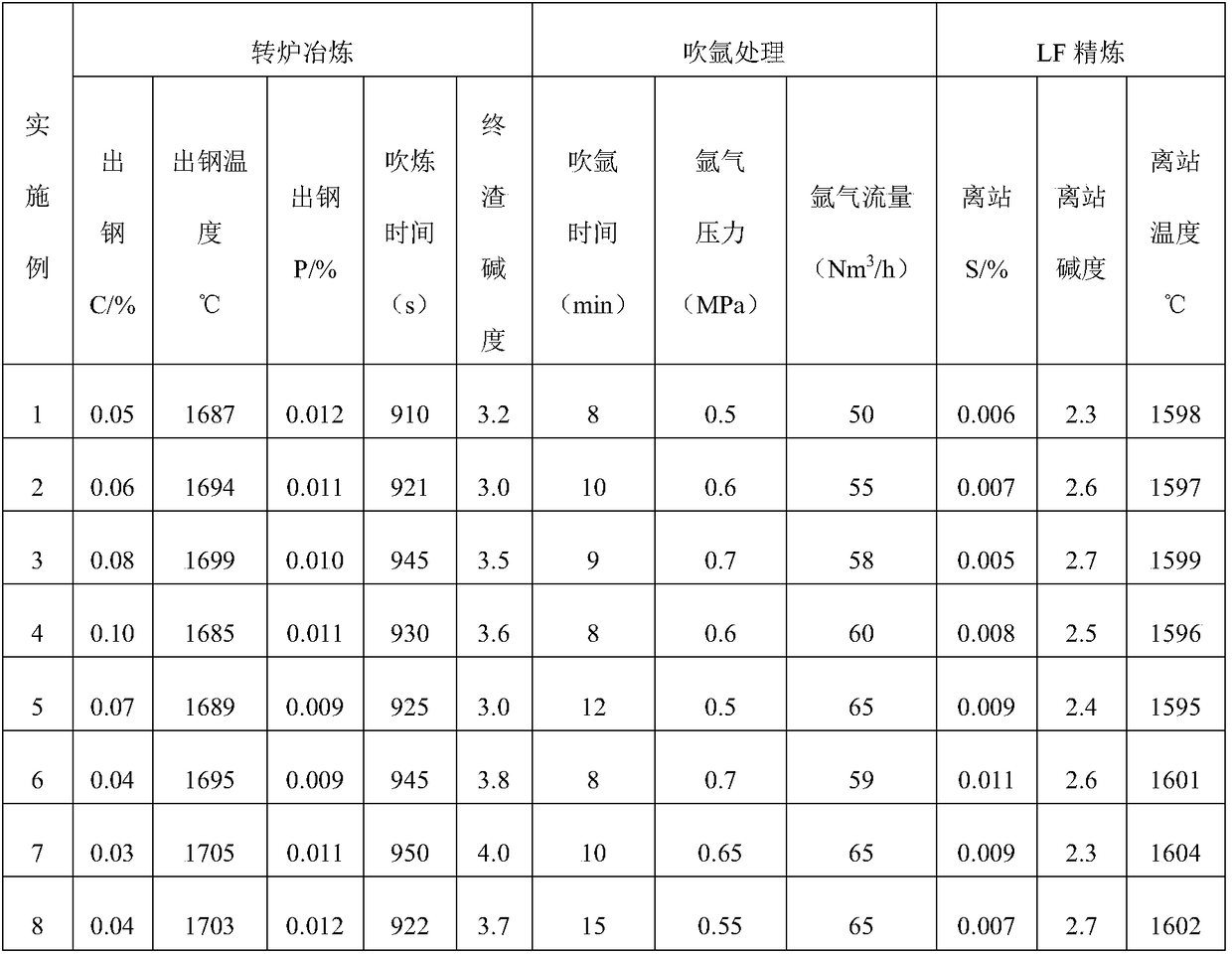

Bainite rail steel with ultra-low aluminium content and high strength and production method thereof

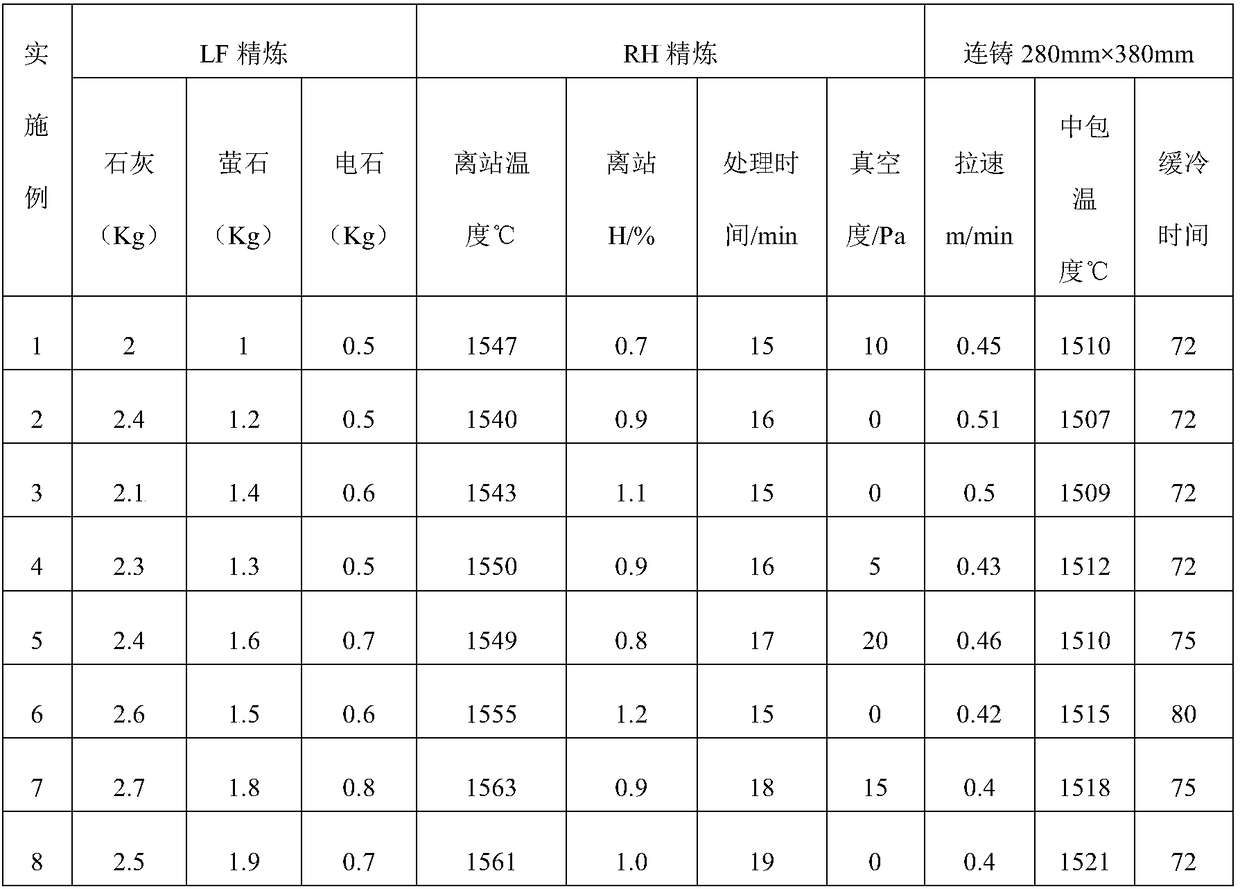

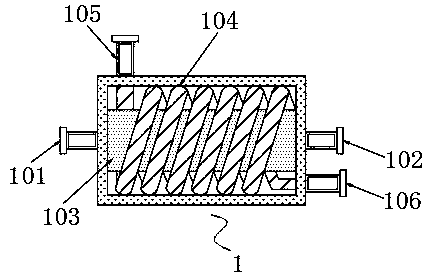

InactiveCN109023035AImprove fatigue resistance and service lifeImprove purityManufacturing convertersAluminiumSmelting

The invention discloses bainite rail steel with an ultra-low aluminium content and high strength and a production method thereof. The rail steel comprises the chemical components of, by weight, 0.10%-0.25% of C, 1.50%-1.90% of Si, 1.40%-1.90% of Mn, less than or equal to 0.025% of P, less than or equal to 0.025% of S, 1.10%-1.50% of Cr, 0.40-0.70% of Mo, 0.40%-0.75% of Ni, 0.04%-0.15% of V, less than or equal to 0.004% of Alt and the balance Fe and unavoidable impurities. The production method adopts top-bottom combined blowing converter smelting, LF refining and RH vacuum treatment, the totalaluminum content of the bainite rail steel can be effectively controlled below 40*10<-4>%, and the harm of alumina inclusions in the steel is effectively reduced.

Owner:武汉钢铁有限公司

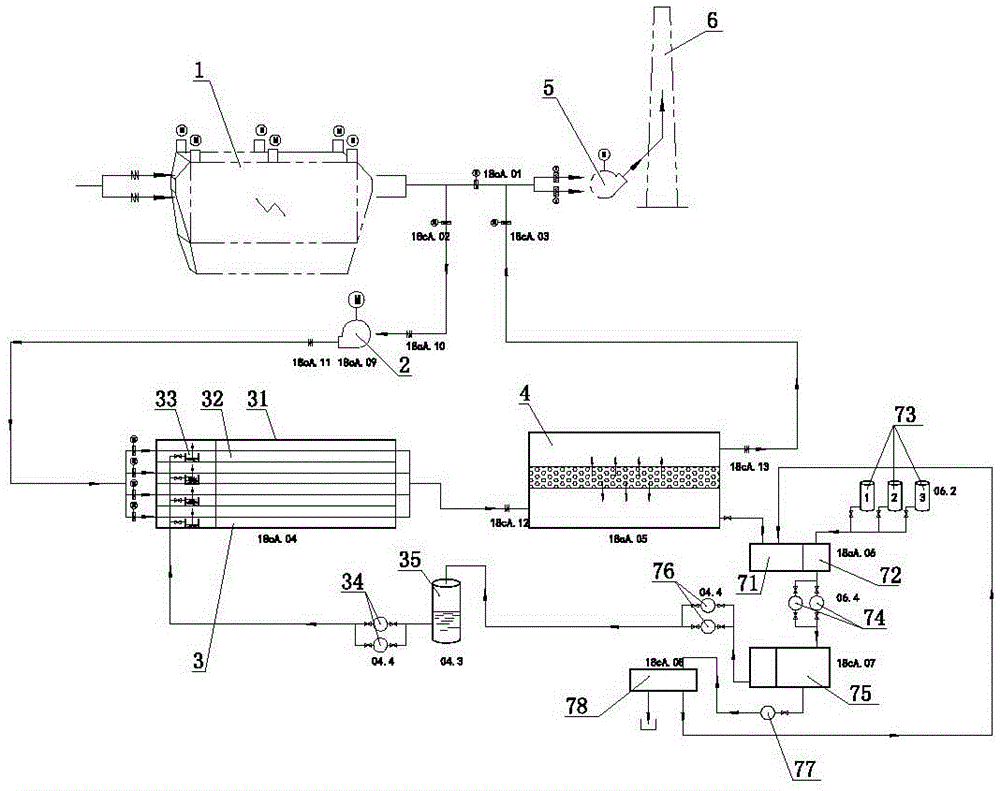

Treatment device for non-ferrous metal smelting exhaust gas

InactiveCN110813033AReduce noise pollutionReduce the temperatureGas treatmentDispersed particle separationVulcanizationDust control

The invention discloses a treatment device for non-ferrous metal smelting exhaust gas and relates to the technical field of non-ferrous metals. The treatment device comprises an afterheat recovery tank, wherein a vulcanization column is arranged at one side of the afterheat recovery tank, a first pipeline is mounted at a joint of the afterheat recovery tank and the vulcanization column, an electrostatic dust collection box is mounted at one side of the vulcanization column, a second pipeline is mounted at a joint of the vulcanization column and the electrostatic dust collection box, and an activated charcoal adsorption box is arranged at one side of the electrostatic dust collection box. According to the treatment device, the structure is reasonable, and the cost is relatively low; throughthe arranged afterheat recovery tank, afterheat of flue gas can be recycled; through the arranged vulcanization column, sulfur dioxide can be effectively removed from the flue gas to achieve the aimof exhaust gas desulfurization; through the arranged electrostatic dust collection box, dust and solid particles can be effectively removed from the flue gas to achieve the work of dust collection; and through the arranged activated charcoal adsorption box, the exhaust gas is further subjected to purifying treatment, the purification effect of the exhaust gas is improved, and the energy-saving andenvironment-friendly effects are remarkable.

Owner:CHANGDE FEIERMEI CHEM TECH CO LTD

Coal saving agent and preparation process thereof

The present invention relates to a coal saving agent and a preparation process thereof, wherein the coal saving agent comprises, by weight, 6-12% of catalyst, 1-7% of a combustion-supporting agent, 25-35% of a penetrant, 25-35% of a leavening agent, 7-15% of a cleaning agent, 10-20% of a dispersing agent, and 7-12% of a sulfur-fixing agent. According to the present invention, the coal saving agent has effects of furnace combustion condition improving, coal seam gas permeability improving, complete coal combustion, coal-fired thermal efficiency improving, smoke dust emission reducing, heat conduction efficiency improving, sulfur fixing, smoke reducing, CO and SO2 emission reducing and environmental pollution reducing so as to achieve the purposes of combustion supporting, sulfur fixing, energy saving and desulfurization, wherein the coal can be saved by 5-10%, the fire power can be increased by more than or equal to 10%, the carbon deposition can be eliminated by 50-90%, and the sulfur can be reduced by 20-50%.

Owner:QINGDAO WEIYE FORGING & STAMPING MACHINERY CO LTD

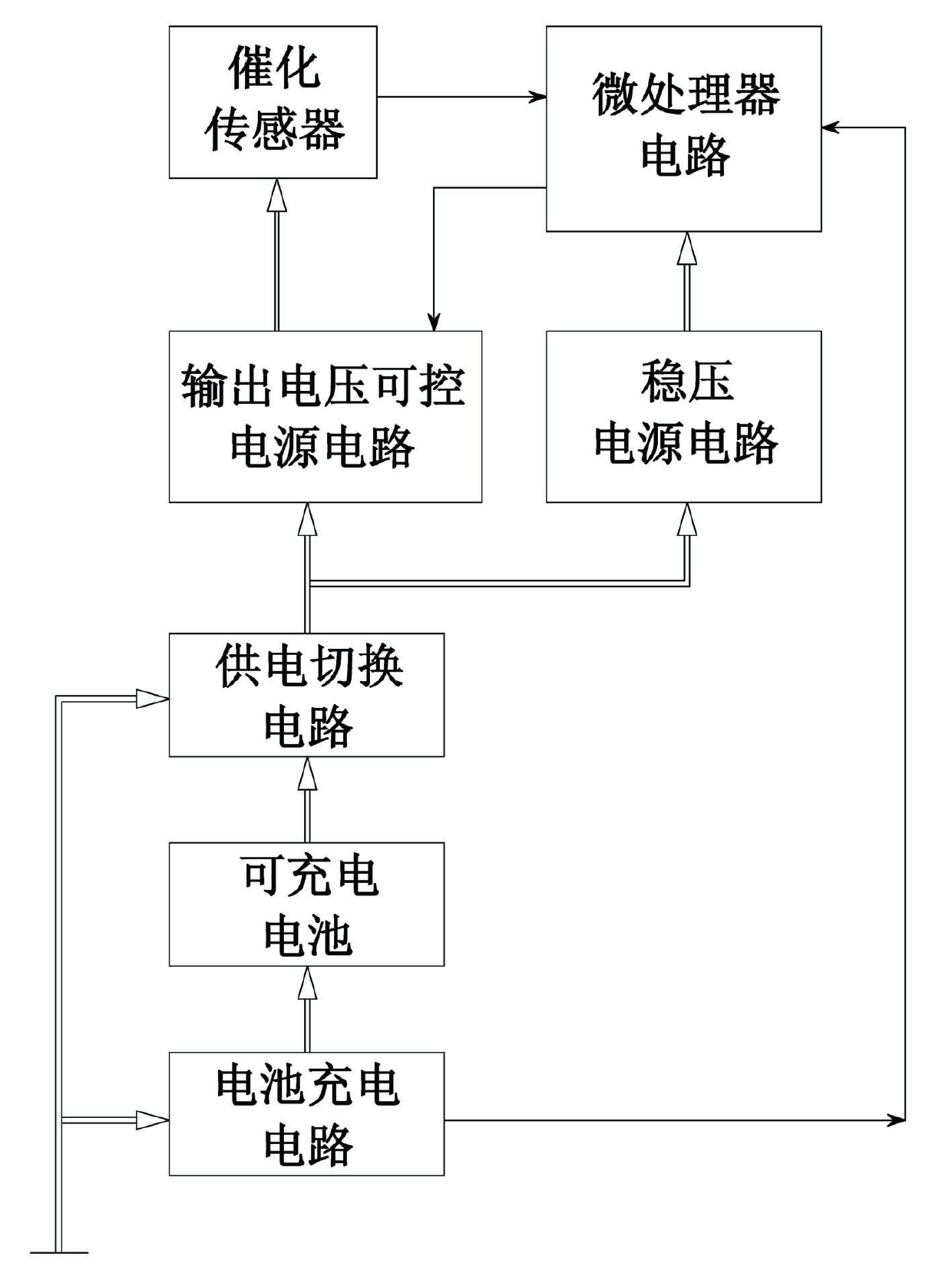

Inflammable gas detecting instrument and desulphurization method thereof

ActiveCN102507666ADesign scienceEasy to usePreparing sample for investigationMaterial resistanceCombustible gasVoltage control

The invention provides an inflammable gas detecting instrument and a desulphurization method thereof, wherein the detecting instrument comprises a microprocessor circuit, a catalytic sensor connected with the microprocessor circuit, and an output voltage controllable power supply circuit; a sensor voltage output end of the output voltage controllable power supply circuit is connected with a power source end of the catalytic sensor, and an voltage control end of the microprocessor circuit is connected with a sensor voltage adjustment control end of the output voltage controllable power supply circuit; the desulphurization method comprises the following steps: the microprocessor circuit controls the output voltage controllable power supply circuit for voltage adjustment; the output voltage of the sensor voltage output end is improved to 1.5 times of the normal working voltage and the time is delayed for 120s; the output voltage controllable power supply circuit is continued to be controlled so as to enable the output voltage of the sensor voltage output end to be zero or normal working voltage. The detecting instrument has the advantages of automatic desulphurization, accurate measuring result, safety and reliability; furthermore, the desulphurization method is simple and practical, and is easy to realize.

Owner:HENAN HANWEI ELECTRONICS

Dry desulfurization agent pretreatment system and pretreatment method

InactiveCN104324605ASimple structureLess investmentDispersed particle separationGas purification by treating with solidsSodium bicarbonatePretreatment method

The invention discloses a dry desulfurization agent pretreatment system, which is provided with a sodium hydrogen carbonate storage tank, an expansion device, a buffer tank, a sodium carbonate storage tank and a grinding device, which are communicated in sequence; a proportional valve is arranged in the communication pipeline of the sodium hydrogen carbonate storage tank and the expansion device, and a heating and roasting device is arranged in the expansion device; an instantaneous pressure relief valve is arranged in the communication pipeline of the expansion device and the buffer tank, and the buffer tank is communicated with the atmosphere. Sodium hydrogen carbonate is heated by a heating system to be decomposed to generate sodium carbonate; when the pressure reaches a certain value in the reaction, the pressure is instantaneously relieved to the buffer tank. The generated sodium carbonate is grinded by the grinding device and is sprayed into a desulfurizing tower by an ejection system after reaching a certain number to react with SO2 so as to desulfurize. The system has the advantages of simple structure, little investment, convenience in operation and the like.

Owner:ANHUI TONGXING ENVIRONMENTAL PROTECTION ENG

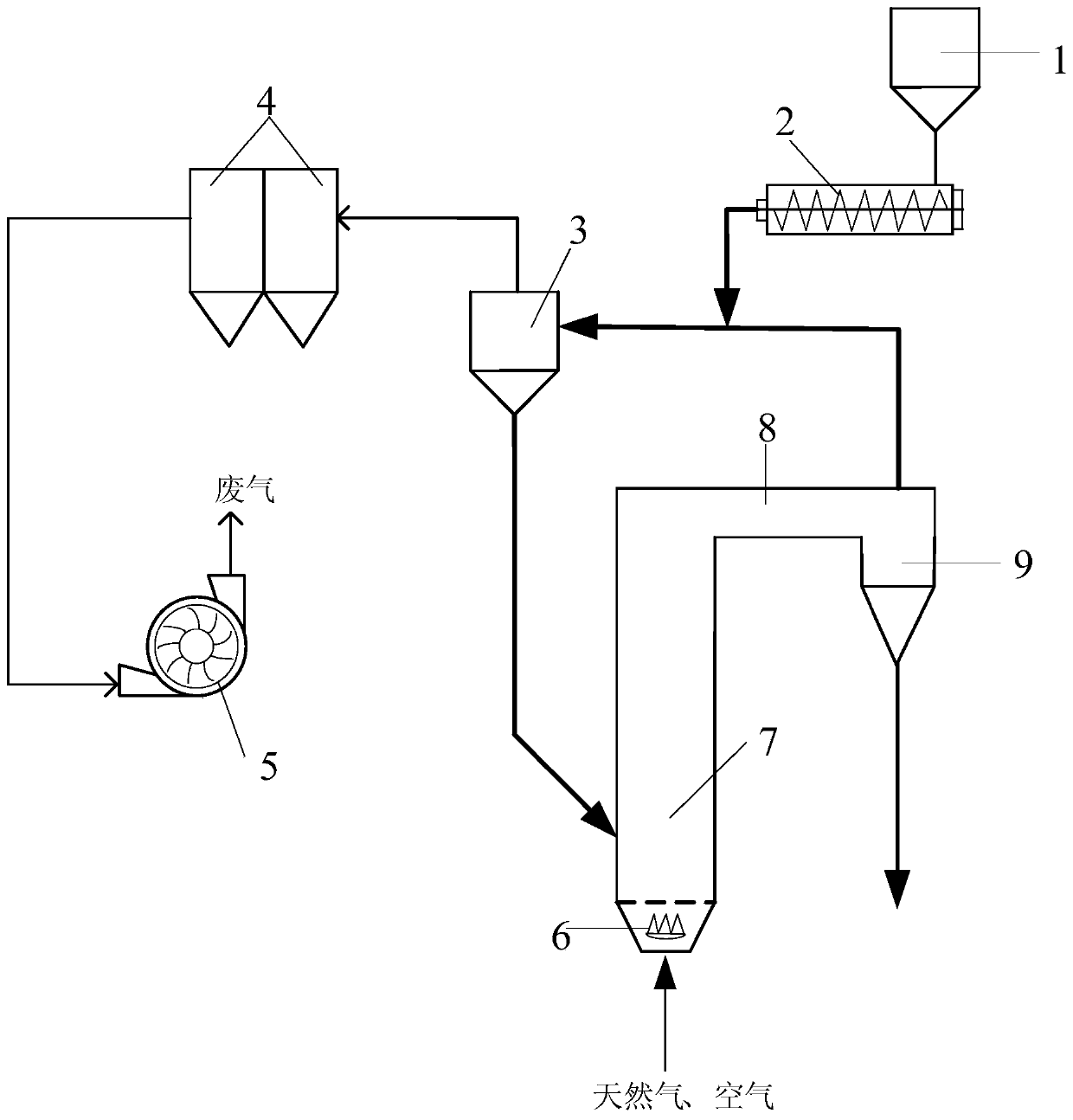

Device and method for high-sulfur bauxite suspension roasting oxidative desulfurization

The invention provides a device and a method for high-sulfur bauxite suspension roasting oxidative desulfurization. The device comprises a stock bin, a spiral feeder, a primary cyclone separator, a suspension roasting furnace, a secondary cyclone separator and dust removal and desulfurization equipment. The method comprises the following steps that (1) high-sulfur bauxite is crushed and dried in the stock bin; (2) an induced draft fan is started to form negative pressure in a system; (3) natural gas and air is introduced into a burner, and ignited to form high-temperature oxidizing gas; (4) high-sulfur bauxite powder is fed into the primary cyclone separator, and generated primary solid materials are enabled to enter a suspension roasting furnace; (5) the primary solid materials are oxidized and roasted, and the reacted materials are fed into the secondary cyclone separator; and (6) second-stage solid materials are discharged through a discharging pipe. The method is simple in processflow, low in comprehensive energy consumption, high in gas-solid mass transfer and heat transfer efficiency, stable in product property, and high in production efficiency.

Owner:NORTHEASTERN UNIV

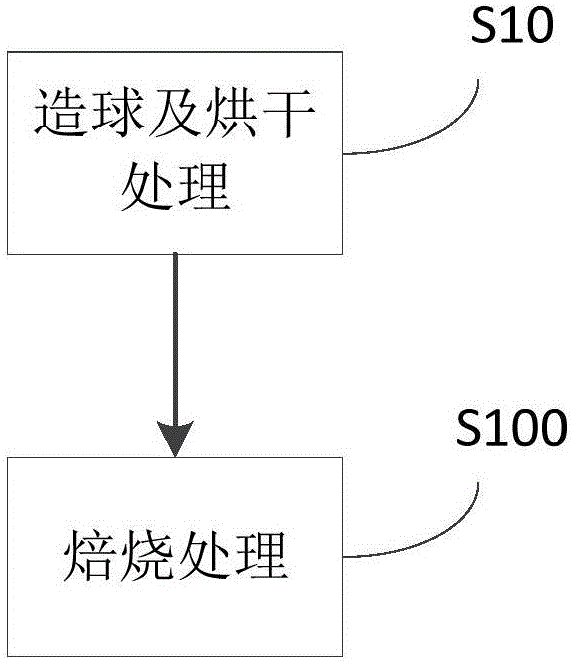

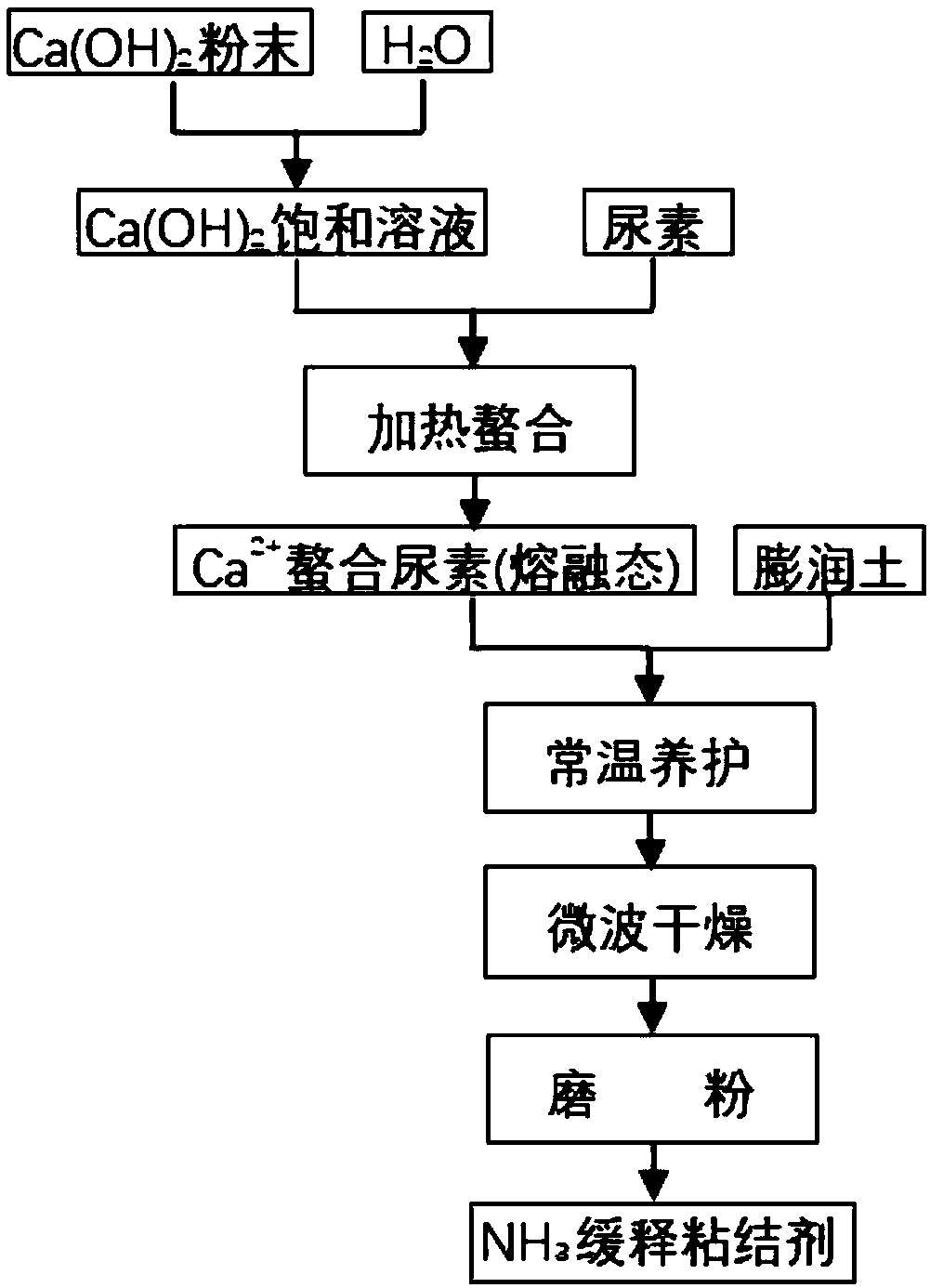

Pelletizing binder with desulfuration function and preparation method and application of pelletizing binder

ActiveCN109371234AWith desulfurization functionDesulfurization achievedSodium BentoniteMaterials science

The invention discloses a pelletizing binder with a desulfuration function and a preparation method and application of the pelletizing binder and belongs to the field of preparation of ferrous metallurgy blast furnace materials. The pelletizing binder with the desulfuration function contains the following components including, by weight, 2.5-10 wt.% of urea, 2.5-10 wt.% of Ca(OH)2 and 80-95 wt.% of bentonite. The pelletizing binder is powder which contains at least 95 wt.% of particles smaller than 0.074 mm in particle size. The defect of high cost of iron ore pellet production and desulfuration in the prior art is overcome. The pelletizing binder has the desulfuration function, can be applied to desulfuration in a pellet production process, can effectively reduce the content of SO2 in pellet smoke, relieves burden of a desulfuration system and does not affect normal pellet production. The preparation method has the advantages of being low in preparation cost and high in efficiency and is suitable for being applied and popularized.

Owner:句容康泰膨润土有限公司

Desulfurization assistant

InactiveCN104673427ATo achieve the purpose of desulfurizationSettling fastSolid fuelsBarium nitrateCroscarmellose sodium

The invention discloses a desulfurization assistant which is prepared from the following raw materials in parts by weight: 10-20 parts of iron oxide, 10-20 parts of barium nitrate, 10-20 parts of phosphorus pentoxide, 5-10 parts of potassium persulfate, 5-10 parts of sodium hexametaphosphate, 5-8 parts of sodium diacetate, 2-5 parts of potassium oxalate, 5-10 parts of sodium hypophosphite, 5-10 parts of sodium tripolyphosphate, 5-10 parts of methyl acetate, 2-5 parts of butyric acid, 5-10 parts of croscarmellose sodium, 3-5 parts of methylcellulose, 1-5 parts of Tween 80 and 200-250 parts of water. According to the desulfurization assistant disclosed by the invention, sulfide layer and salt layer which are attached to coal are stripped off, infiltrated and dispersed by the acidity and excellent complexing capacity of the carried active group; and a sulphur element is complexed in a cleaning agent to reach the targets of coal washing and desulfurization. The desulfurization assistant is good in desulfurization effect and the environment is not polluted.

Owner:黄文武

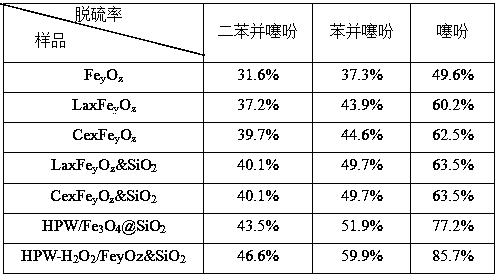

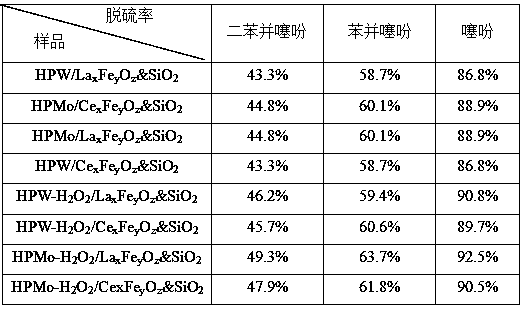

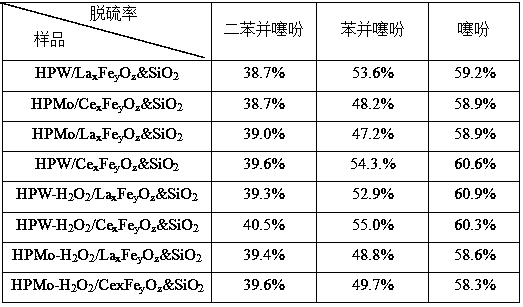

Magnetic attraction-oxidation desulfurizing agent and preparation method

InactiveCN110064361AImprove catalytic oxidation desulfurization activityAvoid wastingOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsCompound aLanthanide

The invention discloses a magnetic attraction-oxidation desulfurizing agent and a preparation method. The magnetic attraction-oxidation desulfurizing agent is formed by compounding a magnetic iron composite oxide containing iron and lanthanide series metal, silicon dioxide and a peroxided polyacid compound, wherein the magnetic iron composite oxide containing the iron and the lanthanide series metal is coated with the silicon dioxide, and the peroxided polyacid compound is supported on the outer surface of the silicon dioxide, and the mass ratio of the magnetic iron composite oxide containingthe iron and the lanthanide series metal to the silicon dioxide to the peroxided polyacid compound is (10-50):(5-30):(85-20). The preparation method comprises the steps that the magnetic iron composite oxide containing the iron and the lanthanide series metal is subjected to silanization to prepare the silicon dioxide-coated magnetic iron composite oxide containing the iron and the lanthanide series metal, and the peroxided polyacid compound is supported on the outer surface of the silicon dioxide, and through washing, drying and calcination, the magnetic attraction-oxidation desulfurizing agent is prepared.

Owner:LIAONING NORMAL UNIVERSITY

Desulfurization method and desulfurization device for industrial mixed gas

ActiveCN111744355ATo achieve the purpose of desulfurizationAchieve regenerationGas treatmentDispersed particle separationEnvironmental chemistrySorbent

The invention belongs to the field of atmospheric purification and environmental protection, and particularly relates to a desulfurization method and a desulfurization device for industrial mixed gas.The desulfurization method of the industrial mixed gas provided by the invention comprises the following steps: enabling the industrial mixed gas to be in contact with an organic sulfur hydrolytic agent and a hydrogen sulfide adsorbent in sequence for desulfurization, so as to obtain desulfurized industrial mixed gas, a desulfurized organic sulfur hydrolytic agent and a desulfurized hydrogen sulfide adsorbent; and sequentially contacting the desulfurized industrial mixed gas with a desulfurized hydrogen sulfide adsorbent, a deoxidizing agent and a desulfurized organic sulfur hydrolytic agentto regenerate the desulfurized hydrogen sulfide adsorbent and the desulfurized organic sulfur hydrolytic agent. According to the desulfurization method, online continuous regeneration of the organic sulfur hydrolytic agent and the hydrogen sulfide adsorbent is realized, and the defects that the organic sulfur hydrolytic agent and the hydrogen sulfide adsorbent need to be continuously replaced, theprocess is complex and resources are wasted are avoided.

Owner:中琉科技有限公司

Biogas fermentation stirring and biogas desulfurization method

PendingCN110551612APrevent sinkingImprove contact effectBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental engineeringBiogas production

The invention discloses a biogas fermentation stirring and biogas desulfurization method. The biogas fermentation stirring and biogas desulfurization method comprises the following steps: compressingair through an air blower and blowing the air into a biogas fermentation reactor through an air distributor on the bottom of the biogas fermentation reactor; mixing and stirring feed liquid in the biogas fermentation reactor by an air rising effect and controlling stirring time and frequency; and after air escapes from the fermented feed liquid, enabling the air to enter space of the top of the biogas fermentation reactor; and generating elemental sulfur or sulfate from microorganisms which are cultured and domesticated in the space of the top of the biogas fermentation reactor by oxidizing hydrogen sulfide through oxygen in the air. The air is controllably pumped into the biogas fermentation reactor, an explosion-proof motor is not needed, the method is not affected by biogas production,other stirring modes are not needed in an assisted manner, and moreover, a desulfurization function is further fulfilled.

Owner:BIOGAS SCI RES INST MIN OF AGRI

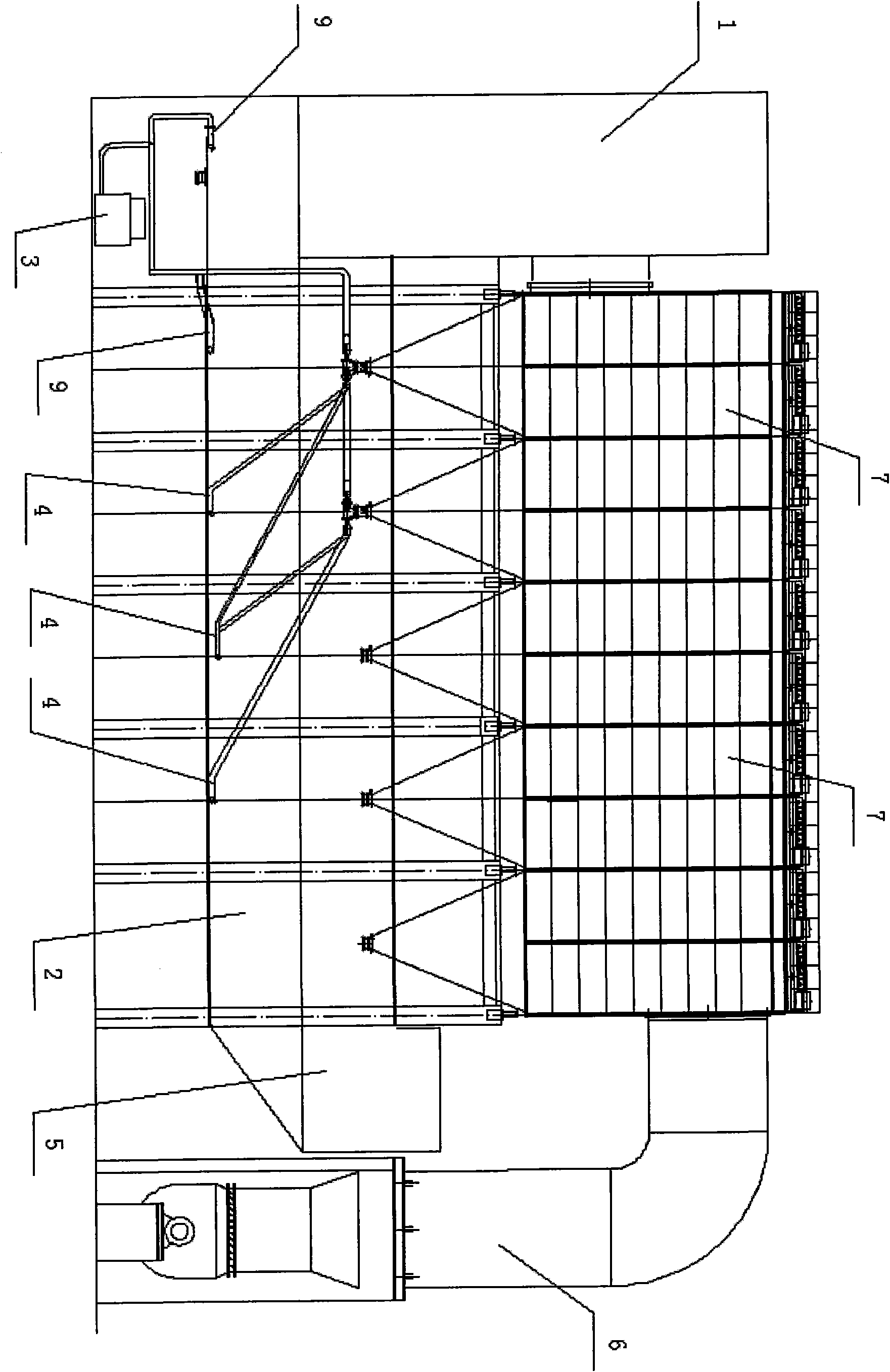

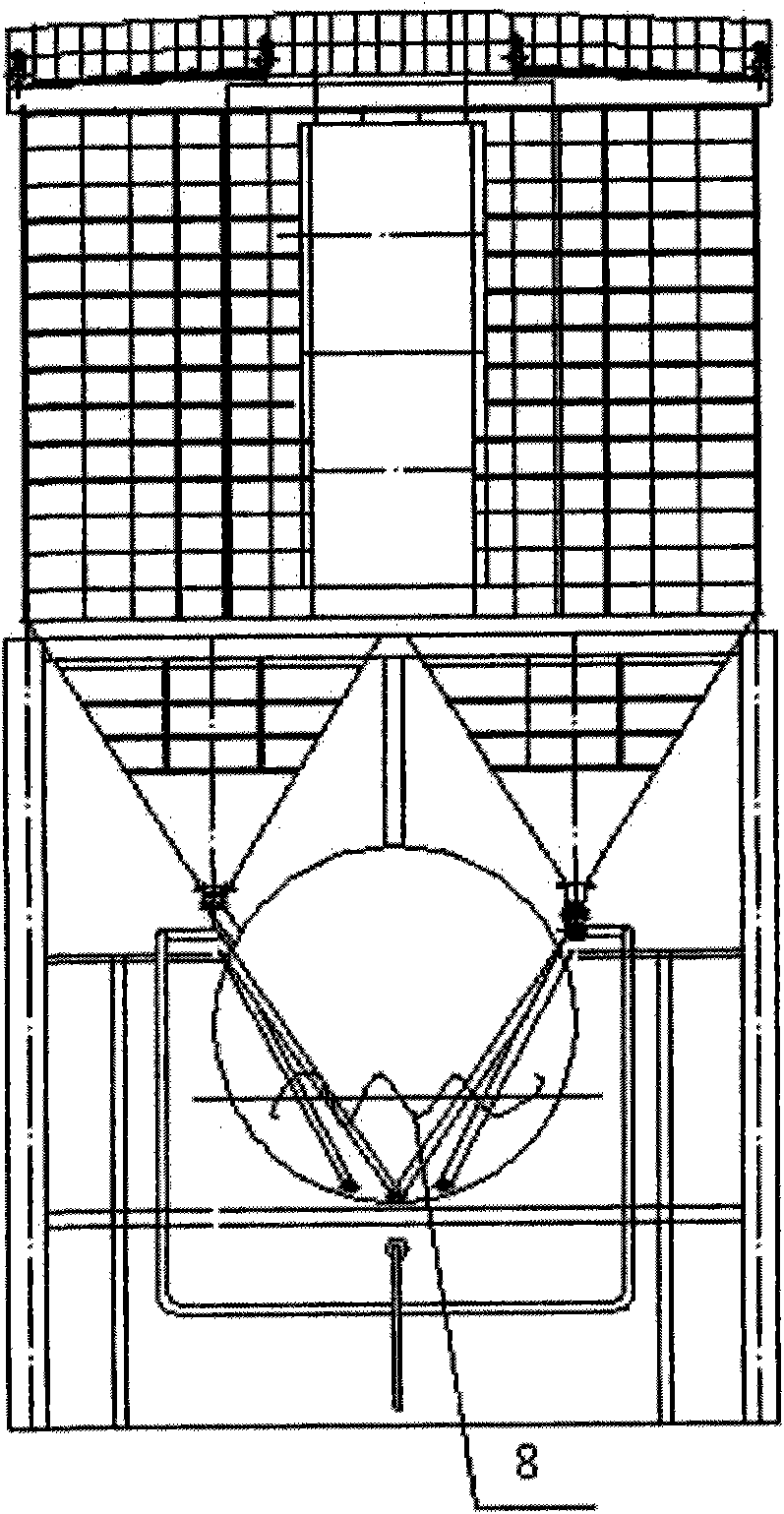

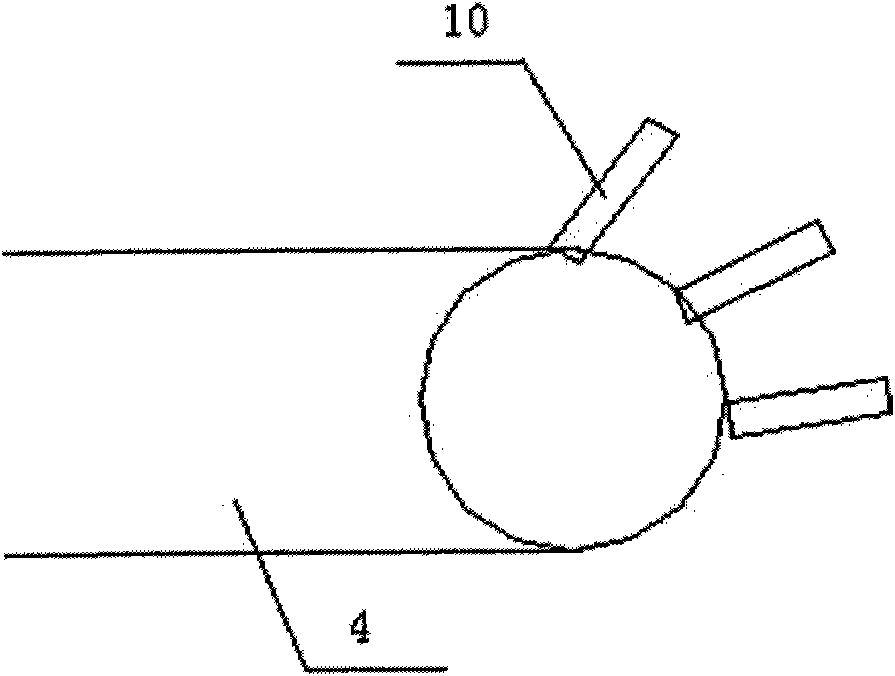

Horizontal dense-phase circulating fluidizing dry-tower desulfurization device

ActiveCN101920164AReduce loadSmall footprintDispersed particle separationChemical/physical processesHigh energyBaghouse

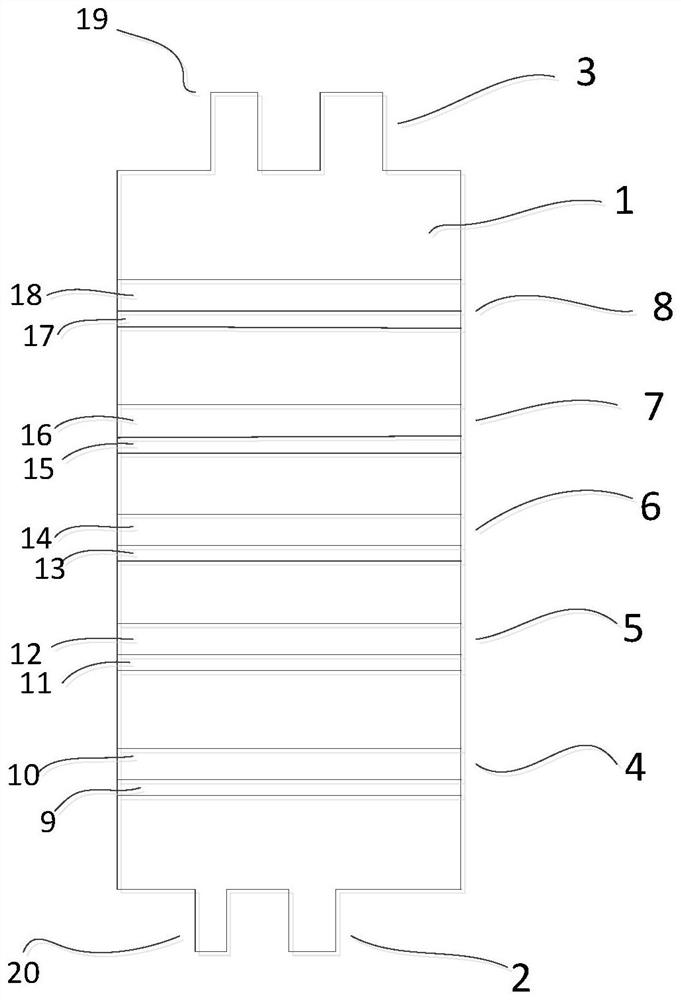

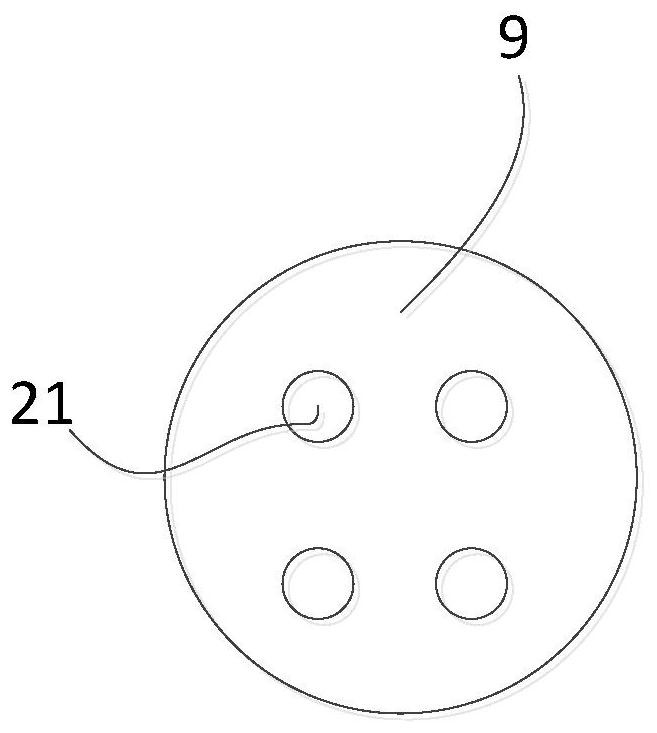

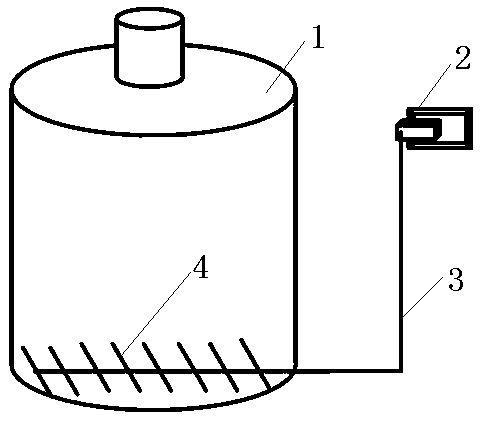

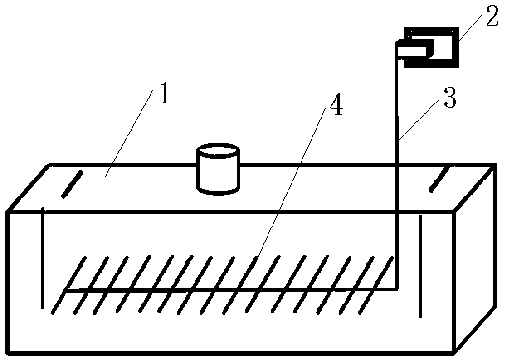

The invention relates to a horizontal dense-phase circulating fluidizing dry-tower flue-gas desulfurization device belonging to the field of environmental engineering. The horizontal dense-phase circulating fluidizing dry-tower flue-gas desulfurization device comprises a circulating fluidizing chamber (1), a dense-phase chamber (2), a Roots blower (3), a feeding pipe (4), a flue gas inlet (5), a booster fan (6) and a bag-type dust collector (7) and is characterized in that a stirring shaft (8), a gas pipe (9) and a gas distribution pipe (10) are arranged, wherein the stirring shaft (8) is mounted in the dense-phase chamber and provides more collision chances for a desulfurizer and the flue gas in the dense-phase chamber so as to improve the desulfurization efficiency; the gas pipe (9) is connected with the Roots blower for providing the circulating fluidizing chamber and the dense-phase chamber with fluidized wind power; and the gas distribution pipe (10) is mounted at the tail ends of the gas pipe (9) and the feeding pipe (4), and the wind power of the Roots blower is blown to all directions through the gas distribution pipe (10). The invention solves the problems of higher energy consumption, easy foot pedal blockage, great occupied area, and the like existing in the traditional dense-phase circulating fluidizing dry-tower desulfurization device and improves the desulfurization efficiency.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

Method for enhancing activated carbon absorption activity

InactiveCN104096549AHole bigImprove adsorption capacityOther chemical processesActivated carbonPotato starch

The invention discloses a method for enhancing activated carbon absorption activity. The method comprises three steps as follows: step one, starch calcification: sweet potato starch, potato starch and calcium carbonate powder are uniformly mixed according to the mass ratio of sweet potato starch, potato starch and calcium carbonate powder of 100: (55-70): (10-20), pressed into block and then smashed into 150-180 meshes to obtain calcified starch; step two, calcification of activated carbon: common activated carbon absorbs the calcified starch in calcified starch atomizing air, and the activated carbon is taken out when the absorption quantity of the calcified starch is 3%-7% of an activated carbon absorption saturation limiting value to obtain the calcified activated carbon; and step three, activation enhancement of activated carbon: the calcified activated carbon is placed in water steam containing carbon dioxide at the temperature of 1,000-1,200 DEG C for activating treatment for 5-13 minutes, and the activated carbon is cooled to the room temperature under the oxygen-free condition to obtain super-absorption activated carbon. The method for enhancing the activated carbon absorption activity is easy to implement, convenient to operate and low in production cost.

Owner:广东博尔睿水处理技术有限公司

Coal-saving agent and preparation process thereof

InactiveCN108795533APromote combustionImprove combustion conditionsSolid fuelsHeat transmissionSulfur

The invention relates to a coal-saving agent and a preparation process thereof. The coal-saving agent comprises, in weight percent, 6-12% of catalysts, 1-7% of combustion improvers, 25-35% parts of penetrating agents, 25-35% parts of bulking agents, 7-15% of cleaners, 10-20% of dispersing agents and 7-12% of sulfur fixing agents. According to the coal-saving agent, combustion conditions of a furnace body can be improved, coal seam permeability is enhanced, coal is sufficiently combusted, coal burning heat efficiency is improved, soot emission volume is reduced, heat transmission efficiency isimproved, sulfur is fixed, smoke is reduced, emission of CO and SO2 is reduced, environmental pollution is reduced, so that combustion is facilitated, the sulfur is fixed, energy is saved, the sulfuris removed, coal can be saved by 5%-10%,heat power is improved by 10% or more, carbon deposit is removed by 50-90%, and the sulfur is reduced by 20-50%.

Owner:纪和春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com