Patents

Literature

73 results about "Raschig ring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Raschig rings are pieces of tube, approximately equal in length and diameter, used in large numbers as a packed bed within columns for distillations and other chemical engineering processes. They are usually ceramic or metal and provide a large surface area within the volume of the column for interaction between liquid and gas vapours. Raschig rings are named after their inventor, German chemist Friedrich Raschig.

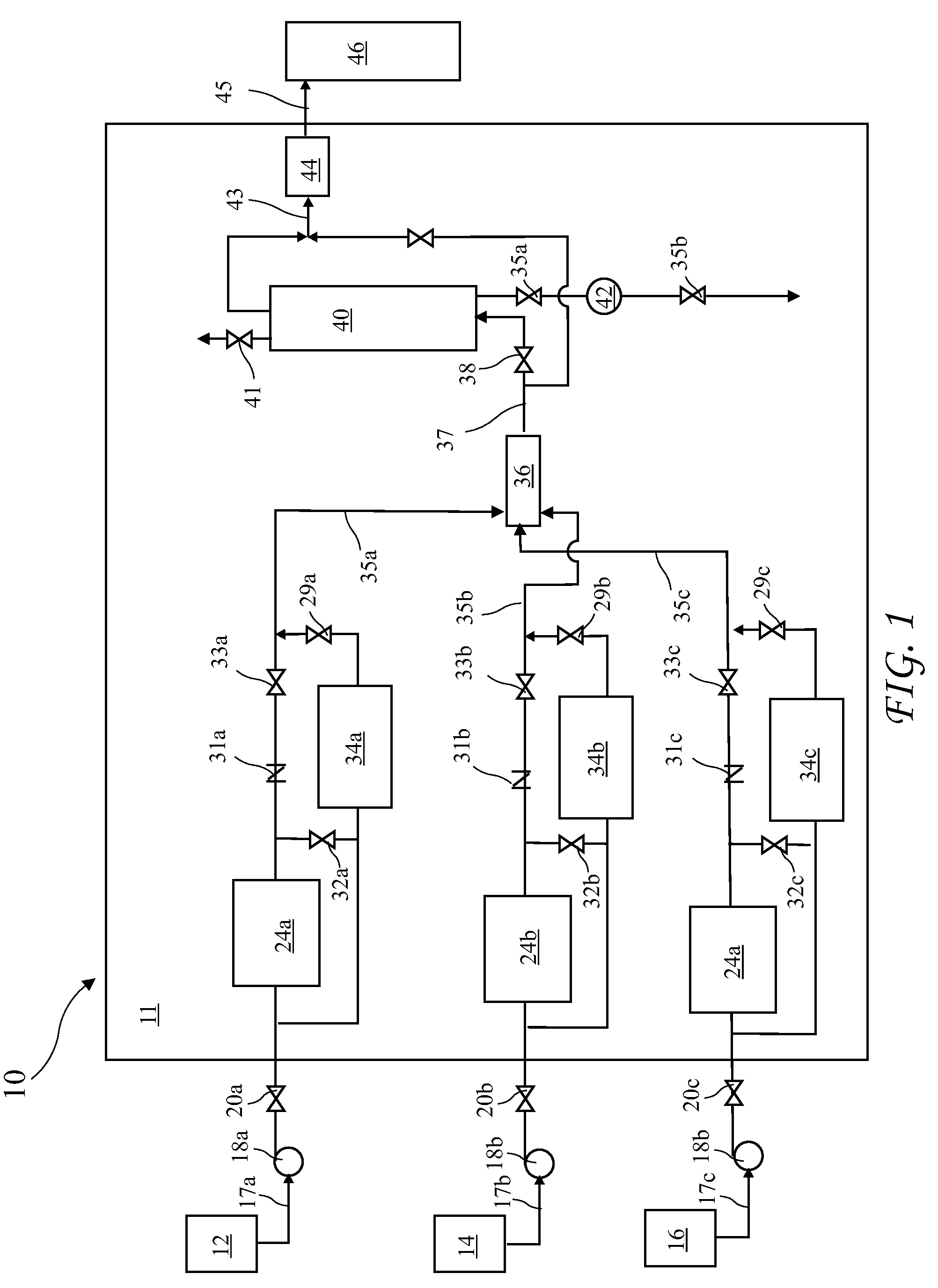

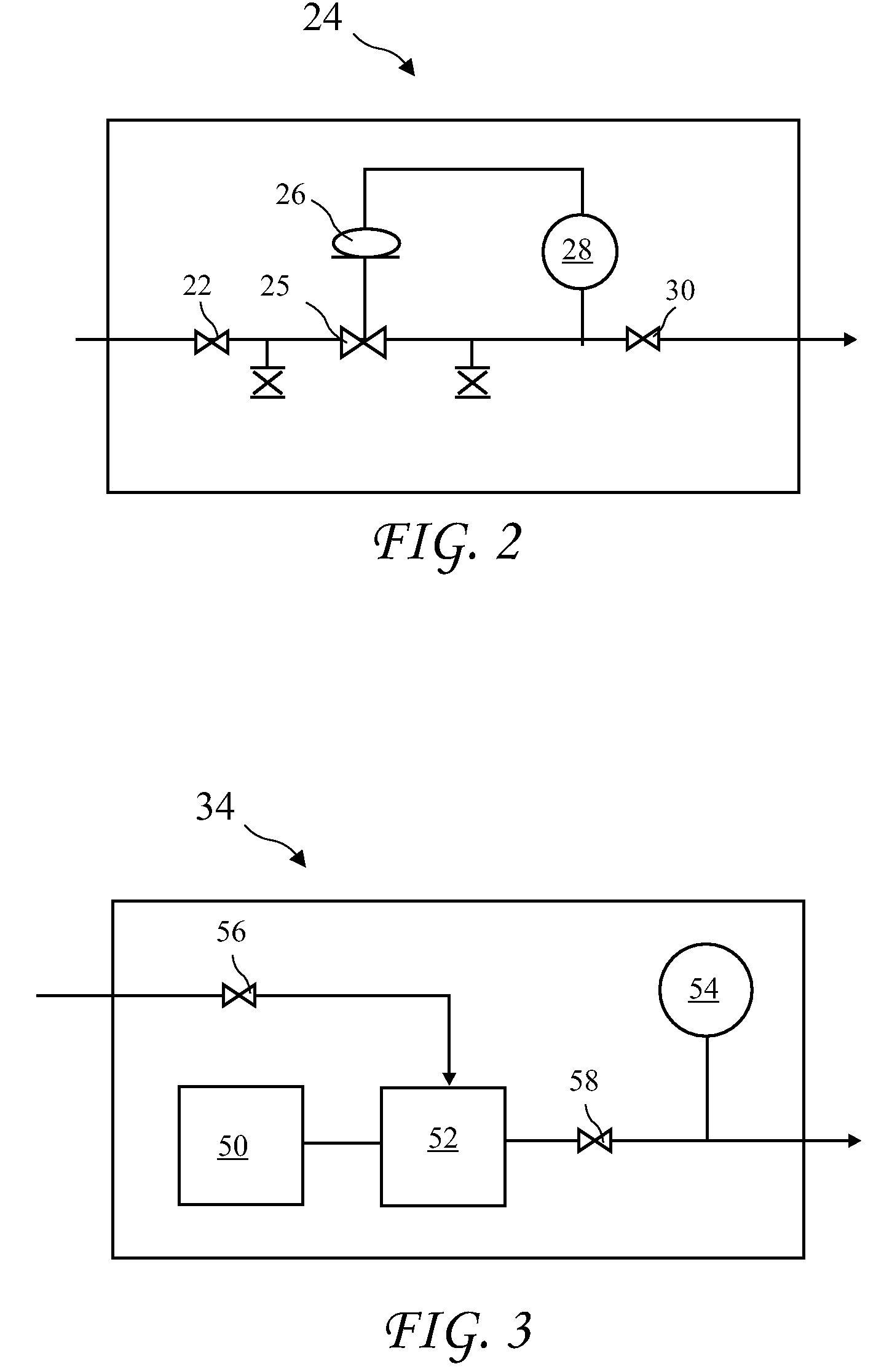

Apparatus and method for Rapid Biodiesel Fuel Production

InactiveUS20100107474A1Minimizing undesiredReduce energy costsBiofuelsLiquid carbonaceous fuelsVegetable oilBiodiesel

Apparatus and method for rapid production of biodiesel fuel. The apparatus includes a packed column followed by a high pressure kinetic reactor. A homogeneous stream of feed oil (vegetable oil or animal fat), methanol, and a catalyst is metered, mixed, fed into a packed column, and finally into the high pressure kinetic reactor where the conversion into biodiesel fuel is completed. The packed column is packed with rings (either Raschig rings or pall rings or equivalent). The homogeneous stream enters from the bottom with rings kept in a fluidized bed state to allow greatest surface area for reaction to take place. Approximately 40 to 70 percent reaction is typically achieved in the packed column. The high pressure kinetic reactor receives the partially reacted homogeneous stream and breaks fluid molecules into nano molecules with very high instantaneous temperatures and availability of large surface areas which allow complete reaction without external heat.

Owner:TALWAR MAHESH +2

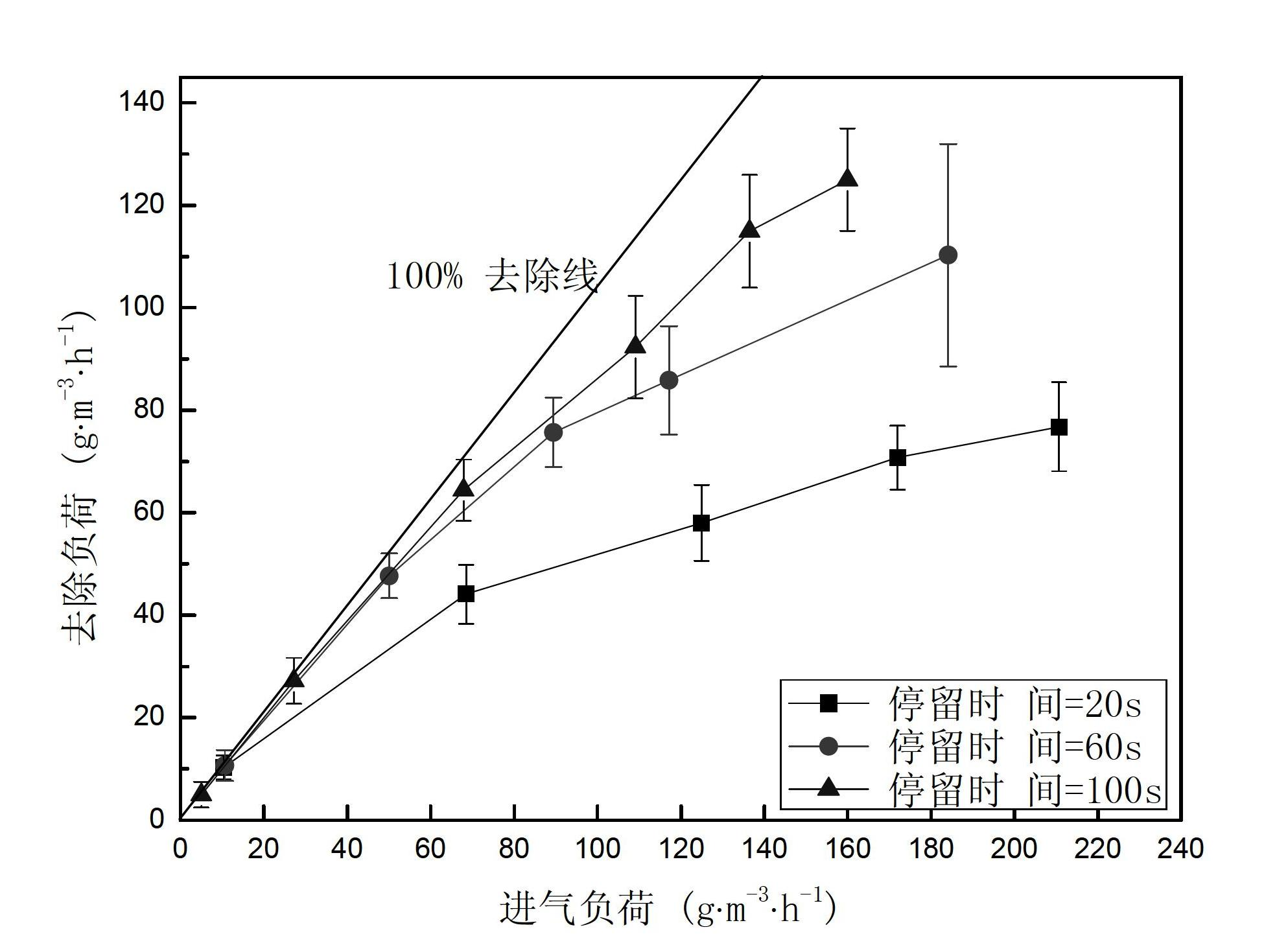

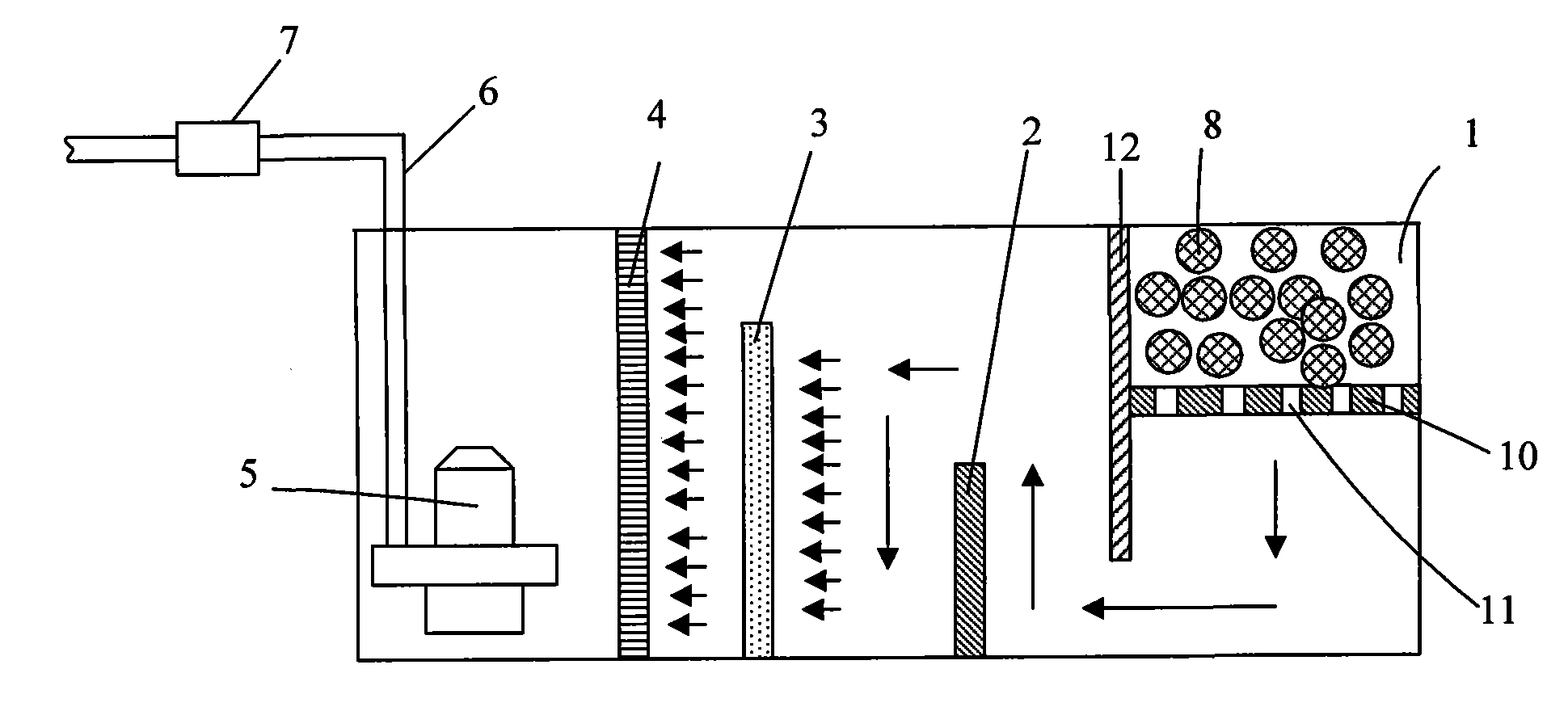

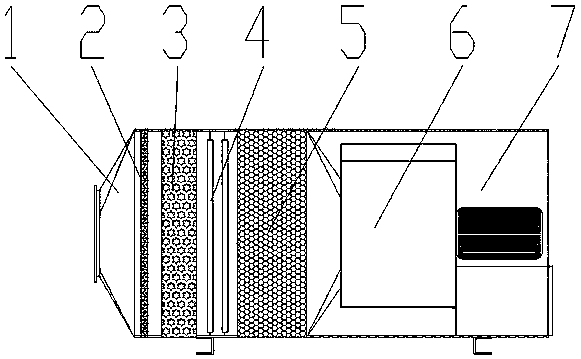

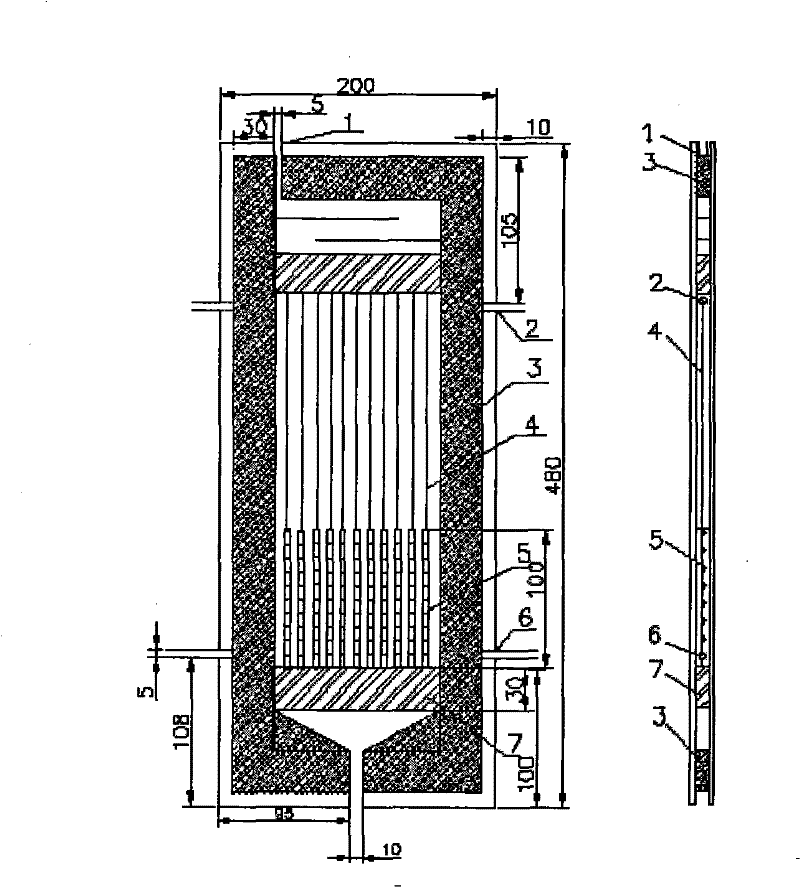

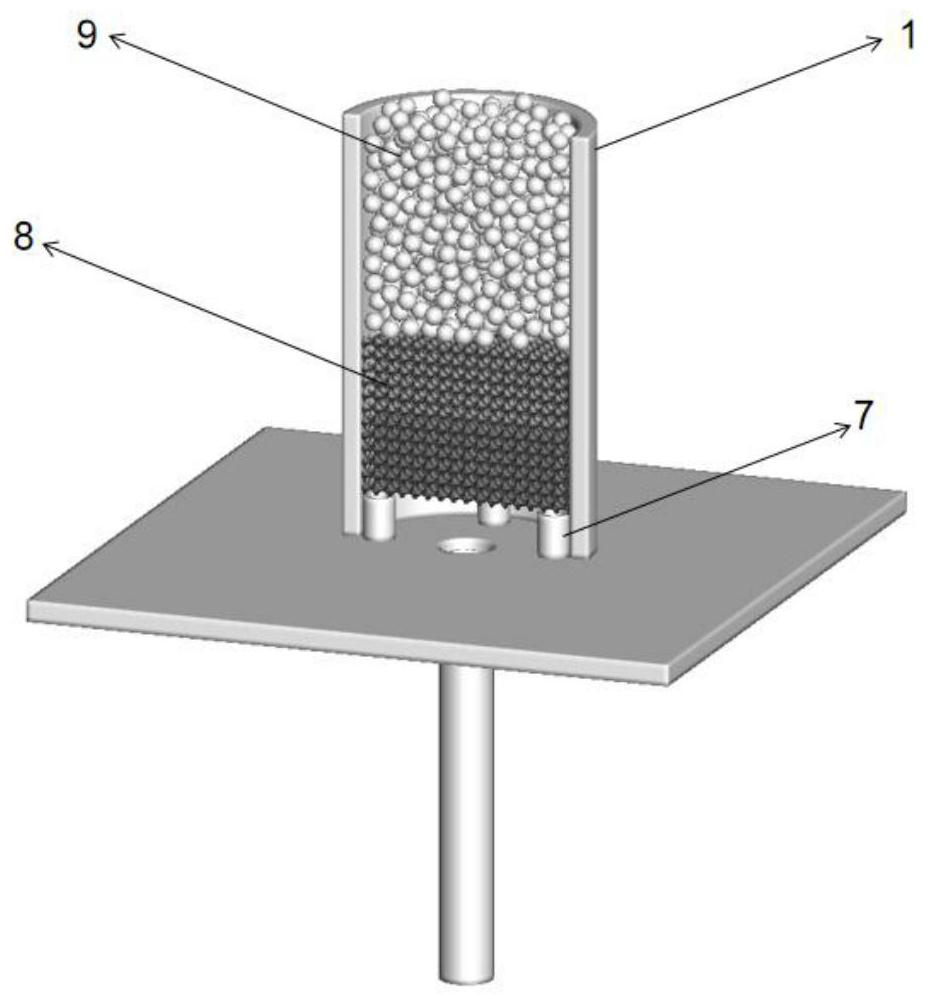

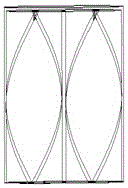

Raschig ring and porous medium combined biologic filling

ActiveCN102671615AFree combinationFlexible combinationDispersed particle separationChemical/physical/physico-chemical processesPorous mediumEngineering

The invention discloses a Raschig ring and porous medium combined biologic filling which is composed of two inert biologic fillings. The Raschig ring and porous medium combined biologic filling comprises a Raschig ring which is internally and fixedly filled with a porous medium. In a preferred scheme, the inner wall of the tubular Raschig ring is provided with a sawtooth fixing bar, and the outer wall of the Raschig ring is provided with a plurality of strip-shaped grooves along an axial direction, so that specific surface area and microorganism adhesive force of the Raschig ring are increased greatly, and uniform flow of a liquid-state fluid is facilitated. The Raschig ring and porous medium combined biologic filling, disclosed by the invention, has the advantages of simple manufacturing process, big specific surface area, and high porosity, easy bio-film formation, great unit volume biomass, high pollution removal charge, low stacking density, low resistance coefficient and good support intensity, is good for uniform flow of the liquid-state fluid and particularly suitable for a biologic dropping and filtering device, can greatly reduce energy consumption of the biologic dropping and filtering device and can fully improve purification efficiency of organic waste gas.

Owner:ZHEJIANG UNIV

Preparation method of tobacco absolute

InactiveCN102994228AAdd aroma componentsImprove qualityTobacco treatmentEssential-oils/perfumesRaschig ringInorganic chemistry

The invention relates to a preparation method of a tobacco absolute. The preparation method comprises the following steps: uniformly mixing 70g of crude extract of aromatic tobacco with chemical fillers and stirring; extracting the mixture in an extraction kettle at 40 to 45 DEG C under 25 to 30MPa; introducing overcritical CO2 at flow rate being about 2 to 5L / min and adding 4 to 8% of entrainer (volume ratio) at the same time; and extracting for 3 to 5 hours after the extracting condition is met, thus obtaining the tobacco absolute, wherein the chemical fillers can be the ceramic fillers such as glass bead, Raschig ring or Intalox ring. The preparation method can be used for preparing the tobacco absolute rich in aromatic components simply, conveniently and easily.

Owner:罗瑞雪

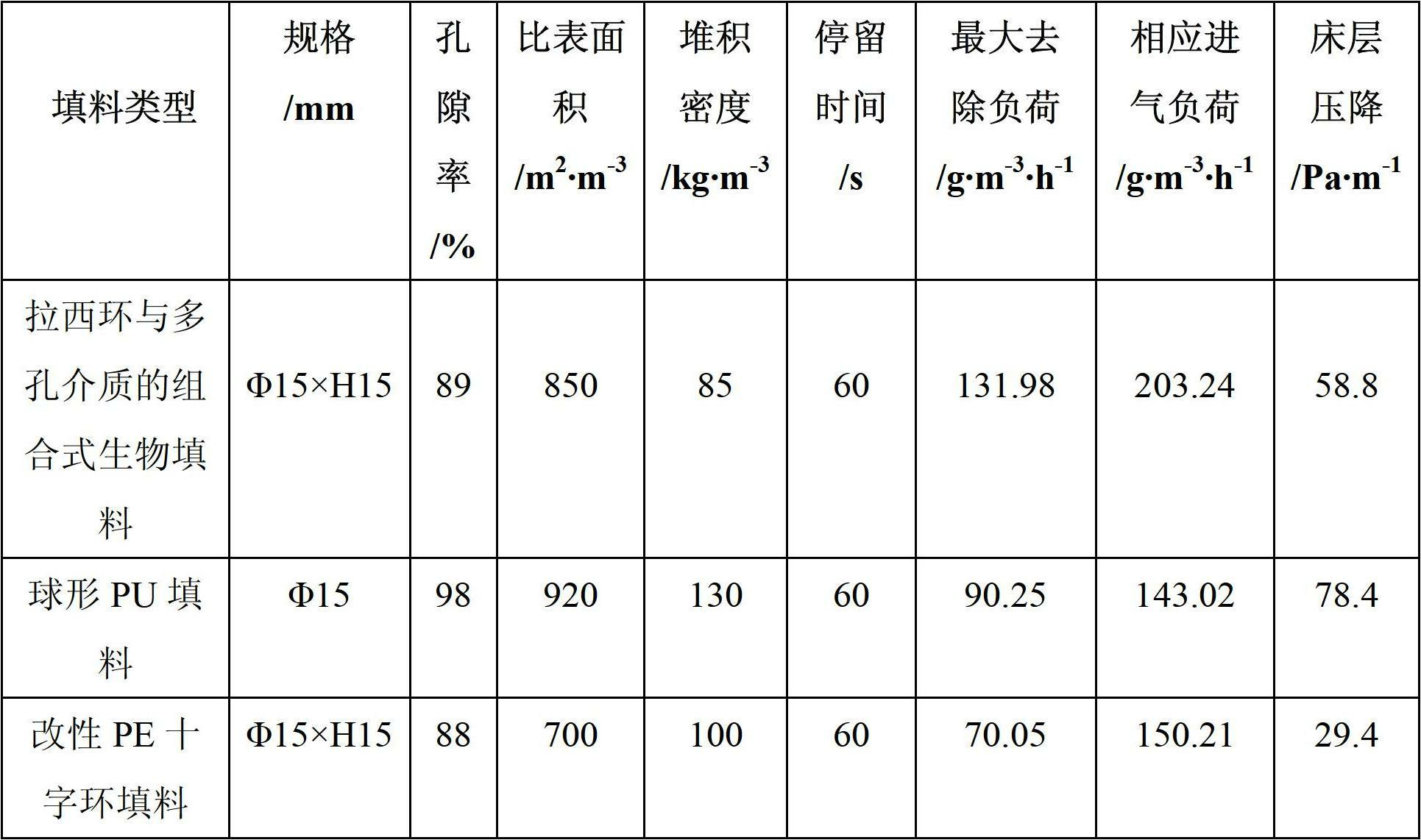

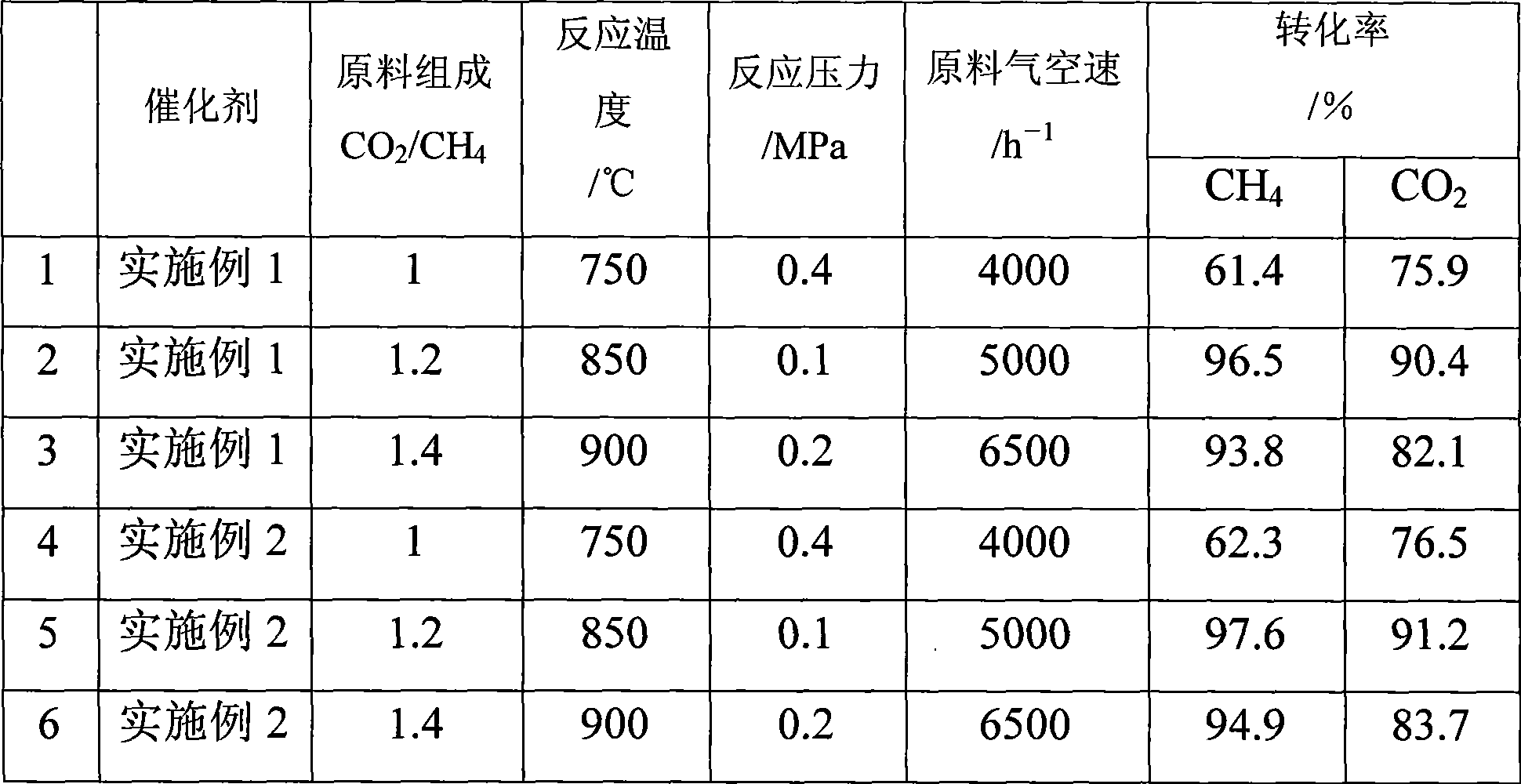

Synthetic gas preparation catalyst through reforming natural gas and carbon dioxide

InactiveCN101450310AHigh activityImprove performanceGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsMolecular sieveActive ingredient

The invention relates to a catalyst for preparing synthetic gas by reforming natural gas-carbon dioxide. The catalyst comprises the following compositions by weight percentage: 5 to 20 percent of active ingredient nickel and 75 to 90 percent of carrier, wherein the carrier is gamma-Al2O3, SiO2, molecular sieves, MgO or ZrO2 with the diameter between 1 and 10 millimeters, and has a spherical structure, a cylindrical structure, an annular structure, a clover structure or a Raschig ring structure, and the catalyst is prepared by a constant volume impregnation method. The catalyst prepared by the method can make the conversion rate of natural gas and the selectivity of CO and H2 reach more than 95 percent, and the activity of the catalyst is stable for a long time.

Owner:SHANGHAI HUAYI ENERGY CHEM

Desulfuration and denitration catalyst and preparation method thereof

InactiveCN101797505AWide variety of sourcesEasy accessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAdhesiveRaschig ring

The invention discloses a desulfuration and denitration catalyst, which comprises the following components in percentage by weight: 5-15% of CuO, 80-90% of gamma-Al2O3 and 2-5% of catalyst promoter (Na2O, NiO or ZnO). The preparation method of the catalyst comprises the following steps: (1) mixing main catalyst CuO, catalyst promoter, carrier Al2O3, kieselguhr adhesive and wood-dust pore forming agent, adding water, and completely stirring into paste; (2) molding into cylindrical bodies, spherical bodies or Raschig ring bodies; and (3) drying, calcining, and activating to prepare into the catalyst. The prepared catalyst can realize the desulfuration and the denitration simultaneously, is low in the material cost, and can be recycled. Besides, the byproducts can be recycled, thereby being free of the secondary pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for treating dioxine and pollutants in tail gas in waste incineration

The invention discloses a method for treating dioxine and pollutants in tail gas in waste incineration, relates to a method for treating the tail gas in the waste incineration, and provides a method for treating the dioxine and the pollutants in the tail gas in the waste incineration with simple process, thorough treatment and easy control and optimization. The method for treating the dioxine and the pollutants in the tail gas in the waste incineration comprises the following steps of: introducing the tail gas in the waste incineration into a Raschig ring packed tower for alkali liquid absorption in the Raschig ring packed tower; introducing the smoke subjected to the alkali liquid absorption of the Raschig ring packed tower into a plate hydrocyclone tower for oxidization in the plate hydrocyclone tower; entering the soot of the smoke subjected to the alkali liquid absorption into an activated carbon collection tank, and recycling the alkali liquid after the alkali liquid is cooled; introducing the smoke subjected to the oxidization of the plate hydrocyclone tower into a ball-through sieve tray tower for reduction in the ball-through sieve tray tower; introducing the smoke subjected to the reduction of the ball-through sieve tray tower into a turbulent ball tower for biological treatment; and discharging the smoke subjected to the biological treatment of the turbulent ball tower into the atmosphere through an induced draft fan.

Owner:苏国强

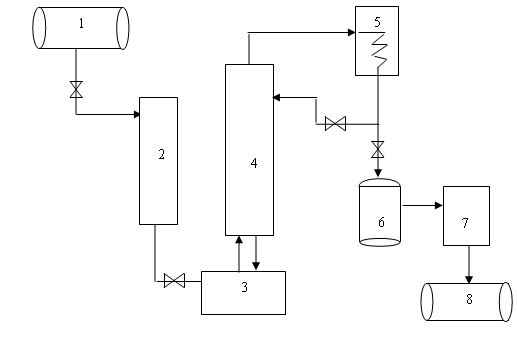

Equipment and process for preparing electronic grade nitric acid having a concentration of 68% from industrial grade nitric acid having a concentration of 98%

Equipment for preparing electronic grade nitric acid having a concentration of 68% from industrial grade nitric acid having a concentration of 98% is disclosed. The equipment comprises a rectifying tower provided with heating coils made of metal tantalum. The rectifying tower is filled with a glass raschig ring filling material. The diameter of the rectifying tower is 180-250 mm and the height of the rectifying tower is 5-10 m. A process for preparing the electronic grade nitric acid having a concentration of 68% from the industrial grade nitric acid having a concentration of 98% is also disclosed. The diameter of the rectifying tower is set to be 180-250 mm, the height of the rectifying tower is set to be 5-10 m, the reflux ratio is controlled to be 1:2-1:5, the heating coils in the rectifying tower are made of the metal tantalum, and the rectifying tower is filled with the glass raschig ring filling material. According to the equipment and the process, a finished high-purity product of the electronic grade nitric acid can be prepared by one time of distillation, thus saving resources and reducing pollution.

Owner:SUZHOU JIMCEL ELECTRONICS NEW MATERIAL

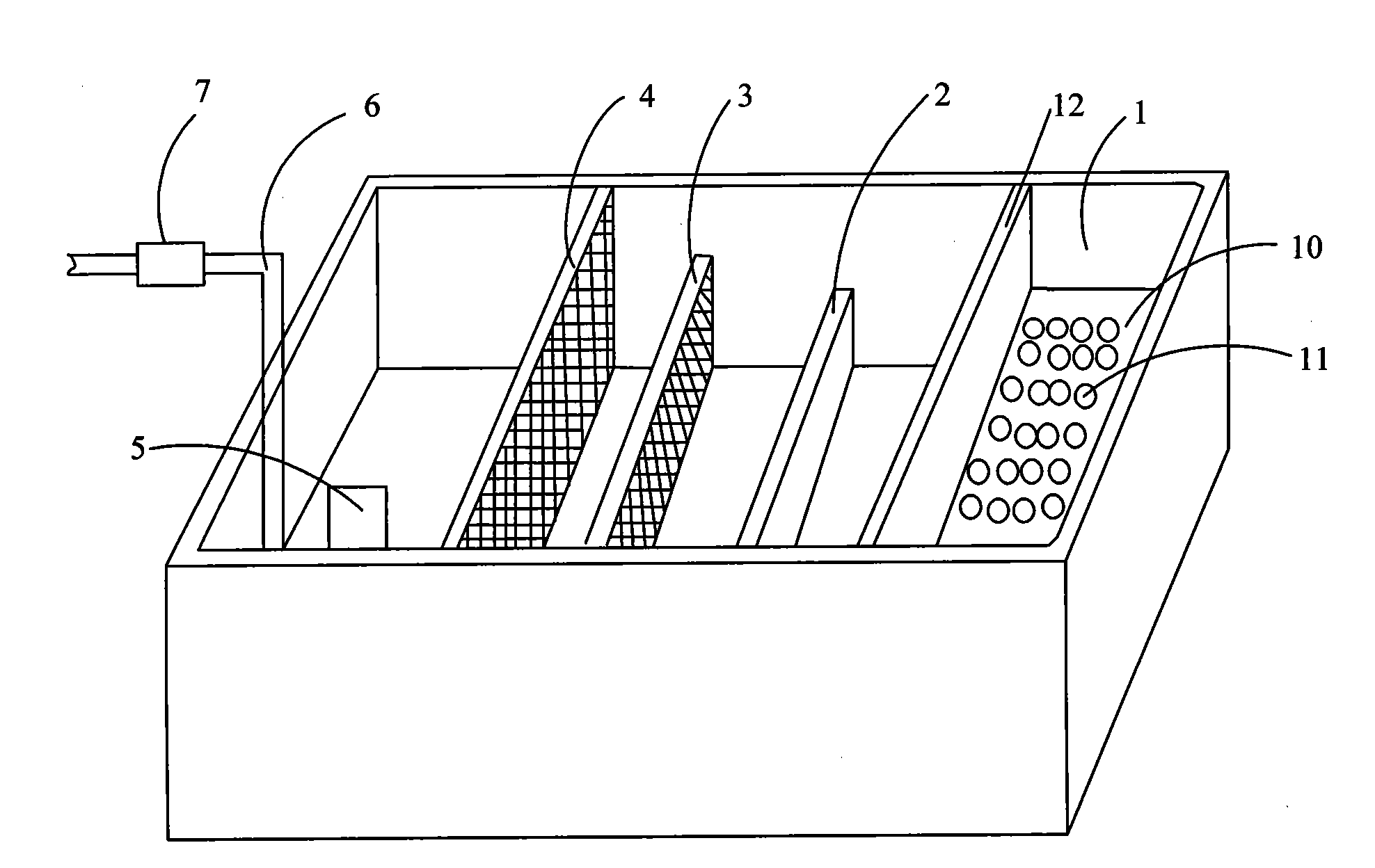

Cleaning device of raschig ring

The invention provides a cleaning device of a raschig ring. At present, no cleaning device specially used for a raschig ring occurs. The cleaning device supplied by the invention comprises a cleaning groove and a filter alternately arranged, wherein the cleaning groove is used for placing the raschig ring, and the filter is used for filtering waste water generated by cleaning; the depth of the cleaning groove is smaller than that of the cleaning device, and a plurality of holes smaller than the raschig ring are arranged on the cleaning groove. The cleaning device also comprises an overflowing plate positioned between the cleaning groove and the filter, wherein the height of the overflowing plate is smaller than that of the cleaning groove; the overflowing plate blocks the waste water flowing through the cleaning groove and blocks precipitated impurities; and the filter filters the waste water flowing over the overflowing plate. The cleaning device not only can be matched with a high pressure water gun to effectively clean dirt accumulated on the raschig ring, but also can filter the waste water and can recycle the waste water generated by cleaning, thereby saving water resources.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Fume removal device for asphalt road maintenance vehicle

PendingCN108310890ANo pollution in the processMeet the requirements of environmental standardsCombination devicesGas treatmentActivated carbonEnvironmental standard

The invention discloses a fume removal device for an asphalt road maintenance vehicle. The fume removal device for the asphalt road maintenance vehicle comprises a filter pipe, wherein a settlement plate, a Raschig ring demisting plate, a UV (ultraviolet) photolysis oxidation pipe and an activated carbon adsorption cavity are sequentially arranged in the filter pipe from an air inlet end to an airoutlet end. An asphalt fume is filtered through the Raschig ring demisting plate, photolyzed through VOCs (Volatile Organic Chemicals) and adsorbed through activated carbon, so that a heating processof the fume removal device configured for a heating wall of the asphalt road maintenance vehicle is free of pollution, and the treated fume can meet the requirement of a national environmental standard.

Owner:JIANGSU JITRI ROAD ENG TECH & EQUIP RES INST CO LTD

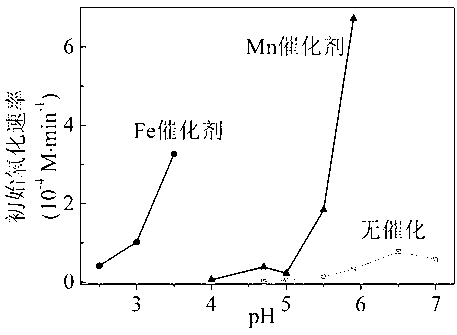

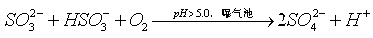

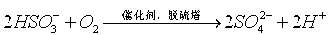

Novel desulfurizer packing material for seawater desulfurization and preparation method thereof

ActiveCN103191638AReduce dosageSave design volumeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMass ratioHigh energy

The invention discloses a novel desulfurizer packing material for seawater desulfurization and a preparation method thereof. The novel desulfurizer packing material for seawater desulfurization is prepared through the following steps of: adding a steeping liquor and porous Raschig ring washed by sulfuric acid into a stainless steel reaction kettle, wherein mass ratio of the steeping liquor to the Raschig ring is at 1:(10-1):1; stirring, regulating pH value to 3.0-5.0 through sulfuric acid, heating to 25-60 DEG C, stirring for 12-36 hours at constant temperature, heating to 85-100 DEG C, stirring, depositing and steeping at constant temperature for 24-48 hours, washing by water until discharged water is colorless, and calcining for 3-5 hours at 400-800 DEG C to obtain the novel desulfurizer packing material for seawater desulfurization. The method is simple and materials are cheap and easily available, and the defects of the conventional seawater desulfurization process which is incomplete in sulfite radicle oxidization of seawater absorbing liquid, large occupied room of aerator, high energy consumption and the like are overcome; and the novel desulfurizer packing material realizes coupling of absorption and oxidization in a desulfurization packing tower, and is environmental-friendly and economical.

Owner:ZHEJIANG UNIV

Production technology of catalyst for producing hydrogen by reforming methanol vapour at high temperature and application of catalyst

The invention discloses a production technology of a catalyst for producing hydrogen by reforming methanol vapour at a high temperature, and the application of the catalyst. According to the production technology disclosed by the invention, pseudo-boehmite, titanium dioxide, citric acid and graphite are used as raw materials for producing a catalyst carrier, besides, the carrier is pressed into a Raschig ring shape, and the catalyst can be suitable for a hydrogen production reaction by reforming the methanol vapour at the high temperature under the reaction condition of 300-600 DEG C; The production technology and the application of the catalyst disclosed by the invention have the beneficial effects that the catalyst does not use a noble metal catalyst, and besides, a conventional coprecipitation method is not selected for use, so that the cost and resources are greatly reduced, and the catalyst has an actual application value; the catalyst produced by the production technology disclosed by the invention uses the Raschig ring shape, so that the specific surface of the catalyst is larger, and the mass transfer effect and the heat transfer effect are better. The catalyst is simple to apply, and can be used when a reactor is directly heated to use temperature and raw gas can be used; in the process of heating, no physical water is drained, and the volume contraction of the catalyst is small.

Owner:四川蜀泰化工科技有限公司

Electronic grade high-purity nitric acid purification method

The invention discloses an electronic grade high-purity nitric acid purification method. A rectifying tower is included. A heating coil is arranged inside the rectifying tower. The material of the heating coil is metallic nickel. The rectifying tower is filled with a polypropylene Raschig ring filler. The tower diameter of the rectifying tower is 150-280 mm, and the tower height is 3-15 m. The invention also discloses a process of preparing electronic grade 68% nitric acid from industrial grade 98% nitric acid. The tower diameter of the rectifying tower is set as 150-280 mm, the tower height is set as 3-15 m, and the reflux ratio is controlled to be 1:2-1:5. The material of the heating coil in the rectifying tower is set as metallic nickel. The rectifying tower is filled with the polypropylene Raschig ring filler. By one-time distillation, the electronic grade high-purity nitric acid product can be obtained finally. The resources are saved, and the pollution is reduced.

Owner:张妮妮

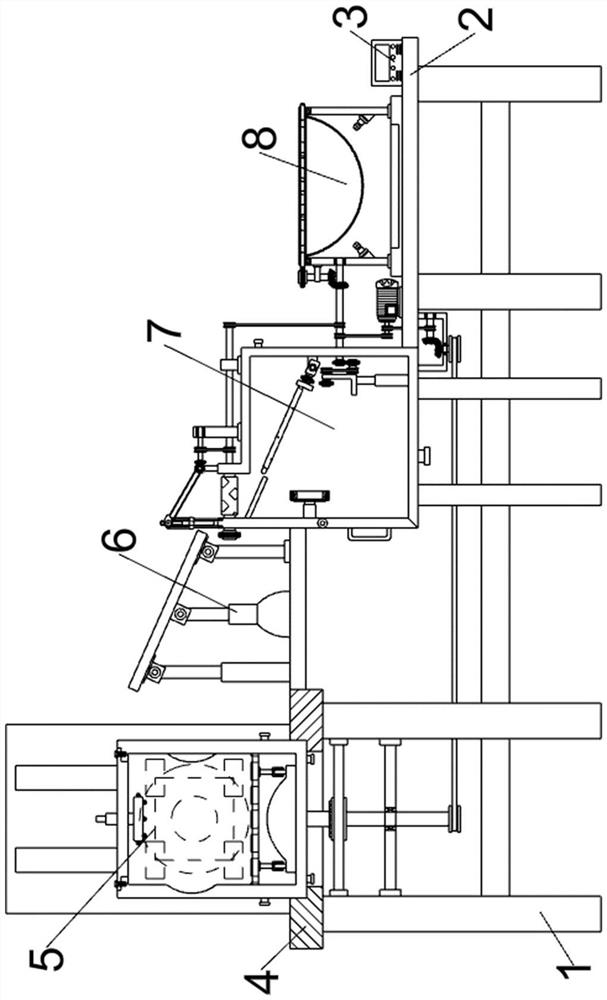

Water sample pretreatment device for environmental monitoring laboratory

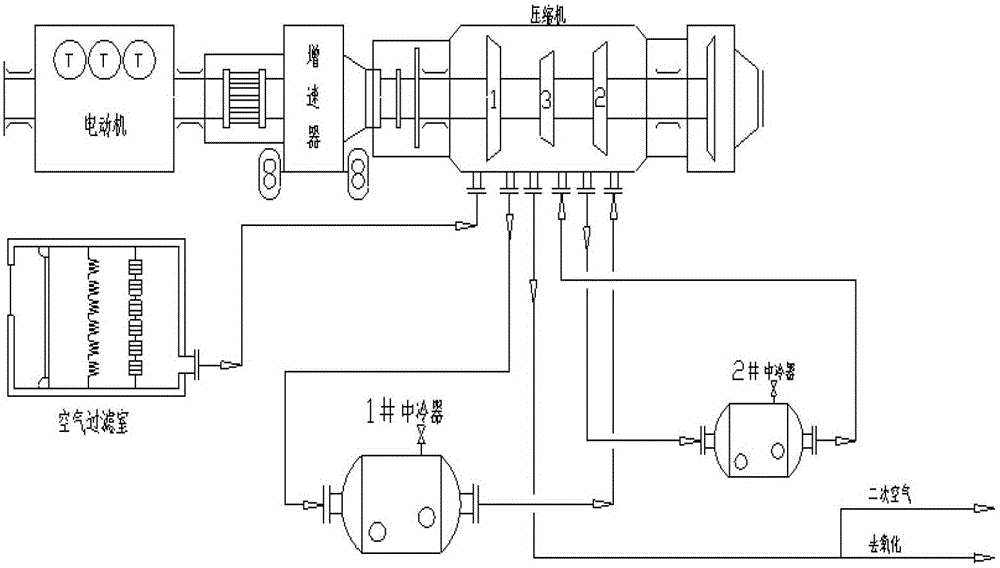

ActiveCN105865884ASpeed up filteringSimple structurePreparing sample for investigationWater storage tankAir compressor

The present invention relates to a water sample pretreatment device for an environmental monitoring laboratory. The device comprises an air compressor pump; the outlet of the air compressor pump is connected to the inlet of a water storage tank; an outlet pipe of the water storage tank is connected to a sediment cleanup device; and the sediment cleaning device includes a closed filter barrel. A water sample is injected into the water storage tank, the air compressor pump pressurizes the water storage tank to inject the water in the water storage tank into a filter screen barrel through the outlet pipe; a motor drives the filter screen barrel to rotate, and under the action of centrifugal force, the water injected into the filter screen barrel is thrown out; the thrown water falls onto a spacer plate, and penetrates through a Raschig ring filling material to a water storage chamber of a filter barrel below the separator plate; and water sample sampling is carried out by a water outlet in communication with the water storage chamber. The water sample pretreatment device for the environmental monitoring laboratory has simple structure; due to the rotary filter screen barrel and Raschig ring filling material with less resistance, the filtering is quick; a water outlet filter is arranged on the water outlet pipe; and three stages of filtration can quickly filter the water sample and has ideal filtering effect.

Owner:SHANDONG CAYON TESTING TECH

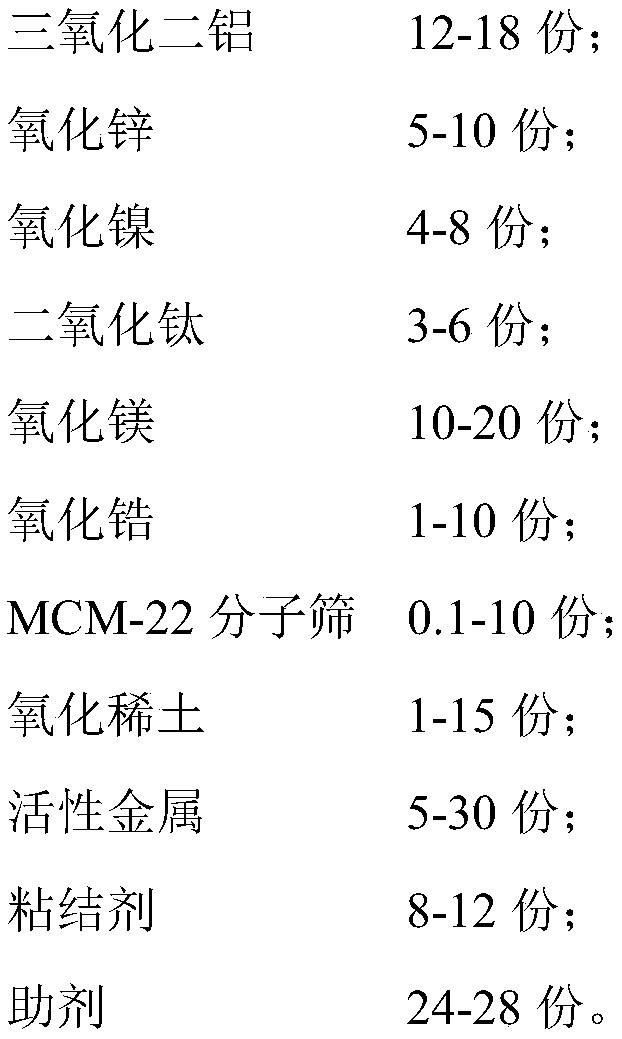

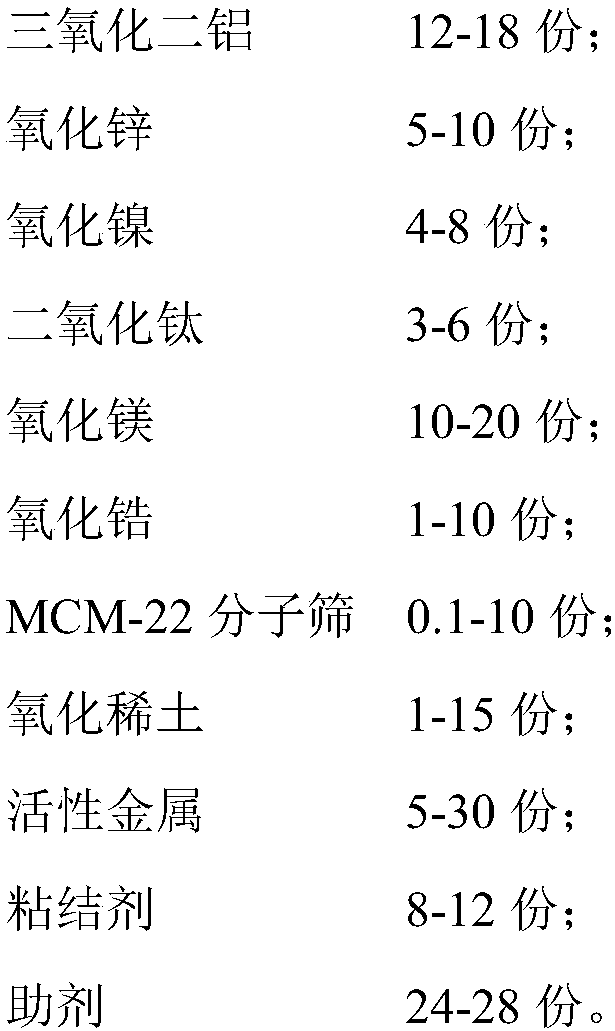

Desulfurization catalyst

InactiveCN108579802AHigh activityHigh catalytic efficiencyMolecular sieve catalystsHeterogenous catalyst chemical elementsAdditive ingredientRare earth

The invention provides a desulfurization catalyst, which is composed of the following ingredients (by weight): 12-18 parts of aluminium oxide, 5-10 parts of zinc oxide, 4-8 parts of nickel oxide, 3-6parts of titanium dioxide, 10-20 parts of magnesium oxide, 1-10 parts of zirconia, 0.1-10 parts of MCM-22 molecular sieve, 1-15 parts of rare earth oxide, 5-30 parts of active metal, 8-12 parts of a binder, and 24-28 parts of an auxiliary agent. By the addition of aluminium oxide, zinc oxide, nickel oxide, titanium dioxide, magnesium oxide, rare earth oxide and active metal, activity of the product can be enhanced, the catalytic effect is good, and catalytic efficiency is high. With the addition of the binder, the product can be made into various shapes such as granular shape, columnar shape,cellular shape, Raschig ring shape and the like. The product can be selected for a fluidized bed and a fixed-bed reactor, has a wide application range, and is suitable for industrial promotion.

Owner:天津浩创节能环保设备有限公司

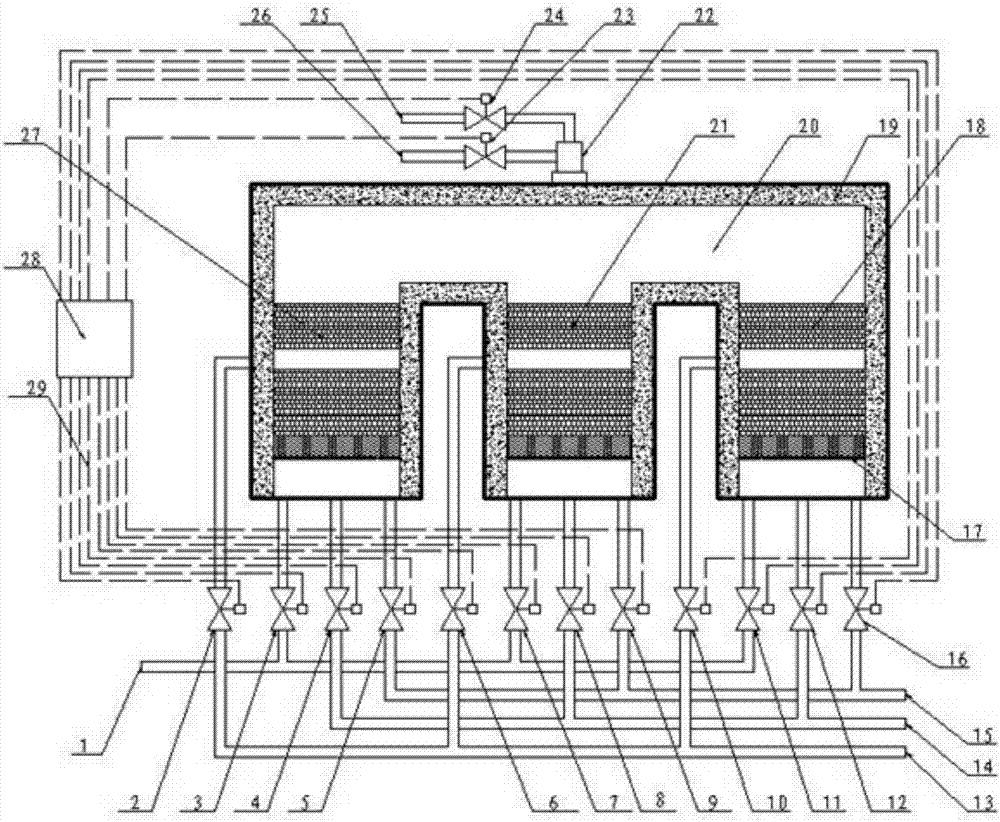

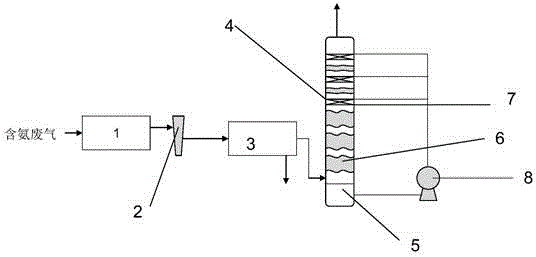

Incinerator for isophthalonitrile tail gas treatment

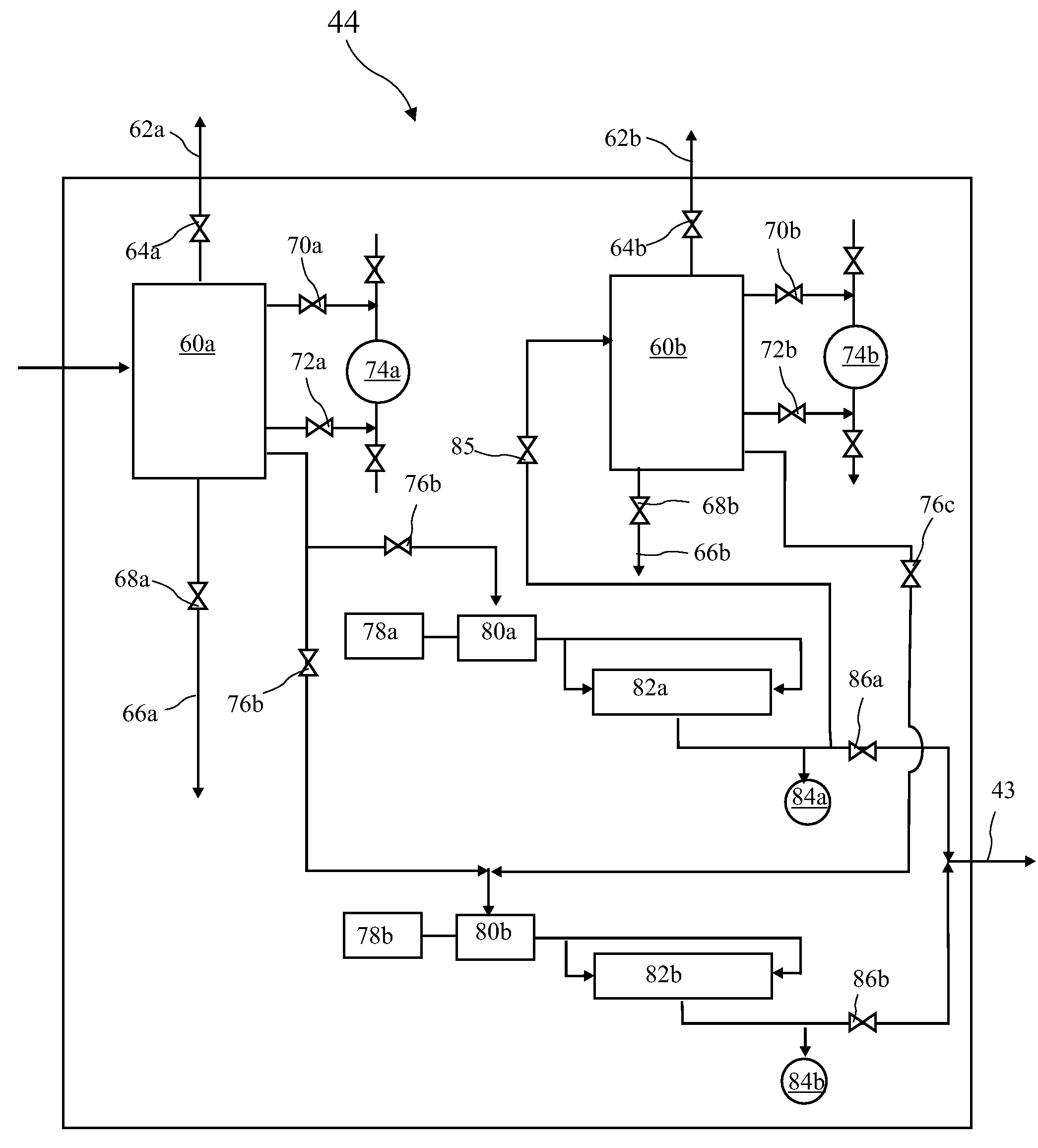

PendingCN107543177AIncrease oxidation rateAvoid cloggingIncinerator apparatusCombustion chamberFlue gas

The invention relates to an incinerator for isophthalonitrile tail gas treatment. The incinerator comprises a plurality of parallelly-arranged oxidation beds, supporting grid meshes and heat accumulators, wherein the upper parts of the oxidation beds are connected with one another so as to form a combustion chamber; the supporting grid meshes are arranged at the bottoms of the oxidation beds; ceramic raschig rings are arranged on the supporting grid meshes; the heat accumulators are arranged on the ceramic raschig rings; an isophthalonitrile tail gas inlet pipeline, a flue gas extraction pipeline, a flue gas outlet pipeline and a sweeping pipeline are connected with each oxidation bed; switching valves are arranged on all the above pipelines; a fuel pipeline and a combustion-supporting airpipeline are connected with the combustion chamber; and control valves are arranged on both the above valves. Compared with the prior art, the incinerator provided by the invention has the advantagethat the oxidation rate of ammonia gas and organic waste gas in isophthalonitrile tail gas can exceed 99%.

Owner:JIANGSU XINHE AGROCHEM

Polypropylene acid mist and waste gas purification tower

InactiveCN105642100ACompact structureSmall footprintGas treatmentDispersed particle separationMetal frameworkAgricultural engineering

The invention discloses a polypropylene acid mist and waste gas purification tower, which comprises a purification-tower tower body, wherein the lower end of the purification-tower tower body is provided with a liquid storage tank in a connection manner; a two-layer structure is adopted for the purification-tower tower body; a polypropylene material is adopted for an inner layer; a metal framework is adopted for an outer layer; the upper end of the purification-tower tower body is provided with a spray opening; the spray opening is connected with a circulating water pump through a spray pipeline; the circulating water pump is connected with the liquid storage tank through a pipeline; the lower end of the spray opening is provided with a filling layer; a Pall ring or a Raschig ring structure is adopted for a filling. The polypropylene acid mist and waste gas purification tower provided by the invention is compact in equipment construction, small in floor space, strong in corrosion resistance and long in service life, and is convenient to operate.

Owner:TAICANG YUNQUAN CHEM ANTICORROSION EQUIP CO LTD

Method for decolorizing peach gum hydrolysate

InactiveCN101433309BIncrease the number ofEfficient use ofFood preparationPhotocatalytic reactionHydrolysate

Owner:FUZHOU UNIV

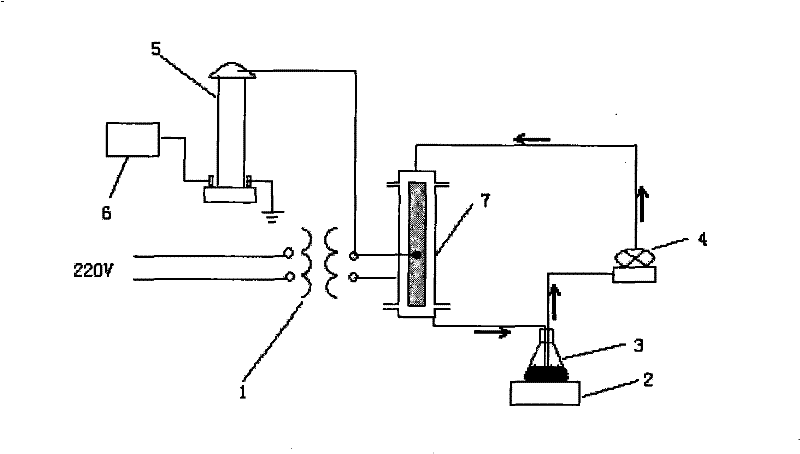

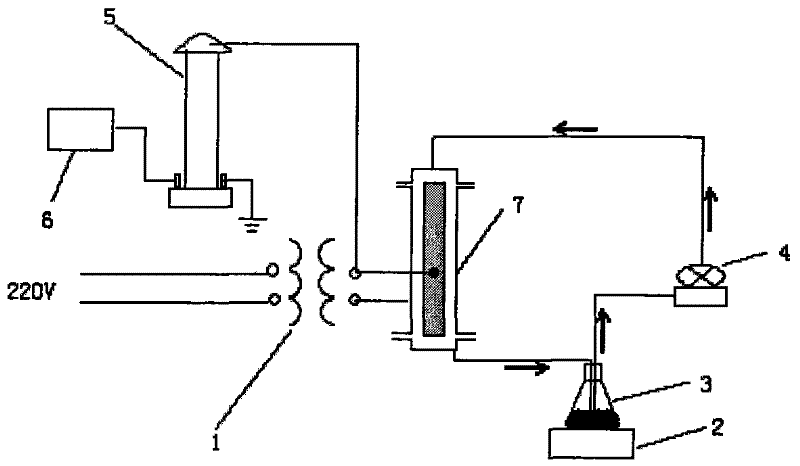

Cleaning device for ammonia-containing waste gas

InactiveCN105457472AImprove purification efficiencySimple structureGas treatmentDispersed particle separationLiquid tankEngineering

The invention relates to a cleaning device for ammonia-containing waste gas. The cleaning device comprises a heater, a cyclone separator, a condenser and an absorption tower which are connected in order. The ammonia-containing waste gas is firstly fed into the heater, then is fed into the separator, the condenser and the absorption tower in order, and is discharged from the tower top of the absorption tower. The ratio of the height to the diameter of the absorption tower is 10:1. The adsorption tower comprises an adsorption liquid tank at the bottom, and three spraying layers at the upper part of the absorption tower. Filler layers are disposed below the spraying layers. The ratio of the total thickness of the spraying layers to the total thickness of the filer layers is 1:6.3. Raschig rings are adopted as a filler in the filler layers. A circulating pump is connected to the absorption liquid tank (5) and the spraying layers. A sulfur acid solution is adopted as an absorption liquid. The cleaning device is suitable for cleaning ammonia-containing waste gas produced in a fertilizer production workshop and is high in cleaning efficiency, simple in structure, easy to operate and good in economical efficiency.

Owner:华文蔚

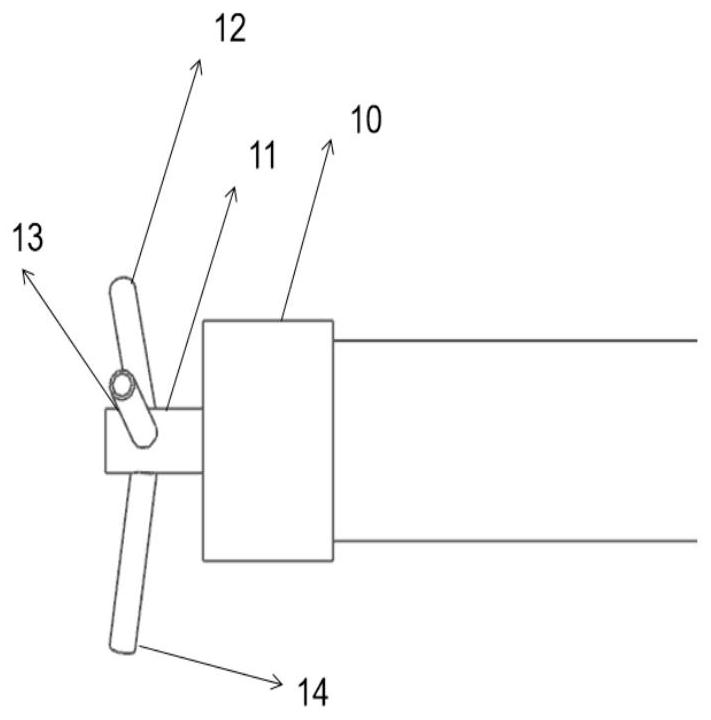

Novel wake flow combustor with random accumulation structure

PendingCN112128746ARapid coolingUniform temperature distributionPulverulent fuel combustion burnersGaseous fuel burnerTemperingPorous medium

The invention discloses a novel wake flow combustor with a random accumulation structure. The novel wake flow combustor comprises a combustion cavity, the bottom of the combustion cavity is connectedwith a gas mixing pipeline, a gas backflow area, two layers of foamed ceramics and an accumulation chamber are sequentially arranged in the combustion cavity from bottom to top, a Raschig ring is arranged at the bottom in the combustion cavity, the two layers of foamed ceramic are supported through the Raschig ring, and the gas backflow area is formed; and silicon-containing aluminum oxide pelletsare randomly accumulated in the accumulation chamber to form a porous medium layer, the combustion rate is increased through the silicon-containing aluminum oxide pellets, and the tempering phenomenon in the combustion process is reduced.

Owner:JIANGSU UNIV

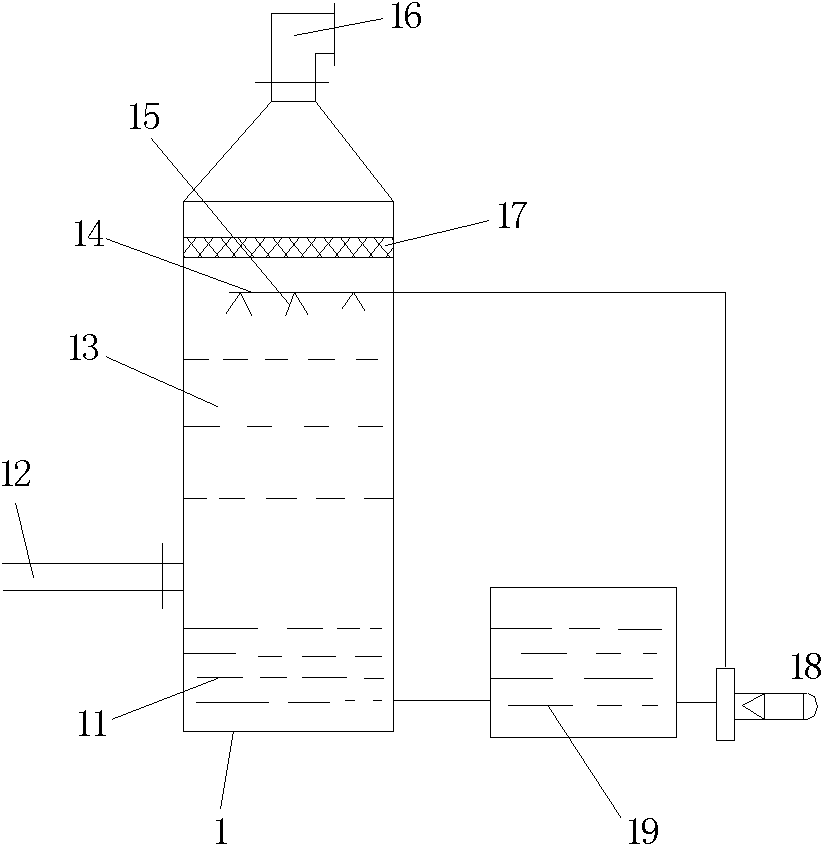

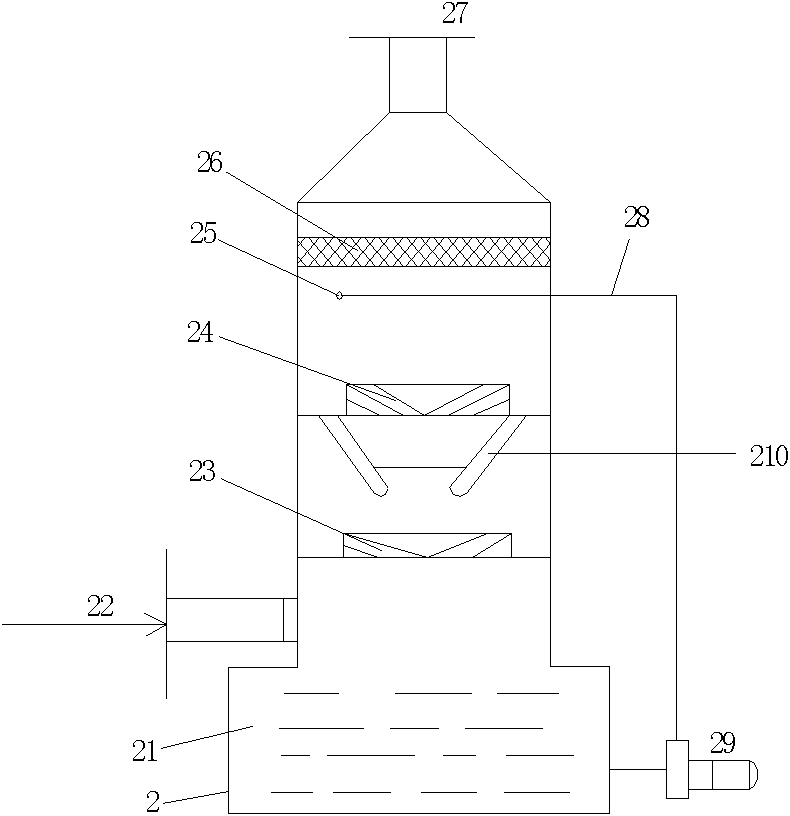

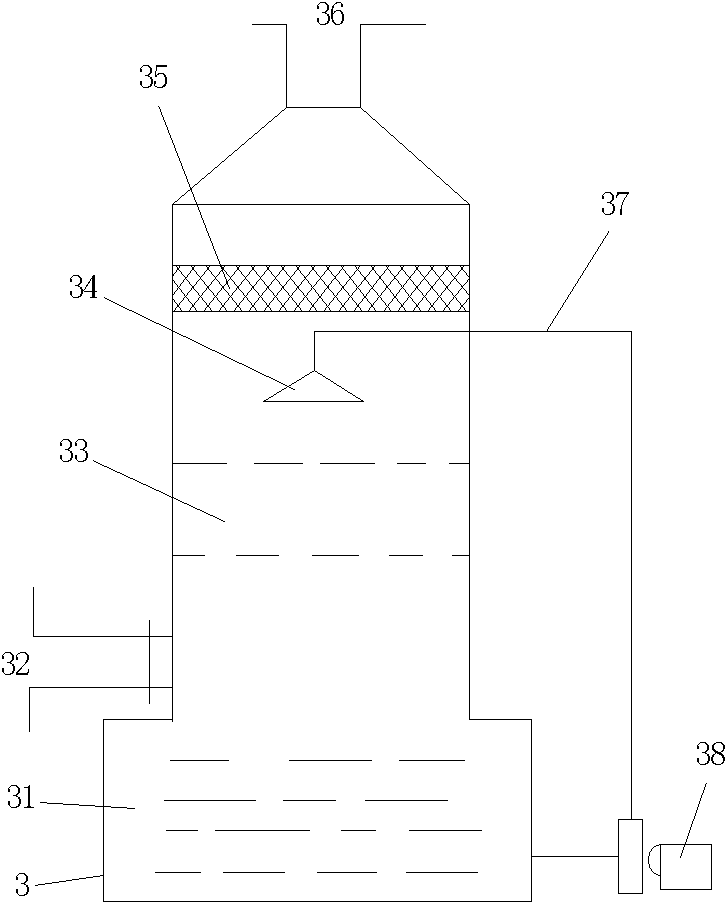

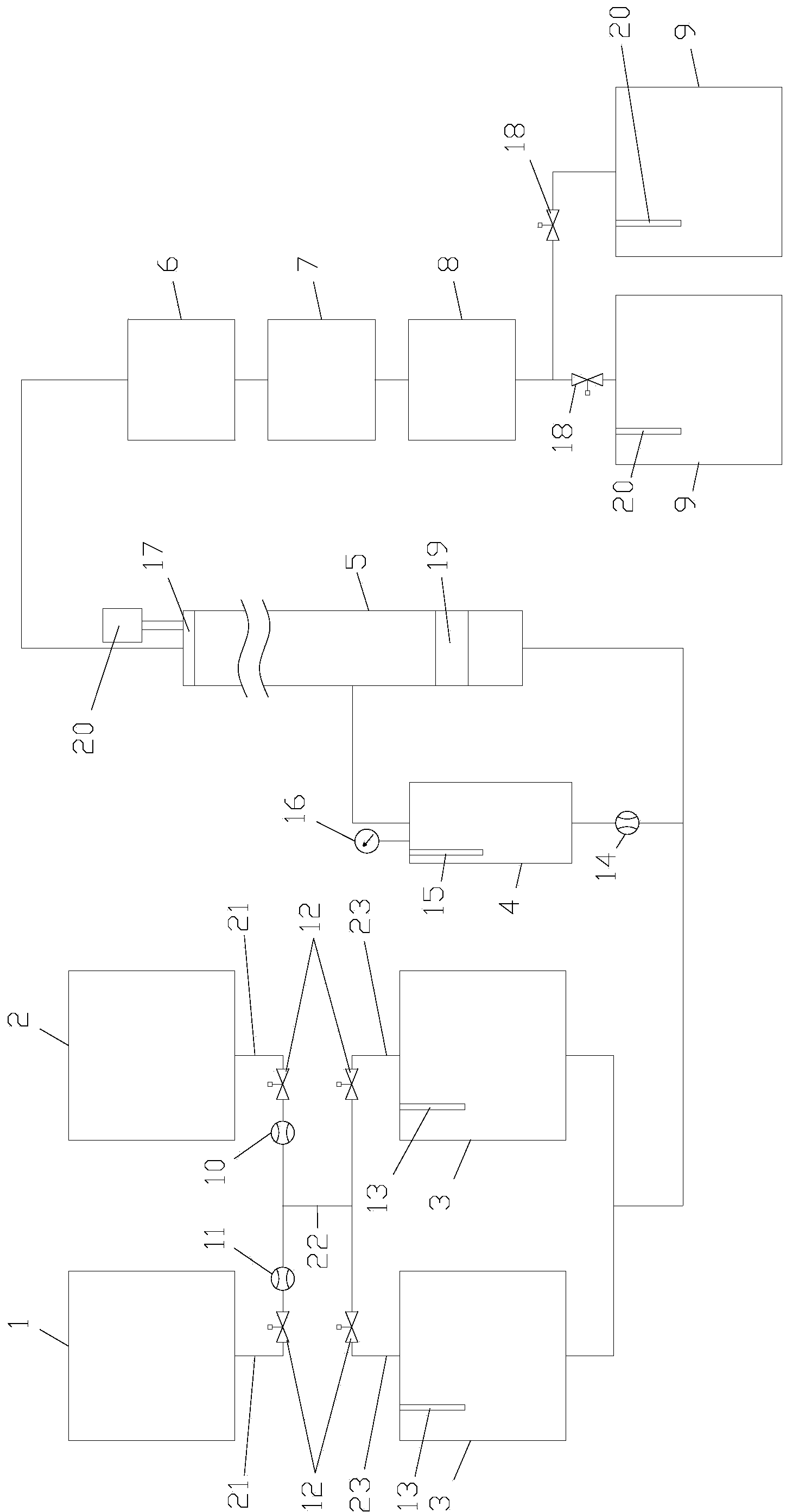

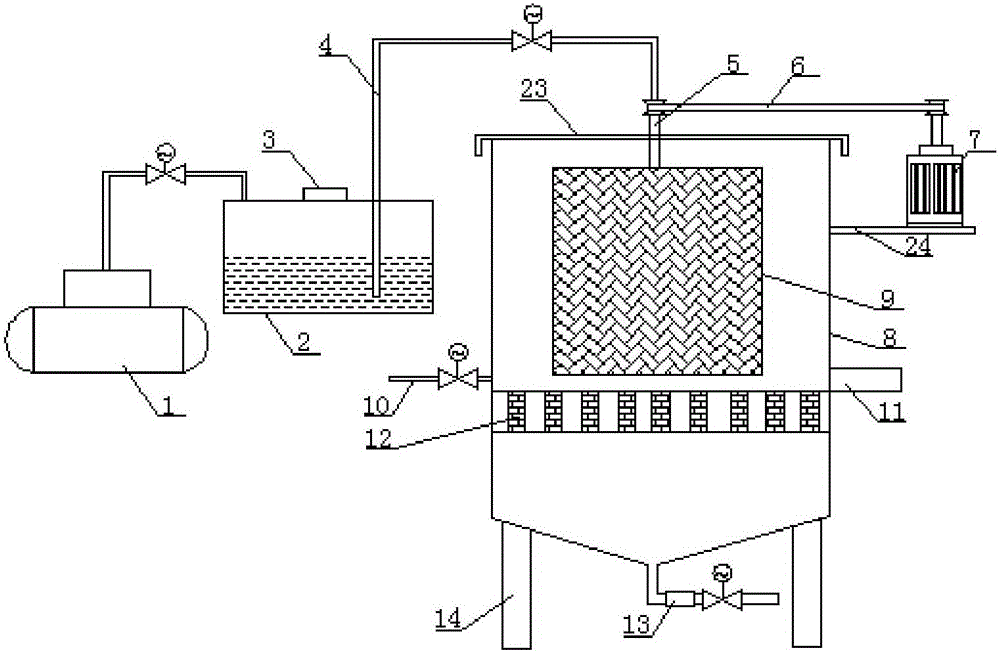

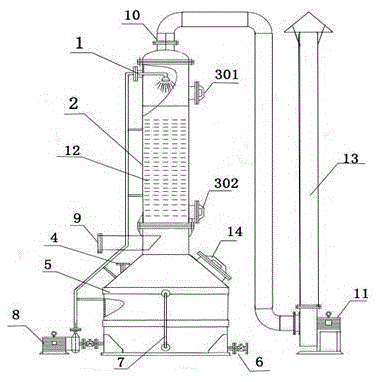

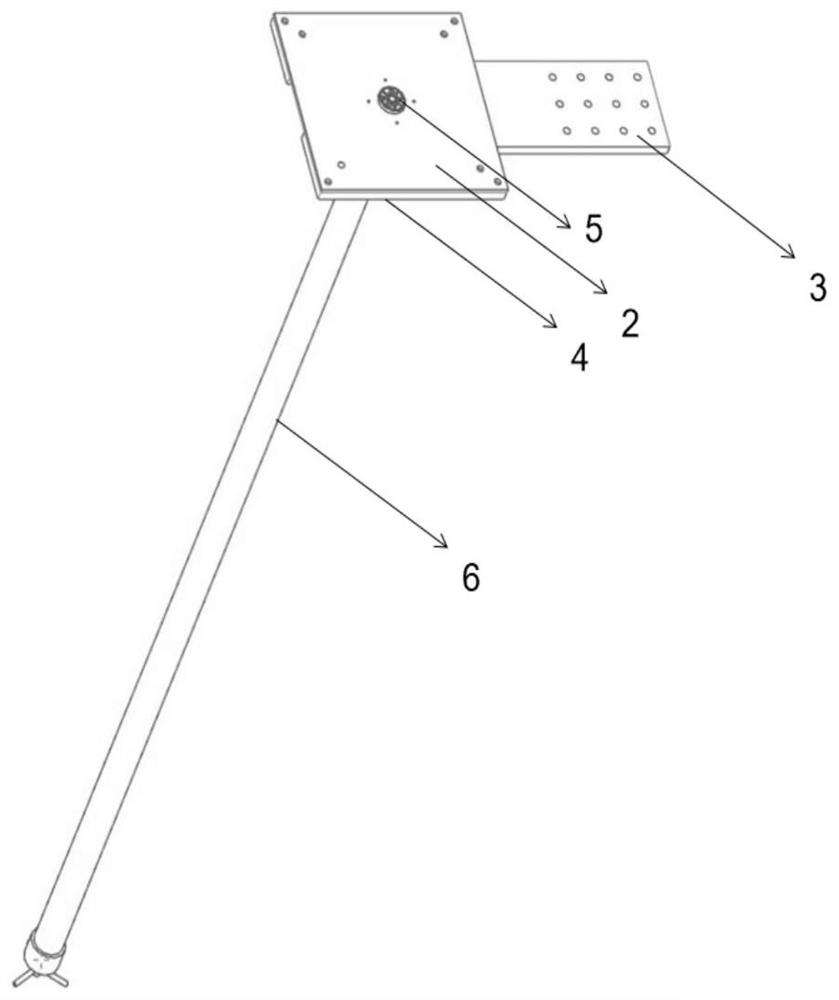

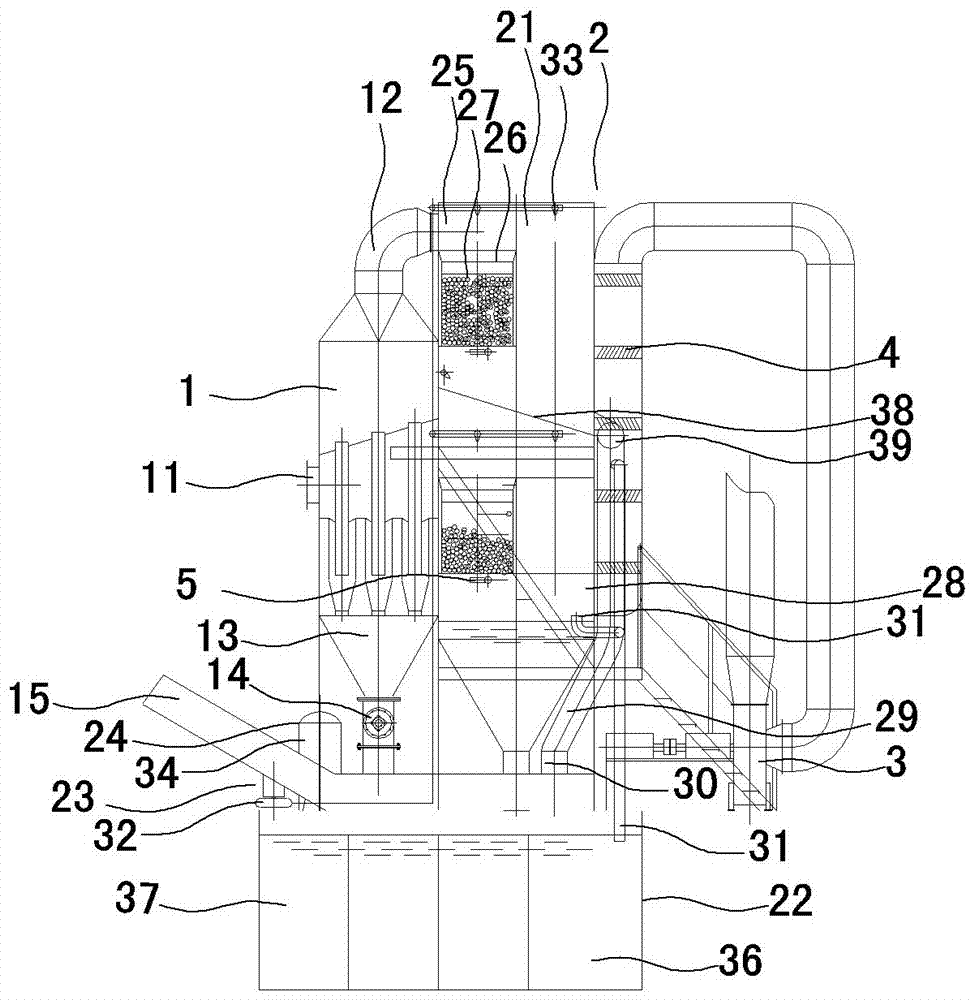

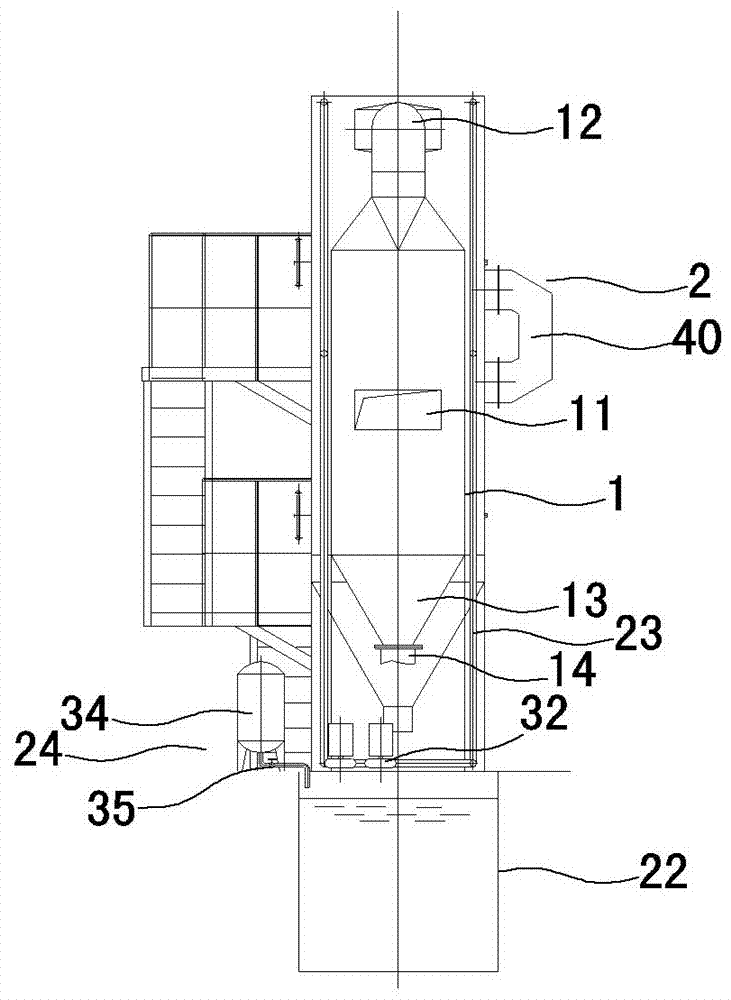

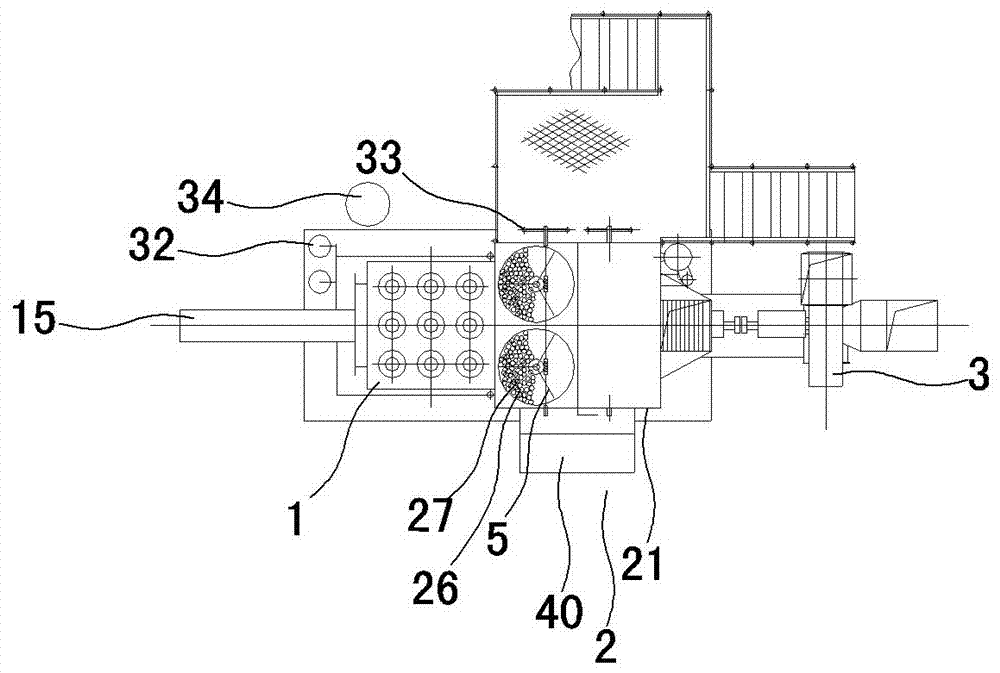

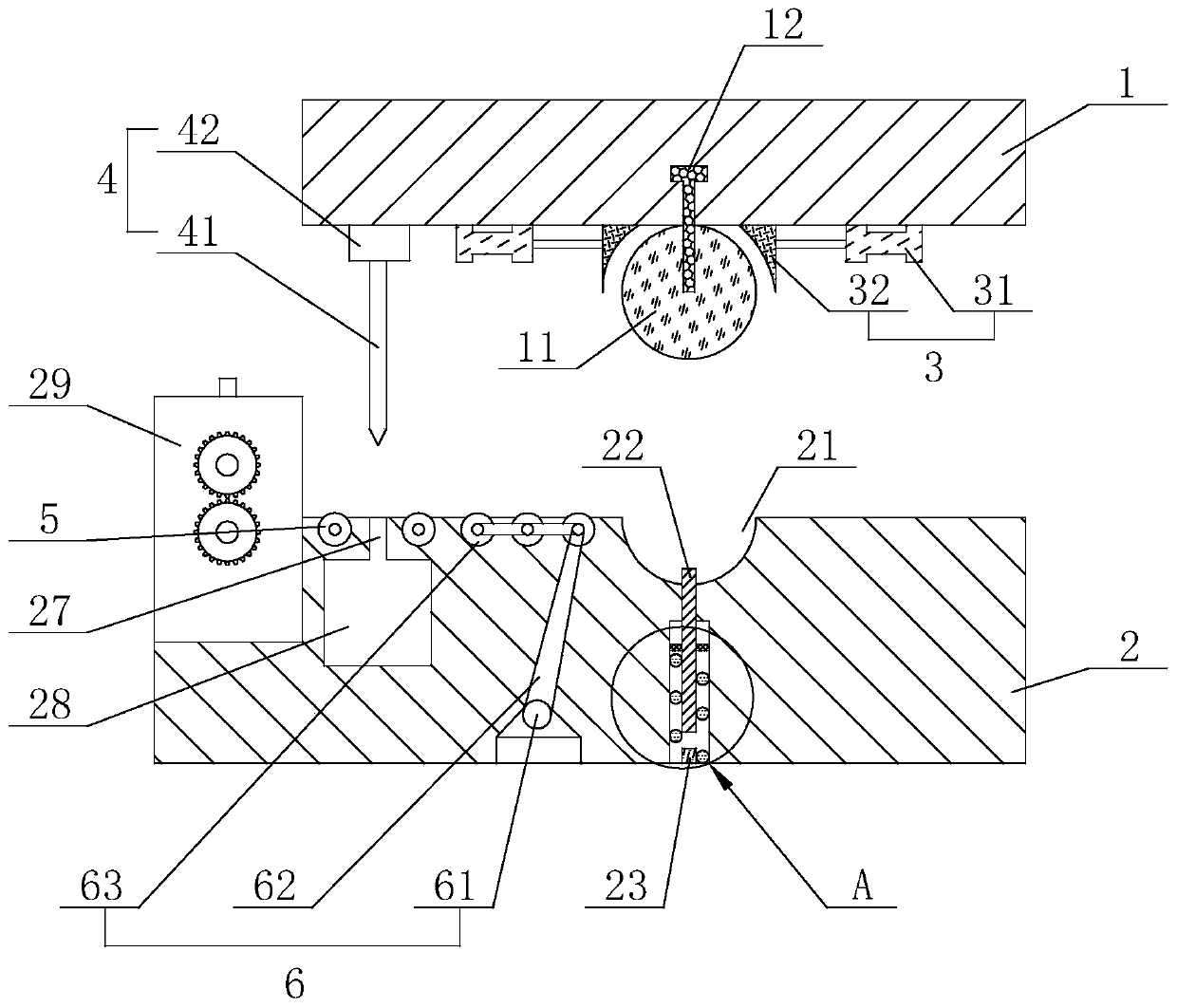

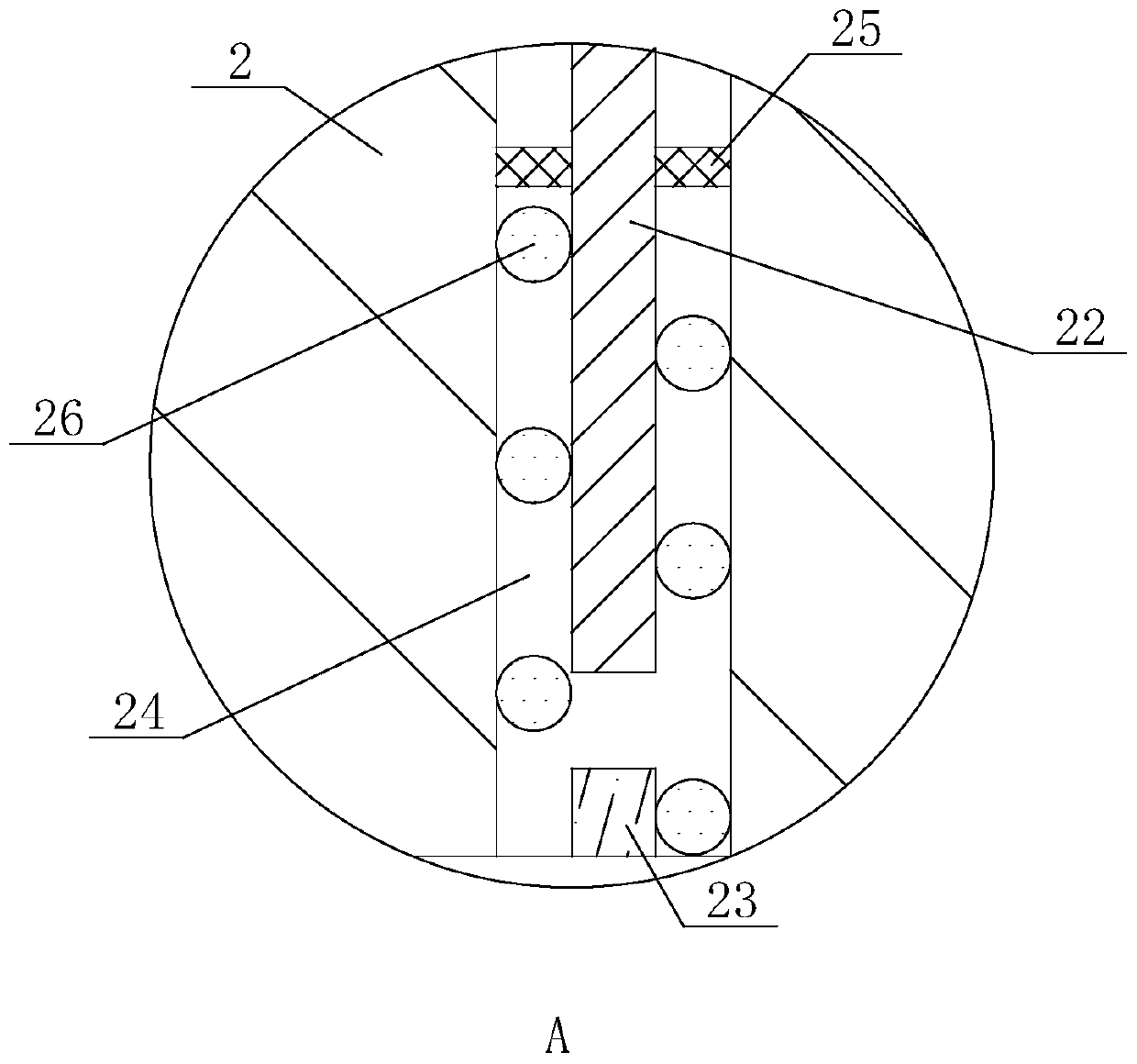

High-efficiency boiler dedusting desulfurization denitrification device

InactiveCN107042033ALow temperature range requirementsLower exhaust gas temperatureGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention relates to a high-efficiency boiler dedusting desulfurization denitrification device. The high-efficiency boiler dedusting desulfurization denitrification device comprises a dedusting device (1), a desulfurization denitrification device (2), and an induced draft fan (3); the desulfurization denitrification device is composed of a desulfurization denitrification tower (21), a circulation sedimentation tank (22), a urea spraying mechanism (23), and a drug adding mechanism (24); a wind outlet (12) of a cyclone multi-tube dust collector is communicated with a flue gas inlet (25) of the desulfurization denitrification tower; a plurality of raschig ring filter subassemblies (26) are arranged in the desulfurization denitrification tower; a flue gas outlet of the desulfurization denitrification tower is communicated with a wind inlet of the induced draft fan (3); the urea spraying mechanism (23) is composed of a circulating pump (32), and a plurality of spray nozzles (33) arranged in the desulfurization denitrification tower (21); the drug adding mechanism (24) is composed of a urea tank (34) and a drug adding pump (35). The high-efficiency boiler dedusting desulfurization denitrification device is high in desulfurization denitrification efficiency, and excellent in dedusting effect, and is capable of reducing boiler flue gas temperature and increasing boiler heat effciency; requirement on flue gas temperature range is low; and production operation cost is low.

Owner:鲍守明 +1

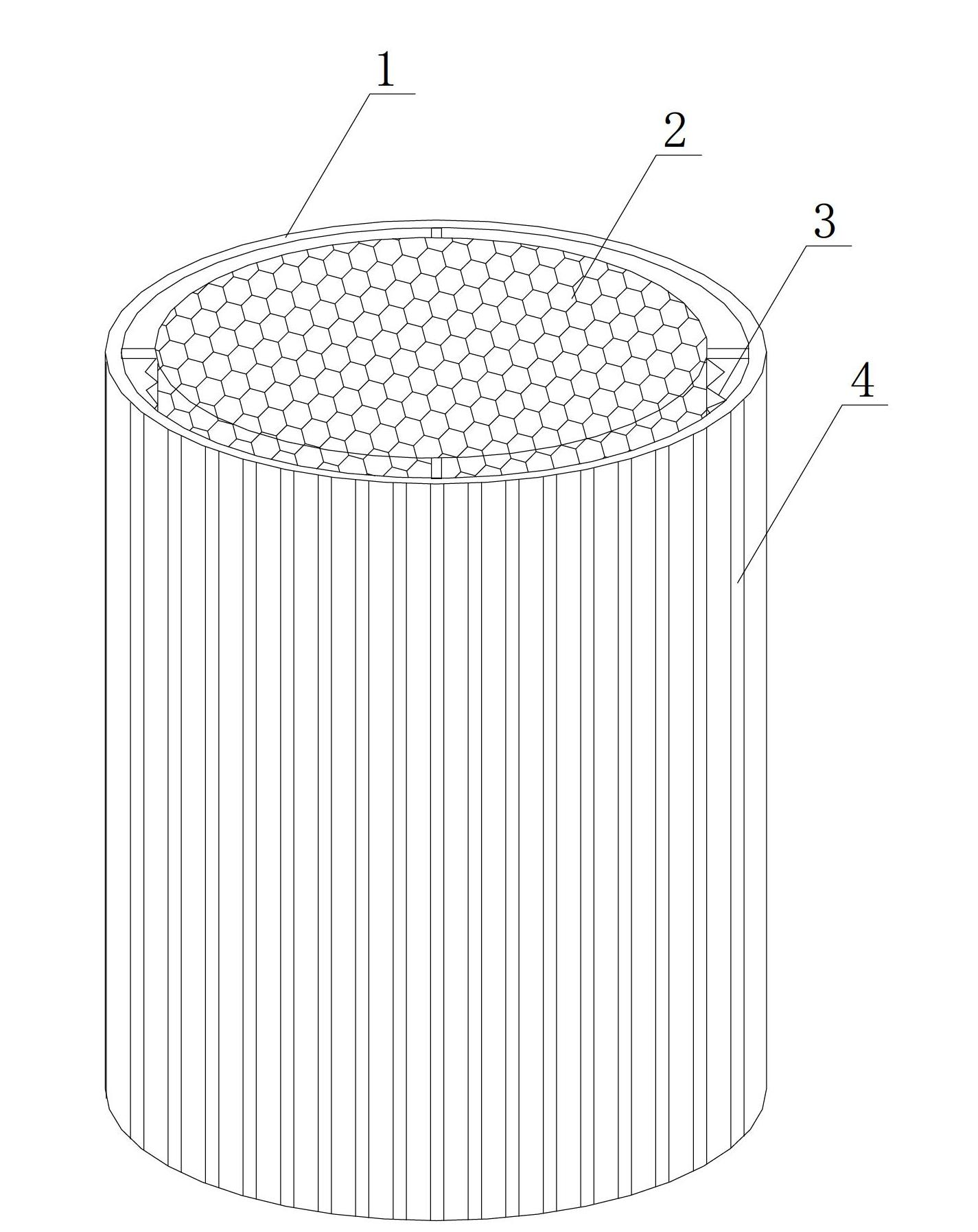

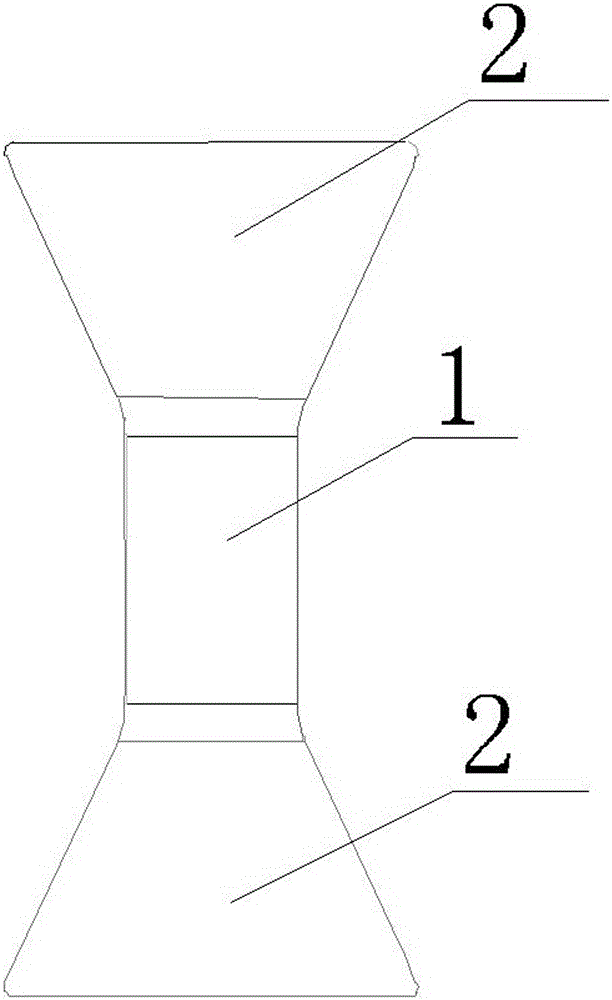

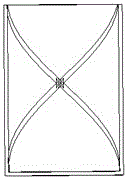

Raschig ring filling material

InactiveCN105013427AEvenly distributedExtended service lifeChemical/physical/physico-chemical processesPorosityEpoxy

The invention relates to a raschig ring filling material, which belongs to the technical field of petroleum chemical mass transfer separating equipment. The raschig ring filling material comprises a tubular body, the symmetrical trumpet-shaped flarings are arranged at two ends of the tubular body; a corrosion resisting coating is sprayed on the surface of the raschig ring filling material, the corrosion resisting coating comprises the following components by weight percentage: 10-20% of terephthalate epoxy resin, 10-15% of polyvinyl formal, 11-15% of cross-linking agent, 6-8% of anhydrous auxiliary agent, 2-3% of catalyst, and the balance of water. The symmetrical trumpet-shaped flaring are arranged at two ends of the tubular body, each filling material enables point contact while stacking, distribution is more uniform, porosity is increased, channeling and wall flow phenomena can be effectively prevented, wetting on the surface in the filling material is convenient due to trumpet-shaped flaring, and production efficiency is increased.

Owner:SUZHOU KD PETROCHEM ENG

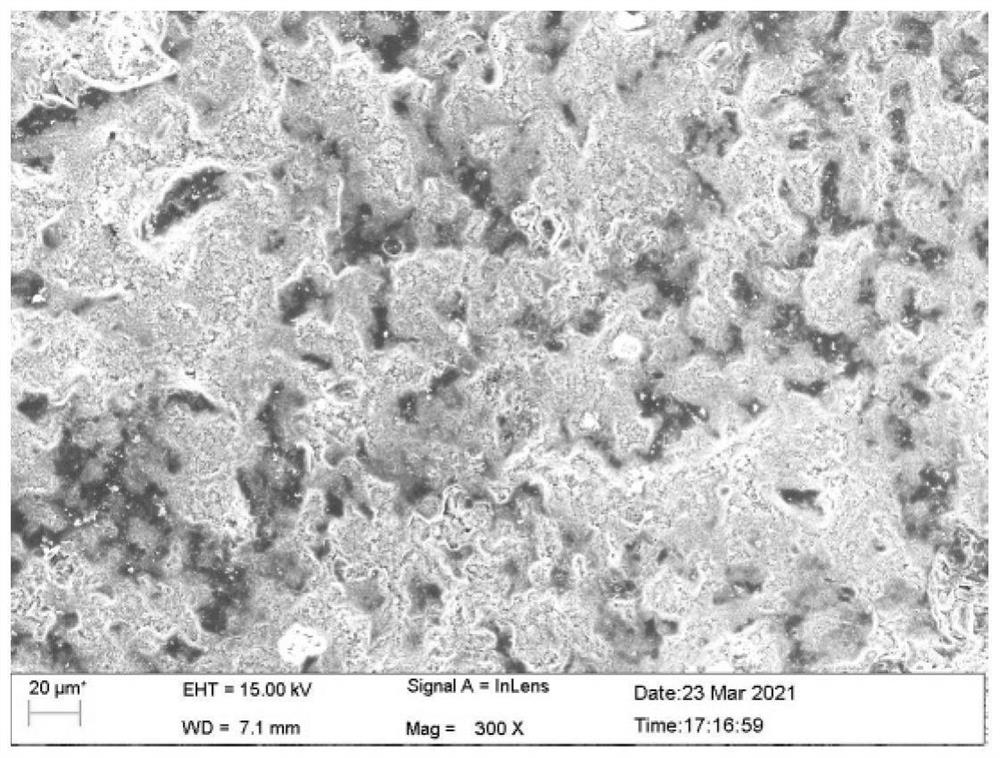

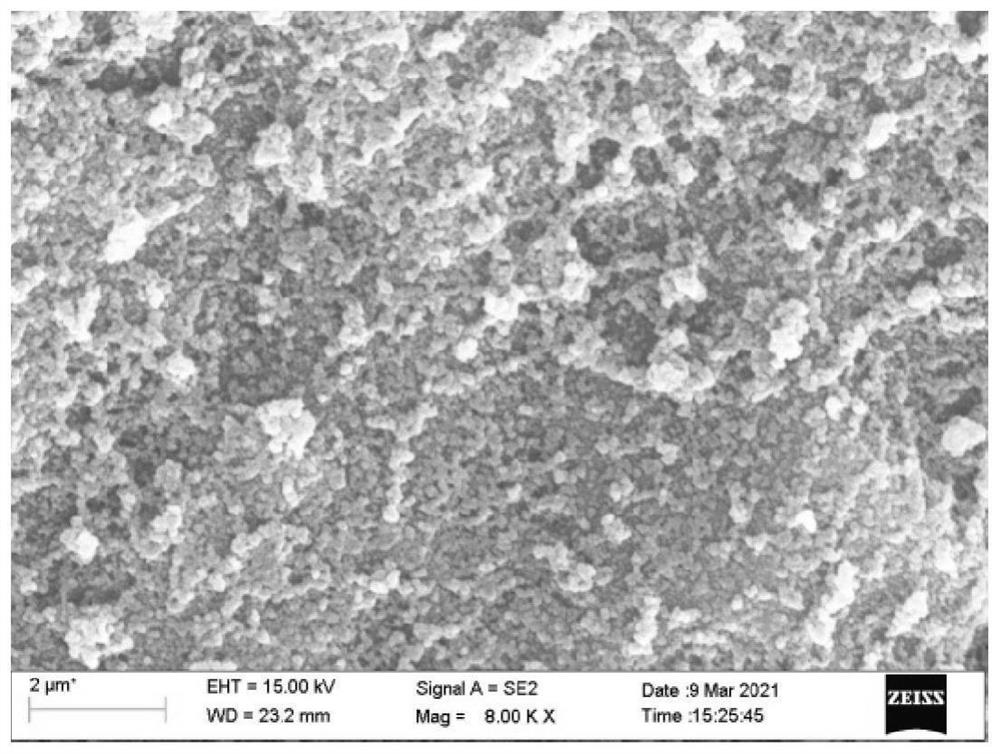

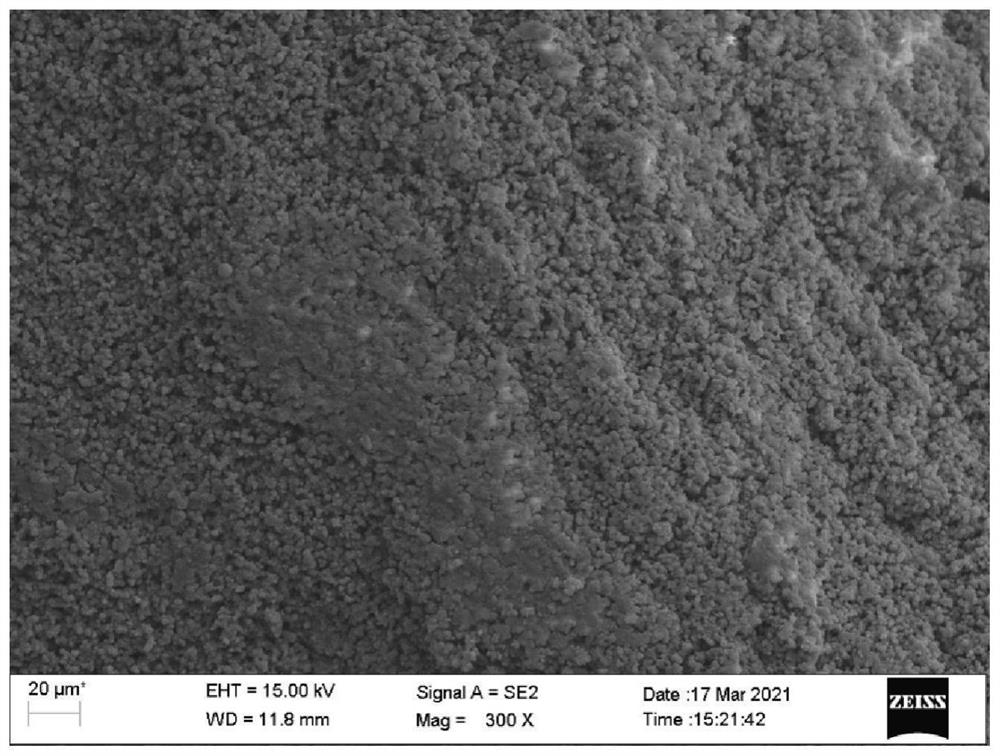

Preparation method of ceramic surface supported catalytic filler

ActiveCN113198535AImprove bindingNot easy to fall offOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

A preparation method of a ceramic surface supported catalytic filler comprises the following steps of: (1) performing surface treatment on a ceramic Raschig ring filler: washing the filler with alkali and water until the filler is neutral, drying the filler, adding the filler into a compound system of a Tris-HCl buffer solution and absolute ethyl alcohol for infiltration, adding tannic acid, amino silane and vinyl silane, and heating for crosslinking; (2) preparing vinyl imidazole, a cross-linking agent and an initiator, immersing the Raschig ring, knocking and oscillating in a negative pressure state, pre-curing, and putting the Raschig ring and ethyl acetate into a digestion tank for treatment; and (3) introducing a sulfonic acid group into the Raschig ring obtained in the step (2) through quaternization reaction, and exchanging with dilute sulphuric acid to obtain a strongly acidic Raschig ring with catalytic capability. The supported catalytic filler is prepared through in-situ grafting of polyimidazole sulfonate on the surface of ceramic through cooperation of a catechol structure with high adhesiveness and vinyl silane, the catalytic efficiency is high, the defects that a traditional catalyst package is high in mass transfer resistance and the like can be overcome, and the supported catalytic filler has potential application value in the field of reactive distillation.

Owner:XIAMEN UNIV

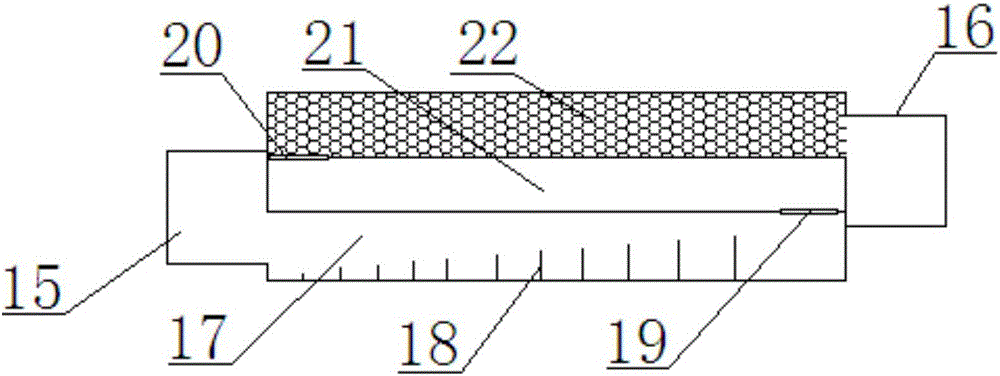

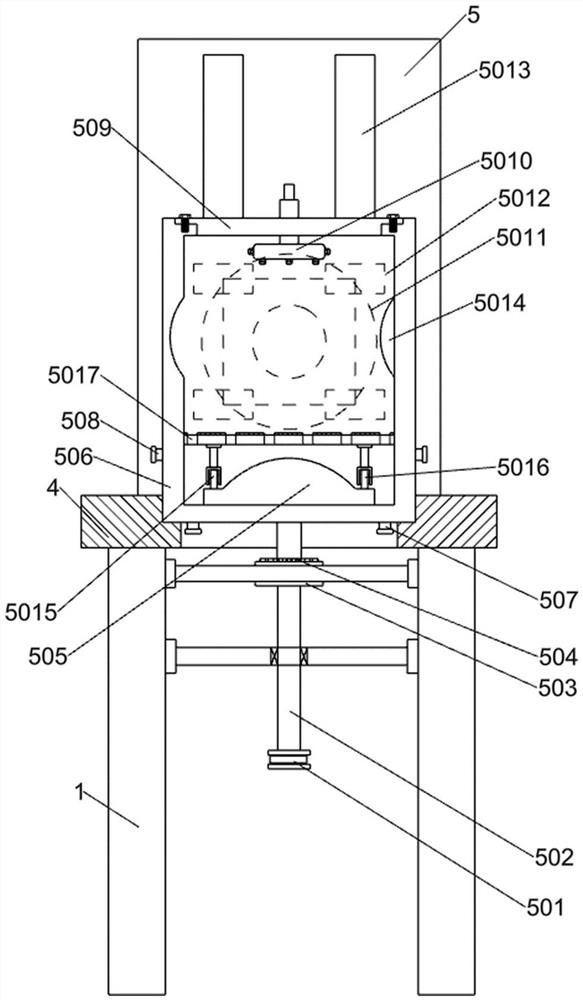

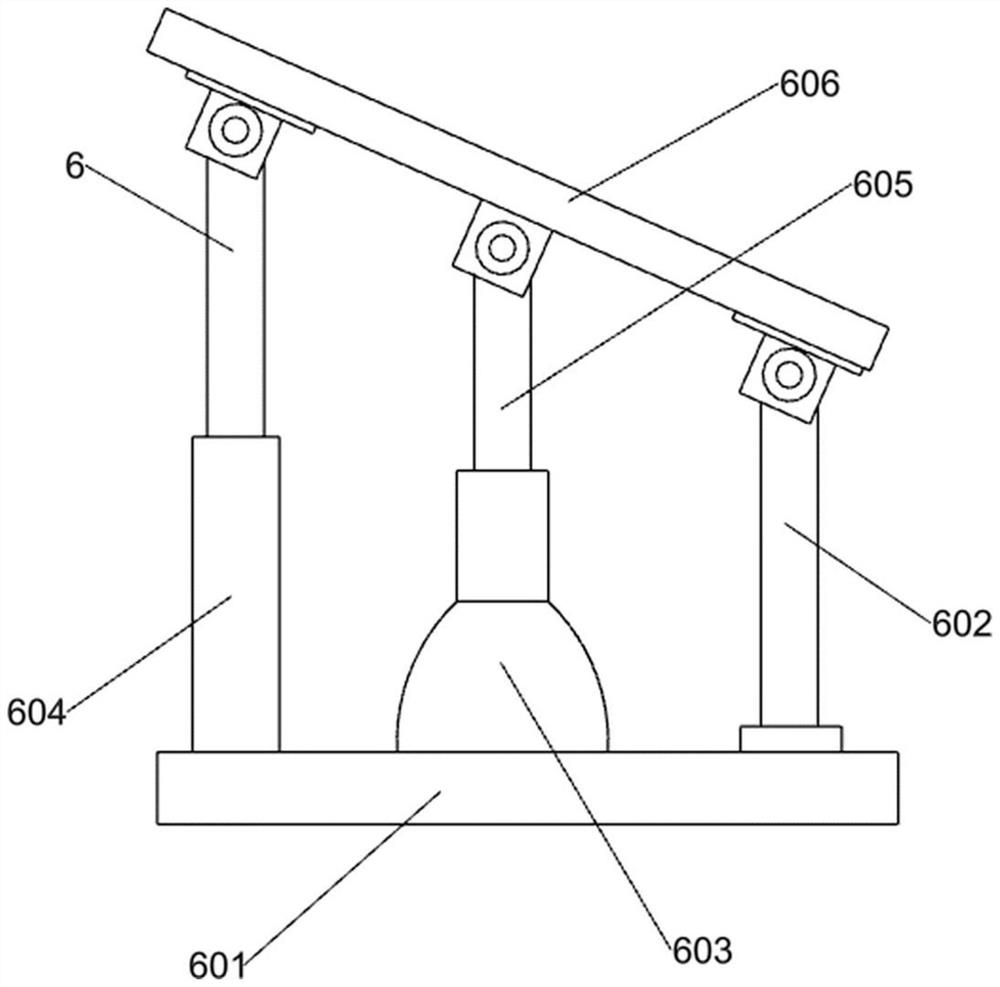

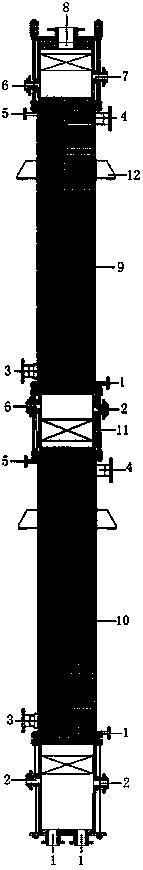

Raschig ring one-step forming die

InactiveCN111589924AEasy to disengageEasy to press and formShaping toolsMetal-working feeding devicesPunchingClassical mechanics

The invention relates to a Raschig ring one-step forming die which comprises an upper die and a lower die. The surface, close to the lower die, of the upper die is detachably and fixedly connected toa forming die, and extrusion mechanisms for laminating a stainless steel plate to the forming die are separately arranged on the left and right sides of the forming die. A forming groove where the forming die is embedded is formed in the lower die, a sliding bar is arranged at the bottom of the forming groove, the sliding bar is elastically and slidably arranged in the lower die, one end of the sliding bar penetrates from the lower die, a stroke switch is arranged below the other end of the sliding bar, the stroke switch is in control connection to the extrusion mechanisms, a cutting device isarranged on one side of the forming die, and the cutting device is fixed to the surface, close to the lower die, of the upper die. A Raschig ring is formed in one step in the whole punching process,so that the Raschig ring one-step forming die is simple and skillful in structure, and the production efficiency is improved to a great extent.

Owner:江西省萍乡市迪尔化工填料有限公司

A method for reducing emissions of nitrogen oxide tail gas

InactiveCN103230743BReduce pollutionCaused by pollutionAmmonium nitratesDispersed particle separationDecompositionSuperheater

The invention provides a nitrogen oxide tail gas emission reduction method. The method is characterized in that during a nitric acid production process, a Raschig ring catalyst is arranged between a platinum net and a bottom superheater of an oxidation furnace, such that nitrogen oxide in mixed gas is decomposed into nitrogen and oxygen; and the gases are cooled in subsequent processes and are applied in absorption stations. With the method provided by the invention, tail gas nitrogen oxide during the nitric acid production process can be effectively decomposed and recycled, such that environment pollution can be reduced, and a product ammonium nitrate can be recovered. The decomposition catalyst is tested and the effect thereof is analyzed. With the catalyst, NOX in nitric acid tail gas can be decomposed into nitrogen and oxygen. The environment is not polluted after nitrogen and oxygen are produced.

Owner:内蒙古乌拉山化肥有限责任公司

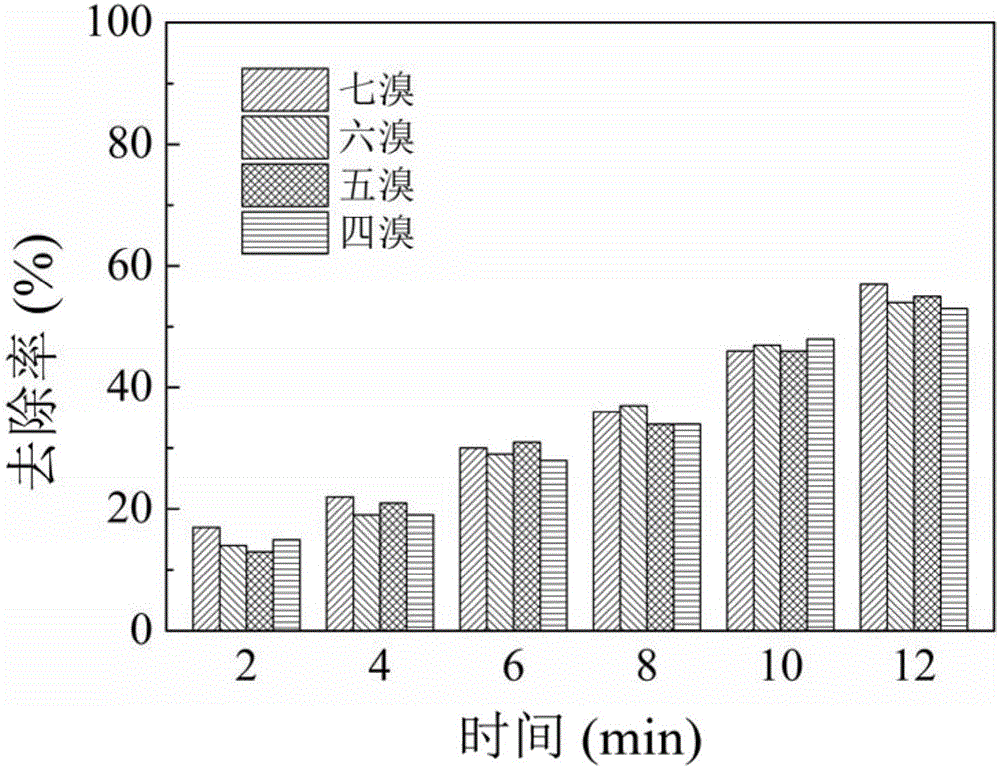

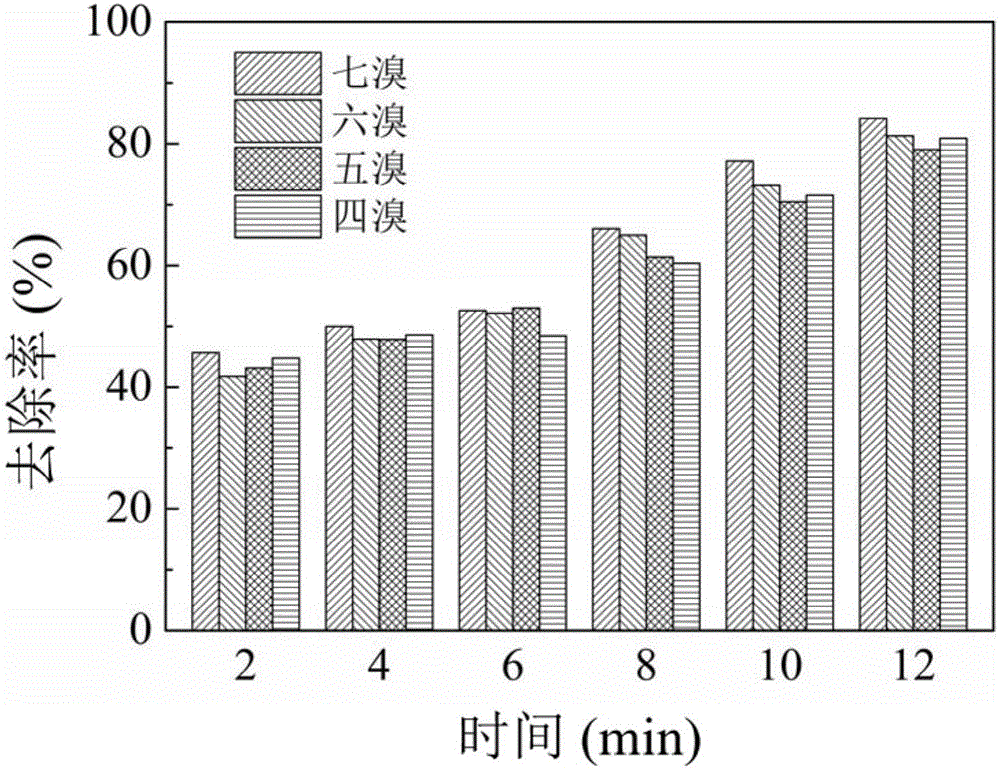

Method for degrading tail gas generated by polybrominated-diphenyl-ether polluted soil restoration by thermal desorption technique

ActiveCN106823783AEasy to detectEfficient detectionCatalyst carriersGas treatmentReaction temperatureElectrochemistry

The invention relates to a method for degrading tail gas generated by polybrominated-diphenyl-ether polluted soil restoration by a thermal desorption technique. The method comprises the following steps: automatically growing a nano-pore-structure aluminum oxide film on the surface of an aluminum matrix under electrochemical actions to form a structurized carrier; carrying at least one metal and / or metal oxide on the structurized carrier to form a structurized catalyst; restoring polybrominated-diphenyl-ether polluted soil by a thermal desorption technique to generate tail gas; and inserting the structurized catalyst into a microchannel reactor or filling a fixed-bed reactor with a mixture of the structurized catalyst and 20-40-mesh Raschig ring, and introducing the tail gas into the reactor to carry out reaction at the reaction temperature of 200-500 DEG C under atmospheric pressure, wherein the air speed is 1500-90000 mL / (g.h). The structurized catalyst is utilized to degrade the tail gas generated by polybrominated-diphenyl-ether polluted soil restoration by the thermal desorption technique, so that the tail gas reaches the discharge standard.

Owner:EAST CHINA UNIV OF SCI & TECH

Polytetrafluoroethylene packing treatment device

InactiveCN112221364AFully cleanedQuick coverage drying effectRotating receptacle mixersTransportation and packagingMechanical engineeringRaschig ring

The invention relates to the field of polytetrafluoroethylene packing, in particular to a polytetrafluoroethylene packing treatment device. The technical problem of the invention is to provide a tetrafluoro filler treatment device. According to the technical scheme, the polytetrafluoroethylene packing treatment device comprises a mixing mechanism, a discharging control mechanism, a cleaning mechanism, a drying mechanism and the like; one side of the upper portion of a working rack plate is connected with a working table plate, and the other side of the upper portion of the working rack plate is connected with an embedded fixed working table. When Raschig rings are used for mixing gas and liquid, the stacked Raschig rings are subjected to up-down and left-right layered movement dislocationtreatment, a liquid film formed after the surfaces of the stacked Raschig rings are stained with the liquid is damaged, so that gas below the stacked Raschig rings is not blocked by a liquid film in the ascending process, and the Raschig rings are driven to eccentrically rotate through eccentric rotation; and the inner surface and the outer surface are fully cleaned, and the effects of rapid rotating, covering and drying are achieved.

Owner:程敬奇

Trapping agent for recovering platinum group metal from nitrate industrial ammonia oxidation furnace and application of trapping agent

The invention relates to a trapping agent for recovering platinum group metal from a nitrate production process. The technology comprises the following processes: (1) adding 1 part of ethanediamine, 0.2-1 part of cholamine and 2-6 parts of water to a container, adding 0.7-1.5 parts of potassium bispalladate dehydrate and 0.05-0.2 part of nickel oxalate when agitating, controlling the temperature of a solution at 20-30 DEG C in the agitating process, and agitating for 2-3 hours; (2) soaking a raschig ring by using the solution obtained in the step (1) at 10-50 DEG C for 30-60 minutes; (3) putting the raschig ring obtained in the step (2) into a sealed electric furnace, filling nitrogen, warming to 100 DEG C within 20-40 minutes, carrying out heat preservation at 100-120 DEG C for 1-2 hours, then warming to 300 DEG C within 20-40 minutes, carrying out heat preservation at 300-400 DEG C for 1-2 hours, then warming to 500 DEG C within 20-40 minutes, naturally cooling to obtain the trapping agent after heat preservation at 500-650 DEG C for 1-3 hours. The trapping agent can be used for 6-8 months, and is low in platinum group metal recovery cost, the production efficiency of the nitrate is not affected, and the purity of the recovered platinum can be up to 99.96%.

Owner:KUNMING NANBO REGENERATION RESOURCE TECH RES

Method for preparing high-voltage electrophoresis reagent acetone

ActiveCN102329200AEfficient removalStable reverse electrical performanceCarbonyl compound separation/purificationPotassium carbonateDust particles

The invention relates to a method for preparing a high-voltage electrophoresis reagent acetone, which is used for an electrophoresis glass passivation process for a complementary metal-oxide-semiconductor (CMOS) silicon rectification device. The method comprises the following steps of: performing absorption treatment on raw material acetone by using a chromatographic column loaded with a 3A molecular sieve and anhydrous potassium carbonate; transferring the acetone into a distillation still, heating until the acetone is boiling, distilling, and collecting an acetone distillate at the temperature of between 55 and 57 DEG C, wherein a filler is a Raschig ring or a stainless steel Dixon ring; and finally, filtering the acetone distillate by using an organic filtering membrane with the aperture of 0.2mu m, wherein the filtering membrane is made of polyamide or polytetrafluoroethylene. The acetone prepared by the method can effectively remove harmful metal ion impurities which influence the composition of electric double layers and Zeta potential of glass dust particles. A prepared electrophoresis solution has low dielectric loss, and the apparent electrical conductivity and electrophoretic mobility are easy to regulate and control. The glass dust particles can automatically form a uniform coating on a silicon substrate, so that a glass passivation layer of a PN-junction groove of a device has consistent thickness; and the reverse electrical performance of the prepared device is stable.

Owner:TIANJIN BENCHMARK CHEM REAGENT

Improved-type methyl chloroformate tower reactor

The invention discloses an improved-type methyl chloroformate tower reactor. The improved-type methyl chloroformate tower reactor comprises a tower body, as well as a material outlet, a material inlet, a drain outlet, a frozen water inlet, a frozen water outlet, a gas inlet and a tail gas outlet which are formed in the tower body, wherein the tower body consists of an upper tower body and a lower tower body; a flexible joint is installed between the upper tower body and the lower tower body; the sealing surface of the tower joint is a graphite surface, and a seal line is carved on the surface; emptying openings and temperature meter openings are both formed in the upper tower body and the lower tower body; the gas inlet in the tower body is provided with a graphite Raschig ring used as a re-distributor; the top of the upper tower body is also provided with a demister. The tower reactor disclosed by the invention can enable the capacity of methyl chloroformate to be increased from 4t / h to 10t / h, and enable the content of the methyl chloroformate to be increased from 85%-95% to 92%-98%; moreover, the leakage cannot be generated in the production field environment as the graphite seal surface is adopted.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

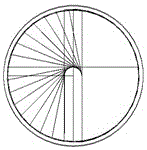

Filler used for tower and capable of making gas and liquid in rotational flow contact and liquid and liquid in rotational flow contact

ActiveCN105771871ALarge gas and liquidLarge liquid-liquid contact surfaceChemical/physical/physico-chemical processesRotation flapEngineering

The invention discloses a filler used for a tower and capable of making gas and liquid in rotational flow contact and liquid and liquid in rotational flow contact and relates to a reaction tower filler. The filler is composed of a round outer sleeve and twisting rotation blades, the twisting rotation blades can be in single rotation, double rotation, three rotation and four rotation, the rotation direction can be left handed or right handed, a twisting rotation angle is 180-270 DEG C, a fluid circulating channel in a common Raschig ring is divided through the twisting rotation blades, gas and liquid flow in a rotational flow mode in the channel because of the twisting rotation effect of the blades, gas and liquid distribution can be improved, the turbulence degree of fluid is enhanced, and interphase mass transfer is facilitated; the gas and liquid contact surface can also be increased through the surfaces of the twisting rotation blades. The novel filler is simple in structure and free of flowing dead angles, effectively eliminates the channeling and wall-flow phenomena of the fluid in the tower, and improves the interphase mass transfer effect. The filler can be applied to tower equipment in various process industries.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com