Patents

Literature

1423results about How to "Save costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Template-free dynamic website generating method

InactiveCN101025738AEasy to createRealize free typesettingSpecial data processing applicationsWeb siteDatabase

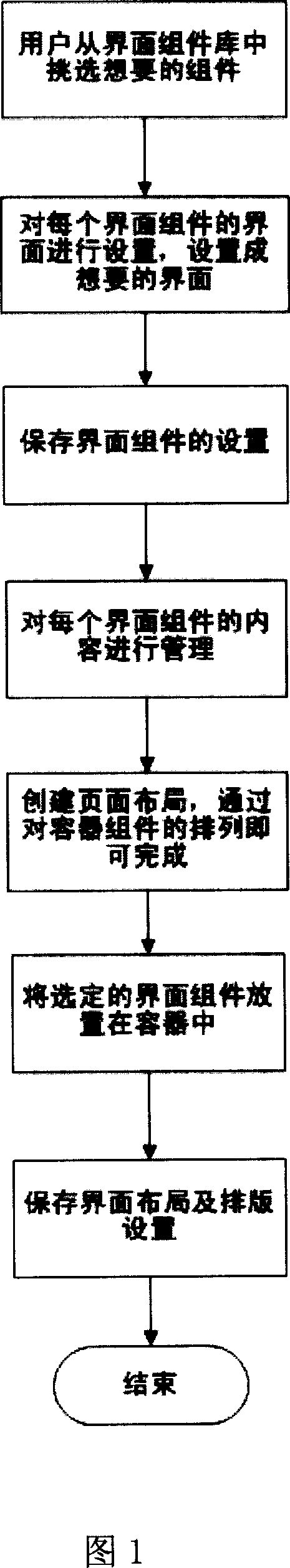

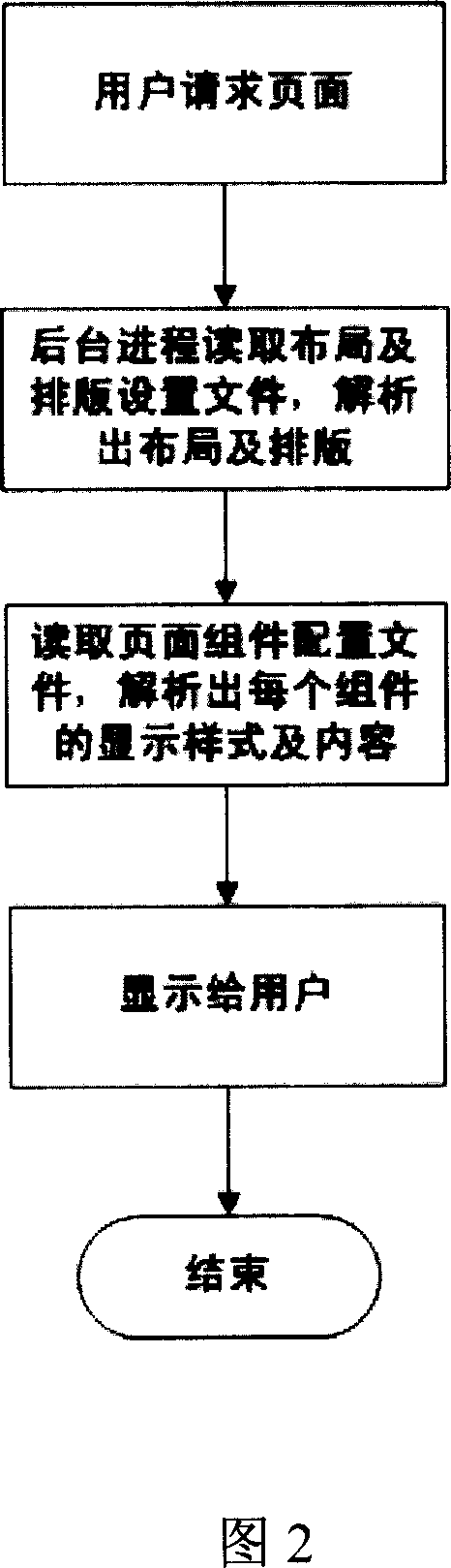

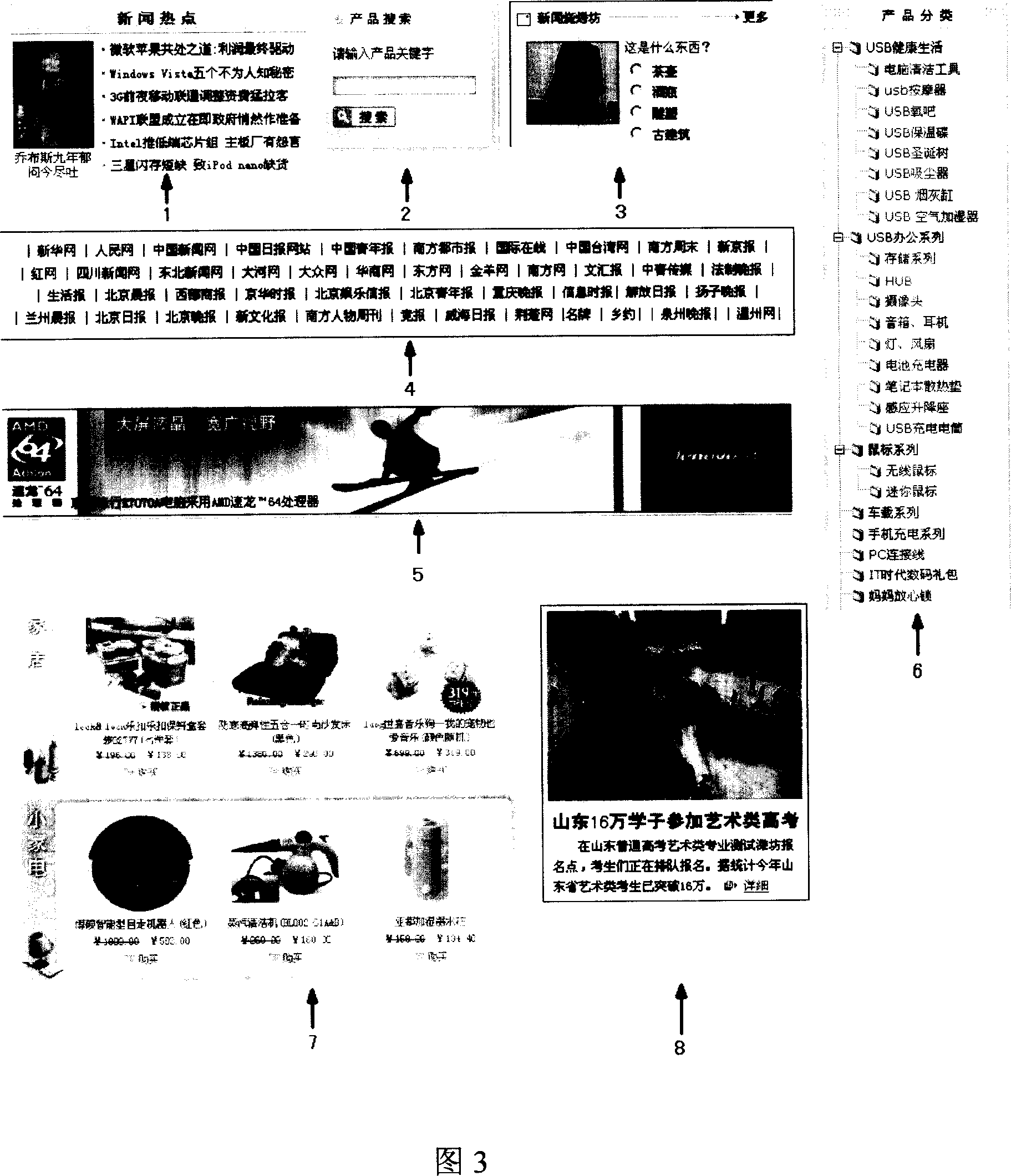

The invention discloses a template-free dynamic website generating method, mainly comprising the steps of: (A) building page component library for users to call as building websites; (B) calling the needed page components from the page component library and setting user-required interface contents and then saving the setting; (C) building page layout and freely composing the page components and saving the interface layout and composition setting, where the page component library is an extensible page component library; each page component is a dynamic maintainable page component comprises color, font, display style and other attributes. And the method is based on dynamic page components to implement free composition and can convert the user's work of writing program as building a dynamic website into the work of calling and maintaining page components, and can quickly build an extremely individual dynamic website without professional software engineer and artistic designer.

Owner:李定

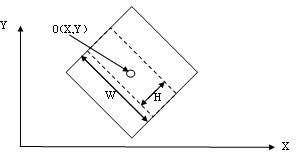

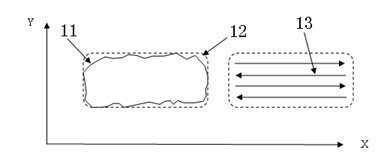

Multi-photosource linear array imaging system and method

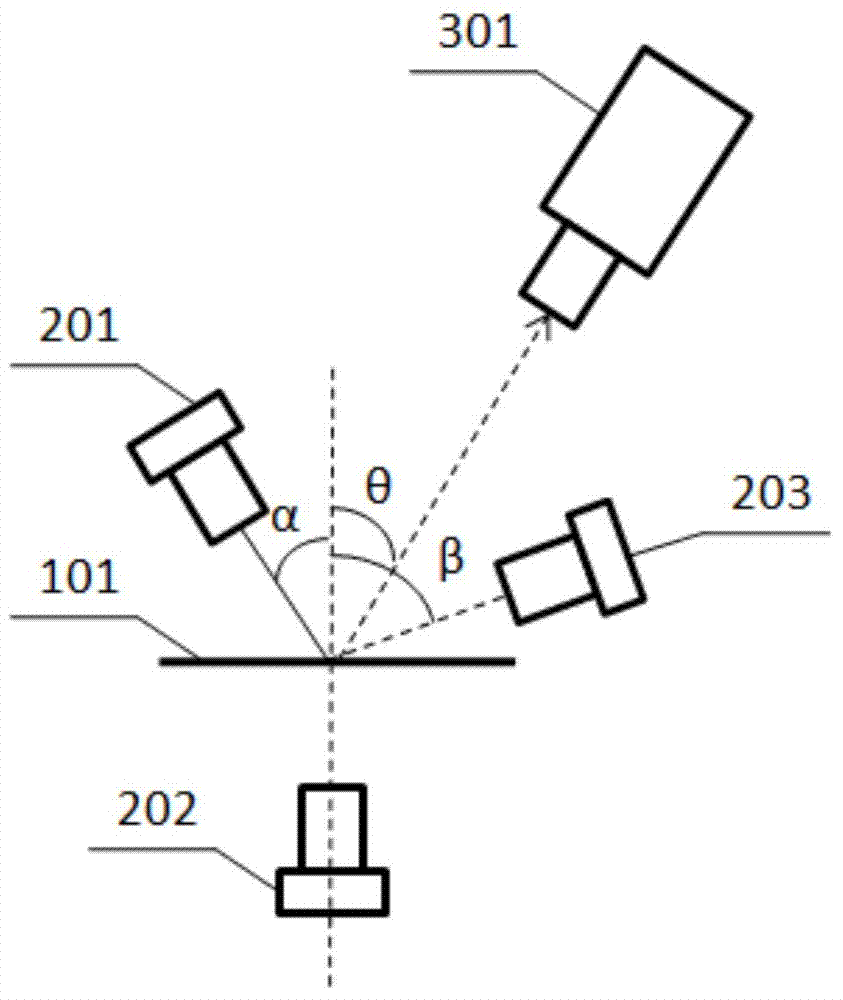

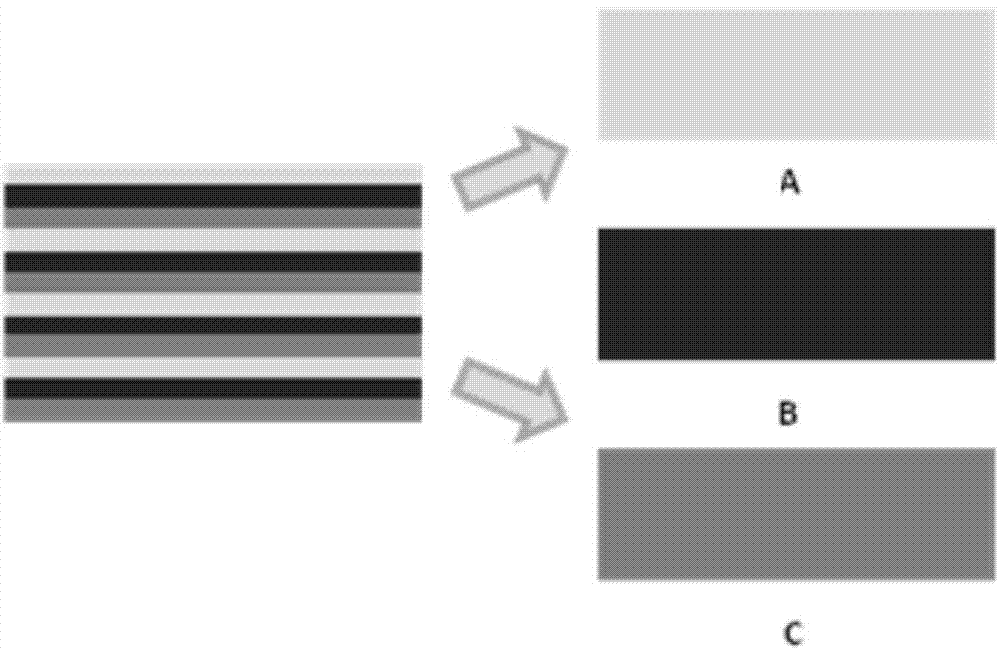

ActiveCN103884650AHigh resolutionSave costsOptically investigating flaws/contaminationImage resolutionSpace requirements

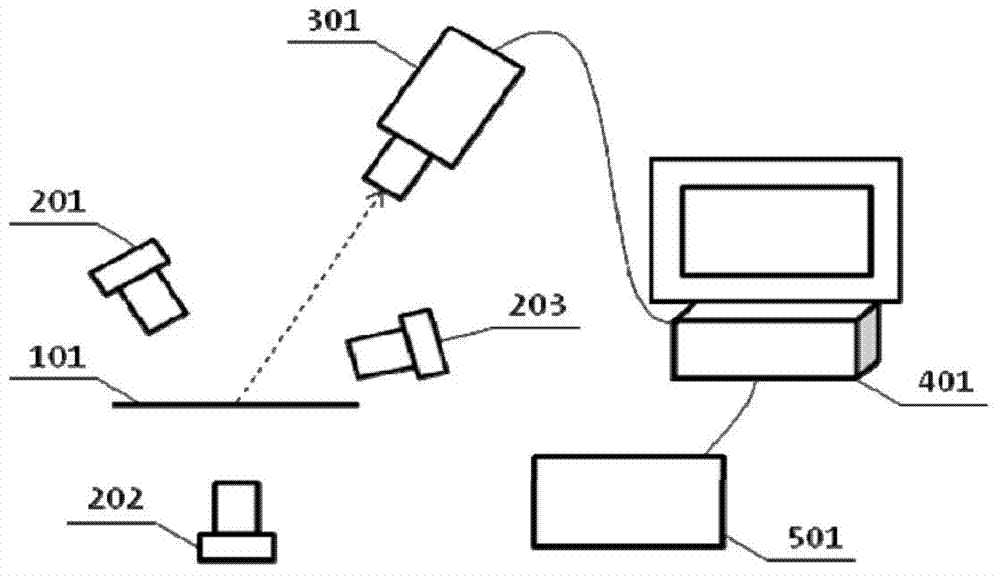

The invention provides a multi-photosource linear array imaging system and method. The multi-photosource linear array imaging system is used for imaging a detected product at a plurality of angles. The multi-photosource linear array imaging system comprises a plurality of photosoures, a linear array imaging device, a stroboflash control module and an image collecting and processing device. The multi-photosource linear array imaging system adopts the plurality of photosoures to light the detected product in sequence at different angles, adopts the same linear array imaging device to collect images under different lighting conditions, and then extracting lines of the images and jointing the images to obtain the images of the detected product under the different lighting conditions. The device and the method are capable of fully taking the advantages of high speed and high resolution ratio of a linear array detection system, and collecting images in a plurality of lighting manners at a same working station by a single imaging device, thereby greatly saving the cost and lowering the field space requirements.

Owner:BEIJING DAHENG IMAGE VISION

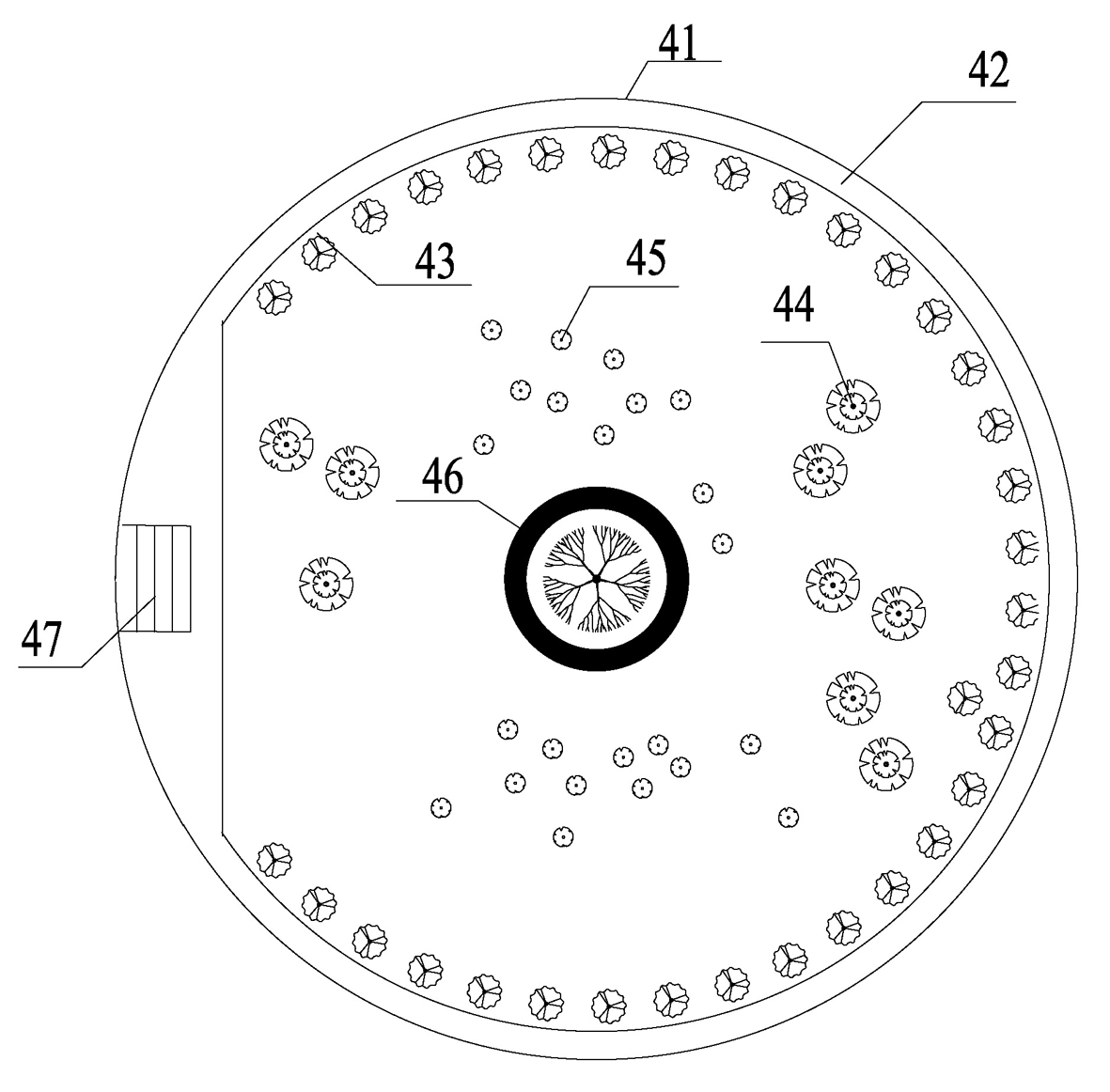

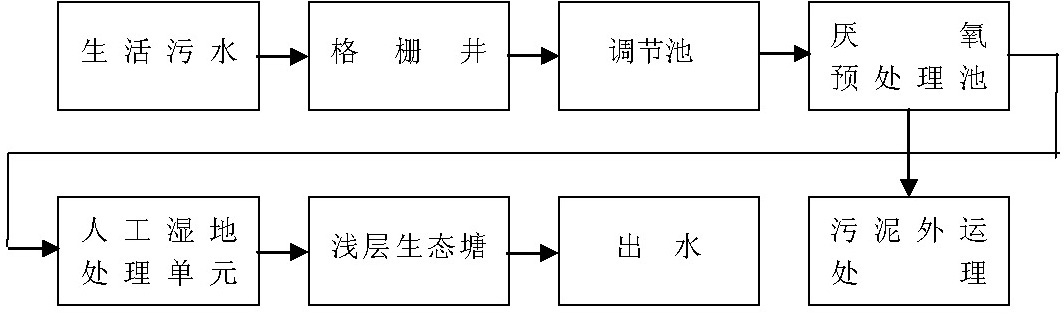

Ecological greenbelt treatment process and system for treating rural domestic sewage

ActiveCN101948214AEasy to handleLess investmentTreatment using aerobic processesWaste based fuelConstructed wetlandReclaimed water

The invention relates to an ecological greenbelt treatment process for treating rural domestic sewage, which mainly comprises the steps of: (1) anaerobic pretreatment: performing anaerobic hydrolysis pretreatment to domestic sewage; (2) artificial wetland treatment: performing artificial wetland treatment to pretreated domestic sewage; and (3) shallow ecological pond aerobic biotreatment: further performing shallow ecological pond aerobic biotreatment to outlet water treated by the artificial wetland, degrading and converting organic matters and nutrients entering the pond, and recycling purified sewage as a regenerated water resource. The invention adopts an ecological greenbelt treatment system comprising the anaerobic pretreatment, the artificial wetland and the shallow ecological pond to treat the rural domestic sewage, and has the characteristics of good treatment effect, recycling on site, low investment, low system operating cost, simple maintenance, obvious ecological benefit and the like.

Owner:浙江博世华环保科技有限公司

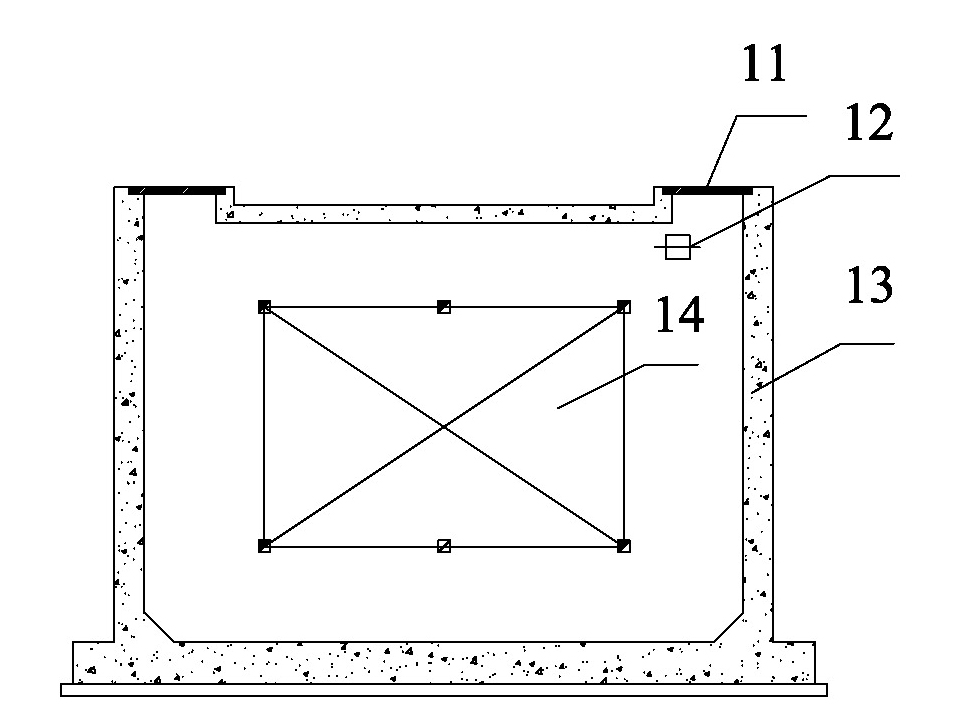

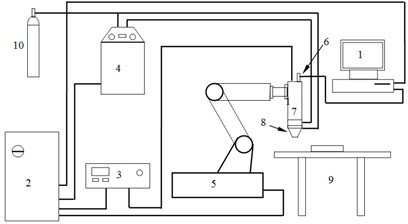

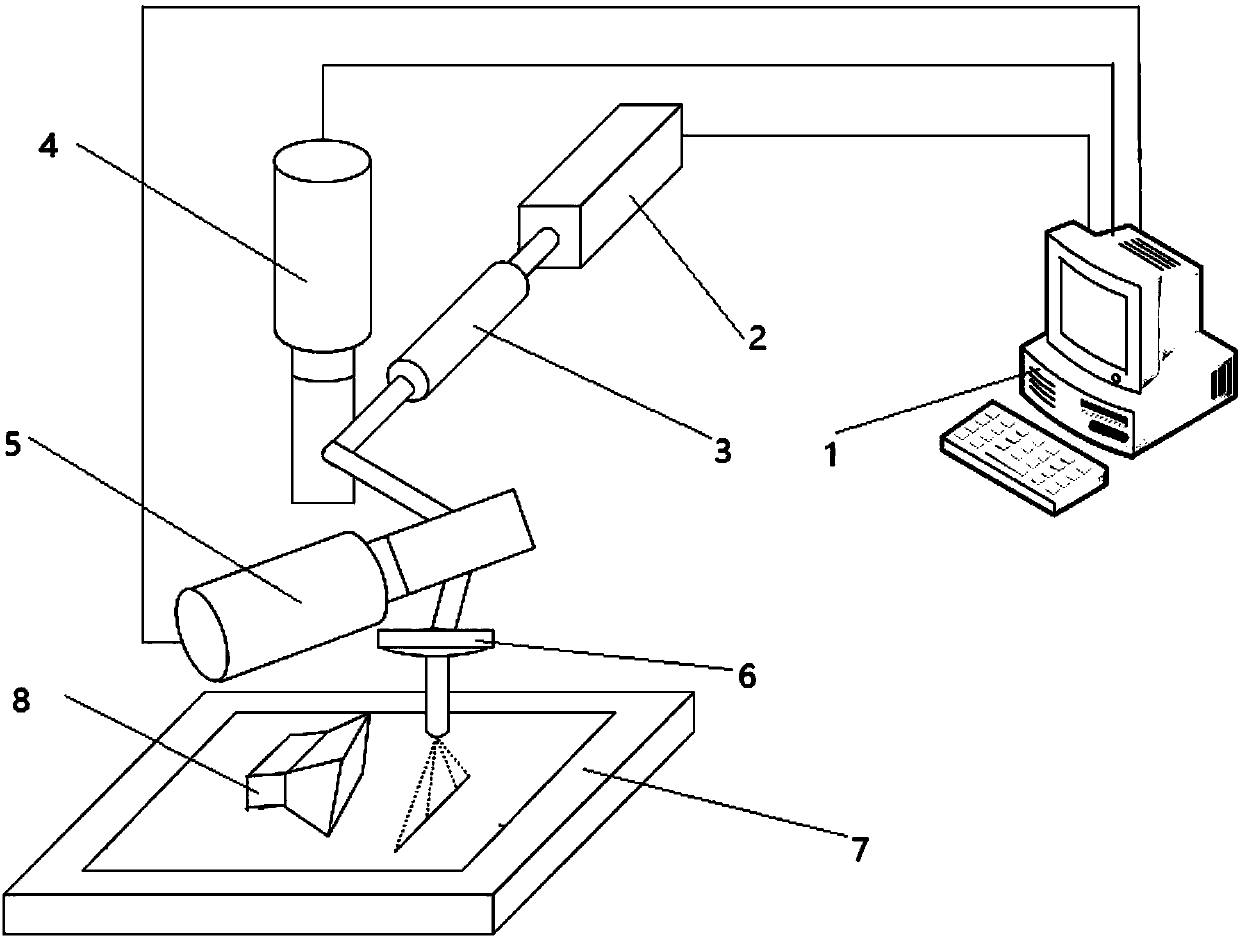

Rapid laser repair method and device for defect of aluminum alloy guide blade

ActiveCN102424971AImprove Laser Repair EfficiencyIncrease productivityMetallic material coating processesLaser beam welding apparatusLaser rangingLaser light

The invention belongs to the technical field of rapid laser repair, and particularly relates to a rapid laser repair method and a device for a defect of an aluminum alloy guide blade. The device is characterized by comprising an industrial control computer, a robot control cabinet, an optical fiber laser, a powder feeding device, a robot body, a camera, a laser ranging sensor, a laser light path unit, a coaxial powder feeding nozzle, a workbench and an argon gas cylinder, wherein the industrial control computer is connected with the camera and the laser ranging sensor through cables and is connected with the robot control cabinet through an Ethernet cable, the robot control cabinet is connected with a robot body through a cable, is connected with an I / O (input / output) port of the optical fiber laser through an I / O port and is connected with the powder feeding device through a cable, and the optical fiber laser is connected with the laser light path unit through a conductive optical fiber. The device has high efficiency and good reliability, and the quality of repaired parts is stable.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

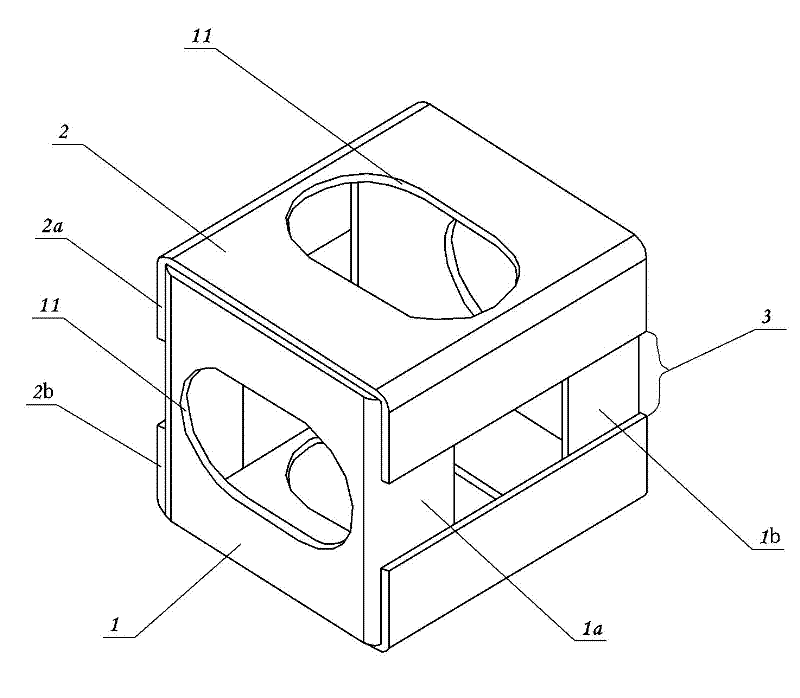

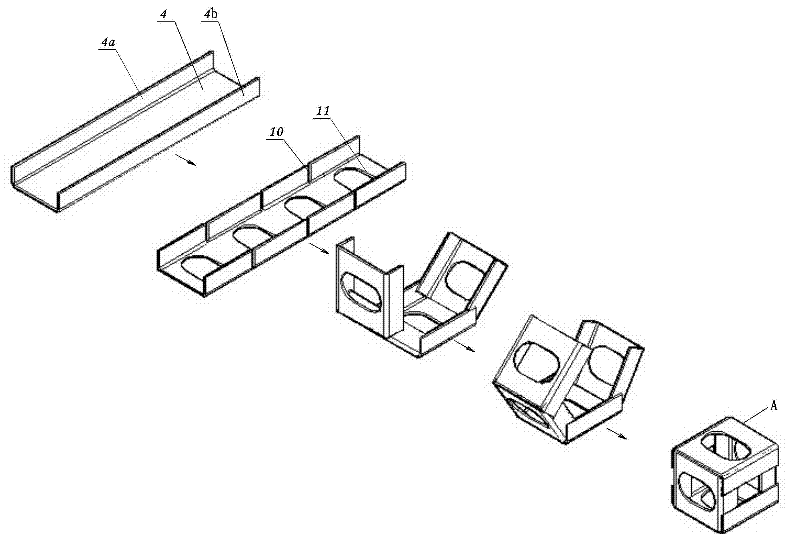

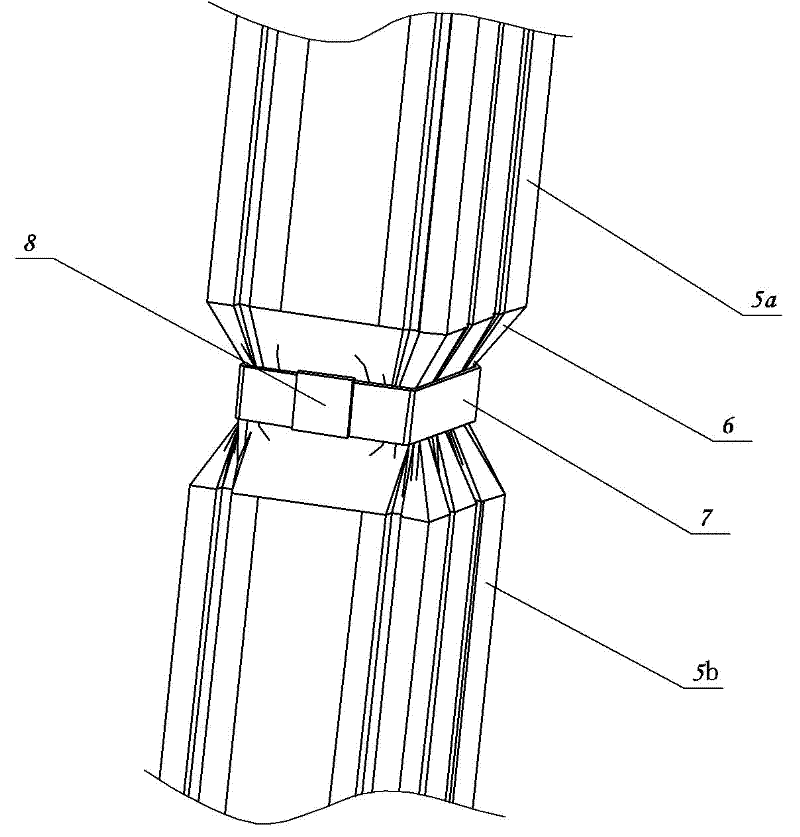

Ultrathin-wall steel structure connector and connecting structure

InactiveCN102359191AImprove bearing capacityEasy to operateBuilding constructionsUltimate tensile strengthMechanical engineering

The invention discloses an ultrathin-wall steel structure connector and an ultrathin-wall steel structure connecting structure. The connector is a hollow square or oblong connector, the front and rear side plates of the connector are two buckled groove type steels, and the upper and lower side plates are two buckled and noncontact groove type steels, wherein two side wing plates of the upper and lower groove type steels are fixed at the outer sides of the front and rear groove type steel wing plates, and a hoop groove is formed at the noncontact part between the upper and lower groove type steel wing plates. The connector is simple, convenient and fast in operation, and has high strength and good axial constraint performance; and the node has strong integrity, local buckling of the end when the ultrathin-wall profile steel is stressed is effectively controlled, and the bearing capacity of a member is improved. The connector has the characteristic of allowing two connecting members in the same direction, and is suitable for mutual butting of two ultrathin-wall profile steels when the ultrathin-wall profile steel members are not long enough. The connector is simple in installation mode, practical and convenient and fast in operation, and the cost and the working time can be greatly saved.

Owner:河南华斯豪智能科技有限公司

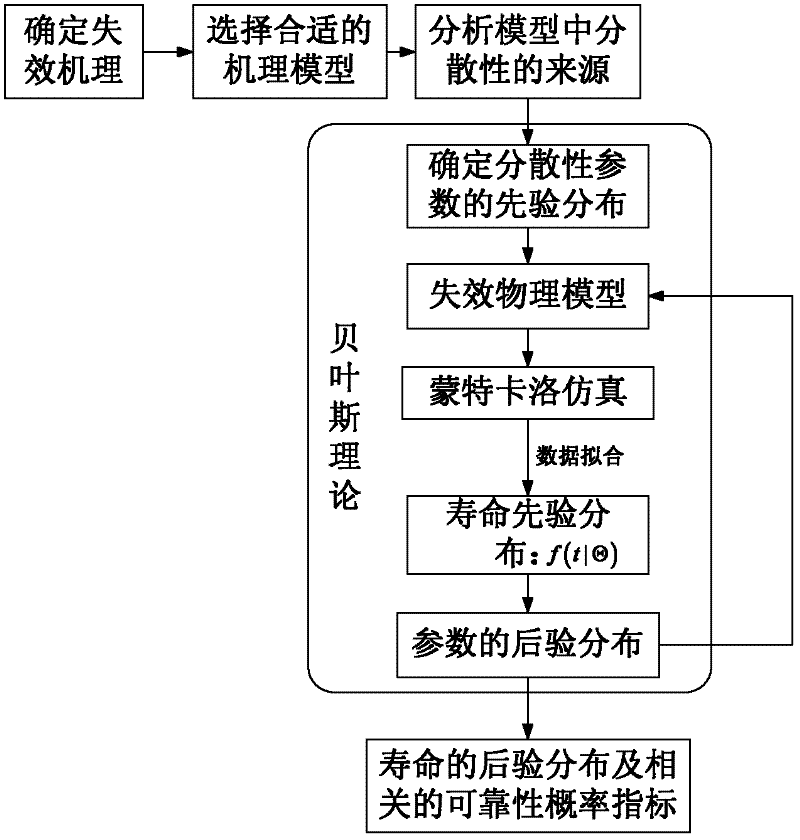

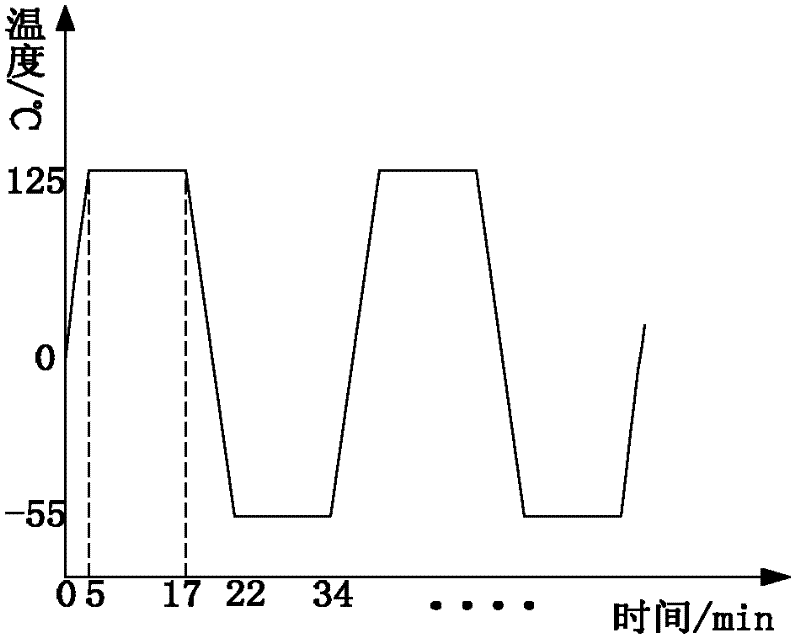

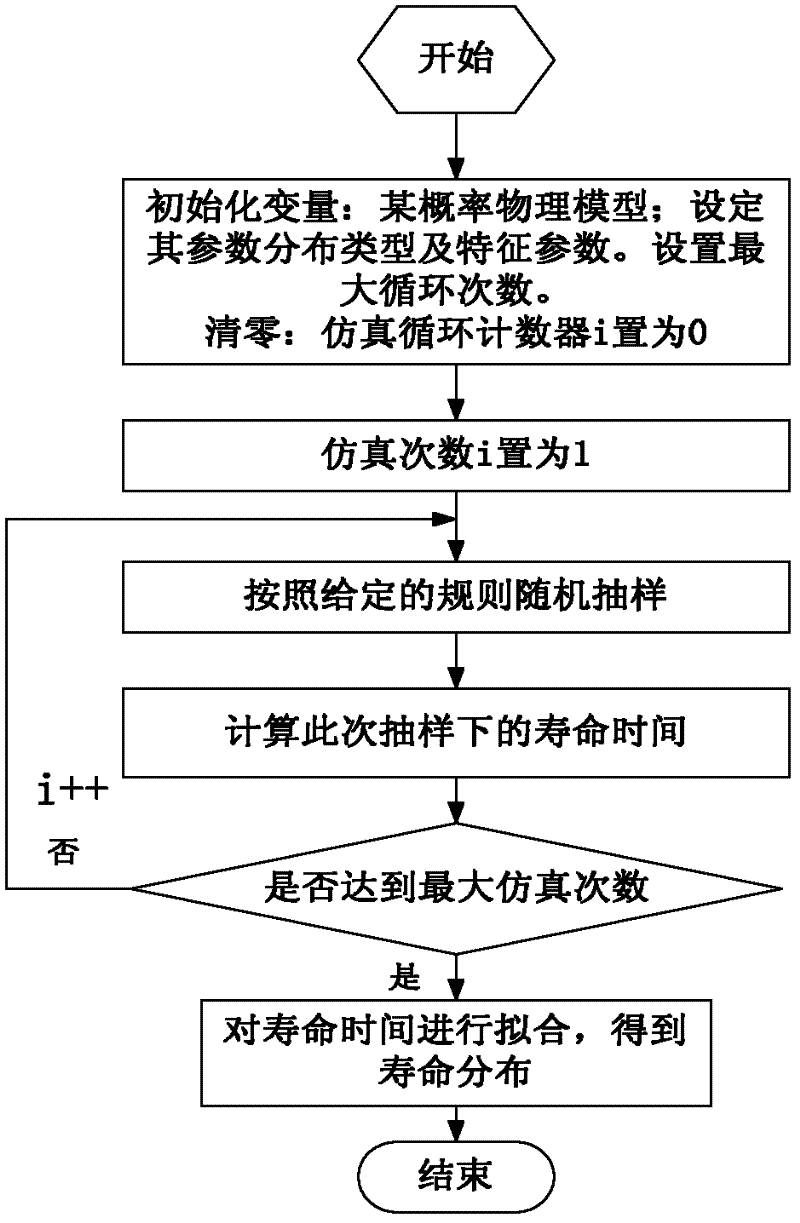

Probability method of electronic product service life model based on Bayesian theory

ActiveCN102651054AShorten the timeSave costsSpecial data processing applicationsPhysical modelParameter distribution

The invention discloses a probability method of an electronic product service life model based on a Bayesian theory. The probability method comprises four steps of: step 1, determining a main failure mechanism and a physical model; step 2, determining the source and a characterization method of each dispersibility in the main failure mechanism; step 3, determining the service life distribution obeyed by the main failure mechanism; and step 4, updating the parameter distribution according to the Bayesian theory, and obtaining the numerical solution of a probability service life model by combining a failure physical model and utilizing a Monte Carlo sampling method. The method disclosed by the invention is used for calculating the failure probability of a highly-reliable and long-service-life electronic product based on a stress damage model; and by analyzing diepersibility and a description method of factors such as the attribute, the size and the stress of each material causing the electronic product failure and considering the dispersibility factors on the basis of the traditional failure physical model, the probability of the failure physical model is realized, and a new approach is provided for describing the failure more accurately and forecasting the product storage life.

Owner:BEIJING LANWEI TECH CO LTD

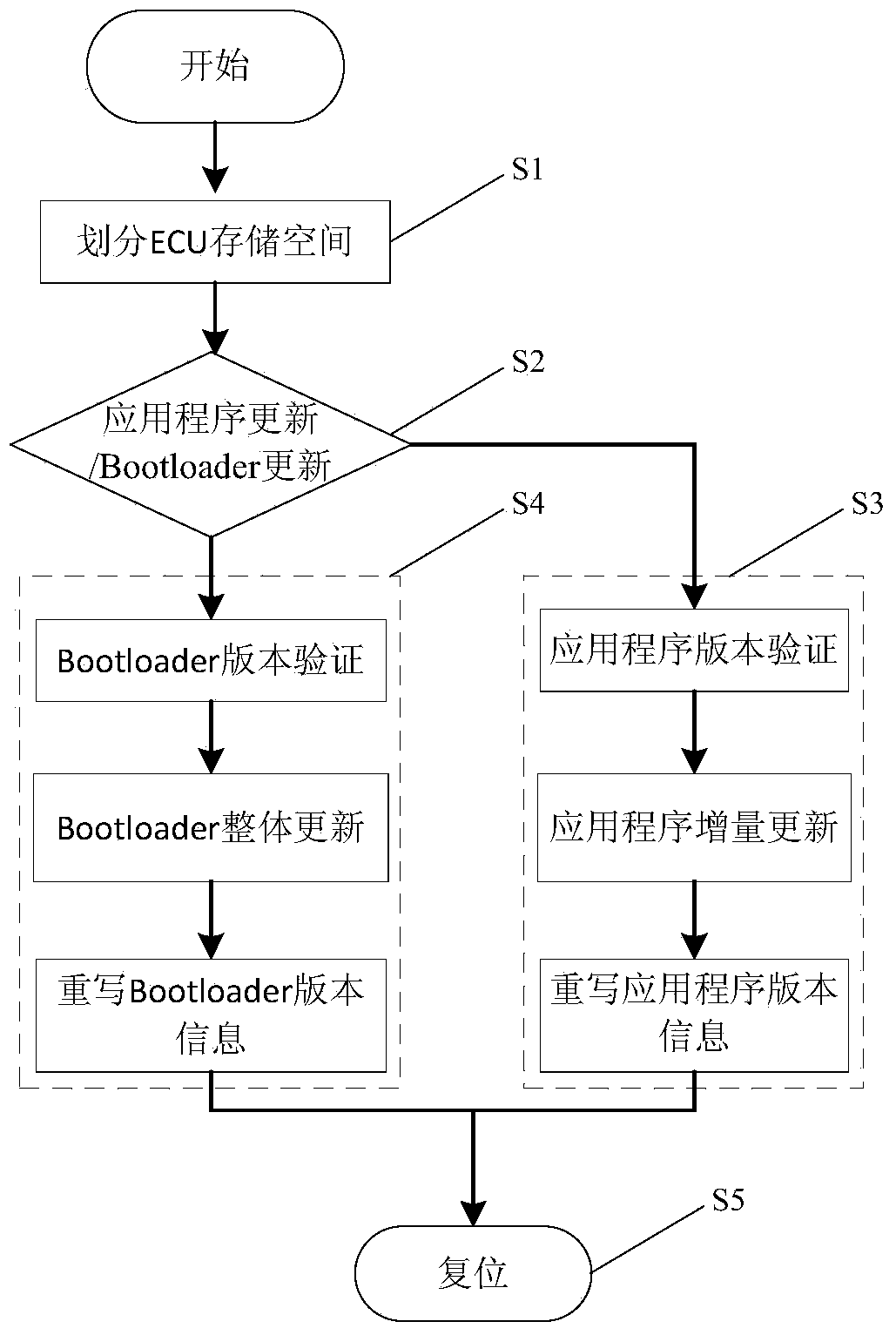

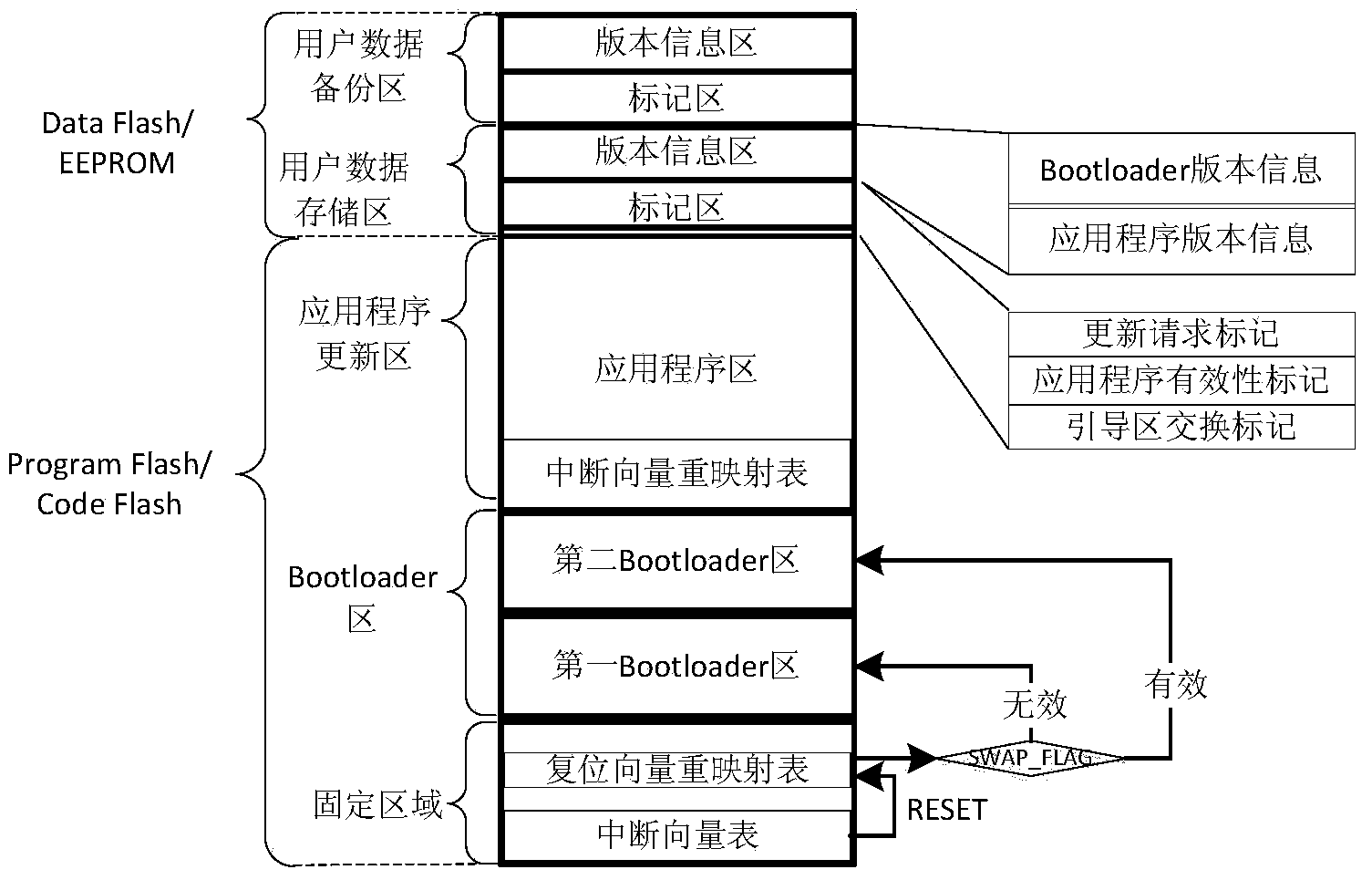

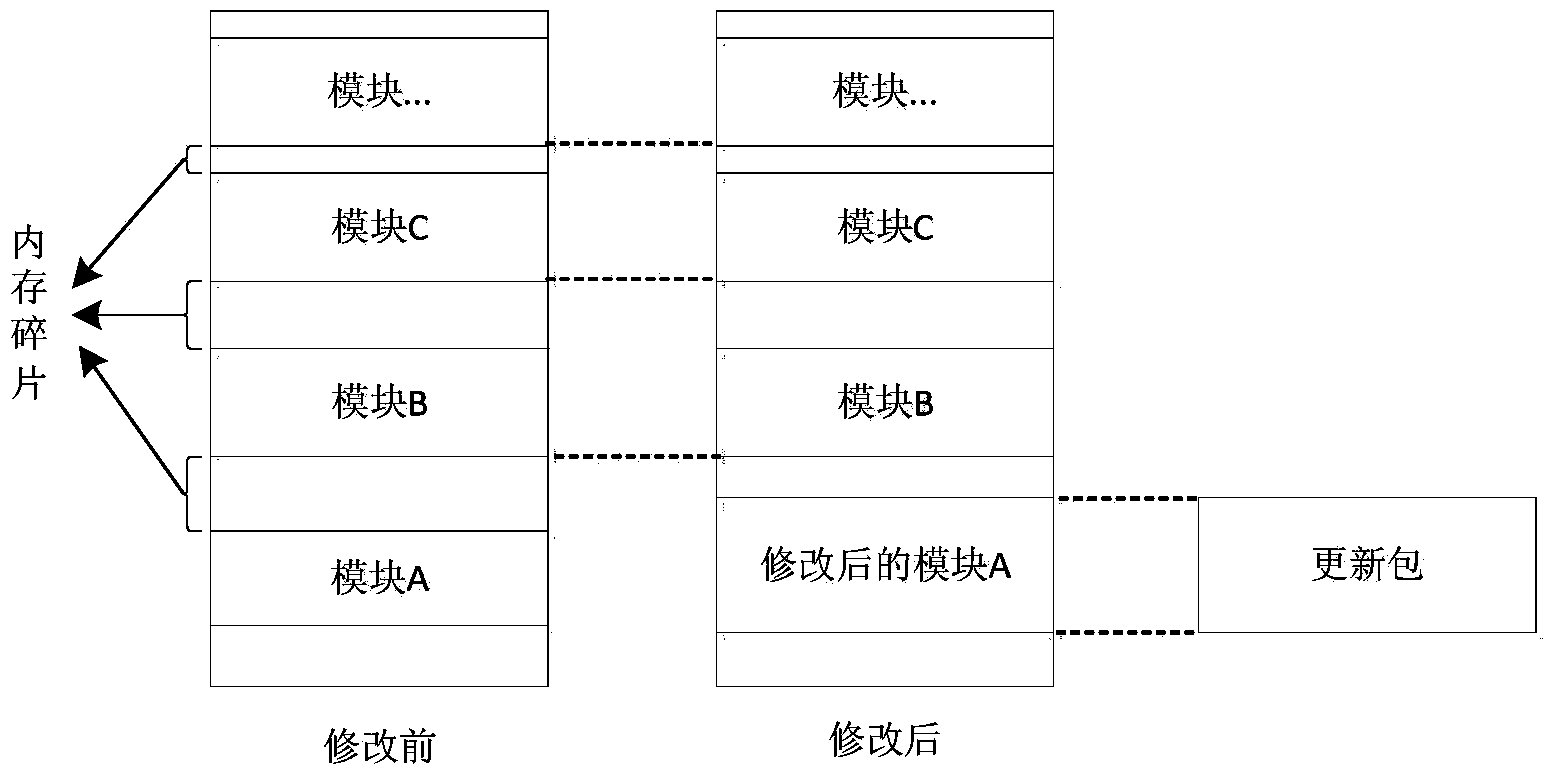

ECU (electronic control unit) firmware updating method based on Bootloader self update

ActiveCN104360877AShorten the timeSave costsSoftware engineeringProgram loading/initiatingApplication softwareProgramming process

The invention relates to an ECU (electronic control unit) firmware updating method based on Bootloader self update. The ECU firmware updating method based on the Bootloader self update comprises the following steps: S1: dividing the storage space of an ECU system; S2: judging whether the ECU system receives an application program updating request or a Bootloader updating request, if the application program updating request is received, executing the step S3, and if the Bootloader updating request is received, executing the step S4; S3: updating codes in an application code area in a way of incremental update, and executing thestep S5; S4: performing integral self update on codes in a Bootloader area by using a Bootloader program, and executing the step S5; S5: rewritting corresponding version information in a version information area, and resetting the ECU system. Compared with the prior art, the ECU firmware updating method based on the Bootloader self update has the advantages that the time and the cost are saved, the security of the Bootloader is ensured, and the programming process is more efficient and reliable.

Owner:TONGJI UNIV

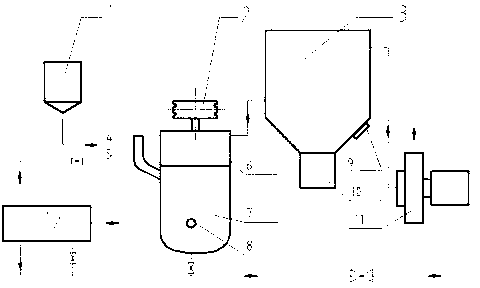

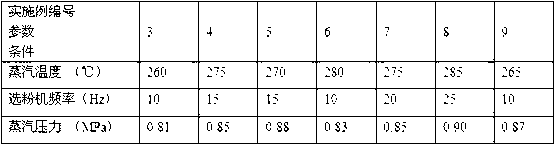

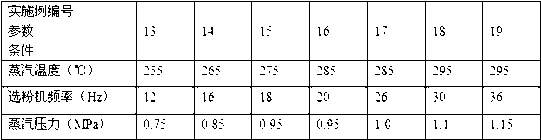

Method for producing phosphorus building gypsum by phosphorous gypsum

The invention discloses a method for producing phosphorus building gypsum by phosphorous gypsum. The method is characterized by comprising the following steps of drying industrial residual phosphorous gypsum by a pneumatic drier to a state that water content is smaller than 5%; sending the dried phosphorous gypsum to a steam jet mill, grinding the industrial residual phosphorous gypsum by the steam jet mill and dewatering, collecting the grinded phosphorous gypsum by a dust collector and cooling the phosphorous gypsum to obtain the phosphorus building gypsum, wherein the power medium of the steam jet mill is superheated steam; a frequency of a powder concentrator is 10 Hz-40 Hz; the temperature of the superheated steam is 250 DEG C-300 DEG C; and a pressure of the superheated steam is 0.7 MPa-1.2 MPa. In the method, the industrial residual phosphorous gypsum is used as a raw material; the superheated steam generated by industrial waste heat is used as a power for the steam jet mill to prepare the phosphorus building gypsum. The method has the characteristics of wide available raw materials, simple production equipment, high yield, low cost, large-scale production, etc. The prepared phosphorus building gypsum can be used for preparing building functional mortar and producing gypsum boards and building blocks, and has strong practicality.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method of forming fractures by means of hydrofracturing assisted by alternate spraying of high- and low-temperature fluids in deep hot dry rock

ActiveCN108979609AImprove the problem of difficult hydraulic fracturingIncrease the number ofFluid removalFracturing fluidMicro fracture

The invention provides a method of forming fractures by means of hydrofracturing assisted by alternate spraying of high- and low-temperature fluids in deep hot dry rock. The method herein includes: setting out a well network, and performing primary hydrofracturing to form main fractures; injecting a high-temperature high-pressure fluid and low-temperature water alternately into the main fractureswithin short alternate time; forming micro fractures in the rock at the surface of the main fractures under the thermodynamic action of a great temperature difference and the impact action of a jet; allowing multilevel fracturing to enable the micro fractures to further expand and form more micro fractures under the action of a low-temperature waterborne fracturing fluid and the action of high pressure; repeating until the main fractures and the micro fractures are in mutual lap joint and communication so that a fracture cluster and / or a fracture belt is formed between injection wells and production wells; injecting a sand-carrying fluid, a proppant and a displacing fluid, and closing the wells to complete fracture forming so as to construct an efficient heat exchange reservoir. The methodenables the quantity of the fractures to be significantly increased via the thermal stress action of the temperature difference, so that a fracture network is formed; heat exchange efficiency of a heat storage space is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

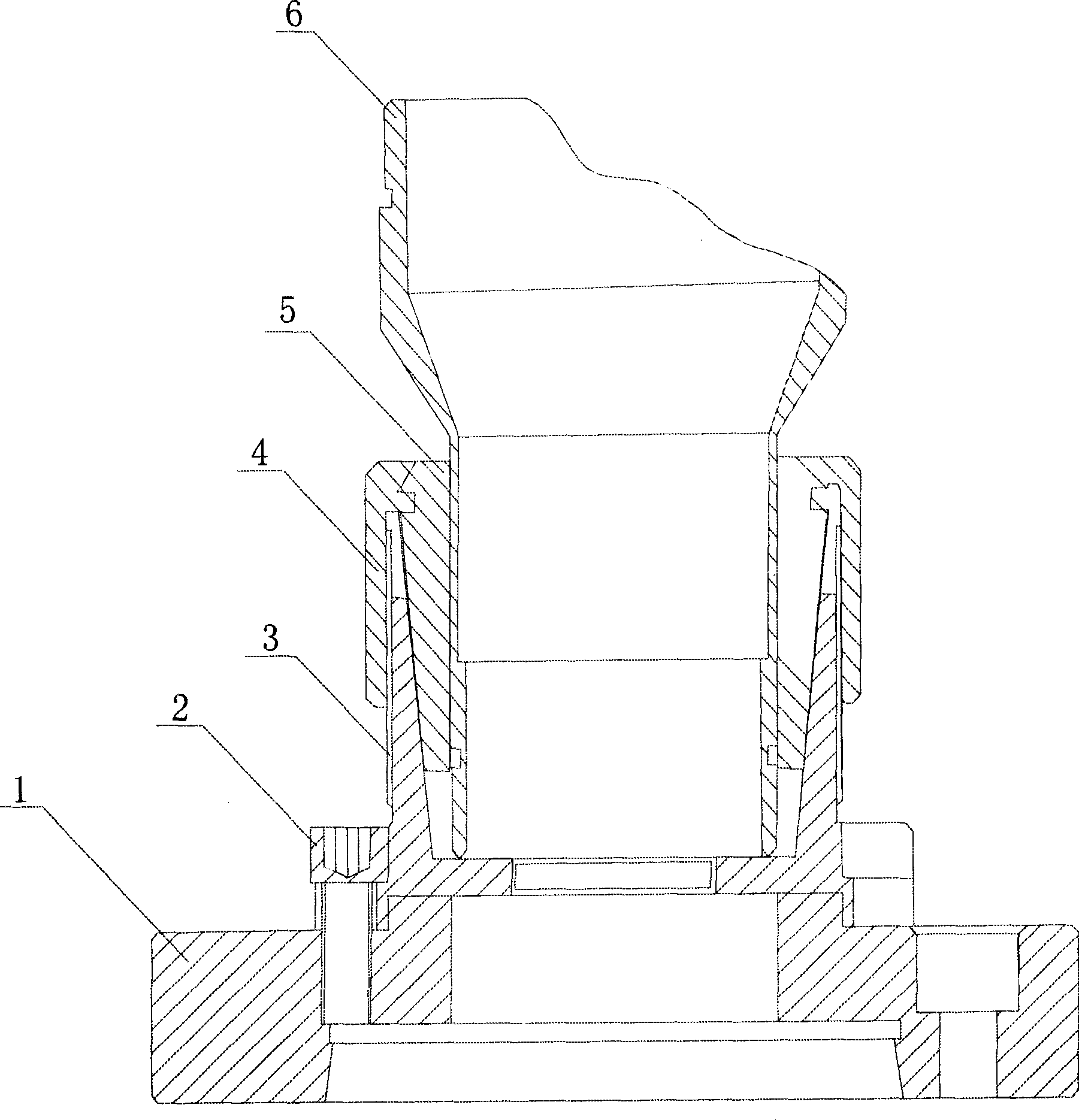

Precision positioning and clamping device of lathe

InactiveCN101518875AAdvanced technologyWork lessPositioning apparatusMetal-working holdersAxial displacementEngineering

The invention relates to a precision positioning and clamping device of a lathe, which comprises a clamp base, a clamp body, an elastic sleeve and a clamp nut, wherein the clamp body is connected and fixed with the clamp base by a screw, the clamp nut is fixed with the bolt of the clamp body and the upper end of the elastic sleeve is connected and fixed with the clamp nut, wherein a plurality of slits are evenly distributed at two ends of the elastic sleeve and the number thereof is the multiple of 3, and the distances between any two slits are equal; workpieces are arranged in the elastic sleeve and the axial direction is restricted by a positioning block; the external conical surface of the elastic sleeve and the corresponding conical surface of the clamp body are centered by taper fitting; and the clamp nut is rotated to generate an axial displacement by driving the elastic sleeve, thus changing the internal diameter of the sleeve and further tightly clamping the workpieces. The device can be configured with a certain number of elastic sleeves according to the demand of part family so as to lead the internal diameter to be changed, thus being applicable to parts with various sizes and avoiding the increase of repeated designing work of the technique and frock in the machining process, thereby further saving time and cost.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

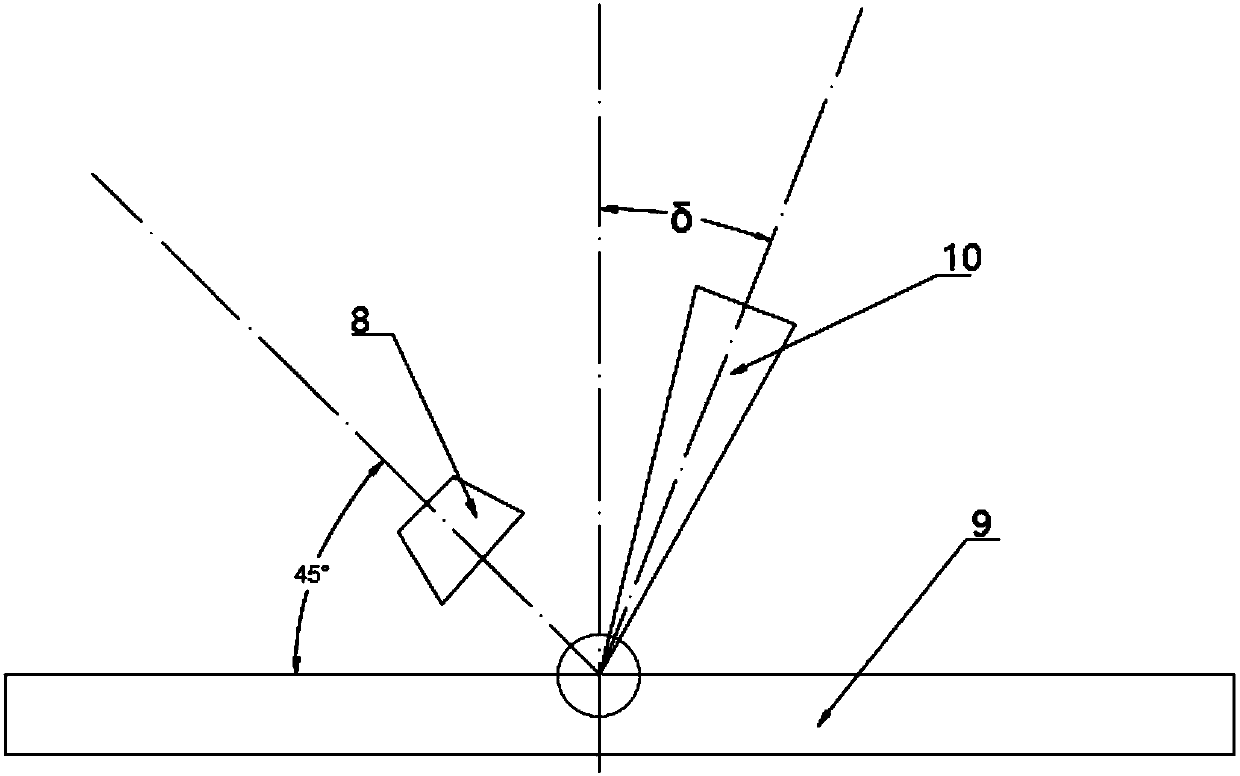

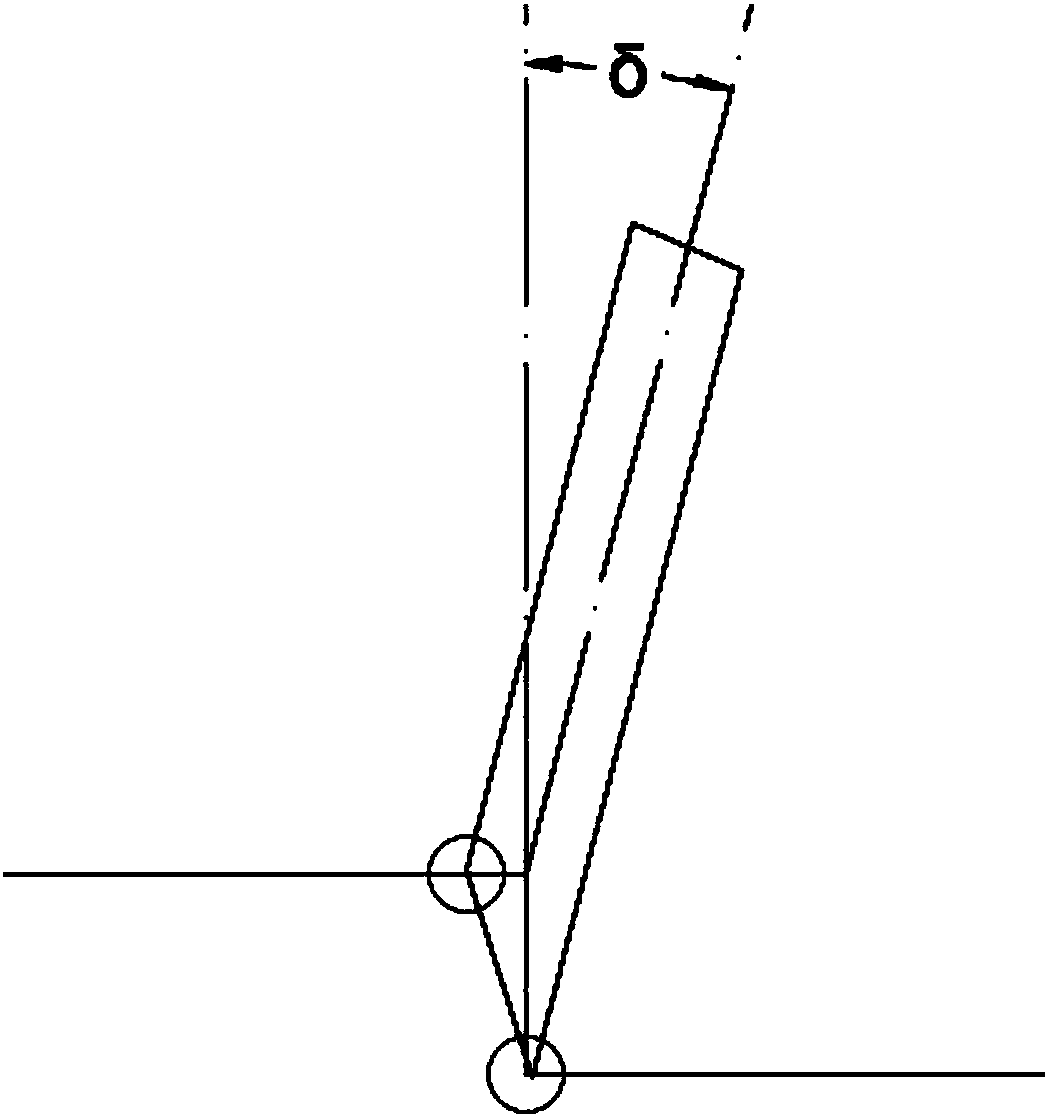

Surface remediation process for large-size metallic component

InactiveCN104651832AReduce tedious workOvercome the problem of poor powder bundle convergenceMetallic material coating processesOptoelectronicsWorkload

The invention discloses a surface remediation process for a large-size metallic component. The surface remediation process comprises the following steps: 1, associating process parameters of a laser cladding nozzle with powder beam gathering length at the outlet of the laser cladding nozzle; 2, establishing a three-dimensional model; 3, generating a scanning track route of the laser cladding nozzle; 4, confirming the maximum inclination angle of the laser cladding nozzle, selecting the process parameter of the laser cladding nozzle and the powder beam gathering length according to the association relationship established in the step 1, and controlling the laser cladding nozzle to remedy the surface of the metallic component to be remedied according to the scanning track route generated in the step 3. In the remediation process disclosed by the invention, the laser cladding nozzle can continuously move in a posture variable manner, so that the axis direction of the laser cladding nozzle is constantly kept being overlapped with the normal direction of the surface of the remedied component, rapid laser cladding remediation on the surfaces of large-size components and equipment is achieved, and the tedious workload of moving and clamping workpieces before remediation is reduced.

Owner:SUZHOU UNIV

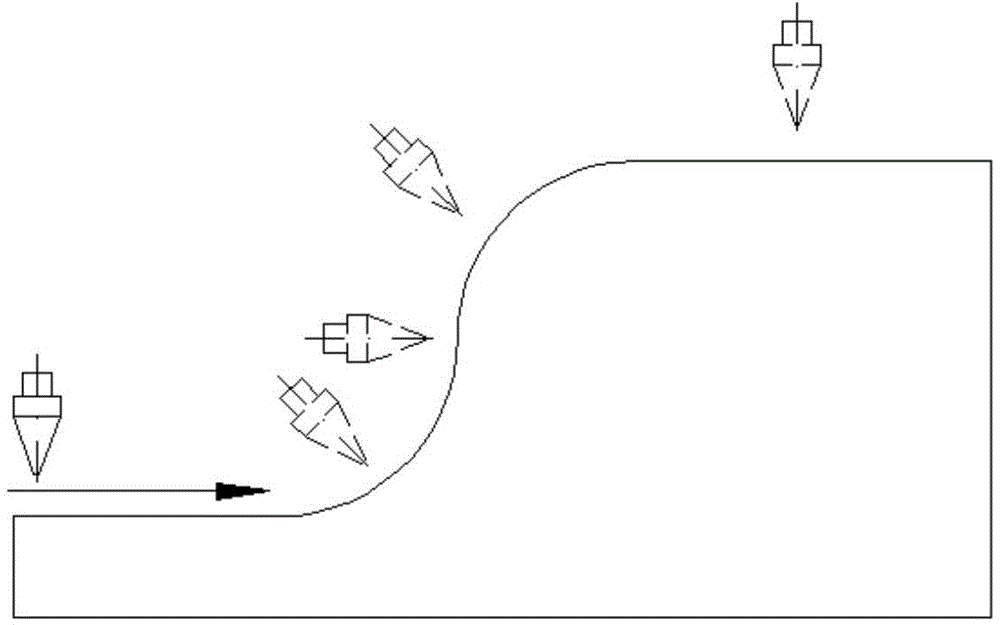

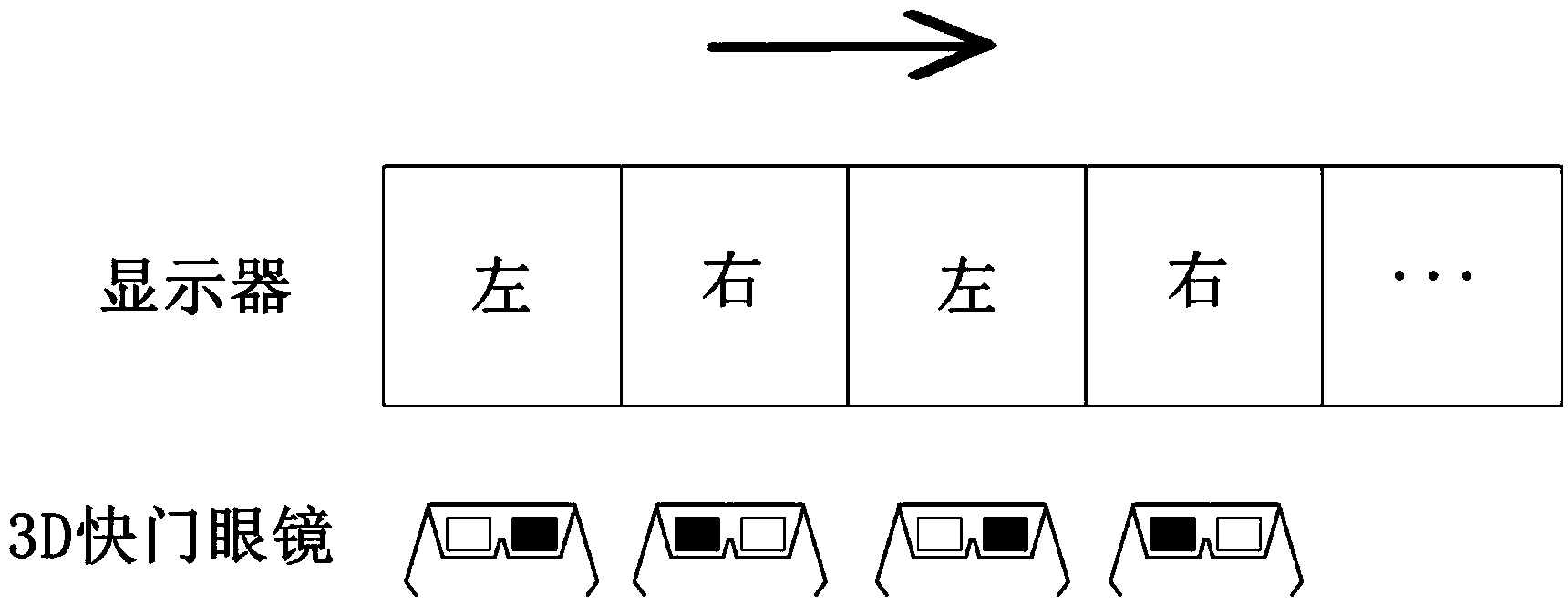

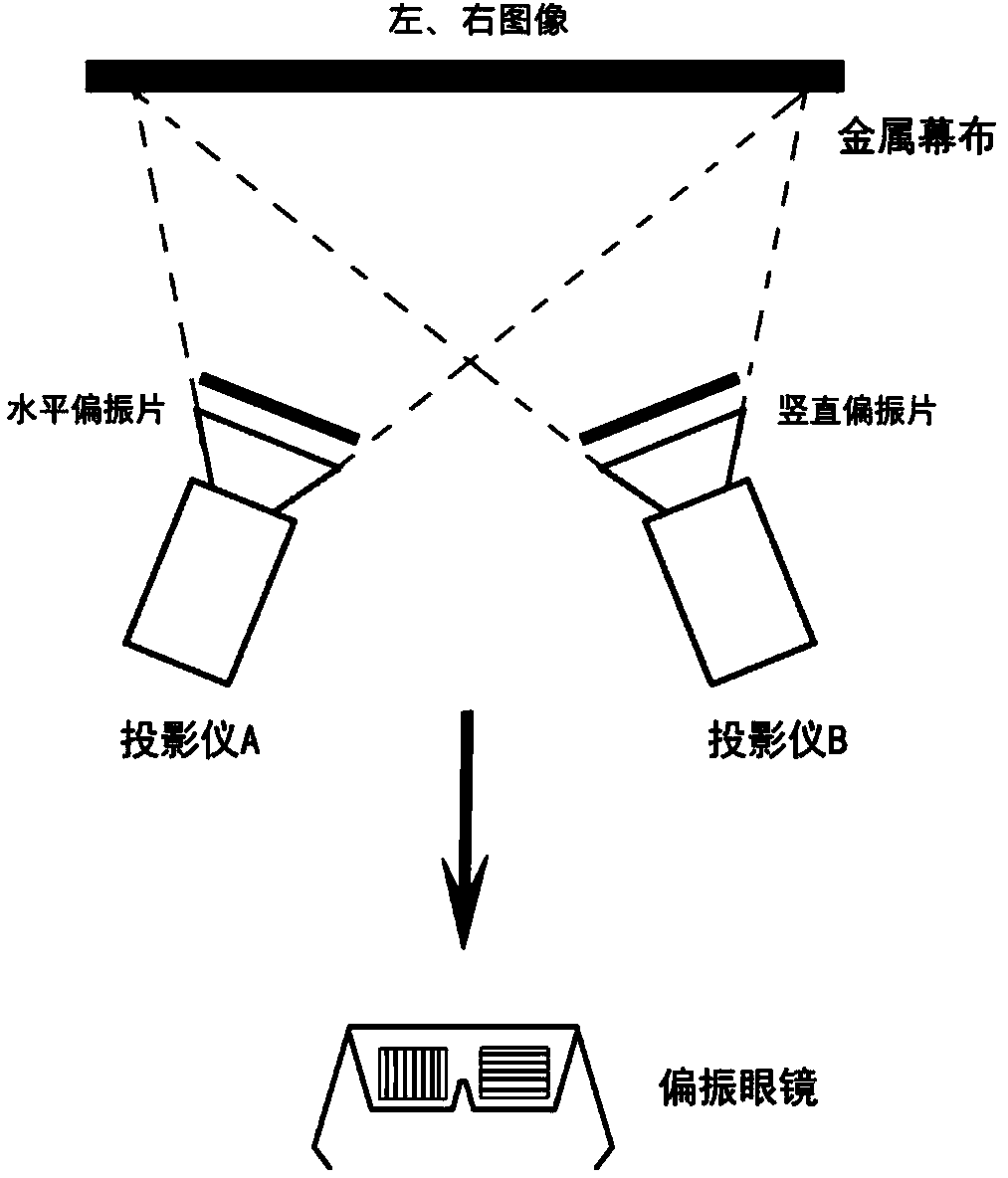

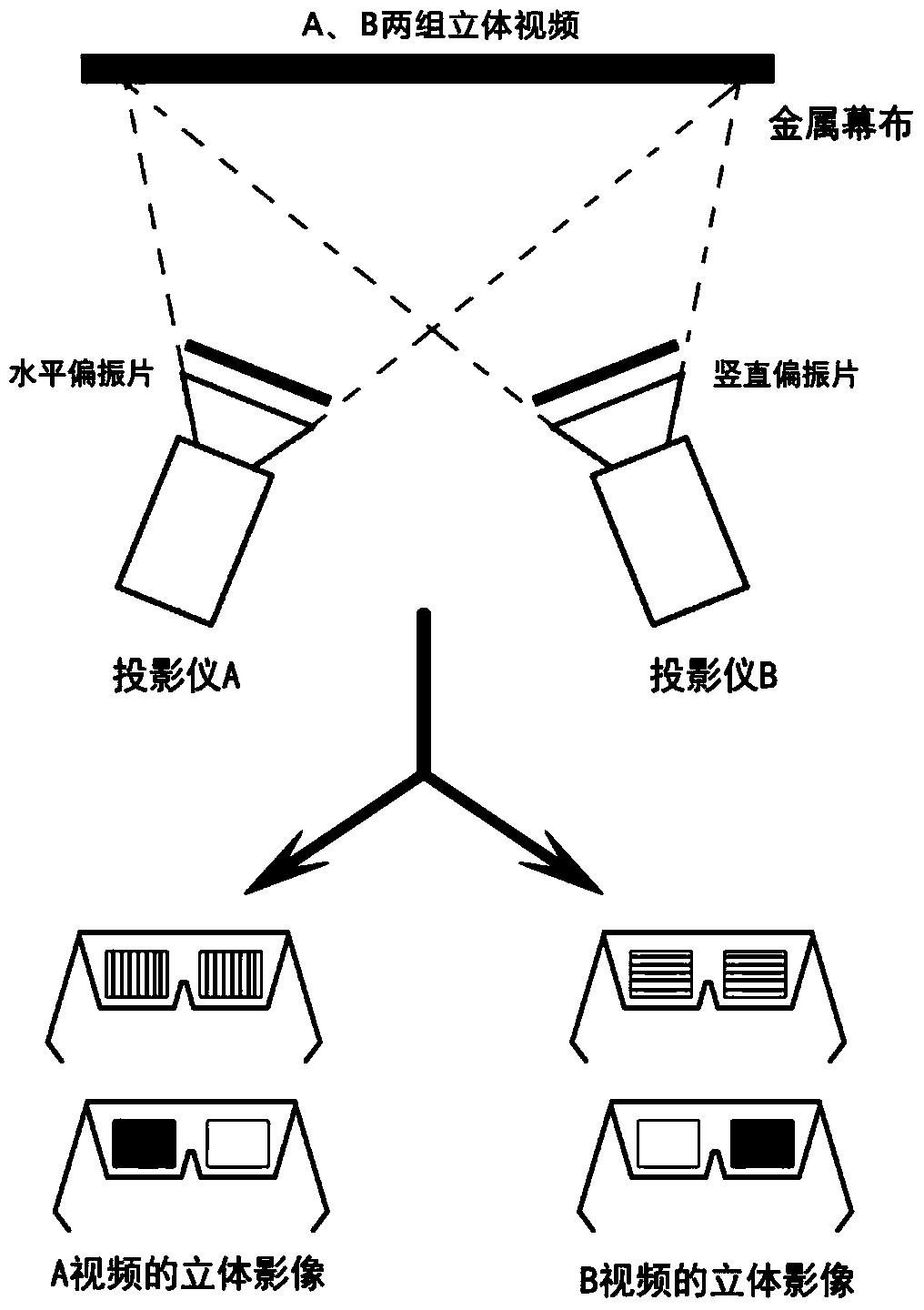

Virtual simulation system and method of antagonistic event with net based on three-dimensional multi-image display

InactiveCN104394400AExpand the scope of activitiesReal interactionVideo gamesSteroscopic systemsNetwork connectionDisplay device

The invention discloses a virtual simulation system and method of an antagonistic event with a net based on three-dimensional multi-image display. The system comprises a network connection module, a game logic module, an interaction control module, a physical engine module, a three-dimensional rendering module and a dual-image projection display module, wherein the network connection module comprises a server sub-module and a client sub-module and is used for network communication and data transmission; the game logic module is used for storing game rules, controlling the play of character animation and performing mapping by position; the interaction control module is used for controlling corresponding game characters in a virtual tennis game scene to move and shooting three-dimensional images of different sight points; the physical engine module is used for efficiently and vividly simulating the physical effects of a tennis ball, such as rebound and collision through a physical engine and enabling the game scene to be relatively real and vivid. According to the system, the three-dimensional multi-image display operation can be performed on a same display screen, and the same game scene can be rendered in real time based on different sight angles.

Owner:SHANDONG UNIV

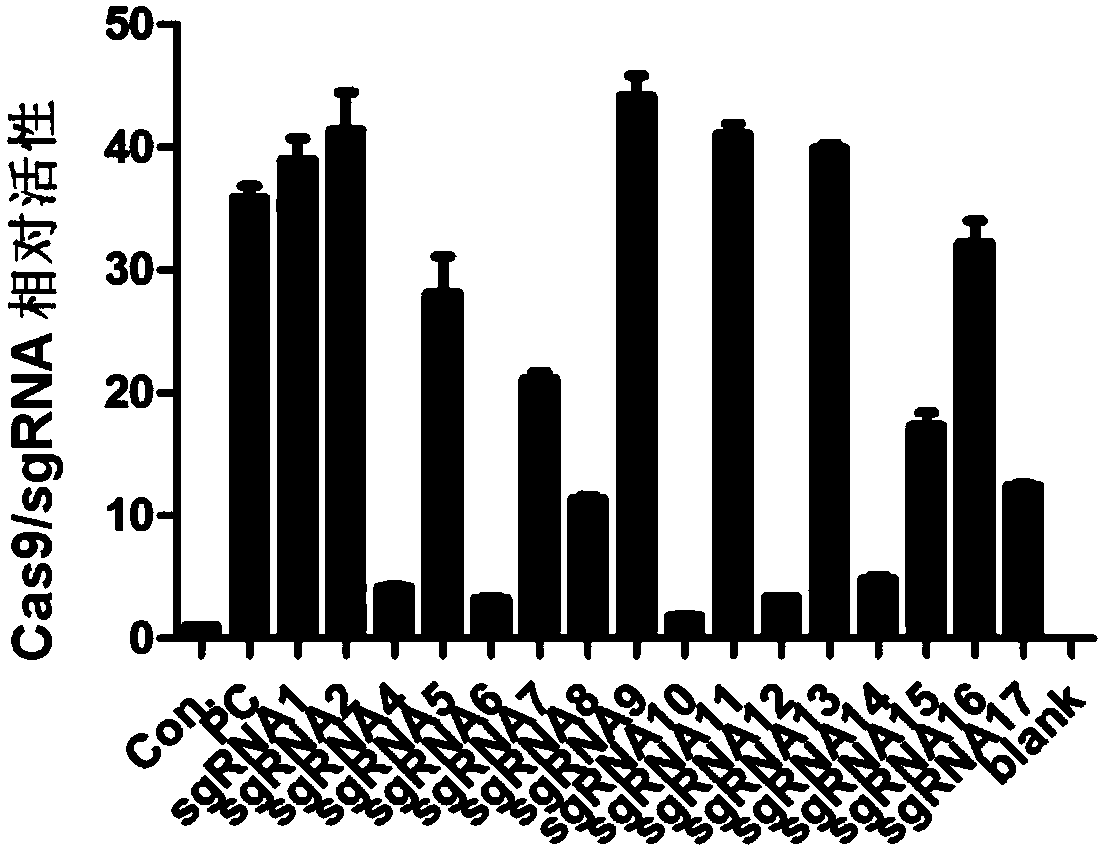

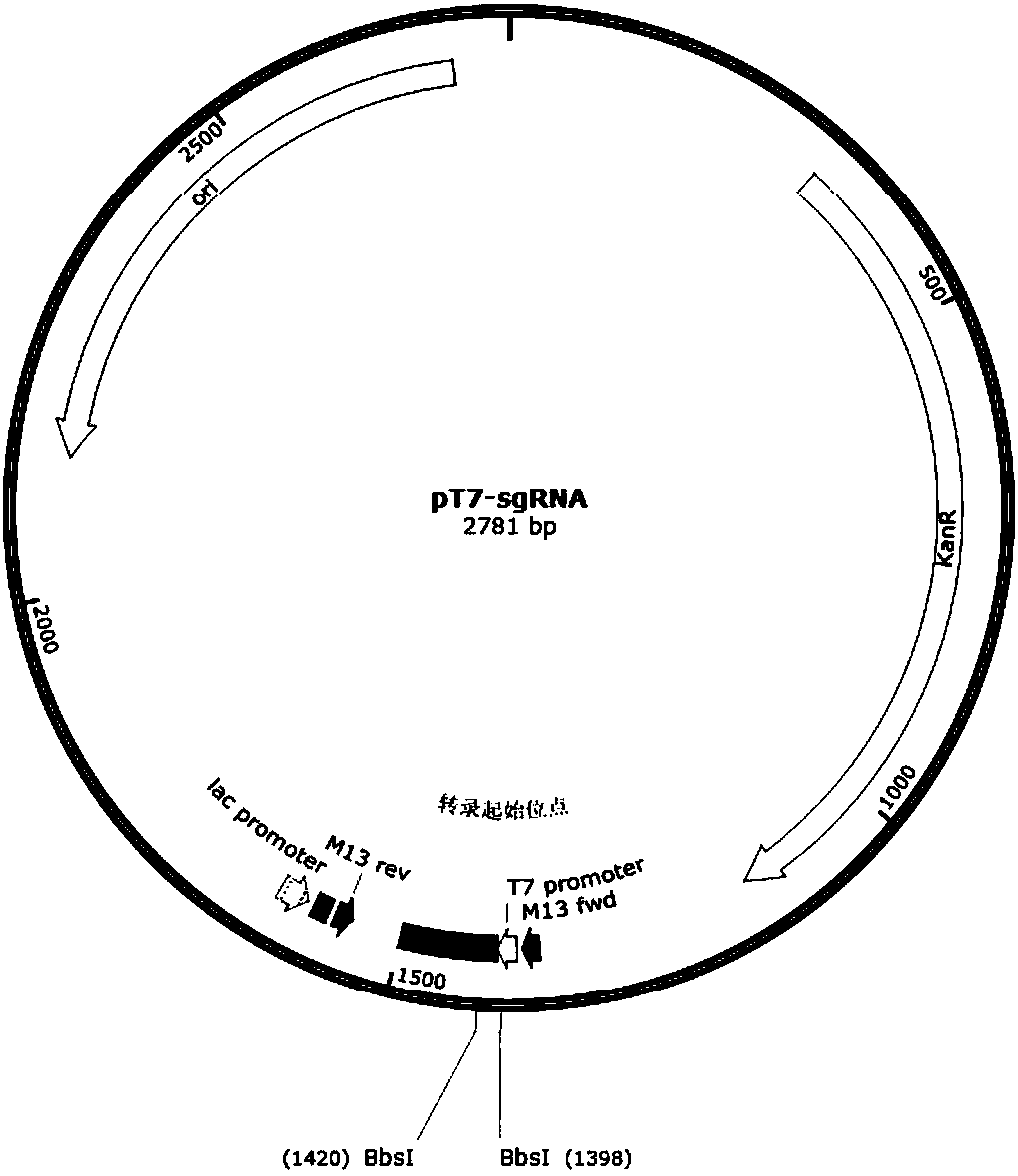

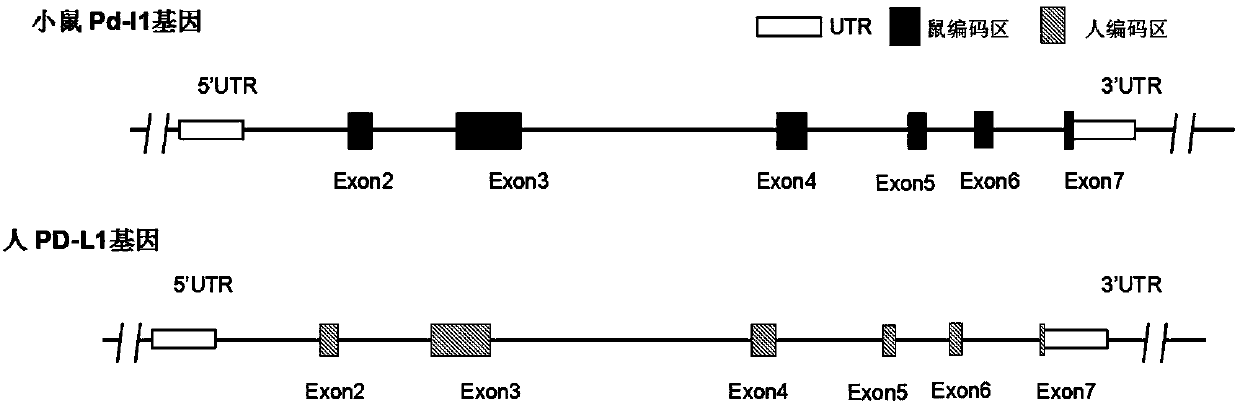

Preparation method and application of humanized gene modification animal model

ActiveCN107815466AReduce development riskSpeed up the R&D processCell receptors/surface-antigens/surface-determinantsSugar derivativesPD-L1Gene Modification

The invention relates to a humanized gene genetically modified non-human animal, particularly a genetically modified rodent, especially a genetically modified mouse, and in particular relates to a construction method of a humanized PD-L1 gene animal model and application of the model in the biomedicine field.

Owner:BIOCYTOGEN JIANGSU CO LTD +1

3D curved glass panel forming method and 3D curved glass panel obtained through forming method

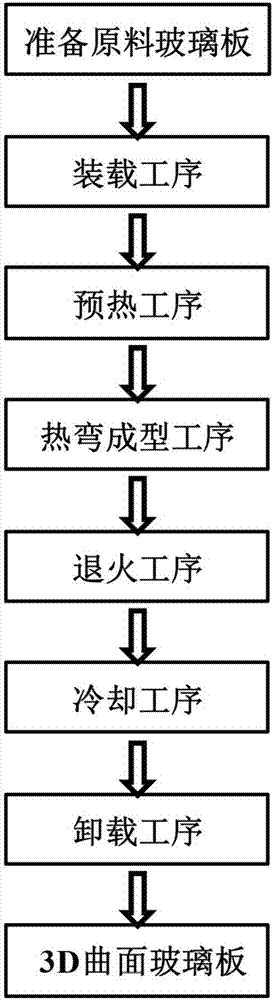

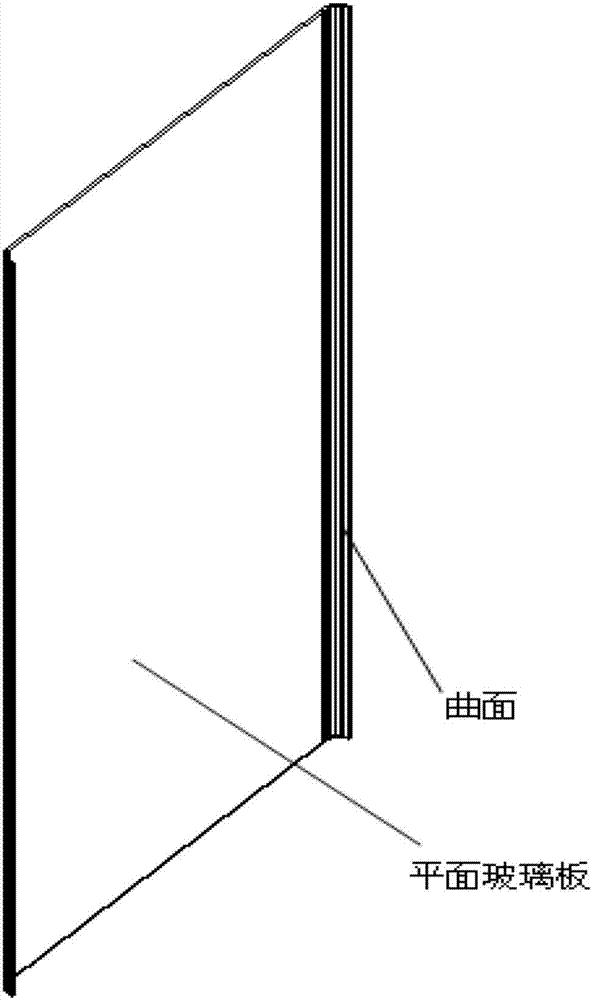

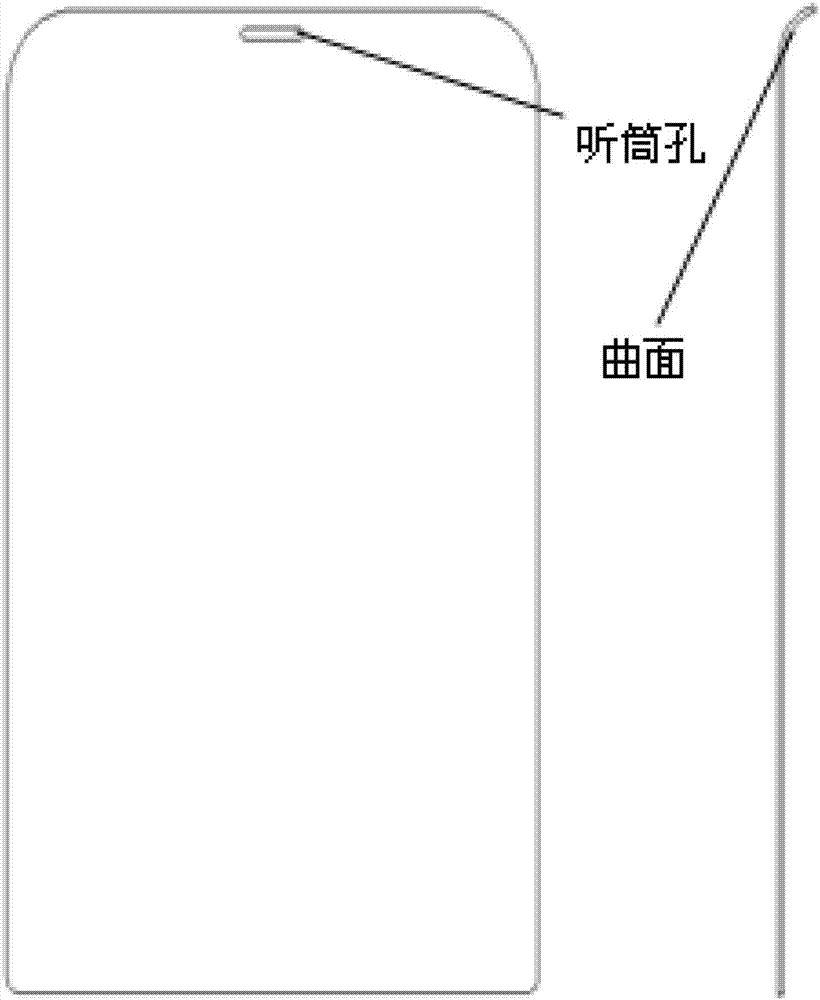

The invention provides a specific 3D curved glass panel forming method which can inhibit oxidation of forming molds and achieve material / mold reutilization, energy and cost saving. The 3D curved glass panel forming method comprises at least the following processes of a loading process where a raw material glass panel is put into a forming mold and loaded as the forming mold, a forming with hot bending process where the raw material glass panel is compressed as a curved glass panel in a 3D surface shape corresponding to the forming mold after being heated up to a temperature of forming with hot bending, an annealing process where the curved glass panel obtained in the forming with hot bending process is annealed, a cooling process where the annealed curved glass panel is subjected to cooling molding, and an unloading process where the mold is unloaded and the 3D curved glass panel is output.

Owner:SICHUAN XUHONG OPTOELECTRONICS TECH

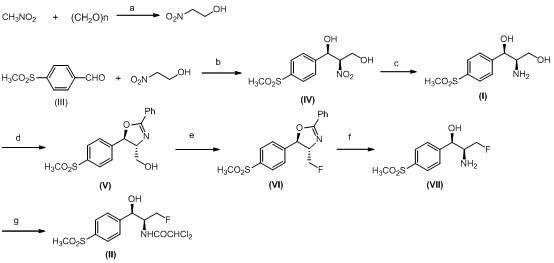

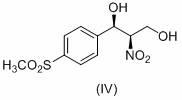

Method for analyzing (1R, 2R)-2-amino-1-(4-(methylsulfonyl)-phenyl)-1,3-propylene glycol as intermediate of florfenicol

ActiveCN101941927AEasy to manufactureHigh yieldOrganic chemistryOrganic compound preparationPtru catalystBenzaldehyde

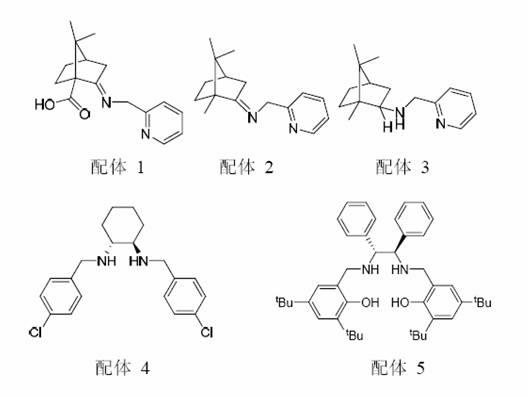

The invention relates to a method for analyzing (1R, 2R)-2-amino-1-(4-(methylsulfonyl)-phenyl)-1,3-propylene glycol as an important intermediate of florfenicol, which is chloramphenicol spectrum antibiotic special for animals. The method comprises the following steps of: performing a reaction of methylsulfonyl benzaldehyde and nitro alcohol at 0-40 DEG C in the presence of a chiral catalyst to obtain (1R, 2R)-2-nitro-1-(4-(methylsulfonyl)-phenyl)-1,3-propylene glycol; and reducing the (1R, 2R)-2-nitro-1-(4-(methylsulfonyl)-phenyl)-1,3-propylene glycol through hydrogen to obtain the intermediate. In the invention, the compound (1R, 2R)-2-amino-1-(4-(methylsulfonyl)-phenyl)-1,3-propylene glycol with a high e.e. value is obtained by adopting the chiral catalyst, and the compound has the advantages of strong reaction selectivity, high productivity, simple process, low cost, easy preparation of raw materials and low price, is suitable for industrial production, avoids chiral separation frequently used in industry at present and saves the raw materials and the cost. The compound (1R, 2R)-2-amino-1-(4-(methylsulfonyl)-phenyl)-1,3-propylene glycol is used for preparing florfenicol and can reduce the preparation cost.

Owner:MASTEAM BIO TECH

Water-soluble salt core type metal powder injection molding technology

The invention provides a water-soluble salt core type metal powder injection molding technology and relates to the technical field of metal powder injection molding. The technology comprises the steps of mixing, water-soluble salt core preparing, mold core inlaying and mold clamping, injection molding, core-removing drying, degreasing and sintering. According to the technology, a fused and poured water-soluble salt core forms a part cavity and can be dissolved and removed through clean tap water at indoor temperature, the removal time is short, the safety is high, the environmental friendliness is high, and the potential problems of production insecurity, environmental pollution and strength reduction of green bodies caused by polymer core removal can be effectively solved. Part products manufactured through the technology are uniform in internal structure, high in compactness, high in surface smoothness, high in dimensional precision and stable in quality, a great deal of time and cost are saved for volume production of small and precision parts provided with closed or complicated cavity structures and made of various metal materials, the economic benefit is good, and the application prospect is good.

Owner:QILU UNIV OF TECH

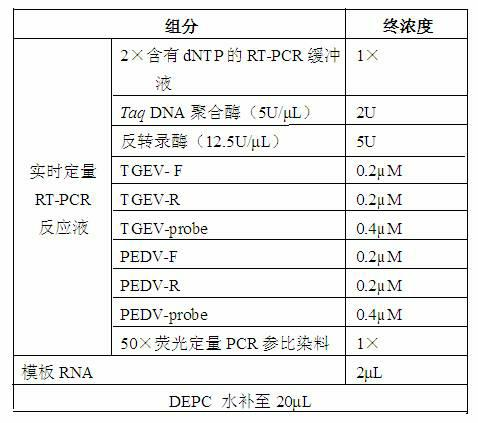

Primers, probes and detection kits for detection of porcine transmissible gastroenteritis virus and porcine epidemic diarrhea virus

InactiveCN102277454AShorten the timeSave costsMicrobiological testing/measurementFluorescence/phosphorescenceDuplex pcrDiarrhea

The invention discloses a primer, a probe and a detection kit for detecting porcine transmissible gastroenteritis virus and porcine epidemic diarrhea virus. The detection primers and probes are SEQ ID NO: 1 to SEQ ID NO: 6 in the sequence table, wherein the sequences SEQ ID NO: 1 and SEQ ID NO: 2 are sense primers and antisense primers for detecting porcine transmissible gastroenteritis virus respectively, and the sequence SEQ ID NO: 3 For detecting the fluorescent probe of porcine transmissible gastroenteritis virus, sequence SEQIDNO: 4 and SEQIDNO: 5 are sense primer and antisense primer for detecting porcine epidemic diarrhea virus respectively, and sequence SEQIDNO: 6 is the detection primer of porcine epidemic diarrhea virus fluorescent probe. The invention also provides detection kits for porcine transmissible gastroenteritis virus and porcine epidemic diarrhea virus. The primers and probes selected by the present invention have very strong specificity. The total viral RNA extracted from porcine diarrhea does not need to be transcribed into cDNA first. The synthesis of the first strand of cDNA and double PCR are completed in one step, and two viruses can be detected at one time. ,Improve efficiency.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Solar heat storing and collecting device

InactiveCN101915465ASimple structureSave costsSolar heating energySolar heat devicesCross-linkHeat conducting

The invention relates to a solar heat storing and collecting device based on the combination of vacuum pipes and a casing pipe in the technical field of solar energy utilization. The device comprises a plurality of glass vacuum pipes, a heat transfer casing pipe, a heat conductance material, an elastic corrugated ribbed plate, a heat-insulating plug and a condensing plate, wherein the heat conductance material comprises the following components in percentage by volume: 50 percent of solid-solid phase-change heat storage material, 20 percent of graphite powder and 30 percent of heat conducting oil; and the solid-solid phase-change heat storage material refers to cross-linked high-density polyethylene, laminated perovskite or polyalcohol. The solar heat storing and collecting device has the advantages of simple structure, safe and reliable operation, high and stable heat efficiency of a system, and capability of greatly saving cost and space due to integrated design; and the device has a regulating function of storing heat on sunny days and releasing the heat on cloudy days, so the temperature of an air or steam working medium at an outlet can be stabilized in a certain specific temperature range of between 120 and 190 DEG C.

Owner:SHANGHAI JIAO TONG UNIV +1

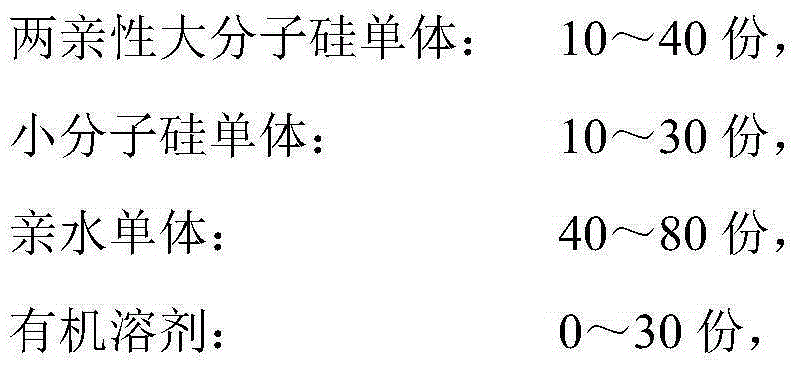

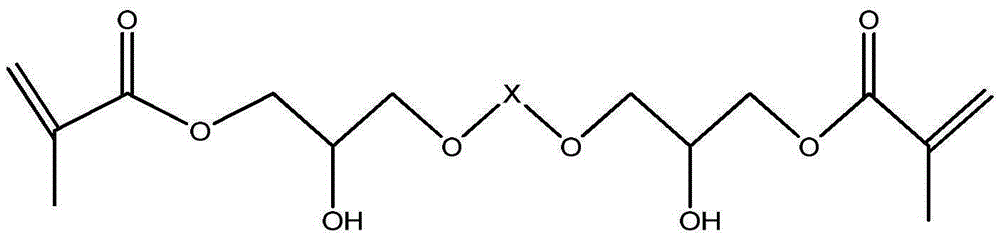

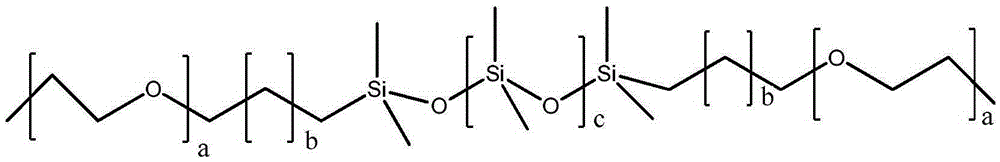

Silicon hydrogel material having high oxygen permeability, corneal contact lens, and preparation method thereof

ActiveCN105418858AHigh oxygen permeabilityGood light transmissionOptical partsOrganic solventSilicon

The invention discloses a silicon hydrogel material having high oxygen permeability. The silicon hydrogel material is prepared, through a polymerization reaction, from following components including, by mass, 10-40 parts of an amphipathic macro-molecular silicon monomer, 10-30 parts of a small-molecular silicon monomer, 40-80 parts of a hydrophobic monomer, 0-30 parts of an organic solvent, and an initiator and a crosslinking agent. The silicon hydrogel material and a corneal contact lens have the high oxygen permeability, are low in cost and are easy to prepare.

Owner:JIANGSU HORIEN CONTACT LENS +1

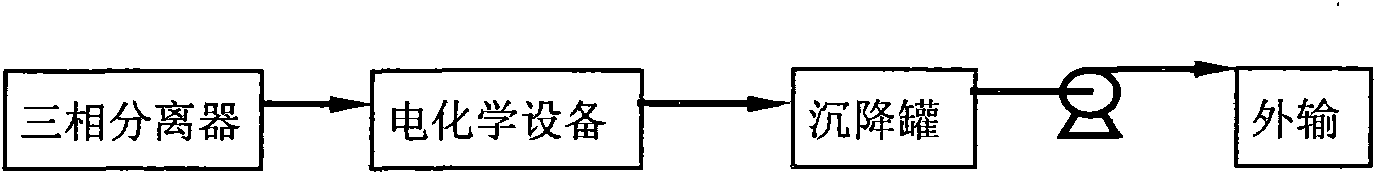

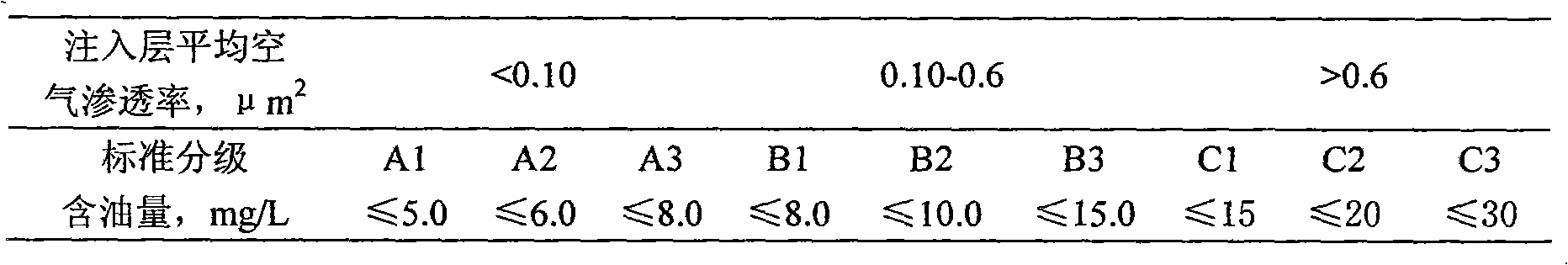

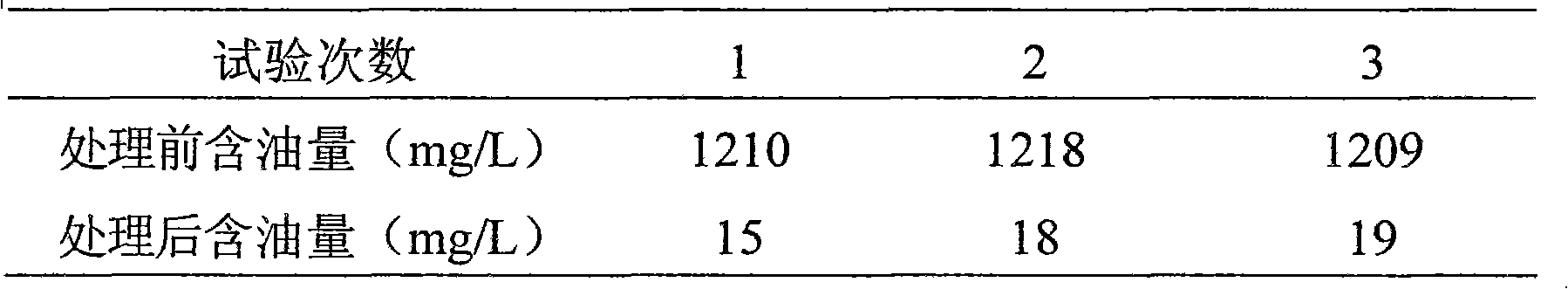

Electrochemical method of oil removal of wastewater produced in oil extraction by polymer flooding displacement

InactiveCN101602531AEasy to separateSave construction investmentWater/sewage treatment by flotationElectrolysisWater quality

The invention discloses an electrochemical method of oil removal by polymer flooding oil recovery wastewater, which comprises the following steps of: 1, electrolysis; 2, sedimentation. In the process of the electrolysis, tiny oil droplets in the wastewater lose electrons due to discharge on the surface of an anode, charges on the surface of the oil droplets are reduced, and electric potential of interface xi is decreased; and residual polymer pieces in the wastewater after the electrolysis are oxidized and degraded, viscosity of the wastewater is decreased, and water film intensity on the interface of oil / water is reduced. Therefore, the tiny oil droplets after the electrolysis are liable to be converged into large oil droplets and are rapidly separated from the wastewater under the action of cathode hydrogen. As treated by the method, crude oil in wastewater produced in oil extraction by polymer flooding displacement is quite easy for removal with no need for large use of sedimentation tanks, thus saving construction fund for oilfield; the invention has simple process, requires no drug, saves resource and cost and conforms to green chemistry process, quality of the wastewater after the oil removal is obviously crystal-clear; in addition, the device is convenient and safe in operation, easy to control and realize automation, extensively adapted to the amount of water, and convenient for popularization and application.

Owner:SOUTH CHINA UNIV OF TECH

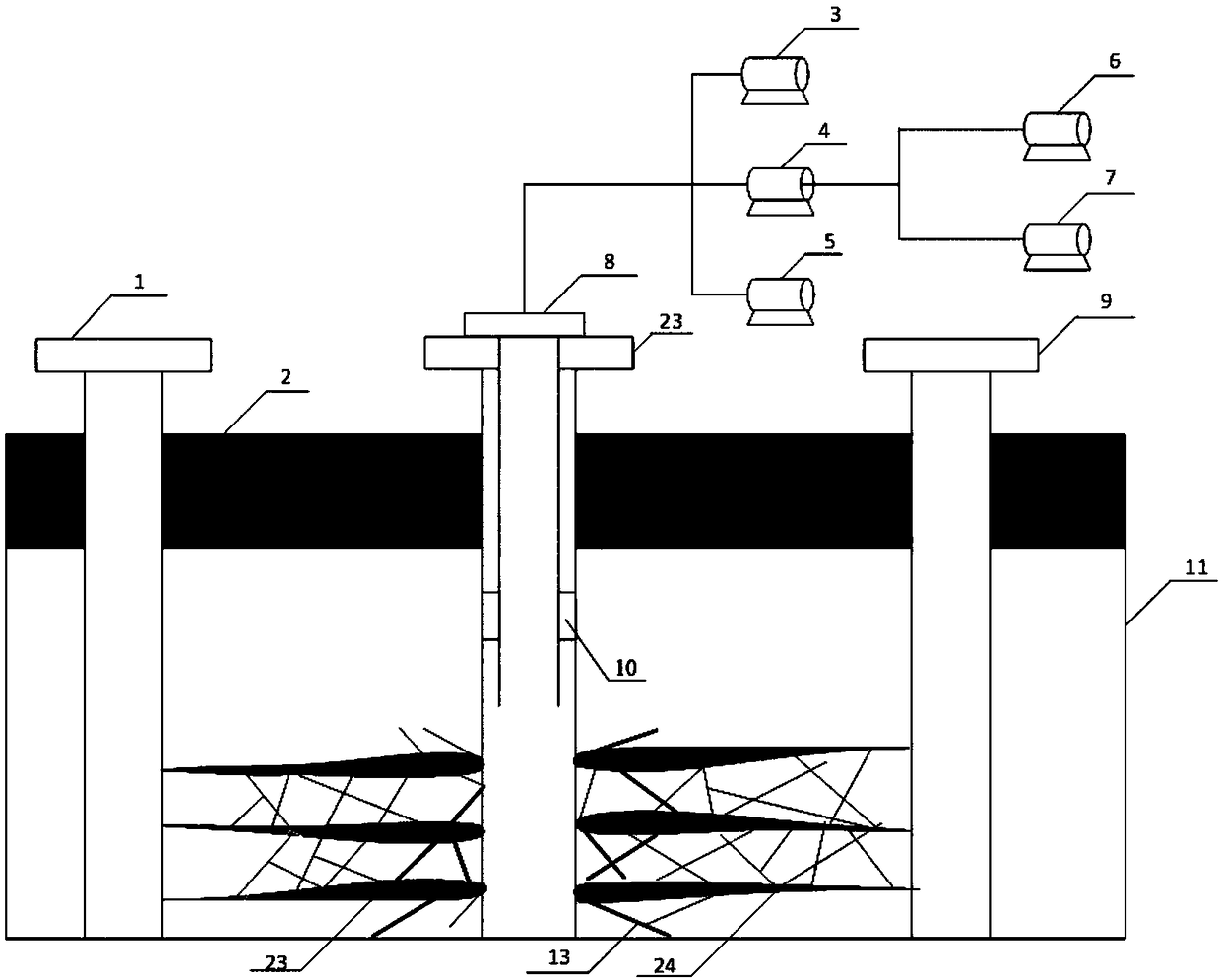

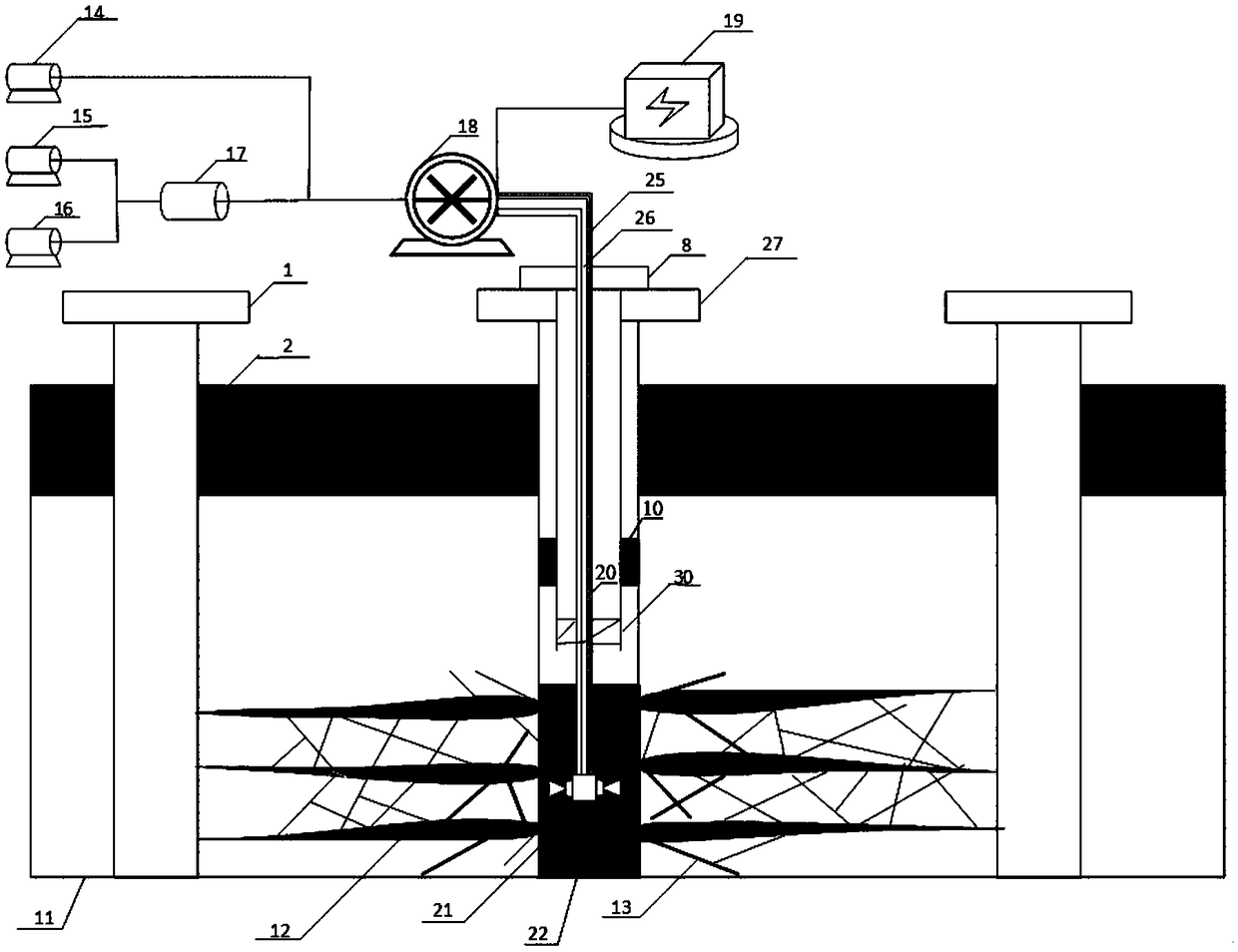

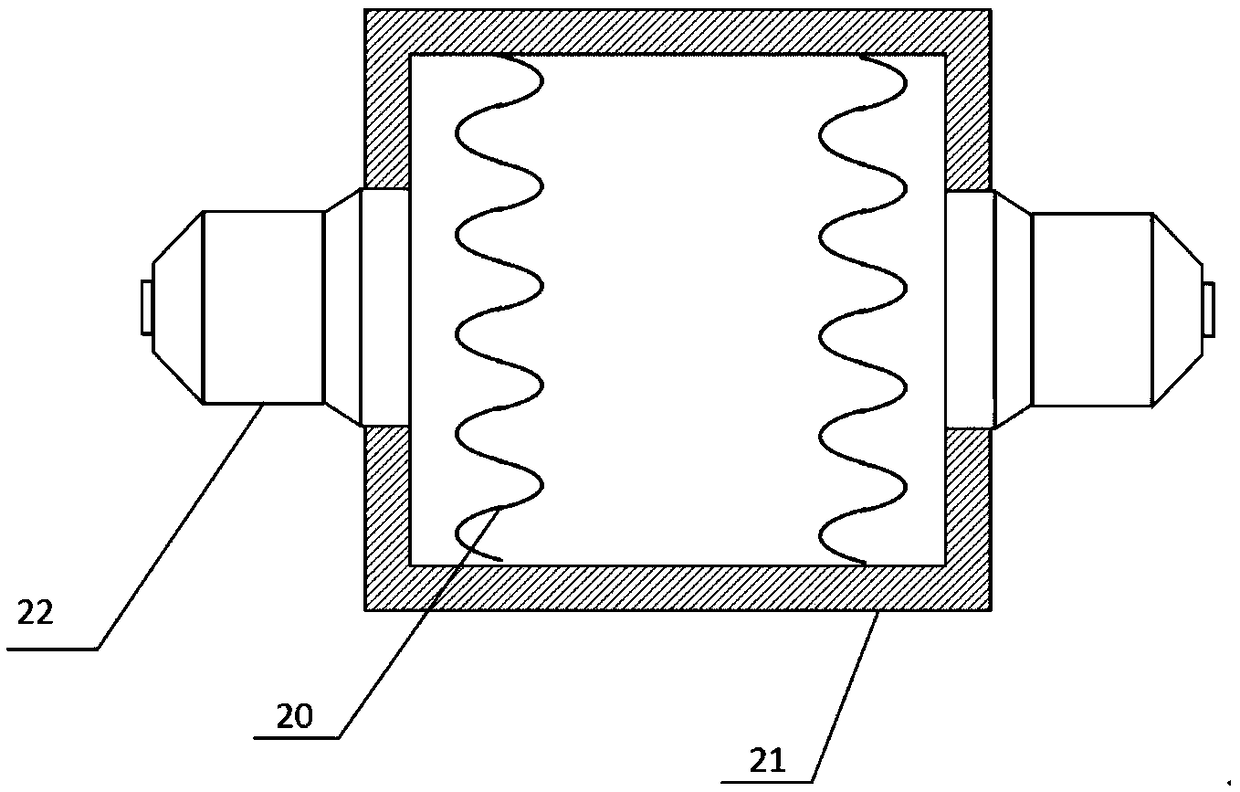

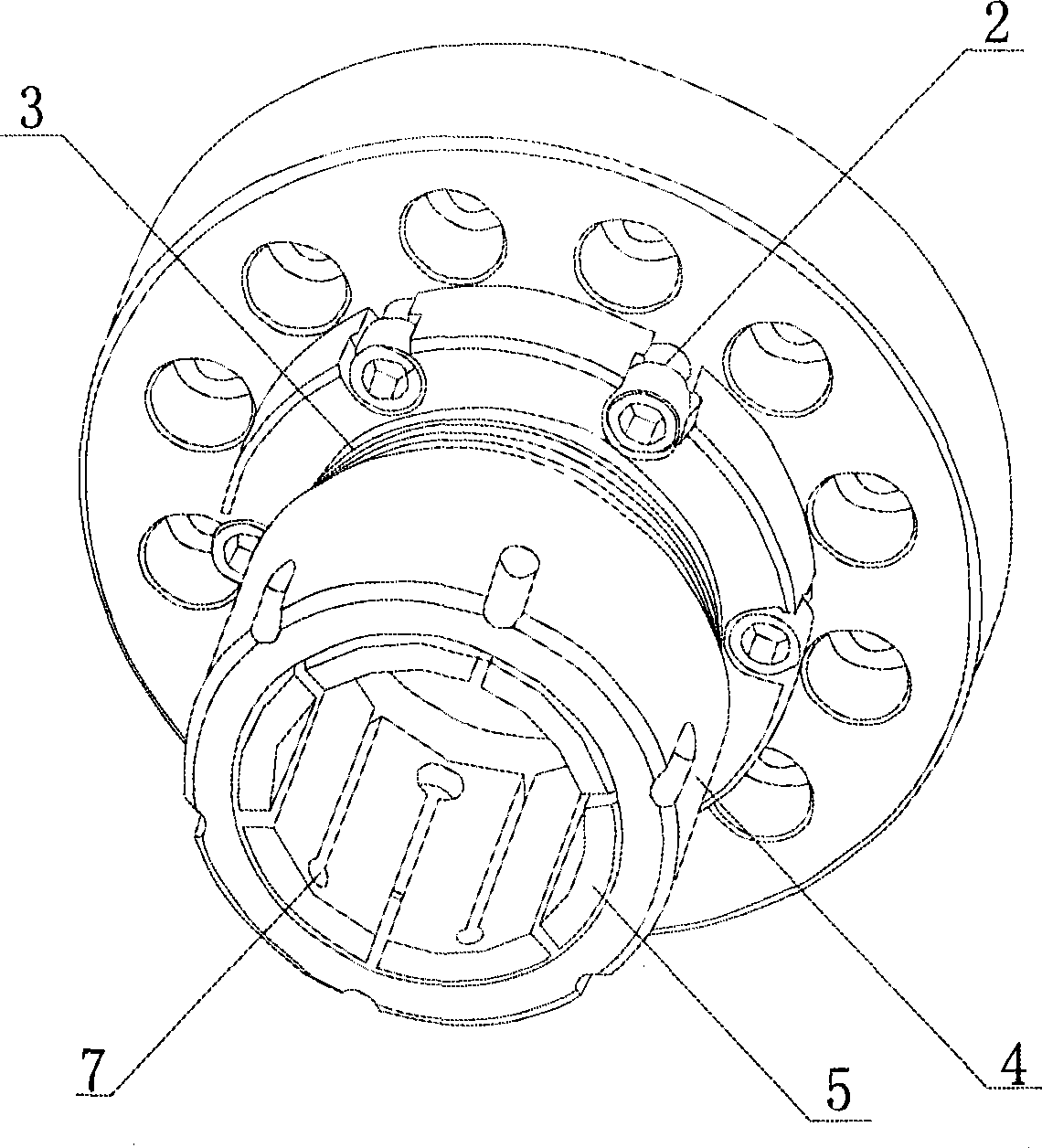

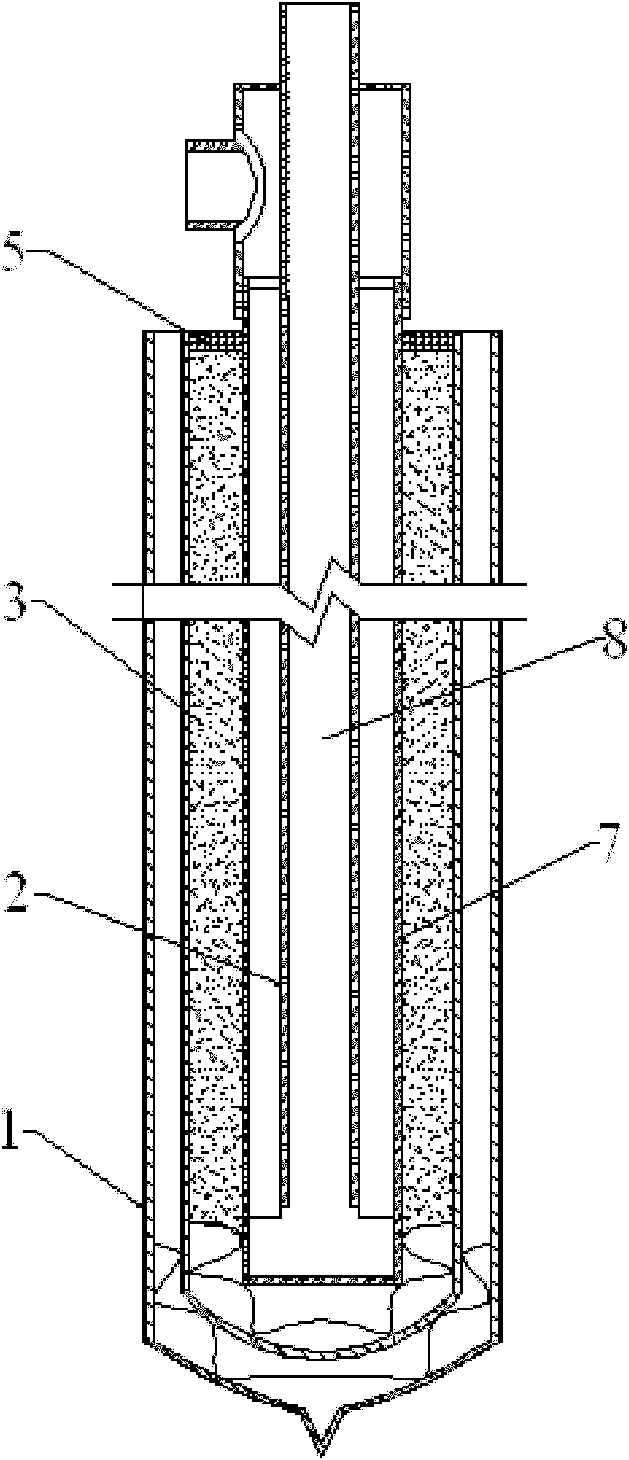

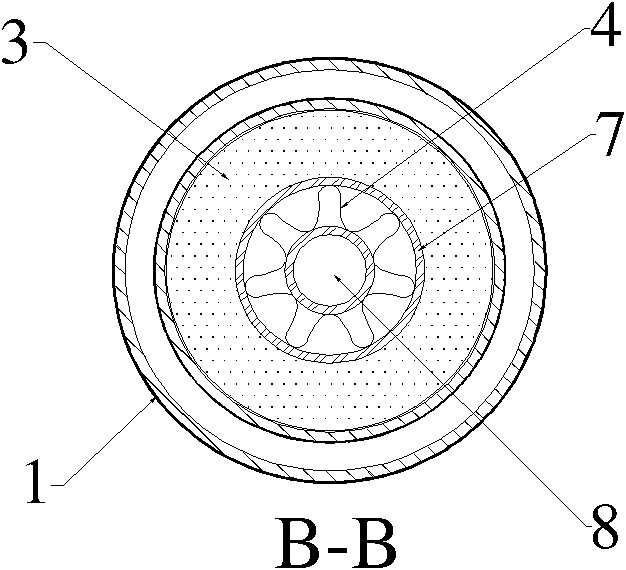

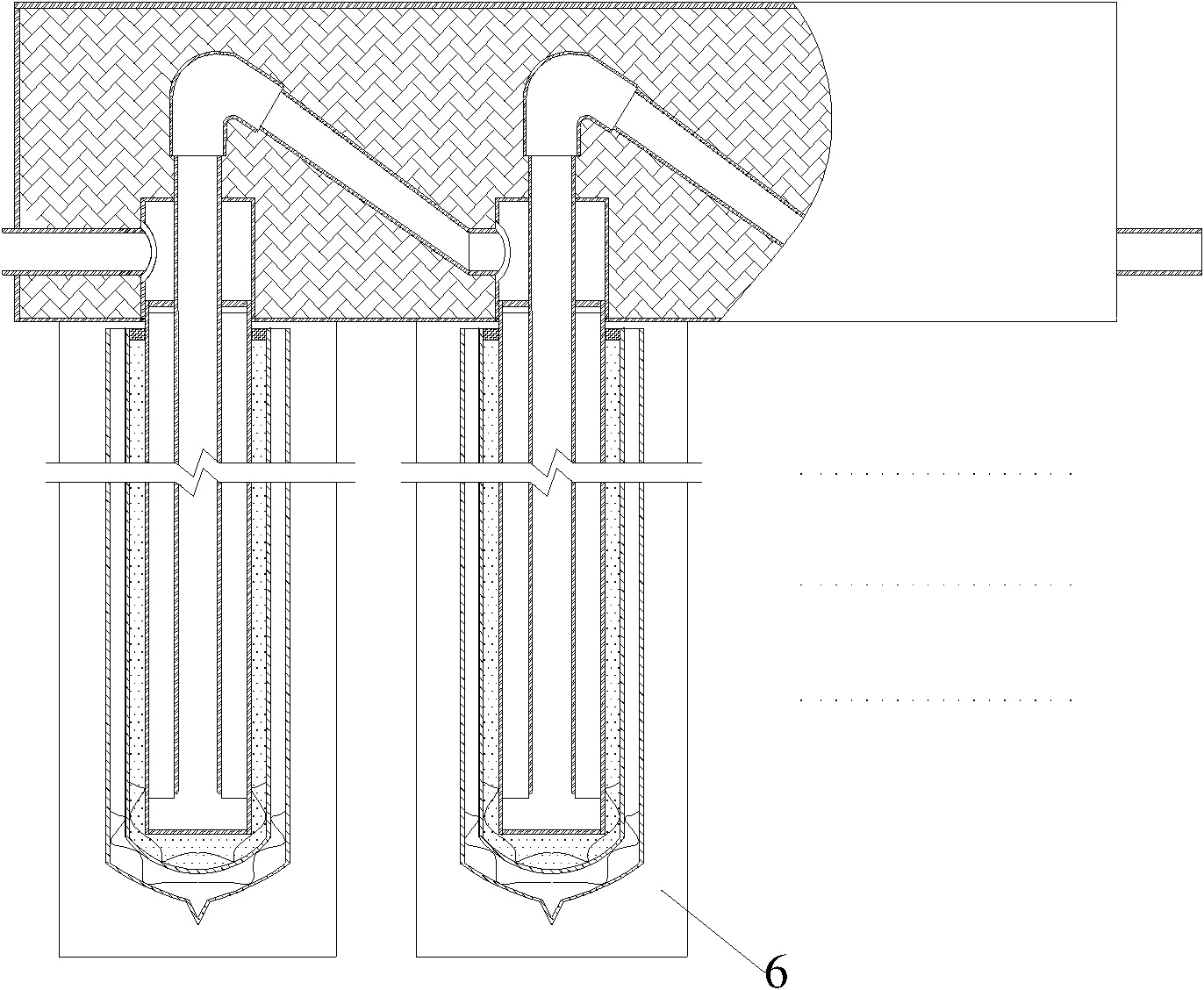

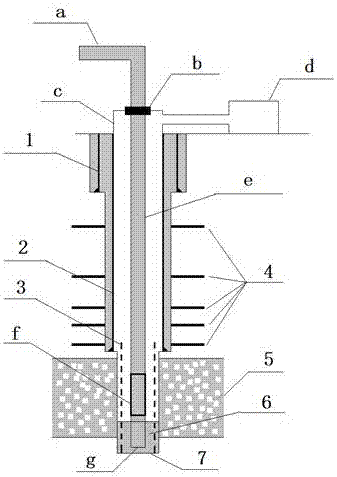

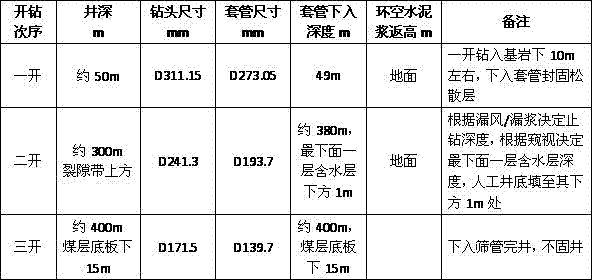

Drainage and gas production integrated goaf gas extraction well body structure and construction method thereof

ActiveCN107401393APrevent inflowImprove sealingFluid removalDrilling machines and methodsOutfallMechanical engineering

The invention belongs to the technical field of coal mine goaf gas ground extraction, specifically relates to a drainage and gas production integrated goaf gas extraction well body structure and a construction method thereof, and solves the technical problems of simultaneously draining goaf accumulated water and extracting goaf gas. The drainage and gas production integrated goaf gas extraction well body structure comprises a well depth structure portion and an equipment portion, wherein the well depth structure portion comprises a first spud sleeving pipe disposed at the uppermost layer, the bottom of the first spud sleeving pipe is connected with a second spud sleeving pipe disposed at the aquifer depth position, the bottom of the second spud sleeving pipe is connected with a third spud screen pipe disposed at the goaf and fissure zone depth position, and the bottom of the third spud screen pipe is disposed at the well bottom position; and the equipment portion comprises an oil pipe disposed in the first spud sleeving pipe, the second spud sleeving pipe and the third spud screen pipe, the top of the oil pipe is provided with a water outlet, a lower portion of the oil pipe is provided with a drainage pump, the bottom of the oil pipe is provided with a water suction port, the top of the first spud sleeving pipe is a well head, an oil pipe suspending and sealing device is disposed at the well head position, and a gas extraction pump is communicated with the well head. Functions of draining goaf accumulated water and extracting goaf gas through one well can be fulfilled.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

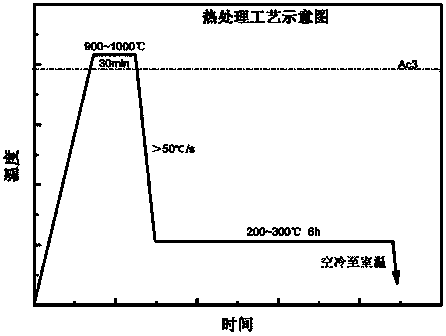

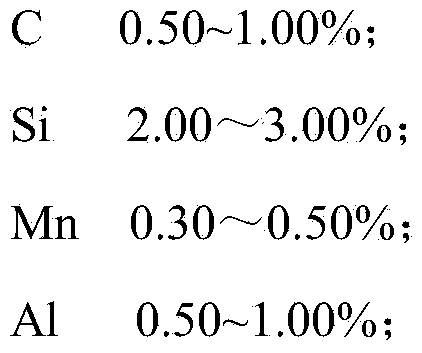

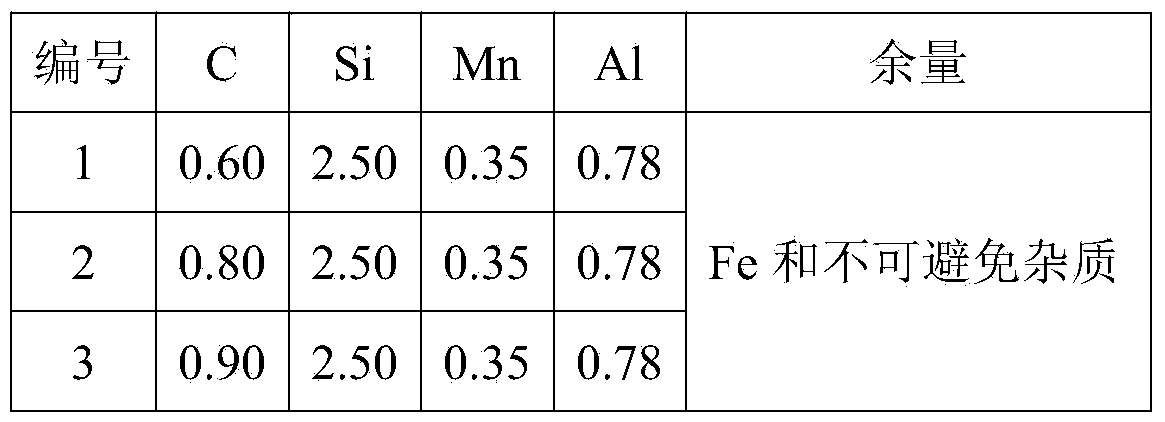

Preparation method for 2400MPa class low-cost nano bainitic steel

The invention discloses a preparation method for 2400MPa class low-cost nano bainitic steel, belonging to the field of metal materials. The steel is C-Si-Mn-Al high and medium carbon alloy, without addition of expensive alloy elements of Cr, Mo and the like. The preparation method comprises the following steps: carrying out heat preservation to a forging block for 0.5-1 hour at 900-1000DEG C, and then directly feeding in a salt bath hardening furnace for preserving heat for 3-6 hours, thus being capable of producing carbide-free nano bainite with tensile strength of 2400MPa class. According to the method, the component optimization of reducing Mn and increasing C and Si is carried out, the preparation technology is simplified, the high-temperature dispersion annealing and hot rolling processes are not required, the forging block is directly subjected to low-temperature isothermal heat treatment, to obtain the final product, so that the production cost can be greatly lowered.

Owner:UNIV OF SCI & TECH BEIJING

Laser dry type cleaning equipment and method for aluminum alloy anodic oxide films

InactiveCN107639083AImprove cleaning efficiencyEasy to cleanDirt cleaningCleaning using gasesLaser transmitterControl system

The invention discloses laser dry type cleaning equipment for aluminum alloy anodic oxide films. The laser dry type cleaning equipment comprises a cleaning platform and a laser cleaning device, the laser cleaning device comprises a laser cleaning main machine and a light source emitting system arranged on the laser cleaning main machine, and the laser cleaning main machine is of an all-in-one machine frame type; the light source emitting system comprises a control system and a laser emitter, the control system is used for controlling the laser emitter, and a laser device in the laser emitter is a pulse laser; the cleaning platform is located at the bottom of the light emitting surface of the laser cleaning device, and a workbench is used for placing aluminum alloy workpieces to be machined. The cleaning equipment is used for solving the problems existing in the prior art; a laser cleaning head is used for emitting linear light spots to clean the anodic oxide films of the aluminum alloyworkpieces, the cleaning effect is guaranteed, a cleaning solution is not needed, and the cleaning equipment is an environment-friendly cleaning scheme. The invention further provides an aluminum alloy anodic oxide film laser dry type cleaning method high in cleaning efficiency and good in cleaning effect.

Owner:武汉翔明激光科技有限公司

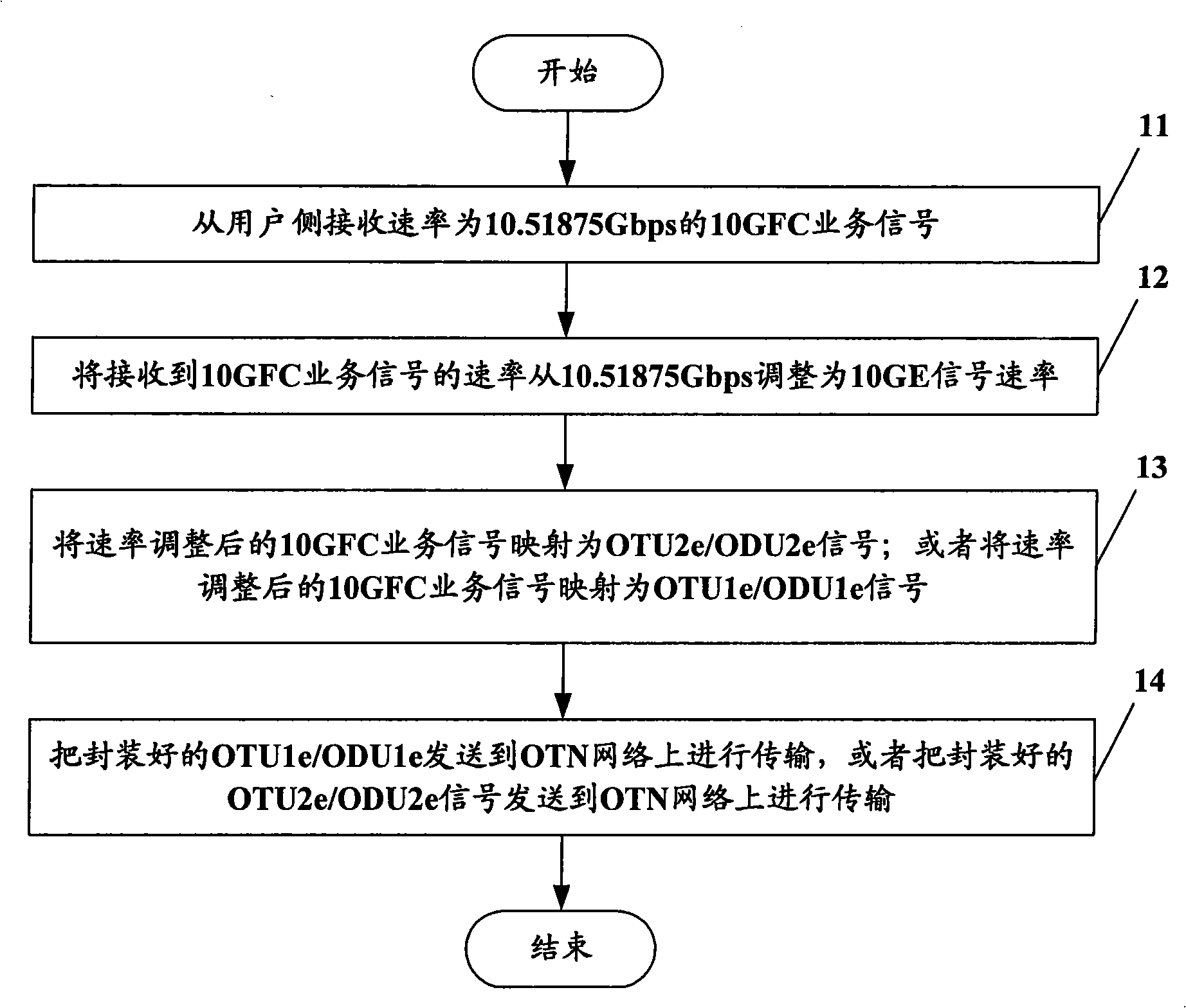

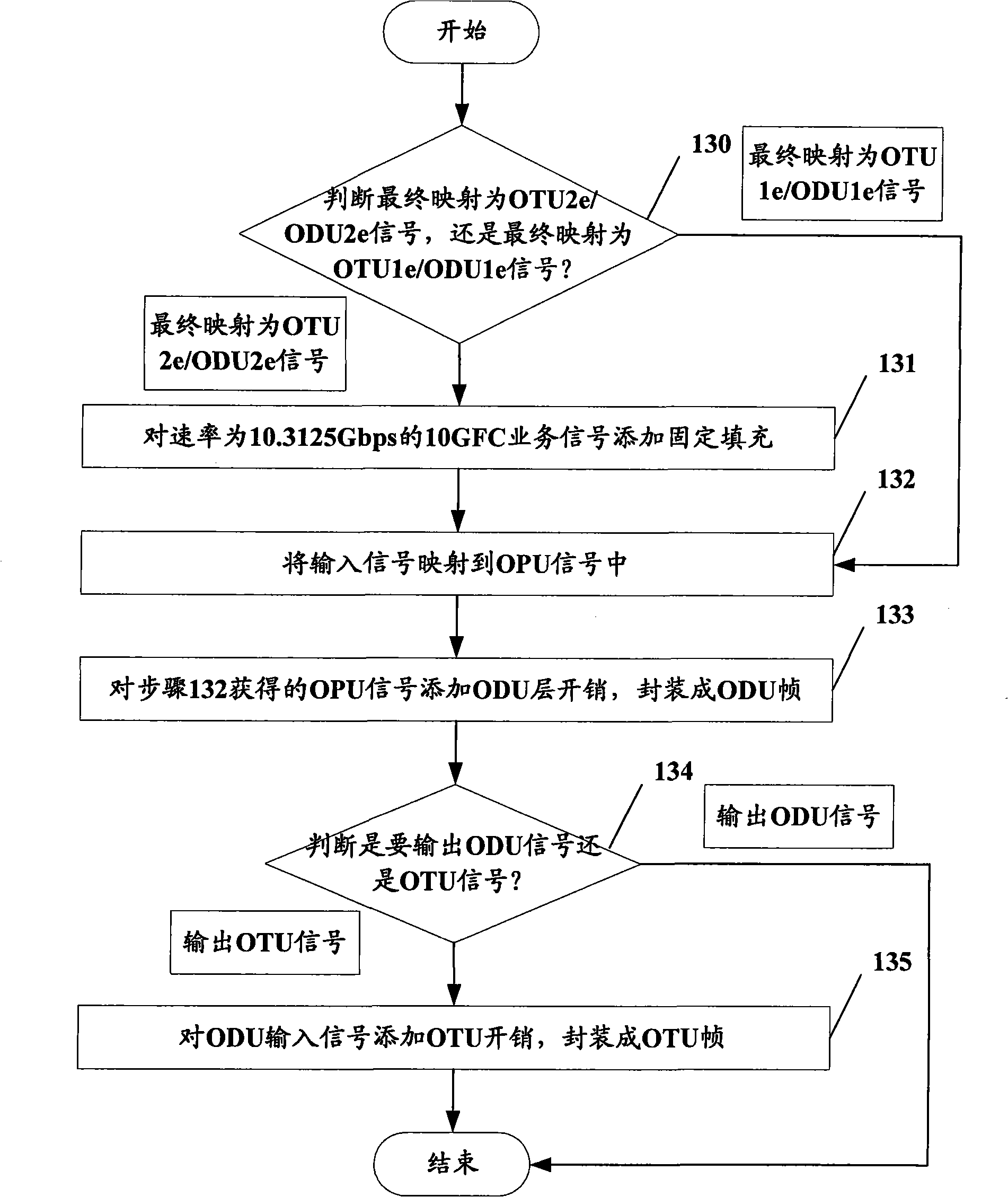

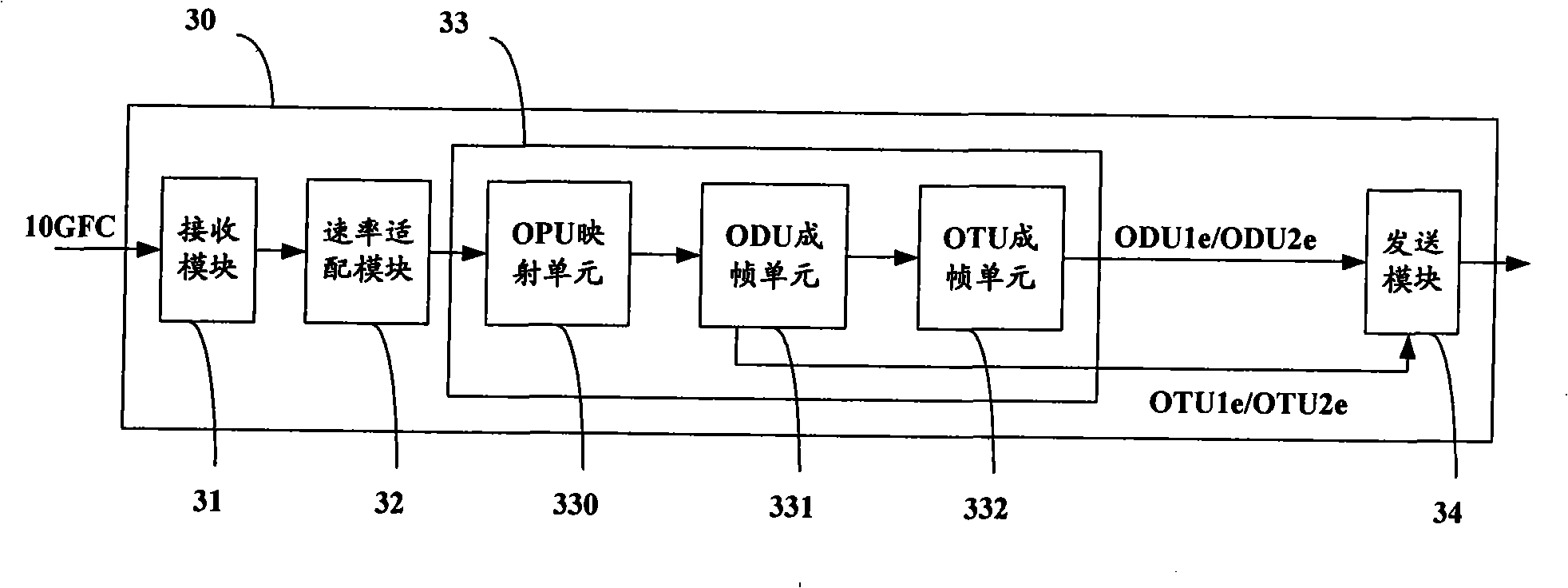

Method and apparatus for transmitting 10G bit optical fiber channel service in optical transmission network

InactiveCN101355821AFlexible configurationSave costsMultiplex system selection arrangementsTime-division multiplexFiberGigabit

The invention discloses a method and a device for transmitting the 10 gigabit fiber channel service in an optical transmission network, belonging to the technical field of the optical transport network. The method comprises the following steps: firstly, a sender adjusts the speed rate of the user side receiving the 10 GFC service signal to the 10GE signal speed rate; secondly, the 10 GFC service signal with the adjusted speed rate is mapped into OTU2e / ODU2e signal or OTU1e / ODU1e signal sent to the optical transmission network to transmit; the receiver receives the OTU2e / ODU2e from the network side, or the OTU1e / ODU1e signal performs the decoding frame process to be the 10 GFC service signal with 10 GE speed rate; then the speed rate of the 10GFC service signal is adjusted to the standard; and finally, the 10GFC service signal with the adjusted speed rate is sent to the client side, thereby facilitating the mixing syntaxis access of various 10G services and utilizing the bandwidth resources of the optical transmission network more effectively.

Owner:ZTE CORP

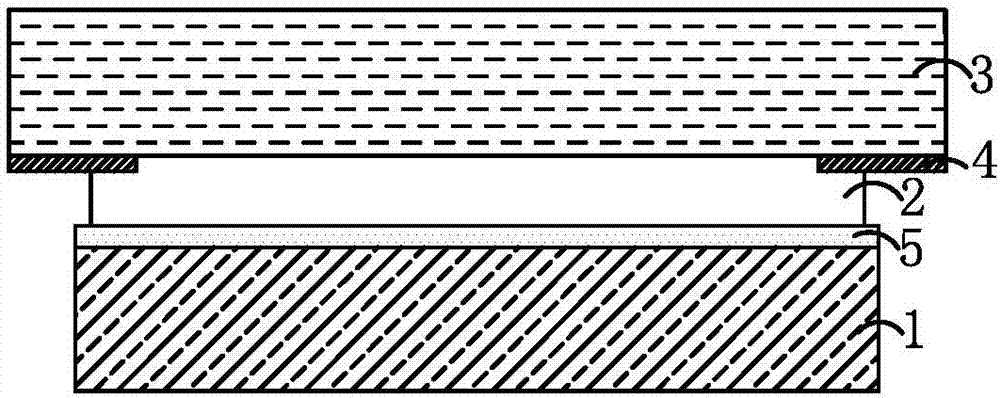

OLED display screen and manufacturing method thereof

ActiveCN106941132AImpact strength is not affectedAchieve one blackSolid-state devicesSemiconductor/solid-state device manufacturingTransmittanceEngineering

The present invention relates to the technical field of electronic equipment displays and particularly relates to an OLED display screen and a manufacturing method thereof. The manufacturing method of the OLED display screen comprises the steps of preparing a display module and a cover plate glass; machining the cover plate glass to enable the visible light transmittance of the cover plate glass to be less than or equal to 65%; printing: printing a black ink layer on the surface partial region of the cover plate glass, so as to form a visual area in the cover plate glass and a non-visual area with the black ink layer; laminating: laminating the cover plate glass above a display module, and enabling the surface of the cover plate glass, printed with the black ink layer, to be opposite to the display module. According to the display screen manufactured by the above manufacturing method, the one-piece black of the display screen can be truly realized. Meanwhile, the strength of the cover plate glass is given consideration to at the same time.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

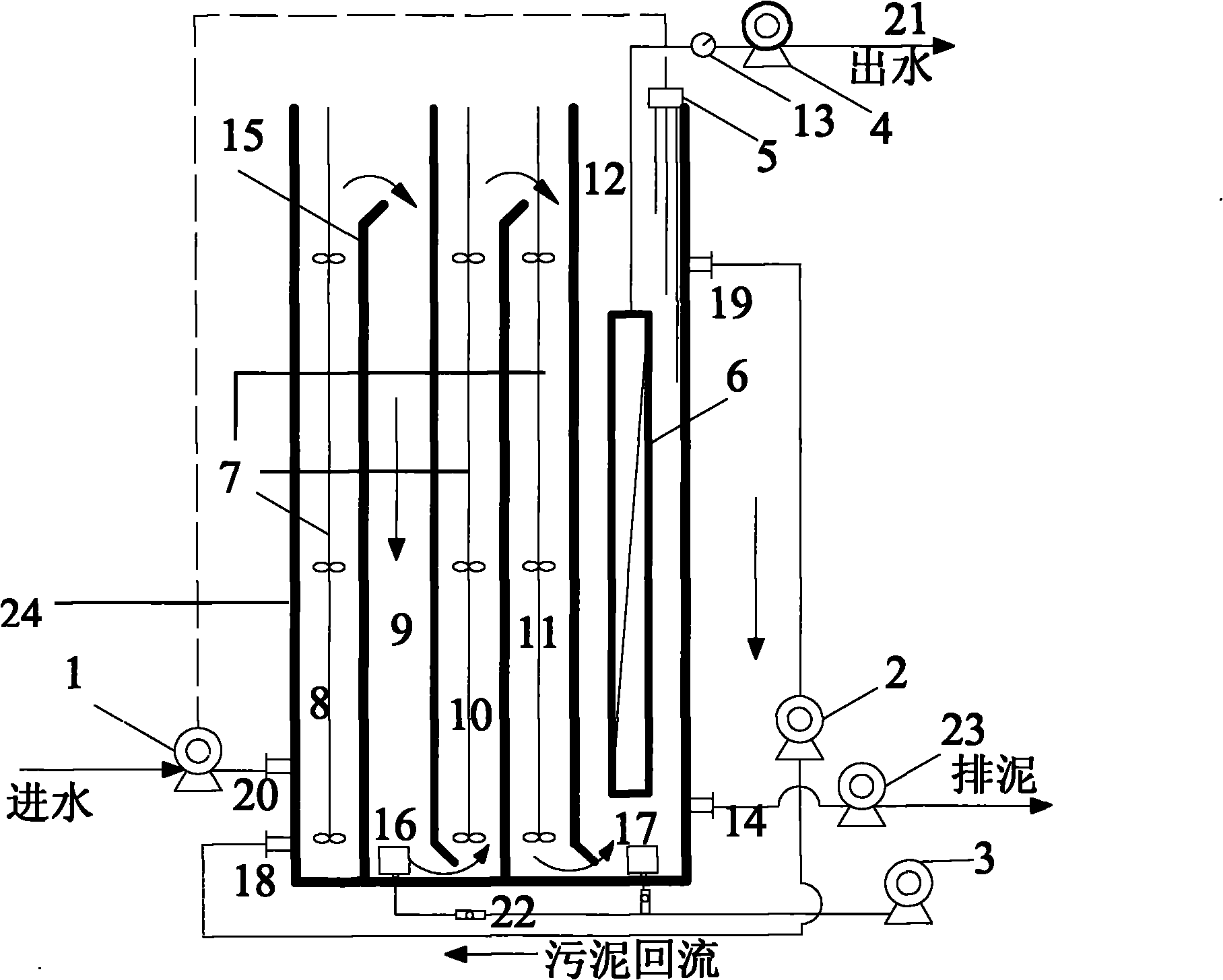

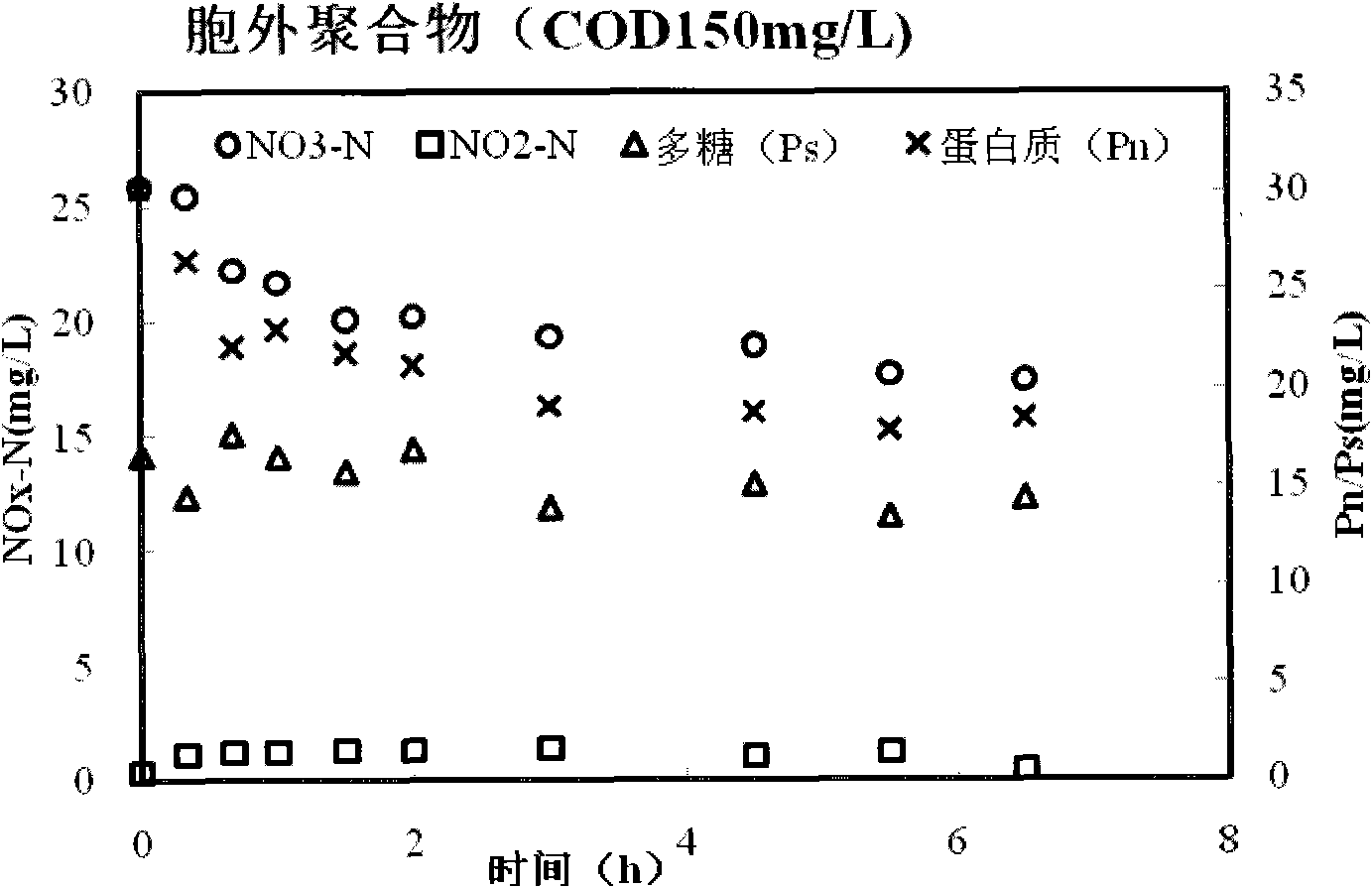

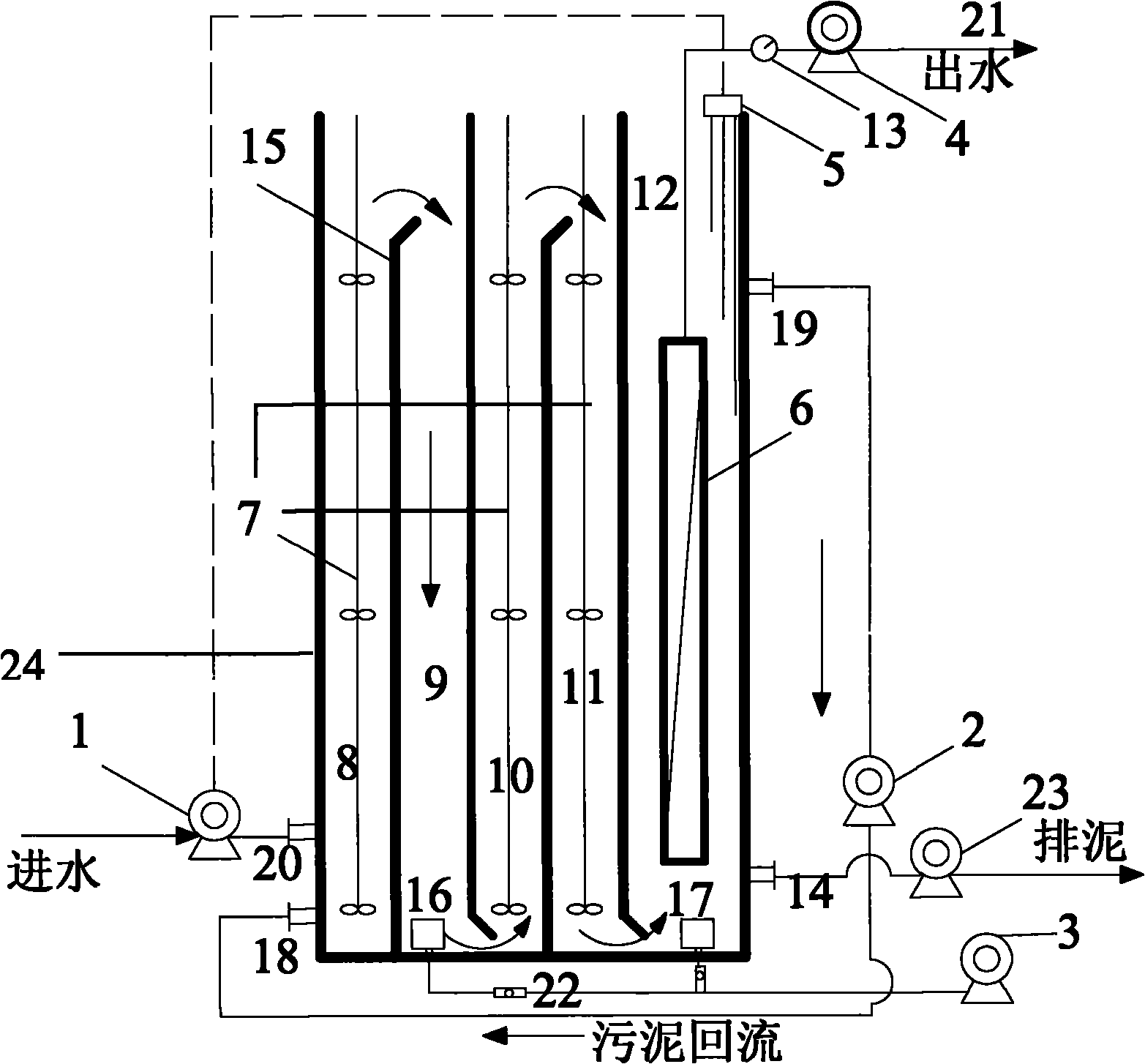

Membrane bioreactor for denitrification and waste water denitrification method

InactiveCN101863586AImprove water qualityRealize deep denitrification treatmentMultistage water/sewage treatmentFiltrationTrapping

The invention belongs to the field of environment protection and discloses a membrane bioreactor for denitrification and waste water denitrification method thereof. The membrane bioreactor is divided into a first anoxic pond, an aerobic pound, a second anoxic pound, an anaerobic pond and a membrane pound by a vertical deflecting baffle plate and an aeration device, wherein the ponds are five independent and communicated reactor chambers; after waste water enters the process, the biochemical treatment processes such as the degradation, nitrification and denitrification of organic matters are completed under the action of microorganisms; and effluent is obtained by membrane filtration and pumping. The bioreactor and the method have the advantages that: sludge mixed liquid flows in a piston flow mode in the whole system, but is in a fully mixed state in a single cell and a refluxing device is used, so the degree of mixing in the entire reactor is high and the mass transfer effect is good; under a condition of not adding extra carbon source, the process strengthens the denitrification by using high sludge concentration, so deep denitrification treatment is realized and the pollution to the membrane is relieved; and at the same time, due to the high efficiency trapping and separation characteristic of the membrane, the quality of effluent of filtration is high.

Owner:SUN YAT SEN UNIV

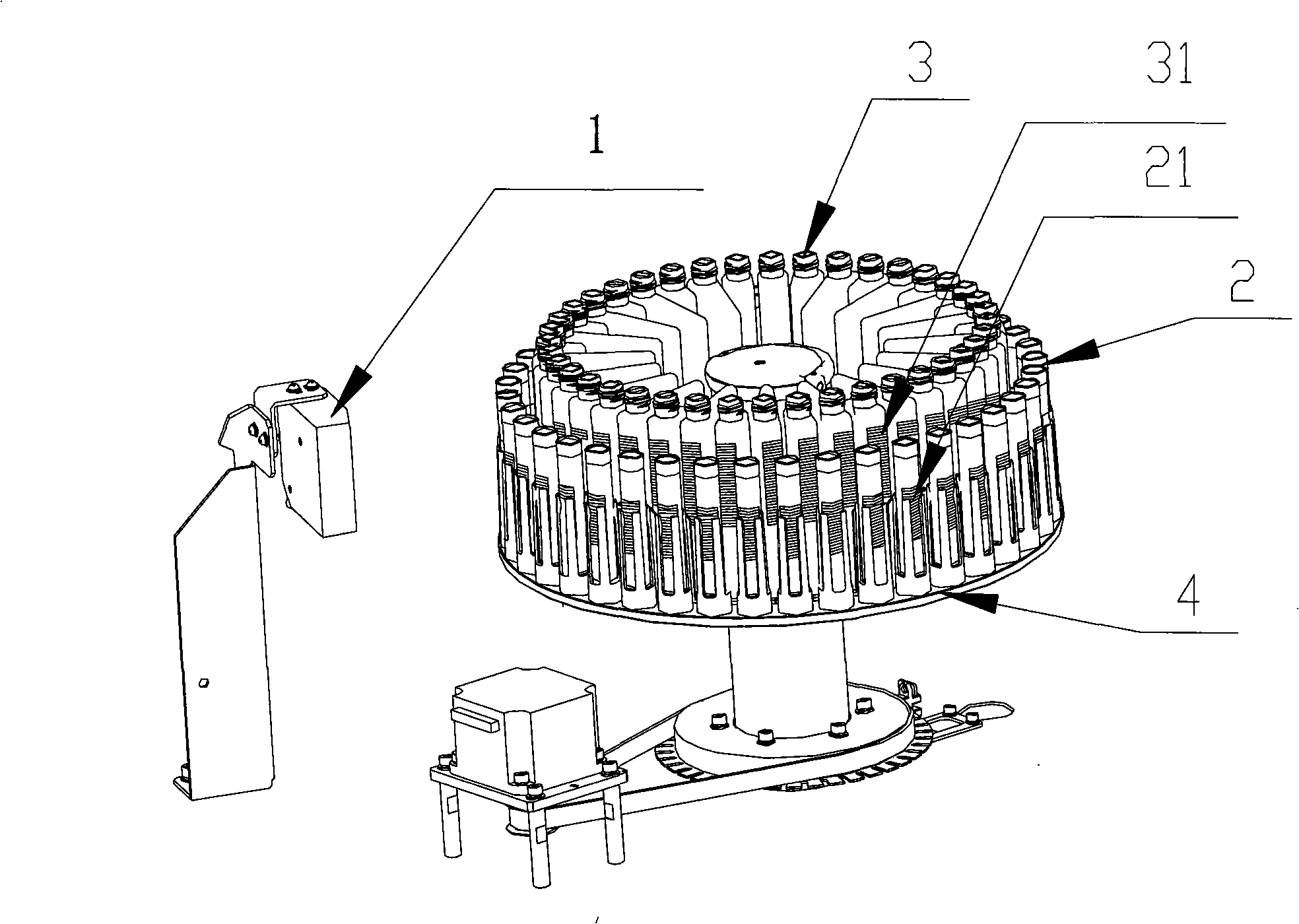

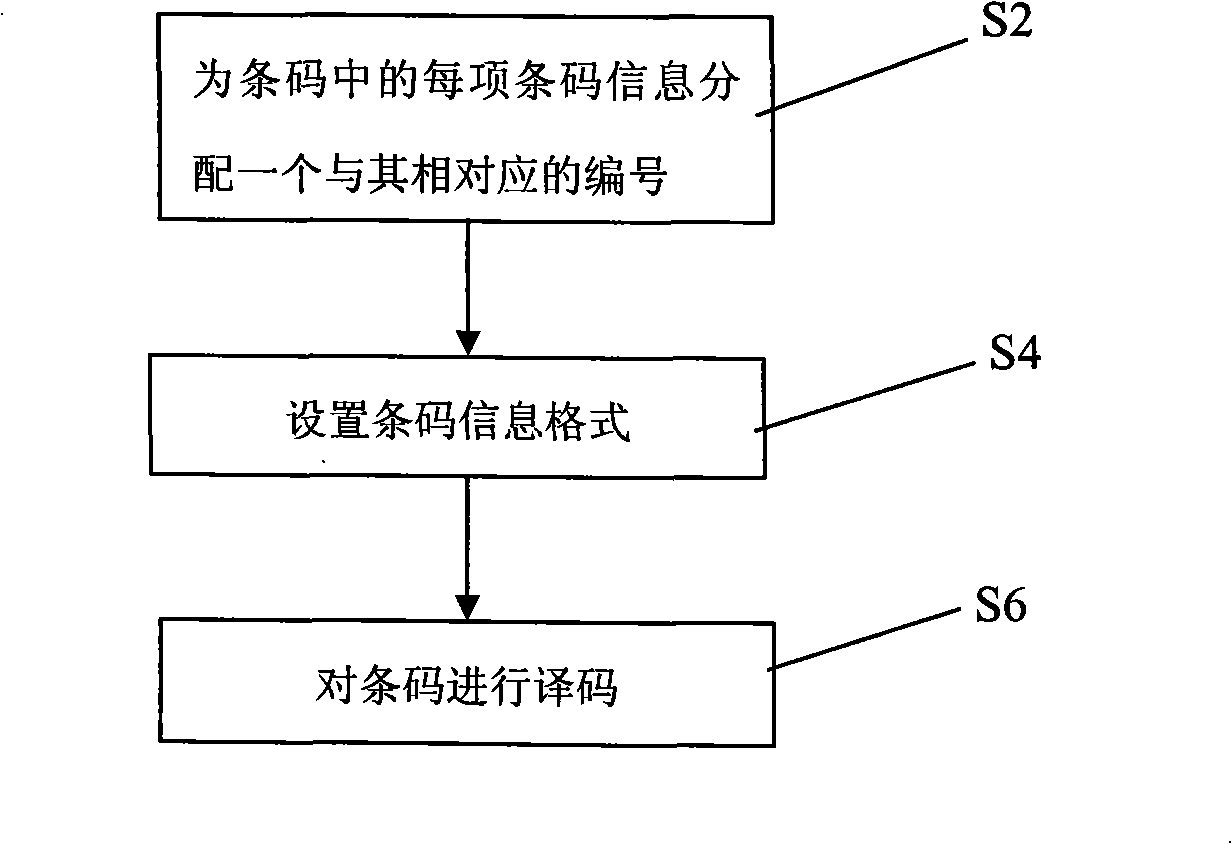

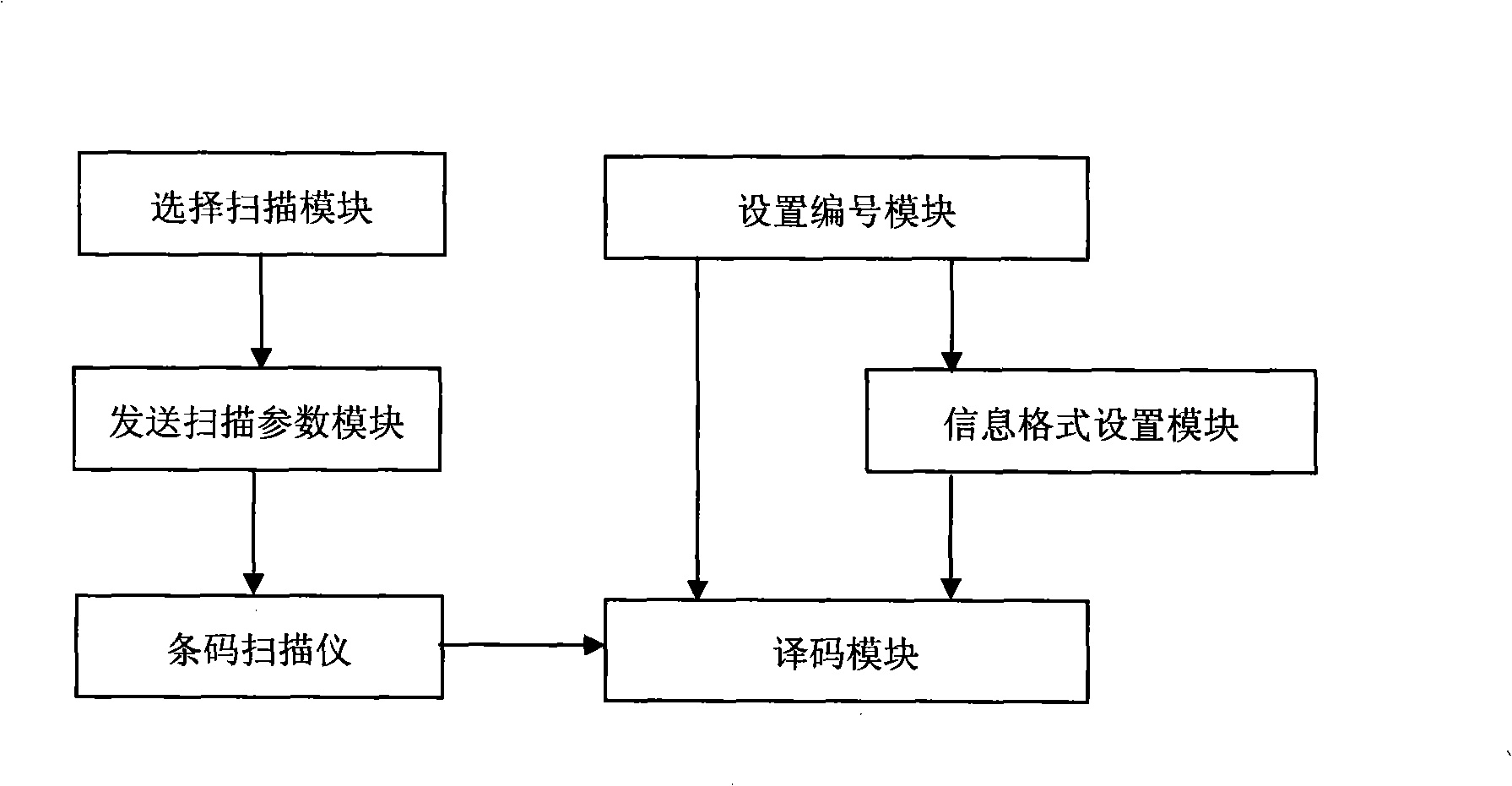

Method and system for acquiring bar code information of biochemistry instrument

ActiveCN101276393AHigh degree of freedom of useImprove the speed of inputting sample informationSensing record carriersBiological testingBarcodeWorld Wide Web

The invention discloses a method and device for obtaining barcode information of a biochemical instrument, wherein the method comprises following steps: A1, distributing each of barcode information in the barcode with a corresponding number according to usage condition; B1, setting format of barcode scanned by a barcode scanner; C1, decoding the barcode scanned by the barcode scanner according to settings in step A1, B1 in order to obtain content information of the barcode. According to a sample barcode, the sample information can not only be inputted from the LIS, but also can be extracted from the barcodes with different formats and contents, in order to enhance the usage freedom degree of barcode and raise the speed for inputting the sample information from the biochemical instrument; according to the reagent barcode, the barcode information management system can extract reagent information from the reagent barcode with different format and contents, in order to enhance the open degree for the biochemical instrument in reagent usage.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

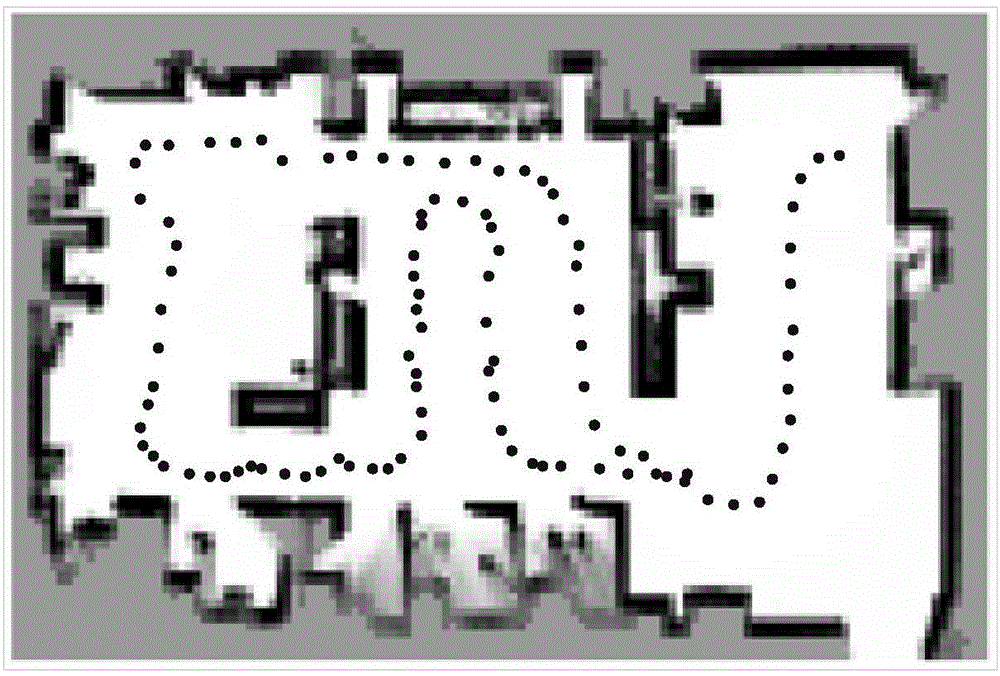

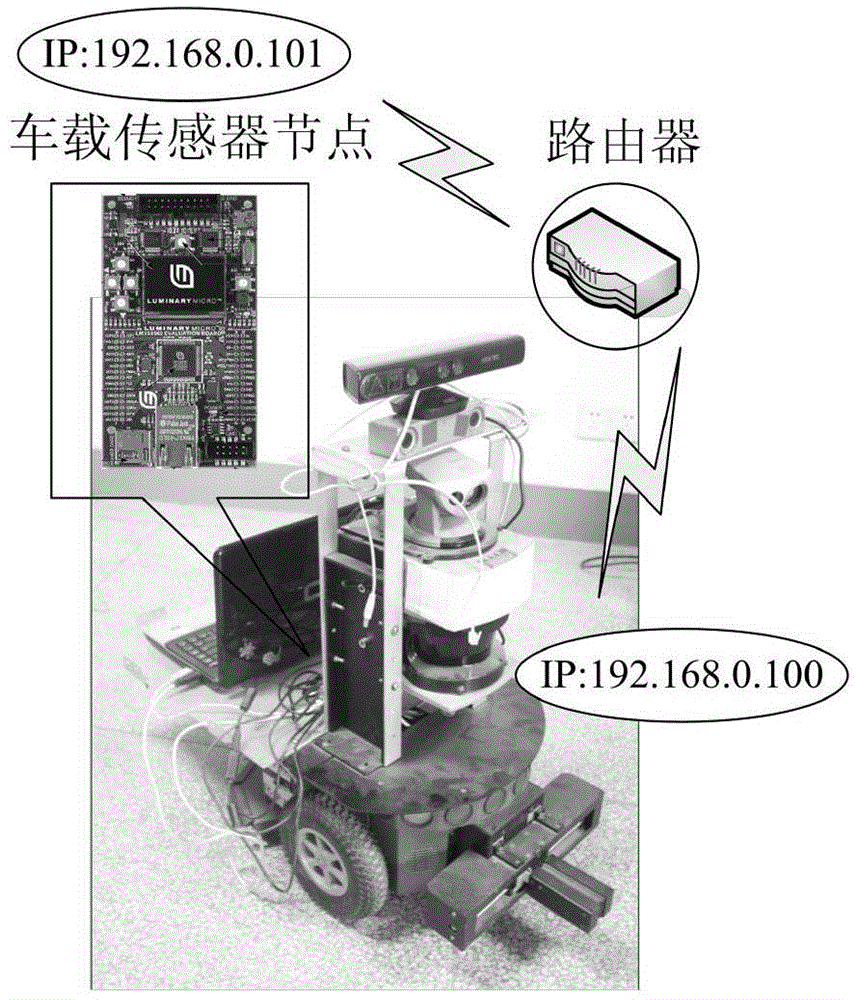

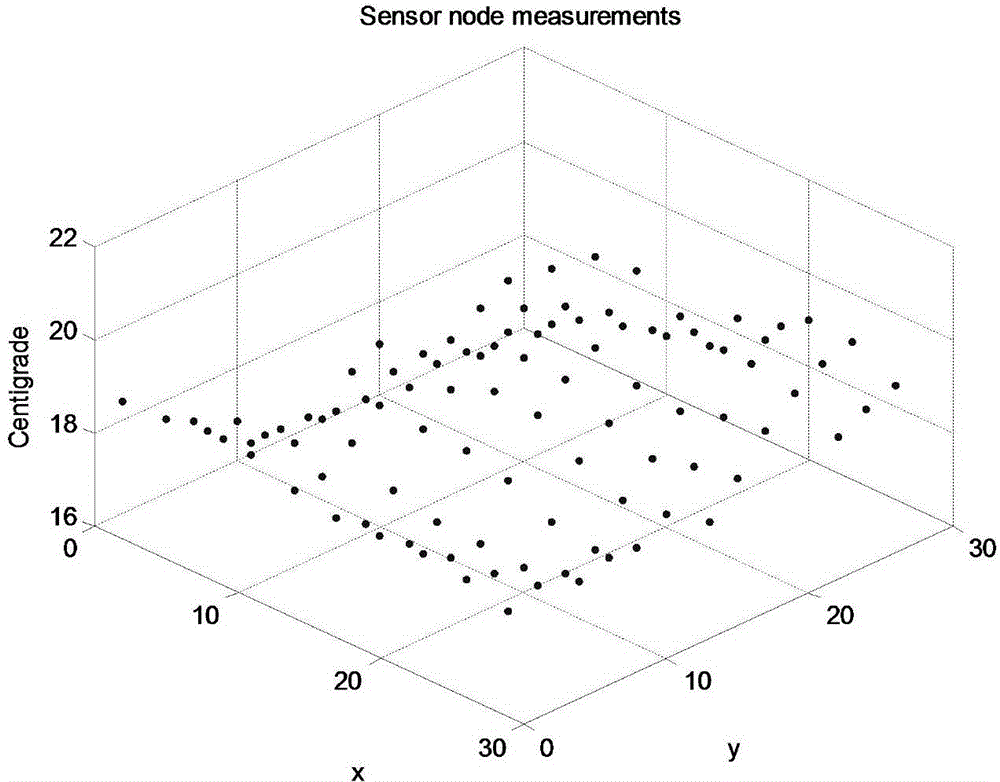

Building environment sensor measuring point optimization method based on Gauss process model

InactiveCN103984981ASolve the optimal placement problemReconstruction of environment parameter (field) distributionBiological modelsGreedy algorithmSensor node

The invention relates to the field of building distributed environment monitoring and discloses a building environment sensor measuring point optimization method based on a Gauss process model. The method comprises the steps that a teleoperation moving robot is used for carrying an environment measuring sensor node to be used as a moving measuring platform, and environment parameters and measuring point positions in an unknown building are collected; the environment parameters obtained by collecting are used as data samples, a Gauss process regression model is used for carrying out fitting on continuous probability distribution of the environment parameters, and measured values at unarranged measuring points are predicted; a greedy algorithm is used for solving a group of optimum sensor position set; and the optimum sensor position set and complementary selecting results of the main measuring point positions in a building room are combined, and finally the measuring point distribution results with the limited number and the optimum positions are obtained. According to the method, optimum arranging of environment measuring sensors in a large area of the unknown building can be achieved, the smallest number of sensors are used for reestablishing environment parameter field distribution effectively, and a traditional experience arranging method is replaced.

Owner:SOUTHEAST UNIV

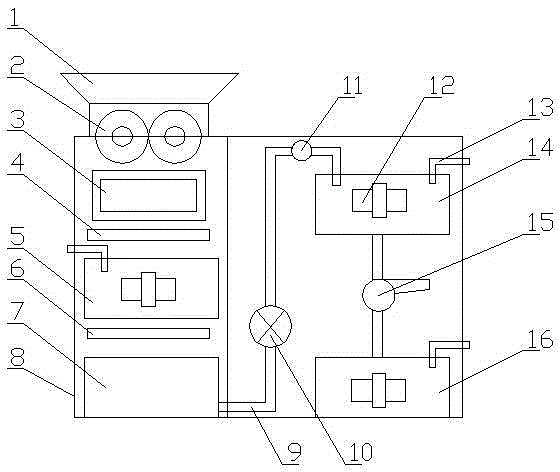

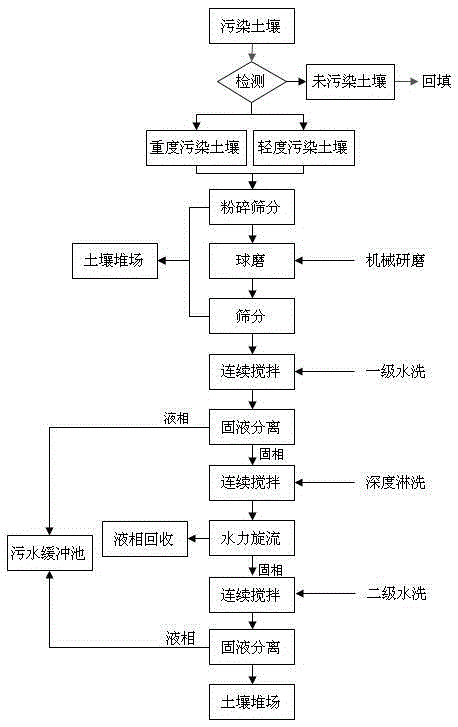

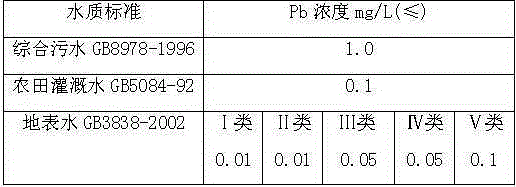

Heavy metal contaminated soil remediation equipment and remediation process thereof

ActiveCN105268737AOverall small sizeSmall footprintContaminated soil reclamationSoil scienceSoil remediation

The invention relates to heavy metal contaminated soil remediation equipment. The heavy metal contaminated soil remediation equipment comprises a machine frame, a feeding hopper, grinding rollers, a ball mill, a screen sieve, a first-level rinsing pool, a linear vibrating screen, a slurry buffer pool, a slurry pump, a centrifugal machine, a deep leaching pool, a belt filter press and a second-level rinsing pool. Contaminated soil is subjected to mechanical grinding, first-level rinsing, first-level solid-liquid separation, deep leaching, second-level rinsing and second-level solid-liquid separation to be remedied. The heavy metal contaminated soil remediation equipment is advanced in process, good in treatment effect, high in working efficiency and high in automation degree.

Owner:GUANGZHOU FIRST MUNICIPAL ENG CO LTD

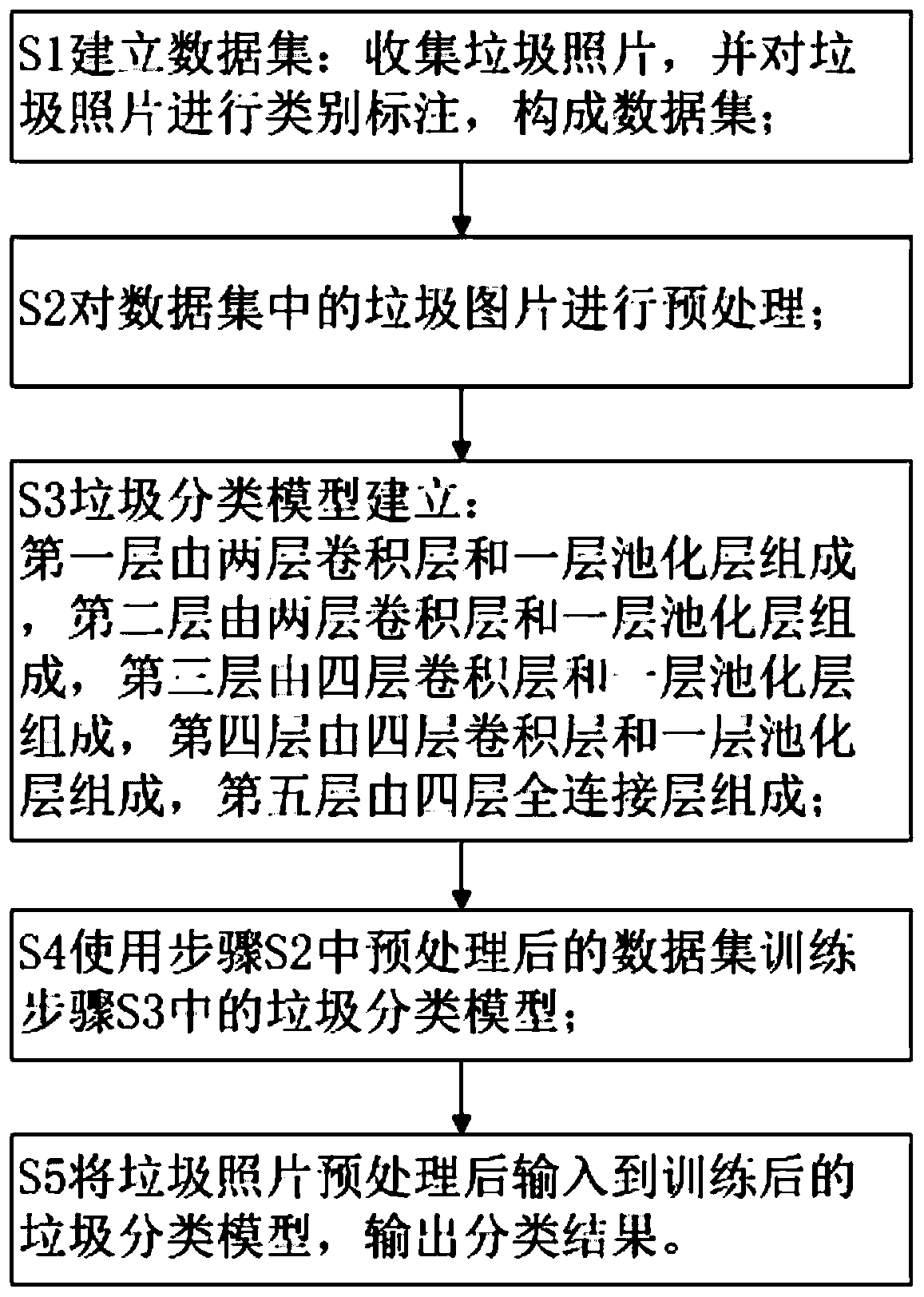

Garbage classification and recognition method based on artificial intelligence

InactiveCN110598800AImprove classification efficiencyShorten the timeCharacter and pattern recognitionNeural architecturesData setImaging processing

The invention discloses a garbage classification and recognition method based on artificial intelligence, and relates to the technical field of image processing. The method comprises: establishing a data set, and preprocessing junk pictures in the data set; forming a garbage classification model by a convolutional deep neural network, and training the garbage classification model by using the dataset preprocessed in the step; preprocessing junk photos to be classified, inputting the preprocessed junk photos into the trained junk classification model, and outputting a classification result. According to the method, the garbage image set is trained through the established deep neural network to complete establishment of the garbage recognition model, the thrown garbage is accurately recognized through the established garbage recognition model, the garbage classification efficiency of a user can be improved, and time and cost are saved.

Owner:INSPUR ARTIFICIAL INTELLIGENCE RES INST CO LTD SHANDONG CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com