Precision positioning and clamping device of lathe

A precision positioning and clamping device technology, applied in the field of lathe fixtures, can solve the problems of increased repetitive design work of process and tooling, waste of time and resources, and increased cost, and achieve the effect of avoiding increased repetitive design work and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

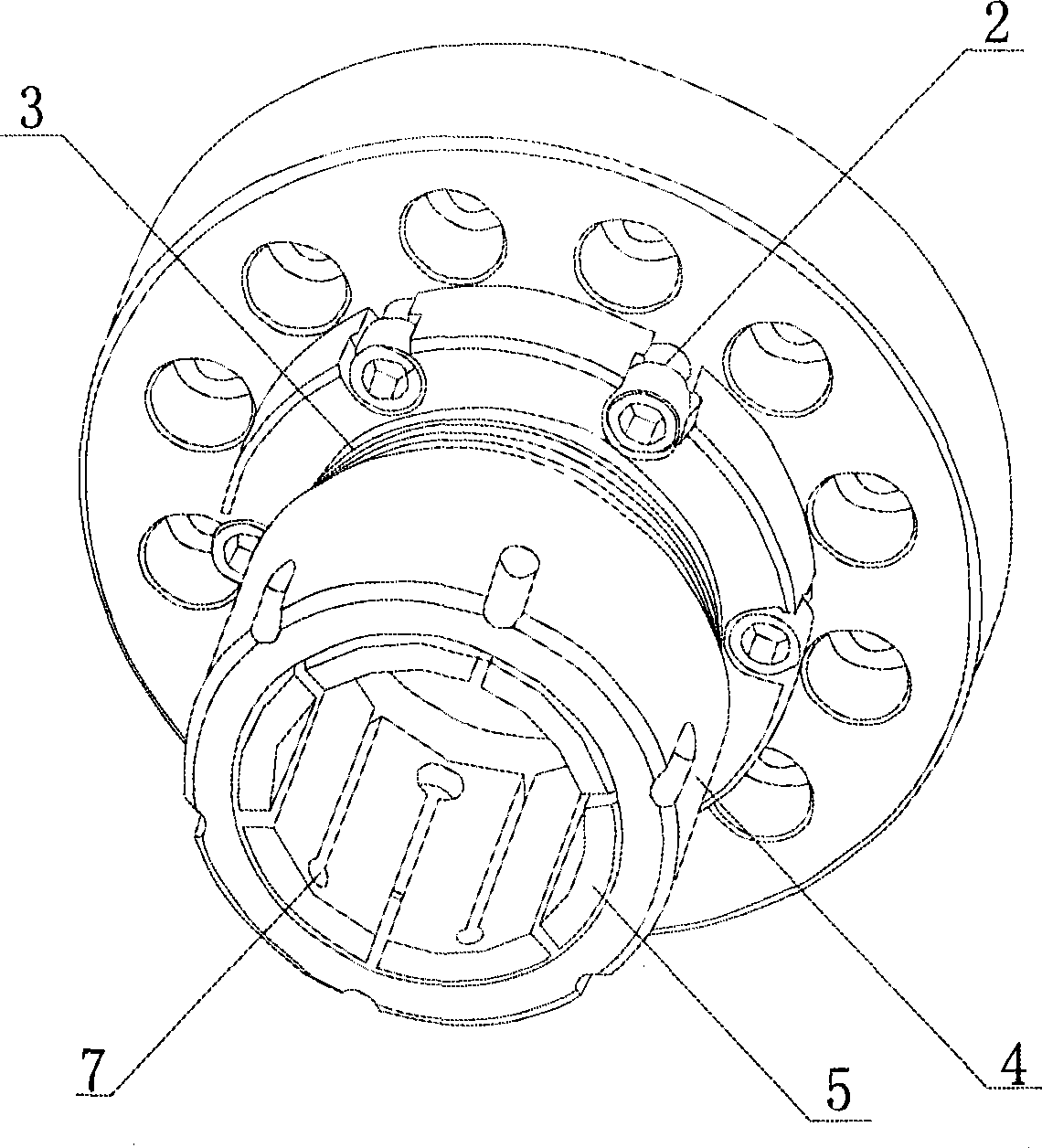

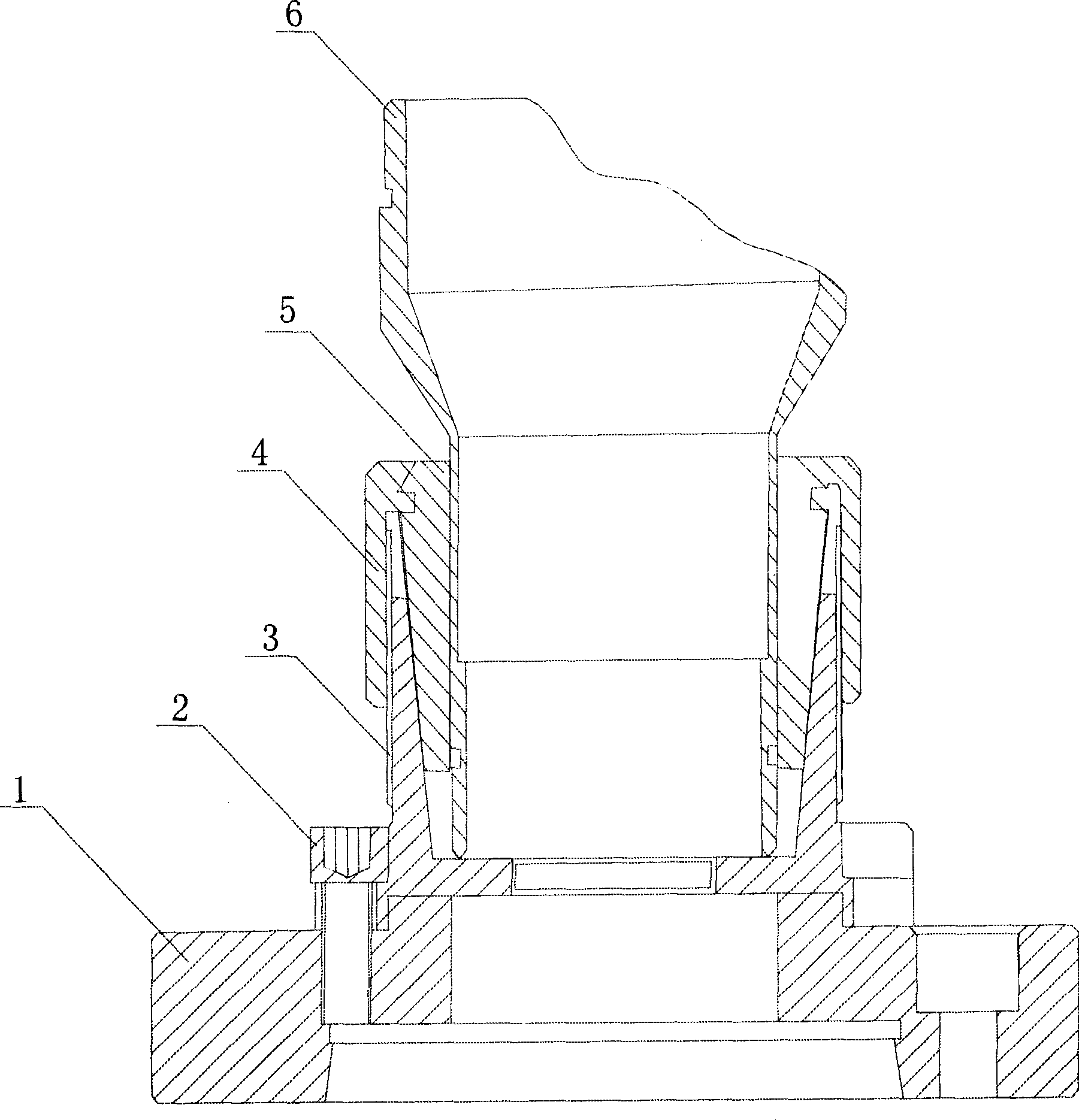

[0012] refer to figure 1 , figure 2 , a precision positioning clamping device for a lathe, including a clamp base 1, a clamp body 3, an elastic sleeve 5, and a fastening nut 4. The clamp body 3 is connected and fixed with the clamp base 1 by the screw 2, a number of slits 7 are evenly arranged at both ends of the elastic sleeve 5, and the distance between any two slits 7 is equal, and the outer tapered surface of the elastic sleeve 5 is in contact with the inner tapered surface of the clamp body 3. Correspondingly, the fastening nut 4 and the clip body 3 are fixed by bolts. The slits 7 set on the elastic sleeve 5 are used to weaken the radial deformation stiffness of the sleeve, reduce the deformation resistance, and increase the contact area and contact stiffness between parts. The number of slits 7 is set according to the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com