Patents

Literature

79 results about "Group technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Group technology or GT is a manufacturing technique in which parts having similarities in geometry, manufacturing process and/or functions are manufactured in one location using a small number of machines or processes. Group technology is based on a general principle that many problems are similar and by grouping similar problems, a single solution can be found to a set of problems, thus saving time and effort.

Internet-based group website technology for content management and exchange (system and methods)

ActiveUS8353012B2Data processing applicationsDigital data processing detailsDomain nameContent management system

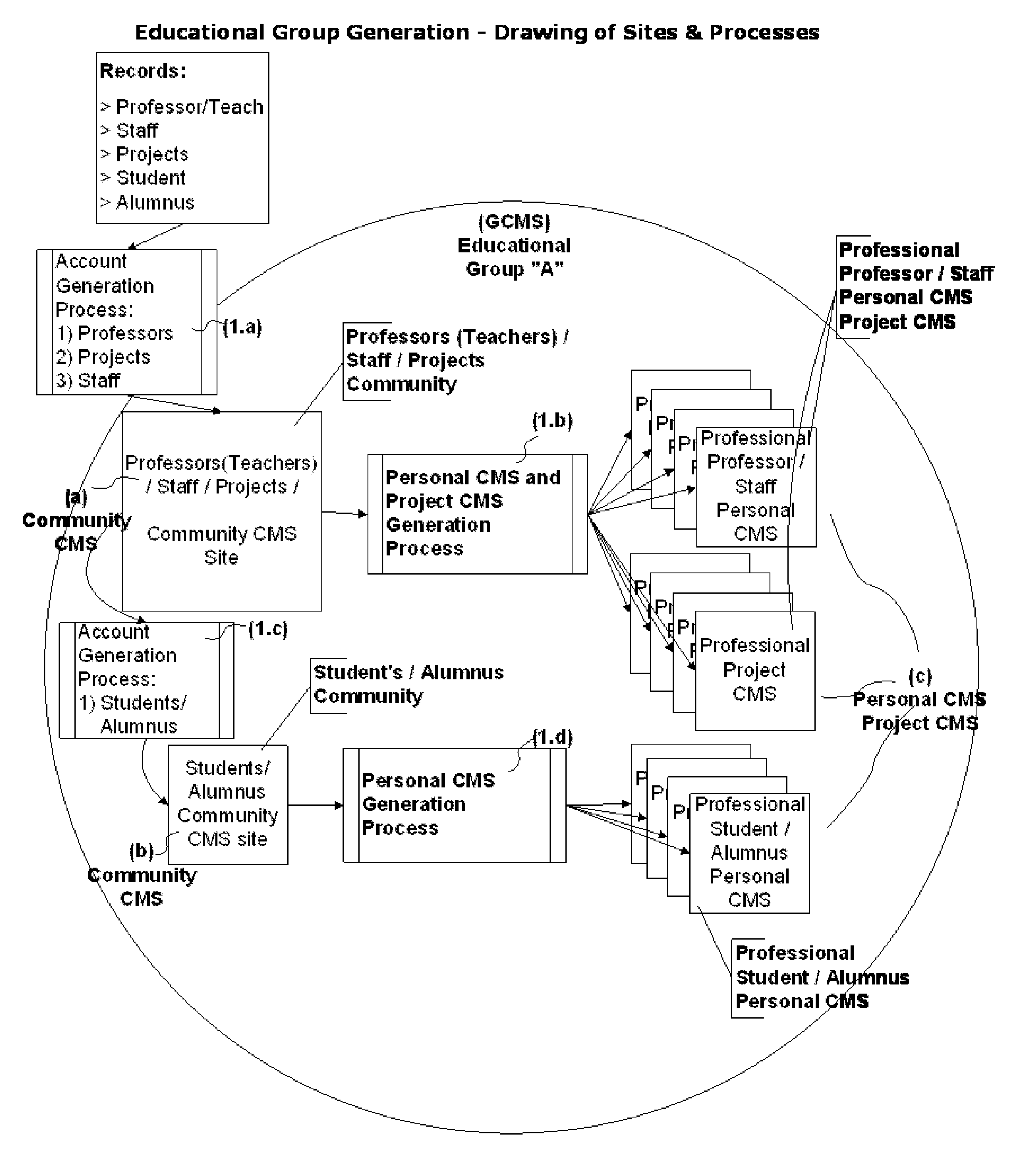

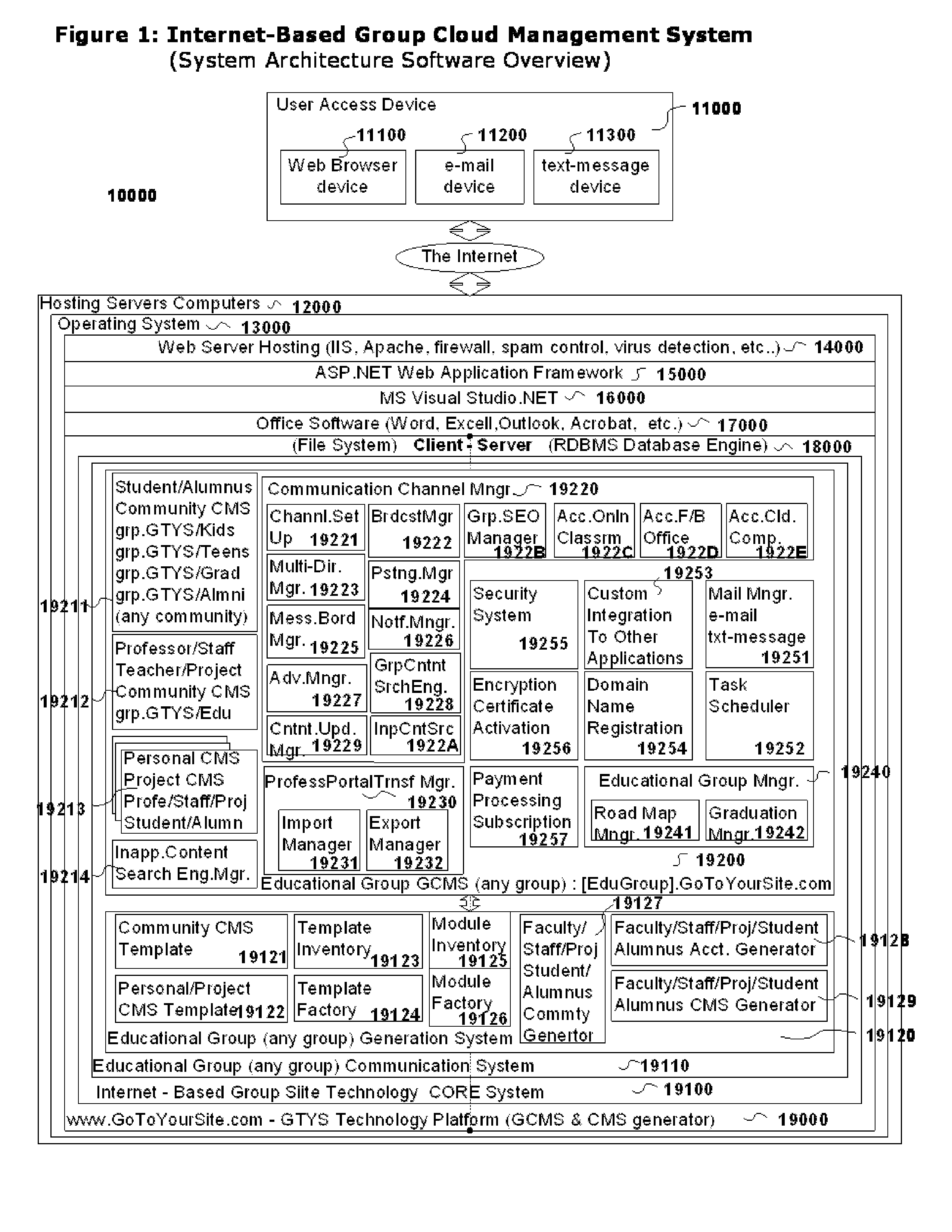

System and Methods for implementing a Internet-Based Group Cloud Management System (GCMS) comprised by several Cloud Management System sites (CMS sites), where providing institutions, means for: A) The Creation of the Educational Group comprised by: A1) Community CMS sites for Campuses and / or Groups of Users, A2) Personal CMS Sites for each Faculty, Staff, Student and Alumnus, A3) Project CMS sites for each Project Team. B) Communication within the Educational Group: B1) Among CMS Sites, B2) to e-mail and text-messaging devices. The CMS sites are reachable by their own domain names or sub-domain from the GCMS, and by any search engine. Each CMS site is multi-user and includes its own security system, user-defined and predefined pages for among others, Professional Profile, Web Apps, Virtual Desktop / Apps and Web / Cloud Services. Each CMS site is connected to the GCMS, allowing the Exchange of Information among CMS sites within the GCMS and among GCMS sites.

Owner:CITRIX SYST INC

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

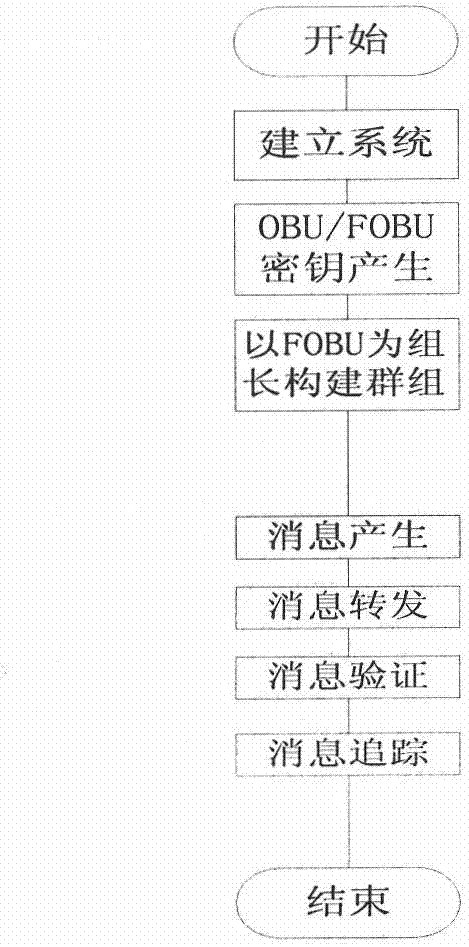

Floating vehicle-based traceability vehicle self-networking communication privacy protection method

InactiveCN102740286AIncrease coverageReduce overheadNetwork topologiesSecurity arrangementPrivacy protectionEngineering

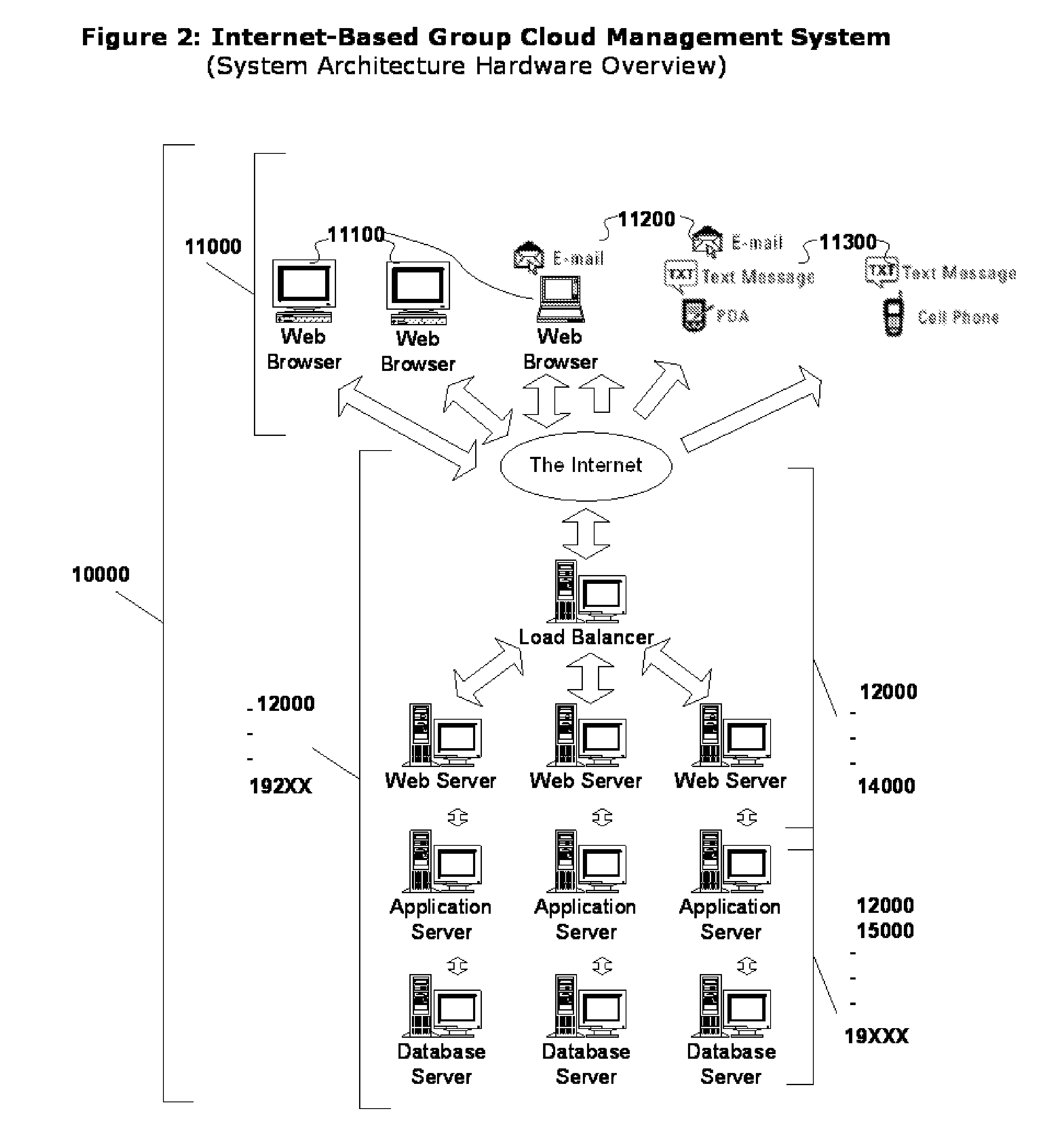

The invention discloses a floating vehicle-based traceability vehicle self-networking communication privacy protection protocol, which is characterized in that a floating vehicle is used as a mobile RSU (Remote Subscriber Unit), a floating vehicle auxiliary grouping technology is adopted, the floating vehicle F adopts V2V communication, vehicles running in the same direction in an effective communication radius are united to spontaneously form a group, F is used as a group leader and is in charge of authorizing the validity of the vehicles and maintaining a group key and a specified group parameter; and F and all members respectively have a one-to-one secret channel negotiated by anonymous certificates issued by an authentication center (TA), the members sends messages to be broadcasted to the F by using the channels, the F is subjected to the message anonymilization and encrypted by using a group key-based symmetric encryption algorithm and then forwarded to other members or other groups, and when the messages are disputed, under the authorization of the TA, the real identity of the vehicle generating the messages can be accurately located.

Owner:杨涛

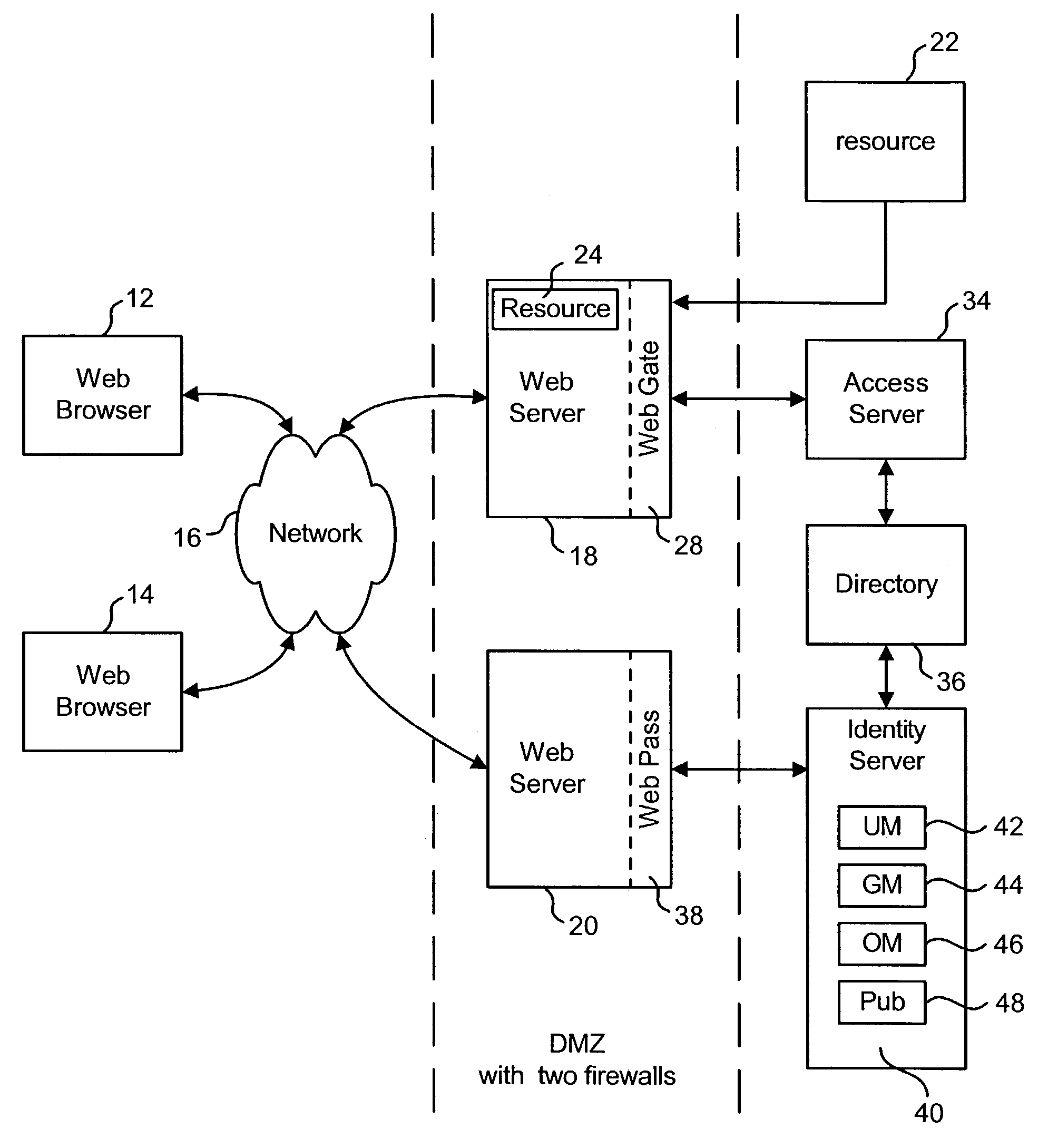

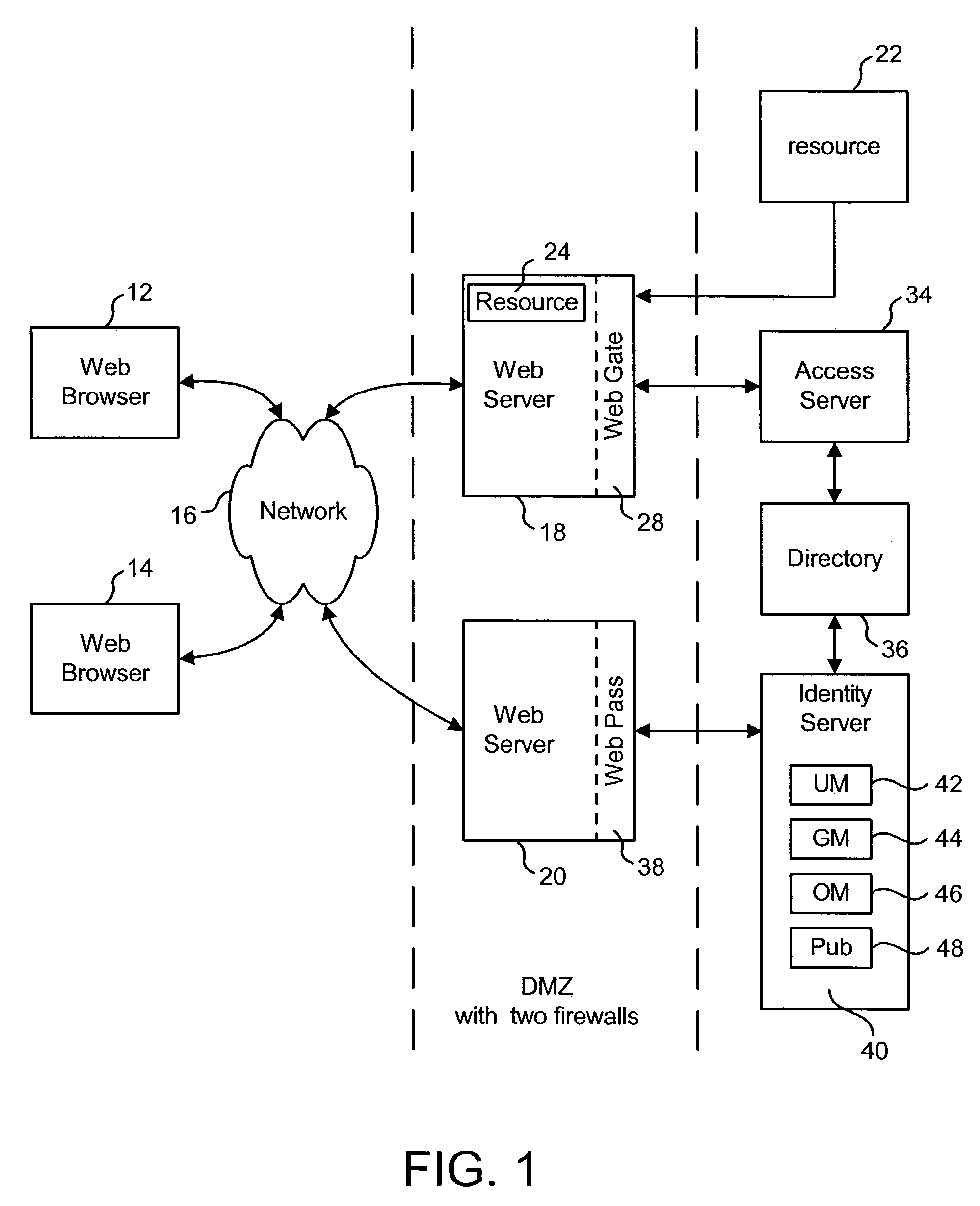

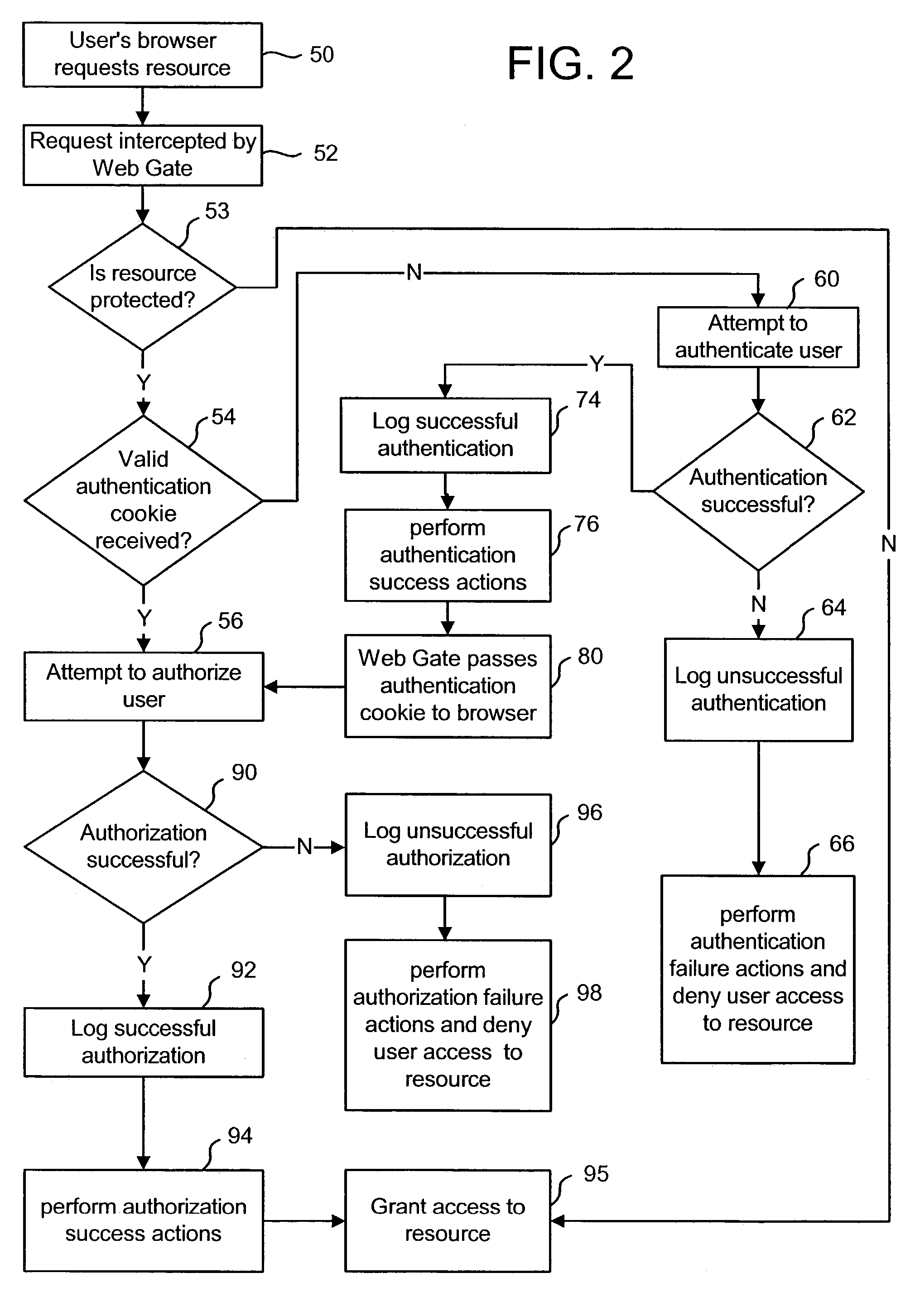

Identifying dynamic groups

ActiveUS20040010606A1Data processing applicationsDigital data protectionSoftware engineeringTest set

Technology is disclosed for identifying dynamic groups that correspond to a user of a system. A system partitions a set of dynamic groups into multiple test sets of dynamic groups. The system selects a test set and determines whether the user corresponds to the test set. In one implementation, the system combines the filters for the dynamic groups in each test set into a single test set filter. The test set filter is satisfied if the filter of any dynamic group in the test set is satisfied. This allows the system to perform a single comparison between the resulting test set filter and the user's profile to determine whether the user is a member of any dynamic group in the test set. If the user is not a member of any dynamic group in the test set, the system eliminates all of the test set's dynamic groups from consideration, based on the single comparison. Otherwise, the dynamic groups in the test set remain in a list of groups that may include the user. This process is repeated for each test set. After each test set has been evaluated, new test sets are repeatedly generated and evaluated in the above-described fashion using the dynamic groups that are still in consideration. In each iteration, each test set contains fewer dynamic groups. This continues until each test set only contains one dynamic group. After performing an iteration with each test set containing one dynamic group, the only remaining dynamic groups are the ones that include the user as a member.

Owner:ORACLE INT CORP

Identifying dynamic groups

ActiveUS7206851B2Reduce in quantityData processing applicationsDigital data processing detailsSoftware engineeringTest set

Owner:ORACLE INT CORP

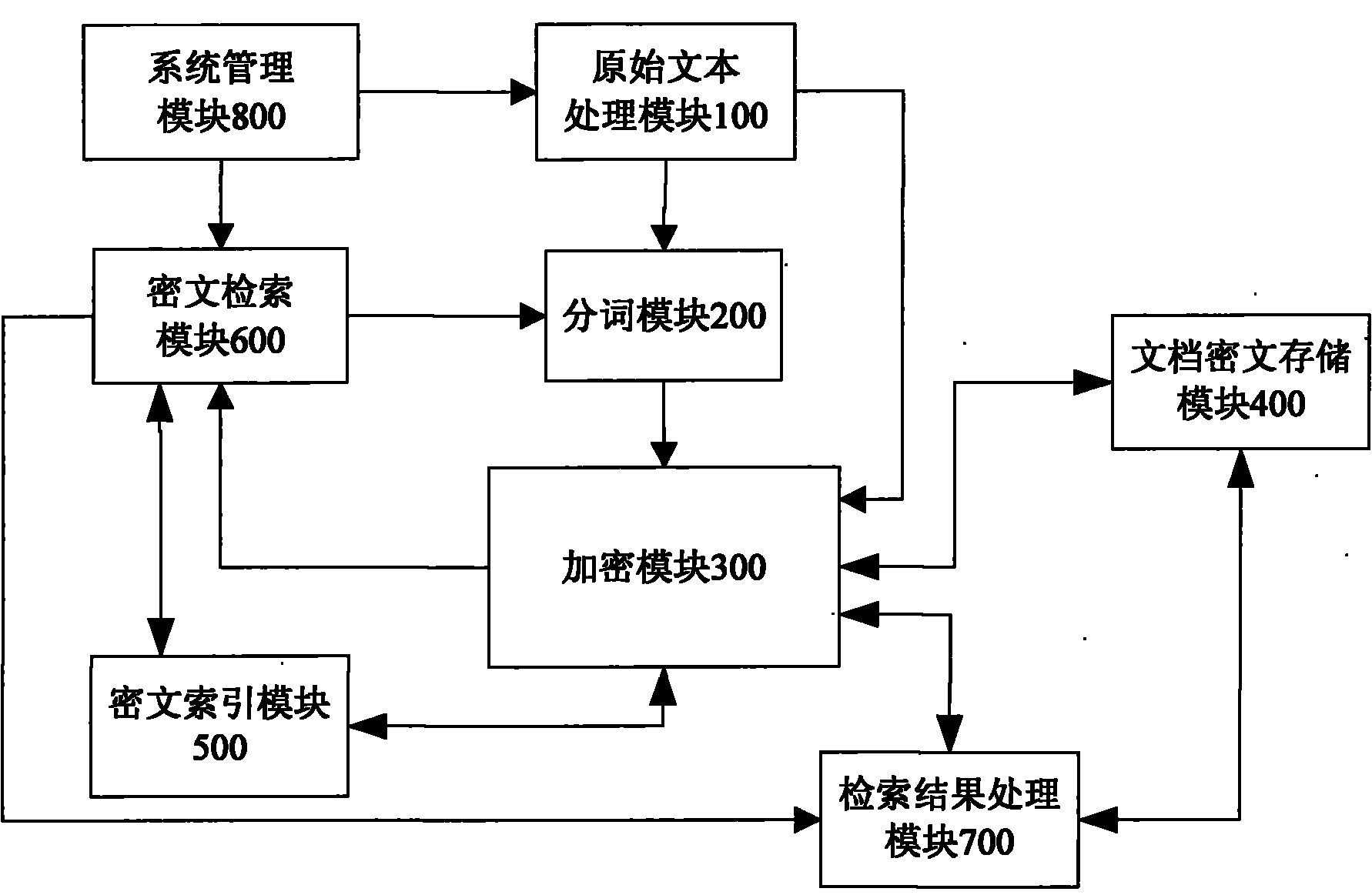

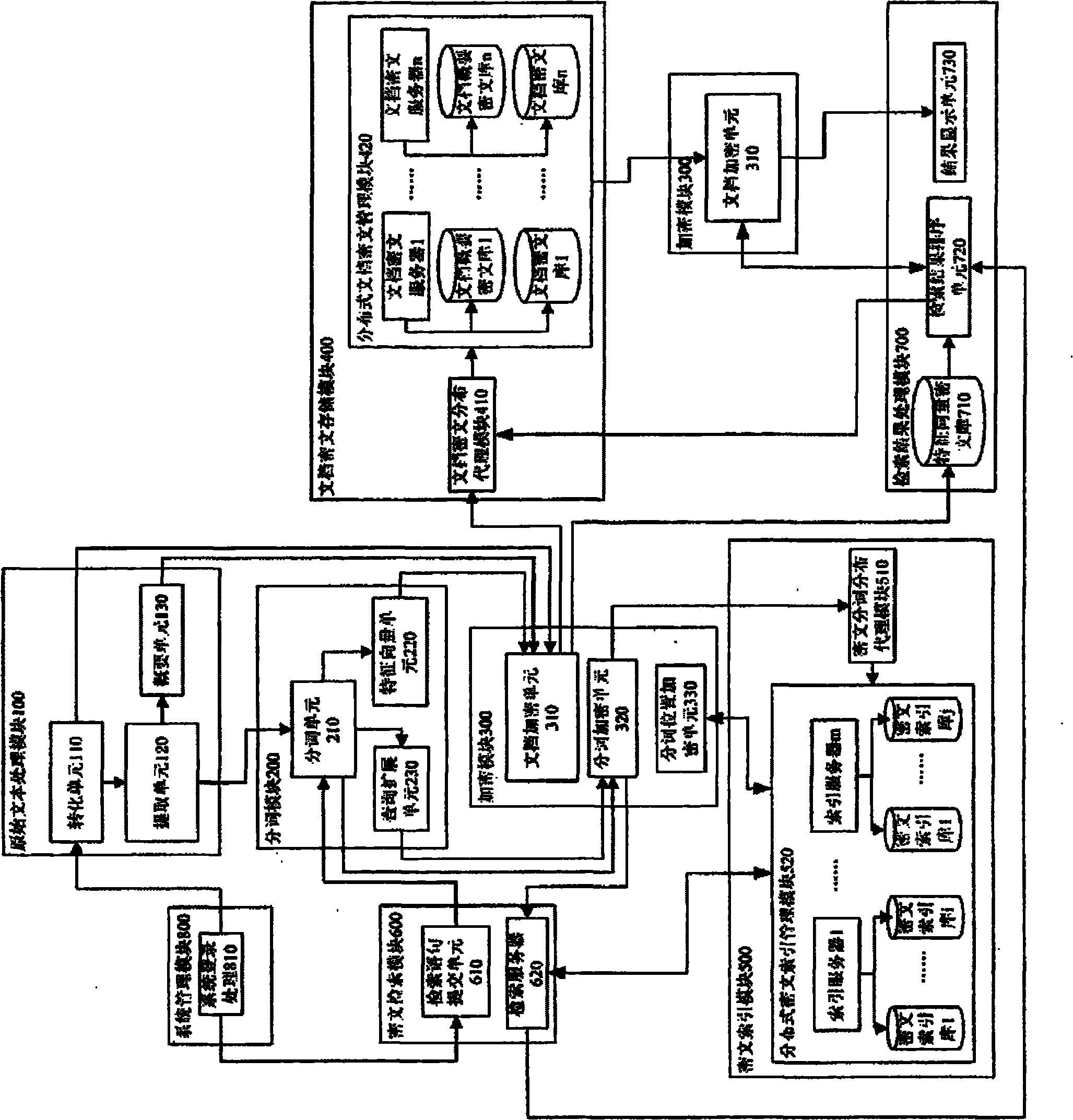

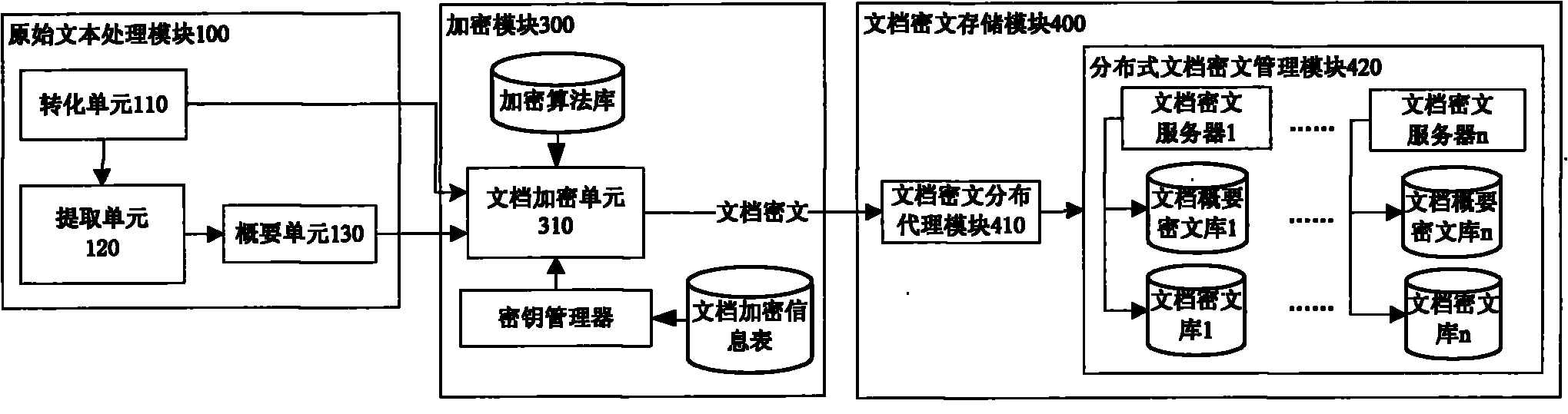

Ciphertext full-text search system

InactiveCN101859323ASafe and efficient dynamic updateSafe and efficient creationSpecial data processing applicationsFull text searchResource utilization

The invention discloses a ciphertext full-text search system, comprising an original text processing module, a word segmentation module, an encrypting module, a file ciphertext storage module, a ciphertext index module, a ciphertext search module, a search result processing module and a system management module. The system adopts a ciphertext dynamic sequential tree index structure, a word segmentation group technology and a file local ciphertext dynamic sequential tree index updating method, and can realize index establishment, dynamic index updating, full-text search and substring query under a ciphertext state. The system also can realize peer-to-peer full text research for a safety overlay network in a P2P network and introduces an index file carbon copy replication mechanism based ona peer-to-peer network hubs and nodes. In addition, the ciphertext full-text search system has good expandability, solves the problems of distribution storage and search of massive data index files, increased no occupation of network bandwidth, and has high network resource utilization ratio.

Owner:GUANGXI UNIV

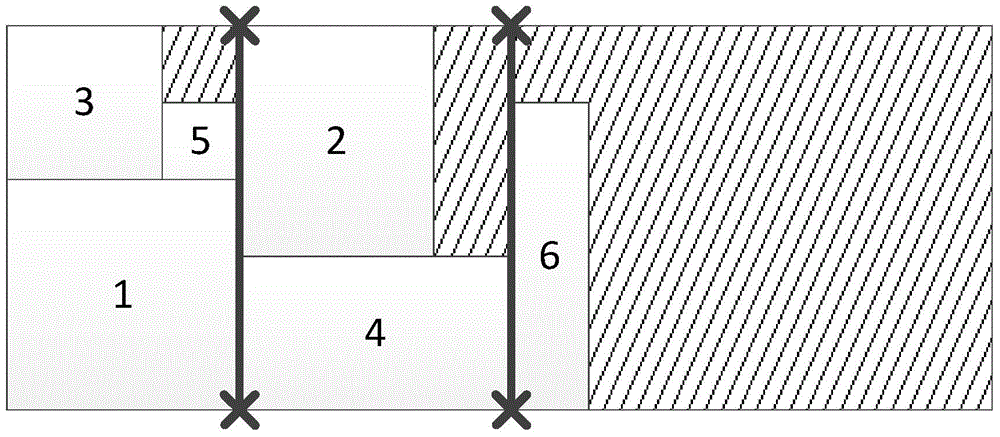

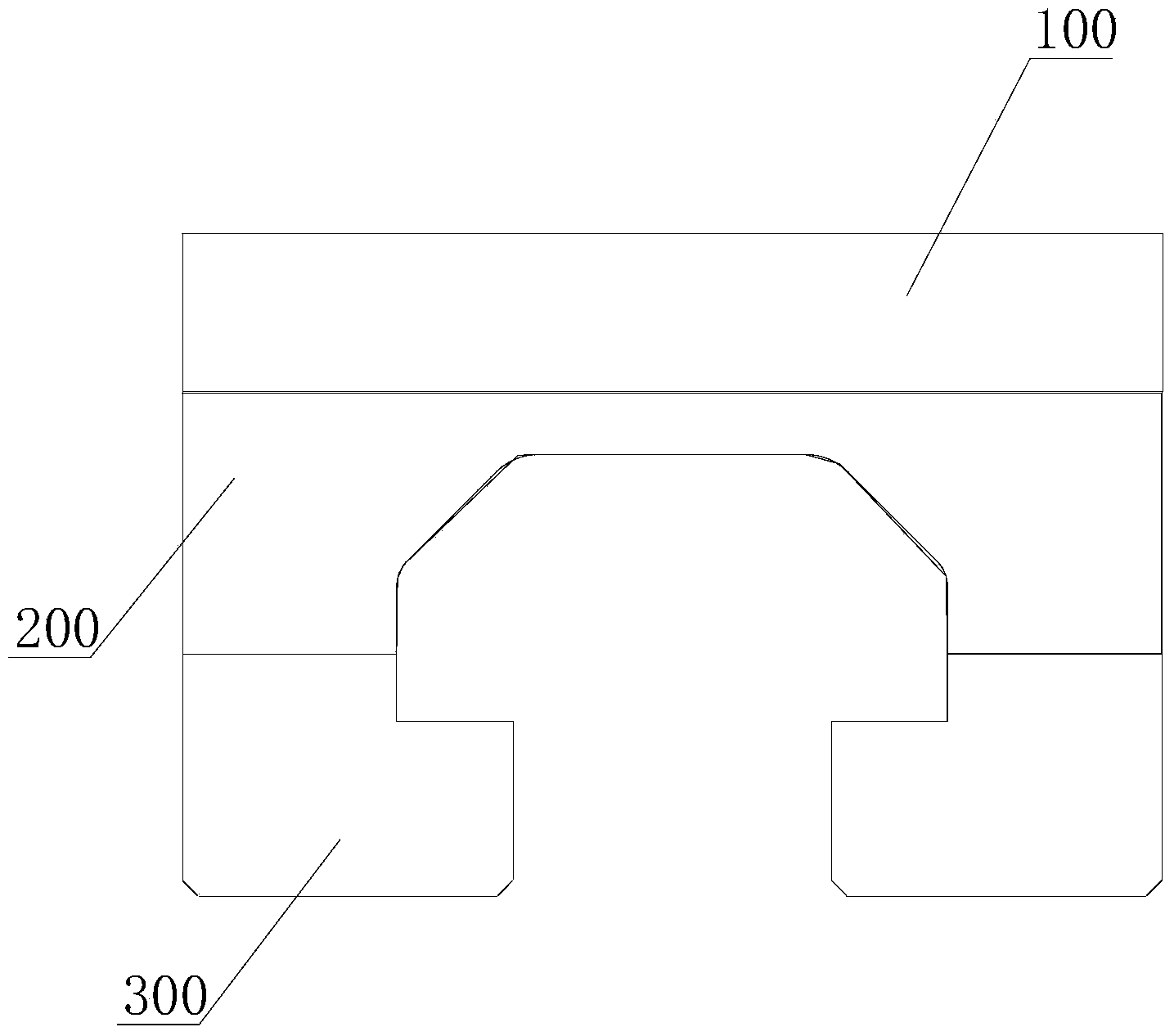

Rectangular part stock layout method based on grouping technology

ActiveCN104008145AReduce retrieval timeFast constructionForecastingSpecial data processing applicationsProcess engineeringIndustrial engineering

The invention discloses a rectangular part stock layout method based on a grouping technology. The method includes the following steps that firstly, rectangular parts with the same length or the same width in all rectangular parts are combined into combined rectangular parts; secondly, all the rectangular parts and the combined rectangular parts are recorded in an auxiliary storage structure; thirdly, through the combined rectangular parts and the auxiliary storage structure and according to the size characteristics of the rectangular parts to be laid out, the combined rectangular parts with stock layout priority are quickly retrieved; fourthly, by the combination of the quick retrieval method and according to the geometrical characteristics of raw materials, an optimal stock layout scheme is searched for through the method combining stock layout with optimization. Each combined rectangular part is a part of the optimized stock layout scheme, and the optimal solution can be quickly constructed and found; the retrieval time of the combined rectangular parts is effectively shortened through the auxiliary storage structure; then the solution quality is improved and the solution speed is increased in general. The rectangular part stock layout method based on the grouping technology can be widely applied to the fields of two-dimensional discharge stock layout.

Owner:刘强

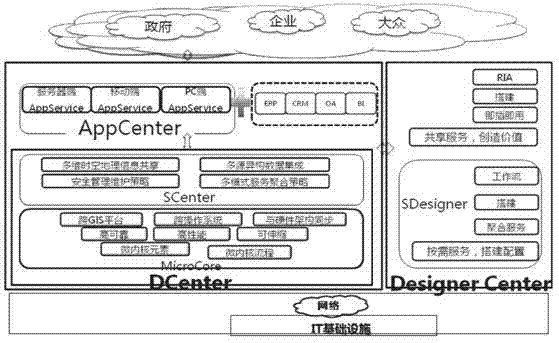

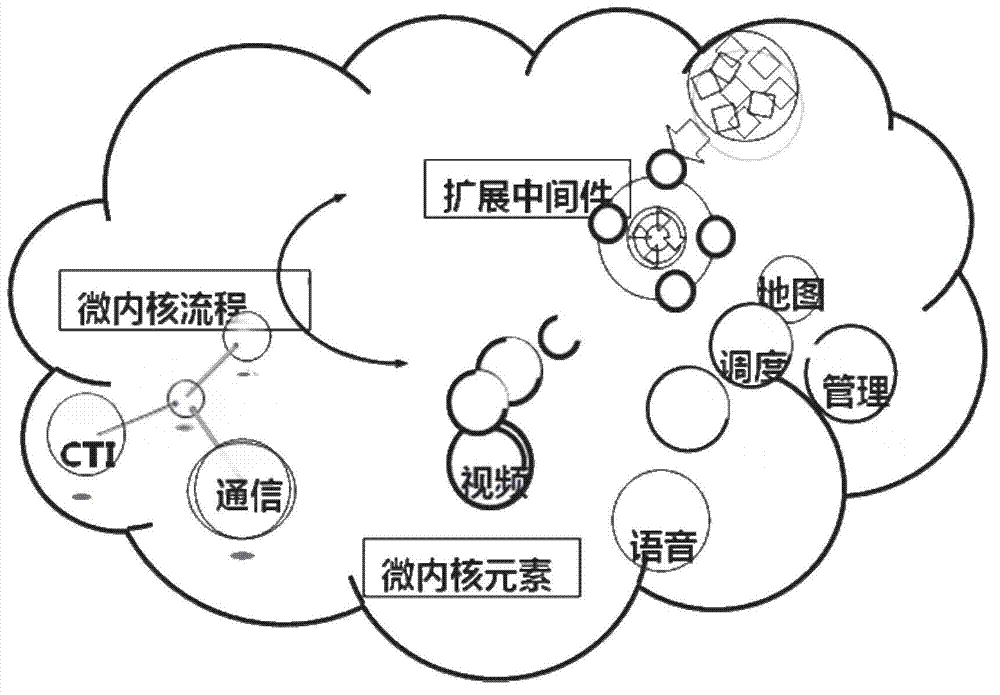

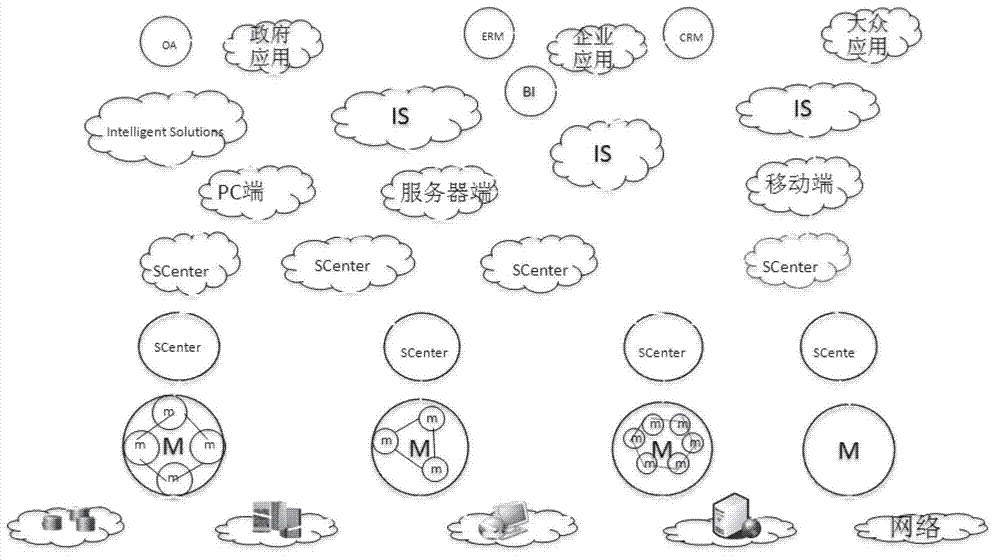

Cloud computing-oriented comprehensive emergency management platform architecture

InactiveCN102880933AGuaranteed professionalismLow costResourcesTransmissionStructure of Management InformationData link layer

The invention relates to a cloud computing-oriented comprehensive emergency management platform architecture. The platform architecture adopts a three-layer structure comprising a system service layer at the uppermost layer, a platform service layer at the middle layer and a data layer at the lowermost layer, wherein the system service layer comprises independent subsystems and provides system-level service support for PC (personal computer) terminal, WEB terminal and mobile terminal applications; the platform service layer adopts microkernel group technology and is divided into a plurality of microkernel groups each of which comprises a group of microkernels; one microkernel group provides a group of functions; the data service layer uniformly provides service for all the microkernels; and the data provided by the data service layer are stored in a physical storage device of a cloud platform by adopting the storage virtualization technology, and the data service layer provides an data service engine including data operation, data processing and the like for each database. The platform architecture effectively solves the problem of multi-user demand of the platform and can be widely applied to the design of the comprehensive emergency management platform architecture.

Owner:GUANGDONG ELECTRONICS IND INST +1

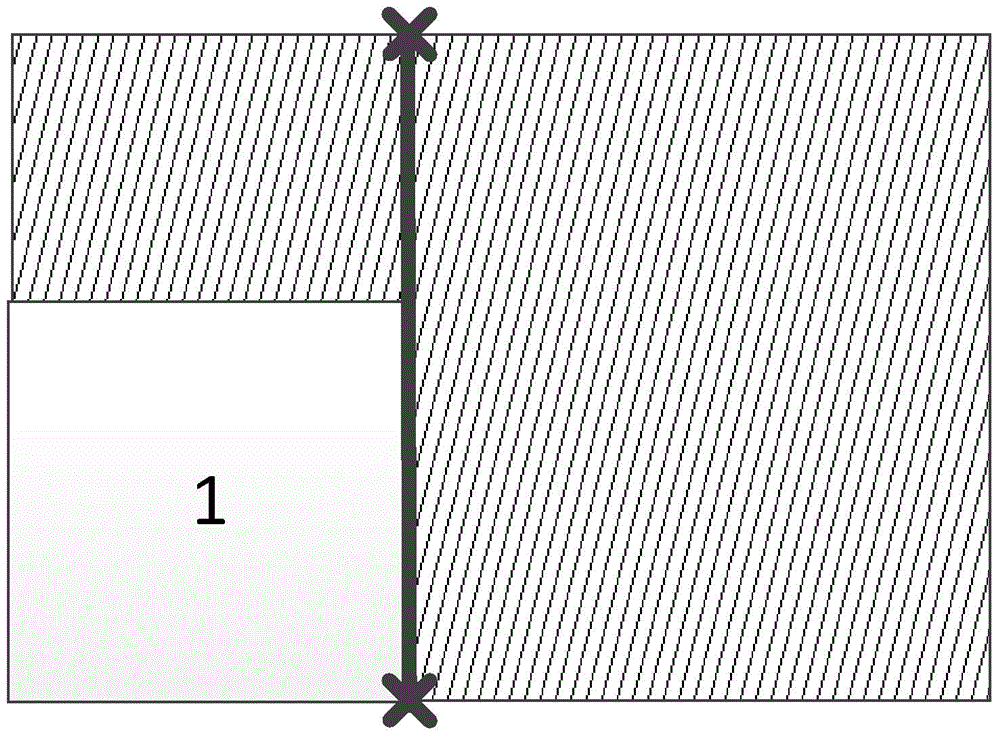

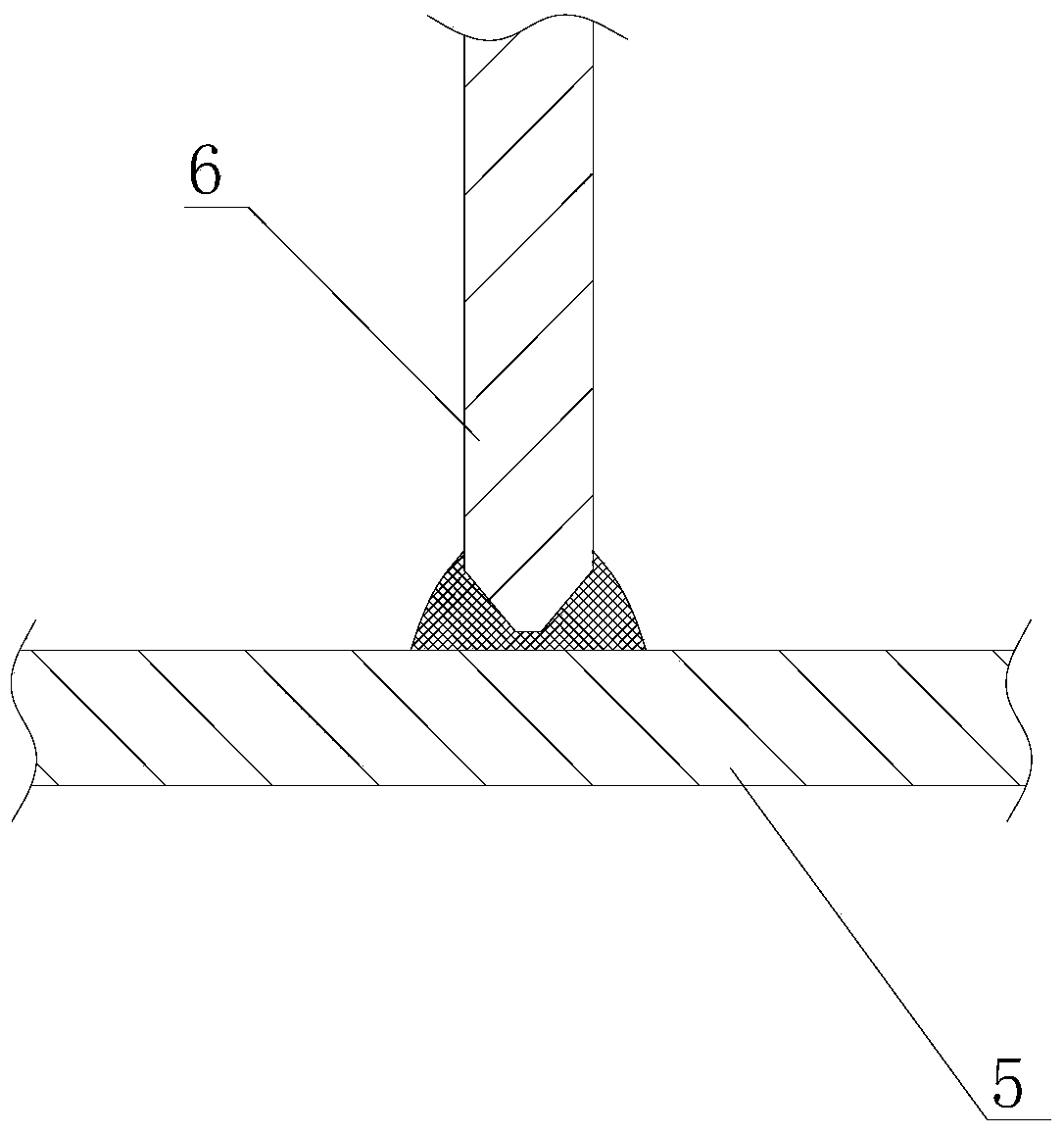

Cross structure area segmentation manufacturing process of CSS platform and special-purpose inclined cutting jig frame

ActiveCN103523168AReduce chances of interleavingOptimize assembly processVessel partsFillet weldElevation angle

The invention provides a cross structure area segmentation manufacturing process of a CSS platform and a special-purpose inclined cutting jig frame. An inner side outer plate assembly is additionally arranged, an inner side outer plate inclined cutting jig frame is utilized in the assembly, therefore assembling and welding processes are improved, an assembling procedure and a welding position are optimized, fillet welds between a main structure of a cross structure area and an outer plate are all improved from elevation angle welding into horizontal fillet welding, welding quality and construction efficiency are improved, and special position full penetration welding requirements are met; by widening an operation range, a group technology of segmentation manufacturing processes is boosted, alternate operation choices of various work types are reduced, therefore the construction environment is improved, production efficiency is improved, and the segmentation manufacturing period is shortened.

Owner:FUJIAN MAWEI SHIPBUILDING

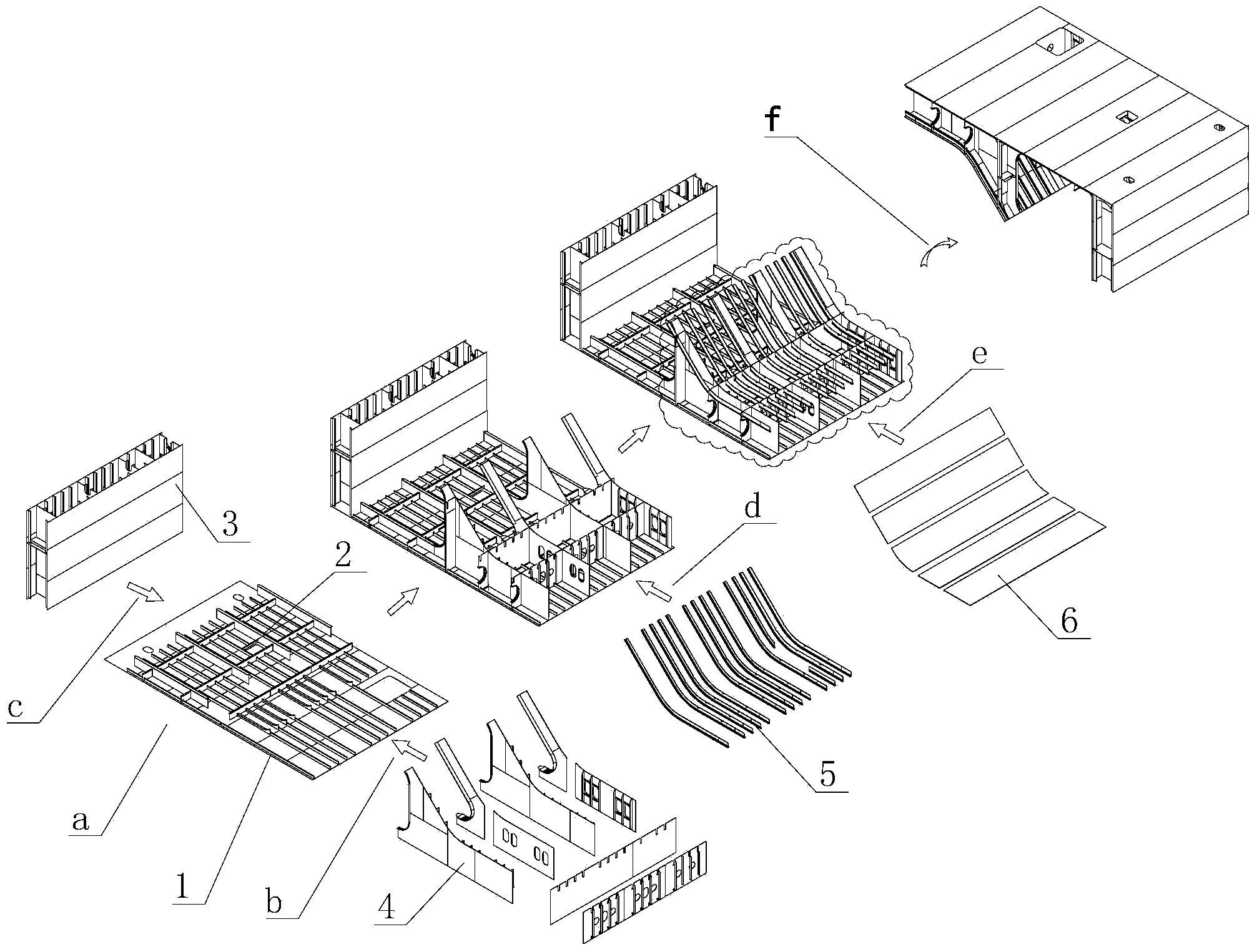

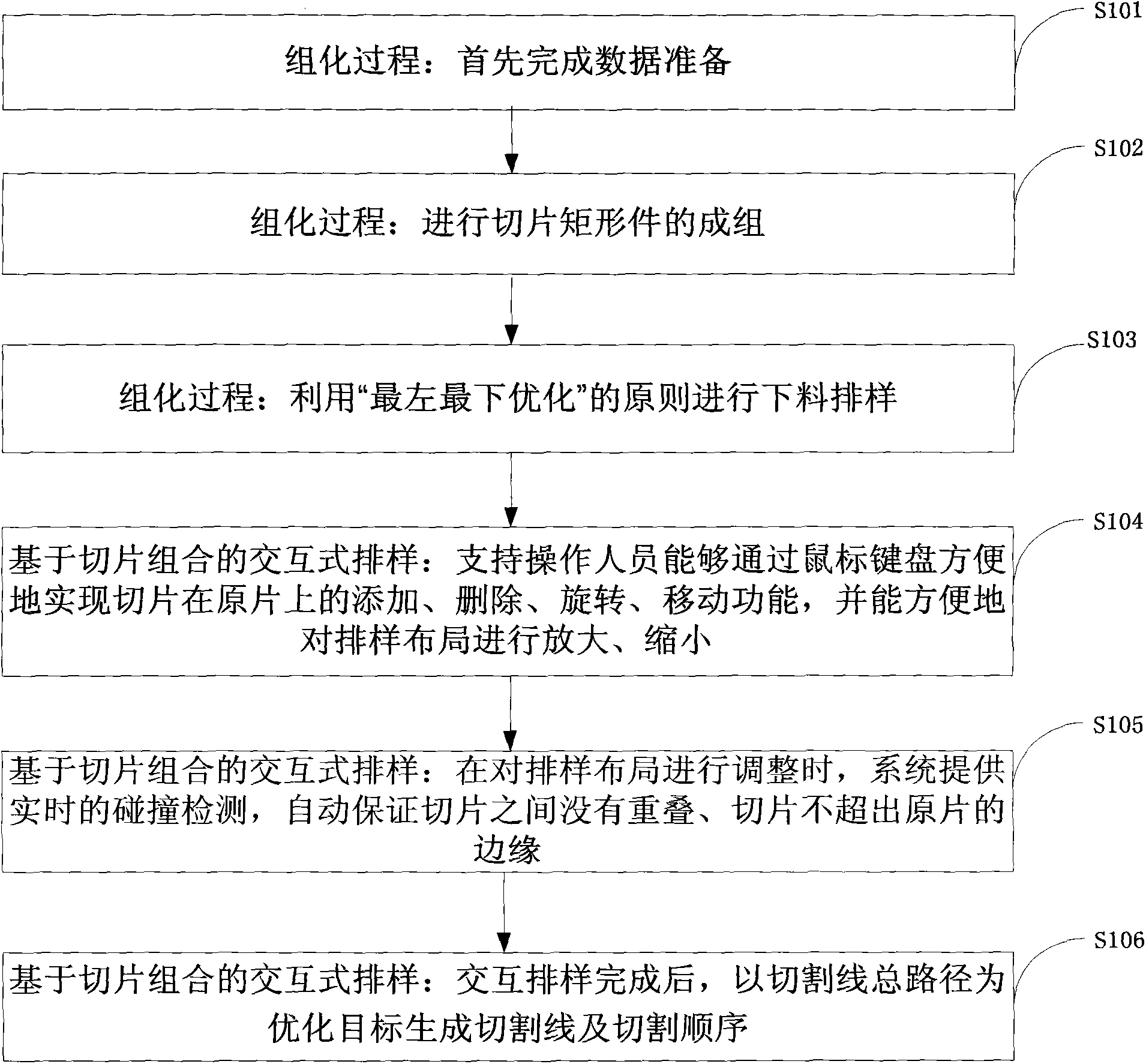

Two-dimensional rectangular part interactive layout optimization method based on grouping technology

ActiveCN103559554ASolving Interactive Nesting ProblemsSolve build problemsForecastingCollision detectionMan machine

The invention discloses a two-dimensional rectangular part interactive layout optimization method based on a grouping technology. The method includes the steps that firstly, data preparation is completed; grouping of sliced rectangular parts is performed; a leftmost and bottommost optimization principle is used for material discharging and layout; the functions that an operator can adding, deleting, rotating and moving slices on an original sheet conveniently through a mouse and a keyboard are supported, and the layout can be zoomed in and zoomed out conveniently; when the layout is regulated, a system provides real-time collision detection, and the situations that the slices do not overlap and cannot exceed the edge of the original sheet are guaranteed automatically; after interactive layout is completed, a cutting line total path is used as an optimization objective to generate cutting lines and cutting sequences. According to the two-dimensional rectangular part interactive layout optimization method, in the rectangular part discharging process, the problems of follow-up processes, workshop transportation, utilization of residual blank areas after the layout, raw material defect avoiding and temporary slice adding are considered, and problems generated by man-machine interactive layout and the cutting lines after layout are solved.

Owner:GUANGDONG UNIV OF TECH

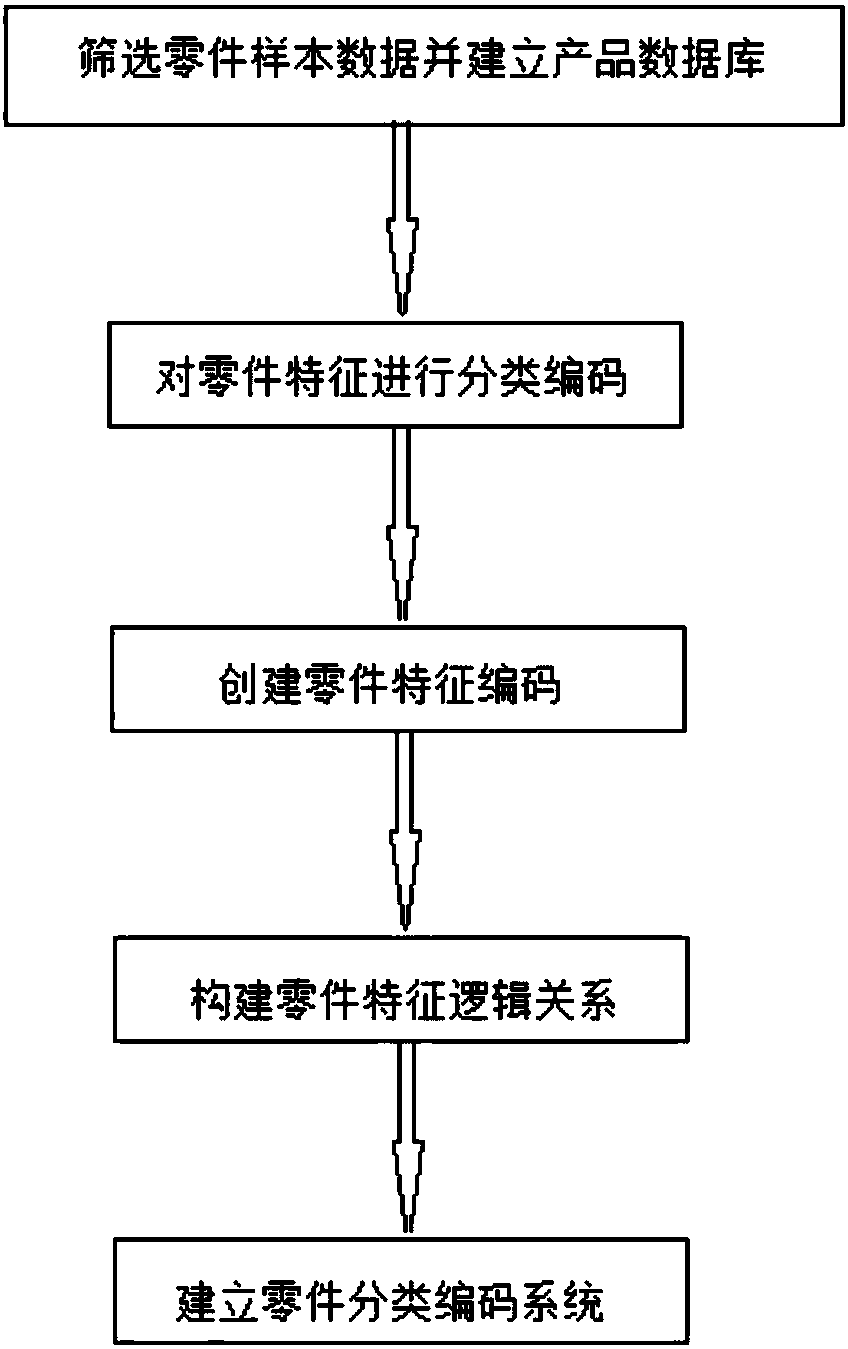

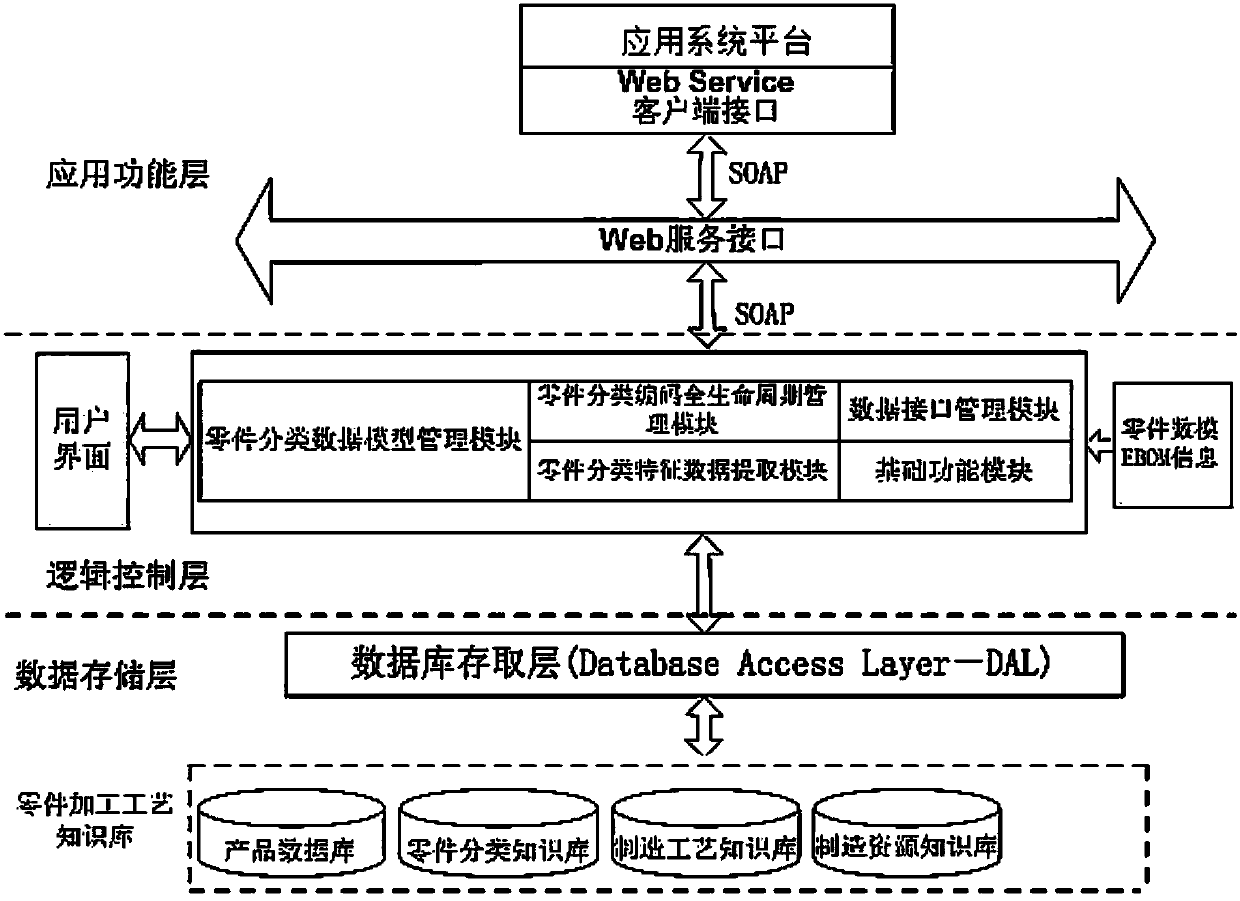

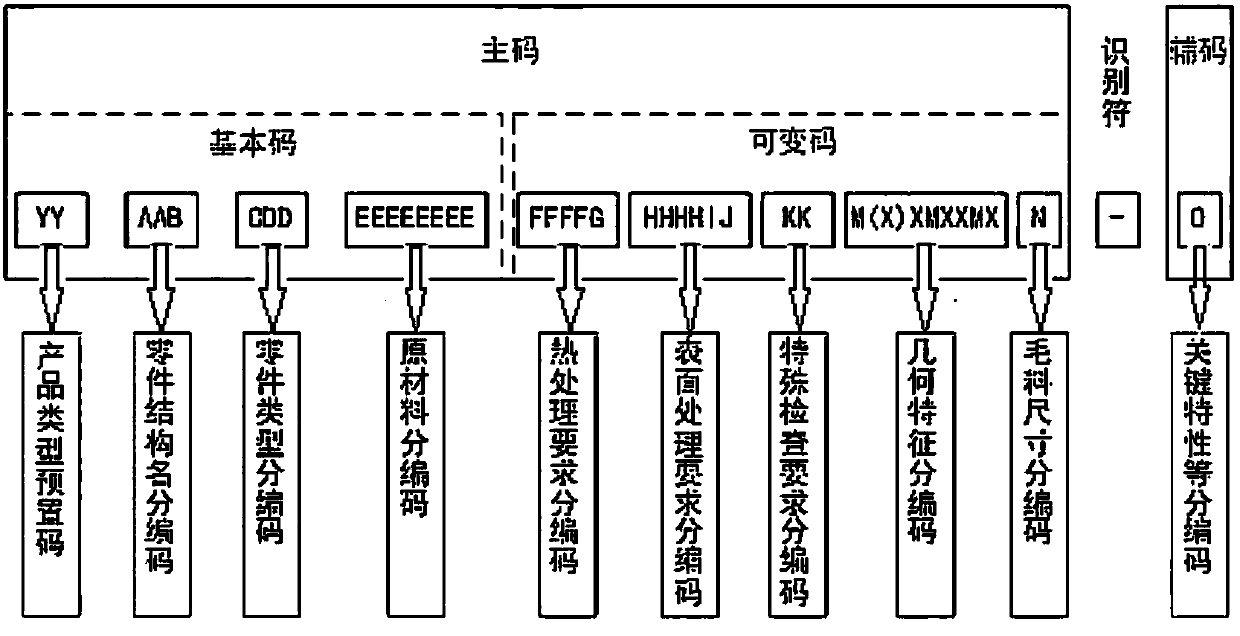

Product parts classifying and coding system establishing method based on grouping technology

ActiveCN107862094AImprove process design efficiencyIncrease production levelsDatabase management systemsRelational databasesStructure of Management InformationDesign information

The invention belongs to the technical field of parts coding and relates to a product parts classifying and coding system establishing method based on grouping technology. The method includes following steps: S1, screening parts sample data, and building a product database; S2, classifying and coding parts features; S3, creating parts feature codes; S4, establishing a parts feature logic relation;S5, establishing a parts classifying and coding system, wherein first-stage parts classifying and coding are completed on the basis of design information and synchronized with parts scheme and preliminary design, second-stage parts manufacturing process coding is gradually formed, completed and released along with the process of process scheme design and process plan design on the structural basis of first-stage parts classifying and coding, and third-stage parts manufacturing resource coding combines second-stage typical processing procedures, respectively defines according to typical partstype and codes resources like manufacturing workshop capacity and equipment, and the product parts classifying and coding system comprises an application functional layer, a logic control layer and adata storage layer.

Owner:CHINA AERO POLYTECH ESTAB

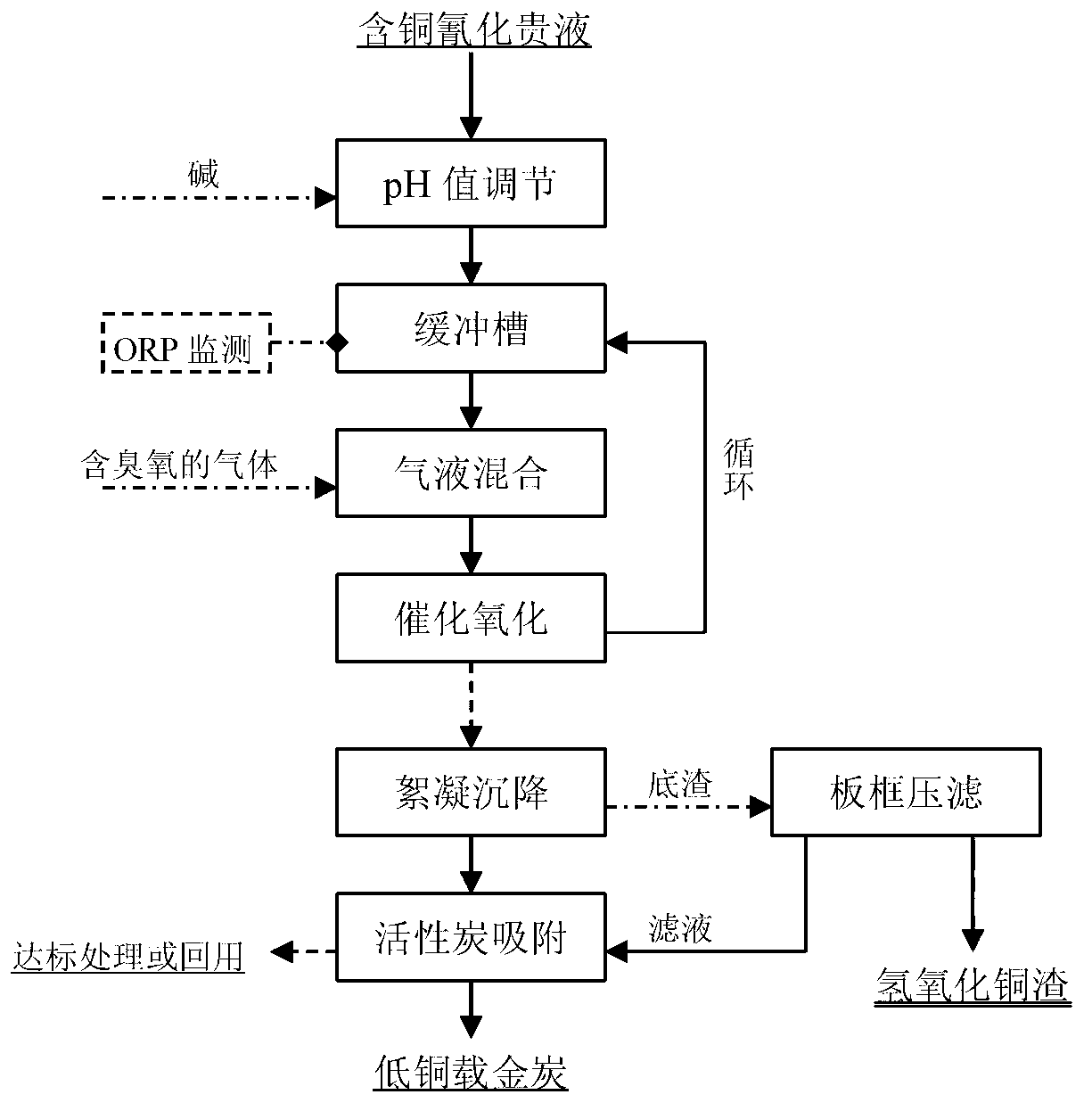

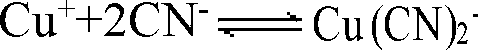

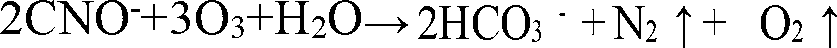

Method for separating and recovering gold and copper from copper-bearing cyanide pregnant solution

The invention relates to a method for separating and recovering gold and copper from a copper-bearing cyanide pregnant solution. A group technology of a catalytic oxidation method, a chemical precipitation method and an active carbon adsorption method is adopted to selectively remove copper from the copper-bearing cyanide pregnant solution, gold and copper in the pregnant solution are separated and recovered to the greatest extent, copper is recovered in a copper hydroxide slag form, and gold is recovered in a low copper gold-loaded carbon form.

Owner:ZIJIN MINING GROUP

WLAN device dynamic channel allocation method based on alliance

ActiveCN103997790AShorten convergence timeFast convergenceWireless communicationDynamic channelCurrent channel

The invention discloses a WLAN device dynamic channel allocation method based on an alliance. The WLAN device dynamic channel allocation method includes the steps that a DFS control node collects and maintains information including current channels, ID of neighbor AP nodes and the like of AP nodes to generate a DFS network topological graph; the DFS network topological graph is divided into independent communicated sub-graphs, and DFS groups are formed by the final divided sub-graphs; as for the DFS groups without boundary division nodes, the nodes, with the highest total receiving signal intensity, in the DFS groups are selected as starting nodes of a dynamic channel selection algorithm; as for the DFS groups with multiple boundary division nodes, the division nodes with the highest total receiving signal intensity are selected as starting nodes of the dynamic channel selection algorithm; beginning with the starting nodes, neighbors with the highest total receiving signal intensity are preferentially selected to carry out channel selection. By means of the WLAN device dynamic channel allocation method, the convergence rate of whole network dynamic channel adjustment is increased through the grouping technology, and the channel selection convergence time is shortened.

Owner:BEIJING JIAOTONG UNIV

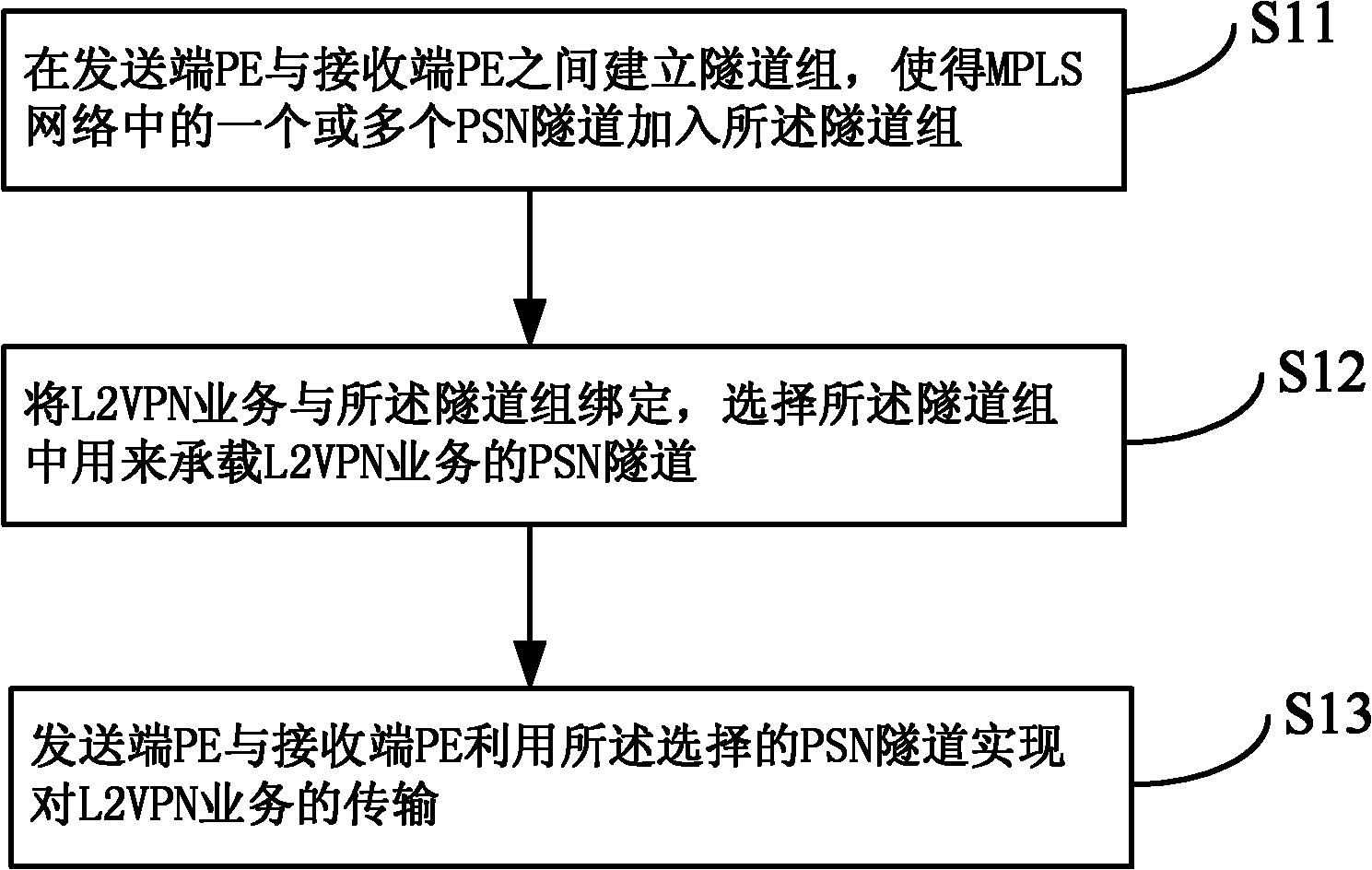

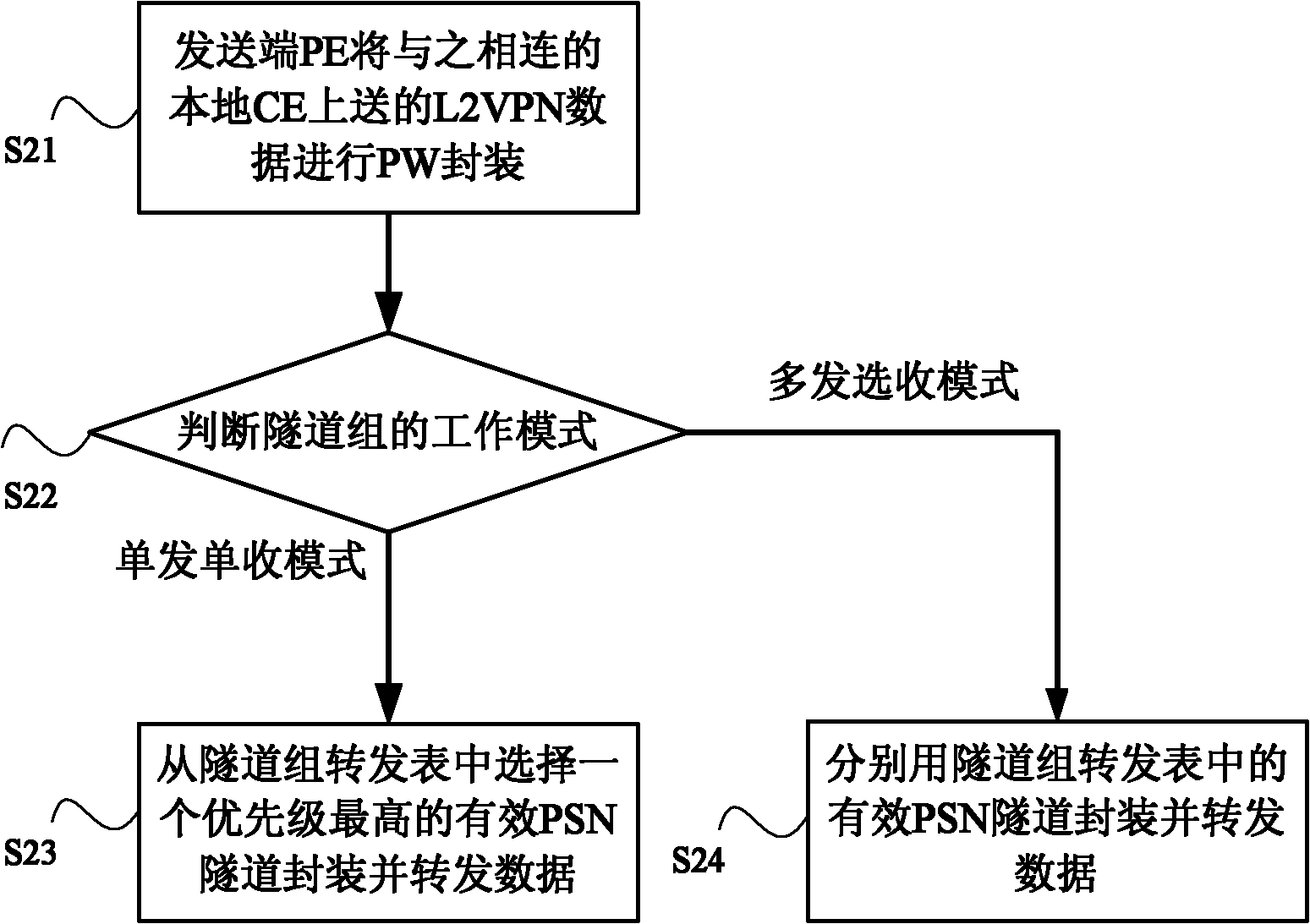

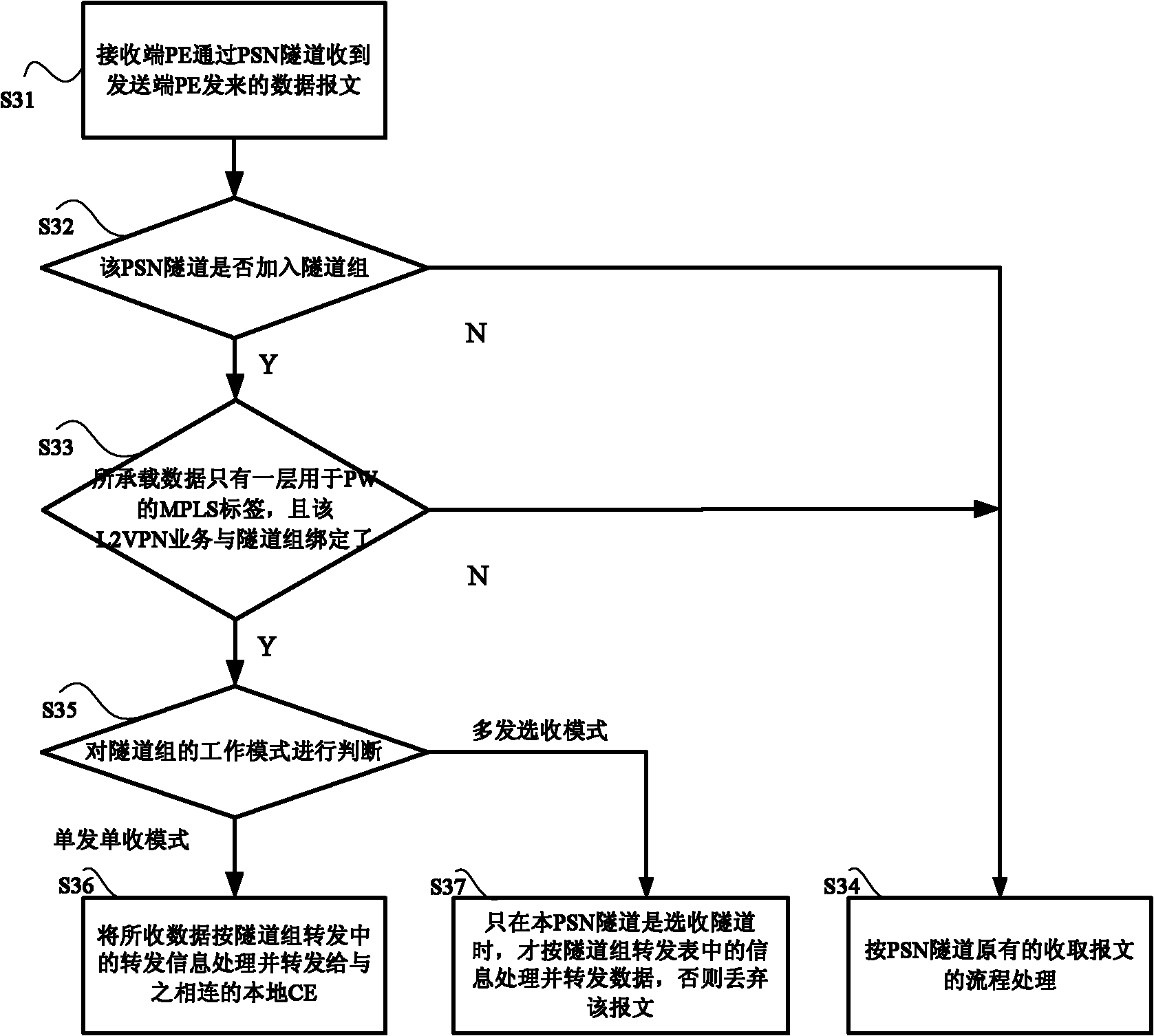

Method and device for transmitting L2VPN service by using tunnel group in MPLS network

InactiveCN102065020AImprove scalabilitySimple configurationNetworks interconnectionExtensibilityPrivate network

The invention relates to a method and a device for transmitting a layer 2 virtual private network (L2VPN) service by using a tunnel group in a multi-protocol label switching (MPLS) network. The method comprises the following steps of: establishing the tunnel group between a transmitting end provider edge device (PE) and a receiving end PE, so that one or more packet switching network (PSN) tunnels in the MPLS network join in the tunnel group; binding the L2VPN service with the tunnel group, and selecting a PSN tunnel for bearing the L2VPN service in the tunnel group; and transmitting the L2VPN service by using the transmitting end PE and the receiving end PE through the selected PSN tunnel. The protection of pseudo wires (PWs) can be neglected in the L2VPN service, and the tunnel group can protect the PWs. The tunnel group technology has high extensibility, can support the conventional MPLS tunnel technology, and also can conveniently support MPLS tunnel technology which possibly occurs in the future. The tunnel group is easy to configure, and the configuration of the tunnel group can be dynamically modified in the state that the L2VPN service is not interrupted.

Owner:ZTE CORP

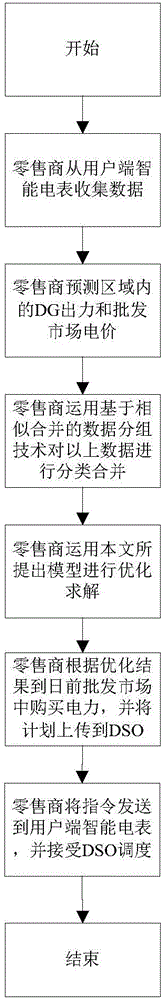

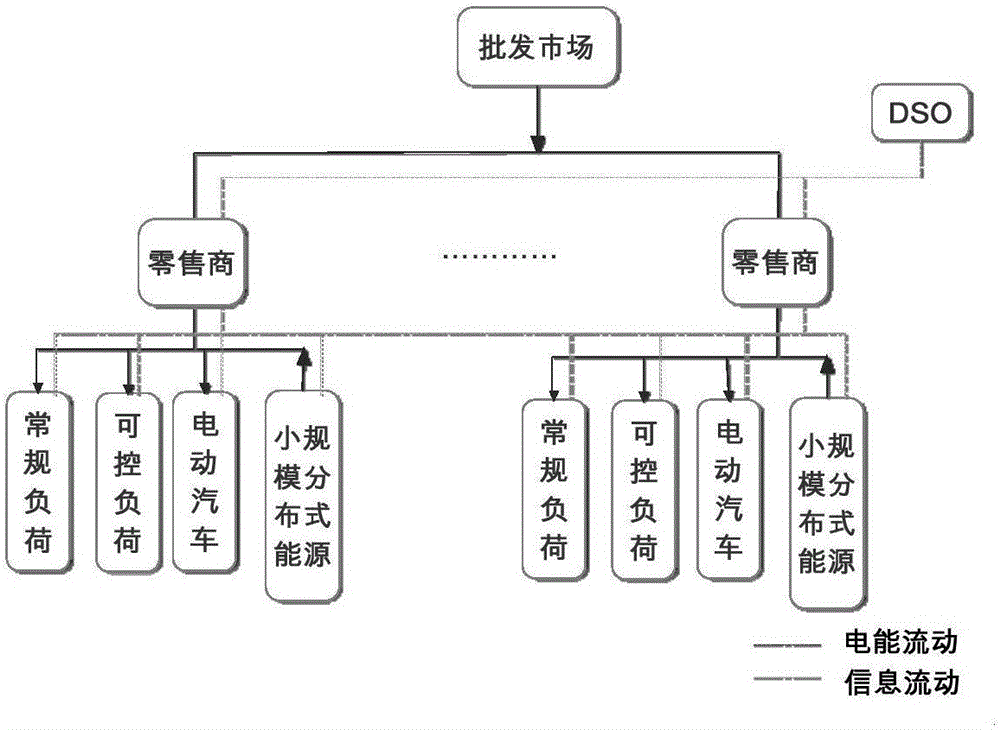

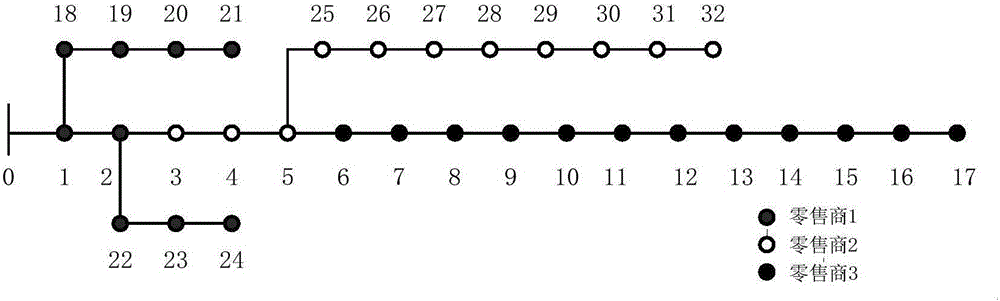

Method for determining electric power retailer day-ahead energy acquisition with demand response resources being considered

InactiveCN105976079ASolving the Problem of Integrating Demand Response ResourcesResourcesElectricity priceAcquisition Scheme

The present invention is a method for determining the day-ahead energy acquisition of electricity retailers considering demand response resources, which includes the following steps: 1) The retailer collects data from the smart meter at the user end, including the user's next day's electricity demand and demand response resources etc.; 2) The retailer predicts the DG output and electricity price in the wholesale market in the area; 3) The retailer uses the data grouping technology based on similarity to classify and merge the above data to reduce the scale of problem solving; 4) The retailer uses the data proposed in this paper The model is optimized and solved; 5) The retailer purchases electricity in the power day wholesale market according to the optimized result obtained, and uploads its own related plans to the DSO; 6) The retailer sends the instruction to the smart meter at the user end and accepts the DSO dispatch . The invention can effectively solve the problem of integrating demand response resources and provide a basis for formulating day-ahead energy acquisition schemes for retailers on the electricity retail side.

Owner:STATE GRID HENAN ELECTRIC POWER +3

Electric vehicle-used rechargeable tire and tire-type wireless charging belt system

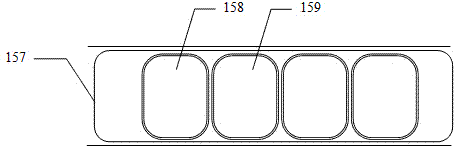

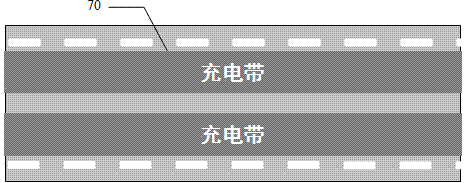

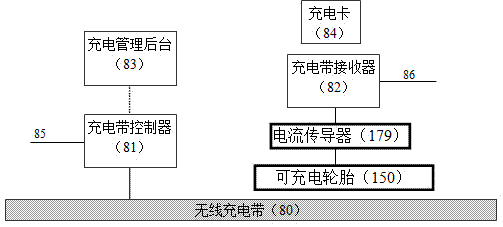

InactiveCN104333145AImprove battery lifeImprove charging efficiencyTyre partsBatteries circuit arrangementsCharge currentCoil array

The invention provides a rechargeable tire and a tire-type wireless charging belt system which can support the rechargeable tire to charge the electric vehicle in high-speed driving or stopping process, and belongs to the field of new-energy vehicles. The rechargeable tire uses the charging receiving antenna coil array technology and the multi-layer receiving antenna coil dislocation array group technology, wireless charging current sent by the tire-type wireless charging belt system can be effectively received, and the rechargeable tire is tightly attached to the tire-type wireless charging belt, thereby effectively improving the wireless charging efficiency and reducing harmful electromagnetic radiation. According to the ultra-thin tire-type wireless charging belt technology, the design and production technology method and the laying, installation and construction method, the production and construction efficiency can be effectively improved, the cost is reduced, laying construction is extremely simple, and the wireless charging technology can be quickly executed in a large area.

Owner:刘跃进

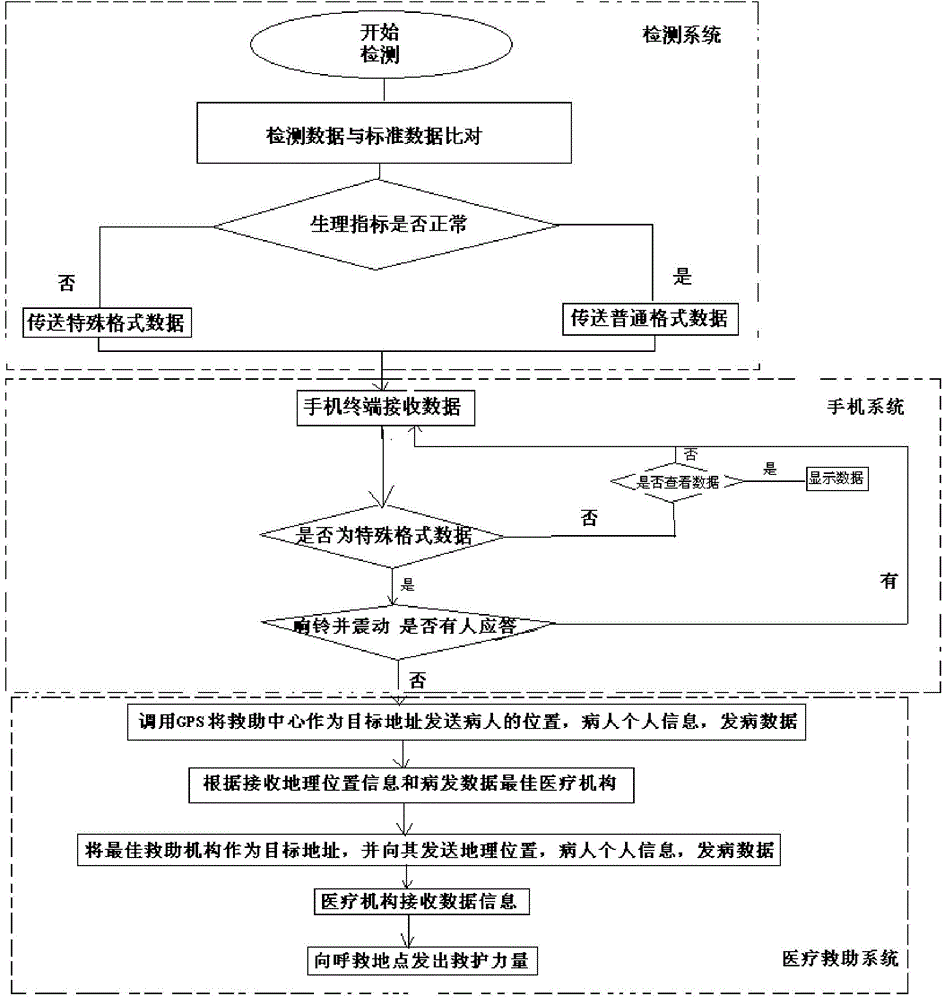

Mobile phone help-calling system and rescue method

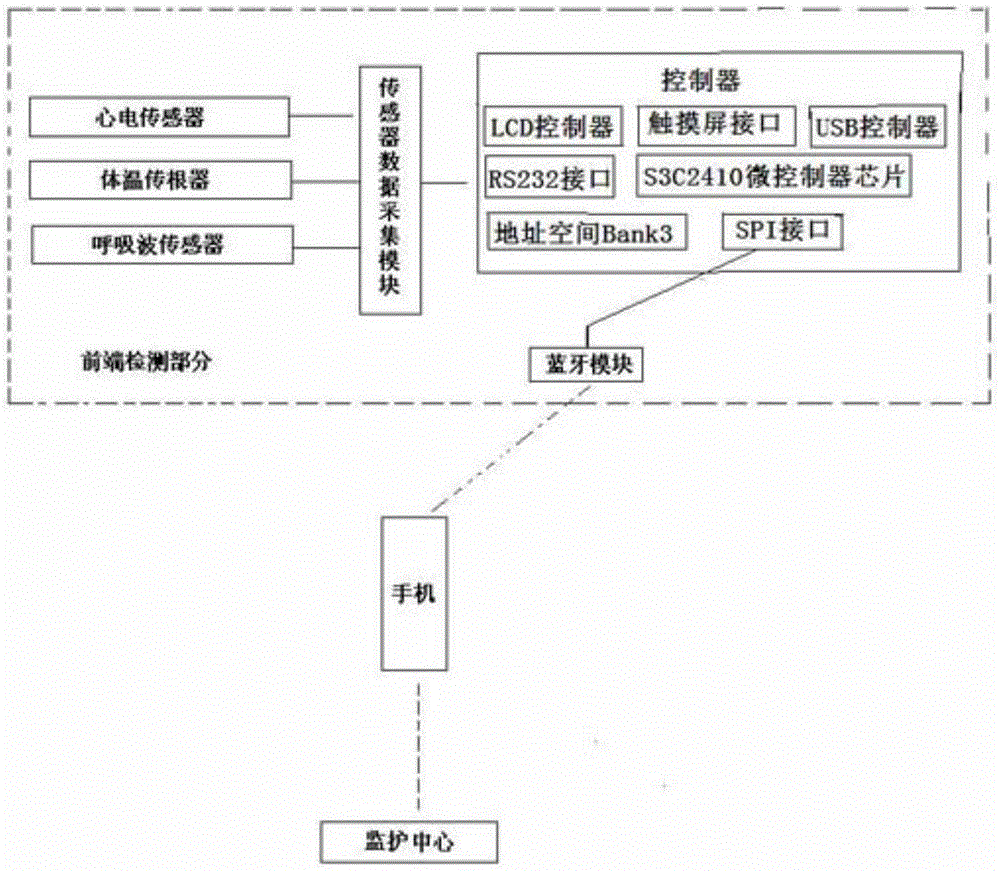

InactiveCN103561160AAccurately know the abnormal state of the bodyEnsure safetyRespiratory organ evaluationSensorsIncidence dataEmergency rescue

The invention discloses a mobile phone help-calling system and a rescue method, and belongs to the technical field of wireless communication. The mobile phone help-calling system comprises a strap, a front end detection part and a mobile phone, wherein the front end detection part is arranged in the strap and transmits detected human body physiological signals to the mobile phone through a Bluetooth module of the front end detection part. The mobile phone recovers to a normal state if the mobile phone is answered in set time; the mobile phone recovers the normal state if no people answer the mobile phone in set time; if no people answer the mobile phone in set time, a GPS positioning function is started to obtain current geographic position coordinates (x, y, z). A rescue center receives an IP to serve as a target IP, and the mobile phone IP serves as a host IP. The wireless grouping technology is utilized, the target IP, the host IP, personal information, geographic coordinate values and incidence data of a patient serve as a data packet, and the data packet is sent to an emergency rescue center.

Owner:DALIAN NATIONALITIES UNIVERSITY

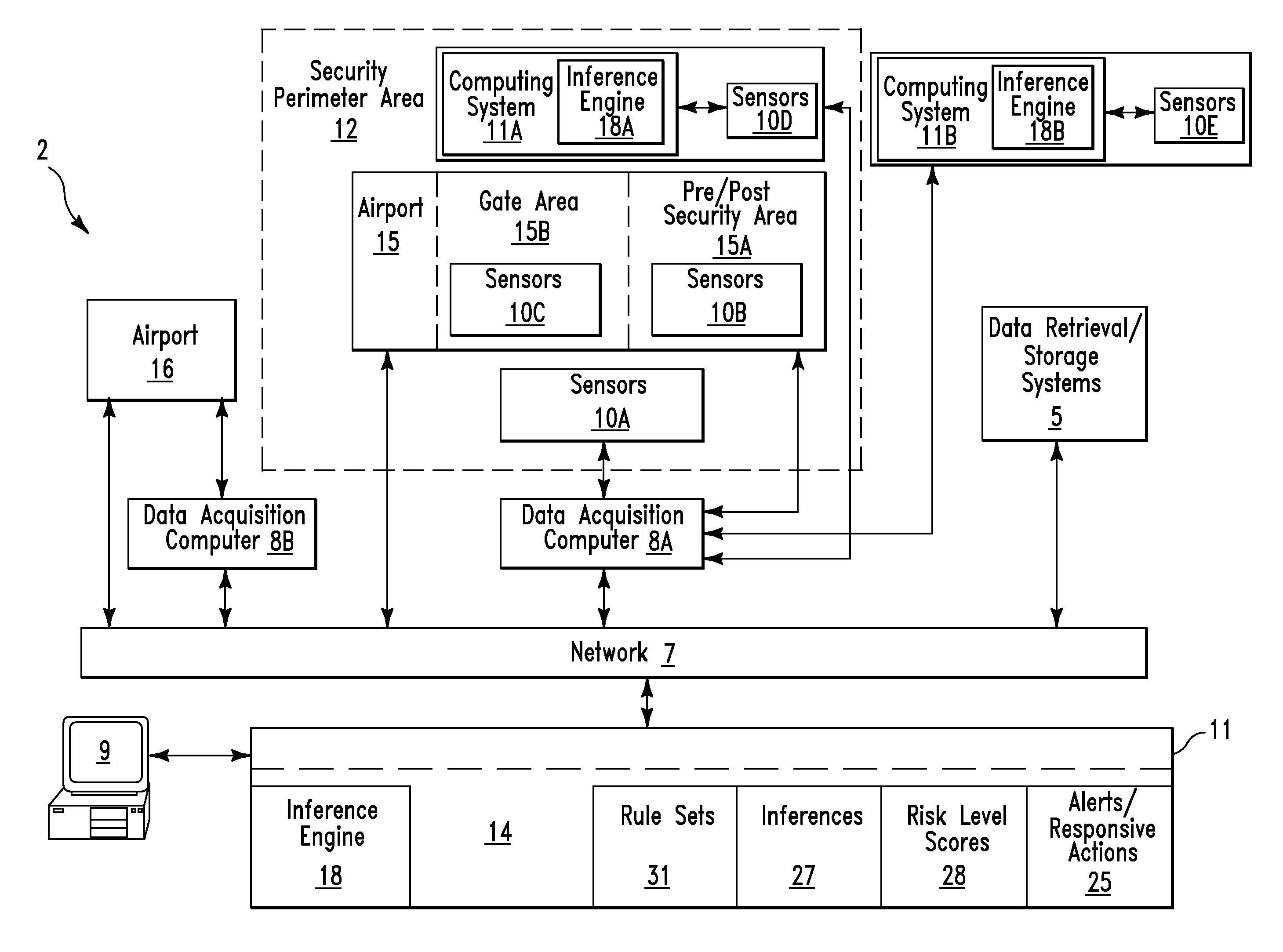

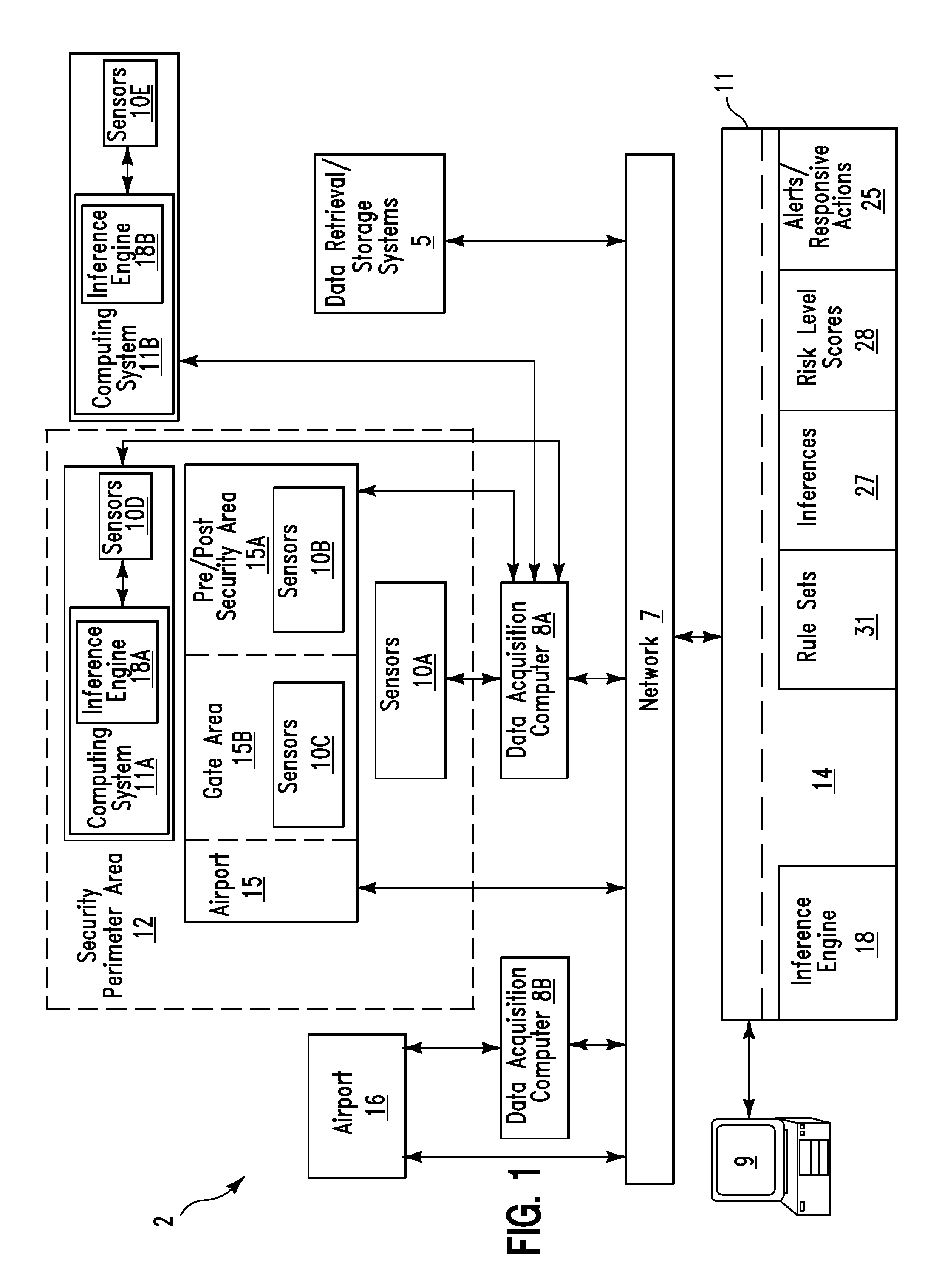

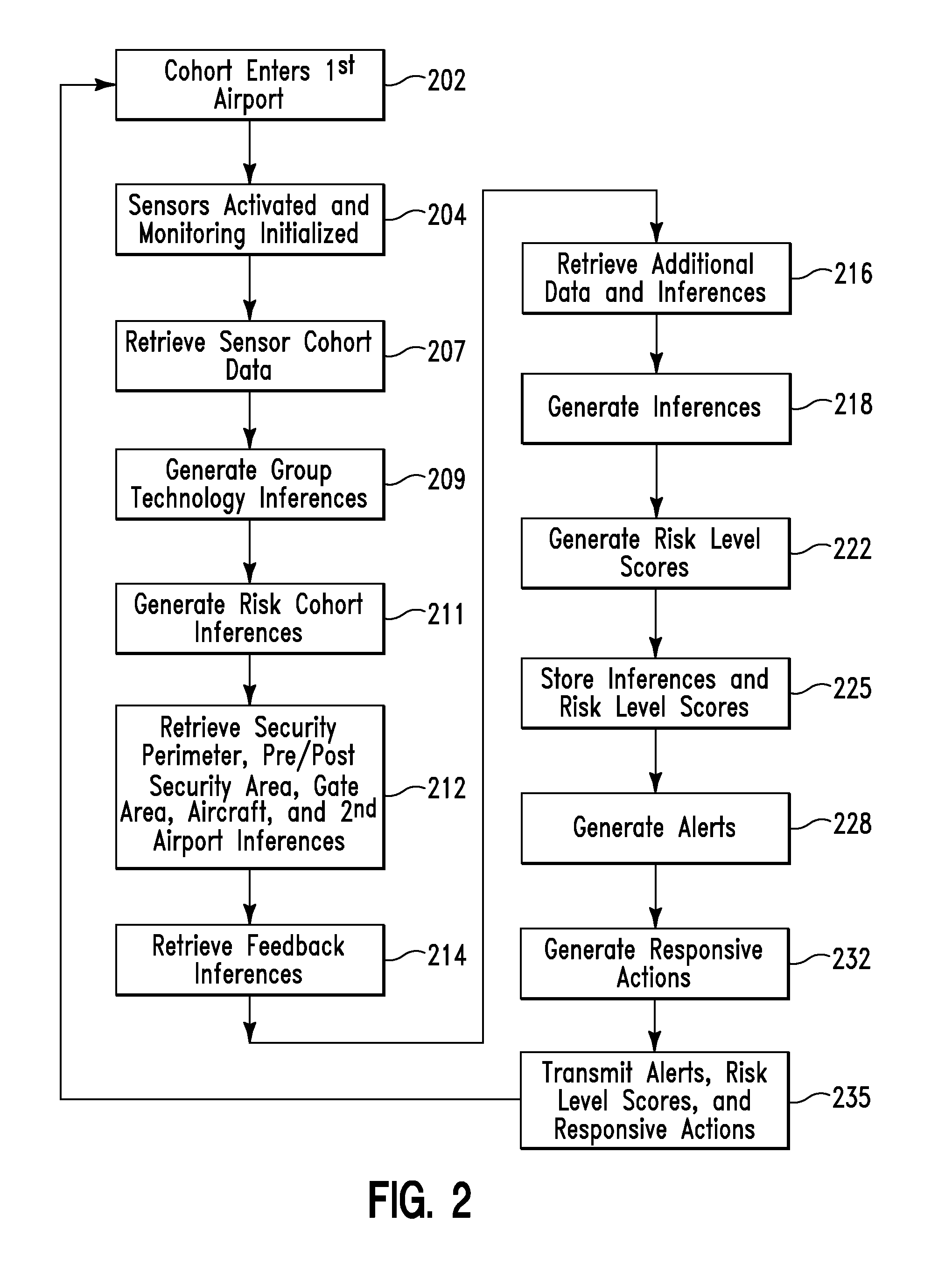

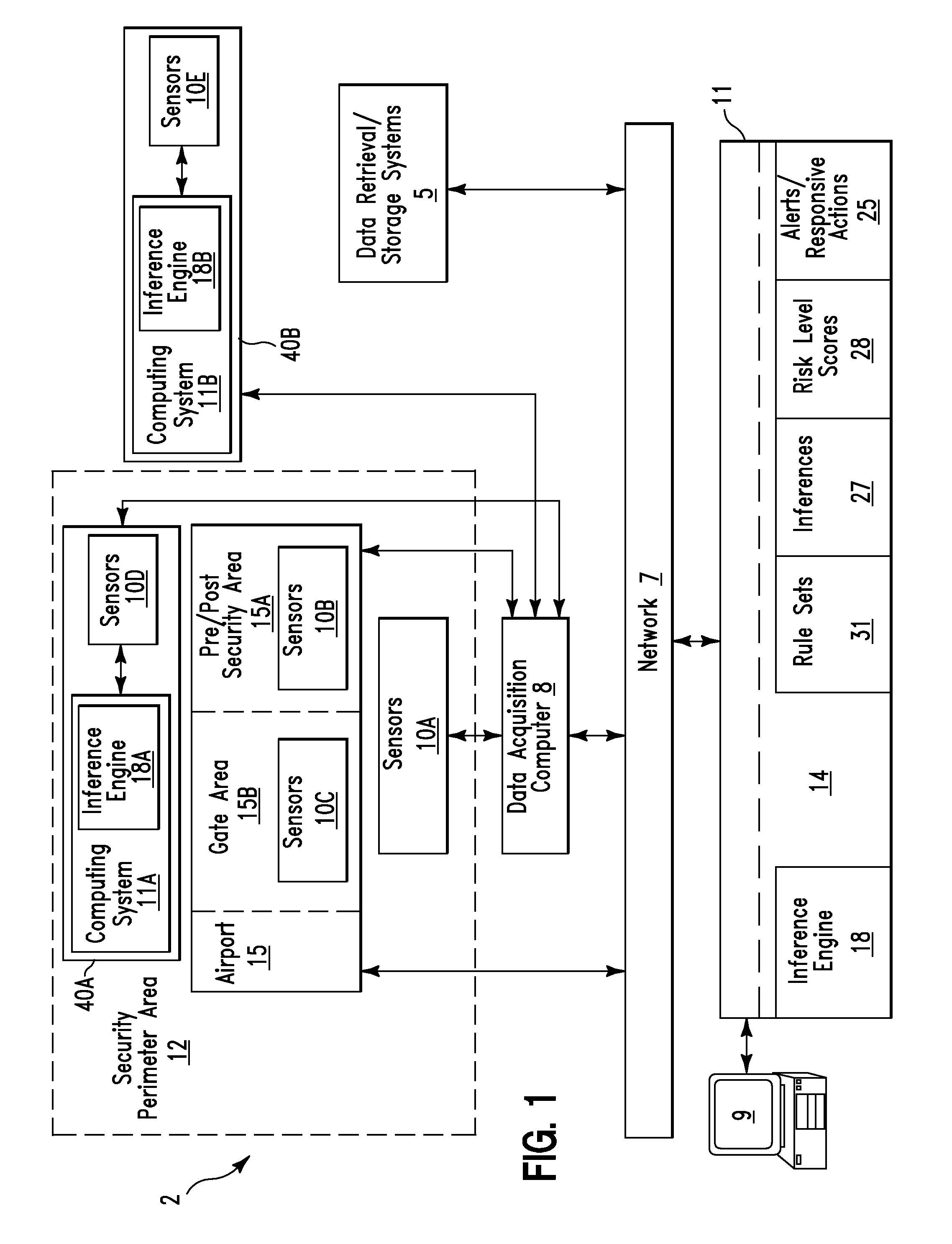

Risk assessment between airports

Owner:IBM CORP

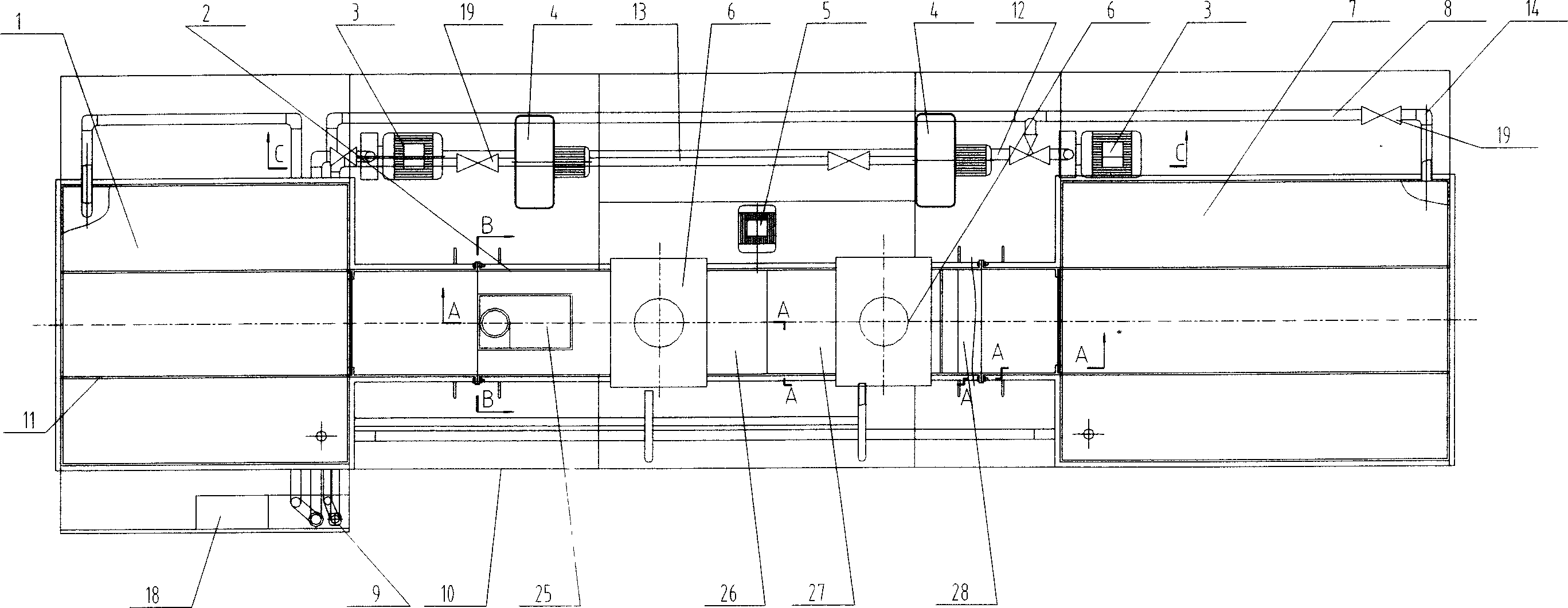

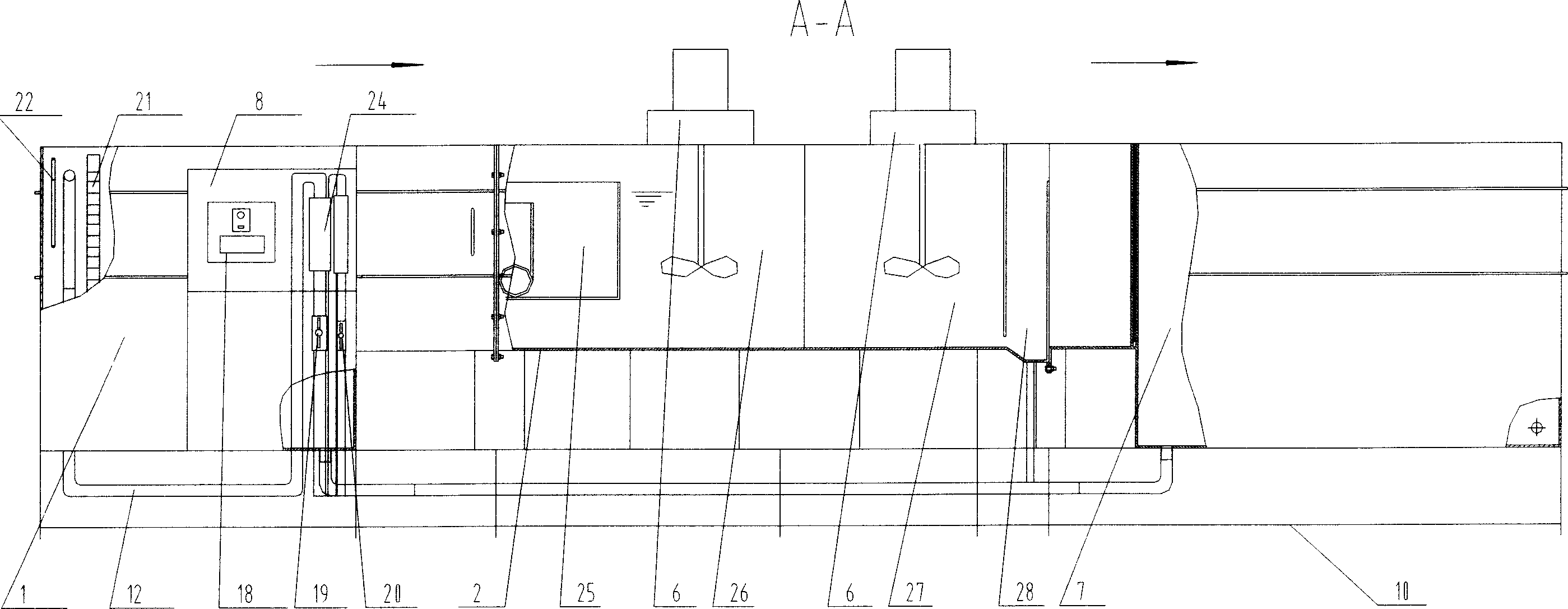

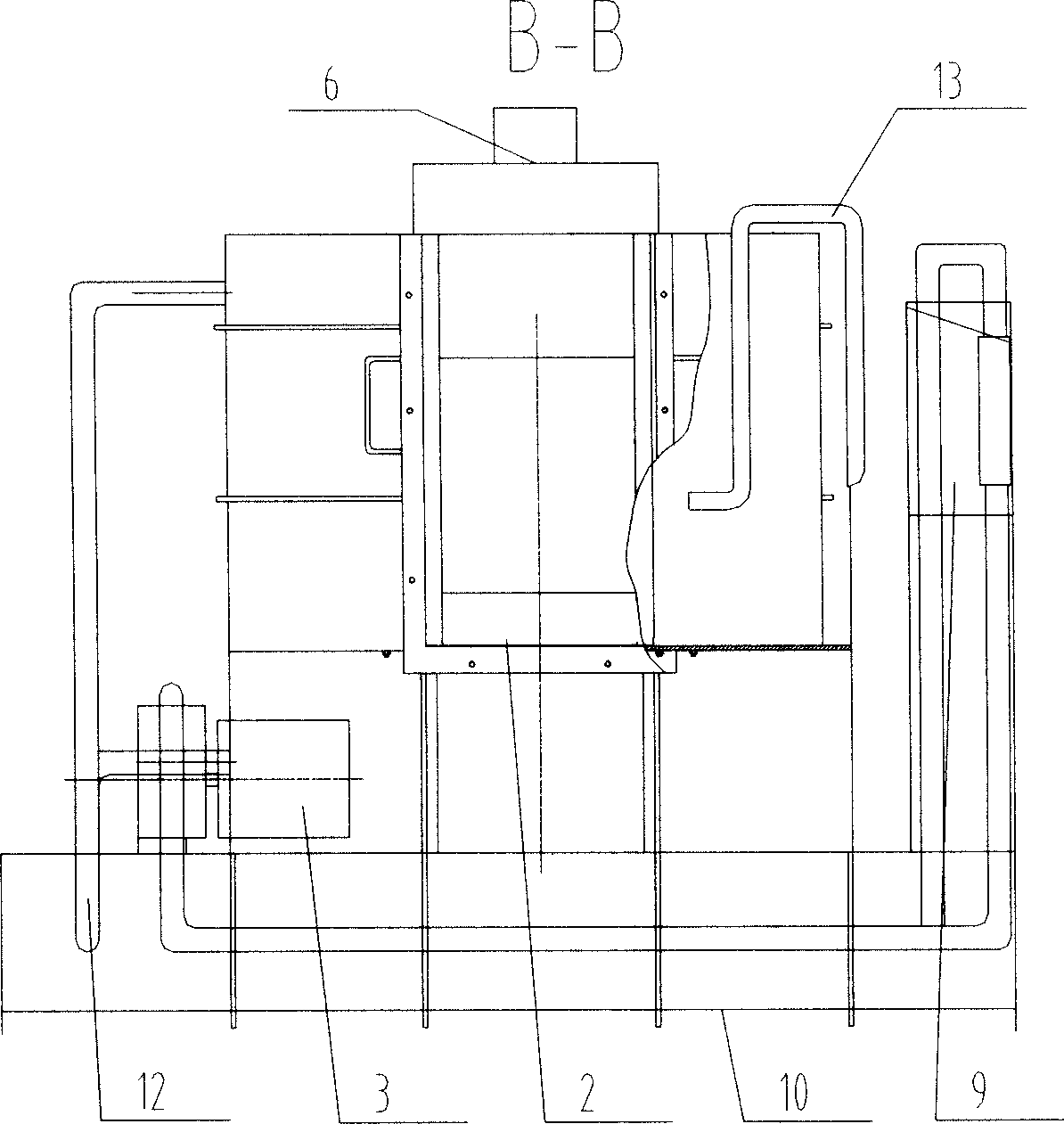

Multifunctional sewage treatment simulant experiment device

The invention relates to a multi-function sewage treatment analog experiment apparatus which comprises: unit analog experiment, group technology analog experiment and step treatment technology analog experiment. It is formed by a water entered tank, a water pump, an air pump, a reactor module, a driving motor, an agitator, a water exit tank, a pipe module, an electrical equipment automatic control module, a holding frame and a guiding rail. It integers the water entered tank, the reactor module and the water exit tank as an integer and chooses the corresponding reactor module by the need of the experiment when using it; it adopts pipe module to combine all of the pipe systems and fixes the corresponding water value, air value control unit; it adopts electrical equipment automatic control module to combine each control wire and achieves the automatic control.

Owner:SOUTH CHINA UNIV OF TECH

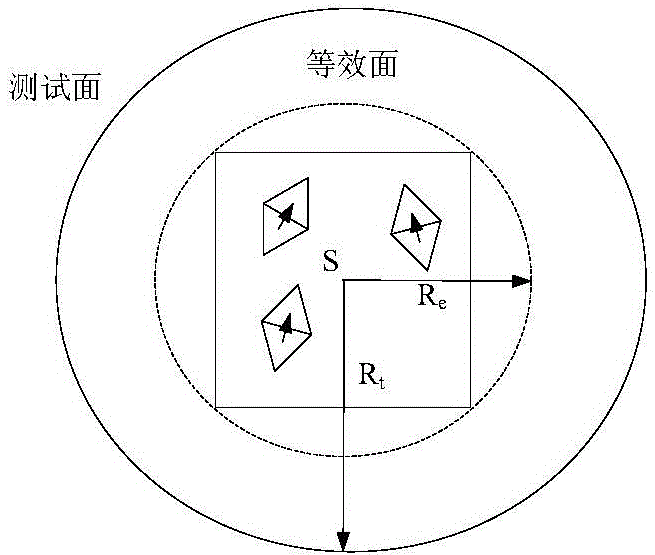

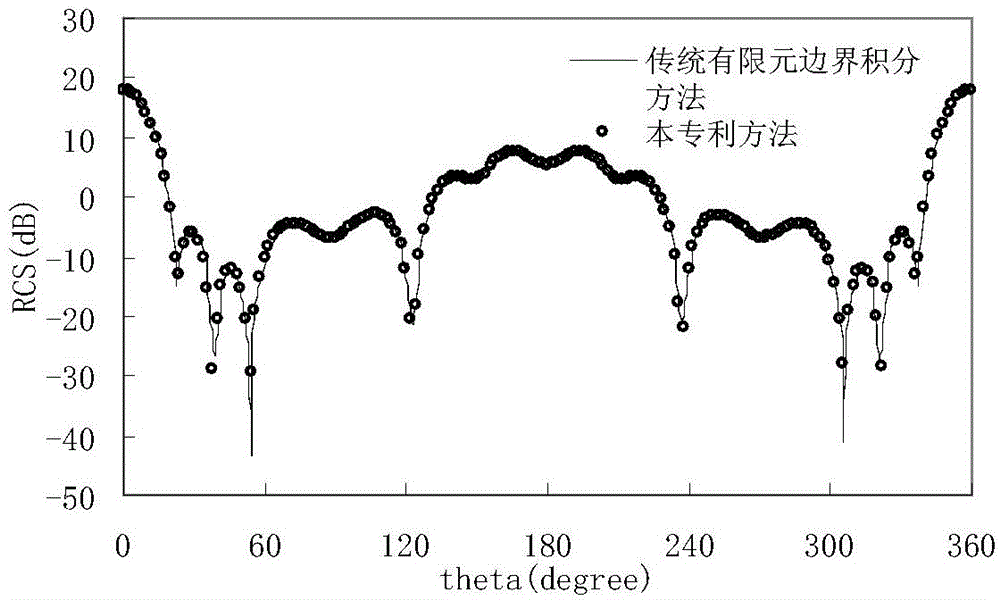

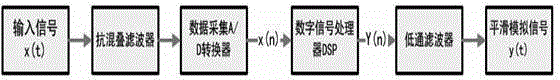

Finite element boundary integral method for rapidly analyzing electromagnetic scattering properties of non-uniform targets

ActiveCN106294894AReduce complexityFlexible and effective analysisSpecial data processing applicationsComputer scienceEquivalence principle

The invention discloses a finite element boundary integral method for rapidly analyzing electromagnetic scattering properties of non-uniform targets. According to the method, a multilayer complex point source rapid method and the finite element boundary integral method are combined to analyze the electromagnetic scattering properties of non-uniform targets. According to the method, an octree grouping technology is adopted to group analyzed problems, and the action, on a far field, of primary functions in the groups is equivalent to the action, on the far field, of complex point sources, the quantity of which in the aspect of equivalent surfaces in the groups is much less than the quantity of the primary functions in the groups by utilizing an equivalence principle. According to the method disclosed by the invention, the calculation time and memory requirements can be effectively saved in the analysis of the electromagnetic scattering properties of non-uniform targets for calculation of fine-grid subdivision.

Owner:NANJING UNIV OF SCI & TECH

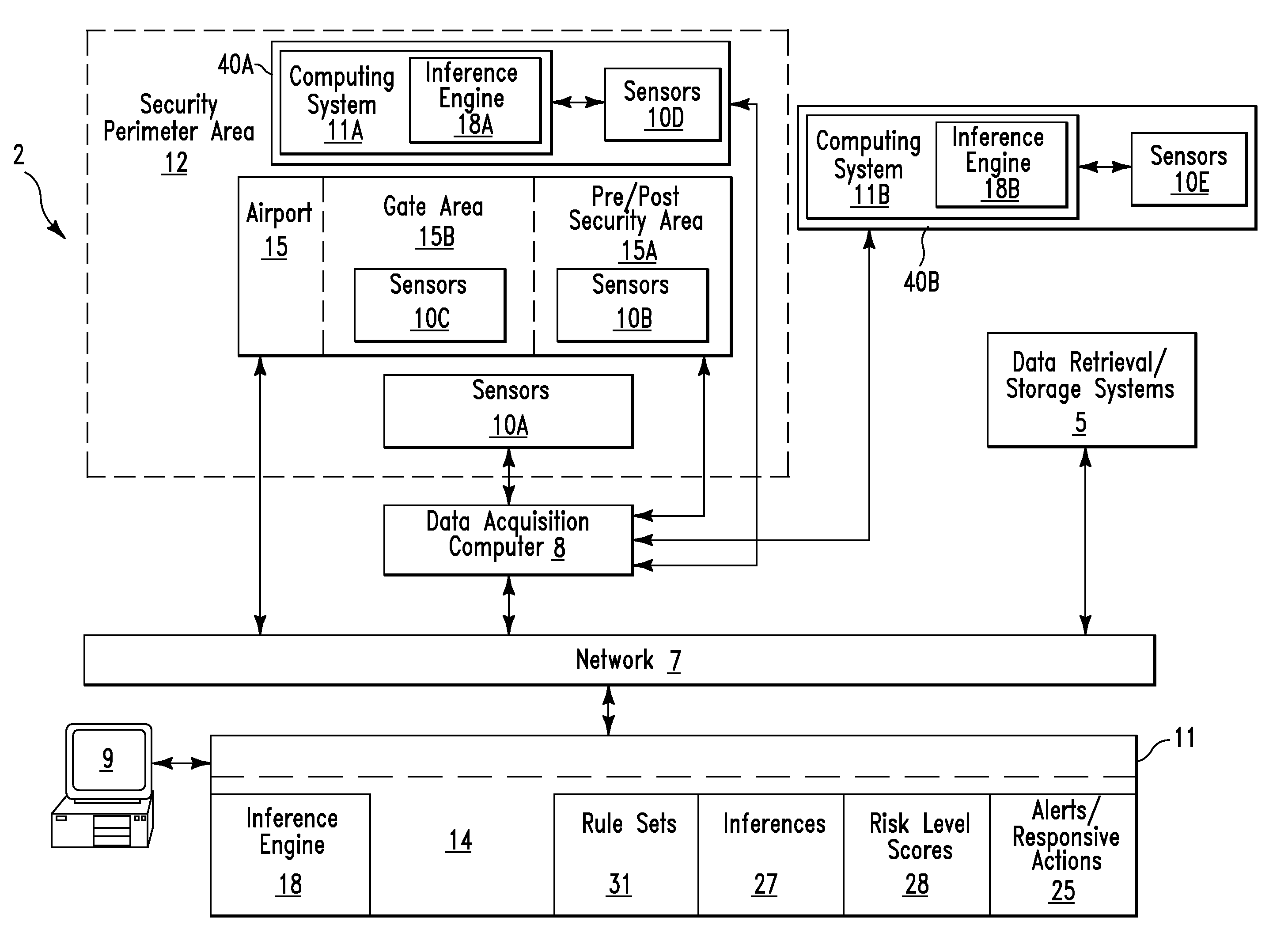

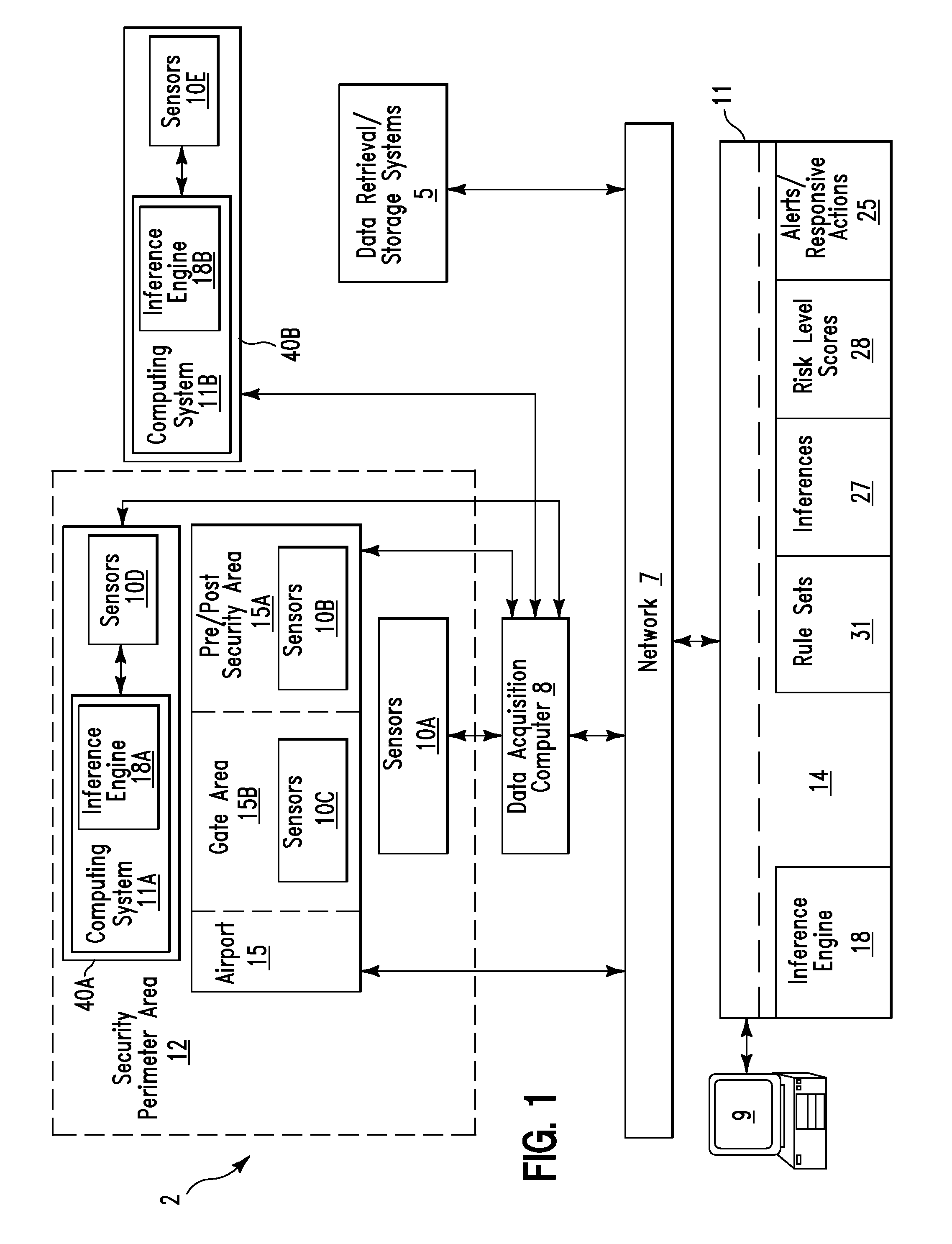

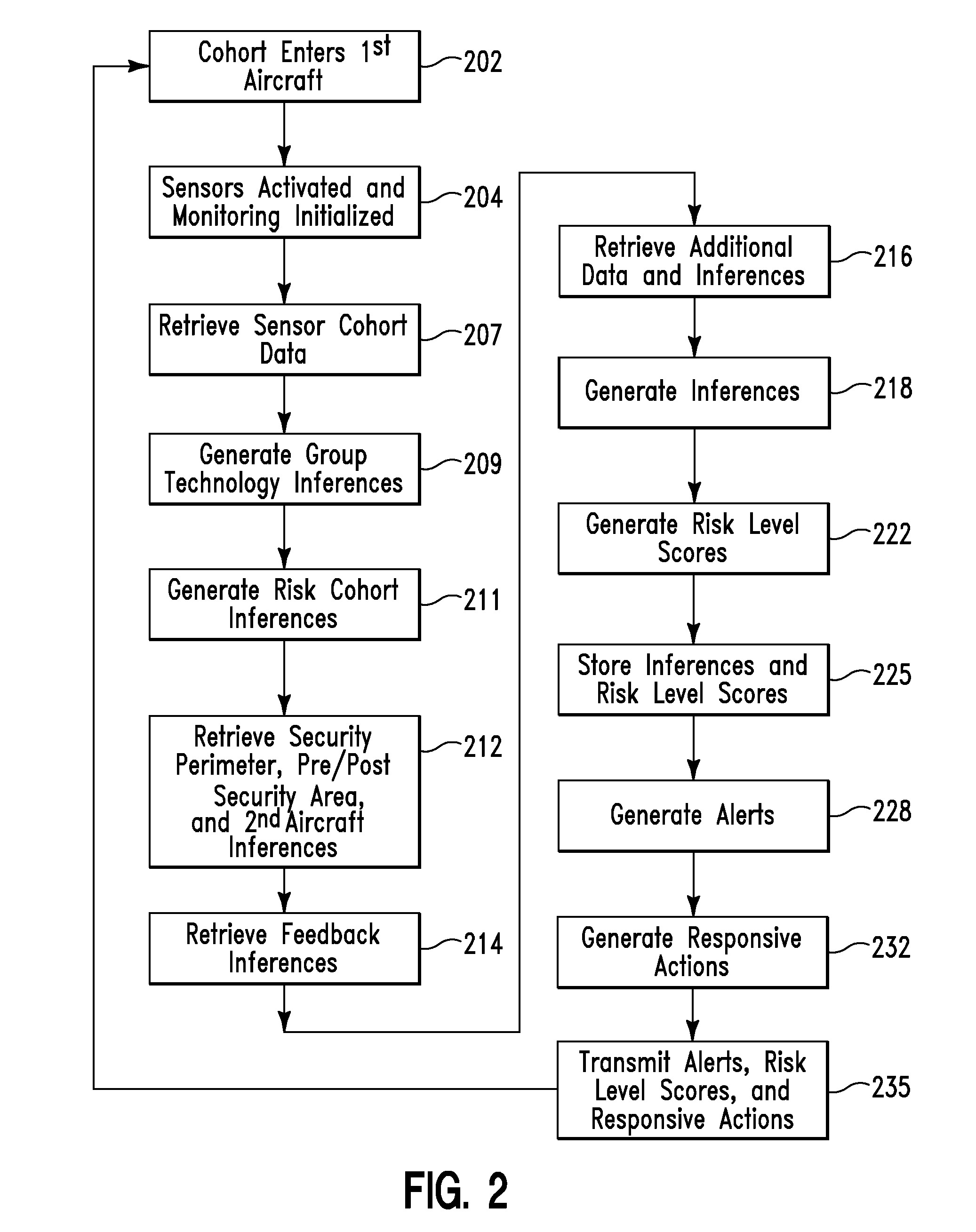

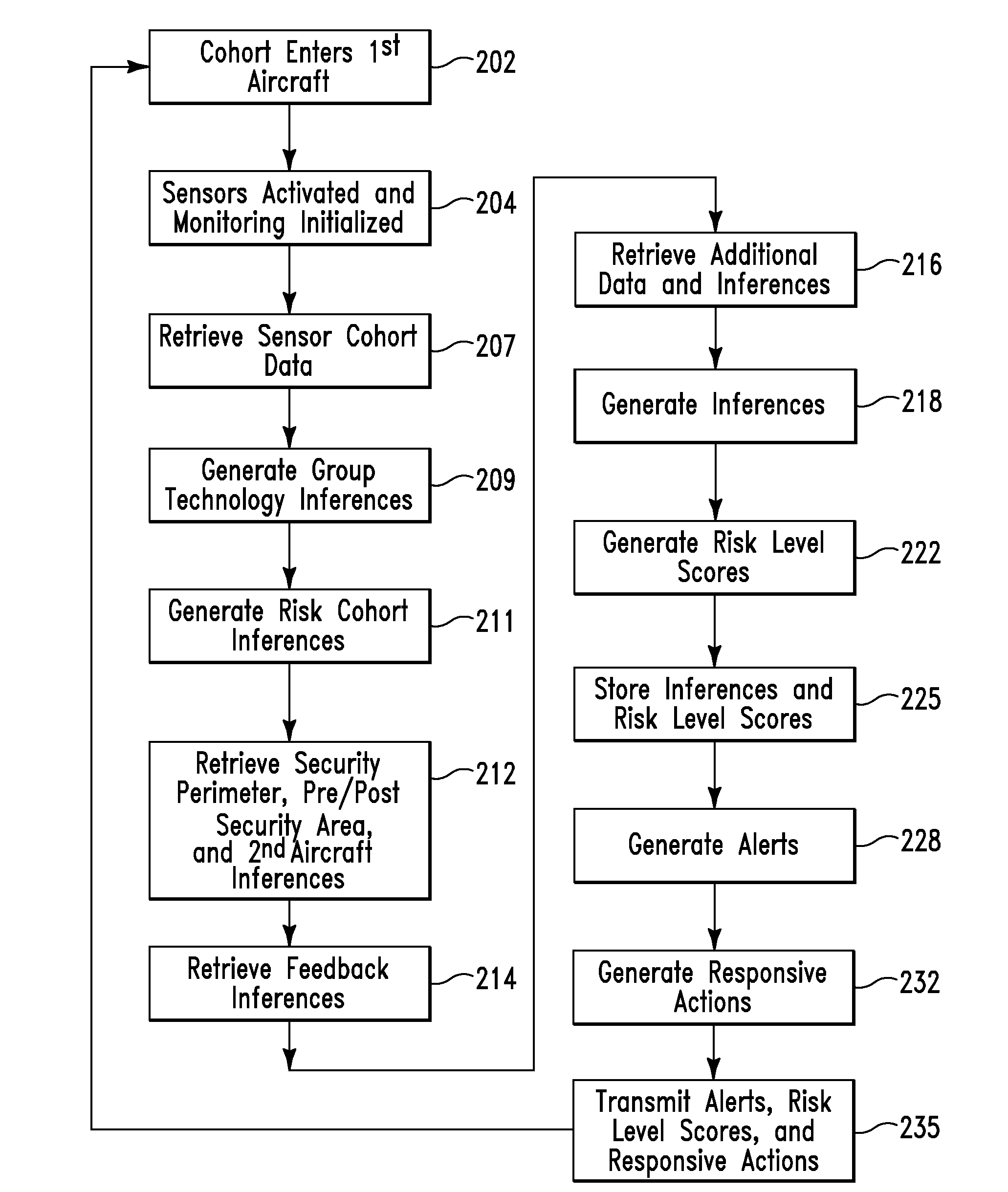

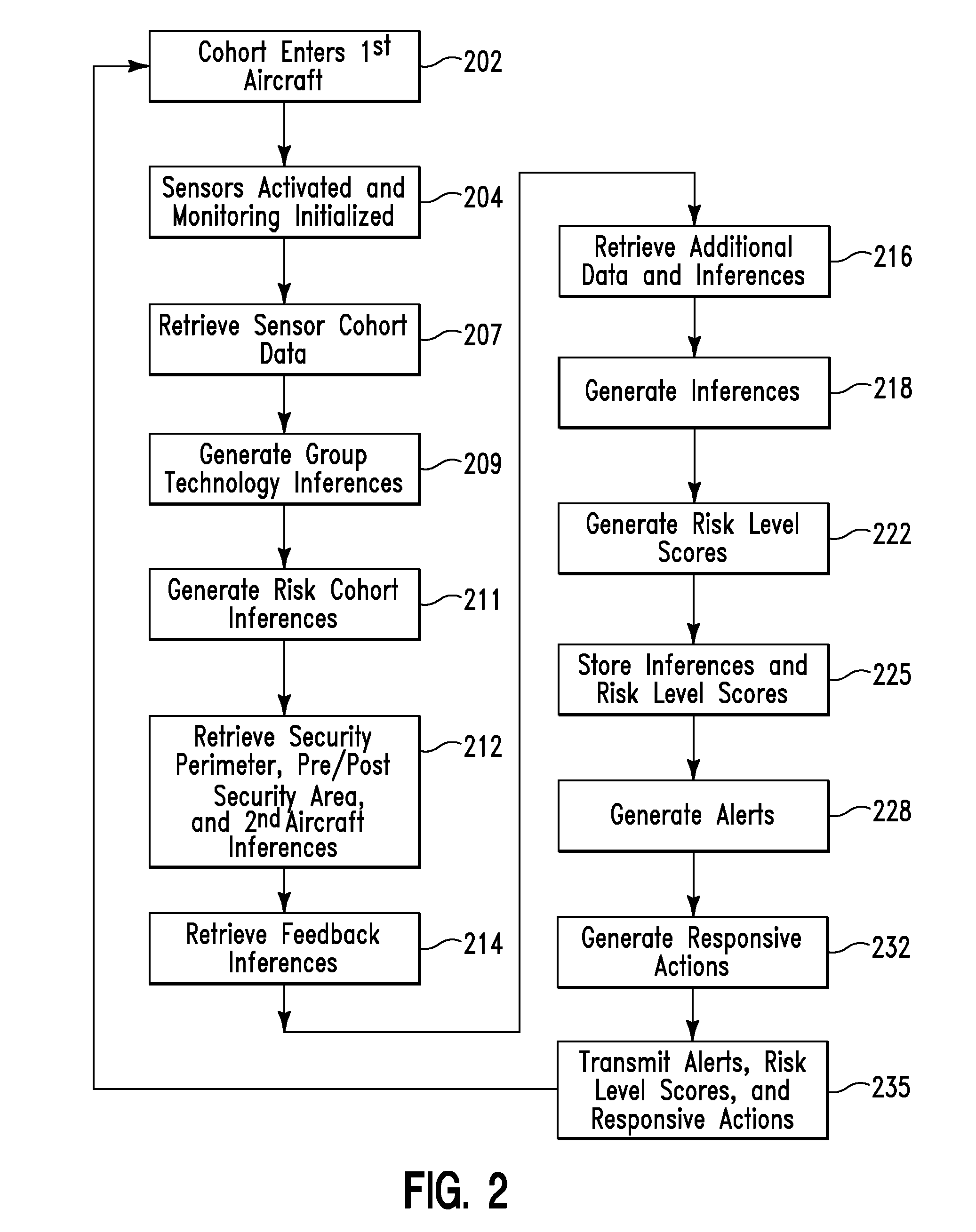

Risk assessment between aircrafts

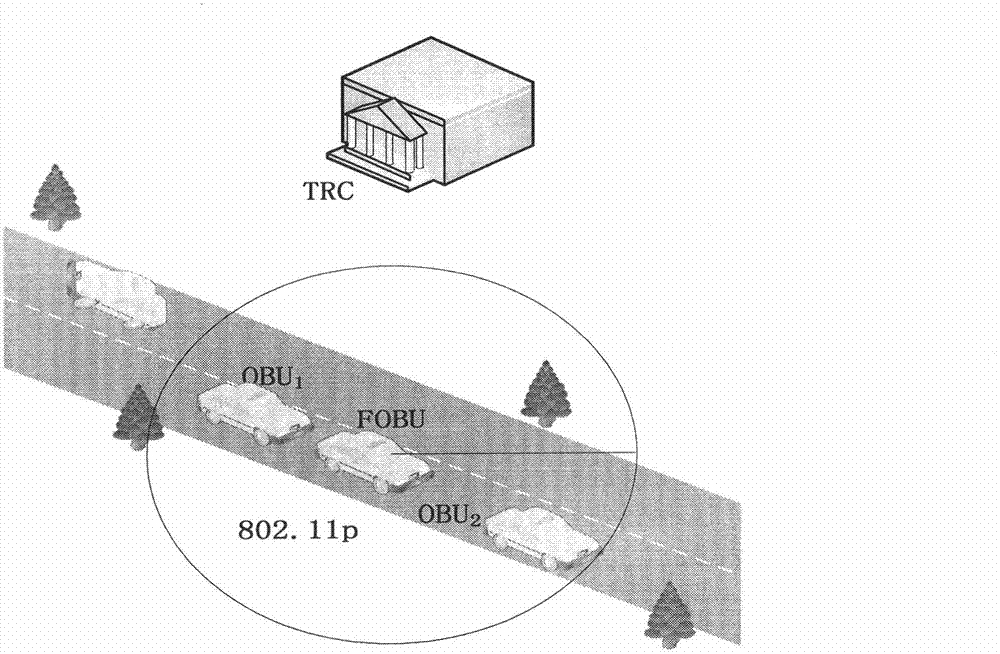

A risk assessment method and system. The method includes receiving by an inference engine, first sensor cohort data associated with a first cohort located within a first aircraft. The inference engine receives first group technology inferences associated with the first cohort. The inference engine generates first risk cohort inferences based on the first group technology inferences and the first sensor cohort data. The inference engine receives first inference data comprising a first plurality of inferences associated with the first cohort. The inference engine generates second inference data comprising a second plurality of inferences associated with the first cohort. The second inference data is based on the first inference data and the first risk cohort inferences. The inference engine generates a first associated risk level score for the first cohort. The computing system stores the second inference data and the first associated risk level score.

Owner:LINKEDIN

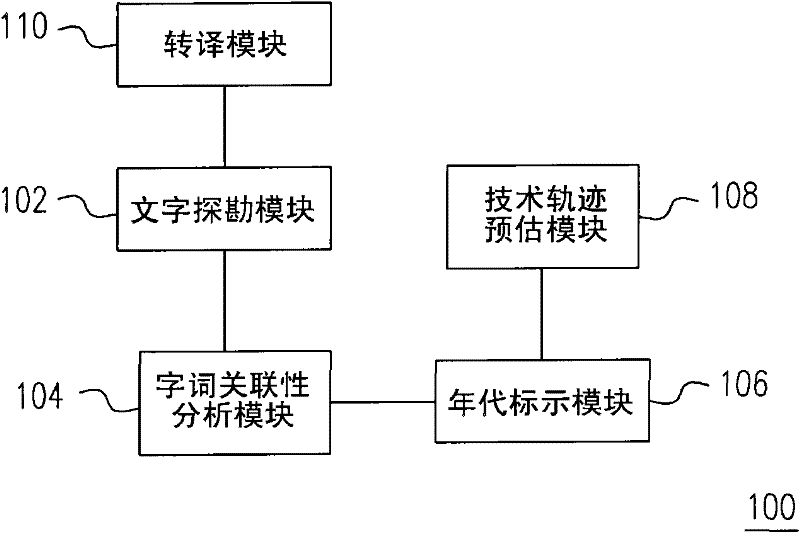

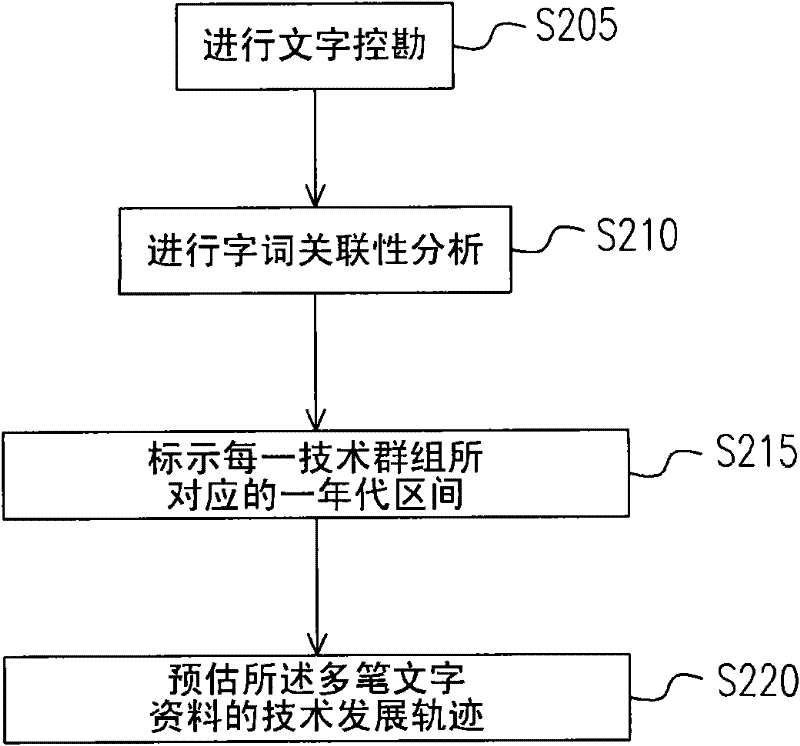

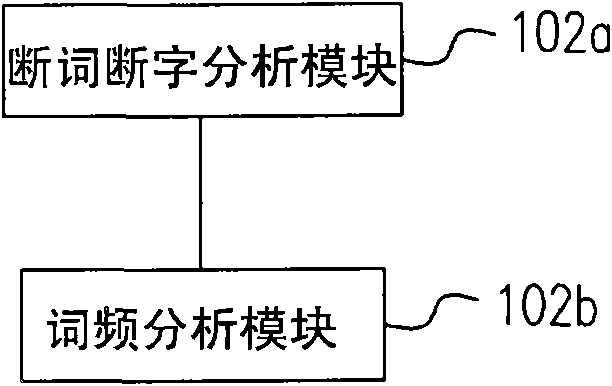

Technical document analysis method and technical document analysis system

InactiveCN102262639ADrawn preciselyQuick diagrammingSpecial data processing applicationsText miningDocument analysis

The invention discloses a technical document analysis method and a technical document analysis system, which are suitable for analyzing a plurality of technical textual materials, wherein each said technical textual data contains a documental data respectively, and the method includes: performing a text search, and A plurality of technical words are respectively extracted from the plurality of technical text data, wherein each of the technical words corresponds to at least one technical text data. A word correlation analysis is performed to divide the plurality of technical words into a plurality of technical groups. According to the multiple technical words that make up each of the technical groups, and the literature data contained in the multiple technical text materials corresponding to them, mark a corresponding one of each of the technical groups. age range. According to the original data of each technical group respectively corresponding to the age interval, a technical development track of the plurality of technical text data is drawn. The present invention can quickly chart the technological development track hidden behind the technical documents.

Owner:ALETHEIA UNIVERSITY

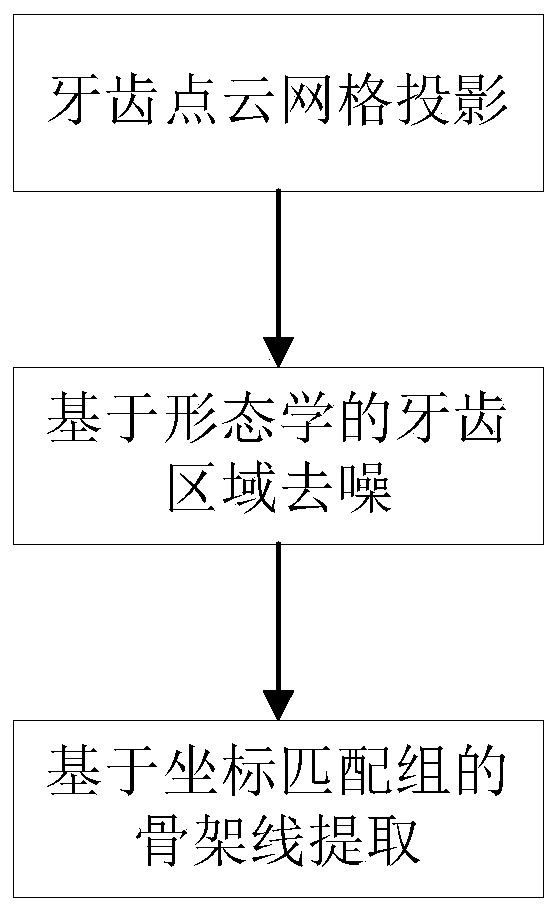

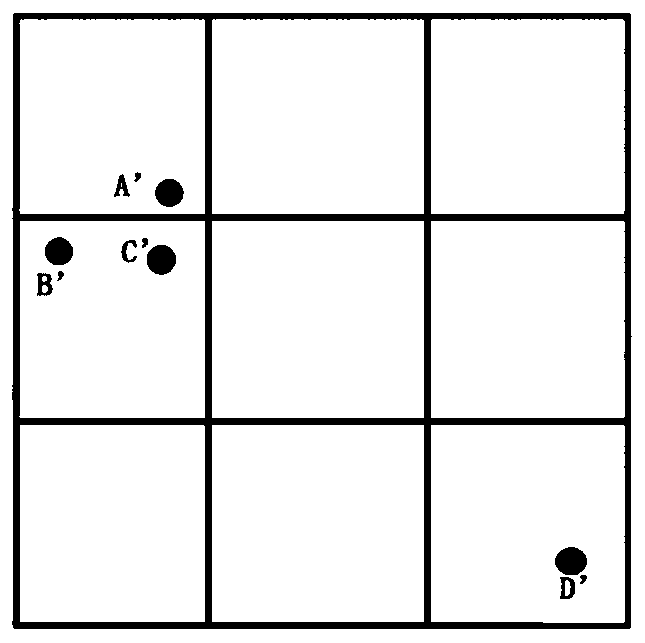

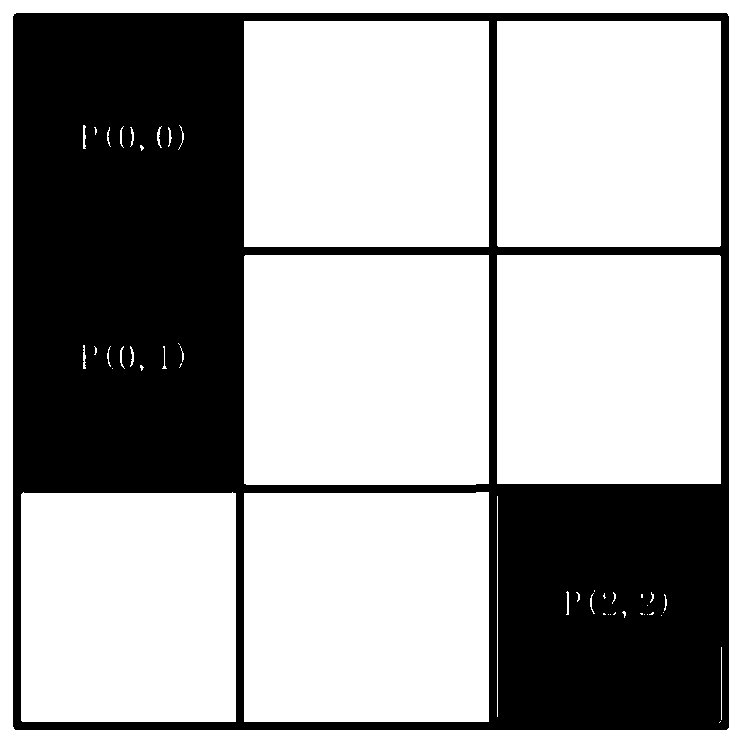

Skeleton line extraction method based on projection matching group

ActiveCN110288517AGood effectTime-consuming optimizationGeometric image transformationPoint cloudComputer science

The invention discloses a skeleton line extraction method based on a projection matching group, which comprises the following steps: mapping tooth point cloud to a two-dimensional plane by utilizing a grid projection technology, denoising by utilizing morphological operation to obtain a tooth structure, and then obtaining a three-dimensional tooth skeleton line by utilizing a coordinate matching group technology; compared with a traditional method, the skeleton line extraction method provided by the invention has the advantages that the effect and the consumed time are obviously improved, and the accuracy and the reliability of overlapping region positioning are greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

Risk assessment between aircrafts

A risk assessment method and system. The method includes receiving by an inference engine, first sensor cohort data associated with a first cohort located within a first aircraft. The inference engine receives first group technology inferences associated with the first cohort. The inference engine generates first risk cohort inferences based on the first group technology inferences and the first sensor cohort data. The inference engine receives first inference data comprising a first plurality of inferences associated with the first cohort. The inference engine generates second inference data comprising a second plurality of inferences associated with the first cohort. The second inference data is based on the first inference data and the first risk cohort inferences. The inference engine generates a first associated risk level score for the first cohort. The computing system stores the second inference data and the first associated risk level score.

Owner:LINKEDIN

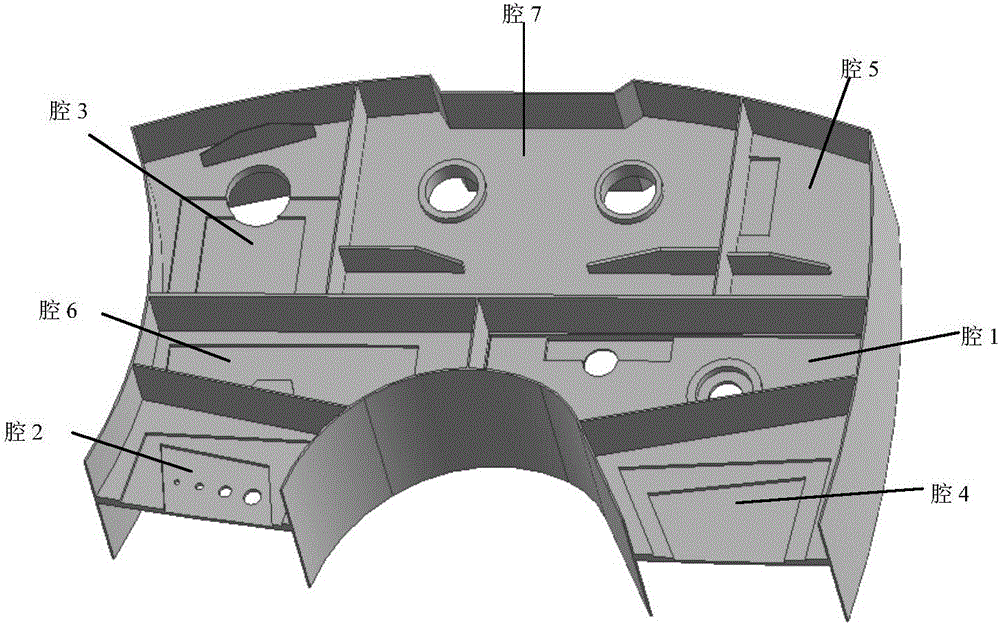

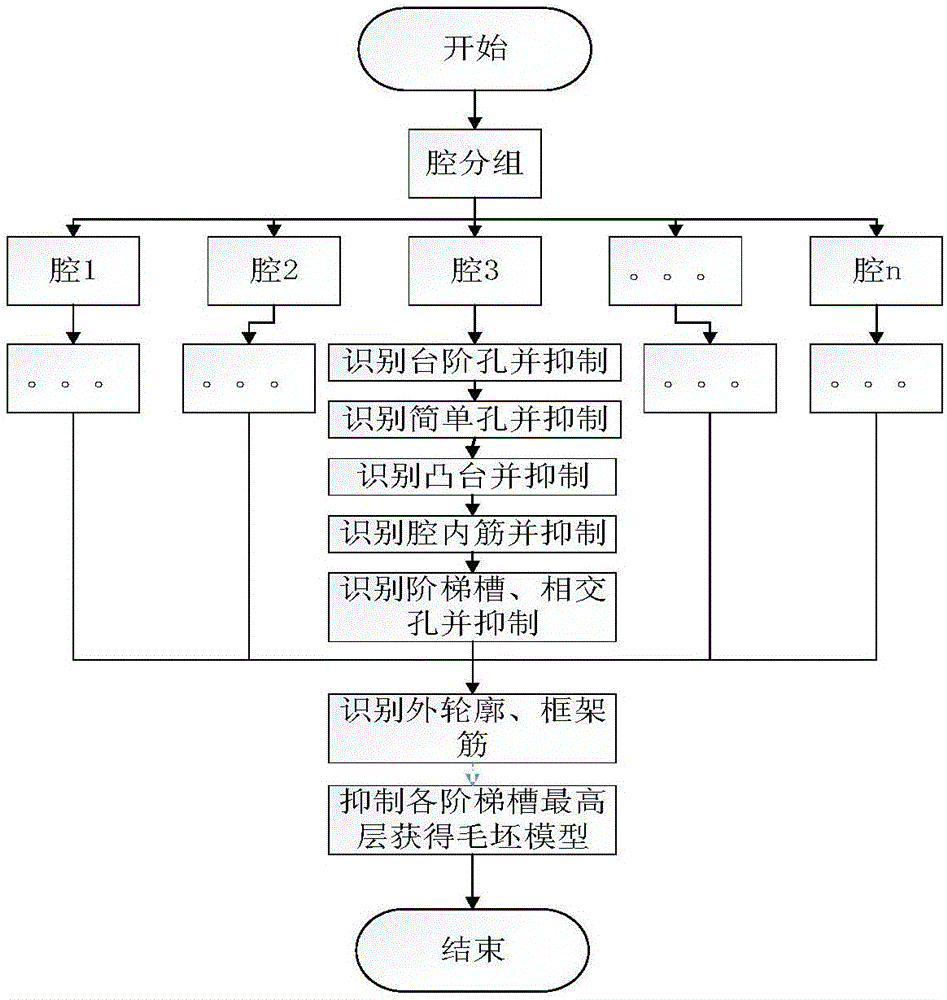

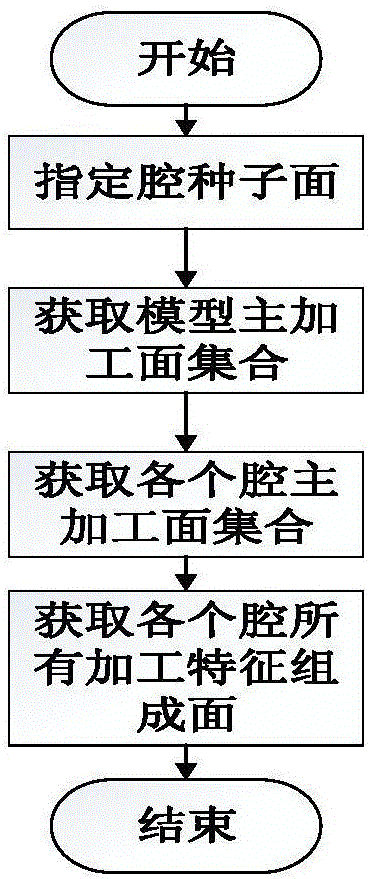

Thin-wall multi-cavity component processing characteristic identification method based on cavity grouping and characteristic suppression

ActiveCN106485218AImprove recognition efficiencyEasy to identifyGeometric CADDesign optimisation/simulationCharacteristic typeTopology information

A thin-wall multi-cavity structure component processing characteristic identification method based on cavity grouping and characteristic suppression is disclosed. The method is characterized by using a cavity grouping technology to segment a model, and carrying out parallel identification on a processing characteristic so that identification efficiency is increased; and using a characteristic suppression technology to directly carry out modeling operation on the model so as to realize identification of an intersection characteristic, according to an intersection characteristic type and feasibility of three-dimensional modeling, arranging an identification sequence, and after the identification is completed, acquiring a blank model. Because characteristic data in each cavity is mutually independent, by using the method of the invention, identification efficiency of the processing characteristic can be increased. In the invention, according to the intersection characteristic type and the feasibility of three-dimensional modeling, the identification sequence is arranged; and through the modeling operation which is directly performed on a three-dimensional model, an identified characteristic is suppressed from the three-dimensional model, and topology information receiving destructions is automatically restored so as to simplify identification of the intersection characteristic.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

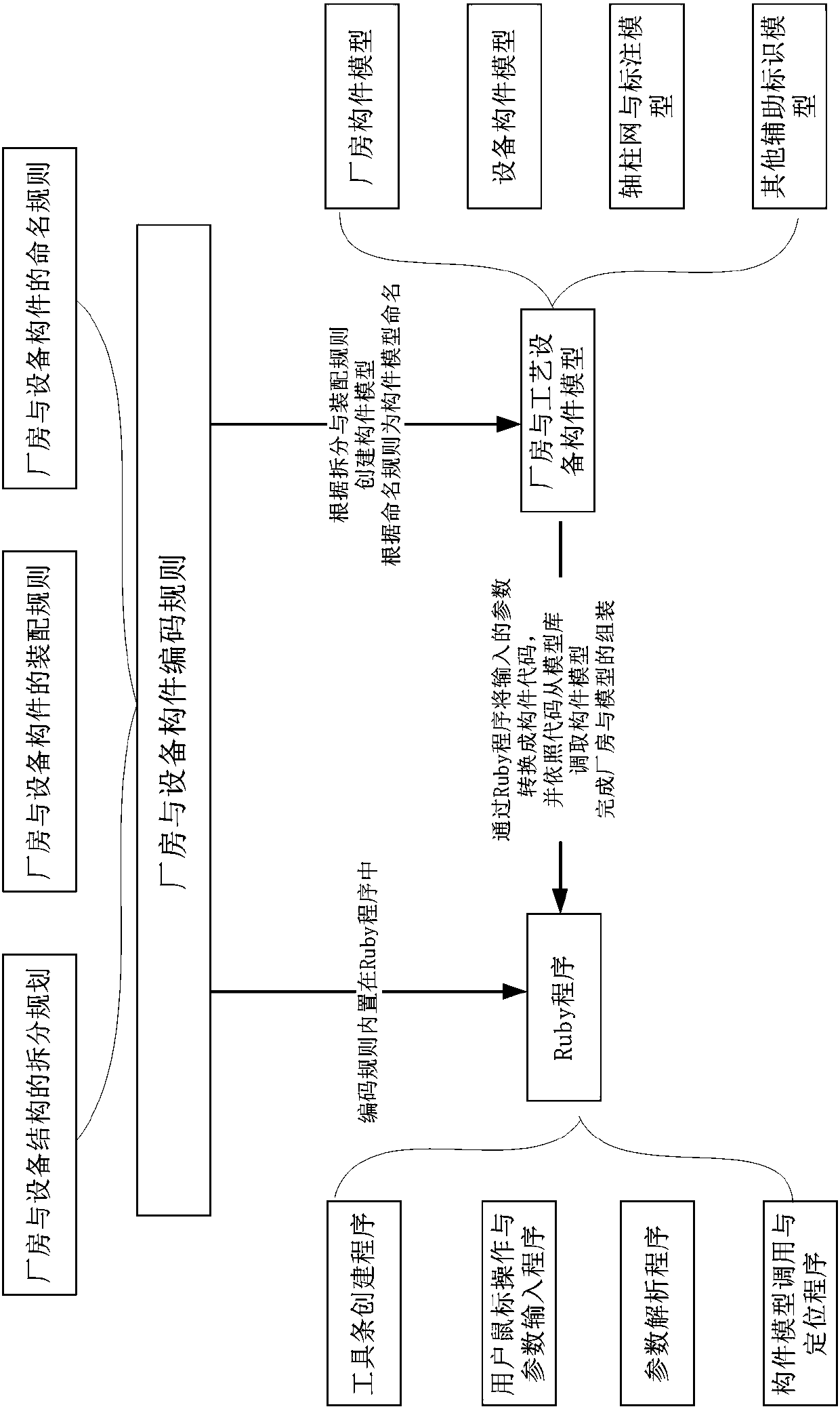

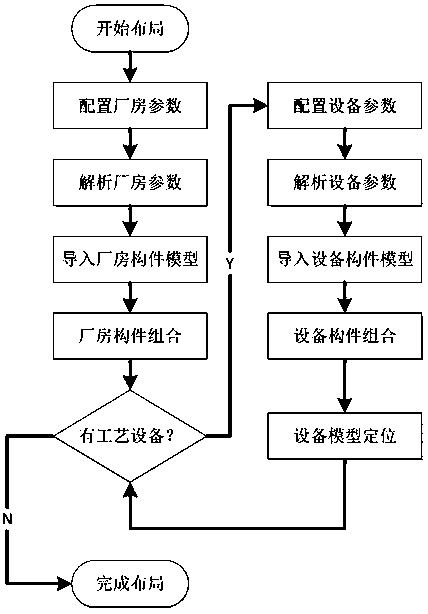

'Sketch Up' plant process designing method based on 'Ruby' language

ActiveCN107729703AImprove integrityHigh precisionGeometric CADSpecial data processing applicationsPlant StructuresDimensional modeling

The invention discloses a 'Sketch Up' plant process designing method based on a 'Ruby' language. The 'Sketch Up' plant process designing method is characterized in that the method adopts a group technology to conduct member disassembly and classification on plant structure characteristics and device assembly characteristics, then a set of encoding rules is created according to disassembly and classification results, plant members and device members are correspondingly encoded according to the rules, the 'Ruby' language is utilized to generate a three-dimensional model of a plant process deviceby a computer in 'Sketch Up', and quick three-dimensional layout of plant process design is achieved. Compared with prior art, by adopting the 'Sketch Up' plant process designing method, high-precision plant and process device three-dimensional layout is quickly created, alternation and modification of design schemes are also facilitated, the accuracy of process scheme expression is greatly improved, designers can be liberated from complicated, overloaded and repeated three-dimensional modeling work, and the project designing quality and efficiency are improved.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Combined process for processing heavy oil

ActiveCN100366709CEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

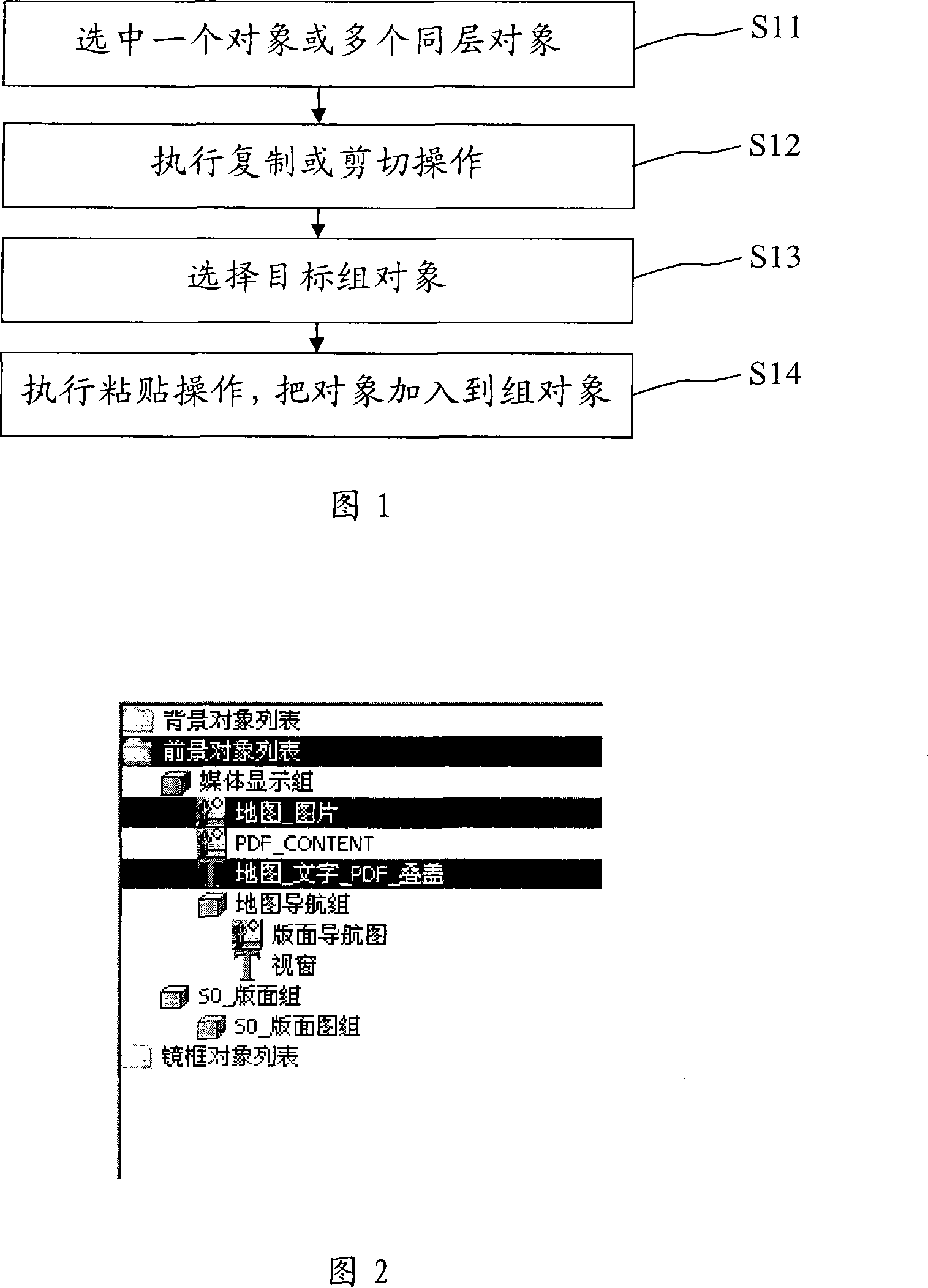

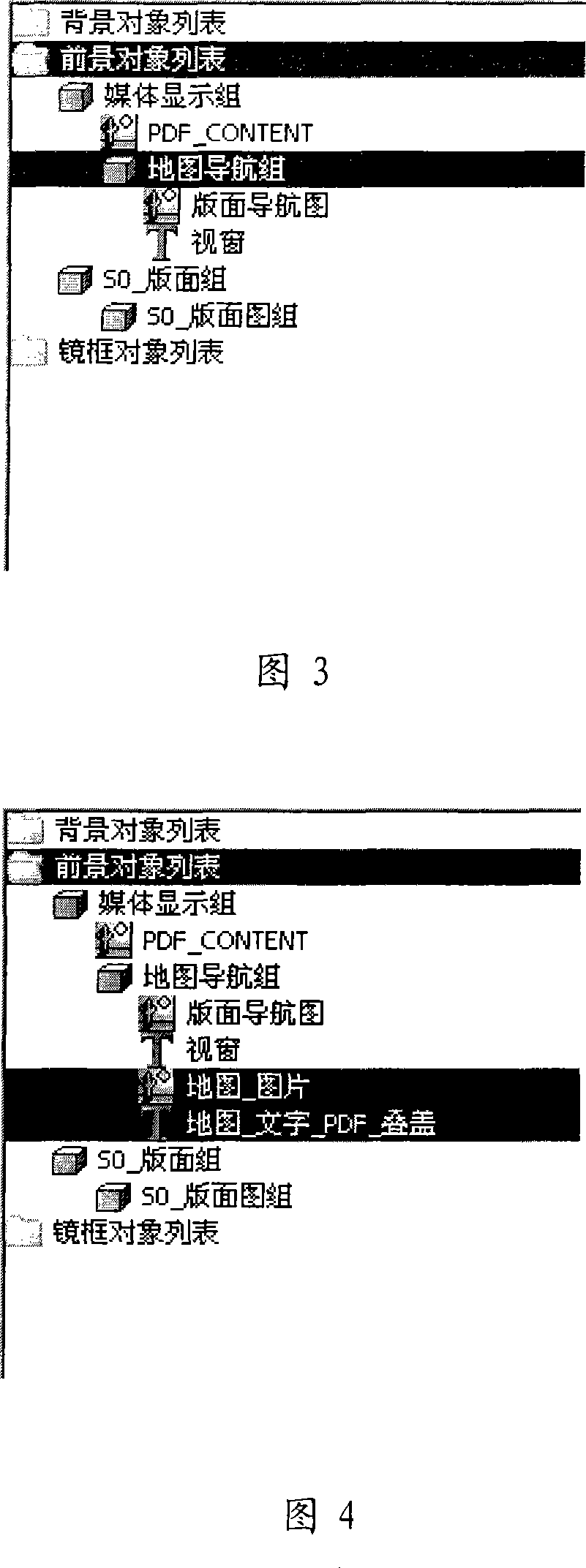

Rapid object grouping method for supporting pasting

ActiveCN101241436AImprove operational efficiencyHierarchy relationships are not affectedSpecific program execution arrangementsComputer graphics (images)Group method

The present invention provides a quick object grouping method of supporting plaster, belonging to object grouping field. In the present object grouping technology, the normal method of dynamic adding or deleting object in the group object achieves movement in the ''object tree'' by dragging mouse. The method can occupy limited screen area, and suitable for lower frequency, and waste time when opening-closing window of the ''object tree'', difficult to apply in the senstive location of the operating efficiency. The method is selecting one or more objects having same layer; executing duplication or cutting operation; selecting one aim group object; executing plasting operation, inserting selected one or more objects in the aim group object. the method of the invention can achieve ability of dynamic adding object to the group objects, so as to improve operating efficiency of the object group, and better apply in the sensitive location of the operating efficiency.

Owner:NEW FOUNDER HLDG DEV LLC +2

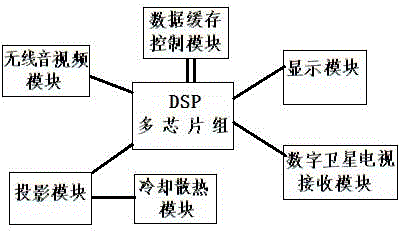

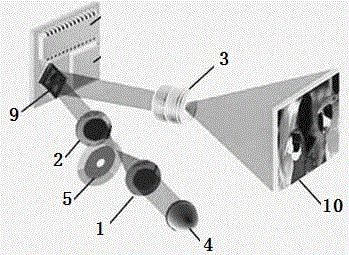

Wireless servo portable high-integration digital multimedia all-in-one machine

InactiveCN103957437AReduce power consumptionGood output performancePrintersProjectorsVideo transmissionImaging technology

A wireless servo portable high-integration digital multimedia all-in-one machine comprises a DSP multi-chip group, a data cache control module, a projection module, a WIFI wireless audio and video module, a display module, a digital satellite television receiving module and a cooling heat dissipation module. According to the wireless servo portable high-integration digital multimedia all-in-one machine, the DSP multi-chip group technology and the data cache technology are developed, so that quick task processing responding is realized and the processing power consumption is further reduced; the DLP projection imaging technology is developed, and by developing a DLP projection imaging system with a three-color LED light source for illumination, the projection image output performance is better; the OSD technology is developed, so that the expansibility and the character flexibility of the system are further enhanced; through development of a WIFI wireless audio and video transmission system, the product applicability is improved; the multi-channel non-pressure-loss cooling heat dissipating technology is developed, so that the cooling efficiency is further increased, energy consumption is lowered and the system service life is prolonged.

Owner:JIAN YINGJIA ELECTRONICS TECH

Super-large-scale water conservancy project and construction technology thereof

PendingCN105064264AConducive to prosperityGood for peaceArtificial water canalsHydraulic engineering apparatusUltra high pressureEngineering

The invention discloses a super-large-scale water conservancy project and a construction design scheme thereof, and aims to provide a water conservancy project construction technical scheme which is greater in water transfer scale and quicker in investment return, and further has the benefits of flood discharge, power generation (including a power transfer peak for pumped storage power generation), transportation and the like. A stepped type or relay type underground continuous wall group technology is adopted to dig and build a deep canal; dug-out soil, sand and the like are used for boosting mud flat to make land or encircling the sea (or a river or a lake) to make land or building an ultra-wide river wall to make construction land; according to a super-large-scale water conveying (transferring) pipeline resistant to ultra-high pressure, a reinforcing frame consisting of triangles is arranged above (or in) the pipeline top wall; and soil, sand and the like which are produced by ditching are filled into wall groups on the pipeline to make land, press and fix the pipeline. According to the super-large-scale water conservancy project and the construction design scheme thereof disclosed by the invention, the economic benefits and the social benefits are obviously greater than those in a current technical scheme.

Owner:赵金龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com