Patents

Literature

85 results about "Catalytic cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a catalytic cycle is a multistep reaction mechanism that involves a catalyst. The catalytic cycle is the main method for describing the role of catalysts in biochemistry, organometallic chemistry, bioinorganic chemistry, materials science, etc.

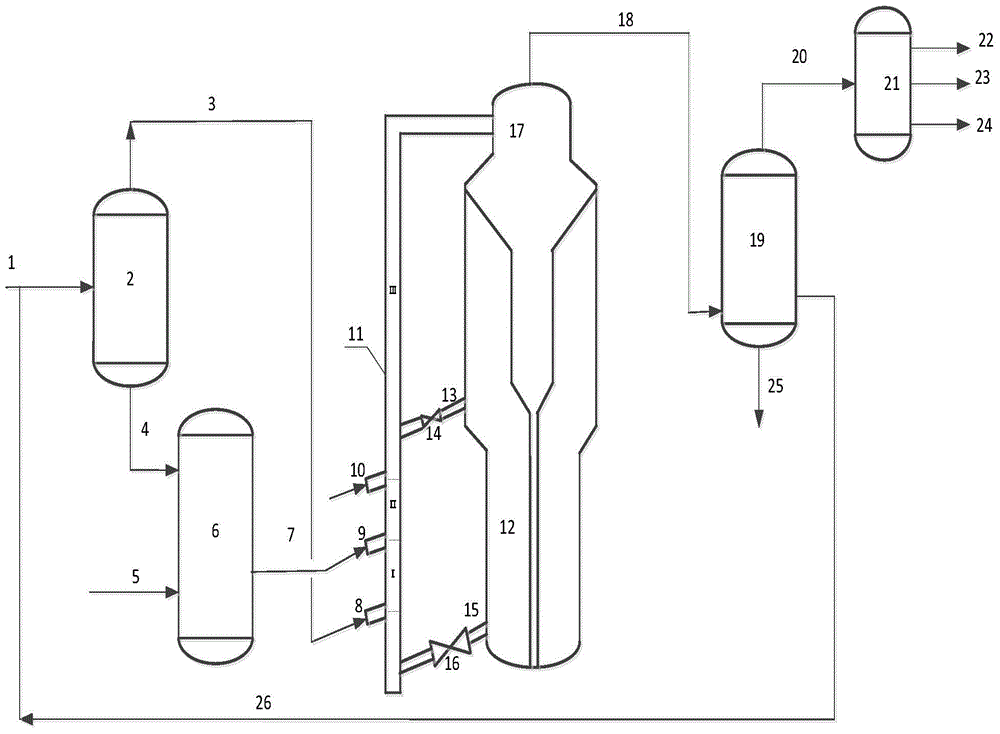

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

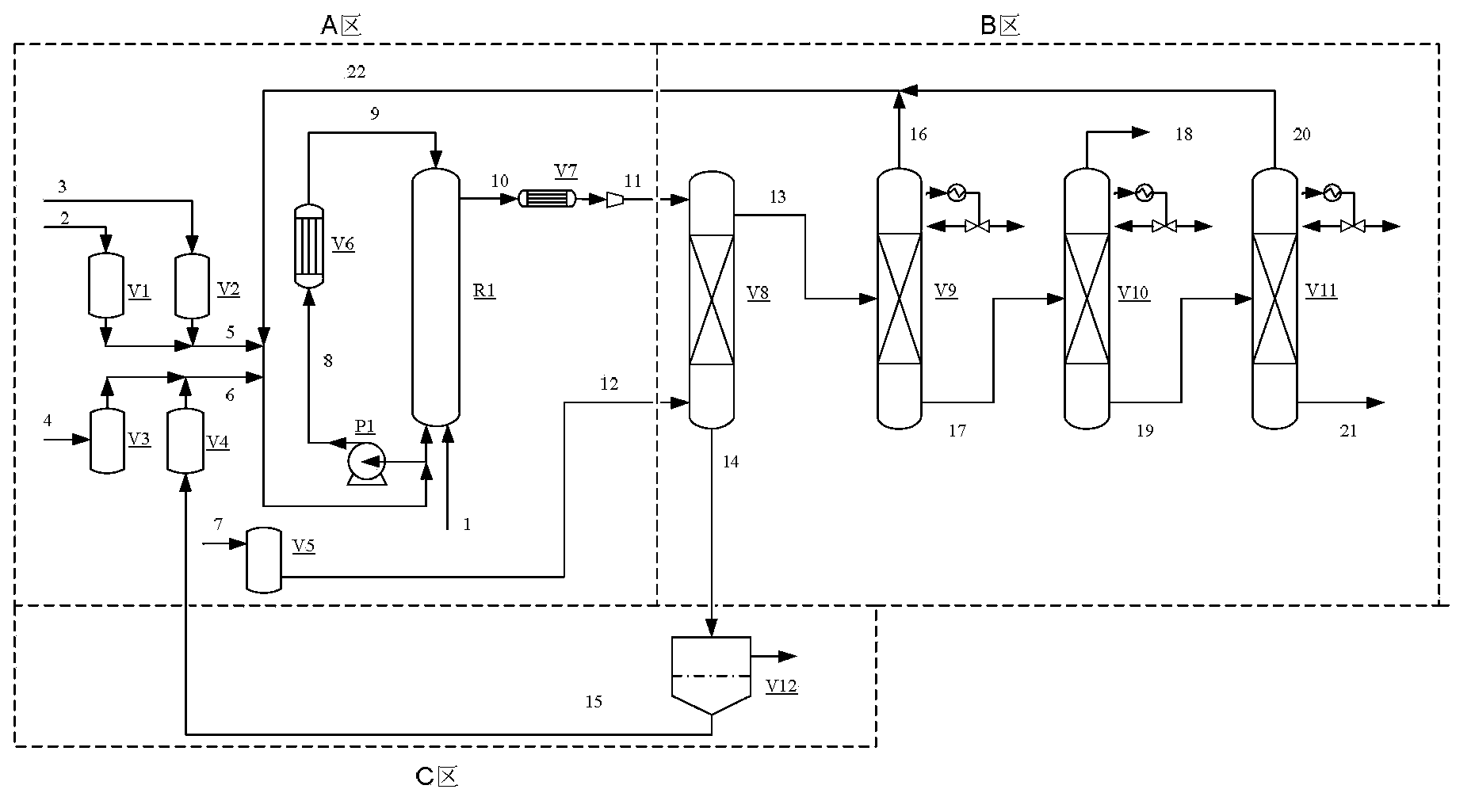

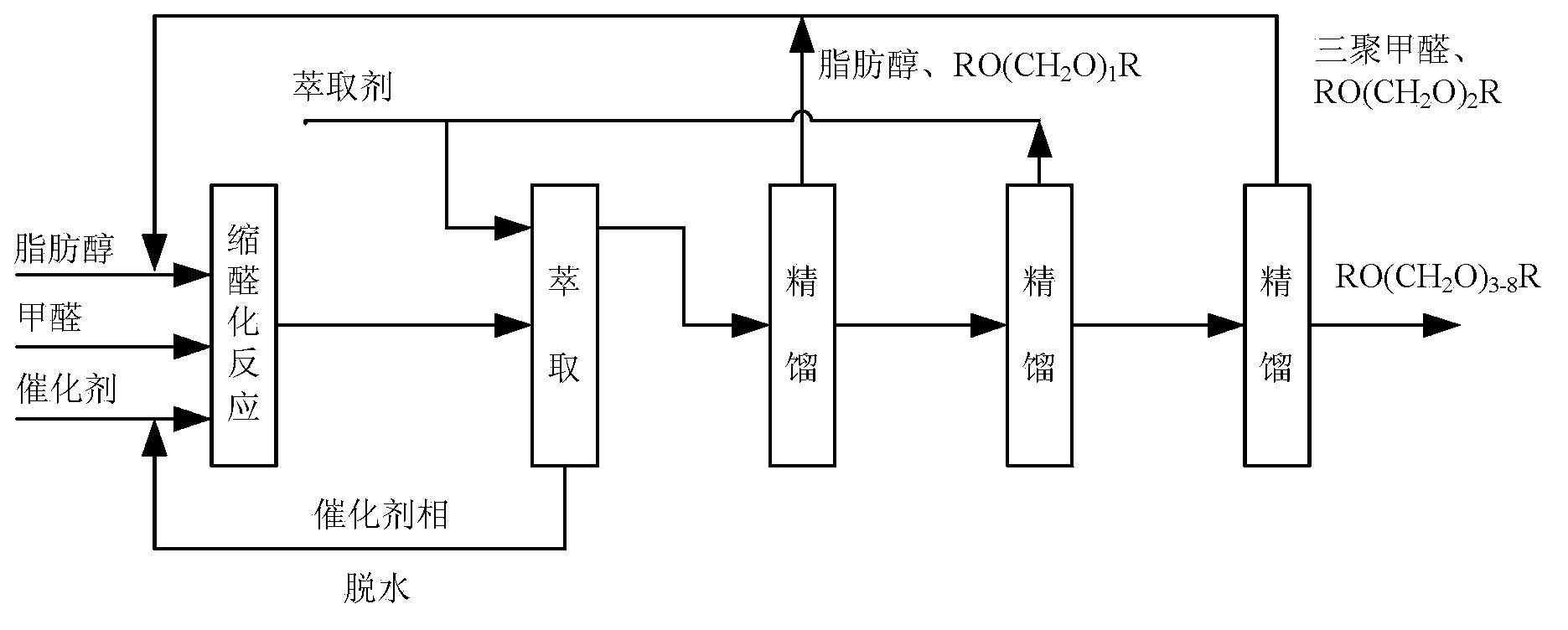

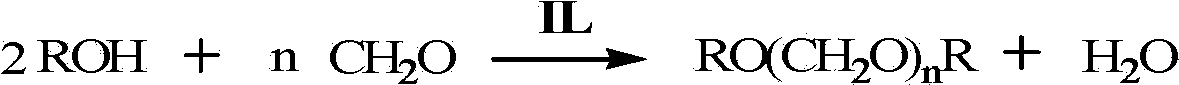

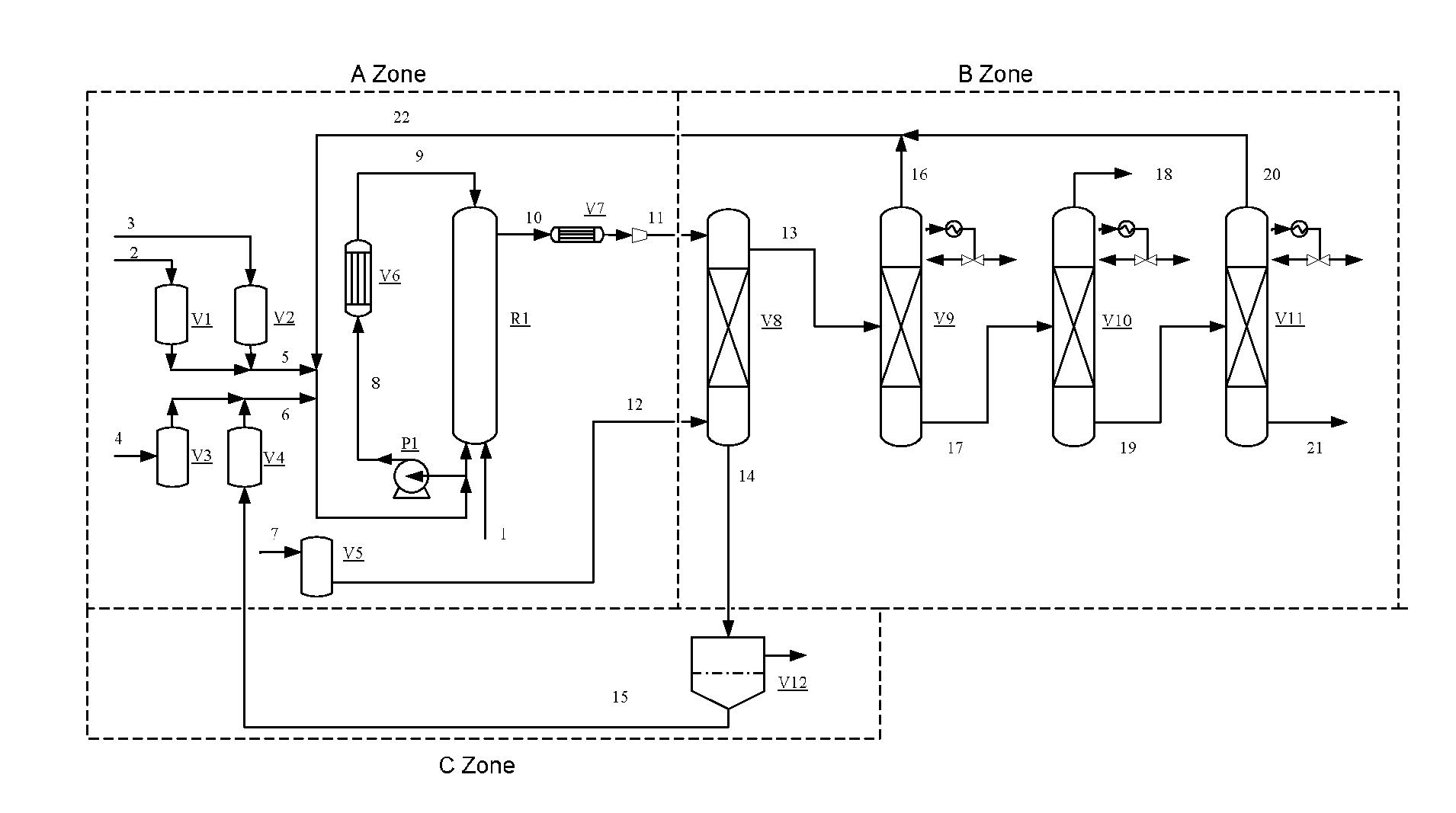

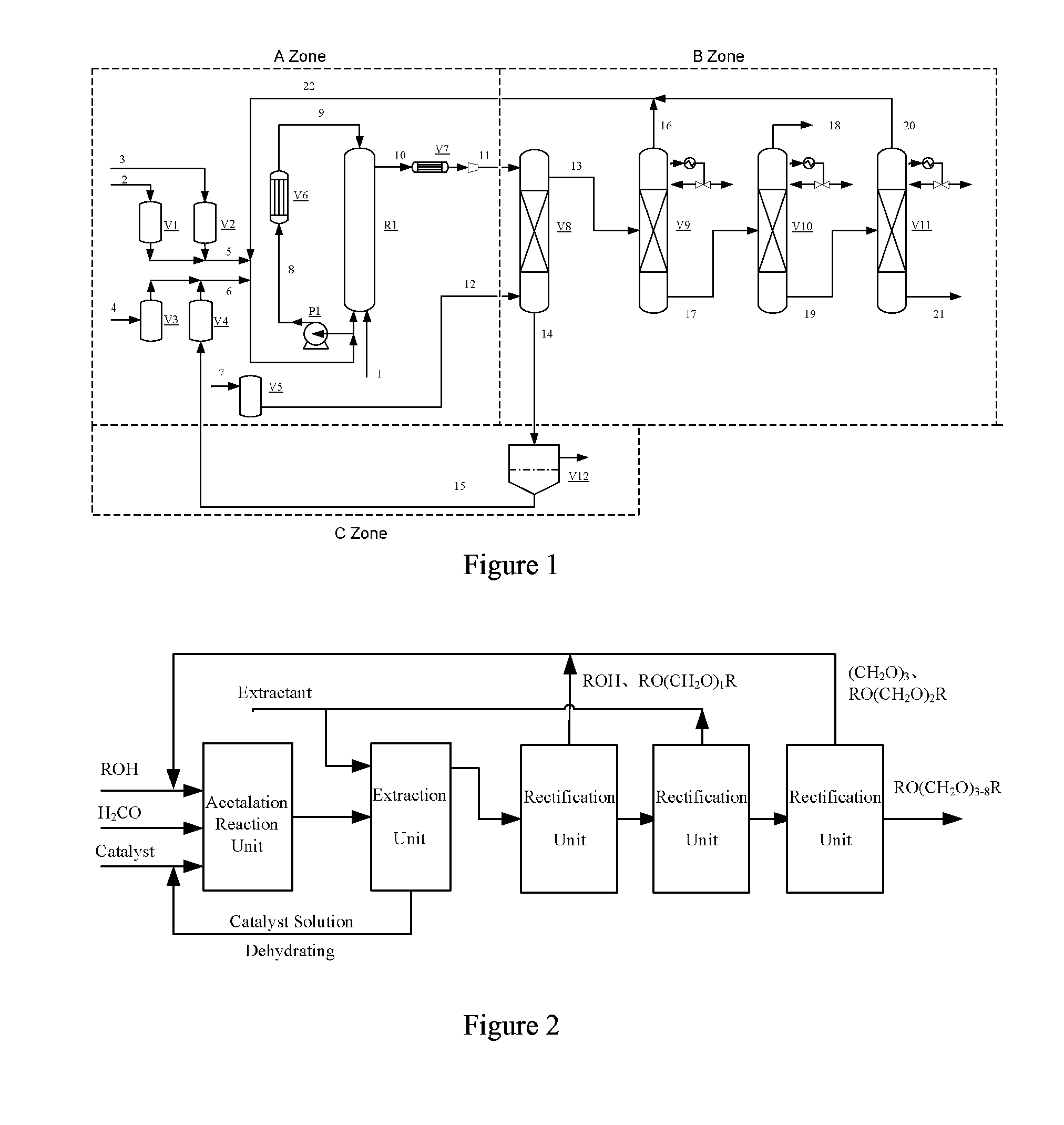

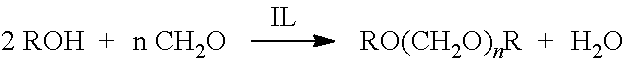

Reaction system for continuously preparing polyoxymethylene dialkyl ether, and process thereof

InactiveCN103772164AAchieve separationAchieve regenerationOrganic compound preparationChemical/physical/physico-chemical processesProcess equipmentAlcohol

The invention discloses a process apparatus system for preparing polyoxymethylene dialkyl ether (RO(CH2O)nR, n=1-8) through a continuous acetalation reaction of formaldehyde and fatty alcohol under the catalysis of an acidic ionic liquid, and a process thereof. A process apparatus used in the method comprises an acetalation reaction unit, a product separation unit and a catalyst regeneration unit. The adoption of the extraction and rectification combined separation mode in the invention effectively realizes the separation of circulating materials and the above catalyst and makes the recovery rate of the catalyst reach above 99%; the separation of byproduct water from the reaction system is realized, and the azeotropy of water, alcohol, aldehyde and RO(CH2O)nR is destroyed, so the product separation is simple; and a catalyst regeneration technology is simple, so catalytic cycle is realized.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

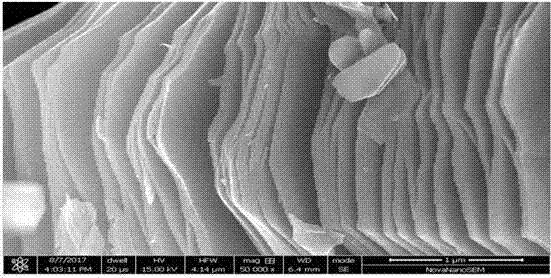

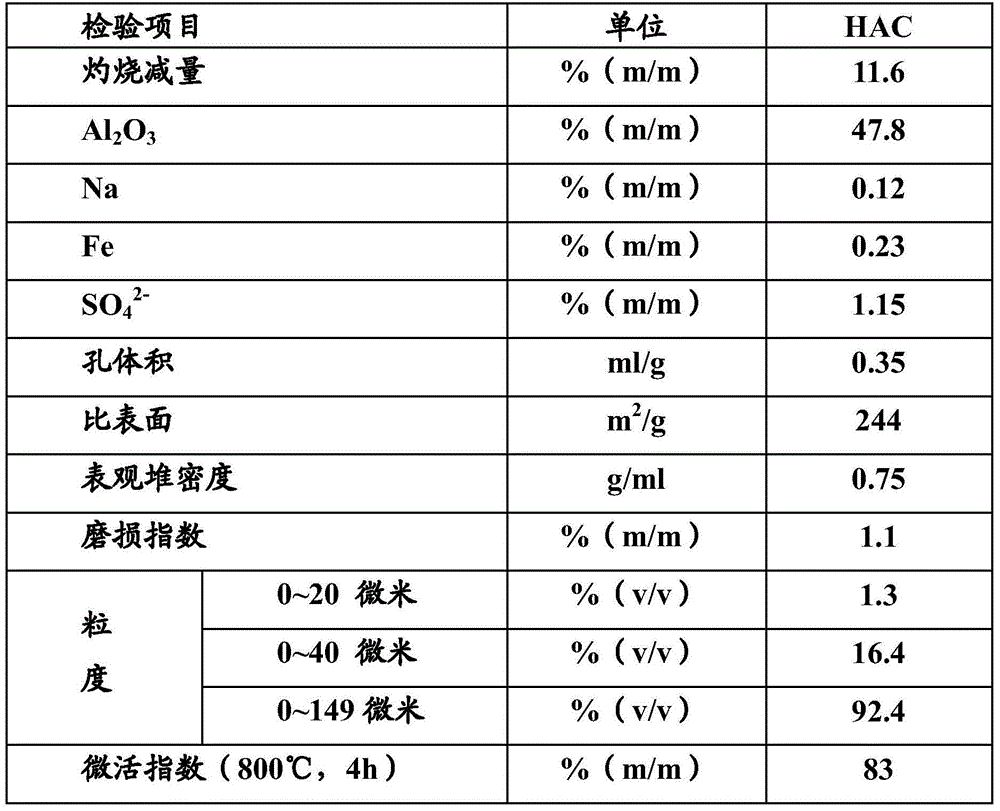

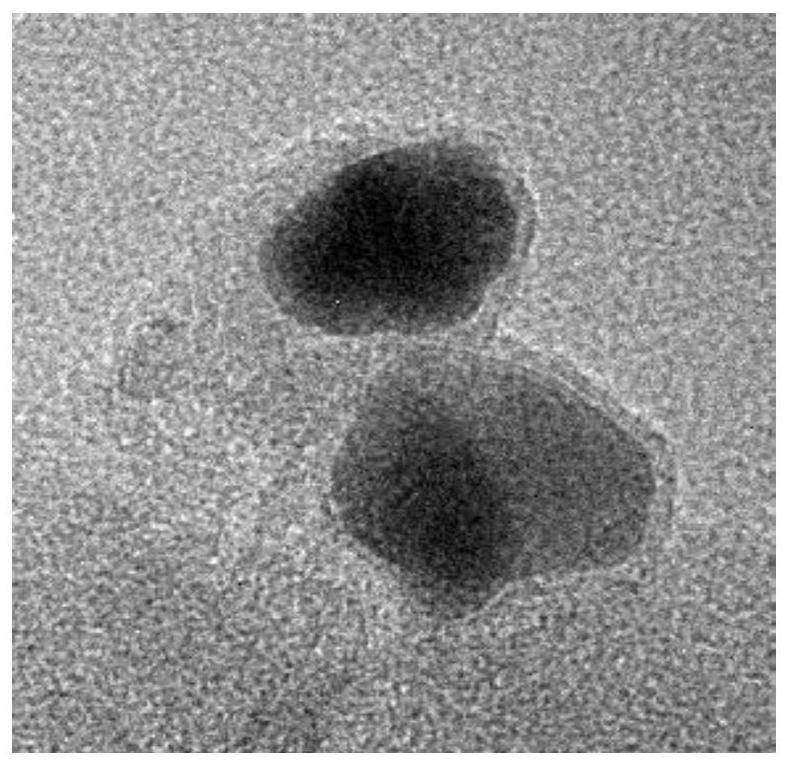

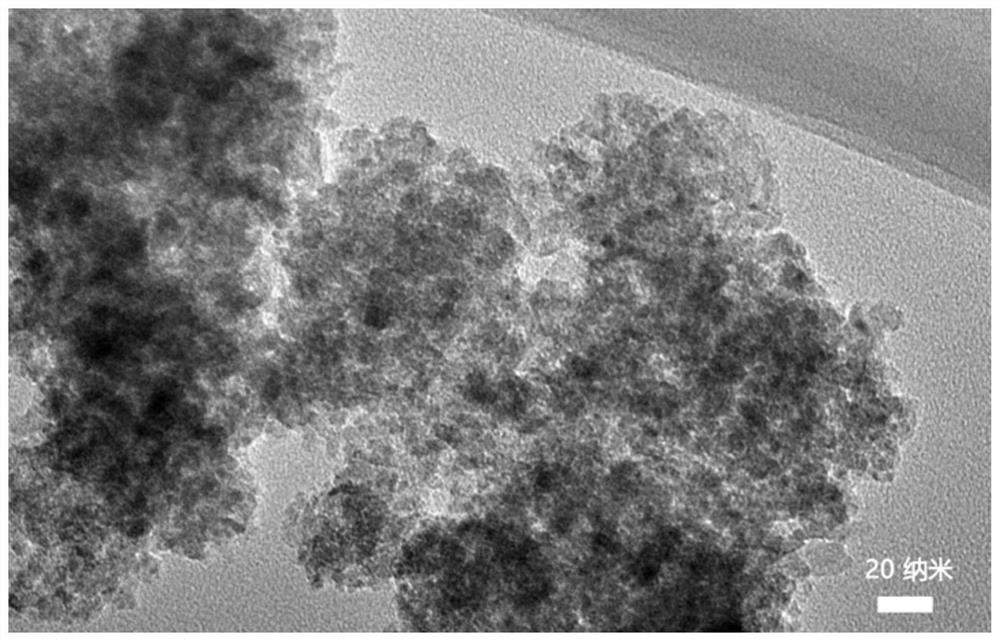

MXene(Ti3C2)-loaded palladium catalyst and preparation method and application thereof

ActiveCN107537540AHigh selectivityIncrease reaction rateOrganic chemistryPhysical/chemical process catalystsDispersityPalladium catalyst

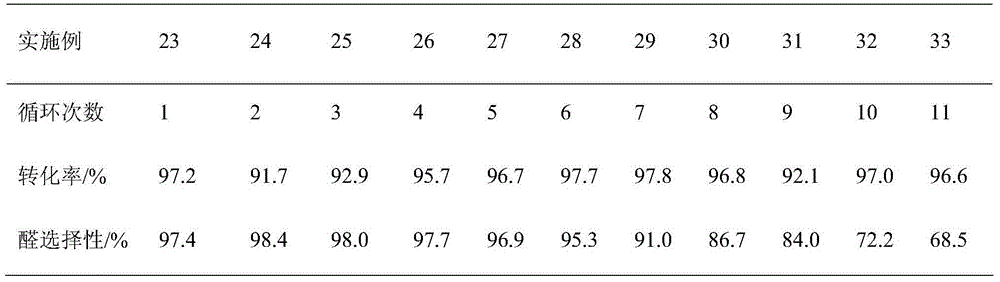

The invention discloses a MXene(Ti3C2)-loaded palladium catalyst and a preparation method and application thereof. The MXene(Ti3C2)-loaded palladium catalyst is prepared from a MXene(Ti3C2) carrier and palladium which is carried on the MXene(Ti3C2) carrier, the carried quantity of palladium accounts for 2-6 wt.% of the mass of the carrier, and the prepared MXene(Ti3C2)-loaded palladium catalyst isused for vanillic aldehyde catalytic hydrogenation to prepare 2-methoxy-4-methylphenol. According to the MXene(Ti3C2)-loaded palladium catalyst, after the palladium catalyst is carried, precious metal particles are small, the dispersity degree of the metal particles is high, the cost is low, the mechanical strength of the MXene(Ti3C2)-loaded palladium catalyst is good, and the stability of a catalytic cycle is good; the MXene(Ti3C2)-loaded palladium catalyst is used for the vanillic aldehyde catalytic hydrogenation to prepare 2-methoxy-4-methylphenol simply by using water as solvent of reaction, the cost is low, the preparation method is environmentally friendly, the toxicity is low, the yield of high, the technological processes are simple, and the operation is easy, which is conducive to industrial production; by using a gas chromatography mass spectrometer for qualitative and quantitive analysis, it is indicated that the conversion rate of vanillic aldehyde is 98%-100%, and the selectivity of 2-methoxy-4-methylphenol is 98%-100%.

Owner:ZHEJIANG UNIV OF TECH

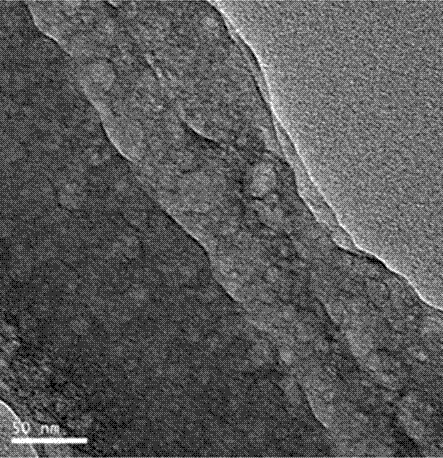

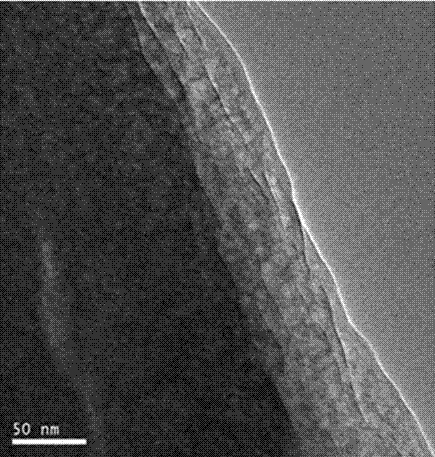

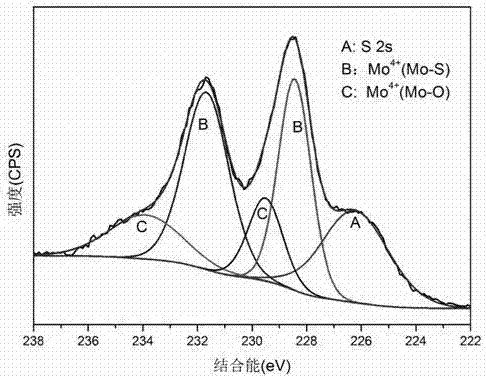

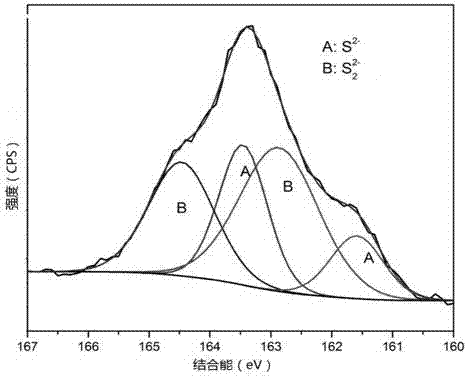

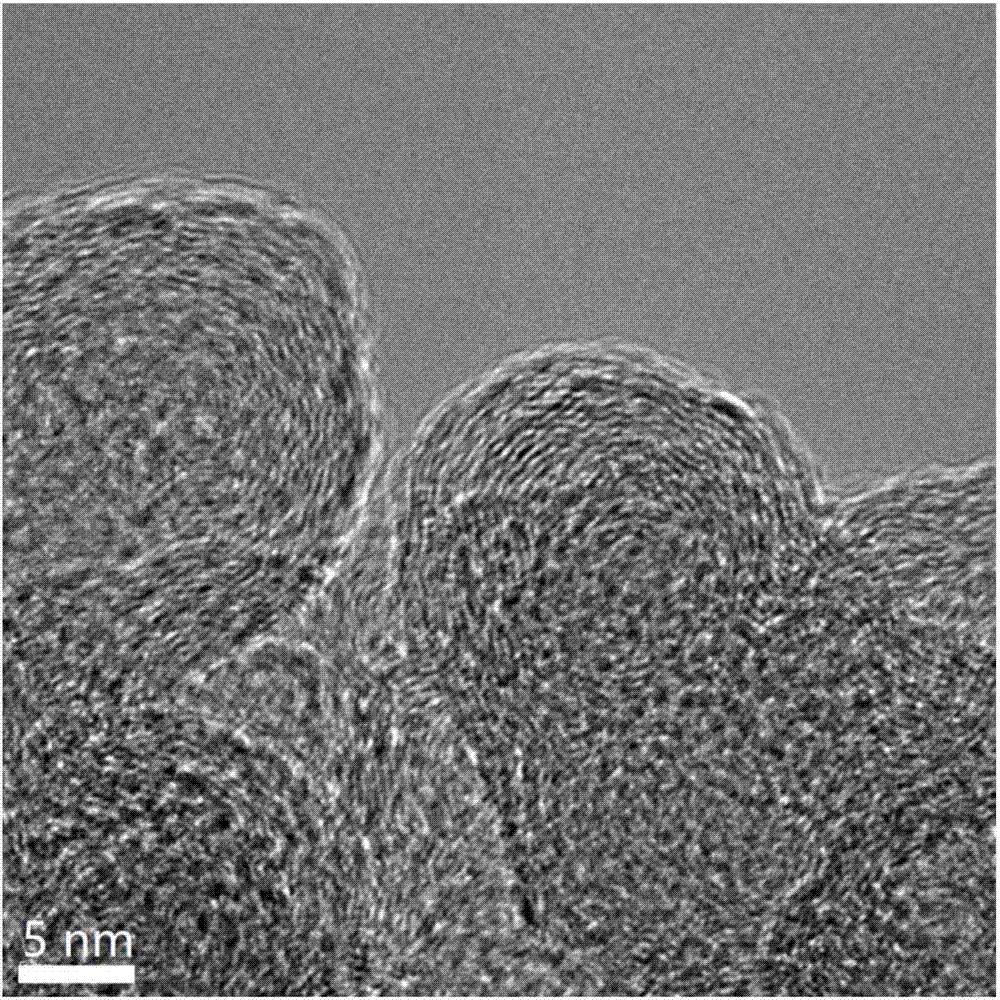

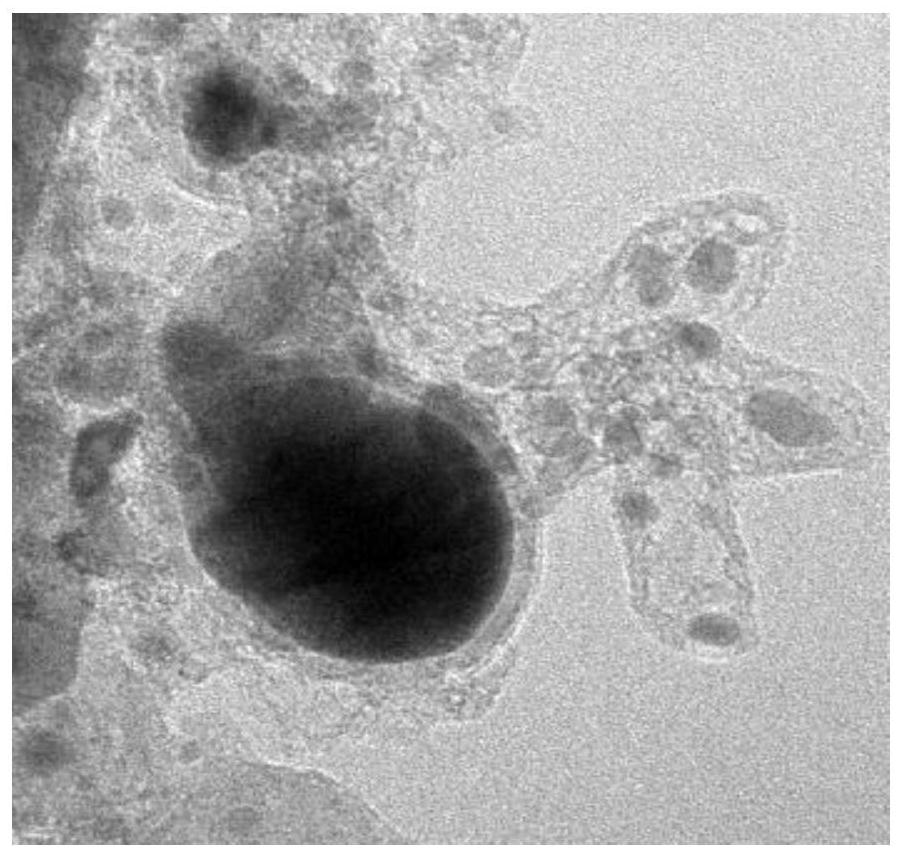

MoSxOy/carbon nanometer composite material, and preparation method and application thereof

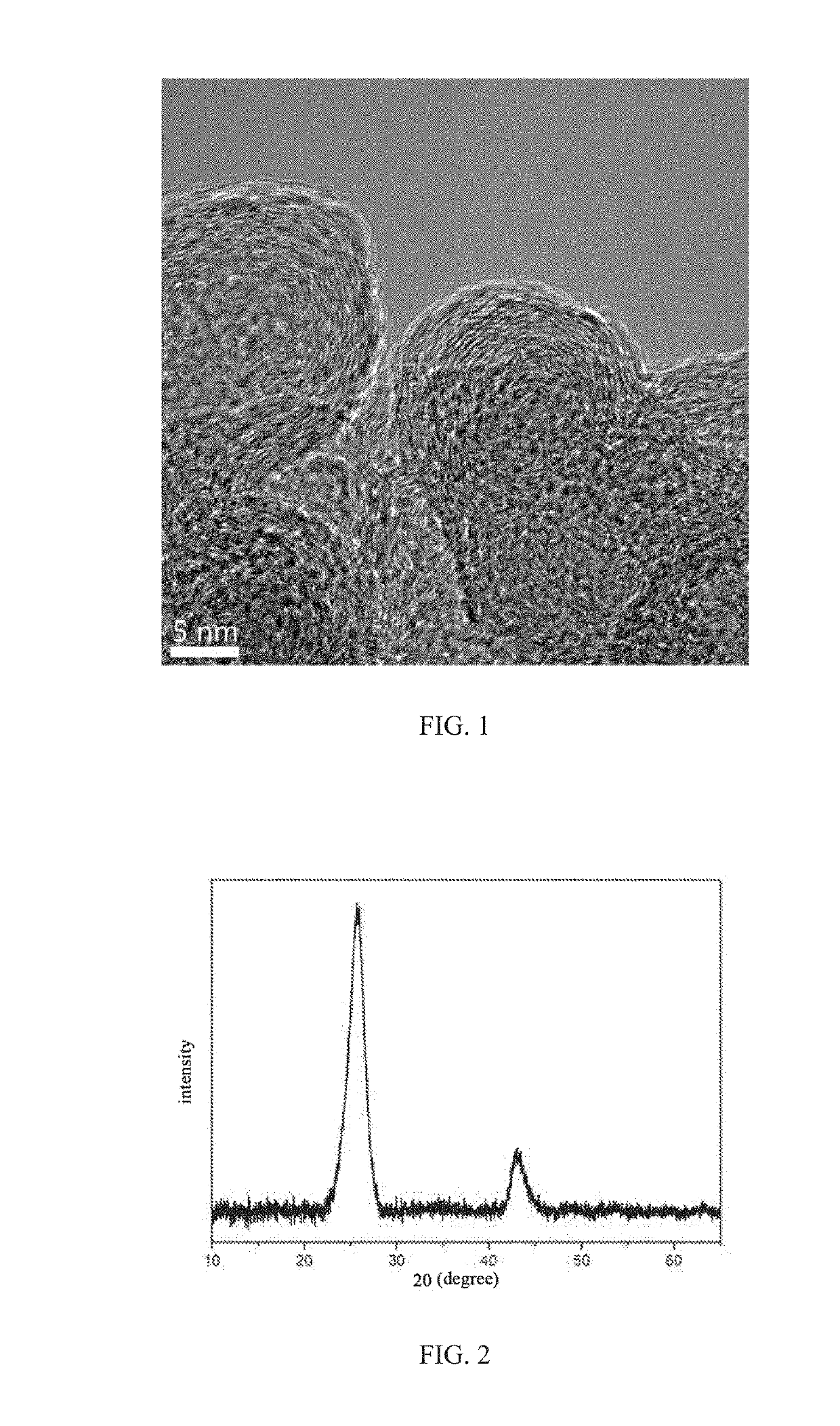

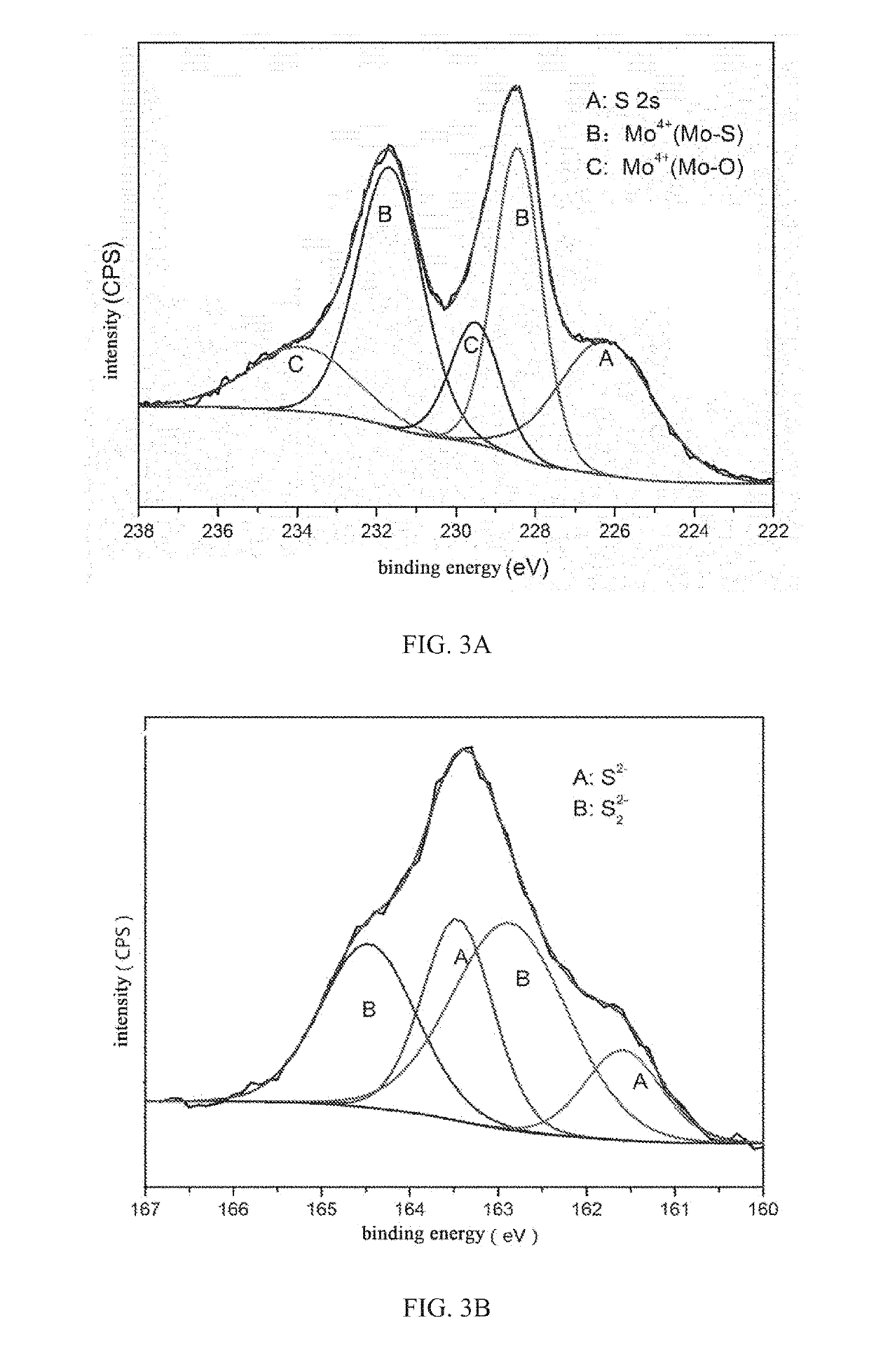

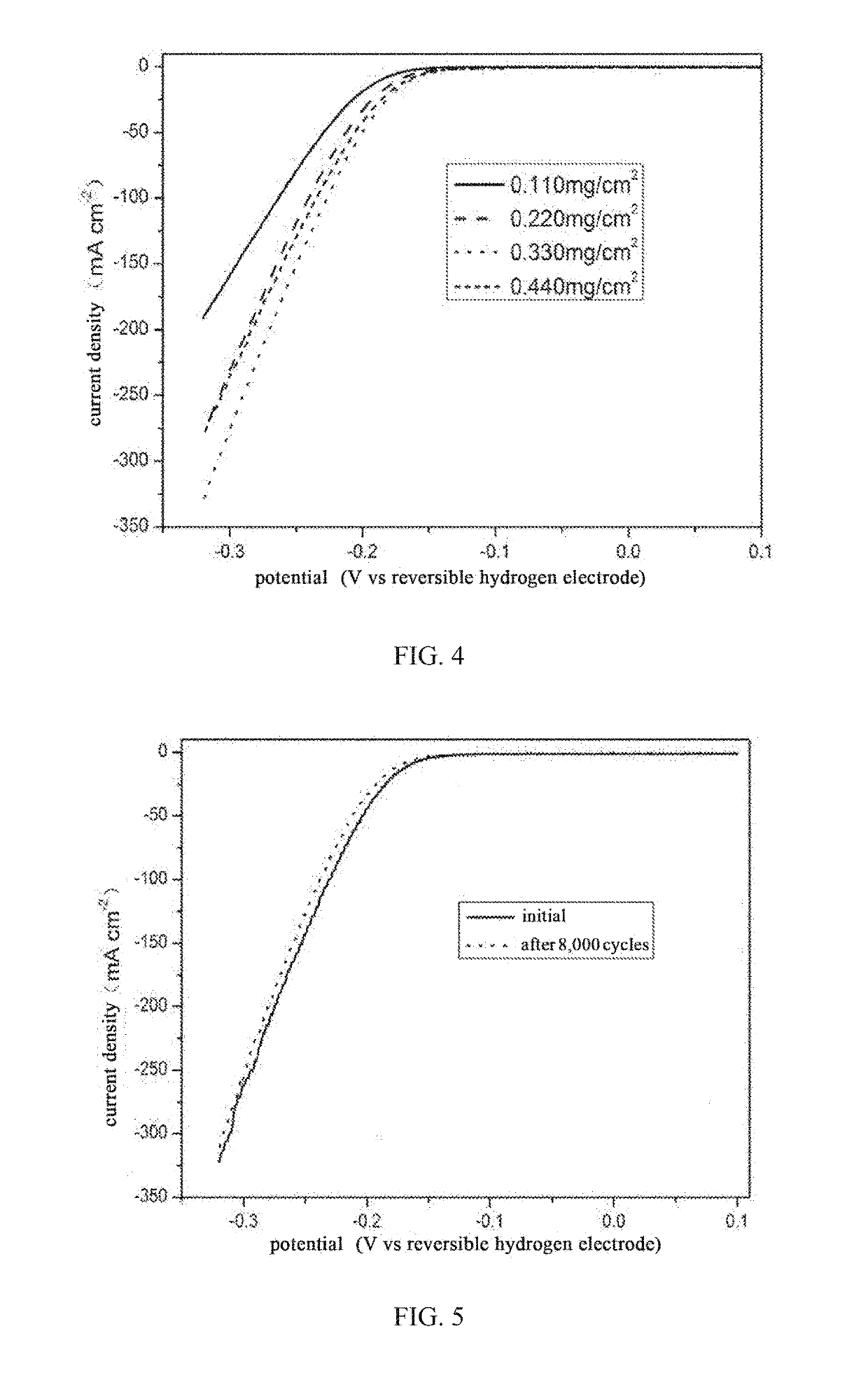

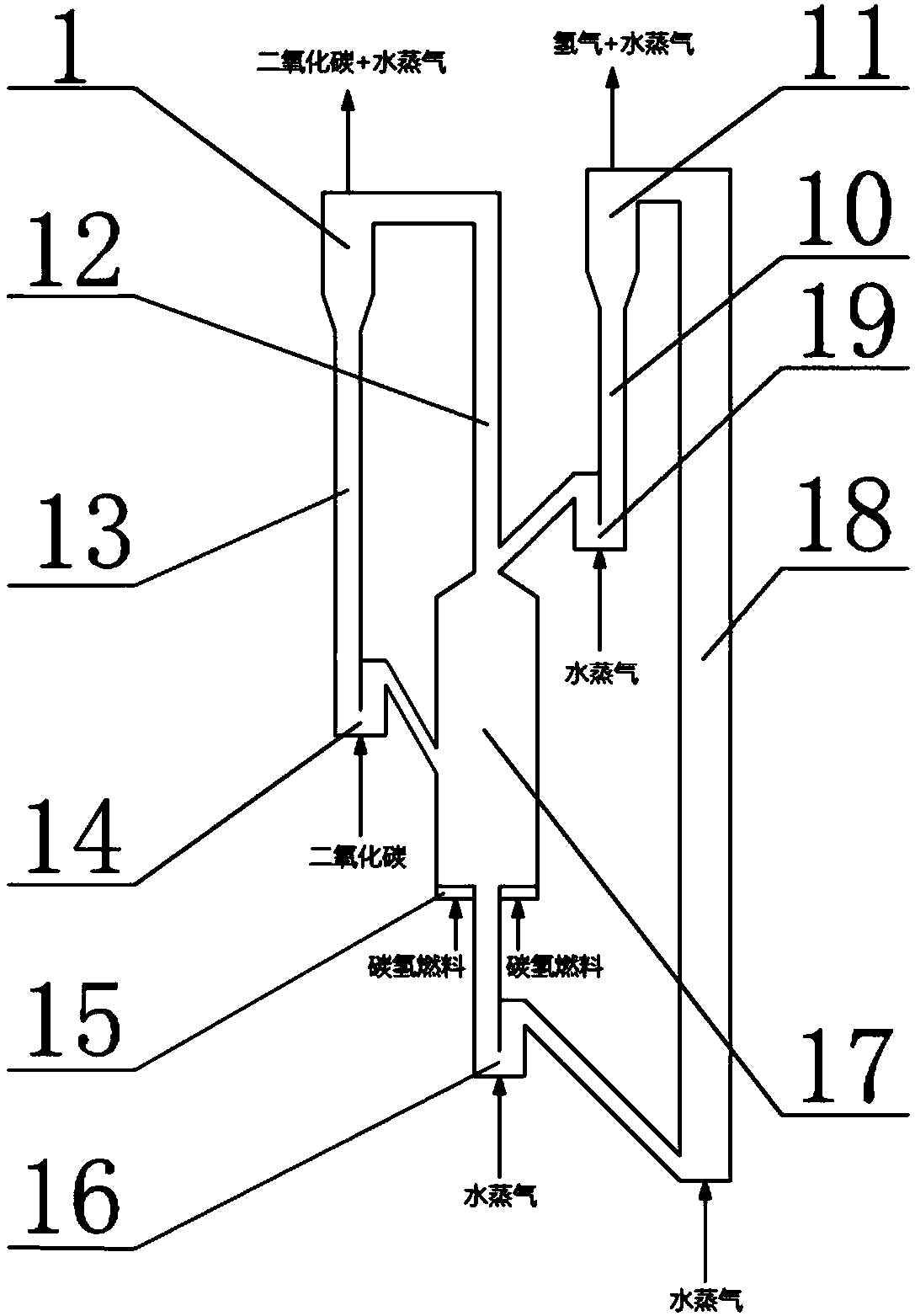

ActiveCN107010670AImprove conductivityIncrease the number of active sitesPositive electrodesNano-carbonPtru catalystCarbon nanocomposite

The embodiment of the invention discloses a MoSxOy / carbon nanometer composite material, and a preparation method and application thereof, wherein in the MoSxOy / carbon nanometer composite material, x is greater than or equal to 2.5 but is smaller than or equal to 3.1; y is greater than or equal to 0.2 but is smaller than or equal to 0.7; on the basis of the total mass of the nanometer composite material, the mass percentage of the MoSxOy is 5 to 50 percent. When the prepared MoSxOy / carbon nanometer composite material is used as an electrocatalysis hydrogen evolution reaction catalyst, the current density during the overpotential of 300mV is equal to or higher than 150 mA / cm<2>; the performance has small differences from a commercial 20-percent Pt / C catalyst, or is even identical to that of the commercial 20-percent Pt / C catalyst. The performance is much better than that of the existing MoS2 composite material. In addition, the prepared MoSxOy / carbon nanometer composite material also has good catalysis stability; after the 8000 times of catalysis circulation, the current density is only lowered by 3 percent; excellent catalysis performance and circulation stability are shown.

Owner:PEKING UNIV

Catalytic conversion method of hydrocarbon oil

ActiveCN104560167AReduce hydrogen consumptionImprove operating conditionsTreatment with hydrotreatment processesHydrocarbon oils treatment productsGasolineCatalytic cycle

The invention provides a catalytic conversion method of hydrocarbon oil. The method comprises the following steps: cutting light catalytic cycle oil into light fraction and heavy fraction; hydrotreating the heavy fraction to obtain hydrotreated heavy fraction; adding the light fraction, the hydrotreated heavy fraction and heavy hydrocarbons raw materials into a riser reactor from bottom to top by layering; cracking in the presence of a catalytic cracking catalyst; and separating a reaction product to obtain a product containing gasoline and light cycle oil. According to the method, the raiser is divided into different areas at three layers, and a regenerated catalyst is supplemented at different positions to respectively process different fractions of heavy oil and light cycle oil, which is beneficial for the optimizing of operation conditions of the three raw materials, and therefore, catalytic gasoline with high octane number can be produced to the maximum.

Owner:CHINA PETROLEUM & CHEM CORP +1

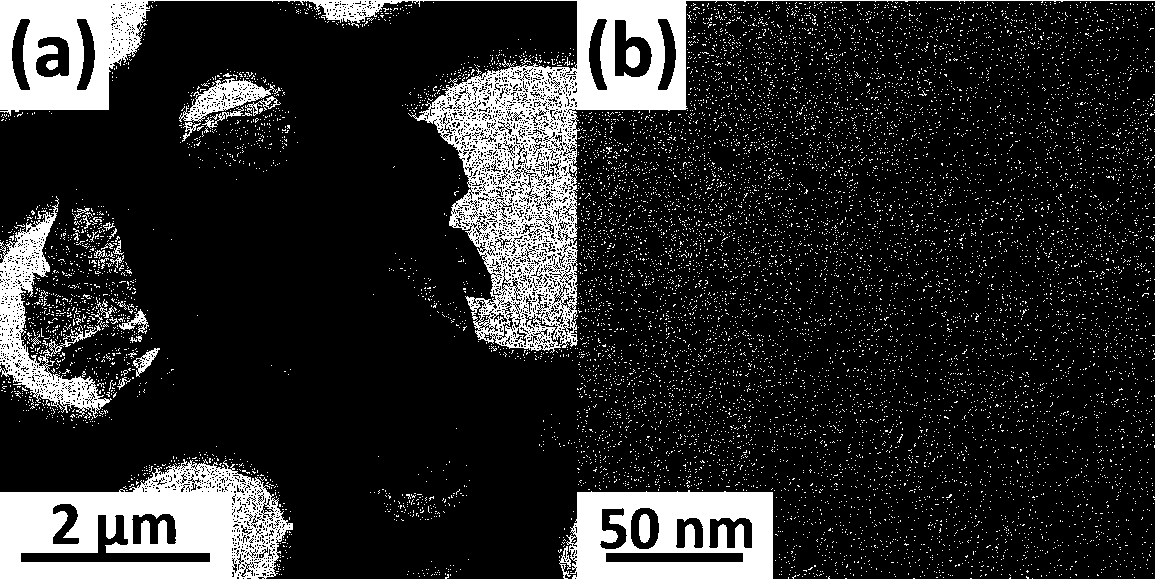

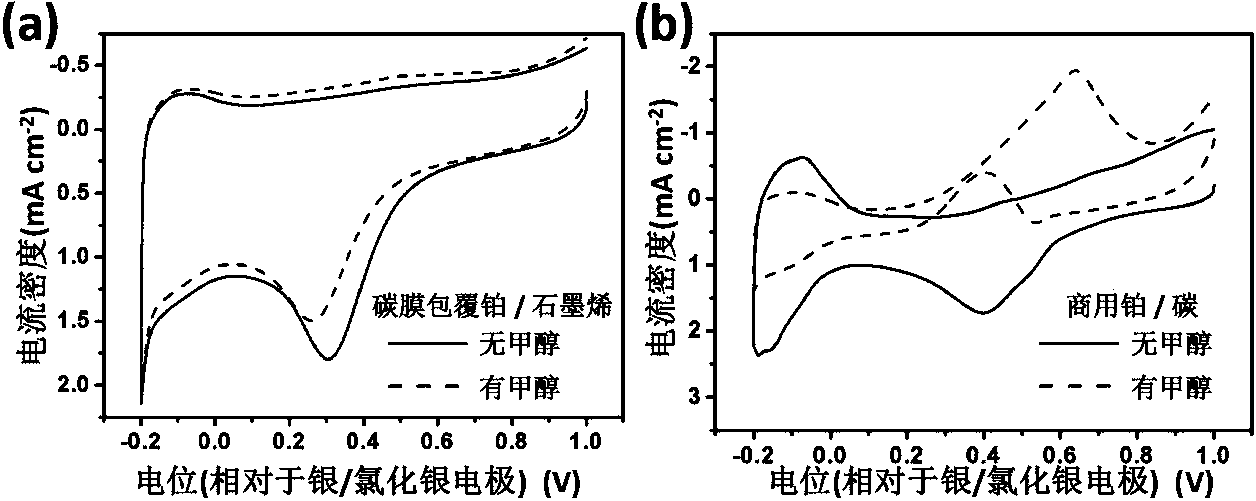

Preparation method of carbon film coated platinum/graphene catalyst

InactiveCN104014333AHigh reactivityImprove cycle performanceCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon filmCarbonization

The invention discloses a preparation method of a carbon film coated platinum / graphene catalyst. Graphene is adopted as a carrier for the catalyst to hydrothermally reduce oxidized graphene, saccharides, polyvinyl pyrrolidone and chloroplatinic acid, and then high-temperature carbonization is carried out to obtain a cathode oxygen reduction reaction catalyst of a fuel battery, wherein the platinum loading amount is 10-50wt%. The catalyst has excellent methanol tolerance and catalytic cycle stability, the performances of the catalyst are greatly improved in 1000 times of cyclic voltammetry testing, and the catalyst is superior to the commercial platinum / carbon catalyst.

Owner:安徽百特新材料科技有限公司

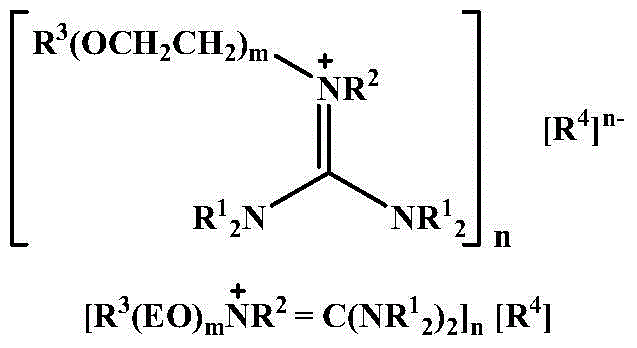

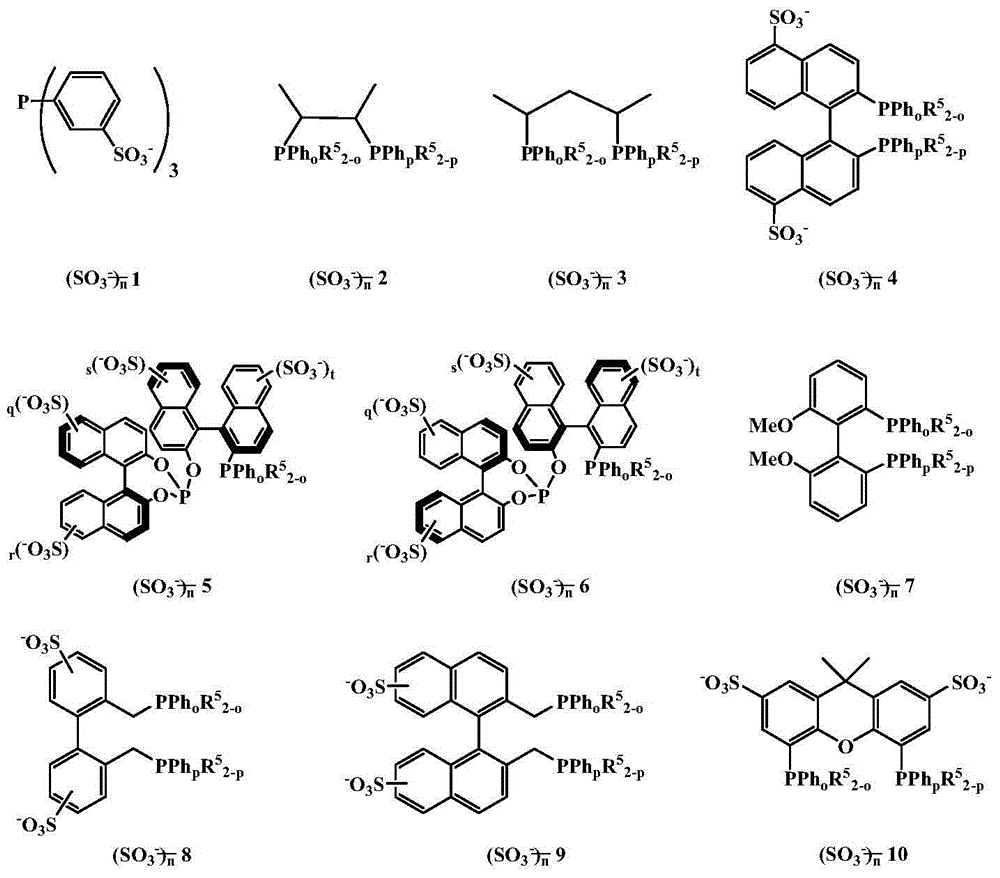

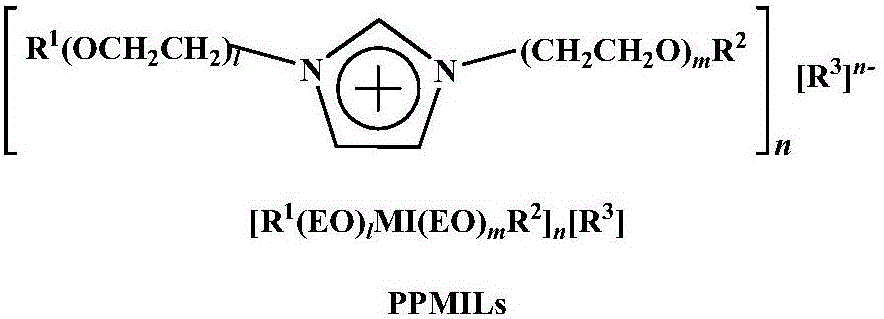

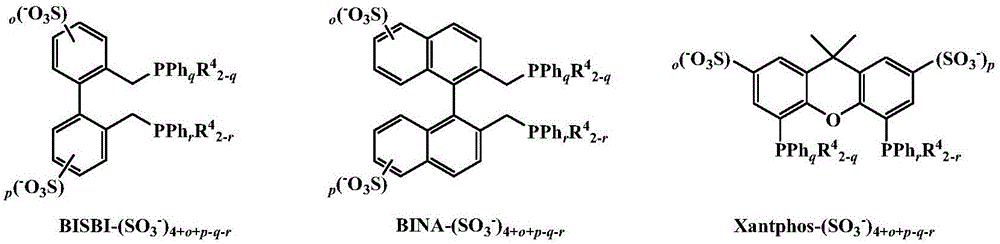

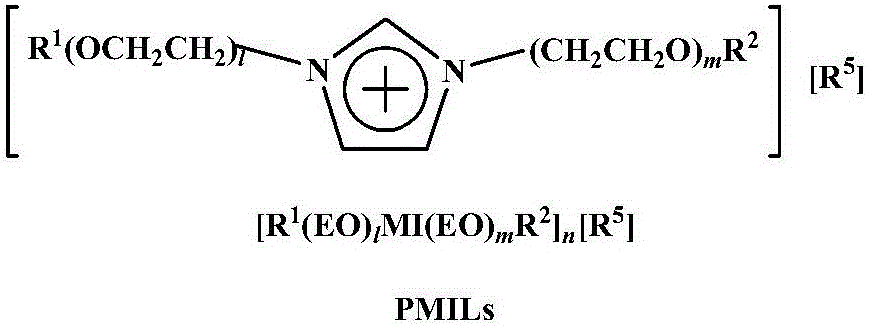

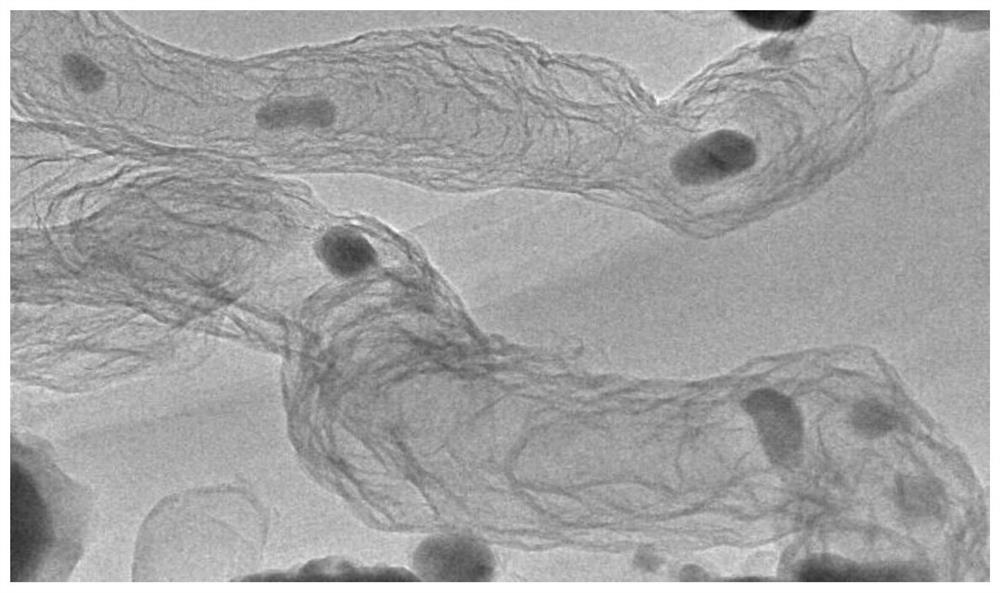

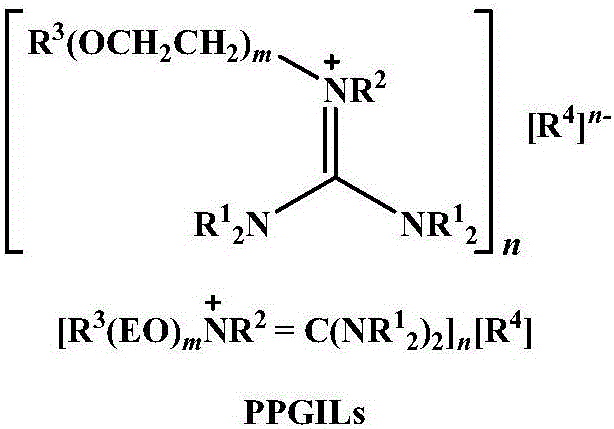

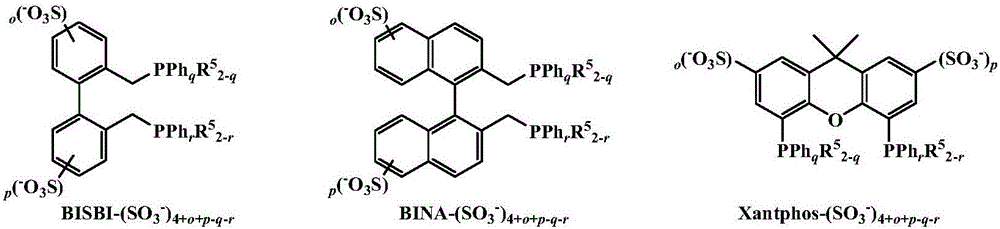

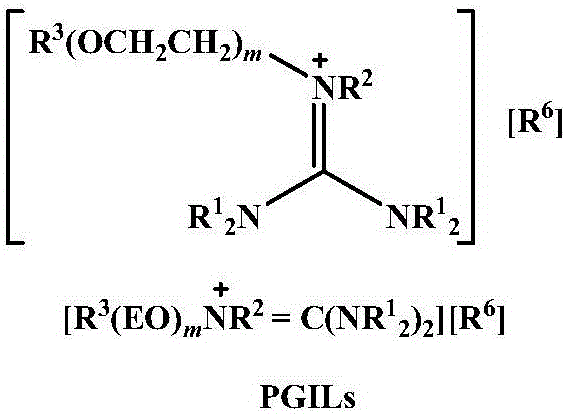

Method for biphasic hydroformaylation of olefins based on phosphine-functionalized polyether alkyl guanidine salt ionic liquid

ActiveCN105017317ASolve the problem of excessive usageEliminate negative effectsOrganic compound preparationGroup 5/15 element organic compoundsSyngasReaction temperature

The present invention relates to a method for biphasic hydroformaylation of olefins based on a phosphine-functionalized polyether alkyl guanidine salt ionic liquid. A biphasic catalytic system is used in the method, wherein the catalytic system consists of the phosphine-functionalized polyether alkyl guanidine salt ionic liquid, a rhodium catalyst, a reaction substrate - olefins and a reaction product - aldehydes; liquid / liquid biphasic hydroformylation of olefins is performed at a certain reaction temperature and syngas pressure; the phosphine-functionalized polyether alkyl guanidine salt ionic liquid acts both as a phosphine ligand and as a rhodium catalyst carrier; there is no need to add any other ionic liquid to the system; separation and recycling of the rhodium catalyst are realized by liquid / liquid biphasic separation after the reaction; the rhodium catalyst is capable of being recycled for multiple times with no obvious decrease in catalytic activity or selectivity; the TOF value of the system reaches 240-2700h-1; and the highest catalytic cycle cumulative TON value reaches 47138.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

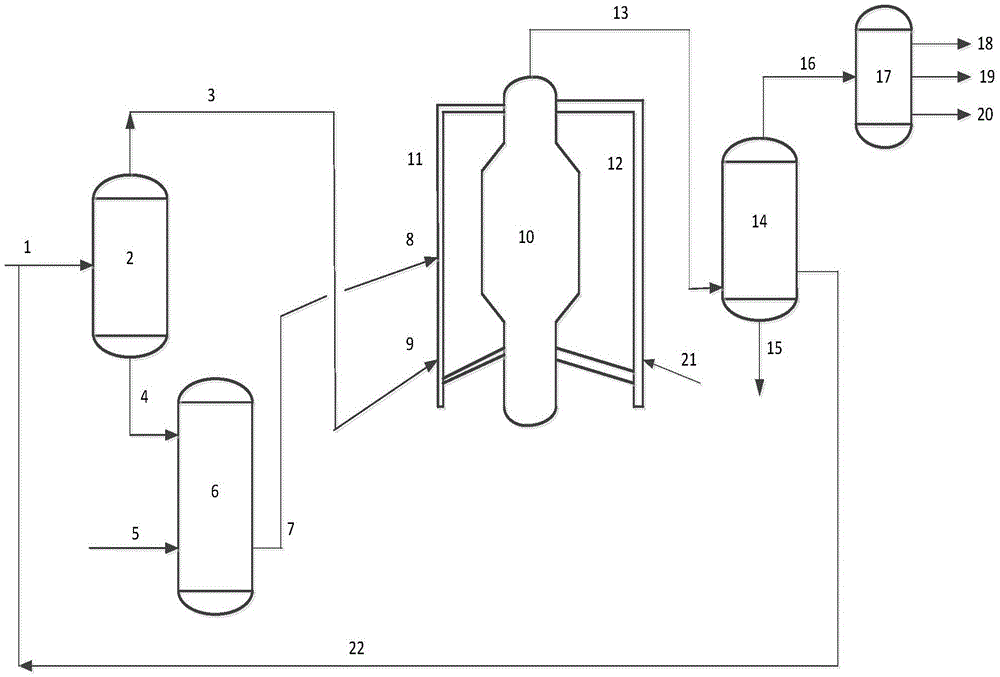

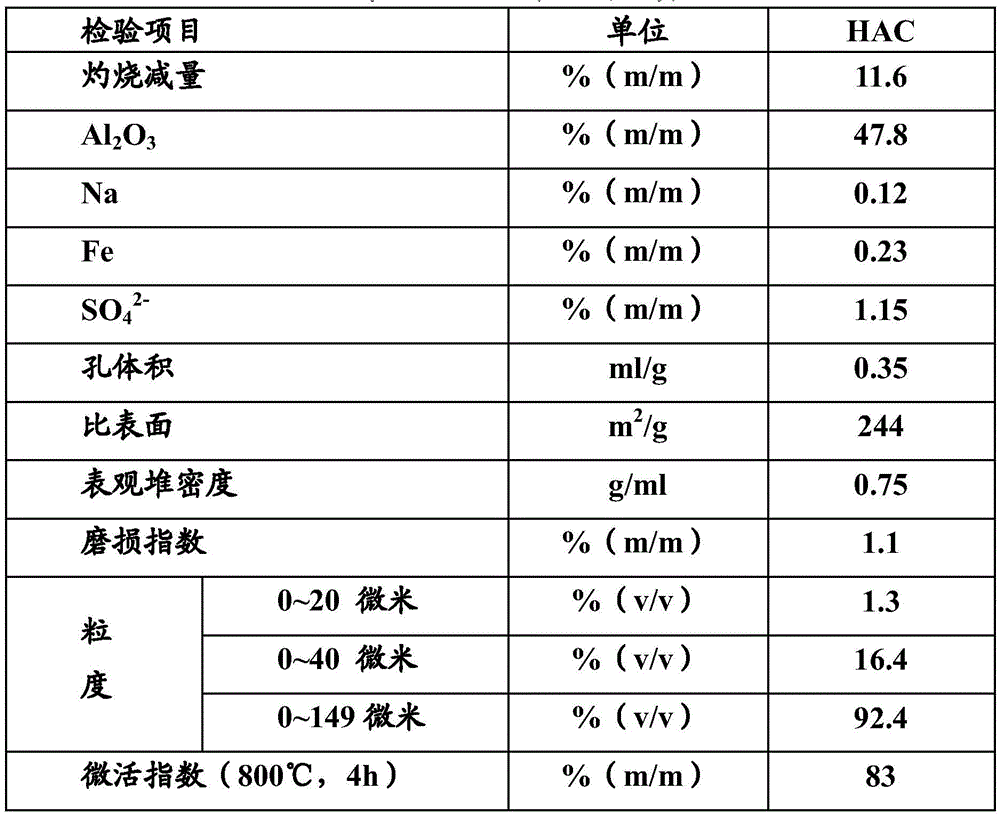

Catalytic conversion method utilizing petroleum hydrocarbon to produce high-octane gasoline

ActiveCN104560166AReduce hydrogen consumptionImprove operating conditionsTreatment with hydrotreatment processesGasolineCatalytic cycle

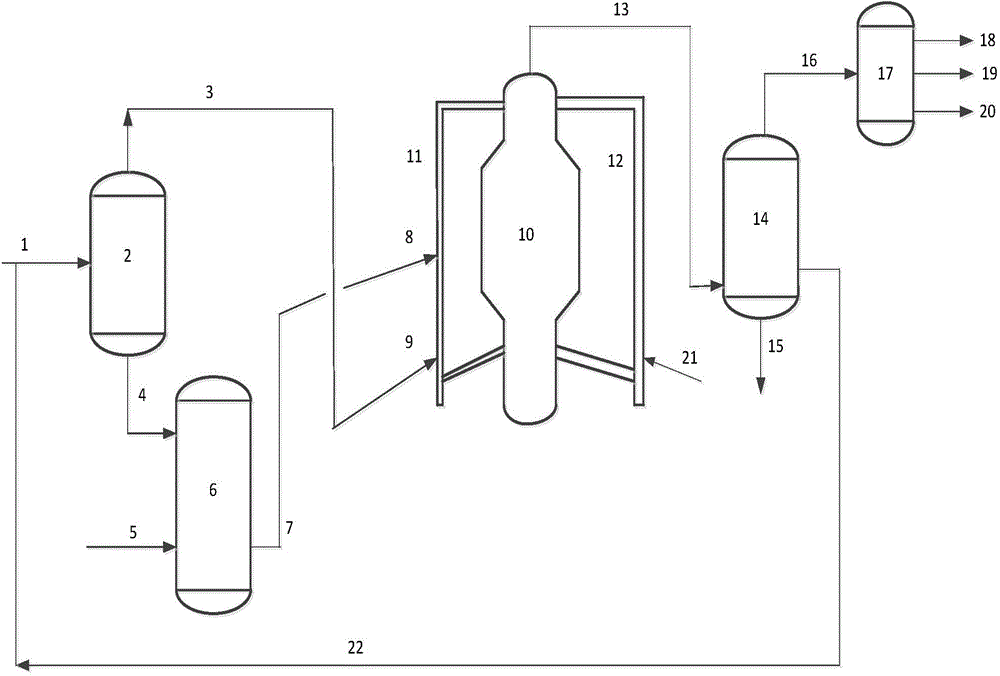

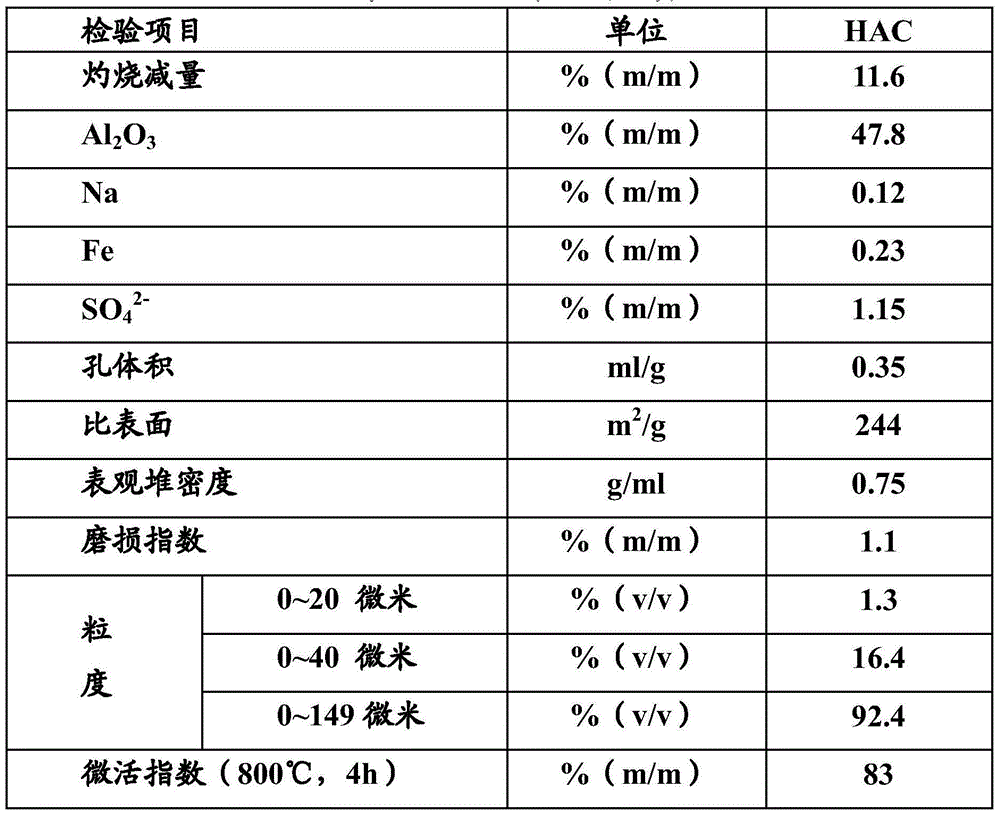

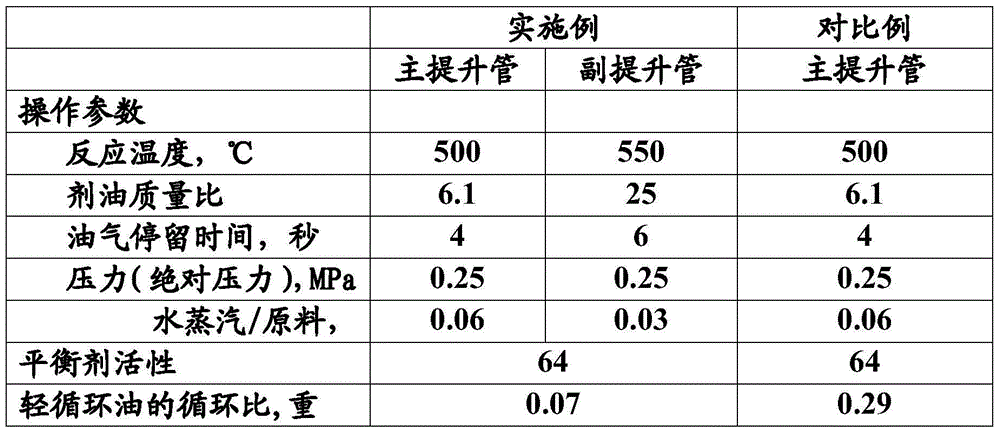

A catalytic conversion method utilizing petroleum hydrocarbon to produce high-octane gasoline comprises the following steps: light catalytic cycle oil is cut to obtain light fractions and heavy fractions, the heavy fractions are subjected to hydrotreatment to obtain hydrogenized heavy fractions, the light fractions and the hydrogenized heavy fractions separately enter an auxiliary riser reactor of a catalytic cracking unit, heavy petroleum hydrocarbons enter a main riser reactor of the catalytic cracking unit, cracking reaction is realized in the presence of a catalytic cracking catalyst, and the resultant is separated to obtain products including gasolene and light cycle oil. According to the invention, the light fractions of light cycle oil and the hydrogenized heavy fractions enter the auxiliary riser reactor layer by layer, so that severe conditions required for catalytic cracking reaction of different fractions of light cycle oil can be optimized and satisfied to the utmost extent, and accordingly, high-octane catalytic gasoline can be produced to the maximum extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalytic conversion method for producing high-octane gasoline from petroleum hydrocarbons

ActiveCN104560166BReduce hydrogen consumptionImprove operating conditionsTreatment with hydrotreatment processesGasolineCatalytic cycle

A catalytic conversion method utilizing petroleum hydrocarbon to produce high-octane gasoline comprises the following steps: light catalytic cycle oil is cut to obtain light fractions and heavy fractions, the heavy fractions are subjected to hydrotreatment to obtain hydrogenized heavy fractions, the light fractions and the hydrogenized heavy fractions separately enter an auxiliary riser reactor of a catalytic cracking unit, heavy petroleum hydrocarbons enter a main riser reactor of the catalytic cracking unit, cracking reaction is realized in the presence of a catalytic cracking catalyst, and the resultant is separated to obtain products including gasolene and light cycle oil. According to the invention, the light fractions of light cycle oil and the hydrogenized heavy fractions enter the auxiliary riser reactor layer by layer, so that severe conditions required for catalytic cracking reaction of different fractions of light cycle oil can be optimized and satisfied to the utmost extent, and accordingly, high-octane catalytic gasoline can be produced to the maximum extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

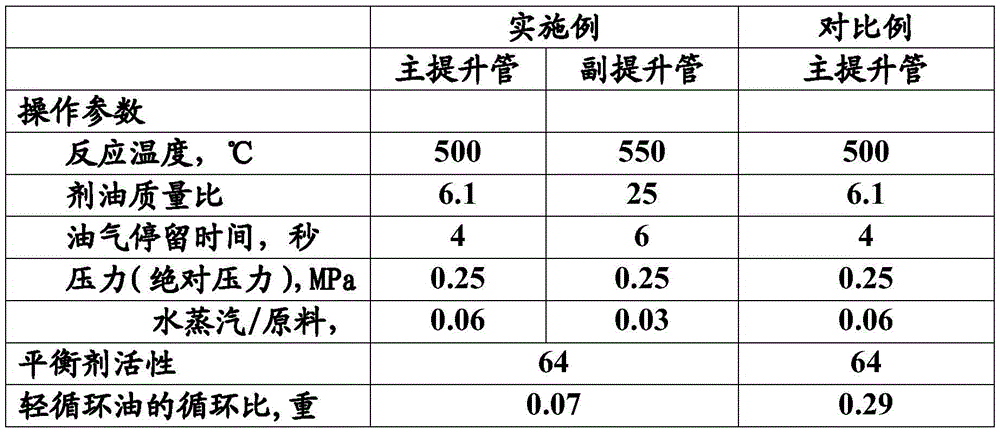

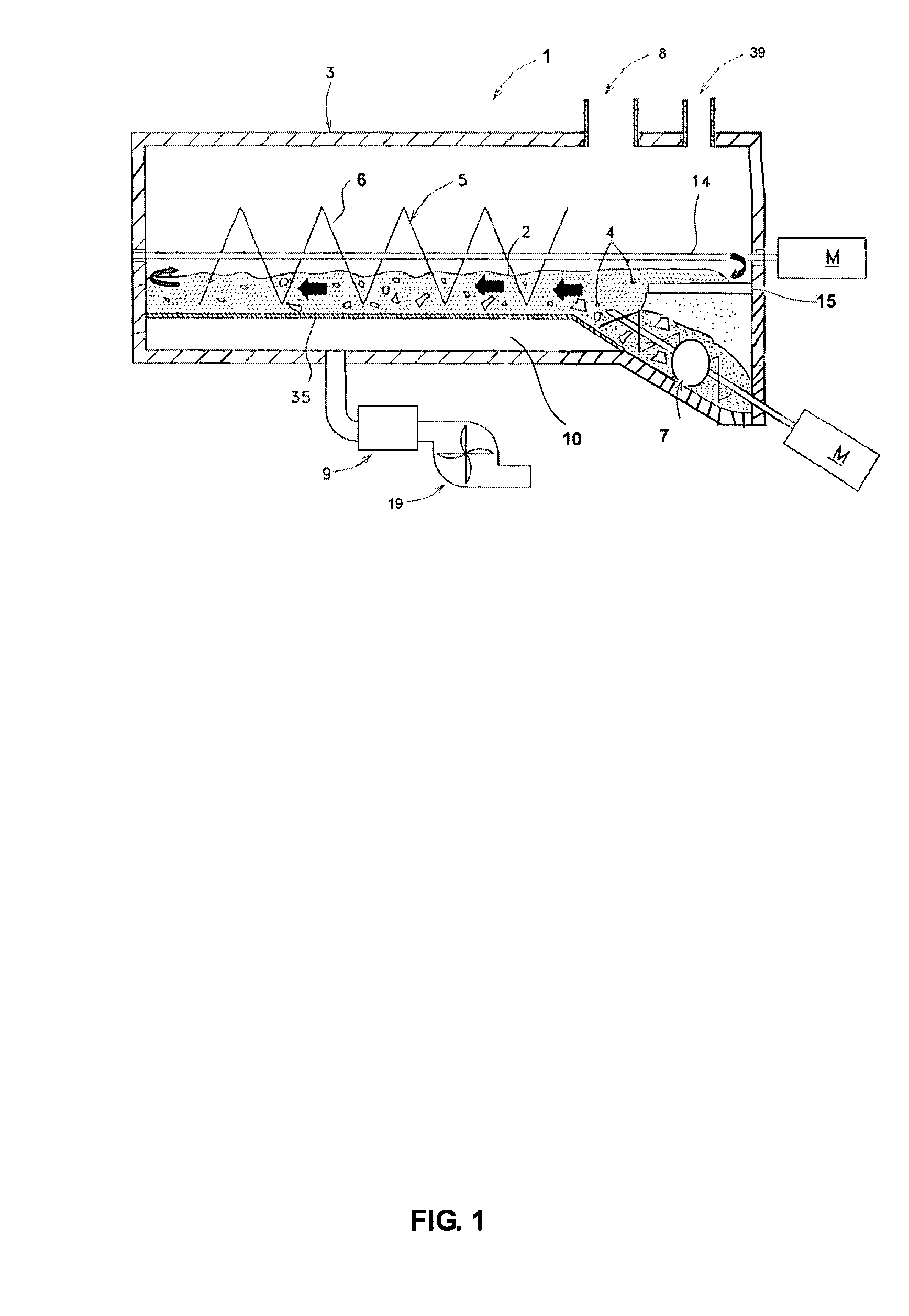

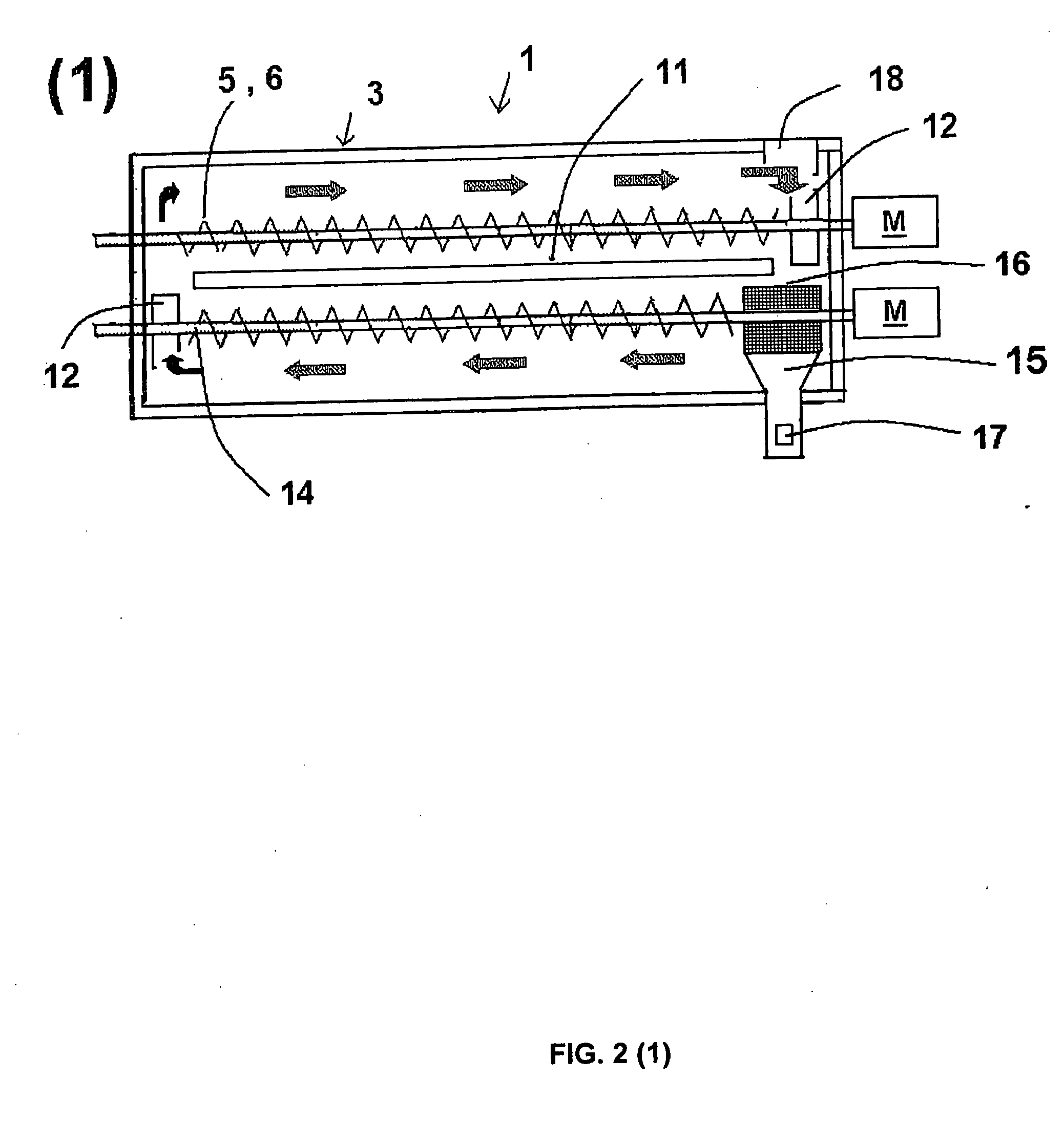

Apparatus of Catalyst-Circulation Type For Decomposing Waste Plastics and Organics, and System Thereof

ActiveUS20070249887A1Easy to useSuppress supplyGaseous fuelsPlastic recyclingPtru catalystProcess engineering

To provide a decomposition apparatus and a decomposition system which can prolong the catalyst life and which can efficiently decompose a large amount of waste plastics and organics. The inventors of the present invention established a decomposition apparatus and a decomposition system which allow the catalyst to circulate therein, thus perfected the present invention.

Owner:RAPAS INT LTD

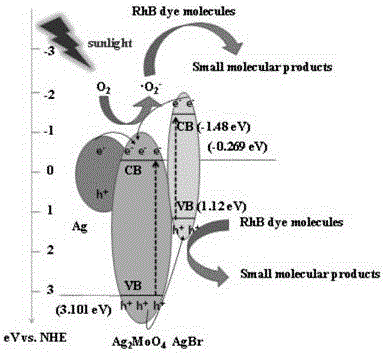

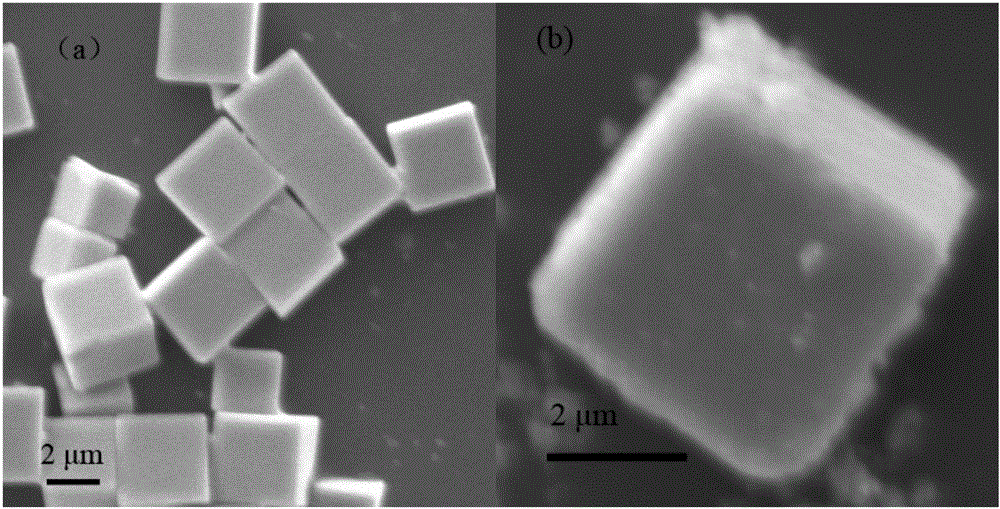

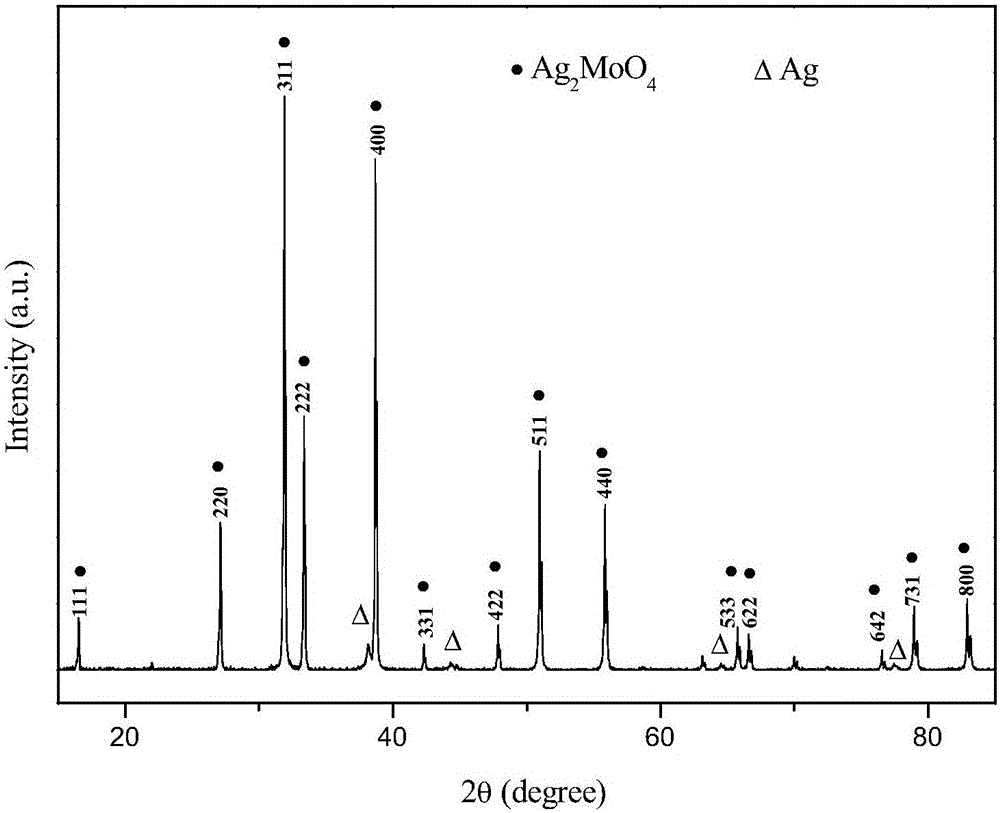

Block-shaped Ag2MoO4@Ag@AgBr ternary complex and preparation method and application thereof

ActiveCN106268881ALow costEasy to preparePhysical/chemical process catalystsWater/sewage treatment by irradiationIon exchangeSolvent

The invention relates to a block-shaped Ag2MoO4@Ag@AgBr ternary complex, a preparation method thereof and application of the block-shaped Ag2MoO4@Ag@AgBr ternary complex to photocatalysis. With sodium molybdate and silver nitrate being raw materials and ethylene glycol being a reaction medium, the pH value of a system is controlled to be 6-8 on the condition that PVP is added, a reaction is carried out, and then block-shaped Ag2MoO4@Ag is obtained; next, based on the principle of ion exchange, with CTAB being a bromine source and ethyl alcohol being a solvent, a reaction with the Ag2MoO4@Ag is carried out, and then the final product, namely the block-shaped Ag2MoO4@Ag@AgBr ternary complex, is obtained. The final product has a single appearance and is even in size; when the final product is used as a catalyst to degrade RhB(15mg / L) dye solution, the degrading rate reaches 91% within 35 minutes under visible light, and complete degrading is achieved within 20 minutes under sunlight. in addition, under the visible light, a catalytic cycle reaction is carried out four times on the ternary complex, and the catalysis effect is not influenced greatly, which shows that the block-shaped Ag2MoO4@Ag@AgBr ternary complex has high catalytic activity and stability.

Owner:XUCHANG UNIV

System and method for continuously producing polyoxymethylene dialkyl ethers

InactiveUS20140114093A1Efficient separationWork lessOrganic compound preparationChemical/physical/physico-chemical processesEtherCatalytic cycle

A reaction system and method for producing polyoxymethylene dialkyl ethers (RO(CH2O)nR, n=1-8) by continuous acetalation of formaldehyde and aliphatic alcohol in the presence of an acid ionic liquid catalyst. The reaction system includes an acetalation reaction unit, a product separation unit, and a catalyst regeneration unit. The recyclable material and catalyst are separated by combining extraction and rectification, and a recovery rate of more than 99% for the catalyst is achieved. Water, as the byproduct, is separated from the reaction system by destroying the azeotrope of water, alcohol, aldehyde, and RO(CH2O)nR, so that the product separation and catalyst regeneration are facilitated and the catalytic cycle is achieved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

MoSxOy/CARBON NANOCOMPOSITE MATERIAL, PREPARATION METHOD THEREFOR AND USE THEREOF

ActiveUS20190237751A1Improve catalytic performanceImprove catalytic stabilityPositive electrodesNano-carbonHydrogenCarbon nanocomposite

Owner:PEKING UNIV

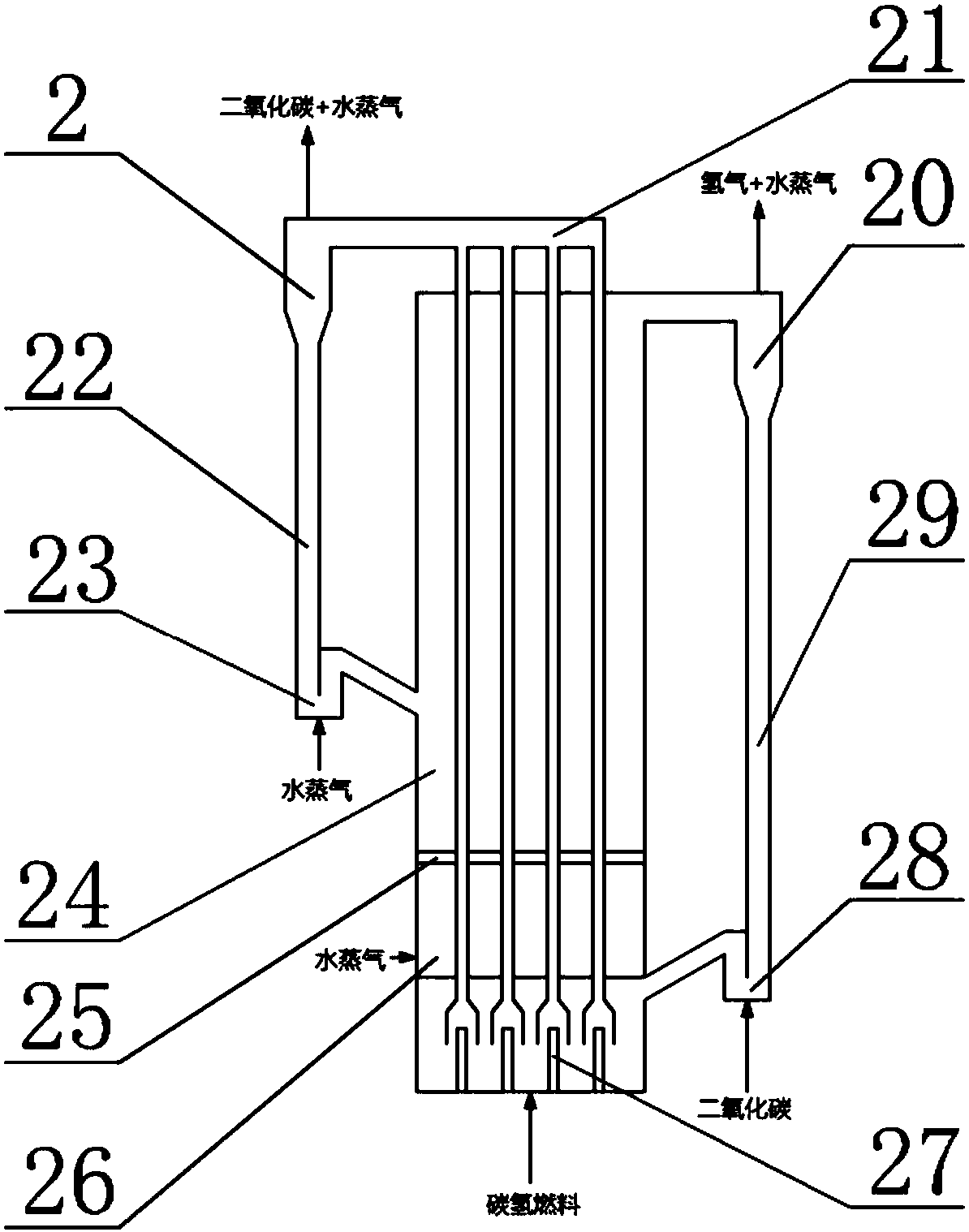

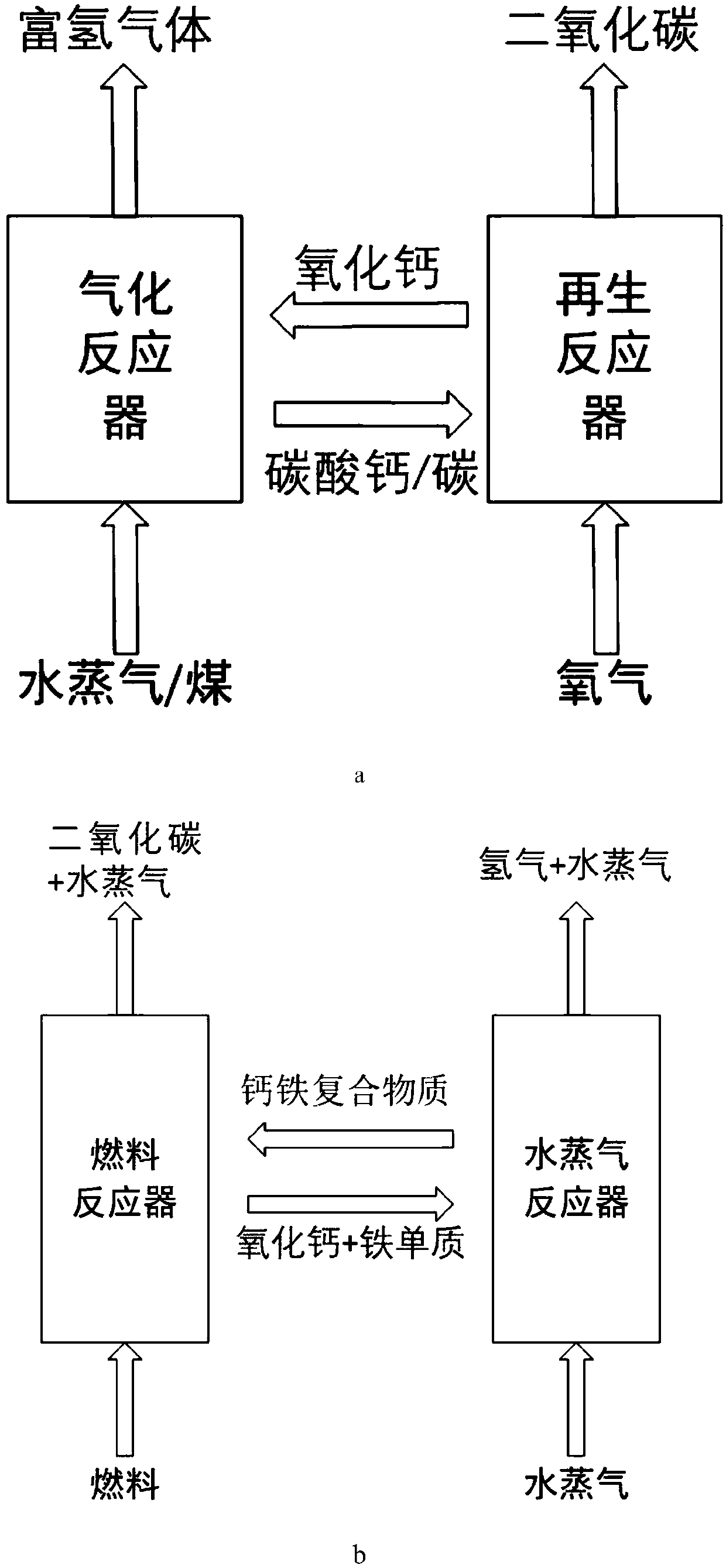

Method and device for synergic catalytic cycle hydrogen production and carbon dioxide trapping on basis of CaFe2O4/Ca2Fe2O5

The invention discloses a method and a device of synergic catalytic cycle hydrogen production and carbon dioxide trapping on the basis of CaFe2O4 / Ca2Fe2O5. The method prepares high-purity hydrogen andtraps carbon dioxide by a one-step reaction of CaFe2O4 and Ca2Fe2O5 composite calcium iron powder, and the reaction occurs circularly. The device is a folded circulating fluid bed or a nested fluid bed. The method and the device have the following advantages that: the method of the synergic catalytic cycle hydrogen production and the carbon dioxide trapping on the basis of CaFe2O4 / Ca2Fe2O5 produces the hydrogen by the one-step reaction; carbon dioxide and the high-purity hydrogen can be trapped at the same time; a CaFe2O4 and Ca2Fe2O5 oxygen carrier adopted by the method has higher strengththan an iron-based oxygen carrier and a calcium-based oxygen carrier used independently; the utilization in the fluid bed is facilitated; the reaction time is shorter; the deactivation possibility islow; the prepared hydrogen is high in purity; the folded circulating fluid bed and the nested circulating fluid bed are simple in structure and can effectively trap carbon dioxide and the high-purityhydrogen.

Owner:SOUTHEAST UNIV

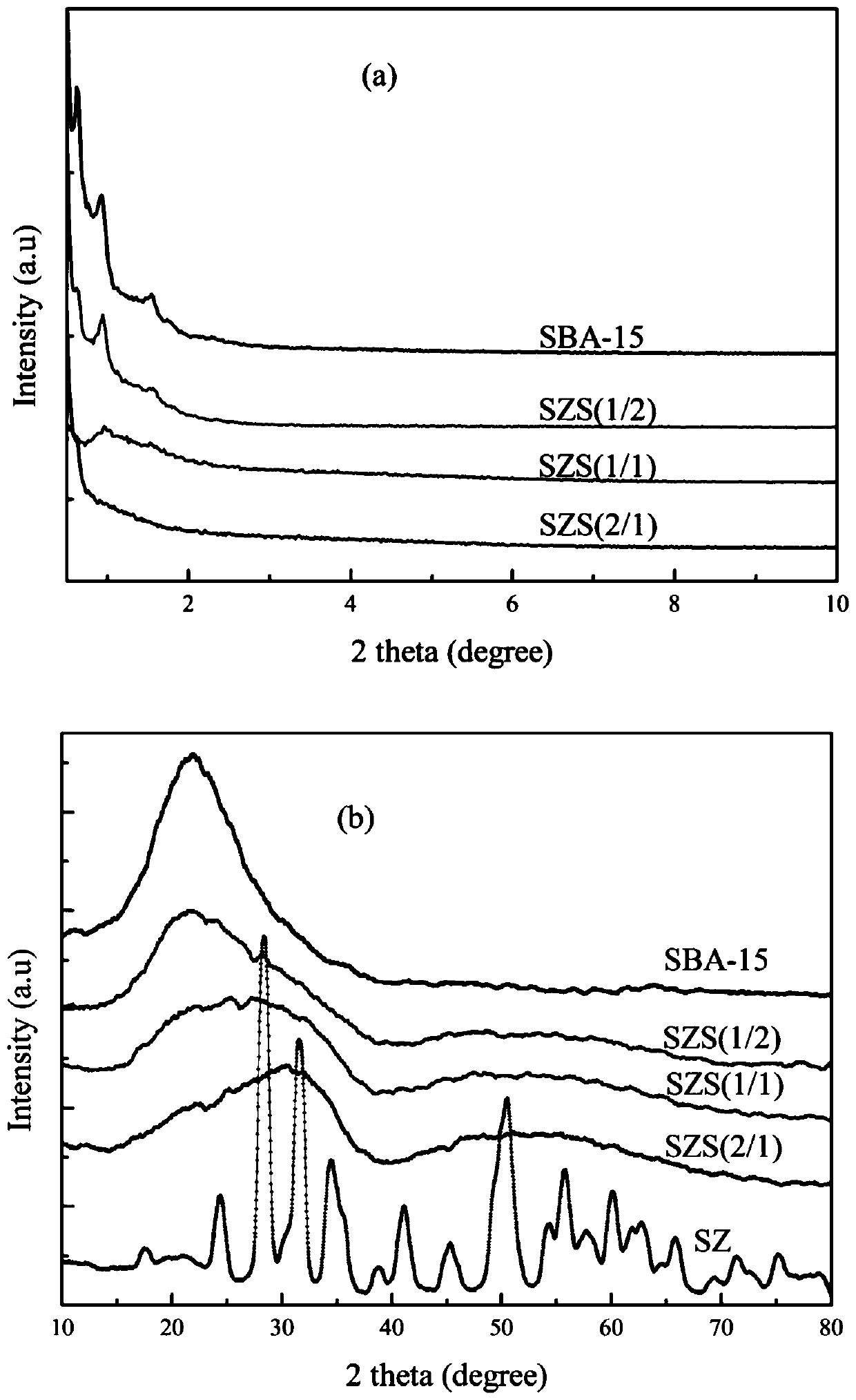

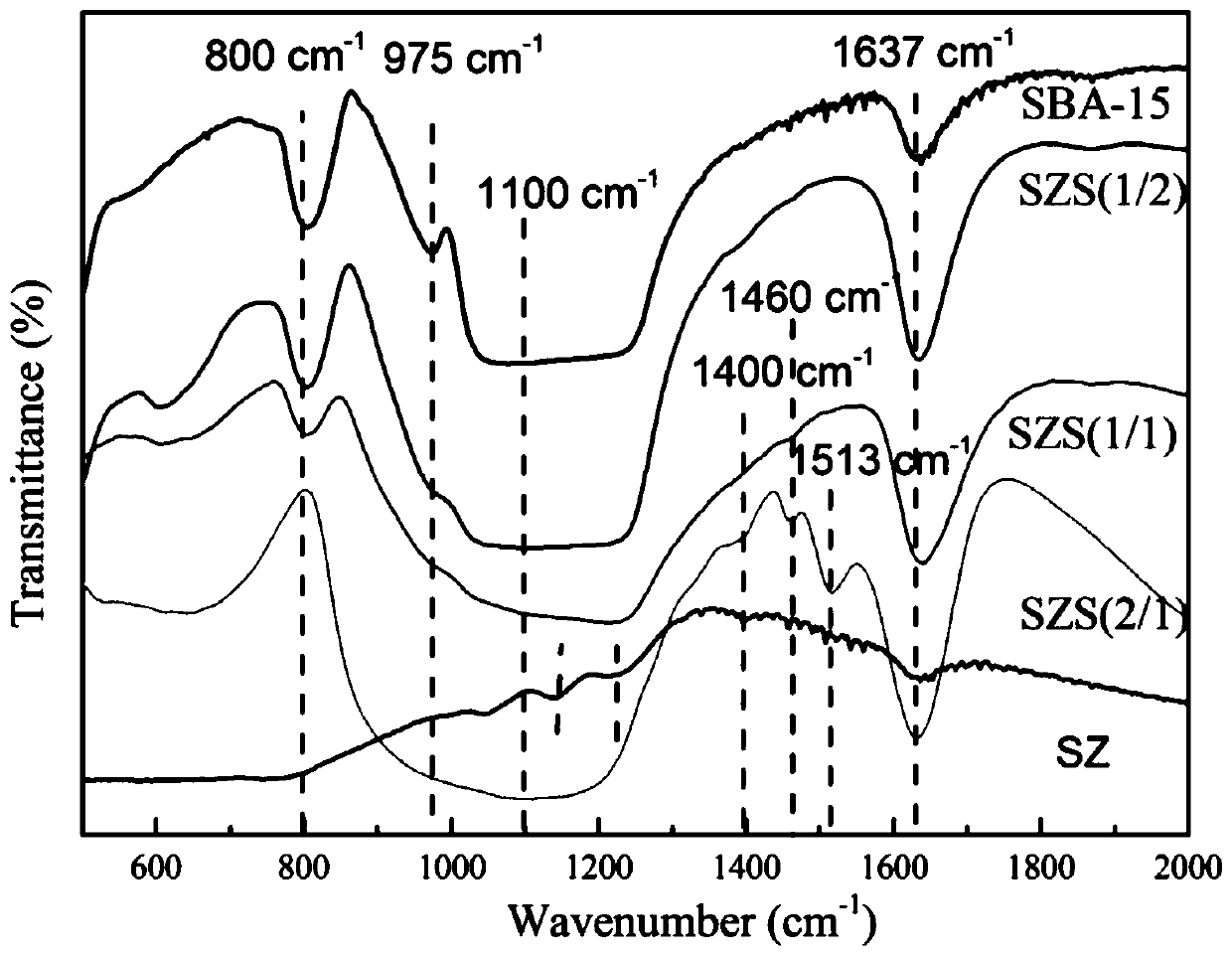

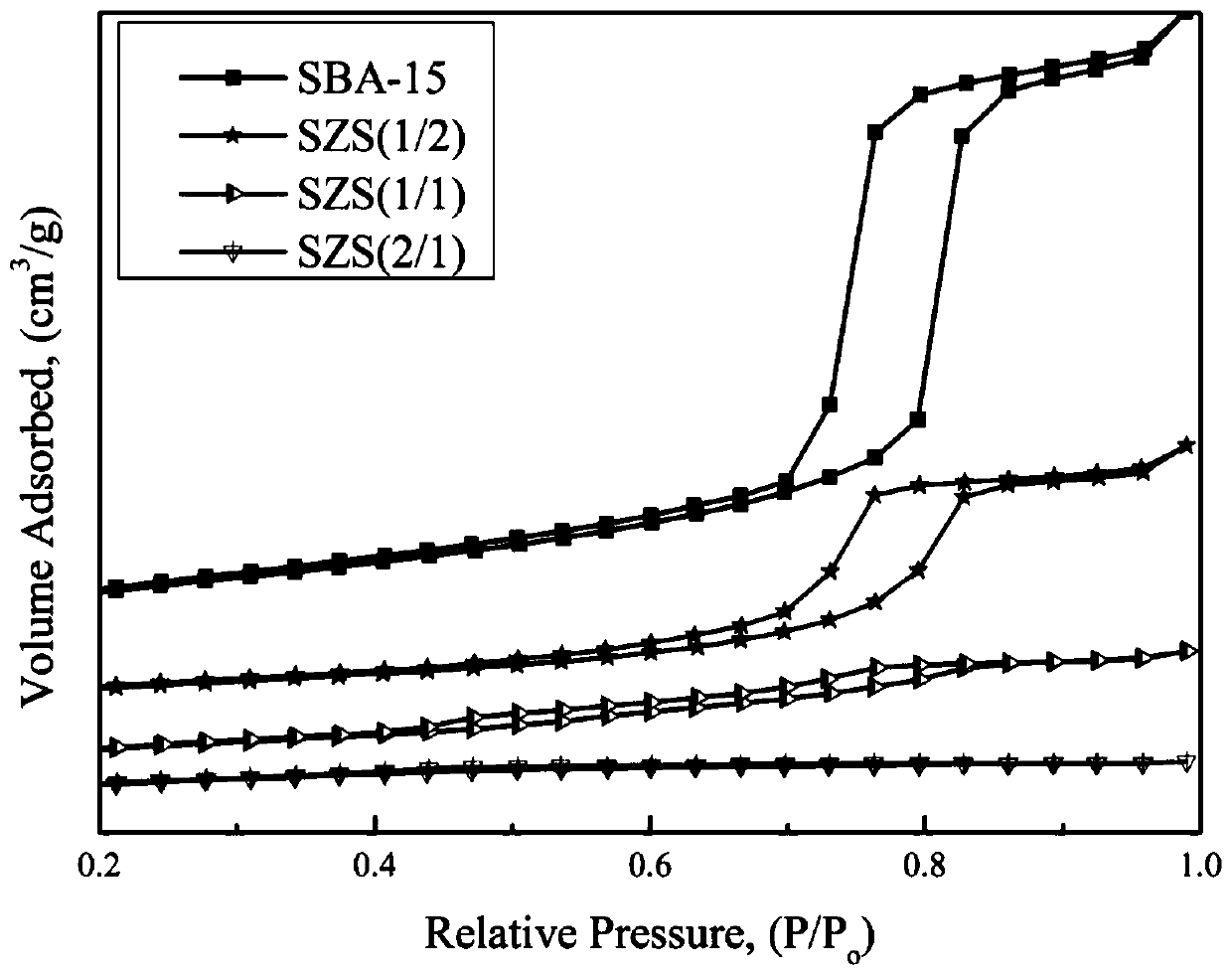

Preparation method of SBA-15 molecular sieve-based supported catalyst for desorption of CO2-rich amine solution

ActiveCN110681410AEasy to operateLow priceMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

The invention discloses a preparation method of a SBA-15 molecular sieve-based supported catalyst for desorption of a CO2-rich amine solution. The supported catalyst is obtained by supporting a metaloxide (a transition metal oxide or an amphoteric oxide) acidified by sulfuric acid on SBA-15 molecular sieve by a hydrothermal synthesis method, and the main experimental procedure is as follows: putting molecular sieve SBA-15 and urea into a round bottom flask, adding an appropriate amount of deionized water, and performing ultrasonic treatment for 0.5 h to obtain a solution A; adding a soluble metal salt into the solution A, and performing reflux stirring for 6 h at 90 DEG C to obtain a gel-like solution B; filtering and washing the solution B, mixing obtained solids, and performing drying and calcination to obtain a composite catalyst MOX / SBA-15 (C); and acidifying the composite catalyst MOX / SBA-15, and performing filtering and drying and calcination to finally obtain the SBA-15 molecular sieve-based supported catalyst. Compared with the prior art, the catalyst has stable performance, wide sources of raw materials, and cheap prices; the catalyst is convenient for separation, and hasgood regeneration performance; the catalyst has better catalytic performance than single molecular sieve and an acidified metal oxide; and the catalyst has relatively good catalytic cycle stability,and has no effects on the absorption performance of an amine solution.

Owner:HUNAN UNIV

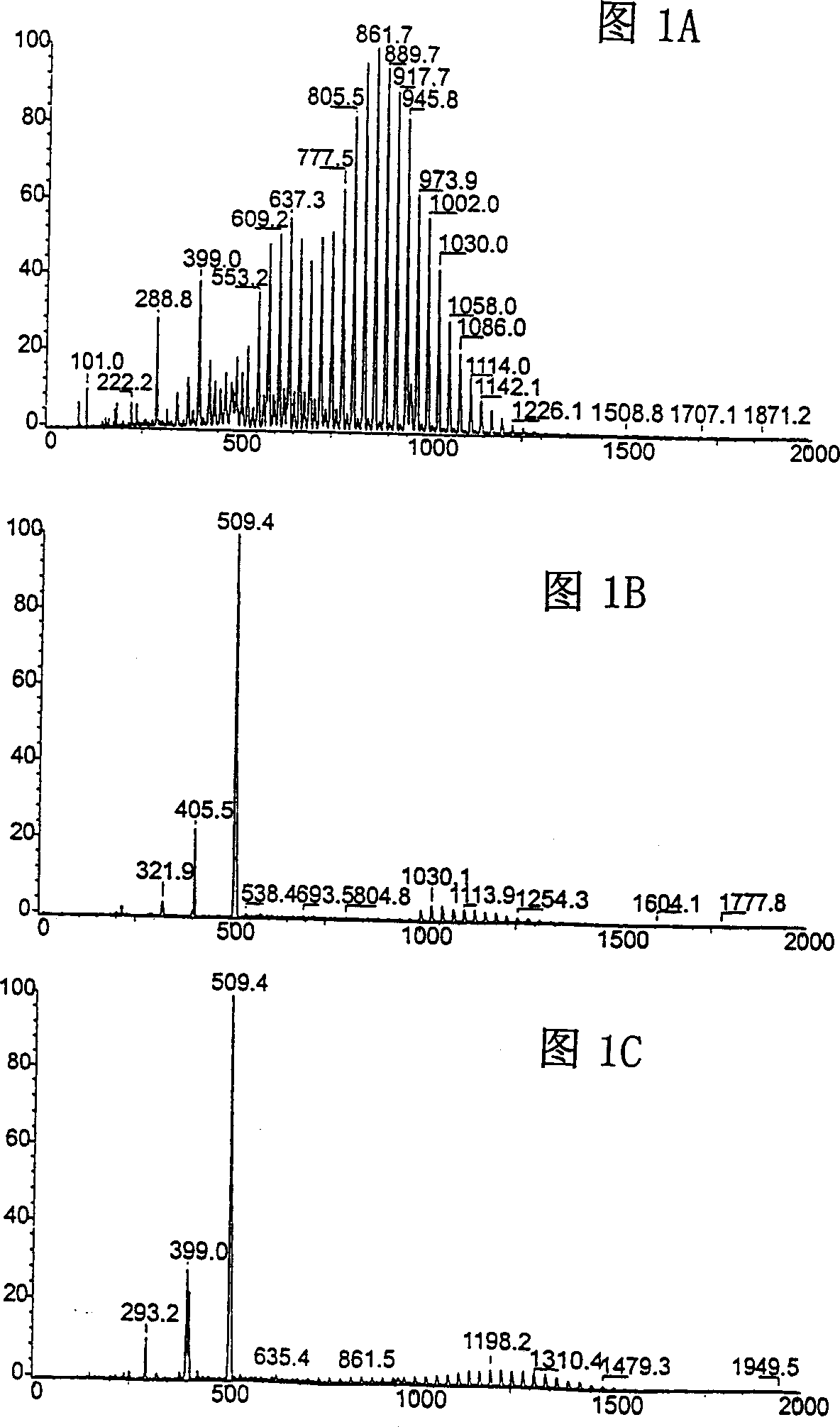

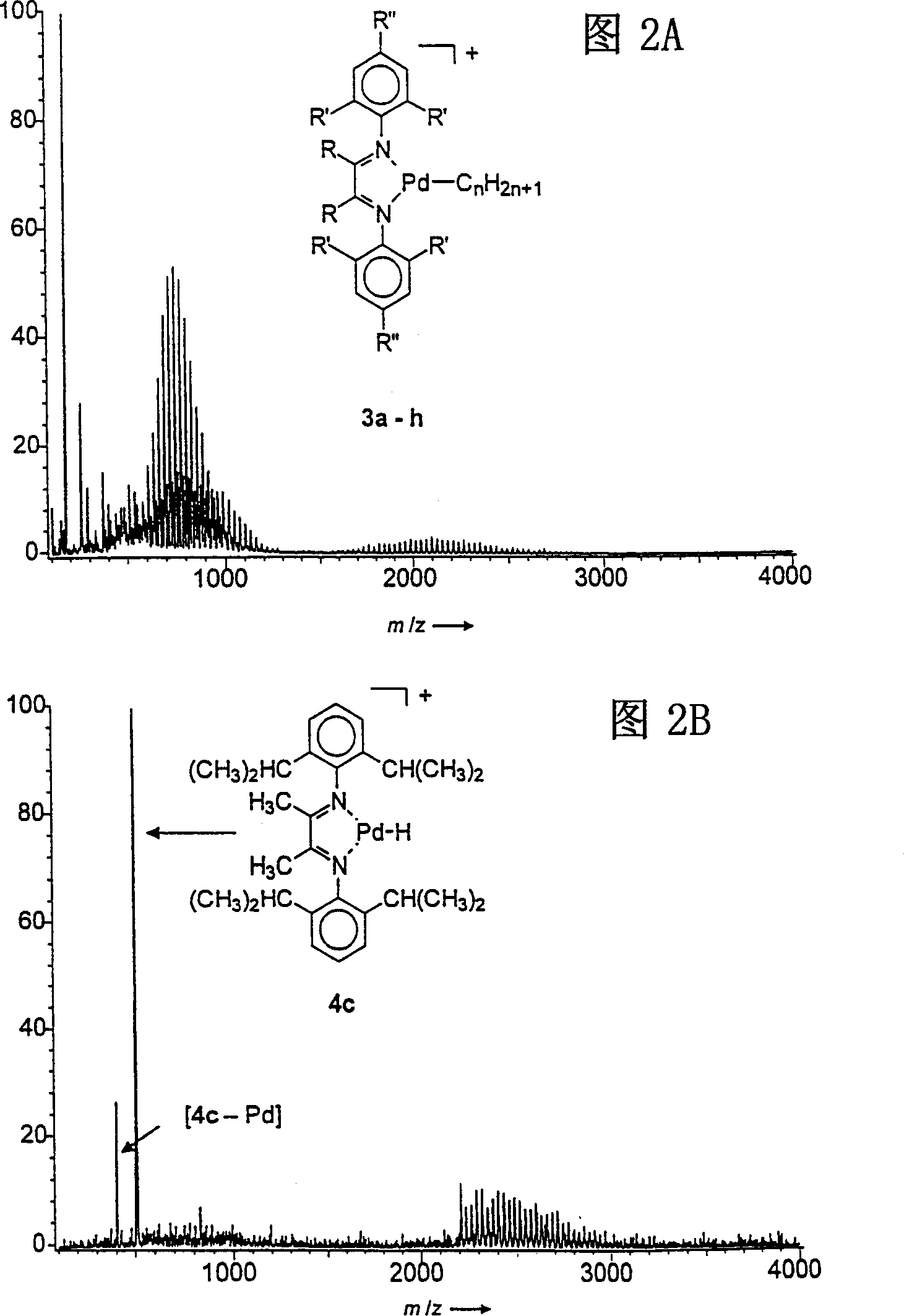

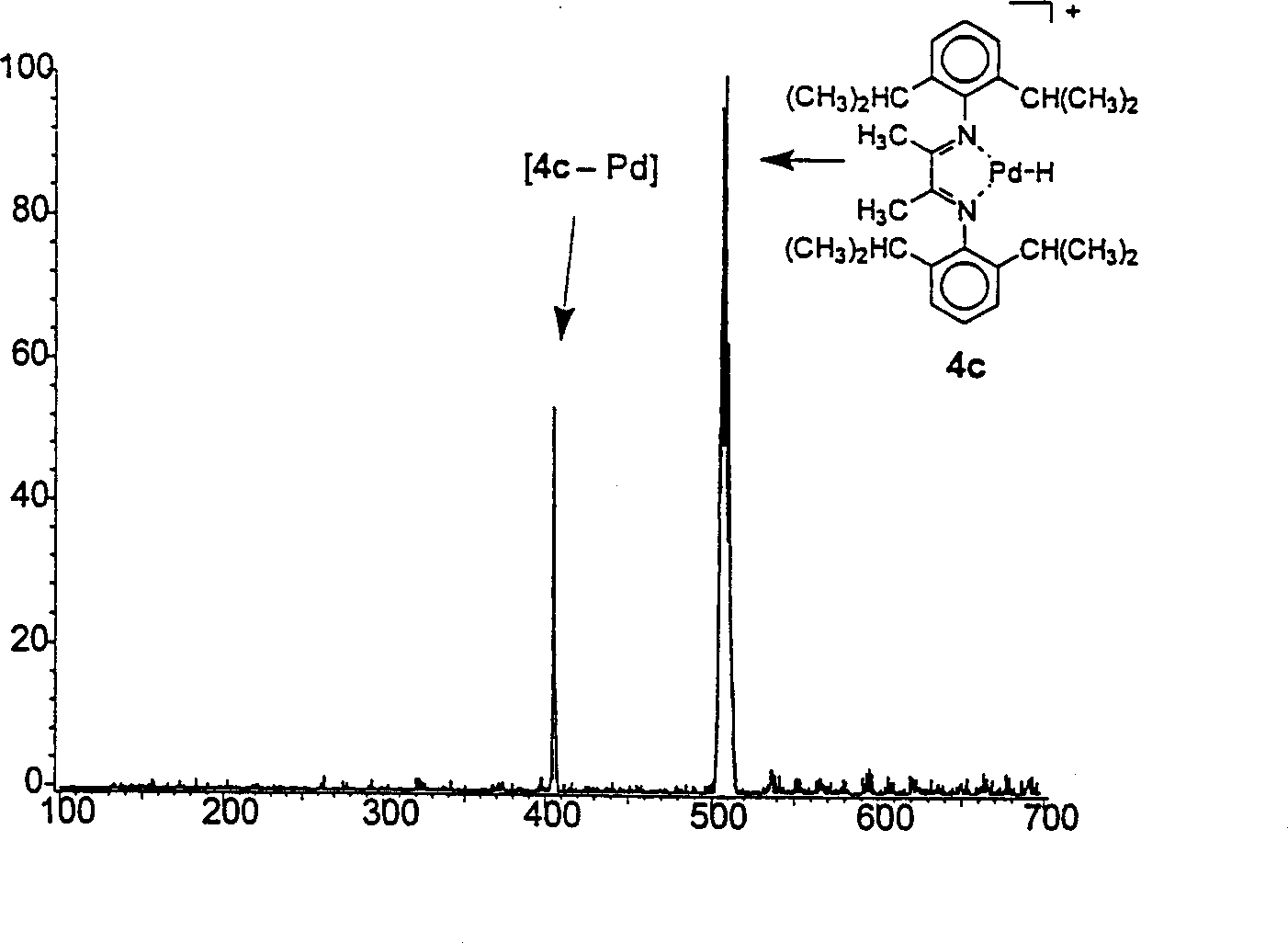

Mass spectrometric screening of catalysts

InactiveCN1340160AStability-of-path spectrometersChemical analysis using catalysisScreening methodCatalytic function

Screening methods to identify catalysts or to identify improved catalysts using mass spectrometric analysis of products of catalysis, particularly catalyst-bound intermediate products in the catalytic cycle. The methods are applicable, in particular, to screening of organometallic compounds for catalytic function. Moreover, the methods are applicable, in particular, to screening for catalysts for polymerization reactions. More specifically, the methods employ a two stage (or two step) mass spectrometric detection method in which ions formed in a first stage ionization and which are linked to catalyst performance are selected and the catalyst associated with the selected ion is identified in a second stage employing tandem mass spectrometry. In specific embodiments, the screening methods of this invention avoid explicit encoding because the identity of the catalyst is implicitly contained in the product molecular mass (typically an intermediate product), since the catalyst (or a portion thereof) remains attached to the product.

Owner:苏黎世公司

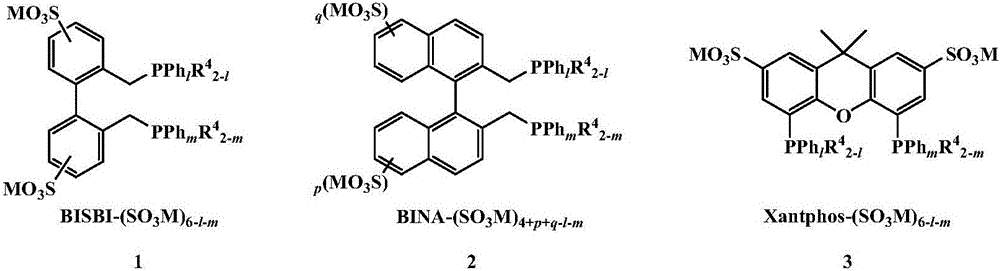

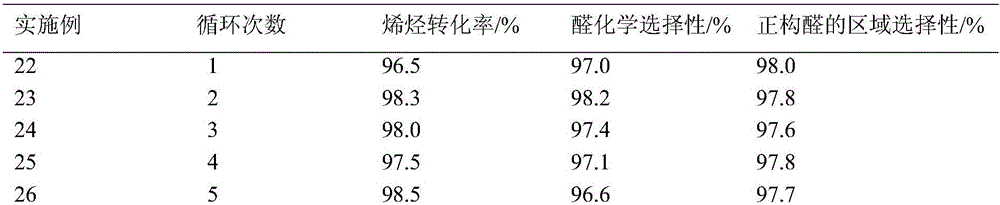

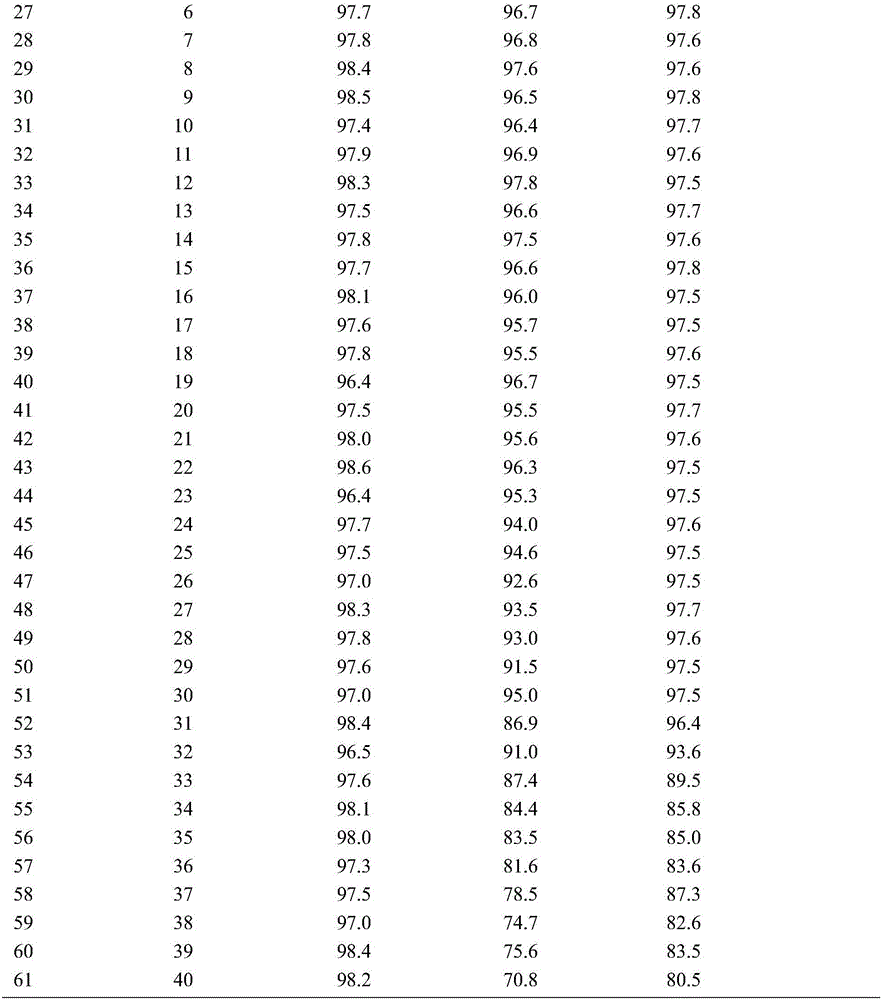

Method for high-selectivity preparation of normal aldehyde through olefin two-phase hydroformylation on basis of phosphine-functionalized polyether imidazolium salt ionic liquid

ActiveCN105753669AHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsReaction temperatureCatalytic cycle

The invention relates to a method for high-selectivity preparation of normal aldehyde through olefin two-phase hydroformylation on the basis of a phosphine-functionalized polyether imidazolium salt ionic liquid. According to the method, a two-phase catalytic system is adopted, the catalytic system comprises a phosphine-functionalized polyether imidazolium salt ionic liquid, a polyether imidazolium salt ionic liquid, a rhodium catalyst, a reaction substrate olefin and a reaction product aldehyde, a liquid / liquid two-phase hydroformylation reaction is performed at certain reaction temperature and under certain synthesis gas pressure, the rhodium catalyst is separated and cycled through simple two-phase separation after the reaction ends, the rhodium catalyst can be recycled multiple times, and the catalytic activity and the selectivity are not remarkably reduced. The TOF value of the system reaches 400-3,300 h<-1> and the catalytic cycle accumulated TON value reaches 33,975.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

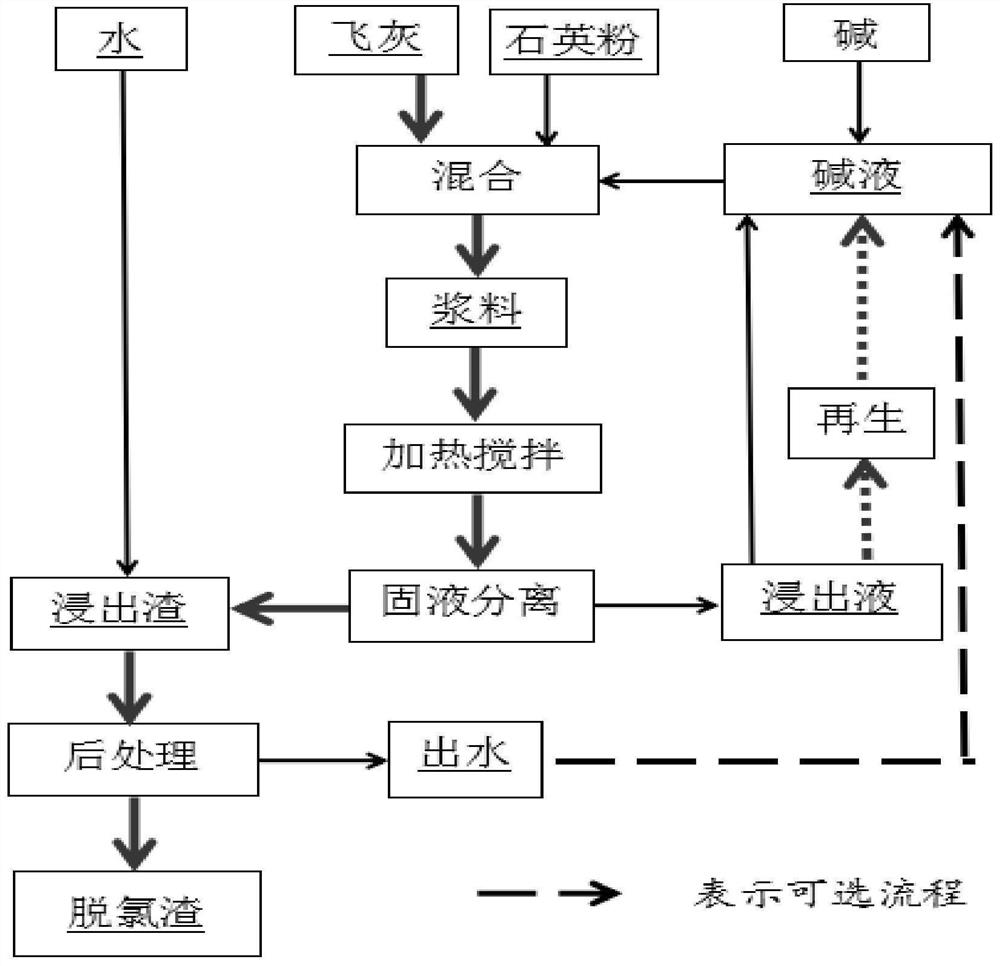

Pretreatment method for waste incineration fly ash

PendingCN112934912AEasy to followResource optimizationSolid waste disposalTransportation and packagingPregnant leach solutionPretreatment method

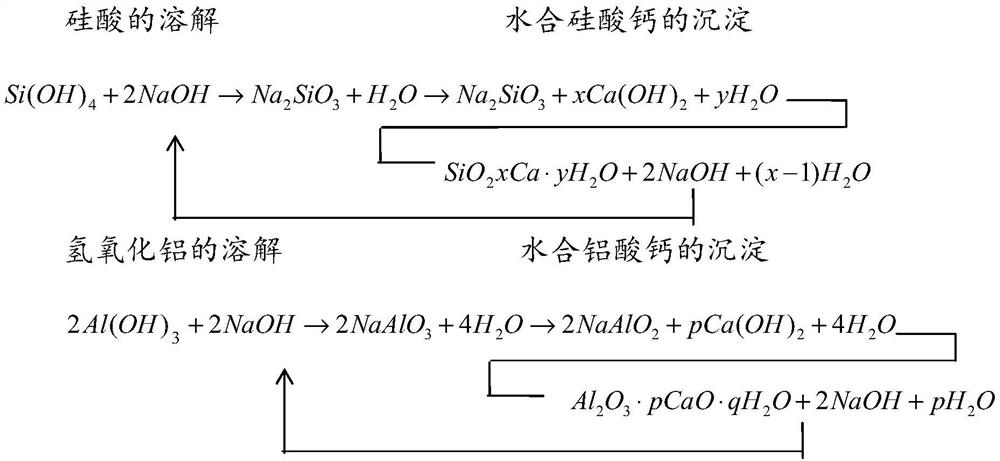

The invention discloses a pretreatment method for waste incineration fly ash. The pretreatment method comprises the following steps of: 1, mixing: mixing the waste incineration fly ash with quartz powder and an alkali liquor into slurry; 2, heating and stirring: carrying out catalytic circular reaction under heating and stirring conditions; 3, solid-liquid separation: carrying out solid-liquid separation on the reacted slurry to obtain a leaching solution and leaching residues, and returning the leaching solution to the alkali liquor for recycling; and 4, post-treatment: carrying out cleaning, drying, ball milling, forming and the like on the leaching residues to obtain dechlorinated residues. The method has the advantages of simple raw materials, short process, easiness in industrial application and significance of resource saving and environment friendliness.

Owner:湖南青涟环保科技有限公司

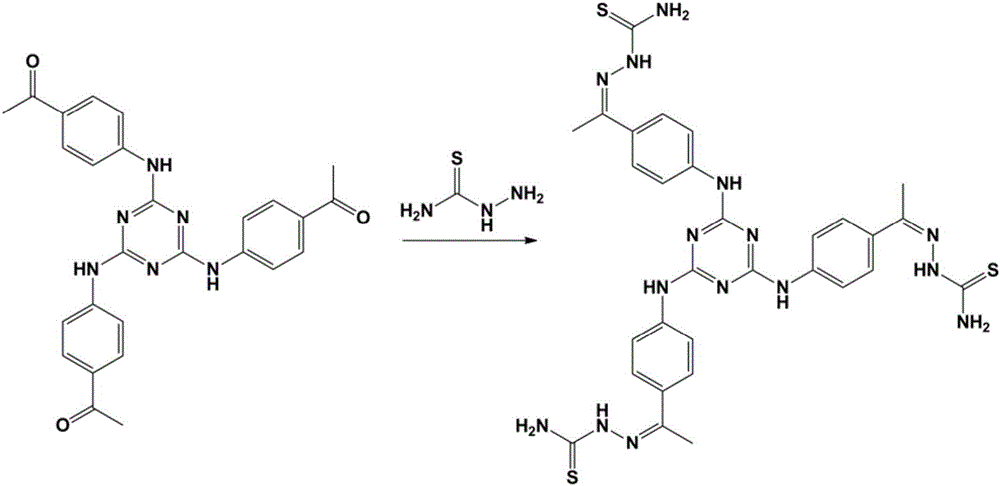

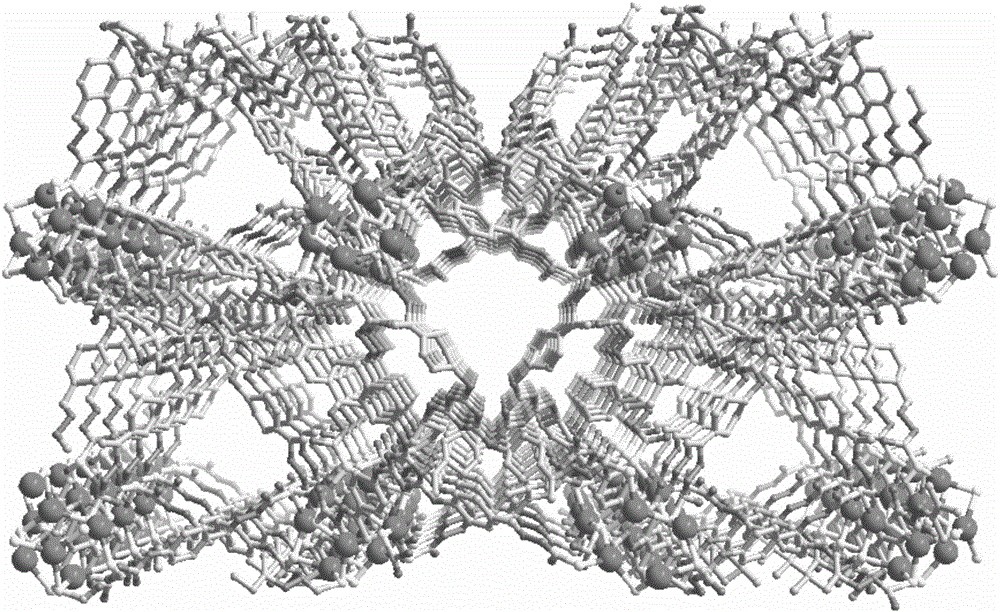

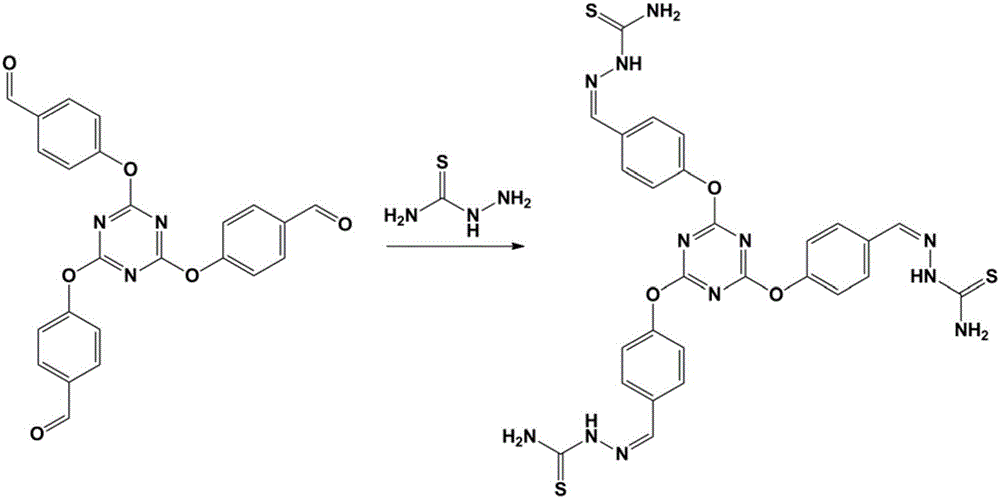

Preparation method of MOFs with pi-activation catalytic action

ActiveCN106279053AEasy to synthesizeEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsSilver organic compoundsMetal clustersCatalytic cycle

The invention relates to the technical field of heterogeneous catalytic materials, in particular to a preparation method of MOFs with a pi-activation catalytic action. The preparation method is characterized in that L1 and L2 are used as ligands; the ligands and metallic silver salt Tm are prepared by a stratified dispersal method to obtain a catalyst Ag8-MOF or Ag4-MOF with a plane coordination configuration, metal cluster nodes and the pi-activation catalytic action. A synthetic route of the catalyst is as follows: Tm+L1-Ag8-MOF or Tm+L2-Ag4-MOF; the ligand L1 is selected from TzNPAMeTs, and the L2 is selected from TzOPATs; the metallic silver salt Tm is selected from AgCF3COO or AgBF4. According to the preparation method disclosed by the invention, the synthesis of the catalyst is simple and easy to operate; catalytic reaction raw materials are low in price and high in yield, and are easy for large-area popularization and application. By regulating and controlling immobilization and coordination configuration of precious metal through thioamide ligands, the activity of the catalyst and catalytic conversion number are greatly improved; the easiness for recycling is realized, and the utilization rate of the precious metal is greatly improved, thereby reducing the integration cost of the whole catalytic cycle; the preparation method is suitable for meeting industrial large-scale production.

Owner:DALIAN UNIV OF TECH

Nitrogen-doped iron nanotube and preparation method and application thereof

InactiveCN112007677AImprove stabilityImprove cycle stabilityWater contaminantsCatalyst activation/preparationNitrogen gasCatalytic cycle

The invention belongs to the field of environmental functional materials, and provides a preparation method and electrocatalytic application of a nitrogen-doped iron (FeN) nanotube. In the nitrogen-doped iron nanotube, FeN active sites are dispersedly packaged in a tubular NC shell layer. The preparation method comprises the following steps: enabling Fe to grow nitrogen-doped iron nanotubes through autocatalysis, and packaging FeN active sites in a tubular NC shell layer in a dispersed manner. The FeN nanotube has a high specific surface area, a large pore volume, wide pore size distribution,high-density and high-stability FeN active sites and a one-dimensional electron transfer channel; a working electrode prepared from the FeN nanotube shows high denitrification performance in the fieldof environment, the nitrate removal rate can reach 88-96%, and the nitrogen selectivity is 85-91%; and relatively high denitrification activity and nitrogen selectivity are still kept in a wide pH value range and after multiple electrocatalytic cycles.

Owner:TONGJI UNIV

Combined process for processing heavy oil

ActiveCN100366709CEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Method for highly selective preparation of linear aldehyde by olefin two-phase hydroformylation based on phosphine functionalized polyether alkyl guanidine salt ionic liquid

ActiveCN105837419AHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsReaction temperatureCatalytic cycle

The invention relates to a method for highly selective preparation of linear aldehyde by olefin two-phase hydroformylation based on a phosphine functionalized polyether alkyl guanidine salt ionic liquid. The method adopts a two-phase catalytic system, the catalytic system is composed of the phosphine functionalized polyether alkyl guanidine salt ionic liquid, a polyether alkyl guanidine salt ionic liquid, a rhodium catalyst, a reaction substrate olefin and a reaction product aldehyde, liquid / liquid two-phase hydroformylation reaction is carried out under certain reaction temperature and synthesis gas pressure, simple two-phase separation is carried out at the end of the reaction to realize separation and circulation of the rhodium catalyst, the rhodium catalyst can be used repeatedly, and the catalytic activity and selectivity do not decrease significantly. The TOF value of the system reaches 300-3400h<-1>, and the catalytic cycle cumulative TON value reaches 30832.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

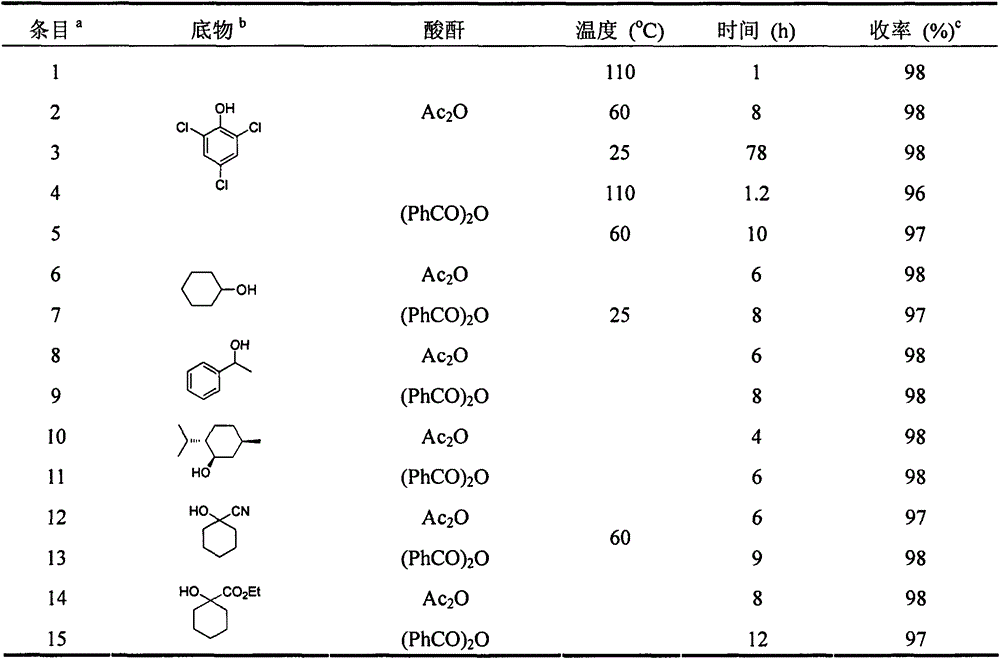

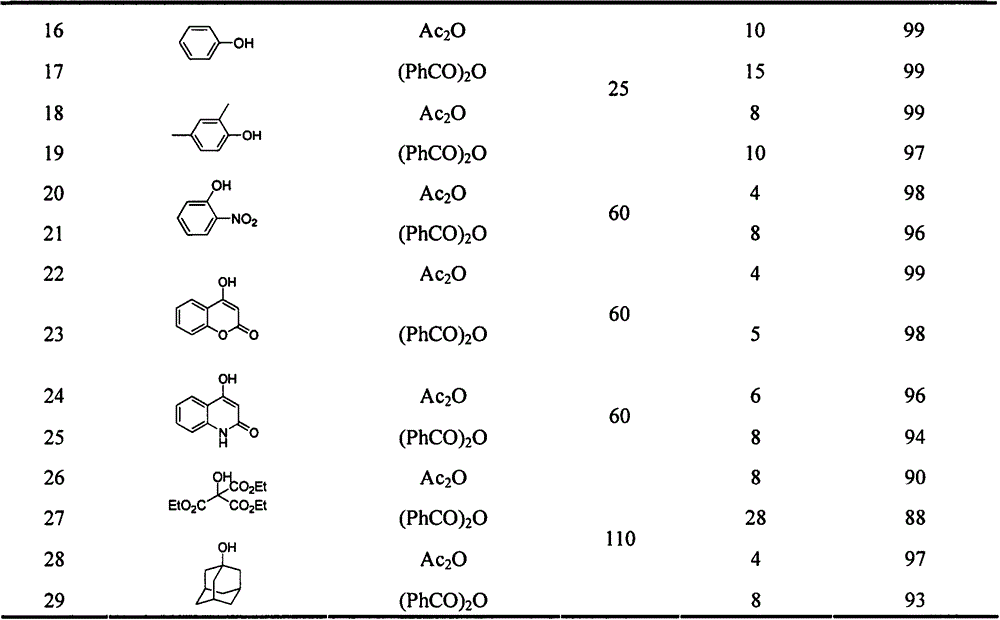

Preparation and application of DMAP hydrochloride as catalyst of recoverable acylation reaction

ActiveCN104418771APreparation from carboxylic acid halidesCarbamic acid derivatives preparationRecyclable catalystPtru catalyst

The present invention relates to an application of dimethylaminopyridine (DMAP) hydrochloride serving as recyclable catalyst in an acylation reaction (as represented by equation I). The application comprises: dissolving DMAP into a nonpolar solvent, aerating with dry hydrogen chloride gas, and filtrating the solution to obtain DMAP hydrochloride; adding a catalytic amount of DMAP hydrochloride to inert alcohol, phenol and amine under a solvent-free or organic solvent condition, and completely reacting with an acylation reagent at 0-130 ℃; adding a nonpolar solvent, and filtrating the recyclable catalyst, that is, the DMAP hydrochloride; and conducting washing, caustic scrubbing, liquid separation and organic phase drying on the filtrate, and evaporating and removing the solvent to obtain the acylated product. The recycled DMAP hydrochloride can be used in the next catalytic cycle.

Owner:NANKAI UNIV +1

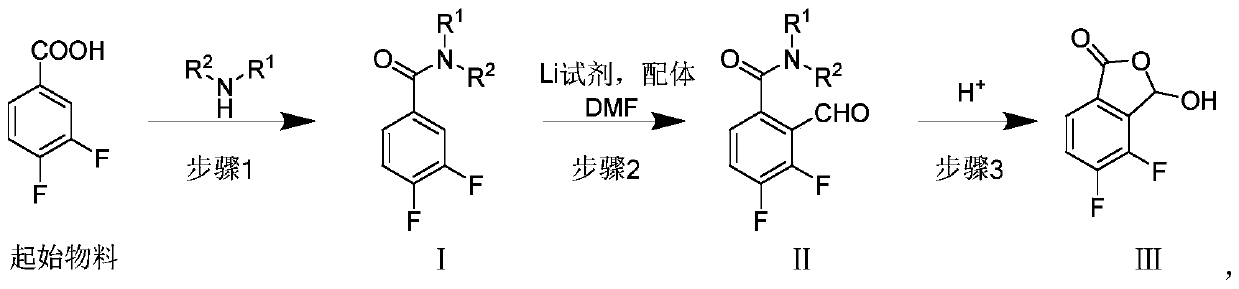

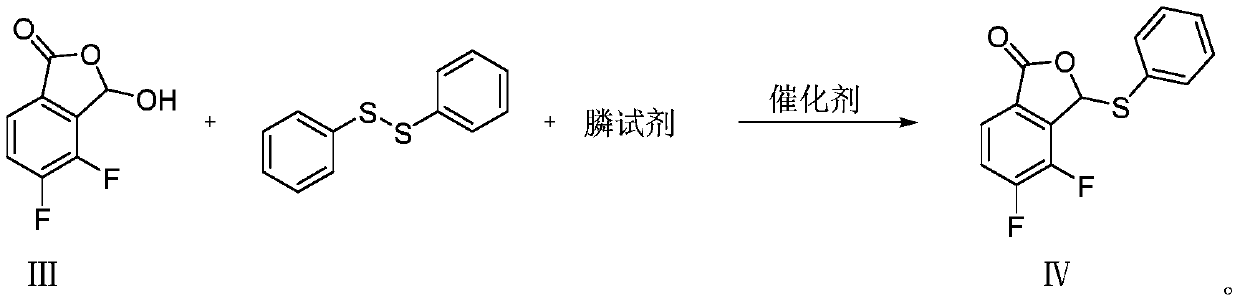

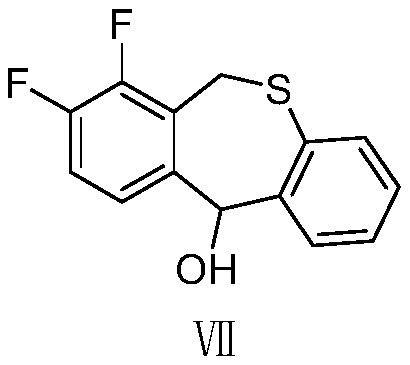

Synthesis method of baloxavir marboxil intermediate

ActiveCN110143941AHigh yieldReduce manufacturing costOrganic chemistrySynthesis methodsCombinatorial chemistry

The invention provides a synthesis method of a baloxavir marboxil intermediate. The invention provides a synthesis method of a compound (III), which is prepared through three steps. The yield is improved, and the production is easy to control. At the same time, a synthesis method of a compound (IV) is provided. According to the synthesis method, the compound (III) and disulfide diphenyl carry outone-pot self-catalytic circulation reactions to generate the compound (IV). The invention provides a method for preparing a baloxavir marboxil intermediate (VIII) through the reactions mentioned above. Through the one-pot self-catalytic circulation reactions, thiophenol, which is strongly toxic and is strictly controlled, is not used, a safe baloxavir marboxil synthesis method is provided, and thesynthesis method is suitable for industrial production.

Owner:BEIJING SIHUAN PHARMA +2

A kind of preparation method of 2,3-dichloropyridine

ActiveCN107721913BNo package issuesGood dispersionOrganic chemistryPalladium on carbonHigh water content

Owner:LIER CHEM CO LTD

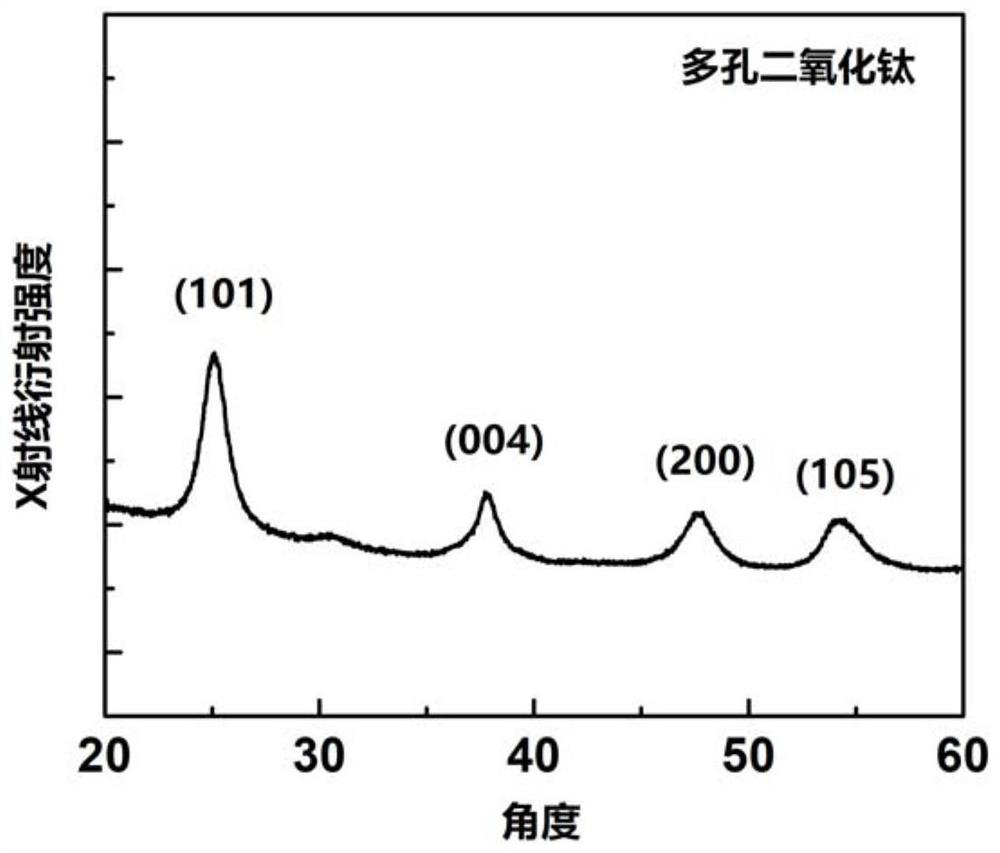

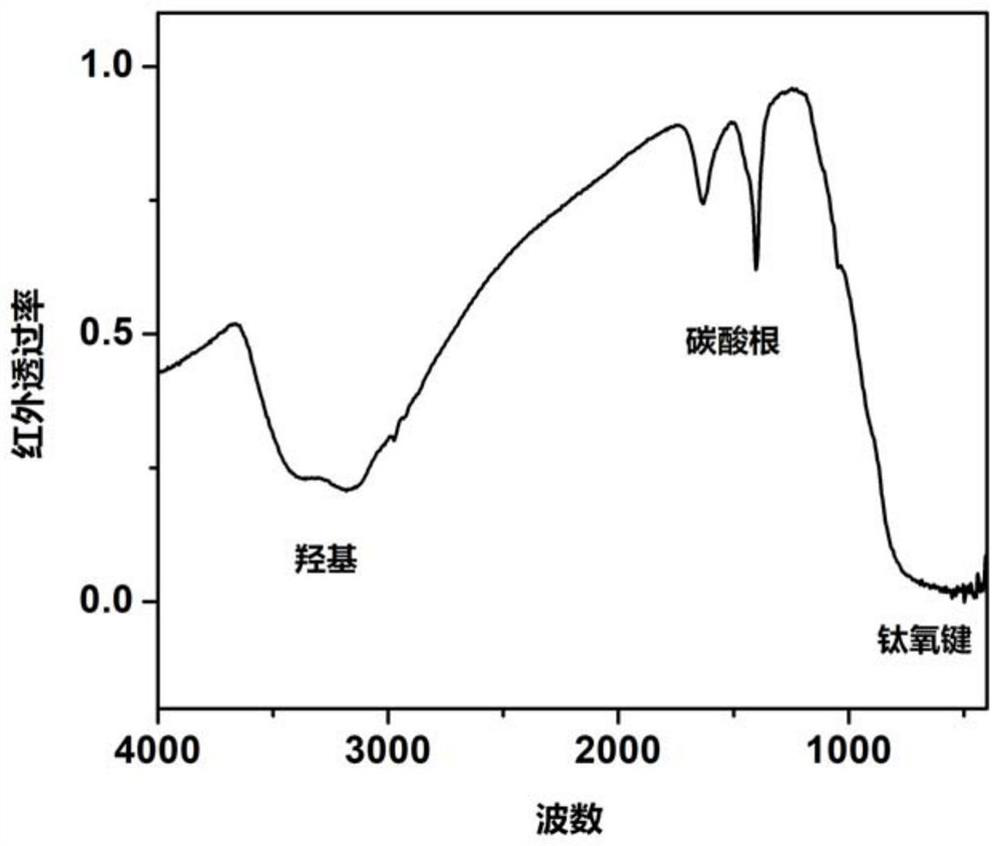

Porous titanium dioxide nano material, metal nanoparticle modified porous titanium dioxide photocatalytic material and preparation method and application of metal nanoparticle modified porous titanium dioxide photocatalytic material

PendingCN113600162AReduce the rate of hydrolysisHigh degree of homogenizationCatalyst activation/preparationHydrocarbon by hydrocarbon condensationPtru catalystCatalytic cycle

The invention discloses a porous titanium dioxide nano material, a metal nanoparticle modified porous titanium dioxide photocatalytic material and a preparation method and application of the metal nanoparticle modified porous titanium dioxide photocatalytic material, and belongs to the technical field of methane photochemical catalysis. The photocatalytic material provided by the invention is porous titanium dioxide and a composite material of porous titanium dioxide modified multiple metal nanoparticles, can perform photocatalysis on methane at a temperature as low as room temperature, avoids high energy consumption and danger in a high-temperature thermal catalytic reaction process, and can prevent methane from being excessively reduced to generate carbon deposition in a mild reaction process, and thus the service life of the catalyst is improved. Through different combinations of titanium dioxide and metal in the catalyst, the variety and distribution of hydrocarbons generated by the catalytic reaction can be regulated and controlled, and olefins are generated in a relatively high proportion. Good catalytic activity is shown by investigating the durability of the catalytic reaction in a catalytic cycle form, the catalytic reaction cycle can be stabilized for at least 50 times, and the total catalytic reaction time at least reaches 2 weeks.

Owner:曹洋

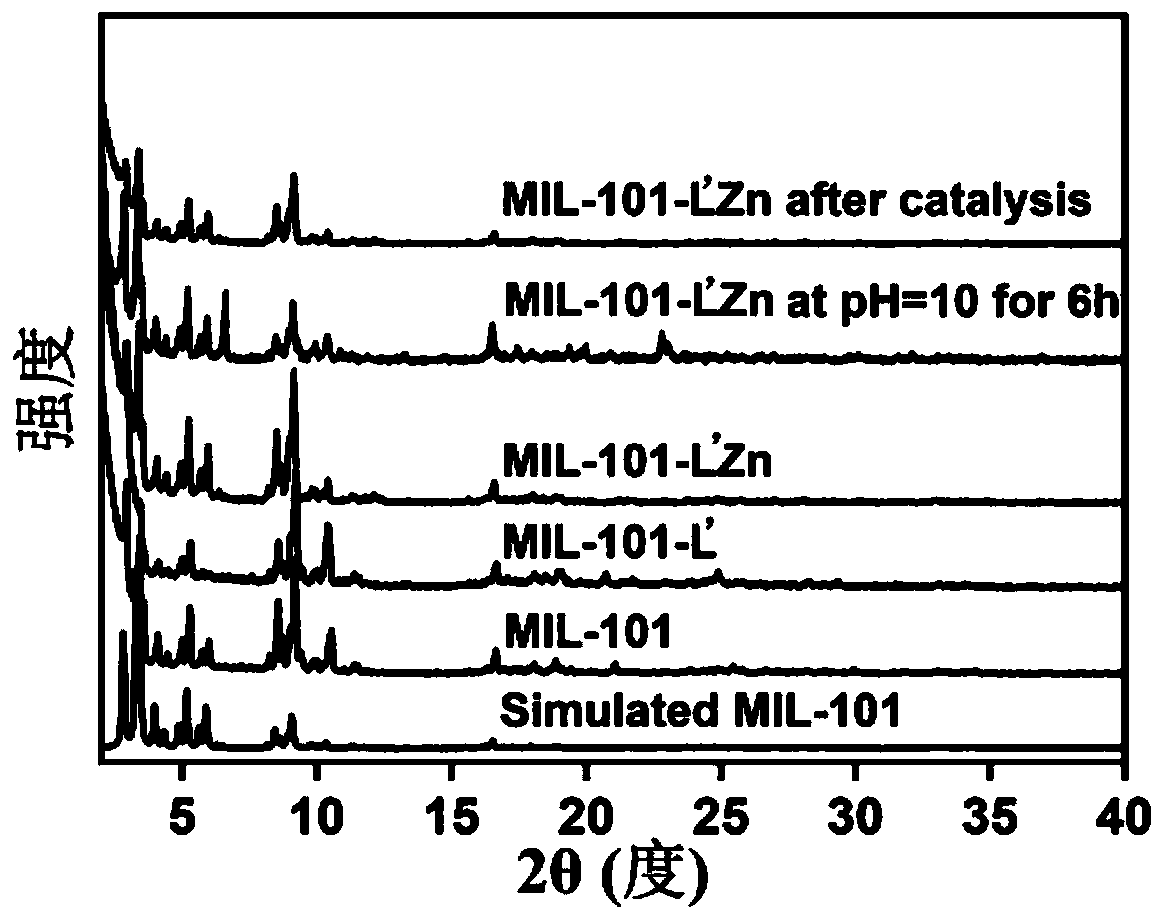

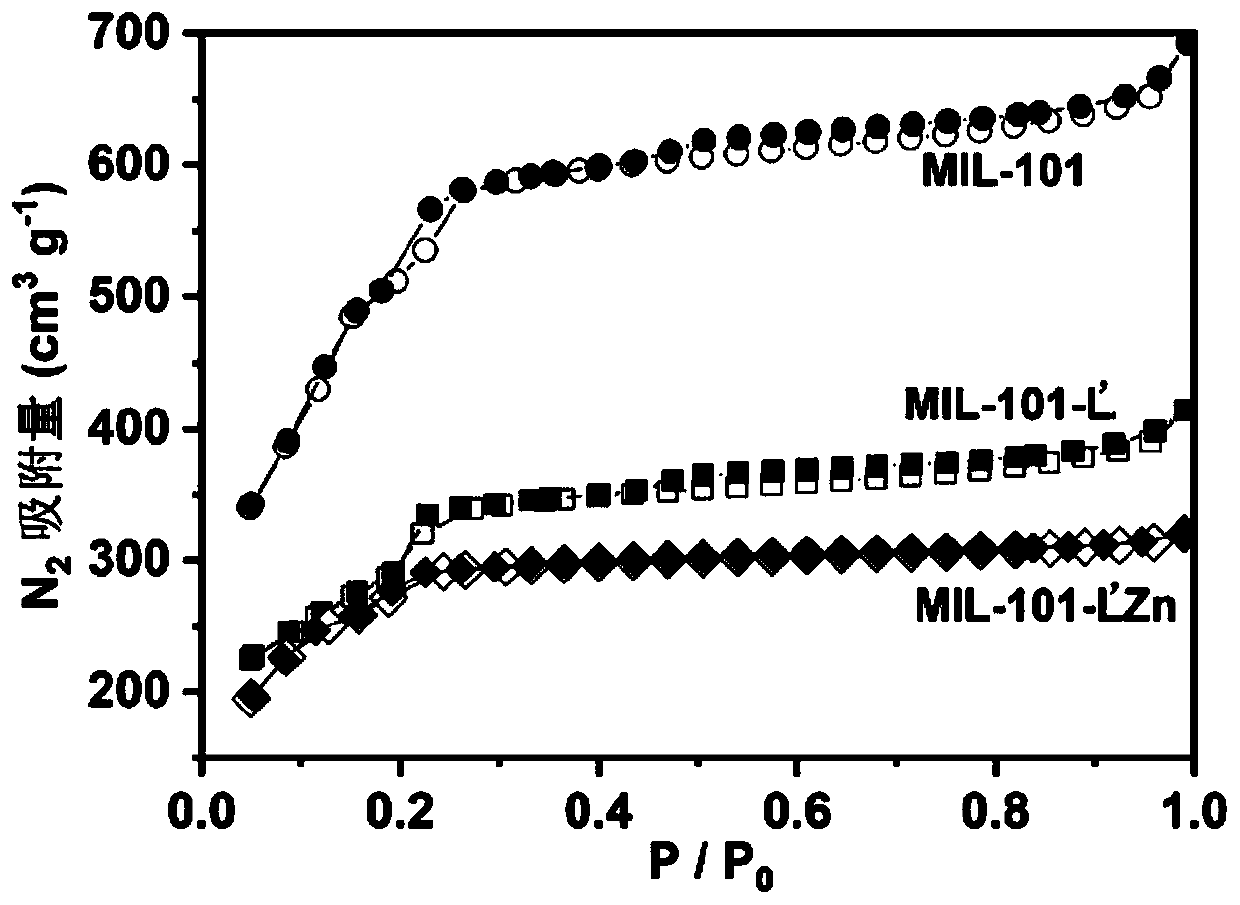

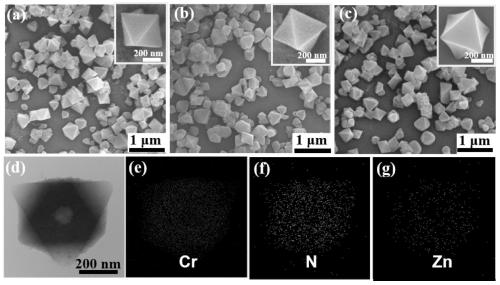

Hybrid material of polypyridine zinc complex modified MIL-101, preparation method and application in catalyzing degradation of organic phosphorus

ActiveCN111195531AGood catalytic cycleOvercoming activityOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPhosphate

The invention discloses a hybrid material of polypyridine zinc complex modified MIL-101, a preparation method and application in catalyzing degradation of organic phosphorus. A zinc complex capable ofcarrying out site separation is modified on a node of an activated chromium-based metal organic framework compound, a composite catalyst with multiple active centers is constructed, lewis acid activation of organic phosphorus by the zinc complex and MOFs hybrid material and catalytic breaking of P-O bonds by lewis base of the zinc complex on an MOF node are realized under a weakly alkaline condition, and the catalyst is used for degrading organic phosphorus. The hybrid material prepared by the method disclosed by the invention is relatively high in hydrolysis activity of catalyzing diethyl p-nitrophenol phosphate; the catalytic turnover frequency TOF of the hybrid material is 0.244 h<-1> and is improved by 40.2% compared with that of unmodified MIL-101, the hybrid material shows good catalytic cycle stability, the activity of the hybrid material is still kept at 95.7% after five cycles, and the hybrid material can be applied to degradation of organic phosphine poison.

Owner:ANHUI NORMAL UNIV

Method for preparing normal aldehyde based on olefin two-phase hydroformylation high selectivity of polyether quaternary ammonium salt ionic liquid

ActiveCN105712852AOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsOligomerRegioselectivity

The invention relates to a method for preparing normal aldehyde based on olefin two-phase hydroformylation high selectivity of polyether quaternary ammonium salt ionic liquid. According to the method, the two-phase catalytic system is adopted, the catalytic system is composed of polyether quaternary ammonium salt ionic liquid, a rhodium catalyst, a diphosphate ligand, an oligomer olefin and a reaction product aldehyde, a liquid / liquid two-phase hydroformylation reaction is performed under the certain reaction temperature and the synthesis barometric pressure, the rhodium catalyst is recycled through simple two-phase separation after the reaction is ended, and the catalytic system has the high catalytic activity, the high selectivity, the super long service life and the quite low rhodium catalyst loss amount, wherein the TOF value reaches 160-2100 h<-1>, the formal aldehyde regioselectivity reaches up to 96-97%, the catalytic cycle accumulative TON value reaches 30000 or above to the highest extent, and the rhodium catalyst loss amount is 0.05-0.1%.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

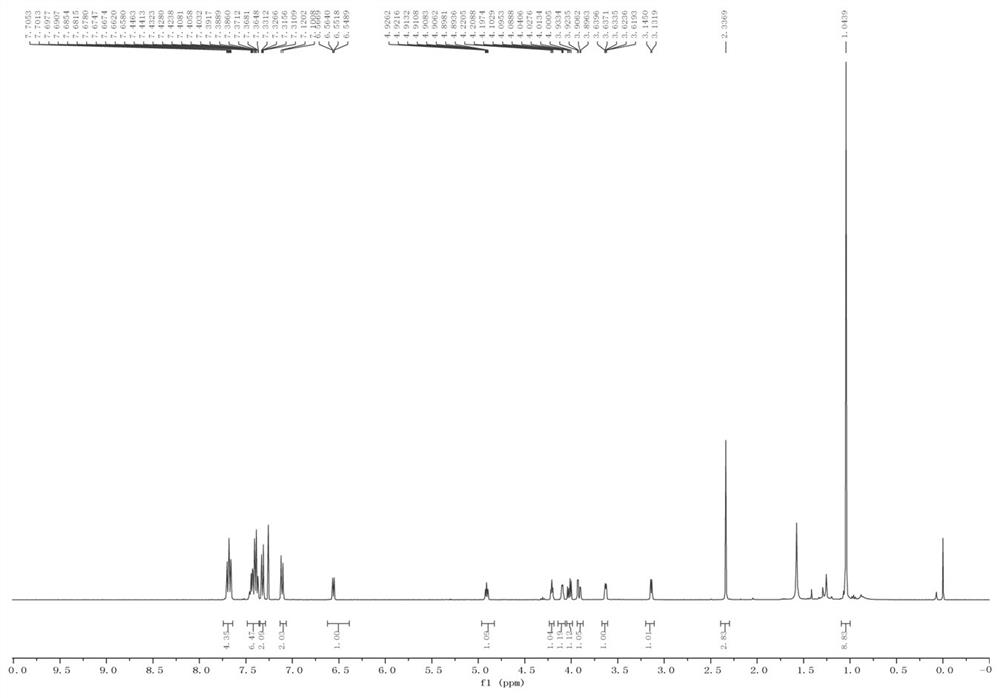

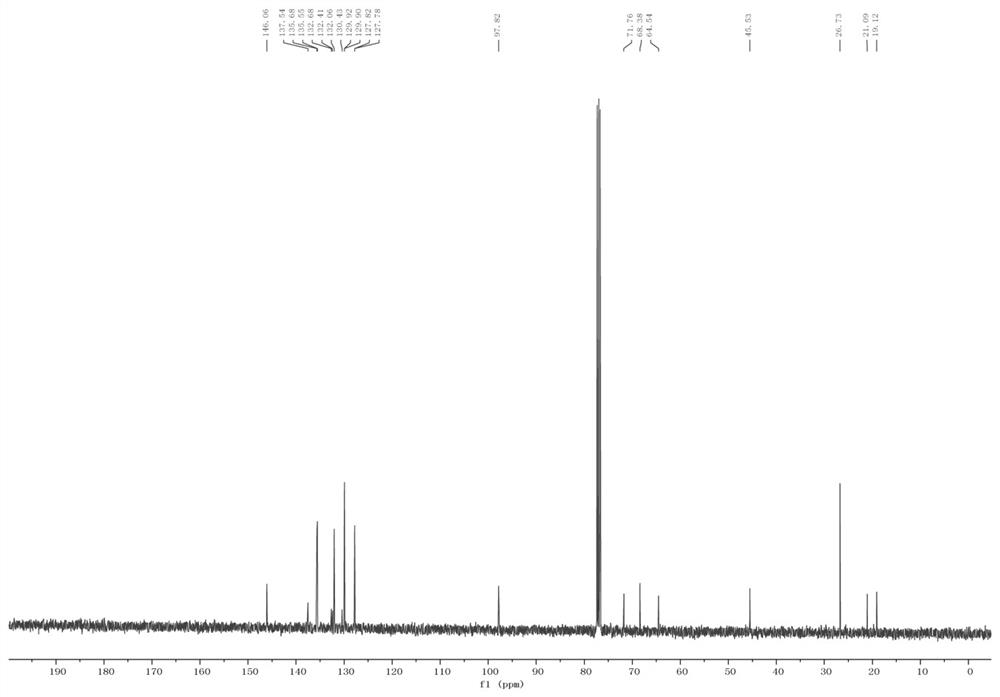

Synthesis method of 3-sulfur-1-glycal compound

ActiveCN111995638AGroup 4/14 element organic compoundsOrganic chemistry methodsBenzoic acidPtru catalyst

The invention provides a synthesis method of a 3-sulfur-1-glycal compound. The preparation method comprises the following steps of: adding a catalyst, a ligand and galactan into an organic solvent andmercaptan / phenol; adding zinc powder, stirring and reacting at the temperature of 100 to 120 DEG C; detecting the reaction process through TLC, terminating the reaction when the galactan raw materialcompletely disappears, thereby obtaining 3-sulfur-1-glycal. The structural formula of mercaptan / phenol is R2-SH, and the structural formula of R2 comprises any one of methylene carboxylate, benzyl, alkyl, phenyl, substituted phenyl and five-membered or six-membered heterocyclic groups; and R1 comprises any one of a silicon group, an alkyl group, a C1-C18 alkyl group, a benzyl group, a phenyl group, a triphenylmethyl group, a pyridyl group, benzoate, pyridine acid ester and quinolinecarboxylic acid ester. According to the method, the cheap cobalt catalyst is adopted, the proper ligand and solvent are added to facilitate formation of a high-activity catalytic intermediate, and the zinc powder is added to promote smooth catalytic circulation of the cobalt catalyst.

Owner:CHINA THREE GORGES UNIV

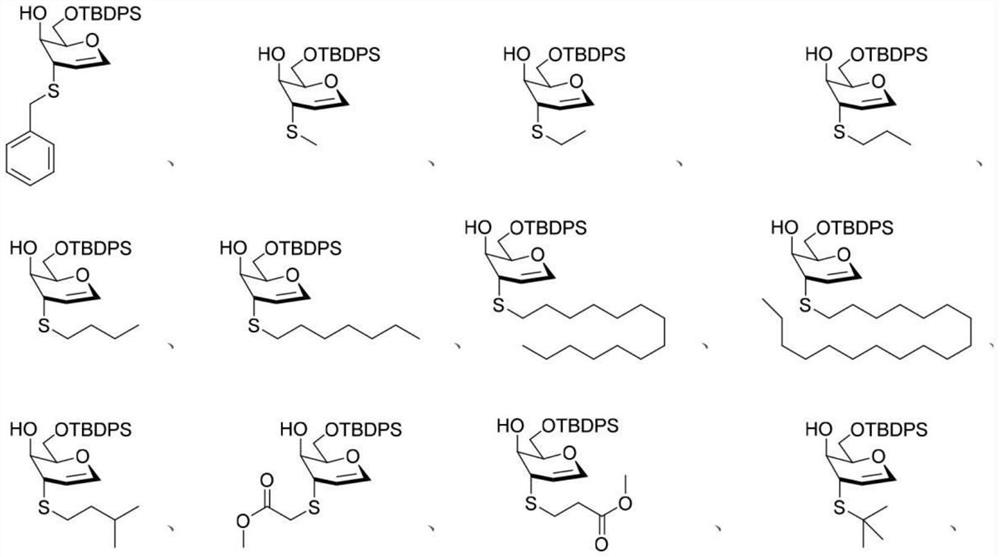

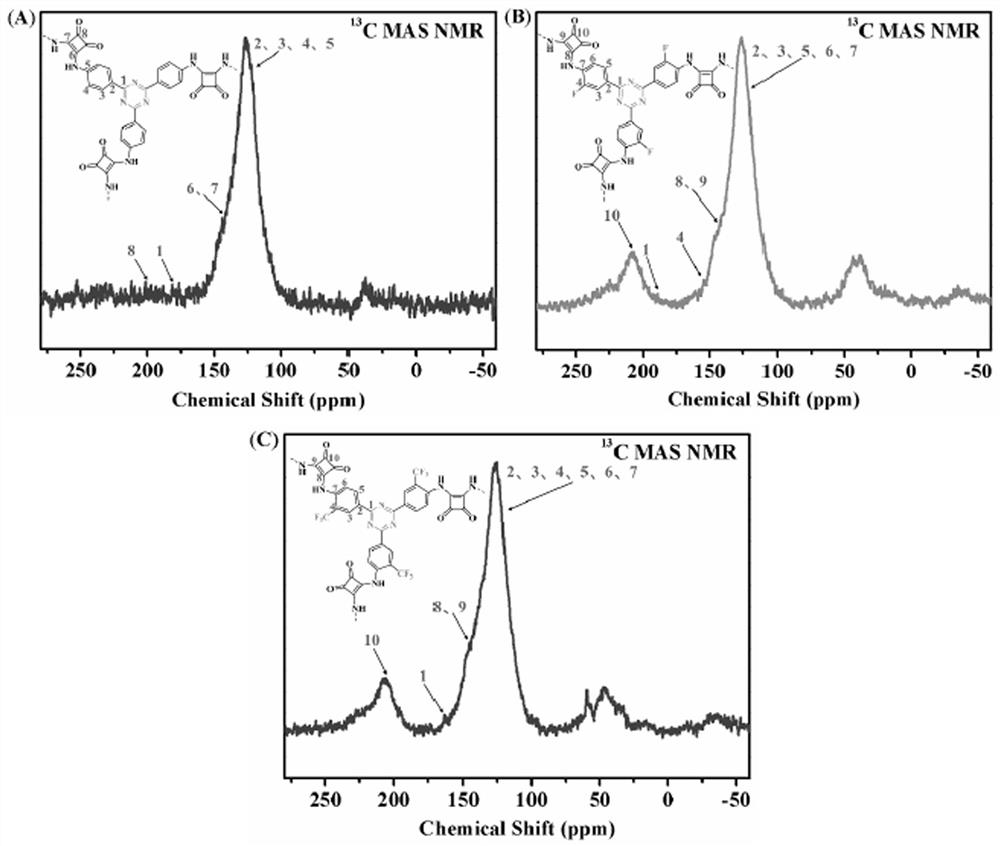

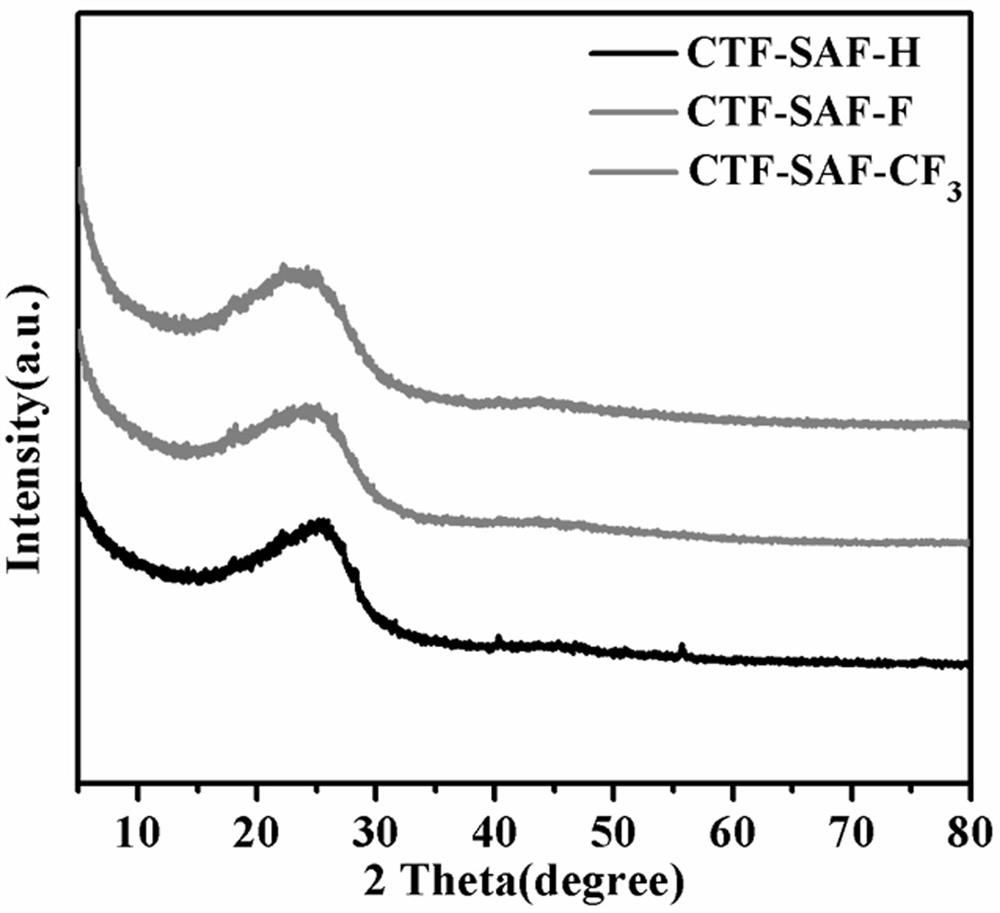

Squaramide derivative covalent triazine skeleton polymer and application thereof in catalyzing coupling of carbon dioxide and epoxide to prepare cyclic carbonate

ActiveCN114437363ALarge specific surface areaHigh nitrogen contentOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

The invention relates to a squaramide-derived covalent triazine skeleton polymer and application thereof in catalyzing coupling of carbon dioxide and epoxide to prepare cyclic carbonate. Squaramide monomers are used as raw materials, a series of squaramide-derived covalent triazine skeleton polymers are synthesized through a high-temperature ionothermal method, and the squaramide-derived covalent triazine skeleton polymers are used as catalysts to prepare cyclic carbonate. According to the method, carbon dioxide and epoxide with different substituent groups are used as raw materials, corresponding cyclic carbonate is synthesized under the conditions that the reaction pressure is 0.1-2.5 MPa, the reaction temperature is 70-110 DEG C and the reaction time is 2-6 hours, and high-selectivity catalysis of synthesis of cyclic carbonate under mild, metal-free and solvent-free conditions is realized. The polymer shows excellent adsorption and conversion dual functions on carbon dioxide, the catalytic activity is not obviously reduced after five catalytic cycles, the problem that a homogeneous catalyst is not easy to separate is solved, and the polymer has a good application prospect.

Owner:QINGDAO UNIV OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com