Preparation method of SBA-15 molecular sieve-based supported catalyst for desorption of CO2-rich amine solution

A supported catalyst, molecular sieve technology, applied in molecular sieve catalysts, physical/chemical process catalysts, separation methods, etc., can solve the problems of easy blockage of pores, reduced desorption energy consumption, unstable catalytic performance, etc., and achieve stable catalytic performance. The preparation technology has simple operation and good catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

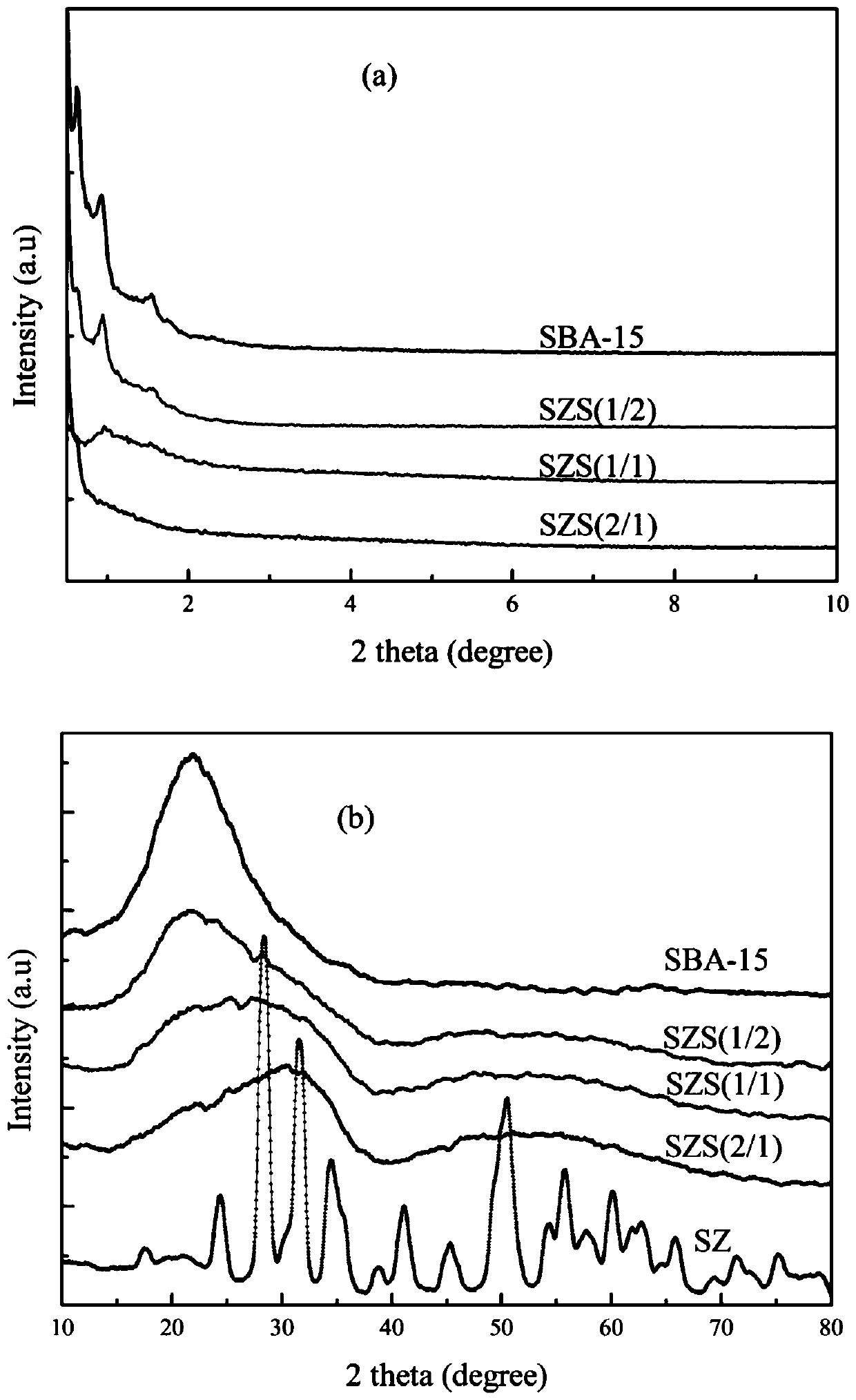

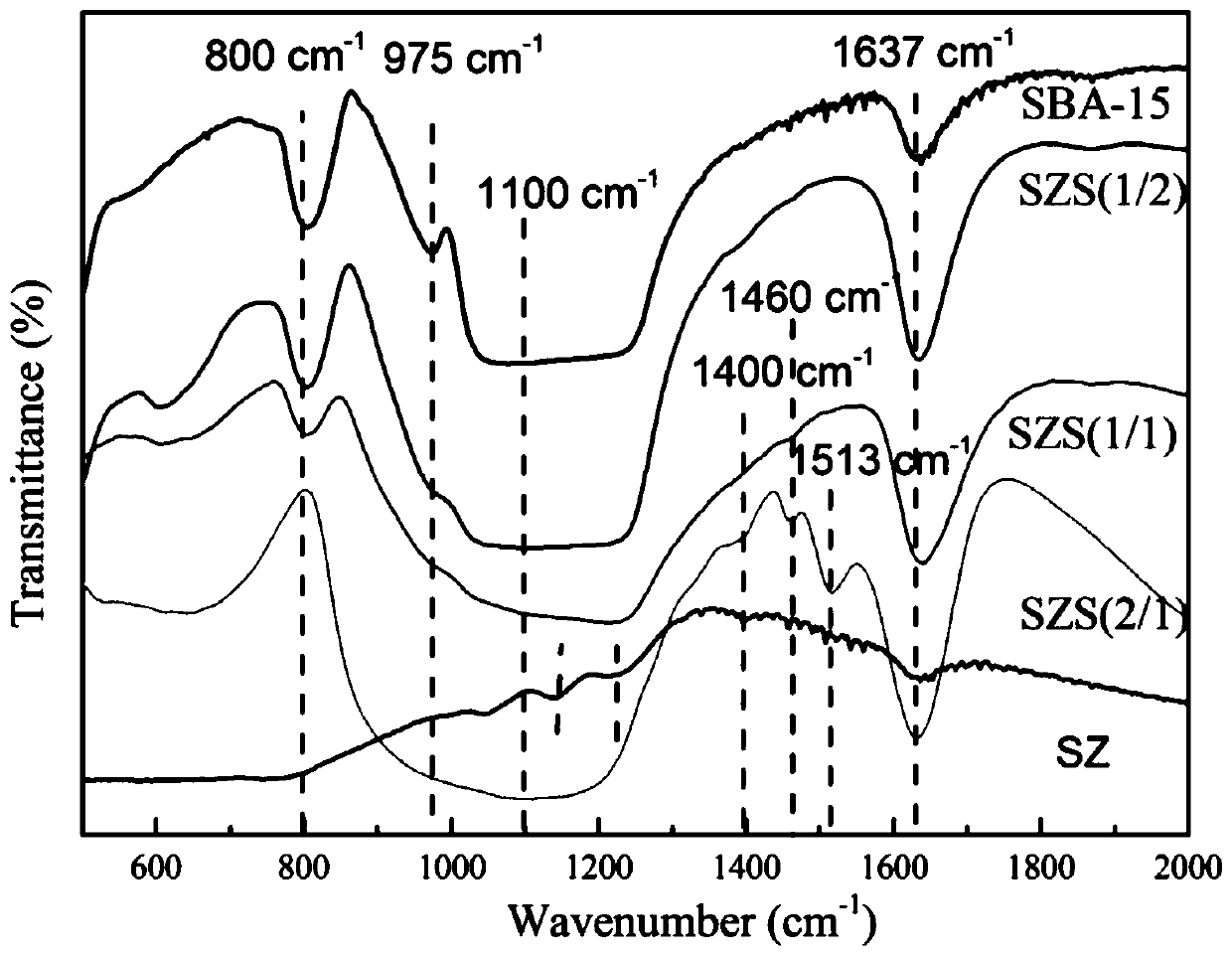

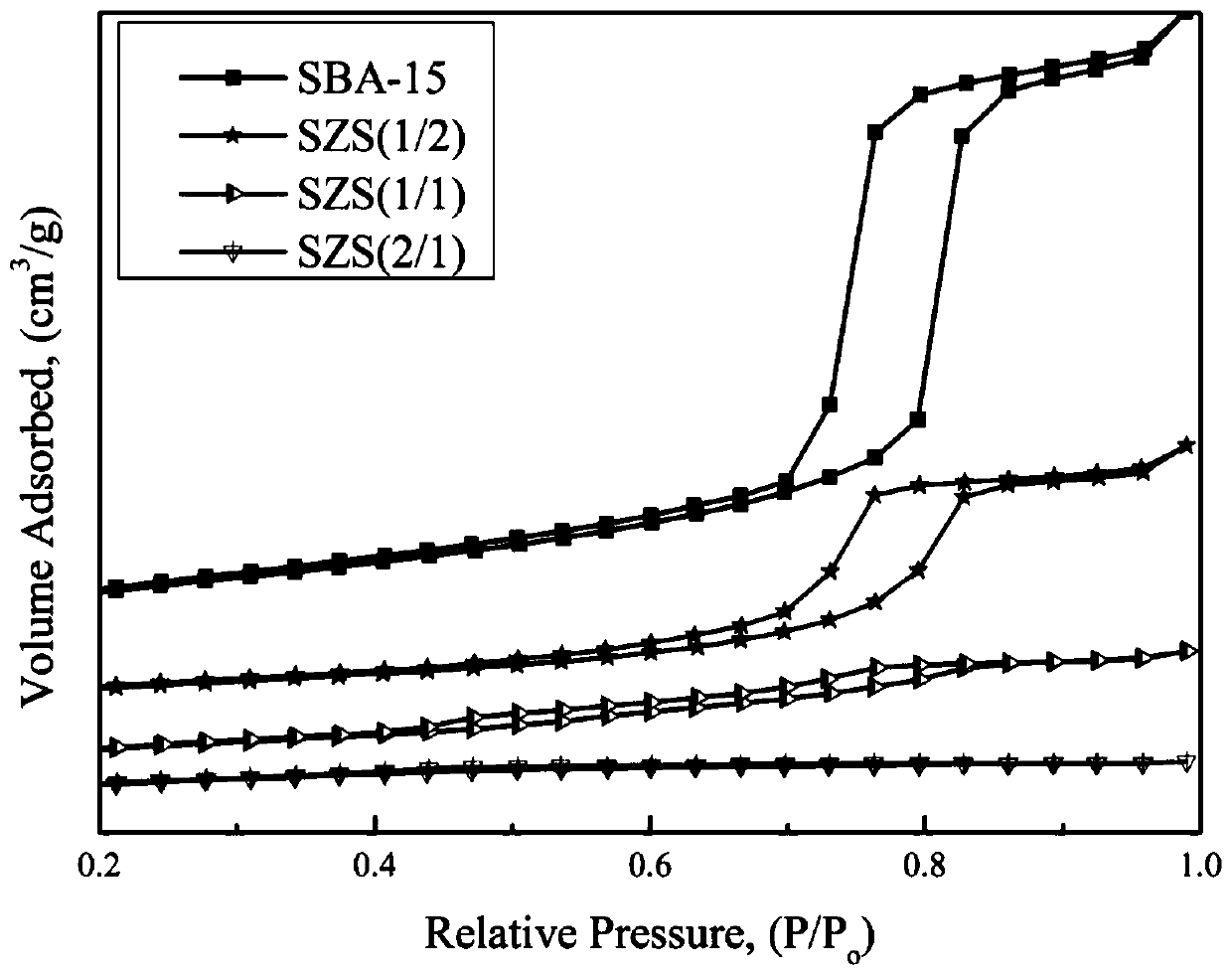

[0038] Example 1: SO 4 2- / ZrO 2 @SBA-15 molecular sieve catalyst

[0039] First, put 7.0g of SBA-15, 50g of urea and 120mL of deionized water into a round-bottomed flask, and sonicate for 0.5h. Then, 9.35g of ZrOCl 2 ˙8H 2 O was added to the mixed solution, sonicated for 0.5h to obtain a mixed solution. The mixed solution B was stirred and refluxed in an oil bath at 90° C. for 6 hours, the pH value of the solution was 8-9, and a gel-like solution B was obtained. Solution B was washed and filtered to remove chloride ions, and further dried in air at 110°C for 12 hours; subsequently, it was calcined in air at 550°C for 6 hours to obtain a solid substance ZrO 2 / SBA-15. Grind the solid substance C, acidify C with sulfuric acid, the concentration of sulfuric acid is 1mol / L and 1g of C corresponds to 15mL of 1mol / L H 2 SO 4 . Solid substance C and sulfuric acid were placed in a beaker and stirred at room temperature for 3h. Finally, the mixture was filtered and dried, and...

Embodiment 2

[0043] With embodiment 1, its difference is that in catalyst preparation process ZrO 2 The mass ratio to SBA-15 is 1:2, abbreviated as SZS(1 / 2).

Embodiment 3

[0047] With embodiment 1, its difference is that in catalyst preparation process ZrO 2 The mass ratio to SBA-15 is 2:1, abbreviated as SZS(2 / 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com