Method and device for synergic catalytic cycle hydrogen production and carbon dioxide trapping on basis of CaFe2O4/Ca2Fe2O5

A carbon dioxide, ca2fe2o5 technology, applied in the field of chemical chain hydrogen production, can solve the problems of easy surface sintering, long reaction time, deactivation of calcium-based catalysts, etc., and achieve the effects of simple device structure, short reaction time, and not easy deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

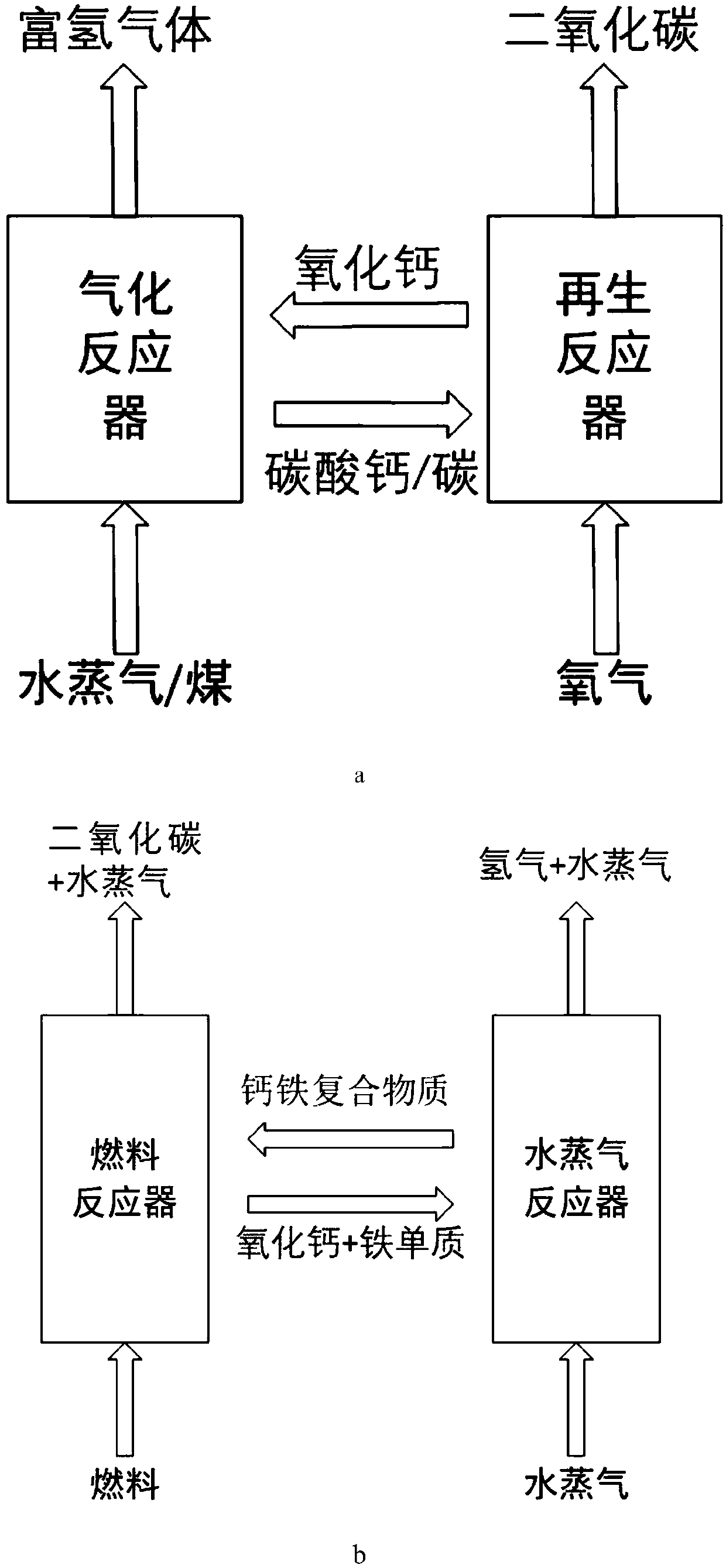

[0023] A CaFe-based 2 o 4 / Ca 2 Fe 2 o 5 A method for synergistic capture of carbon dioxide for catalytic cycle hydrogen production using CaFe 2 o 4 and Ca 2 Fe 2 o 5 Composite calcium-iron powder reacts in one step to produce high-purity hydrogen and capture carbon dioxide, and the reaction is carried out in a cycle.

[0024] Gas or solid fuel needs to be added in the reaction, and carbon monoxide is selected in this embodiment.

[0025] The reaction formula of described reaction is as follows:

[0026] Ca 2 Fe 2 o 5 +3CO→2CaO+2Fe+3CO 2 (1)

[0027] CaFe 2 o 4 +3CO→CaO+2Fe+3CO 2 (2)

[0028] 2CaO+2Fe+3H 2 O→Ca 2 Fe 2 o 5 +3H 2 (3)

[0029] CaO+2Fe+3H 2 O→CaFe 2 o 4 +3H 2 (4)

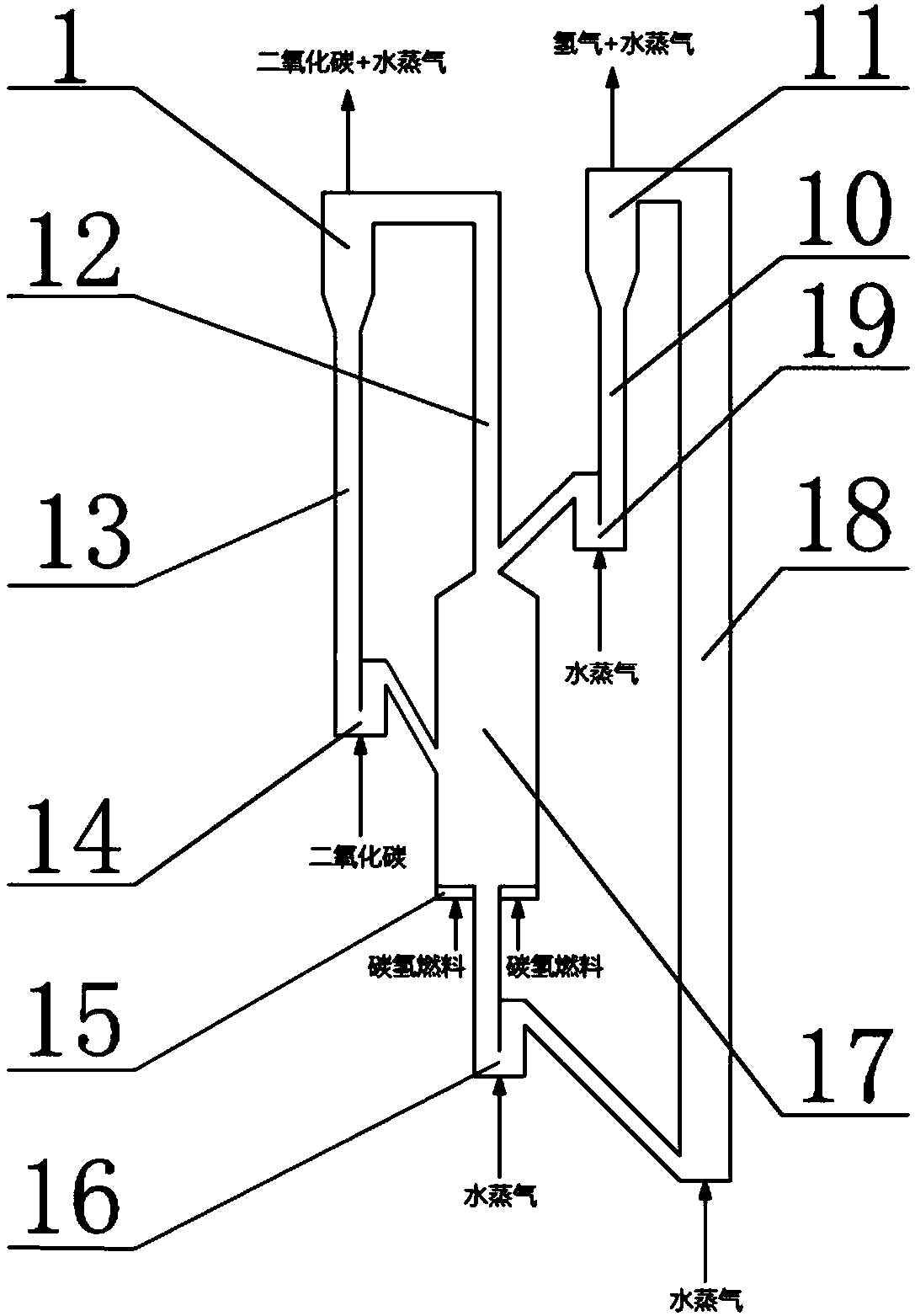

[0030] use as figure 1 Shown stacked circulating fluidized bed carries out above-mentioned reaction, and described device is:

[0031] A CaFe-based 2 o 4 / Ca 2 Fe 2 o 5 The device for synergistically capturing carbon dioxide for catalytic cycle hydrogen production...

Embodiment 2

[0034] A CaFe-based 2 o 4 / Ca 2 Fe 2 o 5 A method for synergistic capture of carbon dioxide for catalytic cycle hydrogen production using CaFe 2 o 4 and Ca 2 Fe 2 o 5 Composite calcium-iron powder reacts in one step to produce high-purity hydrogen and capture carbon dioxide, and the reaction is carried out in a cycle.

[0035] Gas or solid fuel needs to be added in the reaction, and carbon monoxide is selected in this embodiment.

[0036] The reaction formula of described reaction is as follows:

[0037] Ca 2 Fe 2 o 5 +3CO→2CaO+2Fe+3CO 2 (1)

[0038] CaFe 2 o 4 +3CO→CaO+2Fe+3CO 2 (2)

[0039] 2CaO+2Fe+3H 2 O→Ca 2 Fe 2 o 5 +3H 2 (3)

[0040] CaO+2Fe+3H 2 O→CaFe 2 o 4 +3H 2 (4)

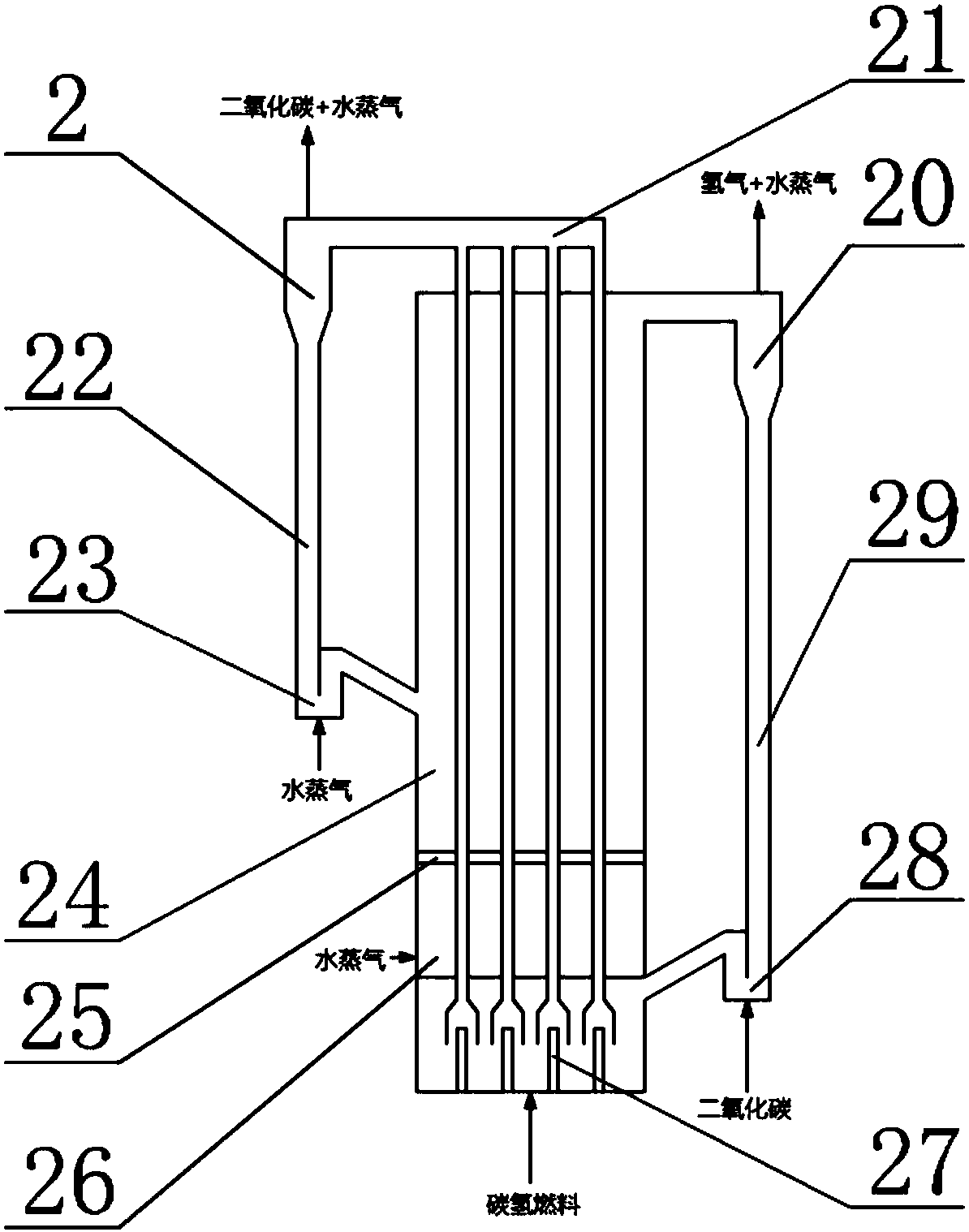

[0041] use as figure 2 Shown nested circulating fluidized bed carries out above-mentioned reaction, and described device is:

[0042] A CaFe-based 2 o 4 / Ca 2 Fe 2 o 5 The catalytic cycle hydrogen production co-capturing device of carbon dioxide, said device is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com