Patents

Literature

226 results about "Fuel conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and methods for improved emission control of internal combustion engines using pulsed fuel flow

InactiveUS7082753B2Save oilReducing greenhouse gas emissionExhaust apparatusCombustion enginesPartial oxidationExternal combustion engine

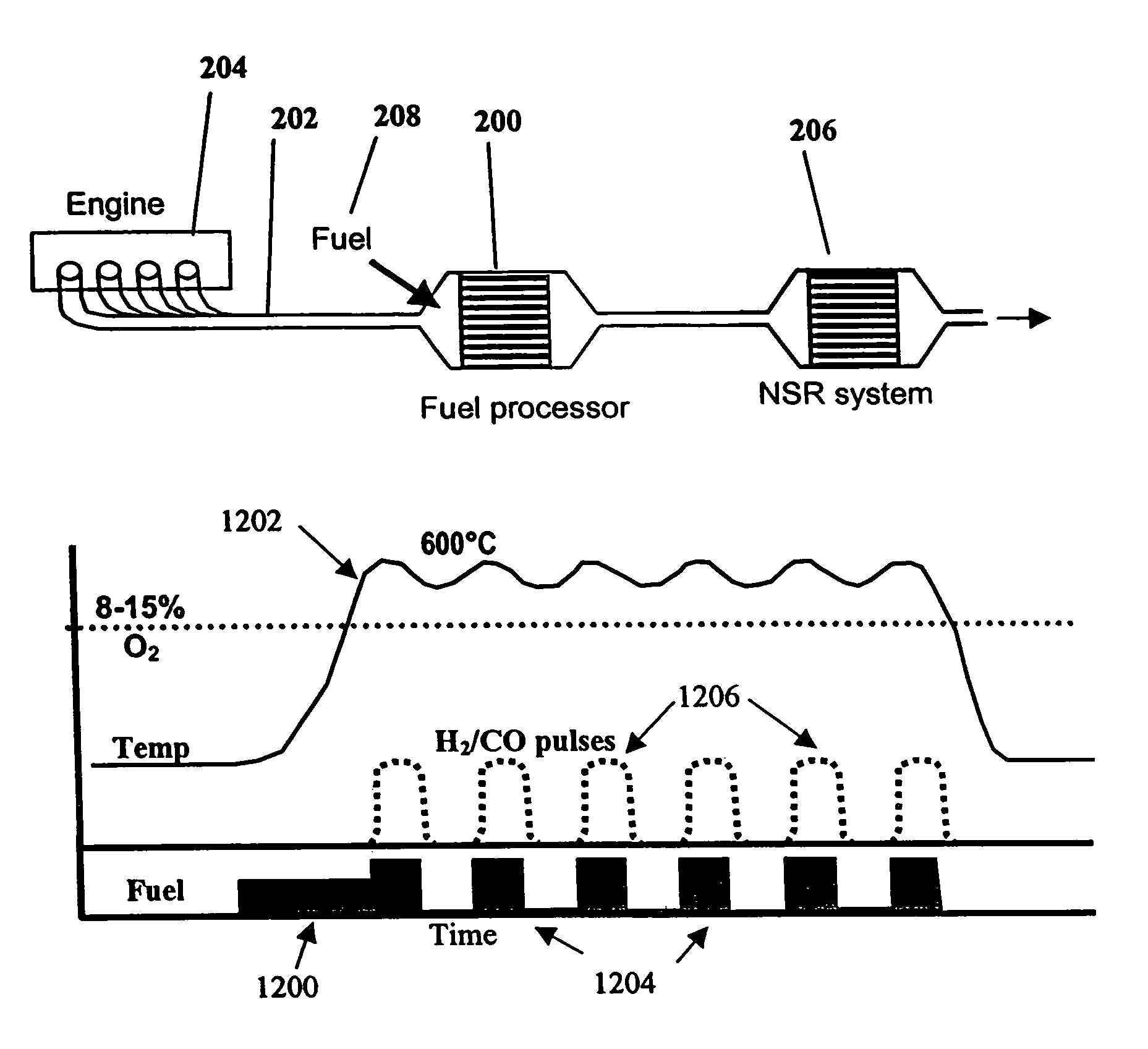

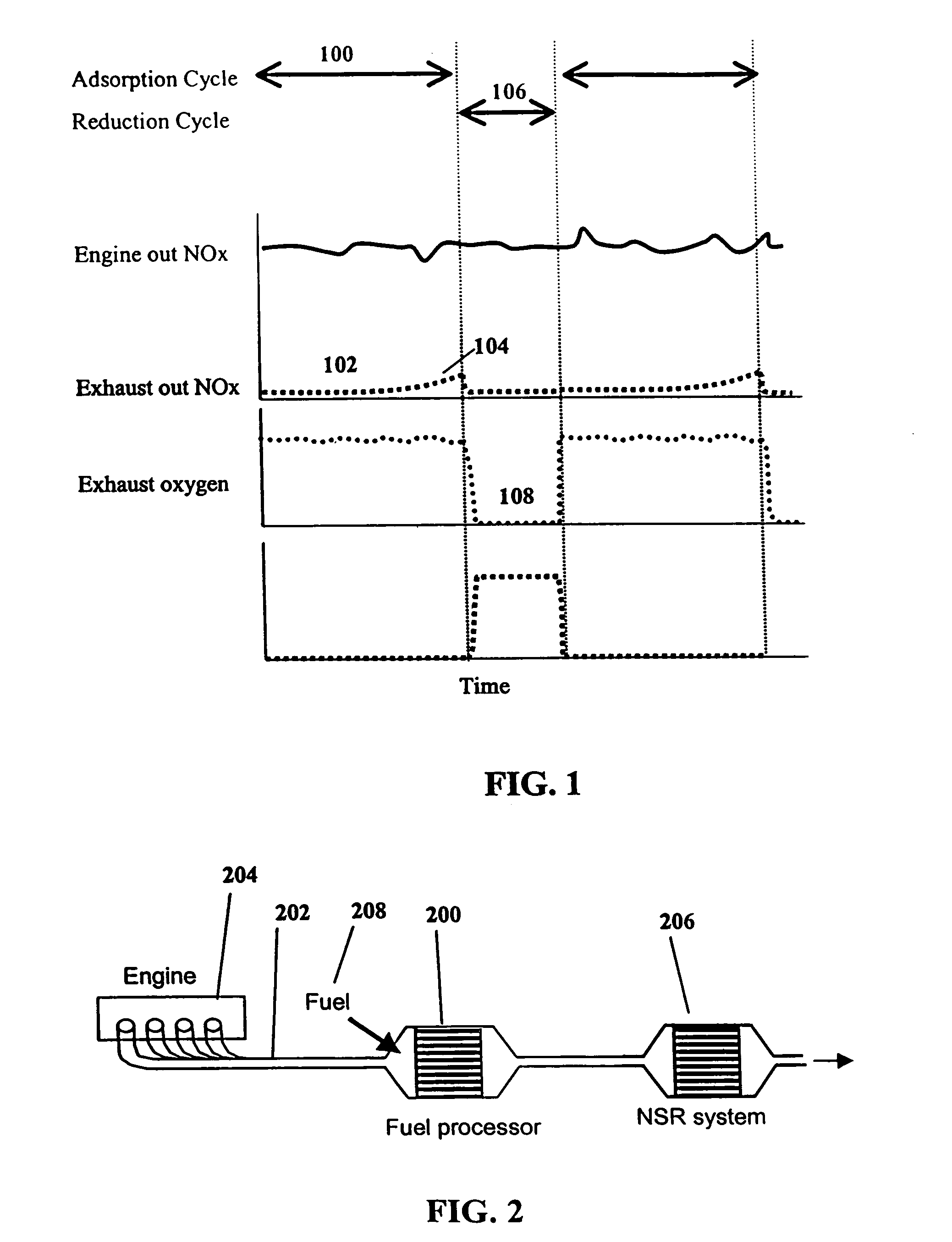

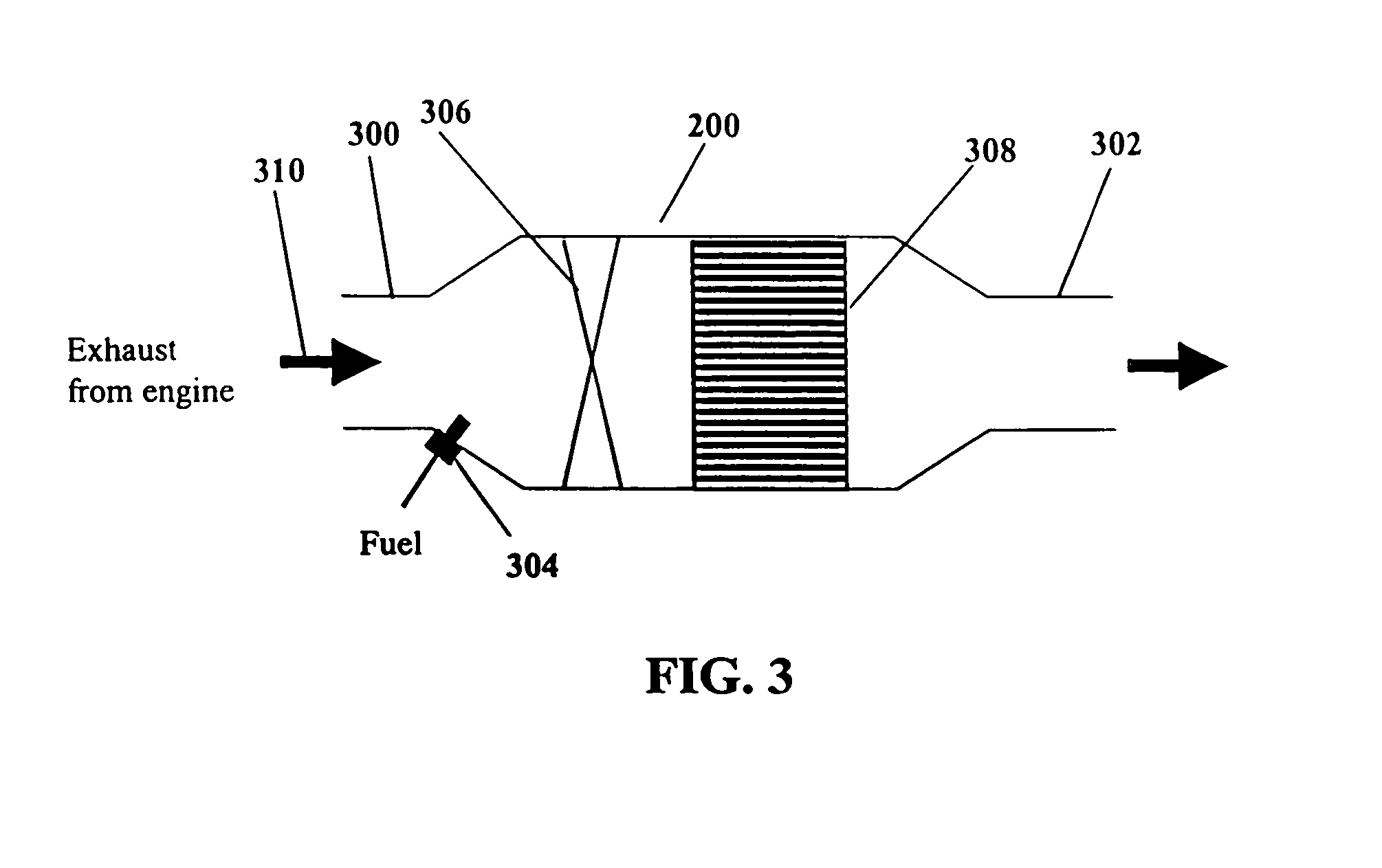

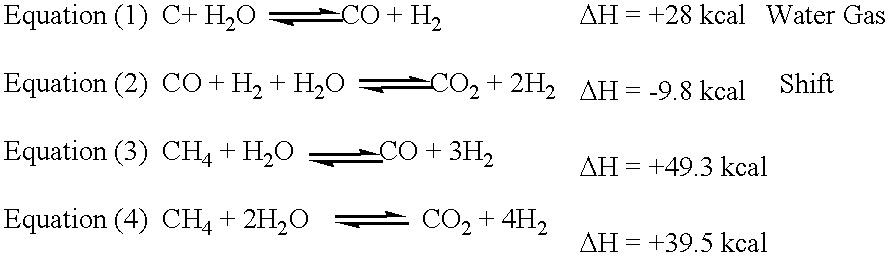

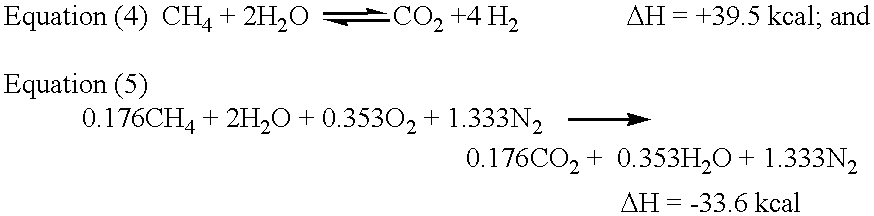

The present invention provides systems and methods to improve the performance and emission control of internal combustion engines equipped with nitrogen oxides storage-reduction (“NSR”) emission control systems. The system generally includes a NSR catalyst, a fuel processor located upstream of the NSR catalyst, and at least one fuel injection port. The fuel processor converts a fuel into a reducing gas mixture comprising CO and H2. The reducing gas mixture is then fed into the NSR catalyst, where it regenerates the NSR adsorbent, reduces the NOx to nitrogen, and optionally periodically desulfates the NSR catalyst. The fuel processor generally includes one or more catalysts, which facilitate reactions such as combustion, partial oxidation, and / or reforming and help consume excess oxygen present in an engine exhaust stream. The methods of the present invention provide for NSR catalyst adsorbent regeneration using pulsed fuel flow. Control strategies are also provided.

Owner:INT ENGINE INTPROP CO LLC

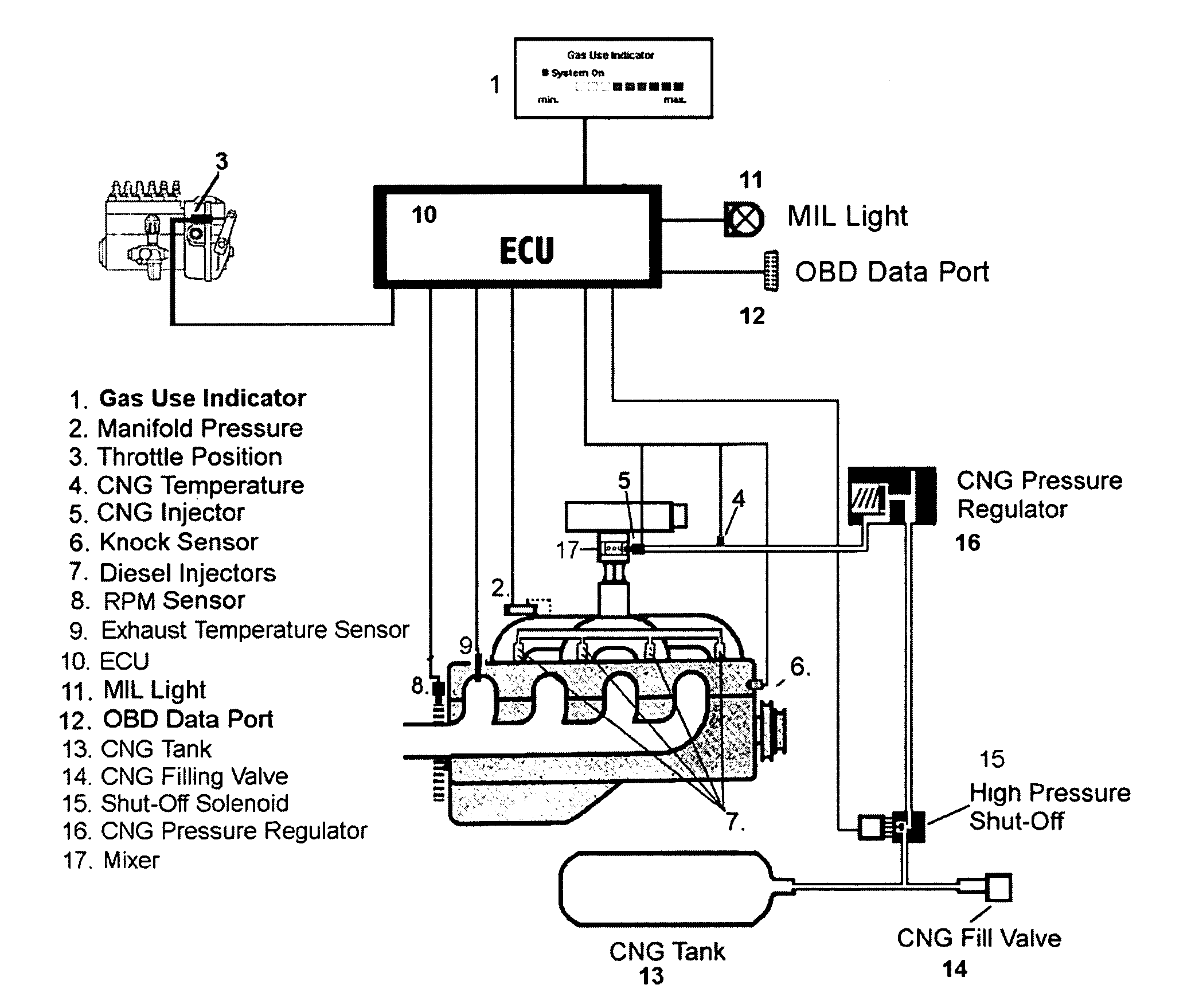

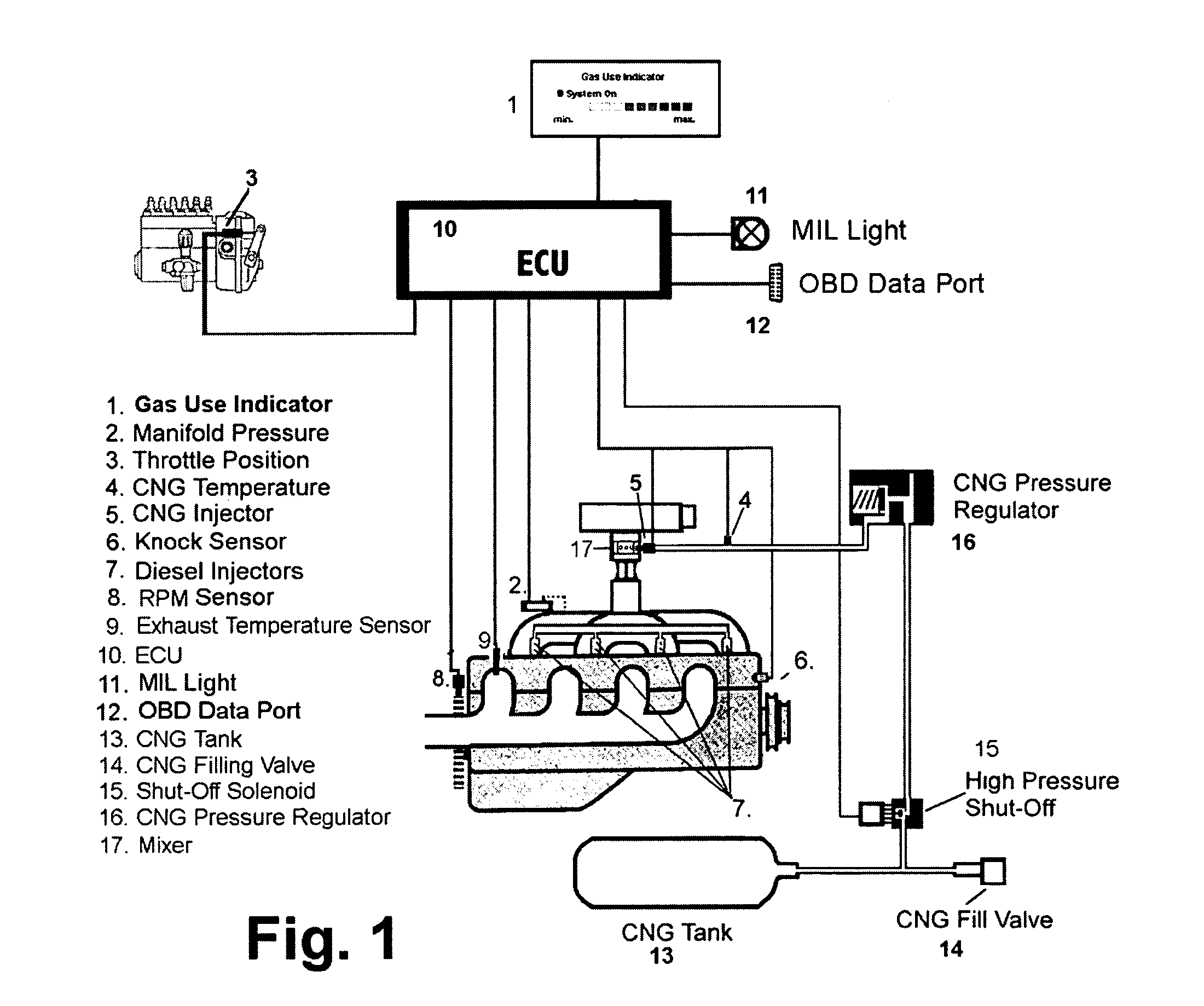

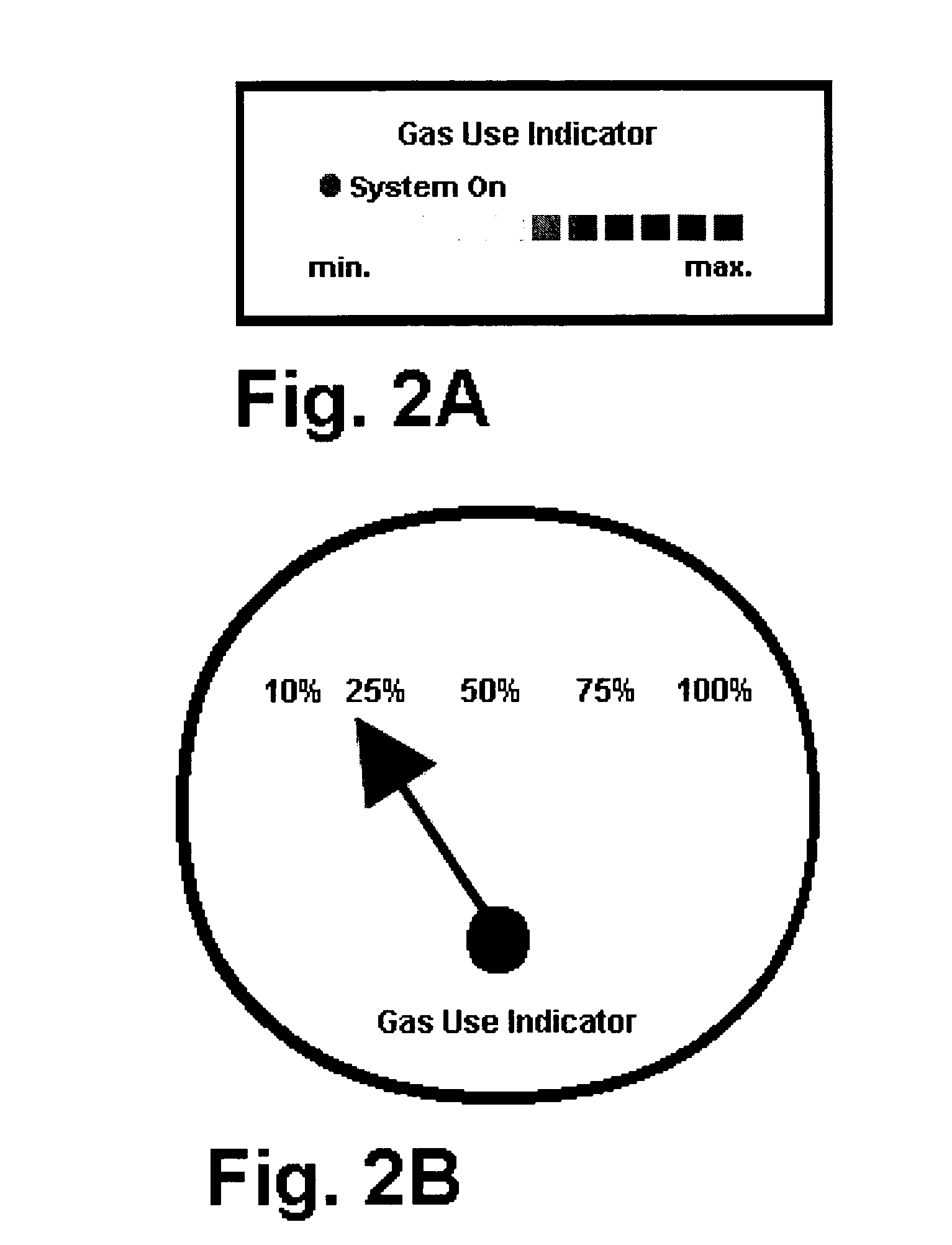

Multi-fuel engine conversion system and method

Systems, methods and apparatus' of converting an engine into a multi-fuel engine are provided. One embodiment reduces particulate emissions and reduces the amount of combusted gasoline or diesel fuel by replacing some of the fuel with a second fuel, such as natural gas, propane, or hydrogen. One feature of the present invention includes a control unit for metering the second fuel. Another feature of the present invention includes an indicator that indicates how much second fuel is being combusted relative to the diesel or gasoline. This Abstract is provided for the sole purpose of complying with the Abstract requirement rules that allow a reader to quickly ascertain the subject matter of the disclosure contained herein. This Abstract is submitted with the explicit understanding that it will not be used to interpret or to limit the scope or the meaning of the claims.

Owner:OMNITEK ENG

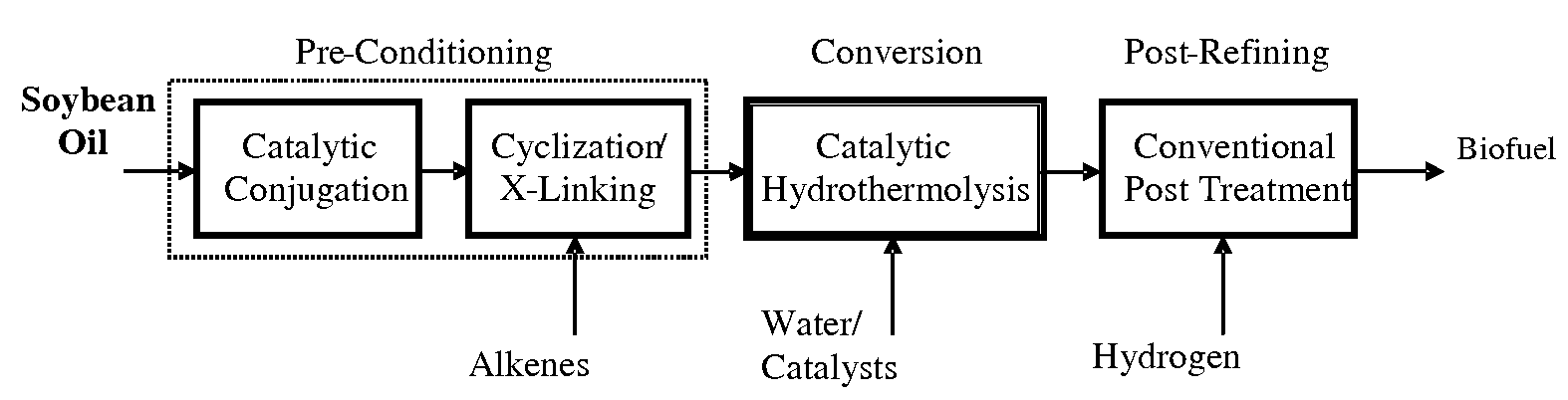

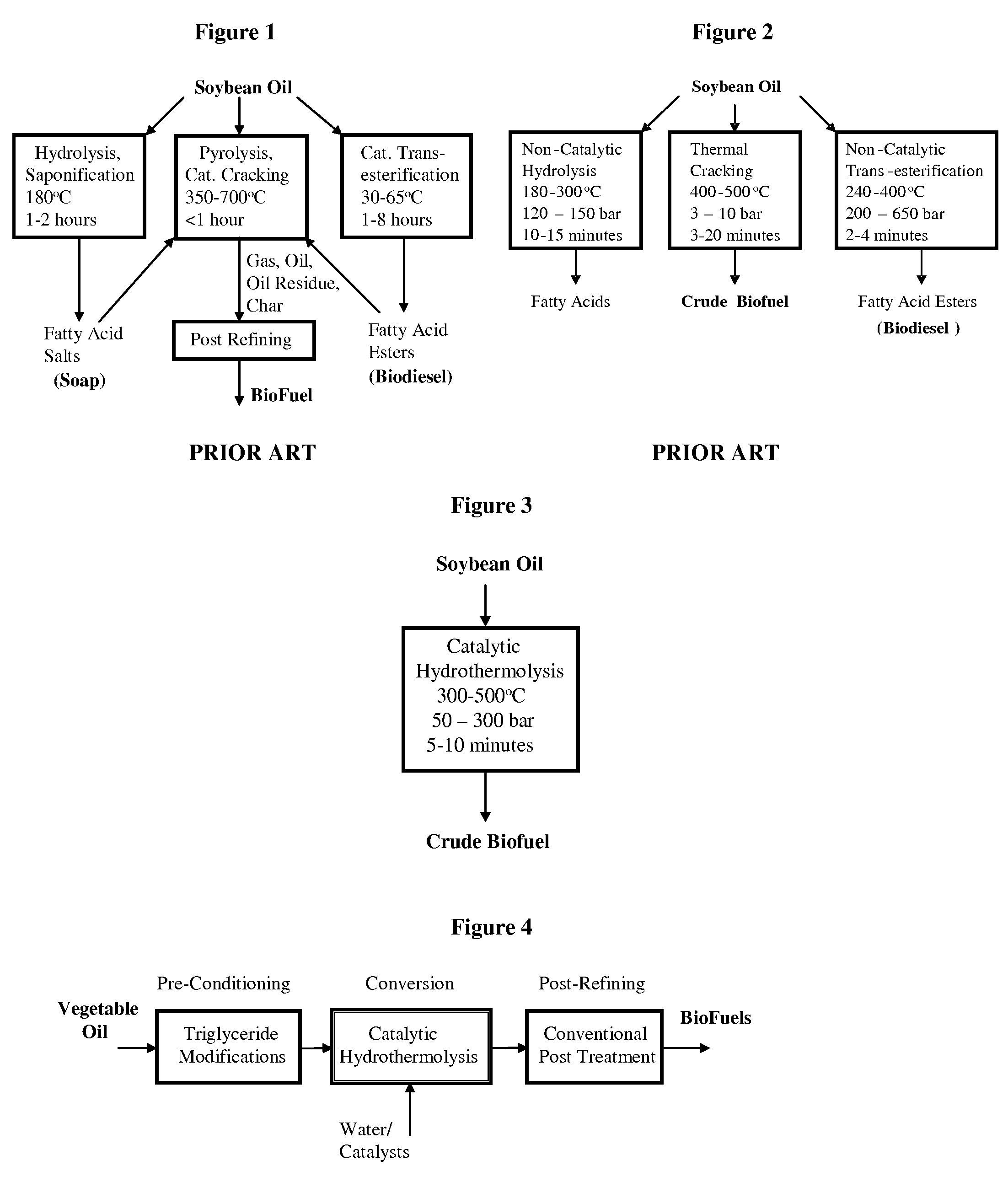

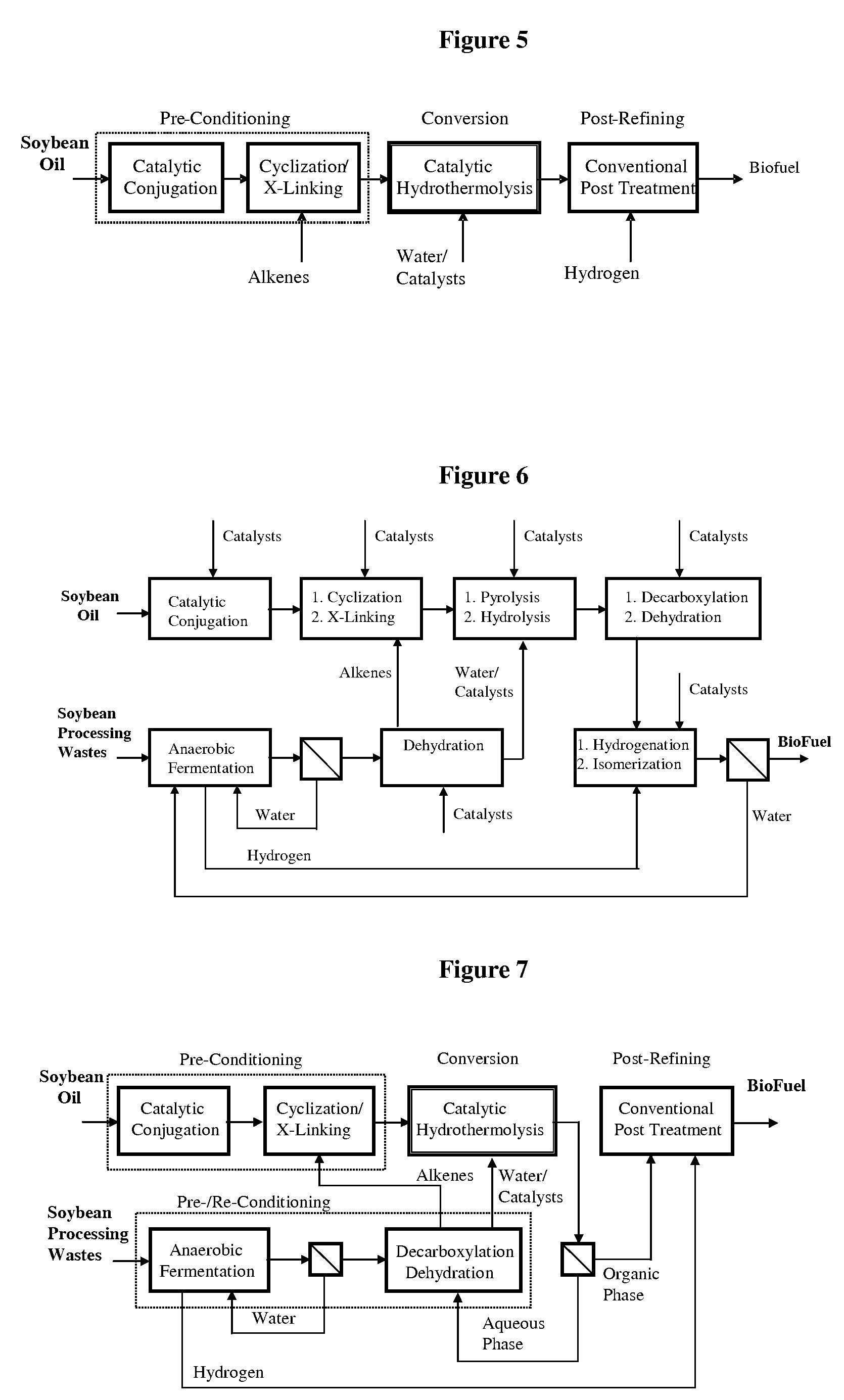

Method of converting triglycerides to biofuels

ActiveUS7691159B2Improve chemical and physical and combustion qualityImprove thermal stabilityFatty acid chemical modificationOrganic compound preparationCross-linkIsomerization

A triglyceride-to-fuel conversion process including the steps of (a) preconditioning unsaturated triglycerides by catalytic conjugation, cyclization, and cross-link steps; (b) contacting the modified triglycerides with hot-compressed water containing a catalyst, wherein cracking, hydrolysis, decarboxylation, dehydration, aromatization, or isomerization, or any combination thereof, of the modified triglycerides produce a crude hydrocarbon oil and an aqueous phase containing glycerol and lower molecular weight molecules, and (c) refining the crude hydrocarbon oil to produce various grades of biofuels. A triglyceride-to-fuel conversion process further including the steps of (a) carrying out anaerobic fermentation and decarboxylation / dehydration, wherein the anaerobic fermentation produces hydrogen, volatile acids, and alcohols from fermentable feedstocks, and the decarboxylation / dehydration produces alkenes from the volatile acids and alcohols, respectively; (b) feeding the alkenes to the cyclization process; (c) feeding the hydrogen to the post refining process; and (d) recycling the aqueous phase containing glycerol to the decarboxylation / dehydration process. A biofuel composition including straight-chain, branched and cyclo paraffins, and aromatics. The paraffins are derived from conversion of triglycerides. The aromatics are derived from conversion of either triglycerides, petroleum, or coal.

Owner:APPLIED RES ASSOCS INC

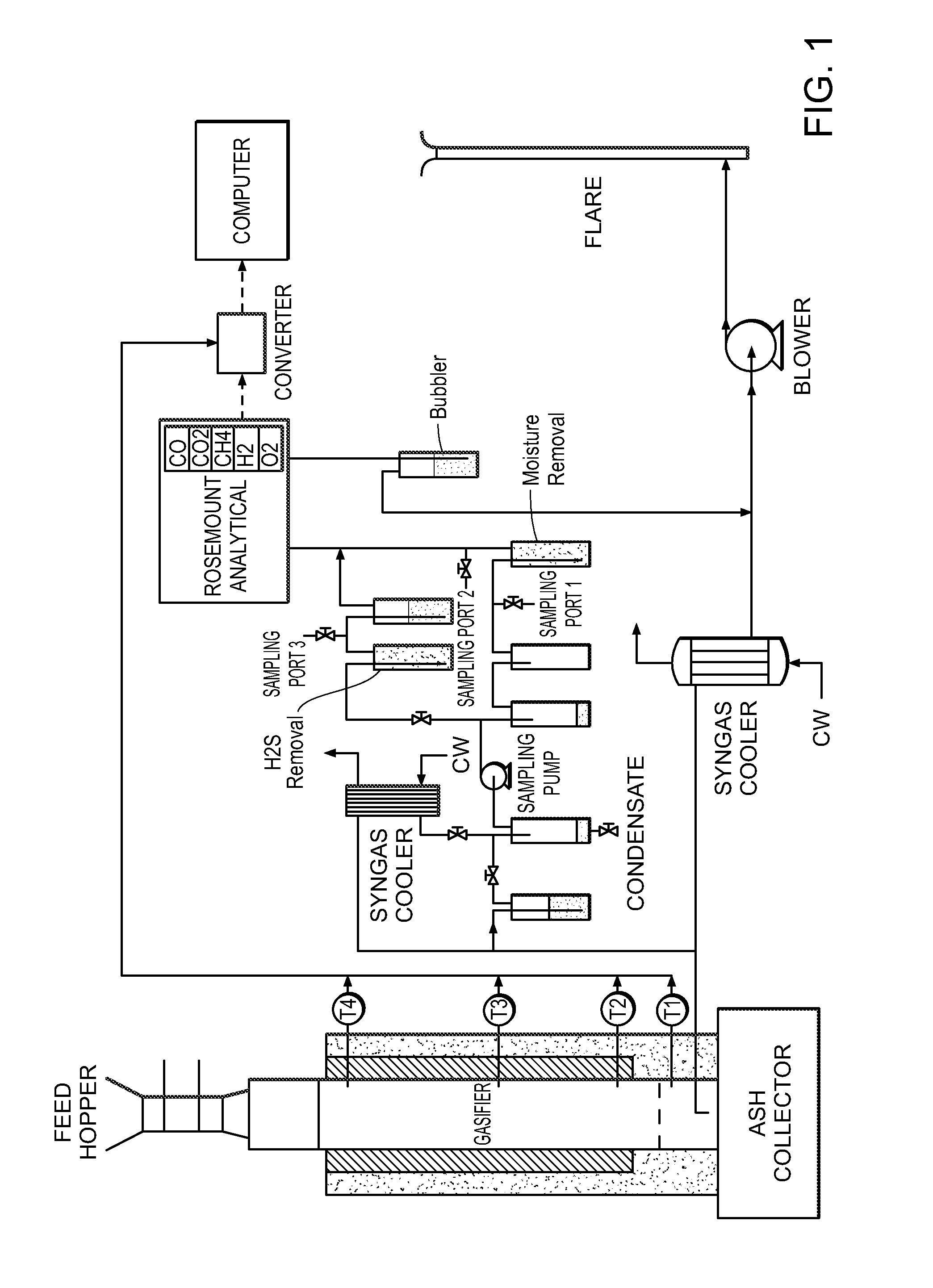

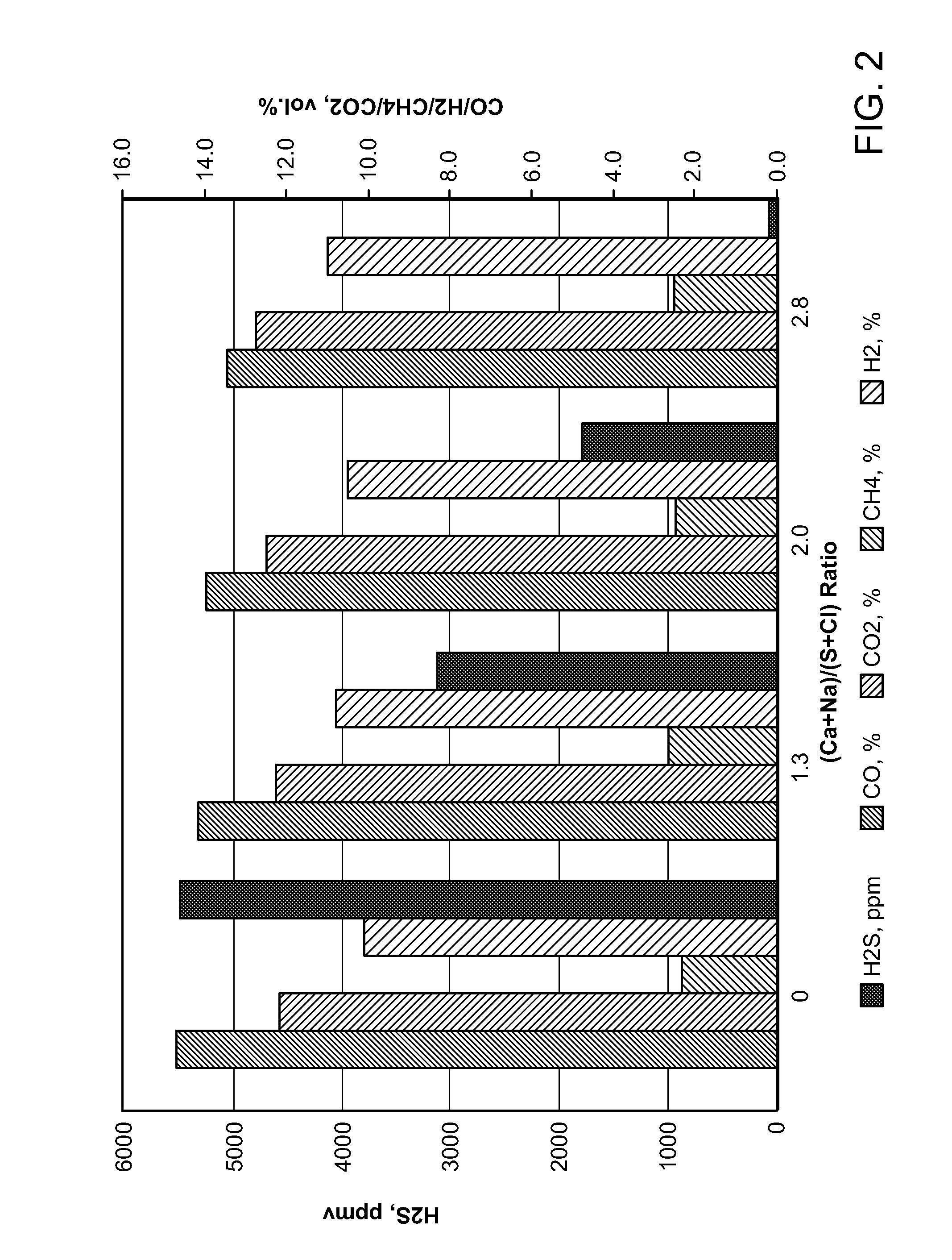

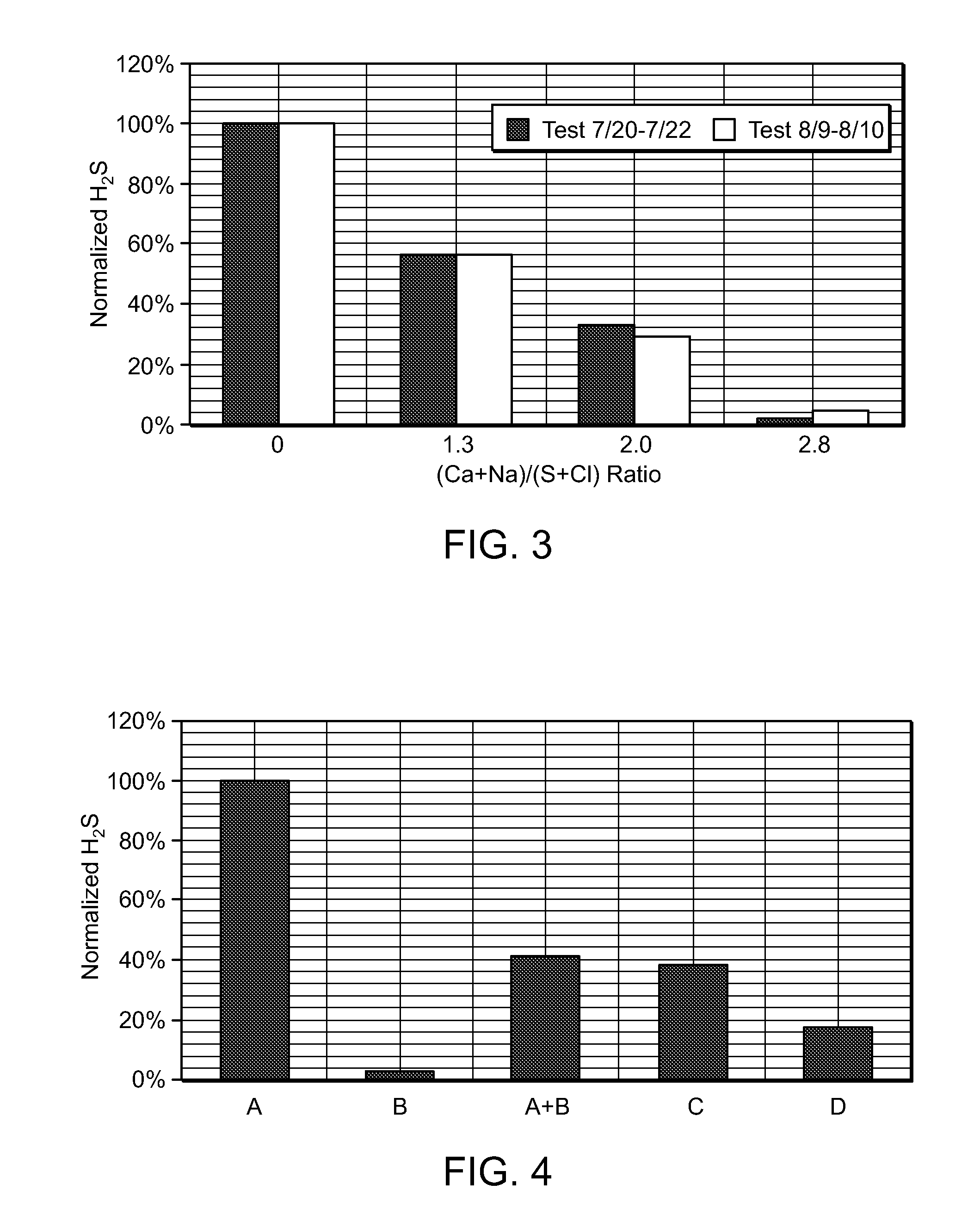

Sorbent containing engineered fuel feed stock

ActiveUS20110099890A1Less-harmful emissionEmission reductionSolid fuel pretreatmentBiofuelsPower stationCombustion

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, methods of making the fuel feed stocks, methods of producing energy from the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles and contain a sorbent. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels. In addition, one or more sorbents can be added to the feed stocks in order to reduce the amount of a variety of pollutants present in traditional fuel and feed stocks, including, but not limited, sulfur and chlorine. Further, these feed stocks with added sorbent can mitigate corrosion, improve fuel conversion, extend power generating plant lifetime, reduce ash slagging, and reduced operating temperature.

Owner:REPOWER IP LLC

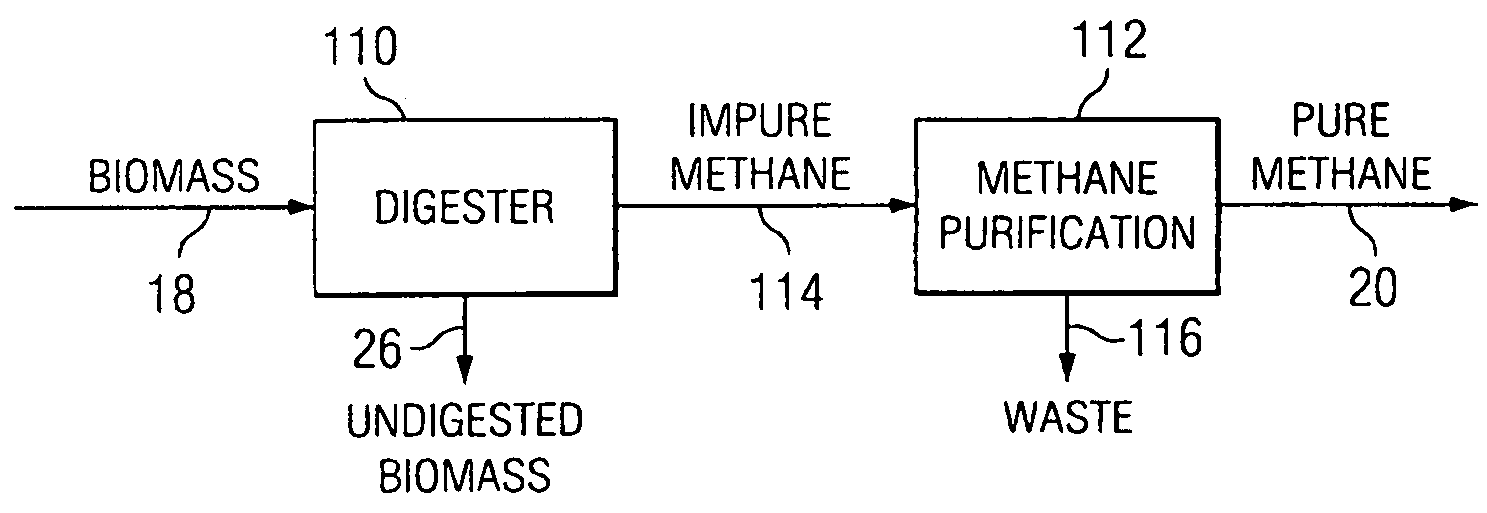

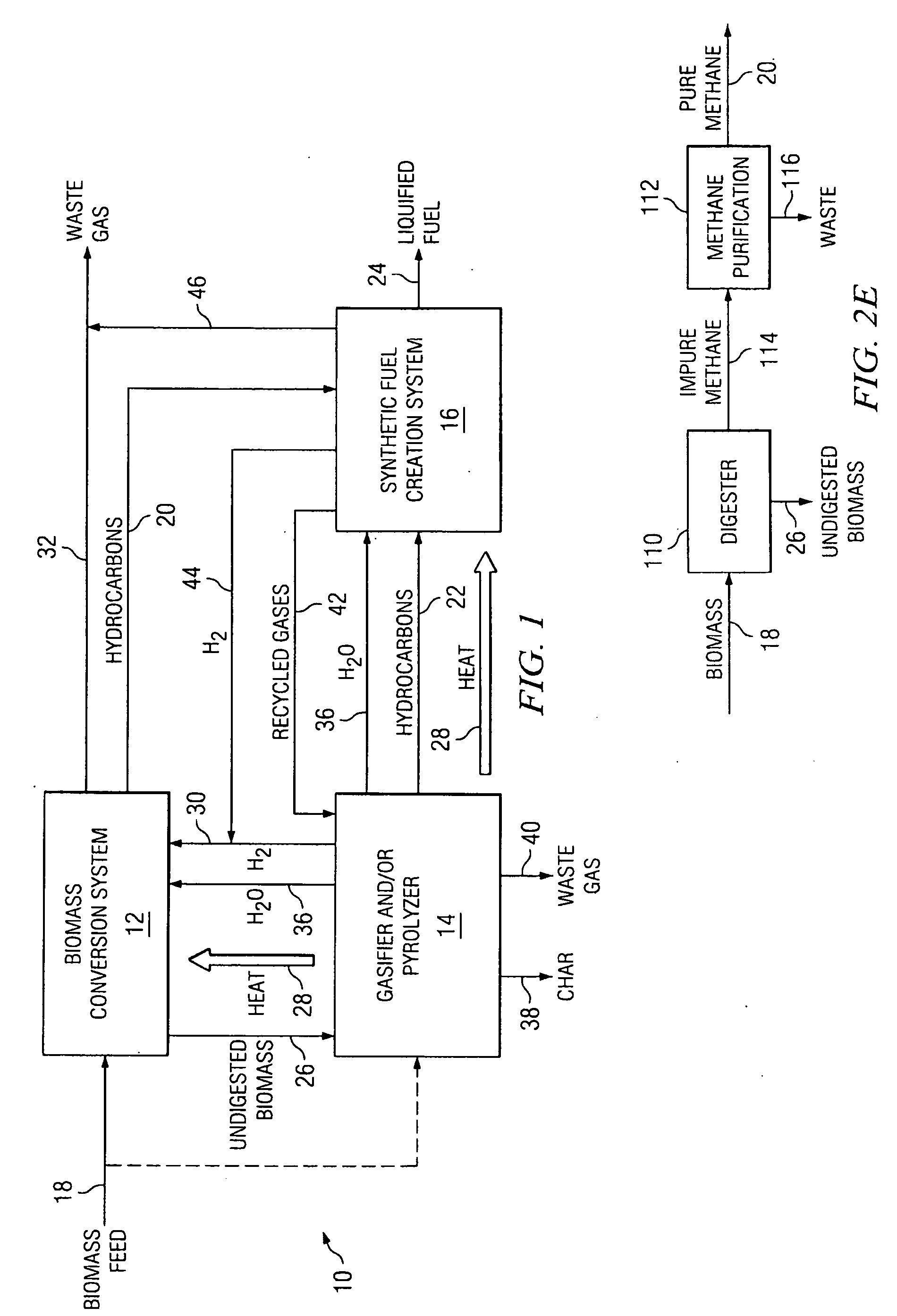

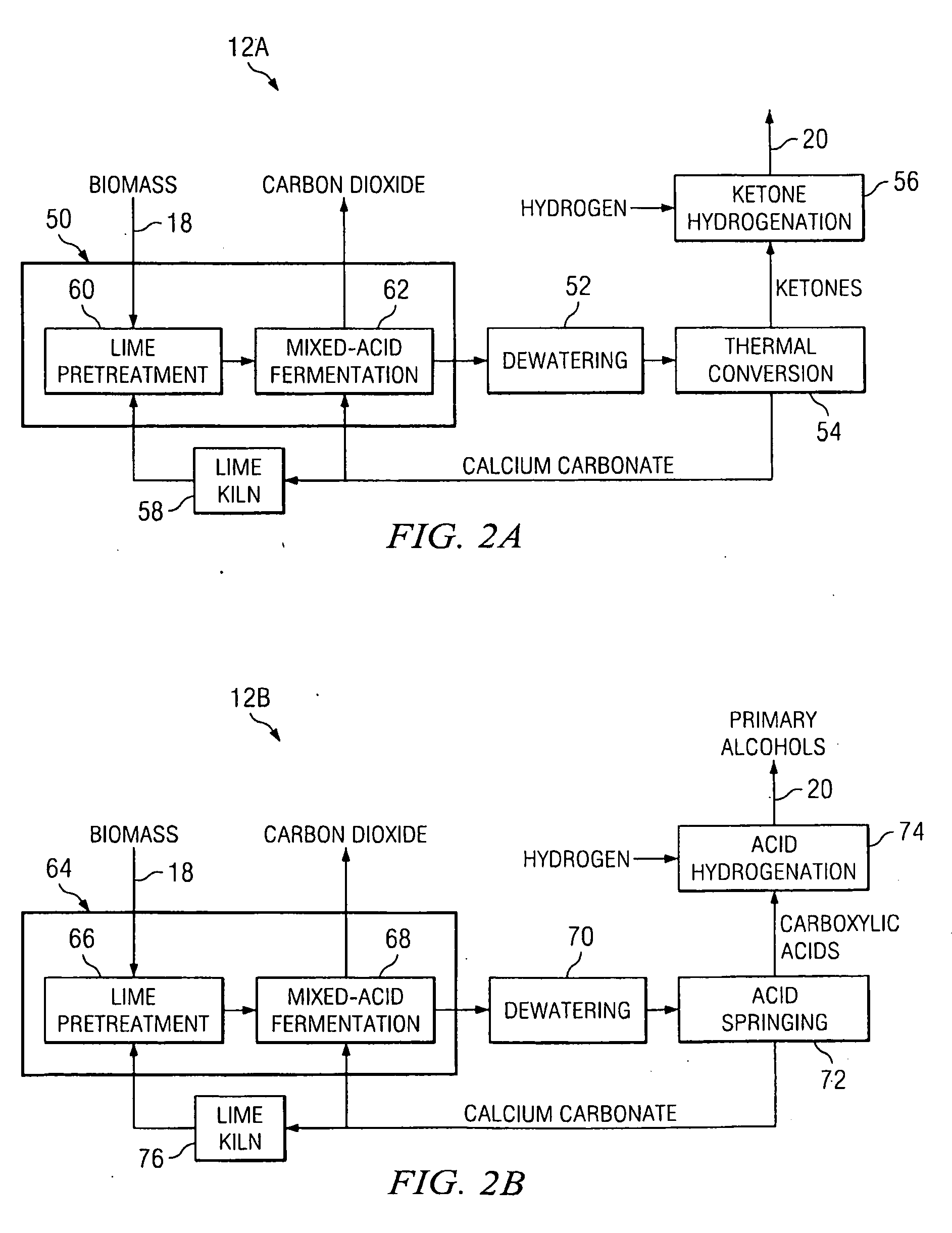

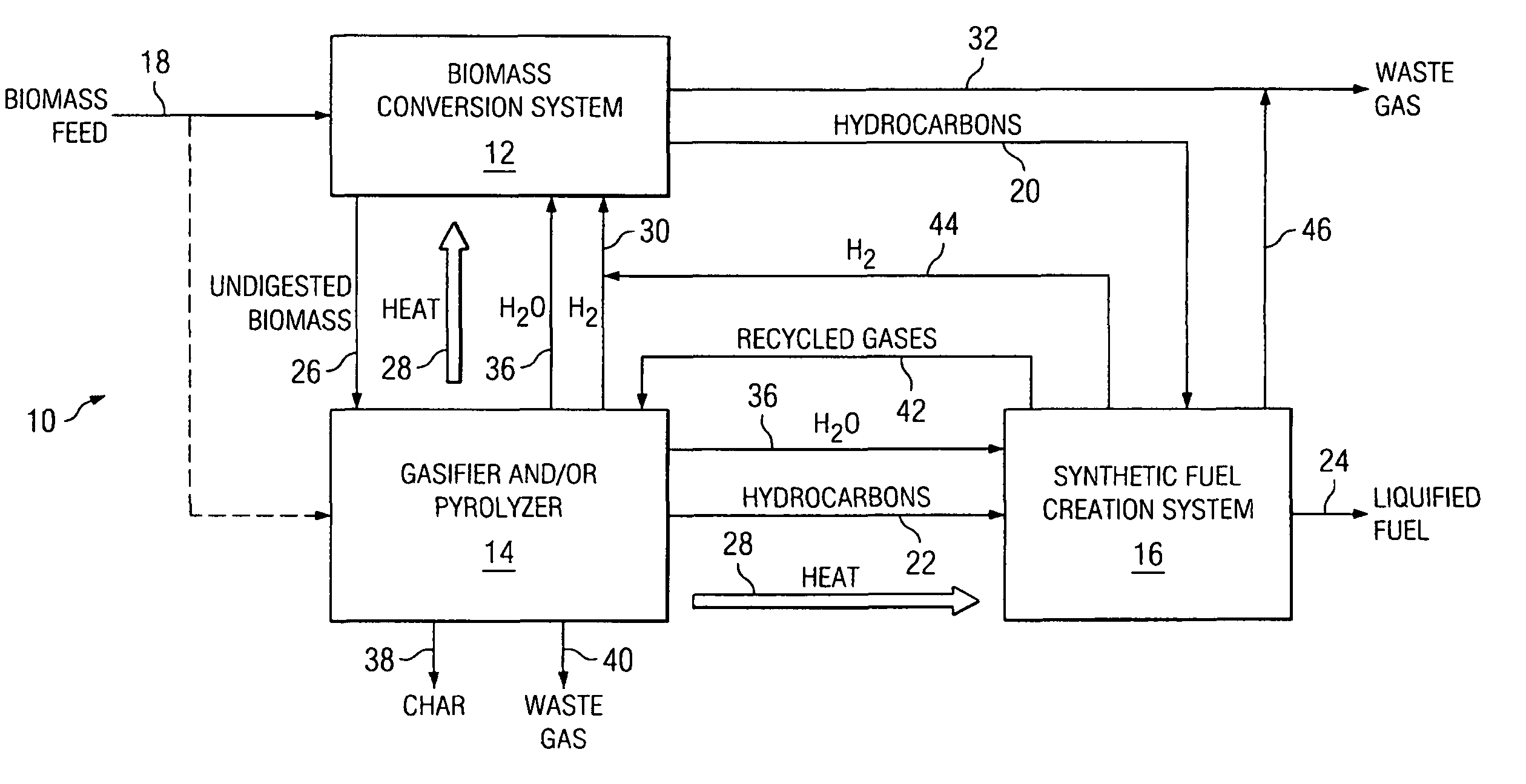

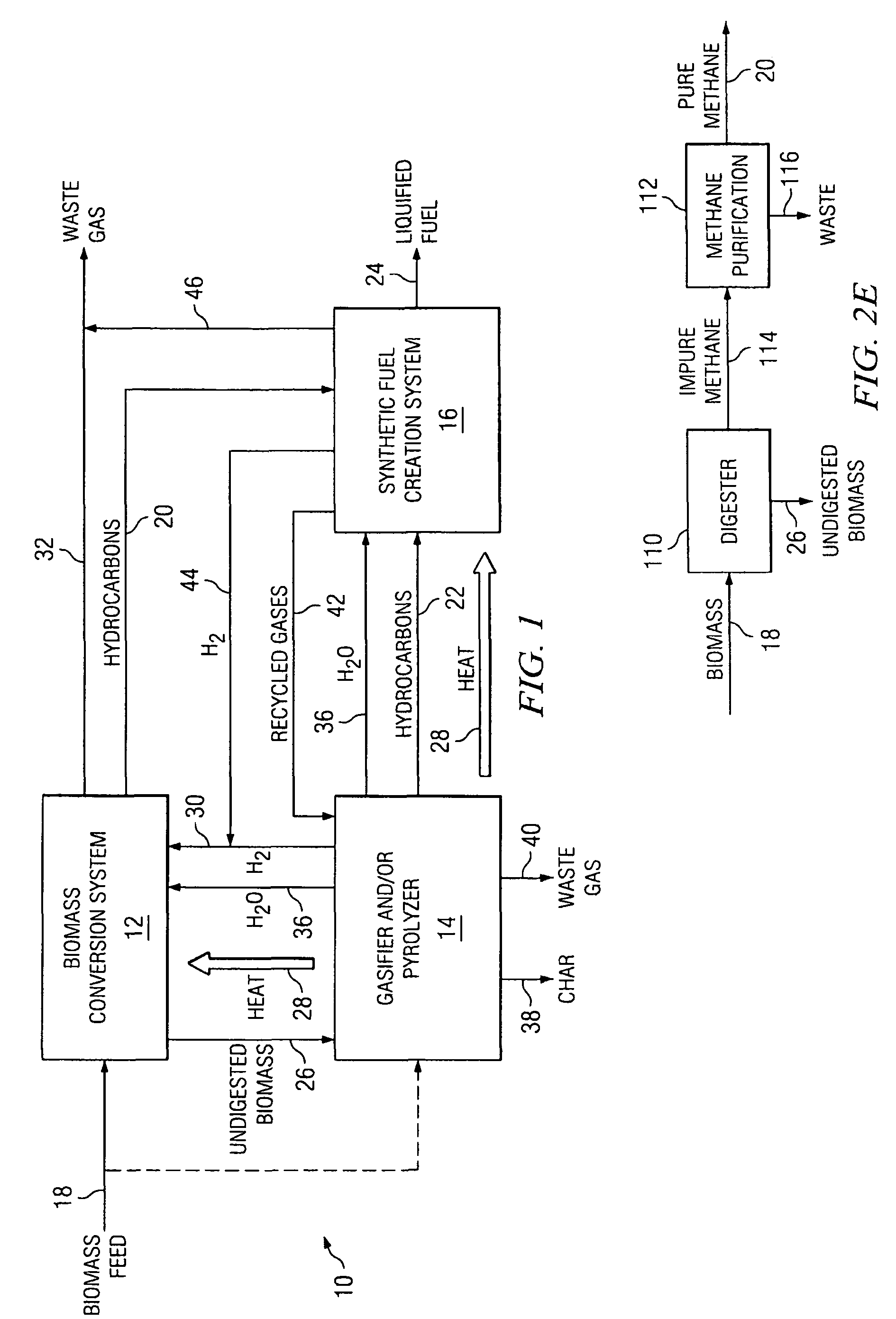

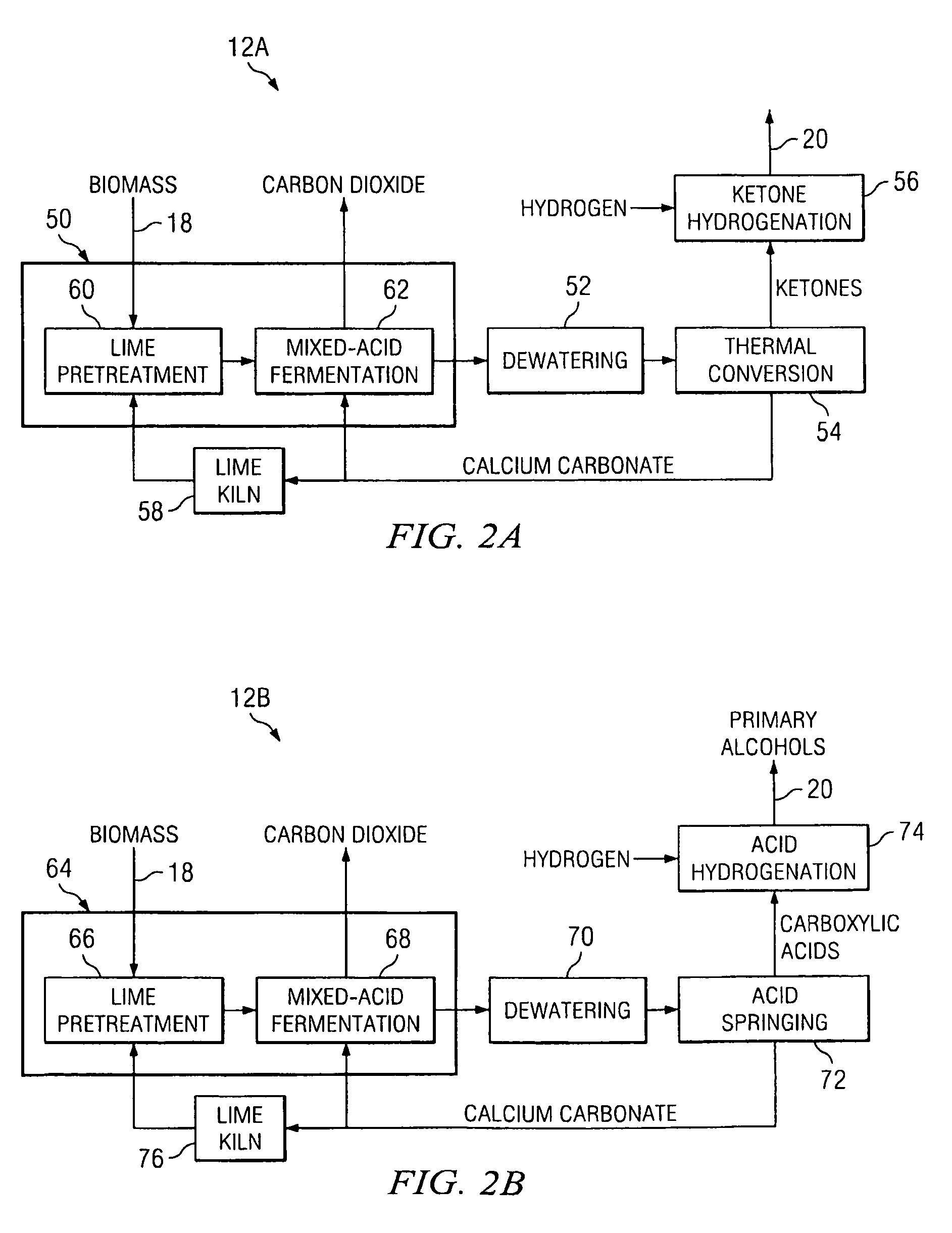

Integrated Biofuel Production System

InactiveUS20090239279A1Increase energy densityImprove conversion efficiencyWaste based fuelSedimentation separationThermal energyResidual biomass

According to an embodiment, a biomass conversion subsystem produces methane and / or alcohol and residual biomass. A pyrolysis or a gasification subsystem is used to produce thermal energy and / or process gasses. The thermal energy may be stored thermal energy in the form of a pyrolysis oil. A fuel conversion subsystem produces liquid hydrocarbon fuels from the methane and / or alcohol using thermal energy and / or process gasses produced by the gasification or pyrolysis subsystem. Because the biomass production system integrates the residual products from biomass conversion and the residual thermal energy from pyrolysis or gasification, the overall efficiency of the integrated biomass production system is greatly enhanced.

Owner:TEXAS A&M UNIVERSITY

Integrated biofuel production system

InactiveUS8153850B2Improve efficiencyIncrease energy densityGas production bioreactorsWaste based fuelThermal energySystem integration

According to an embodiment, a biomass conversion subsystem produces methane and / or alcohol and residual biomass. A pyrolysis or a gasification subsystem is used to produce thermal energy and / or process gasses. The thermal energy may be stored thermal energy in the form of a pyrolysis oil. A fuel conversion subsystem produces liquid hydrocarbon fuels from the methane and / or alcohol using thermal energy and / or process gasses produced by the gasification or pyrolysis subsystem. Because the biomass production system integrates the residual products from biomass conversion and the residual thermal energy from pyrolysis or gasification, the overall efficiency of the integrated biomass production system is greatly enhanced.

Owner:TEXAS A&M UNIVERSITY

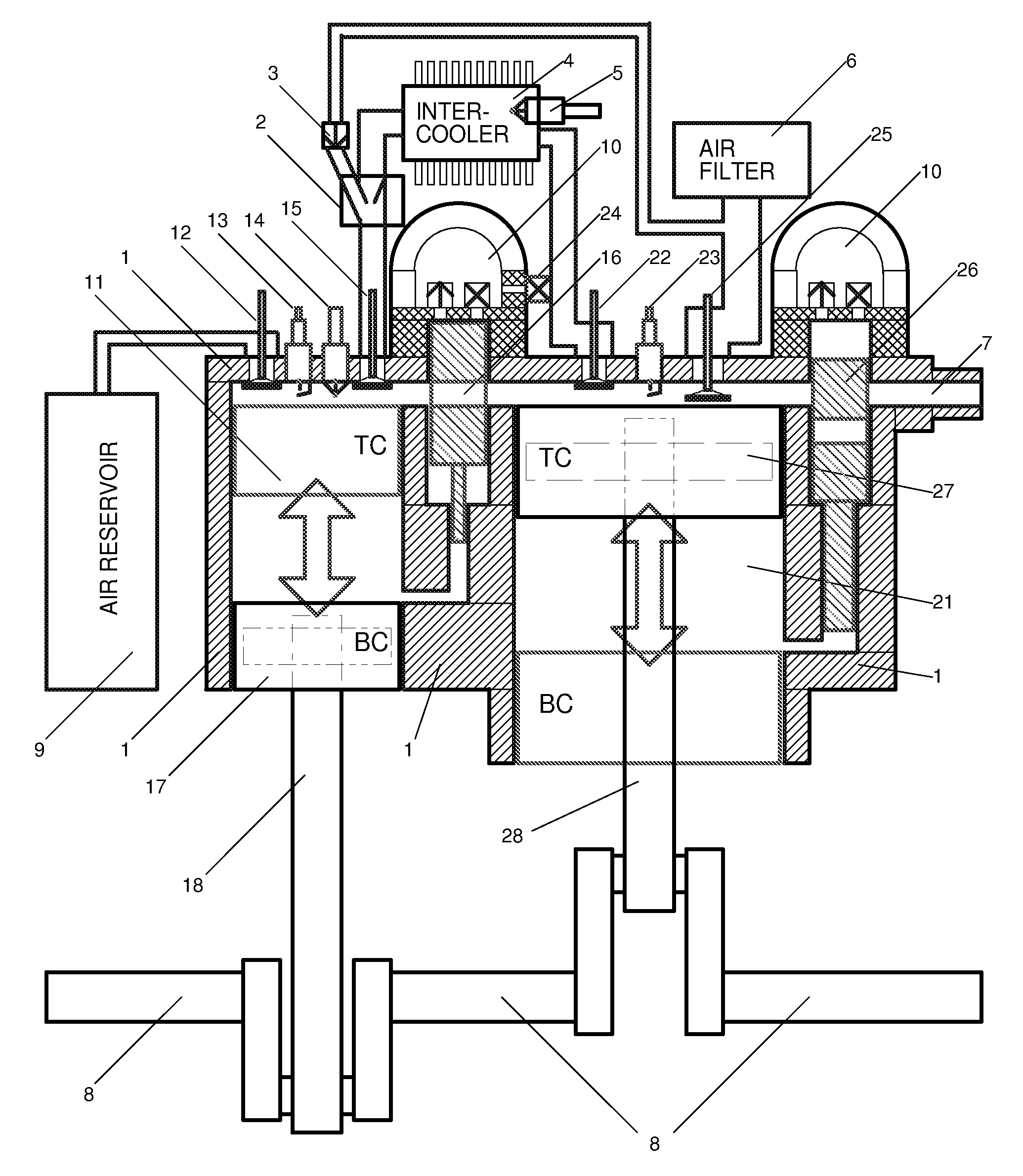

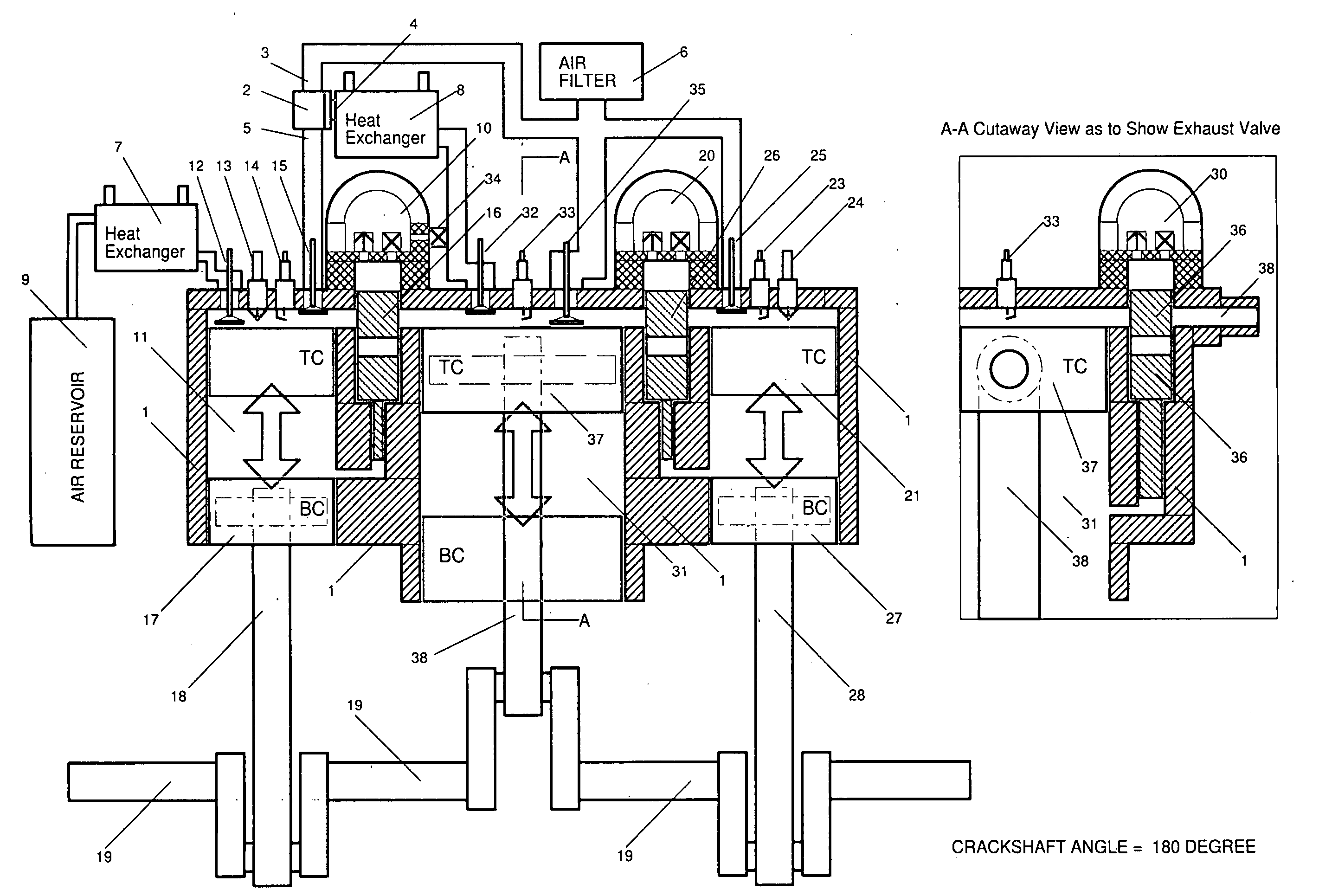

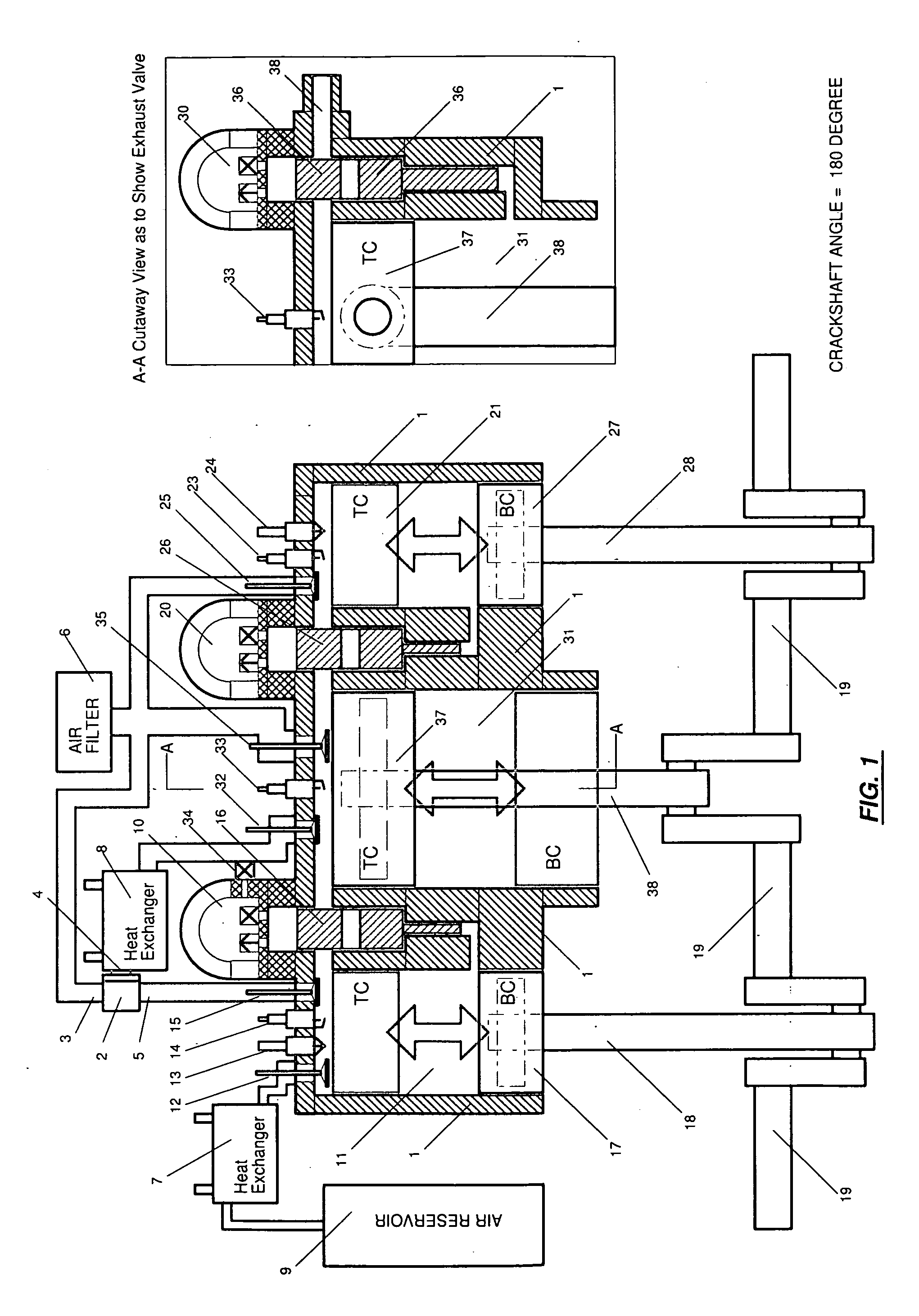

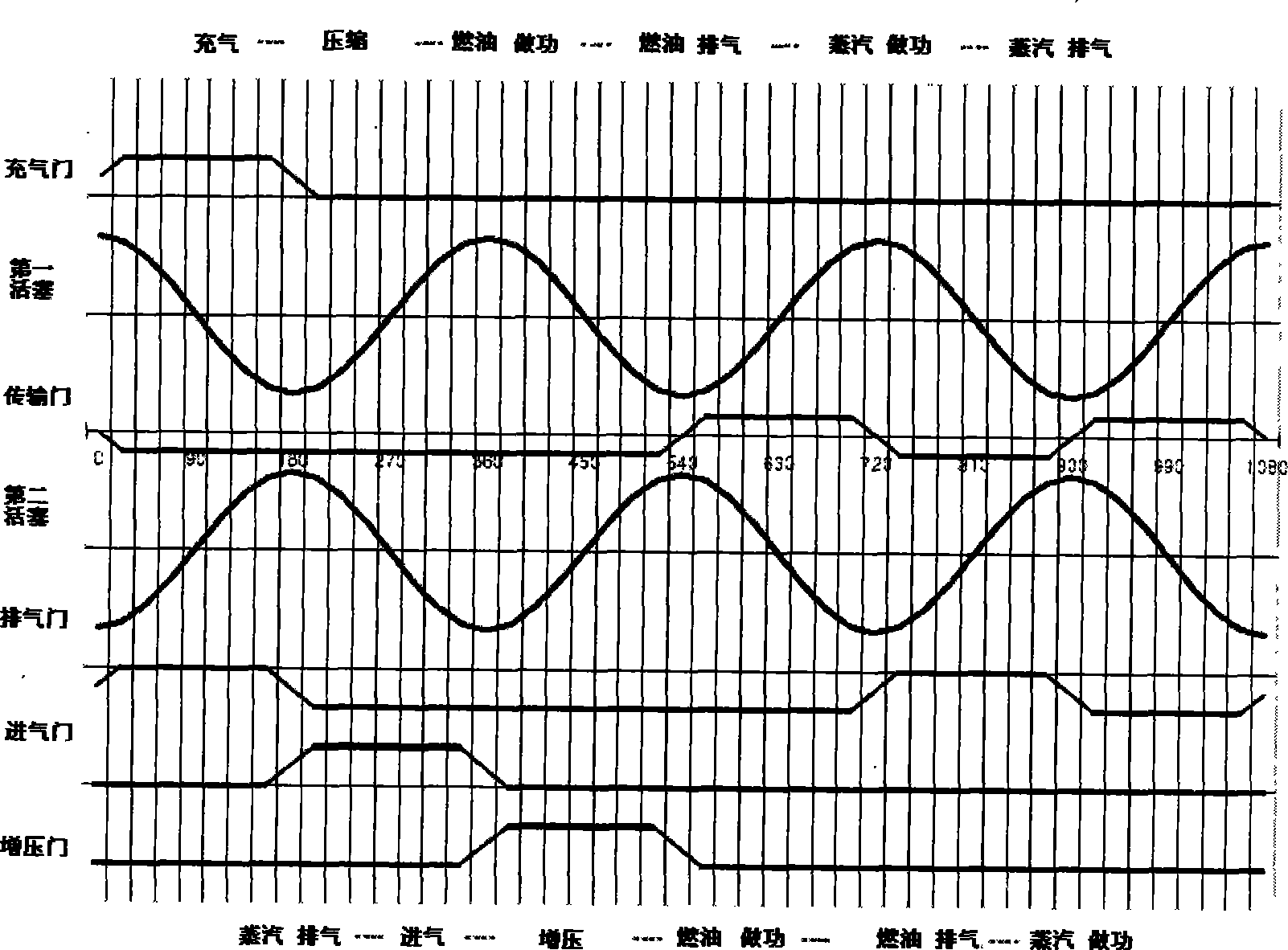

High efficiency integrated heat engine (HEIHE)

InactiveUS20090056331A1Reduce heat lossEfficient heatingInternal combustion piston enginesSteam engine plantsWork periodWorking fluid

The present invention is a High Efficient Integrated Heat Engine, or HEIHE for short. HEIHE is a reciprocal combustion engine integrated with both compound cycle and combined cycle. HEIHE comprises twin compound cylinder structure, with the first cylinder being the primary combustion and / or expansion cylinder; the second cylinder being the secondary combustion and / or expansion cylinder. Power strokes driven by expansions of different working fluids such as air-fuel combustion products, steam and compressed air, are integrated into one engine block. Twin cylinder structure provides compound expansions of three (3) different fluids as to recover the energies that would be lost with the exhaust fluids or during braking. All of these make HEIHE work around six (6) periods with twelve (12) operation strokes. Among six (6) working periods involved, four (4) periods contain four (4) different power strokes but only one of the power strokes consumes the fuel. Thus the fuel conversion efficiency could be greatly increased, or even be doubled comparing with the conventional internal combustion engine (ICE).

Owner:ZHAO YUANPING +1

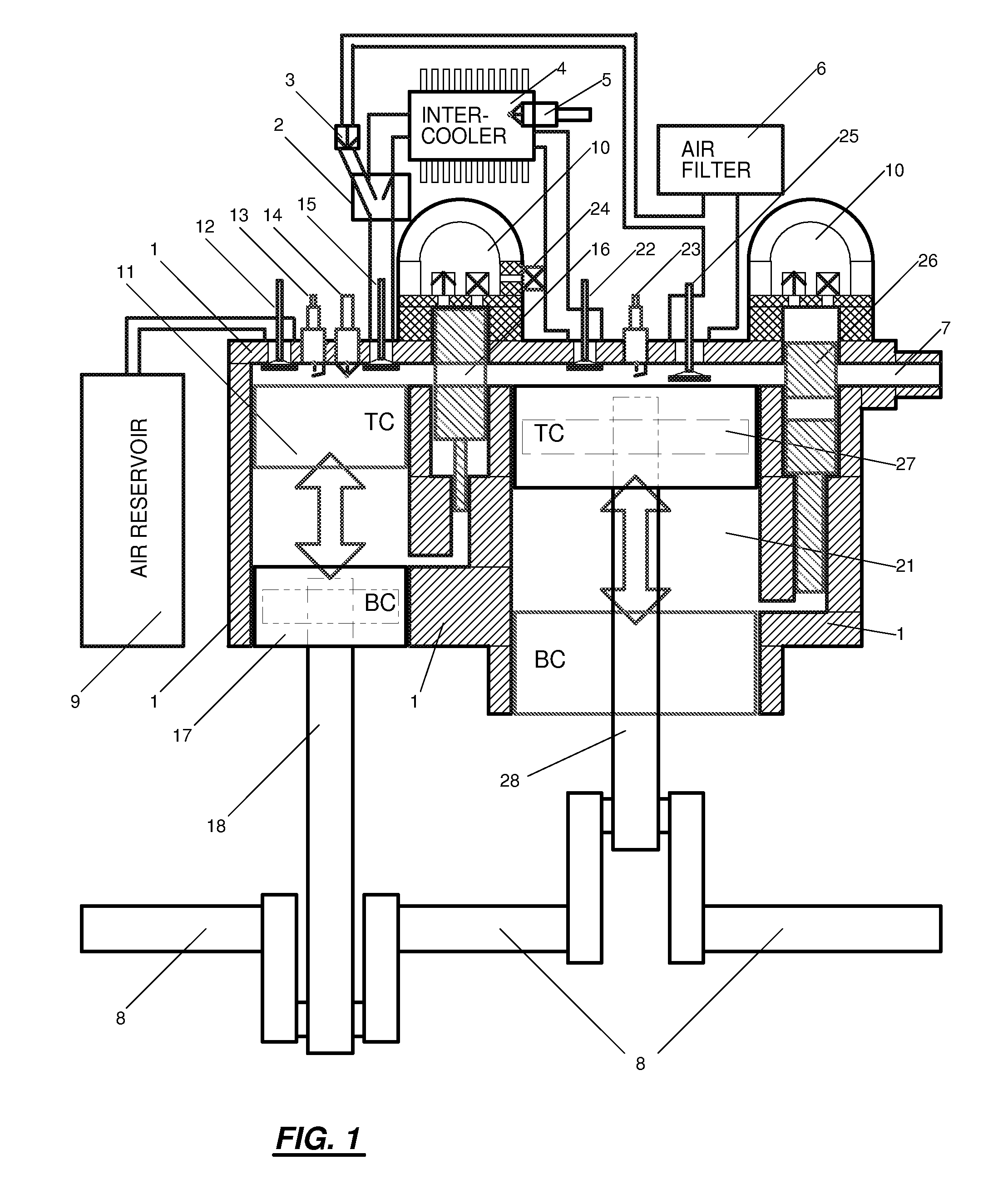

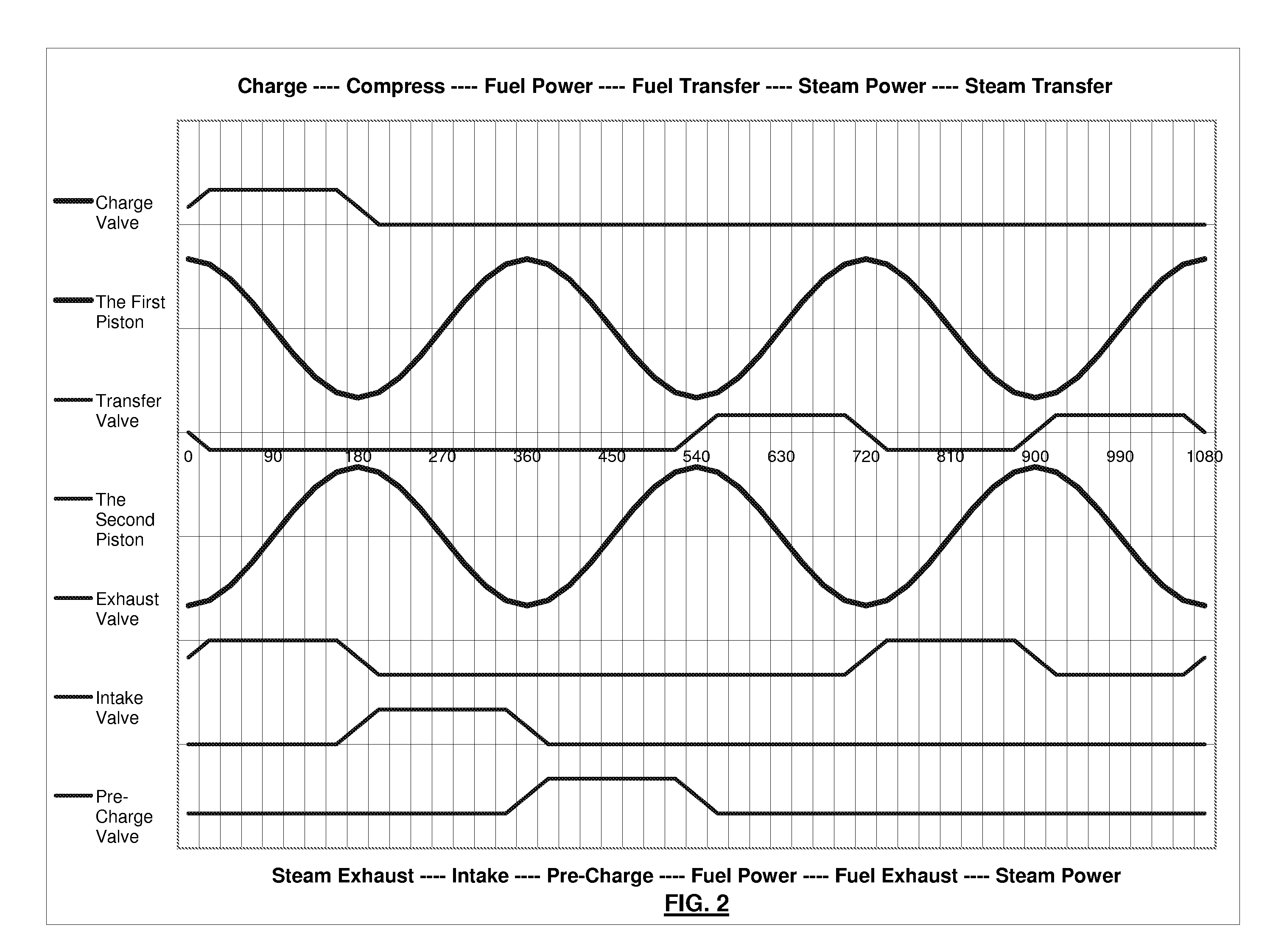

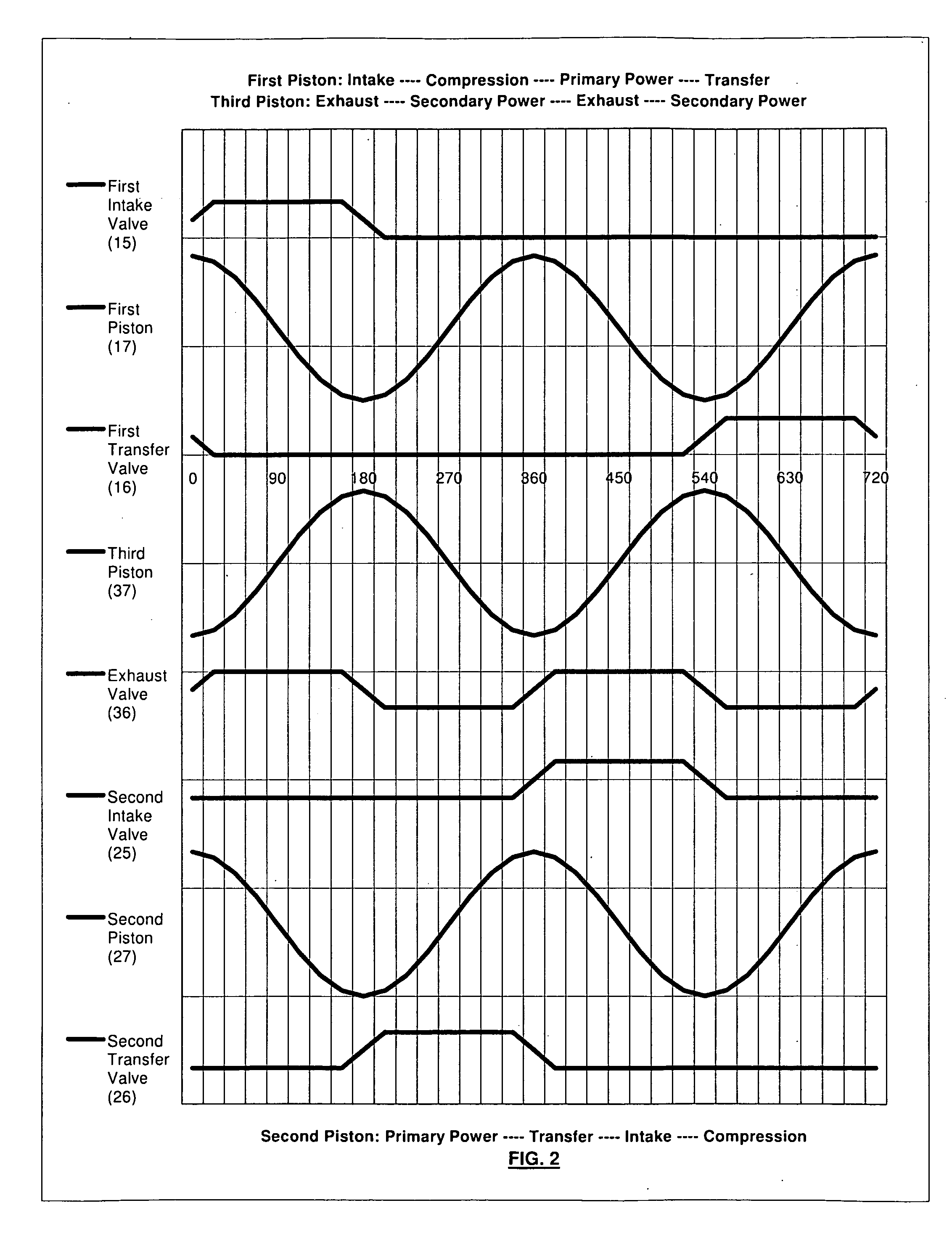

High efficiency integrated heat engine-2 (heihe-2)

InactiveUS20090056670A1Improve efficiencyImprove conversion efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelWork periodWorking fluid

The present invention is a second kind of High Efficiency Integrated Heat Engine, or HEIHE-2 for short. HEIHE-2 is a reciprocal combustion engine integrated with both compound cycle and combined cycle. HEIHE-2 comprises triple compound cylinder structure, with the first cylinder and the second cylinder being the primary combustion and / or expansion cylinders; and the third cylinder being the secondary combustion and / or expansion cylinder. Power strokes driven by expansions of different working fluids such as air-fuel combustion products, steam and compressed air, are integrated into one engine block. Triple cylinder structure provides compound expansions of three (3) different fluids as to recover the energies that would be lost with the exhaust fluids or during braking. All of these make HEIHE-2 work around four (4) periods with six (6) different operation strokes. All four (4) working periods contain four (4) different power strokes but only two (2) of them consume the fuel. Thus the fuel conversion efficiency could be greatly increased, or even be doubled comparing with the conventional internal combustion engine (ICE).

Owner:ZHAO YUANPING +1

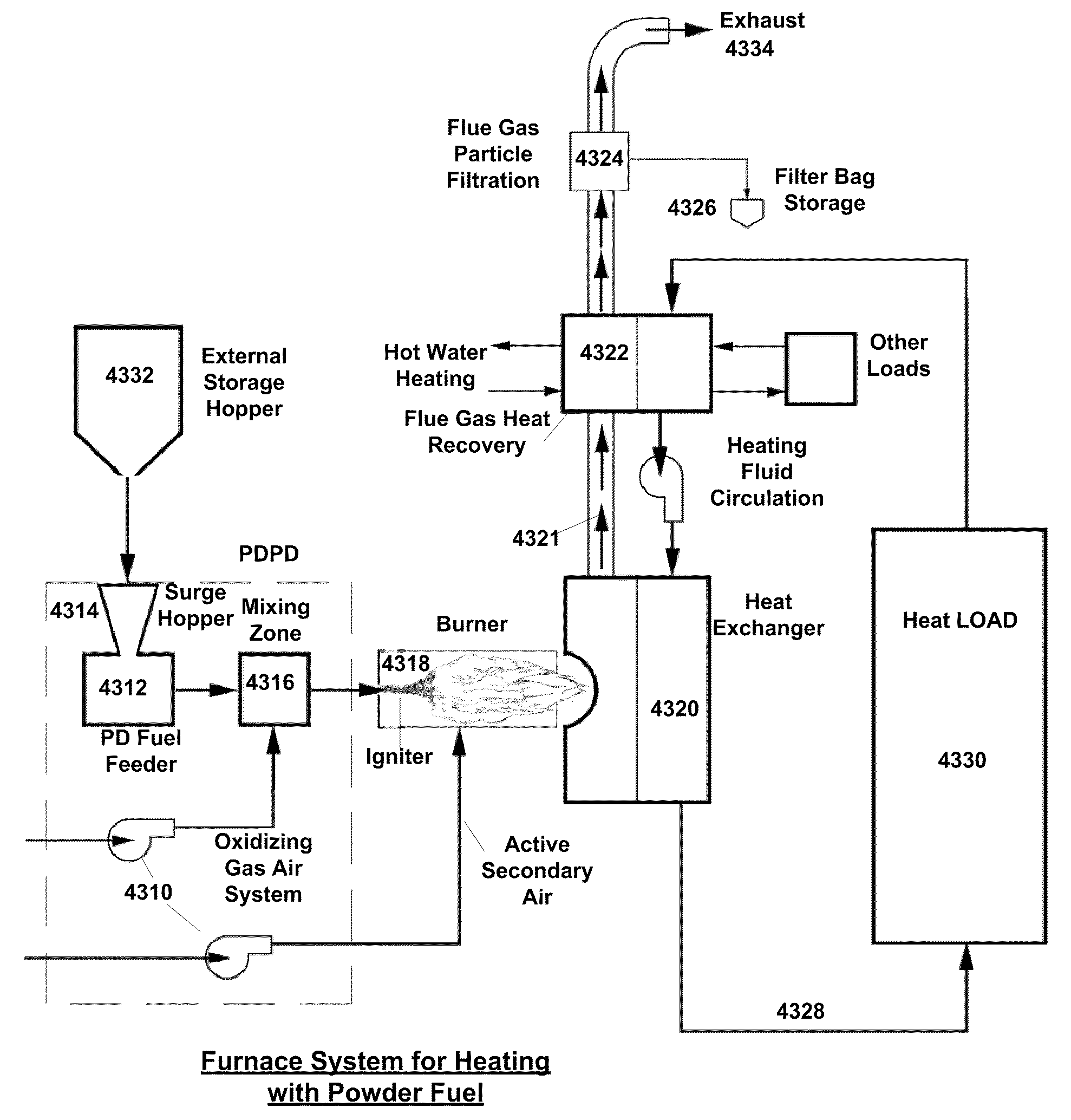

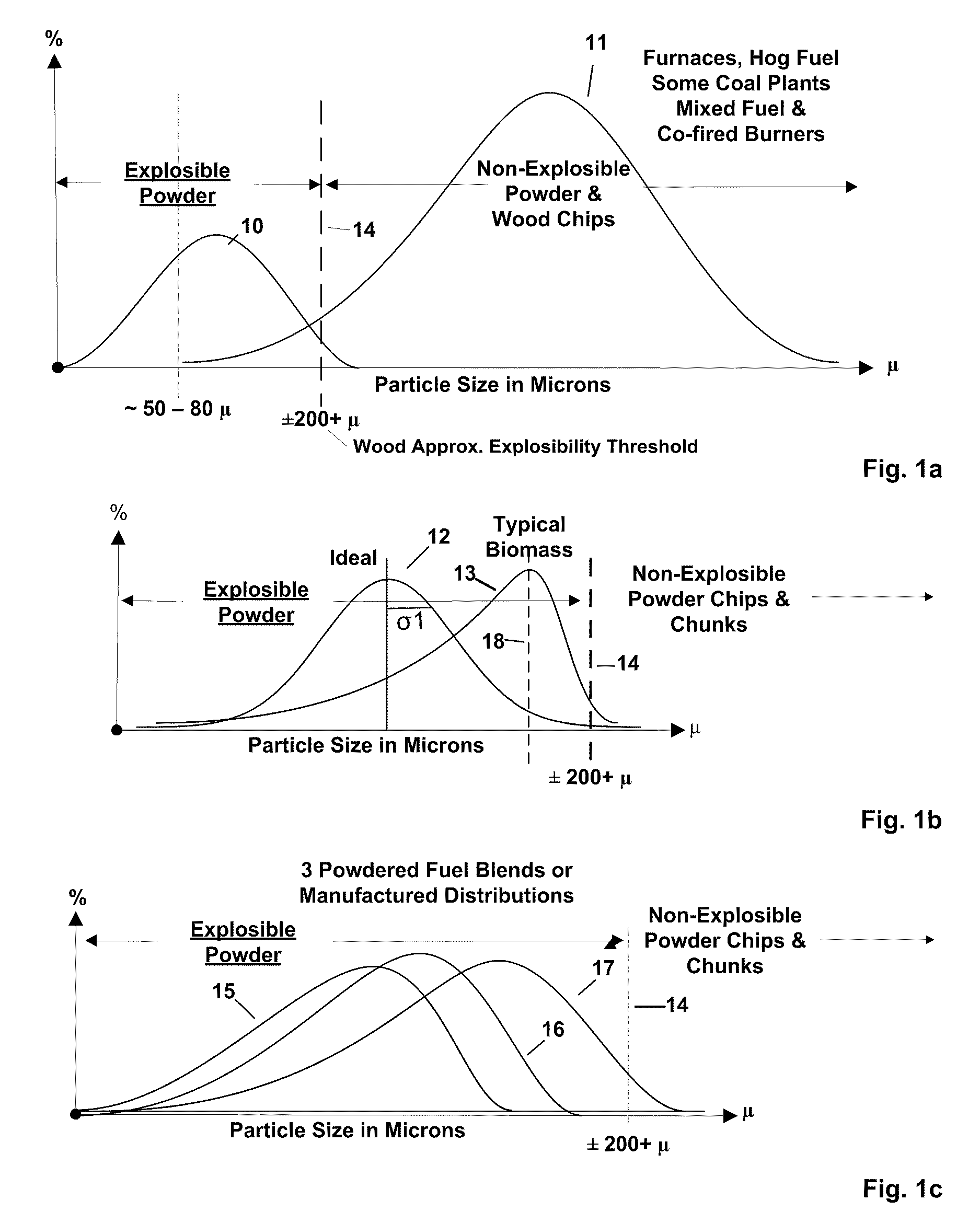

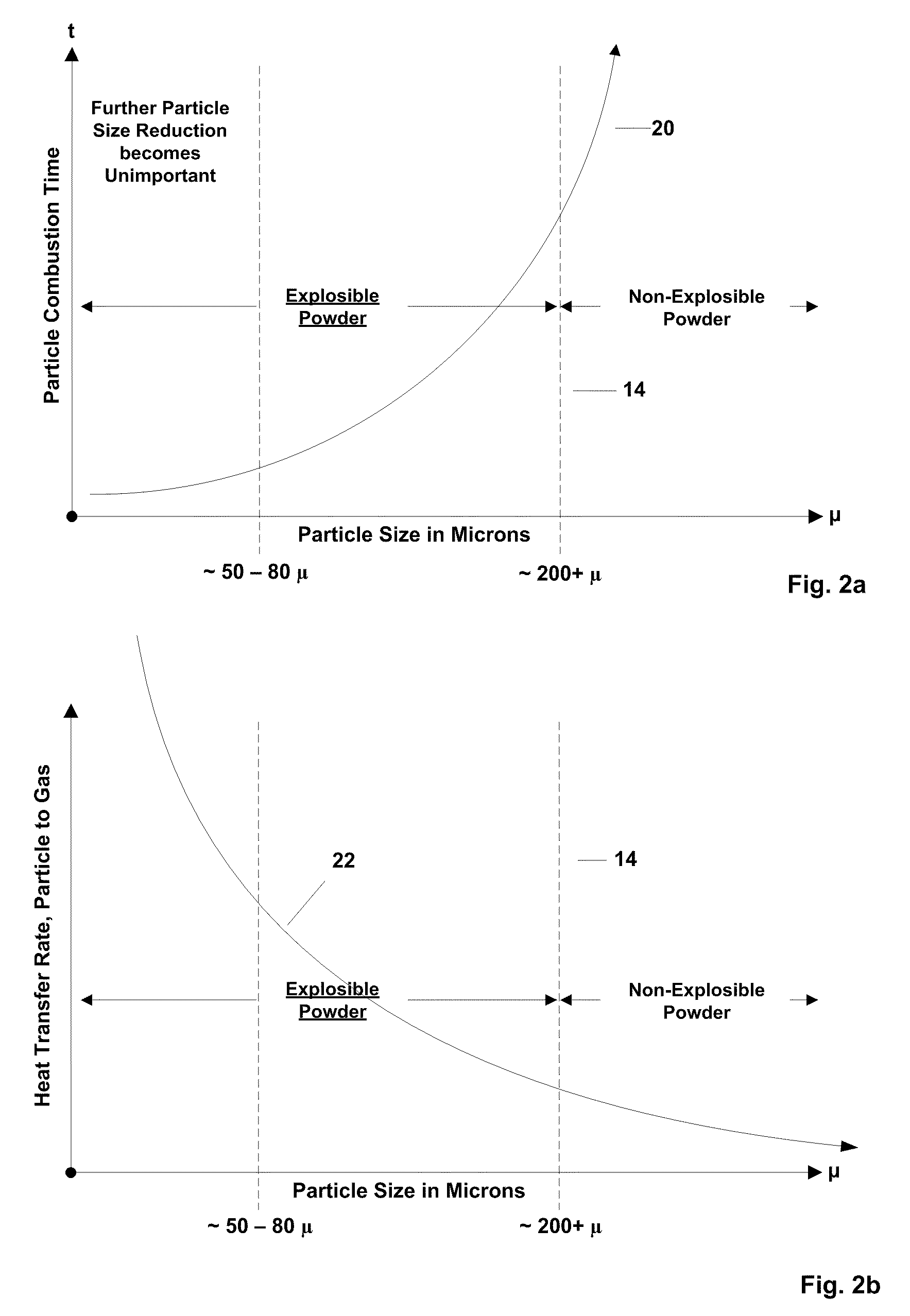

Powdered fuel conversion systems and methods

The burner preferably exclusively burns substantially explosible solid fuels and preferably has instant ON-OFF thermostat control, wastes no energy preheating the enclosure or external air supply, achieves stable combustion the moment the powder-air mix is ignited in our burner, is used in the upward vertical mode except for oil burner retrofits, burns a solid fuel in a single-phase regime as if it were a vaporized liquid or gas, is designed to complete combustion within the burner housing itself rather than in a large, high temperature furnace enclosure which it feeds, has an ultra-short residence time requirement, is a recycle consuming burner with self-contained management of initially unburned particles, is much smaller, simpler and lower cost, has a wider dynamic range / turndown ratio, is more efficient in combustion completeness and thermal efficiency, and operates with air-fuel mix approximately at the flame speed.

Owner:MCKNIGHT JAMES K +2

Methods of adjusting the Wobbe Index of a fuel and compositions thereof

Novel methods of providing fuels to a gas-to-liquids facility are disclosed. A gas-to-liquids facility typically operates in a remote location and therefore must supply its own energy needs. These facilities are often sustained by fuels having different heating values, and for smooth operation while transitioning from one fuel to another, (such as during startup, shut down, and emergencies) the Wobble Indices of the two fuels cannot greatly vary from one another. According to embodiments of the present invention, the Wobble Index of either or both of the fuels is adjusted such that their ratio is less than or equal to about 3. The fuel having the higher Wobble Index may be natural gas, and materials such as nitrogen, carbon dioxide and flue gas may be added to lower its Wobble Index. The fuel having the lower Wobble Index may be the tail gas of a Fischer-Tropsch synthesis, and materials such as methane, ethane, LPG, or natural gas may be added to raise its Wobble Index. Alternatively, carbon dioxide may be removed from the tail gas to raise its Wobble Index.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

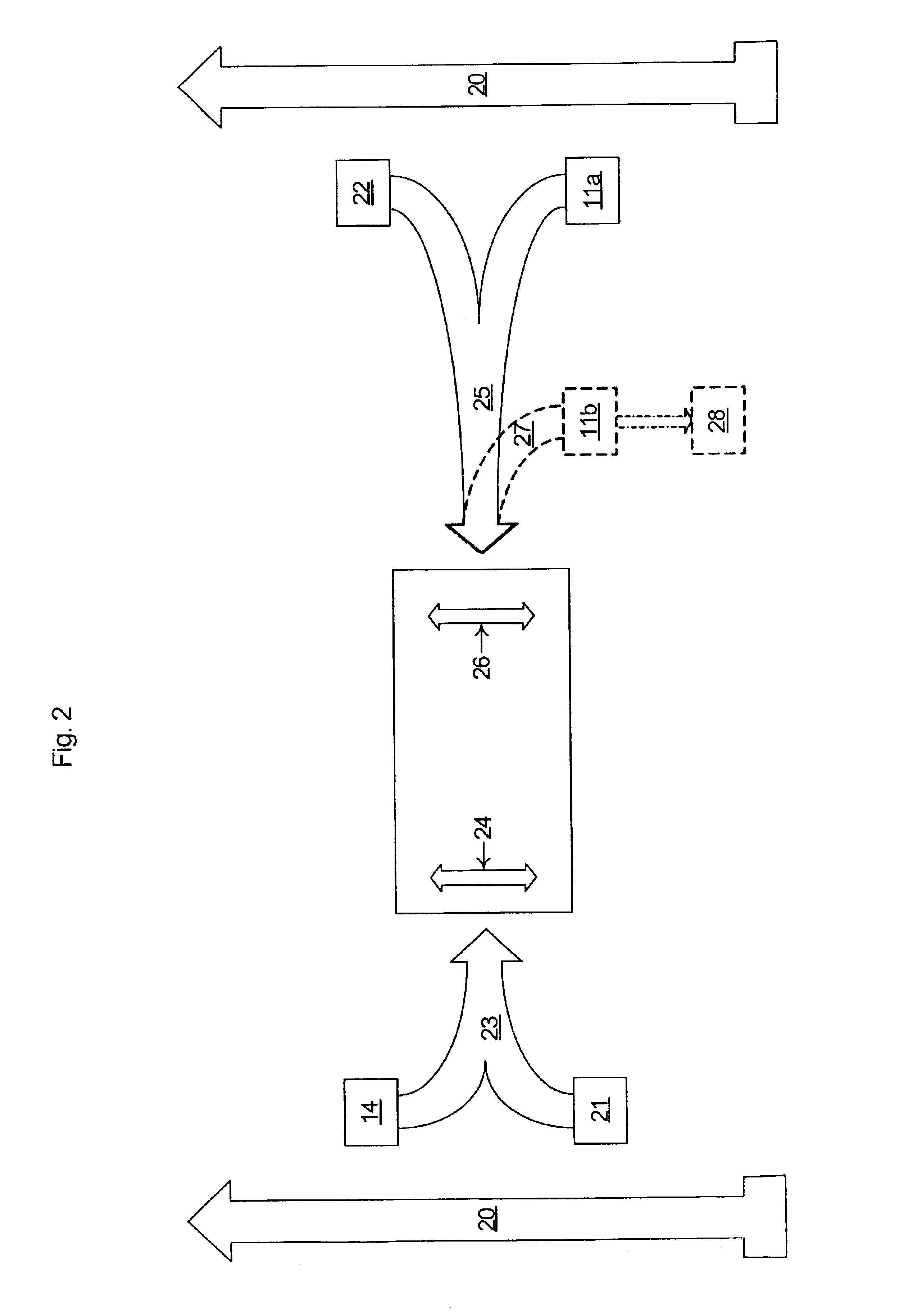

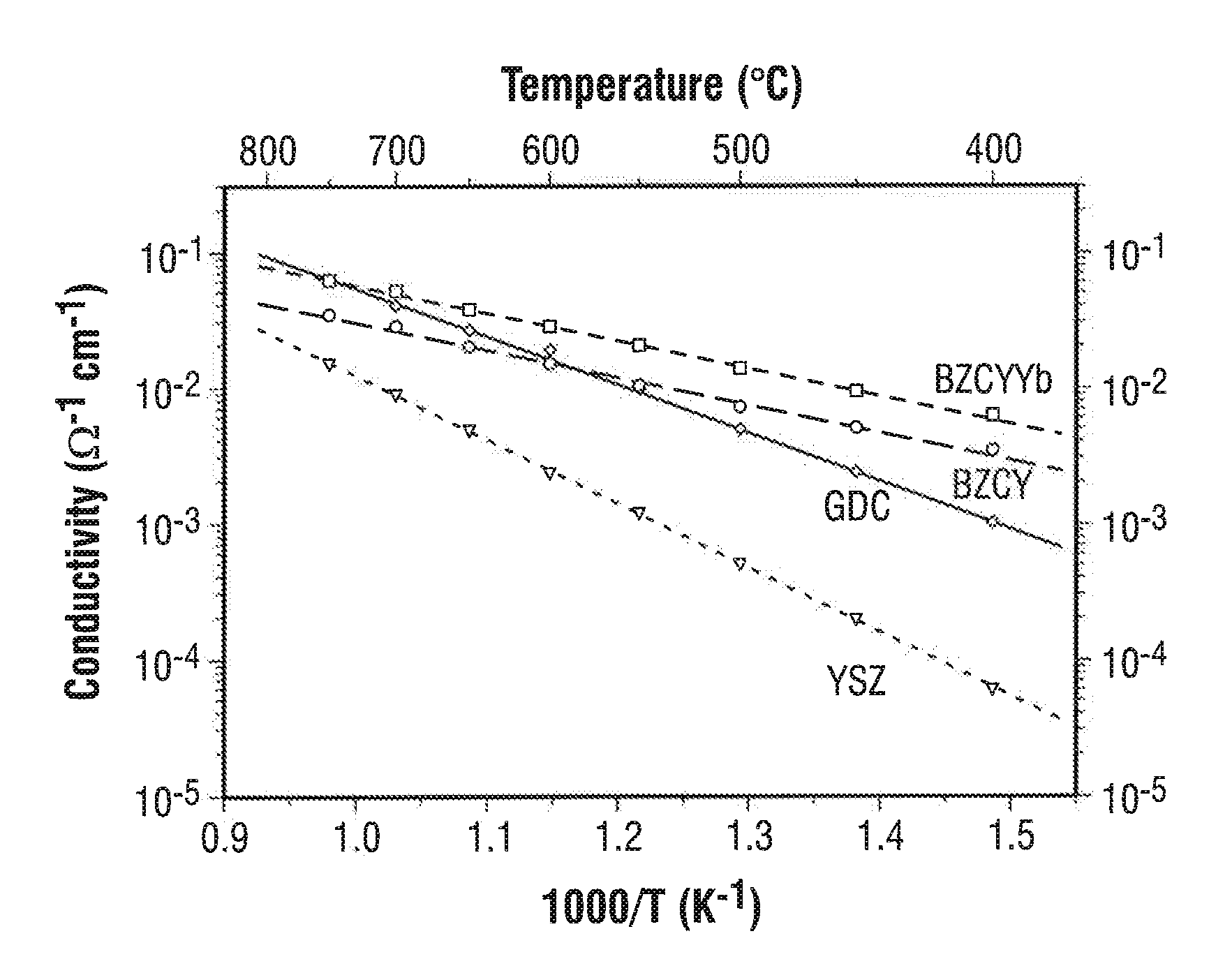

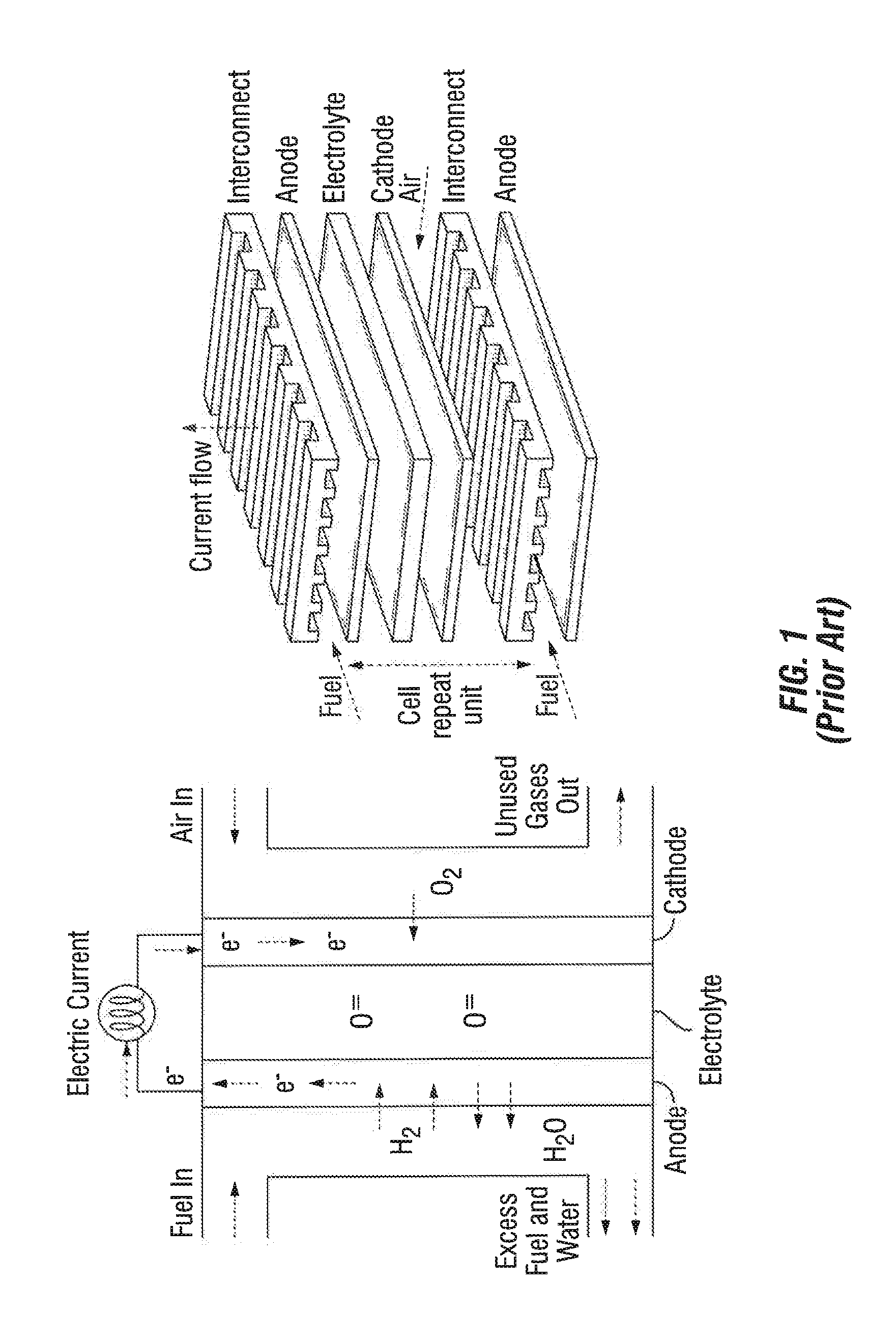

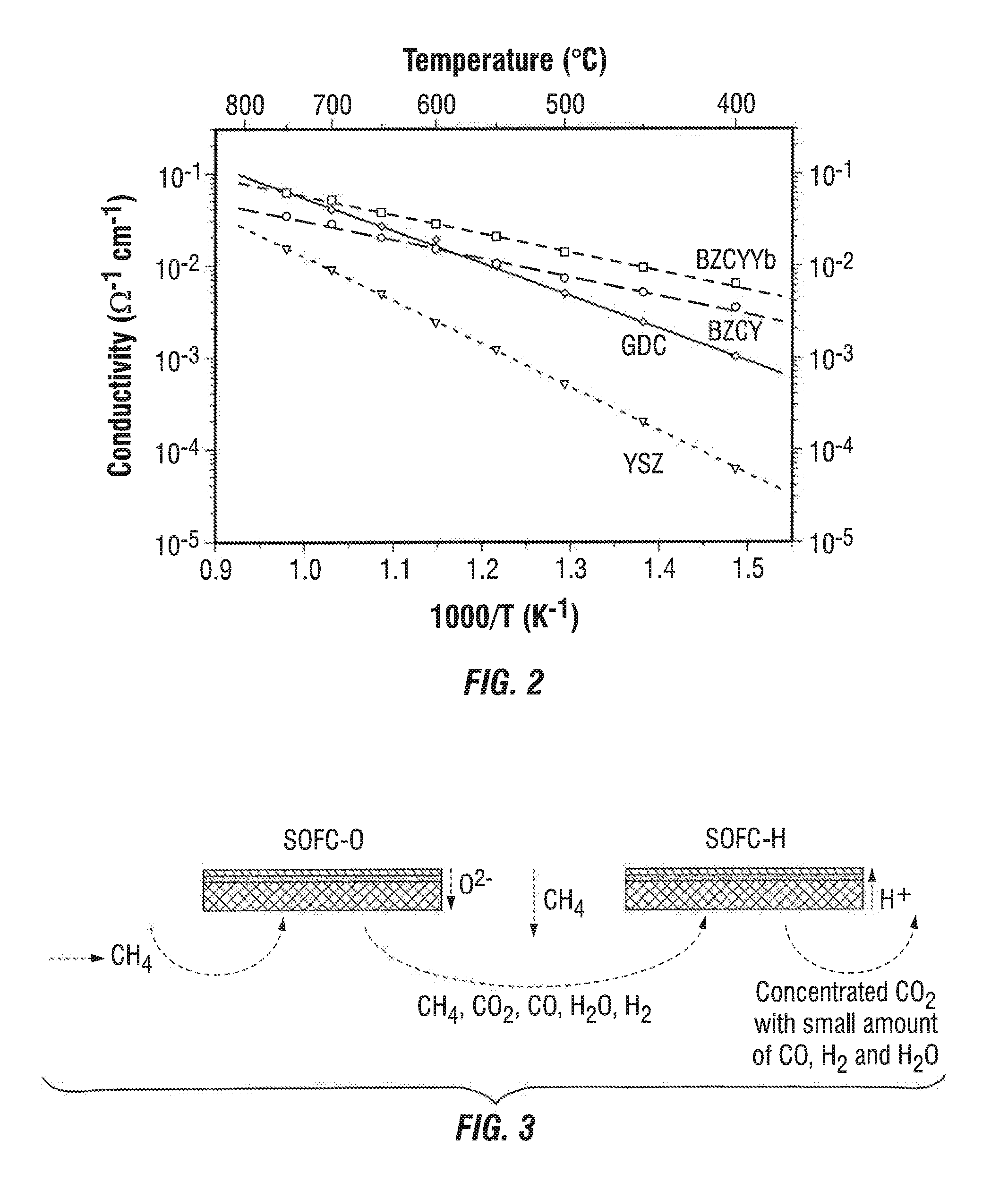

Integrated natural gas powered sofc systems

ActiveUS20130209904A1Improve performanceHigh fuel utilizationElectrolytesSolid electrolyte fuel cellsSteam reformingProcess engineering

The present invention discloses an integrated SOFC system powered by natural gas. Specifically, a SOFC-O cell is combined with a SOFC-H cell so as to take advantage of the high operating temperature and steam reforming capabilities of the SOFC-O cell as well as the higher fuel conversion efficiency of the SOFC-H cell.

Owner:GEORGIA TECH RES CORP +1

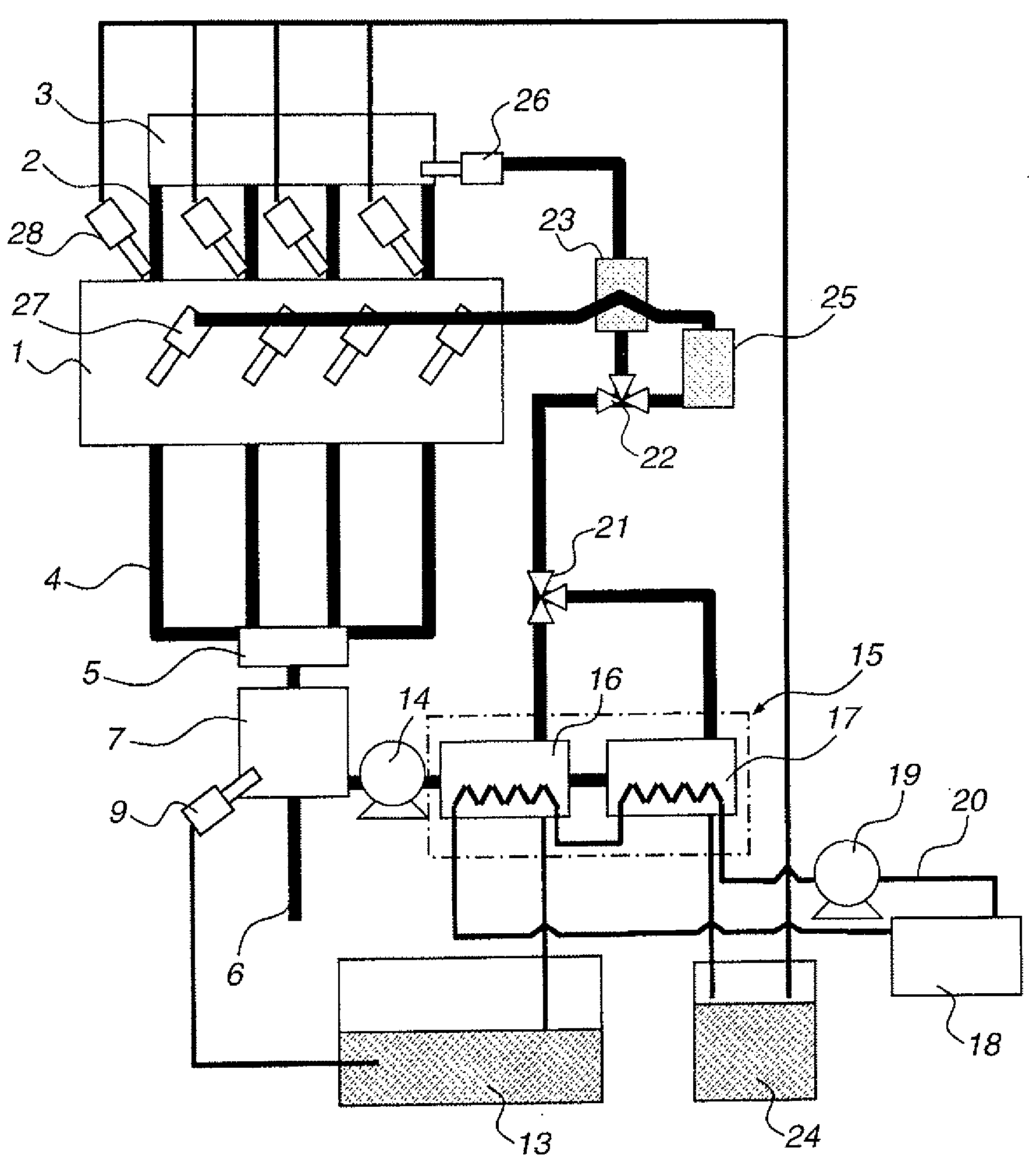

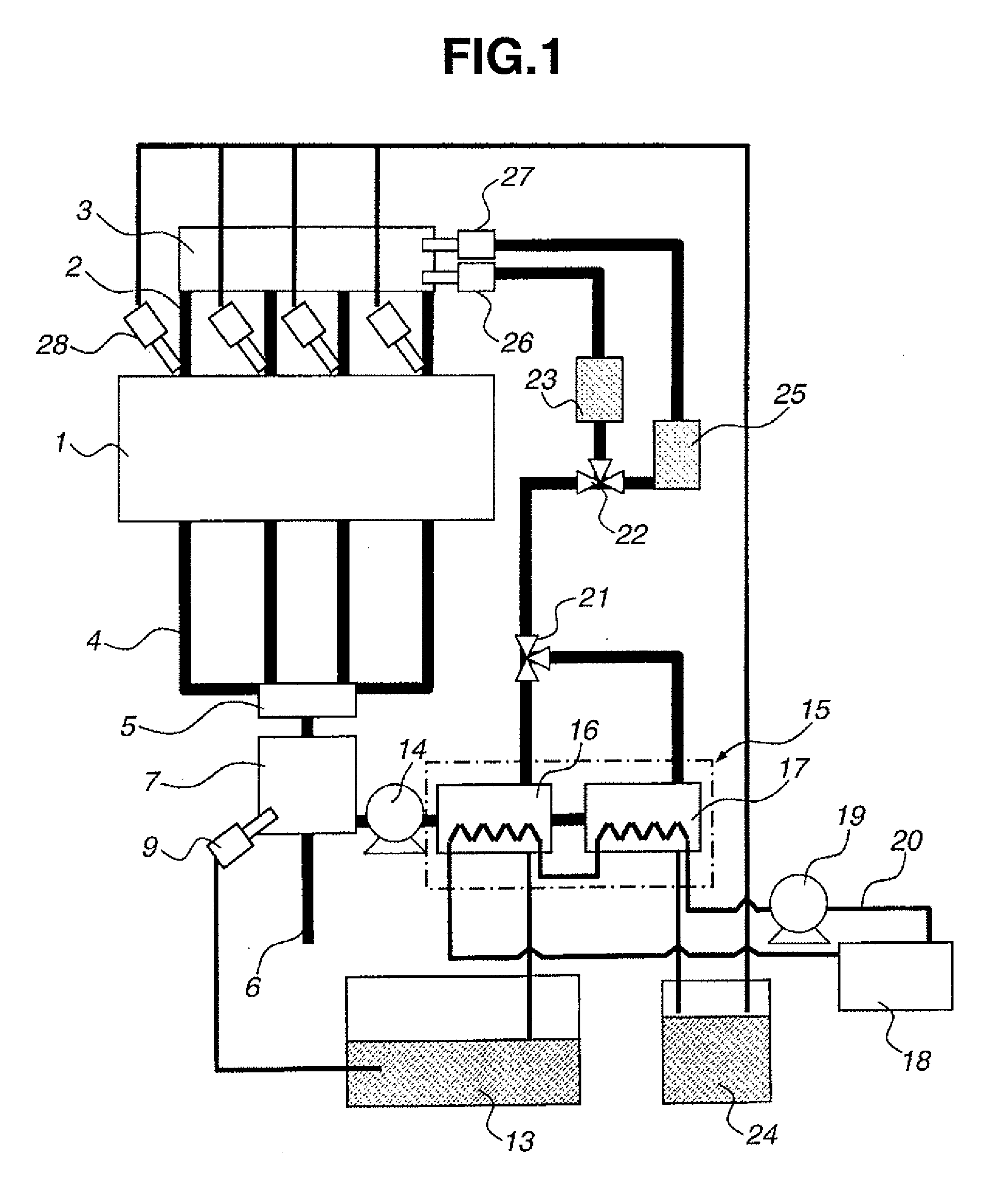

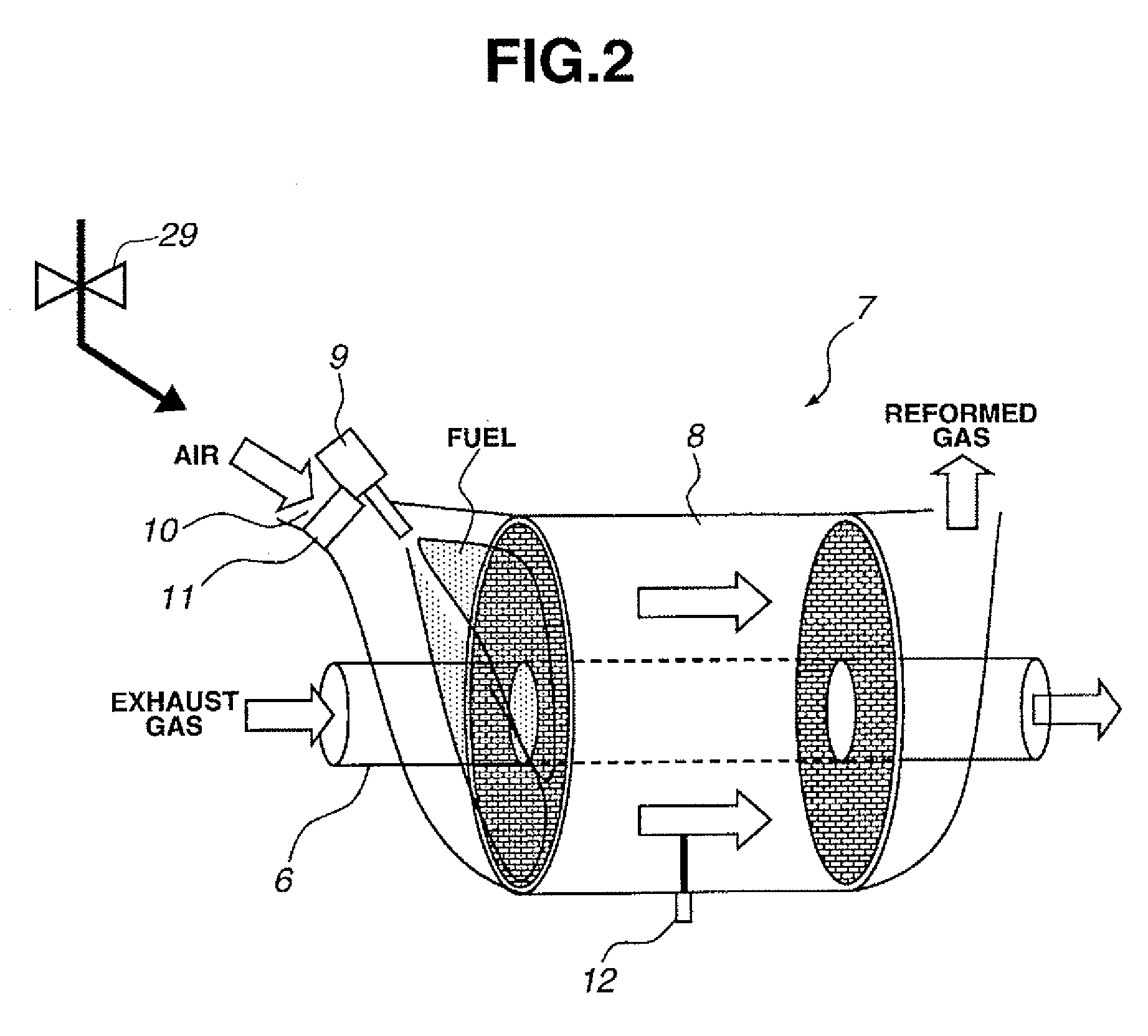

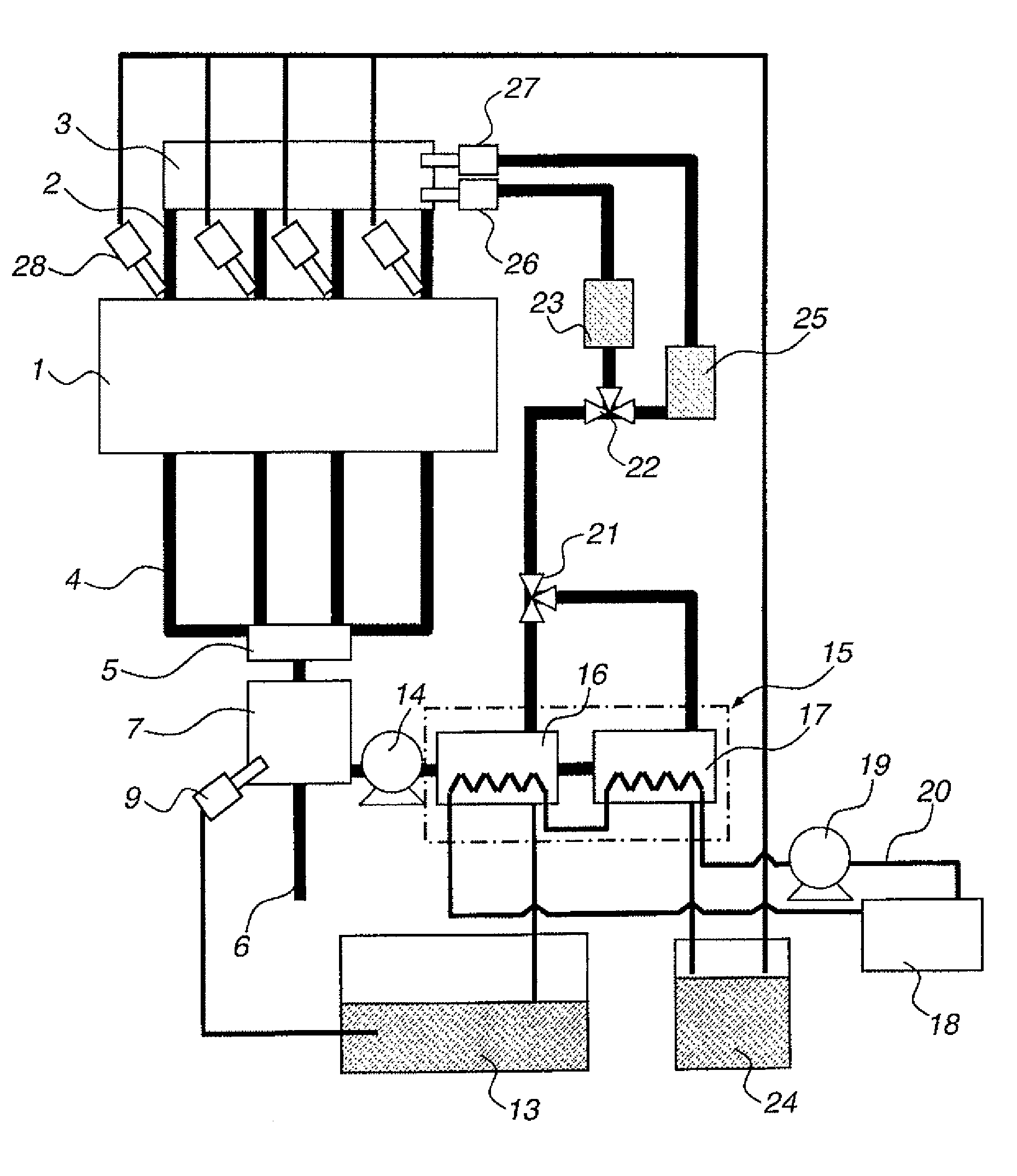

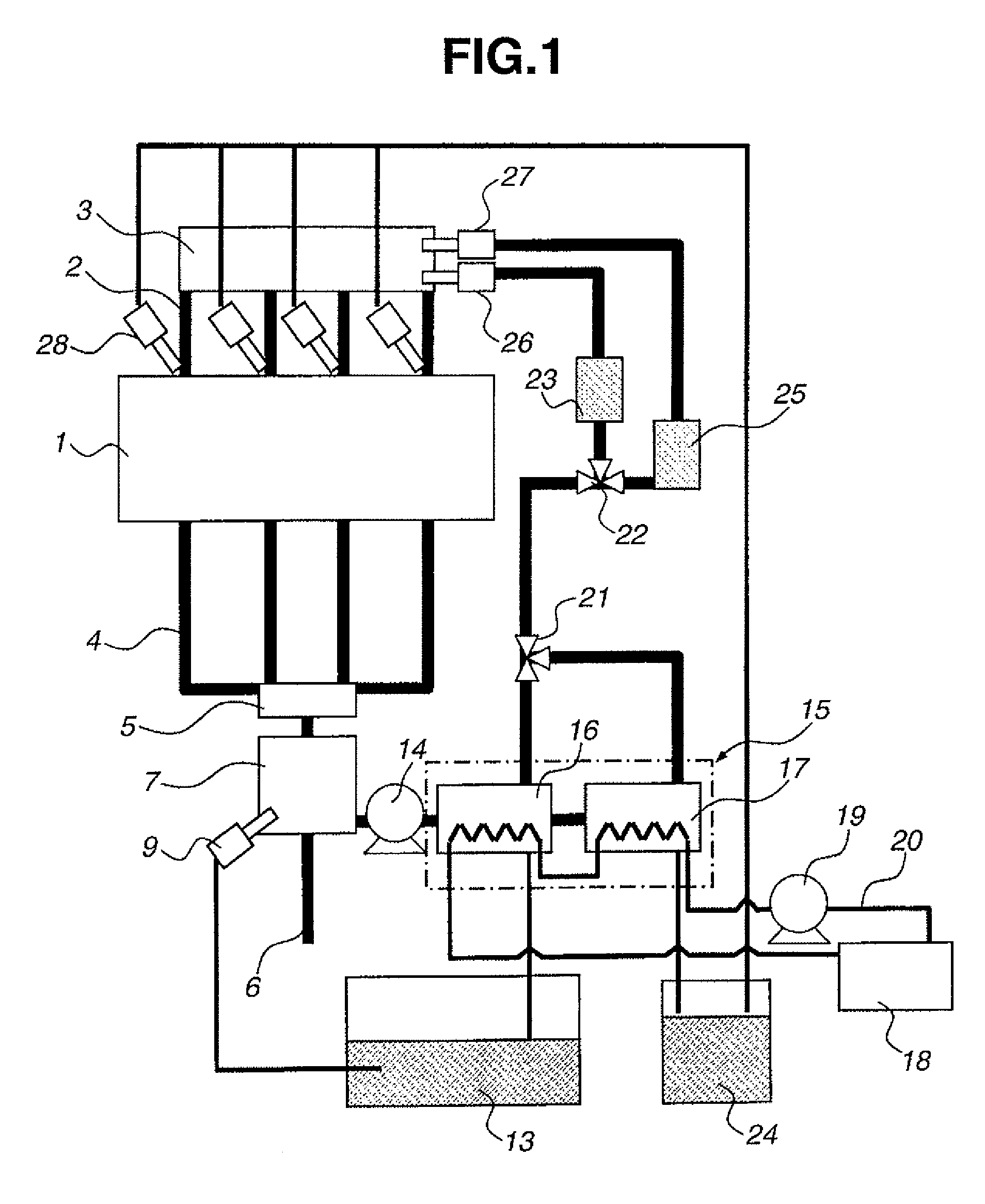

Power plant and fuel supply method therefor

InactiveUS20080257301A1Point becomes highFuel flow is suppressedHydrogenElectrical controlPower stationInternal combustion engine

A power plant, including an internal combustion engine, a fuel conversion device that coverts a fuel to be supplied to the internal combustion engine from a before-conversion fuel to an after-conversion fuel, a first fuel supply device that supplies the fuel conversion device with the before-conversion fuel, a second fuel supply device that supplies the internal combustion engine with the after-conversion fuel, the after-conversion fuel being the fuel that has been converted by the fuel conversion device, and a controller that is communicated with the internal combustion engine, the fuel conversion device, the first fuel supply device and the second fuel supply device. The controller is configured to supply the fuel conversion device with the before-conversion fuel by operating the first fuel supply device, control the temperature of the fuel conversion device in a first temperature range to evaporate the before-conversion fuel to produce a first after-conversion fuel, control the temperature of the fuel conversion device in a second temperature range to reform the before-conversion fuel to produce a second after-conversion fuel, and supply the internal combustion engine with the after-conversion fuel by operating the second fuel supply device.

Owner:NISSAN MOTOR CO LTD

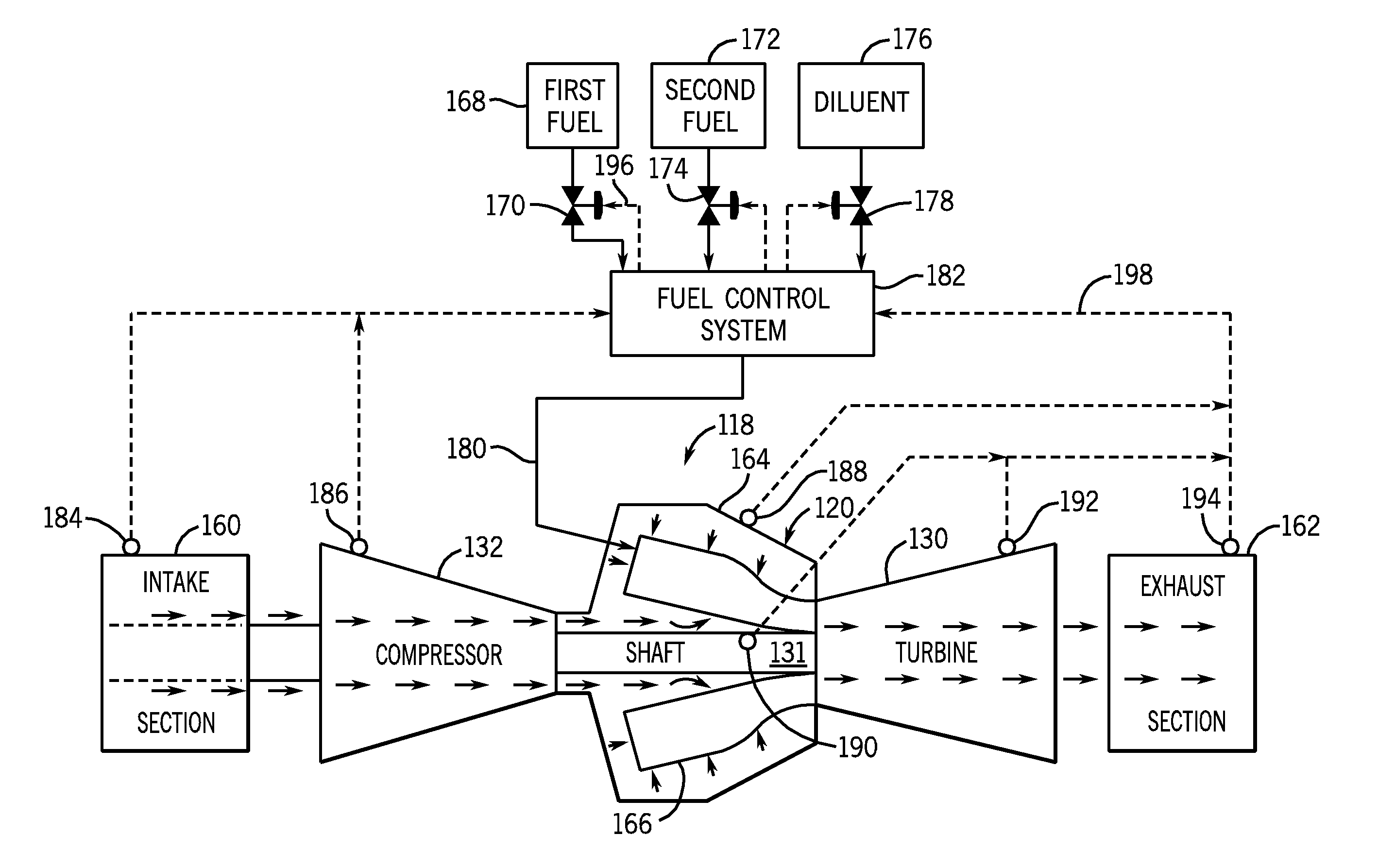

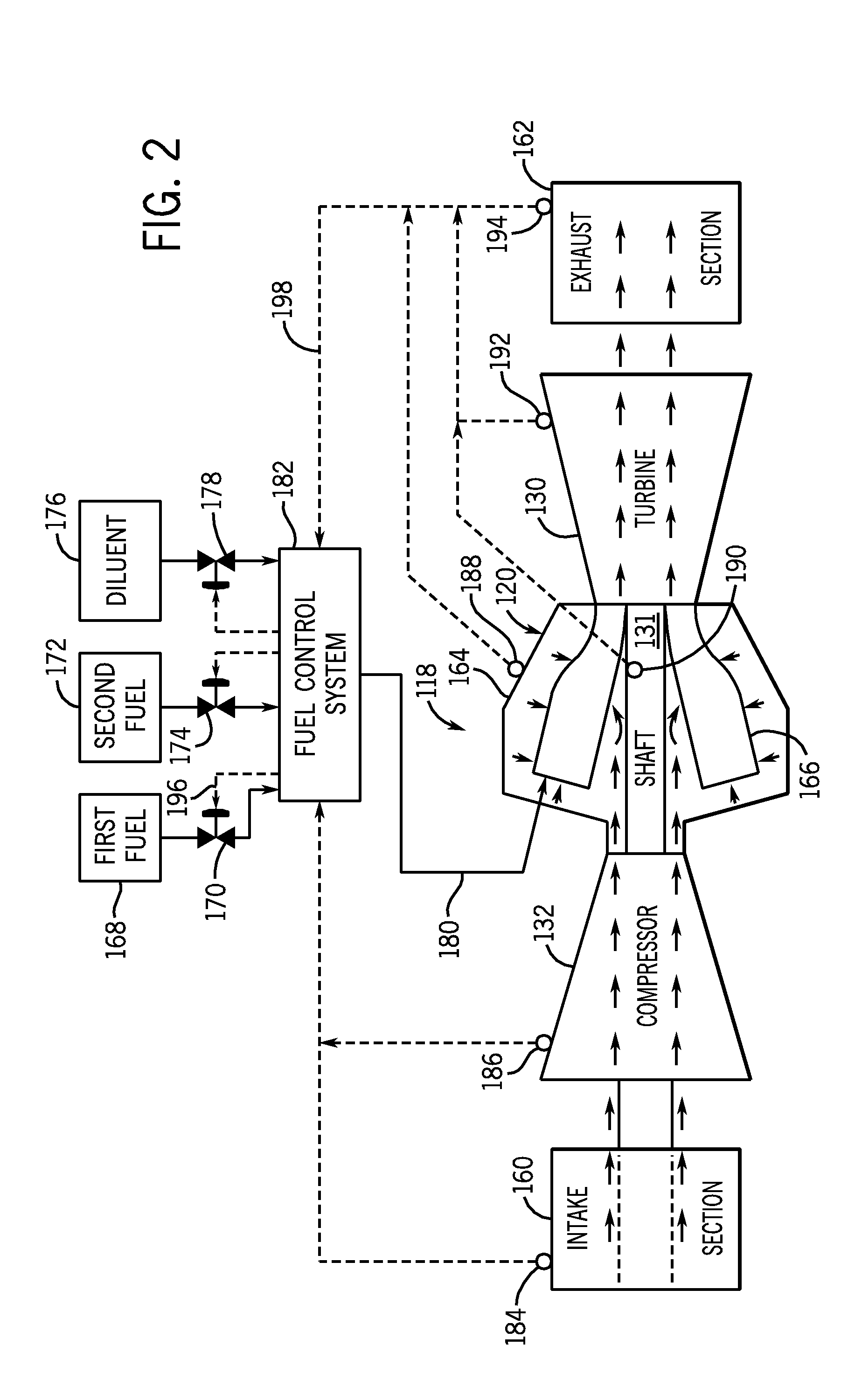

System for fuel and diluent control

InactiveUS20110289932A1Reduce loadTurbine/propulsion engine ignitionTurbine/propulsion engine startersCombustion systemControl system

According to various embodiments, a system includes a fuel controller configured to control a fuel transition between a first flow of a first fuel and a second flow of a second fuel into a fuel nozzle of a combustion system. The fuel controller is configured to adjust a third flow of a diluent in combination with the second flow of the second fuel to maintain a pressure ratio across the fuel nozzle above a predetermined operating pressure ratio.

Owner:GENERAL ELECTRIC CO

Method and apparatus for total energy fuel conversion systems

InactiveUS6350394B1Thermal non-catalytic crackingInternal combustion piston enginesPeak loadElectric power

An independent and conserved source of fuel and / or power comprises a top stage rocket engine firing up to 5000 F. at very high pressures, delivering jet flows up to transonic velocities into a near adiabatic tunnel for mixing in general and / or for transforming reactants introduced to suit specific objectives. The related compression is supplied by an independent prime mover which compresses its exhaust and other recoverable fluids. Low grade flows, thereby upgraded in temperature and pressure, are adiabatically contained, are further upgraded in the tunnel to become part of the prescribed fuel for export at the tunnel ends; or fuel to be fired in a prime mover for electric or other power, or hydrogen for chemical use. Expansion turbines for this purpose are relieved of the load used to compress the excess air in standard gas turbines thus increasing export power. A portion of the expansion turbine's exhaust becomes part of recoverable fluids. When oxygen is used instead of air, the gases through turbines are nitrogen-free with more heat capacity reducing turbine inlet temperatures for the same power. When reactant transformation is specified, the larger water vapor content in the cycle enhances the water gas / shift autothermally for ammonia and / or power and alternatively for pyrolysis cracking for olefins and diolefins. Further, staging rocket engine reactors increases efficiency in boilers and steam turbines; and staging can produce sponge iron and / or iron carbide as well as expansion turbine power and fuel cells for peak and off-peak loads.

Owner:EGT ENTERPRISES

Zirconium dioxide-based electrode-electrolyte pair (variants), method for the production thereof (variants) and organogel

InactiveUS20060134491A1Improve efficiencyHighly efficient, economically advantageous and durable fuel cellFinal product manufacturePrimary cellsHydrocotyle bowlesioidesEngineering

This invention relates to the field of electric power generation by direct transformation of the chemical energy of gaseous fuel to electric power by means of high-temperature solid oxide fuel cells. The invention can be used for the fabrication of miniaturized thin filmed oxygen sensors, in electrochemical devices for oxygen extraction from air and in catalytic electrochemical devices for waste gas cleaning or hydrocarbon fuels conversion. The technical objective of the invention is the production of a low-cost electrode-electrolyte pair having an elevated electrochemical efficiency as the most important structural part of a highly efficient, economically advantageous and durable fuel cell. Furthermore, the invention achieves additional objectives. The achievement of these objectives is exemplified with two electrode-electrolyte pair designs and their fabrication methods, including with the use of a special organogel.

Owner:HILCHENKO GALINA VITALEVNA +1

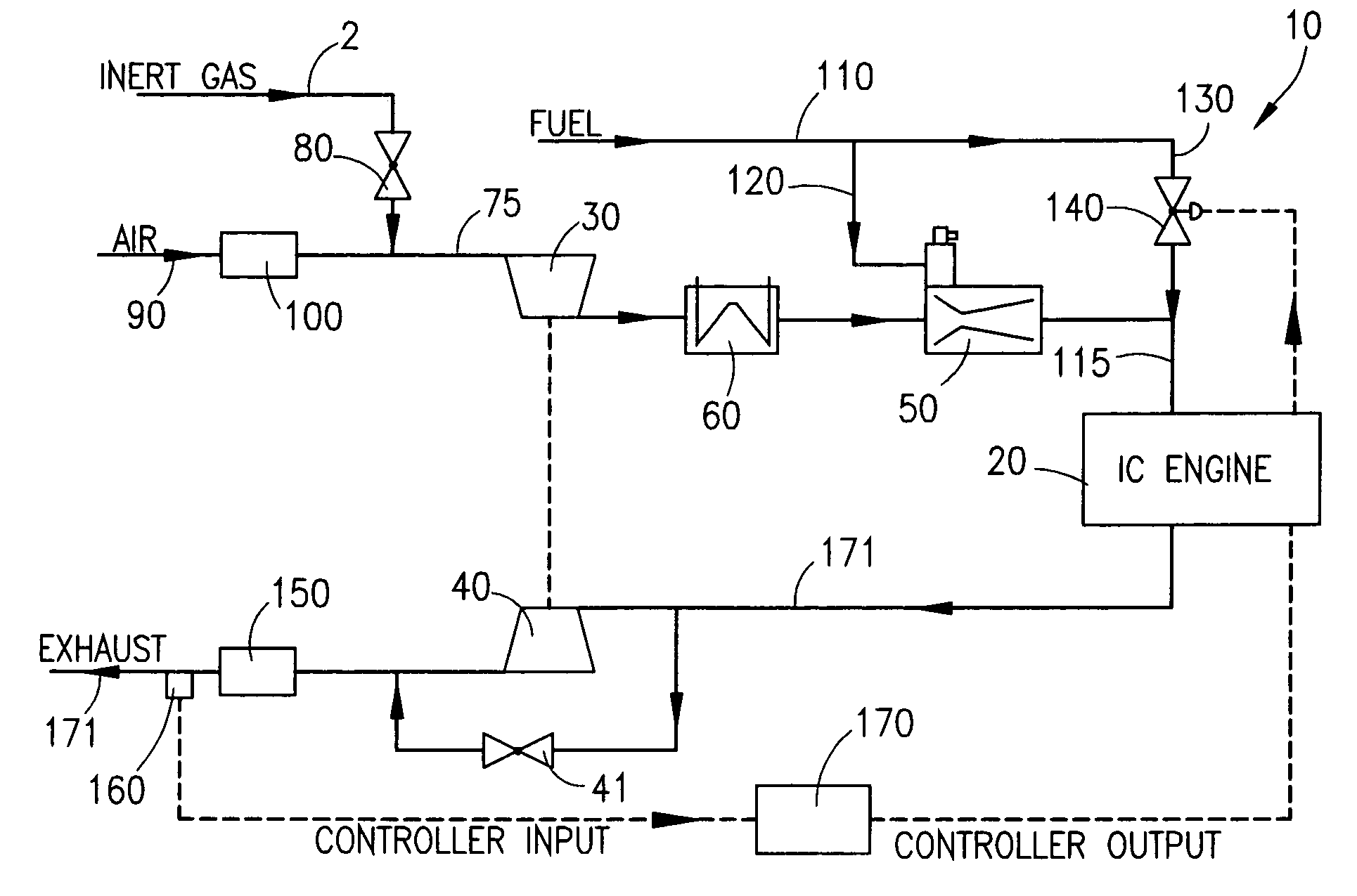

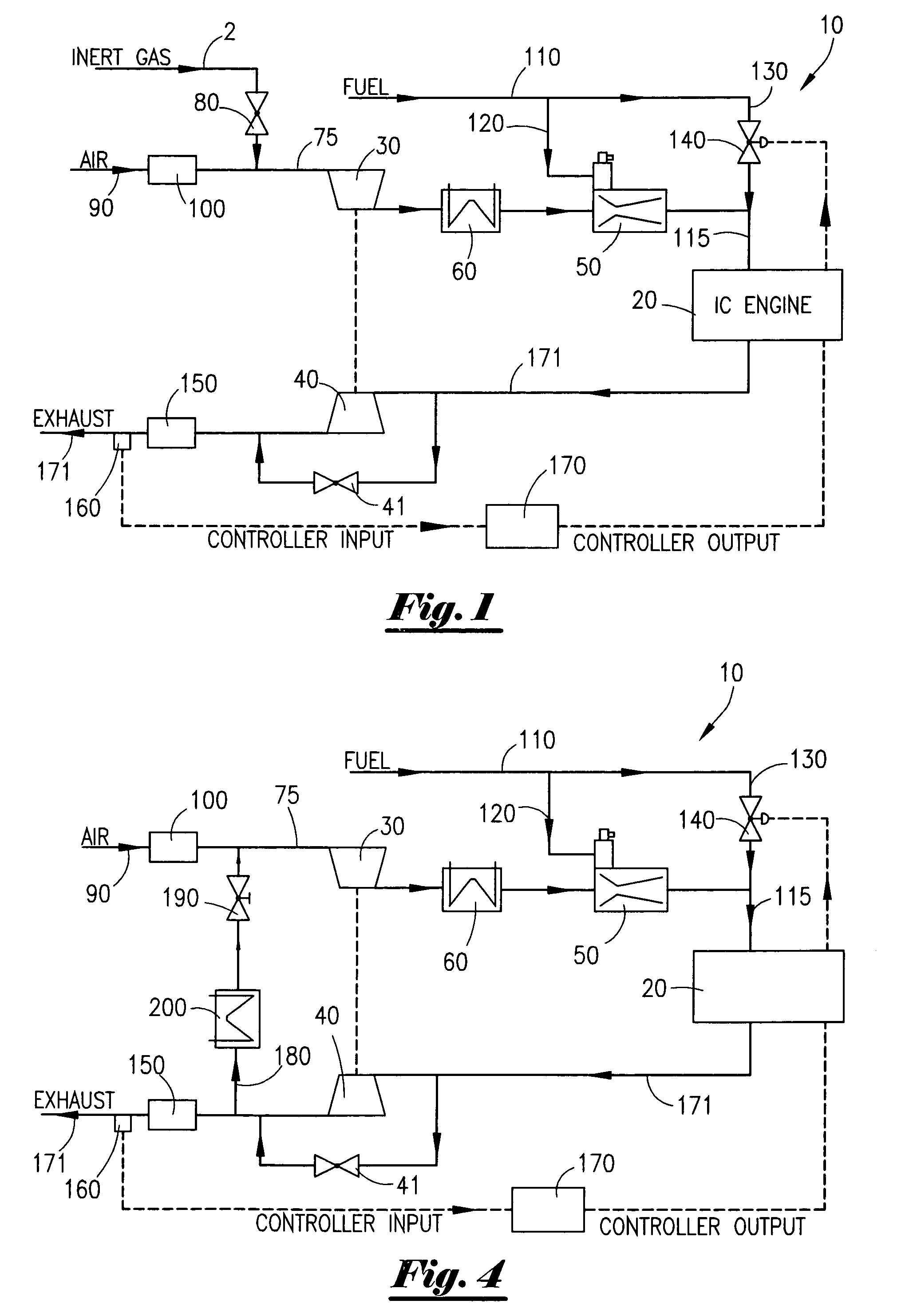

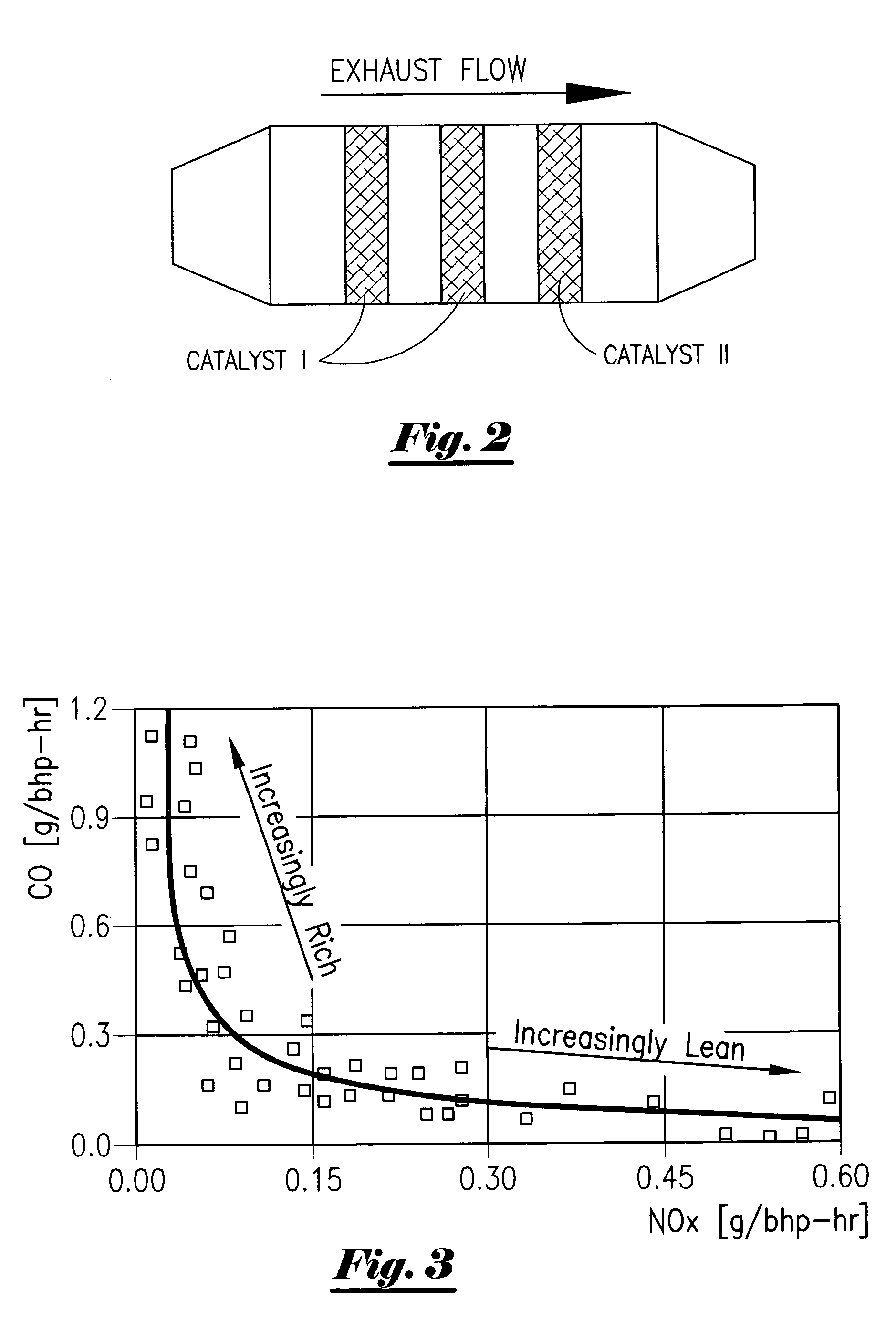

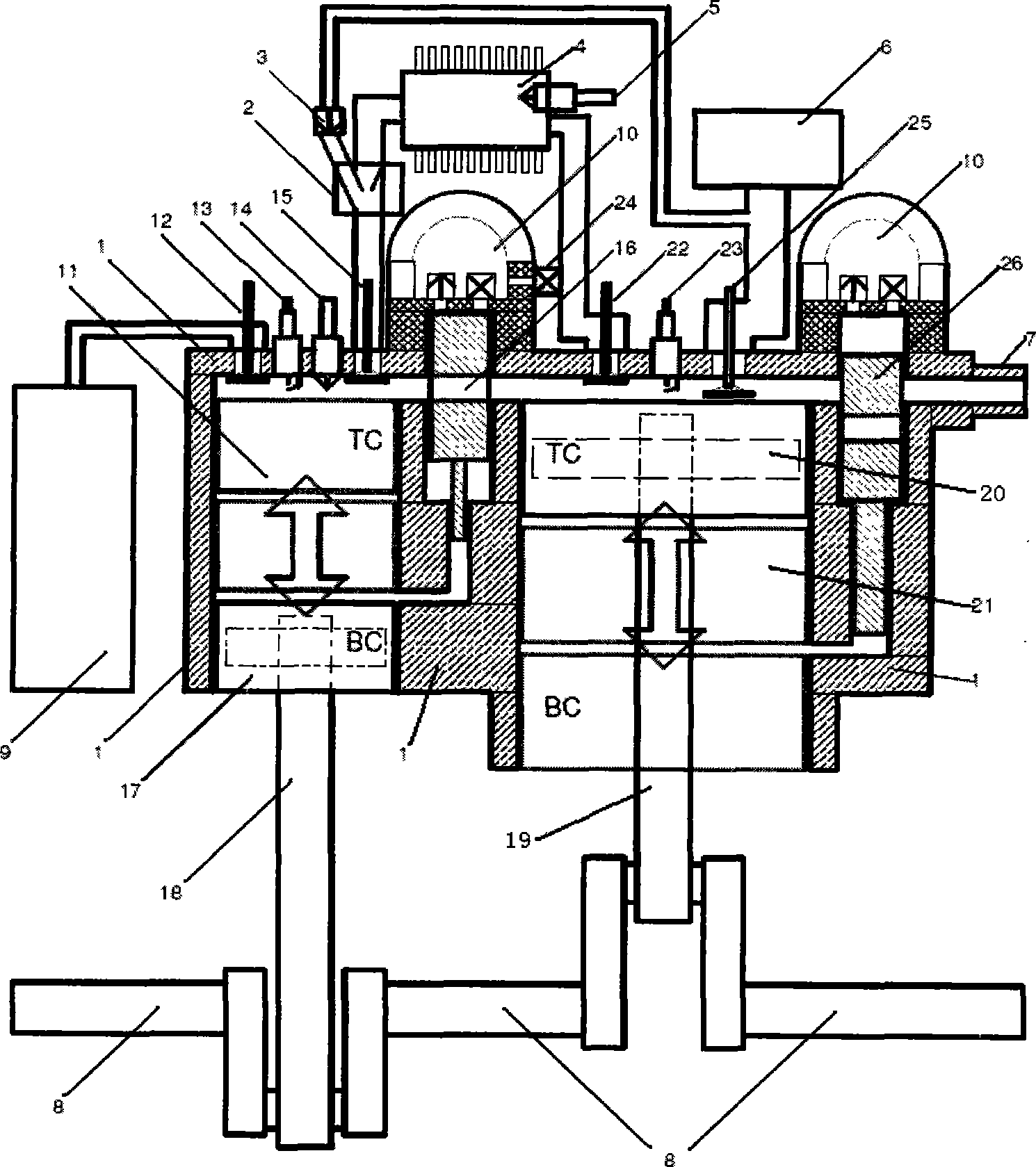

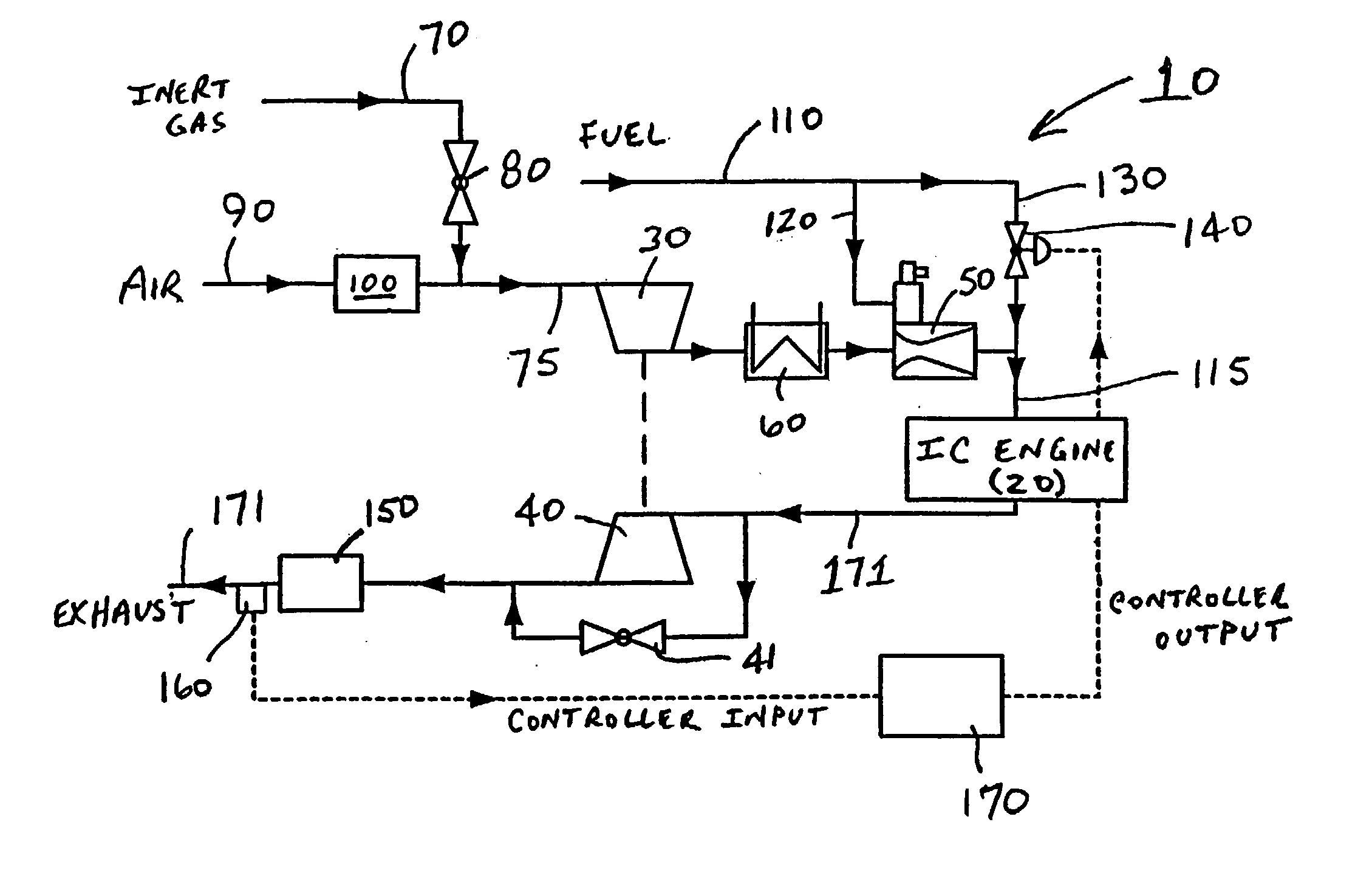

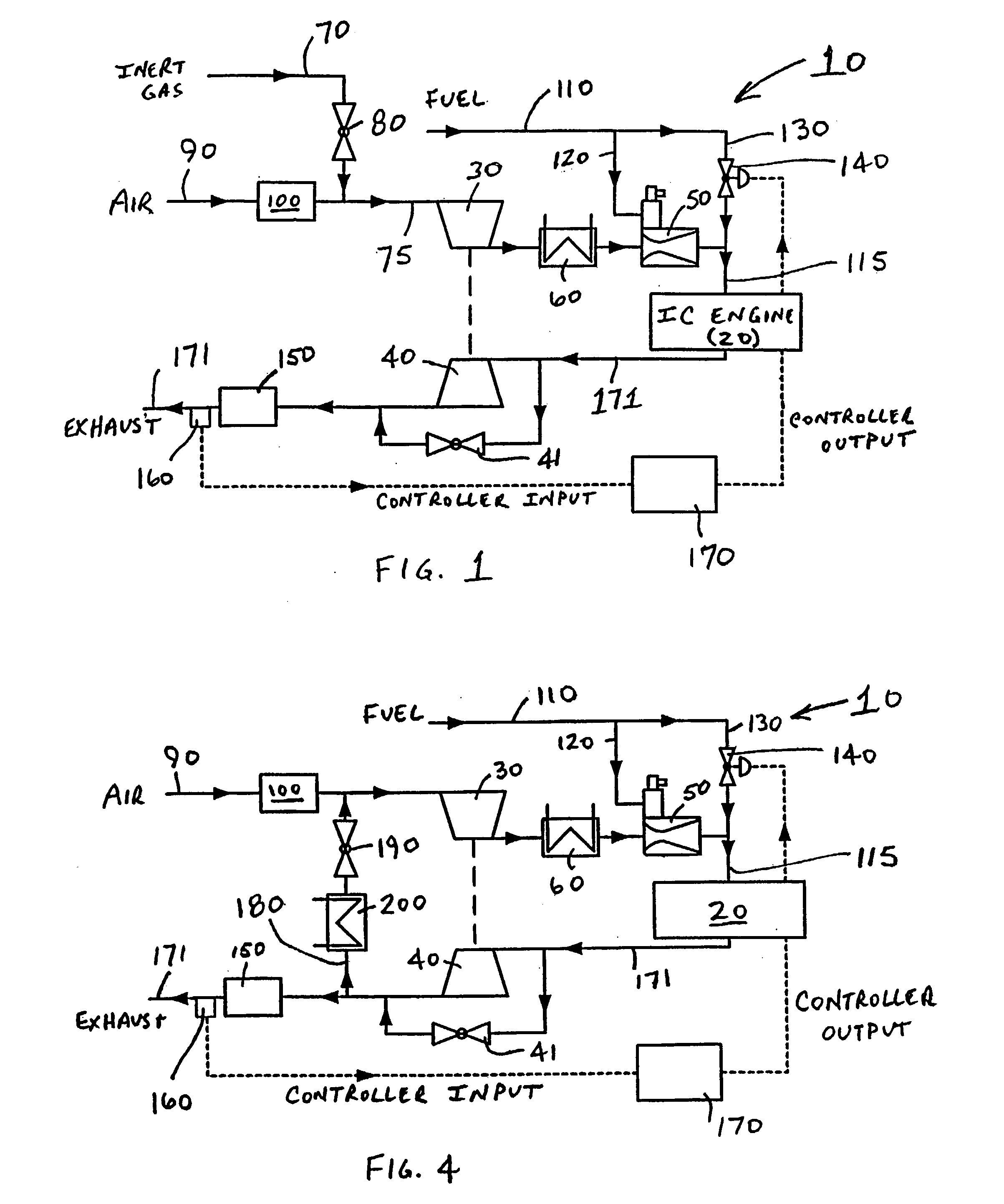

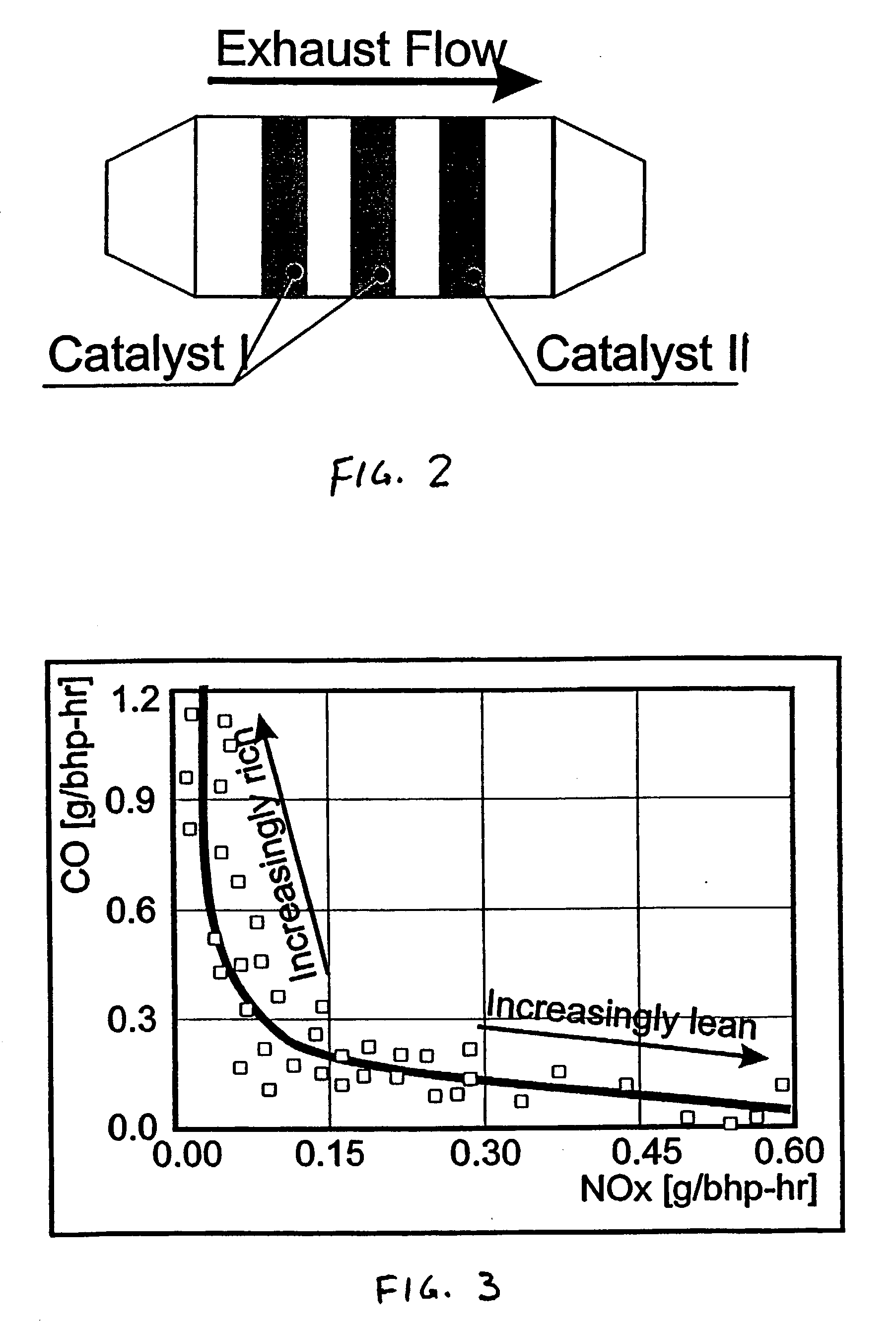

High efficiency, reduced emissions internal combustion engine system, especially suitable for gaseous fuels

InactiveUS6968678B2Internal combustion piston enginesNon-fuel substance addition to fuelChemical reactionMass ratio

Internal combustion (“IC”) engine system for high fuel conversion efficiency and low exhaust emissions, particularly although not exclusively with gaseous fuels. An IC engine operates at approximately stoichiometric (λ=1) air / fuel mass ratios. A higher-than-normal compression ratio for typical stoichiometric operation is possible for the engine, due to the introduction of an inert (i.e., not chemically reactive in the combustion process) gas into the air / fuel mixture. The inert gas slows the combustion rate to avoid uncontrolled combustion rates and engine “knock.” The elevated compression ratio yields higher fuel conversion efficiency. Stoichiometric air / fuel ratio permits catalytic processing of the exhaust gas stream to reduce CO, NOx, and HC emissions via a combination of non-selective catalytic reduction process.

Owner:ATTAINMENT TECH

Highly effective integration heat engine

The invention relates to a high efficiency heat engine having combined heat-work conversion process, especially an heat engine integrated with multiple working strokes and multiple working media. The invention has duplex combined type cylinder structure, wherein a first cylinder is a one-time combustion / expansion cylinder, and a second cylinder is a secondary combustion / expansion cylinder. The multiple working strokes driven by the multiple working media are integrated into a whole. These different working media comprise air-fuel burnt products, steam, and compression air under the brake energy regenerating mode of air mixing type. The duplex combined type cylinder structure provides places for the composite expansion of three different working media, and can capture the energy lost in the working media emission and braking process. The structure causes the heat engine of the invention can work in six work periods composed of twelve strokes. In the six work periods, four periods comprises four different working strokes, but only one working stroke consumes fuel. Therefore, the fuel conversion efficiency can be greatly improved, and is even two times of the conventional internal combustion engine (ICE).

Owner:赵元藩

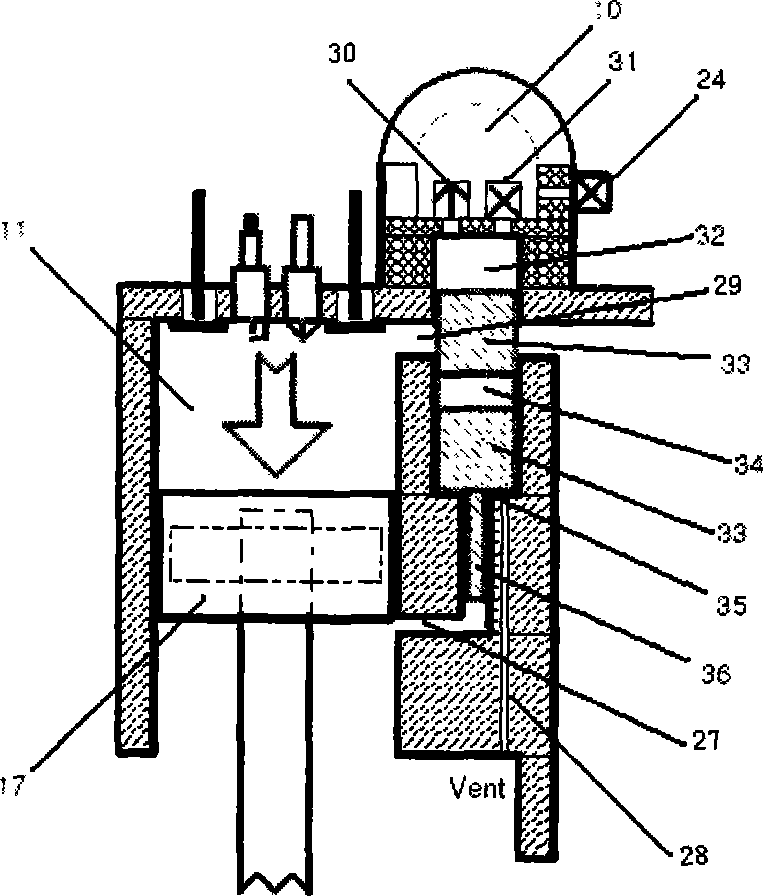

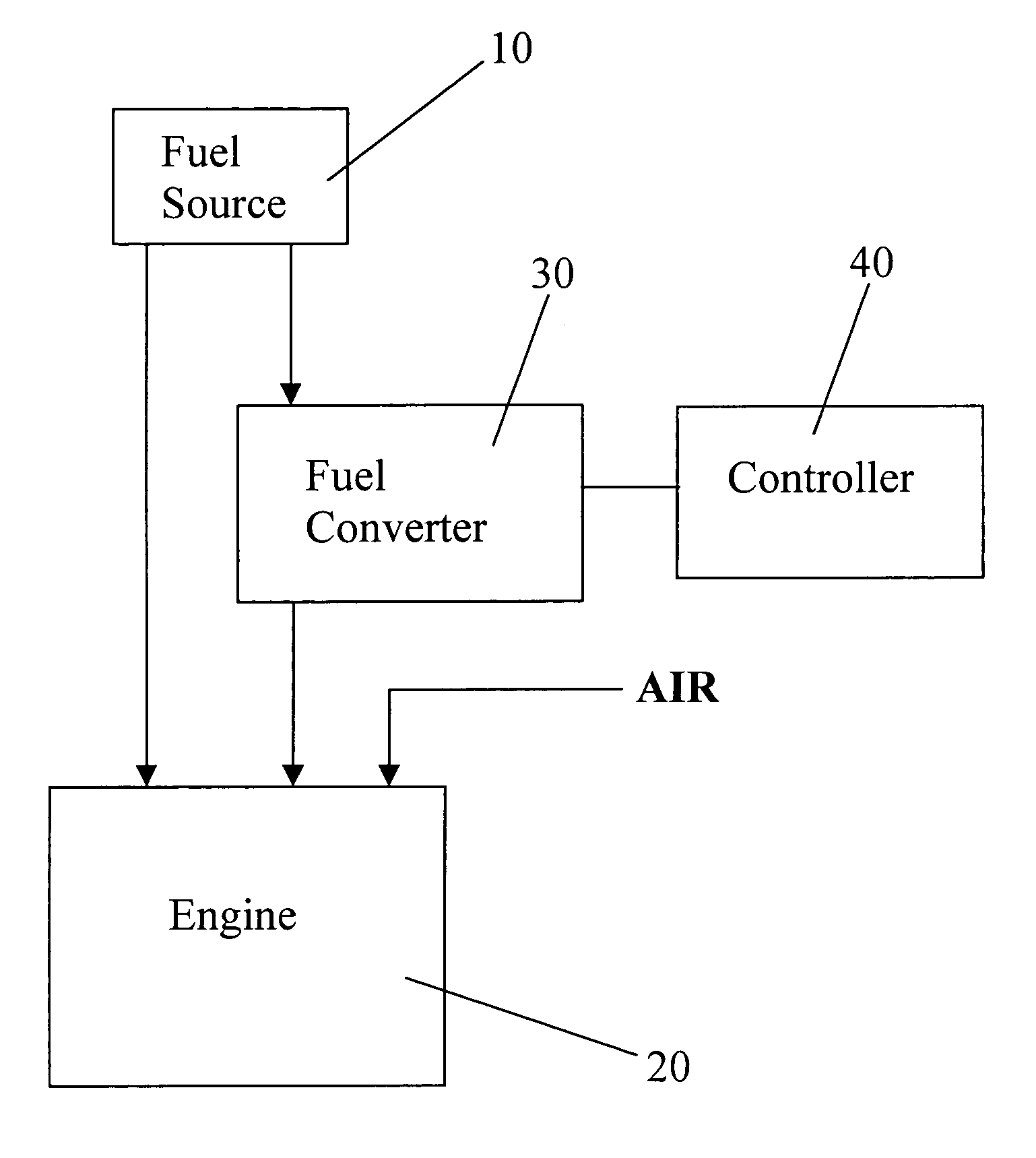

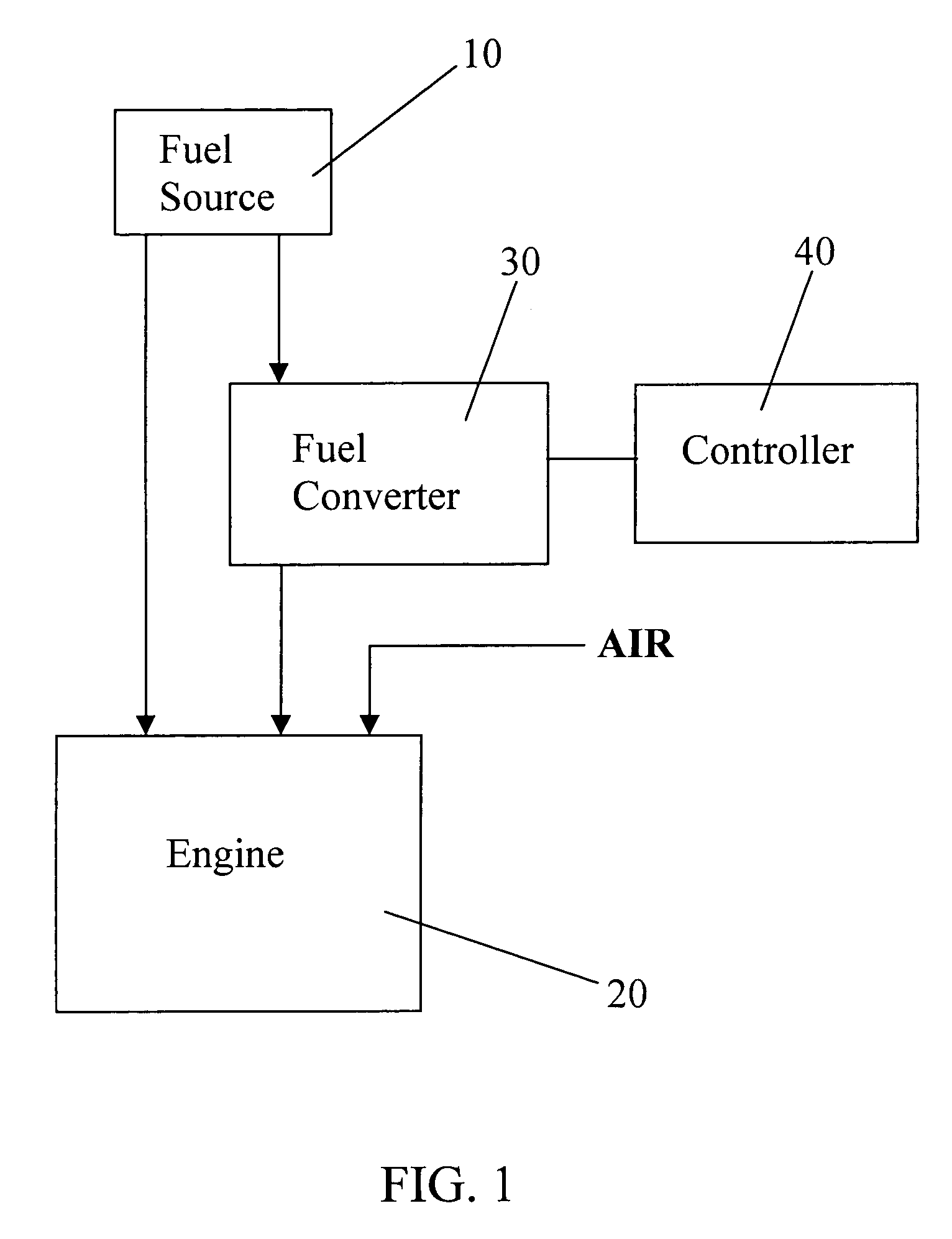

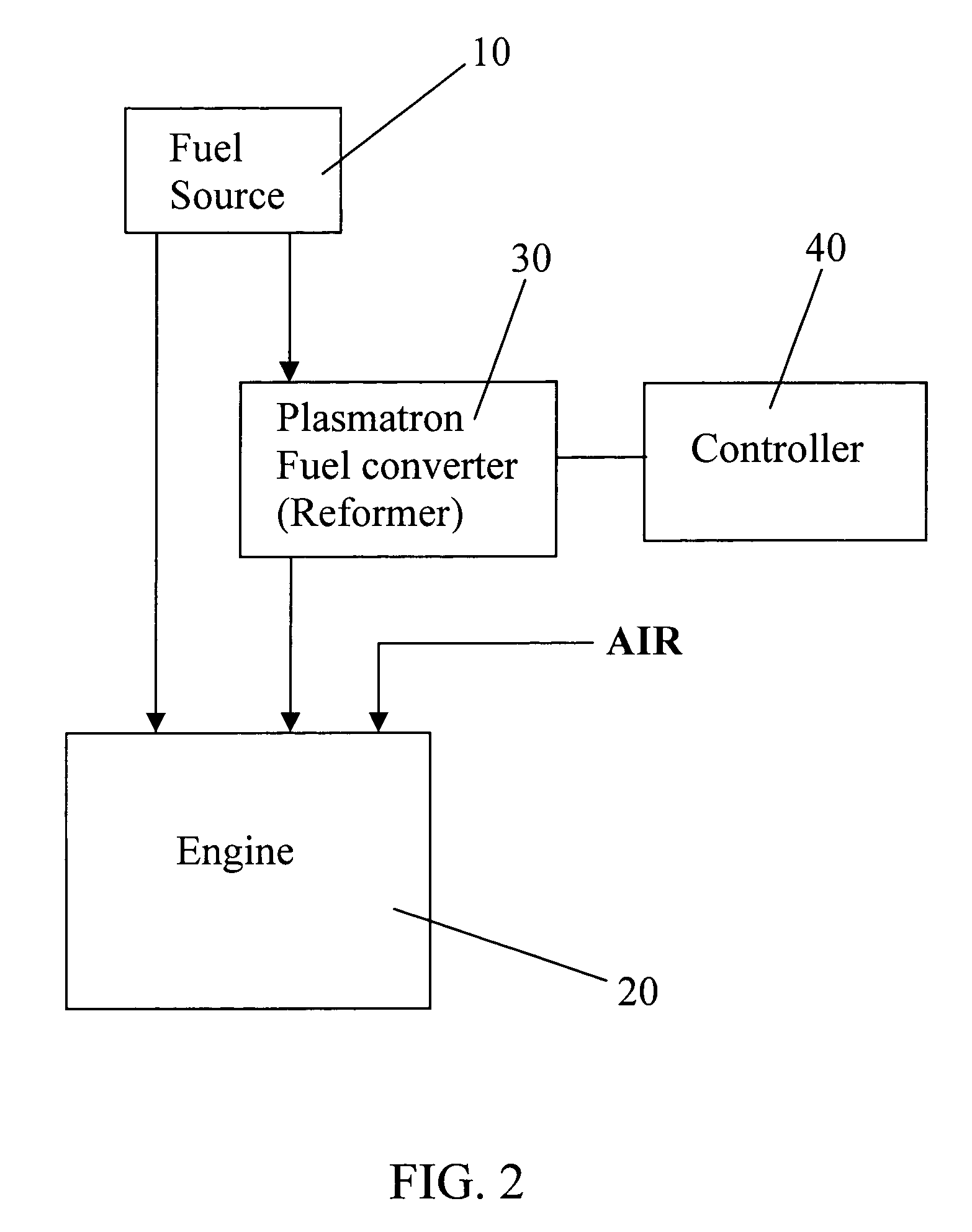

Homogeneous charge compression ignition control utilizing plasmatron fuel converter technology

ActiveUS6981472B2Alters compositionProcess control/regulationHydrogenHomogeneous charge compression ignitionHydrogen

A method and apparatus for operation of an internal combustion engine running under a homogeneous charge compression ignition (HCCI) mode with fuel partially reformed by an onboard fuel reformer. In one embodiment, the onboard fuel reformer is a plasmatron fuel converter. The temperature and composition of the gaseous charge into the cylinders of the engine can be adjusted by mixing the charge into the cylinder (which contains air, exhaust gas and / or unreformed fuel) with hydrogen rich gas from the onboard reformer. The fuel reformer transforms the fuel to a mixture of hydrogen, CO and other light hydrocarbons. By adjusting operation in the reformer, the composition of the reformate can be altered. In addition to thermal management of the cylinder charge, the reformate can be used as a fuel blending agent in order to adjust the octane / cetane number of the air charge and thus control the ignition timing of the overall fuel / air charge to the cylinder.

Owner:MASSACHUSETTS INST OF TECH

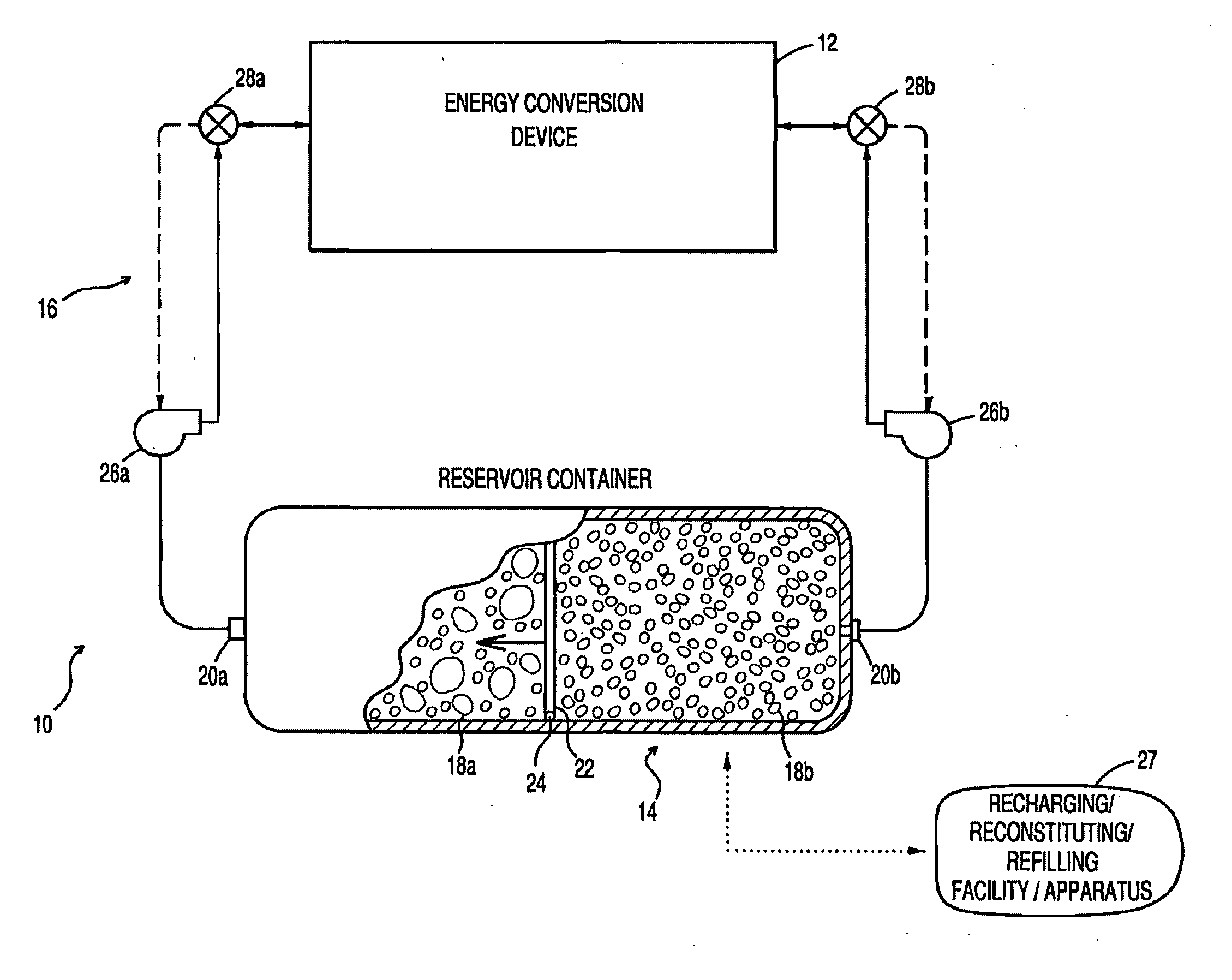

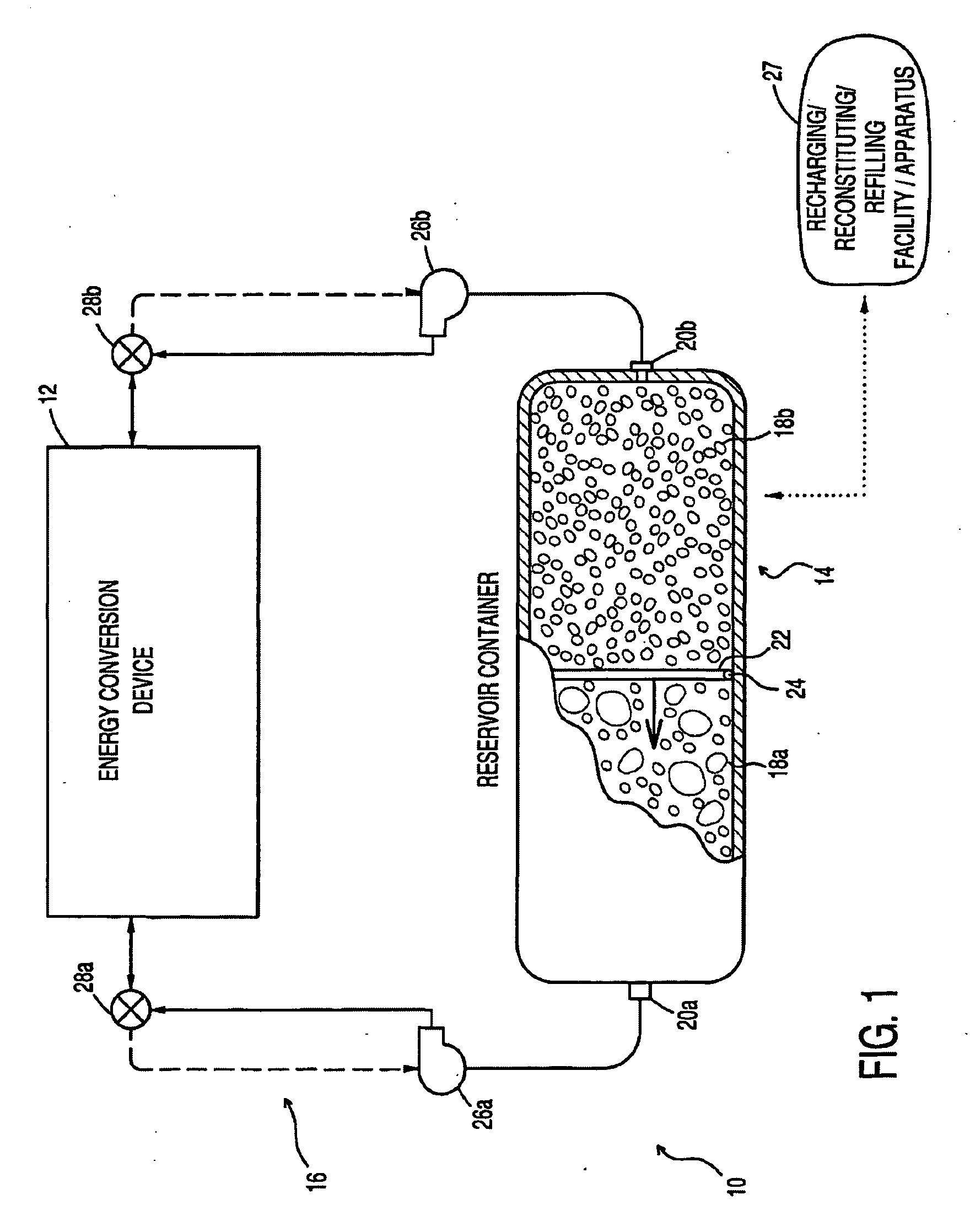

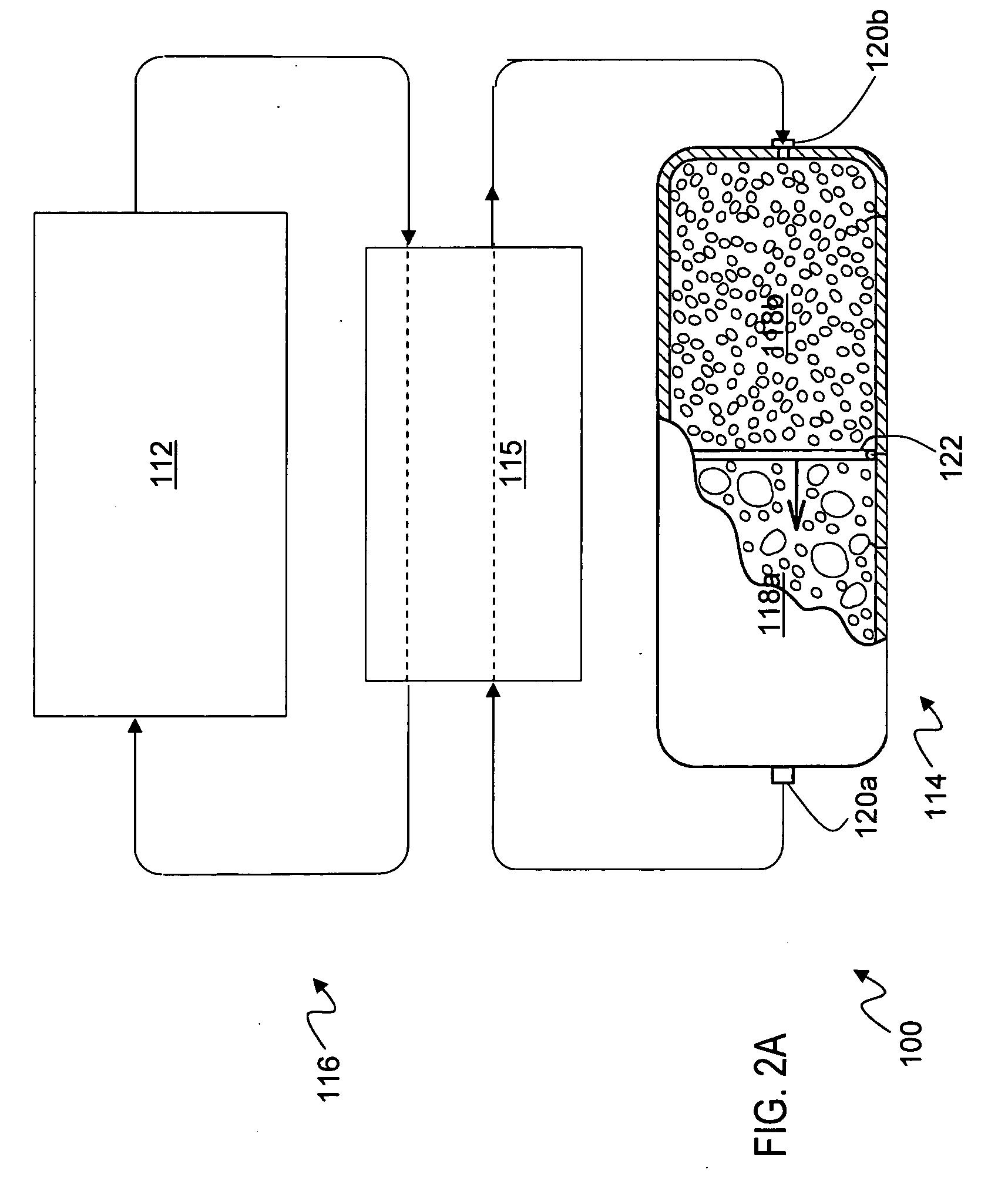

Fuel containment and recycling system

InactiveUS20060127731A1Improve economyMaximize useSeveral cell simultaneous arrangementsFuel and primary cellsEngineeringFuel conversion

An energy conversion system is provided including at least one energy conversion device. A reservoir container is provided for storing a quantity of fuel and a quantity of exhaust. The reservoir container includes a container body including at least two chambers of inversely variable volume disposed within said container body for respectively storing a quantity of fuel and receiving a quantity of exhaust, and a structure for decreasing the volume of the first chamber while concurrently increasing the volume of the second chamber. The auxiliary container is in fluid communication with the at least one energy conversion device, the first chamber and the second chamber. The auxiliary container is configured for receiving a quantity of fuel from the first chamber, providing said quantity of fuel to the at least one energy conversion device, receiving a quantity of fuel partially converted from said energy conversion device, and returning a portion of said partially converted fuel to said energy conversion device.

Owner:FARIS SADEG M

On-line monitoring method and device for a fossil fuel converter apparatus

InactiveUS20070184556A1Sound scientific basisSatisfies of ash contentFuel supply regulationSolid fuelsMaterial balanceEnergy balanced

An online monitoring method and device for a fossil fuel converter apparatus. The method monitors fuel compositions in real time by measuring operating data of the converter apparatus and comprises the following steps: determining reactant compositions and number of variables thereof; determining fuel compositions and number of variables thereof; determining compositions of incomplete products and number of variables thereof; determining relationship between the fuel compositions and calorific value; establishing an equation set involving the fuel compositions, the reactant compositions and the resultants compositions, according to energy balance relationship and material balance relationship in the combustion process; providing given conditions for independent relationships concerning variables in the above equation set; measuring boiler operating data and assigning the variables in the above equation set; and finding the solution to the equation set and obtaining real-time monitoring data of the converter apparatus.

Owner:WANG ZHEN

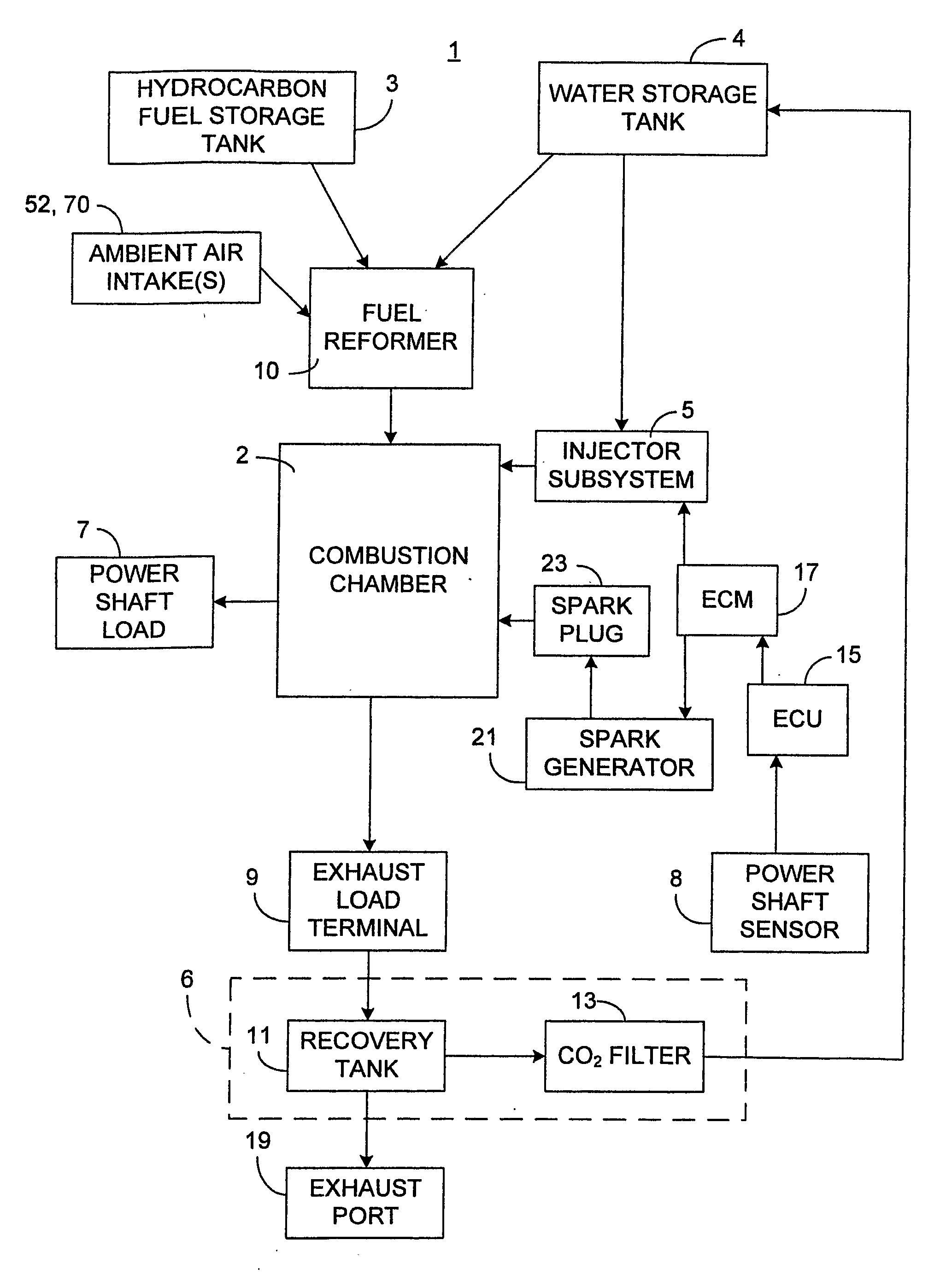

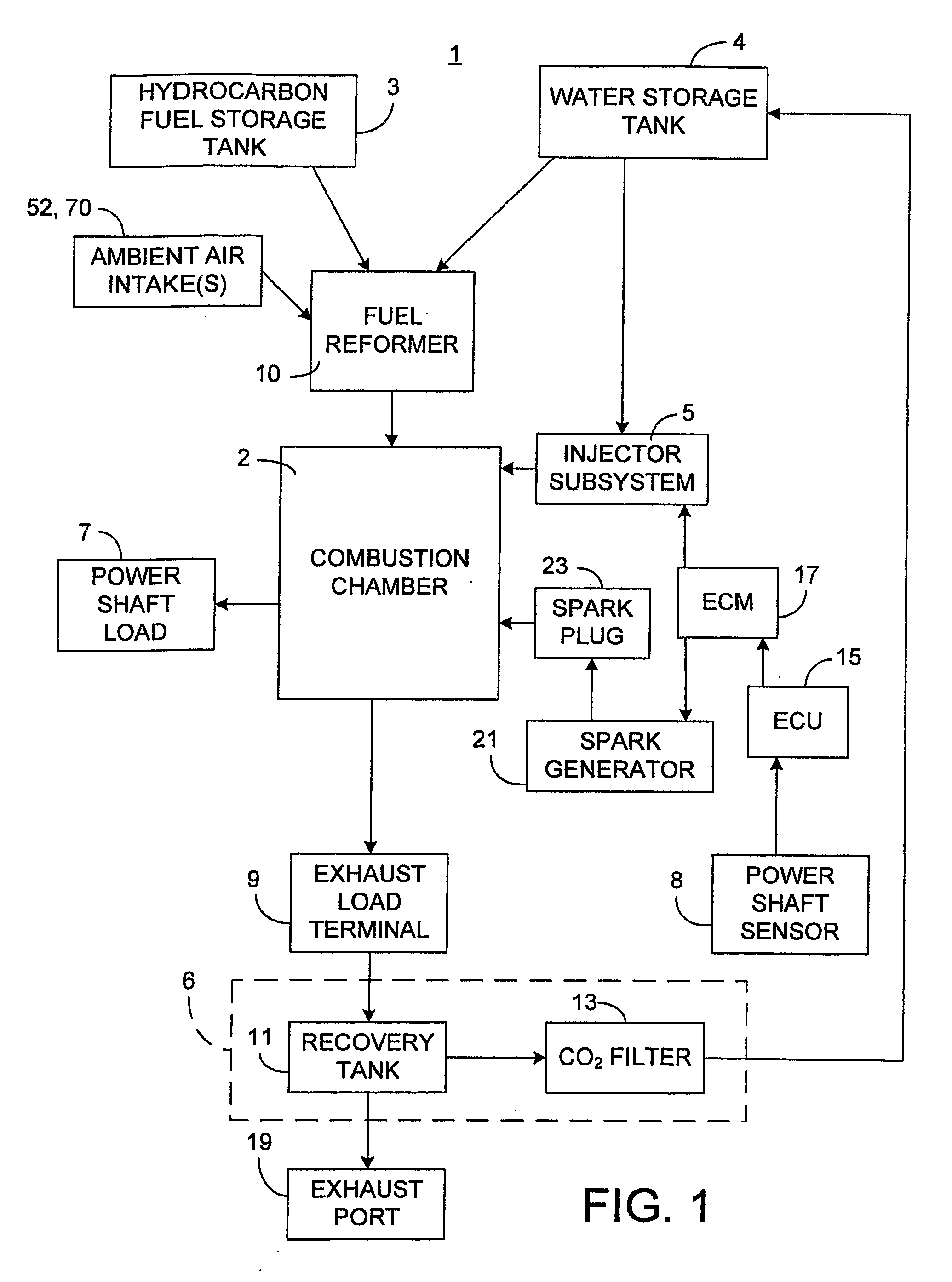

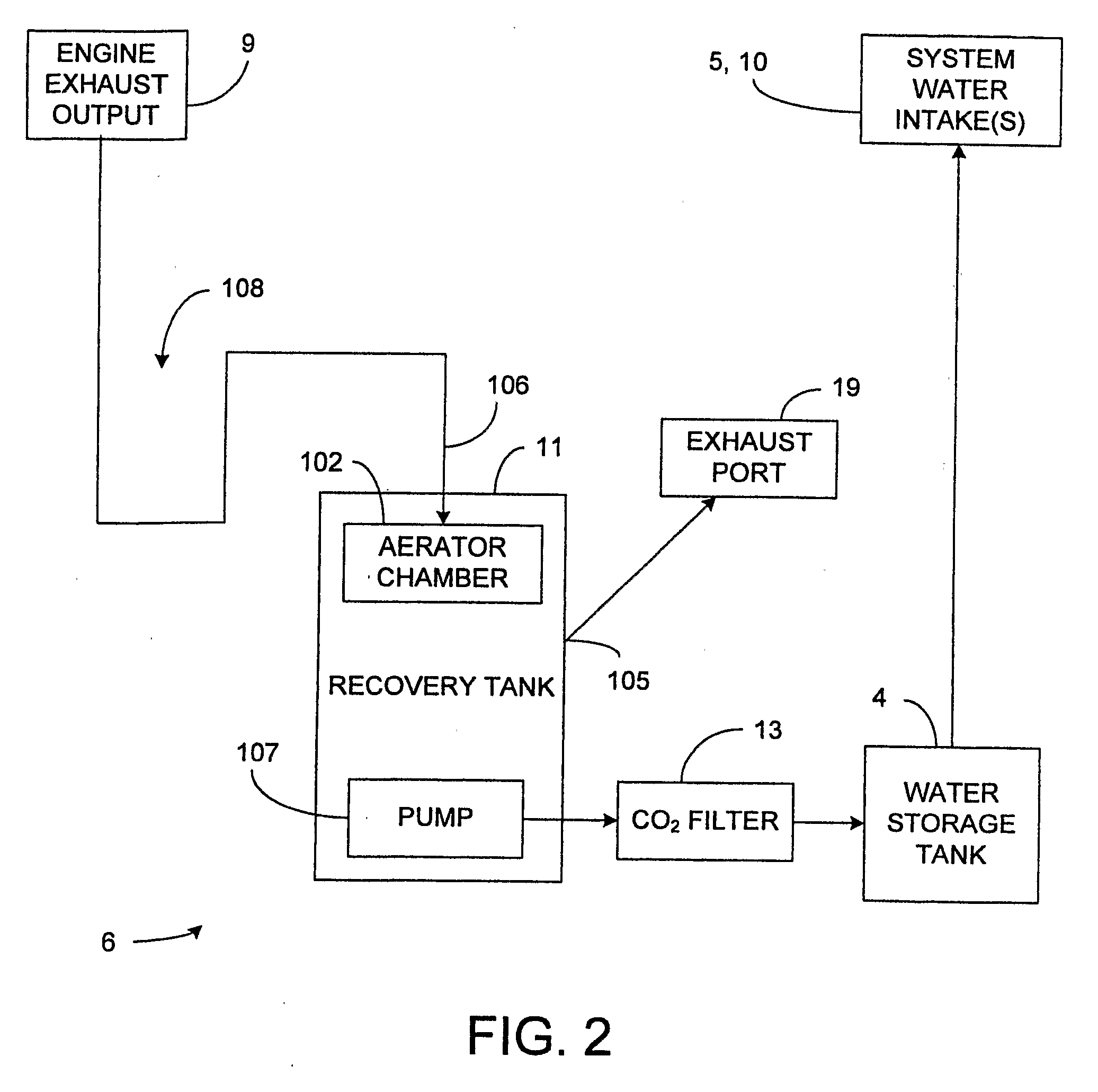

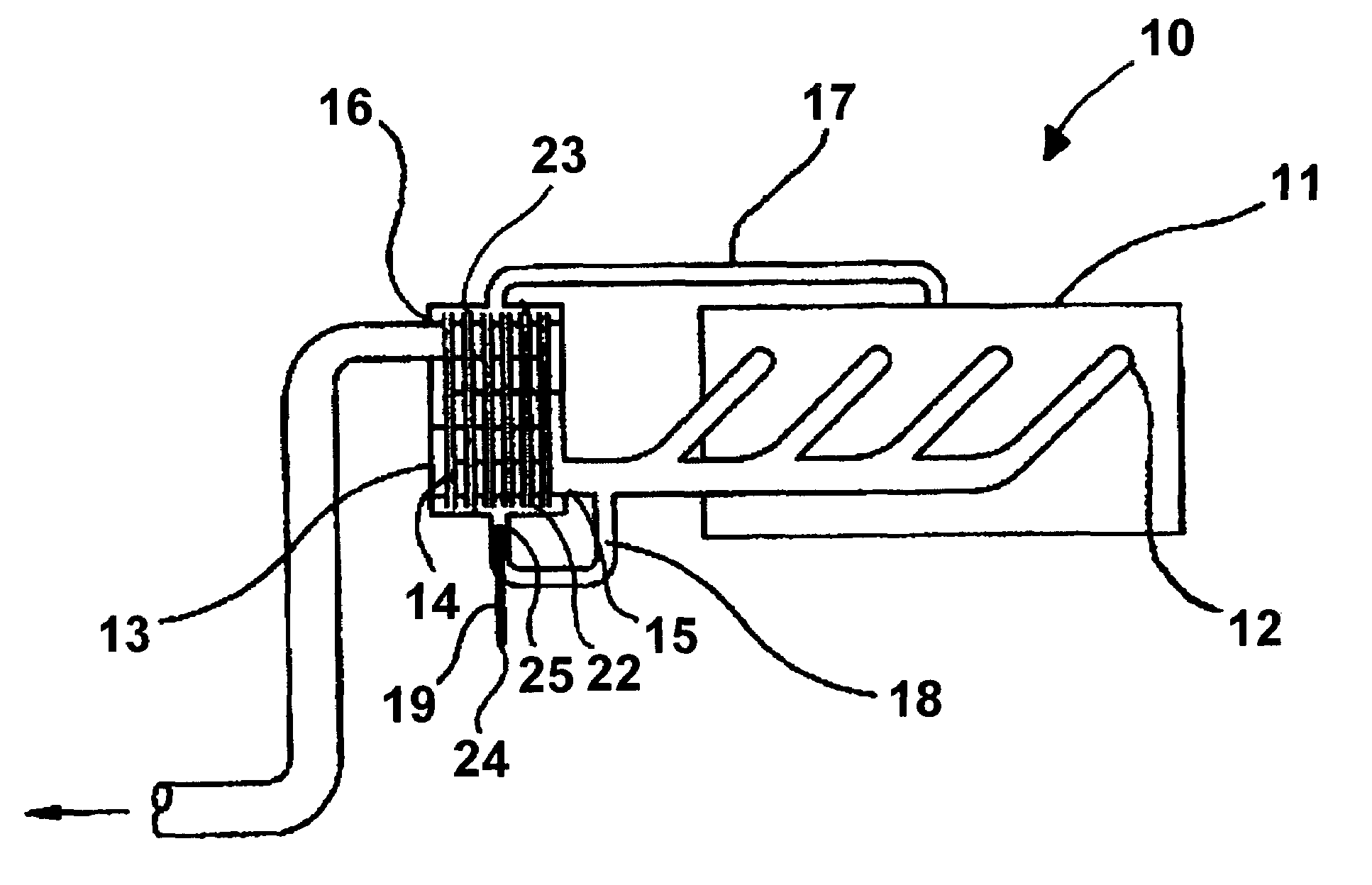

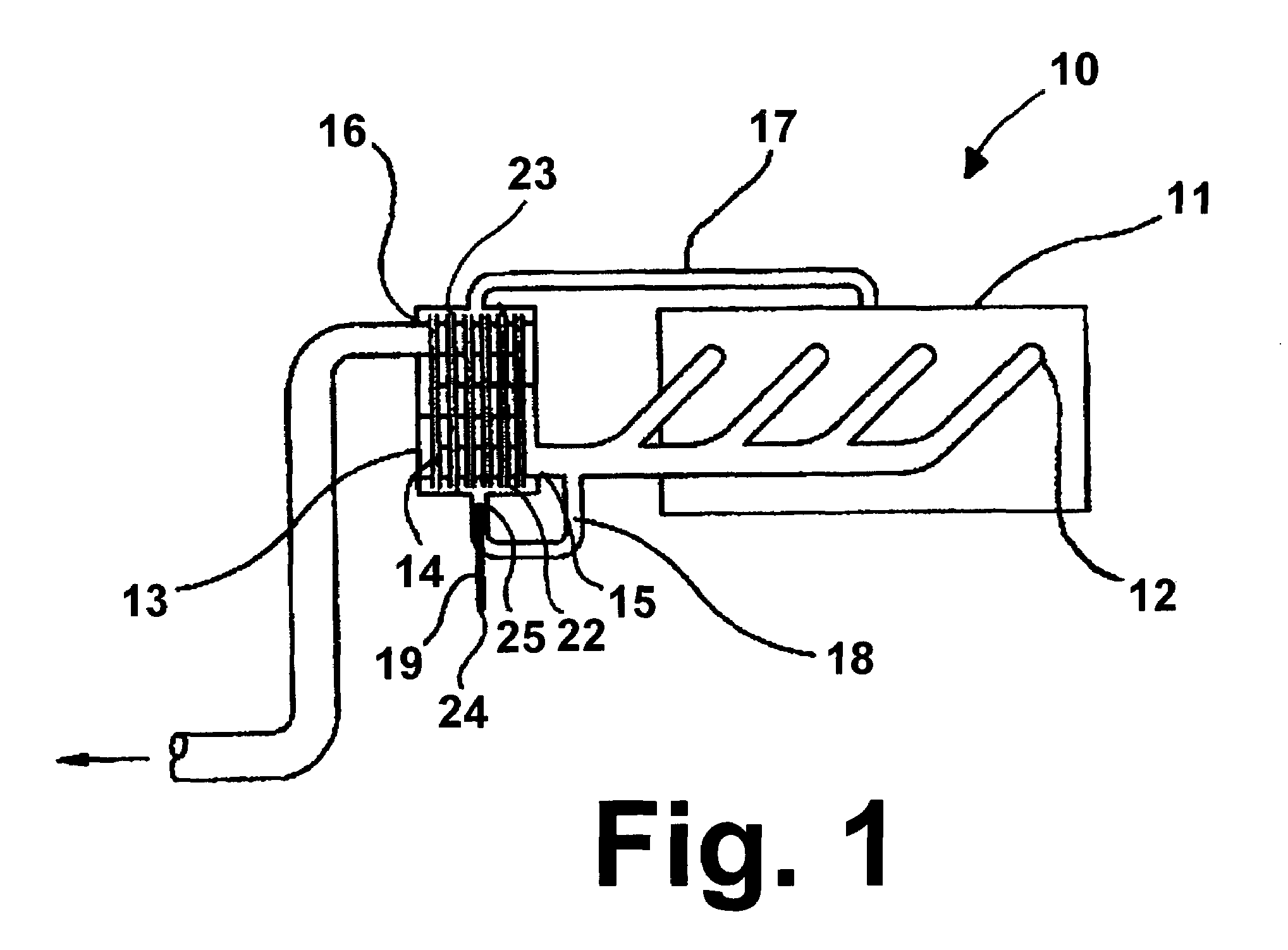

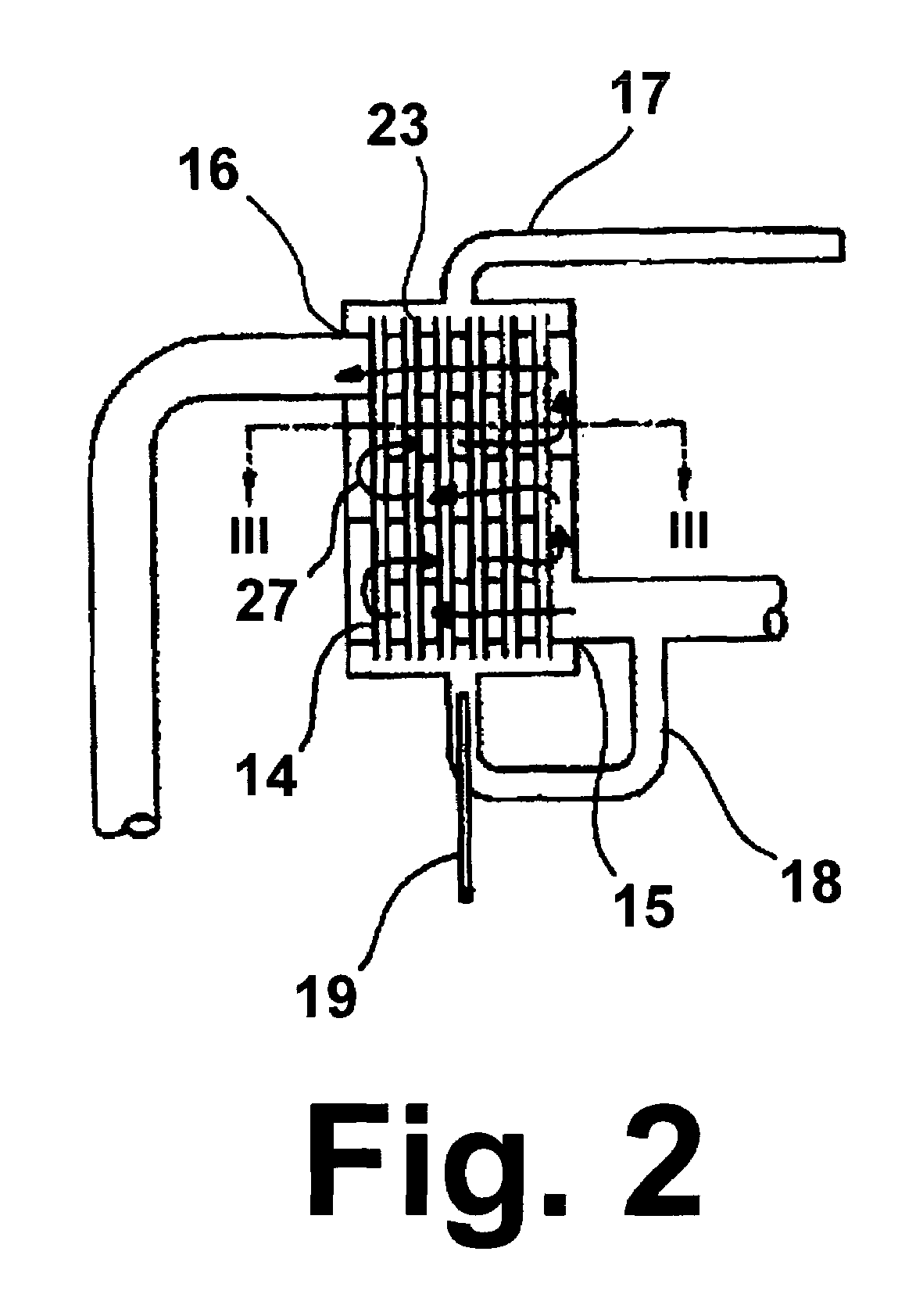

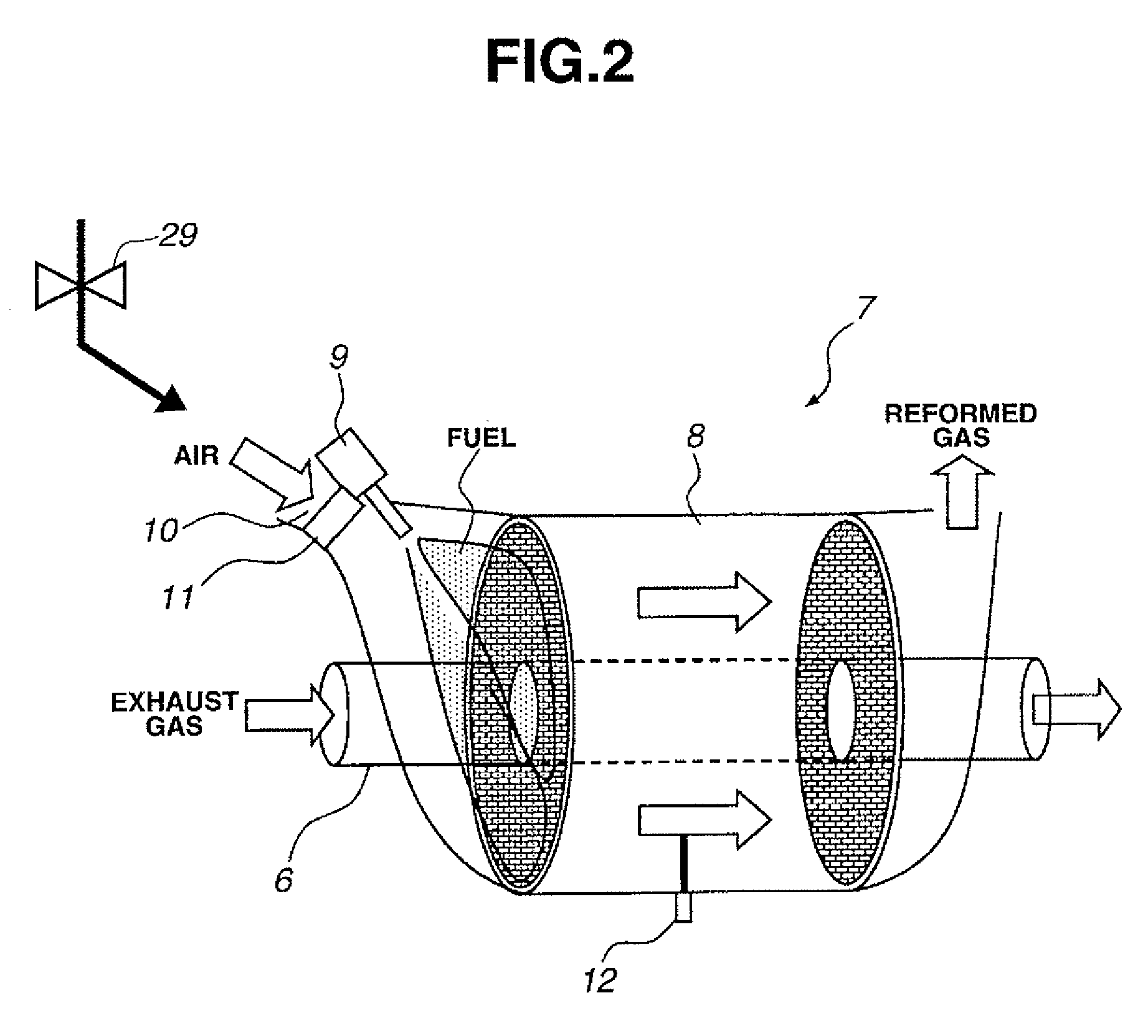

Fuel Supply System for a Vehicle Including a Vaporization Device for Converting Fuel and Water into Hydrogen

InactiveUS20090194042A1Internal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberHydrogen

A fuel supply system (1) is disclosed for use with an internal combustion engine or a fuel cell system (408). The fuel supply system may include a water supply (4) for supplying water; a fuel supply (3) for supplying fuel; a fuel reformer (10) including an air inlet (52,70) converts the water, air, and fuel into hydrogen and byproducts, and supplies the hydrogen to combustion chambers (2) of an internal combustion engine; and an injector subsystem (5) coupled to the water supply injects water into the combustion chambers following ignition of the hydrogen in the combustion chambers. The fuel supply system may include a water recovery subsystem (6) coupled to an exhaust output (9) of the internal combustion engine, the internal combustion engine producing an exhaust including water vapor and CO2, the water recovery subsystem comprising a filter (13) for removing CO2, from the water vapor.

Owner:TYMA

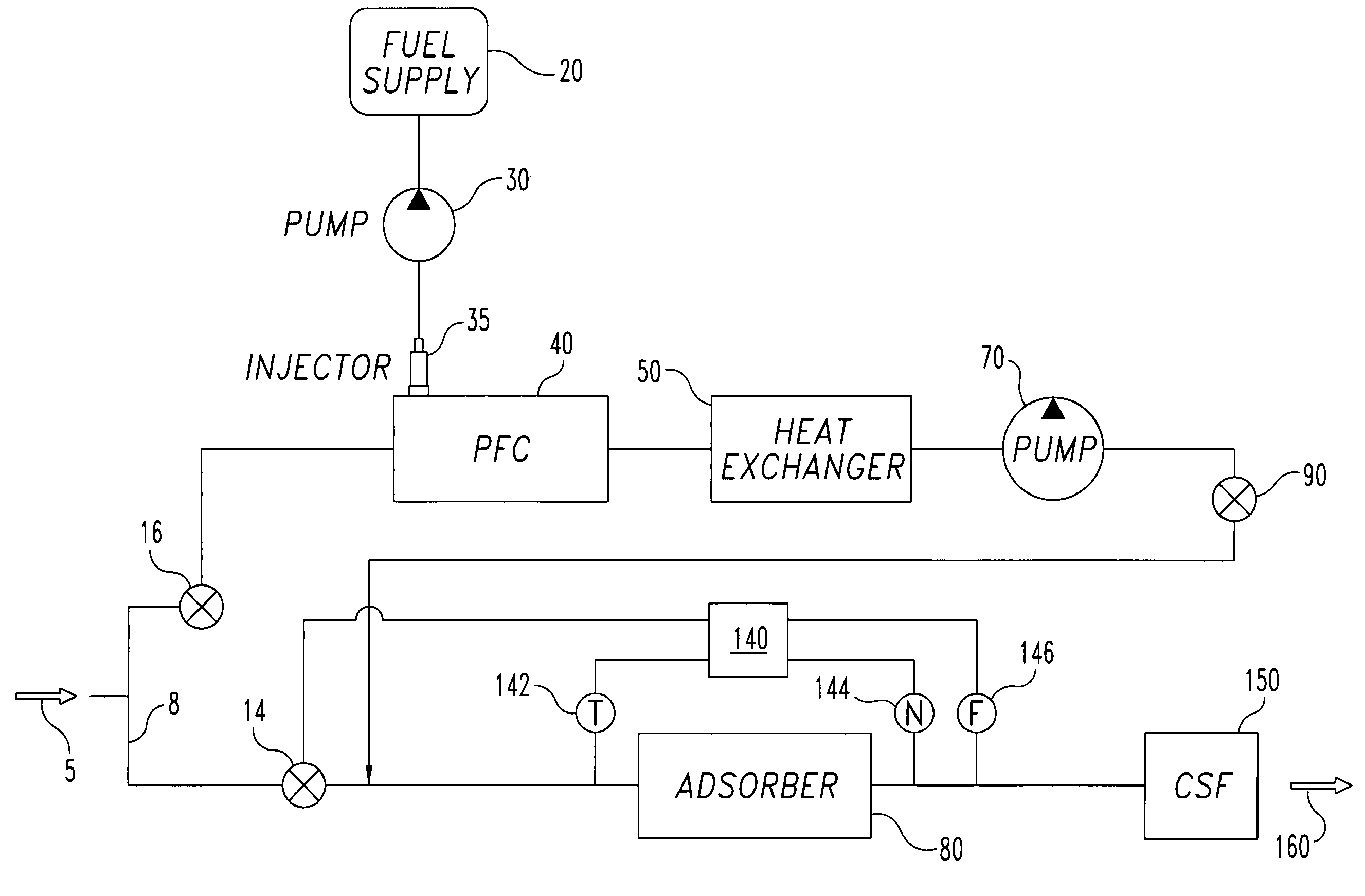

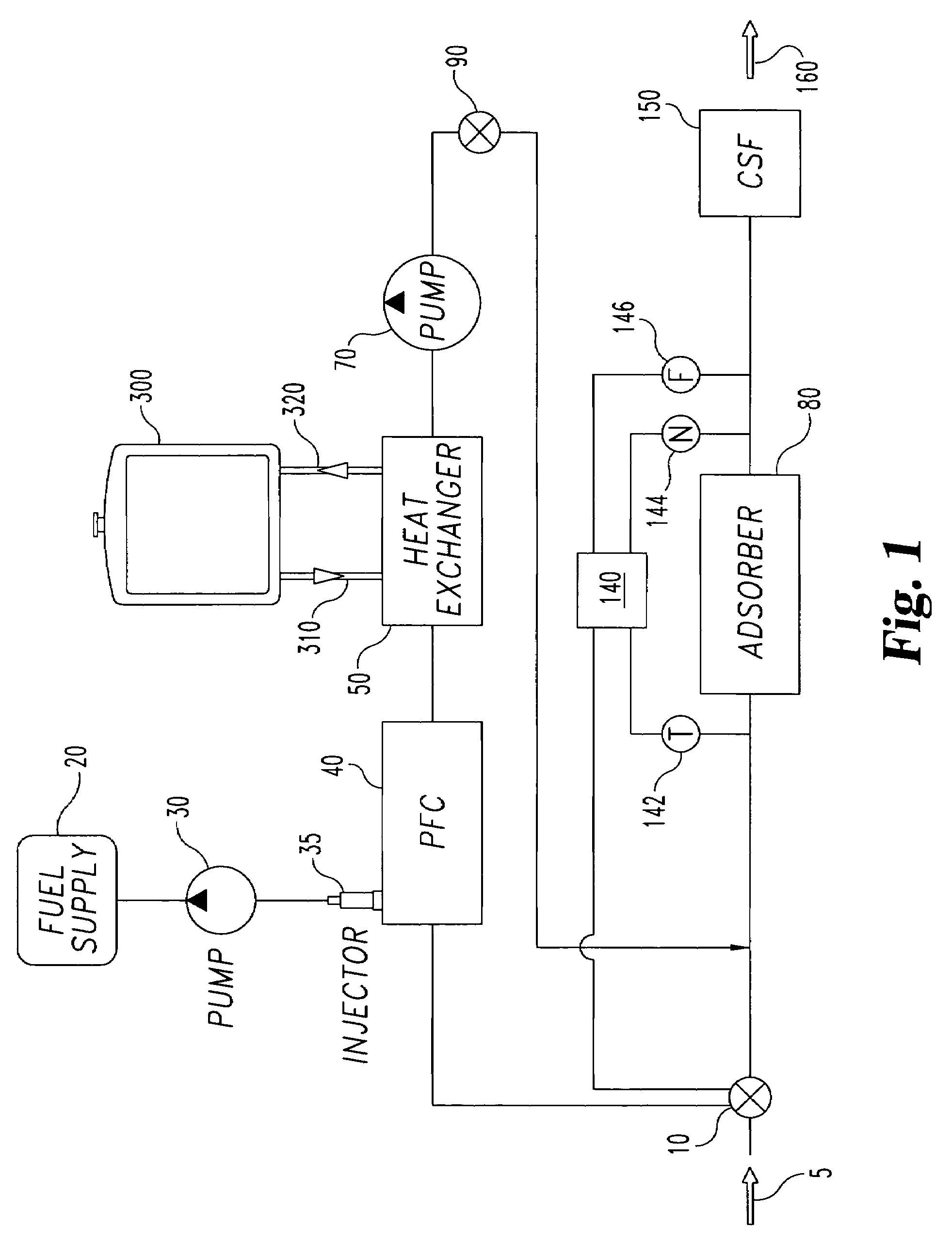

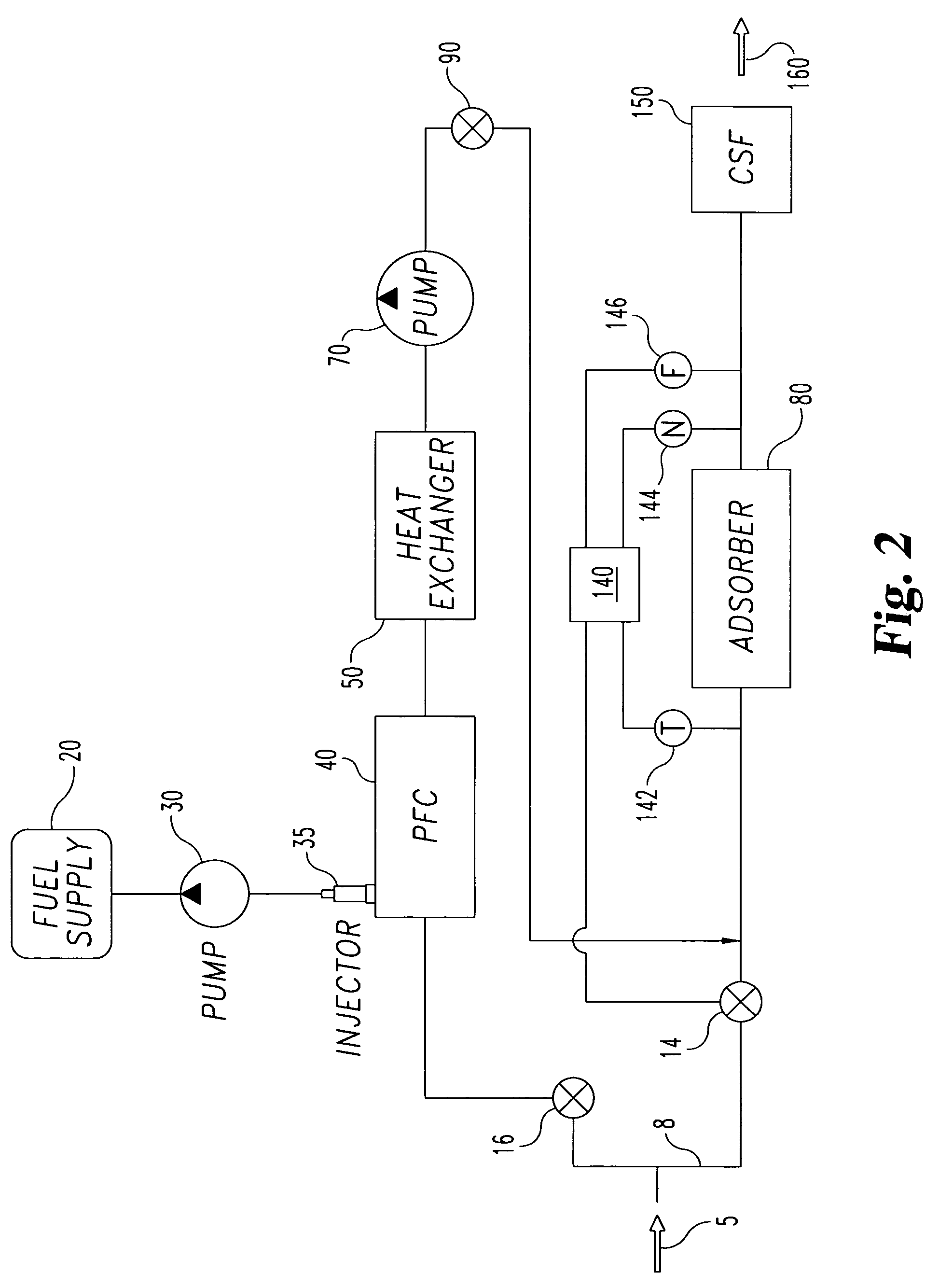

Plasma fuel converter NOx adsorber system for exhaust aftertreatment

InactiveUS7377101B2Increase production and deliveryChange trafficExhaust apparatusSilencing apparatusControl systemExhaust fumes

The invention provides a NOx adsorber aftertreatment system for internal combustion engines which utilizes a plasma fuel converter operatively coupled to at least one NOx adsorber to aid in the regeneration of the NOx adsorber. Fuel and engine exhaust is injected into a plasma fuel converter upstream of a NOx absorber producing reductant such as H2, and CO, which are inlet into the NOx absorber. Reductants such as H2 and CO acting along and together help to efficiently regenerate the NOx Adsorber which in turn releases exhausts products such as CO2 and N2. Using the reductants generated by the plasma fuel converter NOx adsorbers, catalytic soot filter, and the like can be regenerated at exhaust temperatures less than 250° C. The plasma fuel converter, NOx adsorber regenerating aftertreatment system of the present invention may be used with any suitable control system.

Owner:CUMMINS FILTRATION INC

High efficiency, reduced emissions internal combustion engine system, especially suitable for gaseous fuels

InactiveUS20040083715A1Internal combustion piston enginesNon-fuel substance addition to fuelChemical reactionMass ratio

Internal combustion ("IC") engine system for high fuel conversion efficiency and low exhaust emissions, particularly although not exclusively with gaseous fuels. An IC engine operates at approximately stoichiometric (lambda=1) air / fuel mass ratios. A higher-than-normal compression ratio for typical stoichiometric operation is possible for the engine, due to the introduction of an inert (i.e., not chemically reactive in the combustion process) gas into the air / fuel mixture. The inert gas slows the combustion rate to avoid uncontrolled combustion rates and engine "knock." The elevated compression ratio yields higher fuel conversion efficiency. Stoichiometric air / fuel ratio permits catalytic processing of the exhaust gas stream to reduce CO, NOx, and HC emissions via a combination of non-selective catalytic reduction process.

Owner:ATTAINMENT TECH

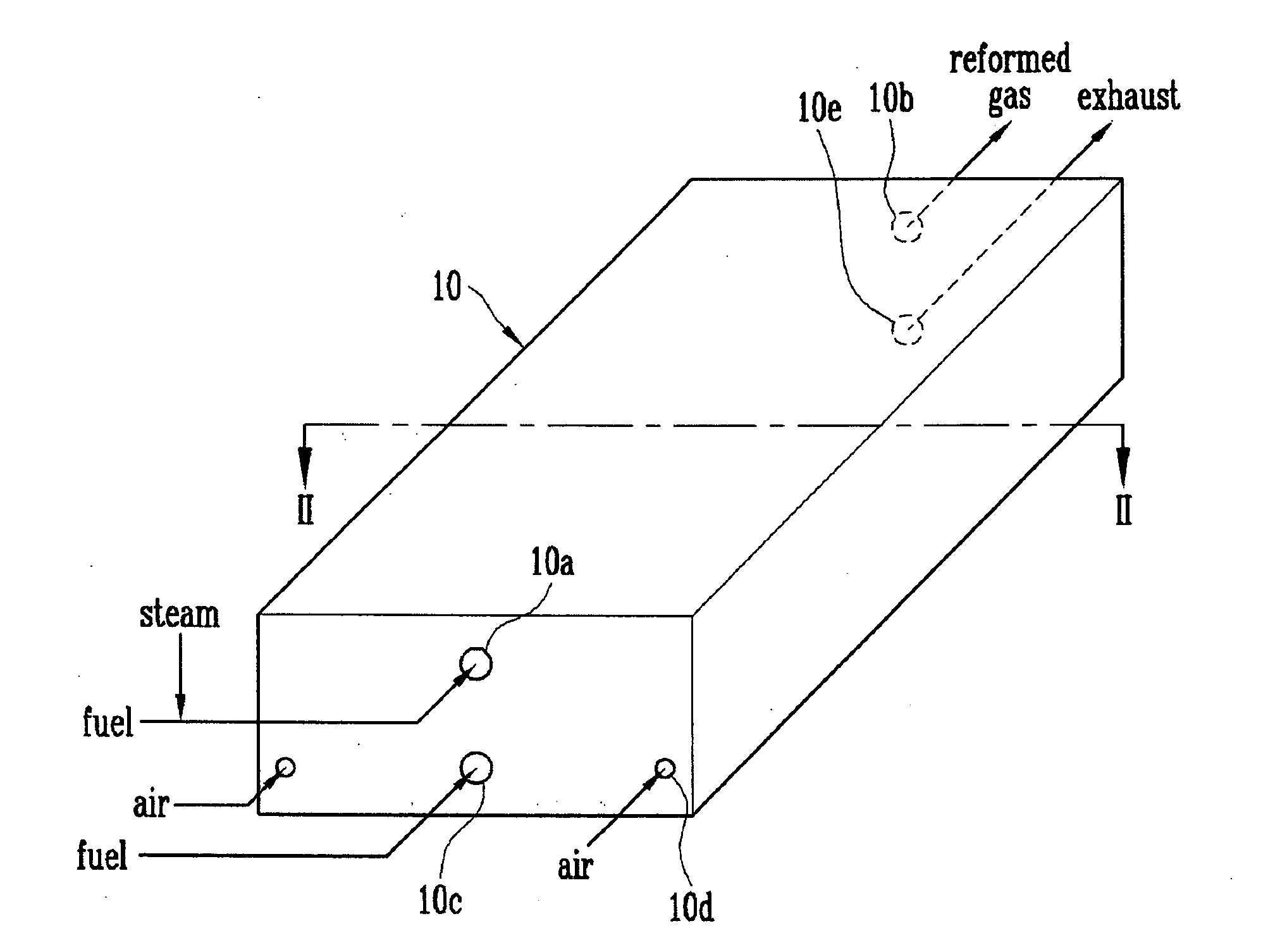

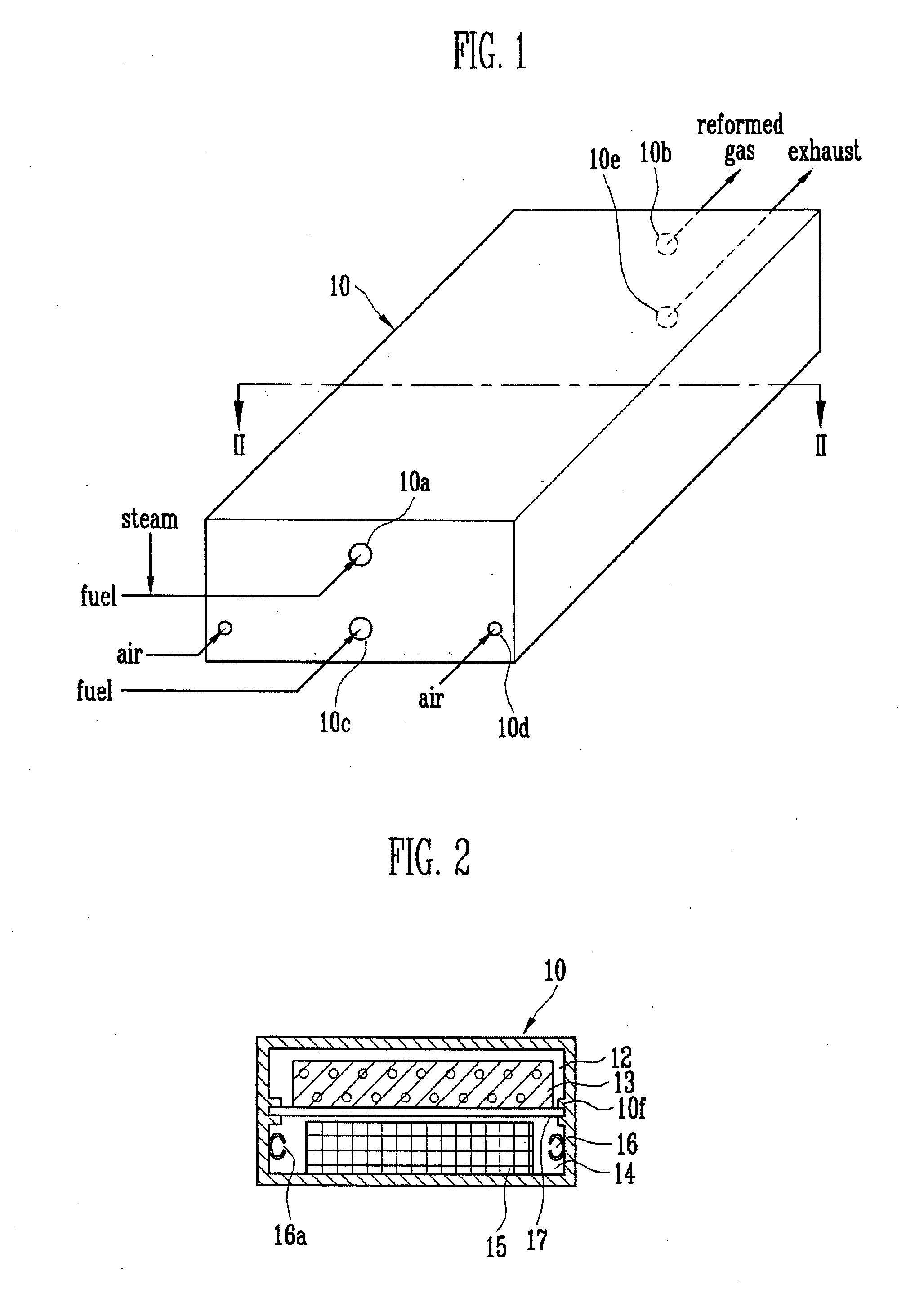

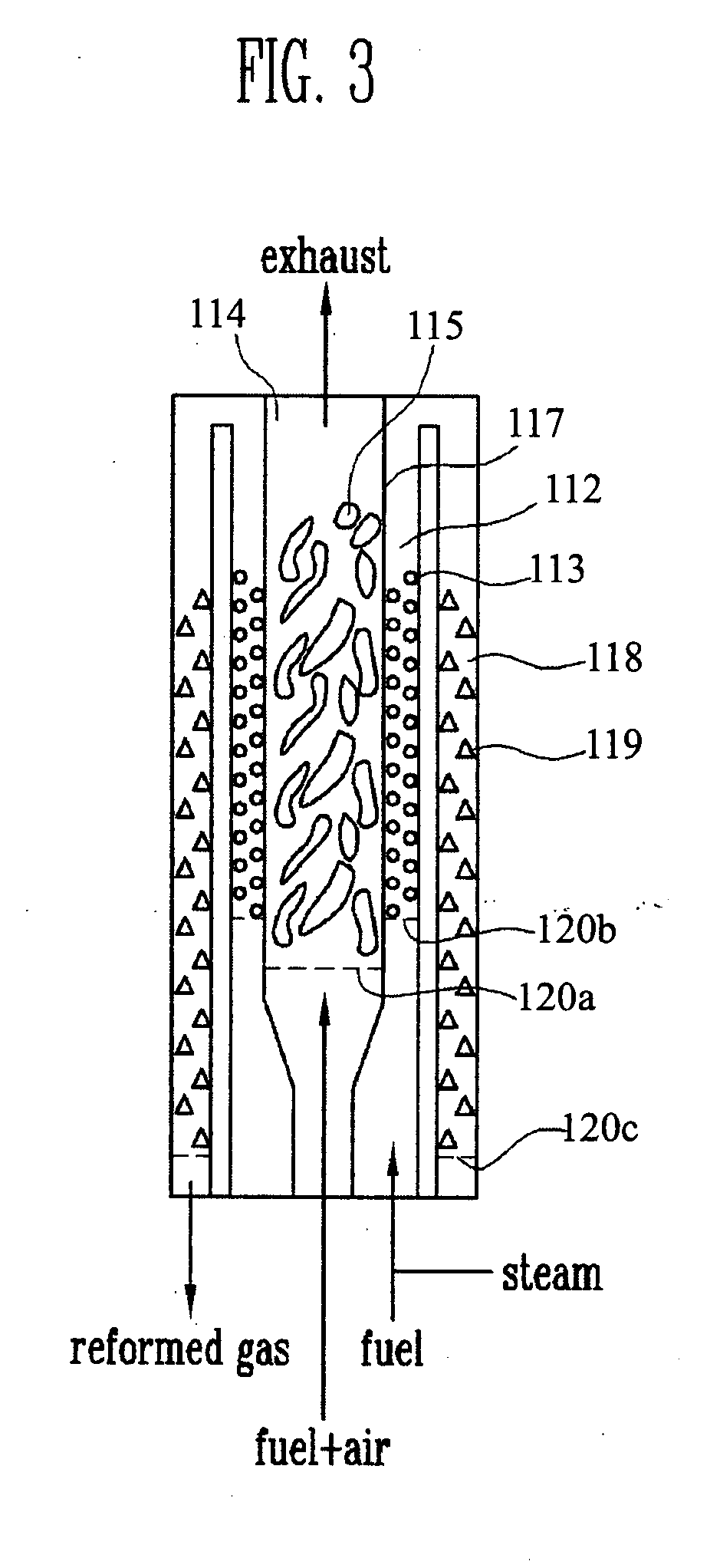

Fuel reformer using radiation

InactiveUS20080170975A1Lower temperature of heaterPreventing deterioration of durabilityHydrogenHydrogen/synthetic gas productionThermal energyNuclear engineering

A fuel reformer using radiation comprises: a reforming reactor including a reforming catalyst for shifting fuel into a desired substance; a heater for supplying heat to the reforming catalyst; and a transparent inner wall positioned between the reforming reactor and the heater. With the present invention, the heat energy of the heater is transferred to the reforming catalyst in a radiation form so that the thermal efficiency of the fuel reformer can be improved.

Owner:SAMSUNG SDI CO LTD

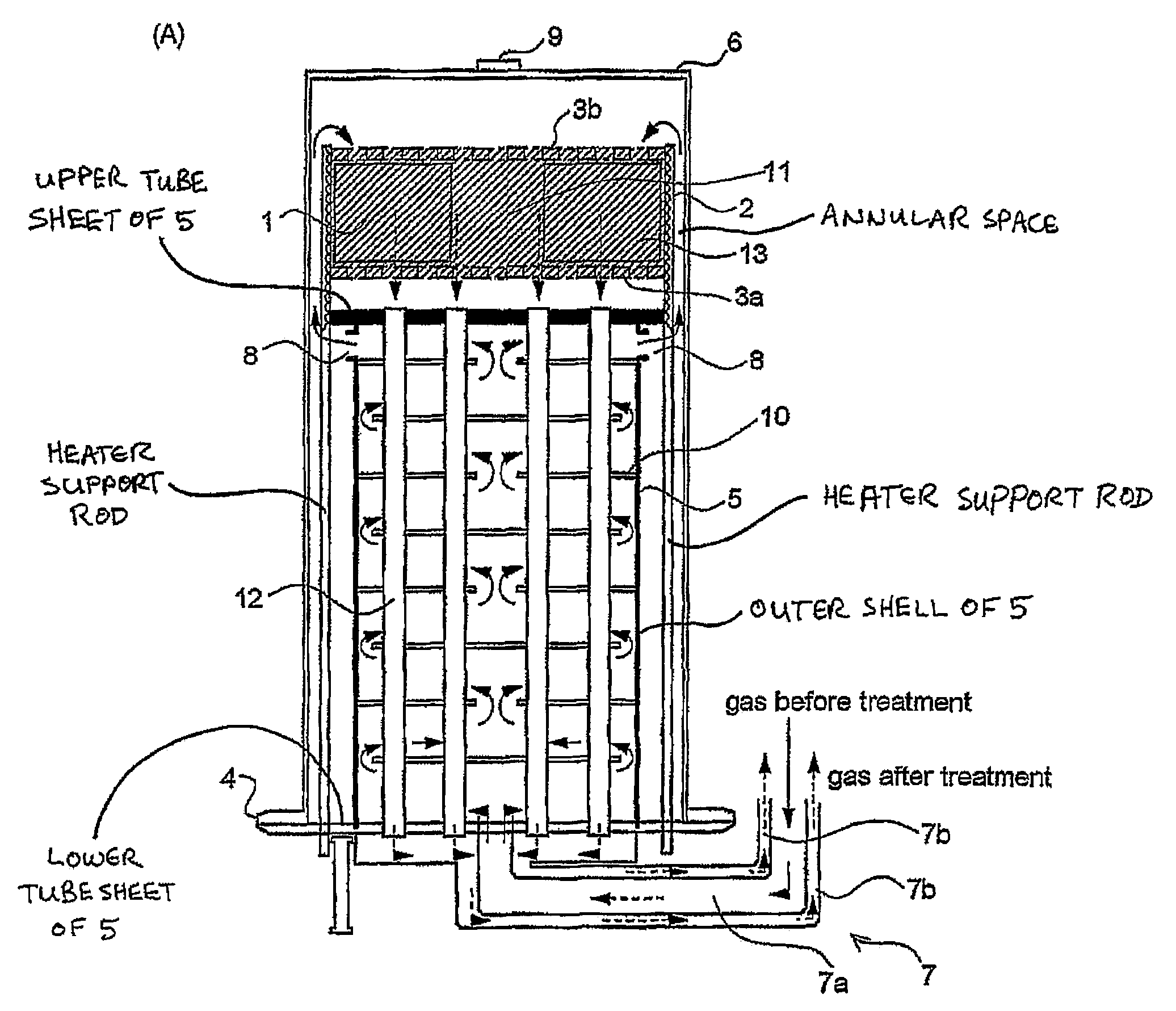

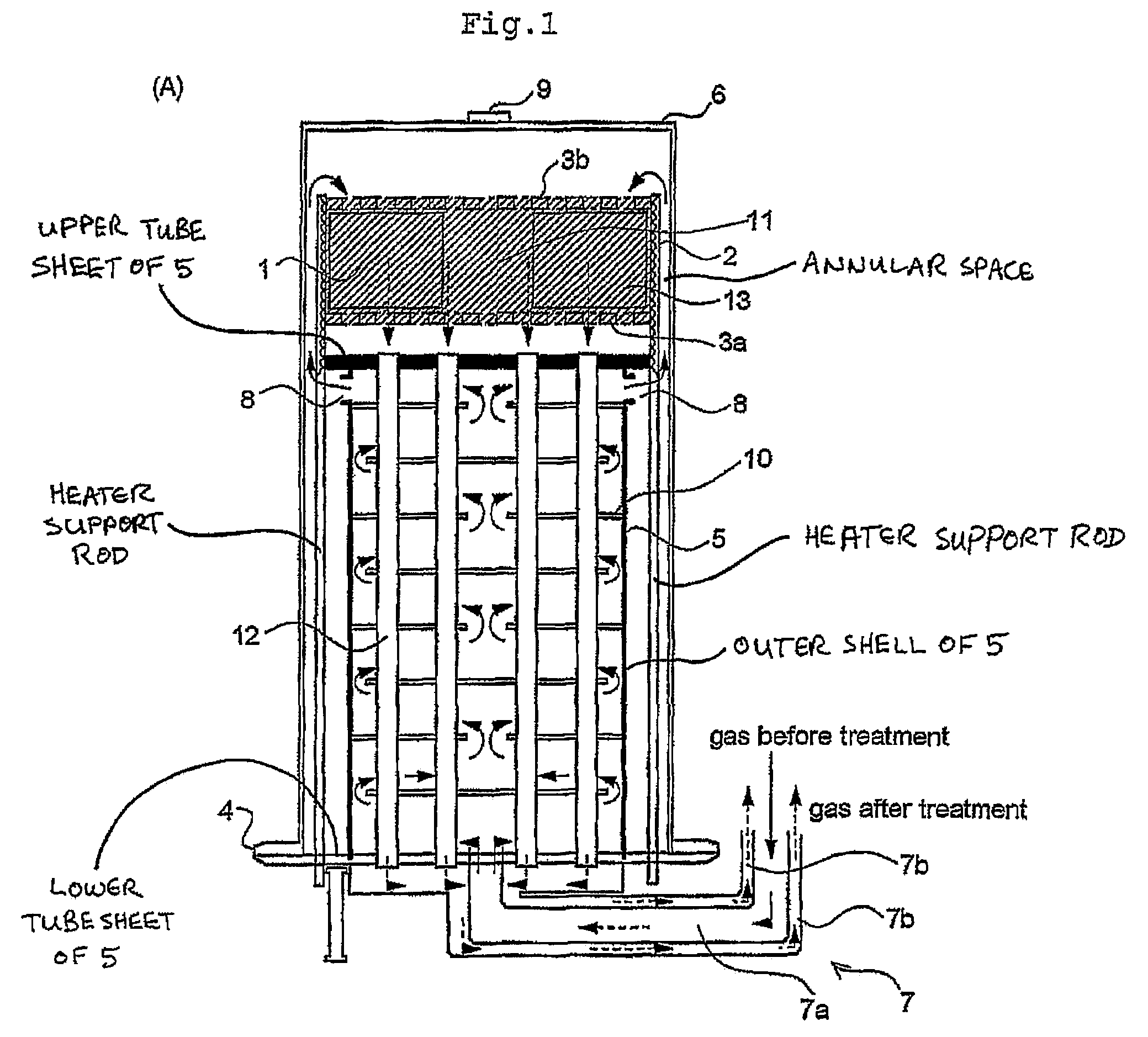

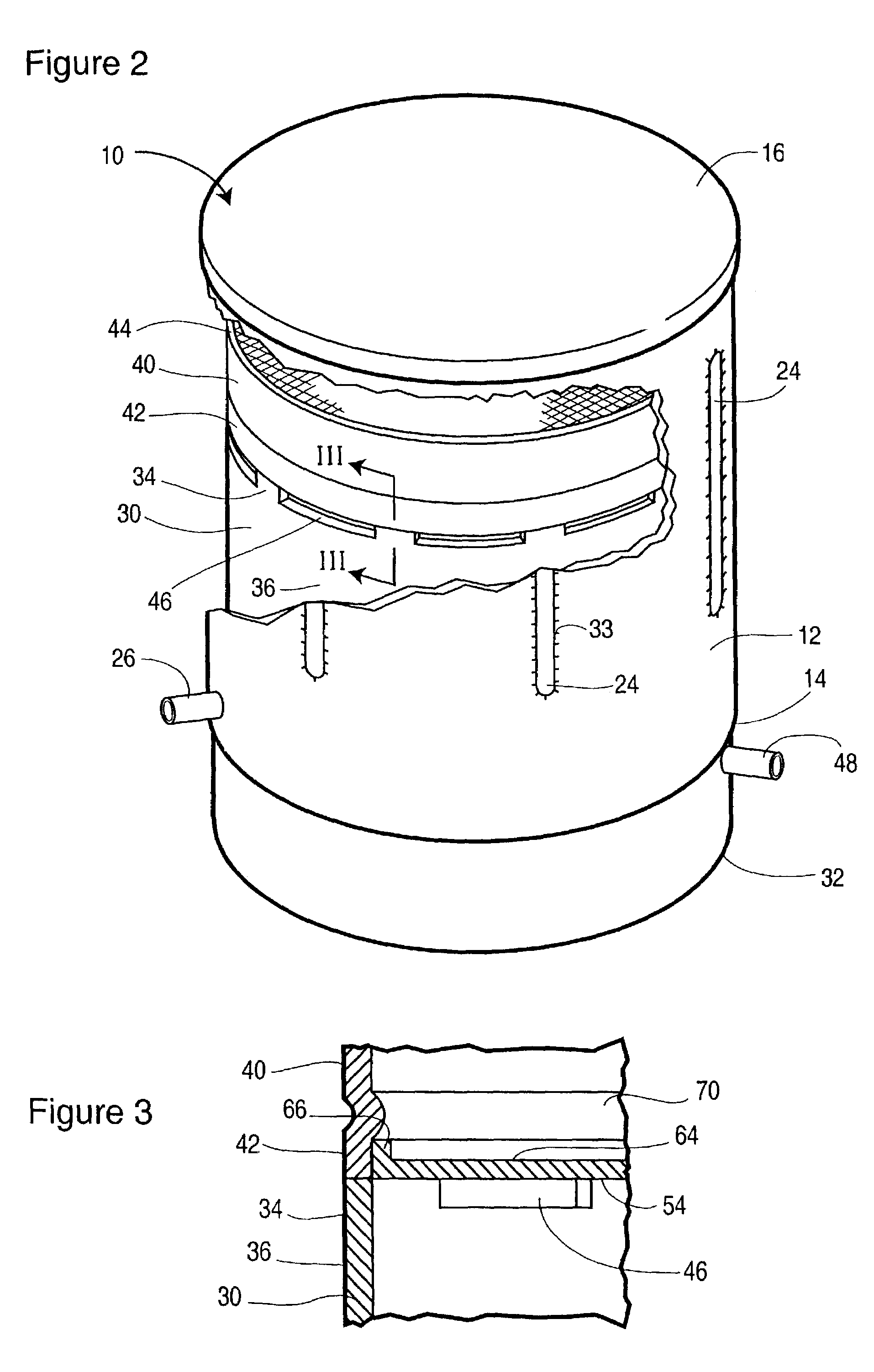

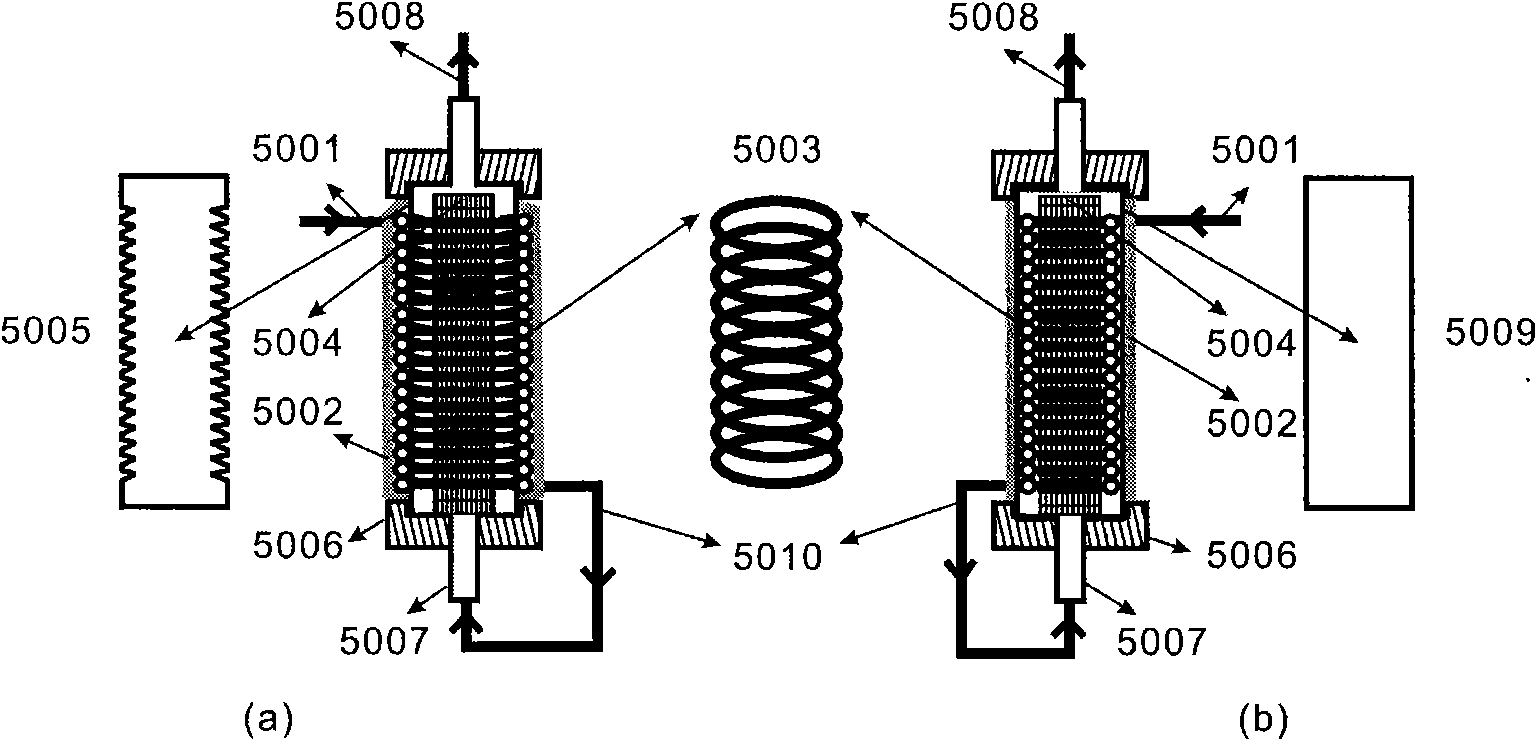

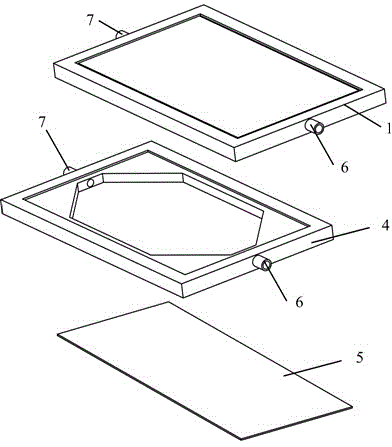

Fuel conversion reactor

ActiveUS7220392B2Hydrogen/synthetic gas productionHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

A fuel conversion reactor includes a shell-and-tube heat exchanger for controlling the temperature of a hot gaseous mixture produced by catalytic or non-catalytic reaction of a fuel with a gaseous fluid, and for controlling the temperature of the gaseous fluid and / or the fuel prior to the reaction. The reactor is either a catalytic or non-catalytic burner, or a fuel reformer for converting a fuel to hydrogen. A preferred reactor includes an outer shell having first and second ends and an inner surface, a primary inner shell extending into the outer shell, the primary inner shell defining a heat exchanging chamber and having primary and secondary ends, and a secondary inner shell having a first end located adjacent the secondary end of the primary inner shell. One or more outlet apertures are formed between the two inner shells for passage of the gaseous fluid out of the heat exchanging chamber. There are also a plurality of heat exchange tubes extending through the heat exchanging chamber between first and second tube sheets and connected to same. The first tube sheet is mounted in the primary inner shell while the second tube sheet is connected to the secondary inner shell. The tubes form passages for flow of the hot gaseous mixture in heat exchange contact with the gaseous fluid through the heat exchanging chamber, thereby preheating the gaseous fluid prior to reaction with the fuel. The adjacent ends of the inner shells form a disconnected joint and the secondary inner shell is free to move relative to the primary inner shell upon thermal expansion of the tubes.

Owner:DANA CANADA CORP

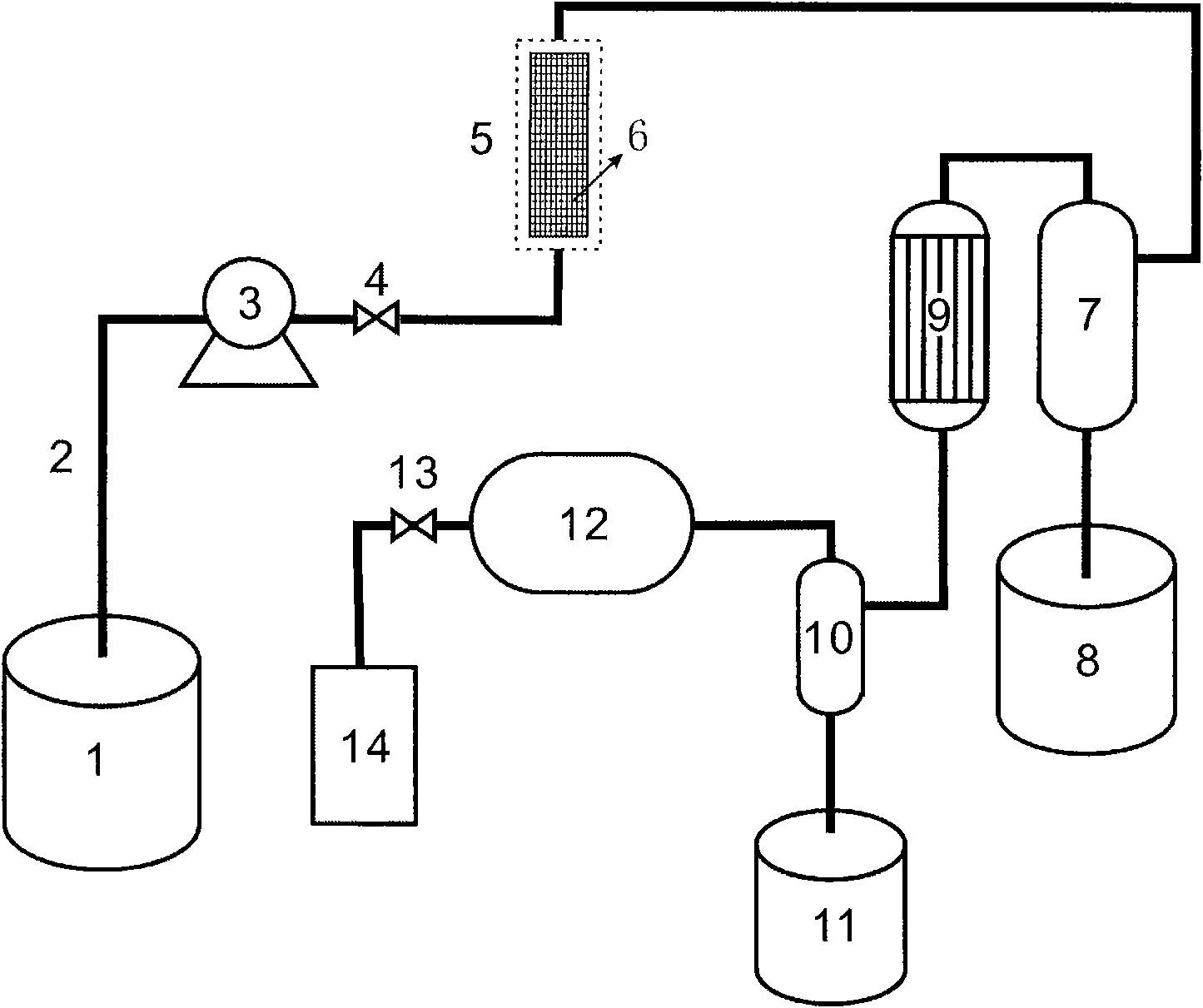

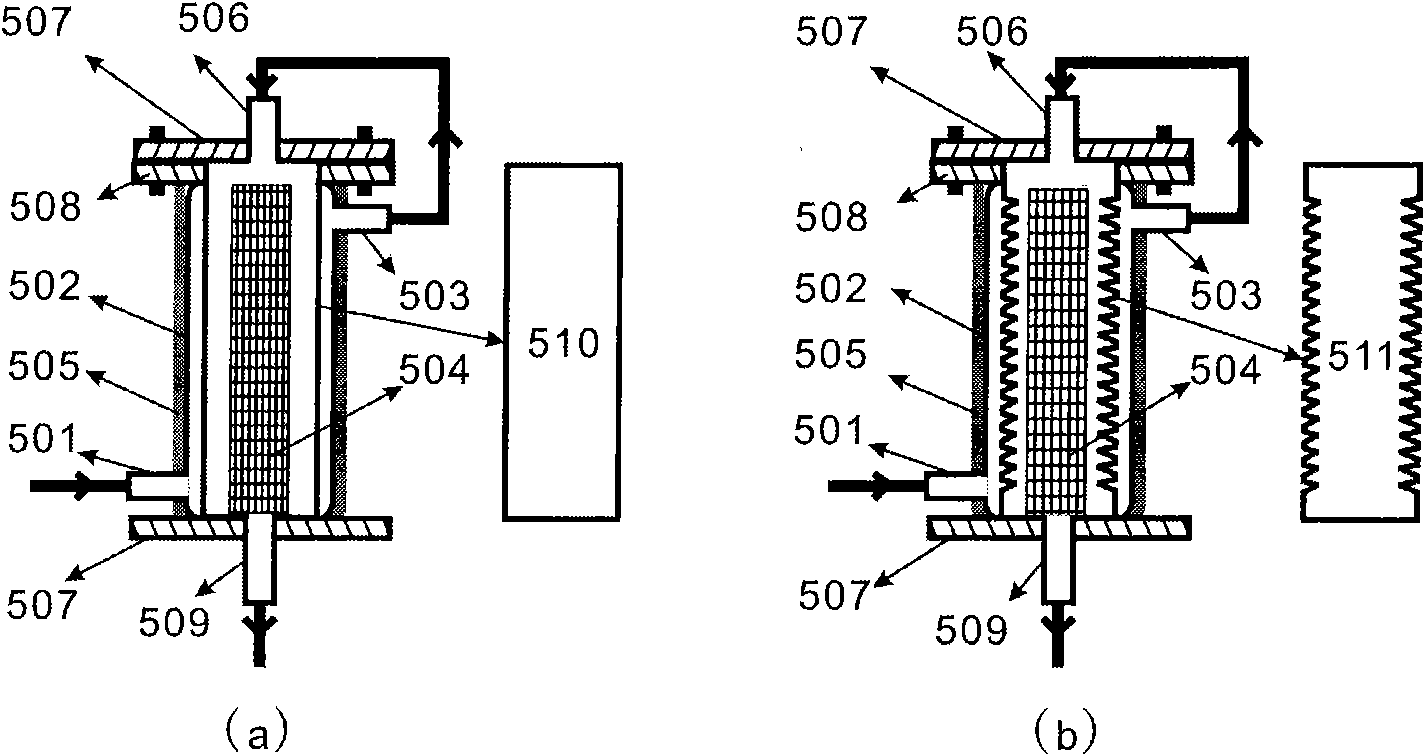

Device and method for chemical hydride catalytic-hydrolysis hydrogen production suitable for onboard hydrogen source

InactiveCN101597023AReal-time adjustment of flow rateIncrease flow rateChemical industryHydrogen productionHydrogen pressureHydrogen fuel cell

The invention relates to a hydrogen storage and production technology, in particular to a device and a method for chemical hydride catalytic-hydrolysis hydrogen production suitable for an onboard hydrogen source. The hydrogen production device mainly comprises a catalytic reaction chamber provided with a heat exchanger, a gas-liquid separator, a fuel pump and a controlling unit, and the hydrogen production method is used for controlling the contact and the separation between liquid fuel and catalyst to achieve the purpose of prompt hydrogen production as required. Since the heat exchanger is additionally arranged at the periphery or inside the catalytic reaction chamber, the heat from hydrolysis reaction is effectively utilized, the initial temperature of the liquid fuel is remarkably improved, the hydrogen-production rate of the device, the fuel conversion ratio and the system energy efficiency are greatly improved; and in addition, due to the design of the controlling unit, the continuous automatic adjustment of the delivery rate of the liquid fuel is realized, the stable hydrogen pressure of the system is ensured, and the hydrogen-storage density of the device is improved when the hydrogen supply demand at the hydrogen use terminal is responded in real time. The provided device for prompting hydrogen production can provide the onboard hydrogen source for hydrogen fuel-cell vehicles and various military and civil portable power supplies.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Catalytic core reactor for thermochemical heat recovery

InactiveUS7207323B1Improve engine efficiencyReduce operating costsHydrogenInternal combustion piston enginesNuclear reactorExhaust fumes

A fuel conversion system having an exhaust gas generator, such as an engine or a furnace, having a heated exhaust gas outlet, a reactor vessel having a heated exhaust gas inlet in fluid communication with the heated exhaust gas outlet, having a cooled exhaust gas outlet, and containing at least one reactor tube having an exhaust gas inlet in fluid communication with the heated exhaust gas outlet, a convertible fuel inlet, and a converted fuel outlet, and a monolithic fuel conversion catalyst structure substantially centered within the at least one reactor tube and shaped to form at least one flow channel between the monolithic fuel conversion catalyst structure and an inside wall of the at least one reactor tube.

Owner:UTILIZATION TECH DEV NFP

Power plant and fuel supply method therefor

InactiveUS7587998B2Point becomes highFuel flow is suppressedHydrogenElectrical controlPower stationInternal combustion engine

A power plant, including an internal combustion engine, a fuel conversion device that coverts a fuel to be supplied to the internal combustion engine from a before-conversion fuel to an after-conversion fuel, a first fuel supply device that supplies the fuel conversion device with the before-conversion fuel, a second fuel supply device that supplies the internal combustion engine with the after-conversion fuel, the after-conversion fuel being the fuel that has been converted by the fuel conversion device, and a controller that is communicated with the internal combustion engine, the fuel conversion device, the first fuel supply device and the second fuel supply device. The controller is configured to supply the fuel conversion device with the before-conversion fuel by operating the first fuel supply device, control the temperature of the fuel conversion device in a first temperature range to evaporate the before-conversion fuel to produce a first after-conversion fuel, control the temperature of the fuel conversion device in a second temperature range to reform the before-conversion fuel to produce a second after-conversion fuel, and supply the internal combustion engine with the after-conversion fuel by operating the second fuel supply device.

Owner:NISSAN MOTOR CO LTD

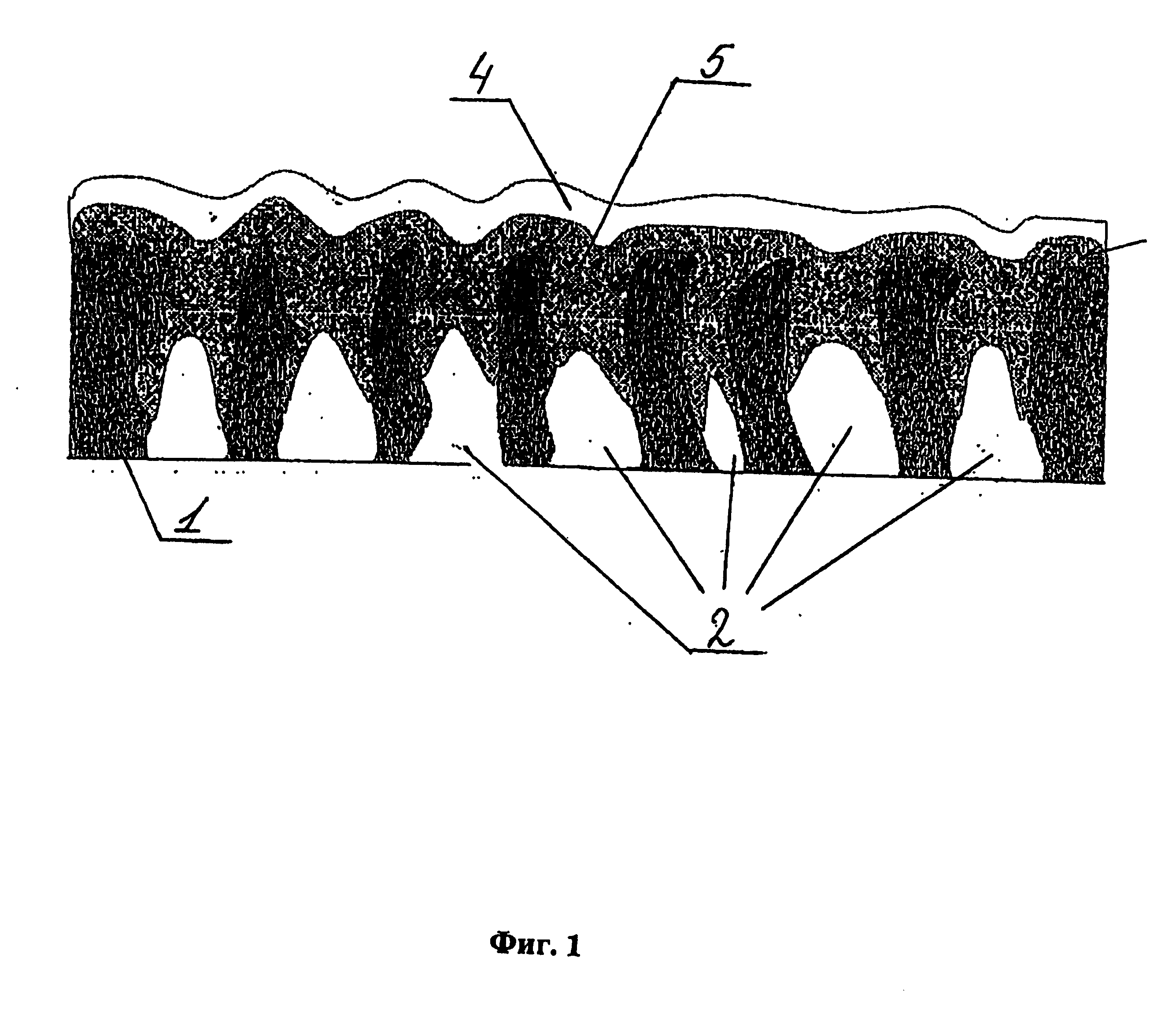

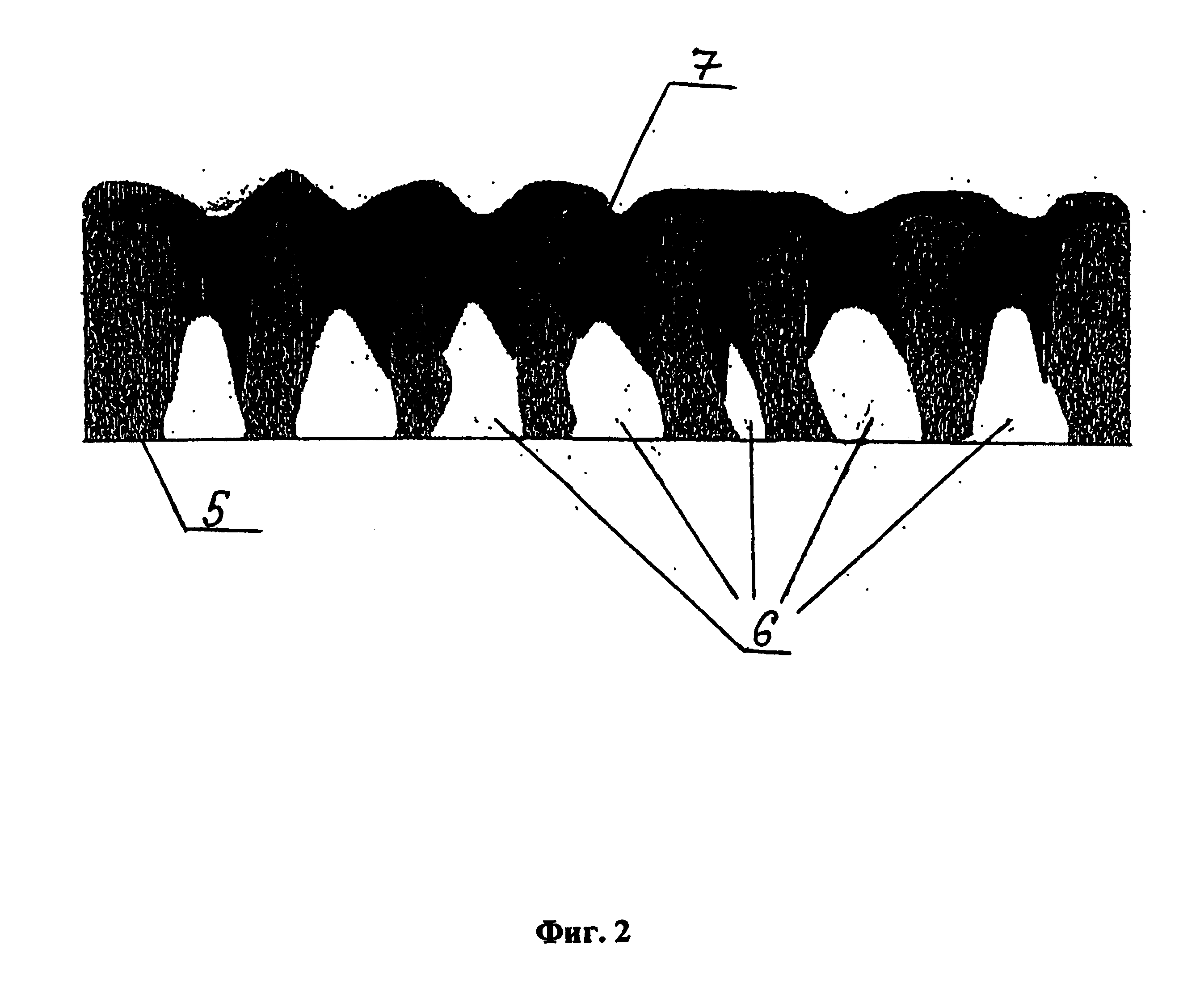

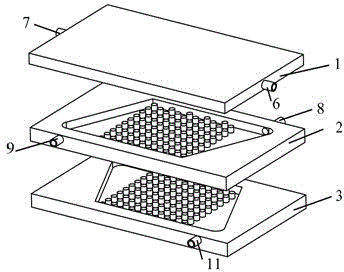

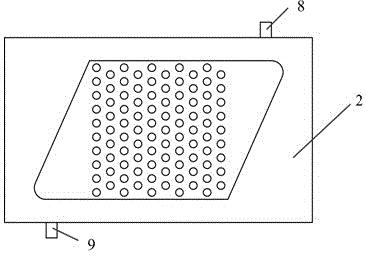

Self-heating staggered-arrangement micro-boss array type alcohol reforming device

InactiveCN103601151AEnhance heat and mass transferHigh heat and mass transfer efficiencyHydrogenHydrogen fuel cellHydrogen fuel

The invention discloses a self-heating staggered-arrangement micro-boss array type alcohol reforming device. The self-heating staggered-arrangement micro-boss array type alcohol reforming device comprises a hydrogen purification component, a reforming hydrogen production plate and a catalytic combustion plate sequentially from top to bottom. A reforming hydrogen production cavity is arranged in the reforming hydrogen production plate and loaded with a hydrogen production catalyst which is used for alcohol reformation so as to produce hydrogen; a catalytic combustion cavity is arranged in the catalytic combustion plate and loaded with a combustion catalyst which is used for alcohol combustion and heat supply. Heat is supplied for the reforming hydrogen production through alcohol combustion, so that the natural operation of the alcohol reforming device can be realized. Staggered-arrangement micro-boss array structures are arranged in the reforming hydrogen production cavity and the catalytic combustion cavity, so that the specific area is large and the heat transfer and mass transfer efficiency is high. In addition, the alcohol reforming device comprises the hydrogen purification component, so that the fuel conversion efficiency of the reforming hydrogen production cavity can be improved, and hydrogen at an outlet can be directly used for a hydrogen fuel battery. The self-heating staggered-arrangement micro-boss array type alcohol reforming device is compact in structure, convenient for catalysts to load, easy for the whole structure to assemble, and capable of being used in intermediate and small flow alcohol reforming hydrogen production situations.

Owner:ZHEJIANG UNIV

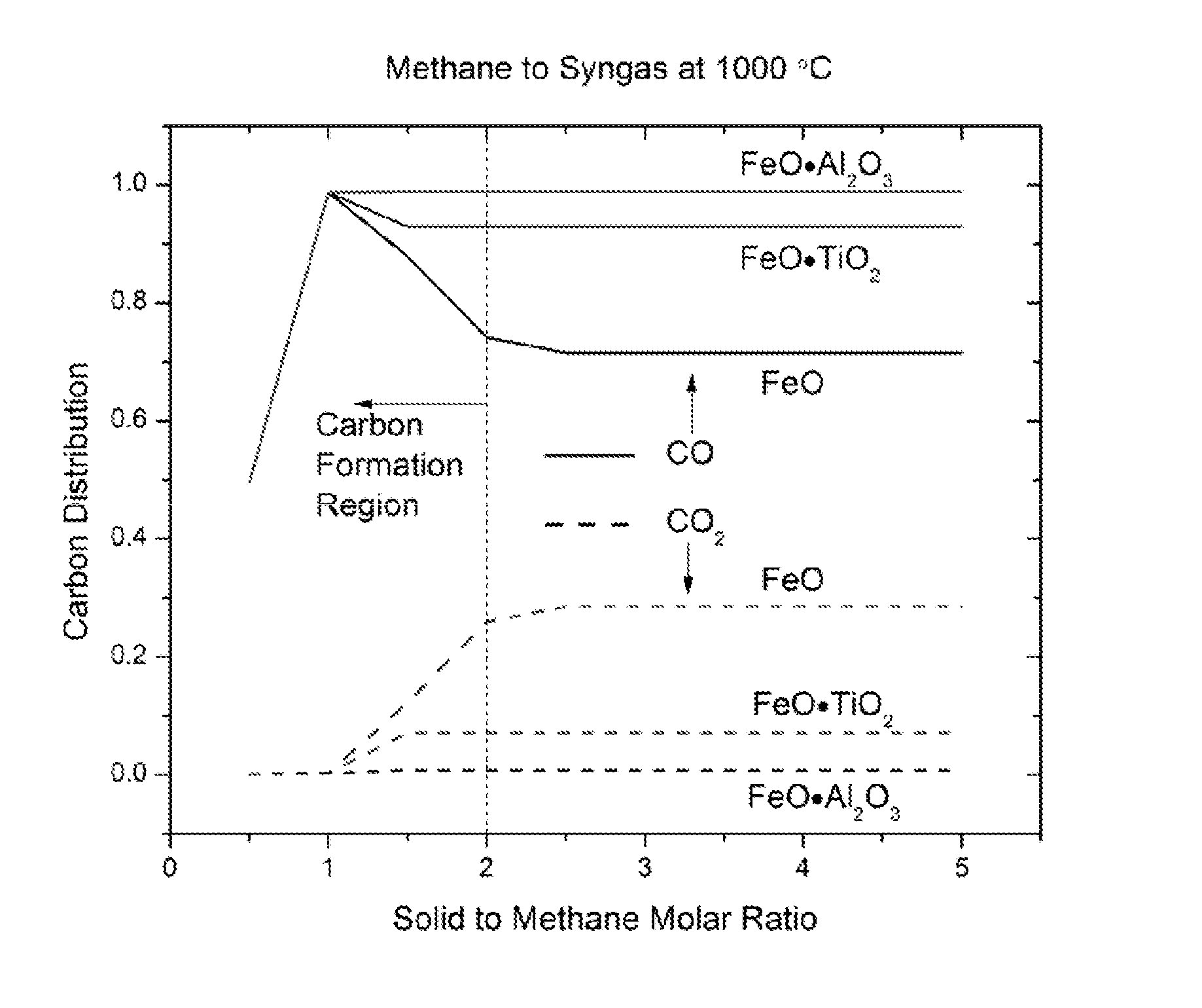

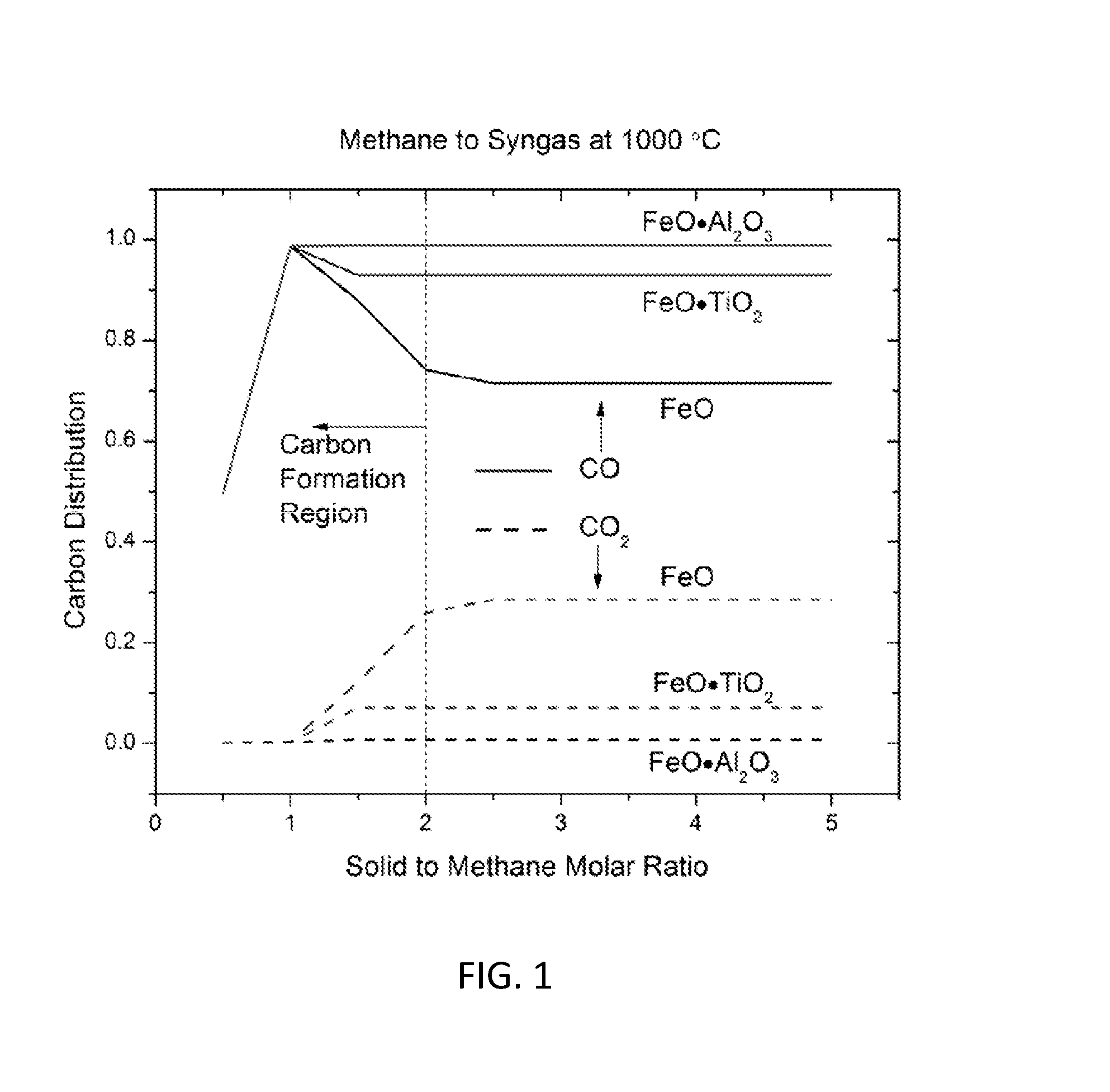

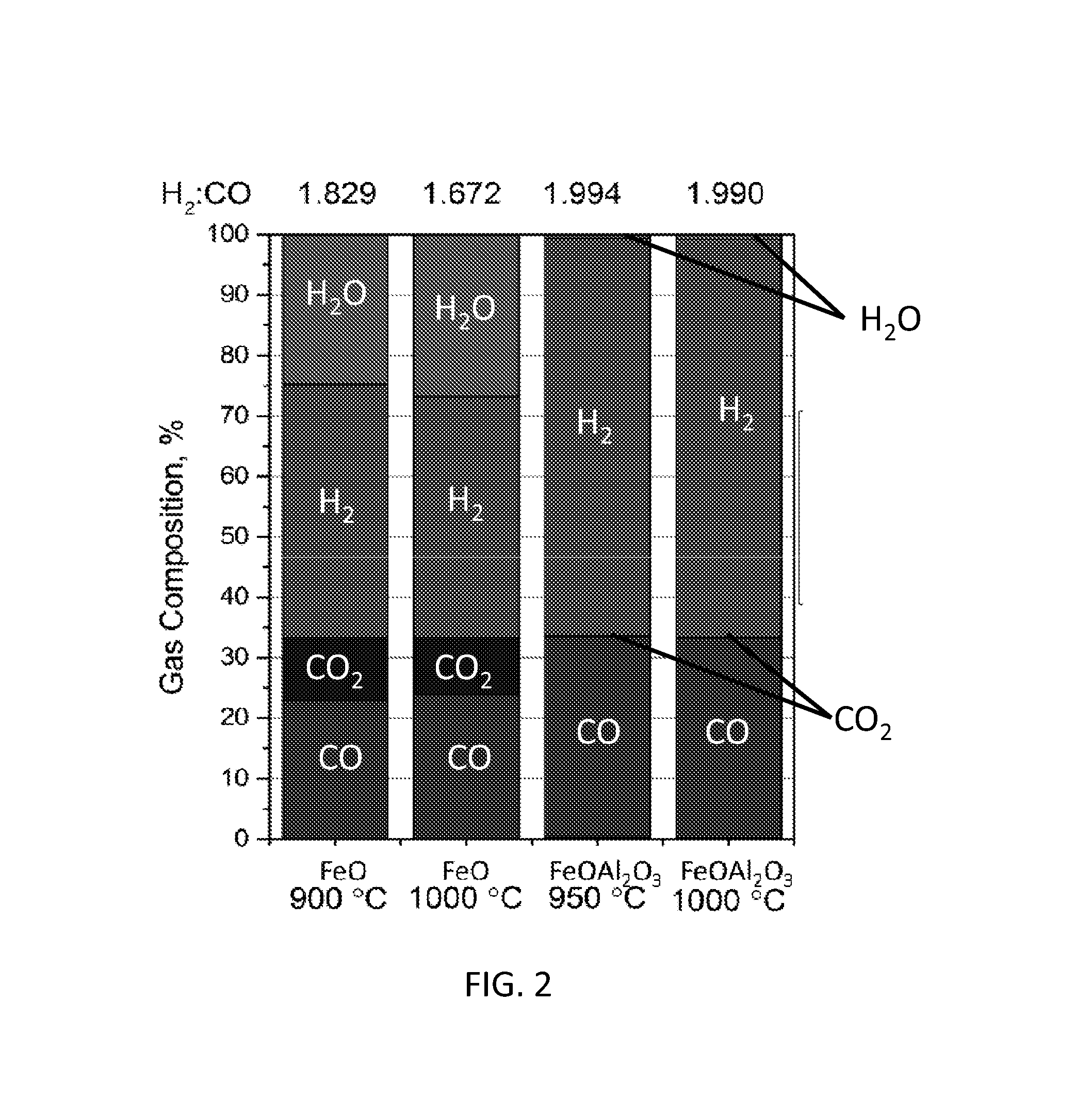

Methods for fuel conversion

In one embodiment described herein, fuel may be converted into syngas by a method comprising feeding the fuel and composite metal oxides into a reduction reactor in a co-current flow pattern relative to one another, reducing the composite metal oxides with the fuel to form syngas and reduced composite metal oxides, transporting the reduced composite metal oxides to an oxidation reactor, regenerating the composite metal oxides by oxidizing the reduced composite metal oxides with an oxidizing reactant in the oxidation reactor, and recycling the regenerated composite metal oxides to the reduction reactor for sub-sequent reduction reactions to produce syngas. The composite metal oxides may be solid particles comprising a primary metal oxide and a secondary metal oxide.

Owner:OHIO STATE INNOVATION FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com