Highly effective integration heat engine

An integrated, thermal engine technology, applied in mechanical equipment, engine components, combustion engines, etc., can solve problems such as not having a compound secondary combustion mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

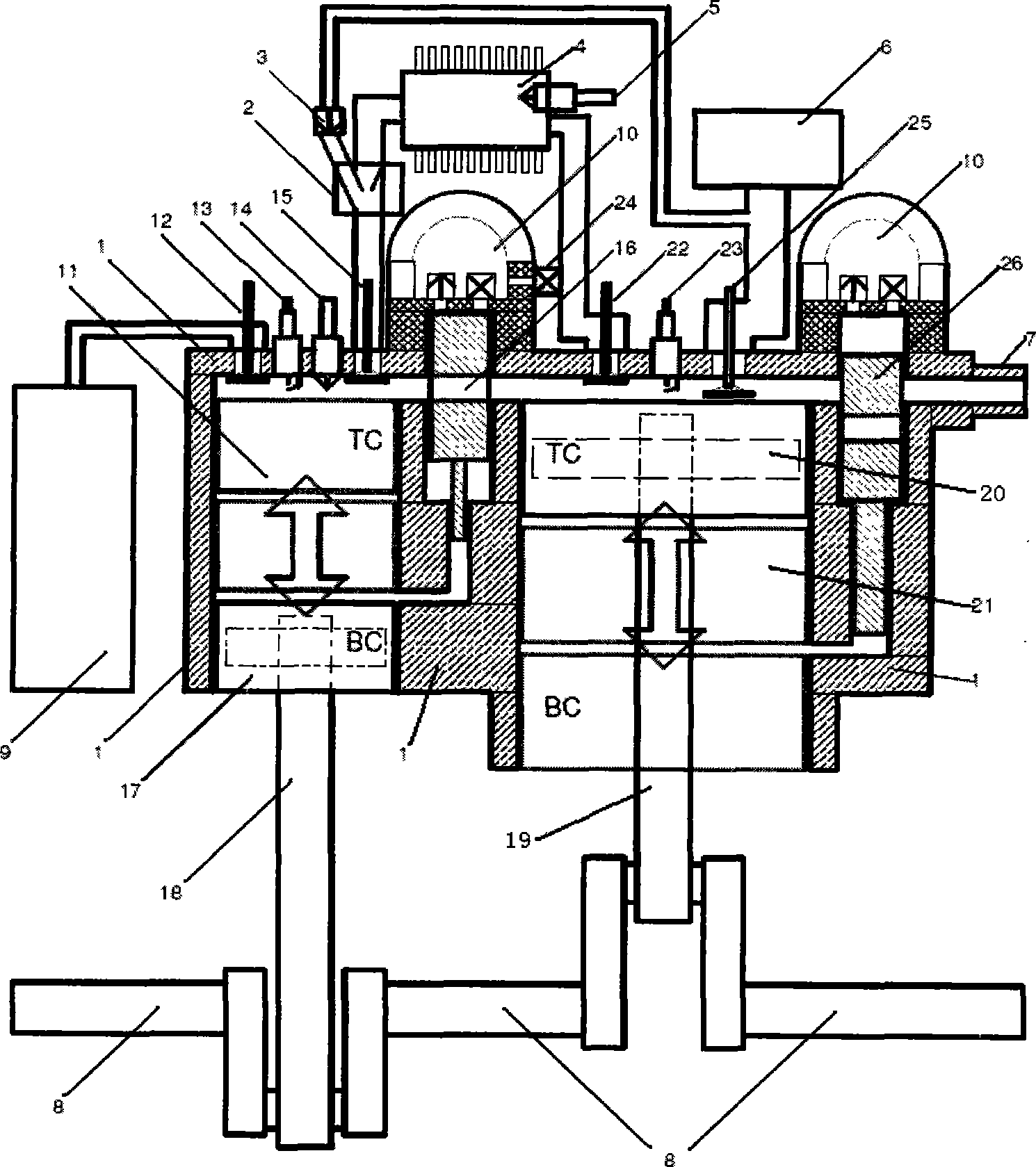

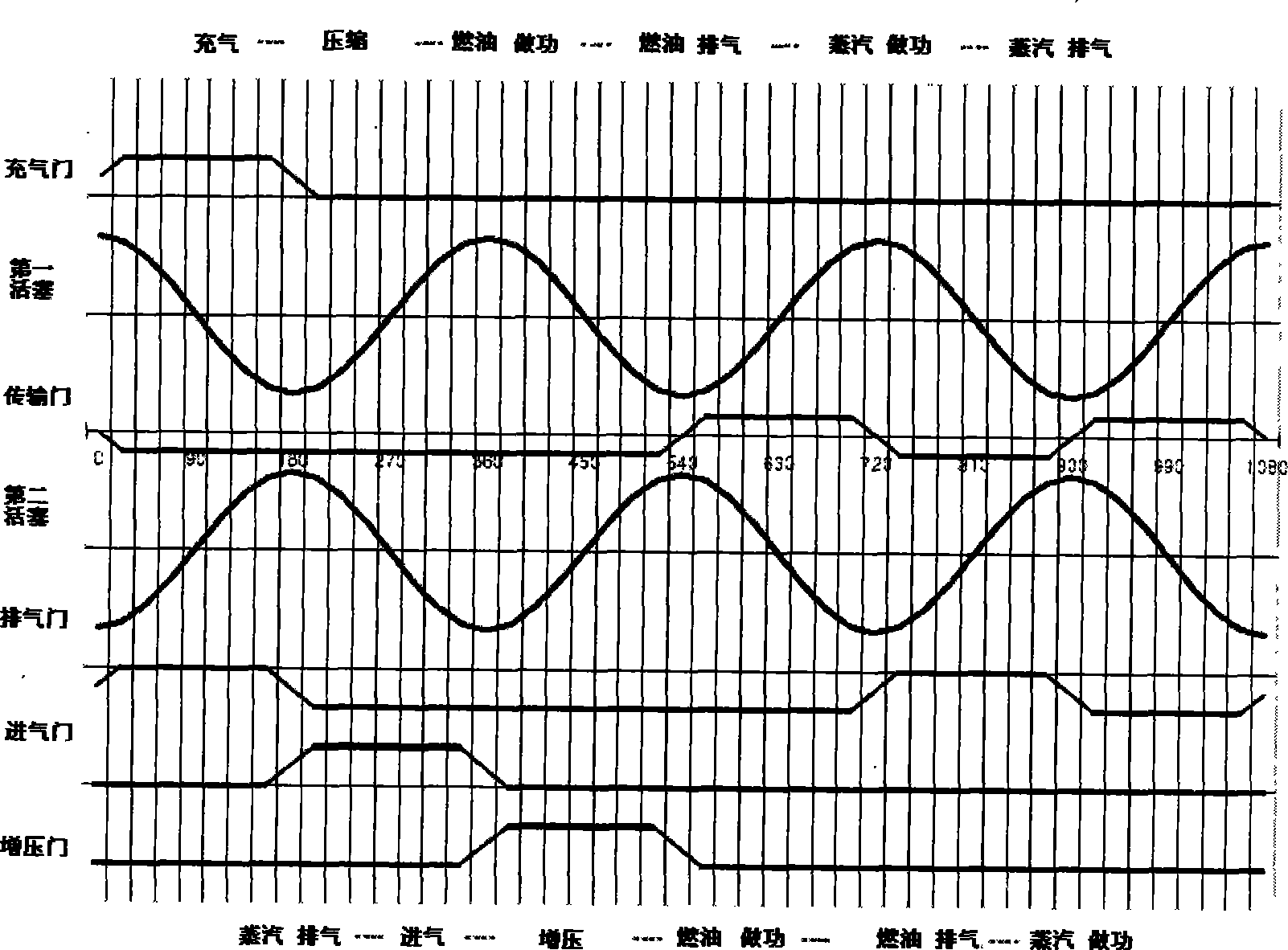

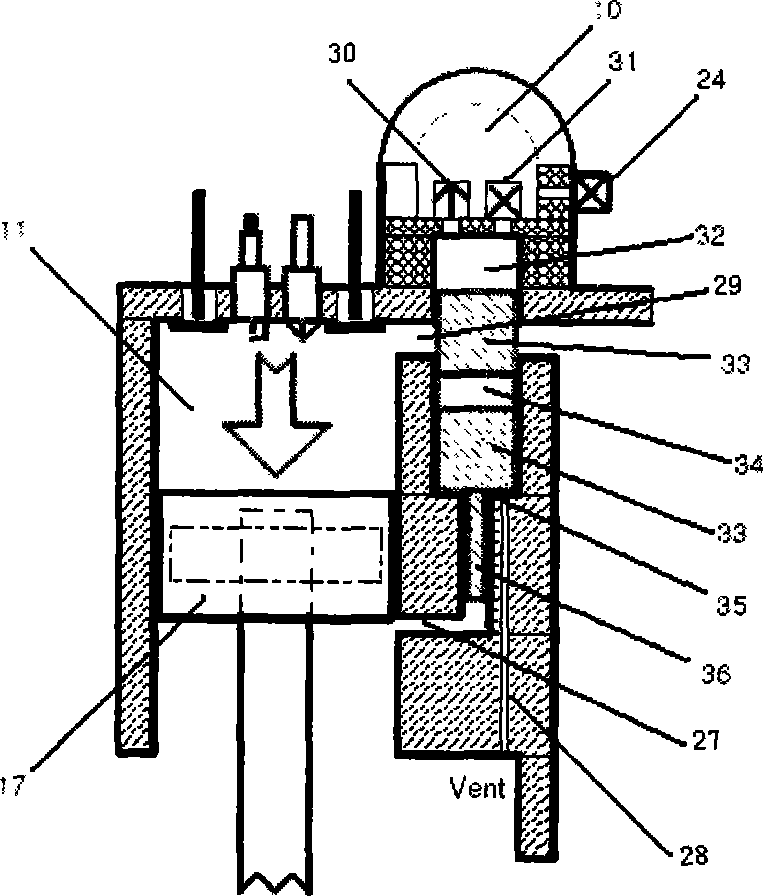

[0061] The following detailed description of the invention will be based on the preferred implementation examples of the present invention in the near future. For the detailed structure of each implementation example, please refer to the accompanying drawings.

[0062] The present invention relates to High Efficiency Integrated Heat Engines (HEIHE). HEIHE is a heat engine that integrates a combined heat-to-power conversion process. A double compound cylinder is used as the basic structure of the HEIHE, the first cylinder of which is a primary combustion / expansion cylinder, and the second cylinder of which is a secondary combustion / expansion cylinder. The power strokes driven by the expansion of various working fluids are integrated into the same engine block. These working fluids include: air-fuel combustion products, steam, and compressed air in the air hybrid braking energy regeneration mode. Various other efficiency improvement methods can also be integrated into the HEIH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com