Patents

Literature

57results about How to "Accelerate Design Cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

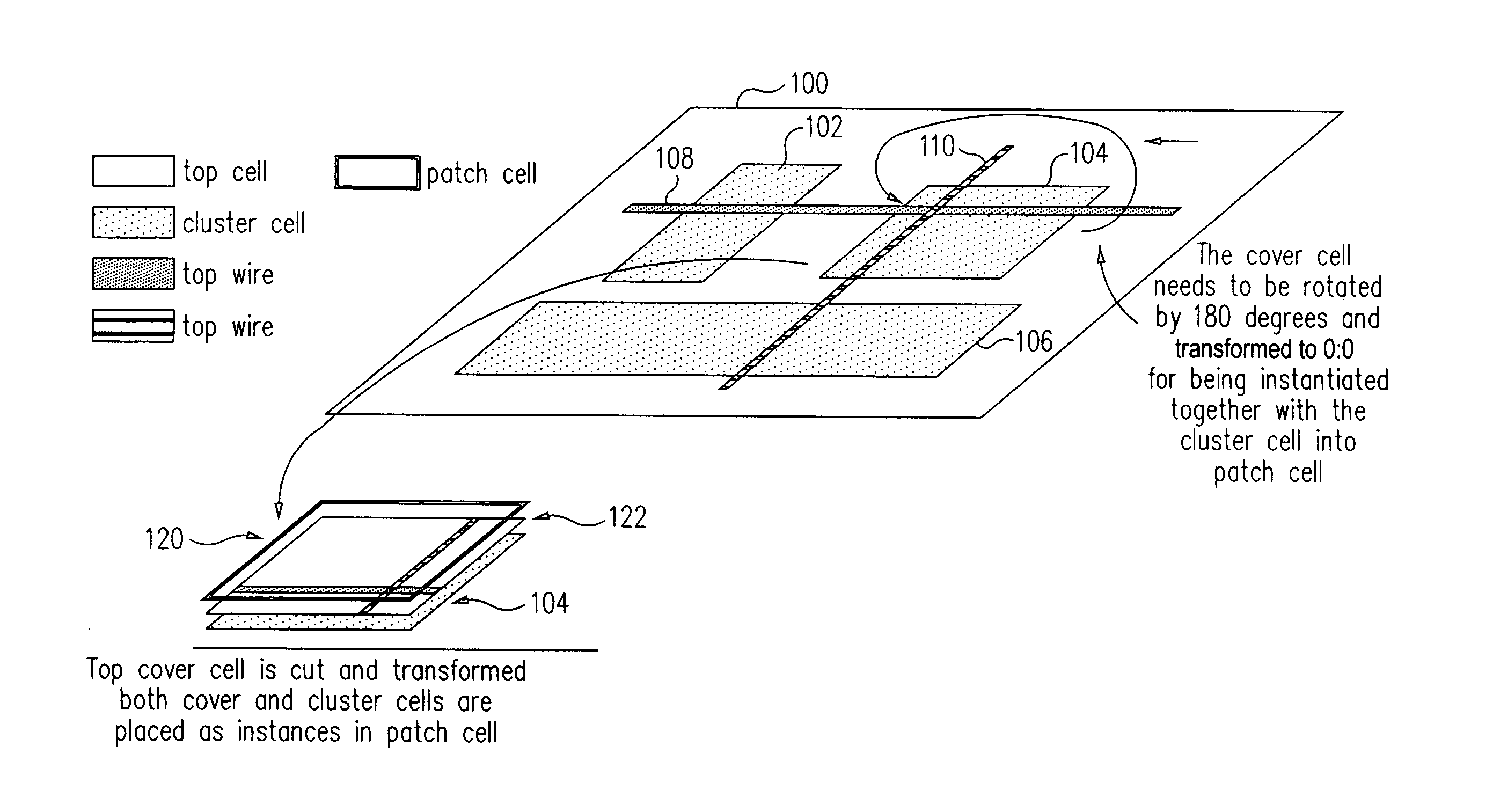

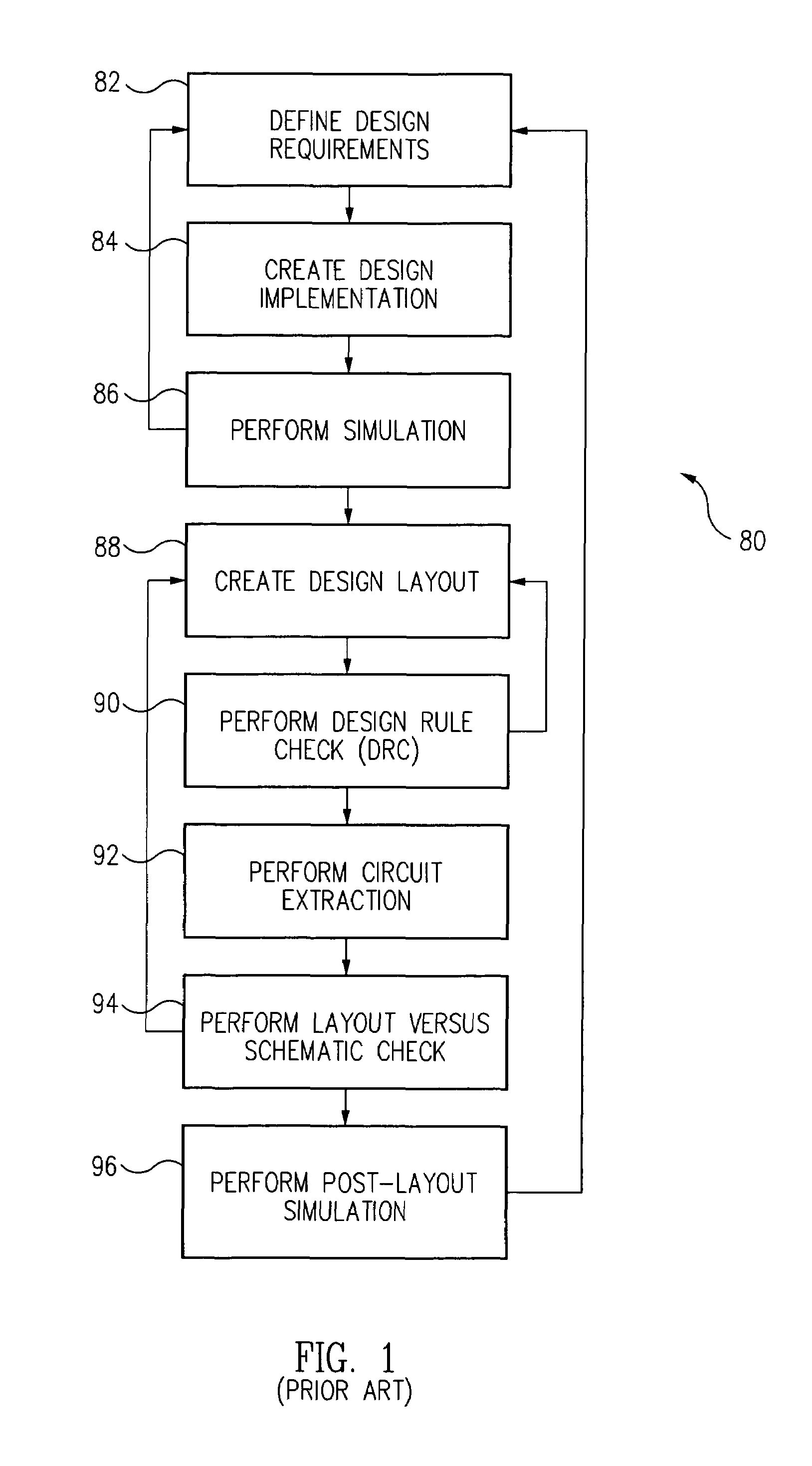

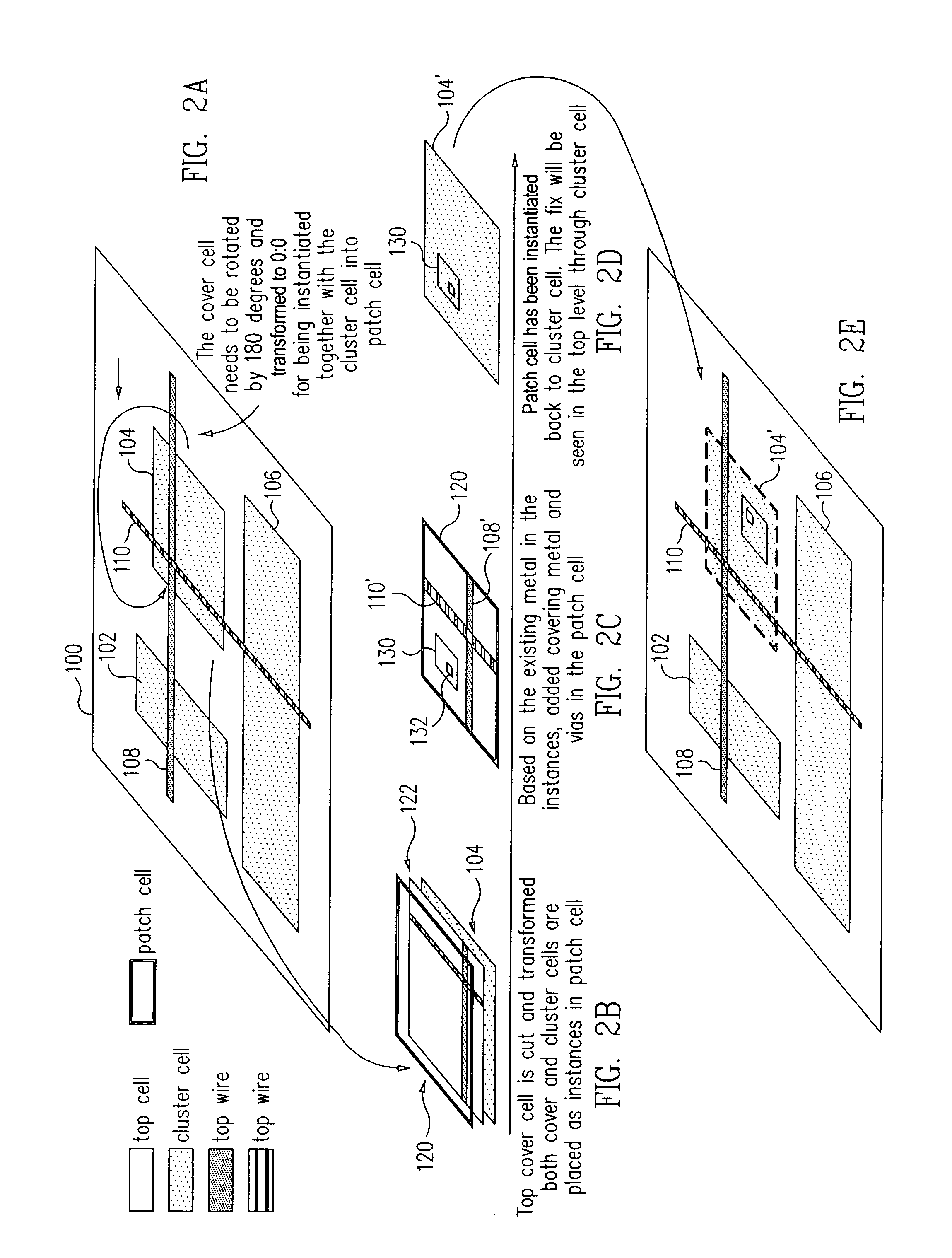

Method and apparatus for efficiently locating and automatically correcting certain violations in a complex existing circuit layout

ActiveUS7096447B1High failure rateReduce riskComputer aided designSoftware simulation/interpretation/emulationCluster cellEngineering

An exemplary CAD design flow modifies an existing large scale chip layout to reinforce the redundant via design rules to improve the yield and reliability. The flow operates on each metal-via pair from bottom up to locate and correct isolated via rule violations by adding metal features and vias in a respective patch cell associated with each cluster cell. A large complex design is thus divided into cells so that multiple processes can work concurrently as if every process were working on the top level of the design layout.

Owner:ORACLE INT CORP

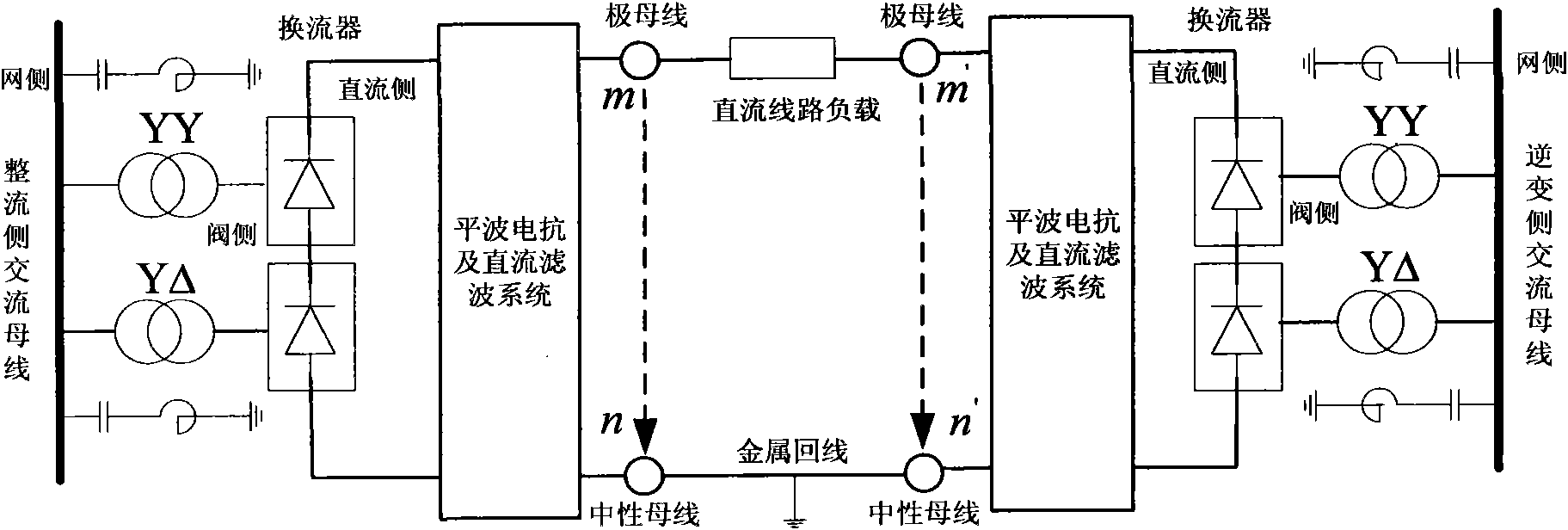

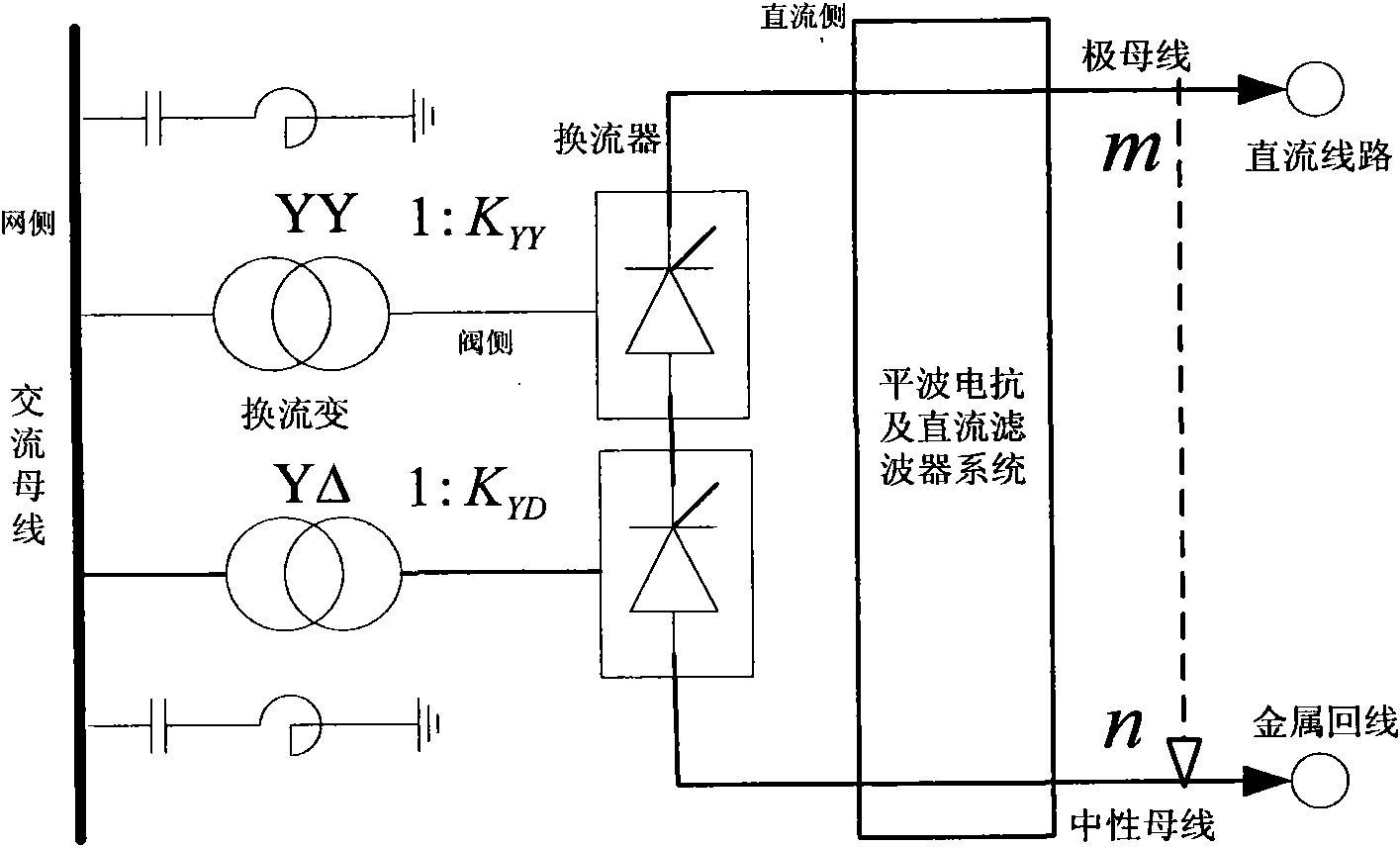

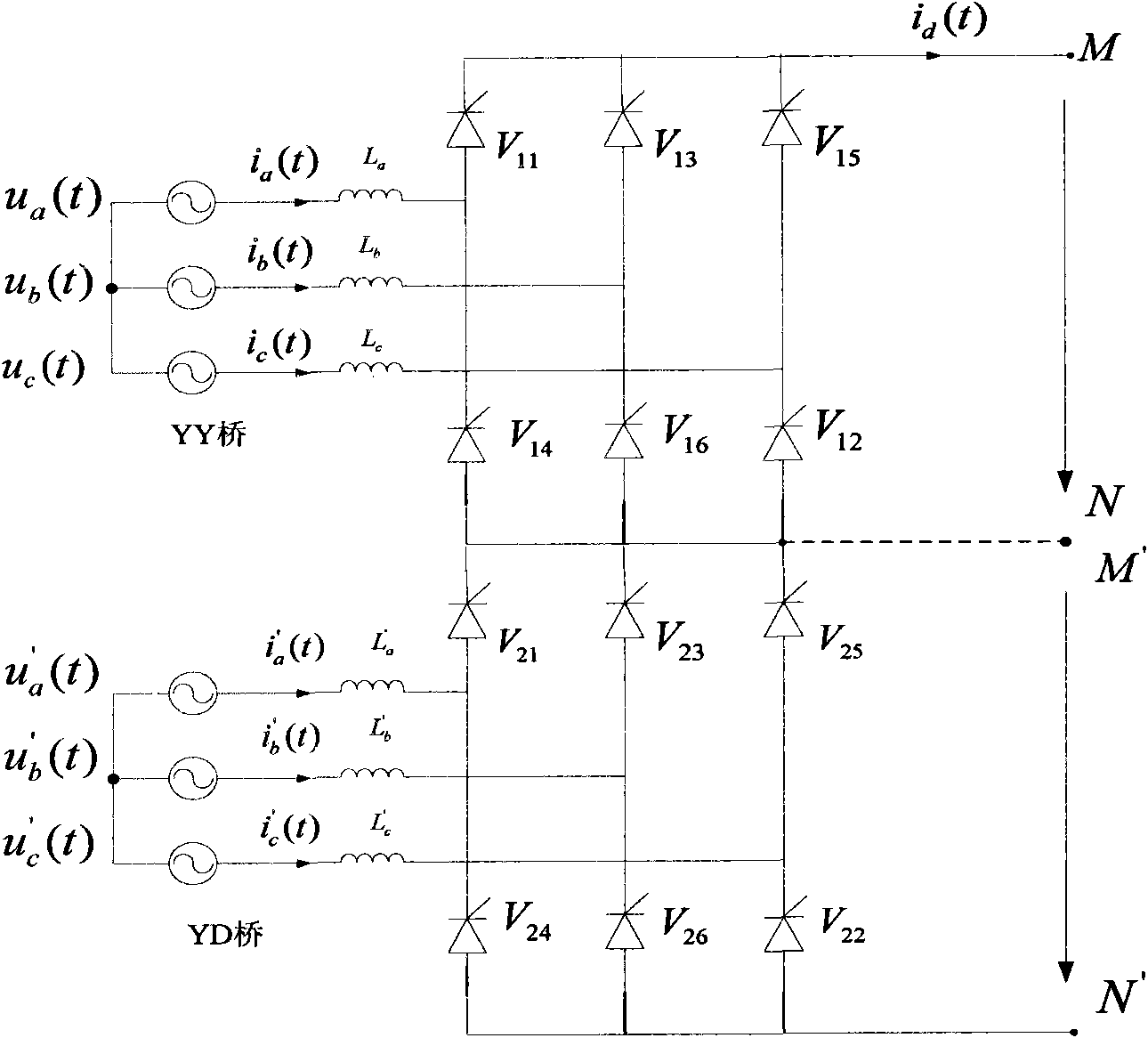

Determination method of network side harmonic current of high-voltage direct current power transmission system

InactiveCN101860037AAccelerate Design CycleImprove design qualityElectric power transfer ac networkHarmonic reduction arrangementTransformerInternal resistance

The invention discloses a determination method of network side harmonic current of a high-voltage direct current power transmission system. The determination method comprises the following steps: if the harmonic current voltage at a direct current power transmission line inlet is zero, decoupling and equalizing a rectifying side and an inverting side into a plurality of independent six-pulse moving bridge units; dividing a work period of the six-pulse moving bridge units into six phase converting sections and six non-phase converting sections; calculating a phase converting overlapping angle of each phase converting section; equalizing a current converter into a harmonic current voltage source containing internal resistance; calculating the direct current side harmonic current according to the concrete forms of a smoothing reactor and a direct current filter; obtaining valve side harmonic current according to an equivalent circuit of the current converter; and converting the valve side harmonic current to a network side according to a connecting structure of a transformer to obtain the network side harmonic current. The invention considers background harmonic current and other nonideal factors, and can quickly and accurately obtain the harmonic current at the network side of a converter transformer, accelerate the period for designing an alternating current filter in the high-voltage direct current power transmission engineering and improve the design quality and the design efficiency.

Owner:ZHEJIANG UNIV

Automated analog layout

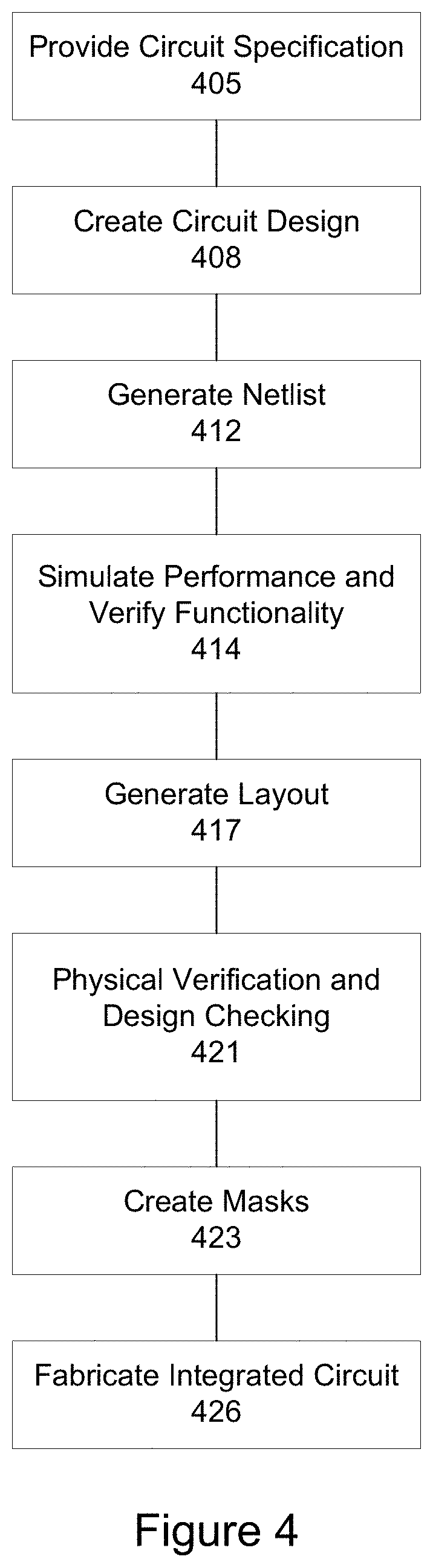

ActiveUS10783292B1Accelerate Design CycleFast resultsSpecial data processing applicationsSymbolic schematicsDesign cycleElectrical and Electronics engineering

An automated analog layout tool creates not just one, but many electrically correct layouts from an input schematic. Designers can explore multiple layout options in a fraction of the time needed to produce just a single layout by hand. Because the tool produces layout results so quickly, parasitics are available for simulation early in the design process, further speeding the entire design cycle. The tool considers place and route concurrently.

Owner:PULSIC

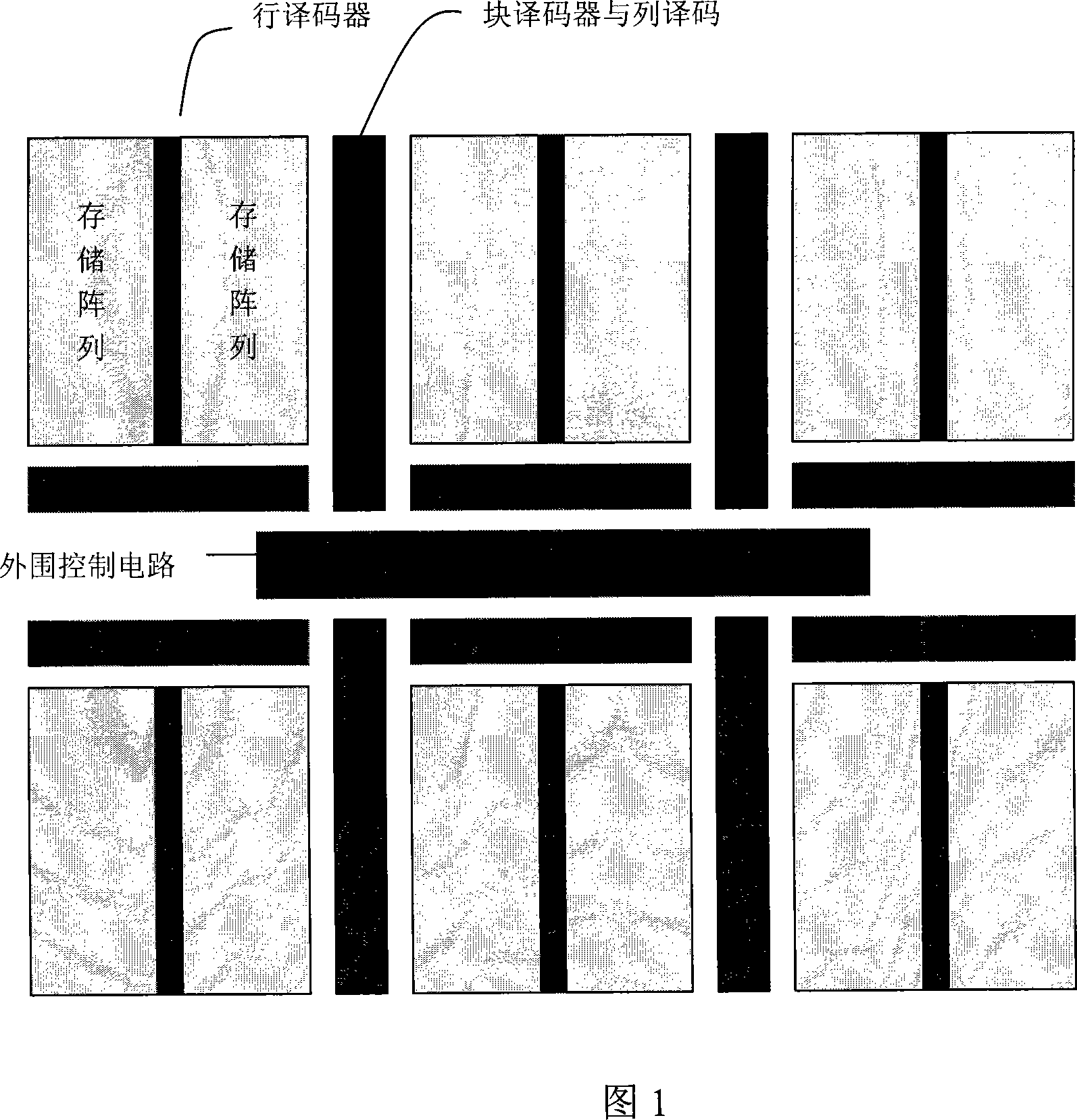

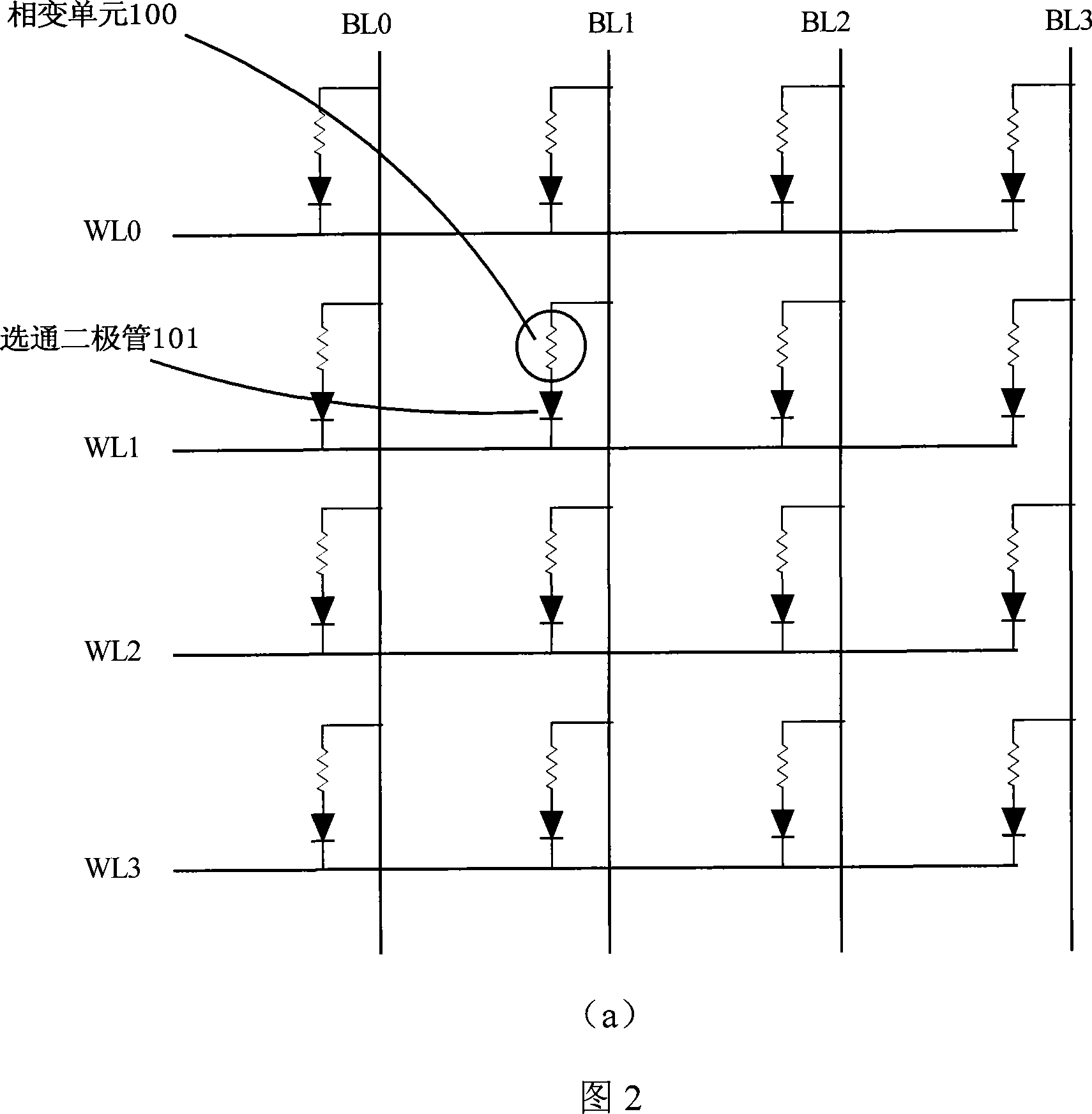

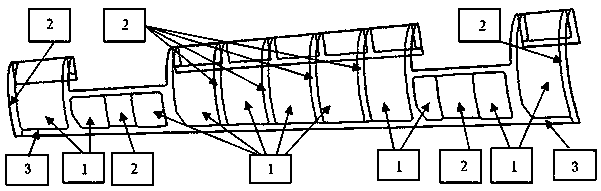

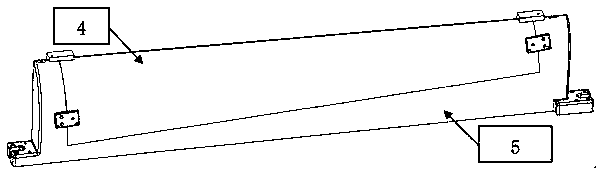

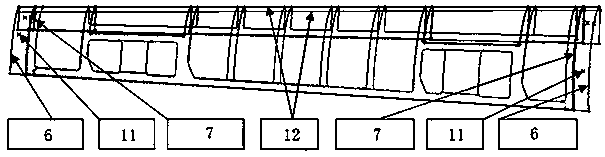

Circuit design standard and implementation method for 3-D solid structure phase change memory chip

ActiveCN101236780AAccelerate Design CycleSolid-state devicesRead-only memoriesMemory chipPhase-change memory

The invention relates to a circuit design criteria and a realization method for a three-dimensional structure phase transition memory chip. In order to utilize the memory area to a maximum extent, the invention requires that the whole memory chip is studded with memory arrays. The circuit structure provided is an optimization proposal aiming at the characteristic that the whole memory chip is studded with the memory arrays. The invention has the advantages that the whole memory chip can be studded with the memory arrays. In order to realize the advantage, firstly, peripheral circuits under the memory arrays are divided reasonably; secondly, a set of solution proposal is provided for mutual control problem of the peripheral circuits after division; thirdly, a splicing proposal of the peripheral circuits is provided on the basis of the first step and the second step. Therefore, the three-dimensional structure phase transition memory chip is completely realized in the aspect of circuit design.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

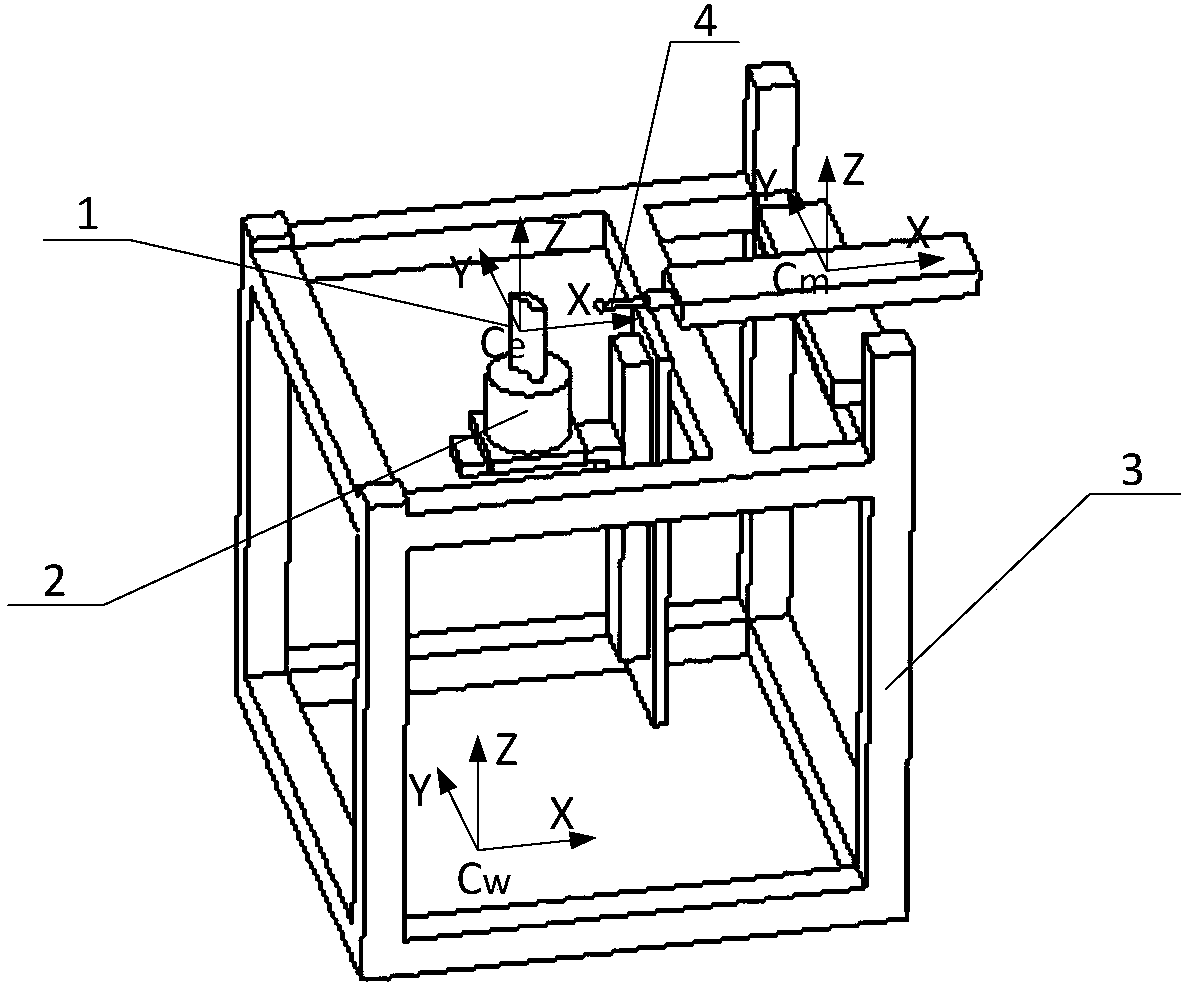

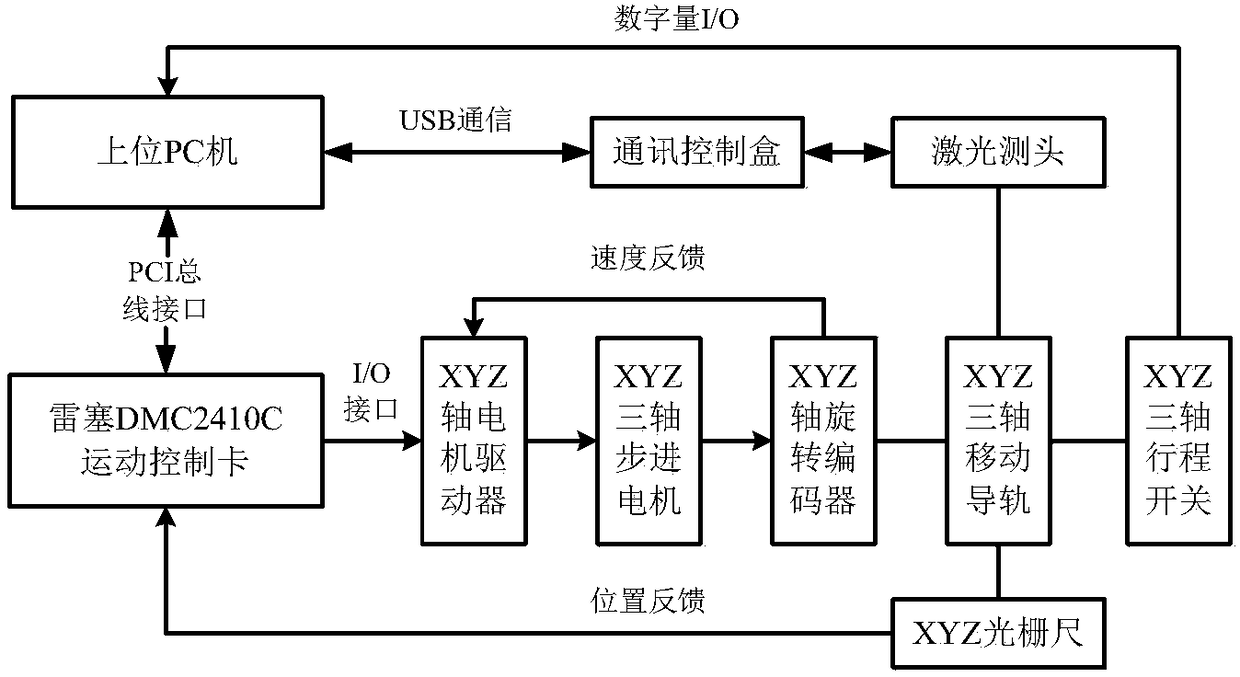

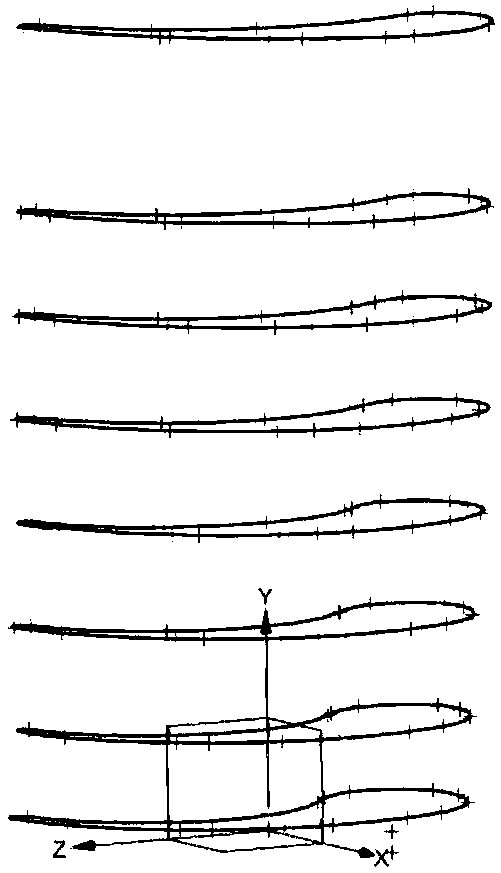

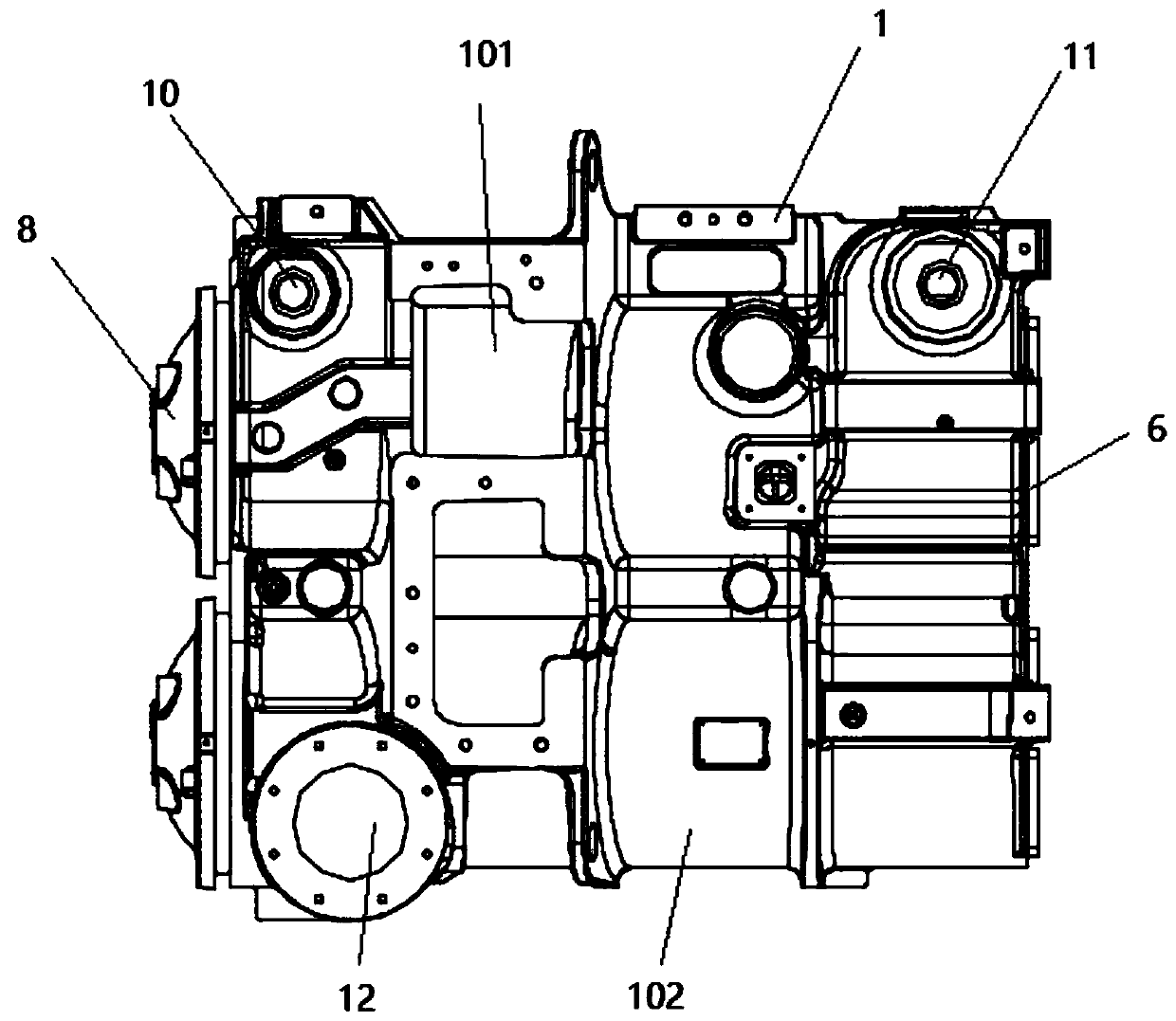

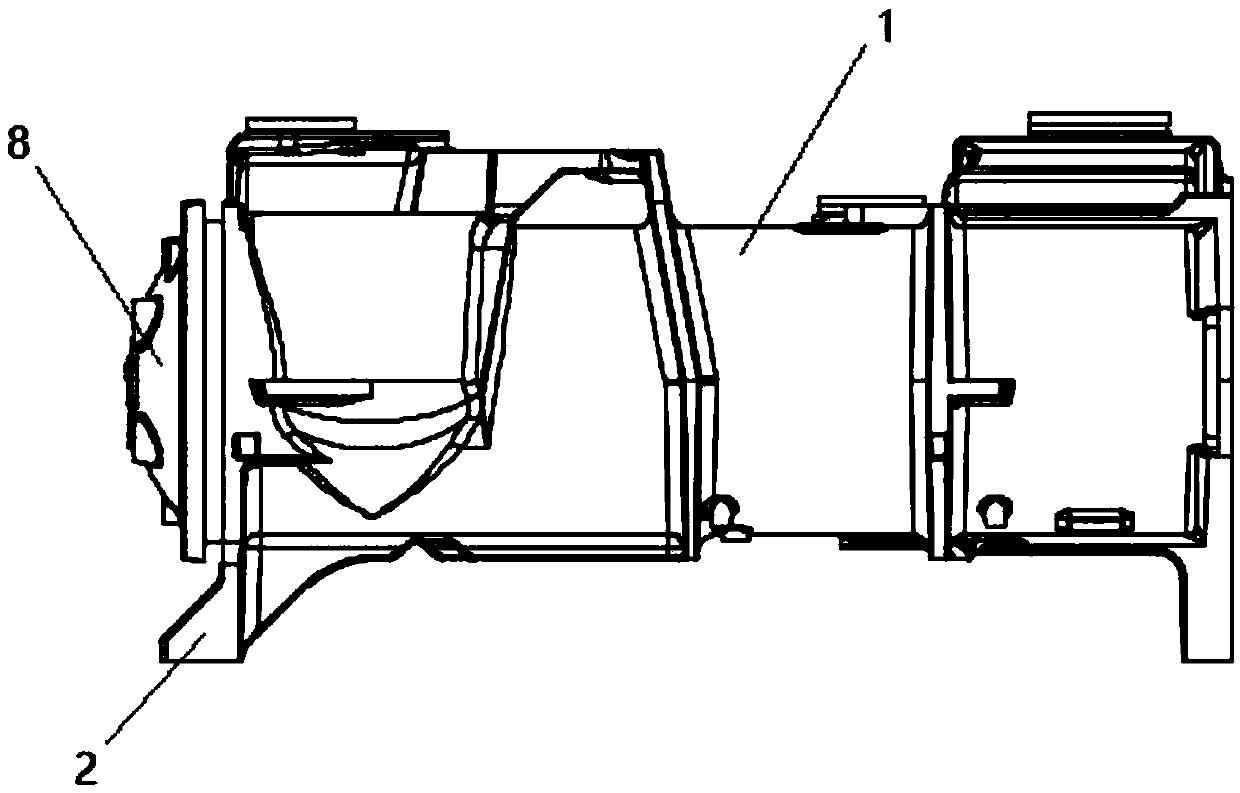

Four-axis blade measurement system and method

InactiveCN108562243AImprove detection efficiencyAccelerate Design CycleUsing optical meansNumerical controlRotary stage

The invention discloses a four-axis blade measurement system and method. The four-axis blade measurement system comprises a four-axis computer numerical control (CNC) platform, a laser sensor, computer measurement software and a motion control card; the laser sensor is mounted on a Y-axis moving guide rail of the four-axis CNC platform through a fixture, and the relative position requirements between a measuring head and a blade profile are met through linear motions of X, Y and Z axes; a blade is mounted on a rotating table C axis of the four-axis CNC platform through a chuck, and the rotation motion of the rotating table C axis keeps a relative angle to a laser beam; according to a planned measurement path and measurement strategies, the profile data of the blade is obtained through position information fed back by a grating sensor and a saser sensor, coordinate system transformation and an MATLAB fitting algorithm. The four-axis blade measurement system and method disclosed by the invention can improve the blade measurement accuracy, have the advantages of being simple to operate and high in measurement efficiency, can be used for solving the technical difficulty of quick measurement on the blade and promote the production and the continuous development of a special blade measuring device.

Owner:XIAN TECHNOLOGICAL UNIV

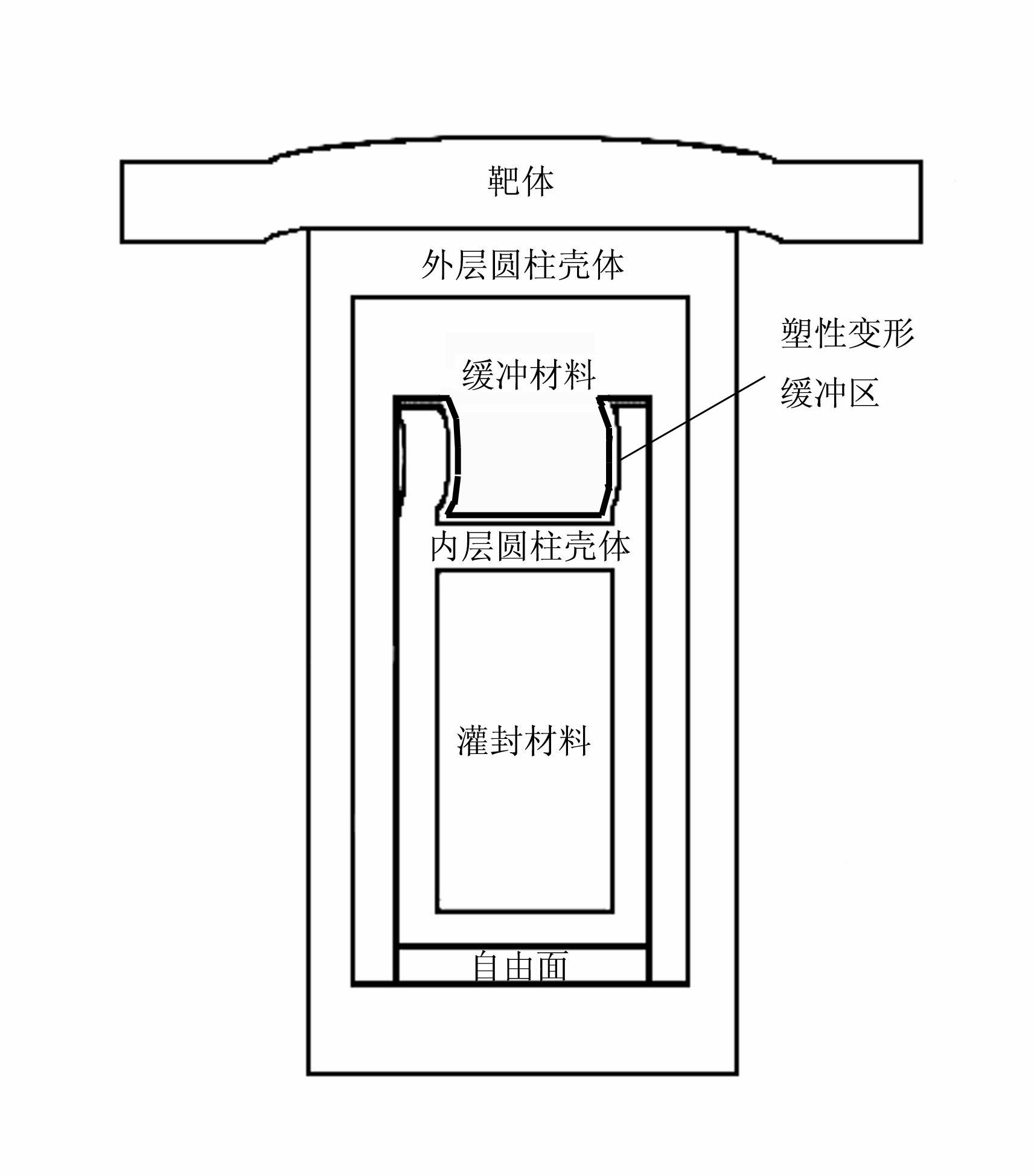

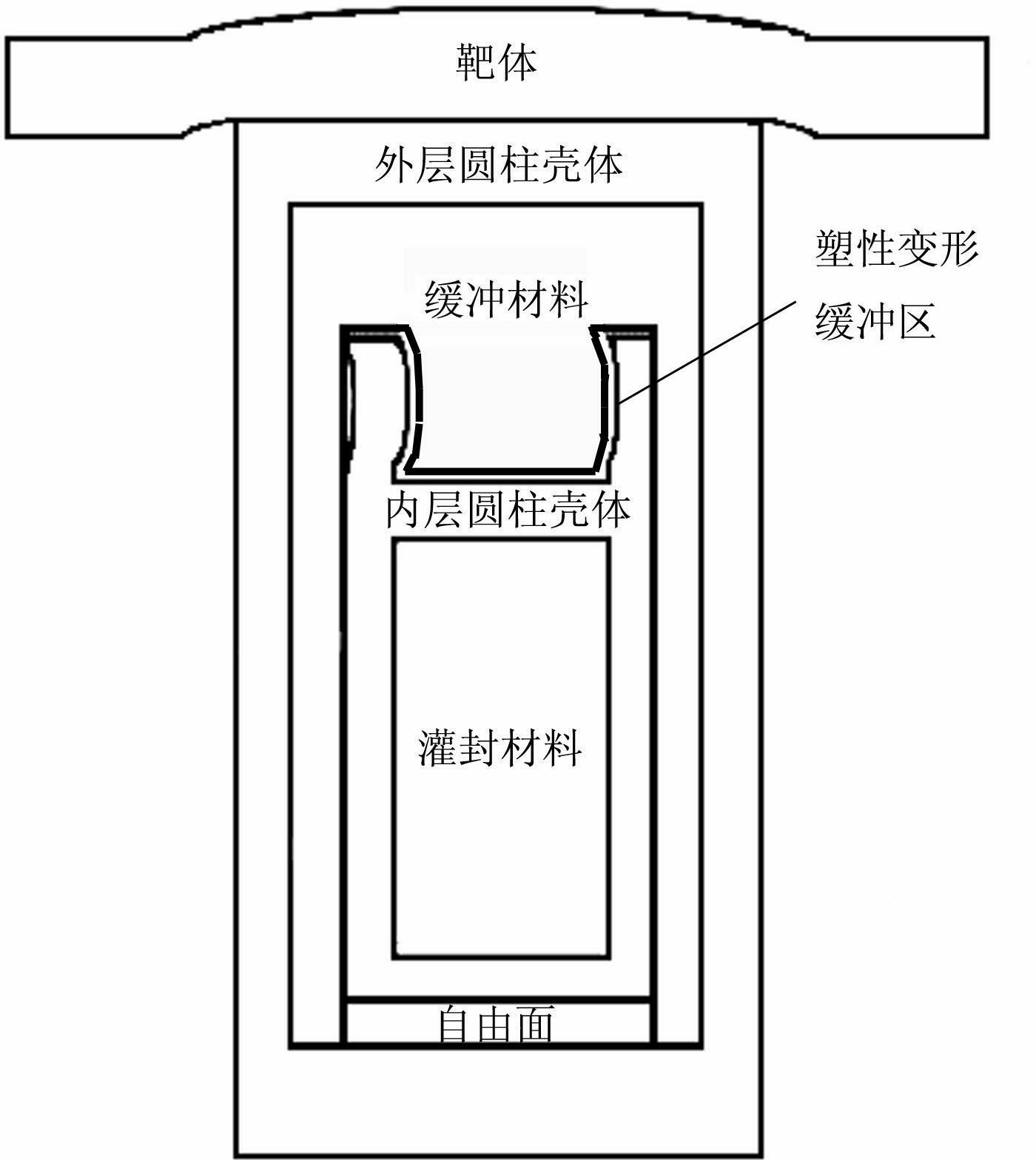

Structural Design Method for Shock-resistant Protective Shell of Test Equipment

InactiveCN102279014AImprove reliabilityEasy to controlMeasurement apparatus housingsUniform designShock resistance

The invention relates to a design method of a shock-resistance protection shell structure of test equipment, in particular to a design method of a shock-resistance protection shell structure of test equipment. The invention solves the problems that the traditional design method of the shock-resistance protection shell structure of the test equipment is not beneficial to uniforming design methods of the test equipment to cause that the design period of the test equipment is prolonged and the design cost is increased. The design method of the shock-resistance protection shell structure of the test equipment comprises the following steps of: (1) designing and determining a shape structure of the shock-resistance shell; (2) quantitatively determining the buckling speed of an inner cylindricalshell, the yield speed of an outer cylindrical shell and the rupture limit of a circuit board; (3) determining the top cover thickness of the inner cylindrical shell, the top cover thickness of the outer cylindrical shell, the thickness of a buffering material and the thickness of an encapsulating material; (4) designing a buffering structure resistant to large shock; and (5) designing an anti-slabbing structure. According to the invention, the design methods of the test equipment can be ensured to tend to uniform while facing to different test environments.

Owner:ZHONGBEI UNIV

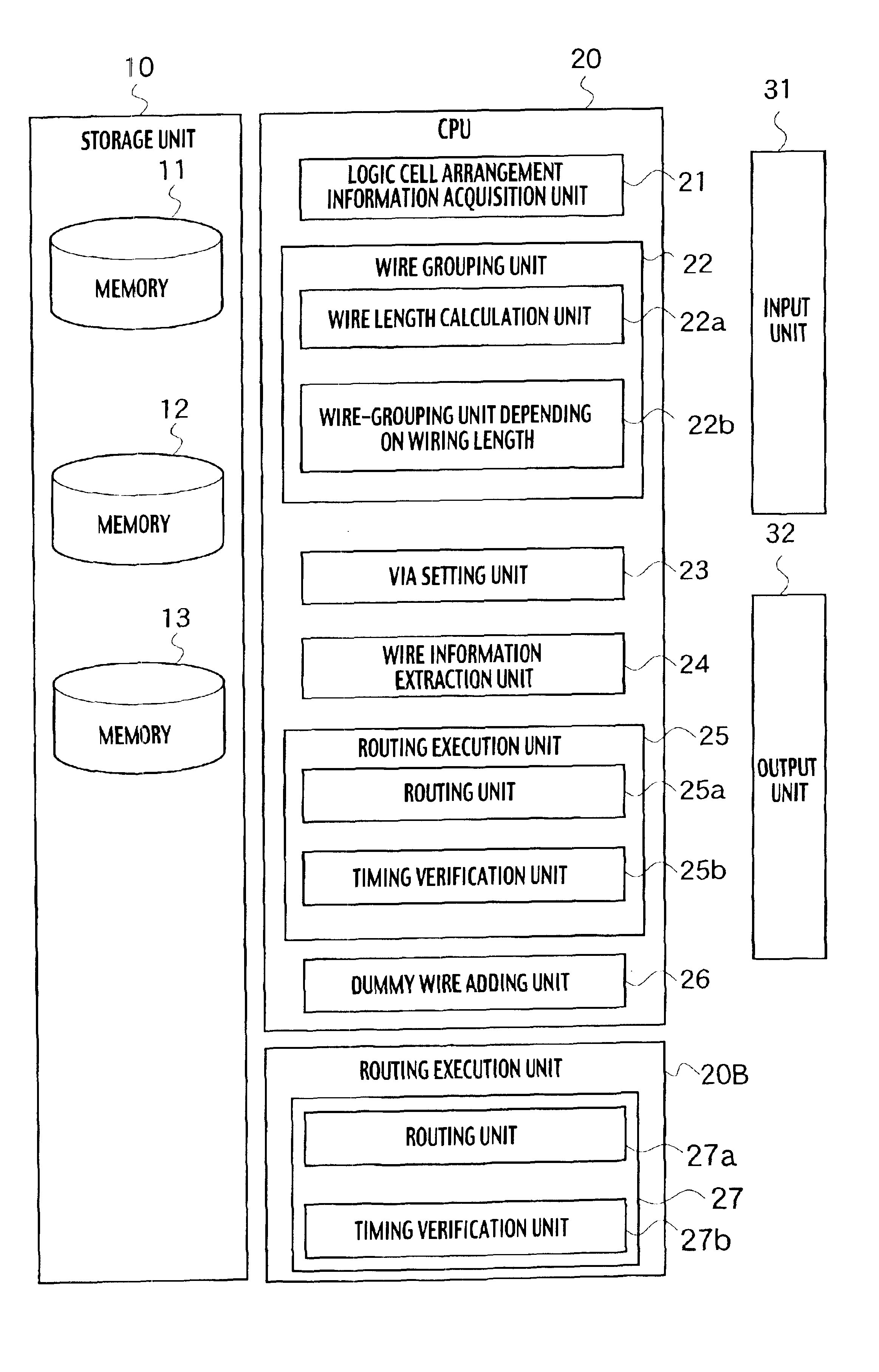

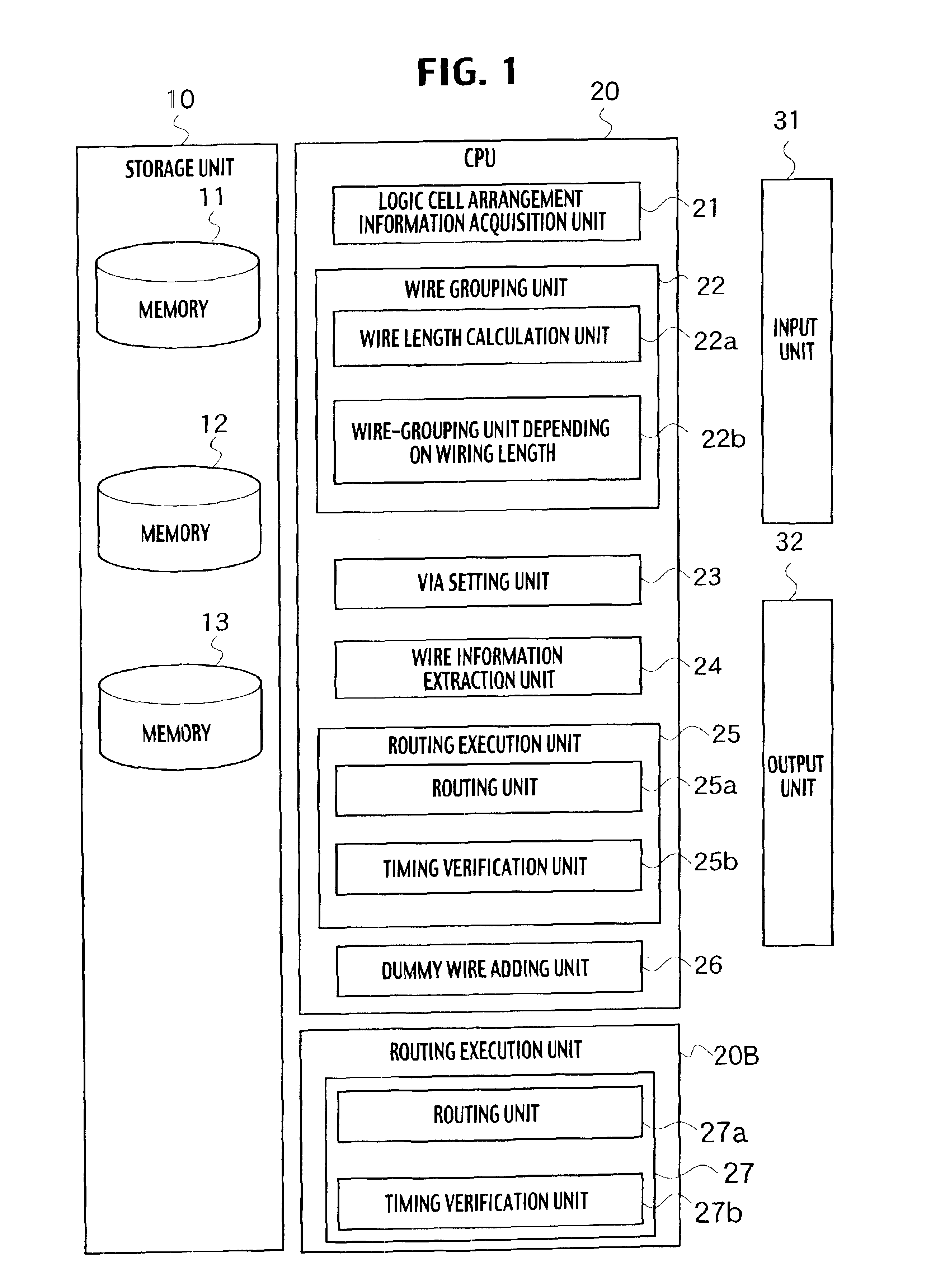

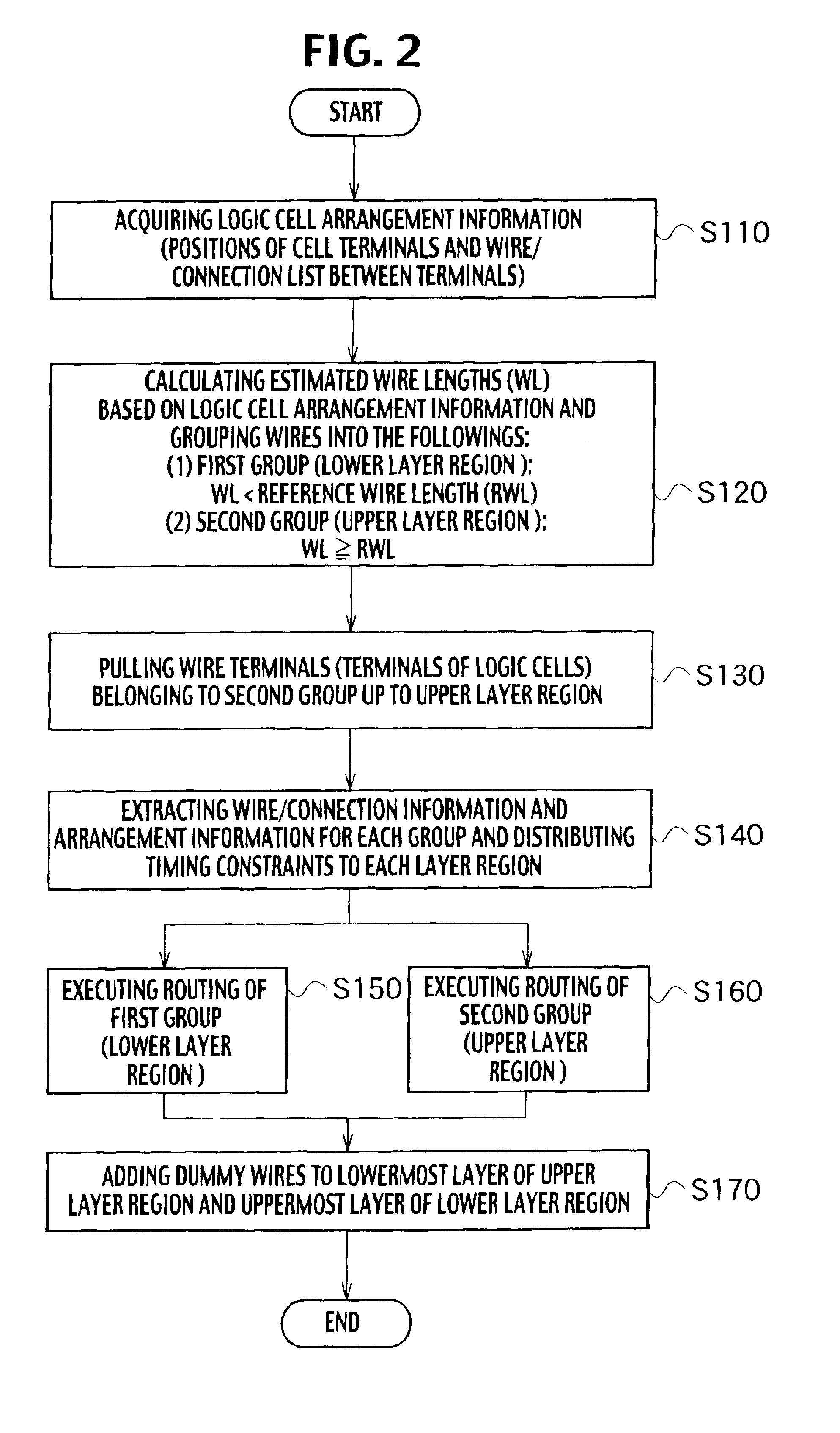

Wire layout design apparatus and method for integrated circuits

InactiveUS6951007B2Limited degree of flexibilityIncrease the areaSemiconductor/solid-state device manufacturingComputer aided designLogic cellExecution unit

An apparatus executes wire layout design in an integrated circuit. The apparatus includes a logic cell arrangement information acquisition unit which acquires information concerning a logic cell arrangement on a chip, a wire-grouping unit which estimates wires between logic cell terminals based on the acquired information and groups the estimated wires into each wire layer region, a via setting unit which sets via wire for pulling a logic cell terminal up to a wire layer region, a wire information extraction unit which extracts wire information for each of the wire groups and a routing execution unit which executes routing between the logic cell terminals for each of the wire layer regions based on the extracted information. A method for executing wire layout design in an integrated circuit includes acquiring information concerning a logic cell arrangement on a chip, executing wire-grouping, setting via wire for pulling a logic cell terminal up to a wire layer region, extracting wire information for each of the wire groups, and executing routing between the logic cell terminals for each of the wire layer regions based on the extracted information. The wire-grouping contains estimating wires between logic cell terminals based on the acquired information concerning the logic cell arrangement and dividing the estimated wires into each group of a wire layer region.

Owner:KK TOSHIBA

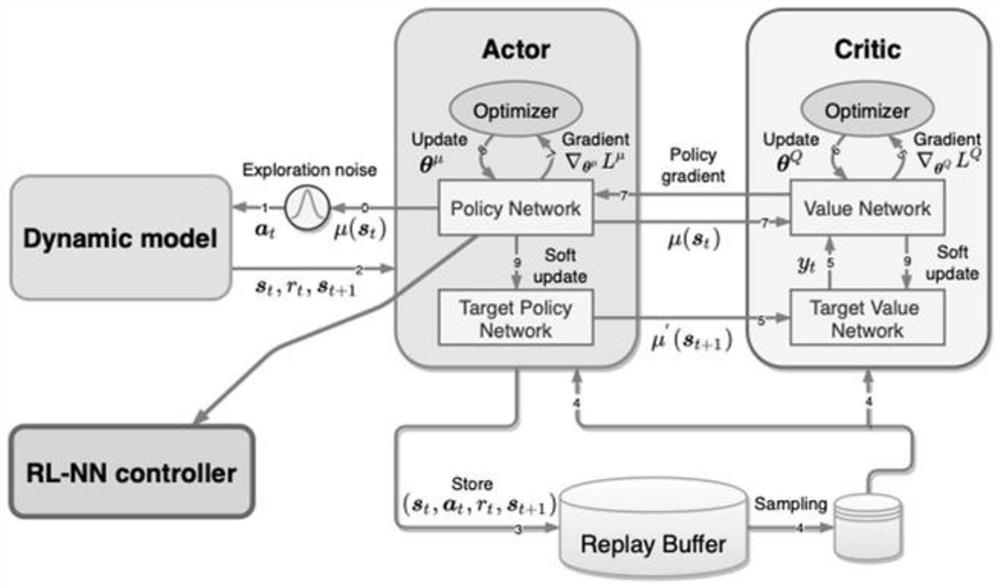

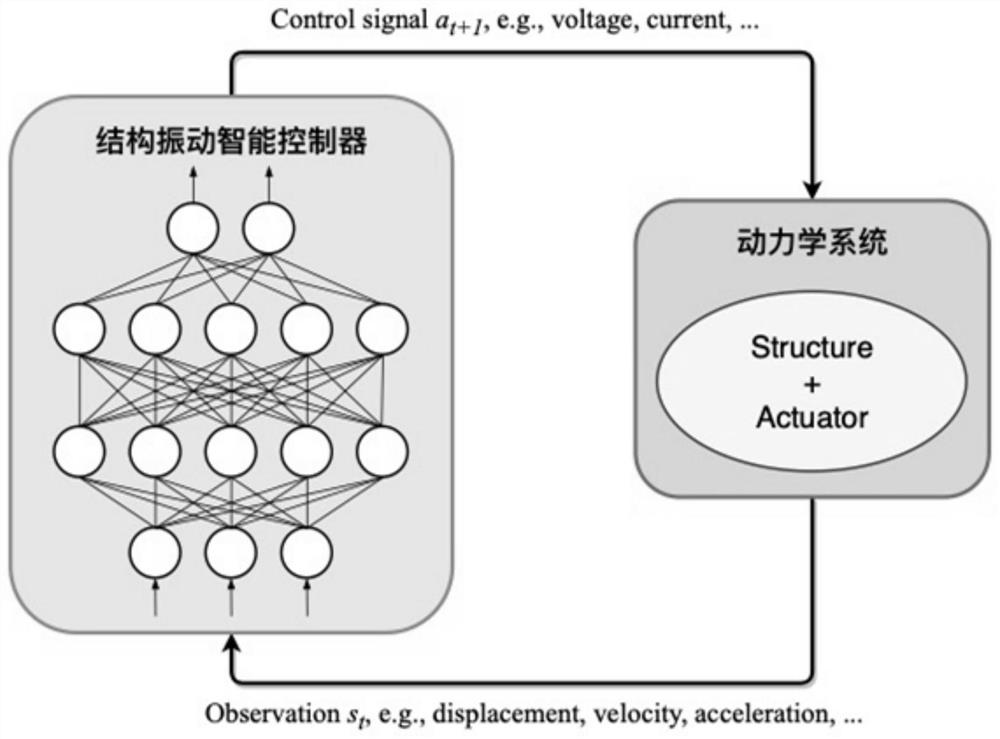

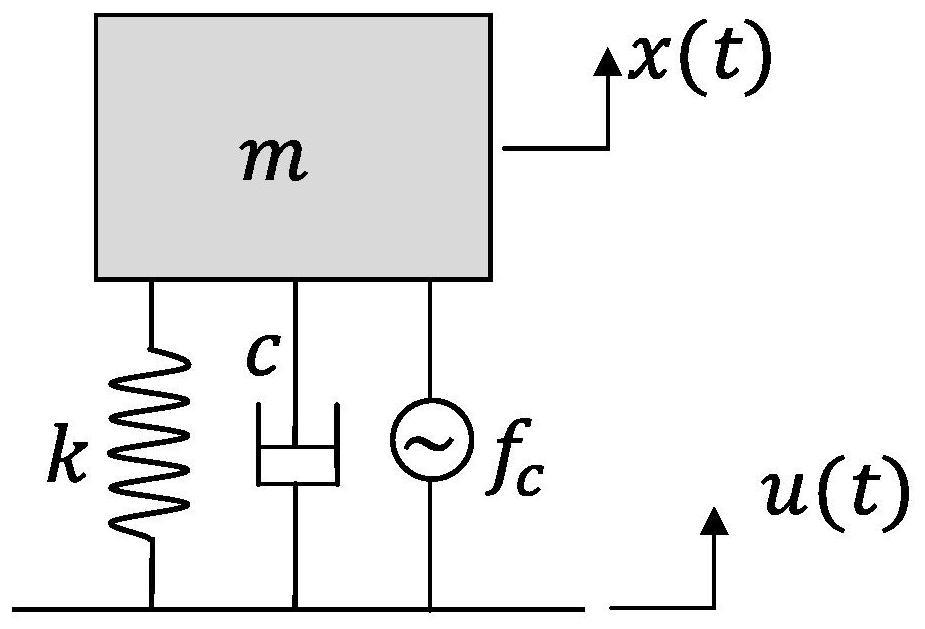

Structural vibration control method based on reinforcement learning, medium and equipment

ActiveCN112698572AImprove performanceRealize vibration intelligent controlSustainable transportationNeural architecturesVibration controlControl signal

The invention discloses a structural vibration control method based on reinforcement learning, a medium and equipment. The method comprises the following steps: establishing a kinetic equation and a reward function of a controlled system; establishing and initializing a strategy network, a target strategy network, a value network and a target value network; establishing a playback pool; data interaction is achieved. Meanwhile, the control signal, the feedback signal and the reward signal are stored in a playback pool, the control signal, the feedback signal and the reward signal are provided for a reinforcement learning algorithm in a random sampling mode to update parameters of a strategy network and a value network, and a soft update mechanism is adopted to update parameters of a target strategy network and a target value network; obtaining a final strategy neural network as a controller; and deploying a controller, taking the feedback signal acquired by the sensor as the input of the neural network, and outputting a control signal after the forward calculation of the neural network to complete the control operation of the structural vibration. The invention provides a more intelligent control method for vibration control of a complex structure, and has excellent control performance and engineering practicability.

Owner:XI AN JIAOTONG UNIV

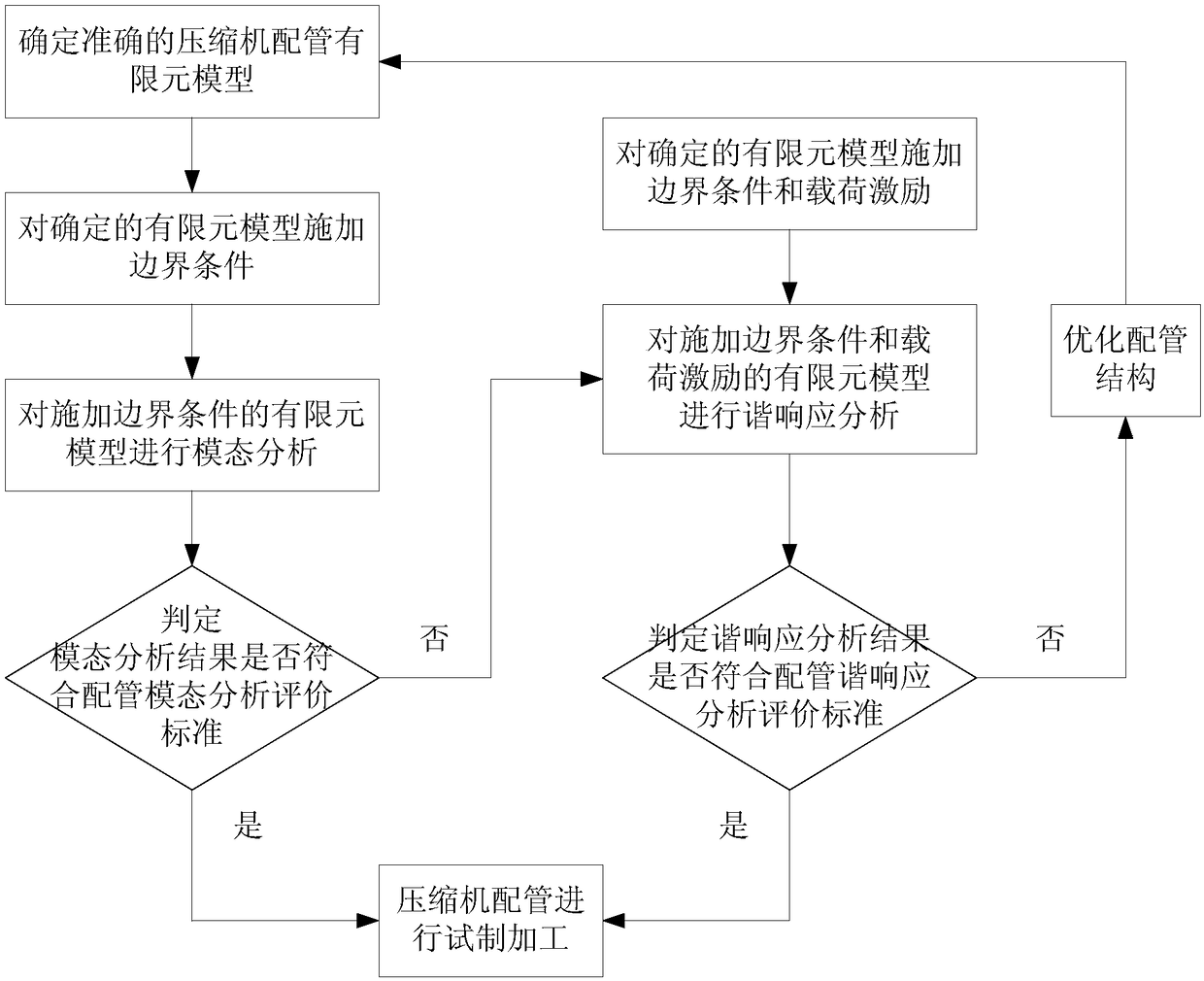

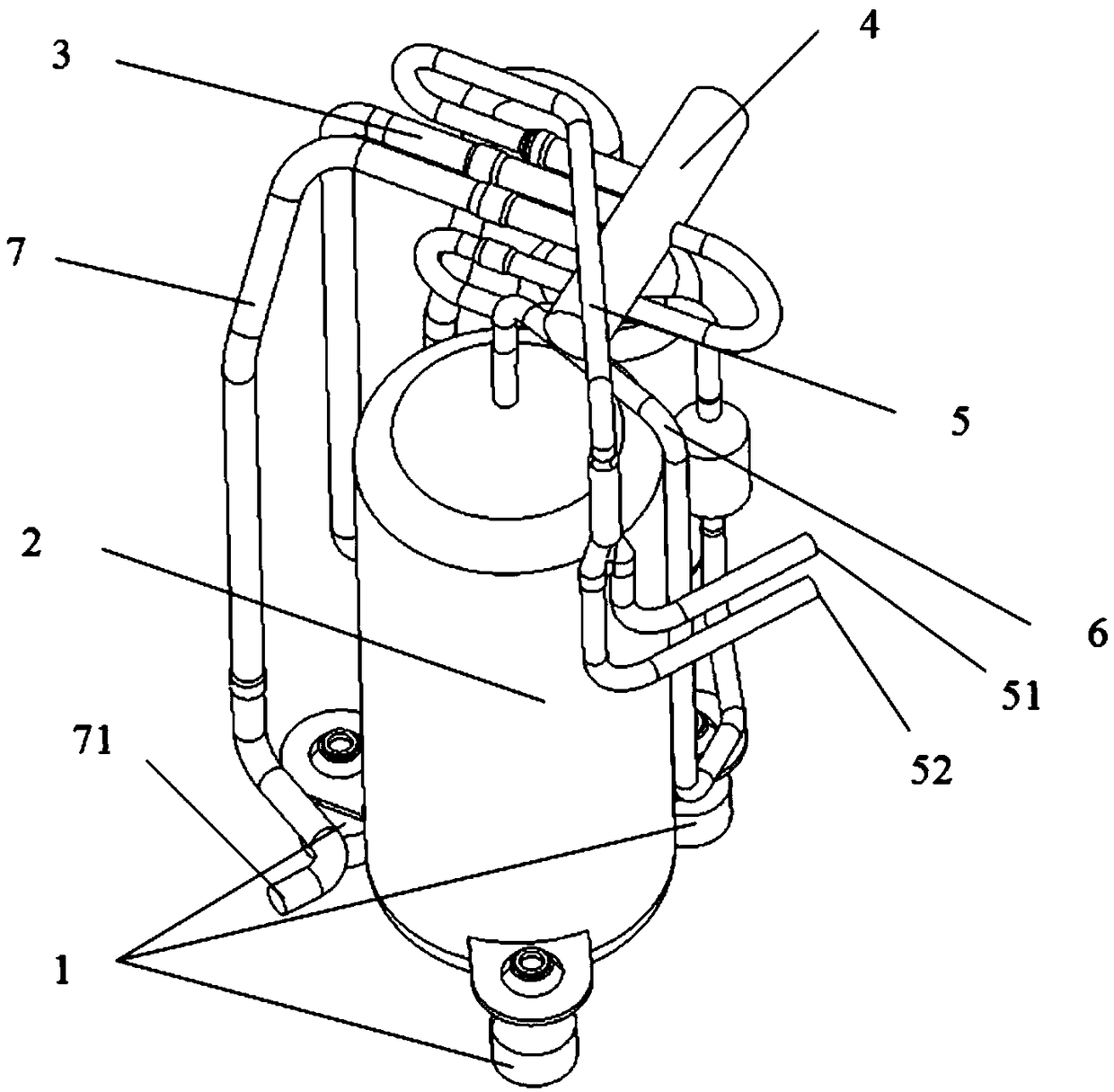

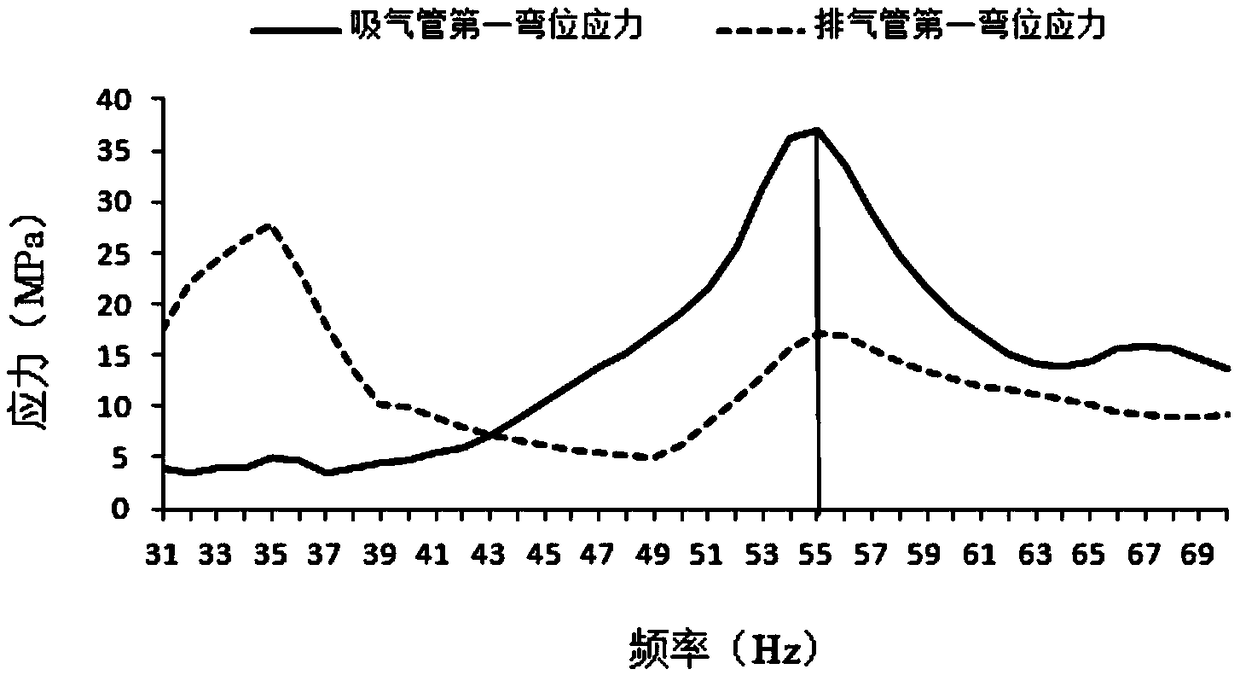

Simulation evaluation method of compressor piping vibration of constant frequency air conditioner

InactiveCN108763715AQuickly assess vibration conditionsAccurate vibrationGeometric CADDesign optimisation/simulationConstant frequencyElement model

The invention relates to the piping field of a compressor of a fixed frequency air conditioner. The invention solves the problems that the piping mode analysis of the fixed frequency air conditioner can not be quantified and the natural frequency point of the pipe which is close to the operation frequency of the compressor can not be accurately judged according to the piping mode analysis, and a simulation evaluation method of the compressor piping vibration of the constant frequency air conditioner is presented. The main points of the technical scheme are as follows: firstly, the accurate finite element model of the compressor pipe is determined; secondly, the boundary conditions are applied to the finite element model and the modal analysis is carried out; then, whether the modal analysis result accords with the evaluation standard of piping modal analysis is judged, if so, the compressor pipe is trial-manufactured, otherwise, boundary conditions and load excitation are applied to the determined finite element model, and harmonic response analysis is performed; then whether the harmonic response analysis result accords with the piping harmonic response analysis evaluation criteria is determined, if so, the compressor pipe is trial-manufactured, otherwise, the finite element model is re-determined after pipe structure optimization.

Owner:四川长虹空调有限公司

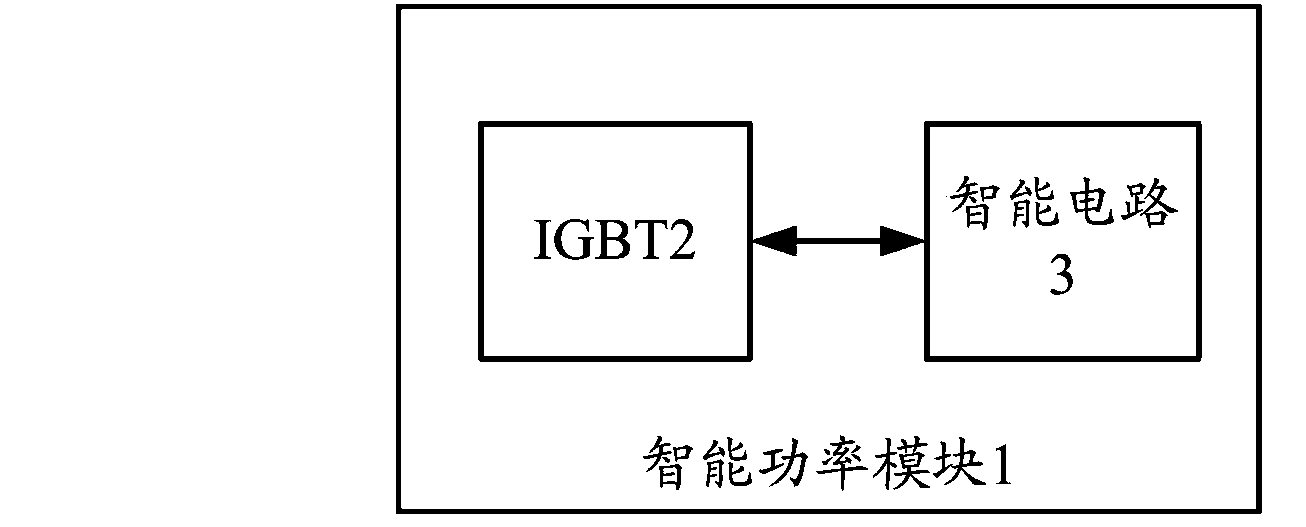

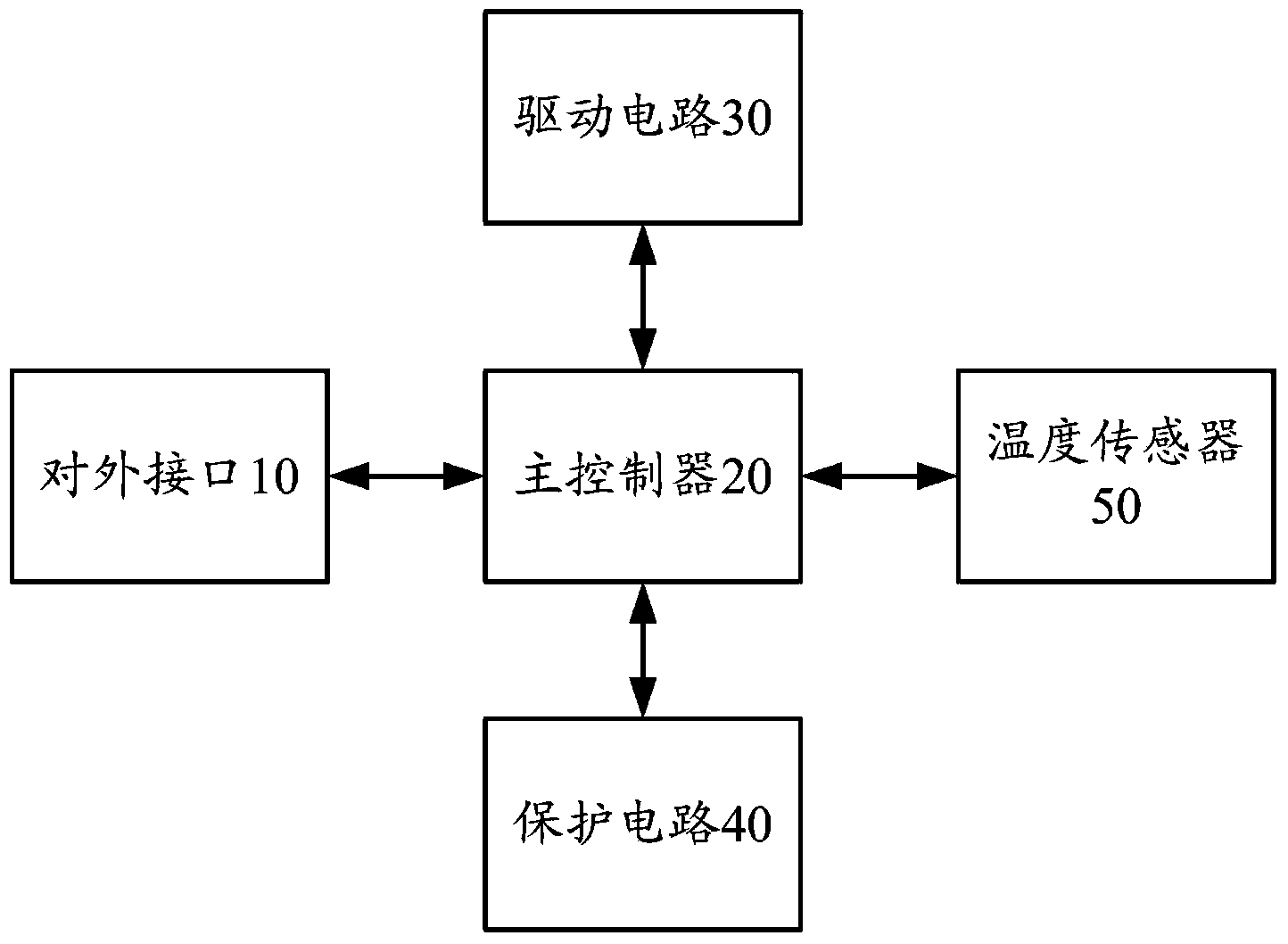

Intelligent power module

InactiveCN103595227AAccelerate Design CyclePower conversion systemsCircuit protectionCharge and discharge

An intelligent power module comprises an IGBT and an intelligent circuit. The IGBT is connected with the intelligent circuit. The intelligent circuit includes an external interface (10), a master controller (20), a drive circuit (30), a protection circuit (40) and a temperature sensor (50), wherein the external interface (10) is connected with the master controller (20), and the drive circuit (30), the protection circuit (40) and the temperature sensor (50) are respectively connected with the master controller (20); the master controller (20) is used for supplying working signals to the drive circuit (30) and receiving IGBT abnormal information fed back by the protection circuit (40), and the master controller (20) is further used for communication with a master control system of a user. The drive circuit (30) is connected with the IGBT and used for charging and discharging a grid electrode for the IGBT. The protection circuit (40) is connected with the IGBT and used for providing circuit protection for the IGBT. The temperature sensor (50) is used for detecting the temperature of the intelligent power module during the working process and feeding back the temperature to the master controller (20).

Owner:XIAN YONGDIAN ELECTRIC

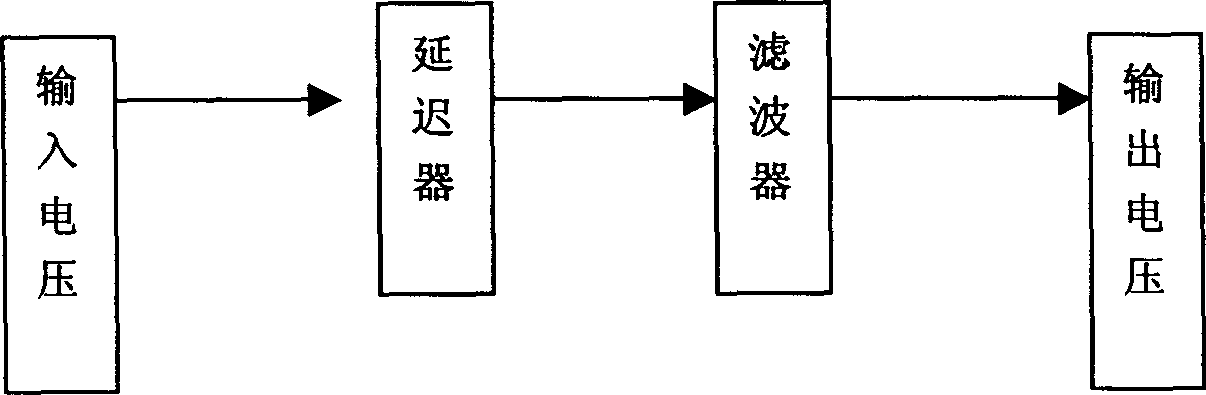

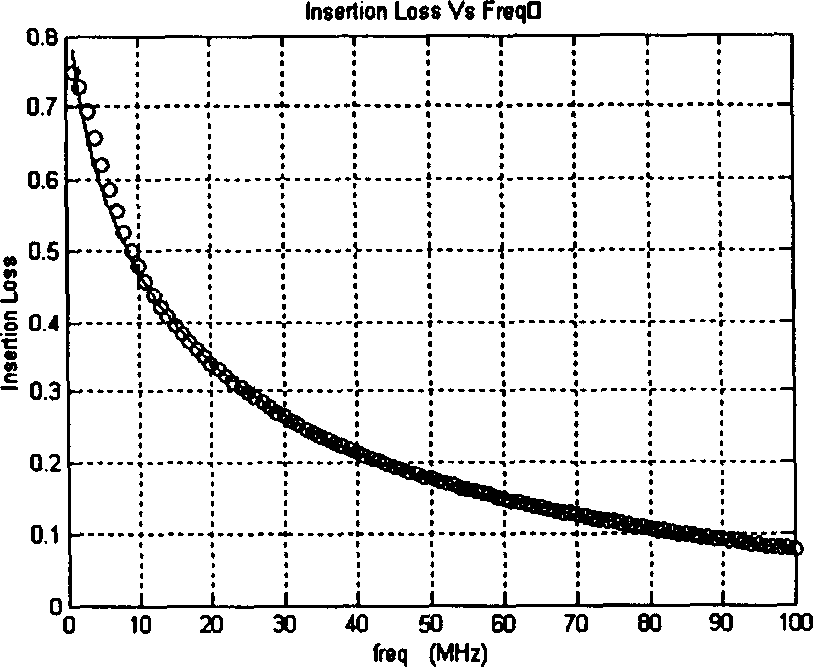

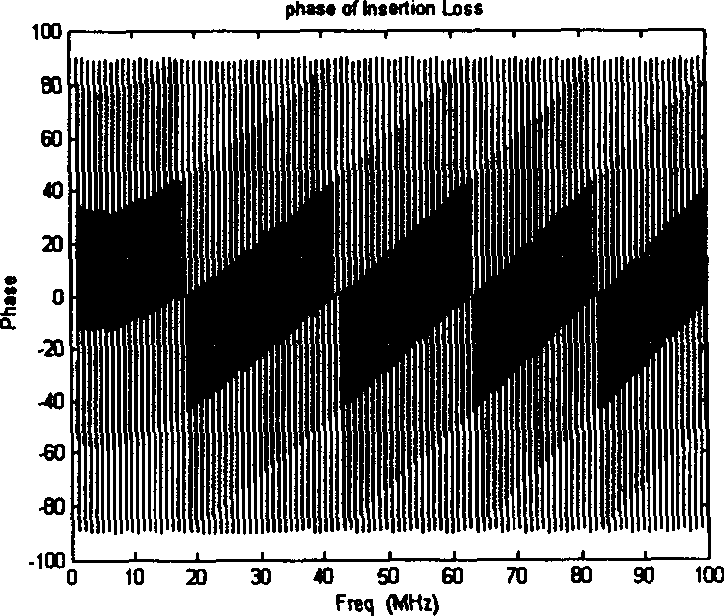

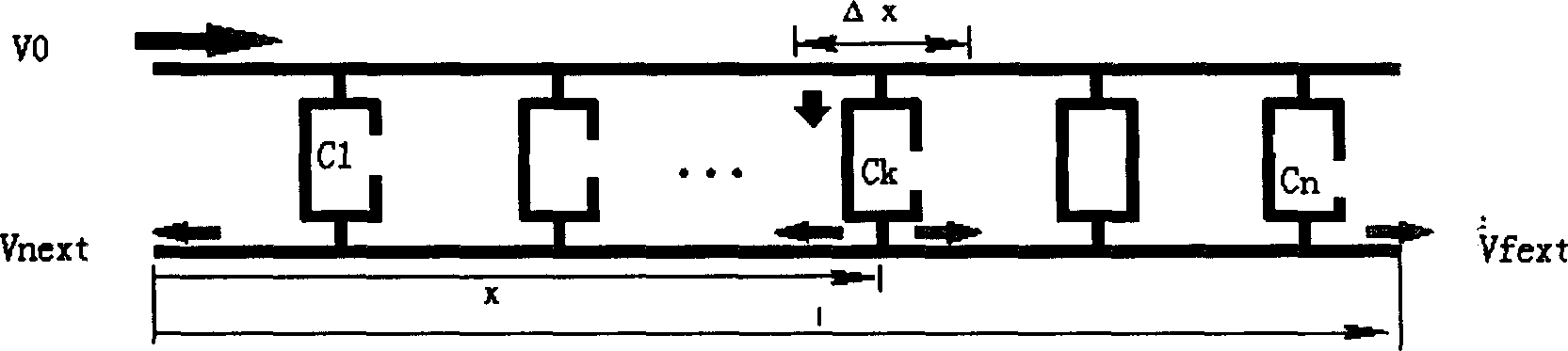

Method for simulating insertion loss of twisted-pairs in designing high-speed data communication system

InactiveCN1447565AAccelerate Design CycleImprove reliabilityData switching by path configurationSystems designCommunications system

First, the method builds the new insertion loss model so as to obtain the amplitude information and the phase information of the insertion loss. Then, the design of equivalent electric circuit elements is carried out for the said information in order to embed the designed elements into entire design system to execute the system simulation. The invention shortens system design cycle greatly and raises accuracy of designs.

Owner:FUDAN UNIV

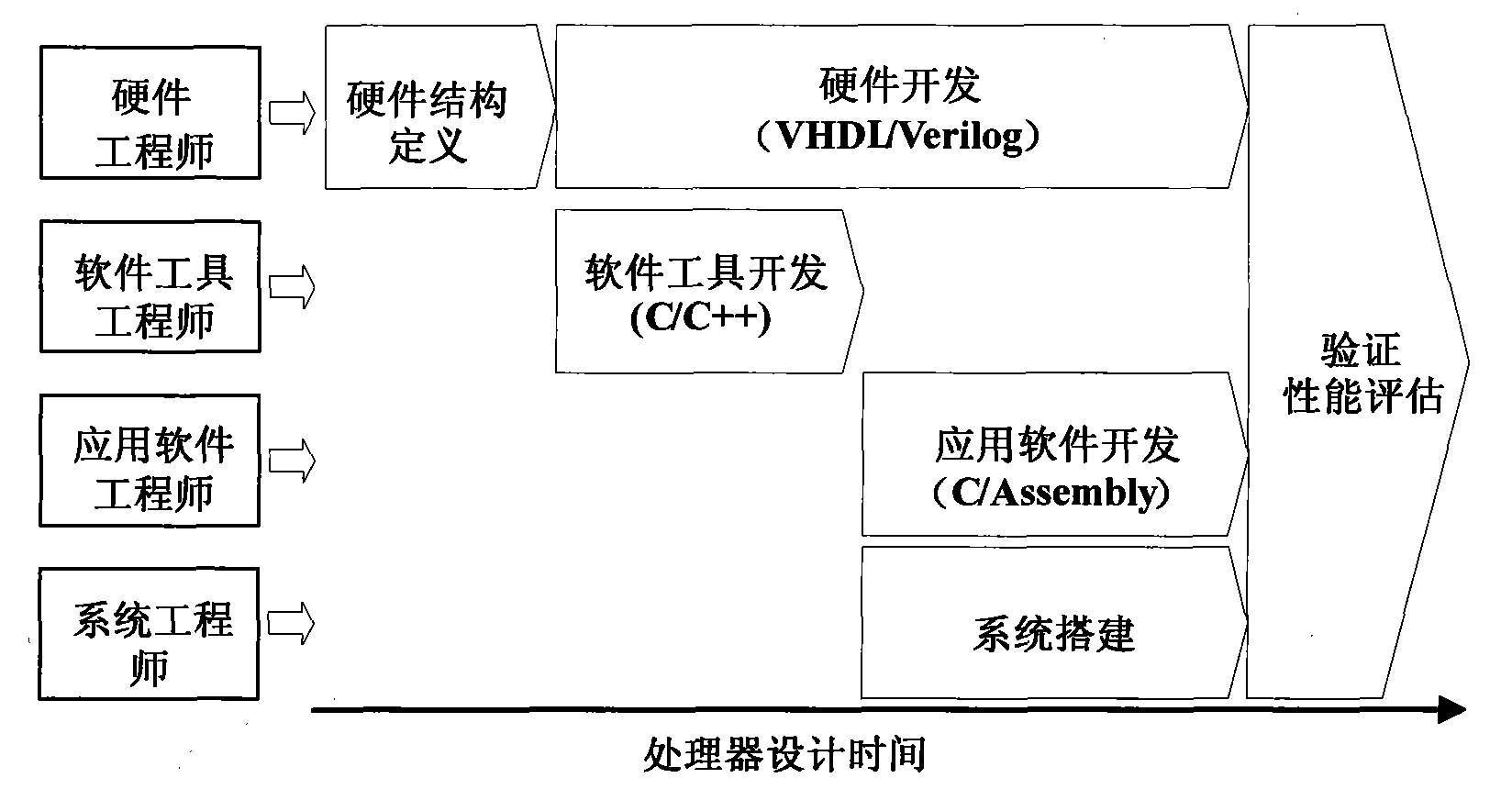

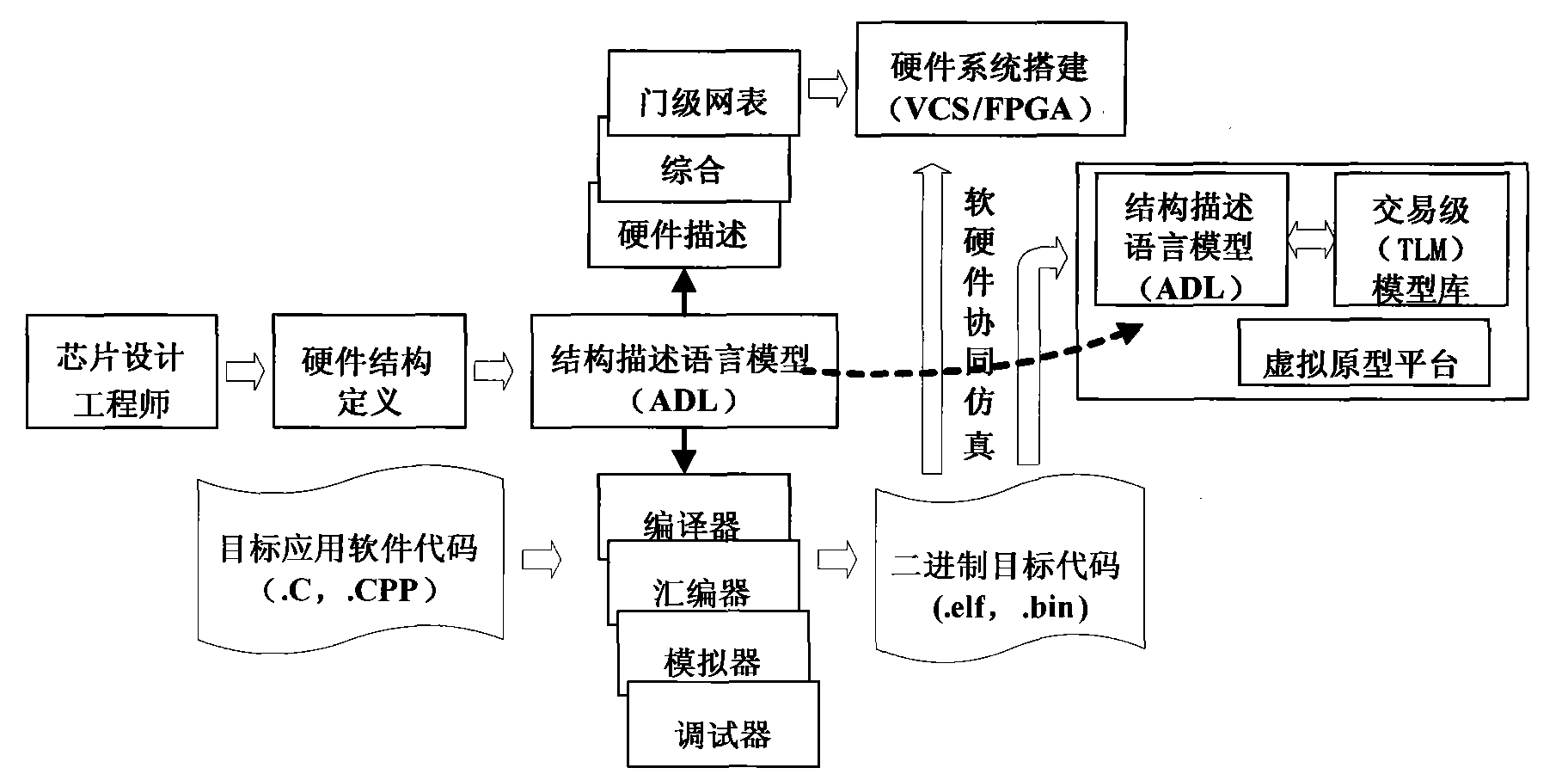

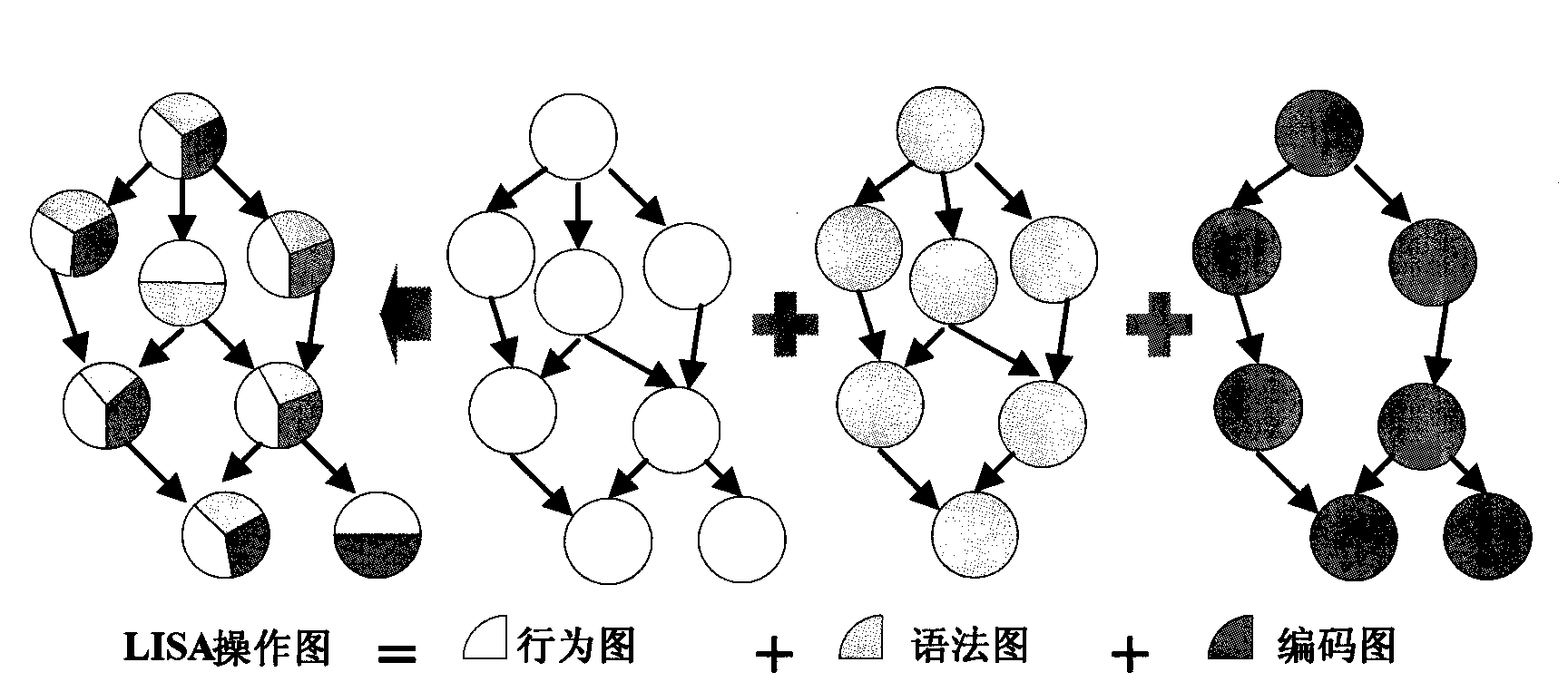

Method for designing specific instruction set processor

ActiveCN101561833AAccelerate Design CycleImprove performanceSpecial data processing applicationsProcessor modelComputer architecture

The invention relates to a method for designing a specific instruction set processor, and the method can make the accuracy performance evaluation at the beginning of designing a chip, advance the test of a specific application, speed up the design process and reduce the re-design possibility which is because the performances of the chip can not achieve the requirements. The method establishes an LISA processor model at the early stage of the design, generates a corresponding software tool by the LISA model, builds up a virtual prototyping platform which is similar to the performances of real hardware on an ARM ESL, including a AHB bus model with precise cycle, an EMI model and an SDRAM model which are needed for designing the platform, searches out the performances under the different situations by repairing the models of the processor, obtains an optical software / hardware dividing method, directly verifies on the models and speeds up the design cycle of the processor.

Owner:SOUTHEAST UNIV

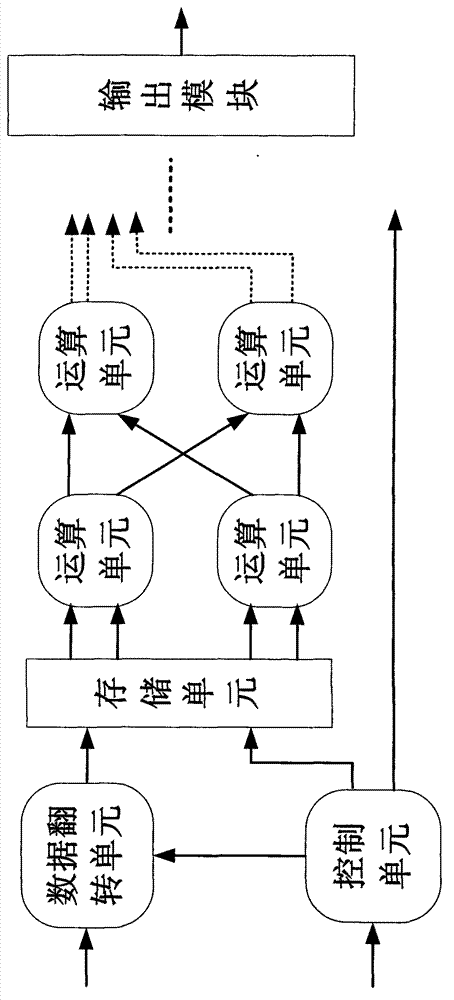

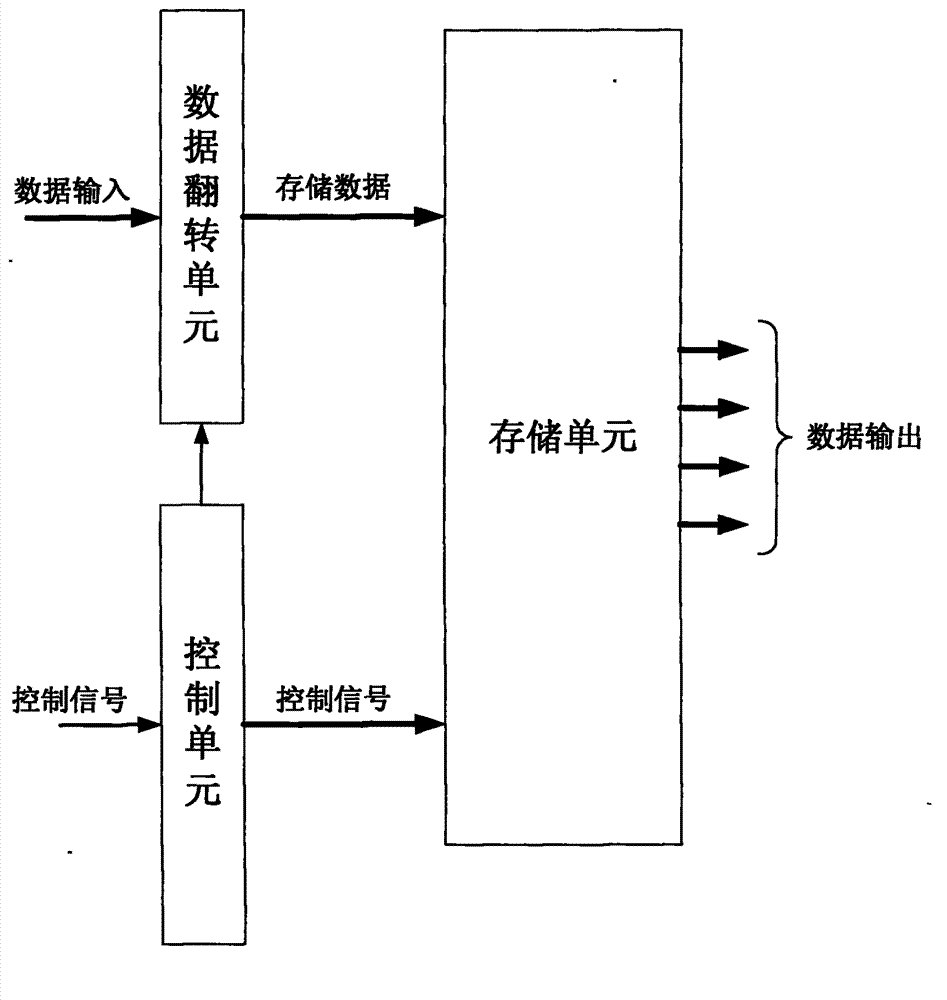

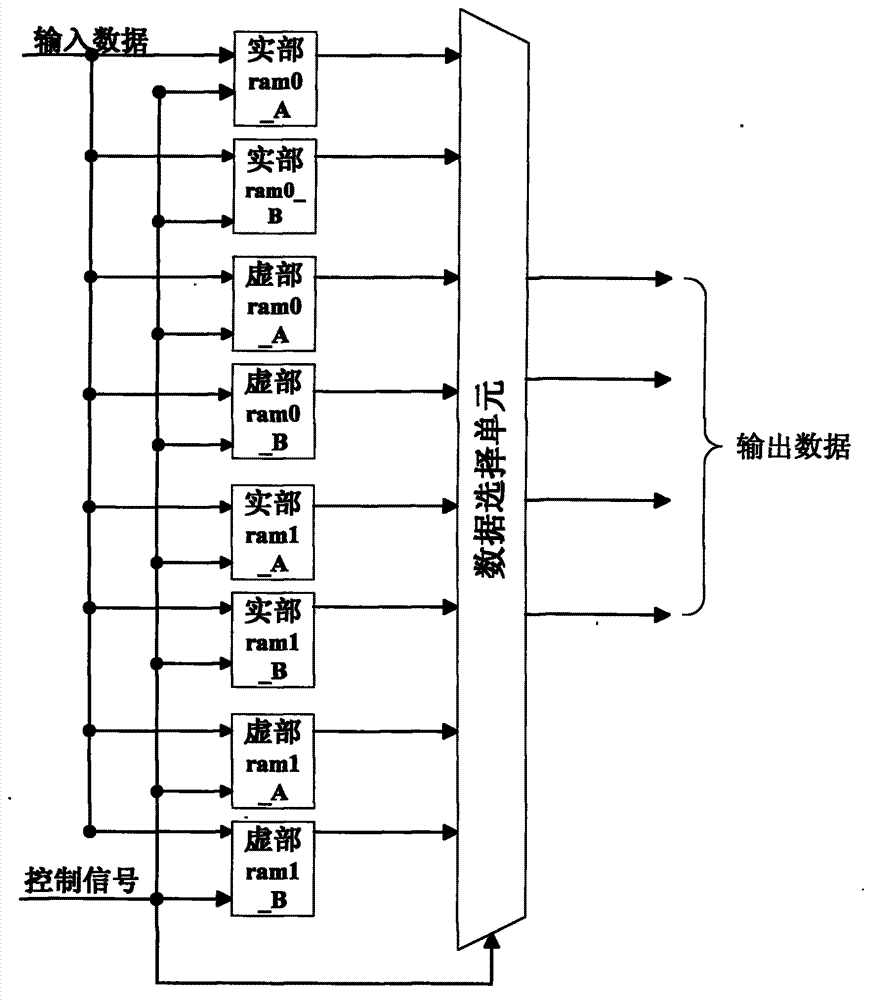

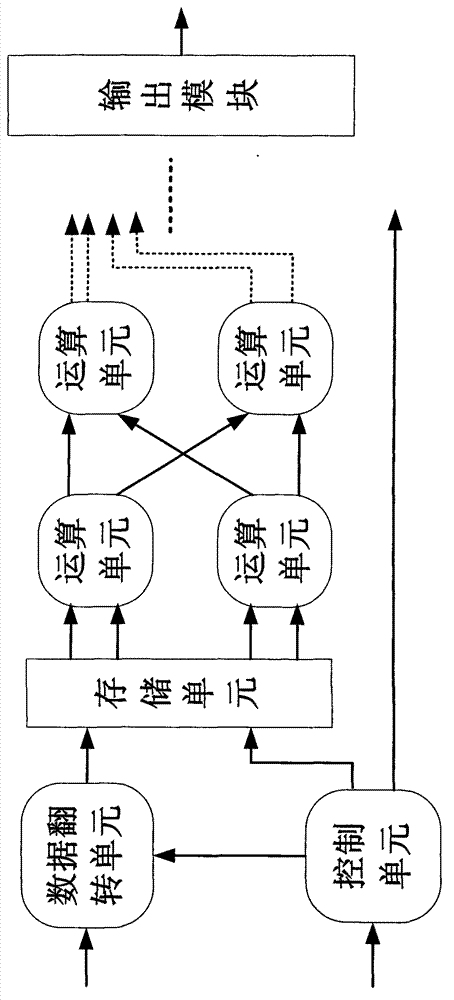

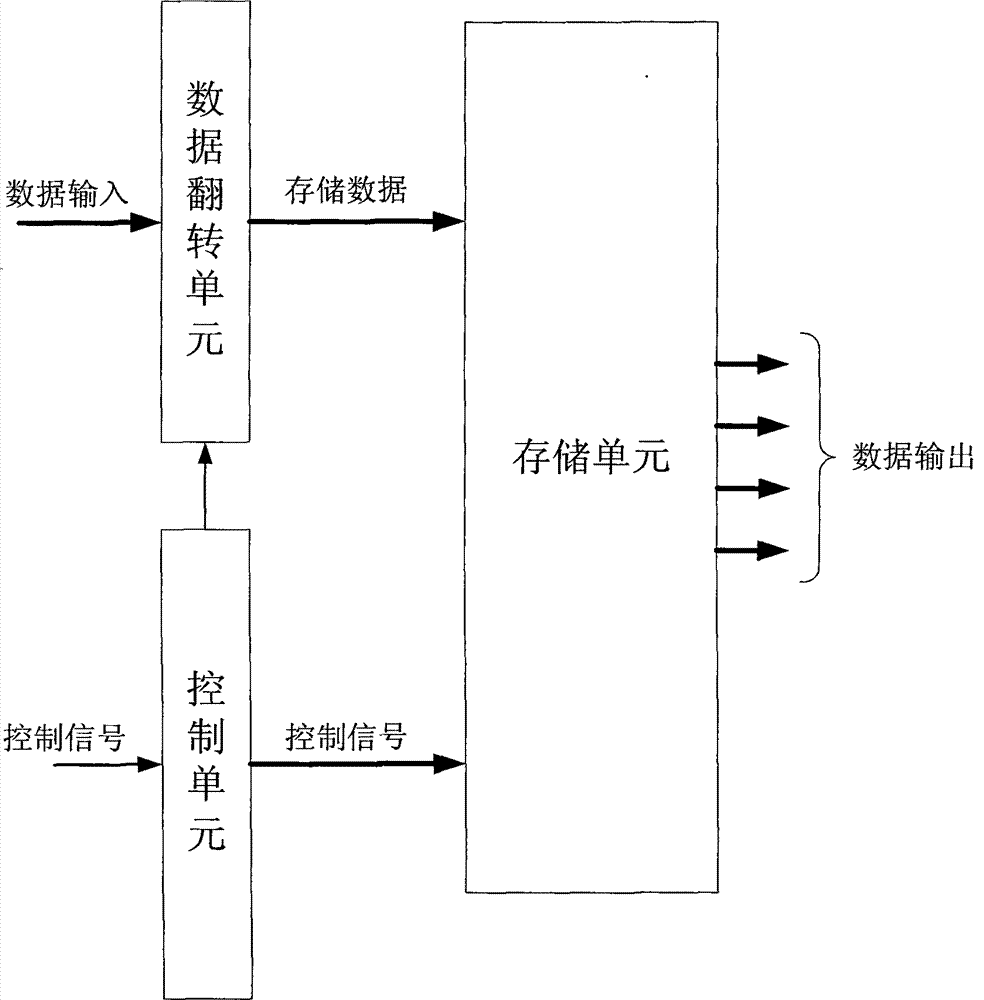

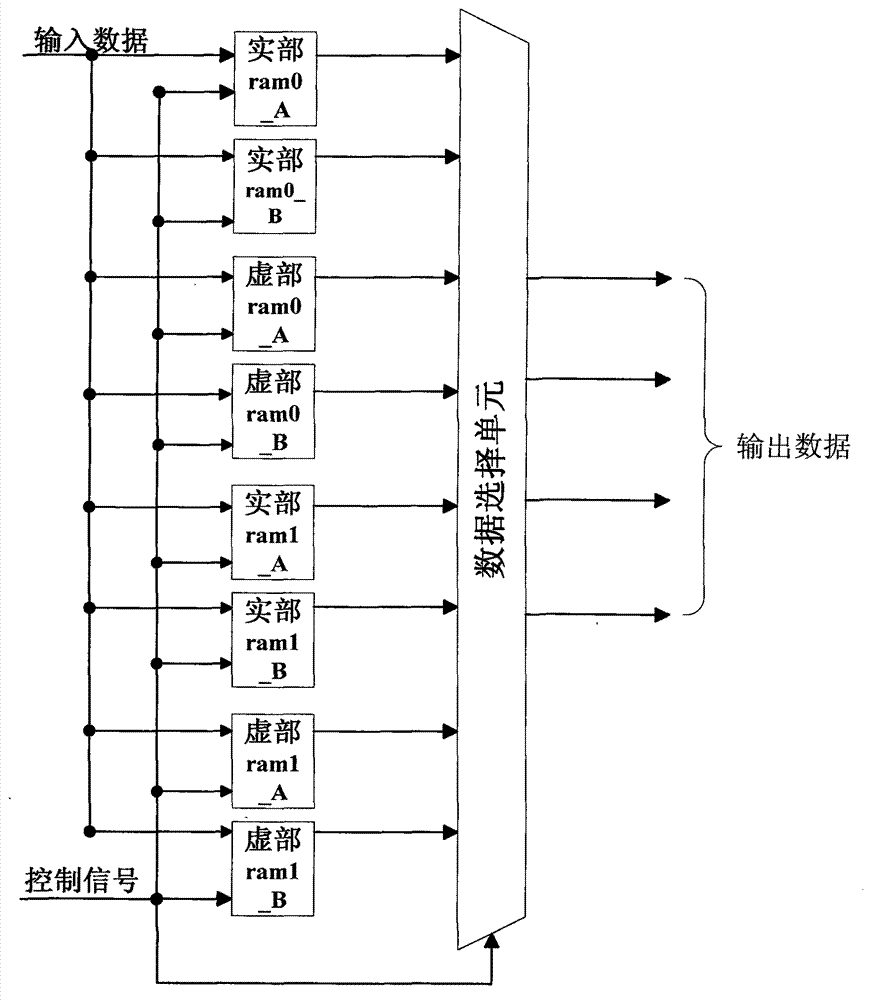

High-speed fixed point fast fourier transformation (FFT) processor based on field programmable gate array (FPGA) and processing method for high-speed fixed point FFT processor

InactiveCN102929837AAccelerate Design CycleReduce overheadComplex mathematical operationsFast Fourier transformComputer module

The invention discloses a high-speed fixed point fast fourier transformation (FFT) processor based on a field programmable gate array (FPGA) and a processing method for the high-speed fixed point FFT processor. The FFT processor comprises a multi-stage FFT processing module and a one-stage bit-reversed order output module. The processing method comprises the following steps of: 1, receiving data; 2, turning the data; 3, storing the data and performing disk-type processing on the data; 5, judging whether calculation is finished or not; 6, adjusting the position of the processed data; 7, storing the adjusted data; and 8, outputting a bit-reversed order. By adopting a pipeline architecture and a multi-data parallel processing method, high-speed and high-precision FFT calculation is realized; the shortcomings of long design period and high hardware cost of the conventional FFT processor based on a digital signal processor (DSP) and the shortcoming that the conventional FFT processor cannot process the data in parallel are overcome; and the working frequency and the data processing rate of the FFT processor are improved.

Owner:XIDIAN UNIV

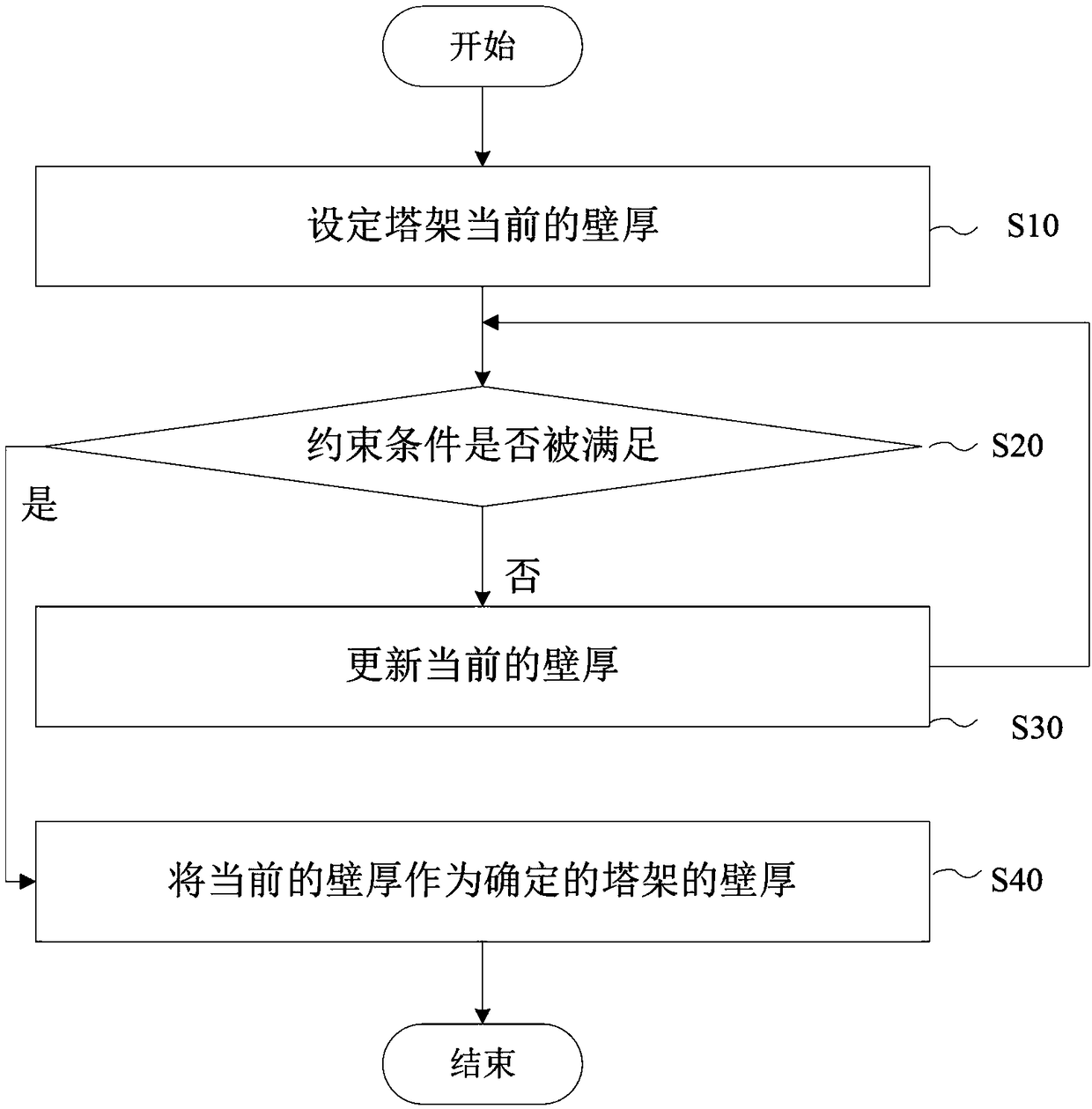

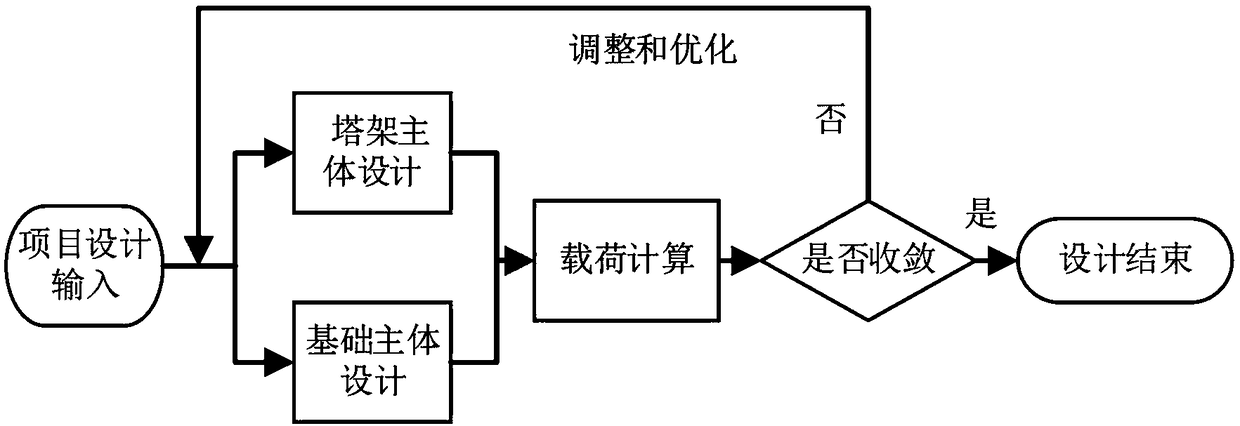

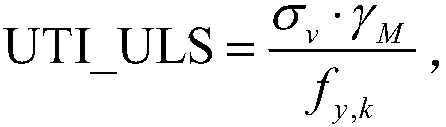

A method and apparatus for designing the wall thickness of a tower of a wind turbine generator system

InactiveCN109271722ALow costDesign lightweight optimizationGeometric CADSpecial data processing applicationsEngineeringTower

A method and apparatus for designing the wall thickness of a tower of a wind turbine generator system, and the design method includes: for each tower, an optimization algorithm is adopted to determinethe wall thickness of each section of tower separately, wherein the optimization objective of the optimization algorithm is to minimize the mass of each section of tower, and the constraint conditionof the optimization algorithm is that the safety factor of the ultimate strength, the safety factor of the buckling strength and the safety factor of the fatigue strength of each section of tower satisfy the preset safety margin value. In the method and apparatus for designing the wall thickness of a tower of a wind turbine generator system according to an embodiment of the present invention, bysetting the optimization objective of the optimization algorithm of the wall thickness of the tower to minimize the tower mass, and setting the constraint condition to be that the safety factor of ultimate strength, the safety factor of buckling strength and the safety factor of fatigue strength of each tower satisfy the preset safety margin value, so as to ensure the tower to realize the functions required to be realized and reduce the cost of the tower.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

Preparation method of sectional chemical milling sample plate

ActiveCN110321607AImprove molding cycle efficiencySimple designDesign optimisation/simulationSpecial data processing applicationsSoftwareChemical milling

The invention relates to a preparation method of a sectional chemical milling sample plate, which comprises the following steps: opening a part process model in CATIA software according to the requirements of a chemical milling process model and the customization requirements of the chemical milling sample plate, and adding process elements consisting of a sample plate form and position line, a sectional line, a sample plate positioning hole, a chemical milling allowance and an allowance line to obtain the chemical milling process model; designing various scribed lines on the chemical millingprocess model on a sample plate material thickness dimension surface inwards away from the die surface; sample plate shape and bit lines are essential; forming a sample plate positioning hole consistent with the drawing die positioning hole in position in the thickness dimension surface of the sample plate material, wherein the hole is used for positioning a chemical milling sample plate in the lineation process on chemical milling skin; then designing the thickness dimension surface of the sample plate material in a segmented mode according to requirements, namely, the segmented chemical milling sample plate can be directly used for designing a skin part chemical milling sample plate with large curvature change and large area, and the efficiency of the complex chemical milling sample plate design period and the complex chemical milling skin part forming period is greatly improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

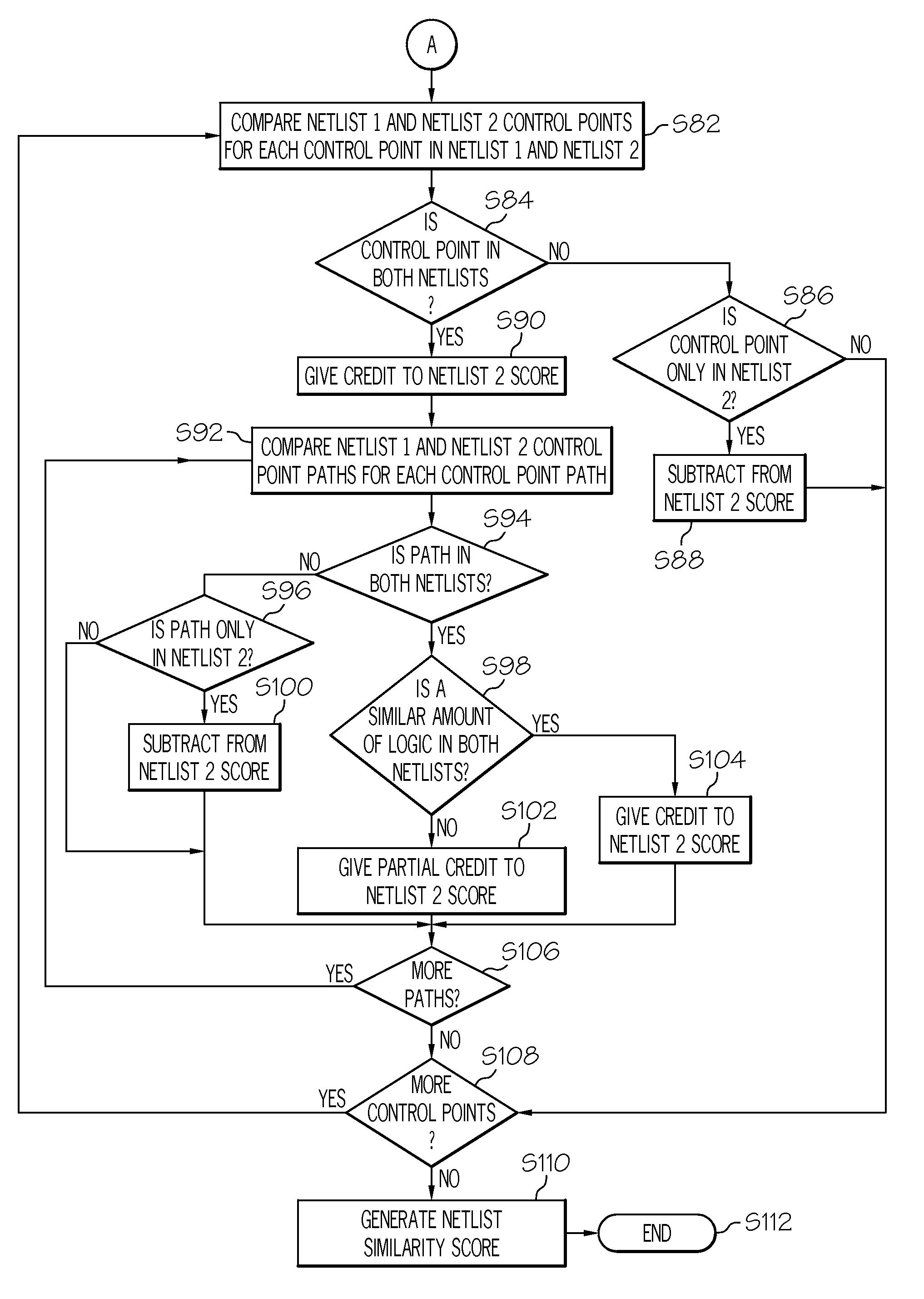

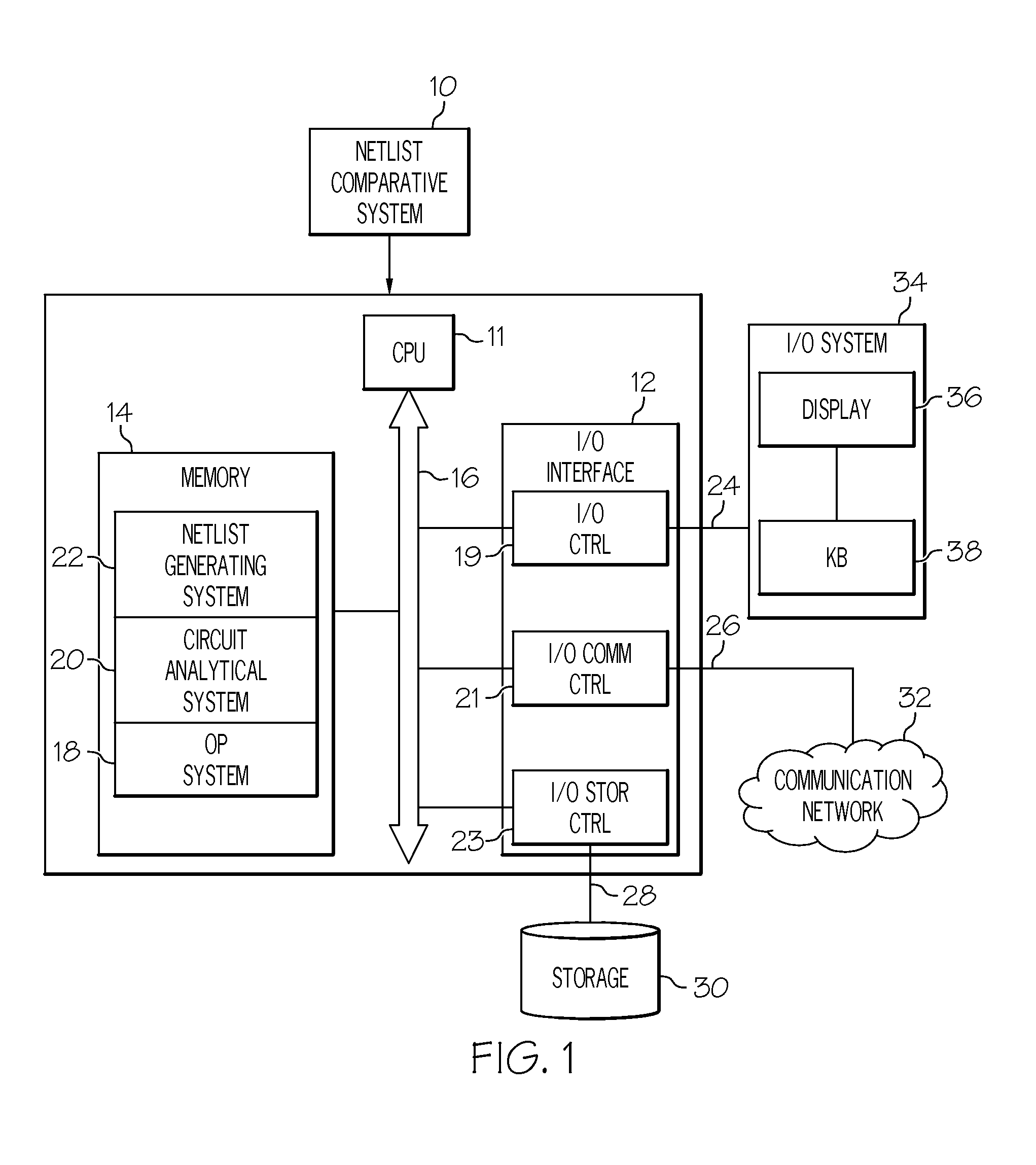

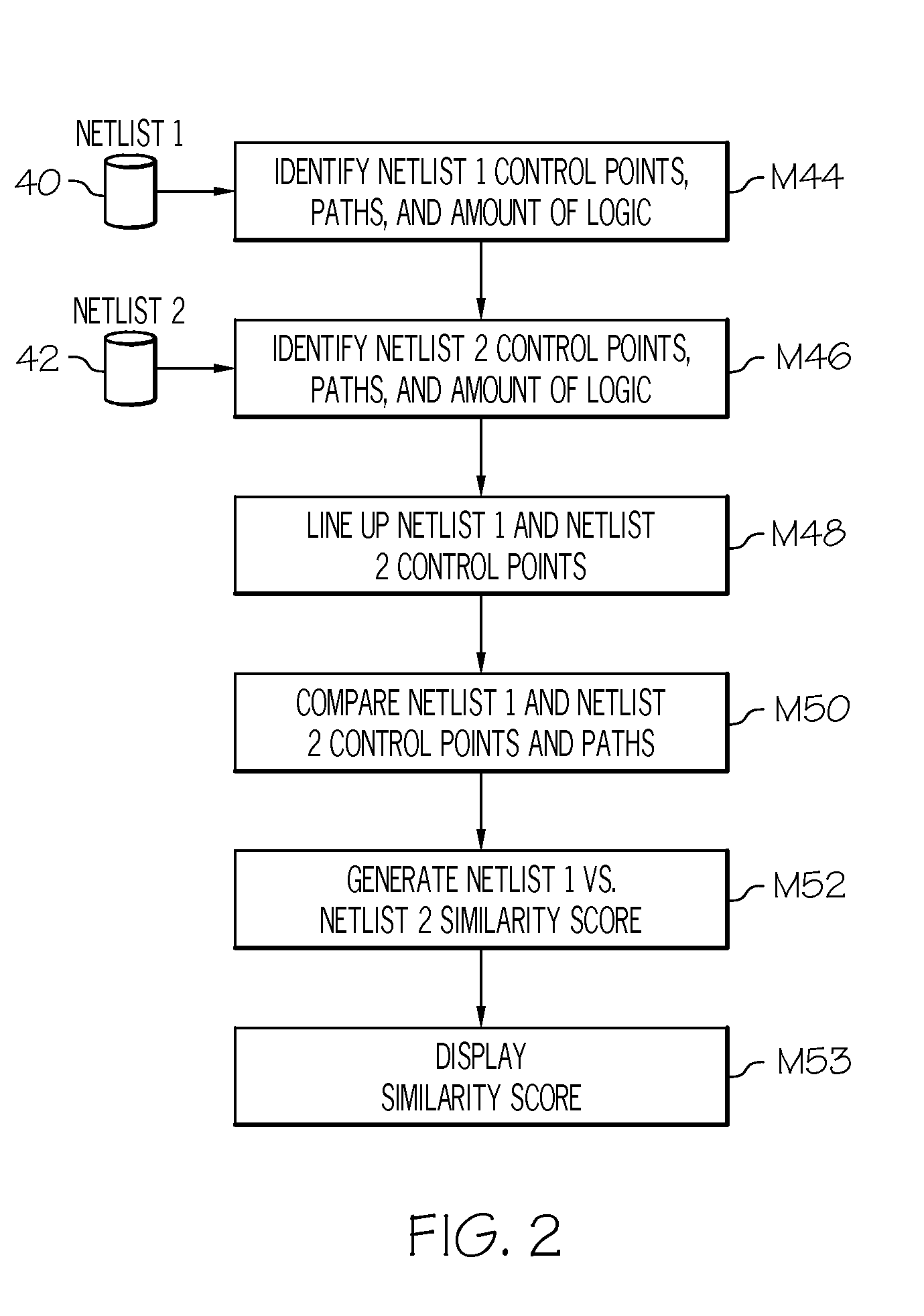

Development tool for comparing netlists

ActiveUS20110047521A1Accelerate Design CycleComputer programmed simultaneously with data introductionCAD circuit designData miningNetlist

System, method, and program product analyze netlists for related electrical circuit designs by comparing predefined physical characteristics between the netlists. A baseline reference score is generated for one of the netlists and a normalized score is generated for the other netlist. The baseline reference score and the normalized score are used to generate a similarity score that is displayed on a display monitor. Preferably, the similarity score is displayed as a percentage.

Owner:MARVELL ASIA PTE LTD

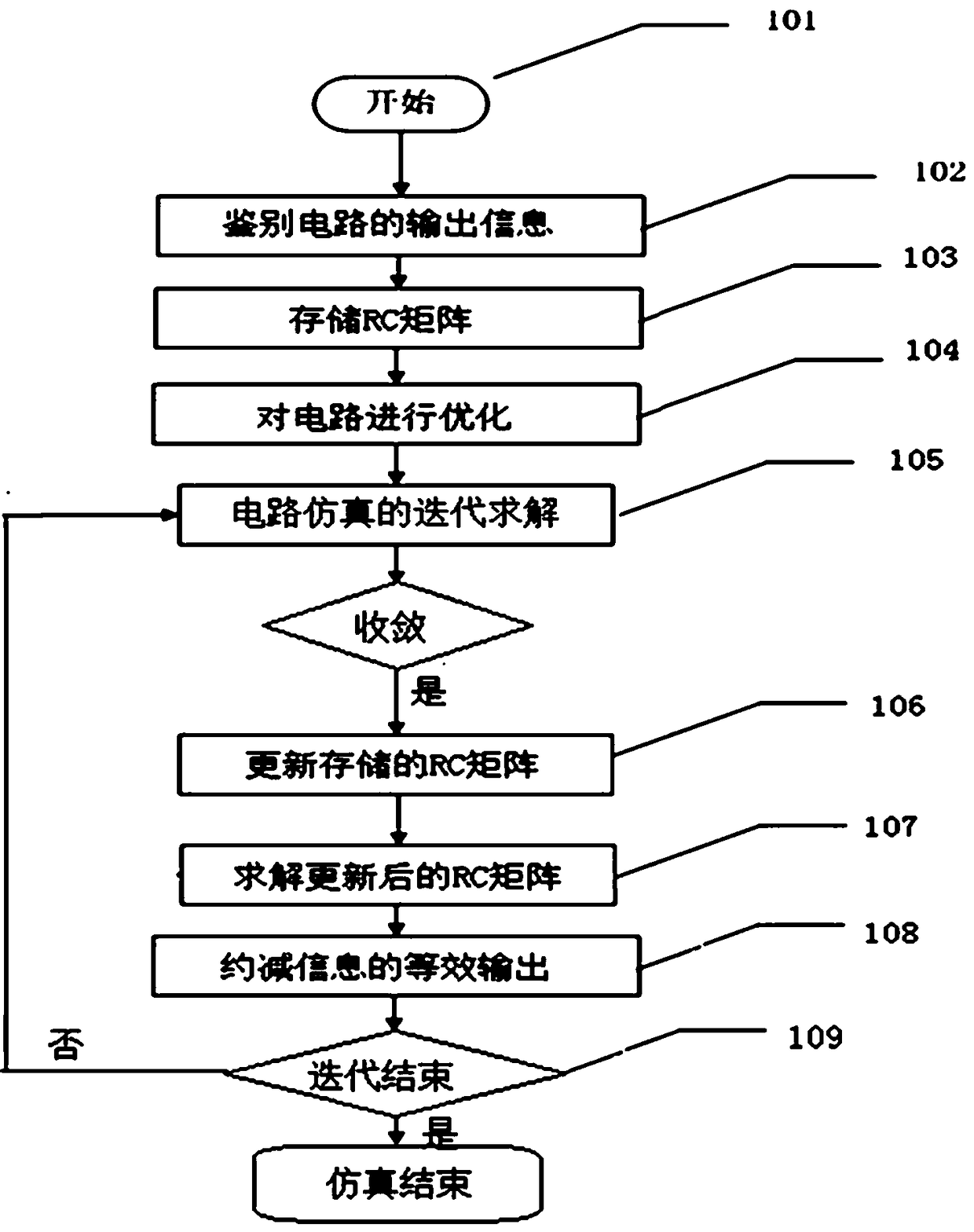

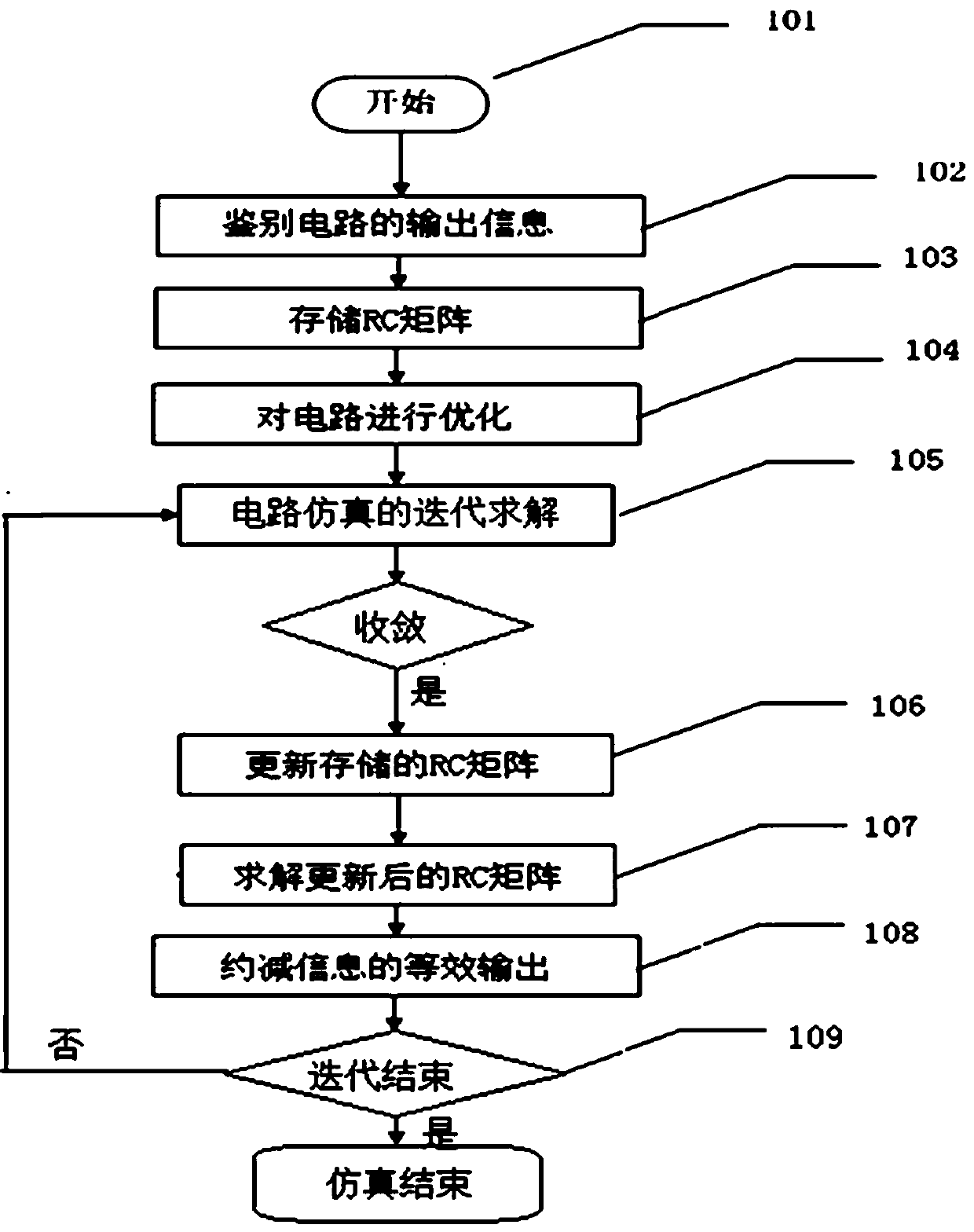

A method for optimizing that equivalent output of a post-simulation circuit

ActiveCN109376471AAchieve friendlyIntegrity guaranteedDesign optimisation/simulationCAD circuit designComputer scienceUser friendliness

A method for optimizing that equivalent output of post-simulation circuit comprises the follow steps: 1) discriminating the output information required by circuit simulation and filter the equivalentoutput information; 2) storing the RC matrix before optimization in advance; 3) optimize that circuit and storing the optimize node information; 4) updating the RC matrix before optimization and solving to obtain the corresponding output information of the optimized node; 5) outputting the equivalent output information of the node. The method of the equivalent output after optimization of the post-simulation circuit of the invention ensures the integrity of the output according to the equivalence of the post-simulation circuit and realizes user-friendliness.

Owner:SHENZHEN HUADA EMPYREAN TECH CO LTD

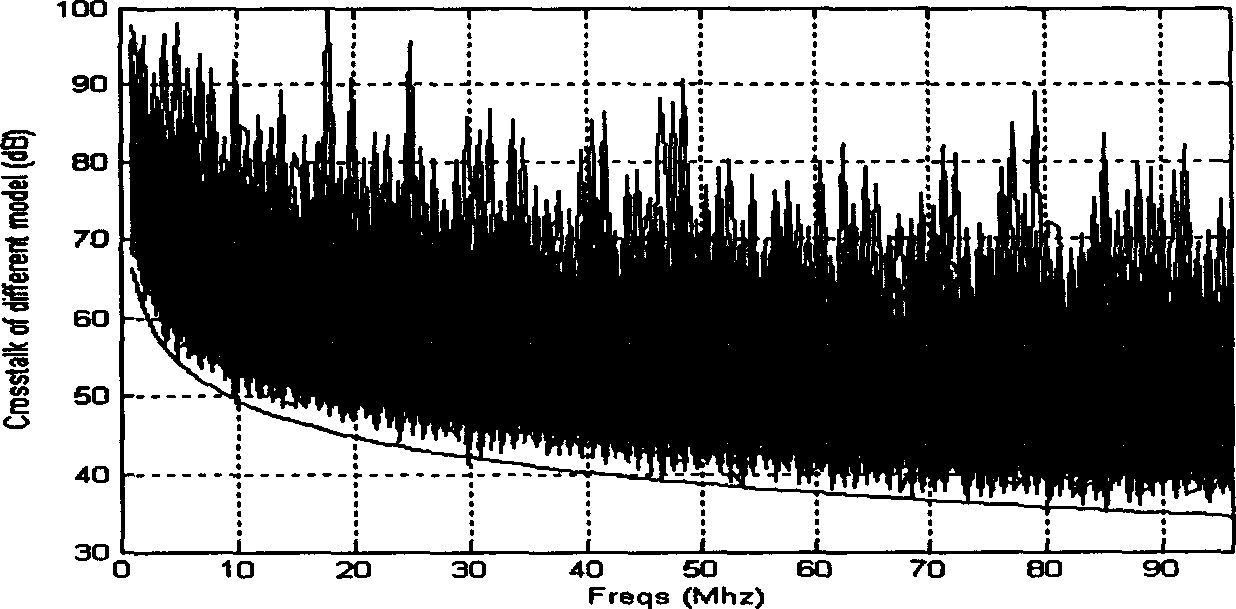

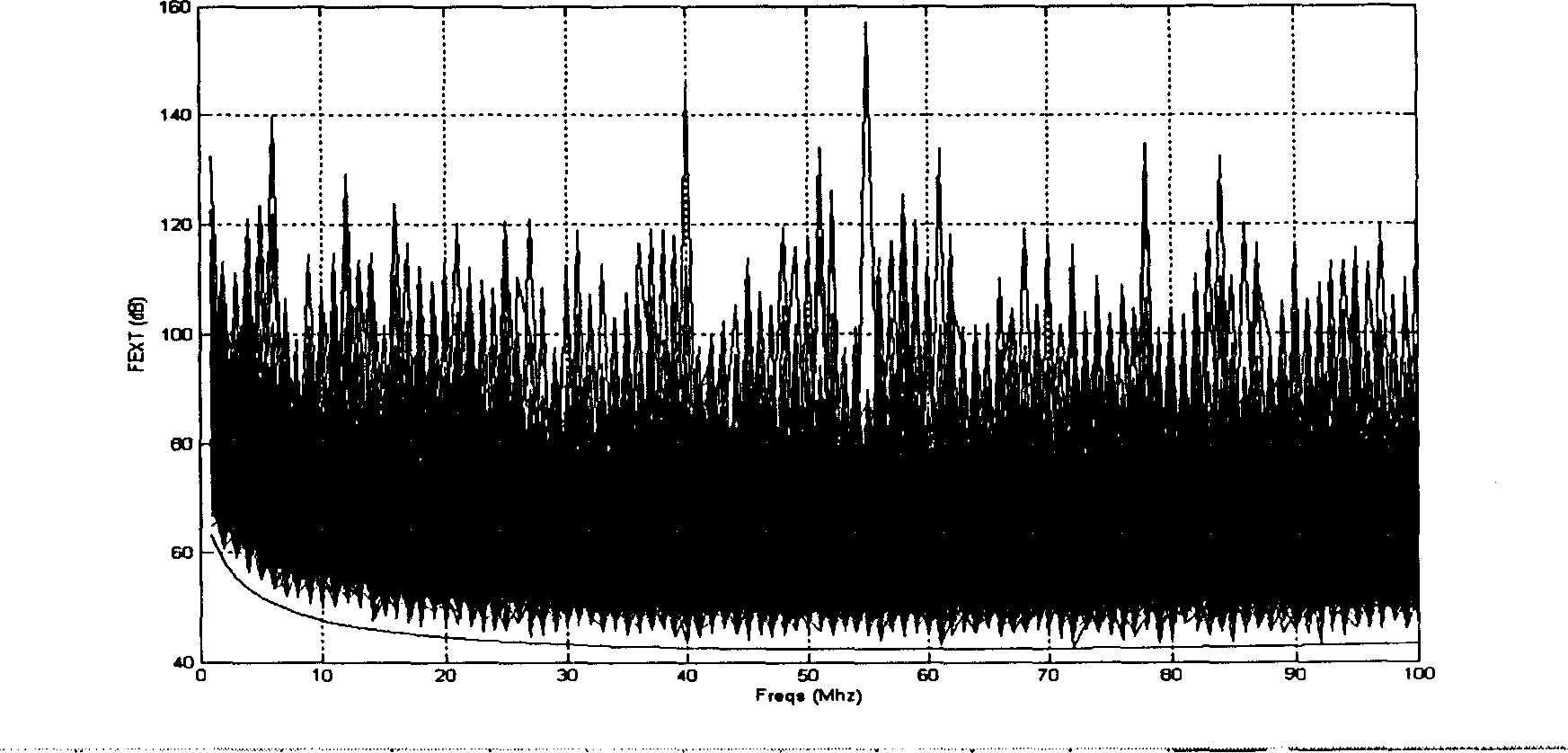

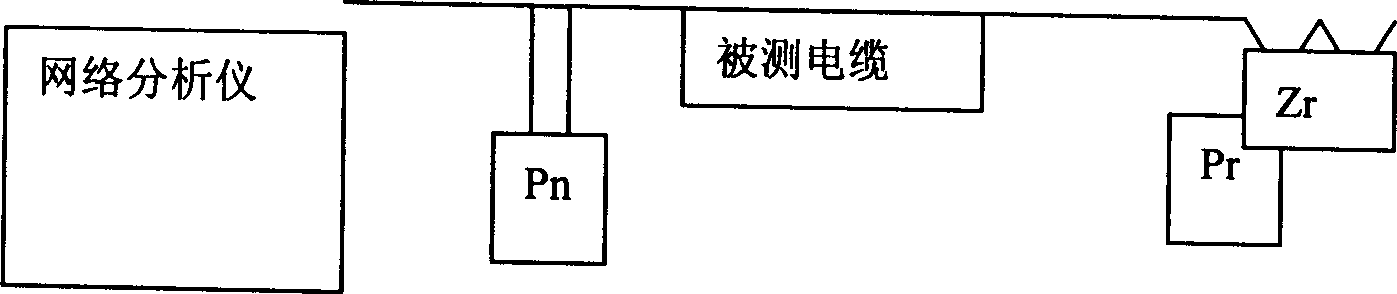

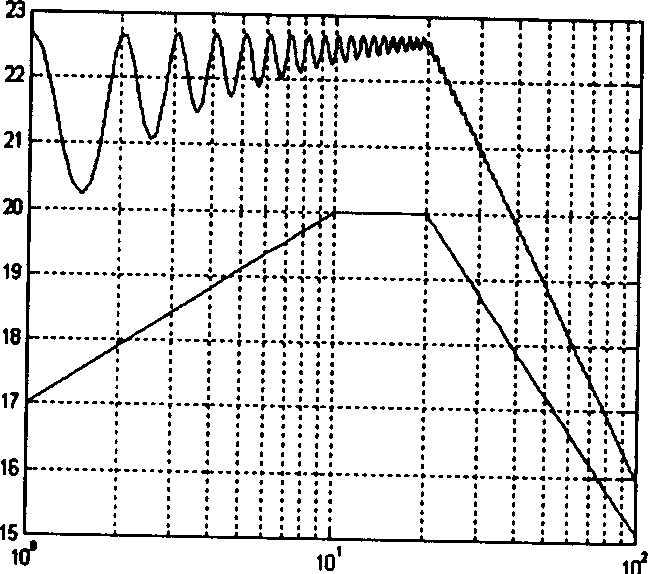

Method for simulating cross talk loss at far and near ends of twisted-pairs in designing high-speed data communications system

InactiveCN1447533AReliable frequency response characteristicsAccelerate Design CycleUnbalanced current interference reductionArtificial linesSystems designCommunications system

First, the method builds the model of the new cross talk loss at far and near ends of twisted-pairs so as to obtain the amplitude information and the phase information of the return loss so that the result with more truthfulness is gotten. Then, the design of equivalent electric circuit elements is carried out for the said information in order to embed the designed elements into entire design system to execute the system simulation. The invention shortens system design cycle greatly and raises accuracy of designs.

Owner:FUDAN UNIV

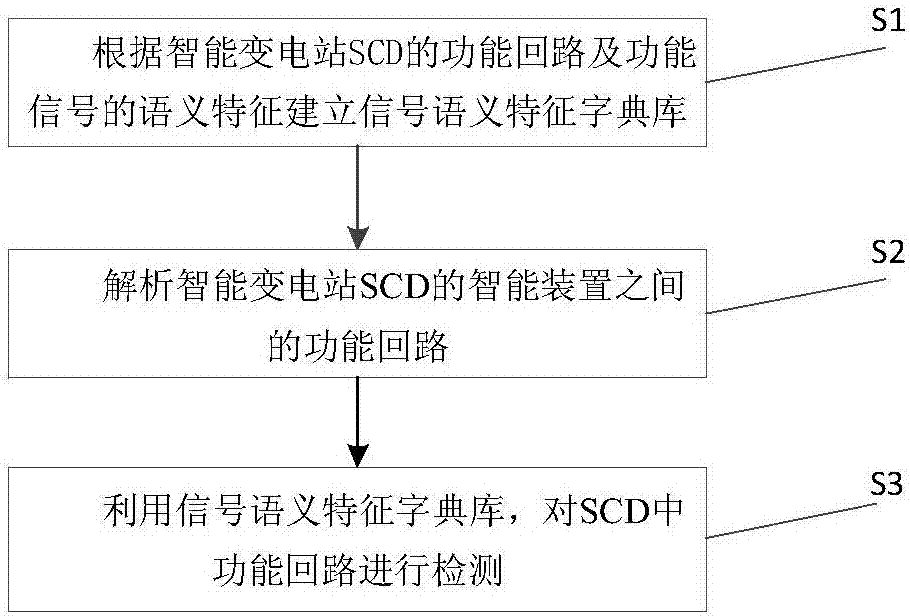

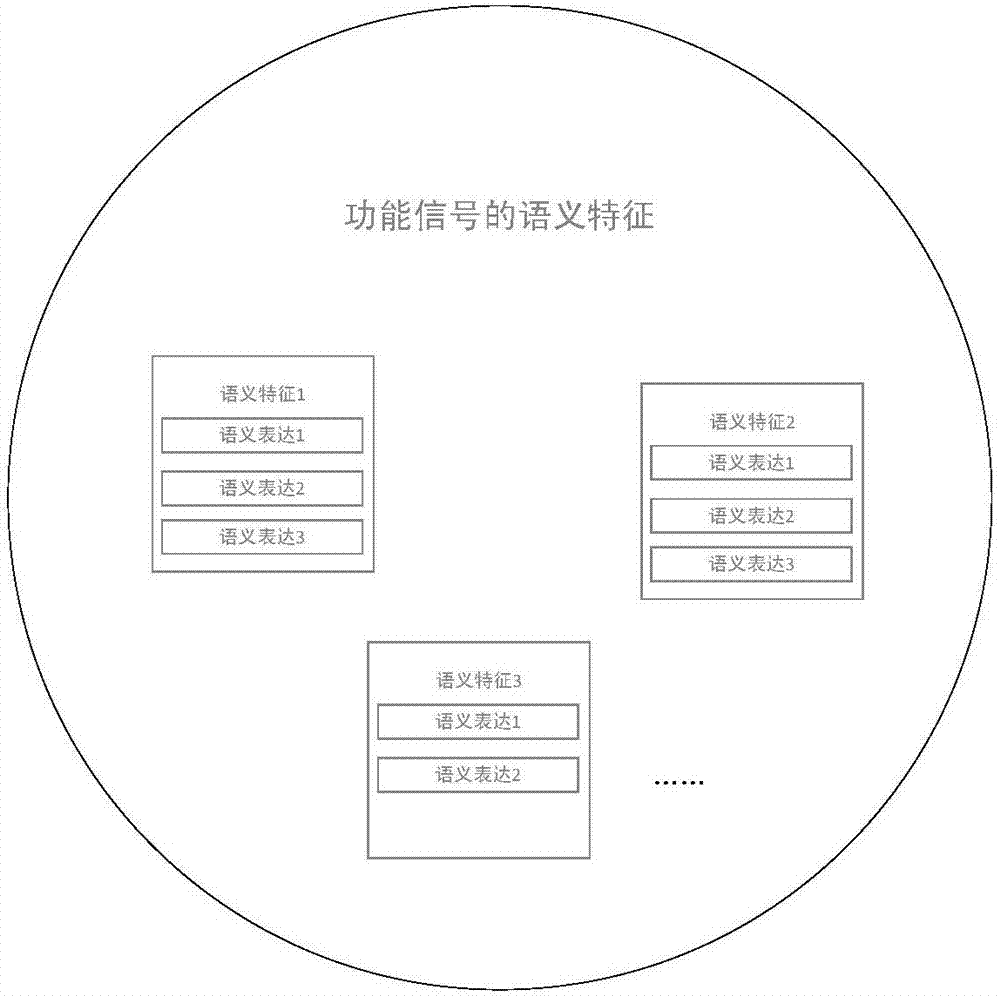

Intelligent SCD loop checking method and device

PendingCN107391812AGuaranteed efficiencyAccelerate Design CycleSpecial data processing applicationsSmart substationSemantic feature

The invention relates to an intelligent SCD loop checking method and device. The method comprises the steps that a signal semantic feature dictionary database is established according to a functional loop and semantic features of functional signals of intelligent SCD; the functional loop between intelligent devices of the intelligent SCD is analyzed; the signal semantic feature dictionary database is used for detecting the functional loop in the intelligent SCD. Therefore, the reliability of finally obtained detection results and checking reports is high, and the method is an effective method for design examination of an intelligent transformer substation, so that the design and debugging period of the intelligent transformer substation is greatly improved.

Owner:CHINA ELECTRIC POWER RES INST +4

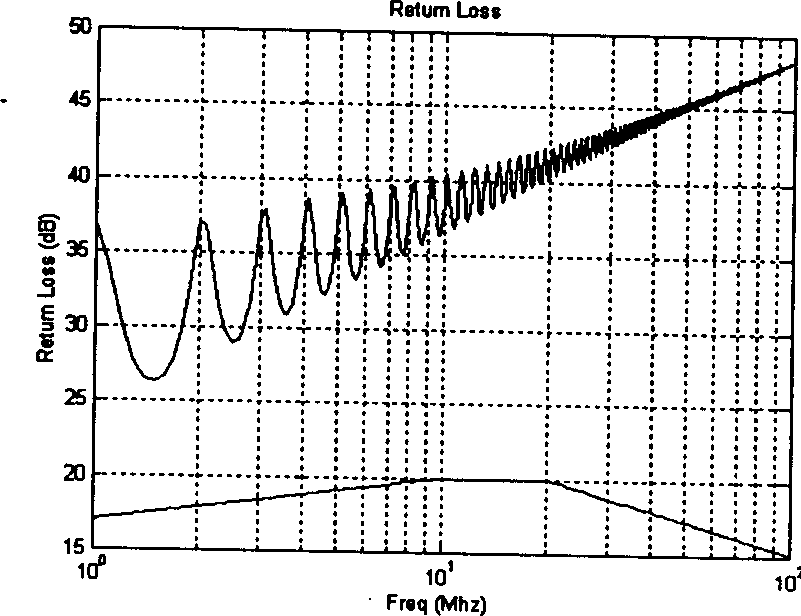

Methof for simulating return loss of twisted-pairs in designing high-speed data communication system

InactiveCN1447532AAccelerate Design CycleImprove reliabilityTransmission monitoringLine-transmission monitoring/testingSystems designCommunications system

First, the method builds the new return loss model with the structure loss being added so as to obtain the amplitude information and the phase information of the return loss so that the result with more truthfulness is gotten. Then, the design of equivalent electric circuit elements is carried out for the said information in order to embed the designed elements into entire design system to execute the system simulation. The invention shortens system design cycle greatly and raises accuracy of designs.

Owner:FUDAN UNIV

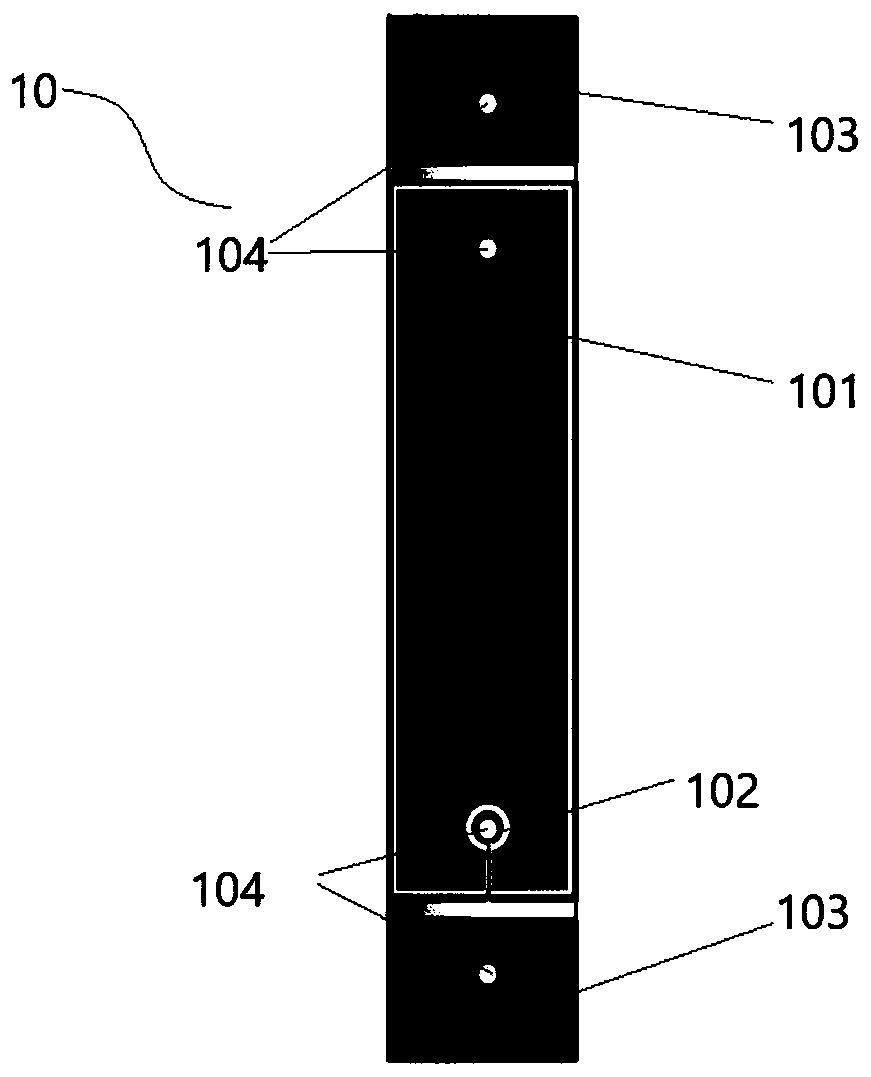

Multi-modal sensor

ActiveCN110068583AAccelerate Design CycleSimple designMaterial analysis using microwave meansMaterial resistanceResonant cavityElectrical resistance and conductance

The invention discloses a multi-modal sensor composed of four-port flexible PCB electrodes. The multi-modal sensor comprises an insulated support tube with a measured field inside, and the insulated support tube includes a first cross section and a second cross section which are adjacent to each other along the longitudinal axis of the insulated support tube; a resistance / capacitance tomography sensor arranged at the first cross section, wherein the resistance / capacitance tomography sensor comprises a plurality of four-port flexible PCB electrodes uniformly distributed along the circumferenceof the inner wall of the insulated support tube, and a radial shielding metal shell fixed to the outer wall of the insulated supporting tube, wherein the longitudinal axis of each four-port flexiblePCB electrode is parallel to the longitudinal axis of the insulated support tube; and a resonant cavity sensor arranged at the second cross section. According to the multi-modal sensor provided by theinvention, the four-port electrode design is adopted, a resistance tomography sensor and a capacitance tomography sensor are integrated, and the integration is integrated with a resonant cavity to form the multi-modal sensor, so that the multi-phase flow with different conductivity can be measured.

Owner:BEIHANG UNIV

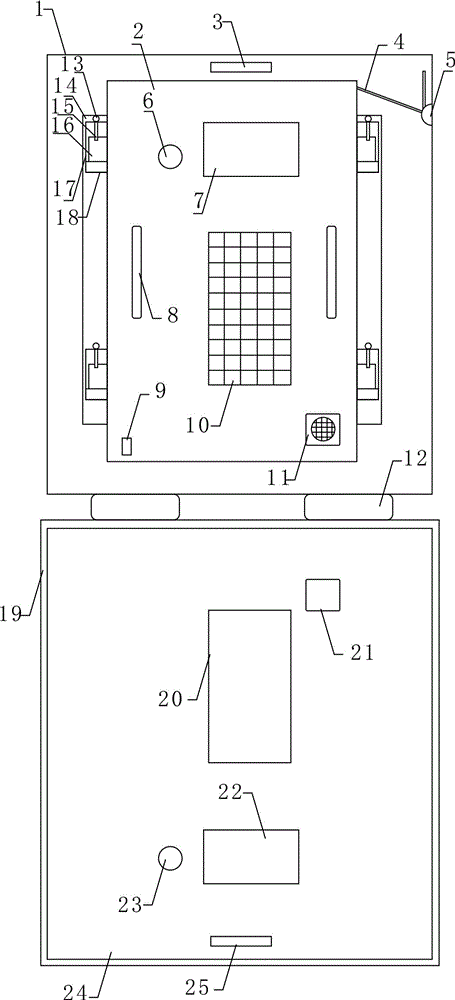

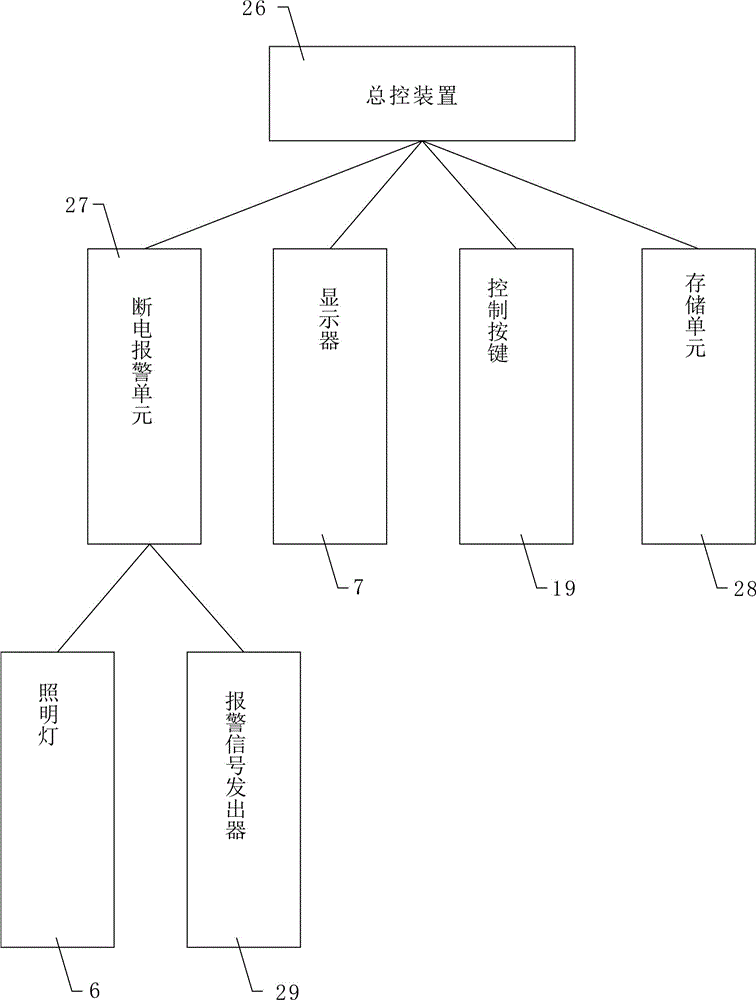

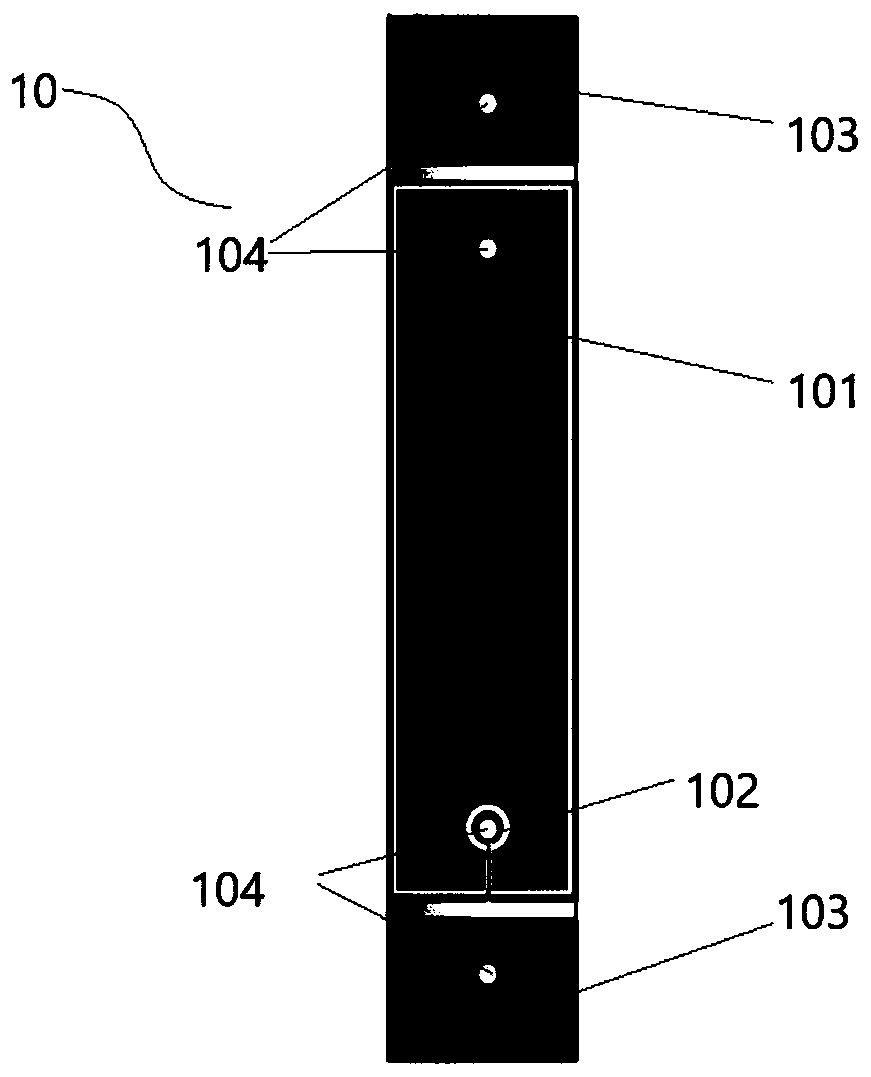

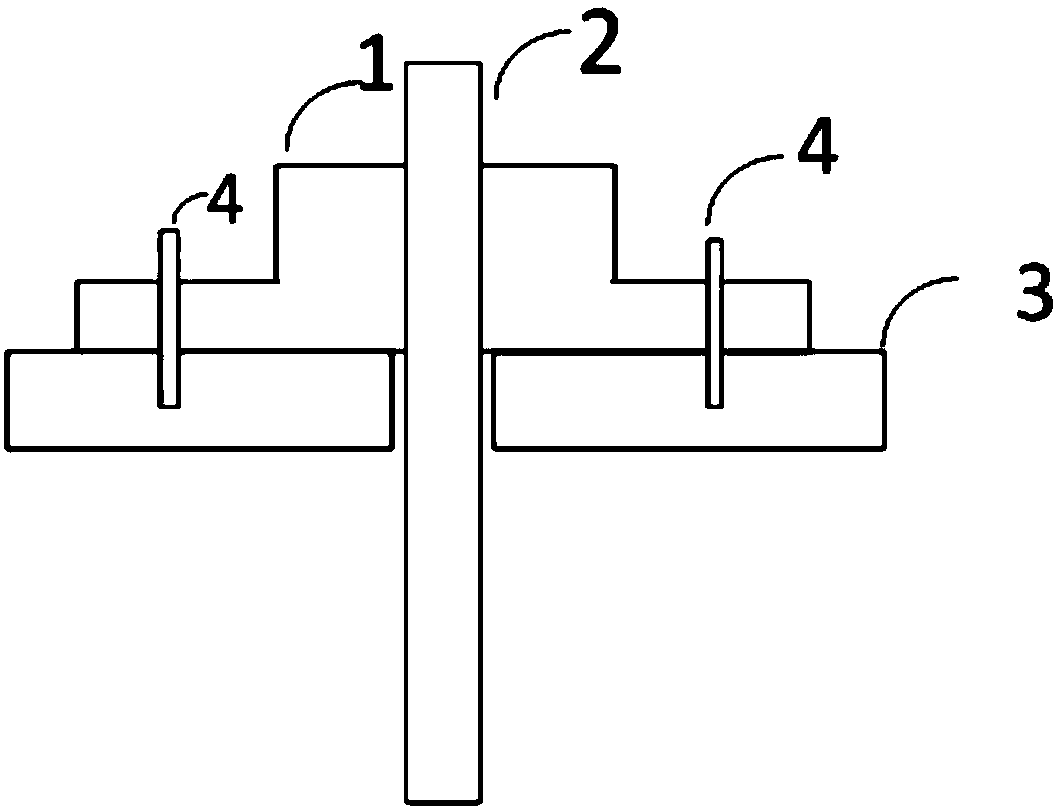

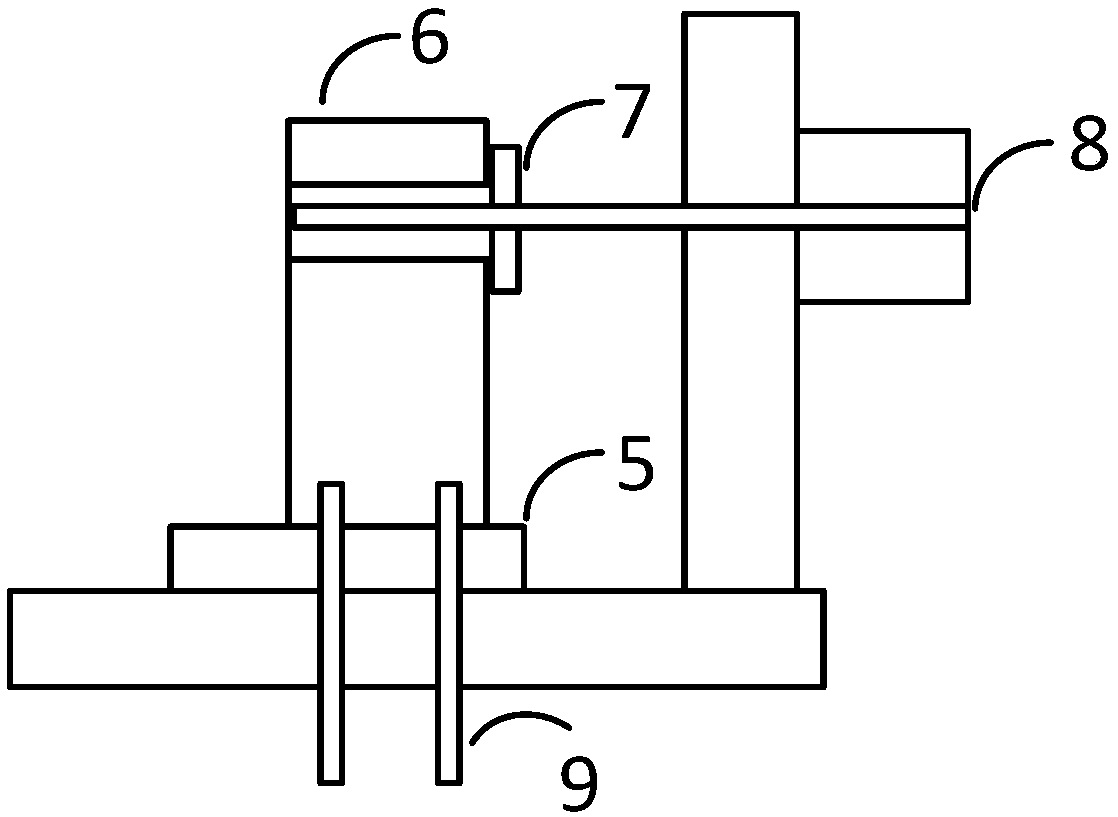

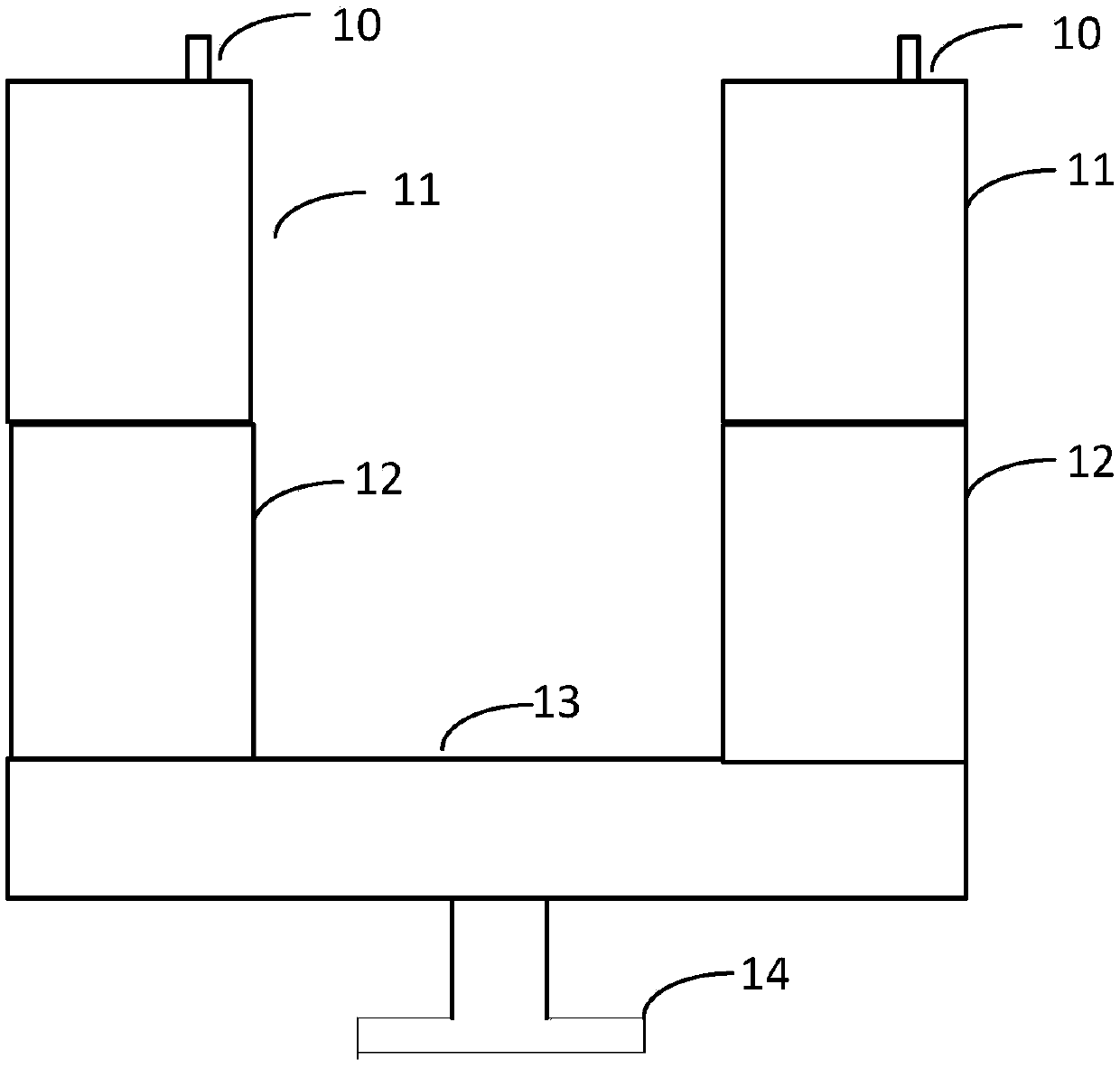

Integrated operating box

The invention provides an integrated operating box. The integrated operating box comprises an elevator wall hollow-out cavity, an operating box body and a cover plate, wherein the operating box body and the cover plate are arranged inside the elevator wall hollow-out cavity. The cover plate is connected with the elevator wall hollow-out cavity through connecting rotary shafts. Four fixed components are arranged inside the elevator wall hollow-out cavity. The end faces of the two sides of the operating box body are provided with two blocks. The elevator wall hollow-out cavity is fixed to the operating box body through the fixed components and the blocks. The fixed components are provided with fixed notches. The tops of the upper portions of the fixed notches are provided with fixed rotary shafts. The fixed rotary shafts are rotatably connected with fixed rotary plates. The bottoms of the fixed components are provided with blocking sheets.

Owner:XUZHOU FANGDA MOTOR CO LTD

High-speed fixed point fast fourier transformation (FFT) processor based on field programmable gate array (FPGA) and processing method for high-speed fixed point FFT processor

InactiveCN102929837BAccelerate Design CycleReduce overheadComplex mathematical operationsFast Fourier transformFft processor

The invention discloses a high-speed fixed point fast fourier transformation (FFT) processor based on a field programmable gate array (FPGA) and a processing method for the high-speed fixed point FFT processor. The FFT processor comprises a multi-stage FFT processing module and a one-stage bit-reversed order output module. The processing method comprises the following steps of: 1, receiving data; 2, turning the data; 3, storing the data and performing disk-type processing on the data; 5, judging whether calculation is finished or not; 6, adjusting the position of the processed data; 7, storing the adjusted data; and 8, outputting a bit-reversed order. By adopting a pipeline architecture and a multi-data parallel processing method, high-speed and high-precision FFT calculation is realized; the shortcomings of long design period and high hardware cost of the conventional FFT processor based on a digital signal processor (DSP) and the shortcoming that the conventional FFT processor cannot process the data in parallel are overcome; and the working frequency and the data processing rate of the FFT processor are improved.

Owner:XIDIAN UNIV

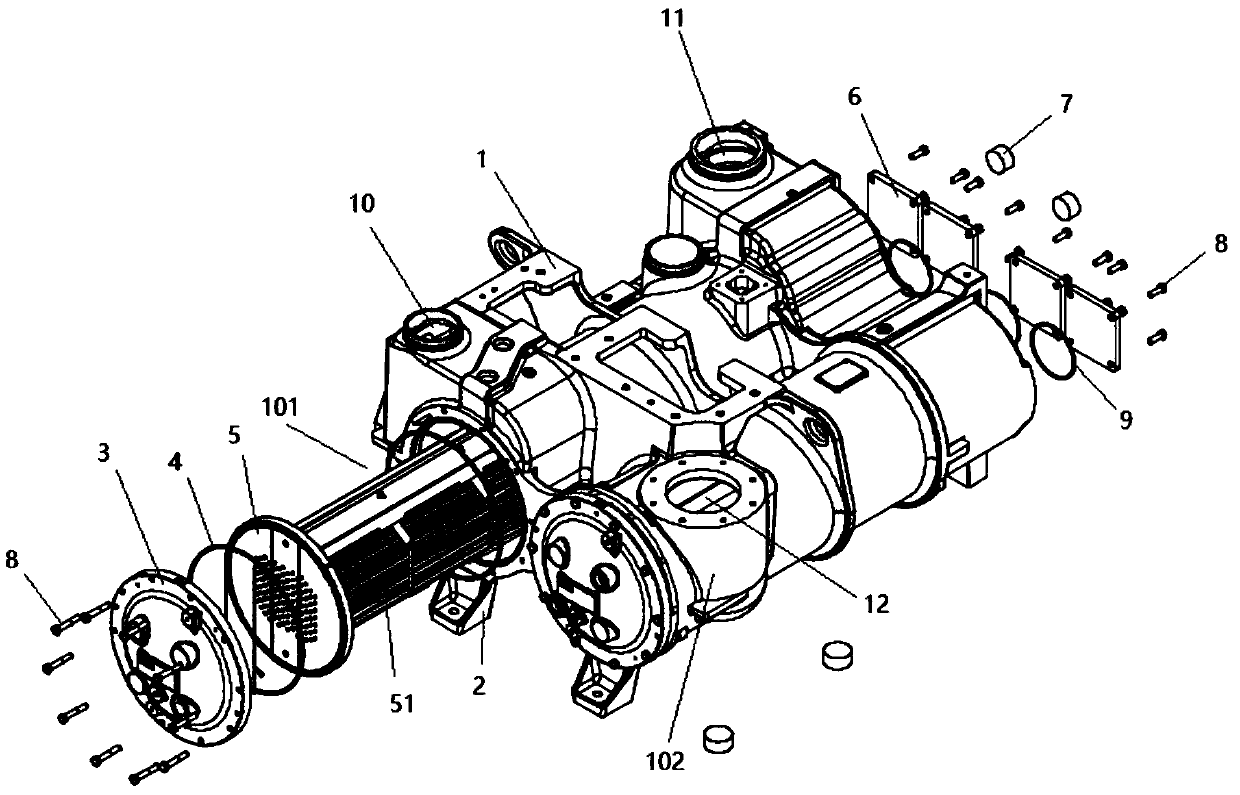

Shell heat exchanger of double-barrel casting

PendingCN109579563AExtend the production cycleShorten the production cycleHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerDesign cycle

The invention discloses a shell heat exchanger of a double-cylinder casting, comprising a double-cylinder shell, a base, casting end sockets, an end socket sealing ring, a heat exchange core, a rear sealing cover plate, a threaded plug, a fastening bolt, a cover plate sealing ring, an air inlet, an air outlet and a standby air inlet; the double-barrel shell comprises a first tube and a second tube, the openings of the first tube and the second tube are positioned at one side of the double-barrel shell, and the casting end sockets are arranged on the openings of the first tube and the second tube; the other side of the double-barrel shell is provided with the rear sealing cover plate; the top side of the double-barrel shell is provided with the air inlet, the air outlet and the standby airinlet. The shell heat exchanger provided by the invention has the characteristics of improving the passing rate of one-time test, improving the overall yield rate, shortening the production cycle of the heat exchanger, shortening the design cycle, reducing the outage maintenance loss and having strong capability.

Owner:API HEAT TRANSFER SUZHOU

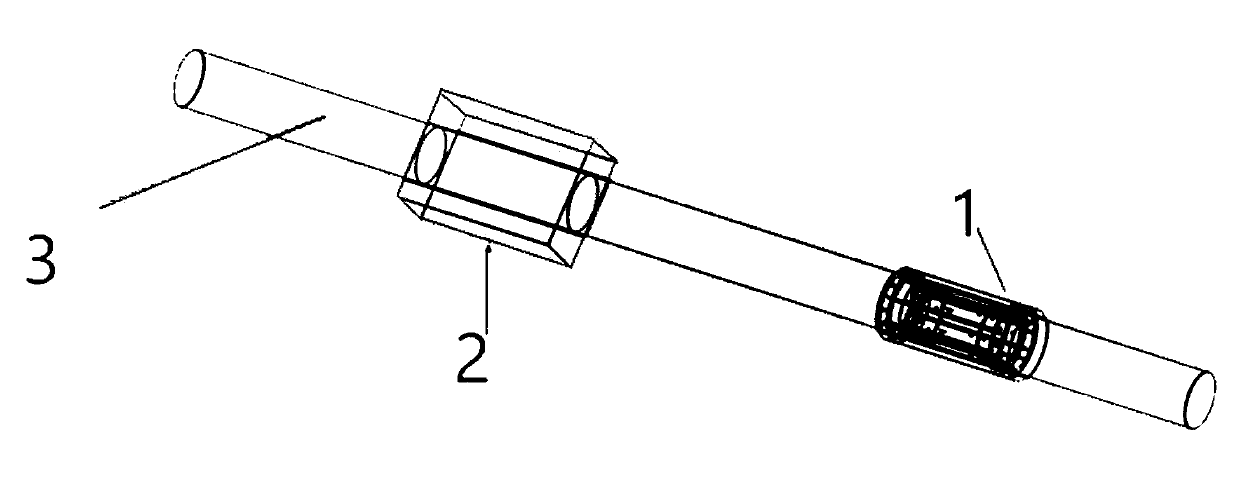

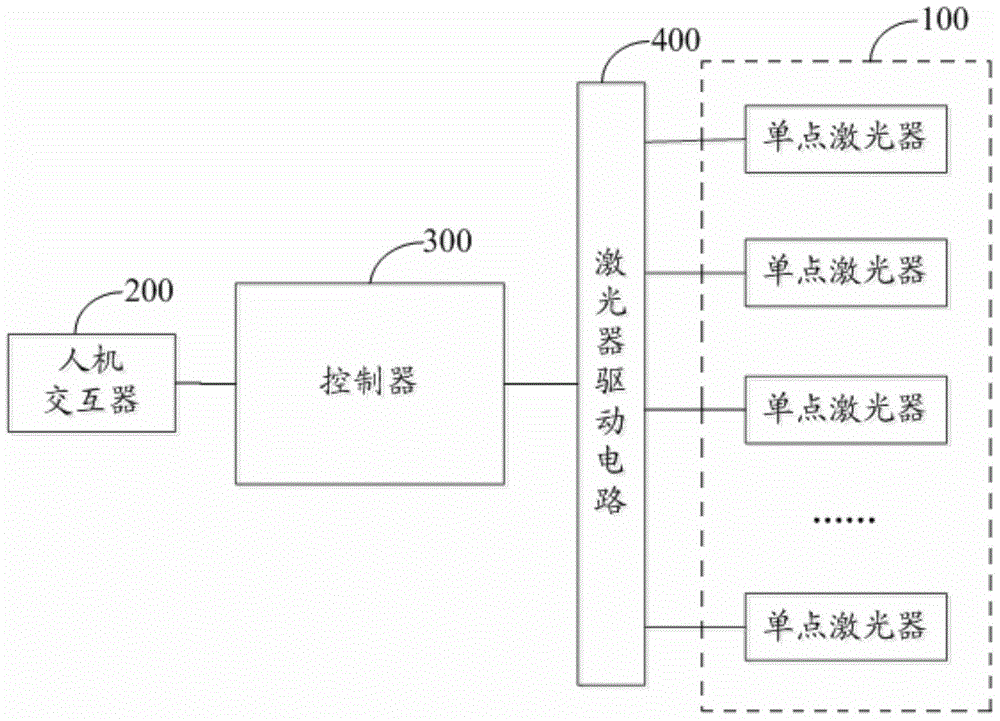

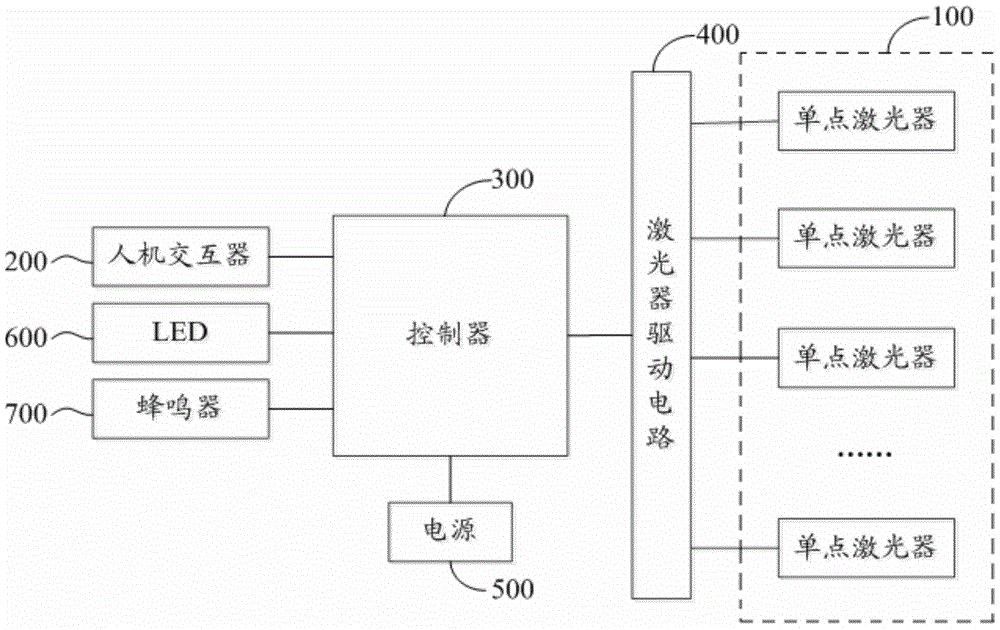

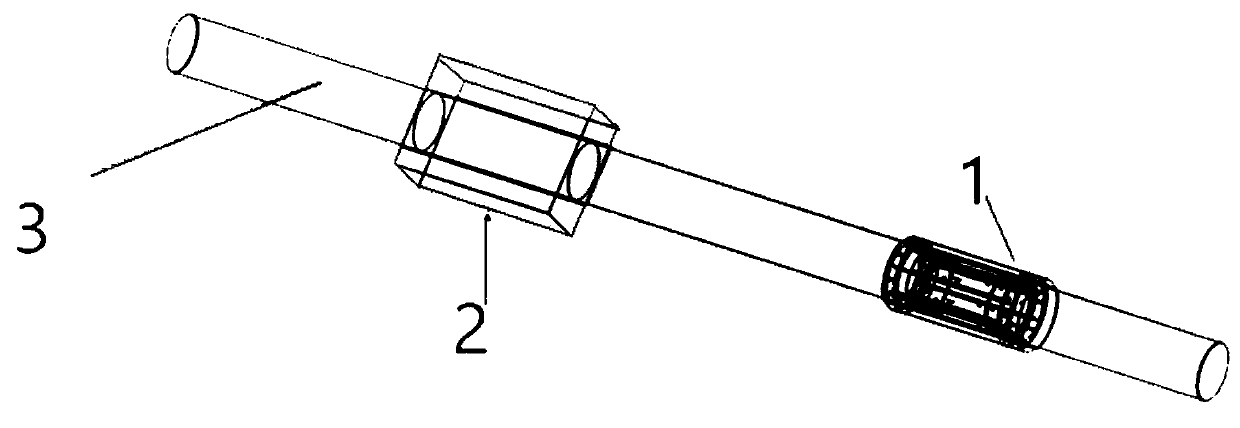

Multipoint laser

ActiveCN104932321AReduce workloadReduce development costsComputer controlSimulator controlLight beamPrism

The invention discloses a multipoint laser. The multipoint laser comprises N single-point lasers, a man-machine interaction device, a controller and a laser driving circuit, wherein the N single-point lasers serve as N light emitting points of the multipoint laser, and emission of N laser beams is realized; and the controller controls the on-off states of the N single-point lasers under the indication of the man-machine interaction device, so that the control over switching-on or switching-off of the N laser beams is realized. The laser beams emitted by the N single-point lasers are sent without the help of an optical system formed by a reflector, a prism and the like, and existing N single-point lasers can be adopted to serve as the required N single-point lasers. Thus, the multipoint laser overcomes defects of an existing five-point laser which are caused by that the required five light emitting points are generated by an optical system and the sending of the laser beams is performed by the optical system, and the identification of the optical system is not needed in the instrument, so that the generation and control workload of the plurality of laser beams is lowered, the design period is shortened, and the researching and production costs are reduced.

Owner:NORTHWEST INSTR SHANGHAI

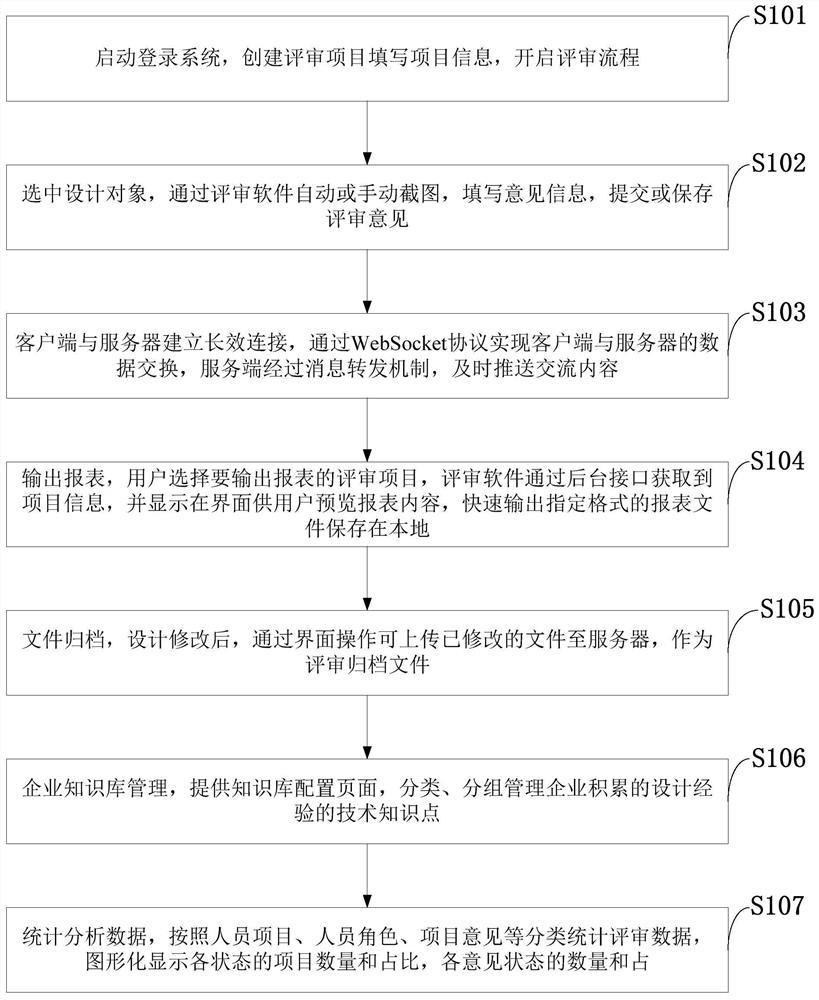

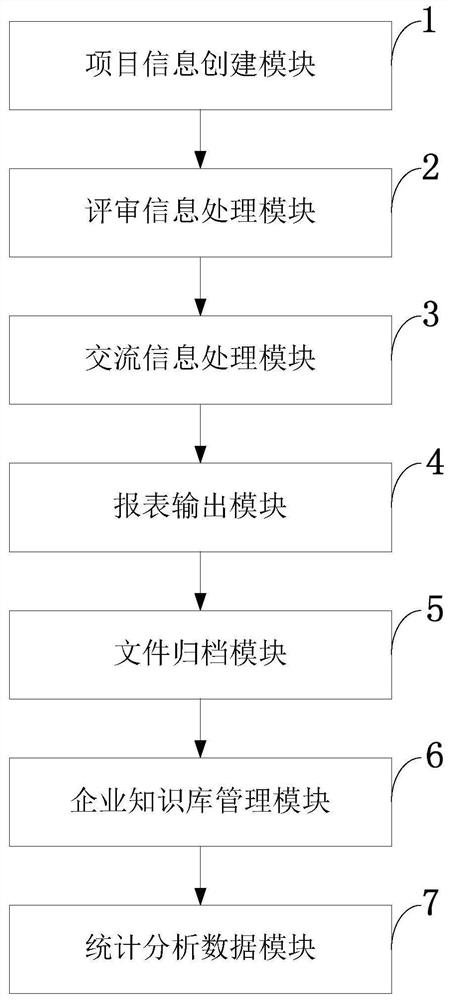

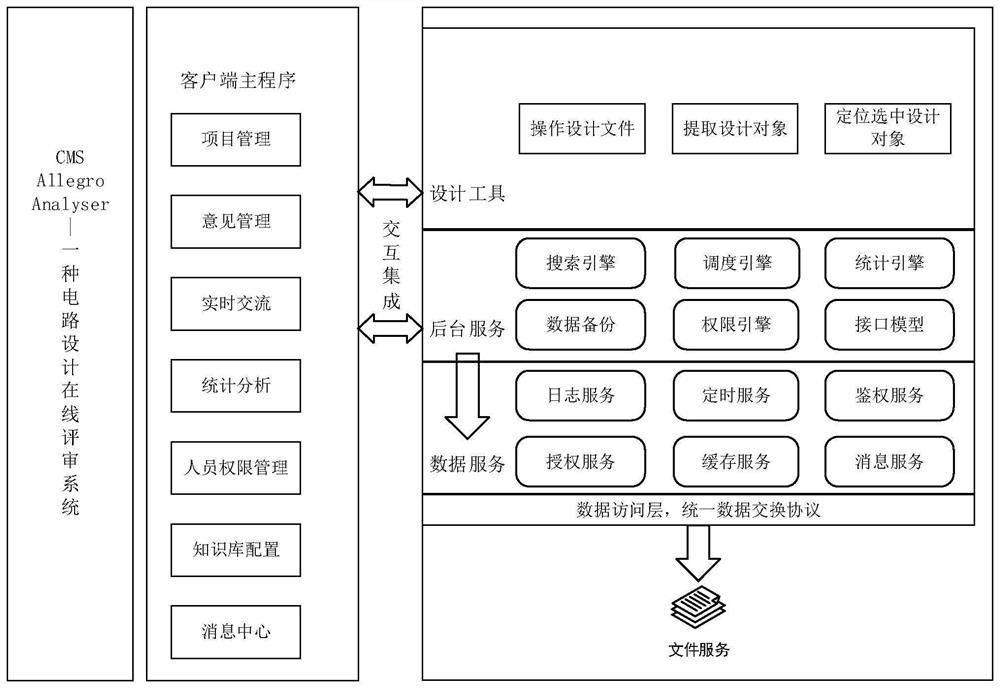

Circuit design online review method and system, medium, equipment, terminal and application

The invention belongs to the technical field of online circuit design review, and discloses a circuit design online review method and system, a medium, equipment, a terminal and an application. The method comprises the steps of starting a login system, creating a review project to fill in project information, and starting a review process; selecting a design object, filling in opinion information,and submitting or storing review opinions; establishing long-acting connection between a client and a server, and pushing communication content; outputting a report, quickly outputting a report filein a specified format and storing the report file locally; archiving the file; carrying out enterprise knowledge base management; and carrying out data statistical analysis. According to the method, design review opinions are rapidly collected and gathered on line and fed back to designers, the design review opinions and design tools are developed and integrated, the review opinions and design data are bound, the designers can position questions through one key, restore question views and modify and reply the review opinions in time, the efficiency of the design review process is greatly improved, resource waste caused by repeated conference holding is avoided, and the design period is accelerated.

Owner:北京迪浩永辉技术有限公司

A multimodal sensor

ActiveCN110068583BAccelerate Design CycleSimple designMaterial analysis using microwave meansMaterial resistanceResonant cavityResistance capacitance

The invention discloses a multi-modal sensor composed of four-port flexible PCB electrodes. The multi-modal sensor comprises an insulated support tube with a measured field inside, and the insulated support tube includes a first cross section and a second cross section which are adjacent to each other along the longitudinal axis of the insulated support tube; a resistance / capacitance tomography sensor arranged at the first cross section, wherein the resistance / capacitance tomography sensor comprises a plurality of four-port flexible PCB electrodes uniformly distributed along the circumferenceof the inner wall of the insulated support tube, and a radial shielding metal shell fixed to the outer wall of the insulated supporting tube, wherein the longitudinal axis of each four-port flexiblePCB electrode is parallel to the longitudinal axis of the insulated support tube; and a resonant cavity sensor arranged at the second cross section. According to the multi-modal sensor provided by theinvention, the four-port electrode design is adopted, a resistance tomography sensor and a capacitance tomography sensor are integrated, and the integration is integrated with a resonant cavity to form the multi-modal sensor, so that the multi-phase flow with different conductivity can be measured.

Owner:BEIHANG UNIV

Device for reducing passive intermodulation of circular waveguide duplexer and method thereof

The invention, which relates to the field of microwave wireless communication, discloses a device for reducing the passive intermodulation of a circular waveguide duplexer and a method thereof. According to the invention, metal-air-metal contact is realized by using a dielectric flange and metal-non-conductive-dielectric-metal contact is realized by using a dielectric sheet, so that passive intermodulation of microwave parts is suppressed. The device comprises a non-conductive dielectric flange, metal screws required by fixing the non-conductive dielectric flange, a non-conductive dielectric sheet, a non-conductive dielectric sleeve, and non-conductive dielectric screws. The device has advantages of simple structure, light weight, high design cost rate and short design period. The device and the method thereof can be applied to the fields of aerospace and ground communication widely.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

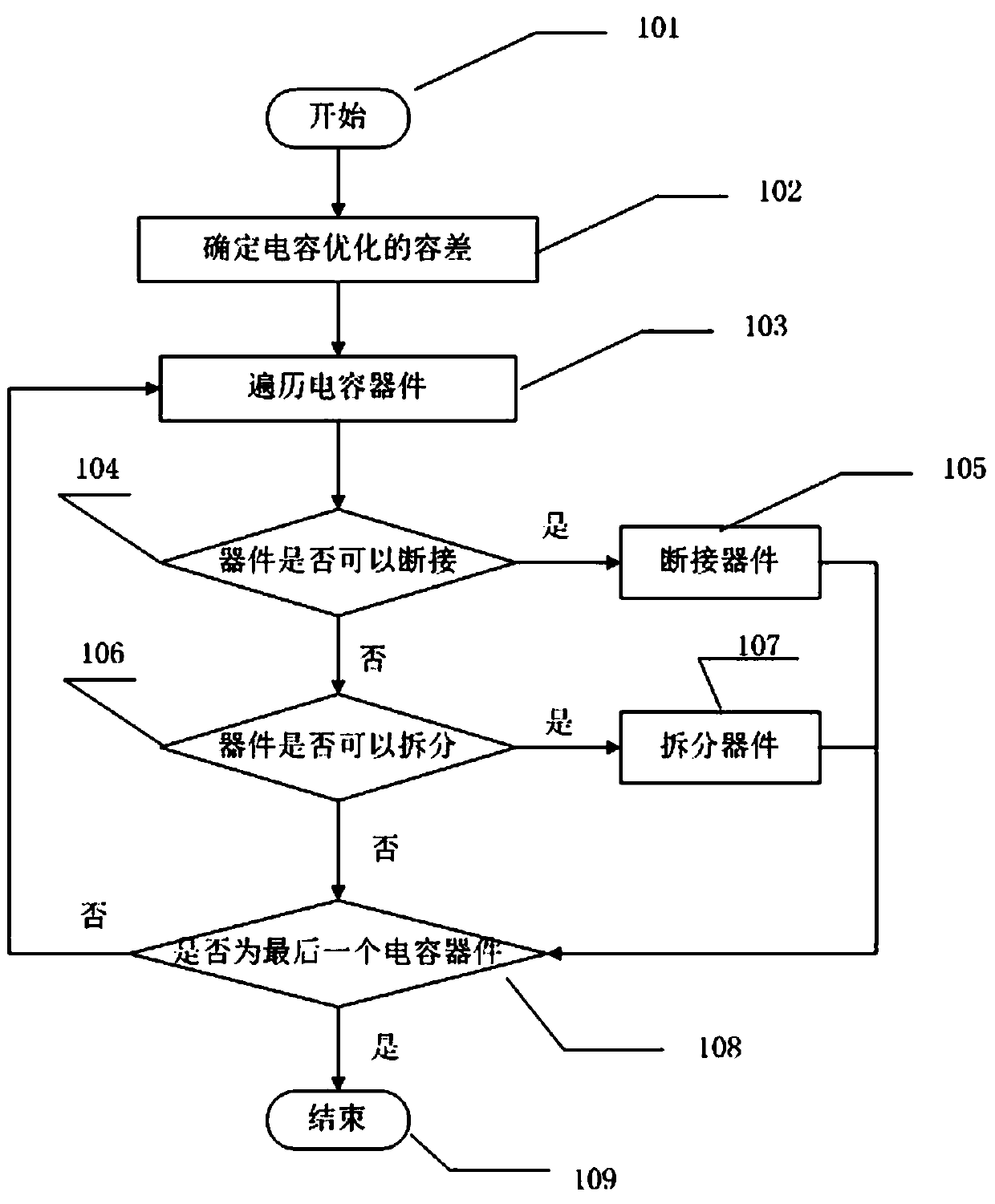

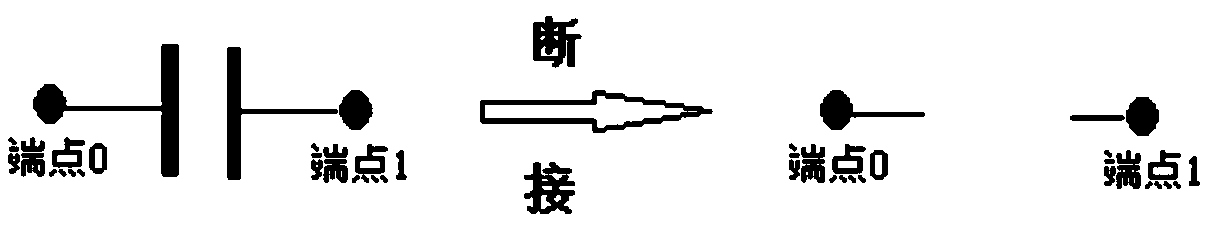

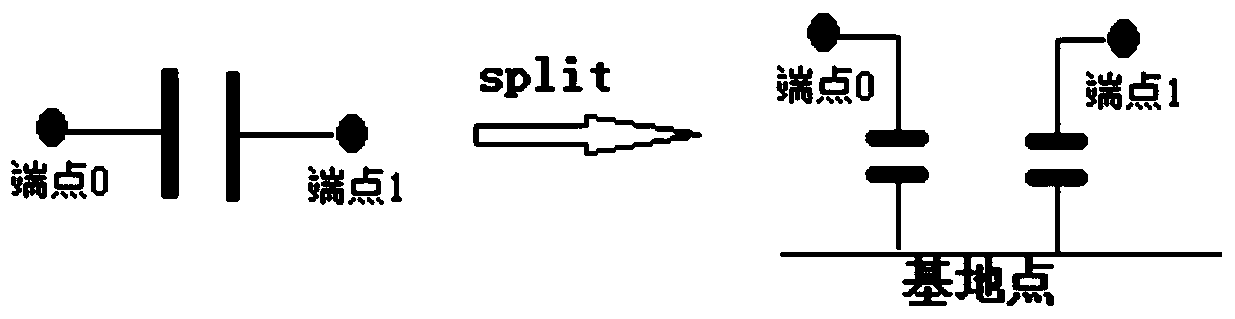

A Method for Reducing Computational Complexity of Equations in Integrated Circuit Design

ActiveCN107977533BReduce dimensionalityReduce the numberCAD circuit designComplex mathematical operationsCapacitanceComputation complexity

The invention discloses a method of reducing calculation complexity of equations in integrated-circuit design. The method is characterized by including the following steps: 1) determining tolerance ofcapacitance optimization; 2) traversing all capacitance devices; and 3) carrying our disconnection or a split on each traversed capacitance device according to the tolerance of capacitance optimization. According to the method of reducing the calculation complexity of the equations in integrated-circuit design of the invention, dimensionality of the equations can be reduced, the number of non-zero elements in a sparse matrix can also be decreased, coupling among rows in the equations can be reduced at the same time, thus the calculation complexity of the equations is reduced, and an overall design cycle of an electronic circuit is improved.

Owner:SHENZHEN HUADA EMPYREAN TECH CO LTD

A method of equivalent output after post-simulation circuit optimization

ActiveCN109376471BAchieve friendlyIntegrity guaranteedDesign optimisation/simulationCAD circuit designSimulationHemt circuits

Owner:SHENZHEN HUADA EMPYREAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com