A method and apparatus for designing the wall thickness of a tower of a wind turbine generator system

A technology for a wind turbine and a design method, which is applied in the directions of calculation, electrical digital data processing, special data processing applications, etc., can solve the problem of high cost of towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

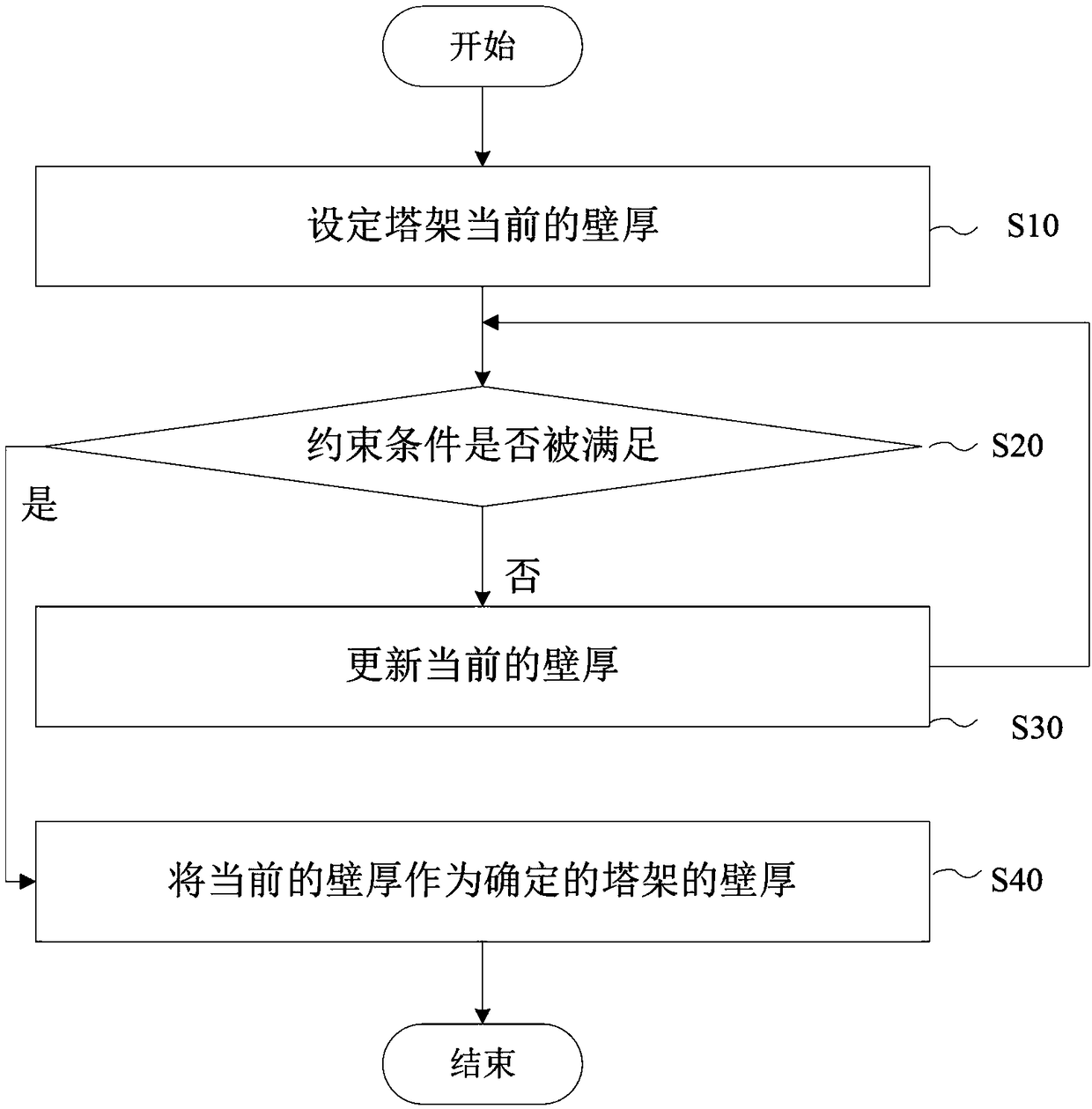

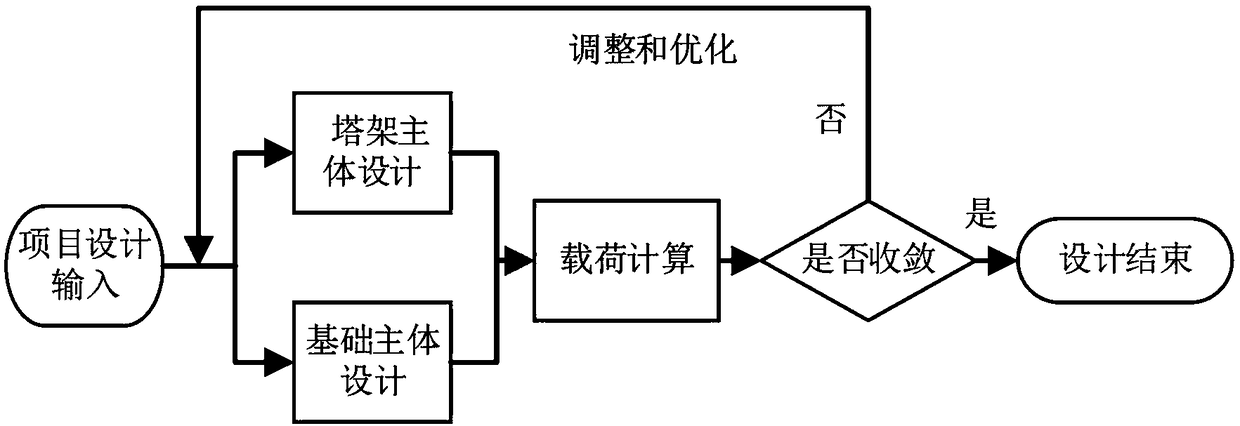

[0052] The following will combine figure 1 An example of the design method of the wall thickness of the tower of the wind power generating set according to the embodiment of the present invention will be described. As an example, the determination of the wall thickness of the tower can be carried out after the height of the tower, the section conditions and the height of the weld seam have been determined.

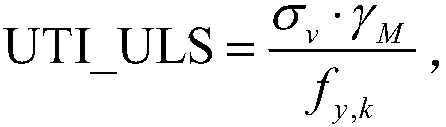

[0053] As an example, the determination of the wall thickness of each section of the tower can be done separately. For each section of the tower, an optimization algorithm is used to determine the wall thickness of each section of the tower, wherein the optimization goal of the optimization algorithm is to minimize the quality of each section of the tower, and the constraint condition of the optimization algorithm is that each section of the tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com