Patents

Literature

45 results about "Virtual prototyping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

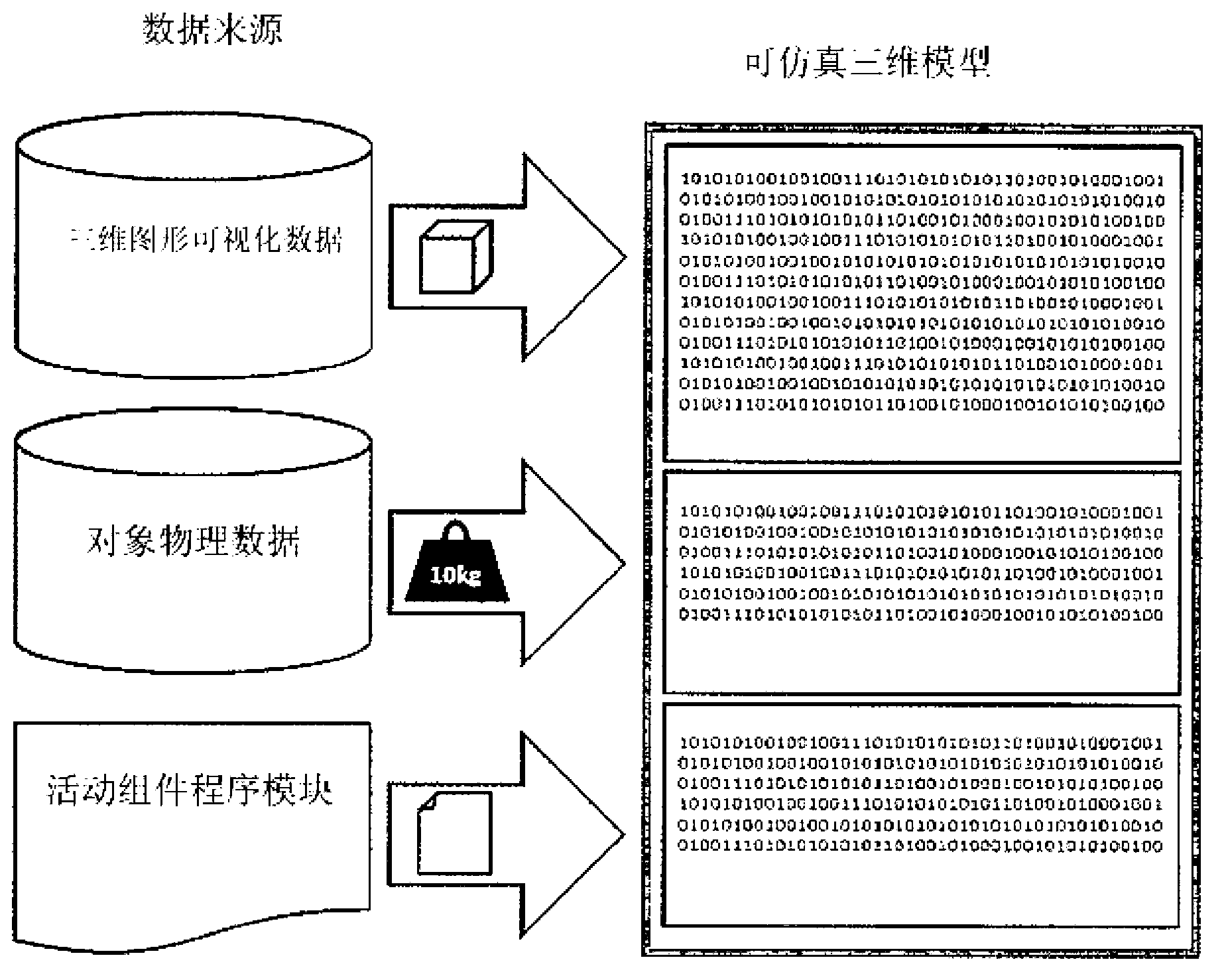

Virtual prototyping is a method in the process of product development. It involves using computer-aided design (CAD), computer-automated design (CAutoD) and computer-aided engineering (CAE) software to validate a design before committing to making a physical prototype. This is done by creating (usually 3D) computer generated geometrical shapes (parts) and either combining them into an "assembly" and testing different mechanical motions, fit and function. The assembly or individual parts could be opened in CAE software to simulate the behavior of the product in the real world.

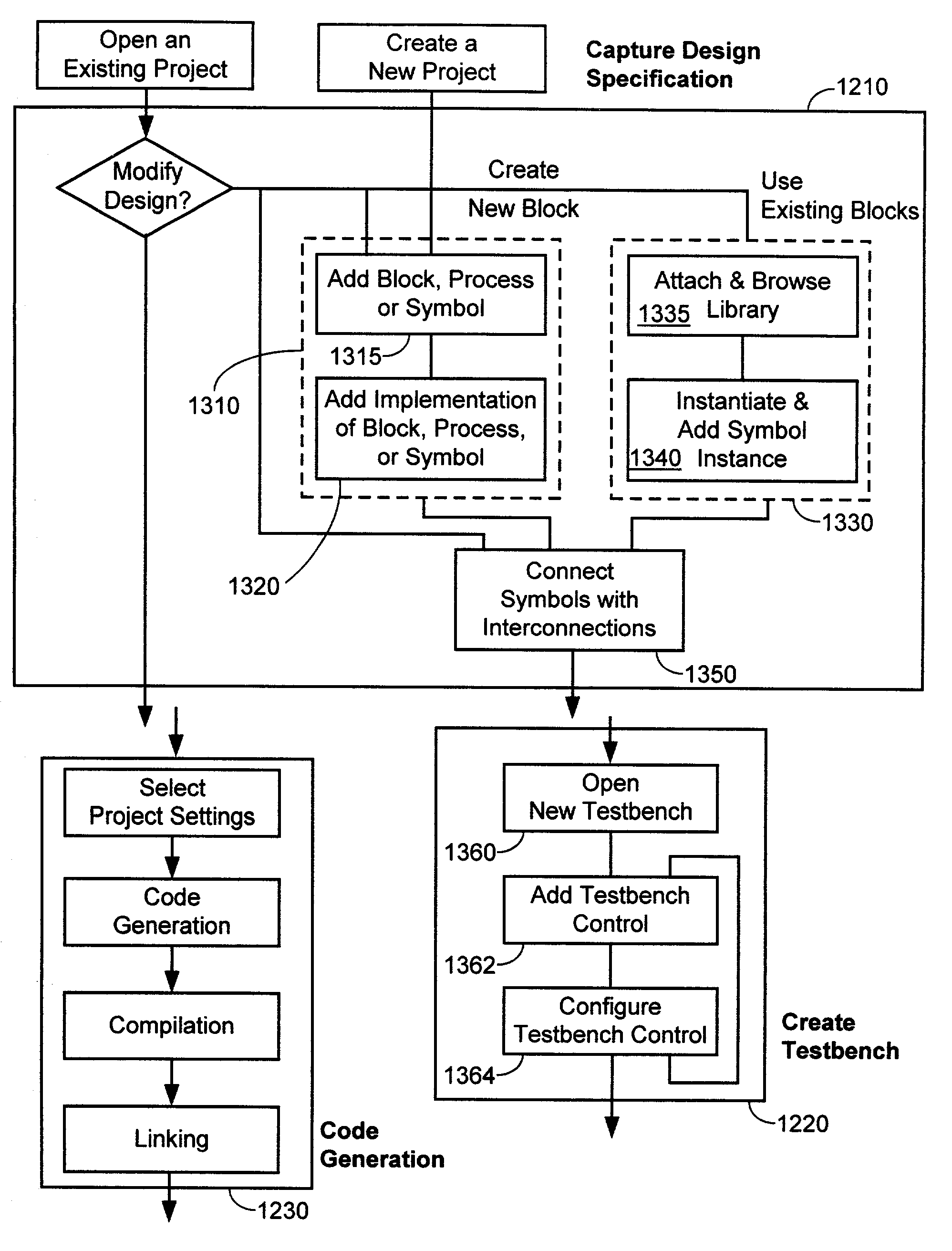

Method and system for virtual prototyping

ActiveUS7613599B2Reduce simulation overheadFast executionElectronic circuit testingError detection/correctionHuman–machine interfaceComputer architecture

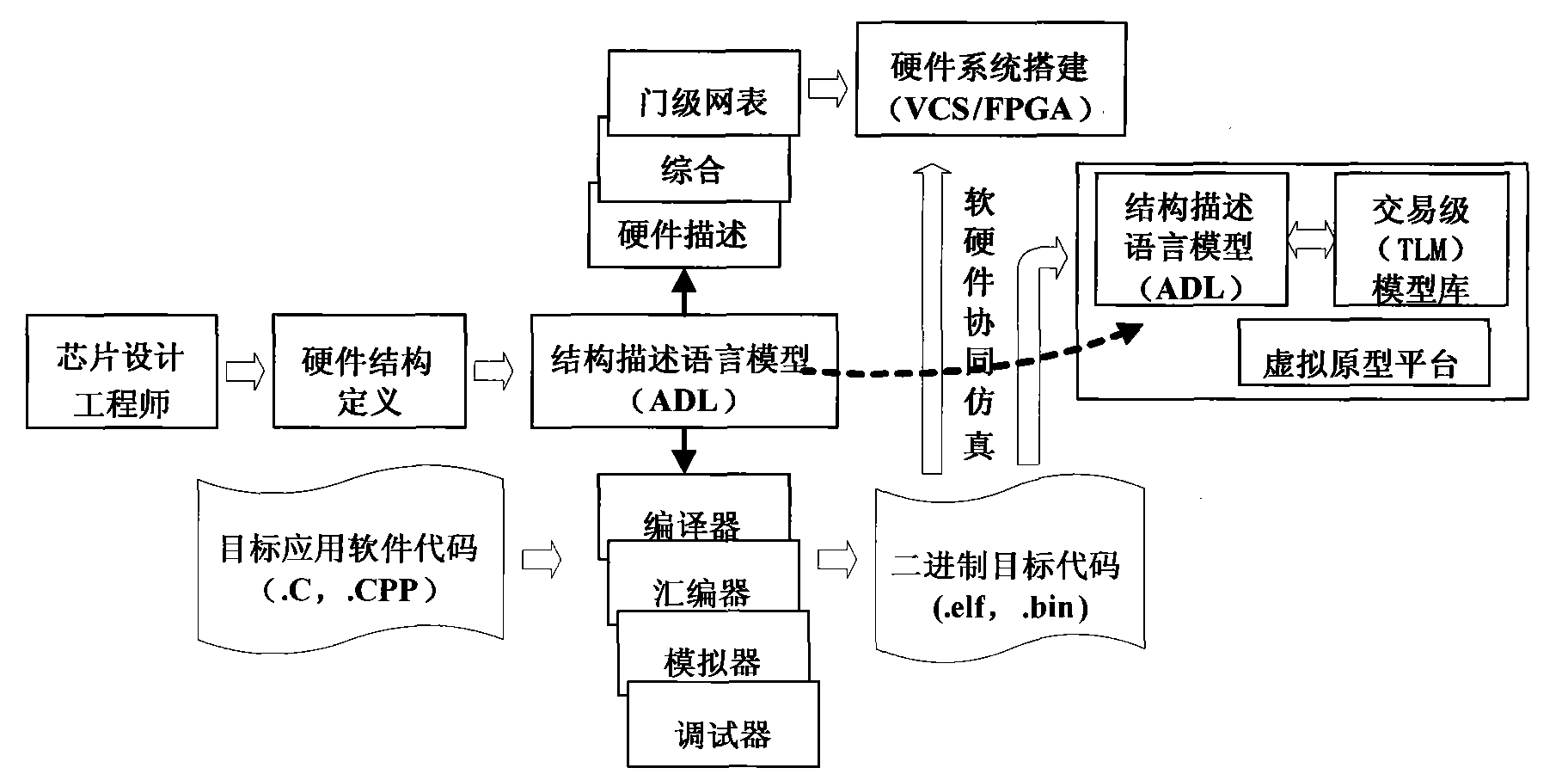

An integrated design environment (IDE) is disclosed for forming virtual embedded systems. The IDE includes a design language for forming finite state machine models of hardware components that are coupled to simulators of processor cores, preferably instruction set accurate simulators. A software debugger interface permits a software application to be loaded and executed on the virtual embedded system. A virtual test bench may be coupled to the simulation to serve as a human-machine interface. In one embodiment, the IDE is provided as a web-based service for the evaluation, development and procurement phases of an embedded system project. IP components, such as processor cores, may be evaluated using a virtual embedded system. In one embodiment, a virtual embedded system is used as an executable specification for the procurement of a good or service related to an embedded system.

Owner:SYNOPSYS INC

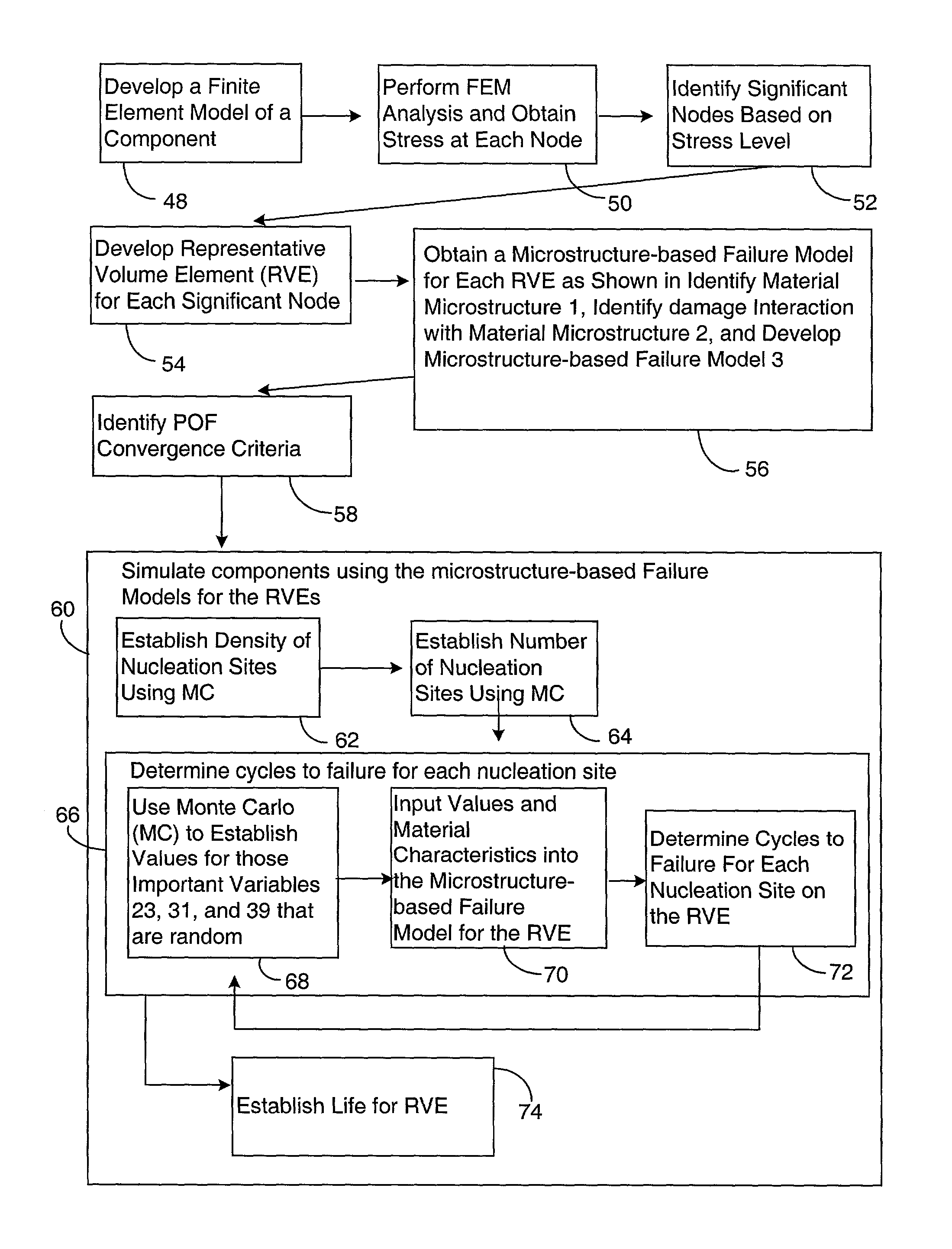

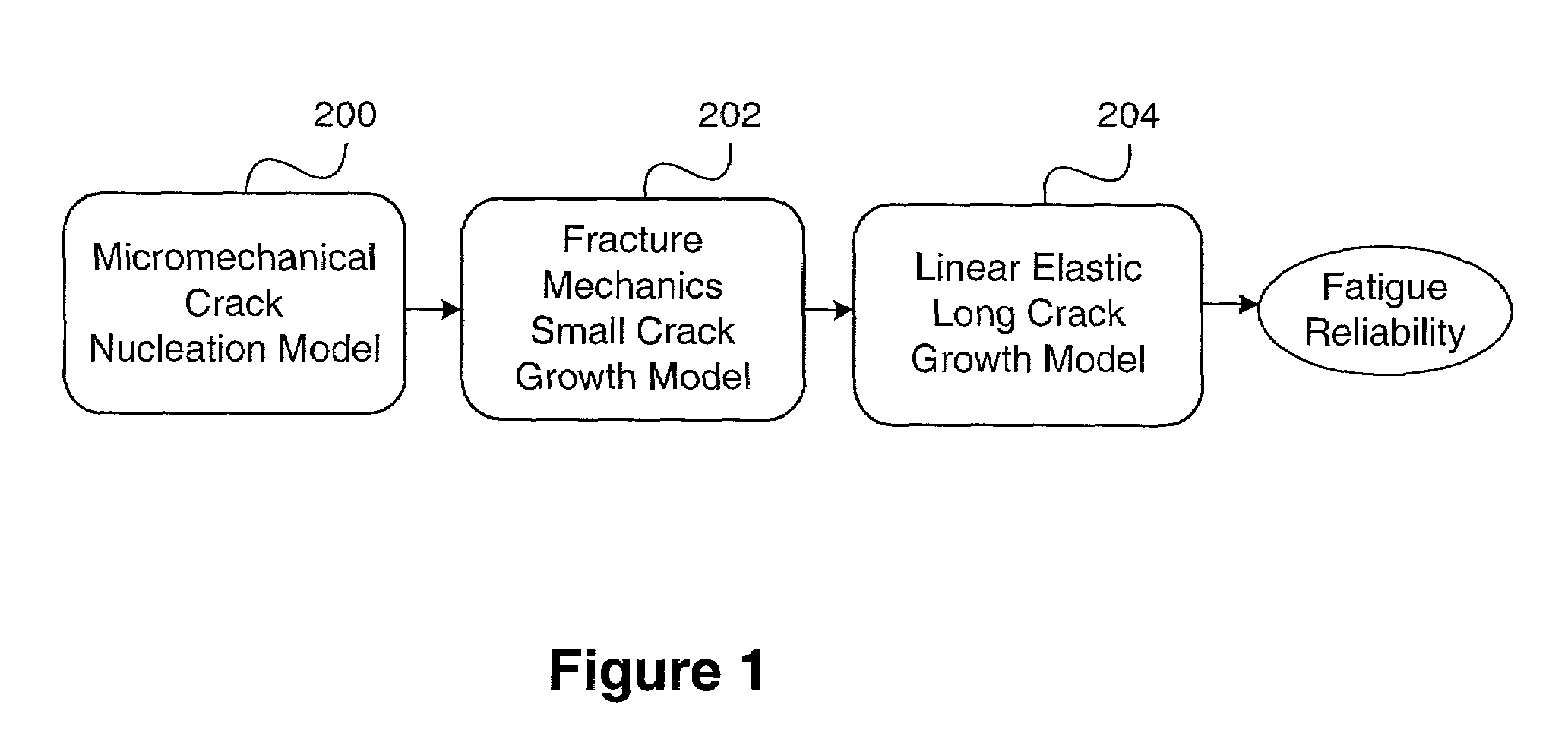

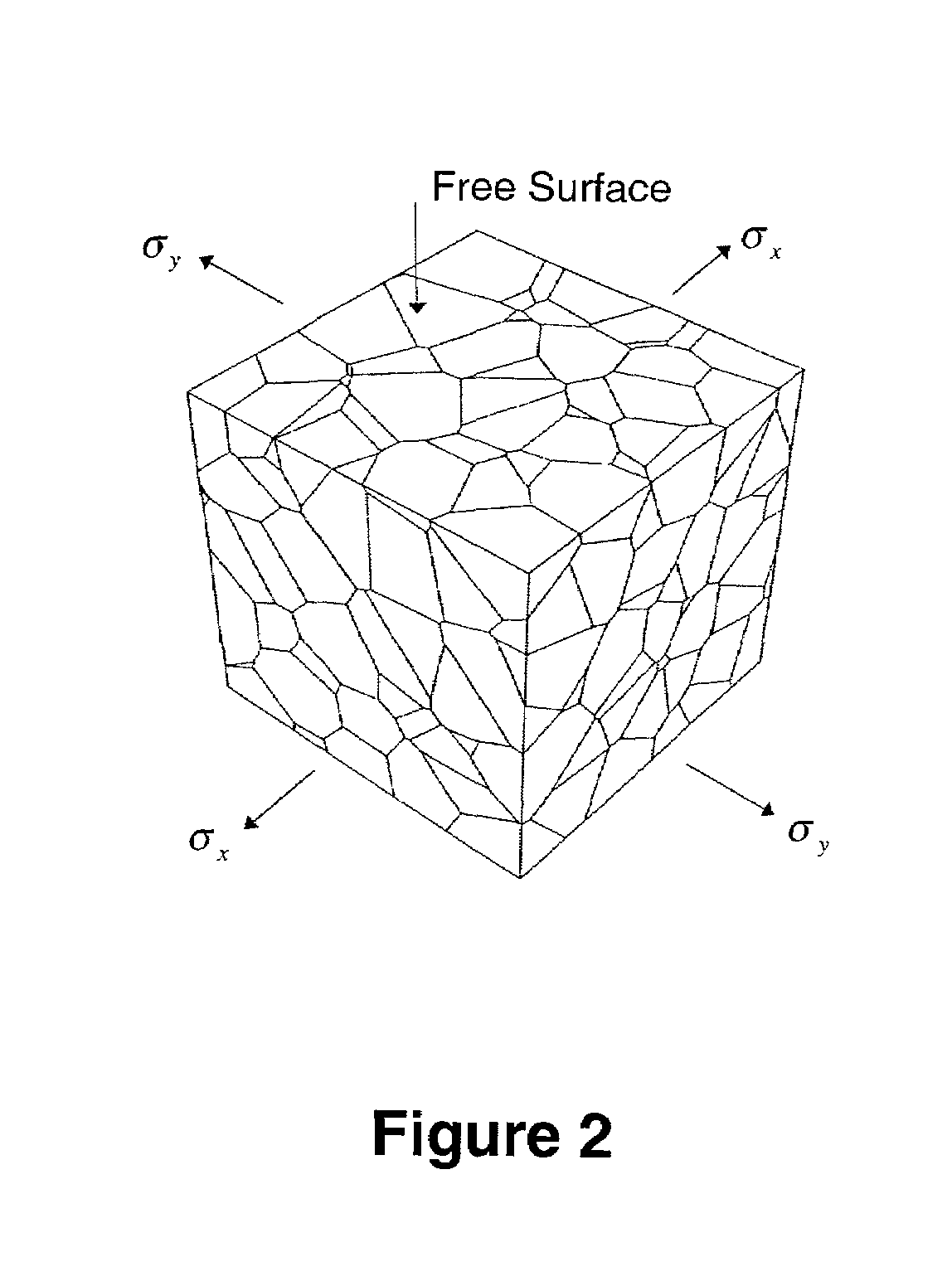

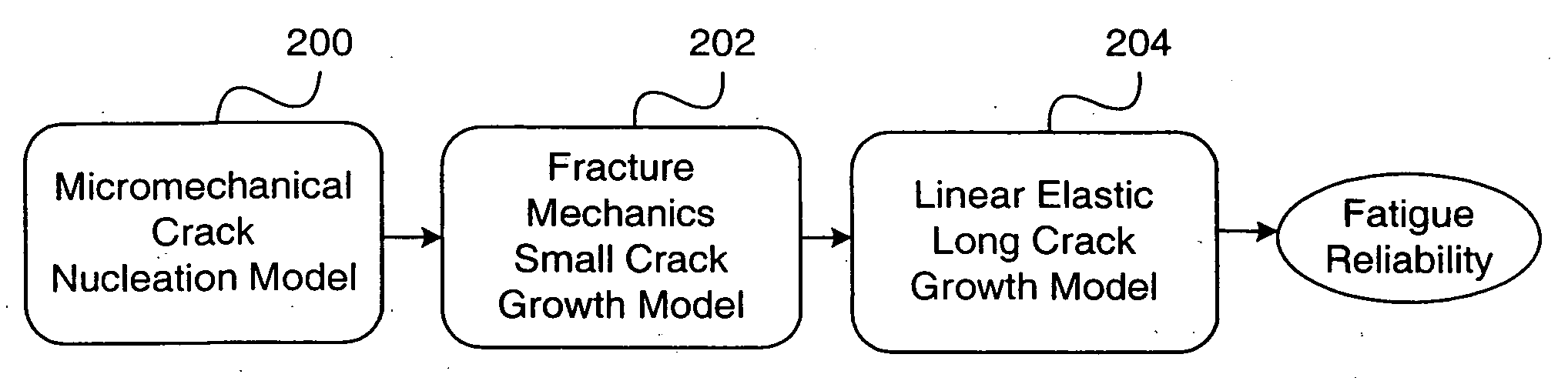

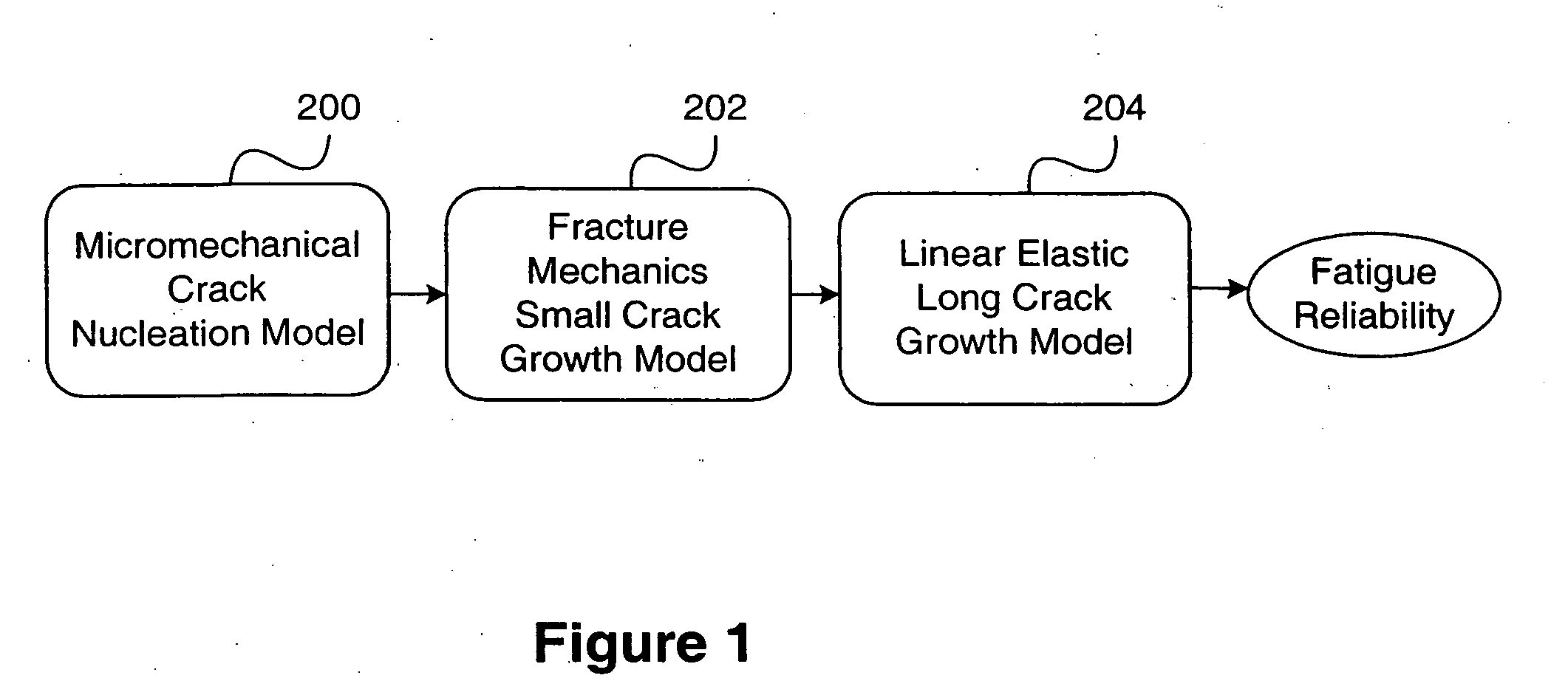

Method and apparatus for predicting the failure of a component

ActiveUS7016825B1Plug gaugesComputation using non-contact making devicesProbit modelComputer science

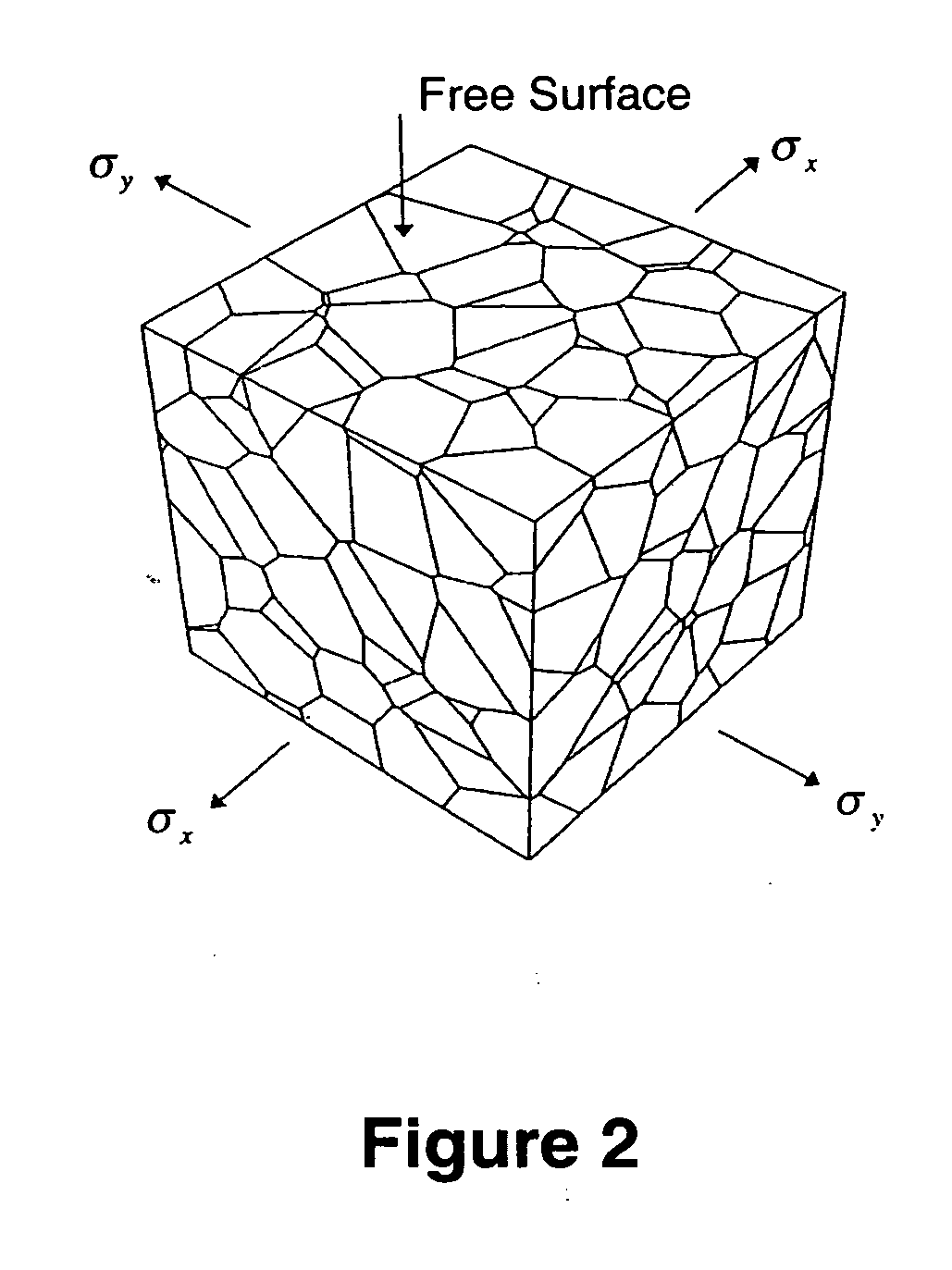

The invention provides a method and apparatus for predicting the failure of a component using a probabilistic model of a material's microstructural-based response to fatigue. The method predicts the component failure by a computer simulation of multiple incarnations of real material behavior, or virtual prototyping. The virtual prototyping simulates the effects of characteristics that include grain size, grain orientation, micro-applied stress and micro-yield strength that are difficult to simulate with real specimens. The invention provides an apparatus for predicting the response of a component to fatigue using the method.

Owner:VEXTEC CORP

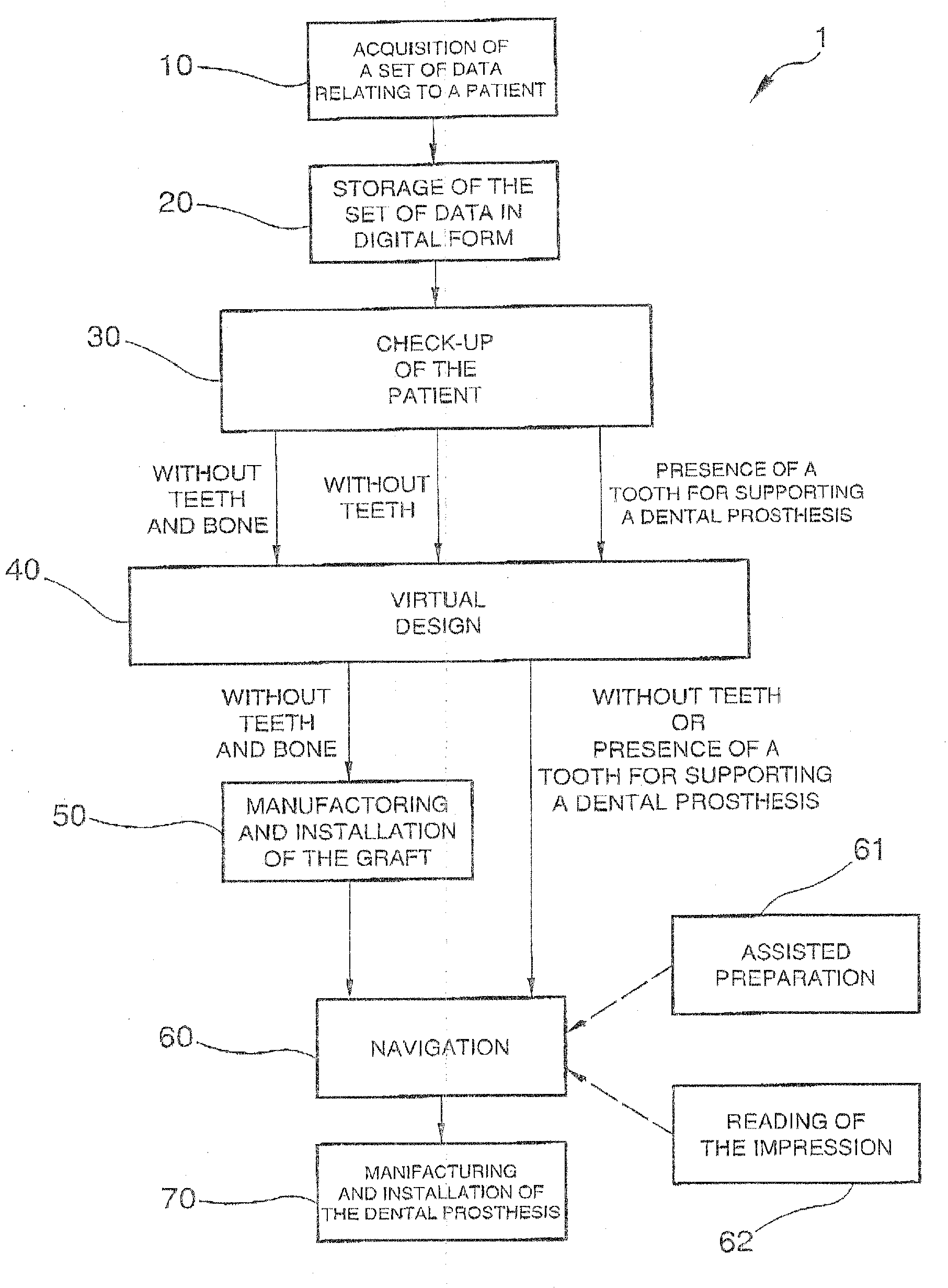

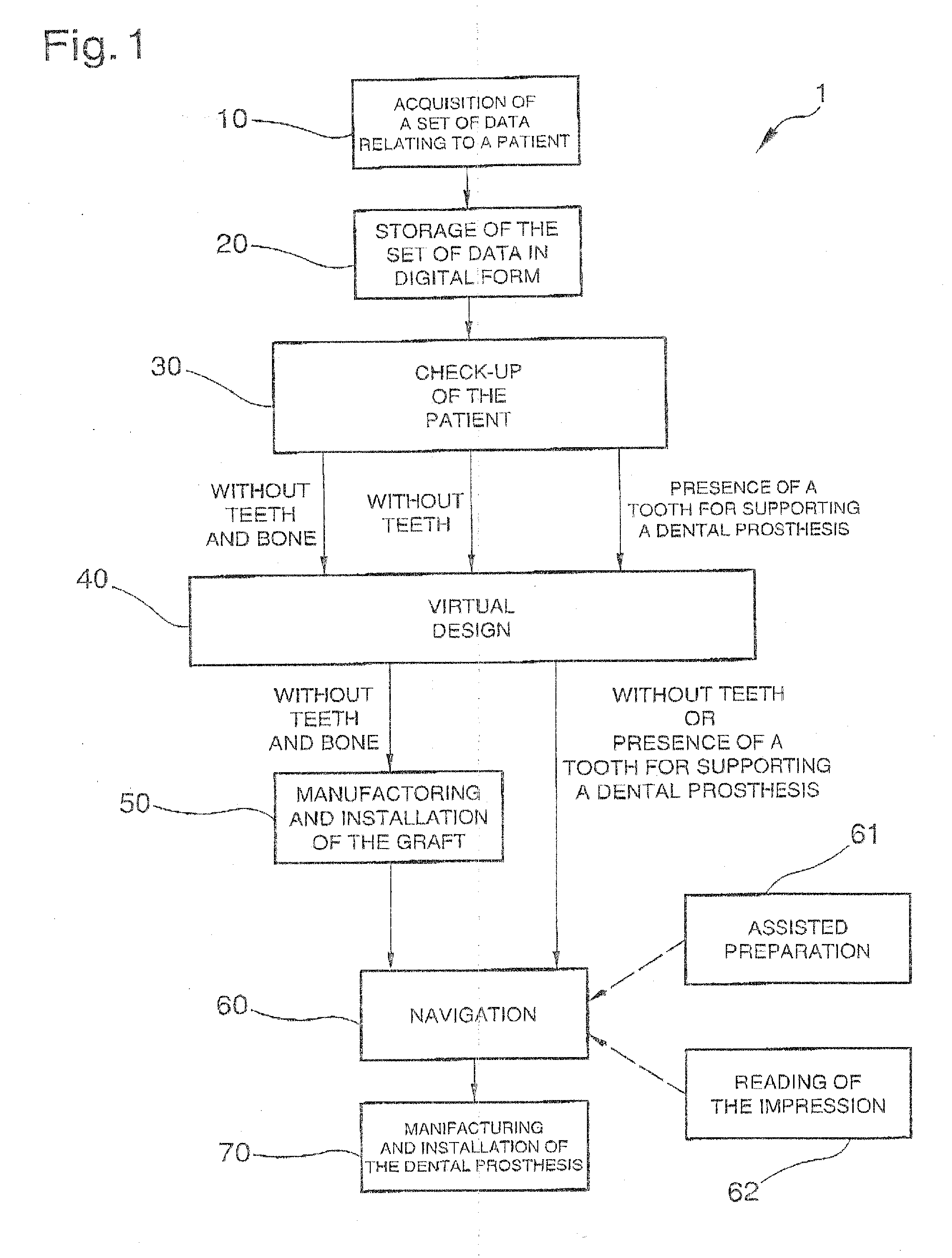

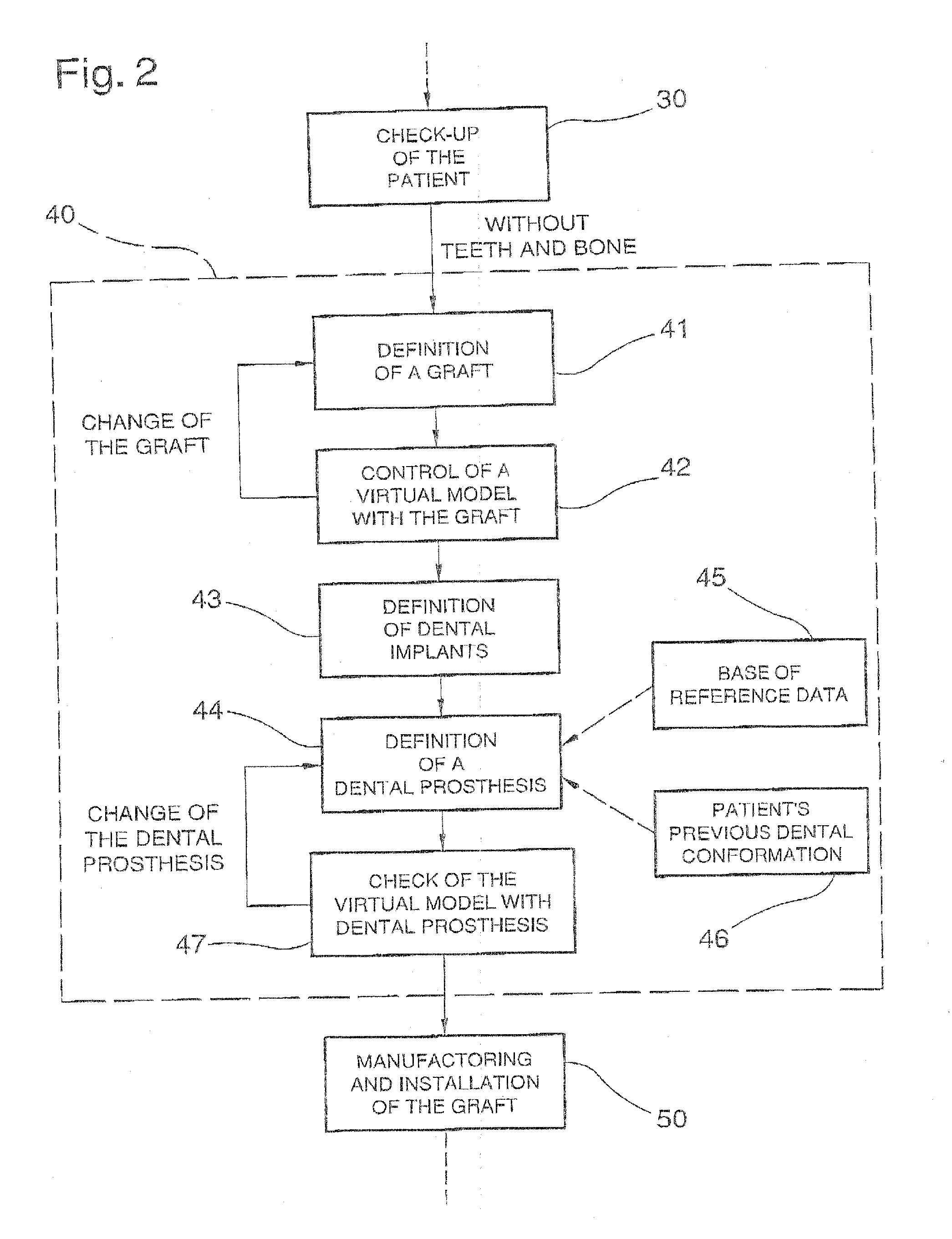

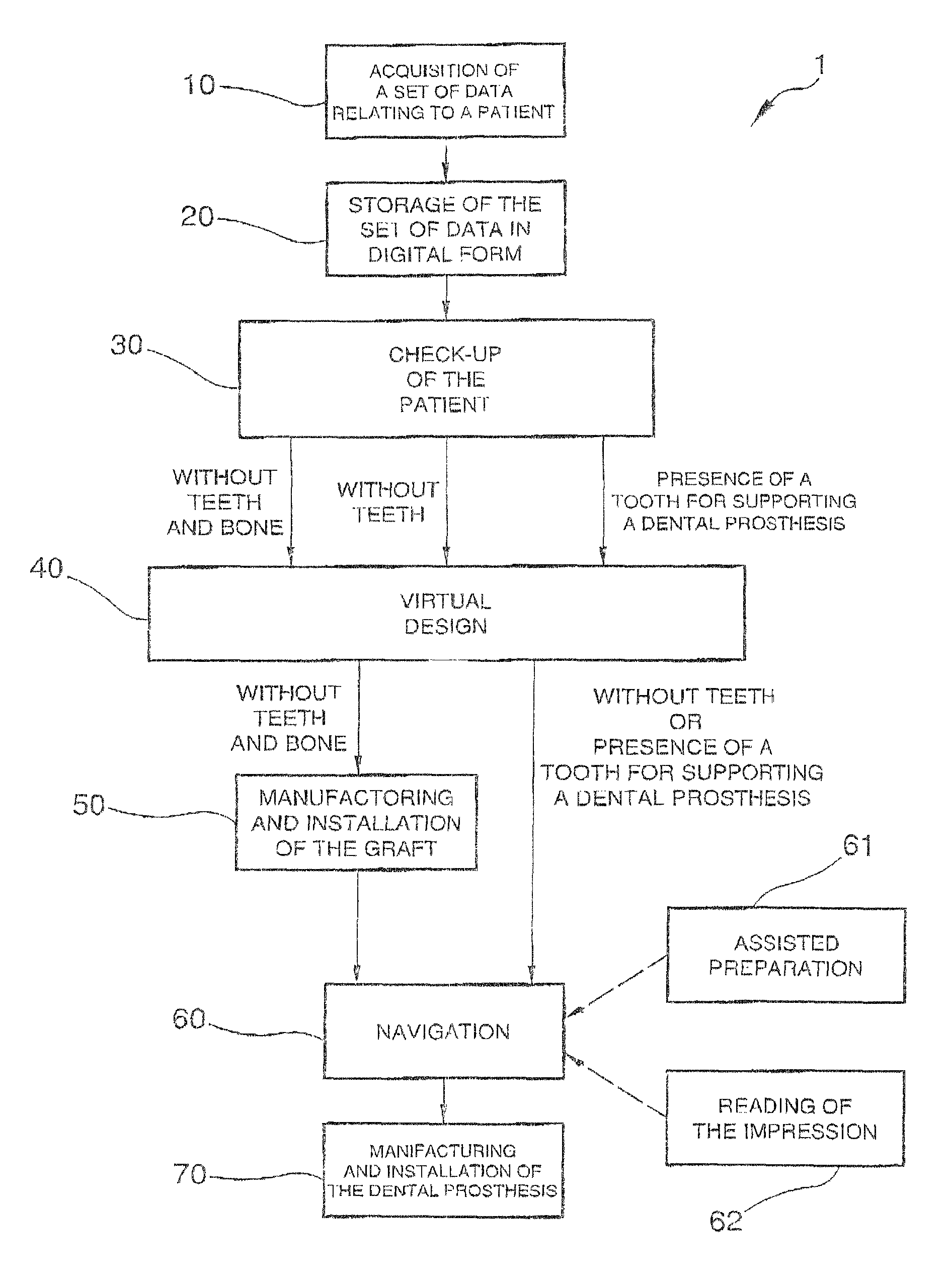

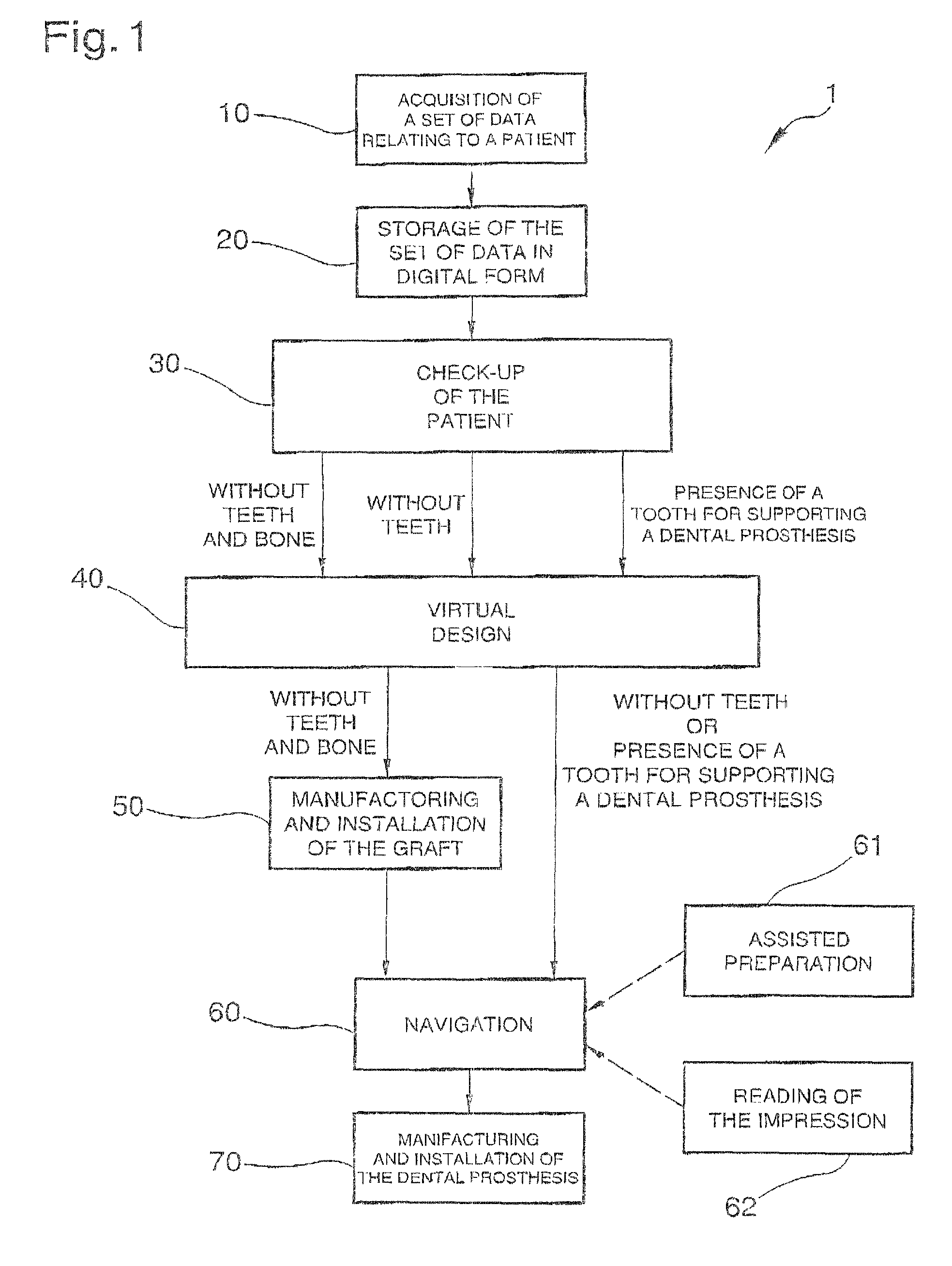

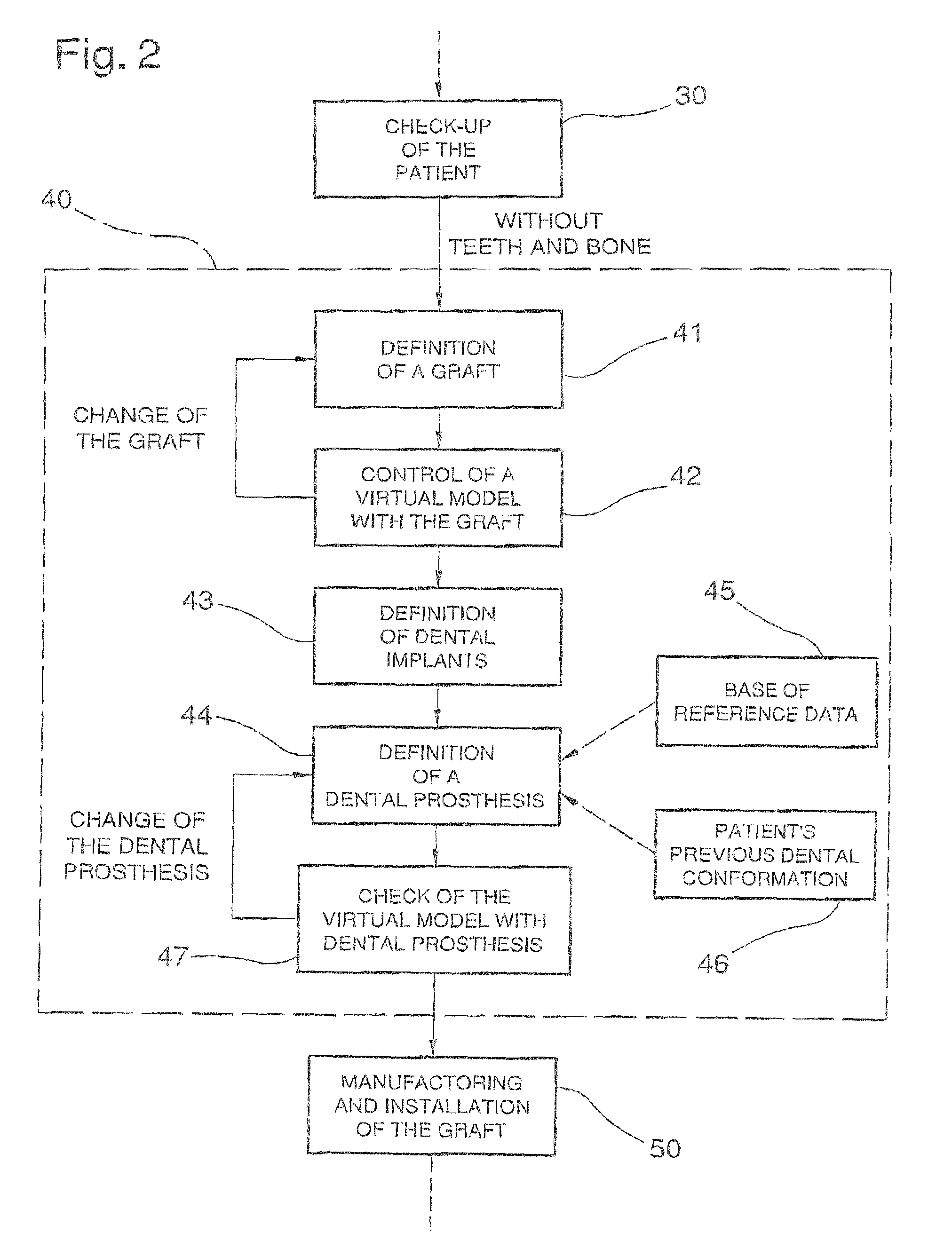

Method for planning and performing dental treatments

InactiveUS20080153061A1Precise preparationEffective and easy to useDental implantsImpression capsData setDesign phase

Method for planning and performing dental treatments comprising: an acquisition phase of a set of data relating to the position, to the conformation and to the dimension of at least one site inside the oral cavity of a patient who has to undergo a dental treatment and relating to the conformation of at least one portion of the patient's face; a design phase of a virtual prototype of at least one dental prosthesis that can be fitted at the site during the treatment, starting from the set of data and by means of a software program implemented on a computer; a determination phase, by means of the software program and starting from the set of data and from the virtual prototype of the dental prosthesis, of at least one virtual model suitable for visually reproducing the portion of the face following the fitting of the dental prosthesis; a preparation phase of the site by means of a dental instrument, with the assistance of the software and starting from the virtual prototype of the dental prosthesis and from the virtual model, before the installation and the manufacture of said dental prosthesis.

Owner:MARCELLO MARCHESI

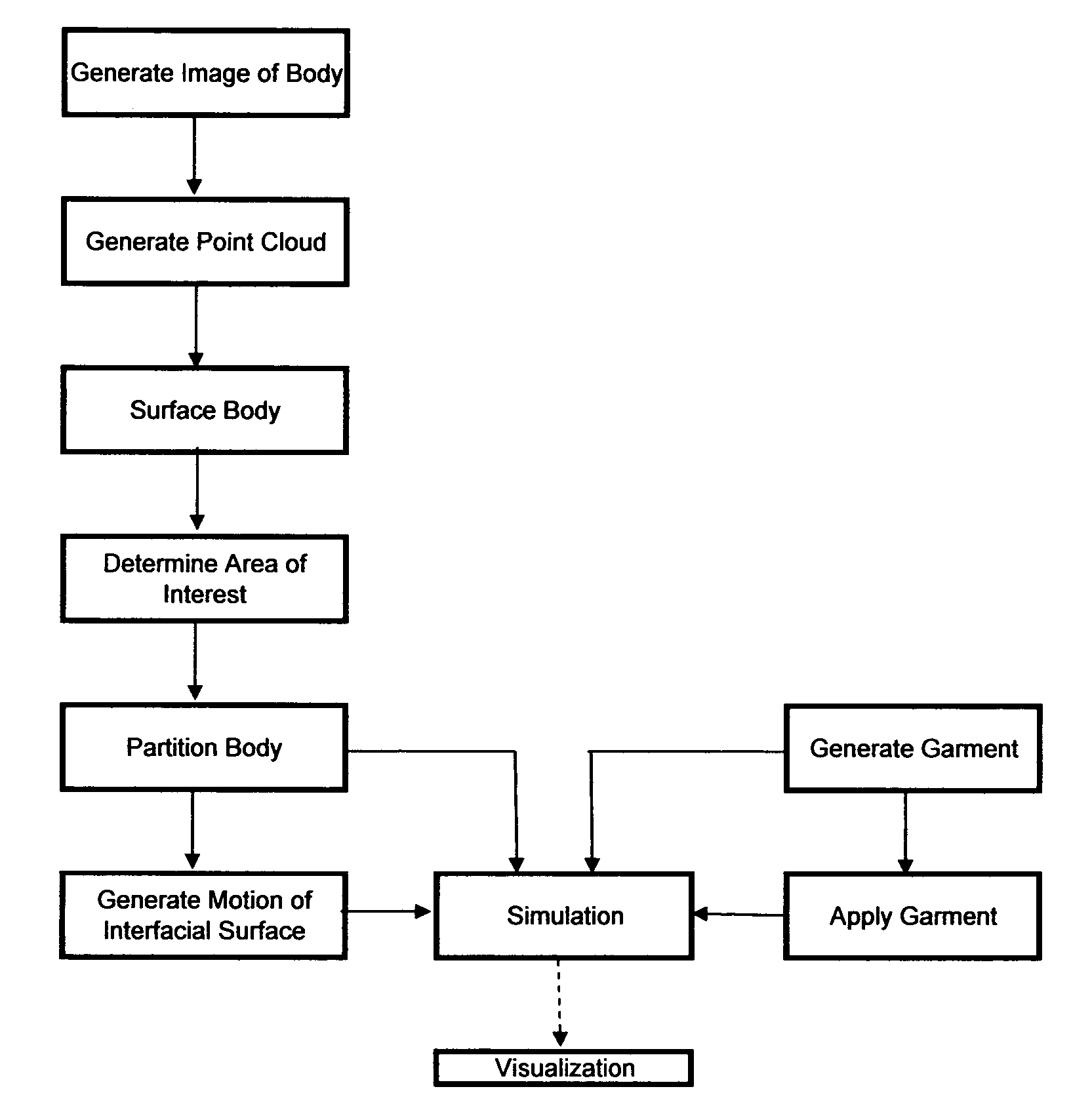

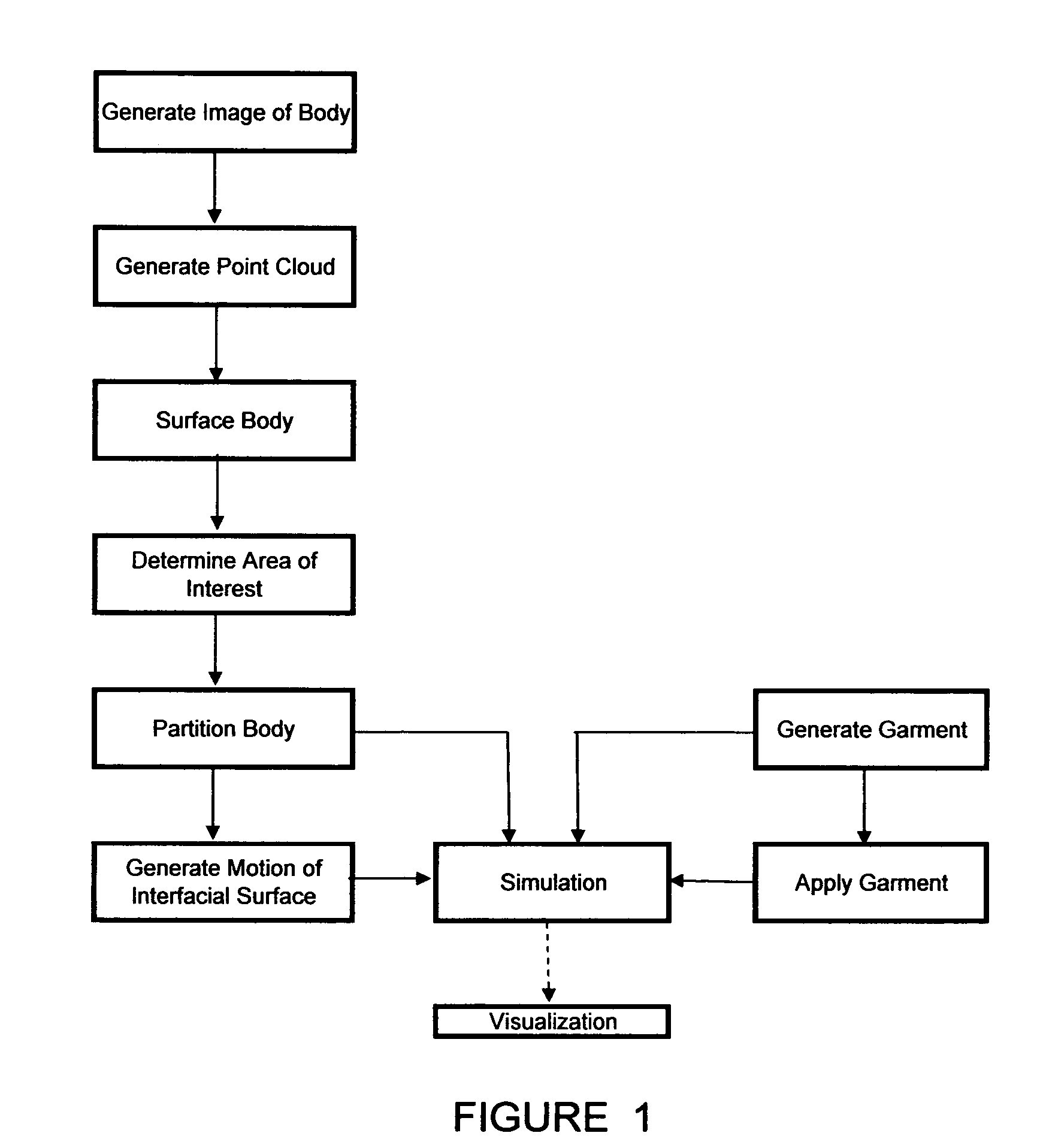

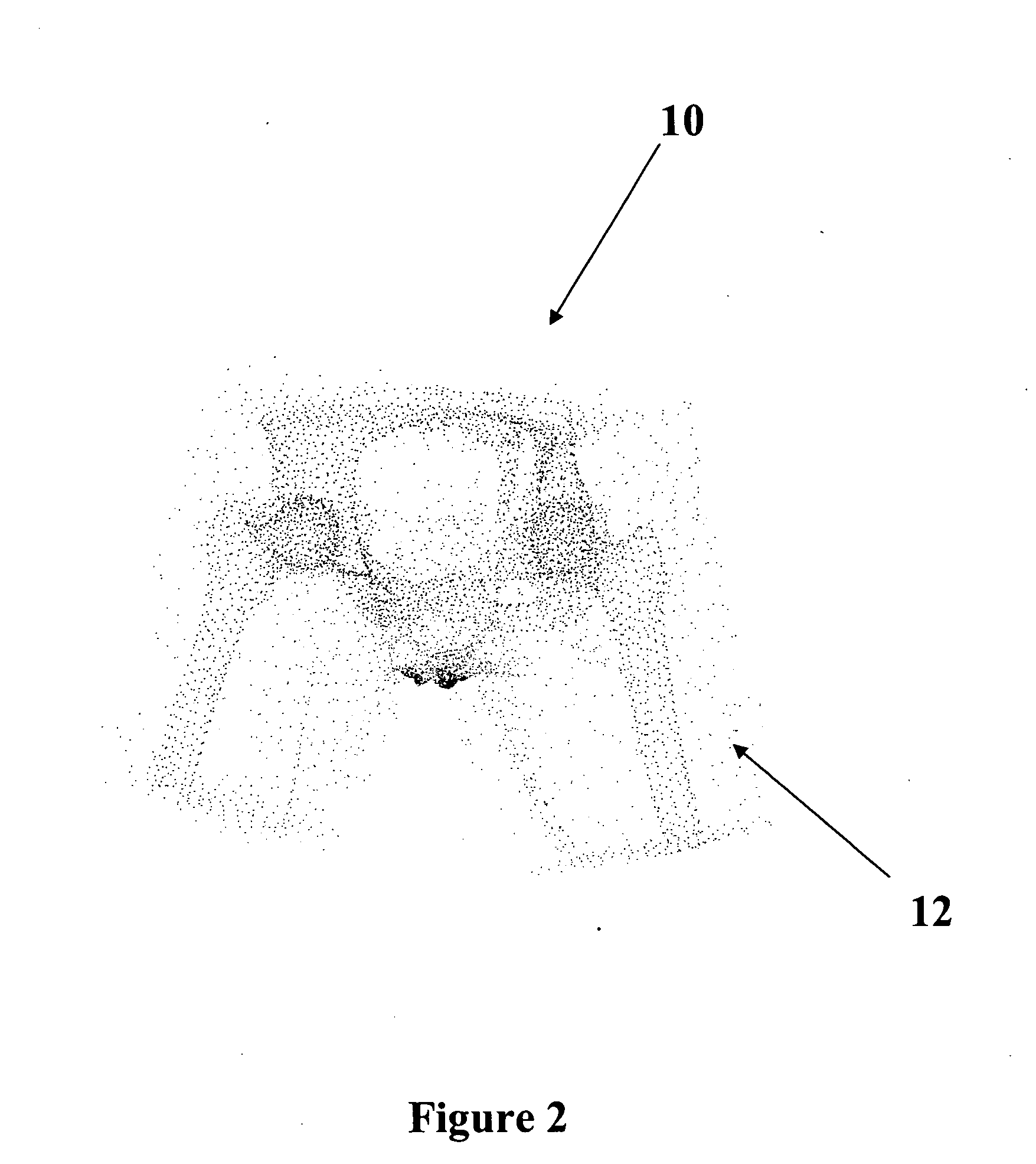

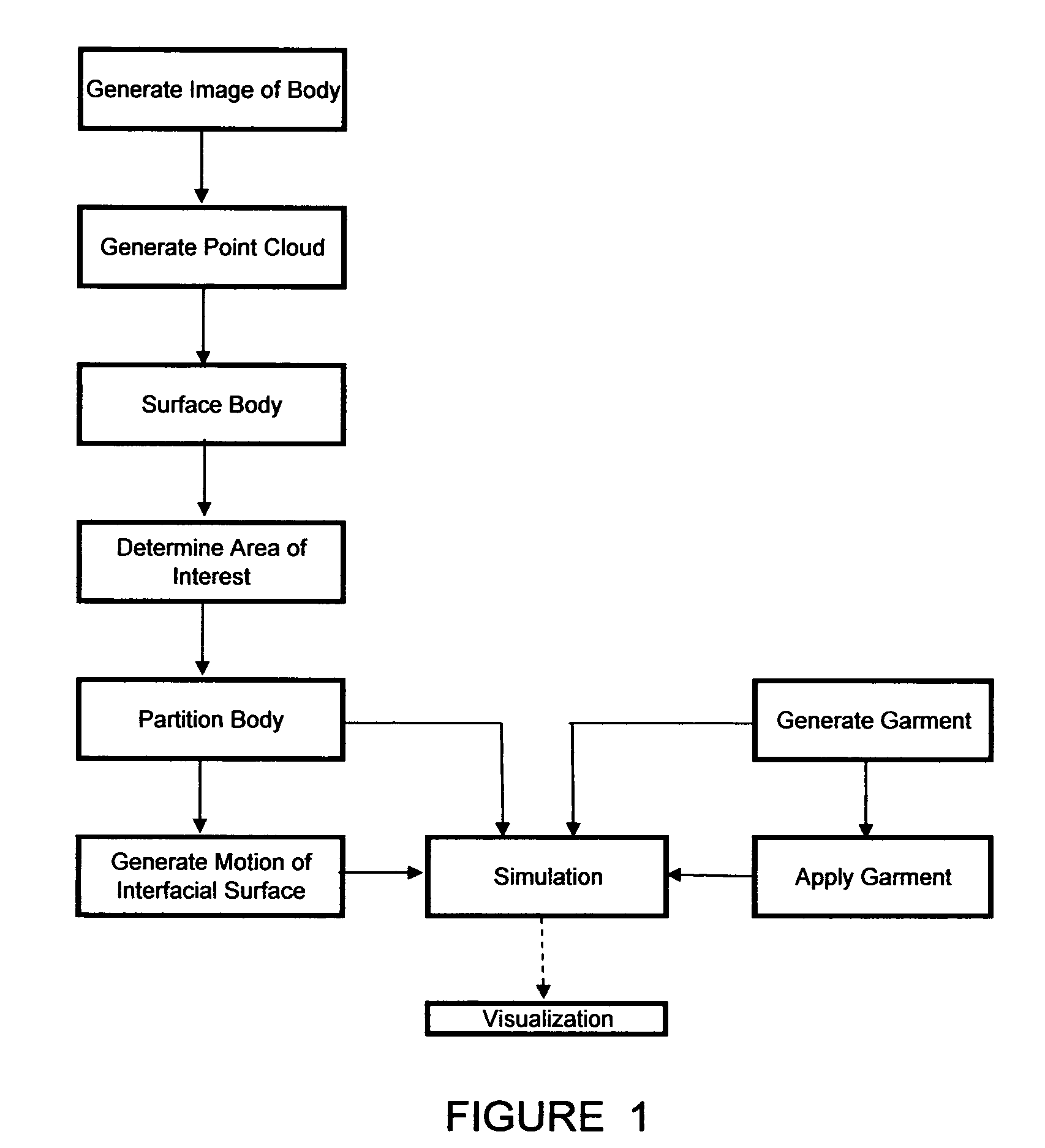

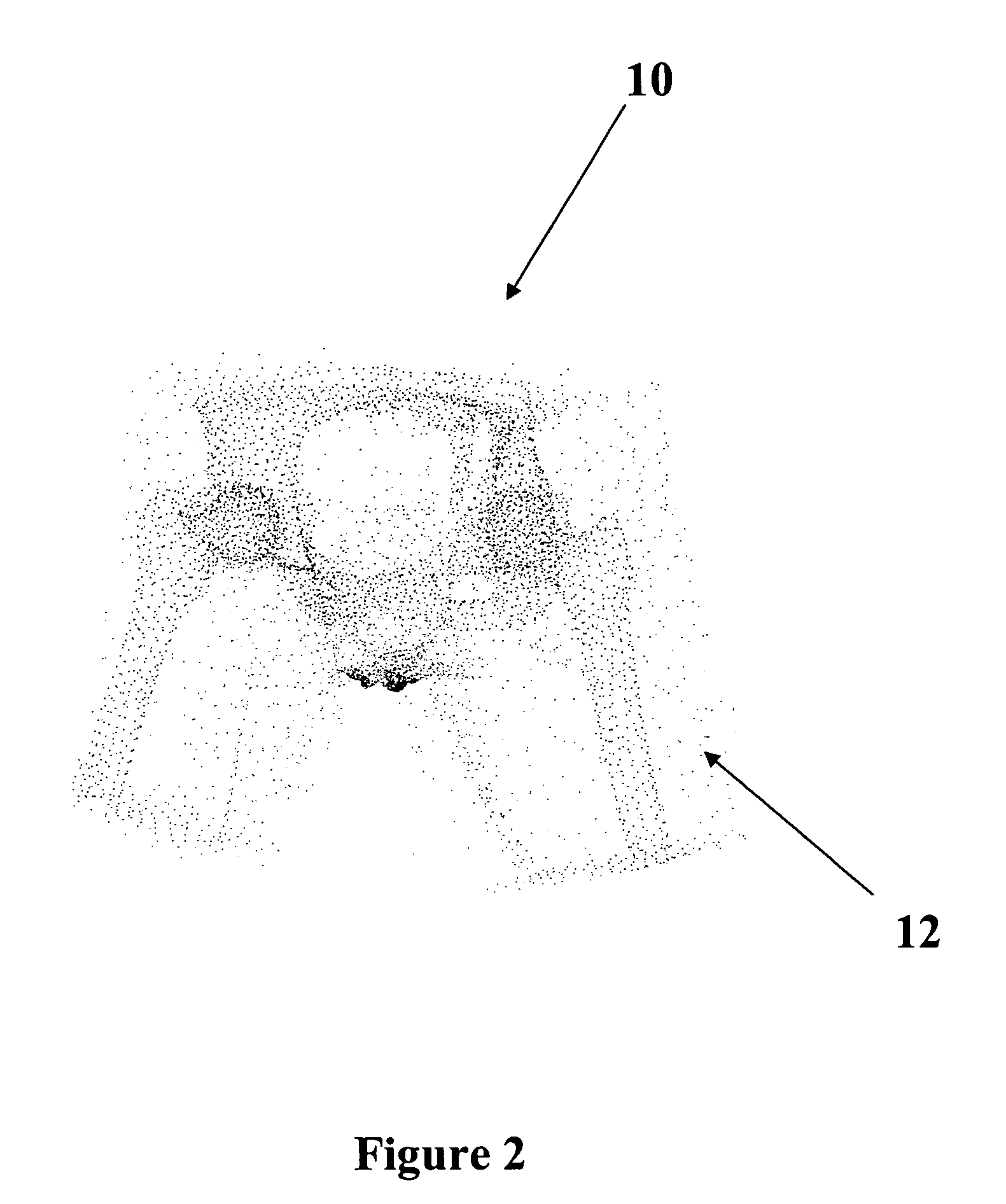

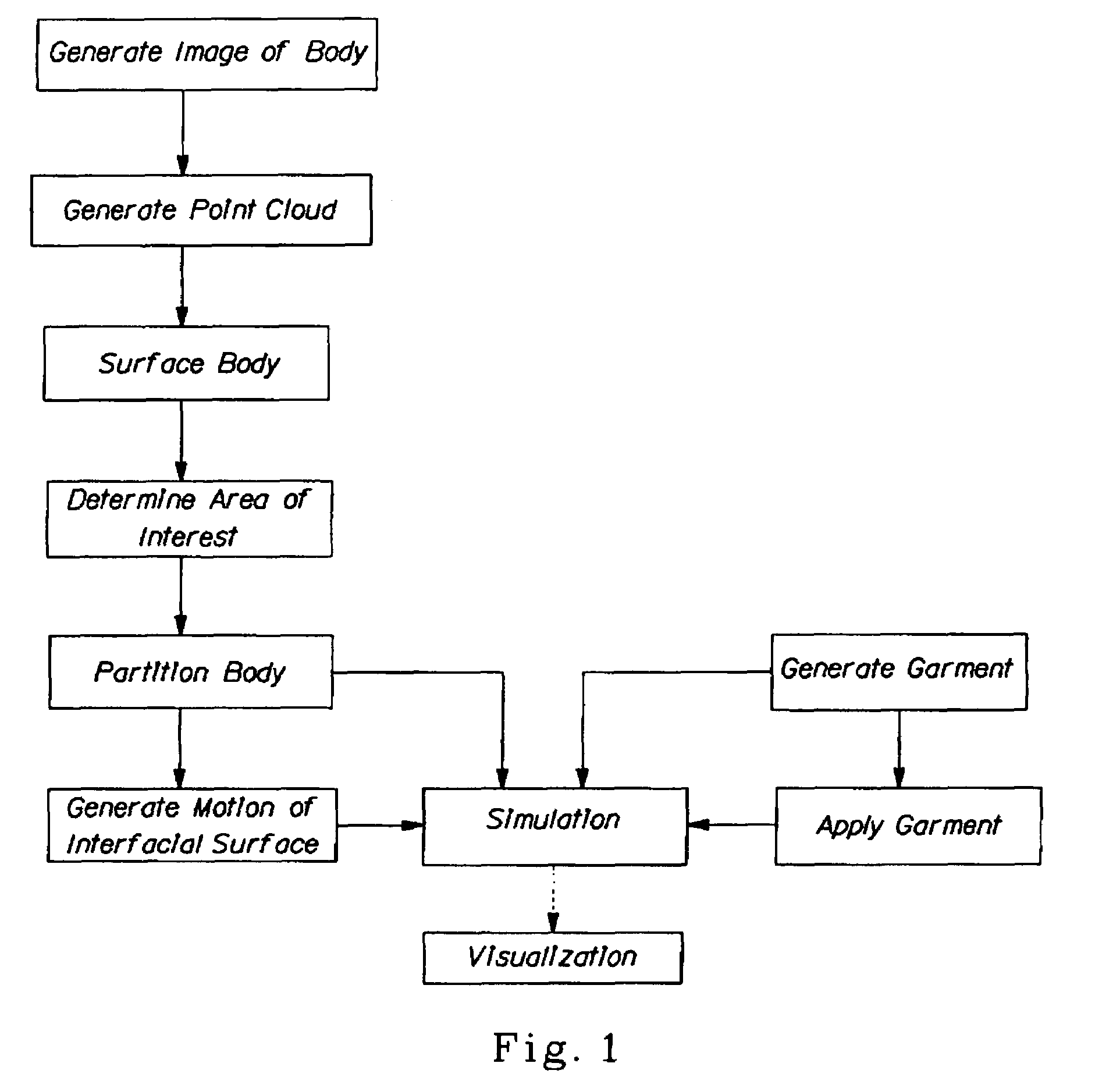

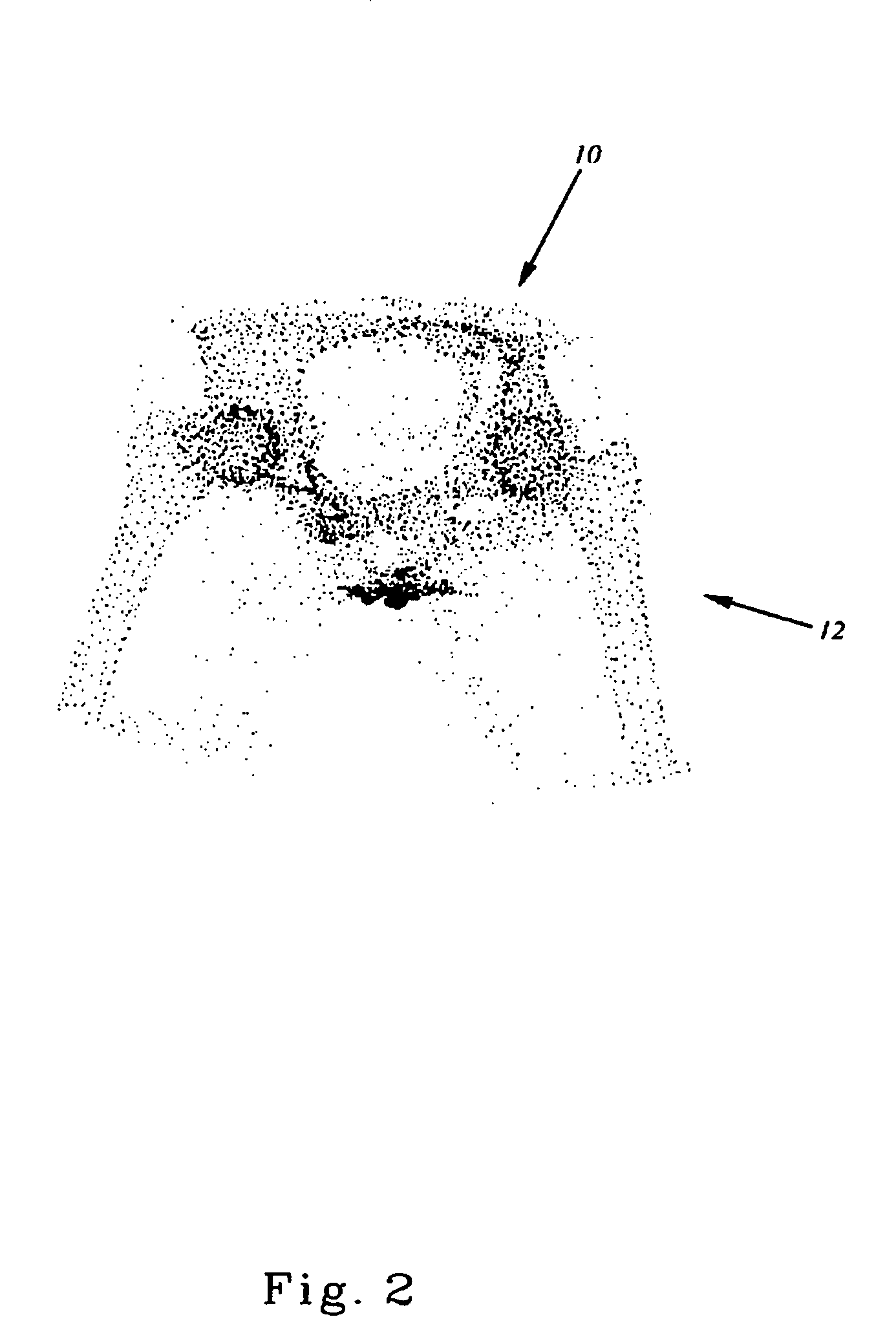

Virtual prototyping system and method

InactiveUS20050264572A1Computation using non-contact making devicesComputation using non-denominational number representationComputer scienceVirtual prototyping

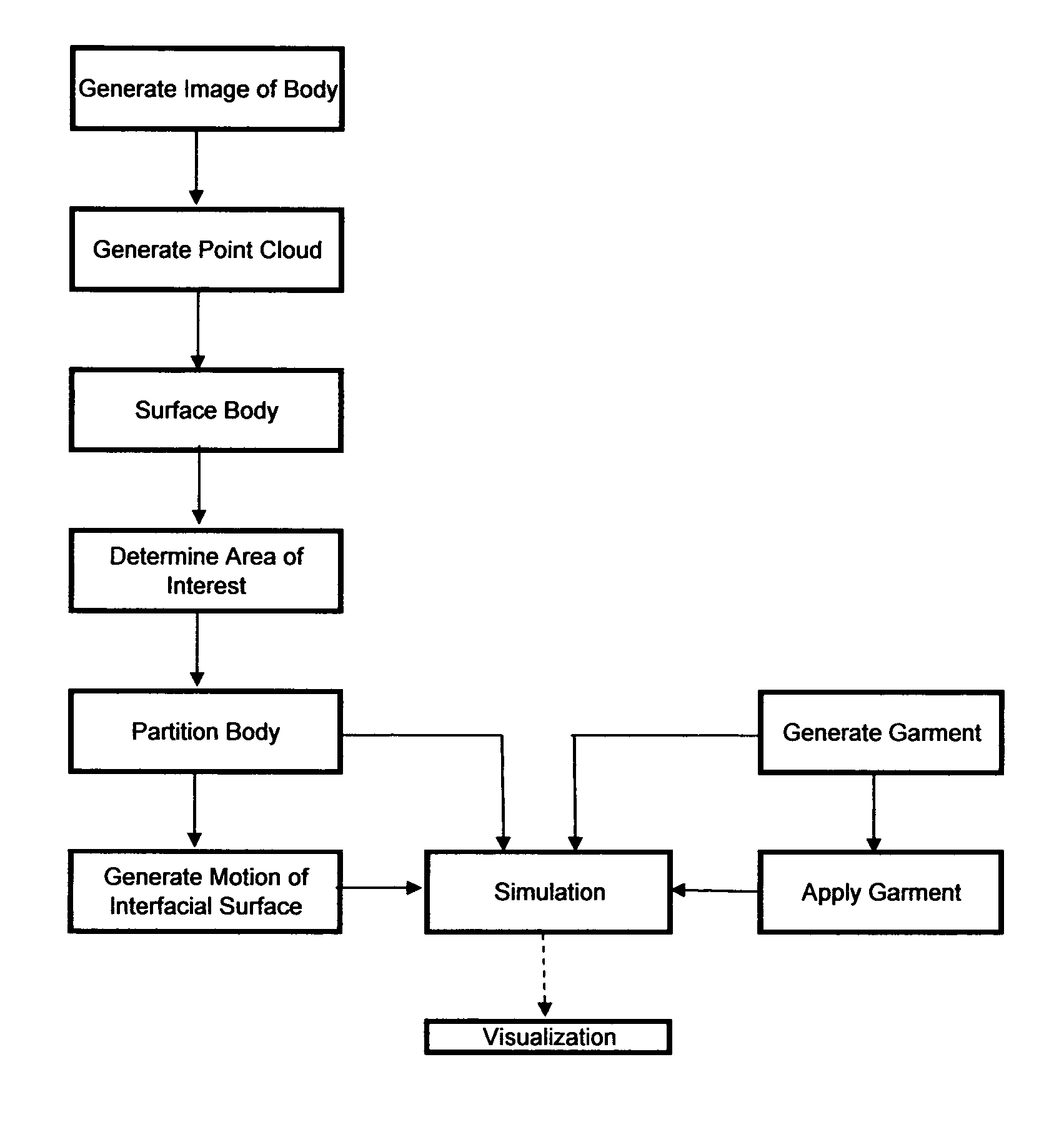

A computer method for simulating motion of at least a portion of a virtual body is disclosed. The method comprises the steps of: providing a surfaced body model; capturing or computing motion data for an external surface of the surfaced body; dividing the body model into at least two volumes, one of the volumes comprising at least a portion of the external surface of the surfaced body and being a deformable volume, and one of the volumes being a prescribed motion volume, the two volumes defining an interfacial surface; moving the external surface of the surfaced body according to the motion data while computing motion of the interfacial surface; and, simulating motion of the portion of a body by driving motion of the interfacial surface through the computed motion to provide an accurately positioned moving deformable surface that can be used in garment design.

Owner:THE PROCTER & GAMBLE COMPANY

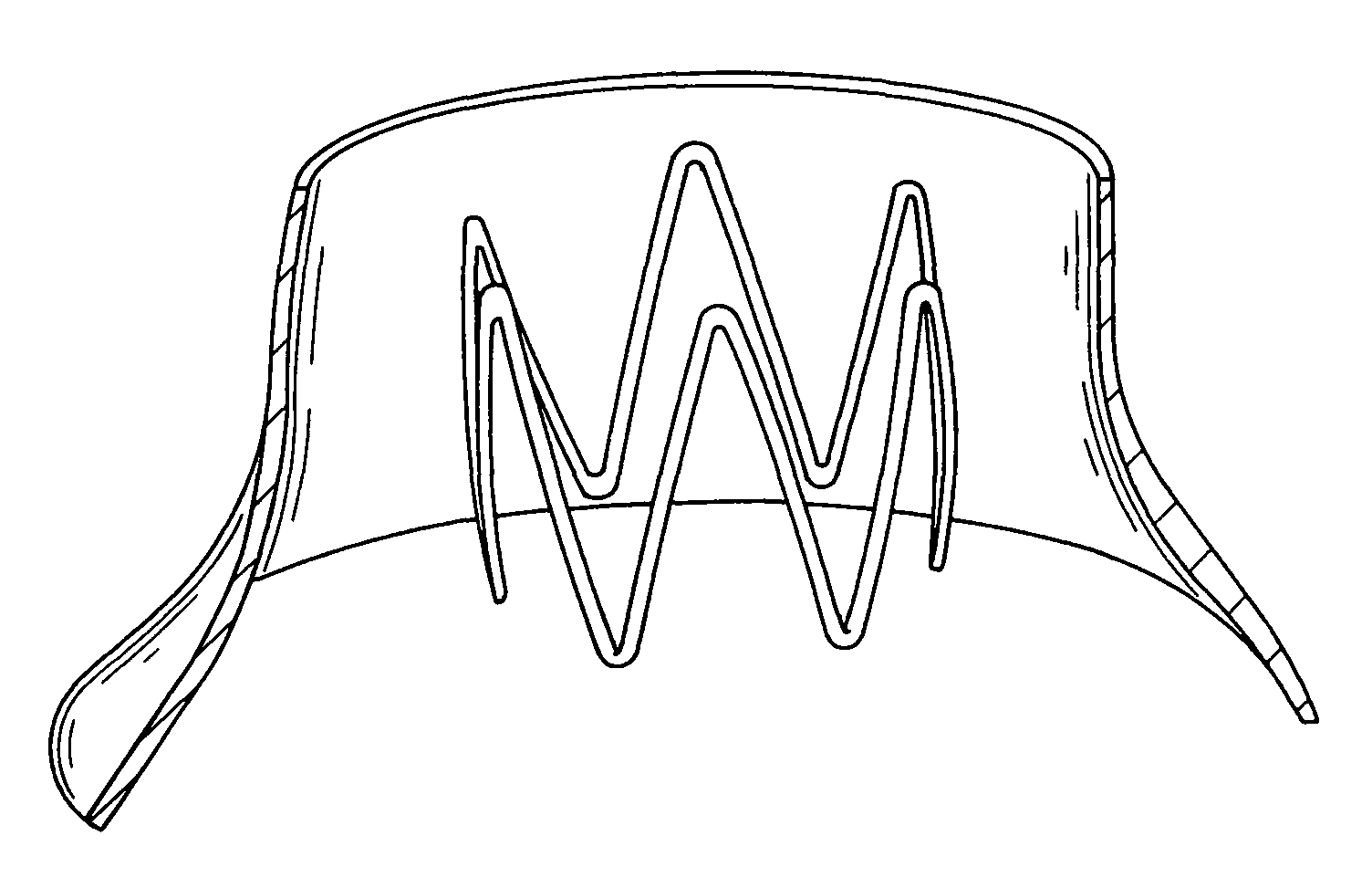

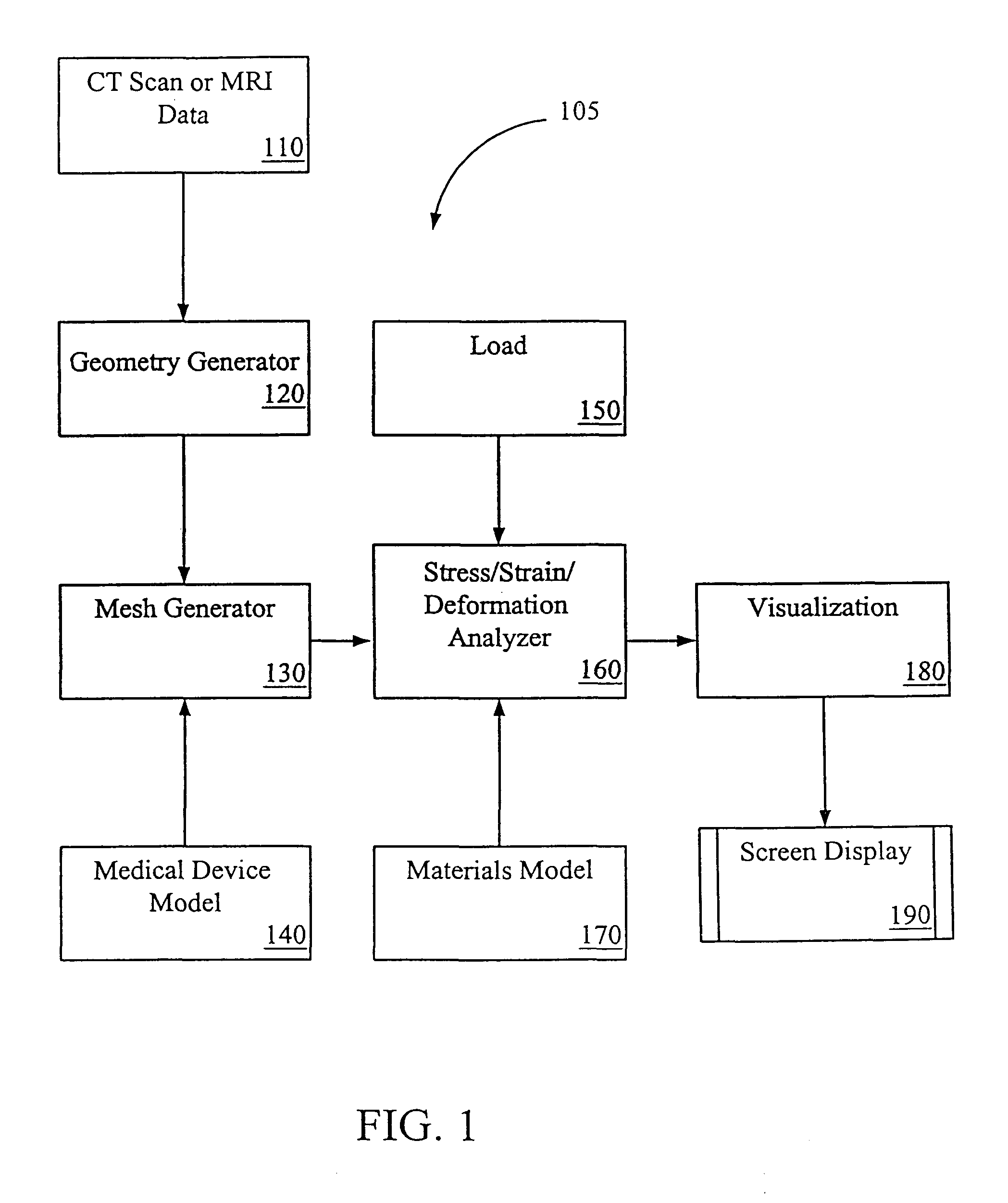

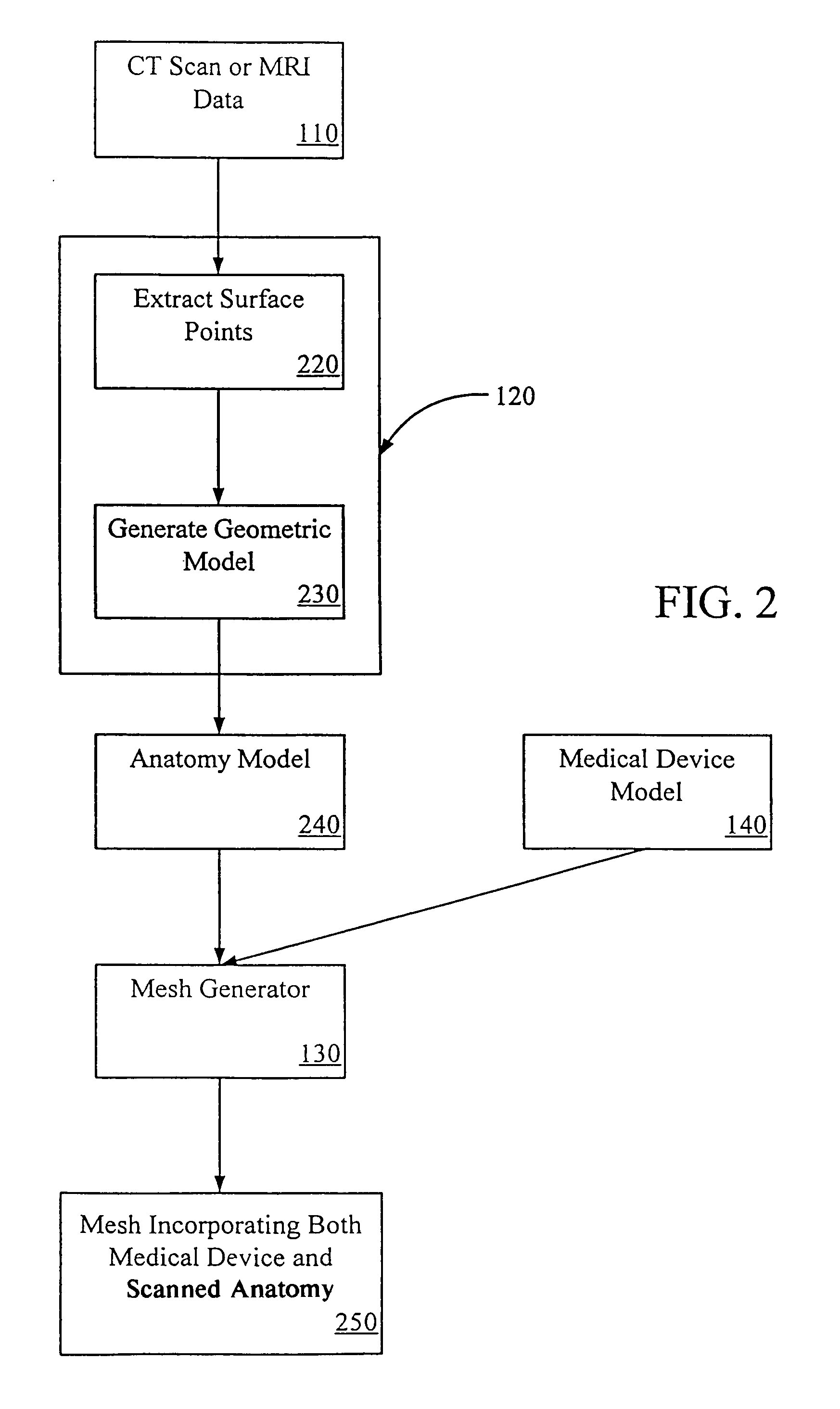

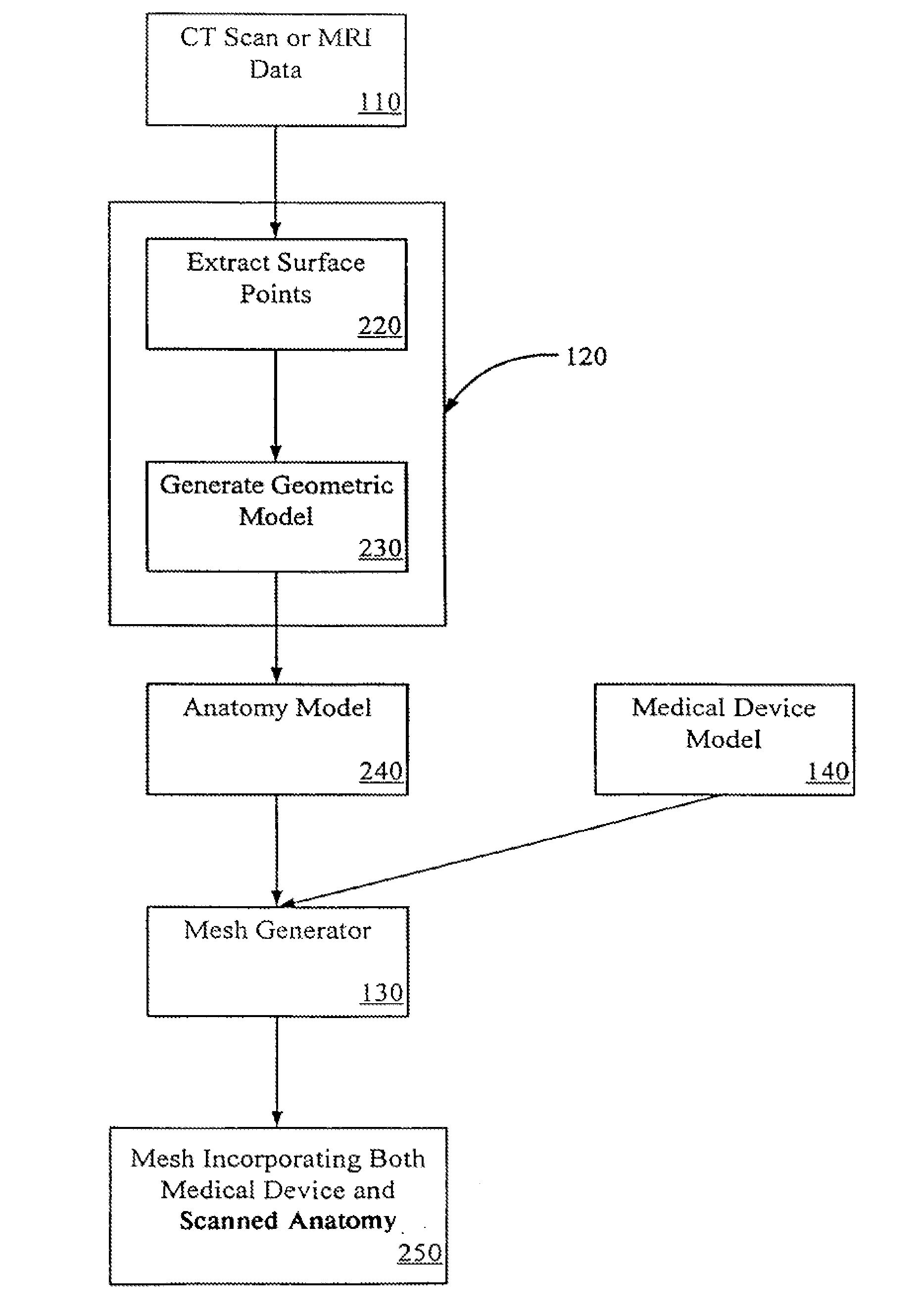

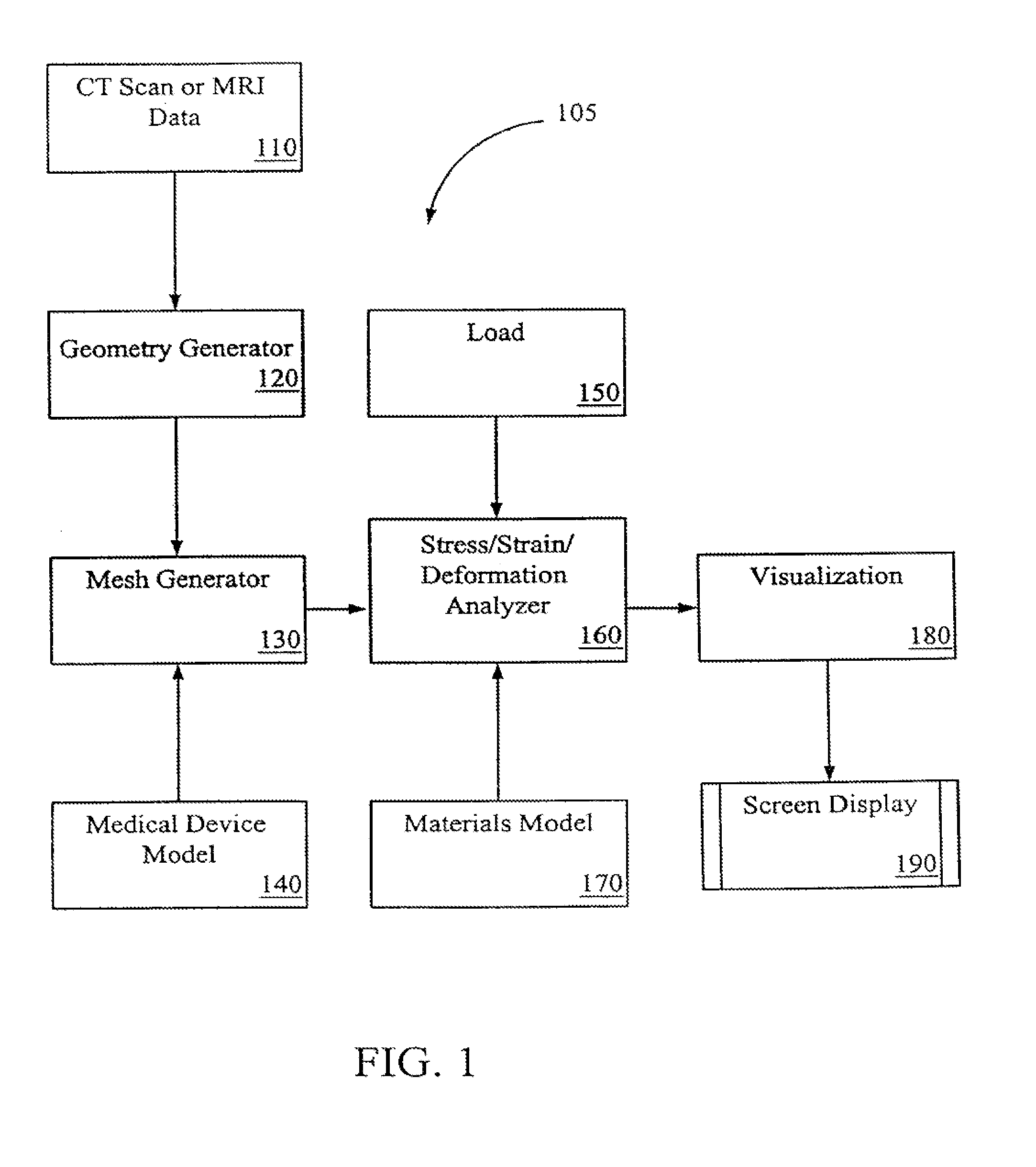

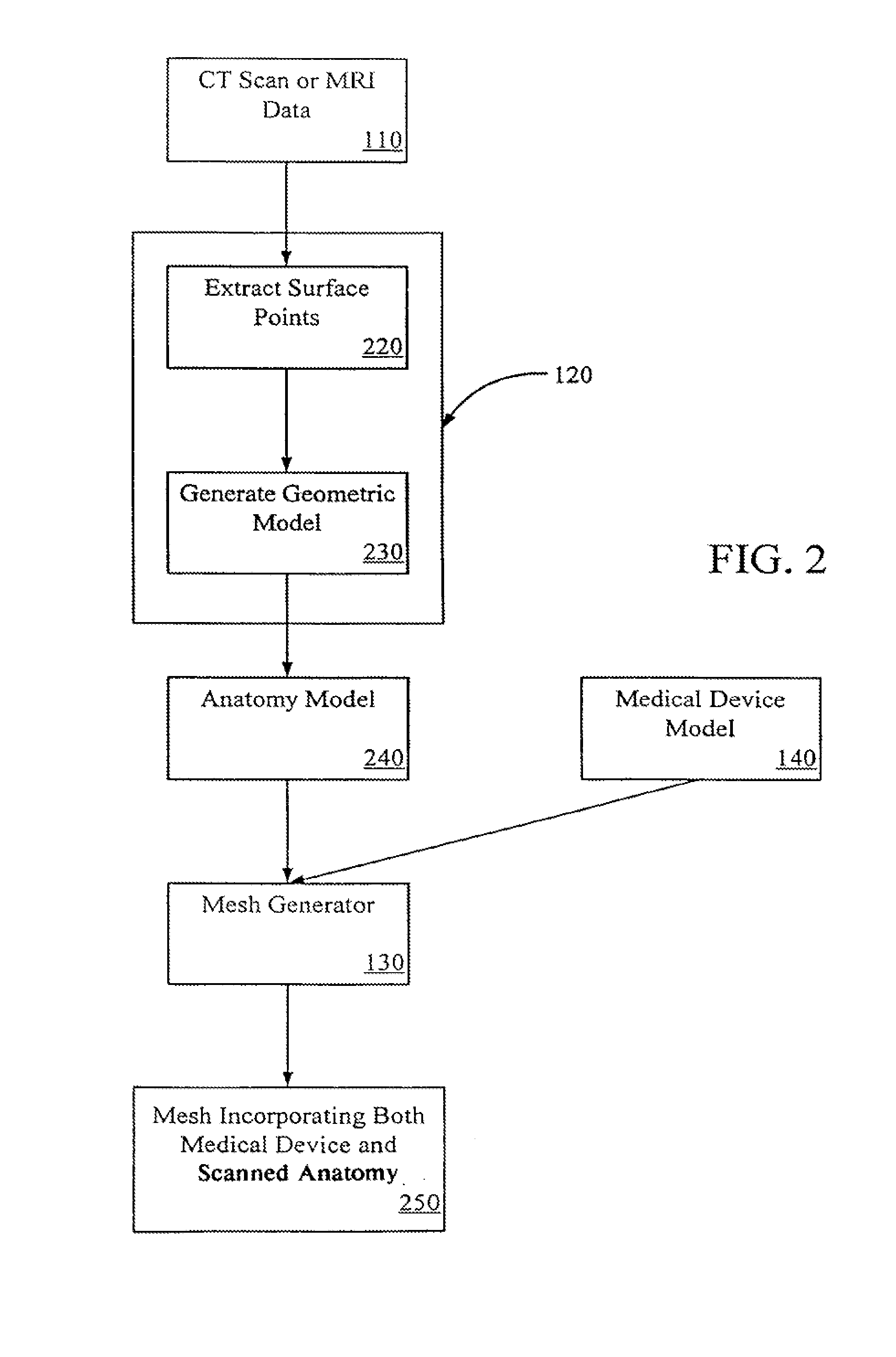

Virtual prototyping and testing for medical device development

A system and method of developing better-designed medical devices, particularly cardiovascular stents and endovascular grafts. The system comprises a geometry generator, a mesh generator, a stress / strain / deformation analyzer, and a visualization tool. In one embodiment, the geometry generator receives three-dimensional volumetric data of an anatomical feature and generates a geometric model. The mesh generator then receives such geometric model of an anatomical feature or an in vitro model and a geometric model of a candidate medical device. In another embodiment, the mesh generator only receives a geometric model of the candidate medical device. Using the geometric model(s) received, the mesh generator creates or generates a mesh or a finite element model. The stress / strain / deformation analyzer then receives the mesh, and the material models and loads of that mesh. Using analysis, preferably non-linear analysis, the stress / strain / deformation analyzer determines the predicted stresses, strains, and deformations on the candidate medical device. Such stresses, strains, and deformations may optionally be simulated visually using a visualization tool.

Owner:BOSTON SCI CORP

Virtual prototyping system and method

InactiveUS7937253B2Computation using non-contact making devicesComputation using non-denominational number representationComputer scienceVirtual prototyping

A computer method for simulating motion of at least a portion of a virtual body is disclosed. The method comprises the steps of: providing a surfaced body model; capturing or computing motion data for an external surface of the surfaced body; dividing the body model into at least two volumes, one of the volumes comprising at least a portion of the external surface of the surfaced body and being a deformable volume, and one of the volumes being a prescribed motion volume, the two volumes defining an interfacial surface; moving the external surface of the surfaced body according to the motion data while computing motion of the interfacial surface; and, simulating motion of the portion of a body by driving motion of the interfacial surface through the computed motion to provide an accurately positioned moving deformable surface that can be used in garment design.

Owner:PROCTER & GAMBLE CO

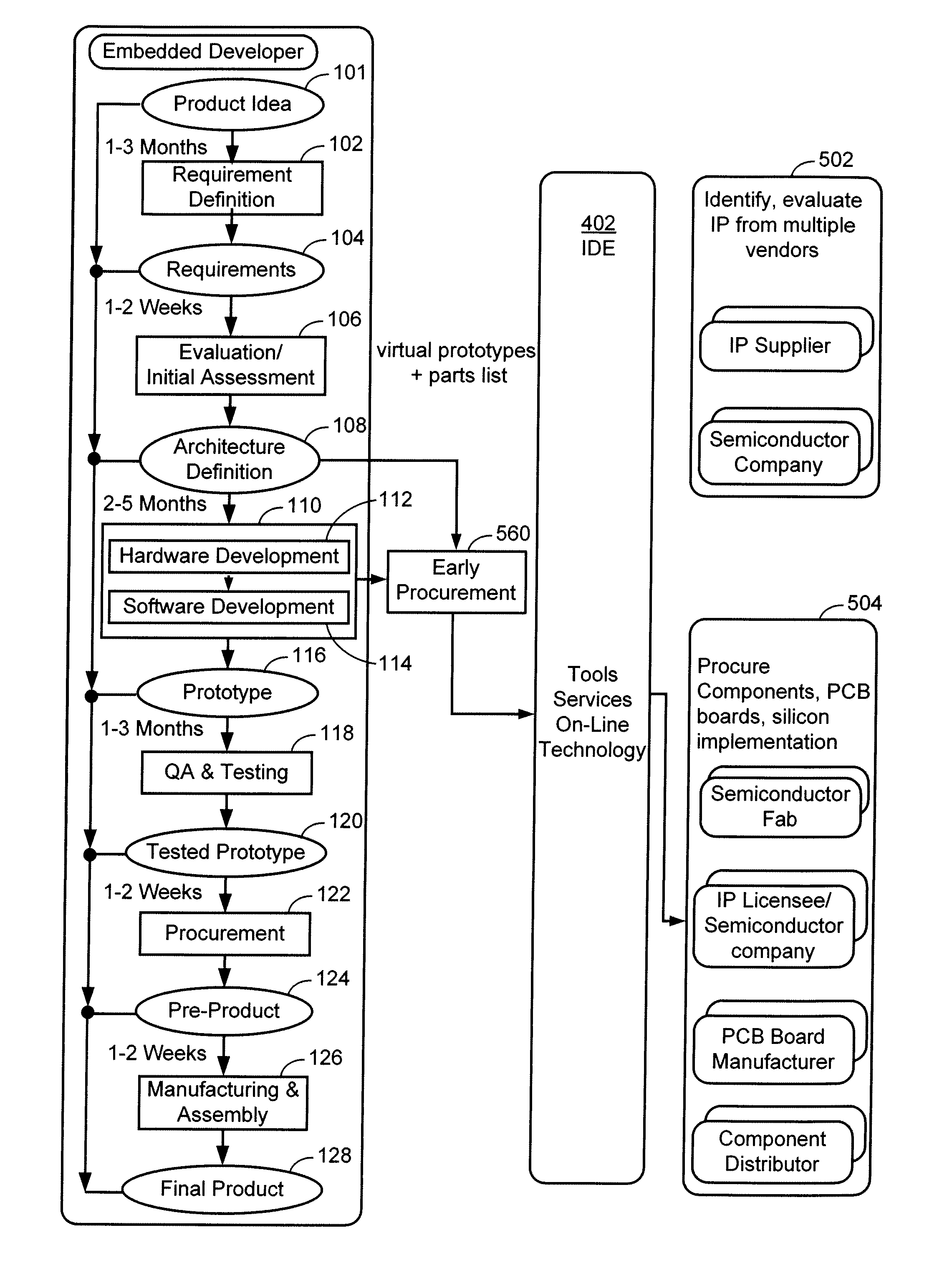

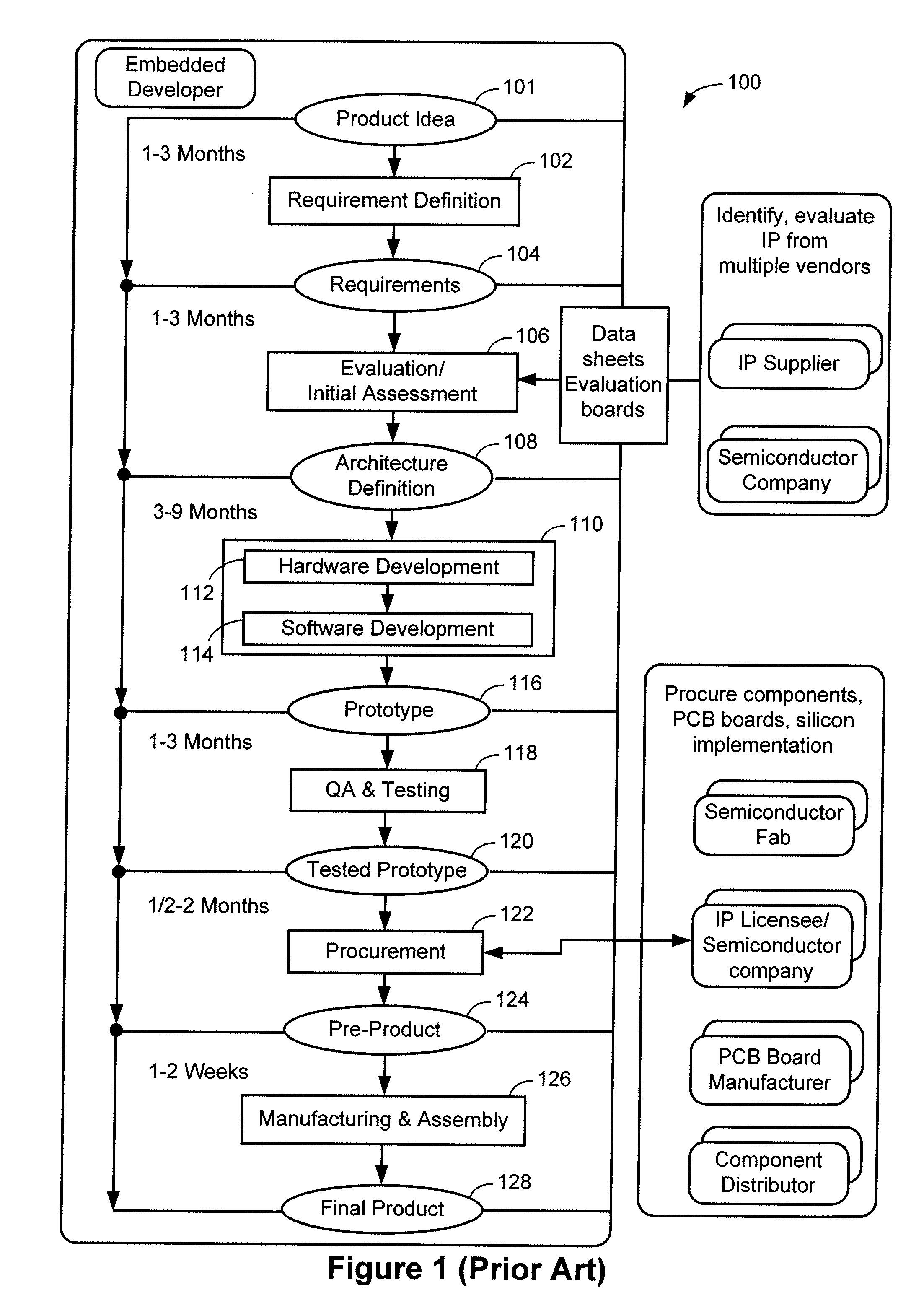

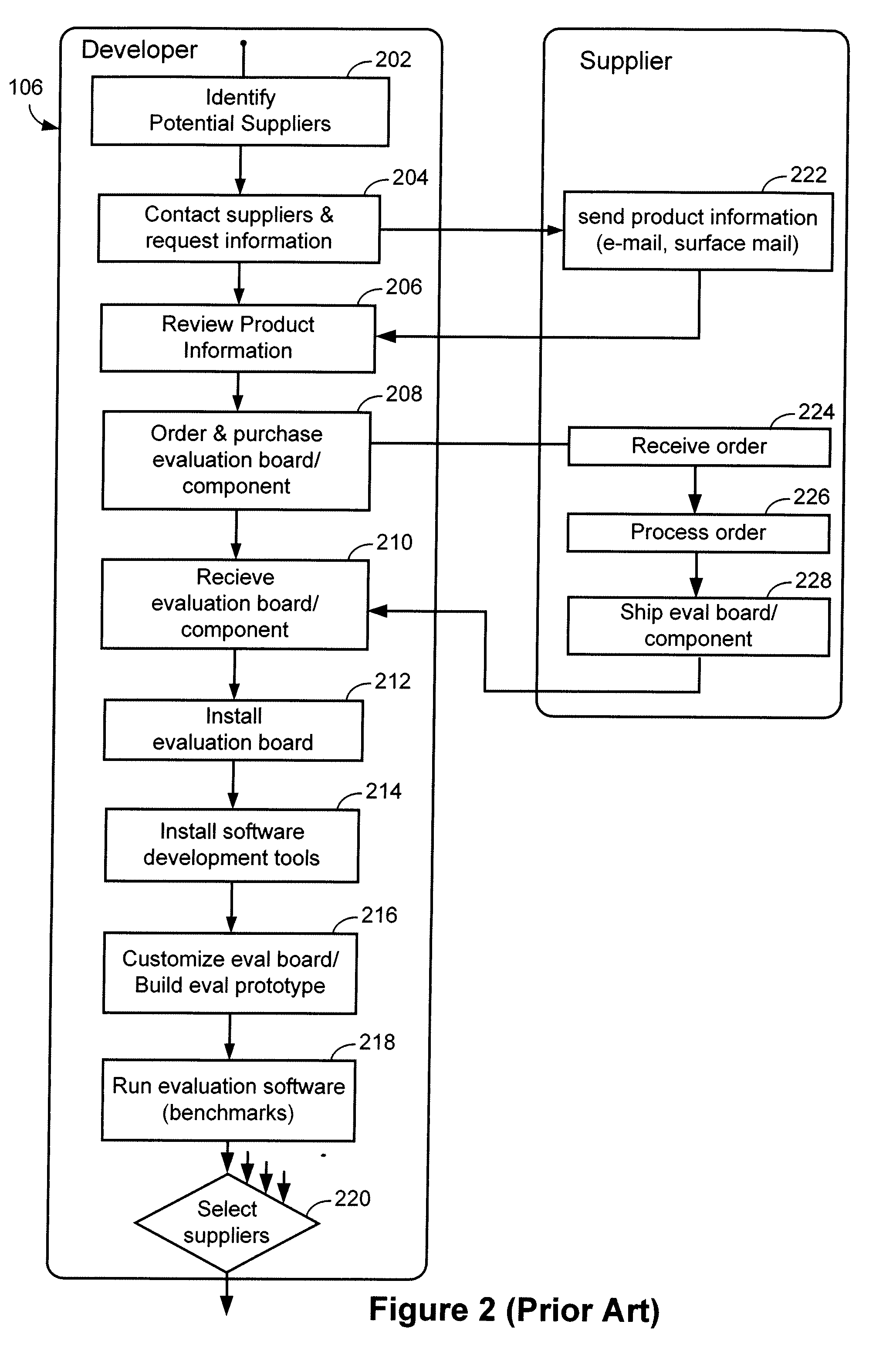

Method And System for Virtual Prototyping

InactiveUS20100017185A1Analogue computers for electric apparatusCAD network environmentHuman–machine interfaceComputer architecture

An integrated design environment (IDE) is disclosed for forming virtual embedded systems. The IDE includes a design language for forming finite state machine models of hardware components that are coupled to simulators of processor cores, preferably instruction set accurate simulators. A software debugger interface permits a software application to be loaded and executed on the virtual embedded system. A virtual test bench may be coupled to the simulation to serve as a human-machine interface. In one embodiment, the IDE is provided as a web-based service for the evaluation, development and procurement phases of an embedded system project. IP components, such as processor cores, may be evaluated using a virtual embedded system. In one embodiment, a virtual embedded system is used as an executable specification for the procurement of a good or service related to an embedded system.

Owner:SYNOPSYS INC

Method for planning and performing dental treatments

InactiveUS7909606B2Precise preparationEffective and easy to useImpression capsTeeth fillingData setDesign phase

Method for planning and performing dental treatments including an acquisition phase of a set of data relating to the position, to the conformation and to the dimension of at least one site inside the oral cavity of a patient who has to undergo a dental treatment and relating to the conformation of at least one portion of the patient's face; a design phase of a virtual prototype of at least one dental prosthesis that can be fitted at the site during the treatment, starting from the set of data and by means of a software program implemented on a computer; a determination phase, by means of the software program and starting from the set of data and from the virtual prototype of the dental prosthesis, of at least one virtual model suitable for visually reproducing the portion of the face following the fitting of the dental prosthesis; a preparation phase of the site by means of a dental instrument, with the assistance of the software and starting from the virtual prototype of the dental prosthesis and from the virtual model before the installation and the manufacture of the dental prosthesis.

Owner:MARCELLO MARCHESI

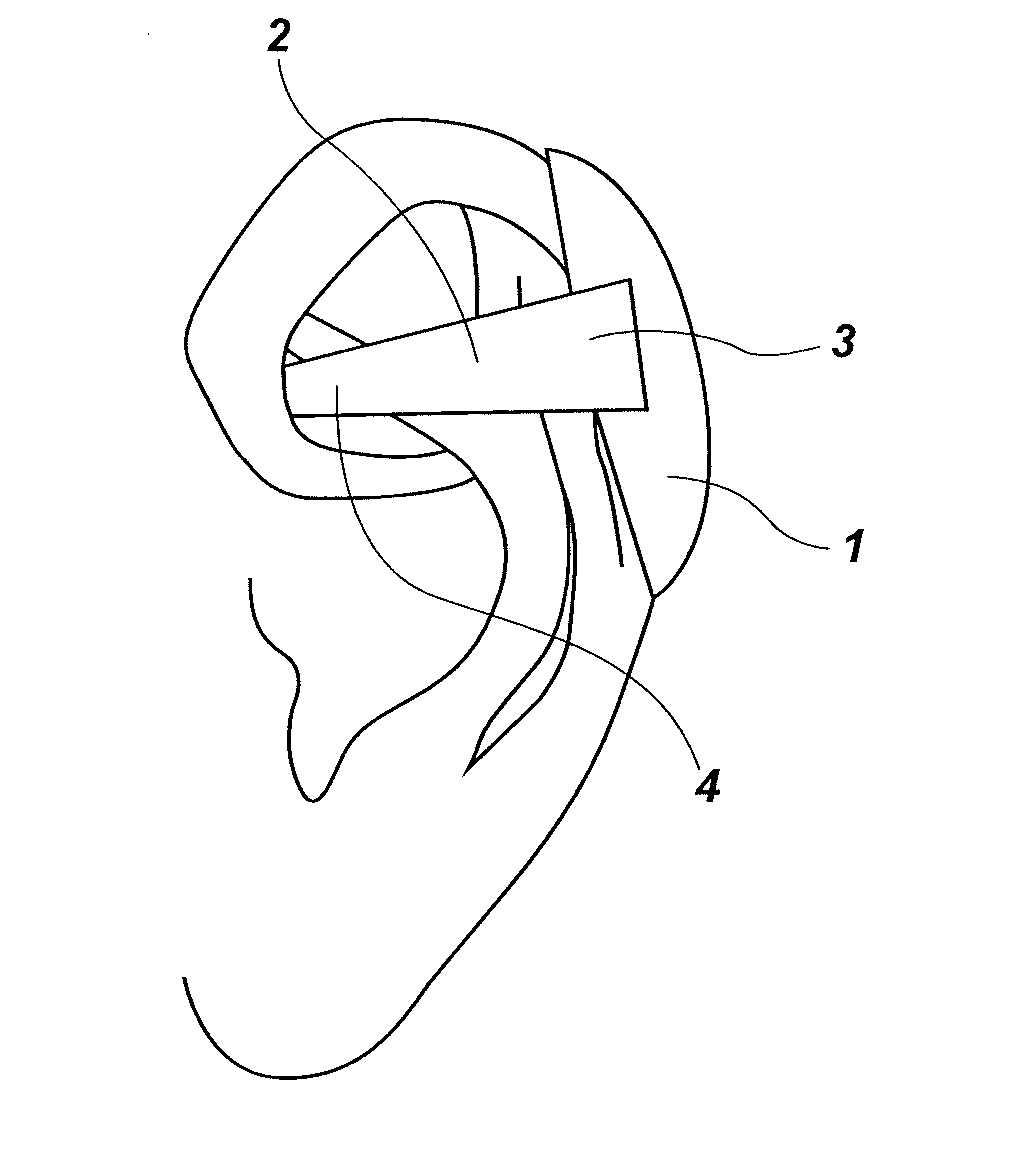

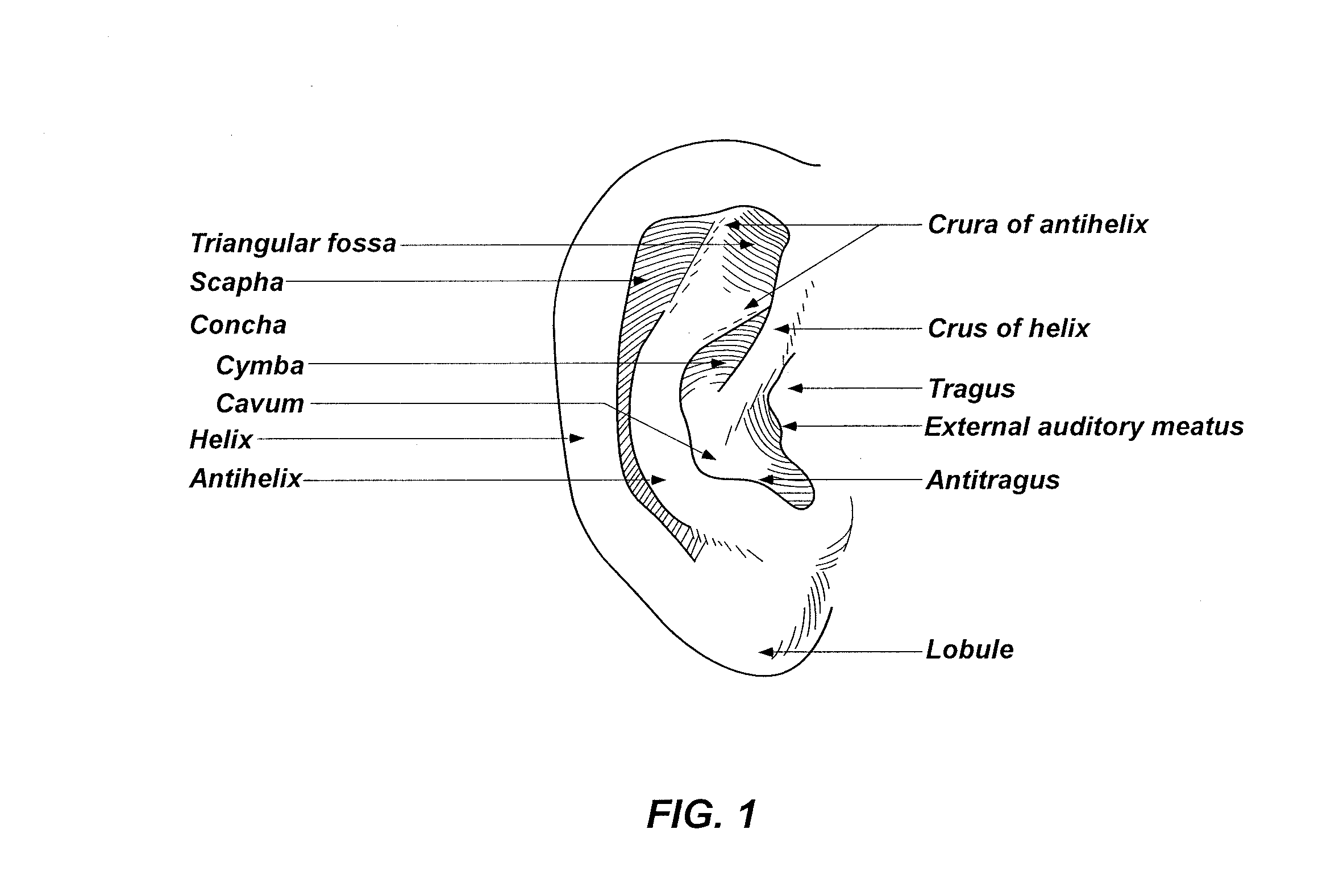

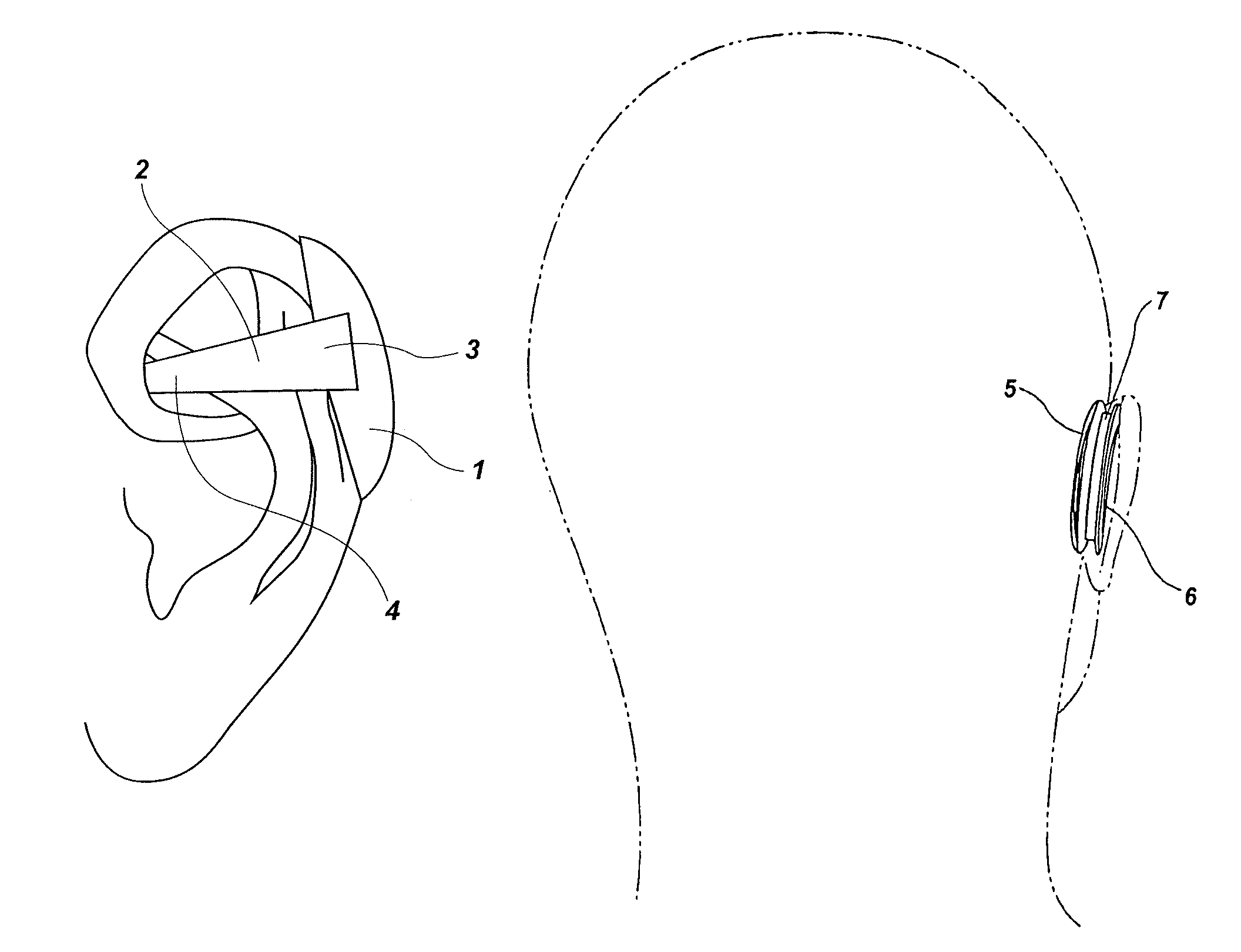

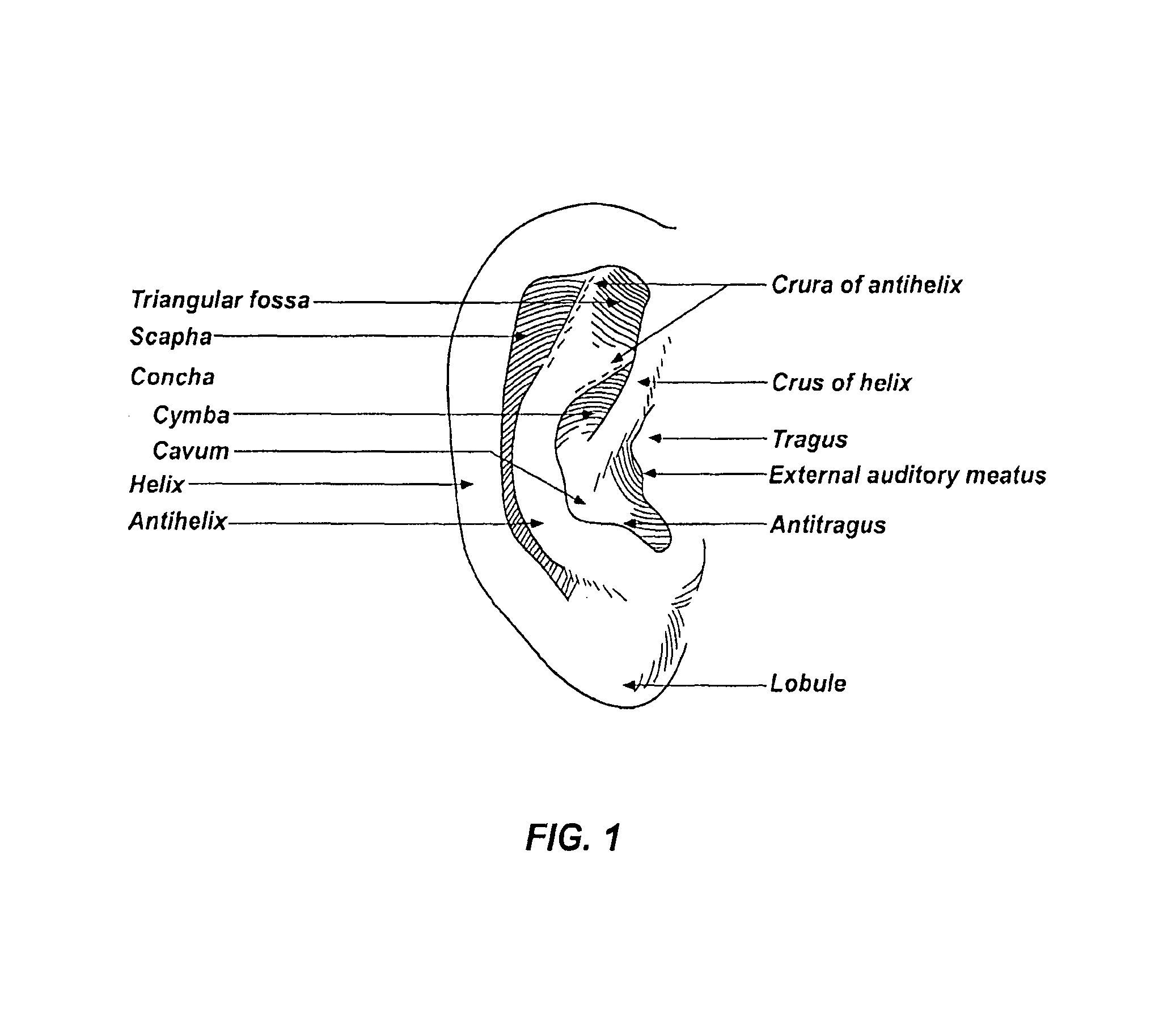

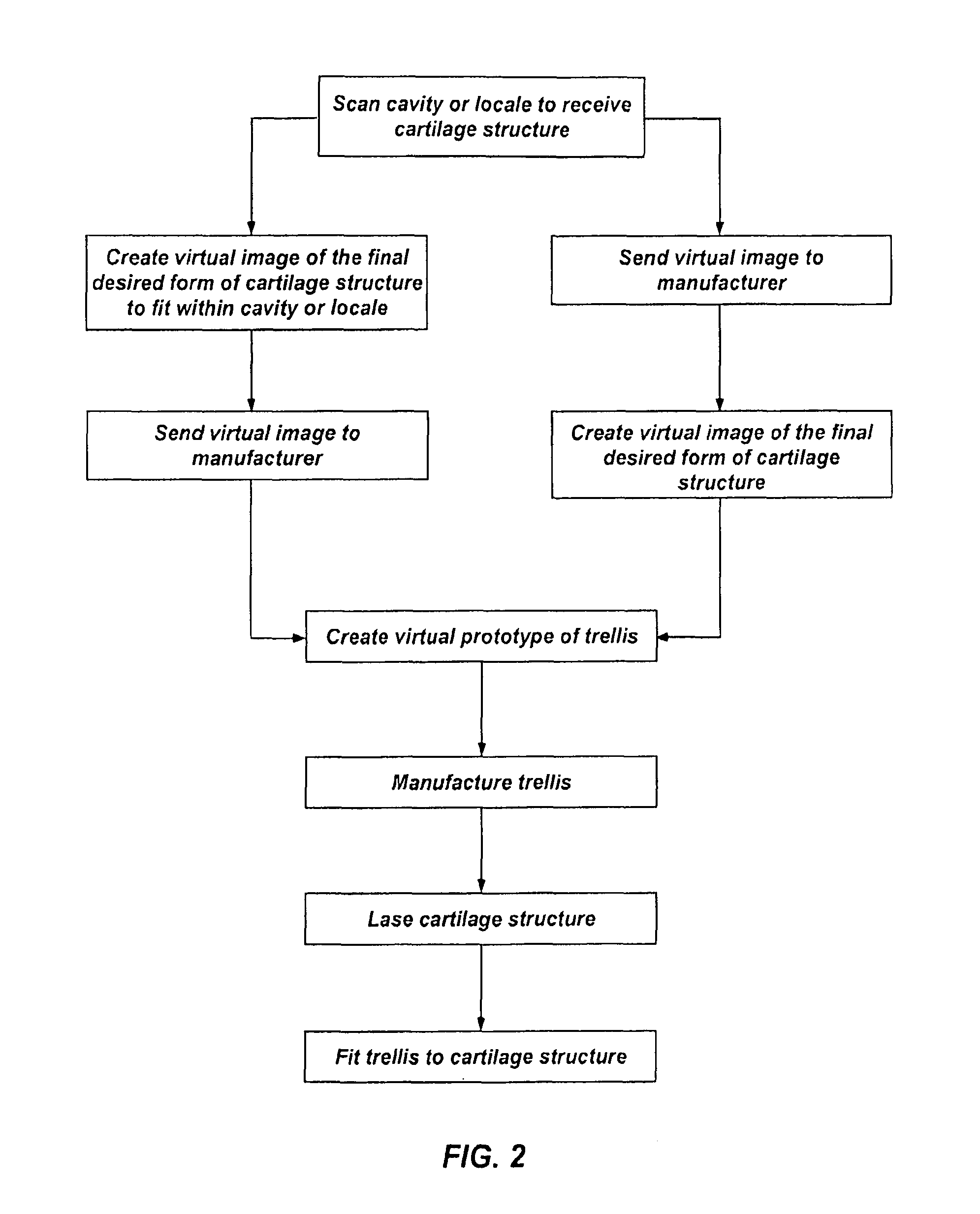

Devices and methods for reshaping cartilage structures

InactiveUS20140188158A1Wide applicabilityLess painfulAdditive manufacturing apparatusEar treatmentComputer scienceVirtual prototyping

Owner:CHONDROCYTE

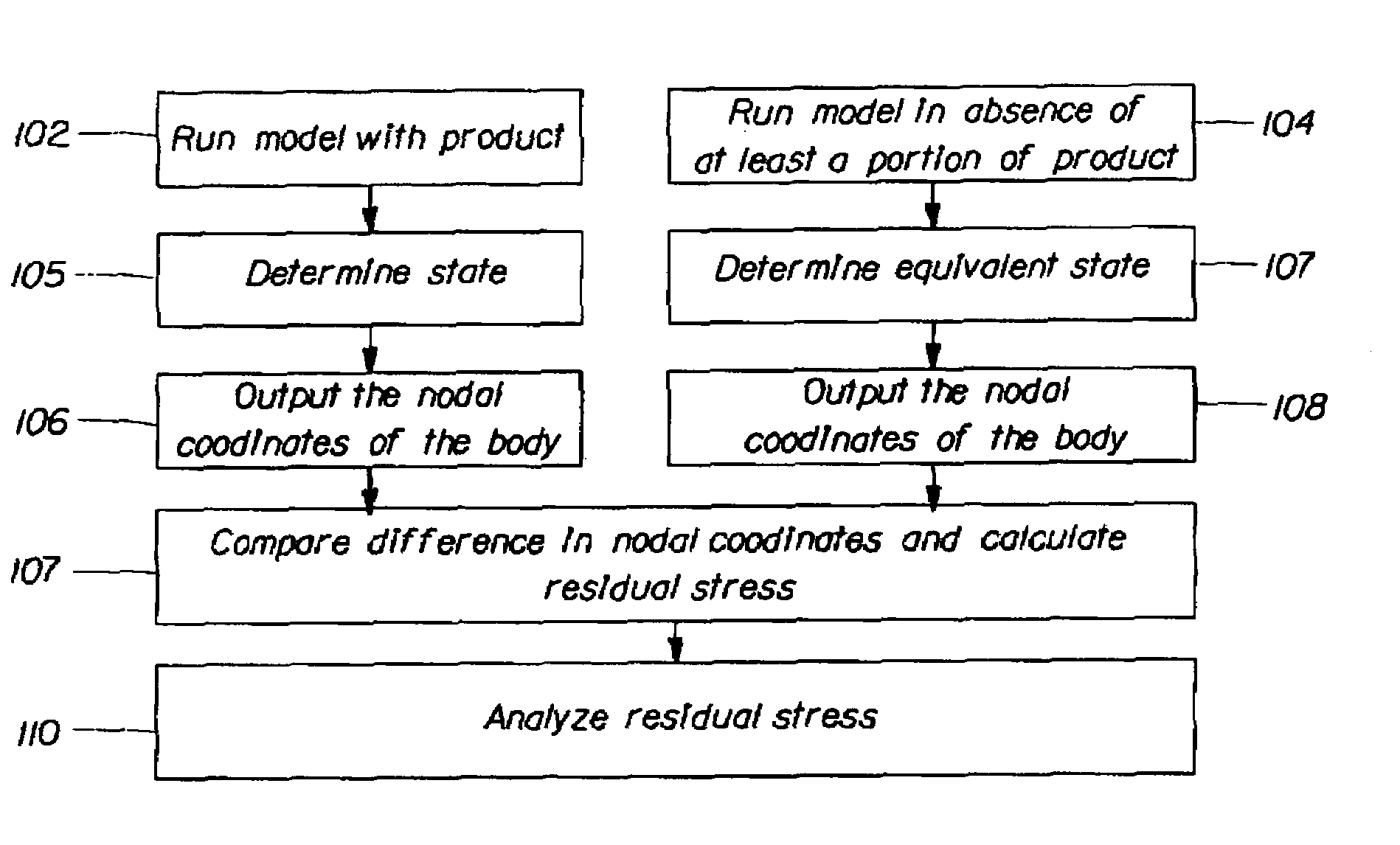

Method of analysis of comfort for virtual prototyping system

A method for analyzing the comfort of an actual product on an actual body by use of a virtual product model and virtual body model to calculate a comfort indicator. The method comprises the steps of: (a) providing a virtual body model; (b) providing a virtual product model; (c) providing virtual simulation software; (d) gathering data from actual users of an actual product of a type modeled by the virtual product model; (e) running a virtual simulation for the virtual product model worn on the virtual body model; (f) running a virtual simulation for the virtual body model in the absence of the virtual product model; (g) calculating a difference in deformation on the virtual body model between the virtual simulations; and (h) correlating the calculated difference to the gathered data to determine a magnitude difference, the magnitude difference being the comfort indicator.

Owner:PROCTER & GAMBLE CO

Method and apparatus for predicting the failure of a component

The invention provides a method and apparatus for predicting the failure of a component using a probabilistic model of a material's microstructural-based response to fatigue. The method predicts the component failure by a computer simulation of multiple incarnations of real material behavior, or virtual prototyping. The virtual prototyping simulates the effects of characteristics that include grain size, grain orientation, micro-applied stress and micro-yield strength that are difficult to simulate with real specimens. The invention provides an apparatus for predicting the response of a component to fatigue using the method.

Owner:VEXTEC CORP

Virtual prototyping system and method

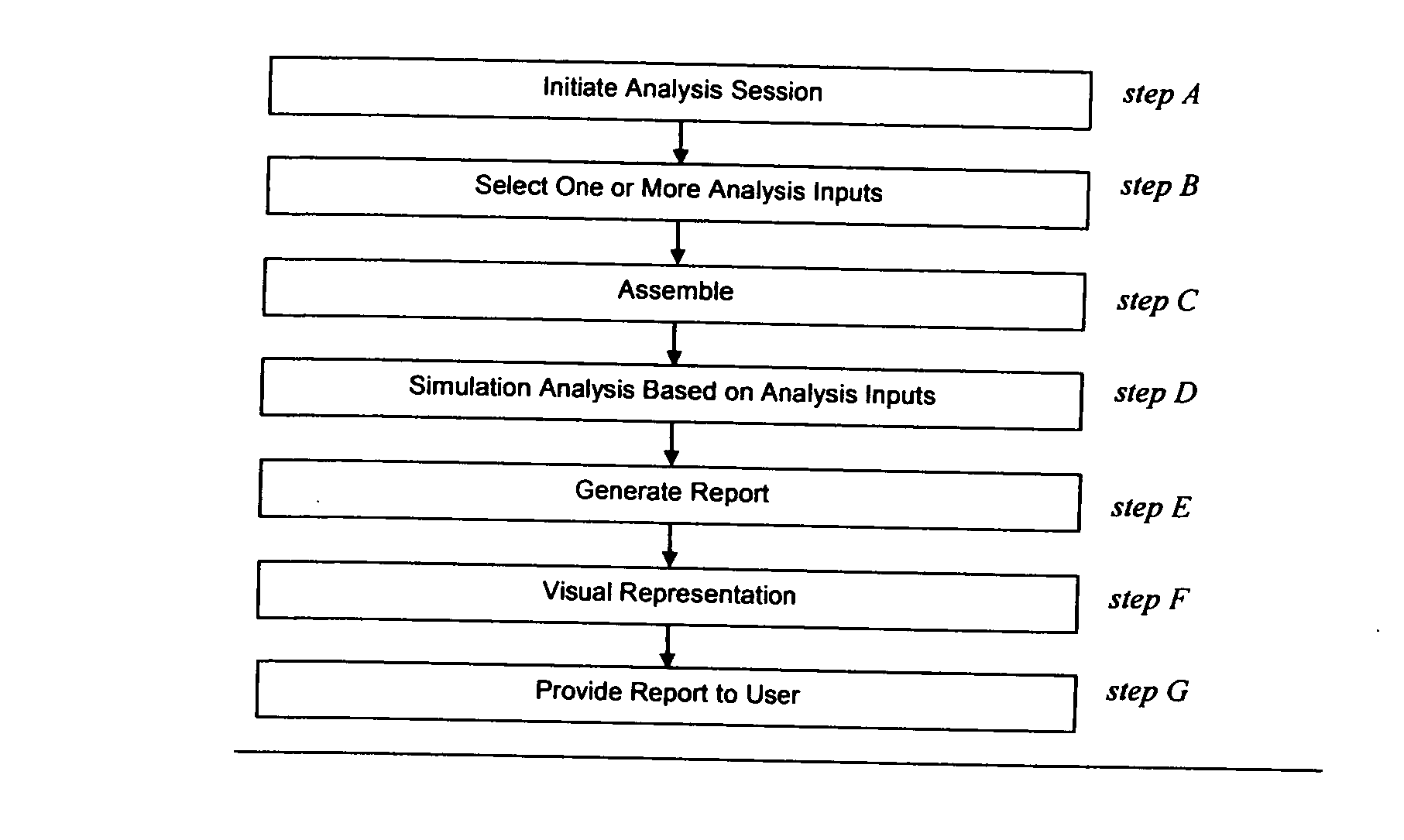

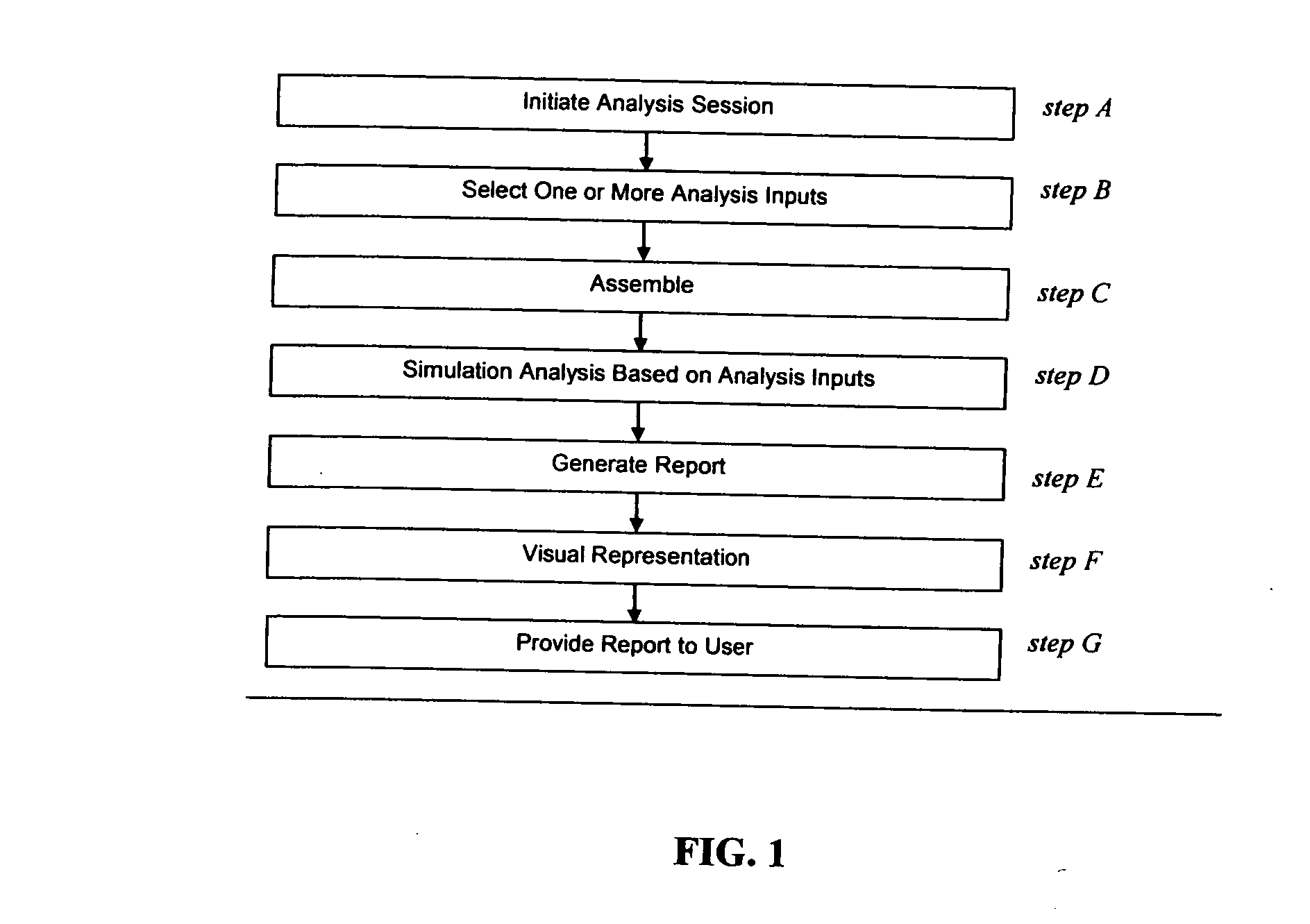

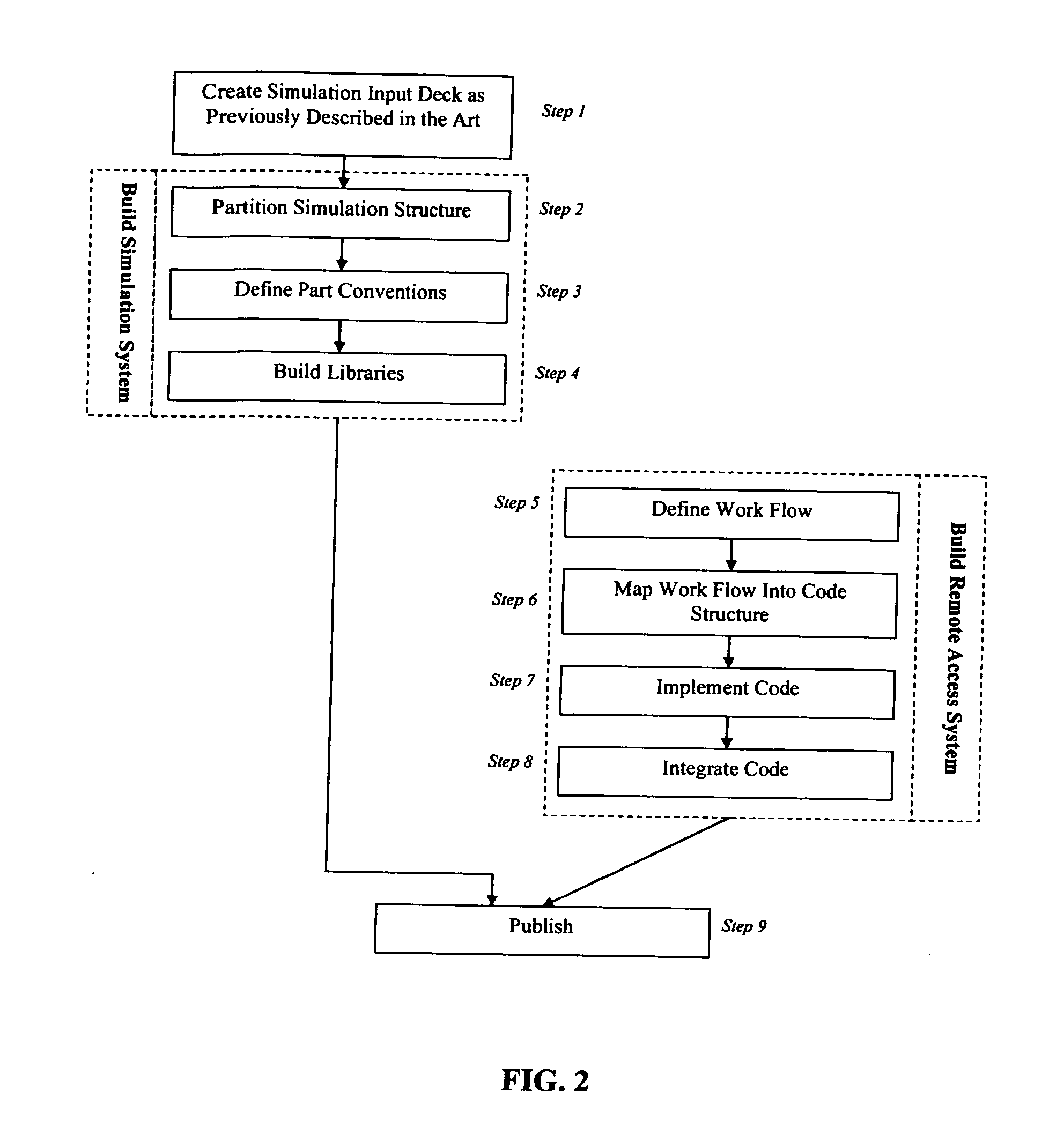

InactiveUS20070203679A1CAD network environmentDesign optimisation/simulationSoftwareVirtual prototyping

A method for modeling design of products, the method comprising: a. providing a user with a computer, the computer having software capability locally or remotely accessible to do the following: i. analyze one or more analysis inputs; ii. assemble the inputs for analysis; iii. perform a simulation analysis; iv. generate a report; b. initiating an analysis session on the computer; c. selecting one or more analysis inputs; d. assembling the analysis inputs; e. running an analysis; f. generating a report of the analysis.

Owner:THE PROCTER & GAMBLE COMPANY

Virtual car crash detecting system and construction method thereof

InactiveCN101625285AGood repeatabilityLow costVehicle testingSpecial data processing applicationsElement modelEntity model

The invention relates to a virtual car crash detecting system and a construction method thereof. The construction method comprises the following steps: constructing a car geometrical entity model according to car total quality, total size, car type base information and the external dimension of parts; constructing a finite element model of a dummy man; respectively constructing a safety belt, a safe air bag and a barrier model; constructing a virtual emulation and calculation testing table; transferring various original models in a virtual testing field to construct a virtual testing field; transferring various virtual models to be presented in a virtual environment; defining collision experimental conditions; and starting a simulation test. The virtual car crash detecting system has short development period, low use cost and realer test result.

Owner:HEFEI VRVIEW INFORMATION TECH

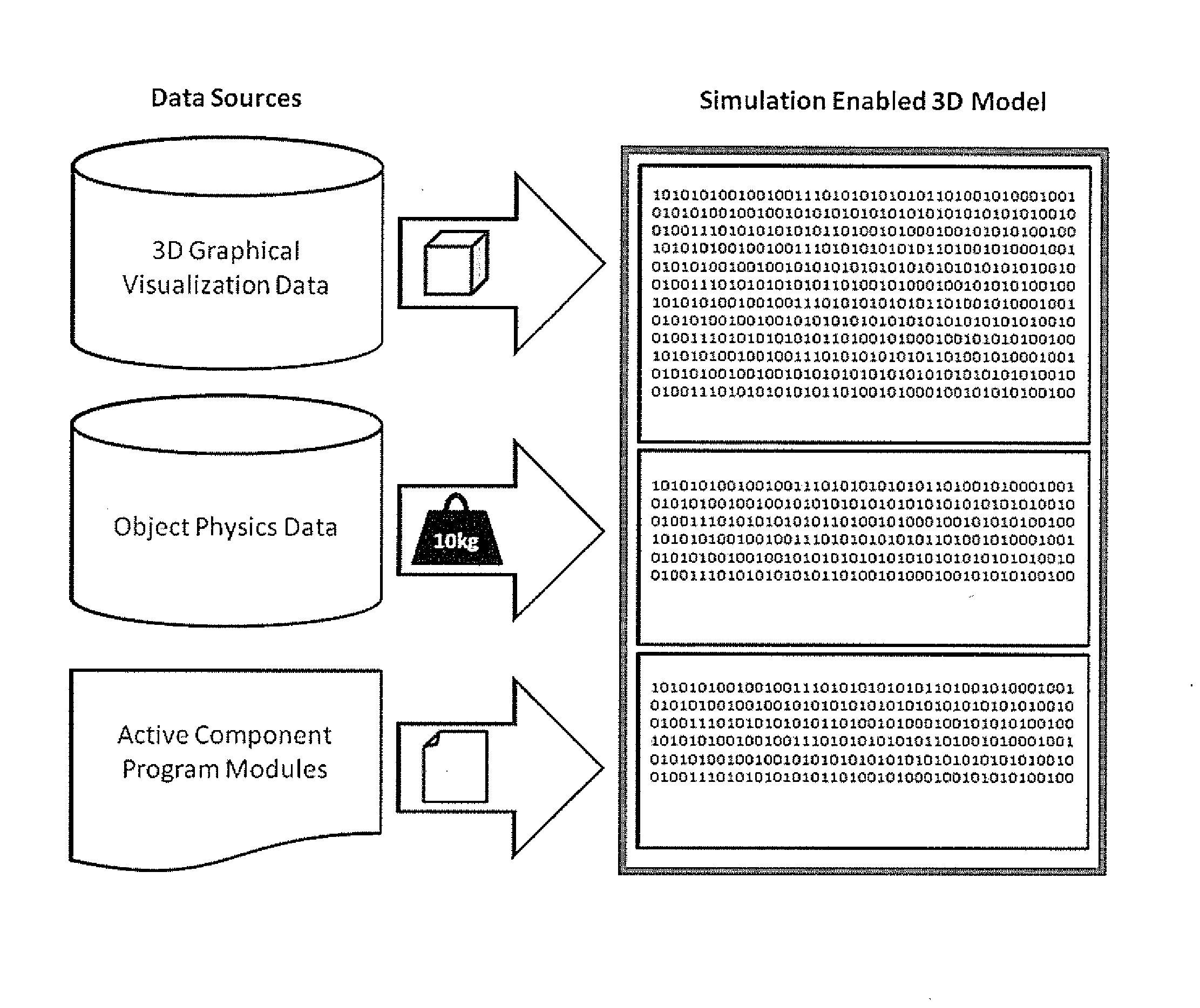

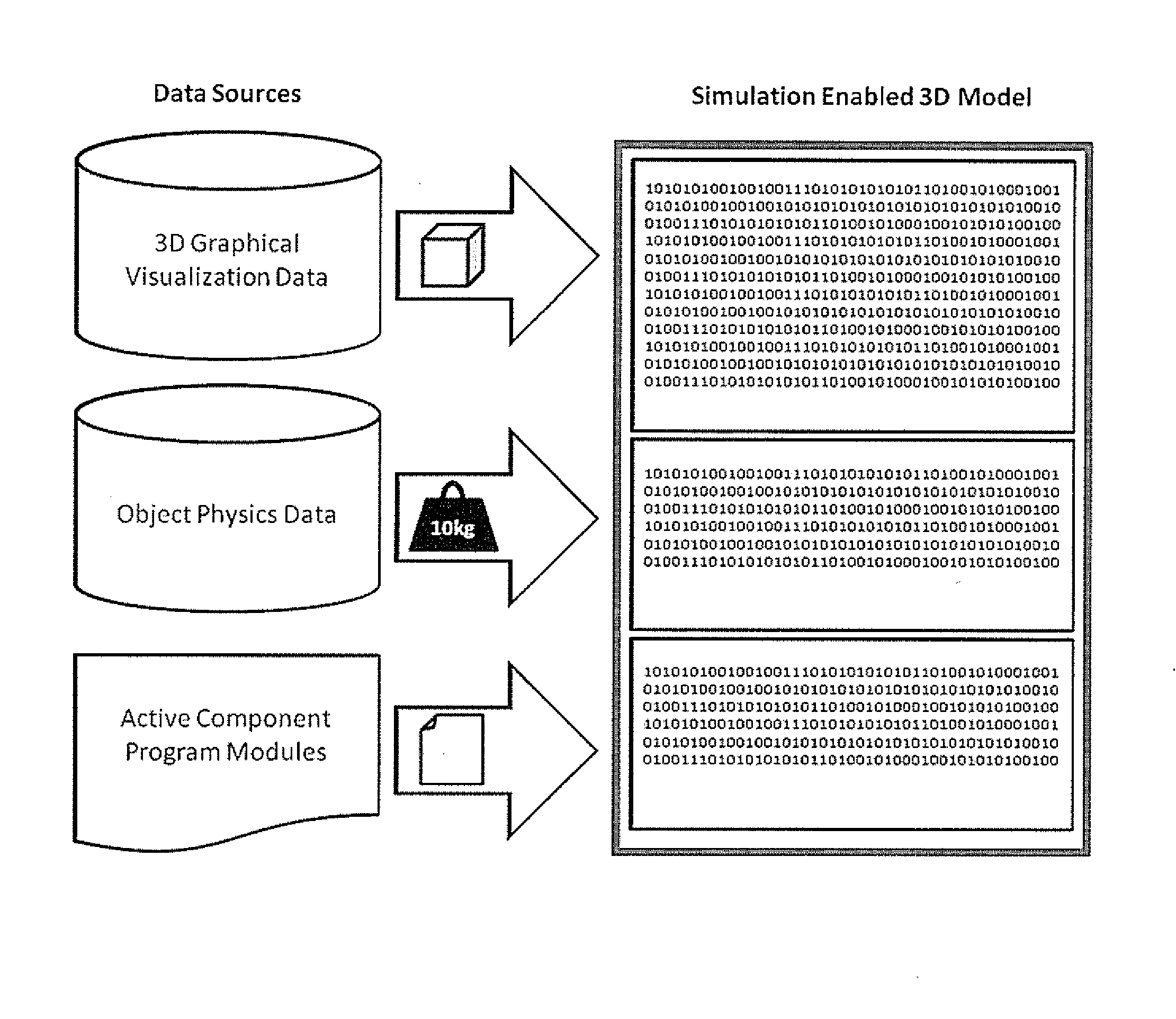

Non-programmer method for creating simulation-enabled 3D robotic models for immediate robotic simulation, without programming intervention

InactiveUS20130275091A1Design optimisation/simulationImage data processingVirtual worldProgram intervention

A system to design a virtual 3D model of the working robot so it can be tested in a virtual world is described. The system and the method for using same can be used to test, refine, redesign and improve multiple virtual prototypes of a robot. Once virtually tested, the optimized design specifications are printed out and used to build the optimized robot design.

Owner:WHITE MAGIC ROBOTICS

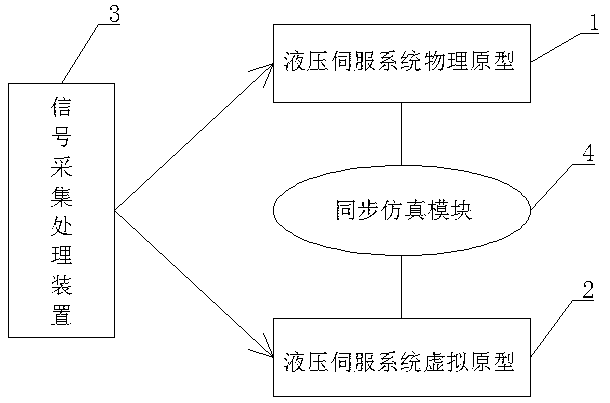

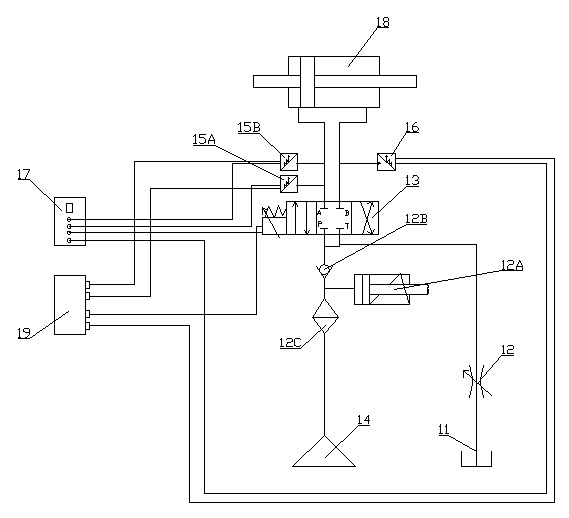

Hydraulic servo system based on virtual prototyping technique

InactiveCN102734274ACompact structureEasy to operateFluid-pressure actuator componentsComputer moduleMotion parameter

The invention discloses a device capable of realizing synchronous simulation of a physical prototype and a virtual prototype of a hydraulic servo device. The device mainly comprises a hydraulic servo device physical prototype (1), a hydraulic servo device virtual prototype (2), a signal acquisition processor (3) and a synchronous simulation module (4). The hydraulic servo device physical prototype mainly comprises a servo valve and a sensor; the hydraulic servo device virtual prototype is a three-dimensional digital model established based on Solidworks; the signal acquisition processor is a virtual instrument platform constructed based on LabVIEW; and the synchronous simulation module is designed according to a LabVIEW SoftMotion module. When an appointed displacement signal is input, the motion of the physical prototype and the virtual prototype is controlled by the signal acquisition processor, motion parameters of the physical prototype are acquired and processed, the synchronous simulation module establishes the communication between the physical prototype and the virtual prototype to feed back a motion state of the physical prototype to the virtual prototype, and thus the synchronous simulation of the physical prototype and the virtual prototype of the hydraulic servo device is realized.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

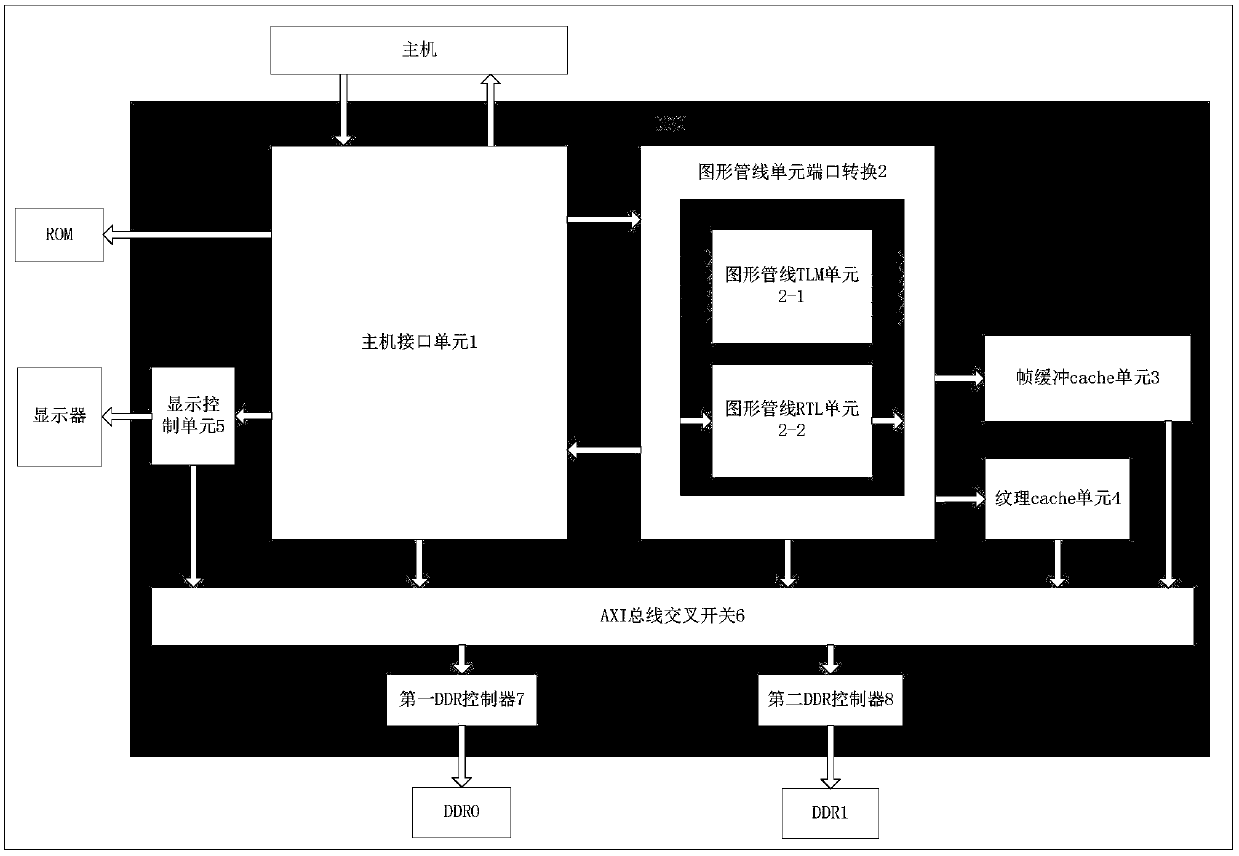

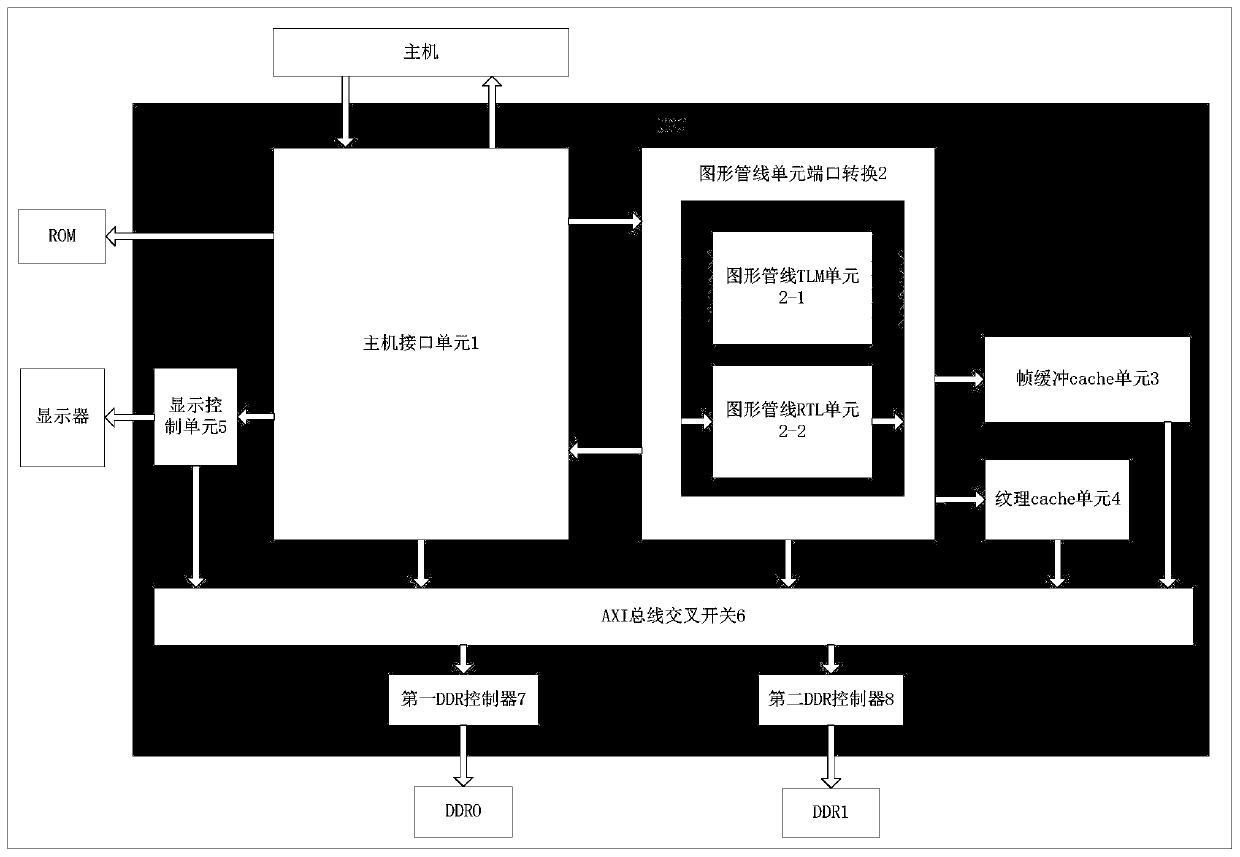

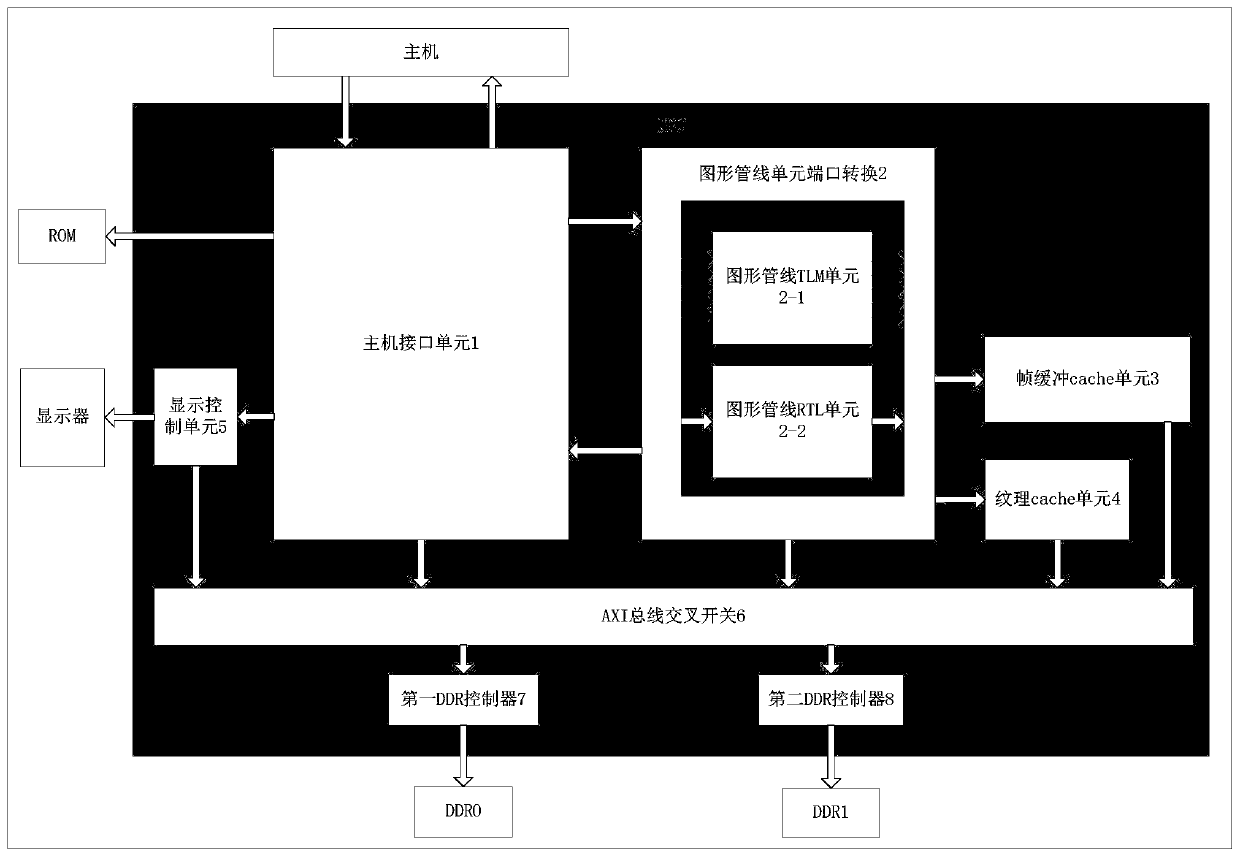

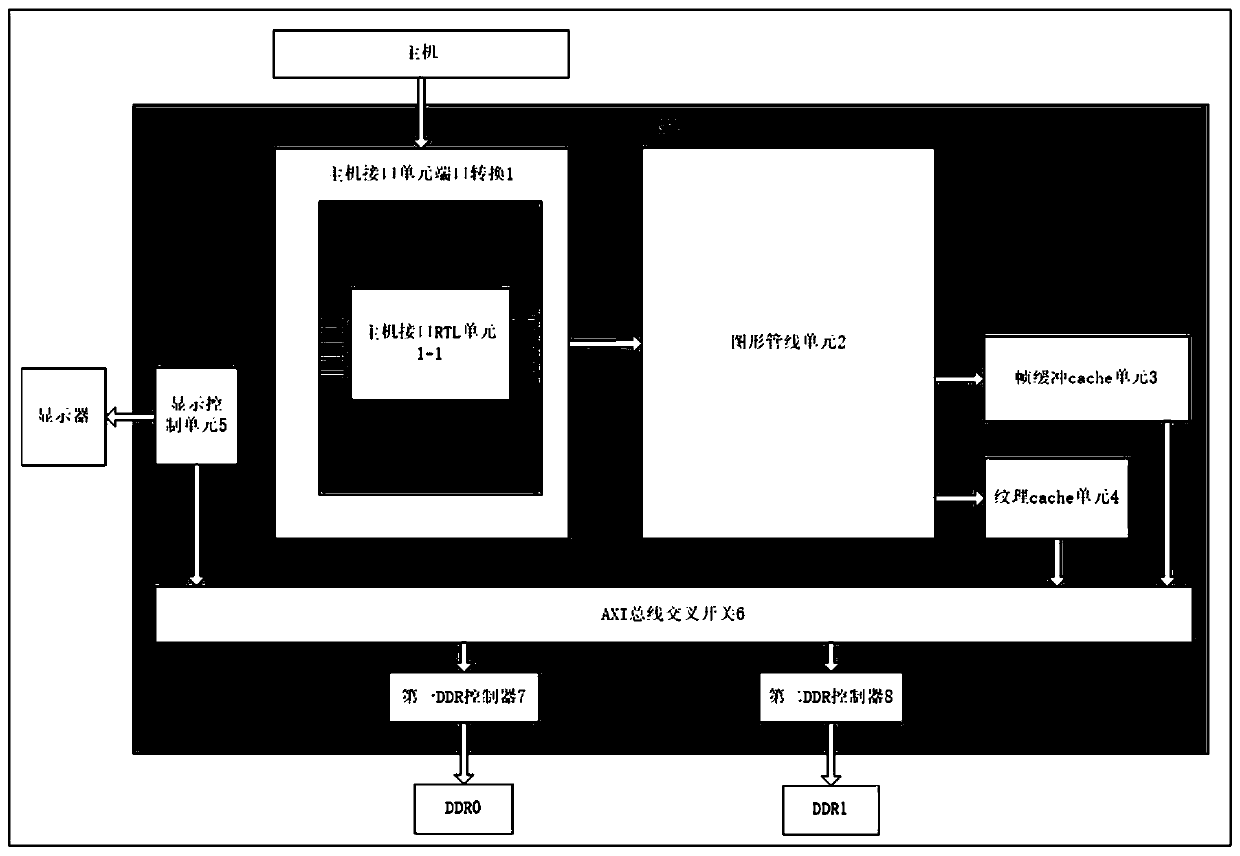

A GPU chip-oriented graphic pipeline unit performance verification method and a platform

The invention relates to the technical field of computer hardware verification, in particular to a GPU chip-oriented graphic pipeline unit performance verification method and a platform. According tothe method, a graphic processing unit (GPU) chip TLM virtual prototype platform based on SystemC is established (the virtual prototype verification platform comprises a host, an ROM, a display, DDR0,DDR1 and a GPU); a TLM transaction level port of a GPU graphic pipeline unit is converted into a hardware signal level port. By embedding the RTL code of the graphic pipeline unit into a TLM virtualprototype platform, and performing module-level and system-level function simulation on the RTL of the GPU to verify whether the RTL of the graphic pipeline unit meets the performance index of the corresponding model or not, whether the performance of the GPU graphic pipeline unit meets the requirement or not can be verified in advance before the FPGA stage, and the development and verification work of a GPU chip in the follow-up stage is accelerated.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

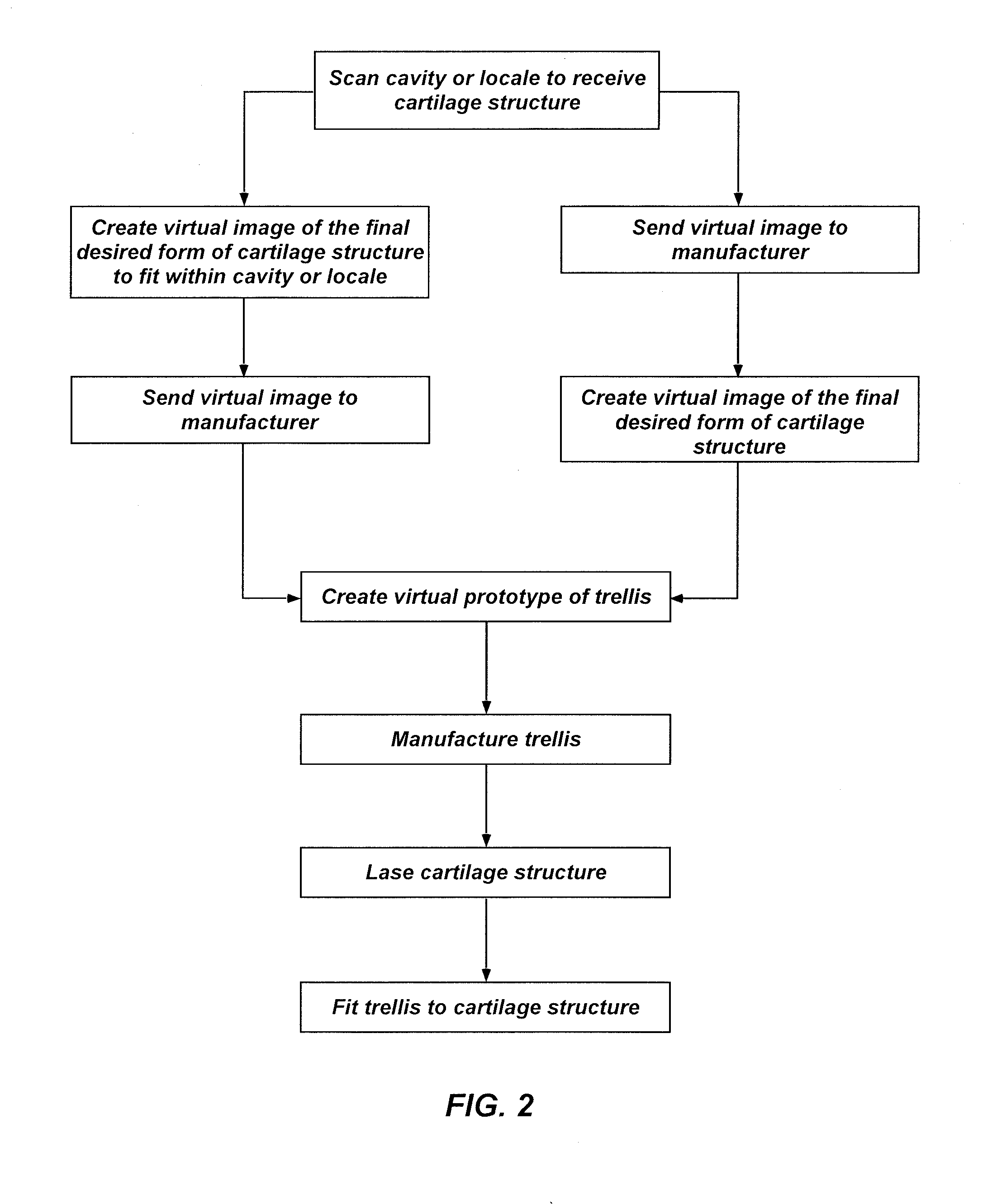

Devices and methods for reshaping cartilage structures

ActiveUS8715347B2Wide applicabilityLess painfulAdditive manufacturing apparatusEar treatmentComputer scienceVirtual prototyping

Described are methods of reshaping a cartilage structure. One such method comprises creating a virtual three dimensional image of the cartilage structure; manipulating the virtual three dimensional image of the cartilage structure so as to obtain a virtual three dimensional image of a desired final shape of the cartilage structure; creating a virtual prototype of a device to hold the cartilage structure in the desired final shape of the cartilage structure; manufacturing the device; lasing the cartilage structure; and fitting the manufactured device to the cartilage structure (e.g., ear).

Owner:CHONDROCYTE

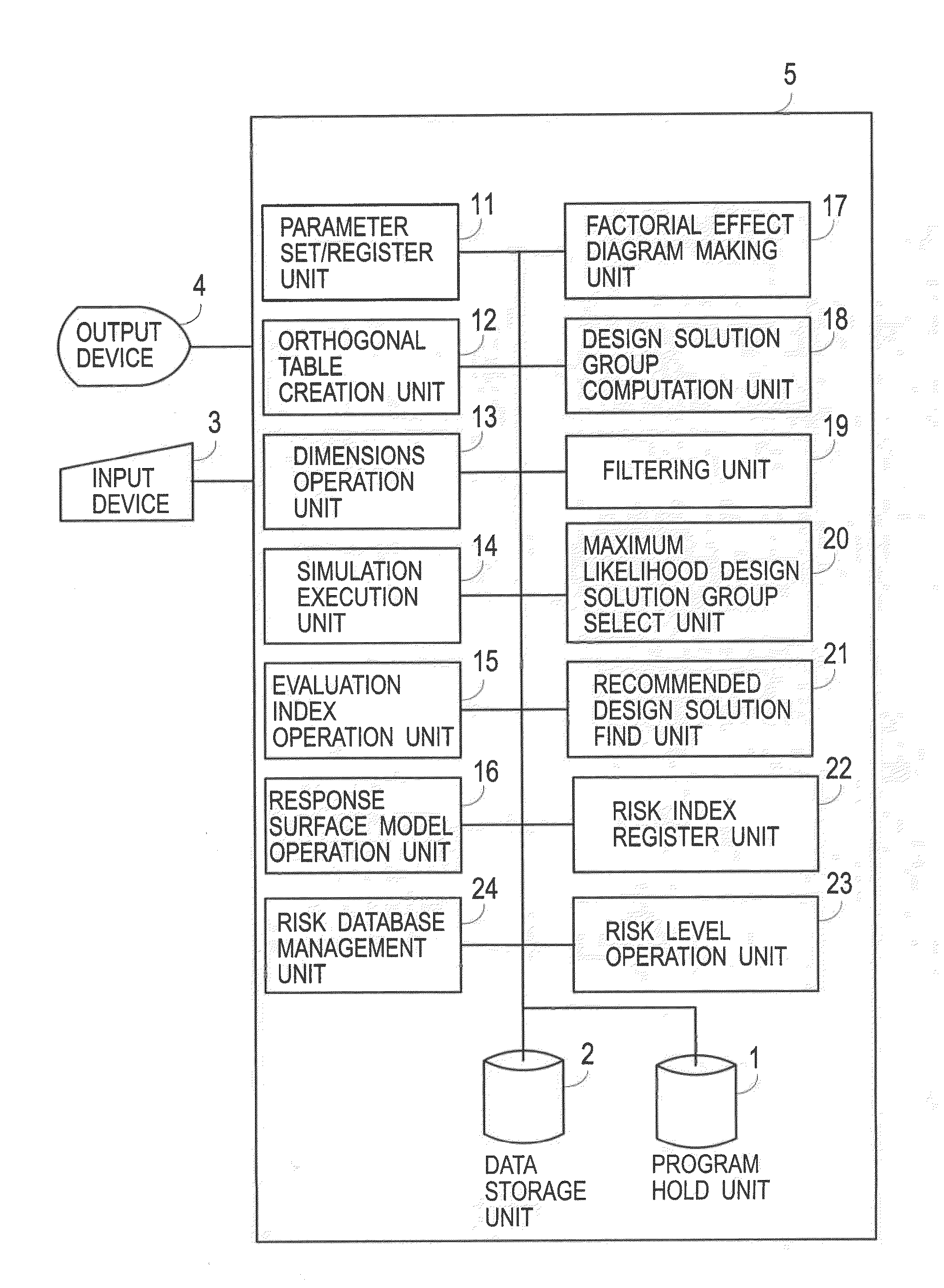

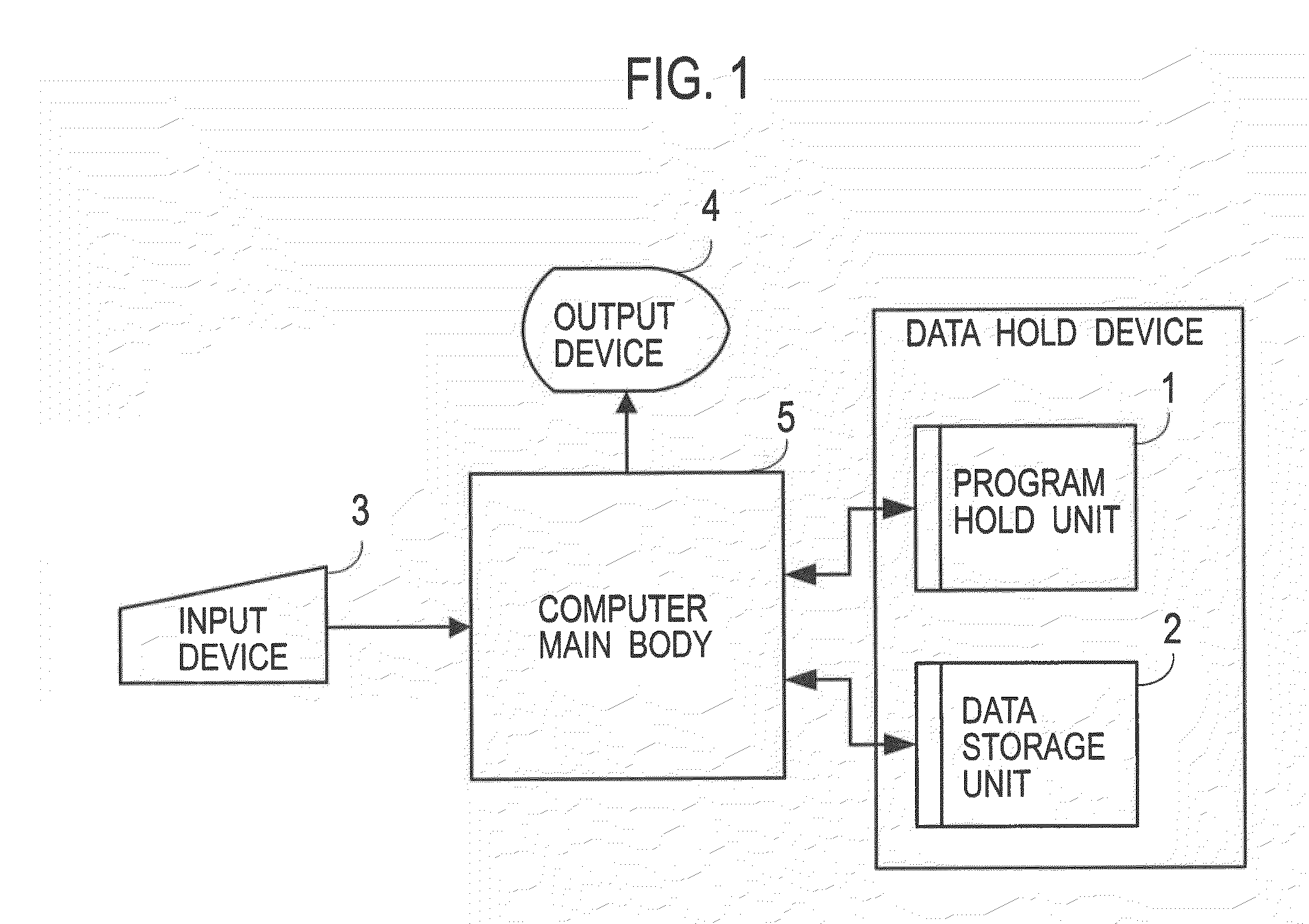

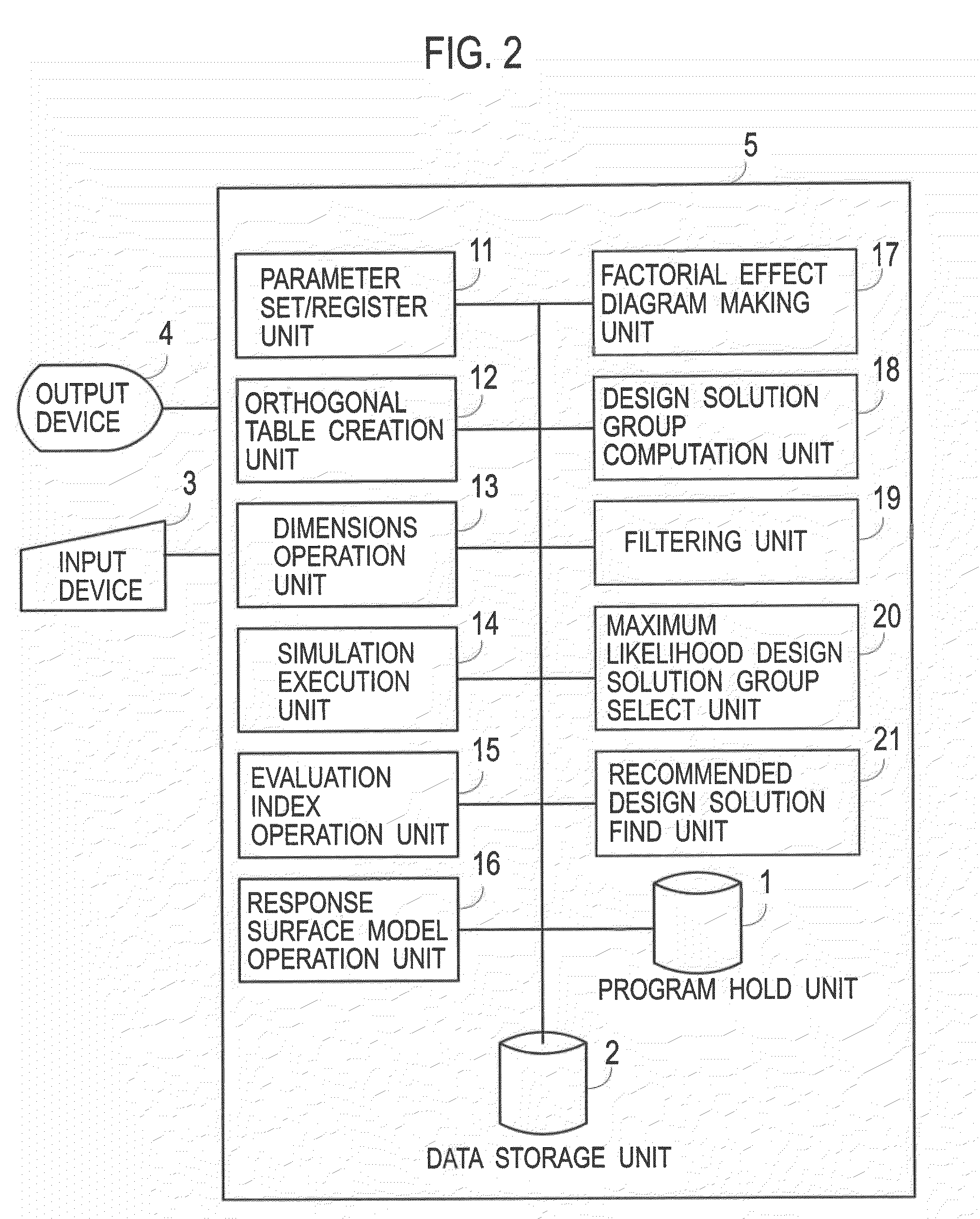

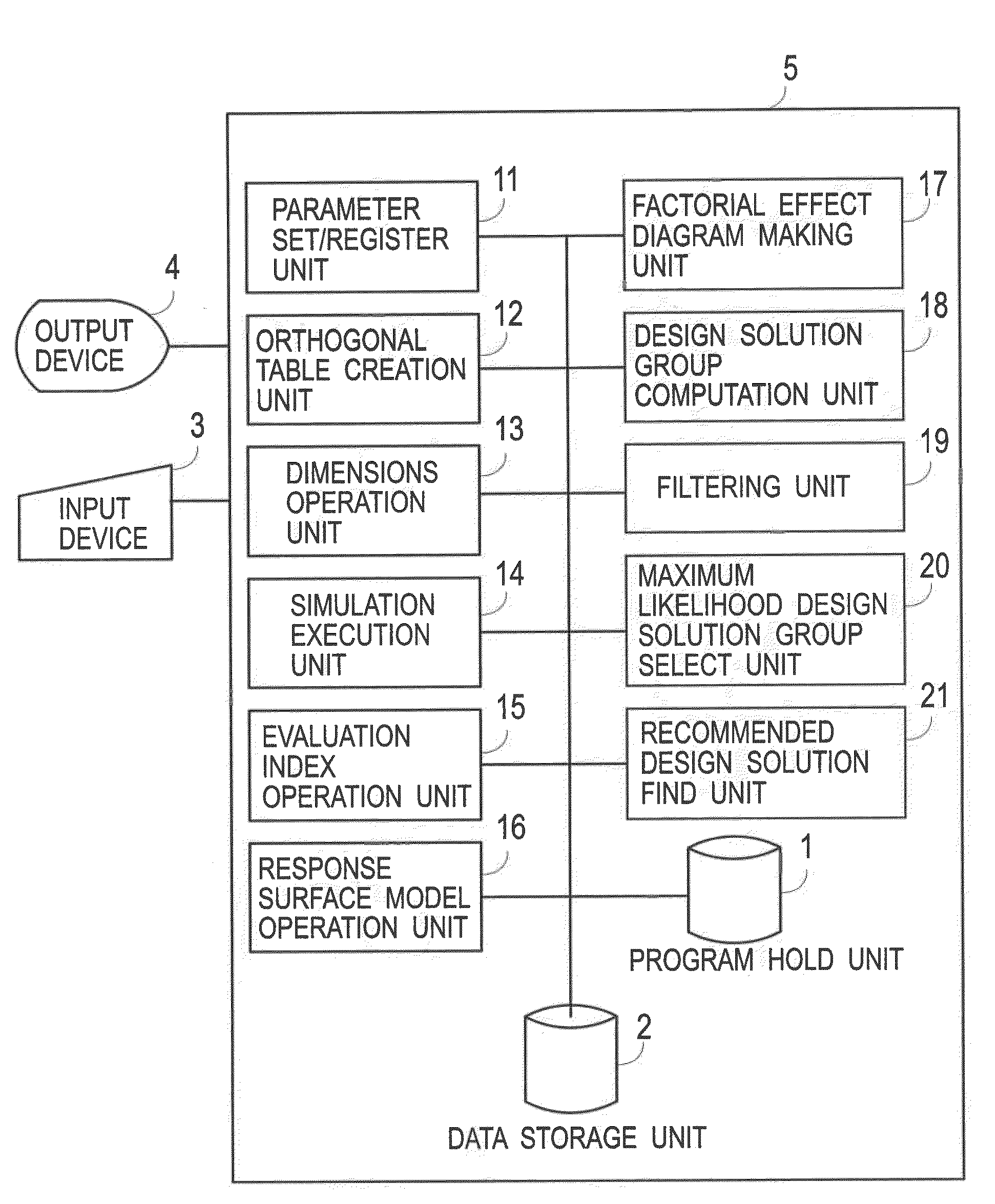

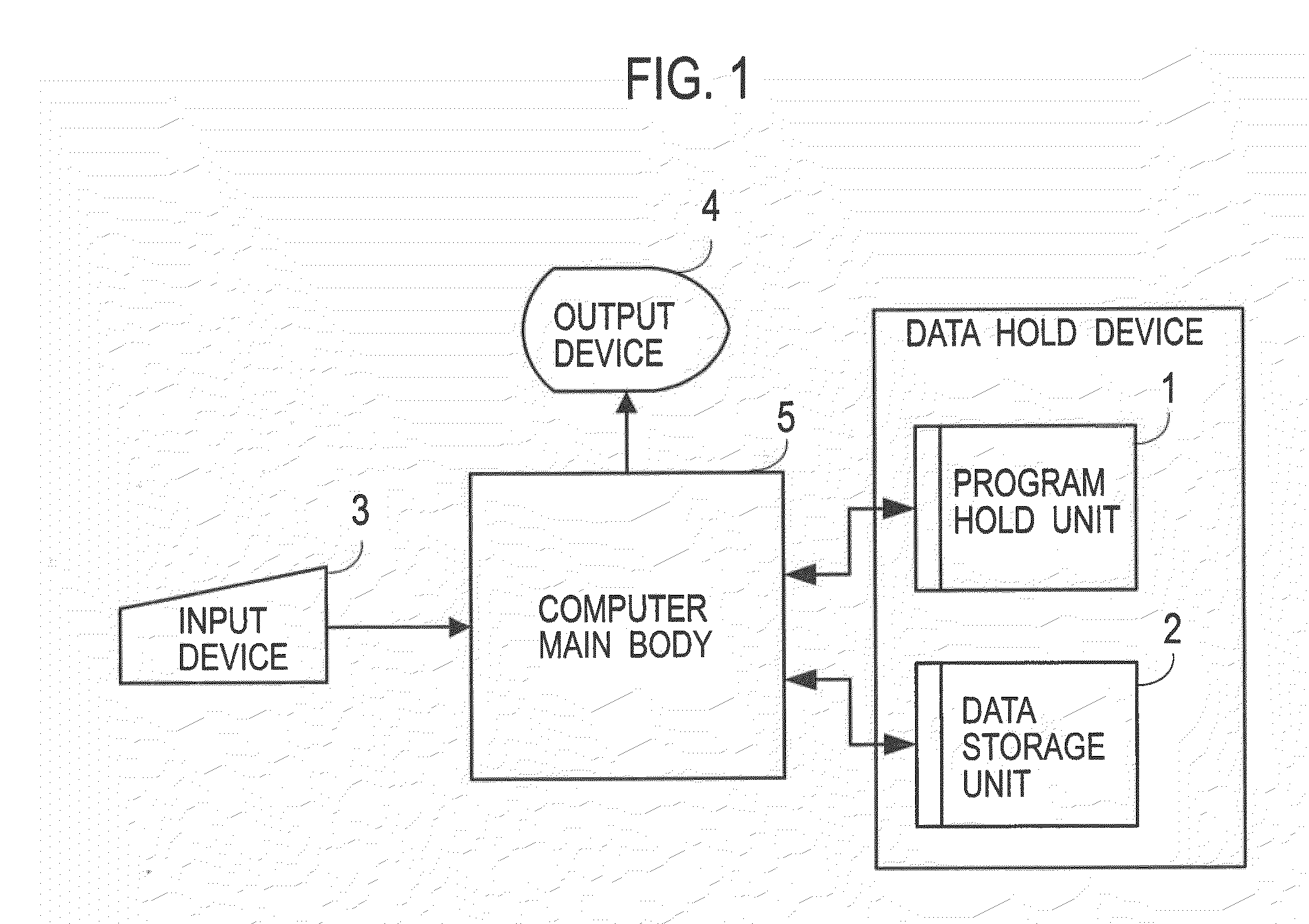

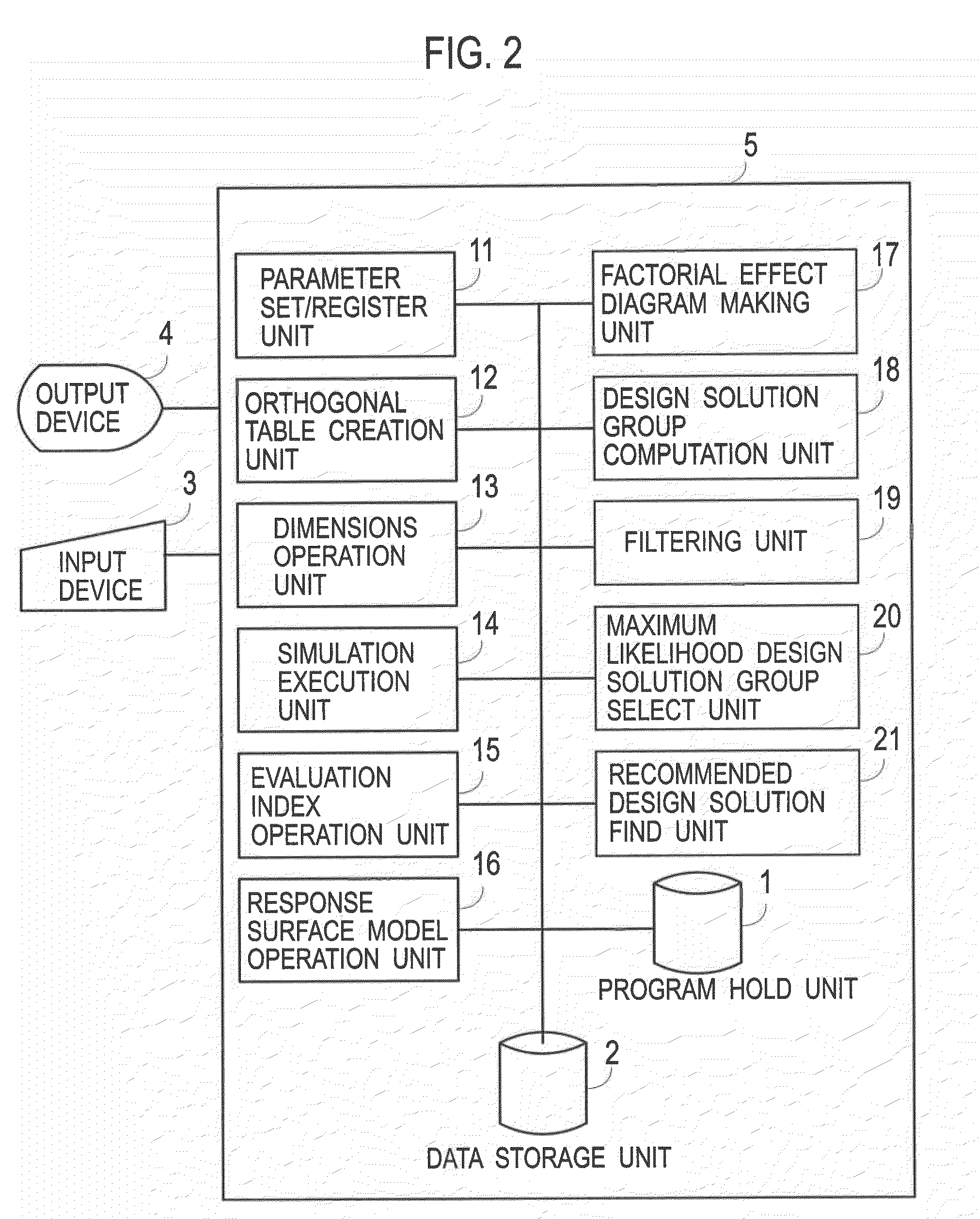

Product design support system and method for simulating a prototype of a design object

ActiveUS8589125B2Short timeSimple designGeometric CADAnalogue computers for electric apparatusSupporting systemDesign plan

The invention relates to a product design support system for supporting product design business so as to design and develop a product in a short time. The system creates an L-row orthogonal table according to set design parameters, executes many times, for each of L sets of design parameter groups, a virtual prototyping operation by adjusting the dimensional tolerance of each part, processes averages and variances of L sets of evaluation indexes obtained by the virtual prototyping operations, to form a response surface and response surface model, makes a factorial effect diagram of design parameters for each evaluation index, examines the factorial effect diagram, forms optional combinations of design parameters sensitive to the evaluation indexes, applies the combinations to the response surface model, forms many design solutions by optionally combining all design parameters that may achieve design target values, conducts filtering to extract a maximum likelihood design solution candidate group that achieves specified evaluation index limit values out of the design solutions, selects a maximum likelihood design solution group from the solution candidate group, and presents the same to a user.

Owner:IHI CORP

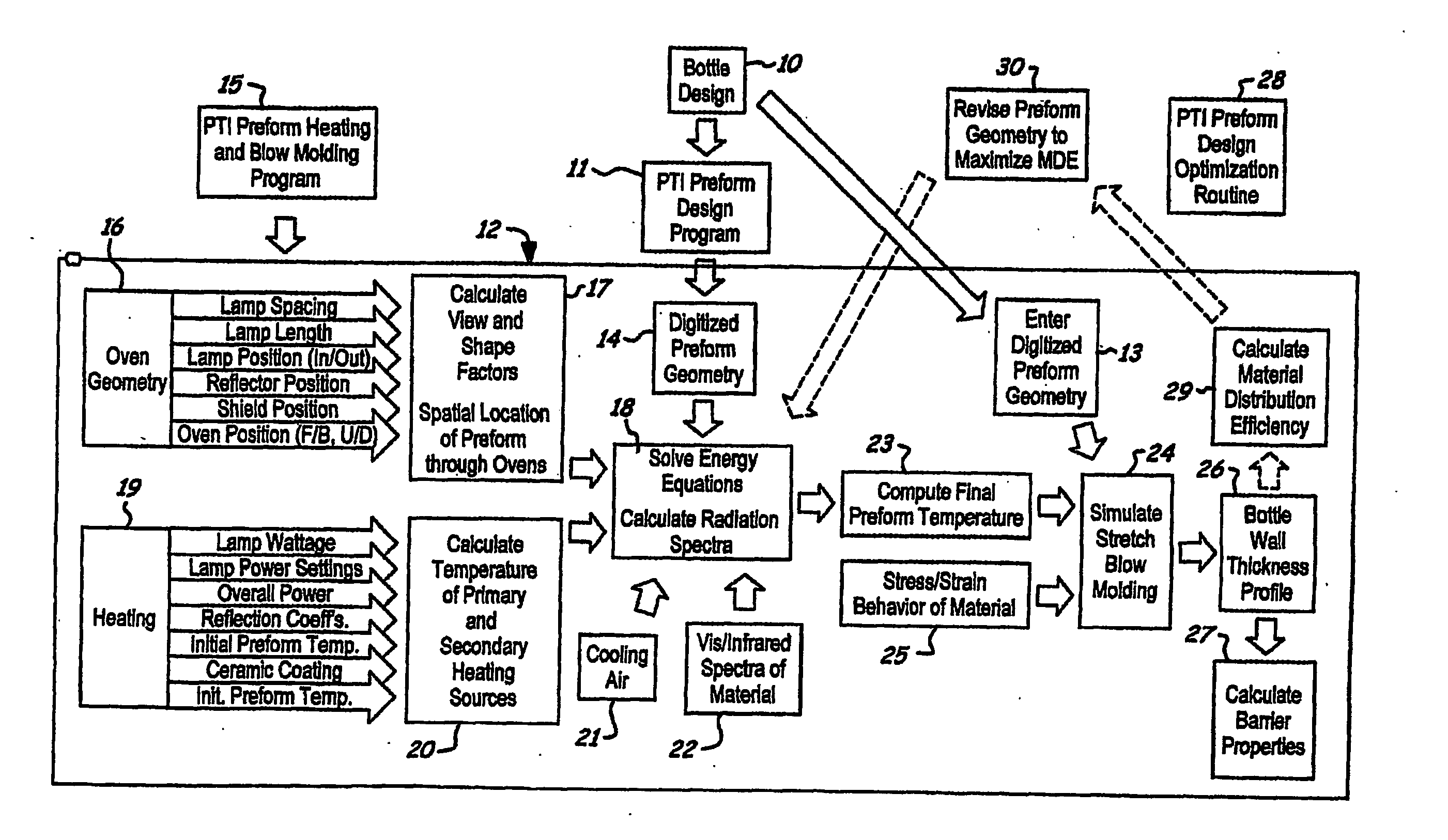

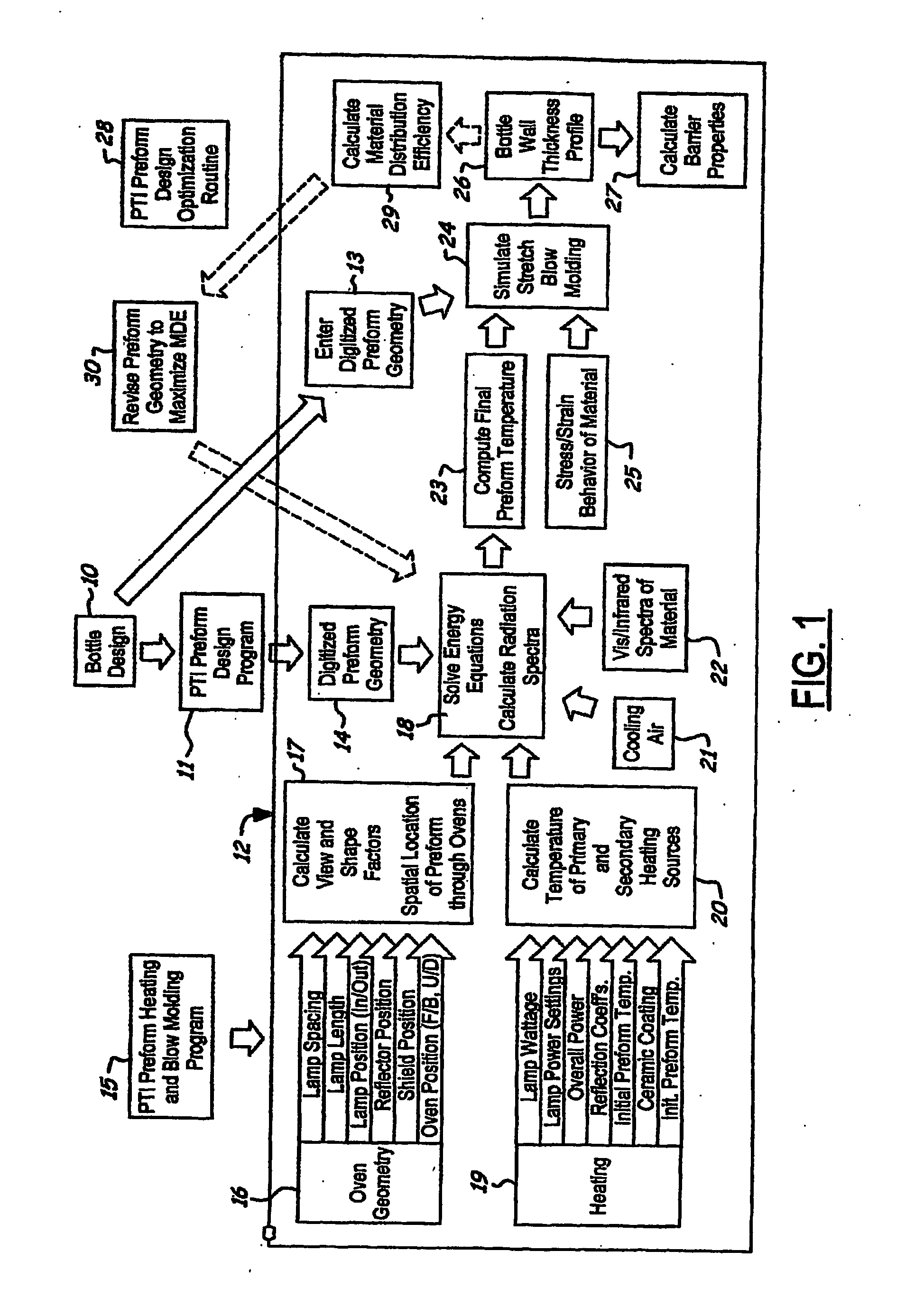

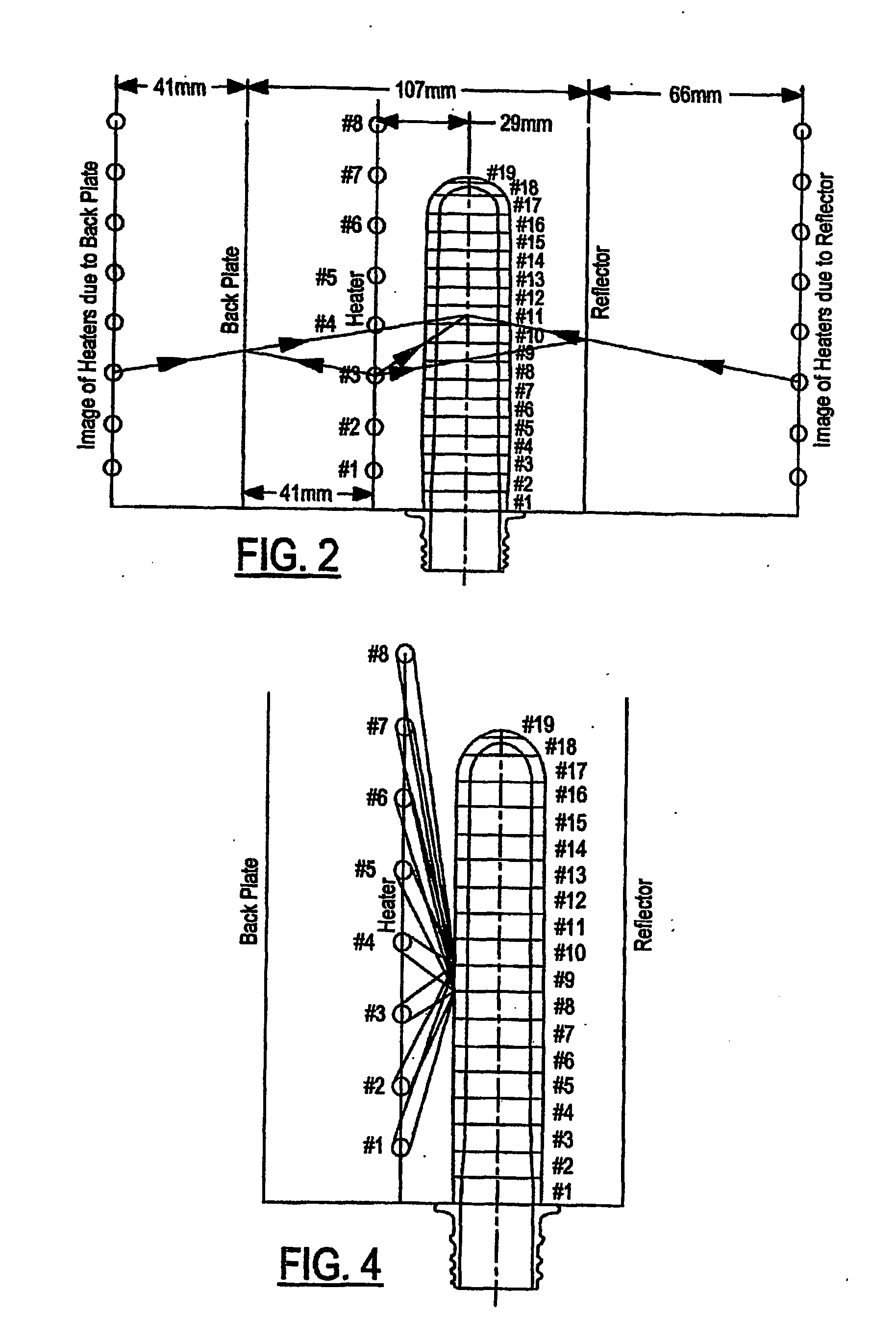

Apparatus and method for virtual prototyping of blow molded objects

InactiveUS20060074614A1Design optimisation/simulationDomestic articlesEnergy equationMaterials science

Owner:PLASTIC TECH INC

Product design support system and method

ActiveUS20100250200A1Short timeSimple designGeometric CADAnalogue computers for electric apparatusSupporting systemLimit value

The invention relates to a product design support system for supporting product design business so as to design and develop a product in a short time. The system creates an L-row orthogonal table according to set design parameters, executes many times, for each of L sets of design parameter groups, a virtual prototyping operation by adjusting the dimensional tolerance of each part, processes averages and variances of L sets of evaluation indexes obtained by the virtual prototyping operations, to fault a response surface and response surface model, makes a factorial effect diagram of design parameters for each evaluation index, examines the factorial effect diagram, forms optional combinations of design parameters sensitive to the evaluation indexes, applies the combinations to the response surface model, forms many design solutions by optionally combining all design parameters that may achieve design target values, conducts filtering to extract a maximum likelihood design solution candidate group that achieves specified evaluation index limit values out of the design solutions, selects a maximum likelihood design solution group from the solution candidate group, and presents the same to a user.

Owner:IHI CORP

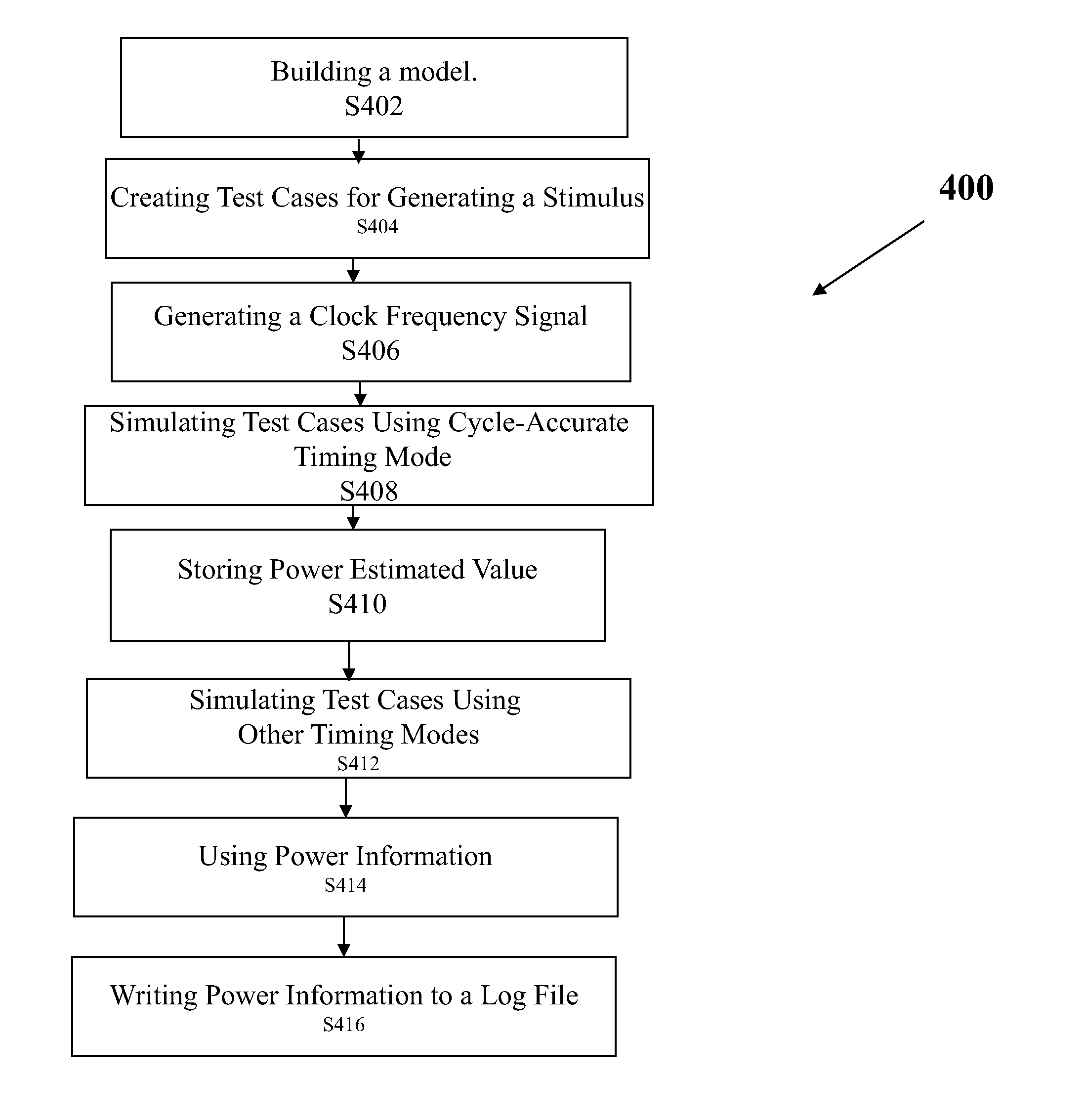

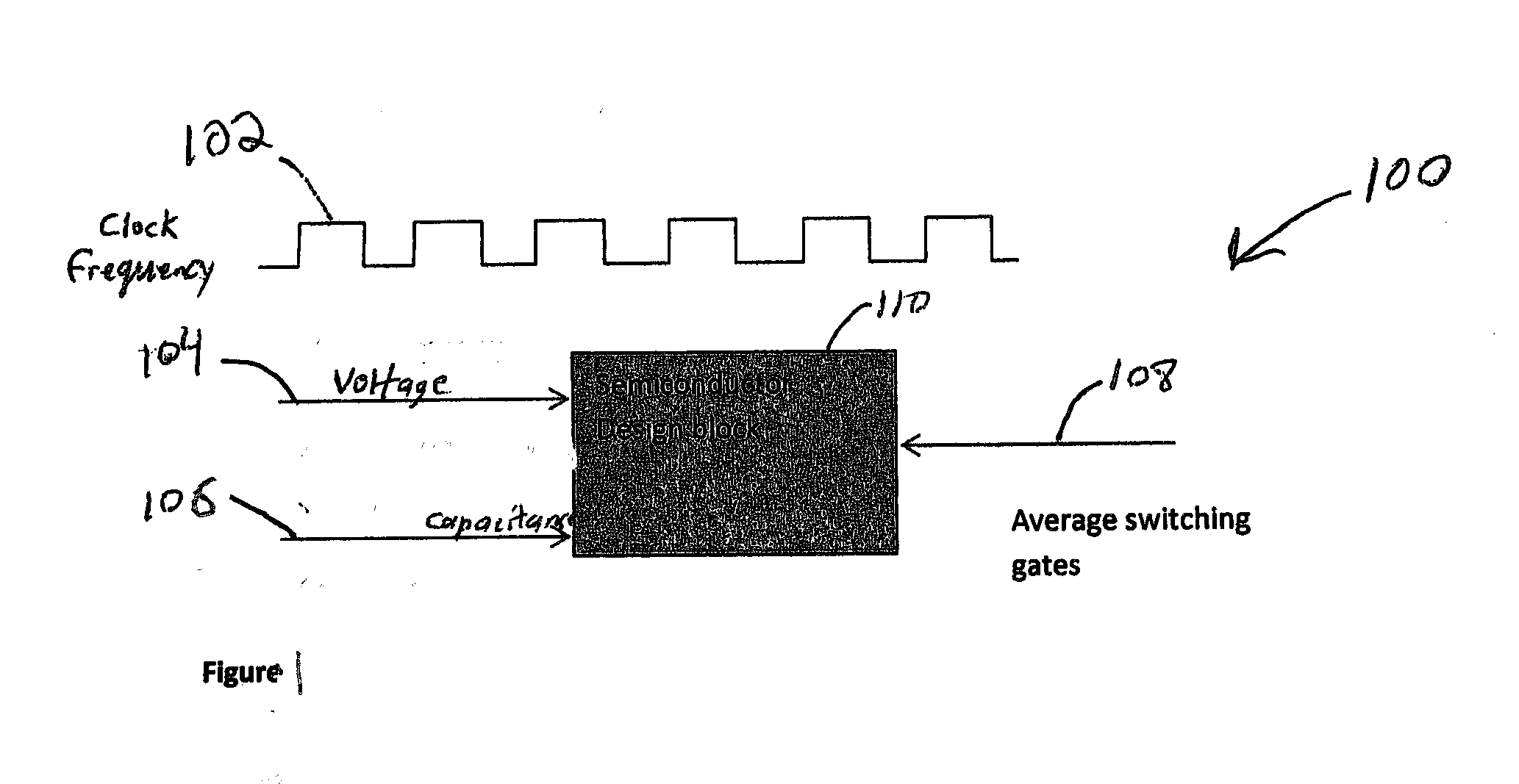

Method for power estimation for virtual prototyping models for semiconductors

ActiveUS20150067634A1Detecting faulty computer hardwareDesign optimisation/simulationComputer scienceSemiconductor

The present invention may comprise an apparatus and method for calculating power consumption, including a unit for generating a clock-level analysis without synthesis of an algorithm description and calculating operating ratios of storage elements and arithmetic units. The invention may also comprise a method for estimating the power to be consumed by a SystemC model. By estimating this value, a user may gauge the amount of power a specific semiconductor design might consume, once manufactured into a chip.

Owner:HUILGOL NINAD

A GPU chip-oriented graphic pipeline unit function simulation method and platform

PendingCN109711003ASolve the problem that is not easy to buildConvenience to workSpecial data processing applicationsGraphicsSystemC

The invention relates to the technical field of computer hardware verification, in particular to a graphic pipeline unit function simulation method and platform for a graphic processing unit (GPU) chip. According to the method, a graphic processing unit (GPU) chip TLM virtual prototype platform based on SystemC is established (the virtual prototype verification platform comprises a host, an ROM, adisplay, DDR0, DDR1 and a GPU); a TLM transaction level port of a GPU graphic pipeline unit is converted into a hardware signal level port, an RTL code of the graphic pipeline unit is embedded into aTLM virtual prototype platform, and module level and system level function simulation is carried out on the RTL of the GPU. Therefore, the problem that the behaviors of the GPU module-level RTL simulation environment model and the GPU system-level RTL simulation environment model are not unified is solved through the TLM virtual prototype platform, the reusability of the simulation environment isimproved, and the development and verification work of the GPU chip RTL is accelerated.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

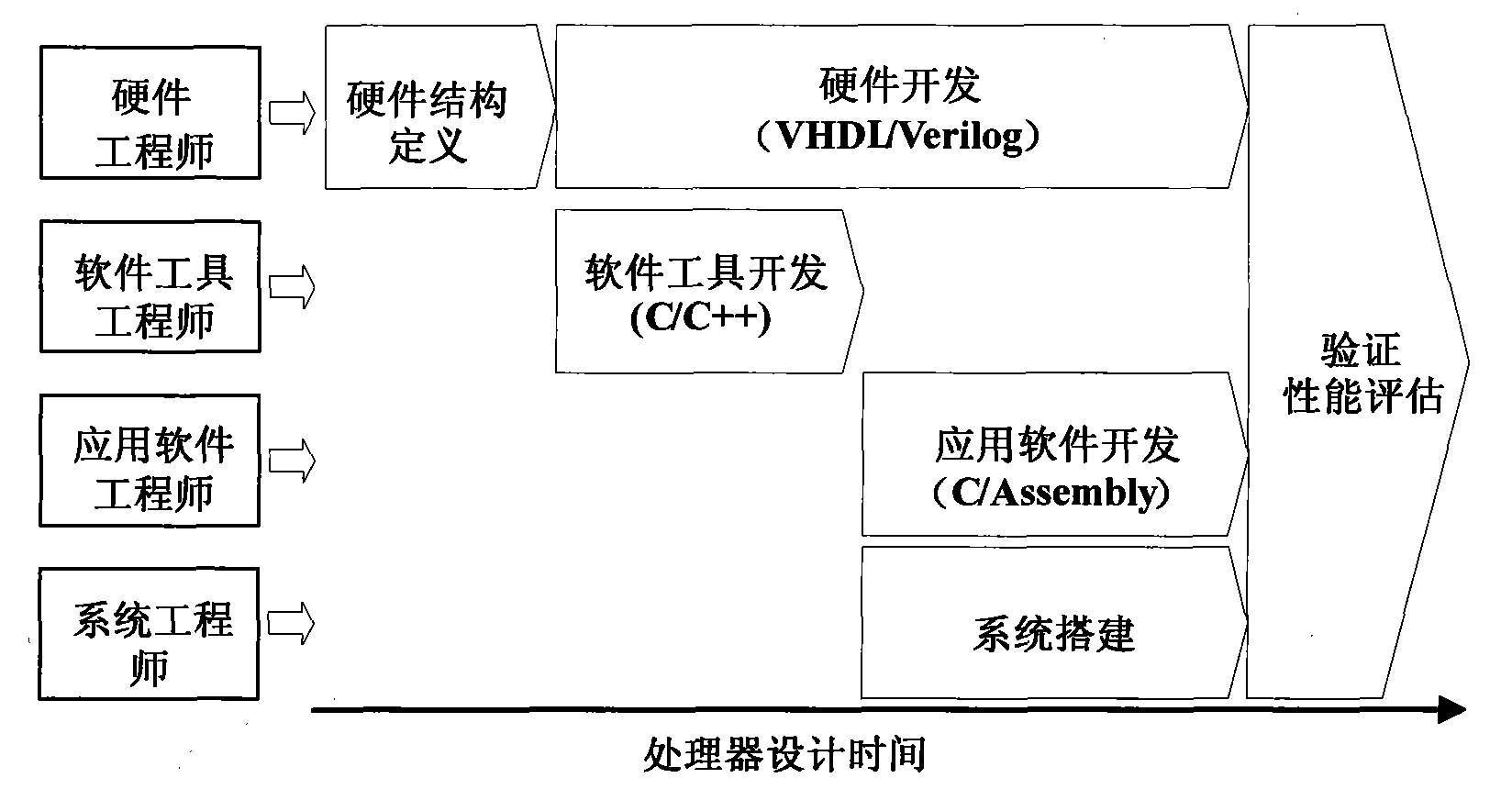

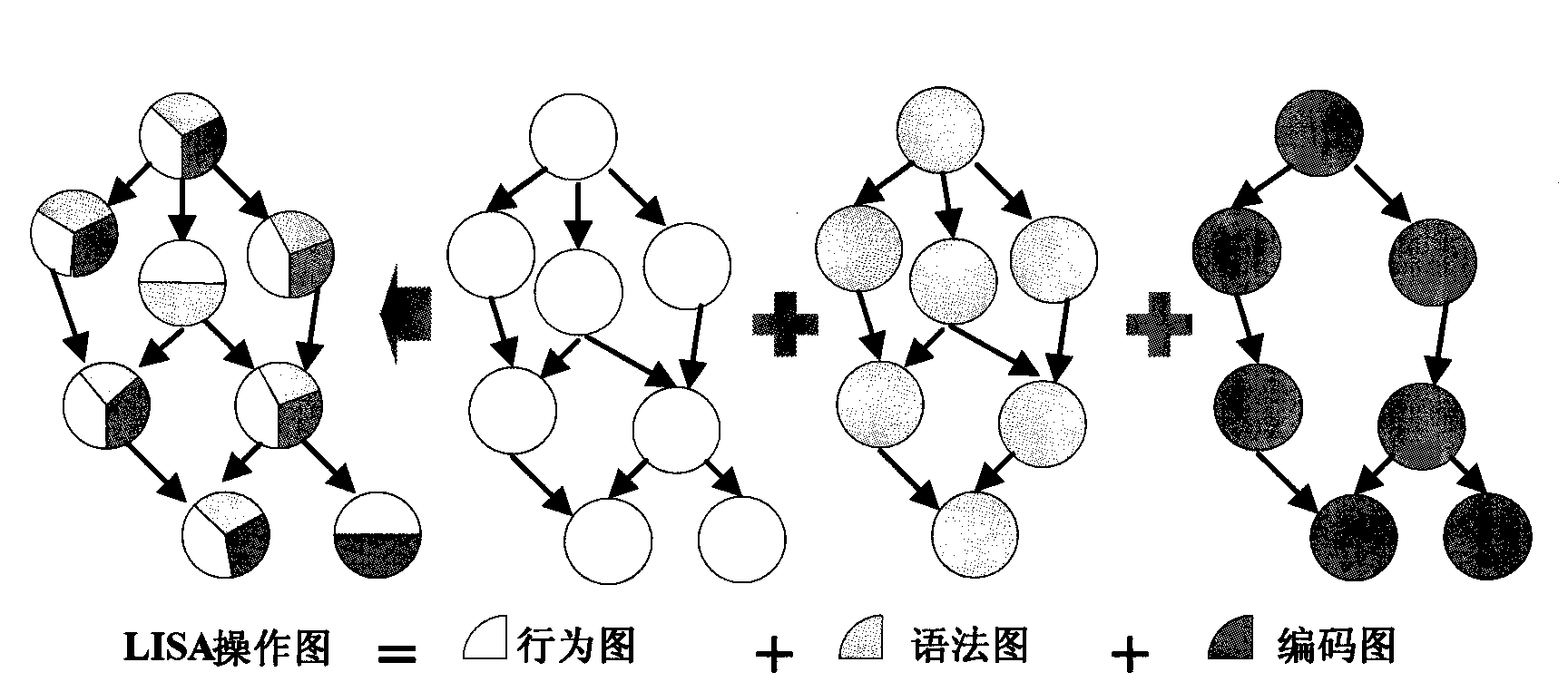

Method for designing specific instruction set processor

ActiveCN101561833AAccelerate Design CycleImprove performanceSpecial data processing applicationsProcessor modelComputer architecture

The invention relates to a method for designing a specific instruction set processor, and the method can make the accuracy performance evaluation at the beginning of designing a chip, advance the test of a specific application, speed up the design process and reduce the re-design possibility which is because the performances of the chip can not achieve the requirements. The method establishes an LISA processor model at the early stage of the design, generates a corresponding software tool by the LISA model, builds up a virtual prototyping platform which is similar to the performances of real hardware on an ARM ESL, including a AHB bus model with precise cycle, an EMI model and an SDRAM model which are needed for designing the platform, searches out the performances under the different situations by repairing the models of the processor, obtains an optical software / hardware dividing method, directly verifies on the models and speeds up the design cycle of the processor.

Owner:SOUTHEAST UNIV

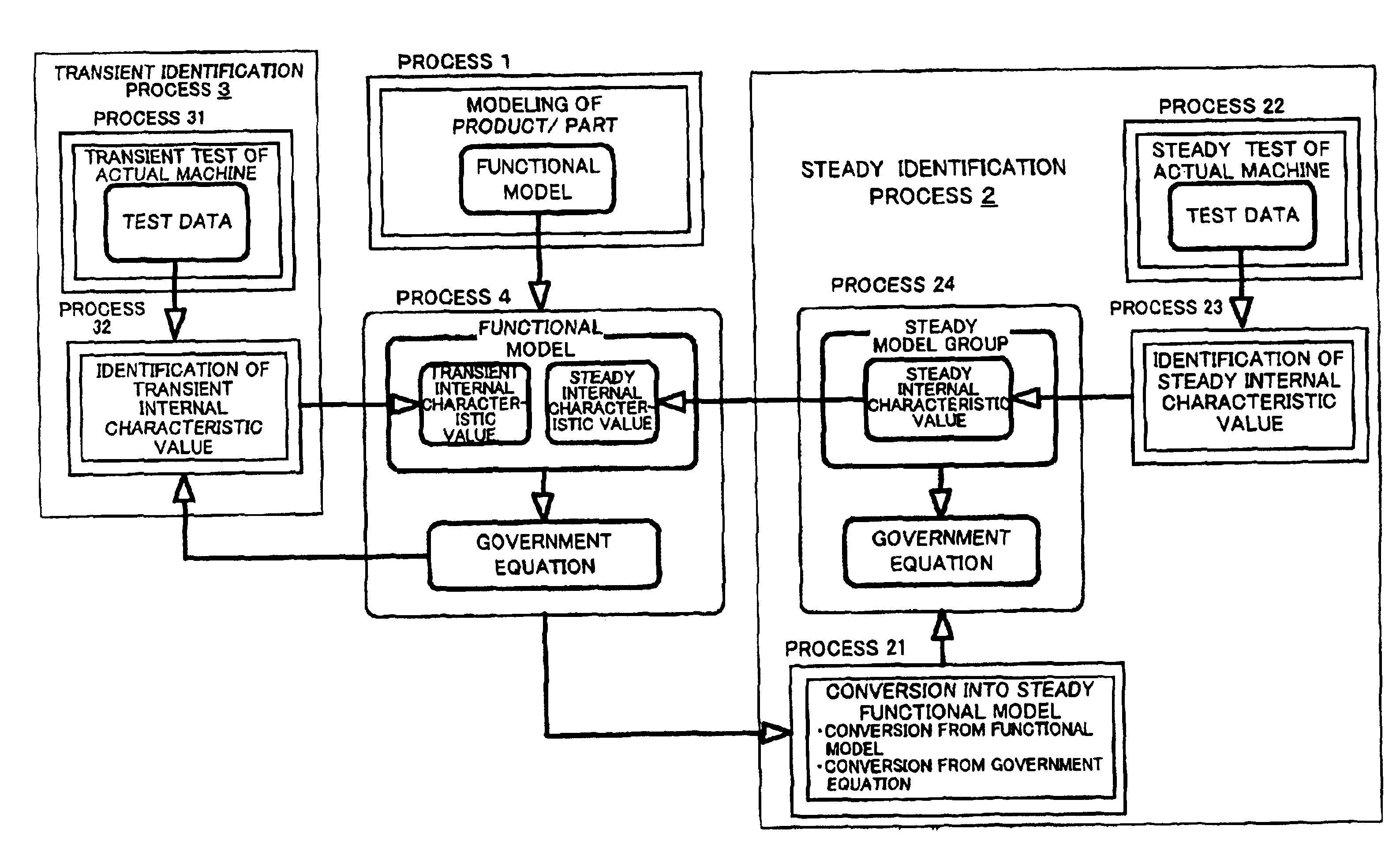

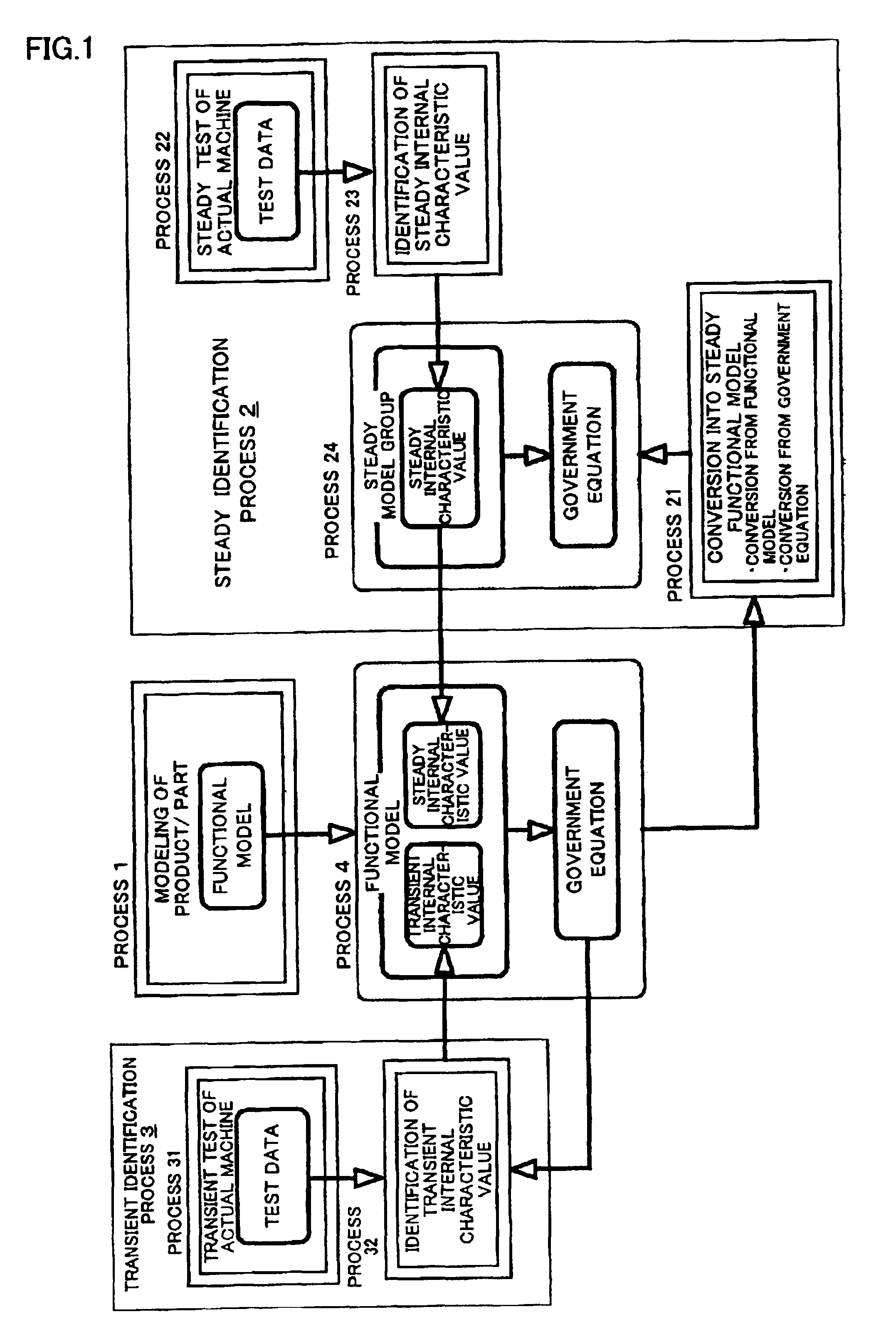

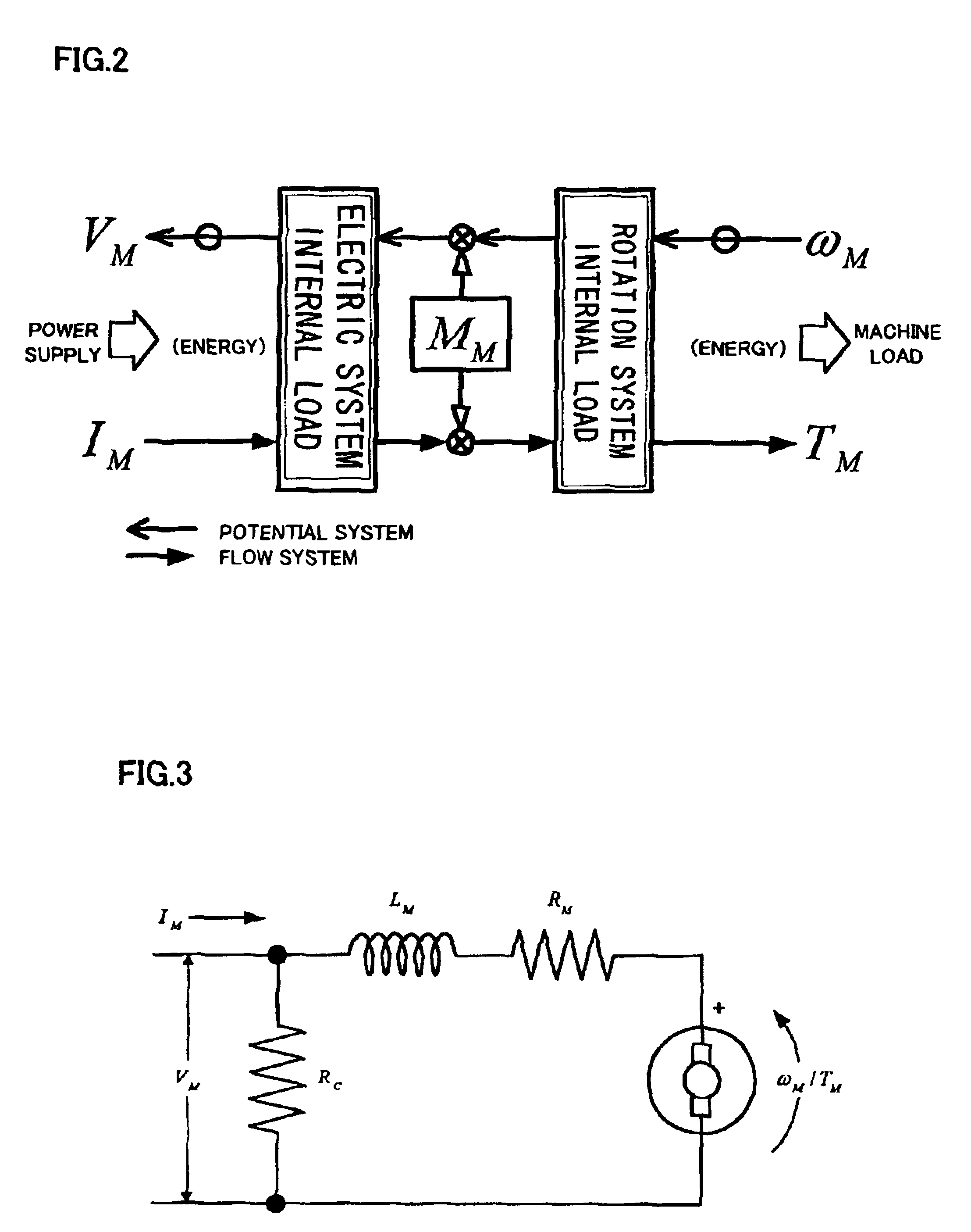

Method and apparatus for identifying characteristic value

InactiveUS6920413B2Accurate identificationQuick identificationAmplifier modifications to reduce noise influenceSimulator controlTransient stateRe identification

A characteristic value identification method and an apparatus therefor which can develop each model to be integrated into an entire model, similar to a product in which individual parts are combined, are provided. A functional model of a part is prepared based on a potential quantity and a flow quantity representing a strength and a quantity of energy applied to the part, a steady internal characteristic value of the functional model in a steady state is identified, and a transient internal characteristic value of the functional model in a transient state is identified by using the identified steady internal characteristic value. Furthermore, the functional model having the characteristic value identified by such an identification apparatus is incorporated into a virtual testing system as a virtual prototype, an internal characteristic value of the virtual prototype is evaluated by providing a driving operation condition and an environment condition, actual machine test data obtained by the driving operation condition and the environment condition are compared with the internal characteristic value, and a re-identification is performed depending on the comparison result if necessary.

Owner:ISUZU MOTORS LTD

Virtual prototyping and testing for medical device development

InactiveUS20110029297A1Advanced technologyFaster rateStentsDiagnosticsCardiovascular stentElement model

A system and method of developing better-designed medical devices, particularly cardiovascular stents and endovascular grafts. The system comprises a geometry generator, a mesh generator, a stress / strain / deformation analyzer, and a visualization tool. In one embodiment, the geometry generator receives three-dimensional volumetric data of an anatomical feature and generates a geometric model. The mesh generator then receives such geometric model of an anatomical feature or an in vitro model and a geometric model of a candidate medical device. In another embodiment, the mesh generator only receives a geometric model of the candidate medical device. Using the geometric model(s) received, the mesh generator creates or generates a mesh or a finite element model. The stress / strain / deformation analyzer then receives the mesh, and the material models and loads of that mesh. Using analysis, preferably non-linear analysis, the stress / strain / deformation analyzer determines the predicted stresses, strains, and deformations on the candidate medical device. Such stresses, strains, and deformations may optionally be simulated visually using a visualization tool.

Owner:ENDOLOGIX LLC

A non-programmer method for creating simulation-enabled 3d robotic models for immediate robotic simulation, without programming intervention

A system to design a virtual 3D model of the working robot so it can be tested in a virtual world is described. The system and the method for using same can be used to test, refine, redesign and improve multiple virtual prototypes of a robot. Once virtually tested, the optimized design specifications are printed out and used to build the optimized robot design.

Owner:COGMATION ROBOTICS

Method and apparatus for checking the buildability of a virtual prototype

InactiveUS20160357879A1Valid checkFaster and errorComputer aided designSpecial data processing applicationsComputerized systemSimulation

A method for checking the buildability of a virtual prototype includes an automatic ascertainment of possible problem points that may arise in the course of assembling the virtual prototype from virtual components and do not satisfy predetermined structural, physical and / or aesthetic requirements. The method includes an assessment, assisted by a computer system, of at least one of the possible problem points as a critical or uncritical problem point, depending on several structural, physical and / or aesthetic features of the respective possible problem point. Furthermore, an apparatus is proposed for checking the buildability of a virtual prototype. With methods and apparatuses according to exemplary embodiments, the effort in terms labour and time and also faulty assessments are capable of being reduced by an automatic assessment of problem points and by a more efficient assessment of problem points.

Owner:INVENIO VIRTUAL TECH GMBH

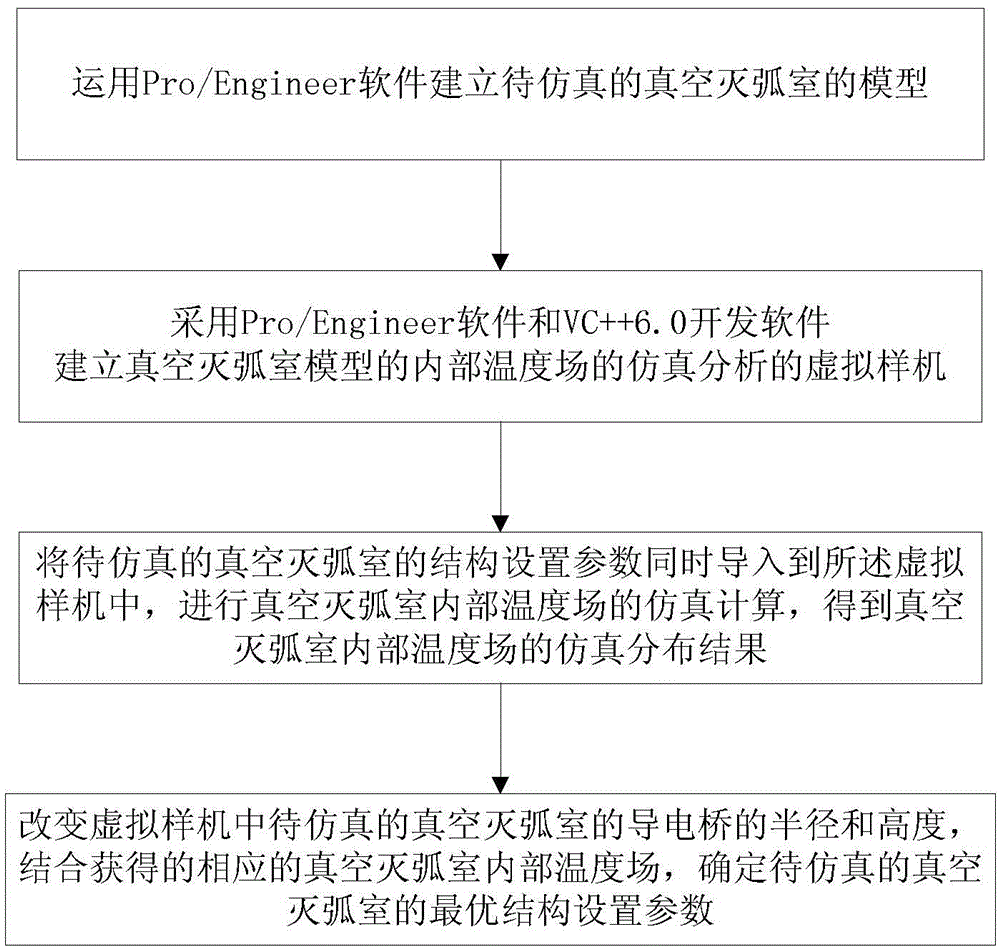

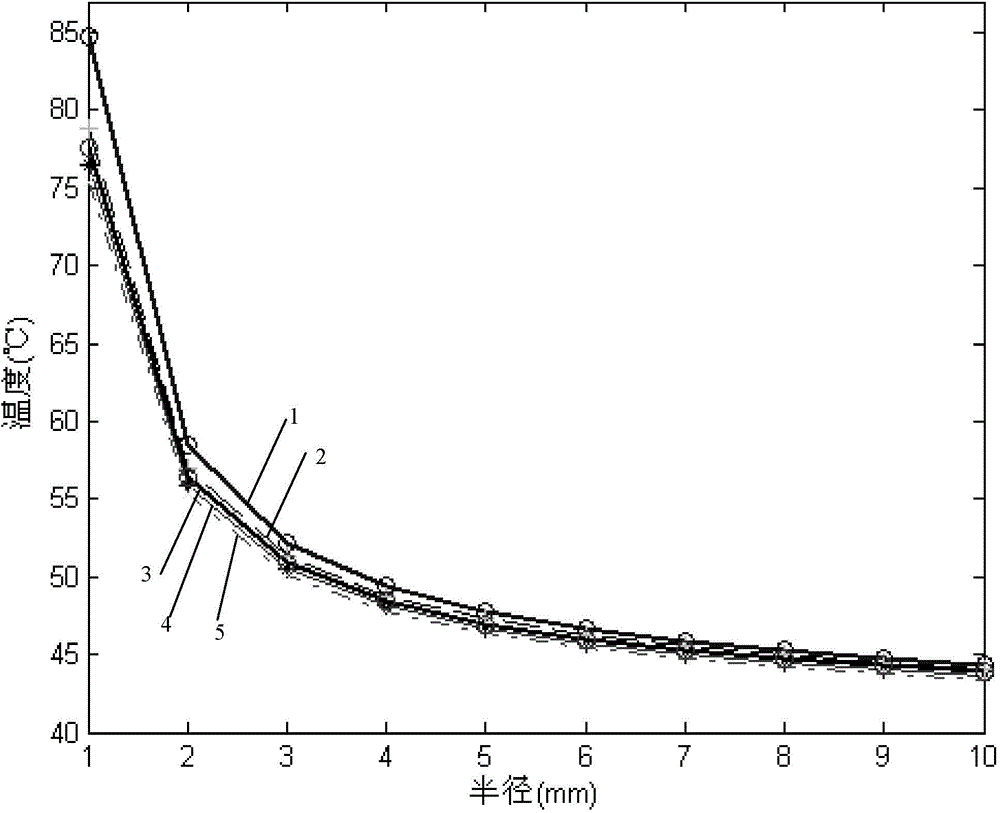

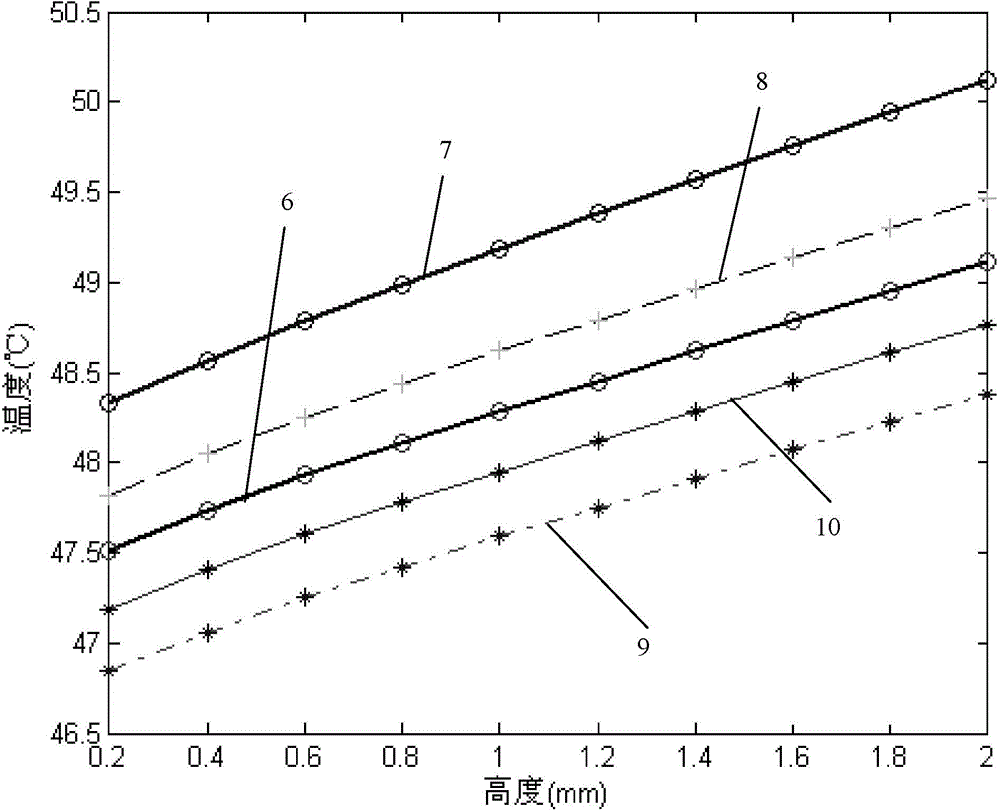

Vacuum interrupter simulation method and device of medium voltage vacuum interrupters internal temperature field based on virtual prototyping technology

ActiveCN103605855AShorten the design cycleSimplify the simulation processSpecial data processing applicationsModel parametersInternal temperature

Disclosed is a vacuum interrupter simulation method and device of a medium voltage vacuum interrupters internal temperature field based on a virtual prototyping technology. The invention relates to a simulation method and device, and aims to solve the problem that by means of an existing simulation method of the vacuum interrupters internal temperature field, when a model is established, a design period of an interrupter is prolonged when simulation model parameters are modified continuously. Function expansion can be performed on Pro / Engineer software through VC + +6.0 development software, a virtual prototype used for simulation analysis of the vacuum interrupters internal temperature field is established, the simulation model is inputted into the virtual prototype, simulation calculation of the interrupters internal temperature field is performed, influences on the interrupters internal temperature field by the radius and height of a conductive bridge of the vacuum interrupter can be analyzed according to simulation results, and optimal structural arranging parameters of the vacuum interrupter is determined. The method and device are used for simulating the vacuum interrupter.

Owner:STATE GRID CORP OF CHINA +2

GPU chip-oriented host interface unit performance simulation method and platform

PendingCN110955572ASolve the problem that is not easy to buildConvenience to workFunctional testingSystemCModelSim

The invention belongs to the technical field of computer hardware verification, relates to a GPU performance simulation method and platform based on a SystemC TLM virtual prototype,especially to a GPUchip-oriented host interface unit performance simulation method and platform. According to the method, the SystemC is adopted to perform TLM modeling on the performance of the GPU according to moduledivision, and TLM modules of any scale and any level in the GPU can be replaced with RTL codes, so that the RTL module simulation platform of the GPU can reuse a GPU virtual prototype platform.According to the method, the SystemC is adopted to perform TLM modeling on the performance of the GPU according to module division, and the whole TLM model of the GPU can be replaced with the RTL codes, sothat the RTL system simulation platform of the GPU reuses the GPU virtual prototype platform. According to the method and the platform, coordination of work among software personnel, hardware module RTL developers and simulation verification personnel is facilitated, and unnecessary iteration is reduced.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

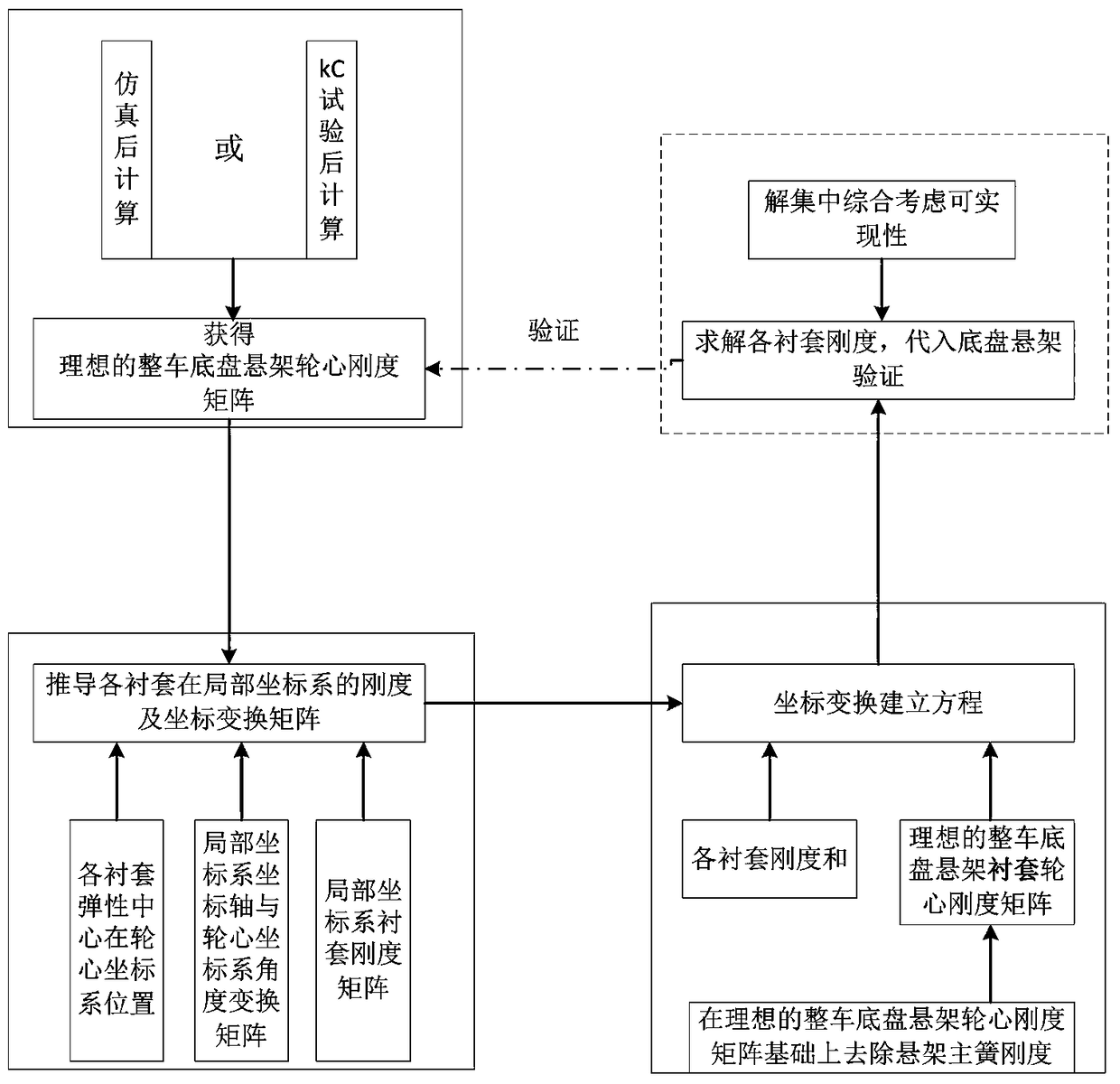

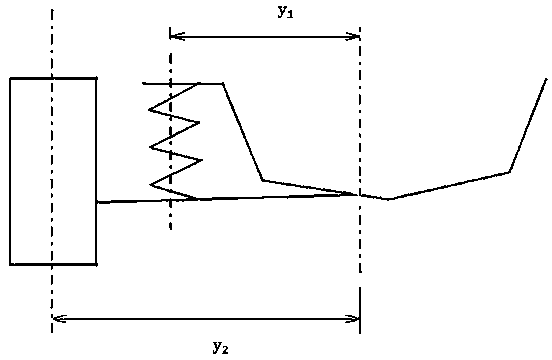

Automobile chassis lining matching method based on rigidity matrix

InactiveCN108202573AAvoid trial and errorOptimize the development matching processSuspensionsDesign optimisation/simulationKinematicsDesign stage

The invention discloses an automobile chassis lining matching method based on a rigidity matrix and relates to an automobile chassis system. As for determining of the rigidity of linings of suspension, all possible combinations of the rigidity of linings of a chassis for meeting target elastic kinematics performance are precisely provided; through the method, the current situations that the linings are selected according to experience and based on single parts, and systematic understanding to the chassis linings is lacked are improved, repeated trials and errors during matching of the chassissuspension linings are avoided, and the number of the trials is greatly decreased; the suspension development matching process is optimized, and a large number of costs can be saved in application; meanwhile, the virtual prototyping development trend of current automobile development is also met, the elastic kinematics performance of the chassis suspension can be optimized directionally without the need of manufacturing an actual automobile, the suspension matching time is shortened, and the automobile development progress is accelerated; and the optimal solution of the elastic kinematics performance of a given target can be achieved with a minimum number of the linings, the possible design redundancy at the chassis suspension lining designing stage is removed, and the automobile cost is saved.

Owner:BRILLIANCE AUTO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com