Hydraulic servo system based on virtual prototyping technique

A hydraulic servo and prototype technology, applied in fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the problems of long production cycle and high cost, and achieve convenient operation, compact structure and easy promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention can be implemented according to the accompanying drawings, which will be further described in detail below in conjunction with the accompanying drawings.

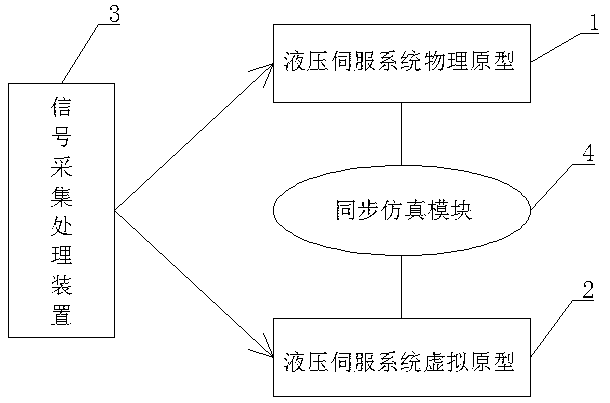

[0021] Depend on figure 1 A new hydraulic servo device based on virtual prototype technology is shown, which is mainly composed of a physical prototype 1 of a hydraulic servo device, a virtual prototype 2 of a hydraulic servo device, a signal acquisition and processing device 3 and a synchronous simulation module 4 .

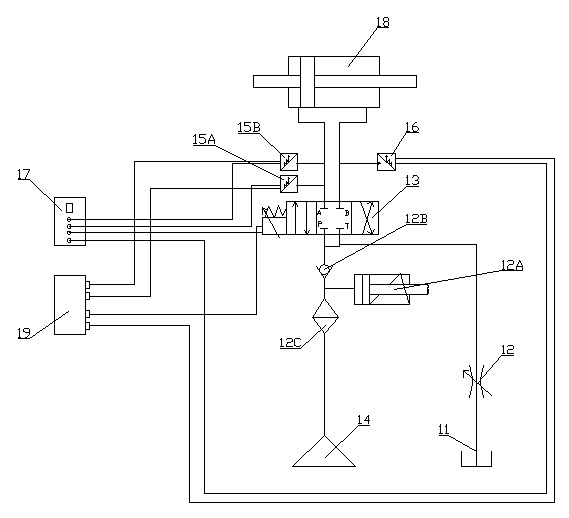

[0022] Depend on figure 2 It shows a schematic diagram of the physical prototype structure of the hydraulic servo device. The physical prototype 1 of the hydraulic servo device consists of a fuel tank 11, a throttle valve 12, an overflow valve 12A, a one-way valve 12B, an oil filter valve 12C, a servo valve 13, a hydraulic pump 14, and a pressure sensor. 15A, a displacement sensor 15B, a flow measuring device 16, a 24V DC power supply 17, a workbench 18 and a signal acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com