Patents

Literature

158 results about "Linear analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

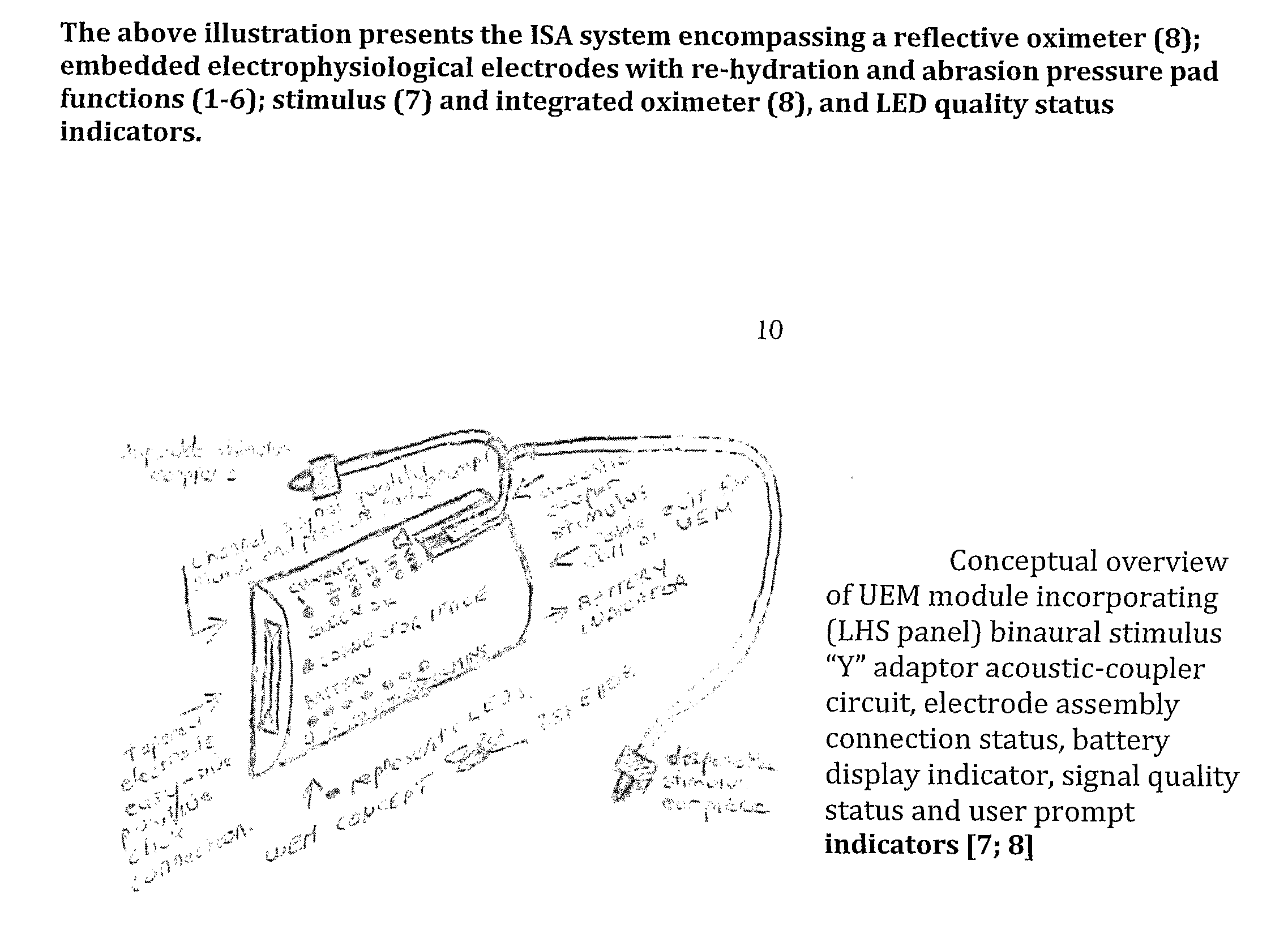

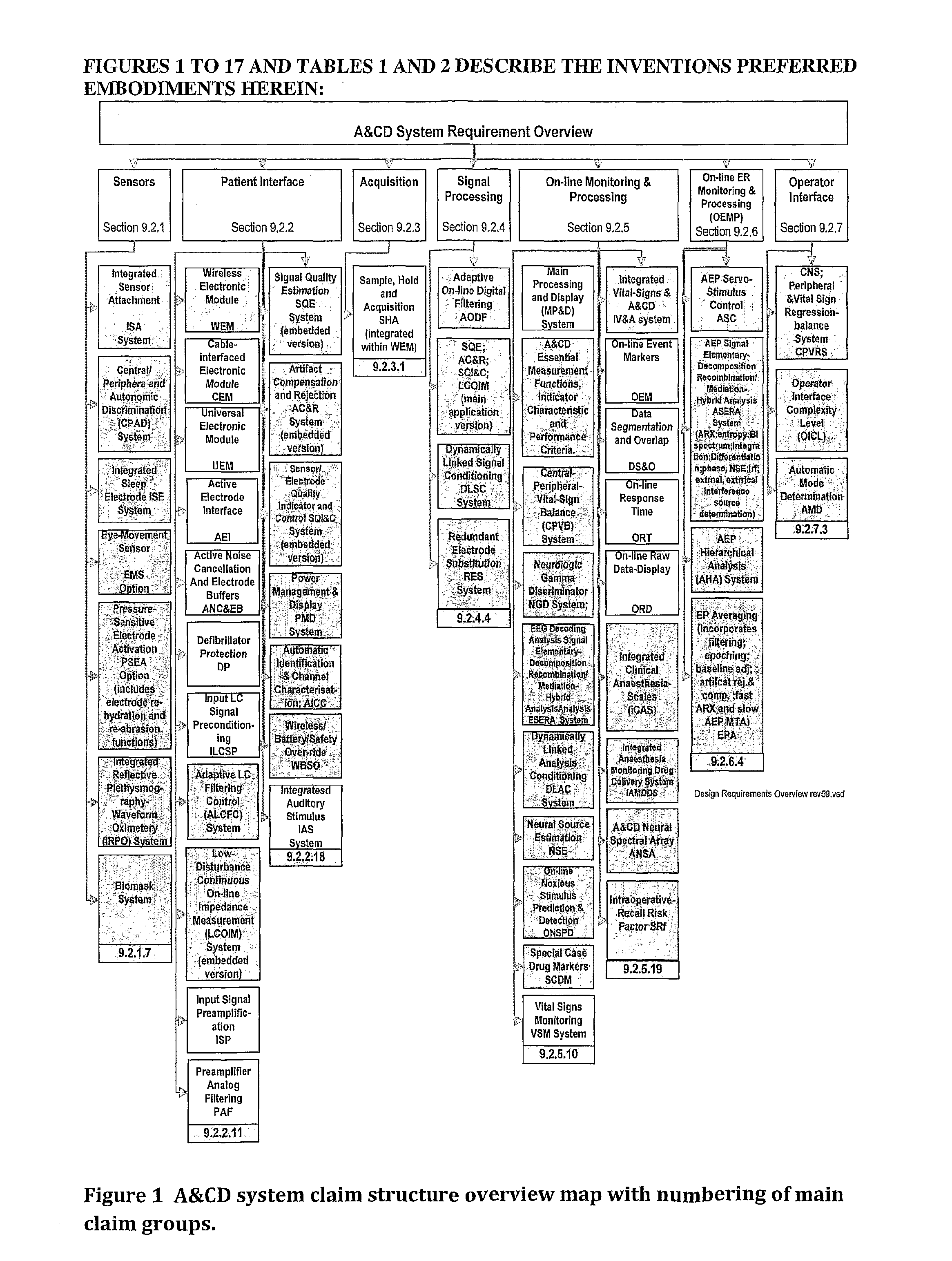

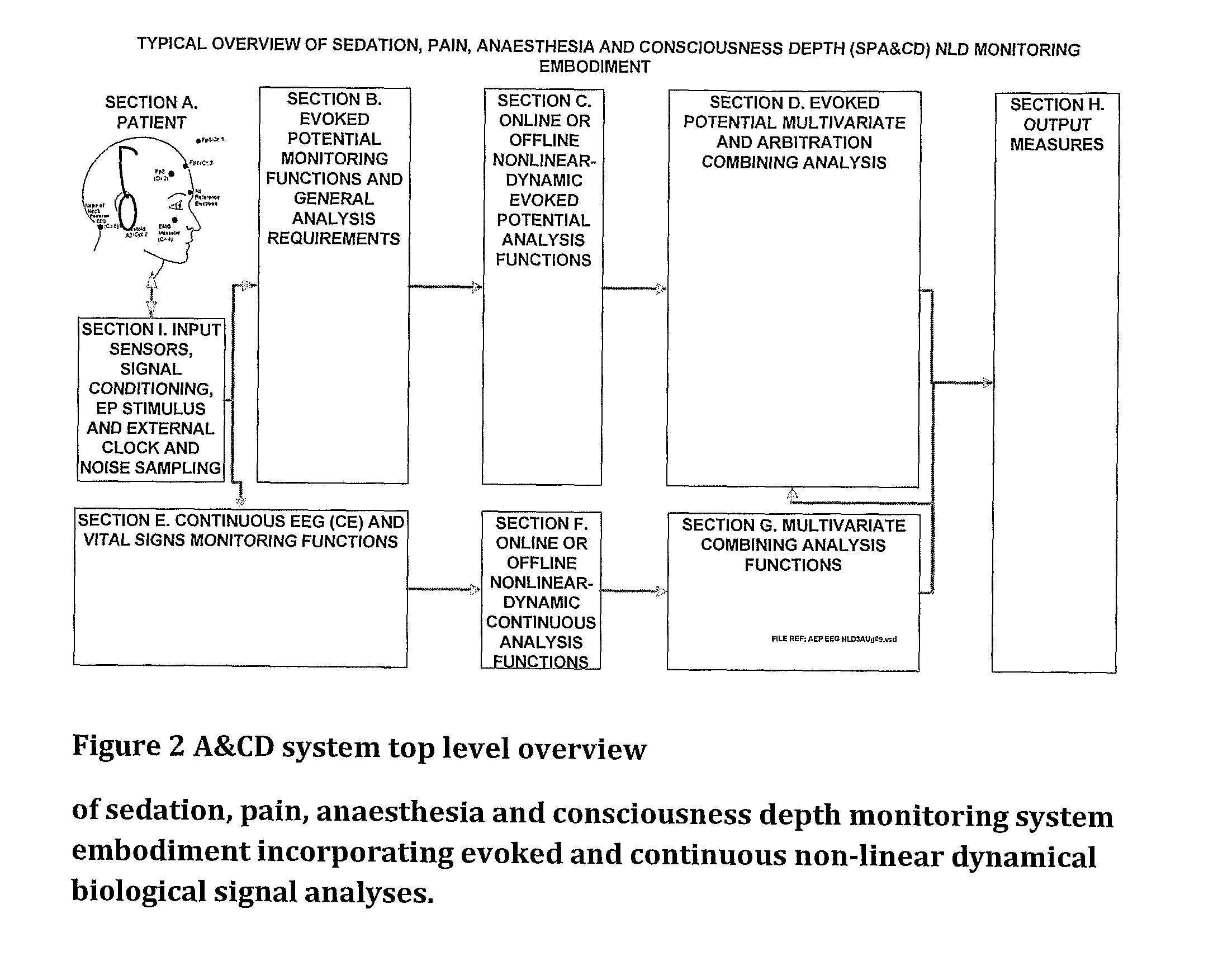

Anaesthesia and consciousness depth monitoring system

ActiveUS20120277548A1Minimize unwanted external signal interferenceGood signalElectroencephalographyElectrocardiographyBiological bodyNervous system

Methods and systems incorporating non-linear dynamic (NLD) analysis such as entropy or other complexity analysis monitoring continuous or evoked signals from a biological subject are presented, where such a system comprises of processing steps including: a) the combination of a biological signal evoked as a result of patient stimulation presented to a biological subject and a non-linear analysis method capable of capturing temporal changes in signal order or regularity; b) any combination of processed evoked or continuous central nervous or peripheral physiological mechanisms b) a means to generate a measure indicative of a patient's level of anaesthesia and consciousness depth (A&CD), sedation or sleep / wake state. Methods and systems incorporating a NLD analysis means to improve the discrimination between different signals origins including any combination of: a) central nervous system (CNS), b) peripheral control or nervous system (PNS), c) autonomic control or nervous system (ANS), d) arousals, and e) artifacts.

Owner:BURTON DAVID

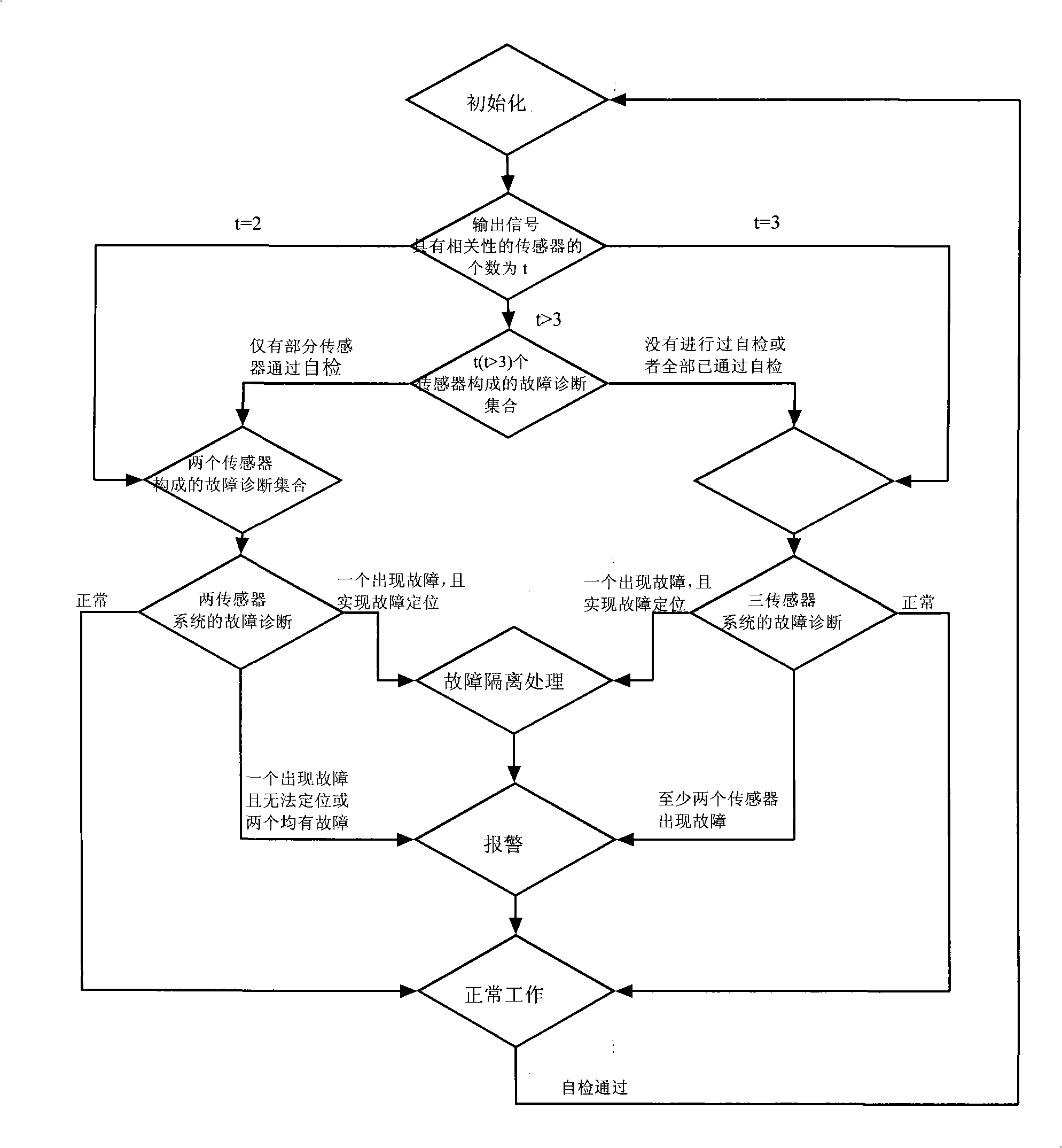

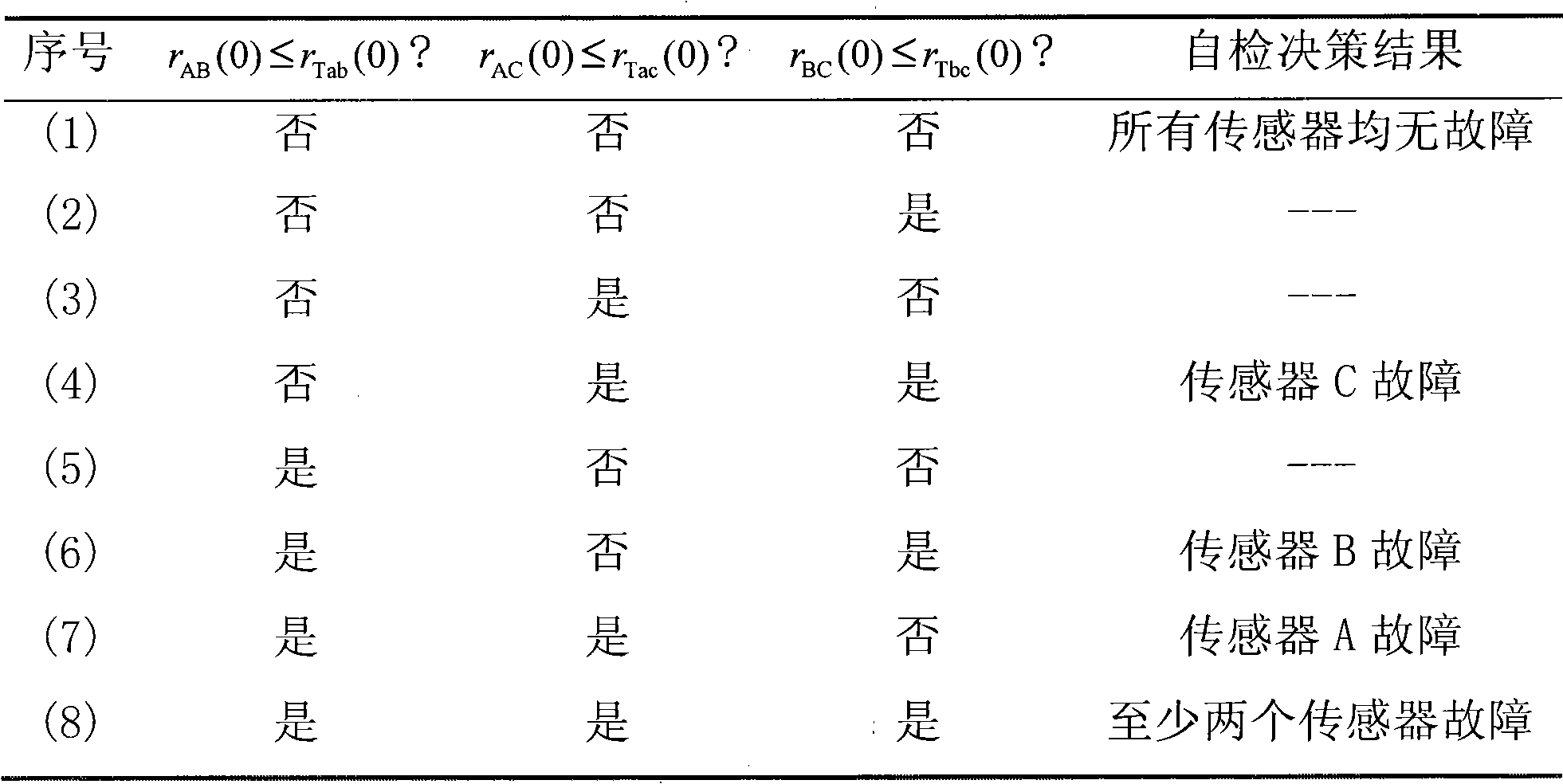

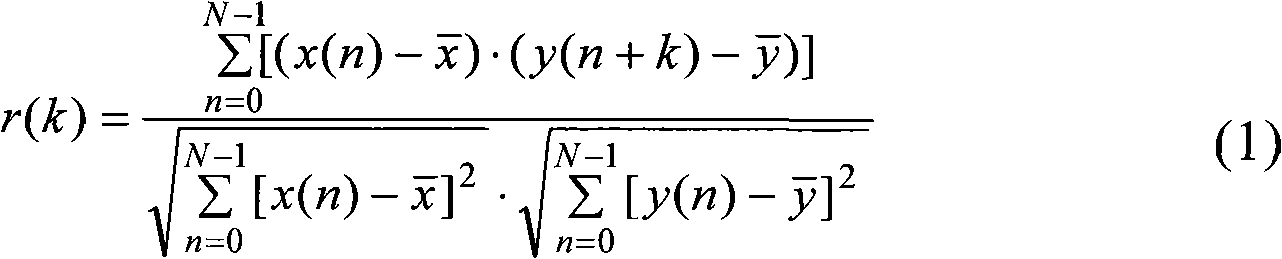

Multi- sensor system fault self-diagnosis method

The invention provides a fault self-diagnostics method for multi-sensor system, which includes the following steps: firstly, carrying out linear analysis to the information obtained from each sensor of the multi-sensor system having relativity output, and then comparing corresponding relativity and setting threshold value to realize sensor array fault self-diagnostics of the multi-sensor, wherein, as the number of the sensor having relativity output is two, fault-diagnostics of the sensor system can be realized thereby providing alarm information; as the number of the sensor having relativity output is three, fault-diagnostics of the sensor system can be realized thereby providing alarm information and isolating the fault to guarantee normal operation of the system. The effects of the invention are that self-diagnostics, alarm and fault-isolation for the sensor are realized and single system for monitoring sensor operation status is saved thereby simplifying the system configuration and increasing stability of the self-diagnostics system through using the relativity between the information measured by each sensor in the multi-sensor system and using multi-channel measuring signal.

Owner:徐立军

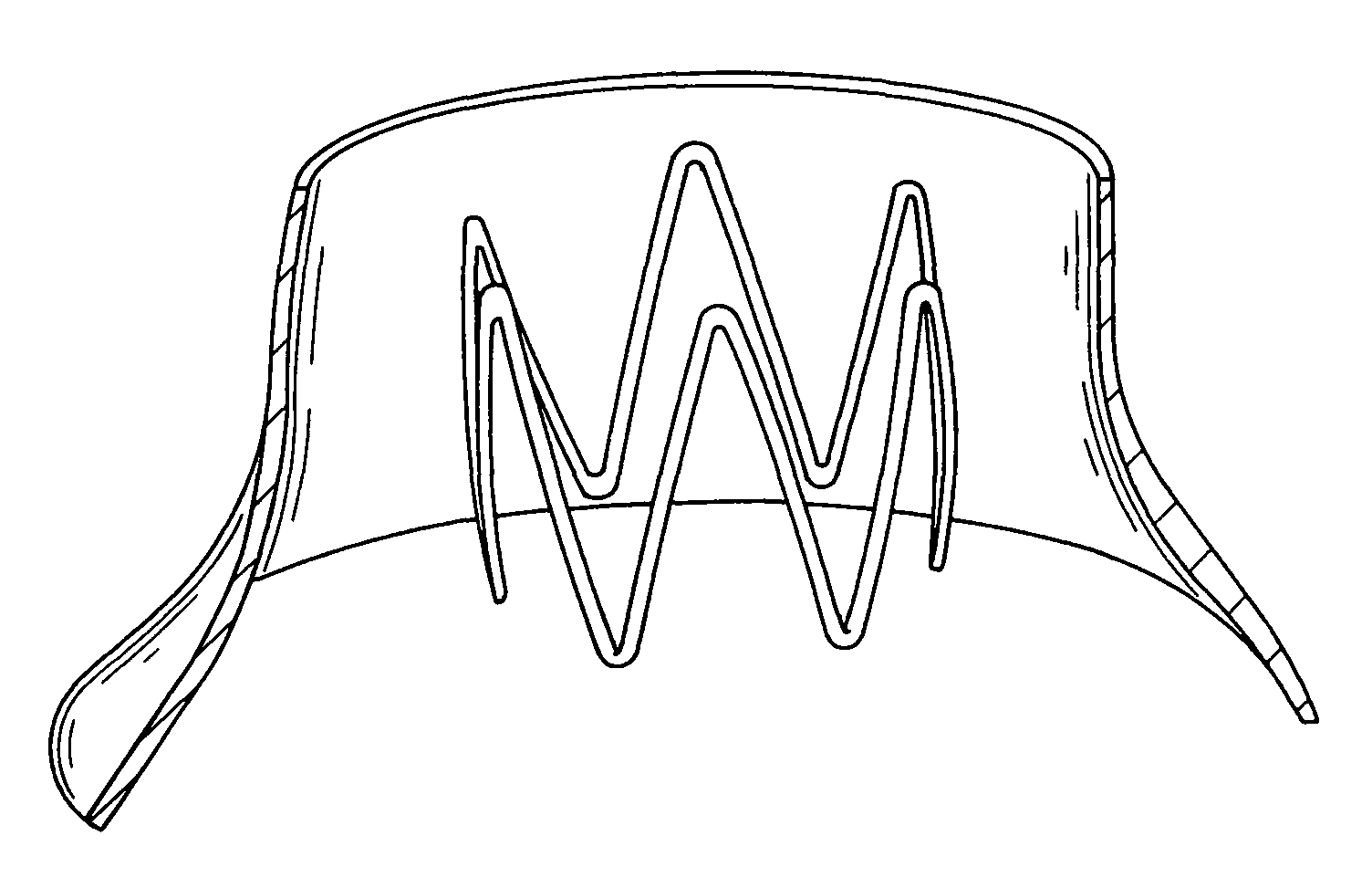

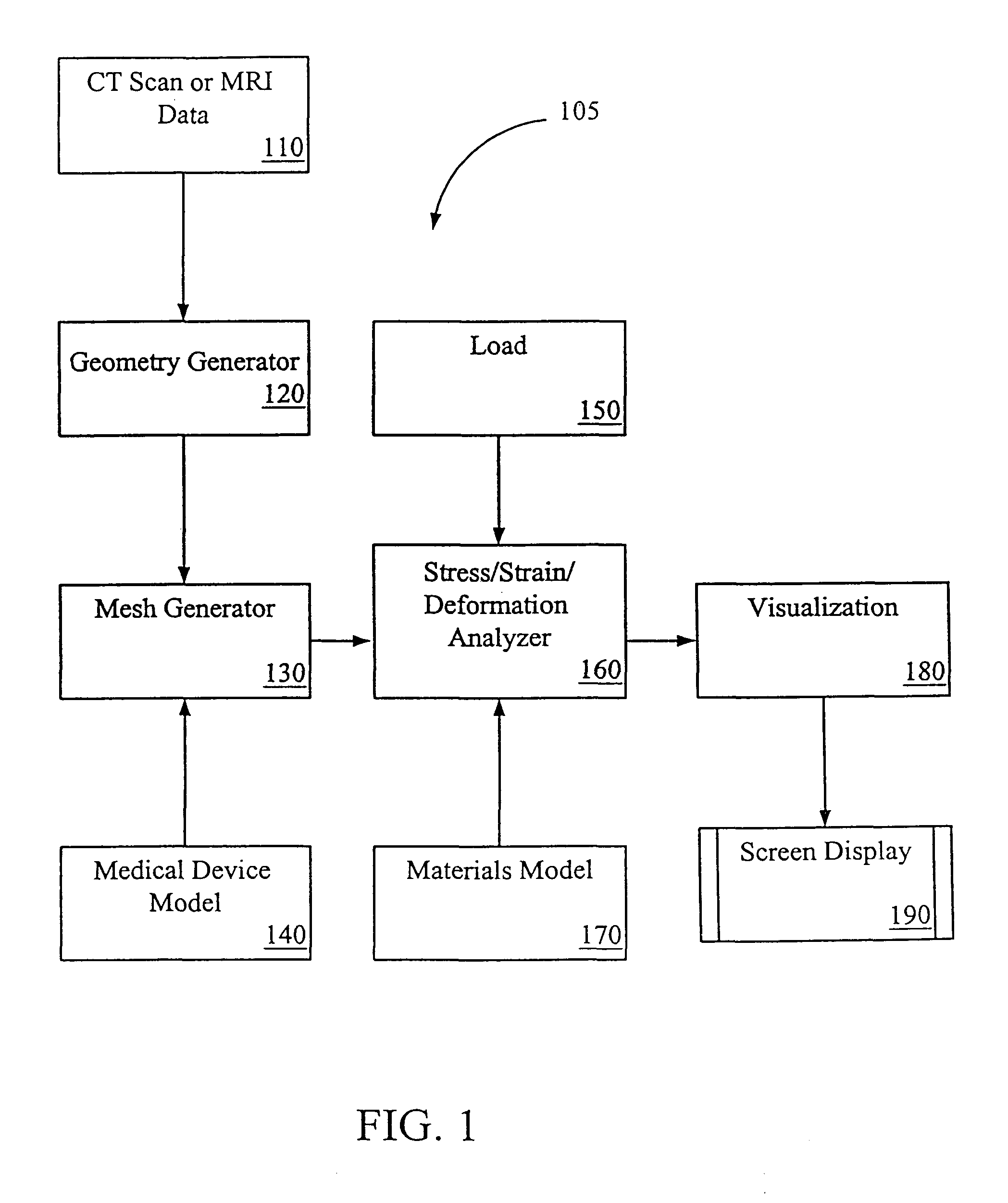

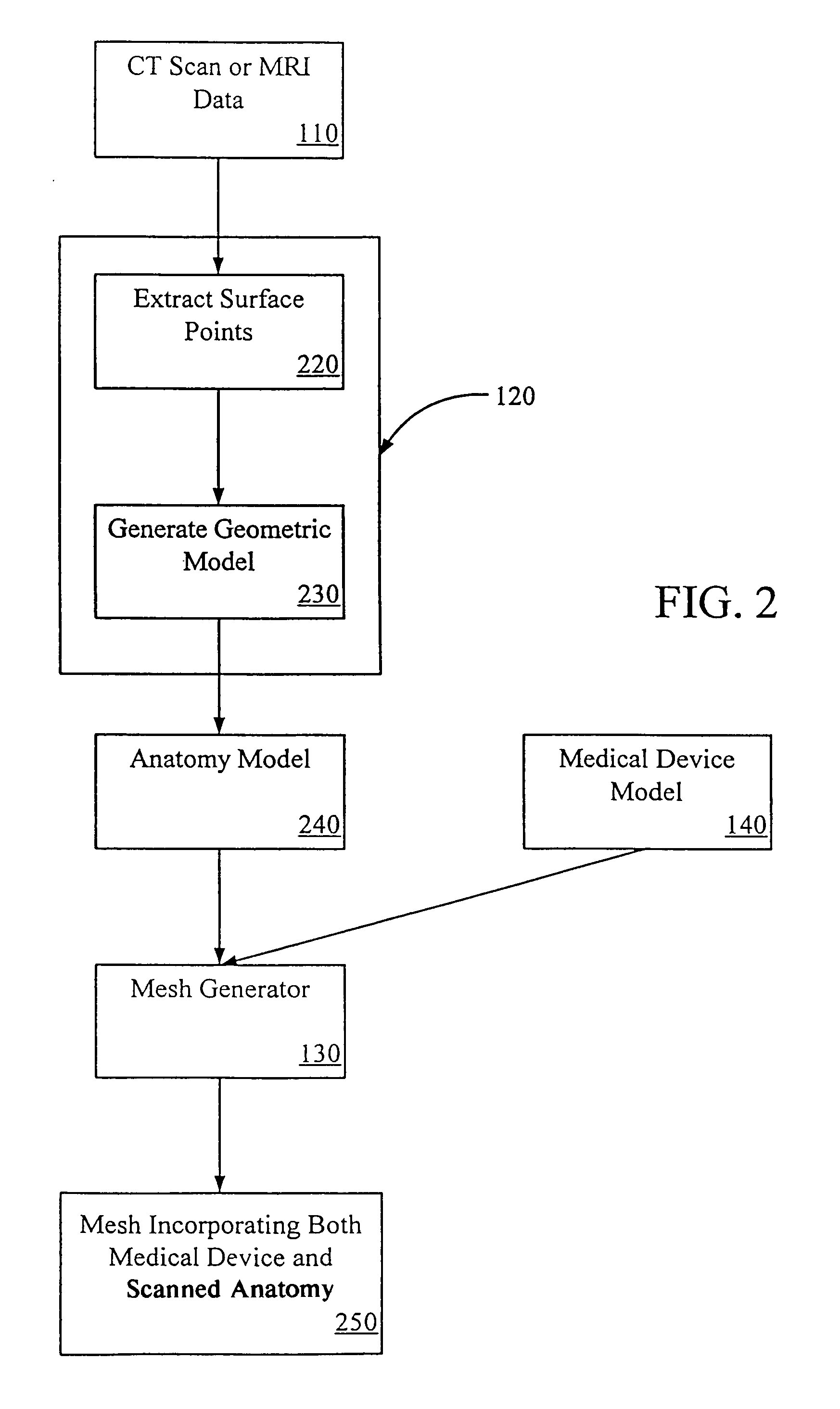

Virtual prototyping and testing for medical device development

A system and method of developing better-designed medical devices, particularly cardiovascular stents and endovascular grafts. The system comprises a geometry generator, a mesh generator, a stress / strain / deformation analyzer, and a visualization tool. In one embodiment, the geometry generator receives three-dimensional volumetric data of an anatomical feature and generates a geometric model. The mesh generator then receives such geometric model of an anatomical feature or an in vitro model and a geometric model of a candidate medical device. In another embodiment, the mesh generator only receives a geometric model of the candidate medical device. Using the geometric model(s) received, the mesh generator creates or generates a mesh or a finite element model. The stress / strain / deformation analyzer then receives the mesh, and the material models and loads of that mesh. Using analysis, preferably non-linear analysis, the stress / strain / deformation analyzer determines the predicted stresses, strains, and deformations on the candidate medical device. Such stresses, strains, and deformations may optionally be simulated visually using a visualization tool.

Owner:BOSTON SCI CORP

Nucleic acid mapping using linear analysis

InactiveUS20050112620A1Microbiological testing/measurementNanoinformaticsNucleic acid mappingLinear analysis

The invention relates to the use of nucleic acid binding agents for labeling polymers such as nucleic acid molecules. The nucleic acid binding agents are nucleic acid binding proteins that bind nucleic acid molecules non-specifically, in some embodiments.

Owner:U S GENOMICS INC

Linear analysis of polymers

InactiveUS20060160231A1Large amount of informationImprove efficiencyMicrobiological testing/measurementBiological testingLinear analysisPolymer

The invention relates to linear analysis of polymers and provides techniques to improve the amount and quality of information used to analyze polymers.

Owner:U S GENOMICS INC

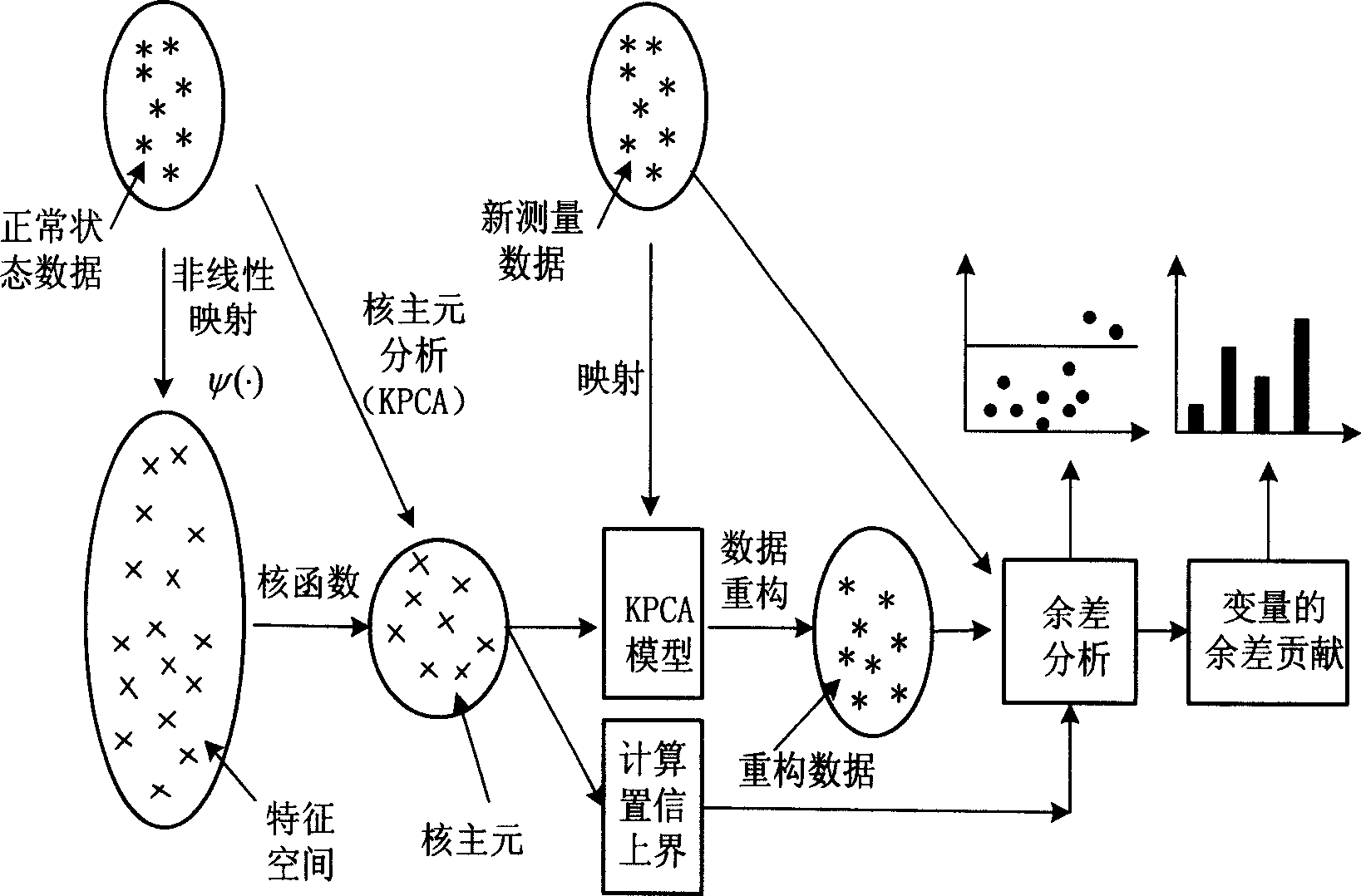

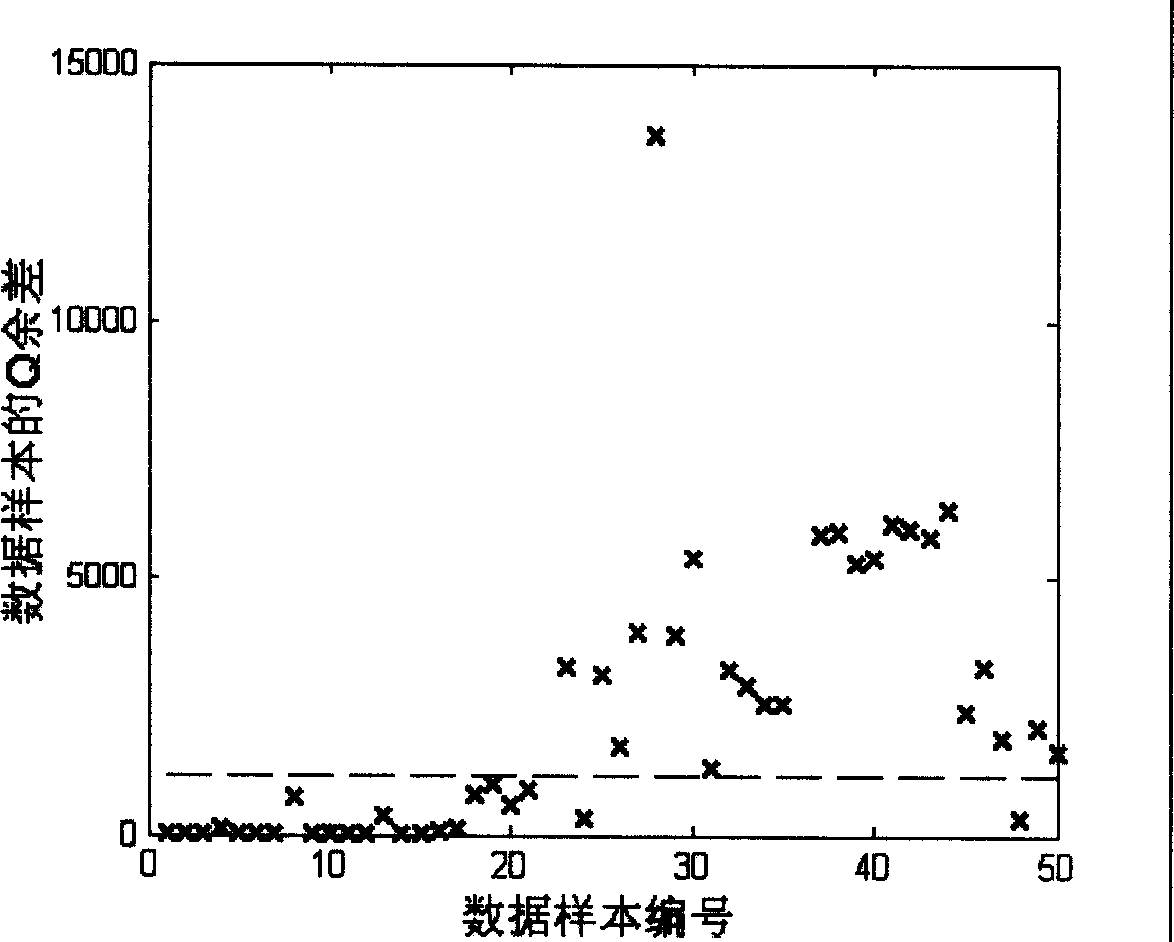

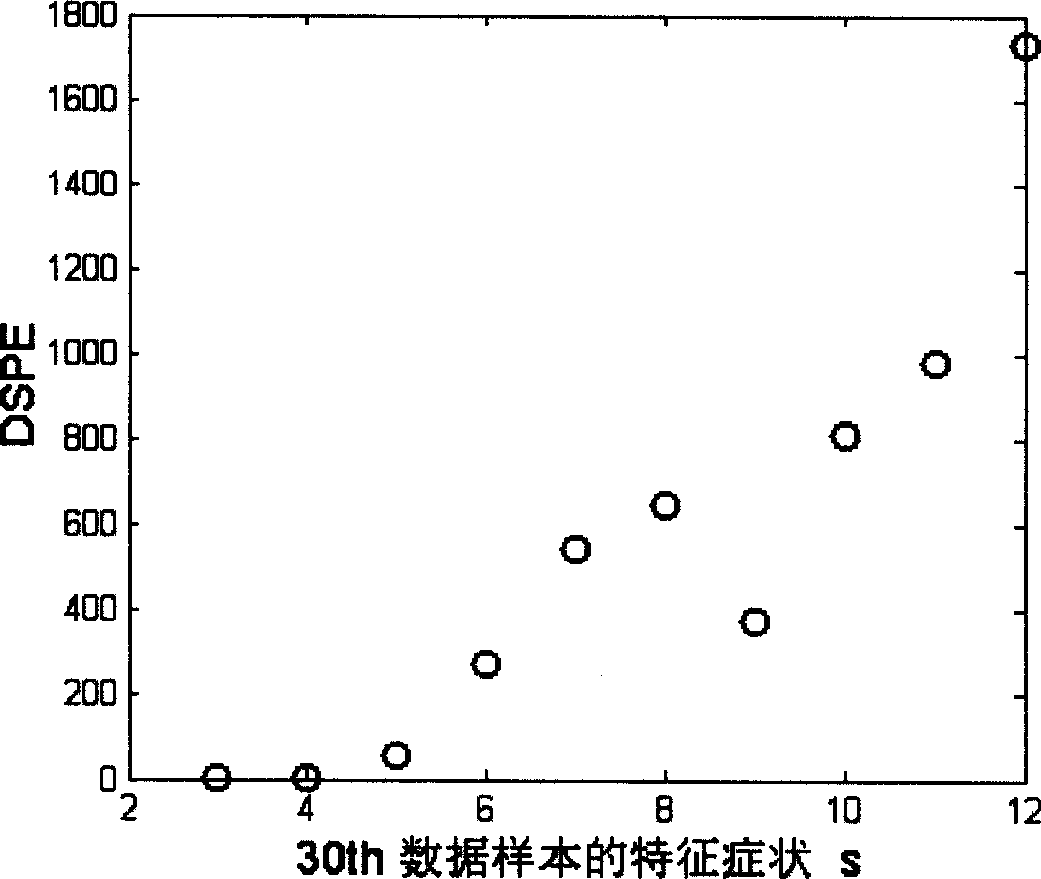

Non-linear fault diagnosis method based on core pivot element analysis

A non-linear fault diagnosis method based on kernel pivot analysis carries out non-linear analysis with the monitor data of a normal state system to pick up the non-linear pivot information and applies the kernel pivot model of important non-linear structure system at normal state, images the new measured data of the system to the kernel pivot model to reconstruct the data to the character information picked up by the new test data, judges the working condition of the system by the difference between the computed new tested data and reconstruction to it by the kernel pivot model. When the difference exceeds the top confidence limit, the new test data is judged to be fault, and the system is at fault state.

Owner:SHANGHAI JIAO TONG UNIV

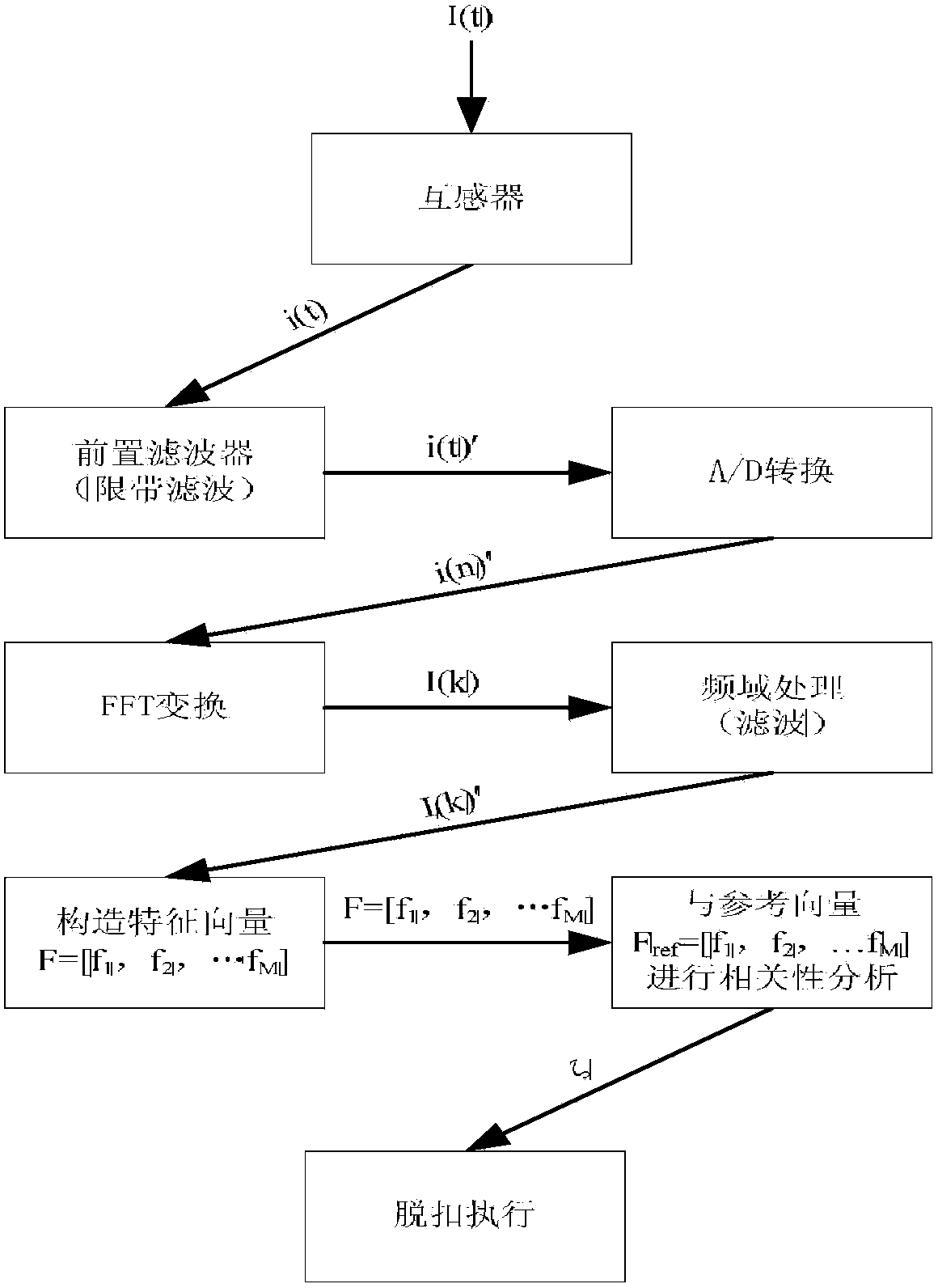

Fault arc frequency domain detection device

The invention relates to a fault arc frequency domain detection device. The fault arc frequency domain detection device mainly comprises a mutual inductor, a prefilter, an A / D converter, an FFT converter, a frequency spectrum pre-processor, a feature vector constructing device and a device for relative linear analysis and trip execution of feature vectors. As transient-state high-frequency currents can be caused in a circuit while fault arcs are generated in a power utilization loop and have certain regularity, FFT conversion is carried out on high-frequency current signals, the feature vectors Fref=[f1, f2, ... fM] of the high-frequency currents on a frequency domain when the arcs are generated are further extracted for serving as reference feature vectors, same processing is carried out on linear current signals, including the linear current signals without knowing whether the arcs are generated or not in advance, at any moment, feature vectors F =[f1, f2, ... fM] of the linear current signals on the frequency domain are obtained, correlation analysis is carried out on the feature vectors and the reference feature vectors, and whether the fault arcs are generated or not is judged according to the correlation degree. The limitation and the shortcomings in arc fault detection according to time domain features are overcome.

Owner:三科电器集团有限公司

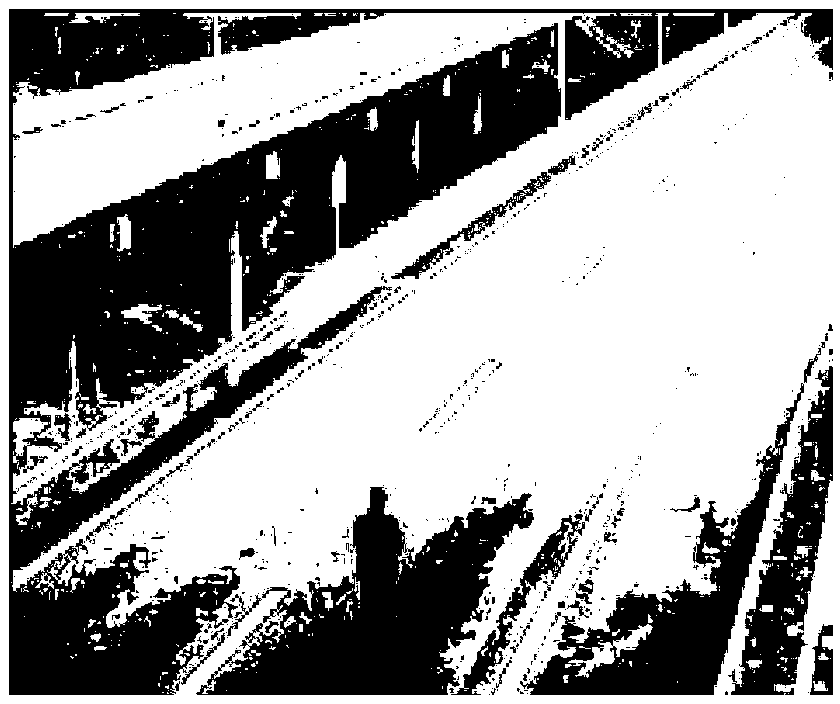

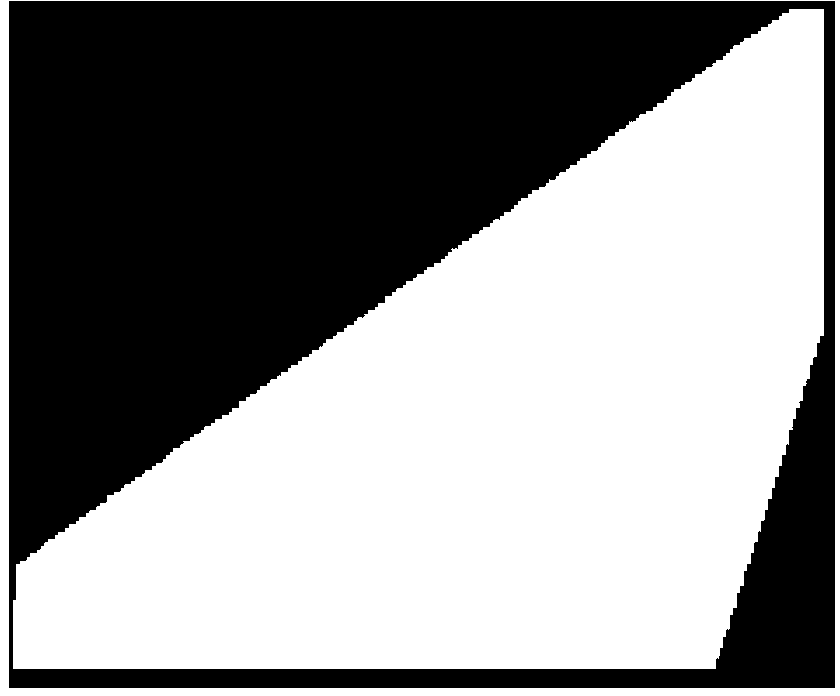

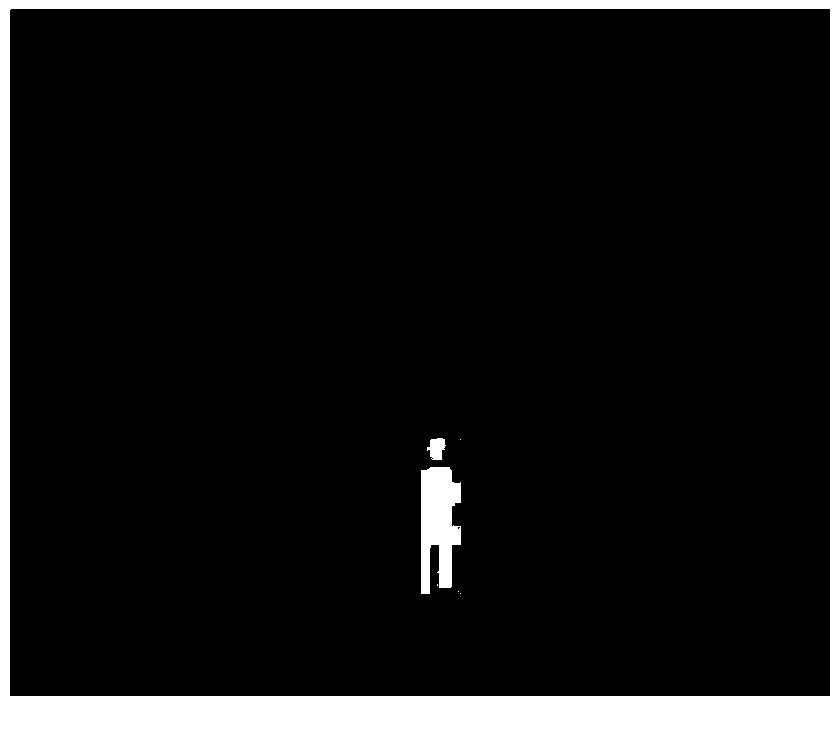

Pedestrian event detection method based on shape features and trajectory analysis

ActiveCN103324913AImprove accuracyAccurate target speed informationImage analysisCharacter and pattern recognitionLinear analysisTraffic scene

The invention provides a pedestrian event detection method based on shape features and trajectory analysis. A foreground target is obtained through target segmentation by means of background differencing, a connected domain of the same target is marked through a block-based method, meanwhile an enclosing rectangle of the connected domain is recorded and geometric shape characteristics of the enclosing rectangle are extracted, and target recognition is finished. When a target similar to a pedestrian is recognized, corner points of the target are extracted, and the corner points are tracked and matched by means of corner point position information. The preceding processes are repeated, and the motion track of the target is obtained. Segmented inflection points of the track are obtained, and linear analysis is carried out in each segment where the inflection points are formed, so that the speed of the target is obtained. Therefore, pedestrian and event state information is analyzed, and traffic safety warning is finished. The detection method is suitable for complex and changeable traffic scenes, can precisely recognize, track and early warn the pedestrian appearing in a monitoring video range, is high in practical value, and has wide application prospects.

Owner:CHANGAN UNIV +1

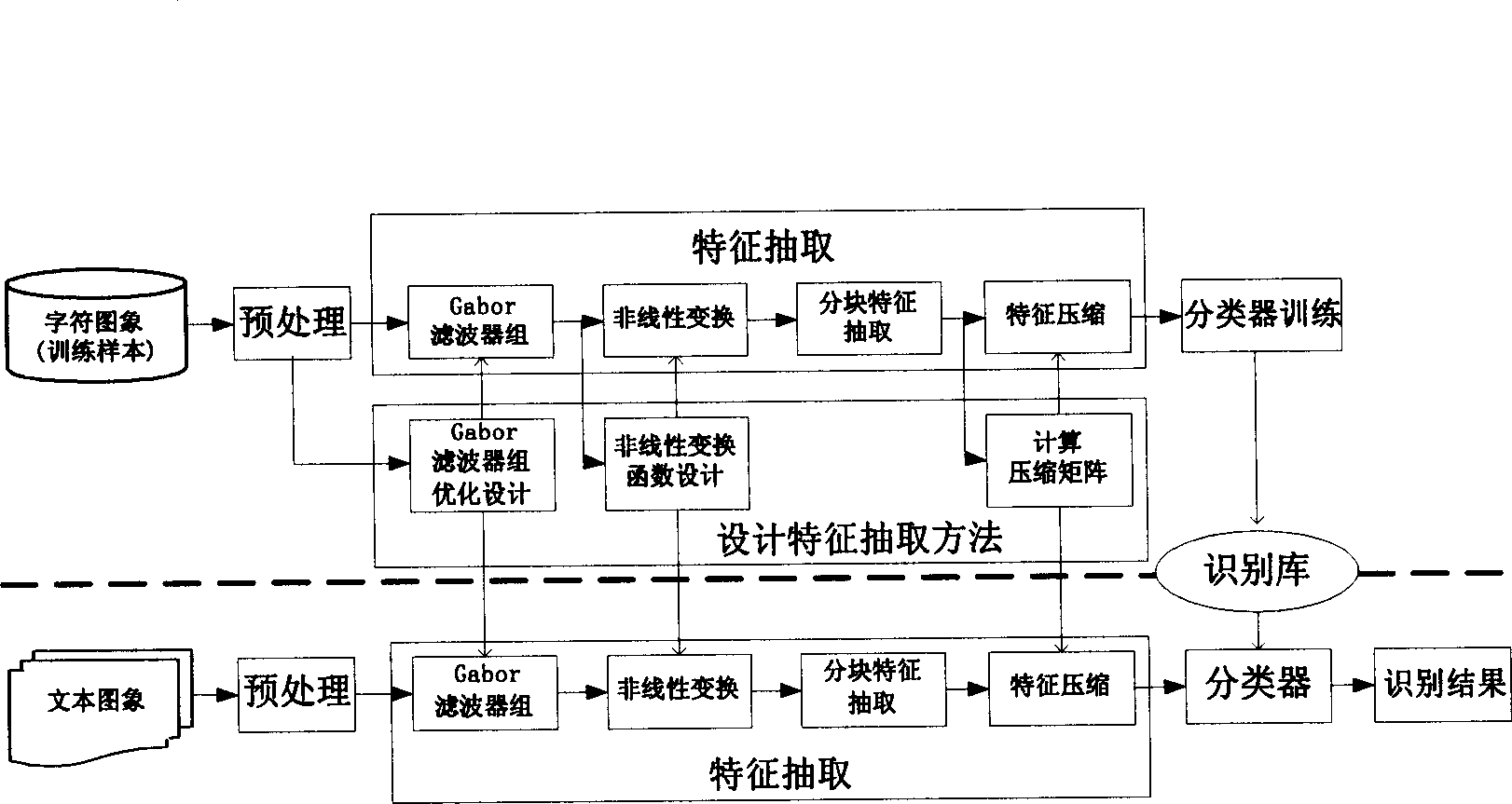

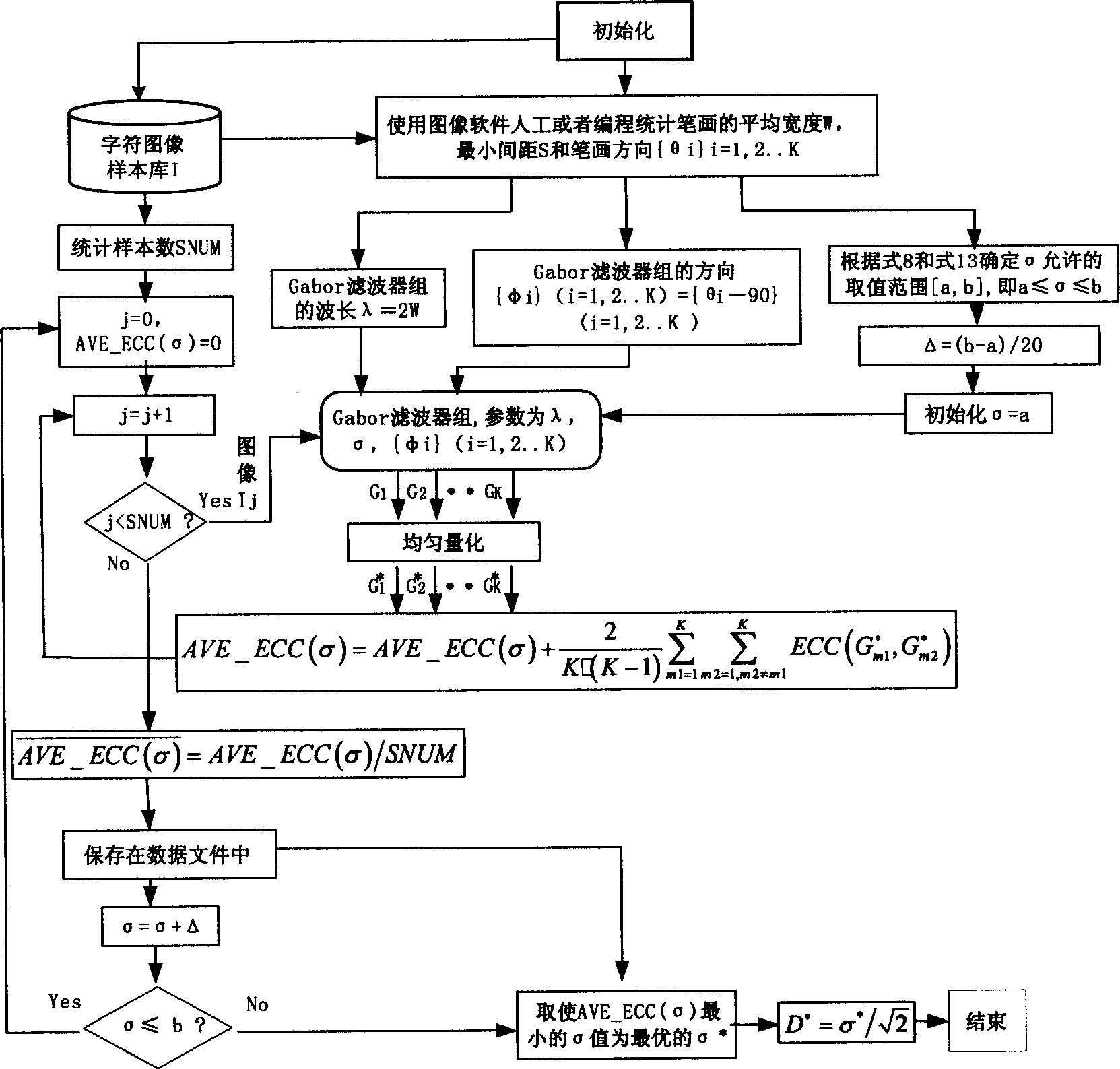

Character identification technique based on Gabor filter set

InactiveCN1459761AAchieve the desired purposeImage analysisCharacter recognitionLinear analysisGaussian filter

A character recognizing technology based on Gabor filter group includes using Gabor filter group to extract the strokes of a character image in different directions, finding out optimal filter parameters, non-linear post-processing to the output of Gabor filter group for increasing the resistance of recognizing system to brightness, contrast change and interference of image, calculating the recognizing characteristics of the positive and negative values in said output, combining them, together to obtain a multi-dimension characteristic vector, and reducing its number of dimensions by linear analysis method to improve its recognizing performance. Its advantage is high recognition percentage.

Owner:TSINGHUA UNIV

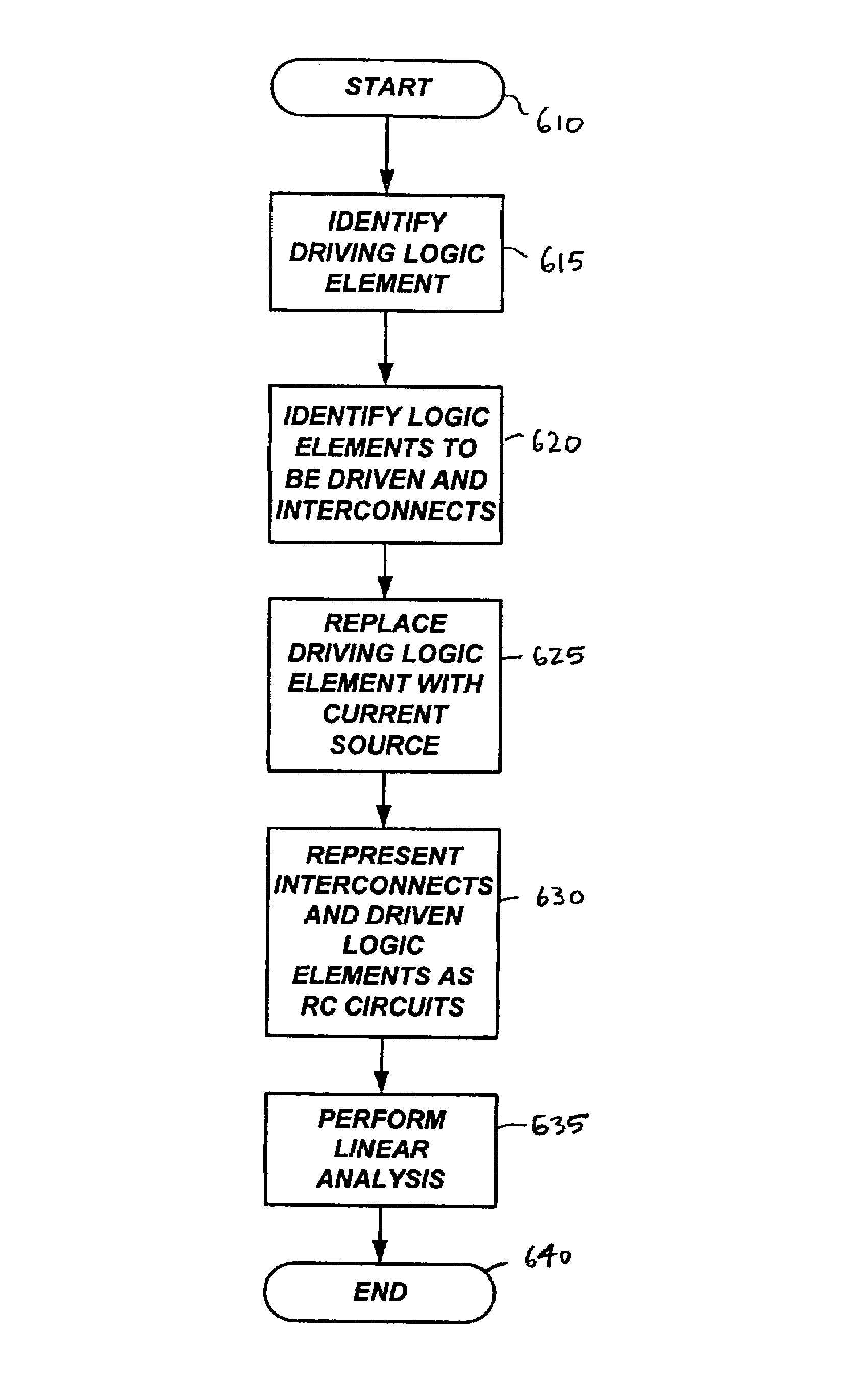

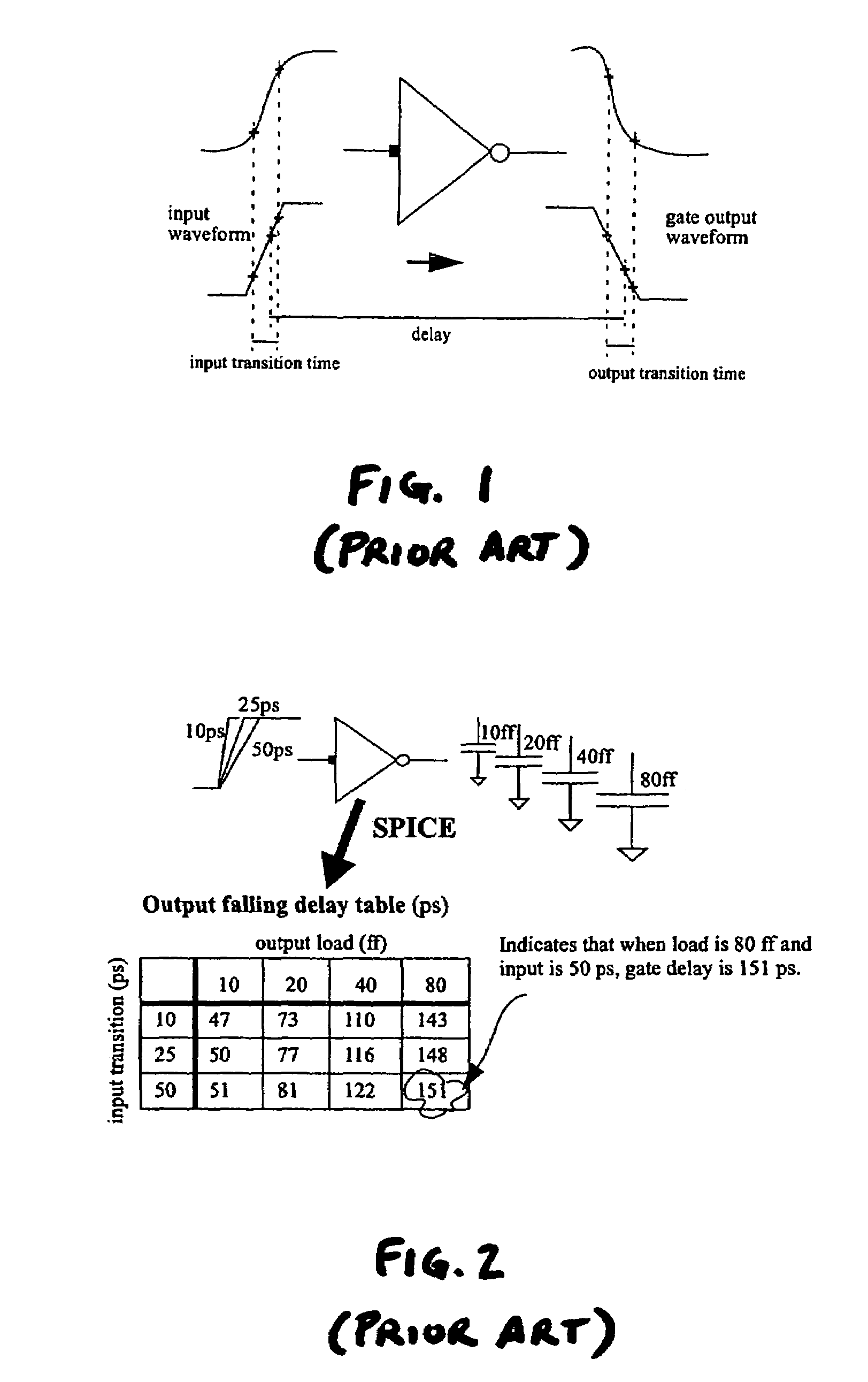

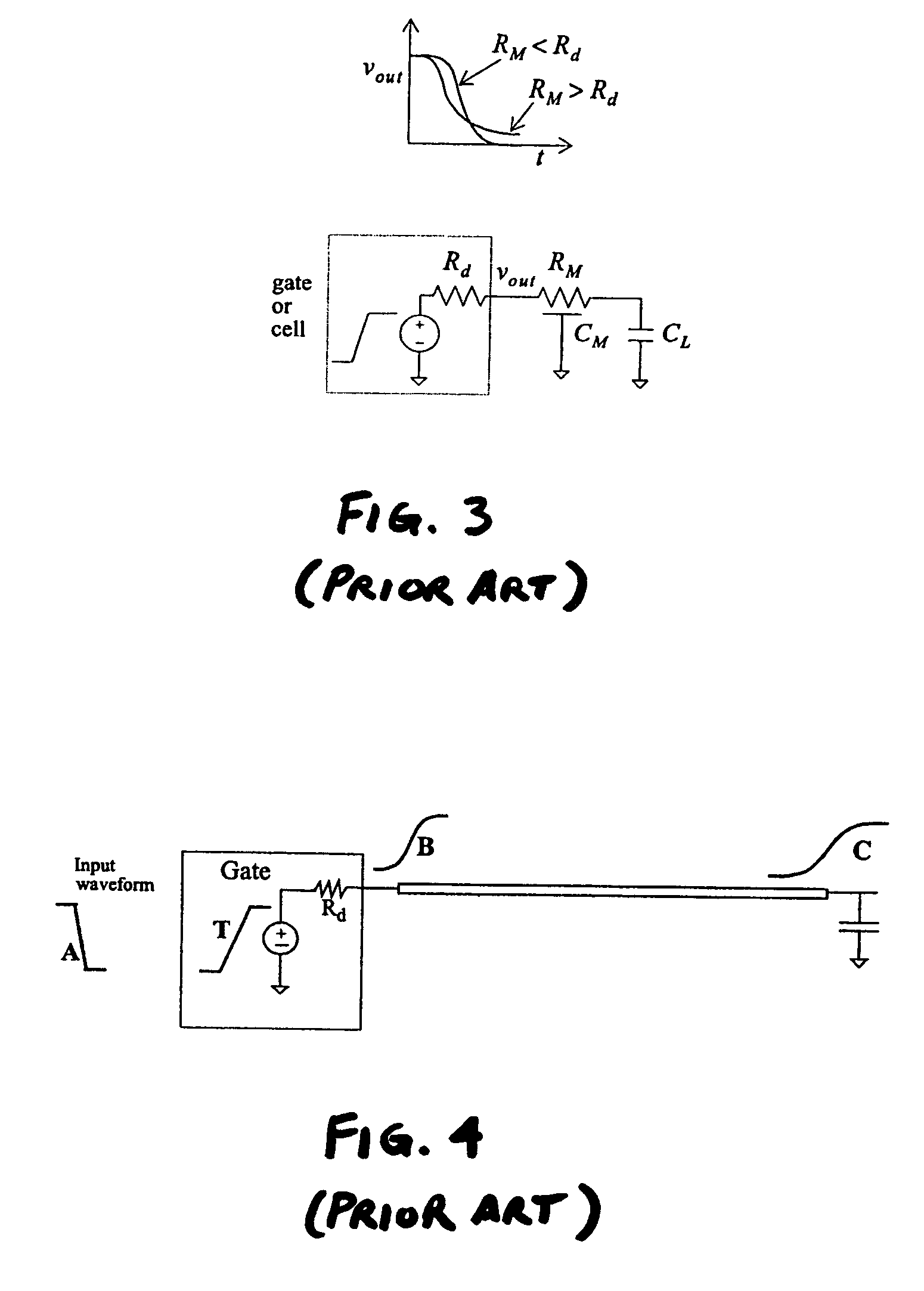

Modeling interconnected propagation delay for an integrated circuit design

ActiveUS7213221B1Analogue computers for electric apparatusComputation using non-denominational number representationCapacitanceStart time

A system and a method are disclosed for performing a timing or signal propagation delay analysis on a circuit. The disclosure includes representing a drive logic stage as a representative linear circuit driven by a current source. The current source is represented as a function of a current at a constant value, a start time, a tail-start time, and a time constant of an equivalent capacitive circuit. Once the current source model is constructed, a logic stage can be analyzed for timing or signal propagation delay using conventional linear circuit analysis techniques. The disclosure also is applicable to resistance capacitance (“RC”) interconnect circuits using a current source model in which an RC load is represented as an effective capacitance and the current source for use in a linear analysis is constructed using an iterative approach.

Owner:SYNOPSYS INC

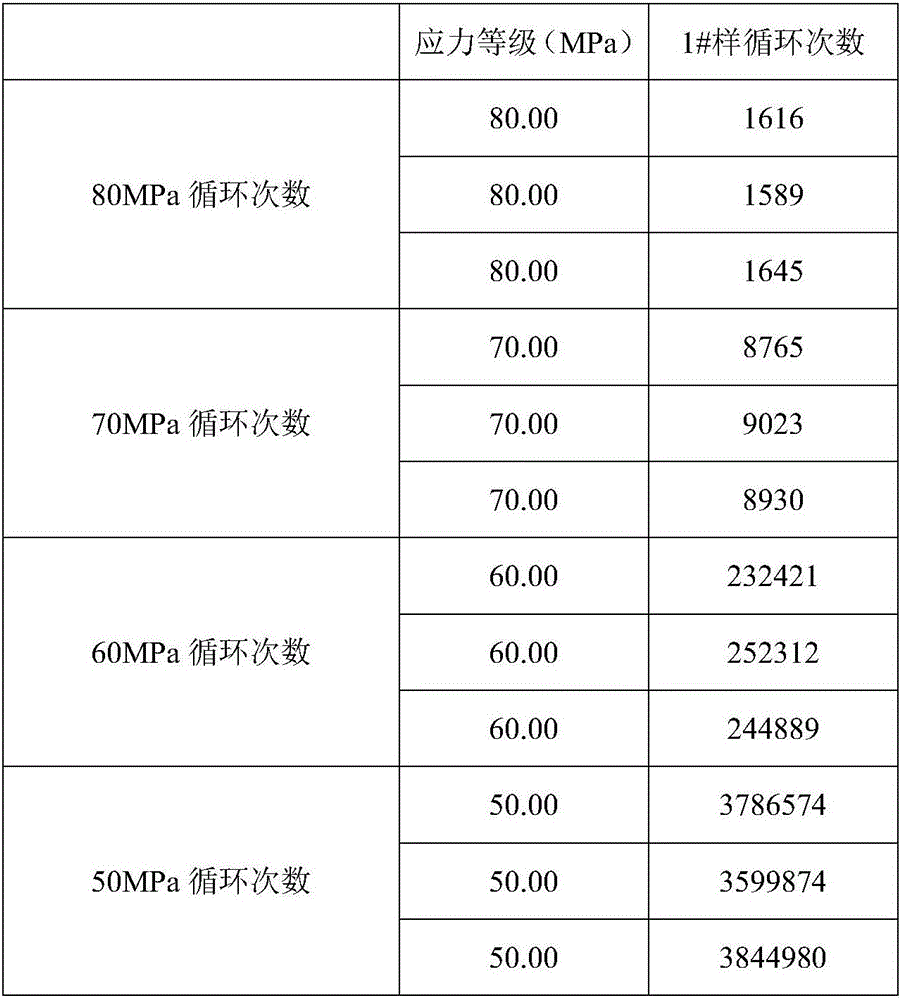

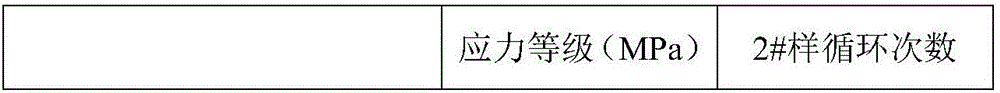

Bending fatigue testing method of fiber reinforced material

ActiveCN105928810ASolving Bending Fatigue TestingCompare Fatigue Test LifeMaterial strength using repeated/pulsating forcesStress levelStress–strain curve

The invention discloses a bending fatigue testing method of a fiber reinforced material, comprising the following steps: step S1 of testing basic parameters and determining test conditions; step S2 of adjusting a test span; step S3 of setting a test compensation path; step S4 of determining the maximum stress; step S5 of carrying out a plurality of stress level tests to obtain a bending performance test and a stress-strain curve, finding dependent variables of corresponding stress values by means of getting points, and calculating a deflection value of strain corresponding to each stress based on a deflection value calculation formula; step S6 of setting test stress parameters; step S7 of carrying out bending fatigue tests at different times; and step S8 of linear fitting: drawing an S-N curve of test values by means of a regression linear analysis based on the test result in the step S7 by taking N as a vertical coordinate and S as a horizontal coordinate, and fitting out a fitted equation of log10(stress)=a-blog10(times) or (stress)=a*(times)<(-b)> based on the S-N curve. The bending fatigue testing method of the fiber reinforced material disclosed by the invention provides a method evidence for a bending fatigue test of the fiber reinforced material, and fatigue test life can be quickly obtained by the fitted equation.

Owner:JUSHI GRP CO

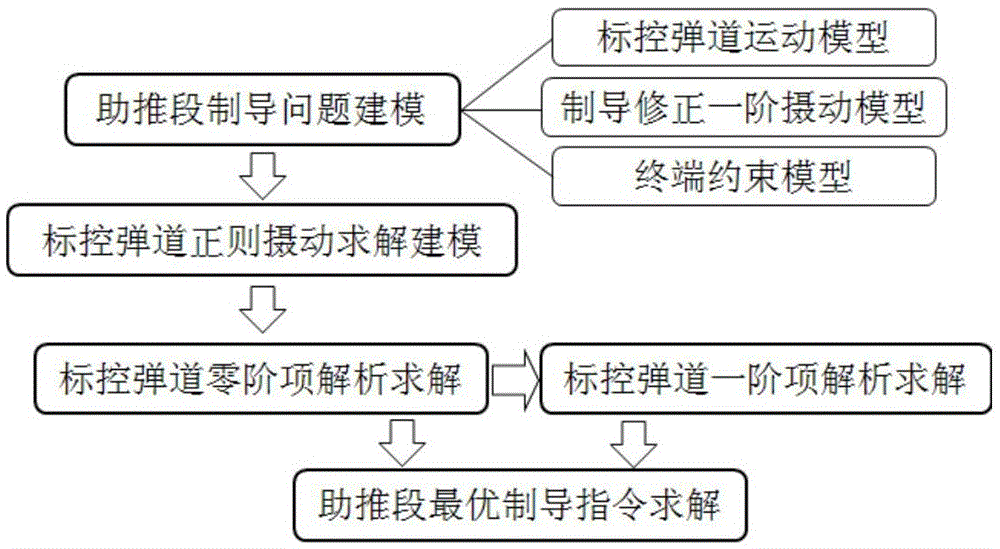

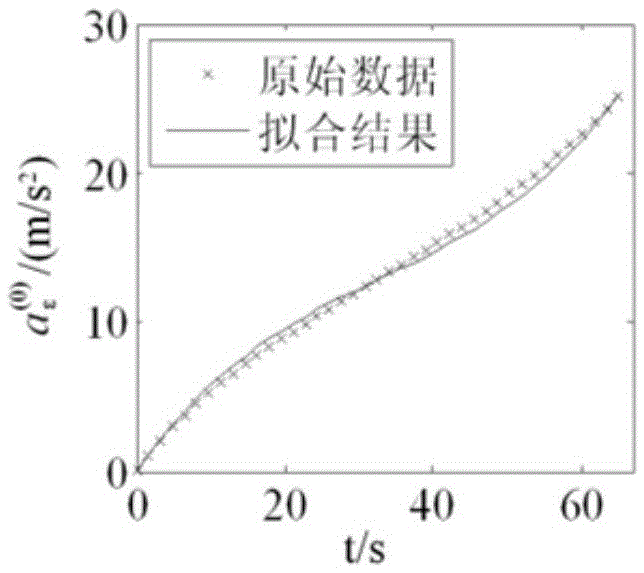

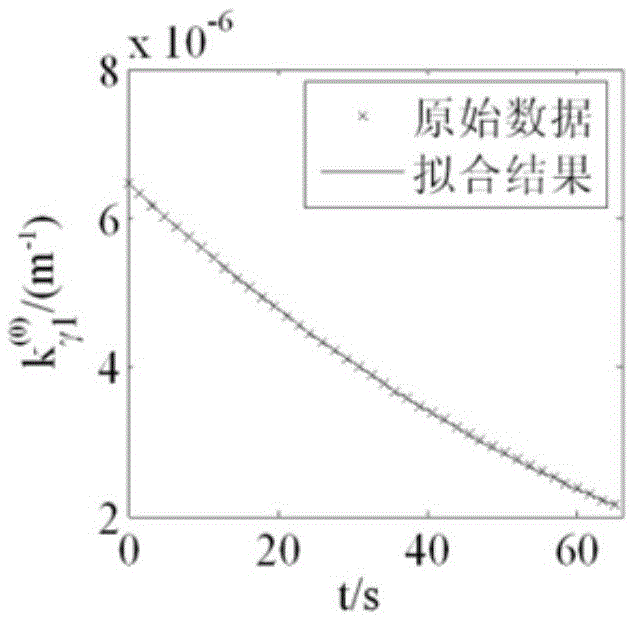

Boost phase generalized standard miss distance analysis guidance method

ActiveCN105549387AReduce speed lossSimplify the equations of motionAdaptive controlTask demandFirst order perturbation

The invention relates to a boost phase generalized standard miss distance analysis guidance method. The method comprises steps that 1, boost phase guidance problem modeling is carried out, including standard ballistic movement modeling, guidance correction first-order perturbation modeling and terminal constraint modeling; 2, boost phase standard ballistic regular perturbation solution modeling is carried out; 3, boost phase standard ballistic zero-order item analysis solution on the basis of regular perturbation is carried out; 4, boost phase standard ballistic first-order item analysis solution on the basis of regular perturbation is carried out; and 5, boost phase optimal guidance instruction solution on the basis of the standard miss distance is carried out. Through the method, zero-incidence is taken as boost phase ballistic standard control, analysis solution is carried out by employing a regular perturbation method, and thereby an analyzed standard miss distance is acquired; an optimal control method is employed to solve a guidance instruction of the correction standard miss distance, and thereby a non-linear analysis optimal guidance method satisfying boost phase task demands is acquired.

Owner:BEIHANG UNIV

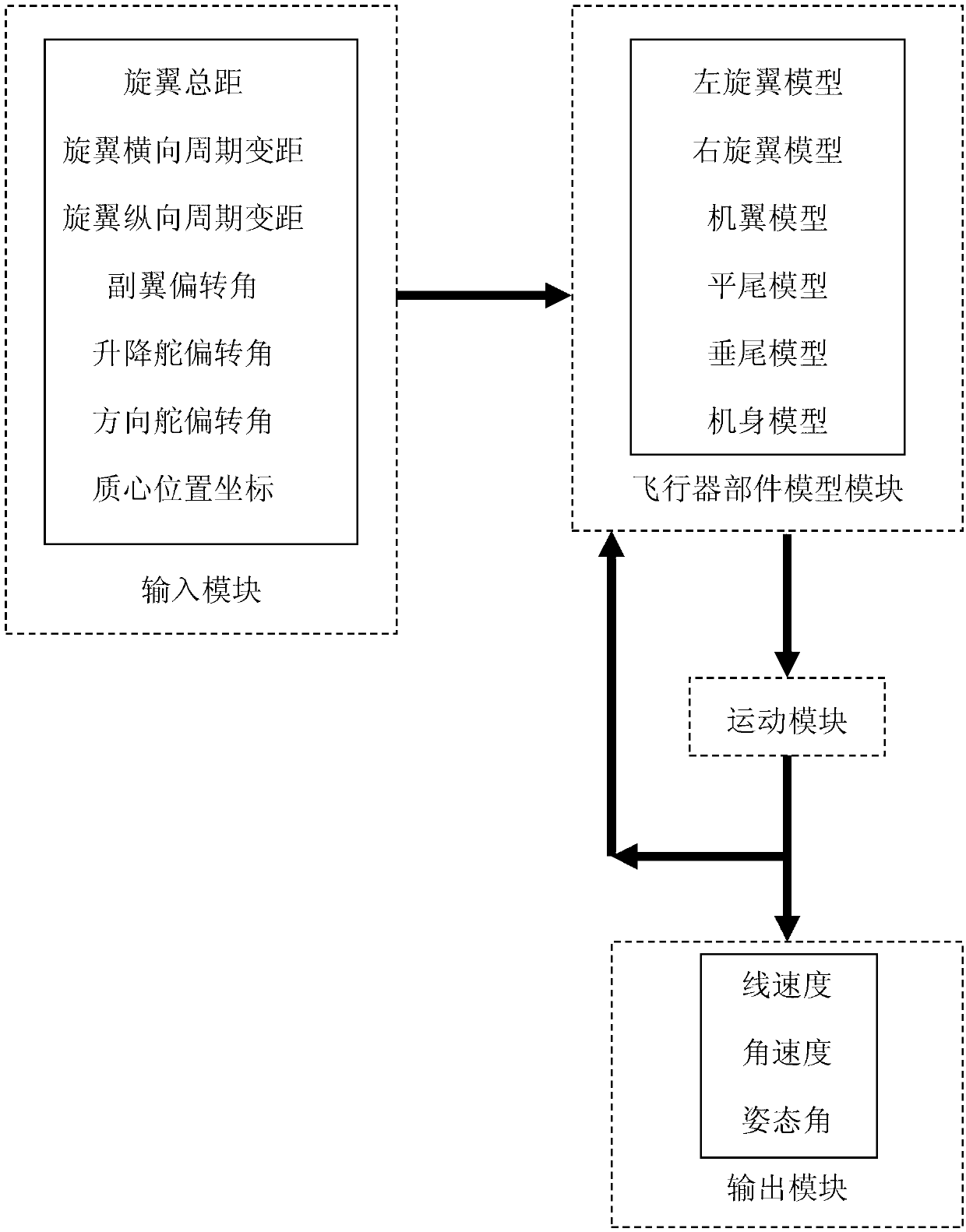

Method for determining transient process switching corridor of tilt rotor unmanned aircraft

InactiveCN103144781AExcellent transition routeGround installationsNonlinear modelClassical mechanics

The invention discloses a method for determining a transient process switching corridor of a tilt rotor unmanned aircraft, comprising the steps that a kinetic model of the tilt rotor unmanned aircraft is built, a nonlinear model of the tilt rotor unmanned aircraft is obtained, the feature of the helicopter mode and the feature of the fixed wing aircraft of the tilt rotor unmanned aircraft are respectively subjected to linear analysis, a linear model of the tilt rotor unmanned aircraft is obtained, the linear model is subjected to handling characteristic analysis, the maximum speed and the minimum speed in the range of trim angle of pitch are figured out, and the step of determining the borderline of the transient process switching corridor of the tilt rotor unmanned aircraft is finally carried out. According to the method, an optimal transient path is given by taking the minimum pitch trim attitude angle of the aircraft in the switching process as the index.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

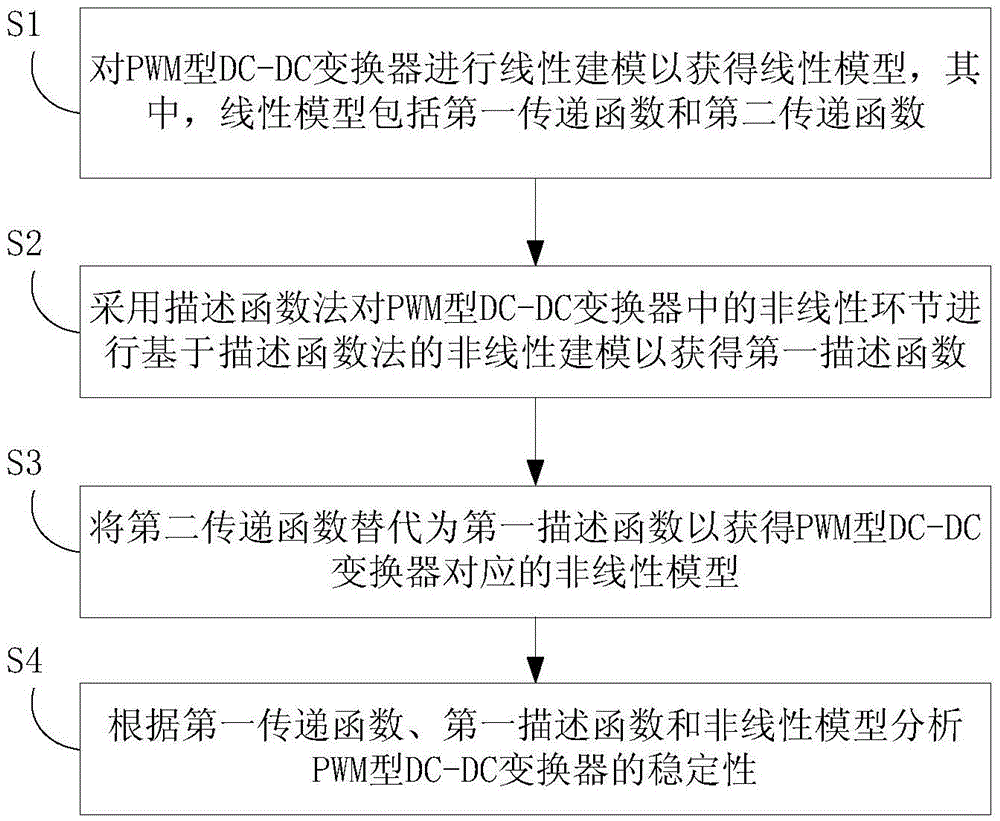

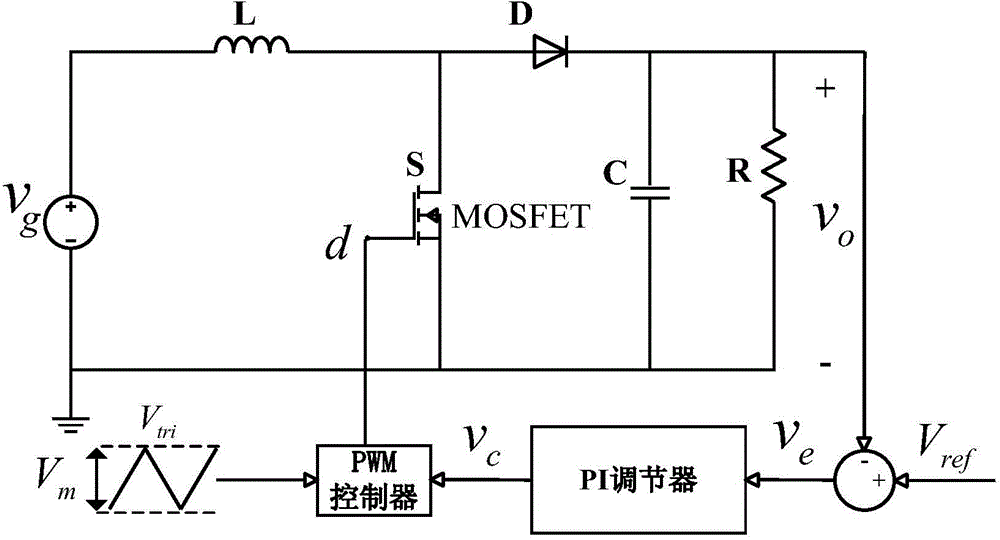

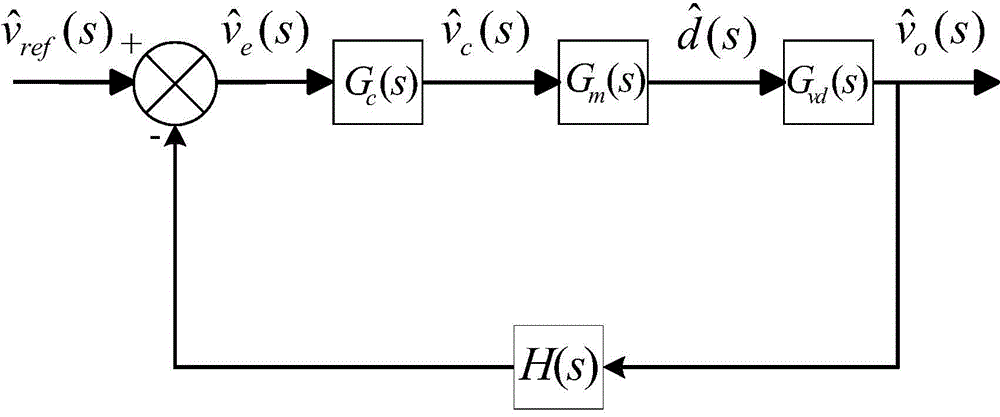

DC-DC convertor stability analysis method based on describing function method

ActiveCN104578776AAccurate Low Frequency Oscillation PhenomenaAccurately judge the phenomenon of low frequency oscillationDc-dc conversionElectric variable regulationNonlinear modellingNon linear model

The invention discloses a PWM type DC-DC convertor stability analysis method based on a describing function method. The stability analysis method includes the following steps that a PWM type DC-DC convertor is linearly modeled to obtain a linear model, a first transfer function and a second transfer function; the describing function method is adopted to carry out non-linear modeling on a non-linear link in the PWM type DC-DC convertor to obtain a first describing function; the second transfer function is replaced by the first describing function to obtain a non-linear model; according to the first transfer function, the first describing function and the non-linear model, the stability of the PWM type DC-DC convertor is analyzed. The PWM type DC-DC convertor stability analysis method can accurately analyze the critical stable state of the PWM type DC-DC convertor, an obtained result is more accurate than that obtained by a traditional linear analysis method, thus the low frequency oscillation phenomenon occurring in the PWM type DC-DC convertor can be analyzed, and the analysis accuracy is high.

Owner:BEIJING JIAOTONG UNIV

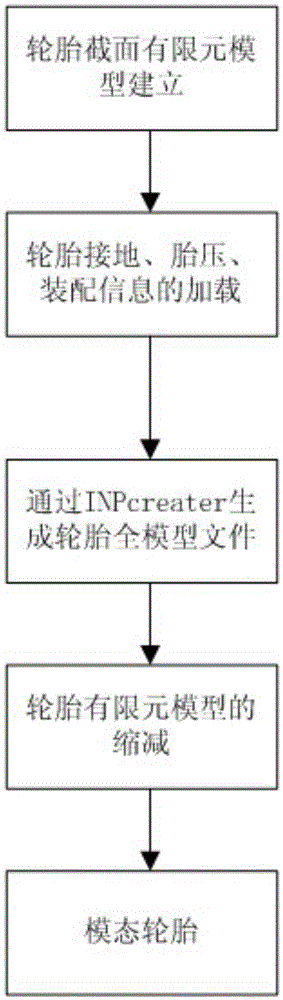

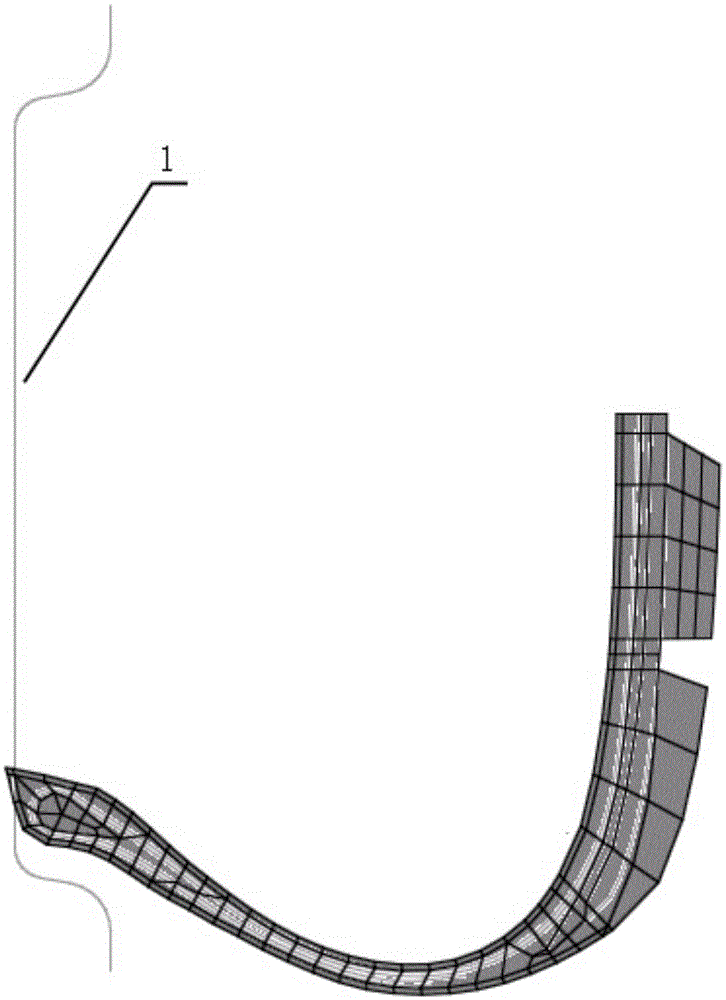

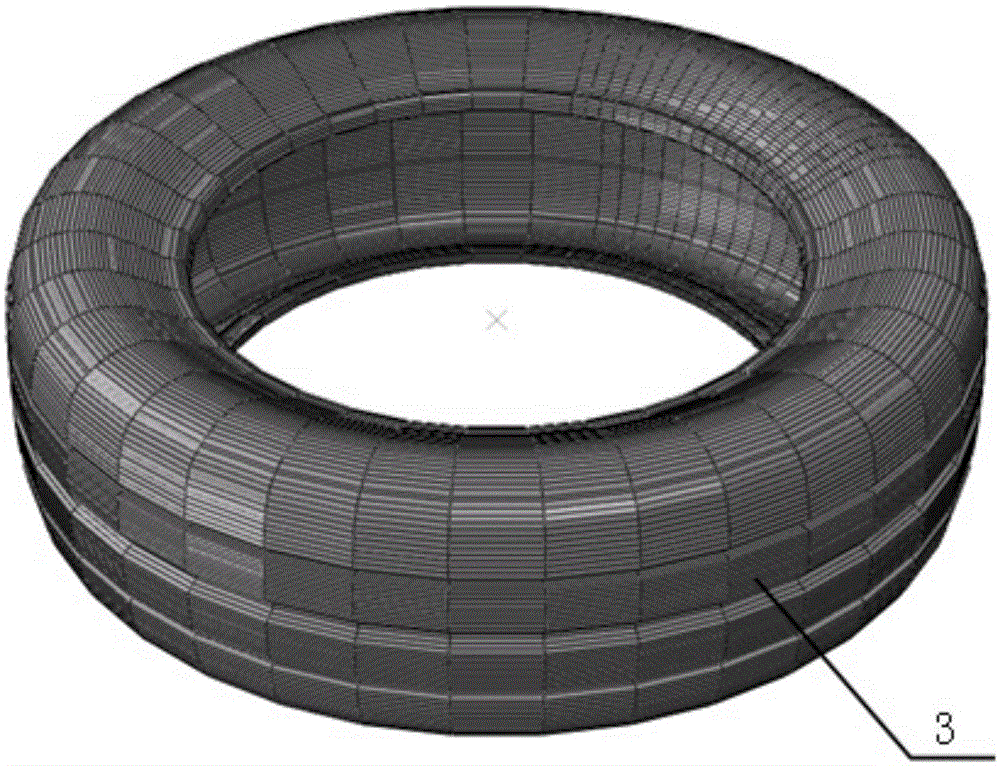

Modal tire modeling method for whole-vehicle vibration noise simulation

InactiveCN105138796ASolve the key technology of vibration and noise virtual simulationSpecial data processing applicationsElement modelEngineering

The invention relates to a modal tire modeling method for whole-vehicle vibration noise simulation. Under set loads and tire pressure, an accurate tire finite element model is obtained through the actual structure and size and material property of a tire, the tire finite element model is converted into a tire reduction model for whole-vehicle linear analysis through reduction, the tire reduction model and the whole-vehicle NVH finite element model are matched, and therefore the tire model and vibration noise performance simulation are conducted in NASTRAN software, and a new method is provided for road vibration noise performance simulation. The modal tire modeling method is an engineering tire modeling method, and by automatically reducing the tire integrated finite element model, an engineer can establish the tire finite element model through the tire modeling method; meanwhile, the modal tire model for whole-vehicle vibration noise virtual simulation is obtained through an automatic reduction program, and the key technology for stimulating inside-vehicle vibration noise virtual simulation on a road surface is achieved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

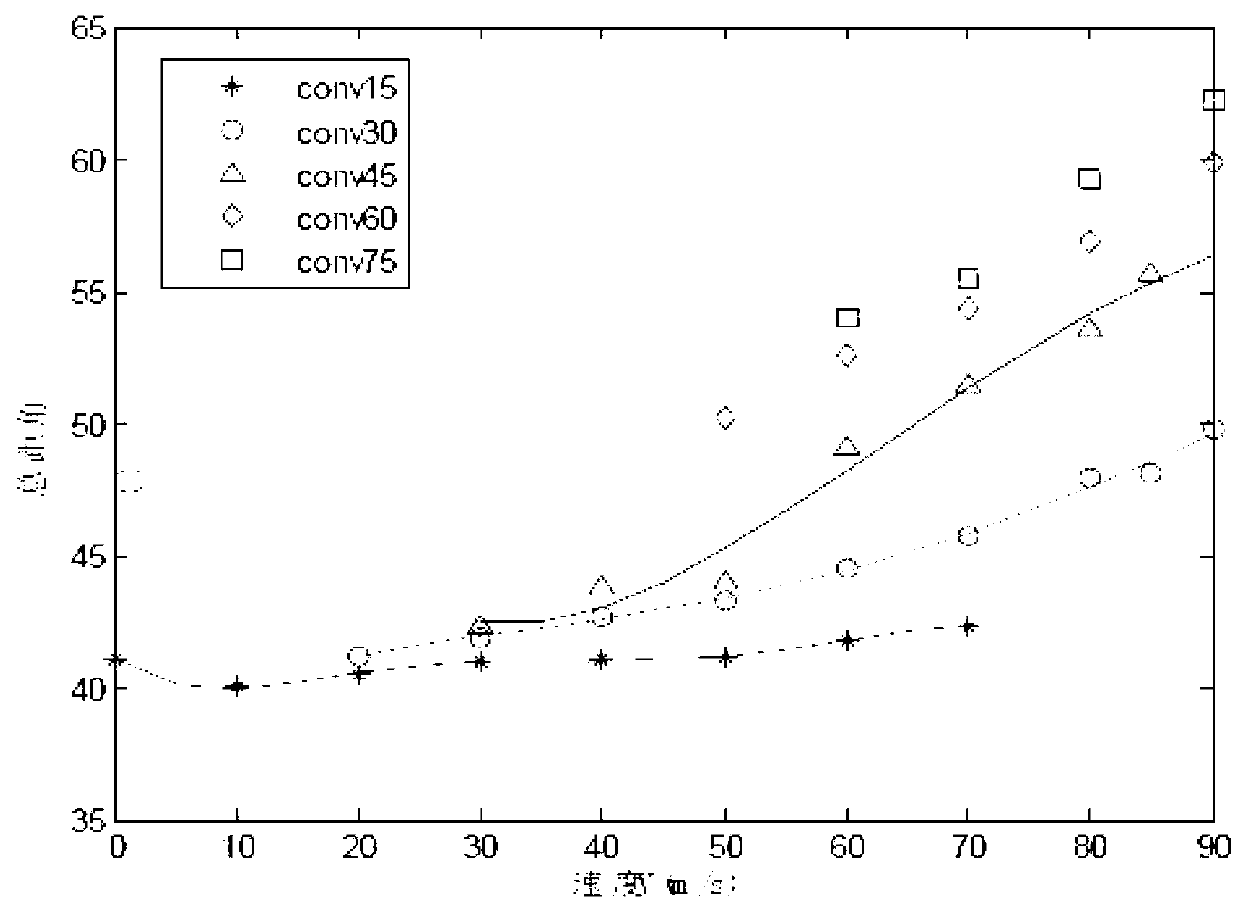

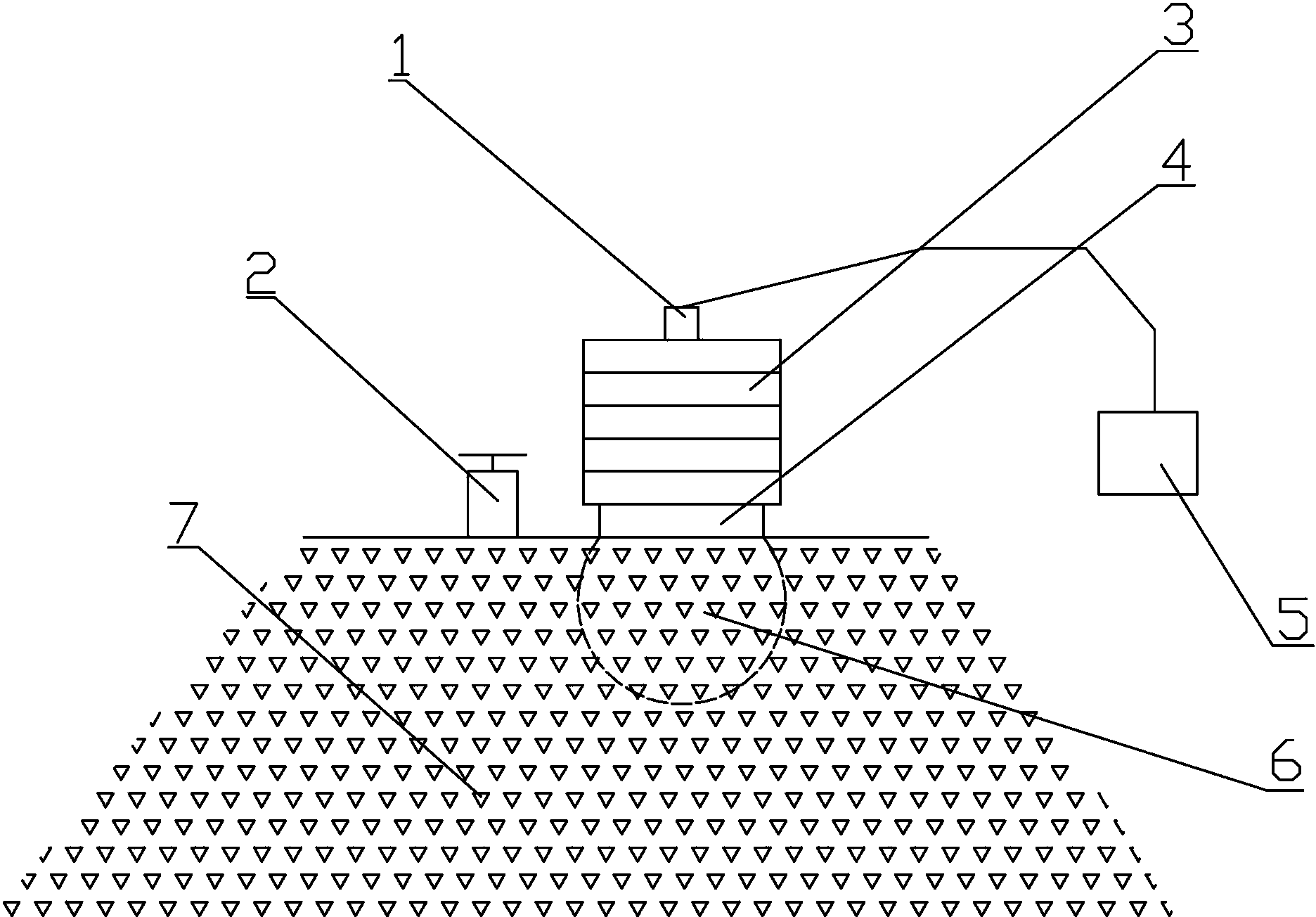

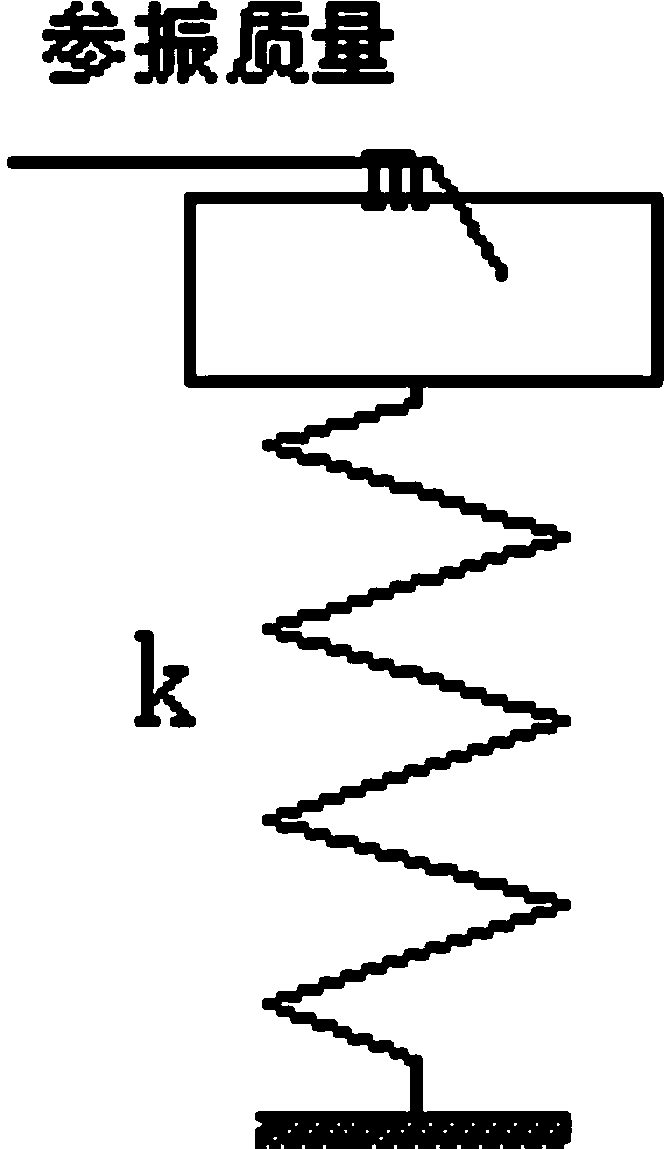

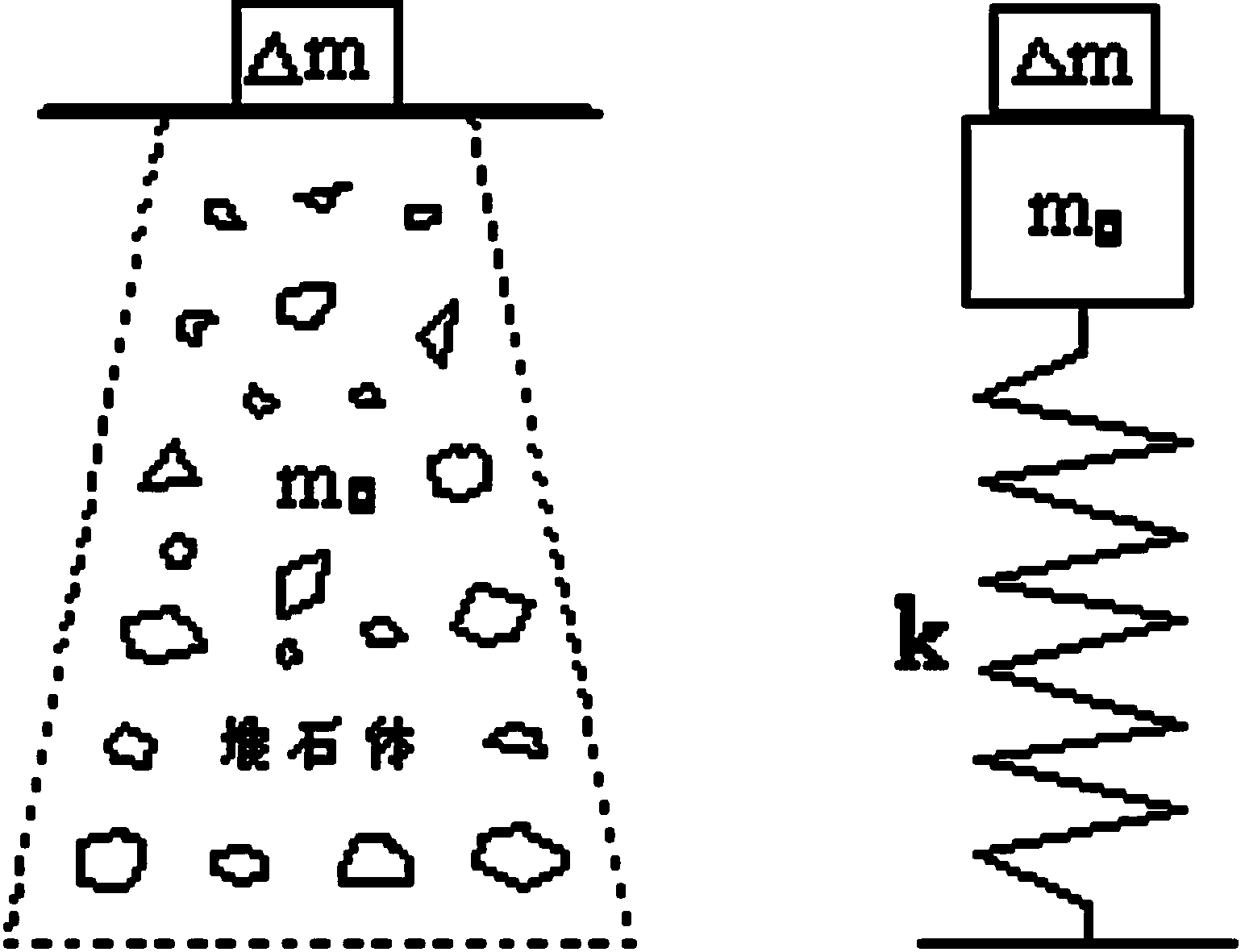

Rock-fill object density measure system

A rock-fill object density measure system comprises a bearing plate placed on the surface of a rock-fill object, counterweight blocks stacked on the bearing plate, an excitation hammer disposed at one side of the bearing plate and used for providing excitation force, and a wave detector installed on the upper surface of the counterweight block and connected with a vibration frequency tester. The bearing plate and the counterweight blocks are cylinders. The weight of the excitation hammer is 40-60 Kg. By bonding the wave detector on the counterweight blocks, the vibration frequency f of a system composed of surface dam material, the bearing plate and the counterweight blocks can be tested through a vibration source, then the dry density of the rock-fill object is tested by performing a pit measure process, thus the relation curve between the system vibration frequency f and the rock-fill object dry density is established, and a linear analysis formula of the rock-fill object dry density is obtained. The provided rock-fill object density measure system has the advantages of time saving, labor saving, rapidness, no damage, high accuracy and the like.

Owner:HUBEI GEZHOUBA TESTING

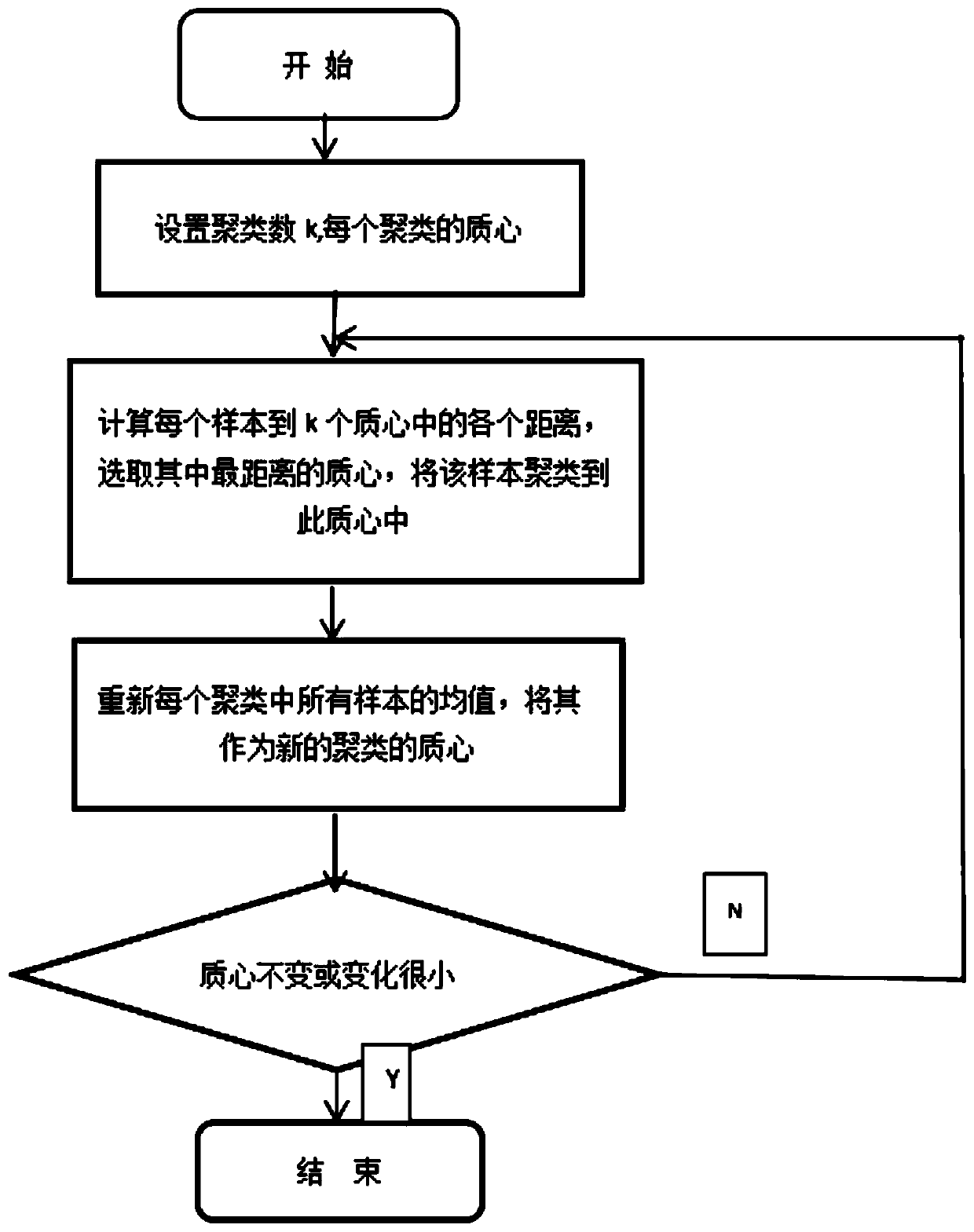

Traffic state prediction method based on clustering analysis and Markov model

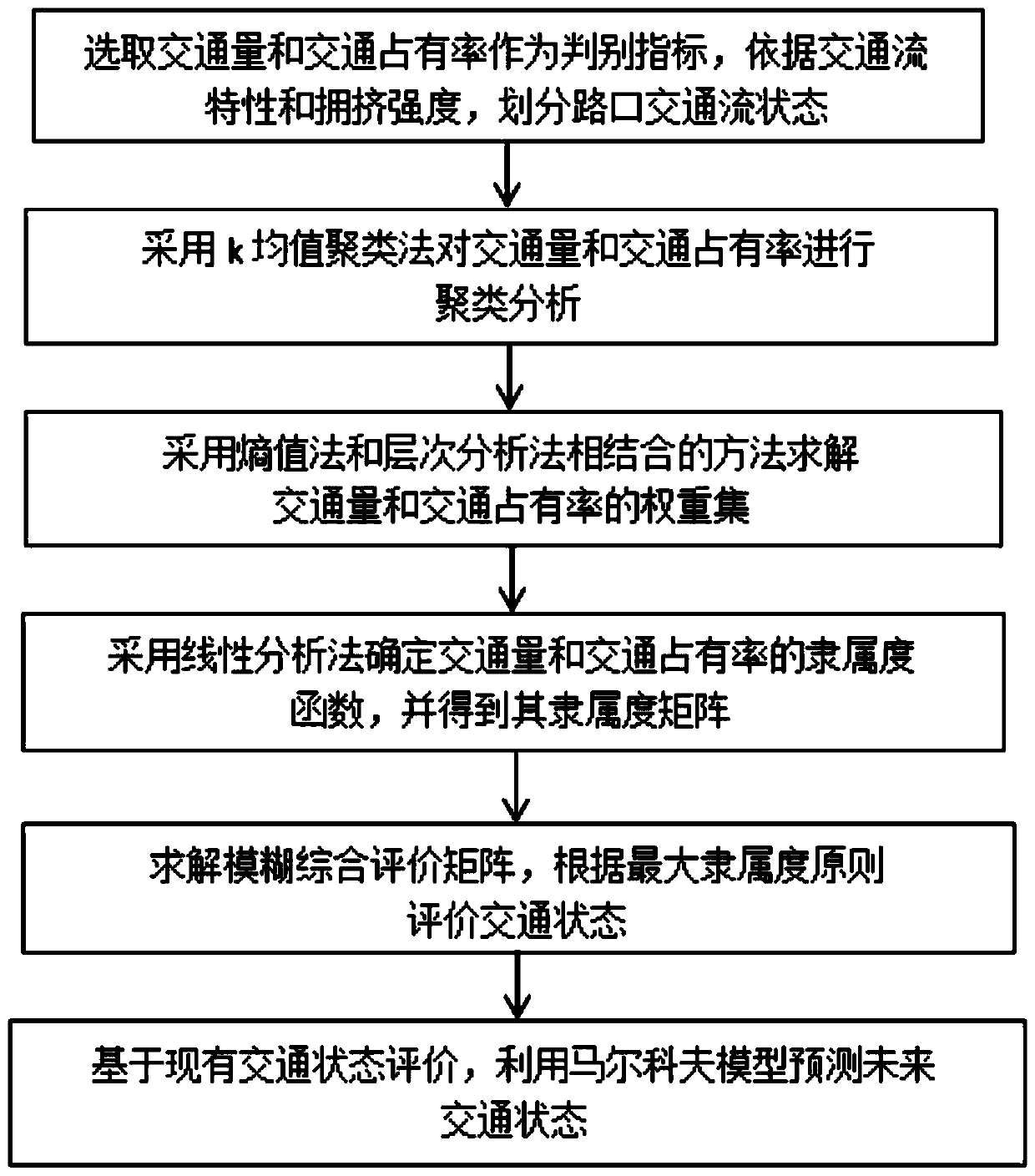

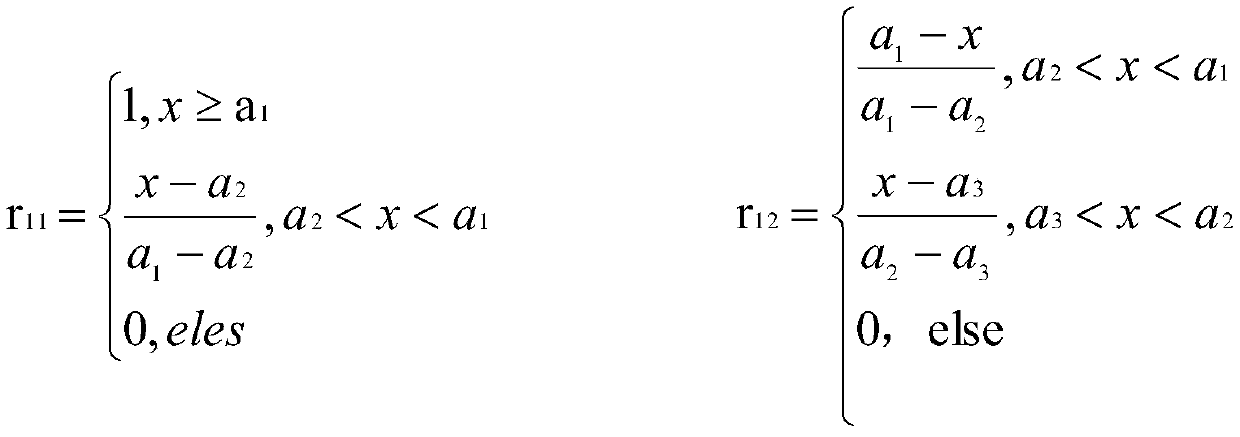

InactiveCN110085026ADetection of traffic movementCharacter and pattern recognitionOccupancy rateState prediction

The invention relates to a traffic state prediction method based on clustering analysis and Markov models. The method comprises the steps of selecting the traffic volume and the traffic occupancy rateas evaluation indexes of the traffic state of urban crossroads; performing clustering analysis on the traffic volume and the traffic occupancy rate by a K means clustering method according to a largenumber of traffic flow data collected by a traffic control center; determining a weight set of the traffic volume and the traffic occupancy rate by a method combining an entropy evaluation method andan analytic hierarchy method; determining a membership degree function of the traffic volume and the traffic occupancy rate by a linear analysis method, and obtaining a membership degree matrix; calculating a fuzzy comprehensive evaluation matrix; evaluating the existing traffic state according to the maximum membership degree principle; and predicating the future traffic state on the basis of aMarkov model according to the existing traffic state. The traffic state prediction method is applicable to practical cases; and the prediction precision is improved.

Owner:CHINA HIGHWAY ENG CONSULTING GRP CO LTD

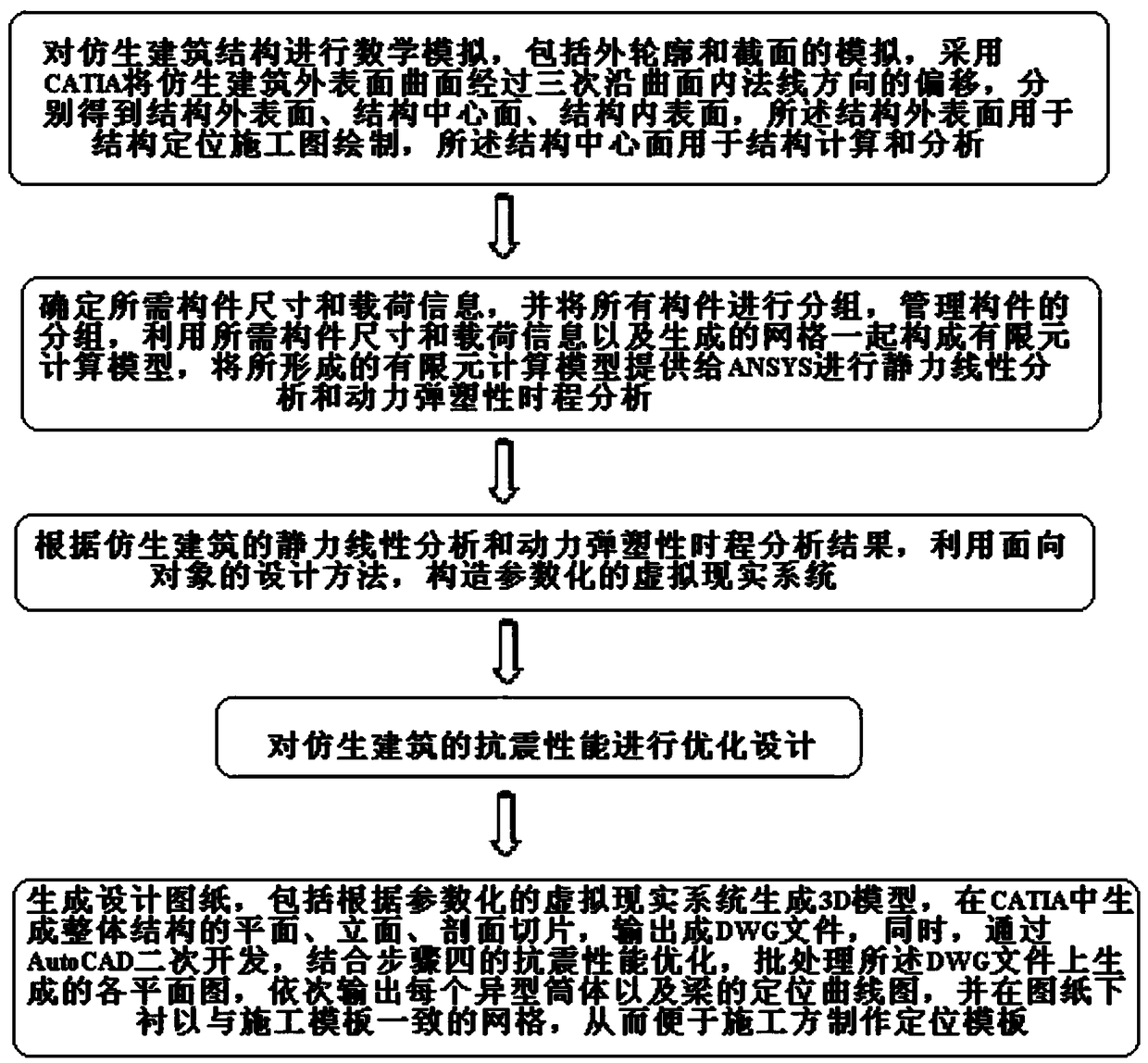

A method for model and designing a bionic build structure

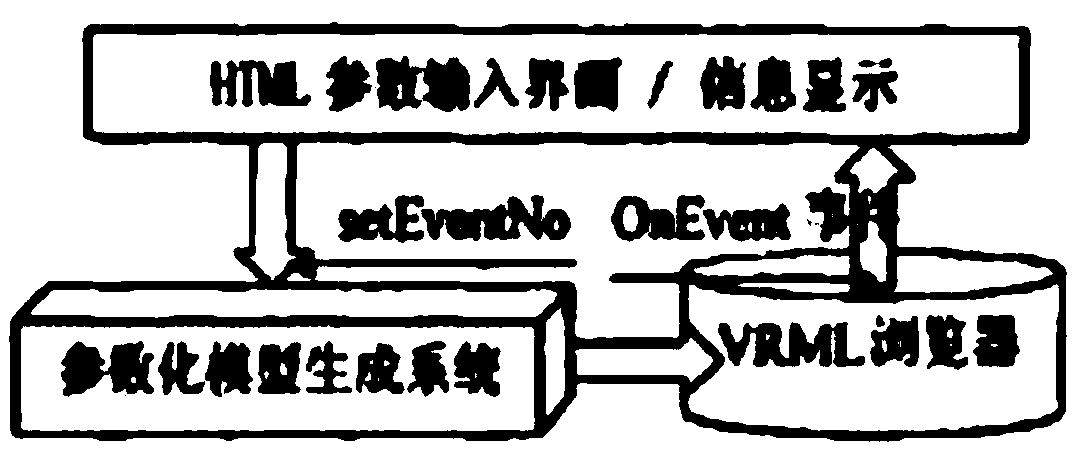

PendingCN109214142APrecise structurePrecise designGeometric CADDesign optimisation/simulationGenerative DesignLinear analysis

The invention provides a modeling and design method of a biomimetic building structure. 2, determining the required component size and load information to form a finite element calculation model, andprovide the formed finite element calculation model to ANSYS for static linear analysis and dynamic elastoplastic time history analysis; 3, according to the results of static linear analysis and dynamic elastoplastic time history analysis of the biomimetic building, constructing a parameterized virtual reality system by using an object-oriented design method; 4, optimizing the seismic performanceof the biomimetic building; 5, generating design drawings accord to that steps 3 and 4, and lining the drawings with a grid consistent with the construction template, thereby facilitating the construction party to make a positioning template. Combined with engineering design to design complex space biomimetic shape building, accurate structural modeling and design, for the implementation of the project to lay the foundation of accurate positioning and shaping.

Owner:许江锋 +2

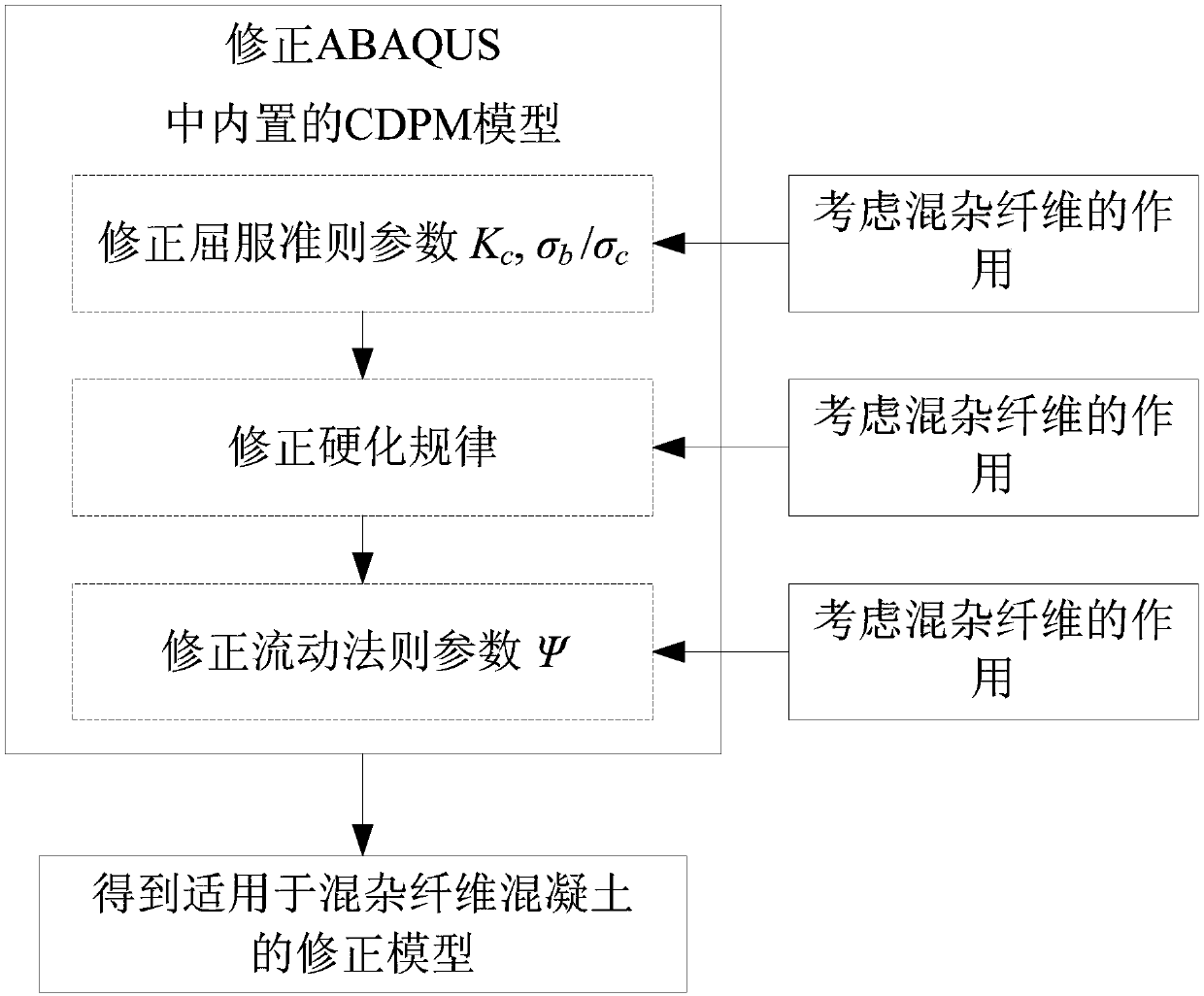

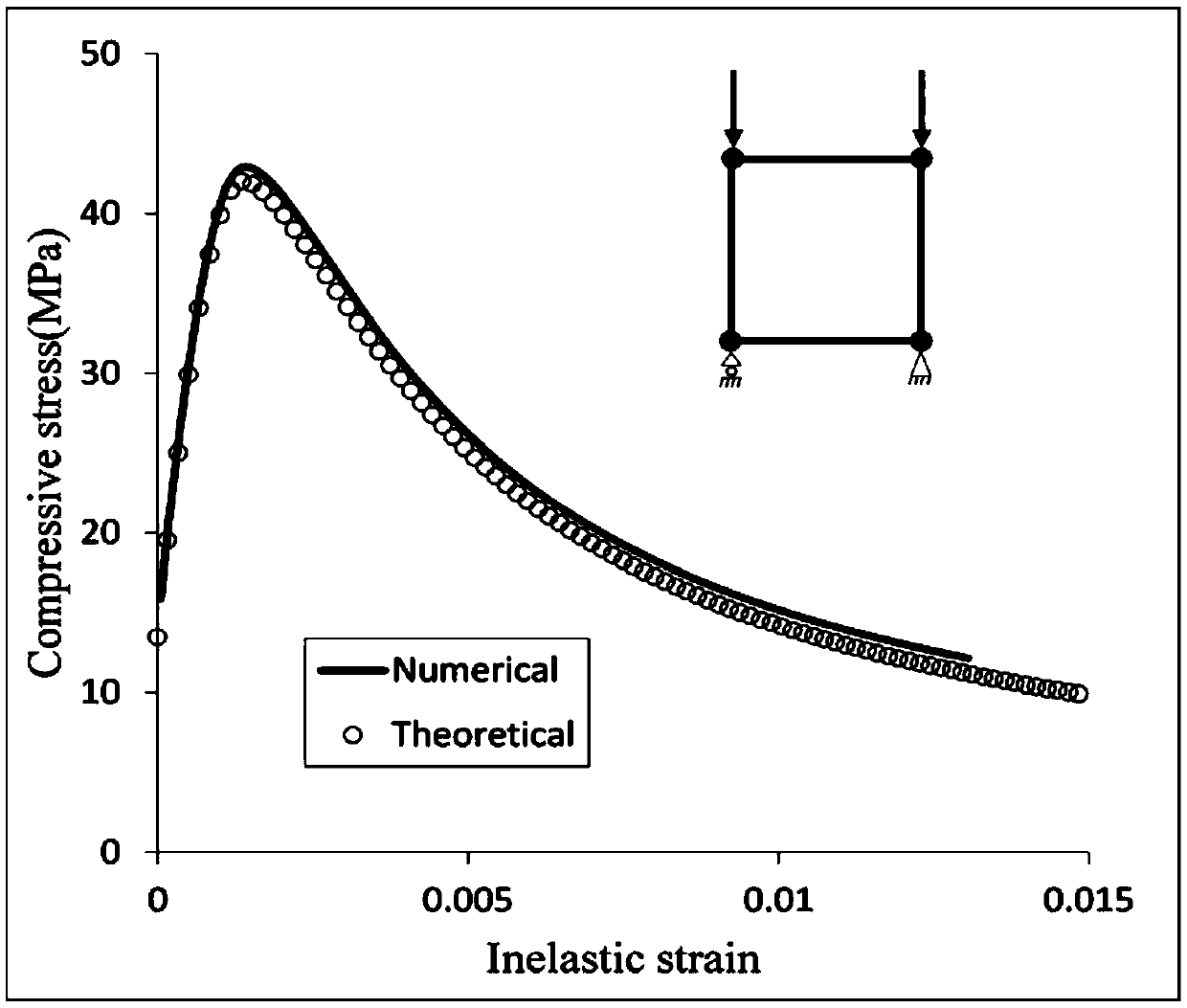

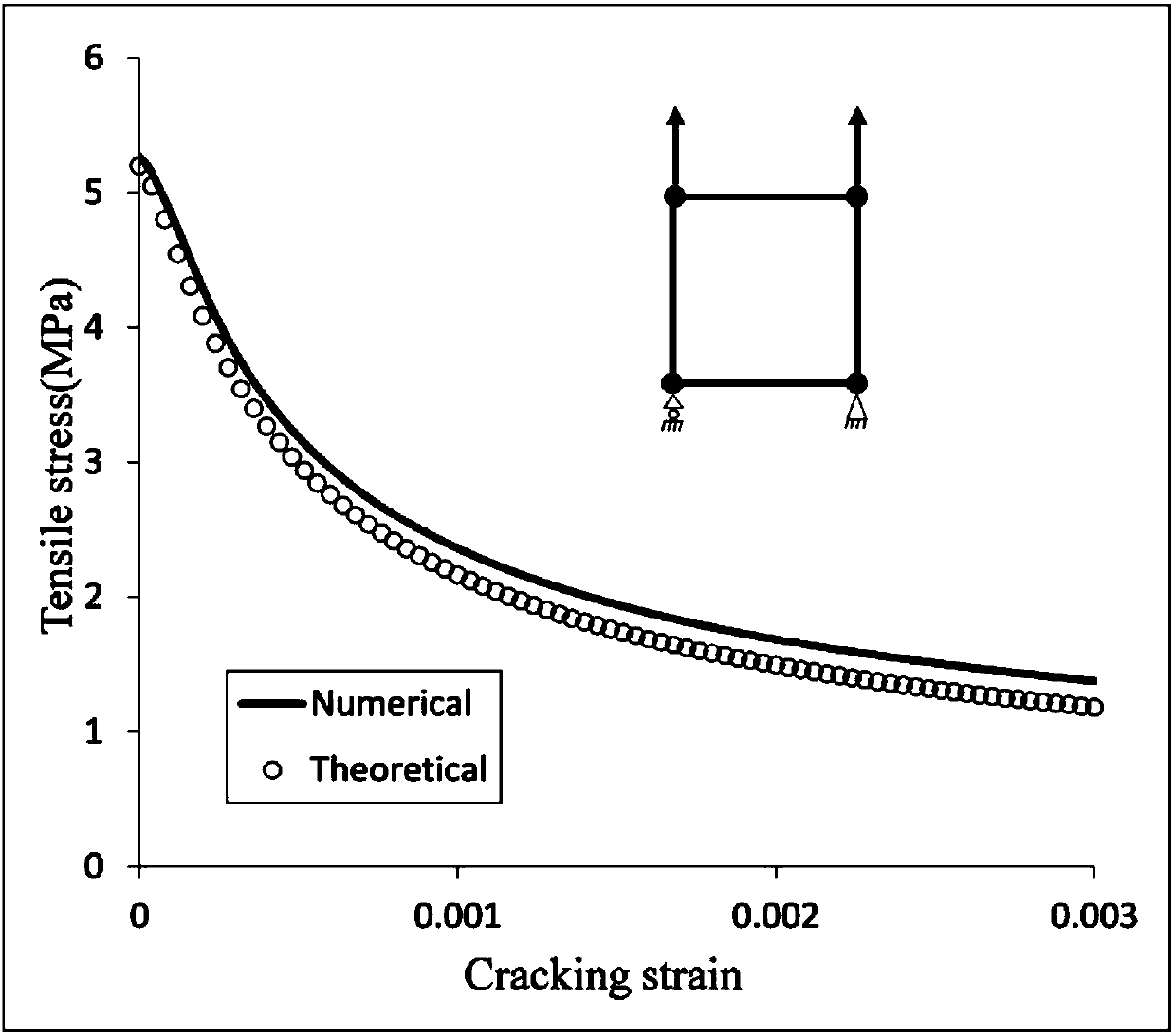

Valuing method of plastic constitutive parameters of steel-polypropylene hybrid fiber concrete in ABAQUS

ActiveCN106326567APredict multiaxial strengthPredict volume deformationGeometric CADDesign optimisation/simulationLongest DiameterFiber type

The invention discloses a valuing method of plastic constitutive parameters of steel-polypropylene hybrid fiber concrete in ABAQUS. The method sufficiently considers influences on mechanical properties of concrete, caused by factors including different fiber types, volume fractions, long-diameter ratios and the like, and related parameters of a built-in concrete damage plasticity model (CDPM) in the ABAQUS are properly revised, so that the related parameters can be more accurately matched with a yield criterion, a hardening rule and a flowing law of the steel-polypropylene hybrid fiber concrete, and a very good reference is provided or refined non-linear analysis of a fiber concrete structure under a complicated stress state.

Owner:WUHAN UNIV

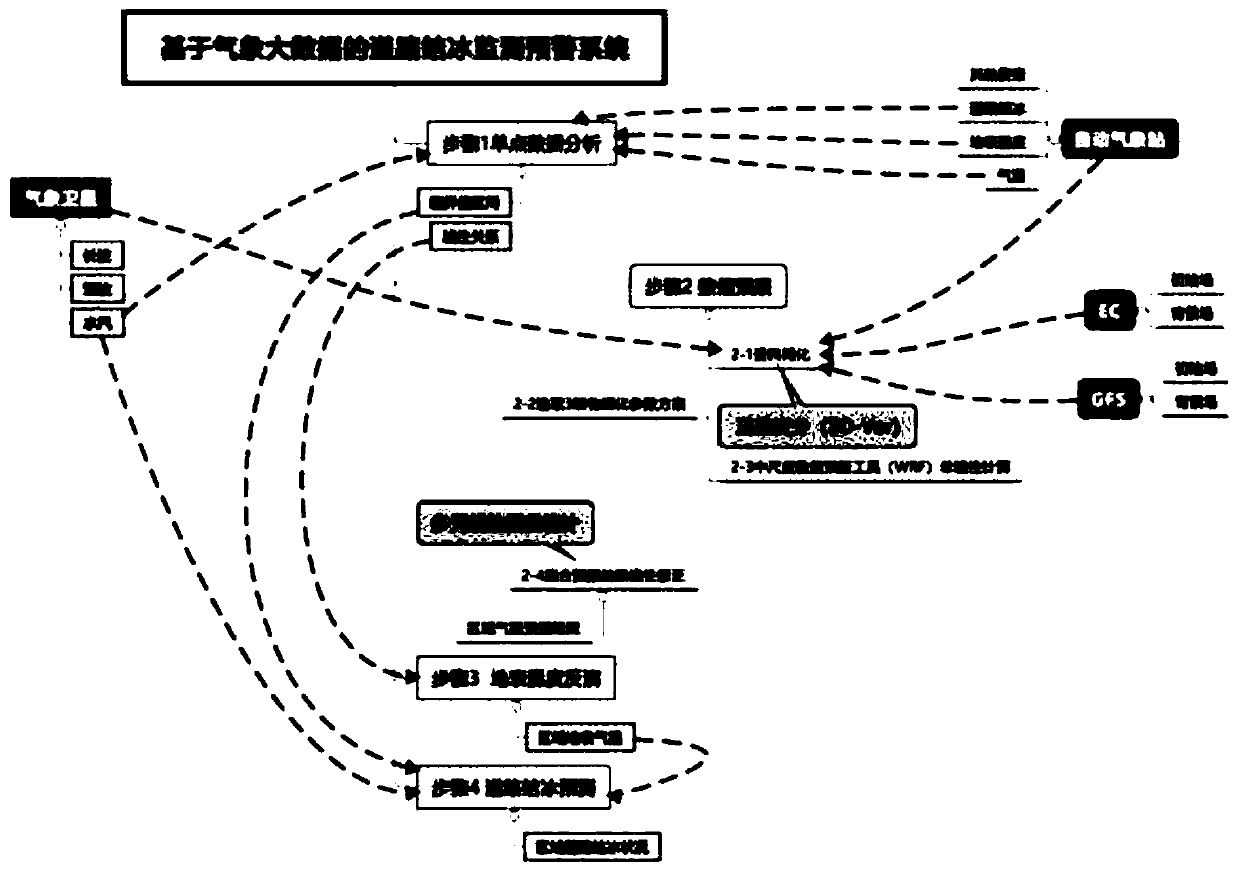

High-precision monitoring and early-warning system for regional road icing based on meteorological big data

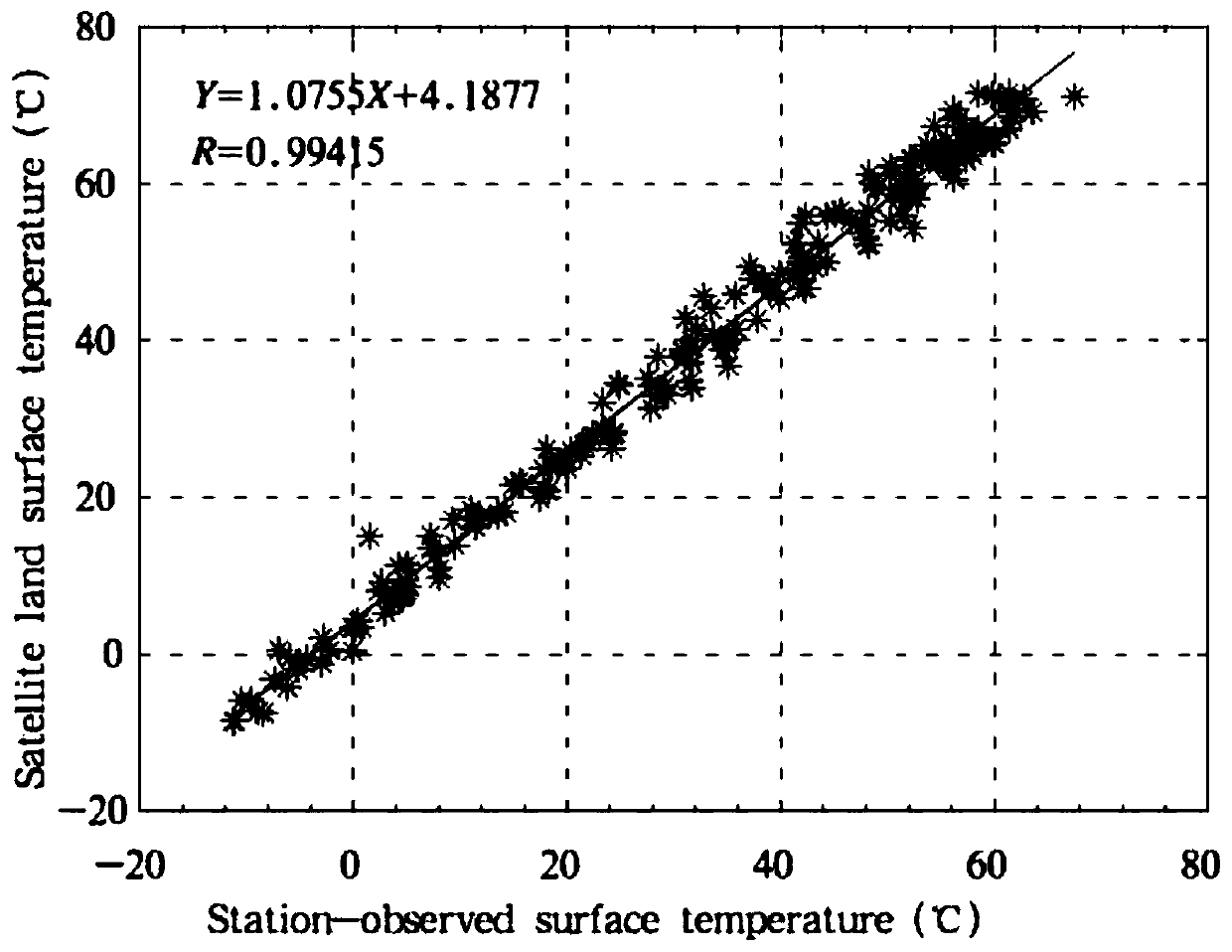

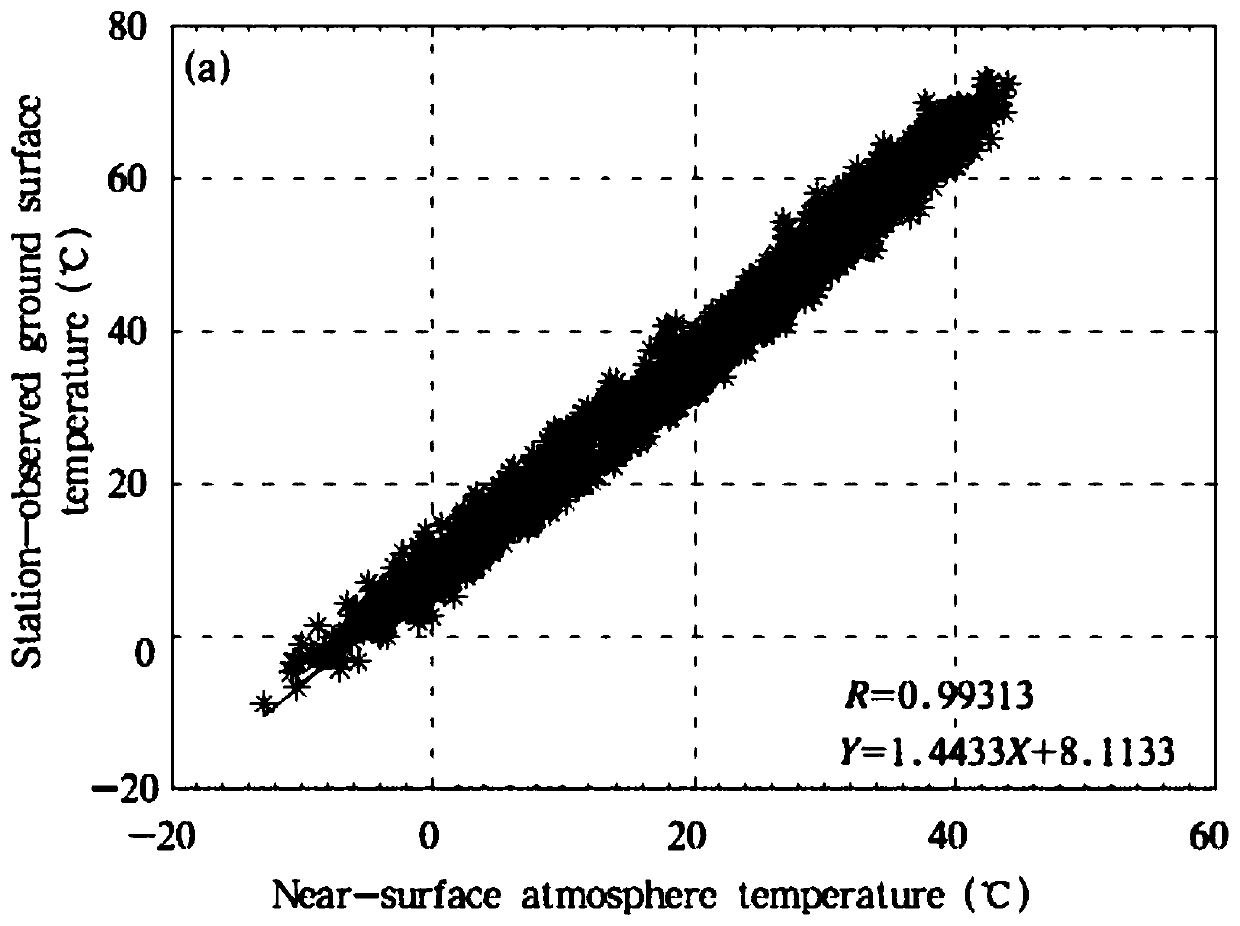

The invention discloses a high-precision monitoring and early-warning system for regional road icing based on meteorological big data. The high-precision monitoring and early-warning system compriseshardware operating environment construction, live data collection and analysis, mesoscale numerical forecasting tool nonlinear calculation, temperature ensemble forecast result linear correction, regional ground surface temperature inversion and regional road icing condition early warning. The high-precision monitoring and early-warning system has the beneficial effects that the high-precision monitoring and early-warning system introduces data of a meteorological satellite, expands the dimension of meteorological observation data, participates in data assimilation of a numerical forecasting mode, and indirectly improves the precision of forecast results; the numerical mode ensemble forecasting is introduced, a sliding training period is adopted when the forecast results are collected, a weight coefficient changes with time, and the precision is improved; and by utilizing various kinds of representative sites, the high-precision monitoring and early-warning system explores relationships among temperature, ground surface temperature and water vapor in different geographical environments through linear analysis, and improves the forecasting precision of regional road icing conditionsfrom point to surface.

Owner:SHANGHAI TONGWANG INFORMATION TECH CO LTD +1

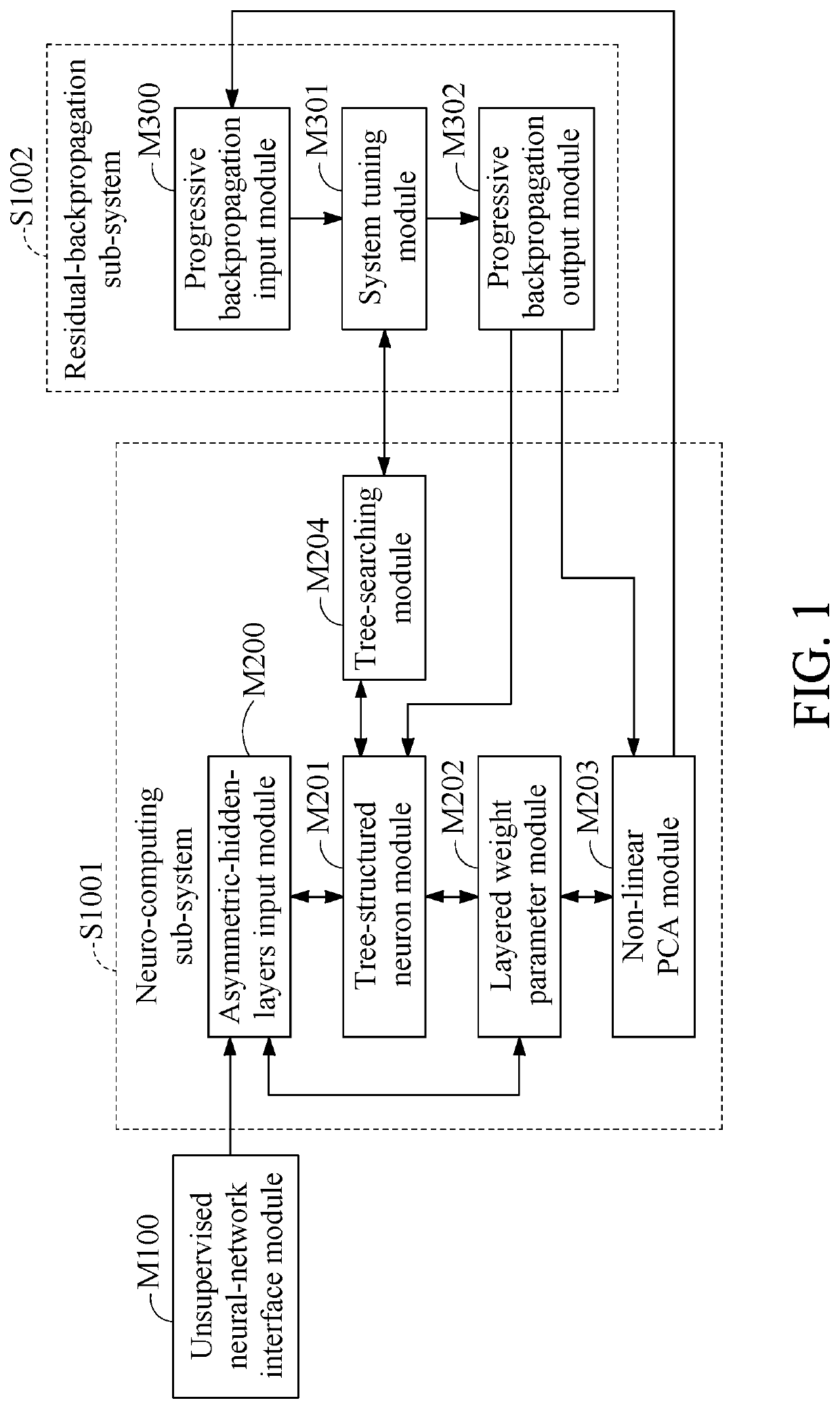

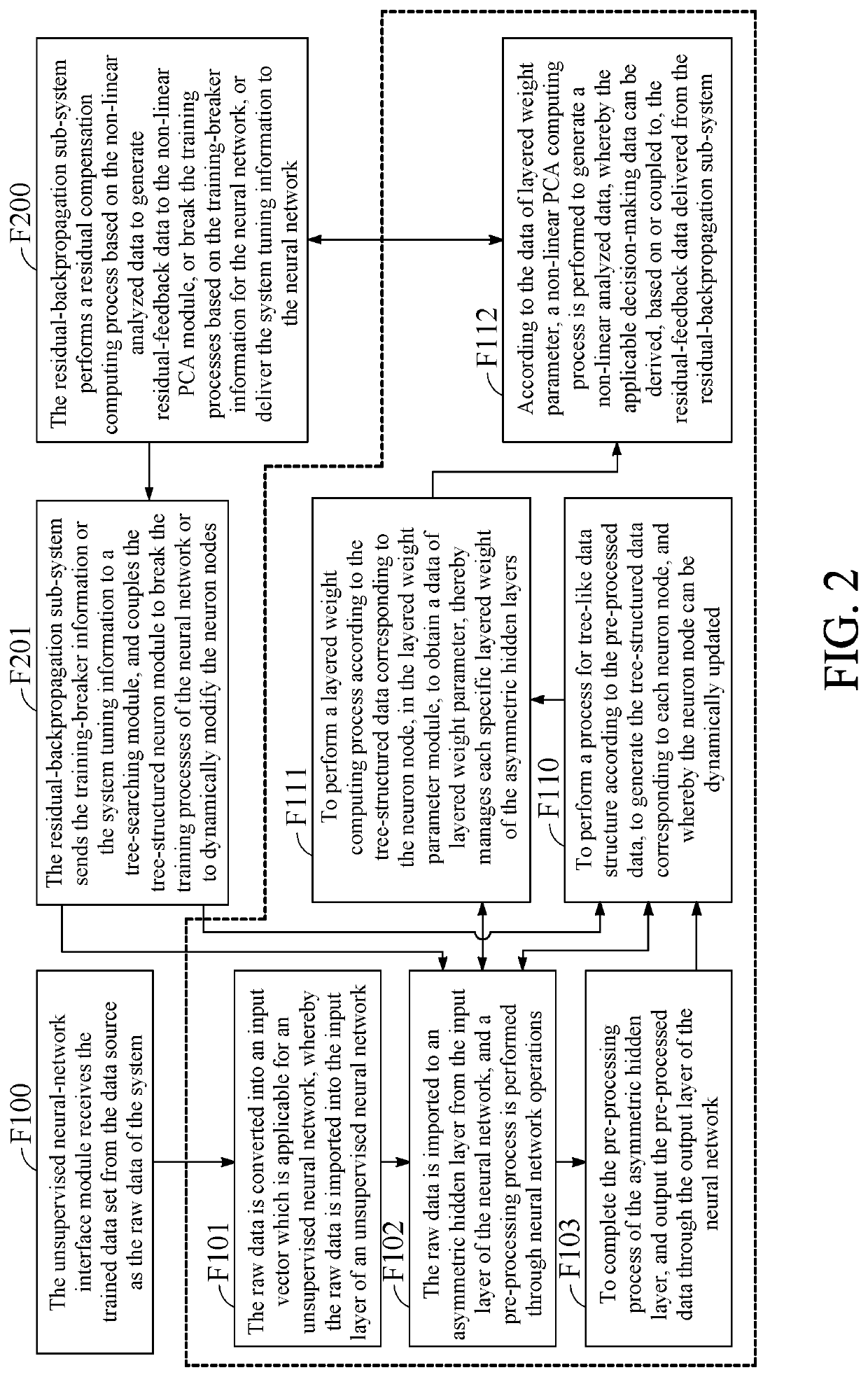

Artificial-intelligence decision-making core system with neural network

ActiveUS20220004839A1Low costEasy to adjustKernel methodsNeural architecturesHidden layerEngineering

An artificial-intelligence decision-making core system with neural network implements asymmetric hidden layers which is constructed by neural network with a dynamic neuron adjusting mechanism via making use of a device with computing unit and storage media, coupled to an independent feedback sub-system which operates a residual-compensation mechanism, thereby the core system can receive various trained data and performs a non-linear analysis process according to the output data derived from the asymmetric hidden layers of an unsupervised neural network, so as to derive individual and applicable decision-making data.

Owner:AHP TECH INC

Method for eliminating transverse cracks at corners of cold-rolled matrix casting blank

The invention provides a method for eliminating transverse cracks at corners of a cold-rolled matrix casting blank. According to the method, the cooling modes of the casting blank at all stages in theaustenite transformation process are determined. Particularly, a, the strong cooling mode is adopted when the casting blank is in a crystallizer and foot roller section, so that MnS is dissolved in austenite before being separated out; b, the strong cooling mode is adopted when the casting blank enters a bent section, so that flake membranaceous ferrite is prevented from being separated out, andthe width of the membranaceous ferrite is controlled to be smaller than or equal to 100 [mu]n; and c, the weak cooling mode is adopted when the casting blank enters a third sectorial section, a fourthsectorial section, a fifth sectorial section and a sixth sectorial section. According to the method for eliminating the transverse cracks at the corners of the cold-rolled matrix casting blank, an empirical equation under different drawing speeds of a continuous casting machine and under different cooling water quantities at different positions is obtained according to the evolvement rule of thesolidification process of the casting blank based on linear analysis of a large quantity of field data. By adoption of the method, the optimal condition can be provided for transforming austenite intoferrite, the membranaceous ferrite is prevented from being separated out, rapid solid solution of second-phase particles MnS is achieved, the precipitation quantity is reduced, and the transverse cracks at the corners of the cold-rolled matrix casting blank are eliminated.

Owner:德龙钢铁有限公司

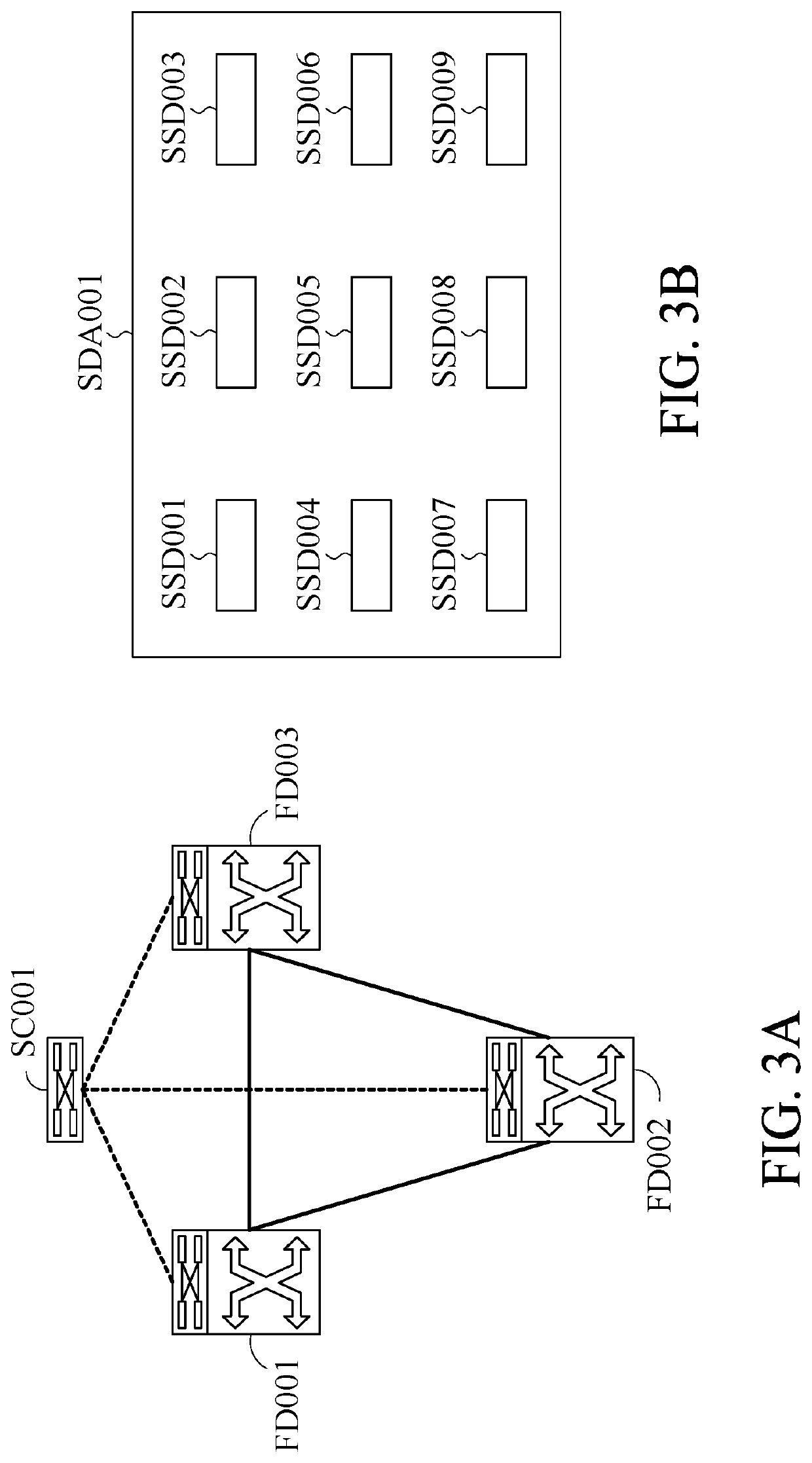

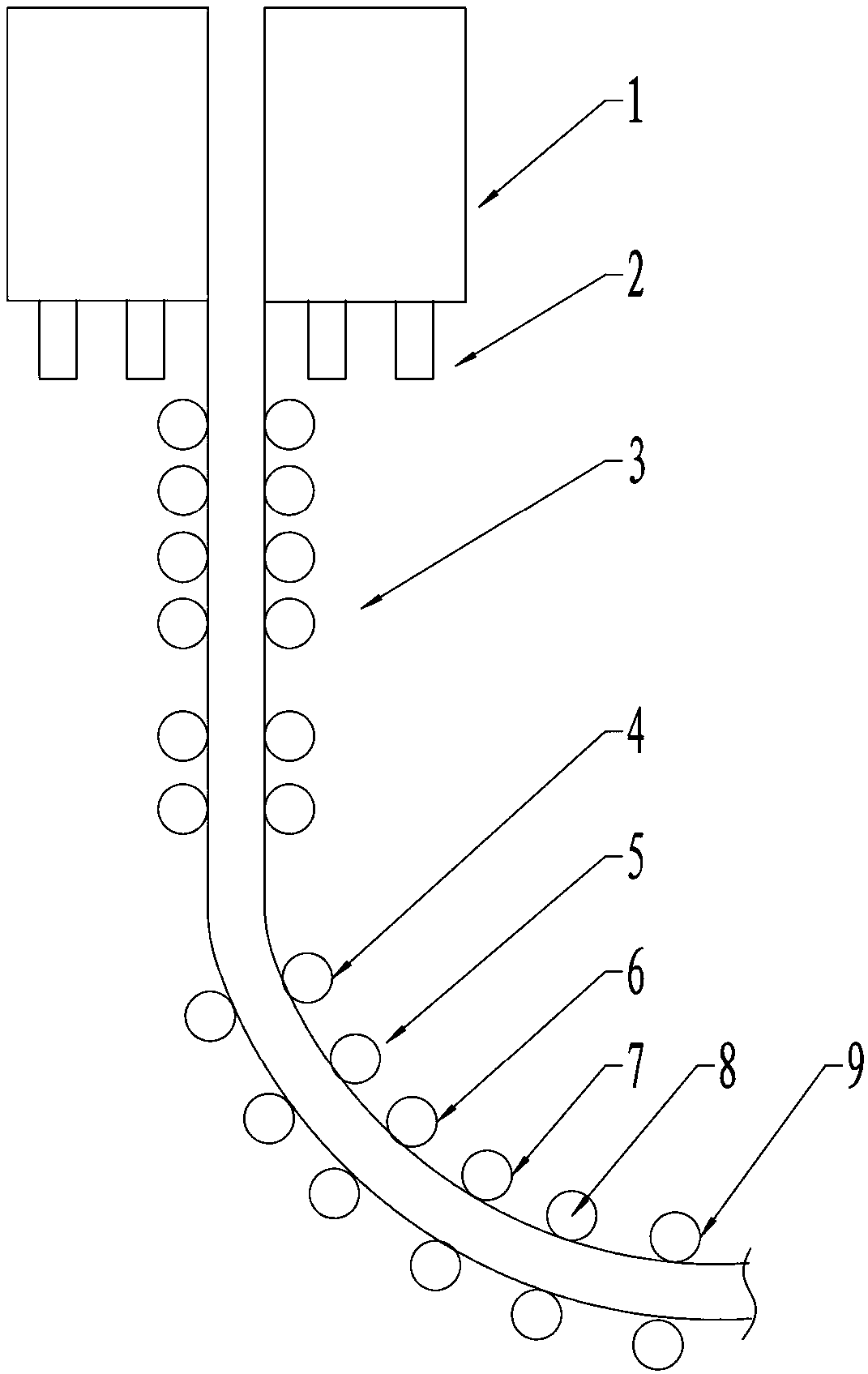

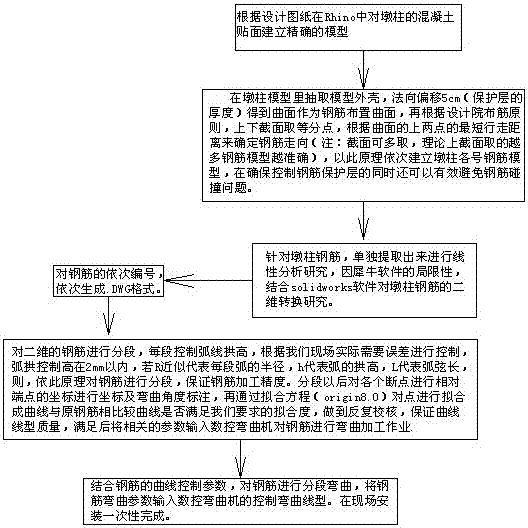

Spacial three-dimensional special-shaped bridge pier rebar construction method based on BIM modelling technology

ActiveCN107366224ASolve processing problemsImprove ergonomicsGeometric CADBridge structural detailsNumerical controlThree-dimensional space

The invention relates to a spacial three-dimensional special-shaped bridge pier rebar construction method based on a BIM modelling technology, and belongs to the field of bridge construction. The method mainly comprises the steps of establishing a pier model, determining the trend of rebar, conducting rebar linear analysis, numbering the rebar, and performing rebar classification and processing. An IGES. format file conversion station is utilized to perform conversion, two-dimensional disintegration is conducted on the spacial three-dimensional special-shaped rebar through solidworks, a dwg format is exported after disintegration to be subjected to parameter extraction, parameters such as angles and coordinates of rebar linear section control points are obtained, then obtained data is input into a numerical control bending machine, and rebar processing is completed. The spacial three-dimensional special-shaped bridge pier rebar construction method based on the BIM modelling technology has the advantages of effectively solving the difficult problem of the spacial three-dimensional special-shaped bridge rebar is hard to process, reducing the difficulty of processing the three-dimensional spacial special-shaped bridge pier rebar, improving the work efficiency of processing the three-dimensional spacial special-shaped bridge pier rebar, improving the precision of the processed rebar, shortening the construction period, and saving the cost.

Owner:CHINA FIRST HIGHWAY ENG +1

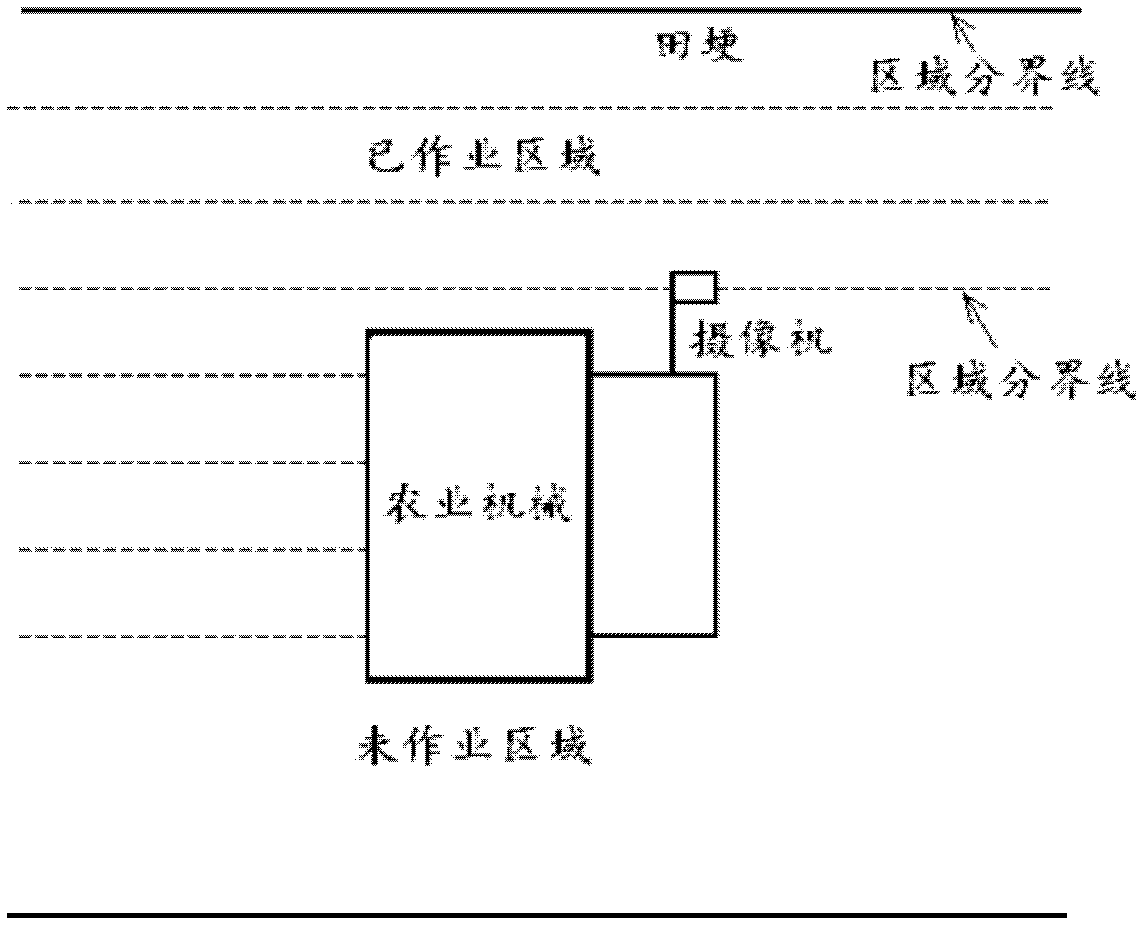

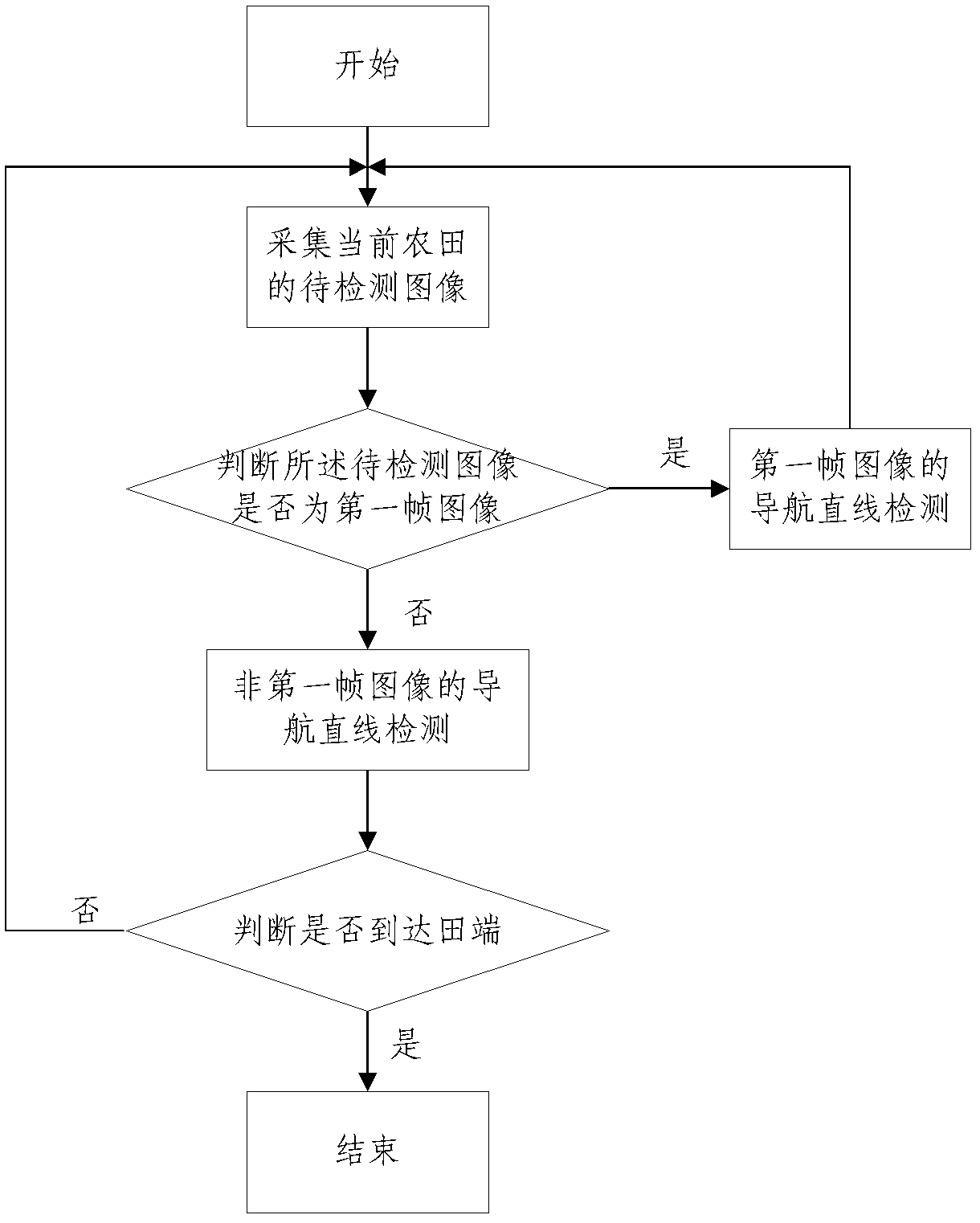

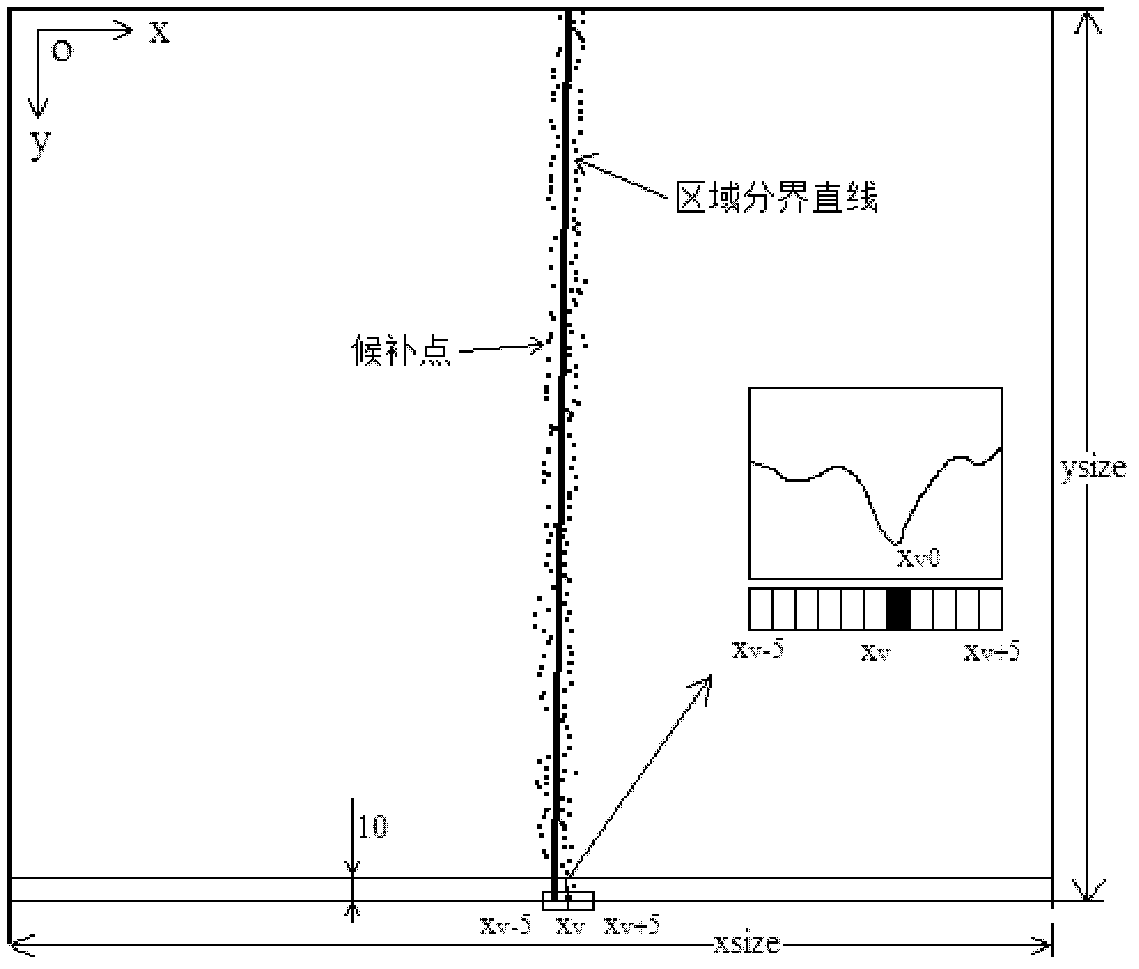

Image detection method of farmland weak navigation information and system thereof

InactiveCN102629317AImplement image recognitionThe test result is accurateCharacter and pattern recognitionHough transformMachine vision

The invention discloses an image detection method of farmland weak navigation information and a system thereof, relating to the field of machine vision navigation technology. The method comprises the following steps of: S1, collecting an image to be detected of current farmland; S2, judging whether the image to be detected is a first frame image, if so, carrying out navigation straight line detection of the first frame image, and returning to the step S1, otherwise, carrying out navigation line detection of a non first frame image; S3, carrying out farmland end detection according to a result of the navigation line detection of the non first frame image, judging whether reaches a farmland end or not, if so, ending the detection, and otherwise, returning to the step S1. According to the invention, by targeting a farmland work environment with weak navigation information, utilizing methods of wavelet transform and linear analysis, mutual association of front and rear frames, segmentation Hough transform and the like, in the condition that dividing lines of farmland areas are not obvious, the image identification of a navigation path is realized, and a detection result is accurate, stable and fast.

Owner:CHINA AGRI UNIV

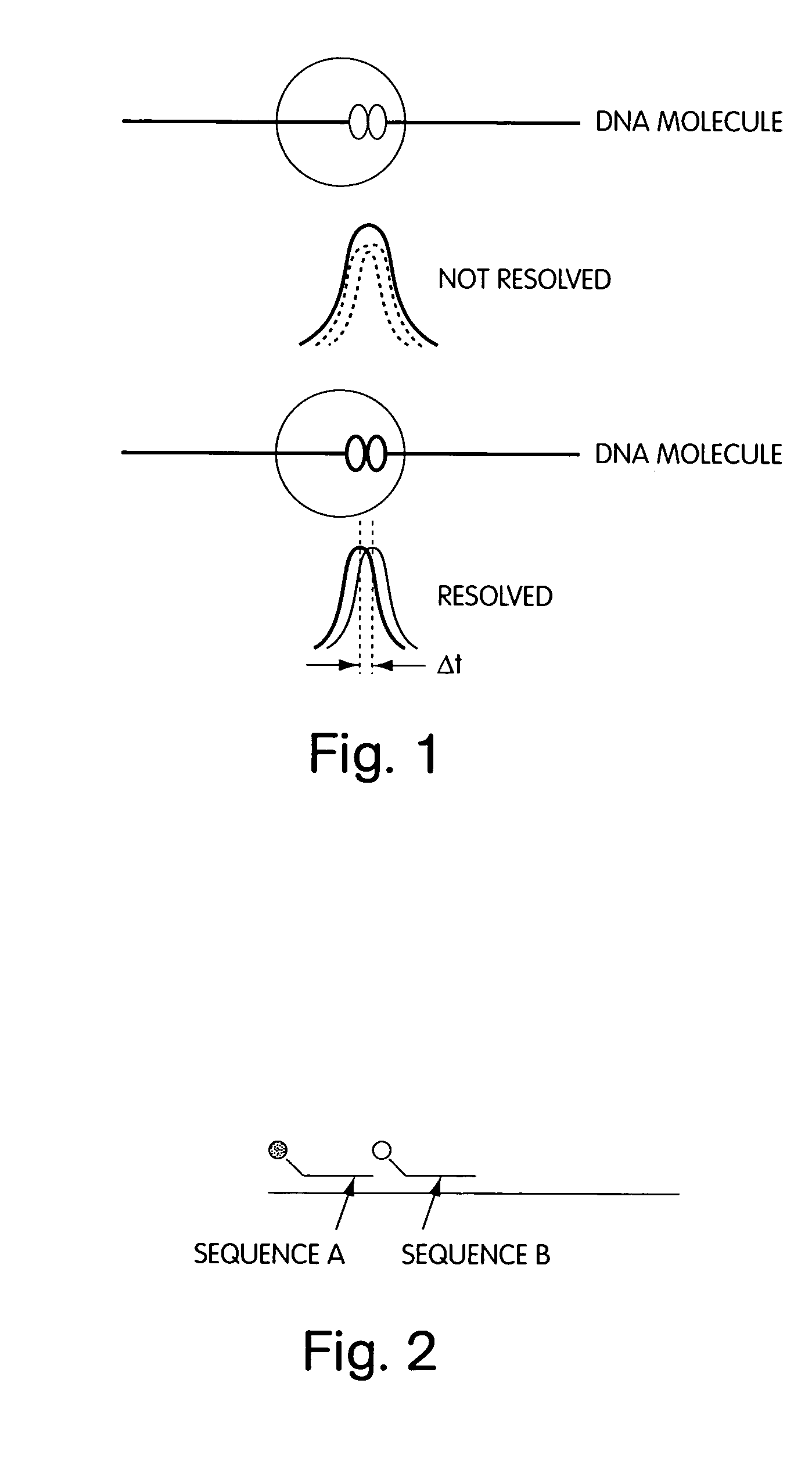

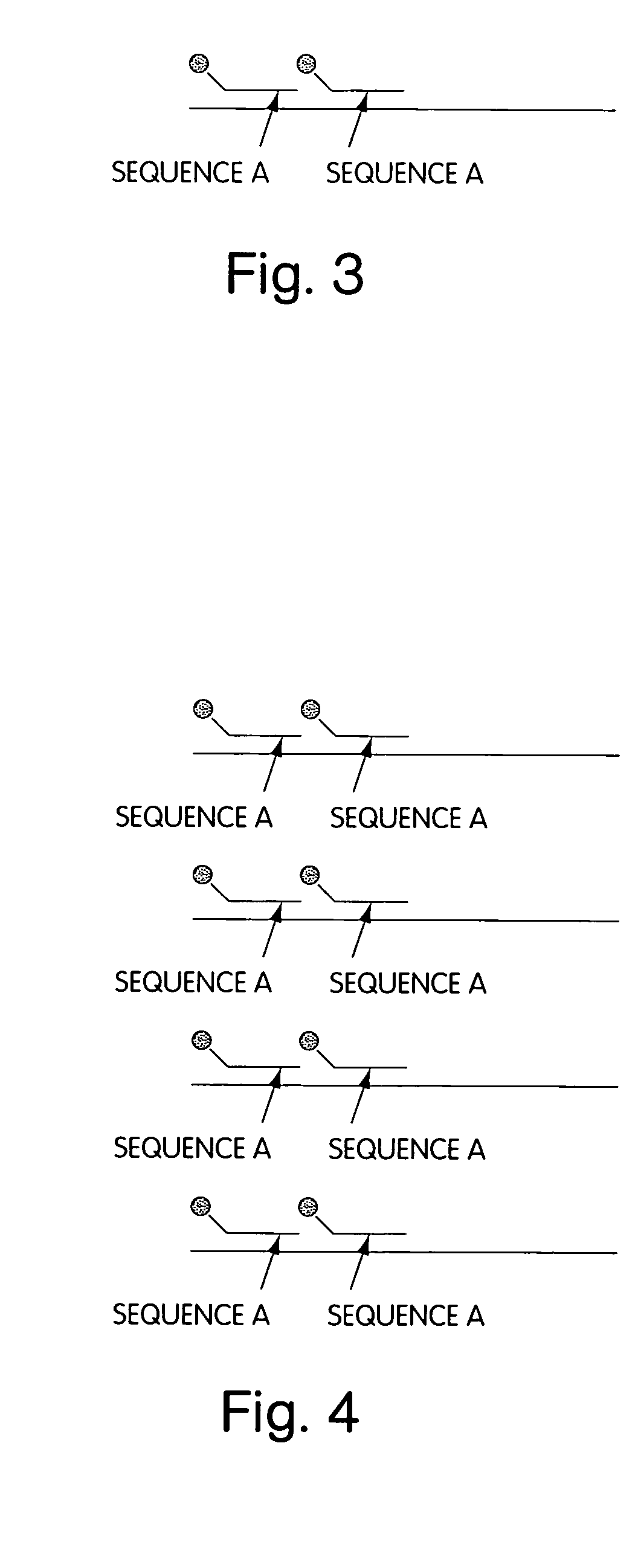

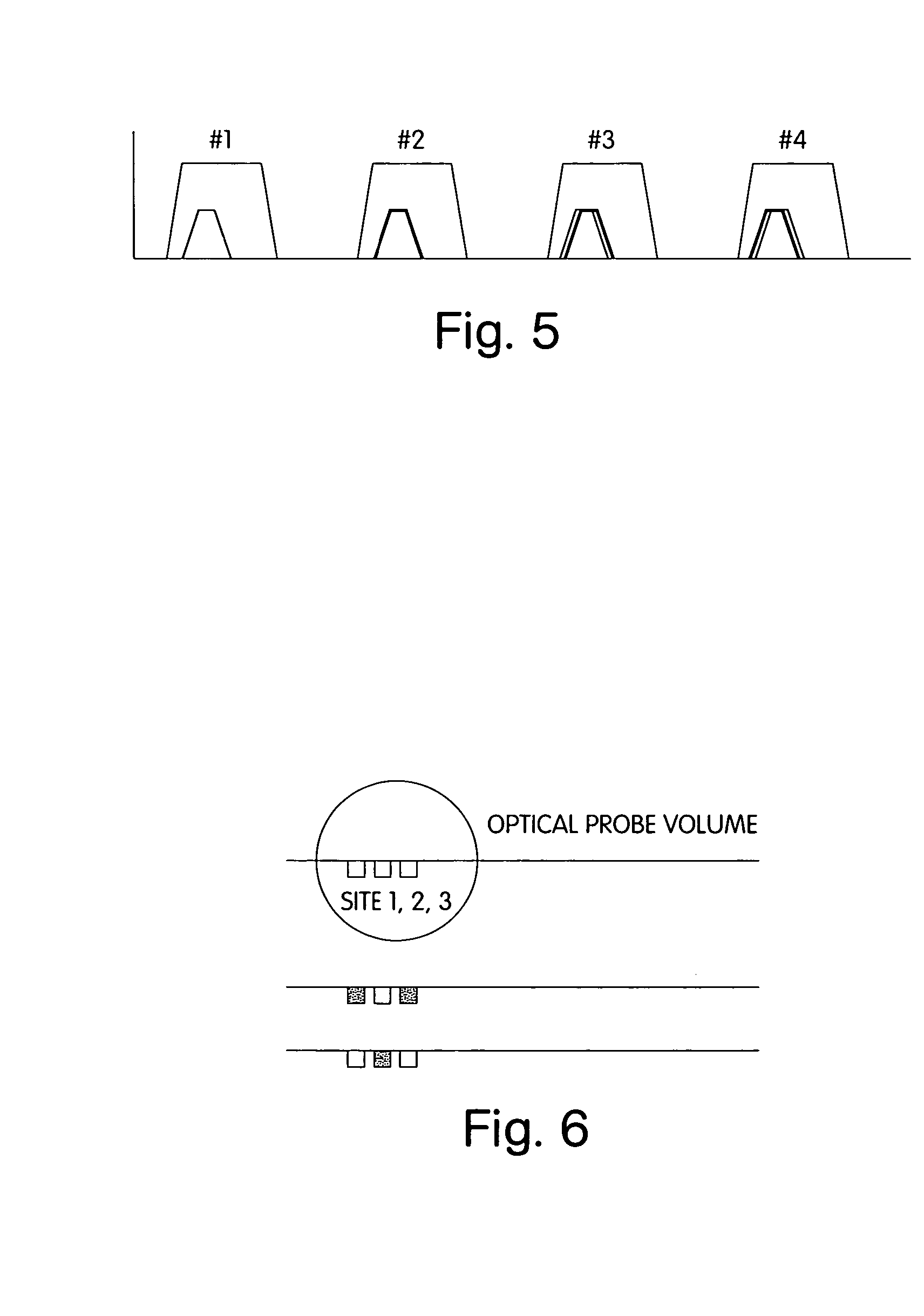

High resolution linear analysis of polymers

InactiveUS8423294B2Improve spatial resolutionImprove efficiencyMicrobiological testing/measurementNanoinformaticsImage resolutionBiopolymer

The invention provides methods and systems for improved spatial resolution of signal detection, particularly as applied to the analysis of polymers such as biological polymers. Some of the methods and systems comprise differentially tagging polymers in order to increase resolution. Some of the methods and systems comprise techniques for improving the precision of separation distance measurements, without necessarily requiring improvements in the known detection resolution of prior art systems.

Owner:PATHOGENETIX

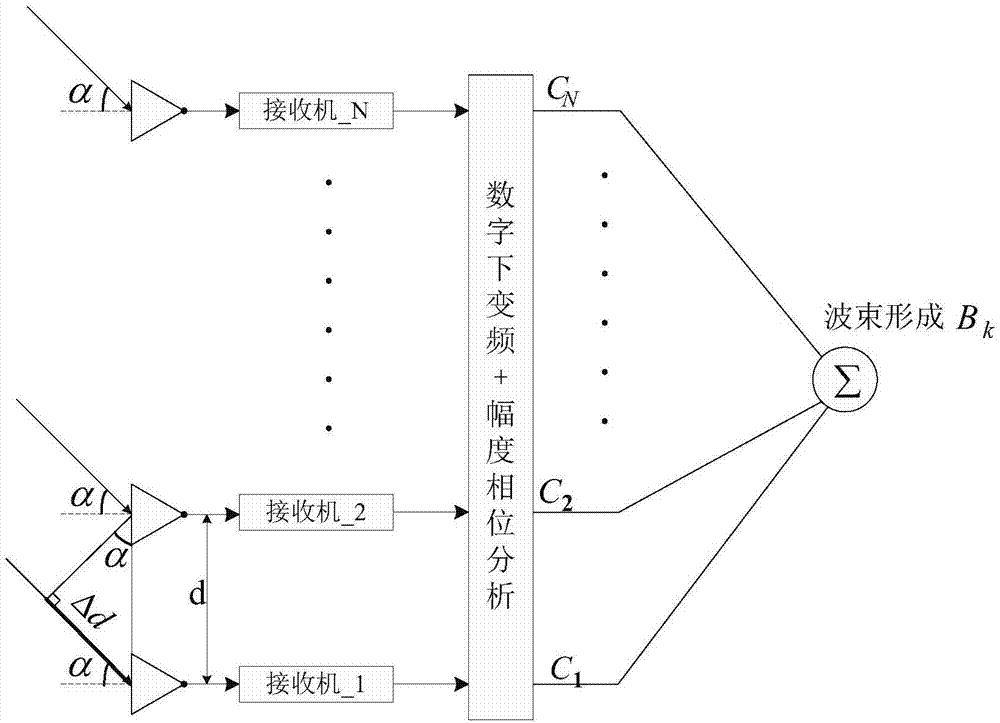

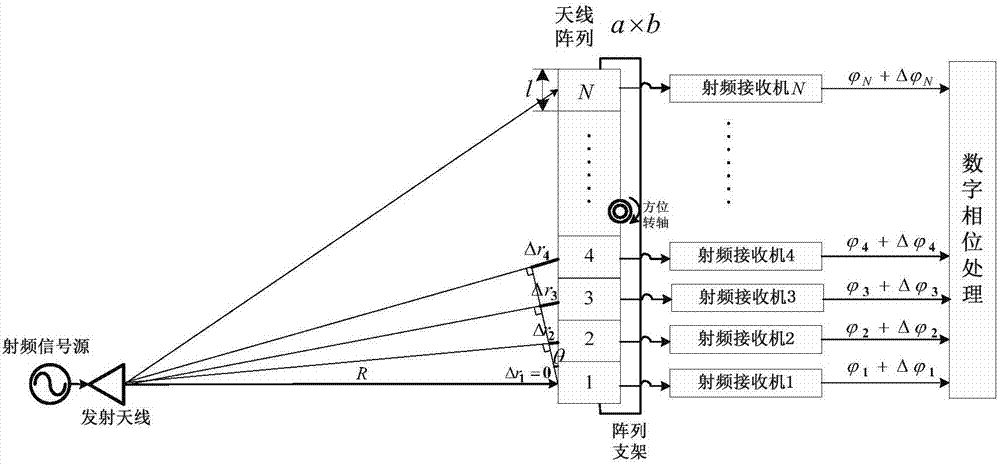

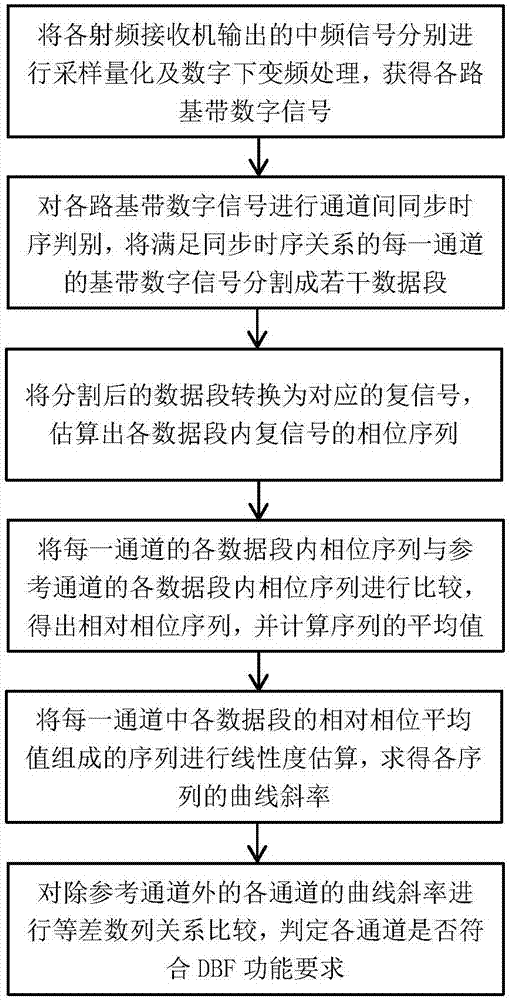

Phase linear analysis method and system for detecting DBF function of radar system

ActiveCN107329127ASimplify complexityShorten test timeWave based measurement systemsData segmentRadar systems

The invention relates to a phase linear analysis method and system for detecting the DBF function of a radar system. The method comprises steps of: segmenting respective baseband digital signals of a radio frequency receiver into several data segments; converting the segmented data segments into corresponding complex signals and estimating the phase sequences of the complex signals in respective data segments; comparing the phase sequences with phase sequences in respective data segments of a reference channel to obtain the relative phase sequences in respective data segments of each channel, and calculating the average value of the relative phase sequences of respective data segments; estimating the linearity of a sequence formed by the relative phase average value of respective data segments in each channel to obtain the curve slopes of respective sequences, and comparing the curve slope of respective channels to obtain a DBF function detection result. The phase linear analysis method and system, by analyzing the relative phase linearity of each channel, eliminates the influence of the inherent phase of respective channels, improves the precision of the DBF function detection, and simplifies the circuit structure of the radar system.

Owner:NAT SPACE SCI CENT CAS

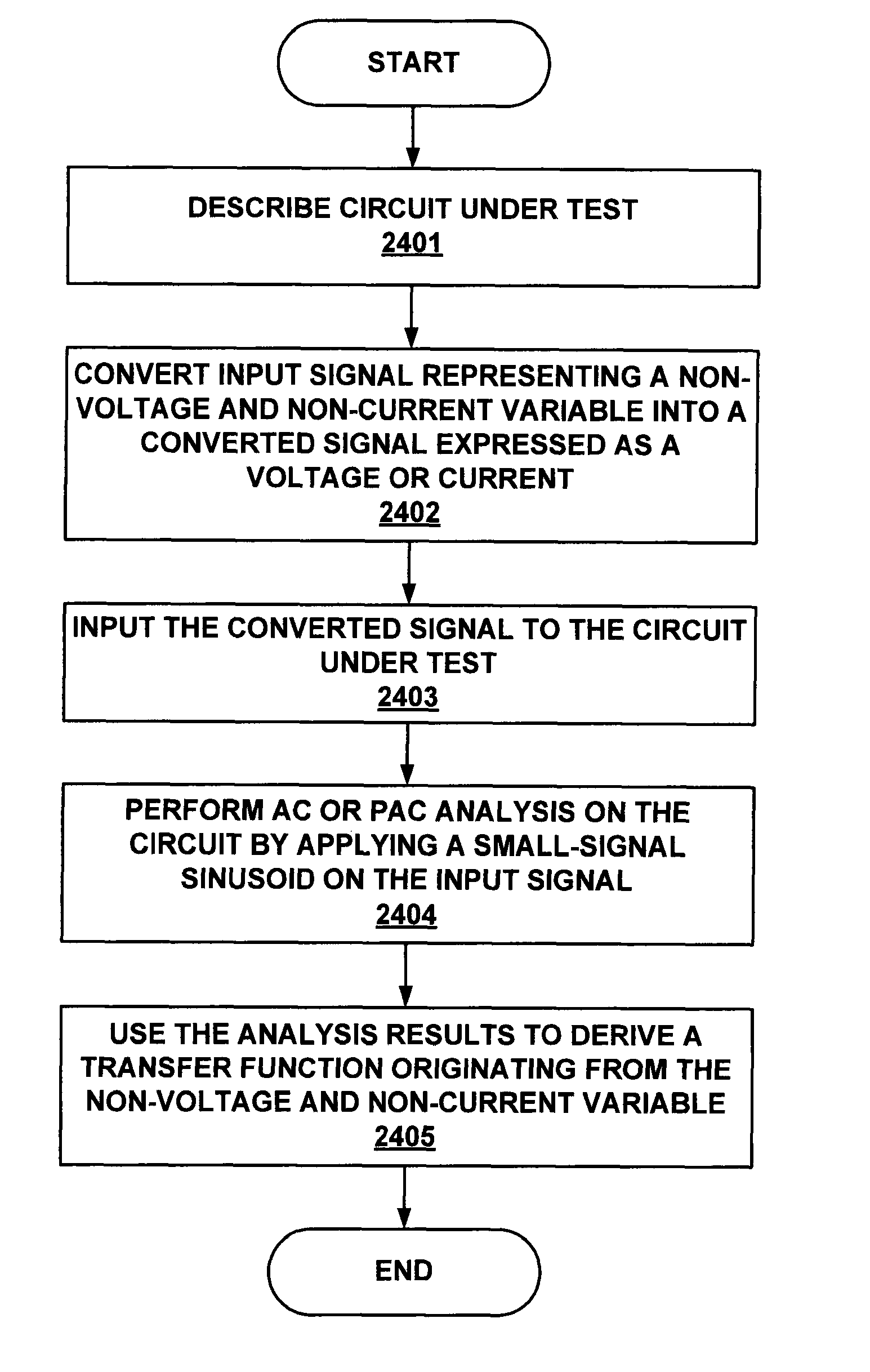

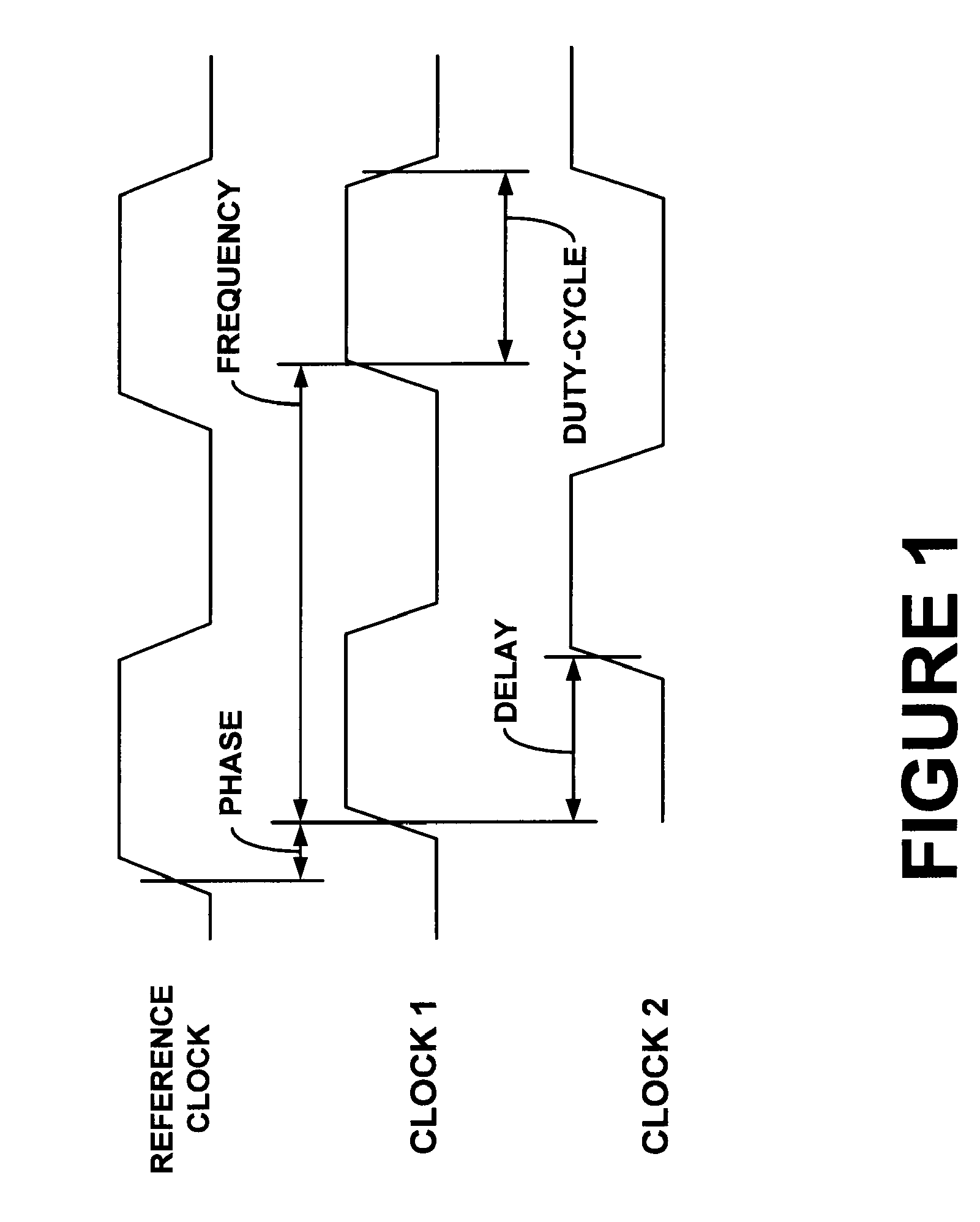

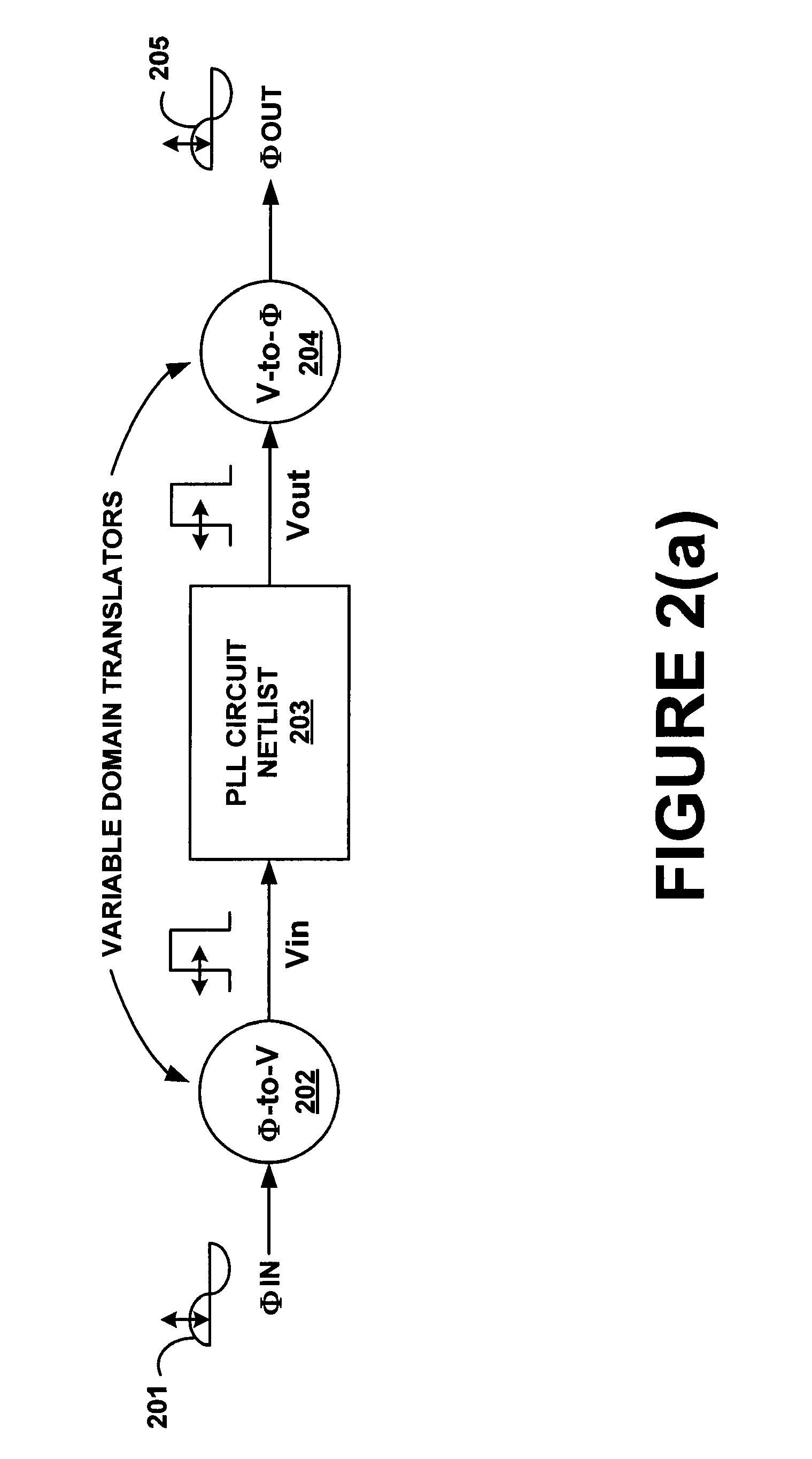

Transforming variable domains for linear circuit analysis

InactiveUS8185853B2Detecting faulty computer hardwareComputer aided designLinear analysisVariable domain

Embodiments in the present disclosure pertain to domain translators. A domain translator converts a variable from one domain to a different domain. Domains include, but are not limited to, voltage, current, frequency, phase, delay, and duty-cycle. In particular, domain translators enable conversion between standard voltage and current domains commonly used by circuit simulators to other domains such as frequency, phase, delay, duty-cycle, etc., so that linear analysis can be performed on a wide range of circuits that exhibit linear behavior in domains other than voltage and current.

Owner:RAMBUS INC

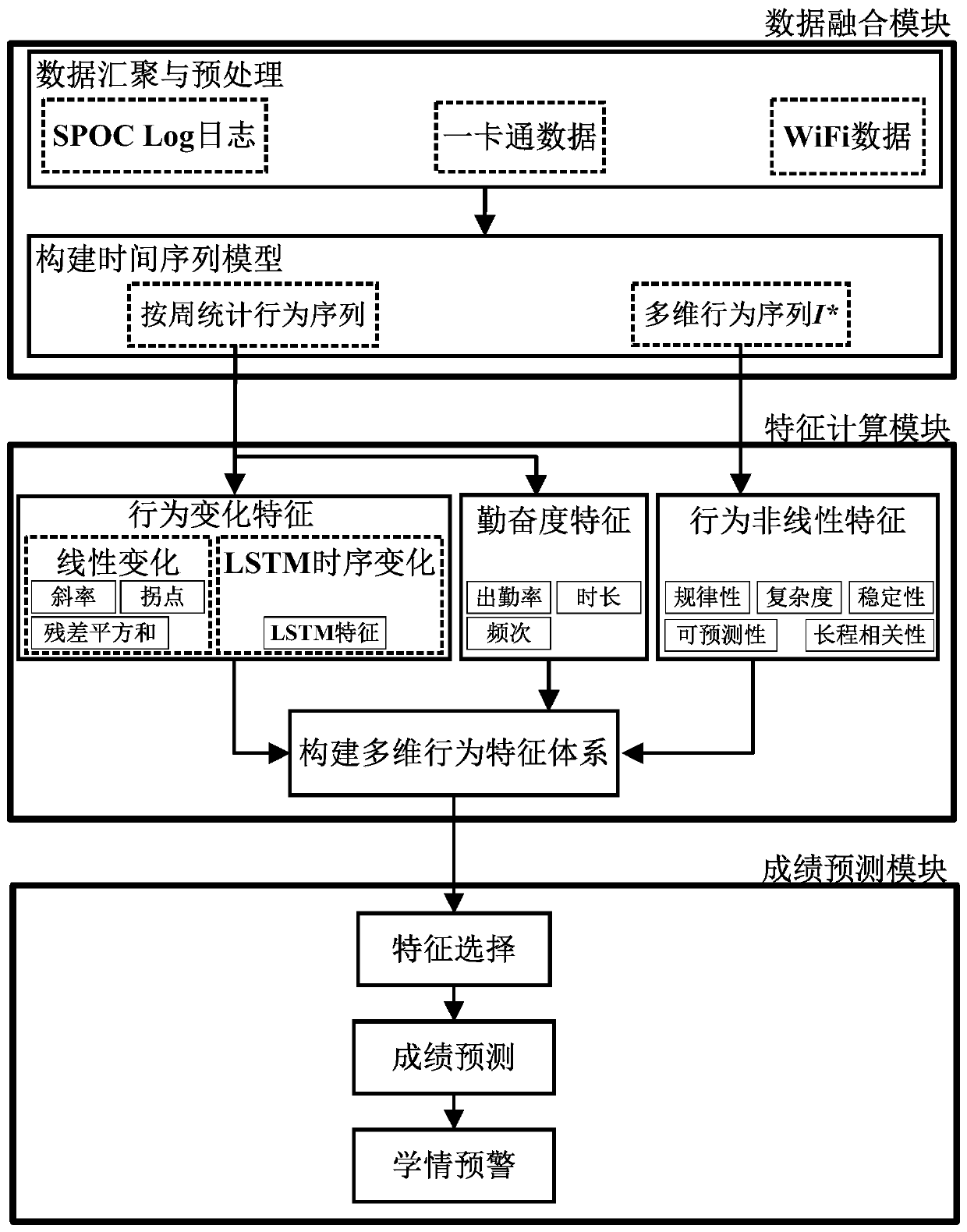

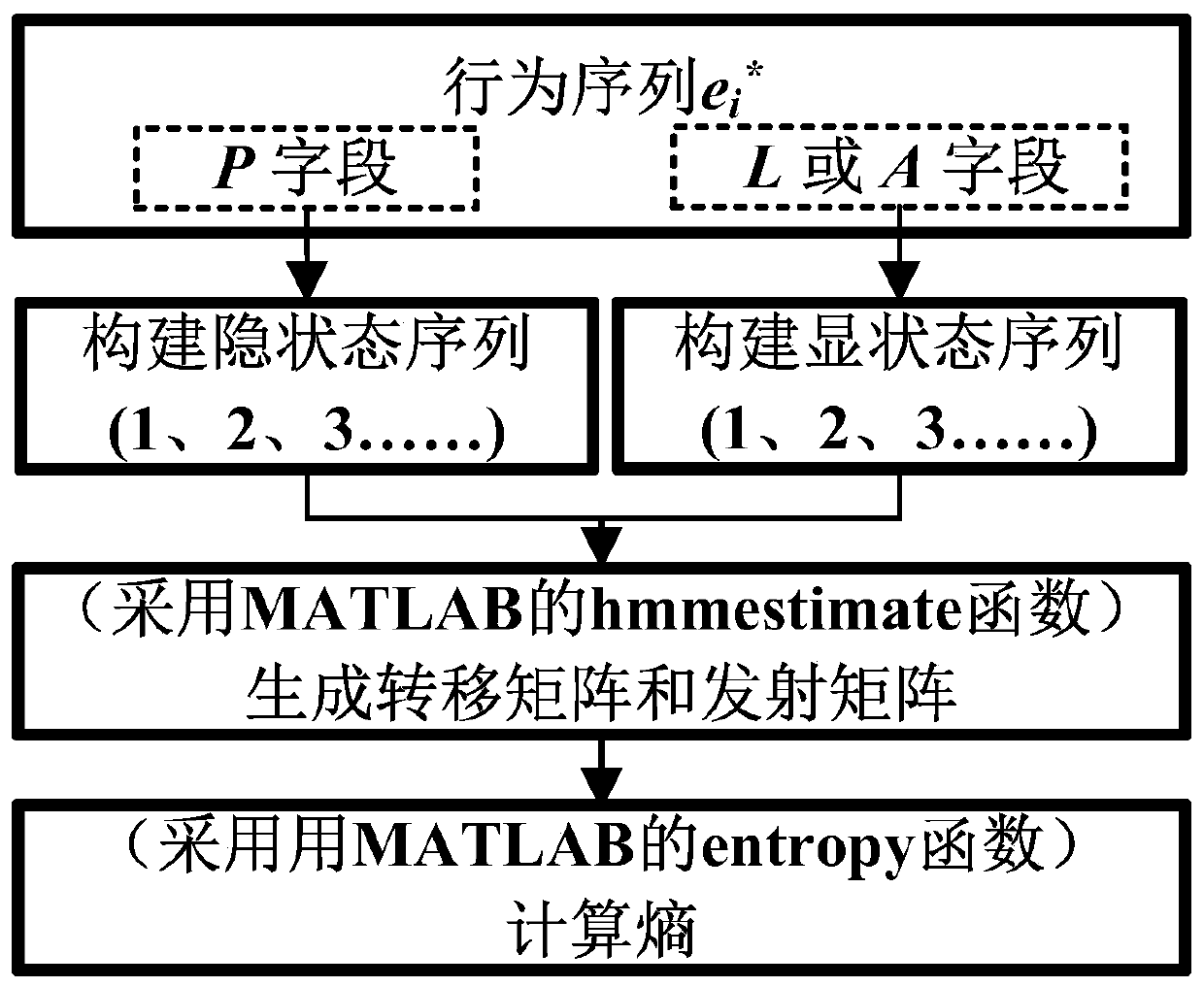

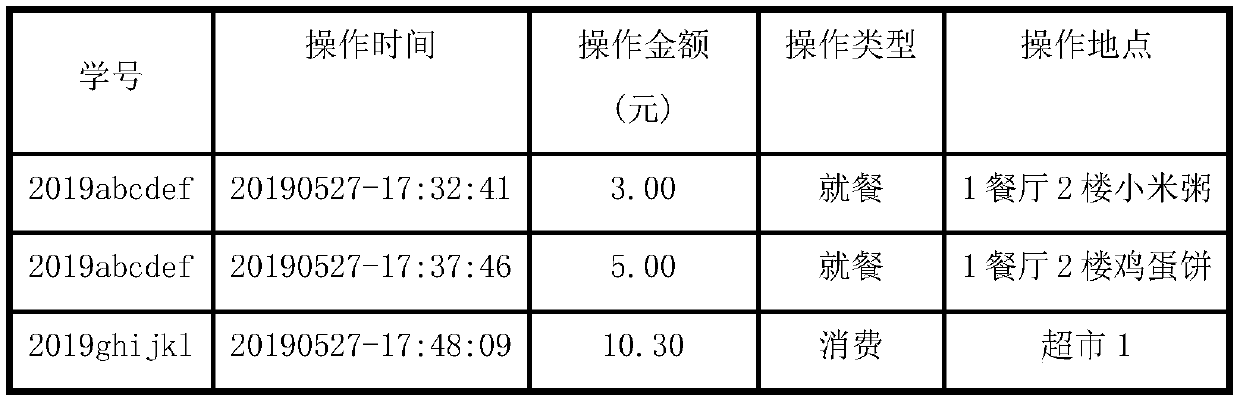

Student score prediction method based on campus big data

InactiveCN111260514AHighlight substantiveSignificant technological progressForecastingResourcesOnline and offlineData acquisition

The invention relates to the field of education data mining, and provides a student score prediction method based on campus big data, which comprises the following steps: (1) data fusion; in a smart campus environment, dynamic and non-invasive data acquisition is carried out by taking learners as centers, so that convergence and fusion of online and offline and in-class and out-of-class multi-dimensional behavior data of students are realized; (2) feature calculation; by comprehensively utilizing linear analysis, deep learning and nonlinear analysis technologies, a student multi-dimensional behavior characteristic system is systematically constructed from three aspects of behavior change, diligence and behavior nonlinearity, and a student behavior mode and dynamic change thereof are deeplymined; and (3) score prediction; based on a machine learning algorithm, a high-precision score prediction model is constructed, and feedback and early warning are provided for high-risk student groups. According to the method, student scores can be scientifically and comprehensively predicted, and early warning is provided for students with high hanging risk.

Owner:HUAZHONG NORMAL UNIV

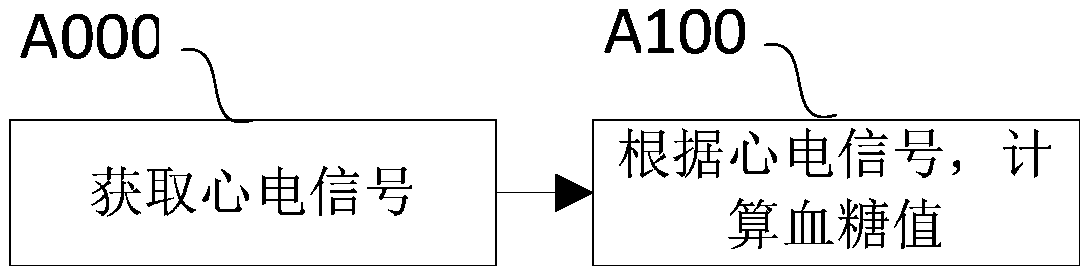

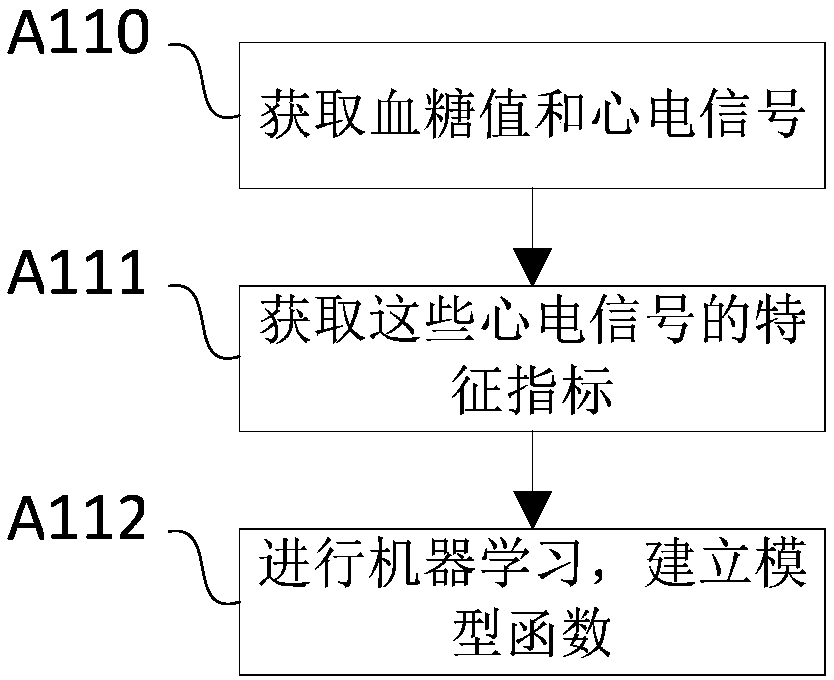

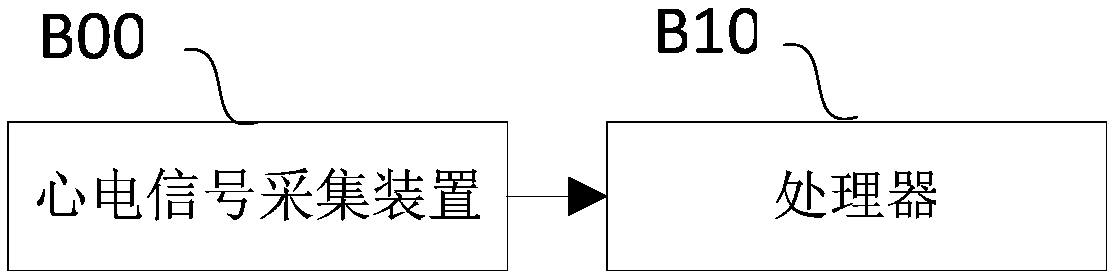

Noninvasive blood glucose detection method and system based on electrocardiosignals

ActiveCN108652640AReduce complexitySmall amount of calculationDiagnostic signal processingSensorsEcg signalGlucose detection

The invention discloses a noninvasive blood glucose detection method and system based on electrocardiosignals. The noninvasive blood glucose detection method comprises the steps that by obtaining theelectrocardiosignals, the corresponding electrocardiosignal pRRx sequence is obtained, through linear analysis and / or nonlinear analysis of the pRRx sequence, corresponding characteristic indexes areobtained, and the calculated characteristic indexes and corresponding blood glucose values are used as input and labels for machine learning and training to obtain a model function of the corresponding relationship between the characteristic indexes of the electrocardiosignals and the blood glucose values; and when the blood glucose value at a certain time point is to be detected, by obtaining theelectrocardiosignal before the time point, calculating and according to the characteristic indexes of the electrocardiosignal, the blood glucose value at the time point can be obtained through the model function. Compared with the prior art, the electrocardiosignals acquired non-invasively are used as source signals, the cost is low, safety and efficiency are achieved, in addition, the calculation amount of the blood glucose detection process of the noninvasive blood glucose detection method is small, the algorithm complexity is low, and the efficiency is high.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

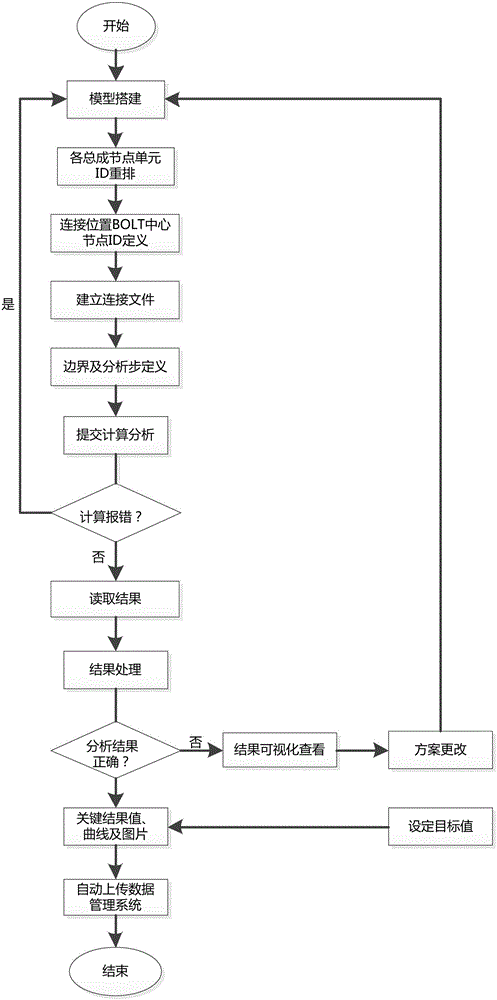

Method for establishing CAE linear analysis sub-assembly connection relation

ActiveCN104992006AEasy to operateShorten the timeSpecial data processing applicationsTrunk compartmentVehicle frame

The invention relates to a method for establishing a CAE linear analysis sub-assembly connection relation. The method is characterized by comprising the following steps of: 1) dividing an assembly: according to a design process of the whole vehicle, dividing a linear analysis model into nine parts, namely a white vehicle body (1), an engine hood (2), left and right front doors (3), left and right rear doors (4), a secondary frame (5), a trunk lid (6), a front-end module (7), an instrument board cross beam (8) and seats (9); 2) defining node and unit sections of each assembly: according to the assemblies divided in the step 1), performing node and unit section definition on a numerical model of each assembly by utilizing ANSA preprocessing software; 3) defining a connection position node number of each assembly: establishing a rigid connection at a connection position in the numerical model of each assembly, and performing redefinition on a central node of the connection position according to a node section in a format; defining the format of a node number of a connection point as follows: first two digits of the minimum value of the section 1# of a part plus first two digits of the minimum value of the section 2# of the part plus node range; and 4) establishing a connection file. ( / b)

Owner:BRILLIANCE AUTO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com