Patents

Literature

215 results about "Bending fatigue test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

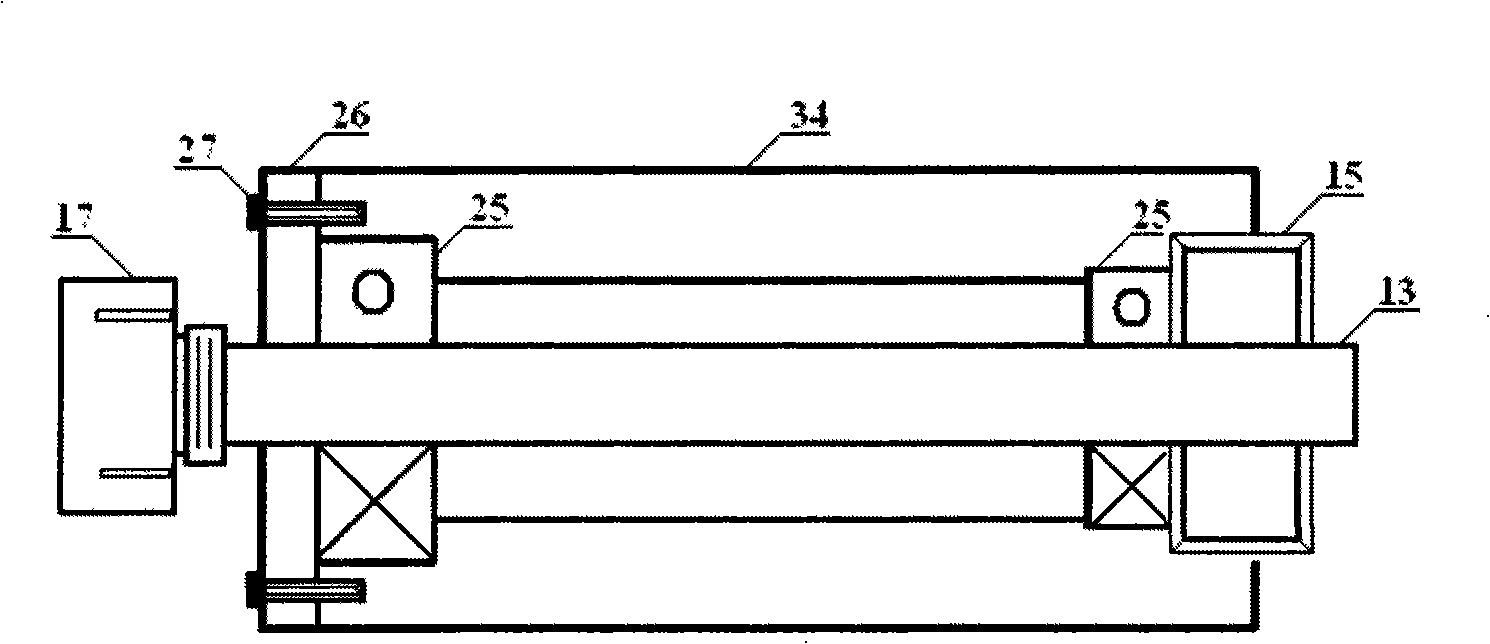

Elevator armored rope bending fatigue state experimental bench

InactiveCN101216397AAvoid heavy operationsCompact structureMaterial strength using repeated/pulsating forcesHydraulic cylinderPull force

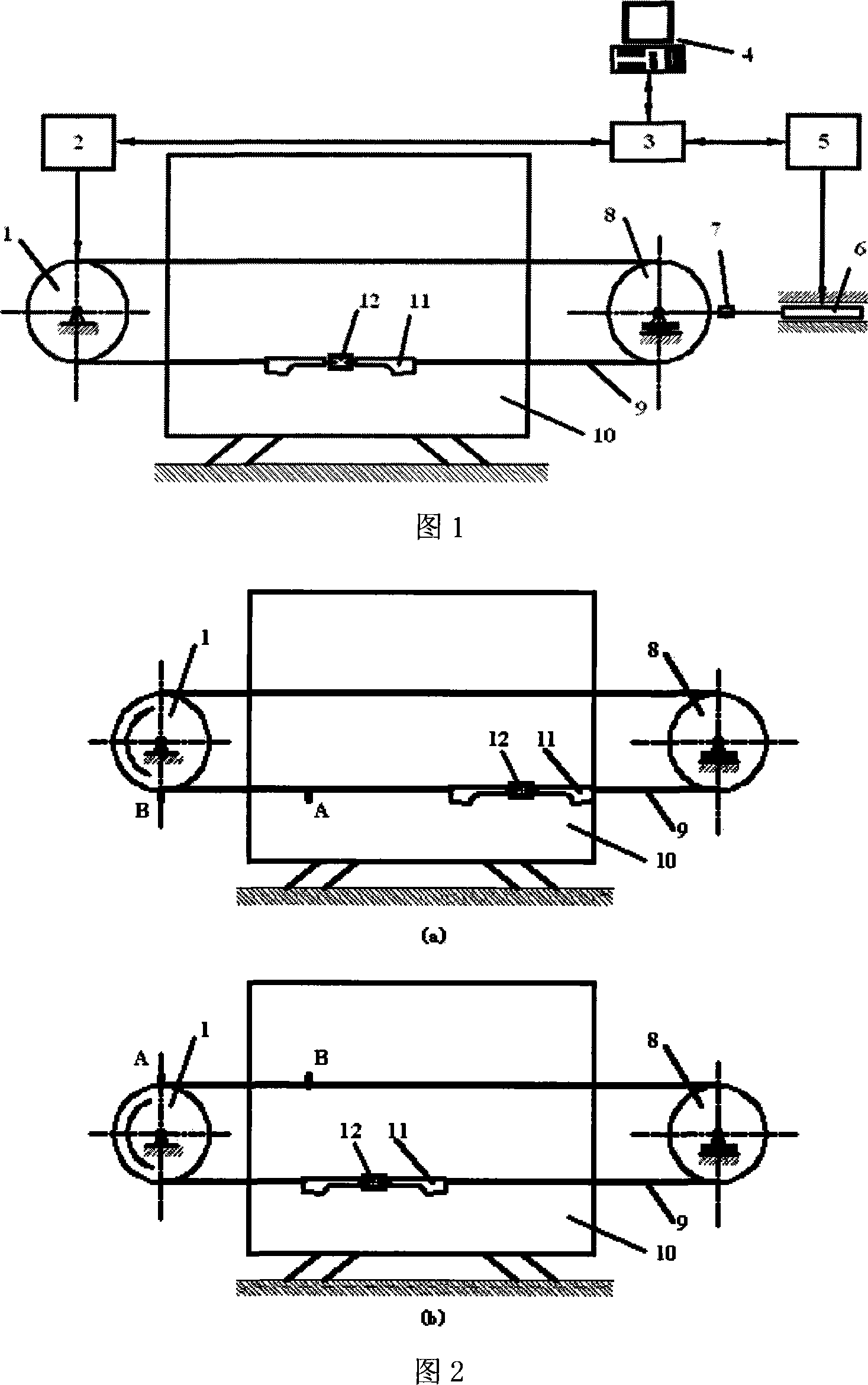

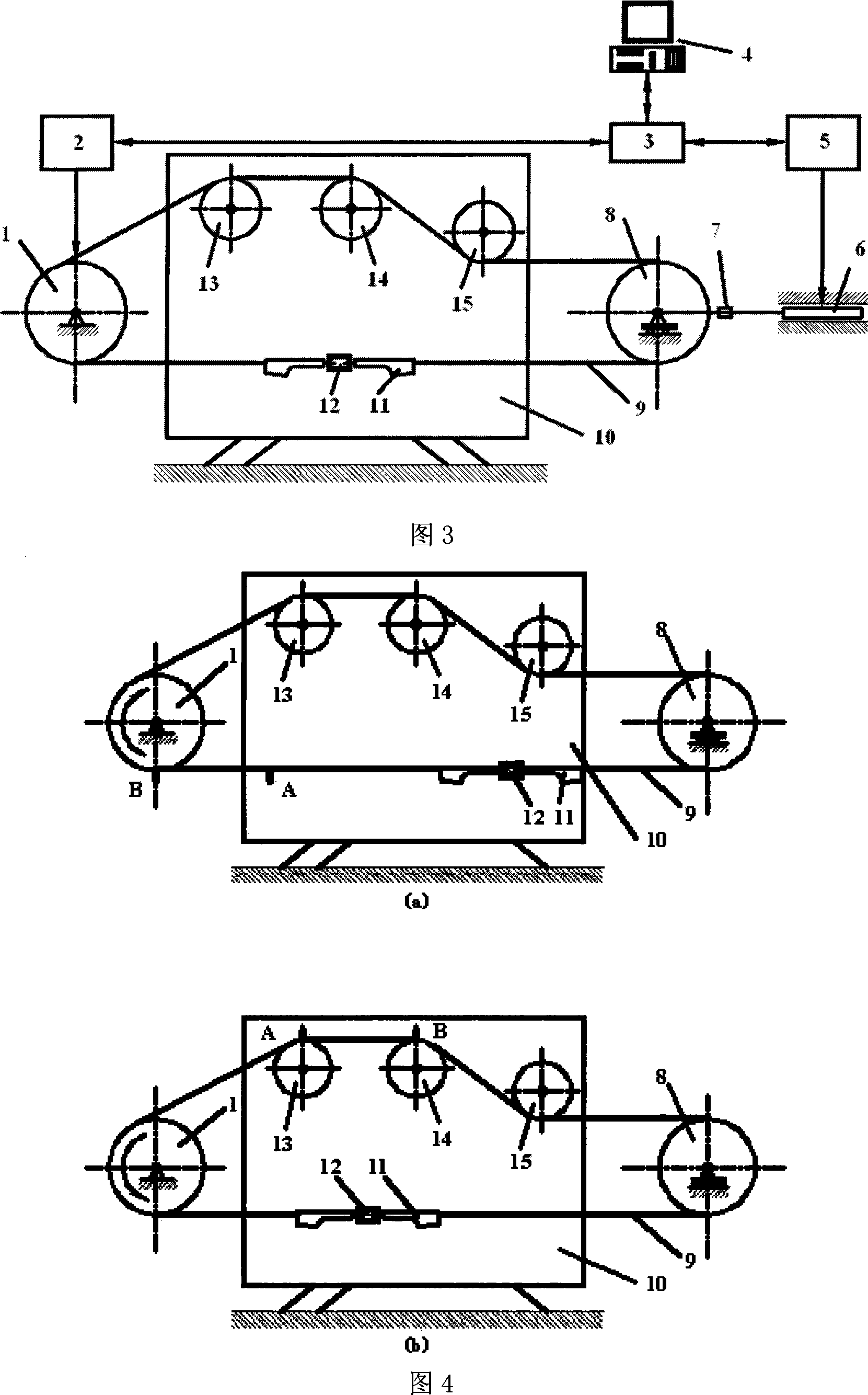

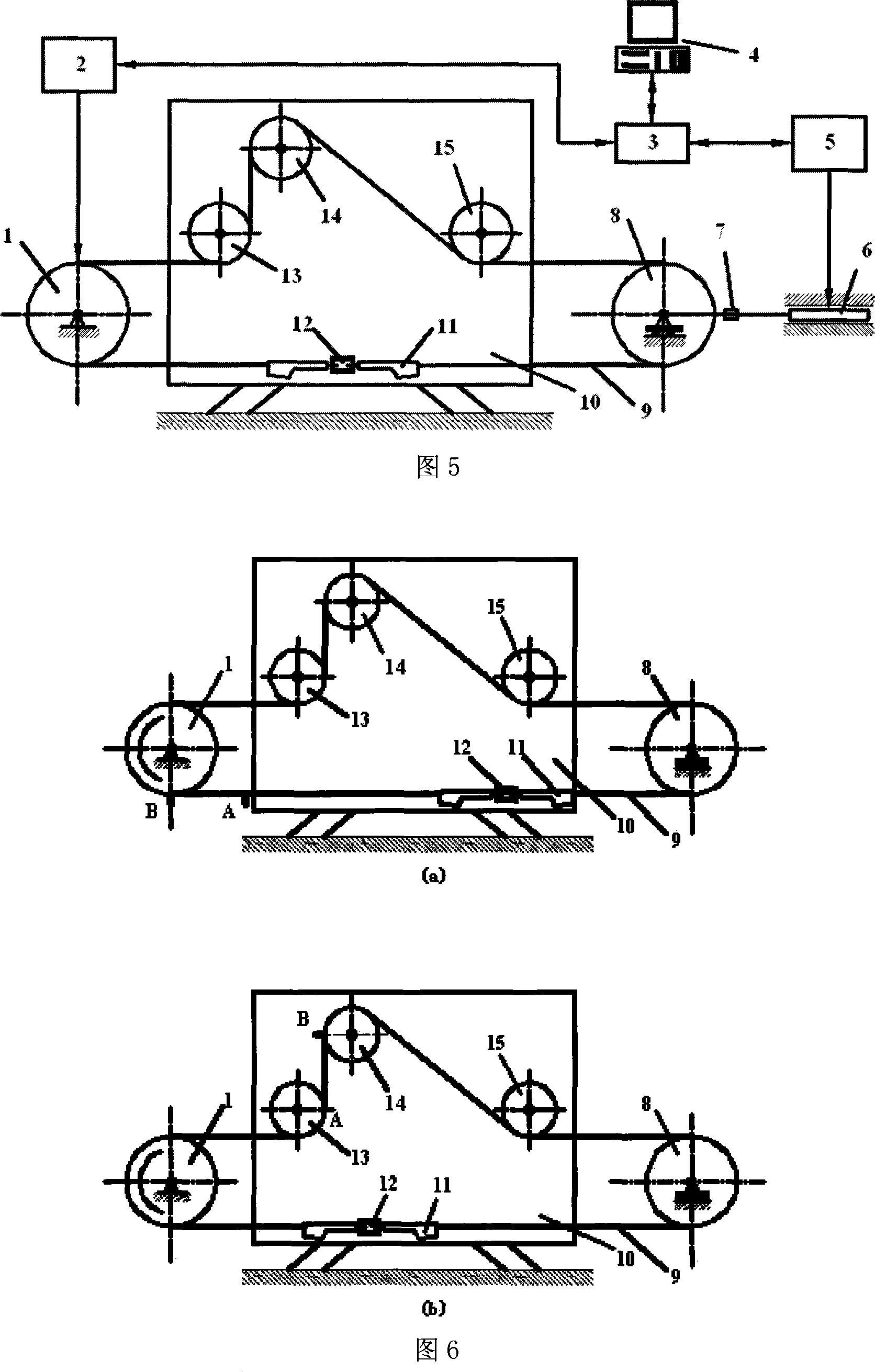

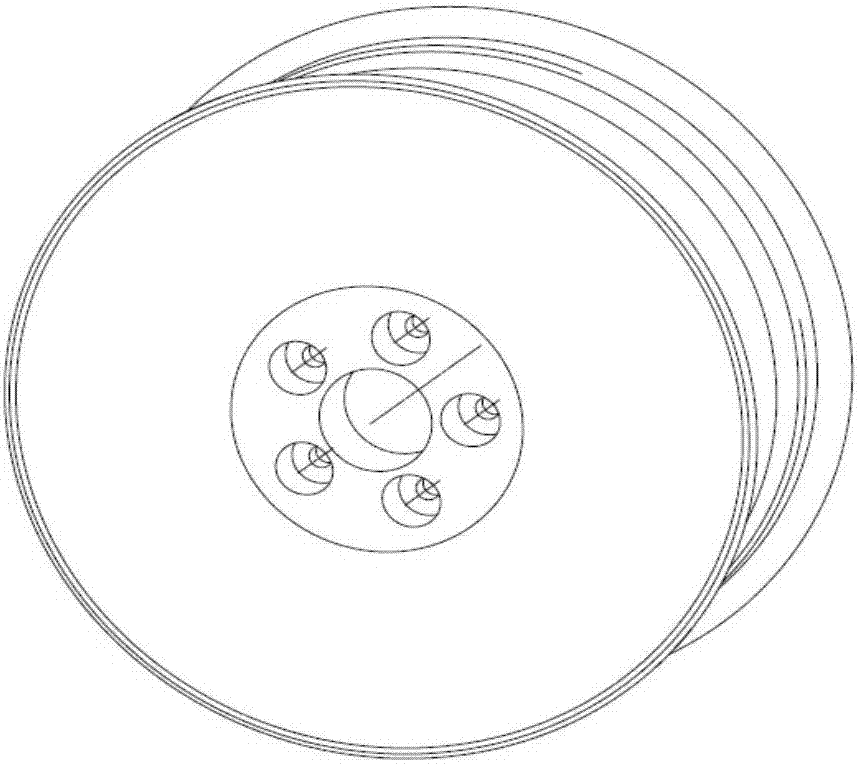

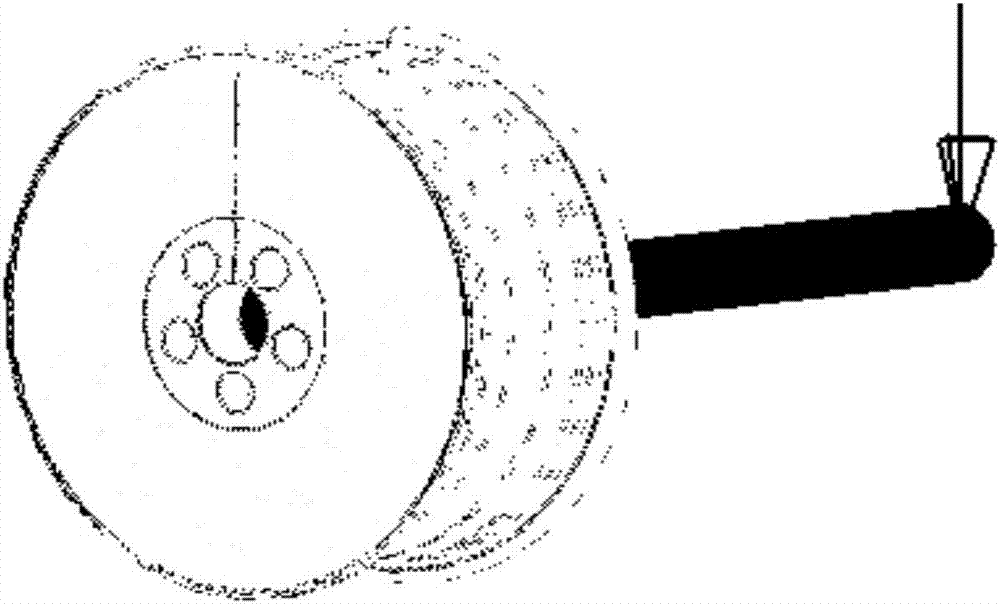

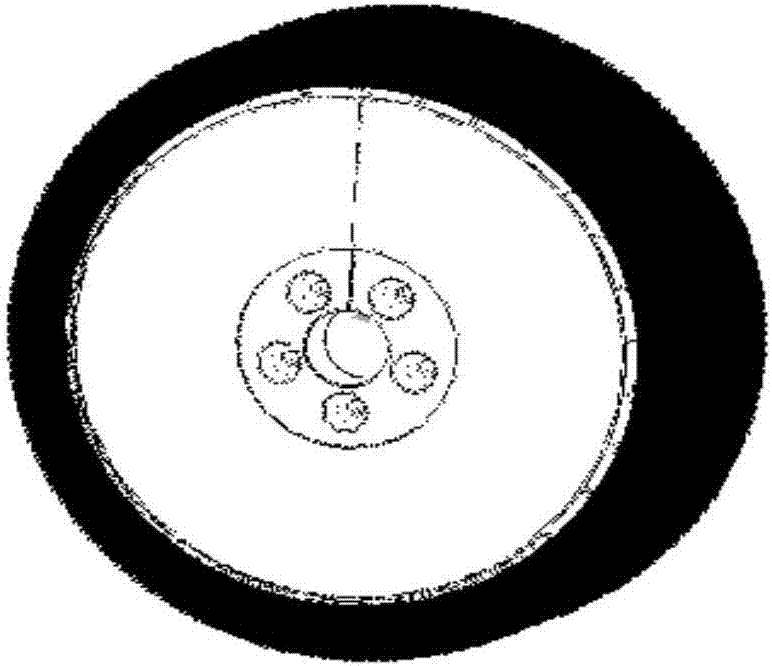

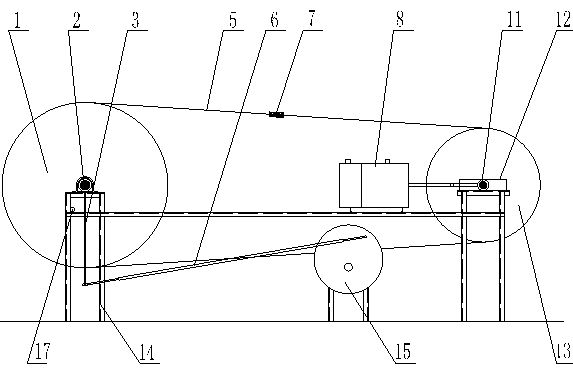

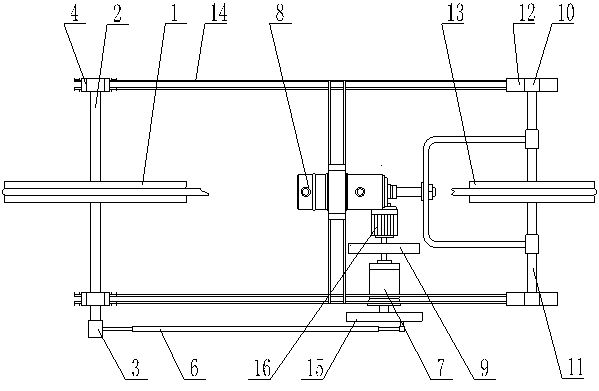

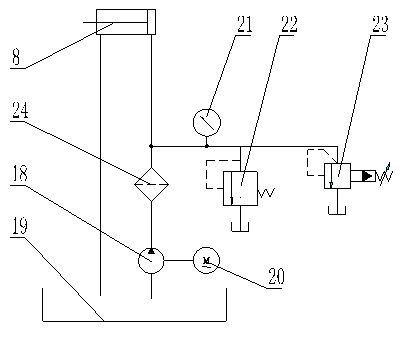

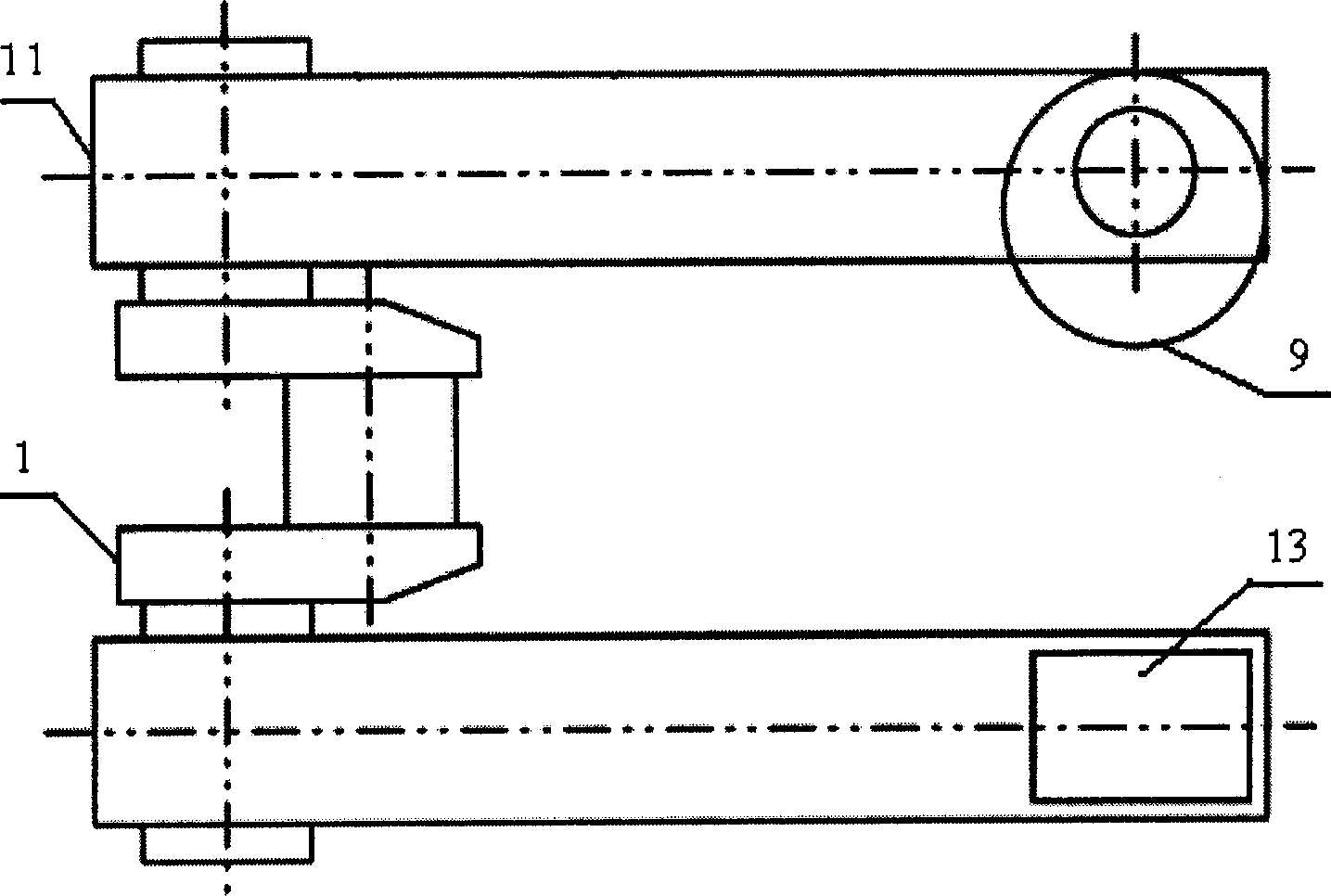

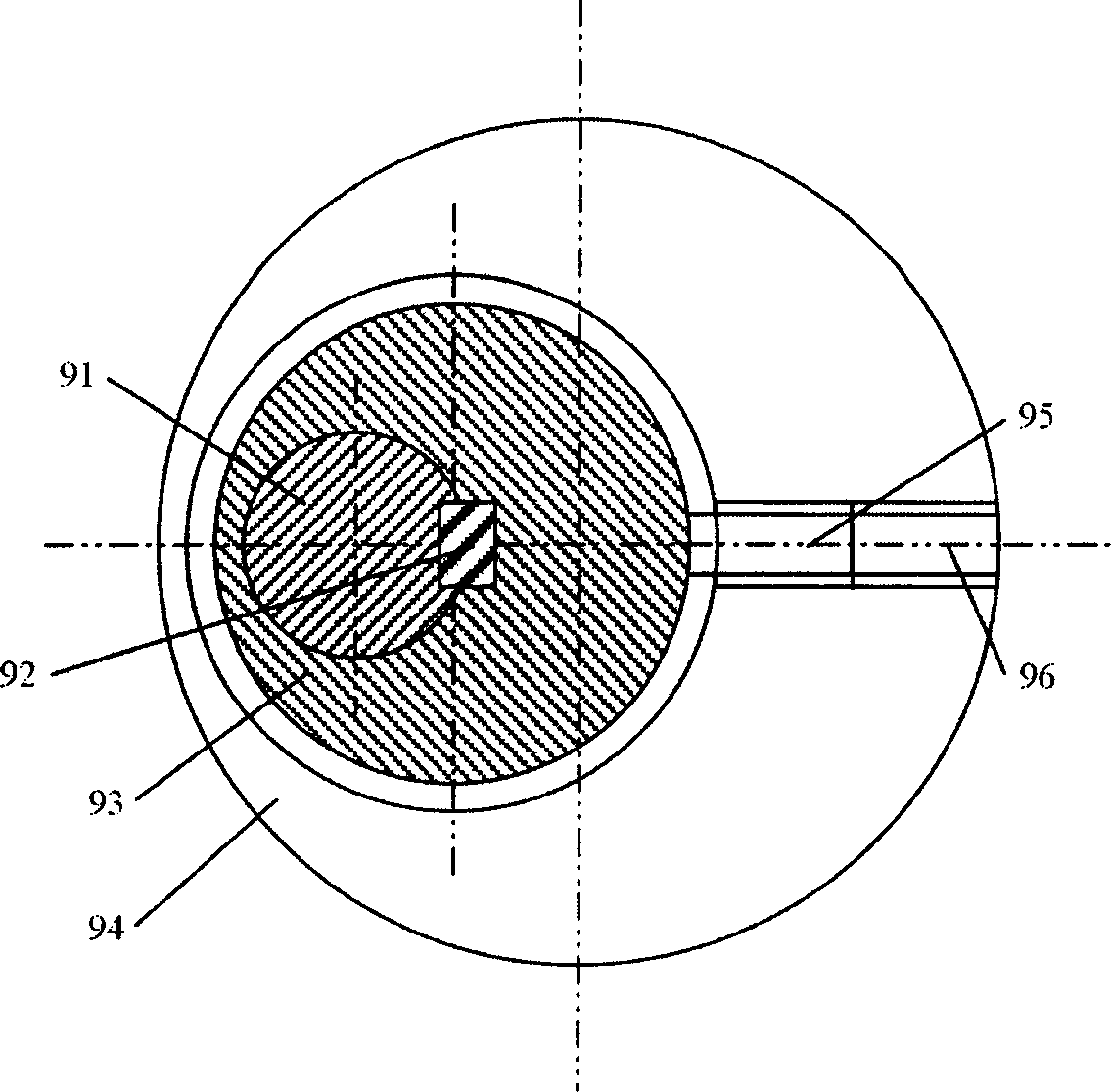

A bending fatigue test platform of wire rope for an elevator in the field of mechanical technology comprises a traction wheel, a frequency-variable motor, a data collecting and control device, a host computer platform, a hydraulic pump, a hydraulic cylinder, a tension sensor, a tension pulley, a wire rope, a rope head device, a connection terminal and a guide support, wherein the traction wheel and the tension wheel are positioned on both ends of the test platform; the guide support is positioned between the traction wheel and the tension pulley; the wire rope is wound in the grooves of the traction wheel, the guide wheel of the guide support and the tension pulley; the shaft of the tension wheel is connected with the tension sensor; the tension sensor is connected with the hydraulic cylinder; the hydraulic cylinder is connected with a hydraulic pump; the frequency-variable motor, the hydraulic pump and the tension sensor are connected with the data collecting and control device; and the data collecting and control device is connected with the host computer platform, which is in charge of monitoring, recording and control. The invention can adjust the wrap angle, the bending state, the tension and the travel of the bending fatigue test of wire rope more flexibly.

Owner:SHANGHAI JIAO TONG UNIV

Multi-objective optimization design method for wheel

ActiveCN107145663AImprove performanceAvoid defects where performance does not meet requirementsGeometric CADSustainable transportationTopology optimizationEngineering

The invention discloses a multi-objective optimization design method for a wheel, relates to the technical field of vehicle engineering and aims at solving the problems that the optimization space is limited and automatic optimization design is not carried out through joint transferring of calculation software with various properties due to the fact that only limited performance of the vehicle is analyzed and optimized and parametric modeling is lost at present. The method comprises the steps of topological optimization of a wheel fatigue test, combined topological optimization modeling, fatigue performance analysis, impact performance analysis, aerodynamic performance analysis and multi-objective optimization. Five working conditions of a dynamic bending fatigue test of the wheel, a dynamic radial fatigue test, an impact test of an impact hammer opposite to a spoke, an impact test of the impact hammer opposite to a window and air dynamics analysis of the wheel are set; the properties, such as the strength, the rigidity, the vibration characteristic, the fatigue life, the fatigue life security coefficient, the impact performance, the air dynamic property and the lightweight performance of the wheel are comprehensively considered; various performance parameters are calculated through finite element software emulation; and optimization design is carried out on the wheel by setting the performance parameters to be constraint conditions or objective functions.

Owner:JILIN UNIV

Torsion fatigue test method for spring steel wire and device

ActiveCN107436263AIncrease flexibilityImprove response speedStrength propertiesTorsion fatigueRolling-element bearing

The invention discloses a torsion fatigue test method for a spring steel wire and a device thereof. By setting of a steel wire test piece, a spring tension-compression fatigue test is equivalent to a torsion fatigue test of the spring steel wire with same parameters. According to the test method, the steel wire test piece is same in size with the steel wire for preparation of a spring product, compared with a material-based rotating bending fatigue test method, the torsion fatigue test method can meet requirements of dimensional factors in the fatigue test, correction factors can be reduced, more reliable results can be obtained, compared with a product-based tension-compression fatigue test method, the torsion fatigue test method has significant advantages in high-stress and large-amplitude test requirements. The test device can meet high frequency long period requirements in the process of the torsion fatigue test method by setting of a spring clamper for clamping and a part rolling bearing and a round head flat key, the test device is safe and reliable in the operation process of the test, a direct-drive servo drive system is used as a transmission mode, and safety and stability of long-period work of the test device can be enhanced.

Owner:中机生产力促进中心有限公司

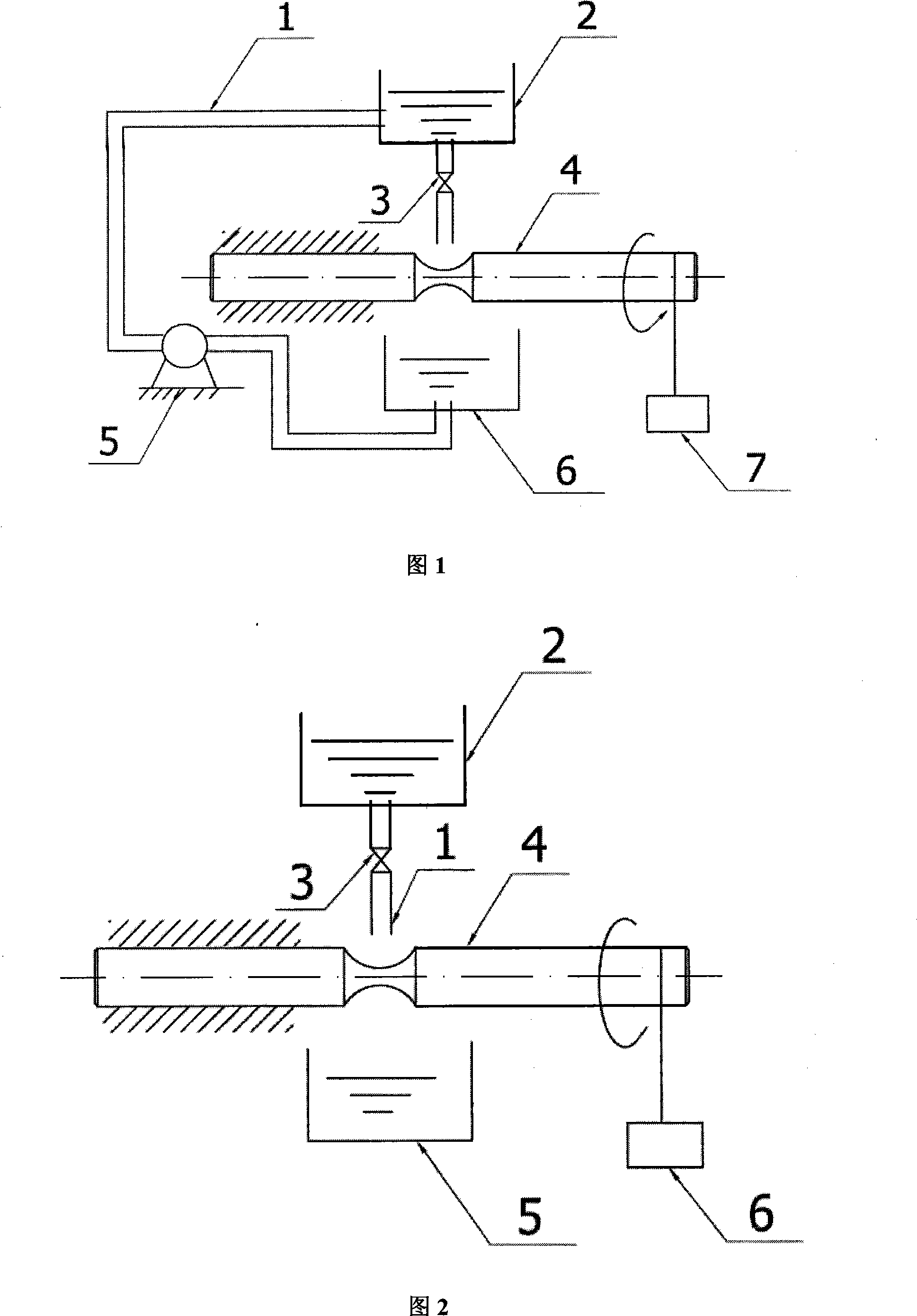

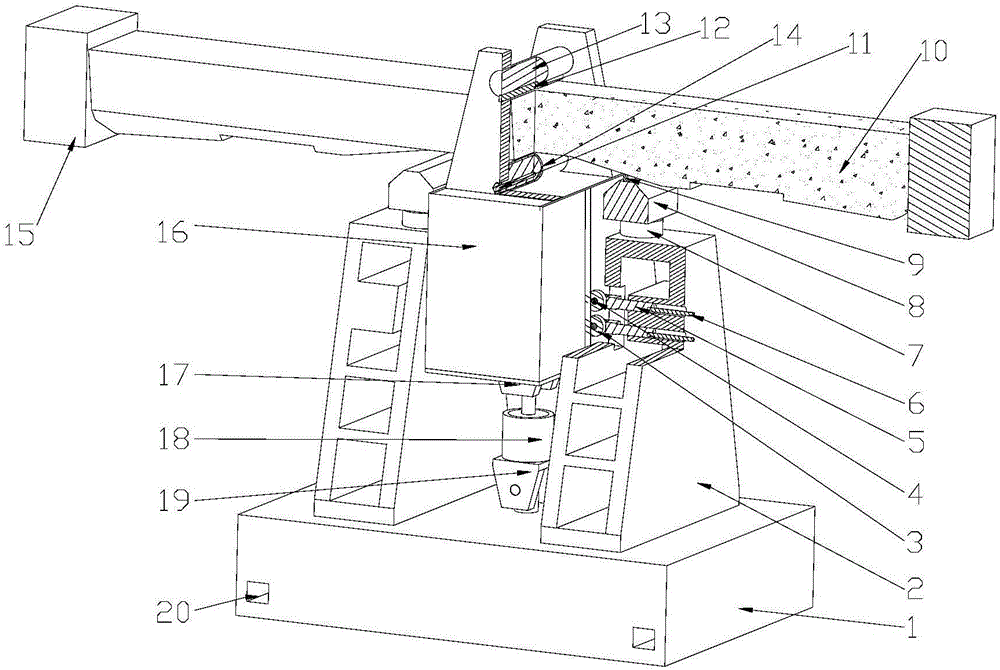

Experimental device for evaluating pumping oil polish rod coating for fatigue strength influence

ActiveCN101281109AFacilitates a true reflection of the effects of fatigue performanceEasy to filterMaterial strength using repeated/pulsating forcesControl systemUltimate tensile strength

The invention discloses a test device for evaluating the effect of an oil pumping polished rod coating upon a fatigue strength, including a three-point bending test machine, a tension-tension fatigue test machine and an analysis sample, the three-point bending test machine includes a pressure adding roller wheel, a pressure head clip, a three-point bending support and a support roller post, the tension-tension fatigue test machine includes an upper fixture, the pressure adding roller wheel and the pressure head clip of the three-point bending test machine which are arranged into integration in the upper fixture, wherein, the upper fixture connects with a control system through a sensor and connecting lines, the analysis sample is horizontally placed on the support roller post of the three-point bending test machine, and the pressure adding roller wheel faces a rod-like fatigue sample. Through combining the control system of the tension-tension fatigue test machine and the support and the pressure head of the three-point bending test machine, a three-point bending test can be carried out to realize the simulation of the bending fatigue process in the scope of 10 centimeters underneath the clip of the oil pumping polished rod in oil field site, when using the device of the invention, the effect of the coating upon the fatigue strength can be effectively evaluated.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Rotating and bending corrosion fatigue testing device

InactiveCN101221108ASimple structureSimple and fast operationMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceBending fatigue testCorrosion fatigue

The invention discloses a rotary bending corrosion fatigue test device. The device includes a rotary bending fatigue test device and a corrosion liquor supplying system; wherein, the rotary bending fatigue test device is used for mounting a test piece and applies bending load on the test piece during the process of driving the test piece to rotate and realizes the test on the fatigue data of the test piece. The corrosion liquor supplying system includes a liquor storage tank, a transfusion pump, a flow adjusting valve and a connecting pipeline. The corrosion liquor supplying system feeds the corrosion liquor to the test piece during testing in real time from an output opening. The invention realizes the testing on the middle, high cycle and ultra-high cycle corrosion fatigue performance of the material by adding the corrosion liquor supplying system based on the existing rotary bending fatigue test device machine. As the design of the test device is approximate to an engineering design, the measured result by using the device has a greater reference value to the engineering design. The corrosion fatigue test device of the invention has the advantages of simple structure and convenient operation, and can get standardized test results.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

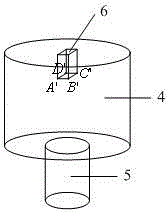

Bending fatigue damage monitoring system for steel wire under action of corrosion-alternating load coupling

InactiveCN104614261ASimple and fast operationVersatileWeather/light/corrosion resistanceMaterial strength using steady bending forcesFatigue damageControl system

The invention discloses a bending fatigue damage monitoring system for a steel wire under action of corrosion-alternating load coupling. The bending fatigue damage monitoring system comprises a driving system, an alternating force loading system, a reversing control system, a surrounding angle adjusting system, a corrosion liquid addition system, a steel wire and a steel wire status monitoring system. According to the bending fatigue damage monitoring system, the bending fatigue test for the steel wire under the action of corrosion-alternating load coupling can be realized, and the quantitative monitoring on the internal damage of the steel wire and the disclosure on the bending fatigue damage failure mechanism can be achieved. The bending fatigue damage monitoring system can be used for exploring the dynamic contact between the steel wire rope and a friction liner of a friction wheel under the working condition of simulating mine hoisting, local microslip amplitude and the dynamic tension evolution of the steel wire rope. The bending fatigue damage monitoring system can provide effective experimental equipment for the quantitative analysis of the bending fatigue failure characteristic of the steel wire under action of corrosion-alternating load coupling; and the bending fatigue damage monitoring system is simple and convenient to operate, complete in functions, good in effect, and has wide practicability in the technical field.

Owner:CHINA UNIV OF MINING & TECH

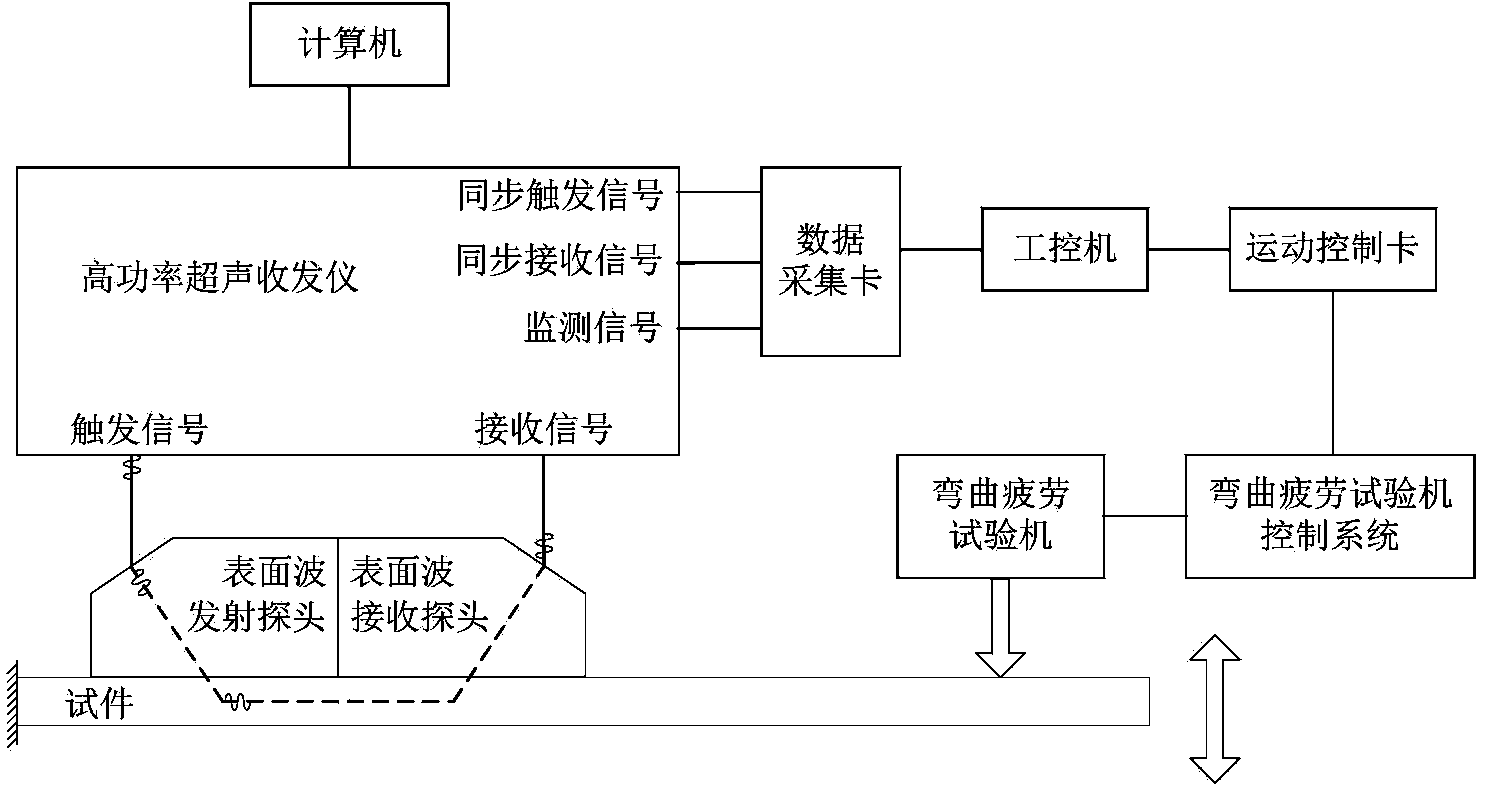

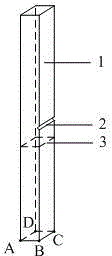

Acoustic surface wave high-order nonlinear parameter representation method for bending fatigue state of metal plate

InactiveCN104359977AAnalysing solids using sonic/ultrasonic/infrasonic wavesTransceiverNonlinear parameters

The invention aims to provide an acoustic surface wave high-order nonlinear parameter representation method for a bending fatigue state of a metal plate, and the method is used for detecting the bending fatigue state of the metal plate in real time and predicting the bending fatigue life of the metal plate and is widely applied to the fields of aerospace, machinery, traffic, chemical engineering, water conservancy and the like. The method comprises the following steps: determining parameters of an excitation signal according to the surface wave transmission distance and the acoustic velocity of a detected material; emitting a pulse string signal by a high-power ultrasonic transceiver, enabling ultrasonic wave beam to be obliquely incident to the material to generate surface waves, and interacting the surface waves with fatigue defects such as microdefects, micro-plastic deformation or microcracks generated in a bending fatigue process to generate a higher harmonic signal; recording the change of nonlinear parameters every a fixed cycle in a bending fatigue test process, comparing with a standard curve, judging whether a test piece has defects or not, emitting an early warning signal, and predicting the residual bending fatigue life of the metal plate.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

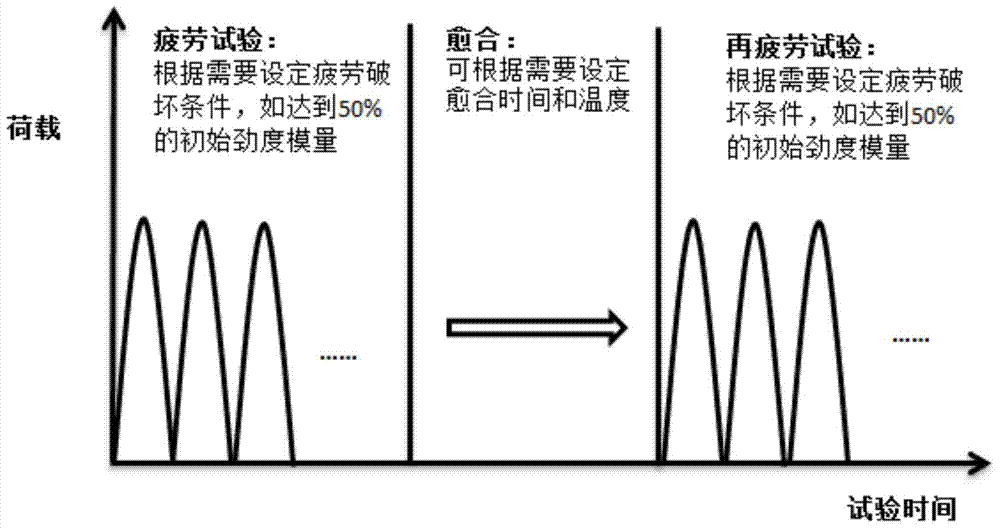

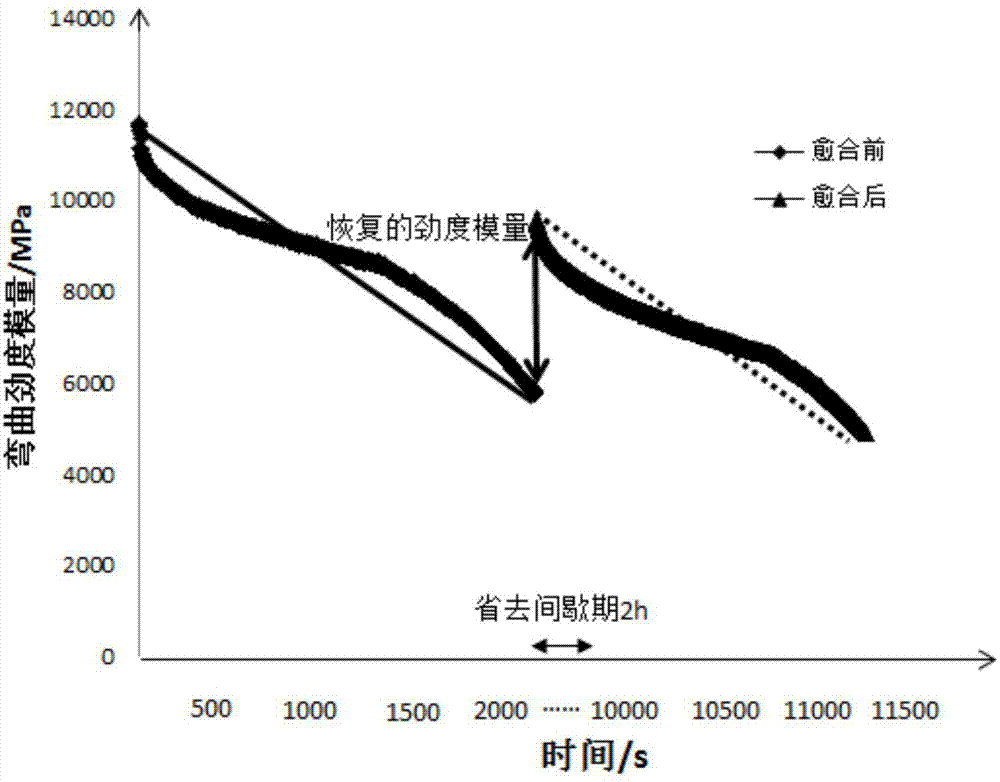

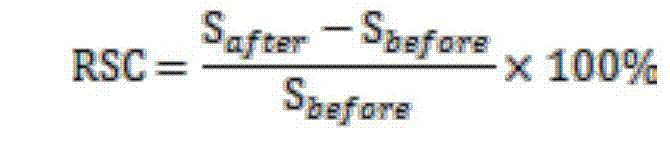

Asphalt mixture self-healing capability evaluating method

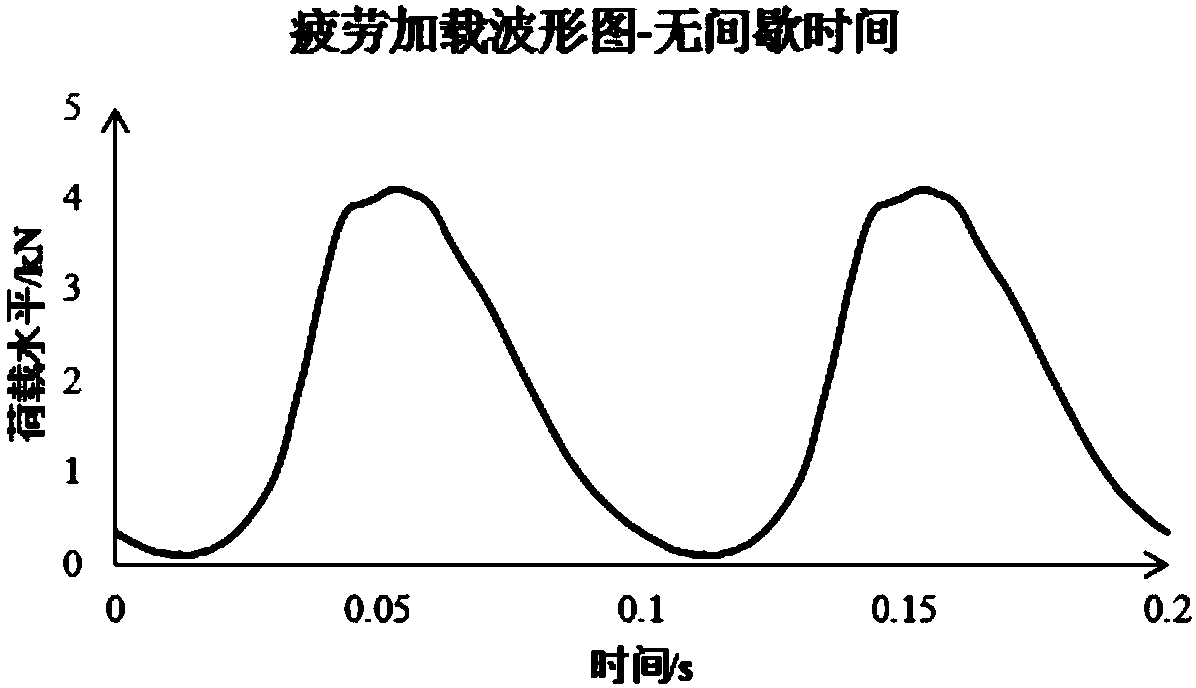

InactiveCN103487333AResilience that reflects the ability to resist the action of a loadThe test data is accurate and reliableMaterial strength using steady bending forcesSelf-healingMedicine

The invention discloses an asphalt mixture self-healing capability evaluating method. An intermission is introduced after a traditional fatigue test step based on an asphalt mixture four-point bending fatigue test, and a testpiece is maintained in certain environment and then undergoes the fatigue test to form a fatigue-healing-fatigue test mode. A healing index function can be established by comparing stiffness modulus change curves of the two-time fatigue test, and a healing index HI is selected as a key index for evaluating the self-healing capability of an asphalt mixture, so the self-healing capabilities of asphalt mixtures of different types can be effectively evaluated, and the influences of factors comprising different self-healing times, self-healing temperature, mixed material damage degrees before self-healing and the like on the asphalt mixture self-healing effect can also be tested. The method has the advantages of simplicity, feasibility, easy operation and accurate and reliable data, and provides a technological index basis for performance based asphalt pavement long-life designing and a full life period asphalt pavement maintenance program making.

Owner:SOUTHEAST UNIV

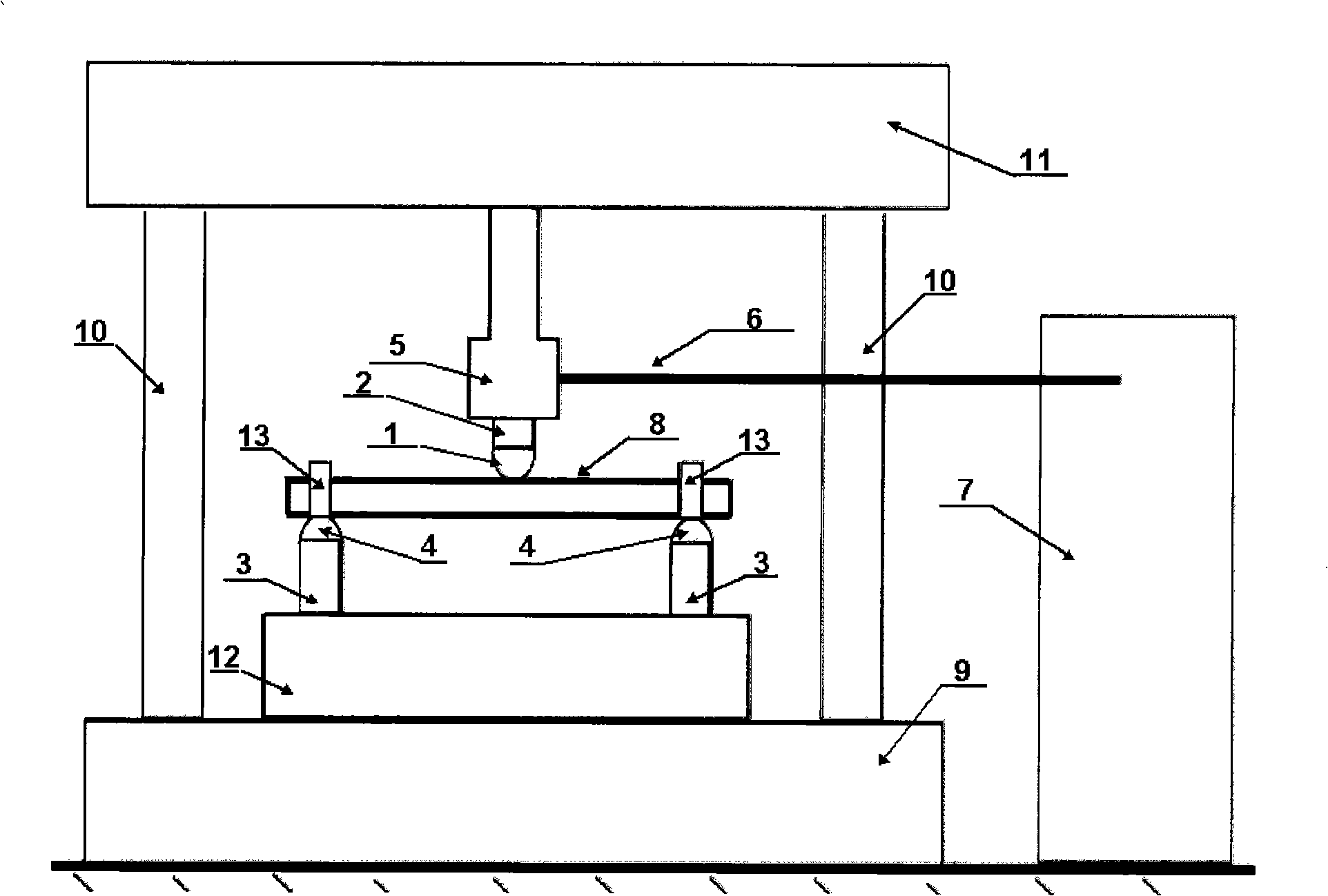

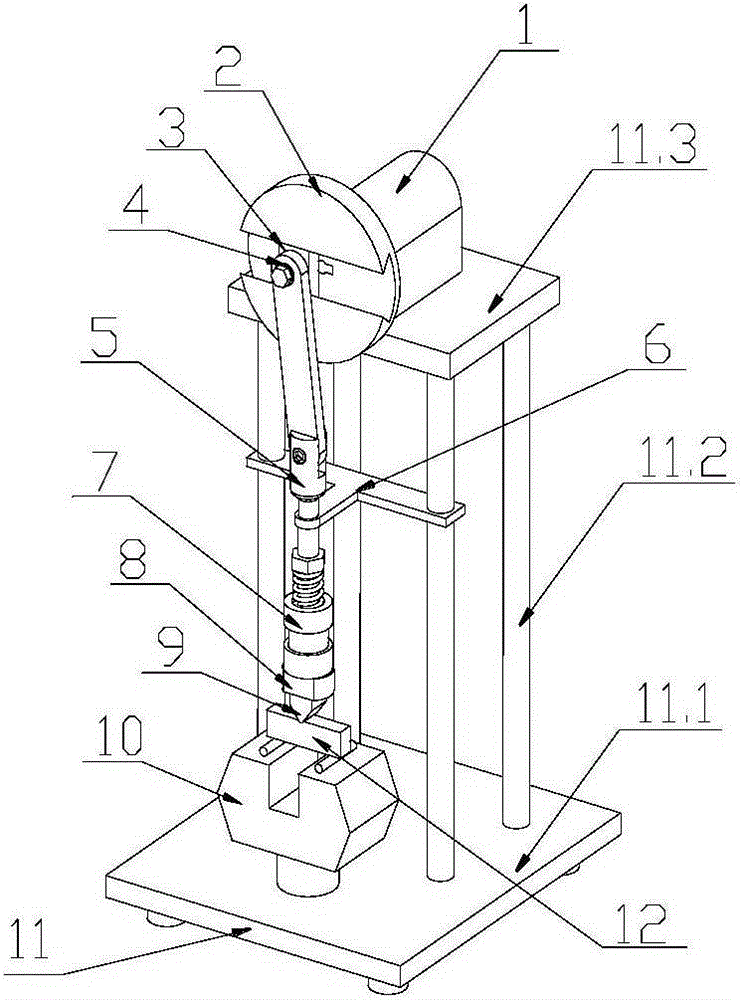

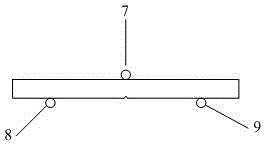

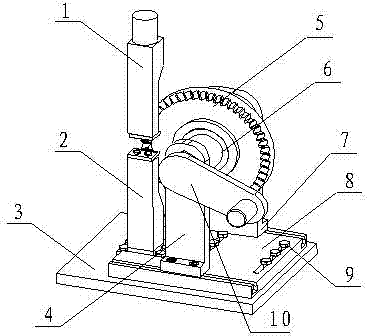

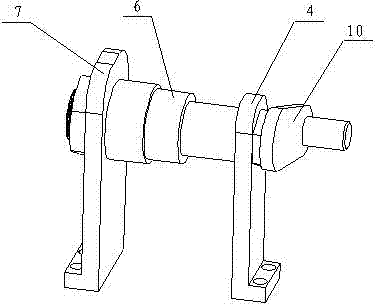

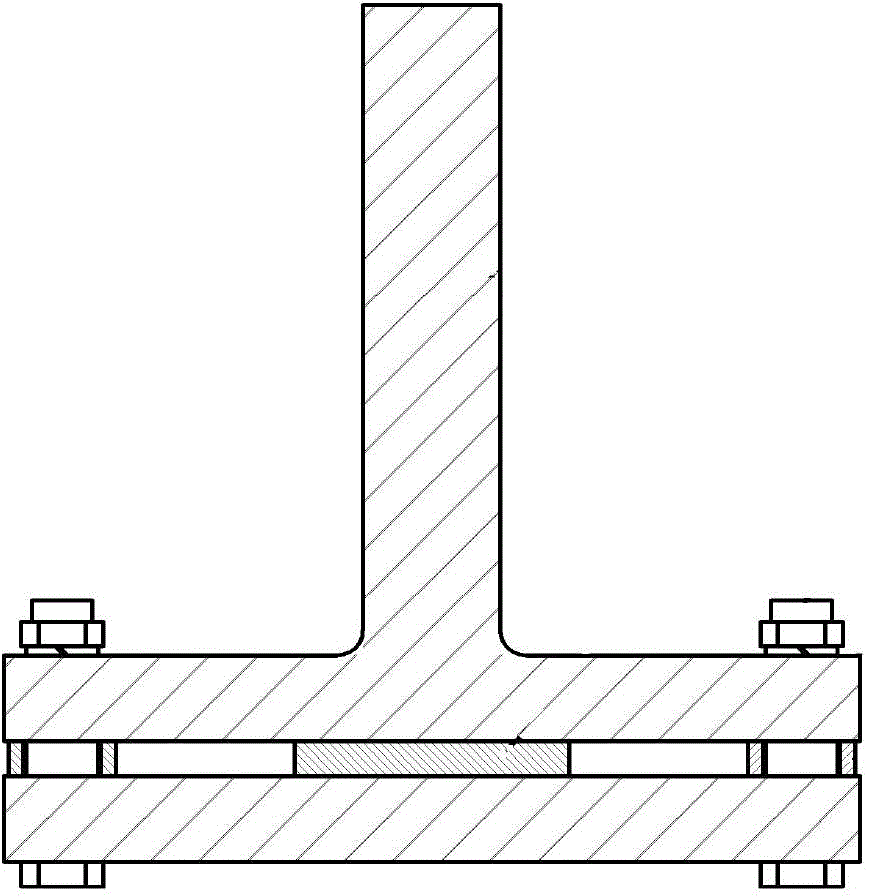

Three-point bending fatigue testing machine

ActiveCN105181481ASimple structureLow costMaterial strength using steady bending forcesElectric machineryEngineering

The invention provides a three-point bending fatigue testing machine which comprises an alternating current servo motor, a rotary table, a bearing, a transmission device, a guide rail, a spring sleeve assembly, a force sensor, a pressing head, a fixture and a test bench bed. The alternating current servo motor is fixedly arranged on the test bench bed and connected with the transmission device through the rotary table. One end of the transmission device is sleeved with the bearing, and the other end of the transmission device is connected with the spring sleeve assembly. The spring sleeve assembly is fixedly connected with the force sensor through bolts. The other side of the force sensor is fixedly connected with the pressing head through bolts. The fixture is fixedly arranged on the test bench bed and can be manually adjusted to be folded and unfolded and lifted. The three-point bending fatigue testing machine is simple in structure, low in cost and capable of conducting three-point bending fatigue tests according to different specifications, the pre-applied force and the loading amplitude are freely adjusted, a loading mode of high frequency can be met, and practicability is high.

Owner:HARBIN ENG UNIV

Flexural fatigue testing machine

ActiveCN102706759AShort test cycleImprove work efficiencyMaterial strength using repeated/pulsating forcesHydraulic motorEngineering

The invention provides a flexural fatigue testing machine, which comprises a hydraulic motor and a deceleration machine used as driving devices, a main shaft, a plurality of eccentric wheels, a main shaft supporting seat and a specimen holder, wherein the main shaft is arranged on the main shaft supporting seat in a rotatable mode, the eccentric wheels on the main shaft are driven to rotate by the hydraulic motor, a specimen is fixed on the specimen holder, the height of the specimen holder and the horizontal distance between the specimen holder and the main shaft are adjustable, and periodic load is applied to the specimen by the eccentric wheels so as to enable the specimen to be bended and deformed repeatedly until the specimen is fractured. According to the flexural fatigue testing machine disclosed by the invention, a flexural fatigue test can be carried out on a plurality of specimens simultaneously every time, fatigue performances of the specimens can be contrasted, the test period is short, and the work efficiency is high; and the flexural fatigue testing machine has a simple structure and is low in cost, the flexural fatigue test can be carried out on specimens with different specifications, different loading positions and loading working conditions can be selected, and the scope of application of the machine is wide.

Owner:SANY HEAVY IND CO LTD (CN)

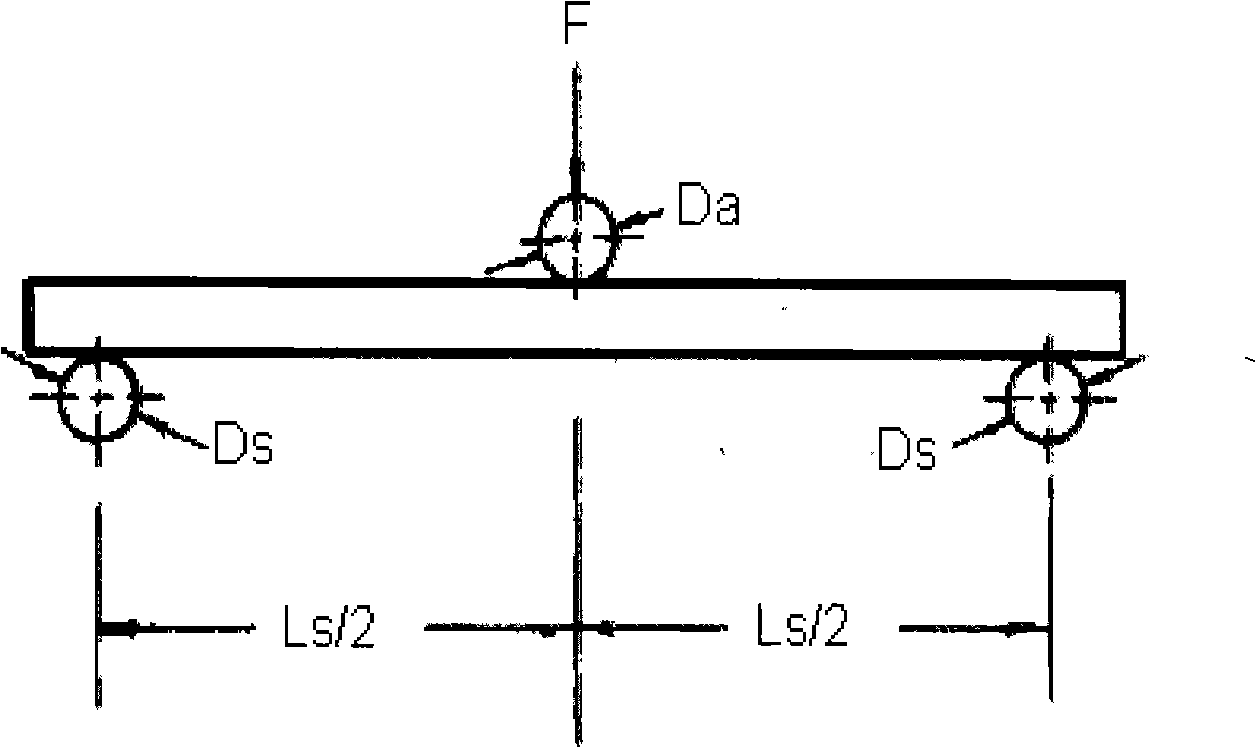

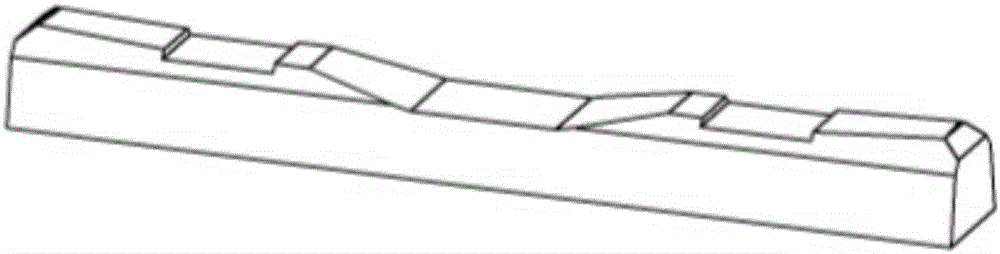

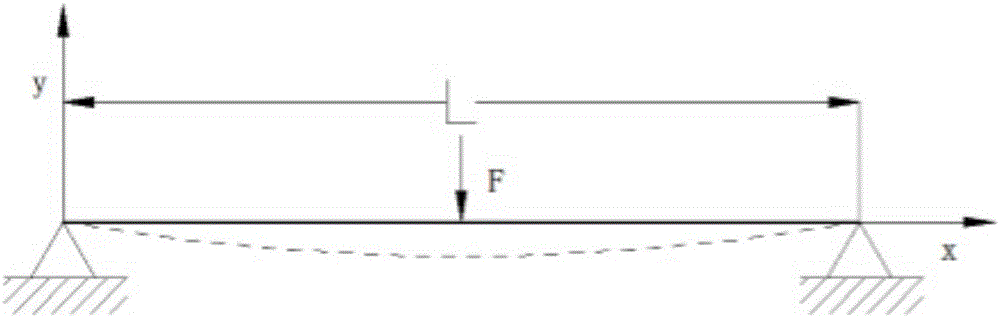

Resonance bending fatigue test machine for railway sleepers and application of resonance bending fatigue test machine

InactiveCN106248509ANo secondary disturbing vibrations should occurGuarantee normal implementationMaterial strength using repeated/pulsating forcesControl systemResonance

The invention discloses a resonance bending fatigue test machine for railway sleepers and application of the resonance bending fatigue test machine, and belongs to the technical field of test machines. The resonance bending fatigue test machine for the railway sleepers comprises a base, two side upright columns, a vibration exciter, a constant-force hydraulic loading system and a control system. The two side upright columns are symmetrically arranged on the upper end surface of the base, force measuring sensors, support blocks and small support plates A are sequentially arranged on the upper end surfaces of the two side upright columns, and a railway sleeper can be supported by the two side upright columns; the vibration exciter is arranged between the two side upright columns, the lower end of the vibration exciter is supported on the upper end surface of the base by a constant-force hydraulic loading mechanism, the upper end of the vibration exciter is fastened and connected with the tested railway sleeper by a fastening support mechanism, and load applied by the vibration exciter acts on a loading location for the tested railway sleeper; force can be loaded on the tested railway sleeper by the constant-force hydraulic loading system via the vibration exciter, and the constant-force hydraulic loading system and the vibration exciter can work under the control of the control system. The resonance bending fatigue test machine and the application have the advantages that test frequencies can be increased by the fatigue test machine on the basis of resonance principles, the test cycle can be shortened, and accordingly the test cost can be saved to a great extent.

Owner:JILIN UNIV

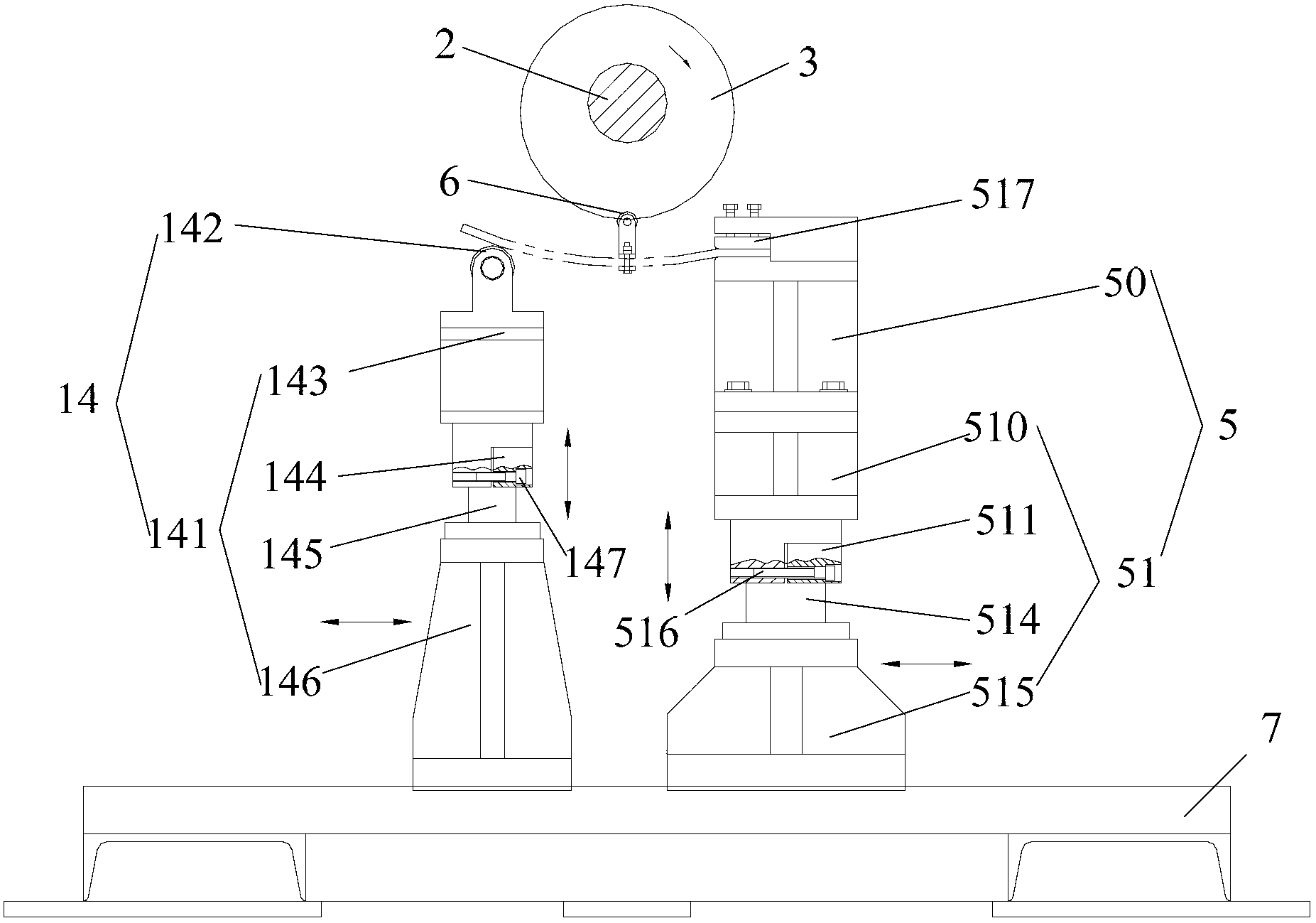

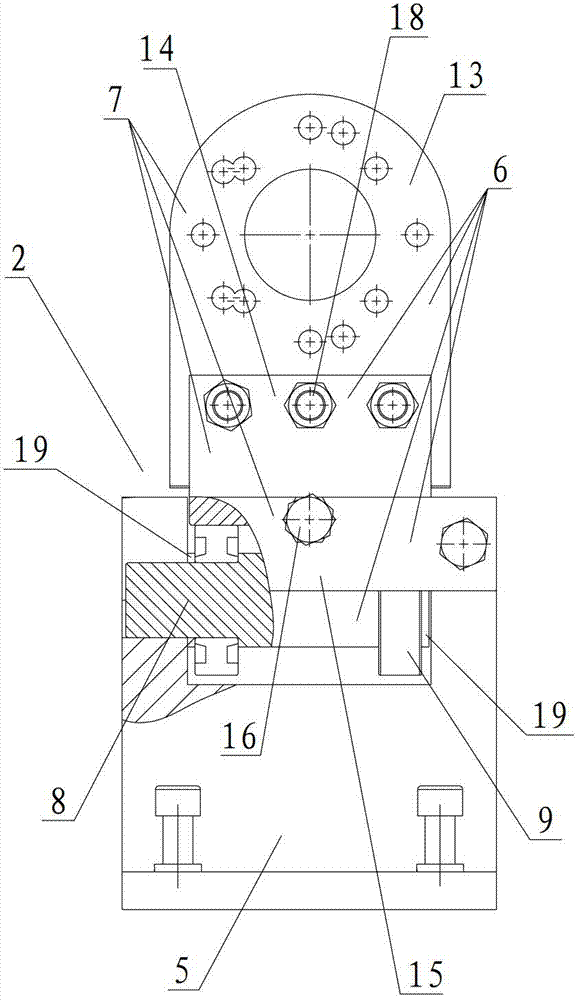

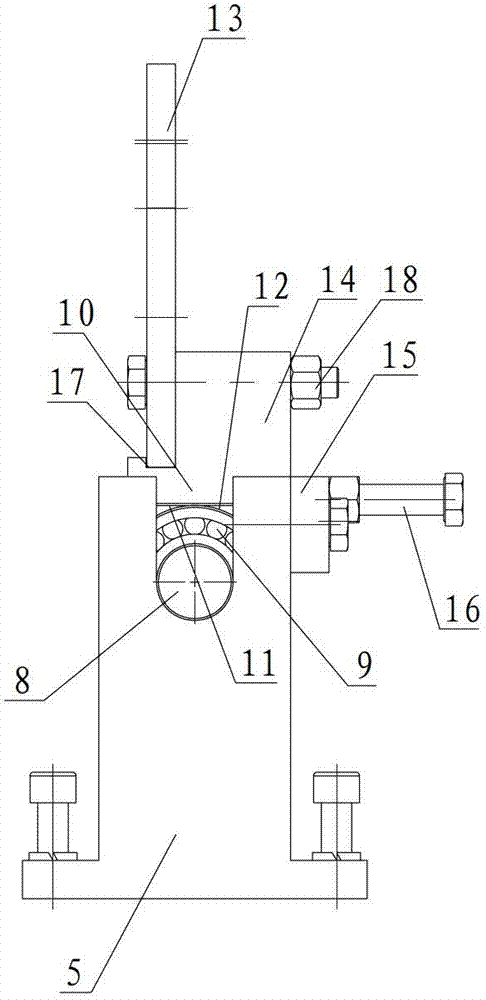

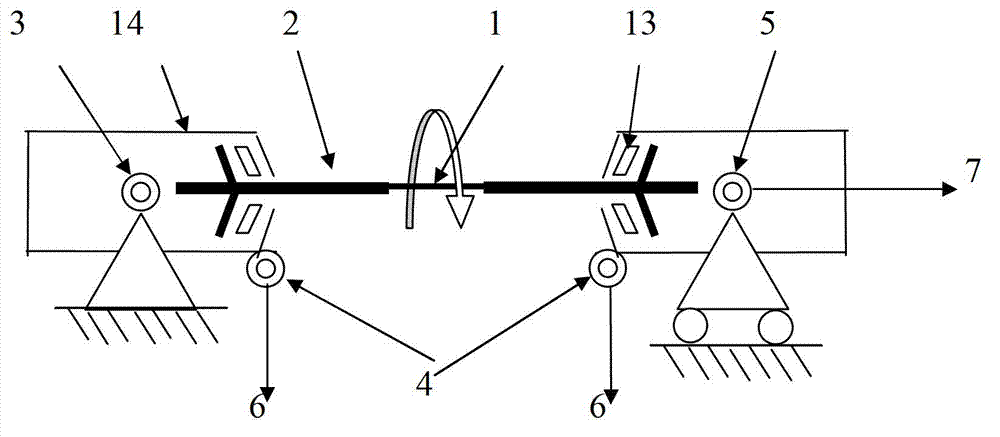

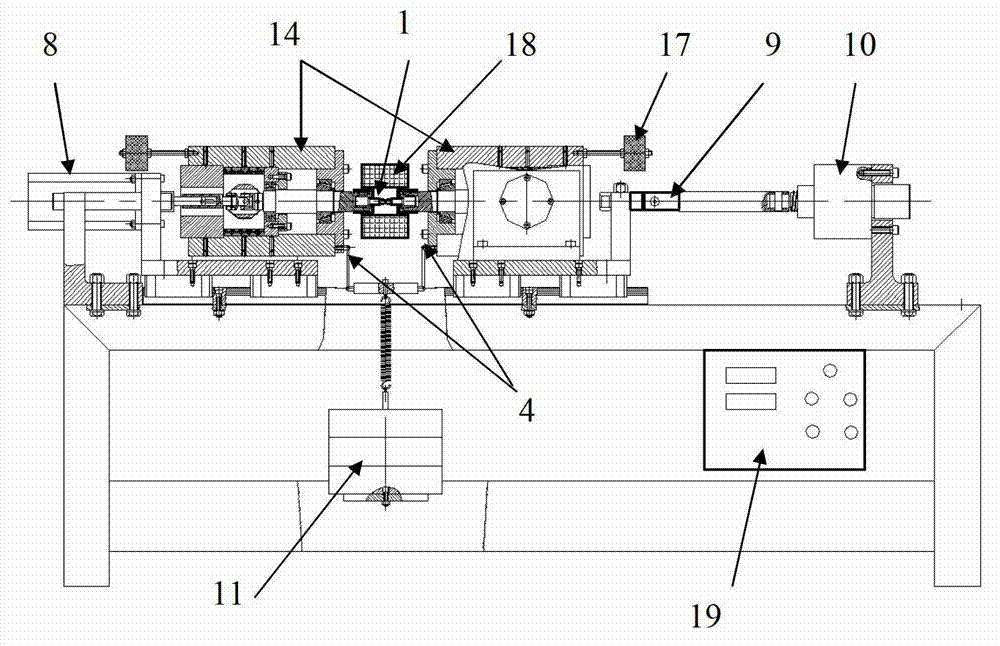

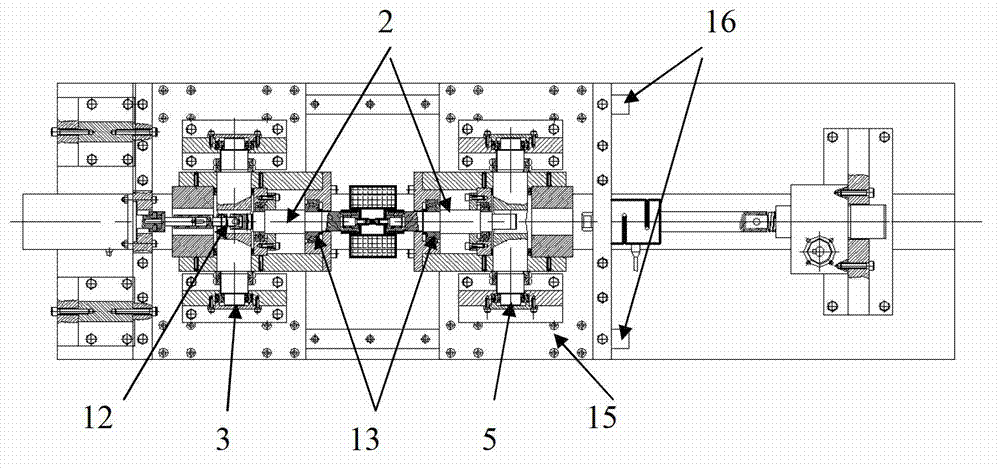

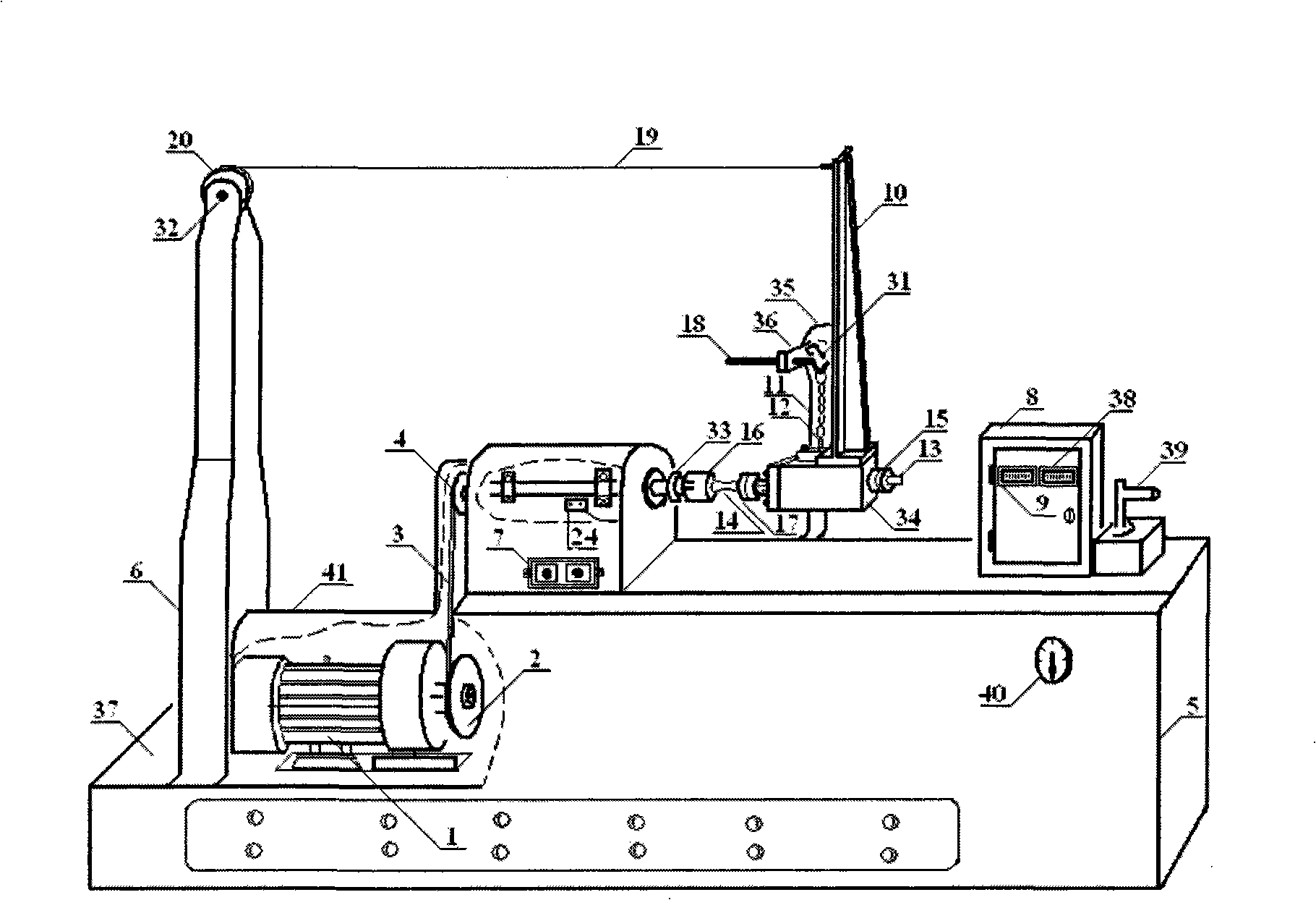

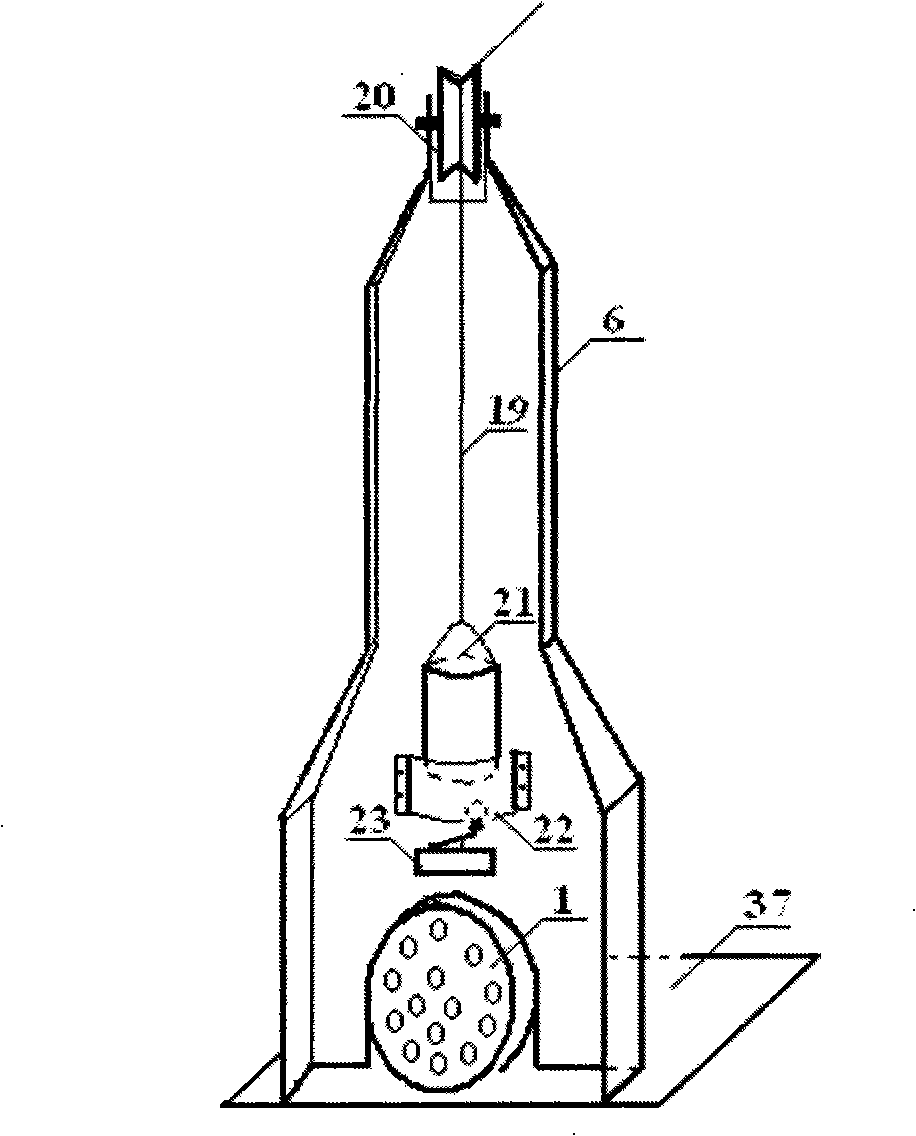

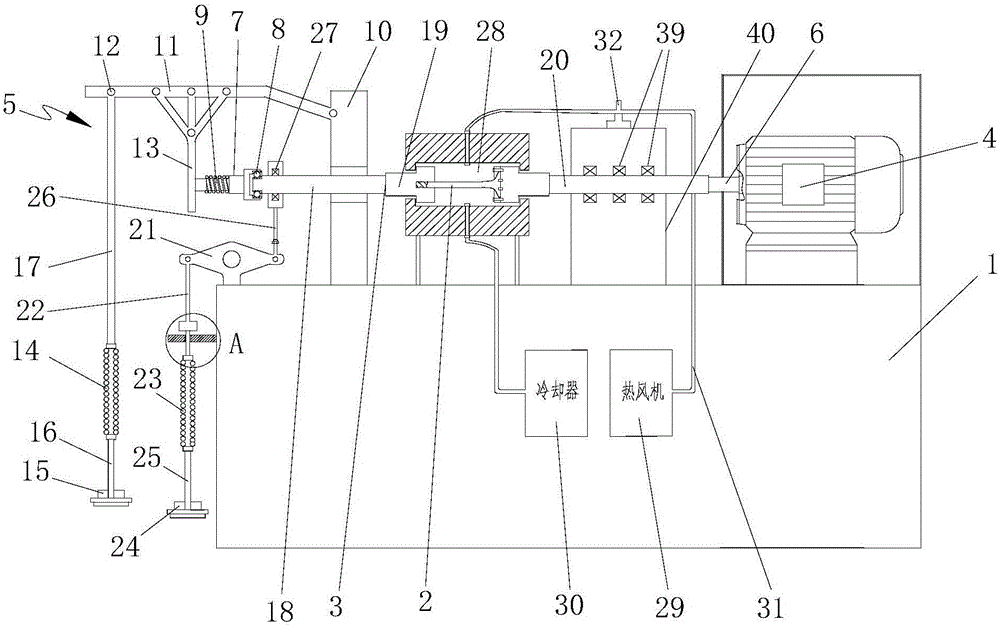

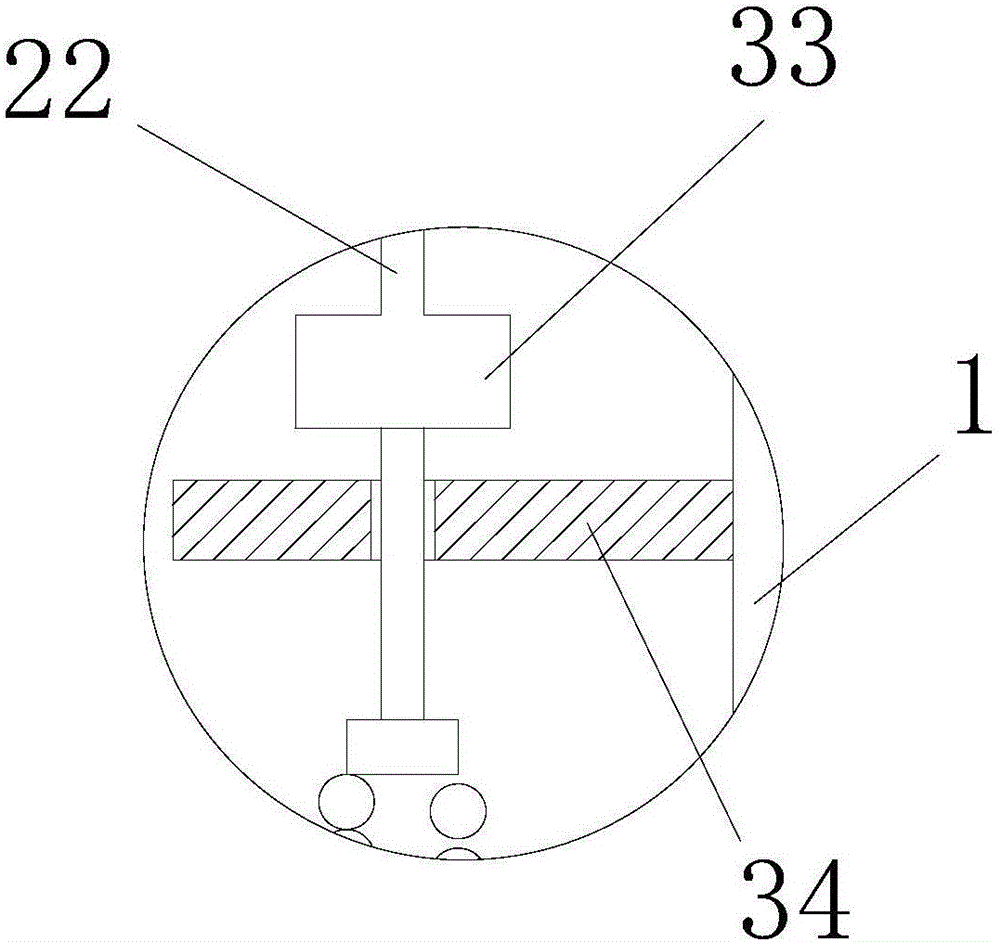

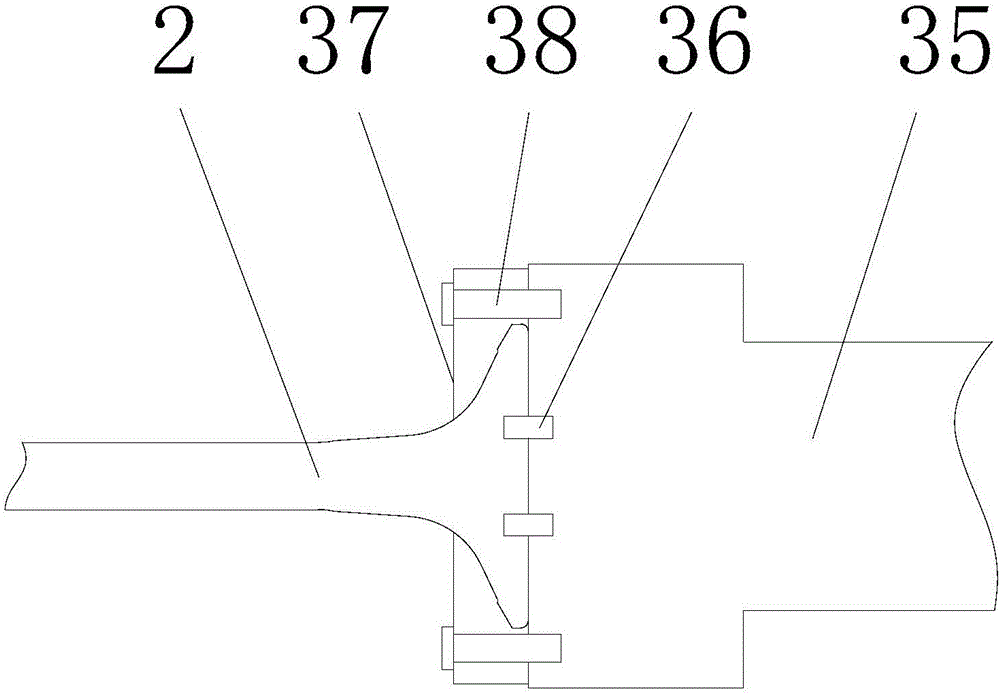

Bending fatigue test machine for steel wire rope in case of alternating load

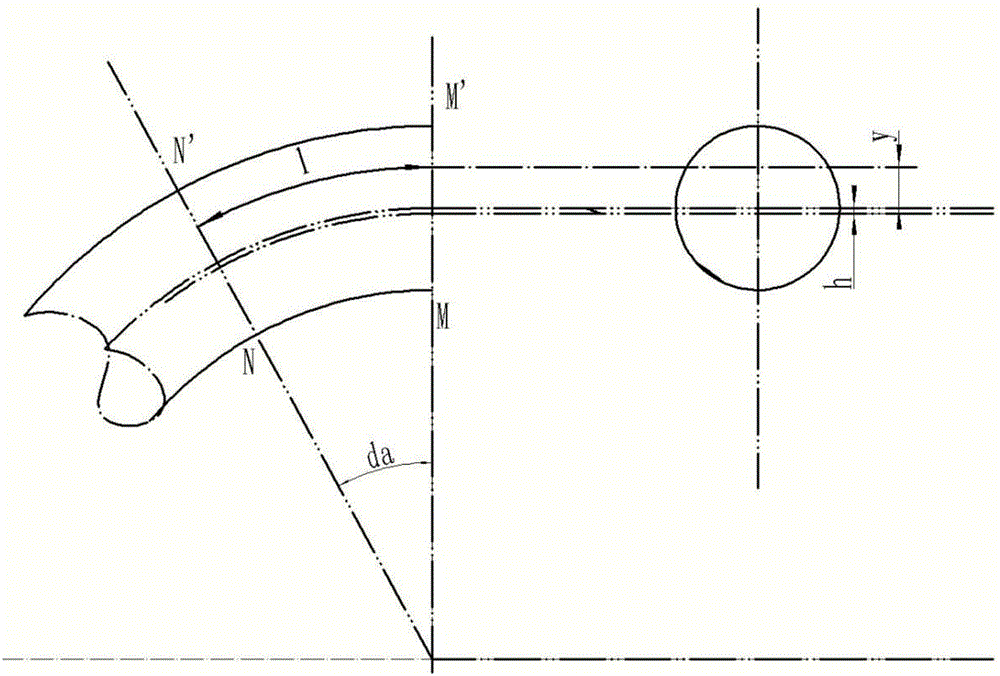

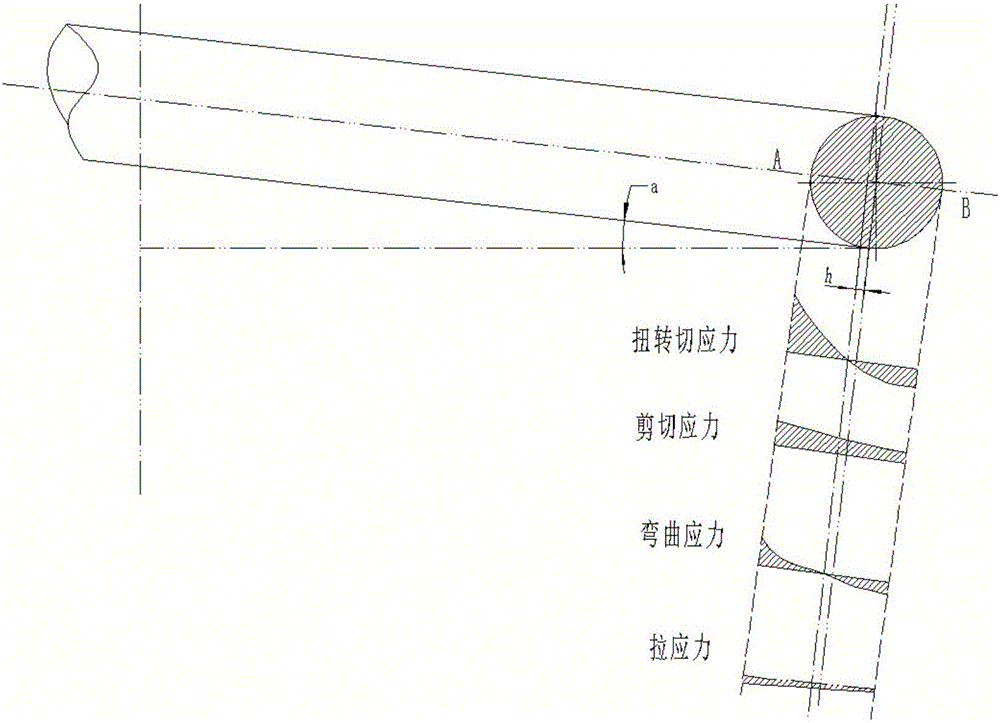

InactiveCN102121889AExtended service lifePromote failure mechanismMaterial strength using repeated/pulsating forcesDrive wheelElectro hydraulic

The invention provides a bending fatigue test machine for a steel wire rope in case of alternating load. The bending fatigue test machine comprises a frame, a steel wire rope test piece, a driving wheel, a drive unit, a proximity switch which are arranged on the frame, a power transmission system for driving the driving wheel to circularly rotate, and an electro-hydraulic servo system for supplying the alternating load to the steel wire rope test piece and a tensioning wheel, wherein the driving wheel, the drive unit and the proximity switch are arranged on the frame. In the invention, every time the tensioning wheel circularly rotates back and forth, the electro-hydraulic servo system changes the stress cycle of the steel wire rope once; then the proximity switch sends a counting signal; and finally the fatigue life of the steel wire rope is measured by counting cycle indexes. The test machine can be used for performing bending fatigue tests on various standard steel wire rope test pieces in the case of the alternating load, and applying various alternating loads on the steel wire rope test pieces. The test machine has a simple structure, and is easy to control.

Owner:CHINA UNIV OF MINING & TECH

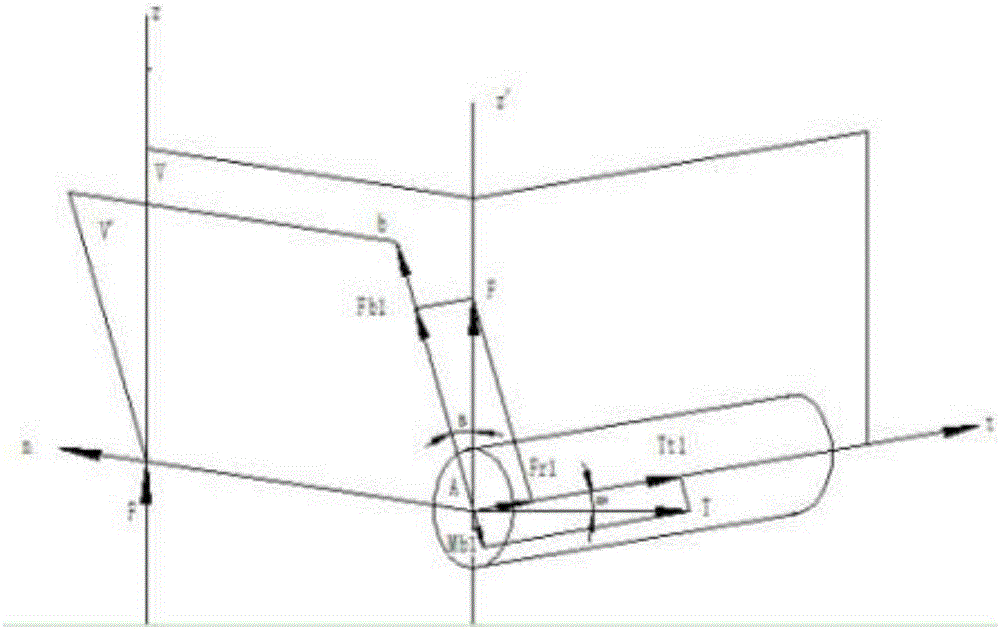

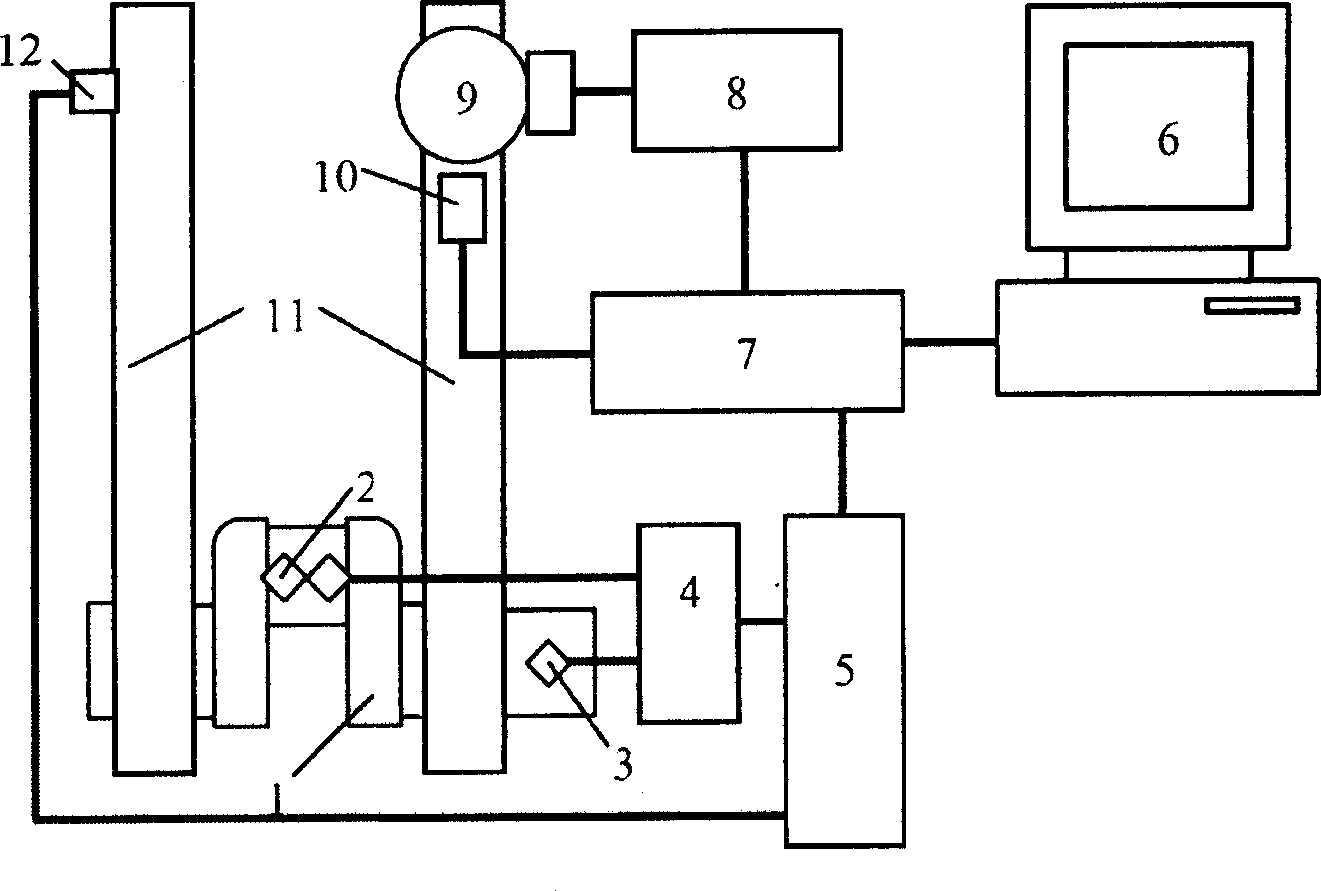

Crankshaft bend fatigue test system and method

InactiveCN1598528AEasy to operateHigh precisionUsing mechanical meansStrength propertiesProgrammable logic controllerResonance

The invention discloses a crank bending fatigue experiment system and method. The system is mainly made up of resonance desk, vibration generator, transducer, programmable logic controller, sensor group, stress amplifier and computer. The invention reduces the manpower burden; the operation is simple and convenient. The accuracy is upgraded greatly.

Owner:ZHEJIANG UNIV

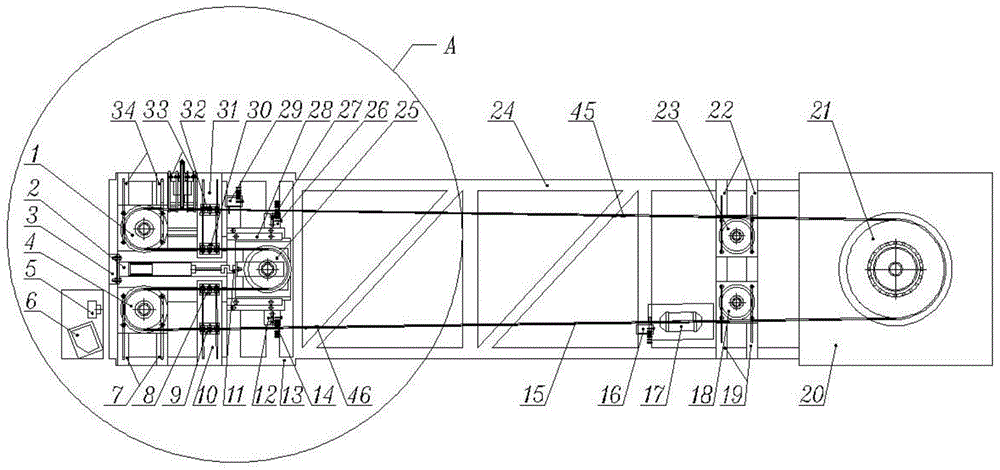

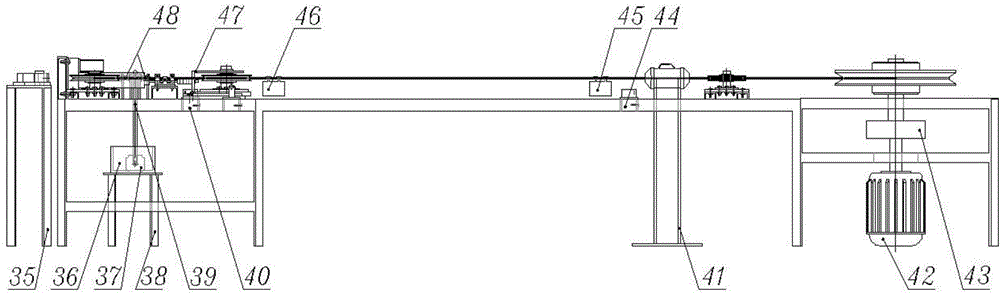

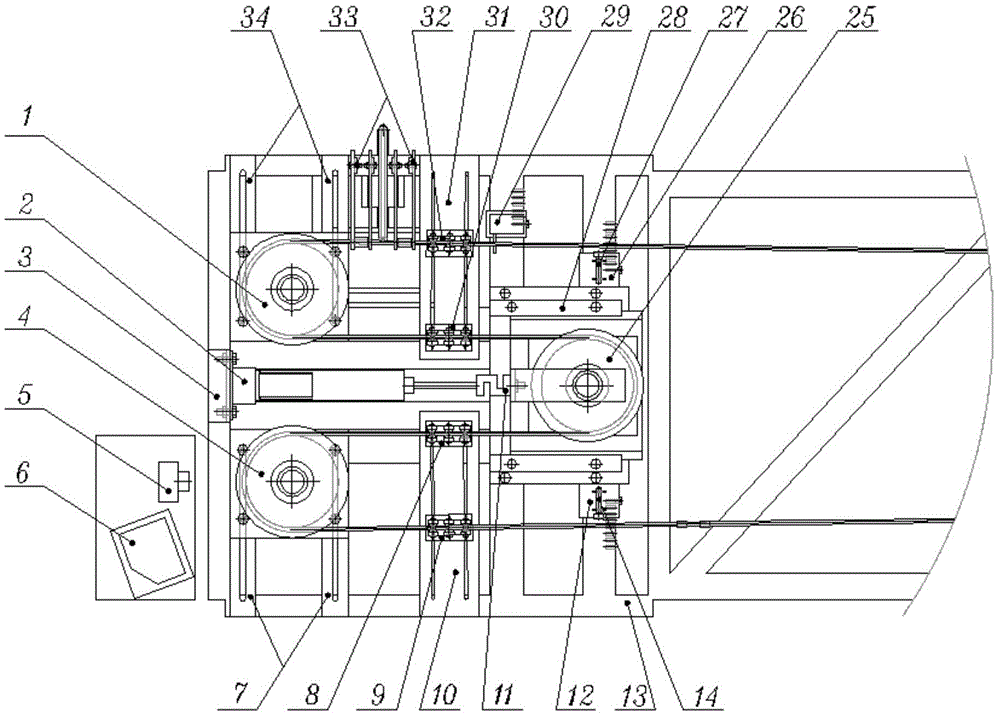

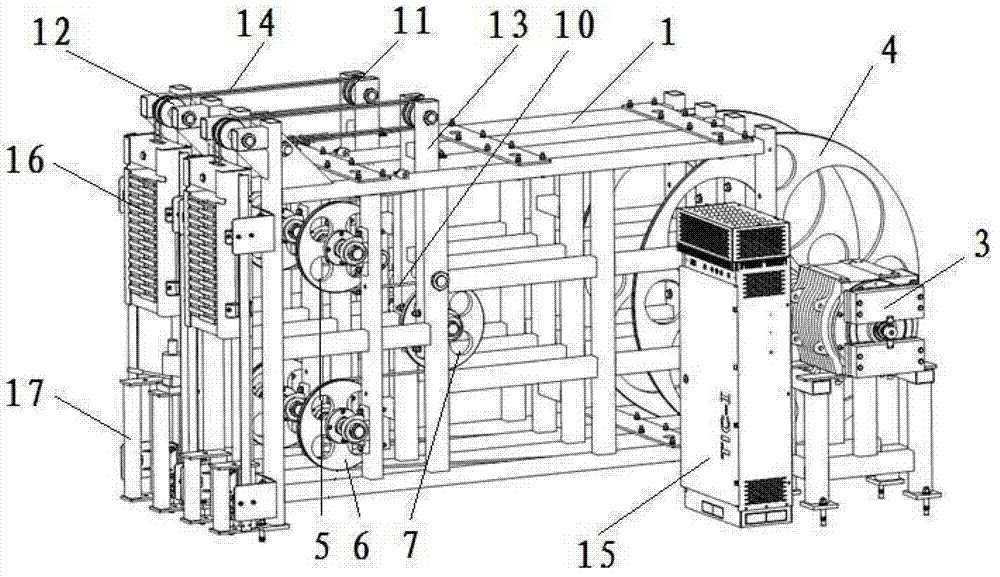

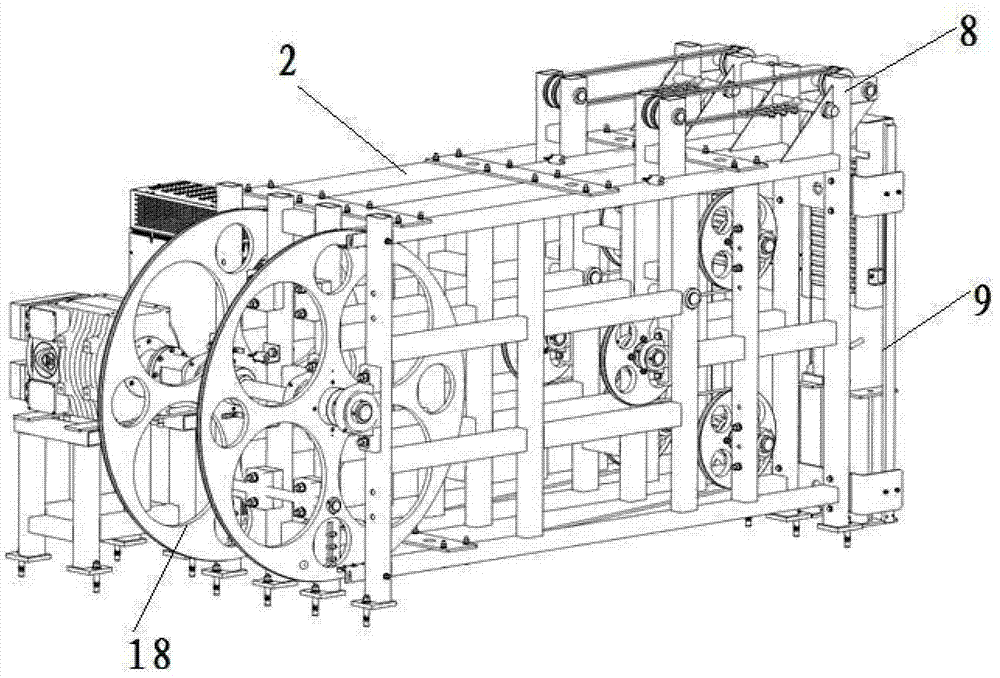

Device for testing bending fatigue of wire rope for elevator, and testing method thereof

ActiveCN102788730AEnable independent testingMaterial strength using steady bending forcesDrive wheelEngineering

The invention discloses a device for testing the bending fatigue of a wire rope for an elevator, and a testing method thereof. The device comprises a support frame and two test mechanisms arranged on the support frame in a mirror symmetry mode and having a same structure, wherein one driving wheel and two traction sheaves in each of the test mechanism are rotatably arranged on two ends of the support frame respectively, a wire rope to be tested is sequentially wound the driving wheel, the first traction sheave, a tension wheel and the second traction sheave, two rope heads of the wire rope to be tested are respectively fixed to the driving wheel to form a ring, a loading device in each of the test mechanism is rotatably arranged on the support frame and positioned between the driving wheel and the two traction sheaves, the tension wheel is fixedly connected with the loading device, and a counterweight device in each of the test mechanism is movably arranged on one side of the support frame opposite to the driving wheel, and is connected with the loading device. The device disclosed in the invention can simulate the practical bending state of the traction wire rope for the elevator, can be used for bending fatigue tests of the wire rope under multi-tension, multi-rope-to-wheel ratio and defection angle conditions, and overcomes the shortages comprising complex driving structure, functions singleness and long test period of present wire rope bending fatigue test devices.

Owner:THYSSENKRUPP ELEVATORS SHANGHAI CO LTD

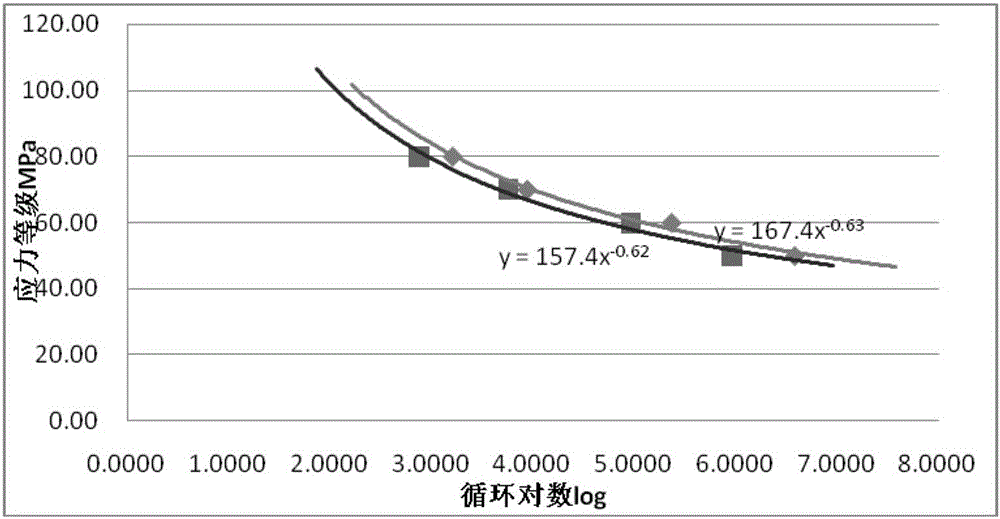

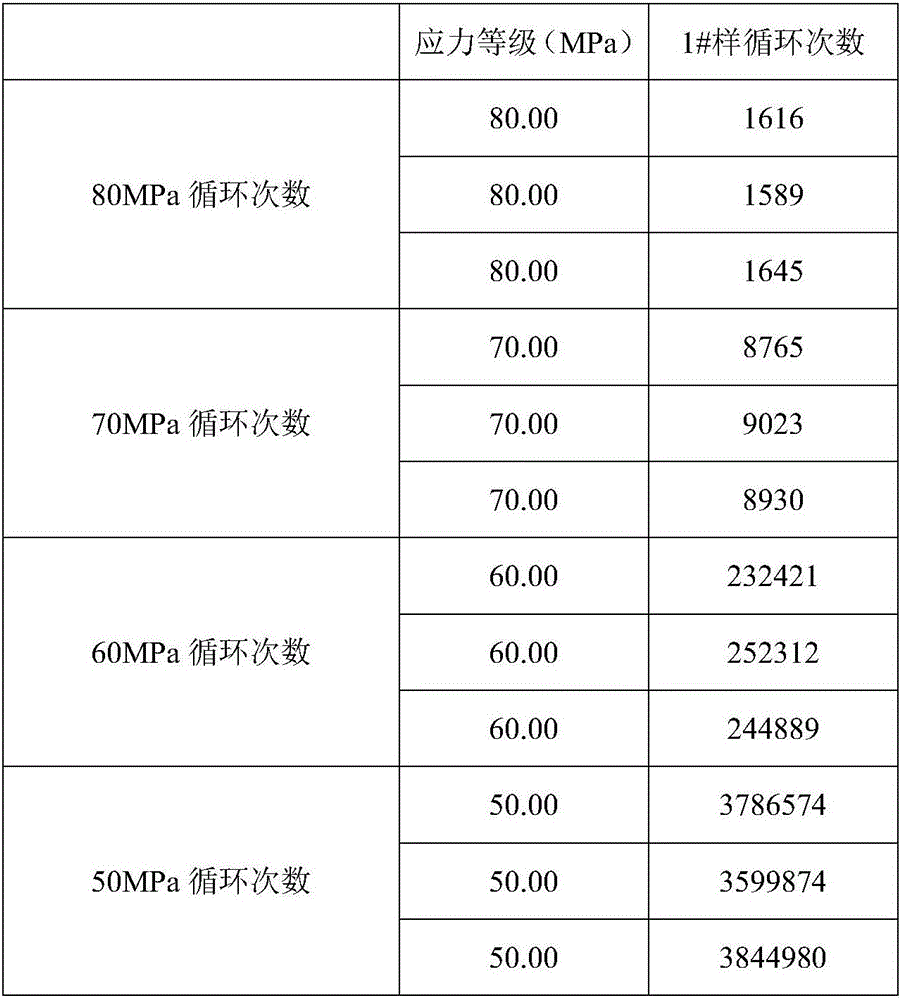

Bending fatigue testing method of fiber reinforced material

ActiveCN105928810ASolving Bending Fatigue TestingCompare Fatigue Test LifeMaterial strength using repeated/pulsating forcesStress levelStress–strain curve

The invention discloses a bending fatigue testing method of a fiber reinforced material, comprising the following steps: step S1 of testing basic parameters and determining test conditions; step S2 of adjusting a test span; step S3 of setting a test compensation path; step S4 of determining the maximum stress; step S5 of carrying out a plurality of stress level tests to obtain a bending performance test and a stress-strain curve, finding dependent variables of corresponding stress values by means of getting points, and calculating a deflection value of strain corresponding to each stress based on a deflection value calculation formula; step S6 of setting test stress parameters; step S7 of carrying out bending fatigue tests at different times; and step S8 of linear fitting: drawing an S-N curve of test values by means of a regression linear analysis based on the test result in the step S7 by taking N as a vertical coordinate and S as a horizontal coordinate, and fitting out a fitted equation of log10(stress)=a-blog10(times) or (stress)=a*(times)<(-b)> based on the S-N curve. The bending fatigue testing method of the fiber reinforced material disclosed by the invention provides a method evidence for a bending fatigue test of the fiber reinforced material, and fatigue test life can be quickly obtained by the fitted equation.

Owner:JUSHI GRP CO

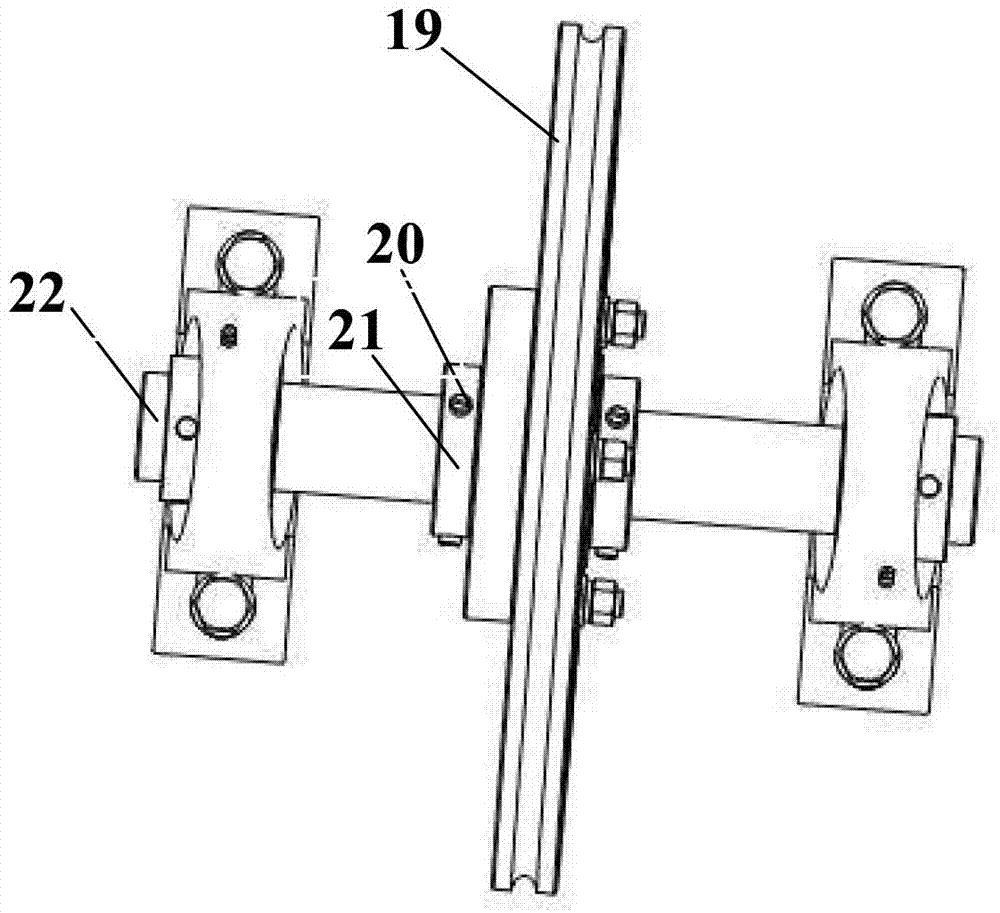

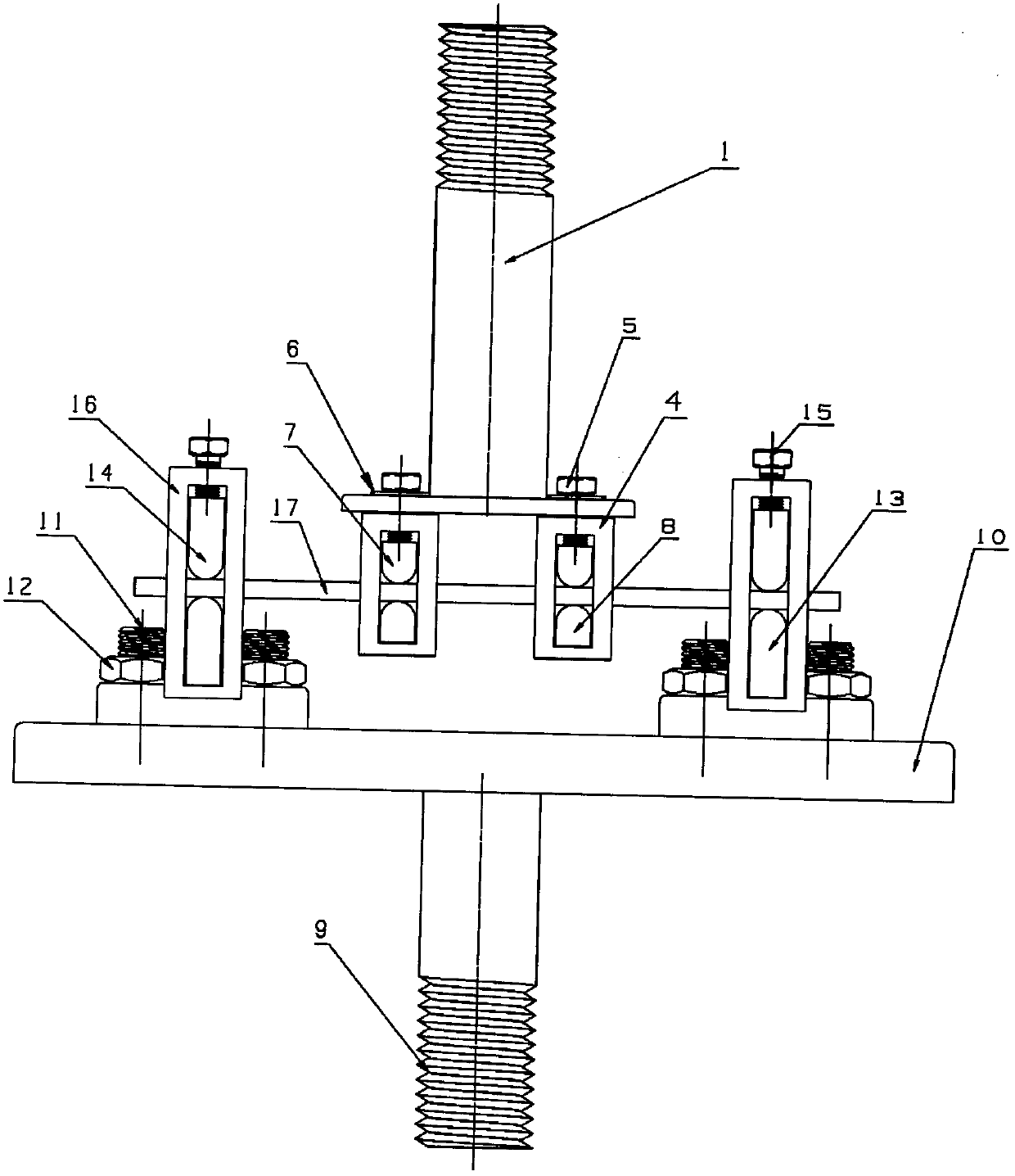

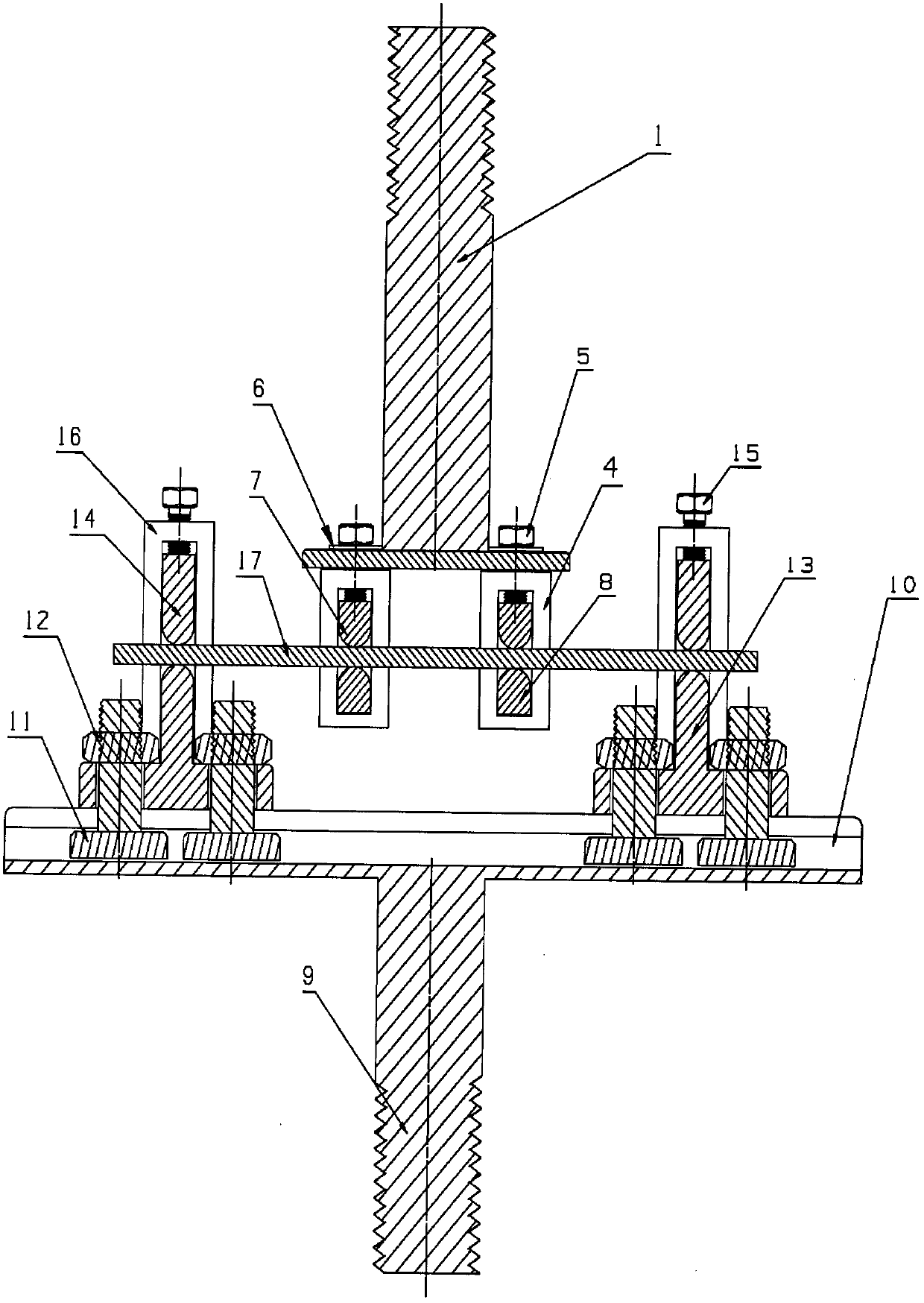

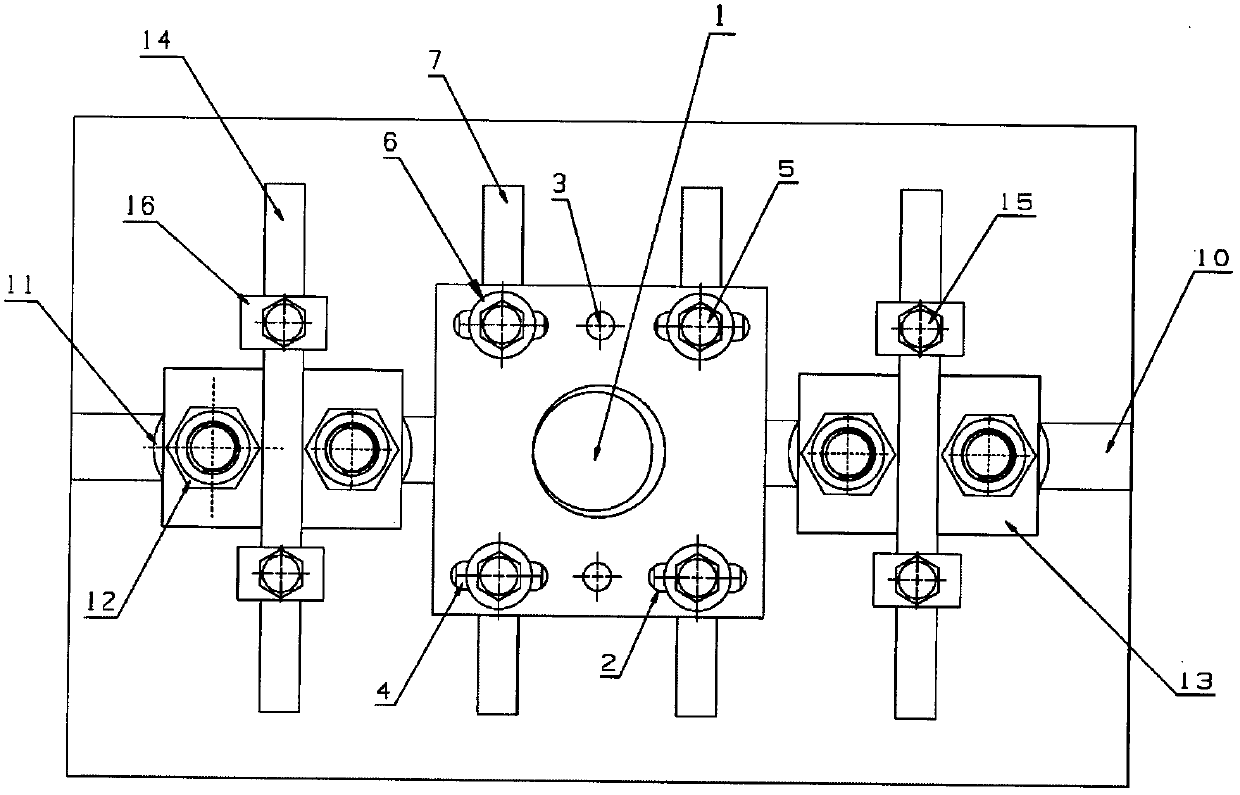

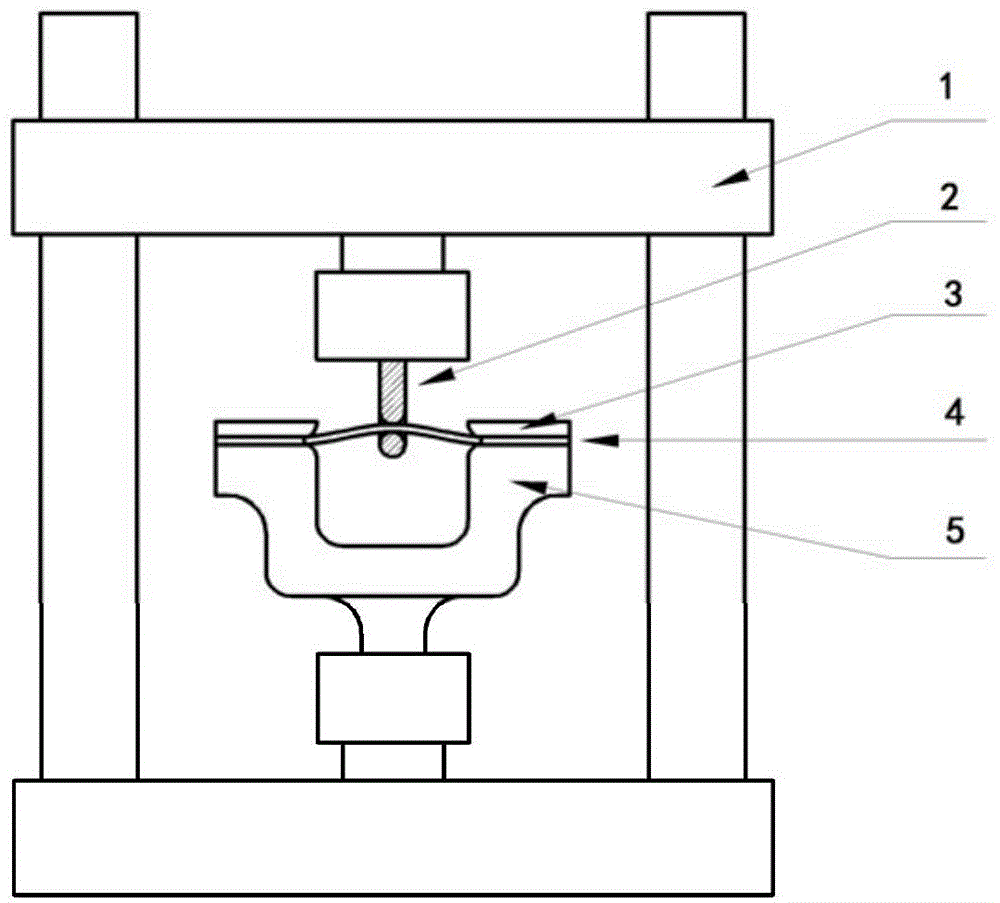

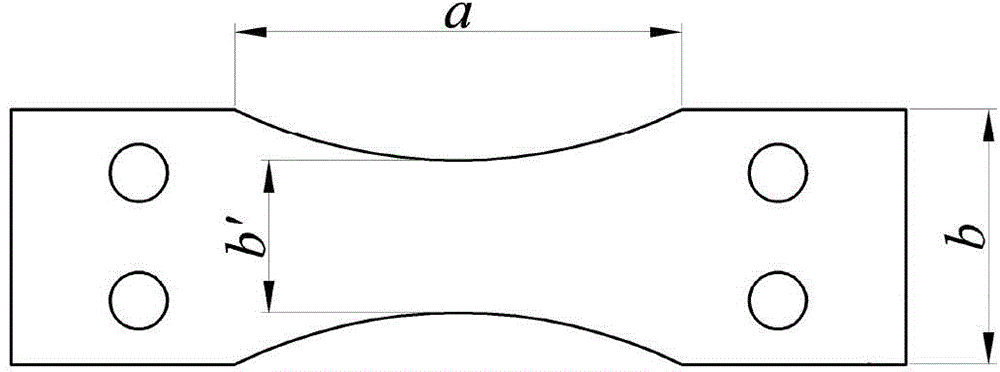

Four-point bending fatigue test clamp

InactiveCN104777033ATest bending fatigue performanceStrength propertiesBending fatigue testFatigue testing

The present invention discloses a four-point bending fatigue test clamp, which is used for carrying out pressing bending or pulling bending on a fatigue tester so as to achieve a four-point bending fatigue test under any load ratios and test the bending fatigue performance of a specimen. According to the clamp, a support member and a loading member are respectively and fixedly arranged on a fatigue tester, the loading member is positioned on the upper portion of the middle of the supporting member, the base of the supporting member is axially provided with a guide track, the bottom plates of two supporting arms are provided with supporting arm locking bolt holes, the two supporting arms are fastened on the guide track of the base through locking bolts and are symmetrically arranged, the distance between the two supporting arms can be adjusted, the upper end portions of the supporting arms are provided with two pairs of bolt locking devices provided with pressing rollers, the four pressing rollers are respectively snapped on the end portions of the two supporting arms, the specimen is fastened between the two pairs of the pressing rollers, two reinforcing plates are respectively fixed under the two pressing rollers, the specimen is arranged on the lower end of the loading member and is fastened between the two pairs of the pressing rollers through the locking bolts, the specimen contacts the pressing roller, pre-tightening is performed, and the load is applied.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

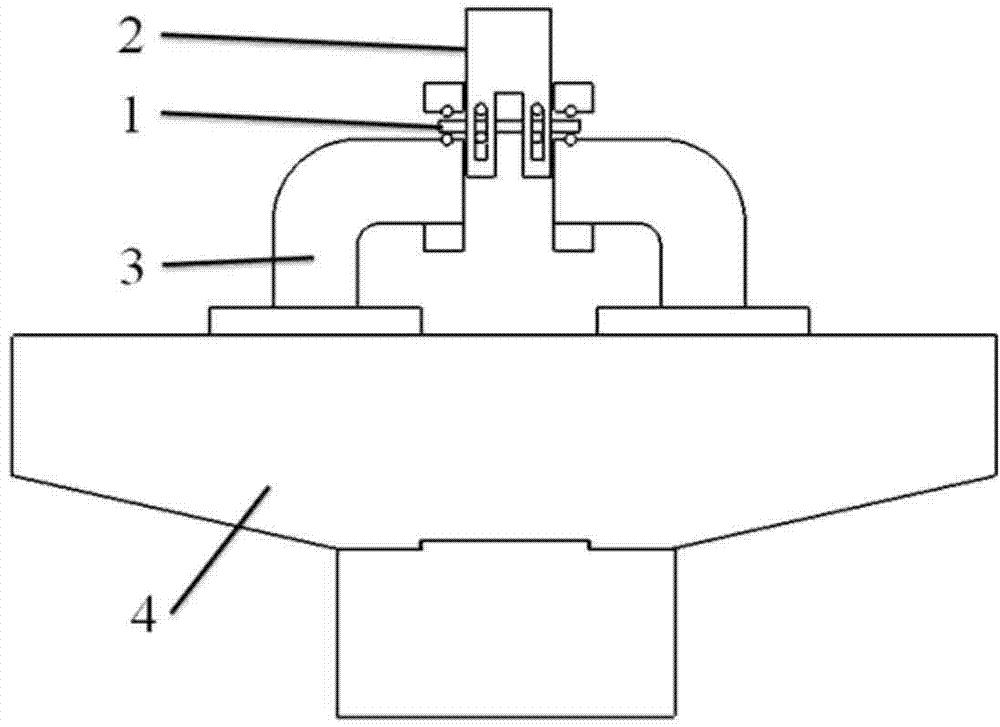

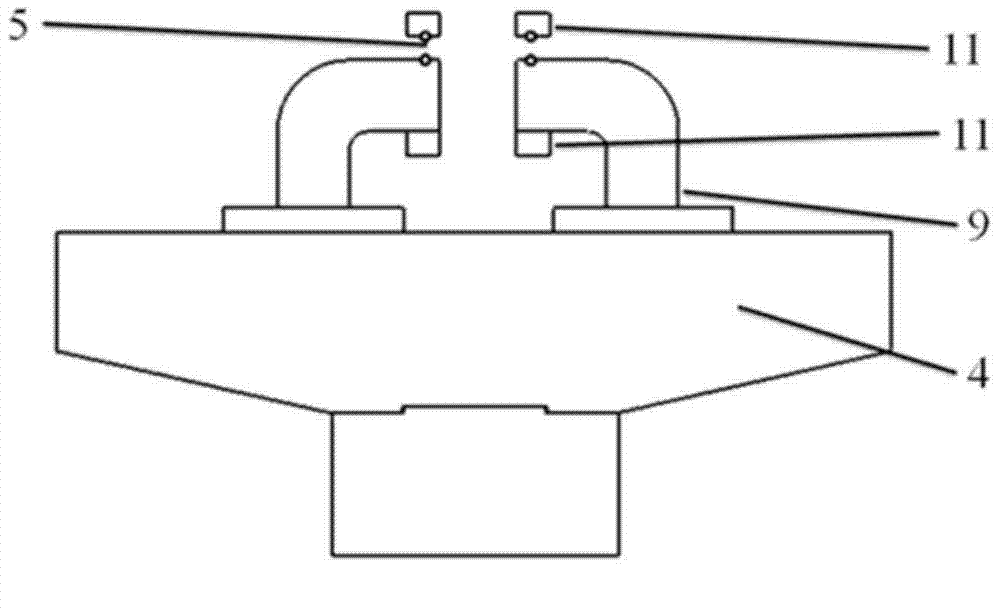

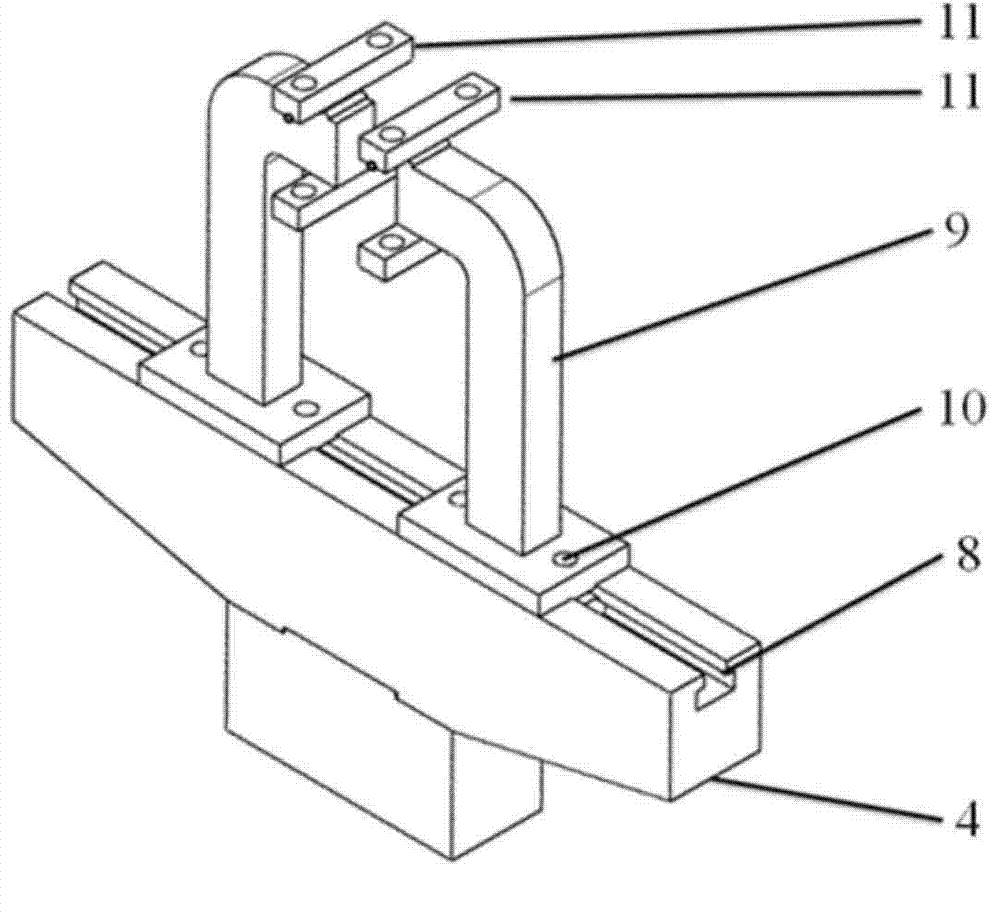

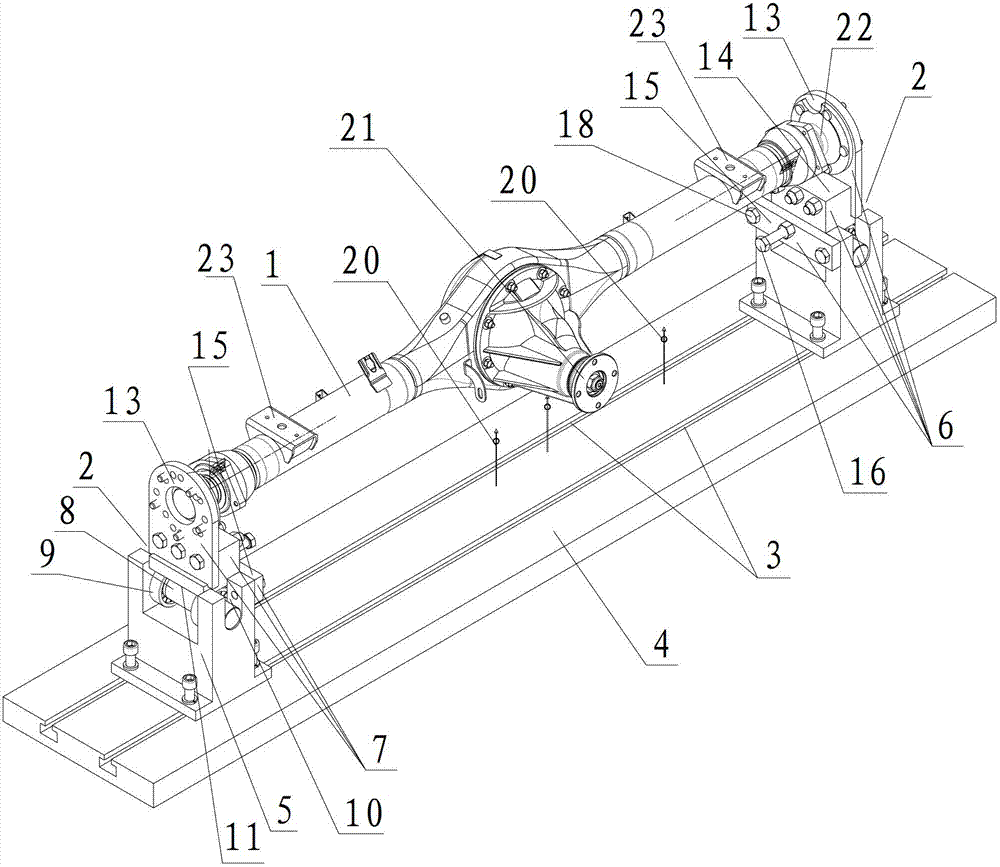

Bending test device for semi-floating drive axle, and test method of same

ActiveCN103196754AImprove practicalityImprove effectivenessVehicle testingMaterial strength using steady bending forcesCar manufacturingStatic strength

The invention discloses a bending test device for a semi-floating drive axle, and a method for performing the bending test on the semi-floating drive axle by the bending test device, belonging to the technical field of automobile manufacturing. A bending test device for the semi-floating drive axle, which can meet the stressing features of the semi-floating drive axle in the semi-floating drive axle bending test, and a method for performing bending test on the semi-floating drive axle by the test device, are provided. A wheel simulator is arranged on the chassis of each support frame for test of a support frame group; when the vertical bending rigid test, the vertical bending static strength test and the vertical bending fatigue test of the semi-floating drive axle are performed, after the semi-floating drive axle sample is connected with the wheel simulators, a workbench for test is supported by the chassis, and a test support counter force identical to the actual service condition is applied on the semi-floating drive axle through the wheel simulators.

Owner:SICHUAN JIANAN IND

Rotating bending fatigue test device and method with axial load control function

InactiveCN102866066AControl load amplitudeImplementing Uniaxial Tensile TestingMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesStress ratioTest sample

The invention discloses a rotating bending fatigue test device and a rotating bending fatigue test method with an axial load control function. The device comprises a rotating bending fatigue loading device and an axial load application and control device for applying axial force to a test sample. The axial load application and control device is additionally arranged on the basis of the conventional rotating bending fatigue test device and the conventional rotating bending fatigue test method, and the sample is subjected to the action of an axial load under a rotating bending fatigue loading condition, so that rotating bending fatigue tests under different stress ratio conditions are realized. The axial load is controlled to be changed along with a time cycle, so that combined fatigue under the action of two different frequency loads is realized. Rotation is stopped, a bending load is removed, and the axial load is controlled to be monotonically increased, so that a monotonic tensile test is realized. The rotating bending fatigue test device with the axial load control function is simple in structure, low in energy consumption, low in manufacture and using cost and suitable for high-cycle and ultrahigh-cycle fatigue tests under an average tensile stress load condition.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Fatigue crack three-dimensional expansion comparative analysis method for off-line CT detection condition

ActiveCN104865139AResolve locationSolving Consistency IssuesMaterial strength using steady bending forcesMaterial strength using repeated/pulsating forcesImage conversionImage registration

The invention discloses a fatigue crack three-dimensional expansion comparative analysis method for off-line CT detection condition. The fatigue crack three-dimensional expansion comparative analysis method comprises the following steps: (1) designing a three-point bending fatigue crack expansion test sample, processing, and performing three-point bending fatigue experiment; (2) designing a CT scanning positioning device; (3) performing microscopic CT scanning and reestablishment of the fatigue sample for different fatigue cycles under off-line conditions; (4) performing CT image registration alignment and image conversion on the fatigue sample in different fatigue cycles; (5) extracting crack body characteristics and extracting curved surfaces of middle positions of a crack body; (6) performing imaging and visualization on the increment of the crack expansion curved surface. The fatigue crack three-dimensional expansion comparative analysis method has the advantages that three-dimensional fatigue crack expansion comparative analysis can be achieved. The processing method is applicable to CT data comparative analysis in different expansion periods under off-line CT three-dimensional imaging detection conditions, can also be used for representing fatigue crack expansion behavior, and has significant guide meanings for advanced structural material crack expansion analysis and service life prediction.

Owner:NANCHANG HANGKONG UNIVERSITY

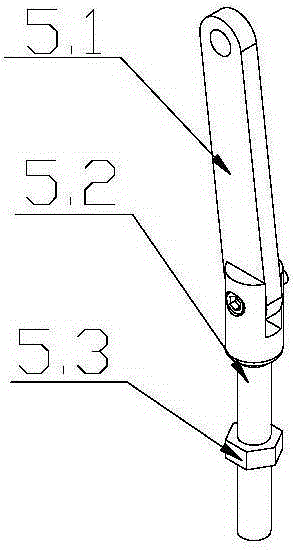

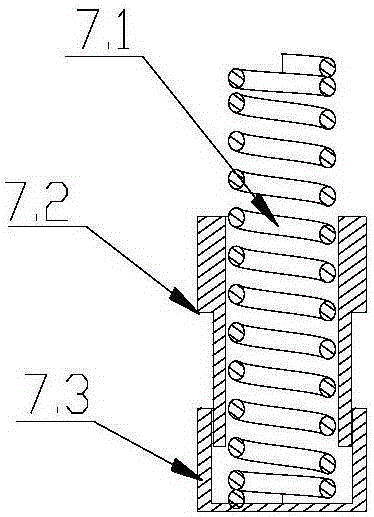

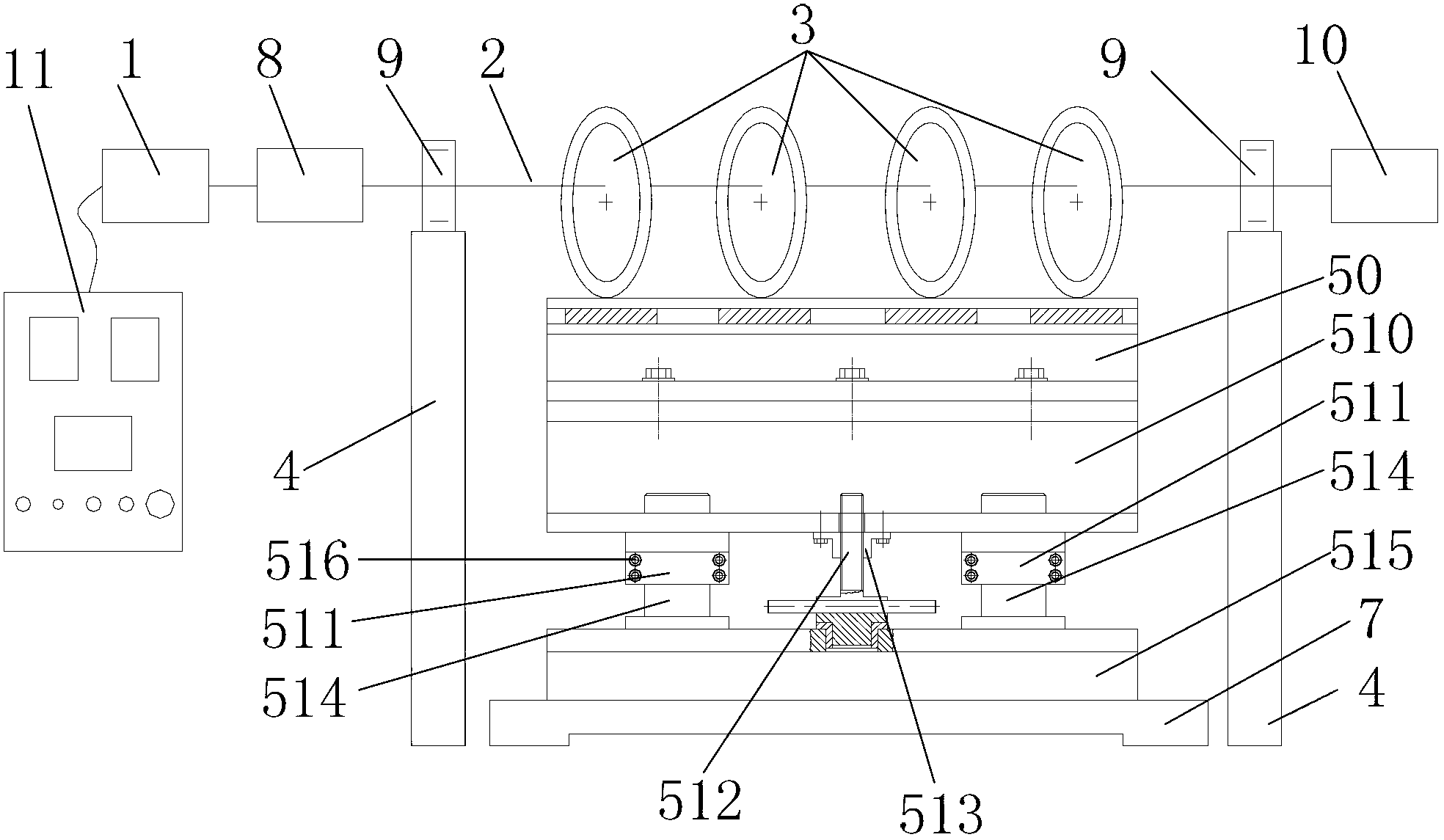

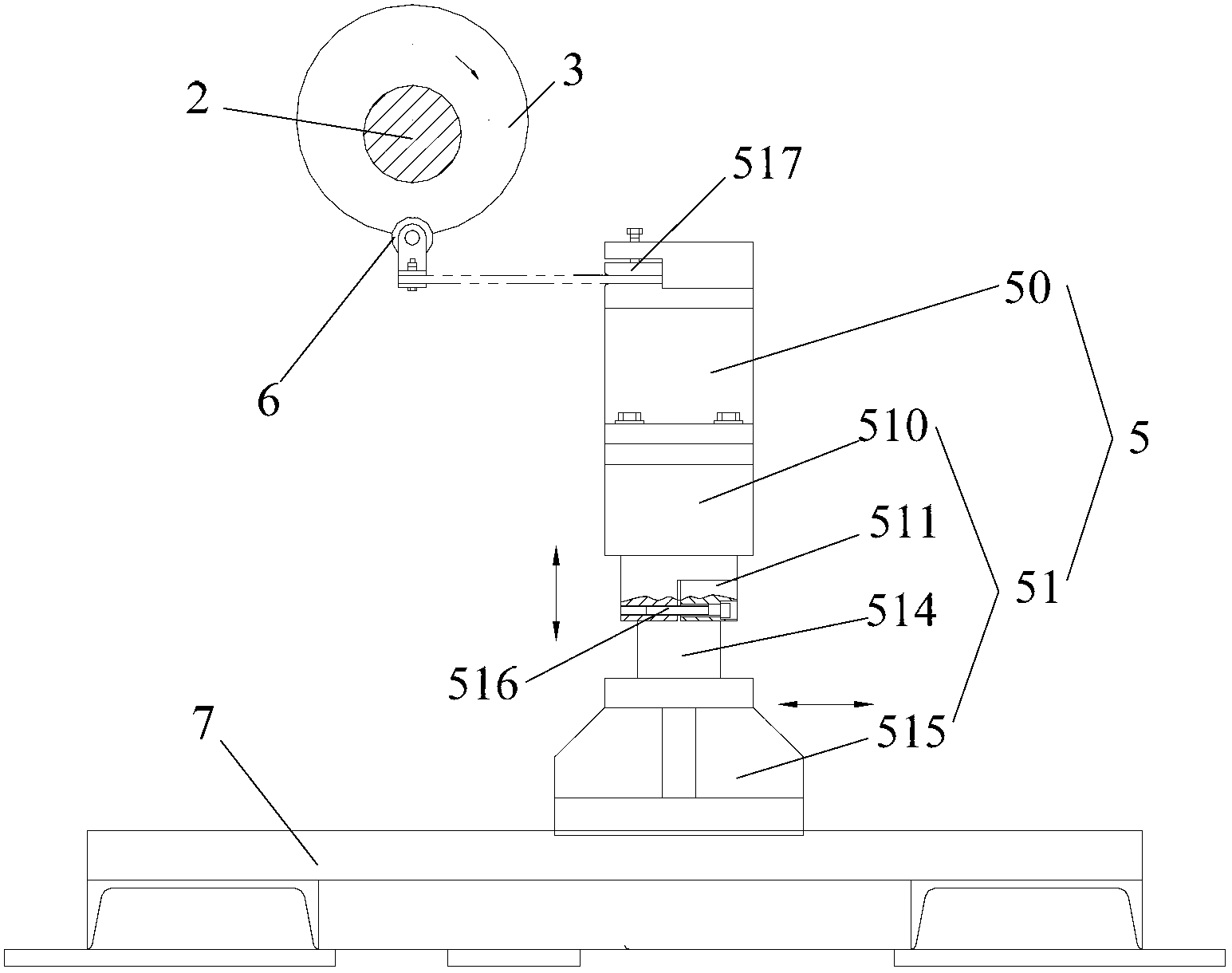

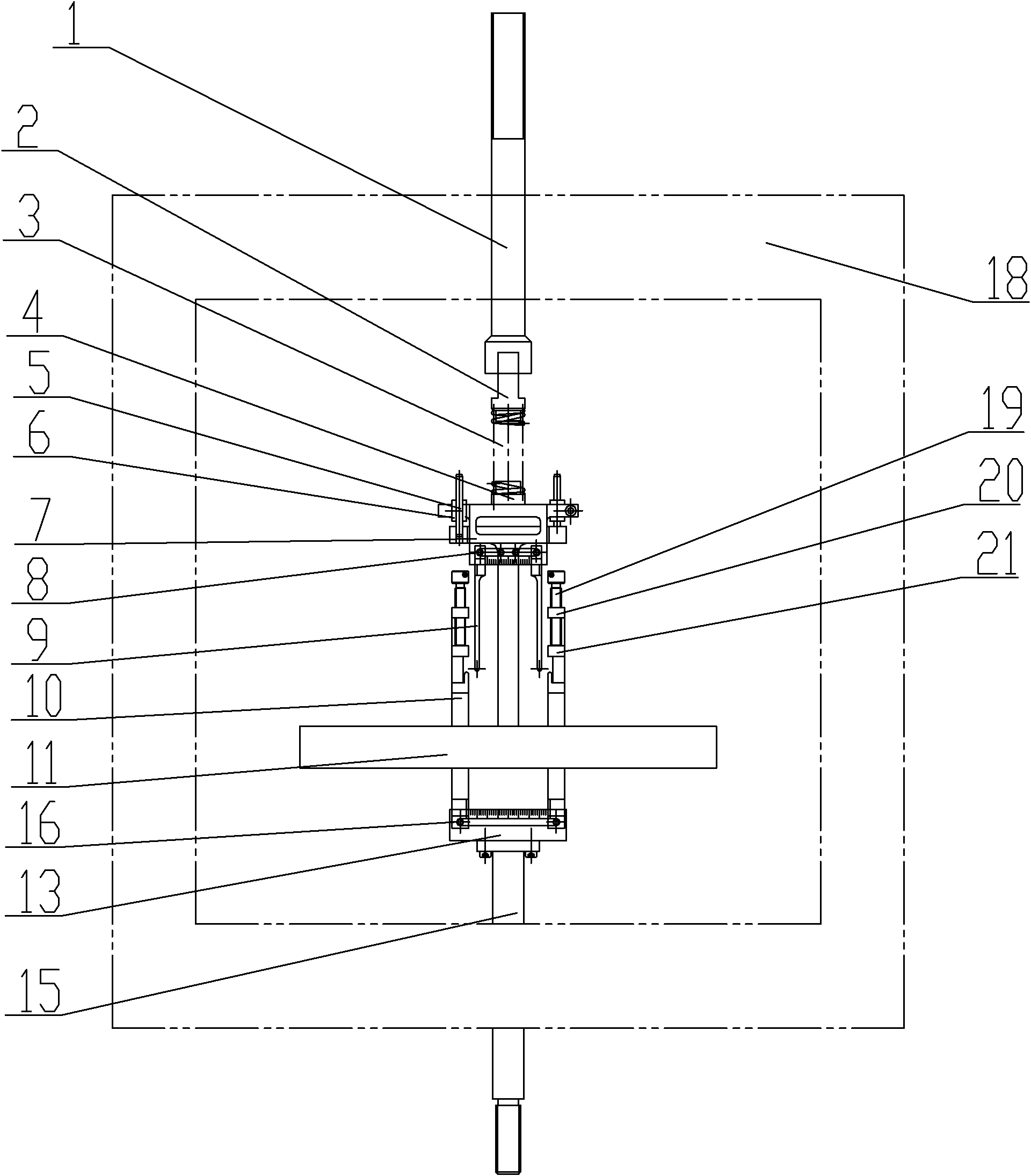

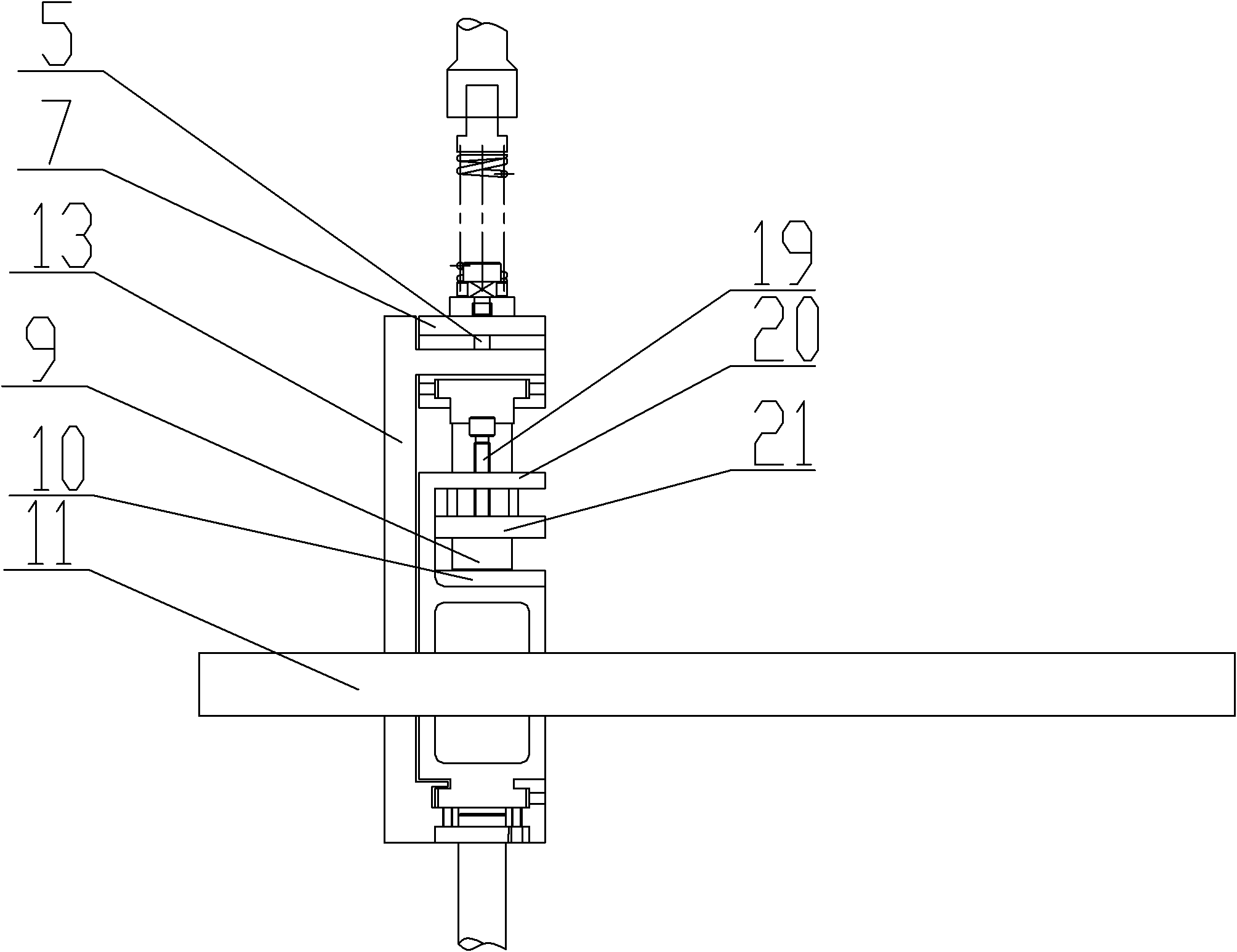

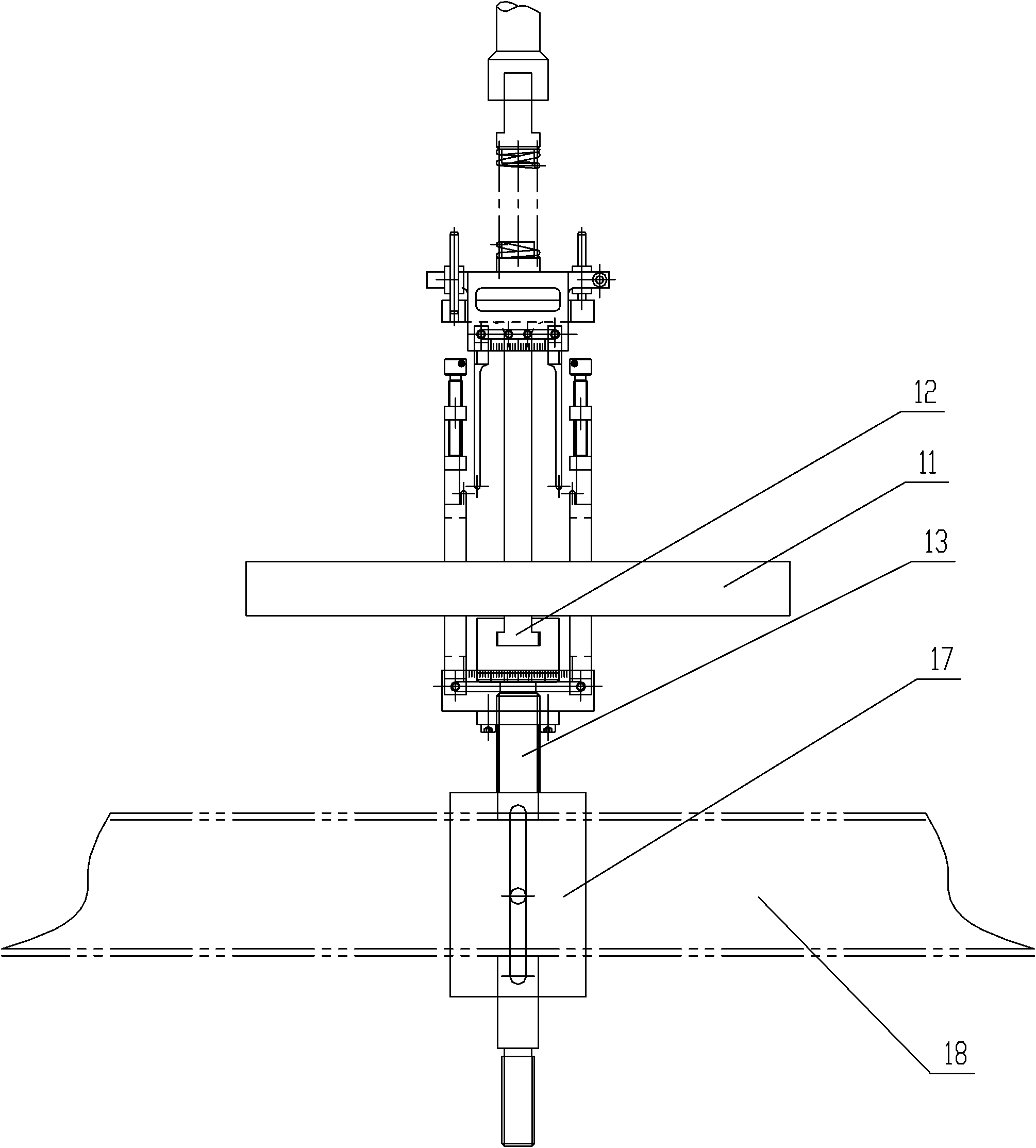

Three-point or four-point bending fatigue test fixture for living rat ulna

The invention discloses a three-point or four-point bending fatigue test fixture for a living rat ulna. The fixture comprises a carrying disc and a foreleg uploading test device, wherein the carrying disc is arranged in a test chamber; the foreleg uploading test device comprises an upper connecting rod, an upper spring connection shaft, a linear elastic spring, a lower spring connection shaft, a T-shaped upper pressure head slide carriage, upper pressure heads, lower support heads, a C-shaped lower slide carriage and a lower connecting rod; the C-shaped lower slide carriage is mounted on the lower connecting rod connected with a main engine load sensor, and the upper end of the C-shaped lower slide carriage is provided with at least two guide pillars; a linear bearing capable of enabling the T-shaped upper pressure head slide carriage to move up and down along the guide pillars is mounted on the T-shaped upper pressure head slide carriage, the top of the T-shaped upper pressure head slide carriage is provided with the lower spring connection shaft connected with the lower end of the linear elastic spring, the upper end of the linear elastic spring is mounted on the lower end of the upper spring connection shaft, and the upper spring connection shaft is mounted at the lower end of the upper connecting rod; and one or more upper pressure heads are arranged under the T-shaped upper pressure head slide carriage, two lower support heads are arranged on the C-shaped lower slide carriage corresponding to the lower part of the upper pressure heads, and the carrying disc is mounted under the lower support heads. The fixture provided by the invention can take a living rat as a carrier, and is simple in structure, convenient to use, precise in acting points, accurate in location and more excellent in microdamage research, thereby being suitable for performing the three-point or four-point bending fatigue test on the living rat ulna.

Owner:CENT SOUTH UNIV

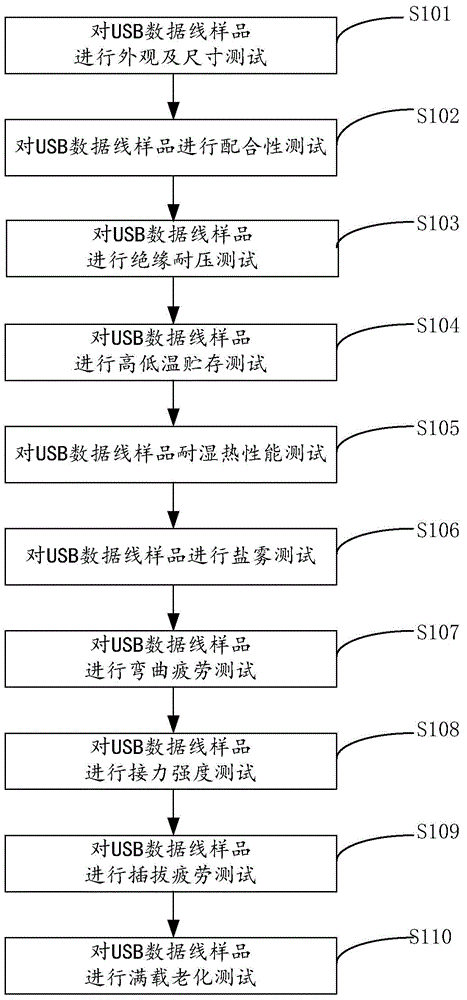

Test method for USB (universal serial bus) data wire

InactiveCN104678199AMeet the needs of long-term useQuality improvementTesting dielectric strengthWeather/light/corrosion resistanceUSBBending fatigue test

The invention provides a test method for a USB (universal serial bus) data wire. The test method is used for carrying out reliability detection on the USB data wire and comprises the following steps that a USB data wire sample is subjected to appearance and dimension test; in addition, after the appearance and dimension test, the USB data wire sample is sequentially subjected to matching performance test, insulation voltage-withstand test, bending fatigue test, connecting force intensity test, plugging and unplugging fatigue test and full-load aging test. The test method for the USB data wire provided by the invention has the advantages that the long-time use process of the USB data wire can be simulated, and the reliability of the USB data wire can be effectively detected.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

Three-point and four-point flexural fatigue general test fixture for composite material

InactiveCN107917844AMeets bending fatigue test standardsStable clampingStrength propertiesStrength of materialsEngineering

The invention discloses a three-point and four-point flexural fatigue general test fixture for a composite material. The three-point and four-point flexural fatigue general test fixture for the composite material belongs to a fixture used for testing mechanical properties of materials, is detachably arranged on the conventional fatigue test machine and carries out three-point and four-point flexural fatigue test. The fixture is divided into a loading part and a supporting part, and the loading part and the supporting part can be connected with a fatigue testing machine in a thread form. The fixture can regulate clamping size according to the size of a sample, domestic and foreign related flexural fatigue test standards are met, and universality is strong. The fixture can guarantee that thesample can be stably clamped in a flexural fatigue testing process without producing slippage, so that an experiment can be accurately and smoothly carried out.

Owner:TIANJIN POLYTECHNIC UNIV

Frequency conversion rotation bending fatigue tester

InactiveCN101290279AReasonable designReduce working noiseStrength propertiesDrive wheelFatigue testing

The invention discloses a frequency converting rotary bending tester, belonging to the material testing technical field, comprising a frame, a motor system, a control system, a balance system and a loading system, wherein, the motor system comprises a motor, metal coatings, a driving wheel, a driven wheel, a strap, a wheel shaft, a left collet and bearings; the motor is connected with the driven wheel through the driving wheel and the strap; the driven wheel is fixed on the wheel shaft; the right end of the wheel shaft is provided with the left collect, and the left end of the wheel shaft is sleeved in the frame through two bearings; and the metal coatings are covered outside the motor, the driving wheel, the driven wheel, the strap and the wheel shaft; and the left end of the frame is provided with a platform which is provided with the motor. Designs of the frame and the motor system are more reasonable, so that test errors caused by vibrations during operating are smaller. The tester frequency converting rotary bending tester has the advantages of simple structure, easy operation, low operating noise, multiple functions and accurate test data.

Owner:SHANGHAI JIAO TONG UNIV

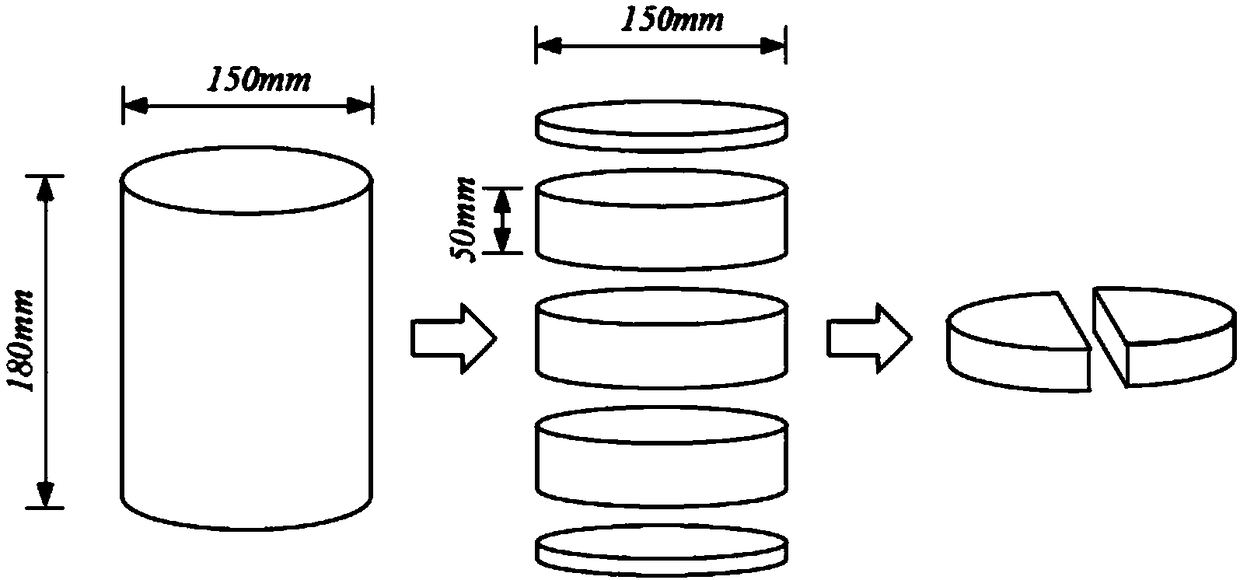

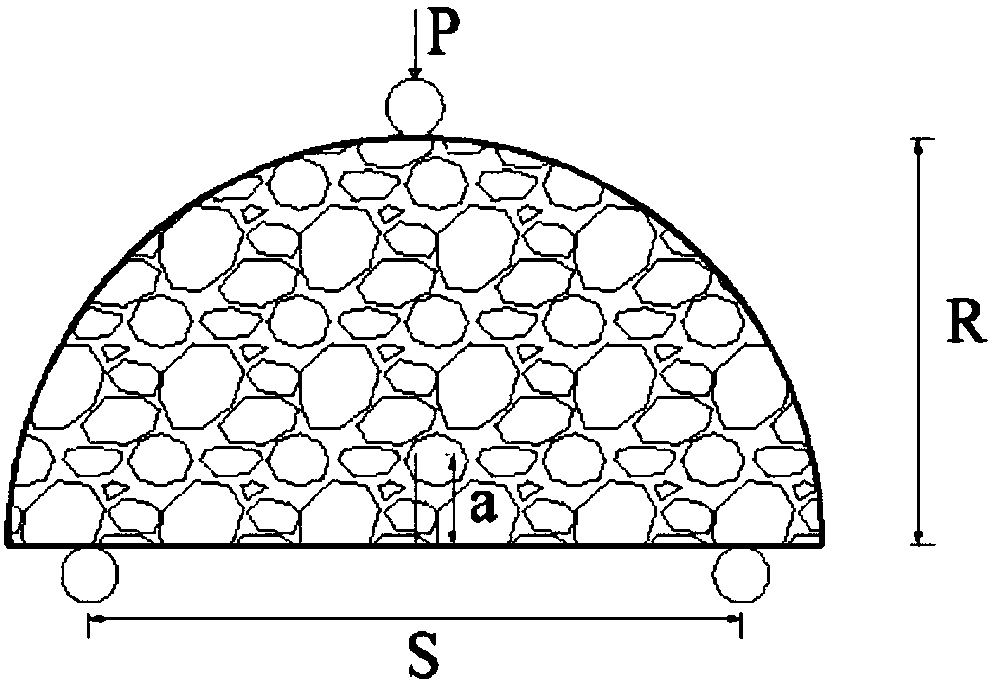

Evaluation method of fatigue damage healing performances of asphalt mixture based on semi-circular bending tests

The invention discloses an evaluation method of fatigue damage healing performances of an asphalt mixture based on semi-circular bending tests. The method comprises the following steps: (1) preparation of a test piece, to be more specific, forming a specimen by using a rotary compaction device, cutting the formed cylindrical specimen into semi-circular test pieces, and screening the semi-circulartest pieces to obtain the test piece meeting requirements; (2) fatigue tests, to be more specific, using the test piece meeting requirements in the step (1) for semi-circular bending strength tests and fatigue tests; and (3) evaluation of the fatigue damage healing performances. The method can effectively evaluate the fatigue damage healing performances of the asphalt mixture and improves an evaluation system of the semi-circular bending fatigue tests.

Owner:SOUTHEAST UNIV

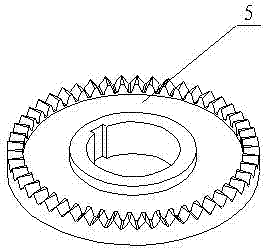

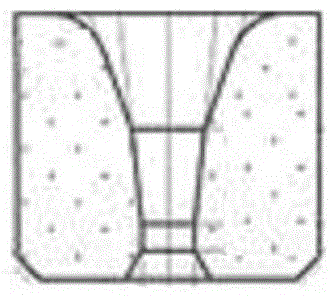

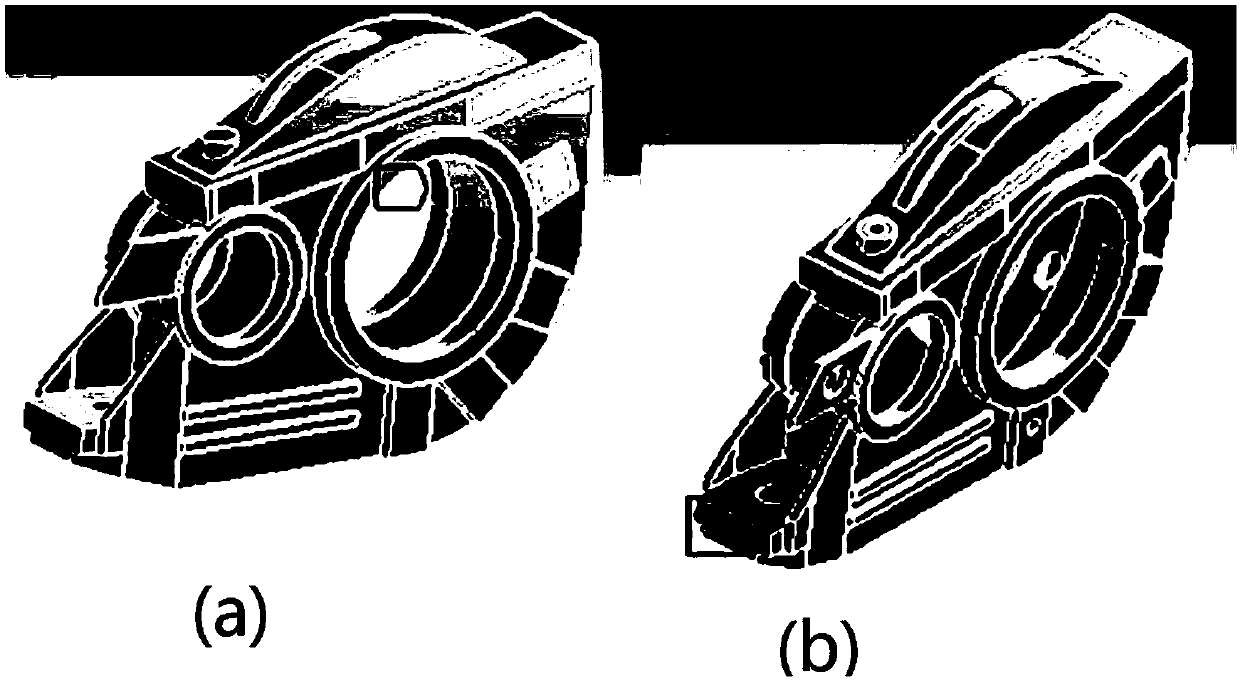

Face-gear bending fatigue test mechanism and method

ActiveCN102967509AMeet the meshing principleTest stress distributionMaterial strength using steady bending forcesGear toothBending fatigue test

The invention relates to face-gear bending fatigue test mechanism and method, and belongs to the field of measurement of gear bearing capacity. The face-gear bending fatigue test mechanism disclosed by the invention meets the meshing relation of face-gears by using an involute profile loading press head and an involute profile supporting press head and can be used for loading any loading points positioned on the face-gears, thereby solving the problem that the traditional loading head can not meet the meshing relation and complicatedly transmits loading force; and besides, the face-gear bending fatigue test mechanism disclosed by the invention has adjustability and is suitable for a face-gear tooth bending fatigue test with different parameters by adjusting the positions of a supporting assembly and a loading assembly which are positioned in the face-gear bending fatigue test mechanism, thereby achieving obvious substantiality characteristics and outstanding advancement.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

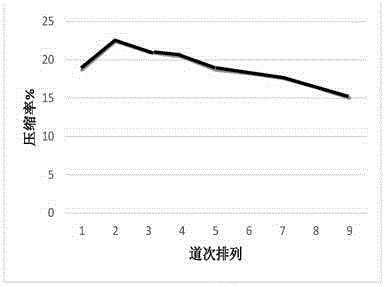

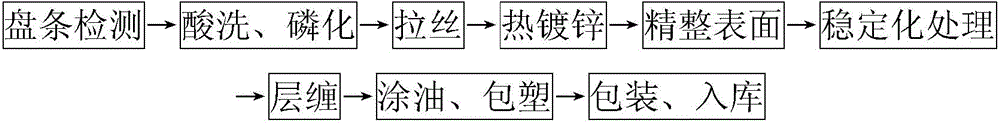

Manufacture method for HDPE hot dip galvanizing prestressed steel strands used for bridge cable ropes

ActiveCN103952932AAvoid surface qualityImprove plasticityHot-dipping/immersion processesTextile cablesSocial benefitsEconomic benefits

The invention discloses a manufacture method for HDPE hot dip galvanizing prestressed steel strands used for bridge cable ropes. The method comprises the steps: wire drawing; hot dip galvanizing; twisting and stabilization treatment; the technical indexes of the hot dip galvanizing prestressed steel strands manufactured by the method are that the tensile strength is larger than or equal to 1860 MPa, the elongation rate with maximum force is larger than or equal to 5.0%, the reduction of area of monofilament is larger than or equal to 25%, a bending and fatigue resistance test of a saddle system applies a cyclic load of 800 MPa, and the steel strands can be used for 2 million times without breaking. The effect of the manufacture method, disclosed by the invention, can reduce 15% of steel consumption, shorten the construction period and guarantee the stable quality of a project when the hot dip galvanizing prestressed steel strands are used during the construction of a bridge. The hot dip galvanizing prestressed steel strands have the features of high corrosion resistance and good fatigue durability, so that the service life of cable ropes can be prolonged more than one time. Obvious economic benefits and social benefits can be generated when the hot dip galvanizing prestressed steel strands are used during the construction of the bridge.

Owner:天津市新天钢钢线钢缆有限公司

Metal diaphragm bending fatigue measurement device and method for diaphragm compressor

InactiveCN104677749AMaintain stabilityMaterial strength using steady bending forcesTension compressionMeasurement device

The invention relates to a metal diaphragm bending fatigue measurement device and method for a diaphragm compressor, provides a simple and easy bending fatigue measurement method for a metal diaphragm with a thickness of smaller than 1mm, and aims to make a bending fatigue test on the metal diaphragm on a tension-compression fatigue tester. A test clamping device consists of a base, a clamping block and a chuck, wherein a sample is fixed by the base and the clamping block; the middle of the sample is clamped by the chuck; the sample is processed into a middle-arc shape, so that the middle of the sample can be fractured. A fatigue tester program is designed, displacement amplitude is positioned for test, and stress variations are observed to judge whether the sample is fractured or not to obtain fatigue cycle data. An elastic mechanics mechanism is used for calculating a corresponding stress value by virtue of displacement amplitude, thereby obtaining a corresponding relationship between stress amplitude and a fatigue cycle. The method is simple in design and convenient to use, and is used for testing the fatigue resistance of the metal diaphragm of the diaphragm compressor.

Owner:UNIV OF SCI & TECH BEIJING

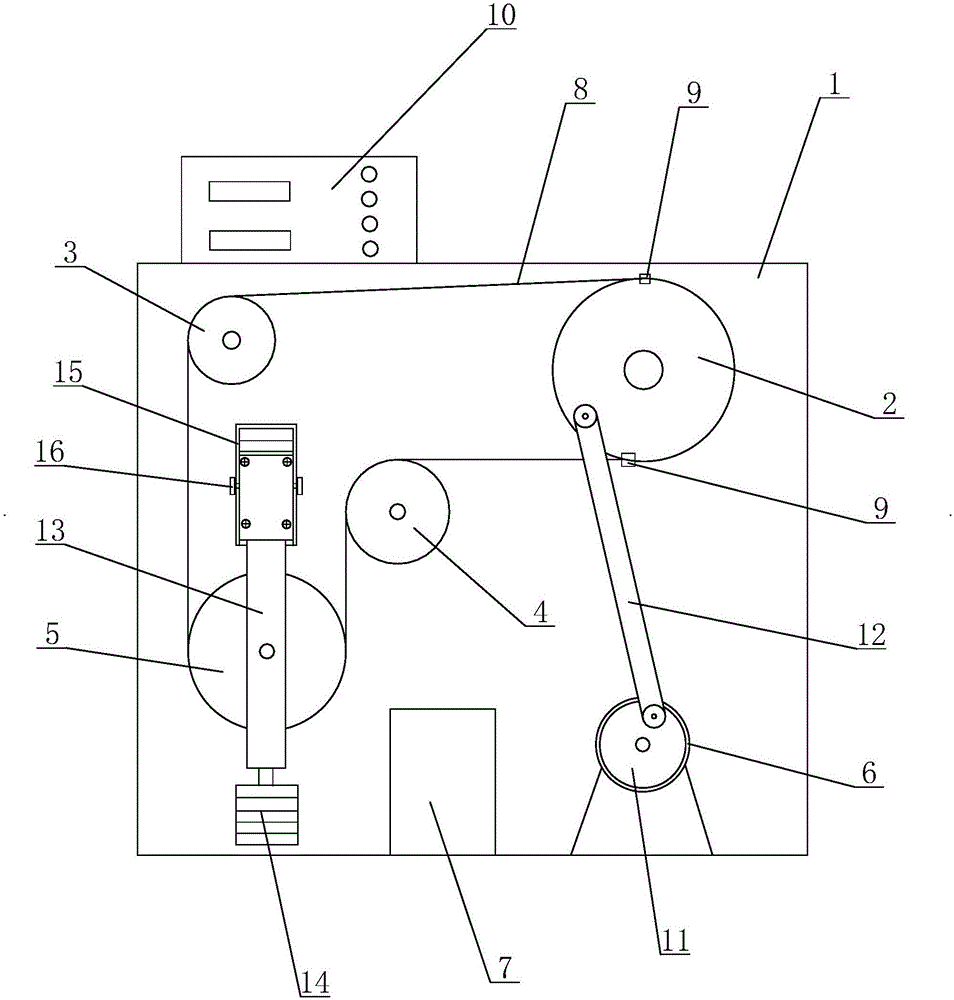

Bending fatigue testing machine for steel wire rope

InactiveCN106198252ASimple structureCompact structureMaterial strength using steady bending forcesDrive wheelBending fatigue test

The invention discloses a bending fatigue testing machine for a steel wire rope. The bending fatigue testing machine comprises a frame and a drive wheel, a testing wheel, a guide wheel, a counterweight wheel, a drive device and a control box which are mounted on the same side of the frame, wherein the drive wheel is mounted on the upper portion of the frame, the testing wheel is located on one side of the drive wheel, the counterweight wheel is arranged below the testing wheel, the guide wheel is located between the counterweight wheel and the drive wheel, a drive rod is connected between the drive device and the drive wheel, one end of the to-be-tested steel wire rope is fixed to the drive wheel, the other end of the to-be-tested steel wire rope sequentially winds around the guide wheel, the counterweight wheel and the testing wheel to be fixed to the drive wheel, and the drive device is electrically connected with the control box. The bending fatigue testing machine is simple and compact in structure, high in testing efficiency and accurate and reliable in testing data.

Owner:WUXI UNIVERSAL STEEL ROPE

Rotating bending fatigue testing machine for valves

ActiveCN105716851ASimple and reliable loading methodHigh precisionMachine part testingEngineeringAxial force

The invention discloses a rotating bending fatigue testing machine for valves.The rotating bending fatigue testing machine for valves comprises a rack, a valve to be tested, a loading input rod, a motor enabling the valve to be tested to rotate, and an axial force loading device used for applying thrust to the valve to be tested through the loading input rod, wherein the motor and the axial force loading device are arranged on the rack, and the two ends of the valve to be tested are fixed to an output shaft of the motor and the loading input rod respectively.According to the rotating bending fatigue testing machine for valves, the axial force and bending moment are loaded on the valve to be tested in a rotating state through the gravity action of a first weight and the gravity action of a second weight respectively, and thus a rotating bending fatigue test is carried out; the loading mode is simple and reliable, and precision is high.The axial force loading device can apply axial force to the valve to be tested, and the axial force is closer to the stress state of the valve under actual working conditions.Thus, the rotating bending fatigue testing machine for valves can carry out a fatigue performance test on valves in more complex stress states.

Owner:SOUTH CHINA UNIV OF TECH

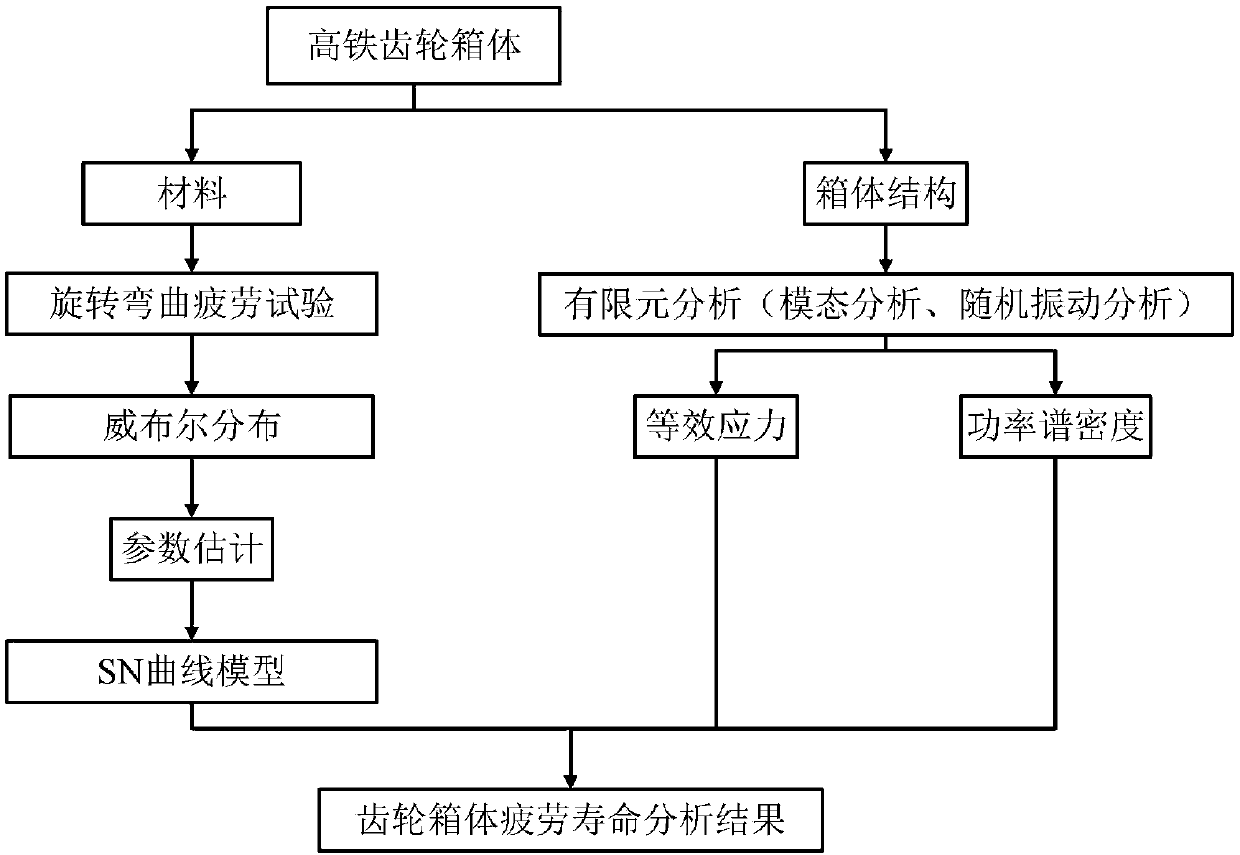

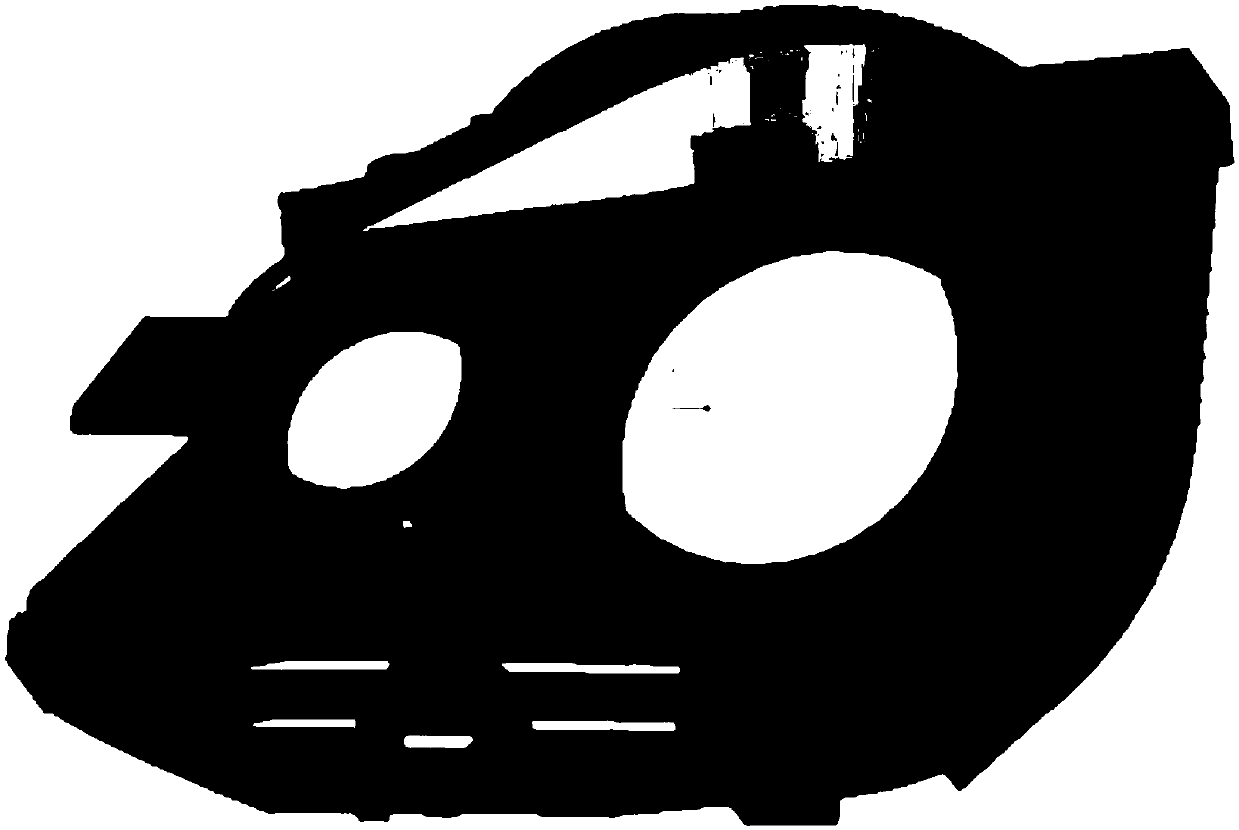

Method for solving insufficient failure data in service life analysis and prediction of high-speed rail gearbox body

InactiveCN109635363ASolve the problem of insufficient invalid dataVerify rationalityGeometric CADSustainable transportationElement analysisStudy methods

The invention discloses a method for solving insufficient failure data in service life analysis and prediction of a high-speed rail gearbox body. The method comprises the following steps: firstly, carrying out finite element analysis on the high-speed rail gear box body by utilizing a finite element simulation technology; secondly, analyzing the distribution law of the fatigue life of the gear boxbody material by utilizing the result of the rotary bending fatigue test of the gear box body material, carrying out parameter estimation, and establishing an SN curve model of the gear box body material; and finally, analyzing and predicting the service life of the gearbox body by combining the finite element simulation data of the gearbox body and the fatigue test data of the material. According to the invention, the high-speed rail gear box body is large; Load complexity, a structure with a long service period is an object; Aiming at the problem of insufficient failure data of the high-speed rail gear box body, the invention provides a method for solving the problem of insufficient failure data in the life analysis and prediction of the high-speed rail gear box body from the perspective of cross-scale, thereby laying a foundation for further predicting the fatigue life of the gear box body and providing a new research method for the fatigue life analysis of such structural parts.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com