Torsion fatigue test method for spring steel wire and device

A technology for torsional fatigue and spring steel wire, applied in the field of spring steel wire torsional fatigue test method and device, can solve the problems of high test cost, major equipment accident, long test cycle, etc., to avoid mechanical wear, eliminate mechanical gap, improve Effects of security and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

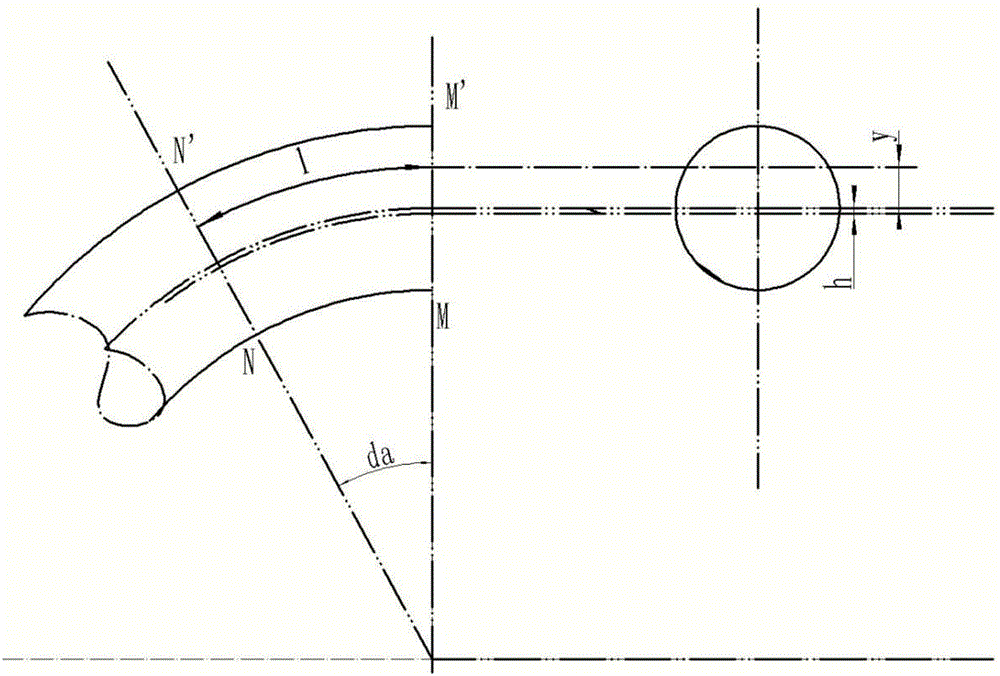

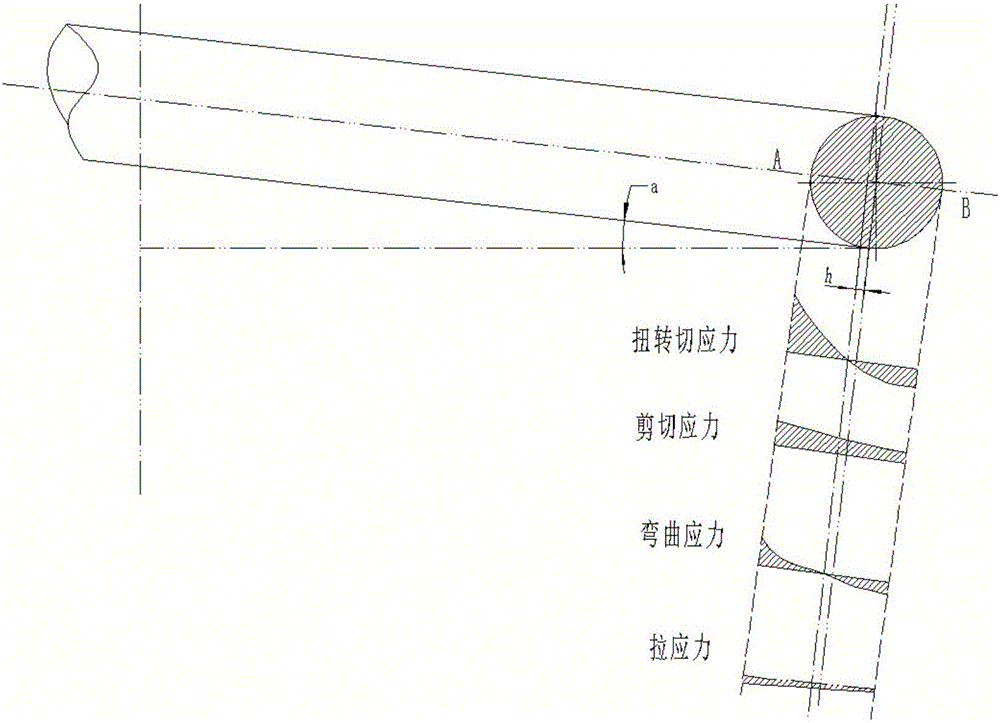

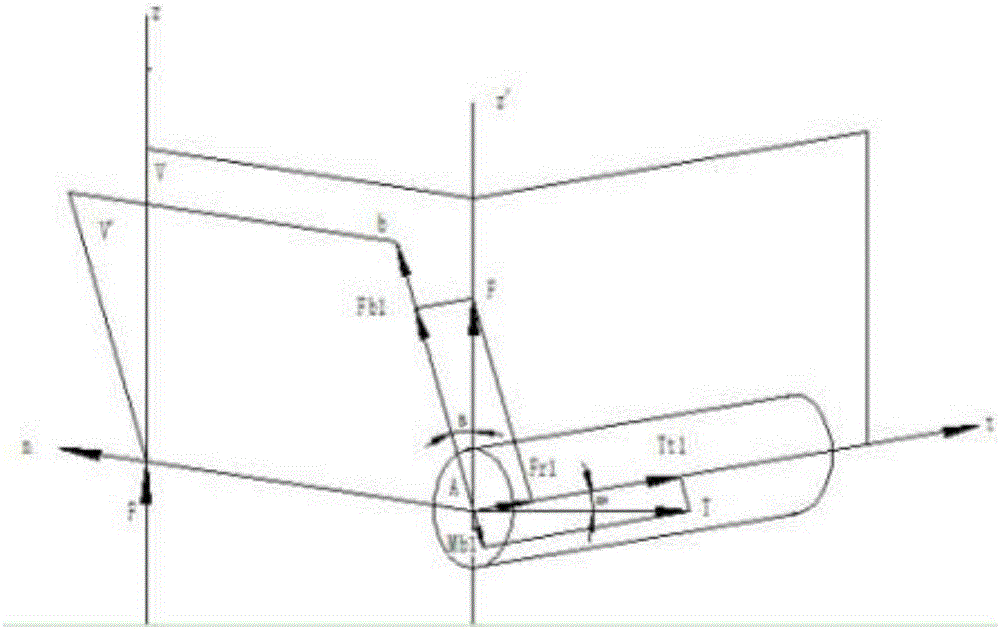

[0121] Embodiment 2, according to the above spring steel wire torsional fatigue test method, the present invention also discloses a spring steel wire torsional fatigue test device, the test device includes a drive system, a clamp system, preferably a hydraulic clamp system, a stationary end and a test bench four The driving mechanism includes a direct drive motor and an output spindle; the hydraulic fixture system includes a hydraulic chuck and a hydraulic pump station; the stationary end includes a torque sensor and a support frame; the test bench is configured to support the entire torsion device, which includes guide rails, preferably It is a linear guide rail, a guide rail slider, a positioning block and a test bench.

[0122] According to JB / T 9370-1999 "Technical Conditions for Torsion Testing Machines", the permissible errors of the indication values of the torsion angle of the testing machine should meet the following requirements:

[0123] a. The maximum permissible...

Embodiment 3

[0251] As a specific embodiment of the present invention, this paper proposes to use the torsional fatigue test of steel wire to replace the tension and compression fatigue test of spring. The specific test requirements are as follows, refer to GB / T16947-2009 "Code for Fatigue Test of Helical Springs".

[0252] Such as Figure 9 As shown, the operation process is as follows:

[0253] The first step: turn on the power; the second step: start the PLC control system; the third step: select the spring steel wire test piece; the fourth step: fix the test piece on the test device; Enter the sixth step, if the slip test is not passed, go to the fourth step to re-fix the specimen; the sixth step: input parameters for the selected test mode; the seventh step: start the test, start the test program, and load the specimen force, so that the test piece does reciprocating torsional movement under the loading force; the eighth step: judge whether the number of torsion times under the loadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com