Patents

Literature

128 results about "Torsion fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

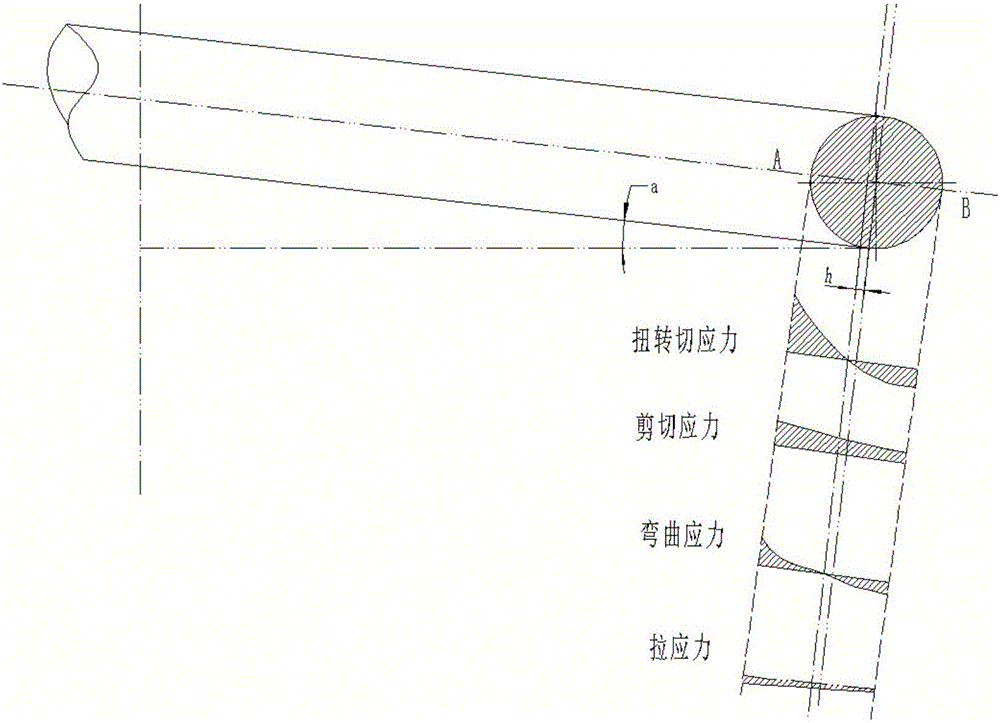

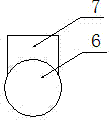

If the angle of a fatigue failure is: Closer to 90 degrees, it is a dominant bending force. Midway between 45 degrees and 90 degrees, it is a combination of torsion and bending forces. Closer to 45 degrees, it is a dominant torsion force.

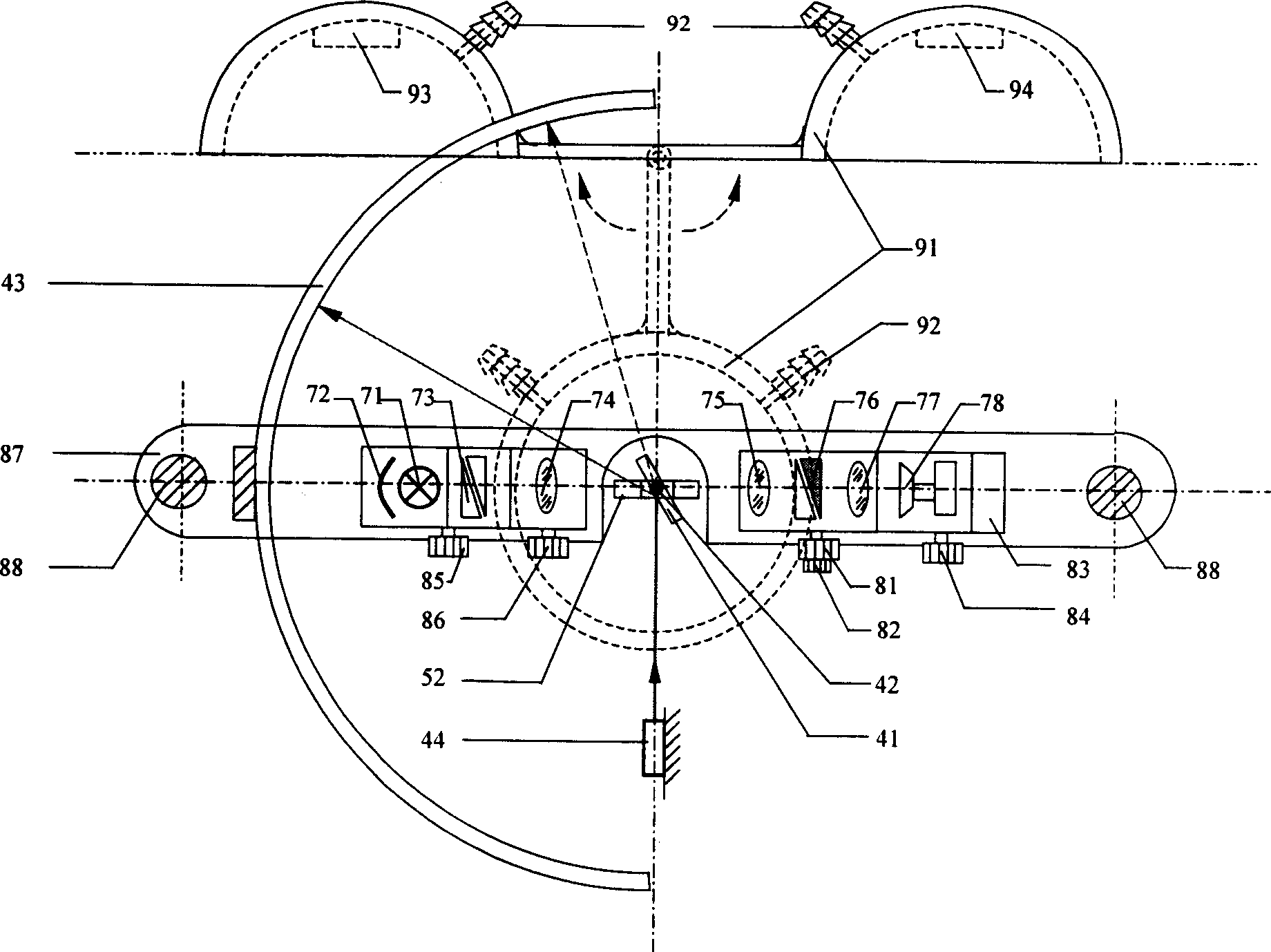

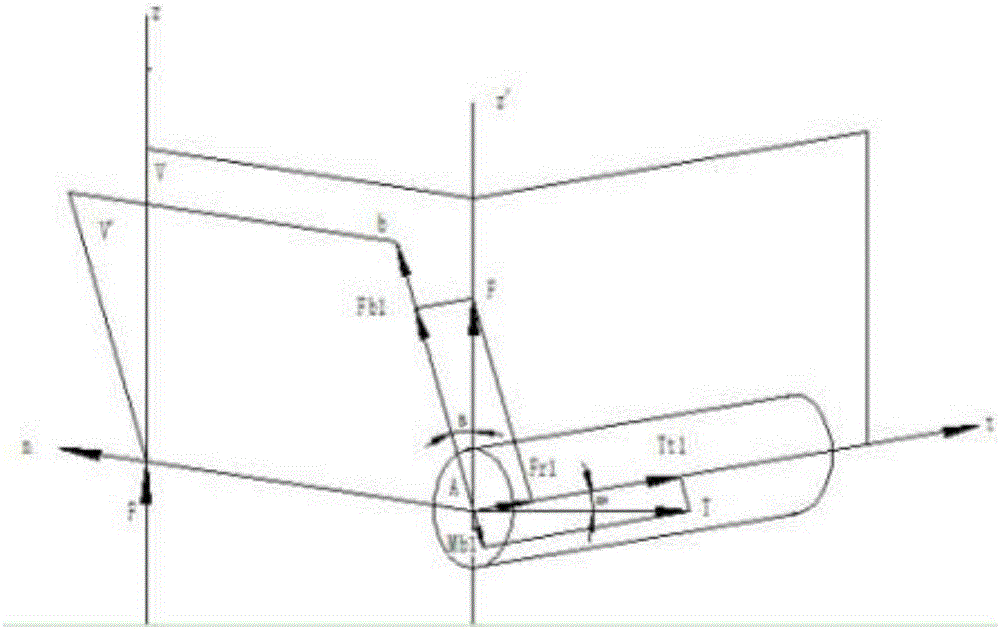

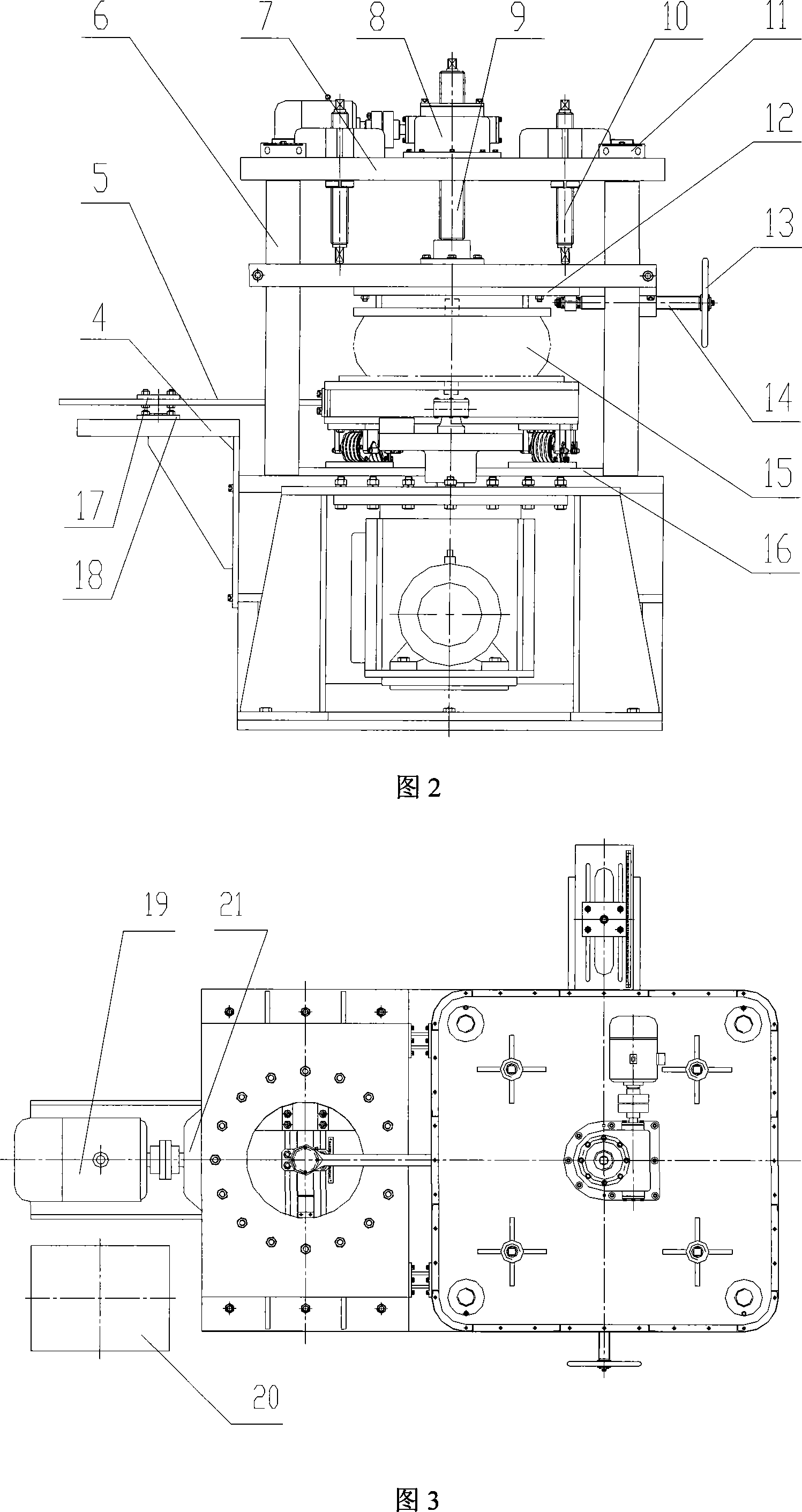

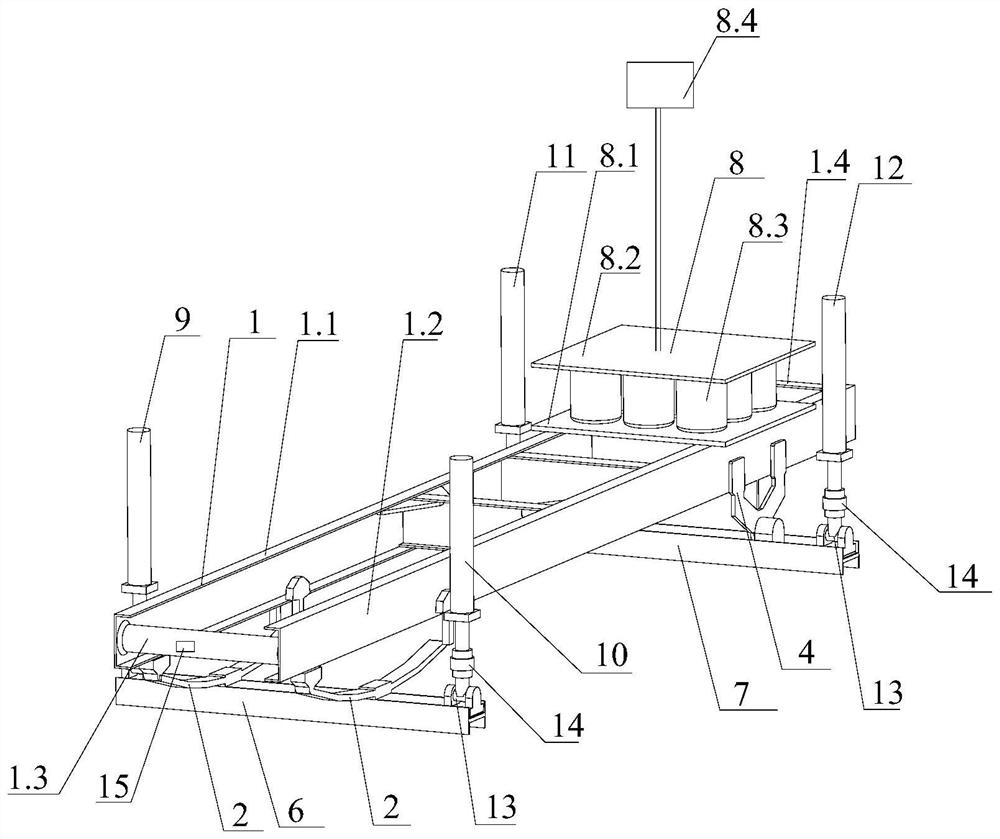

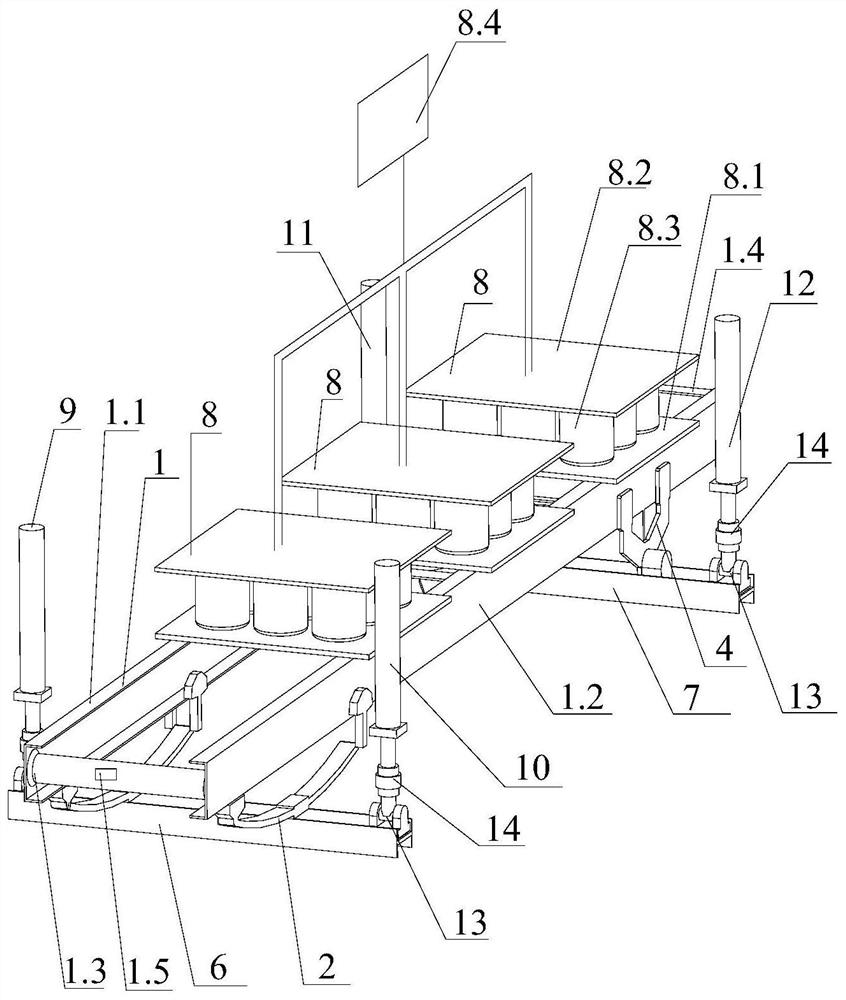

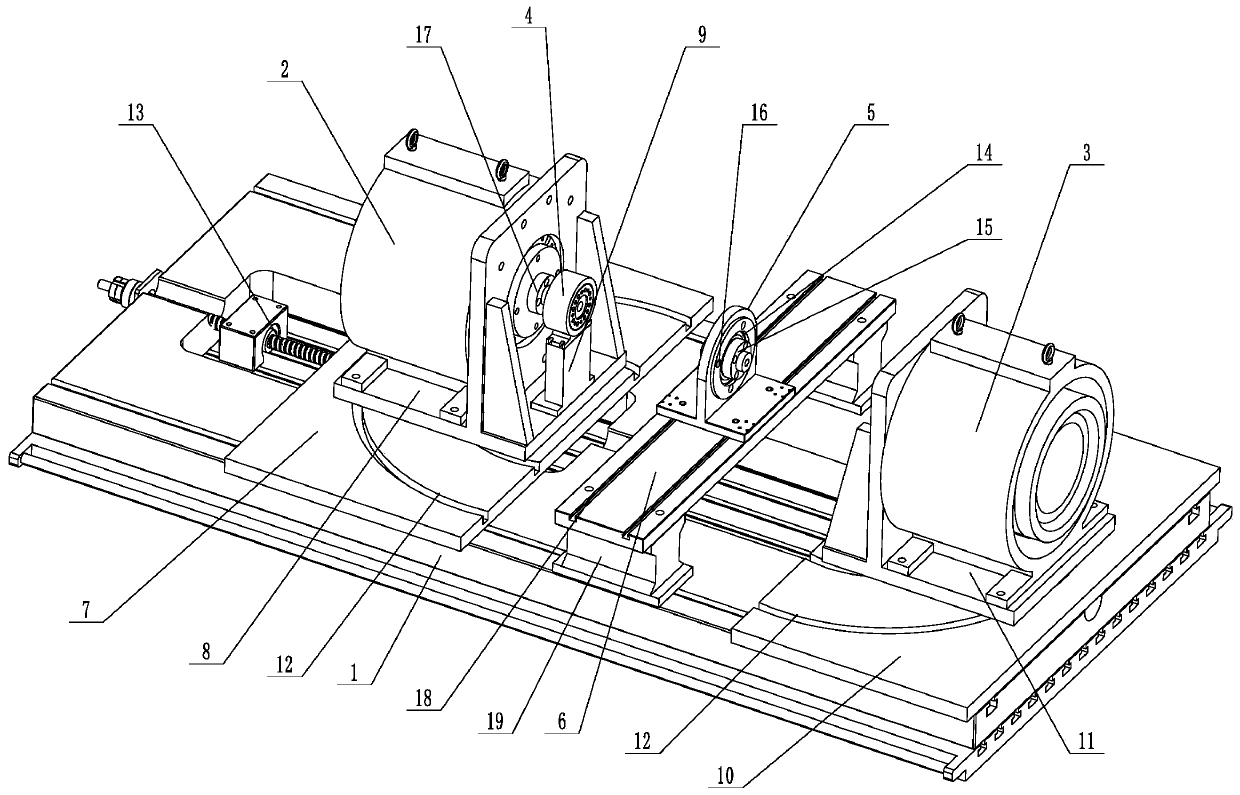

Device and method for multi-axis fretting fatigue test of steel wire

ActiveCN104297046AImprove multi-axis fretting fatigue damage characteristicsAdjust relative position in real timeMaterial strength using tensile/compressive forcesFatigue damageSupporting system

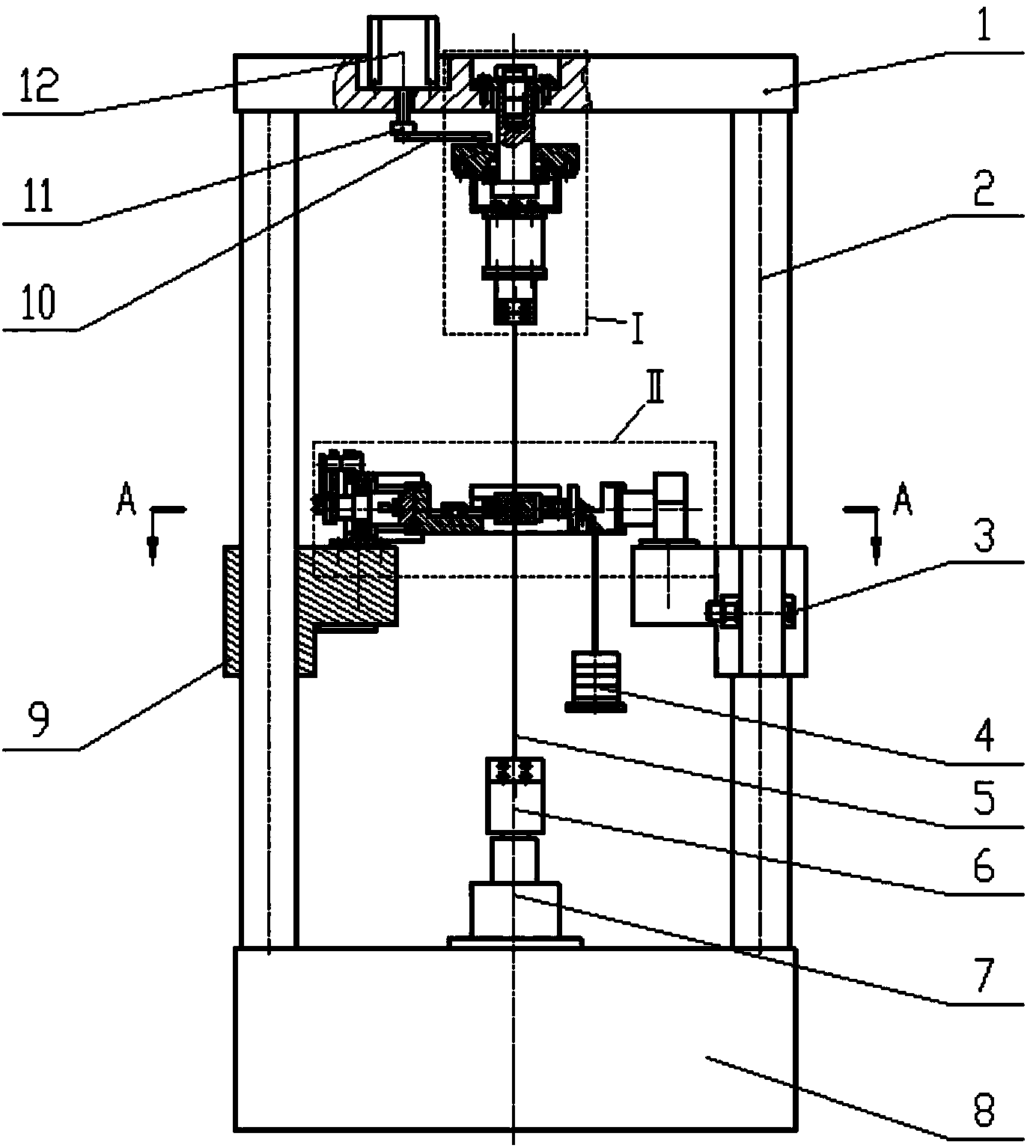

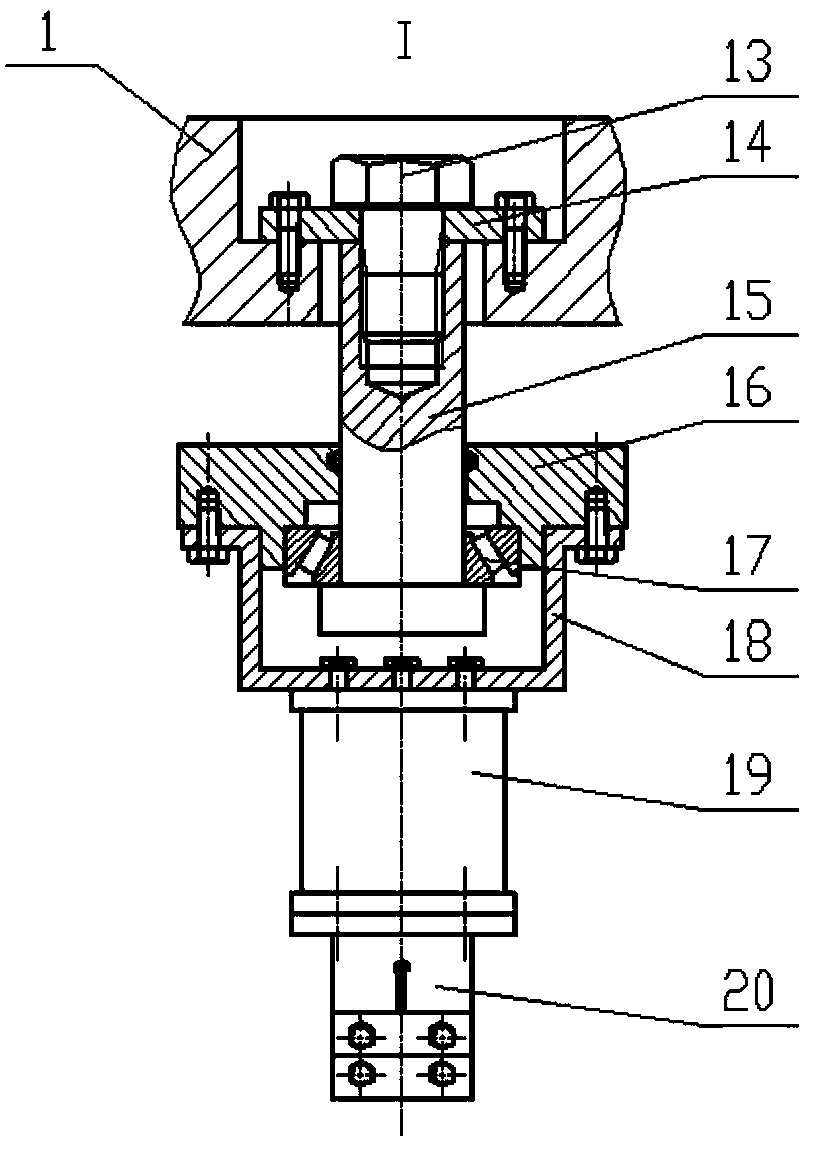

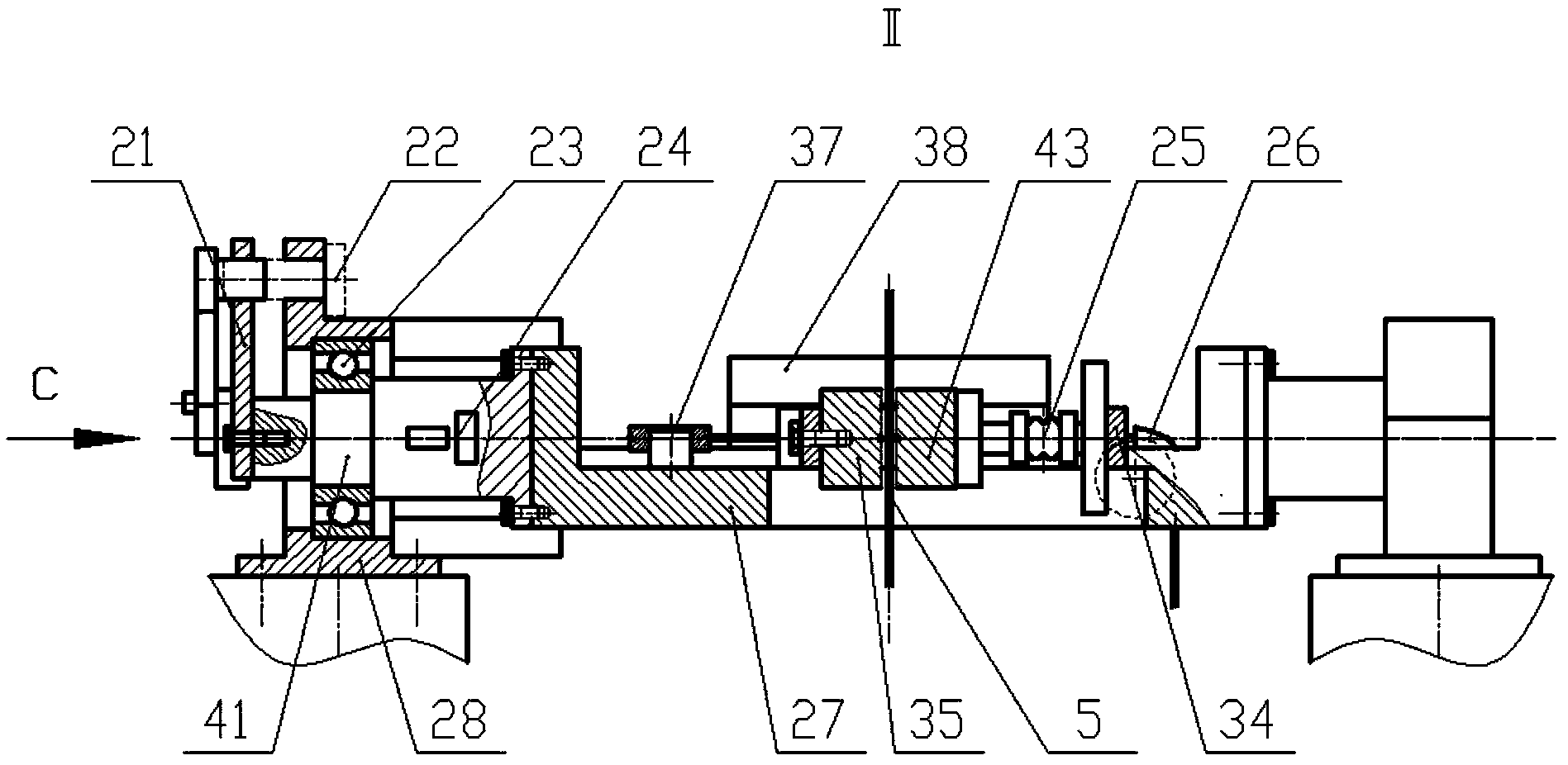

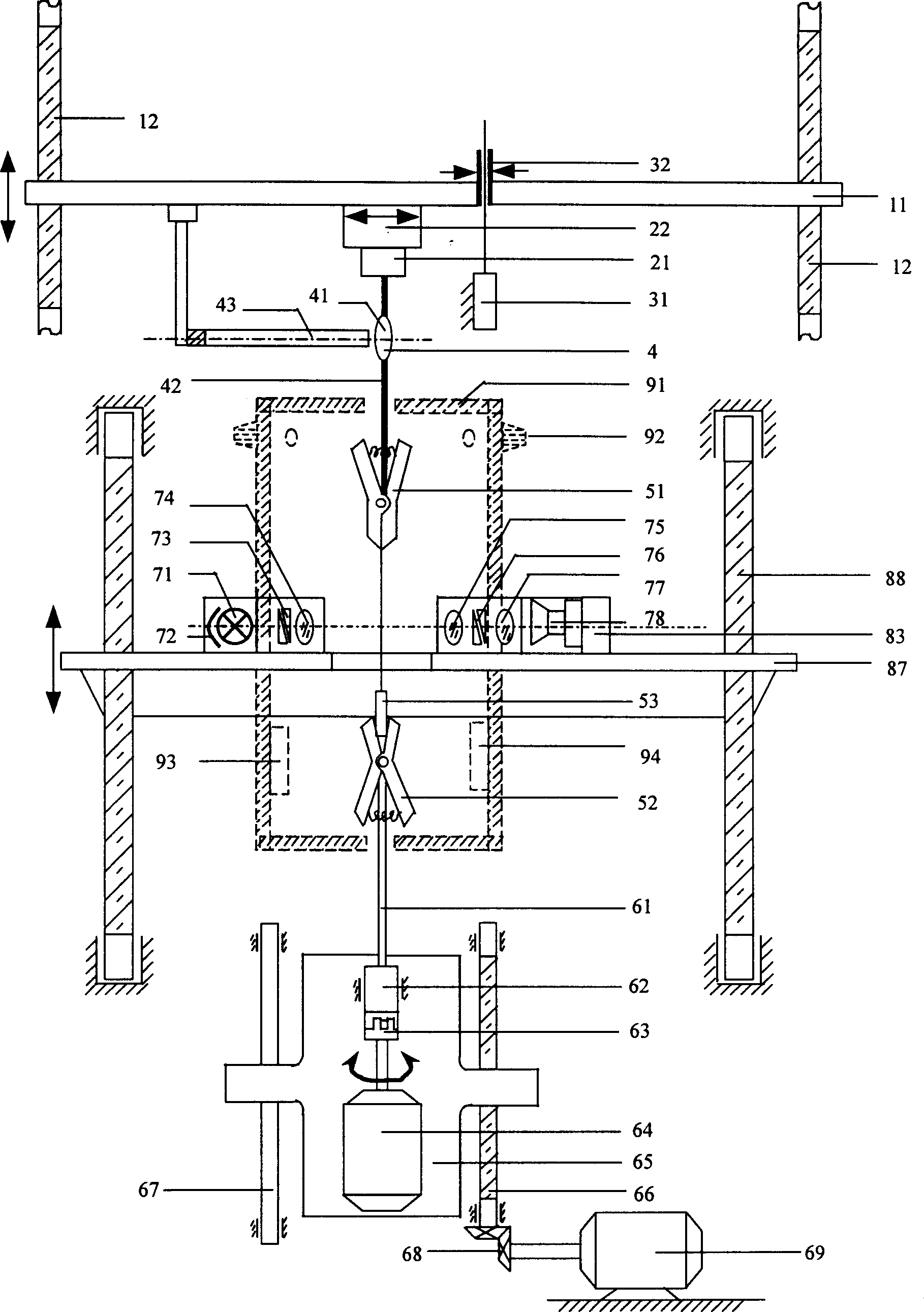

The invention relates to a device and a method for a multi-axis fretting fatigue test of a steel wire. The device comprises a base frame, a pull-torsion fatigue system, a swing loading system and a condition monitoring system, wherein the base frame comprises a base, support stand columns, bearing beams and support fixture blocks, the support stand columns are symmetrically arranged on the base; the bearing beams are respectively arranged on the tops of the support stand columns; the support fixture blocks are respectively arranged in the middle parts of the support stand columns; the pull-torsion fatigue system comprises a support system, a torsion driving system and a pull-pull fatigue system; the swing loading system comprises a swing driving system and a loading system; the condition monitoring system comprises a fretting measurement system, an axial fatigue load measurement system, a torsion measurement system and a swing measurement system. The torsion angle of the fatigue steel wire can be obtained through a crank-link mechanism by adjusting the eccentric position of an eccentric block; the multi-axis fretting fatigue test of the steel wire can be realized in the composite motion modes such as pull-pull fatigue, torsion and variable crossing angle swing and the like; the device and the method are used for disclosing the multi-axis fretting fatigue fracture mechanism of the steel wire, and carrying out quantitative evaluation on multi-axis fretting fatigue damage evolution and multi-axis fretting fatigue life of the steel wire.

Owner:CHINA UNIV OF MINING & TECH

Measuring method and device for twisting property of flexible material

InactiveCN1587969AEffective torsional performance measurementAccurate torsional performance measurementMaterial analysis by optical meansStrength propertiesSelf excitedEngineering

The invention is a torsion property measuring method and apparatus for flexible material. The method is that upper end of simple holds to measure torsion moment and lower end hangs a weight to be revolved to a certain torsion moment or torsion angle then released to rotate back and reciprocate naturally, measuring autooscillation property and torsion modulus of the sample; or lower end is holded to have forced rotation or positive and negative, measuring once of the sample. The apparatus is consisted of moving beam, force, displacement sensor, torsion moment measuring mechanism, upper and lower holder, rotation mechanism, micro polarized light optical circuit and camera mechanism, moving and focusing mechanism, temperature cap, driving system and control circuit, program control and signal processing system, finishing measurement of self excited vibration, torsional fatigue and relaxation performance of flexible material with stationary load or stretch and observing degree of twist transfer of sample in and property change under different temperature, having simple but practical structure, convenient installation, many measurable parameters and accurate measurement.

Owner:DONGHUA UNIV

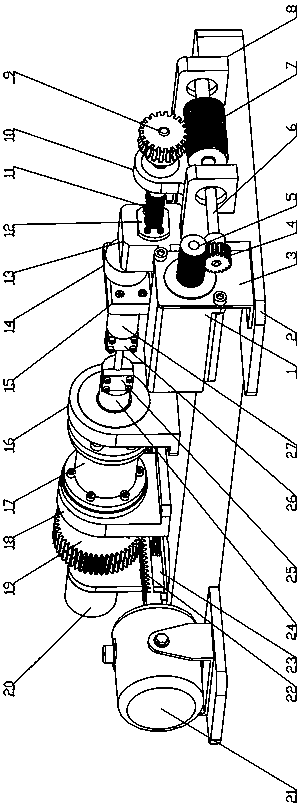

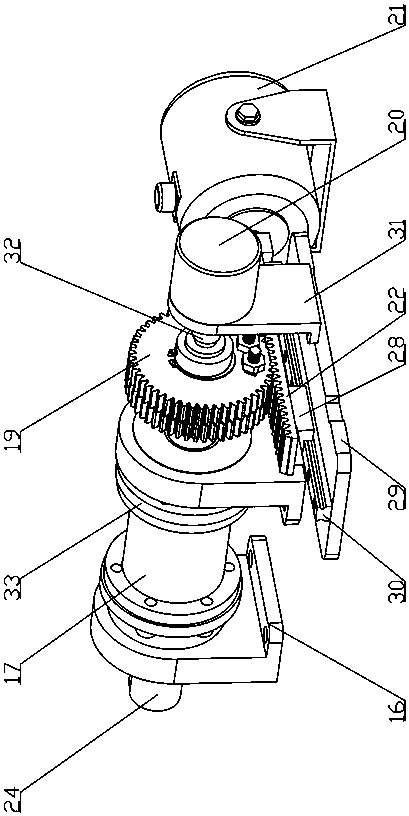

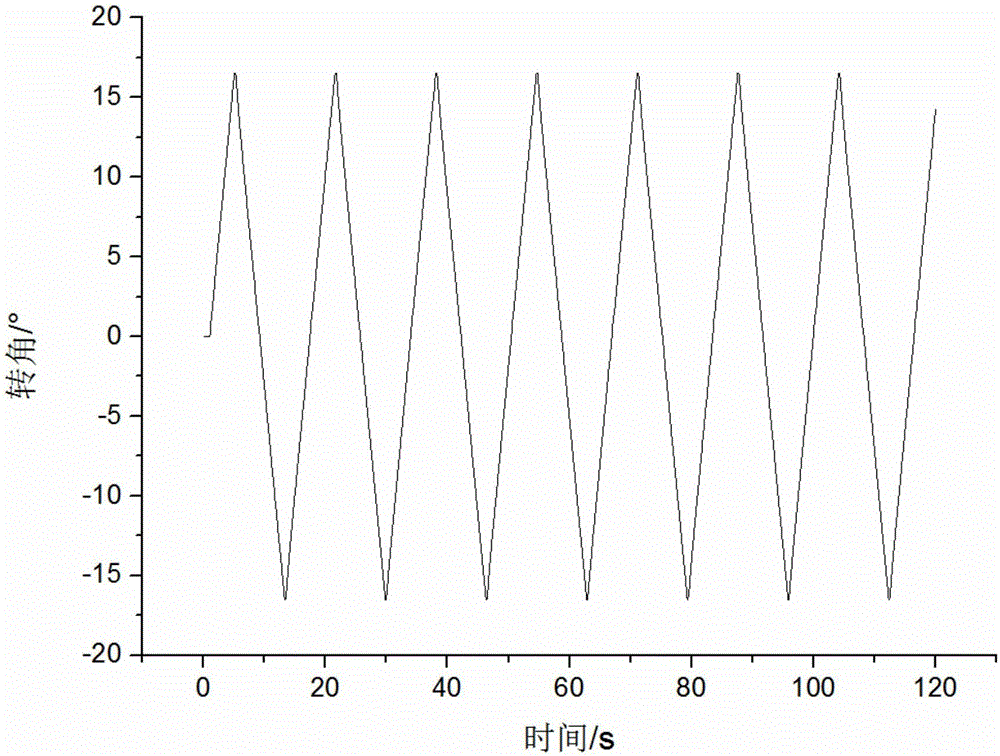

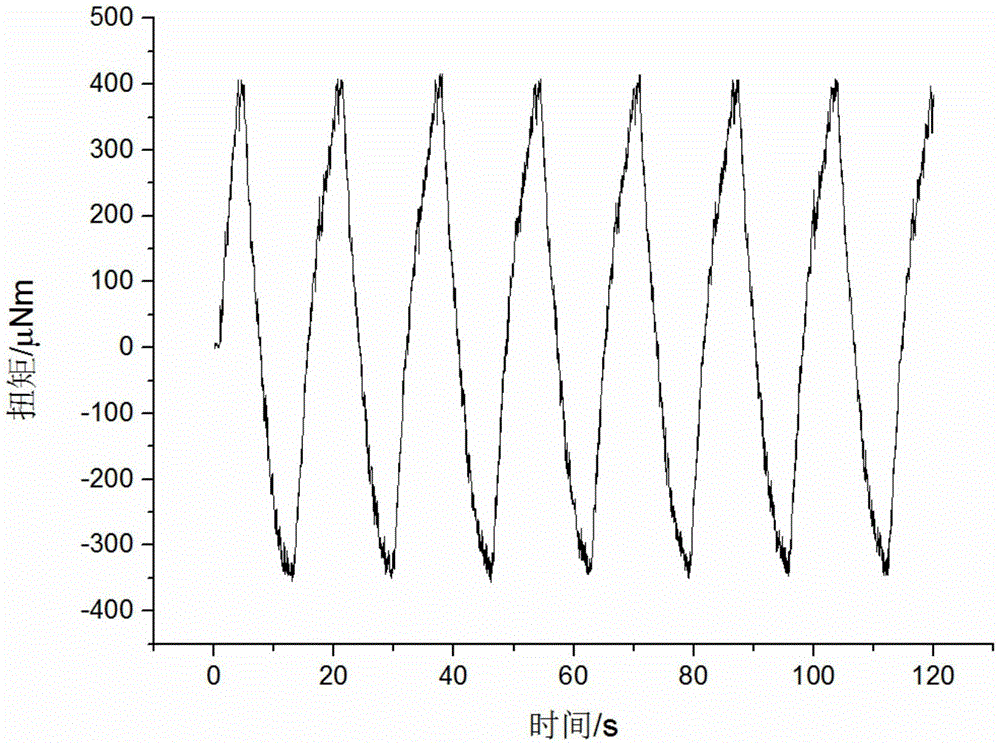

Torsion fatigue test method for spring steel wire and device

ActiveCN107436263AIncrease flexibilityImprove response speedStrength propertiesTorsion fatigueRolling-element bearing

The invention discloses a torsion fatigue test method for a spring steel wire and a device thereof. By setting of a steel wire test piece, a spring tension-compression fatigue test is equivalent to a torsion fatigue test of the spring steel wire with same parameters. According to the test method, the steel wire test piece is same in size with the steel wire for preparation of a spring product, compared with a material-based rotating bending fatigue test method, the torsion fatigue test method can meet requirements of dimensional factors in the fatigue test, correction factors can be reduced, more reliable results can be obtained, compared with a product-based tension-compression fatigue test method, the torsion fatigue test method has significant advantages in high-stress and large-amplitude test requirements. The test device can meet high frequency long period requirements in the process of the torsion fatigue test method by setting of a spring clamper for clamping and a part rolling bearing and a round head flat key, the test device is safe and reliable in the operation process of the test, a direct-drive servo drive system is used as a transmission mode, and safety and stability of long-period work of the test device can be enhanced.

Owner:中机生产力促进中心有限公司

Method for increasing torsional fatigue strength in crankshafts

InactiveUS20100107808A1Improve fatigue strengthImprove torsional fatigue strengthCrankshaftsEngine componentsTorsion fatigueUltimate tensile strength

A method for processing a cast iron crankshaft to improve the torsional fatigue strength of the crankshaft includes forming oil holes into a portion of the crankshaft, treating the portion of the crankshaft to harden an annular area of the portion, and roller burnishing a length of the interior of the oil holes to an increased diameter. The roller burnished length of the oil holes extending from a surface of the crankshaft to at least beyond the hardened annular area.

Owner:CUMMINS INTPROP INC

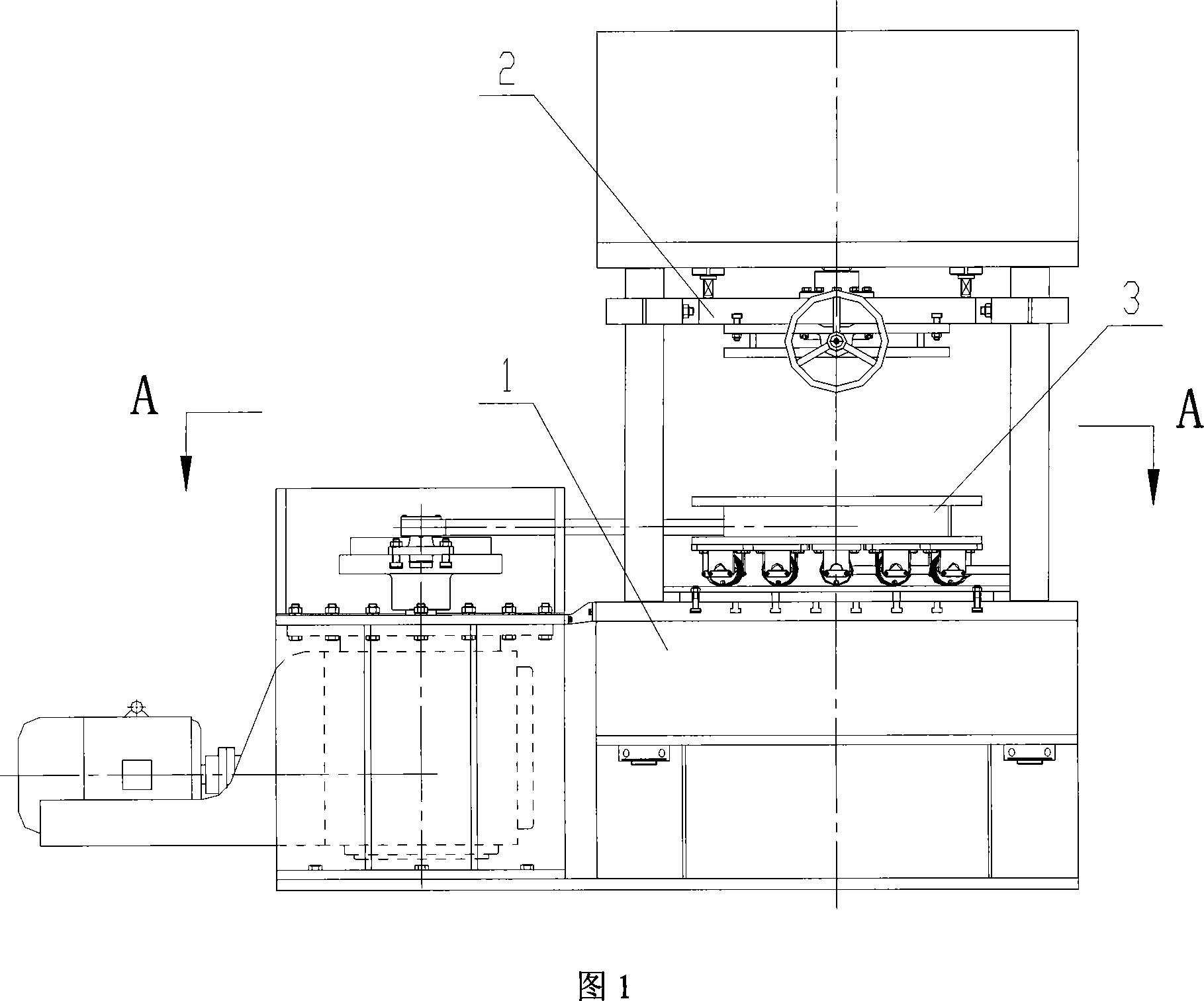

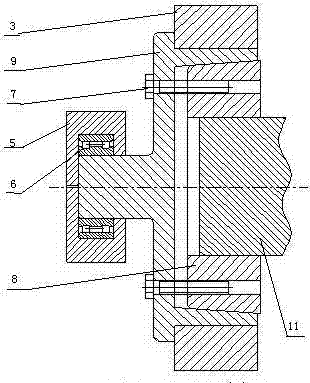

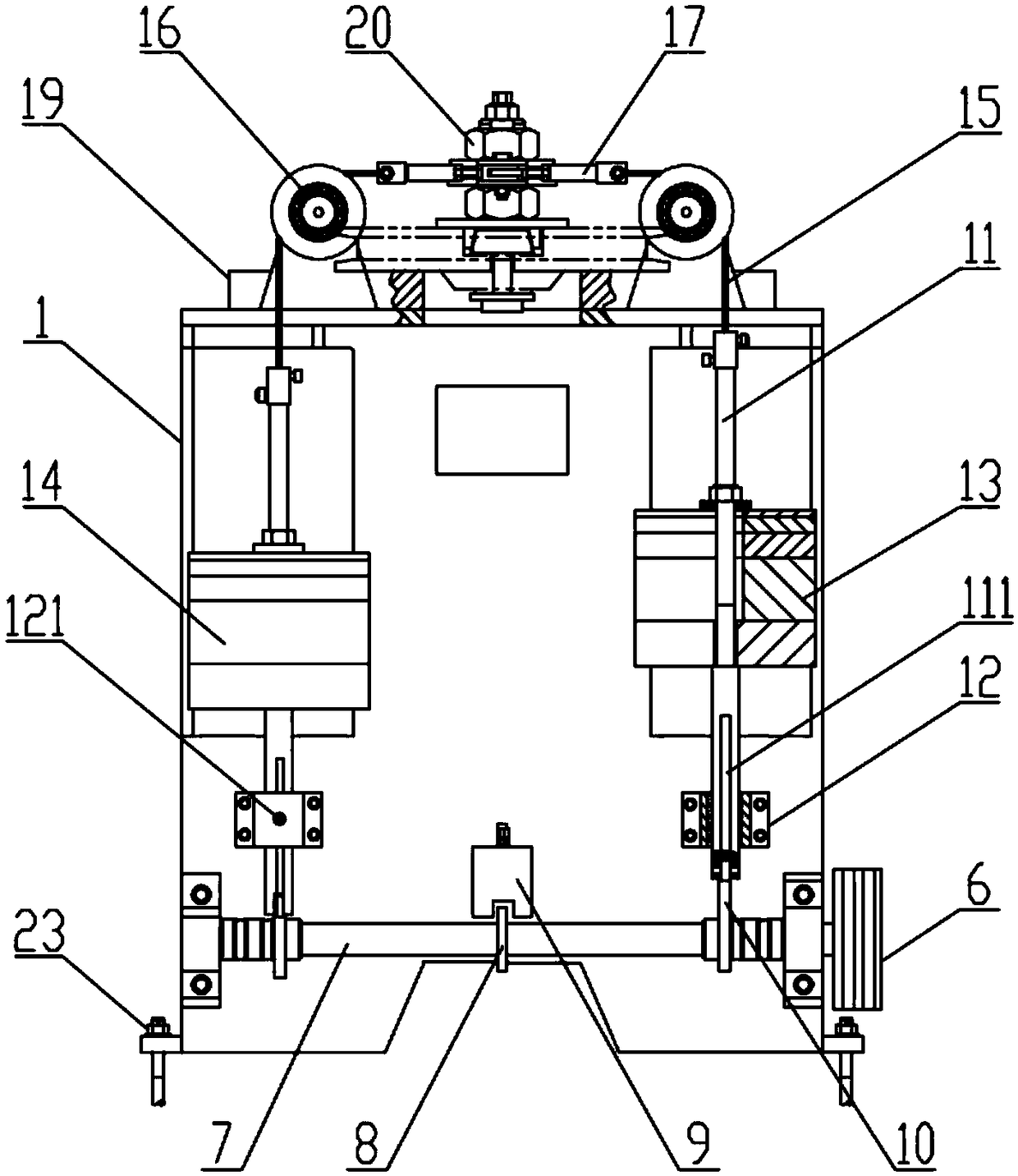

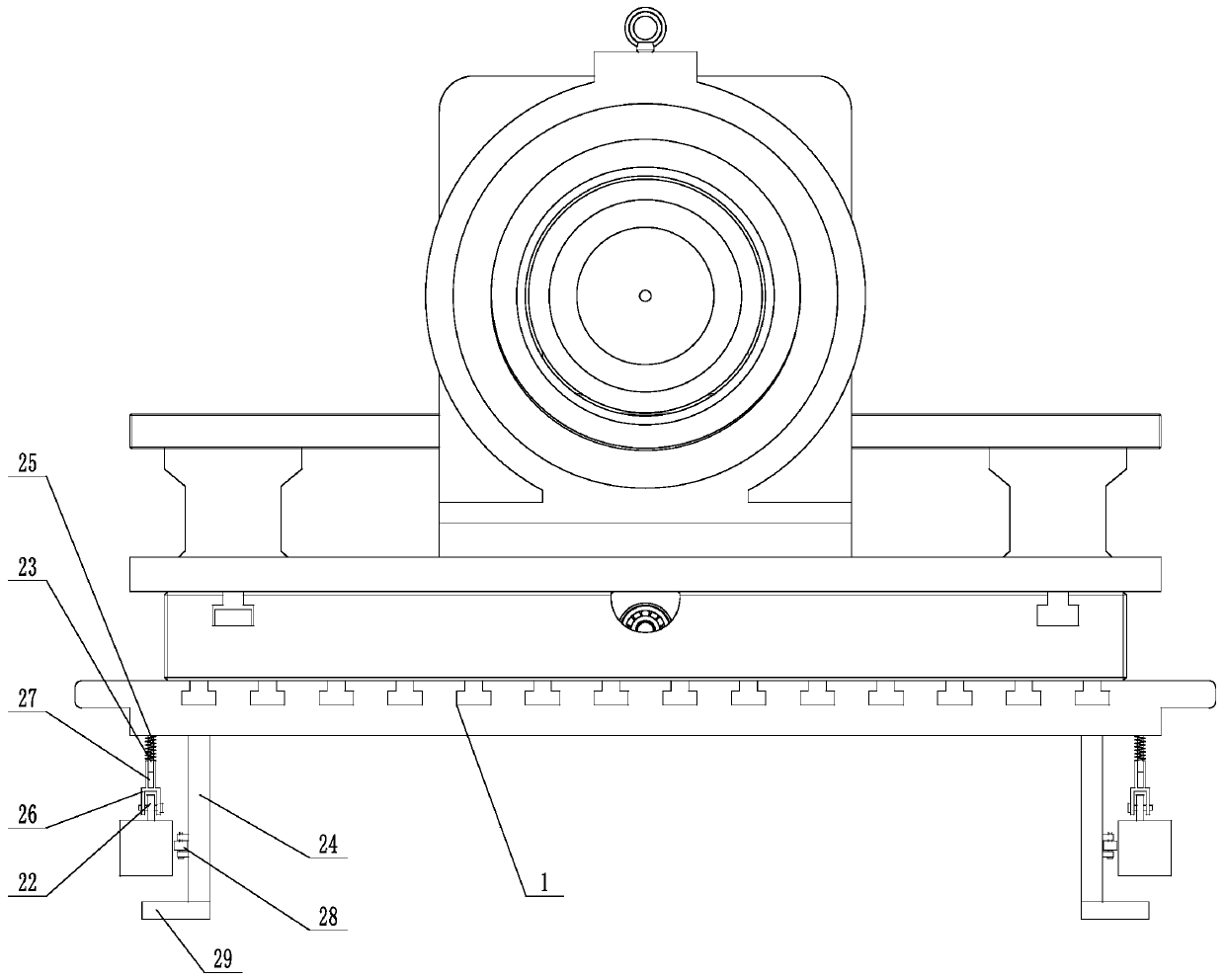

Air spring torsion fatigue test method and device for track traffic

ActiveCN101126677AGuaranteed uptimeSimple control systemMachine part testingFrequency changerTorsion fatigue

The utility model relates to a method and device for the torsion fatigue test for air springs or similar products, which is used in the rail traffic by simulating the actual working state of the air springs through vertical, horizontal and torsion multidimensional load systems. The torsion fatigue tester comprises a frame, a worktable, and an electrical control cabinet; wherein, the frame is in the structure of framed with four columns; an adjustable shelf is arranged at the upper part of the frame; a wobbler mechanism is positioned on the lateral face of the worktable of the frame; the wobbler mechanism can designed into a crank and rocker mechanism, which can drive the worktable into circular arc rotation with the length of the swing arm as the radius; the air spring for testing is positioned between the worktable and the adjustable shelf; a trapezoid screw is arranged on the adjustable shelf for vertically regulating the position of the adjustable shelf; a horizontal adjusting screw is also positioned on the adjustable shelf. The lateral shift is regulated by the horizontal adjusting screw on the adjustable shelf; the swinging radius is adjusted by the length of the swinging arm, and the vibration frequency is regulated by a frequency converter.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

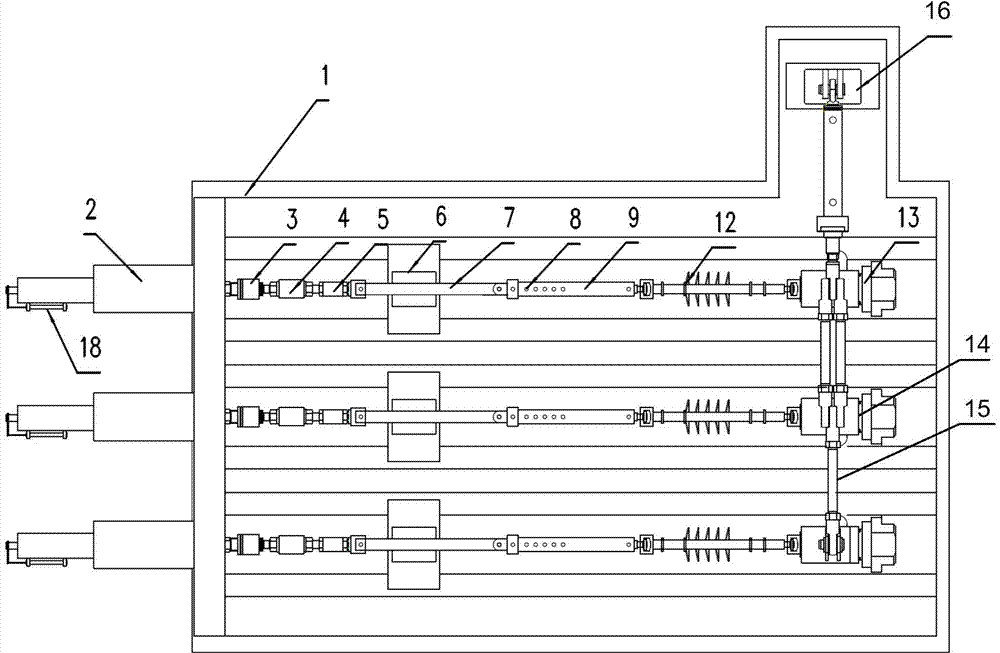

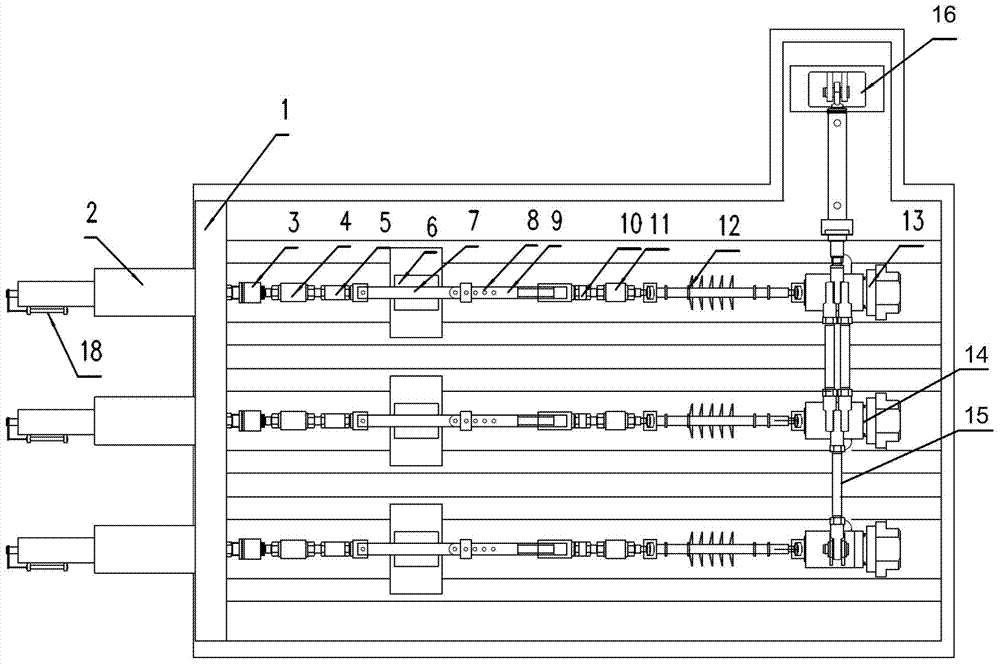

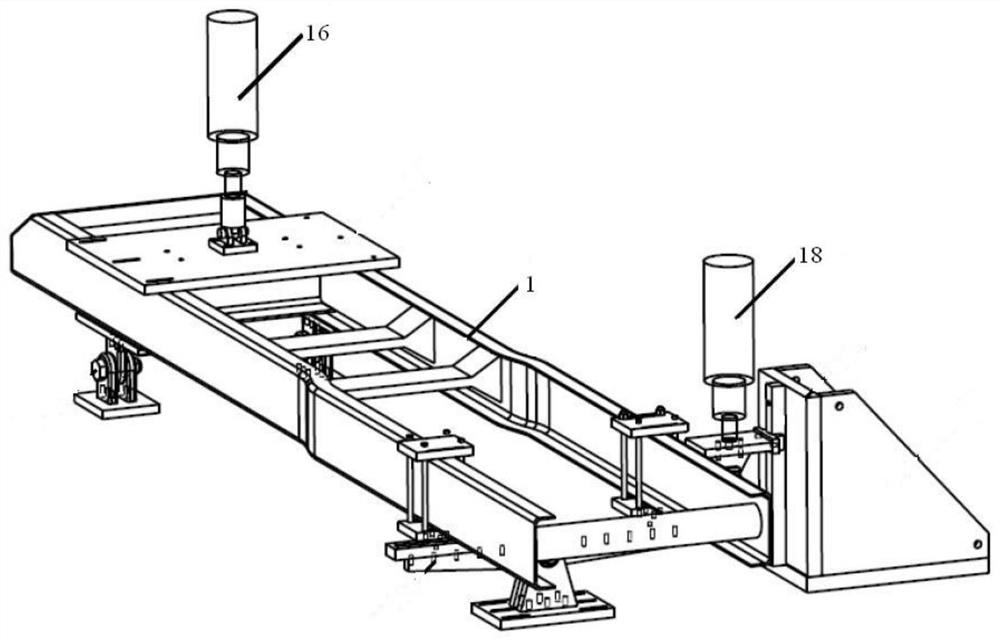

Dynamic torsional fatigue mechanical property test device in tensile preload

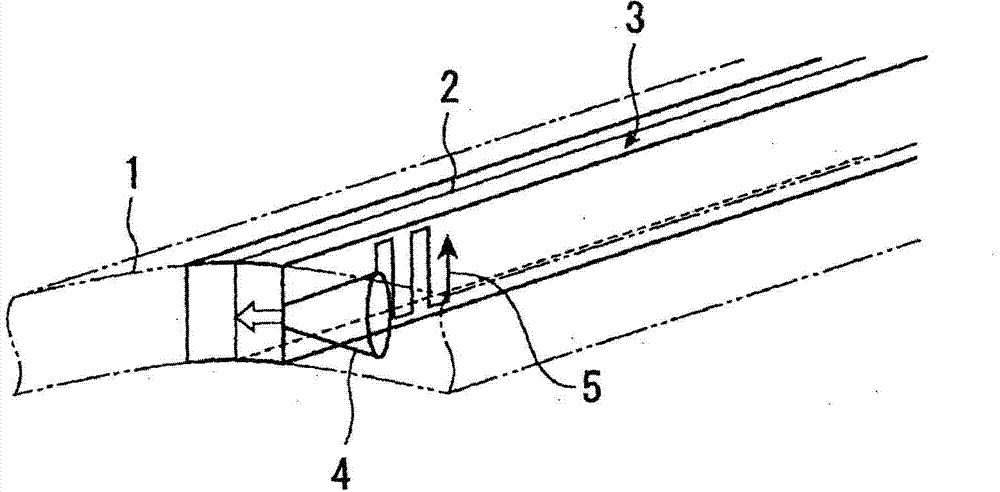

PendingCN107703006AImprove test accuracySimple structureMaterial strength using tensile/compressive forcesTorsion fatigueCoupling

The invention relates to a dynamic torsional fatigue mechanical property test device in a tensile preload, and belongs to the technical field of a precise instrument. The test device is in horizontalarrangement and comprises a tensile unit, a torsional fatigue unit, a force signal and displacement signal detecting unit and a test piece clamping unit, wherein the tensile unit and the torsional fatigue unit are respectively arranged at two sides of test pieces, and are positioned on the same axial line as the test pieces; the tensile unit, the torsional fatigue unit, the force signal and displacement signal detecting unit and the test piece clamping unit are all arranged on a bottom plate; a magnetic field and a heat field are loaded between the tensile unit and the torsional fatigue unit for realizing the force thermomagnetic coupling loading. The dynamic torsional fatigue mechanical property test device has the advantages that the test precision is relatively high; the structure is relatively simple; the realization is easy; the torsional fatigue compound loading under the tensile and torsional fatigue and the tensile preload can be realized; the thermomagnetic coupling loading ofthe force can be realized; the microstructure change such as crack extension during the torsional fatigue bearing of a material can be observed in real time.

Owner:JILIN UNIV

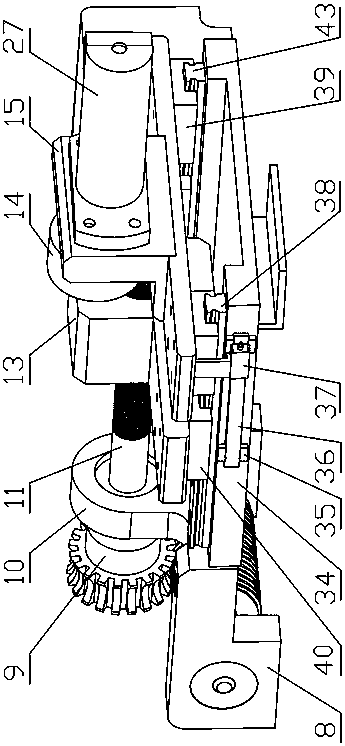

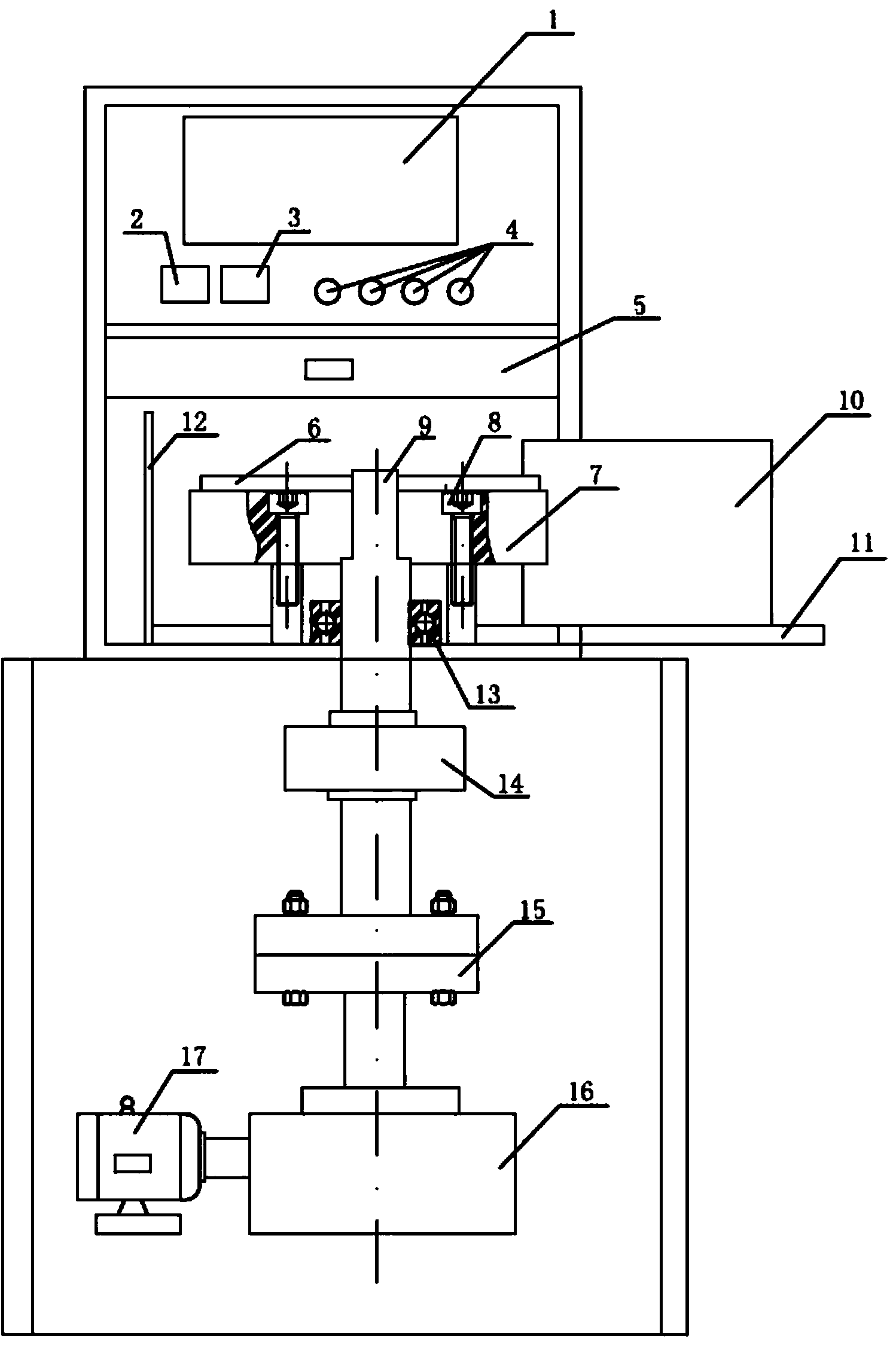

Tension-compression and torsion vibration fatigue test device

ActiveCN103616303AShorten test timeImprove test efficiencyMaterial strength using repeated/pulsating forcesTorsion fatigueTorsion test

The invention discloses a tension-compression and torsion vibration fatigue test device capable of simultaneously accomplishing tension-compression and torsion fatigue tests. The test device comprises a test device rack, a torsion test mechanism and a plurality of tension-compression test mechanisms. In each tension-compression test mechanism, a tension-compression actuating cylinder piston rod, a force sensor, a guide rod, an adjusting rod and a tested workpiece are sequentially connected end to end, wherein the adjusting rod is provided with a plurality of adjusting positions; according to the size of the tested workpiece, the guide rod is connected to the corresponding adjusting position of the adjusting rod; the guide rod does rectilinear movement under the limitation of a guide mechanism. In the torsion test mechanism, a rotating end of each bearing slewing mechanism is connected with the other end of the tested workpiece; oscillating rods of all the bearing slewing mechanisms are connected in series by a link mechanism, and the oscillating rod at one end is connected with the piston rod of a torsion actuating cylinder through a link mechanism. Tension-compression actuating cylinders, the bearing slewing mechanisms and the torsion actuating cylinder are all fixed on the test device rack.

Owner:北京乐冶液压气动设备技术有限公司 +1

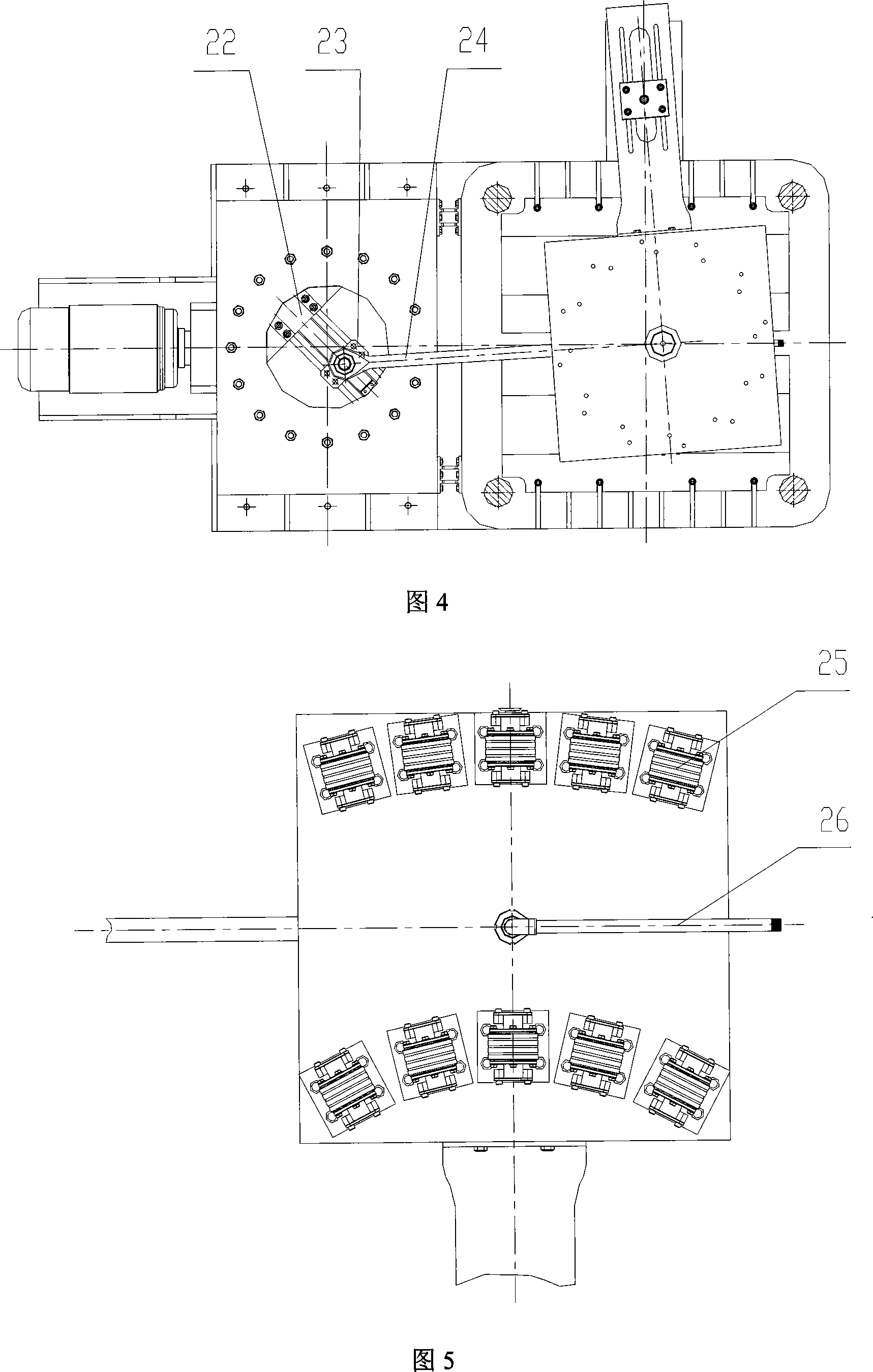

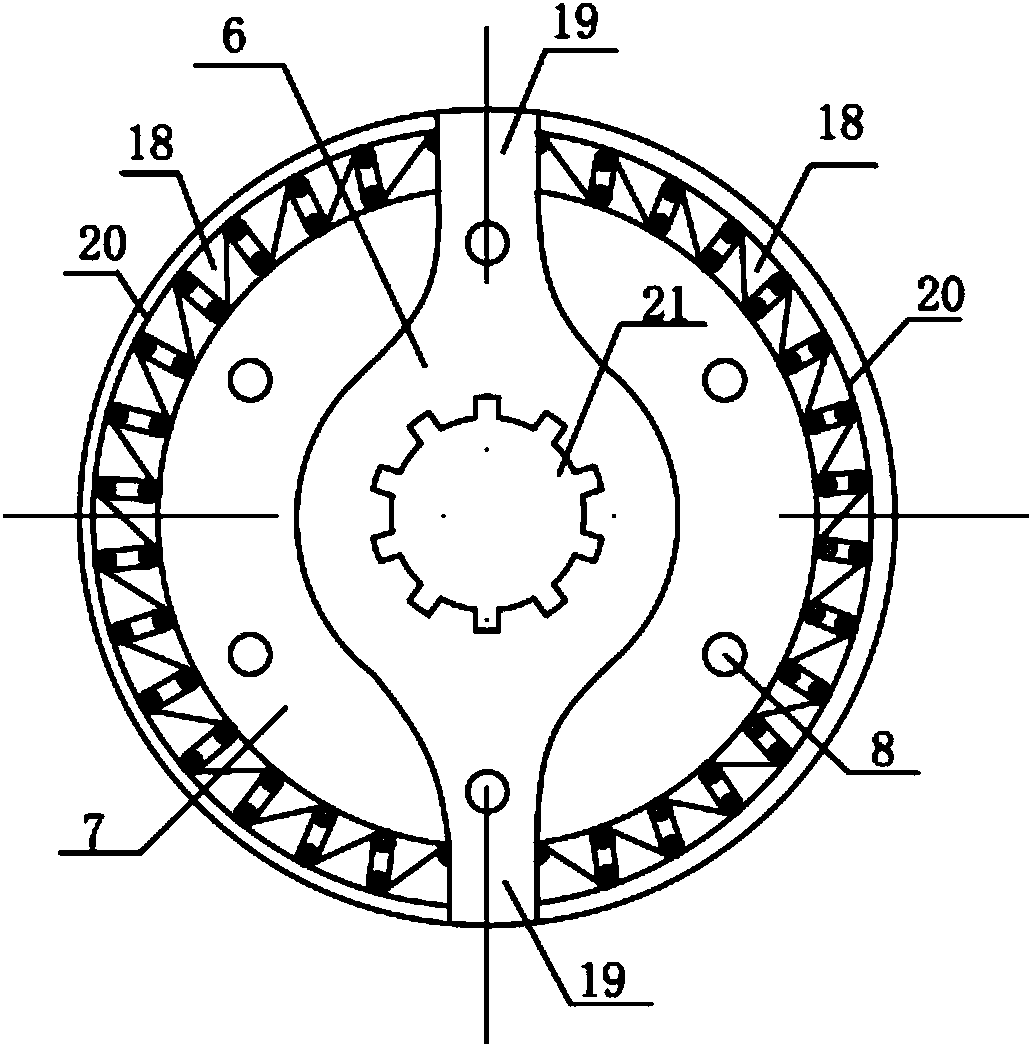

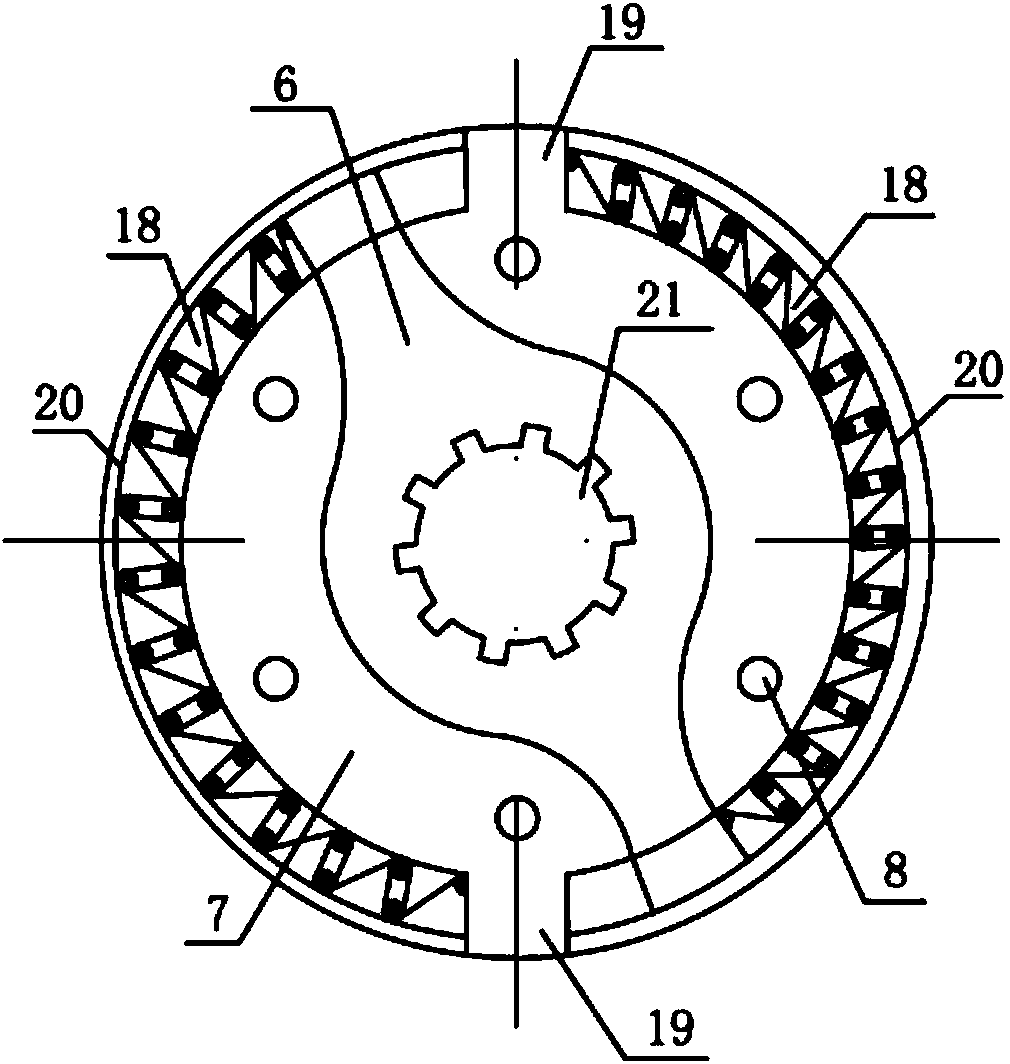

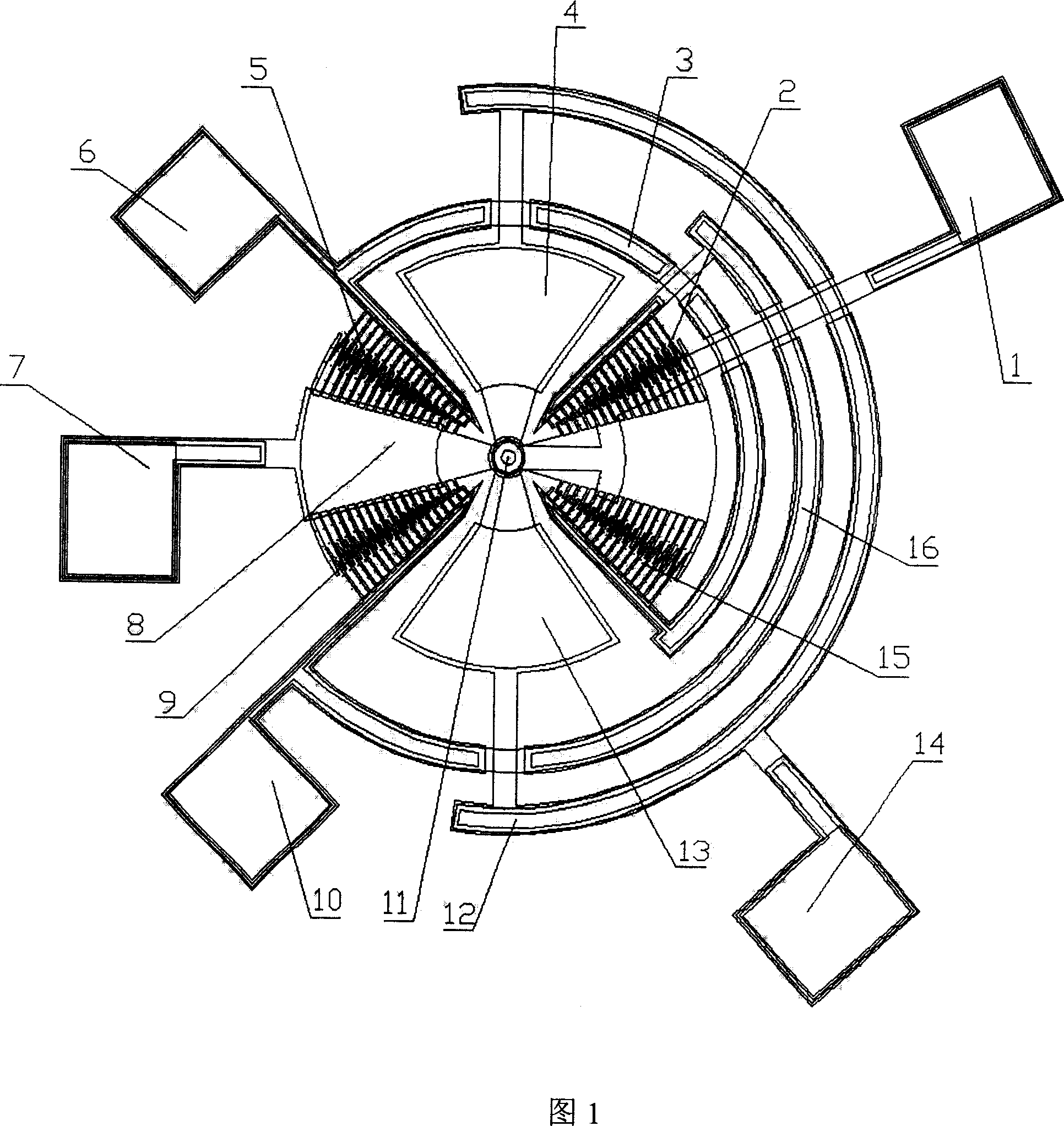

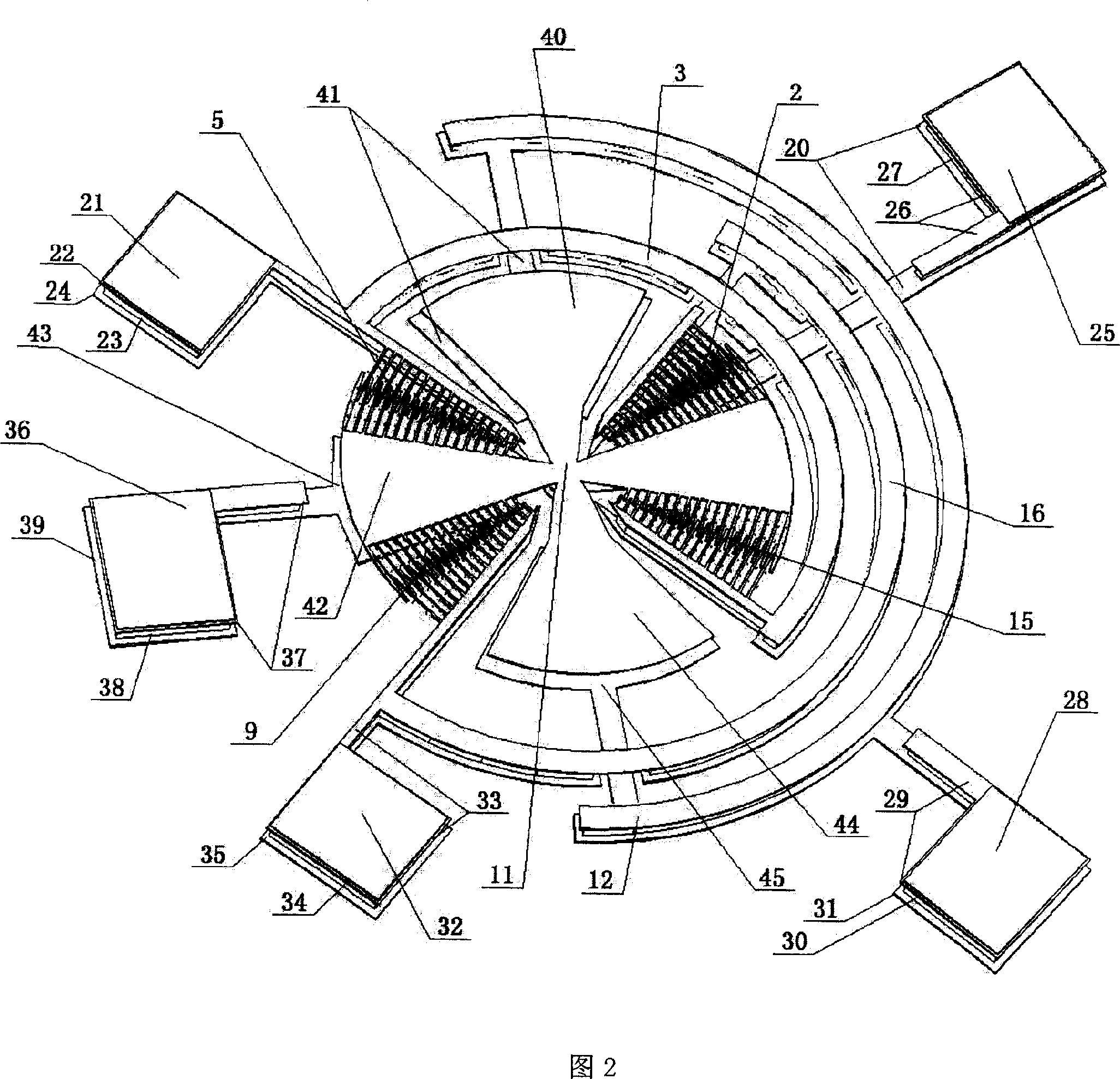

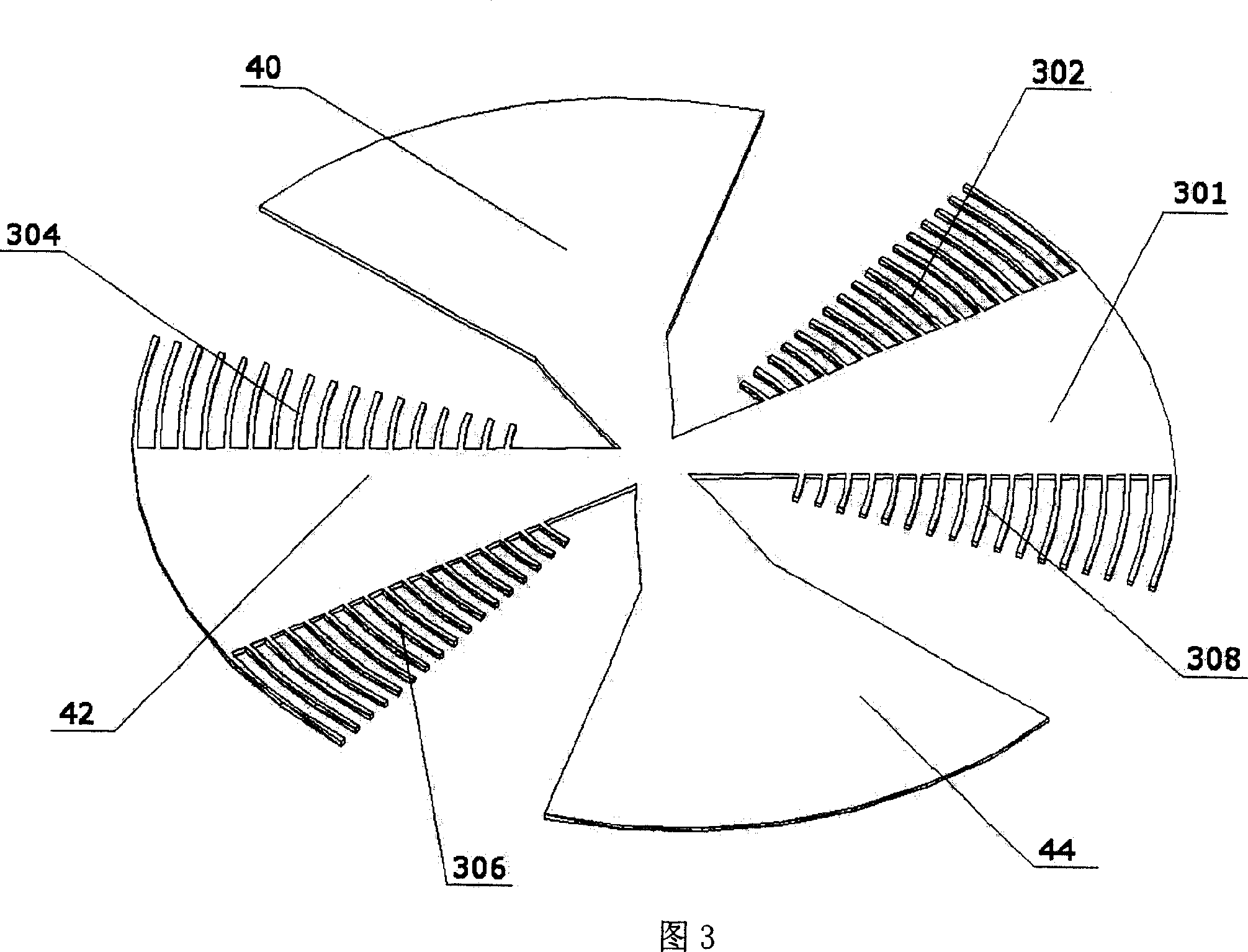

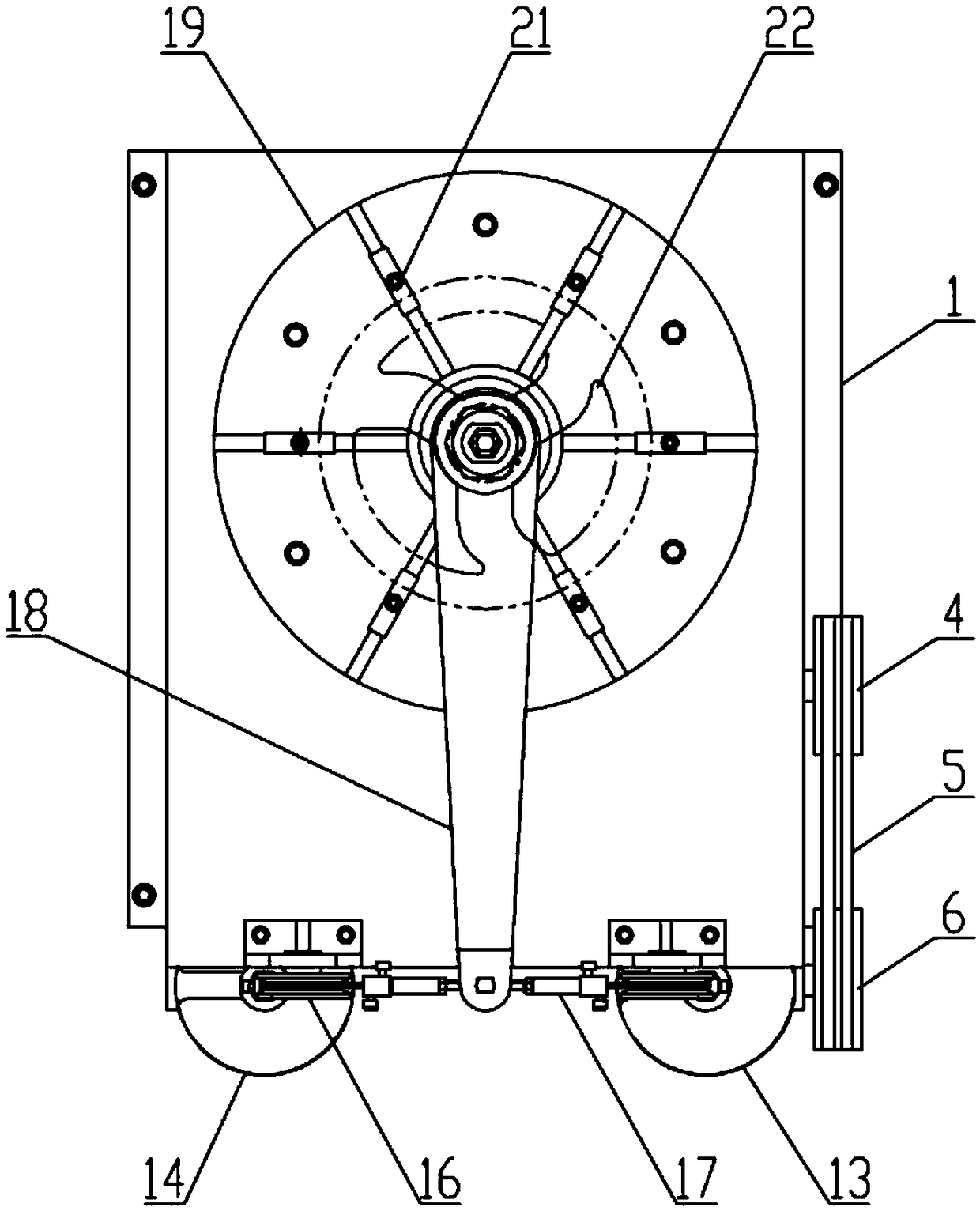

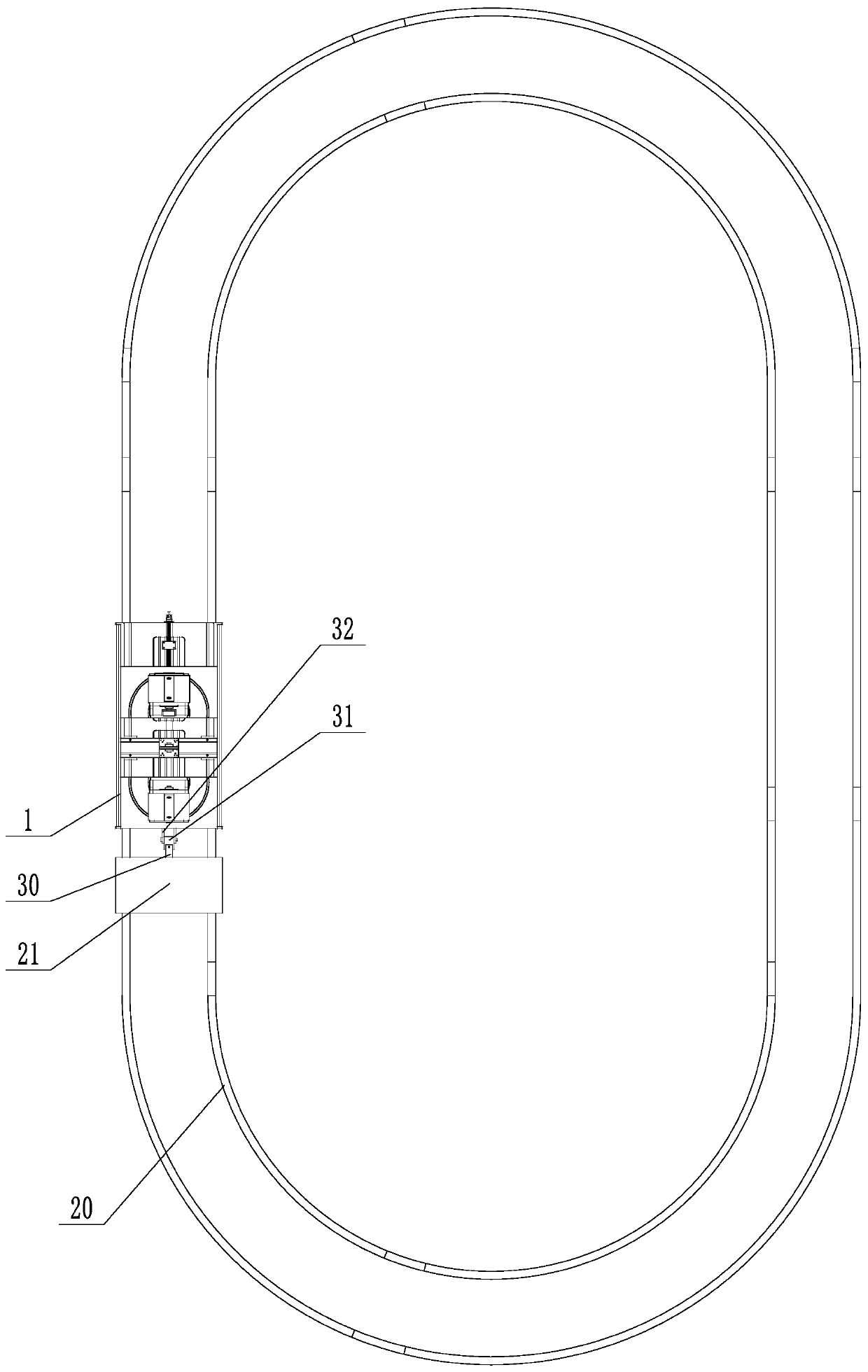

Torsion fatigue test device and method of arc-shaped springs

ActiveCN104266835AGuaranteed fatigue lifeMeet the requirements of different torsional frequenciesMachine part testingTorsion fatigueEngineering

The invention discloses a torsion fatigue test device and method of fixed-torque and fixed-angle arc-shaped springs. The torsion fatigue test device and method of the arc-shaped springs are characterized in that an arc-shaped spring detection mould is arranged, two arc-shaped slideways with opposite openings form an annular way, stop blocks are arranged at the two ends of each arc-shaped slideway, each arc-shaped spring arranged in the corresponding arc-shaped slideway is clamped between the stop blocks at the two ends in a non-compressed state, a rotary torsion disc is arranged in the center of the arc-shaped spring detection mould, a pair of torsion arms extend from the periphery of the torsion disc in the diameter direction of the torsion disc, and the lateral portions of the torsion arms are attached to the end surfaces, protruding out of the arc-shaped slideways, of the arc-shaped springs; the rotary torsion disc applies pressure on the arc-shaped springs through the ends, located at the arc-shaped springs, of the torsion arms, and the arc-shaped springs are made compressed. The torsion fatigue test device and method of the arc-shaped springs are used for realizing a fixed-torque / fixed-angle fatigue test of the arc-shaped springs.

Owner:HEFEI UNIV OF TECH +1

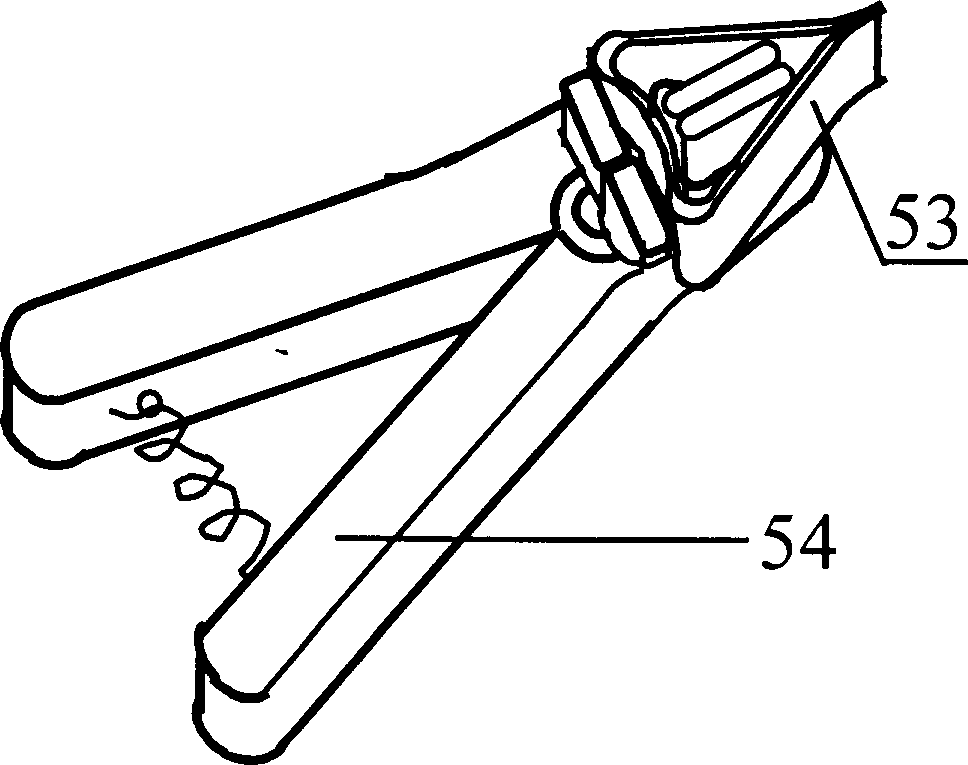

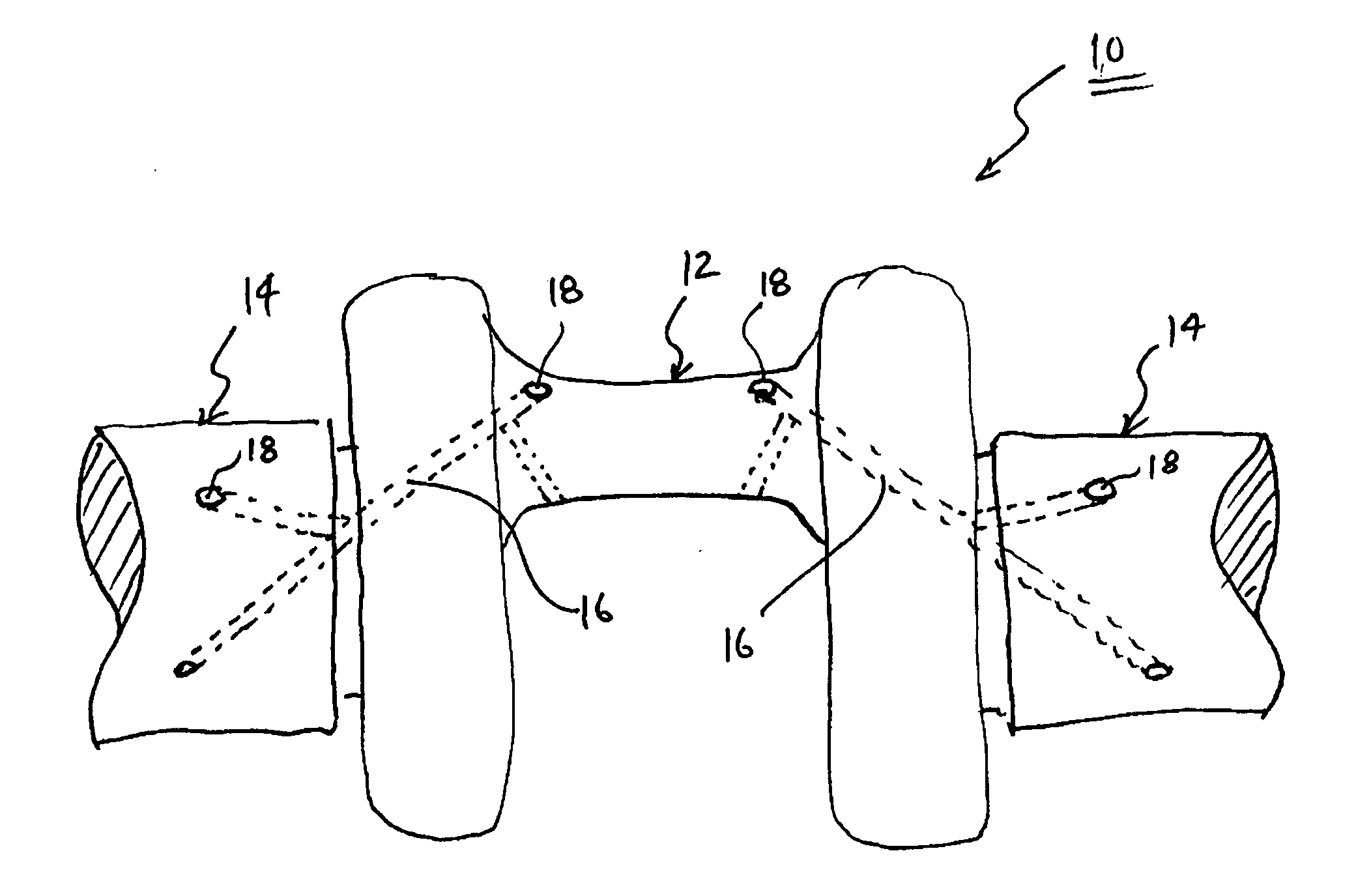

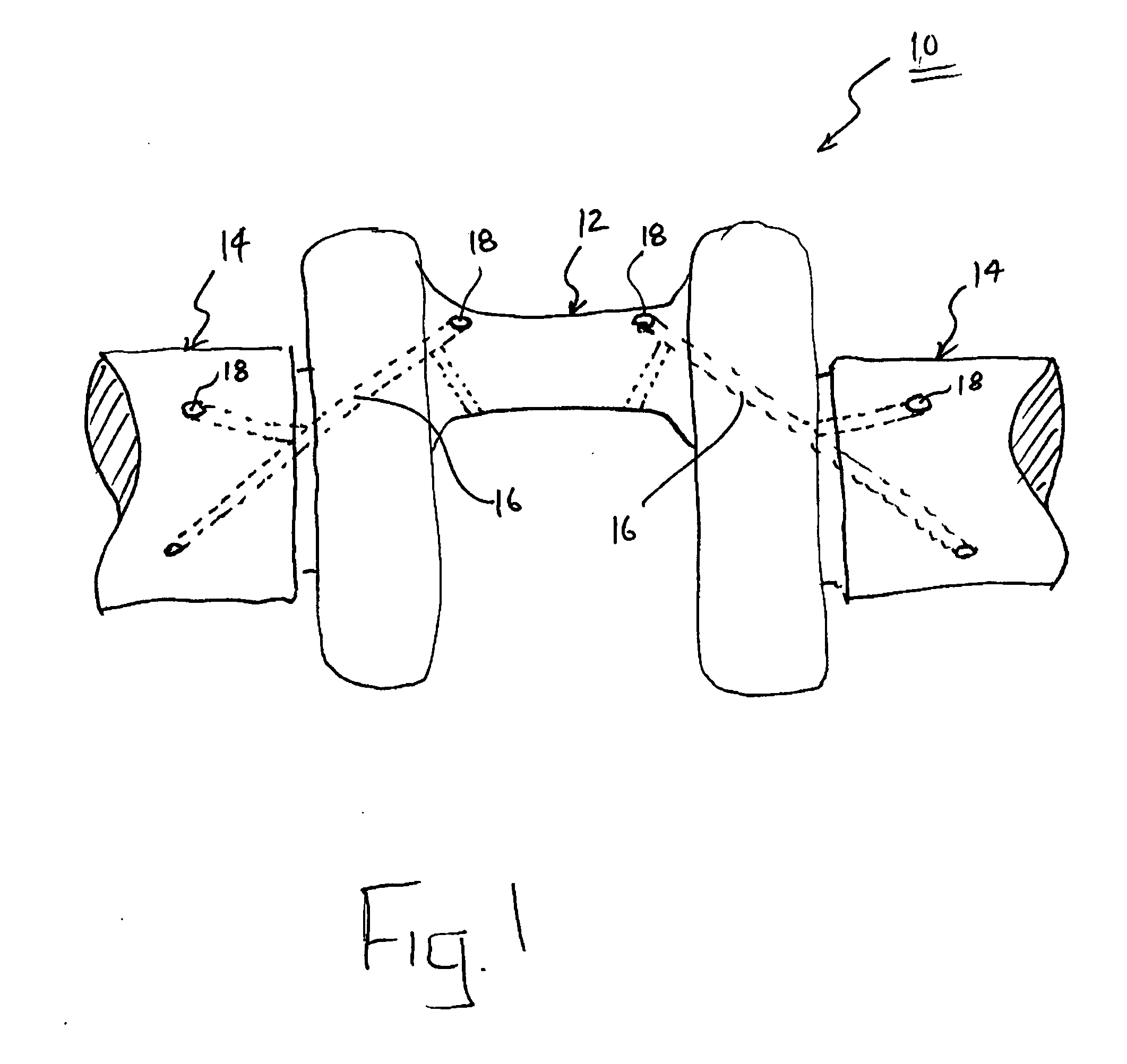

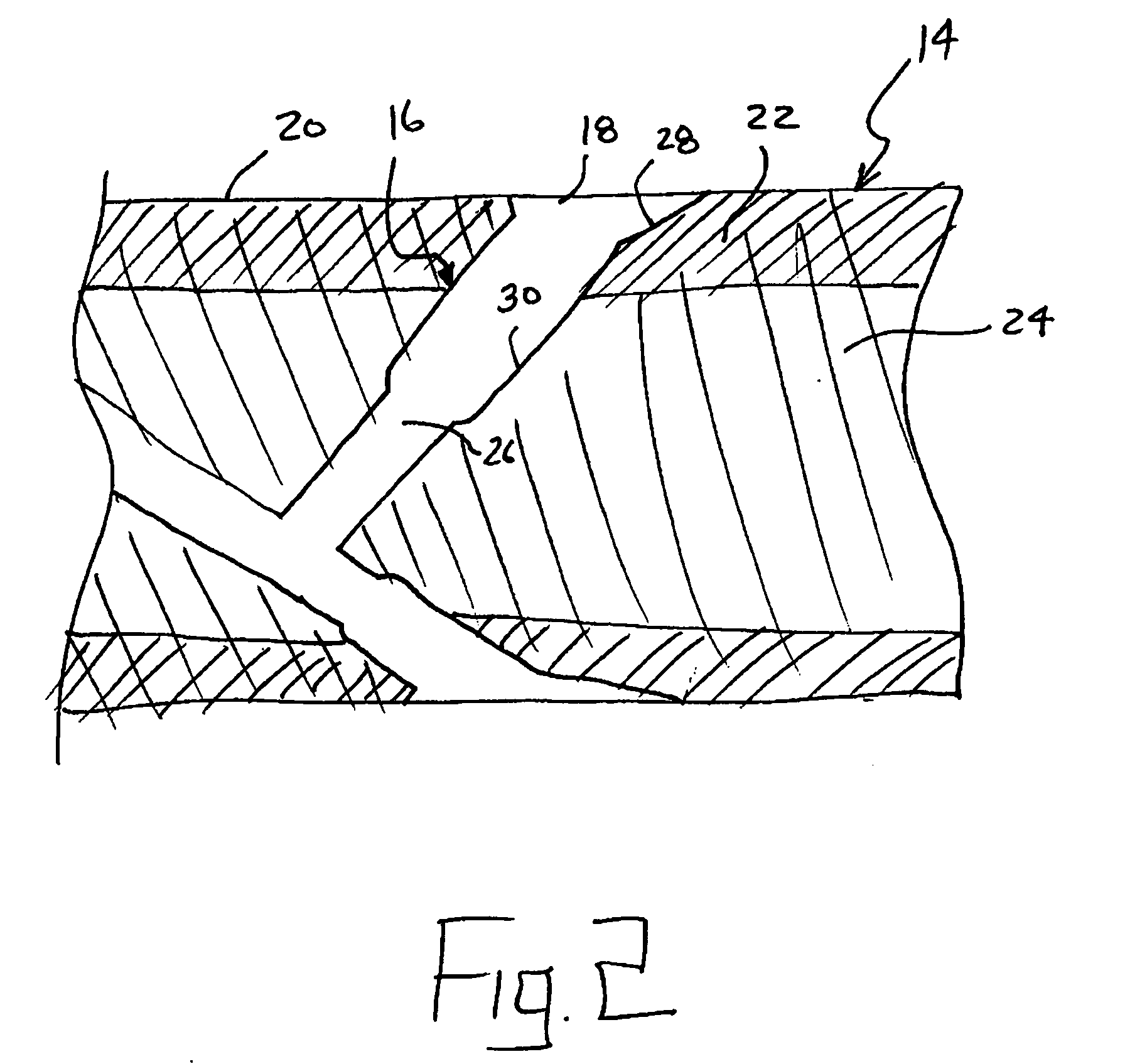

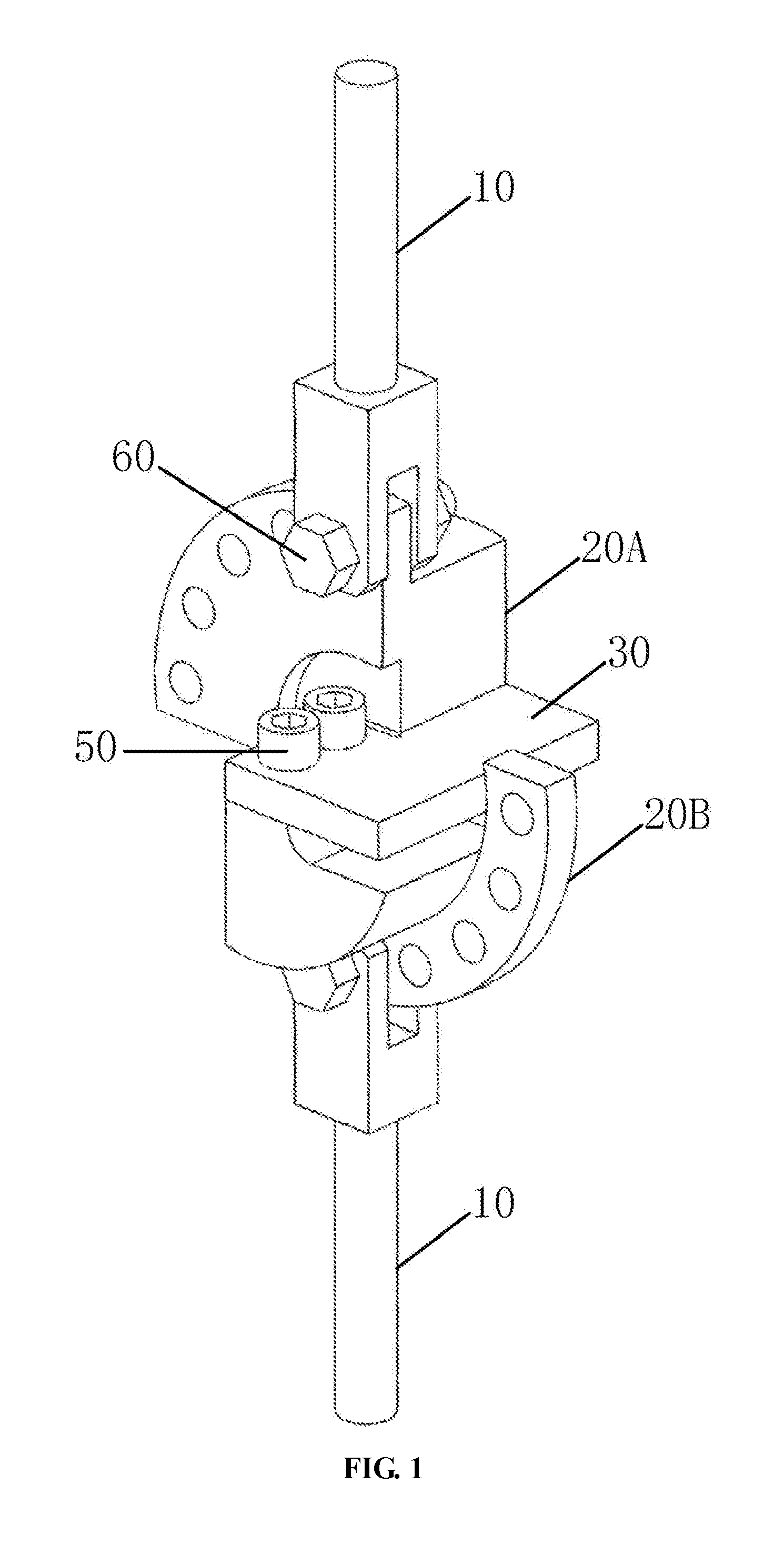

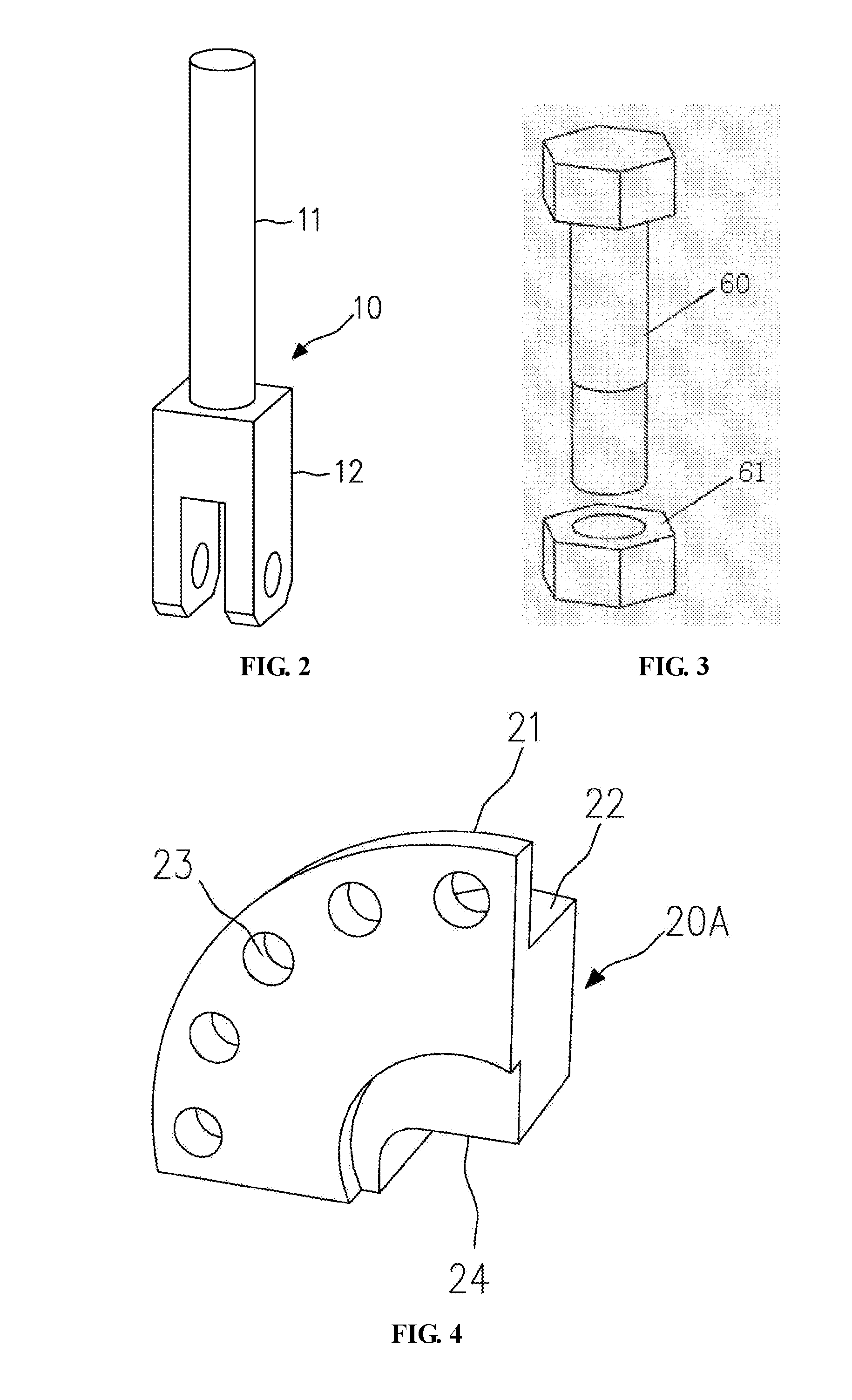

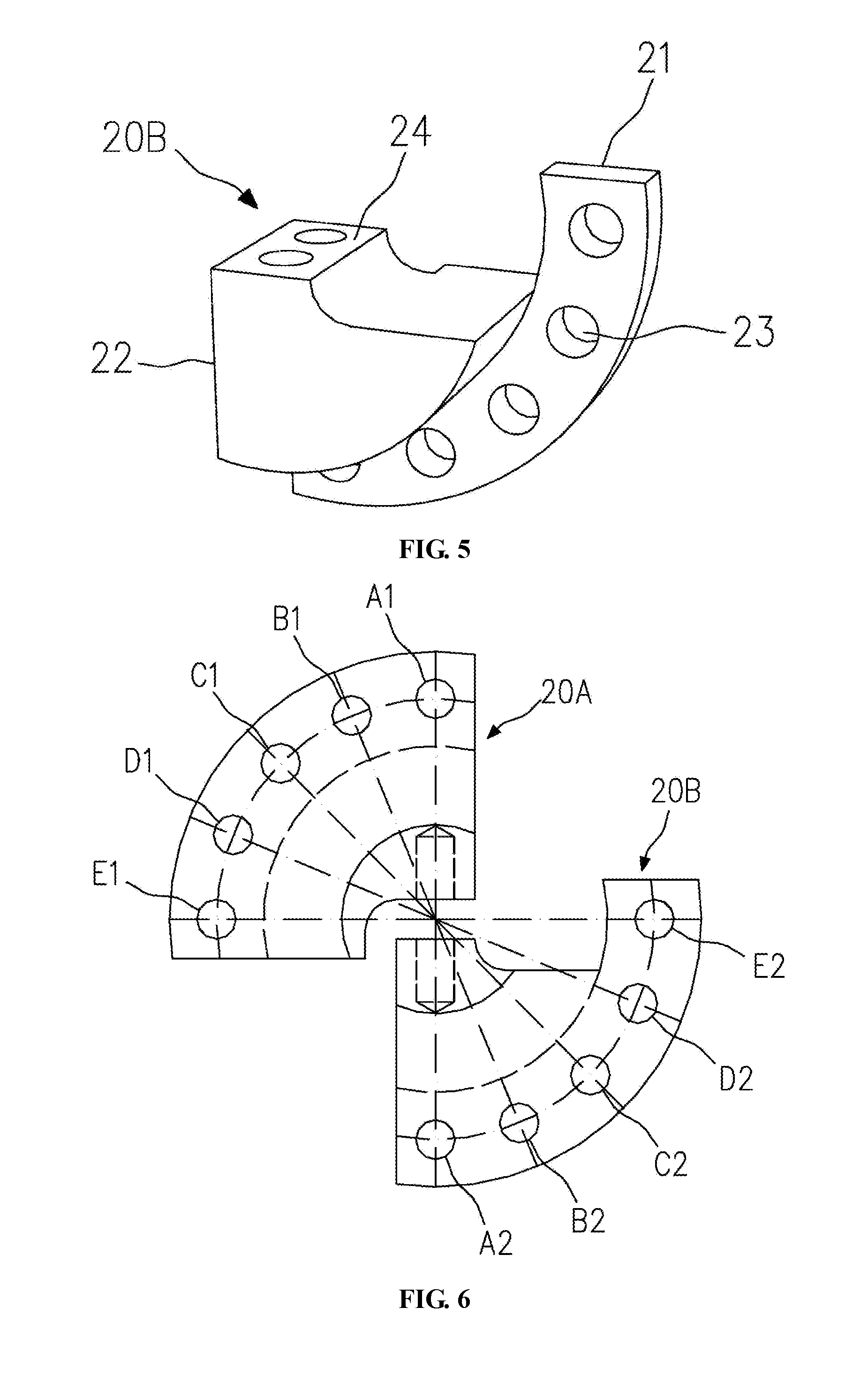

Device for testing mixed-mode fatigue crack growth rate

ActiveUS20160349161A1Efficient measurementEasy to testMaterial strength using repeated/pulsating forcesTension compressionTorsion fatigue

A device for testing mixed-mode fatigue crack growth rate comprises a plate-like specimen, and a first fixture mechanism for exerting stretch, shear and torsion actions on the specimen via a second fixture mechanism; the second fixture mechanism is used for clamping the specimen and enabling the specimen to generate a mixed-mode fatigue crack in cooperation with the first fixture mechanism; the device further comprises a fatigue crack measurement instrument for measuring and recording the length of mixed-mode fatigue crack generated on the specimen. With the help of a common tension-compression fatigue testing machine or a torsion fatigue testing machine, the device drives the first and second fixture mechanisms to exert stretch, shear and torsion actions on the specimen, thus, the requirements of those tests on mode I, mode II, mode III and mixed-mode fatigue crack growth rates can be fully satisfied, and a good foundation is laid for precisely predicting the fatigue life of critical mechanical parts and engineer components under complex working conditions.

Owner:HEFEI GENERAL MACHINERY RES INST

Torque measurement apparatus and method for miniature tension-torsion fatigue testing machine

InactiveCN105021338AHigh precision torque measurement accuracyAvoid axial overload damageMaterial strength using steady torsional forcesApparatus for force/torque/work measurementTorsion fatigueMeasurement device

The invention relates to a torque measurement apparatus and method for a miniature tension-torsion fatigue testing machine. One end of a torque sensor is connected with a bearing main shaft of an air thrust bearing coaxially by an elastic coupling and the other end is connected with a motor coaxially by an elastic coupling. The side of the torque sensor is fixed on a torque sensor fixation plate. The periphery of the air thrust bearing is fixed at a single-side flange bush type bearing fixation element; the bearing fixation element is fastened on a bearing fixation plate by a bolt; and the motor is fixed on a motor fixation plate by a bolt. The high-precision torque sensor measures a torque applied on a test sample by the motor; the air thrust bearing transmits the torque between the torque sensor and a rigid clamp and transmits a test axial load to a test machine rack by the bearing fixation element, thereby preventing the torque sensor from being damaged during axial overloading. According to the torque measurement apparatus and method, accuracy of the 1mNm-level torque measurement result can be guaranteed; and the blank of the micro-Nm-level torque measurement apparatus and method in the miniature tension-torsion fatigue testing system can be filled.

Owner:TIANJIN UNIV

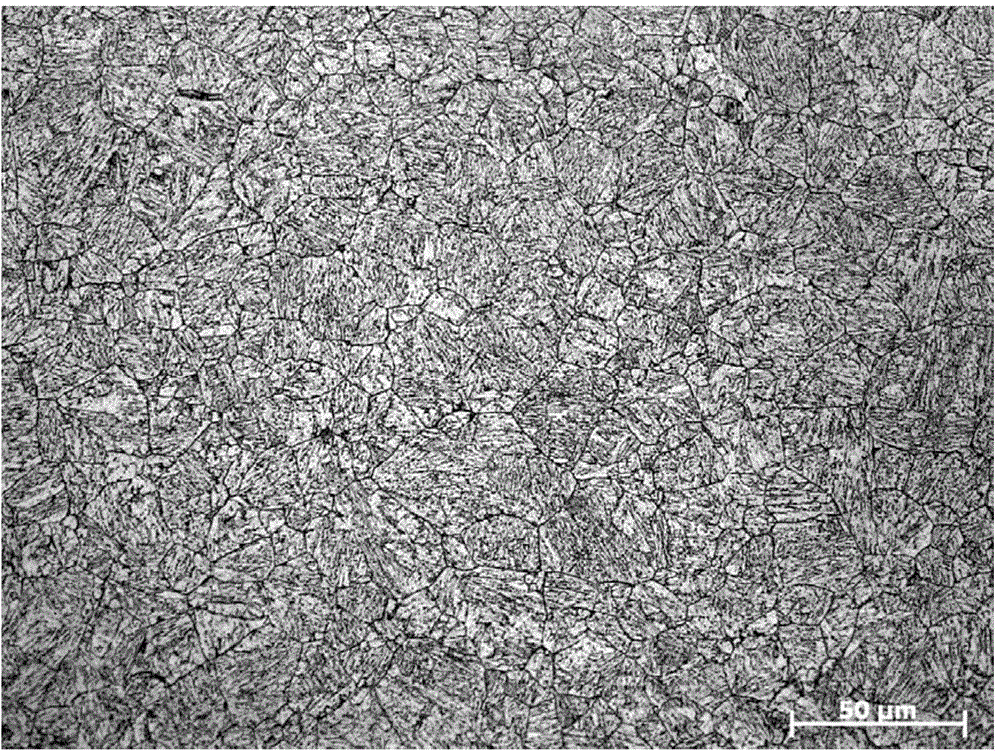

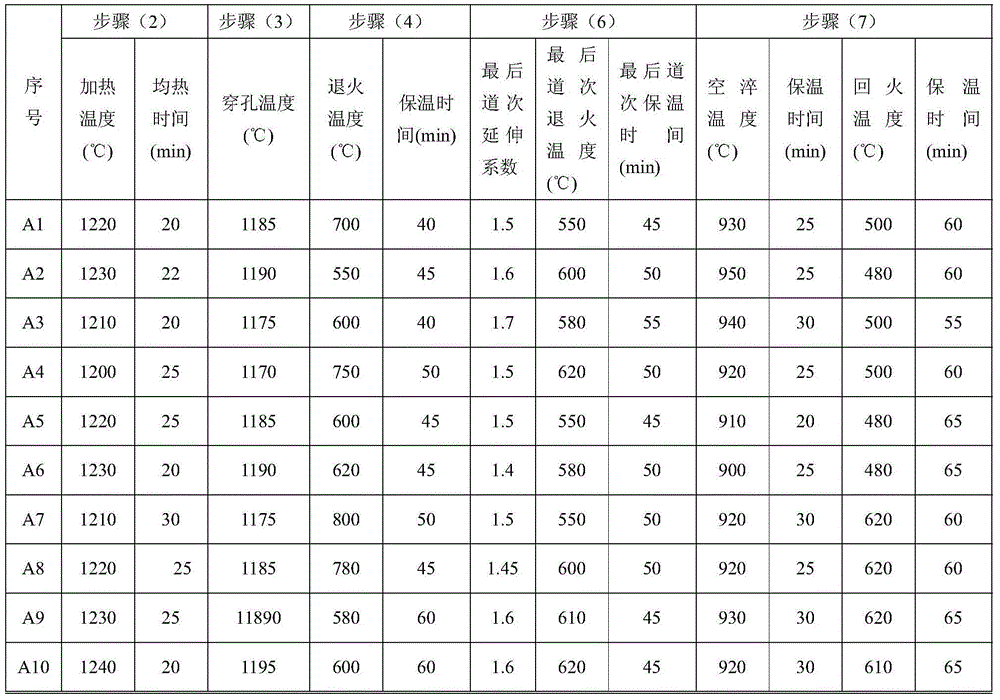

High-strength steel, high-strength plastic seamless steel pipe for automotive driver shafts and manufacturing method of high-strength plastic seamless steel pip

The invention discloses high-strength steel. The high-strength steel comprises the following chemical elements in percentage by mass: 0.07% to 0.15% of C, 0.1% to 1.0% of Si, 2.0% to 2.6% of Mn, 0.05% to 0.6% of Ni, 0.2% to 1.0% of Cr, 0.1% to 0.6% of Mo, 0.001% to 0.006% of B, 0.05% to 0.50% of Cu, 0.015% to 0.060% of Al, 0.02% to 0.1% of Nb, 0.02% to 0.15% of V, and the balance Fe and unavoidable impurities. Correspondingly, the invention further discloses a high-strength plastic seamless steel pipe for automotive driver shafts. The high-strength plastic seamless steel pipe for the automotive driver shafts is manufactured by the high-strength steel. In addition, the invention further discloses a manufacturing method of the high-strength plastic seamless steel pipe for the automotive driver shafts. The high-strength plastic seamless steel pipe for the automotive driver shafts is high in strength, high in strength and ductility product and good in anti-torsion fatigue performance.

Owner:BAOSHAN IRON & STEEL CO LTD

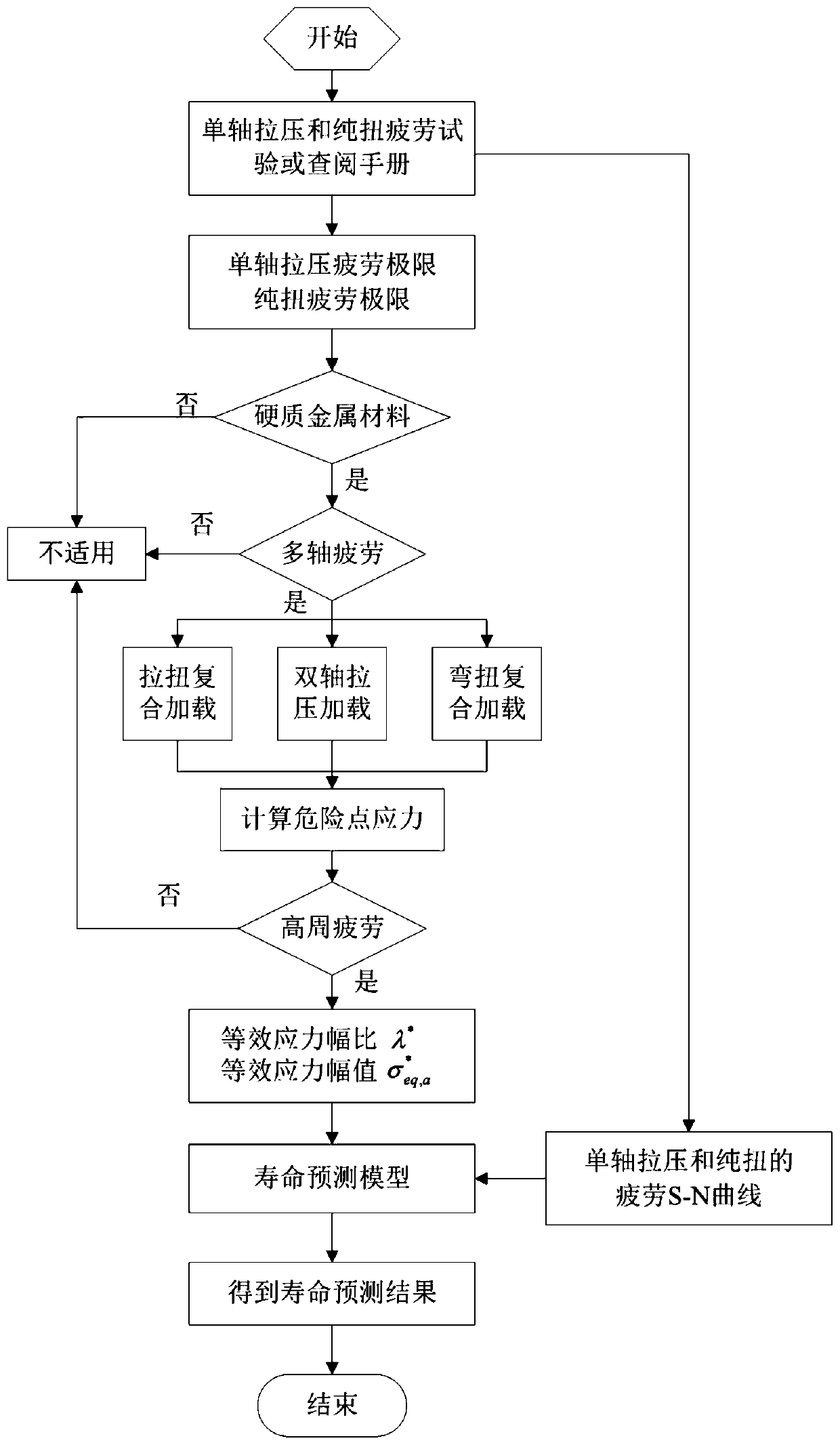

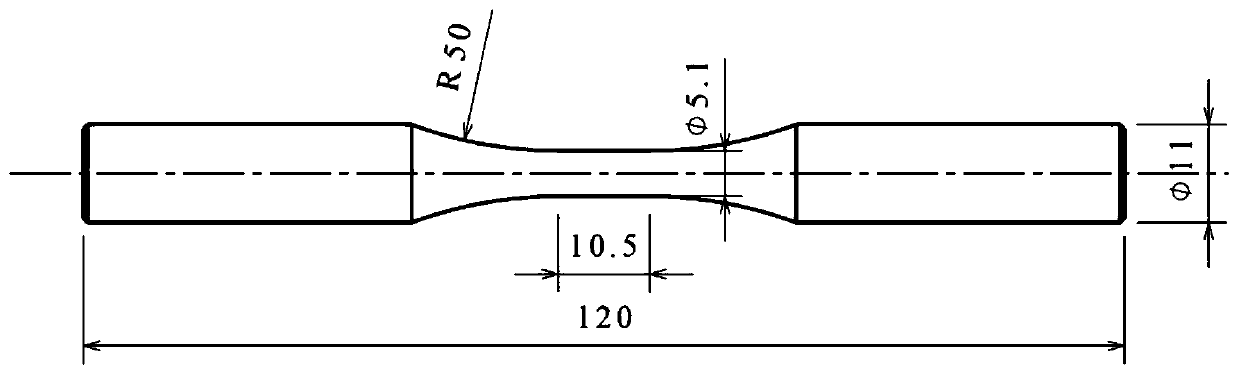

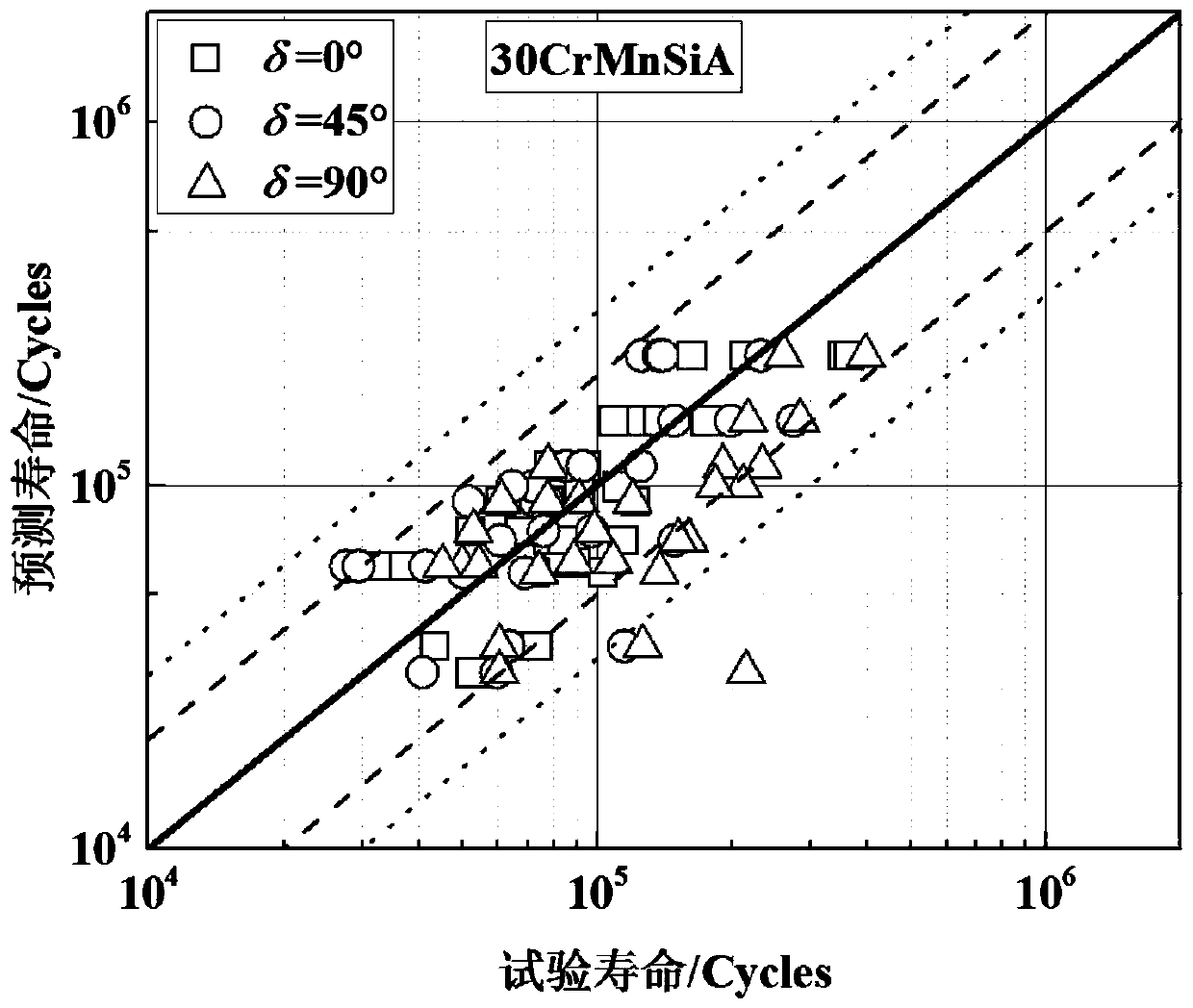

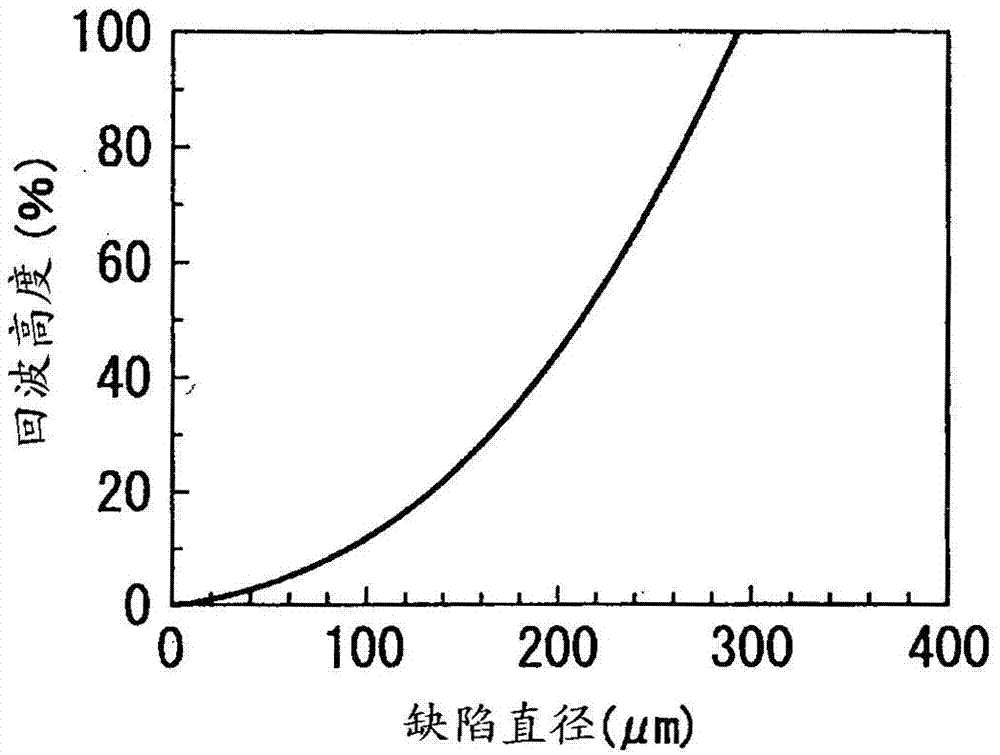

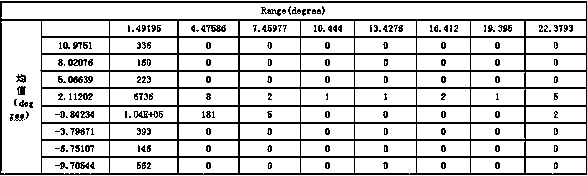

Uniaxial fatigue S-N curve-based hard metal material multi-axis high-cycle fatigue failure prediction method

ActiveCN110274826AWell formedAccurate predictionMaterial strength using tensile/compressive forcesTorsion fatigueFatigue loading

The invention discloses a uniaxial fatigue S-N curve-based hard metal material multi-axis high-cycle fatigue failure prediction method. According to the method, with a uniaxial tension fatigue and pure torsion fatigue S-N curve adopted as a boundary condition, and the equivalent stress amplitude and equivalent stress amplitude ratio of a material in the multi-axis fatigue loading process of the material are calculated; with the equivalent stress amplitude and equivalent stress amplitude ratio adopted as damage parameters, a fatigue S-N curve obtained from uniaxial fatigue is calculated; and a hard metal material multi-axis high-cycle fatigue failure life prediction model containing stress amplitude ratio and average stress influence is established. The method is suitable for a situation where average stress does not exist. Existing multi-axis fatigue life prediction models perform multi-axis fatigue tests under corresponding loading modes, and as a result, test cost is relatively high. Compared with the existing models in the prior art, the method disclosed by the invention is simple in form, and can obtain a uniaxial fatigue S-N curve just through a single-axis fatigue test or manual check, so as to accurately predict the fatigue life of a hard metal material under multi-axis high-cycle fatigue loading in the presence of a stress amplitude ratio and average stress.

Owner:BEIHANG UNIV

Steel tube used for hollow stabilizer bar of automobile and manufacturing method of steel tube

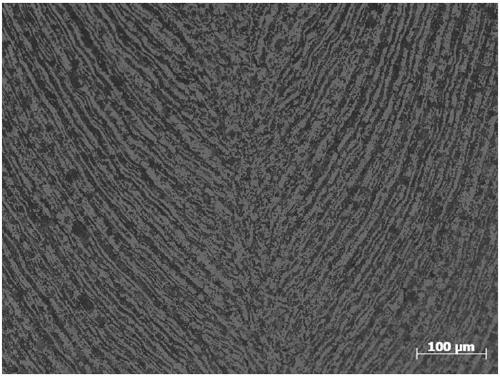

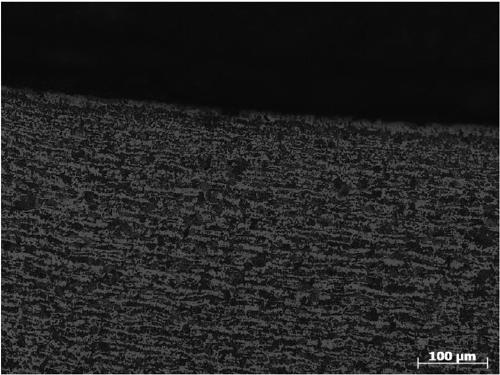

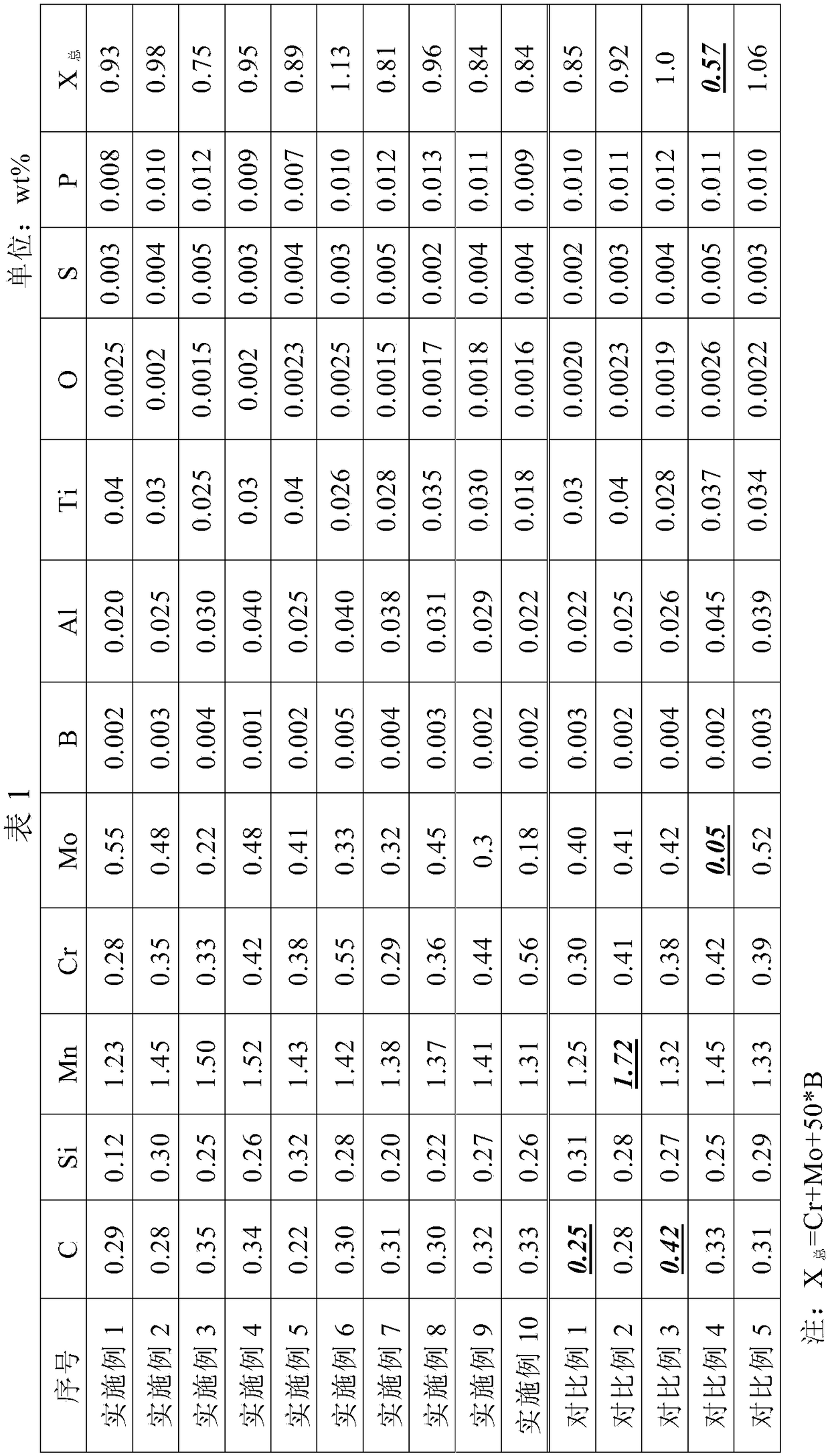

The invention discloses a steel tube used for a hollow stabilizer bar of an automobile and a manufacturing method of the steel tube. The steel tube is prepared from the following chemical components in mass percent: 0.28 to 0.40 percent of C, 0.05 to 0.35 percent of Si, 1.05 to 1.60 percent of Mn, 0.1 to 0.6 percent of Mo, 0.001 to 0.006 percent of B, 0.015 to 0.060 percent of Al, 0.1 to 0.8 percent of Cr, 0.003 to 0.06 percent of Ti, not greater than 0.006 percent of S, not greater than 0.015 percent of P, not greater than 0.003 percent of O and the balance Fe and other inevitable impurities,wherein Mo+50B+Cr is not less than 0.7 percent but is not greater than 1.3 percent. The steel tube disclosed by the invention is high in strength and plasticity, has high torsion fatigue resistance under a relatively high stress level, and can meet the using requirement of the stabilizer bar under a high-stress condition; and the specific performance indexes are shown as follows: as-quenched tensile strength is not less than 1700 MPa, as-quenched yield strength is not less than 1300 MPa, as-quenched ductility is not less than 12 percent, inner surface decarburization depth and outer surface decarburization depth are both 0, and under the condition of 550 MPa, the number of times of torsion fatigue is greater than 1200000.

Owner:BAOSHAN IRON & STEEL CO LTD

Induction hardened hollow driving shaft

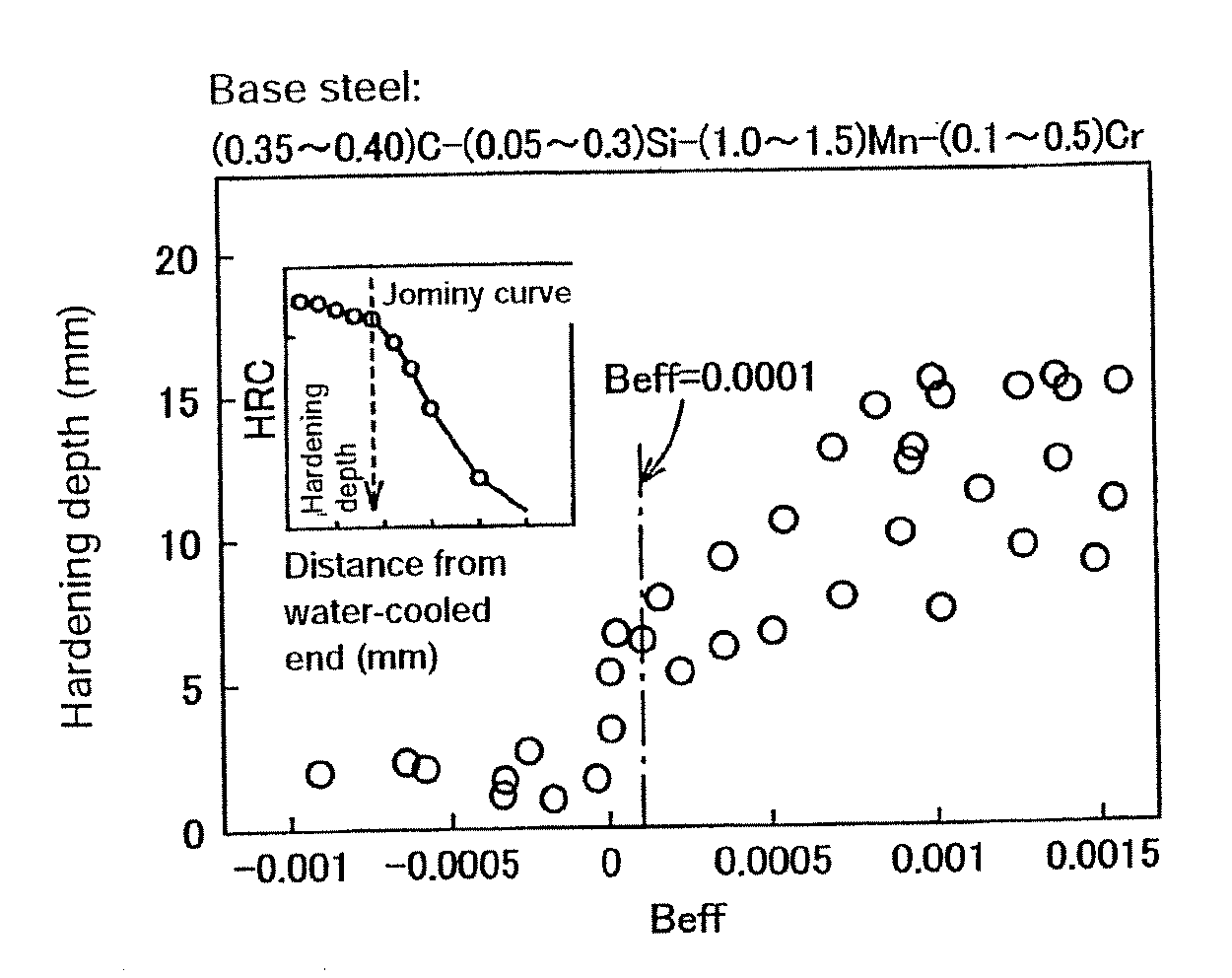

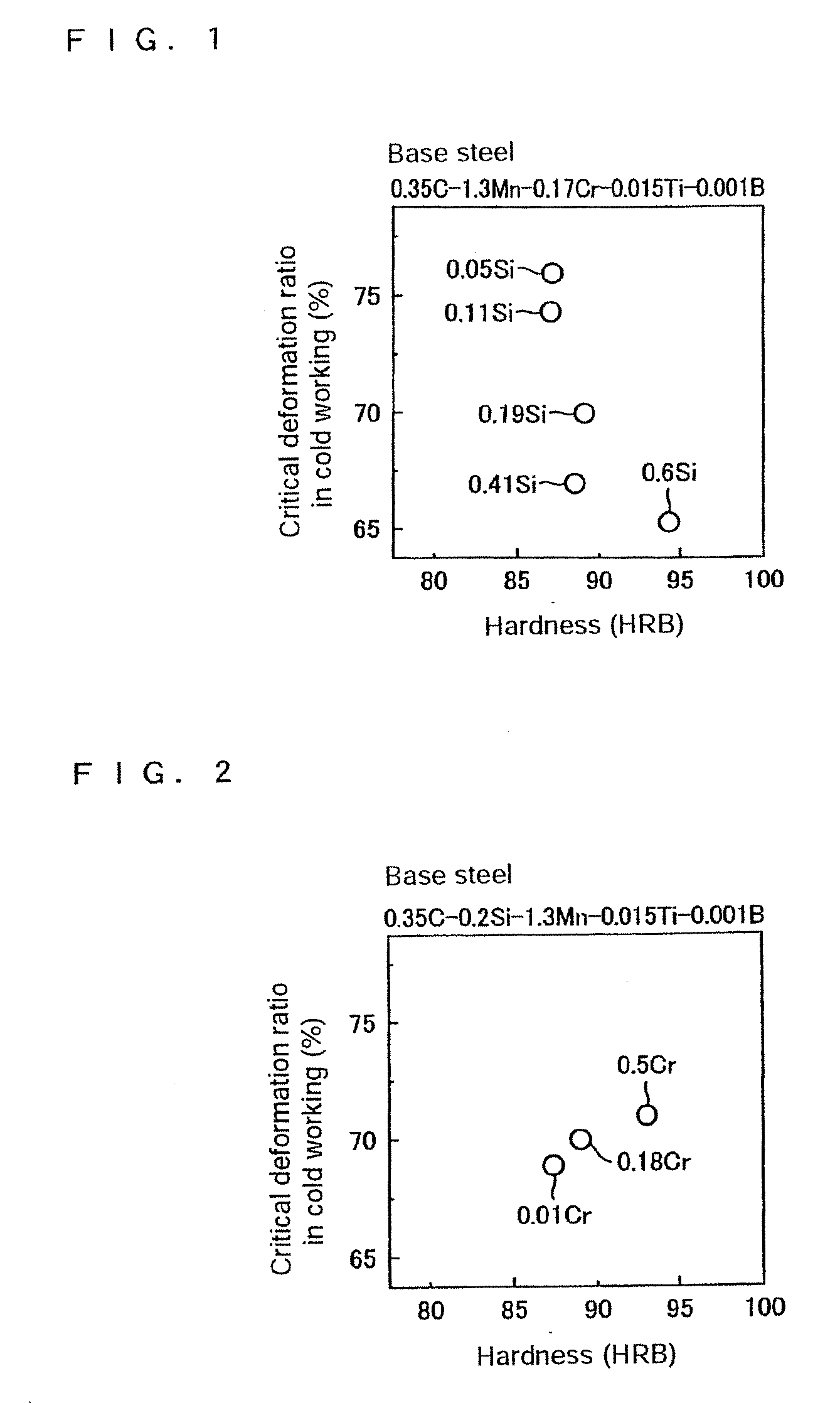

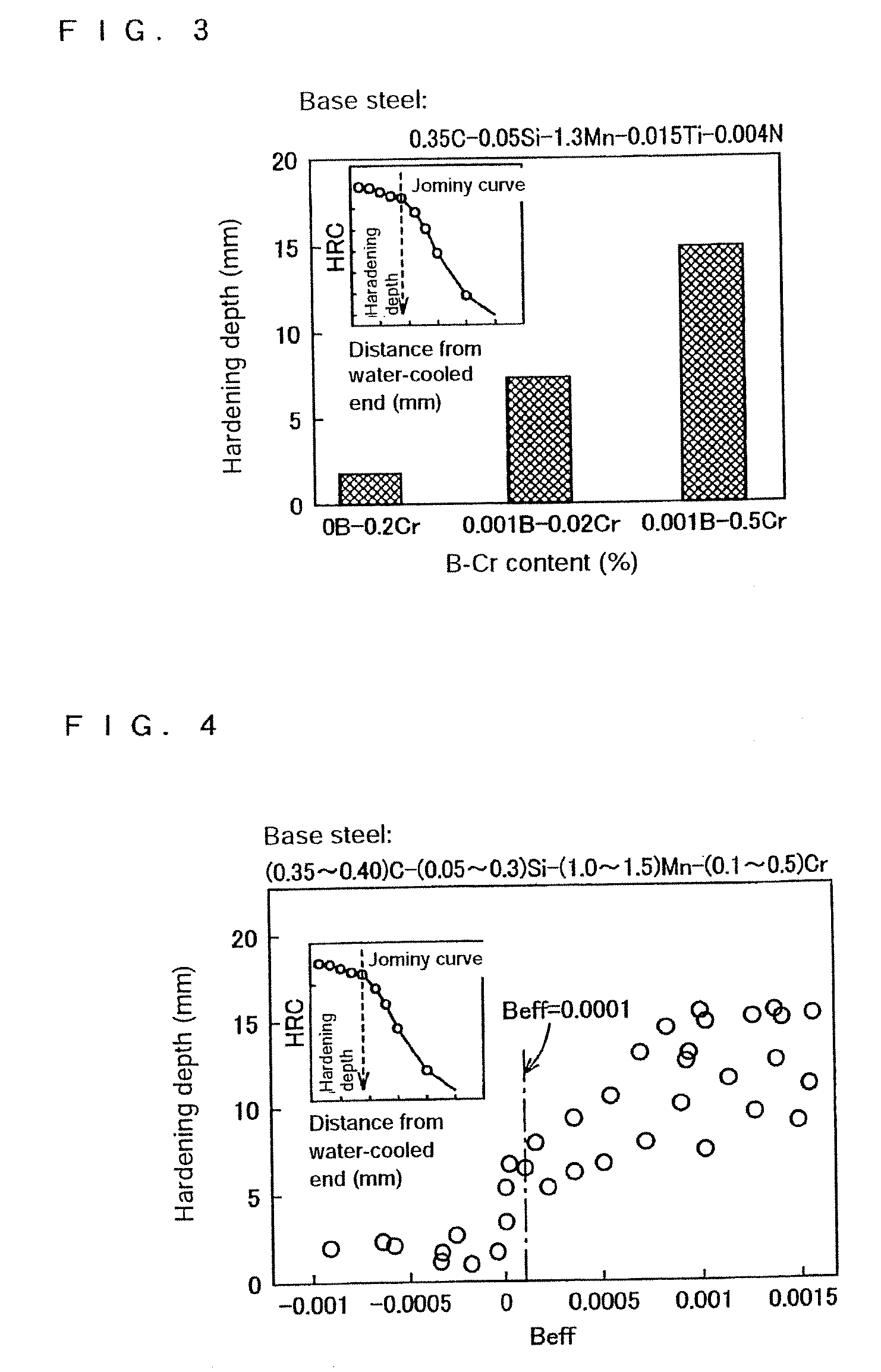

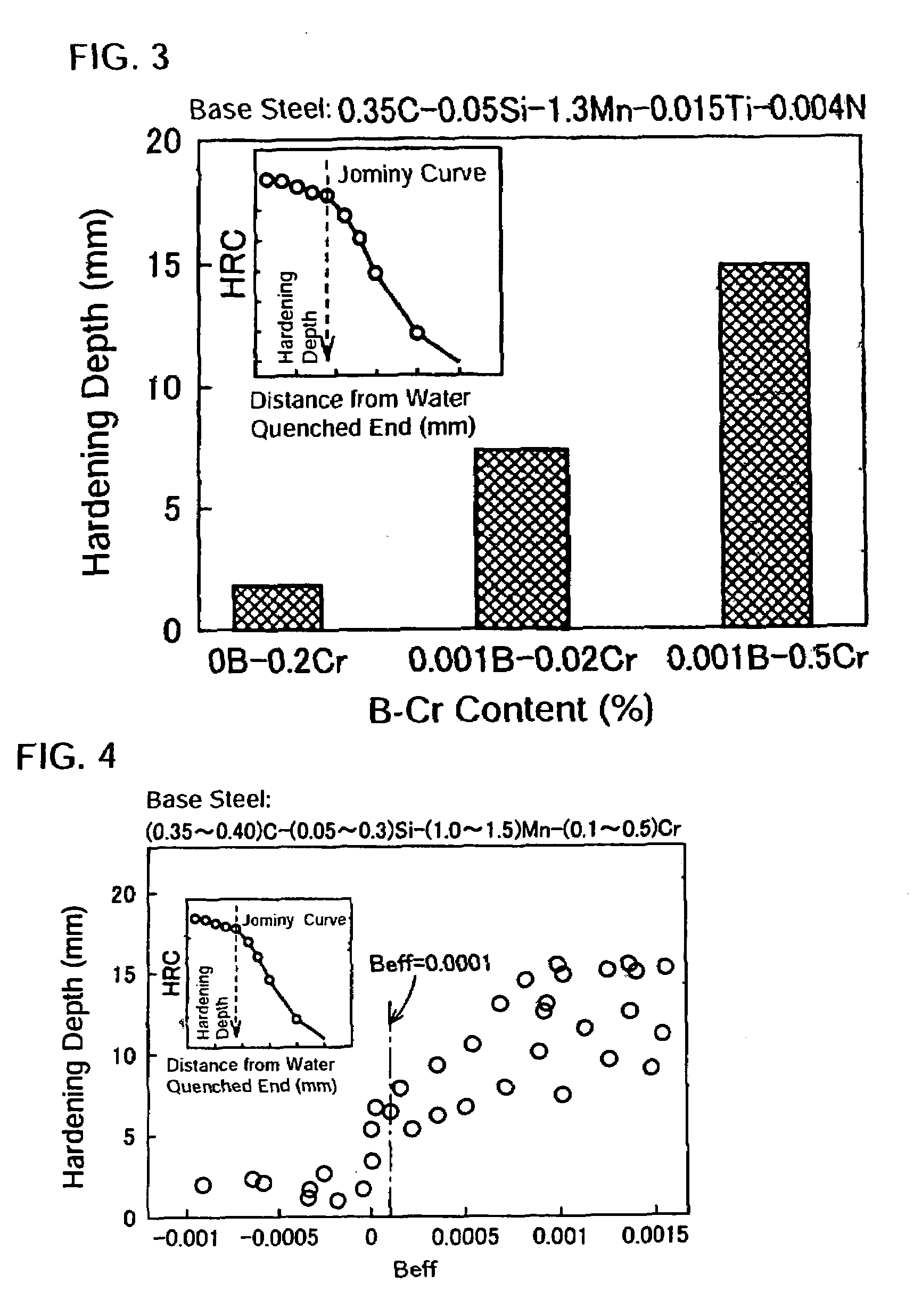

InactiveUS20090023506A1Improved cold working propertiesImprove hardenabilityShaftsFurnace typesAustenite grainDrive shaft

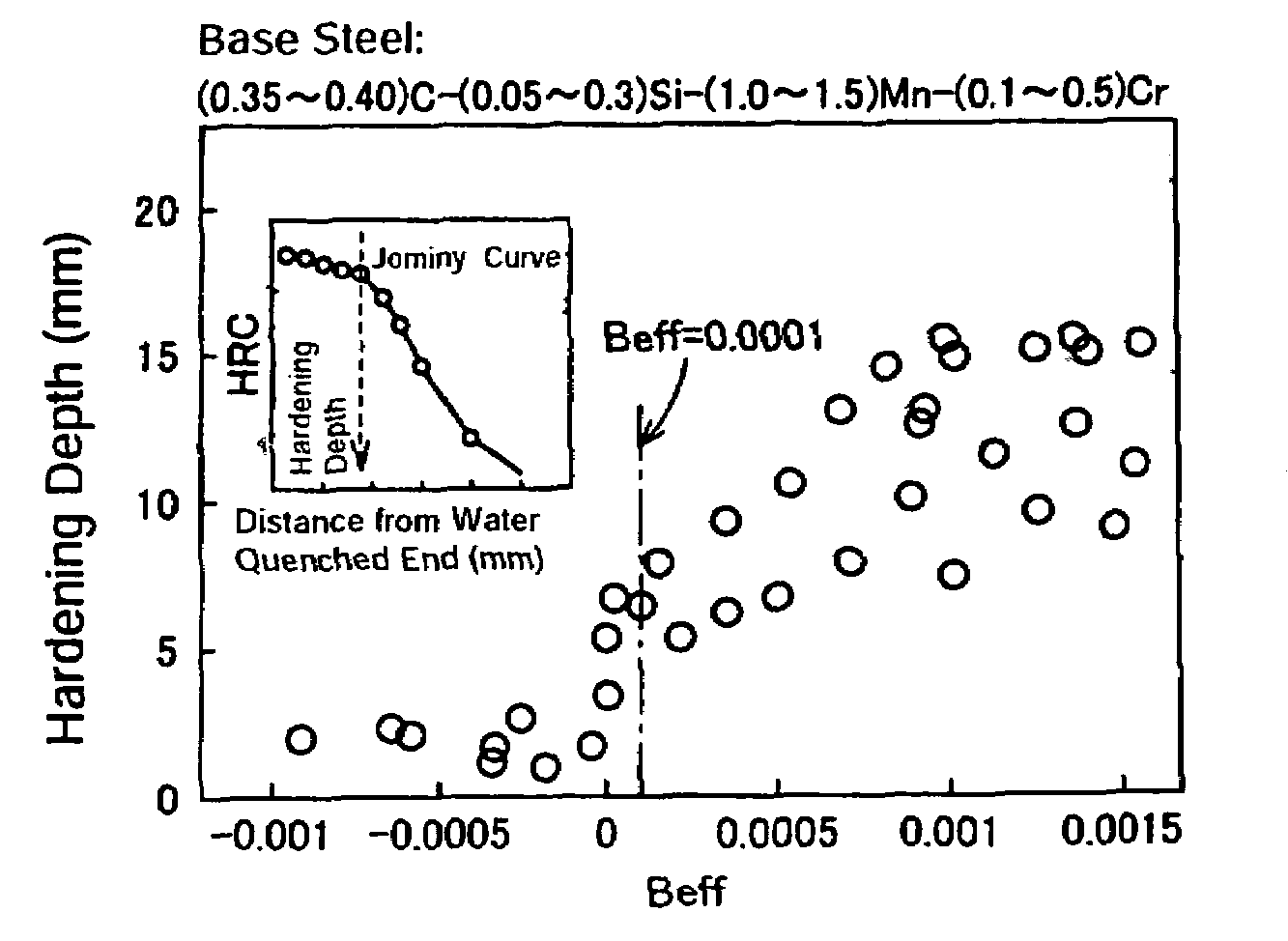

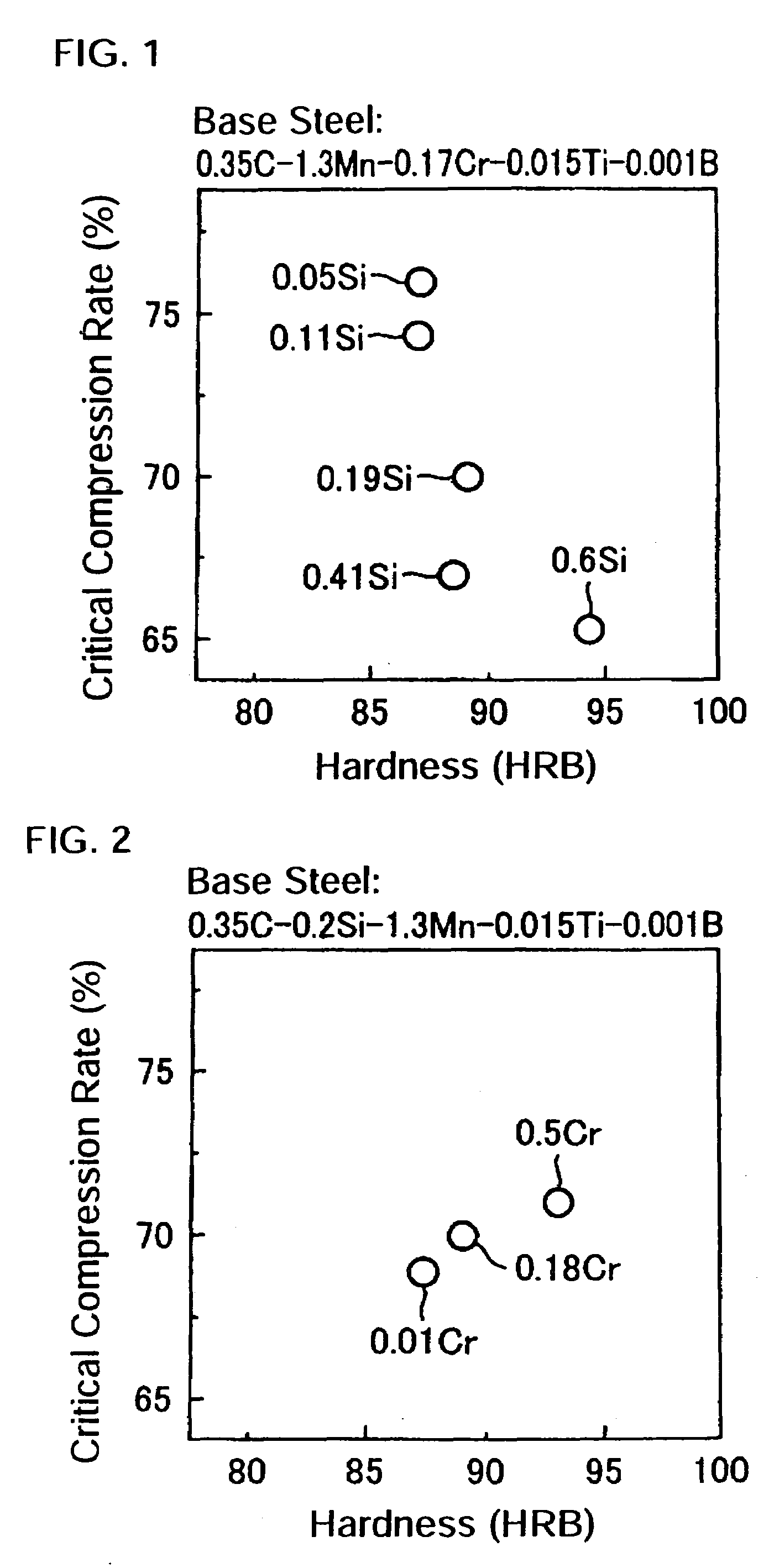

The present invention provides an induction-hardened hollow driving shaft that comprises, as a raw material, a steel pipe that contains, by mass %, 0.30 to 0.47% C, 0.5% or less Si, 0.3 to 2.0% Mn, 0.018% or less P, 0.015% or less S, 0.15 to 1.0% Cr, 0.001 to 0.05% Al, 0.005 to 0.05% Ti, 0.004% or less Ca, 0.01% or less N, 0.0005 to 0.005% B and 0.0050% or less O (oxygen) and the balance Fe and impurities and of which Beff defined by an equation (a) or (b) below is 0.0001 or more, wherein a prior austenite grain size number (JIS G0551) after the hardening is 9 or more. Here, in the case of Neff=N−14×Ti / 47.9≧0, Beff=B×10.8×(N−14×Ti / 47.9) / 14 . . . (a), and, in other cases, Beff=B . . . (b). According to the present invention, a hollow driving shaft that is simultaneously provided with excellent cold workability, hardenability, toughness and torsional fatigue strength and can exert stable fatigue lifetime can be obtained and can be widely utilized.

Owner:SUMITOMO METAL IND LTD

Fatigue tester

InactiveCN101349625AImprove work efficiencyEasy to compareMaterial strength using steady torsional forcesTorsion fatigueEngineering

The invention relates to a fatigue tester, which relates to an instrument for testing, wherein two torsion shafts are vertically arranged in a cabinet through a bearing, the upper ends of the torsion shafts are inserted in a high-temperature cabinet, the upper ends of the torsion shafts are connected with a lower chuck, and the lower ends of the torsion shafts are concentrically connected with a relative wobble wheel, a speed reduction motor is further arranged in the cabinet, the output end of the speed reduction motor is connected with an eccentric wheel, a torque rod is hinged between the eccentric wheel and either of the wobble wheels, a connecting bar is hinged between the two wobble wheels, and an upper chuck is vertically arranged in the high-temperature cabinet. Samples are clamped between the upper chuck and the lower chuck, two groups of samples are led to simultaneously do torsion fatigue tests with different frequencies under different temperature conditions through controlling temperatures in the high-temperature cabinet to improve the work efficiency of tests, and the fatigue tester is further beneficial for comparing test data.

Owner:JIANGDU MINGZHU TESTING MACHINERY

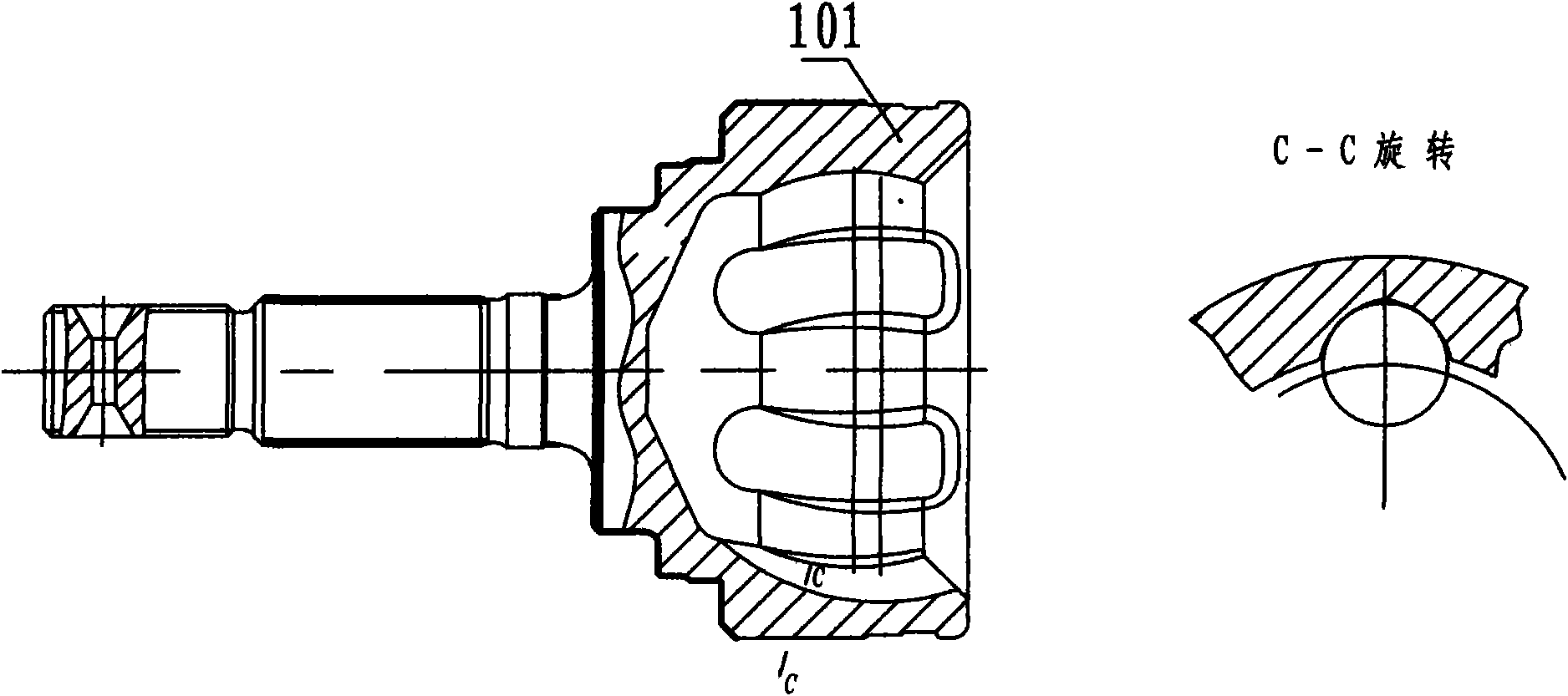

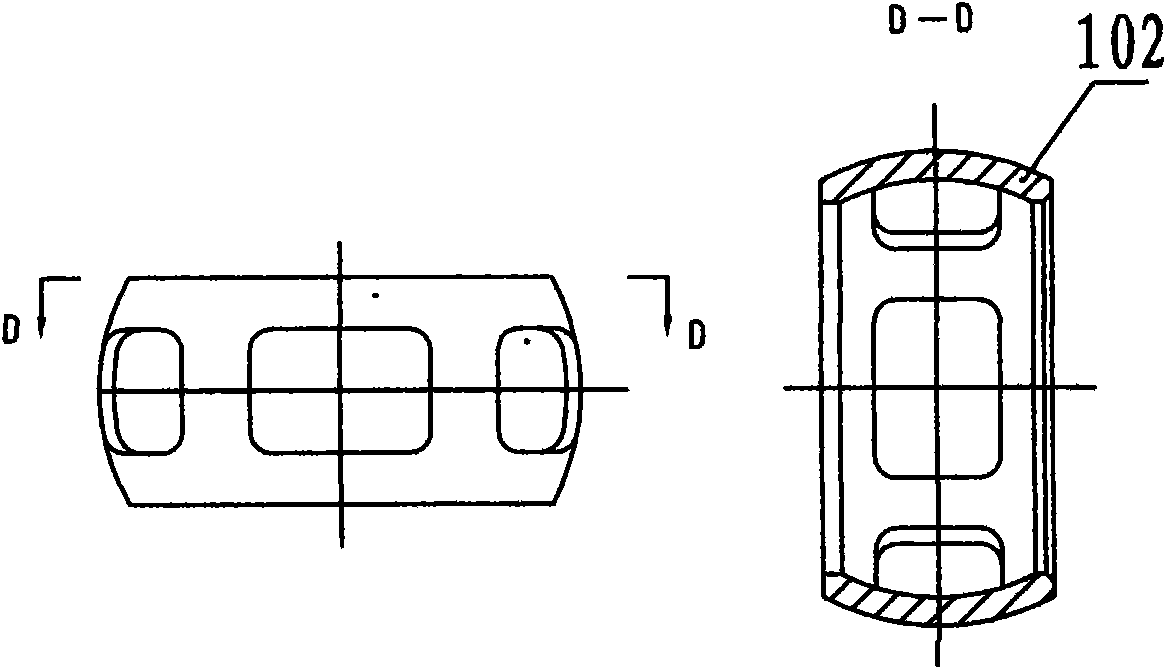

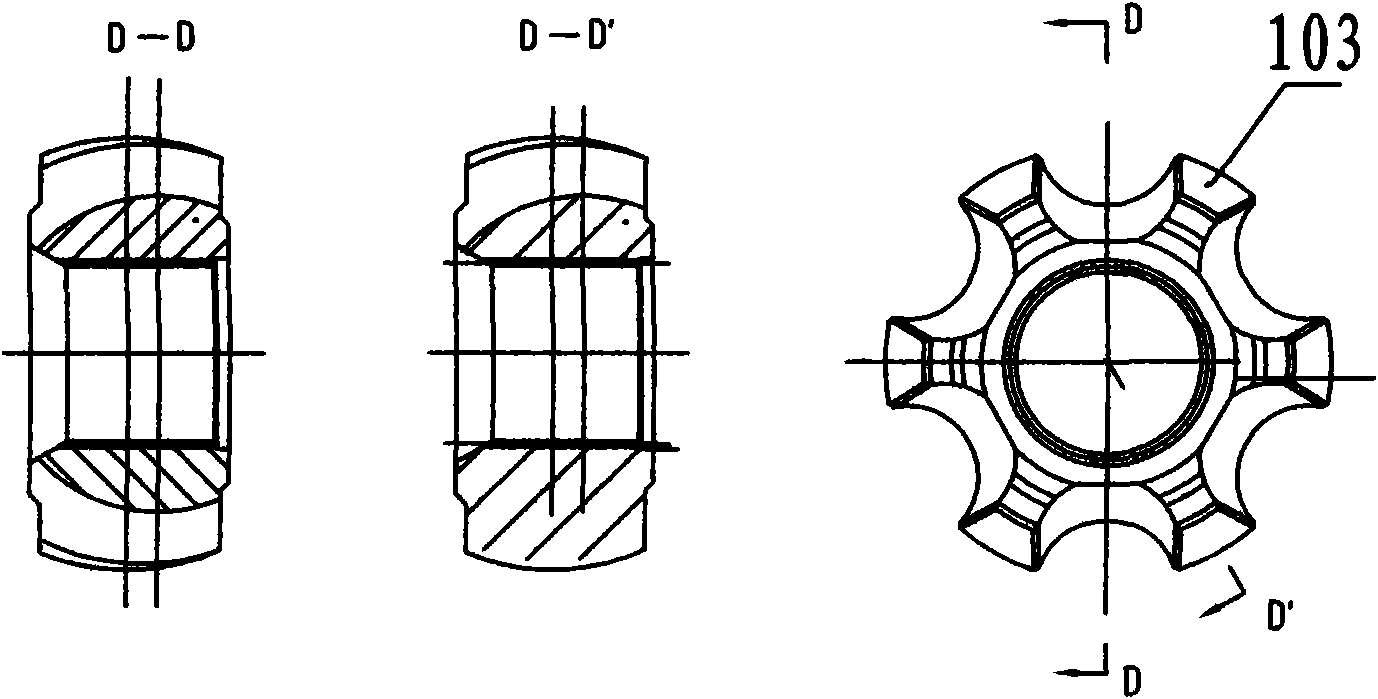

Structure of constant velocity universal joint

The invention discloses a novel assembly structure of a constant velocity universal joint ball cage used for an automotive transmission system, which comprises a spherical shell (1), a retainer (2), astar-shaped sleeve (3), steel balls (4) and an outer spherical seat shaft (6). The inner spherical surface of the spherical shell (1) is connected with the outer spherical surface of the retainer (2), and the inner spherical surface of the retainer (2) is connected with the outer spherical surface of the star-shaped sleeve (3). The structure is characterized in that circular arcs of contact surfaces of the retainer (2) and the star-shaped sleeve (3) are changed, and the way that the radius of the circular arc at the middle section is larger than the radii of the circular arcs at two ends andthe circular arcs are smoothly connected is adopted. After the ball cage is assembled, gaps (7) and (8) at middle sections of the inner contact face and the outer contact surface of the retainer (2) are increased, and the abrasion is reduced; in addition, the structure is favorable for even dispersion of lubricating grease at the cavity of the constant velocity universal joint, increases the lubricating effect, promotes the comprehensive performance, and realizes promotion of torsional fatigue strength of an assembly by more than 20 percent. Meanwhile, the structure is easy to process and assemble, and relatively reduces the manufacturing cost.

Owner:叶祥宝 +1

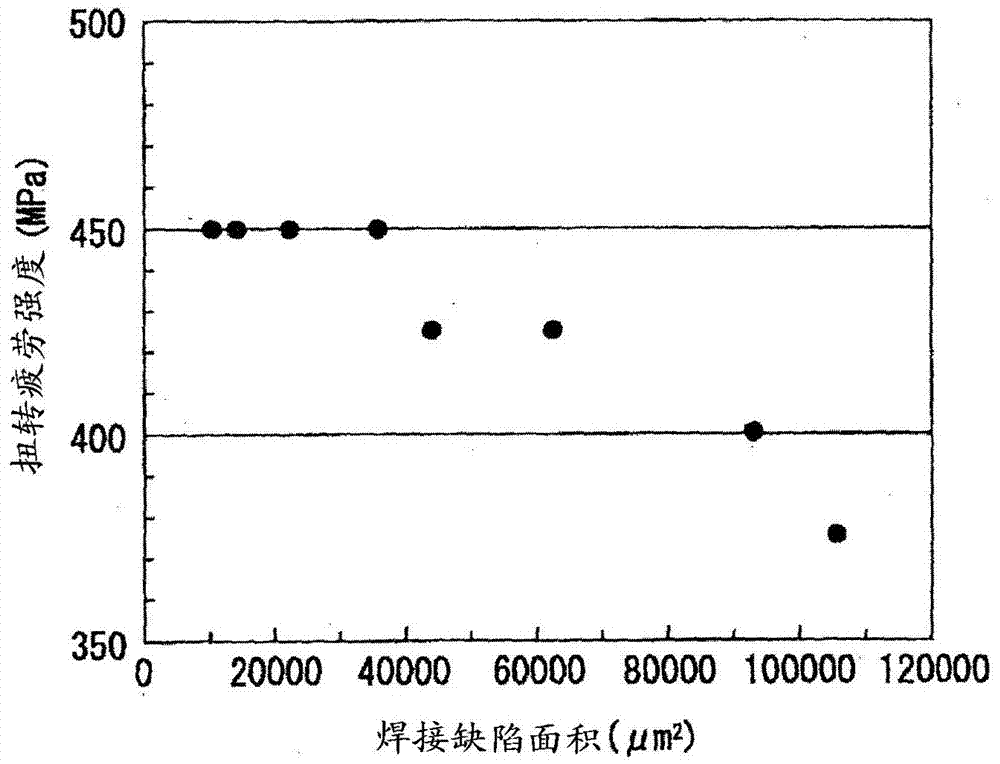

Electric-resistance-welded steel pipe with excellent torsion fatigue resistance and process for producing same

ActiveCN102906293AGuaranteed fatigue resistanceArc welding apparatusFurnace typesElectrical resistance and conductanceTorsion fatigue

Owner:JFE STEEL CORP

Device and method for testing tension and torsion coupling performance of flexible tube cable structure

PendingCN108088747AAccurate coupling effectHigh speedMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesTorsion fatigueEngineering

The invention discloses a device and a method for testing tension and torsion coupling performance of a flexible tube cable structure. The device for testing tension and torsion coupling performance of the flexible tube cable structure comprises a torsion limiter, a torsion screw rod, a spiral baffle and a tension actuator, wherein one end of the torsion limiter is fixed, and the other end of thetorsion limiter is provided with a first tube cable connector for being connected with one end of a cable sample of a flexible tube cable; the outer wall of the torsion screw rod is provided with a spiral bulge, and one end of the torsion screw rod is provided with a second tube cable connector for being connected with the other end of the cable sample of the flexible tube cable; the spiral baffleis provided with a through hole for the torsion screw rod to pass through, and the through hole is provided with a spiral groove meshed with the spiral bulge; and the tension actuator is used for driving the torsion screw rod to perform screw feed relative to the through hole. A single actuator is adopted to finish application of two working conditions, and the coupling effect of the two workingconditions is more accurate than that obtained by adopting two actuators to apply different working conditions; and for a tension and torsion fatigue test (especially fatigue acceleration test), higher speed and better convenience are realized.

Owner:DALIAN UNIV OF TECH

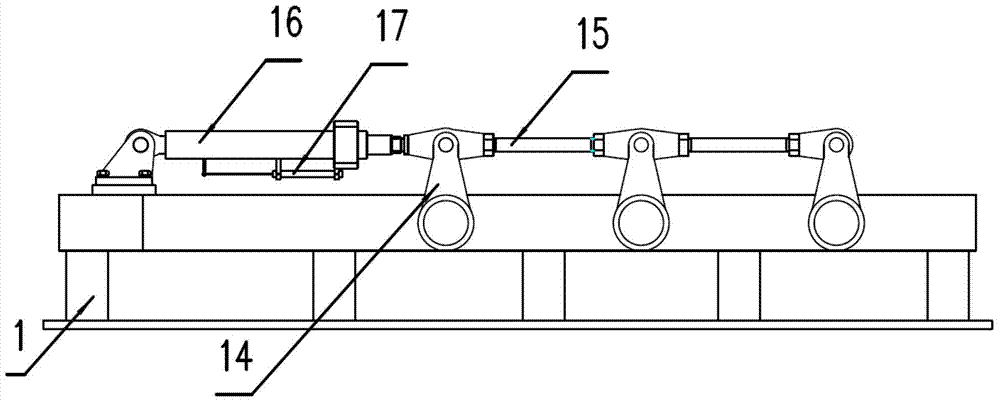

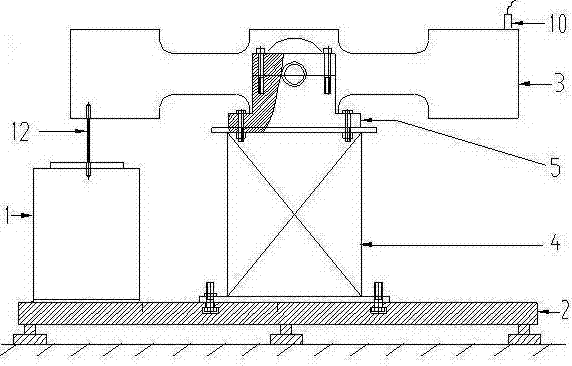

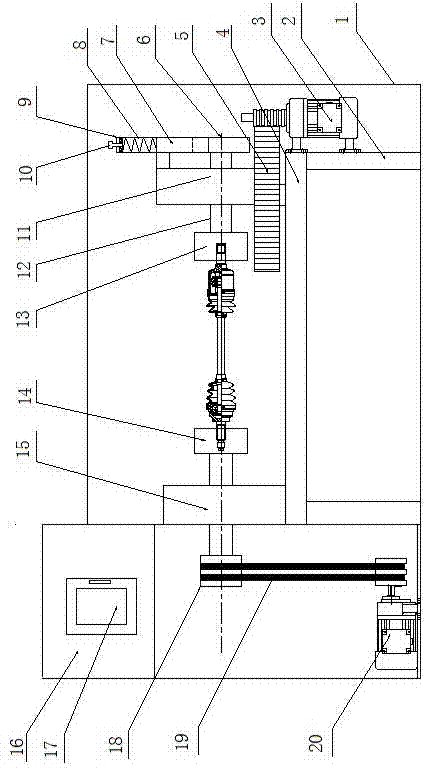

Automobile pipe column type electric power steering gear torsional fatigue test platform and test method

ActiveCN101078671AReduce consumption costSimplify the design processVehicle steering/rolling behaviourElectric power steeringTorsion fatigue

The invention provides a torsion fatigue test bed for automobile tube-column electric power-assist steering and the testing method. The test bed comprises power device, mechanical transmission device and bench component. The power device is connected with measured electric power-assist steering by the mechanical transmission device to drive the electric power-assist steering turn repeatedly. The power device and the mechanical transmission device are set on the bench component. The testing method comprises following procedures. The first procedure is that the power device is used to drive measured electric power-assist steering turn repeatedly by the mechanical transmission device so as to simulate the condition of turning steering wheel by hand in vehicle running until electric power-assist steering can not work normally. The second procedure is that the total number of repeated turning is recorded. The third procedure is that according the number of turning the service life of electric power-assist steering is obtained. The invention solves the problem that prior actual vehicle test is high cost.

Owner:BYD CO LTD

MEMS stretching twisted fatigue feature testing apparatus

InactiveCN1948943AFree of clampingEliminates the hassle of alignmentMaterial strength using tensile/compressive forcesStructural/machines measurementTorsion fatigueParallel plate

The invention relates to MEMS drawing torsion fatigue characteristic experimental apparatus. It includes parallel plate capacitance driver and transducer, comb type capacitance driver and transducer, earthed electrode, drawing and torsion driving electrodes, drawing and torsion detecting electrodes. While in experiment, the drawing and torsion driving electrodes are respectively supplied alternating current signal to parallel plate and comb type capacitance drivers to make the fatigue testing specimen suffer alternating drawing and torsion stress at the same time. The parallel plate and comb type capacitance transducers are electrified direct current respectively by drawing and torsion detecting electrodes to detect fatigue testing specimen drawing and torsion amplitude. The invention has the advantages of easy processing, convenient operation, and high use value for MEMS structural strength study.

Owner:BEIJING UNIV OF TECH

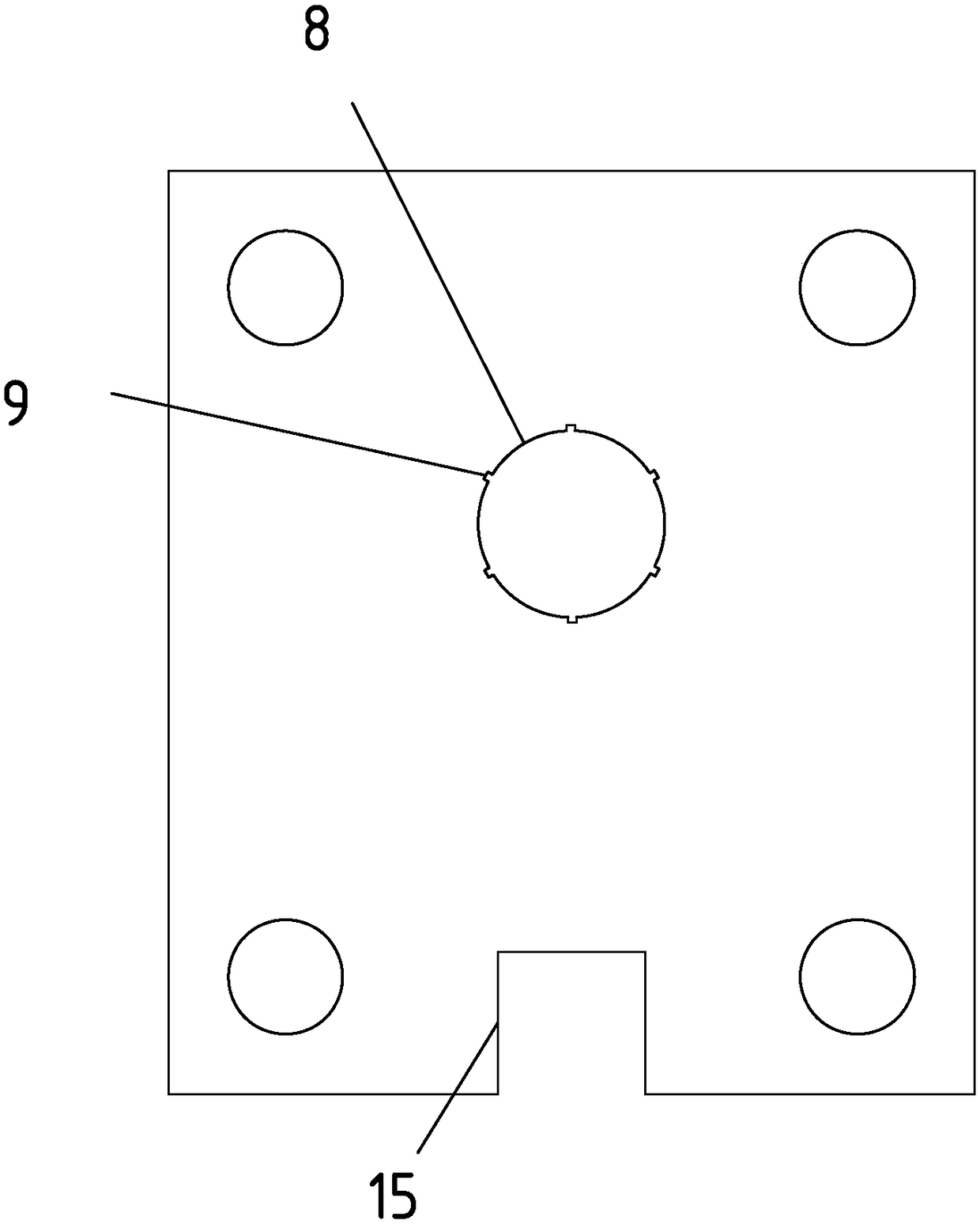

Clamping vibration device for integral torsional fatigue test of crankshaft

InactiveCN102288406AReasonable structureEasy to manufactureMachine gearing/transmission testingInterference fitTorsion fatigue

The invention relates to a clamping vibration exciting device for an integral torsion fatigue test of a crankshaft, which comprises a base, a vibration exciter, one pair of vibrating plates, a testing bracket and clamping apparatuses. The testing bracket is fixed in the center of the base; two clamping apparatuses with bearings are fixed on two sides of the testing bracket; through holes are arranged in the middle of the vibrating plates; outer connecting sleeves are mounted in the through holes in an interference fit way; extending parts at the outer sides of the outer connecting sleeves areconnected with the bearings on the clamping apparatuses in the interference fit way; the inner sides of the outer connecting sleeves are connected with inner connecting sleeves; main shaft necks at two ends of the crankshaft are fixed in the inner connecting sleeves; and the crankshaft and the vibrating plates are integrally mounted on the testing bracket. A clamped crankshaft test piece can be subjected to the fatigue test through a testing system. The clamping vibration exciting device has a reasonable structure, is simple to manufacture, is easy to clamp and disassemble, and is convenient to operate; the whole crankshaft can be subjected to the torsion fatigue test under the condition that the crankshaft is not cut; and the clamping vibration exciting device for the integral torsion fatigue test of the crankshaft is ideal.

Owner:TIANRUN IND TECH CO LTD

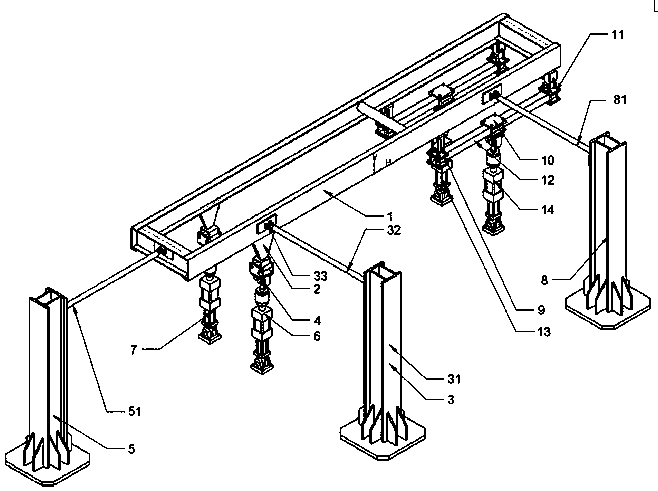

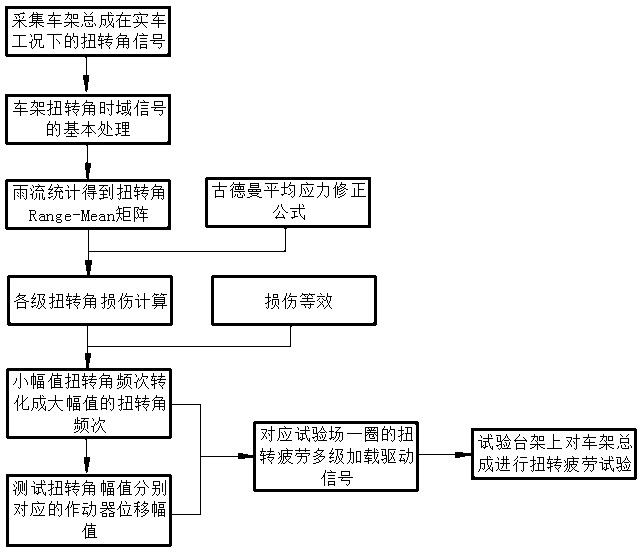

Vehicle frame assembly torsion fatigue loading test stand and test method

ActiveCN107505130ATruly reflect the characteristics of useFacilitate lightweight verificationMachine part testingSustainable transportationVehicle frameTorsion fatigue

The invention relates to a vehicle frame assembly torsion fatigue loading test stand. The test stand is characterized in that a vehicle frame assembly is of a rectangular frame structure, and the back end of the vehicle frame assembly is connected with a second combination support through a connecting rod with a joint bearing; and an end head of a connecting rod of a first combination support is connected with a vehicle frame fixing plate, a third combination support is positioned on the right side of the vehicle frame assembly, a front clamp plate and a rear clamp plate are fixedly connected on the left side and the right side of the front bottom surface of the vehicle frame assembly, square steel is connected between the front clamp plate and the rear clamp plate, and a middle clamp plate is fixedly connected to the square steel. The test stand can reflect the using characteristics of a vehicle frame and the torsion loading spectrum of a test of a test site more really, so the test precision is higher than that of a human defined loading spectrum test. Meanwhile, the number of circulation is controlled through equivalent damage to enable comparison between a test of the test stand and an endurance test of the test site, the meaning of the tests is improved, and lightweighting verification of the vehicle frame is facilitated.

Owner:CHINA FIRST AUTOMOBILE

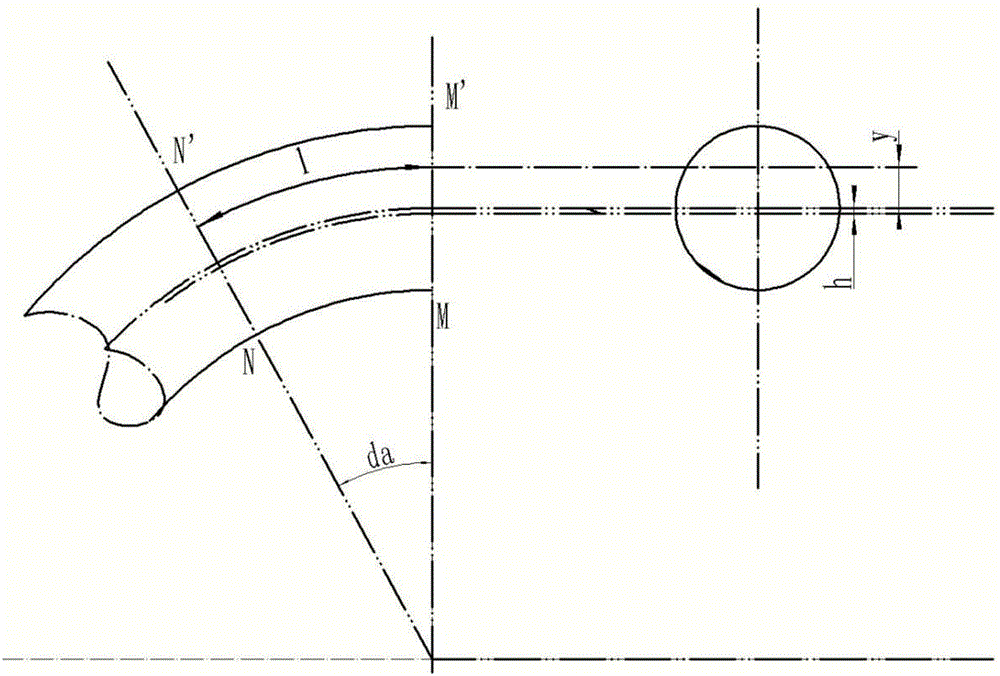

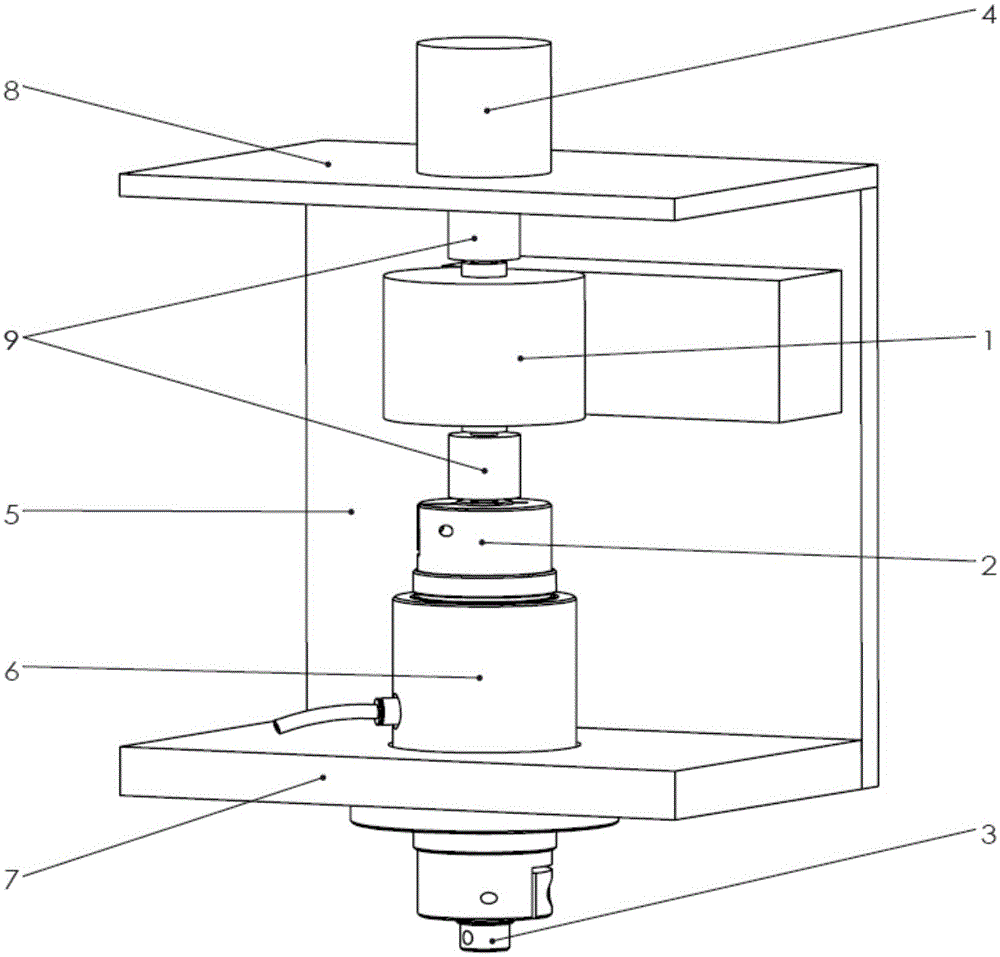

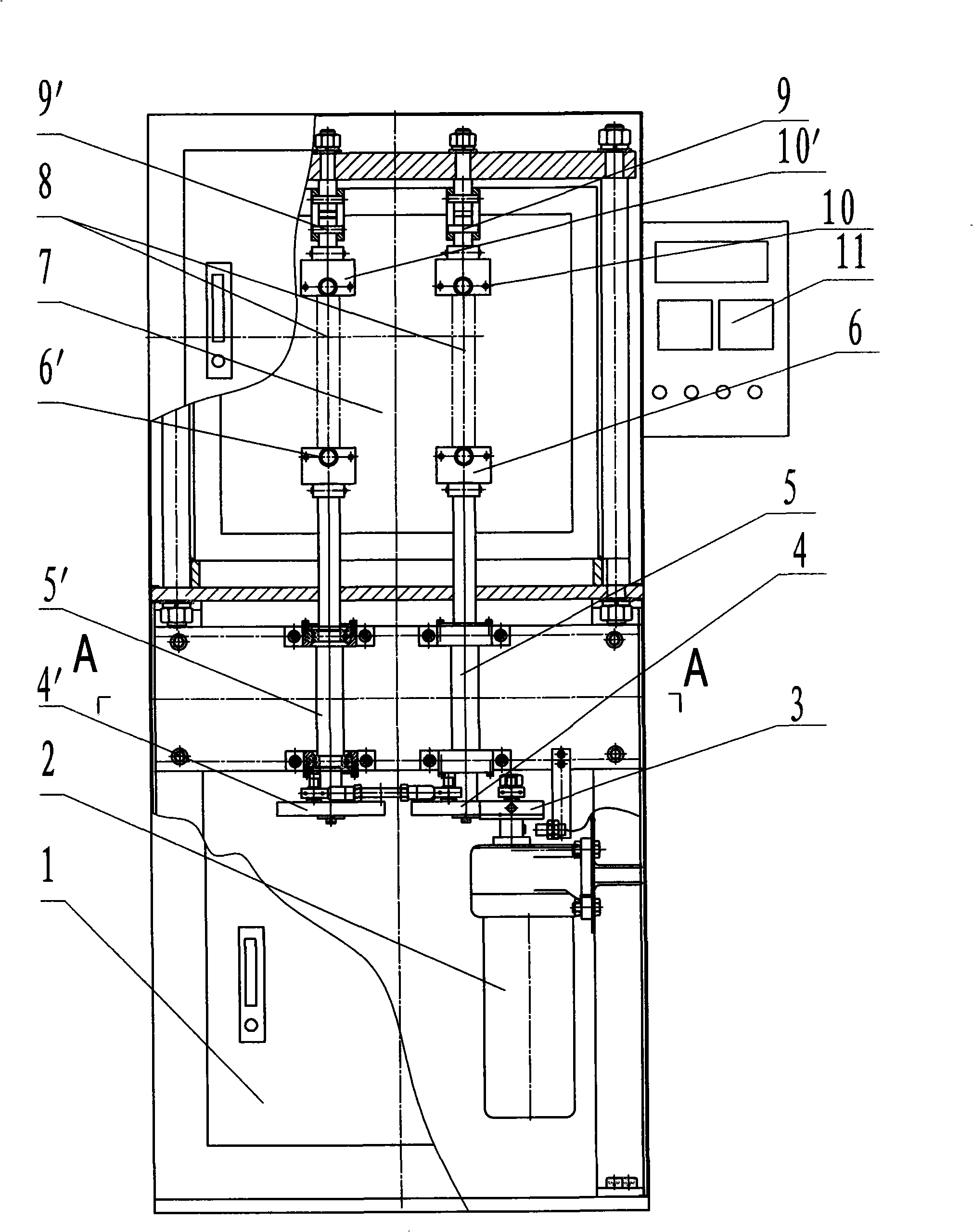

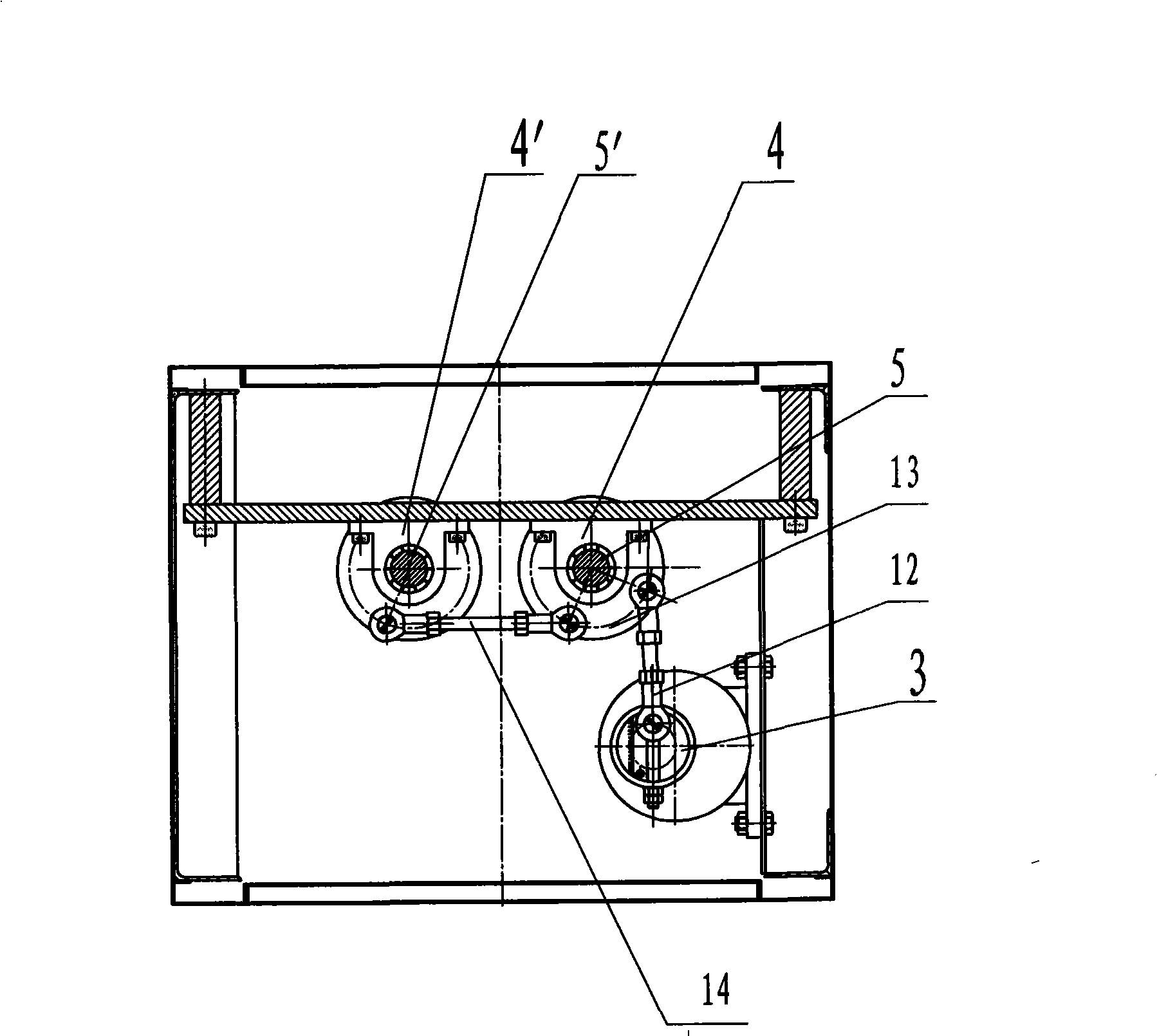

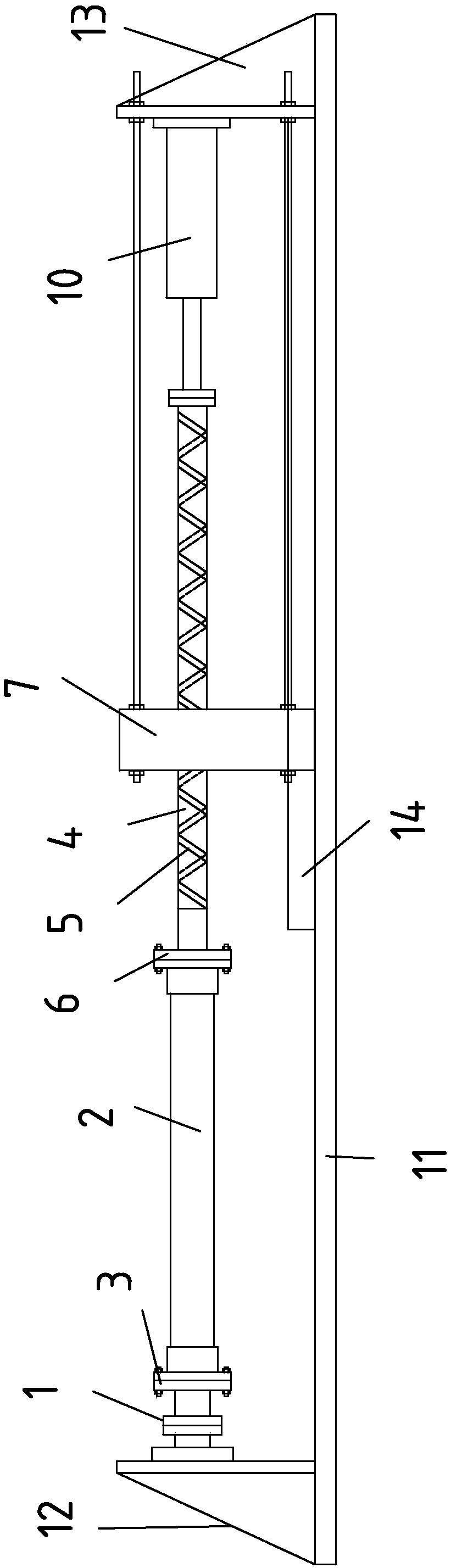

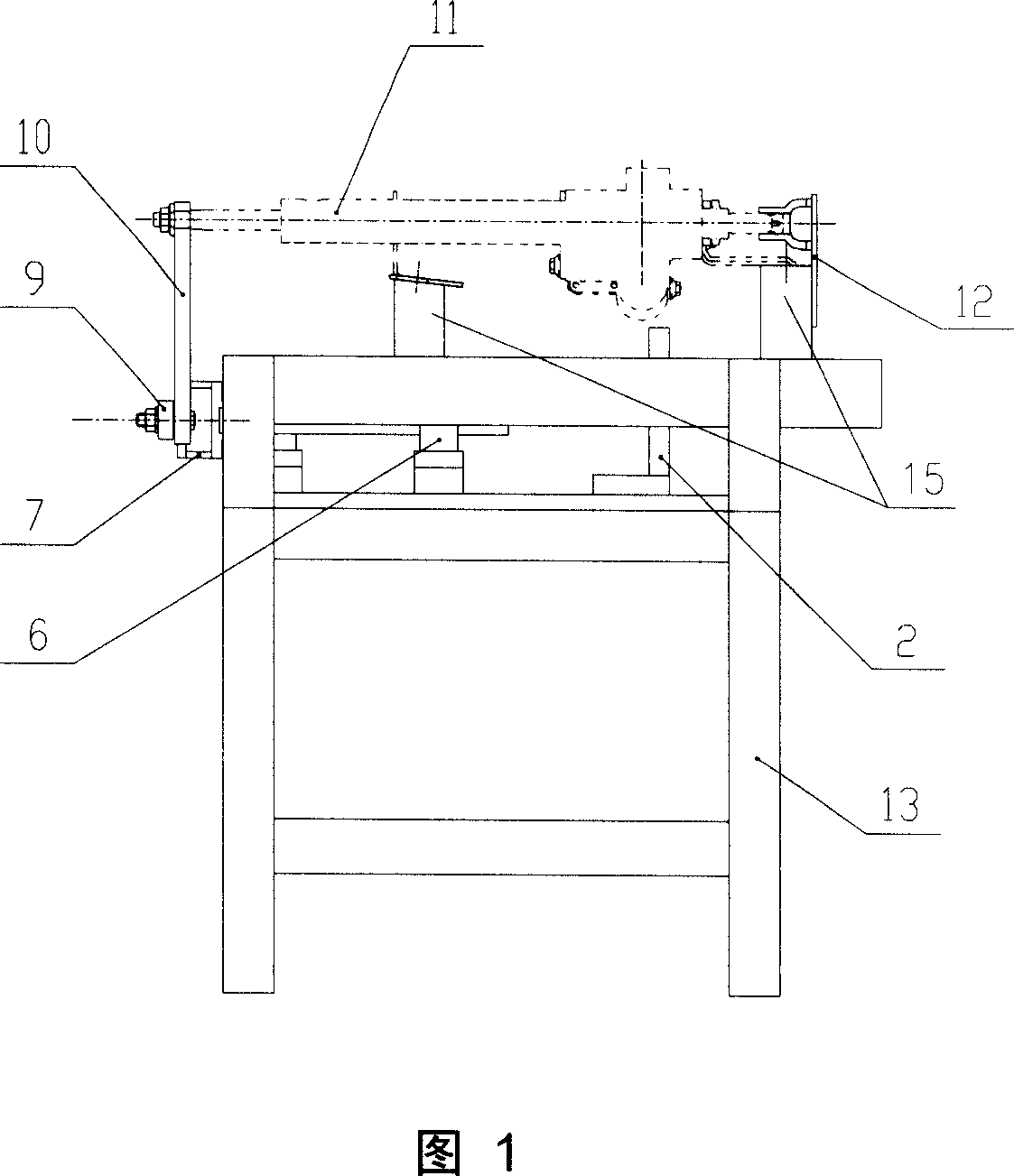

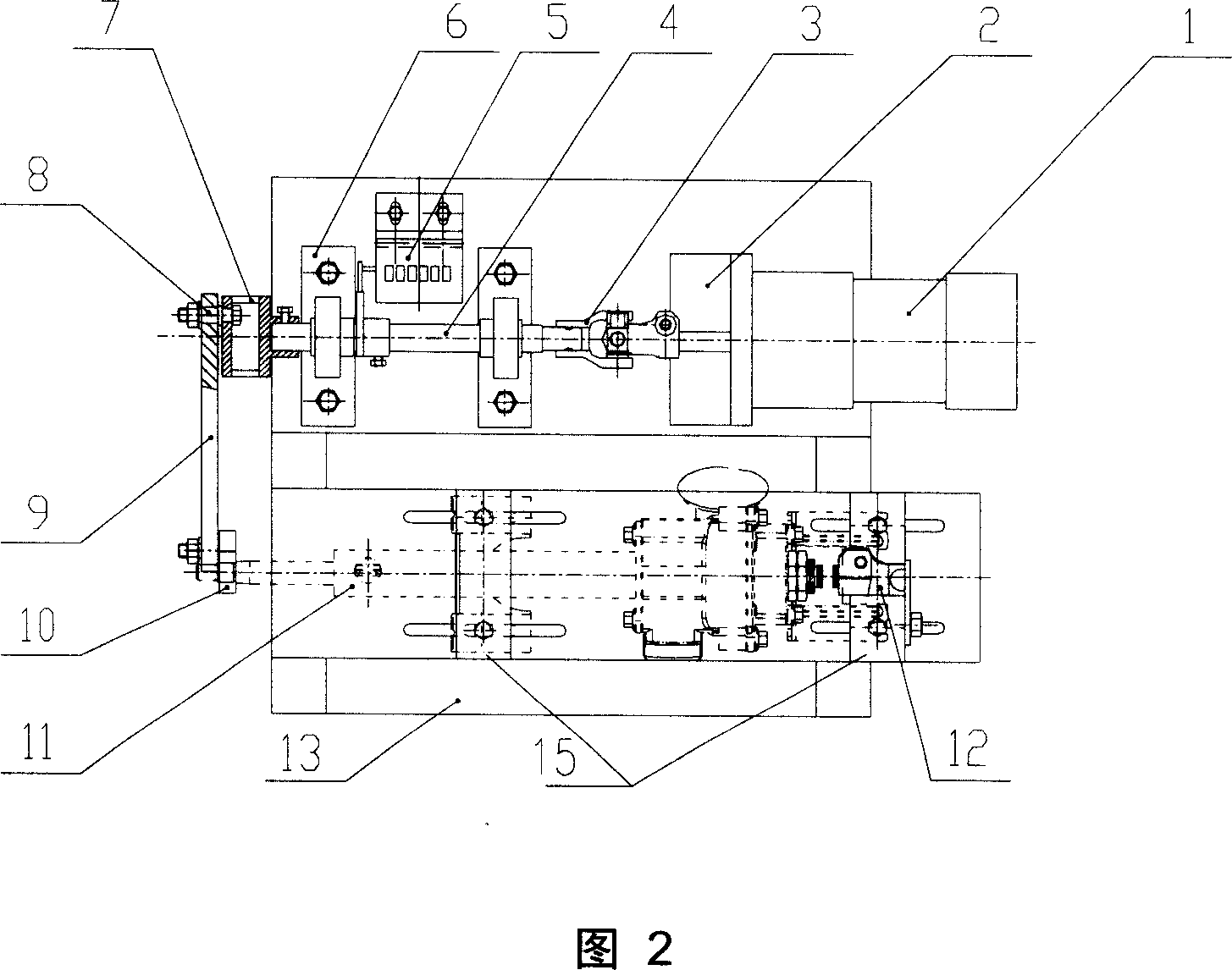

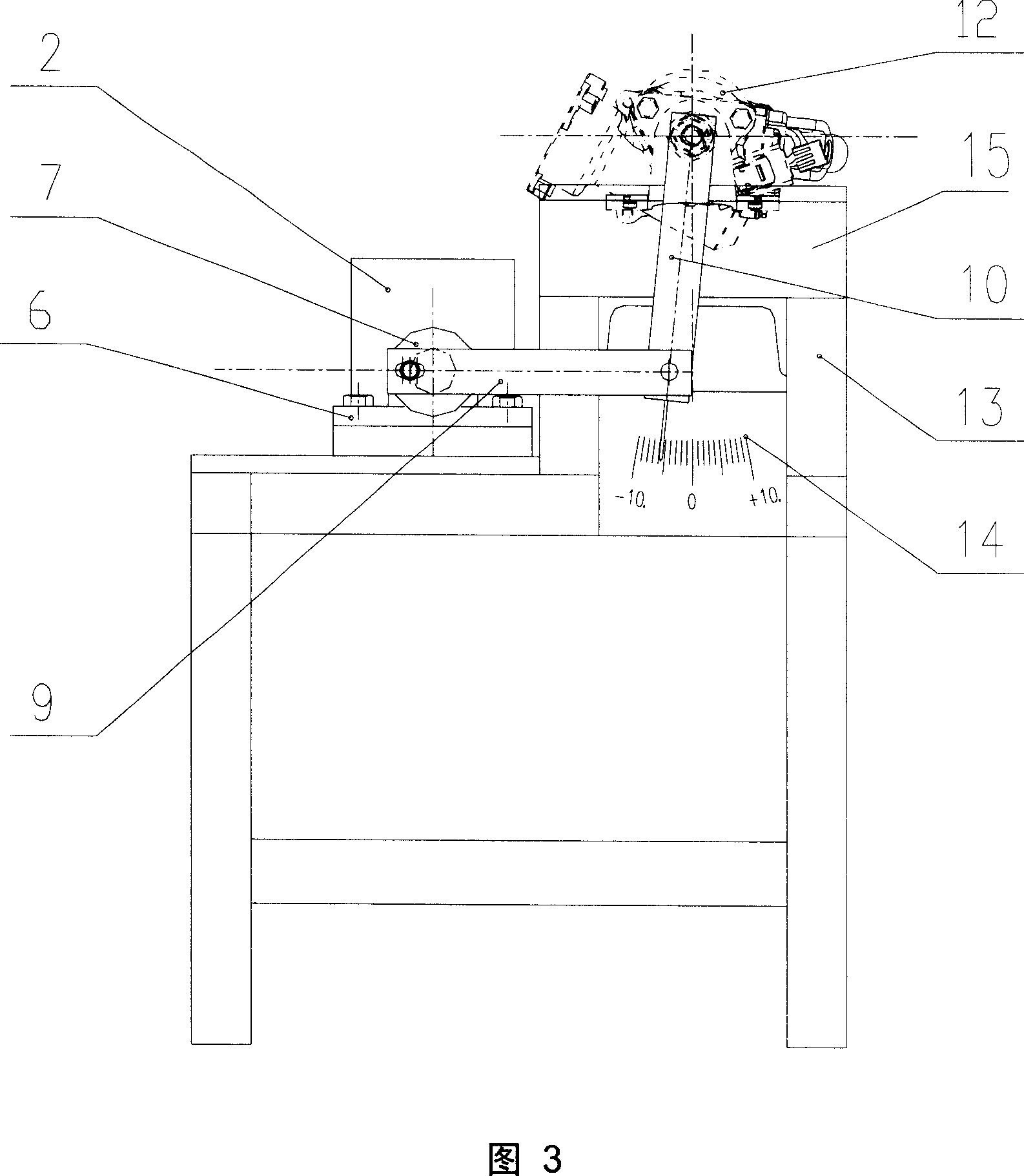

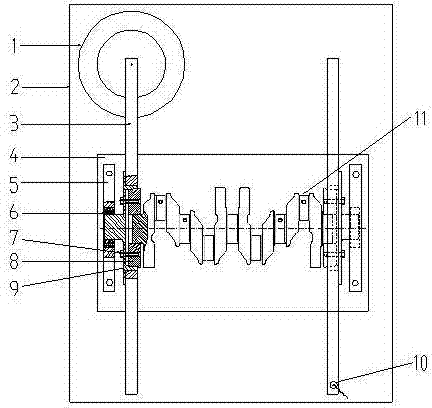

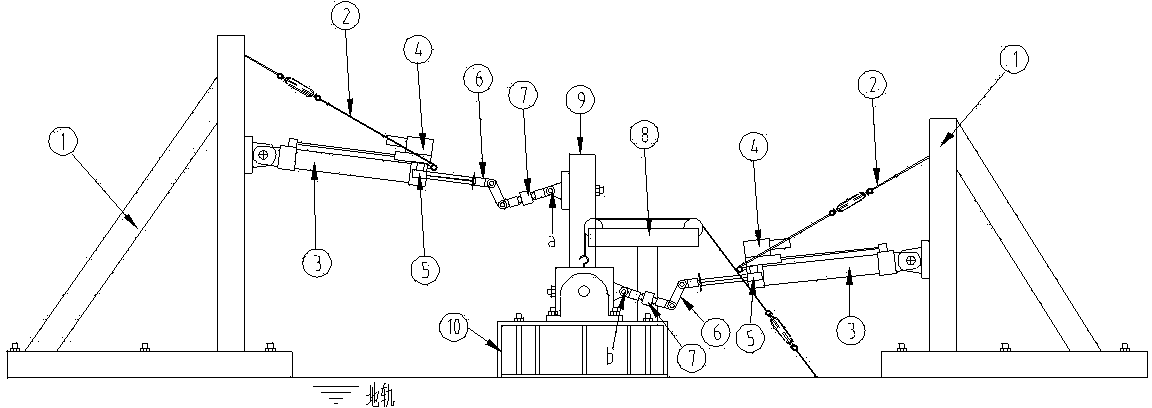

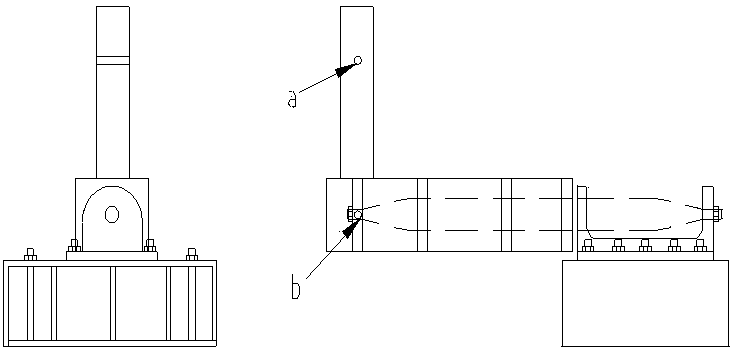

Torsion device used for large horizontal tail shaft torsion fatigue test

The invention discloses a torsion device used for a large horizontal tail shaft torsion fatigue test. The device mainly comprises a power device, a mechanical transmission device and a control system. The power device is a hydraulic system, the mechanical transmission device is composed of a bearing column (1), a steel wire rope (2), a hydraulic oil cylinder (3), a servo valve (4), a displacement sensor (5), a connection rod device (6), a force sensor (7), a bearing device (8), a test piece fixing device (9) and a base (10). The control system is a two-channel coordinated loading system. The hydraulic oil cylinder (3) is fixed to the bearing column (1) through the steel wire rope and is connected with the test piece fixing device (9) through the connection rod device (6). The torsion device has the advantages that due to the loading points of a test piece include a point A and a point B, an actuator cylinder with a reasonable tonnage can be selected according to test loading requirements; when stress is exerted on the loading point A and the loading point B, torsion load can be generated, the torsion device capable of completing the large horizontal tail shaft torsion fatigue test is formed; test cost of the device is low and adaptability of specimens is wide.

Owner:青岛苏试海测检测技术有限公司

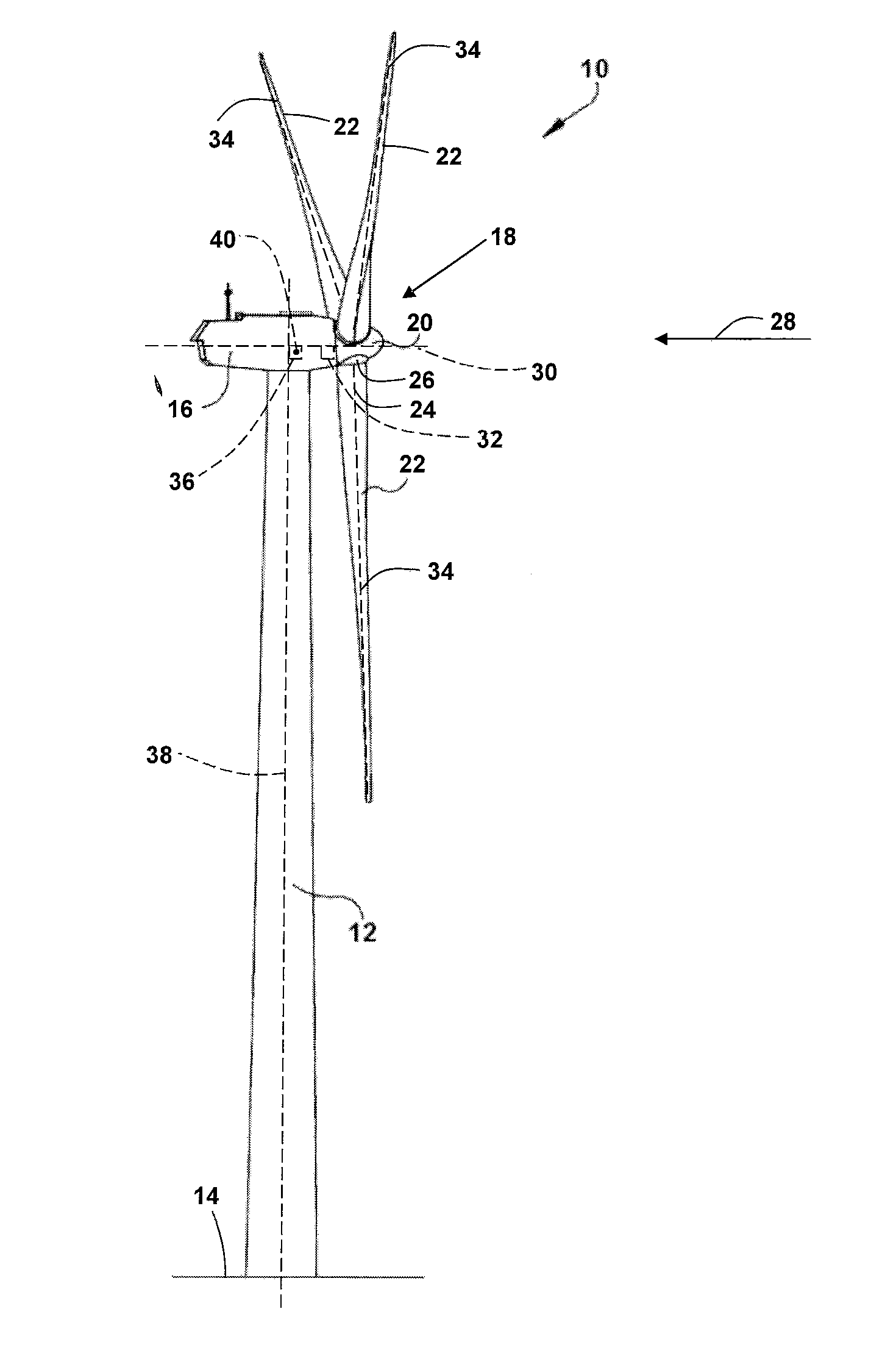

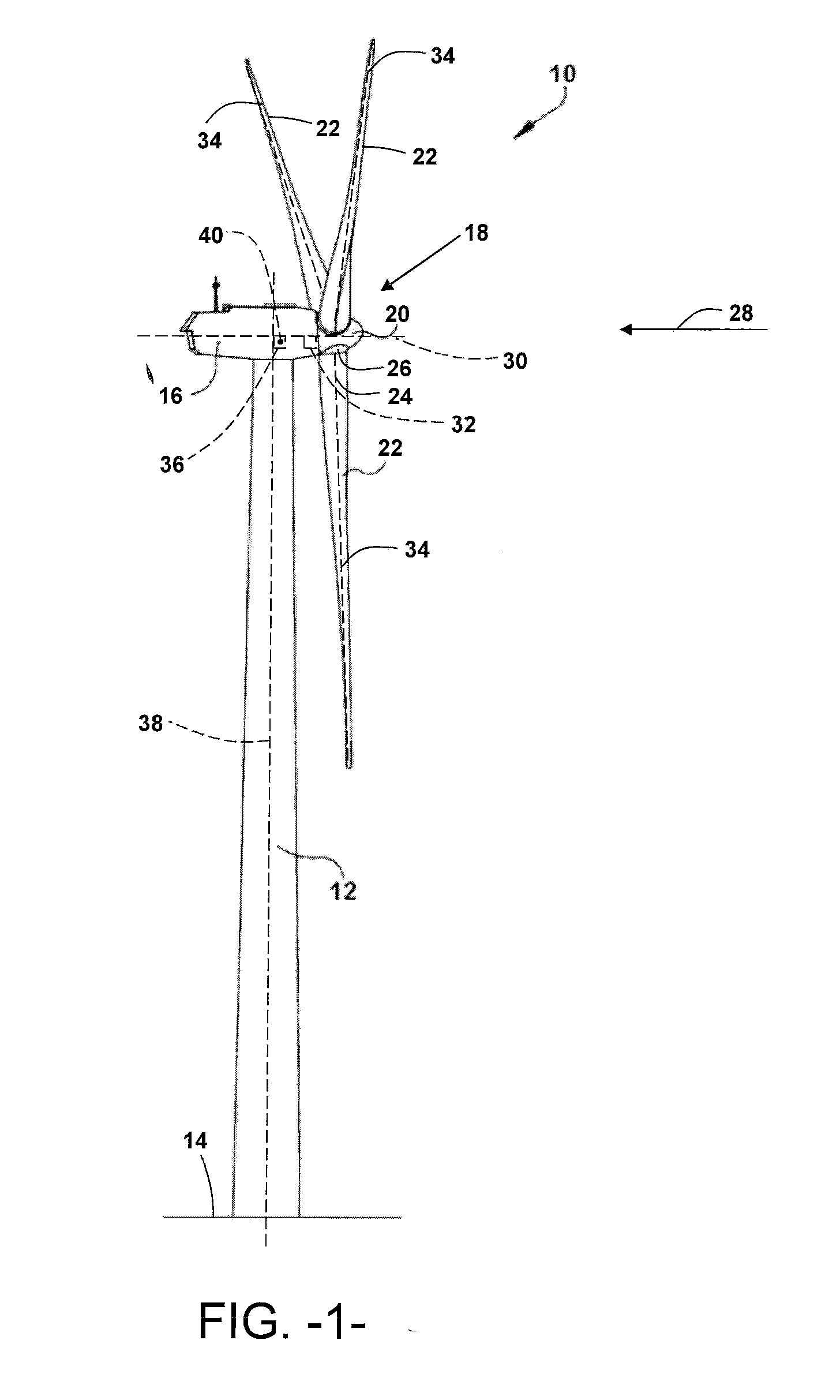

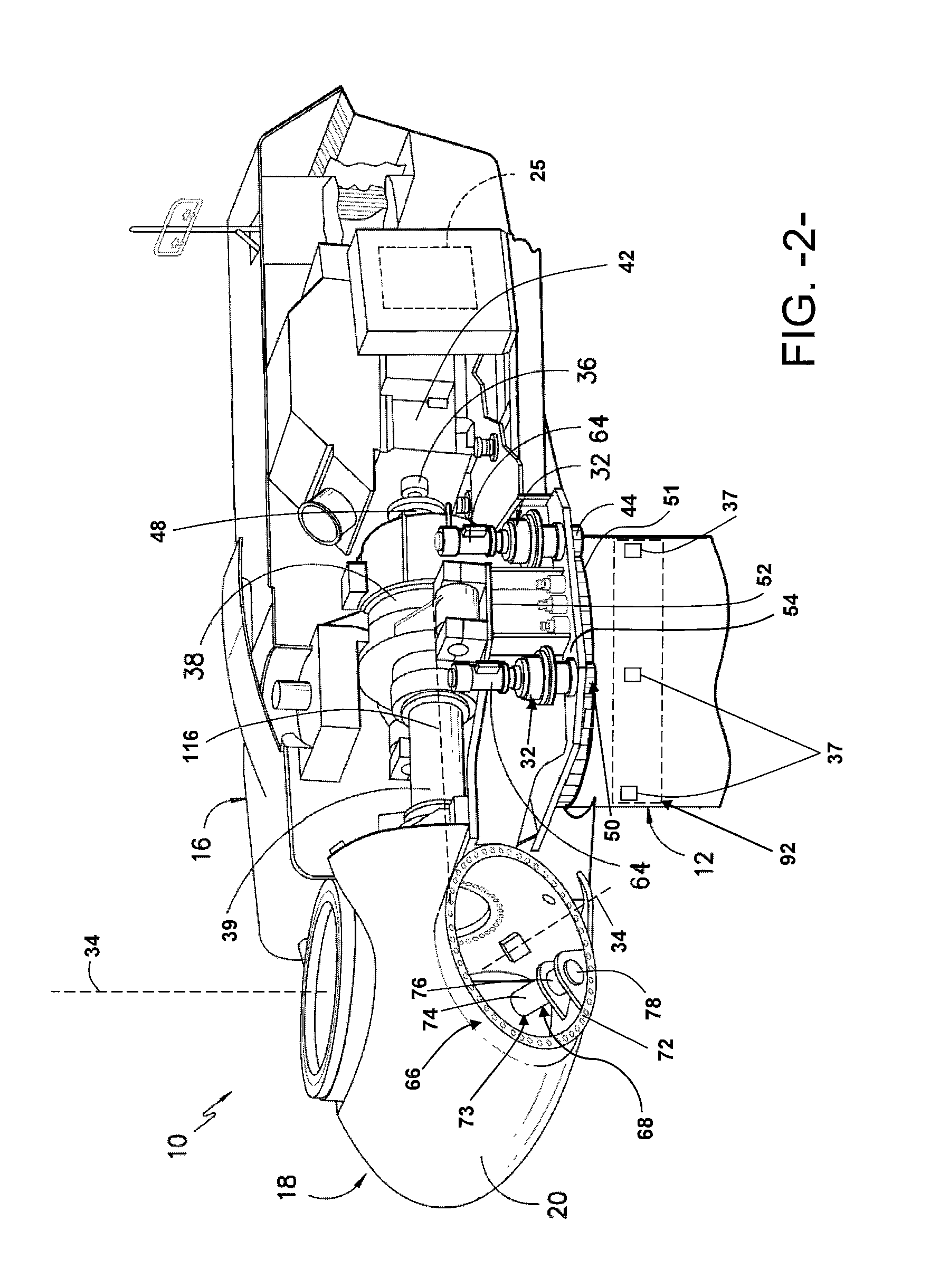

Asymmetric load control for torsion fatigue reduction in a wind turbine tower

A method and system for reducing a torsional movement and / or a torsional loading of a tower of a wind turbine is disclosed includes generating a tower torsion signal with a detection system and providing the signal to an asymmetric load control assembly. The tower torsion signal may correspond to an actual torsional movement of the tower or a torsional loading of the tower. The asymmetric load control assembly is configured to mitigate an asymmetric load acting on the wind turbine using the tower torsion signal.

Owner:GENERAL ELECTRIC CO

Seamless steel tubes and method for producing the same

ActiveUS7316143B2Avoid crackingImprove toughnessFurnace typesMetal rolling arrangementsTorsion fatigueToughness

A seamless steel tube comprising, in mass %, C: 0.30 to 0.50%, Si: 0.5% or less, Mn: 0.3 to 2.0%, P: 0.025% or less, S: 0.005% or less, Cr: 0.15 to 1.0%, Al: 0.001 to 0.05%, Ti: 0.005 to 0.05%, N: 0.02% or less, B: 0.0005 to 0.01% and O (oxygen): 0.0050% or less, wherein Beff defined in following equation (a) or (b) takes a value of 0.0001 or more, where Beff=B−10.8×(N−14×Ti / 47.9) / 14—(a) when Neff=N−14×Ti / 47.9≧0, and Beff=B—(b) when Neff=N−14×Ti / 47.9<0, thus enabling to provide seamless steel tubes having excellent cold workability, hardenability, toughness and torsion fatigue strength and being most suitable for hollow shaft blanks for use in making one-piece type hollow drive shafts as well.

Owner:NIPPON STEEL CORP

Heavy-duty car frame bending torsion fatigue test bench device and method thereof

The invention relates to the technical field of automobile part performance testing, in particular to a heavy-duty car frame bending torsion fatigue test bench device and a method thereof. The heavy-duty car frame bending torsion fatigue test bench device comprises a frame assembly, a front suspension assembly, a rear suspension assembly, a front axle, a rear axle, an air bag loading unit, a firsttorsion oil cylinder, a second torsion oil cylinder, a third torsion oil cylinder and a fourth torsion oil cylinder, the first torsion oil cylinder and the second torsion oil cylinder are movably connected with the two ends of the front axle respectively, and the third torsion oil cylinder and the fourth torsion oil cylinder are movably connected with the two ends of the rear axle respectively; the air bag loading unit is arranged at the rear part of the frame assembly, the air bag loading unit comprises a bottom plate, a top plate, a plurality of air bags arranged between the bottom plate and the top plate, and a ventilation device for injecting gas into each air bag. According to the invention, the cost of the heavy-duty car frame bending torsion fatigue test bench device can be reduced, and the dynamic load state of a real vehicle in the driving process can be truly simulated.

Owner:DONGFENG COMML VEHICLE CO LTD

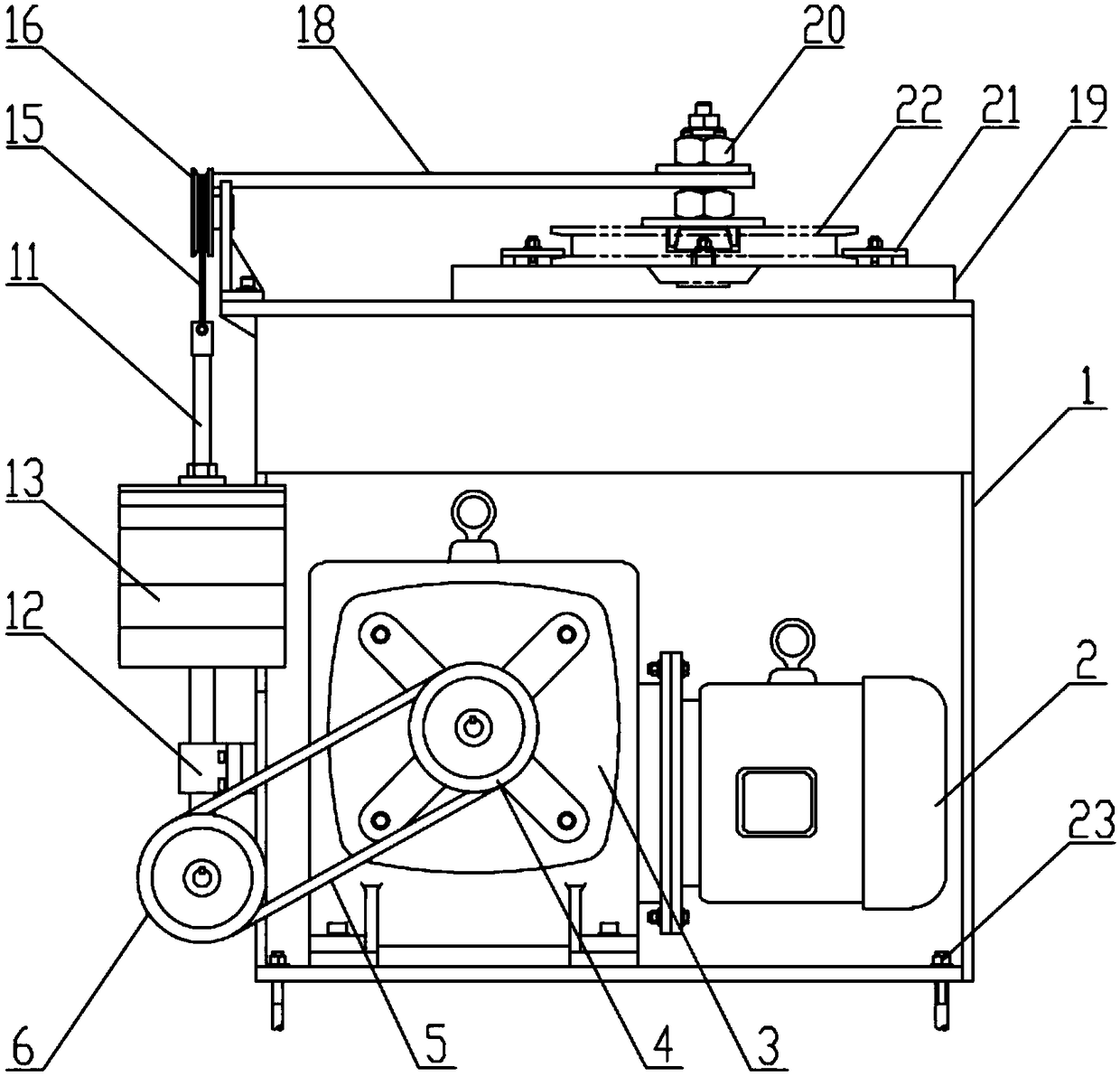

Reciprocating torsion durability test device and test method

PendingCN108732009AMonitoring reciprocating torsional durability performanceAchieve fatigue work effectMaterial strength using repeated/pulsating forcesFatigue testingTorsion fatigue

The invention discloses a reciprocating torsion durability test device and test method, and relates to the field of torsion fatigue testing. The device comprises a box body and also comprises fixed stations, a tensioning mechanism, an oscillating bar, pulley mechanisms, falling devices, cam mechanisms and a power device, wherein the fixed stations are arranged on the top of the box body for fixinga workpiece to be tested; the tensioning mechanism is used as a spindle to be connected with the workpiece to be tested; the pulley mechanisms are symmetrically arranged on the top of the front sideof the box body; the upper ends of the left falling device and the right falling device are connected through a flexible rope; the flexible rope bypasses the pulley mechanisms; one end of the oscillating bar is fixedly connected with the tensioning mechanism, and the other end of the oscillating bar is connected to the middle of the flexible rope; the cam mechanisms are arranged on the front sideof the box body; the lower end of each falling device is in cooperation with the cam mechanisms; the power device is arranged in the box body. According to the reciprocating torsion durability test device, reciprocating torsion force can be applied to the core part of the element to be tested so as to achieve a fatigue work effect on simulating the practical work state of the workpiece, the reciprocating torsion durability performance of the workpiece to be evaluated can be effectively monitored, and in addition, the reciprocating torsion durability test device has the advantages of simple structure and convenience in operation.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

Electric direct-drive shaft torsional fatigue test device and method

ActiveCN111366357ASimple structureLow costMachine gearing/transmission testingTorsion fatigueElectric machine

The invention discloses an electric direct-drive shaft torsional fatigue test device and method, and aims to overcome defects of high cost, poor universality and oil leakage risk of an existing hydraulic fatigue test machine. The device comprises a mounting platform, a power direct-drive main motor, a power direct-drive auxiliary motor, a torque sensor and a connecting seat for clamping a test piece, wherein a movable sliding plate is mounted on the mounting platform, the power direct-drive main motor is rotatably mounted on the sliding plate, the power direct-drive auxiliary motor is rotatably mounted on the mounting platform, the connecting seat is movably mounted between the power direct-drive main motor and the power direct-drive auxiliary motor, the connecting seat is arranged betweenthe power direct-drive main motor and the power direct-drive auxiliary motor, and the torque sensor is arranged between the connecting seat and the power direct-drive main motor. The electric direct-drive shaft torsional fatigue test device is simple in structure, low in cost and good in universality, and the risk of oil leakage is avoided.

Owner:策仕(宁波)工业技术有限公司

Tension-torsion fatigue test bench for automobile flywheel plate

PendingCN108332978AVehicle testingMaterial strength using tensile/compressive forcesAxial displacementTorsion fatigue

The invention relates to a tensile-torsion fatigue test bench for an automobile flywheel plate. The test bench comprises a base, a flywheel plate fixed plate is arranged on the base, a torque applyingdevice applying a torque to a to-be-tested flywheel plate is arranged on the base, at one side of the flywheel plate fixed plate, an axial force applying device applying an axial load on the to-be-tested flywheel plate is arranged on the base, at the other side of the flywheel plate fixed plate, and the torque applying device can move axially together with the to-be-tested flywheel plate under the action of the axial force applying device through a guiding structure arranged on the base. According to the tensile-torsion fatigue test bench for the automobile flywheel plate, when an axial displacement test and a torque test need to be performed simultaneously, the torque applying device is used for applying the torque to the to-be-tested flywheel plate, the axial force applying device is used for applying the axial load on the to-be-tested flywheel plate, the torque applying device moves axially together with the to-be-tested flywheel plate through the guiding structure, so that the axial displacement test and the torque test can be performed simultaneously on the automobile flywheel plate, and the application prospect is good.

Owner:昆山万马五金有限公司

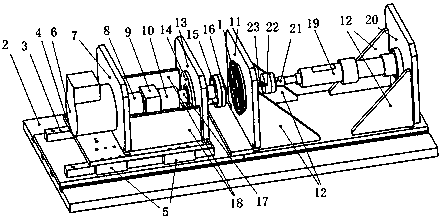

Dynamic torsional fatigue tester for automobile transmission shaft assemblies

InactiveCN104515679ATest service lifeTest fatigue strengthVehicle testingMachine gearing/transmission testingSteering wheelTorsion fatigue

The invention discloses a dynamic torsional fatigue tester for automobile transmission shaft assemblies. The dynamic tester comprises a support and a base disposed within a box. One end of the base is provided with a main reduction drive mechanism, and the other end thereof is provided with a dynamic torsional mechanism. Space between the main reduction drive mechanism and the dynamic torsional mechanism is used for clamping a transmission shaft assembly to be tested. The dynamic torsional mechanism is provided with a loading mechanism. By programming through a control panel, a motor is allowed to drive a spindle to rotate (positively and reversely in turn); the transmission shaft assembly transmits power to a driven shaft; a servo motor drives a steering wheel to rotate to a certain angle, a loading wheel applies certain resistance, and various normal running states of an automobile are simulated: starting, accelerating, turning, parking and the like; thus, the service life and fatigue strength of the transmission shaft assembly during the automobile running is tested.

Owner:JIANGXI KENTE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com