Structure of constant velocity universal joint

A constant velocity universal joint and cage technology, which is applied in the direction of elastic couplings, mechanical equipment, couplings, etc., can solve the problem of large wear of the contact surface between the cage and the star sleeve, and reduce the constant velocity universal joint assembly Problems such as service life and unstable operation process, etc., achieve the effect of easy implementation of production process and process control, reliable production process and process control, and lower manufacturing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 shown.

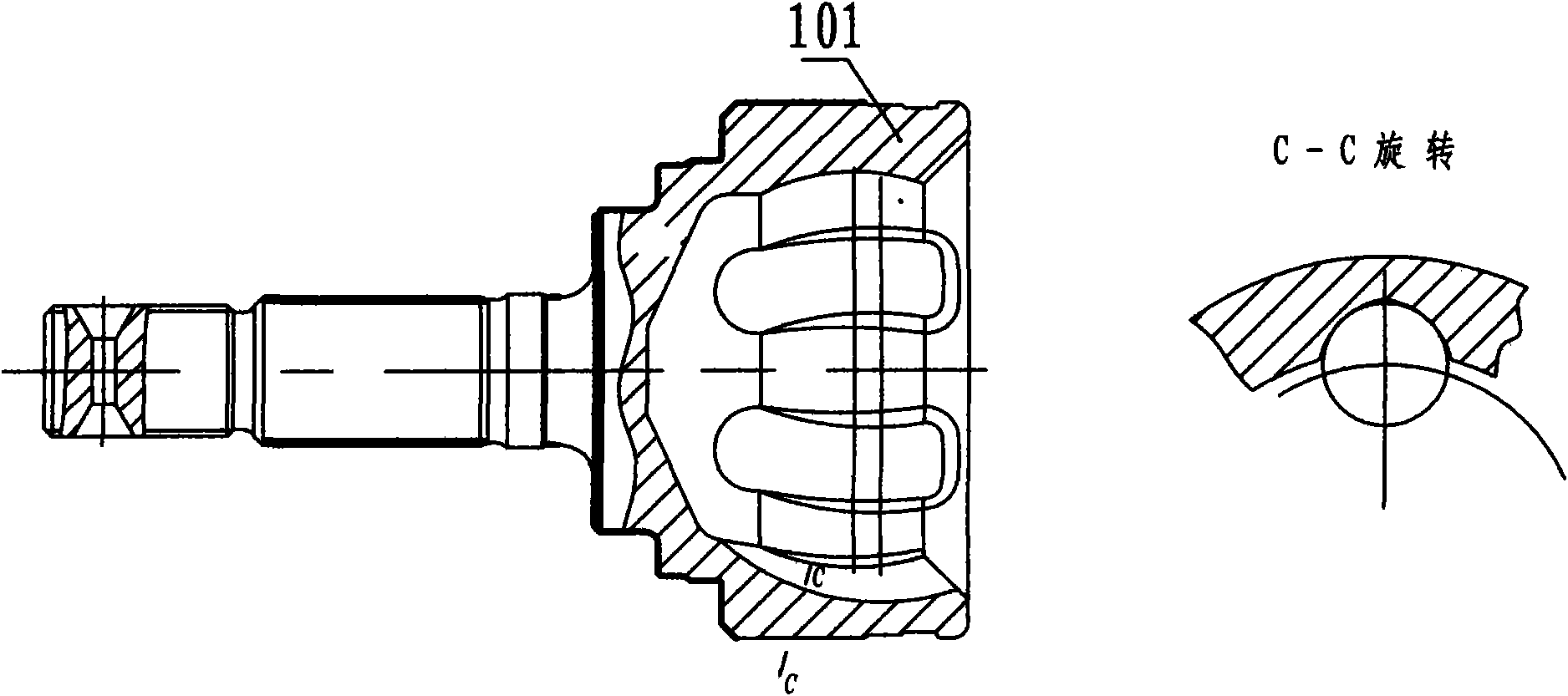

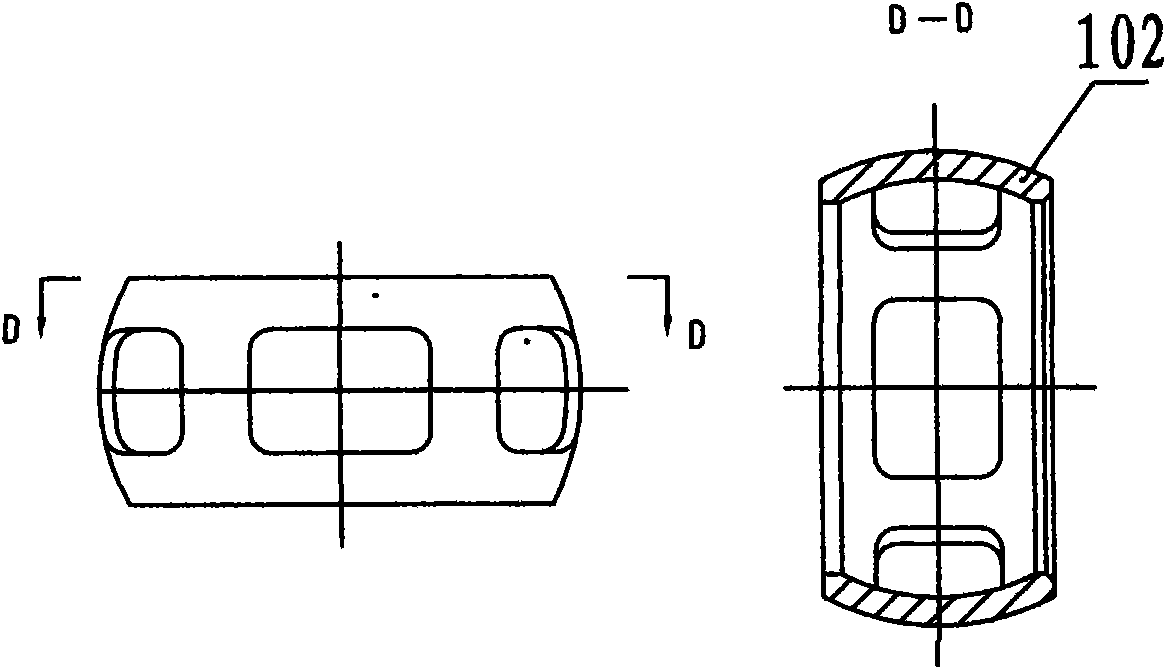

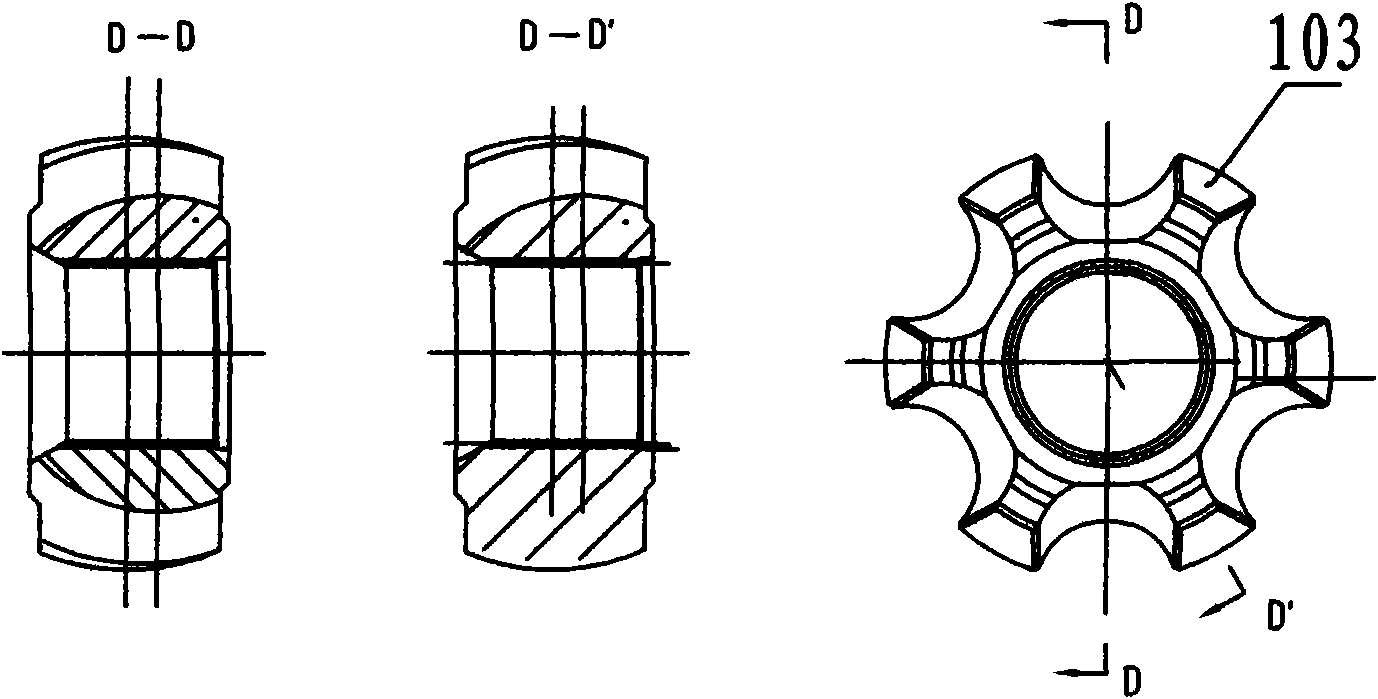

[0027] The inner surface of the spherical shell 101 in the prior art is evenly distributed with circular arc raceways, the inner surface is closely connected with the outer spherical surface of the cage 102, and the inner spherical surface of the cage 102 is closely connected with the outer spherical surface of the star sleeve 103, when the intermediate shaft (driving shaft) When the angle between 105 and the outer ball seat shaft (driven shaft) 106 changes, the inner spherical surface of the spherical shell 101 and the outer spherical surface of the cage 102 slip, and the inner spherical surface of the cage 102 and the outer spherical surface of the star sleeve 103 slip , so that the center of the steel ball is always located on the bisector of the angle betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com