Patents

Literature

262 results about "Fatigue fractures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

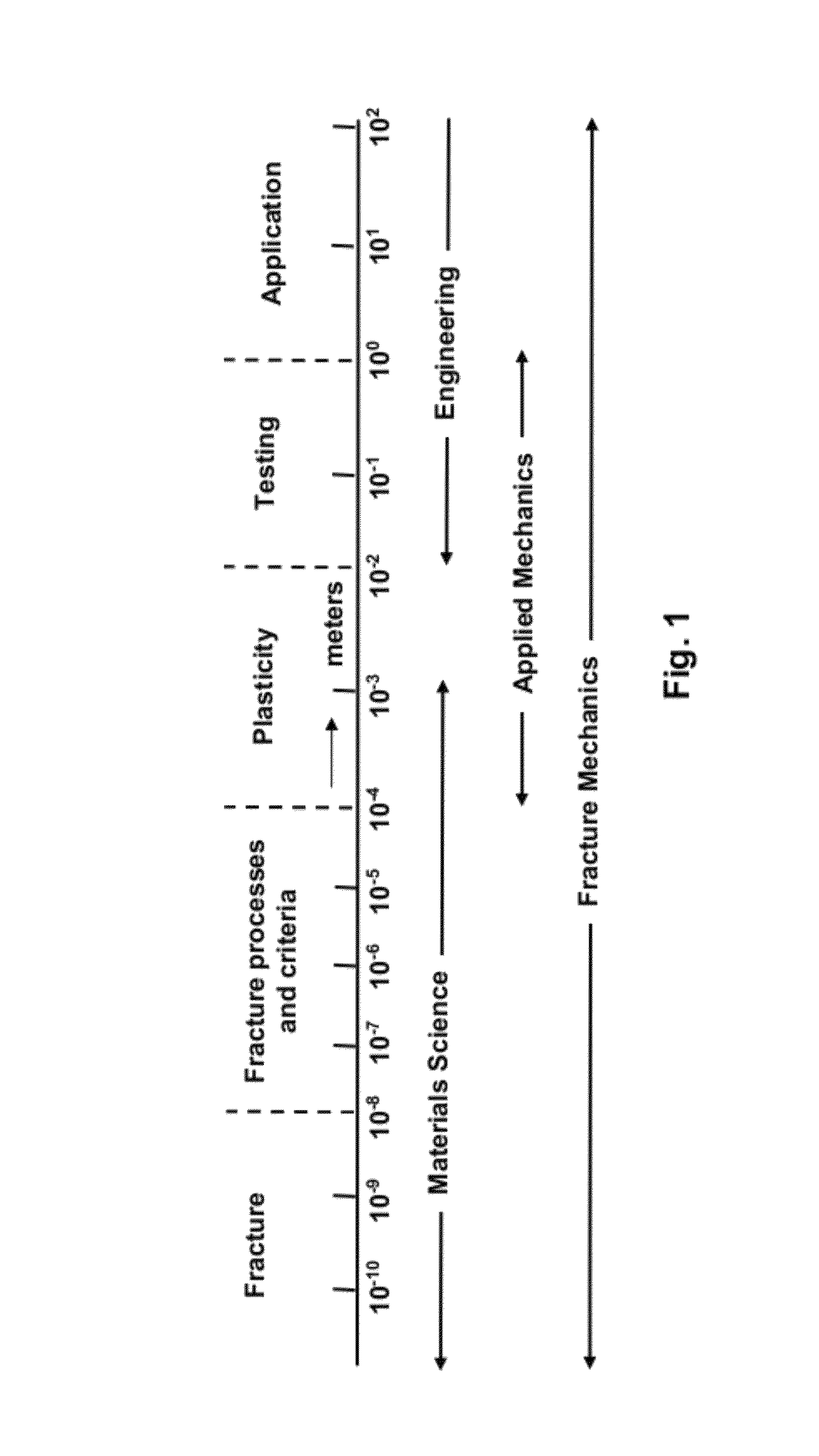

Fatigue fractures are a type of stress fracture due to abnormal stresses on normal bone. They should not be confused with an insufficiency fracture, which occurs due to normal stresses on abnormal bone. Plain radiographs typically demonstrate a linear sclerotic region but have poor sensitivity, especially in early-stage injuries.

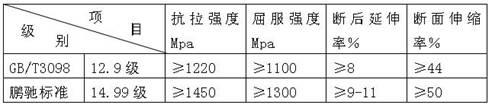

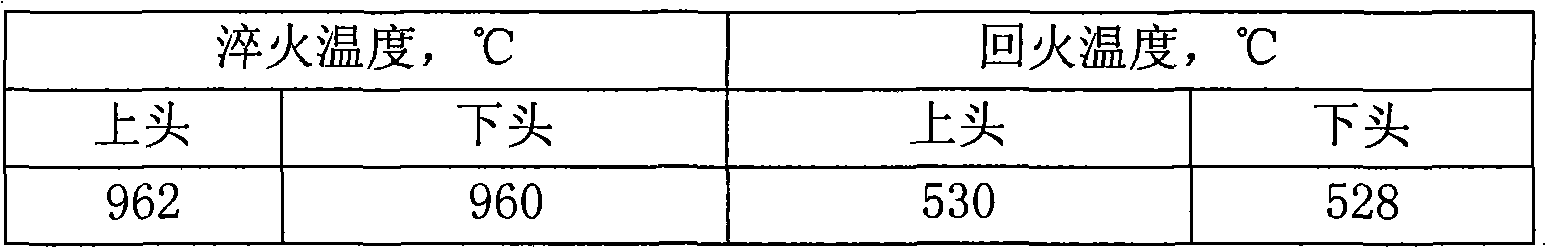

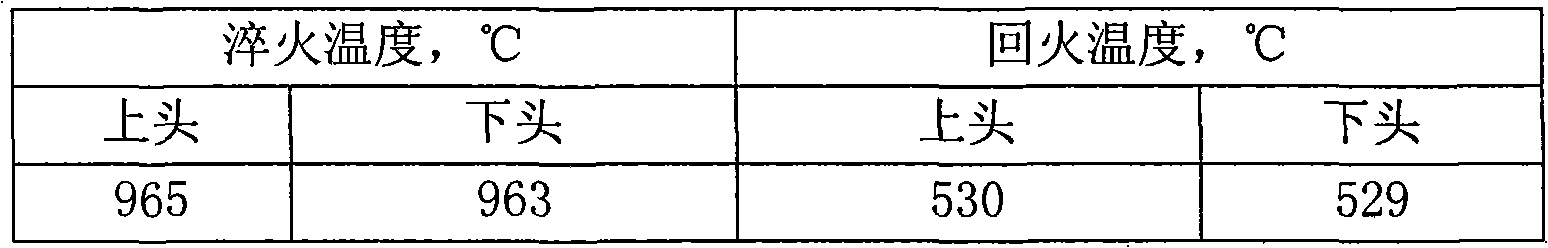

Processing method of high-strength bolts

The invention relates to a processing method of bolts, in particular to a processing method of high-strength bolts. SCM440 and 42CrMoVNb materials are adopted for producing the high-strength bolts. The method is characterized by selecting materials, spheroidizing the materials, acid cleaning the materials and drawing wires from the materials until the materials retract to the required diameter, carrying out extrusion molding on the materials 3-4 times on a multi-station cold forging machine to form the required bolt heads and shanks, carrying out rolling to obtain the required threads and thread length and realizing the required hardness and strength through thermal processing and quench tempering. The processing method in which the cold extruding process of the invention is adopted improves the strength of the bolts, achieves the hardness and strength required by the 12.9-class and 14.9-class high-strength bolts, solves the problems of delayed fracture and fatigue fracture of the bolts under high strength, ensures the bolts to be reliably connected and not to be easily fractured during use, prolongs the lives of the bolts and meets the use requirements of various industries in the society for the high-strength bolts.

Owner:EAGLE METALWARE

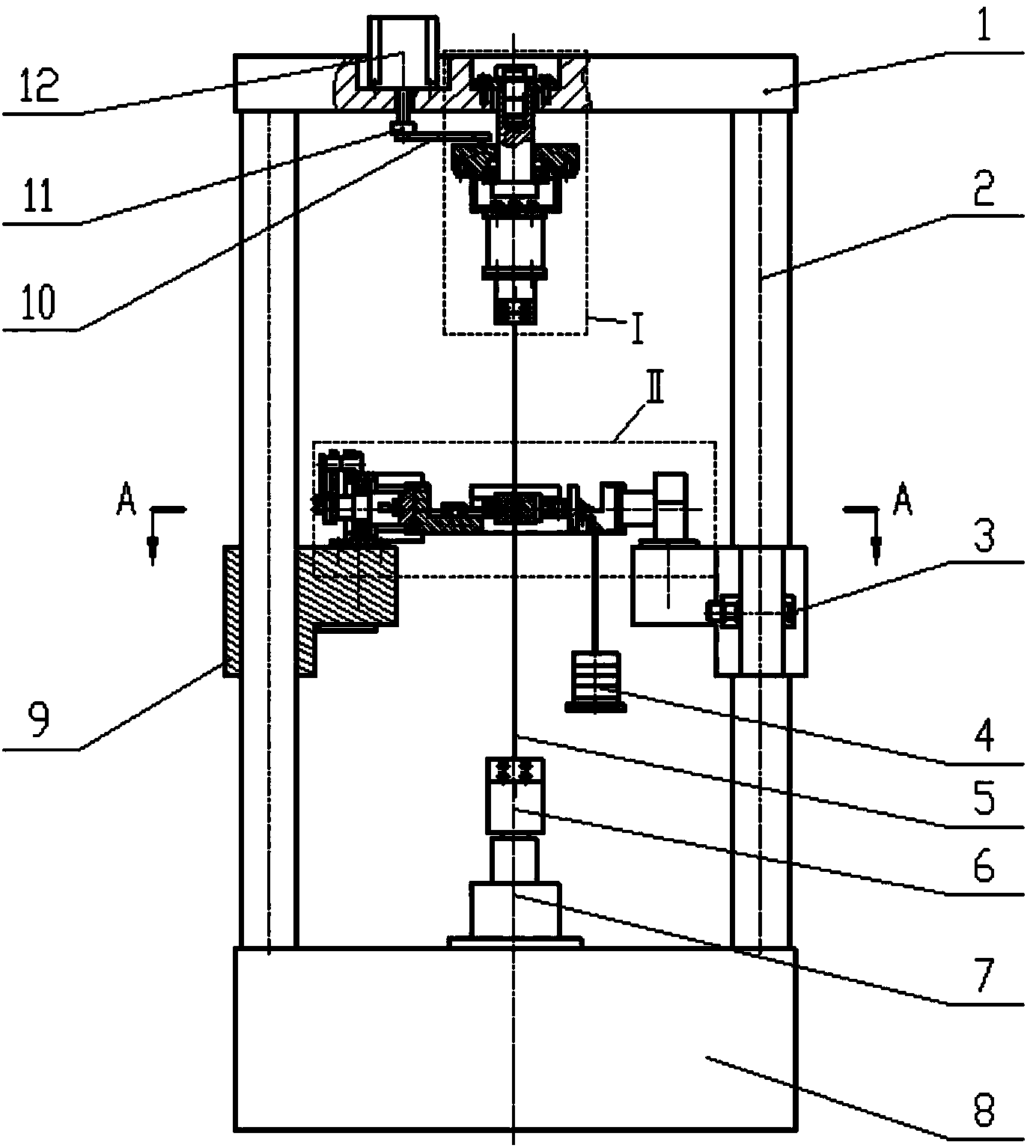

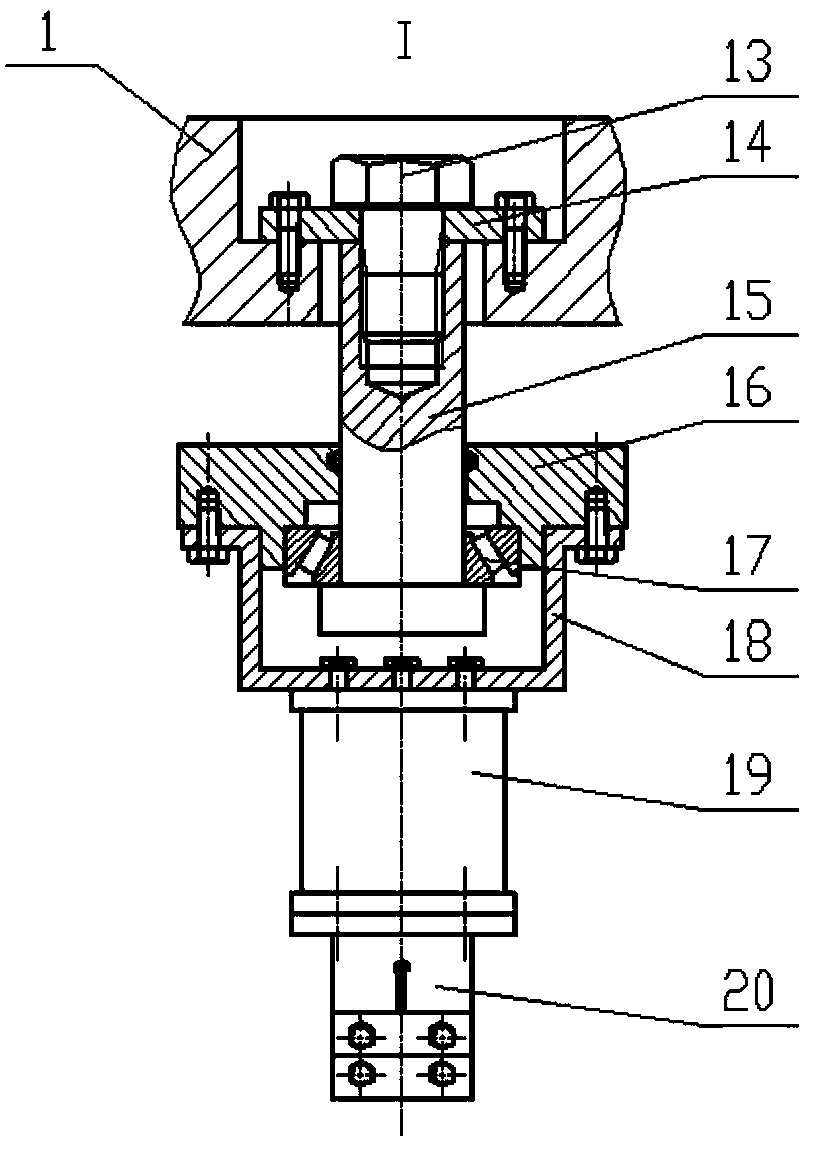

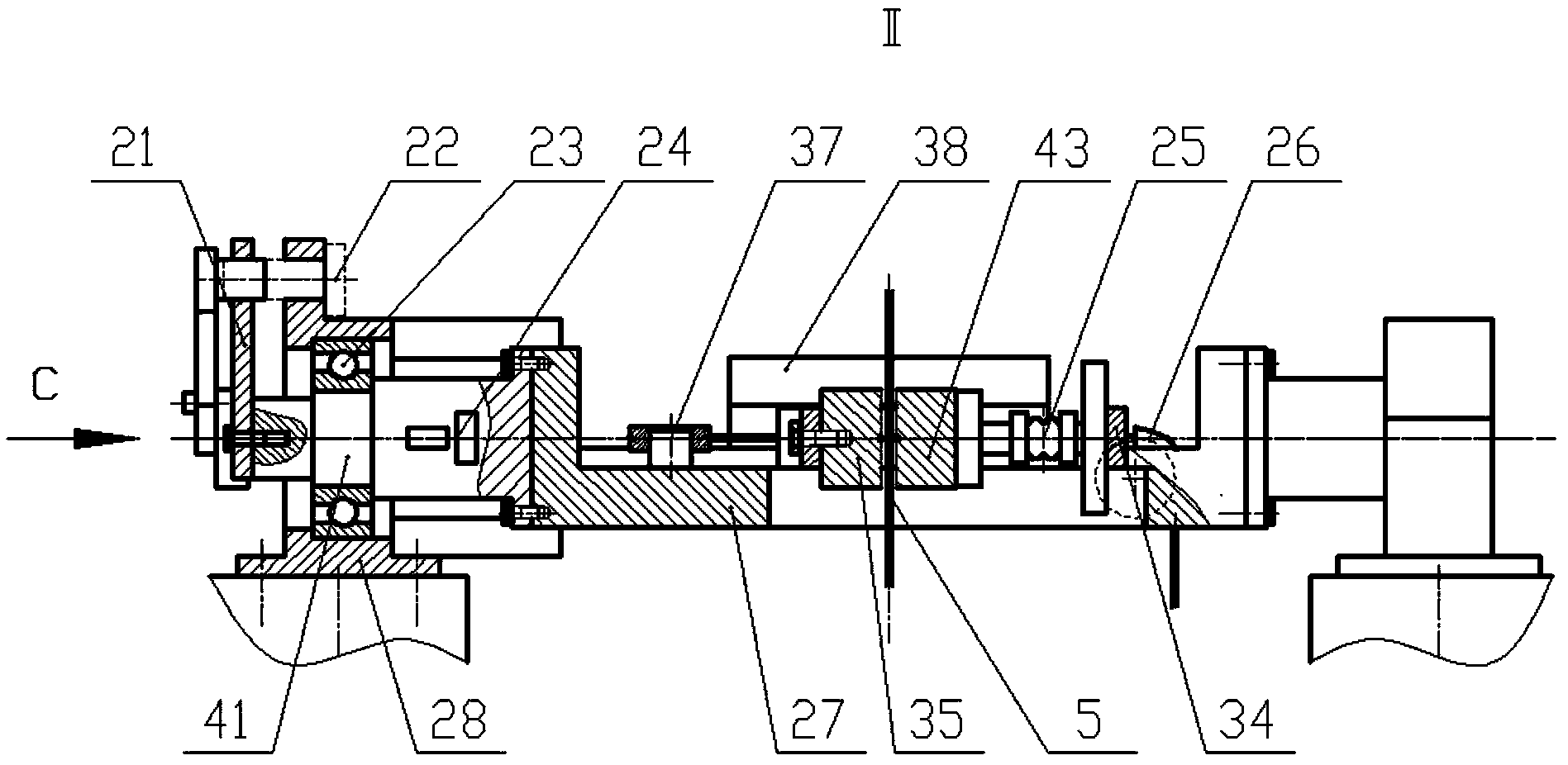

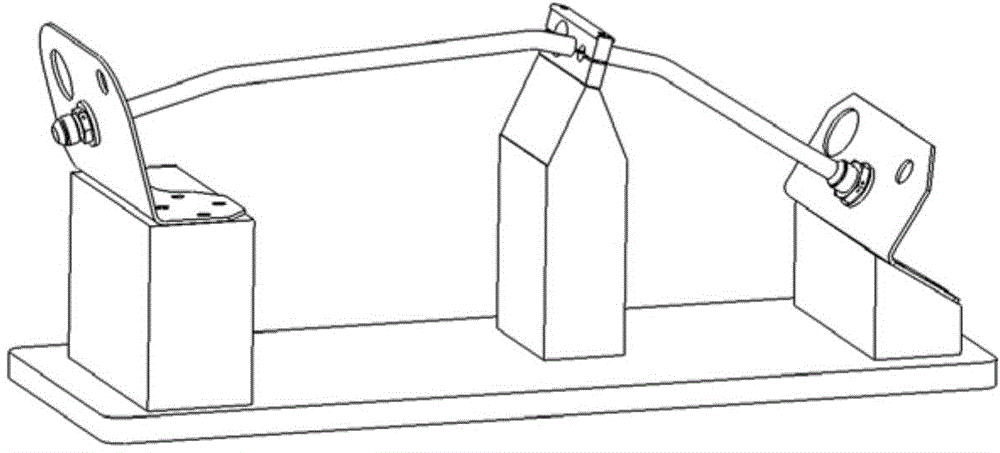

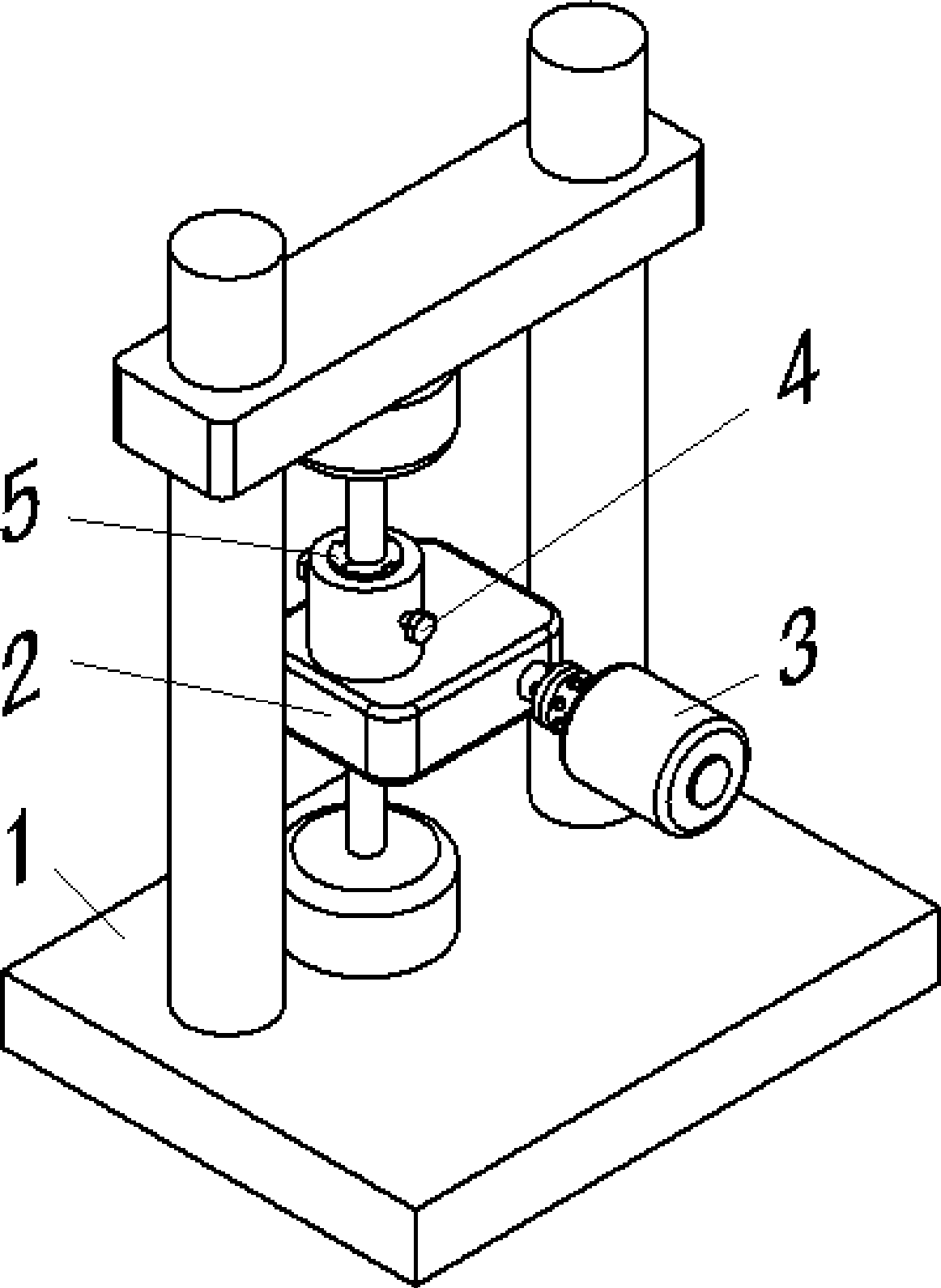

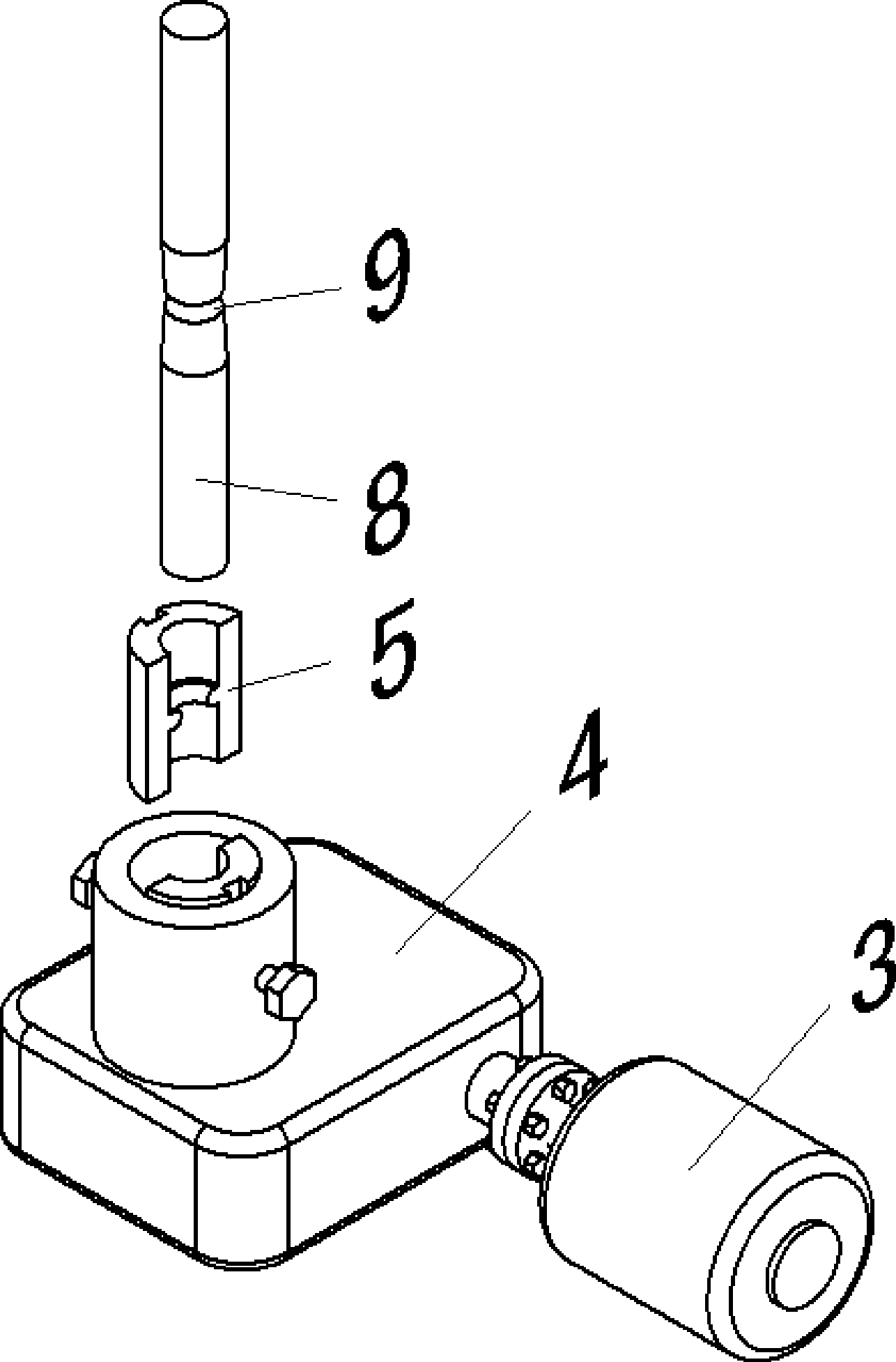

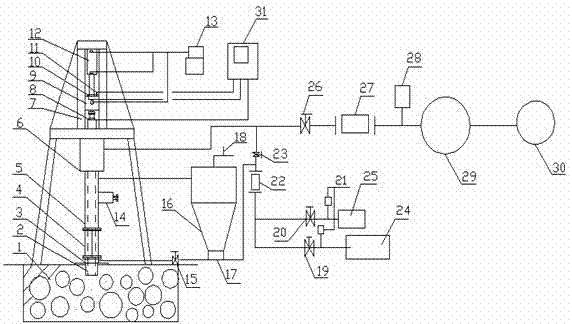

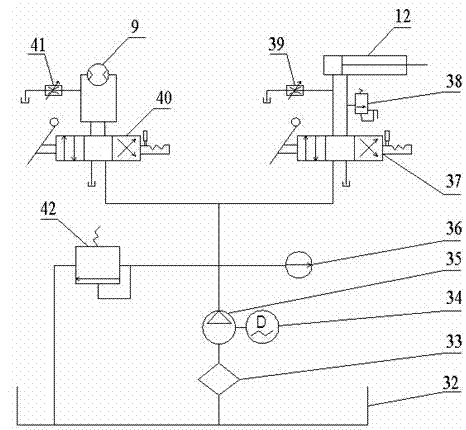

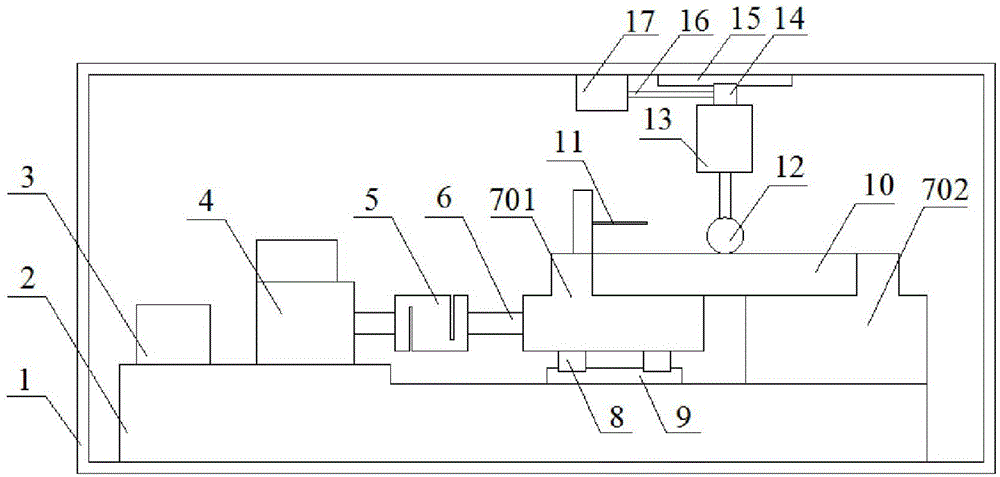

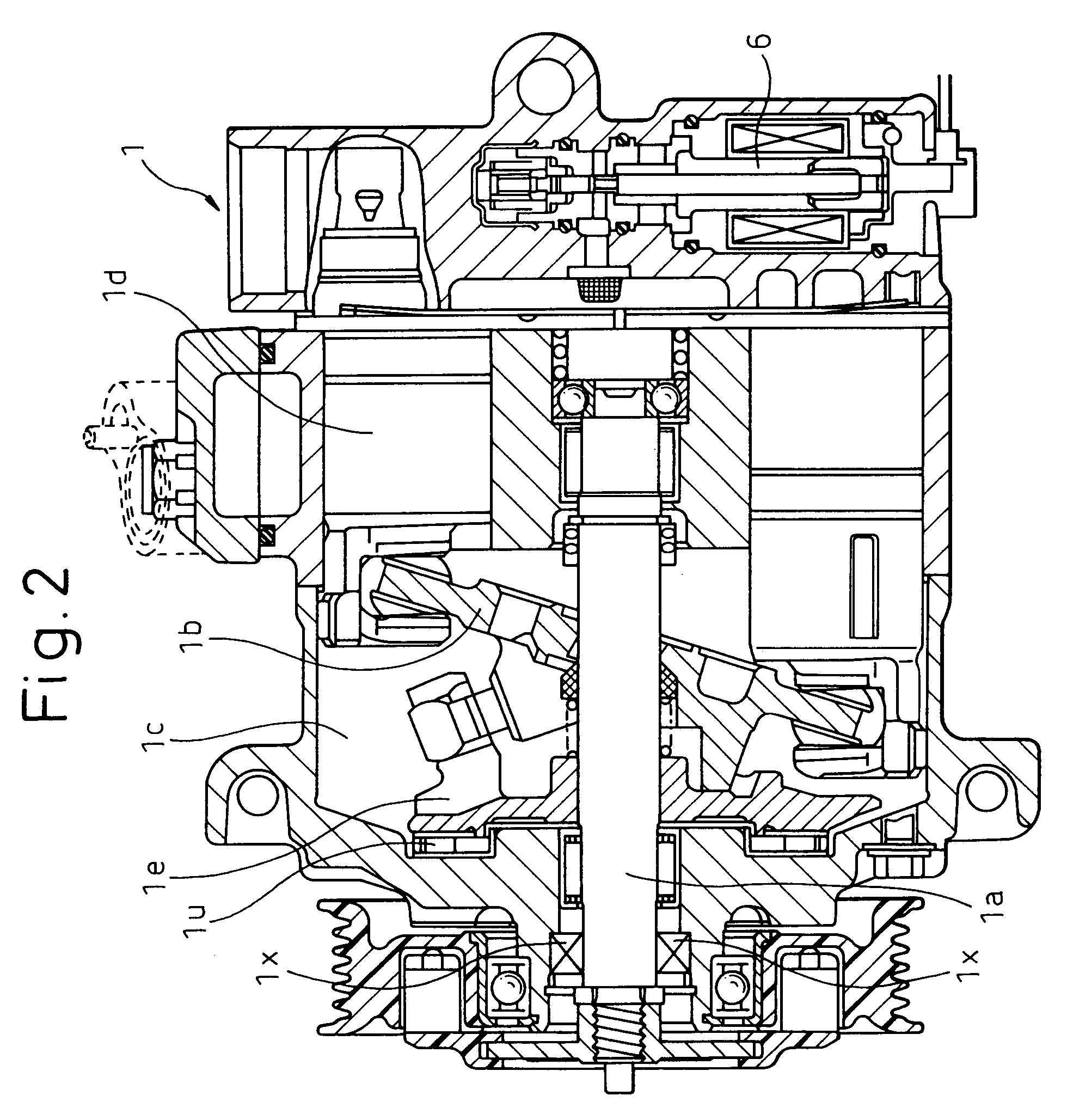

Device and method for multi-axis fretting fatigue test of steel wire

ActiveCN104297046AImprove multi-axis fretting fatigue damage characteristicsAdjust relative position in real timeMaterial strength using tensile/compressive forcesFatigue damageSupporting system

The invention relates to a device and a method for a multi-axis fretting fatigue test of a steel wire. The device comprises a base frame, a pull-torsion fatigue system, a swing loading system and a condition monitoring system, wherein the base frame comprises a base, support stand columns, bearing beams and support fixture blocks, the support stand columns are symmetrically arranged on the base; the bearing beams are respectively arranged on the tops of the support stand columns; the support fixture blocks are respectively arranged in the middle parts of the support stand columns; the pull-torsion fatigue system comprises a support system, a torsion driving system and a pull-pull fatigue system; the swing loading system comprises a swing driving system and a loading system; the condition monitoring system comprises a fretting measurement system, an axial fatigue load measurement system, a torsion measurement system and a swing measurement system. The torsion angle of the fatigue steel wire can be obtained through a crank-link mechanism by adjusting the eccentric position of an eccentric block; the multi-axis fretting fatigue test of the steel wire can be realized in the composite motion modes such as pull-pull fatigue, torsion and variable crossing angle swing and the like; the device and the method are used for disclosing the multi-axis fretting fatigue fracture mechanism of the steel wire, and carrying out quantitative evaluation on multi-axis fretting fatigue damage evolution and multi-axis fretting fatigue life of the steel wire.

Owner:CHINA UNIV OF MINING & TECH

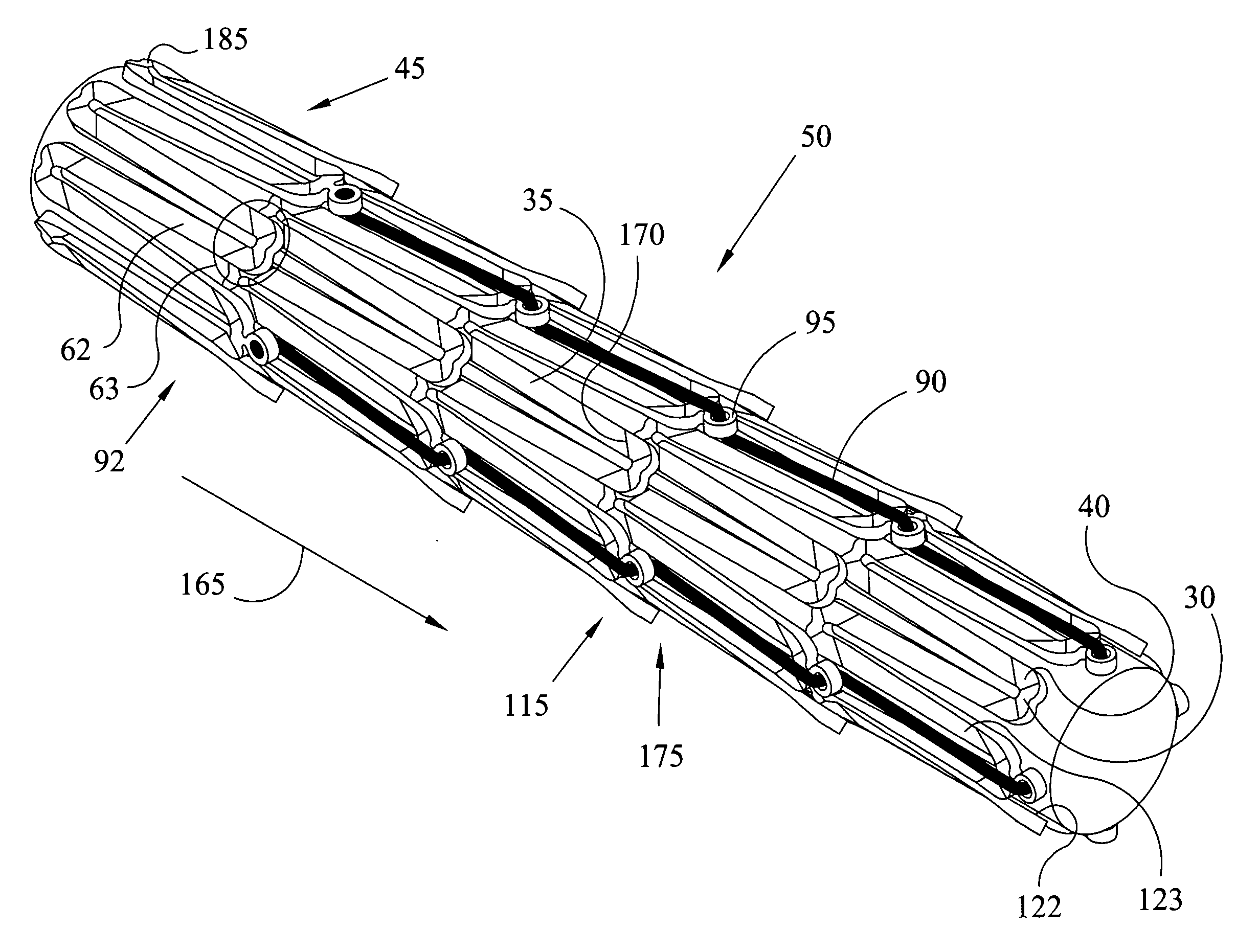

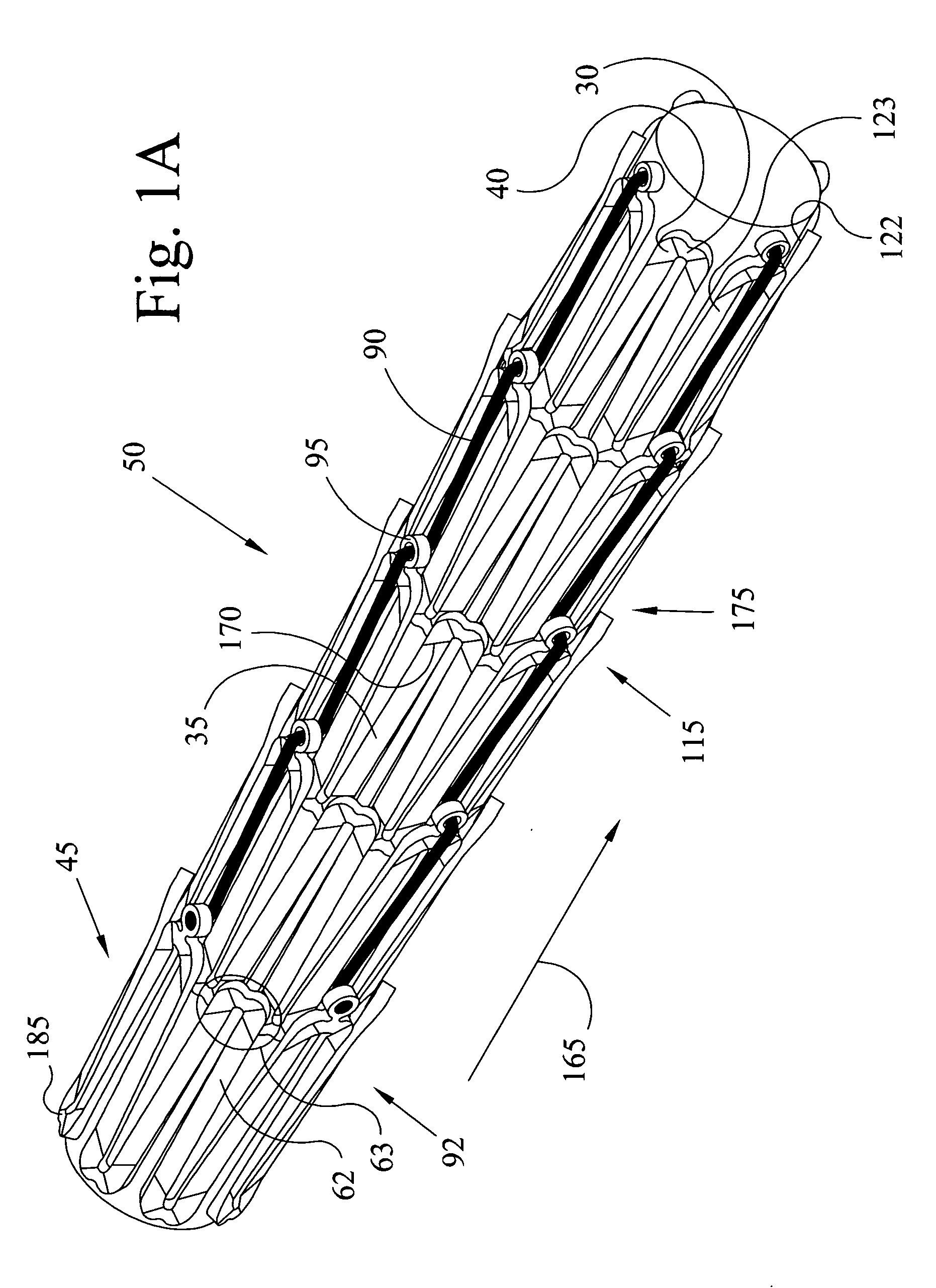

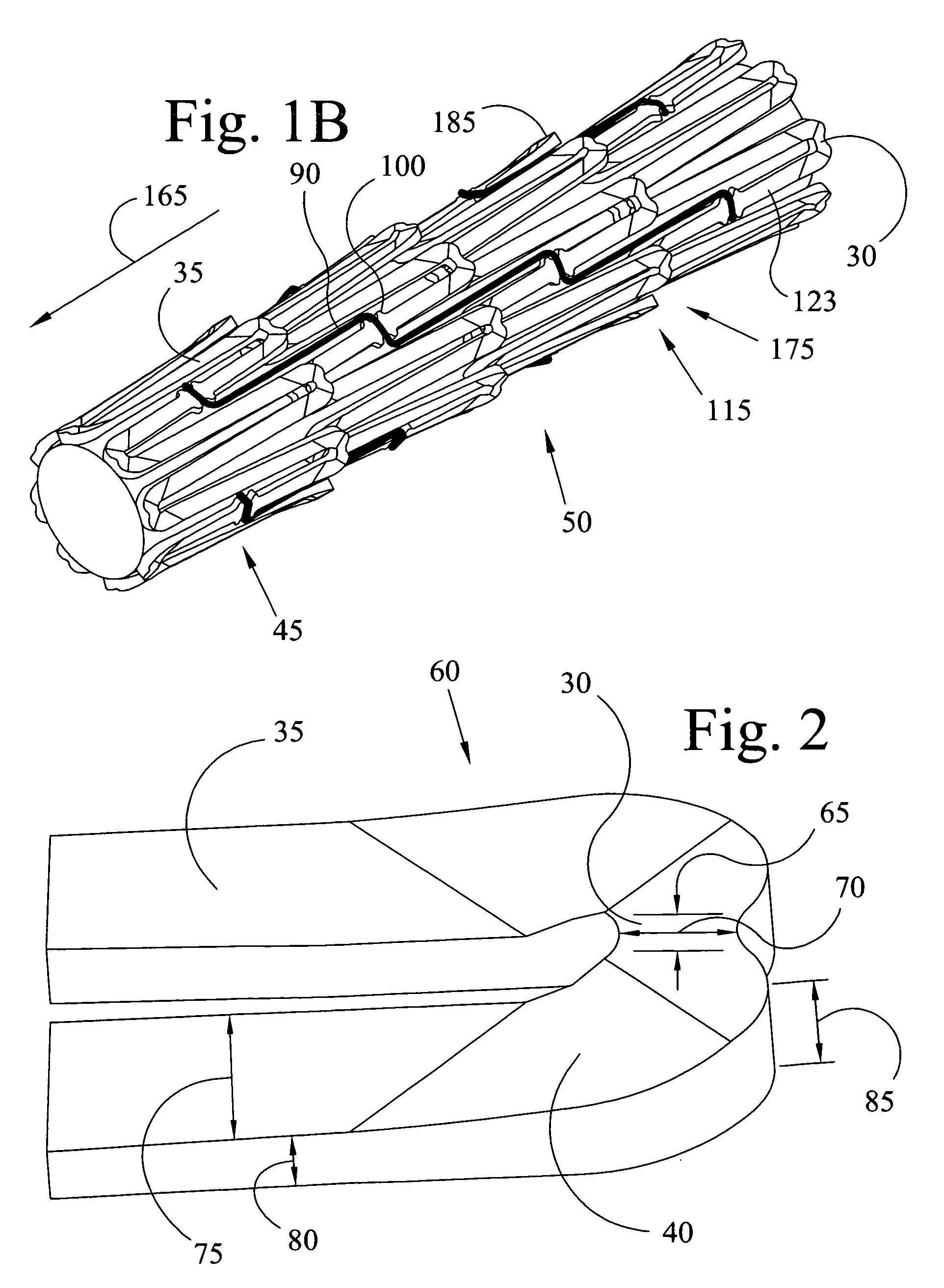

Peripheral overlap stent

A peripheral stent with individual segments reduces the occurrence of fatigue fracture failure seen in vessels and tubes having bending and twisting movement. Segments can be attached via connecting fibers that biodegrade and offer the segments freedom of movement. The segments are balloon-expandable but will not be crushed by external forces placed upon the stent. Hinges and struts provide the stent with a plastic deformation during expansion and remain elastic if exposed to an oval shape. The segments overlap each other to provide improved scaffolding of the vessel wall and a greater flexibility during delivery. A composite stent having both balloon-expandable and self-expanding character has application in the venous system.

Owner:FEMORALIS

Processing technology for high-strength large hexagon head bolt used for steel structure

InactiveCN101549449AHigh strengthExtended service lifeBoltsFurnace typesFatigue fracturesHigh intensity

The invention discloses a processing technology for a high-strength large hexagon head bolt used for a steel structure and belongs to a processing technology for a high-strength connecting piece. The high-strength large hexagon head bolt is processed by less or non cutting including one time of hot forging forming and three times of cold extrusion forming, wherein the hot forging forming is bolt rail forming. The first time of cold extrusion forming is screw forming, the second time of cold extrusion forming is upper screw thread section forming, and the third time of cold extrusion forming is thread forming. The invention mainly adopts the cold extrusion process for bolt production, improves the strength of the bolt, optimizes the production process of the bolt, overcomes the delay fracture and fatigue fracture of the high-strength bolt, ensures that the bolt is not easy to fracture in the use process and reliably connected, prolongs the service life of the bolt and can more meet the use requirement for the high-strength large hexagon head bolt used for the steel net frame bolt ball node in modern society.

Owner:扬州狮鹤高强度螺栓有限公司

Process for manufacturing high-strength bolt

The invention provides a process for manufacturing a high-strength (above) bolt. The process comprises the following steps: selecting a proper steel material, and cutting out a cylindrical blank with proper size; molding the head part and the rod part of the bolt by adopting cold extrusion technology; heating; manufacturing the rod part, including coarse grinding and fine grinding; detecting injury by magnetic powder; manufacturing screw; and performing surface mechanical reinforcement and corrosion resistance treatment. The process solves the technical problems of insufficient strength and fatigue fracture which are easily generated on the bolt existing in the prior art for manufacturing the high-strength bolt, and is a high-strength bolt manufacturing process capable of improving tensile and fatigue strength resistance of the bolt.

Owner:浙江裕泰汽车配件有限公司

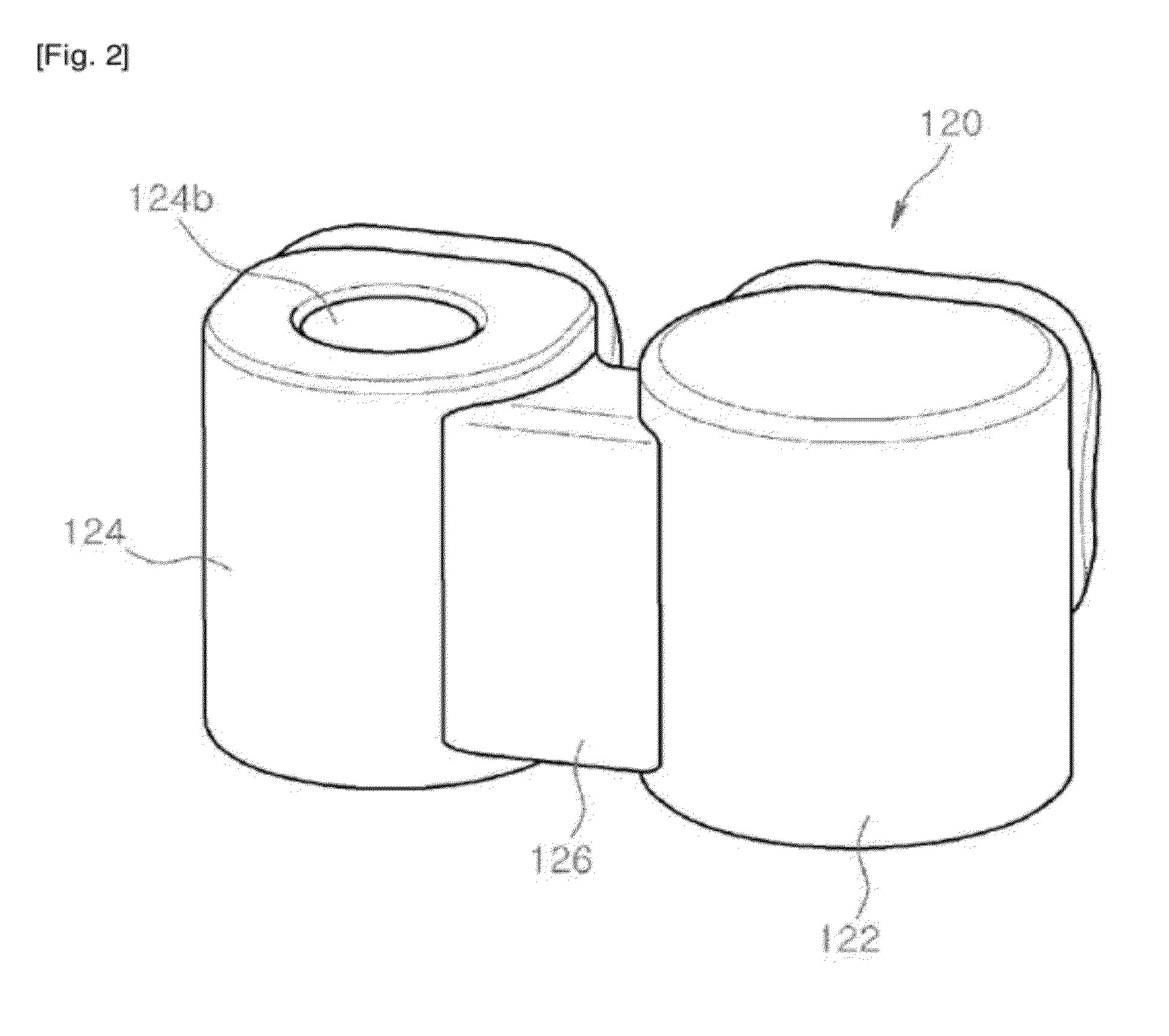

Mounting structure for a direct injection fuel rail

ActiveUS20120138020A1Prevent thermal deformationImprove fatigue resistanceMachines/enginesStress reducing fuel injectionStress concentrationFatigue fractures

The present invention relates to a mounting structure for a direct injection fuel rail. Specifically, a mounting structure 120 for a direct injection fuel rail comprises a mount unit 124 and an injector cup 122 combined with a main pipe 110, wherein the injector cup 122 and the mount unit 124 are connected to and integrated with each other via a bridge 126, wherein the injector cup 122 is bonded to the main pipe 110, and wherein the mount unit 124 is separated from the main pipe 110. As such, concentration of stress due to displacement may be prevented, resistance against fatigue fracture may be increased, thermal deformation and additional concentration of stress may be prevented, manufacturability may be improved, and precise assembling positions may be easily ensured.

Owner:KEFICO

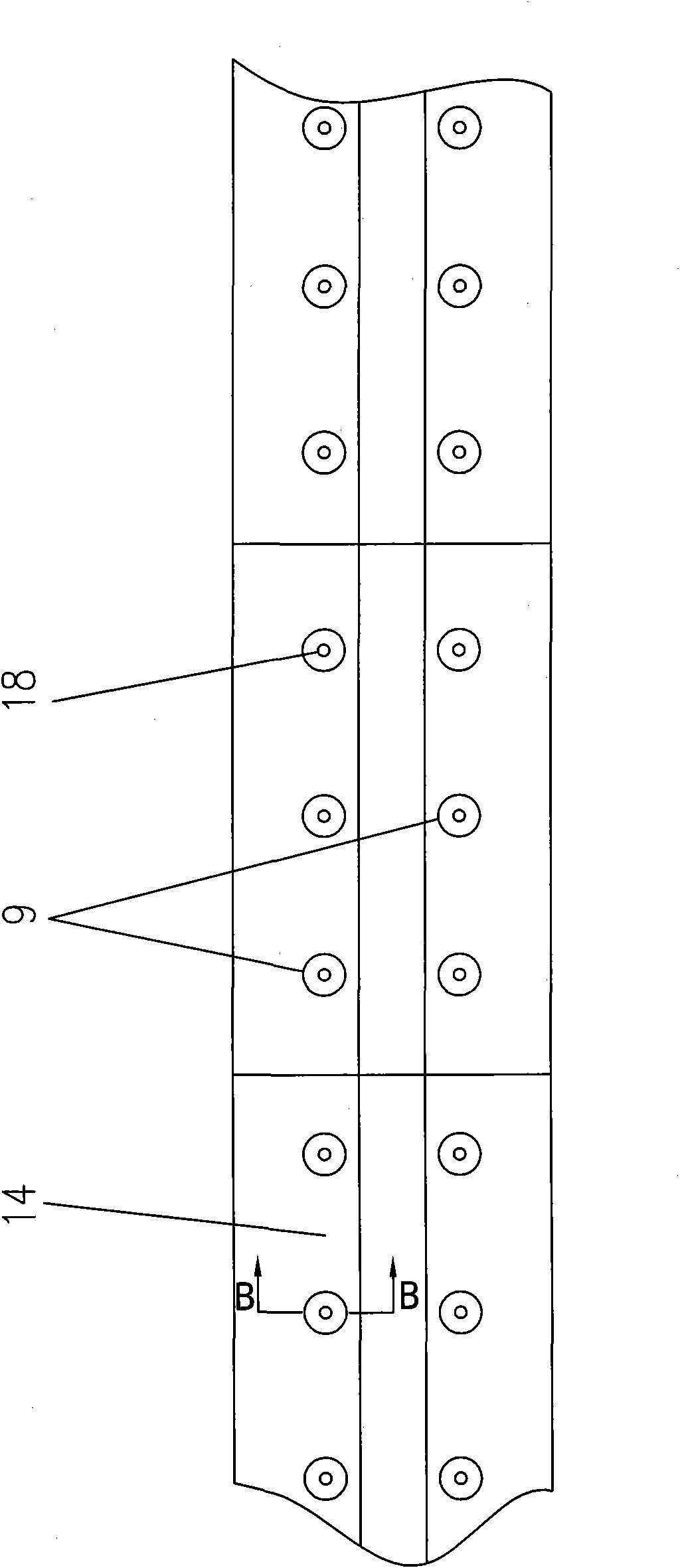

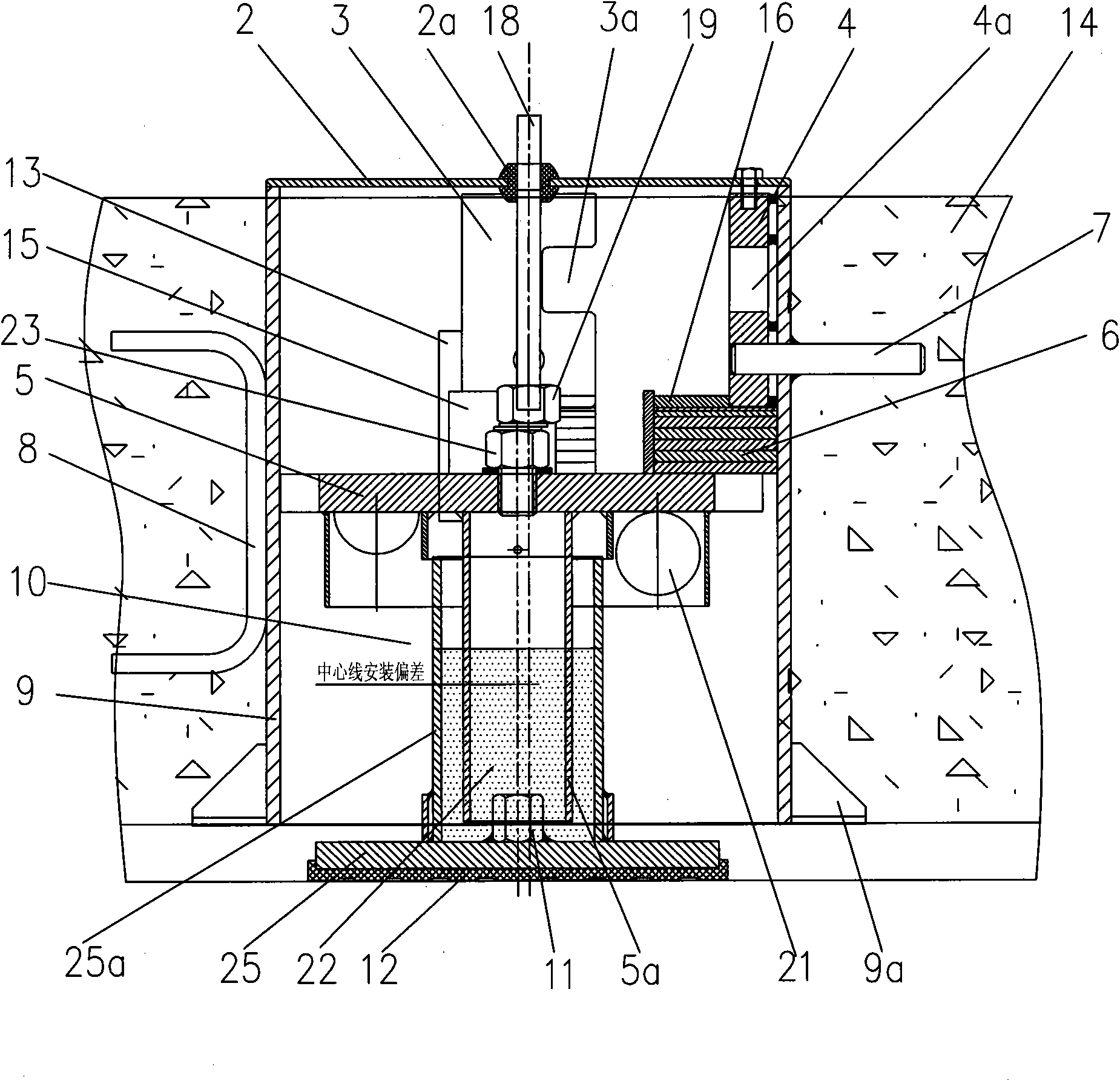

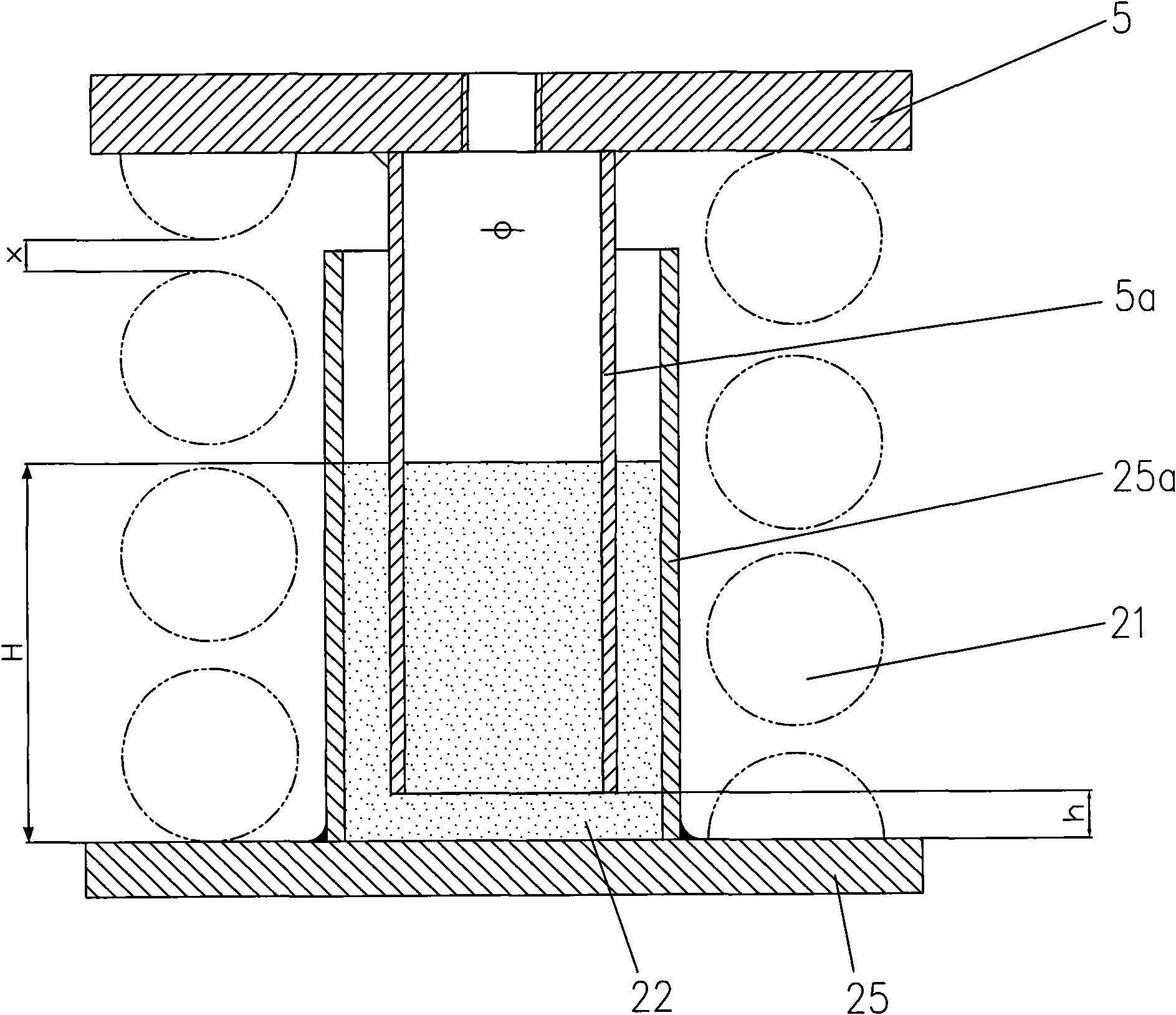

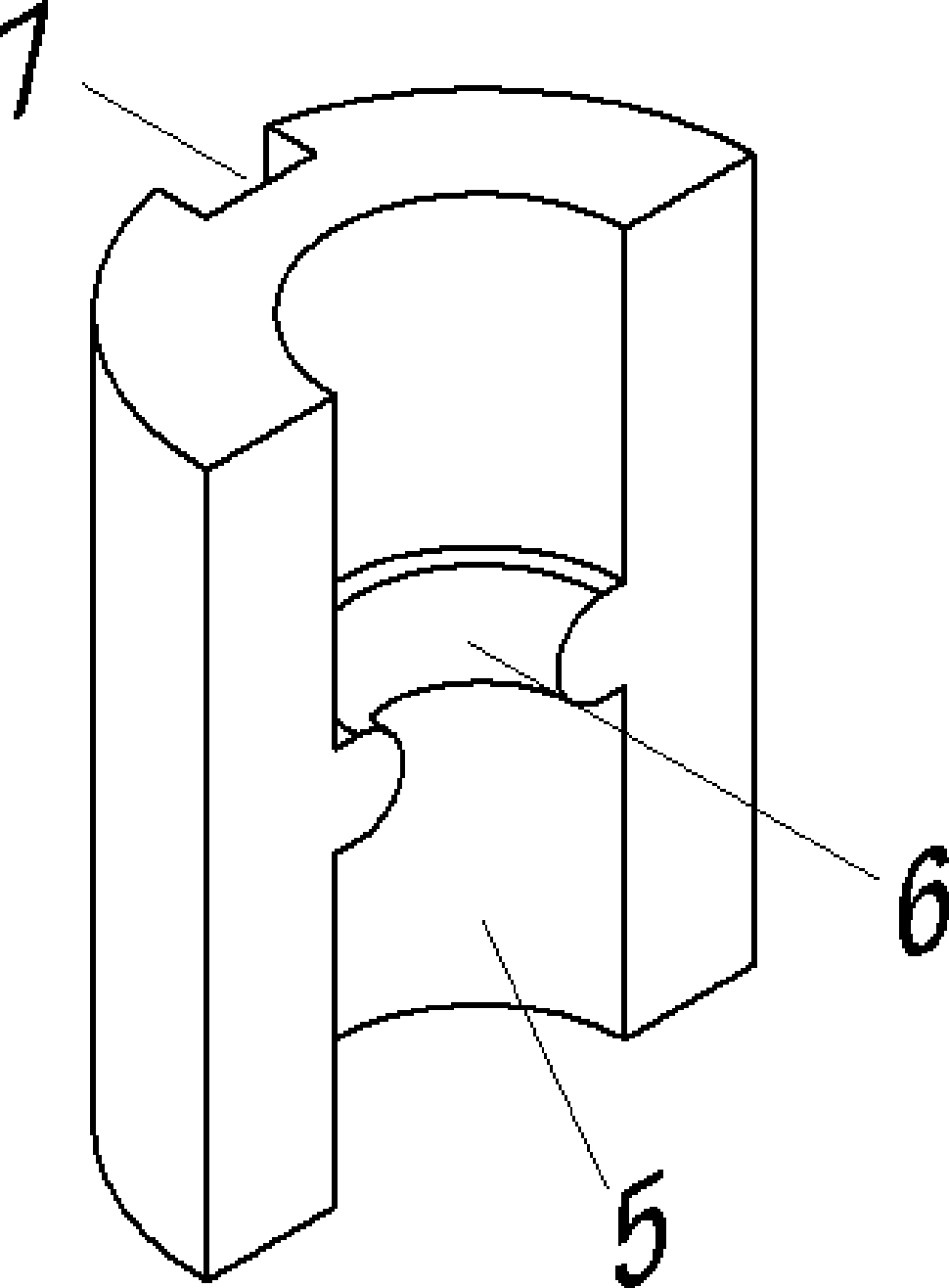

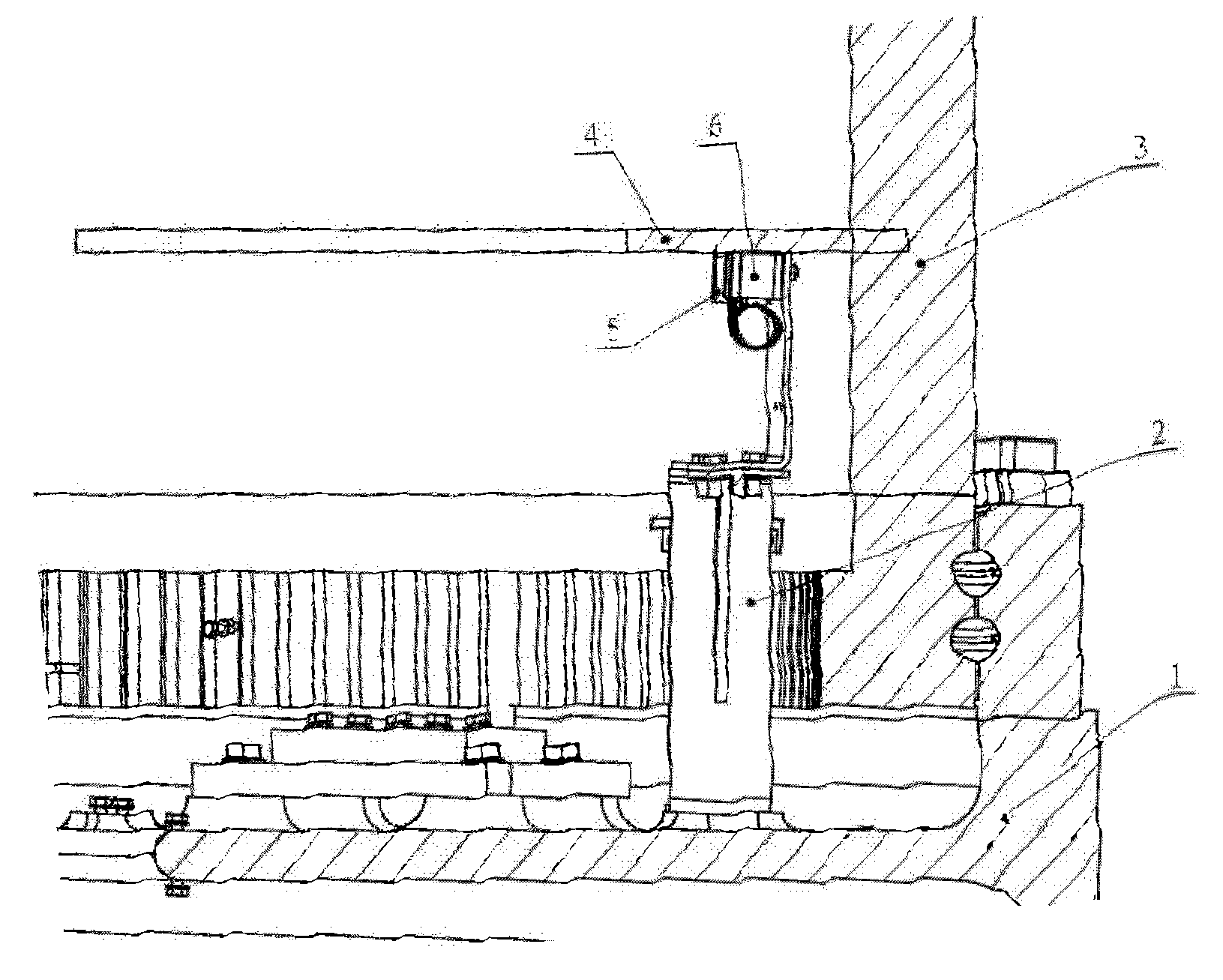

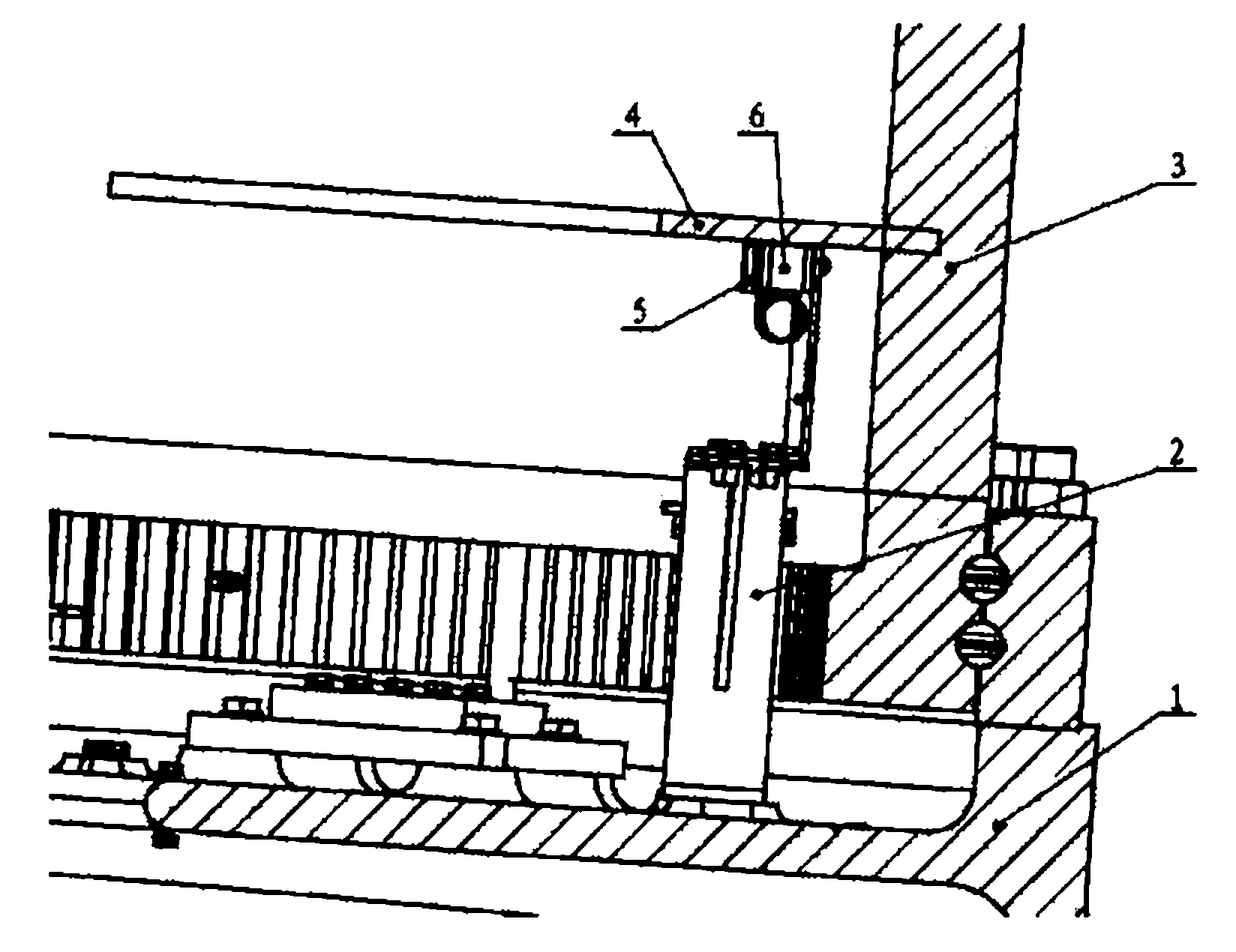

Vibration isolating support structure of damping spring floating track bed and installation method thereof

ActiveCN101775762AReduce dosageGood vibration reduction effectRail fastenersFatigue fracturesEngineering

The invention discloses a vibration isolating support structure of a damping spring floating track bed and an installation method thereof, which comprises a pre-buried sleeve (9) and a vibration isolator component (10). The pre-buried sleeve (9) is cast in a floating plate type track bed body (14) as a whole, bearing convex tables (3, 4 and 17) are fixedly arranged in the pre-buried sleeve (9), a pre-buried anchor bar (8) which extends into the bed body is arranged outside of the pre-buried sleeve (9), and the vibration isolator component (10) is arranged in the pre-buried sleeve (9) and can support the floating plate type track bed body (14) and isolate the vibration of the floating plate type track bed body (14) through the pre-buried sleeve (9). The vibration isolating support structure can provide emergency safety measures under the extreme condition, so that when the fatigue fracture of a large quantity of support springs occurs suddenly, the local settlement of the floating plate type track bed can be limited within the safety limit range of a few millimeters, thereby preventing the spring breakage accident to endanger the safe running of trains, and greatly improving the security coefficient of the floating plate type track bed.

Owner:BEIJING JIUZHOUYIGUI SHOCK & VIBRATION ISOLATION

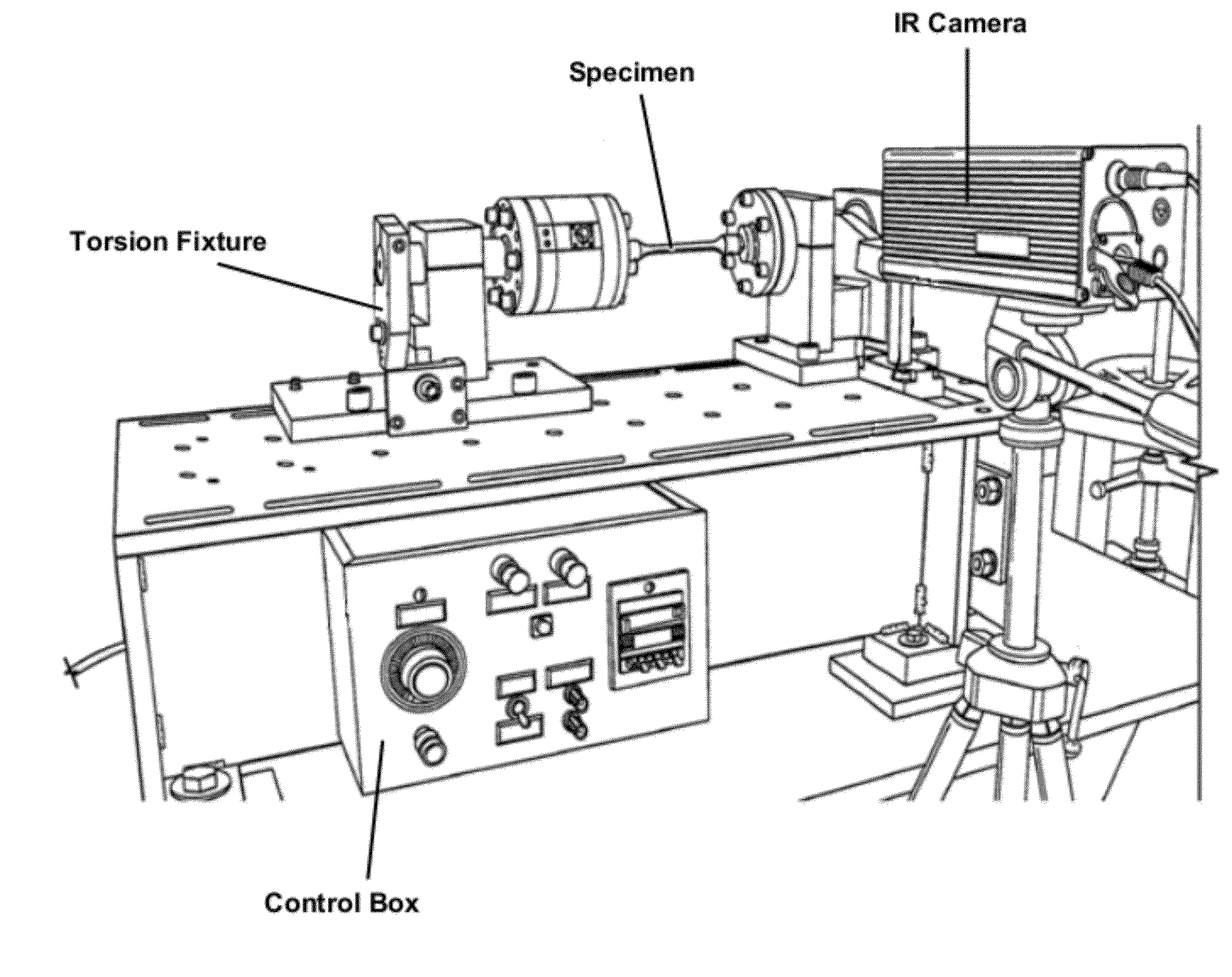

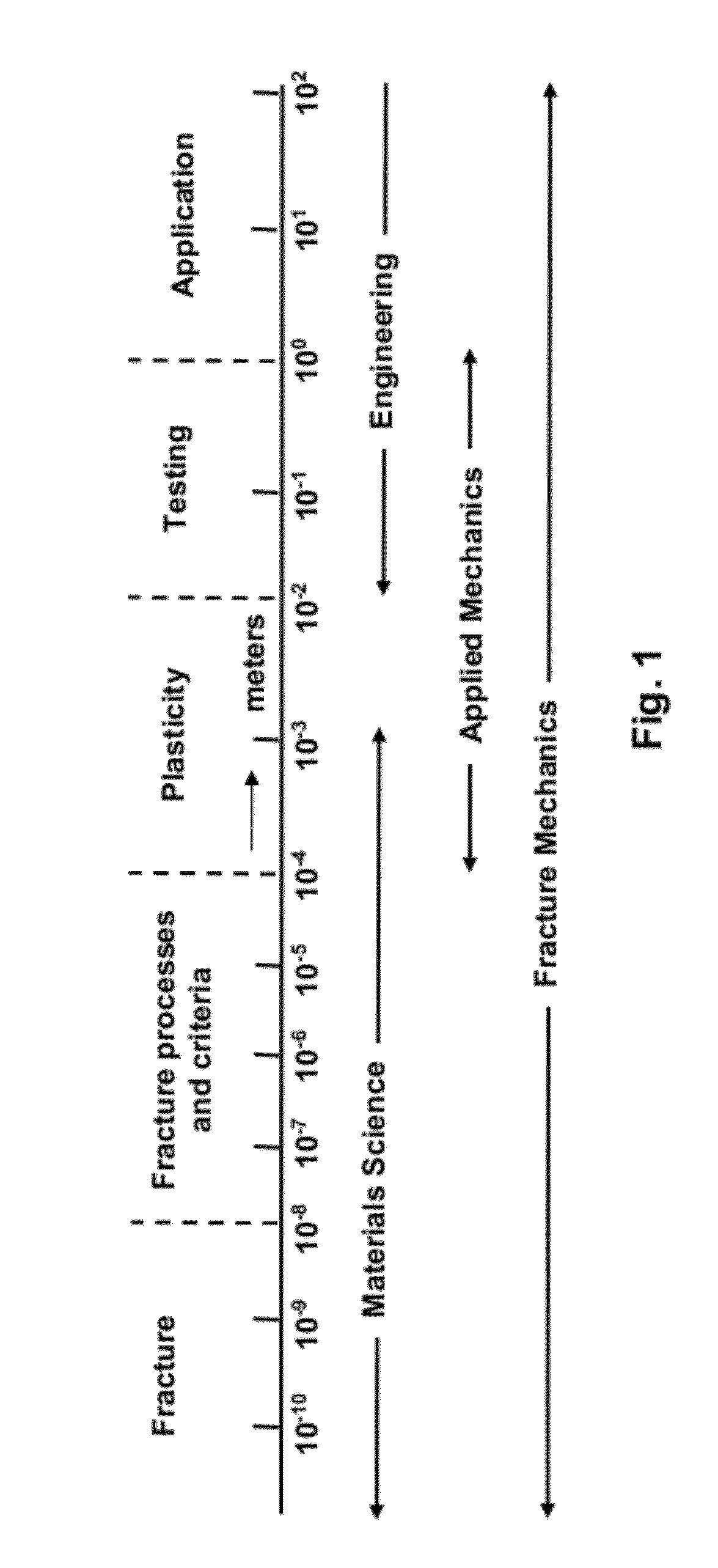

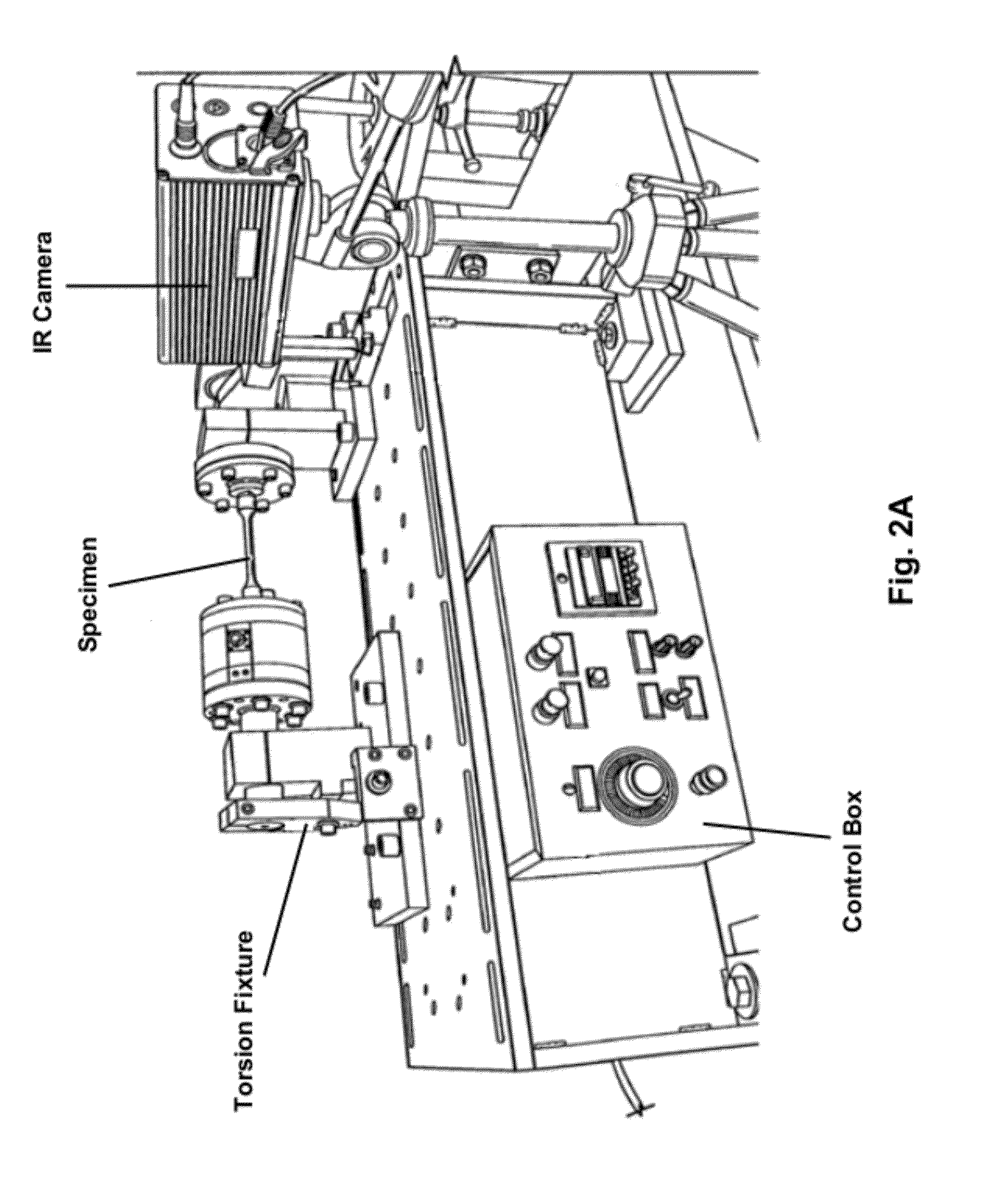

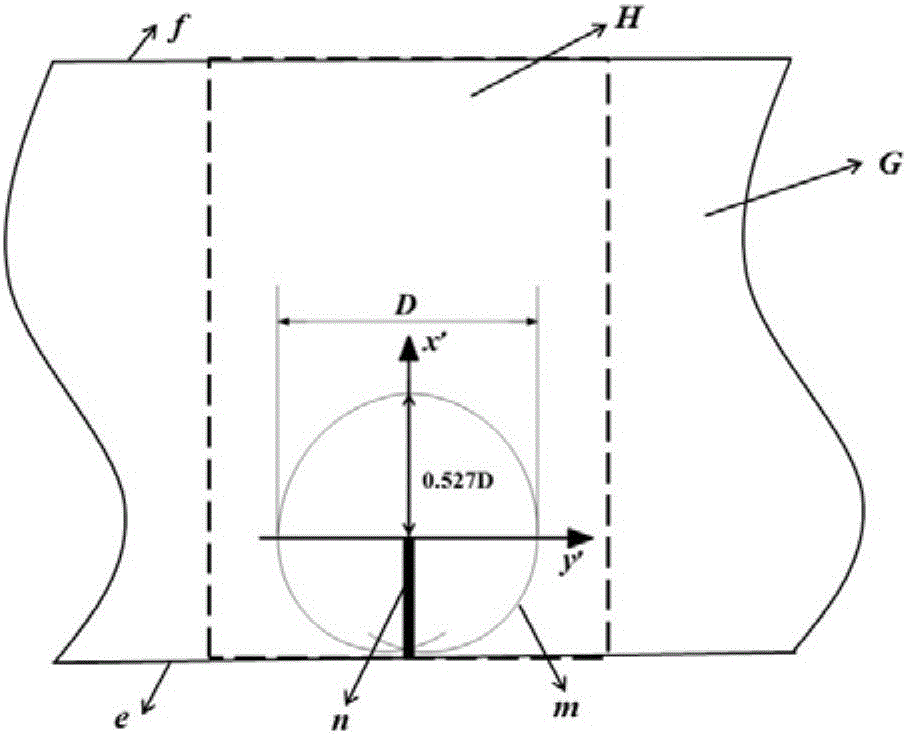

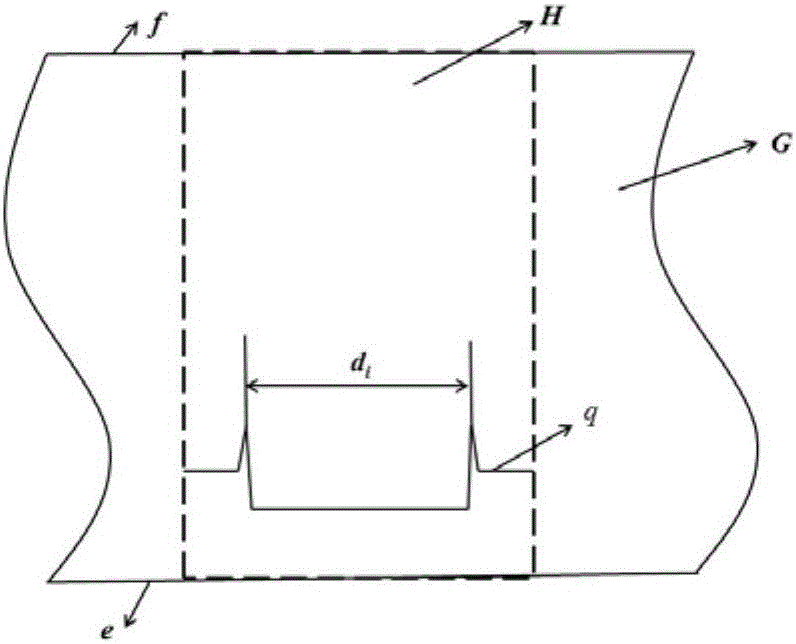

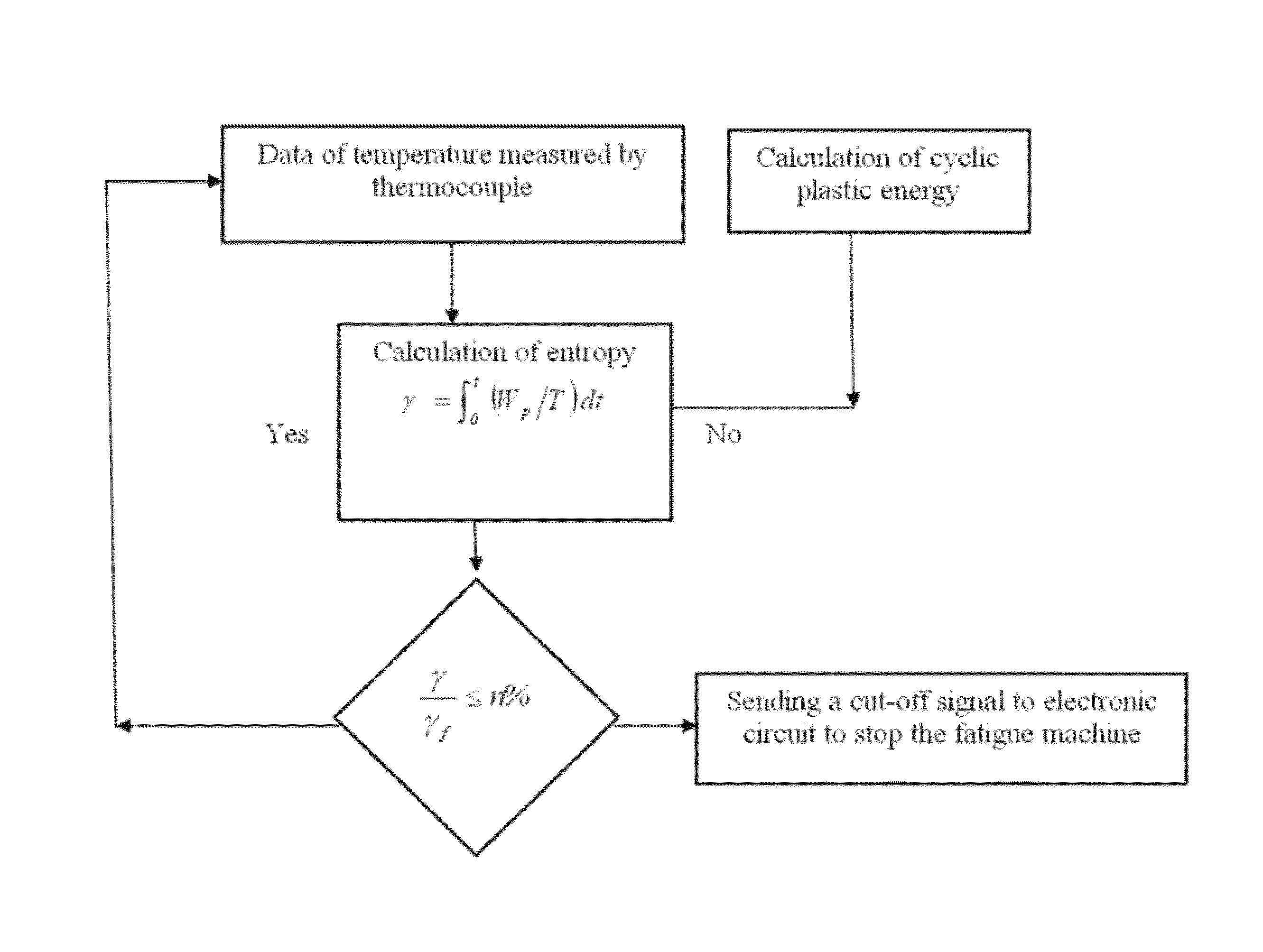

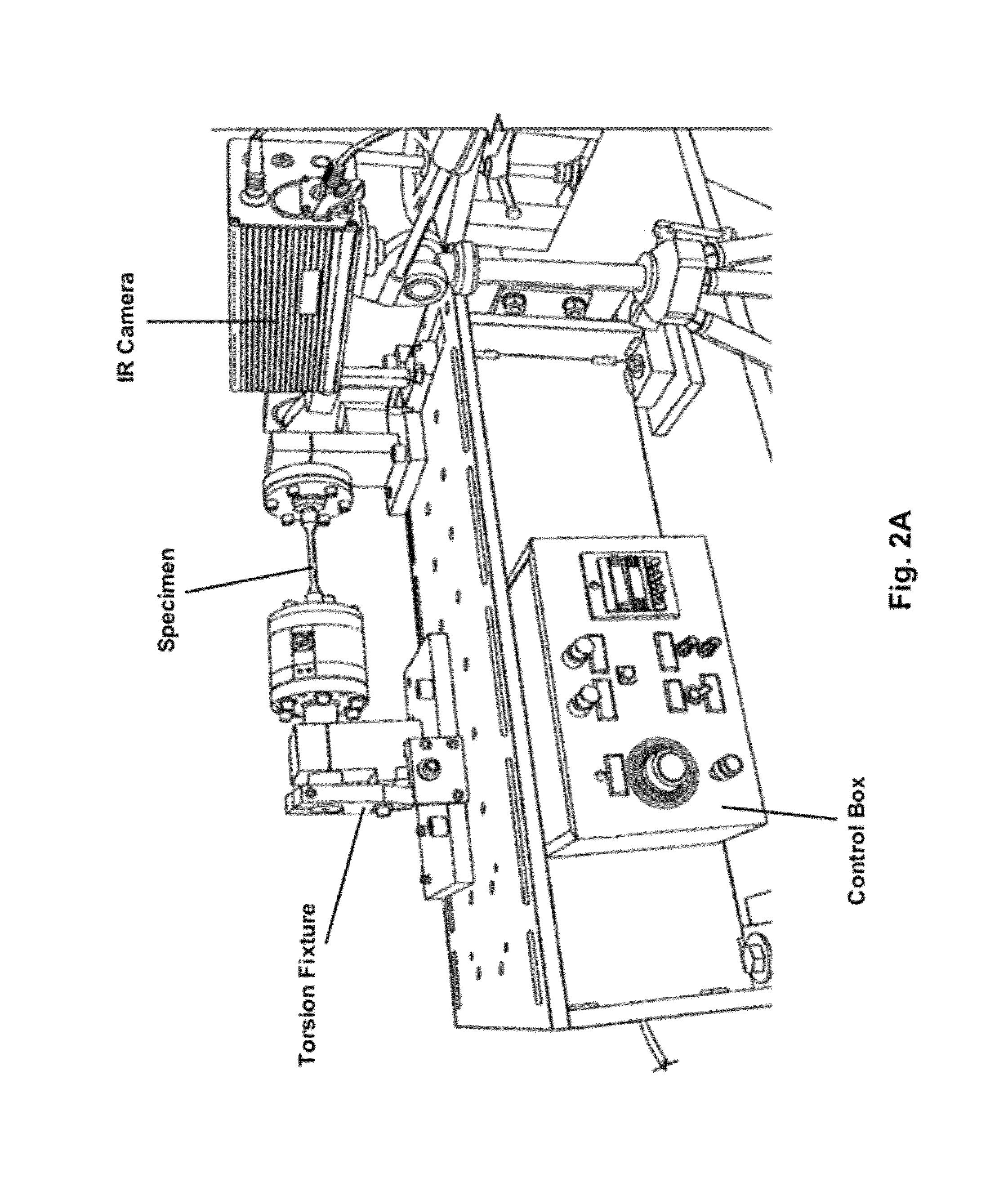

Fracture Fatigue Entropy Determination

ActiveUS20120084019A1Material strength using repeated/pulsating forcesSpecial data processing applicationsDowntimeFatigue fractures

A method and apparatus are disclosed for approximating in real time the fracture fatigue entropy (FFE) of a metallic object subjected to cyclic loading. Such objects experience fatigue, which can lead to failure after a number of loading cycles. The disclosed invention allows for real time monitoring of the entropy increase in a metallic object under cyclic loading, and allows for removing the object from service before fatigue fracture occurs. Through use of the present invention, users may keep metallic objects in service for longer periods, because such objects may be safely taken closer to the fatigue fracture point. The invention therefore can effectively extend the useful life of many critical components and reduce downtime resulting from repair or premature replacement.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

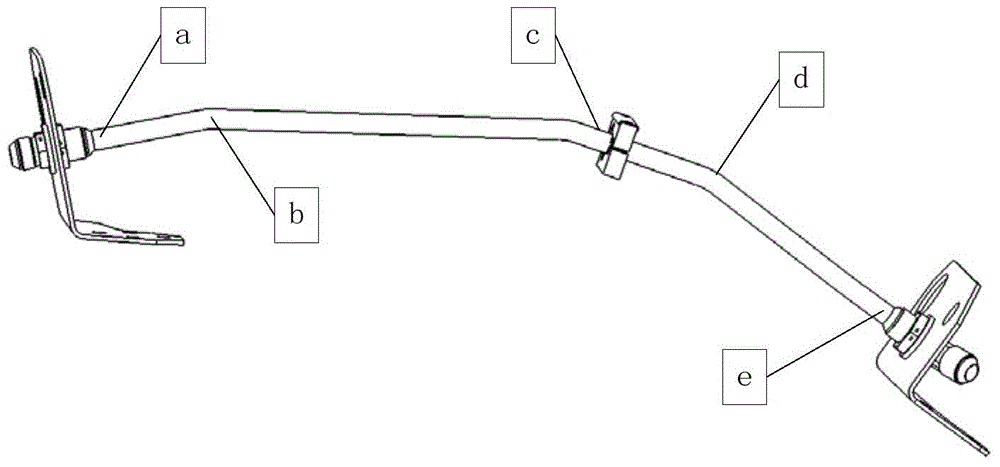

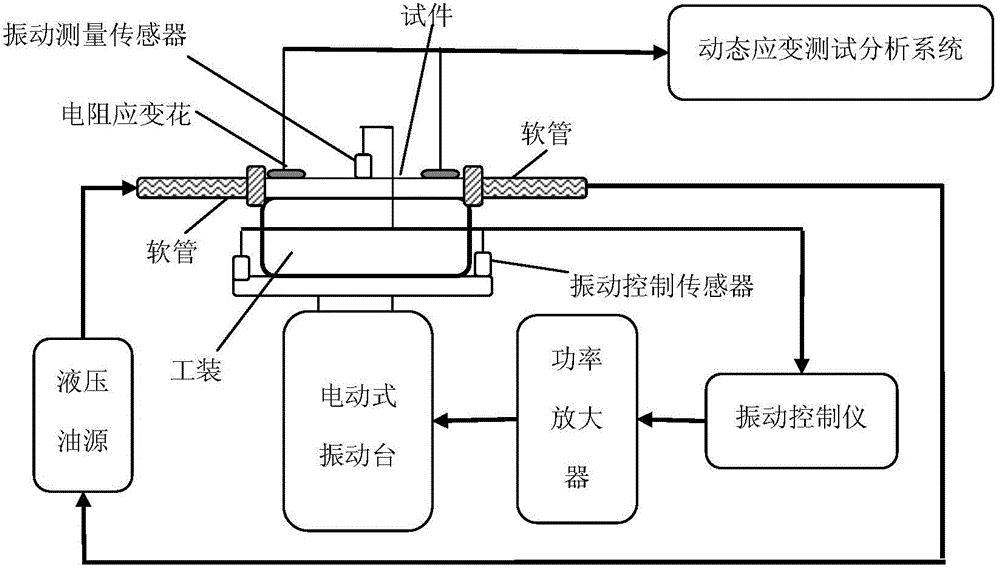

Method for determining fatigue life index of hydraulic conduit

ActiveCN105651496AGuaranteed uptimeNo vibrationMachine part testingVibration testingFatigue fracturesDependability

The invention, which belongs to the hydraulic system of the airplane, discloses a method for determining a fatigue life index of a hydraulic conduit. The method comprises: (1), a monitoring point easily causing a fatigue fracture is found out; (2), a tested piece the same as that of an airplane is employed; (3), a rated working pressure of a system is applied into the tested piece; (4), a foil gauge and an acceleration sensor are loaded at the monitoring point; (5), an output frequency of a vibrating table is controlled to be an inherent frequency of the tested piece; (6), output amplitudes of the vibrating table are controlled to be set successively in a range from 0,75 sigma b to sigma -1 in a descending order according to stress values generated on the conduit, a stress value and an acceleration value at the monitoring point are measured, and the number of times of cycling of the tested piece in a fracture mode is recorded; (7), according to the stress value and the number of times of cycling or the acceleration value and the number of times of cycling, a fatigue life curve of the tested piece is fitted; and (8), a stress value or acceleration value of a position close to a horizontal line on the fatigue life curve is a fatigue life index control value of a hydraulic conduit. With the method, reasonability, reliability, and durability of the airplane hydraulic system pipeline design can be evaluated effectively.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

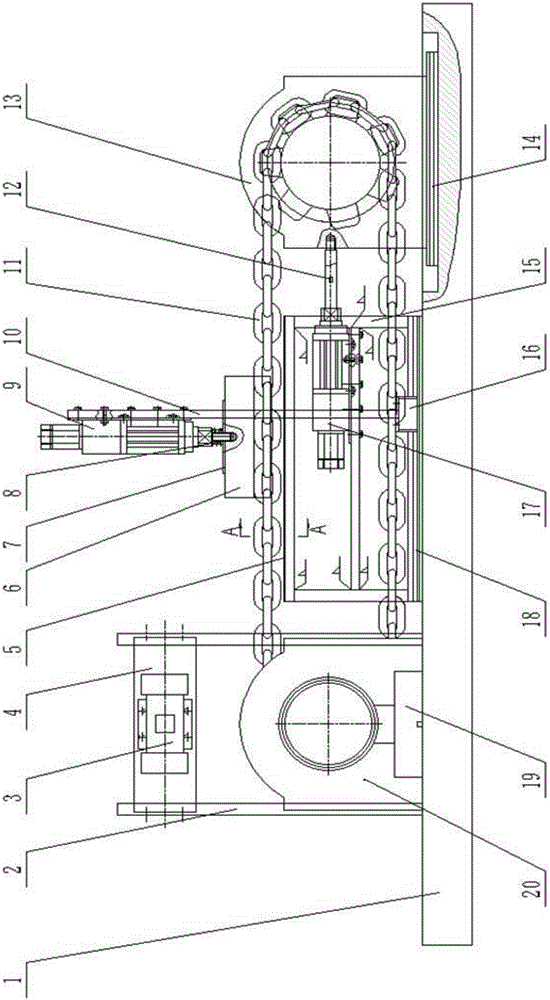

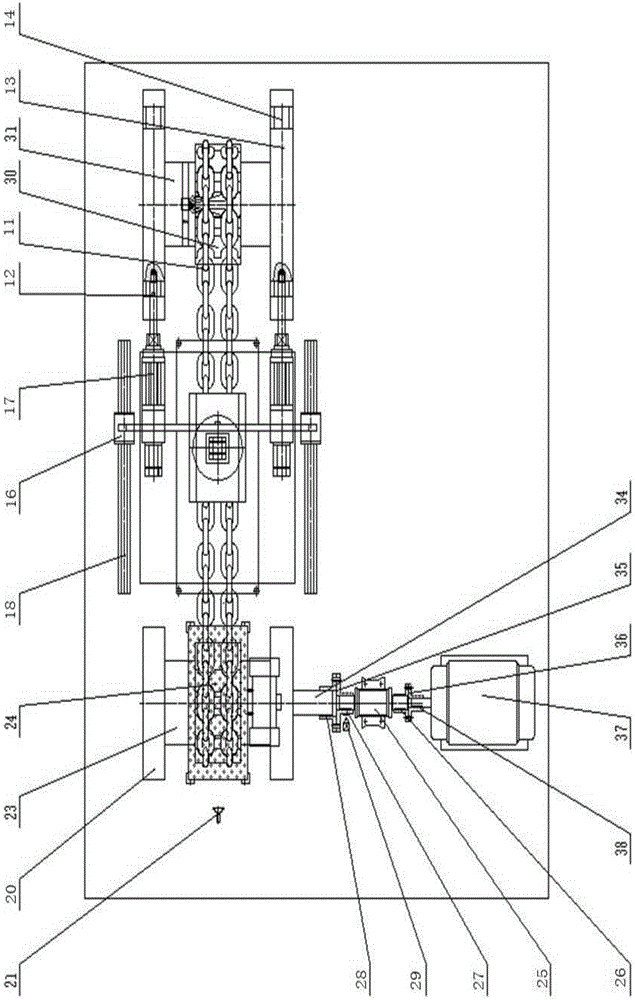

Friction fatigue monitoring device and method of heavy-loading scraper conveyer chain wheels under vibration impact

ActiveCN106404570AMonitor fatigue damageMonitor wearMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceFatigue damageLow speed

The invention discloses a friction fatigue monitoring device and a method of heavy-loading scraper conveyer chain wheels under vibration impact. The friction fatigue monitoring device comprises a base support, a driving system, a circular chain tensioning system, an impact loading system, a coal slime scattering system, and a monitoring system; the driving system comprises a low-speed servo motor, a first low-speed coupler used for connecting the low-speed servo motor with a torque sensor, a second low-speed coupler used for connecting the torque sensor with a transmission shaft, a roller A connected with the transmission shaft, driving chain wheels connected with the roller A, driven chain wheels connected with a roller B via key connection, a circular chain used for winding the driving chain wheels and the driven chain wheels; the circular chain tensioning system comprises a liner and a horizontal electric cylinder connected with a tail frame; the impact loading system comprises an impacting plate connected with a vertical electric cylinder; and the coal slime scattering system comprises a sieve and a vibration exciter. The friction fatigue monitoring device is capable of stimulating friction fatigue fracture of heavy-loading scraper conveyer chain wheels under vibration impact, and monitoring chain wheel fatigue damage and chain wheel wear situations.

Owner:CHINA UNIV OF MINING & TECH

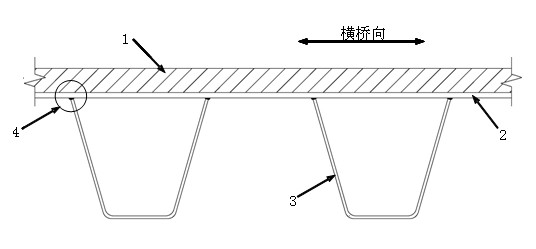

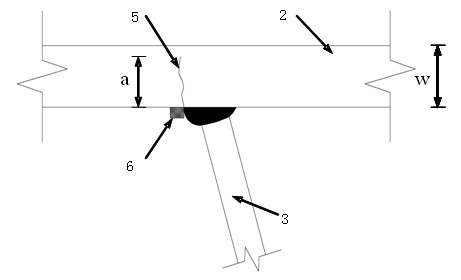

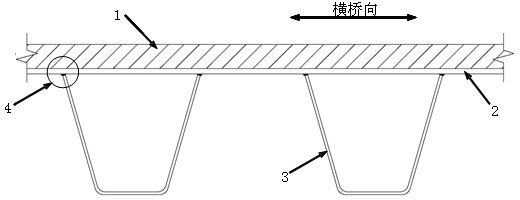

Method for predicting remaining useful life of steel box girder bridge top plate-longitudinal rib welding detail

InactiveCN102621220AStrong implementationOvercome subjectivityAnalysing solids using sonic/ultrasonic/infrasonic wavesStrength propertiesNon destructiveFatigue damage

The invention discloses a method for predicting the remaining useful life of a steel box girder bridge top plate-longitudinal rib welding detail subjected to fatigue cracking in an operating state. The method comprises the following steps of: detecting the fatigue crack of the steel box girder bridge top plate-longitudinal rib welding detail by an ultrasonic non-destructive detection technology, determining the position of the welding detail subjected to fatigue cracking, and measuring the extension depth of the fatigue crack in a top plate; and arranging a strain sensor on the top plate at the welding detail subjected to fatigue cracking to acquire a fatigue load effect spectrum under the action of an actual operating vehicle, establishing a fatigue fracture limit state equation of the welding detail according to a linear elastic fracture mechanics theory, and calculating the remaining useful life of the top plate-longitudinal rib welding detail. By the method, the respective advantages of the non-destructive detection technology and a health monitoring technology can be fully exerted to meet the fatigue evaluation requirement of the steel box girder bridge top plate-longitudinal rib welding detail in the operating state, and the defects of subjectivity and blindness of the traditional fatigue damage evaluation method for a steel box girder bridge are effectively overcome.

Owner:SOUTHEAST UNIV

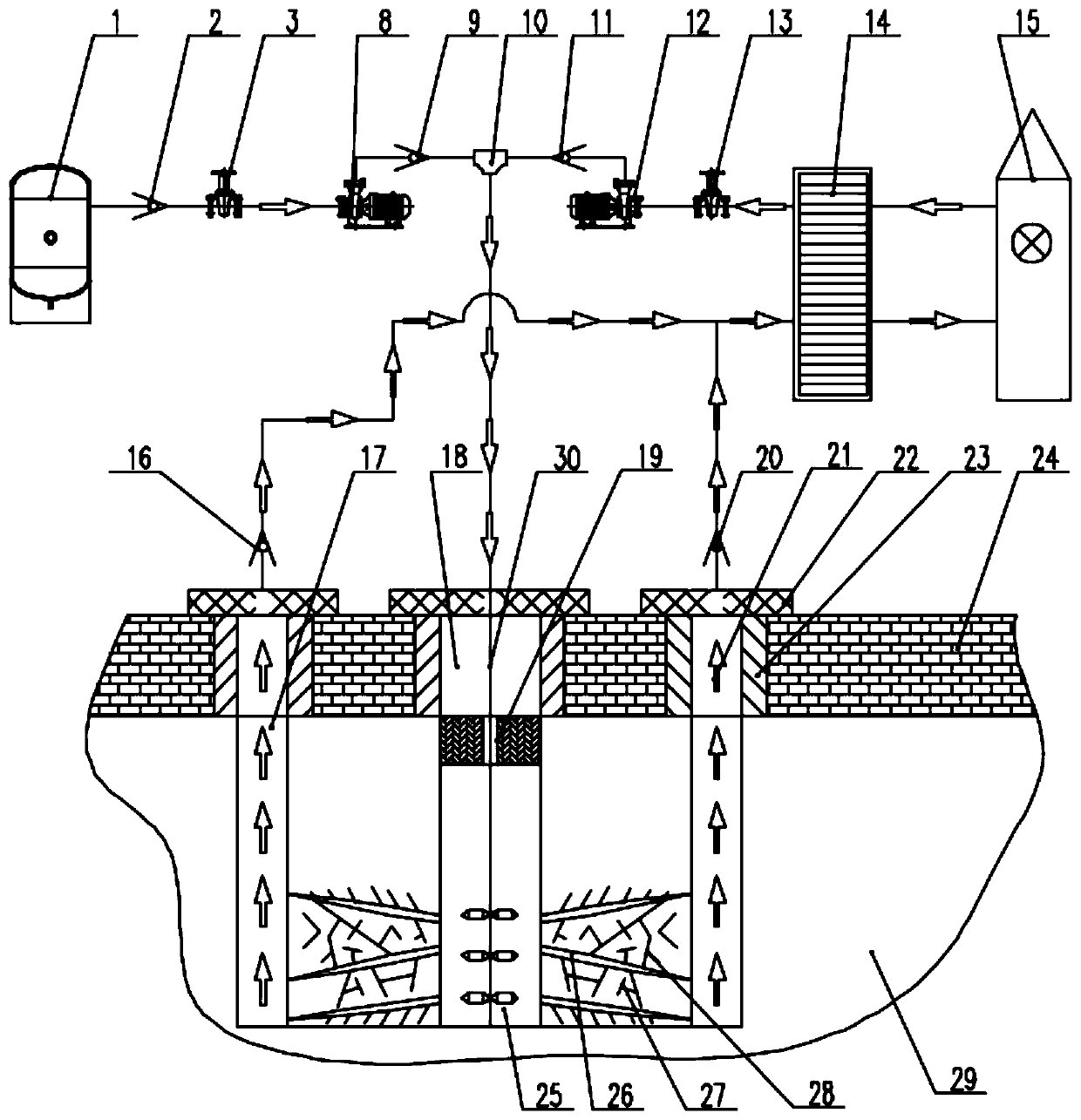

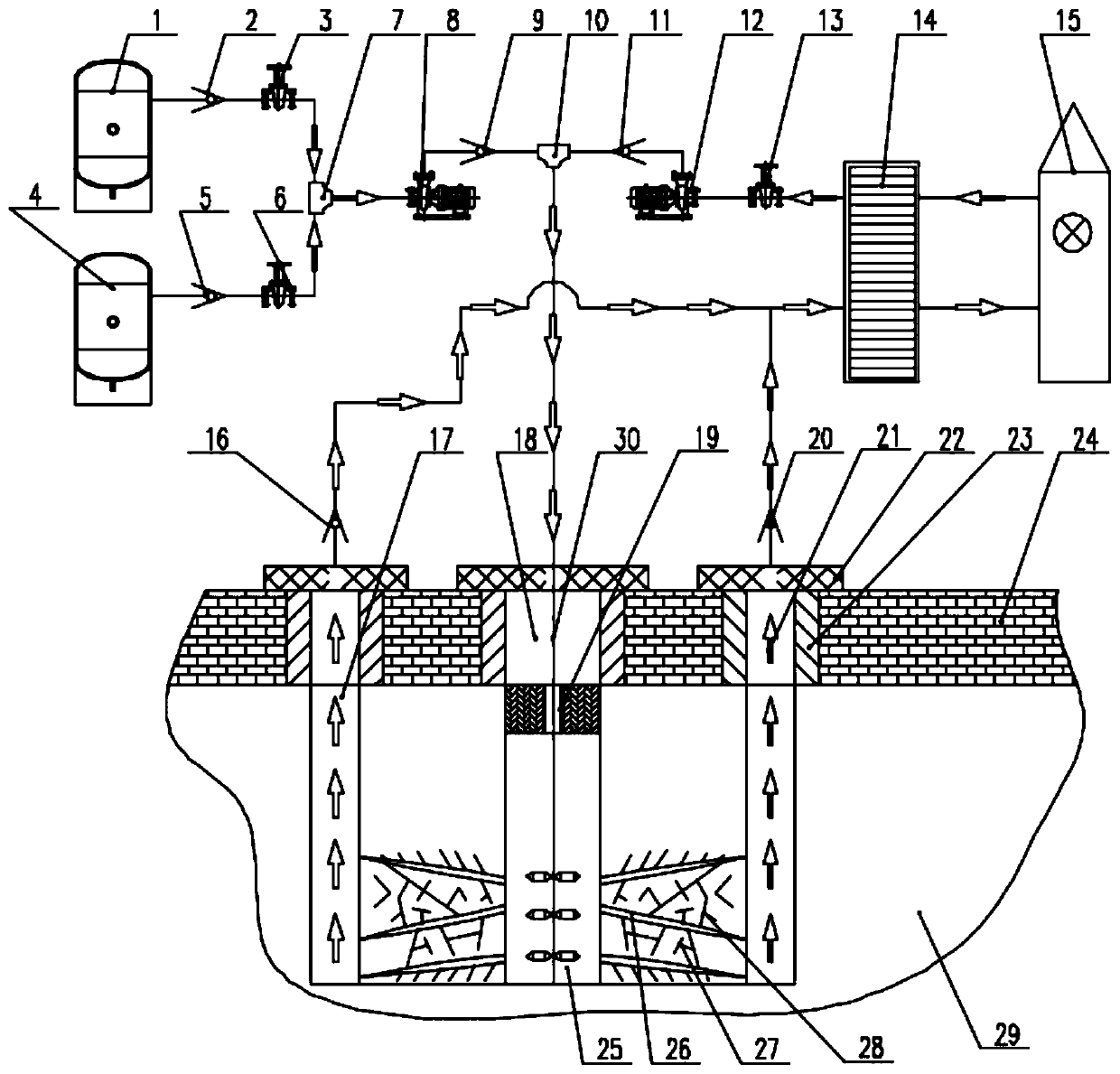

Water-liquid nitrogen alternate fatigue fracturing and heat collection rate improving method for hot dry rock

ActiveCN110173246ASolve the blockageNot corrosiveGeothermal energy generationFluid removalHigh pressure waterHydraulic fracturing

The invention discloses a water-liquid nitrogen alternate fatigue fracturing and heat collection rate improving method for hot dry rock. The water-liquid nitrogen alternate fatigue fracturing and heatcollection rate improving method for the hot dry rock includes: first using high pressure water for fracturing the hot dry rock through jet nozzles in short time so as to form a major fracture, and then stopping hydraulic fracturing, injecting liquid nitrogen into the major fracture through the jet nozzles, and under the circumstance that the hot dry rock containing water generates extremely hugetemperature difference approximating 400 DEG C during the liquid nitrogen gasification process, enabling internal particles of the hot dry rock to generate various degrees of shrinkage distortion through the temperature difference so as to generate microfractures, and simultaneously fracturing the hot dry rock once more by using the expanded nitrogen which is obtained after the gasification and can easily enter the microfractures; repeating the above steps, respectively using the water and the liquid nitrogen for alternately performing fatigue fracturing so as to keep continuous quantity increase and dimension enlargement and achieve interconnection for the fractures of the hot dry rock, and thereby forming a complex and interconnected fracture seam net between an injection well and production wells; and finally, using the water as a heat carrying medium for exploiting geothermal energy. The water-liquid nitrogen alternate fatigue fracturing and heat collection rate improving method for the hot dry rock solves the problem that existing hydraulic fracturing causes blocking to a fracture channel, and improves heat collection rate.

Owner:CHINA UNIV OF MINING & TECH

Axial fatigue experimental approach and apparatus for stacking abrasion load

InactiveCN101368892AImproved strength designAvoid one-sidednessStrength propertiesFatigue loadingReduction drive

The invention discloses an axial fatigue test method with abrasion load superposition and a device thereof. The method is to impose the abrasion load on the specimen when an axial fatigue test machine carries out the axial fatigue experiment on the specimen; and the abrasion load is imposed through an abrasion load device sleeved on the specimen. The device comprises the axial fatigue test machine and the abrasion load device; the abrasion load device comprises a speed reducer; the input shaft of the speed reducer is connected with an adjustable speed motor; the output shaft of the speed reducer is a cylindrical structure; adjusting screws are symmetrically arranged at both sides of the output shaft of the speed reducer; and a friction plate is arranged inside the output shaft of the speed reducer. The invention enables the experimental results in the laboratory to truly reflect the actual service life of the component under various load effects and overcomes the one-sidedness of the existing experimental results. The invention helps finding out the fatigue fracture reasons and fatigue life prediction under the combined effect of simultaneous abrasion load and fatigue load bearing.

Owner:GUIZHOU UNIV

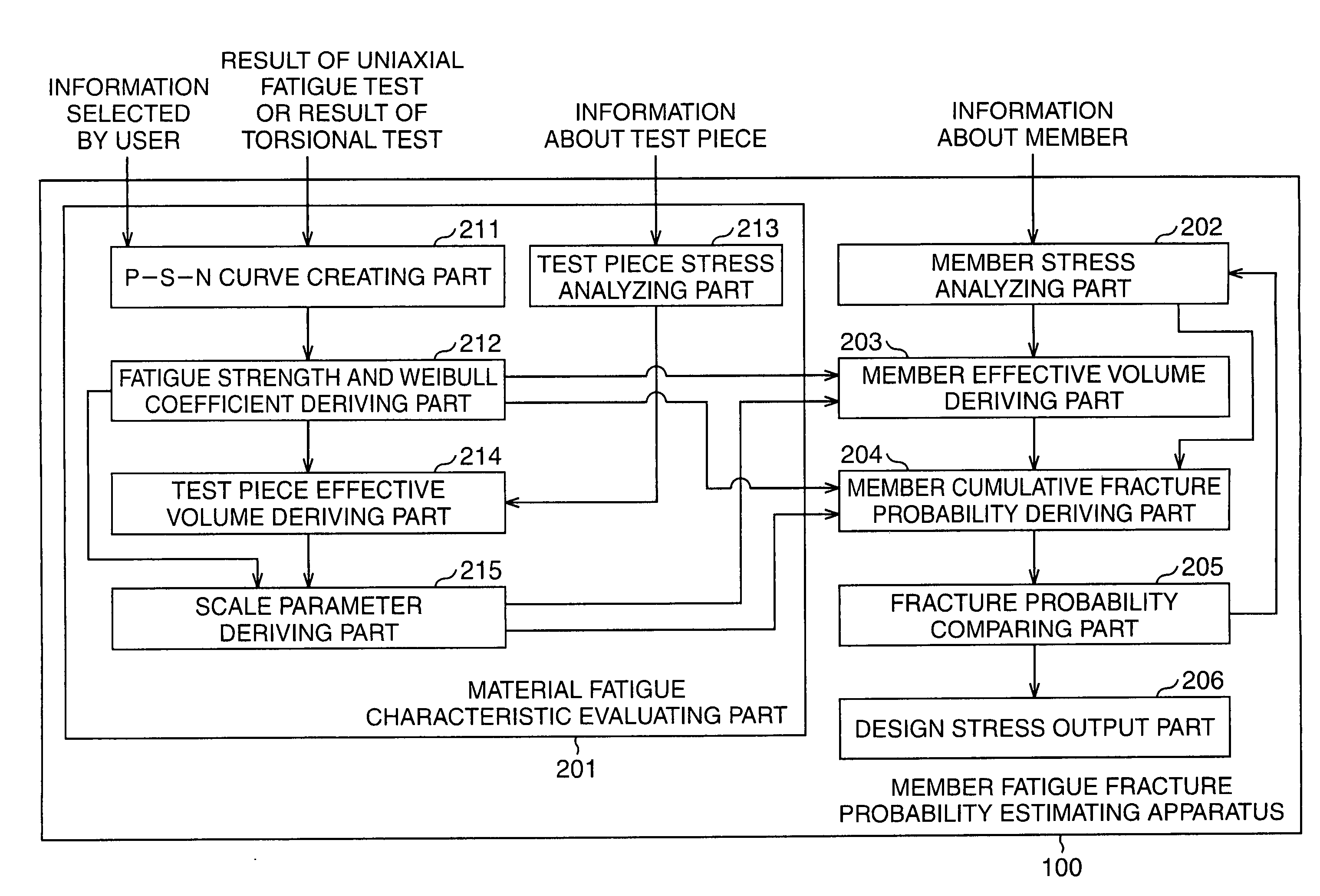

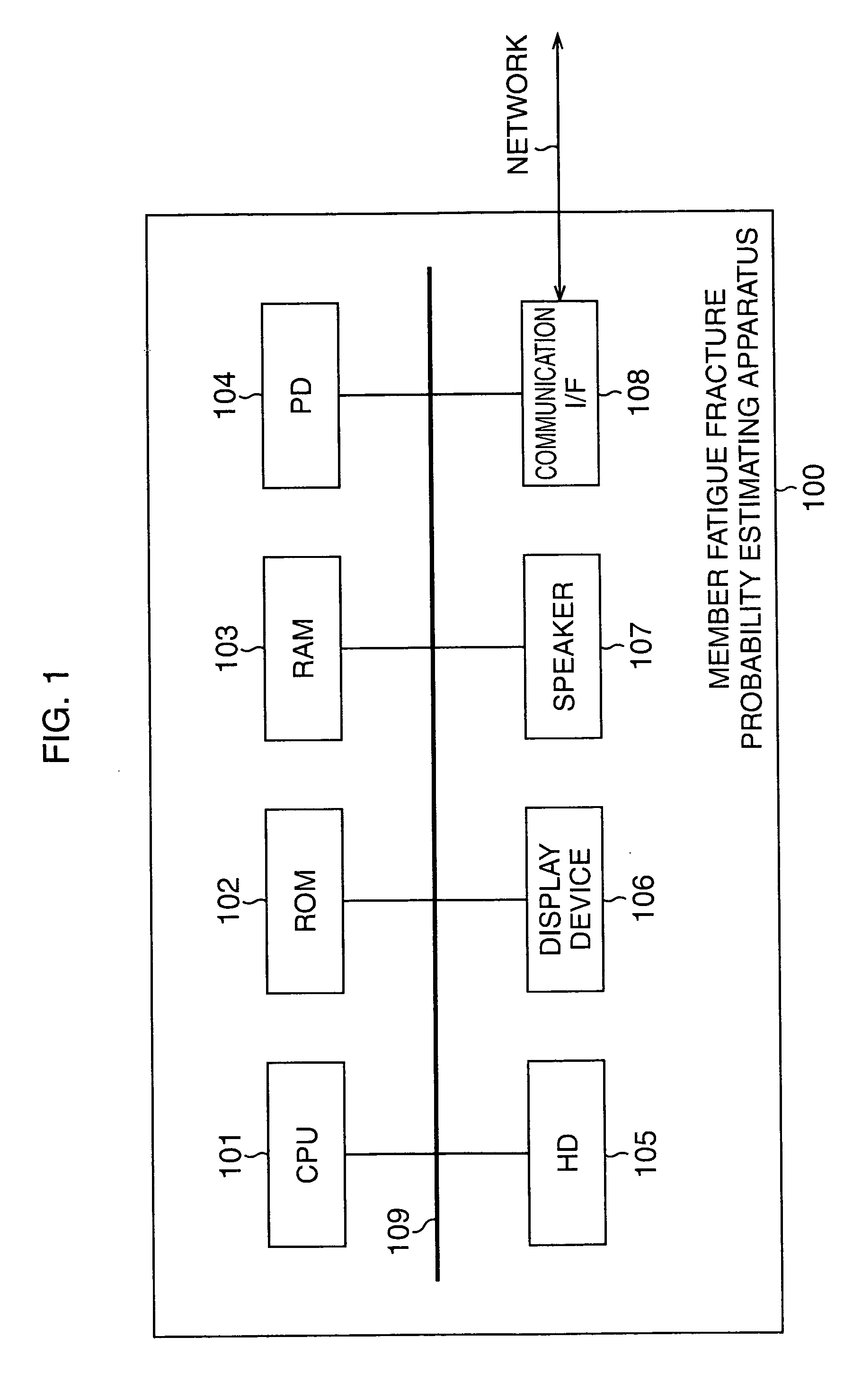

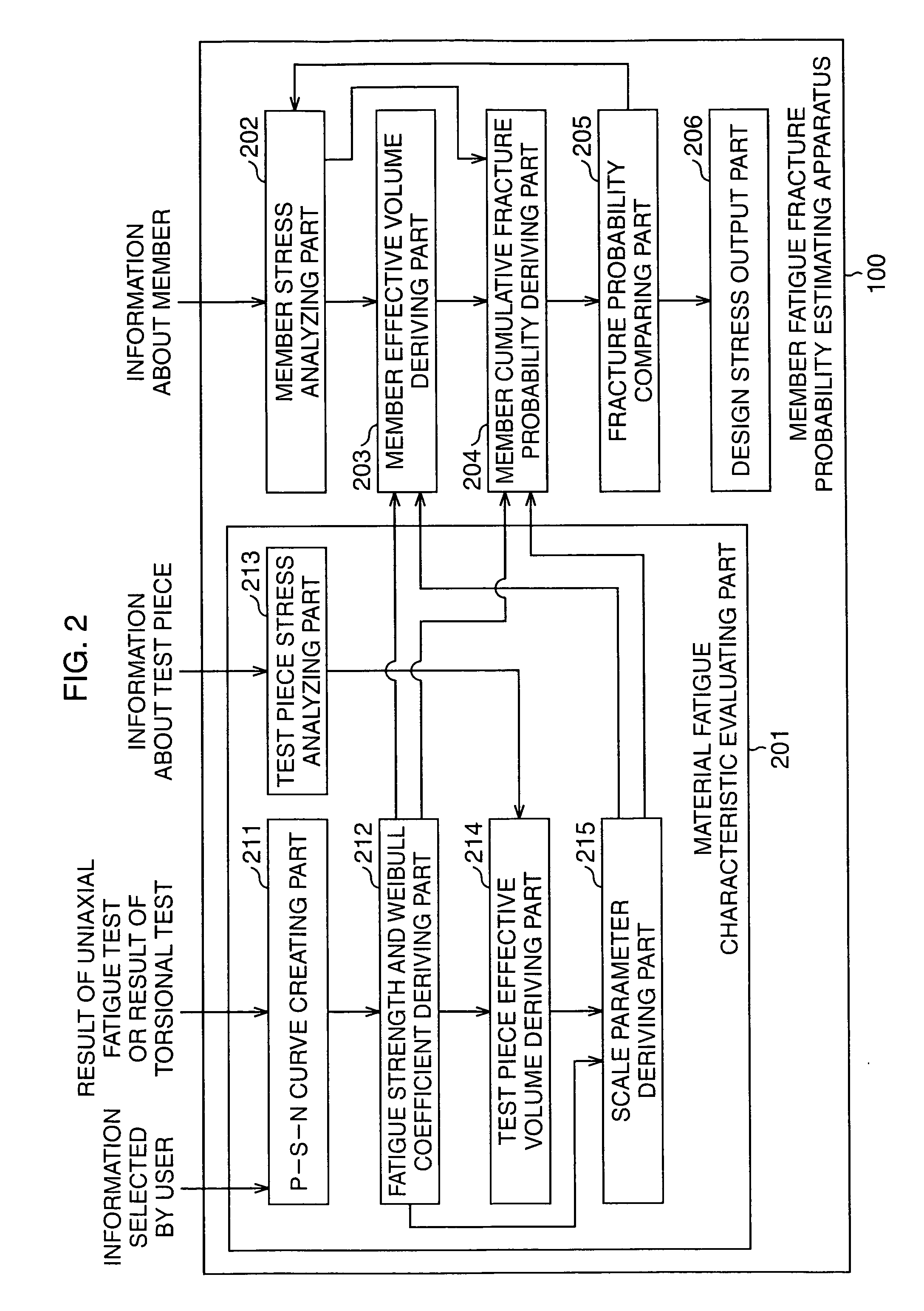

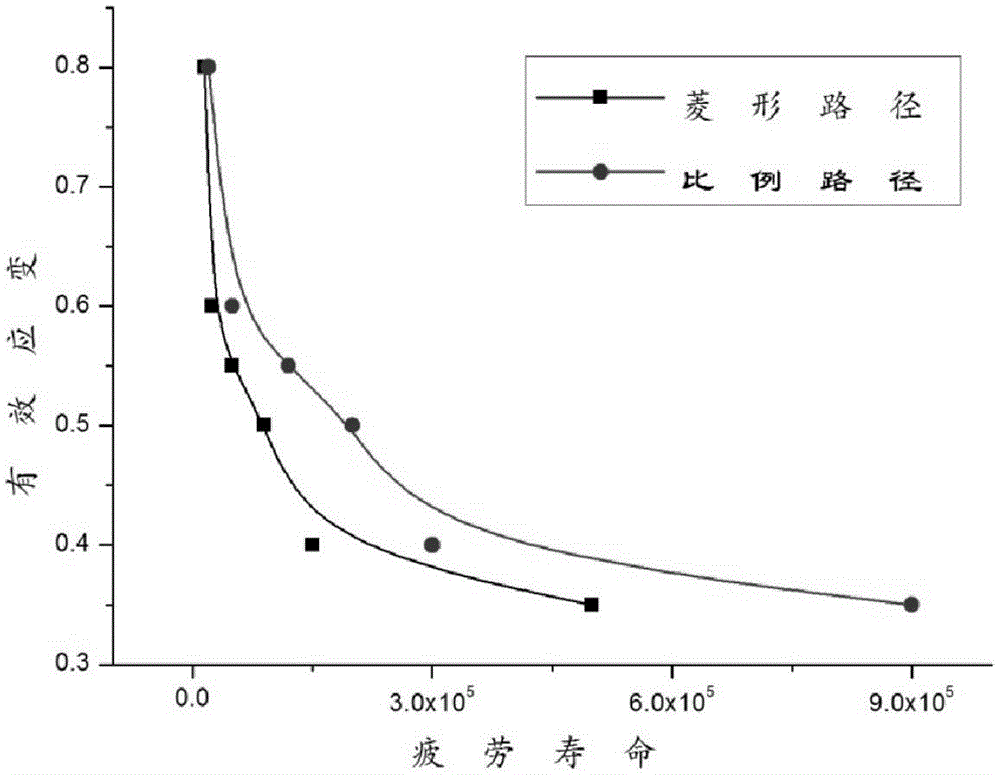

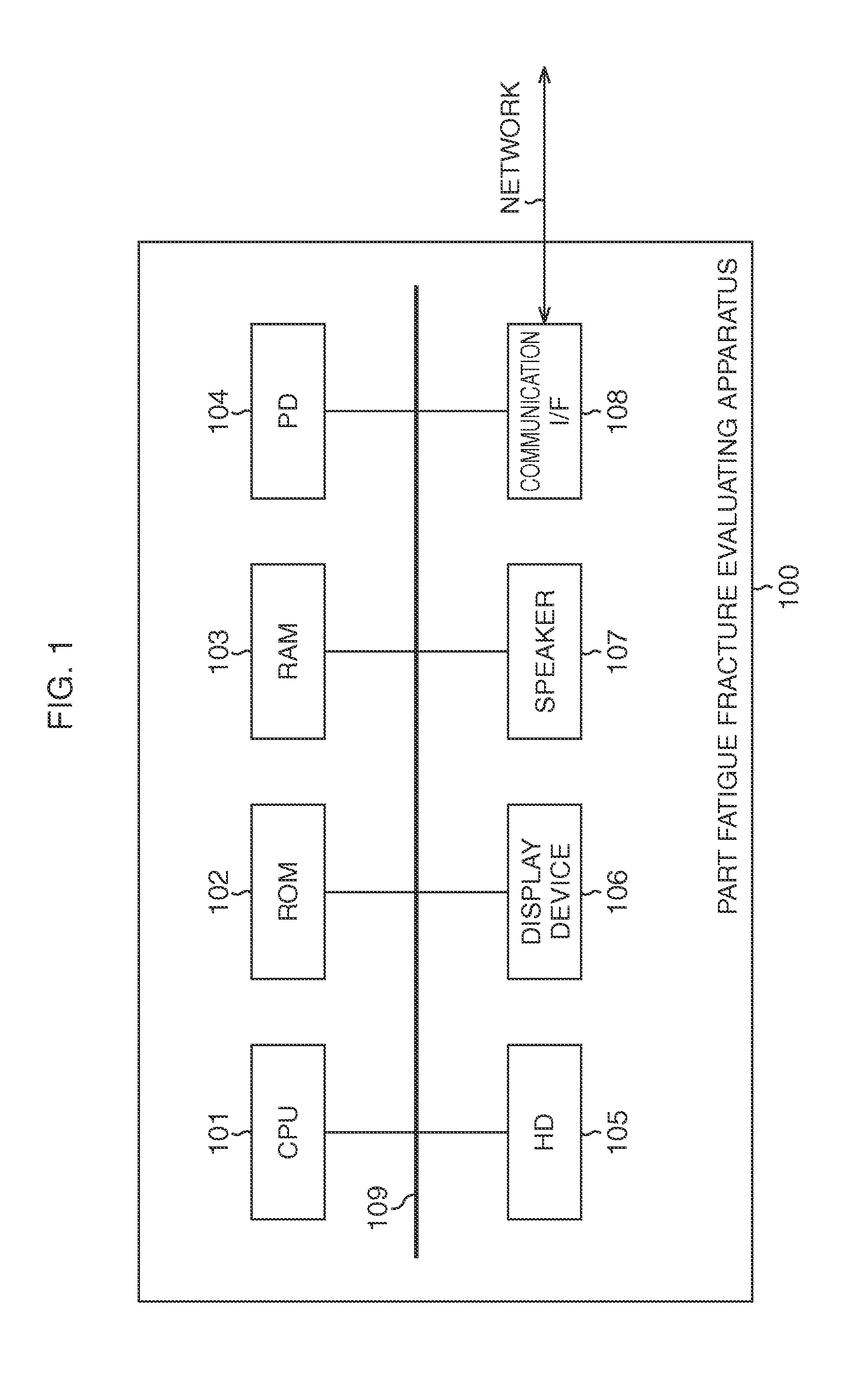

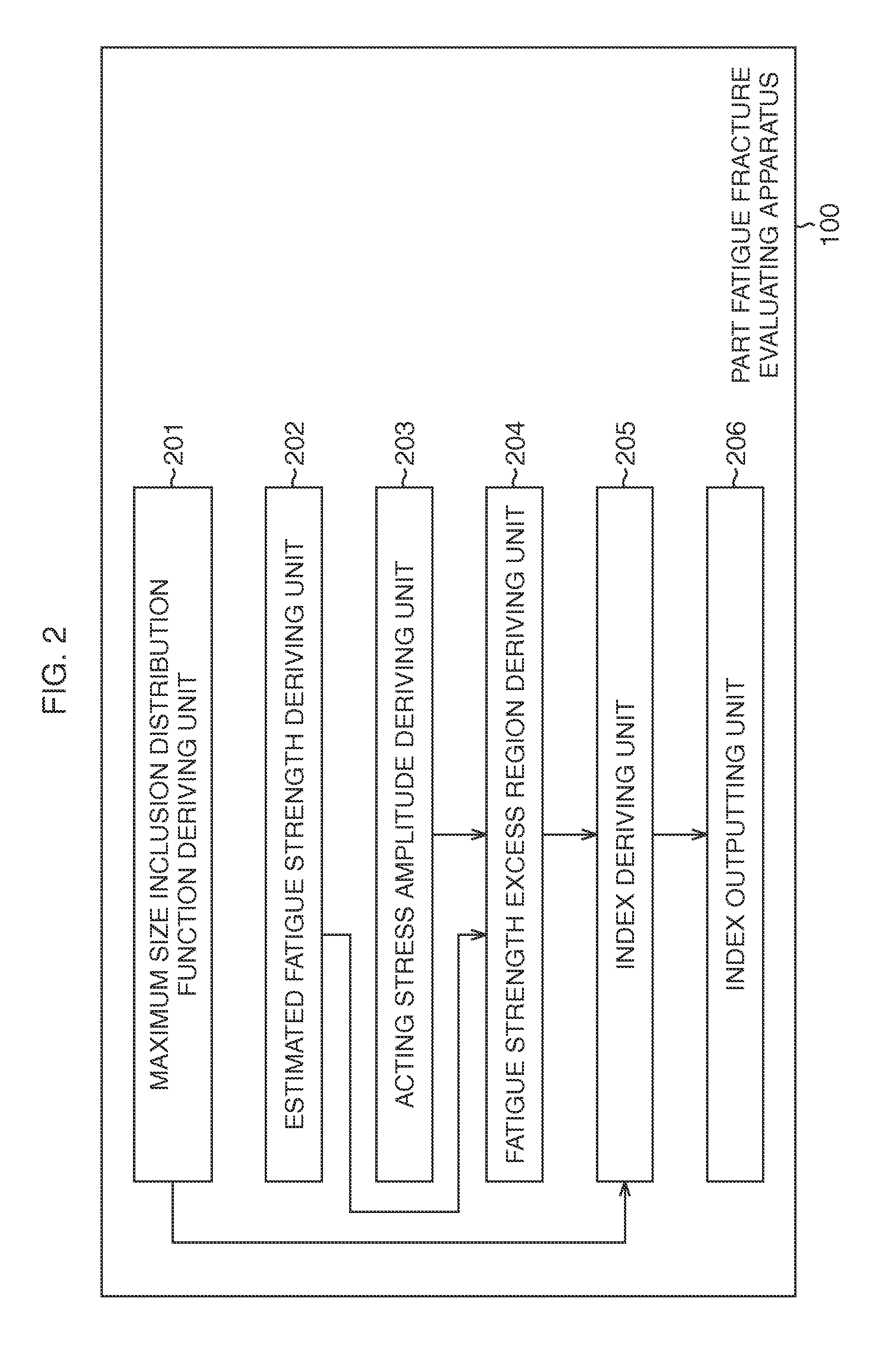

Member fatigue fracture probability estimating apparatus, member fatigue fracture probability estimating method, and computer readable medium

InactiveUS20120065934A1Accurate estimateDigital computer detailsMaterial strength using repeated/pulsating forcesFatigue fracturesMedicine

An effective volume Vep of a member is calculated with a stress correction amount σcorr added to an effective stress (stress amplitude) σip at each position of the member so that a fatigue strength of the member varying corresponding to an average stress varying depending on the position of the member is apparently constant at a value when the average stress on the member is 0 (zero) irrespective of the position of the member, and a cumulative fracture probability Pfp due to fatigue of the member is derived using the effective volume Vep of the member.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

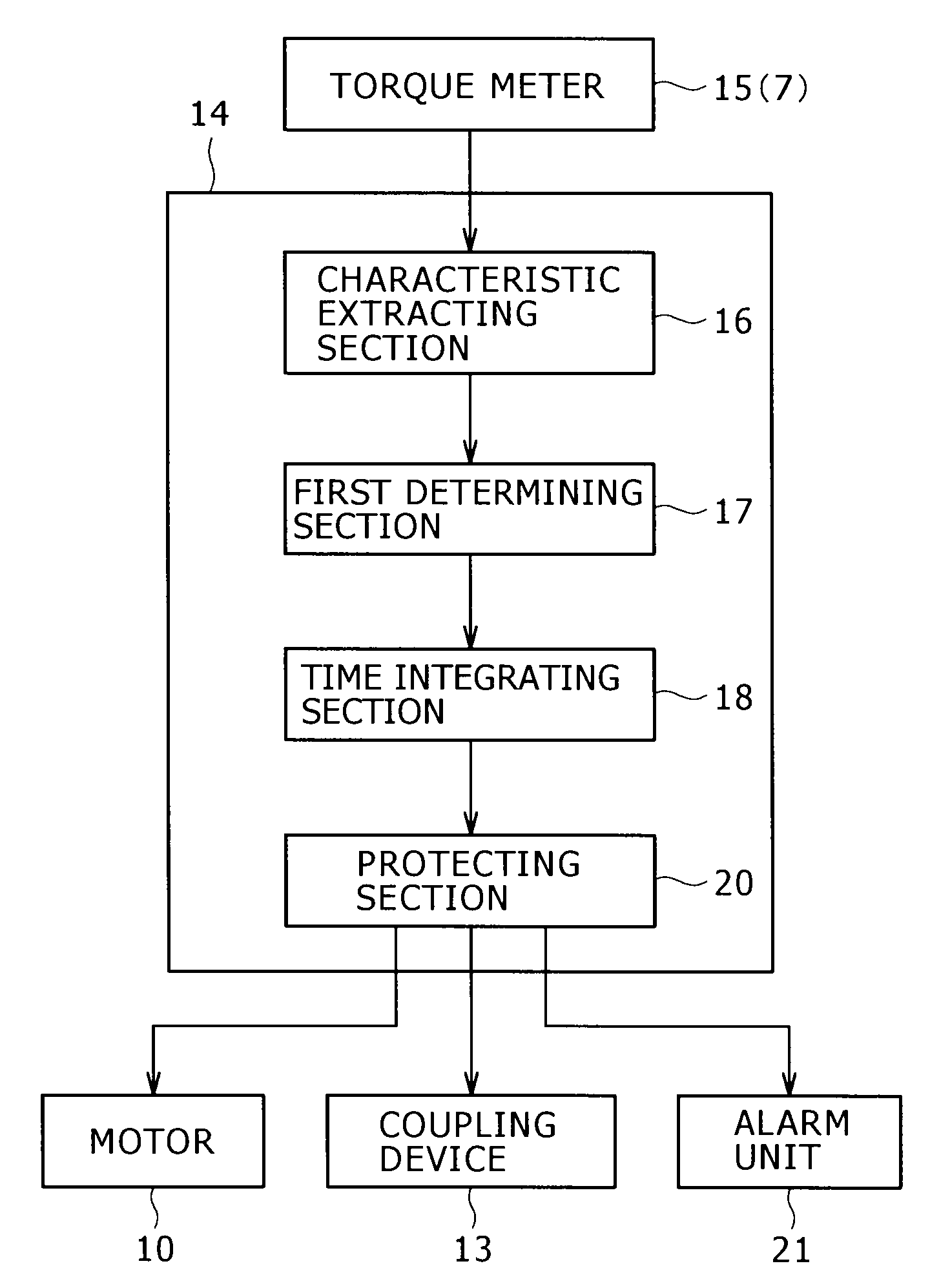

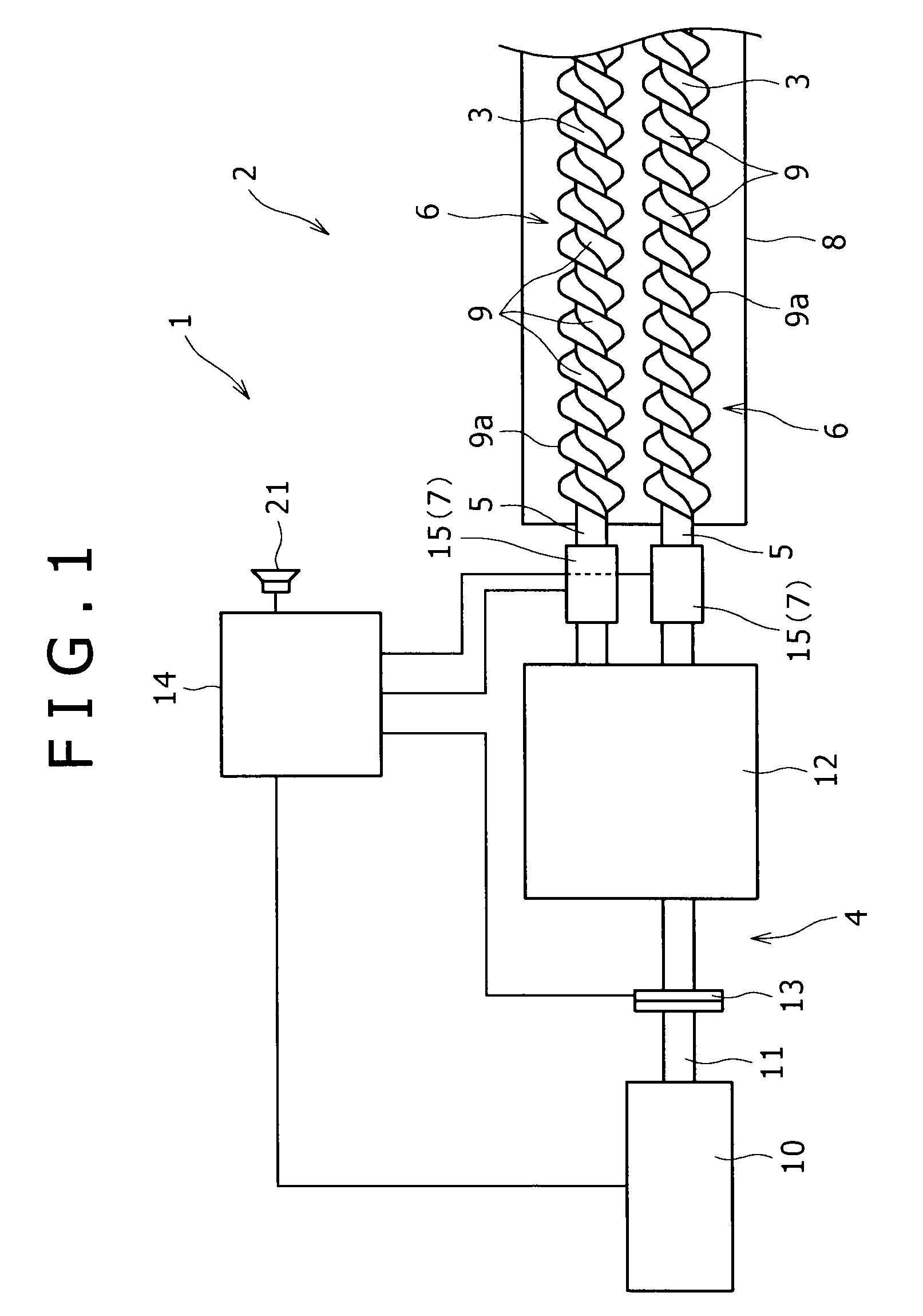

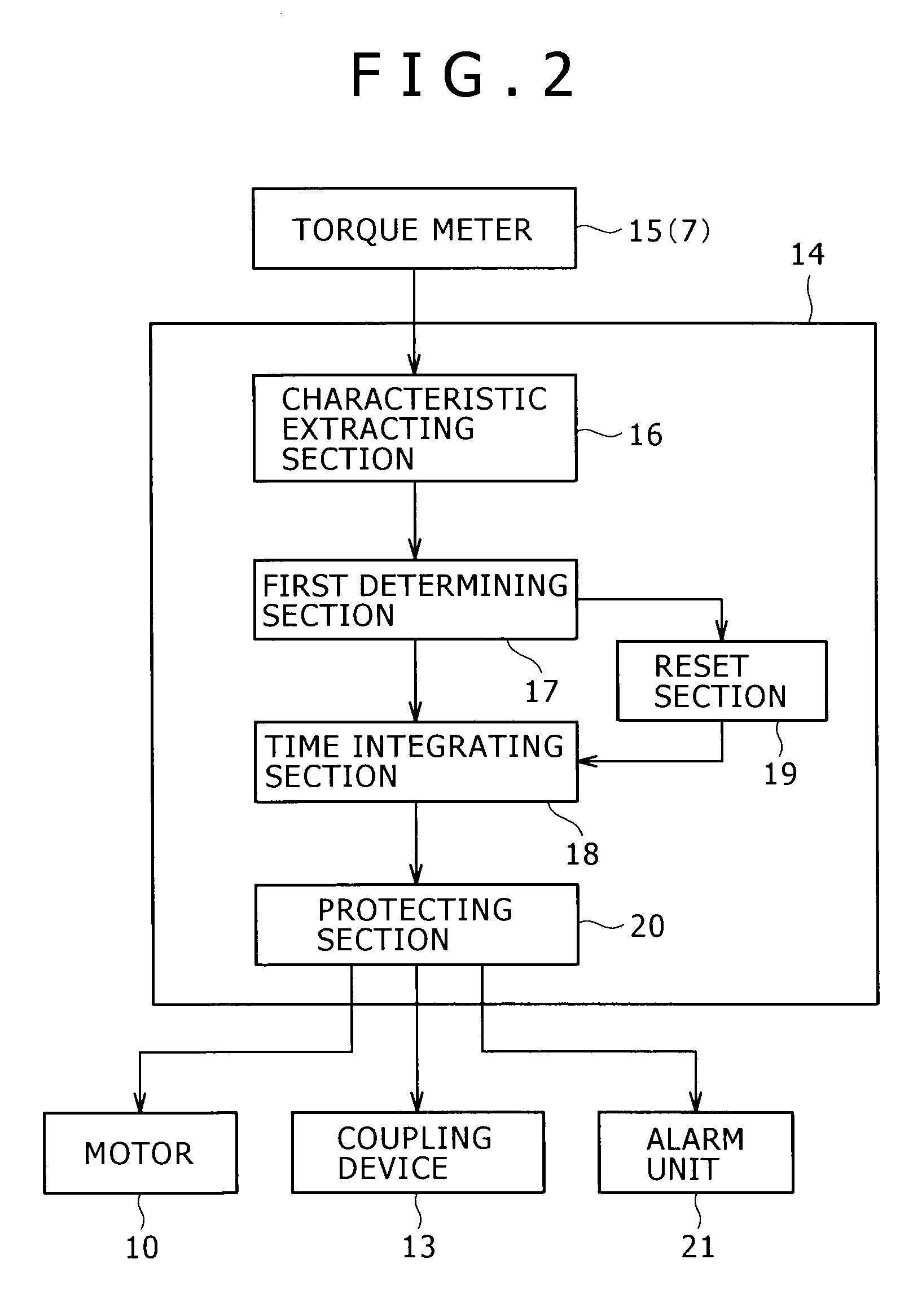

Load monitoring method and load monitoring apparatus for kneading apparatus

ActiveUS20090135016A1AlarmsApparatus for force/torque/work measurementFatigue fracturesUltimate tensile strength

In an extruder or a kneader, load (torque T) values on an input shaft portion of a screw shaft are detected by a load detector installed on the input shaft portion, then an overload condition is determined from a load mean value (Ta) and a load amplitude value (Tw) of the detected load values, and the issuance of an “abnormal” alarm and / or the stop of rotation of the screw shaft are (is) performed when an overload duration time (t0) of maintaining the overload condition exceeds a set time (ts). In this way the screw shaft is protected from fatigue fracture caused by application thereto of such a load as does not exceed a designed mechanical strength but causes fatigue fracture.

Owner:KOBE STEEL LTD

Preparation method of fastening bolt for automobile wheel

ActiveCN103088268AModerate hardnessImprove the lubrication effectThread cutting machinesBoltsChemical compositionFatigue fractures

The invention discloses a preparation method of a fastening bolt for an automobile wheel. The preparation method comprises the following processing steps: a, casting a raw material, wherein the raw material comprises the following chemical components in percentage by weight: 0.4 to 0.8% of C, 0.02 to 0.05% of Si, 0.18 to 0.21% of Mn, 0.16 to 0.18% of P, 0.05 to 0.07% of S, 0.05 to 0.15% of Cr, 0.05 to 0.12% of Ti, 0.11 to 0.13% of Cu, 0.01 to 0.02% of Al, 0.02 to 0.03% of Mg, and the balance of iron; and b, scouring the casted and formed rod material; carrying out line drawing on the rod material according to the requirement of the line diameter of the bolt, so that the rod material shrinks to the line diameter required by the bolt; cutting the rod material which is shrunk to the required line diameter to the length required by the bolt; placing the cut rod material into a die cavity at normal temperature; and using upsetting force to enable the dimensions of a head part and a rod part of the rod material to reach the requirements of the bolt. According to the preparation method of the fastening bolt for the automobile wheel, the bolt is processed by cold extruding process, so that the strength of the bolt is improved, the hardness value and the strength value required by the 12.9 high-strength bolt can be realized, and the delayed fracture and the fatigue fracture of the bolt at high strength can be solved; the fastening bolt is reliable in connection and hardly broken during use, prolongs the service life, and meets the usage demand of various industries in the society to high-strength bolts.

Owner:湖北友谦汽车零部件有限公司

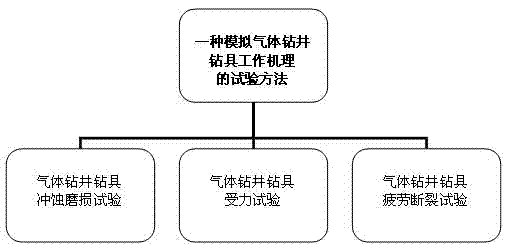

Test method for simulating working mechanism of drilling rig for gas drilling

InactiveCN102175545AReduce volumeLight in massInvestigating abrasion/wear resistanceInvestigating machinabilityFatigue fracturesWell drilling

The invention relates to a test method for simulating a working mechanism of a drilling rig for gas drilling, and the method is used in the field of petroleum and gas drilling. The method comprises an erosion abrasion test method for the drilling rig for gas drilling, a force-bearing test method for the drilling rig for gas drilling and a fatigue fracture test method for the drilling rig for gas drilling, wherein the erosion abrasion test method for the drilling rig for gas drilling comprises the following steps: 1) before testing, fixing a testing derrick on a cement foundation and weighting out the weight of the drilling rig on a test section before testing; 2) starting different combinations of fans and then adjusting and controlling the air pressure and air quantity required by the test; 3) stopping blowing after testing for a period of time and recording the delta 2 at the moment; and 4) taking out the drilling rig on the test section and then weighting the drilling rig, thereby acquiring the abrasion loss of the drilling rig on the test section within unit time. The invention provides a convenient test method for researching the related problems of the working mechanism of the drilling rig for gas drilling in the gas drilling process, such as erosion abrasion, force-bearing and fatigue fracture failure of the drilling rig for gas drilling, and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Steel with underrelaxation and hydrogen corrosion resistance for high-speed railway prestressed pull rod and production method thereof

The invention discloses steel with underrelaxation and hydrogen corrosion resistance for a high-speed railway prestressed pull rod and a production method thereof, which belong to the technical field of steel for railways. By adopting Si as a main enhancing element and micro alloying Cr, Ti and B, the material has excellent comprehensive performances during heat treatment. The production flow comprises working procedures of smelting, refining, continuous casting and rolling, wherein the smelting working procedure is carried out on an electric furnace or a converter; and the material is subjected to LF refining and continuously cast into casting blanks. After treated by a heat treatment process, the raw material has the mechanical property of 1,420-1,480MPa, the elongation percentage of more than or equal to 9.0 percent, the hydrogen stress corrosion fracture resistant time for more than 70 hours, fatigue fracture life for more than 3 millions of times, relaxation less than 3.5 percent for 1,000 hours and low-temperature impact rate not lower than 30KJ and is specially applied to the production of the steel for an unballasted track sleeper prestressed pull rod at a high-speed railway of 350 kilometers / hour.

Owner:SHOUGANG CORPORATION

Preparation method for high-strength foundation bolt

InactiveCN103205641AModerate hardnessImprove the lubrication effectMetal-working apparatusSolid state diffusion coatingFatigue fracturesHigh stress

The invention discloses a preparation method for a high-strength foundation bolt. Processing steps comprise a step of casting of a rod material, wherein chemical components of a rod material blank comprise, by weight, 0.27 to 0.36% of C, 0.25 to 0.33% of Mn, 0.05 to 0.08% of V, 0.25 to 0.35% of Si, 0.01 to 0.04% of W, no more than 0.025% of P, no more than 0.035% of S, 0.45 to 0.60% of Ni, 0.20 to 0.30% of Sn and 0.45 to 0.65% of Cu, with the balance being Fe. According to the invention, a cold extruding process is used for processing of the bolt, so strength of the bolt is improved, a hardness number and a strength value required by a 12.9 high-strength bolt are reached, the problems of delayed fracture and fatigue fracture of the bolt under high stress are overcome, and the bolt has reliable connection and hardly breaks during usage, has a prolonged service life and meets usage demands for high strength bolts by a variety of industries in society.

Owner:繁昌县琪鑫铸造有限公司

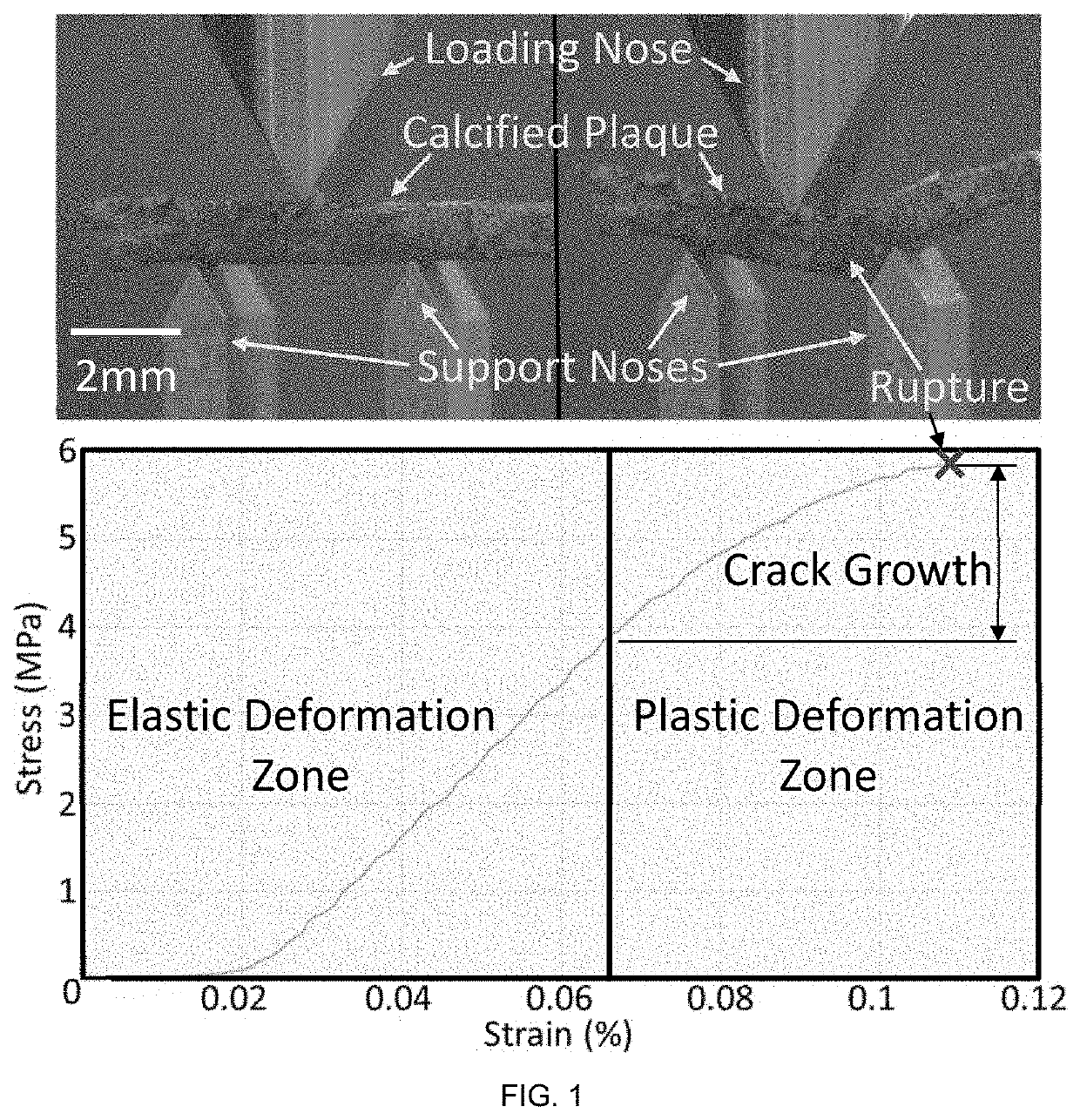

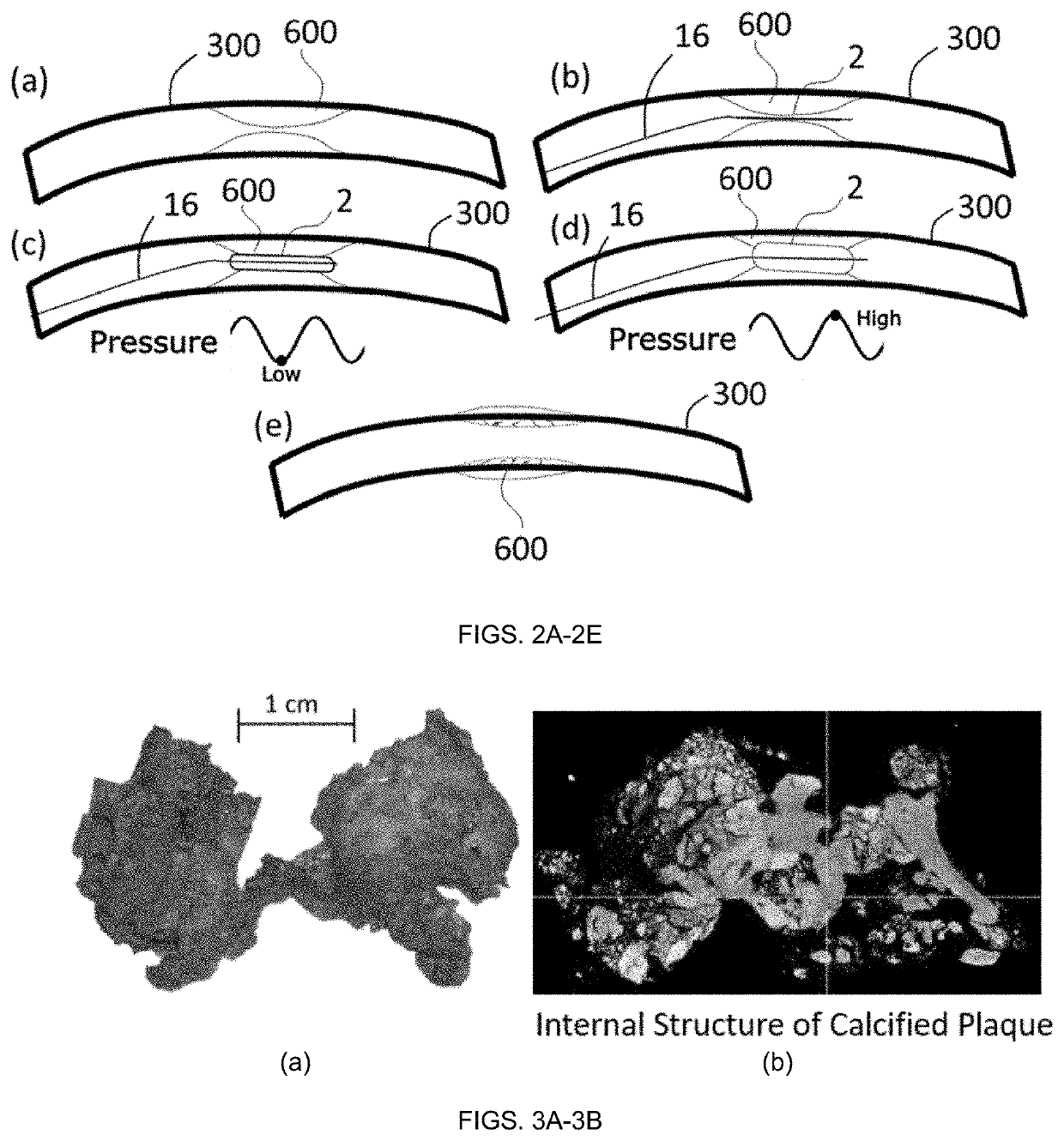

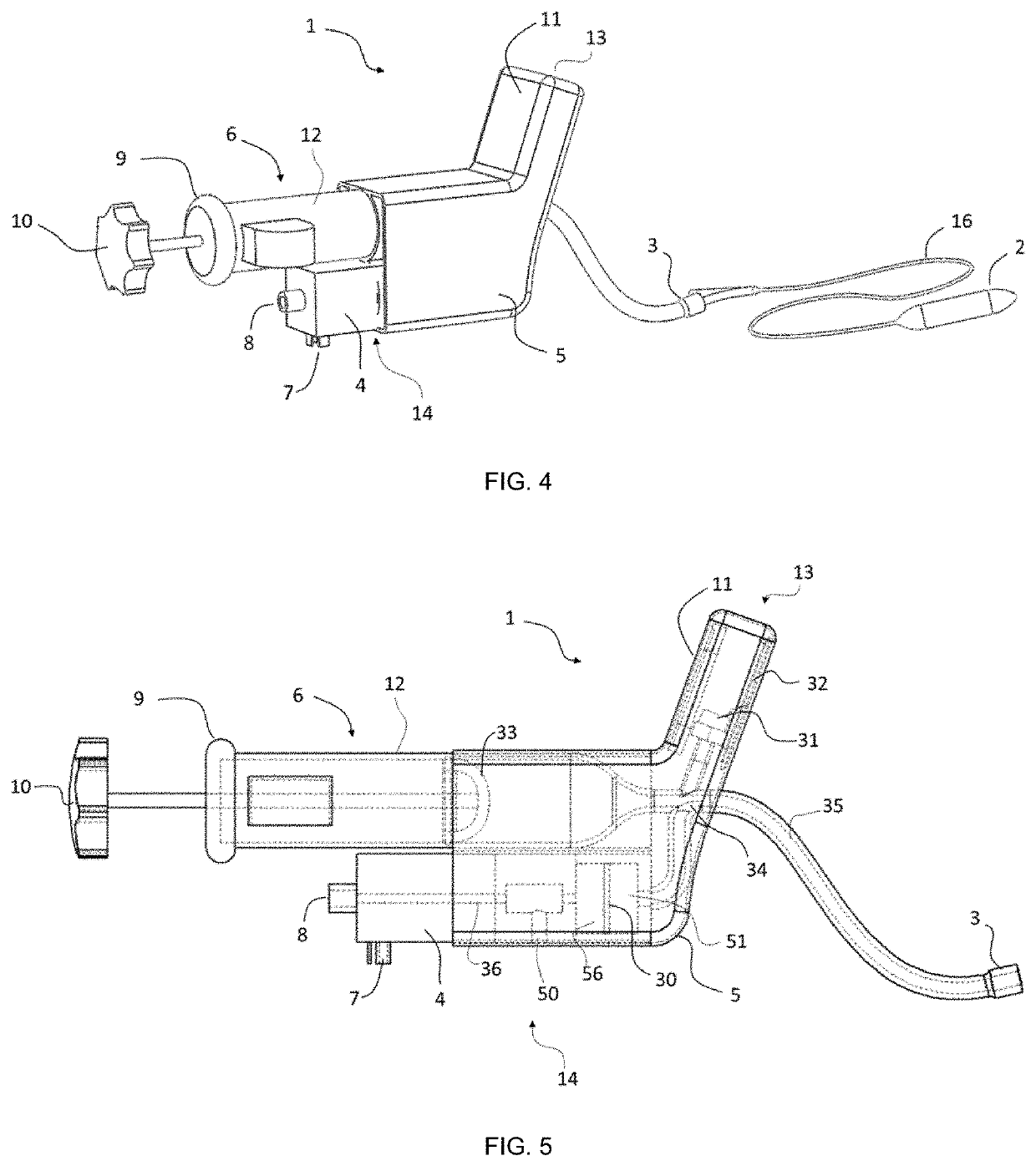

System for effecting and controlling oscillatory pressure within balloon catheters for fatigue fracture of calculi

ActiveUS20200046949A1Improve efficiencyLow pressureBalloon catheterSurgeryAngioplasty balloonControl signal

A dynamic balloon angioplasty system for applying a dynamic pressure to fracture hardened materials embedded within an elastic conduit. The system having a pressure source system outputting at least a first predetermined pressure from a pressure source outlet, and an angioplasty unit fluidly coupled to the pressure source outlet receiving at least the first predetermined pressure. The angioplasty unit having an angioplasty inflation device, an angioplasty balloon connector, and an oscillating mechanism selectively actuated to output a plurality of pressure pulses to the angioplasty balloon via a fluid communication path. A control system is configured to determine an optimal hydraulic pressure oscillation frequency and amplitude for a given procedure and output a control signal to the oscillating mechanism, and monitor a pressure signal to detect fracture of the hardened material within the elastic conduit or system failure or leakage.

Owner:RGT UNIV OF MICHIGAN

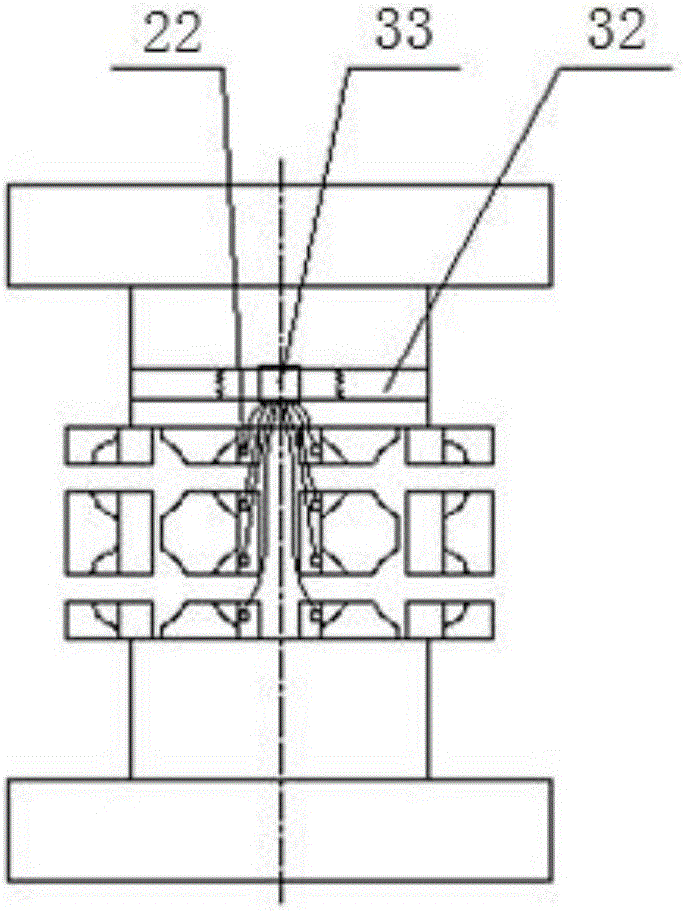

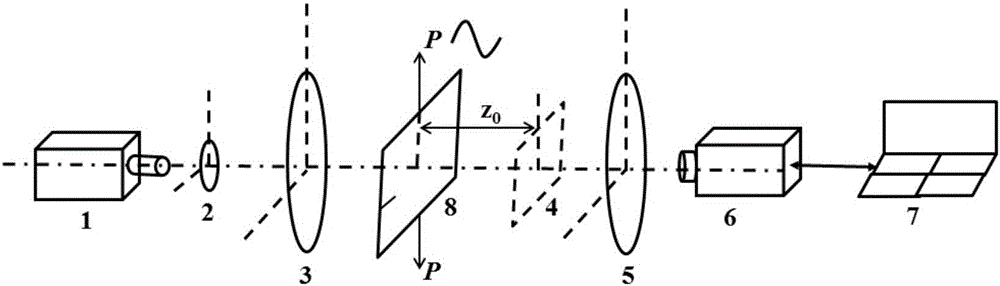

Multi-axial fatigue fracture test equipment for bridge expansion joint material and implementation method of multi-axial fatigue fracture test equipment

InactiveCN105067436AMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesBridge engineeringFatigue fractures

The invention belongs to the technical field of bridge engineering, and relates to multi-axial fatigue fracture test equipment for a bridge expansion joint material and an implementation method of the multi-axial fatigue fracture test equipment. The fatigue fracture test equipment comprises an external frame, a transmission device, a concrete member, the expansion joint material, a temperature sensor and a normal loading device, wherein the concrete member comprises a fixed concrete member and a movable concrete member between which a slit used for accommodating the expansion joint material is reserved; the movable concrete member is used for realizing horizontal movement; the normal loading device comprises a solid rubber wheel which is used for realizing normal loading; the acting force of the wheel to the expansion joint material is simulated through a cylinder and a motor. Compared with the prior art, the fatigue fracture test equipment can sufficiently simulate the actual working condition of the expansion joint material under the combined action of bridge expansion change and vehicle load, so that the fatigue performance of the material under different expansion quantity, vehicle load and expansion frequency can be studied.

Owner:SHANXI PROVINCIAL RES INST OF COMM

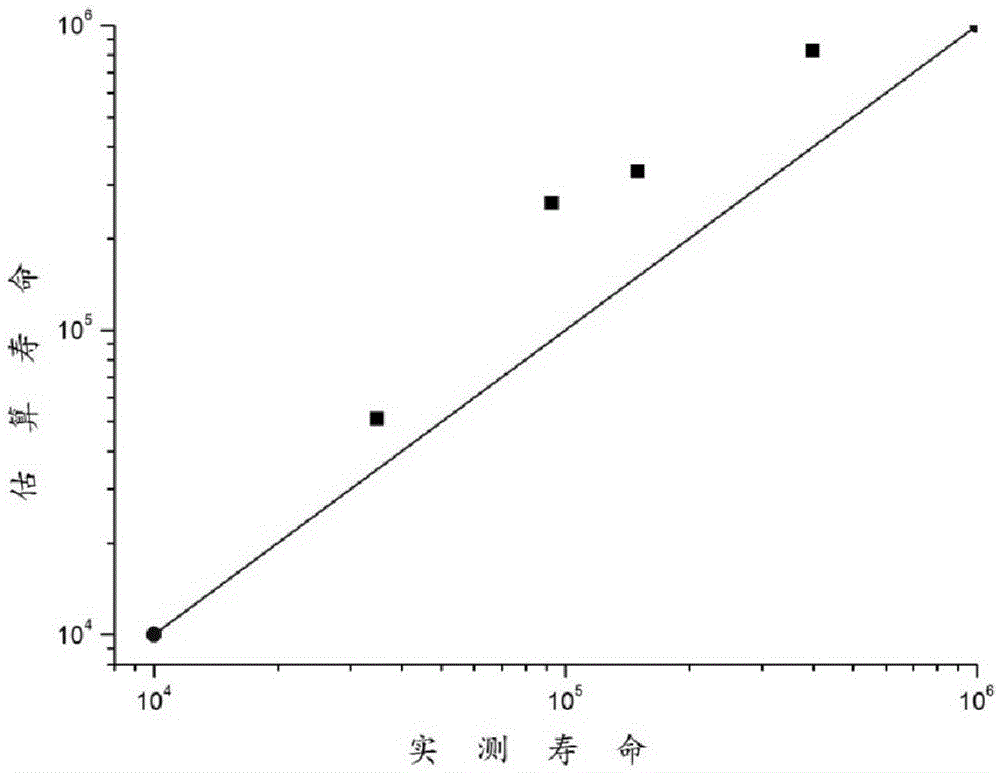

Method for performing online measurement on fatigue crack propagation of organic glass

InactiveCN105699218AReliable Extended Test Measurement AccuracyReduce storageMaterial strength using repeated/pulsating forcesStress strengthCcd camera

The invention provides a method for performing online measurement on fatigue crack propagation of organic glass and belongs to the fields of fatigue fracture mechanics test technologies and digital image technologies. According to the method, a transmission-type caustic optical technology is adopted, a CCD camera is utilized to online and continuously collect propagation processes of shadow spot images and cracks nearby crack tips of an organic glass testpiece containing cracks under different fatigue circle periods, image processing and condition selection are performed on shadow spot images in a cache region of a computer in real time, and the crack length and the crack tip stress strength factor are calculated. A caustic optical testing technology adopted in the method refers to non-contact real-time measurement, is high in intuition, simple in geometrical optics model, easy in stress strength factor calculation, convenient in data processing and accurate and reliable in test result; compared with a traditional fatigue crack propagation measurement method, the method provided by he invention is capable of omitting tedious processes of manually measuring the crack length and solving out the stress strength fact range, and avoiding the influence of crack length halt measurement on the test result.

Owner:TSINGHUA UNIV

Fracture fatigue entropy determination

ActiveUS9243985B2Material strength using repeated/pulsating forcesSpecial data processing applicationsDowntimeFatigue fractures

A method and apparatus are disclosed for approximating in real time the fracture fatigue entropy (FFE) of a metallic object subjected to cyclic loading. Such objects experience fatigue, which can lead to failure after a number of loading cycles. The disclosed invention allows for real time monitoring of the entropy increase in a metallic object under cyclic loading, and allows for removing the object from service before fatigue fracture occurs. Through use of the present invention, users may keep metallic objects in service for longer periods, because such objects may be safely taken closer to the fatigue fracture point. The invention therefore can effectively extend the useful life of many critical components and reduce downtime resulting from repair or premature replacement.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

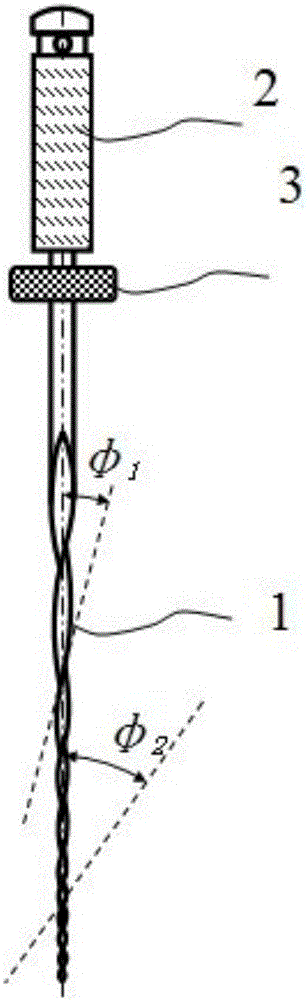

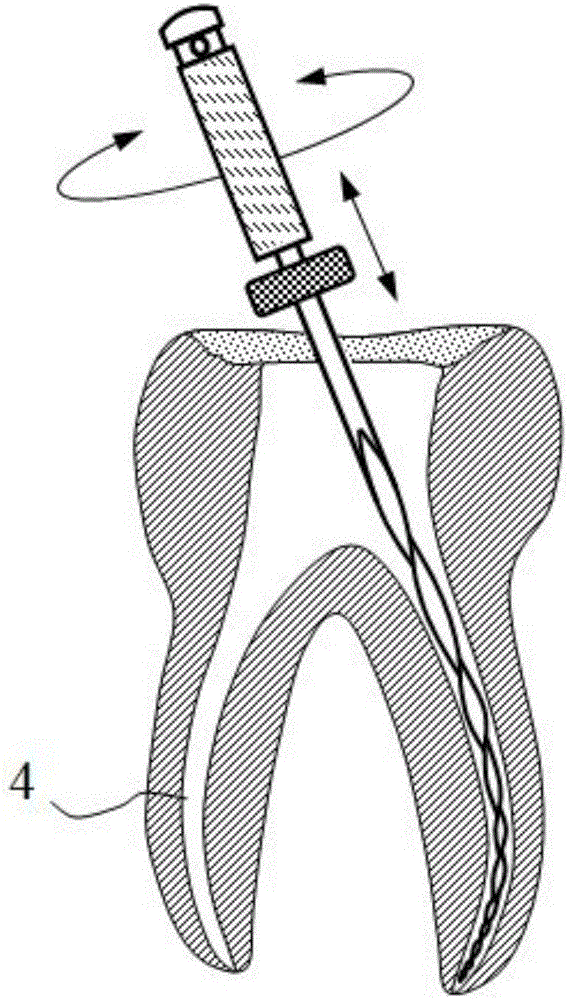

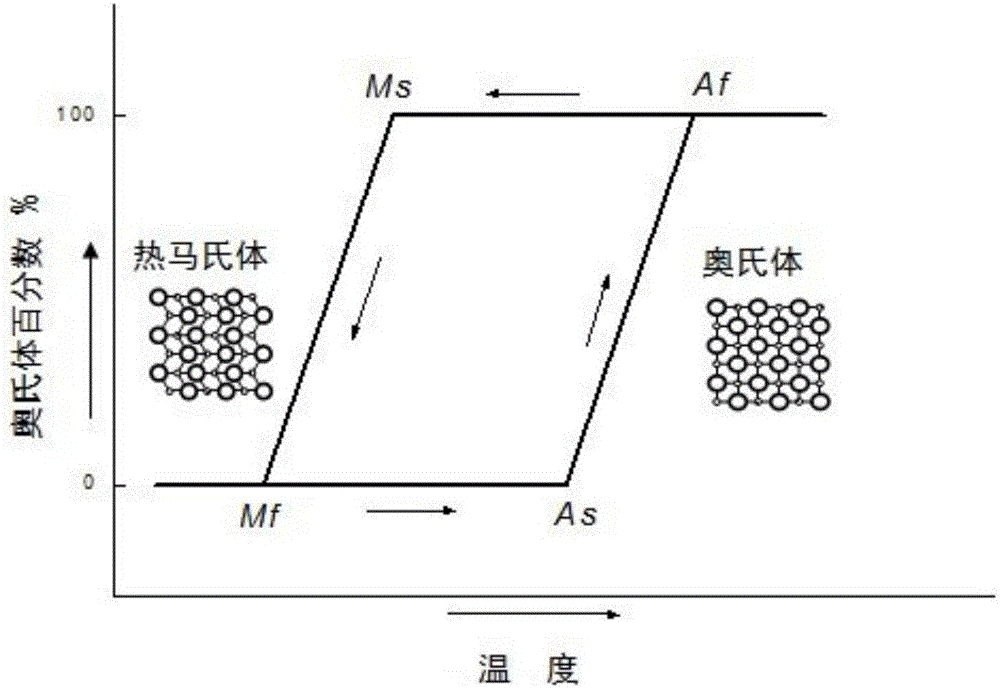

Nickel-titanium alloy gradient flexible root canal file and manufacturing method thereof

The invention provides a nickel-titanium alloy gradient flexible root canal file. The nickel-titanium alloy gradient flexible root canal file comprises a working portion, a handle portion and a positioning ring, the working portion is connected with the handle portion, the working portion comprises a tip section, a transition section and a root section close to the handle portion, the positioning ring is arranged on the root section of the working portion, and the martensite-to-austenite phase transition finishing temperature Af of all points on the nickel-titanium alloy gradient flexible root canal file gradually reduces from the tip of the tip section to the root section along the length direction of the nickel-titanium alloy gradient flexible root canal file. The invention also provides a manufacturing method of the nickel-titanium alloy gradient flexible root canal file. The nickel-titanium alloy gradient flexible root canal file has good cutting ability, good flexibility and high fatigue fracture resistance, and can fundamentally solve the disadvantages of present nickel-titanium alloy root canal files in order to greatly improve the usability, the safety and the life of the root canal files.

Owner:SHENZHEN SUPERLINE TECH

Method for testing fatigue in hydrogen gas

InactiveUS20110005329A1Cost advantageImprove efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing mechanical meansCycle rateHydrogen

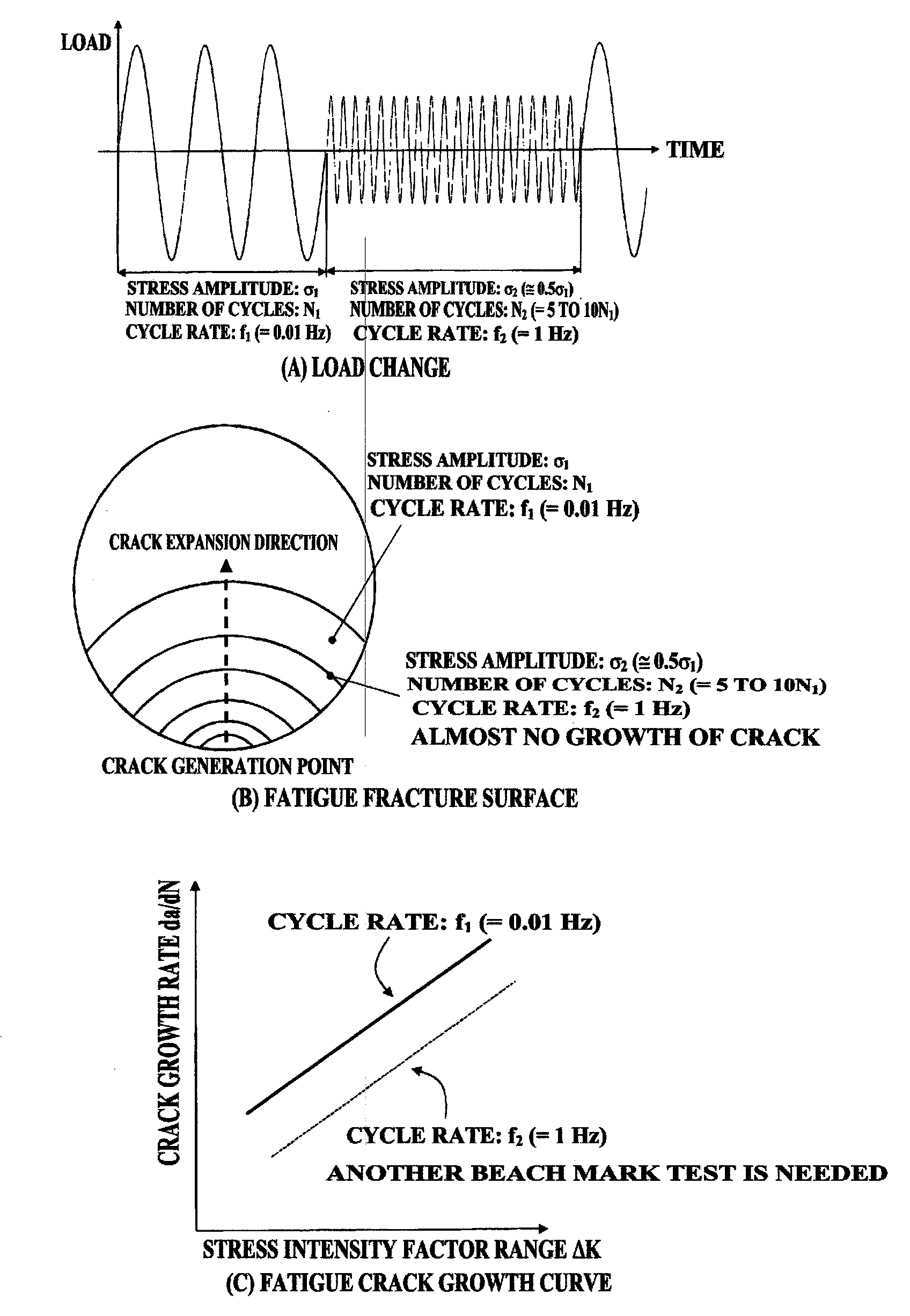

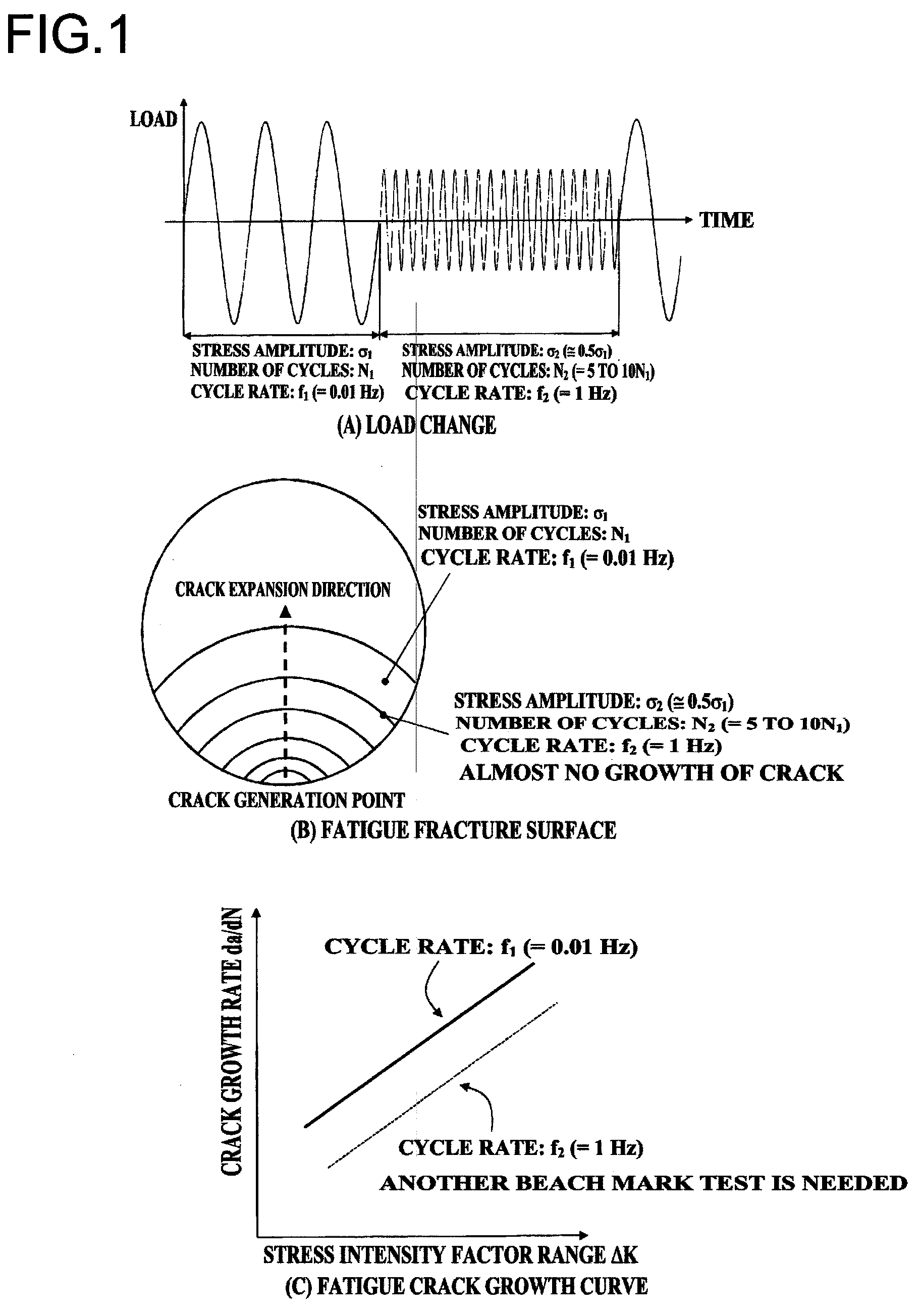

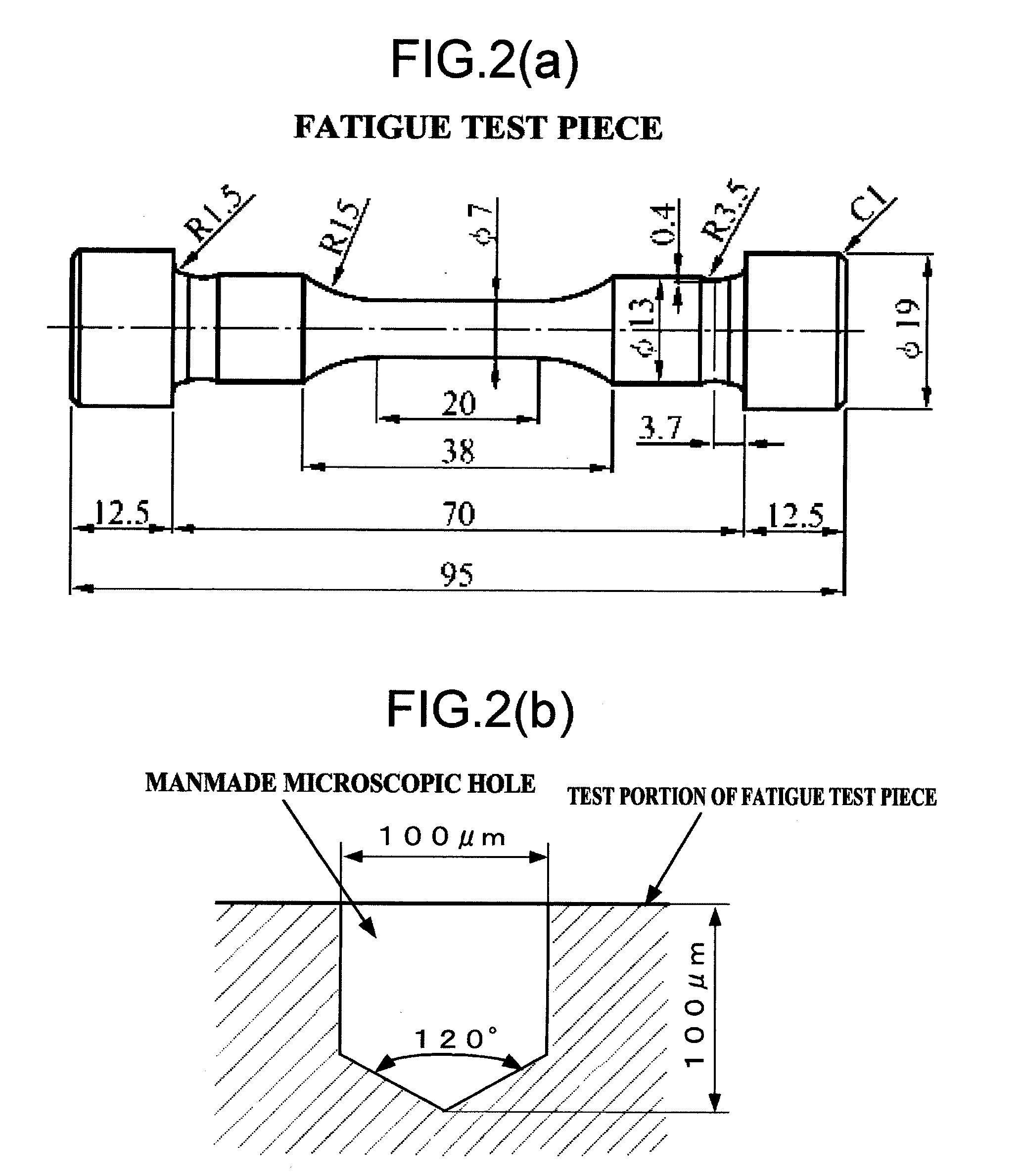

There is provided a fatigue test method with which the crack growth can be checked for a plurality of cycle rates in a single test. At a first cycle rate f1 of 0.01 Hz, hydrogen has a greater effect on crack growth than at a second cycle rate f2 of 1 Hz. As a result, an area of large hydrogen effect (an area developed at the cycle rate f1) and an area of small hydrogen effect (an area developed at the cycle rate f2) appear alternately on the fatigue fracture surface, and since these two areas have different fracture surface morphologies, it is possible to see the boundary lines. Consequently, the lengths of the cracks developed under each set of conditions can be specified, and a fatigue crack growth curve can be acquired for each set of conditions.

Owner:NAT INST OF ADVANCED IND SCI & TECH

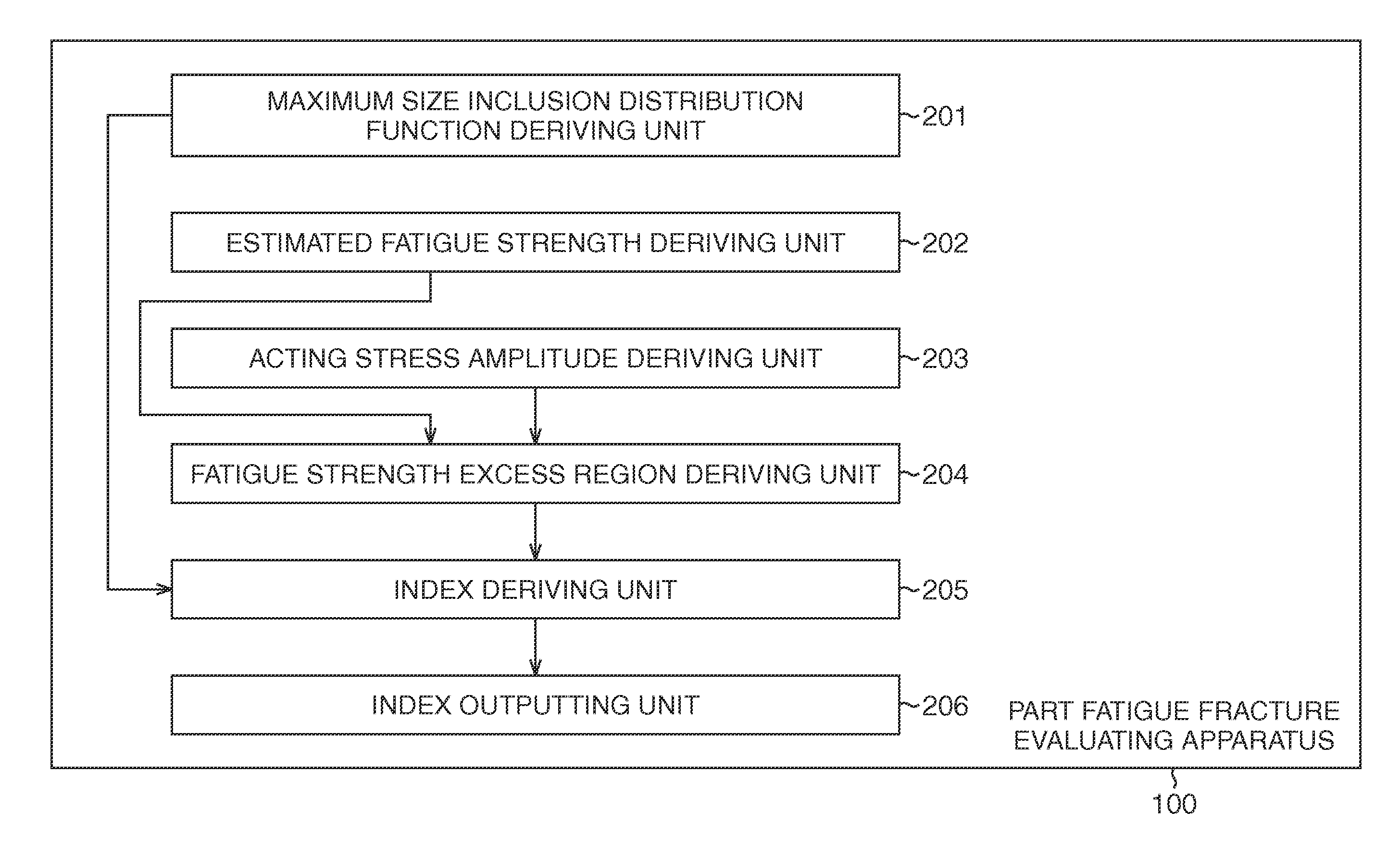

Part fatigue fracture evaluating apparatus, part fatigue fracture evaluating method, and computer program

InactiveUS20130298691A1Flow propertiesMaterial strength using repeated/pulsating forcesFatigue IntensityFatigue fractures

There is derived an index FS (P) obtained by integrating the product of a probability distribution function f (√{square root over ( )}areamax) of an inclusion size √{square root over ( )}areamax of a part and a “size S (P, √{square root over ( )}√{square root over ( )}areamax) of a region of the part” where a stress amplitude σ of an acting stress exceeds a stress amplitude σw of a fatigue strength at each location in the case of a load being applied under a loading condition P set previously by an operator over the inclusion size √{square root over ( )}√{square root over ( )}areamax of the part with the whole region of a range where a probability distribution of the inclusion size √{square root over ( )}areamax exists set as an integral range.

Owner:NIPPON STEEL CORP

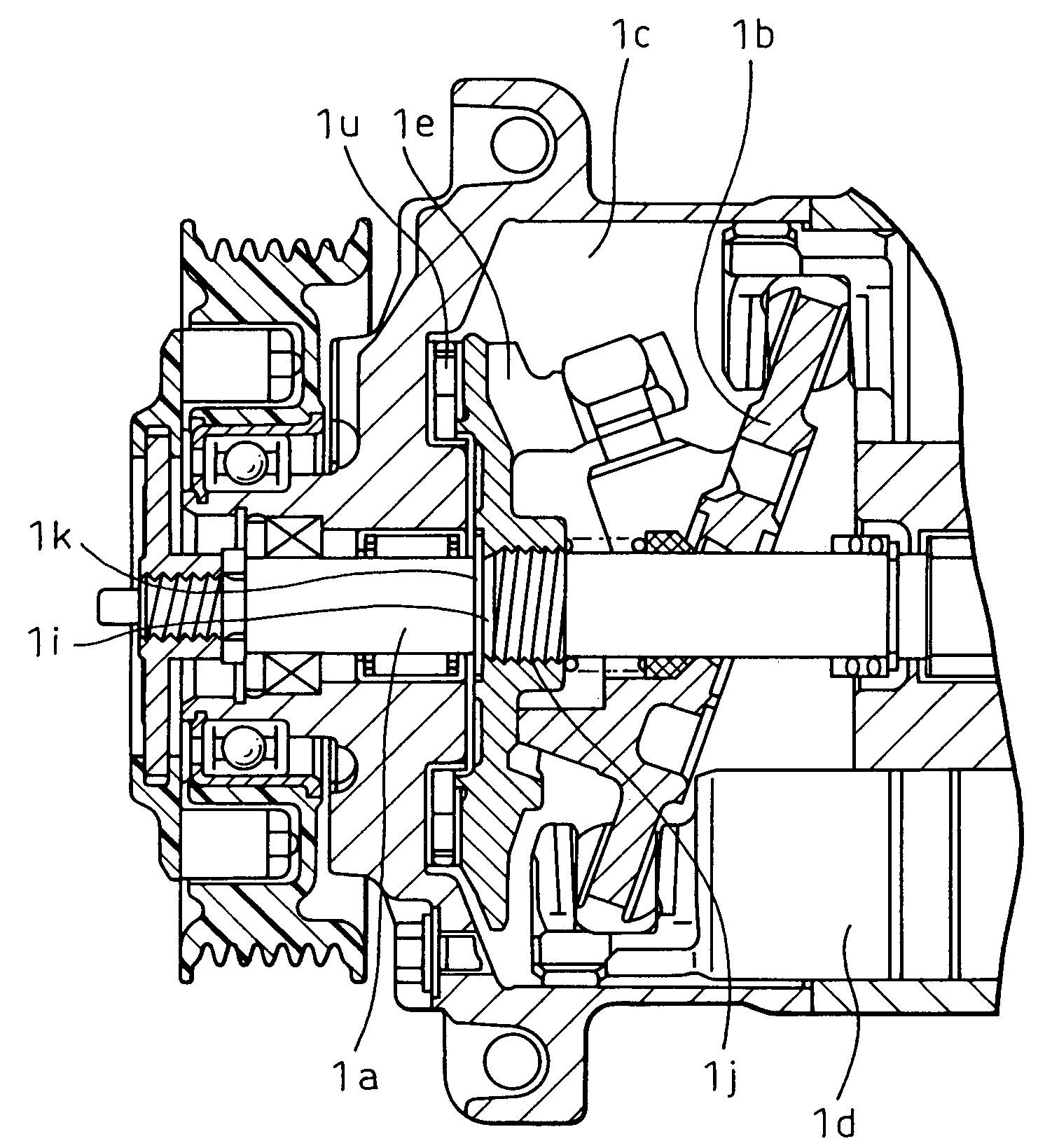

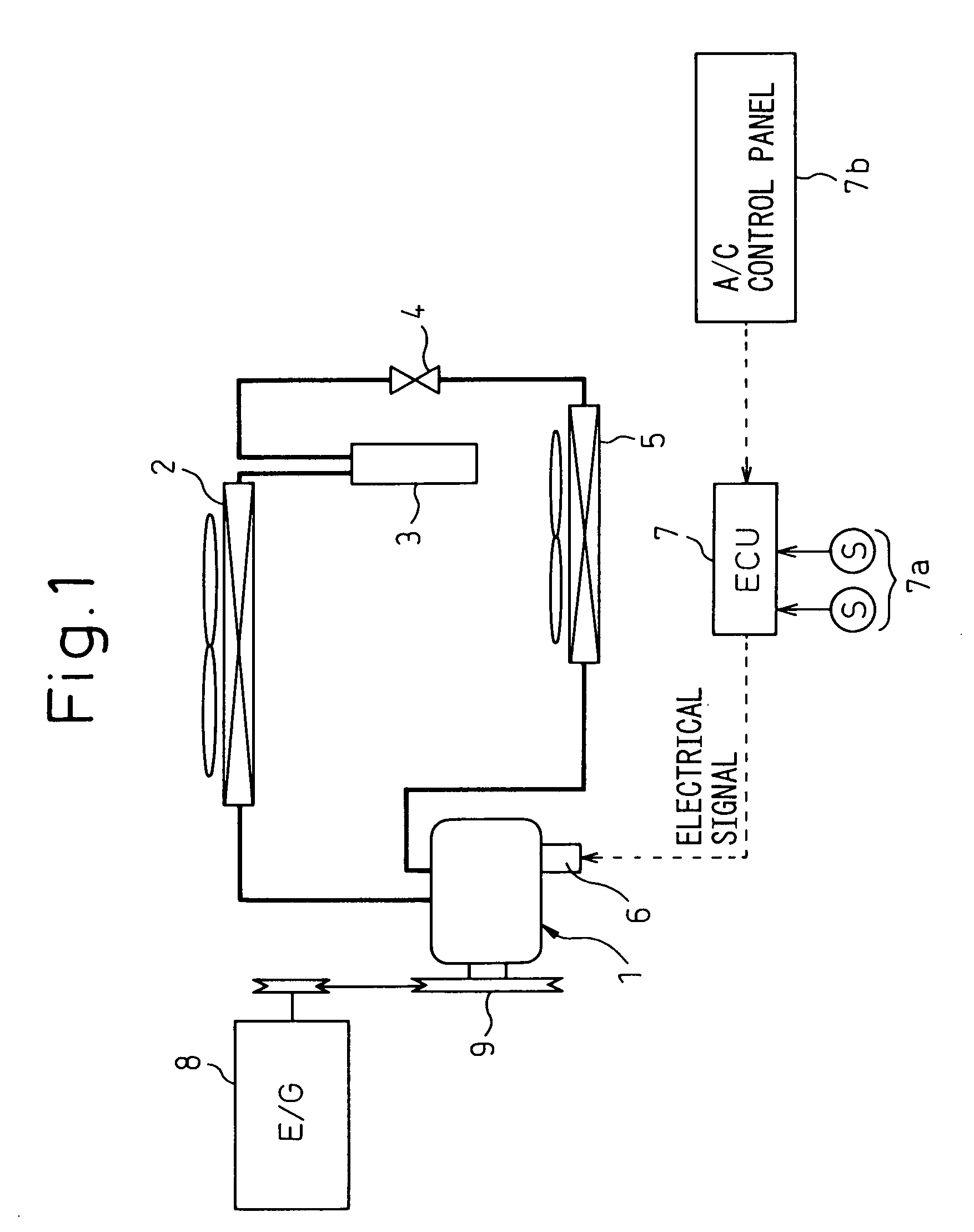

Rotating apparatus with a torque limiter function

ActiveUS7311625B2Novel functionPrevent power transmissionGearingPortable liftingStress distributionFatigue fractures

A screw engagement portion between a pulley and a shaft is provided with a thread in a direction to increase the tightening torque when the pulley is driven. A breakable part broken by the axial tension produced when the tightening torque acting on the screw engagement portion is above a predetermined value, is also provided. The stress to break the breakable part is mainly a tensile stress. The tensile stress is substantially uniformly distributed in a cross section and, hence, the stress distribution of the breakable part can be relatively precisely predicted and analyzed. Consequently, the necessity of determining aspects of the breakable part, such as dimension, material, and the like, by trial and error is reduced. The breakable part can be broken without being subject to fatigue fracture.

Owner:DENSO CORP

Lightening protection device for wind generating set blade

InactiveCN102384044AAvoid distortionAvoid fatigue fractureRotary current collectorMachines/enginesElectricityFatigue fractures

The invention relates to a lightening protection device for a wind generating set blade. A hub is provided with a fixed lightening receiving contact device which is contacted with a lightening protection wiring board; one end of the lightening protection wiring board is fixed to the root of the blade; the fixed lightening receiving contact device comprises a lightening protection carbon brush support connected with the hub; a carbon brush is fixed on the lightening protection carbon brush support, and is connected with an electrode; and the carbon brush and the electrode are directly contacted with the lightening protection wiring board. The fixed lightening receiving contact device is arranged in the hub, the fixed lightening protection wiring board is arranged on the root of the blade, the contact surfaces of the two lightening protection parts slide mutually when the hub and the blade move relatively, and the lightening current in the blade is smoothly led out. A lightening protection lead is prevented from torsion and fatigue fracture, the set can be effectively prevented from suffering lightening due to fracture of a lightening protection wire, the safety and the stability of the set are improved, the maintenance cost of the lightening parts of the set blade is reduced, and the operating efficiency of the set is improved.

Owner:CRRC SHANDONG CO LTD

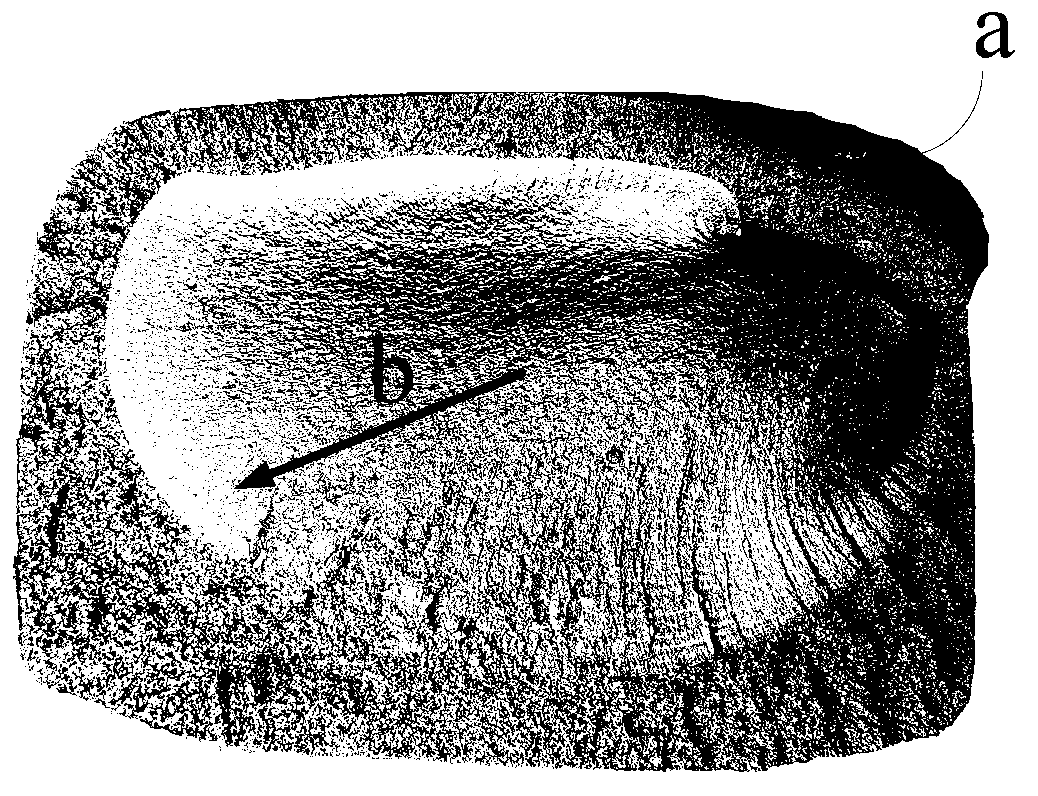

Longitudinal-transverse type core wound rail sampling and fracture analysis method

ActiveCN103235100AEasy to operateWithdrawing sample devicesTesting metalsFatigue fracturesEngineering

The present invention discloses a longitudinal-transverse type core wound rail sampling and fracture analysis method, which comprises: detecting a position of a transverse fatigue crack inside a rail head of a longitudinal-transverse type core wound rail; pressing the transverse fatigue crack to expose a core wound transverse fatigue fracture, observing a macroscopic morphology of the transverse fatigue fracture, and determining a core wound type; cutting the core wound rail from the transverse fatigue fracture surface along a longitudinal surface to obtain a preliminary sample; unclosing a longitudinal fatigue crack of the preliminary sample to obtain a two coupling longitudinal fatigue fracture sample, and observing a position and a size of a fatigue source of the longitudinal fatigue fracture; washing the two coupling longitudinal fatigue fracture sample, and adopting a scanning electron microscopy to observe a microscopic morphology of a fatigue source of the longitudinal fatigue fracture; and adopting a micro-zone energy spectrometer to obtain chemical components of the fatigue source of the longitudinal fatigue fracture and determine types and sources of foreign substances. The longitudinal-transverse type core wound rail sampling and fracture analysis method has a characteristic of simple operation.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

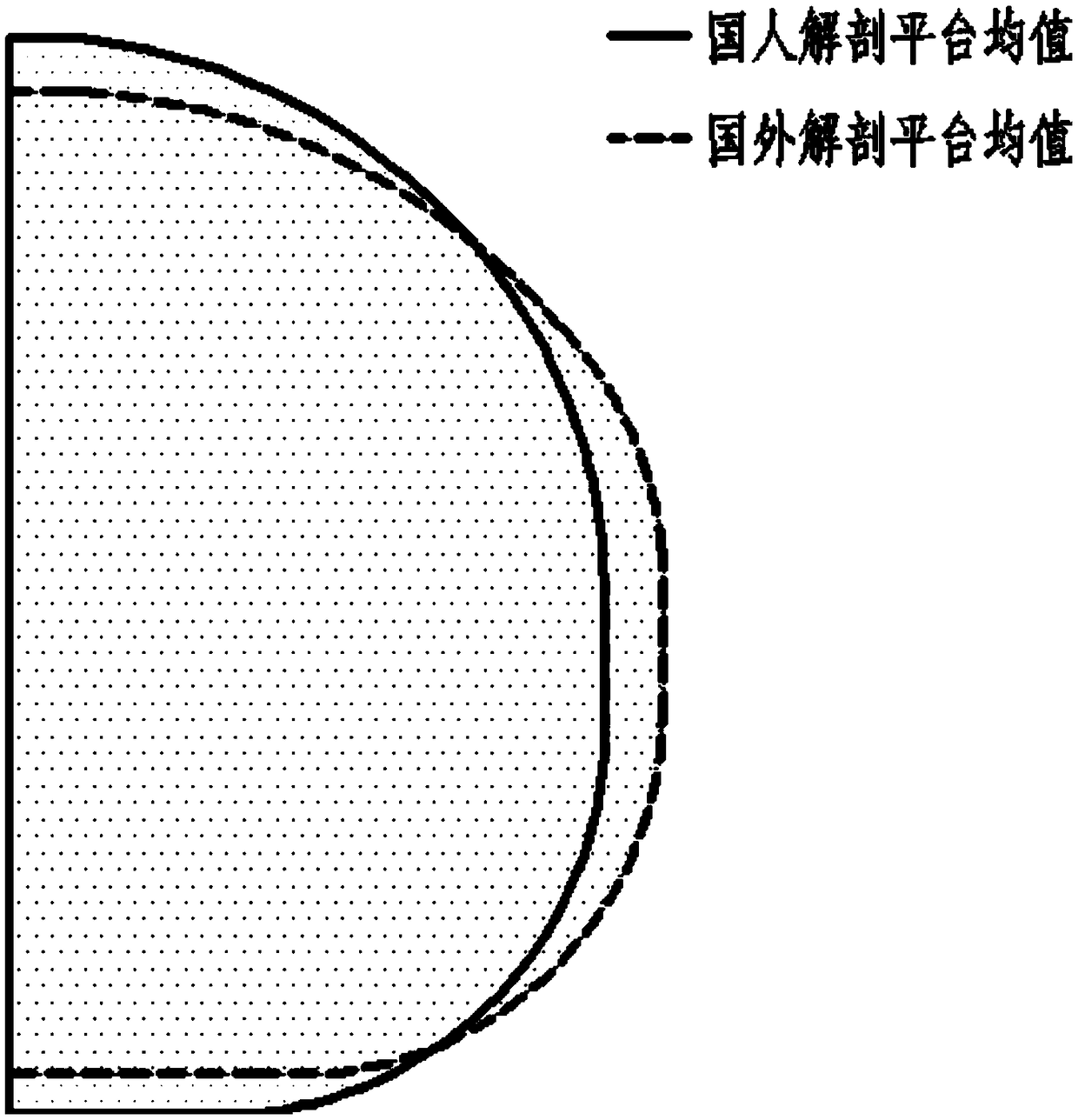

Fixed plateau type unicompartment knee prosthesis and tibial plateau prosthesis designing method

PendingCN108926411AReduced carrying capacityImprove fatigue damageJoint implantsTomographyAnatomical structuresKnee Joint

The invention relates to the field of design of medical apparatuses, and in particular to a fixed plateau type unicompartment knee prosthesis, which comprises a femoral condyle prosthesis, a fixed plateau mat and a tibial plateau prosthesis, wherein the cross section of the tibial plateau prosthesis is similar to a semicircle; a clamping groove is formed in the inner wall of the tibial plateau prosthesis; the fixed plateau mat is clamped in the clamping groove; the upper surface of the fixed plateau mat is a fixed plateau mat is a single-radius cambered surface which is relatively low in curvature; the femoral condyle prosthesis is of a single-radius spherical structure; and the femoral condyle prosthesis is placed on the fixed plateau mat. The product (the fixed plateau type unicompartment knee prosthesis) provided by the invention is strong in bearing capacity, and the product can guarantee stability of buckling and prevent injuries and pain of surrounding soft tissues; the designingmethod of the tibial plateau prosthesis comprises steps of CT scanning, data importing and measuring, data analyzing and designing the Chinese people's anatomical tibial plateau prosthesis, so that the designed tibial plateau prosthesis can conform more to a tibial anatomical structure of Chinese people; therefore, a bone coverage rate and bearing capacity of proximal tibia cortical bone to the plateau prosthesis are improved, a risk of fatigue fracture of the plateau prosthesis is reduced and a survival rate of the prosthesis is improved.

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com