Friction fatigue monitoring device and method of heavy-loading scraper conveyer chain wheels under vibration impact

A scraper conveyor, friction fatigue technology, applied in the field of friction fatigue fracture test monitoring device of heavy-duty scraper conveyor sprocket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the accompanying drawings.

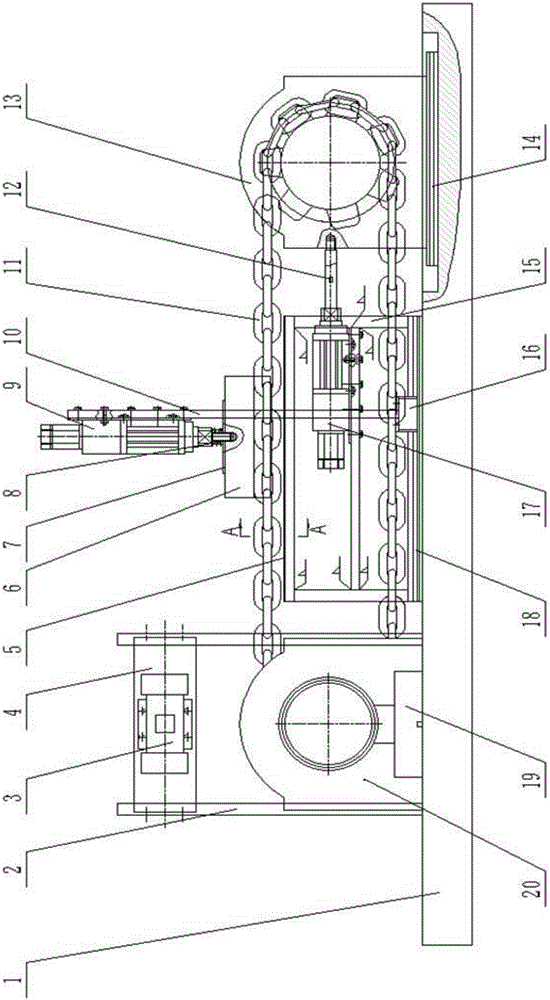

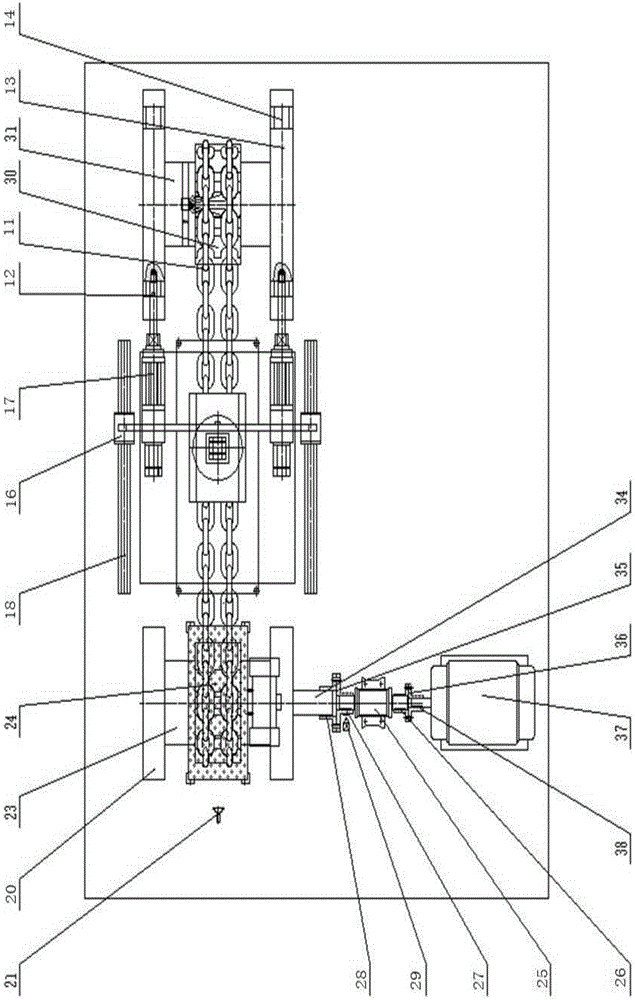

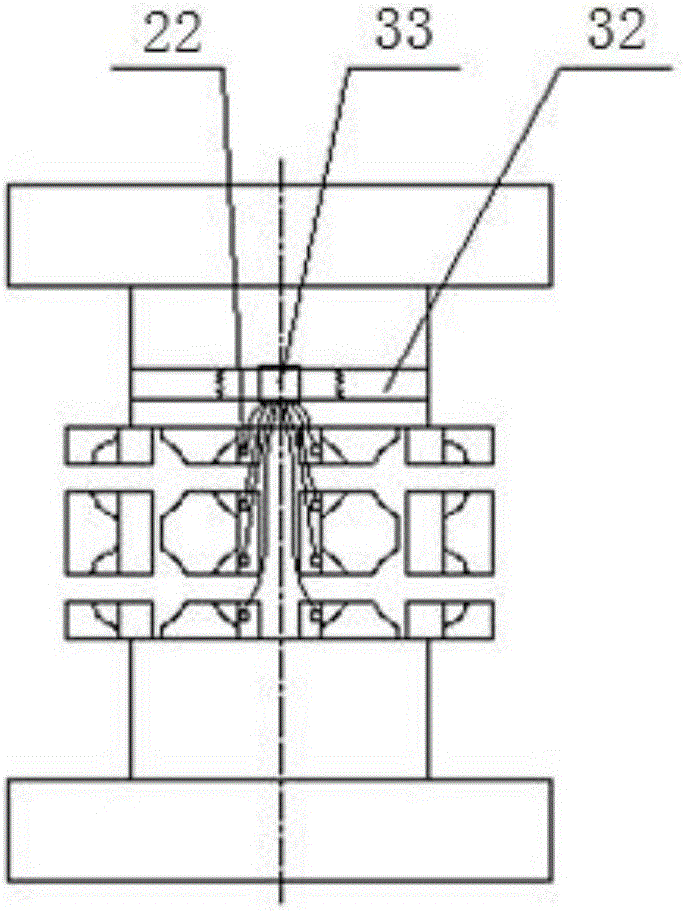

[0031] Such as Figures 1 to 4 As shown, a heavy-duty scraper conveyor sprocket friction fatigue monitoring device under vibration shock of the present invention includes a base frame, a drive system, a ring chain tensioning system, an impact loading system, a slime spilling system and a monitoring system.

[0032] The base frame includes a base plate 1, a low-speed servo motor support 19 fixed on the base plate 1, a head frame 20, a first rectangular guide rail 18, a second rectangular guide rail 14, a coal slime sprinkler system support 2, and a first guide rail. The slide block 16 of 18, the impact loading system bracket 10 fixed on the slide block 16, the tail frame 13 that cooperates with the second guide rail 14.

[0033] Described driving system comprises the low-speed servo motor 37 that is fixed on the motor support 19, the frequency converter that regulates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com