Patents

Literature

67results about How to "Monitor wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

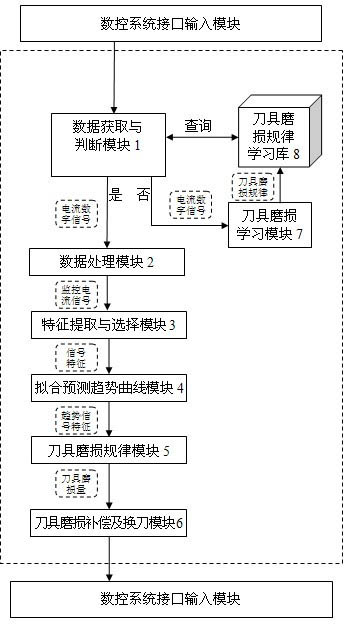

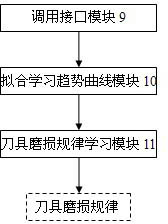

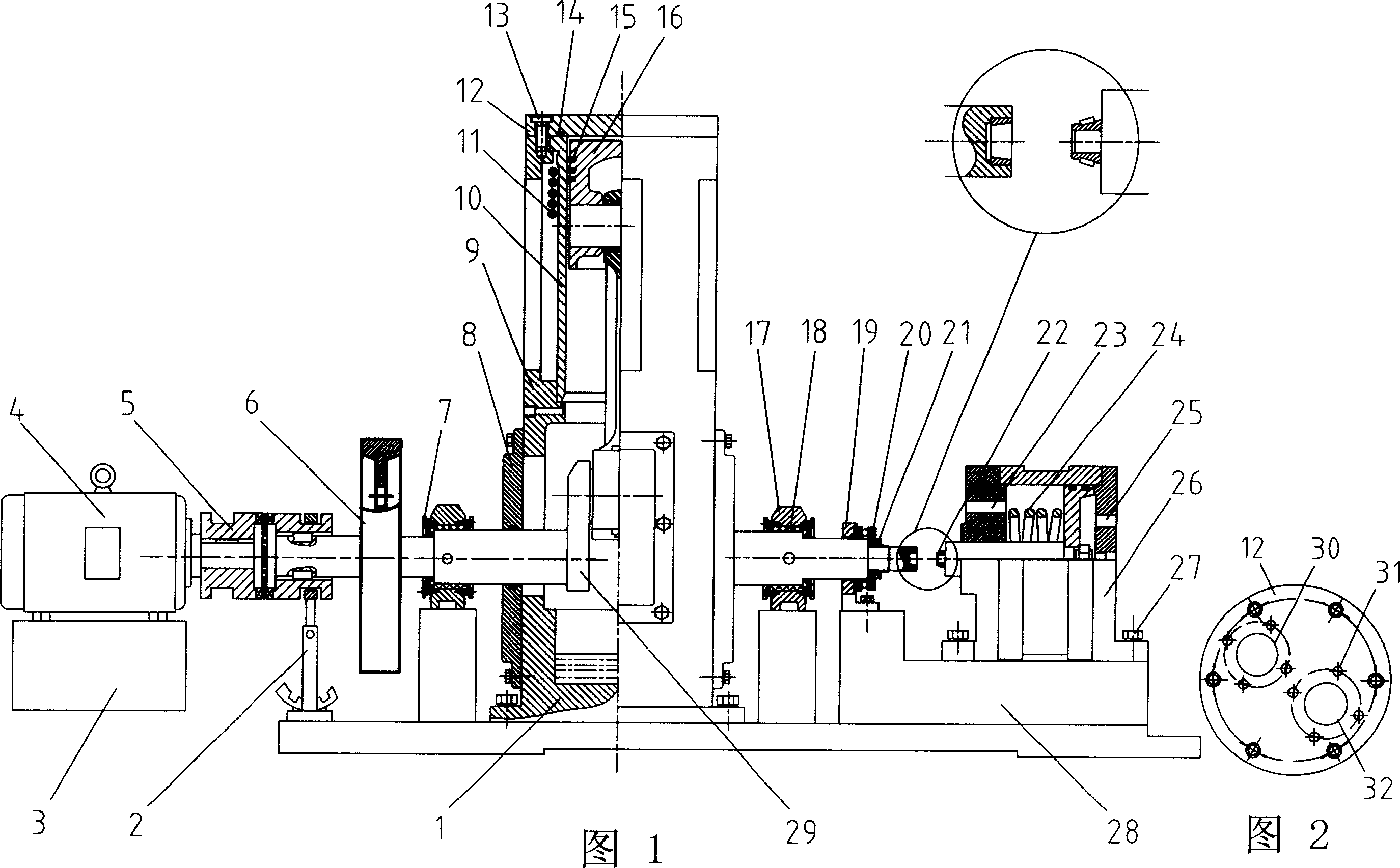

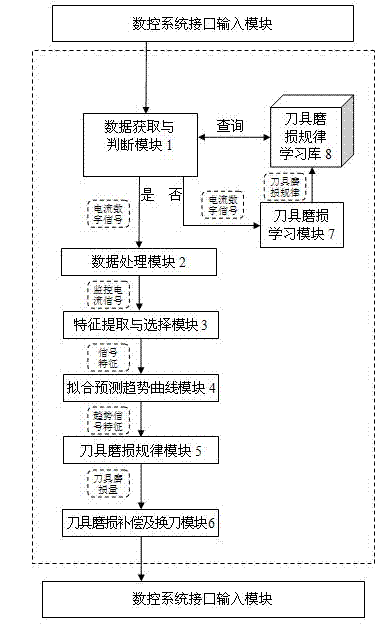

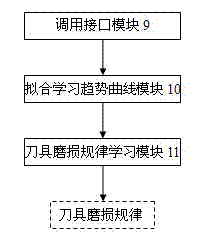

Tool wear monitoring system capable of realizing self-learning in numerical control machining state

InactiveCN102073300ACutting Condition MonitoringReal-time monitoring of cutting statusProgramme controlComputer controlData acquisitionEngineering

The invention discloses a tool wear monitoring system capable of realizing self-learning in a numerical control machining state. The structure of the system is that: a tool wear rule learning library stores learned tool wear rules; a data acquisition and judgment module provides a servo drive current digital signal for a data processing module to perform format conversion and store the signal as a monitoring current signal; a characteristic extraction and selection module selects signal characteristics strongly correlated with tool wear; a fitted predicted trend curve module establishes a signal characteristic-tool machining service life relationship curve; a tool wear rule module obtains the learned tool wear rules from the tool wear rule learning library, and substitutes the trend signal characteristics into the learned tool wear rules to obtain a tool wear extent; and a tool wear compensation and tool replacement module makes a tool wear compensation and tool replacement decision according to the tool wear extent, and provides the tool wear compensation and tool replacement decision for a numerical control system interface input module. The system is applied to the condition offluctuating cutting parameters in mass production, and can achieve relatively higher accuracy under the condition of constant cutting parameters.

Owner:HUAZHONG UNIV OF SCI & TECH +1

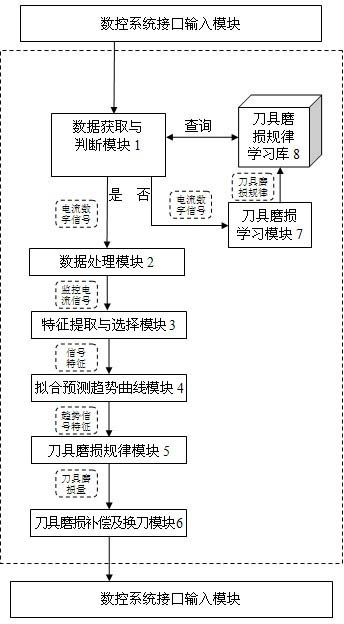

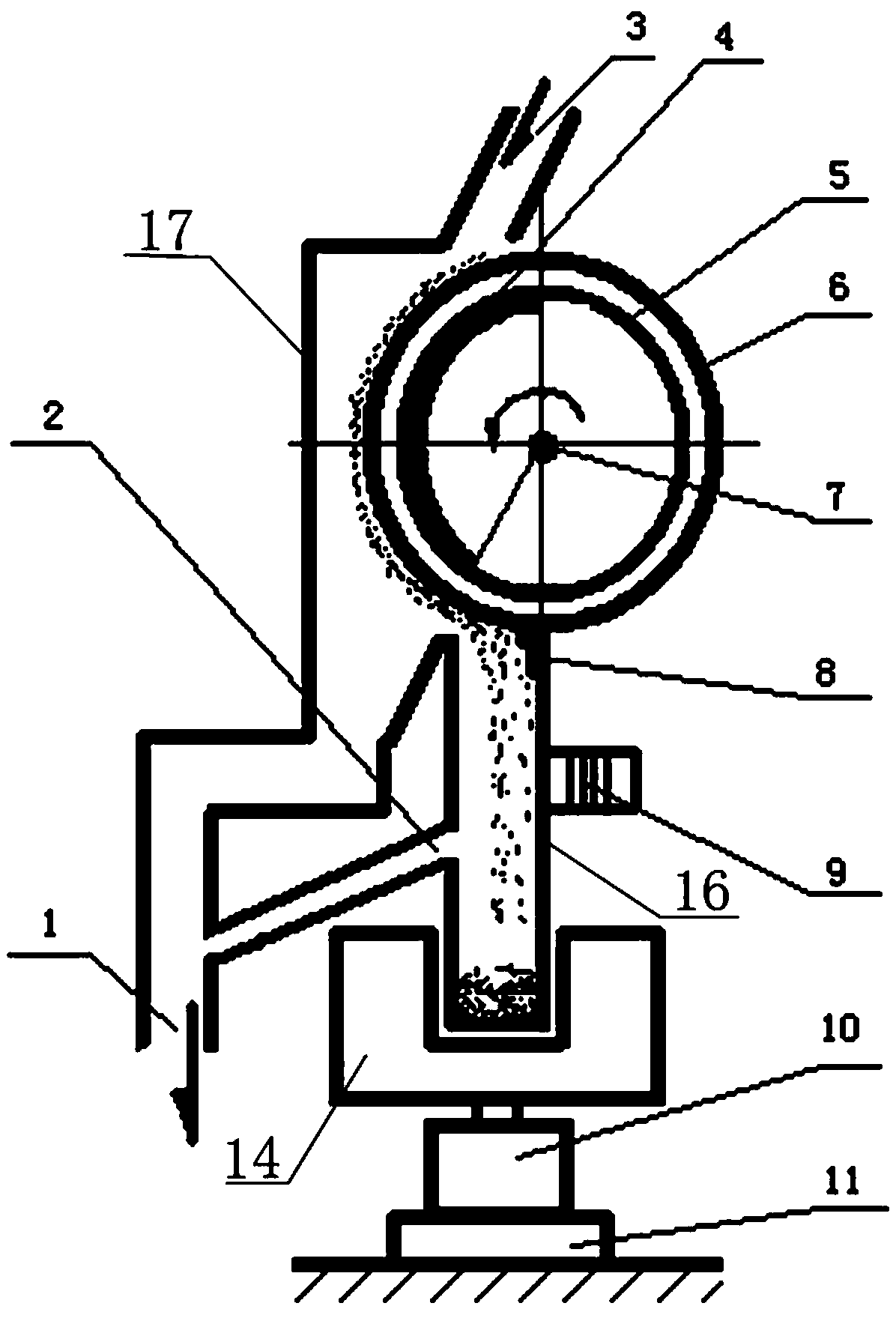

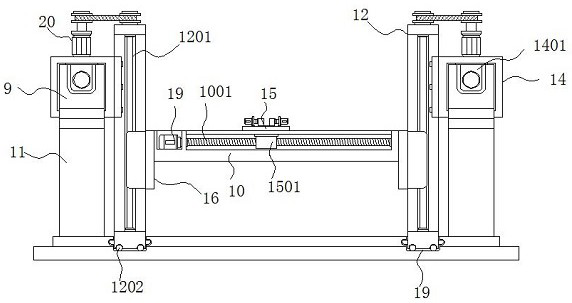

Friction-loss and vibration analog experimental equipment for main motion components of IC engine

InactiveCN1940523AMonitor temperature in real timeReal-time monitoring of abrasive compositionInternal-combustion engine testingInvestigating abrasion/wear resistancePiston ringFriction loss

A tester used for simulating wear-out and vibration of main movable parts on internal combustion engine consists of master driving system formed by air cylinder, piston ring, piston, crankshaft, inlet and outlet of high pressure air; state monitoring system formed by pressure transducer and vibration transducer on bearing base, oil monitoring transducer and temperature transducer as well as vibration transducer on machine rack, and dynamic transducer on crankshaft. It is featured as utilizing high pressure air to simulate explosion pressure in air cylinder and to simulate operation condition causing wear-out and vibration of cylinder sleeve and piston ring pair in said engine.

Owner:WUHAN UNIV OF TECH

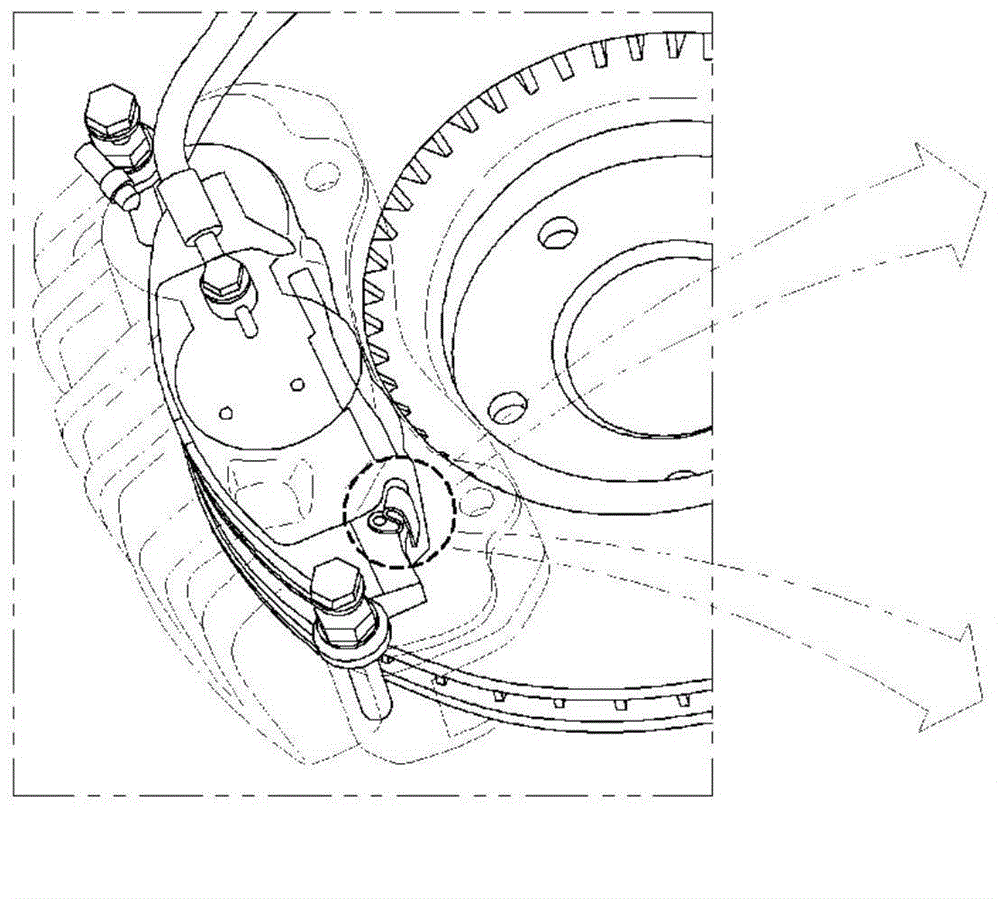

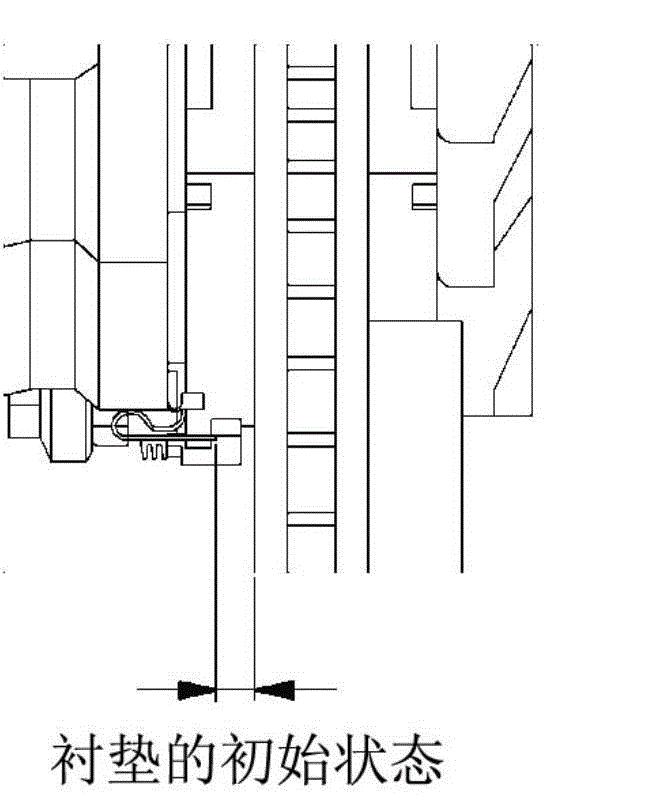

System for abrasion warning of brake friction pad using ESC system

ActiveCN104864006AImprove marketabilityImprove performanceBrake typesWheel speed sensorVehicle brake

Disclosed are system and method for abrasion warning of a brake friction pad of a vehicle. The system may include a friction pad abrasion sensing system (ESC) including a pressure sensor. The ESC system may recognize a speed change in association with a wheel speed sensor of the vehicle, measure a braking pressure using the pressure sensor included in the ESC system when the vehicle is decelerated, calculate and accumulate an abrasion index proportional to the measured braking pressure, and generate and output a notification message when the accumulated abrasion index is more than a predetermined reference value.

Owner:HYUNDAI MOTOR CO LTD

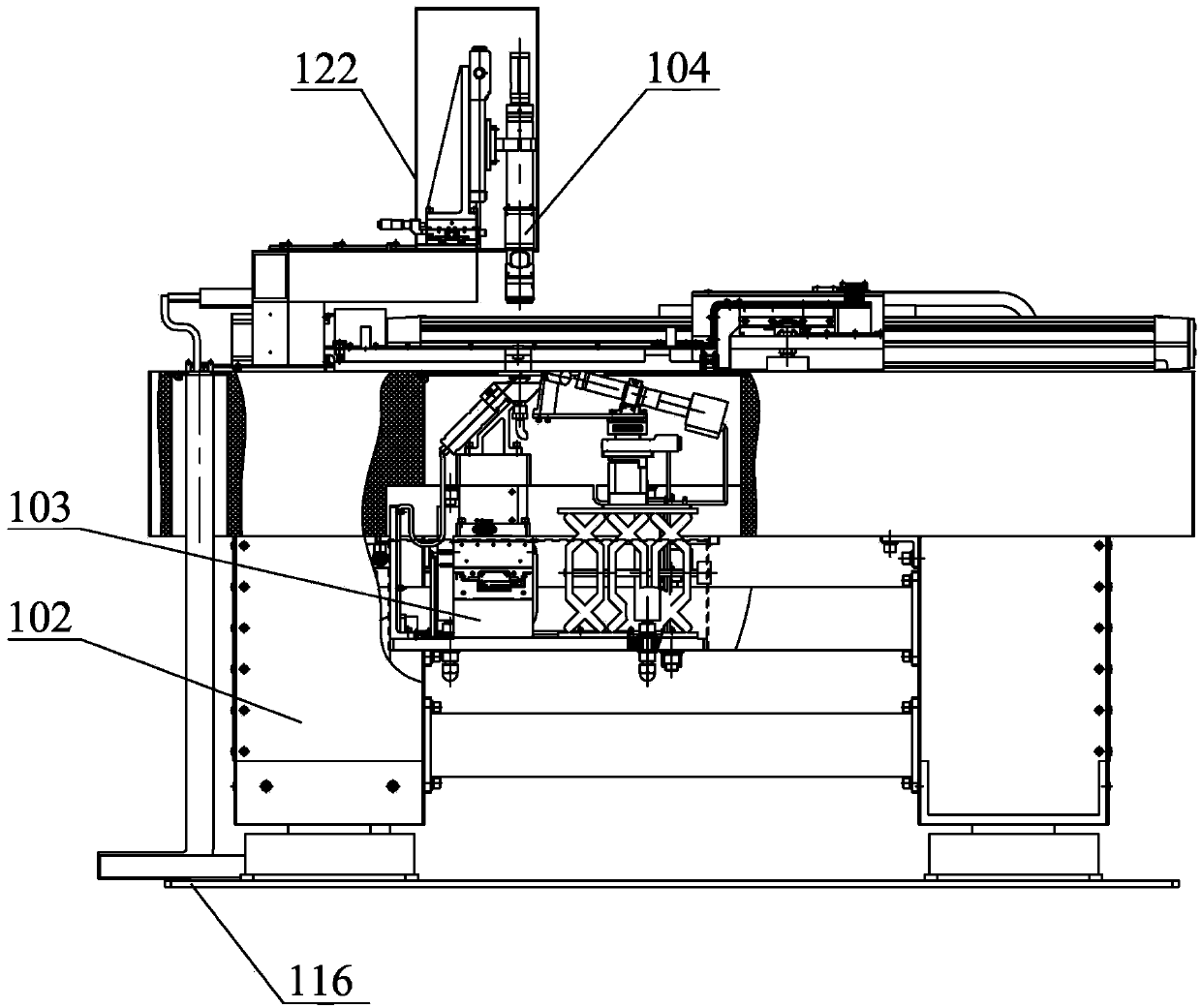

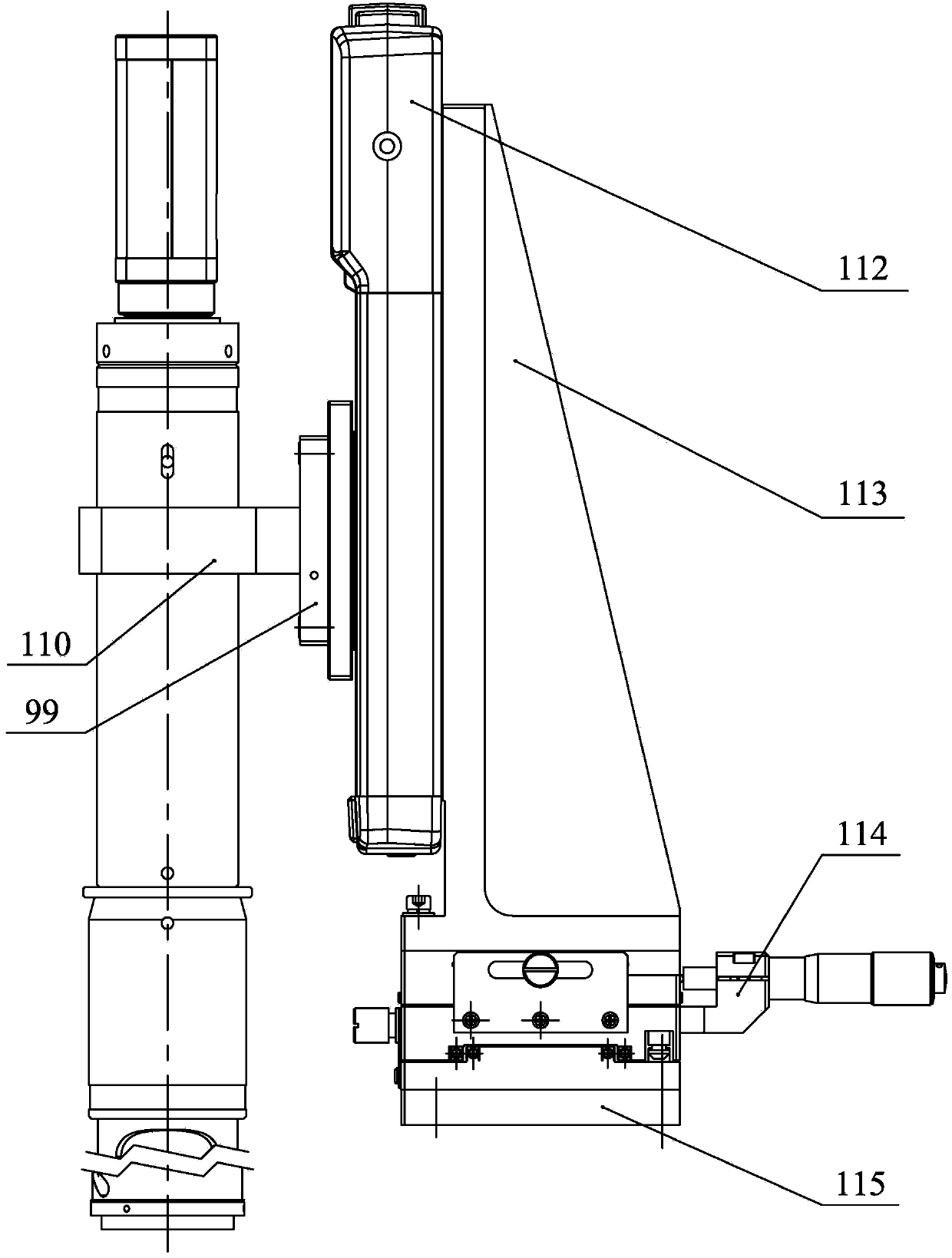

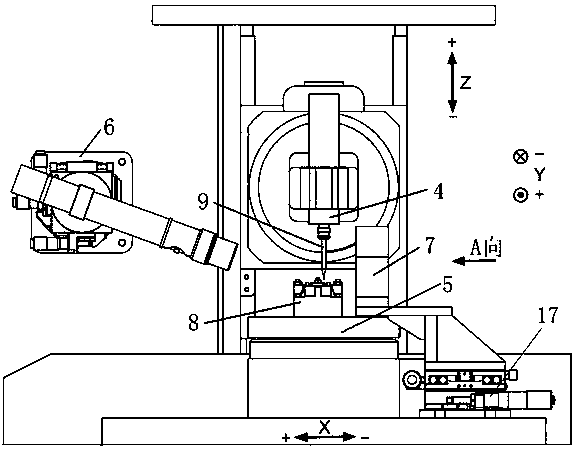

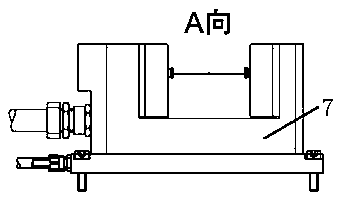

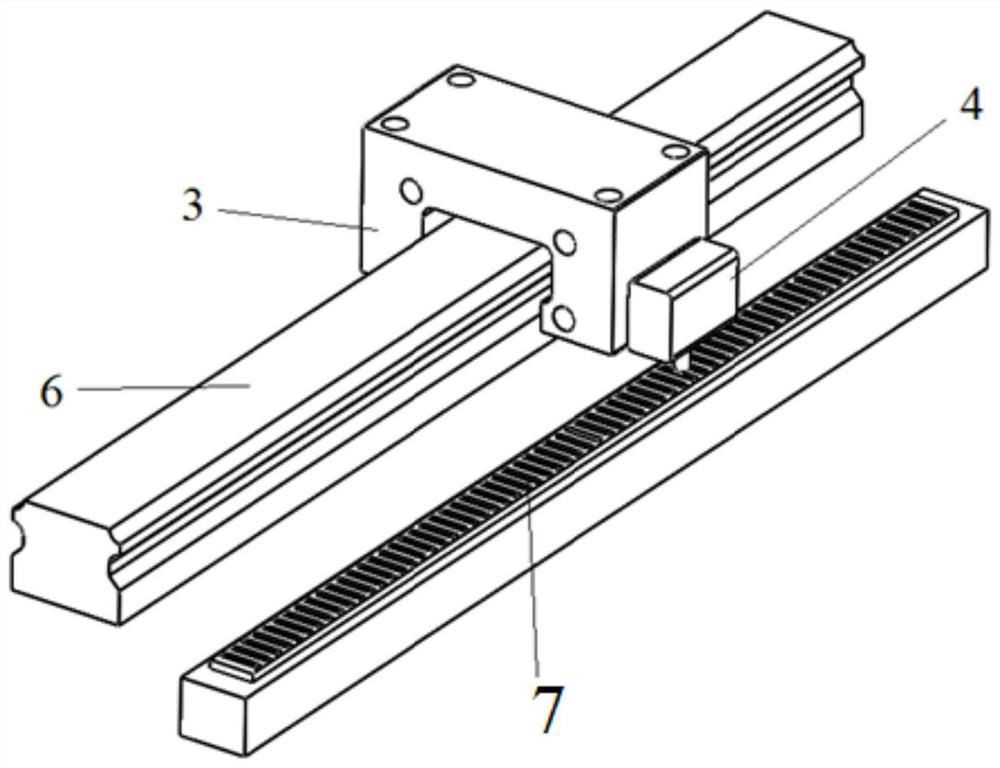

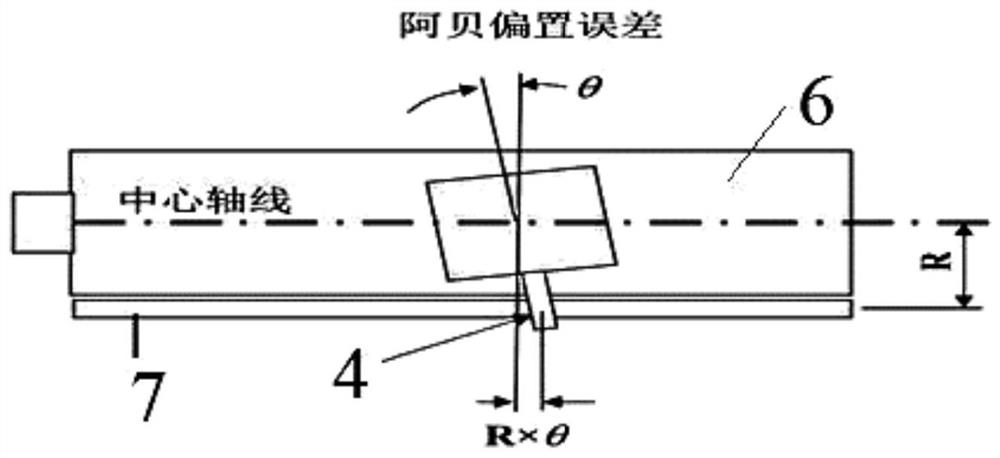

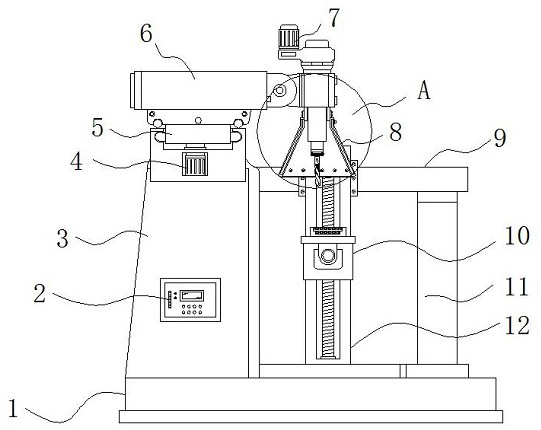

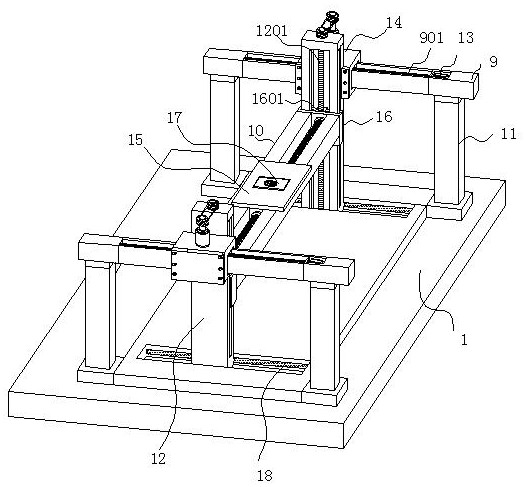

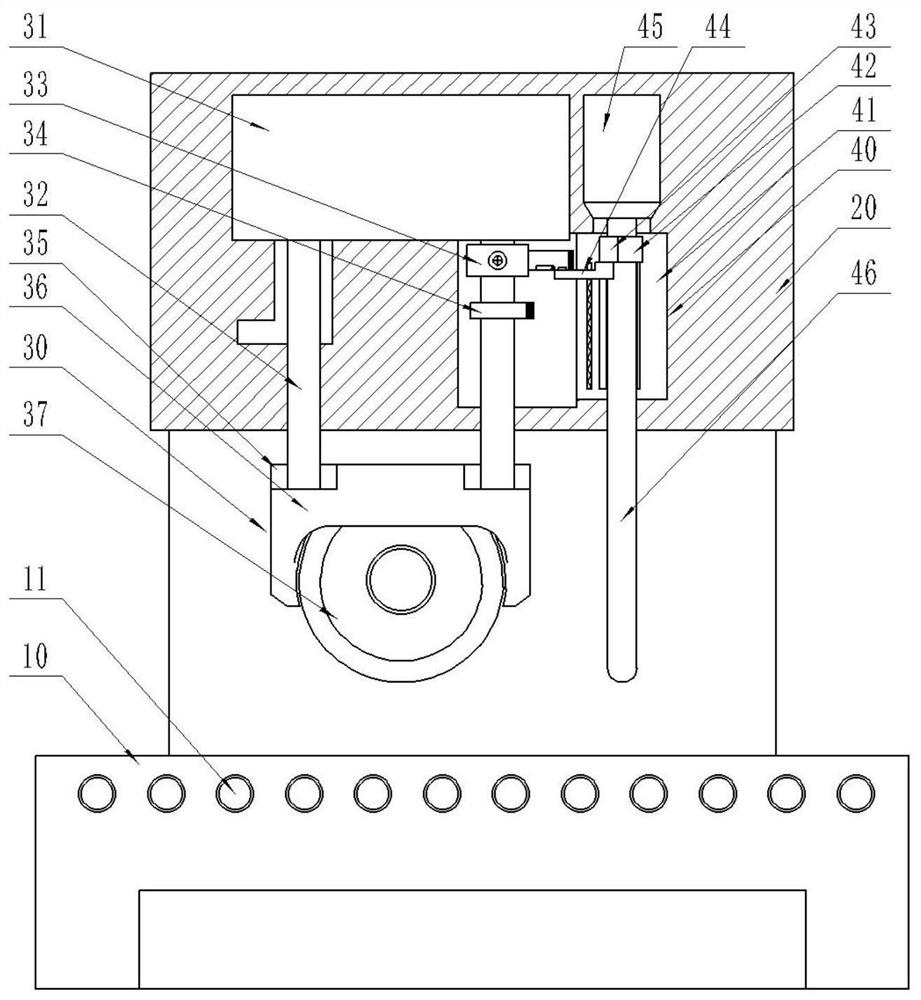

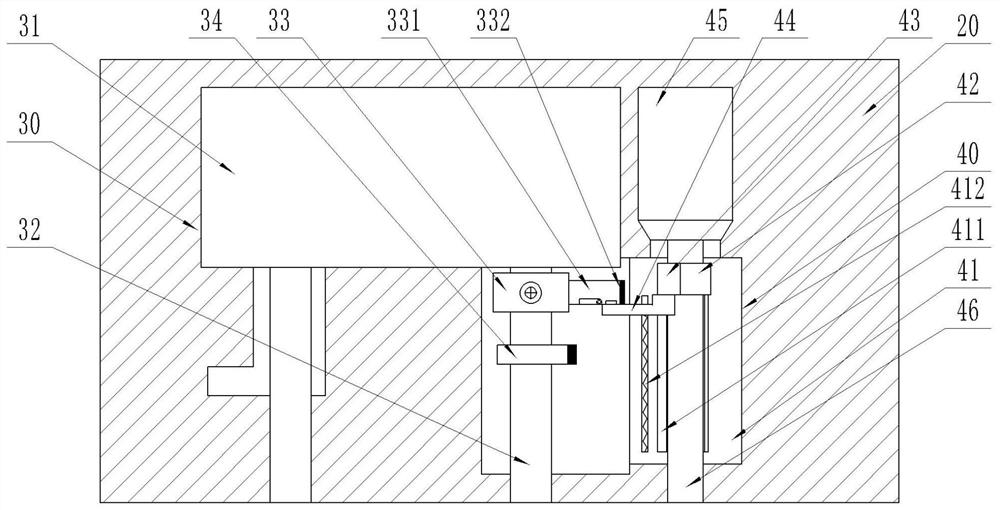

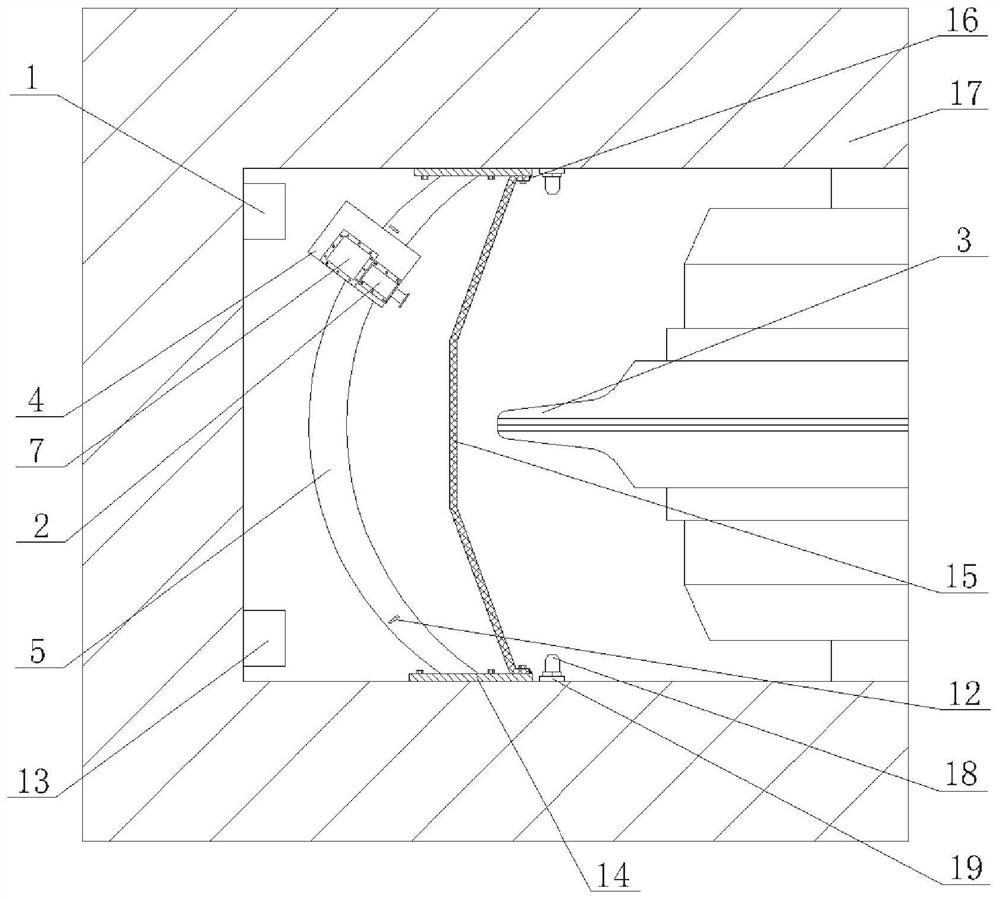

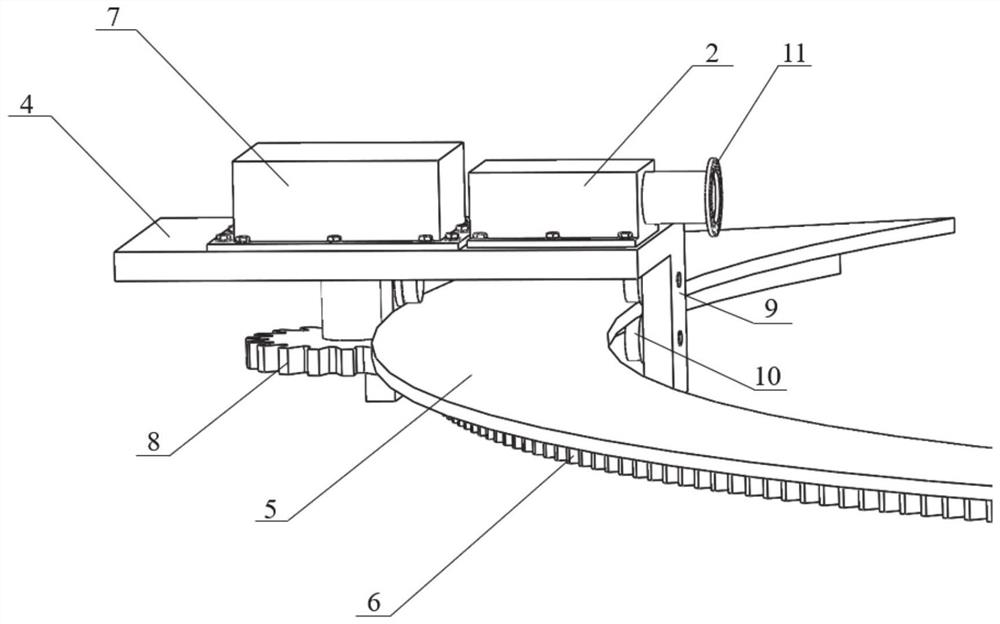

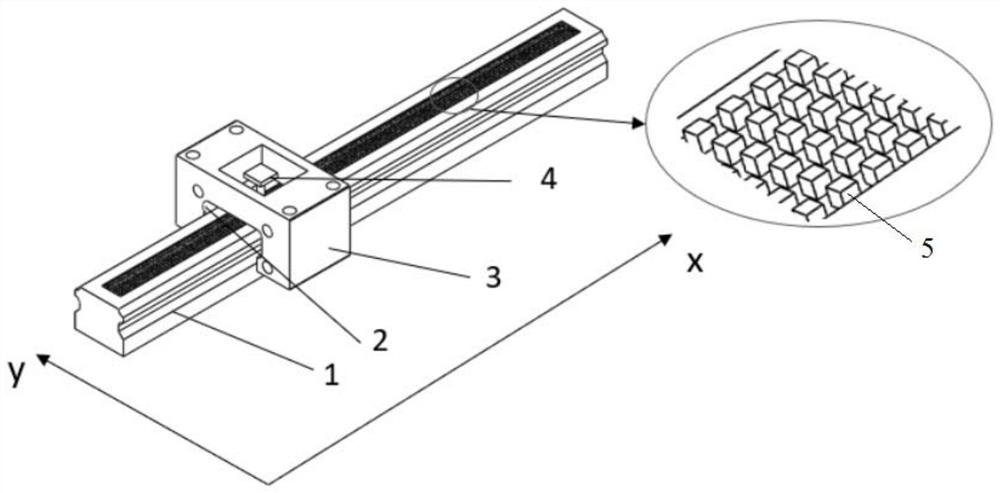

Surface microdefect fast search and micro-milling repair device for large-diameter KDP crystal elements

ActiveCN103692561AHigh movement precisionMonitor wearWorking accessoriesFine working devicesEngineeringMicroscope

The invention relates to a surface microdefect search and repair device for large-diameter KDP crystal elements, in particular to a surface microdefect fast search and micro-milling repair device for large-diameter KDP crystal elements, and aims to solve the problem that presently no device for fast research and micro-milling repair of surface microdefects in large-diameter KDP crystal elements is provided. An integral platform fitting assembly is fixed on a bottom large flat plate. A bottom platform fitting assembly is fixed on the integral platform fitting assembly. A crystal moving platform fitting member is fixed on the integral platform fitting assembly. A crystal microscope moving platform is fixed on the integral platform fitting assembly. First and second drag chains are connected with the crystal moving platform fitting member through guide rail and drag chain connecting blocks. The lower portion of a crystal microscope moving platform support is connected to the upper end face of the integral platform fitting assembly. The crystal microscope moving platform is mounted on the crystal microscope moving platform support. The device is applicable to surface microdefect fast research and micro-milling repair for large-diameter KDP crystal elements.

Owner:HARBIN INST OF TECH

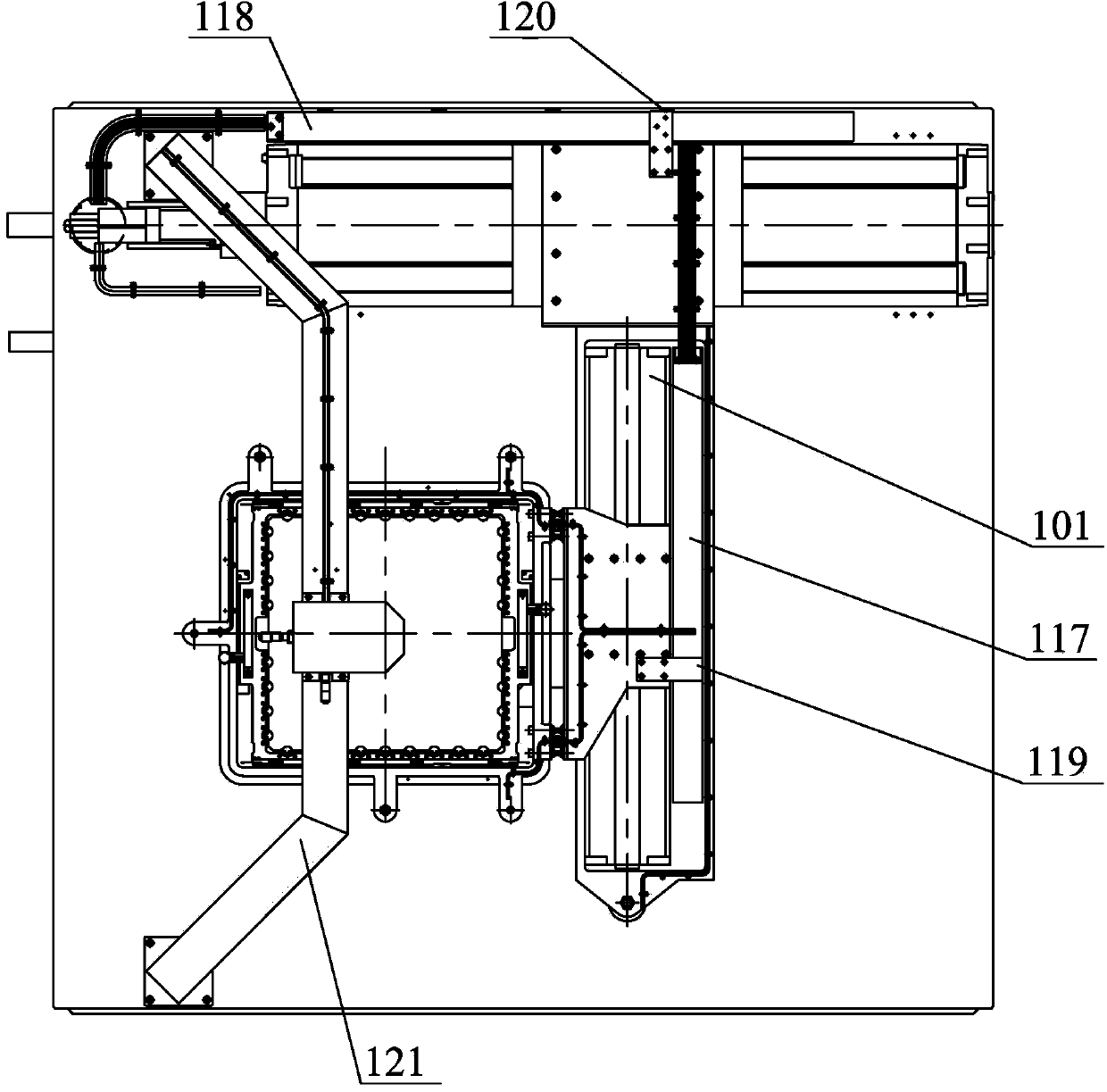

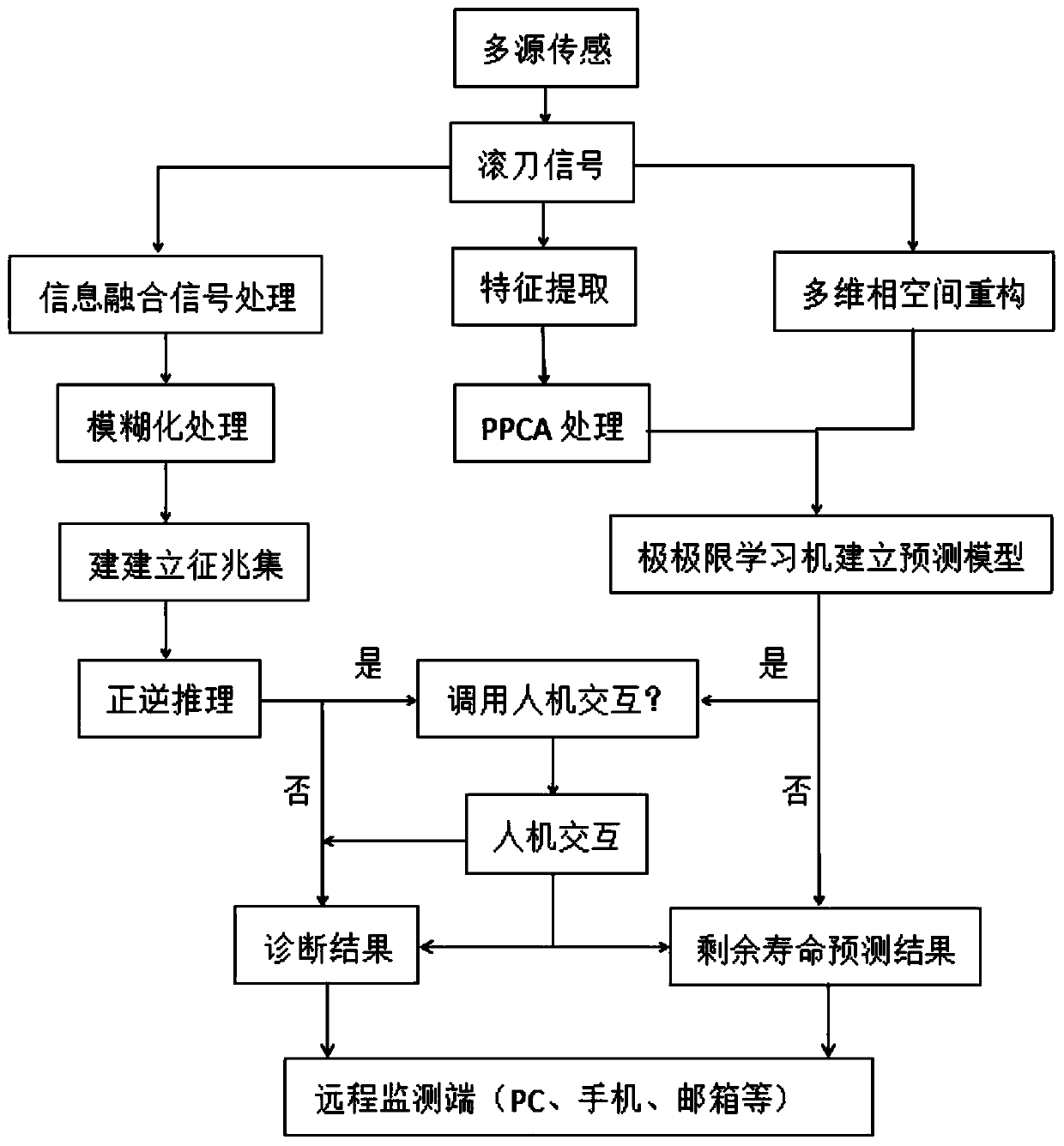

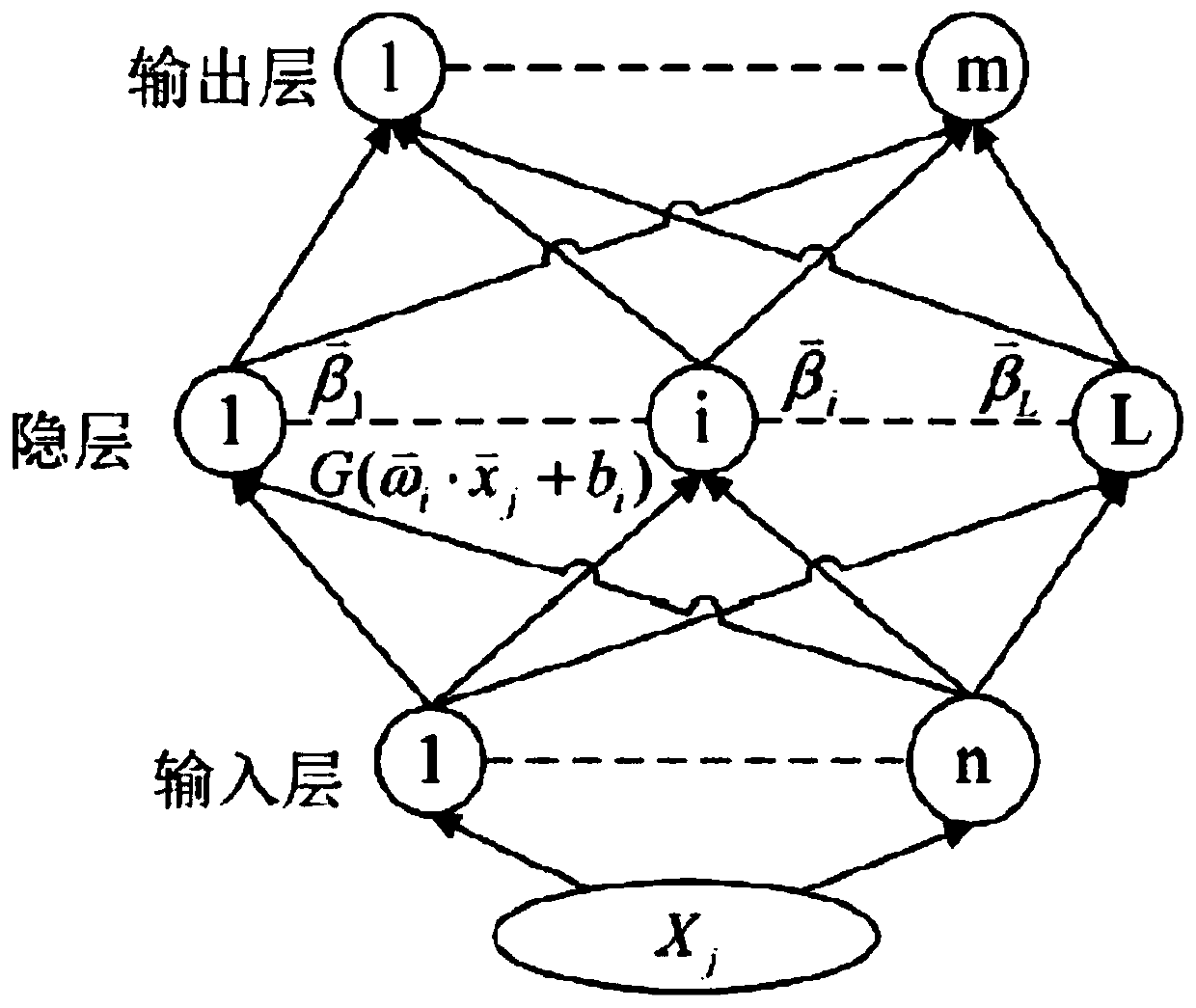

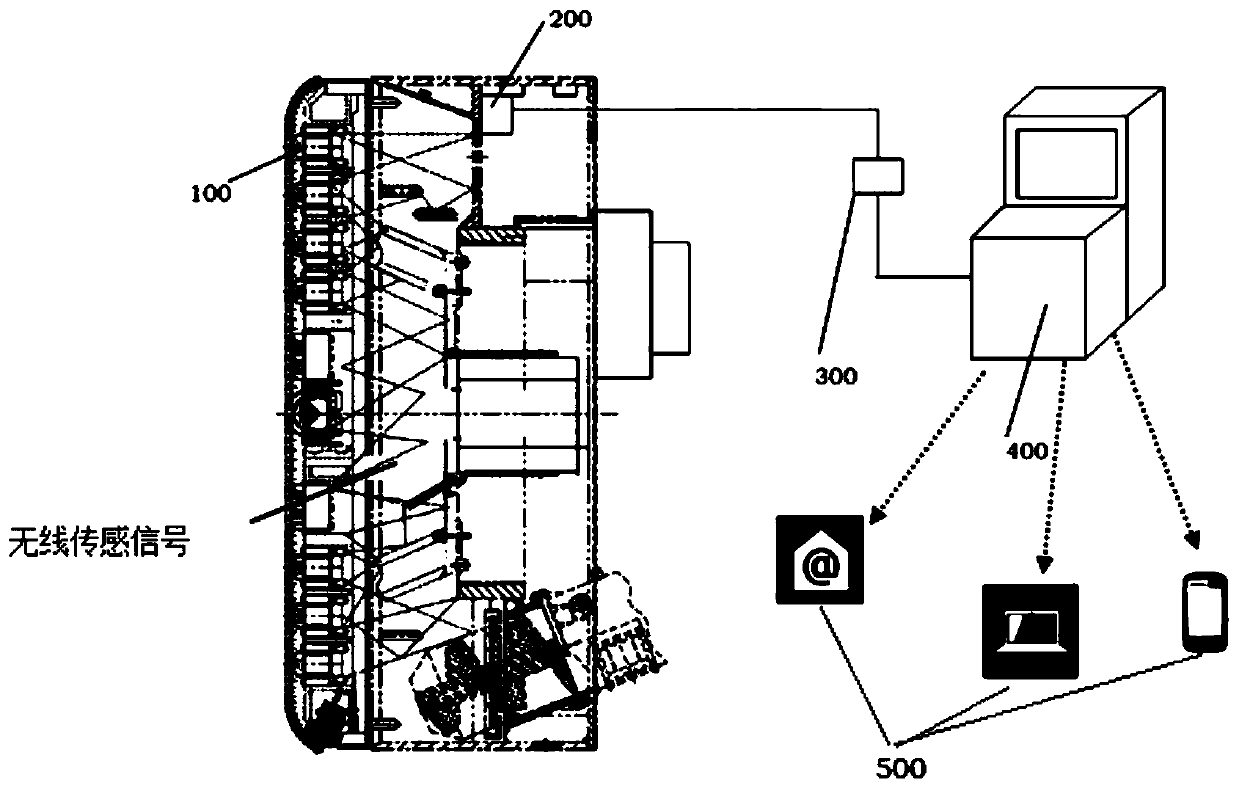

Tool state monitoring and life predicting system based on multi-source information fusion

PendingCN109724785AMonitoring forceThe monitoring device monitors the force in real timeMachine part testingProject managementInformation acquisition

The invention discloses a tool state monitoring and life predicting system based on multi-source information fusion, comprising: an information acquisition module, a signal preprocessing module, a state monitoring module, a life predicting module, and a remote monitoring module. The information acquisition module collects the parameter information of the hob, and sending them to the condition monitoring module and / or the life predicting module after preprocessing by the signal preprocessing module; outputting the hob status by the condition monitoring module; outputting the remaining life of the hob by the life prediction module. The output of the status monitoring module and the life predicting module can be directly viewed on the spot and can be viewed remotely. The tool state monitoringand life predicting system based on multi-source information fusion realizes visual management by real-time monitoring the key parameters such as the force, wear amount, rotation speed, and shape ofthe hob by the hob monitoring device, and monitors the state of the hob in real time and predicts the remaining life of the hob by analyzing and processing the relevant signals of the hob. Further, the communication-related project management staff of the remote monitoring module can view through mobile phones, remote PCs, etc, helping humanely determine if the tool is replaced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

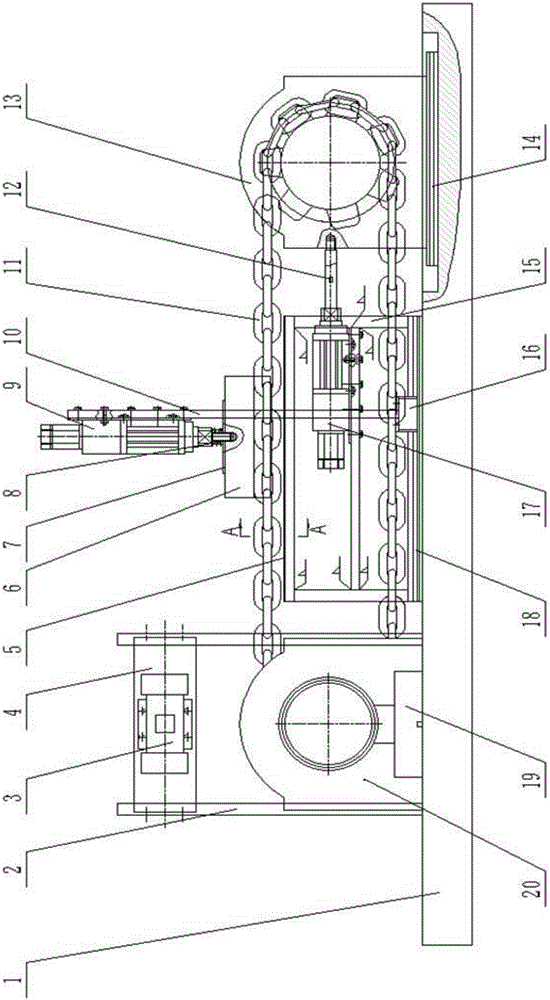

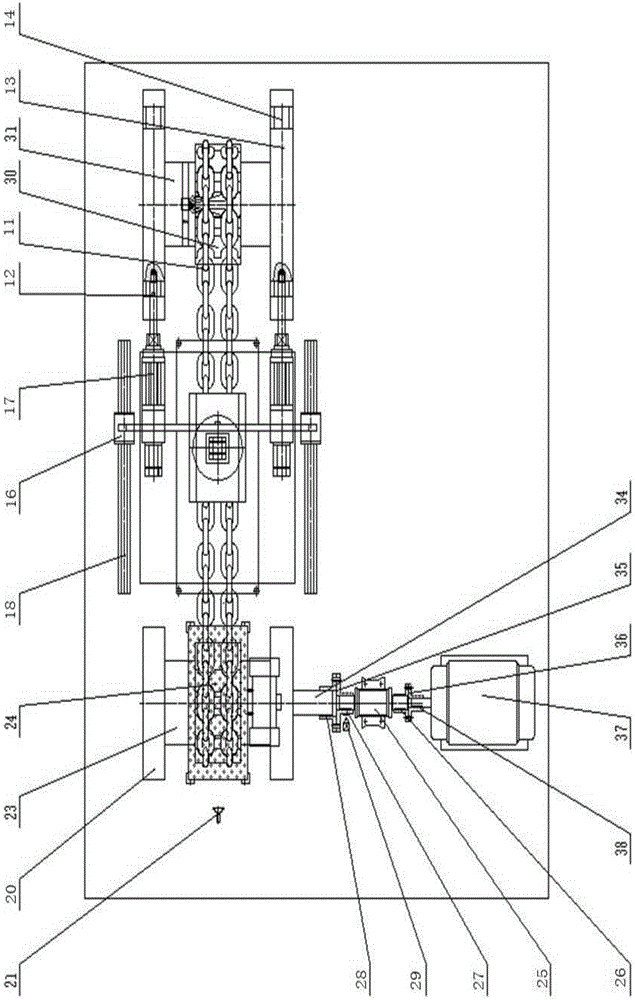

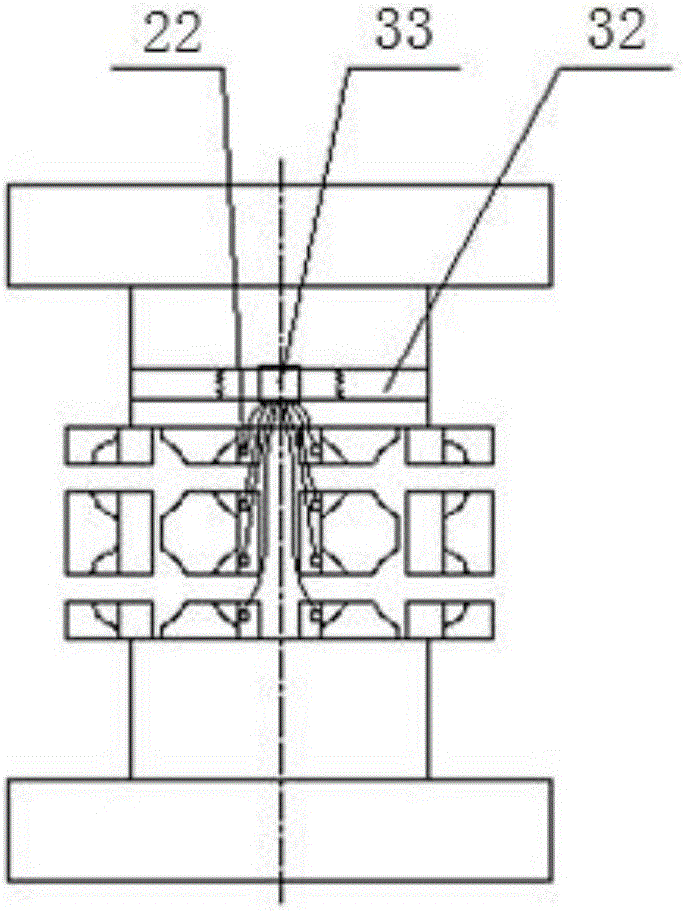

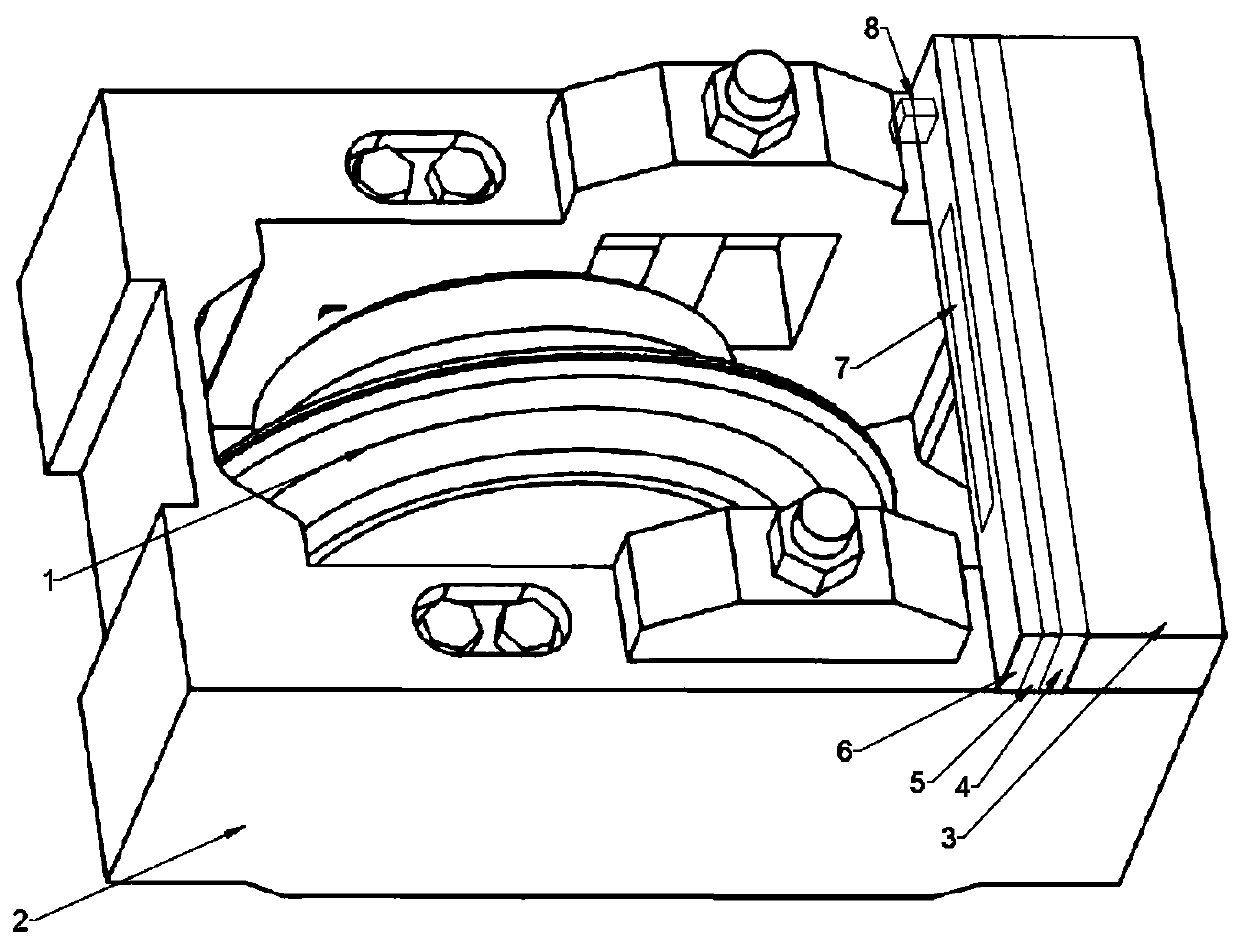

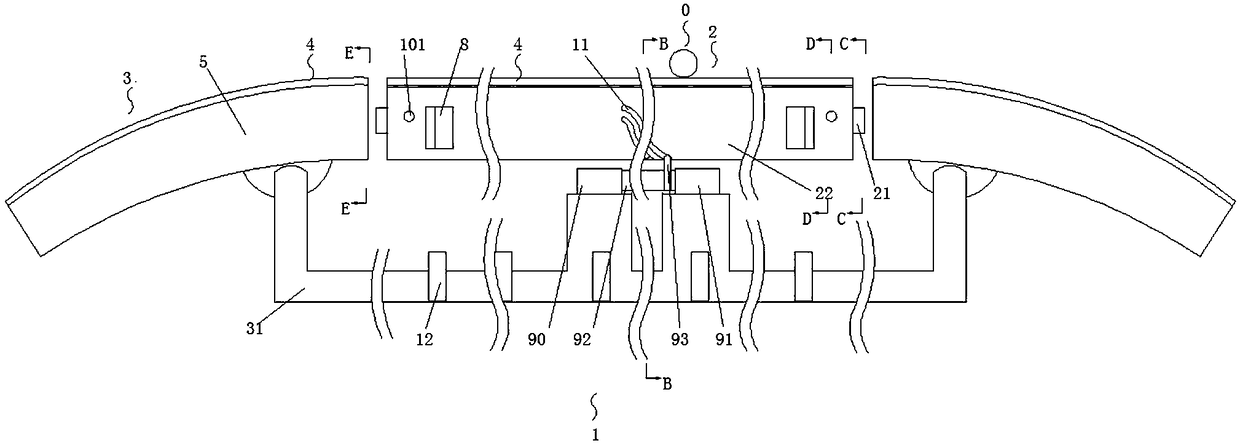

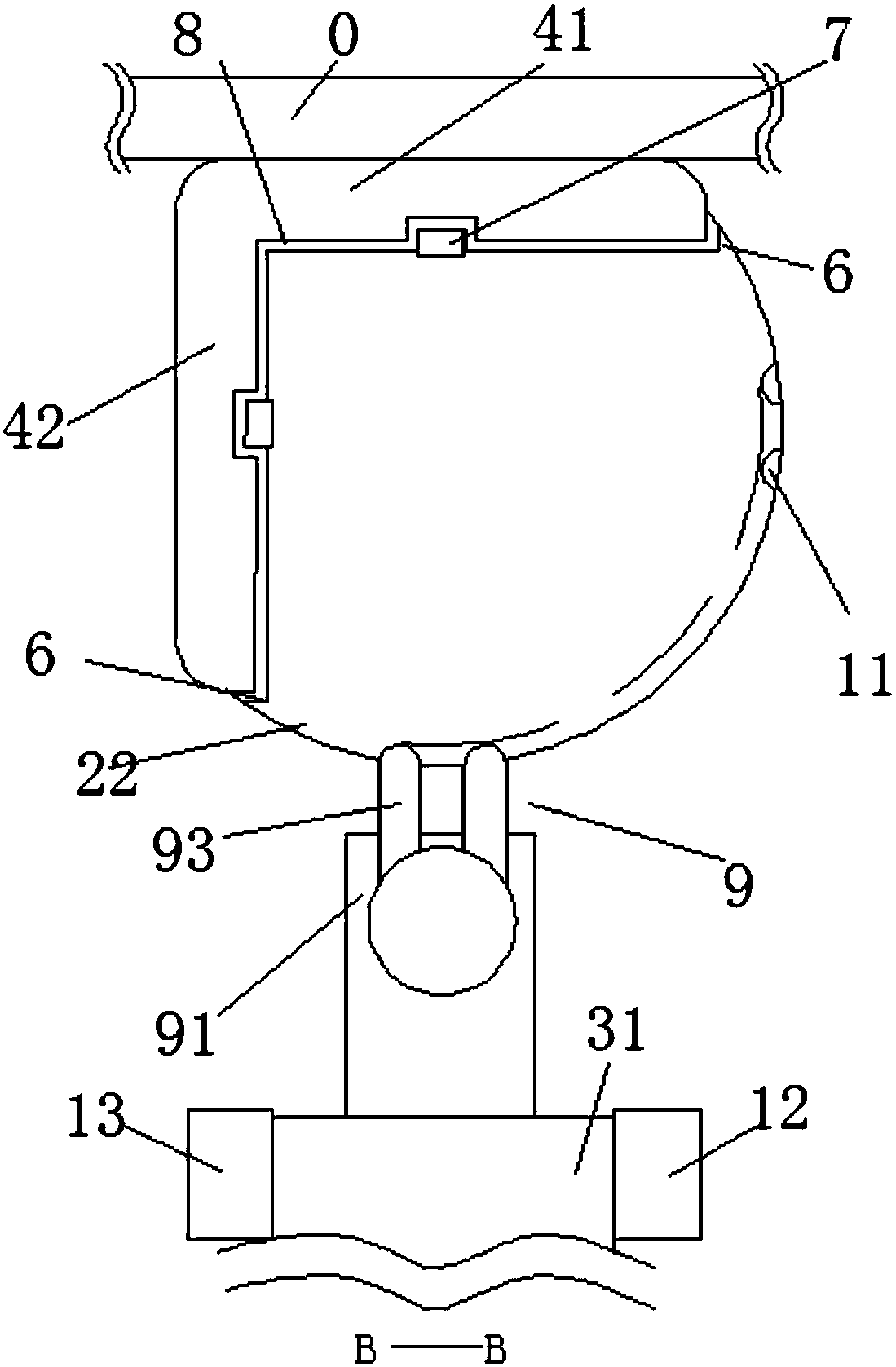

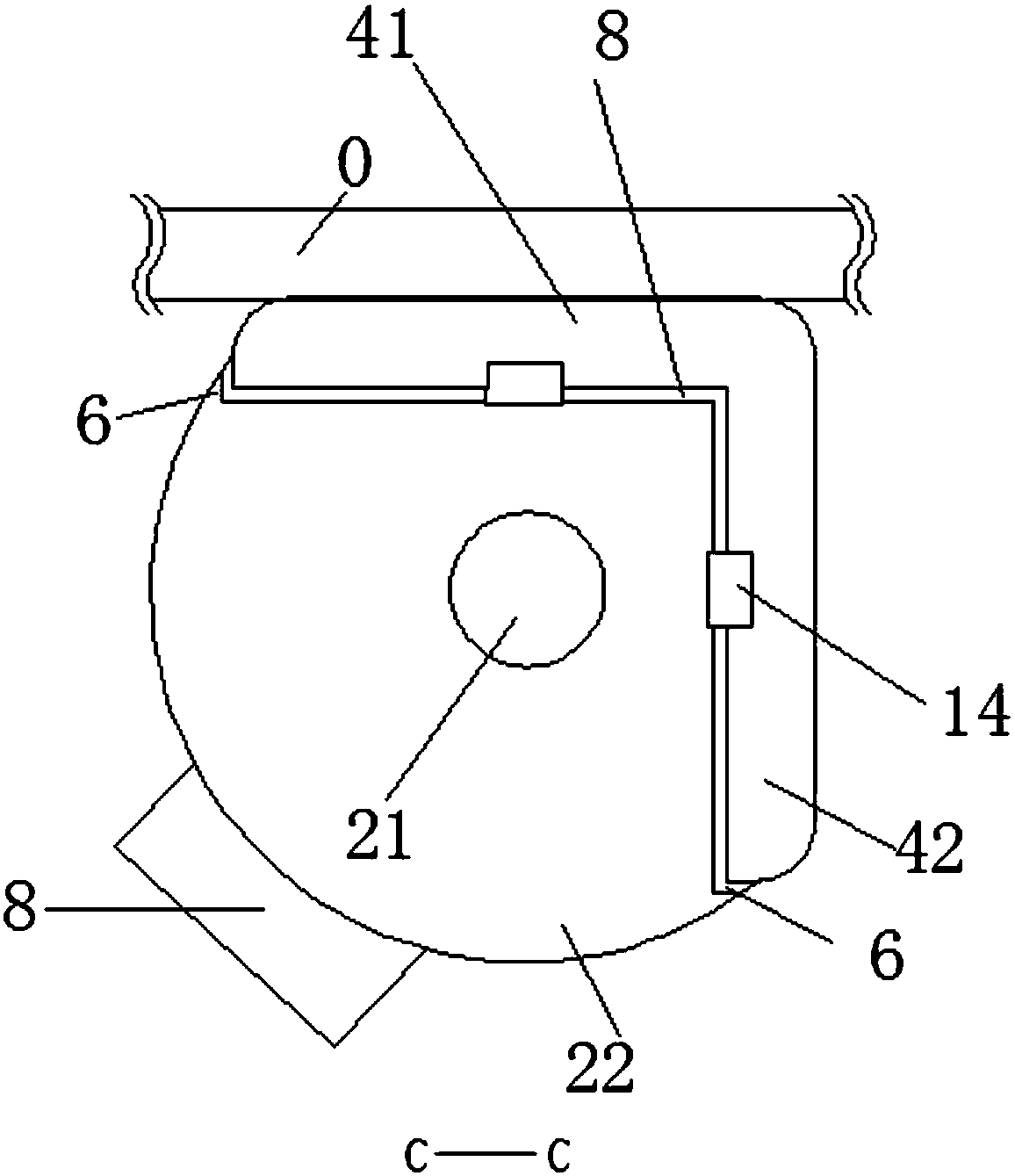

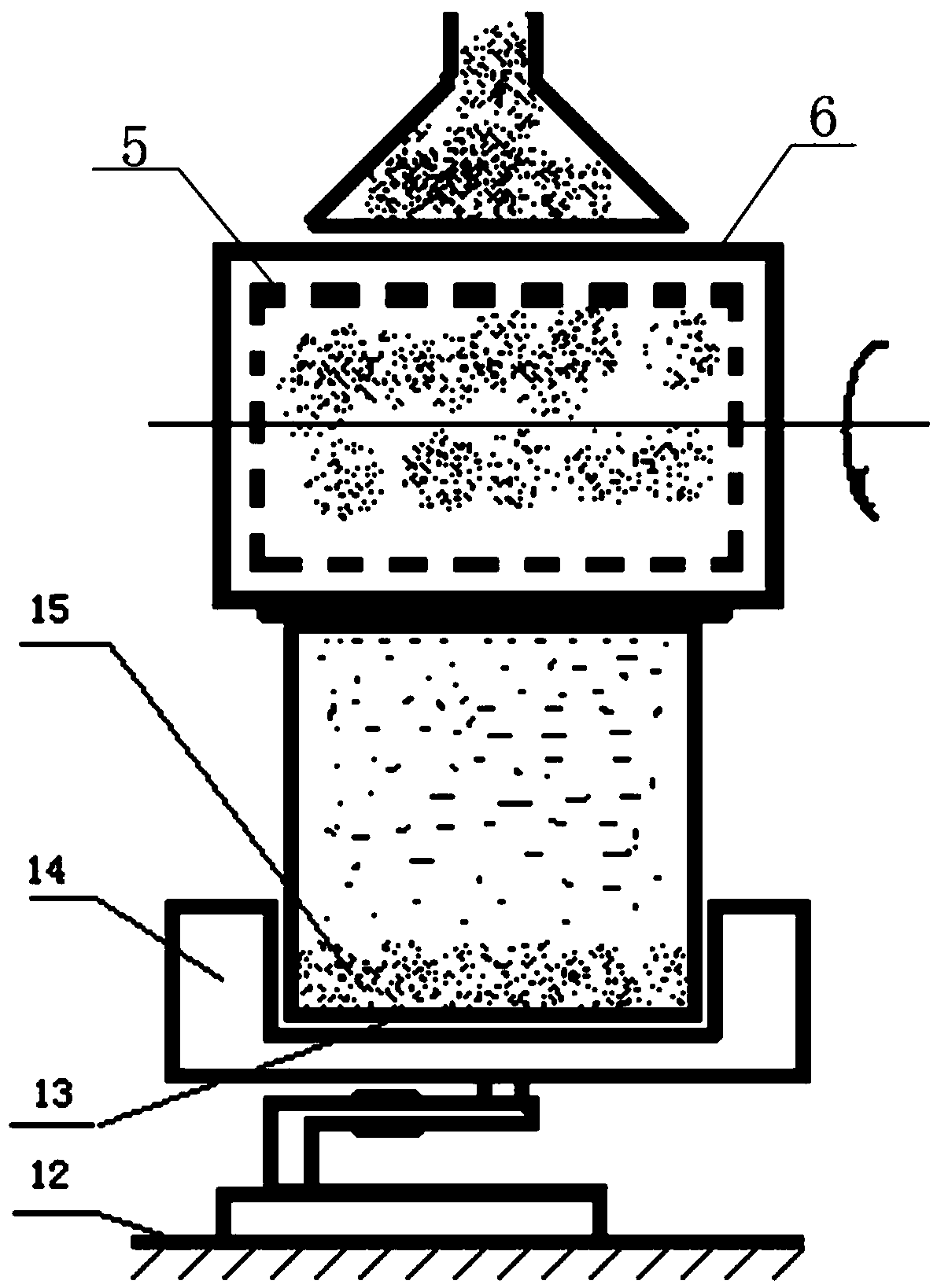

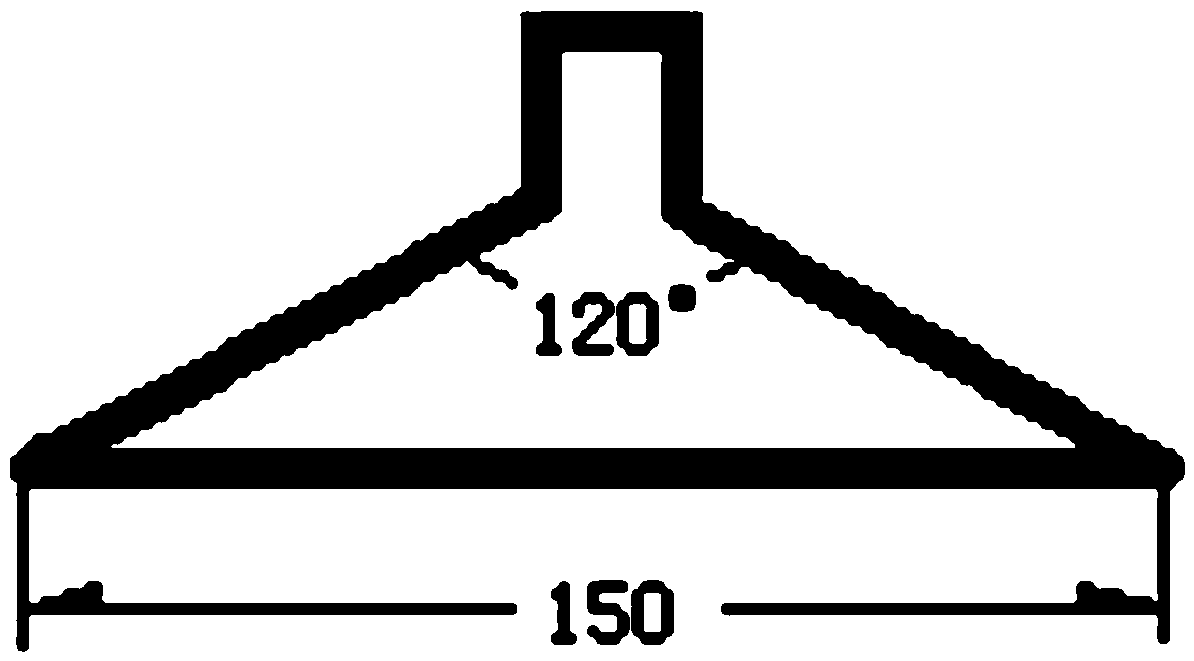

Friction fatigue monitoring device and method of heavy-loading scraper conveyer chain wheels under vibration impact

ActiveCN106404570AMonitor fatigue damageMonitor wearMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceFatigue damageLow speed

The invention discloses a friction fatigue monitoring device and a method of heavy-loading scraper conveyer chain wheels under vibration impact. The friction fatigue monitoring device comprises a base support, a driving system, a circular chain tensioning system, an impact loading system, a coal slime scattering system, and a monitoring system; the driving system comprises a low-speed servo motor, a first low-speed coupler used for connecting the low-speed servo motor with a torque sensor, a second low-speed coupler used for connecting the torque sensor with a transmission shaft, a roller A connected with the transmission shaft, driving chain wheels connected with the roller A, driven chain wheels connected with a roller B via key connection, a circular chain used for winding the driving chain wheels and the driven chain wheels; the circular chain tensioning system comprises a liner and a horizontal electric cylinder connected with a tail frame; the impact loading system comprises an impacting plate connected with a vertical electric cylinder; and the coal slime scattering system comprises a sieve and a vibration exciter. The friction fatigue monitoring device is capable of stimulating friction fatigue fracture of heavy-loading scraper conveyer chain wheels under vibration impact, and monitoring chain wheel fatigue damage and chain wheel wear situations.

Owner:CHINA UNIV OF MINING & TECH

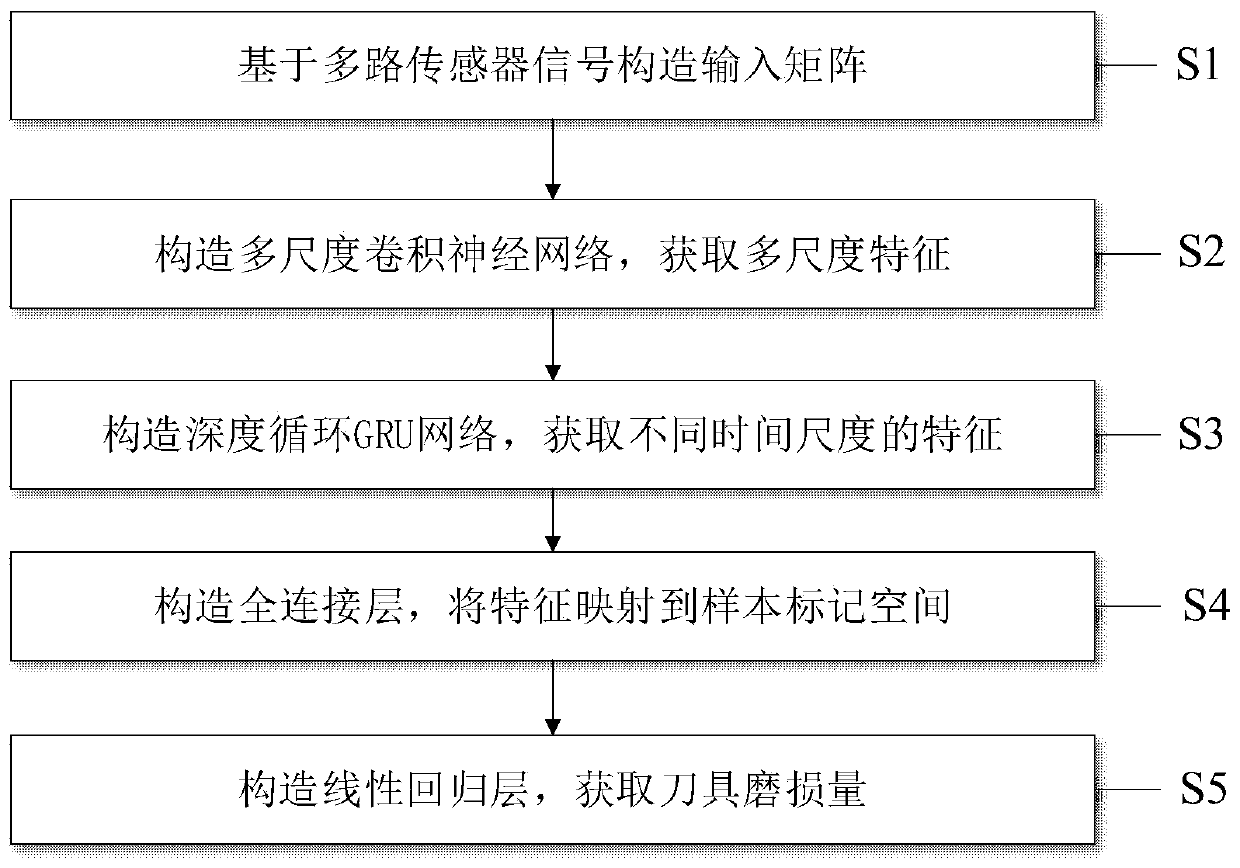

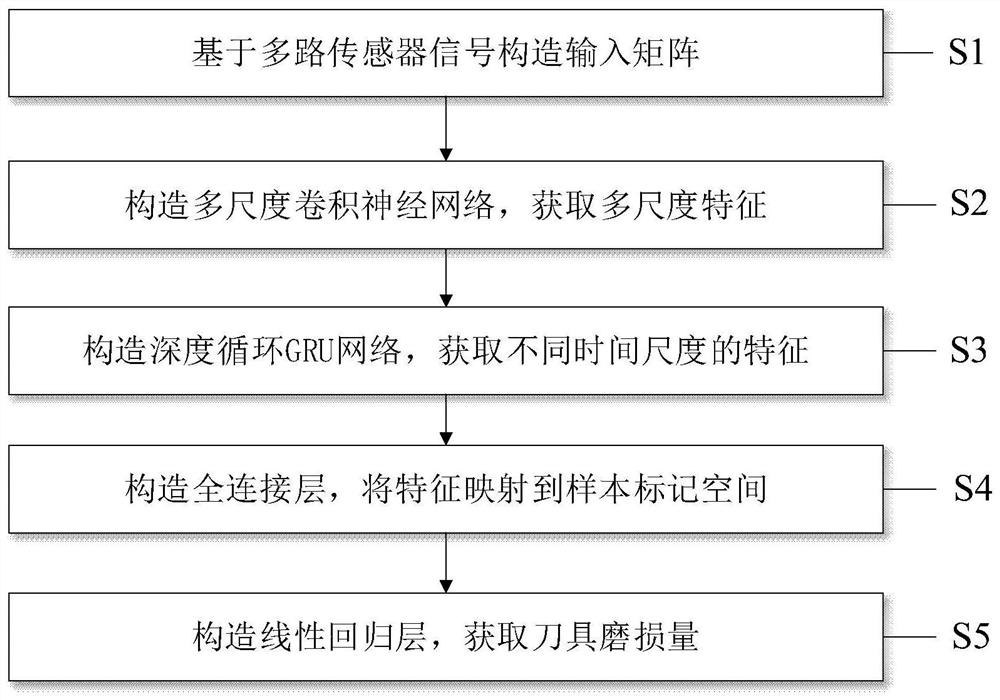

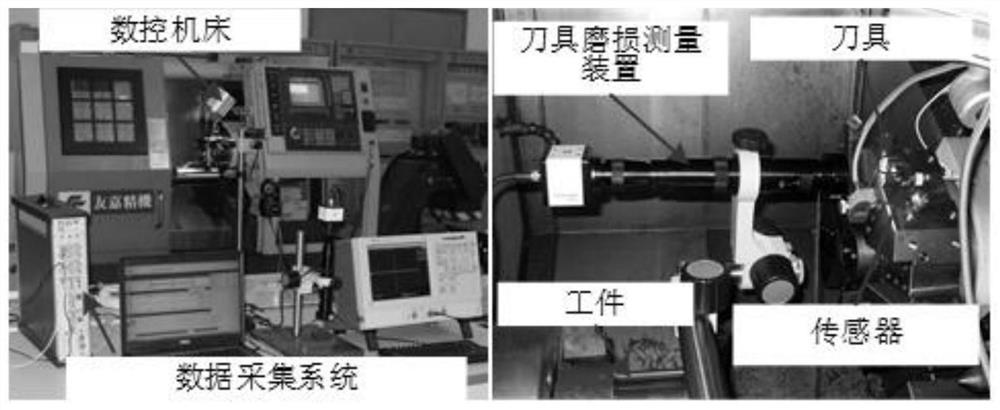

Cutting tool wear monitoring method based on multiscale deep convolutional recurrent neural network

ActiveCN110509109AImprove accuracy and reliabilityReduce the consumption of manpower and material resourcesMeasurement/indication equipmentsCutting tool wearConvolution

The invention discloses a cutting tool wear monitoring method based on a multiscale deep convolutional recurrent neural network. The method comprises the following steps of building an input matrix based on cutting tool data preprocessing data measured by a multipath sensor; building a multiscale convolutional neural network, obtaining multiscale characteristics, carrying out characteristic fusionon each branch of the multiscale convolutional neural network based on the output after pooling a maximum value, and finally obtaining the multiscale characteristics; building a deep cycle GRU network for extracting characteristics and expressions of different time scales, wherein the deep cycle GRU network comprises a first layer of GRU network and a second layer of GRU network, the unit numberof the second layer of GRU network is more than the unit number of the first layer of GRU network, and after the multiscale characteristics are processed through the deep cycle GRU network, the characteristics and the expressions of the different time scales are obtained; building a full connecting layer based on the characteristics, and mapping the characteristics to a sample marking space; and building a linear regression layer based on an output result of the full connecting layer, and obtaining a cutting tool wear capacity.

Owner:XI AN JIAOTONG UNIV

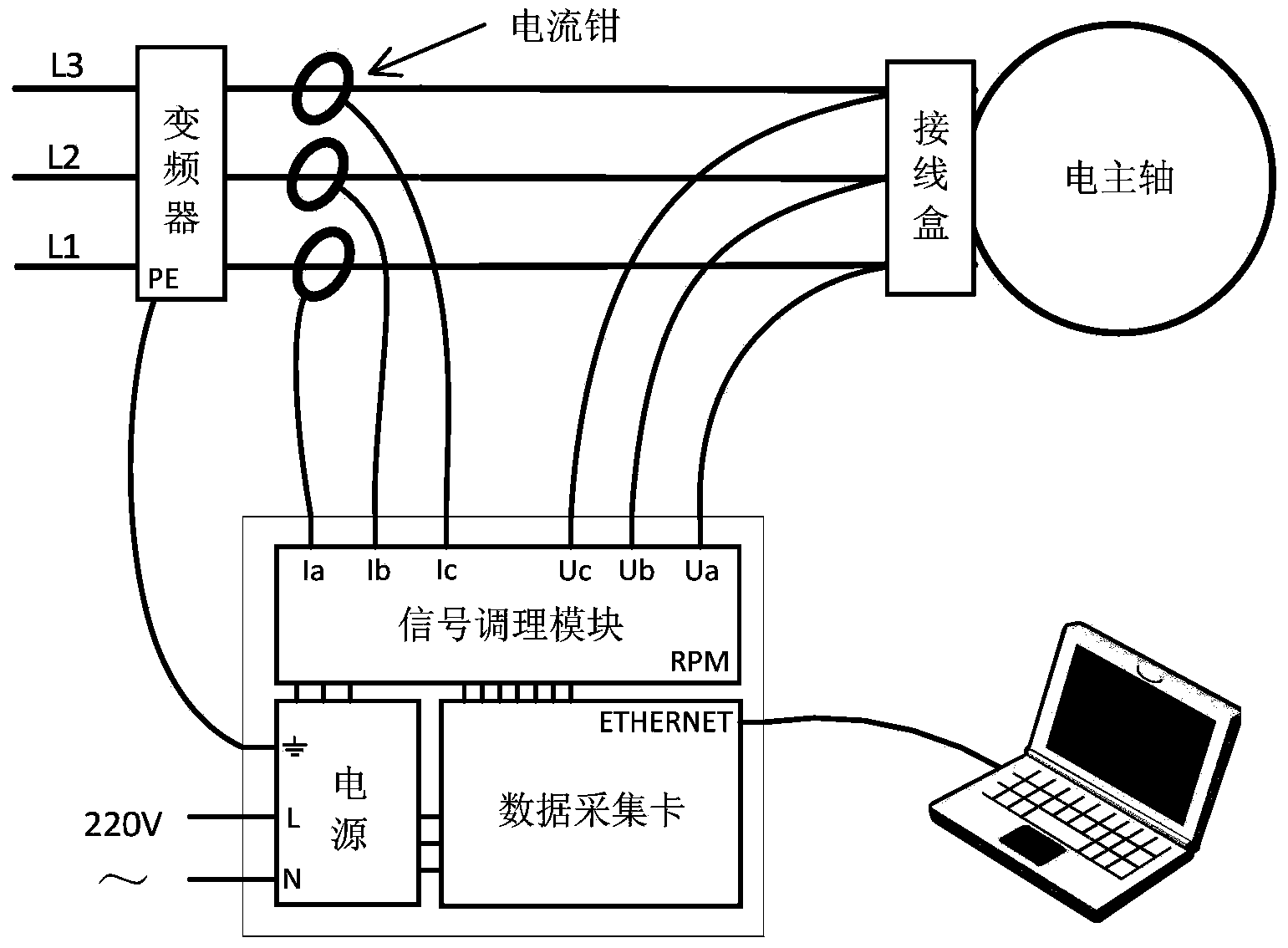

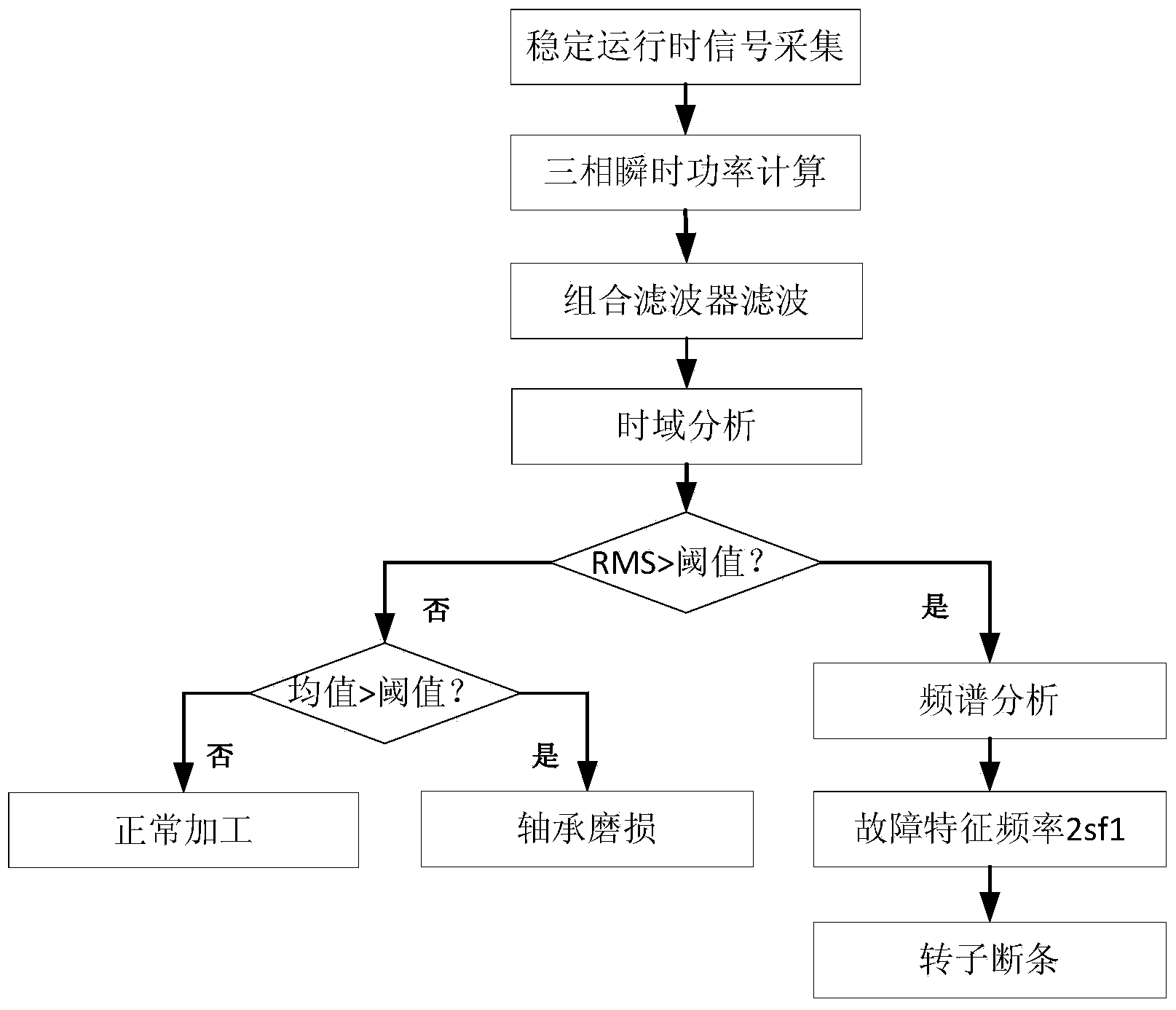

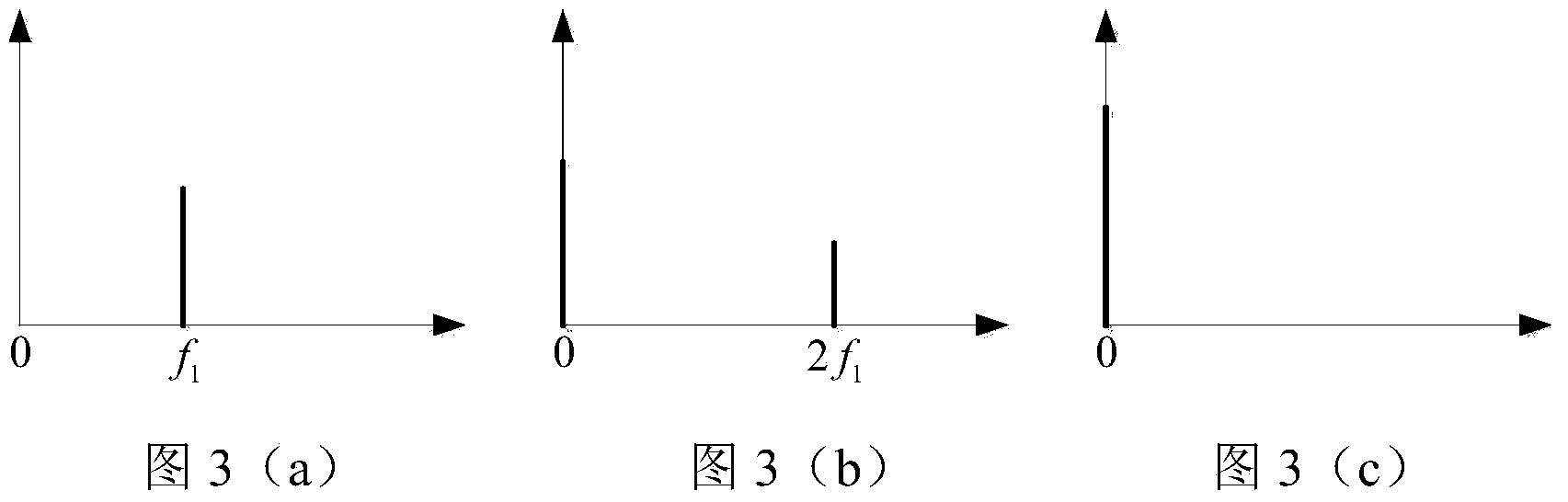

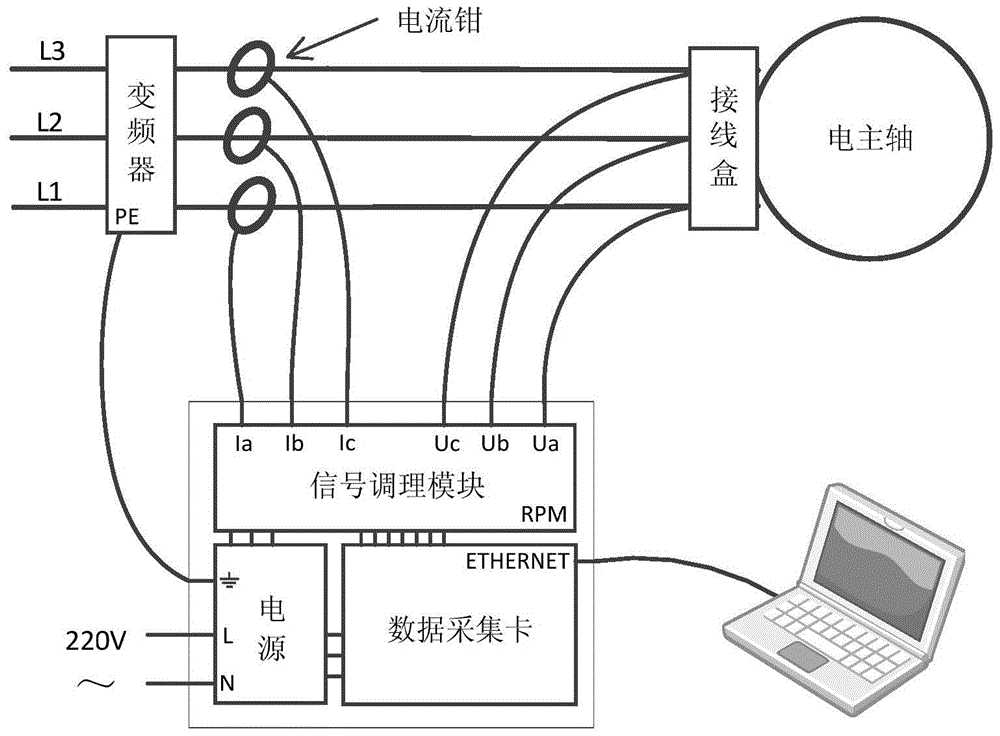

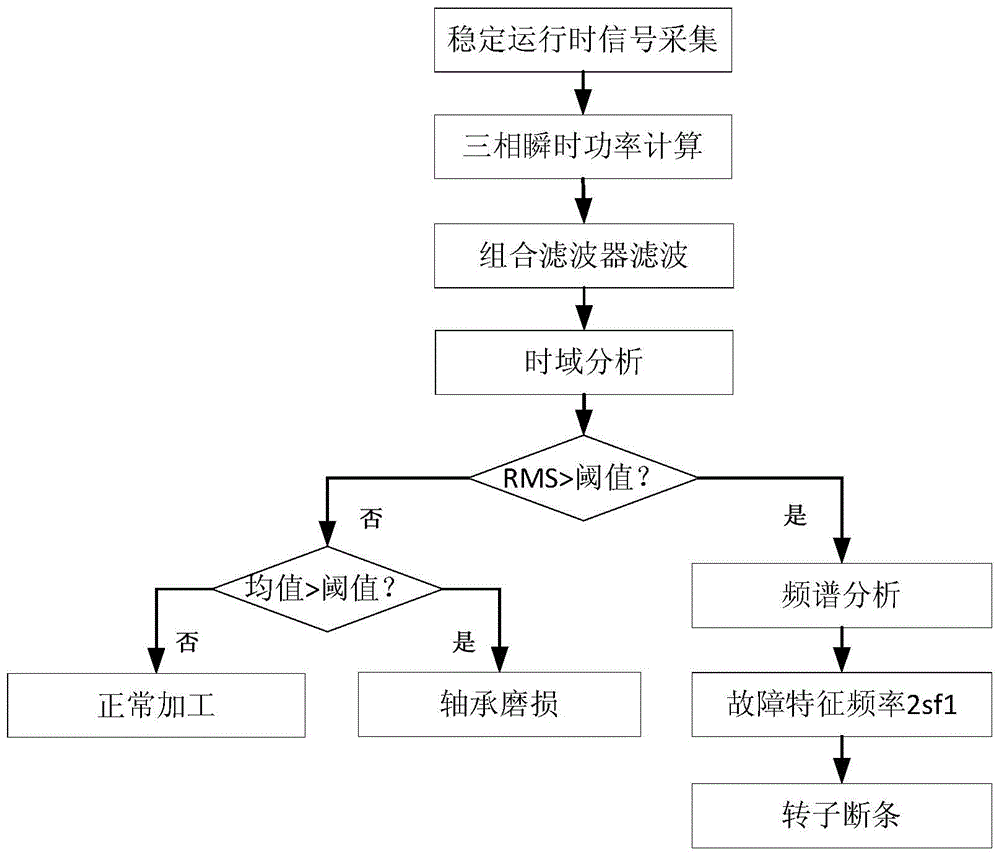

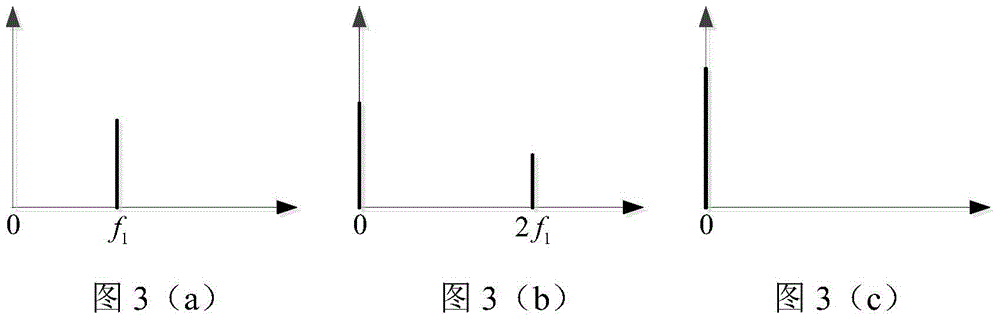

Three-phase instantaneous power based motorized spindle fault monitoring and diagnosing method

The invention discloses a three-phase instantaneous power based motorized spindle fault monitoring and diagnosing method and belongs to the technical field of motorized spindle fault monitoring. According to the three-phase instantaneous power based motorized spindle fault monitoring and diagnosing method, by means of signal demodulation properties and three-phase symmetry characteristics of three-phase instantaneous power, three-phase input voltage and three-phase stator current signals are collected when a motorized spindle is stably operated, three-phase instantaneous power signals are calculated, the influence of supply frequency modulation, frequency rotating and frequency doubling on monitoring and diagnosing results is eliminated through a design of a junction filter, whether the motorized spindle breaks down is determined according to comparison between a mean value and a root-mean-square (RMS) value of the three-phase instantaneous power signals and standard reference values during the operation process, and a fault type is determined according to generation of fault character frequency during spectral analysis, so that monitoring and diagnosing of faults of the motorized spindle are achieved. According to the three-phase instantaneous power based motorized spindle fault monitoring and diagnosing method, the signal collection and processing process is simple, bearing wearing and rotor broken bar faults of the motorized spindle can be effectively monitored, and the method is applicable to state monitoring and fault diagnosing of the motorized spindle on an industrial scene.

Owner:XI AN JIAOTONG UNIV

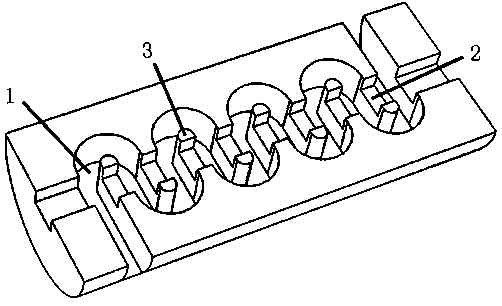

Cutting path planning method applied to folded waveguide slow wave structure

ActiveCN109128316AEnsure structural continuitySolve removalAutomatic control devicesFeeding apparatusWave structureMilling cutter

The invention relates to a cutting path planning method applied to a folded waveguide slow wave structure. The cutting path planning method comprises the following steps: removing oxide scales on thesurface of a material by adopting a milling cutter; selecting a point, positioned outside the starting edge of an S-shaped groove, on a center line of a straight groove as a cutter adjusting point; performing Z-direction cutter adjustment on a workpiece by adopting a CCD cutter adjusting system; dividing the processing stage, planning a cutting path of a micro-milling cutter and adopting a cuttingplan for layered processing of the slow wave structure in the depth direction; finally removing residual burrs through an auxiliary process. The cutting path planning method provided by the inventionhas the benefits that the ultra-precision micro-milling process of the multi-period, large-aspect ratio and thin-walled complex slow-wave structure is realized, and the problems that in the ultra-precision micro-milling process of the part, an island structure is prone to bending and collapsing, the burrs formed at the intersection of the straight groove and the S-shaped groove are hard to remove, the side wall of a deep groove is easy to incline and the like are solved, to meet the relatively stringent processing requirements.

Owner:HARBIN INST OF TECH

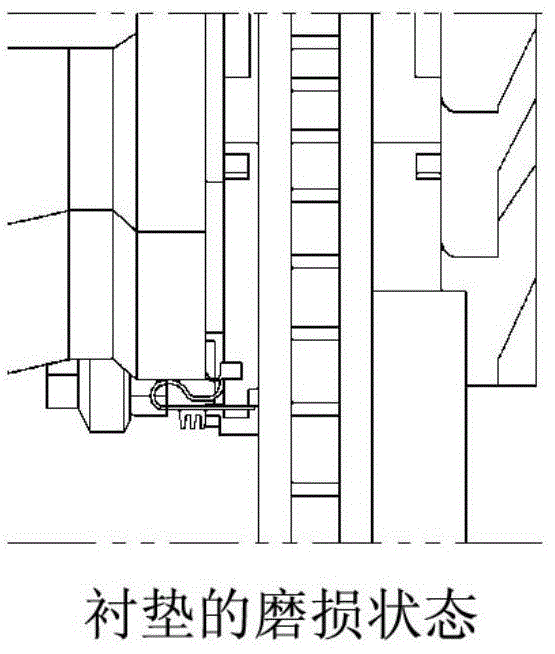

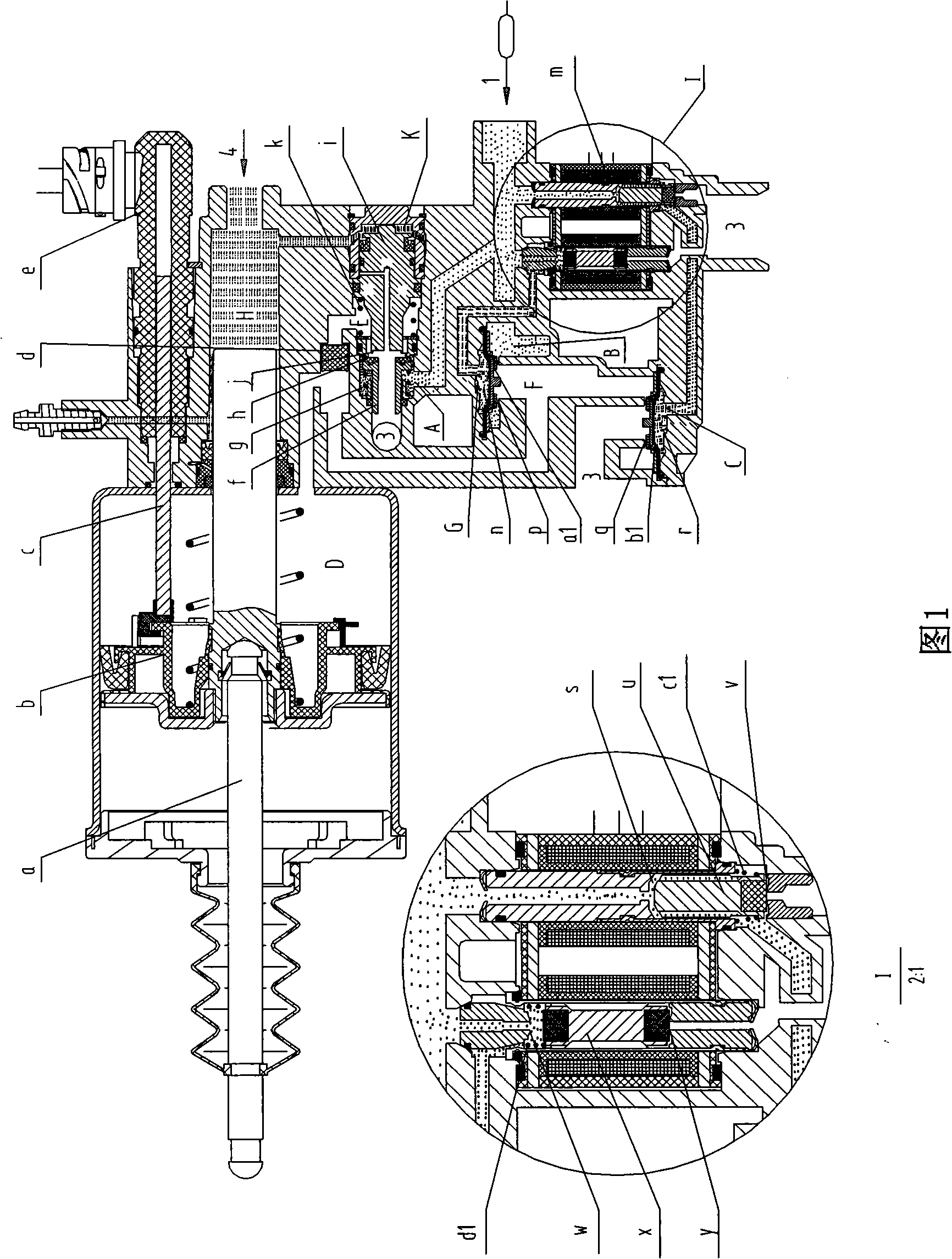

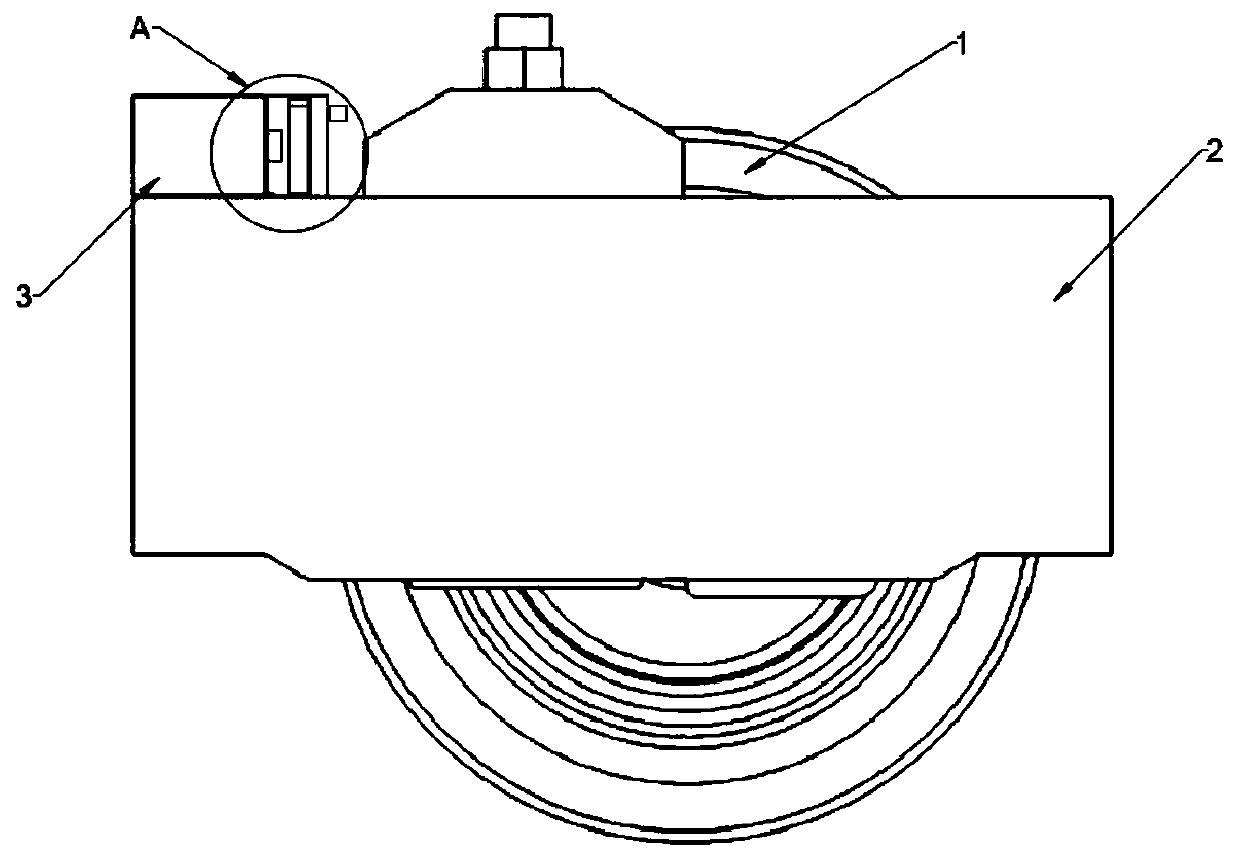

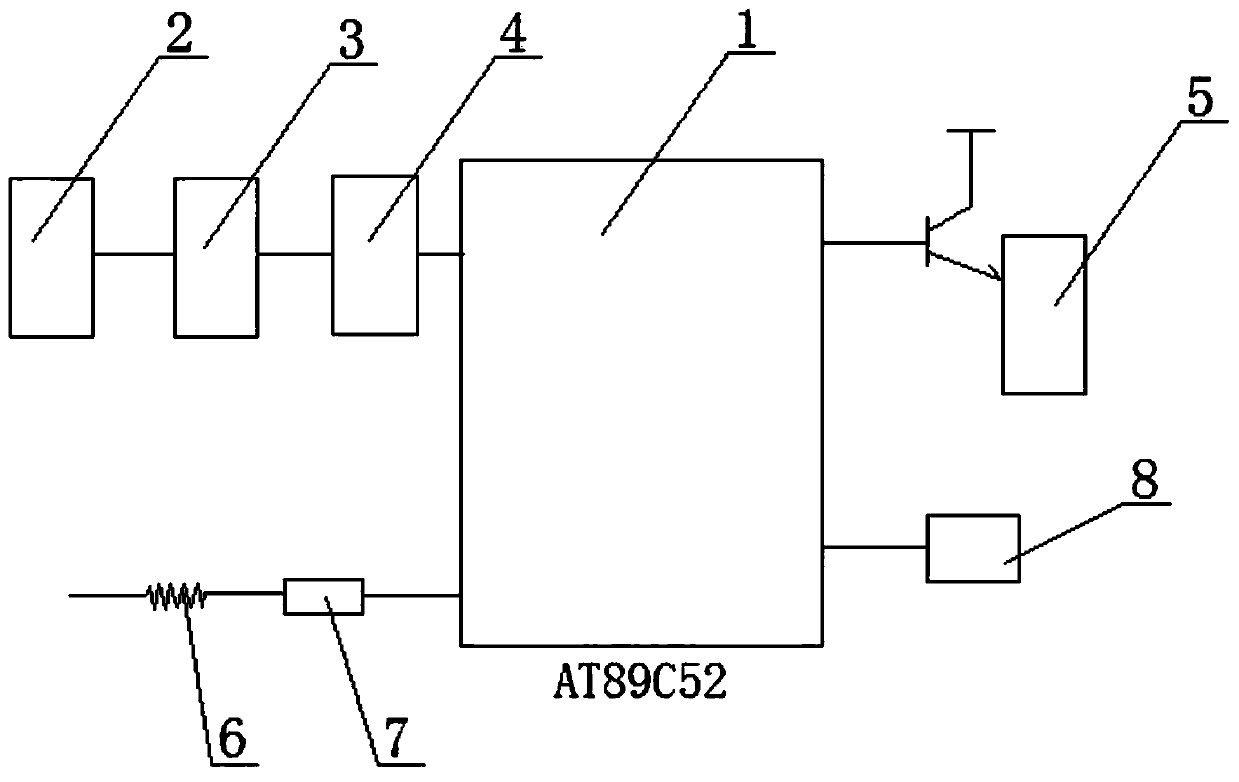

Electric-controlled pneumatic type clutch booster unit and operating method thereof

ActiveCN101280811ARealize clutch operationQuality improvementFluid actuated clutchesFailure rateElectrical control

The invention relates to a pneumatic clutch booster device and an operation method thereof. The device adopts a pure-electric control model to realize the operation of the clutch, and aims at simplifying the structure of the clutch booster and reducing failure rate. The clutch can also be separately controlled by a hydraulic operating mechanism and an electrical control operation mechanism to realize the diversity of vehicles during shifting process, which can, on one hand, realize the leave and joint of the clutch through a traditional clutch hydraulic operating mechanism, and on the other hand, realize the operation of the clutch directly through an electrical control manner, so as to reduce the working frequency of the clutch hydraulic operating mechanism and enhance the quality and service life of the clutch booster device. The pneumatic clutch booster device of the invention is also provided with an attrition alarm device of a clutch friction disc; the attrition alarm device can monitor the attrition condition of the clutch friction disc and emit an alarm signal when the attrition value reach a preset value to remind the user to change the friction disc; the attrition alarm device can also effectively judge the leave and joint status of the clutch.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

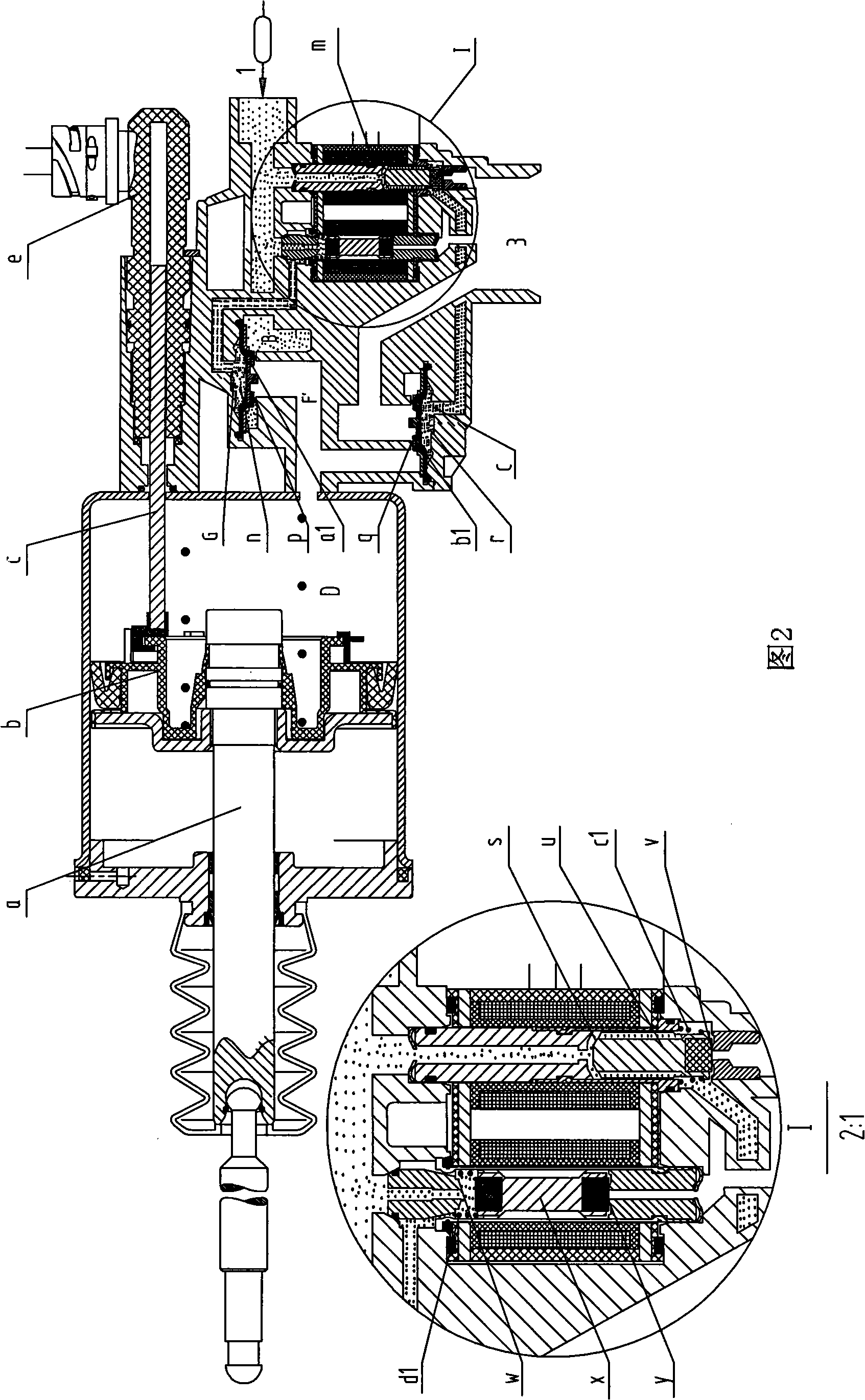

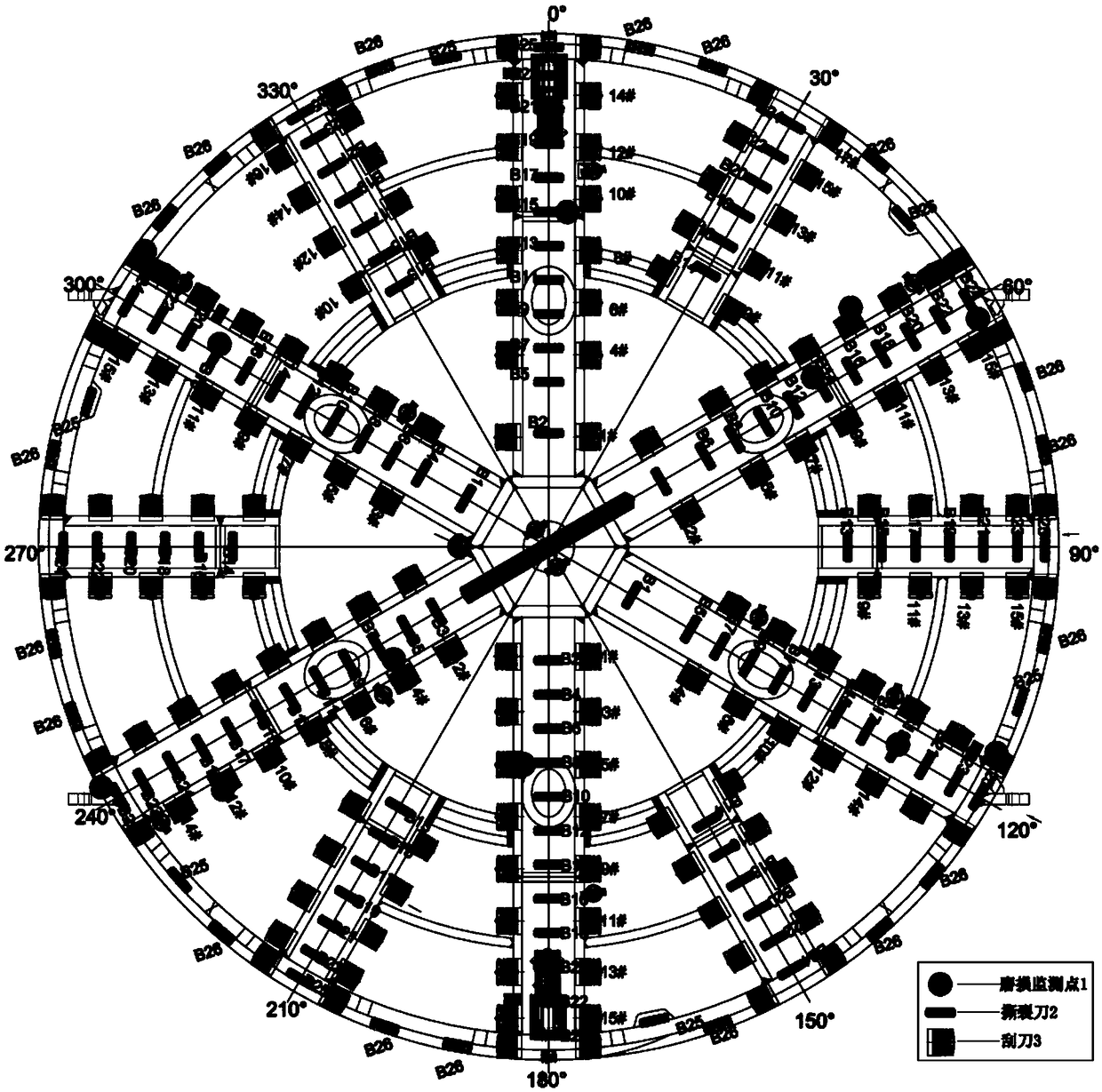

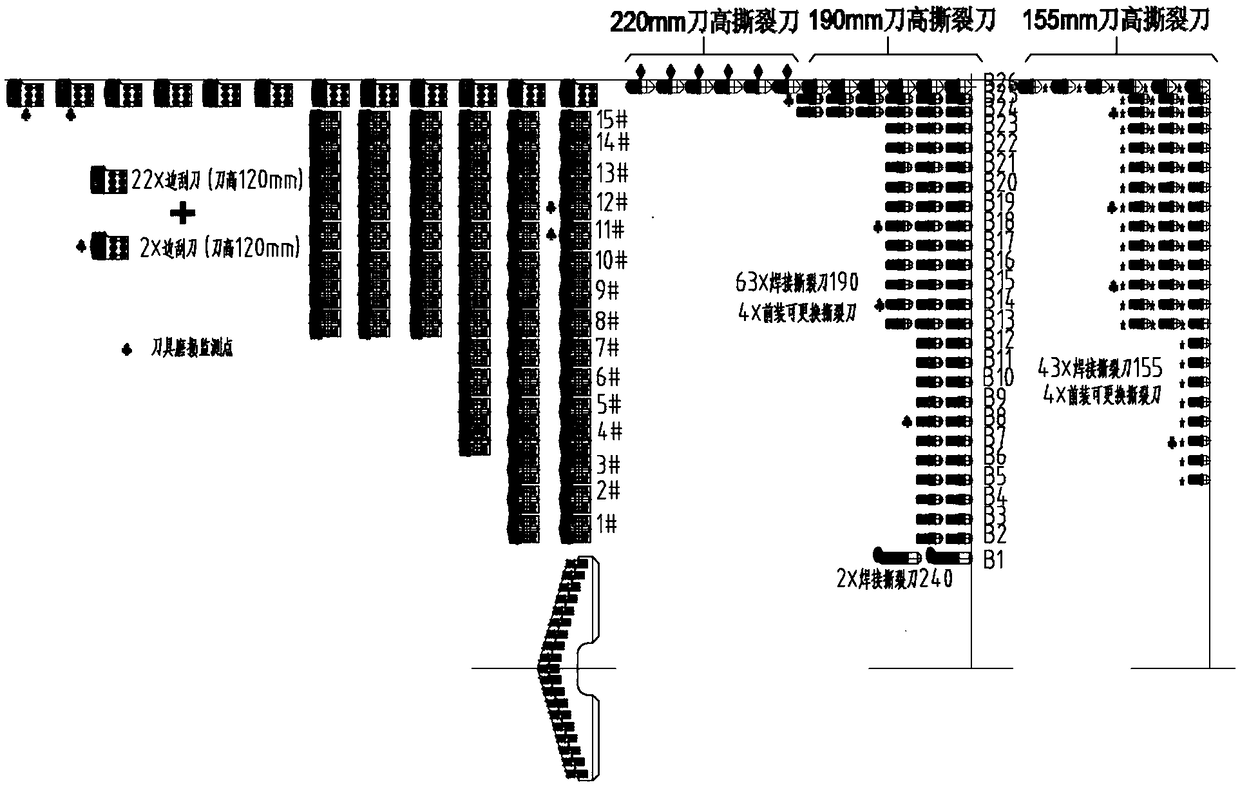

Abrasion monitoring point arrangement method for large diameter inner-city rapid rail tunnel shield tunneling machine cutter and abrasion monitoring method

The invention provides an abrasion monitoring point arrangement method for a large diameter inner-city rapid rail tunnel shield tunneling machine cutter. Refining subdivision is carried out accordingto abrasion monitoring point arrangement of the cutter of cutter heads, analysis is performed from aspects of cutter types, cutter heights, cutter center distance and the like, an abrasion monitoringpoint arrangement principle of the inner-city rapid rail tunnel shield tunneling machine cutter is creatively put forward, abrasion situations of cutters on cutter heads of an inner-city rapid rail tunnel shield tunneling machine with the diameter of 9m can be effectively monitored, the abrasion level of the cutters on the cutter heads of the shield tunneling machine is reflected truthfully at thegreatest extent so as to timely change the cutters when required, a theoretical basis is provided for monitoring shield cutter head and cutter abrasion situation in similar projects in the future, sothat abrasion monitoring is carried out on the cutter head and cutter pointedly depending on the principle, errors brought by cutter abrasion monitoring point arranged by an engineering analogy method are reduced, and valuable experiences are accumulated for subsequent cutter abrasion study.

Owner:北京城建轨道交通建设工程有限公司

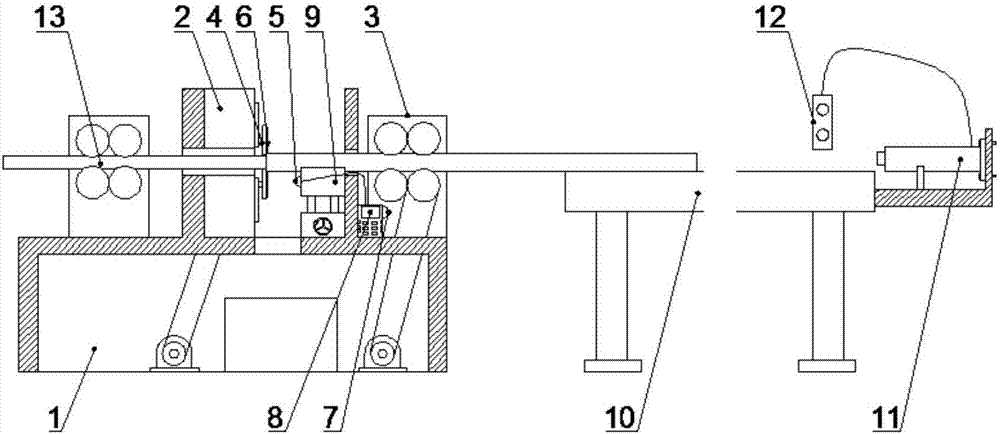

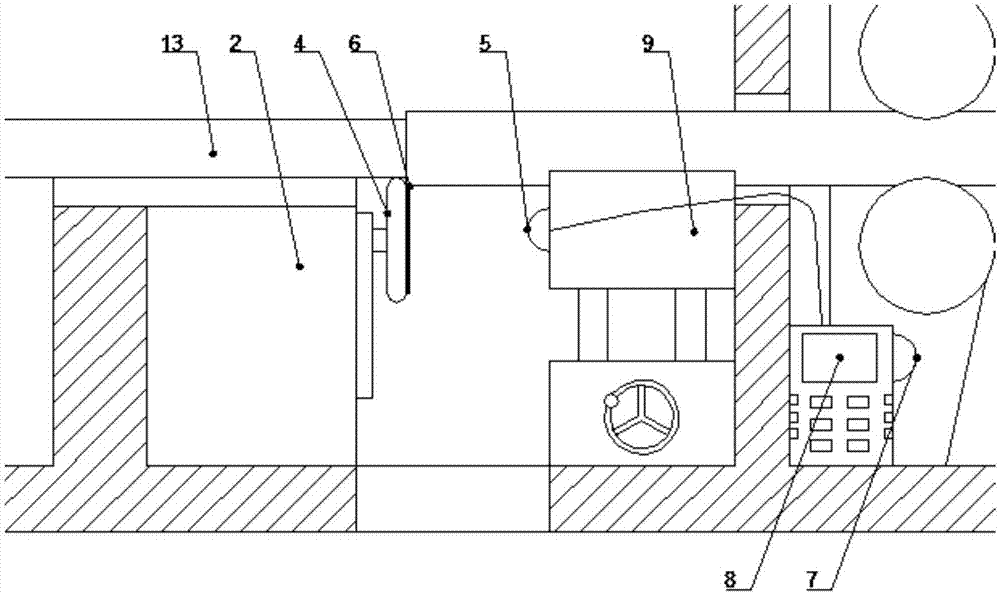

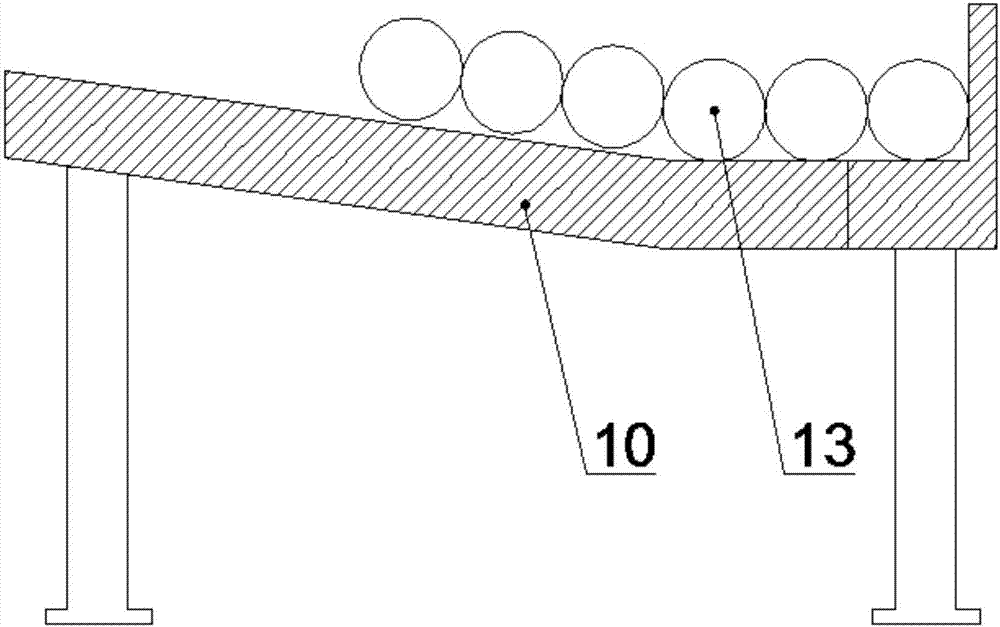

Grinding type stripping machine capable of monitoring grinding disc and working method for grinding type stripping machine

InactiveCN107443229AMonitor wearAvoid the phenomenon of large depth of cutGrinding drivesGrinding machinesPulp and paper industryVision sensor

The invention discloses a grinding type stripping machine capable of monitoring a grinding disc. The grinding type stripping machine comprises a machine frame, a stripping mechanism, a positioning mechanism, feeding and supporting mechanisms, a conveying mechanism and a monitoring mechanism, wherein the stripping mechanism is arranged on the machine frame, the positioning mechanism is arranged on one side of the stripping mechanism, and the monitoring mechanism is arranged on the positioning mechanism; the grinding disc is arranged on the stripping mechanism; and the monitoring mechanism comprises a visual sensor, a marking patch, a buzzer and a PLC, wherein the visual sensor is opposite to the grinding disc, the marking patch is arranged on the grinding disc and covers the side surface of the grinding disc, and the buzzer is arranged on the PLC. The invention further discloses a working method and a monitoring method for the grinding type stripping machine. According to the grinding type stripping machine and the working method and the monitoring method for the grinding type stripping machine, the phenomenon of the large cutting depth can be effectively avoided, and a tool can be protected; the grinding degree of the grinding disc can be automatically monitored, and an alarm can be given; and by means of mechanical feeding, time and manpower resources can be saved.

Owner:TAICANG BEST MECHANICAL EQUIP

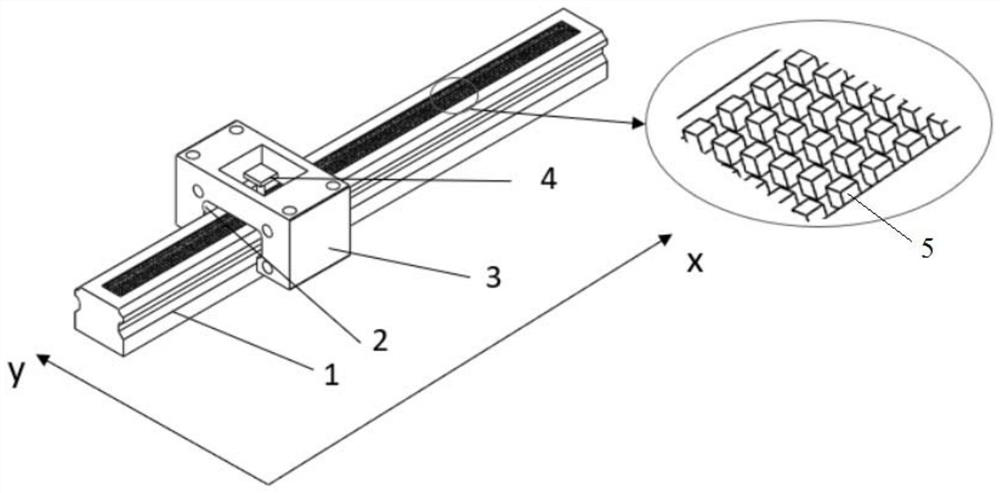

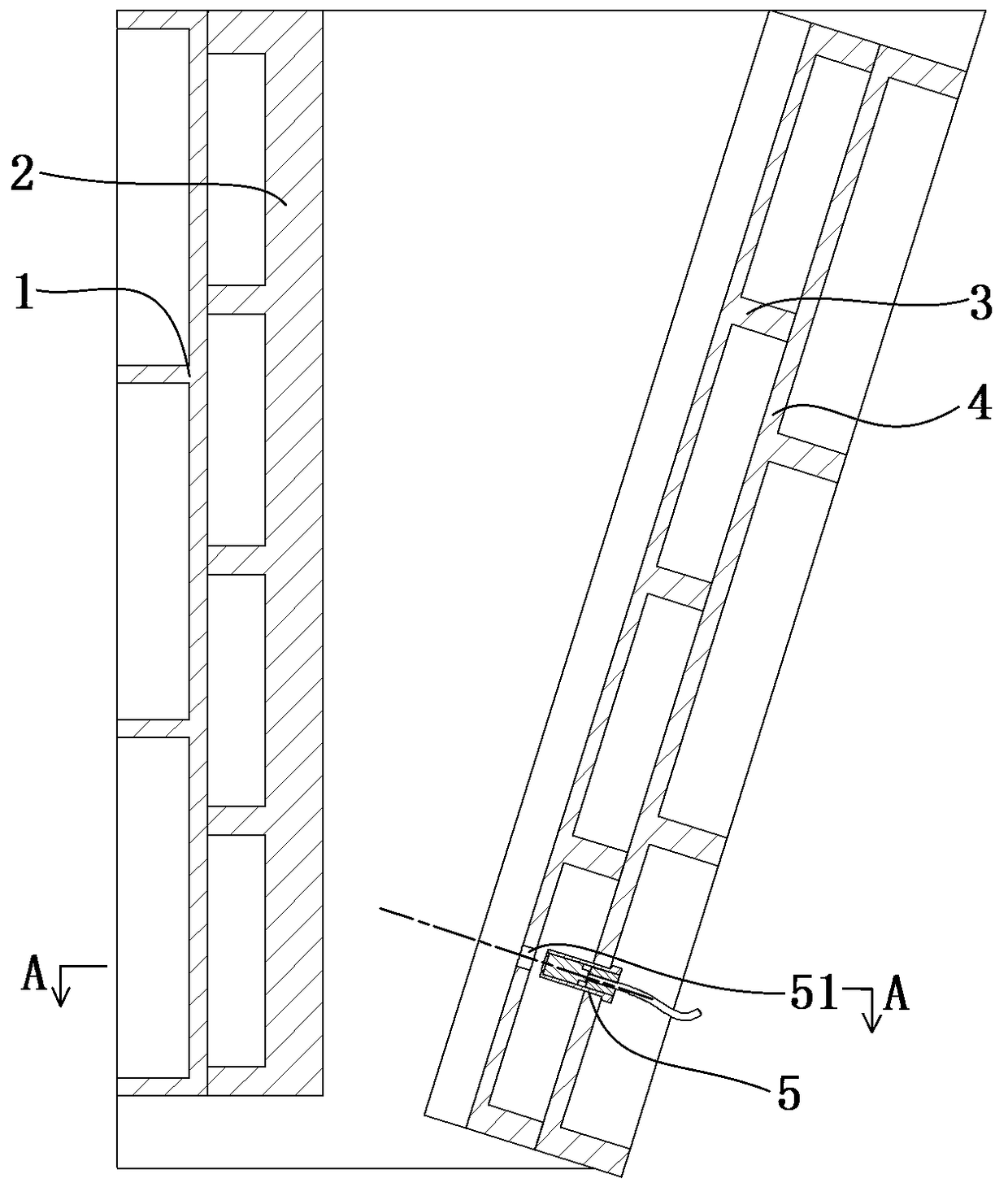

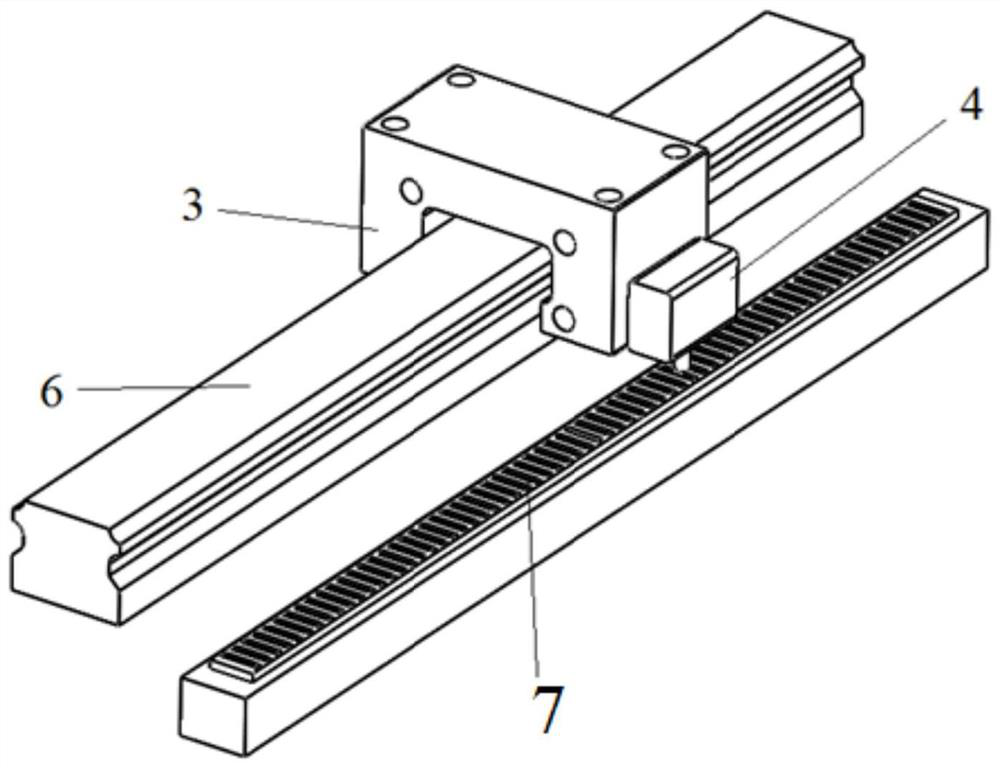

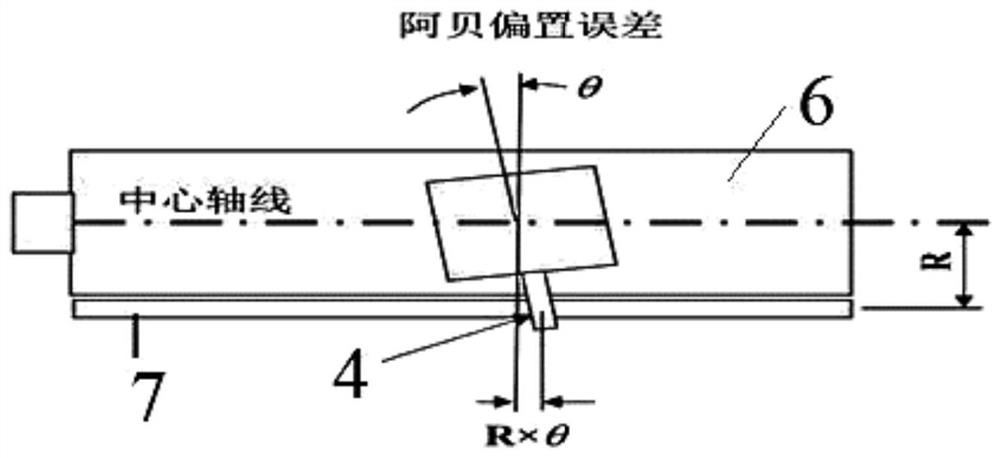

Device and method for synchronous in-situ measurement of linear displacement and straightness of guide rail

ActiveCN111735393AAbbe's error is smallReduce nonlinear errorUsing optical meansGratingMechanical engineering

The invention discloses a device and a method for synchronous in-situ measurement of linear displacement and straightness of a guide rail. For an integrated two-dimensional grating and guide rail, a two-dimensional grating is etched on the upper surface of a linear guide rail, and a reading head is embedded in a sliding block. The specific measurement method comprises the steps that when the sliding block moves on the guide rail, the reading head outputs two pairs of orthogonal sine and cosine signals at the same time, the sine and cosine signals are transmitted to an upper computer through anacquisition card after being subjected to filtering and analog-digital conversion, and displacement and straightness are solved on the upper computer through a method of counting edges through high-frequency pulses, wherein the linear displacement of the guide rail is solved through orthogonal signals generated by the grid lines perpendicular to the x axis, and the straightness of the guide railis solved through orthogonal signals generated by the grid lines perpendicular to the y axis. The method has the advantages of small guide rail pair mounting size, high positioning precision, multi-parameter synchronous in-place measurement and the like, and a new method is provided for displacement and straightness measurement of the guide rail.

Owner:XI AN JIAOTONG UNIV

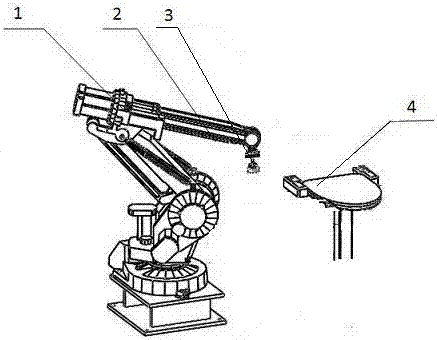

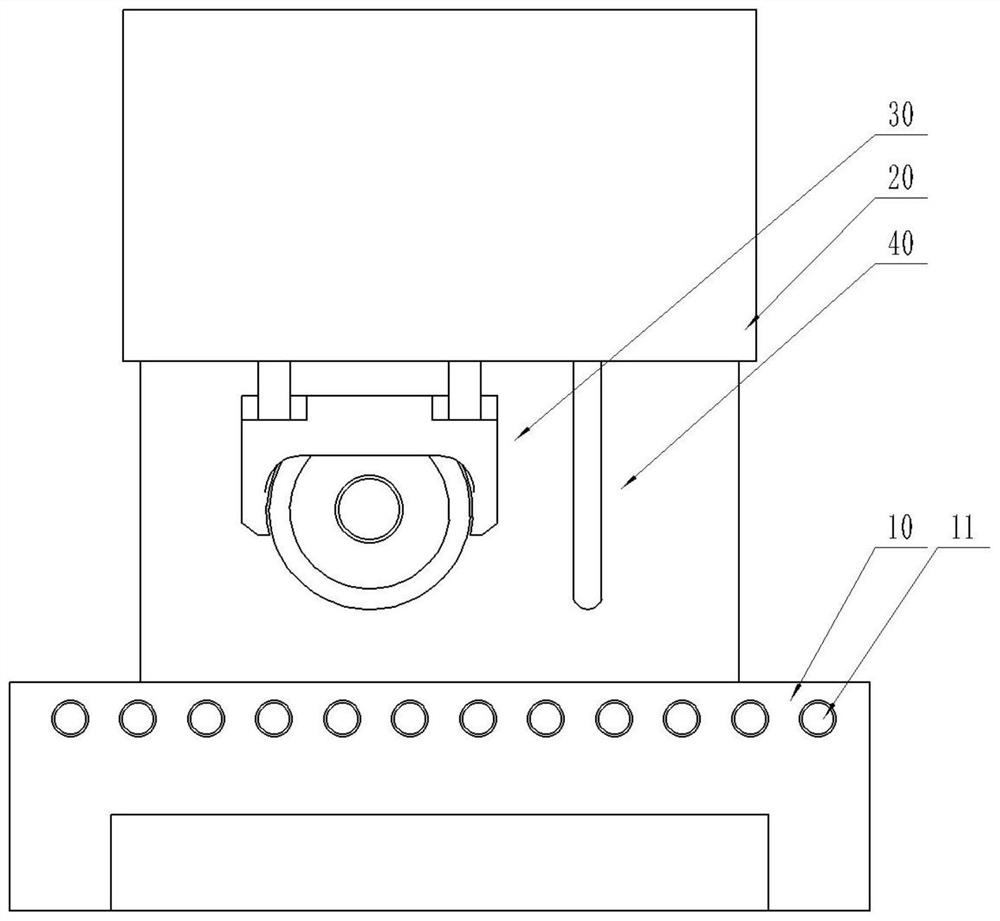

High-speed milling cutter abrasion vision in-place monitoring system and method

PendingCN107398778ADifficult to scatterImage acquisition with high qualityMeasurement/indication equipmentsMachining processMilling cutter

The invention relates to the technology of cutter monitoring, in particular to a high-speed milling cutter abrasion vision in-place monitoring system and method. The system comprises a mechanical hand, a clamp, an industrial microscope lens and an industrial personal computer. The mechanical hand is fixedly installed on a ground foundation. The clamp is installed at the tail end of the mechanical hand. The industrial microscope lens is clamped on the clamp and electrically connected with the industrial personal computer, and obtained workpiece surface image data is transmitted to the industrial personal computer. The monitoring method comprises the steps that the equipment is prepared; the mechanical hand demonstrates; a standard block database is set up; and in-place detection is carried out. According to the system and the method, the industrial microscope lens obtains an image of the machined surface of a workpiece, as the milled surface is a plane, the problems of scattering and the like do not occur easily, the image obtaining quality is high, the surface quality data can be obtained accurately, and thus the abrasion condition of a cutter can be monitored accurately. The mechanical hand selects to carry out measurement during an interval of cutter stopping, and in-place detection is achieved in the cutter machining process.

Owner:詹白勺 +1

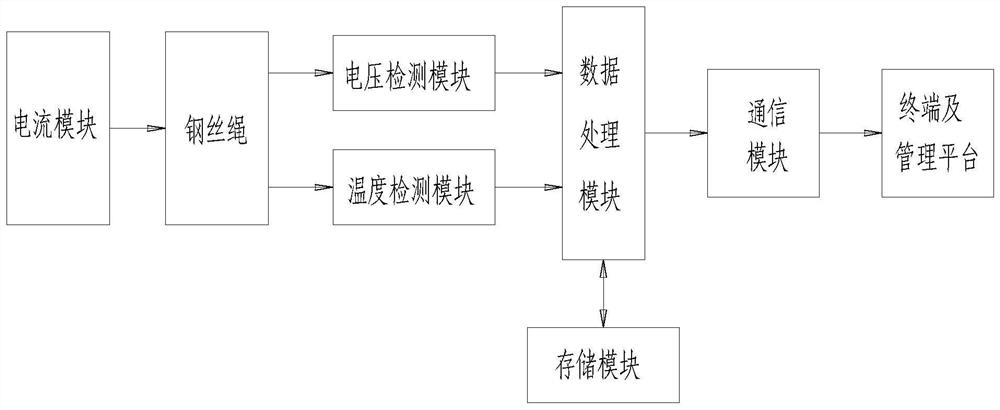

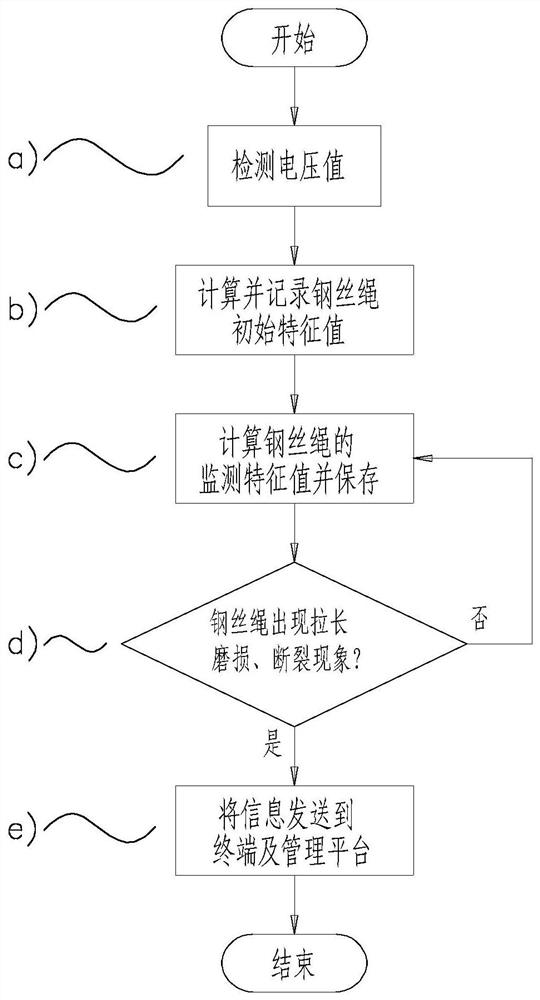

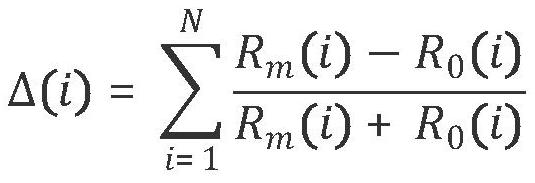

Algorithm model based elevator traction steel wire rope state monitoring and early warning system and method

InactiveCN111847169ALocation Accurate JudgmentRealize real-time monitoringElevatorsEarly warning systemControl engineering

The invention discloses an algorithm model based elevator traction steel wire rope state monitoring and early warning system and method and relates to a monitoring and early warning system and method.The algorithm model based elevator traction steel wire rope state monitoring and early warning method comprises the following steps: a, electrifying a steel wire rope with current I, and detecting the voltage value U of the steel wire rope; b, operating an elevator for one period for the first time, and calculating and recording the initial characteristic value of the steel wire rope when the elevator is in the initial state; c, when the elevator is monitored to operate, collecting and calculating the monitored characteristic value of the steel wire rope within one period and saving the monitoring characteristic value; d, according to the characteristic value of the steel wire rope, judging whether the steel wire rope has the stretching, wearing and rupturing phenomena, if yes, carrying out the step e; otherwise, repeatedly carrying out the step c; and e, sending the stretching, wearing and rupturing information of the steel wire rope and the changing position information of the steelwire rope to a terminal and a management platform. The algorithm model based elevator traction steel wire rope state monitoring and early warning system comprises a current module, a voltage detecting module, a memory module and the like. With adoption of the algorithm model based elevator traction steel wire rope state monitoring and early warning method, manpower and material resources for elevator operation can be reduced, and the risk that the entire steel wire rope fractures to cause a major accident is lowered.

Owner:HECHI UNIV

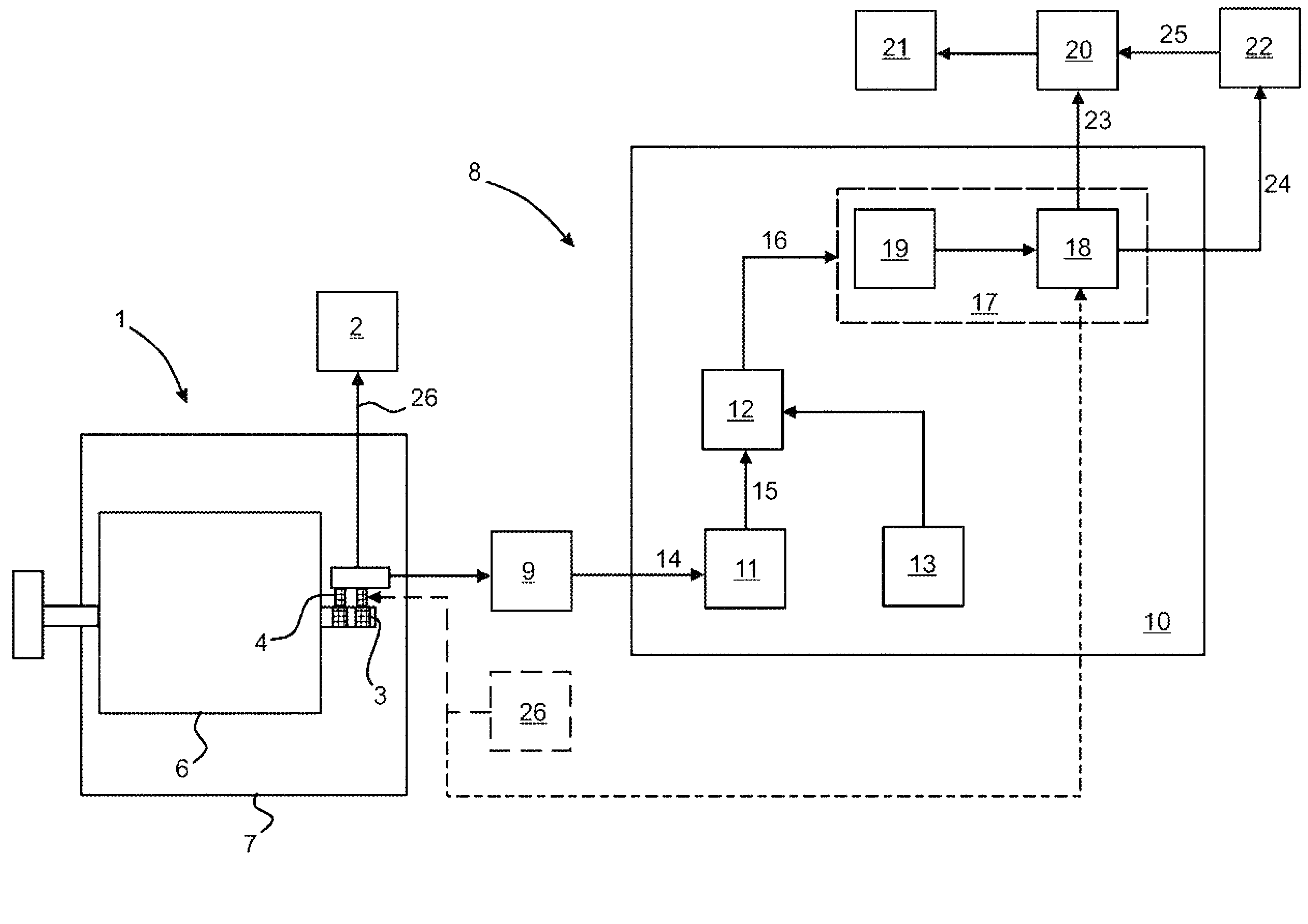

Method and device for monitoring the wear of sliding electrical contacts of a rotating commutator for an automotive vehicle

ActiveCN103004082AWear detectionMonitor wearRotary current collectorModelling/simulations for controlMobile vehicleEngineering

The subject of the invention is a method and a device for monitoring wear of the sliding electrical contacts (4) of a rotating commutator (3) of an electrical machine (1) that generates current for an automotive vehicle. The method consists in detecting (15), using the electrical machine (1) in the current generation phase, data relating to the opening duty cycle (ODC) induced by the generated current. The data relating to the detected ODC are compared (15) with a predefined ODC set-point, and the state of wear of the sliding electrical contacts (4) is deduced with respect to a tolerated wear threshold by incrementing a regulated counter (18) using said comparison (15). A warning is generated (23) when the state of wear of the sliding electrical contacts (4) reaches said tolerated wear threshold. This warning being suppressed (24, 25) upon detecting a value that tends to zero the regulated counter (18), after replacement of the sliding electrical contacts (4).

Owner:PEZHO SITROEN AUTOMOBILS SA

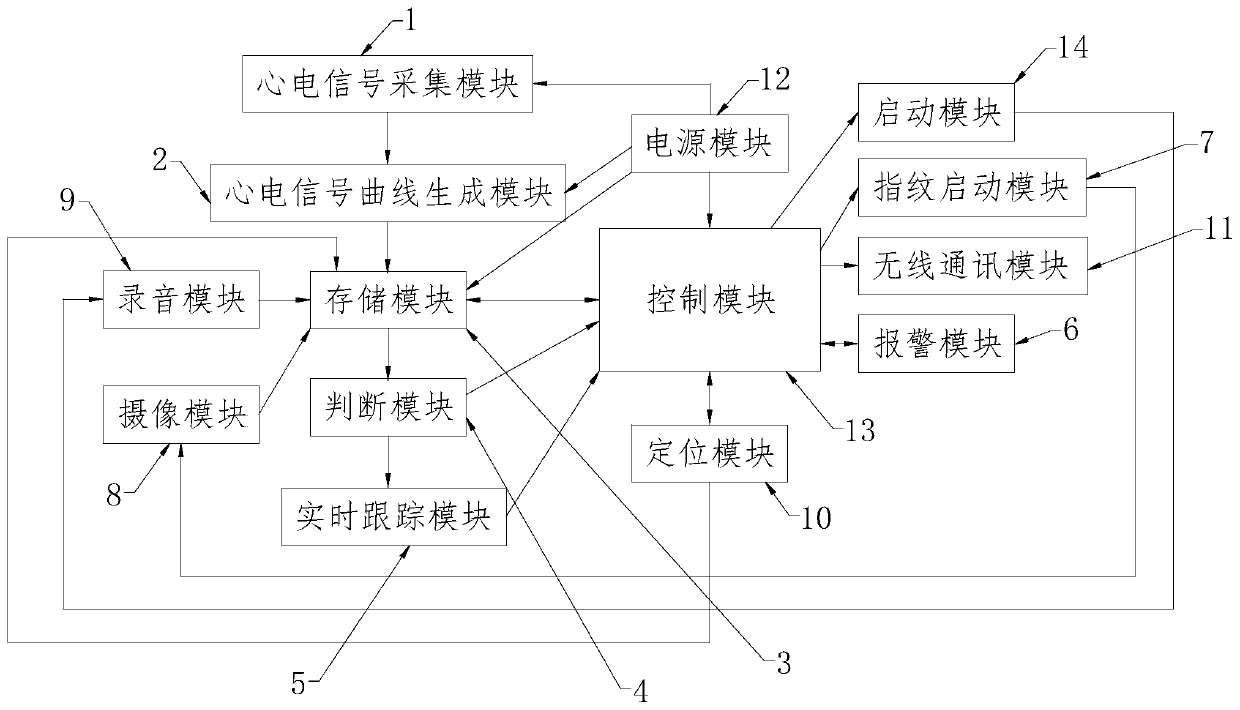

Intelligent antitheft wearable device based on electrocardiograph signal identification

InactiveCN109692006AReal-time acquisitionImprove securityPerson identificationSensorsEcg signalComputer hardware

The invention discloses an intelligent antitheft wearable device based on electrocardiograph signal identification. The wearable device can collect the electrocardiograph signals of a person who wearsthe wearable device. The collected electrocardiograph signal curve chart is compared with an electrocardiograph signal curve chart, which has been stored in a storage module in advance, of the personand the wearable device judges whether two curve charts are identical or not. The heart rate curve is taken as the unlock password of the wearable device, and the safety coefficient is high. Througha real-time tracking module, the wearable device can track the electrocardiograph signal curve information of the person in real time. The real-time tracking module is connected to a control module, which is used to monitor the wearing situation of the person. If the wearable device is taken off, the real-time tracking module cannot track the electrocardiograph signal curve chart, the control module triggers an alarm module to send an alarm, at the same time, the position of the wearable device and the alarm information are sent to a terminal device which has been bonded with the intelligent wearable device, a child who wears the intelligent wearable device is difficult to kidnap, and the safety of the child is guaranteed.

Owner:合肥八爪智能科技有限公司

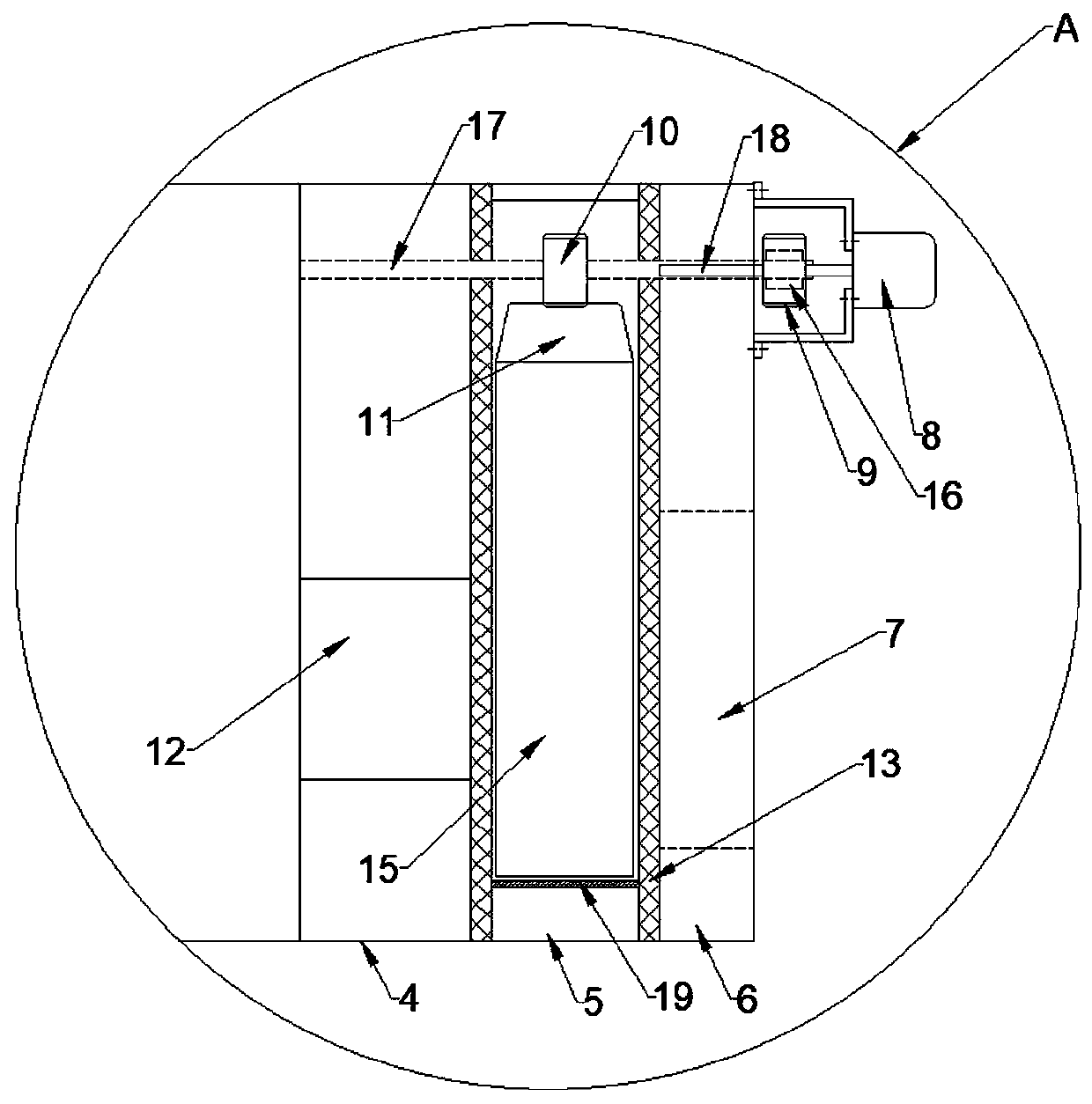

Real-time monitoring device and operation determination method for hob status during shield construction

InactiveCN110595360AProtect left and right movementProtection cleanMachine part testingUsing optical meansSlagLaser sensor

The invention discloses a real-time monitoring device and an operation determination method for a hob status during shield construction. A laser monitoring method is introduced into a cutter head system during shield construction, and related data such as tool wear can be effectively monitored by laser measurement feedback, which not only solves the problem of hob running status monitoring duringthe construction process, but also effectively avoids the disadvantages such as impact wear of the rock slag on the sensor during the construction process. In order to avoid the dirt, oil and other stains from adhering to the lens during the operation, resulting in affecting the sensitivity and accuracy of the laser sensor detection, the sealing strips on the protective lens and the protective device can move relative to one another to scrape off the stains on the protective lens and ensure the cleanness of the lens. The operation determination method for the hob status collects the hob wear data through the hob operation data monitoring device, analyzes the operation status of the hob, determines that the hob is in a normal status such as regular wear, or in an abnormal status, such as side grinding, chipping and jamming, finds the abnormal status of the hob in time, and carries out quick replacement and repair.

Owner:李睿

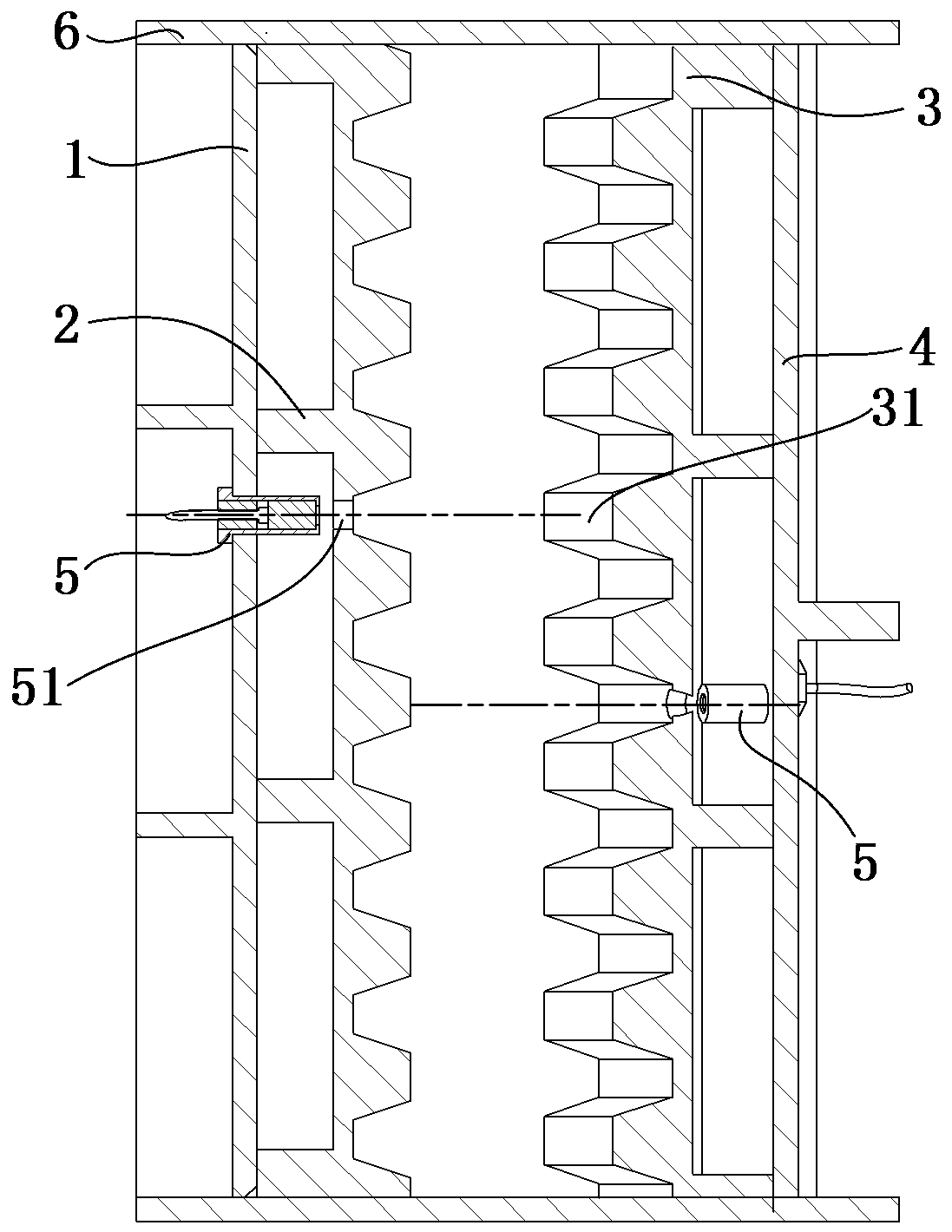

Jaw crusher

The invention relates to a jaw crusher. The jaw crusher is equipped with a distance-measuring sensor; a detection signal of the distance-measuring sensor passes through a signal channel on one jaw plate and is propagated to another jaw plate, so that the distance between the distance-measuring sensor and the jaw plates can be detected. During the use, the two jaw plates perform relative reciprocating motion, and the detection result of the distance-measuring sensor is a waveform curve; when the jaw plates produce wear during the use, the distance between the distance-measuring sensor and the jaw plates can become larger, the maximum and minimum values of the waveform curve of the detection result can become larger, and the variable quantity is the wear amount of the jaw plates, so that thewear amount of the jaw plates can be known according to the detection result of the distance-measuring sensor, and thus the wear condition of the jaw plates can be monitored in time and effectively;the jaw plates can be replaced after the wear amount of the jaw plates reaches a set value. The jaw crusher does not need special arrangement of manpower monitoring and saves labor costs.

Owner:郑州洁普智能环保技术有限公司

Air pressure corner pantograph and monitoring system and monitoring method

The invention provides an air pressure corner pantograph and a monitoring system and a monitoring method. The air pressure corner pantograph.is characterized in that the cross section of the bow is fan shaped. At least two concave guide rails are arranged on the curved surface of the bow body. The steering of the pantograph carbon slide is realized by converting the linear movement of the guide column into the rotation of the bow body. The marginal image of the carbon slider is collected through the fiber optic sights on both sides of the pantograph bracket. Then the marginal image of the carbon slider merged into the whole is matched for the driver to judge the wear of the pantograph, and perform the rotating carbon skateboard or bow down operation.

Owner:山东省阳信铭泰电气有限公司

Automatic measuring system for abrasion of gear reducer

The invention belongs to the field of automatic measurement control, and specifically relates to an automatic measuring system for abrasion of a gear reducer. The system is characterized in that the duckbill design is adopted in an outer lubricating oil circulating process; when mixed liquid of the lubricating oil and abrasive dust flows to a rotating outer cylindrical separating drum, the abrasive dust is adsorbed to the surface of the outer cylindrical surface through adsorption power of inner cylindrical surface of a permanent magnet field; when the adsorbed abrasive dust arrives at the lower part as the outer cylindrical separating drum rotates, an inner magnetic field is removed, and the abrasive dust is guided into a planar container under the effects of gravity, centrifugal force, ultrasonic wave and a dust scrapping device; the abrasive dust at the bottom part of the planar container attracts a magnet adhered to the upper part of a magnetic-electric converter, and thus the pressure of a strain transducer is changed; the change of the pressure of the strain transducer leads to the change of output voltage of the strain transducer, so that the abrasion of the reducer can be measured. According to the system, the measurement is automatically carried out, so that the system is of important significance in monitoring the abrasion of the gear reducer, improving the working efficiency of mechanisms, and prolonging the service lives of the mechanisms.

Owner:ZHONGBEI UNIV

Milling device capable of detecting wear state of cutter and applied to machining of special-shaped crank arm

InactiveCN112025407AEasy to mill in all directionsClamp firmlyMeasurement/indication equipmentsCrankStructural engineering

The invention discloses a milling device capable of detecting the wear state of a cutter and applied to machining of a special-shaped crank arm. The milling device specifically comprises a base plate,a protective cover, a milling base and the special-shaped crank arm; supporting columns are correspondingly installed at the four corners of the top of the base plate; a supporting base is fixed to the middle position of one end of the top of the base plate; longitudinal guide rails are correspondingly installed at the top ends of the supporting columns positioned at the two sides of the supporting base; the longitudinal guide rails are each sleeved with a movable base; the ends, close to the supporting base, of the movable bases are each fixedly provided with a vertical guide rail; lifting bases are installed on the vertical guide rails correspondingly; according to the milling device capable of detecting the wear state of the cutter and applied to machining of the special-shaped crank arm, by arranging two clamping bases which are each internally provided with a first clamping groove and a second clamping groove, raw material blocks can be clamped, and milled special-shaped crank arms can be clamped as well; milling cannot be blocked while stable clamping is achieved, so all-directional milling of the special-shaped crank arm is facilitated, a better clamping effect is achieved,and the machining difficulty is reduced.

Owner:东莞市龙飞数控科技有限公司

Tool wear monitoring system capable of realizing self-learning in numerical control machining state

InactiveCN102073300BCutting Condition MonitoringReal-time monitoring of cutting statusProgramme controlComputer controlData acquisitionEngineering

The invention discloses a tool wear monitoring system capable of realizing self-learning in a numerical control machining state. The structure of the system is that: a tool wear rule learning library stores learned tool wear rules; a data acquisition and judgment module provides a servo drive current digital signal for a data processing module to perform format conversion and store the signal as a monitoring current signal; a characteristic extraction and selection module selects signal characteristics strongly correlated with tool wear; a fitted predicted trend curve module establishes a signal characteristic-tool machining service life relationship curve; a tool wear rule module obtains the learned tool wear rules from the tool wear rule learning library, and substitutes the trend signal characteristics into the learned tool wear rules to obtain a tool wear extent; and a tool wear compensation and tool replacement module makes a tool wear compensation and tool replacement decision according to the tool wear extent, and provides the tool wear compensation and tool replacement decision for a numerical control system interface input module. The system is applied to the condition offluctuating cutting parameters in mass production, and can achieve relatively higher accuracy under the condition of constant cutting parameters.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Surface repairing and polishing device and method

ActiveCN112059826AContact stabilityPrecise control of grinding depthGrinding carriagesGrinding drivesPolishingEngineering

The invention discloses a surface repairing and polishing device, and relates to the technical field of grinding wheel polishing equipment. The surface repairing and polishing device comprises a conveying seat, a top seat, a lifting mechanism, a polishing mechanism and a limiting mechanism. The depth of the detective position of a defective workpiece is measured by a probe in the limiting mechanism at the same height as the grinding wheel, and after measurement is completed, a second magnetic block in the limiting mechanism limits resetting of a limiting block by attracting a magnetic column to move, so that in the process that the lifting mechanism drives the grinding wheel to descend, the limiting block is matched with a limiting plate in the lifting mechanism to limit the descending distance of the grinding wheel, then the polishing depth of the defective workpiece is precisely controlled, the first magnetic block on the side of the limiting plate can attract the magnetic column toreset through descending of the limiting plate, resetting of the limiting block is facilitated, depth detection is repeatedly conducted on the defective workpiece, and the polishing depth is preciselylimited, so that the phenomenon of excessive or insufficient polishing is avoided, and the problem that original structural strength and rigidity cannot be achieved after repairing is solved.

Owner:苏州浩耐特磨具有限公司

Tool Wear Monitoring Method Based on Multi-scale Deep Convolutional Recurrent Neural Network

ActiveCN110509109BMonitor wearImprove accuracyMeasurement/indication equipmentsEngineeringFeature mapping

The invention discloses a tool wear monitoring method based on a multi-scale deep convolutional cyclic neural network. The method includes the following steps: preprocessing data based on tool data measured by multiple sensors, constructing an input matrix; constructing a multi-scale convolutional neural network, Obtain multi-scale features, and each branch of the multi-scale convolutional neural network performs feature fusion based on the output of the maximum pooling, and finally obtains multi-scale features; constructs a deep loop GRU network to extract features and representations of different time scales, deep loop The GRU network includes the first layer GRU network and the second layer GRU network. The number of units in the second layer GRU network is more than that of the first layer GRU network. The multi-scale features are processed by the deep cycle GRU network to obtain features of different time scales. and representation; construct a fully-connected layer based on features, and map the features to the sample label space; construct a linear regression layer based on the output of the fully-connected layer to obtain the amount of tool wear.

Owner:XI AN JIAOTONG UNIV

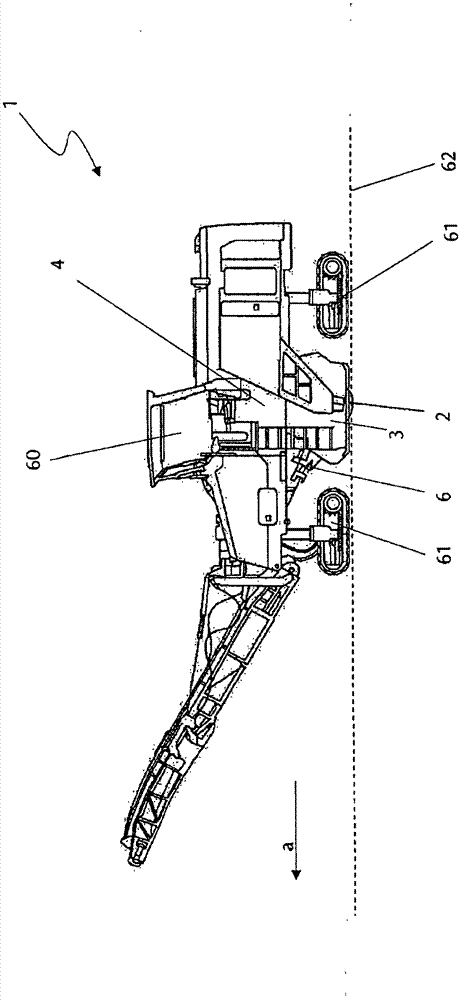

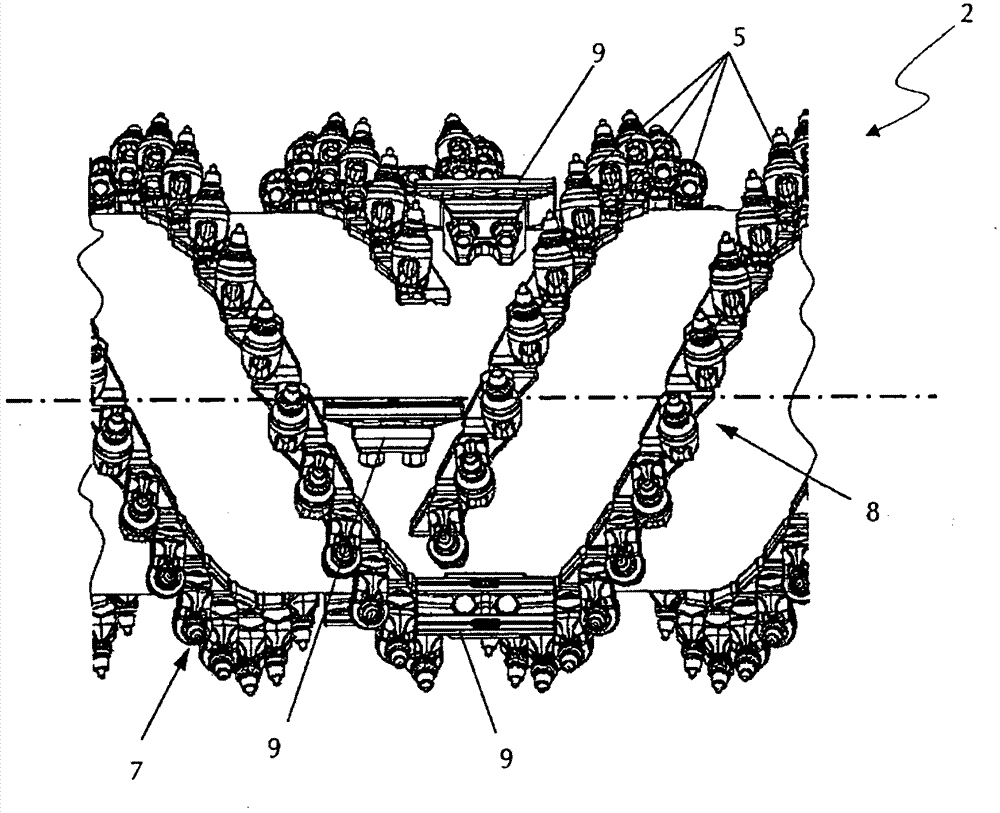

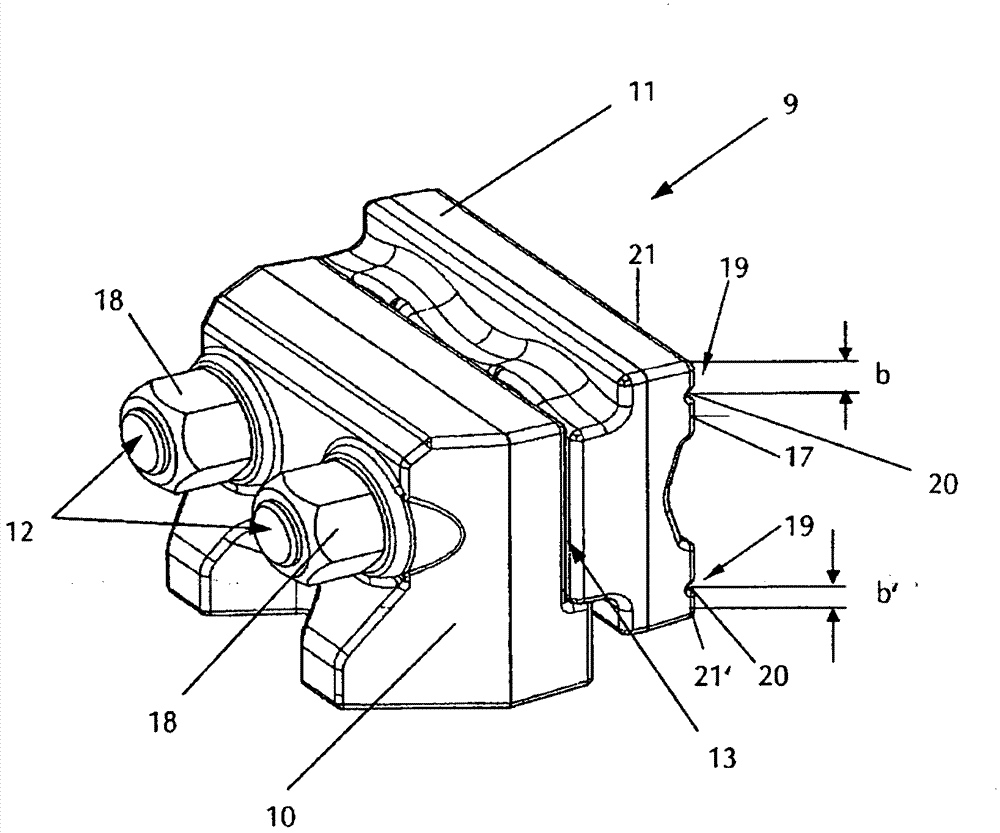

Ejector for a mobile ground preparation machine

Described is an ejector unit for a milling drum of a mobile ground preparation machine comprising a discharge side and a reverse side that is opposite to the discharge side. It comprises a basic unit on the drum and an ejector plate, which is held on the basic unit by means of screw-threaded bolts. There is a positive fit between the basic unit and the ejector plate, which positive fit involves at least one pin, on the one hand, and at least one complementary cylindrical counterbore on the other hand, whereby the at least one pin and the at least one ejector are oriented so as to be coaxial to the longitudinal axis of the screw-threaded bolts. Preferably, a shoulder is also provided along the base of the basic unit on its side facing the ejector plate, and the ejector plate has at least one complementary shoulder, whereby the shoulder on the basic unit and the at least one shoulder on the plate have meshing regions, which in the mounted state prevent transverse displacements in three directions.

Owner:BOMAG

TBM hob abrasion monitoring device and method based on machine vision

PendingCN112184630AIntuitive observation of eccentric wearObserve the eccentric wearImage enhancementImage analysisMicrocontrollerMachine vision

The invention discloses a TBM hob abrasion monitoring device and method based on machine vision. The TBM hob abrasion monitoring device comprises a controller, a moving device and a hob monitoring device body. The microcontroller can control the moving device so as to drive the hob detection device to move; when the hob monitoring device reaches a designated position, the microcontroller controlsthe industrial camera to shoot the hob, and the hob monitoring device can comprehensively monitor the abrasion condition of the hob ring of the TBM hob.

Owner:SHANDONG UNIV

A device and method for synchronously measuring guide rail line displacement and straightness in situ

ActiveCN111735393BAbbe's error is smallReduce nonlinear errorUsing optical meansGratingMechanical engineering

The invention discloses a device and a method for synchronously measuring the line displacement and straightness of a guide rail in situ. The integrated two-dimensional grating guide rail is to etch the two-dimensional grating on the upper surface of the linear guide rail, and the reading head is embedded in the slide block. The specific measurement method is as follows: when the slider moves on the guide rail, the reading head outputs two pairs of orthogonal sinusine and cosine signals at the same time, and after filtering and analog-to-digital conversion, it is transmitted to the host computer through the acquisition card, and the edge is counted by high-frequency pulses. Methods Calculate the displacement and straightness on the host computer; the linear displacement of the guide rail is obtained by the orthogonal signal generated by the grid line perpendicular to the x-axis, and the straightness of the guide rail is obtained by the orthogonal signal generated by the grid line perpendicular to the y-axis. The invention has the advantages of small installation volume of the guide rail pair, high positioning accuracy, multi-parameter synchronous on-site measurement, etc., and provides a new method for the displacement and straightness measurement of the guide rail.

Owner:XI AN JIAOTONG UNIV

A Fault Monitoring and Diagnosis Method of Electric Spindle Based on Three-phase Instantaneous Power

The invention discloses a three-phase instantaneous power based motorized spindle fault monitoring and diagnosing method and belongs to the technical field of motorized spindle fault monitoring. According to the three-phase instantaneous power based motorized spindle fault monitoring and diagnosing method, by means of signal demodulation properties and three-phase symmetry characteristics of three-phase instantaneous power, three-phase input voltage and three-phase stator current signals are collected when a motorized spindle is stably operated, three-phase instantaneous power signals are calculated, the influence of supply frequency modulation, frequency rotating and frequency doubling on monitoring and diagnosing results is eliminated through a design of a junction filter, whether the motorized spindle breaks down is determined according to comparison between a mean value and a root-mean-square (RMS) value of the three-phase instantaneous power signals and standard reference values during the operation process, and a fault type is determined according to generation of fault character frequency during spectral analysis, so that monitoring and diagnosing of faults of the motorized spindle are achieved. According to the three-phase instantaneous power based motorized spindle fault monitoring and diagnosing method, the signal collection and processing process is simple, bearing wearing and rotor broken bar faults of the motorized spindle can be effectively monitored, and the method is applicable to state monitoring and fault diagnosing of the motorized spindle on an industrial scene.

Owner:XI AN JIAOTONG UNIV

Brake pad overheating protection system

InactiveCN107650889AMonitor wearGuaranteed service lifeBrake coolingBrake safety systemsElectricityControl system

The invention discloses a brake pad overheating protection system. The brake pad overheating protection system comprises an actuating mechanism and a controlling system. The actuating mechanism is arranged at the top of a brake pad. The actuating mechanism includes a sensing part and a heat dissipating part. The sensing part is arranged at the side part of the top of the inner surface of the brakepad. The heat dissipating part is arranged on the side, away from the sensing part, of the top of the brake pad. The sensing part is electrically connected with the input end of the controlling system to receive a temperature signal generated in the braking process and convert the temperature signal into an electrical signal to be transmitted to the controlling system. The output end of the controlling system is electrically connected with the heat dissipating part to output different voltage signals to control heat dissipating of the brake pad. According to the adopted technical scheme, thebrake pad can be cooled in time when the brake pad is in high temperature, so that the situation of brake failure in the running process is avoided, the safety of drivers and pedestrians is protected,the service life of brake pad is ensured, and driving safety is improved.

Owner:安徽博耐克摩擦材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com