Patents

Literature

1658results about How to "Contact stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

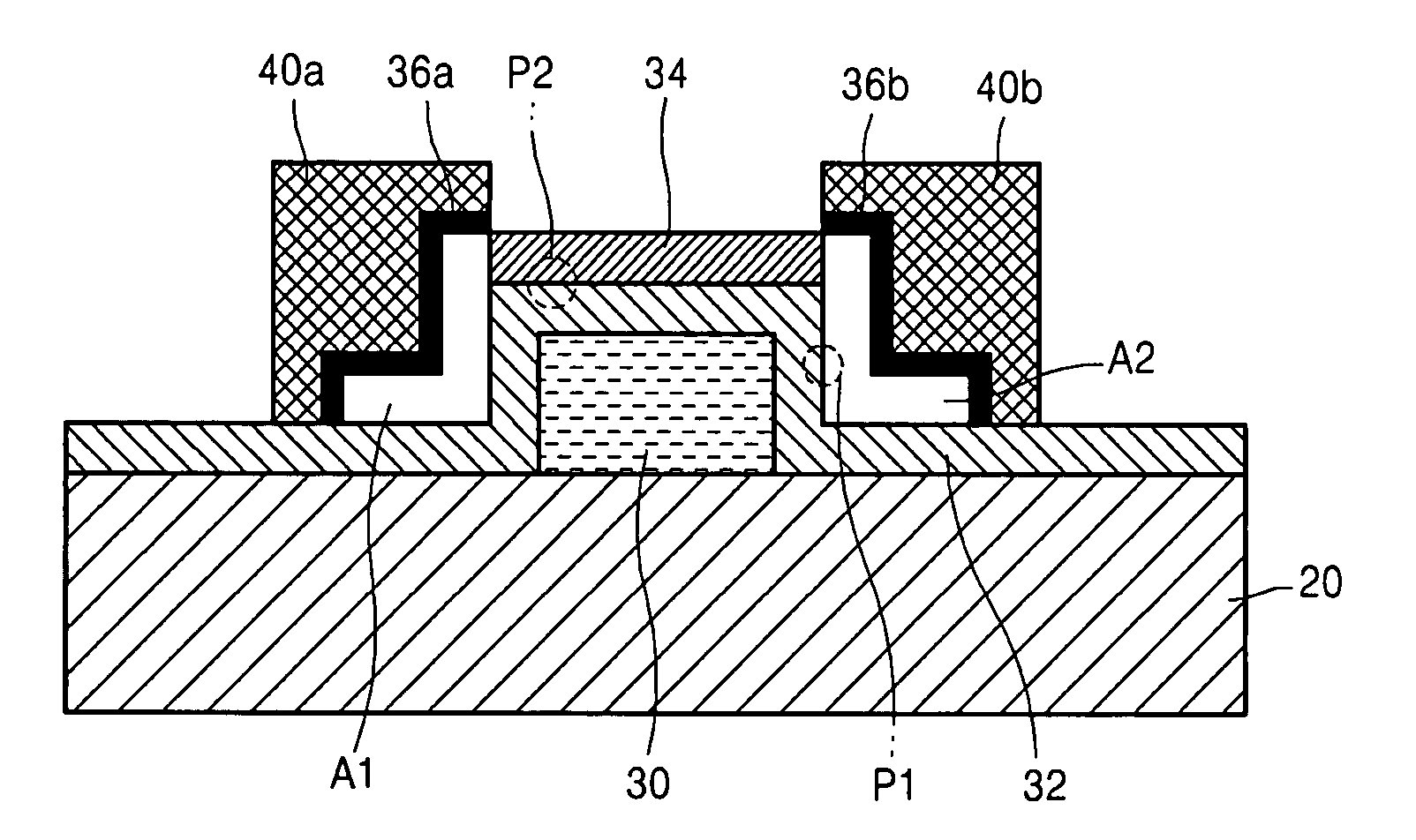

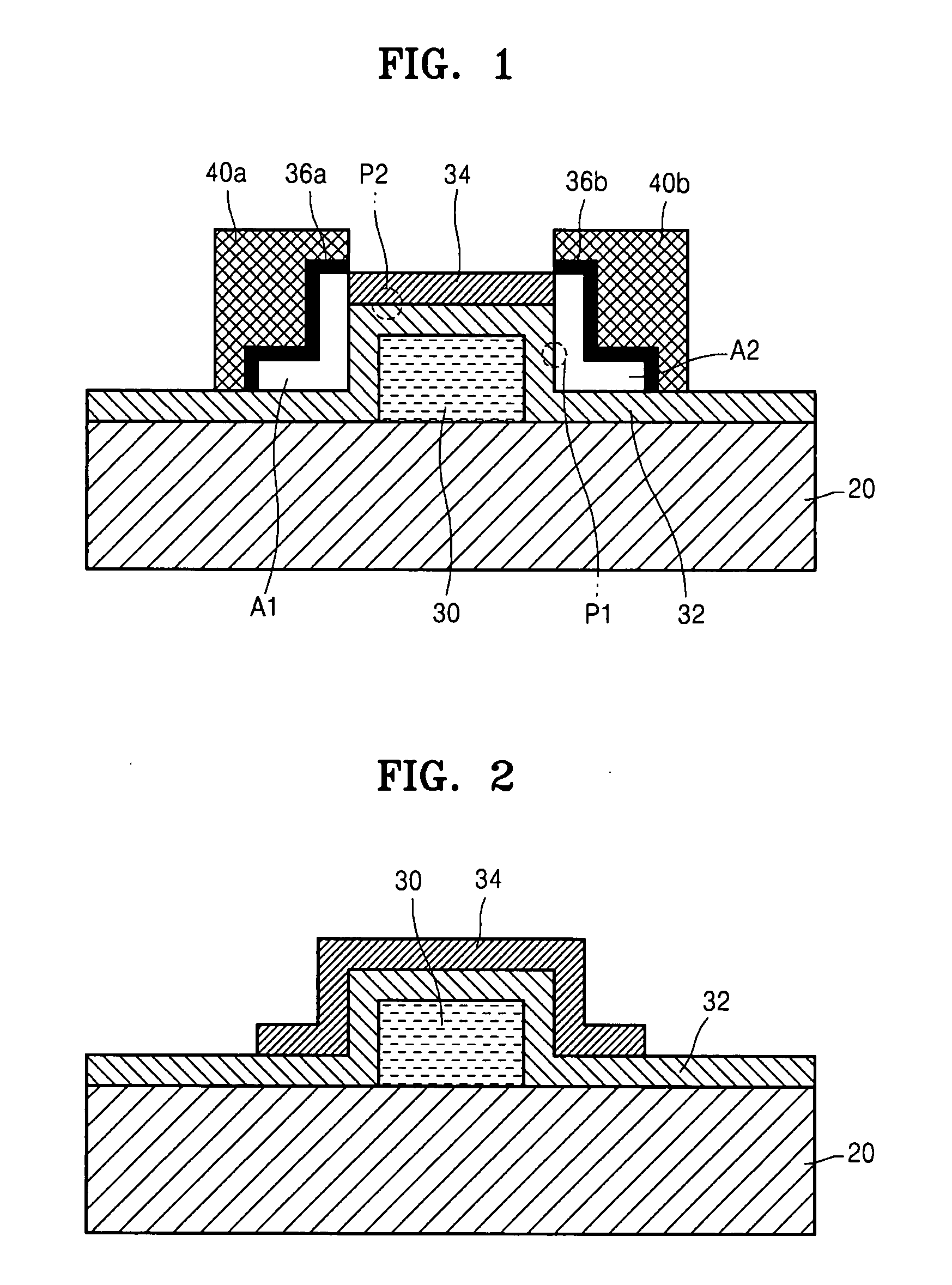

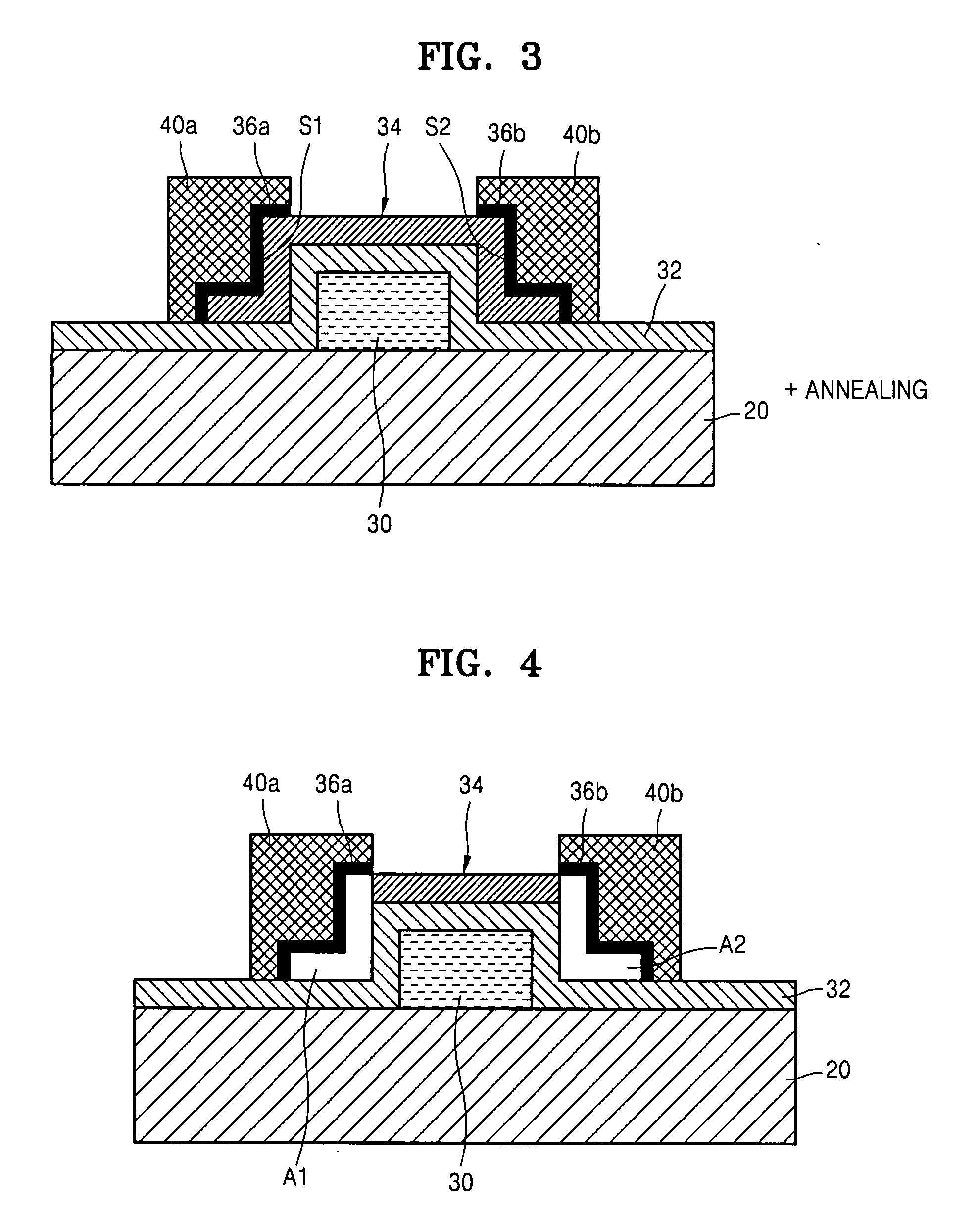

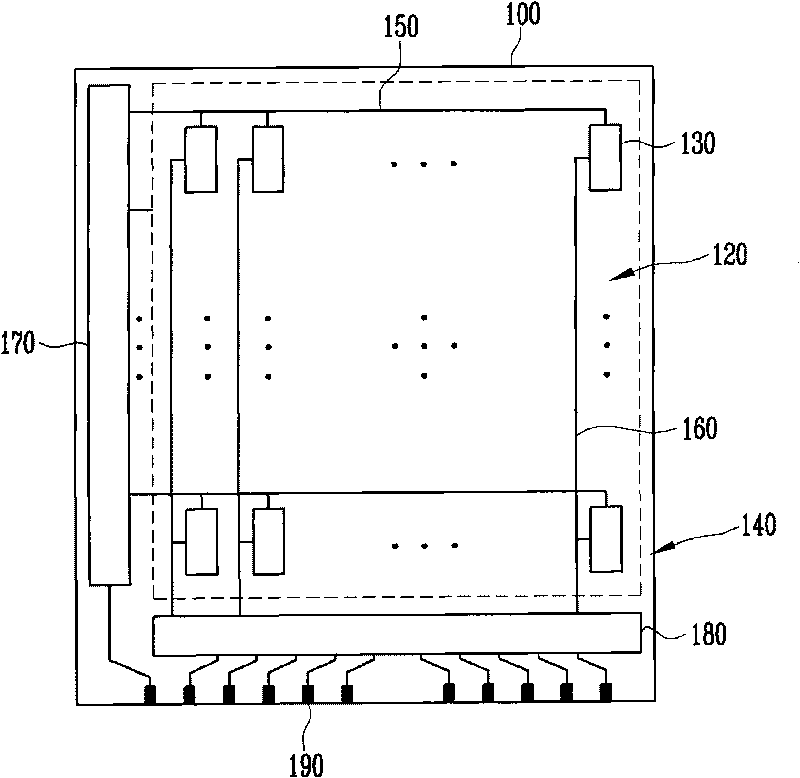

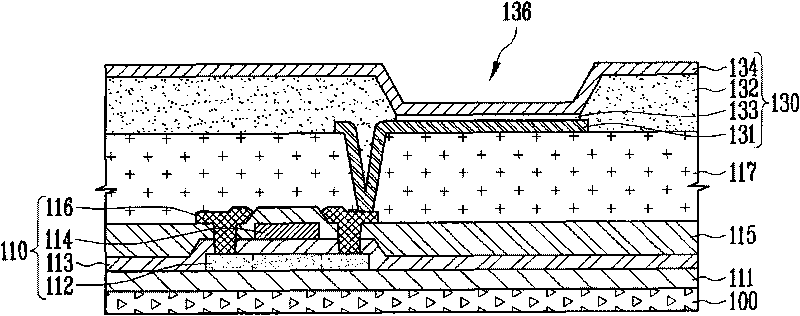

Thin film transistor including selectively crystallized channel layer and method of manufacturing the thin film transistor

ActiveUS20080258140A1Stable contact characteristicHigh carrier mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringIon implantation

Provided are a thin film transistor (TFT) including a selectively crystallized channel layer, and a method of manufacturing the TFT. The TFT includes a gate, the channel layer, a source, and a drain. The channel layer is formed of an oxide semiconductor, and at least a portion of the channel layer contacting the source and the drain is crystallized. In the method of manufacturing the TFT, the channel layer is formed of an oxide semiconductor, and a metal component is injected into the channel layer so as to crystallize at least a portion of the channel layer contacting the source and the drain. The metal component can be injected into the channel layer by depositing and heat-treating a metal layer or by ion-implantation.

Owner:SAMSUNG ELECTRONICS CO LTD

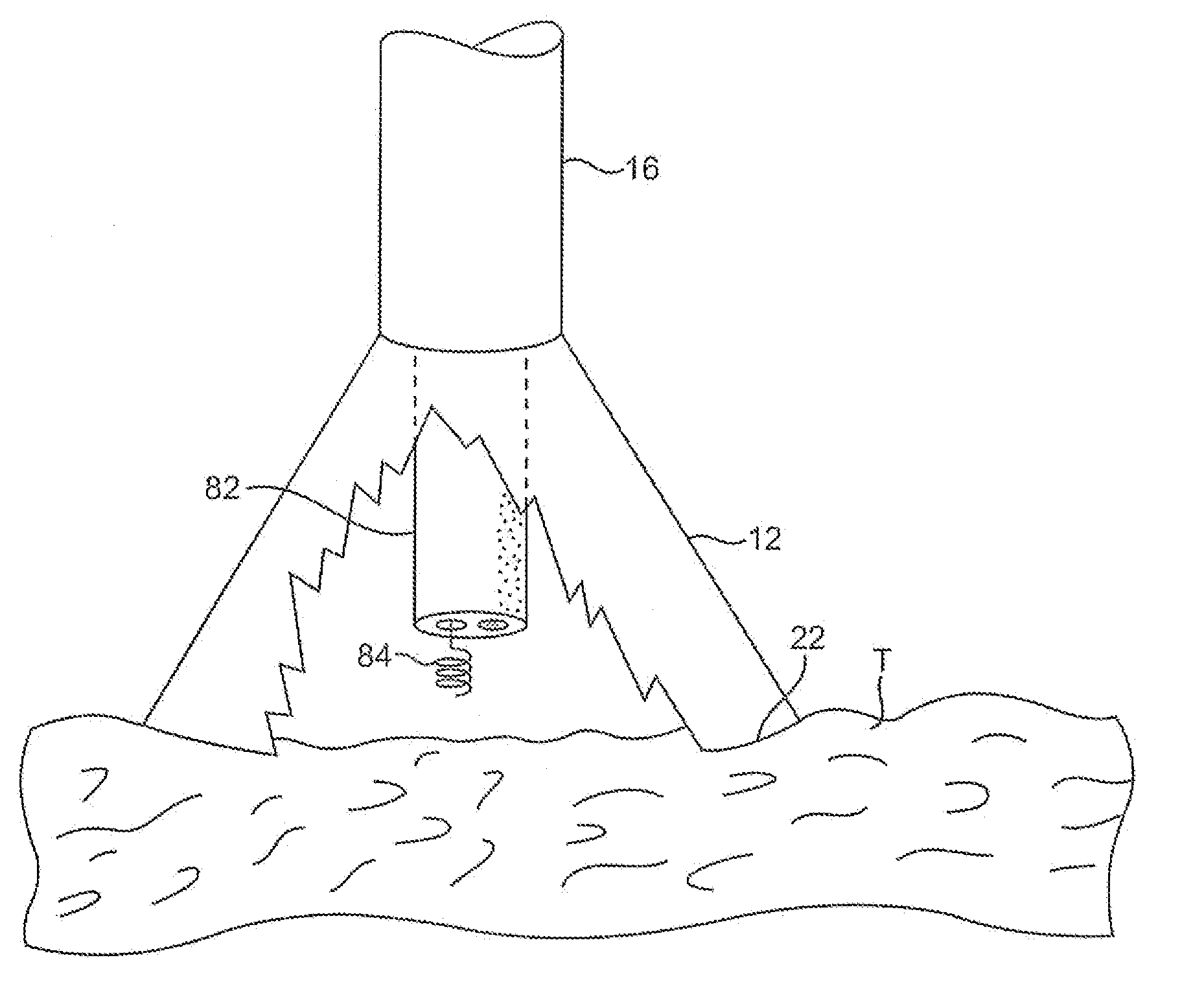

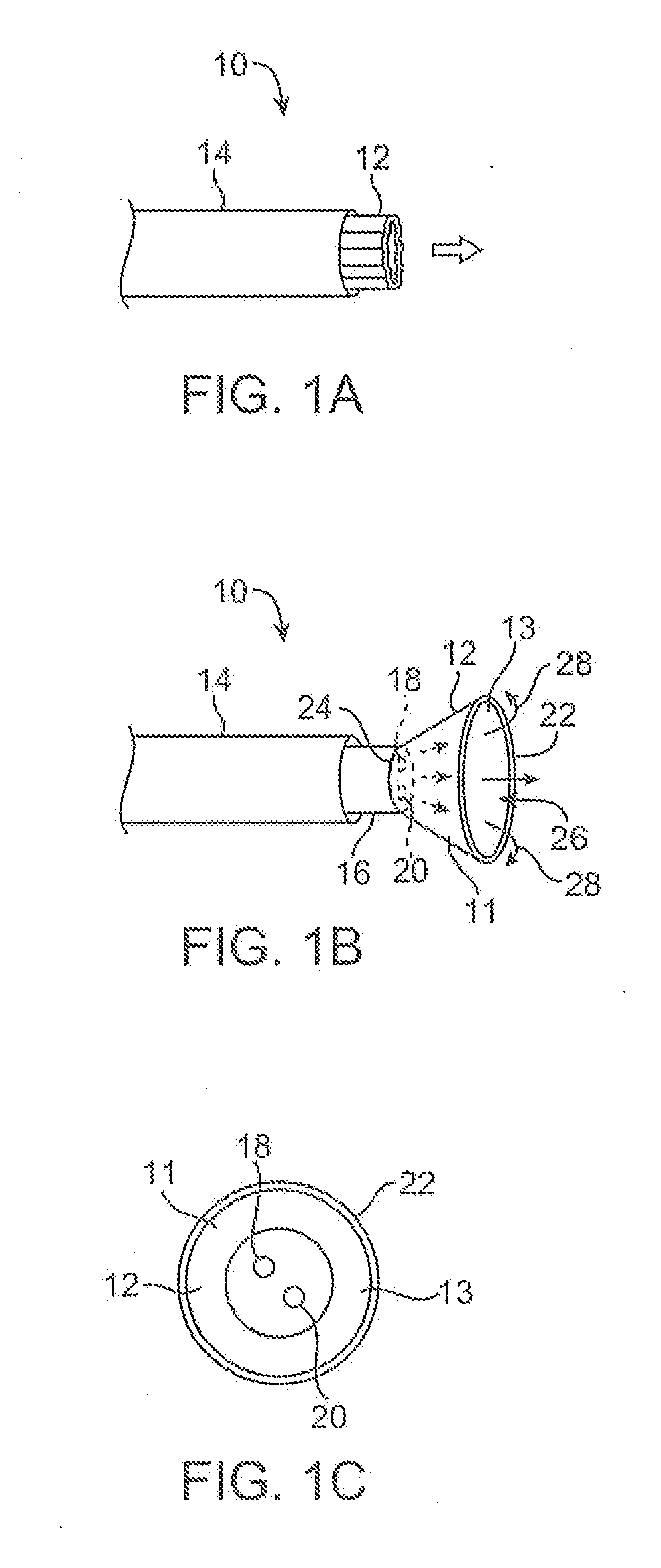

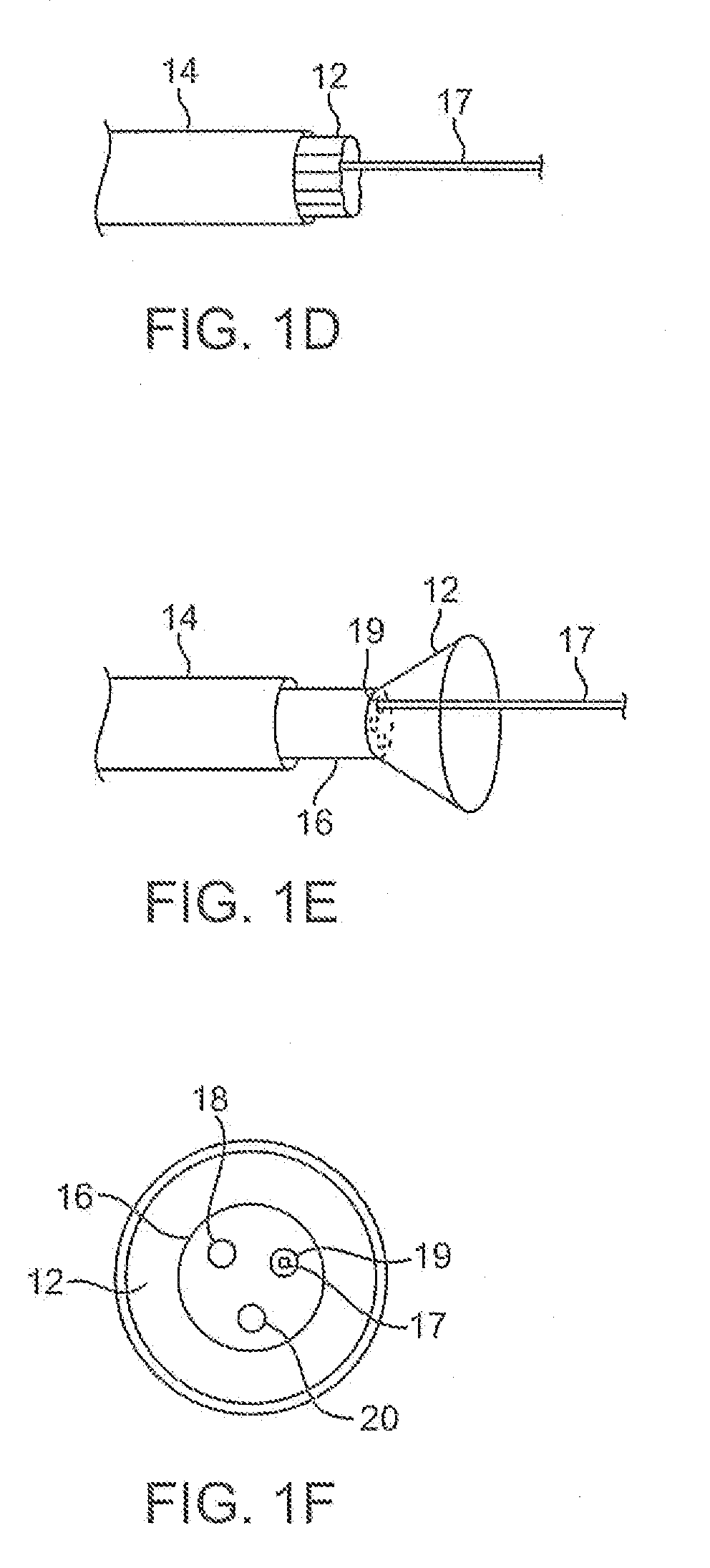

Methods and apparatus for treatment of atrial fibrillation

InactiveUS20080015569A1Early detectionEnabling detectionElectrotherapyEndoscopesBody fluidBiomedical engineering

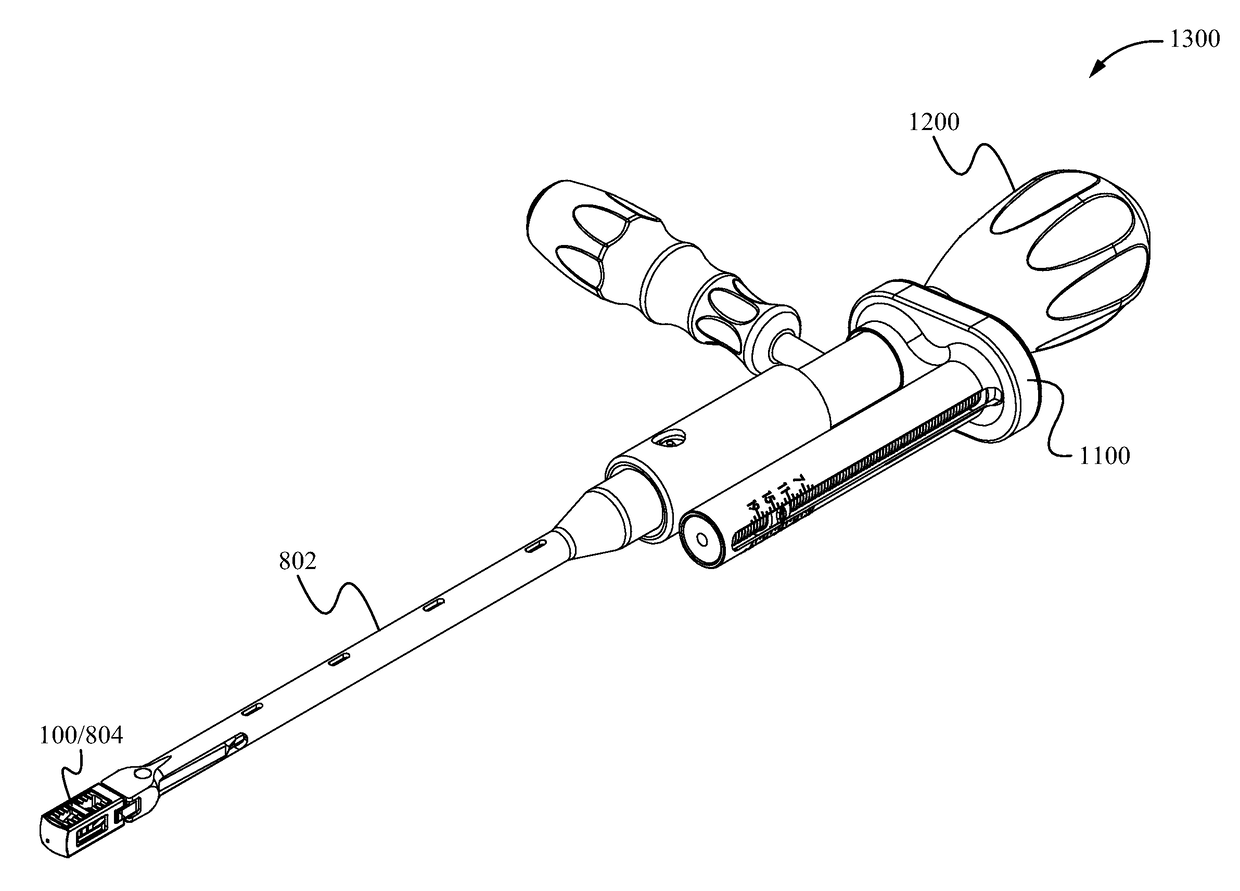

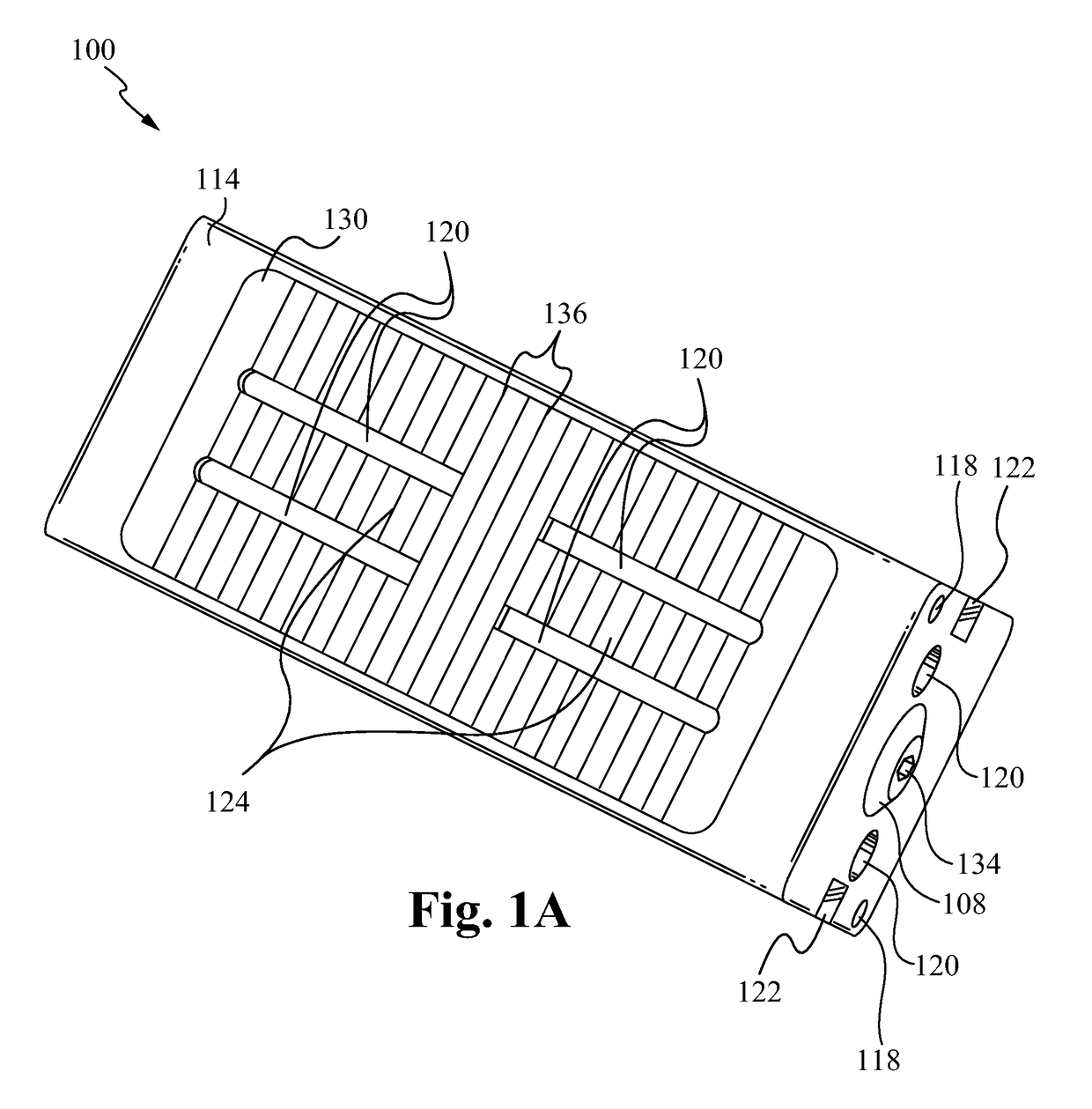

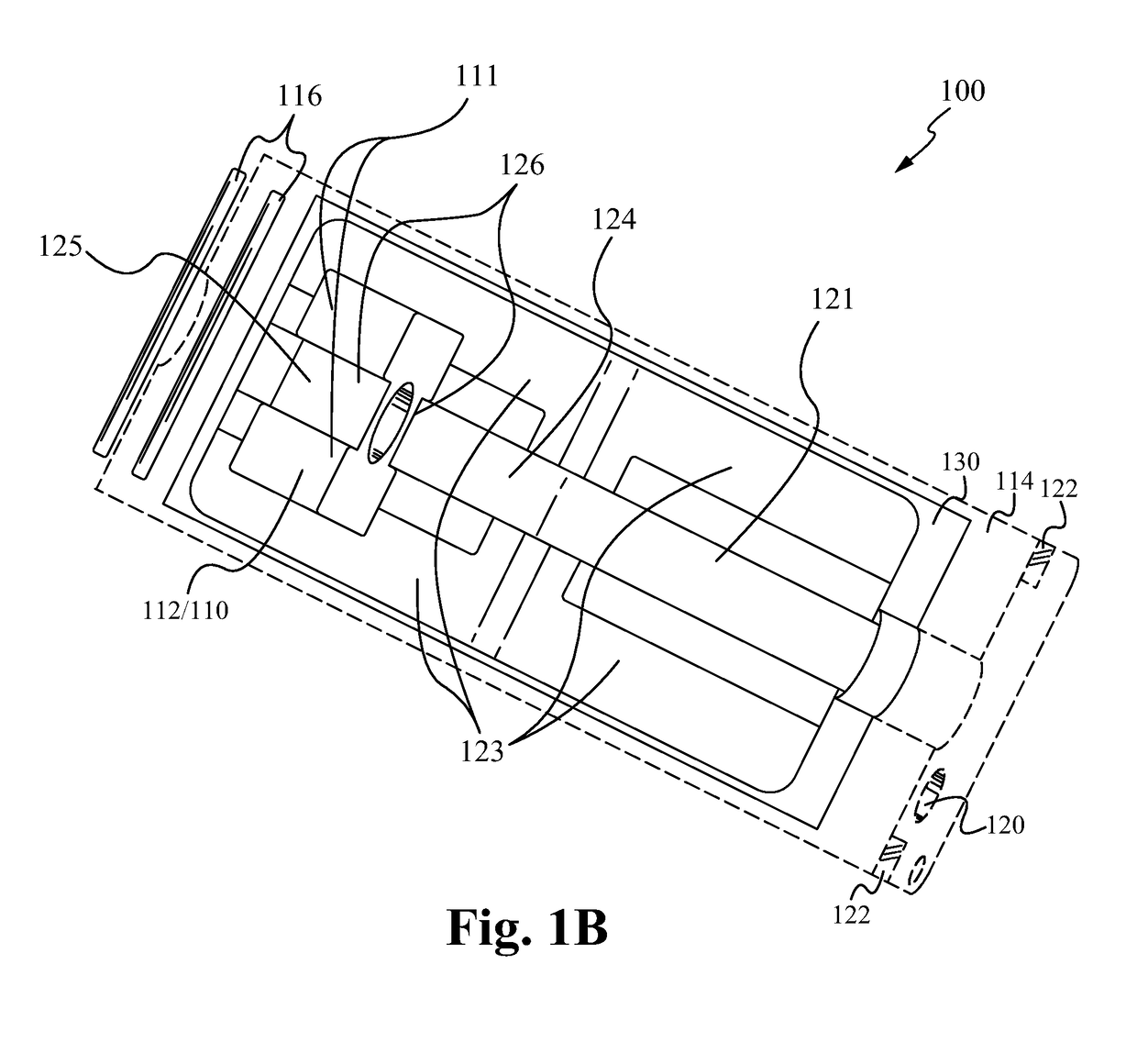

Apparatus and methods for the treatment of atrial fibrillation are described herein where tissue to be ablated may be monitored under direct visualization. Such a system may include a deployment catheter and an attached imaging hood deployable into an expanded configuration. In use, the imaging hood is placed against or adjacent to the tissue to be imaged in a body lumen that is normally filled with an opaque bodily fluid such as blood. A translucent or transparent fluid can be pumped into the imaging hood until the fluid displaces any blood leaving a clear region of tissue to be imaged via an imaging element in the deployment catheter. An ablation probe may be advanced into the contained region where the tissue may be ablated and monitored for changes in color as well as appropriate positioning.

Owner:INTUITIVE SURGICAL OPERATIONS INC

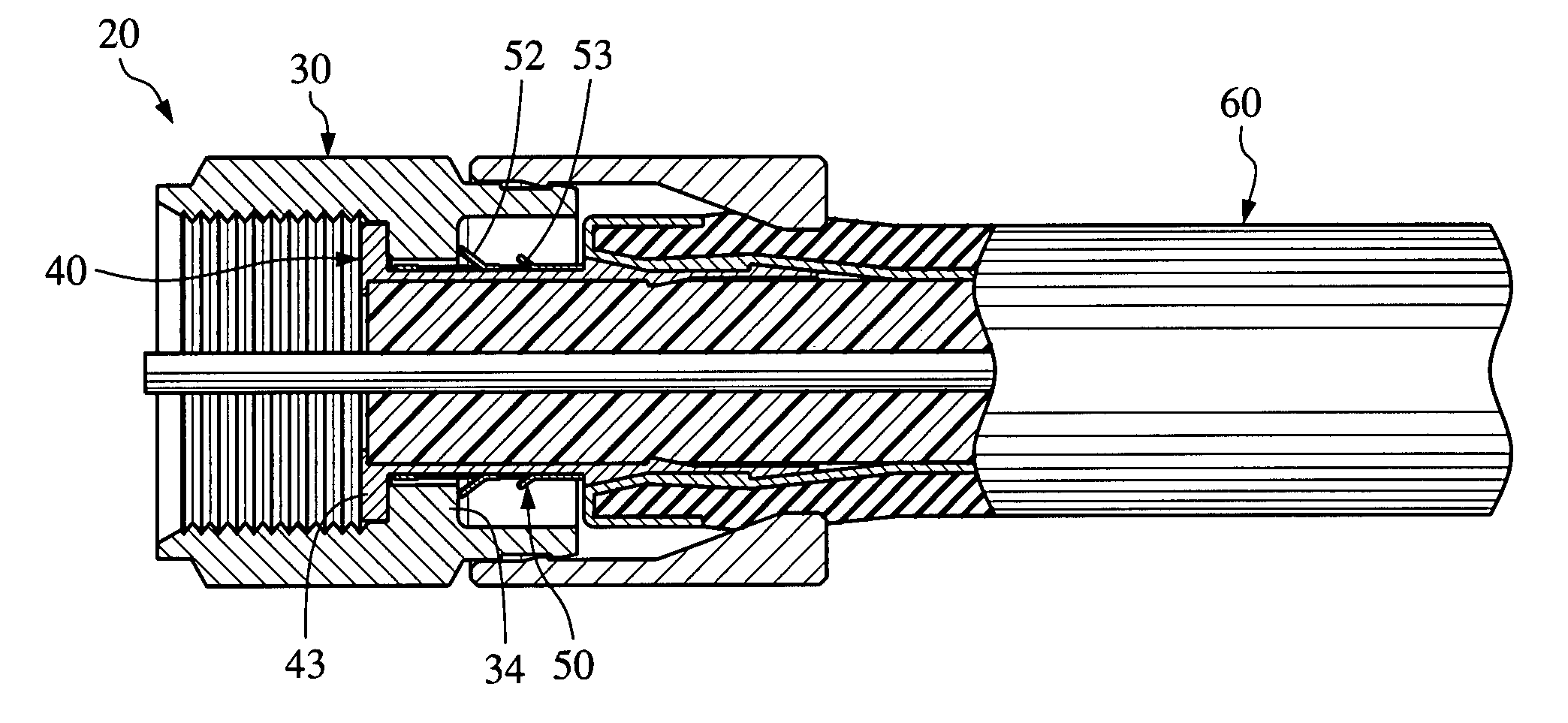

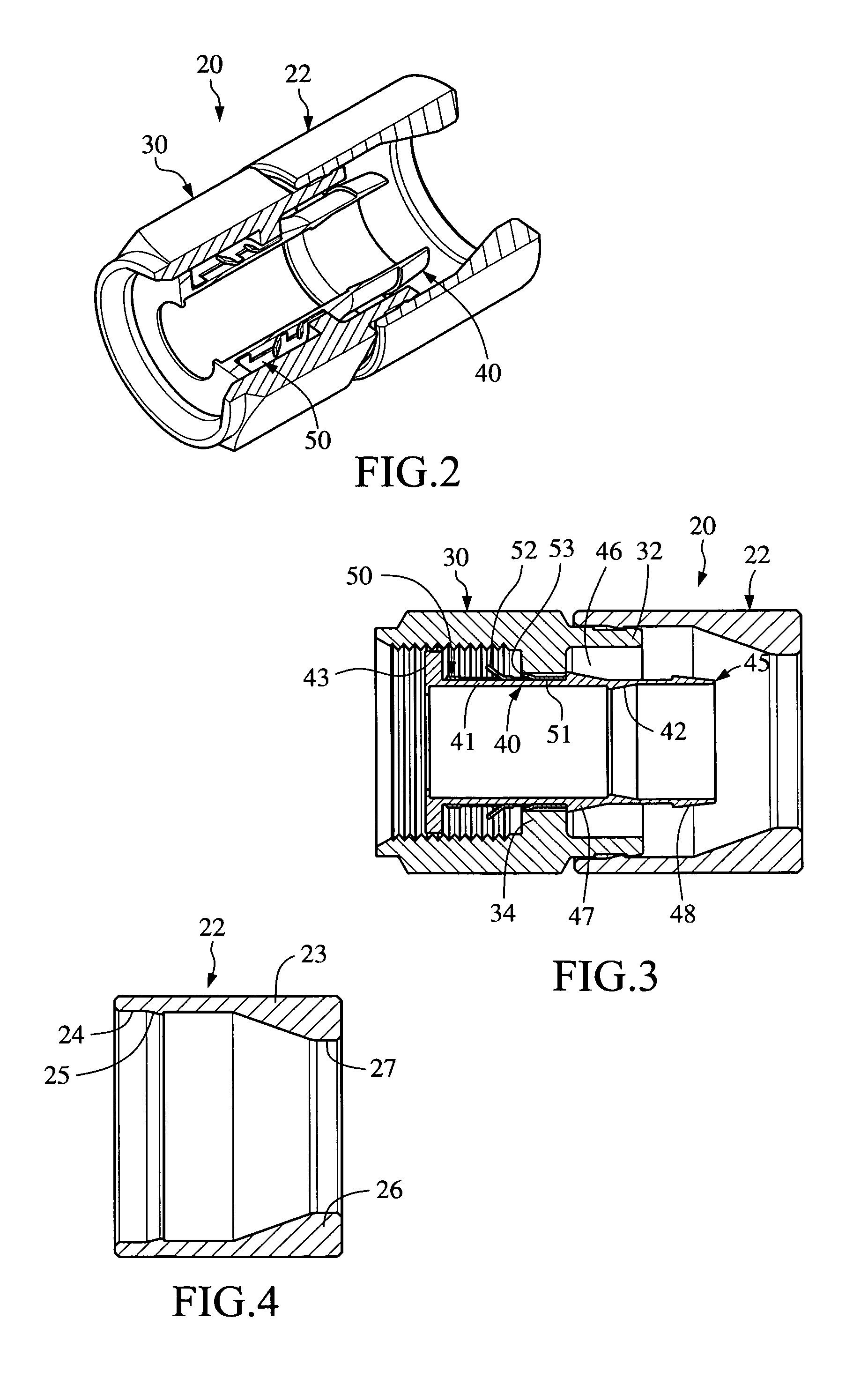

Electrical connector ensuring effective grounding contact

ActiveUS7674132B1Contact stabilityImprove signal transmission qualityElectrically conductive connectionsGround contactElectrical conductor

Owner:EZCONN

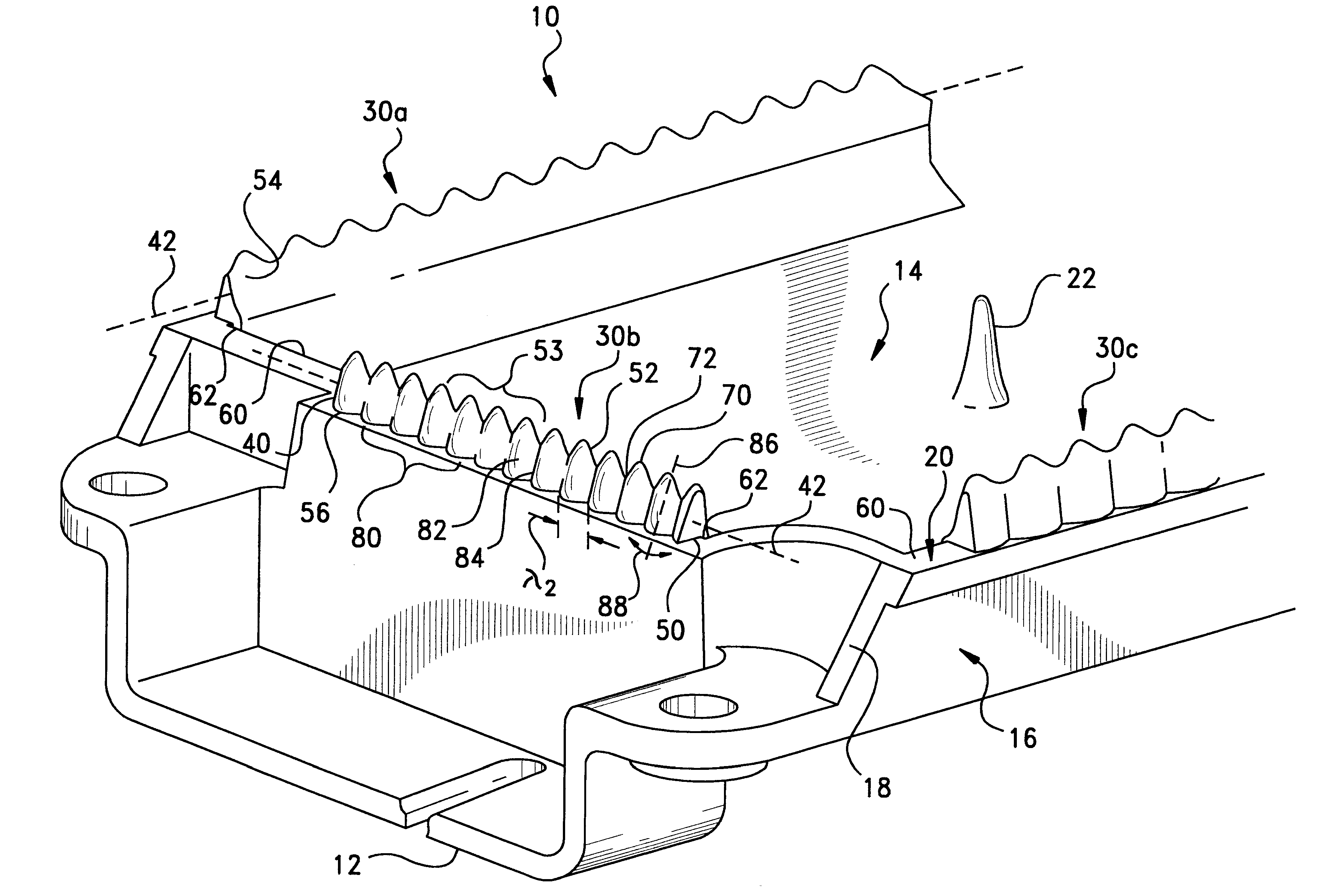

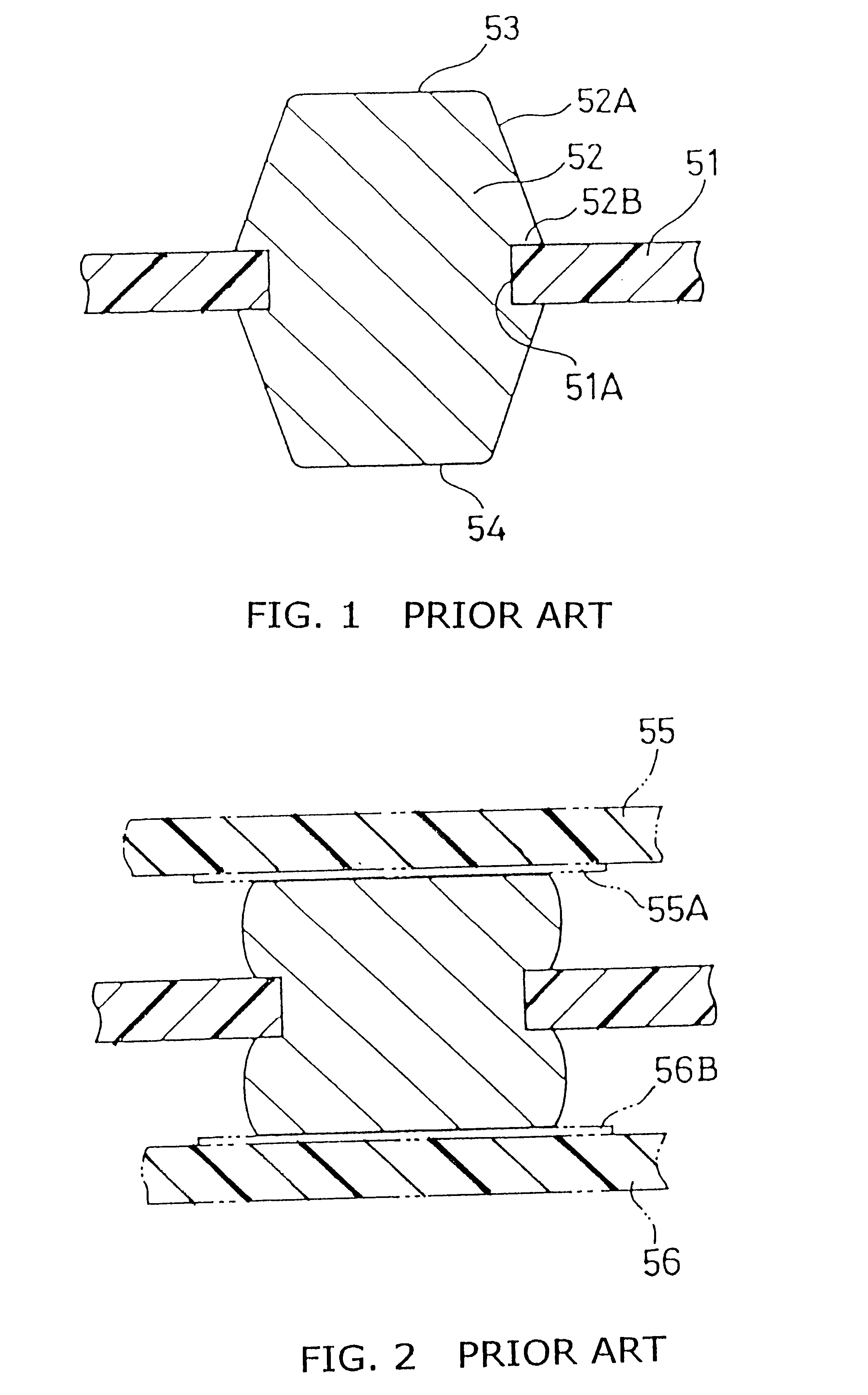

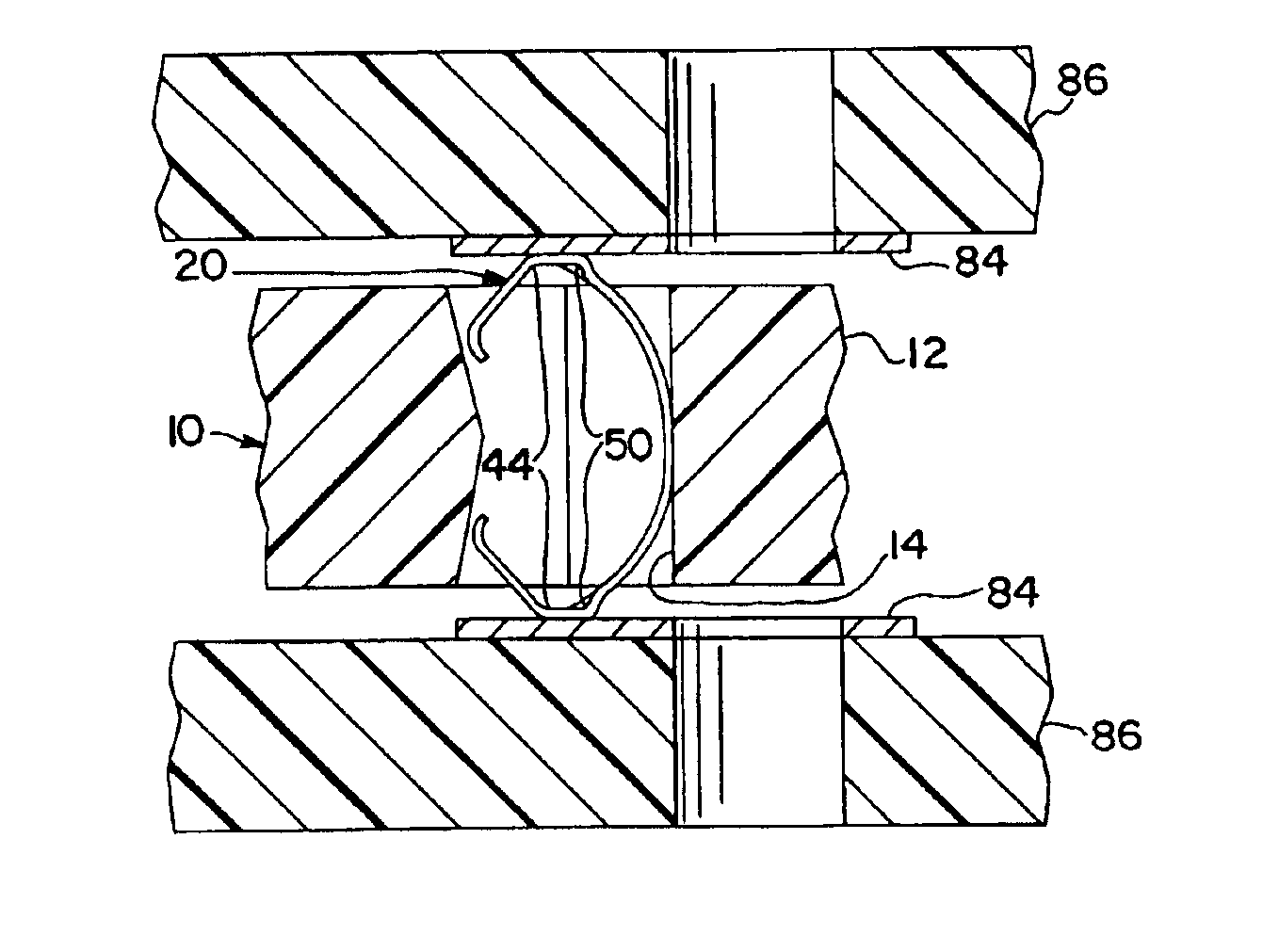

Compound waveform gasket for low closure force EMI shielding applications

InactiveUS6348654B1Reduce loadAssured electrical and physical continuityEngine sealsScreening gaskets/sealsWave shapeEngineering

A resilient EMI shielding and / or environmental sealing gasket for interposition between a first interface surface and an oppositely-disposed second interface surface. The gasket is formed of an elongate body of indefinite length which extends along a longitudinal axis. The body includes base and apex surfaces, and opposing first and second lateral surfaces which extend intermediate the base and apex surfaces. The base surface itself extends along the length the body as configured for proximally supporting the gasket on the first interface surface. The apex surface, in turn, extends radially from the longitudinal axis for distal contact with the second interface surface, and further extends along the longitudinal axis as defining a first waveform profile characterized as having a first periodic series of alternating first high and low amplitude intervals. The second lateral surface also extends along the longitudinal axis as defining a second waveform profile which is disposed generally transverse to the first waveform profile and which is similarly characterized as having a second periodic series of alternating second high and low amplitude intervals. The gasket so formed is deformable under a predetermined compressive force between the first and second interface surfaces into a stressed orientation characterized in that the body is deflected intermediate the base and apex surfaces.

Owner:PARKER INTANGIBLES LLC

Bone fusion device, apparatus and method

Owner:NEUROPRO SPINAL JAXX

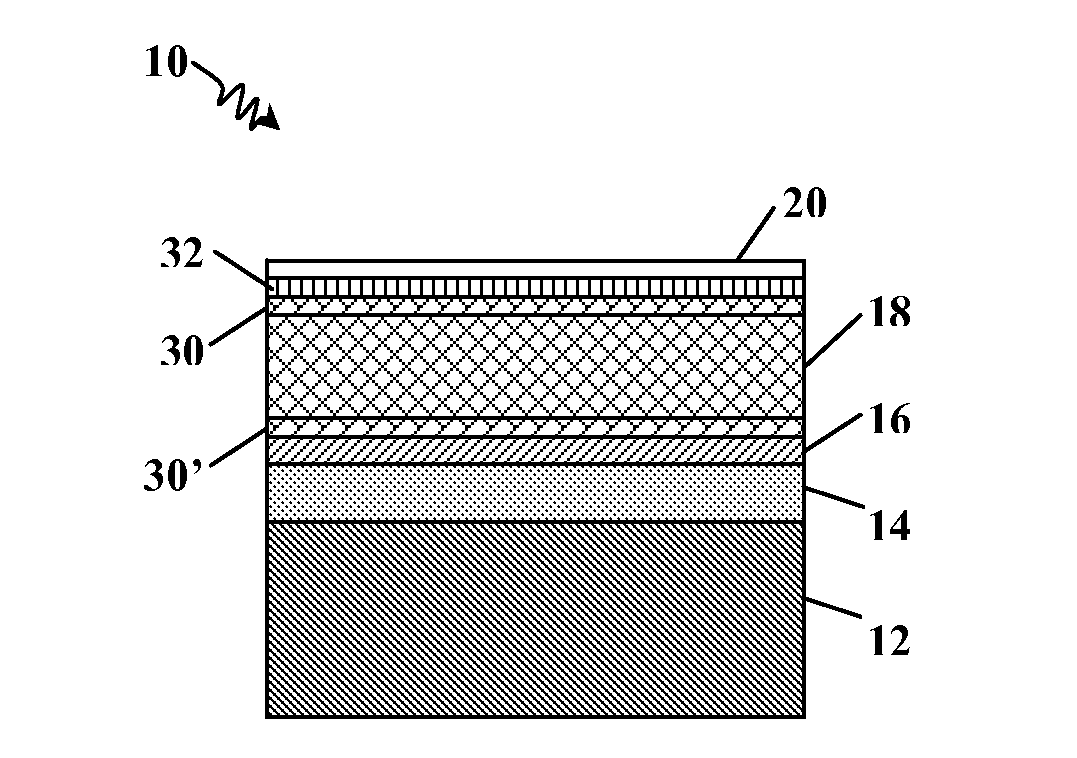

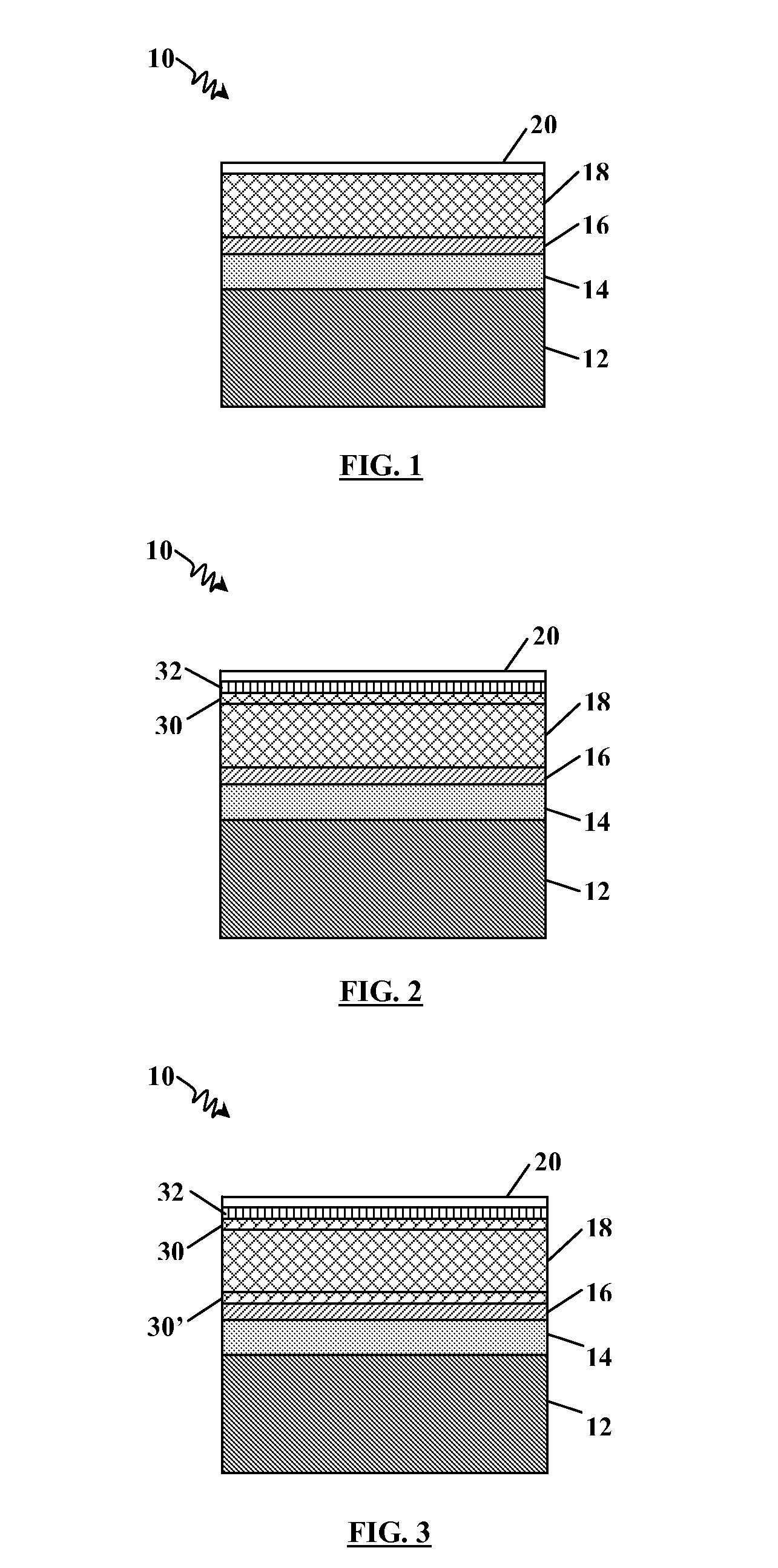

Layers that impede diffusion of metals in group vi element-containing materials

InactiveUS20080251119A1Improve efficiencyContact stabilityFinal product manufactureSemiconductor/solid-state device manufacturingElectrical resistance and conductanceCadmium fluoride

A method of making thermodynamically stable, diffusion-impeded barrier layers within, for example, a photovoltaic cell with a metal-containing electrical contact using exposure to fluorine. Exposing the cadmium telluride surface to fluorine creates a Te-poor barrier layer of cadmium fluoride. Once that barrier layer is formed, the metal-containing electrical contact may be applied or formed. The barrier layer allows tunneling current to occur between the p-type layer and the metal-containing electrical contact establishing a low-resistance, highly uniform, and thermally stable electrical contact.

Owner:FOREHAND DAVID

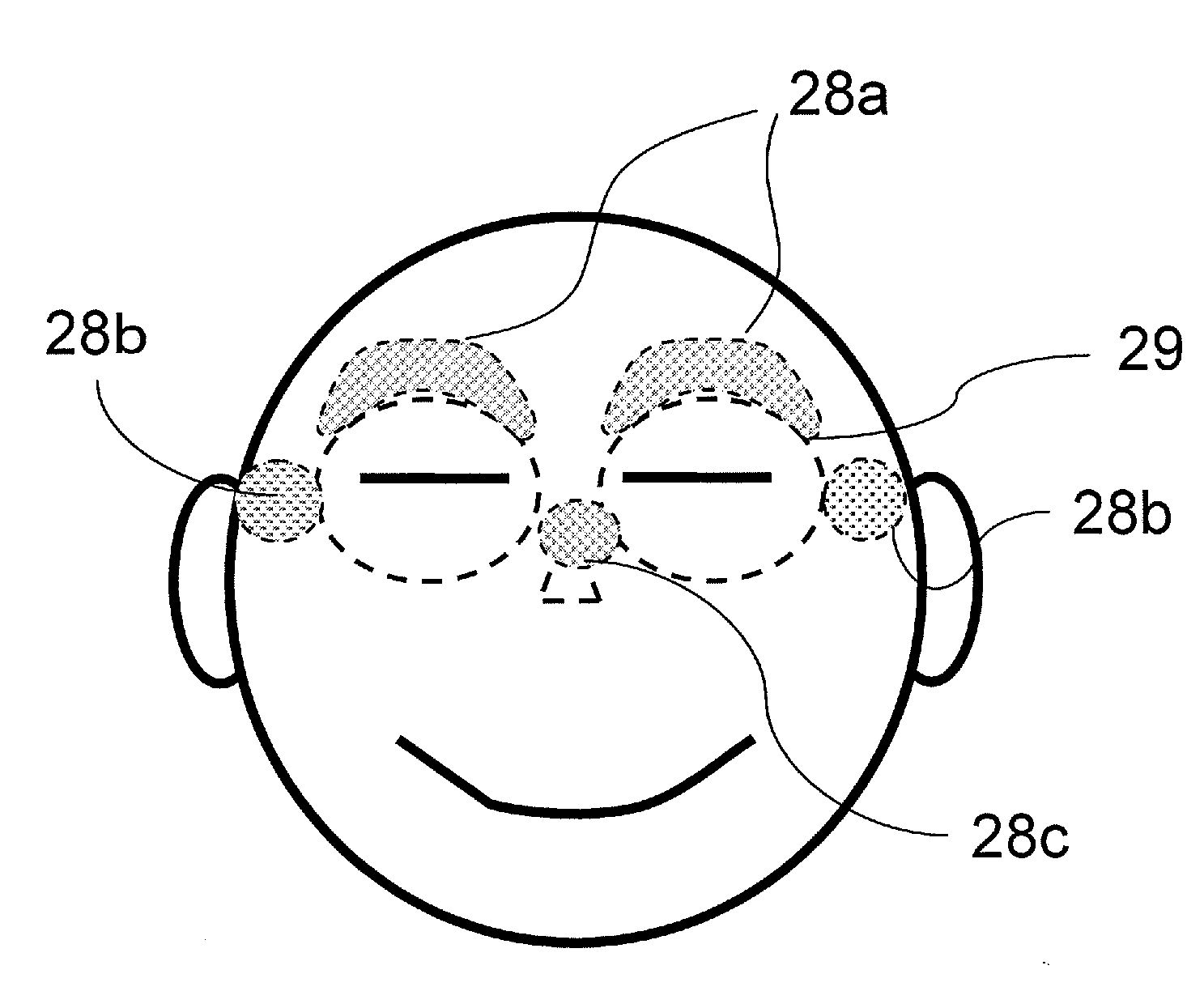

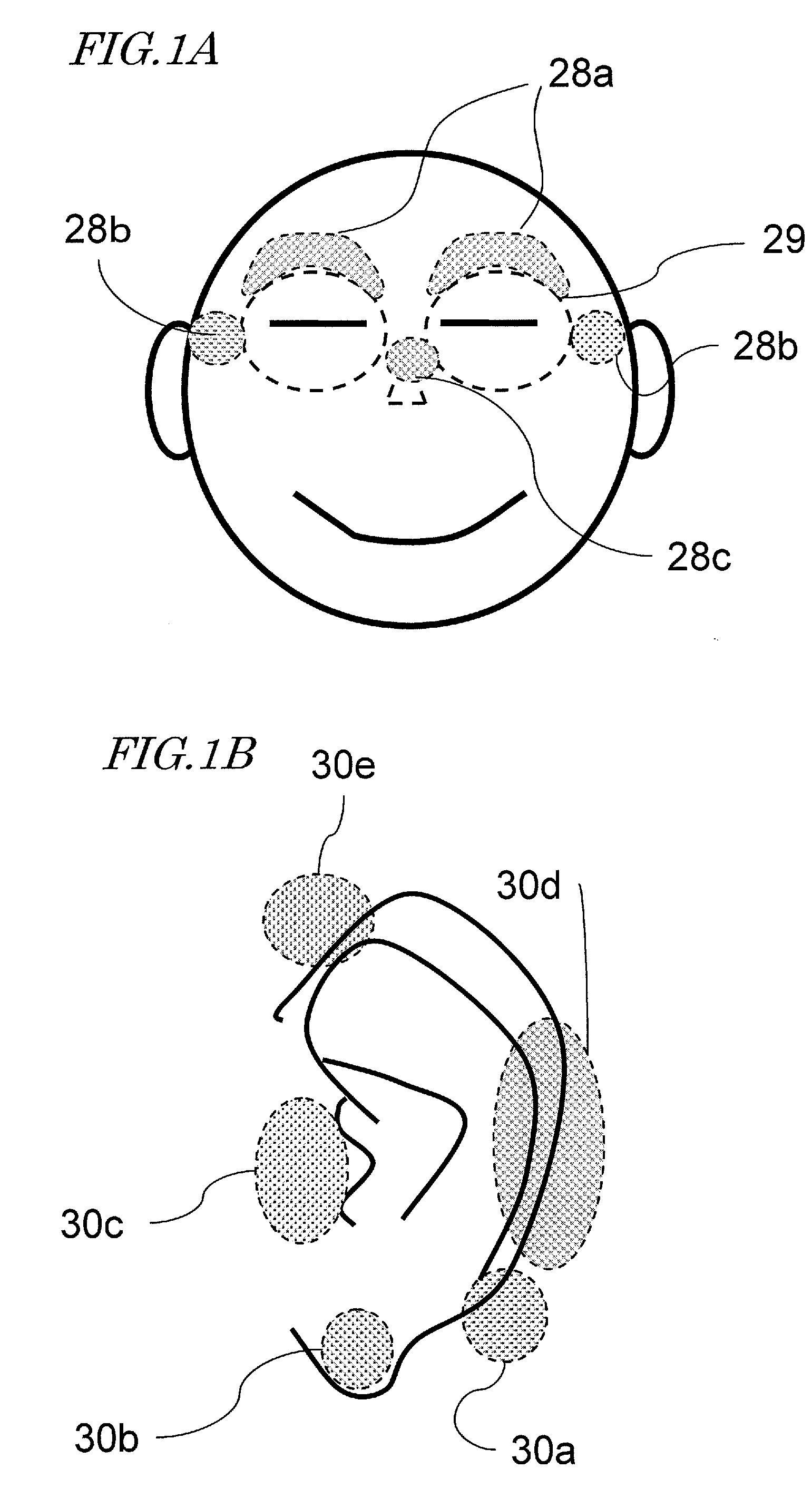

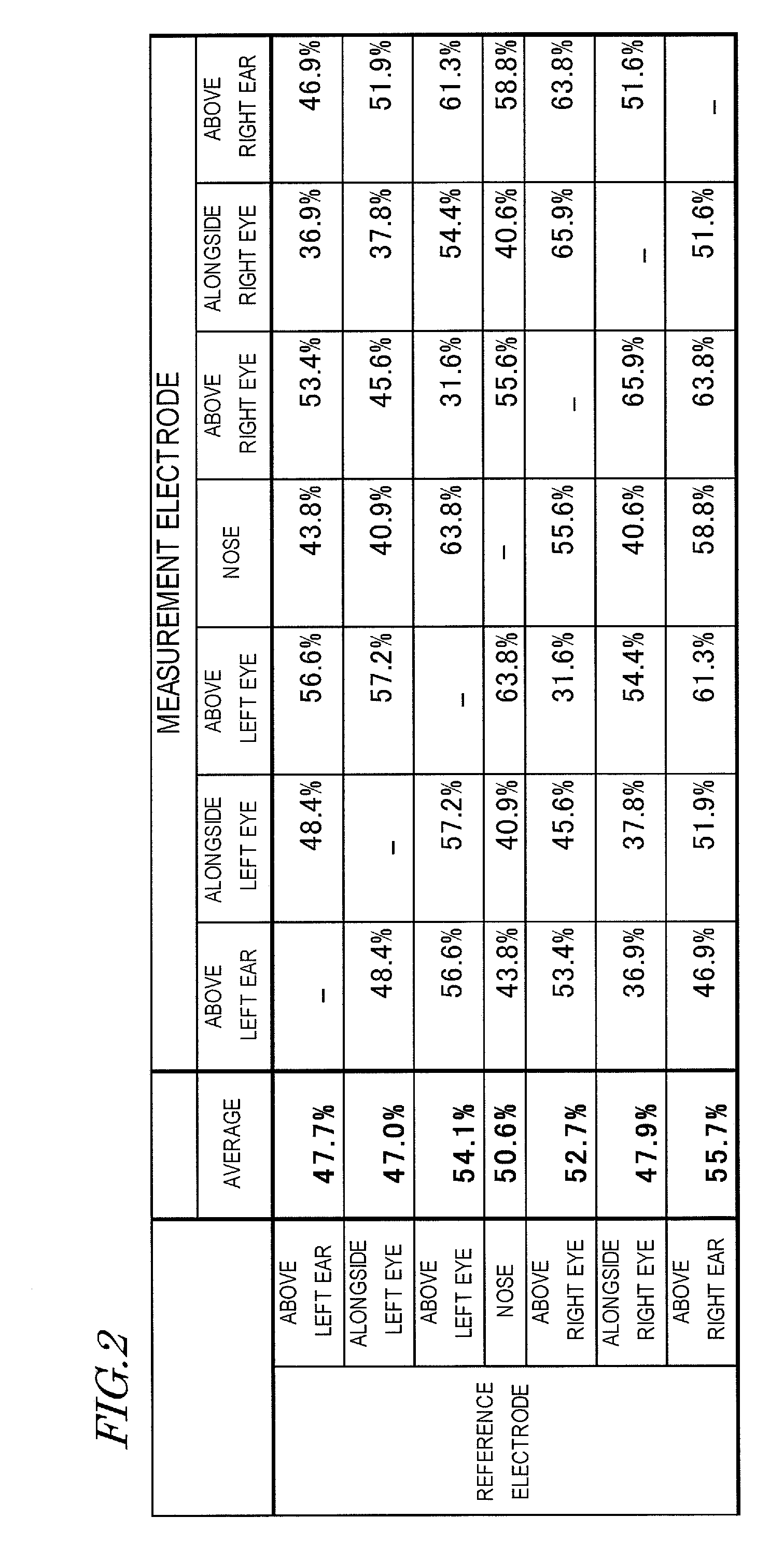

Electroencephalogram interface system

InactiveUS20110071416A1Stable electrode contactContact stabilityElectroencephalographySensorsPotential differenceEvent-related potential

An eyeglass-type electroencephalogram interface system is worn on the head of a user. The system includes: an output section for presenting a visual stimulation to the user; an ear electrode portion disposed at a position coming in contact with an ear of the user when the system is worn; a facial electrode portion disposed at a position coming in contact with the face below a straight line connecting an external canthus and an internal canthus of an eye of the user, such that the mass of the system is supported at the position, when the system is worn; and an electroencephalogram measurement and determination section for measuring an event-related potential on the basis of a potential difference between the ear electrode portion and the facial electrode portion based on the visual stimulation being presented by the output section as a starting point.

Owner:SOVEREIGN PEAK VENTURES LLC

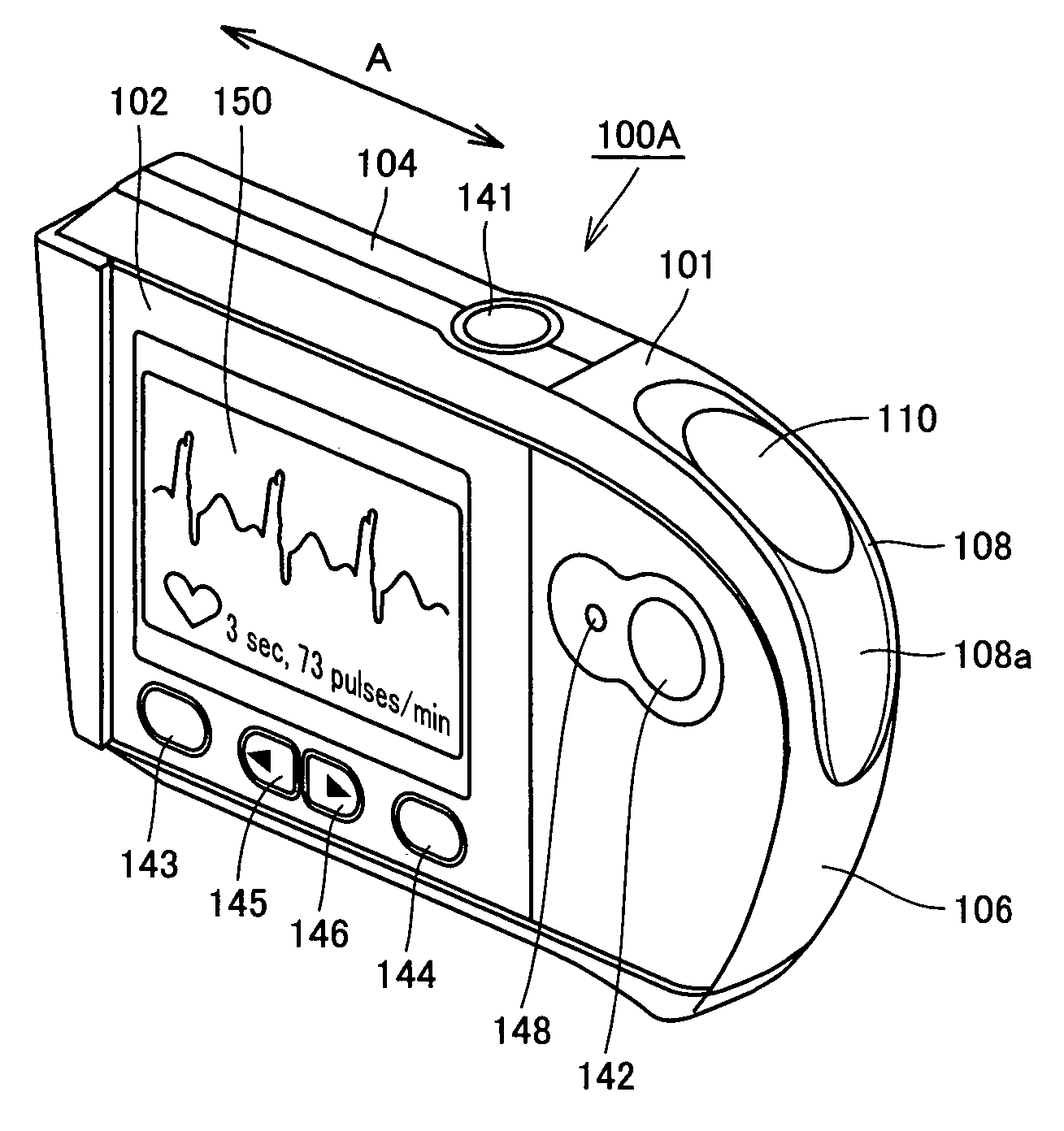

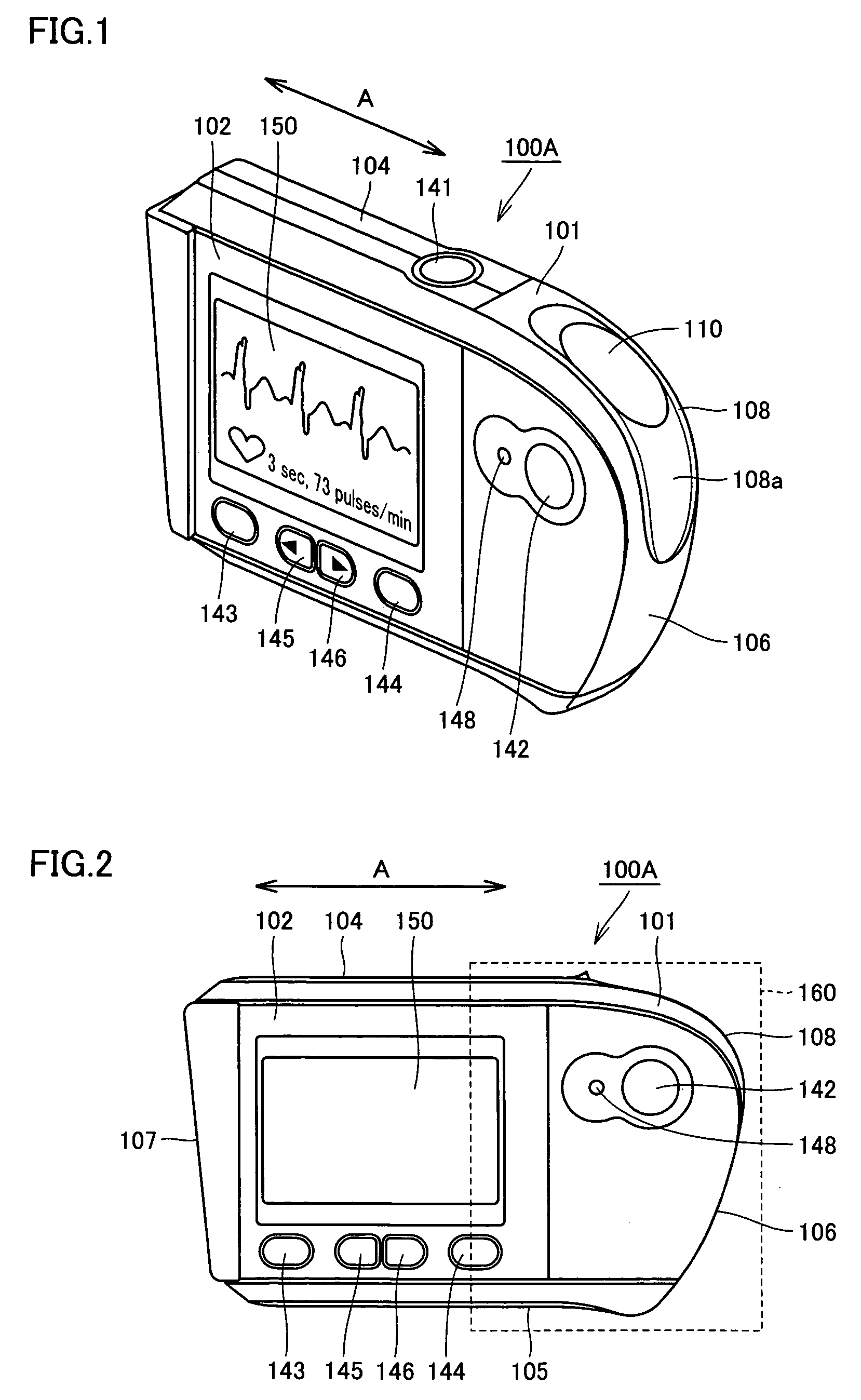

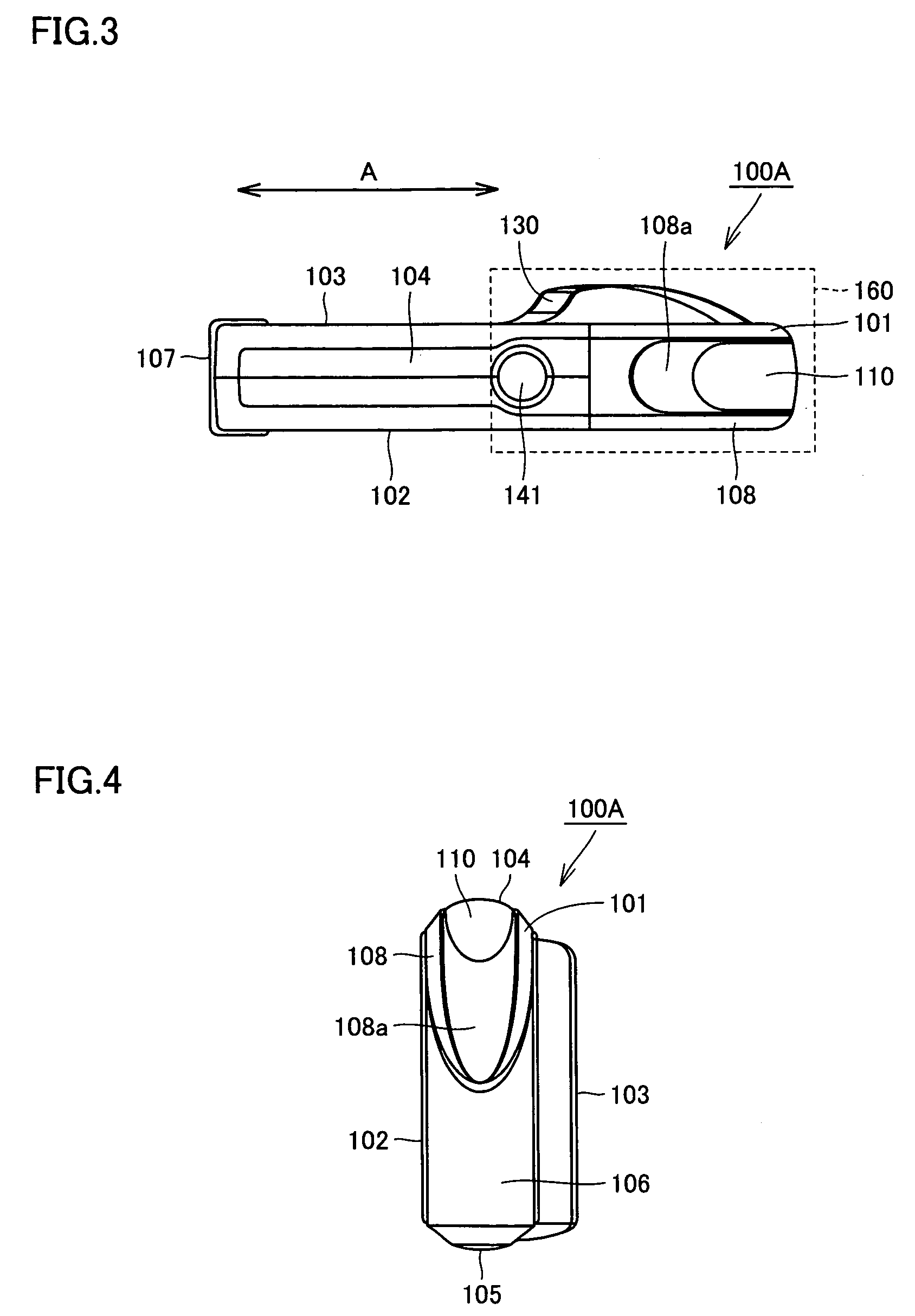

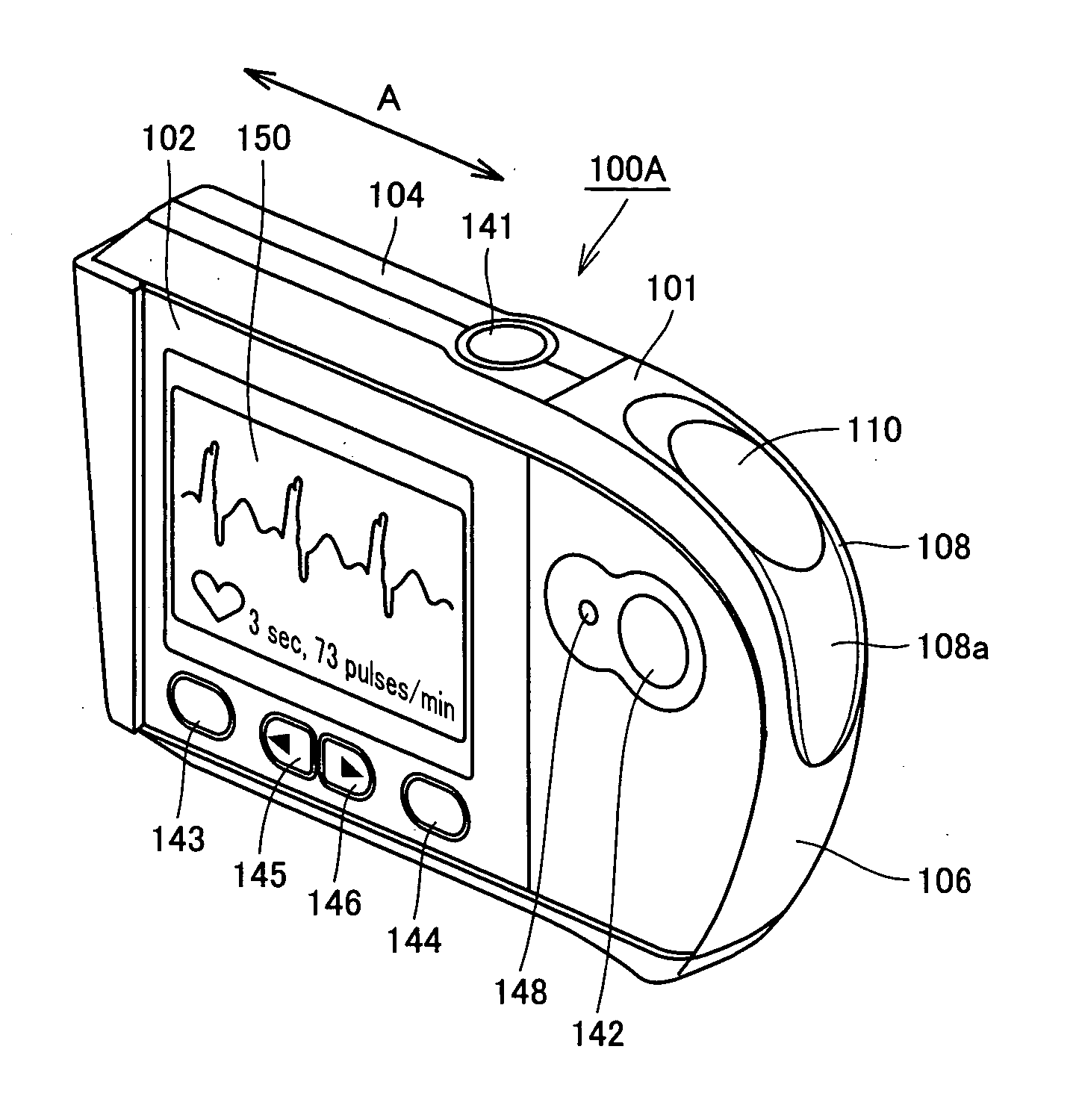

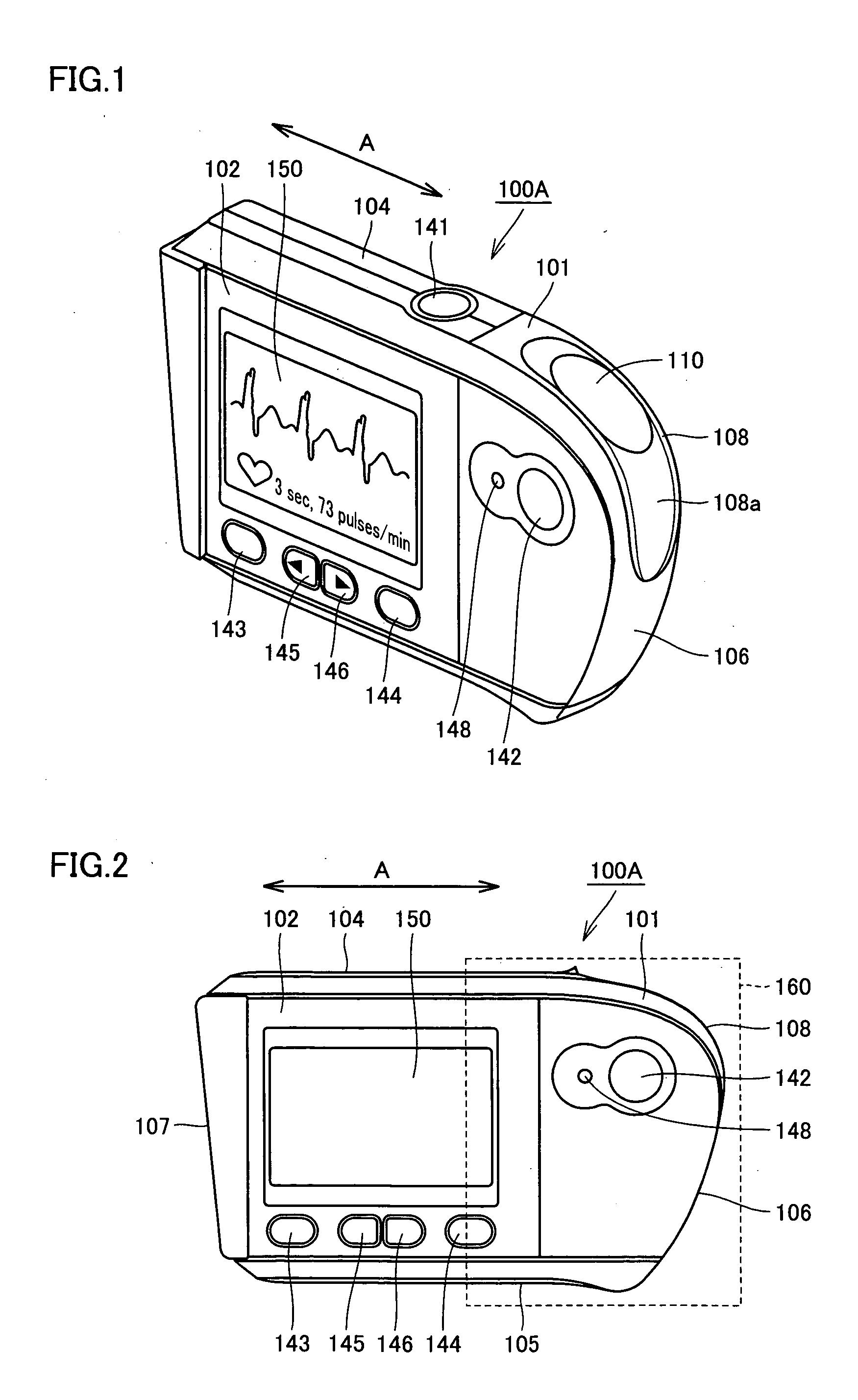

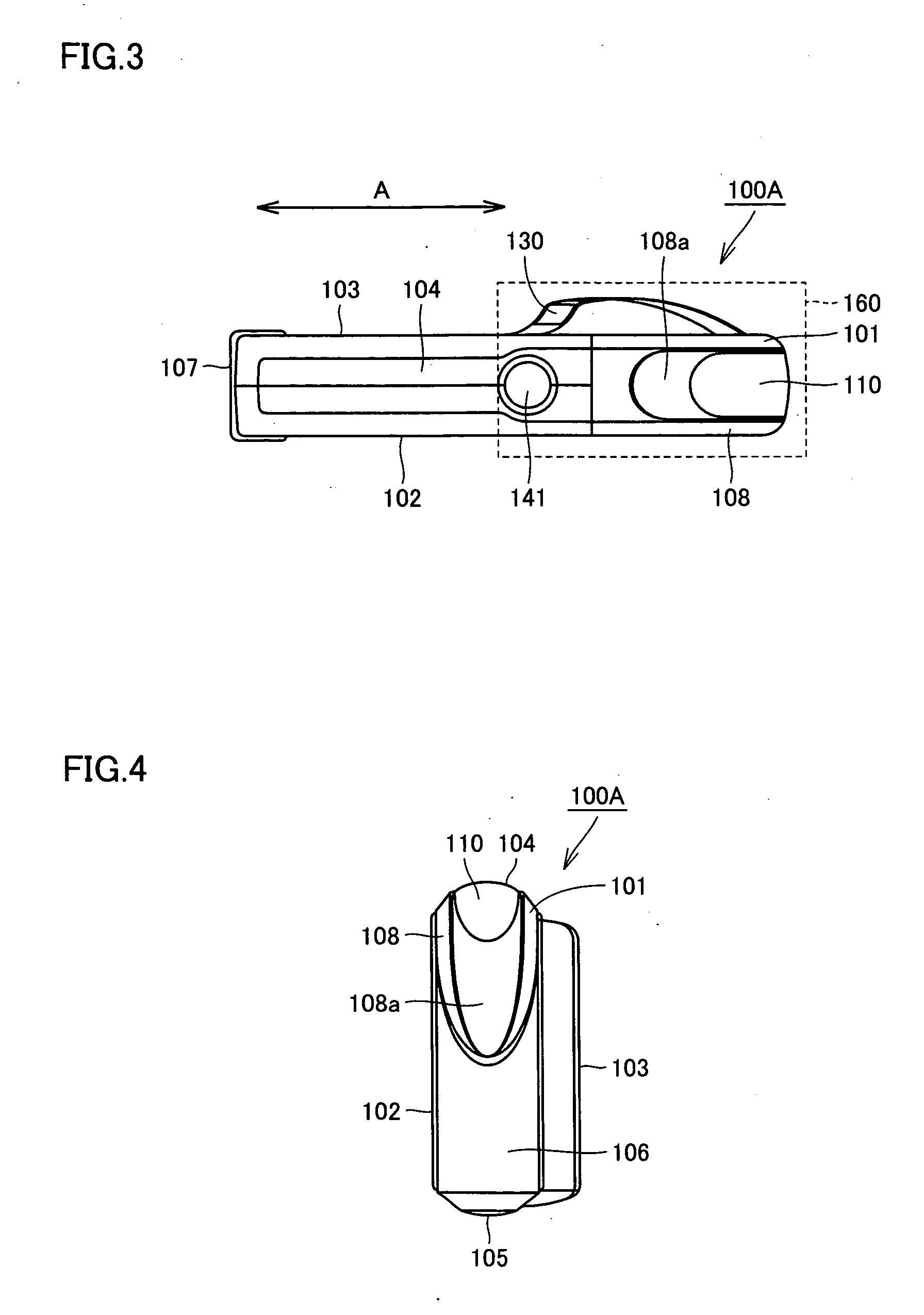

Portable electrocardiograph

A portable electrocardiograph and method of use are disclosed. According to one aspect of the present invention, a portable electrocardiograph is provided which includes: a rectangular housing having at least a first outer surface and a second outer surface; a first electrode provided on the first outer surface of the housing; an electrode formation face provided on the second outer surface of the housing; and a second electrode provided within the electrode formation face; wherein the electrode formation face includes an electrode region in which the second electrode is positioned and a non-electrode region which is positioned so as to surround the electrode region.

Owner:OMRON HEALTHCARE CO LTD

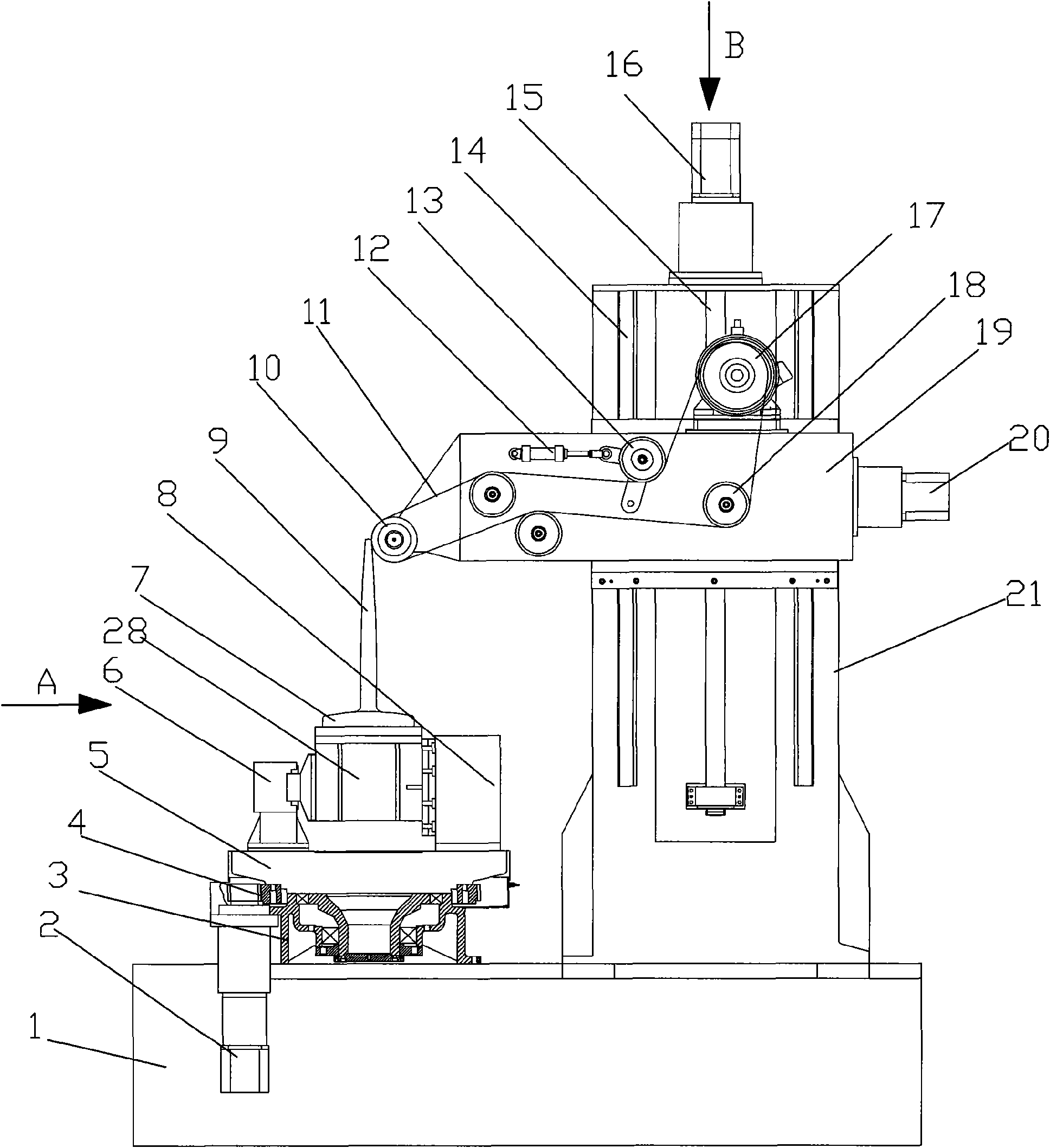

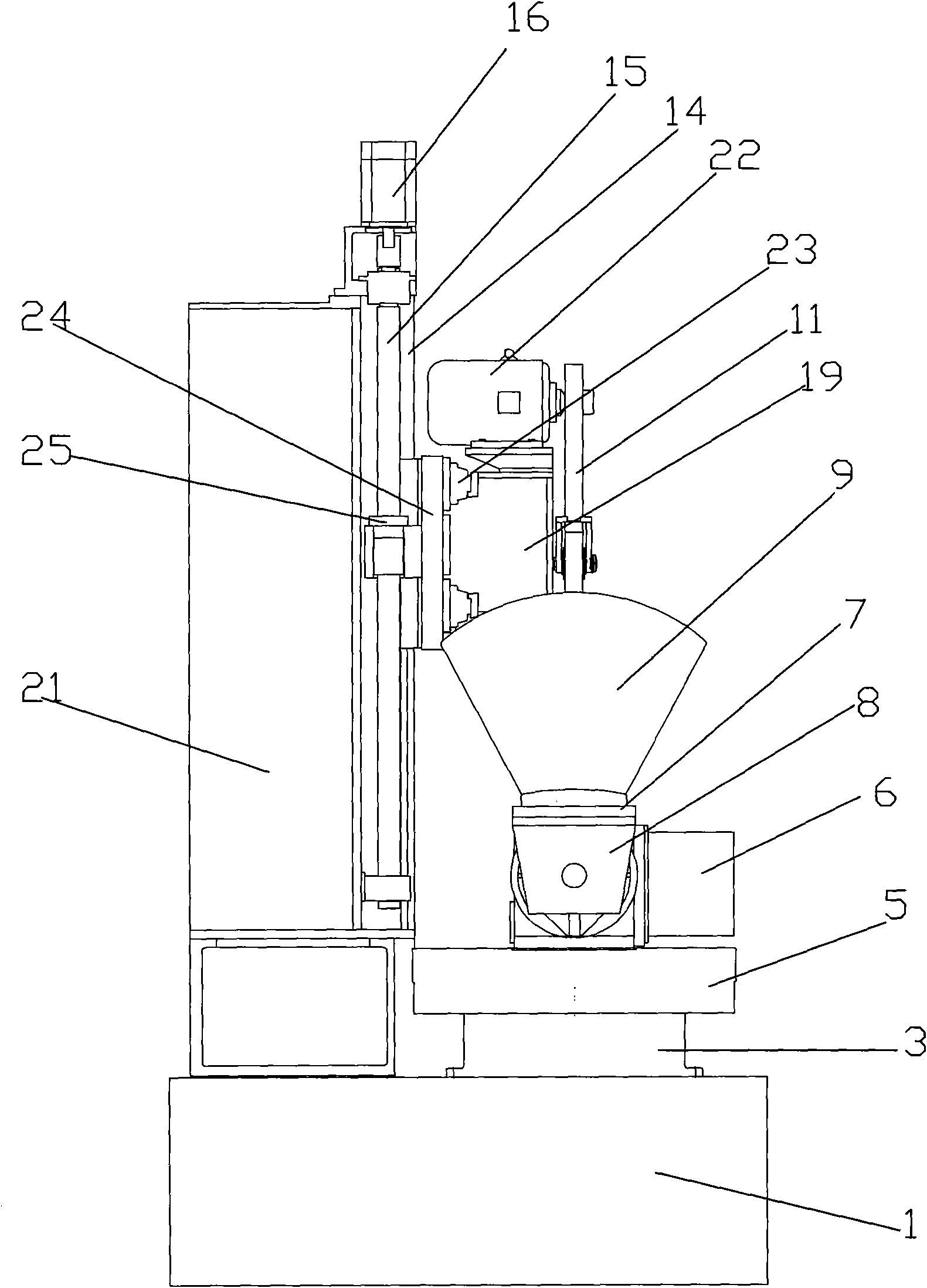

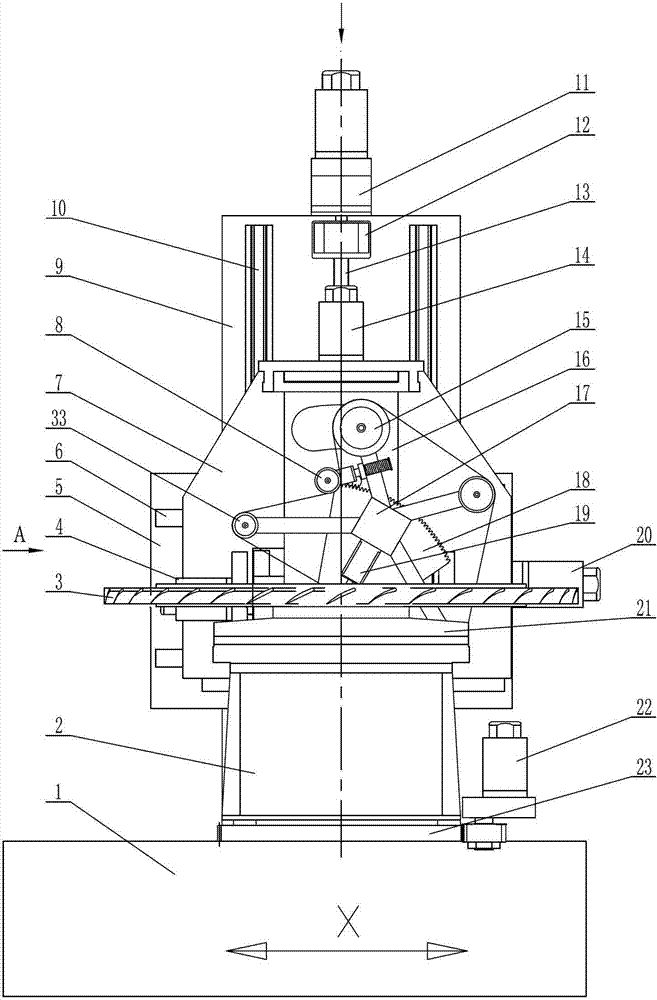

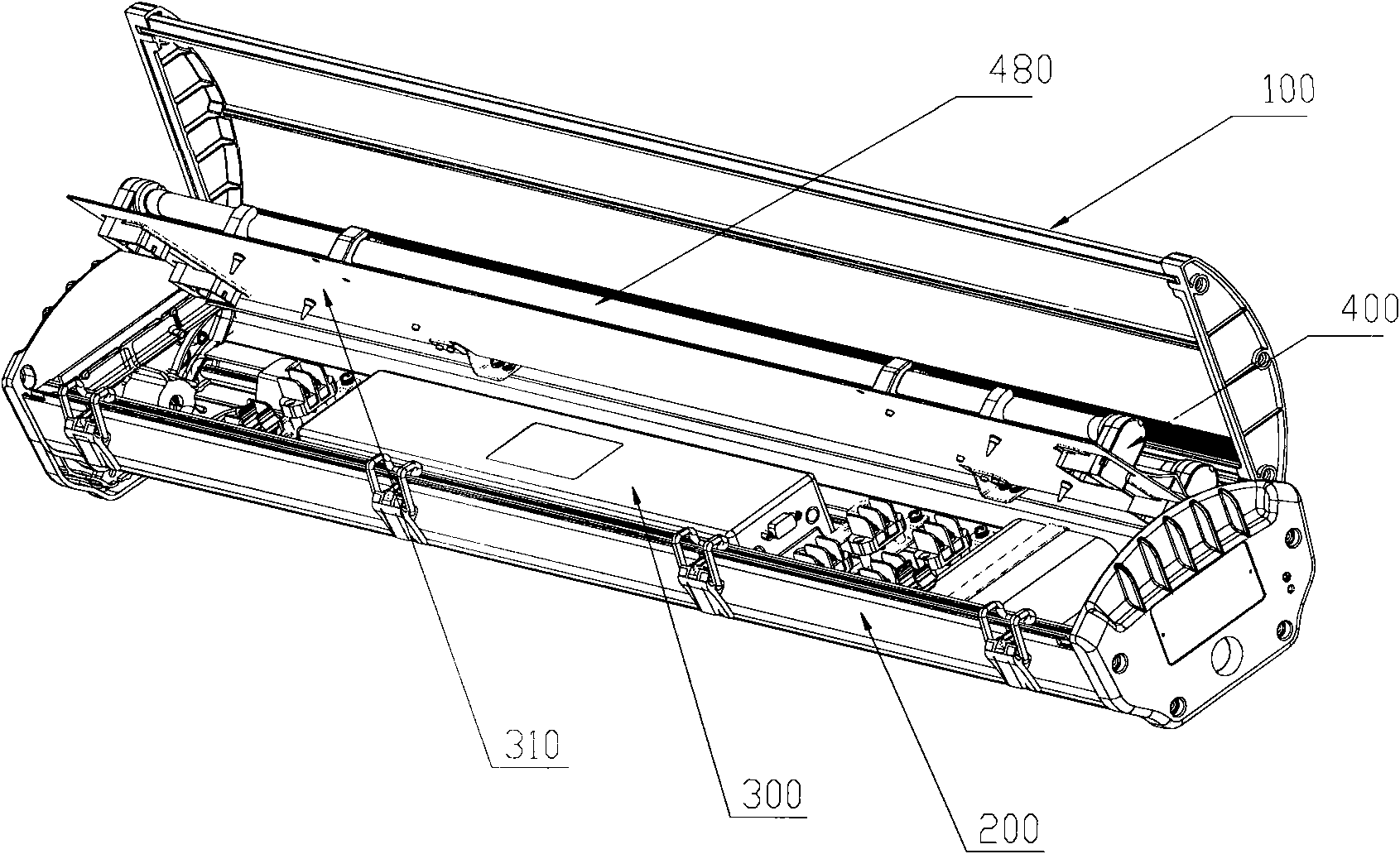

Coated abrasive grinder of propeller blade

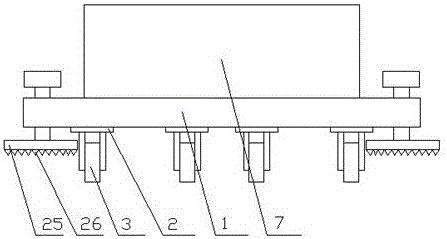

InactiveCN101664897AGuaranteed rigidityGuaranteed machining dimensional accuracyBelt grinding machinesDrive wheelPropeller

The invention discloses a coated abrasive grinder of a propeller blade, which comprises a grinder body, a grinding head mechanism, a grinding head feeding mechanism and a workpiece position adjustingmechaism, wherein the grinding head mechanism comprises an abrasive belt, a driving wheel, a contact wheel, a tensioning wheel and a grinding head drive motor; the grinding head feeding mechanism comprises an axial feed mechanism and radial feed mechanism relative to the workpiece; the coated abrasive grinder realizes combination of four degree of freedom of space by reasonable distribution of grinding head feeding and adjustment of the angle of the workpiece position as well as a shorter drive chain, guarantees the rigidity of the grinding head mechanism and a workpiece clamping mechanism, ensures the contact stabiltiy between the contact wheel and the workpice when the contact wheel rotates with a high speed, and improves work efficiency simultaneously when guaranteeing the process sizeprecision of a complex curve workpiece; and thickness is even in curve polishing, the quality of profiles is ensured, the qualificaiton rate of finished products is improved, the labor intensity of workers is reduced, and the management and production cost is decreased.

Owner:CHONGQING SAMHIDA GRINDING MACHINE

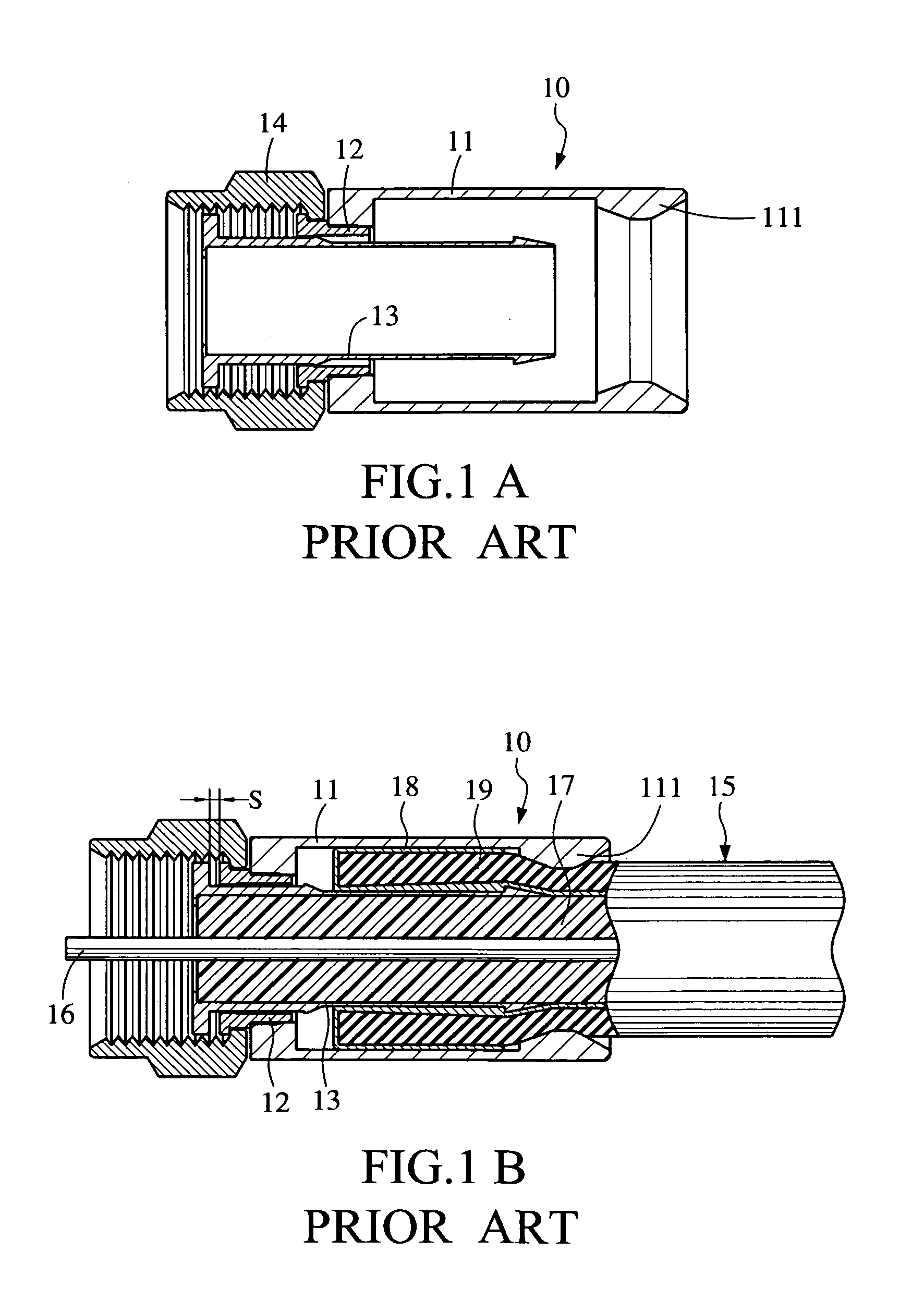

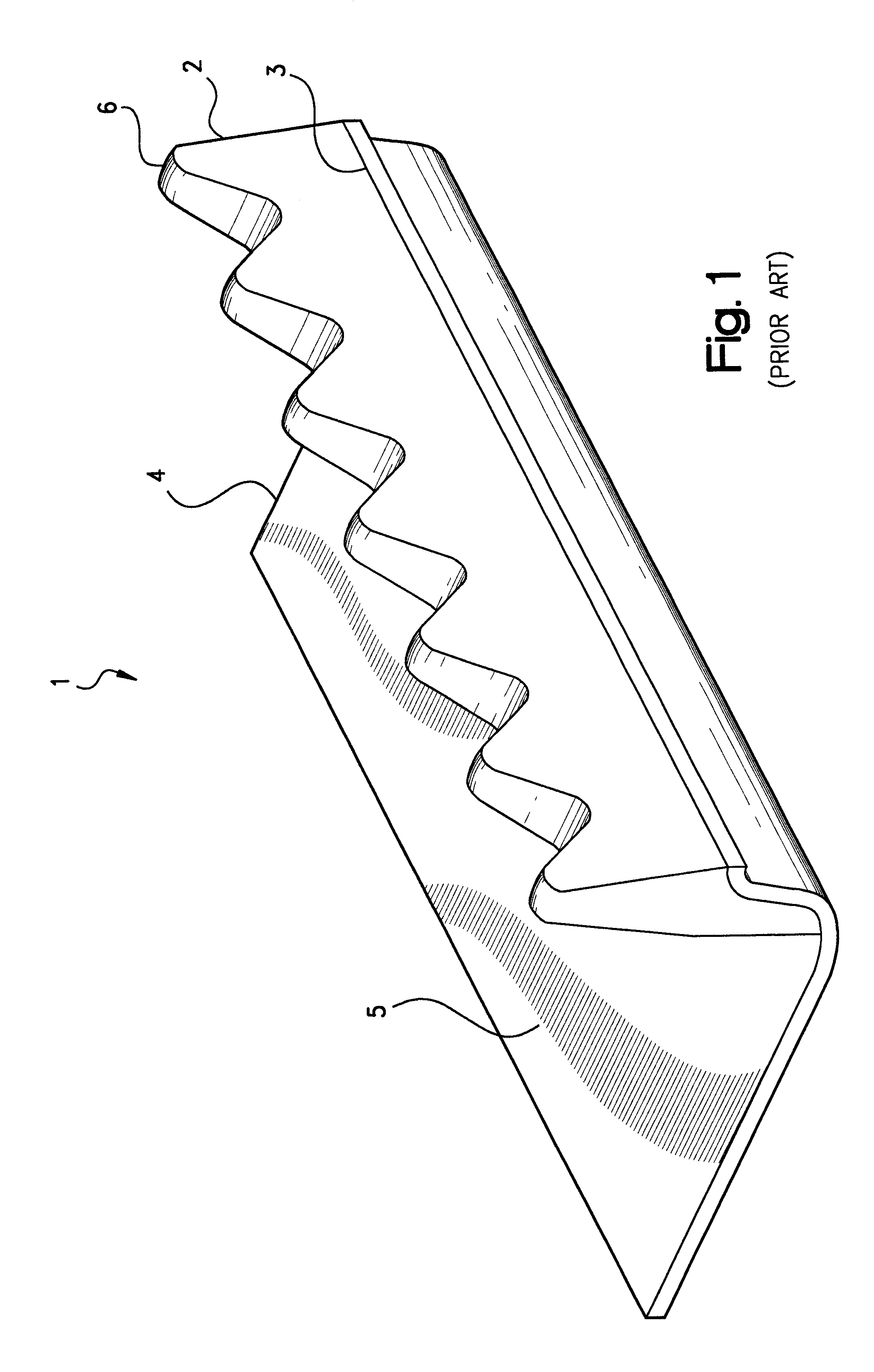

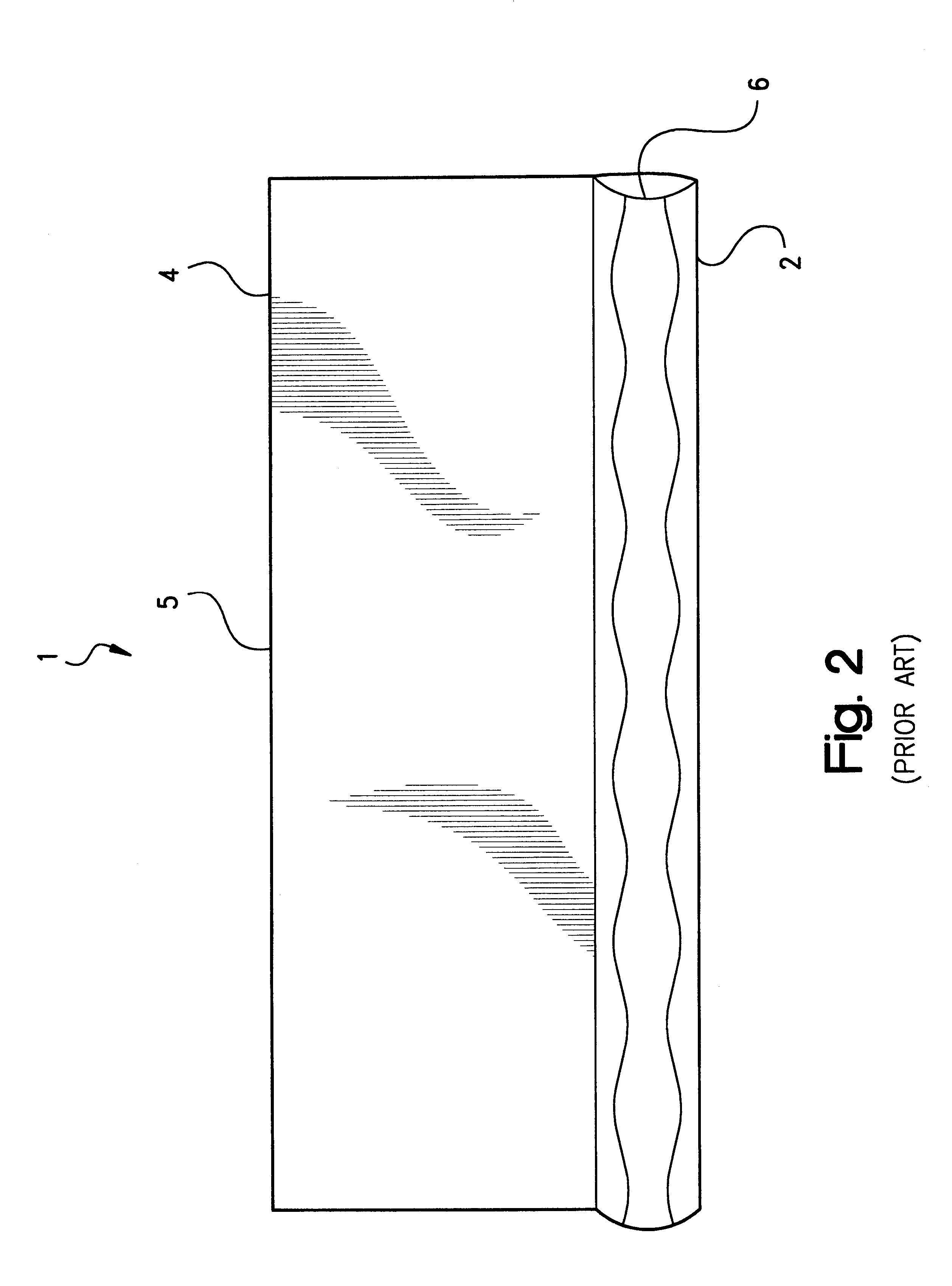

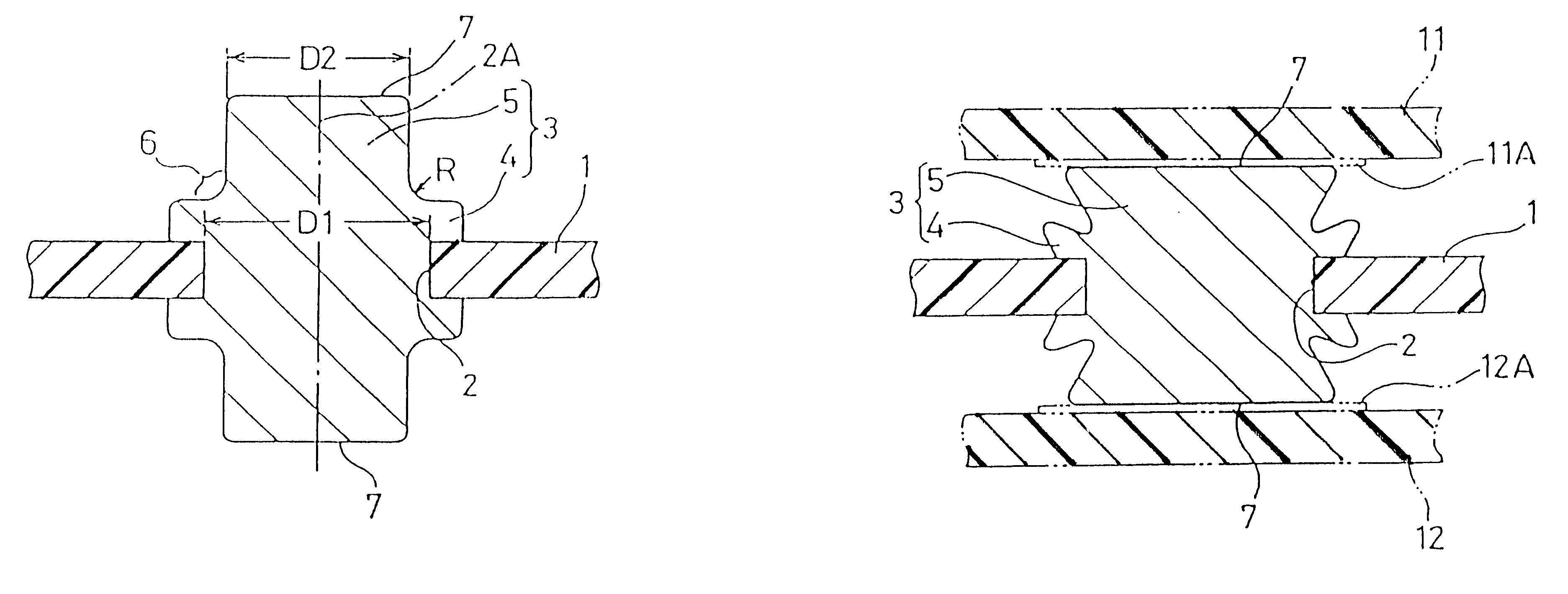

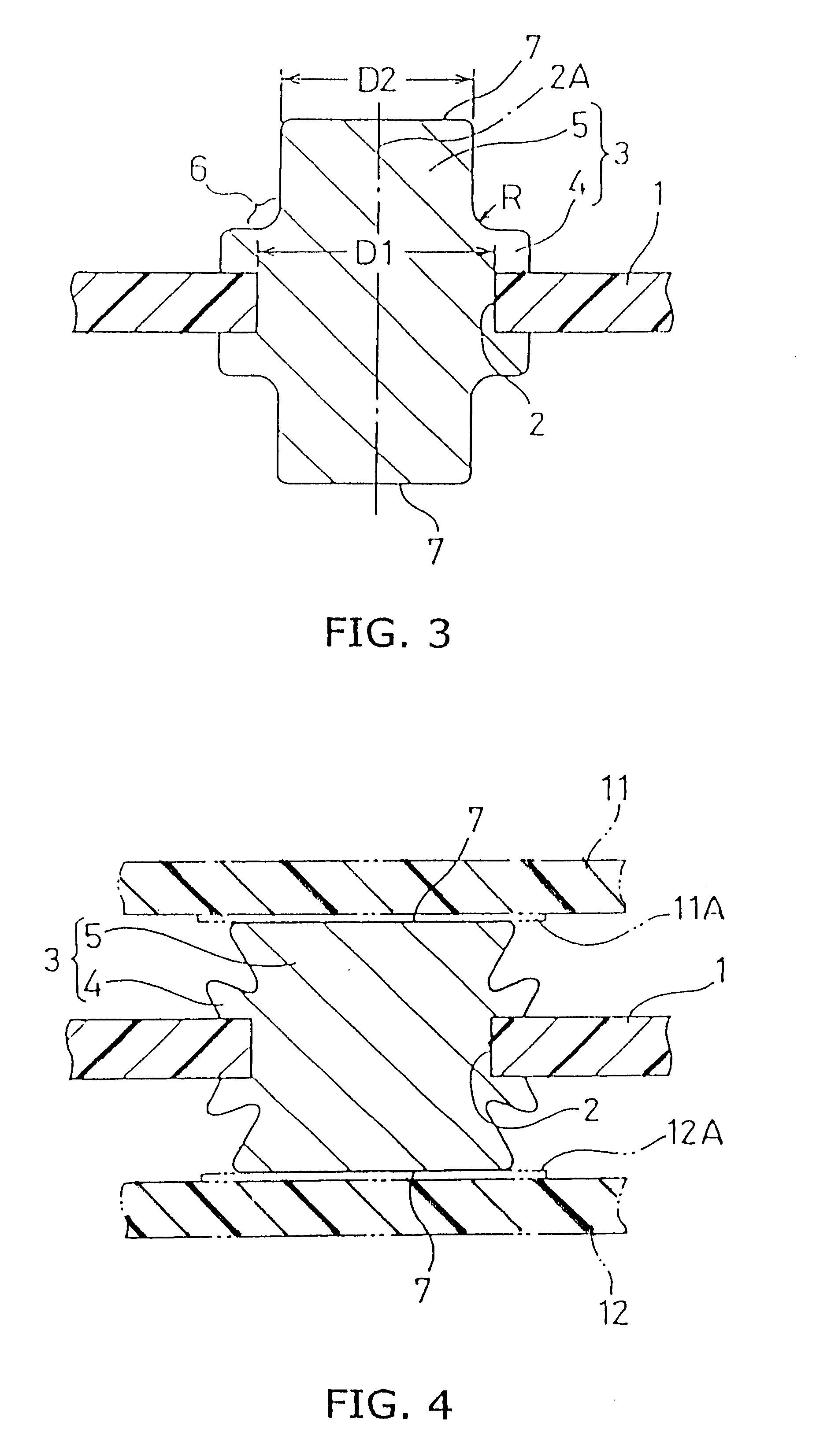

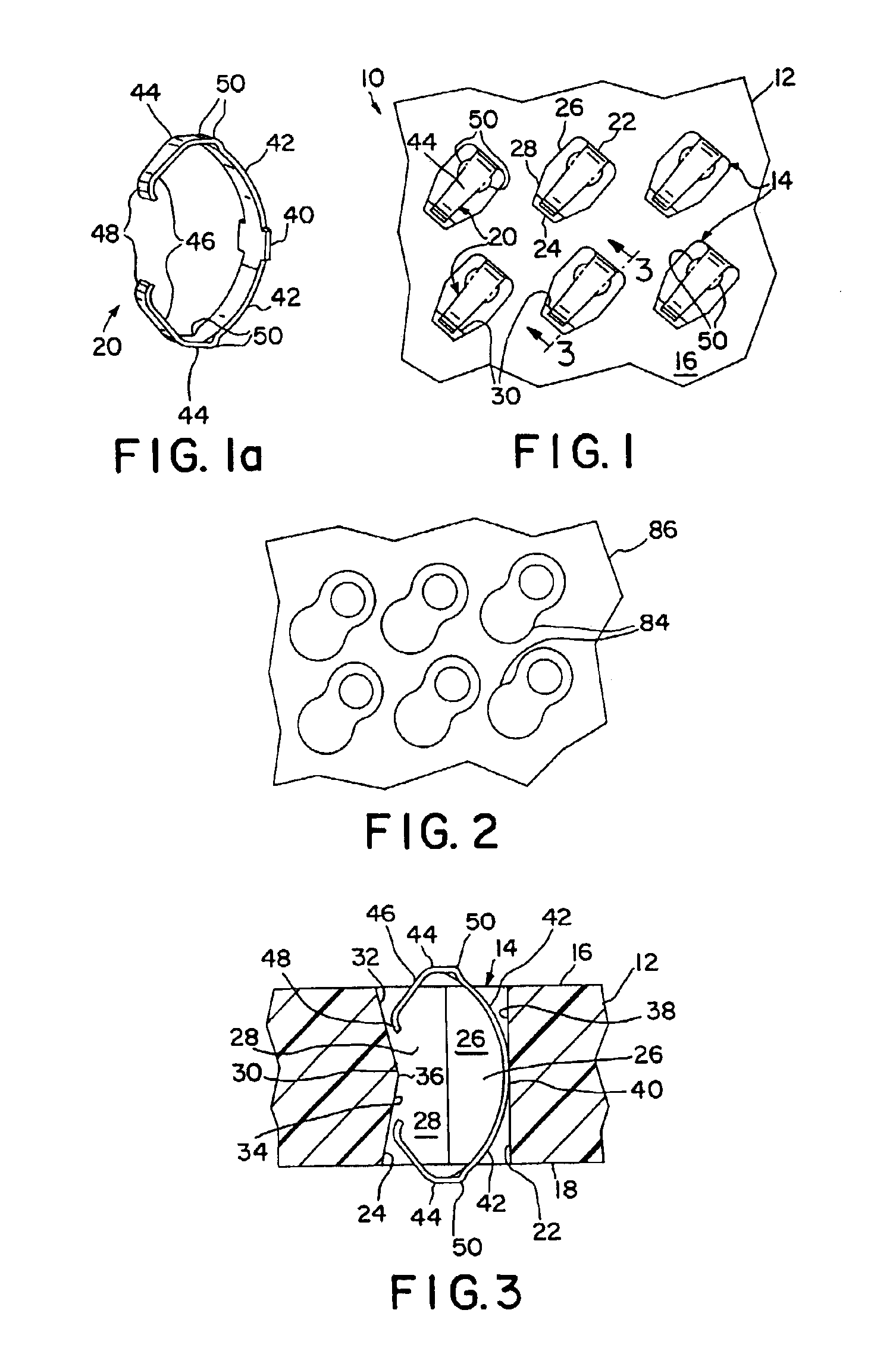

Intermediate electrical connector

InactiveUS6280207B1Large amount of deformationContact stabilityPrinted circuit assemblingSecuring/insulating coupling contact membersElastomerEngineering

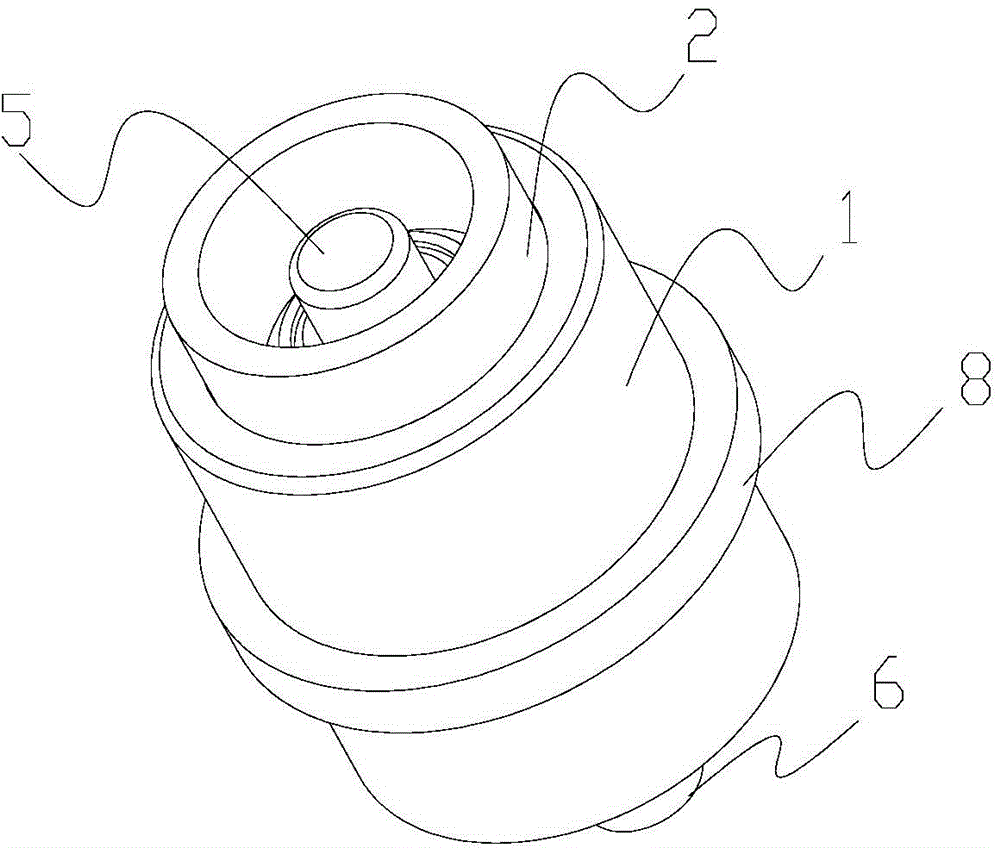

An intermediate electrical connector comprises a support plate (1) which is made of a dielectric material and has at least one support aperture (2) having an inside diameter; and at least one conductive member (3) provided through the support aperture to short-circuit circuit portions of connection objects. The conductive member is made of a conductive elastomer and comprises a retention section (4) with flange portions for engage with the support aperture to attach the conductive member to the support plate; and an elastic protruded section (5). The elastic protruded section extends from the retention section in a direction of thickness of the support plate to form at opposite ends contact faces (7) for elastic contact with the circuit portions (11A, 12A) of the connection objects (11, 12) and has, adjacent to the retention section, shoulder (6) portions having an outside diameter which is smaller than the inside diameter of the support aperture.

Owner:HIROSE ELECTRIC GROUP

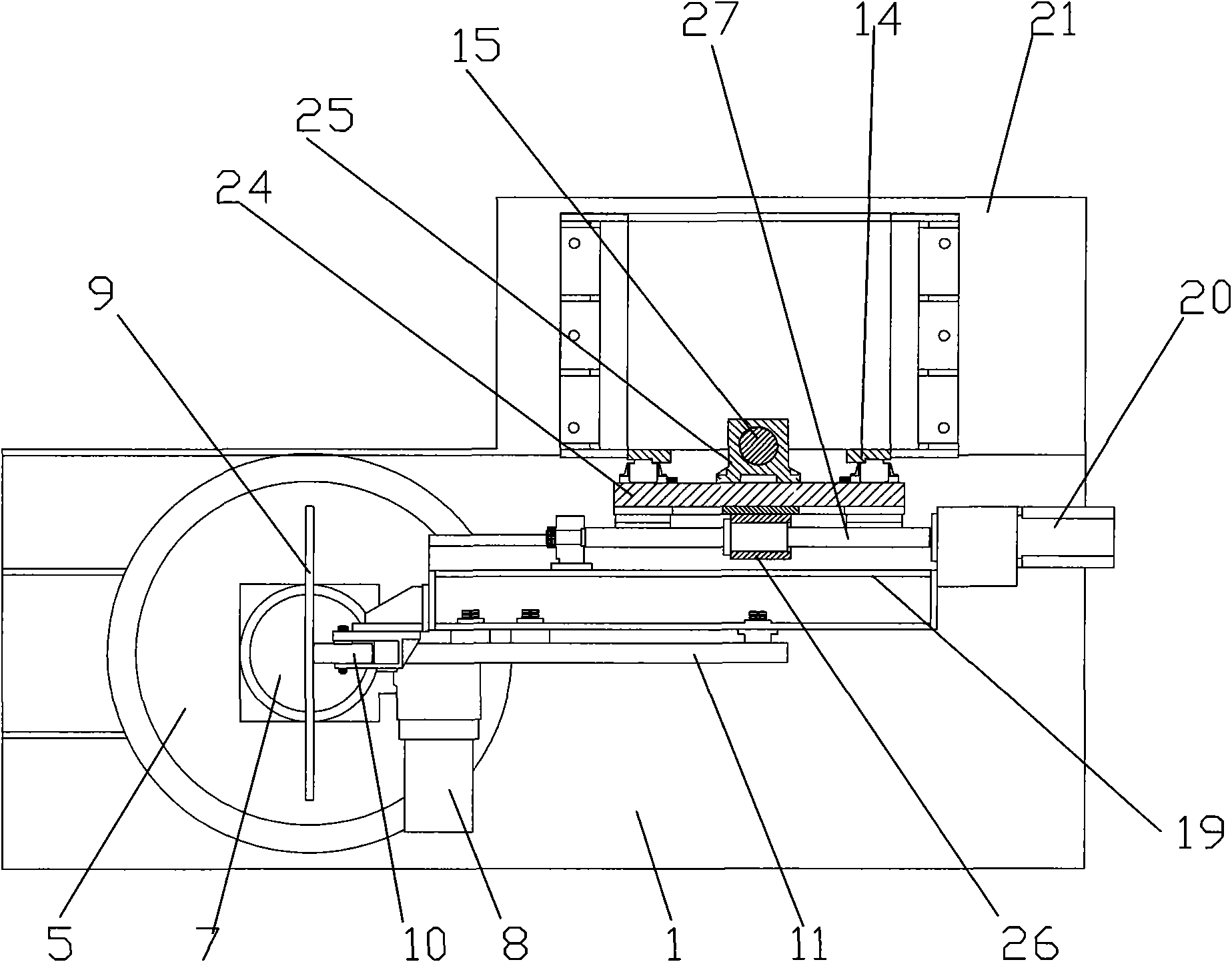

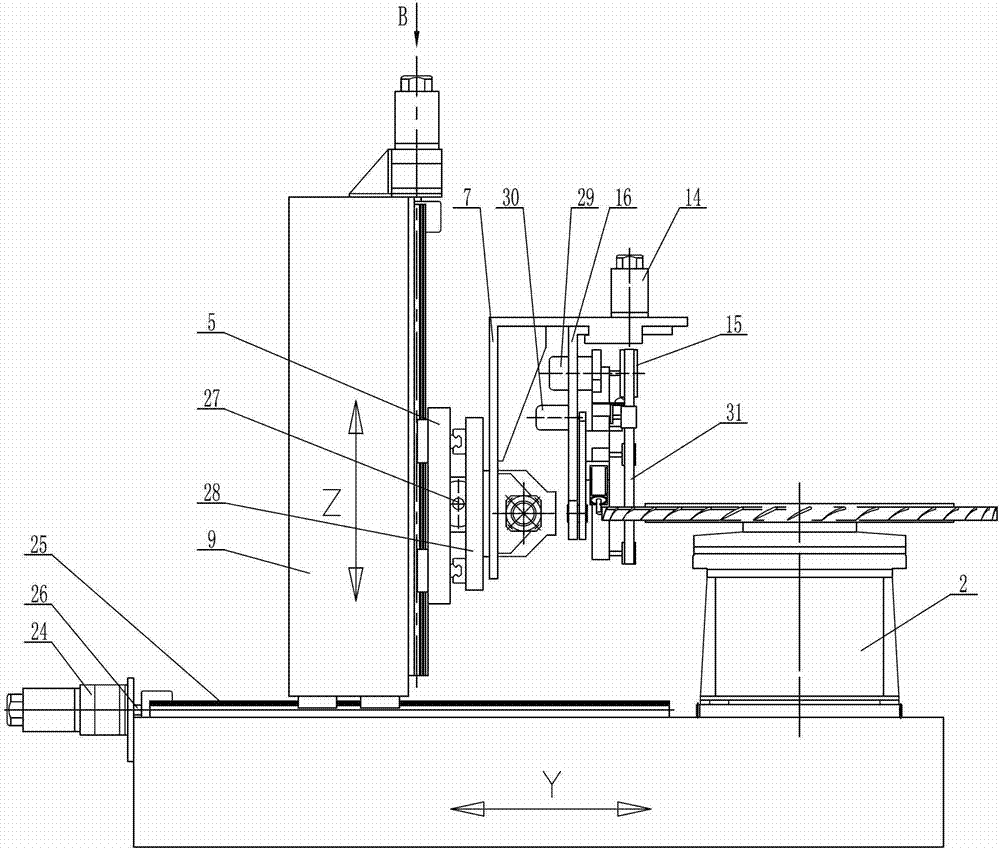

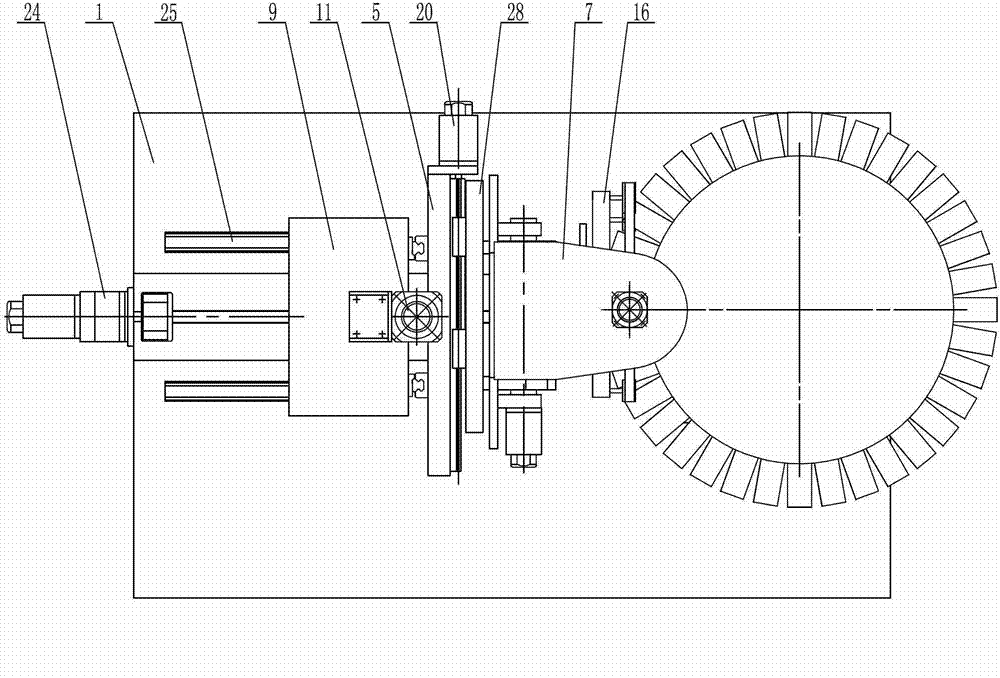

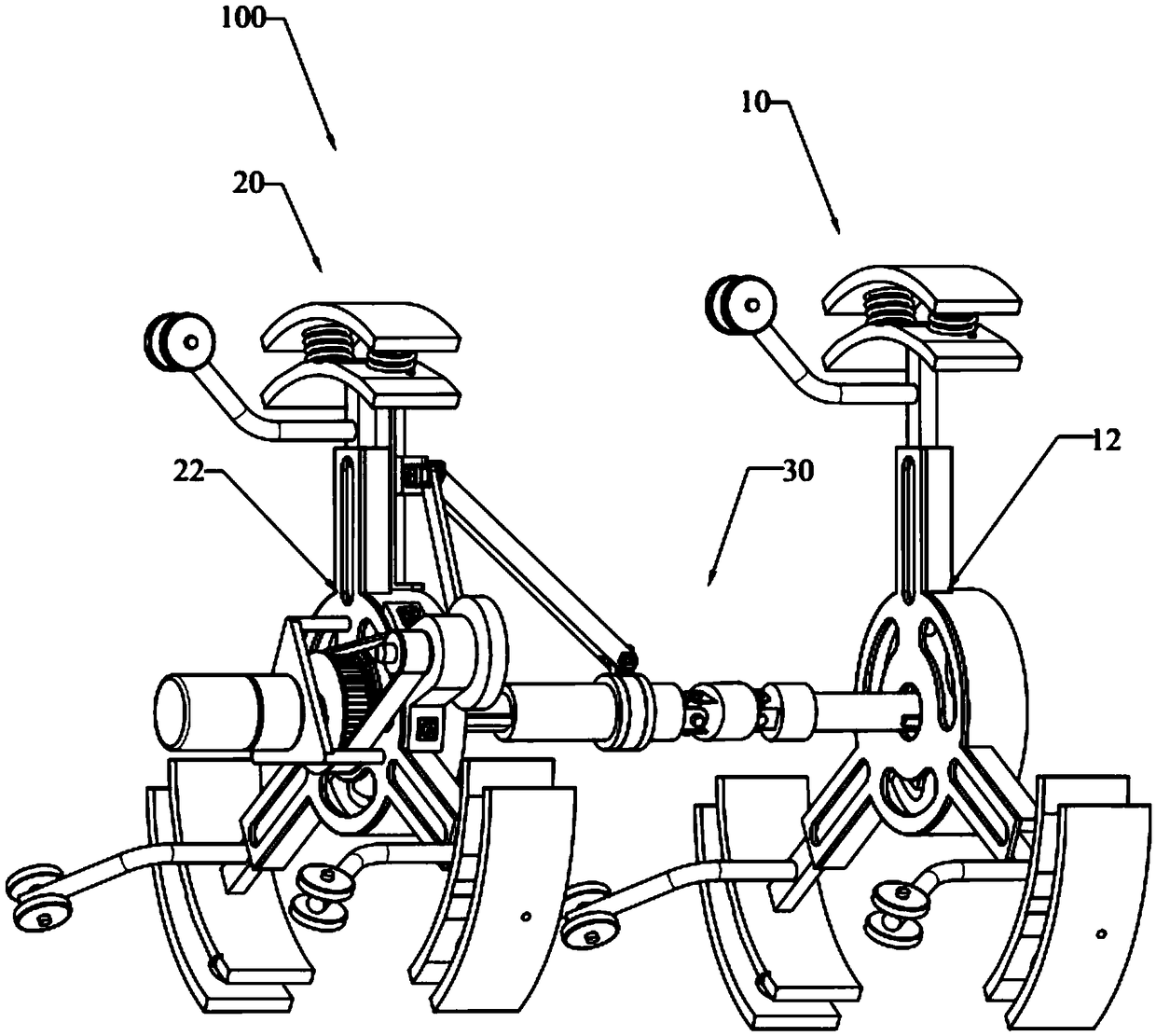

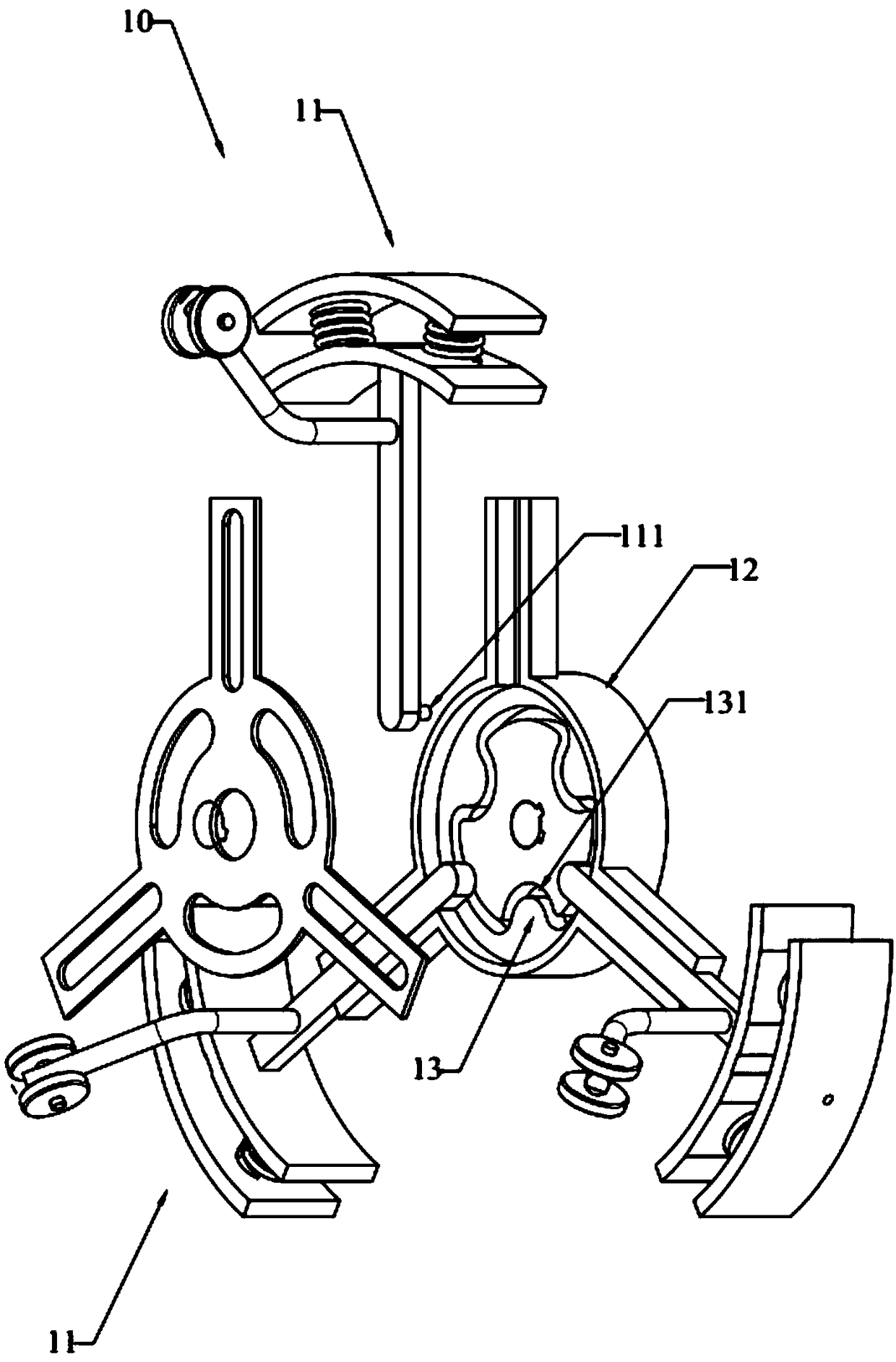

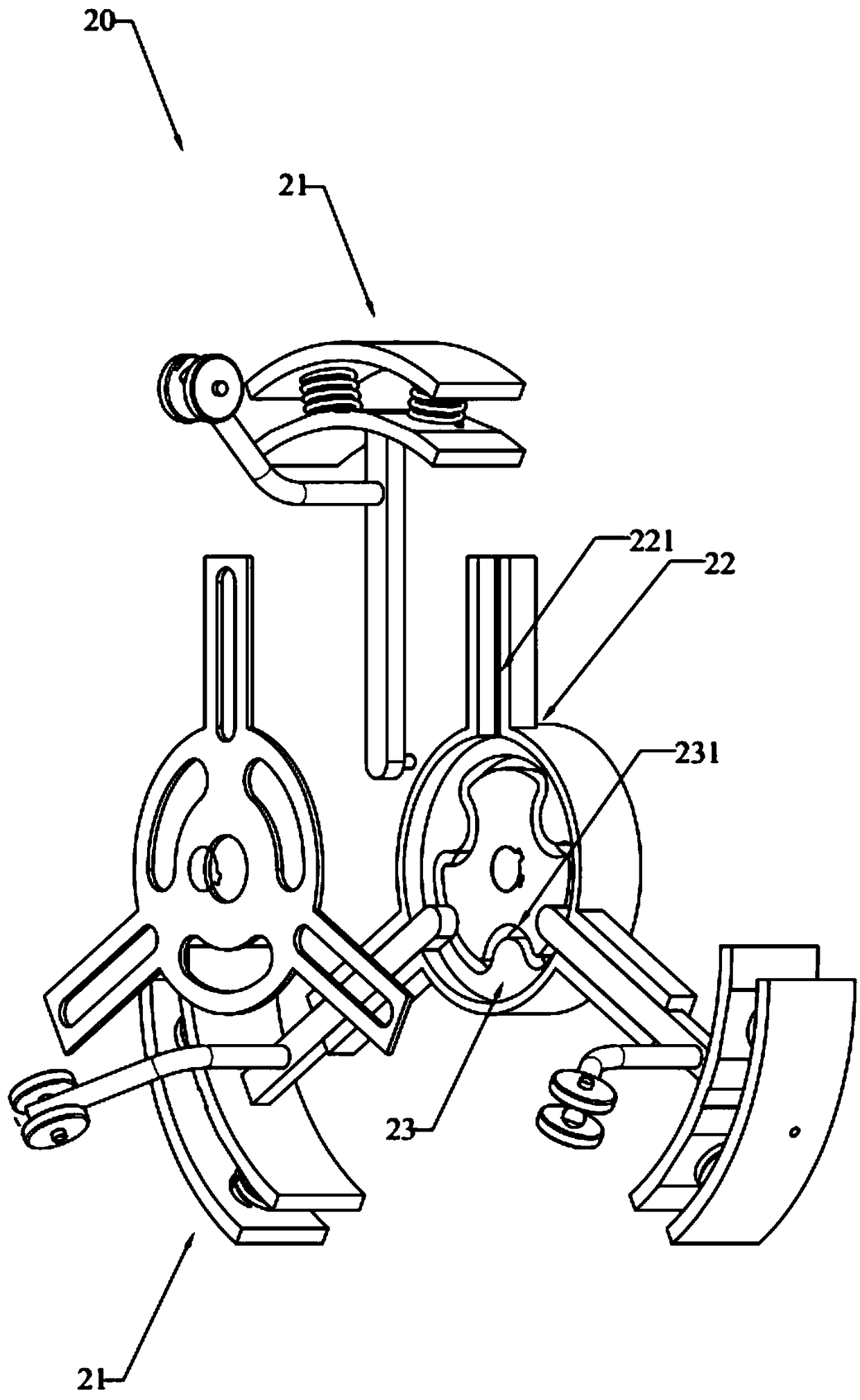

Abrasive belt grinding device applicable to inner and outer cambered surfaces of blades of aerospace blisk

InactiveCN102729124AImprove work efficiencyGuaranteed accuracyBelt grinding machinesSix degrees of freedomBelt grinding

The invention discloses an abrasive belt grinding device applicable to inner and outer cambered surfaces of blades of aerospace blisk. An X axis transverse feed mechanism, a Y axis transverse feed mechanism and a Z axis longitudinal feed mechanism form a grinding head feed mechanism; an A axis deflection motor, an A axis deflection bracket, a B axis motor, a gear train bracket, a C axis motor, a C axis revolving bracket and the like form a position adjusting mechanism of the grinding head. The abrasive belt grinding device provided by the invention guarantees rigidity of a grinding head mechanism and a work piece clamping mechanism through rational distribution of the grinding head feeding, the position adjustment of the grinding head and the position and angle adjustment of the work piece and through combination of space in six degrees of freedom by a short transmission chain; a contact wheel and an abrasive belt can cut into a narrow gap between two blades of the blisk, so as to ensure the contact between the contact wheel and the work piece to be stable when the contact wheel rotates at a high speed; so that the abrasive belt grinding device can improve the work efficiency, and meanwhile, dimensional accuracy of complex cambered surface of the work piece in processing can be guaranteed, the quality of the molded surface is ensured, the rate of qualified products is improved, the labor intensity of workers is reduced and the management and production costs are lowered.

Owner:CHONGQING UNIV +1

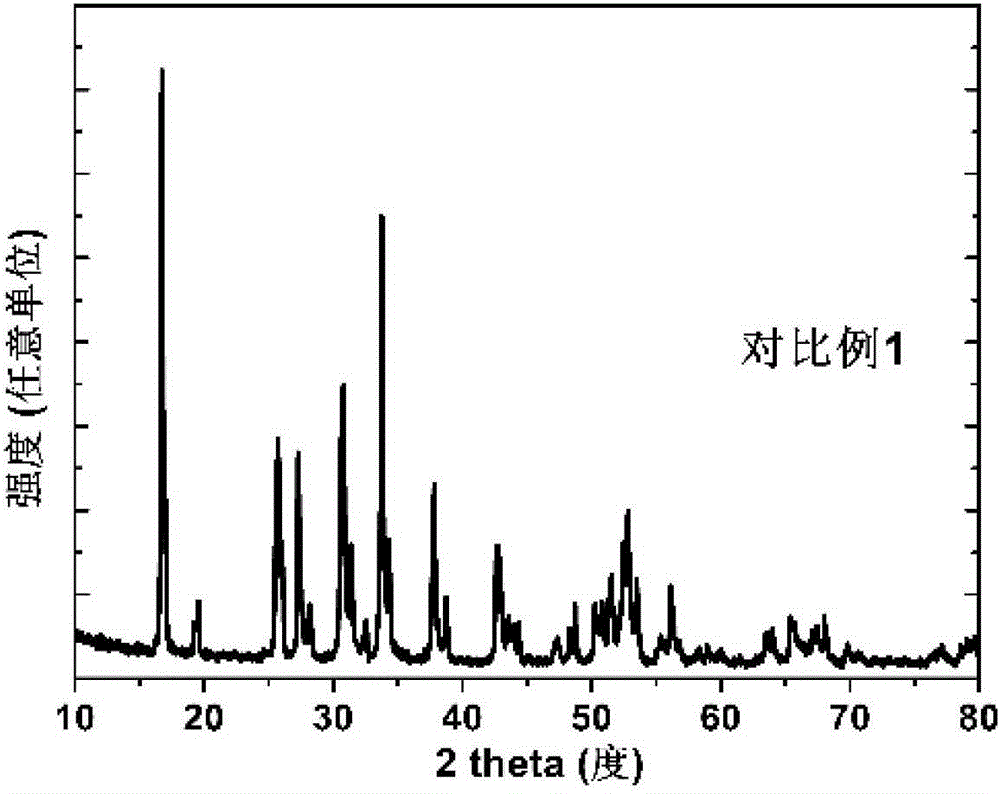

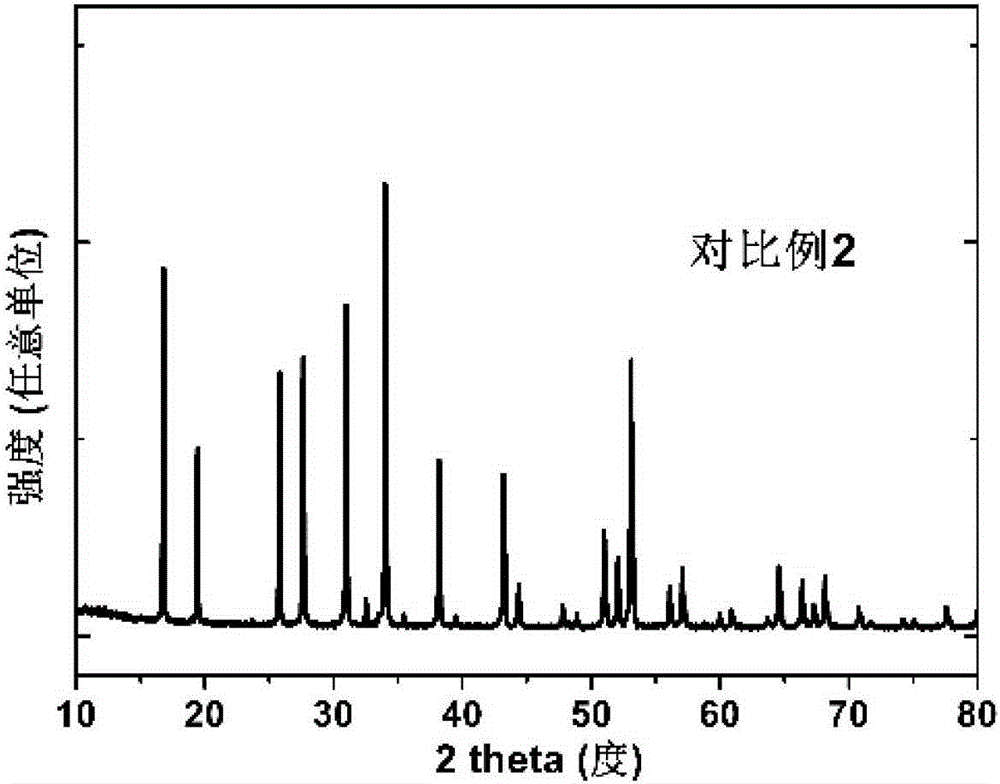

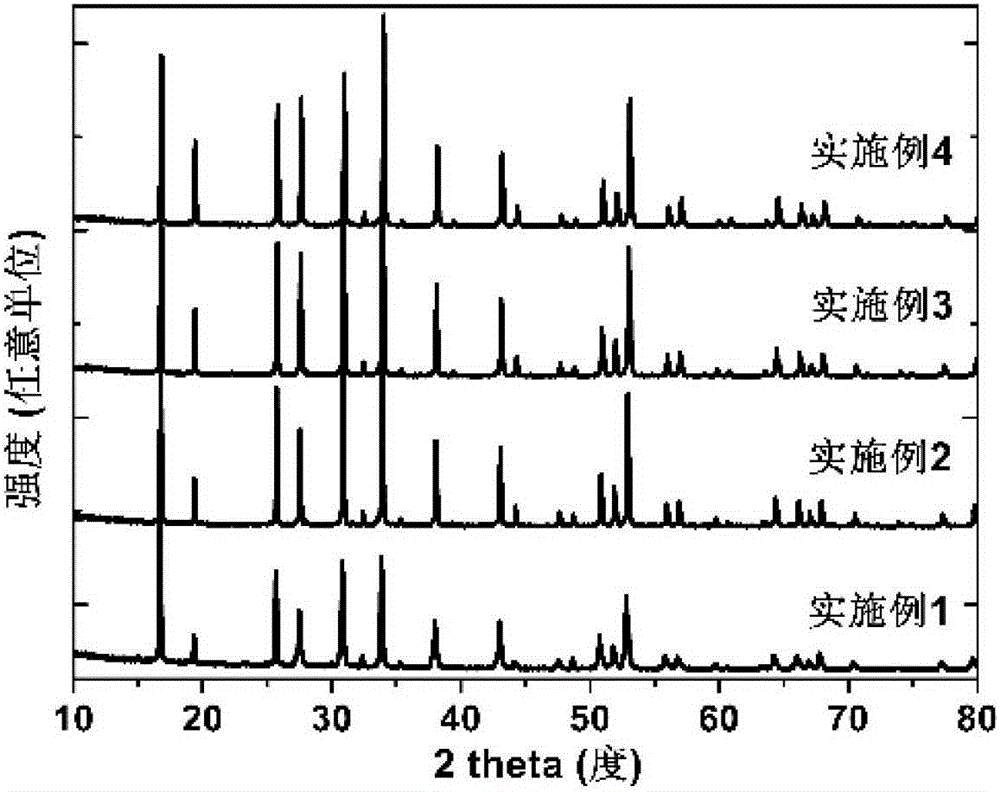

Garnet-structured ceramic electrolyte material, preparation method and application therefor

The invention relates to a garnet-structured ceramic electrolyte material, a preparation method and an application therefor. The chemical composition of the garnet-structured ceramic electrolyte material is (1-z) Li (7-2x+2y) La3Zr (2-x) WxO (12+y)+ zA, wherein x is more than 0 and less than or equal to 1.00; y is more than 0 and less than or equal to 2.00; z is more than or equal to 0 and less than or equal to 10 wt.%; and A is any one of Li2O, MgO, CaO, SrO, BaO, Y2O3, B2O3, SiO2, WO3, CuO or Al2O3. According to the cubic garnet-structured lanthanum zirconate lithium crystal doped with W element provided by the invention, by doping W ion (+6 valence), which is higher than zirconium ions Zr4+ in valence, in the lanthanum zirconate lithium crystal to replace part of zirconium ions Zr4+ in crystal lattices, the number of lithium ions Li+ in the crystal is reduced, the vacancy of the lithium ions Li+ is increased, and the formation of an migration channel for the lithium ions Li+ is facilitated, so that the garnet-structured ceramic electrolyte material is higher in volume phase ionic conductivity.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

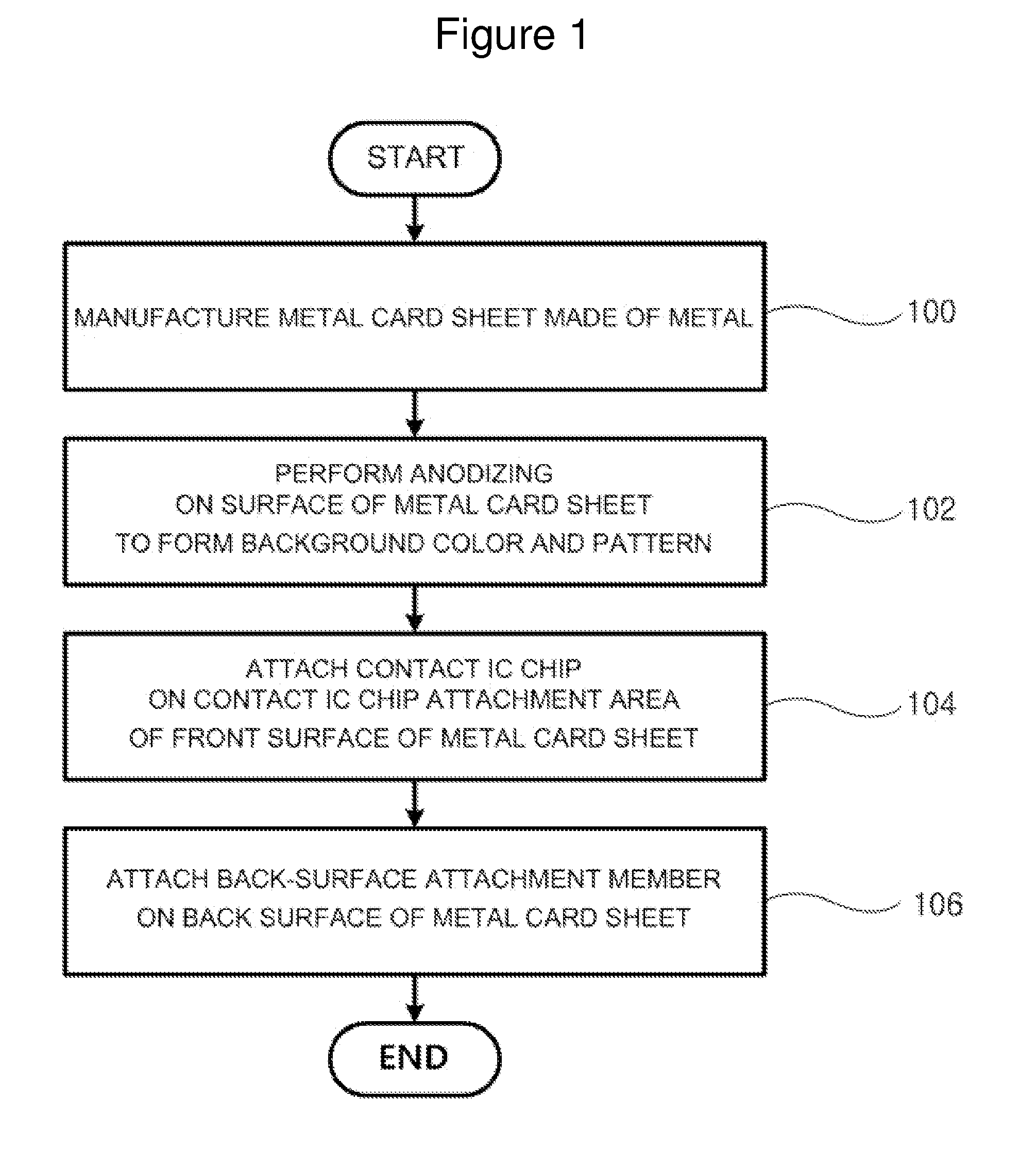

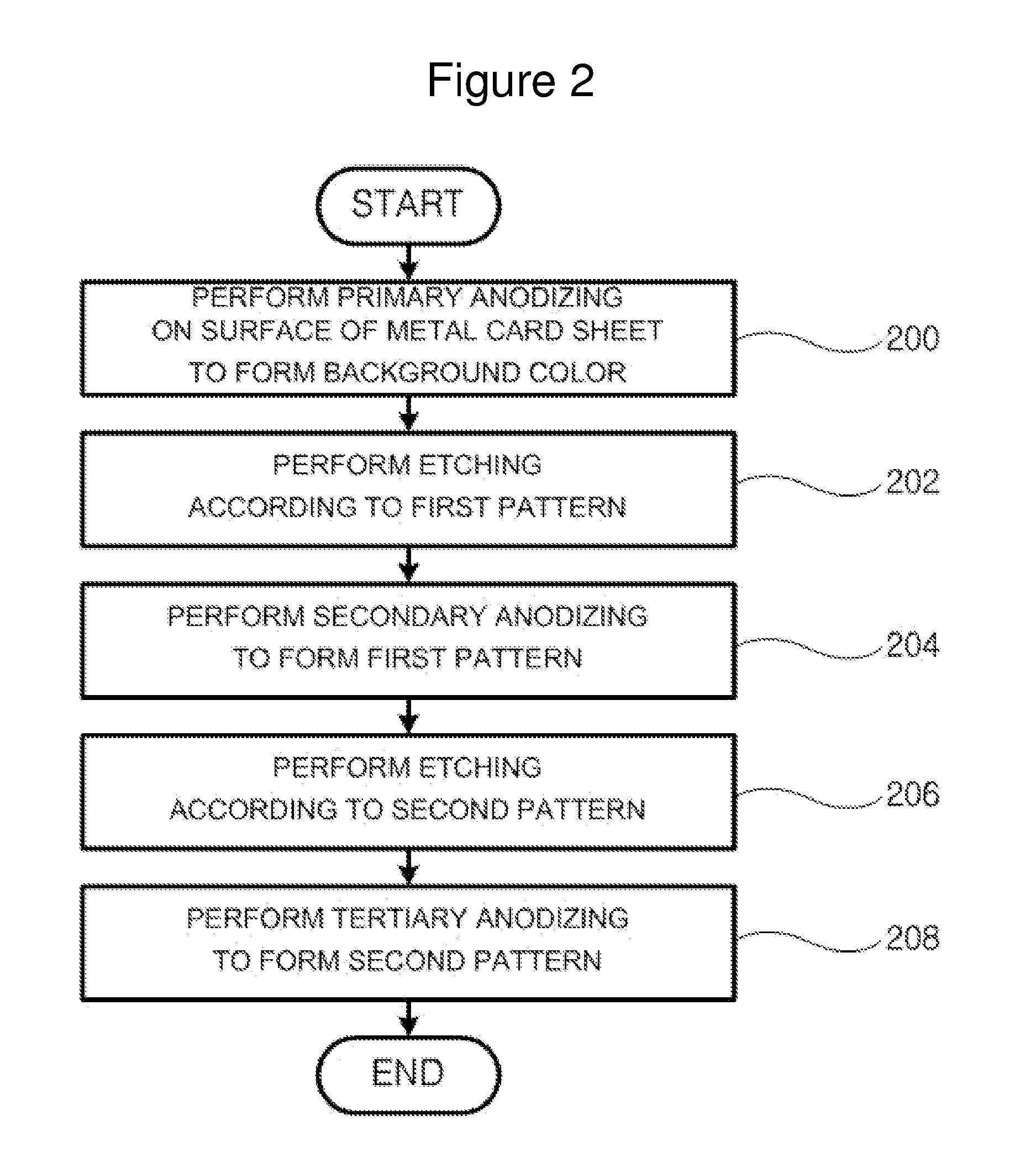

Metal card and manufacturing method thereof

ActiveUS20140144993A1Improve adhesive forceStably attachRecord carriers used with machinesInformation cardsAnodic oxidationElectrolyte

Owner:BIOSMART CORPORATION

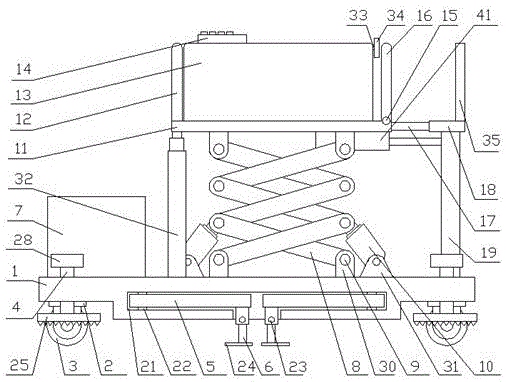

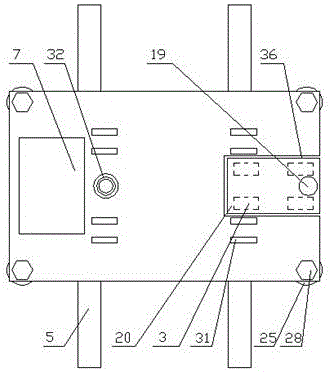

Lifting platform for electric power overhaul

The invention discloses a lifting platform for electric power overhaul. The lifting platform comprises a device base. Support arms are hinged to the two sides of the device base. A lifting rack is arranged in the middle of the device base and matched with a set of lifting oil cylinders arranged on the device base. A lifting platform body is arranged on the lifting rack. Side guard bars are arranged at the two sides of the lifting platform body correspondingly. A controller is arranged on one of the side guard bars. The other end of the lifting platform body is hinged to a step plate guard bar through a pin shaft. The lifting platform body is connected with an extension rack through an extending-and-contracting rod and an extending-and-contracting oil cylinder. The lower portion of the extension rack is connected with a movable vehicle through a support pillar. The lifting platform for electric power overhaul can ascend and descend flexibly; the lifting platform body can be extended, the working area of the lifting platform body is expanded, and overhaul personnel can obtain a larger activity space; much convenience is provided for electric power overhaul; and meanwhile, the device base can be in stable contact with the ground without sliding, so that safety is high.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

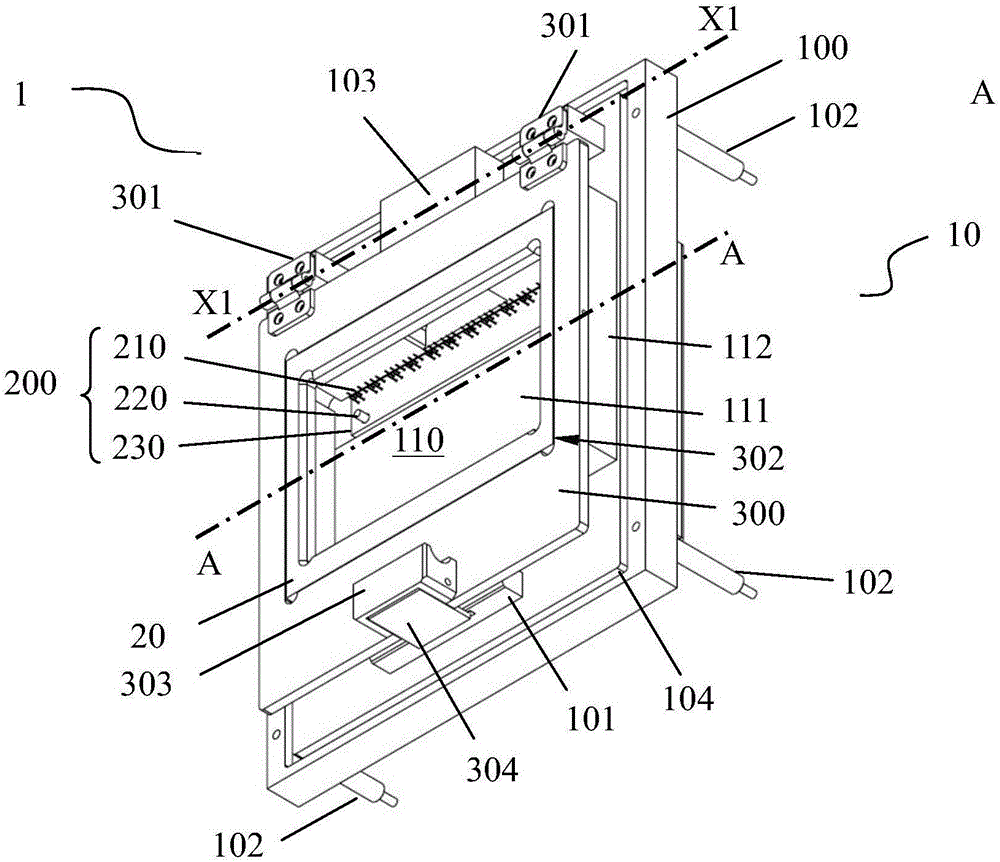

Retaining structure and detector comprising retaining structure

InactiveCN106290476AContinuous and stable transmissionUninterrupted transmissionMaterial analysis by electric/magnetic meansControl circuitBiomedical engineering

The invention relates to a retaining structure for retaining a sample detection porous plate. The porous plate is provided with an electrode and accommodates a sample. The retaining structure comprises a retainer and a pressure conversion plate. The retainer comprises a retainer main body and at least one probe module, wherein the retainer main body has an accommodating part for receiving the porous plate, and the probe module is arranged at the bottom of the accommodating part. The probe module comprises a plurality of contact probes, at least one switch probe and an electric insulating plate, wherein one end of each contact probe comprises an elastic contact terminal translating in a direction perpendicular to the bottom of the accommodating part, and the other end of each contact probe is electrically connected with a retainer control circuit; one end of each switch probe comprises an elastic pressing part translating in a direction perpendicular to the bottom of the accommodating part, and the other end of each switch probe is electrically connected with the retainer control circuit; and the contact probe and the switch probe are arranged on the electric insulating plate in a penetrating manner. When the porous plate is received in the accommodating part, the bottom of the porous plate presses against the elastic contact terminal of the contact probe and the elastic pressing part of the switch probe, the elastic contact terminal is electrically connected with the electrode arranged on the bottom of the porous plate, and the porous plate is disposed between the pressure conversion plate and the bottom of the accommodating part.

Owner:GUANGZHOU EZLIFE BIO CO LTD

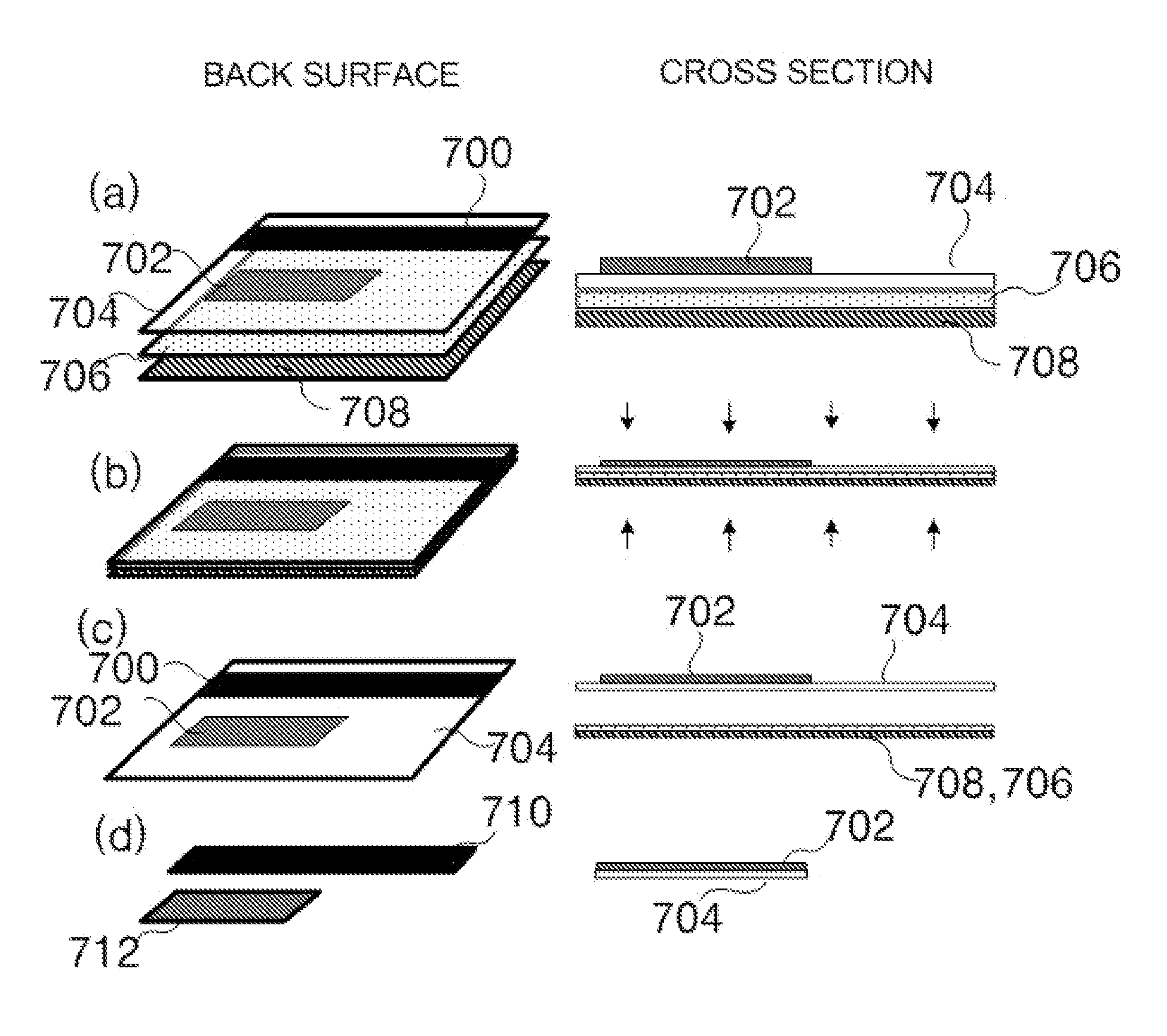

Portable electrocardiograph

A portable electrocardiograph and method of use are disclosed. According to one aspect of the present invention, a portable electrocardiograph is provided which includes: a rectangular housing having at least a first outer surface and a second outer surface; a first electrode provided on the first outer surface of the housing; an electrode formation face provided on the second outer surface of the housing; and a second electrode provided within the electrode formation face; wherein the electrode formation face includes an electrode region in which the second electrode is positioned and a non-electrode region which is positioned so as to surround the electrode region.

Owner:OMRON HEALTHCARE CO LTD

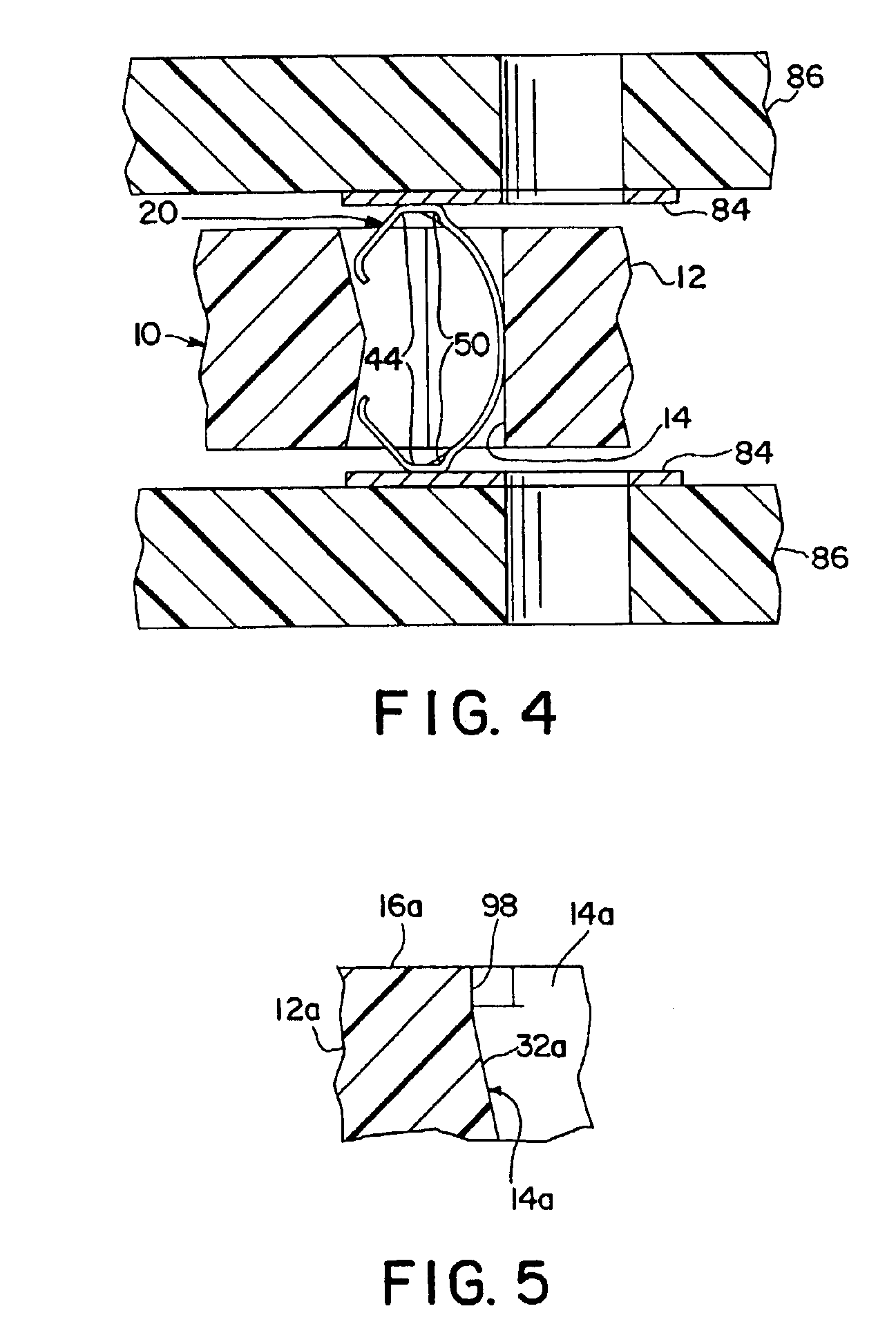

Interposer assembly

InactiveUS6905343B1Increase contact pressureEnsure electrical connection reliabilityContact member manufacturingSemiconductor/solid-state device detailsDielectric plateElectrical connection

An interposer assembly includes a dielectric plate having a plurality of contact passages extending through the plate with a contact in each passage. Each contact includes a pair of laterally spaced contact points at the top and bottom of the plate. Sandwiching of the interposer assembly between two substrates brings the contact points on each spring arm into engagement with a pad, elastically bends the contacts and forms redundant high pressure wiped electrical connections between the contact points and pads.

Owner:INTERCON SYST

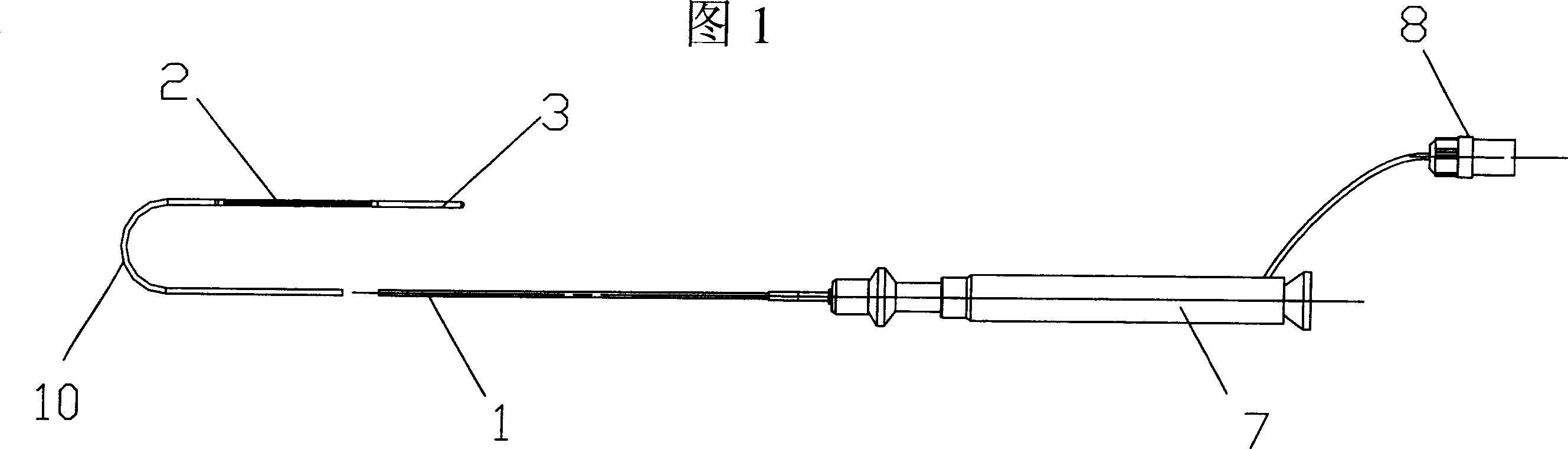

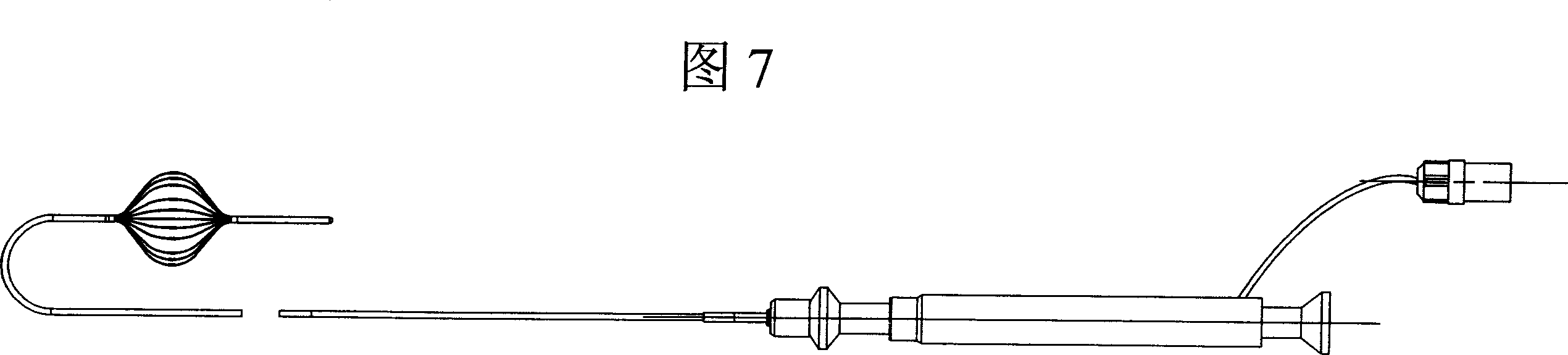

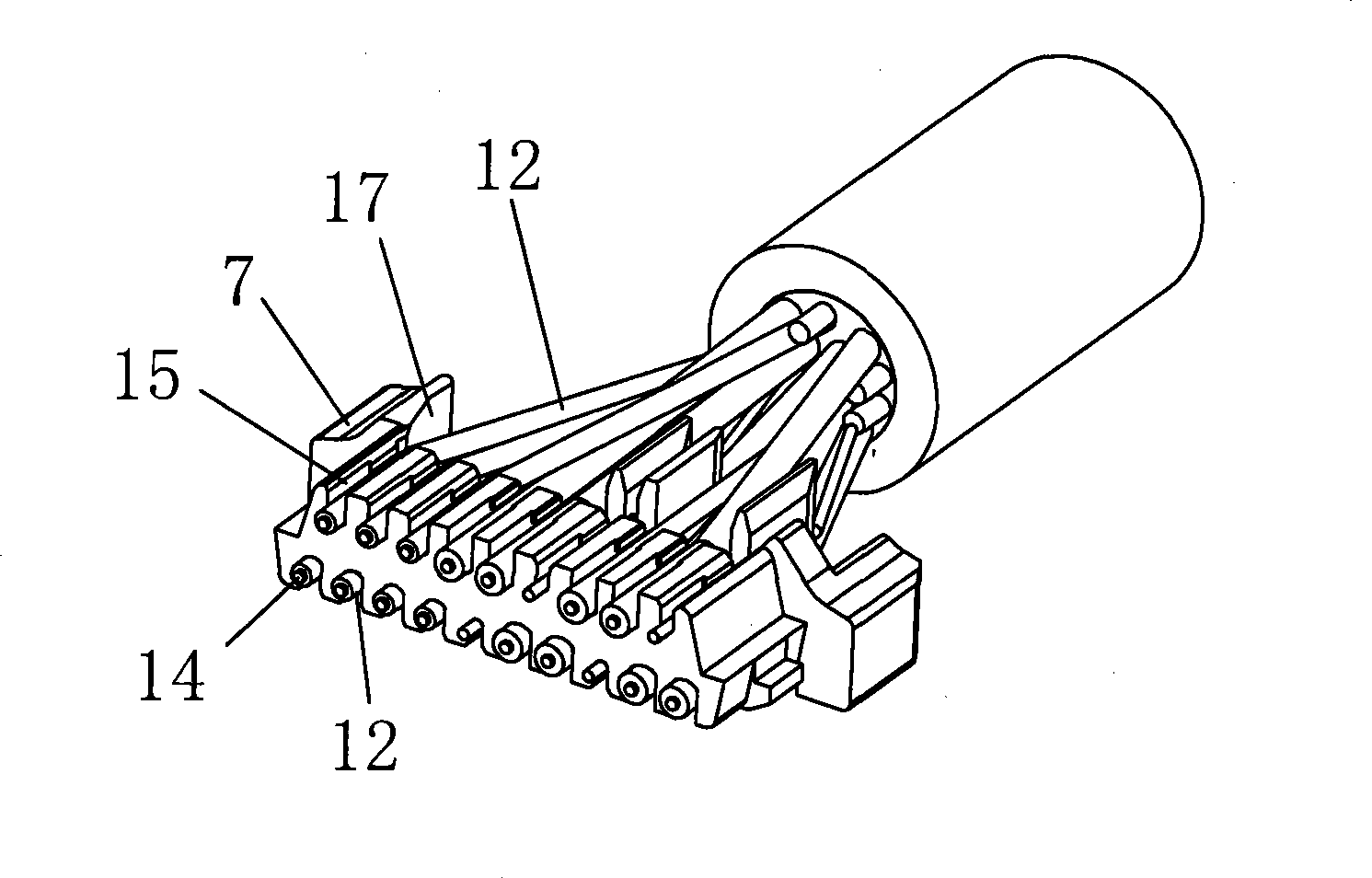

Net-cage electrode catheter

ActiveCN1947810AContact stabilityFully contactedCatheterDiagnostic recording/measuringMetallic electrodeEngineering

A net basket type electrode catheter for the stable contact between electrode and endocardium has a handle unit and a net basket unit consisting of a near-end annular coupler, a far-end annular coupler with soft head, and multiple metallic wires between said both coupler and with coated insulating layer. Said metallic wires are electrically connected to the electrode interface on handle unit. The metallic electrodes are at the middle of said metallic wires. When a push rod is moving forward, said metallic wires are curved to form a spherical body.

Owner:APT MEDICAL INC

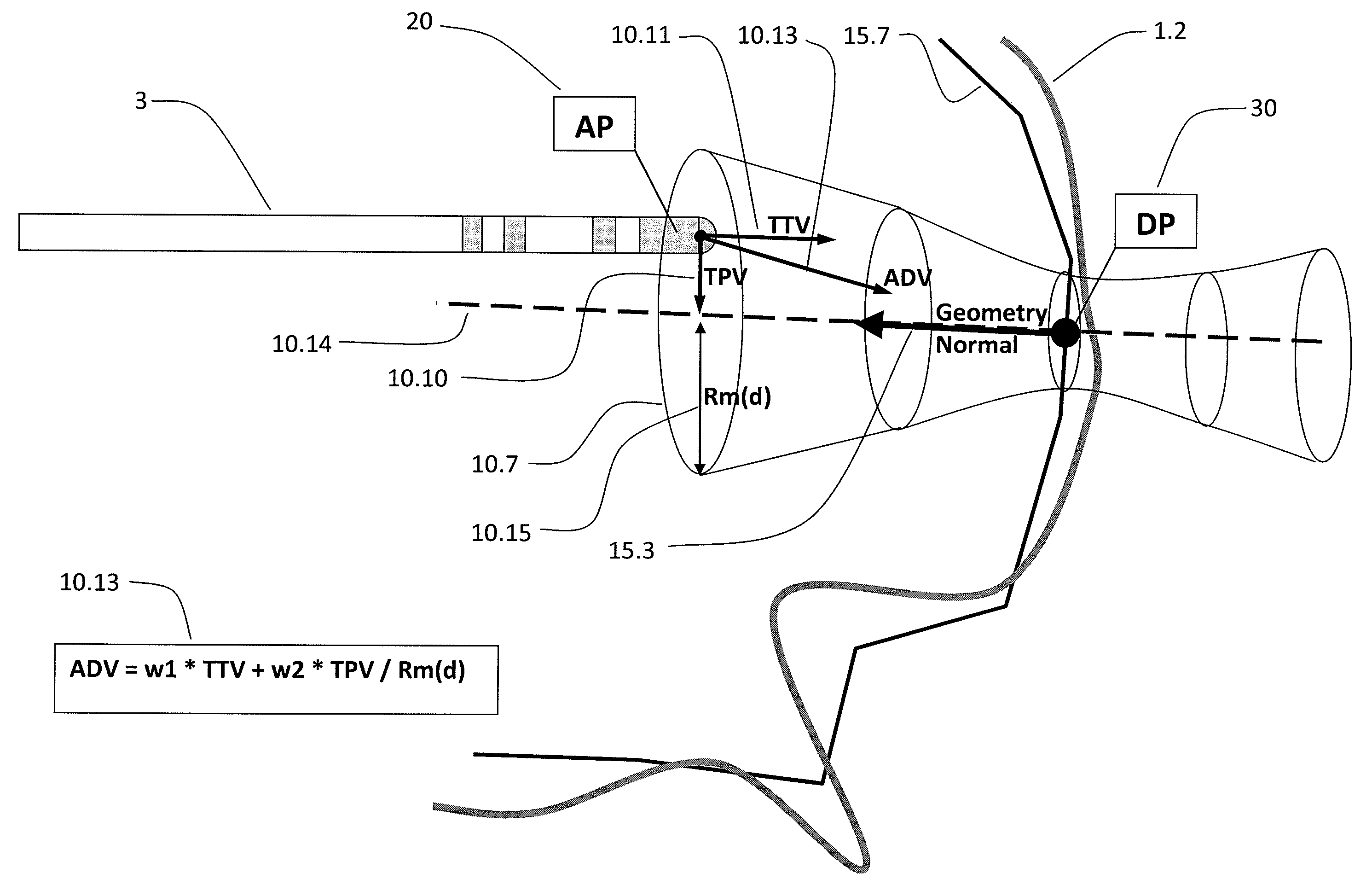

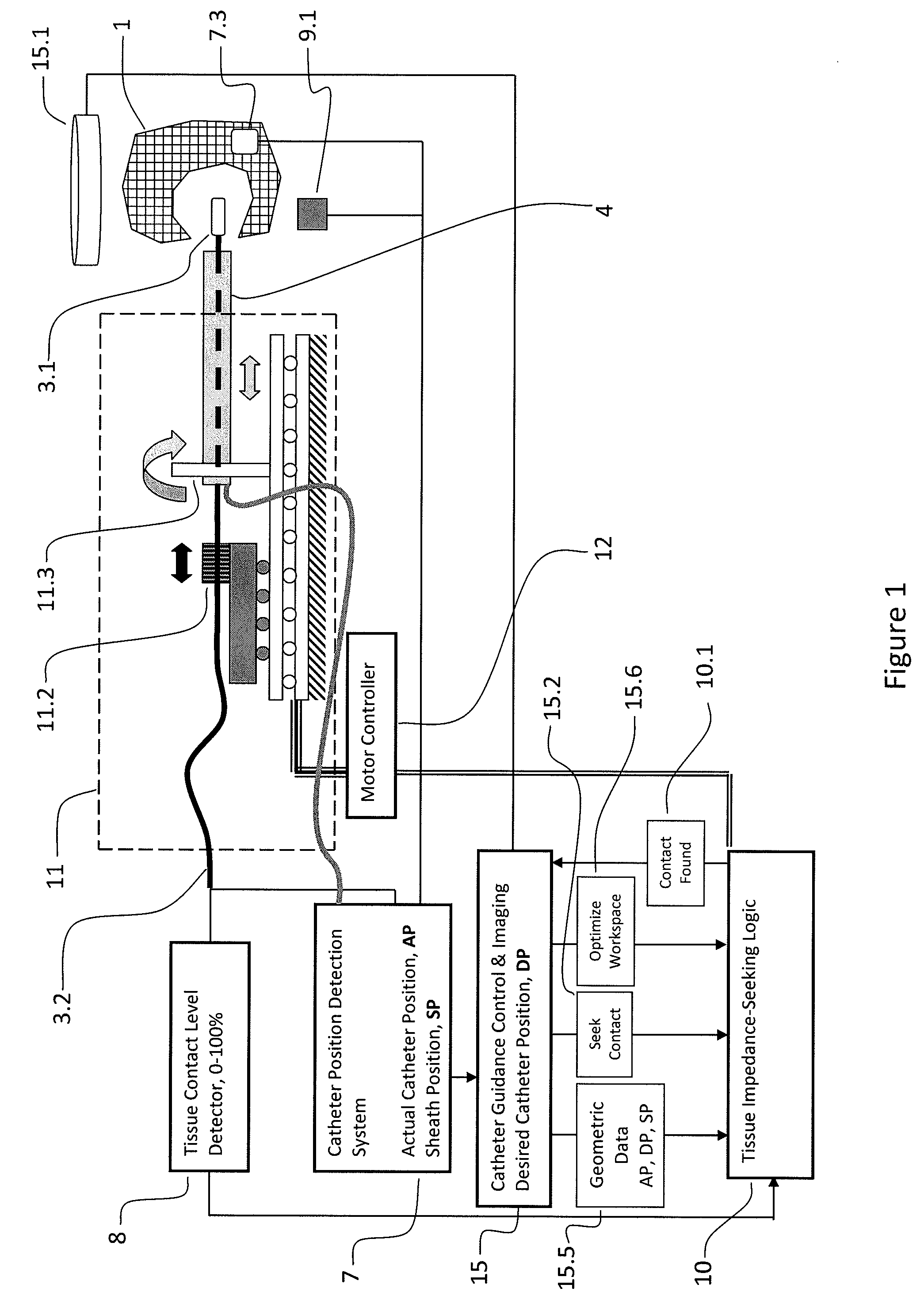

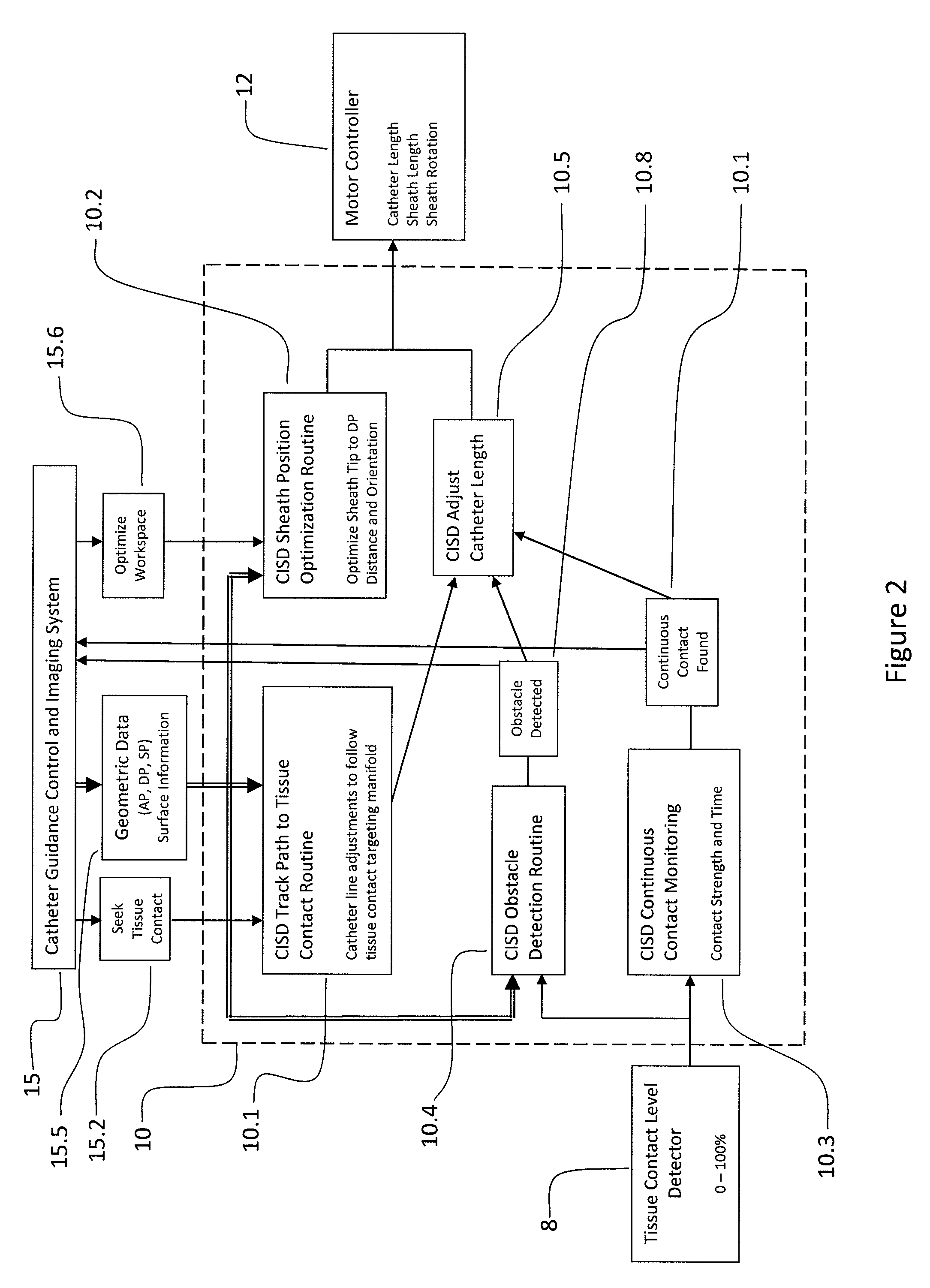

System and method for a catheter impedance seeking device

InactiveUS20100130854A1Optimization orientationEasy to controlDiagnostic recording/measuringSensorsSensing systemCardiac motion

A tissue-contact seeking method and apparatus is described that enhances catheter position detection and control systems in making and maintaining continuous tissue contact in a highly dynamic frame, such as under the rigors of cardiac motion. Tissue-seeking logical routines use a tissue contact sensing system to advance a catheter to relatively continuous tissue contact, or detect obstacles, in cooperation with the catheter position detection and control systems. Additional logical routines are capable of optimizing the contact direction of the catheter tip by controlling the rotation angle and chamber position of the introducer.

Owner:NEURO KINESIS CORP

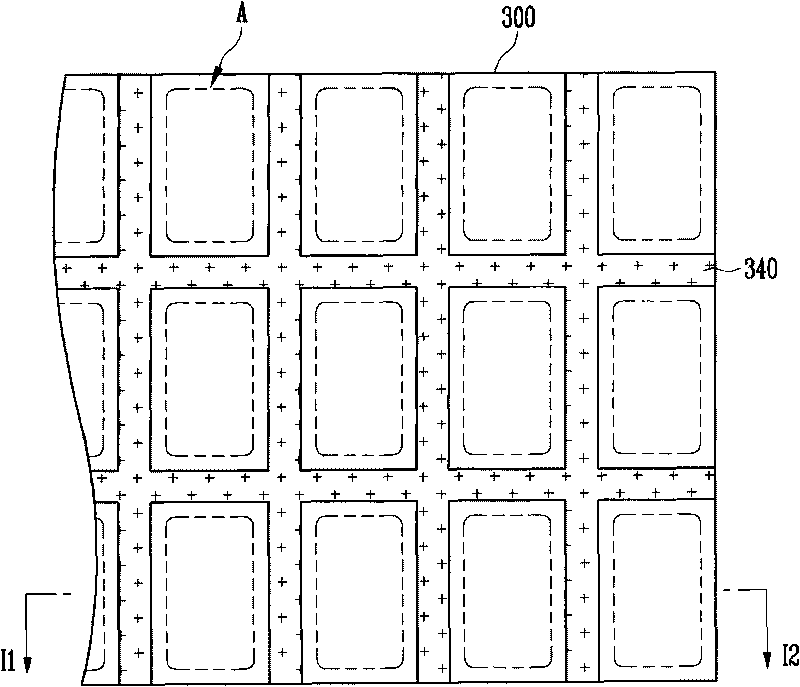

Organic light emitting display device

InactiveCN101728418ASimple structureReduce brightness differenceSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceOptoelectronics

Embodiments of the present invention provide an organic light emitting display device including: a plurality of light emitting elements on a first substrate, each of the plurality of light emitting elements including a first electrode and an organic light emitting layer, and a second electrode on the plurality of light emitting elements; a second substrate facing the first substrate with the plurality of light emitting elements therebetween; spacers on the second substrate corresponding to portions of the second electrode, the portions located on spaces between the plurality of light emitting elements; and an auxiliary electrode on the spacers and contacting the second electrode.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

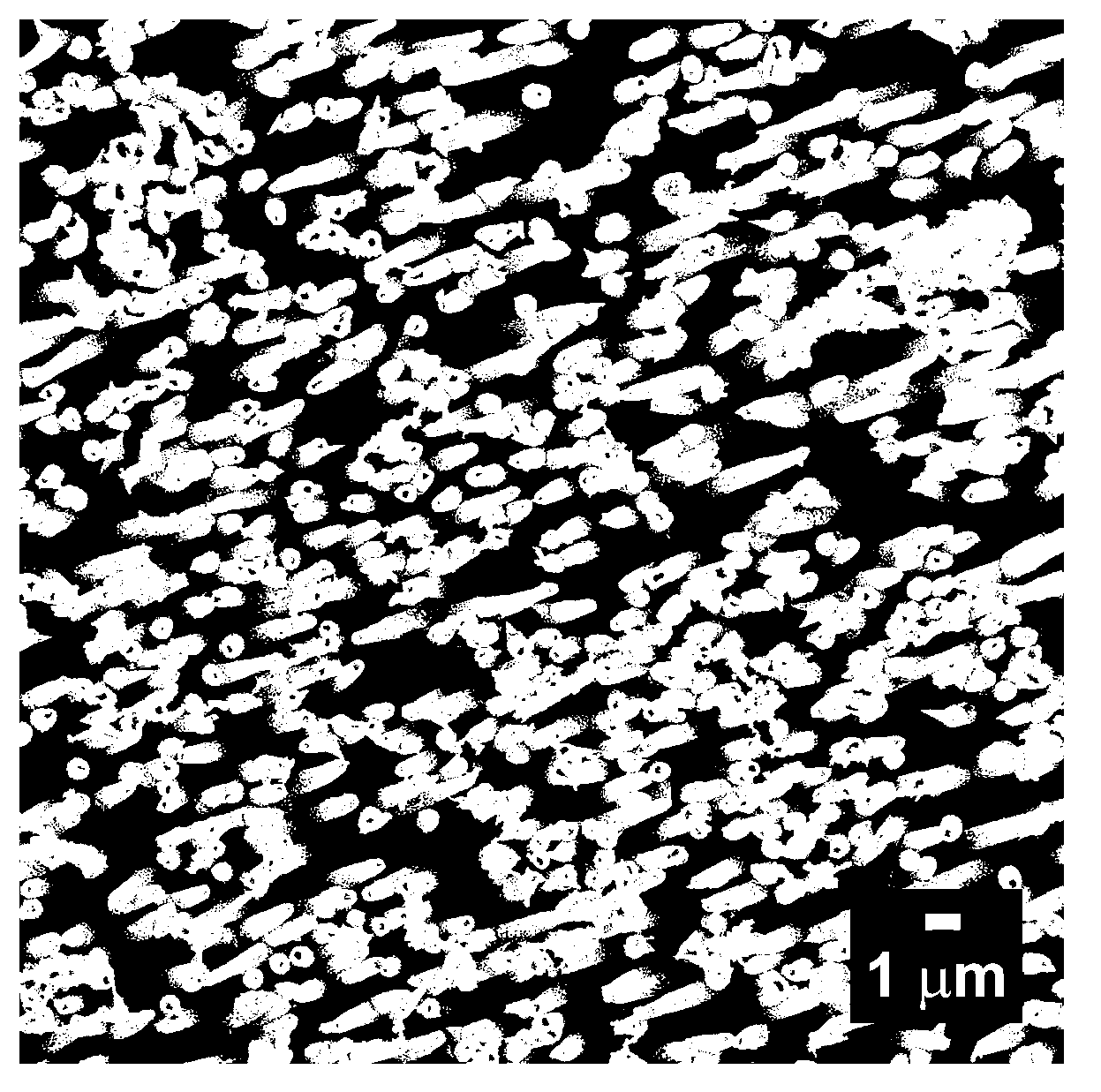

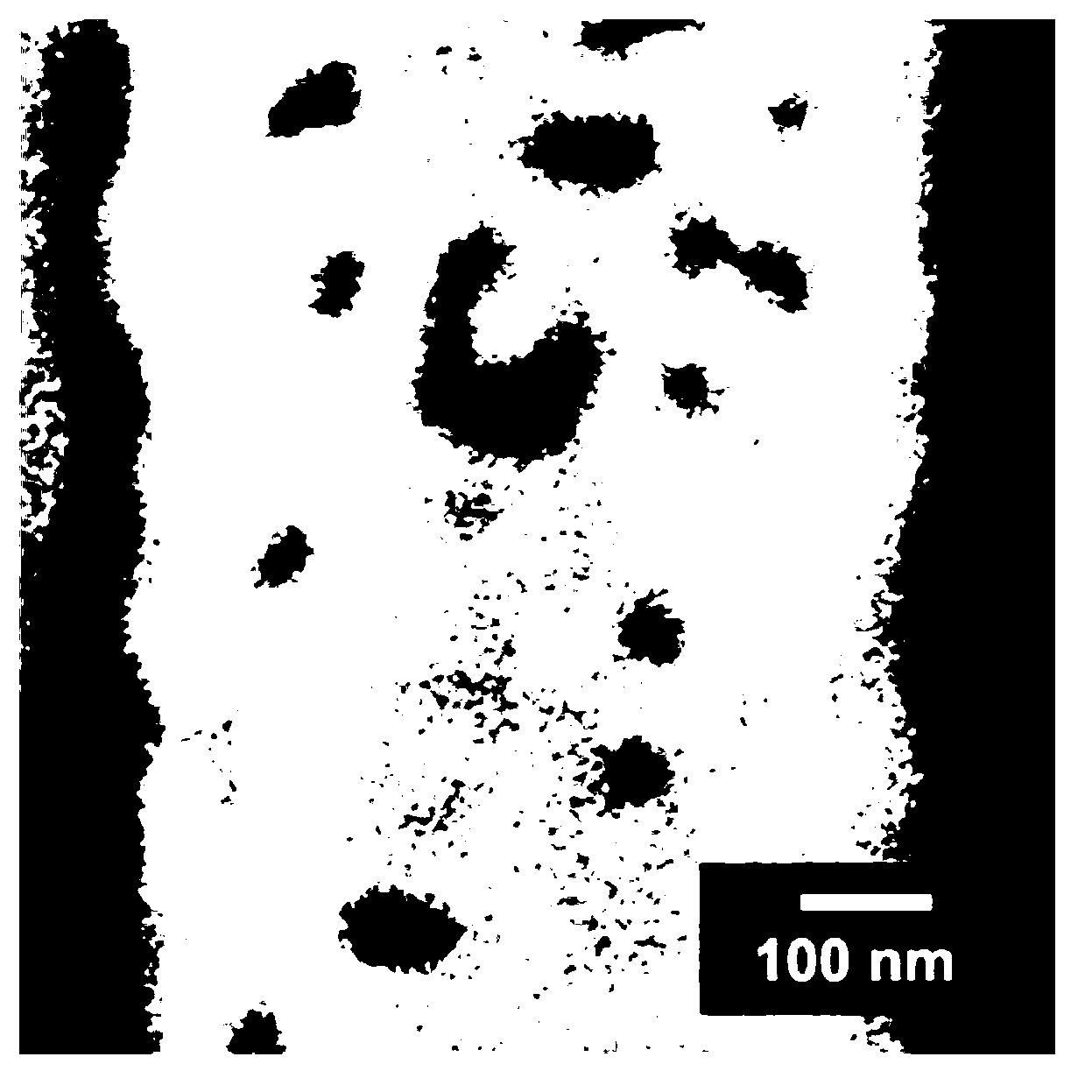

Three-dimensional ordered precious metal nanotube array electrode and preparation method thereof

ActiveCN103303861AArranged evenly and orderlyChemically stableMaterial nanotechnologyDecorative surface effectsPorous membraneAlloy

The invention discloses a three-dimensional ordered precious metal nanotube array electrode which comprises a precious metal nanotube array and a plane substrate electrode, wherein the precious metal nanotube array directly grows and fixed on the surface of the plane substrate electrode. The preparation method of the three-dimensional ordered precious metal nanotube array electrode comprises the steps of: fixing a porous membrane on the surface of the electrode, directly growing a nano short array in a pore passage of the porous membrane on the surface of the electrode through electrochemical deposition, continuously depositing an alloy nonotube in the pore passage of the porous membrane through chemical deposition or electrochemical deposition, performing dealloying on an alloy nonotube array electrode, so as to obtain a precious metal nanotube array electrode with holes in the tube wall, and removing a porous membrane template in membrane removal liquid, so as to obtain the three-dimensional ordered precious metal nanotube array electrode integrated with the electrode. The nanotube array directly grows on the substrate electrode, and a hole wall nanotube has a special structure, so that when the array electrode is applied to electrochemical sensor and biosensor research, stable and credible response signals can be obtained.

Owner:江苏先进无机材料研究院

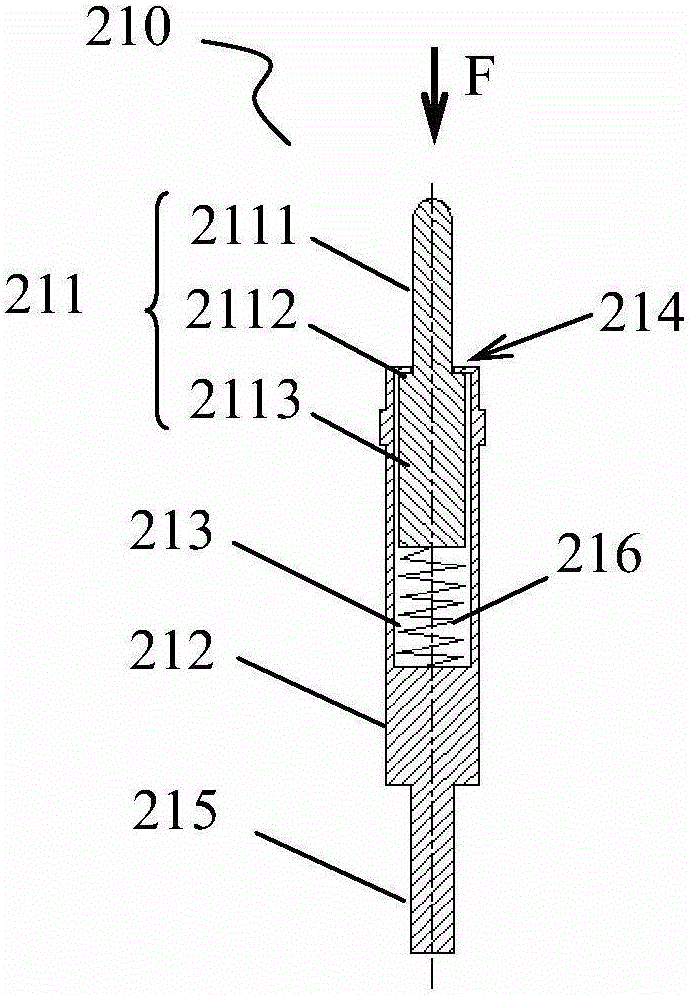

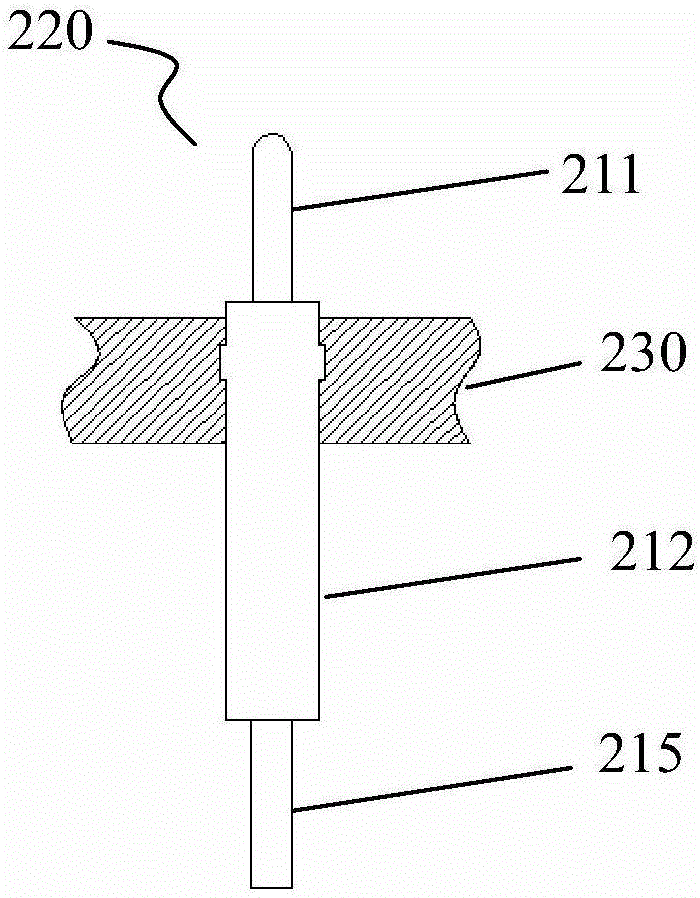

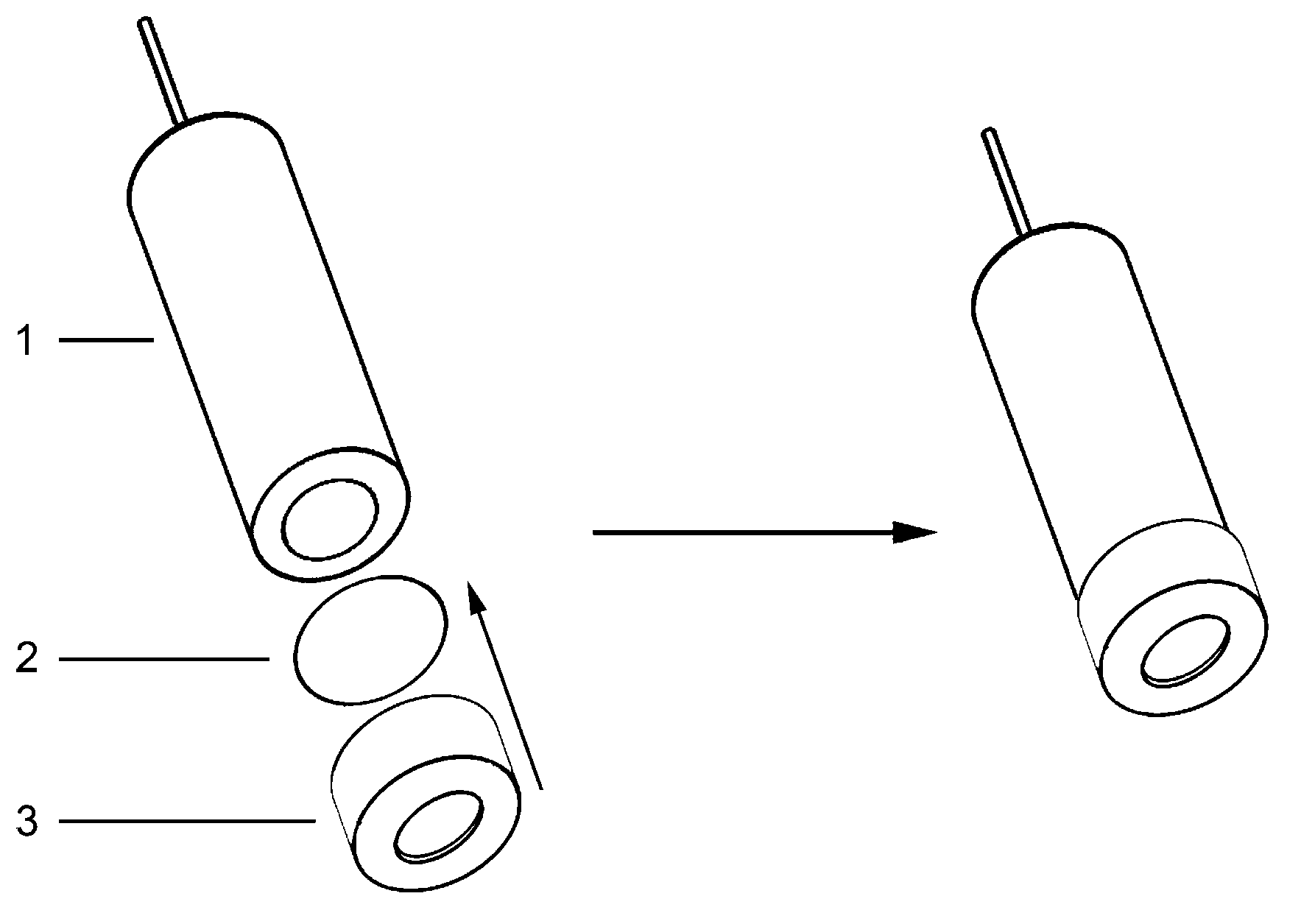

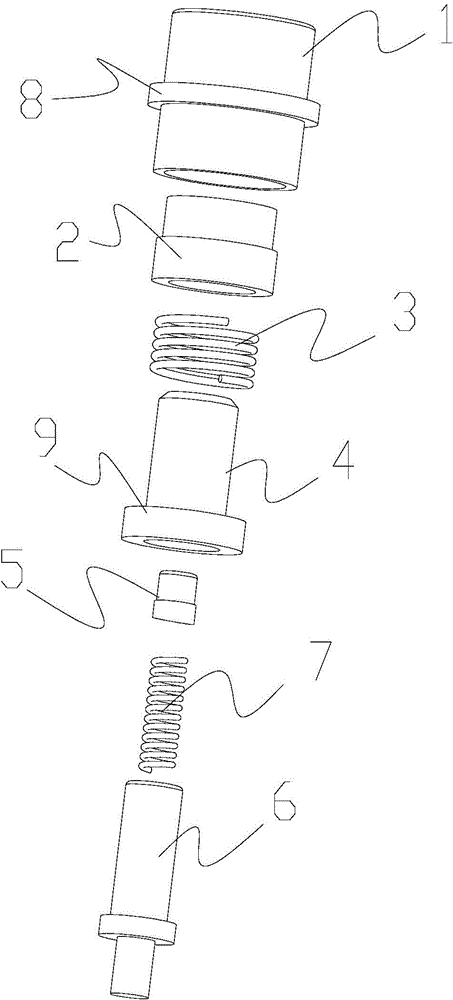

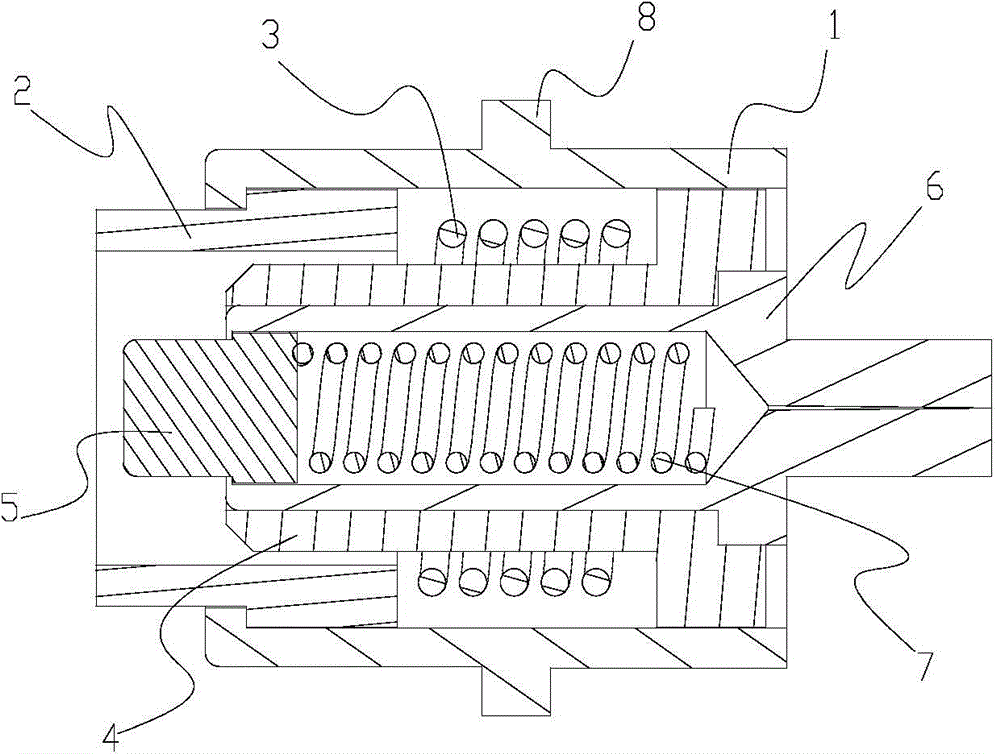

Novel pogo pin

InactiveCN104466484AContact stabilityEasy to installCoupling contact membersTwo-part coupling devicesBiomedical engineeringPogo pin

The invention discloses a novel pogo pin. The novel pogo pin comprises multiple insulated and concentric contact needles. Each contact needle corresponds to a needle tube matched with the contact needle, a tension spring is connected between each contact needle and the needle tube corresponding to the contact needle, and each contact needle can move in a telescopic mode in the axial direction of the corresponding needle tube. The needle tube corresponding to each contact needle is fixedly and electrically connected with a corresponding circuit, and each contact needle is elastically connected with a corresponding conductive terminal. By the adoption of the scheme, the contact needles can move in the telescopic mode along the corresponding needle tubes, it can be guaranteed that the contact needles stably make contact with contacts in the using process, and open circuits are avoided. It can be guaranteed that first contact needles and the second contact needles are independently separated through insulating bushes, and short circuits are avoided. Each contact needle is of a columnar boss structure with the front portion narrower than the rear portion, the contact needles and the needle tubes are easy to install in the assembly process, production efficiency is high, and no additional buckle structure is needed for fixation.

Owner:廖芳

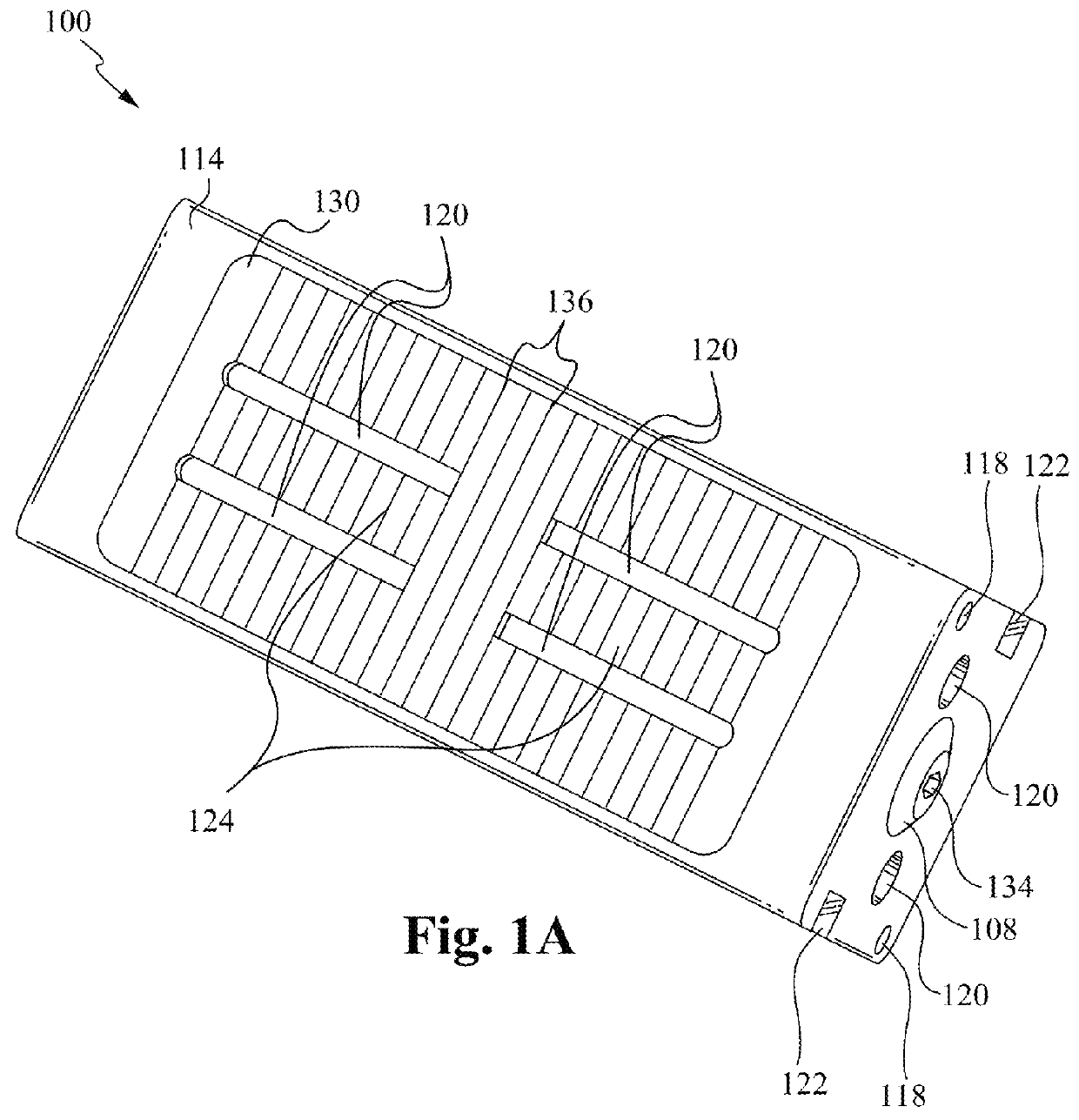

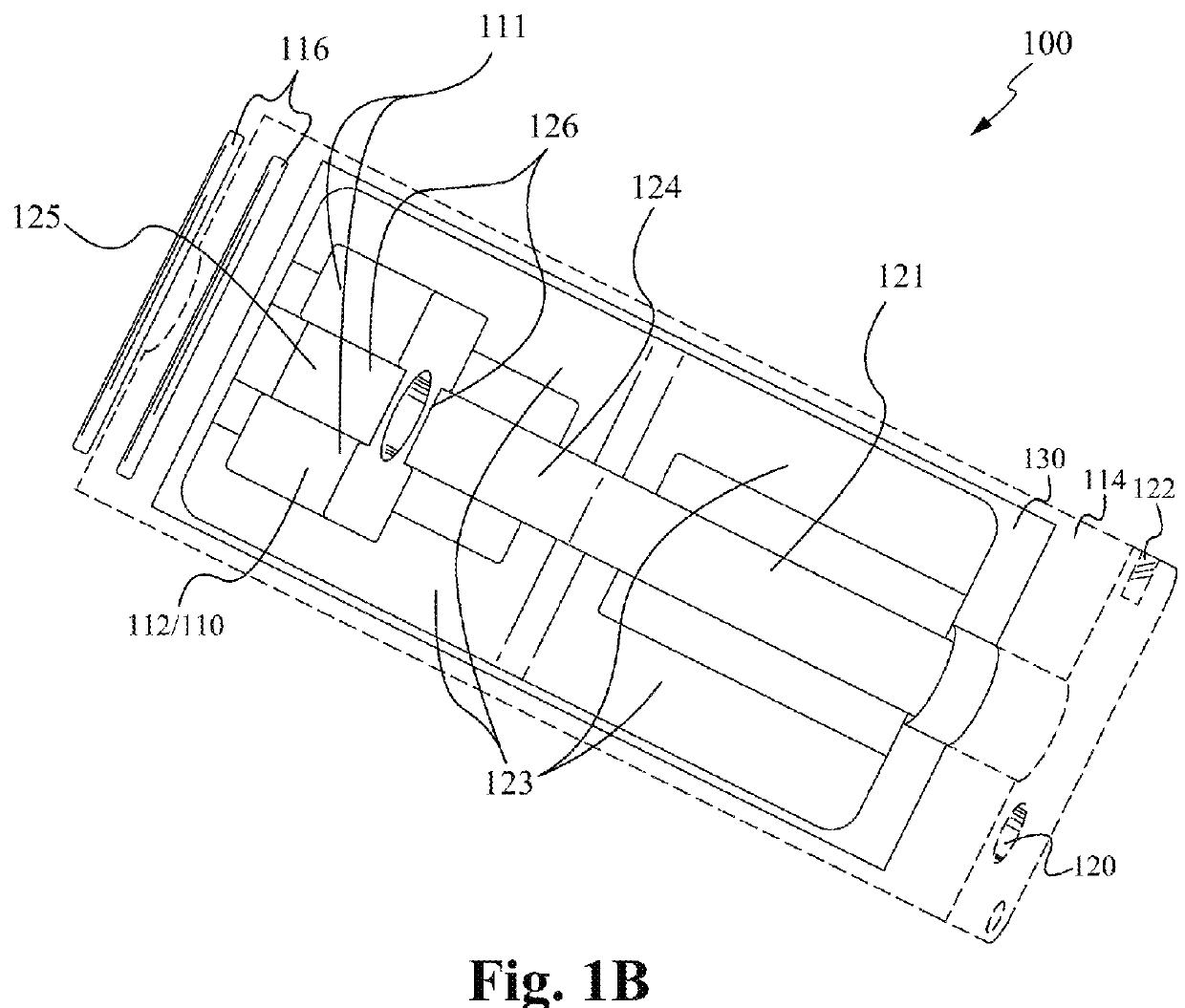

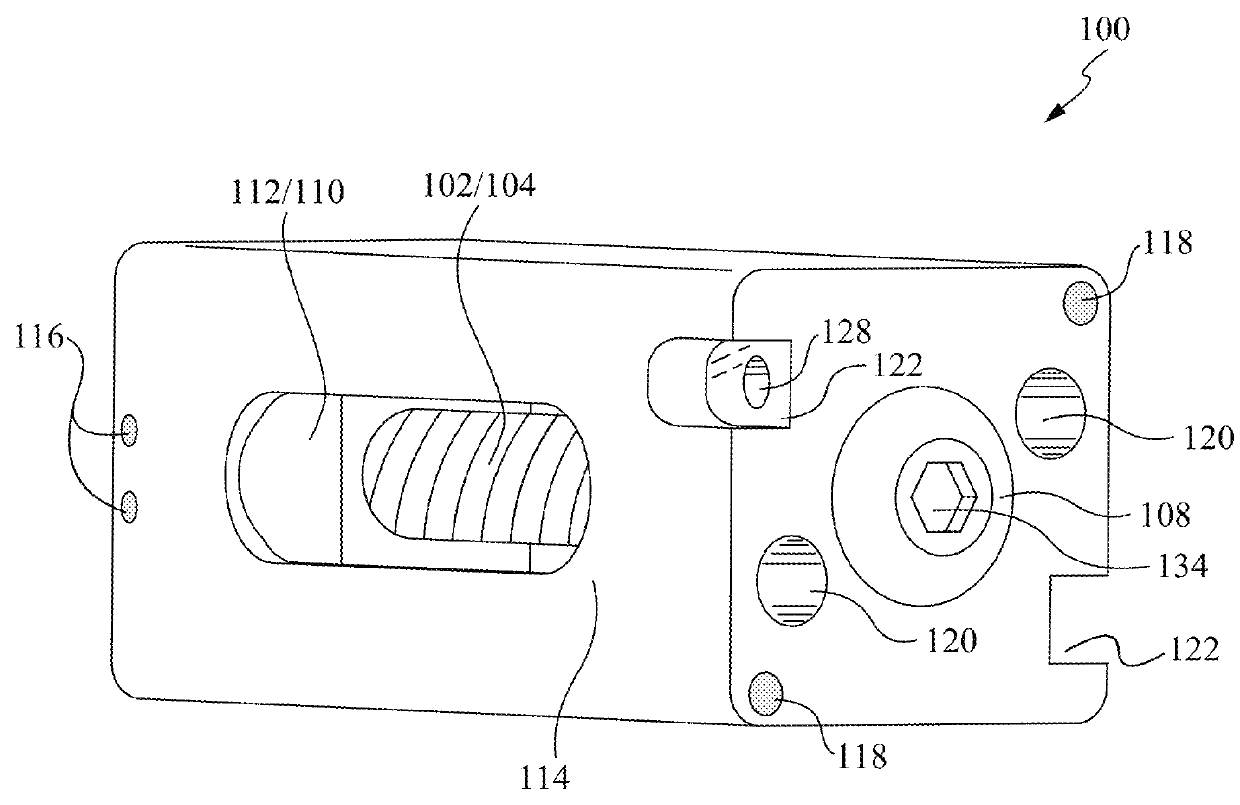

Bone fusion system, device and method including a measuring mechanism

A bone fusion method, system and device for insertion between bones that are to be fused together and / or in place of one or more of the bones, such as, for example, the vertebrae of a spinal column. The bone fusion device comprises one or more extendable tabs having a central rib. The bone fusion device includes one or more support channels configured to receive an insertion instrument that is then secured to the bone fusion device via a coupling mechanism. As a result, the coupled device is able to be securely positioned between vertebrae using the insertion instrument with minimal risk of slippage.

Owner:NEUROPRO TECH

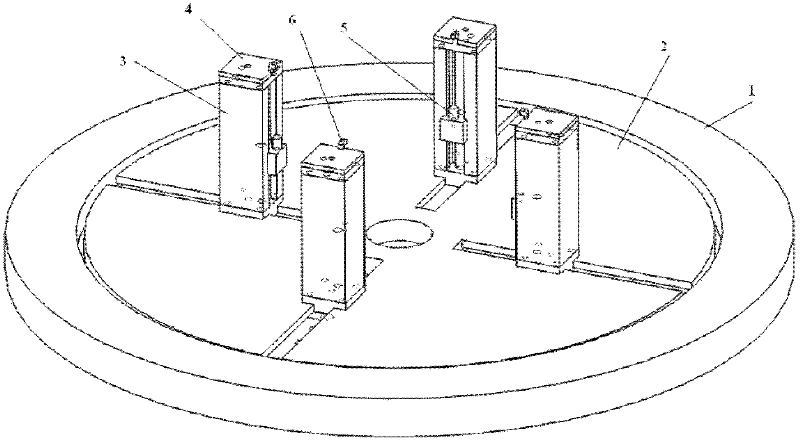

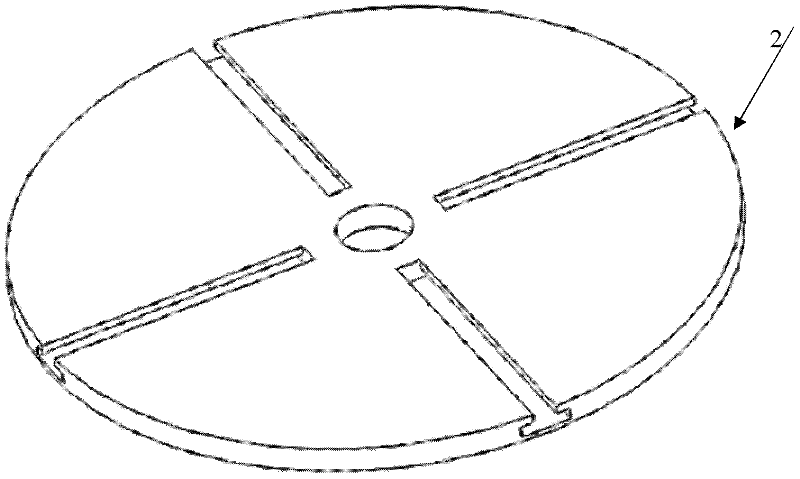

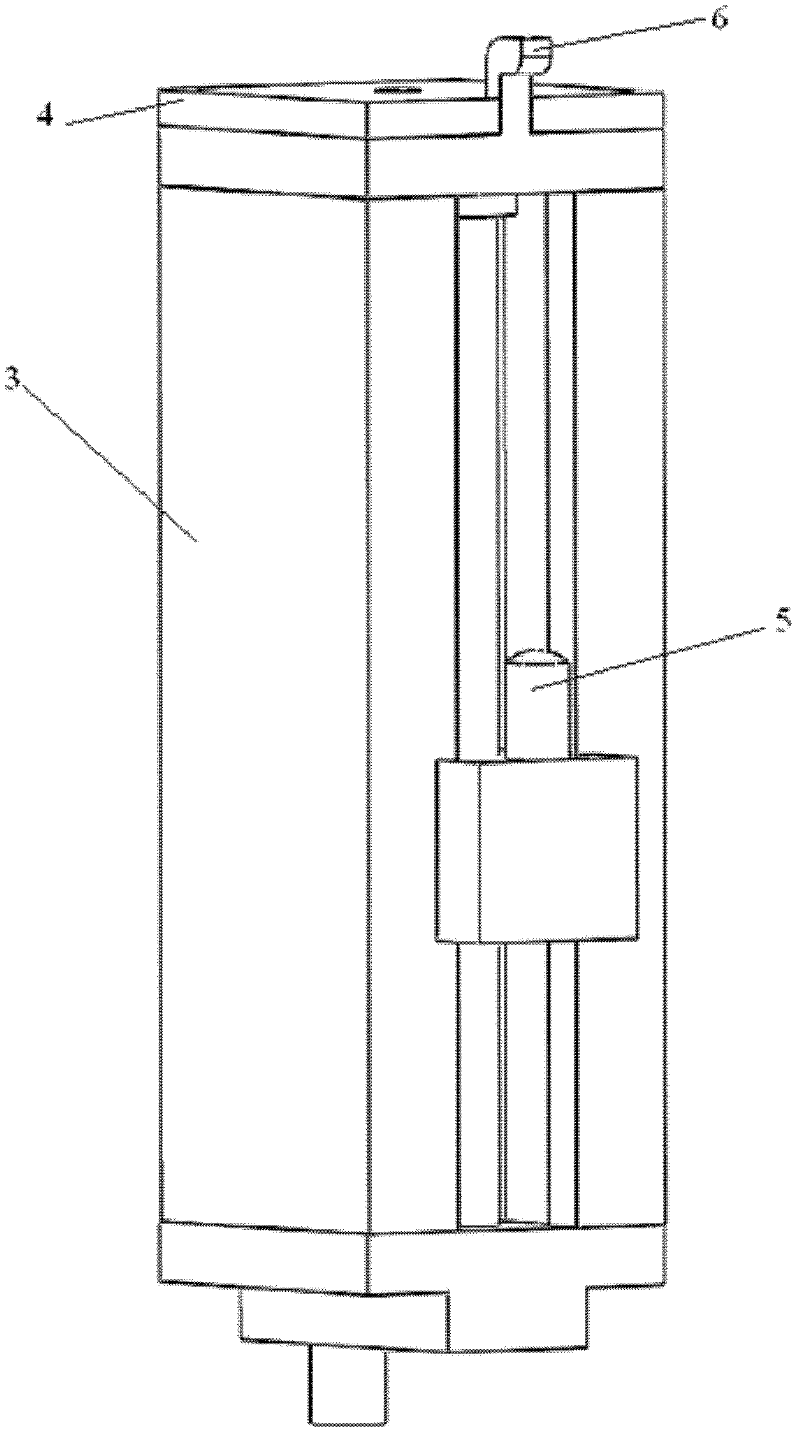

Work piece installing and clamping device in ion beam polishing process and method thereof

ActiveCN102501154ASimple structureSmall length and width dimensionsOptical surface grinding machinesSemiconductor/solid-state device manufacturingEngineeringRotary stage

The invention relates to a work piece installing and clamping device in an ion beam polishing process and a method thereof. The work piece installing and clamping device comprises a four-groove rotary platform which is fixed on a clamping main platform, wherein four grooves are symmetrically distributed on the four-groove rotary platform in orthogonal mode, four slide fixing columns are respectively arranged on the four grooves of the four-groove rotary platform, the slide fixing columns can be fixed or loosened by screwing fixing bolts on the slide fixing columns, ceramic cap pieces are fixed on the upper surfaces of the slide fixing columns, a hanging hook is respectively positioned on the lateral faces of the slide fixing columns, and a lifting support structure is respectively installed and clamped on the slide fixing column on the lower side of the hanging hook. The work piece installing and clamping method is that the four-groove rotary platform is fixed on the clamping main platform, work pieces can be installed and clamped on the four-groove rotary platform structure through the slide fixing columns, and the distance between the work piece and the slide fixing columns can be measured by utilizing a dial gauge to rorate the four-groove rotary platform, the positions of the slide fixing columns can be moved to adjust the same distance to guarantee center uniformity of the centers of the work pieces and the installing and clamping main platform, and accordingly accurate installing and clamping of the positions of the work pieces are achieved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

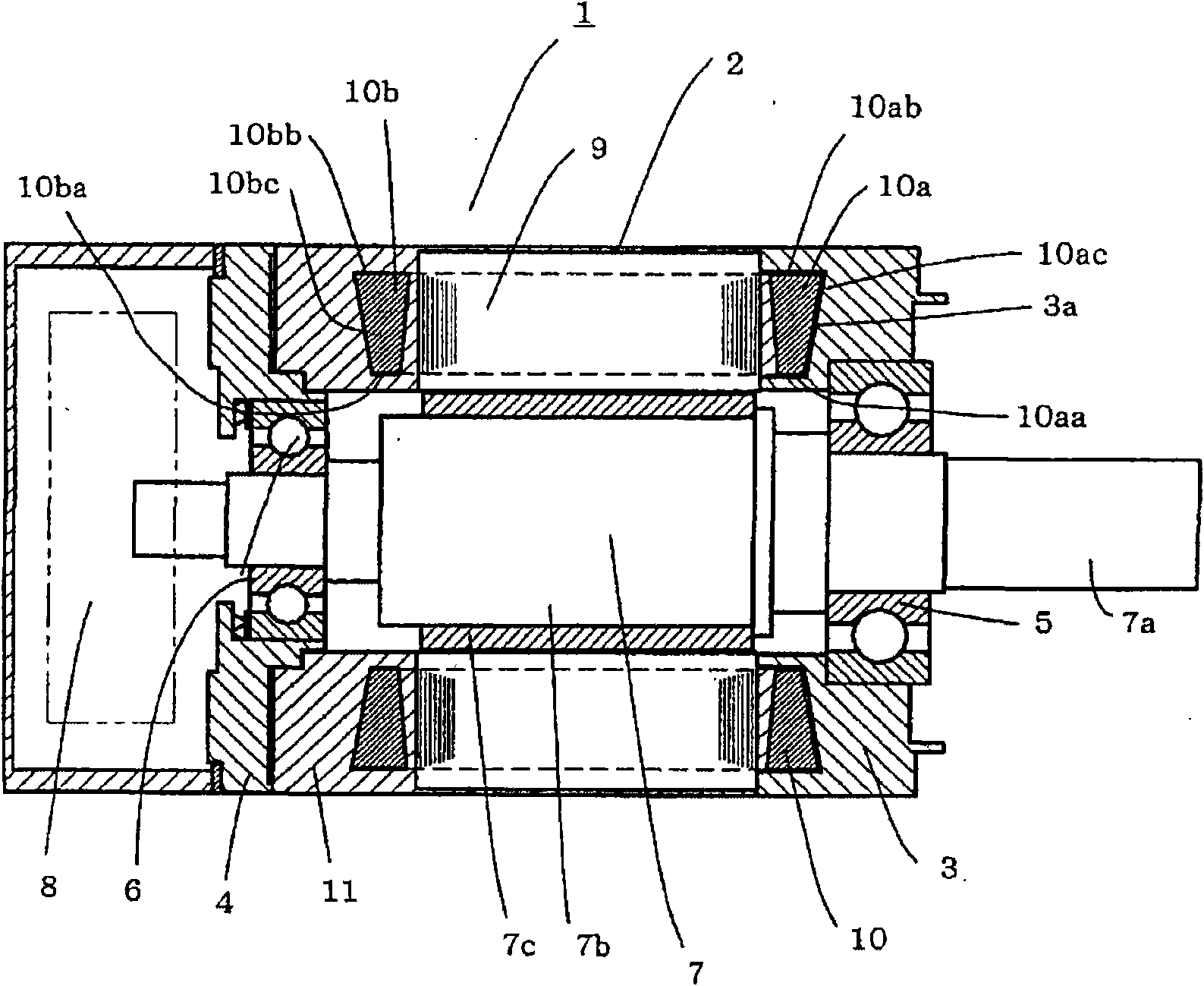

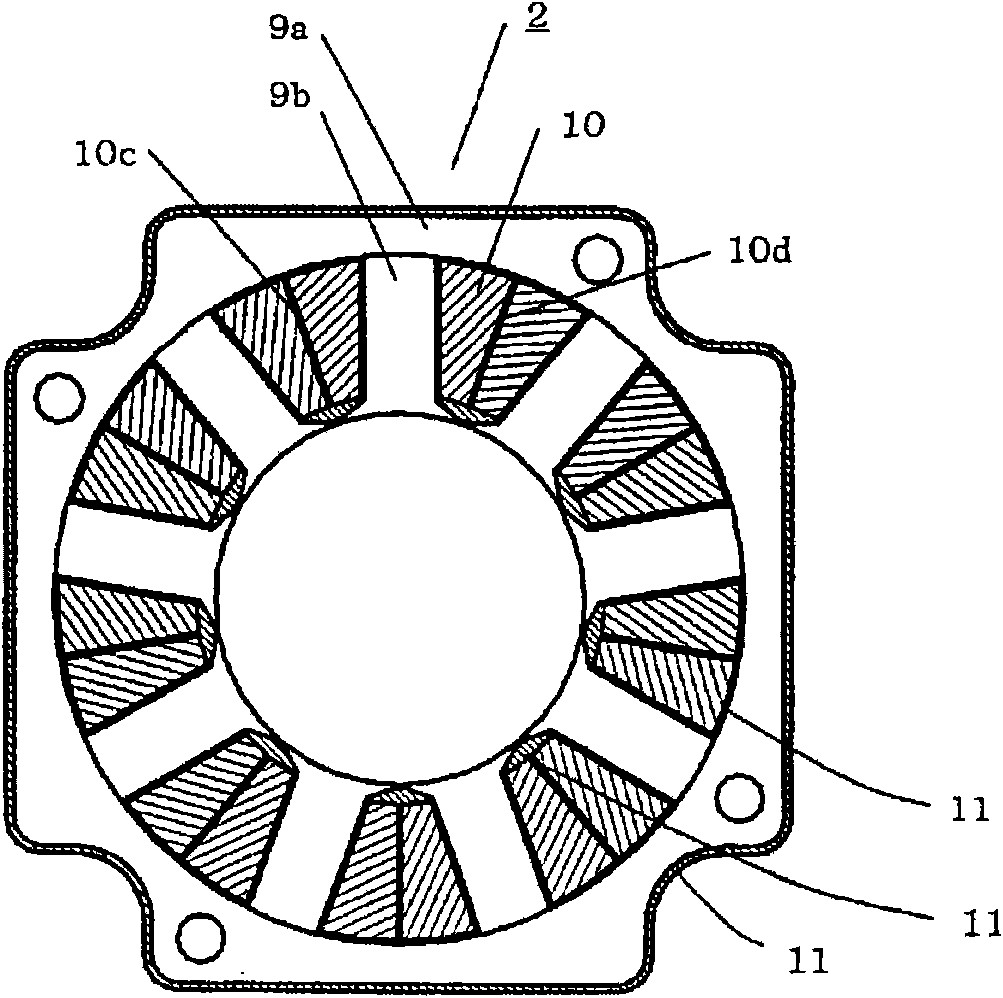

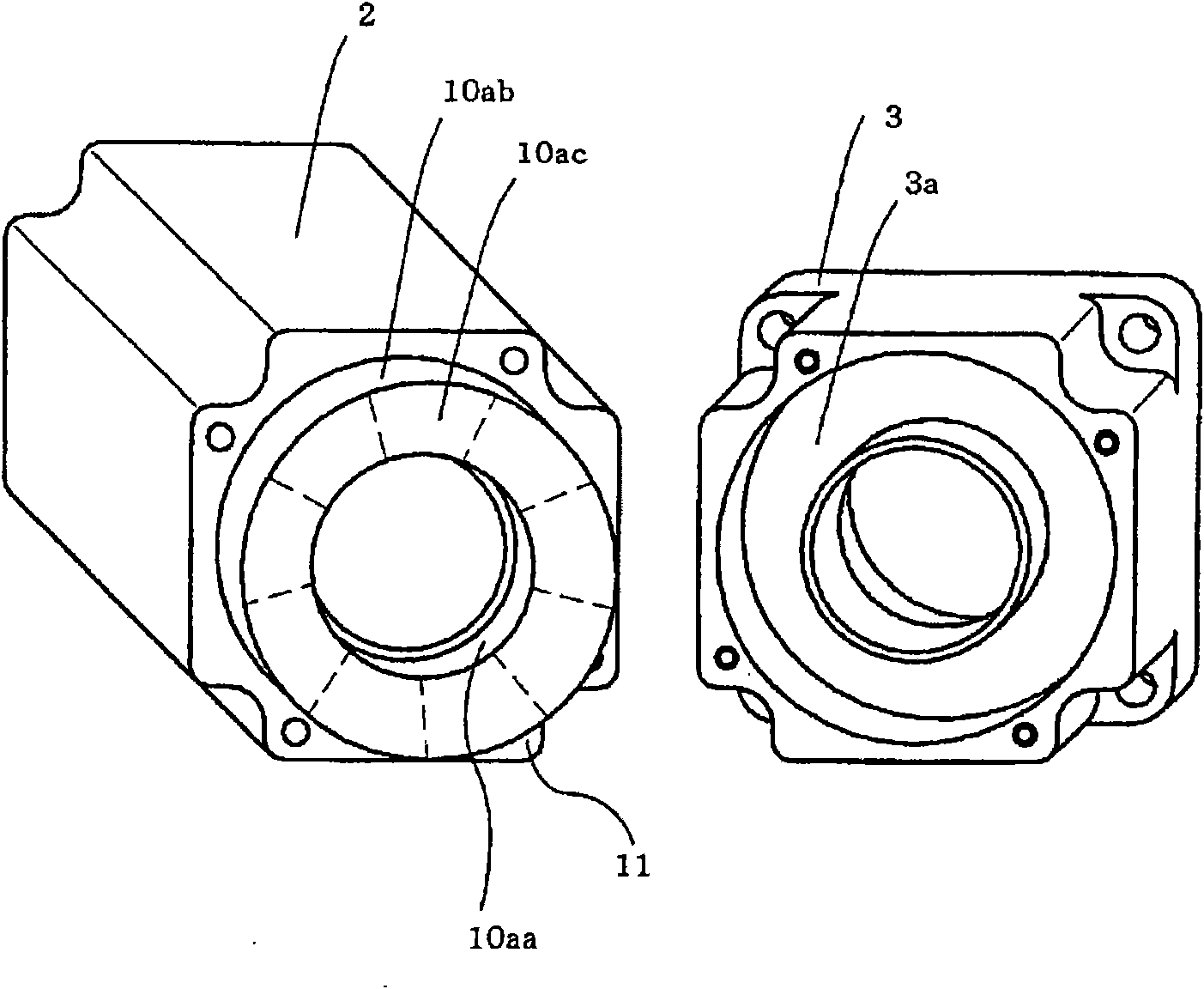

Revolving electric device, and its manufacturing method

ActiveCN101669267AEasy to fixContact stabilityWindings insulation shape/form/constructionManufacturing dynamo-electric machinesStator coilElectric motor

A rotary electric motor includes a cylindrical rotor having an outer peripheral side, a stator provided to surround the outer peripheral side of the rotor with a gap between the stator and the rotor,and a load side bracket having a recess and provided on a load side of the stator. The stator includes stator coils and a stator core having teeth portions around which the stator coils are wound. A load side coil end of each of the stator coils protrudes from a load side end face of the stator core. At least two of an inner peripheral surface, an outer peripheral surface, and an end face of the load side coil end contact an inner surface of the recess via an insulator.

Owner:YASKAWA DENKI KK

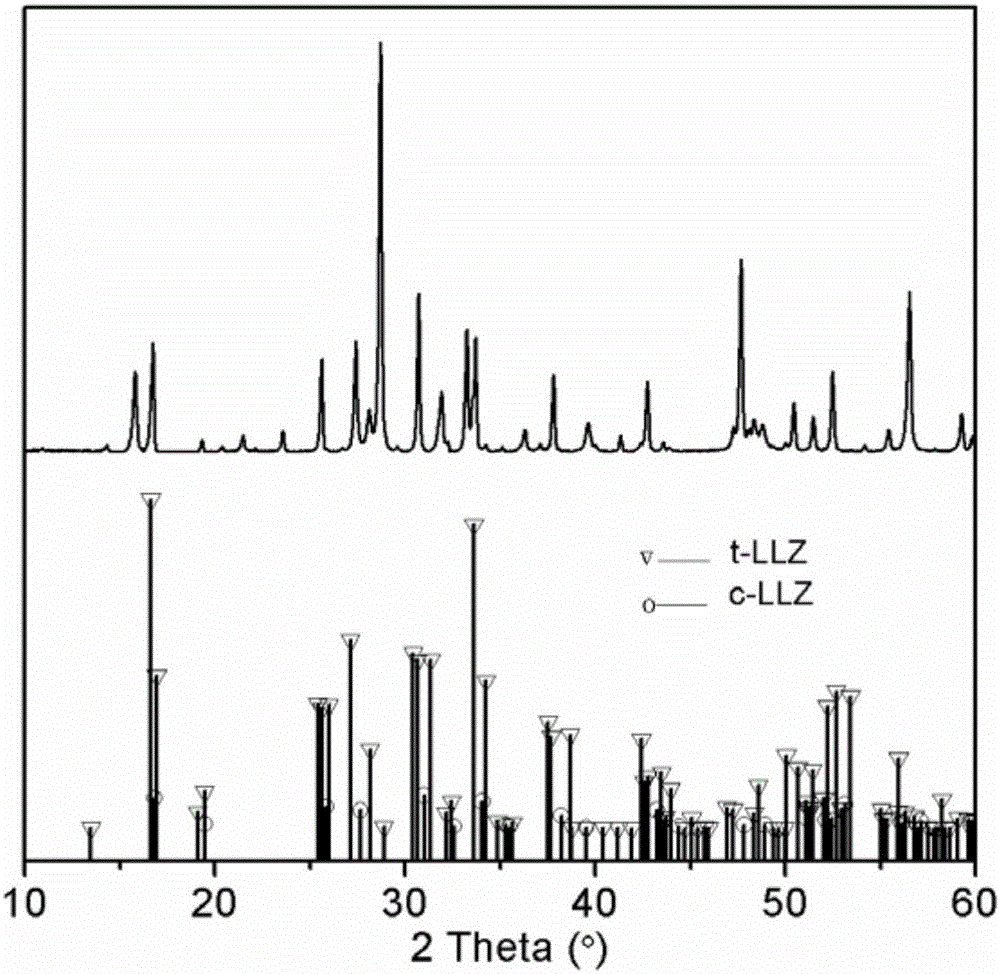

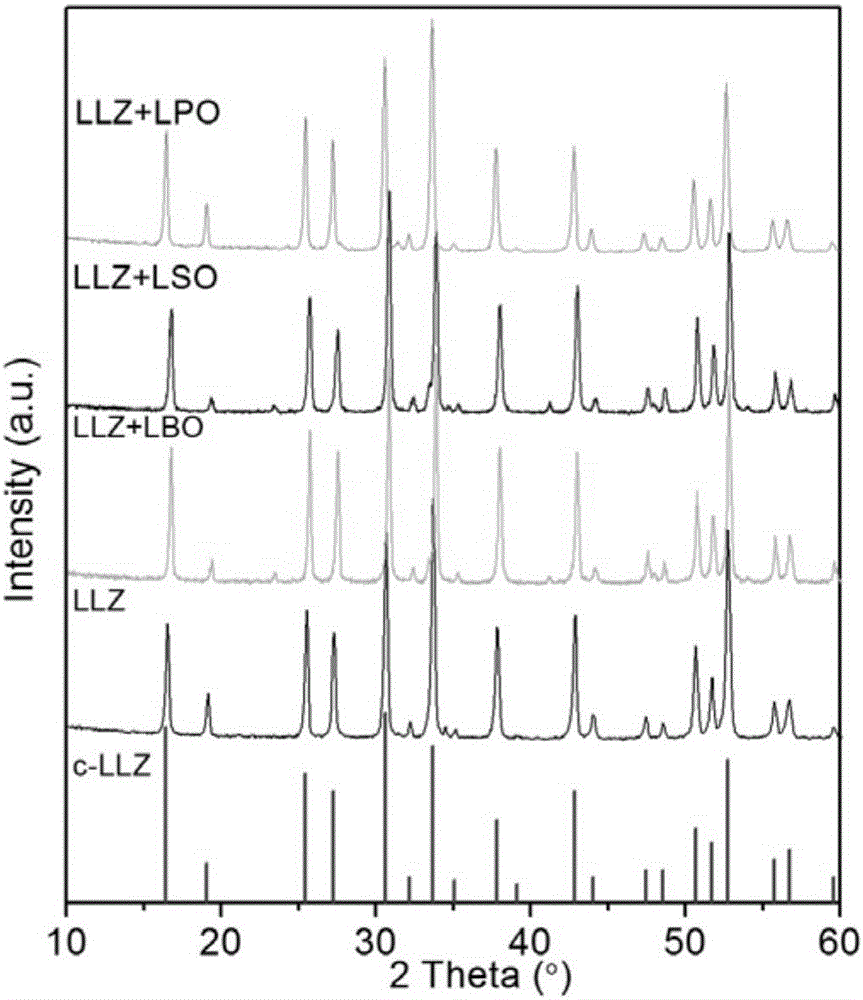

Solid electrolyte for inhibiting lithium dendrites growth in full-solid-state battery, and preparation method thereof

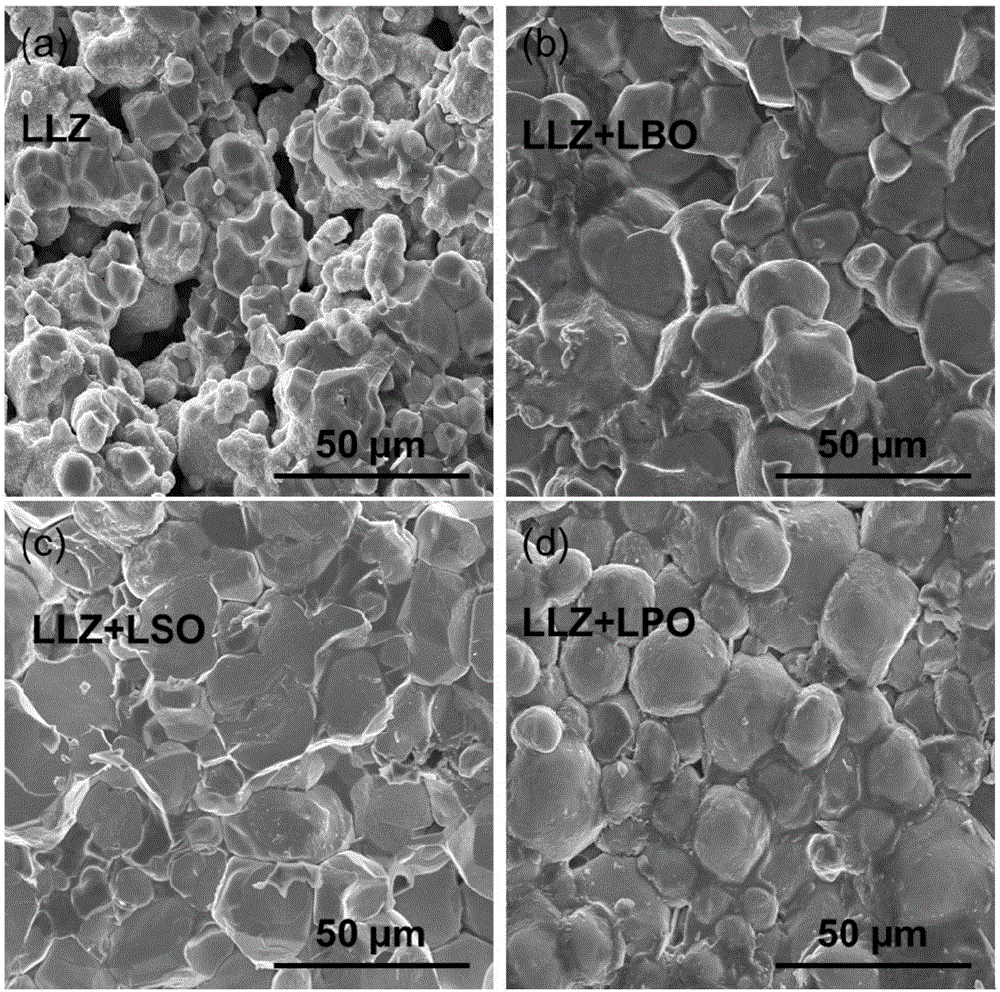

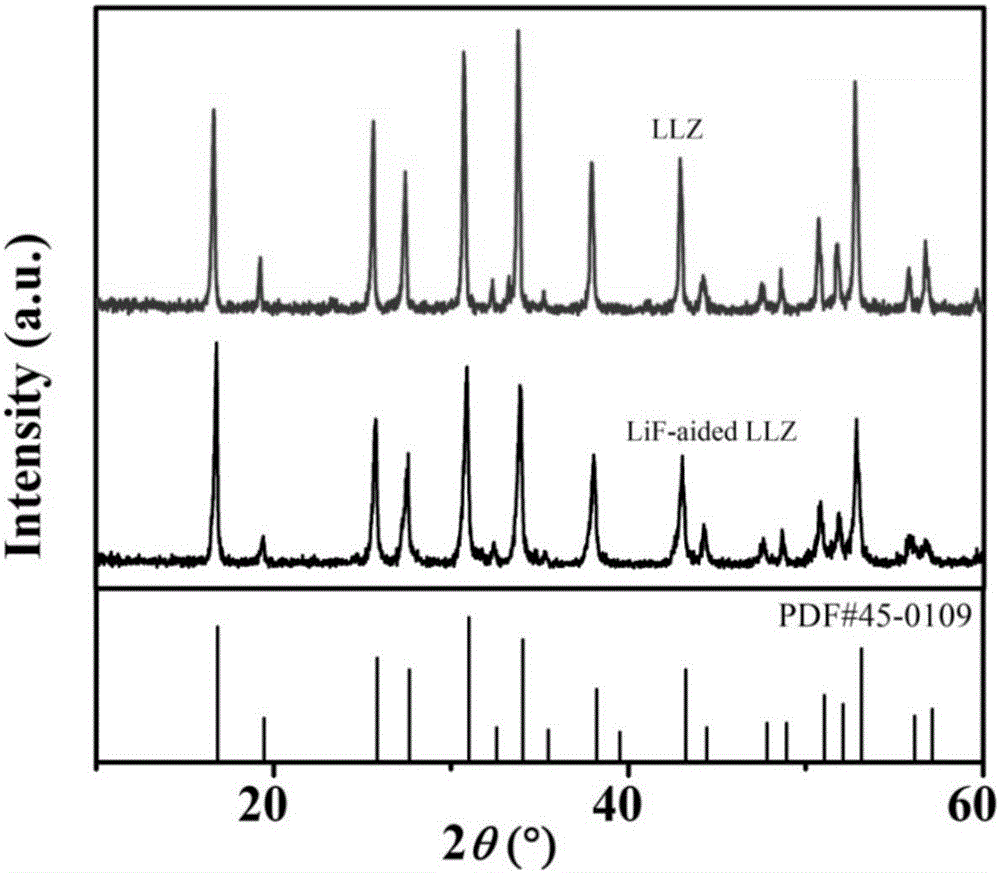

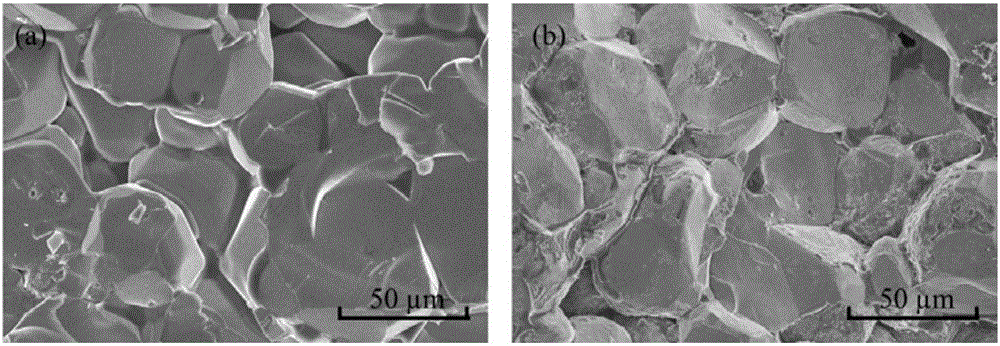

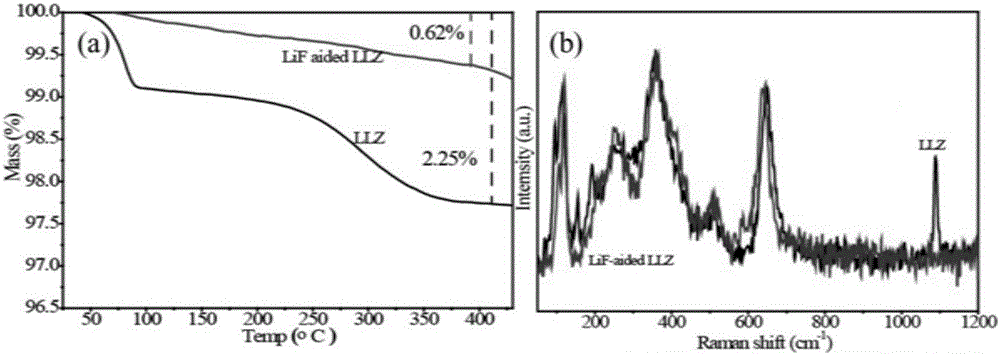

InactiveCN106848392AImprove microstructureImprove sintering performanceSecondary cellsSolid state electrolyteIonic conductance

The invention relates to a solid electrolyte for inhibiting lithium dendrites growth in a full-solid-state battery, and a preparation method thereof. The solid electrolyte is prepared from lithium-lanthanum-zirconium oxide ceramic and 0.1 to 10 weight percent of low-melting-point sintering aid. The preparation method comprises the following steps of dry grinding and uniformly mixing stoichiometric lithium carbonate, lanthanum oxide and zirconium oxide, and then presintering in a muffle furnace at the temperature of 900 DEG C to form a phase; adding the low-melting-point sintering aid into presintering powder, and dry grinding and mixing to obtain a manual pressed sheet sample; densifying during a further high-temperature sintering process to form the solid electrolyte with high ionic conductance, stable performance and high repeatability. Compared with the prior art, without influencing a conductive property of a lithium-contained garnet lithium ion, a low-cost second phase is used so that the conductive property of the lithium ion at a crystal boundary part is improved, the solid electrolyte can better realize lithium ion transmission and plays a role in inhibiting the lithium dendrites growth in the full-solid-state battery, and the safety of the lithium battery is improved.

Owner:SHANGHAI JIAO TONG UNIV

Solid electrolyte capable of lowering interface resistance on metal lithium electrode, and preparation method for solid electrolyte

ActiveCN106129466AReduce lossReduce time lossSecondary cellsElectrolyte immobilisation/gelificationSolid state electrolyteState of art

The invention relates to a solid electrolyte capable of lowering interface resistance on a metal lithium electrode, and a preparation method for the solid electrolyte. The preparation method comprises the steps of mixing lithium carbonate, lanthanum oxide and zirconium oxide, and uniformly grinding the mixture by a dry grinding method; then sintering the mixture in a muffle furnace, and grinding to obtain mother powder, and tabletting the mother powder; putting the tablet-shaped material into a crucible with a cover; then performing mother powder filling and sintering in the muffle furnace to obtain the compact ceramic sheet; and polishing the ceramic sheet until the surface of the ceramic sheet is smooth to obtain the solid electrolyte. Compared with the prior art, the electrolyte prepared by the method has the advantages of absence of impure phase on the surface, high relative density, low interface resistance on the metal lithium electrode, and the like.

Owner:SHANGHAI JIAO TONG UNIV

Single-drive peristaltic pipeline robot

ActiveCN108758166AAvoid Problems That Difficult to Work TogetherSimple structurePigs/molesEngineeringFixed position

The invention discloses a single-drive peristaltic pipeline robot. The single-drive peristaltic pipeline robot comprises a front supporting mechanism and a rear supporting mechanism which can sequentially make contact with the inner wall of a pipeline and have the function of position fixing. The single-drive peristaltic pipeline robot further comprises a pushing mechanism pushing the front supporting mechanism to move relative to the rear supporting mechanism. The rear supporting mechanism comprises a plurality of rear telescopic feet, a rear fixing support and a rear sliding groove rotationdisc, wherein the rear telescopic feet are in sliding connection to the rear fixing support, the rear sliding groove rotation disc is rotationally connected to the rear fixing support, rear guiding grooves are formed in the rear sliding groove rotation disc, and rear positioning columns are arranged at one ends of the rear telescopic feet. The rear positioning columns stretch into the rear guidinggrooves and can slide in the rear guiding grooves so that the positions of the rear telescopic feet relative to the rear fixing support can be adjusted. According to the single-drive peristaltic pipeline robot, only one motor is used for achieving alternate telescopic and relative movement of the front supporting mechanism and the rear supporting mechanism, the structure is simple, reliability ishigh, and self-adaption steering capability is good.

Owner:WUHAN UNIV OF TECH

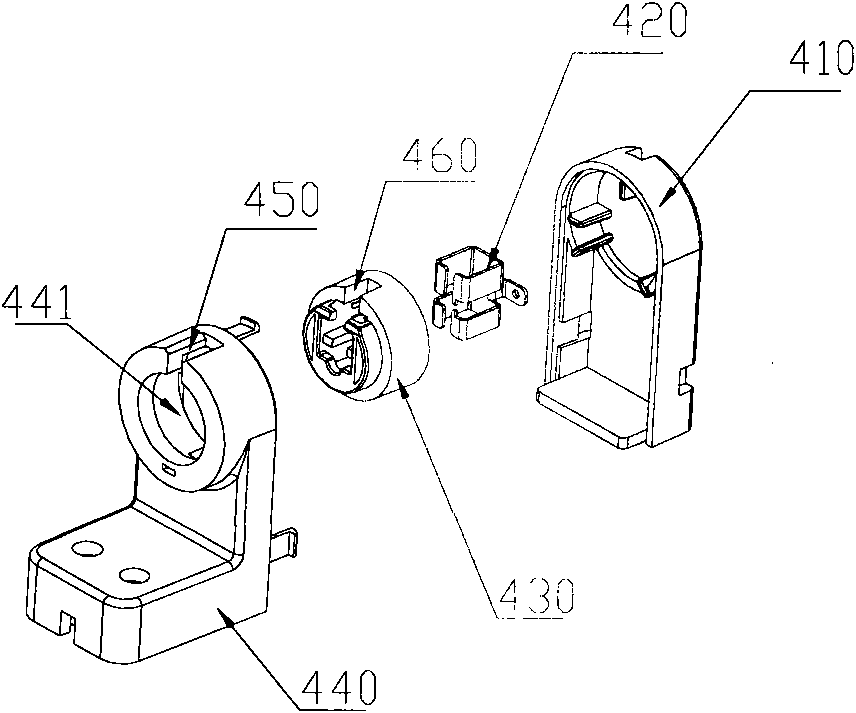

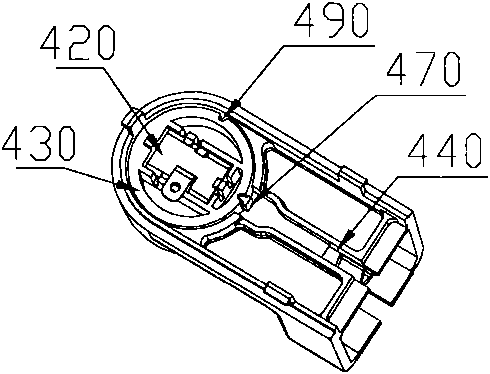

Explosion-proof fluorescent lamp

InactiveCN101655221AEasy to usePrevent rotationLighting support devicesElectric circuit arrangementsEngineeringLight head

The invention relates to an explosion-proof fluorescent lamp comprising a lamp box, a transparent module, a tube and a lamp holder module. The transparent module is fastened with the lamp box to forma sealing cavity. The tube is arranged in the sealing cavity and the lamp holder module is used for fixing an electrode holder and realizing electric connection. The lamp holder module comprises a lamp holder housing provided with a clip hole and a lamp cap holder which is sleeve-connected in the clip hole and rotates relative to the lamp holder housing. The lamp holder housing is provided with afirst bayonet and the lamp cap holder is provided with a second bayonet. The lamp cap holder rotates relative to the lamp holder housing to drive the second bayonet and the first bayonet to be alignedwith each other to form a channel or to be staggered. In the explosion-proof fluorescent lamp, the lamp cap holder capable of rotating relative to the lamp holder housing is arranged on the lamp holder module, and a wedge-shaped notch arranged on the lamp cap holder is adaptive to and clip-connected with a wedge-shaped column arranged on the lamp holder housing to prevent relative rotation between the lamp cap holder and the lamp holder housing, thus avoiding separation of the tube from the lamp holder module and enabling the tube to be fixed with the lamp holder firmly so as to ensure stablecontact between the electrode of the tube and the conductive electrode plate of the lamp holder and ensure normal use of the fluorescent lamp.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

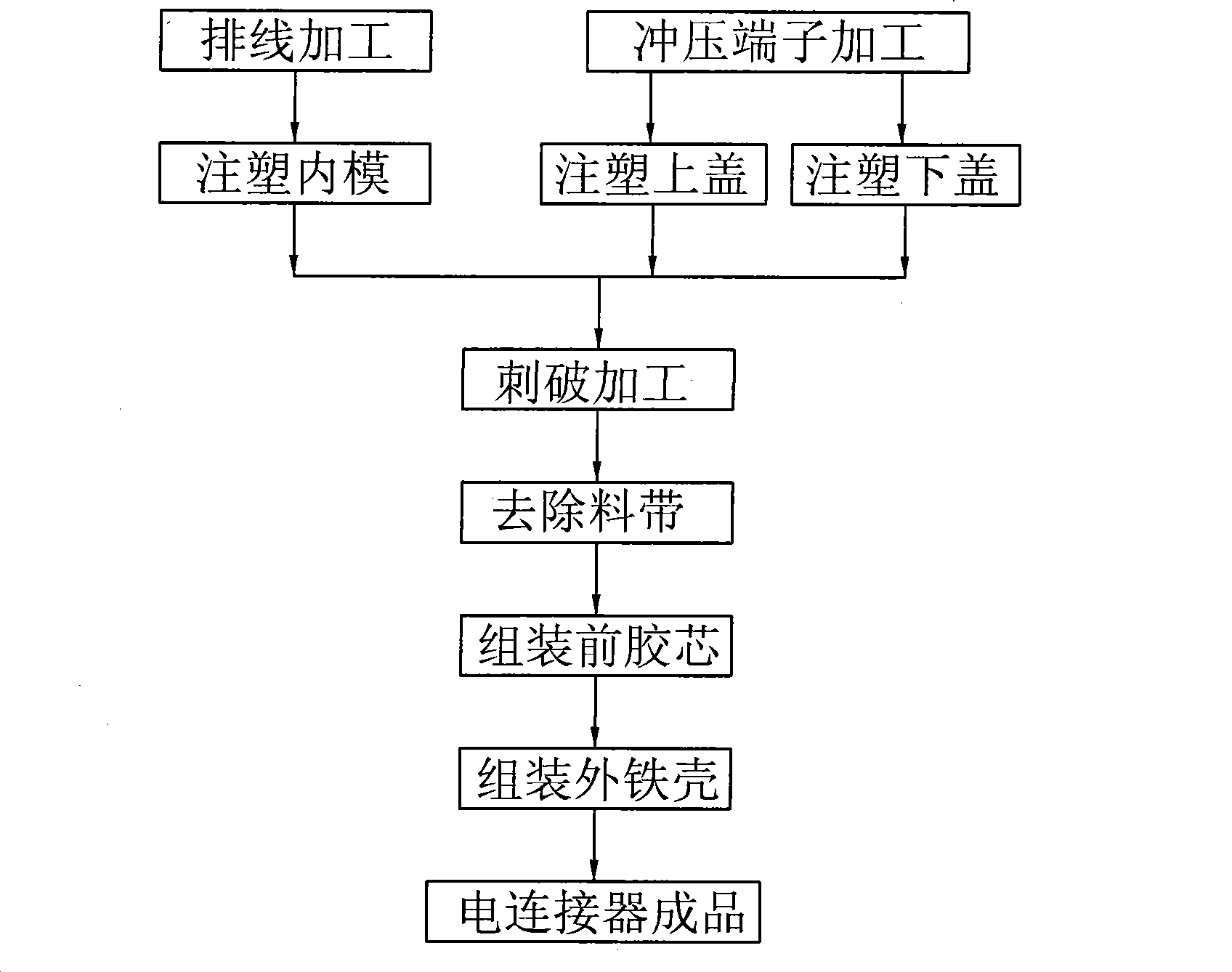

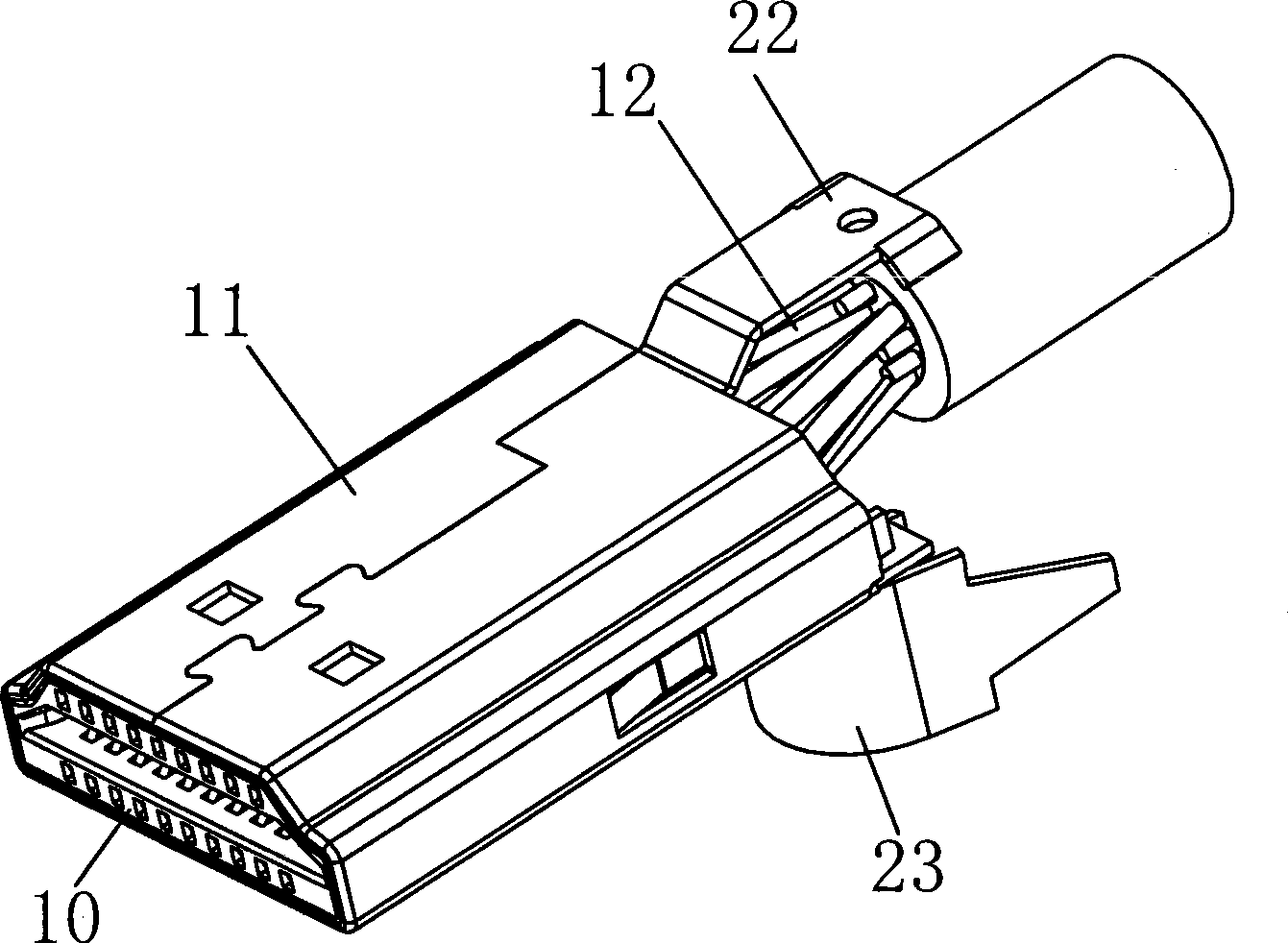

Puncture type terminal, electric connector and technique for producing the same

InactiveCN101465508AMiniaturizationAchieve thinningContact member manufacturingContact member cases/bases manufactureElectricityPunching

The invention relates to an electric connector and the technical field of processing technique, in particular to a puncture type terminal, an electric connector and a manufacturing technique thereof; the processing technique comprises the processing of punching terminals, the processing of wire arrangement, the injection molding of an upper cover and a lower cover, puncture processing, removing strip material, assembling a front rubber core and an outer iron shell; wherein, the upper cover and the lower cover are respectively molding-injected at the middle and rear parts of the corresponding arrayed terminals; the processing technique solves the problem that the existing electric connector can not solve: the contact is unstable and poor, the electrical impedance is high and the electric connector can not be miniaturized; at least two tip teeth, the tip ends of which are distributed in a staggering way, are formed on the electrical connecting part of the puncture type terminal, and the tip tooth is a pyramid shape, and a cambered surface is formed on the inner side surface of the tip tooth; the tip tooth reduces the electrical impedance of the electric connector; the upper cover and the lower cover of the puncture type HDMI electric connector are respectively formed on the arrayed terminals, and the puncture type tip tooth is formed at the rear end of the terminal; the electric connector is more miniaturized and thinned, thus greatly improving the performance of the electric connector.

Owner:YONG TAI ELECTRONICSDONGGUAN LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com