Abrasive belt grinding device applicable to inner and outer cambered surfaces of blades of aerospace blisk

A grinding technology for blisks and abrasive belts, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of limited space and difficult insertion of grinding heads, so as to ensure the quality of the profile and guarantee Rigidity, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

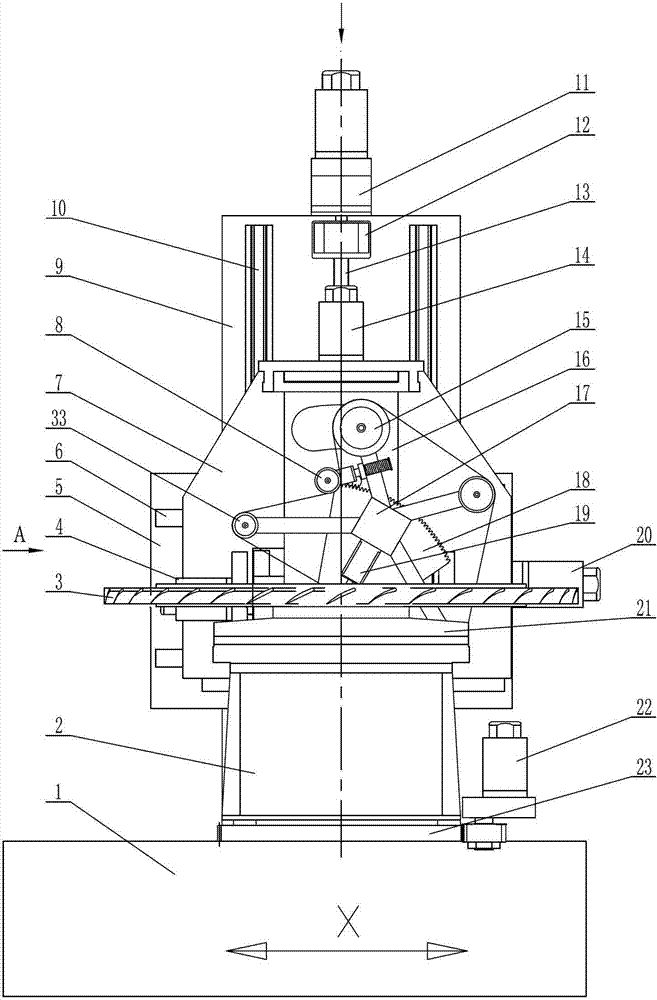

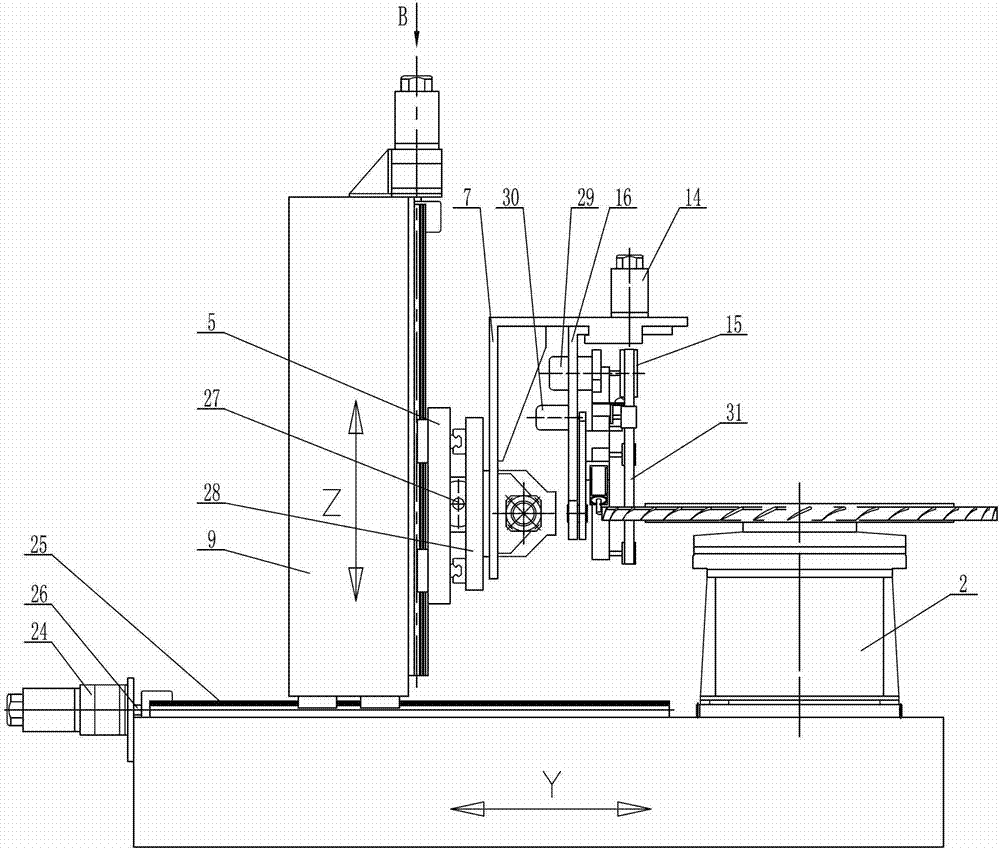

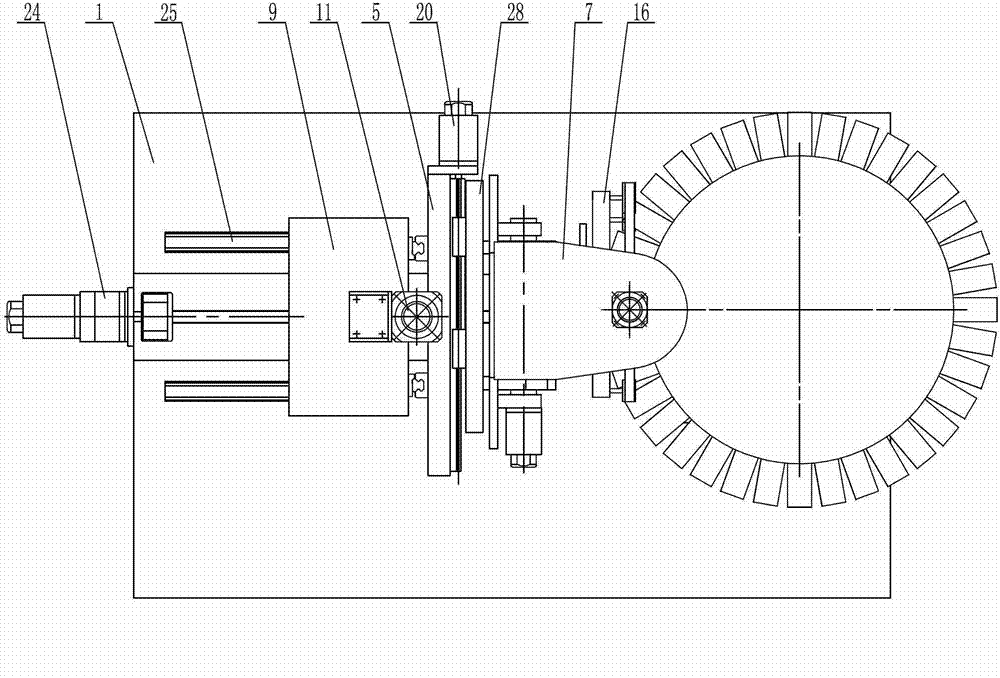

[0034] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0035] Such as figure 1 , figure 2 , image 3 As shown, the bed 1 is a cuboid structure, and the bed 1 is as figure 2 The top of the shown right end is provided with a workpiece turntable 2, and the bottom of the workpiece turntable 2 is provided with a rotary support body 23. The rotary support body 23 is similar to a bearing structure and has an inner ring and an outer ring that can rotate relatively. The inner ring is fixed on the bed 1, the outer ring of the rotary support body 23 is a gear structure, the outer ring gear of the rotary support body 23 is fixed to the workpiece turntable 2, and the outer ring gear meshes with the gear on the output shaft of the workpiece turntable motor 22 . When the workpiece turntable motor 22 is running, the outer ring gear of the rotary support body 23 can be driven by the gear, so that the outer ring gear of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com