Patents

Literature

997 results about "Chemical deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

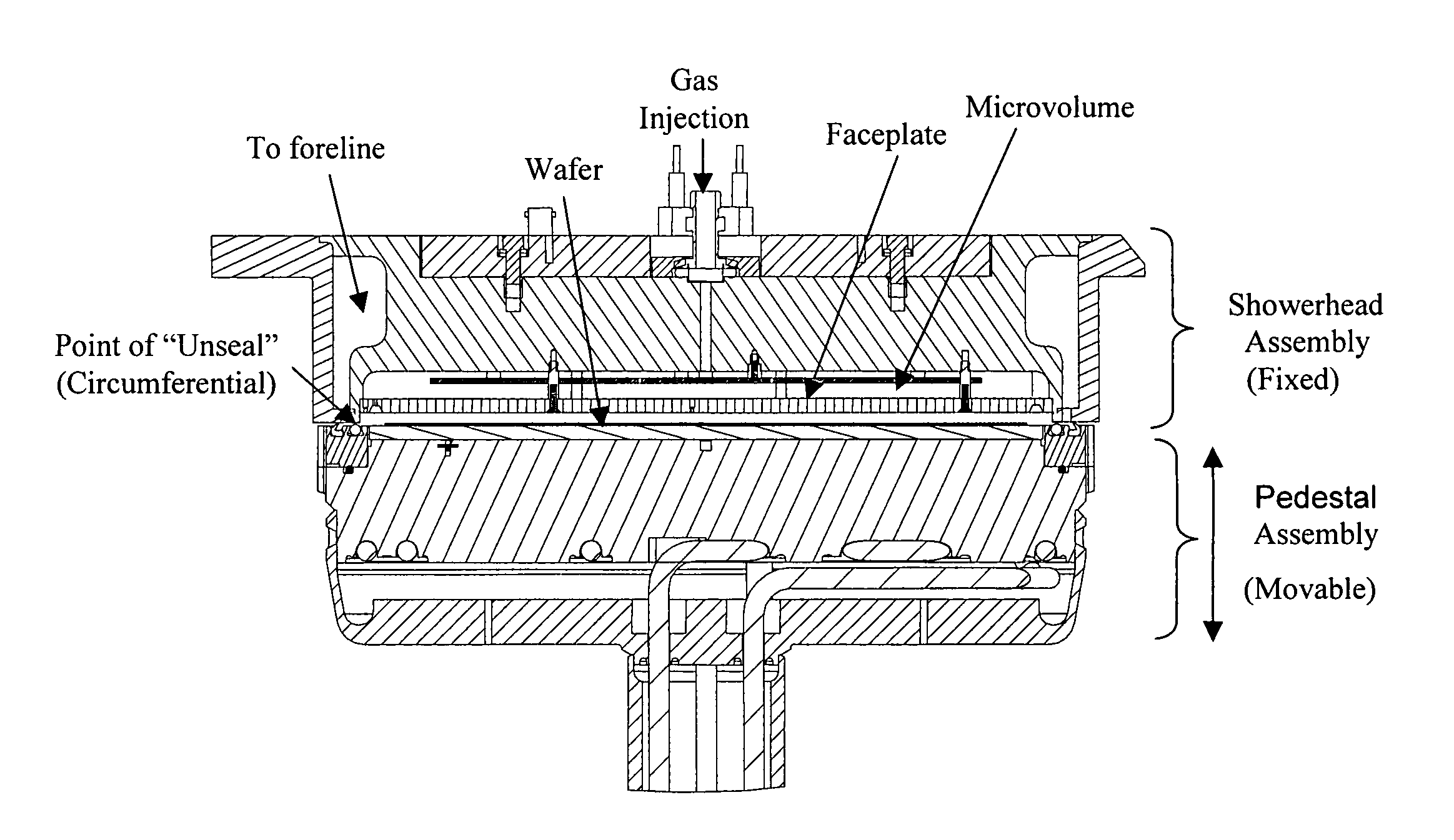

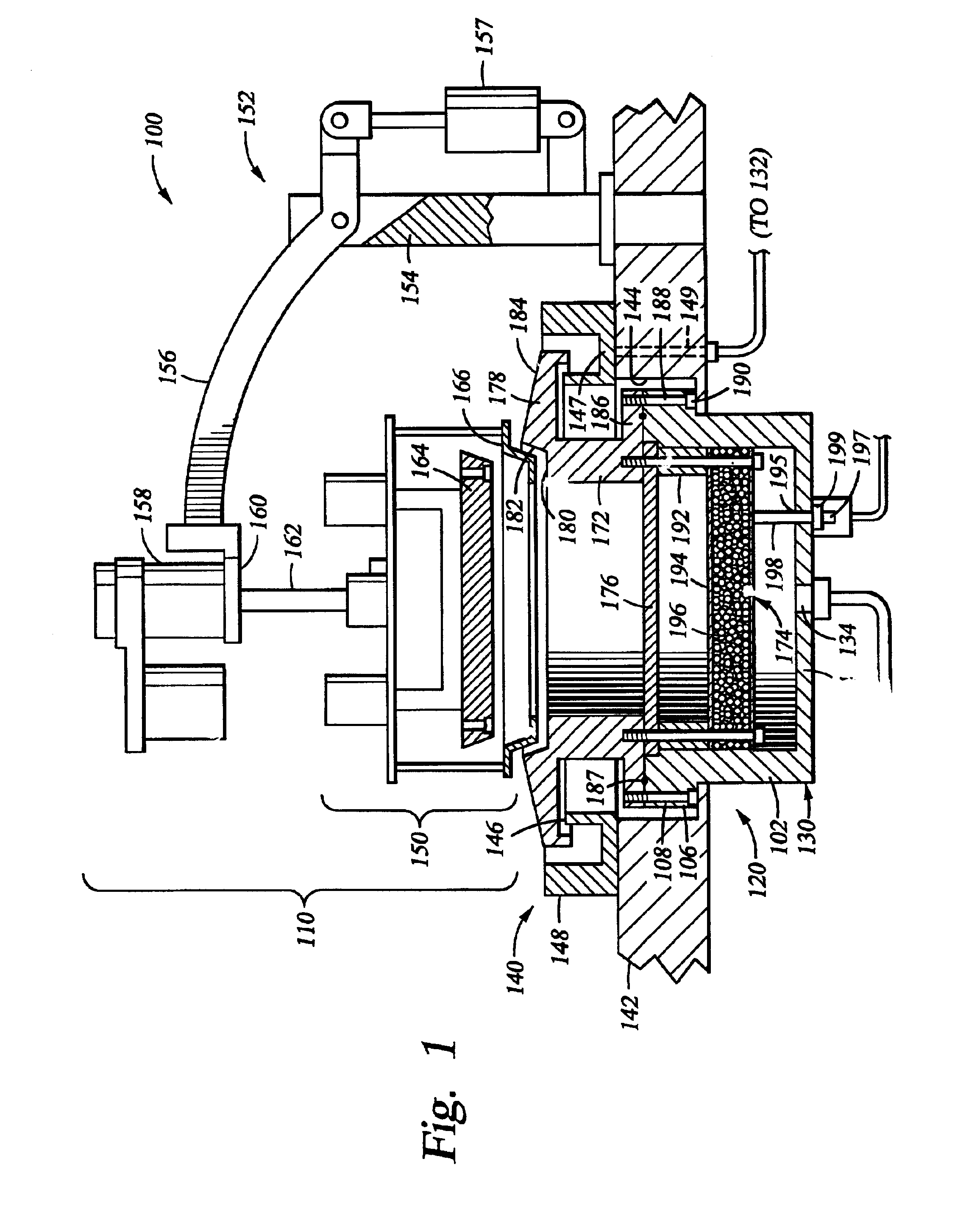

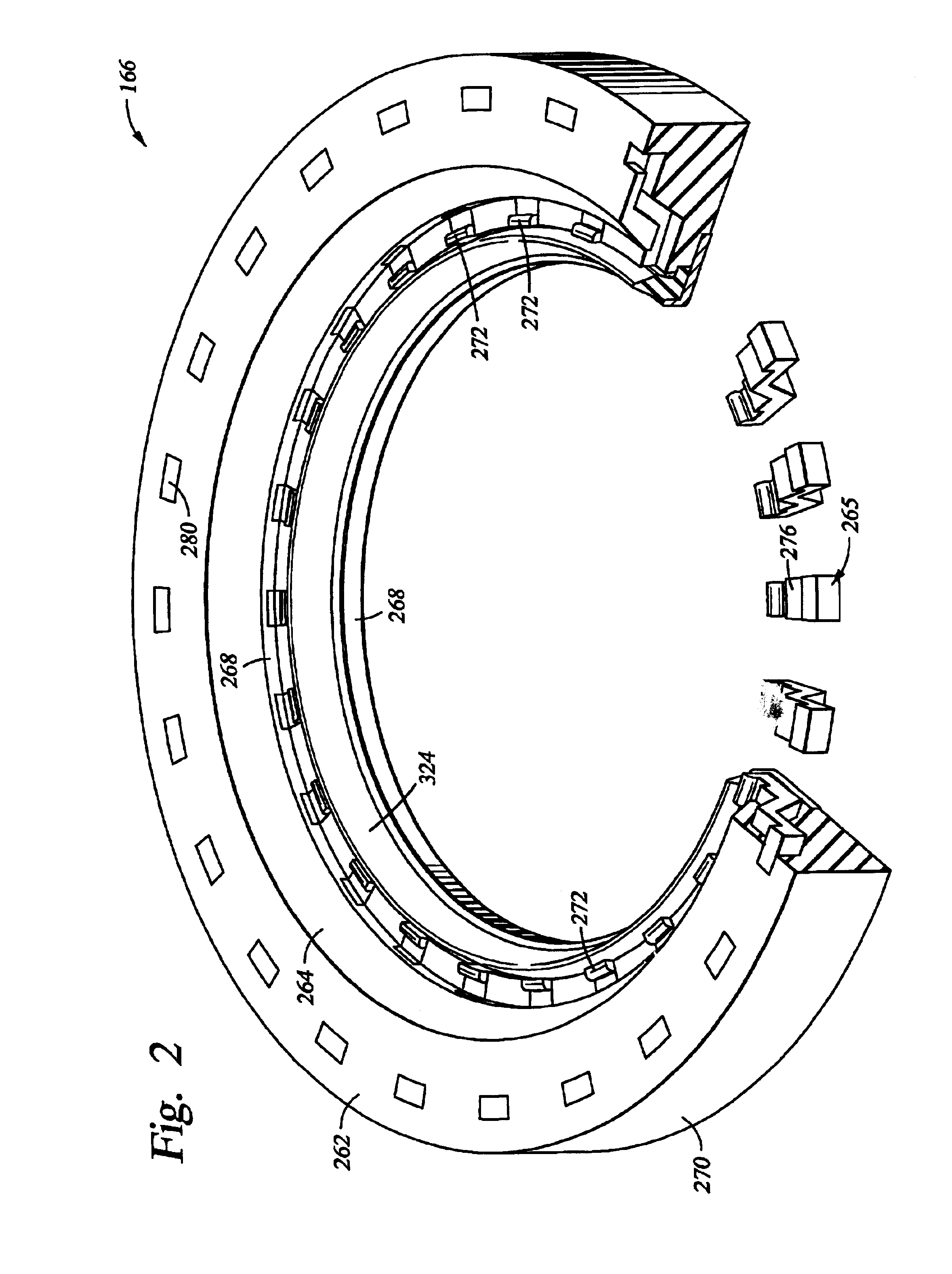

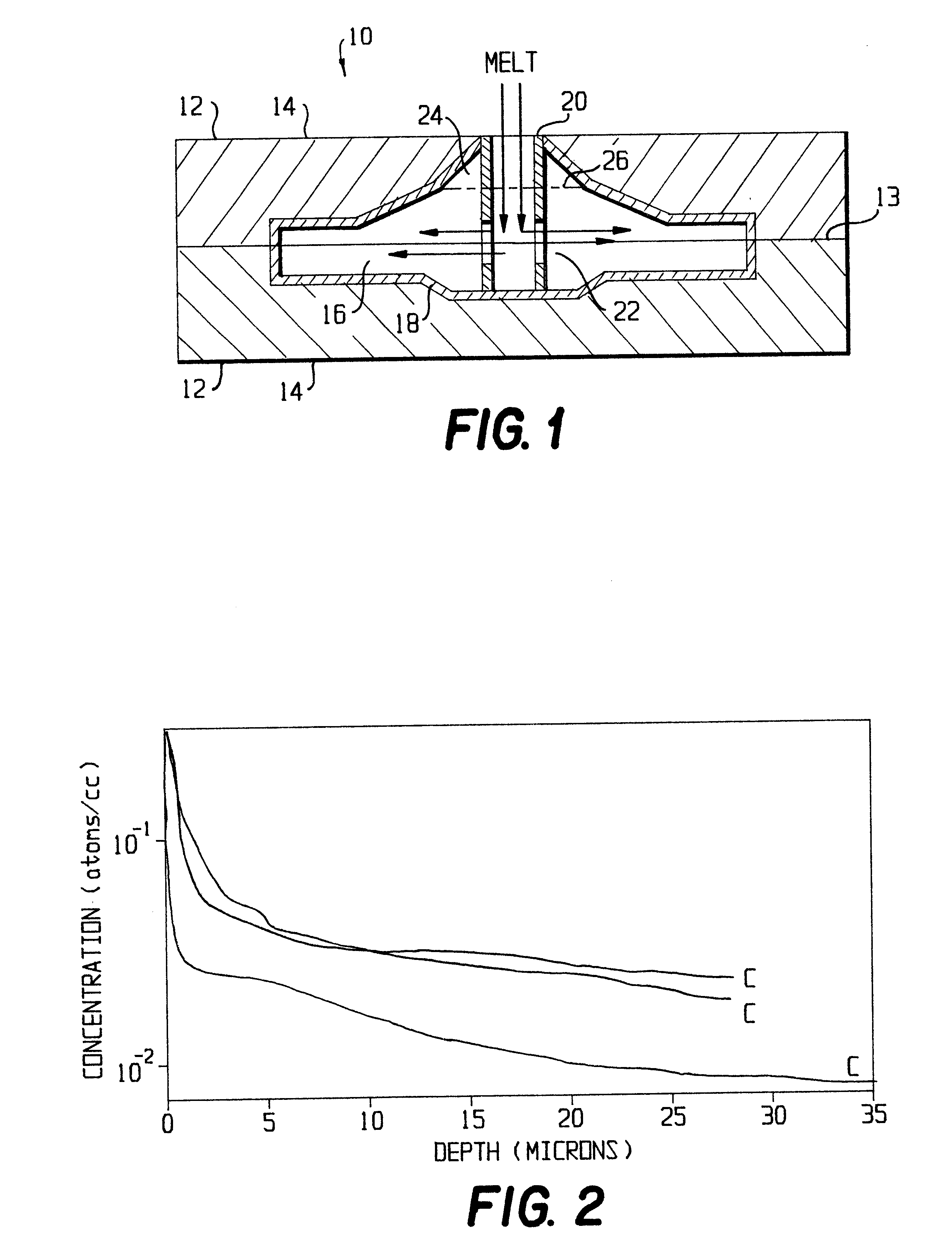

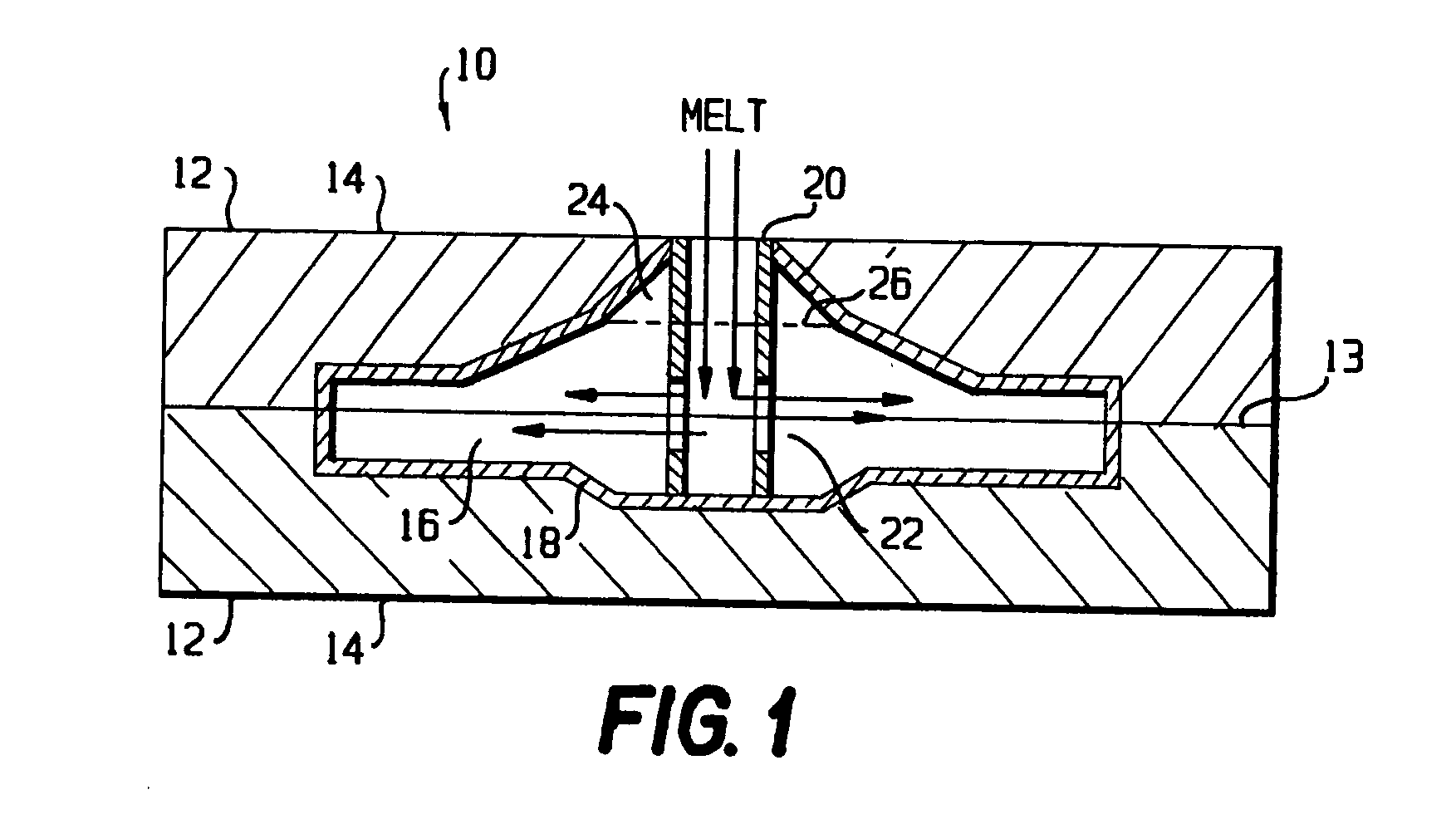

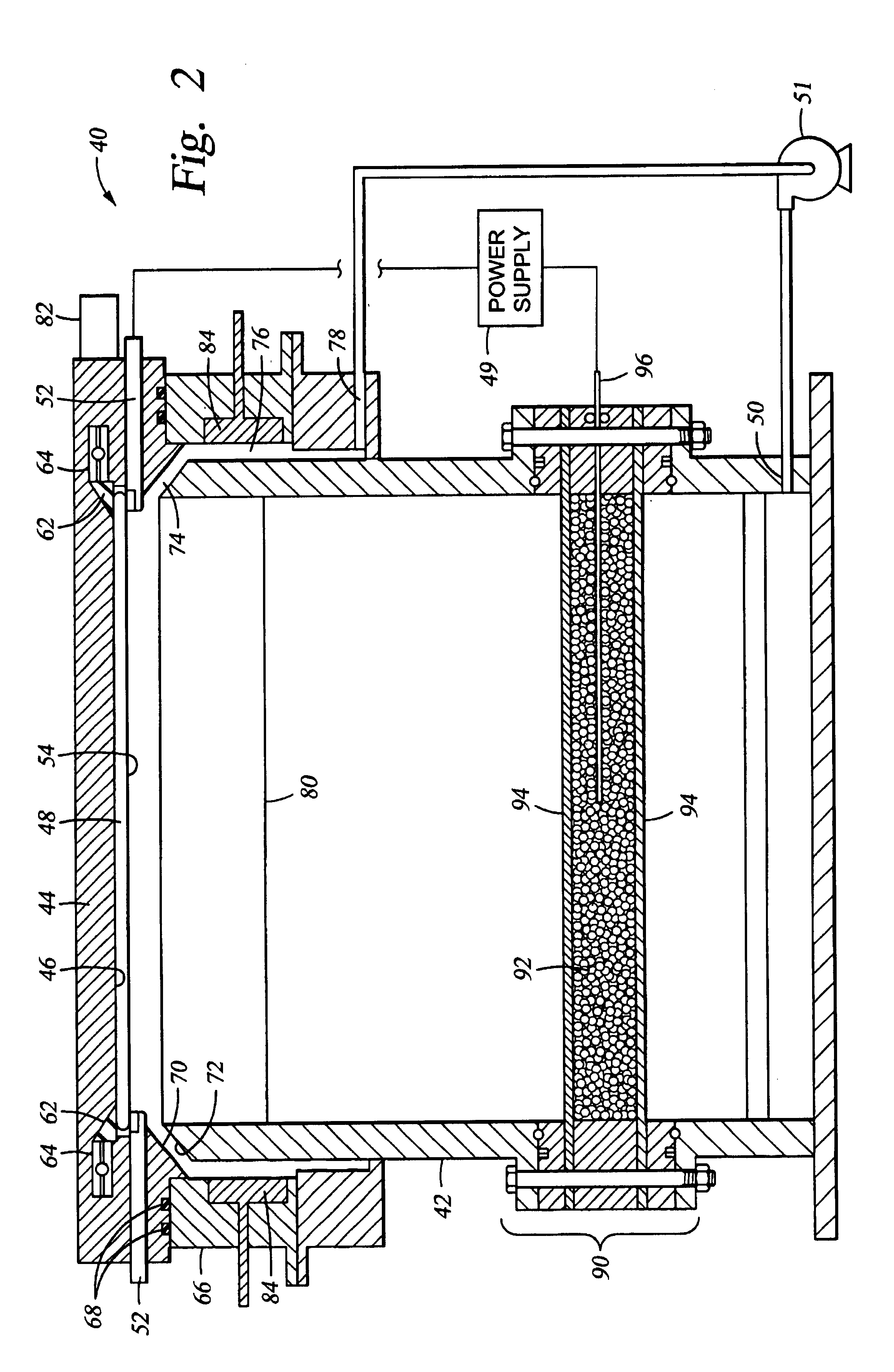

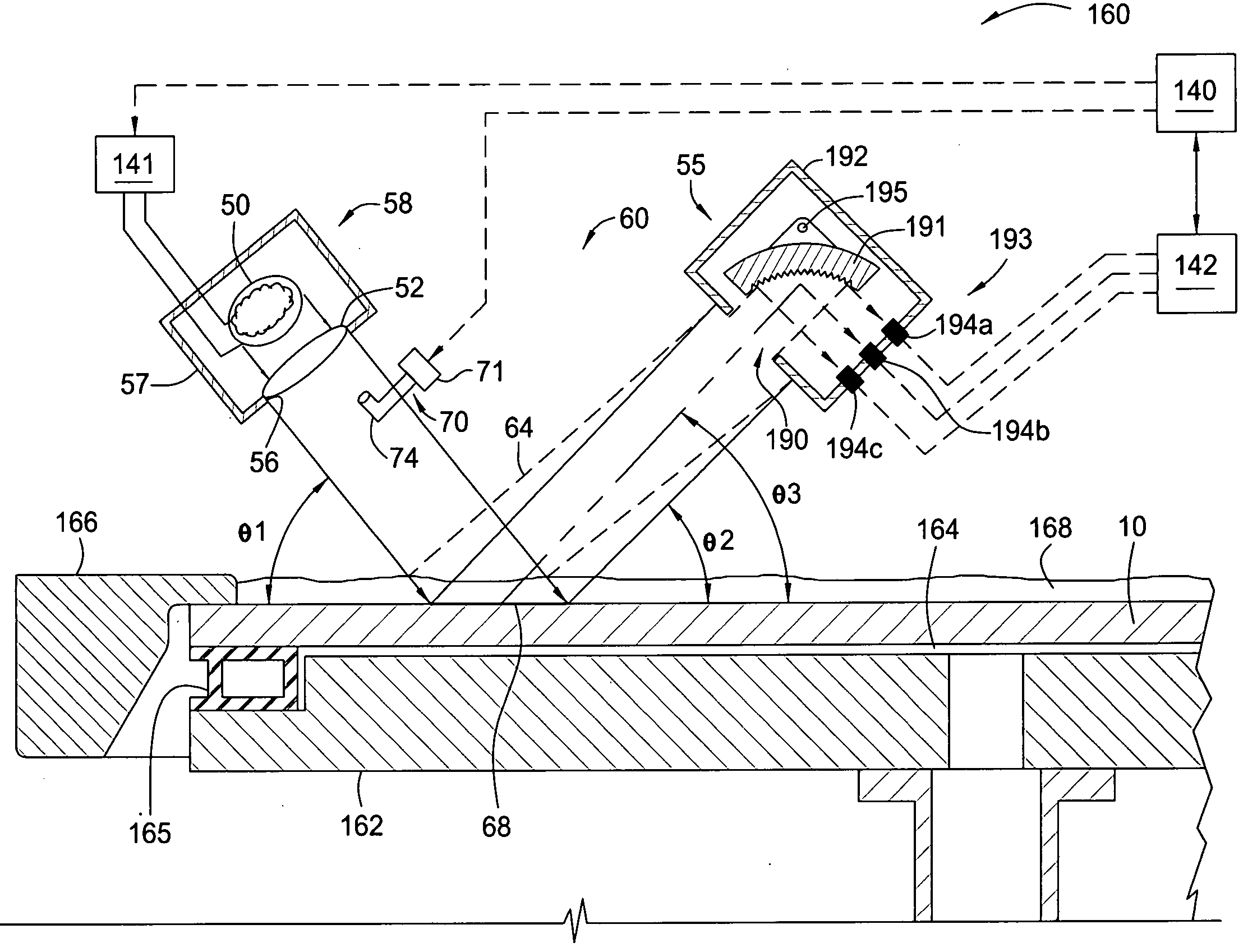

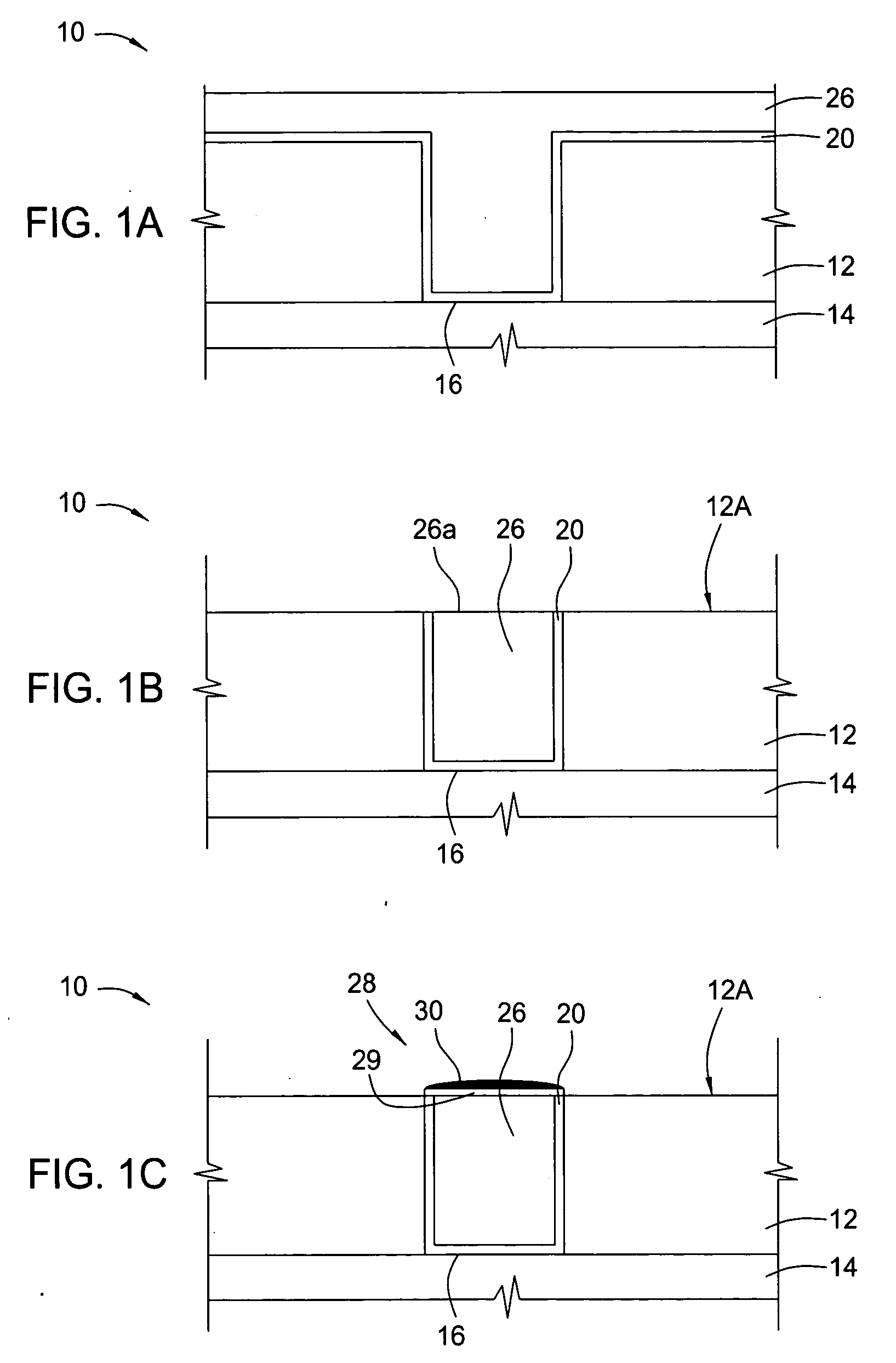

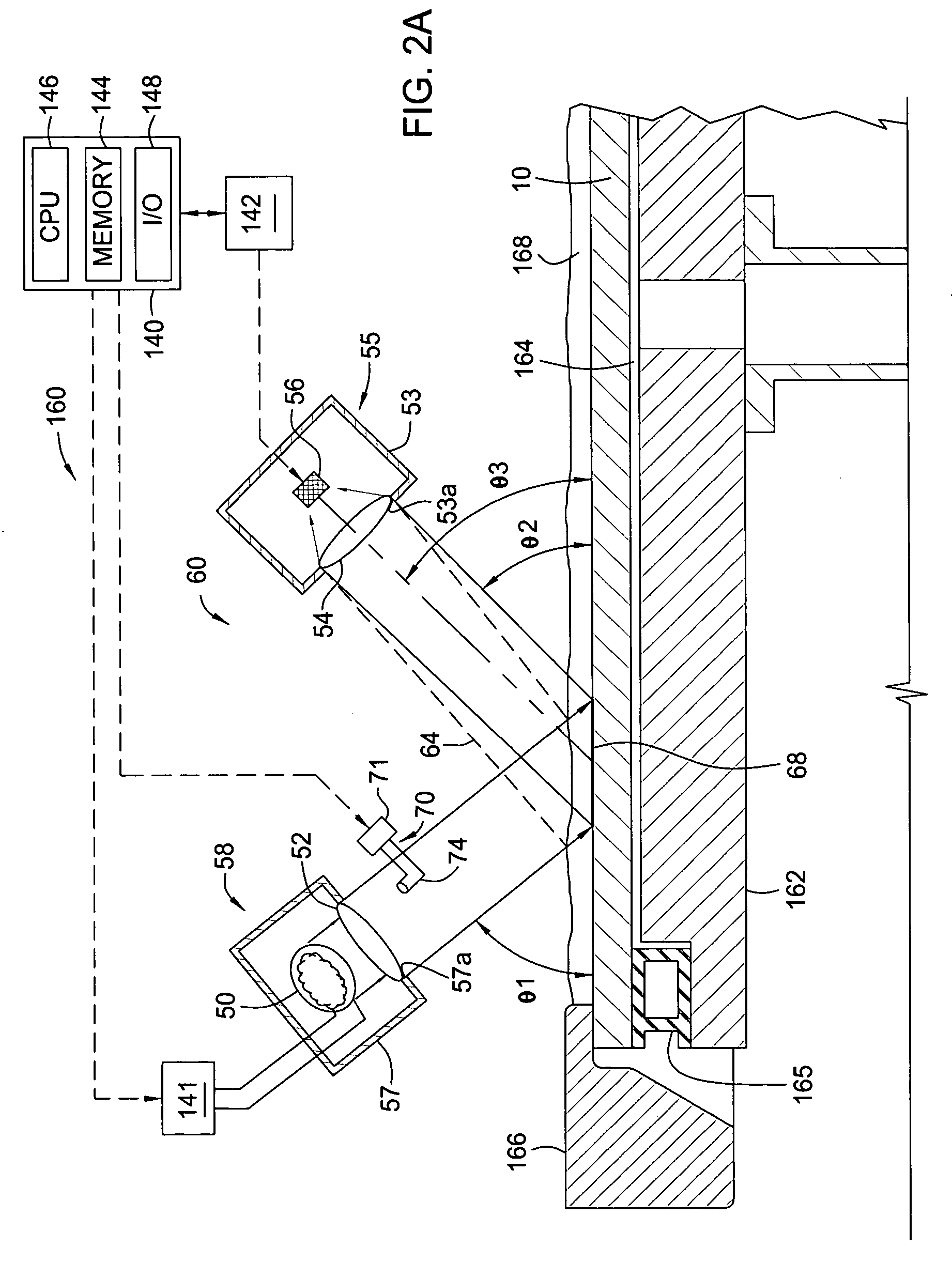

Dual seal deposition process chamber and process

ActiveUS7737035B1Minimal chamber volumeReducing or eliminating dead legsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

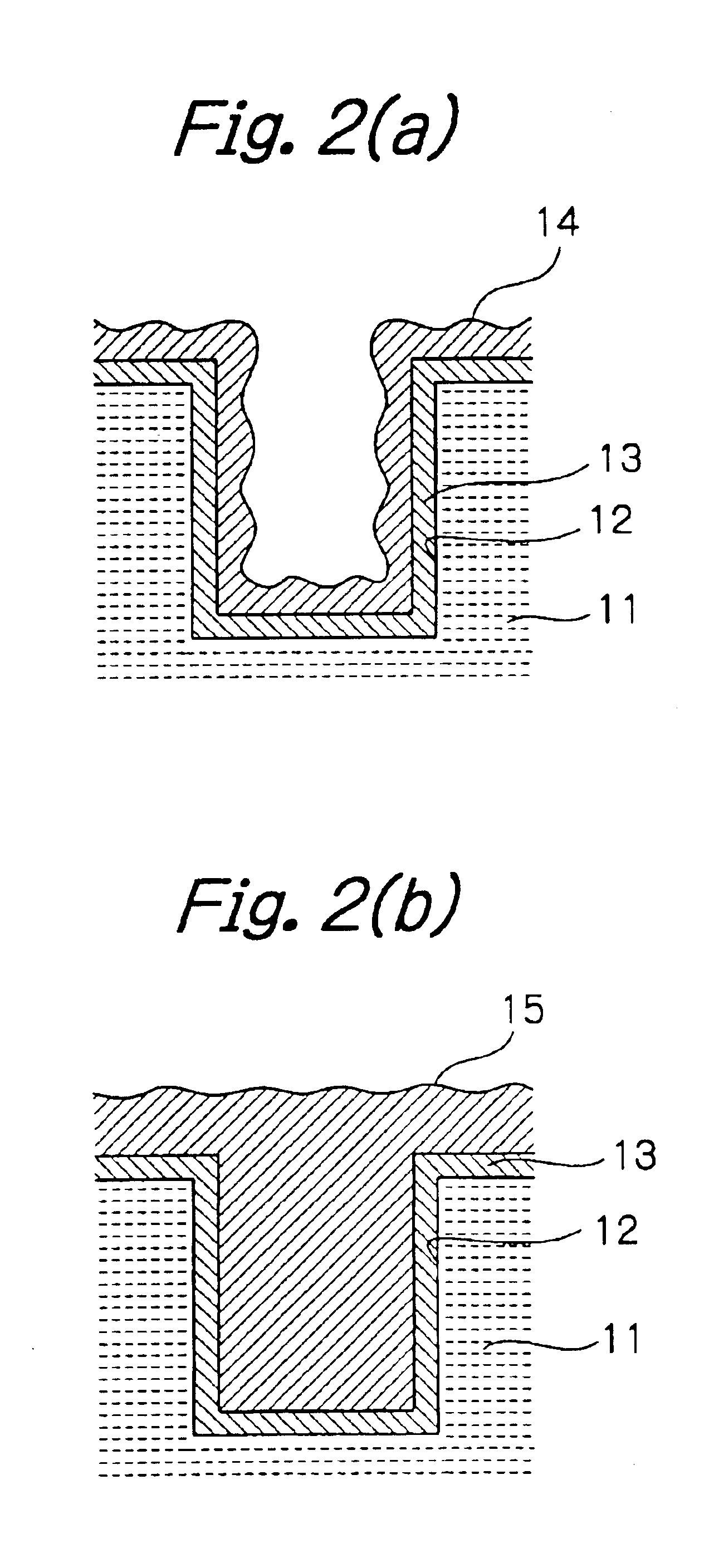

An apparatus and method for sealing and unsealing a chemical deposition apparatus in a chemical deposition process chamber includes a microvolume that has dual sealing elements at its periphery. One seal, the outer seal, is used to seal the inside of the microvolume from the main process chamber. The second (inner) seal is used to seal the inside of the microvolume from a vacuum source. The apparatus and process of the present invention has several advantages for enhanced chamber performance.

Owner:NOVELLUS SYSTEMS

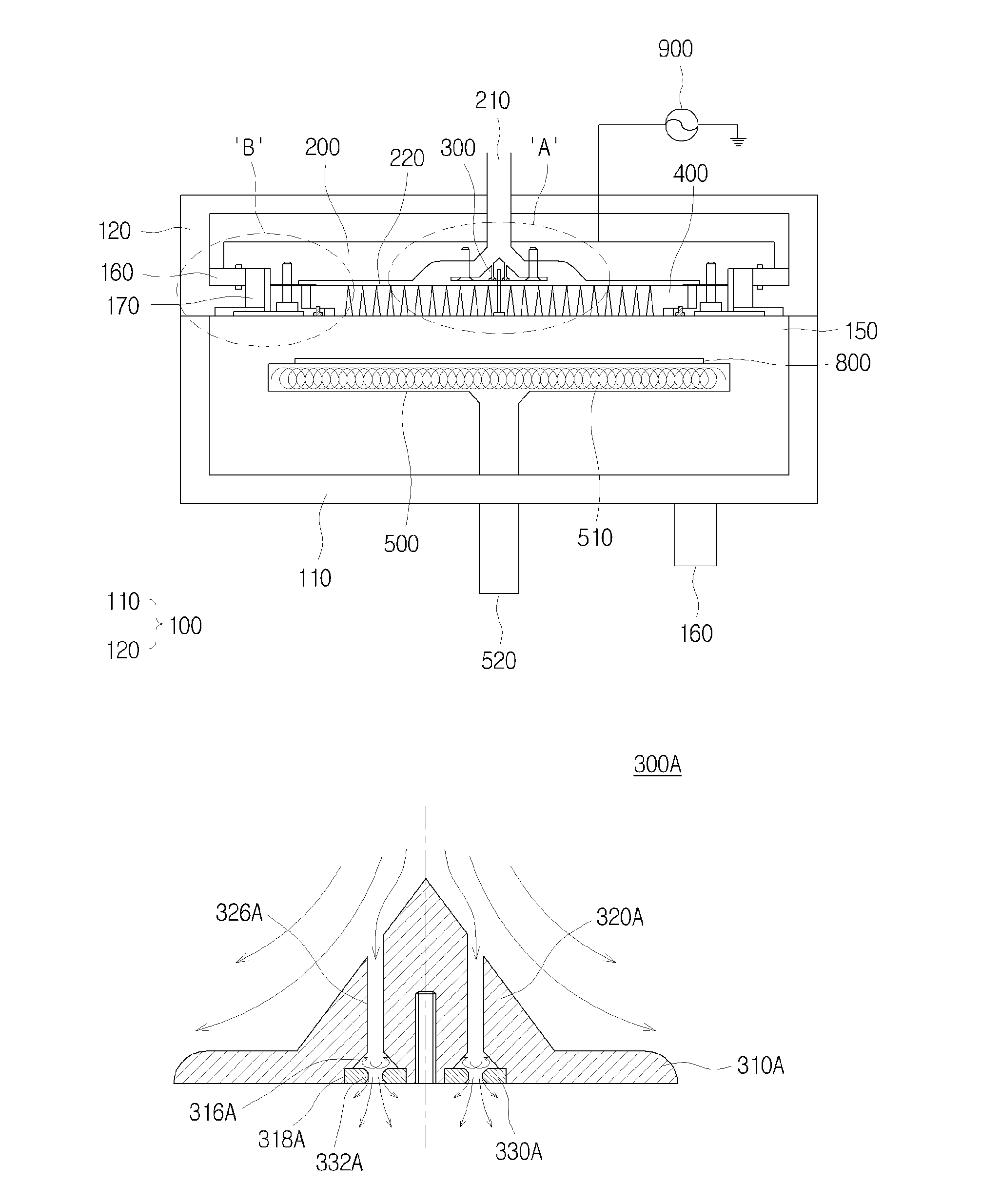

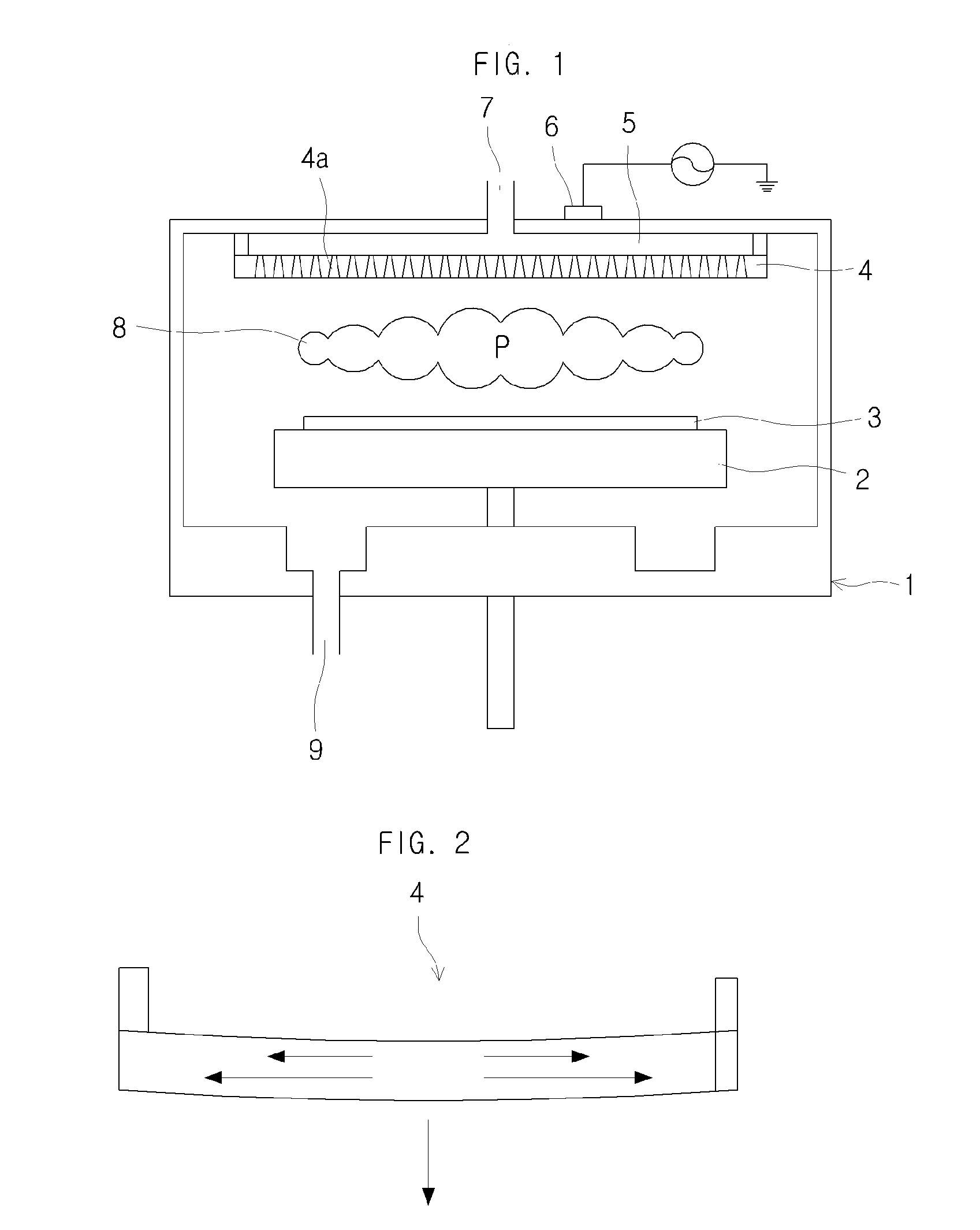

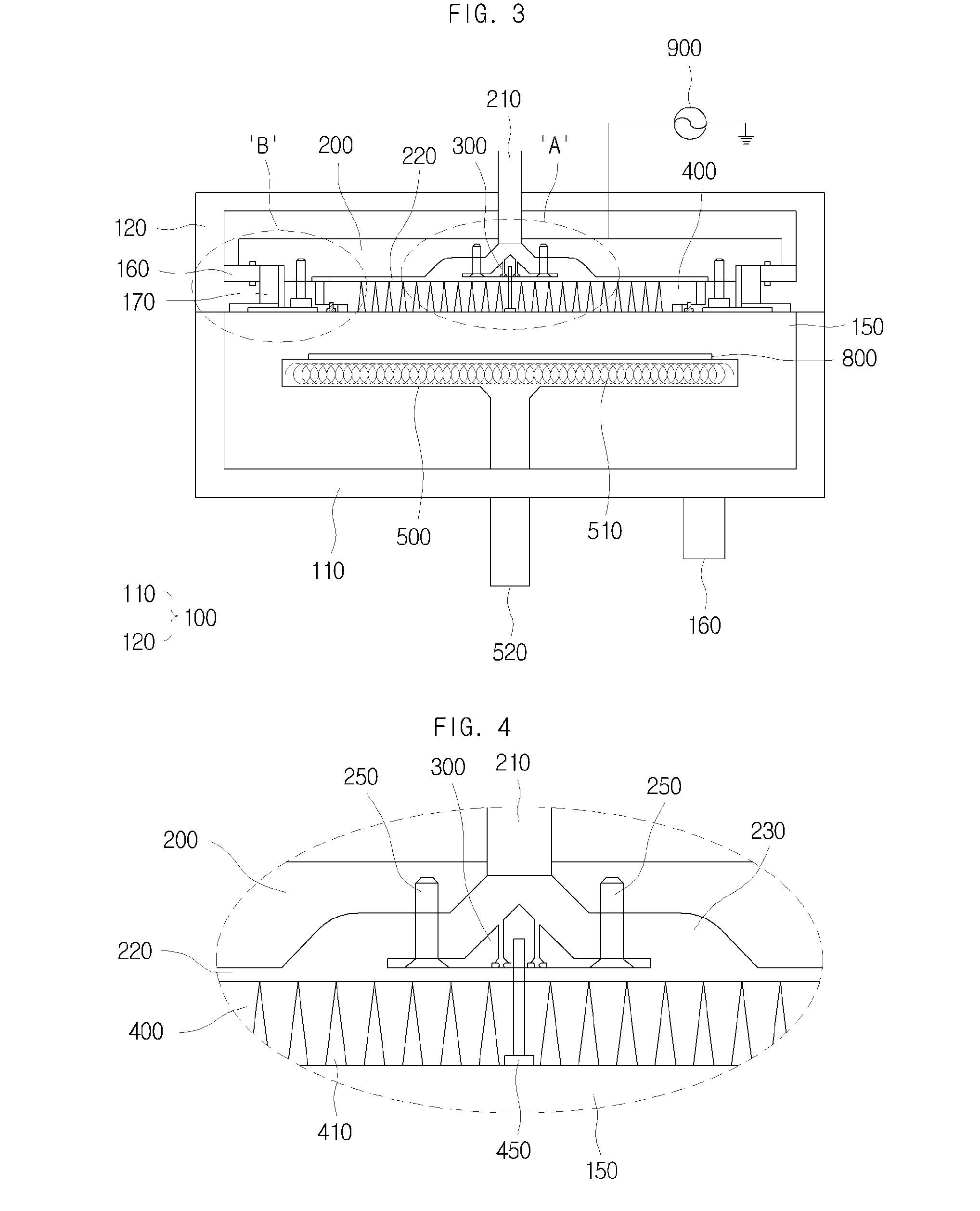

Apparatus for chemical vapor deposition

ActiveUS8980006B2Minimize thermal expansionUniform and good qualitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorCoupling

An apparatus for chemical vapor deposition is disclosed. An aspect of the present invention provides an apparatus for chemical vapor deposition that includes: a process chamber configured to demarcate a reaction space; a back plate placed above the reaction space and having a gas inlet in a middle thereof; a gas diffusion member arranged below and separated from the gas inlet and coupled to the back plate by a first coupling member and configured to diffuse process gas supplied through the gas inlet; a shower head placed below and separated from the back plate and the gas diffusion member and having a middle part thereof coupled to the gas diffusion member by a second coupling member and having a plurality of spray holes perforated therein; and a susceptor arranged below and separated from the shower head and supporting a substrate. The gas diffusion member has a plurality of gas guiding holes that vertically penetrate the gas diffusion member such that the process gas supplied through the gas inlet is diffused toward a lower side of the gas diffusion member.

Owner:DMS CO LTD

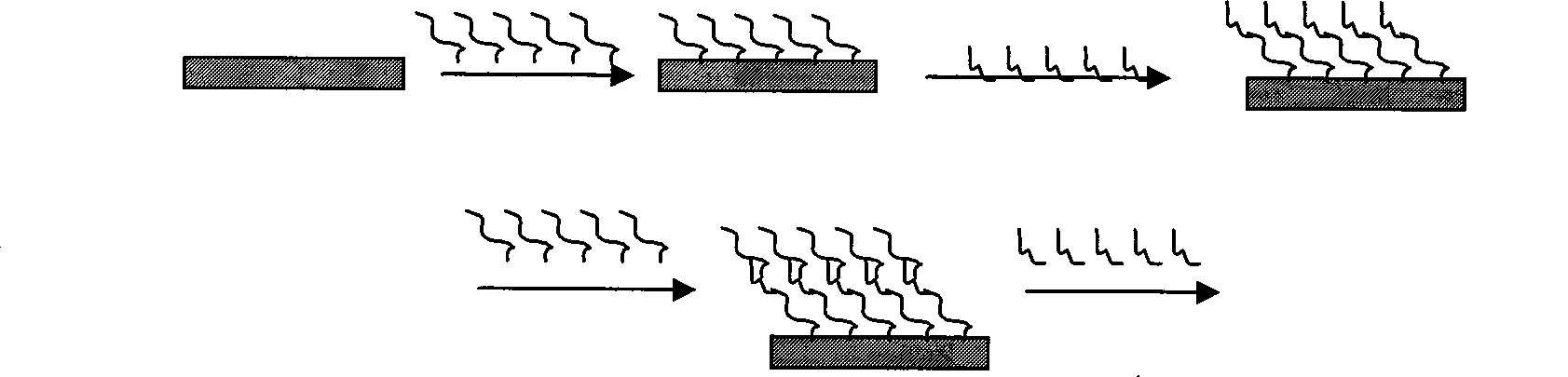

Coating, modification and etching of substrate surface with particle beam irradiation of the same

InactiveUS6921722B2Favorable adhesion (bond) strengthBonding strengthElectric discharge heatingElectric discharge tubesEtchingAtomic beam

There is provided a method of performing a surface treatment, such as coating, denaturation, modification and etching, on a surface of a substrate. The method comprises the steps of bringing a surface treatment gas into contact with a surface of a substrate, and irradiating the surface of the substrate with a fast particle beam to enhance an activity of the surface and / or the surface treatment gas, thereby facilitating a reaction between the surface and the gas. The fast particle beam may be selected from a group consisting of an electron beam, a charged particle beam, an atomic beam and molecular beam. For example, during a coating operation, chemical deposition of predetermined component elements of the gas onto the surface is effected and a predetermined portion of the surface of the substrate is irradiated with a particle beam to form a coating layer on the predetermined portion.

Owner:EBARA CORP

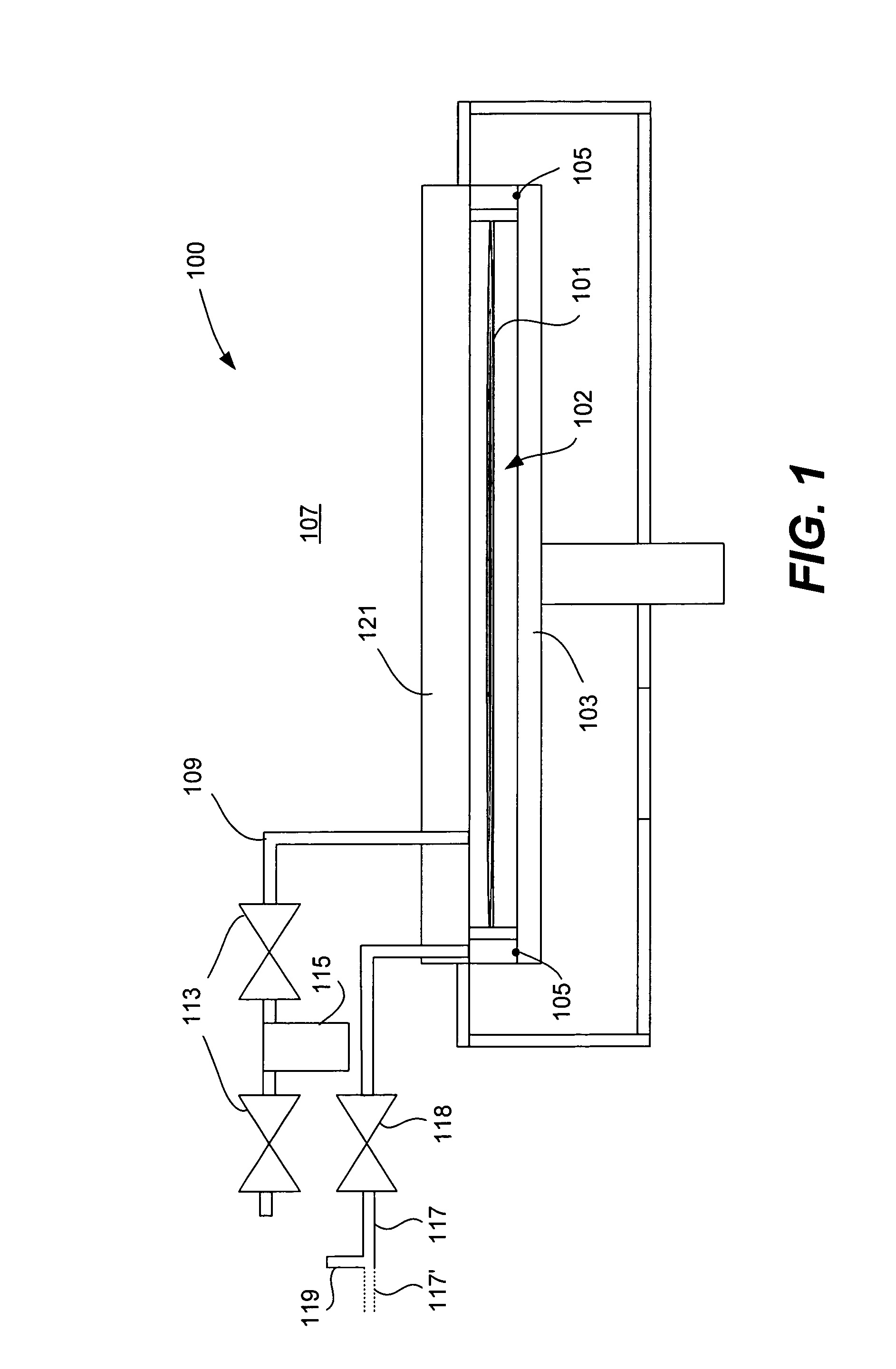

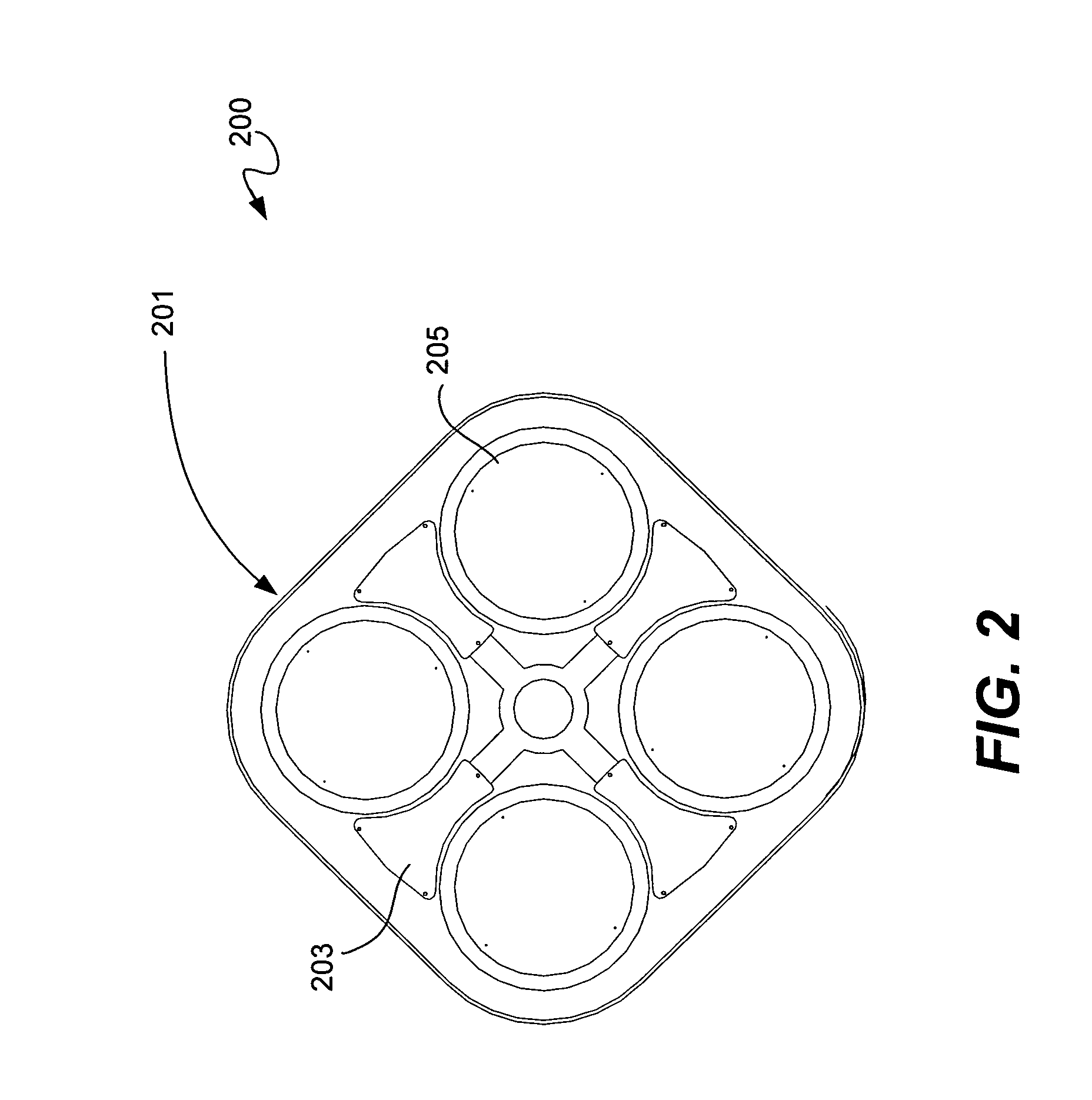

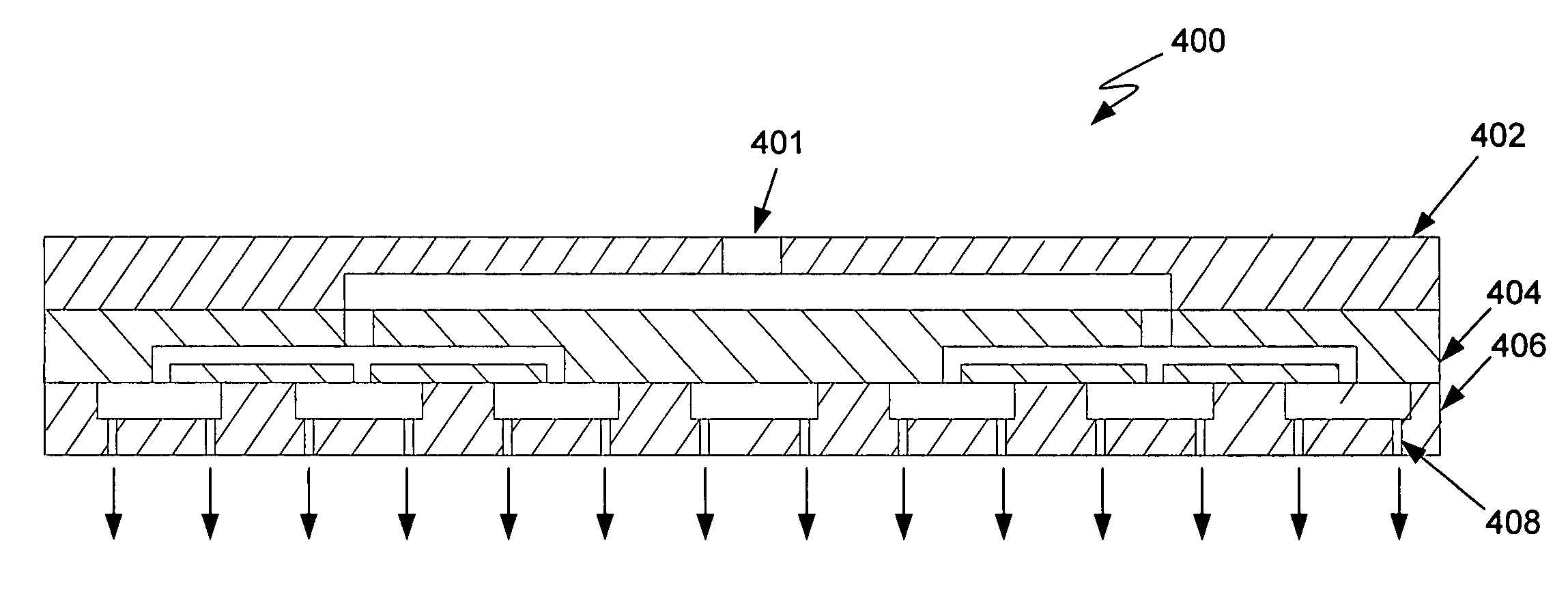

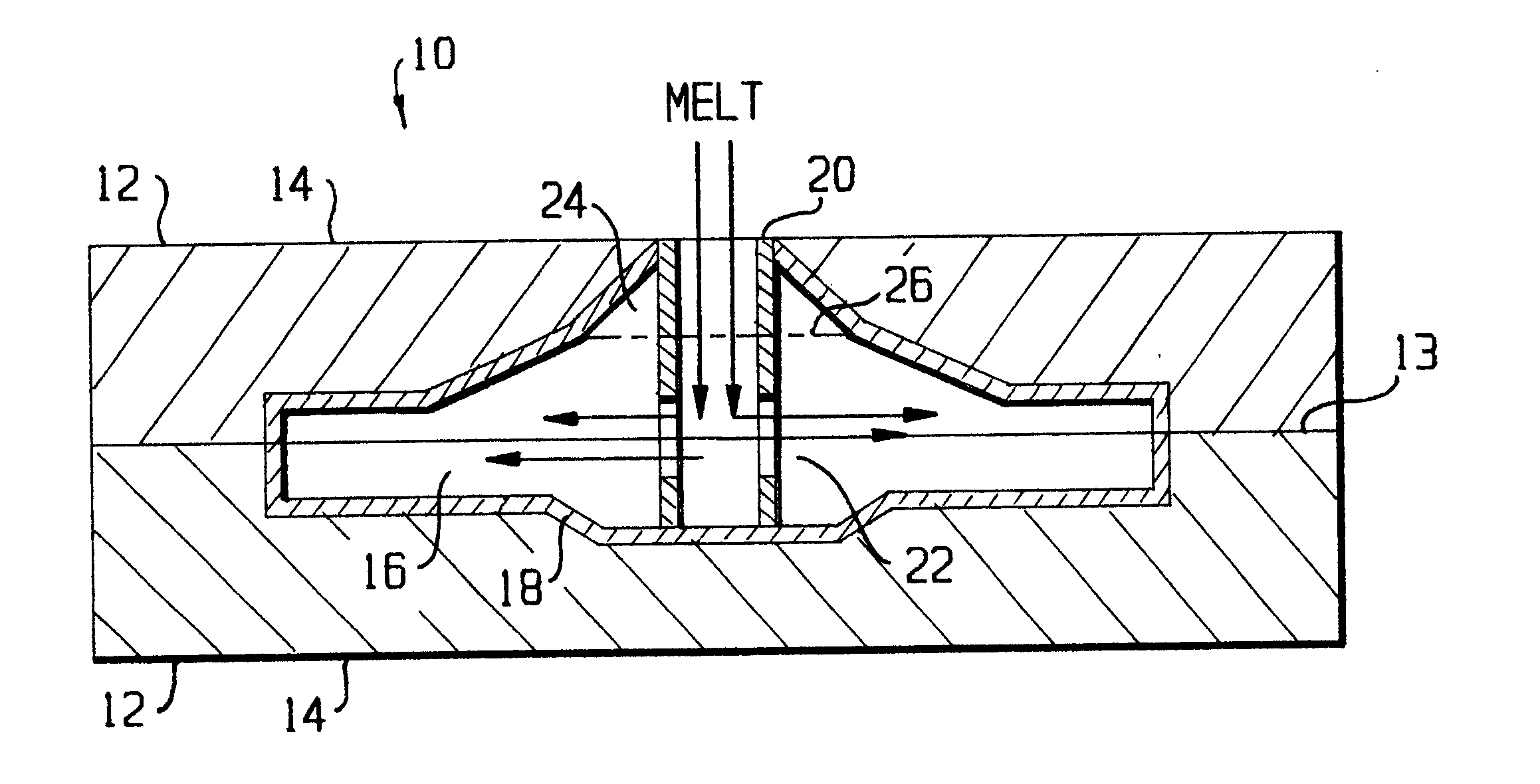

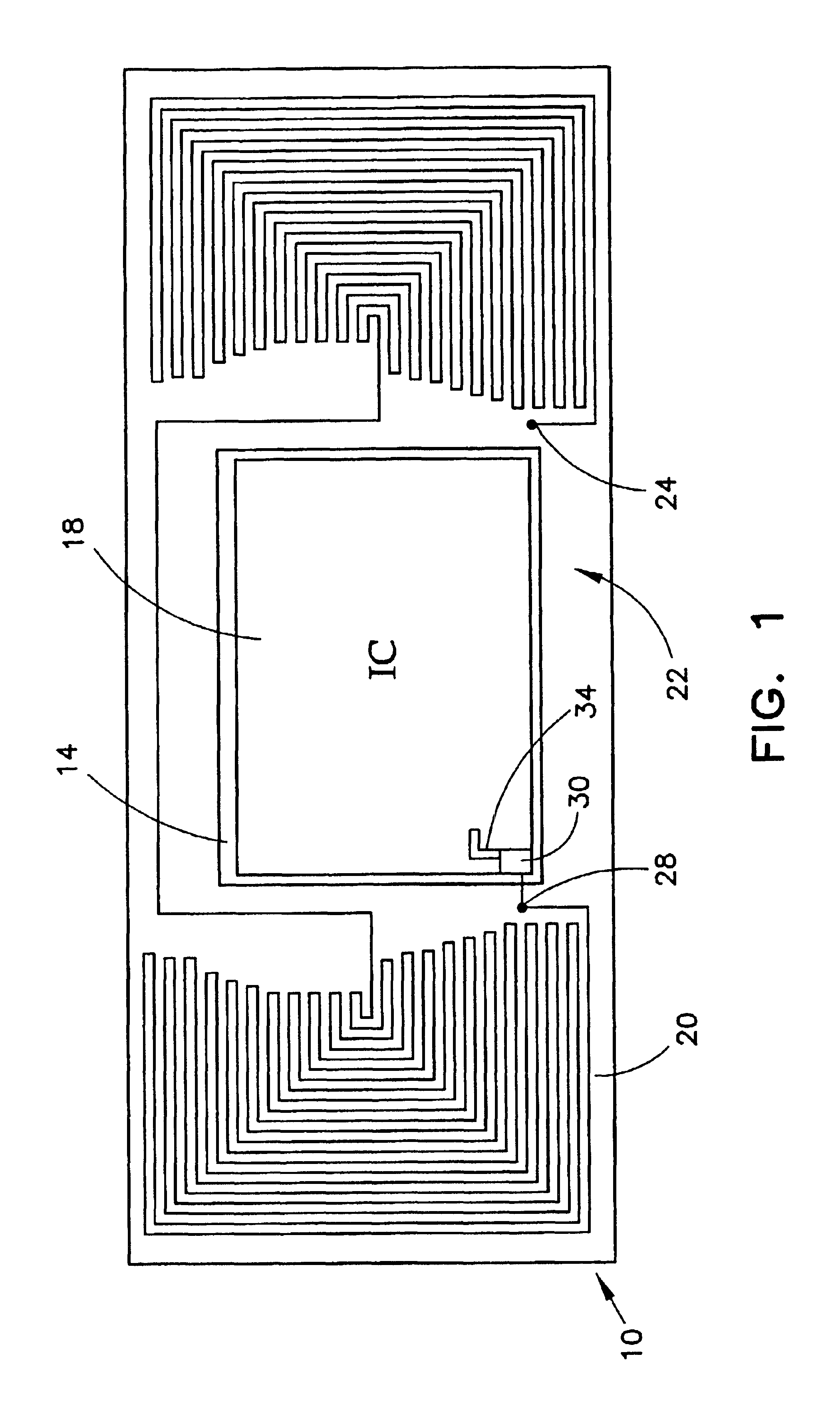

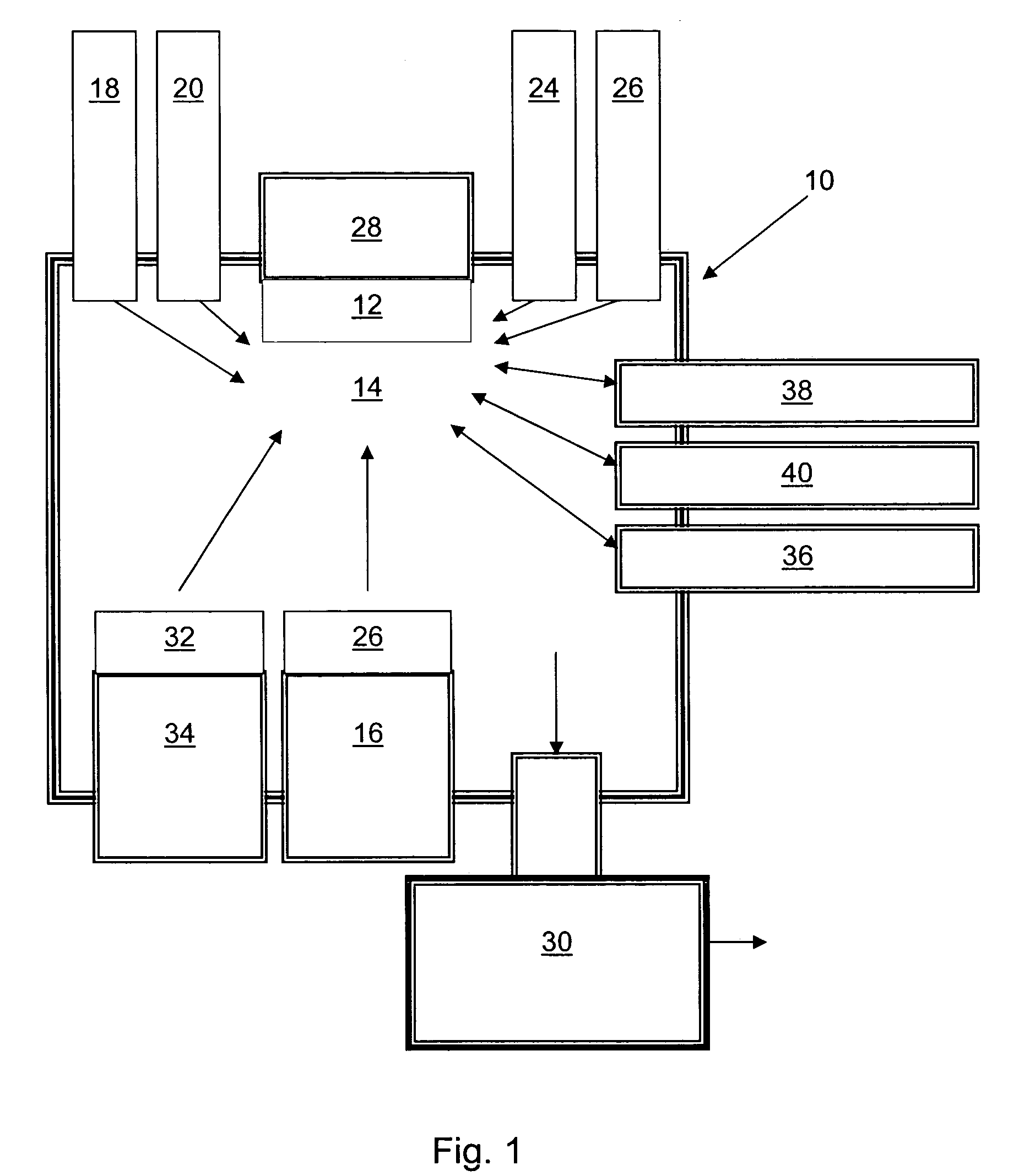

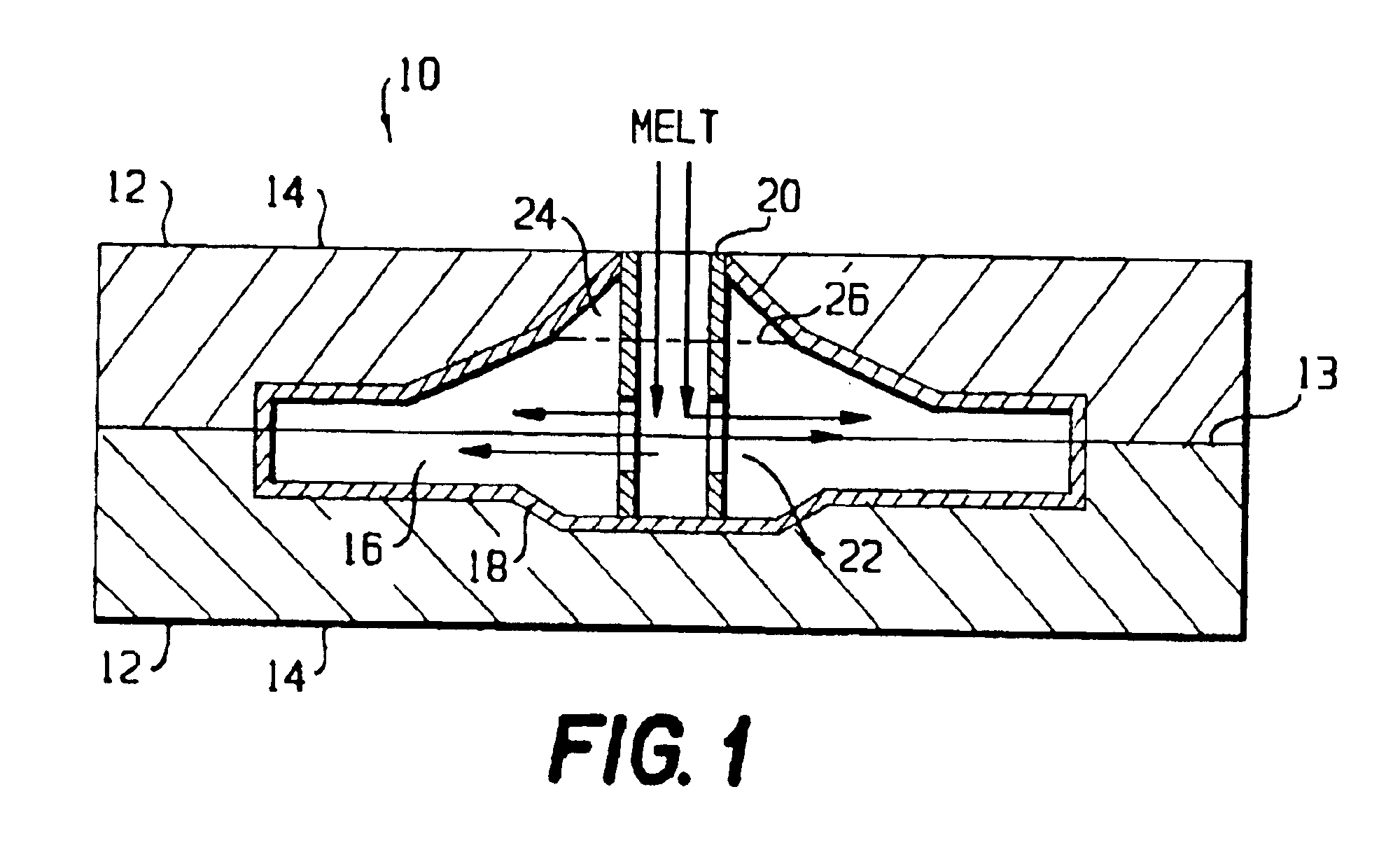

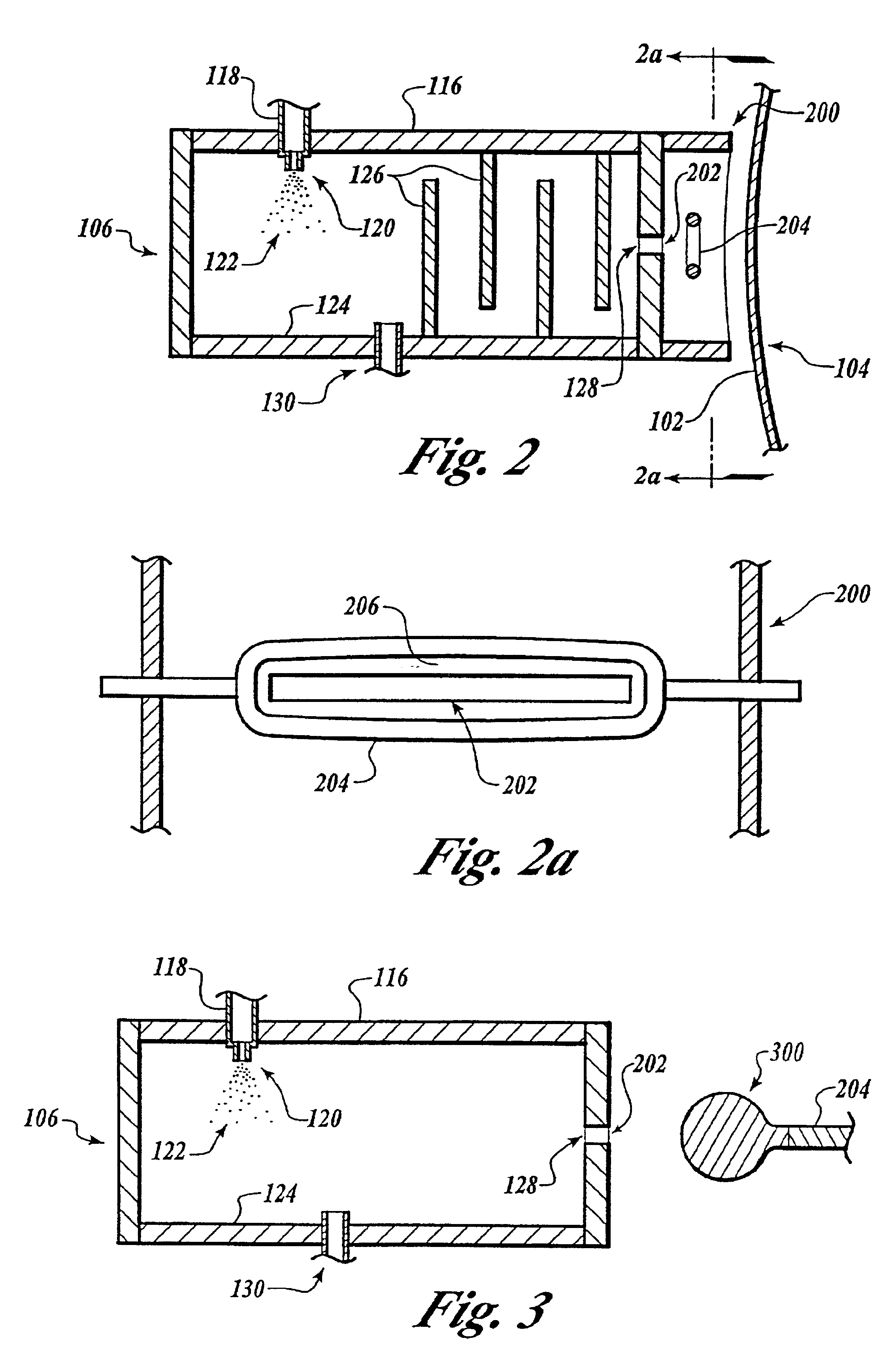

Apparatus and method for delivering uniform fluid flow in a chemical deposition system

InactiveUS20080081114A1Spray nozzlesSemiconductor/solid-state device manufacturingEffective lengthProduct gas

Uniform fluid delivery to a substrate is provider using a diffuser. The diffuser is designed with a series of fluid (gas and / or liquid) passages of equal effective length / flow resistance, such that as the fluid passes through the diffuser, the gas exits all areas at the same time and with the same mass flux. These passages may not be physically the same, however they have the same effective length and flow resistance. The diffuser can be implemented using single or multiple stacked layers, and from several to many passages. The net effect is a uniform gas curtain to the wafer. Since the passages through the diffuser are effectively the same, the uniform gas curtain to the wafer is not sensitive to the quantity of gas, the gas flow rate or the gas pressure. Additionally, a faceplate can optionally be used to smooth out any jet effects of the diffuser exit holes.

Owner:NOVELLUS SYSTEMS

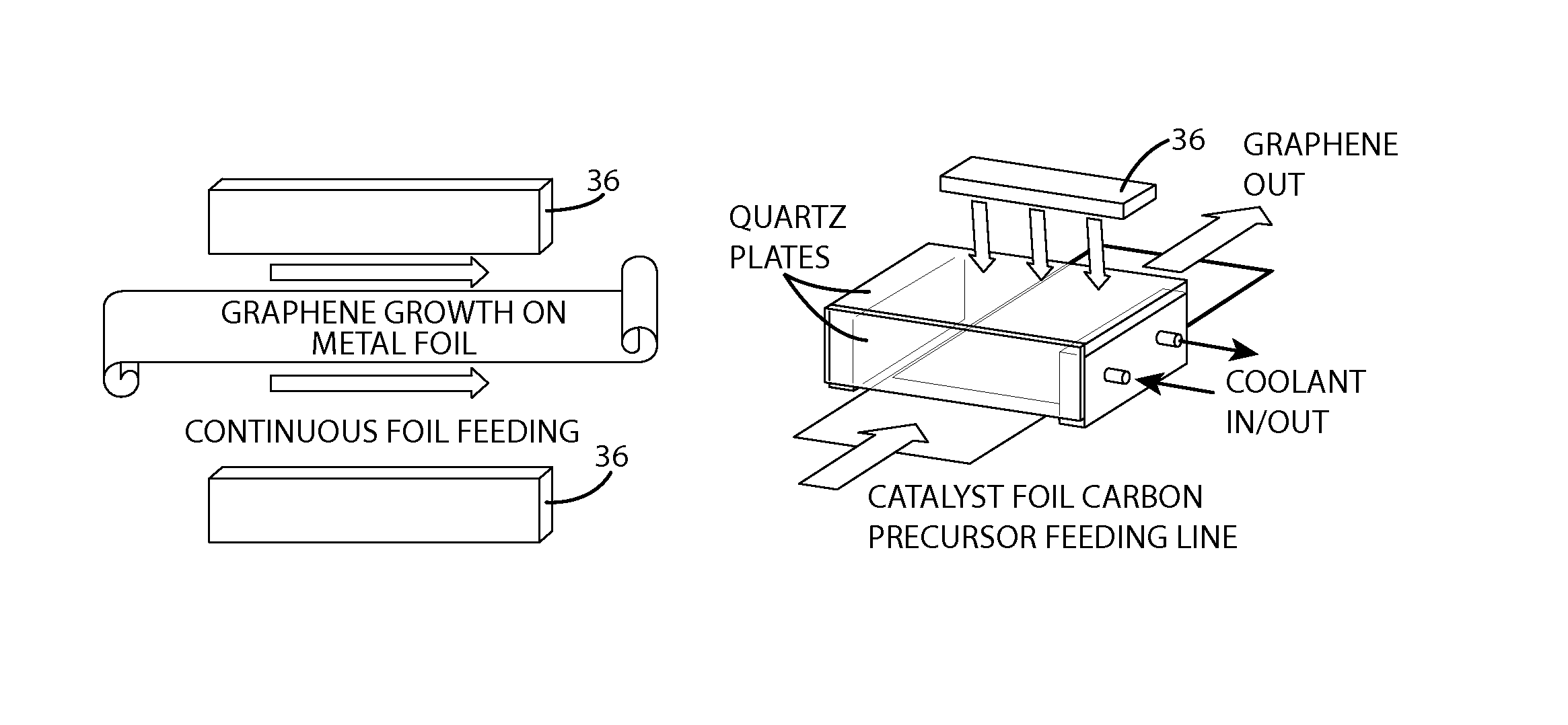

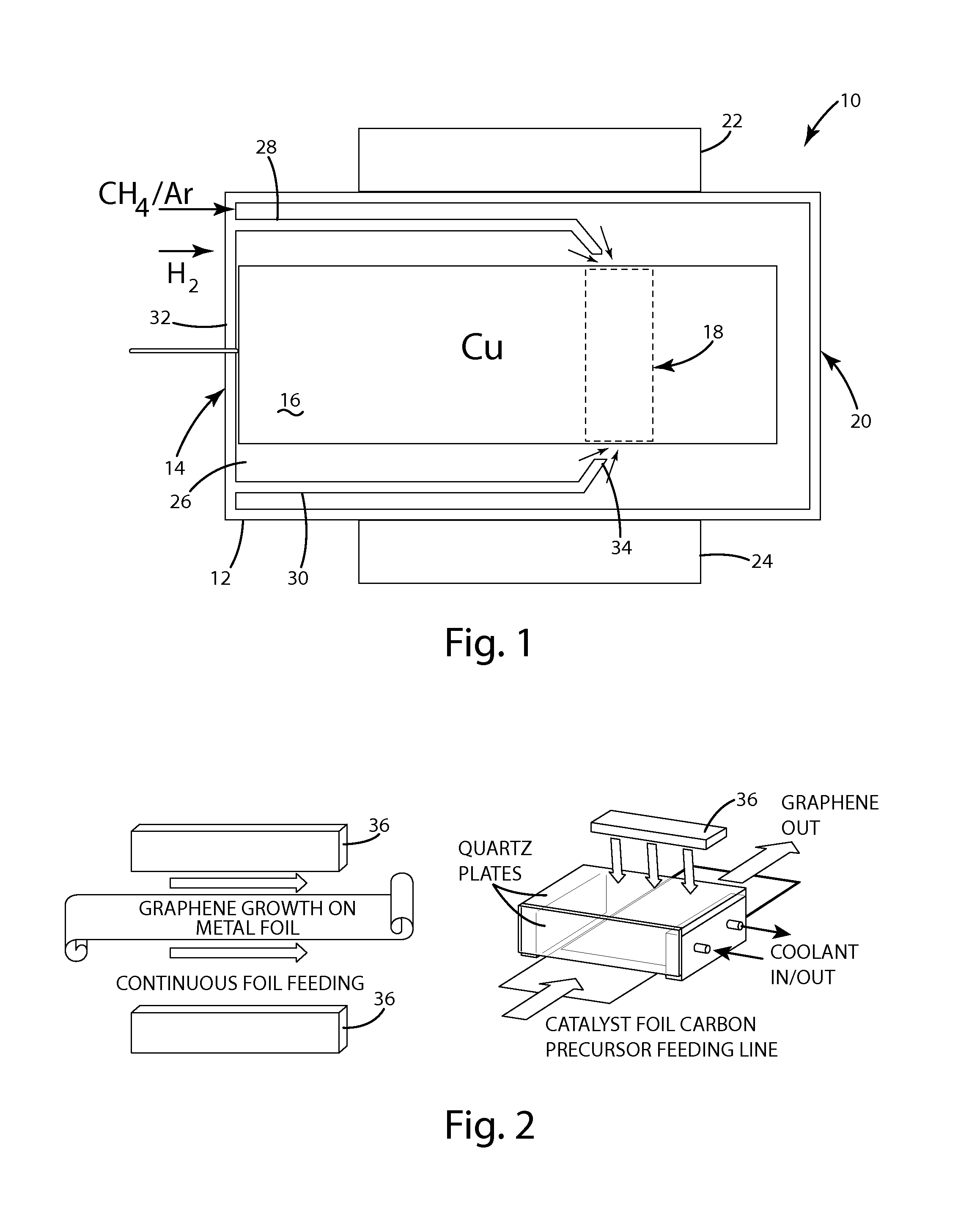

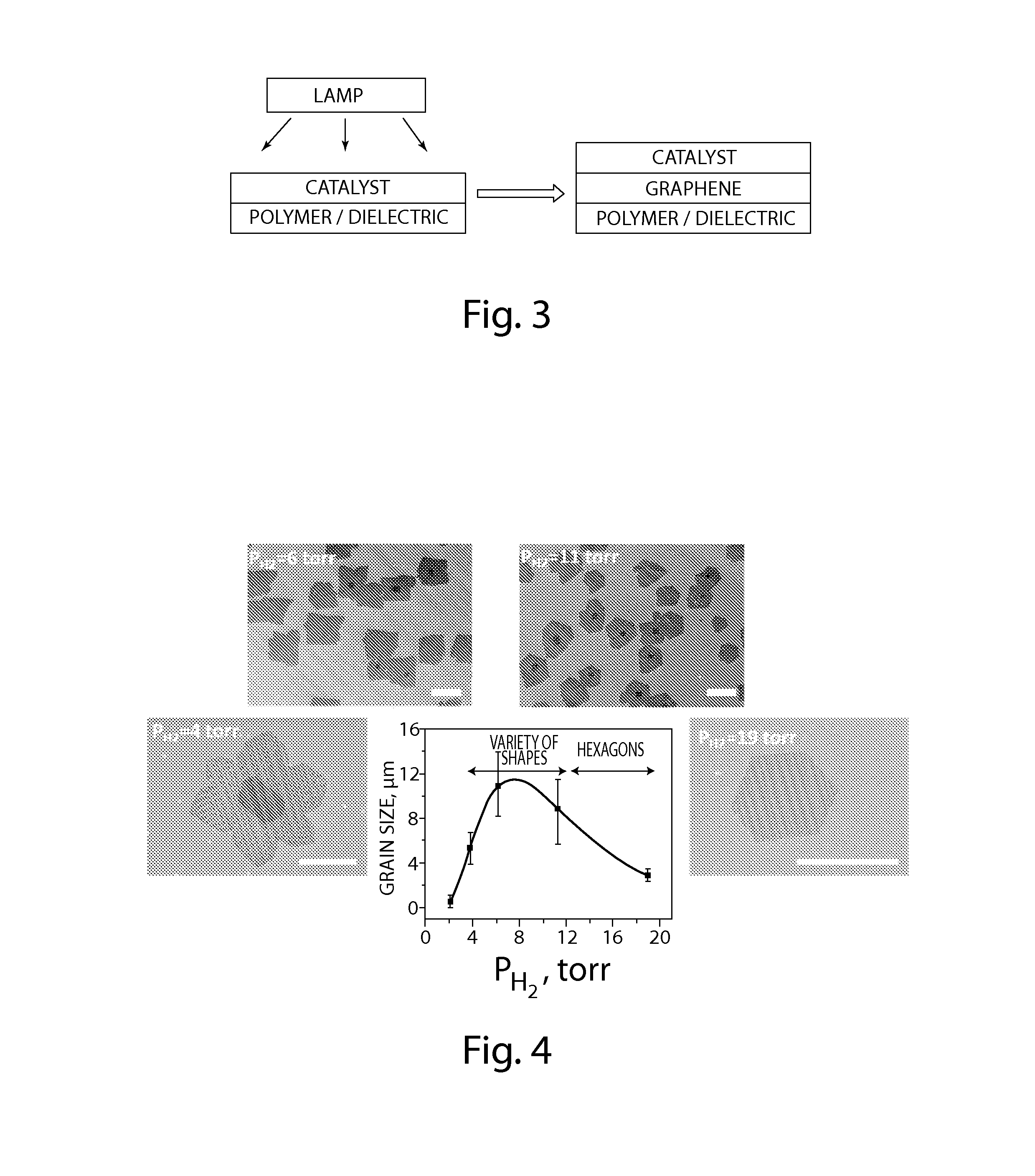

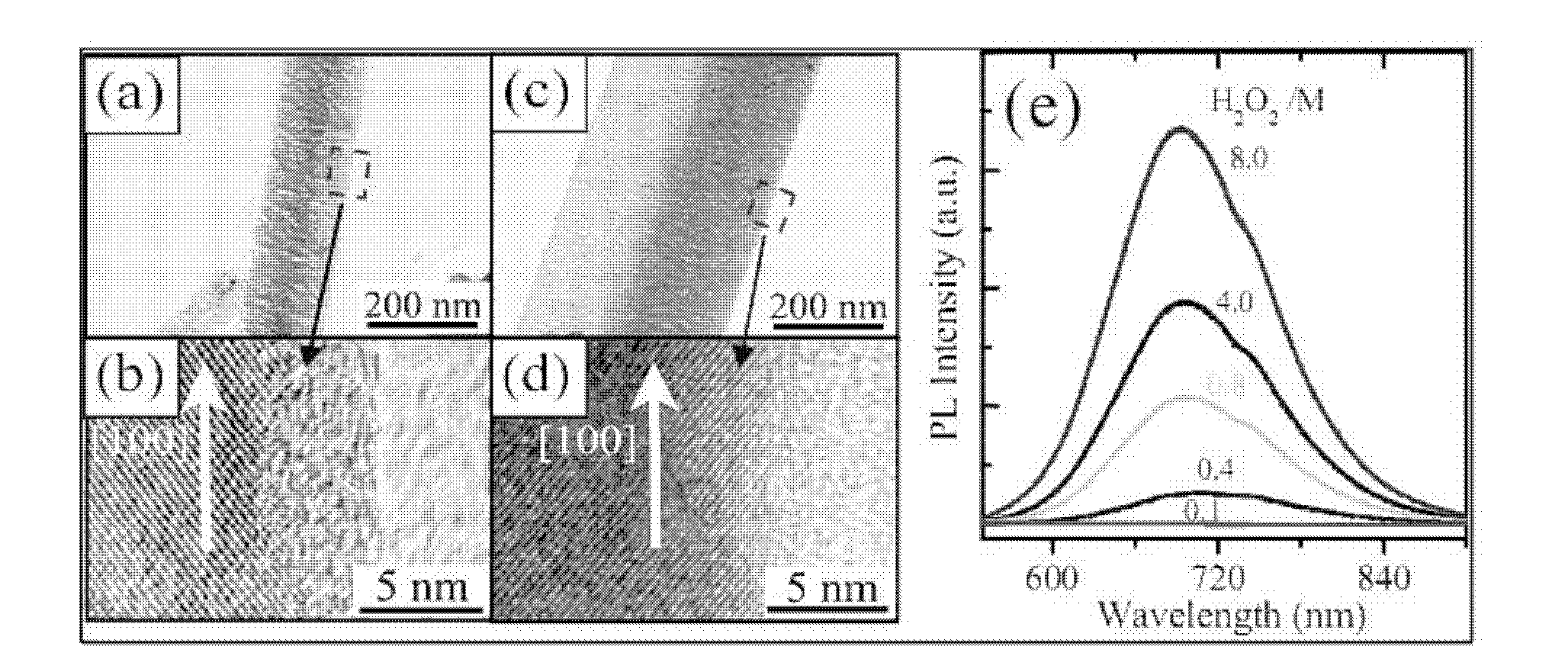

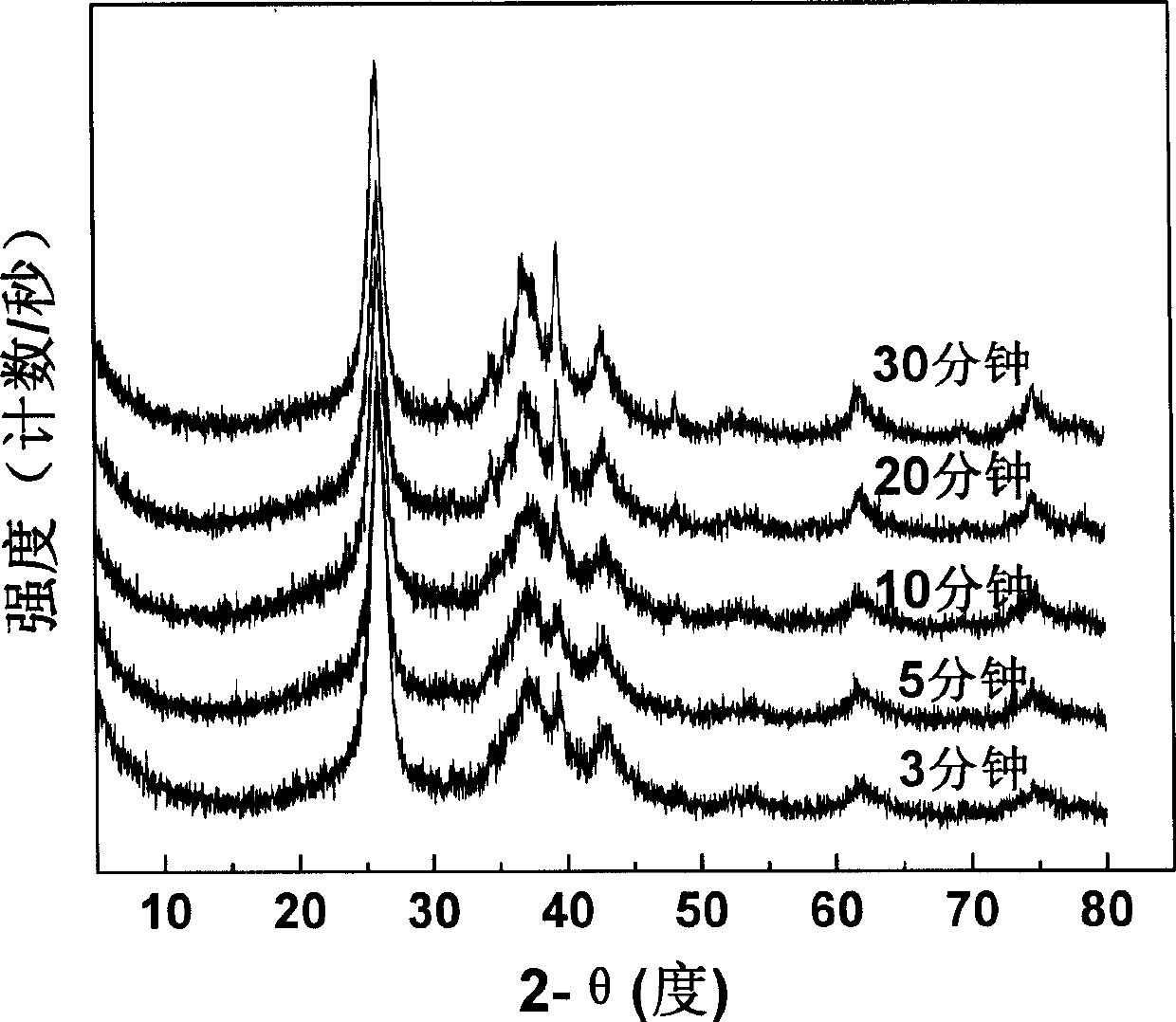

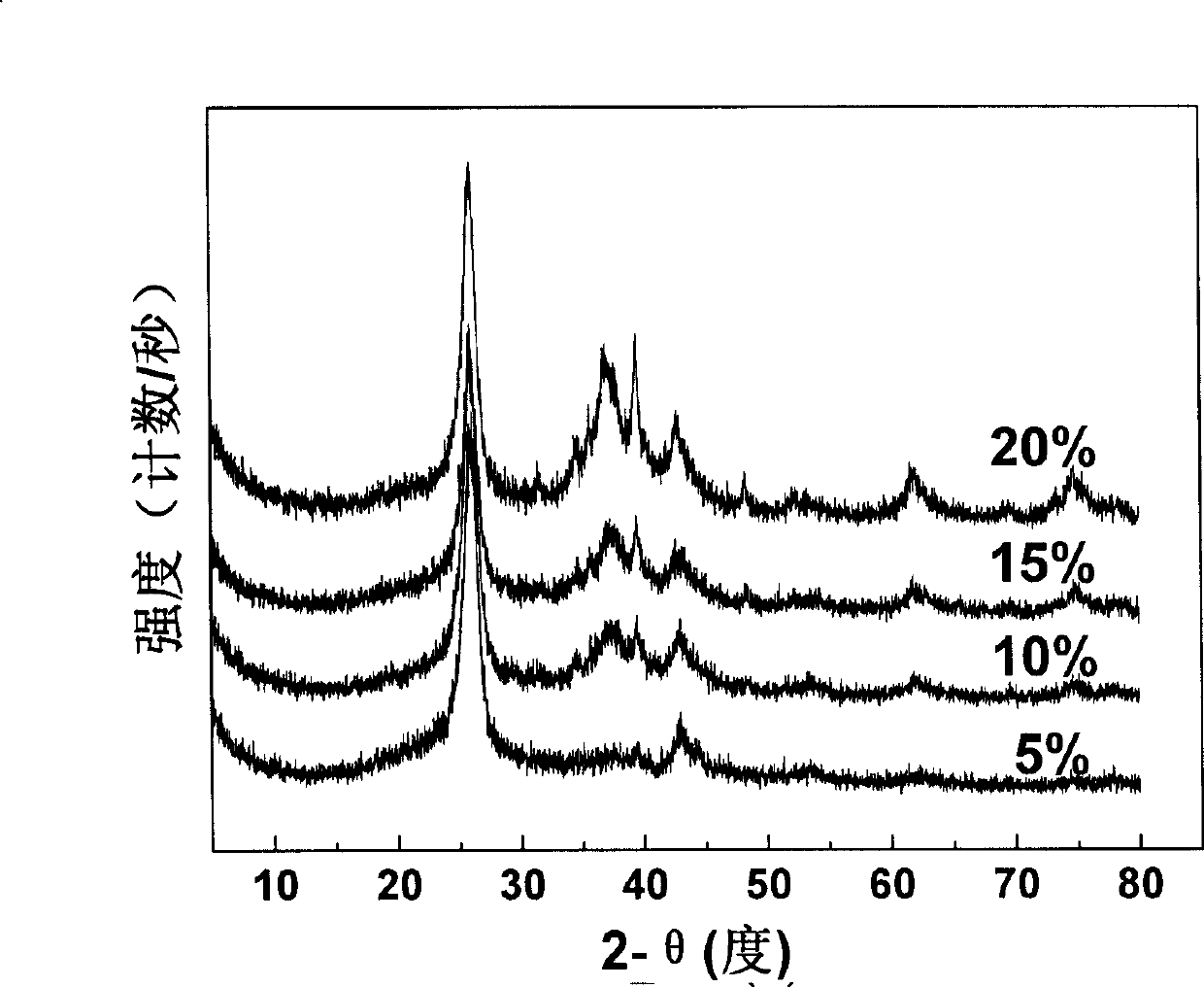

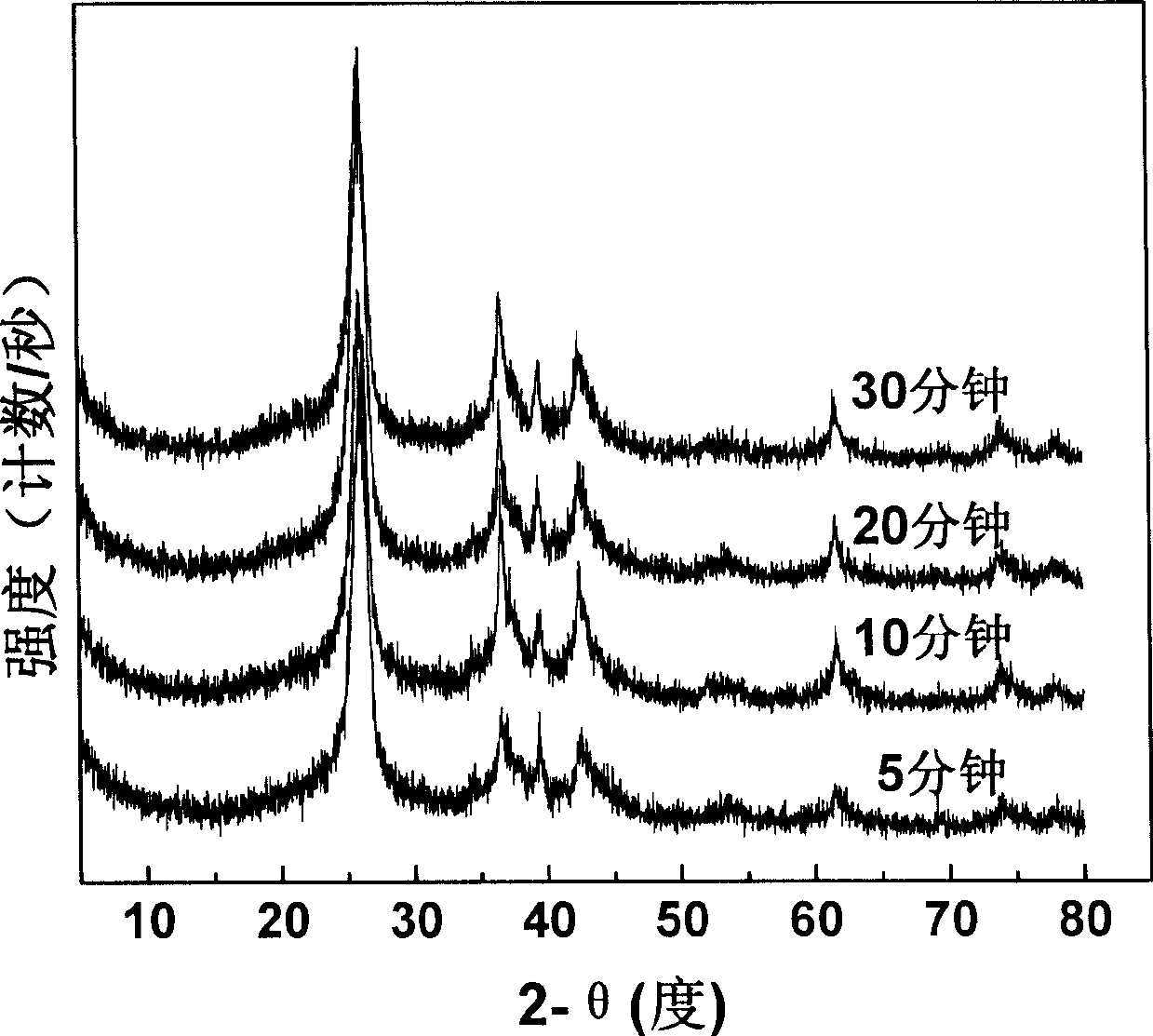

High quality large scale single and multilayer graphene production by chemical vapor deposition

ActiveUS20130174968A1Reduce manufacturing costShorten production timeMaterial nanotechnologySingle layer grapheneNoble gasGas phase

Systems and methods for synthesizing continuous graphene sheets are provided. The systems and methods include passing a catalyst substrate through a heated chemical vapor deposition chamber and exposing the substrate to a reaction gas mixture of hydrogen and hydrocarbon at a preselected location within the chamber. The reaction gas mixture can include hydrogen having a partial pressure of between about 0 Torr and 20 Torr, hydrocarbon having a partial pressure of between about 20 mTorr and about 10 Torr, and one or more buffer gases. The buffer gases can include argon or other noble gases to maintain atmospheric pressure within the chemical deposition chamber. The resulting graphene can be made with continuous mono and multilayers (up to six layers) and have single crystalline hexagonal grains with a preselected nucleation density and domain size for a range of applications.

Owner:UT BATTELLE LLC

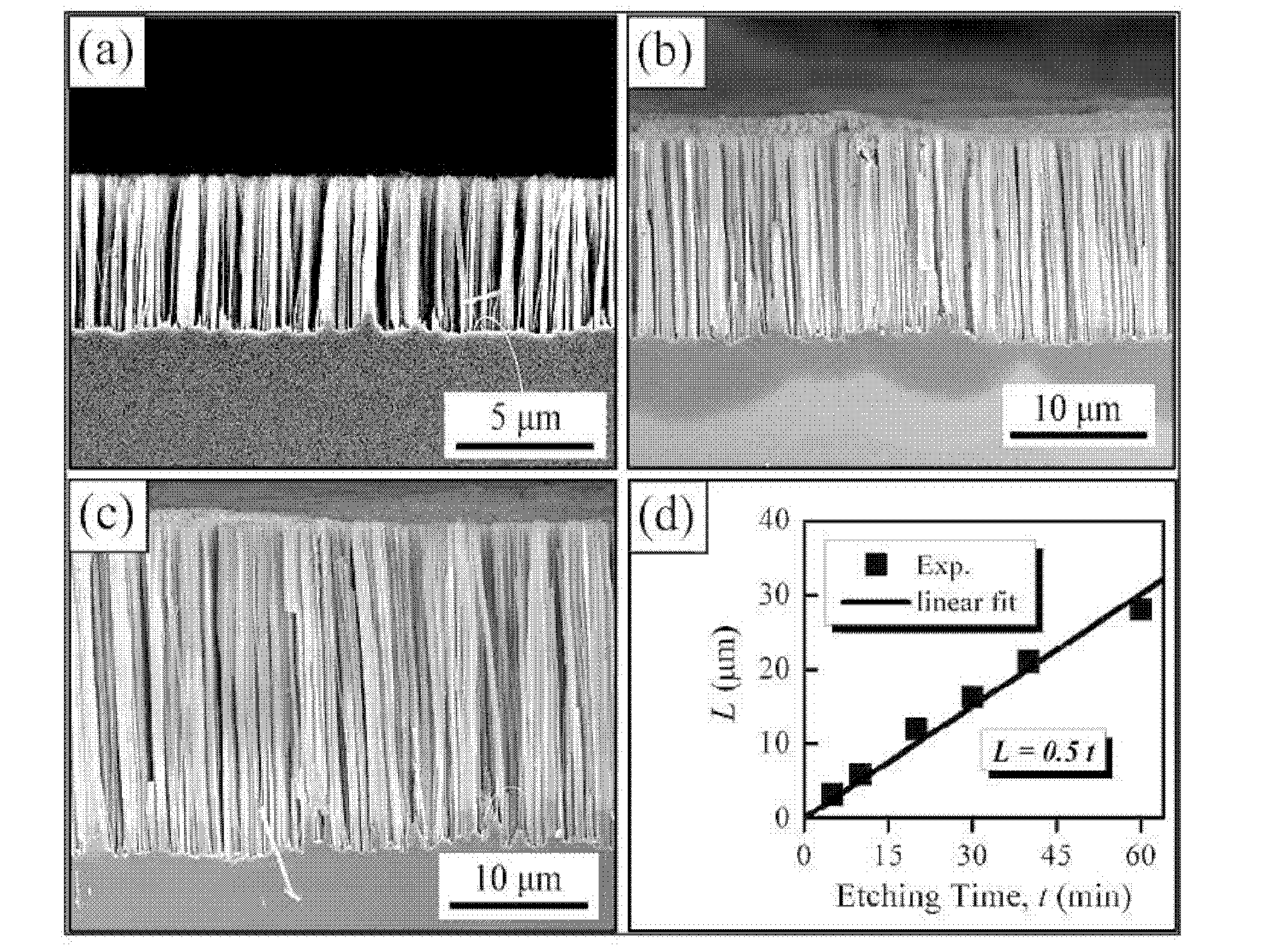

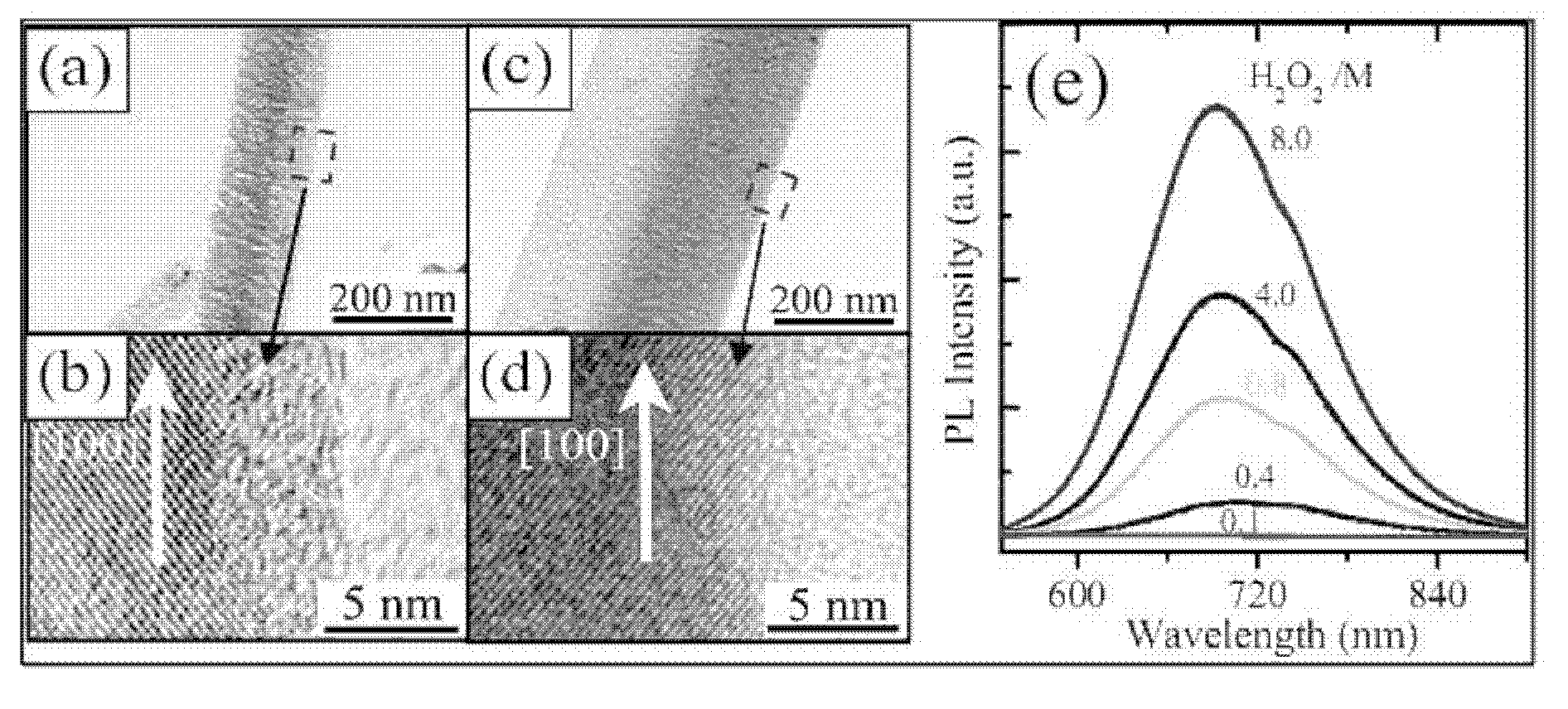

Method for preparing silicon nanowire array with smooth surface

The invention relates to a method for preparing a length-controlled silicon nanowire array with a smooth surface, and belongs to the technology of the preparation of nanometer materials. The method comprises the following steps of: firstly, performing wet chemical cleaning on a silicon wafer; secondly, depositing a silver nanometer granular layer on the surface of the silicon wafer in mixed solution containing hydrofluoric acid and silver nitrate by an electroless chemical deposition method; thirdly, performing chemical etching by mixed solution containing the hydrofluoric acid and hydrogen peroxide; and finally, removing silver nanometer granules by using nitric acid to obtain the silicon nanowire array. In the method, length-controlled silicon nanowires with the smooth surfaces are prepared by regulating the concentration and etching time of the hydrogen peroxide serving as an oxidant simply in a chemical etch system, so the technical problem of preparing the silicon nanowires with fewer surface defects in metal-assisted chemical etching is solved.

Owner:SHANGHAI JIAO TONG UNIV

Vapour deposition in situ reaction method for preparing carbon nanotube reinforced aluminium matrix composite material

InactiveCN1730688AGood dispersionAvoid distractionChemical vapor deposition coatingMetal/metal-oxides/metal-hydroxide catalystsGas phaseCarbon nanotube

The invention provides a process for preparing carbon nano tube reinforced aluminum base composite material through gaseous phase in-situ reaction, which comprises using aluminum-base powder as carrying agent, preparing Ni catalyst with chemical deposition precipitation process, obtaining Al-Ni composite powder, preparing carbon nano tube on composite powder in-situ through chemical deposition precipitation process.

Owner:TIANJIN UNIV

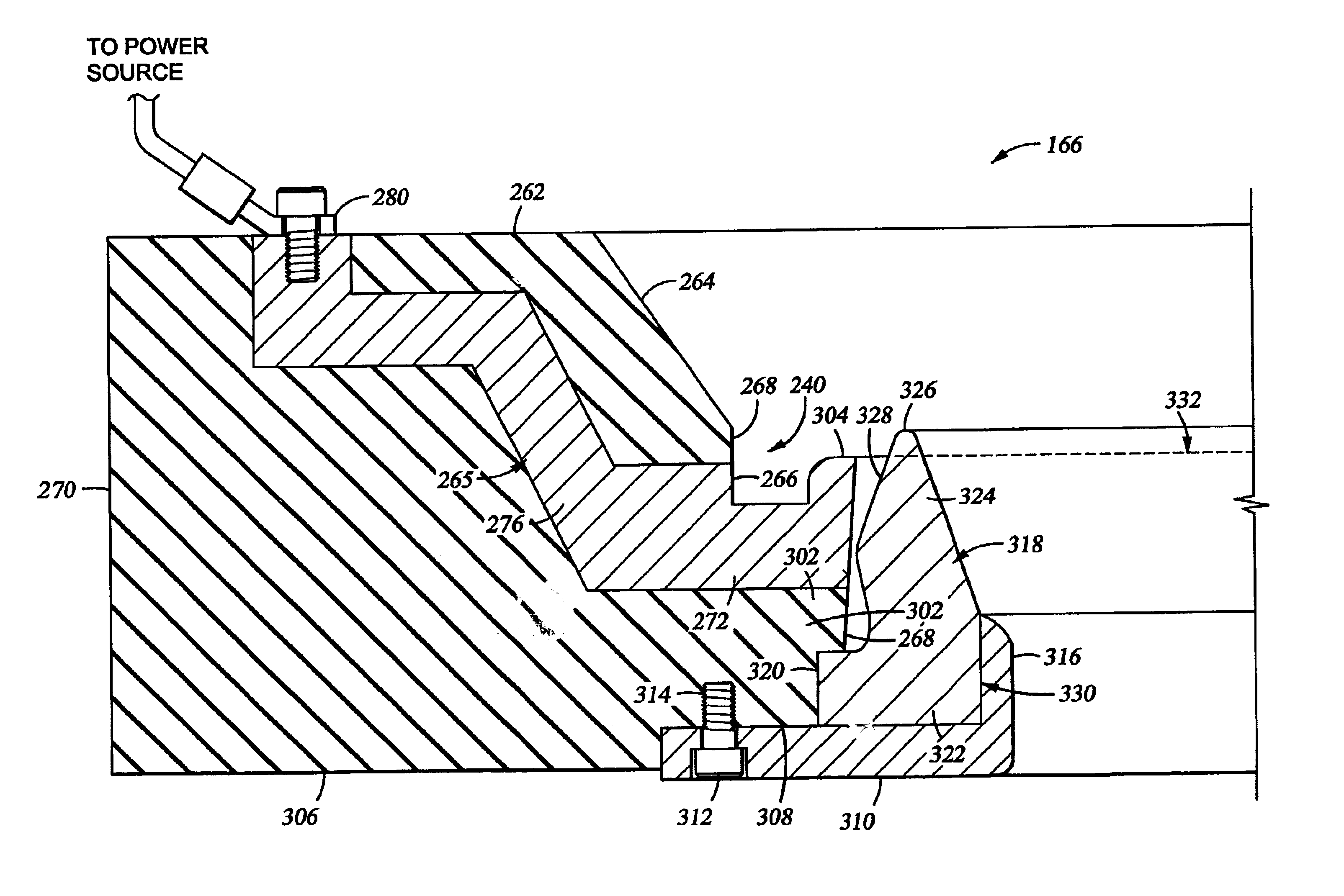

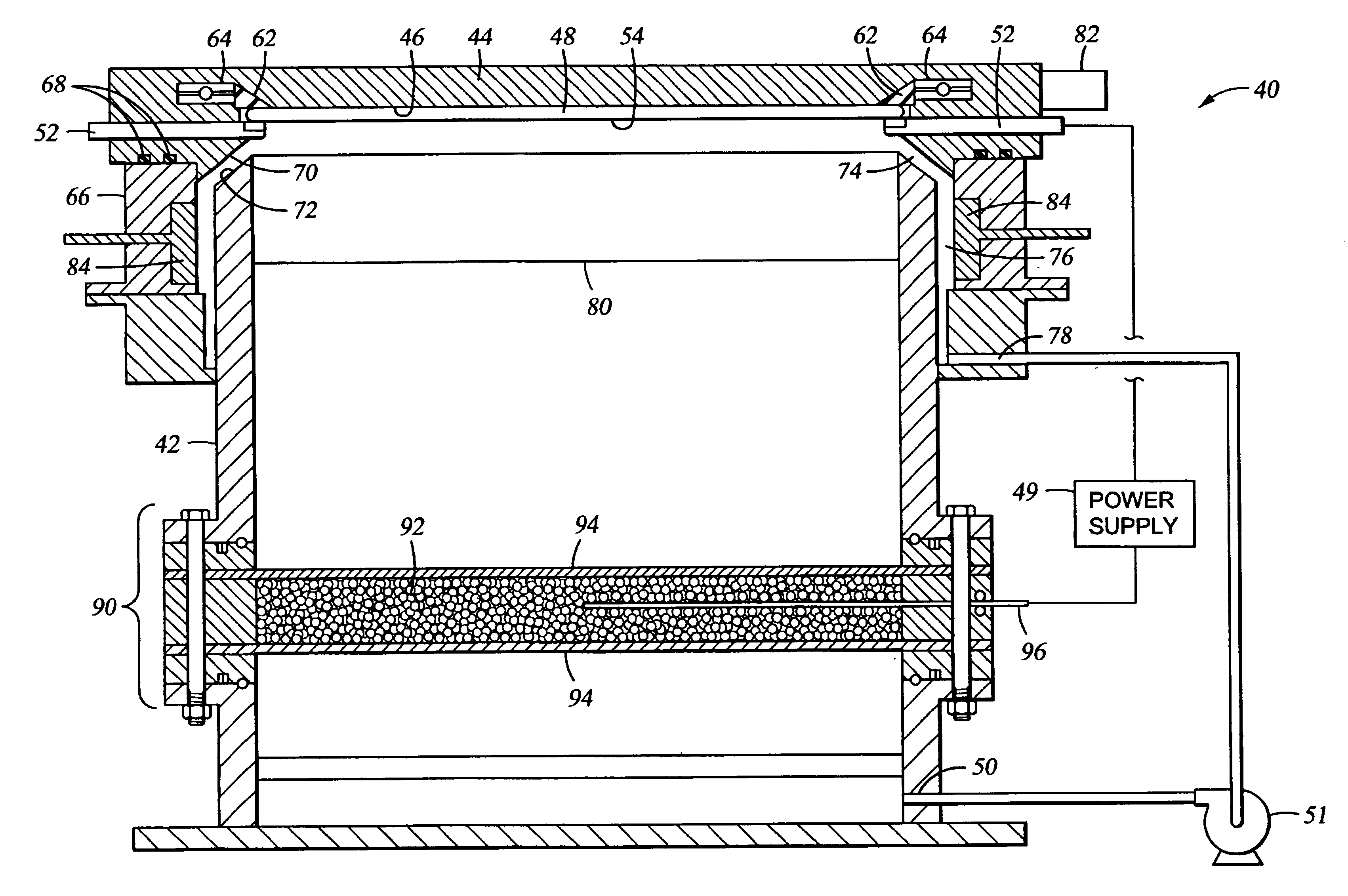

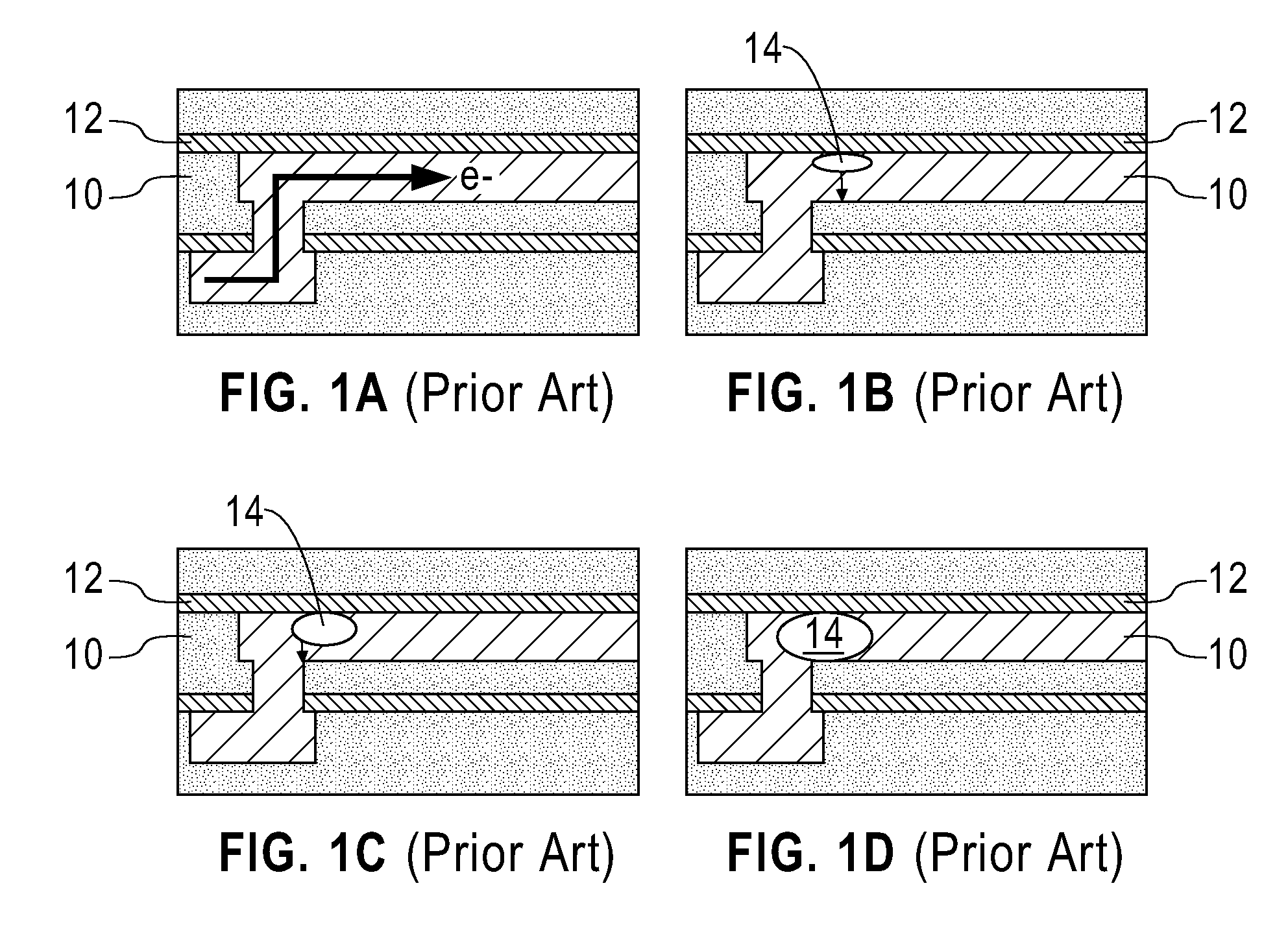

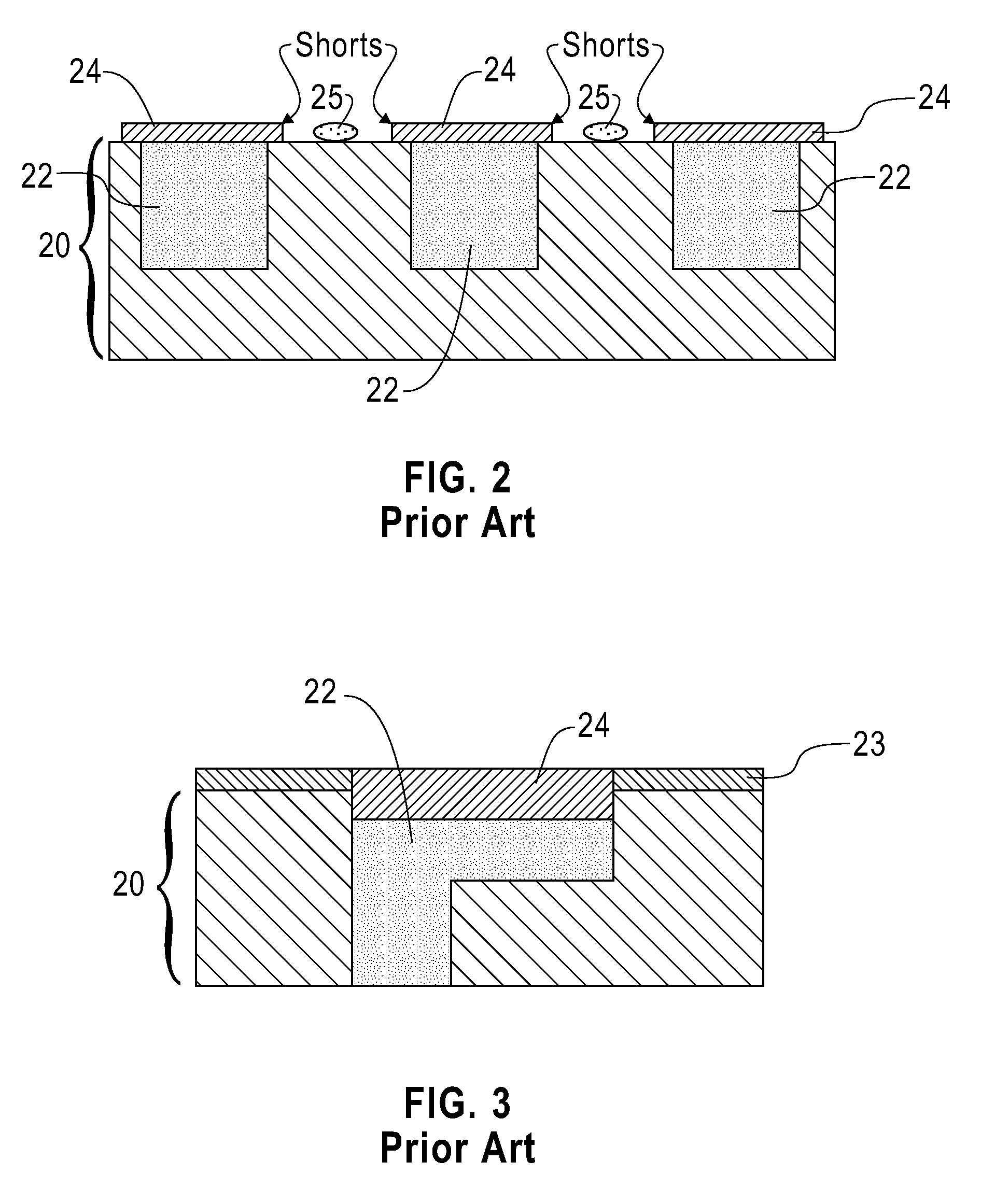

Method and apparatus for encapsulation of an edge of a substrate during an electro-chemical deposition process

InactiveUS6908540B2Easy to understandCellsSemiconductor/solid-state device manufacturingContact padEngineering

An electro-chemical deposition method and apparatus that encapsulates a substrate's edge to prevent deposition thereon is generally provided. In one embodiment, the apparatus includes a contact ring, one or more electrical contact pads disposed on the contact ring and a thrust plate axially movable relative to the contact ring. A first seal is disposed inward of the contact pad and seals with the contact ring. A second seal is coupled to the thrust plate. The first and second seals are adapted to sandwich the substrate therebetween when the contact ring and the thrust plate are moved towards each other. In another embodiment, a third seal provides a seal between the thrust plate and contact ring, and, with the first and second seals, defines an exclusion zone encapsulating the substrate's edge. One or more electrical contact pads are protected from the electrolyte by being disposed within the exclusion zone.

Owner:APPLIED MATERIALS INC

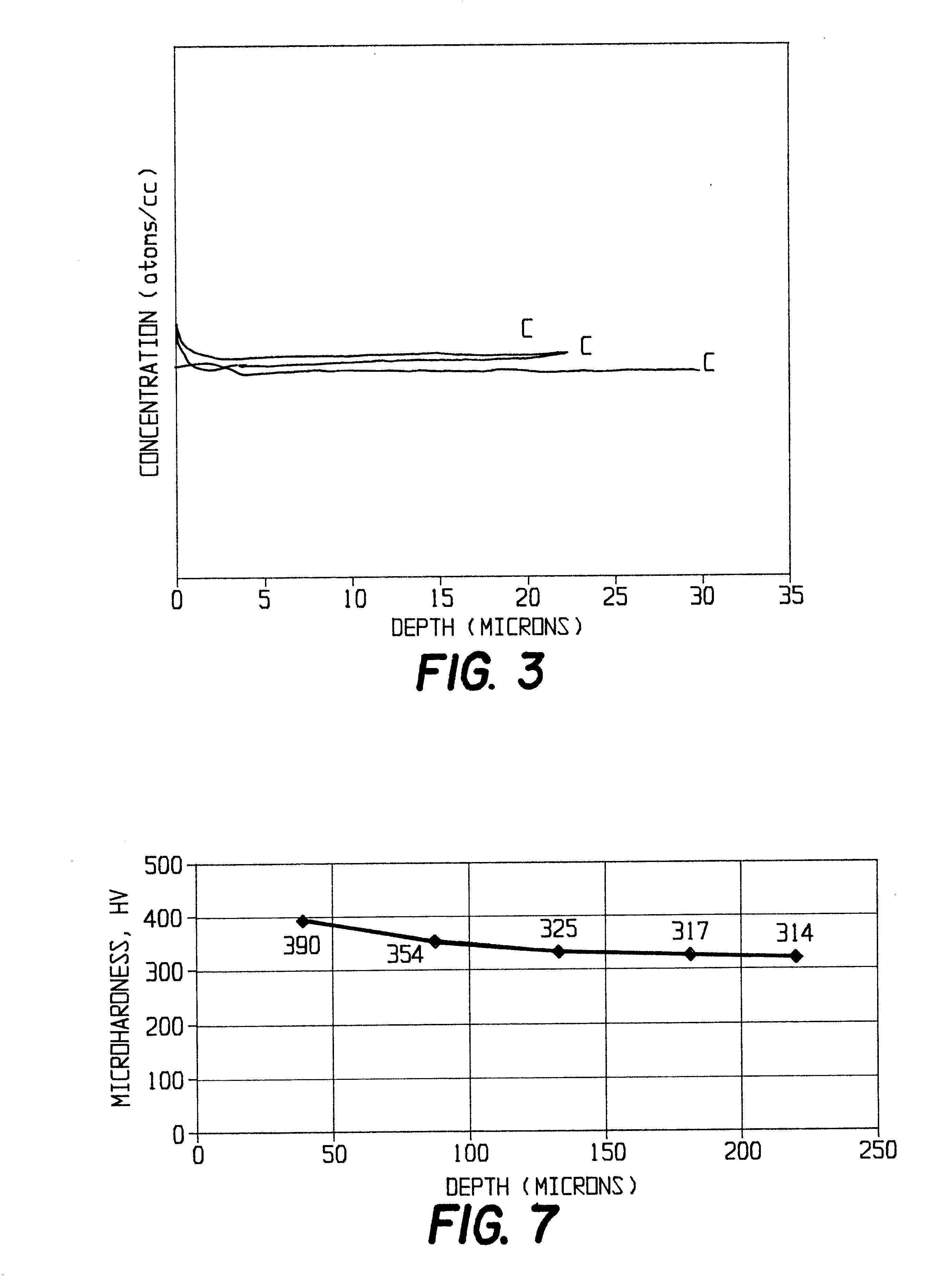

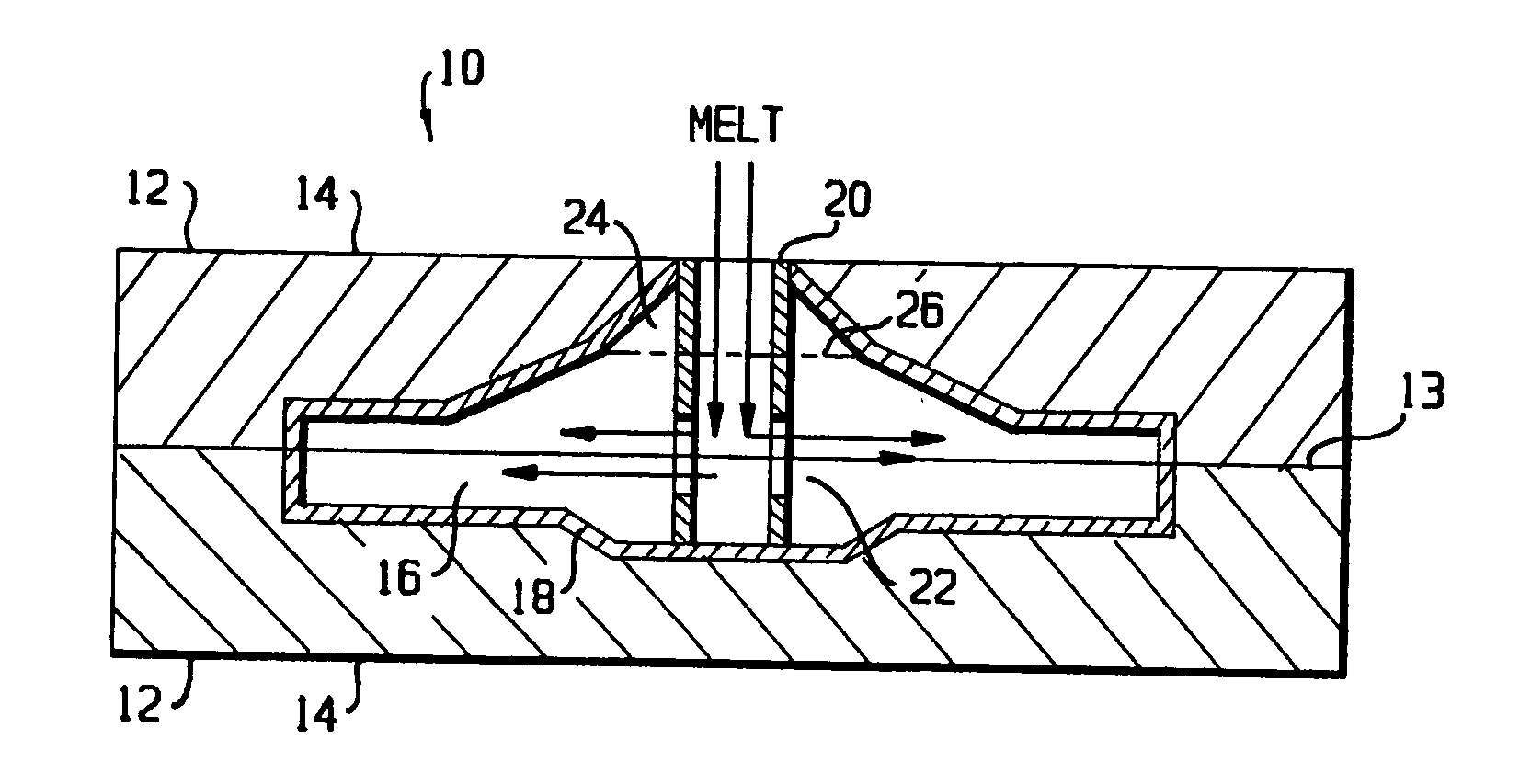

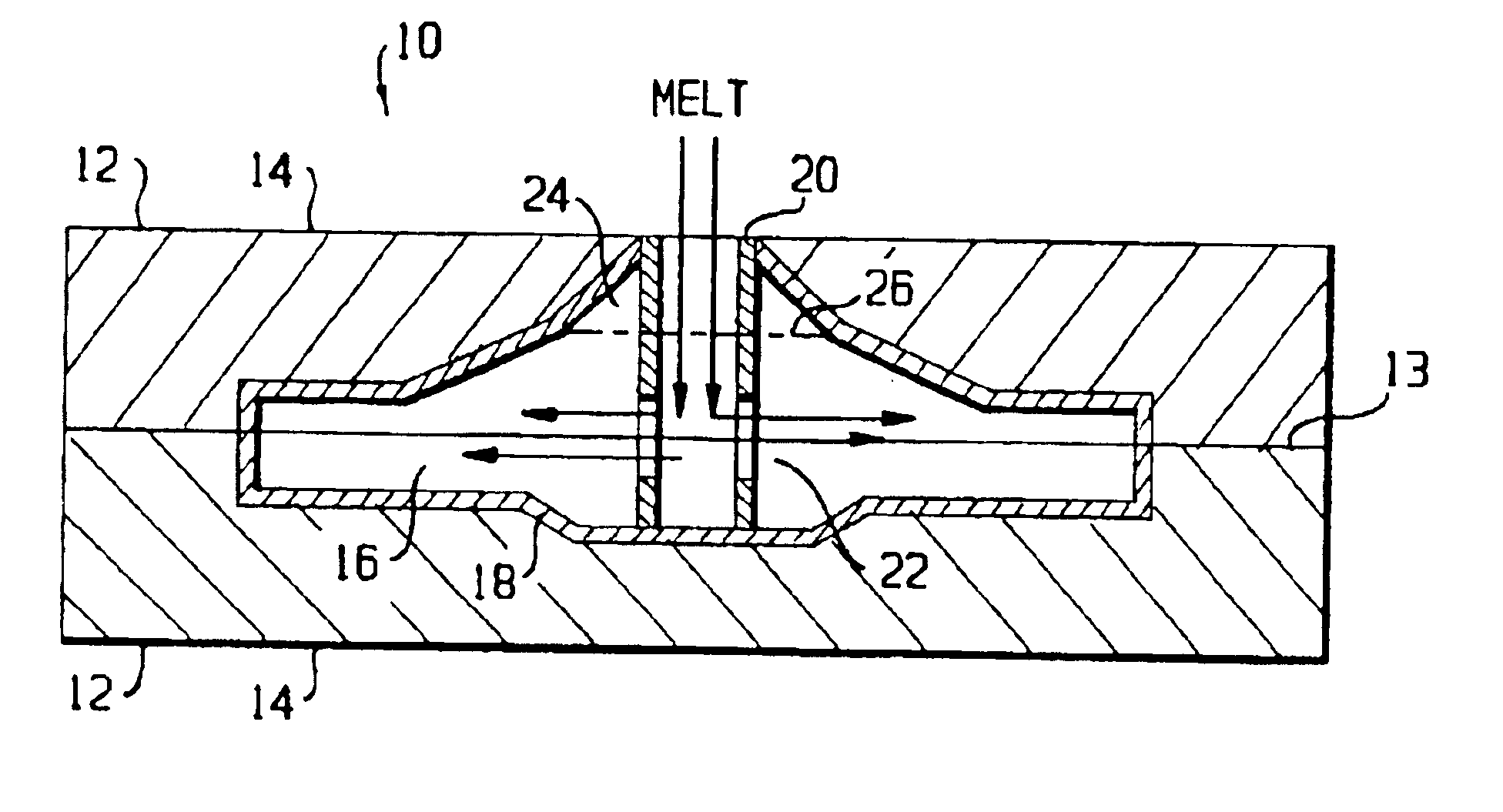

Castings of metallic alloys with improved surface quality, structural integrity and mechanical properties fabricated in anisotropic pyrolytic graphite molds under vacuum

Molds are fabricated having a substrate of high density, high strength ultrafine grained isotropic graphite, and having a mold cavity coated with pyrolytic graphite. The molds may be made by making the substrate (main body) of high density, high strength ultrafine grained isotropic graphite, by, for example, isostatic or vibrational molding, machining the substrate to form the mold cavity, and coating the mold cavity with pyrolytic graphite via a chemical deposition process. The molds may be used to make various metallic alloys such as nickel, cobalt and iron based superalloys, stainless steel alloys, titanium alloys and titanium aluminide alloys into engineering components by melting the alloys in a vacuum or under a low partial pressure of inert gas and subsequently casting the melt in the graphite molds under vacuum or low partial pressure of inert gas.

Owner:SANTOKU CORP

Castings of metallic alloys with improved surface quality, structural integrity and mechanical properties fabricated in refractory metals and refractory metal carbides coated graphite molds under vacuum

InactiveUS20050016706A1Quality improvementImprove mechanical propertiesCasting safety devicesFoundry mouldsSuperalloyTitanium carbide

Molds are fabricated having a substrate of high density, high strength ultrafine grained isotropic graphite, and having a mold cavity coated with a refractory metal such as W or Re or a refractory metal carbide such as TaC or HfC. The molds may be made by making the substrate (main body) of high density, high strength ultrafine grained isotropic graphite, by, for example, isostatic or vibrational molding, machining the substrate to form the mold cavity, and coating the mold cavity with titanium carbide via either chemical deposition or plasma assisted chemical vapor deposition, magnetron sputtering or sputtering. The molds may be used to make various metallic alloys such as nickel, cobalt and iron based superalloys, stainless steel alloys, titanium alloys and titanium aluminide alloys into engineering components by melting the alloys in a vacuum or under a low partial pressure of inert gas and subsequently casting the melt in the graphite molds under vacuum or low partial pressure of inert gas.

Owner:SANTOKU AMERICA

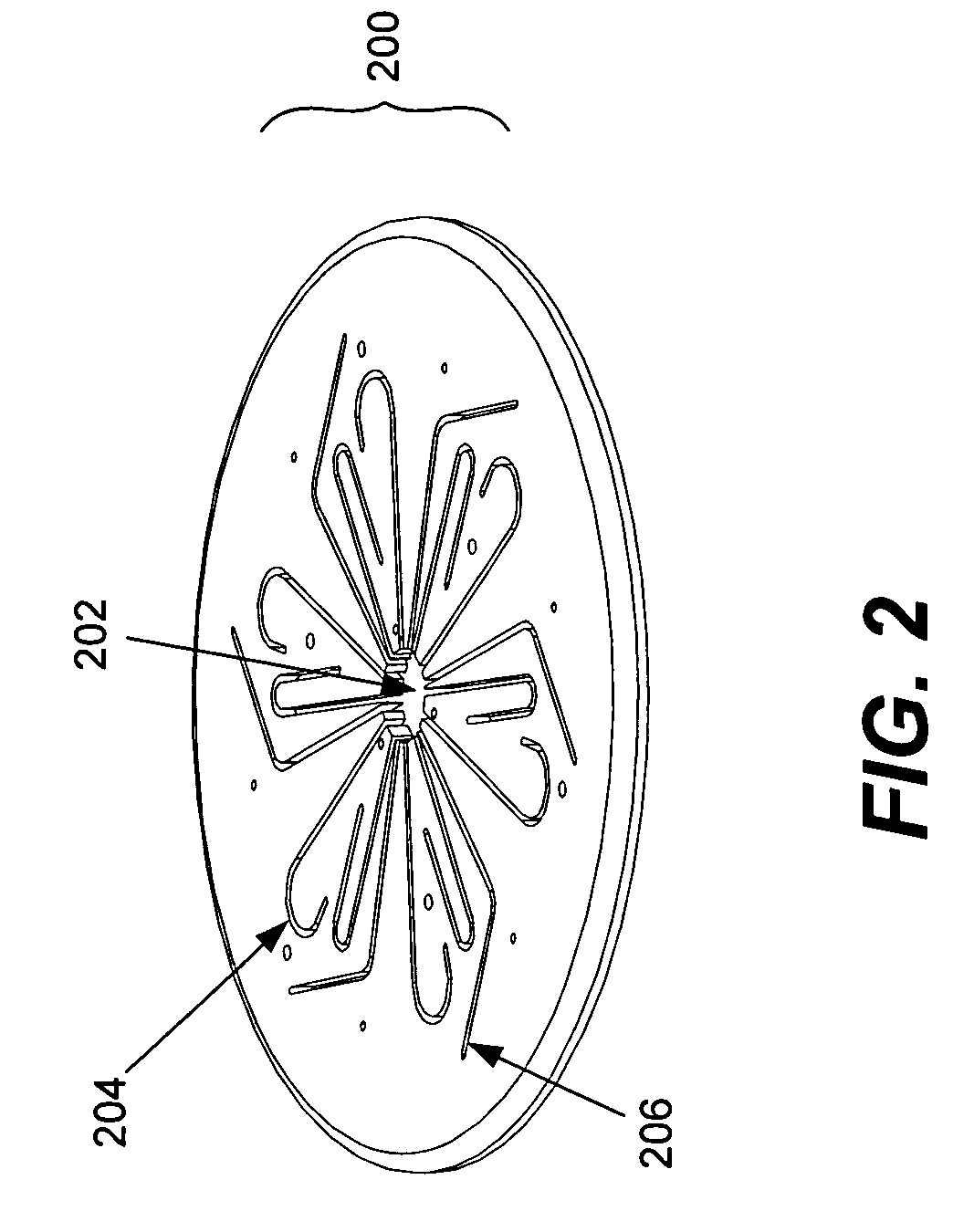

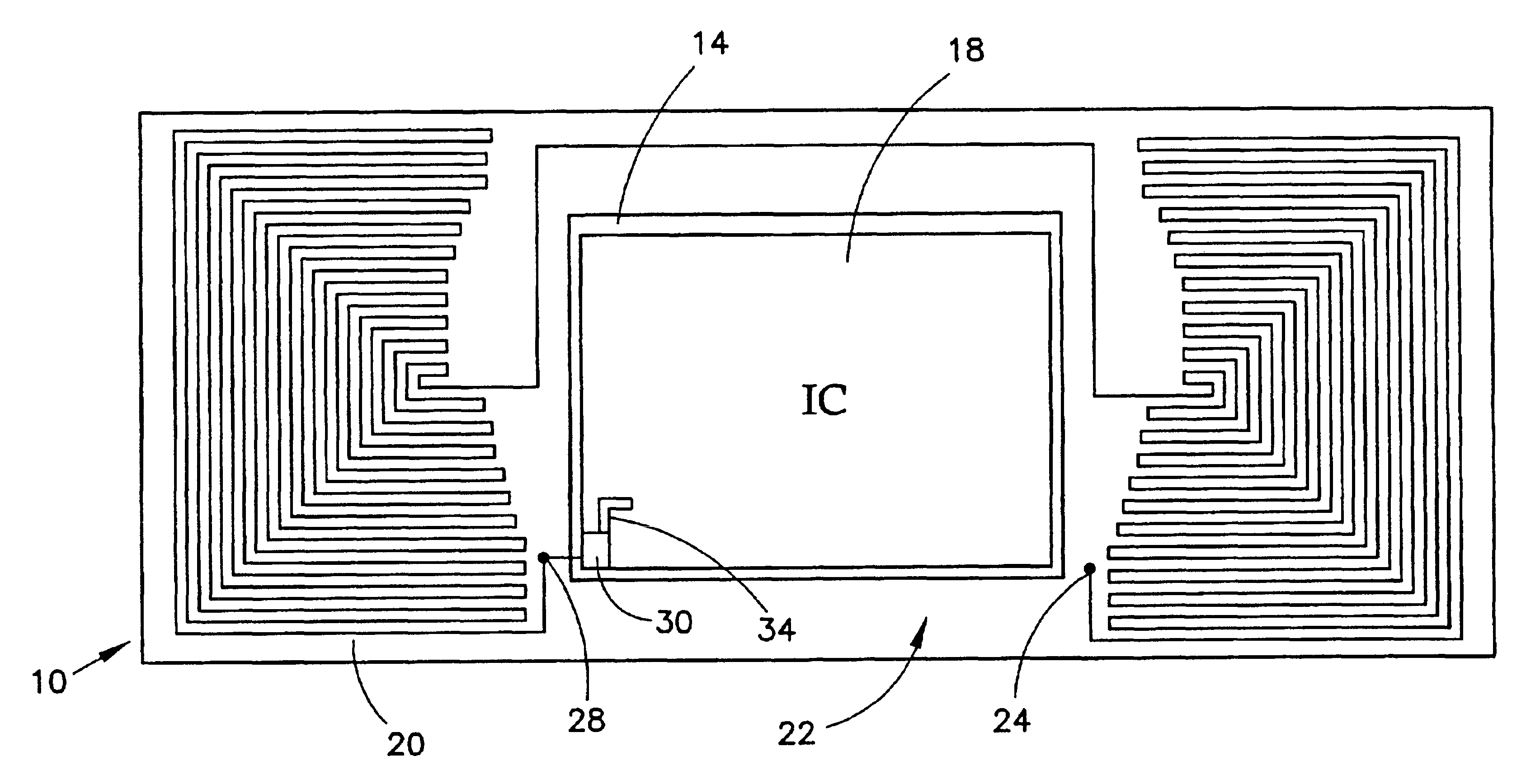

System and method for using film deposition techniques to provide an antenna within an integrated circuit package

InactiveUS6849936B1Reduce the possibilityReduce radio frequency interferenceSemiconductor/solid-state device detailsAntenna supports/mountingsTransceiverEvaporation

An integrated circuit package comprises a cavity for housing an integrated circuit (IC) and an antenna provided as part of the package that is located substantially outside the cavity. The antenna may be located on the floor of the IC package that lies in the region outside of the IC cavity. Alternatively, the antenna may be located on the upper or lower surface of the lid sealing the IC package. The antenna may be placed in the floor or on a surface of the IC lid by forming depressions in the floor or lid surface and depositing conductive material in the depressions. The conductive material deposition may be by sputtering, evaporation, or other known physical or chemical deposition method. Antennas formed in the upper surface of an IC lid may be coupled to a pin of the IC package so that the antenna may be electrically coupled to a transceiver component on the IC within the package. Antennas formed in the lower surface of an IC lid or the floor of the IC package may be coupled by a conductive pin to a component pad of the IC within the package. To reduce electromagnetic noise that may be induced by the radio frequency signals emitted or received by an antenna, a grounding plane may be provided as part of the IC package. The grounding plane may be coupled to an electrical ground reference point through an IC package pin or the IC within the package.

Owner:BELL SEMICON LLC

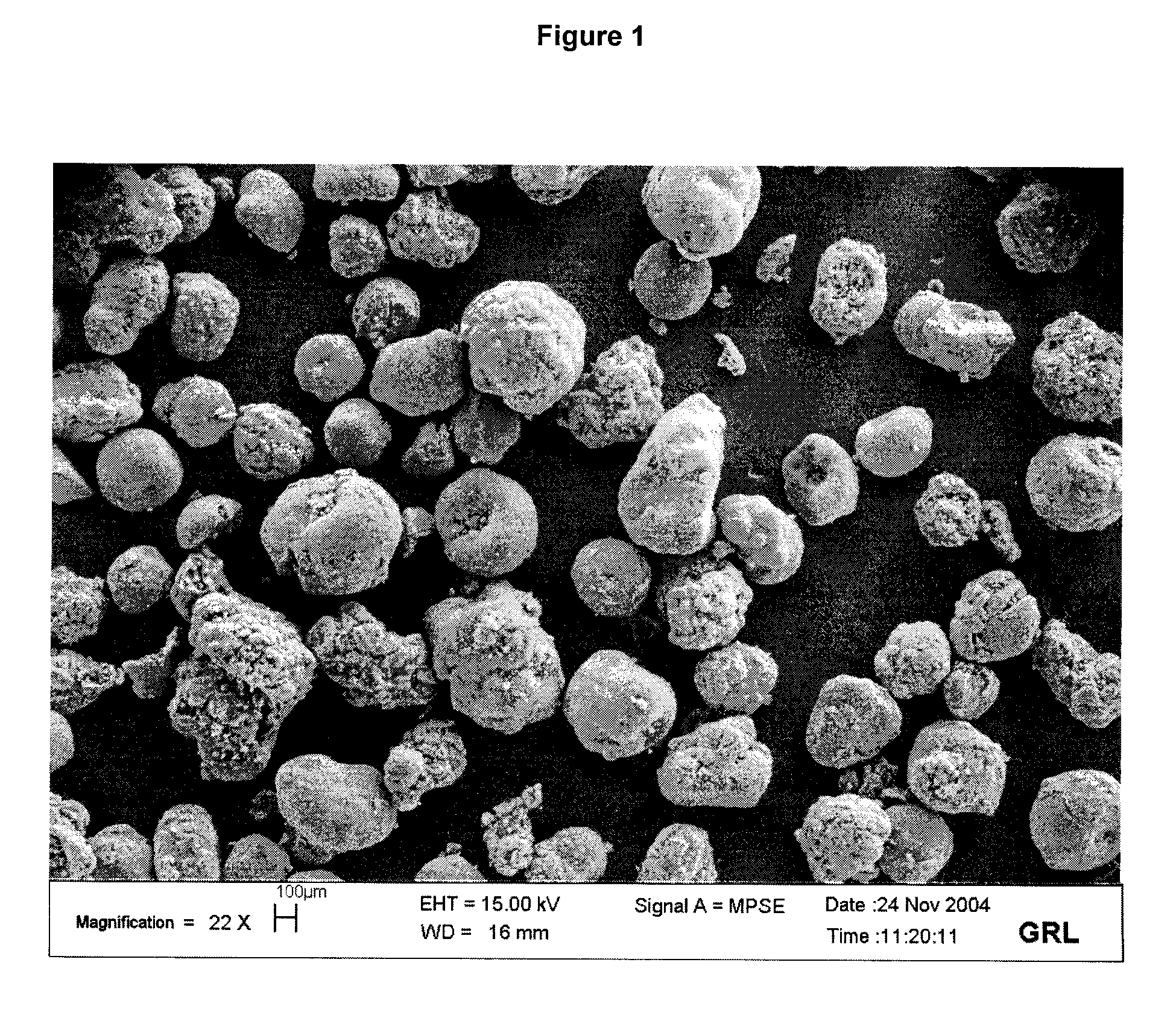

Method for synthesis of carbon nanotubes

The invention relates to a method for synthesis of carbon nanotubes of the highest carbon purity by the process of vapour phase chemical deposition. The nanotubes produced can be used to advantage in all know applications of carbon nanotubes.

Owner:ARKEMA FRANCE SA

Method for synthesis of carbon nanotubes

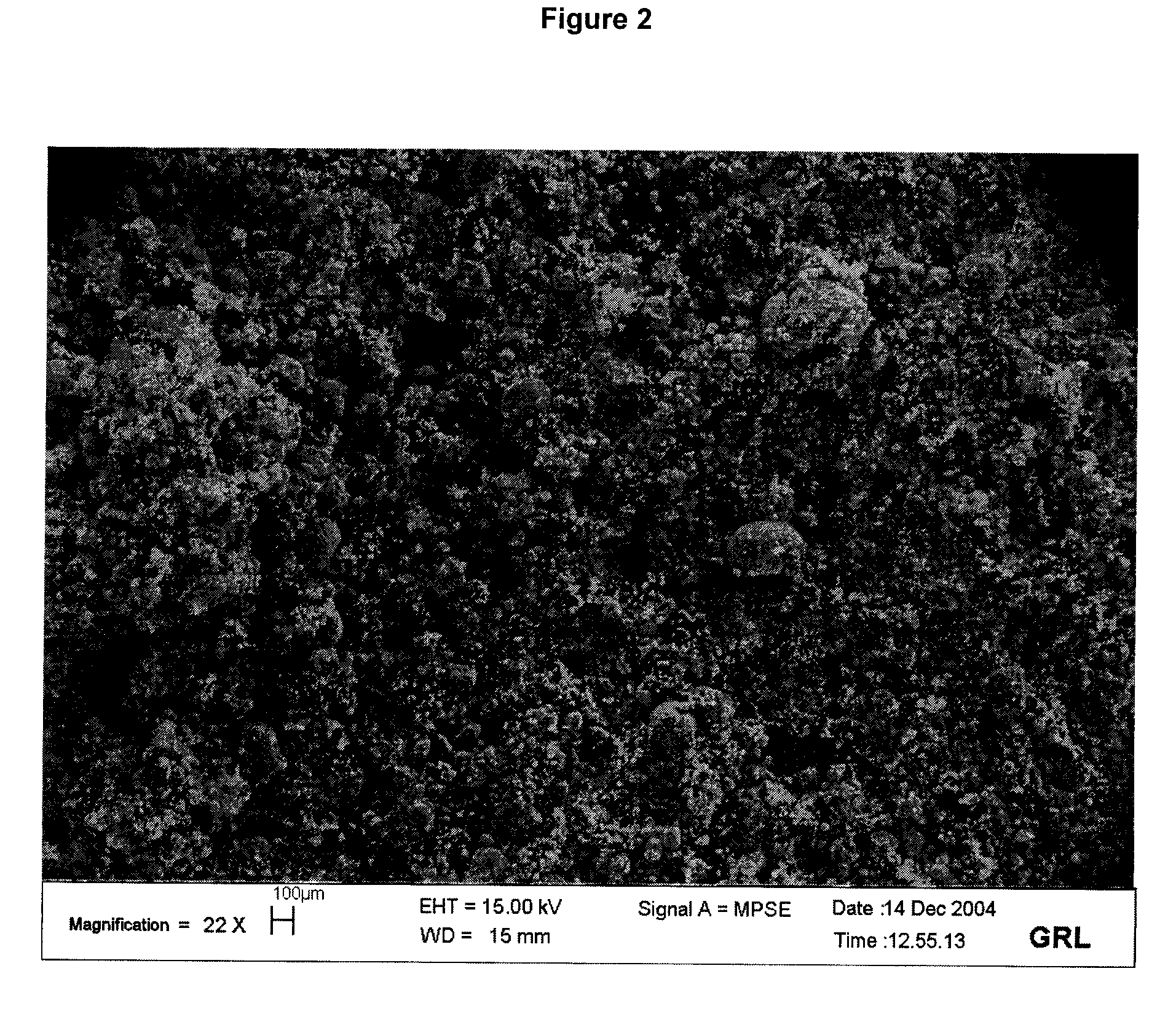

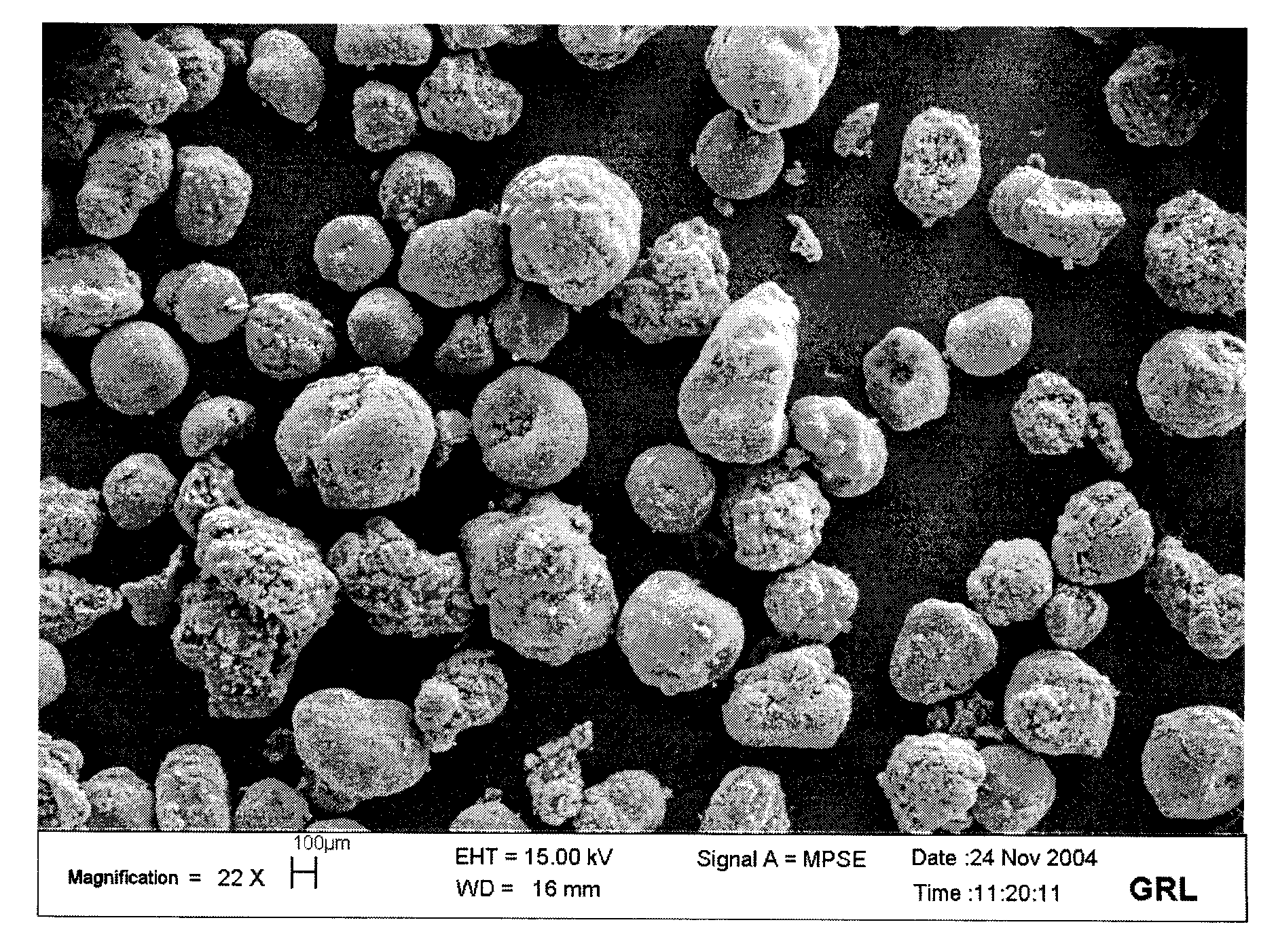

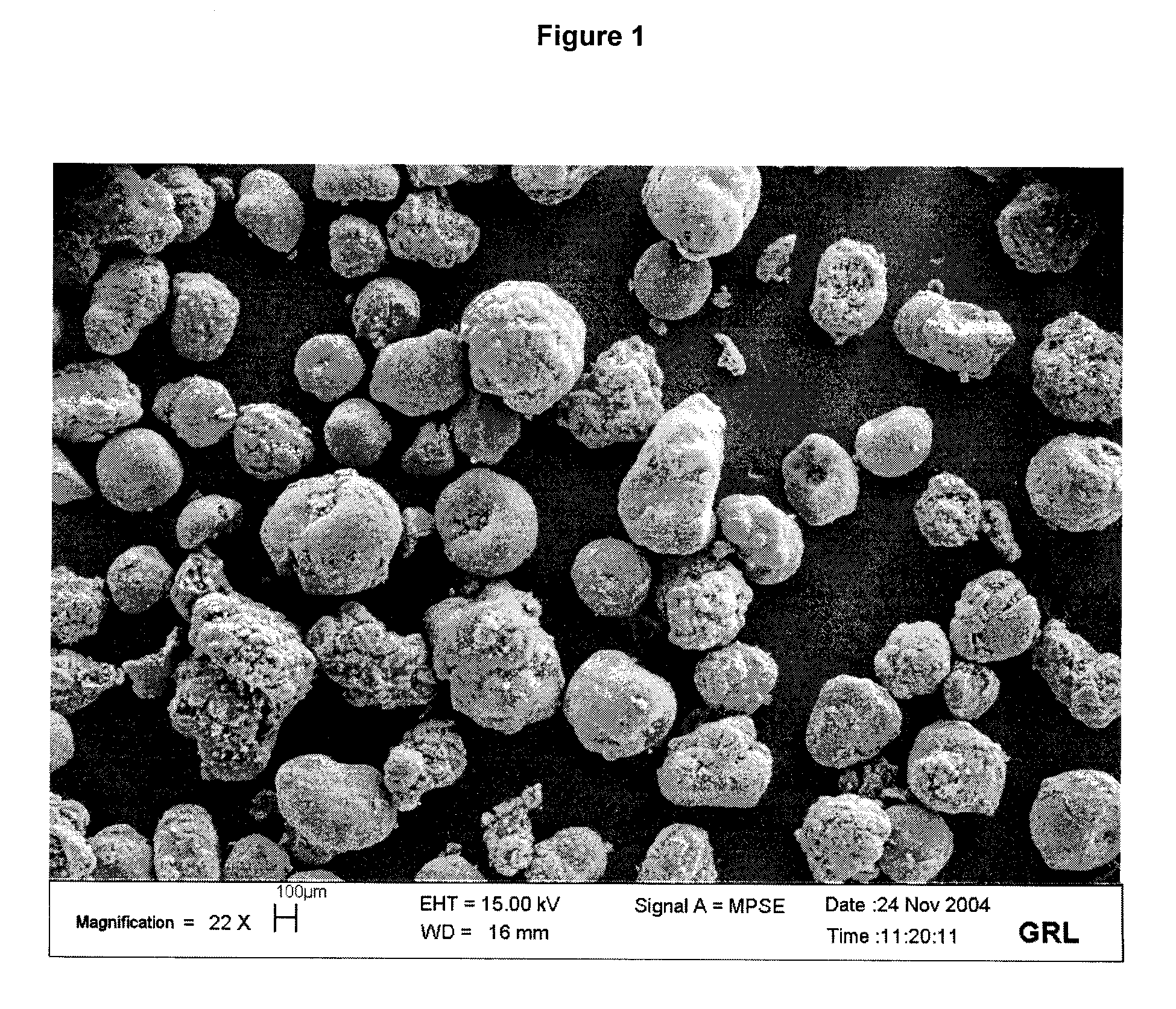

InactiveUS20090134363A1Small particle sizeMaterial nanotechnologyPigmenting treatmentHigh carbonBCN nanotube

The invention relates to a method for synthesis of carbon nanotubes of the highest carbon purity by the process of vapour phase chemical deposition. The nanotubes produced can be used to advantage in all know applications of carbon nanotubes.

Owner:ARKEMA FRANCE SA

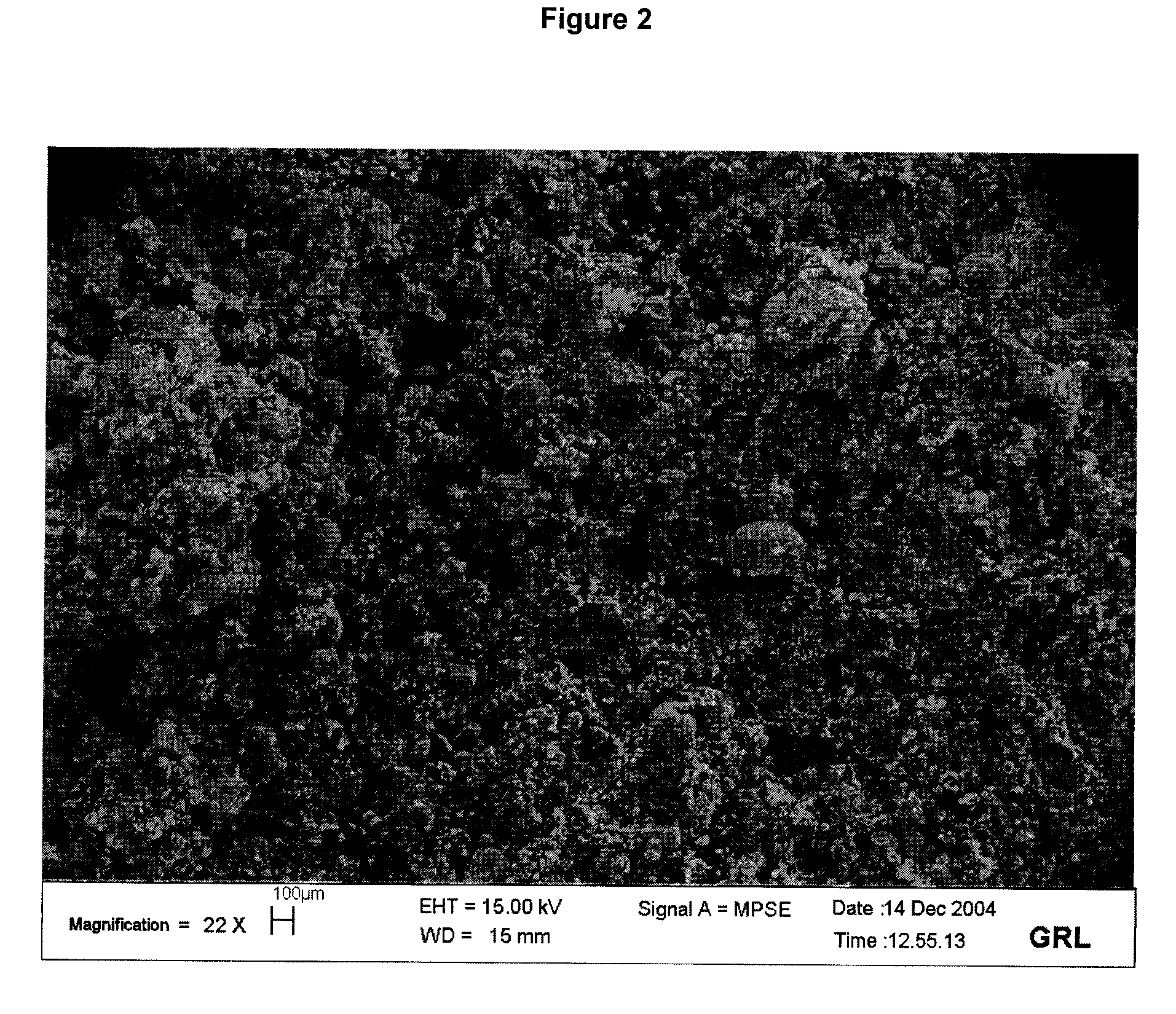

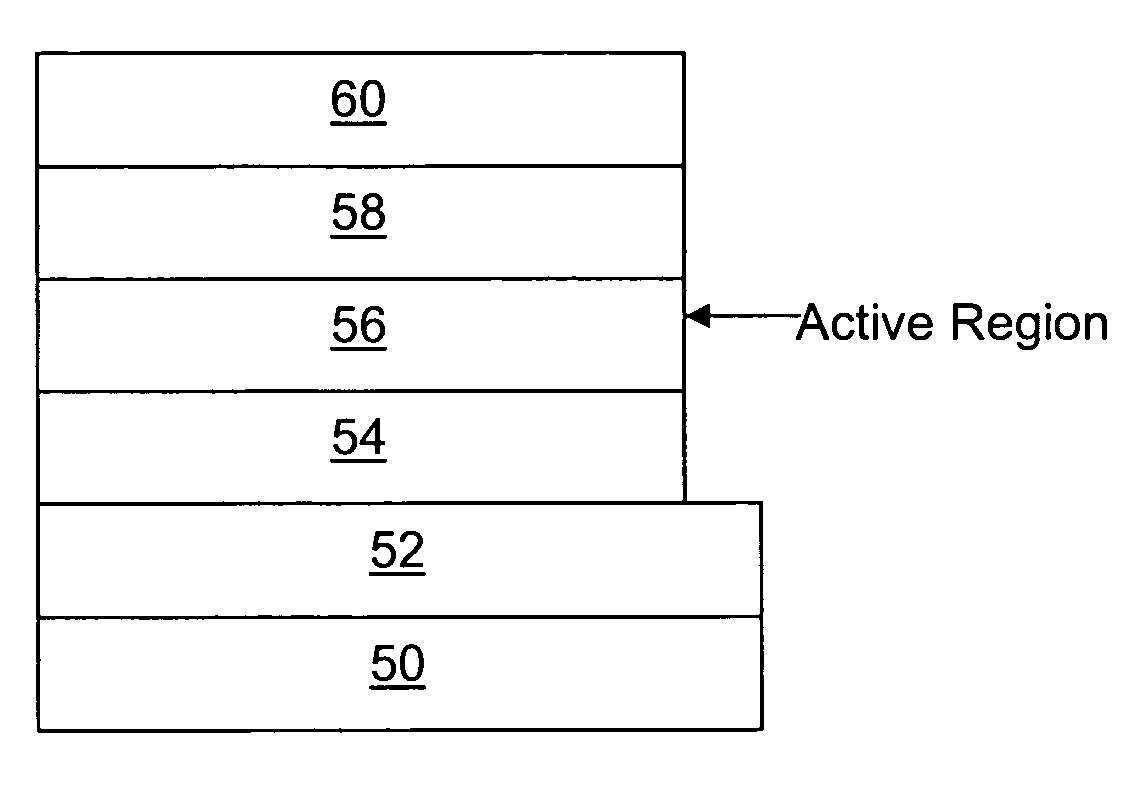

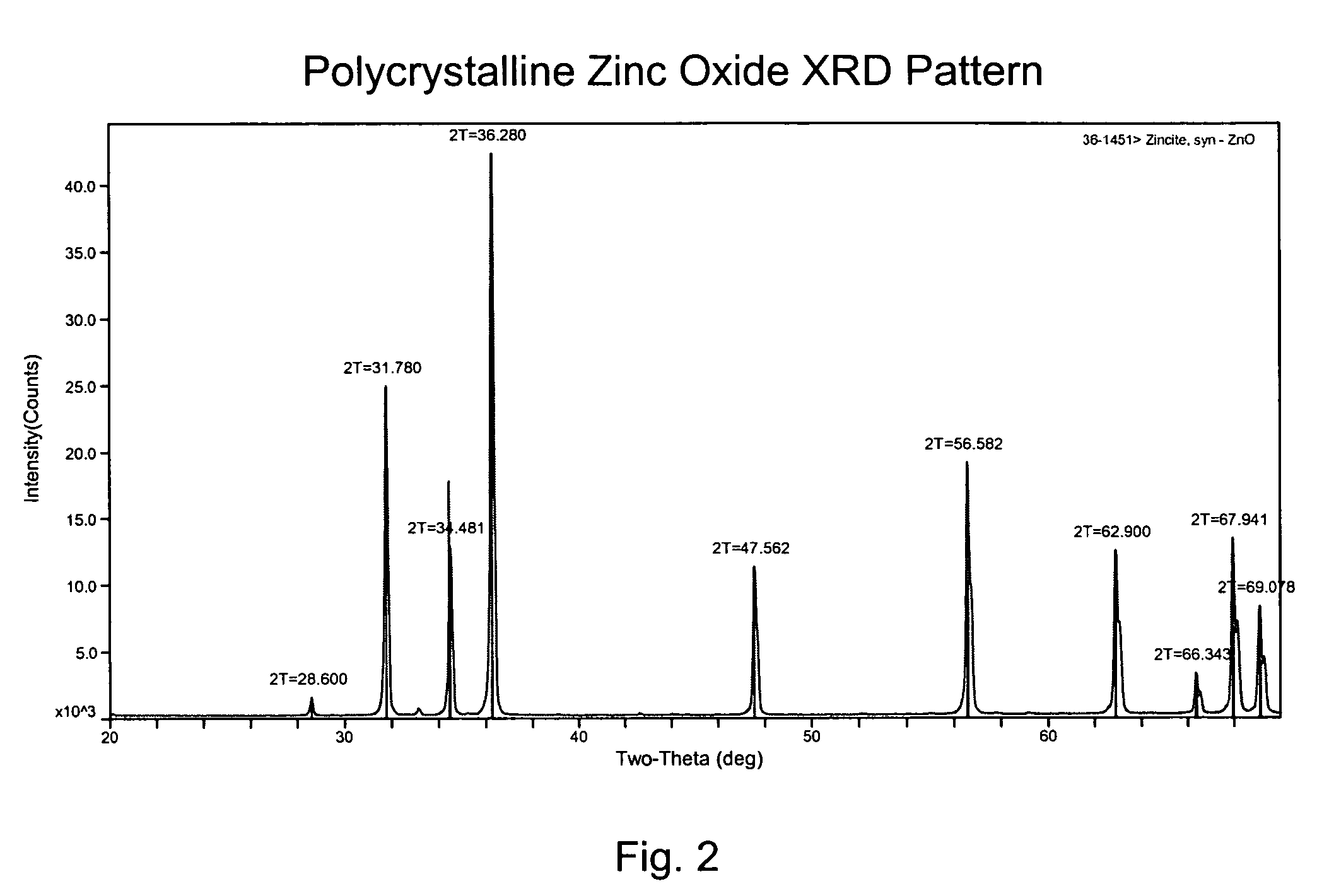

Zinc oxide crystal growth substrate

InactiveUS7172813B2Polycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalSpin coating

A zinc oxide crystal growth substrate is disclosed. The zinc oxide crystal growth substrate includes a thin layer of single crystal zinc oxide deposited on an self supporting substrate surface by a chemical deposition process. The chemical deposition process is selected from RF sputtering, CVD (chemical vapor deposition), MOCVD (metal organic chemical vapor deposition), spin coating, electrophoresis, and hydrothermal growth processes. The self supporting substrate may be amorphous, polycrystalline, or crystalline. The thin layer of zinc oxide has a crystal lattice which permits the crystal growth of a crystal compatible with zinc oxide. The compatible crystal has a lattice parameter within about 5% of a corresponding lattice parameter of the zinc oxide.

Owner:ZENO MATERIALS LLC

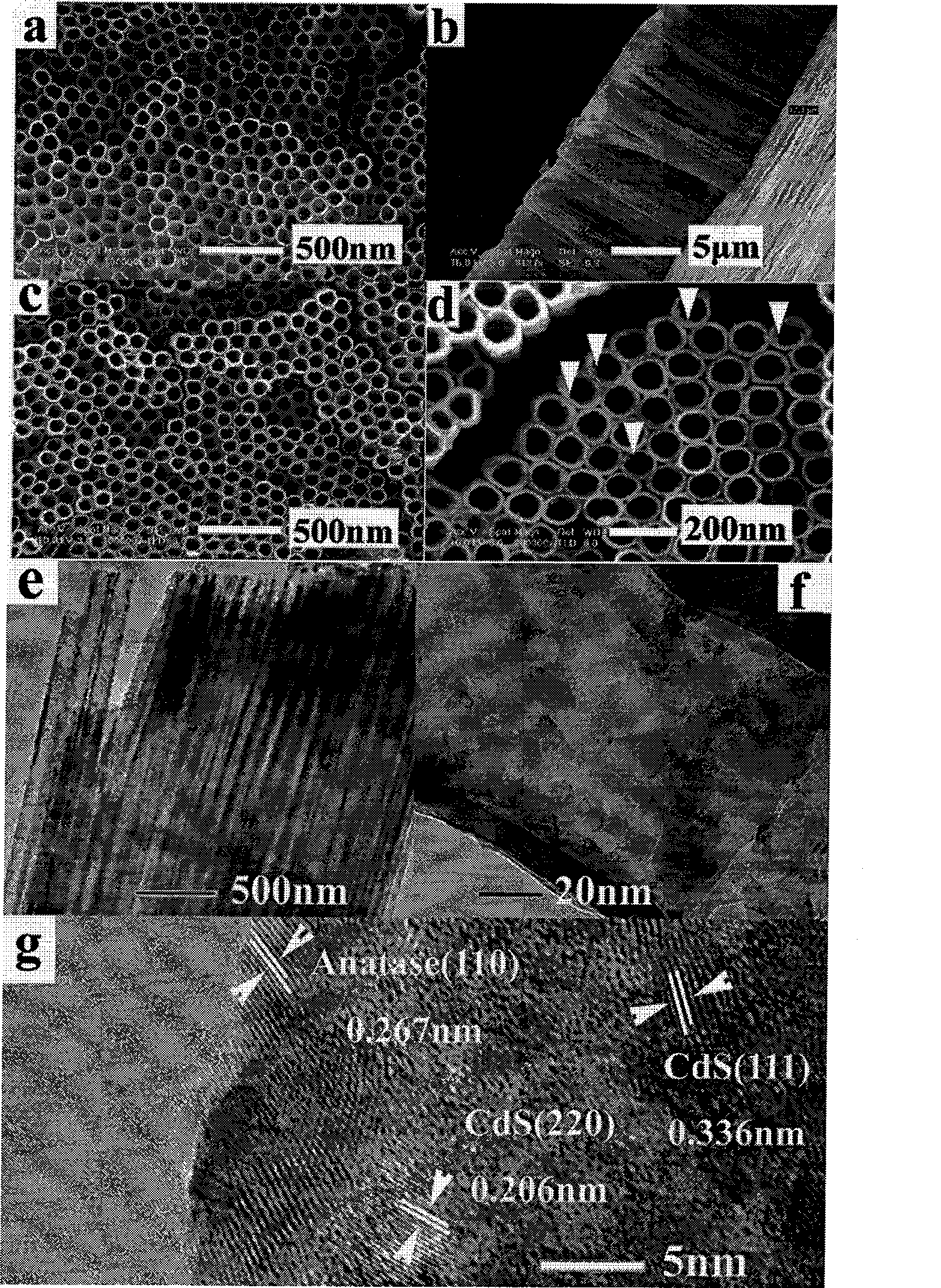

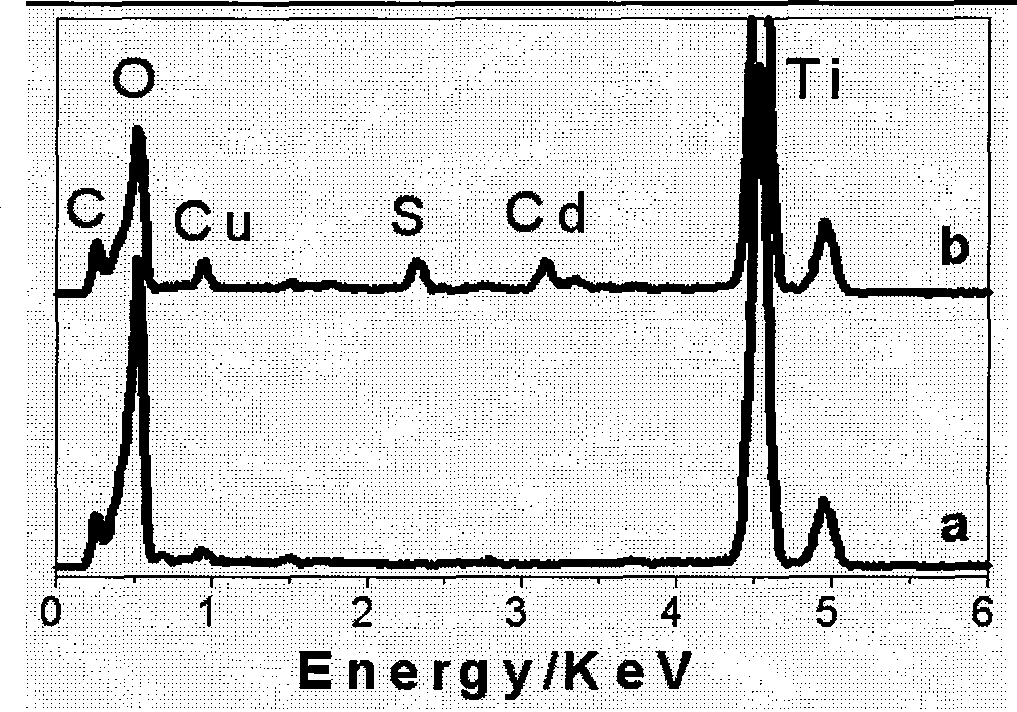

Wide forbidden region semi-conductor nano tube/linear array film, preparation and photoelectric pole thereof

InactiveCN101393938AImprove conversion efficiencyElectrode manufacturing processesLight-sensitive devicesSolar powerPhoto conversion

The invention relates to a wide band gap semiconductor nanotube / line array film characterized by high conversion efficiency and quantum dot sensitization, and a preparation method thereof as well as a photo-electrode adopting the wide band gap semiconductor nanotube / line array film. The wide band gap semiconductor nanotube / line array film provided by the invention comprises a wide band gap semiconductor nanotube / line array and a conductive substrate, and the wide band gap semiconductor nanotube / line array is filled with narrow band gap semiconductor quantum dot nano-particles. According to the preparation method provided by the invention, the anodic oxidation method is used for preparing the wide band gap semiconductor nanotube / line array film, and the chemical deposition method is used for preparing a narrow band semiconductor nanotube / line array film with sensitized quantum dots. The photo-electrode adopting the wide band gap semiconductor nanotube / line array film can be applied to a photo-chemical bath, and the photo conversion efficiency of the photo-chemical bath can be substantially improved. The invention can be widely applied to the technical field of photo-electricity conversion of solar power.

Owner:PEKING UNIV

Castings of metallic alloys with improved surface quality, structural integrity and mechanical properties fabricated in refractory metals and refractory metal carbides coated graphite molds under vacuum

InactiveUS6986381B2Quality improvementImprove mechanical propertiesCasting safety devicesFoundry mouldsTitanium carbideSuperalloy

Owner:SANTOKU AMERICA

Preparation method of titanium pigment used in ship paint

ActiveCN102226043AGood dispersionGood weather resistancePigment treatment with organosilicon compoundsSilicon oxideSlurry

The invention discloses a preparation method of titanium pigment used in ship paint. The method comprises the following steps that: a. metatitanic acid is calcined, such that a titanium pigment crude product is obtained, the titanium pigment crude product is prepared into TiO2 slurry, and sodium hexametaphosphate is added to the slurry; b. the slurry is heated, a silicon-containing compound is added to the slurry, and the slurry is homogenized; c. the pH value of the TiO2 slurry is regulated to 0.8 to 4; d. after the slurry is slaked, an organic dispersant is added to the slurry, an aluminum-containing compound is added to the slurry, and the mixture is homogenized; e. the pH value of the TiO2 slurry is regulated to 4 to 8; f. the TiO2 slurry is slaked; g. the TiO2 slurry is filtered, such that the resistivity of the filter cake is greater than or equal to 100 [omega]M; and the filter cake is dried and heat treated; h. an organic surface conditioning agent is added to the filter cake, and the filter cake is crushed, such that the finished product is obtained. According to the present invention, nano-sized silicon oxide sol and alumina sol are prepared sequentially. Through physical adsorption and chemical absorption, a compact coating layer is formed on the surface of the TiO2 particles. Then, the coating layer is firmly attached to the surface of the TiO2 particles through chemical deposition. With the coating layer, the product provided by the present invention possesses good dispersibility, weatherability and corrosion resistance. Meanwhile, according to the method provided by the present invention, the raw materials are easy to obtain, the processes are smooth and are easy to control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

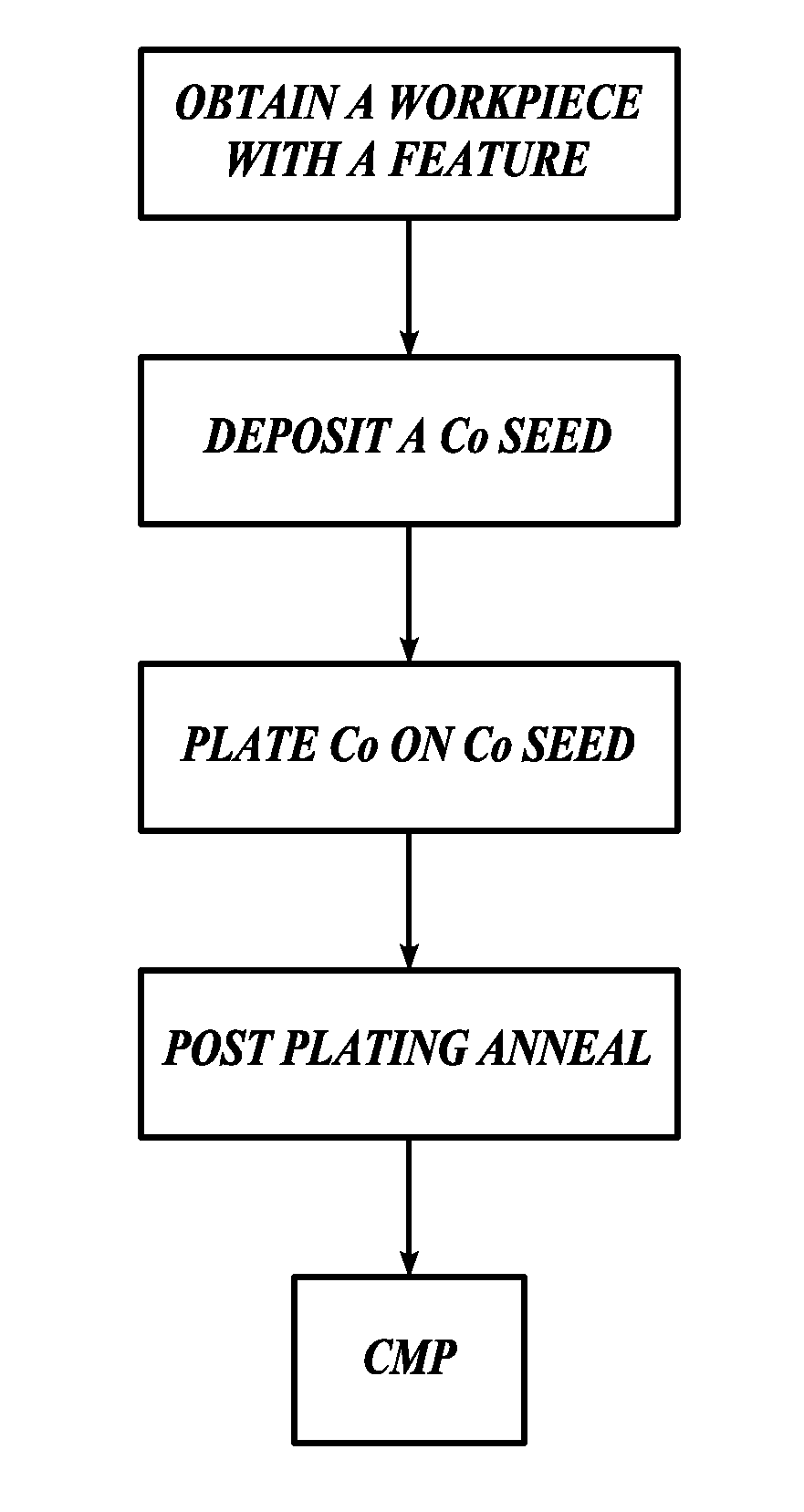

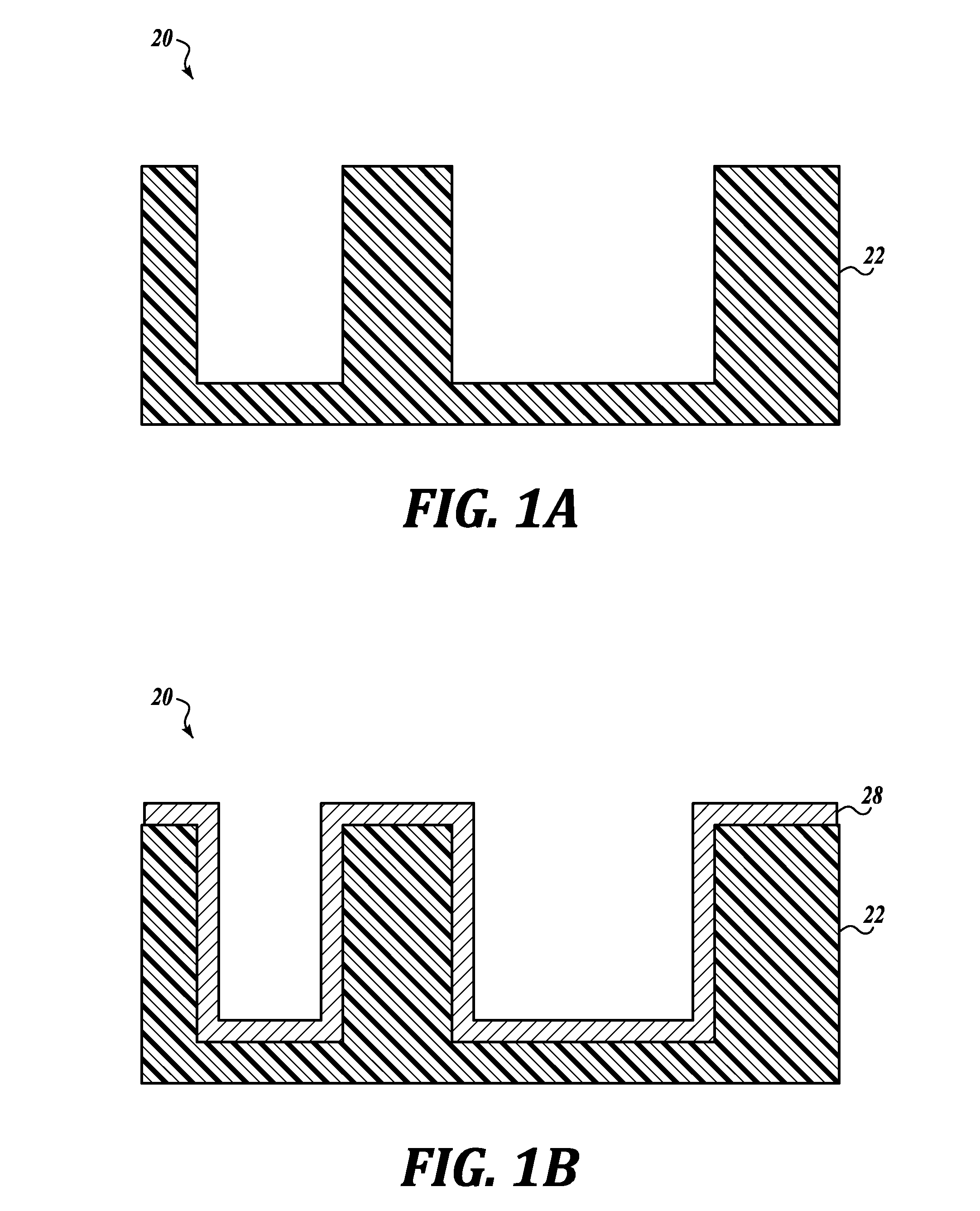

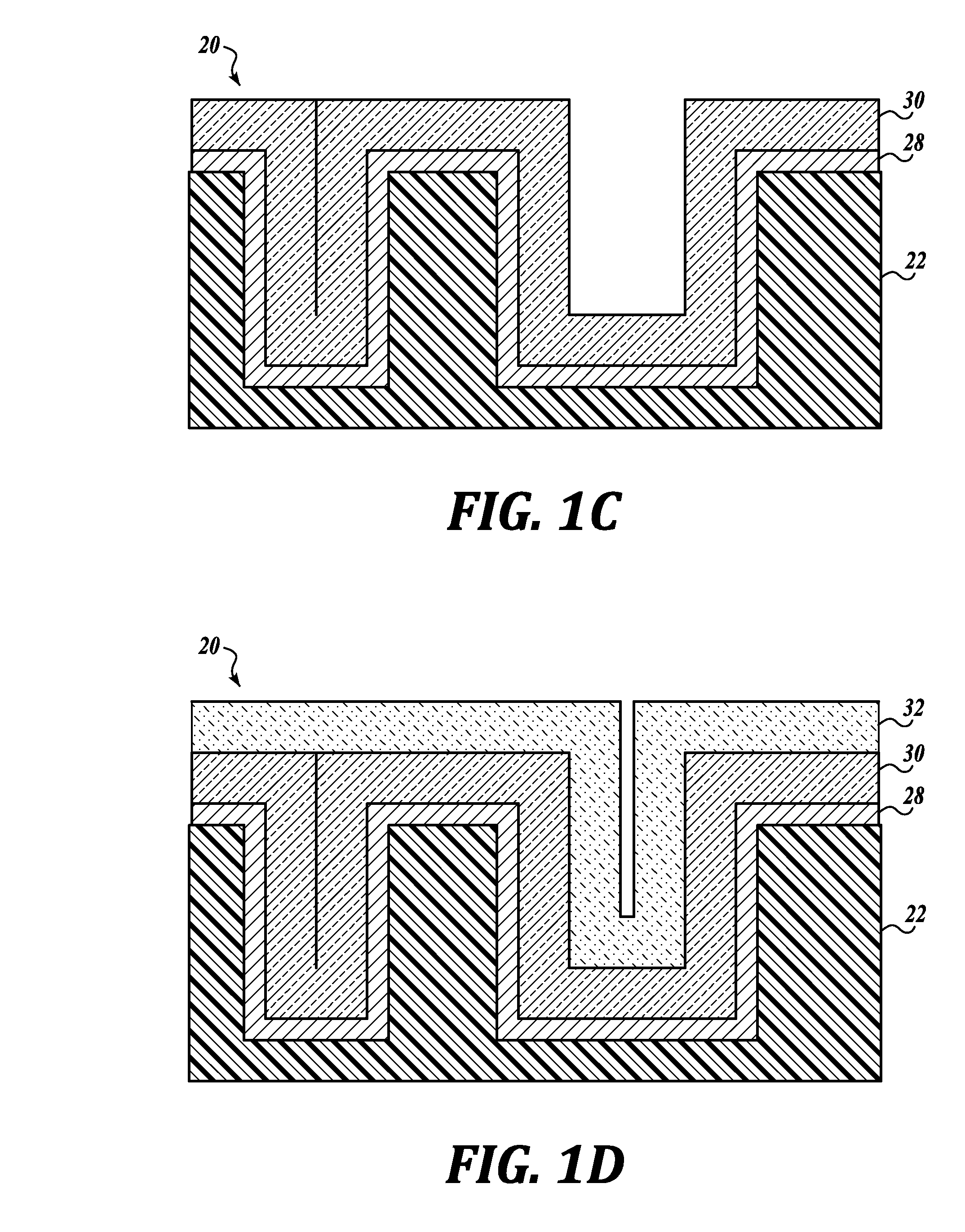

Methods for forming cobalt interconnects

InactiveUS20160309596A1Reduces overburdenLow resistivitySemiconductor/solid-state device detailsSolid-state devicesCobaltElectroplating

A method for depositing metal in a feature on a workpiece includes forming a seed layer in a feature on a workpiece, wherein the seed layer includes a metal selected from the group consisting of cobalt and nickel; electrochemically depositing a first metallization layer on the seed layer, wherein electrochemically depositing the metallization layer includes using a plating electrolyte having a plating metal ion and a pH in the range of 6 to 13; and heat treating the workpiece after deposition of the first metallization layer.

Owner:APPLIED MATERIALS INC

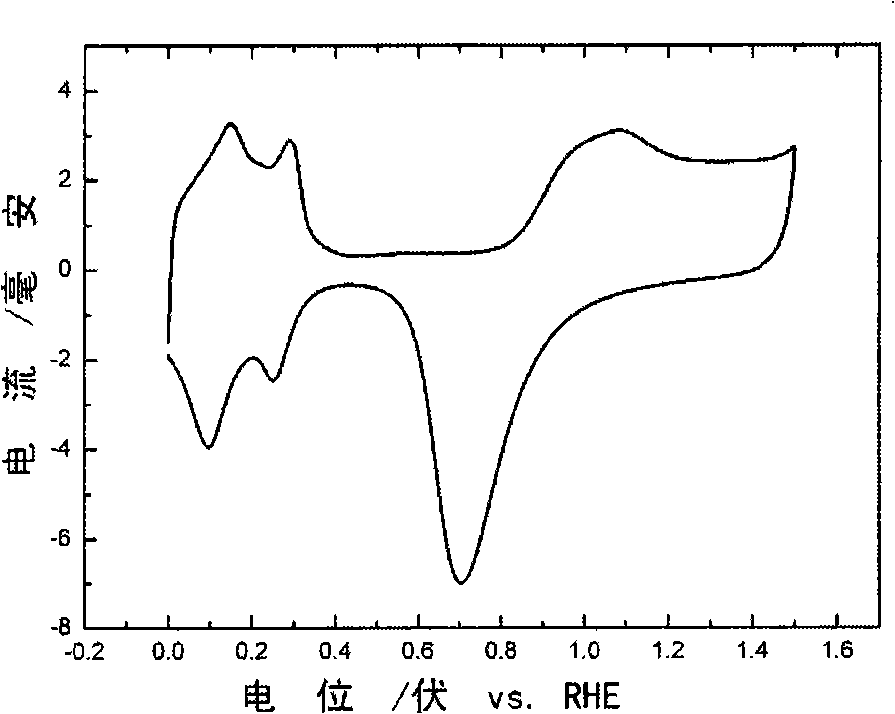

Method for preparing transitional metal carbides catalytic material and use

InactiveCN101371988AThe method is simpleHigh activity and selectivityPhysical/chemical process catalystsOrganic compound preparationDecompositionMolecular sieve

The invention discloses a preparation method and the application of a catalytic material for transition metal carbides, belonging to the preparation technical field of the catalytic material. The invention is characterized in that in the method, carbon material, oxide or molecular sieve, and the like, are used as vectors and transition metal compounds are used as precursors. The vectors and the transition metal precursors are mixed by dipping or mechanical method and a microwave-assisted chemical sedimentation method is adopted to prepare the catalyst for loaded transition metal carbides. The weight percentage of loading of the transition metal compounds is 1-200 percent. Particles of the catalyst for the loaded transition metal carbides are highly uniformly distributed on the surface of the vectors. And the catalyst can be applied to a plurality of reactions of electrocatalysis oxidation of methanol, hydrazine decomposition, acetonitrile hydrogenation, etc. The preparation method and the application have the beneficial effects of simple preparation process and easy operation. And the obtained catalytic material shows high activity in the electrode reaction and a plurality of catalytic reactions of fuel cells.

Owner:DALIAN UNIV OF TECH

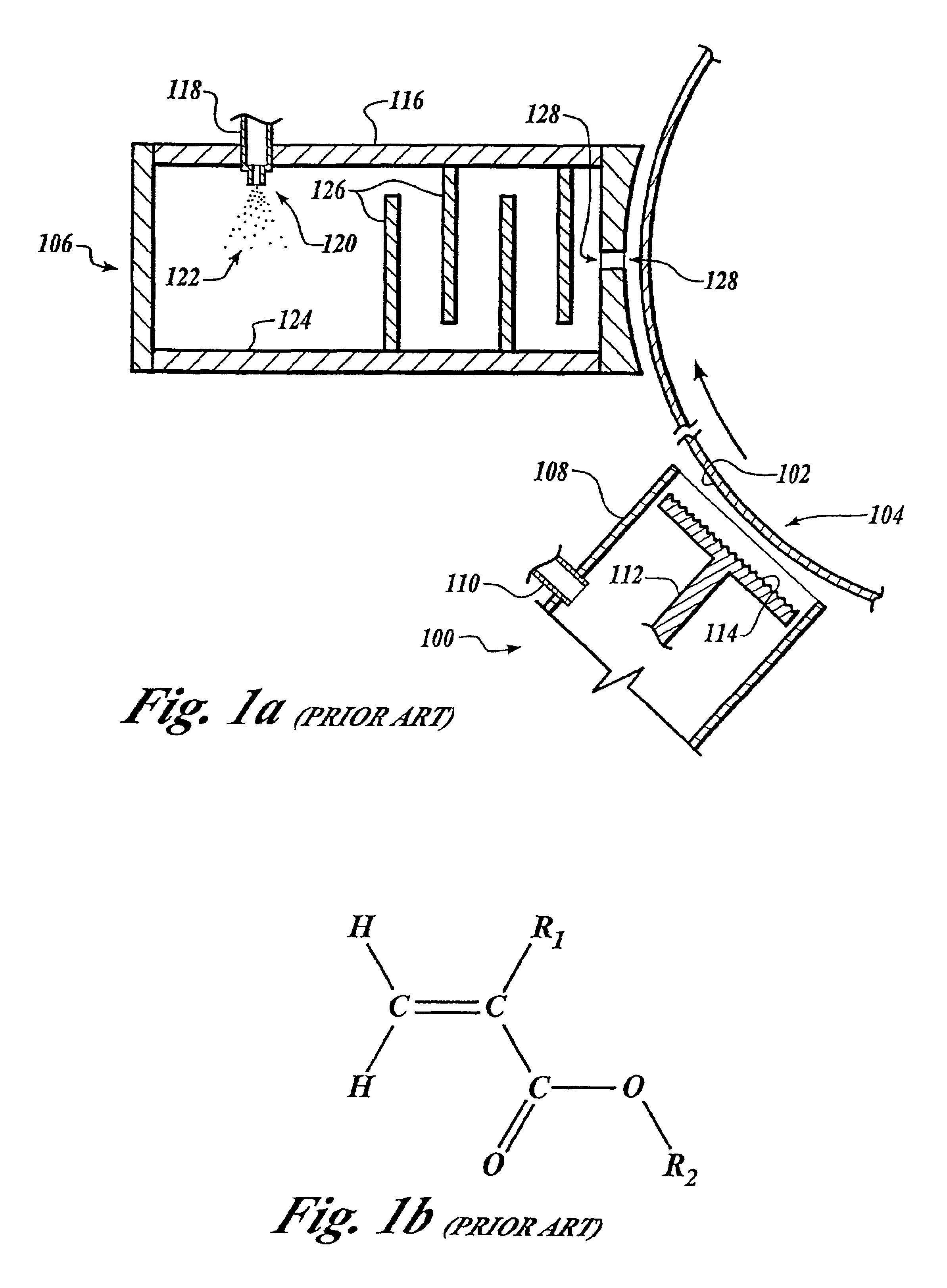

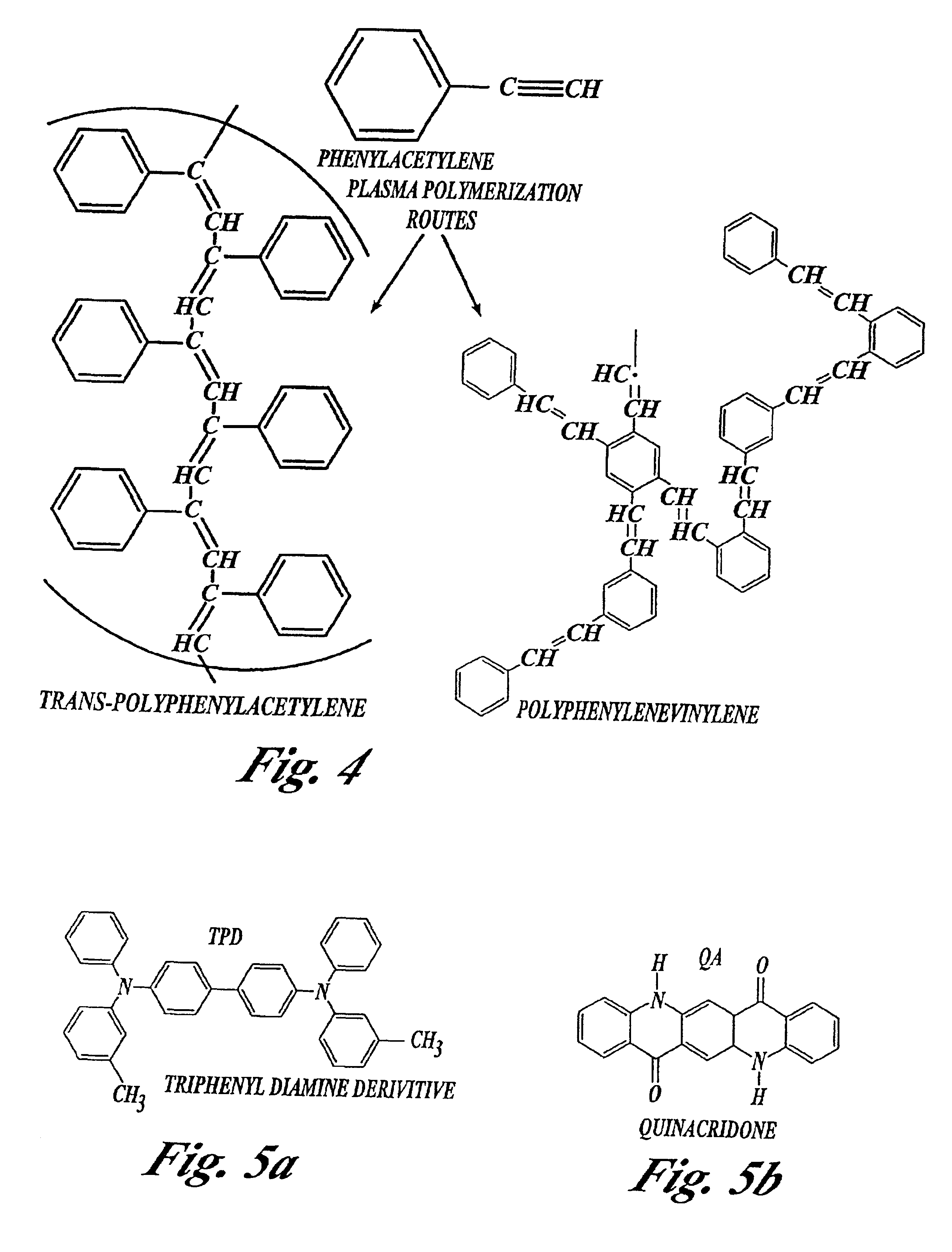

Plasma enhanced chemical deposition for high and/or low index of refraction polymers

InactiveUS6858259B2Enhanced vapor depositionPermit usePretreated surfacesChemical vapor deposition coatingCross-linkPolymer science

A method for making a polymer layer with a selected index of refraction. The method includes flash evaporating a polymer precursor material capable of cross linking into a polymer with the selected index of refraction, forming an evaporate, passing the evaporate to a glow discharge electrode creating a glow discharge polymer precursor plasma from the evaporate, and cryocondensing the glow discharge polymer precursor plasma on a substrate as a condensate and crosslinking the condensate thereon, the crosslinking resulting from radicals created in the glow discharge polymer precursor plasma, forming a polymer having the selected index of refraction.

Owner:SAMSUNG DISPLAY CO LTD

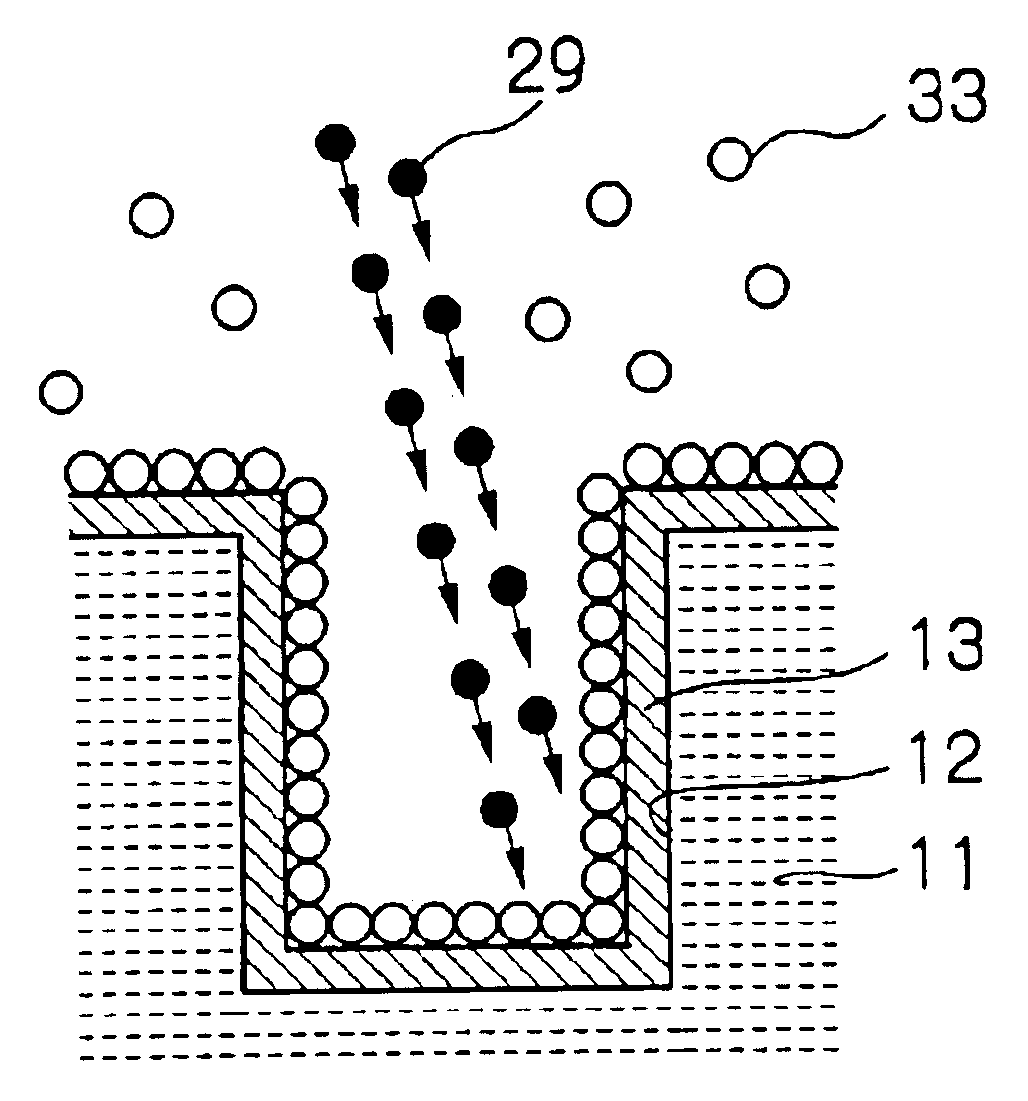

Method for forming carbon nanotubes with intermediate purification steps

InactiveUS6841003B2Promote growthSolve the small densityMaterial nanotechnologyPolycrystalline material growthHydrogenPlasma deposition

Carbon nanotubes are formed on a surface of a substrate using a plasma chemical deposition process. After the nanotubes have been grown, a purification step is performed on the newly formed nanotube structures. The purification removes graphite and other carbon particles from the walls of the grown nanotubes and controls the thickness of the nanotube layer. The purification is performed with the plasma at the same substrate temperature. For the purification, the hydrogen containing gas added as an additive to the source gas for the plasma chemical deposition is used as the plasma source gas. Because the source gas for the purification plasma is added as an additive to the source gas for the chemical plasma deposition, the grown carbon nanotubes are purified by reacting with the continuous plasma which is sustained in the plasma process chamber. This eliminates the need to purge and evacuate the plasma process chamber as well as to stabilize the pressure with the purification plasma source gas. Accordingly, the growth and the purification may be performed without shutting off the plasma in the plasma process chamber.

Owner:CDREAM DISPLAY CORP

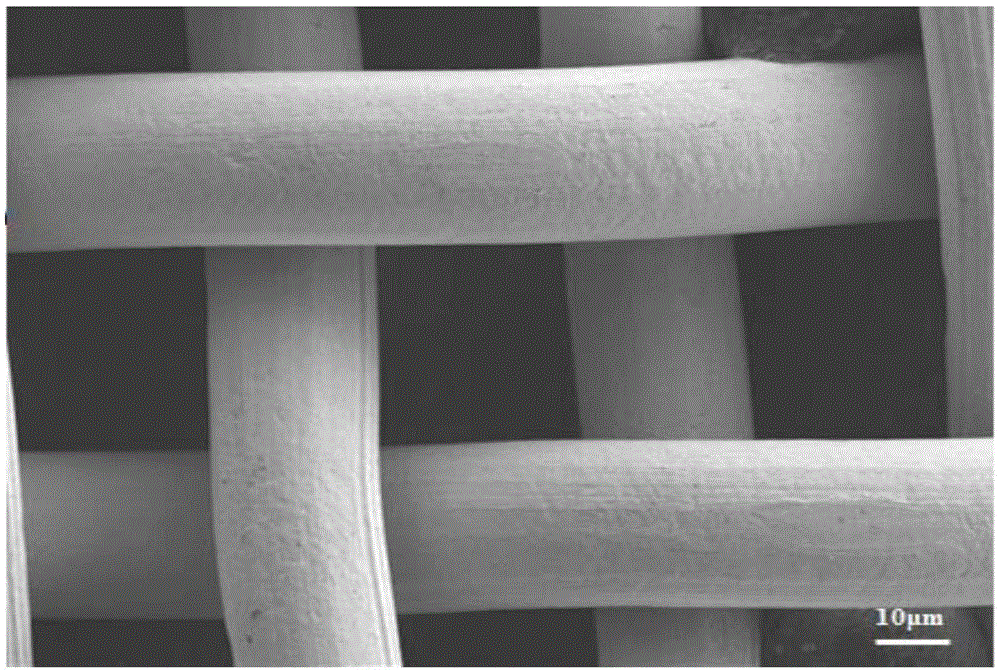

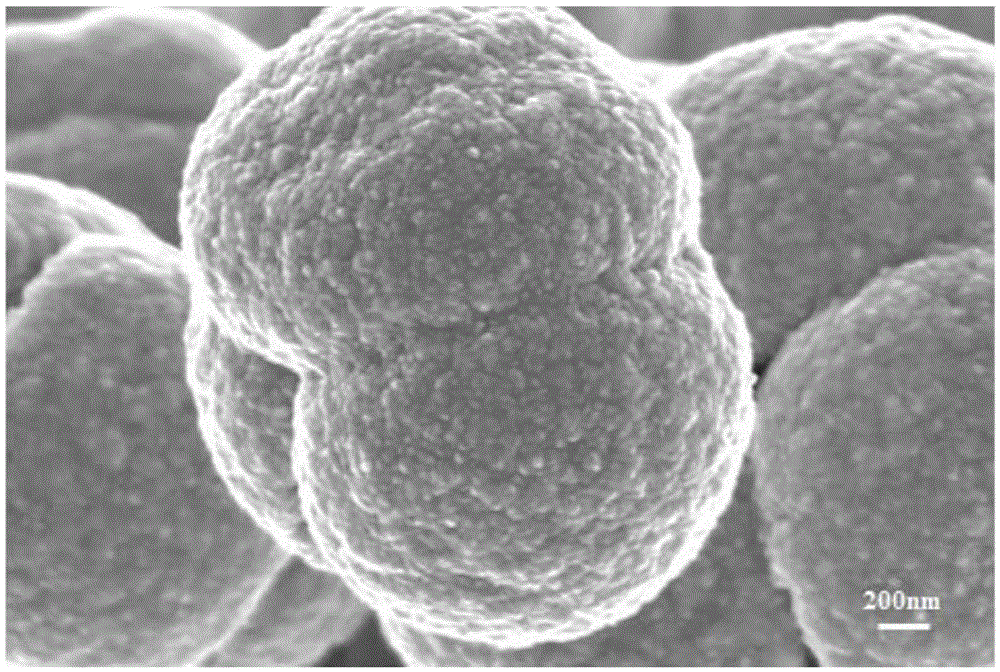

Super-hydrophobic/super-oleophilicity copper wire mesh for oil and water separation and preparation method and application thereof

ActiveCN105536296AImprove separation efficiencyEfficient separationNon-miscible liquid separationKeroseneCopper sulfate

The invention discloses a super-hydrophobic / super-oleophilicity copper wire mesh for oil and water separation and a preparation method and application thereof. The preparation method comprises the steps that firstly, the copper wire mesh is ultrasonically cleaned through diluted hydrochloric acid, absolute ethyl alcohol and deionized water respectively and dried through nitrogen; chemical deposition liquid of copper sulfate and a sodium thiosulfate solution is prepared; the cleaned copper wire mesh is placed into the chemical deposition liquid for a deposition reaction; the copper wire mesh is taken out and cleaned through the deionized water and dried in the air; the dried copper wire mesh is placed in a solution of a curing agent and polydimethylsiloxane with hydroxyl sealed end, and the copper wire mesh is taken out and heated. No expensive fluorine-containing substance is needed, the copper wire mesh has the advantages that the preparation technology is simple, reaction conditions are mild, no strong acidity or strong basicity or corrosivity reagents are needed, and no harm is caused to the environment, separation of oily wastewater can be achieved rapidly and efficiently, the good separation effect on chloroform, normal hexane, petroleum ether, plant oil, diesel oil, aviation kerosene and the like is achieved, and separation of strong acidity, strong basicity and high salinity oily wastewater can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

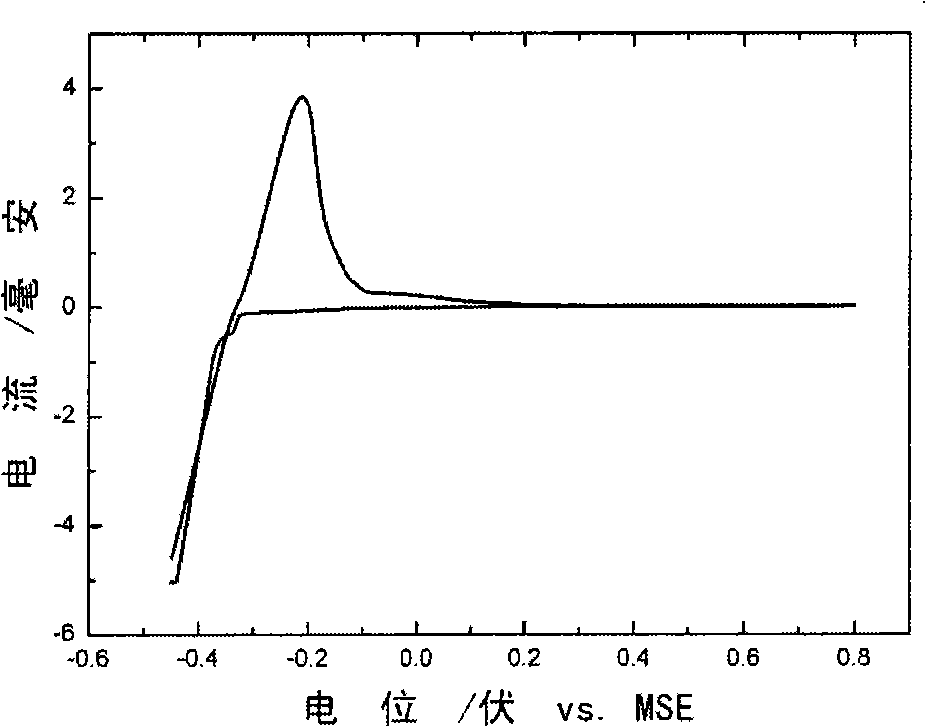

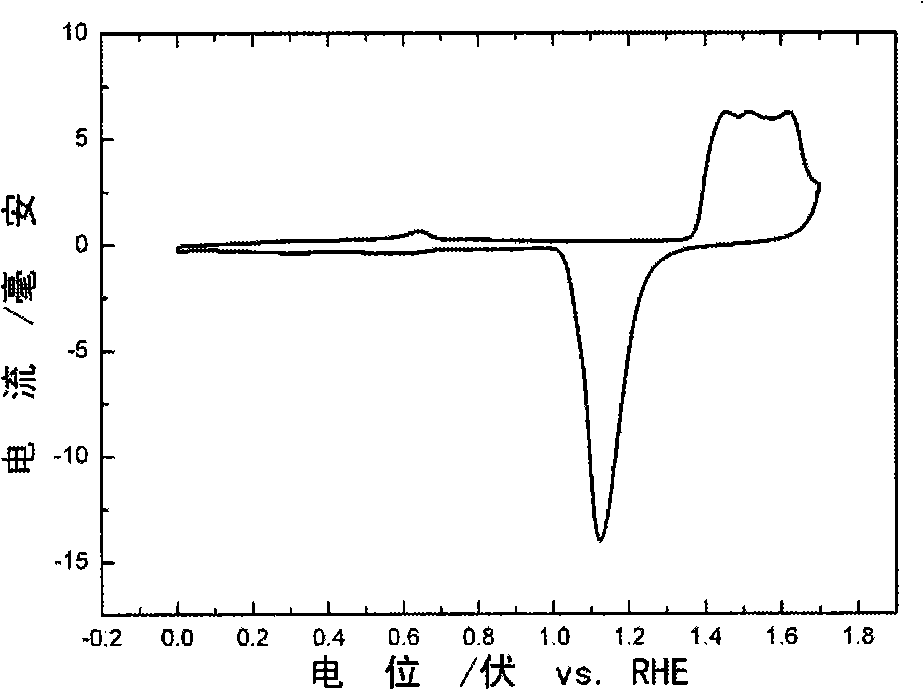

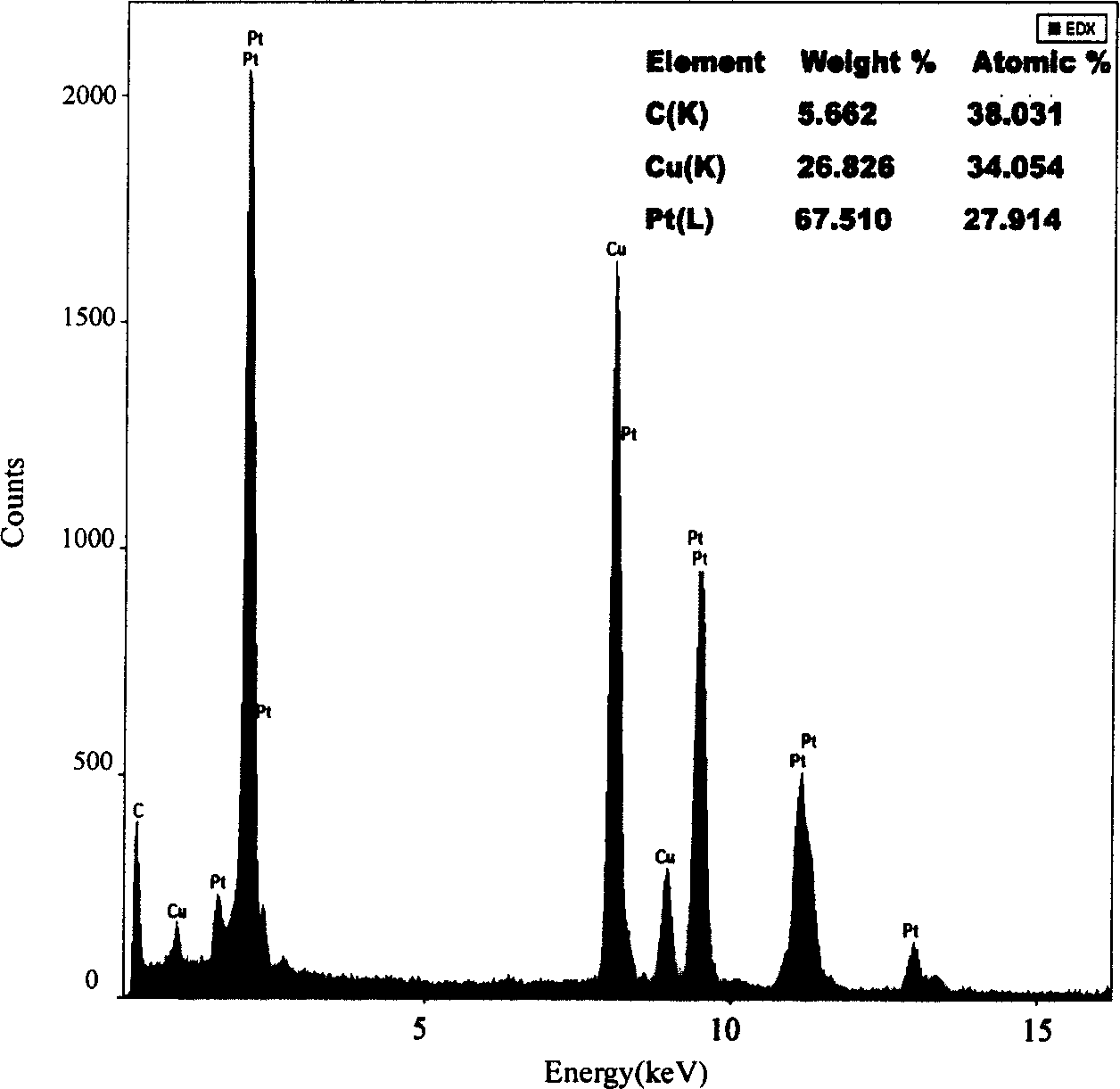

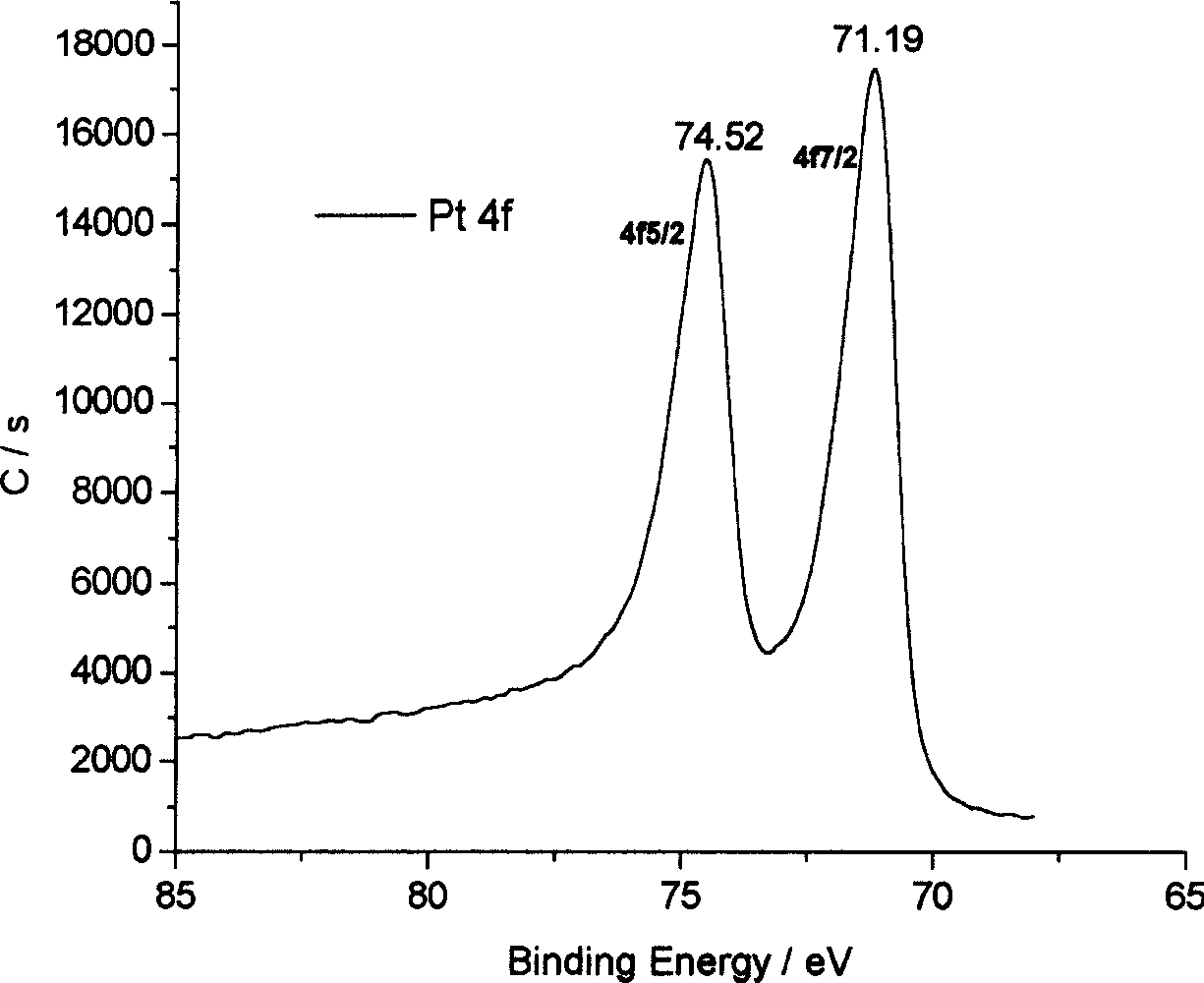

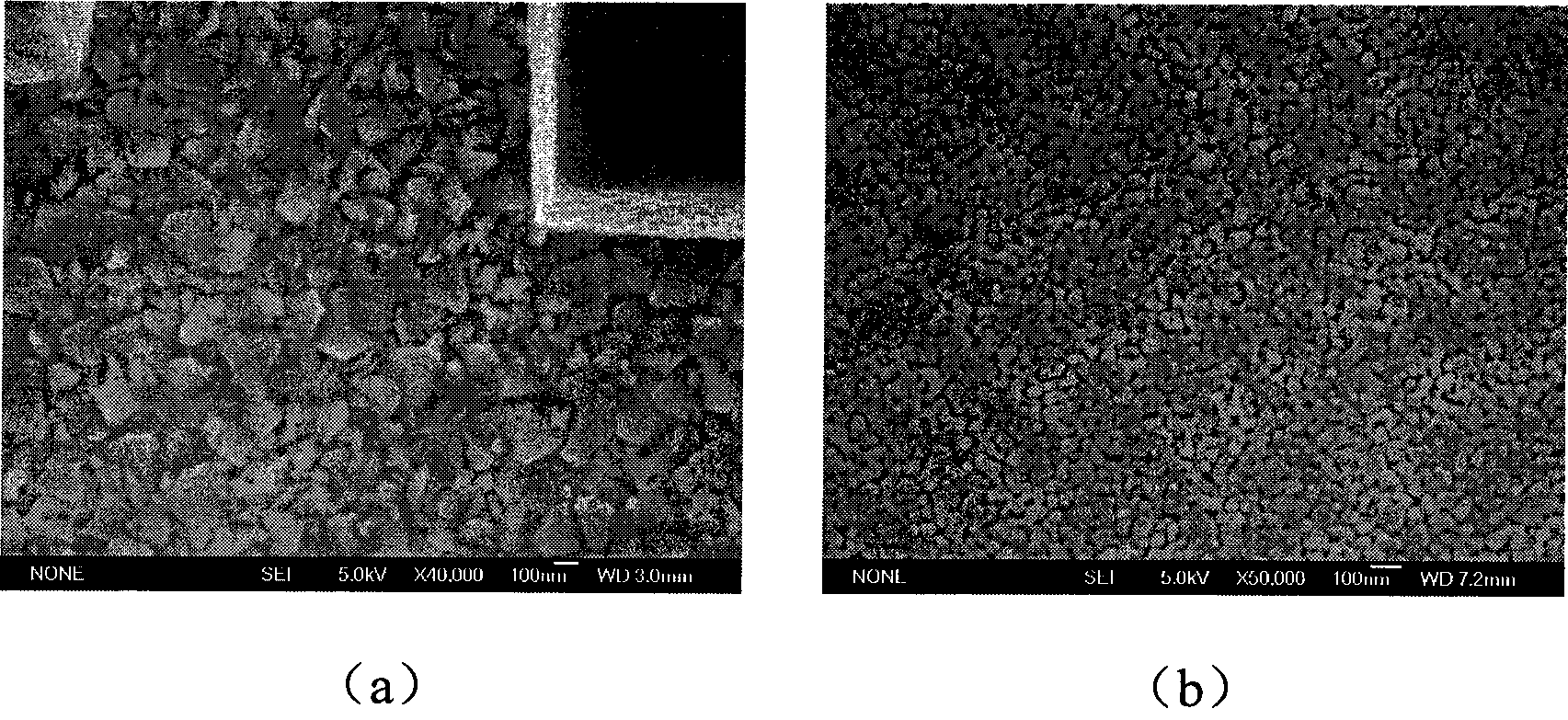

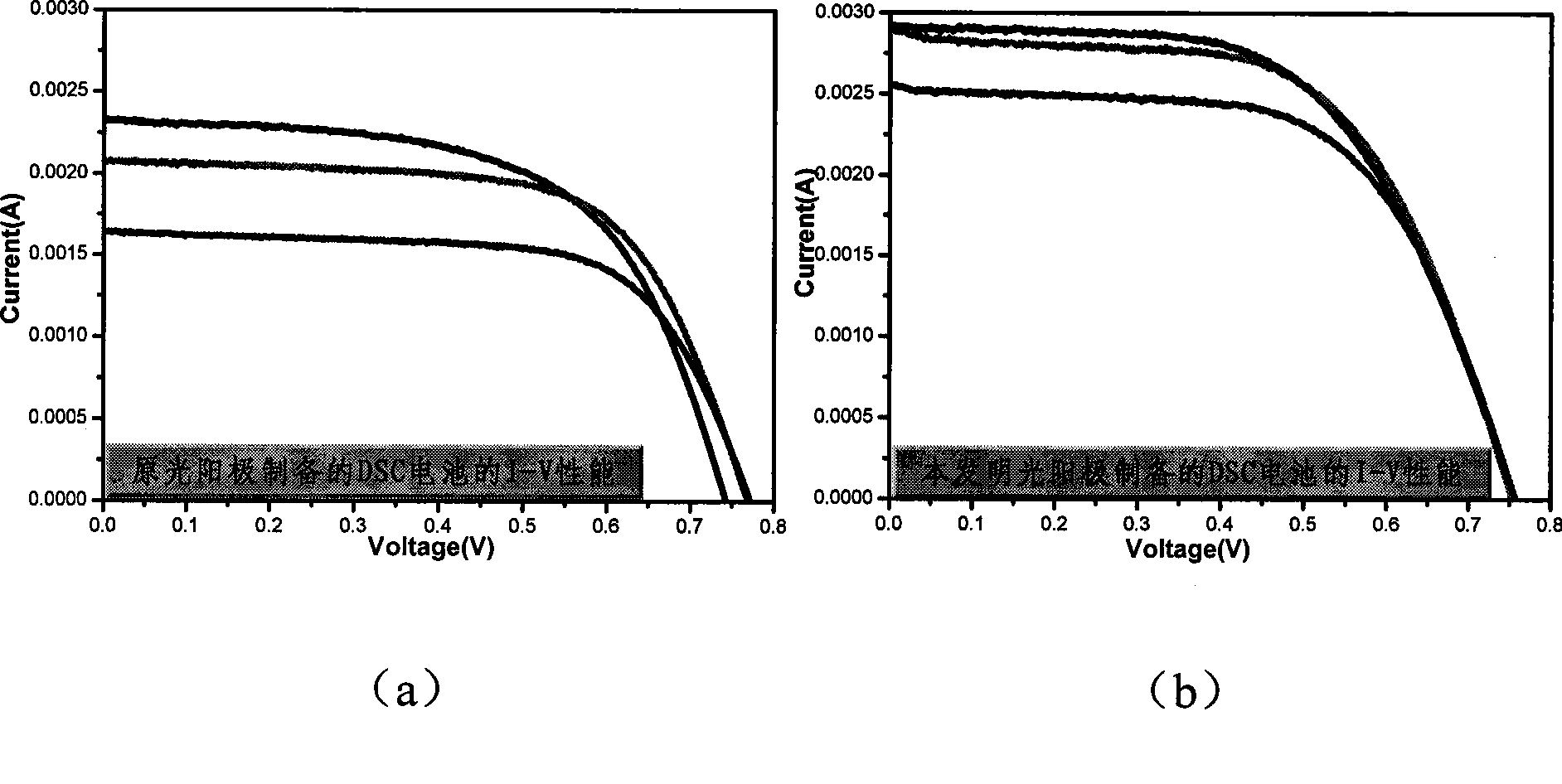

Method of surface nano-crystallization of noble metal catalyst

InactiveCN101337193AHigh catalytic activityImprove performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAlloyElectrochemistry

The invention discloses a method used for improving the surface nano-modification of a noble metal catalyst, and the method comprises the following steps: a relatively active metal (such as copper, silver, nickel, aluminium, etc.) with a certain thickness is deposited on the surface of a platinum wire (or a platinum net, a platinum sheet, a gold wire, a gold plaque, a palladium wire, or the alloy thereof) through the chemical deposition method or the electrochemical deposition method, and annealed under the protection of reducing atmosphere, so an alloy with a certain thickness is formed by the mutual diffusion of the active metal and platinum (or gold, palladium, etc., or other alloys); under proper conditions, the active metal in the alloy and the outside active metal which is not changed into the alloy are corroded, thereby forming a porous surface structure. The method of the invention utilizes and controls the alloying process and the dealloying process to improve the surface nano-modification of the noble metal catalyst material, thereby possessing higher specific surface area, and simultaneously having higher mechanical strength and higher catalytic activity.

Owner:SHANDONG UNIV

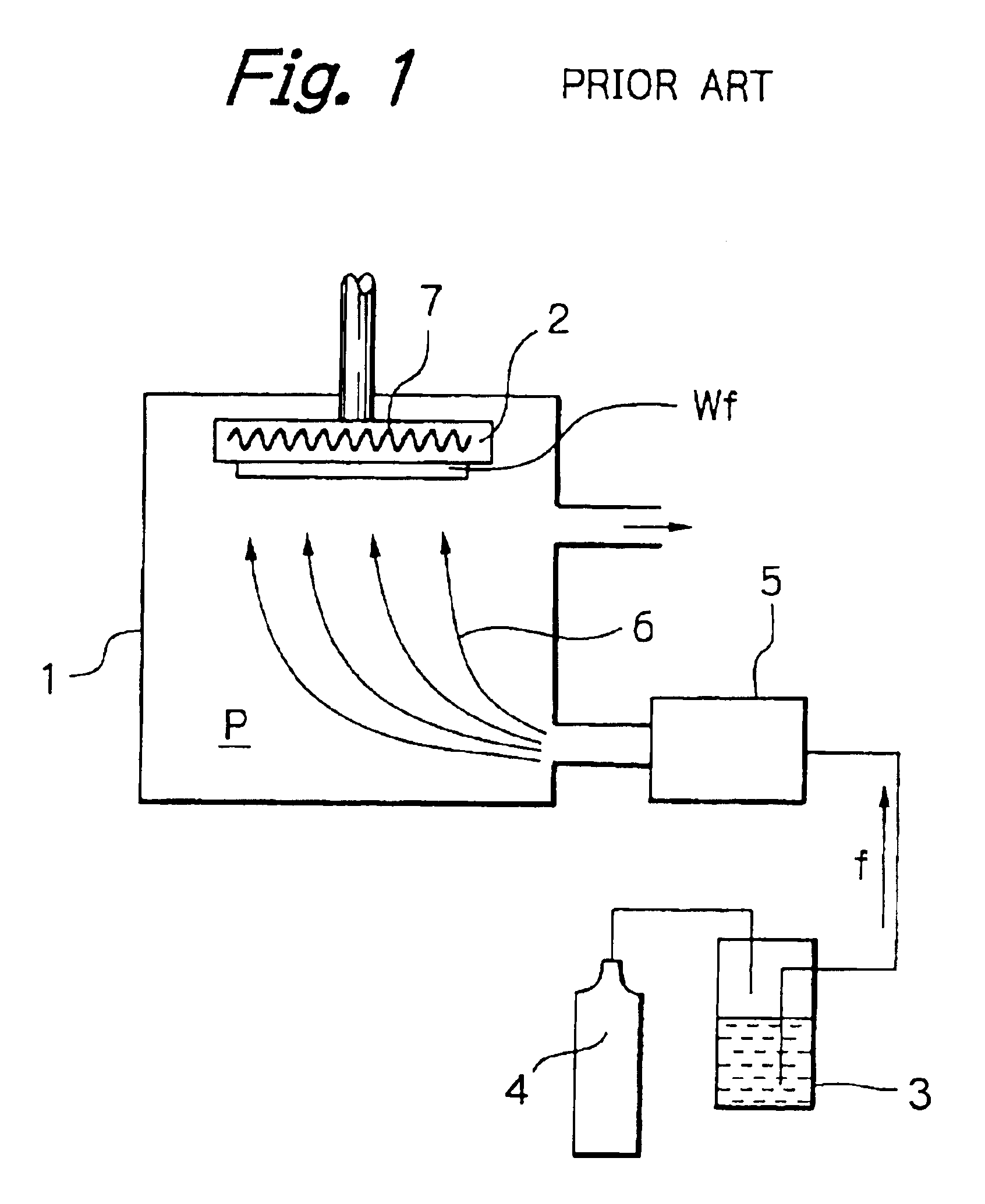

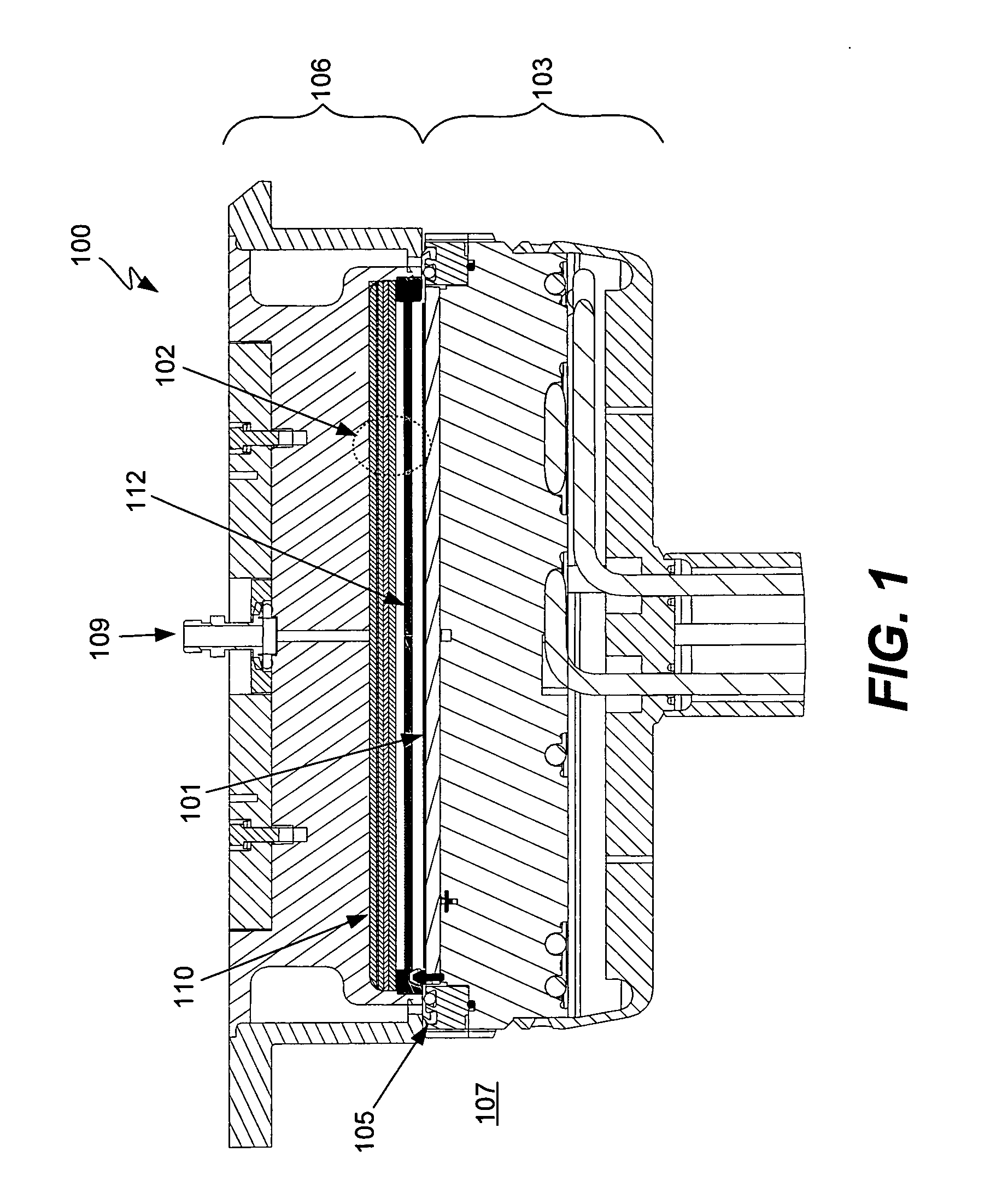

Electro-chemical deposition system and method of electroplating on substrates

InactiveUSRE40218E1Easy maintenanceEvenly distributedAnodisationCellsReverse currentAuxiliary electrode

The invention provides an apparatus and a method for achieving reliable, consistent metal electroplating or electrochemical deposition onto semiconductor substrates. More particularly, the invention provides uniform and void-free deposition of metal onto metal seeded semiconductor substrates having sub-micron, high aspect ratio features. The invention provides an electrochemical deposition cell comprising a substrate holder, a cathode electrically contacting a substrate plating surface, an electrolyte container having an electrolyte inlet, an electrolyte outlet and an opening adapted to receive a substrate plating surface and an anode electrically connect to an electrolyte. Preferably, a vibrator is attached to the substrate holder to vibrate the substrate in at least one direction, and an auxiliary electrode is disposed adjacent the electrolyte outlet to provide uniform deposition across the substrate surface. Preferably, a periodic reverse current is applied during the plating period to provide a void-free metal layer within high aspect ratio features on the substrate.

Owner:LANDAU UZIEL

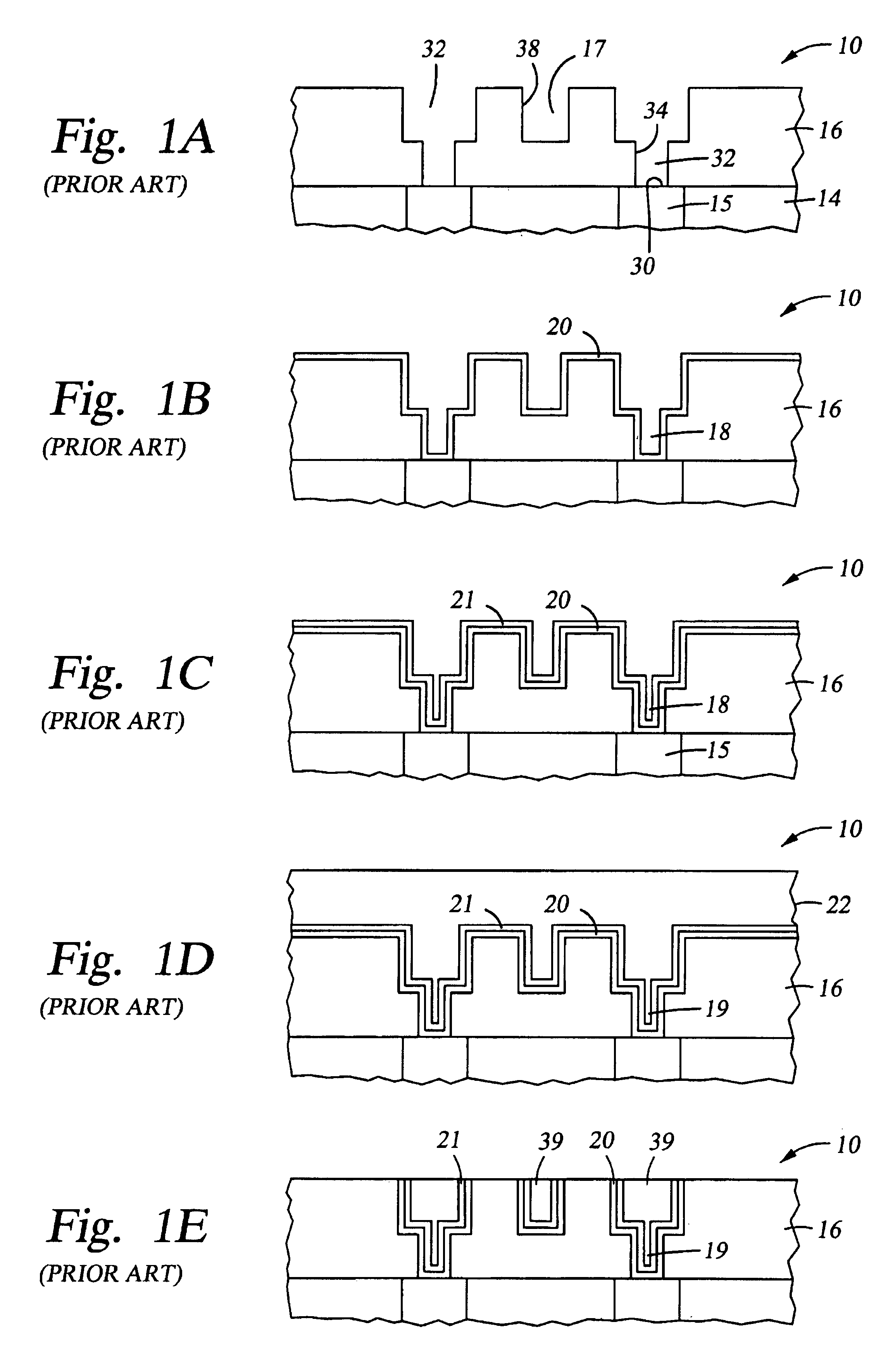

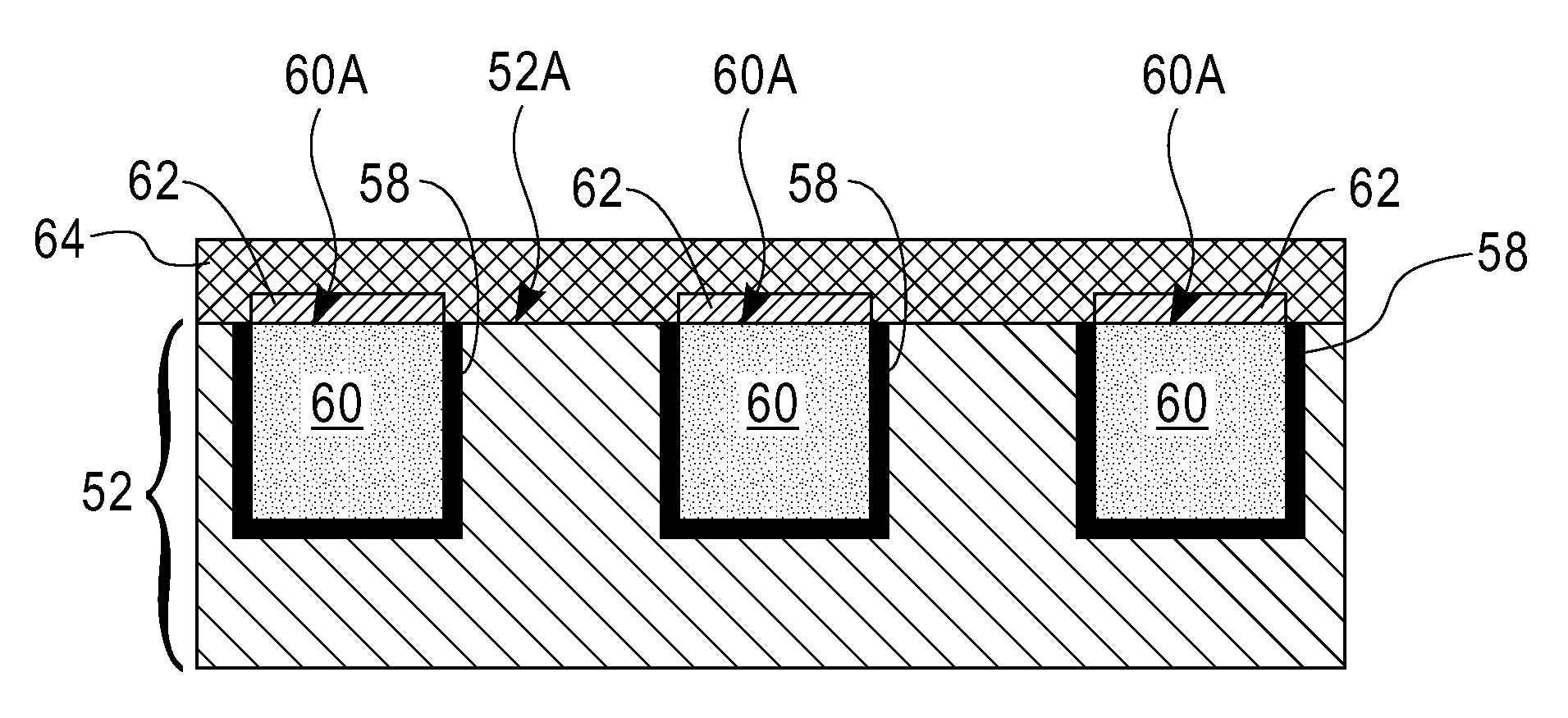

Nitrogen-containing metal cap for interconnect structures

ActiveUS20100038782A1Improved EM reliabilityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesNitrogenConductive materials

An interconnect structure is provided that has enhanced electromigration reliability without degrading circuit short yield, and improved technology extendibility. The inventive interconnect structure includes a dielectric material having a dielectric constant of about 3.0 or less. The dielectric material has at least one conductive material embedded therein. A nitrogen-containing noble metal cap is located predominately (i.e., essentially) on an upper surface of the at least one conductive region. The nitrogen-containing noble metal cap does not extend onto an upper surface of the dielectric material. In some embodiments, the nitrogen-containing noble metal cap is self-aligned to the embedded conductive material, while in other embodiments some portion of the nitrogen-containing noble metal cap extends onto an upper surface of a diffusion barrier that separates the at least one conductive material from the dielectric material. A method of fabricating such an interconnect structure utilizing a low temperature (about 200° C. or less) chemical deposition process is also provided.

Owner:HFC SEMICON CORP

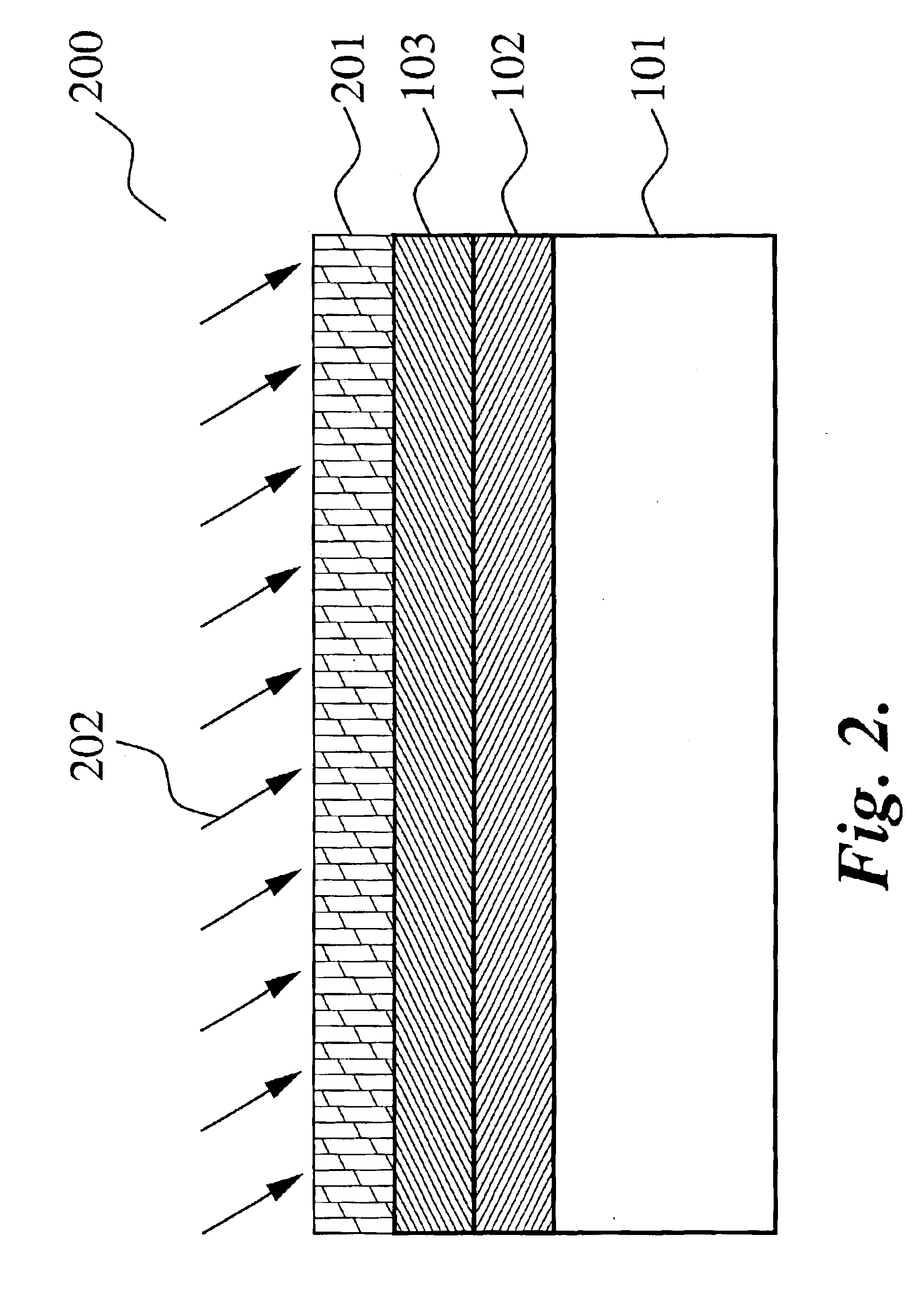

Apparatus and method of detecting the electroless deposition endpoint

InactiveUS20050088647A1Radiation pyrometryLiquid surface applicatorsElectricityElectromagnetic radiation

An apparatus and a method of controlling an electroless deposition process by directing electromagnetic radiation towards the surface of a substrate and detecting the change in intensity of the electromagnetic radiation at one or more wavelengths reflected off features on the surface of the substrate. In one embodiment the detected end of an electroless deposition process step is measured while the substrate is moved relative to the detection mechanism. In another embodiment multiple detection points are used to monitor the state of the deposition process across the surface of the substrate. In one embodiment the detection mechanism is immersed in the electroless deposition fluid on the substrate. In one embodiment a controller is used to monitor, store, and / or control the electroless deposition process by use of stored process values, comparison of data collected at different times, and various calculated time dependent data.

Owner:APPLIED MATERIALS INC

Method of depositing high density loading metal platinum on carbon nanometer pipe surface using oriented chemistry

InactiveCN1559686ASolve the technical problem of reunionImprove performanceCatalyst carriersCatalyst activation/preparationActive agentCarbon nanotube

A process for carrying high-density Pt on the surface of carbon nanotube by directional chemical deposition features that the carbon nanotubes, platium chloride and surfactant take part in reaction in polyol to obtain a catalyst used for oxidization reaction of methanol with high electrocatalytic performance.

Owner:XIAMEN UNIV

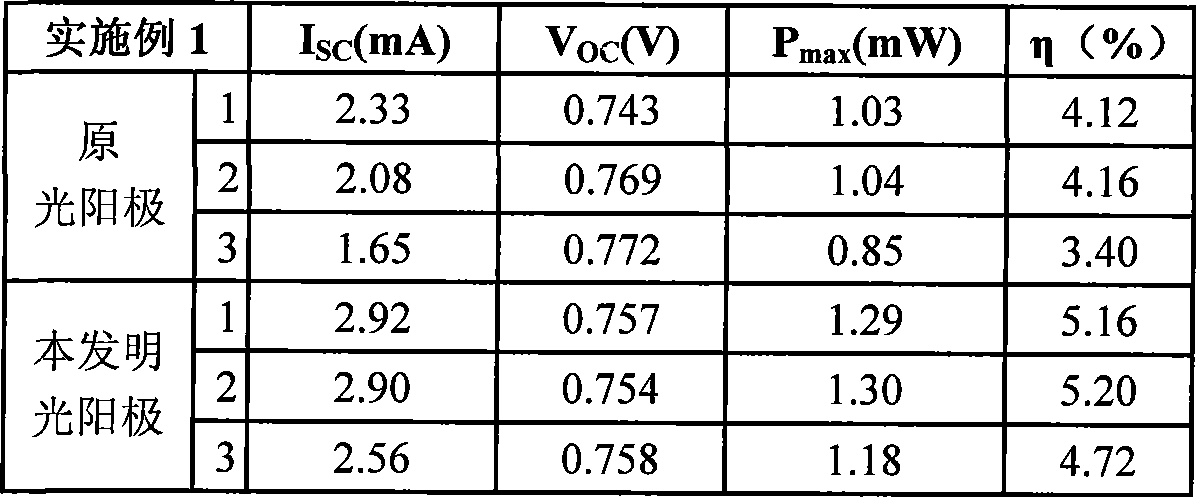

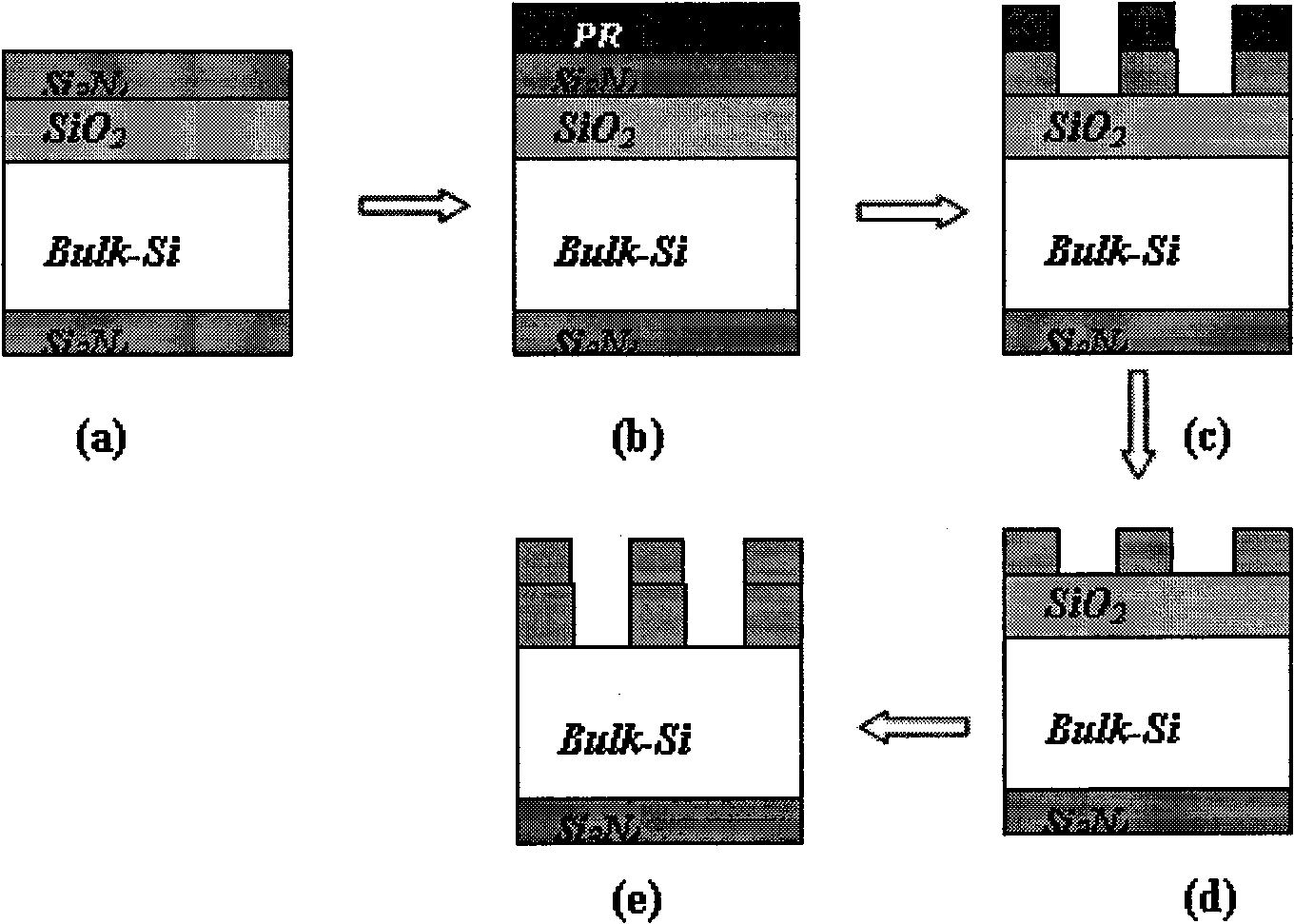

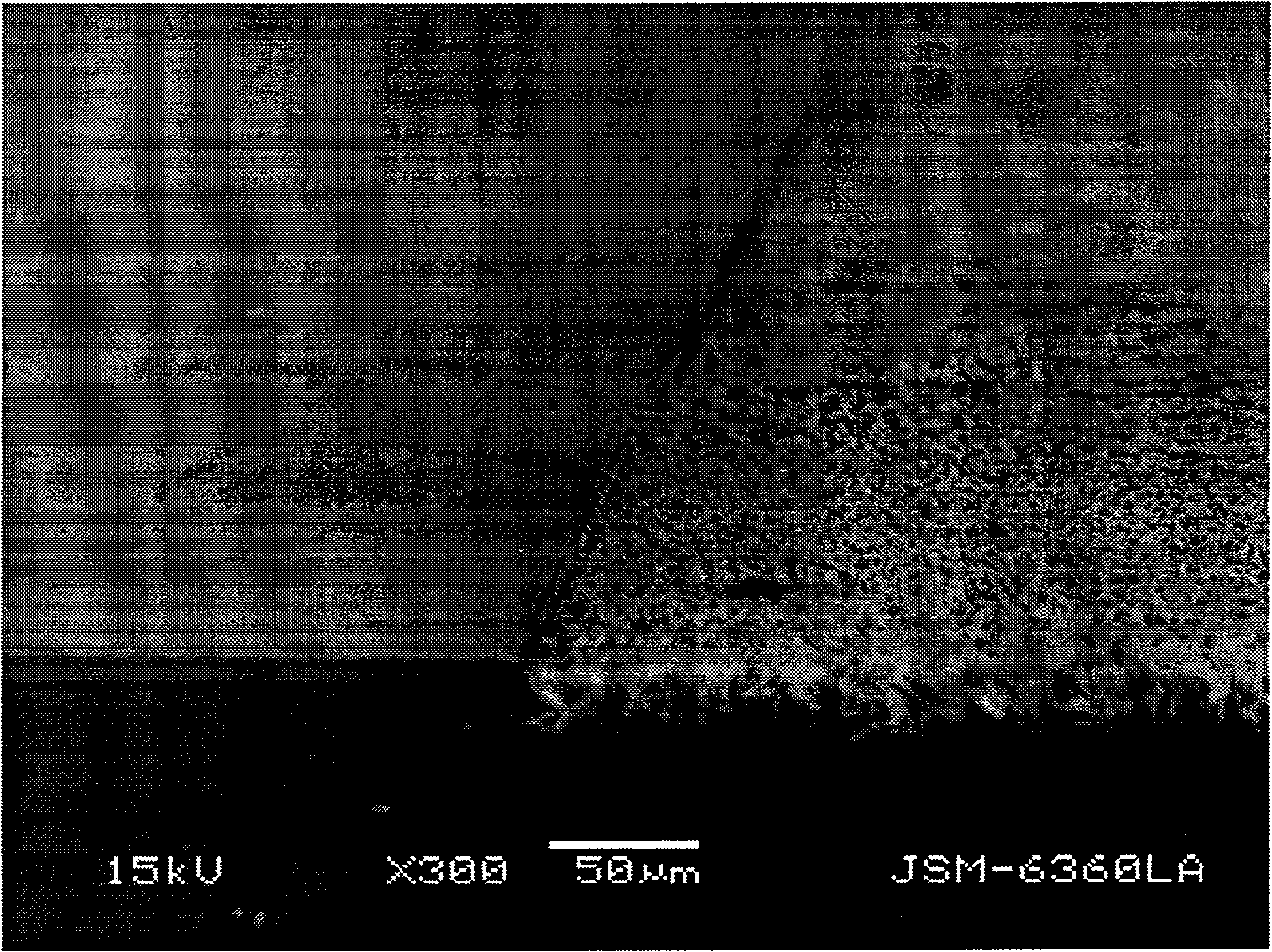

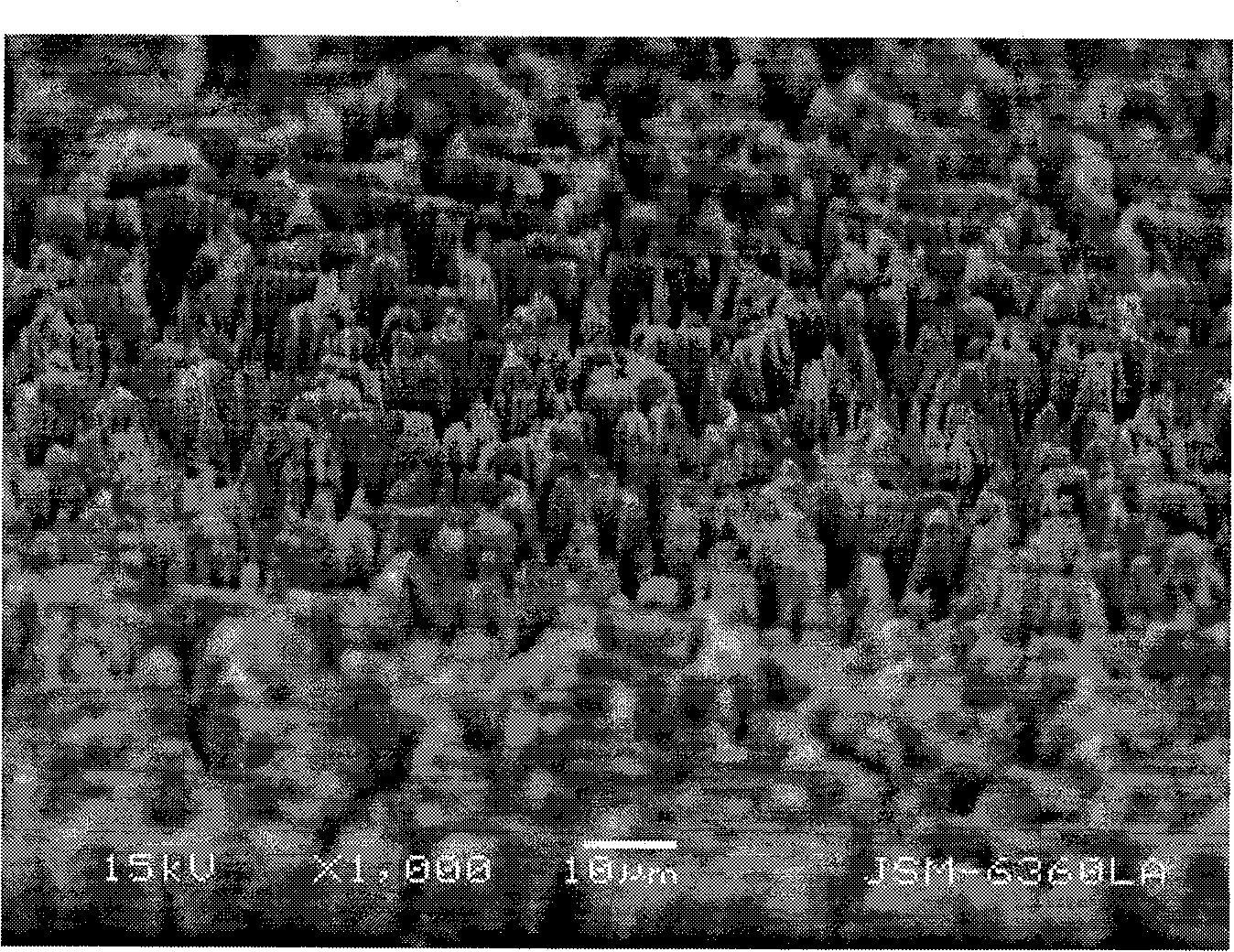

Preparation method for laminated photo-anode film of dye-sensitized solar cell

InactiveCN101521114AReverse RecombinationReduce porosityLight-sensitive devicesFinal product manufactureColloidBattery cell

The invention discloses a preparation method for laminated photo-anode film of dye-sensitized solar cell. A dense film can be prepared by adopting a magnetron sputtering method and a sol-gel spin-coating method, and the quality of the dense film is controlled by controlling magnetron sputtering parameters or the preparation of TiO2 colloid and the rotating speed of spin coating; nano TiO2 grain of small grain diameter (less than 8nm) is formed on the surface of porous nano TiO2 layer film by means of a liquid-phase chemical deposition method; and dye adsorption of the photo-anode film is increased by means of unsaturated bond on the surface of the nano TiO2 of small grain diameter. When the TiO2 photo anode prepared by the method is applied in a dye-sensitized solar cell, the cell has higher photoelectric conversion efficiency and the device has longer service life.

Owner:IRICO

A method for selectively etching silicon nano line

InactiveCN101266919AEvenly distributedThe process is simple and reliableNanostructure manufactureSemiconductor/solid-state device manufacturingSilicon nanowiresNanotechnology

The invention discloses a method for selectively etching silicon nano-wire according to defects in existing technology and market requirement, comprising: a) using ''up to down'' standard microelectronic manufacturing process to open a window on a silicon sheet; b) using ''up to down'' non-electroplating chemical deposition method to etch silicon nano-wires on surface of the silicon sheet with opened window. Compared to the existing technology, the method for selectively etching silicon nano-wire according to the invention can not only make any expected image, but also obtain uniformly arranged silicon nano-wire array with regular size; also it has the advantages of simple manufacturing process, low costs, suitable for batch production, to realize industrial manufacture of silicon nano-wire electrode, and provide a scheme manufacturing nano-electric element based on a plurality of nano-wires.

Owner:EAST CHINA NORMAL UNIV

Method for preparing ultra-fine crystal grain tungsten-copper alloy and tungsten-copper alloy

A method to prepare ultra-fine grain tungsten-copper alloy and the tungsten-copper alloy, it belongs to powder metallurgy technology field. The solution of concentrated HNO3 and solution of Cu (NO3)2 will be added into the solution of (NH4)2WO4 at the condition that they are blended, the chemical deposition reaction will occur in the agitator. And then the deposit will be burned and grinded to produce the composite powder of tungsten-copper oxidate. The composite powder will be reduced at low temperature in the pipe furnace, and nanometer tungsten-copper composite powder can be gained, and then they will be pressed to take shape, the pressed compact will be sintered at the protection of H2 and ultra-fine grain tungsten-copper alloy can be gained. The weight percent of copper in a kind of tungsten-copper alloy produced according to the above method is 20%, the relative density of the alloy is 98.0%-99.7%, the average crystal grain size of the tungsten in the alloy is 0.5-1.5 mu m, the electrical resistance of the alloy is 0.035-0.041X10-6omega .m, the heat-transmit index is 200-223W.m-1.k-1. The advantage of it is that. The densification degree of the alloy is high, the tungsten crystal grain is small and uniform, the copper is highly dispersed to compose a compact net. And the flow of it is short, the technology operation is easy and reliable, the production efficiency is high, the energy and production cost is lower, and an industrial production can be carried on according the method.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com