Method for preparing silicon nanowire array with smooth surface

A silicon nanowire array and smooth surface technology, applied in nanotechnology, chemical instruments and methods, silicon compounds, etc., to achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

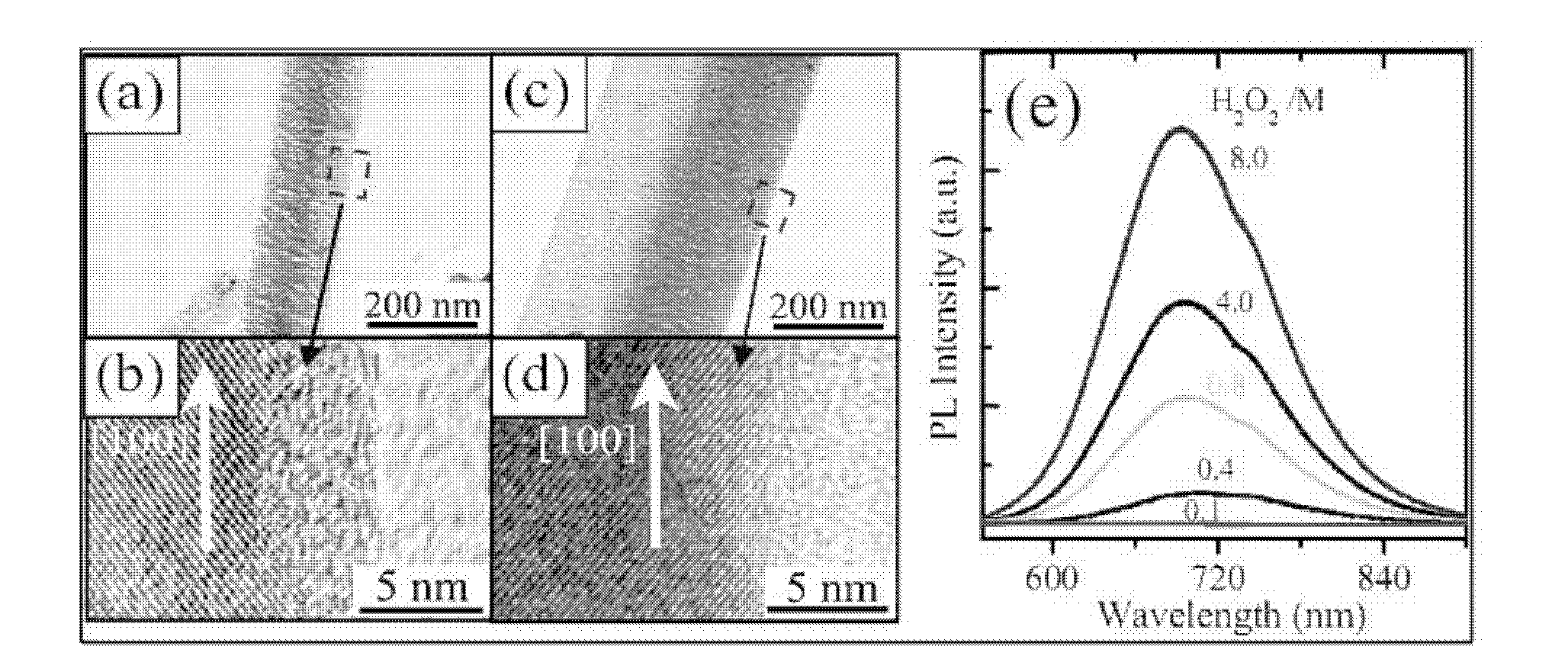

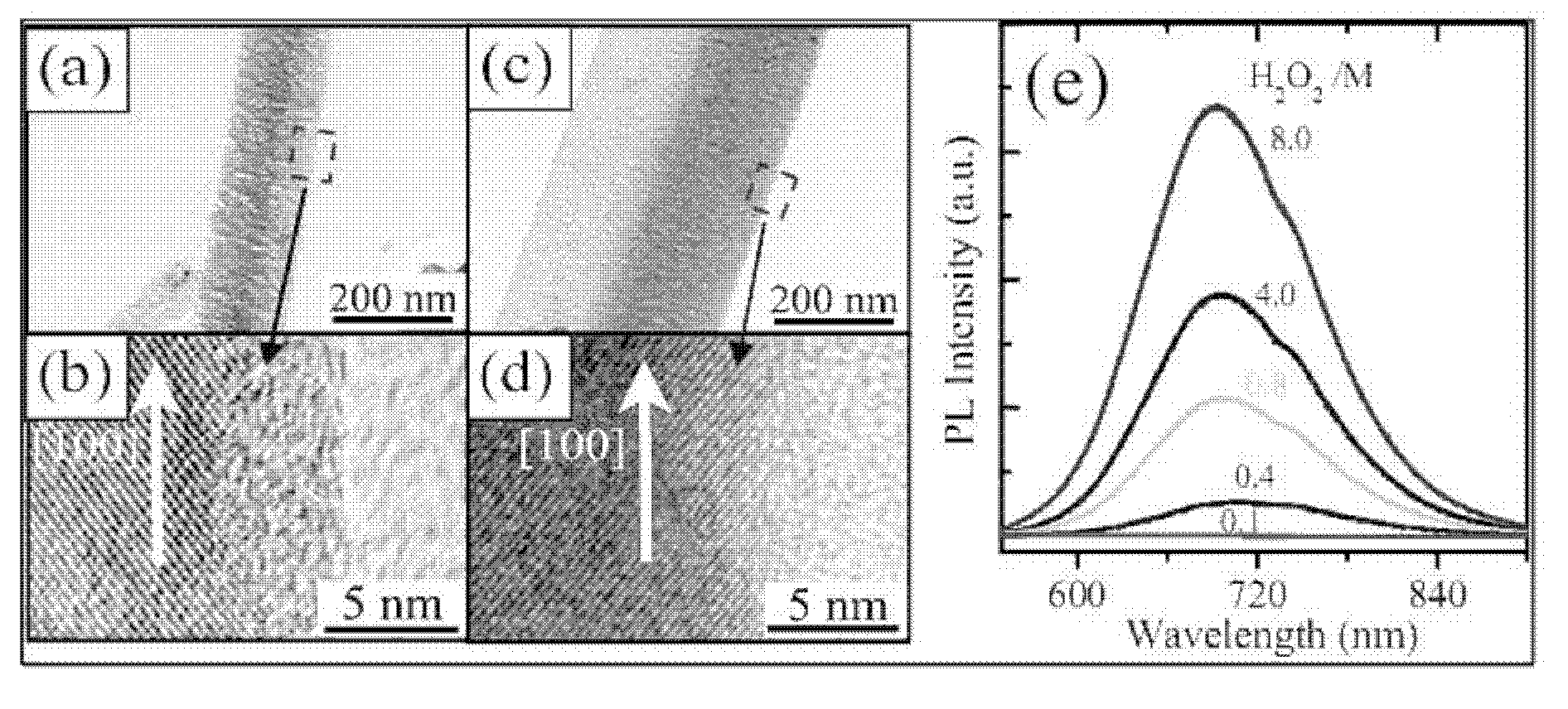

[0018] Using a p-type (100) crystal-oriented electronic-grade silicon wafer with a resistivity of 0.01-0.03Ω·cm, by depositing silver nanoparticles, and then etching them in hydrofluoric acid mixed aqueous solutions at different concentrations of hydrogen peroxide at room temperature; After the etching, the silicon wafers were rinsed with nitric acid and deionized water, dried and then characterized by high-resolution transmission electron microscopy (mainly to study the surface conditions of silicon nanowires). Mann / luminescence spectrometer for photoluminescence test, the excitation light is Ar with a wavelength of 514.5 nm + laser. The specific implementation steps are as follows:

[0019] (1) Silicon wafers were first ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 15 minutes each, and then boiled at 85°C for 15 minutes with ammonia water: hydrogen peroxide: water at a volume ratio of 1:1:5, and then Soak in hydrofluoric acid with a mass fr...

Embodiment 2

[0026] (1) Silicon wafers were first ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 15 minutes each, and then boiled at 85°C for 15 minutes with ammonia water: hydrogen peroxide: water at a volume ratio of 1:1:5, and then Soak in hydrofluoric acid with a mass fraction of 3% for 1 minute to remove the silicon oxide layer; then use hydrochloric acid:hydrogen peroxide:water with a volume ratio of 1:1:5, cook at 85°C for 15 minutes, and finally deionized water Rinse with dilute hydrofluoric acid solution to obtain fluorine-terminated surface-hydrophobic silicon wafers.

[0027] (2) Put the cleaned silicon chip into an aqueous solution with a concentration of 4.0 mol / liter hydrofluoric acid and 10.0 mmol / liter silver nitrate at room temperature, extend the immersion time to 100 seconds, and then take it out quickly, and the surface of the silicon chip is uniform A layer of silver nanoparticles was deposited.

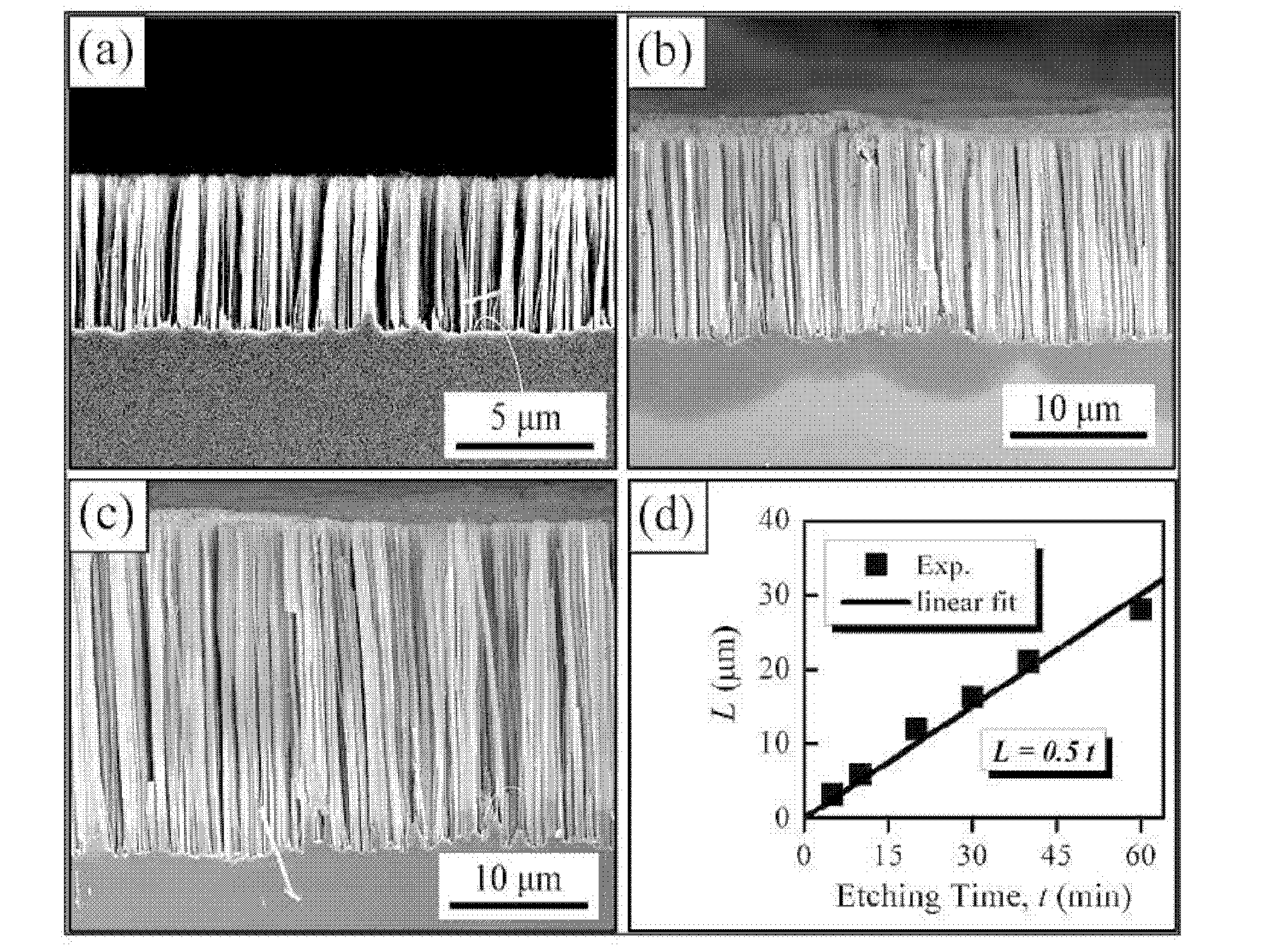

[0028] (3) the silicon chip that deposi...

Embodiment 3

[0033] (1) Silicon wafers were first ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 15 minutes each, and then boiled at 85°C for 15 minutes with ammonia water: hydrogen peroxide: water at a volume ratio of 1:1:5, and then Soak in hydrofluoric acid with a mass fraction of 3% for 1 minute to remove the silicon oxide layer; then use hydrochloric acid:hydrogen peroxide:water with a volume ratio of 1:1:5, cook at 85°C for 15 minutes, and finally deionized water Rinse with dilute hydrofluoric acid solution to obtain fluorine-terminated surface-hydrophobic silicon wafers.

[0034] (2) Put the cleaned silicon chip into an aqueous solution with a concentration of 4.0 mol / liter hydrofluoric acid and 20.0 mmol / liter silver nitrate at room temperature, and the immersion time is 60 seconds, then take it out quickly, and the surface of the silicon chip is evenly deposited layer of silver nanoparticles.

[0035] (3) the silicon chip of depositing the silver n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com