Patents

Literature

1425 results about "Chemical cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical cleaning is a method to derive surfaces and walls of equipment, pipelines, vessels, kettles and heat exchangers of unwanted contaminants. Chemical cleaning also means the purification, conditioning, treatment or disinfection of water.

Membrane filter apparatus with gas discharge cleaning means

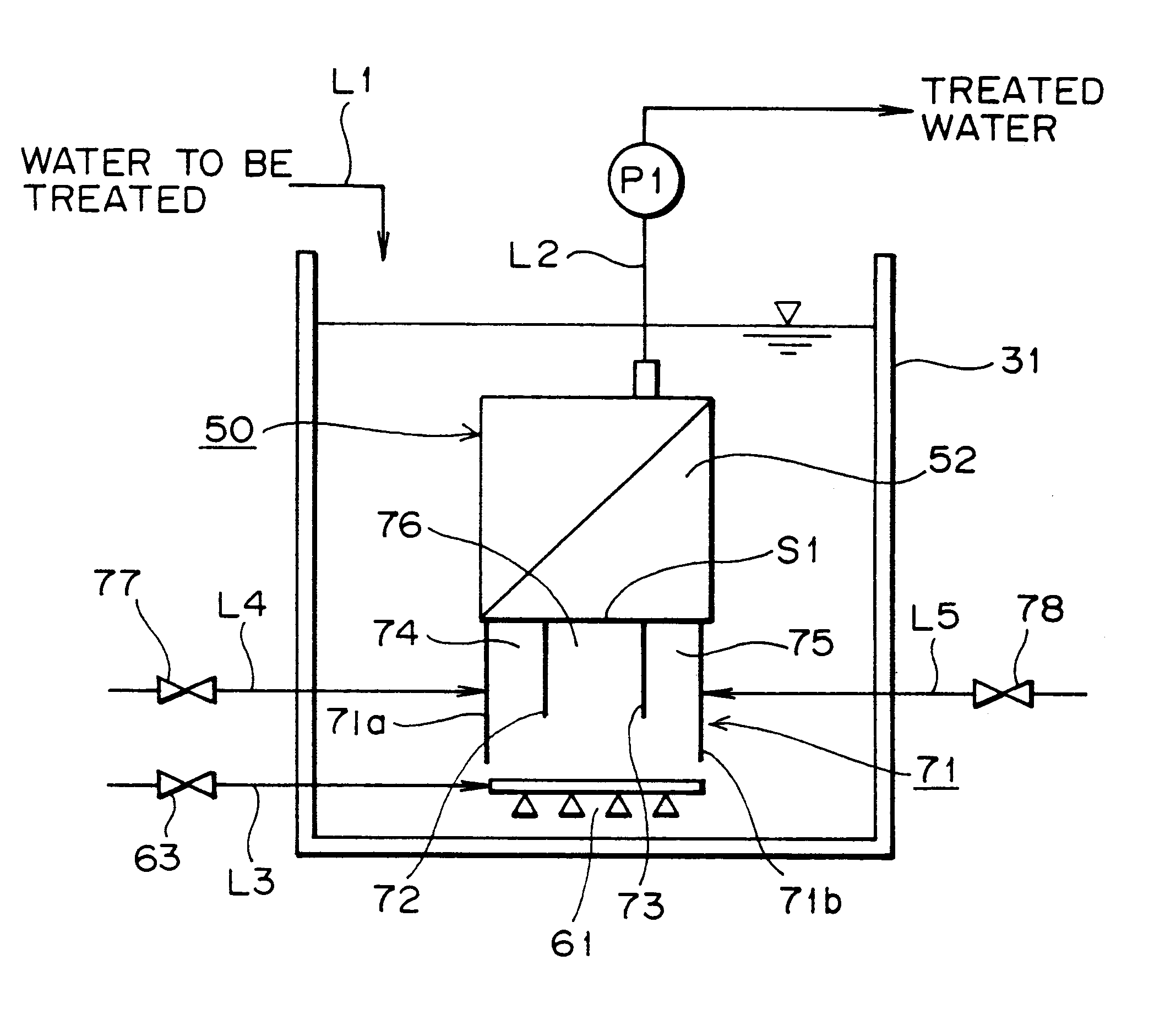

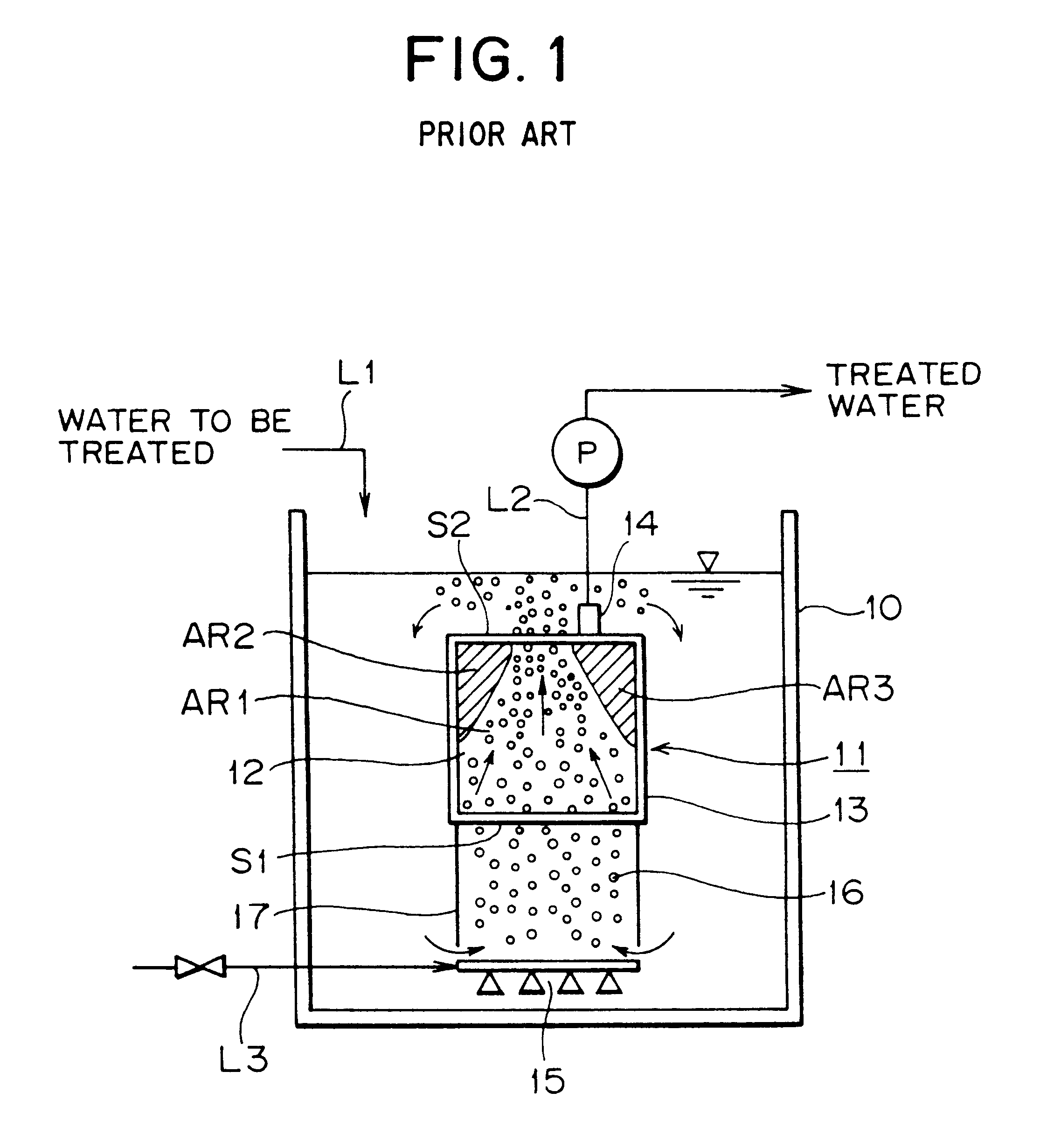

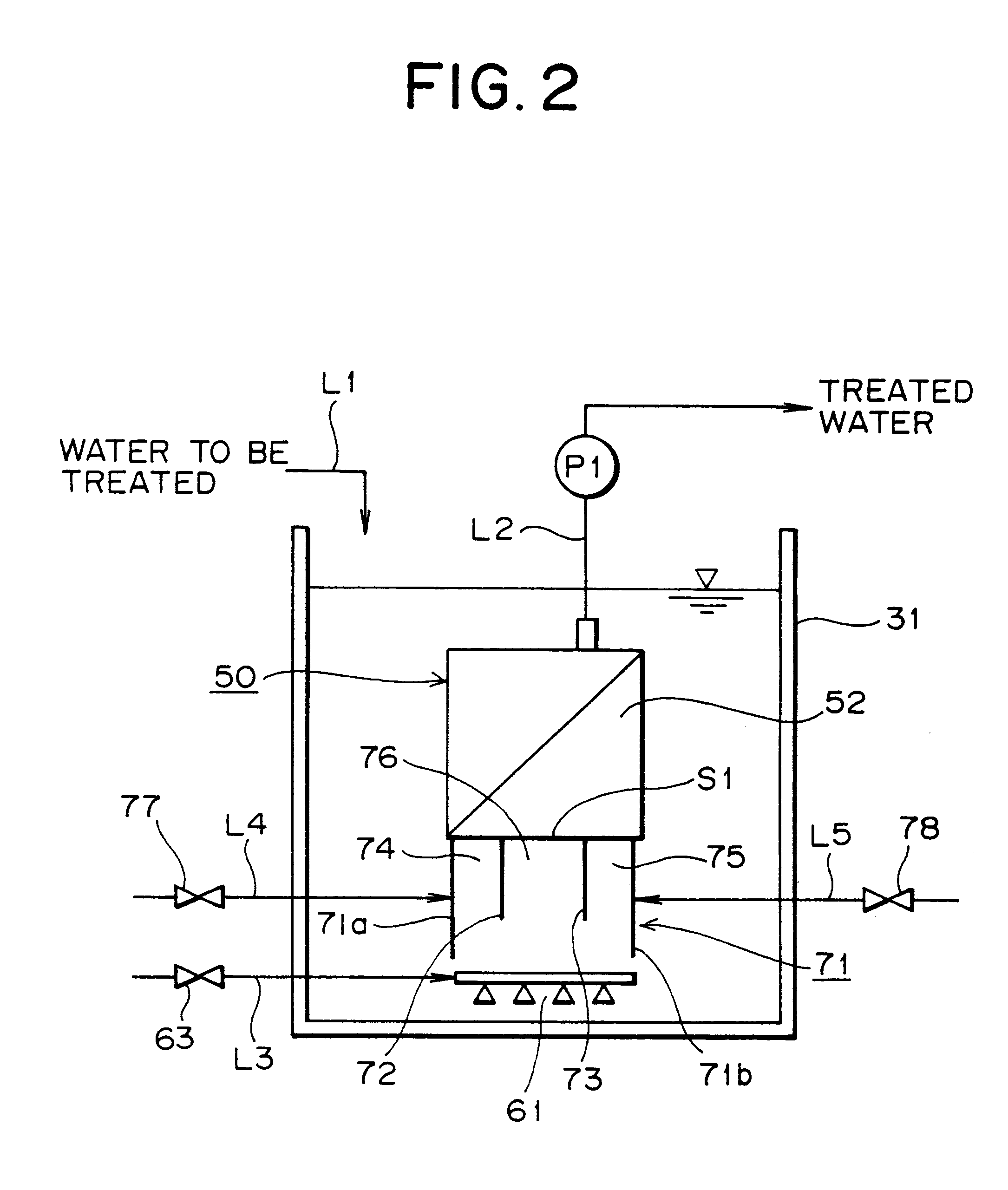

A membrane filter apparatus includes a membrane unit 50 composed of an array of membrane elements 51 disposed within a treatment tank 31. A skirt element 71 is disposed at a bottom portion of the membrane unit and an aerator 61 is disposed under the skirt. A partition is also disposed at the bottom of the membrane unit forming compartments within the skirt element. The gas bubbles discharged from the aerator increase their rising force upon entry into gaps between the membranes. Because of the arrangement of the partition within the skirt element the flow rate of bubbles along the opposite side edge portions of the membrane unit can be increased having the advantage of cleaning the entire surface of each membrane, thereby preventing clogging by sludge, SS, colloid, etc. within the gaps between the membranes. Therefore, filtration can be maintained over a longer period of time and the power required for filtration can be reduced, as well as, the frequency of manual periodic cleaning, chemical cleaning, etc.

Owner:SUMITOMO HEAVY IND LTD

Chemical cleaning for membranes

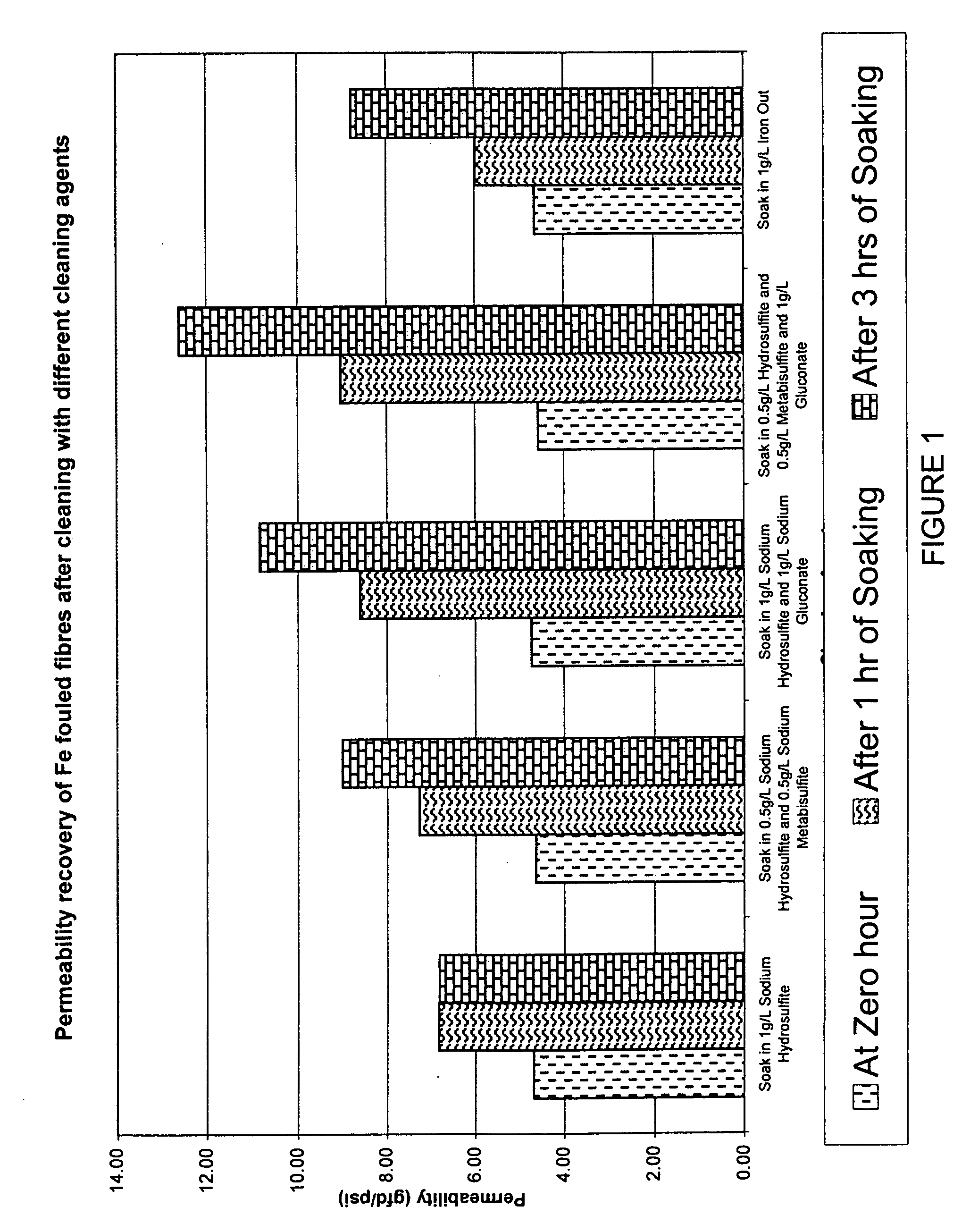

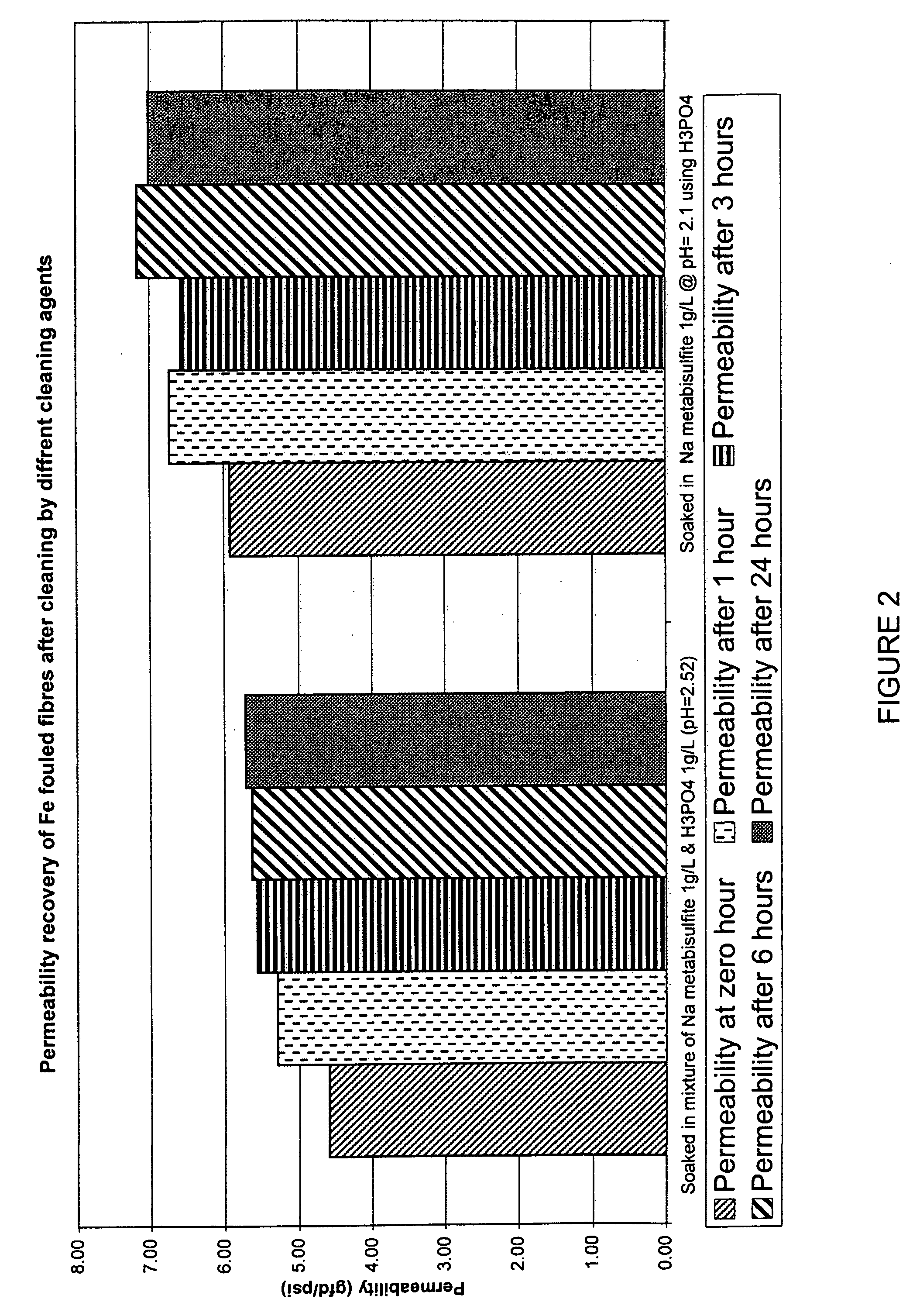

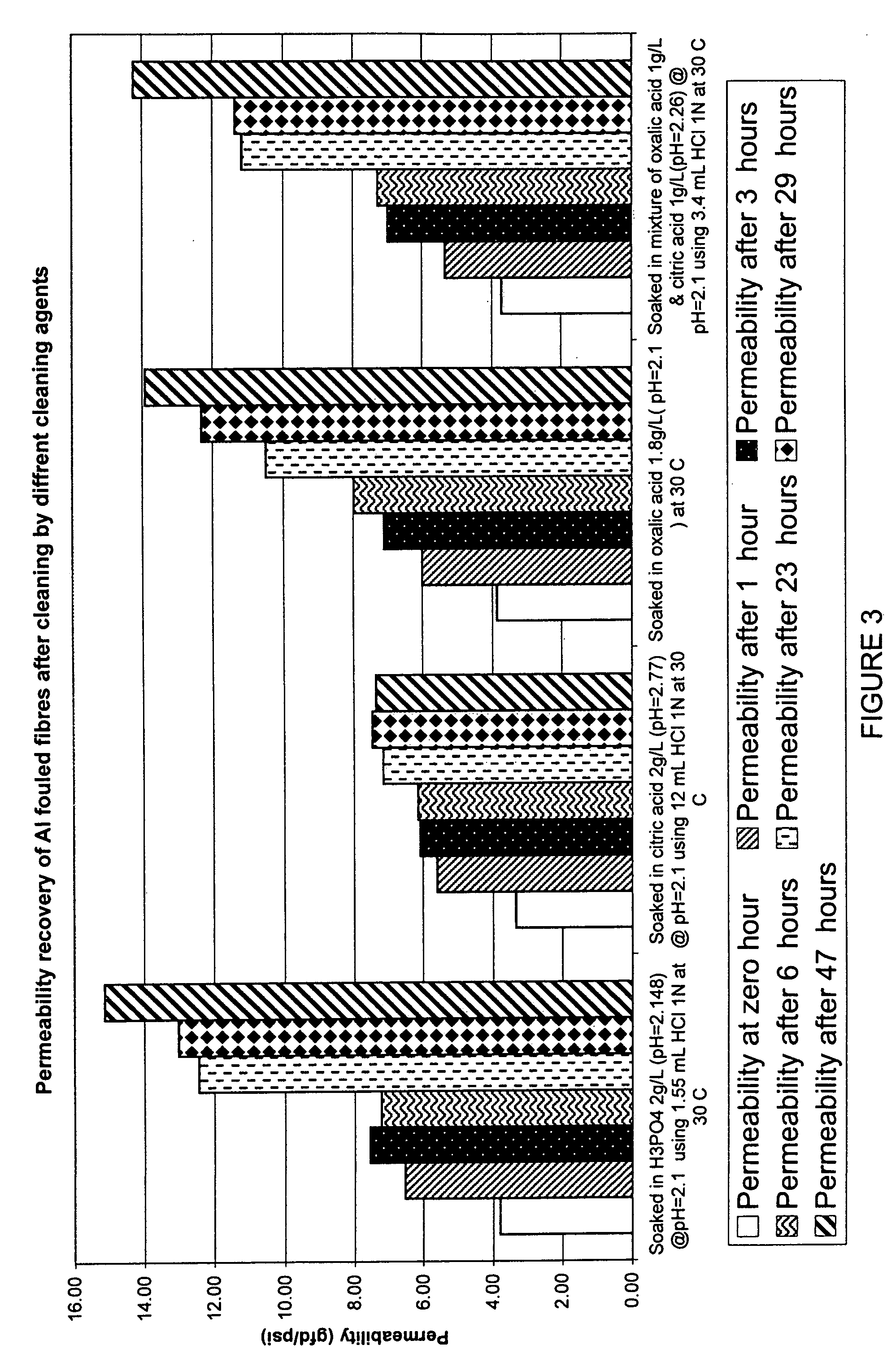

Membranes, for example immersed polymeric ultrafiltration or microfiltration membranes, are cleaned by contacting them with a chemical cleaner comprising one or more of a gluconate, a hydrosulfite, a metabisulfite or an acid, for example phosphoric acid. The membranes may have been exposed to organic or inorganic foulants, some of which may have resulted from pretreatment involving adding coagulants, for example coagulants containing iron or aluminum, to water to be treated. Methods for treating a waste cleaning solution were described.

Owner:SYED MURTUZA ALI +3

Acid-cleaning inhibiter for cleaning boiler and use method thereof

ActiveCN101634030ASlow down the dissolution rateIncrease activation energyBoiler cleaning apparatusThioureaPhosphoric acid

The invention discloses an acid-cleaning inhibiter for cleaning a boiler and a use method thereof. The acid-cleaning inhibiter comprises the following components by weight percent: 2.0%-10.0% of acid liquor, 0.08-0.25% of urotropine, 0.04-0.15% of dimethylbenzene thiourea or thiourea, 0.01-0.05% of thiocyanate, 0.03-0.12% of dodecyl-cetyl phenmethyl chloride or bromide, 0.05-0.12% of a surface active agent and the balance of water. Acids suitable for the acid-cleaning inhibiter include hydrochloric acid, citric acid, sulphuric acid, hydrofluoric acid, aminosulfonic acid and phosphoric acid, which are suitable for boiler steel, mild steel, alloy steel and steam steel. The inhibition effect of the invention is over 98% with less toxicity under the boiler chemical cleaning condition, the value of LD50 (orally taken by mice) is 5.74 g / kg. The invention can be stored for 2 years, resistant Fe<3+> ion is 800 mg / kg in the acid cleaning. The preparation method has simple steps, easily obtained raw materials and convention operation.

Owner:湖南省湘电试验研究院有限公司 +2

Polycrystalline silicon and method for production thereof

Polycrystalline silicon of the invention contains: (a) polycrystalline silicon fragments, wherein at least 90% of the fragments have a size from 10 to 40 mm, (b) <15 ppmw of silicon dust particles having particle sizes <400 μm; (c) <14 ppmw of silicon dust particles having particle sizes <50 μm; (d) <10 ppmw of silicon dust particles having particle sizes <10 μm; (e) <3 ppmw of silicon dust particles having particle sizes <1 μm; and (f) surface metal impurities in an amount ≦0.1 ppbw and ≧100 ppbw. A polycrystalline silicon production method of the invention includes fracturing polycrystalline silicon deposited on thin rods in a Siemens reactor into fragments; classifying the fragments by size; and treating the fragments with compressed air or dry ice to remove silicon dust from the fragments without wet chemical cleaning.

Owner:WACKER CHEM GMBH

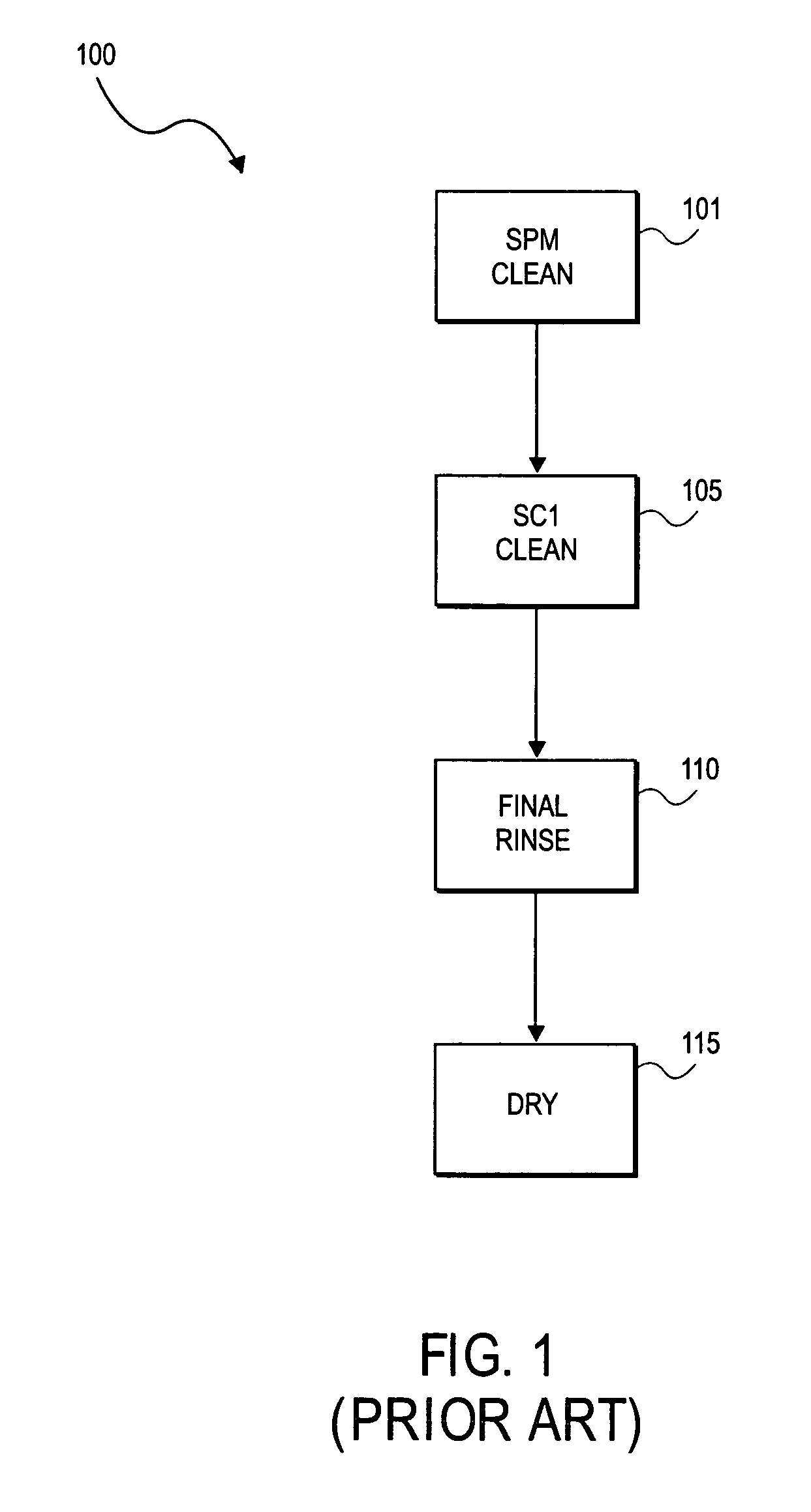

Cleaning method

InactiveUS6348157B1Strong resistanceSuppress formationSemiconductor/solid-state device manufacturingElectrostatic cleaningCleaning methodsChemical cleaning

A cleaning method capable of processing at room temperatures without conducting heating, uses little chemicals and water, and does not require special devices or materials. The chemical cleaning processes and rinse processes employ pure water or ultrapure water in a semiconductor wet cleaning process, rinse water or chemicals which suppresses formation of surface oxide films, removes particles and prevent their redeposition, and aids in the hydrogen termination of the silicon atoms. The cleaning method of the resent invention includes cleaning which is conducted using pure water containing ozone, cleaning conducted using a cleaning liquid containing HF, H2O, and surfactant, while applying vibration having a frequency of 500 kHz or more, cleaning conducted using pure water containing ozone, cleaning conducted using a cleaning liquid containing HF and H2O in order to remove oxide films, and cleaning which is conducted using pure water. After cleaning a material to be cleaned using chemicals, rinsing is conducted using pure water or ultrapure water containing hydrogen gas in an amount of 0.5 ppm or more and containing oxygen gas in an amount of 100 ppb or less.

Owner:OHMI TADAHIRO +1

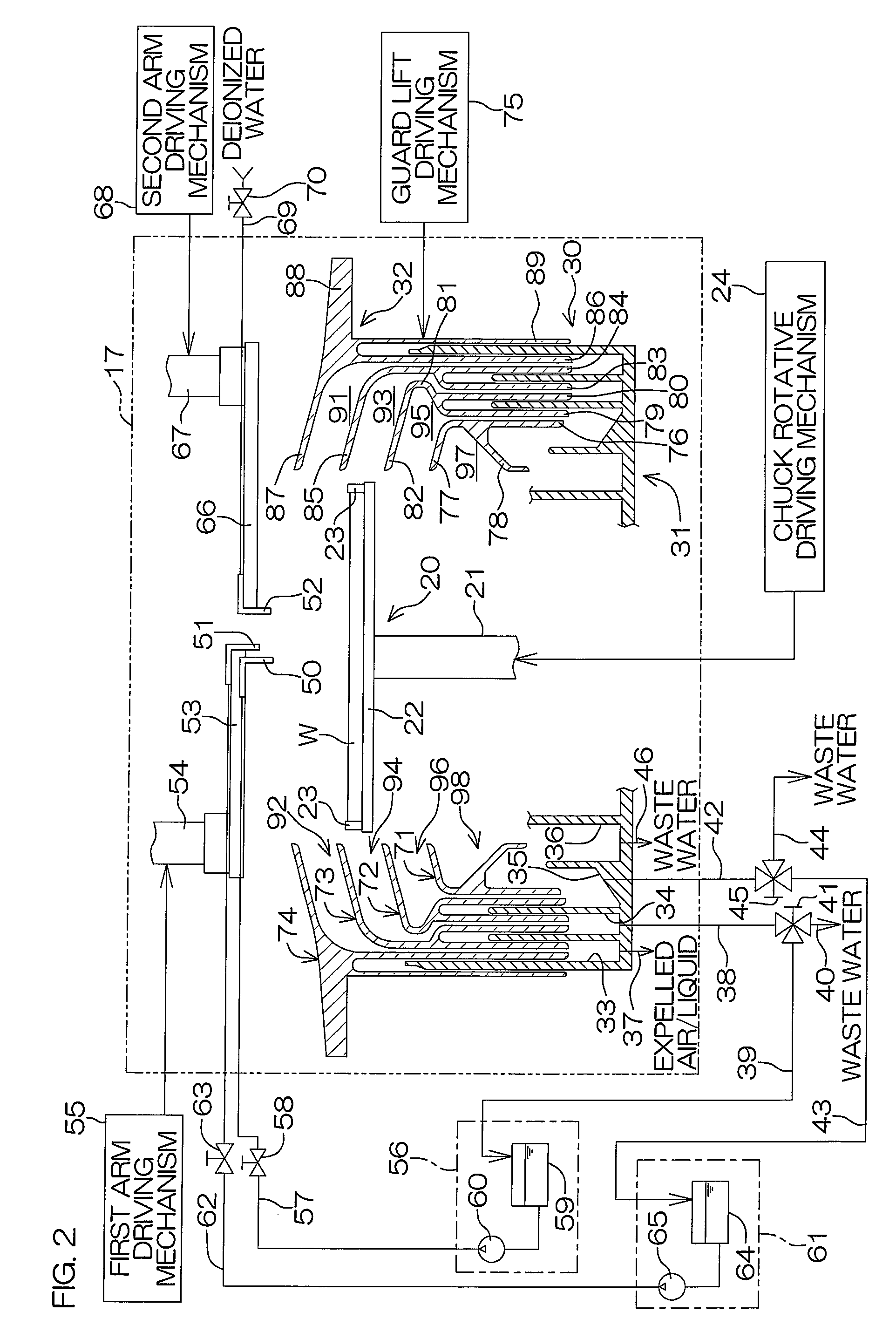

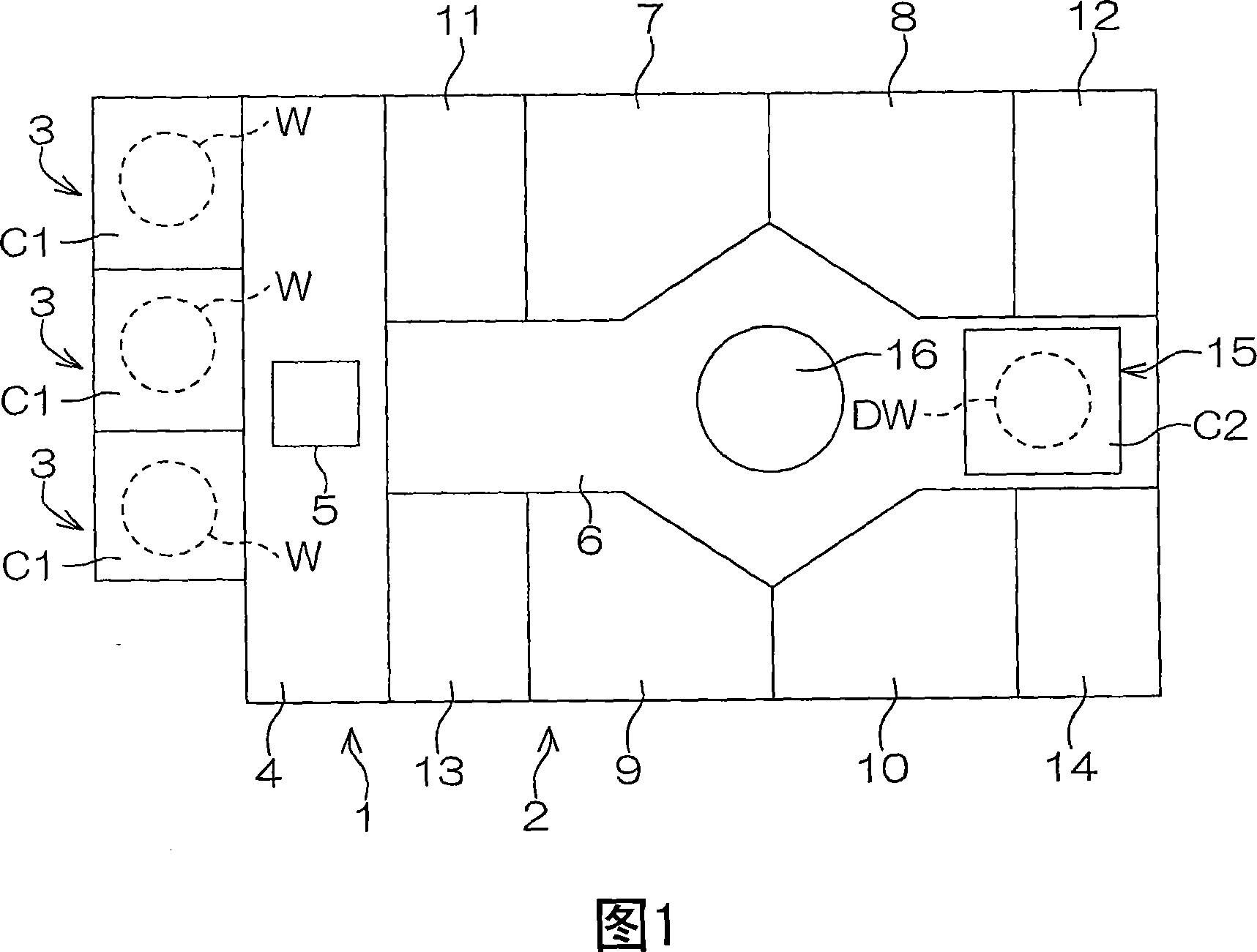

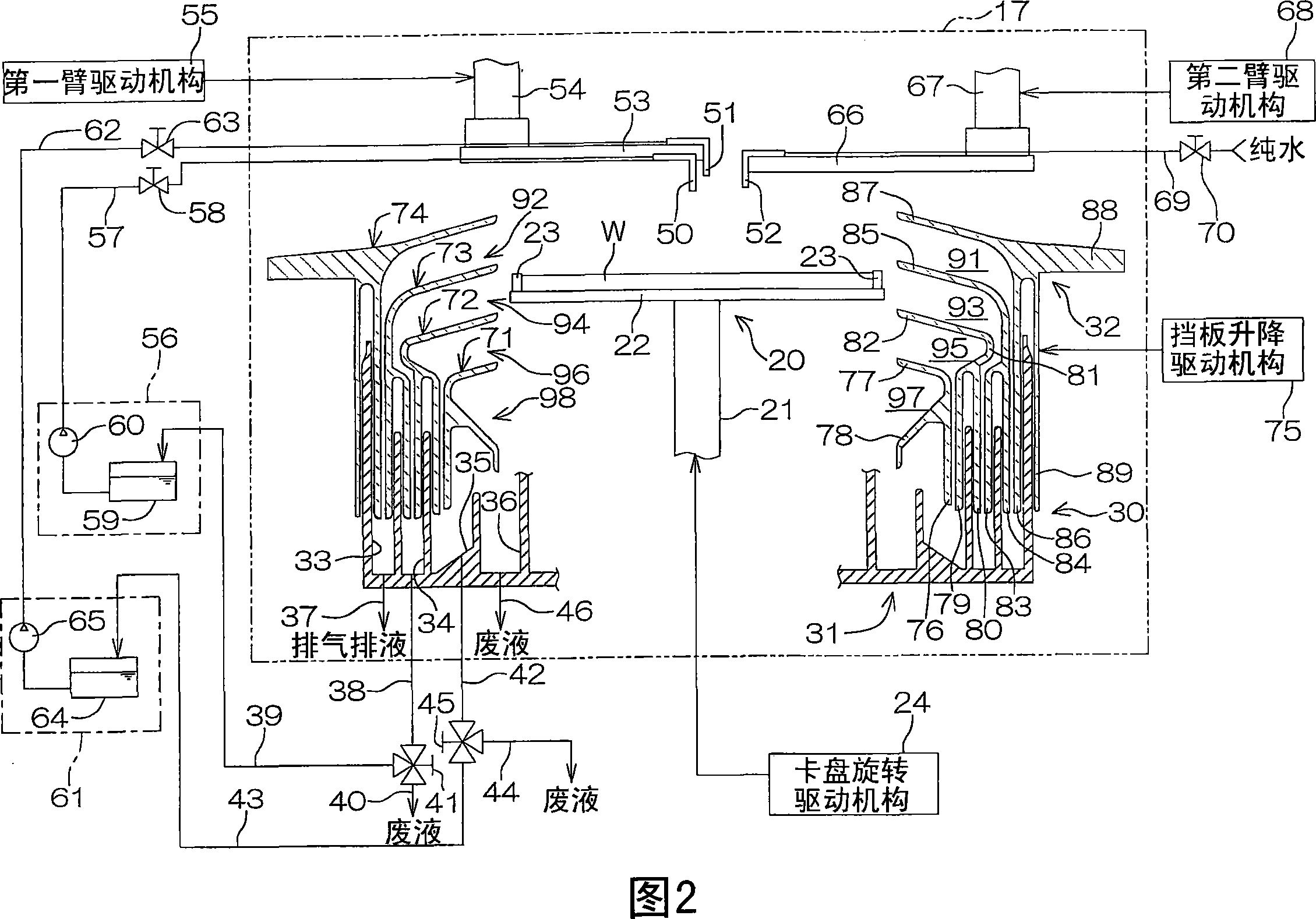

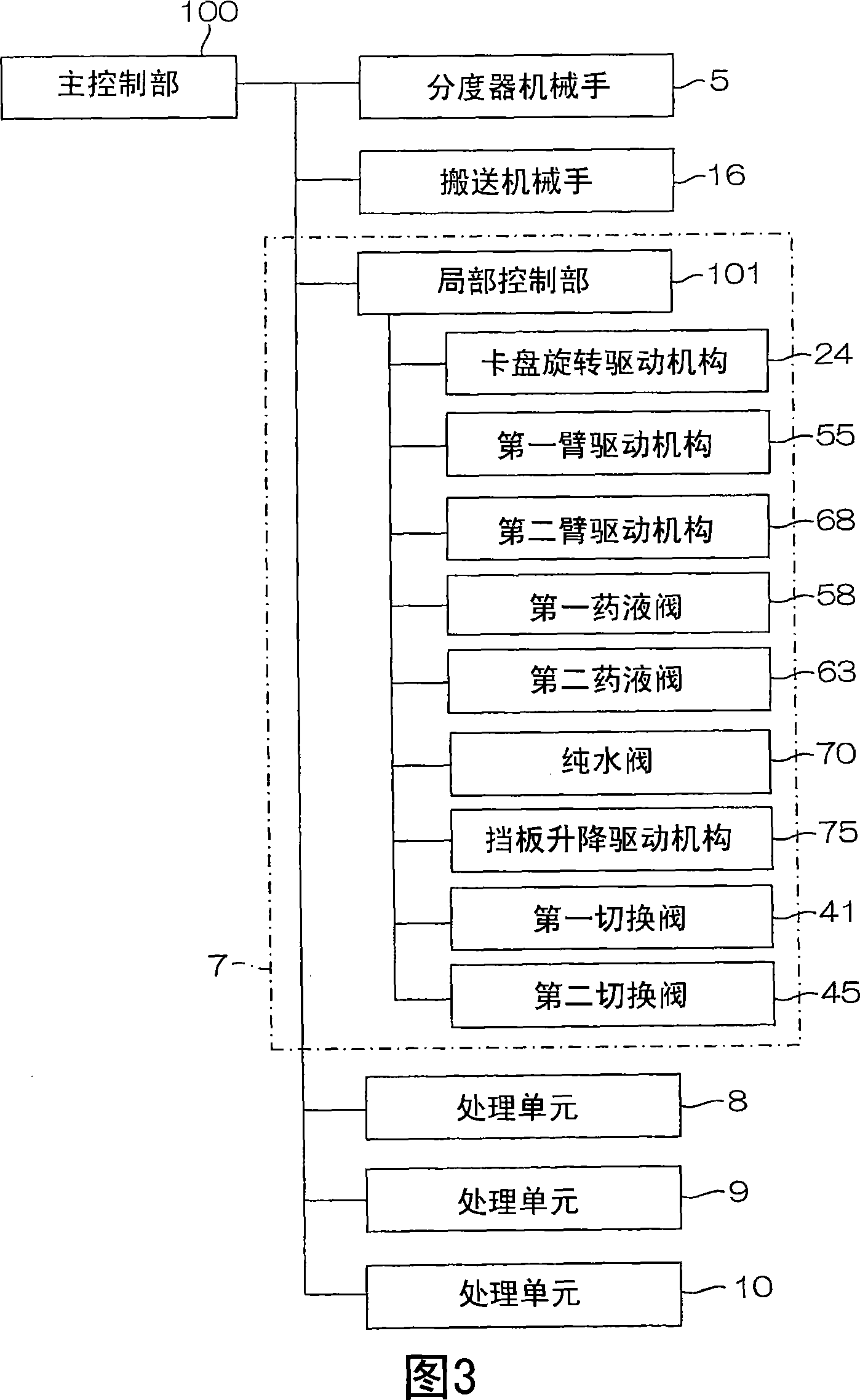

Recovery cup cleaning method and substrate treatment apparatus

InactiveUS20080142051A1Suppression problemSuppress generationHollow article cleaningSemiconductor/solid-state device manufacturingCompound (substance)Cleaning methods

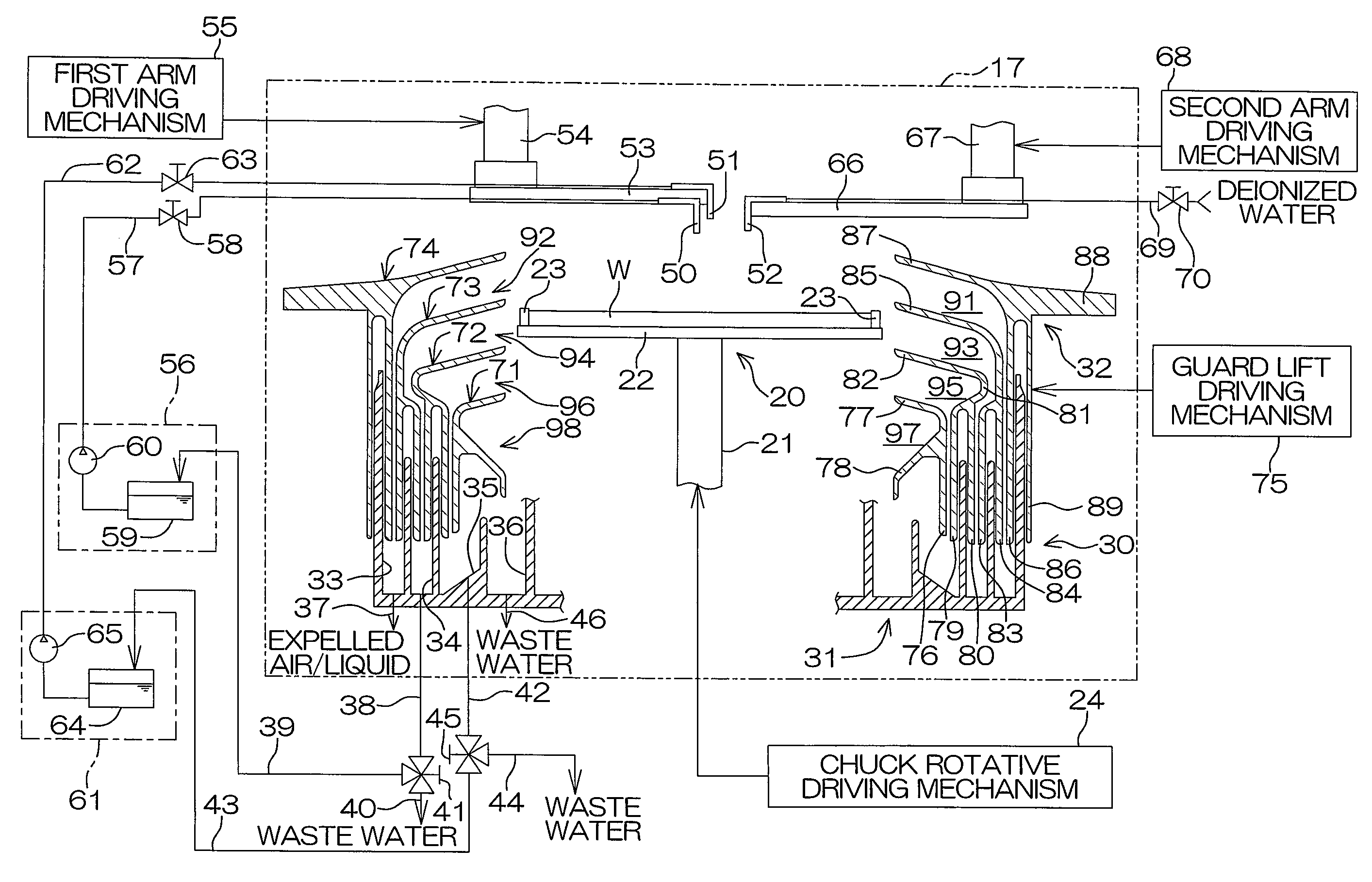

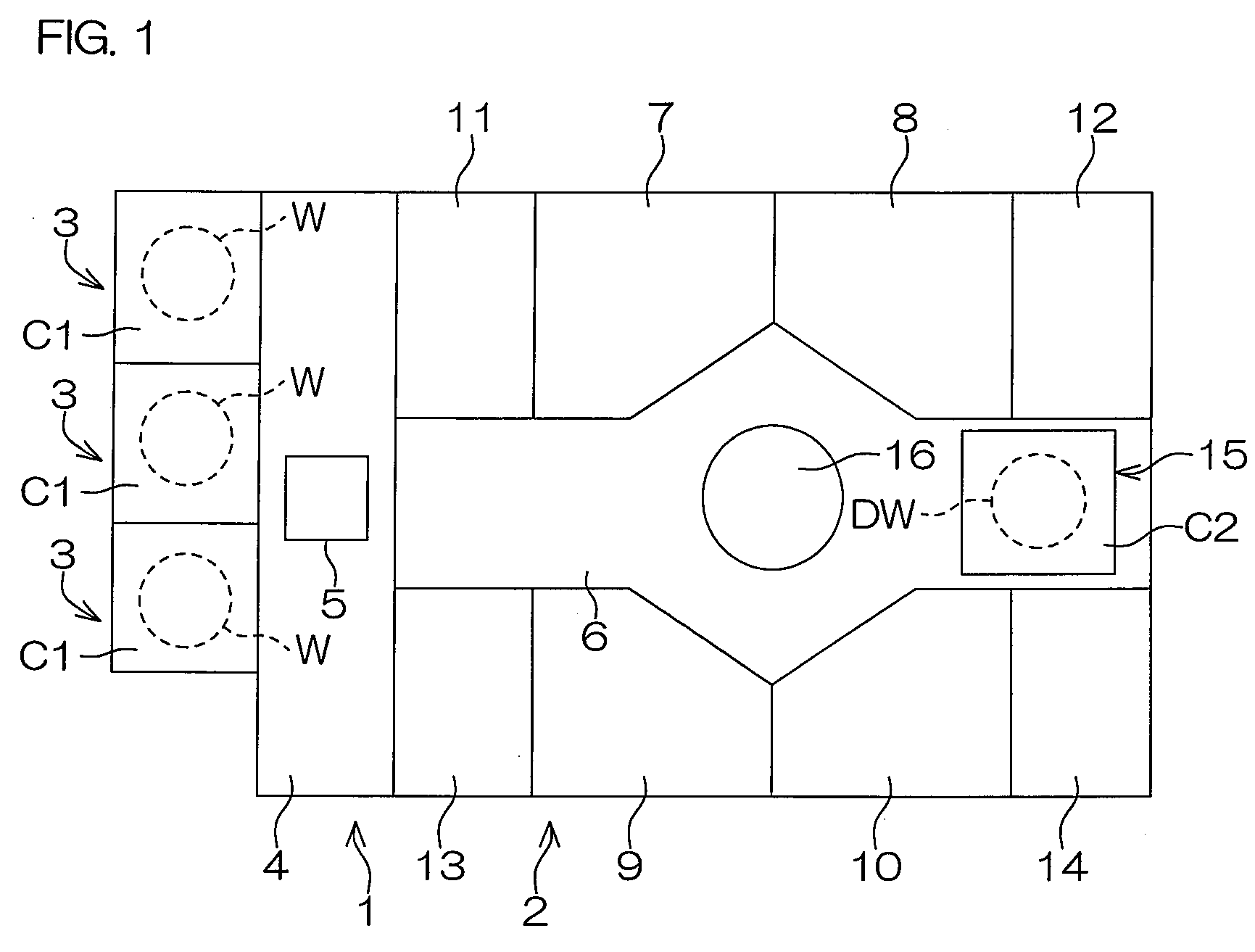

An inventive recovery cup cleaning method is a method for cleaning a recovery cup having an interior wall partitioning a recovery space into which a chemical agent used for treating a substrate is introduced, the recovery cup being configured such that the chemical agent introduced into the recovery space is further introduced into a predetermined chemical agent recovery passage so as to be recovered. The method comprises the steps of: cleaning the interior wall of the recovery space with a cleaning liquid; cleaning the interior wall of the recovery space with a chemical cleaning agent after the step of cleaning with the cleaning liquid, the chemical cleaning agent being of the same type as the chemical agent to be recovered through the recovery space; and draining the cleaning liquid introduced into the recovery space in the step of cleaning with the cleaning liquid and the chemical cleaning agent introduced into the recovery space in the step of cleaning with the chemical cleaning agent through a drain passage which is different from the chemical agent recovery passage.

Owner:DAINIPPON SCREEN MTG CO LTD

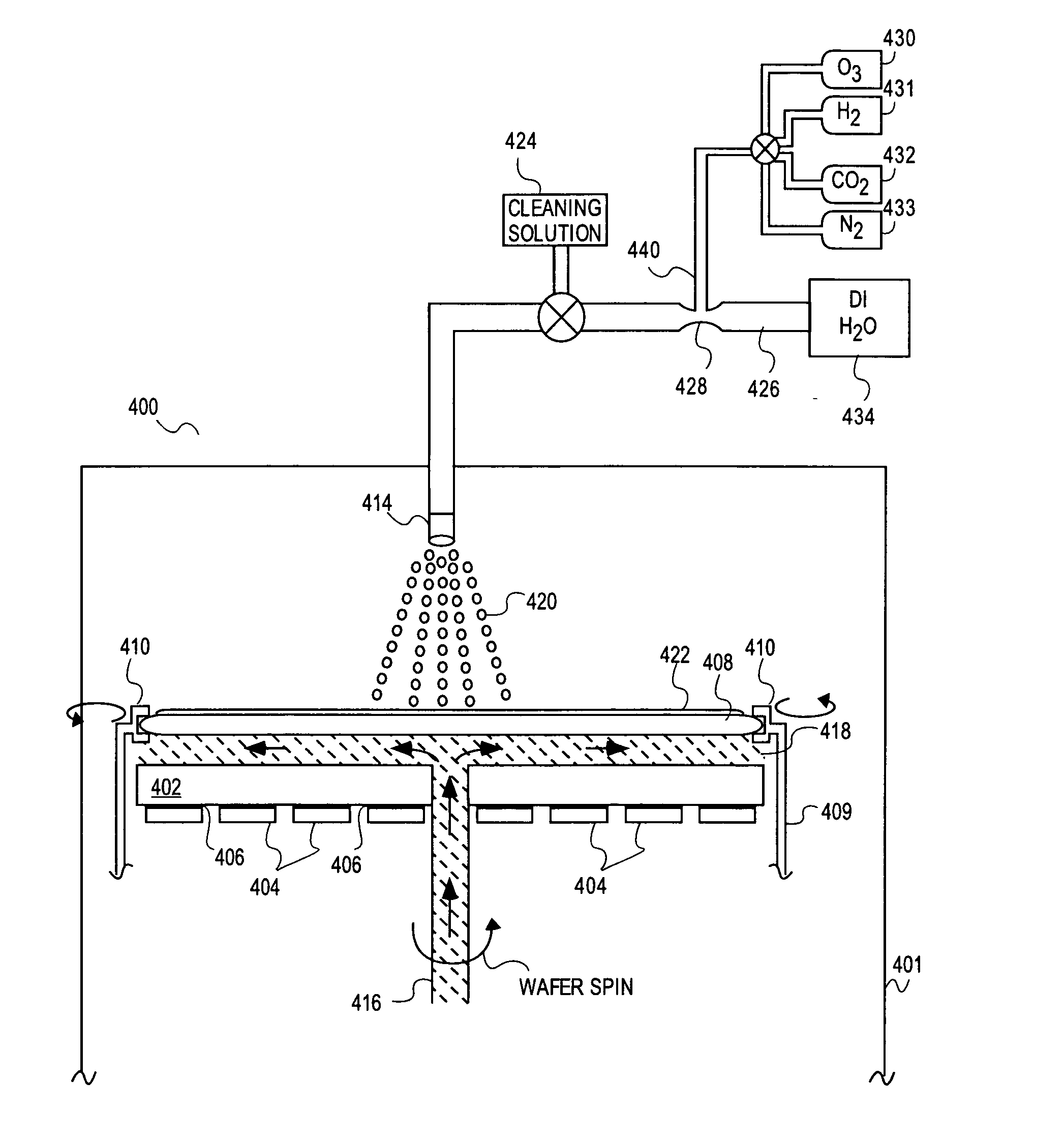

Apparatus and methods for mask cleaning

InactiveUS20070068558A1Semiconductor/solid-state device manufacturingOriginals for photomechanical treatmentParticulatesCompound (substance)

An integrated substrate cleaning processes capable of removing residues and particulates from the surface of a photomask is described. In one embodiment, an ozonated de-ionized water treatment is the first wet cleaning operation. In an embodiment of the present invention, the substrate cleaning process includes a wet cleaning operation employing an ammonium hydroxide-based chemical cleaning solution diluted with hydrogenated de-ionized water. In another embodiment of the present invention, the substrate cleaning process uses a plasma treatment prior to the first wet cleaning operation.

Owner:APPLIED MATERIALS INC

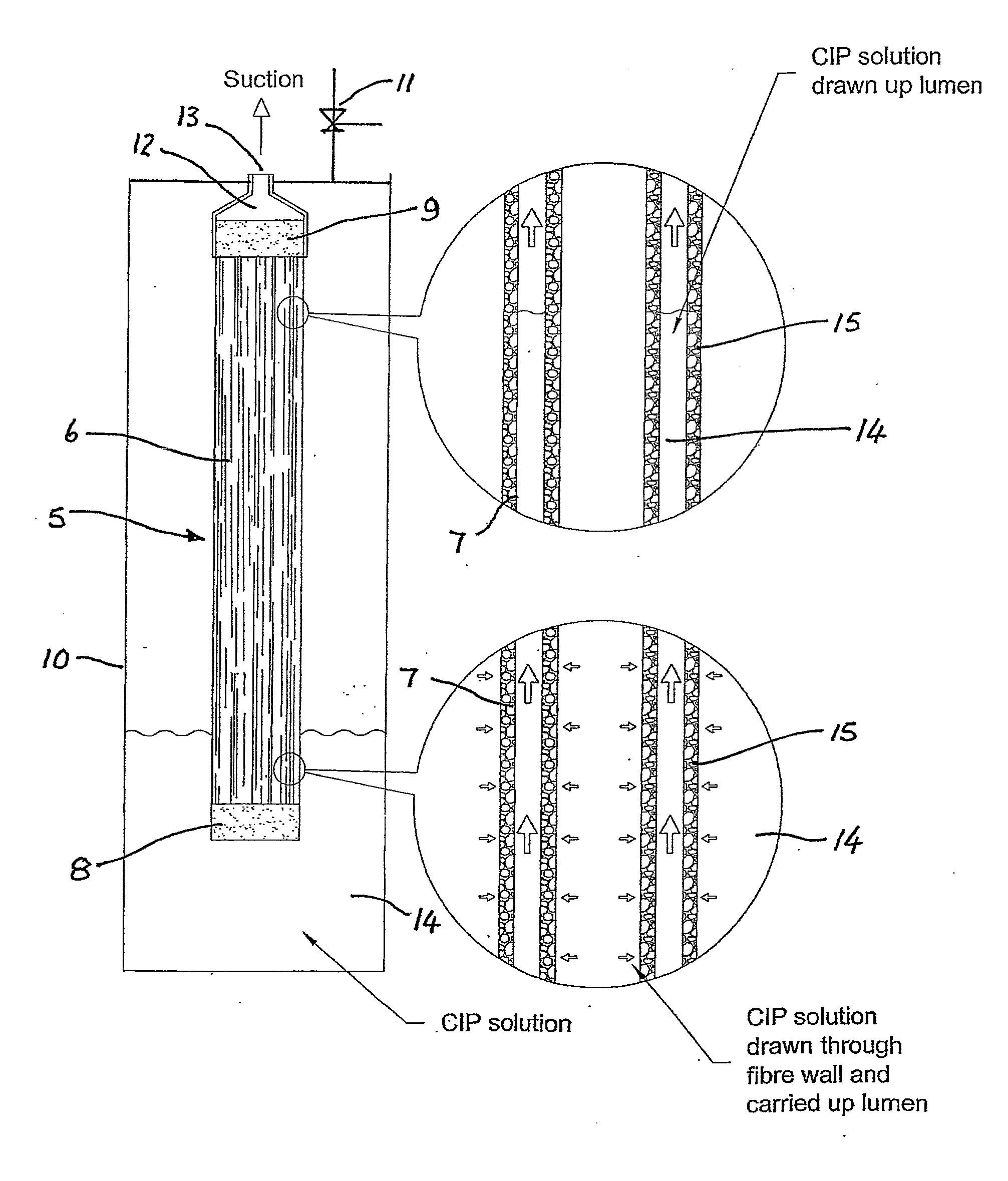

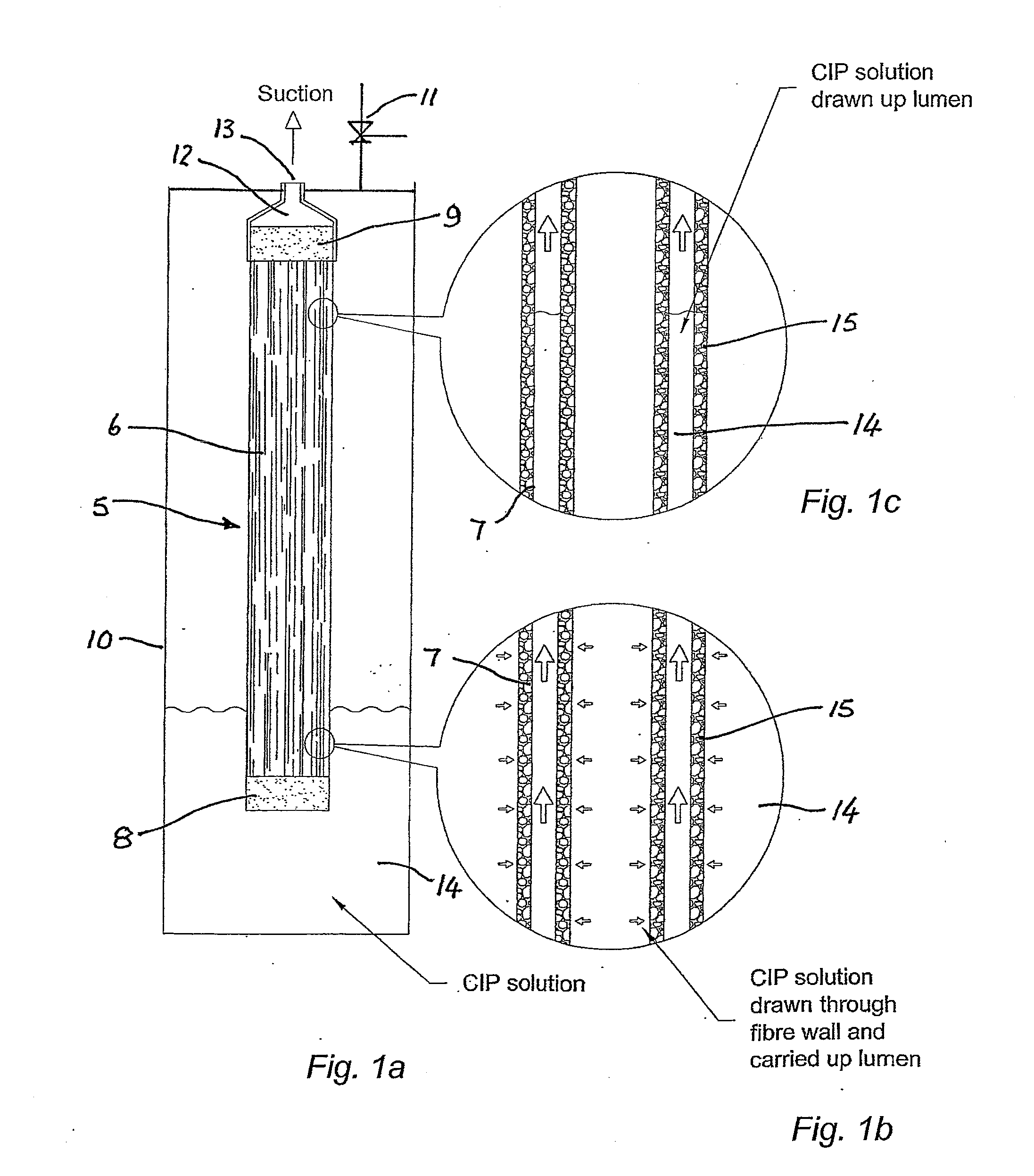

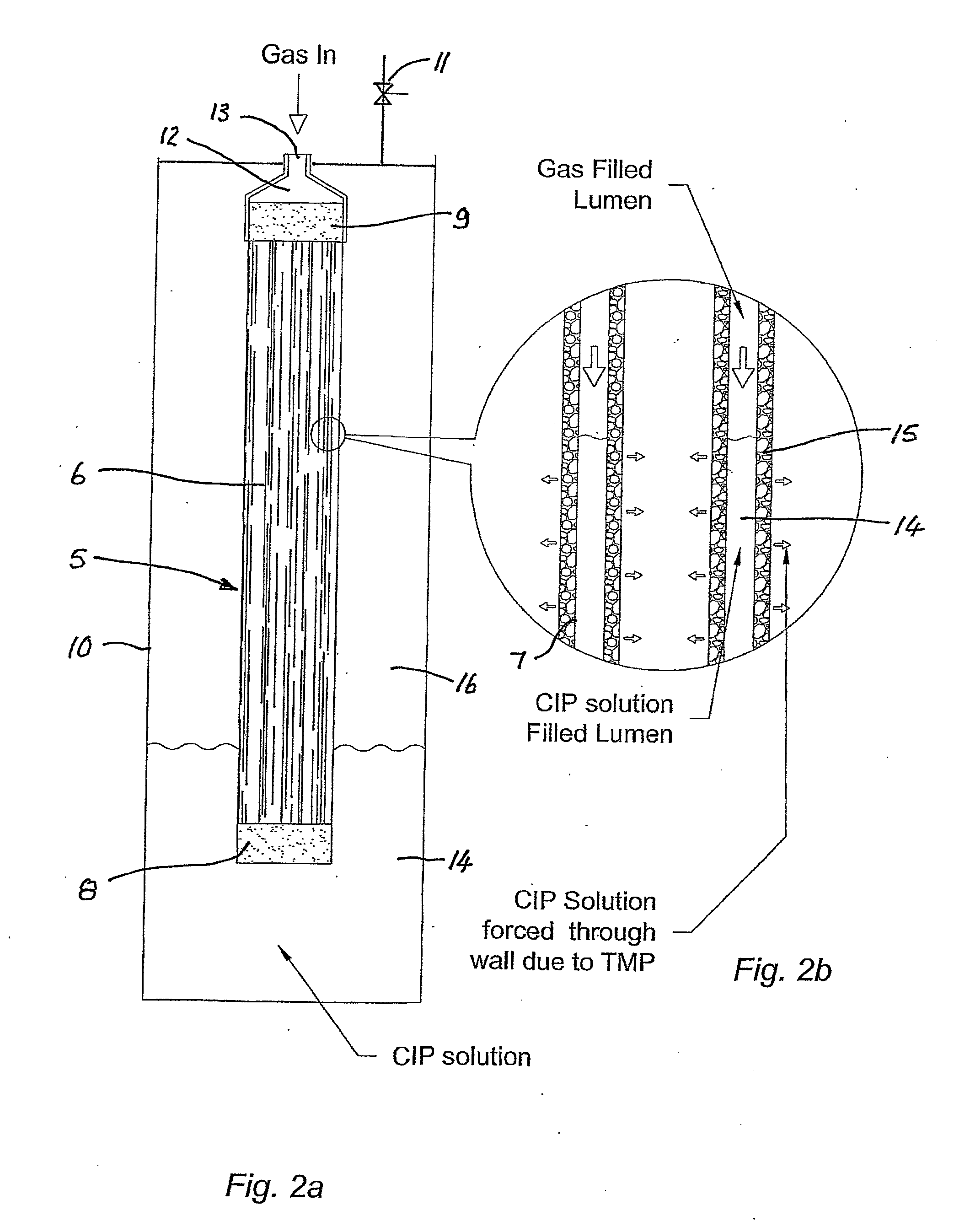

Cleaning in membrane filtration systems

A method of cleaning permeable, hollow membranes (6) in an arrangement of the type wherein a pressure differential is applied across the walls (15) of the permeable, hollow membranes (6) immersed in a liquid suspension, the liquid suspension being applied to the outer surface of the porous hollow membranes (6) to induce and sustain filtration through the membrane walls (15) wherein some of the liquid suspension passes through the walls (15) of the membranes (6) to be drawn off as clarified liquid or permeate from the hollow membrane lumens (7), and at least some of the solids are retained on or in the hollow membranes (6) or otherwise as suspended solids within the liquid surrounding the membranes (6). The method of cleaning comprises the steps of applying a cleaning solution (14) to one side of the membrane wall (15); applying a pressure differential across the membrane wall (15) to cause flow of the cleaning solution (14) through the wall (15) from the one side of the membrane wall (15) to the other side of the membrane wall (15) and applying a reverse pressure differential across the membrane wall (15) to cause flow of the cleaning solution (14) through the wall (15) from the other side of the membrane wall (15) back to the one side of the membrane wall (15). A method of determining the amount of chemical cleaning solution required is also disclosed.

Owner:EVOQUA WATER TECH LLC

Membrane cleaning agent for cleaning reverse osmosis membrane and application method

ActiveCN102553452AEffective elutionGuarantee continuous and stable operationSemi-permeable membranesReverse osmosisEnvironmental engineering

The invention relates to a membrane cleaning agent for polyacrylamide on a reverse osmosis membrane. Acid chemical cleaning agents and alkaline chemical cleaning agents are prepared in the membrane cleaning agent, and the polyacrylamide and organic and inorganic pollutants wrapped by the polyacrylamide on the surface of the polluted reverse osmosis membrane are dissolved, dispersed, peeled and removed specifically. The membrane cleaning agent has the advantages of being easy to prepare and capable of recovering water producing flux and causing on damage to elements of the reverse osmosis membrane, and raw material can be achieved conveniently.

Owner:蓝星工程有限公司

Recovery cup cleaning method and substrate treatment apparatus

InactiveCN101204708AHollow article cleaningSemiconductor/solid-state device manufacturingLiquid wasteCompound (substance)

An inventive recovery cup cleaning method is a method for cleaning a recovery cup having an interior wall partitioning a recovery space into which a chemical agent used for treating a substrate is introduced, the recovery cup being configured such that the chemical agent introduced into the recovery space is further introduced into a predetermined chemical agent recovery passage so as to be recovered. The method comprises the steps of: cleaning the interior wall of the recovery space with a cleaning liquid; cleaning the interior wall of the recovery space with a chemical cleaning agent after the step of cleaning with the cleaning liquid, the chemical cleaning agent being of the same type as the chemical agent to be recovered through the recovery space; and draining the cleaning liquid introduced into the recovery space in the step of cleaning with the cleaning liquid and the chemical cleaning agent introduced into the recovery space in the step of cleaning with the chemical cleaning agent through a drain passage which is different from the chemical agent recovery passage.

Owner:DAINIPPON SCREEN MTG CO LTD

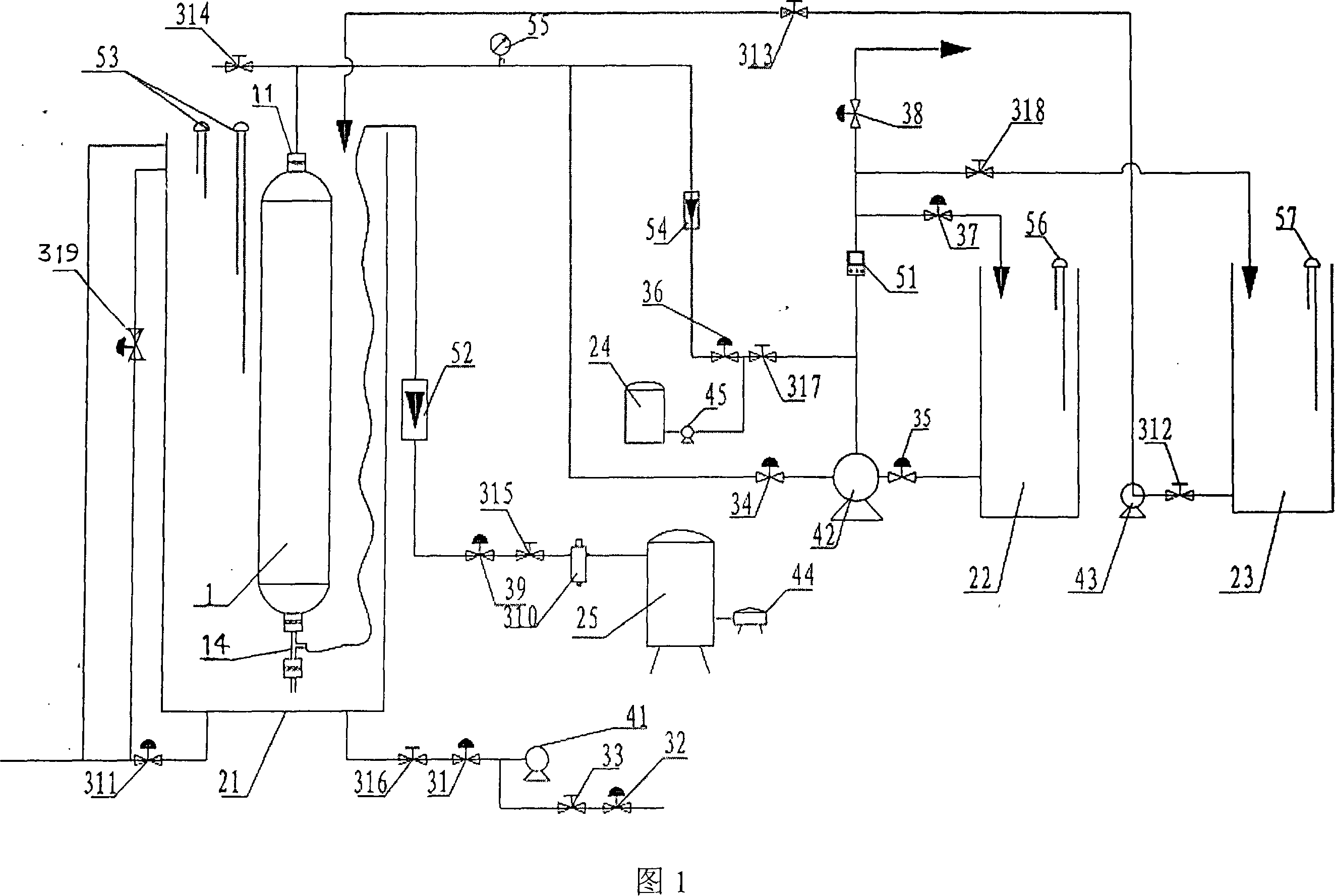

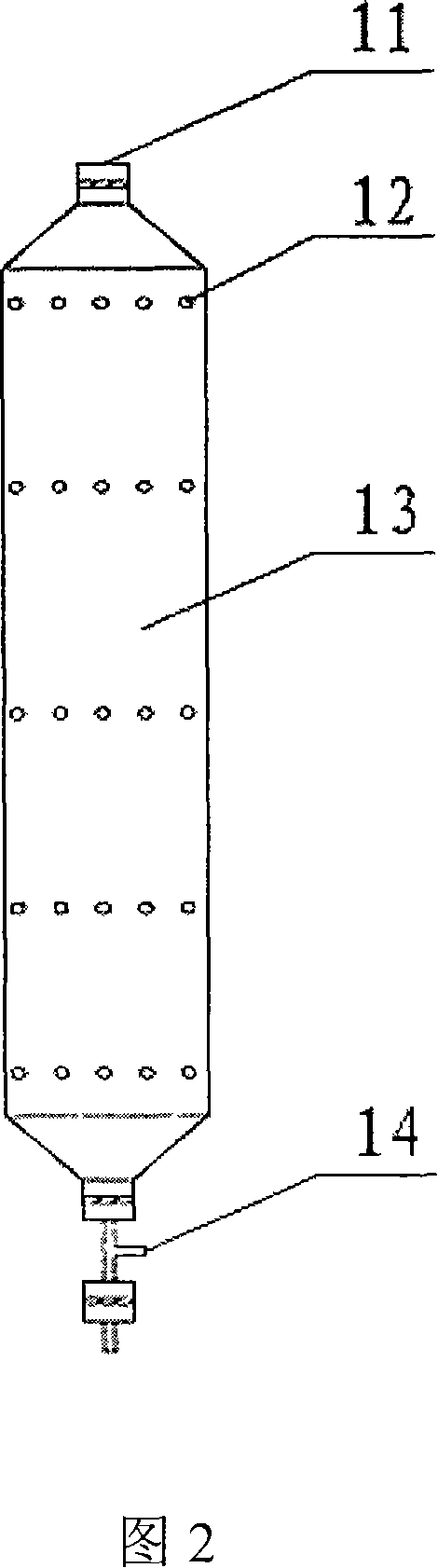

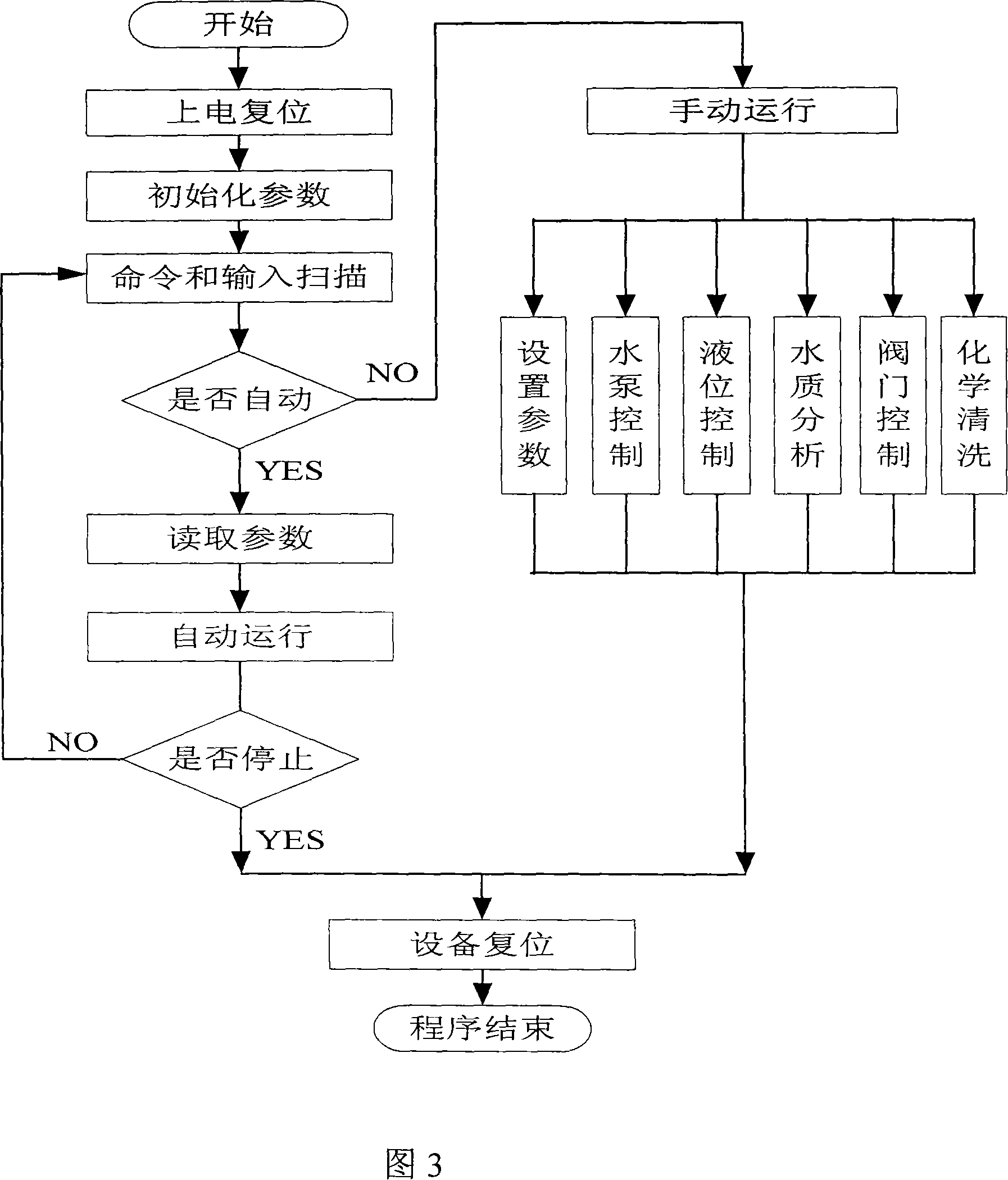

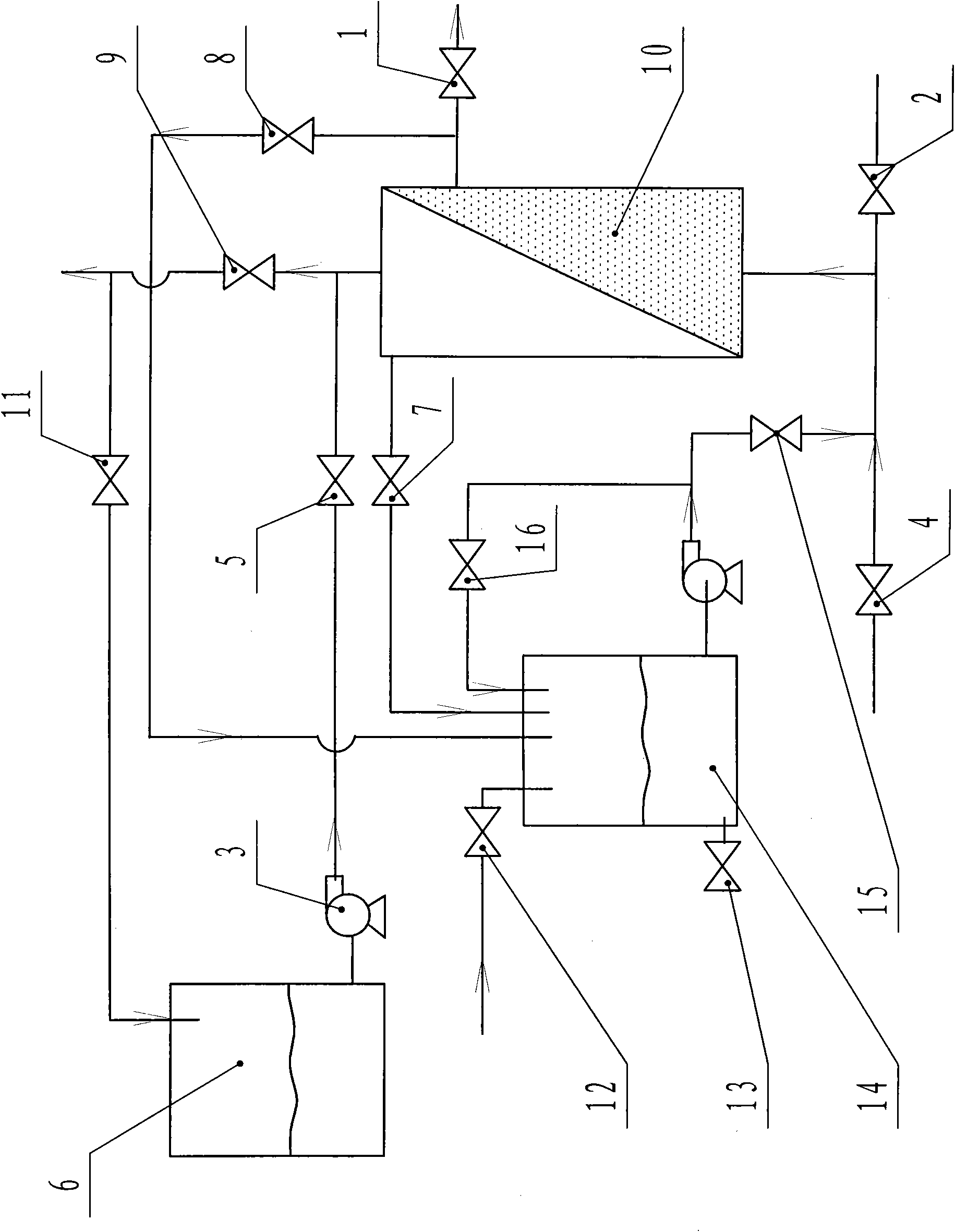

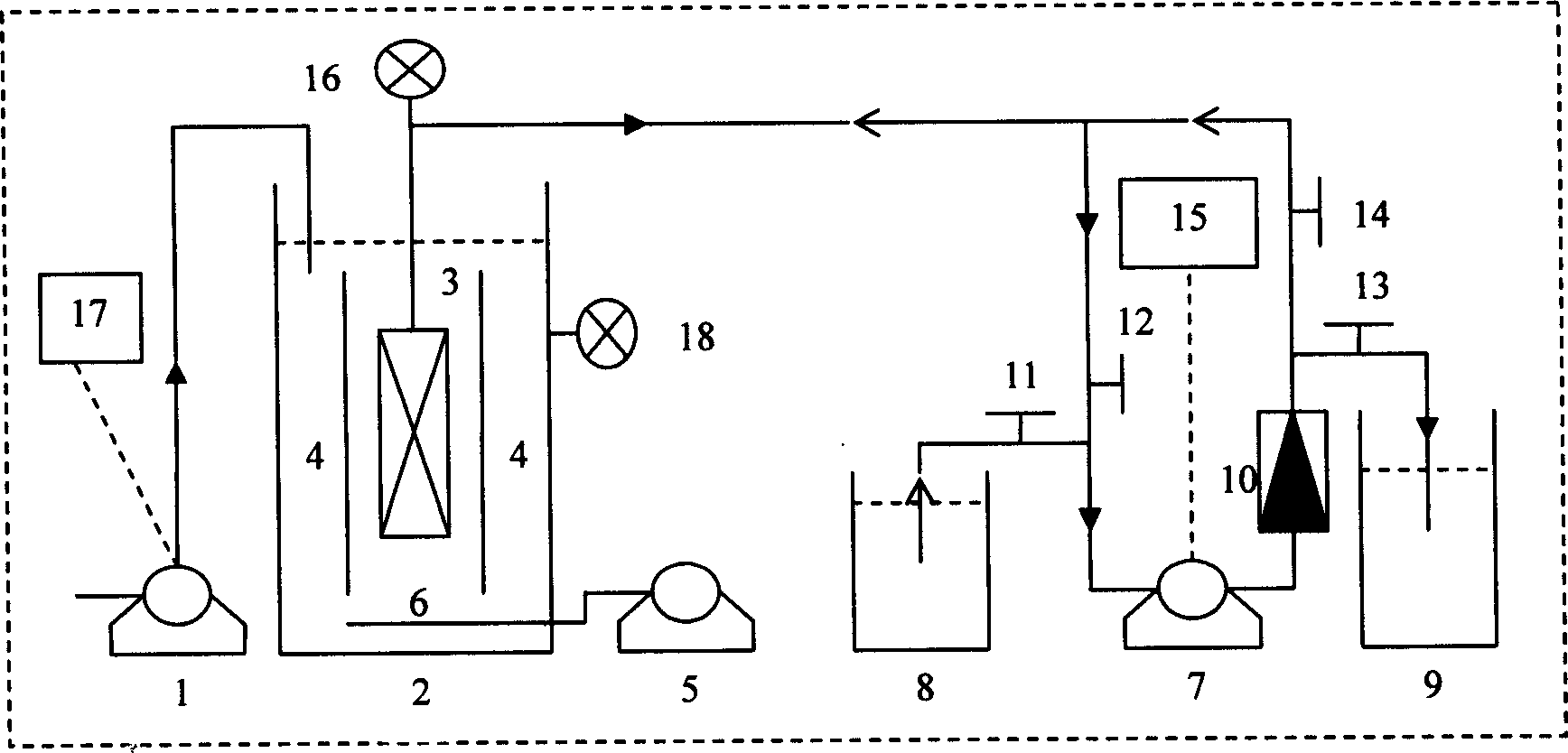

Immersion type hollow fiber membrane separator and its running process

ActiveCN101125281AReduce energy consumptionExtended service lifeSemi-permeable membranesCyclic processFiber

The present invention relates to an immersion hollow fibrous membrane separating device and the operation method thereof. The device comprises a membrane filtration system, a water producing system and a cleaning system which are connected by the tubes and a control system which is connected by a circuit, the present invention is characterized in that the membrane filtration system takes an immersion type, adopting a column external pressure hollow fibrous membrane component, a plurality of holes are arranged at the casing, the device is directly and vertically arranged in the processed water body; the water producing system comprises a pressure gauge, an automatic intake valve, a water producing pump, a flow meter and an automatic discharge valve which are sequentially connected with a water producing opening of the membrane module; the cleaning system comprises a backflushing system, a gas vacuole scrubbing system and a chemical cleaning system, the gas vacuole scrubbing system comprises a flow meter, an air inlet valve, an air adjusting valve, a filtrating pressure reducing valve, an air receiver and an air compressed valve which are sequentially connected with the backflushing air intake of the membrane module. The operation method includes a plurality of cyclic processes as follows: 1. an operating state, a backflushing state, a gas vacuole scrubbing state and a pollution discharge state; 2. the operating state, the backflushing and gas vacuole scrubbing state, an gas vacuole scrubbing state and the pollution discharge state; 3. the operating state, a chemical backflushing state, the gas vacuole scrubbing state and the pollution discharge state.

Owner:TIANJIN MOTIMO MEMBRANE TECH

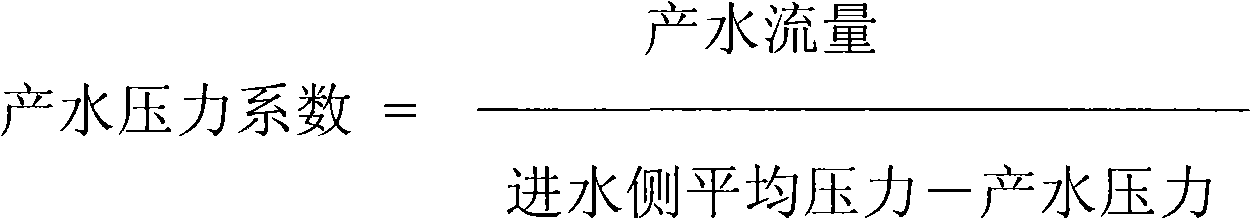

Method for cleaning ultrafiltration membrane

ActiveCN102397752AEliminate pollutionRestore performanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisInlet pressureSewage

The invention provides a method for cleaning an ultrafiltration membrane, which comprises a physical cleaning method and a chemical cleaning method. The physical cleaning method comprises a process of air scrubbing of ultrafiltration membrane components and a process of backwashing of the ultrafiltration membrane components. The process of air scrubbing of the ultrafiltration membrane comprises the following steps: ultrafiltration membrane components discharges concentrated water when compressed air is introduced, wherein the air inlet pressure of the ultrafiltration membrane components is less than 2.5 bar and more than 1.5 bar, compressed air is introduced for 1 minute, sewage in the ultrafiltration membrane components is exhausted after air scrubbing is completed, backwashing for once is carried out according to the backwashing process of the ultrafiltration membrane components. The chemical cleaning method comprises the following steps: carrying out forward cleaning circulation ofthe ultrafiltration membrane components; preparing an alkaline cleaner, carrying out forward cleaning circulation of the ultrafiltration membrane components; immersing the ultrafiltration membrane components. The method for cleaning the ultrafiltration membrane is capable of eliminating the pollution of the ultrafiltration membrane components, recovering the performance of the ultrafiltration membrane components, ensuring the normal operation of the ultrafiltration membrane components and prolonging the usage life of the ultrafiltration membrane components as long as possible.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

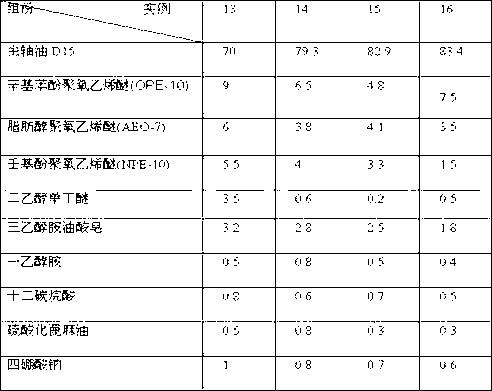

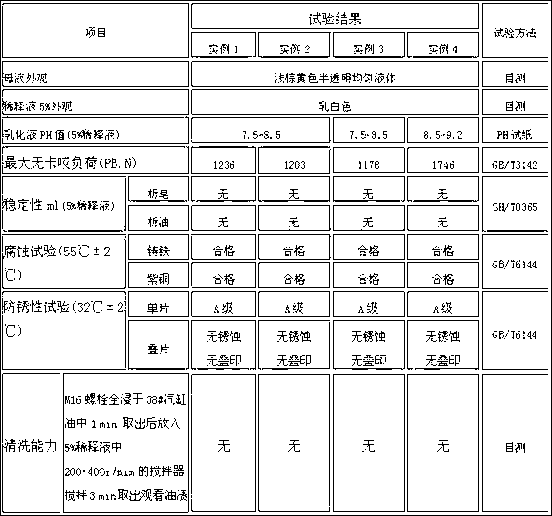

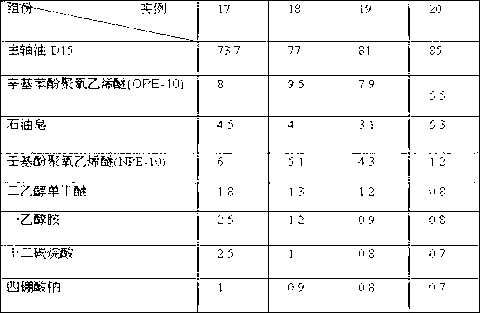

Wear-resistant lubricating cleaning solution for cotton picker picking ingot and preparation method thereof

InactiveCN103320203AImprove wear resistanceExtended service lifeSurface-active non-soap compounds and soap mixture detergentsLubricant compositionPreservativeWear resistant

The invention relates to a chemical cleaning solution formula and a preparation method thereof, and in particular relates to a wear-resistant lubricating cleaning solution for a cotton picker picking ingot and a preparation method thereof. The wear-resistant lubricating cleaning solution of the cotton picker picking ingot comprises the following raw material components by weight percent: 70 to 85 percent of main shaft oil, 8 to 15 percent of a composite emulsifier, 2 to 8 percent of a solubilizer, 1.5 to 5 percent of a corrosion inhibitor and 0.5 to 1 percent of a preservative. The preparation method of the wear-resistant lubricating cleaning solution for the cotton picker picking ingot comprises the following steps of: respectively adding emulsifier formula components into a container to obtain the composite emulsifier; respectively adding solubilizer formula components, stirring the solubilizer formula components until to be transparent; adding corrosion inhibitor formula components to be stirred and dissolved; finally adding the main shaft oil, and heating and stirring the mixture to obtain the cleaning solution. The cleaning solution has excellent wear-resistant, lubricating, cleaning, cooling and antirust comprehensive performances, and the method is simple and convenient to operate and economical and practical.

Owner:新疆三赢农业科技发展有限公司

Chemical cleaning method of ultrafiltration membrane

The invention discloses an ultrafiltration membrane chemical cleaning method and aims at an ultrafiltration membrane that is used for processing purified PTA waste water. The invention uses an acid lotion prepared by citric acid and sodium bisulfite for dissolving and eluting inorganic pollutants that are formed by cobalt and manganese ion hydroxide, deposited and absorbed on the surface of the ultrafiltration membrane, and uses an alkaline oxidative lotion that contains sodium hypochlorite for dissolving and eluting organic colloid pollutants that are deposited and absorbed on the surface of the ultrafiltration membrane. The ultrafiltration membrane chemical cleaning method can effectively elute the pollutants, recover the running flux and running pressure of the ultrafiltration membrane, and ensure stable running of the purified PTA waste water in an ultrafiltration process.

Owner:CHINA PETROLEUM & CHEM CORP +1

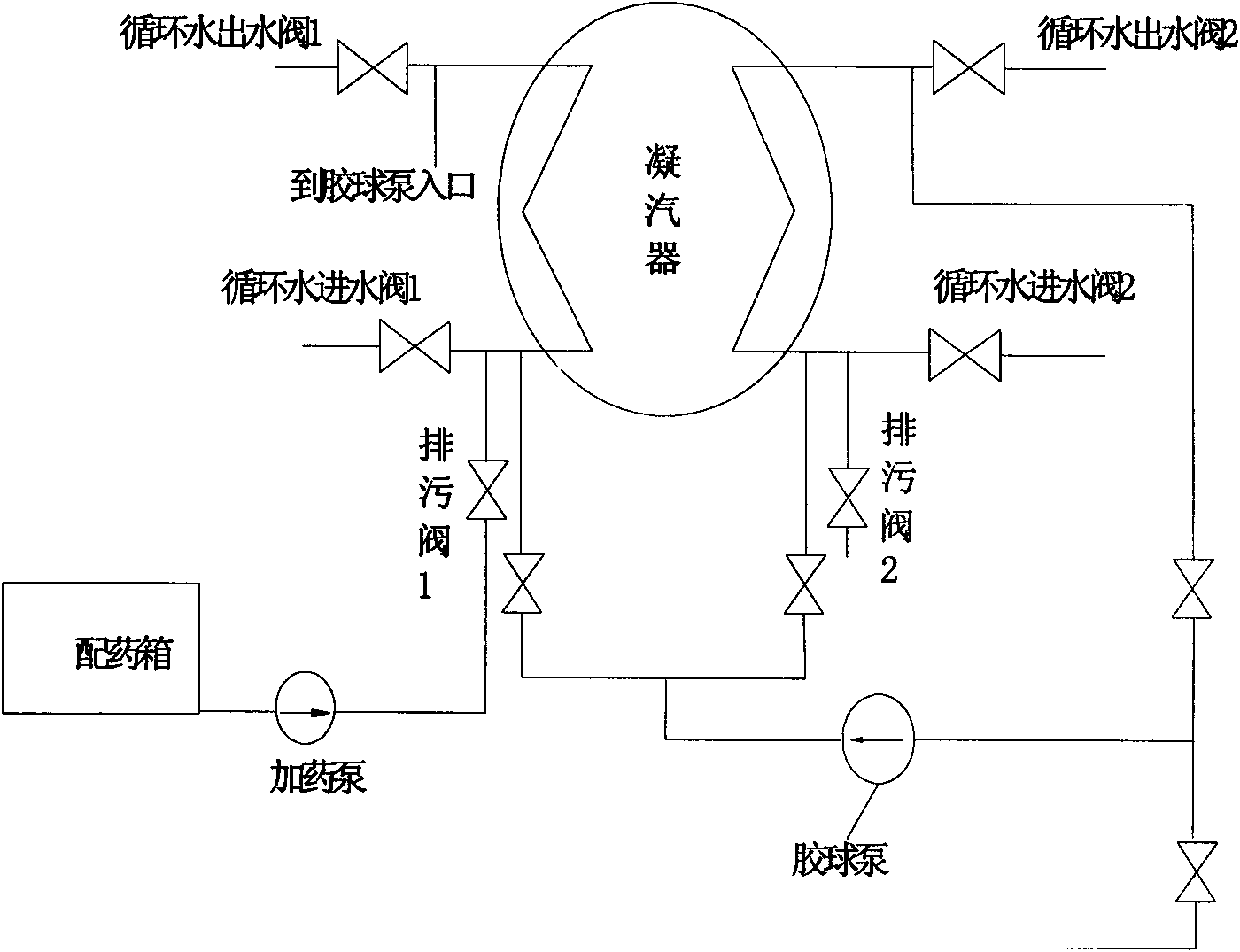

Method for cleaning copper tubes of condenser

A method for cleaning copper tubes of a condenser relates to the cleaning of heat transfer pipelines. The method comprises the following steps: the first step, closing an inlet valve and an outlet valve of circulating water after a turbine condenser is shut down; the second step, flushing the copper tubes of the condenser with clean water; the third step, injecting acid chemical cleaning liquor at water side of the condenser for soak cleaning; the fourth step, neutralizing soak solution with sodium hydroxide; the fifth step, flushing the copper tubes of the condenser with clean water; the sixth step, rinsing the copper tubes of the condenser with clean water; and the seventh step, replacing membrane, and commissioning after cleaning. Compared with the original method of cleaning with chemical agents to be added to a circulating water tank, the method is characterized in that chemical cleaning liquor is added to a single turbine condenser, which can help clean fouling off the copper tubes and improve vacuum degree of the turbine while ensuring no corrosion of the copper tubes, and has the advantages of low agent consumption, low cost, low corrosion rate, good cleaning effect and saving cleaning time. The method can be widely applied to cleaning and maintenance of the copper tubes of the condensers in power plants.

Owner:WENGFU (GRP) CO LTD

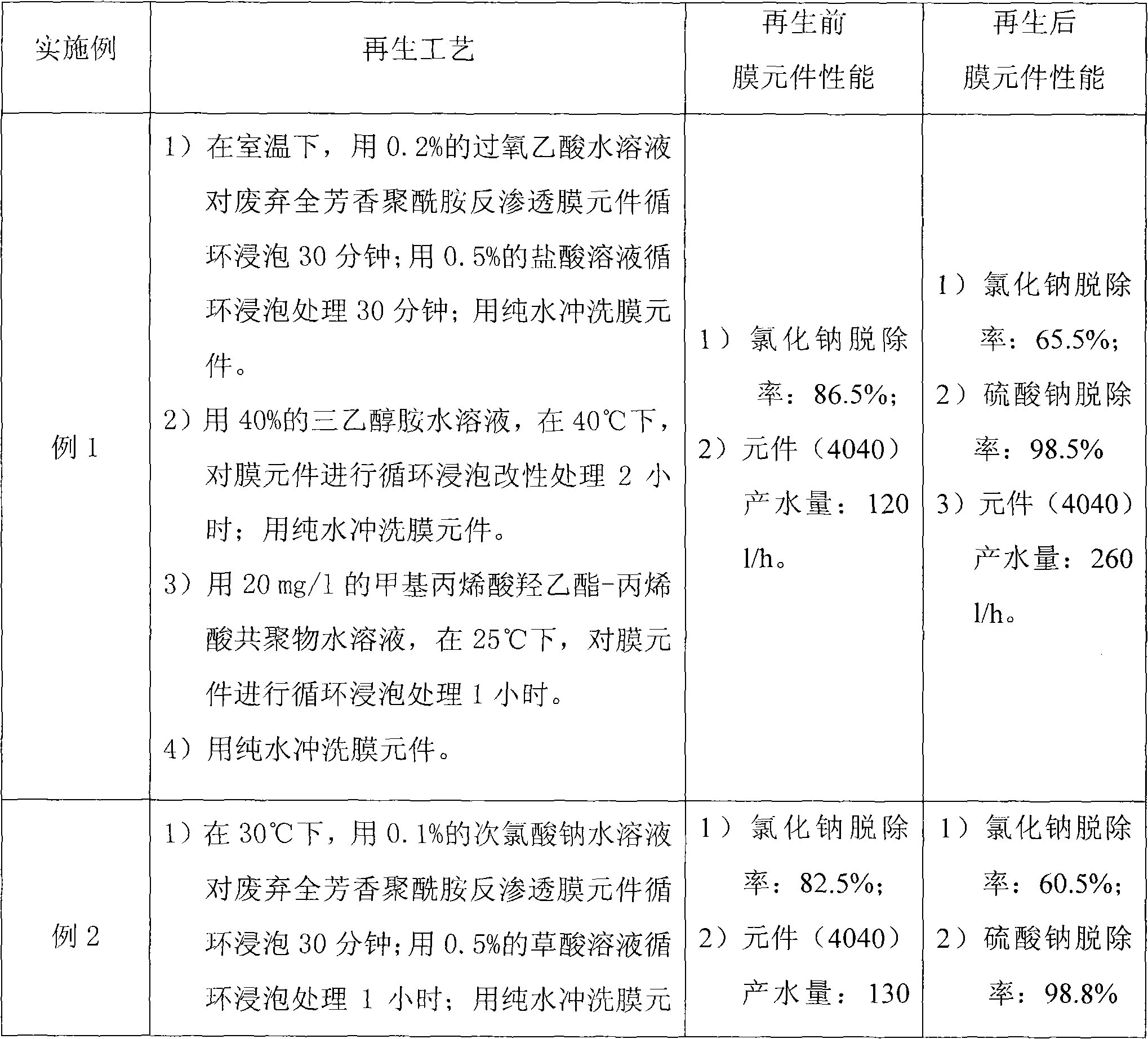

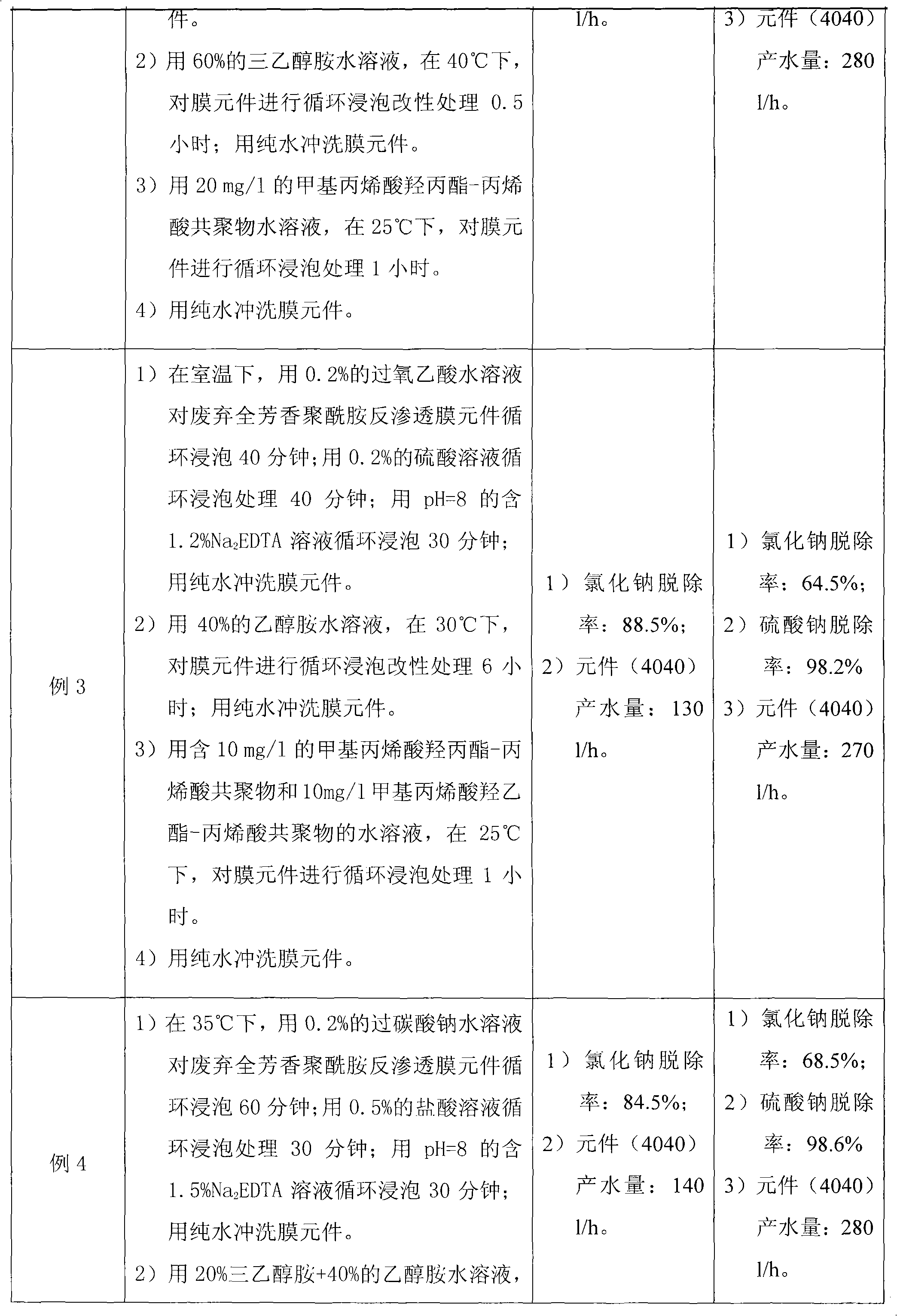

Nanofiltration reproduction method of waste reverse osmosis membrane element

InactiveCN102059056ARealize resource utilizationOpen up manufacturing channelsSemi-permeable membranesResource utilizationReverse osmosis

The invention relates to a reproduction method of a waste reverse osmosis membrane element, in particular to a nanofiltration reproduction method of the waste reverse osmosis membrane element. The nanofiltration reproduction method of the waste reverse osmosis membrane element is characterized by enabling a waste reverse osmosis membrane to have certain special functions of a nanofiltration membrane by carrying out soaking modification processing of an amine-containing solution on the surface of the waste reverse osmosis membrane and carrying out further performance regulation processing on the modified reverse osmosis membrane element by adopting a polymer membrane performance regulator on the basis of carrying out conventional chemical cleaning on the waste reverse osmosis membrane, thereby realizing the nanofiltration reproduction of the waste reverse osmosis membrane element. The invention can effectively realize the resource utilization of the waste reverse osmosis membrane element, develops a new manufacturing way of the nanofiltration membrane and has simpler reproduction process; and in addition, the nanofiltration reproduction method of the waste reverse osmosis membrane element has extensive applications.

Owner:ZHEJIANG SCI-TECH UNIV

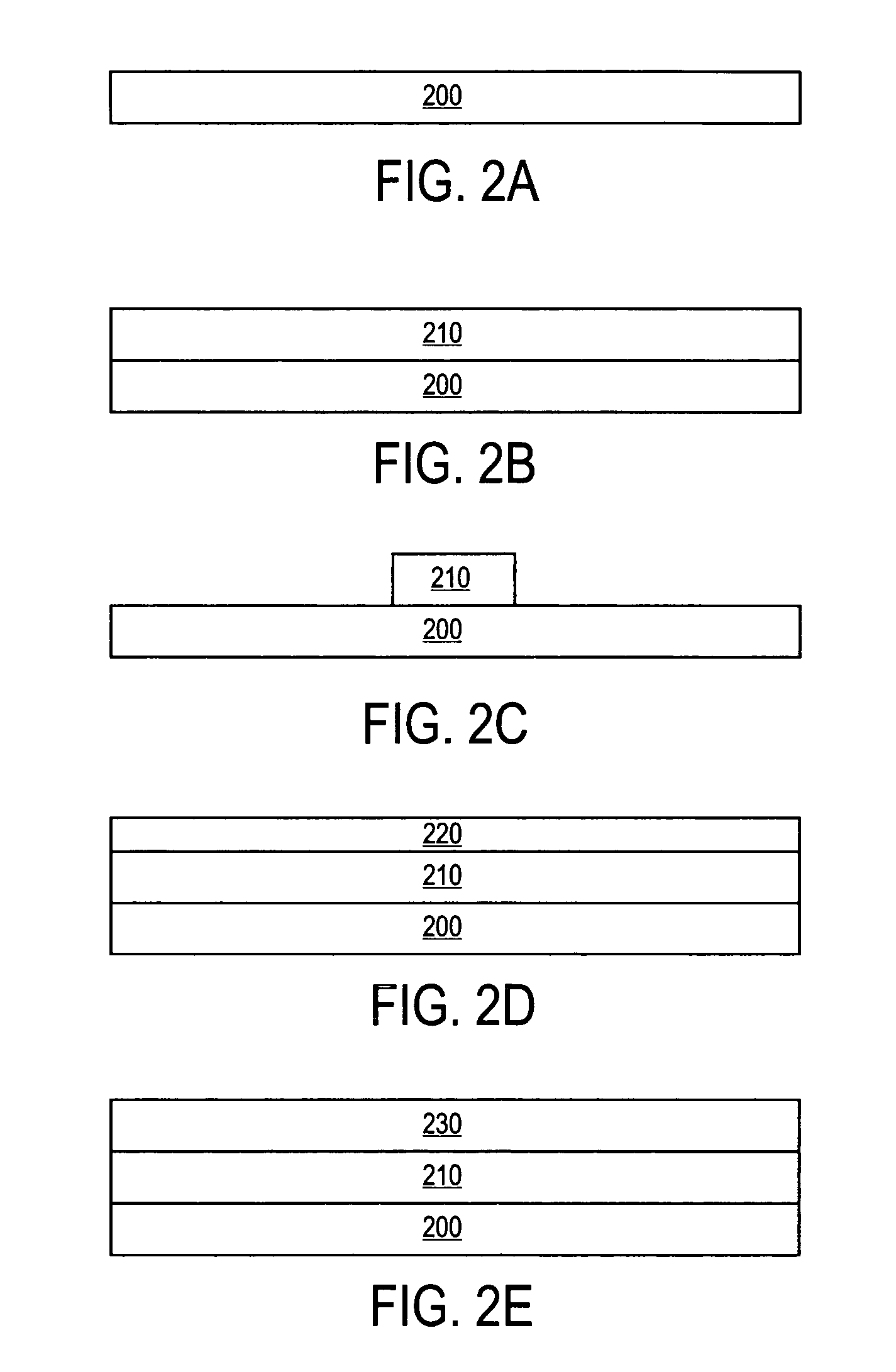

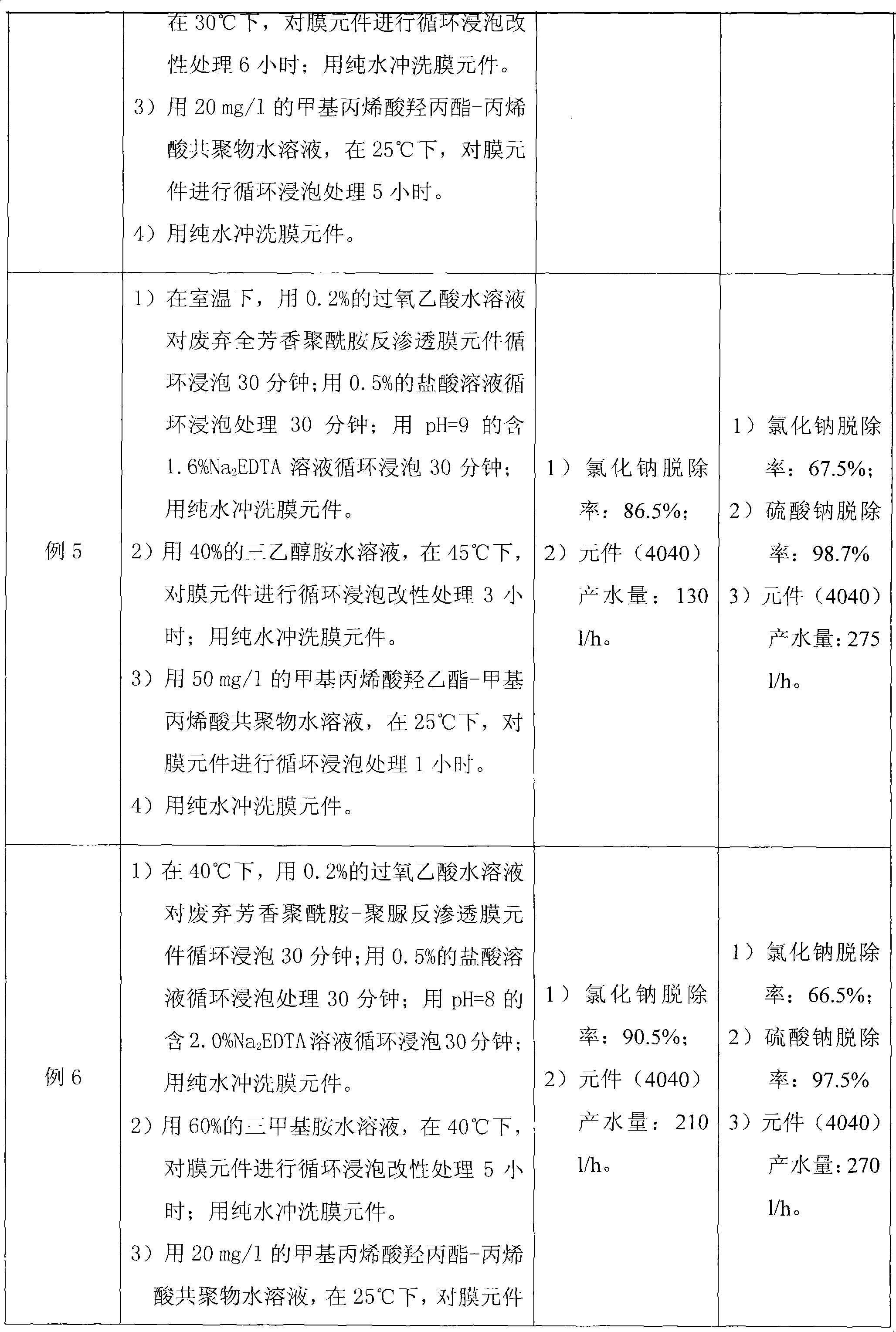

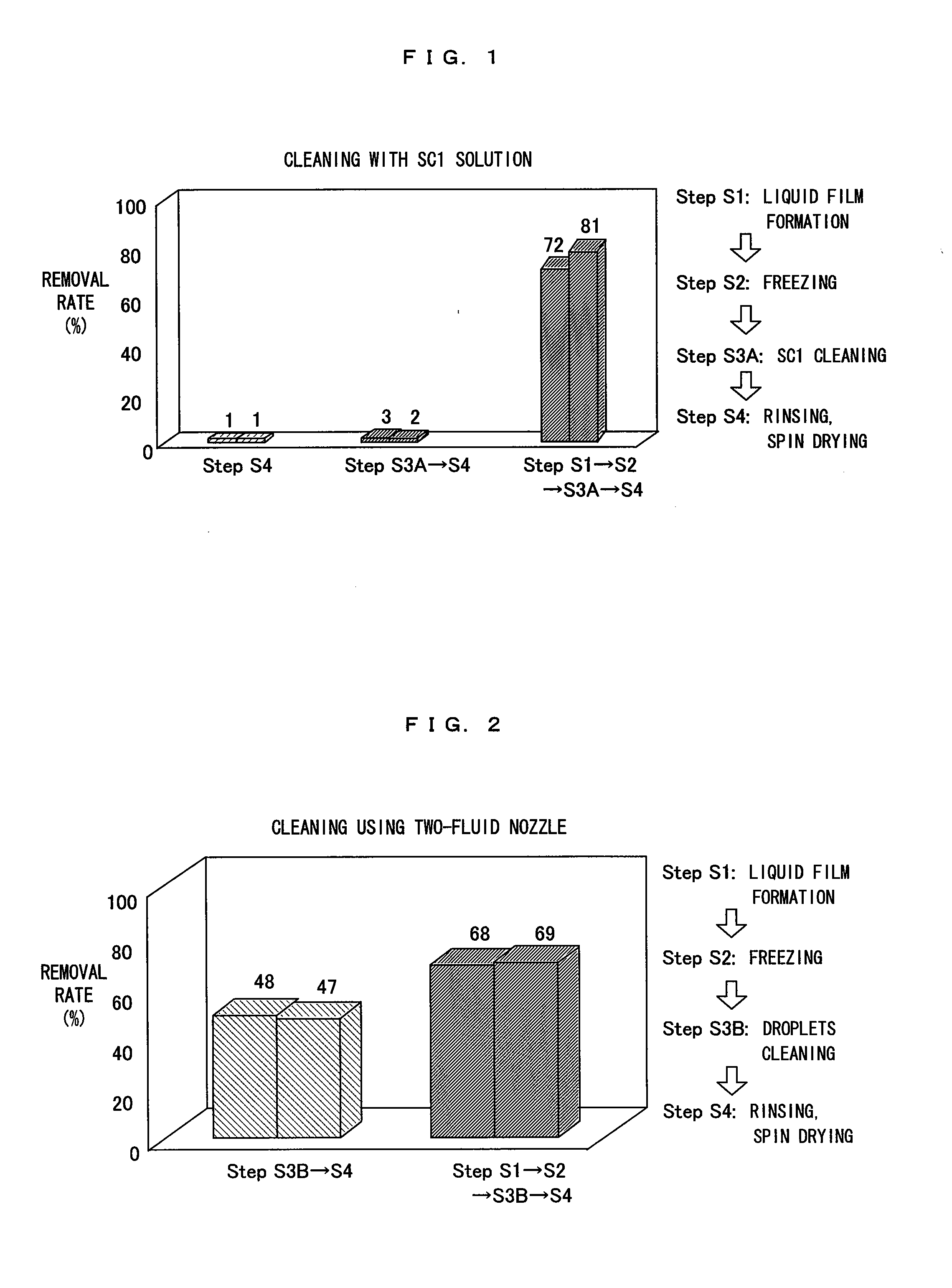

Substrate processing method and substrate processing apparatus

InactiveUS20070235062A1Eliminate processingSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentPre treatmentSubstrate surface

A substrate on the surface of which the liquid film is formed in a cleaning unit is transported to a freezing unit by a substrate transporting mechanism. The liquid film is frozen in the freezing unit and the volume of the liquid film increases. Accordingly, adhesive forces between the substrate and the particles are reduced and the particles even come to separate from the substrate surface. Then the substrate which has been processed freezing is transported from the freezing unit to the cleaning unit again by the substrate transporting mechanism. In the cleaning unit, a physical and / or chemical cleaning is executed to the substrate, and the frozen film is removed from the substrate surface. Thus, the liquid film formation and the freezing of the liquid film is performed as a preprocessing of the physical and / or chemical cleaning in this way, whereby the particles are removed from the substrate surface efficiently.

Owner:DAINIPPON SCREEN MTG CO LTD

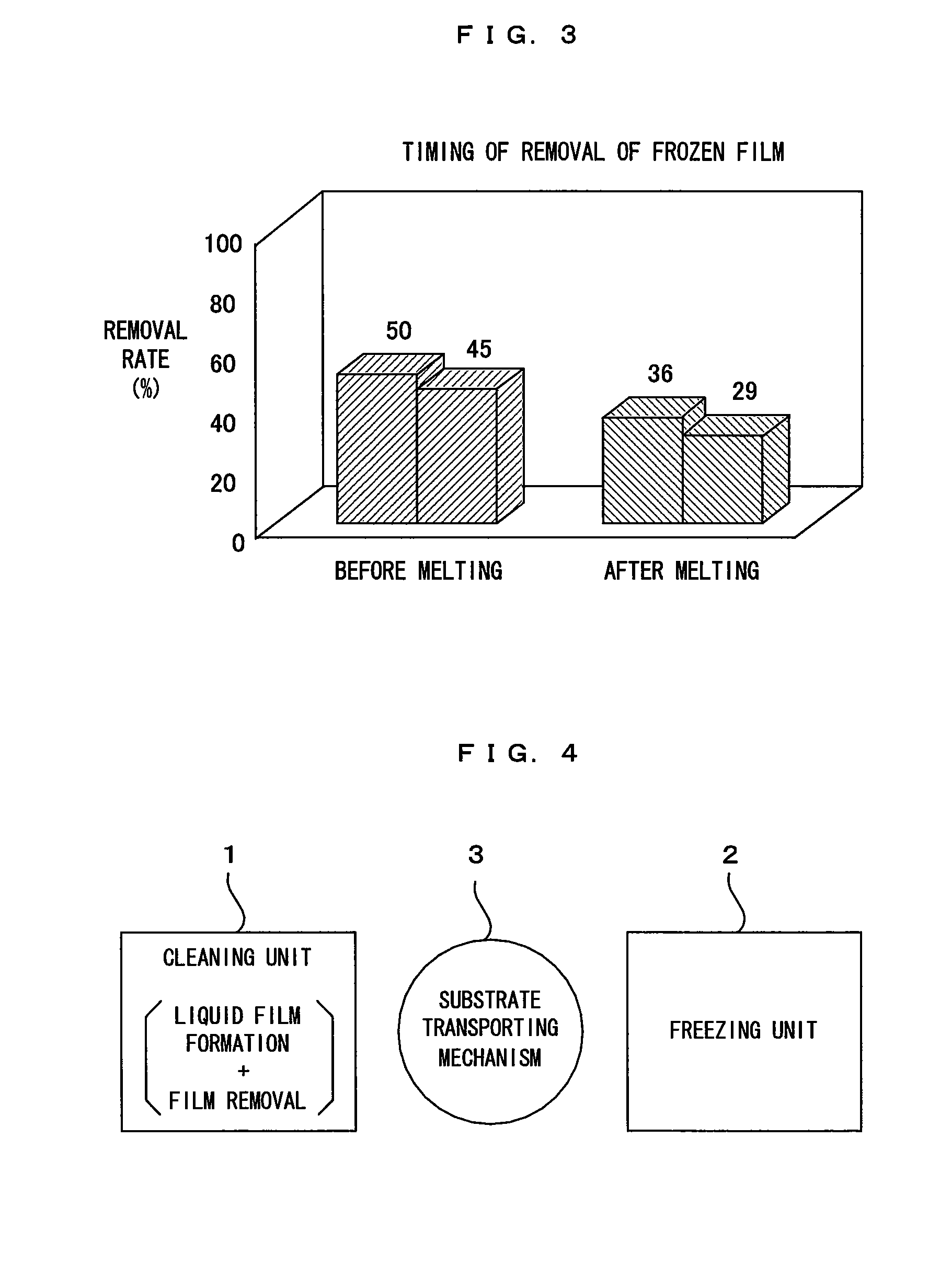

Chemical cleaning method of ultrafiltration membrane

ActiveCN107398185AHigh removal rateIncrease permeate fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisTemperature controlUltrafiltration

The invention discloses a chemical cleaning method of an ultrafiltration membrane. The chemical cleaning method is mainly used for treating the membrane pollution form of inorganic scale coating with organic scales, and comprises the following steps of (1) preparing a basic cleaning solution; (2) performing alkali washing: performing cyclic cleaning on the ultrafiltration membrane by the basic cleaning solution; controlling the pH value of the cleaning solution to be 10.5 to 11.5; controlling the cleaning temperature at 38 to 41 DEG C; (3) performing primary flushing; removing basic cleaning liquid remained in the ultrafiltration membrane; (4) preparing an acid cleaning solution; (5) performing acid washing: performing cyclic cleaning on the ultrafiltration membrane by the acid cleaning solution; controlling the pH value of the cleaning solution to be 1.5 to 3; controlling the cleaning temperature at 38 to 41 DEG C; (6) performing secondary flushing to remove the acid cleaning solution remained in the ultrafiltration membrane. The method provided by the invention has the advantages that various organic matters intercepted on holes of the ultrafiltration membrane can be effectively removed; the water production flow rate of the ultrafiltration membrane can be improved; the operation pressure of the ultrafiltration membrane can be reduced; the stable operation of a landfill leachate ultrafiltration membrane treatment system is ensured.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

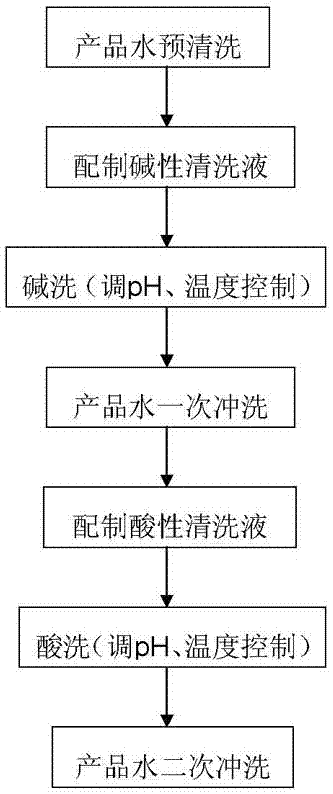

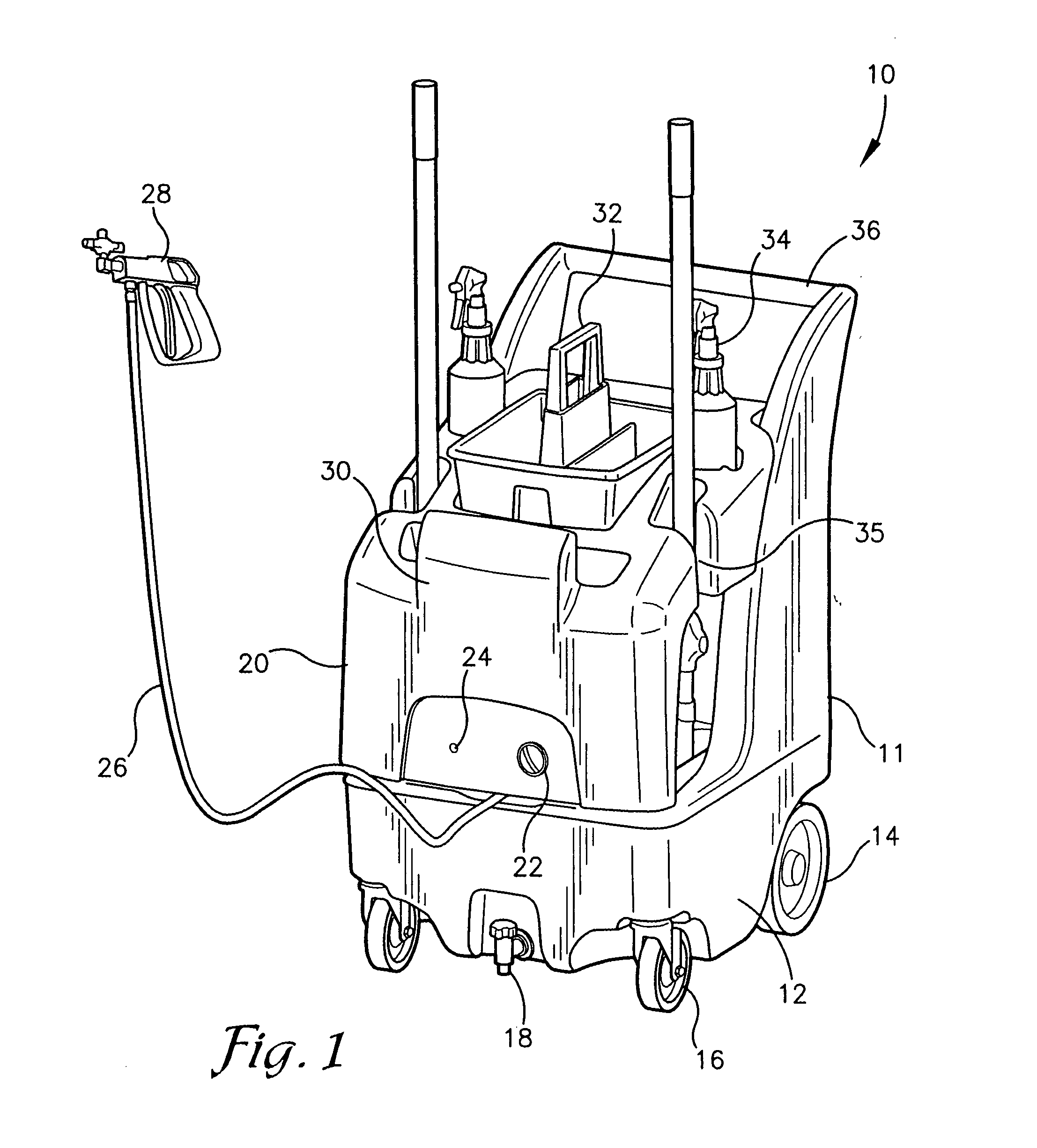

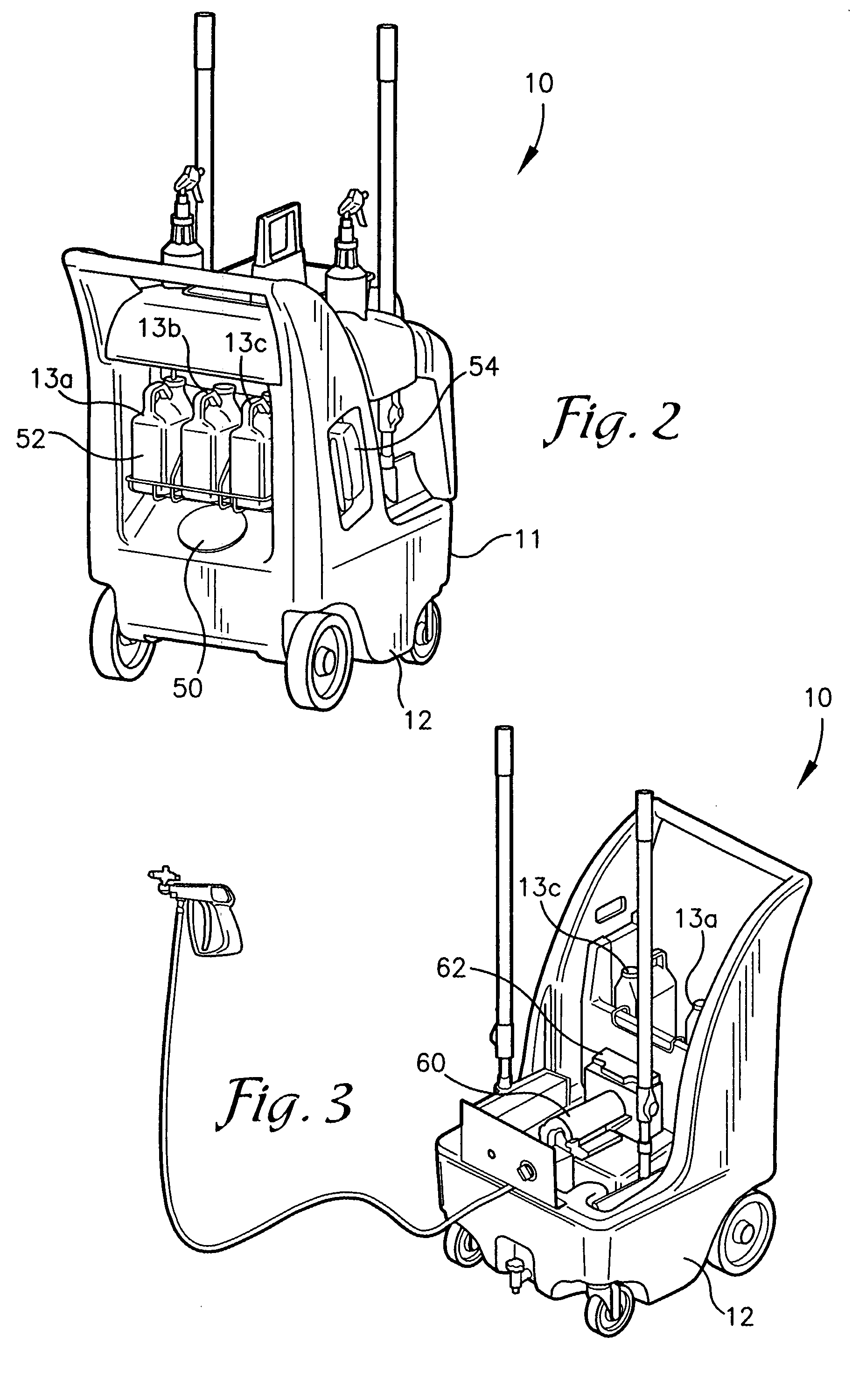

Janitorial handcart with chemical application apparatus

InactiveUS20070187528A1Improve cleaning efficiencyReduce wasteWatering devicesFertiliser distributersChemical solutionChemical cleaning

A wheeled handcart is provided having a rechargeable, battery-powered, low pressure pump and spray apparatus for applying chemical cleaning solutions to sanitize commercial restroom facilitates and for filling hand applicators with diluted chemical solutions.

Owner:ROTH BLAKE H +8

Water curing reverse osmosis membrane chemical cleaning method

InactiveCN101224391AExtended service lifeEasy to cleanReverse osmosisCalcium bicarbonateReverse osmosis

The invention relates to a chemical cleaning method used for a water disposal reverse osmosis membrane, relating to a chemical cleaning method used for cleaning water disposal reverse osmosis membranes in the industrial water disposal process. The invention is characterized in that NaOH solution which contains EDTA is adopted to clean microorganism, organism and silicon dioxide, etc. pollutants on the reverse osmosis membrane; HCI solution is adopted to clean calcium bicarbonate and magnesium bicarbonate filth on the reverse osmosis membrane. By adopting the method of the invention, the reverse osmosis membrane used by captive power plant water disposal can be effectively cleaned in the alumina preparation process. The invention has better cleaning effect, reliable and practiced technique and convenient operation process.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for preparing low temperature solder sheets

ActiveCN107486651AImprove uniformityHigh strengthWelding/cutting media/materialsSoldering mediaLiquid stateMixed states

The invention discloses a method for preparing low temperature solder sheets. The method comprises the following steps: firstly, carrying out chemical cleaning on stains and oxide films on the surface of a foam metal skeleton; filling metal foam with low-melting point solder in an infiltration way; and finally heating the metal foam filled with the low-melting point solder to a solid-liquid mixed state and rolling to obtain composite sheets with certain thicknesses. According to the method disclosed by the invention; the foam metal-reinforced solder is rolled in the solid-liquid mixed state, so that the problems that the foam metal skeleton is stretched to form a thin strip-type fiber structure and is fractured during normal temperature rolling are effectively solved; meanwhile, during rolling in the solid-liquid mixed state, low-melting point metal which is in a liquid state is good in fluidity and can be uniformly filled in the foam metal skeleton, so that the mass percentage of the foam metal skeleton can be increased, the porosity of the foam metal is reduced and the uniformity and the strength of the foam metal-reinforced low melting point solder are increased.

Owner:CHINA NAT ELECTRIC APP RES INST

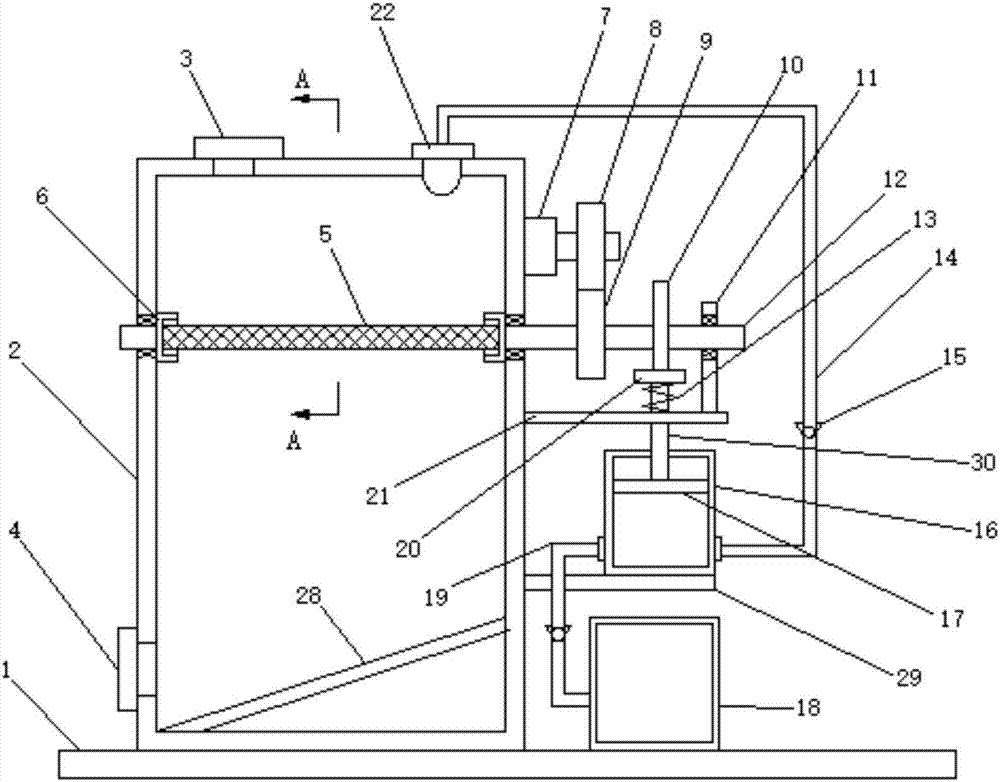

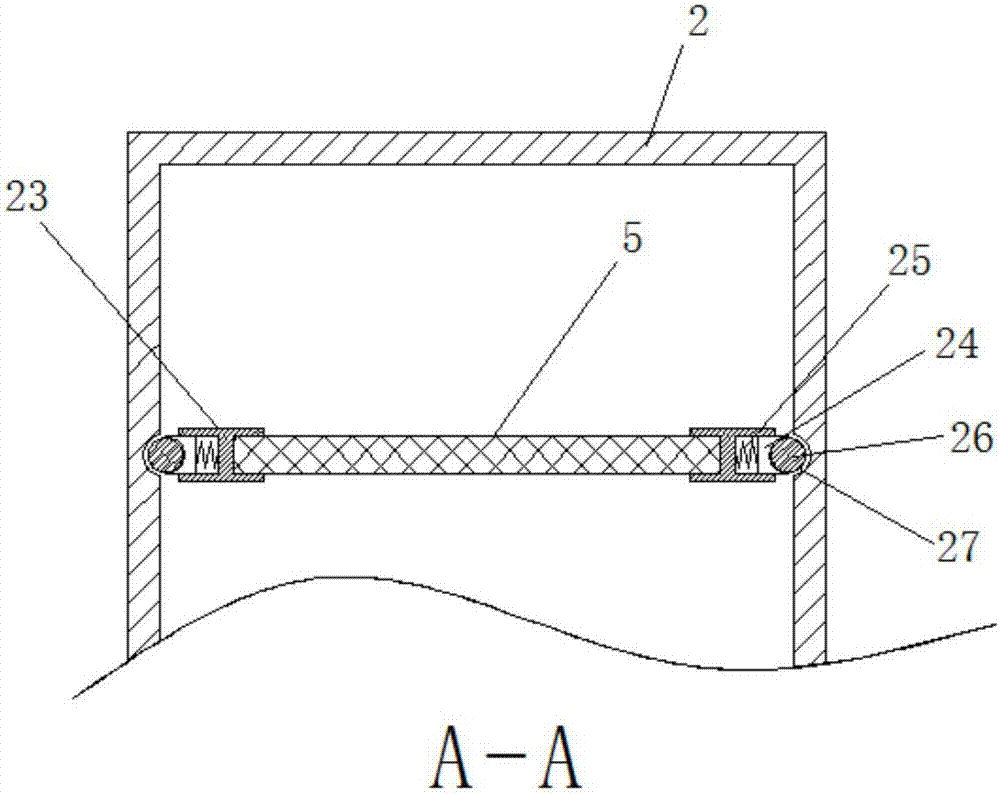

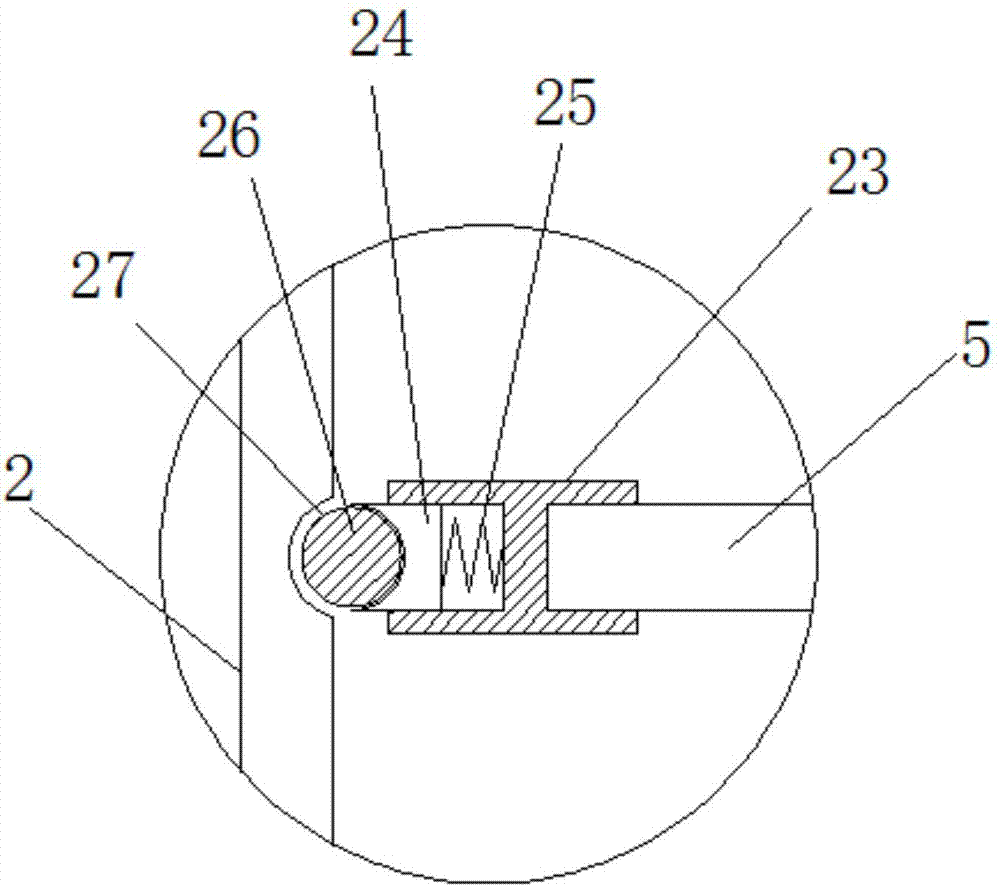

Chemical raw material filtering device capable of cleaning filter plate

InactiveCN106984082AImprove cleaning efficiencyThe effect has no effectStationary filtering element filtersTransverse planeHorizontal axis

The invention discloses a filter device for chemical raw materials capable of cleaning the filter plate, which comprises a bottom plate and a filter box. The filter box is provided with a filter plate, and two of the opposite side walls of the filter plate are provided with card slots. The back side of each of the draw-in slots is provided with a horizontal shaft, the side wall of the filter box is provided with a support plate and a horizontal plate, the horizontal shaft is provided with a cam, and the horizontal plate is provided with a cylinder body, and A piston is arranged in the cylinder body, and a push rod is arranged at the upper end of the piston, and a baffle is arranged at the top end of the push rod, and the lower end of the baffle is connected with the support plate through a spring, and the bottom end of the cylinder body is passed through the first liquid guide The pipe is connected with the spray head arranged on the top of the filter box, and the bottom end of the cylinder body is connected with the water storage tank arranged on the base through the second liquid guide pipe. The invention has the advantages of simple structure, high cleaning efficiency, better cleaning effect, no need for manual operation, reduced labor intensity, simple and convenient operation, and strong practicability.

Owner:合肥九州龙腾科技成果转化有限公司

Chemical cleaning method of reverse osmosis membrane

ActiveCN101721916AEffective elutionThe process is continuous and stableSemi-permeable membranesGeneral water supply conservationReverse osmosisChemical cleaning

The invention relates to a chemical cleaning method of a reverse osmosis membrane. In the method, aiming at a reverse osmosis membrane for processing PTA refining wastewater, inorganic pollutants which are formed by cobalt ions, manganese ions, hydroxide thereof and the like and are deposited and adsorbed on the surface of the membrane are dissolved and eluted by using acid rinse prepared by citric acid and sodium bisulfite; organic colloid pollutants deposited and adsorbed on the surface of the membrane are dissolved and eluted by using alkaline rinse containing sodium dodecyl benzene sulfonate and sodium hydroxide. The method can elute the pollutants on the surface effectively, restore operating flux, operating pressure and desalination rate of the reverse osmosis membrane, and ensure that the process of processing the reverse osmosis membrane for the PTA refining wastewater is stable in operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

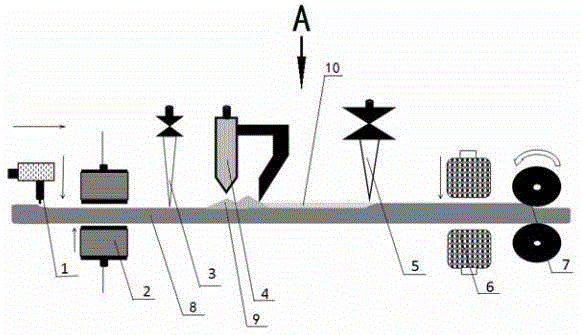

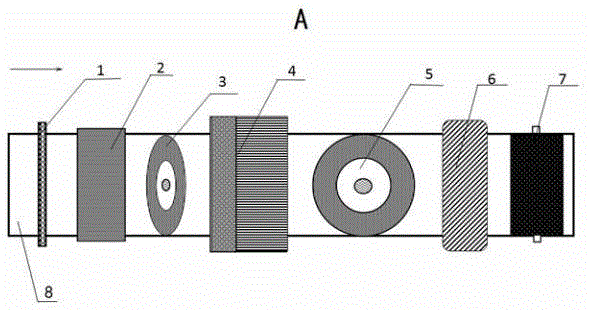

Direct forming manufacturing method of metal-based multilayer/gradient composite board and process unit of direct forming manufacturing method

ActiveCN105643215AHigh bonding strengthEliminate surface stressRoll force/gap control deviceMetal rolling arrangementsHigh energyBound property

The invention discloses a direct forming manufacturing method of a metal-based multilayer / gradient composite board and a process unit of the direct forming manufacturing method. Scale, corrosion materials and other impurities on the joint surface of a base board are removed through chemical cleaning, the cleaned surface is subjected to gradient power electromagnetic induction heating or laser bombardment surface treatment, all phases near the joint surface are fully dissolved, a solid solution is enhanced, toughness and corrosion resistance are improved, the surface stress of the board is eliminated, and surface laser treatment is conducted to improve the binding property of a composite layer; raw materials of the composite layer are added and injected through powder laying, a high-energy heat source is adopted for irradiation or induction heating to melt powder, metallurgical bonding is formed between the composite layer and a base, and control over the final shape of a cold / hot-rolled board is conducted. The obtained multilayer / gradient composite board is compact in surface structure, bonding between the composite layer and the base and between layers is good, and the interlayer bonding performance of the composite board is remarkably improved. The process is high in flexibility, and the production period of the metal-based composite board can be greatly shortened after the process is combined with an existing continuous casting technology.

Owner:SHANGHAI UNIV

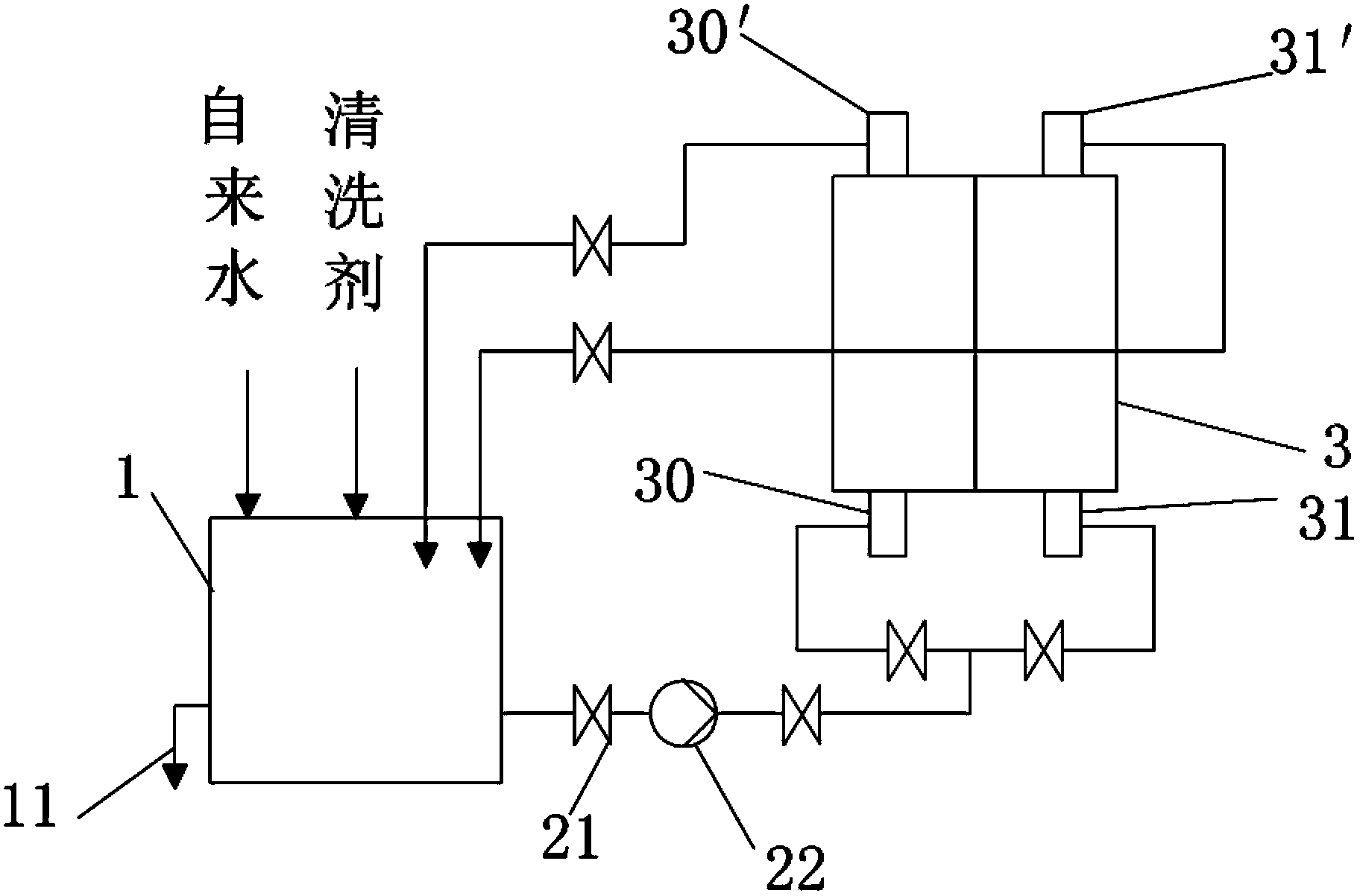

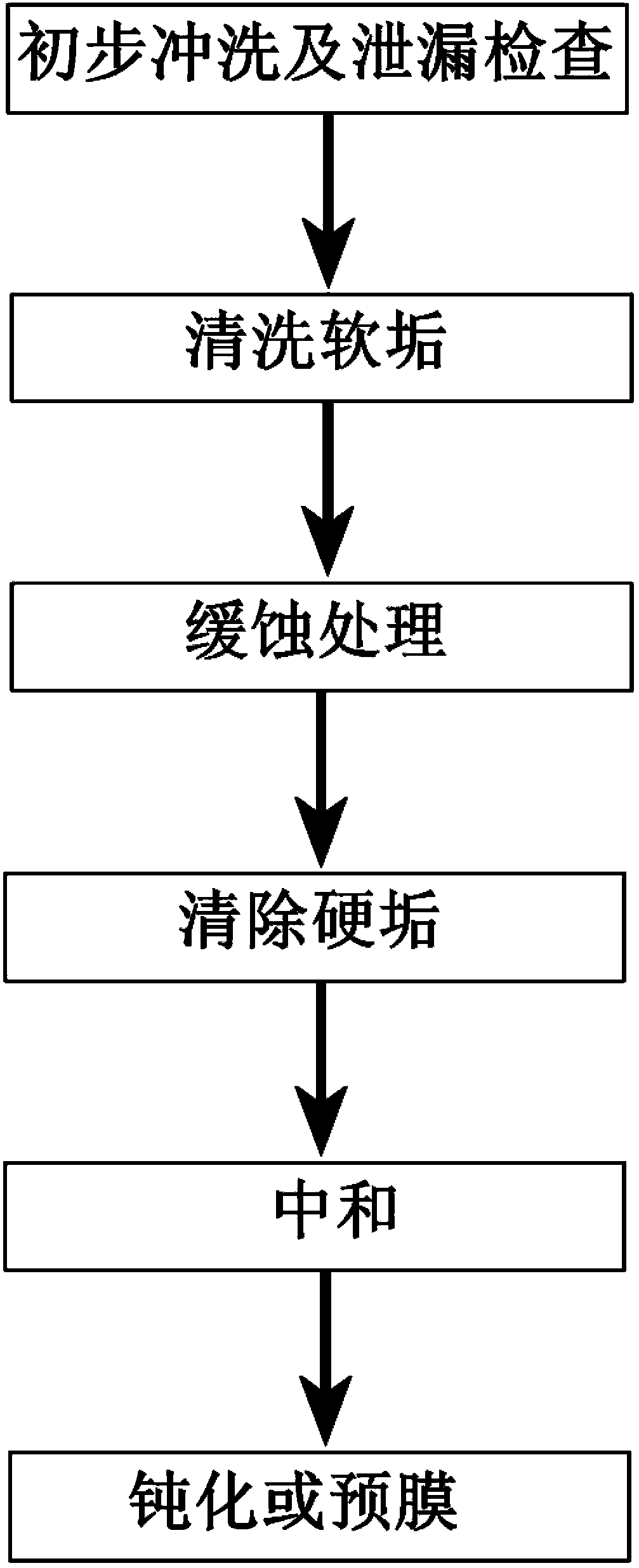

Low-corrosion and high-cleanness chemical cleaning method for condenser

The invention discloses a low-corrosion and high-cleanness chemical cleaning method for condenser. The cleaning process of the method is shown as follows: performing primary washing and leakage detection, adding a disinfectant slime remover for cleaning soft deposits, adding a Lan-826 multipurpose pickling inhibitor and a reducing agent to perform corrosion inhibition treatment, adding aGJ-2E rust removal and descaling agent and a Lan-826 multipurpose pickling inhibitor for removing hard scale, neutralizing with an alkaline cleaning neutralizer, and passivating or pre-filming. The method has the beneficial effects that the biological slime of the condenser is fully cleaned; the used corrosion inhibition method can be used for reducing the corrosion of the pickling cleaning agent to the pipeline of the condenser, and improving the service life of the pipeline of the condenser; meanwhile, the used pickling cleaning agent can be used for fully cleaning the pipeline hard scale, and the pipeline is cleaned more drastically; the cleaning time is short, the descaling efficiency is high, the labor intensity is low, the technology is simple, and the operation parameter of the cleaned set mainly achieves the plate rating.

Owner:HANGZHOU GUANJIE IND CLEANING WATER TREATMENT TECH

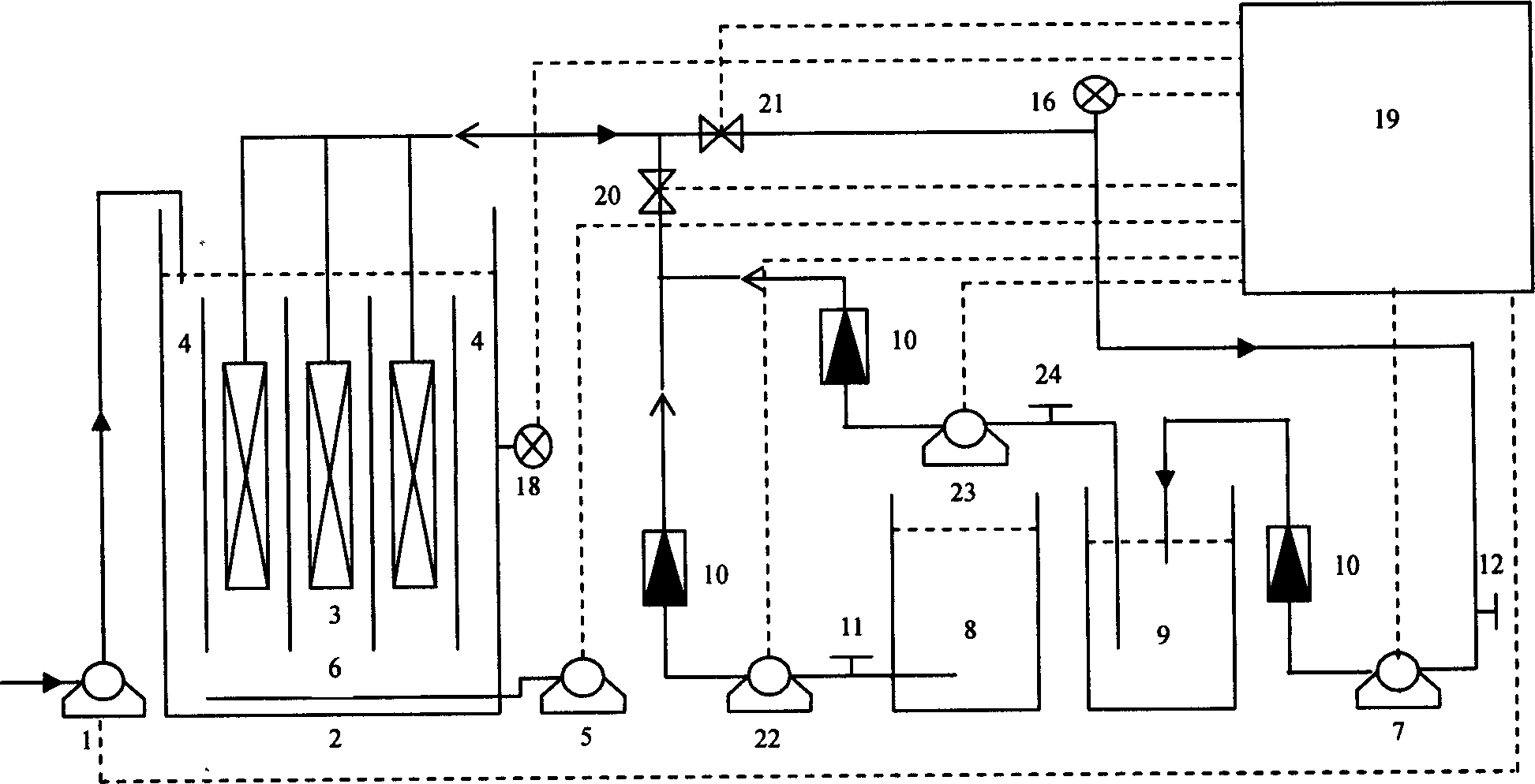

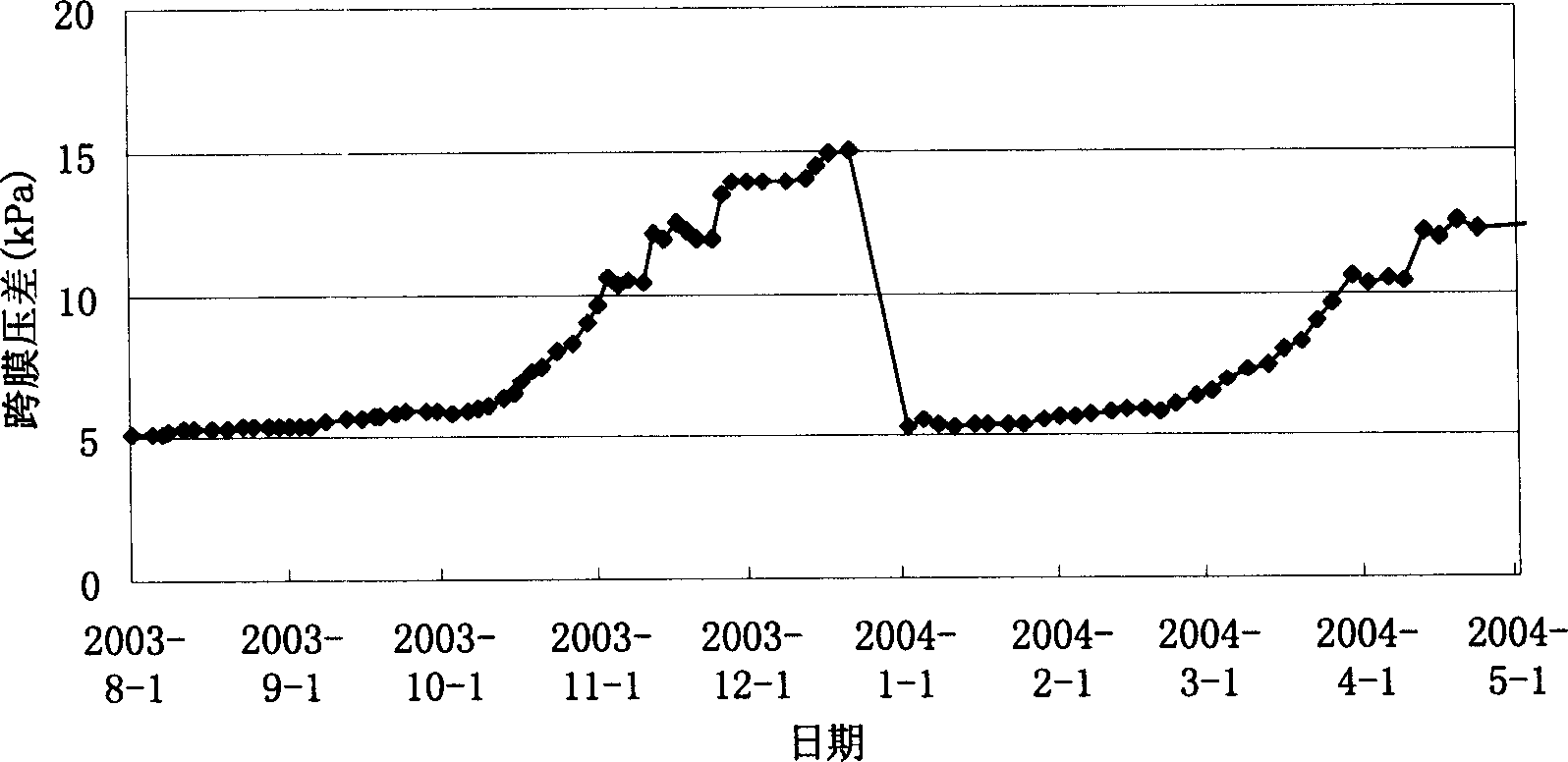

On-line chemical cleaning method for membrane bioreactor

InactiveCN1772355AExtended service lifeLow maintenanceSemi-permeable membranesBiological water/sewage treatmentAcid washingColloid

The present invention belongs to the field of water and waste water treating and purifying technology, and is one kind of on-line chemical cleaning method for controlling the membrane contamination of membrane bioreactor. The chemical cleaning method has alkali washing as the main part and acid washing as the auxiliary part, and for membrane bioreactors of different sizes, two different cleaning modes are recommended. The method can eliminate membrane pore jamming caused by macro molecular organic matter and colloid matter and gel contamination effectively to restore the filtering capacity of the membrane, and has simple operation and low maintenance cost. Applying the method can realize the long term stable operation of the membrane assembly, prolong the service life of membrane assembly and lower the maintenance cost of membrane assembly.

Owner:TSINGHUA UNIV

Pattern electroplating method for two-sided and multi-layer flexible printed circuit board

ActiveCN101119614ANo disconnection issuesLower impedanceConductive material chemical/electrolytical removalConductive pattern polishing/cleaningEngineeringHeight difference

The present invention discloses a figure plating method which in used in double face or multilevel printing line board and has the following steps in orders: baiting, mechanical hole boring, hole discoloring, dry film pressing, exposing, developing, line etching, dry film eliminating, chemical cleaning, dry film pressing again, exposing again, developing again, figure plating, dry film eliminating again, and chemical cleaning again. The present invention does line etching to the copper-clad plate and the etching liquid contacting; no height difference exists between a hole tray and the connected line; the figure plating is carried on after the line etching so that no hole tray and line disconnection happens. The present invention also makes the copper-clad plate after dry film pressing again and developing again contact with the plating liquid; the part which needs to be welded comprises a through hole, the hole tray surface and a plate edge connecting head copper-clad layer and the copper layer of the parts is thick relatively with low impedance so as to improve the welding capability; the flexure, namely the line figure surface, is not plated with copper-clad layer and the copper layer of the parts is thin relatively so as to improve the bending capability.

Owner:靖江市华信科技创业园有限公司

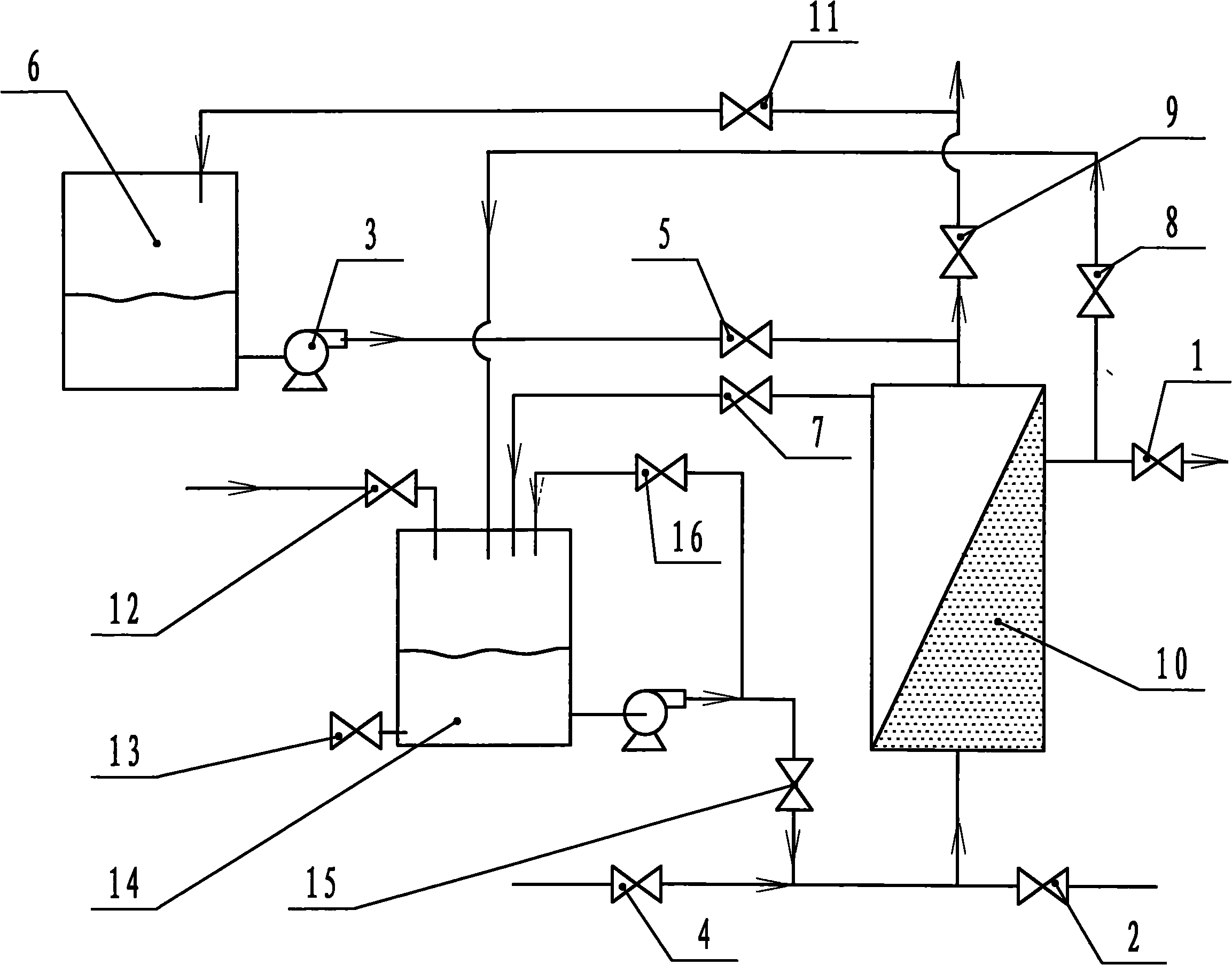

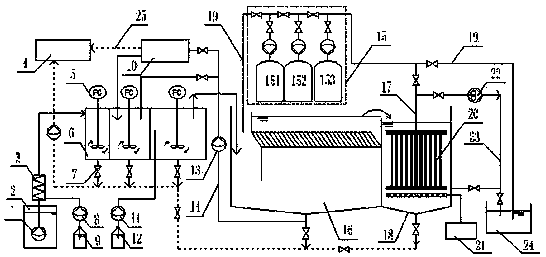

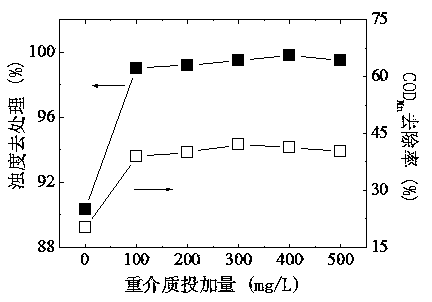

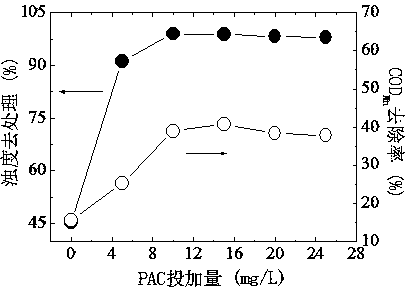

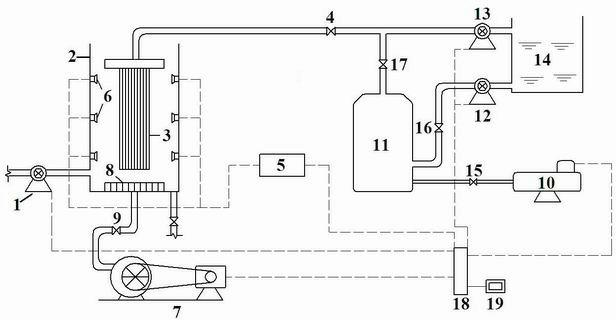

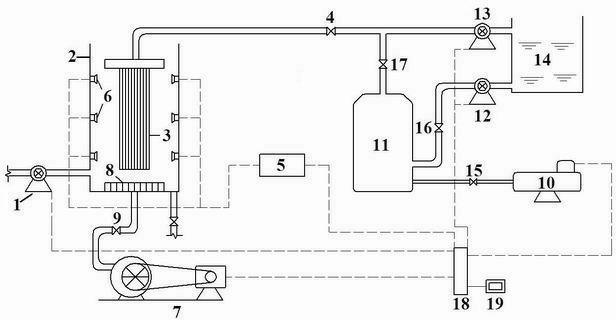

Efficient water treatment device and water treatment method

ActiveCN103739124AShort processReduce volumeWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSludgeSewage

The invention discloses an efficient water treatment device and a water treatment method. The efficient water treatment device is composed of an immersible pump, an original water pool, a pipeline mixer, a sludge pool, a stirring machine, a dense medium coagulation reaction pool, an empty pipe, a PAC (Poly Aluminium Chloride) dosing pump, a PAC storage tank, a dense medium recovery system, a PAM (Polyacrylamide) dosing pump, a PAM storage tank, a sludge pump, a sludge pipe, a disinfectant and chemical cleaning agent dosing device, a rapid settling pool, a water producing or chemical cleaning pipeline, a membrane pool, a disinfectant dosing pipeline, a ultrafiltration membrane module, an aerating system, a cam pump, a water producing or chemical cleaning internal-circulating pipeline, a clean water pool and a sewage draining pipeline. Original water enters the dense medium coagulation reaction pool and then enters the rapid settling pool, excess sludge in the bottom of the settling pool enters the dense medium recovery system, and recovered dense medium reenters a reactor to form circulation. Drained water of the rapid settling pool enters the membrane pool to be filtered and then enters the clean water pool to be disinfected. The efficient water treatment device has the characteristics of saving the used land area and civil engineering cost, good quality of drained water, stable and efficient operation and good economical efficiency, and the dense medium can be recycled.

Owner:PACIFIC WATER TREATMENT ENG

Combined ultra-filtration device with membrane pollution control and ultrasonic cleaning functions

ActiveCN102580545AReal-time controlAvoid stayingSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiltration membraneUltrafiltration

The invention discloses a combined ultra-filtration device with membrane pollution control and ultrasonic cleaning functions. The device mainly comprises an ultra-filtration system, a blowing aeration system, an ultrasonic cleaning system, a pressurized dissolved air backwashing system and a programmable logic controller (PLC) system, wherein the ultra-filtration system consists of an ultra-filtration tank body and an ultra-filtration membrane assembly; the blowing aeration system consists of a blower and an aeration diffusion device; the ultrasonic cleaning system consists of an ultrasonic generator and a transducer; the pressurized dissolved air backwashing system consists of an air compressor, a pressurizing water pump and a dissolved air tank; and the PLC system consists of a PLC cabinet and a control microcomputer. By adopting a combined cleaning strategy, membrane pollution in the ultra-filtration process is well controlled, particularly pollutants can be effectively removed by using pressurized dissolved air backwashing, and the frequency of chemical cleaning is reduced; and by adopting the automatic PLC system, the device has the advantages of low running cost, long membrane service life and convenience in operation.

Owner:SOUTH CHINA UNIV OF TECH

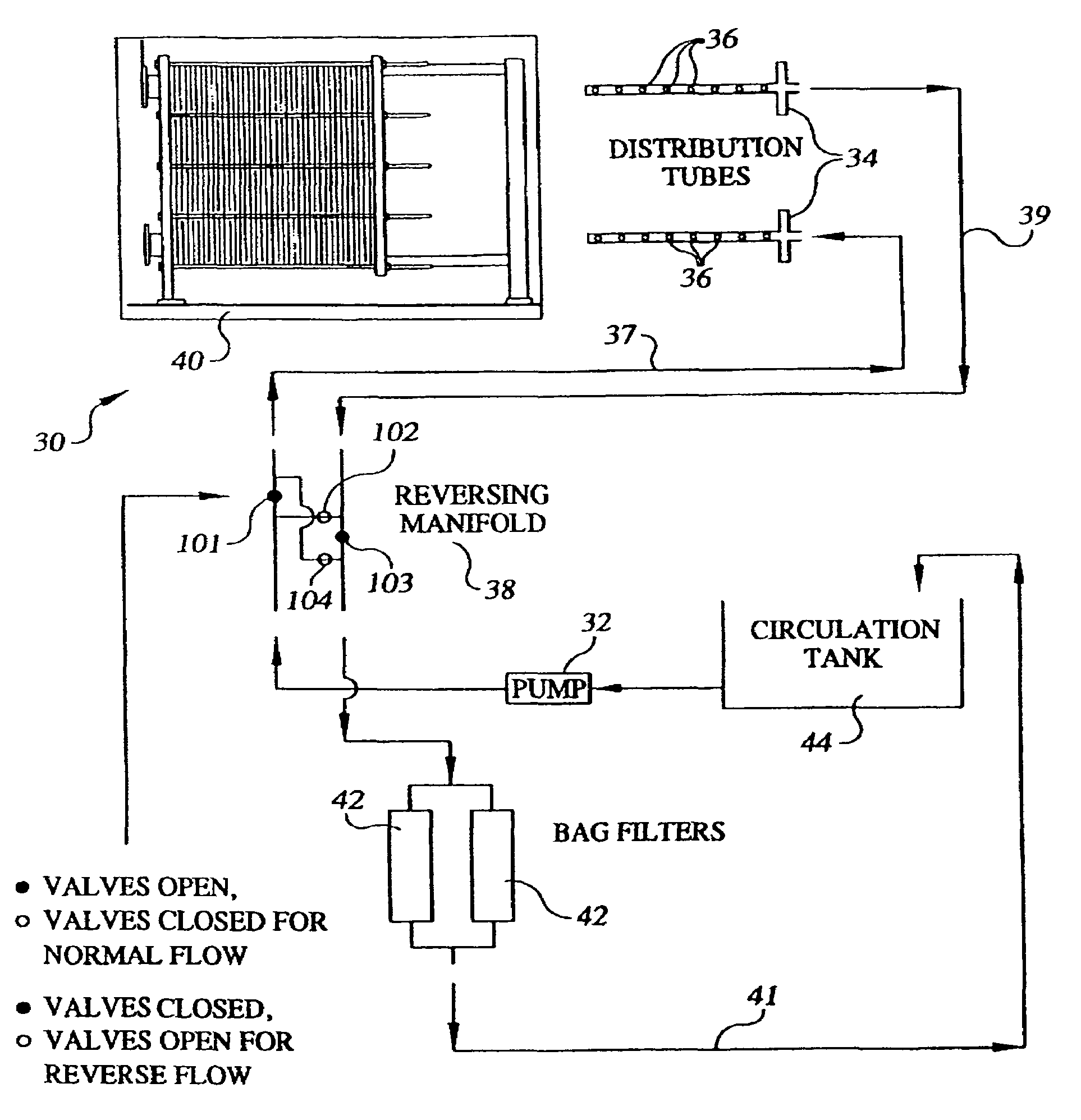

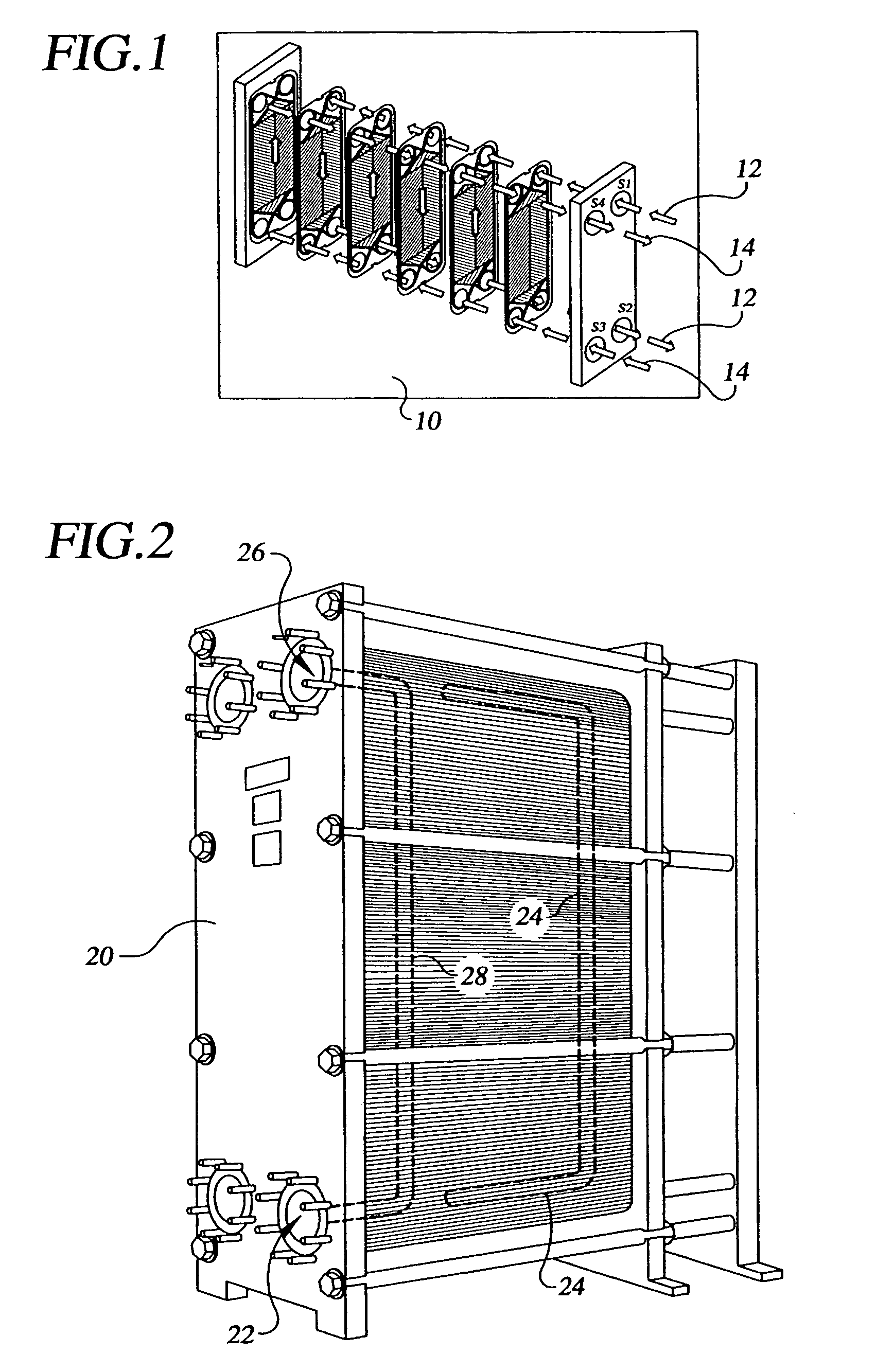

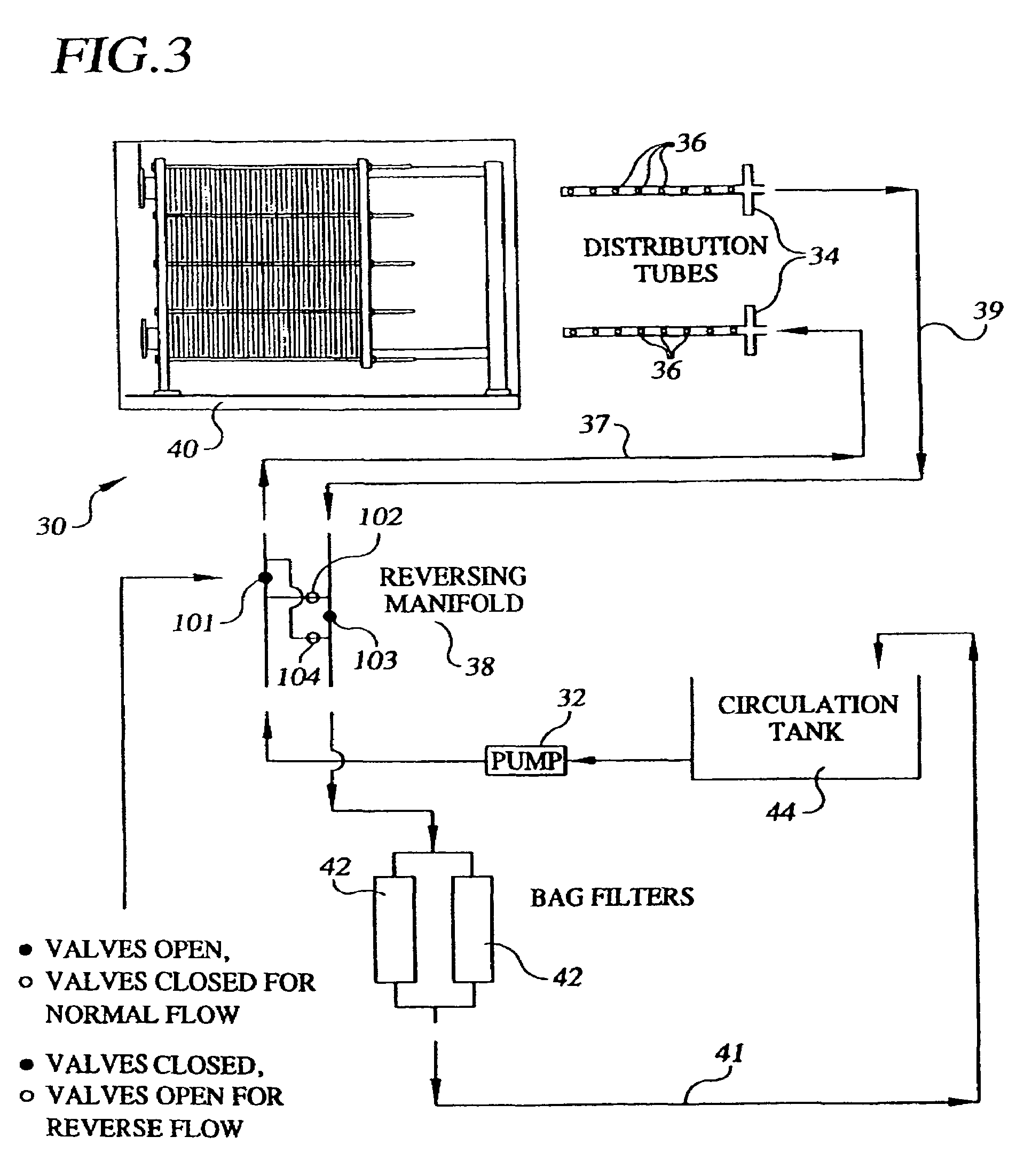

Portable cleaning apparatus and method for single pass plate and frame heat exchangers

InactiveUS6978793B1Reduce the amount requiredEasy extractionCombustion processHollow article cleaningParticulatesWorking fluid

A portable apparatus and method for chemically cleaning a single pass plate and frame heat exchanger allows the cleaning solution to be uniformly distributed across the plate pack. This portable system of one pump of preferably 10-horsepower, capable of 300 gallons per minute flow through a discharge port; at least two distribution / collection tubes with apertures of predetermined diameter and predetermined placement; one reversing manifold; two bag filters; and one circulation tank with a capacity at least on the order of 150 to 200 gallons; attaches to a single pass plate and frame heat exchanger. The single pass plate and frame heat exchanger is configured with at least two removable flanges that, once removed, allow for the installation of the distribution / collection tubes. The apertures in the distribution / collection tubes are placed facing downwards depending upon the direction of the operational fluid to enhance a vacuuming effect for particle and debris removal during cleaning. The distribution / collection tubes are skewed off-center of the flanges, with an ability to be rotated in at least four different directions off-center, and generally located towards the bottom of the single pass plate and frame heat exchanger to facilitate particulate removal and uniform distribution of cleaning solution.

Owner:PHEX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com