Patents

Literature

125 results about "Dithionous acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dithionous acid is a sulfur oxoacid with the chemical formula H₂S₂O₄. It is unstable in pure form, but its salts, known as dithionites, are stable. It was initially assumed that the C₂ symmetric structure HOS(=O)-S(=O)OH is the most stable among molecules with the formula H₂S₂O₄ using ab initio calculations. The reason for this is the existence of intermolecular hydrogen bonds. It is now known that dithionous acid spontaneously decomposes to SO₂ and S(OH)₂.

Chemical cleaning for membranes

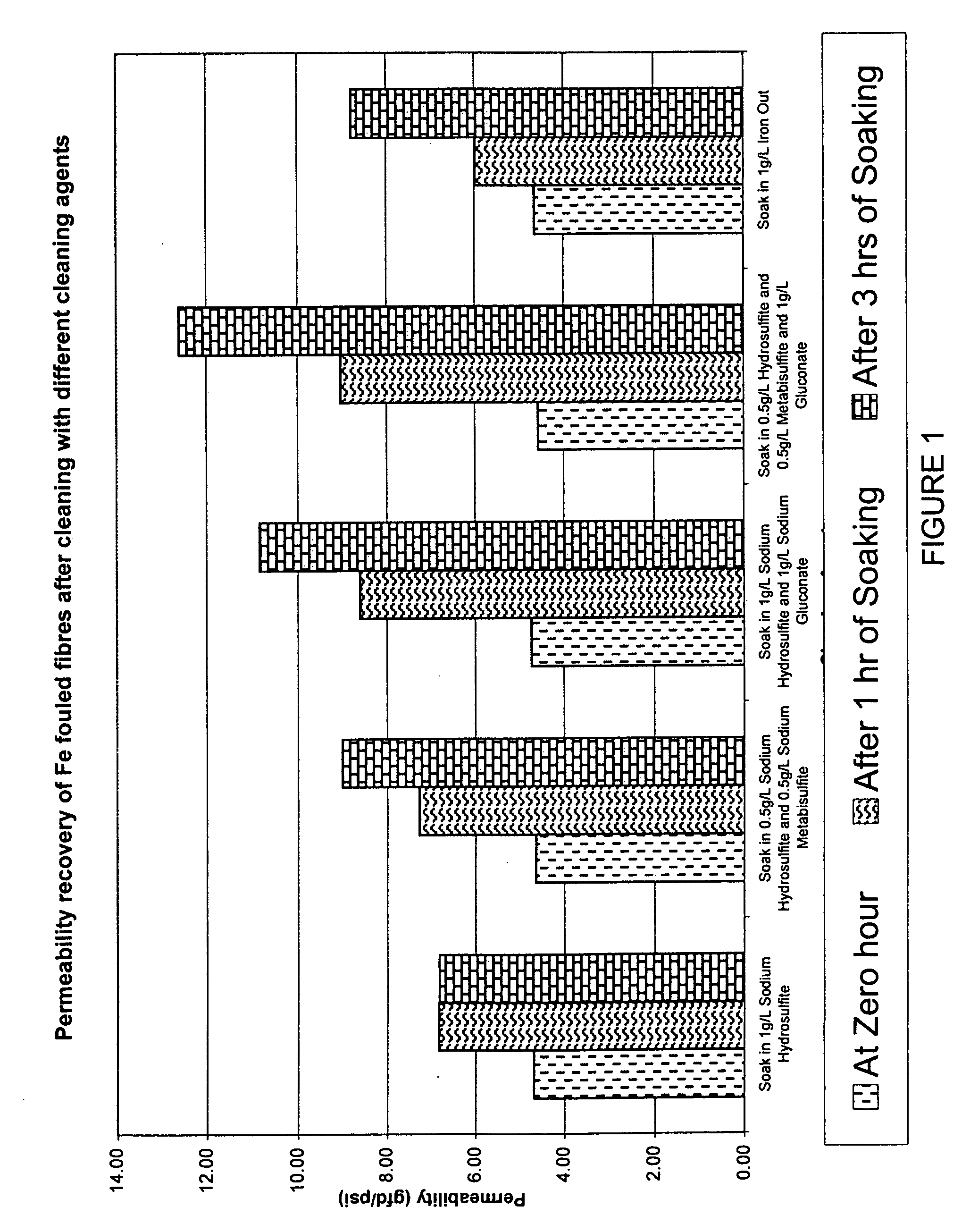

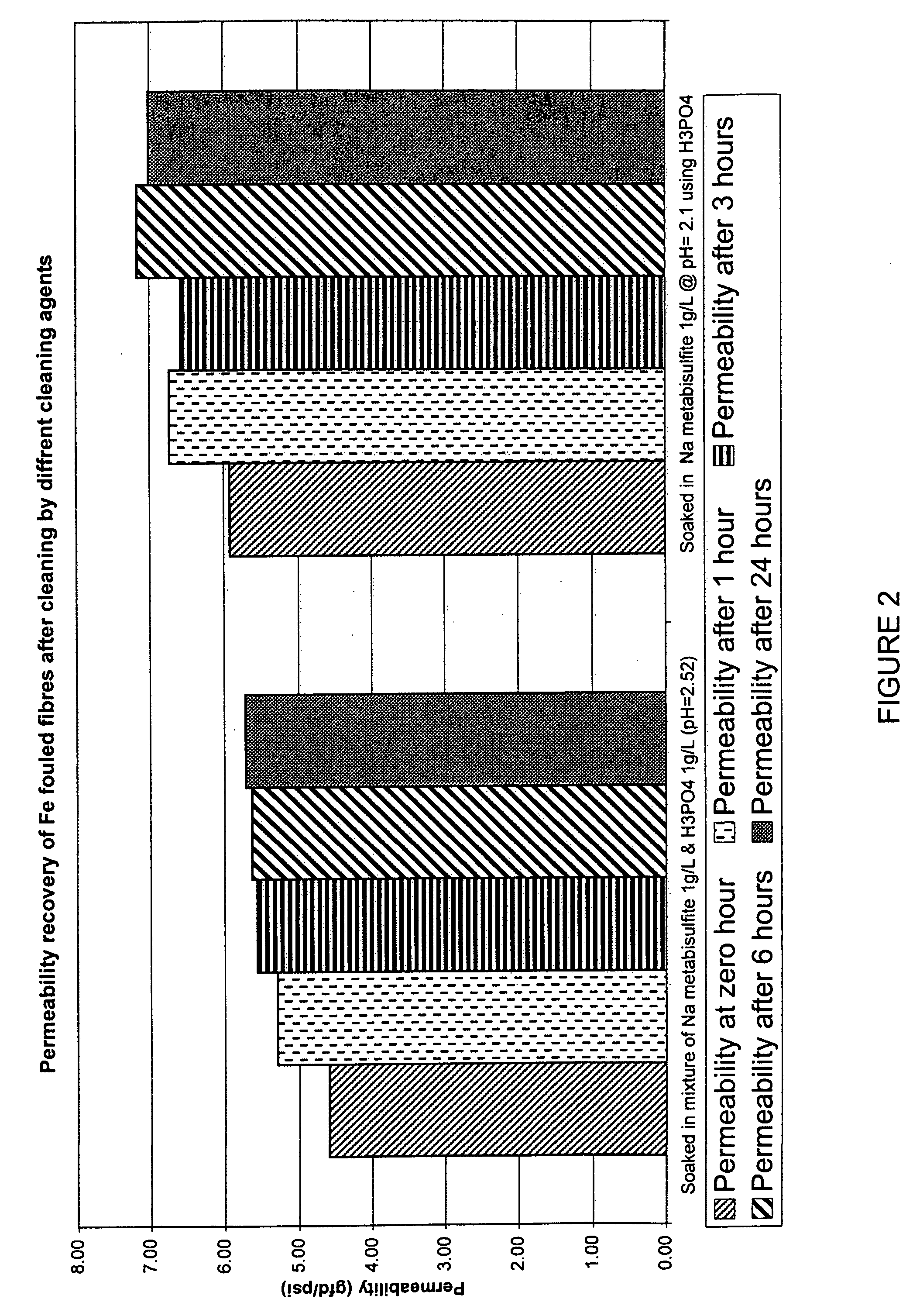

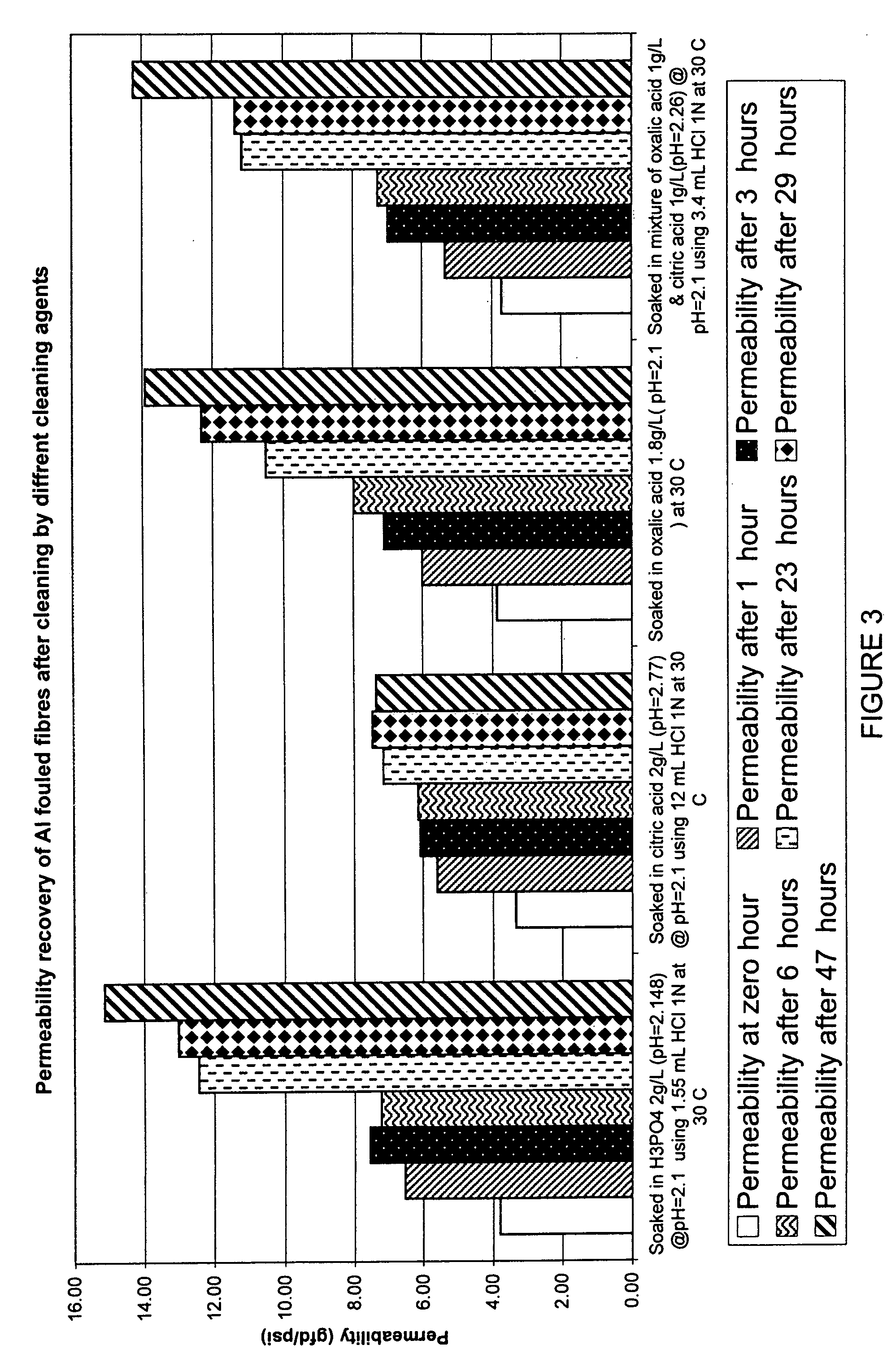

Membranes, for example immersed polymeric ultrafiltration or microfiltration membranes, are cleaned by contacting them with a chemical cleaner comprising one or more of a gluconate, a hydrosulfite, a metabisulfite or an acid, for example phosphoric acid. The membranes may have been exposed to organic or inorganic foulants, some of which may have resulted from pretreatment involving adding coagulants, for example coagulants containing iron or aluminum, to water to be treated. Methods for treating a waste cleaning solution were described.

Owner:SYED MURTUZA ALI +3

Graphene powder, production method thereof, and electrochemical device comprising same

ActiveUS20130302693A1Good dispersionGood effectMaterial nanotechnologyElectrode thermal treatmentOxygenLithium-ion battery

Provided are a graphene powder, a production method thereof, and an electrochemical device comprising the same. The graphene powder has an elemental ratio of oxygen atoms to carbon atoms of not less than 0.07 and not more than 0.13 and an elemental ratio of nitrogen atoms to carbon atoms of not more than 0.01. In the production method, the graphene powder is produced by using a dithionous acid salt as a reducing agent. Since the graphene has a low content of nitrogen atoms and a proper amount of oxygen atoms and a proper defect, the graphene is provided with good performance of both dispersibility and conductive property, and is usable as a good conductive additive, such as the one for a lithium ion battery electrode. The production method has the advantages of low cost, high efficiency and low toxicity.

Owner:TORAY IND INC

Litchi and longan antistaling agent and methods of use

InactiveCN1541543AEliminate browningFew stepsFruit and vegetables preservationDithionous acidSulfate

The present invention discloses one kind of lichi and longan preservative with high preserving effect, no toxicity, no environmental pollution and low cost and suitable for industrial production. The preservative consists of queensland arrowroot powder and bisulfite, pyrosulfite or dithionite capable of releasing SO2 when reacting with water and air. When the preservative is used, it is packed into non-woven polypropylene pocket, the pocket is set inside non-woven polypropylene bag for holding lichi or longan, and the bag is sealed and set into some packing box, with the amount of the preservative being 3.1-8.6 % of the weight of lichi or longan.

Owner:黄海雄

Dyeing process for elastic polyester-polyurethane fabric

InactiveCN101046064AEasy to dyeNo pollution in the processFibre treatmentDyeing processColour fastnessDisperse dye

The dyeing process for elastic polyester-polyurethane fabric includes one dyeing step and one reducing and cleaning step. The dyeing step using disperse dye, ammonium acetate and dyeing assistant is performed in certain bath ratio and at certain temperature. The reducing and cleaning step using sodium hydrosulfite, sodium hydroxide and cleaning assistant is performed in certain bath ratio. The dyeing process can dye polyester component well at low temperature dyeing condition, and has well dyeing on polyurethane component and high color fastness.

Owner:毛中水

Methods to enhance brightness of pulp and optimize use of bleaching chemicals

InactiveUS20050217813A1Low production costAchieve brightnessHydrogen peroxidePulp properties modificationDithionous acidALLYL SUCROSE

Mechanical or Chemical pulp is treated with about 0.01 weight % to about 5 weight % of a Mixture. The Mixture is water; diethylenetriaminepentakis(methyl)phosphonic acid or its known salts; polyacrylic acid or its known salts; and optionally one or more inert compounds. This Mixture acts to either maintain the brightness level of the pulp at the target level or to increase the brightness level of the pulp. In addition the Mixture allows for maintaining the pulp at the target level of brightness even when the amounts of other ingredients, such as hydrogen peroxide, hydrosulfite, sodium silicate and magnesium, that are typically added to the pulp, are reduced.

Owner:ECOLAB USA INC

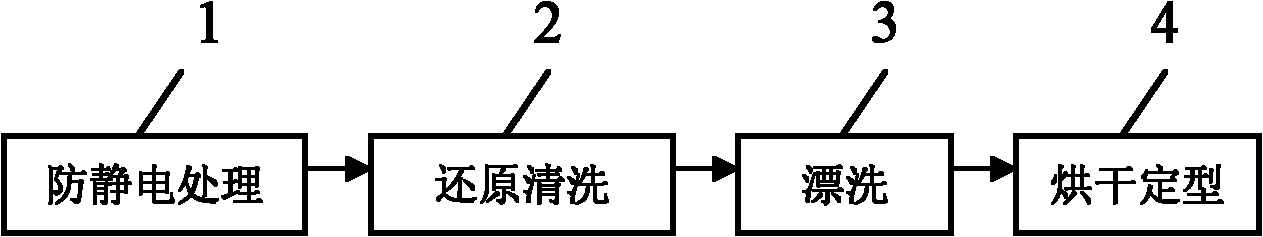

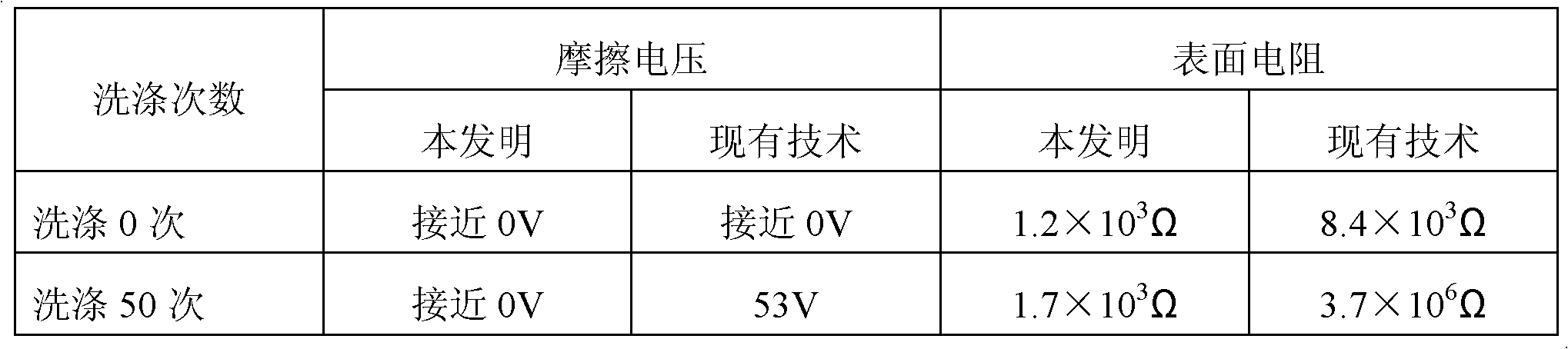

Anti-static/conductive fabric and manufacture method thereof

ActiveCN101845753AGuaranteed validityGuaranteed stabilityDry-cleaning apparatus for textilesVegetal fibresFiberYarn

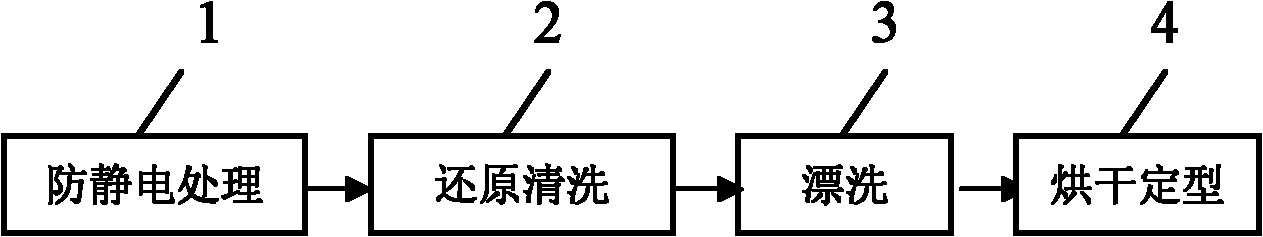

The invention discloses an anti-static / conductive fabric and a manufacture method thereof. The anti-static / conductive fabric is a terylene pure yarn fabric or a polyester-cotton blend fabric the fiber surface layer of which is uniformly compounded with conductive high molecular particles. The manufacture method comprises the following steps of: (1) destaticization: putting the terylene pure yarn fabric or the polyester-cotton blend fabric into a conductive high molecular particle dispersing solution to carry out wet dip dyeing treatment; (2) reduction cleaning: putting the fabric subjected to destaticization into a mixed solution of sodium hydrosulfite and alkali for cleaning; (3) rinsing: rinsing the fabric subjected to reduction cleaning by using water; and (4) drying and sizing: drying and sizing the rinsed fabric to obtain the anti-static / conductive fabric. The anti-static / conductive fabric effectively reduces the frication voltage and the resistance on the surface of the fabric and has good air permeability, enduring anti-static property and better uniformity. The manufacture method has simple process, easy operation, high quality of produced products and low cost.

Owner:SHENZHEN KINGKYLIN ENVIRONMENT TECH CO LTD

Producing method for bright yellow anti-myopia health-care paper

This invention refers to a kind of peak yellow health-care paper protecting from myopia, and its preparation. The process includes crushing wheat stalk, mixing sodium sulfite, sodium hydroxide and anthraquinone with wheat stalk fibers, steam-boiling the said mixture in water to form paper pulp materials, sifting out them to remove impurities, adding liquid chlorine, sodium hydroxide and sodium hypochlorite into them, heating to bleach pulp materials, pulverizing pulp materials; Adding alkali peak yellow, acid violet, aluminum sulphate, rosin glue, dithionite oil etc into pulp materials, diluting paper pulp with water in order to adjust colour, putting paper pulp on shaped net according to meet finished paper thickness, heating and drying to get products. This health-care paper is peak yellow, pretty and without lost fresh and hurt eyes. Its surface is smoothness, water tolerance and oil tolerance, and physical strength and surface strength reaching the write paper standard.

Owner:高立明

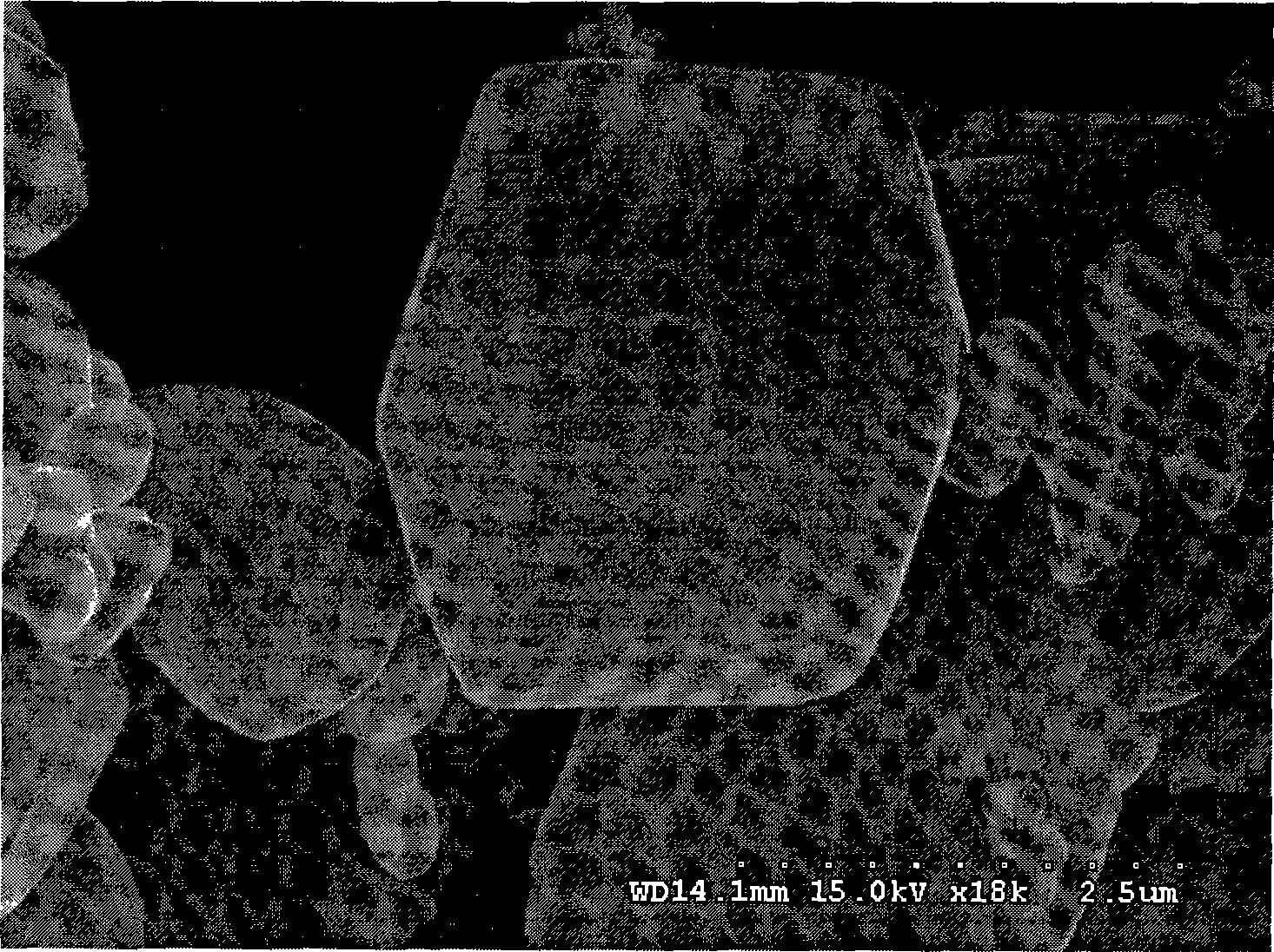

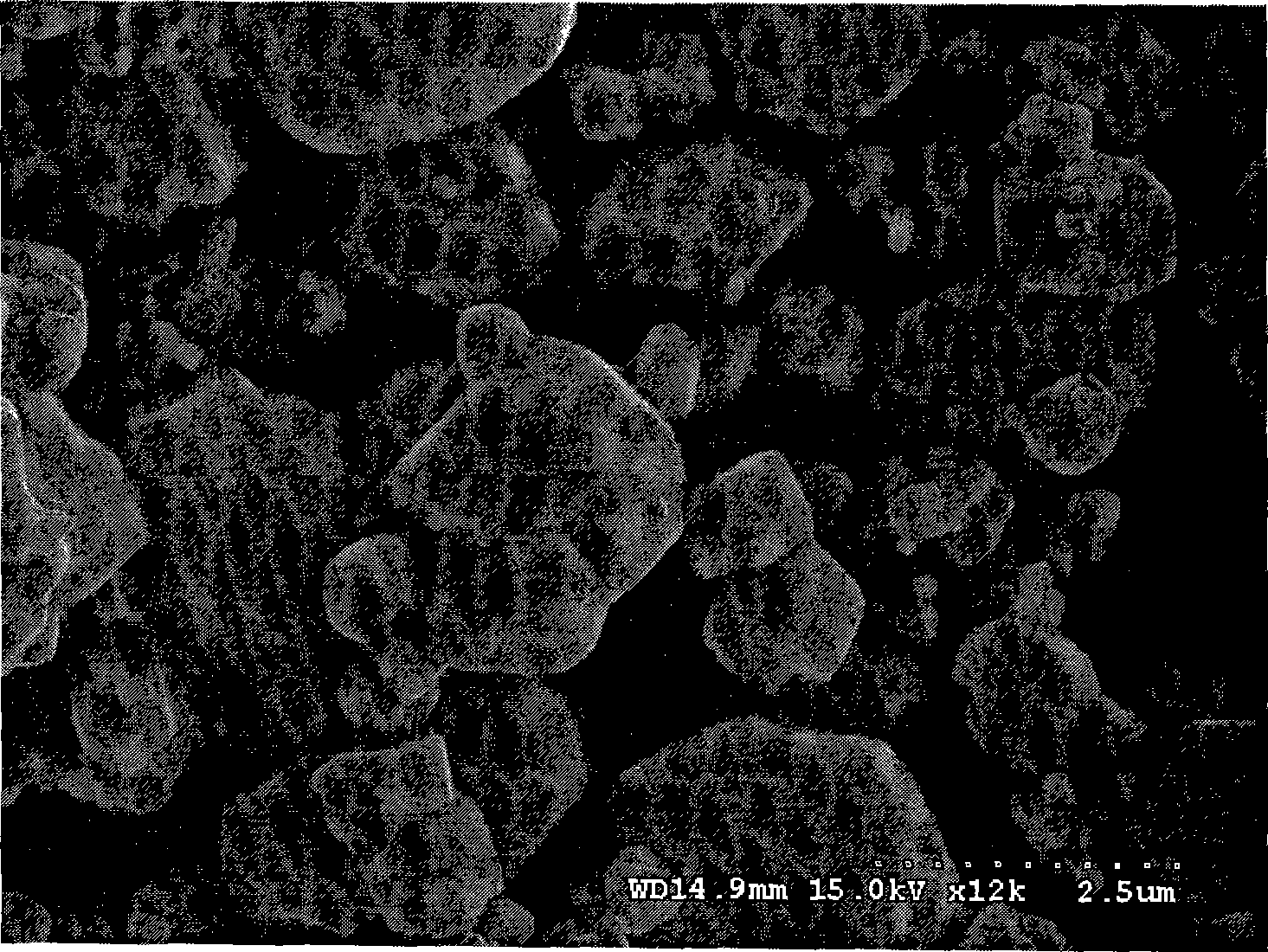

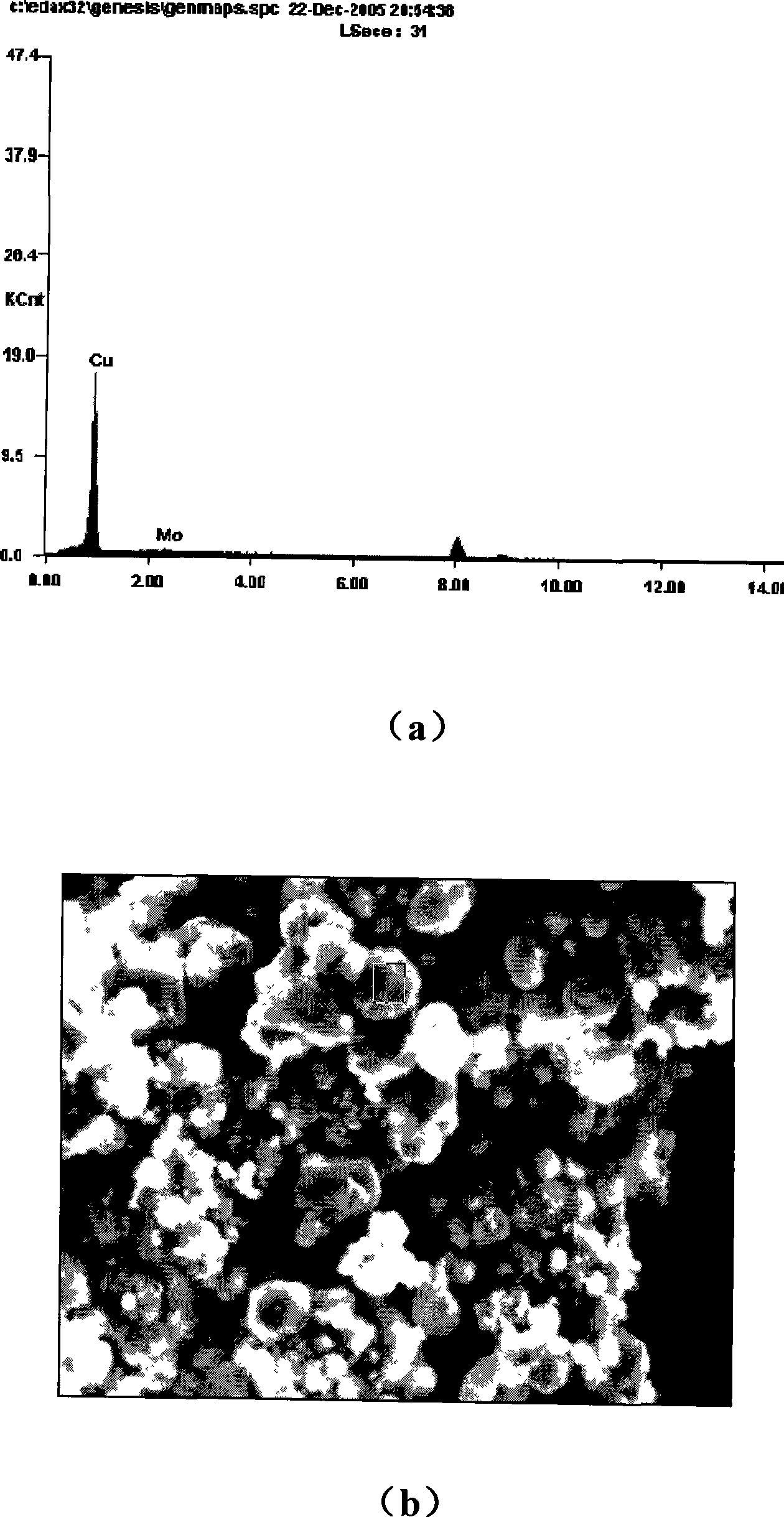

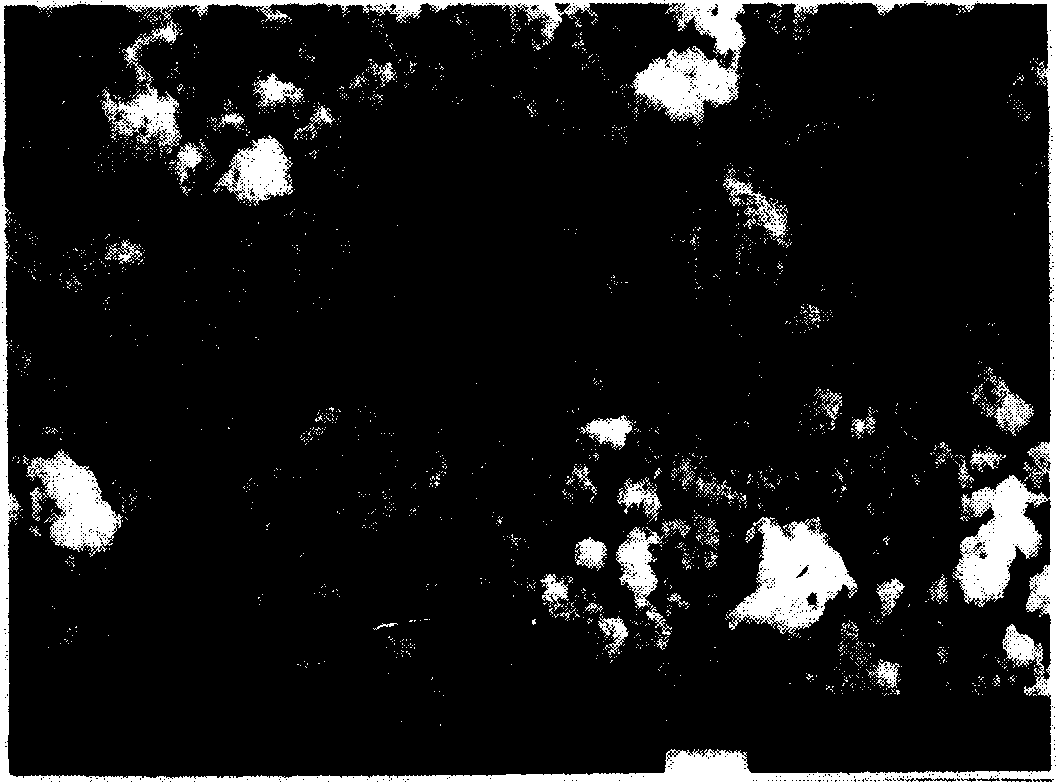

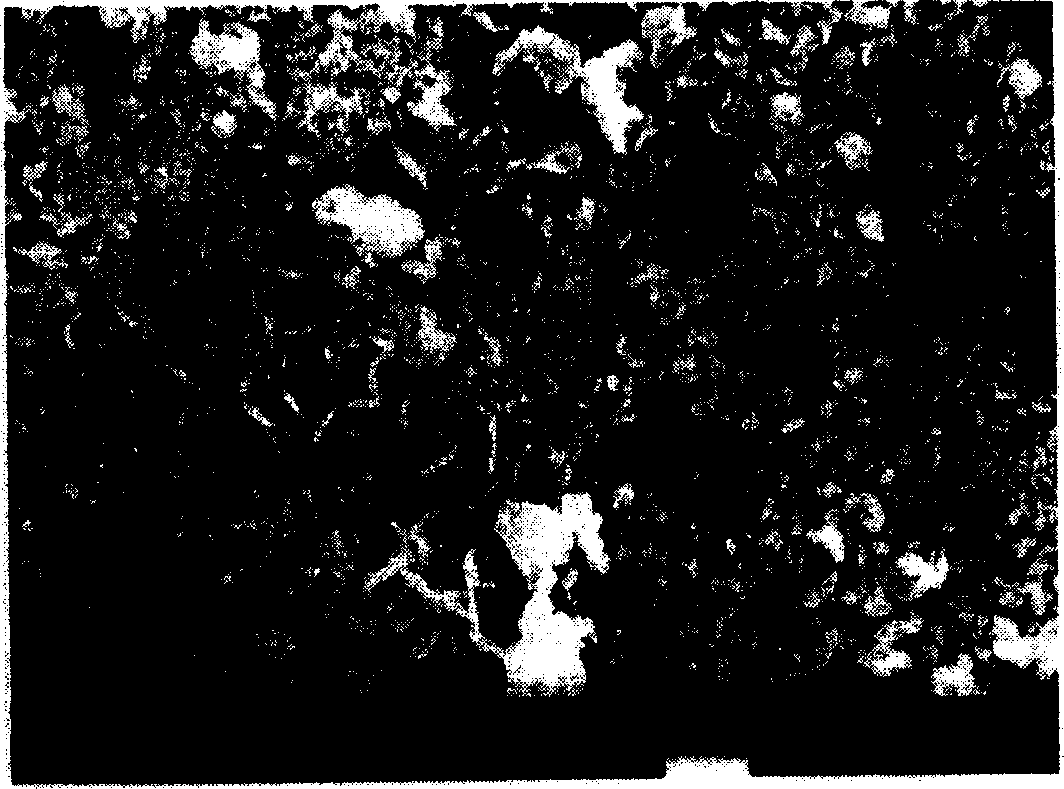

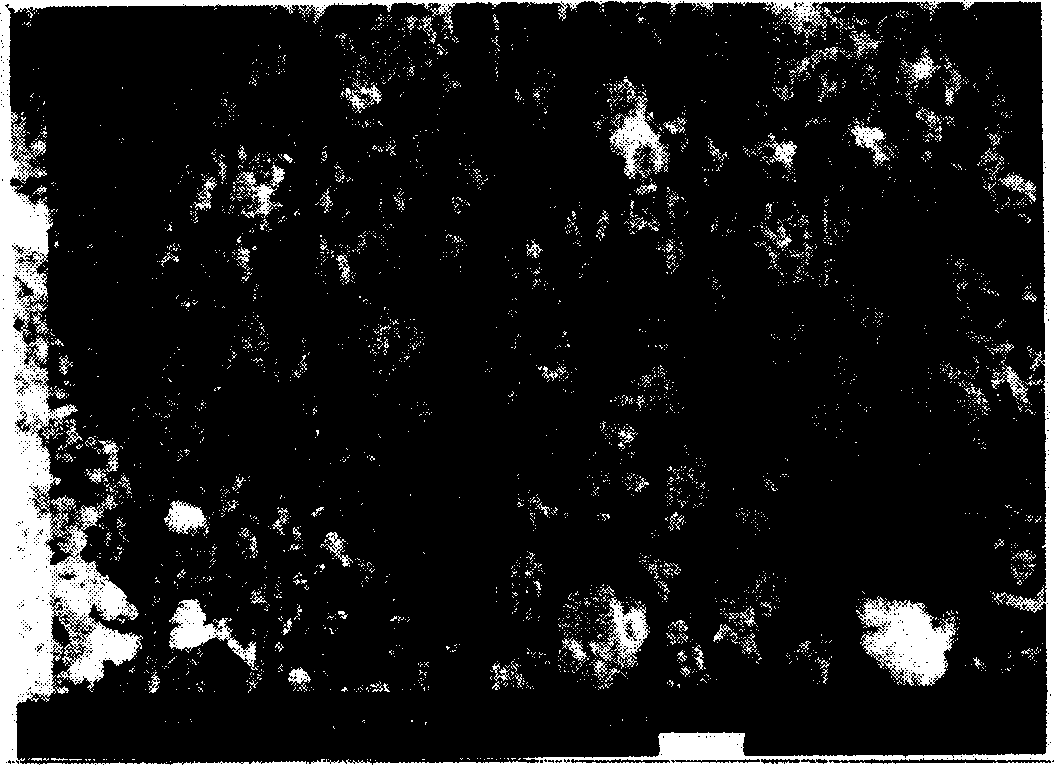

Method of manufacturing ultrafine molybdenum powder or ultrafine tungsten powder surface clad metal copper

The invention relates to a preparation method for a metal copper covered on the surface of ultrafine molybdenum powder or ultrafine tungsten powder, which belongs to the field of new materials. The preparation method is characterized in that the method mainly adopts the ultrafine molybdenum powder or the ultrafine tungsten powder with the average particle diameter D50 not more than 1.3 Mum, which is mixed with Cu<2+> soluble salt solution under the continual stirring, polymeric surfactant of coordination group with N atom and O atom is added, one of hydrazine hydrate, sodium hydrosulfite or sodium hypophosphite is added as reducing agent, and an appropriate amount of alkali is dropwise added to adjust pH value in the period so that pH value of the reaction system is from 5.5 to 12.0; in addition, in the range of 20 to 95 DEG C, the reaction continues for 0.5 to 3 hours; the ultrafine molybdenum powder or the ultrafine tungsten powder is filtered through flushing by diluted NH4Cl or NH4NO3 solution, the powder is pulped by alcoholic solution with 0.2-3.0 percent of fatty acid, and the ultrafine molybdenum powder or the ultrafine tungsten powder is filtered again, the powder is heated and dried by H2, to prepare the ultrafine molybdenum powder or the ultrafine tungsten powder of the metal copper covered with the even surface. Through adjusting the proportion of soluble salt of the ultrafine molybdenum powder or the ultrafine tungsten powder and the copper, the ultrafine molybdenum powder or the ultrafine tungsten powder covered by metal copper with different composition proportions can be prepared to meet different demands.

Owner:GRIMAT ENG INST CO LTD

Bimetallic catalyst for degrading chlorine substitutional organic pollutant, preparation method and application

InactiveCN1915511ALow priceReduce invalid decompositionMolecular sieve catalystsWater/sewage treatment by reductionTrichloroethyleneReducing agent

A bimetal catalyst for degradating the CCl4, trichlorothene and tetrachloroethene is sewage within one hour is composed of the modified zeolite as carrier and the bimetal Fe-Ni in the mass ratio of (1-10): 100. Said bimetal Fe-Ni is prepared by using sodium dithionite as reducer to reduce the Ni ions on the surfaces of Fe filings.

Owner:XINYI AGRI CHEM PLANT JIANGSU PROV

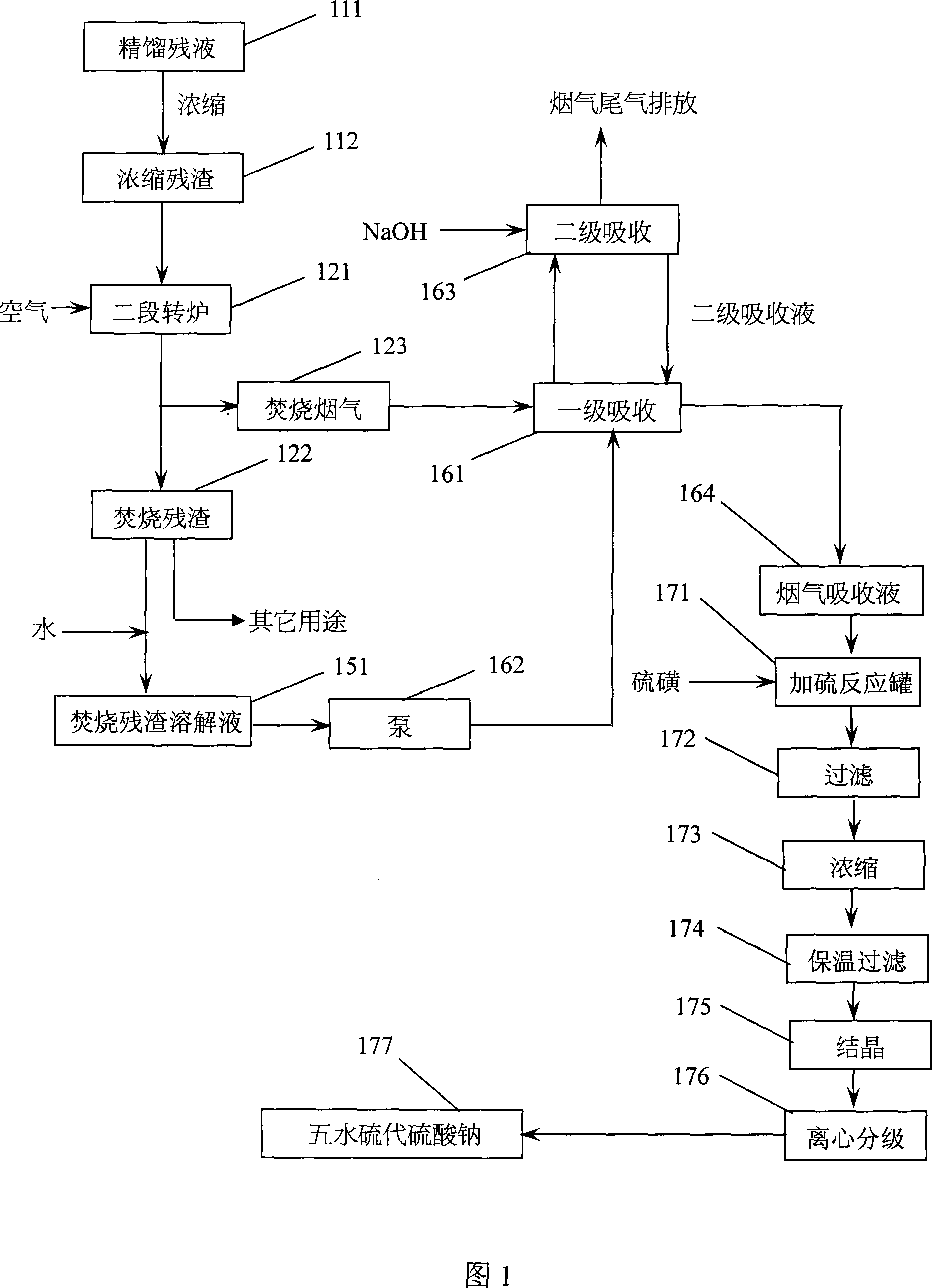

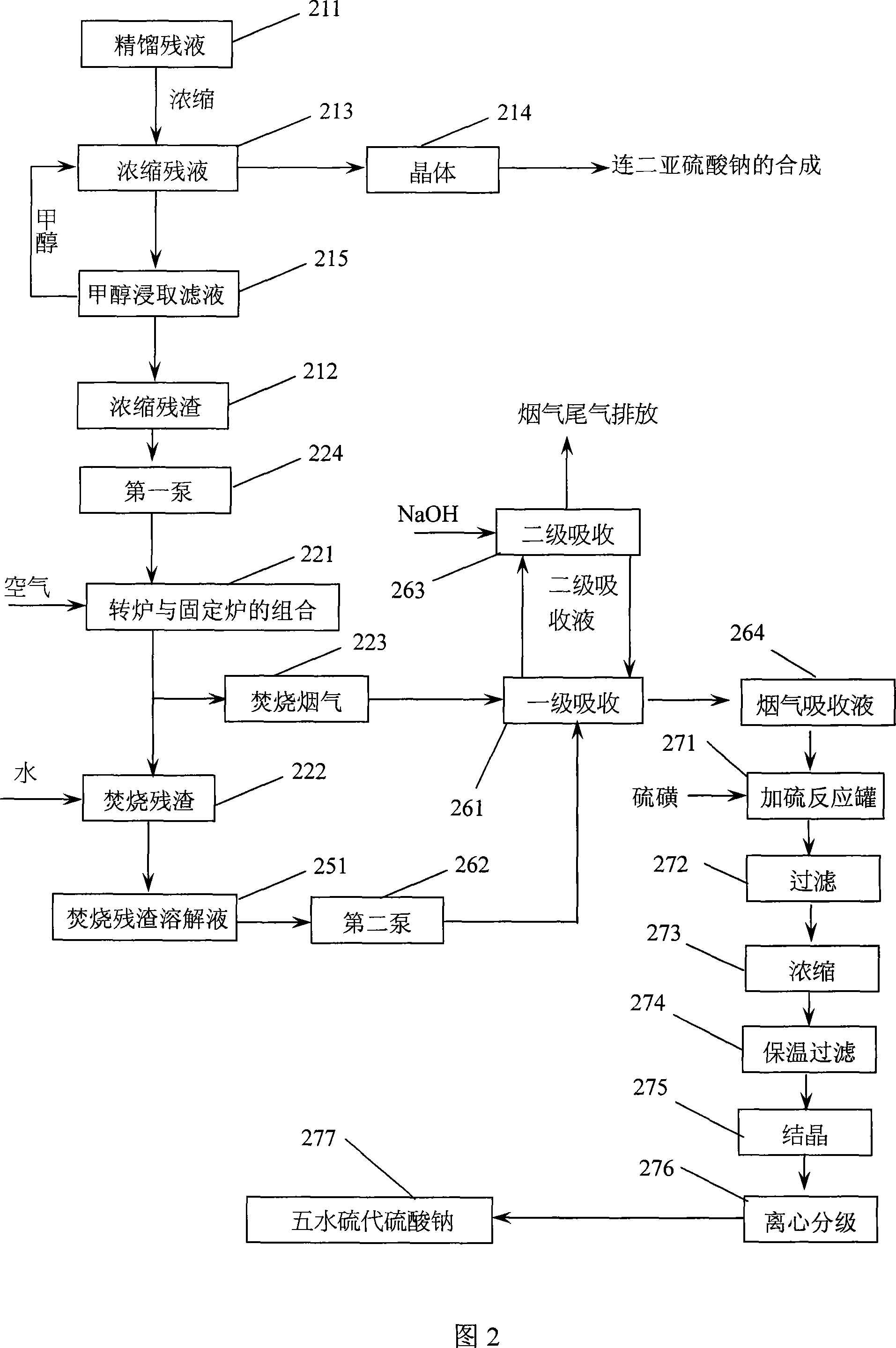

Method for treating residual liquid after mother liquor distillation methanol recovery during production of sodium sulphoxylate by sodium formate process

InactiveCN101081715AEliminate secondary pollutionRecycling resourcesThiosulfates/dithionites/polythionitesDispersed particle separationDithionous acidSulfite salt

The present invention is process of treating mother liquid residue from sodium formate method to produce sodium hyosulfate and after being rectified to recover methanol. The process includes the following steps: 1. concentrating to obtain concentrated residue with or without sodium formate recovery; 2. incinerating the concentrated residue in a converter or one combined furnace to obtain incinerated clinker; 3. discharging high temperature clinker; 4. dissolving the clinker to form water solution; 5. absorbing SO2 from the incinerating fume with the water solution; and 6. adding sulfur to the absorbed solution to prepare sodium thiosulfate. The process can eliminate pollutant while producing sodium thiosulfate as chemical material.

Owner:GUANGDONG ZHONGCHENG CHEM INC LTD

Bleaching method of fenther fabric

The present invention discloses a bleaching method of feather fabric. It includes the following steps: firstly, using ferrous ions to pretreat the feather fabric, then making selective oxidation in hydroperoxide solution, finally making reduction bleaching in sodium hydrosulfite. Said method not only can remove natural colour mater containing in feather fabric, but also can raise whiteness of fabric.

Owner:SOUTH CHINA UNIV OF TECH

Process for preparing high-purity superthin high-whiteness kaolin

The invention relates to a process for preparing high-purity superthin high-whiteness kaolin, which comprises (1) removing impurities, (2) disintegration treatment, (3) wafering and filtering treatment, (4) drying treatment, (5) calcinations treatment, (6) naturally annealing, and cooling down at normal temperature.

Owner:广州市花都区梯面展鹏高岭土厂

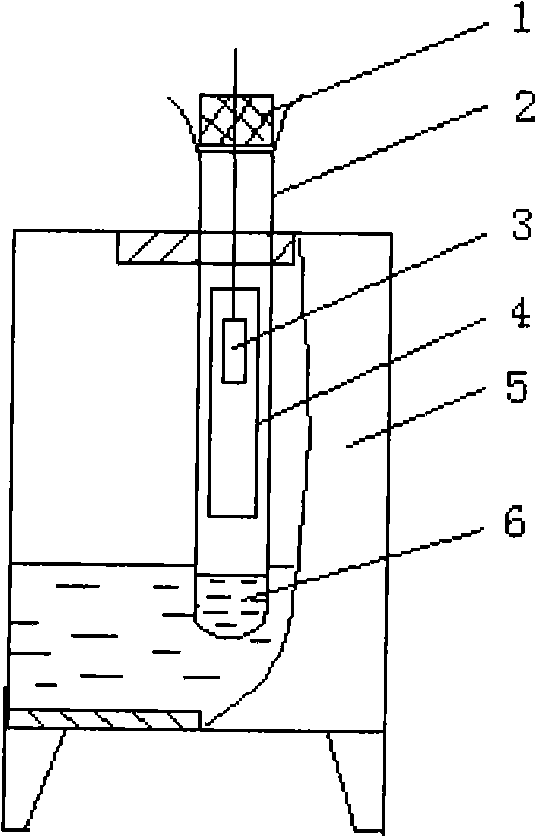

Method for brightening pulp with hydrosulfite solution

InactiveUS20040000380A1Raise the pHLong storagePulp bleachingPulping with acid salts/anhydridesBisulphite saltDithionous acid

A method for brightening pulp at a pH from 4.5 to 9. The method comprises the steps of: (a) combining an alkali metal borohydride, an alkali metal hydroxide, an alkali metal bisulfite and phosphoric acid to form a reducing solution; and (b) adding the reducing solution to a pulp slurry in an amount from 0.1% to 4% of hydrosulfite based on dry pulp fiber.

Owner:ROHM & HAAS CO

Stabilized choline solutions and methods for preparing the same

InactiveUS20140361217A1Reduce and eliminate degradationReduce and eliminate and decomposition reactionOrganic compound preparationOther chemical processesDithionous acidSulfite

A method for the stabilization of an aqueous choline hydroxide solution includes optionally, adding a first stabilizer of a dithionite salt or a dialkylhydroxylamine to an aqueous solution containing reactants that will produce an aqueous choline hydroxide solution; and after the aqueous choline hydroxide solution is formed, adding a second stabilizer of a dithionite salt or a dialkylhydroxylamine to the aqueous choline hydroxide solution. The stabilized choline hydroxide solution may include choline hydroxide, water, and a dithionite salt and / or a dialkylhydroxylamine as a stabilizer present in an amount of about 100 ppm to about 2000 ppm by weight of the stabilized choline hydroxide solution.

Owner:TAMINCO NV

Solution containing vanadium oxalate and preparation method thereof

InactiveCN101362684ACarboxylic acid salt preparationCarboxylic compound separation/purificationOxalateDithionous acid

The invention provides solution containing oxalic vanadium, which is characterized in that the oxalic vanadium is oxalic trivalent vanadium (oxalic vanadium (III)), the molecular formula is V2 (C2O4)3. Meanwhile, the preparation method of the solution containing oxalic vanadium is provided, which comprises the following steps: firstly, the oxalic vanadium is dissolved in water, the vanadium pentoxide is added for reaction, and then the sodium dithionite is added for reaction. The invention has the advantages that the simple reduction method is adopted to acquire the solution containing oxalic trivalent vanadium, and an excellent intermediate is provided for the preparation of the organic low valent vanadium and complex. The invention can be used for synthesizing the products such as vanadium (III) ethyl hexoate and organic vanadium (III) accelerator.

Owner:郑德龙

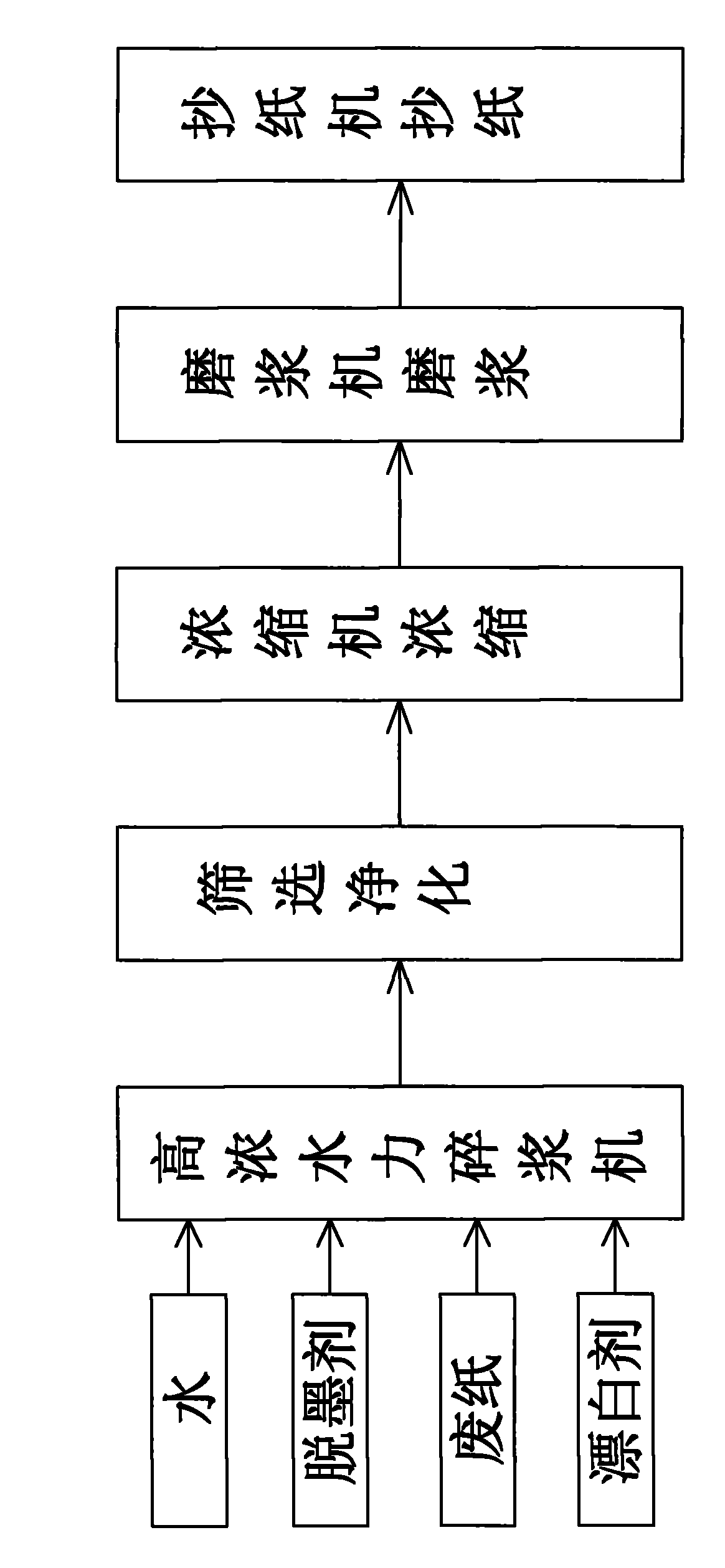

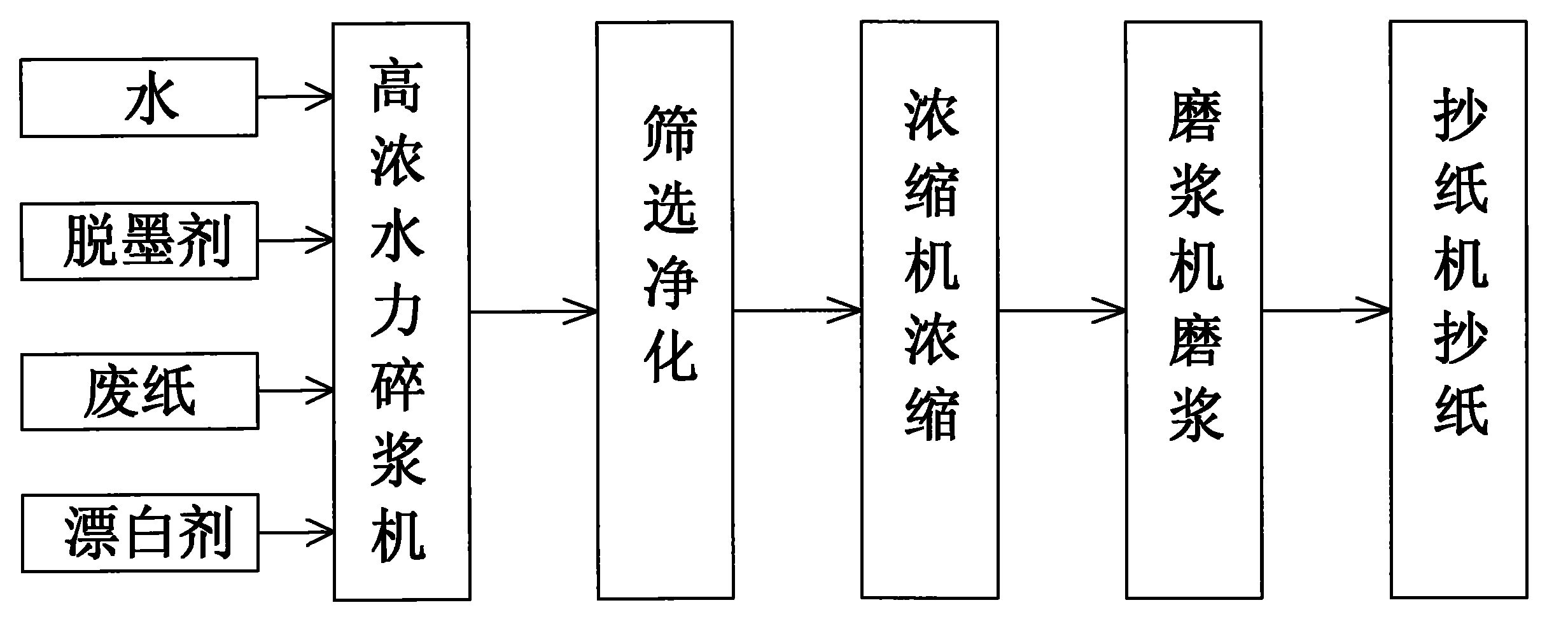

Deinking, bleaching and treating process of waste paper

InactiveCN101775749AHigh whitenessQuality improvementPulp bleachingHigh concentrationBuffering agent

The invention discloses a deinking, bleaching and treating process of waste paper, comprising the following steps of: (1) calculating water consumption and waste paper amount according to the paper pulp concentration of 12-20 percent, adding water into a high-concentration hydrapulper and heating the high-concentration hydrapulper to 70-90DEG C; (2) adding a deinking agent comprising the following substances by 100 parts on the weight of waste paper: 1-3.5 parts of sodium hydroxide, 1.5-4 parts of sodium silicate, 0.1-2 parts of alkylphenoxypolyethyleneoxyethanol, 0.1-2 parts of polyoxyethylene sorbitan monooleate, 0.5-8 parts of sodium dodecyl benzene sulfonate and then feeding the waste paper; (3) carrying out bleaching after operating for 20-25 minutes, adding an acid-alkali buffering agent and a chelating agent and then adding sodium hydrosulfite; and (4) adding hydrogen peroxide after continuing for 30-45 minutes and continuing for 30-50 minutes, carrying out screening, purifying, condensing, and defibrinating and making paper by a paper-making machine. The invention has the advantages that: the deinking and bleaching can be realized in a pulper by one step, so that the production efficiency and the whiteness and the quality of regenerated pulp can be improved; the whitenes can reach over 80 percent ISO; and the invention is especially suitable for producing various high-grade toilet paper.

Owner:杨树香

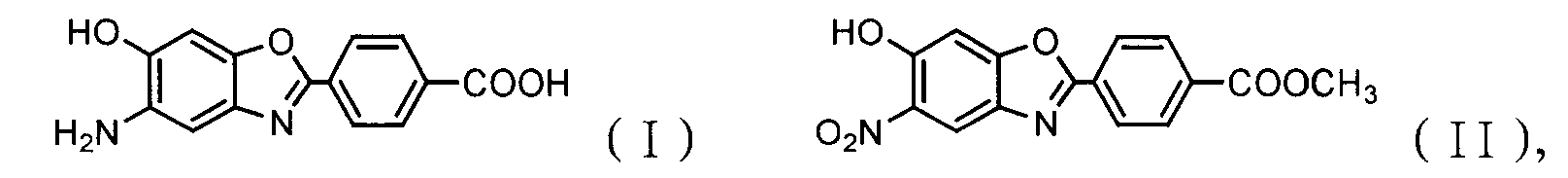

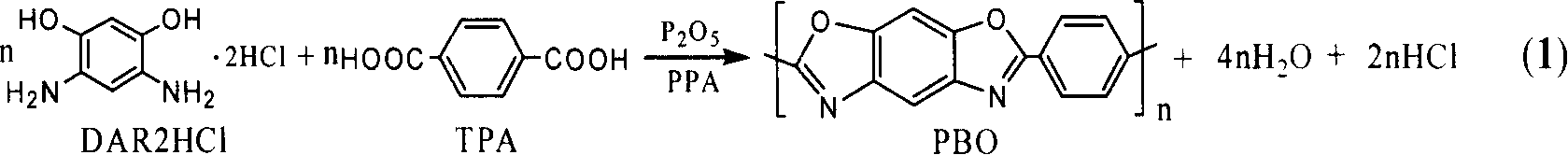

Method for synthesizing 5-amide-6-hydroxy-2-(4-carboxylphenyl)benzoxazole

The invention relates to a synthesis method of 5-amido-6-oxhydryl-2-(4-carboxyl benzyl group) benzoxazole (ABA), which takes 5-nitryl-6-oxhydryl-2-(4-methoxycarbonyl phenyl) benzoxazole (NHAB) as raw material that is put into hydrosolvent for hydrolysis by alkaline substance at 60-100 DEG C and then one-spot method is directly used for preparing the ABA through in situ synthesis with the effect of reducer, wherein, the alkaline substance is carbonate of alkali metals. Mass ratio of feeding of the NHAB to the alkali substance is 1:0.8 to 2.25, and the reducer is sodium hydrosulfite (Na2S2O4) or hydrogen. When the Na2S2O4 is used as the reducer, the dosage is 2.0-3.0 time of the mass of the NHAB. The invention has concise technique, high yield and low requirement for equipment. The solvent used in the invention is water, which avoids induction of organ solvent, thereby reducing production cost without polluting the environment. The prepared ABA has high purity and better polycondensation effect, thereby showing good industrial prospect.

Owner:YANCHENG DRAGON CHEM

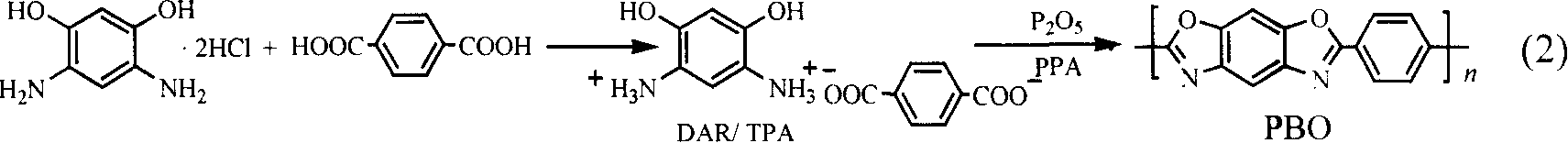

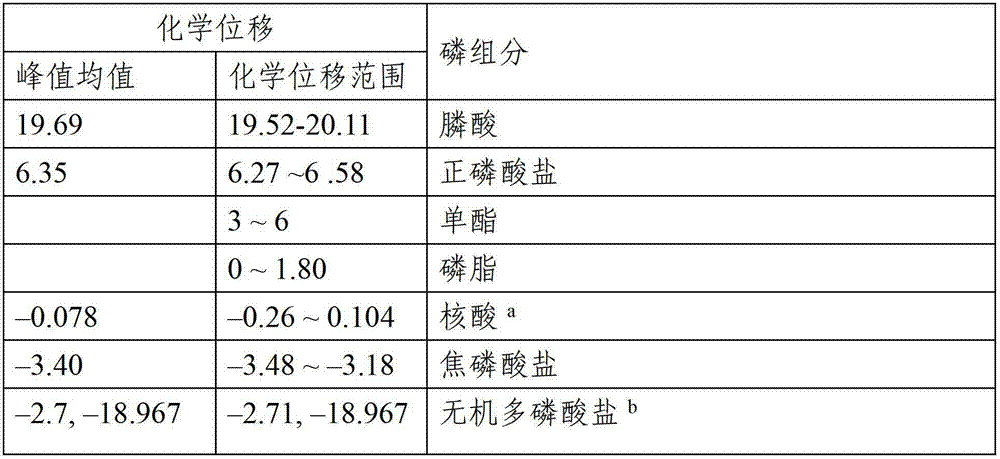

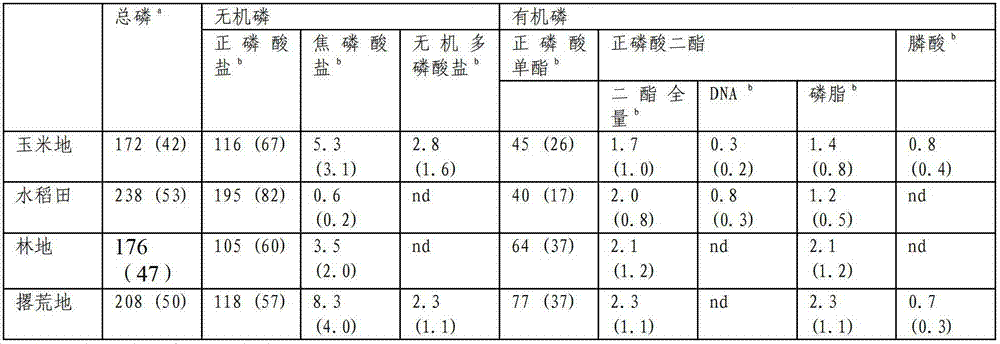

Method for detecting phosphorus component in soil by using BD-liquid 31PNMR (pulse nuclear magnetic resonance)

InactiveCN102818813AReduce hydrolysisIncrease the extraction ratioPreparing sample for investigationAnalysis using nuclear magnetic resonancePulse nuclear magnetic resonanceSodium bicarbonate

The invention relates to the leaching and the detection of a phosphorus component in the soil and particularly relates to a method for detecting a phosphorus component in soil by using BD-liquid 31PNMR (pulse nuclear magnetic resonance). The method comprises the following steps of: dissolving the soil to be detected by using NaOH-EDTA solution, centrifugally separating the dissolved solution to obtain soil phosphorus leach liquor, adding a sodium bicarbonate-hyposulphite buffer solution in the leach liquor, and carrying out freeze-drying treatment; and re-dissolving the powder obtained after the freezing treatment, and finally, detecting by using the 31PNMR to obtain the phosphorus component in the soil to be detected in quantitative and qualitative forms. The phosphorus in the soil is leached and detected by using a physical and chemical combined method, so that the resolution and the veracity of the 31PNMR are increased; and the method is suitable for identification and analysis of the phosphorus component in the soil.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

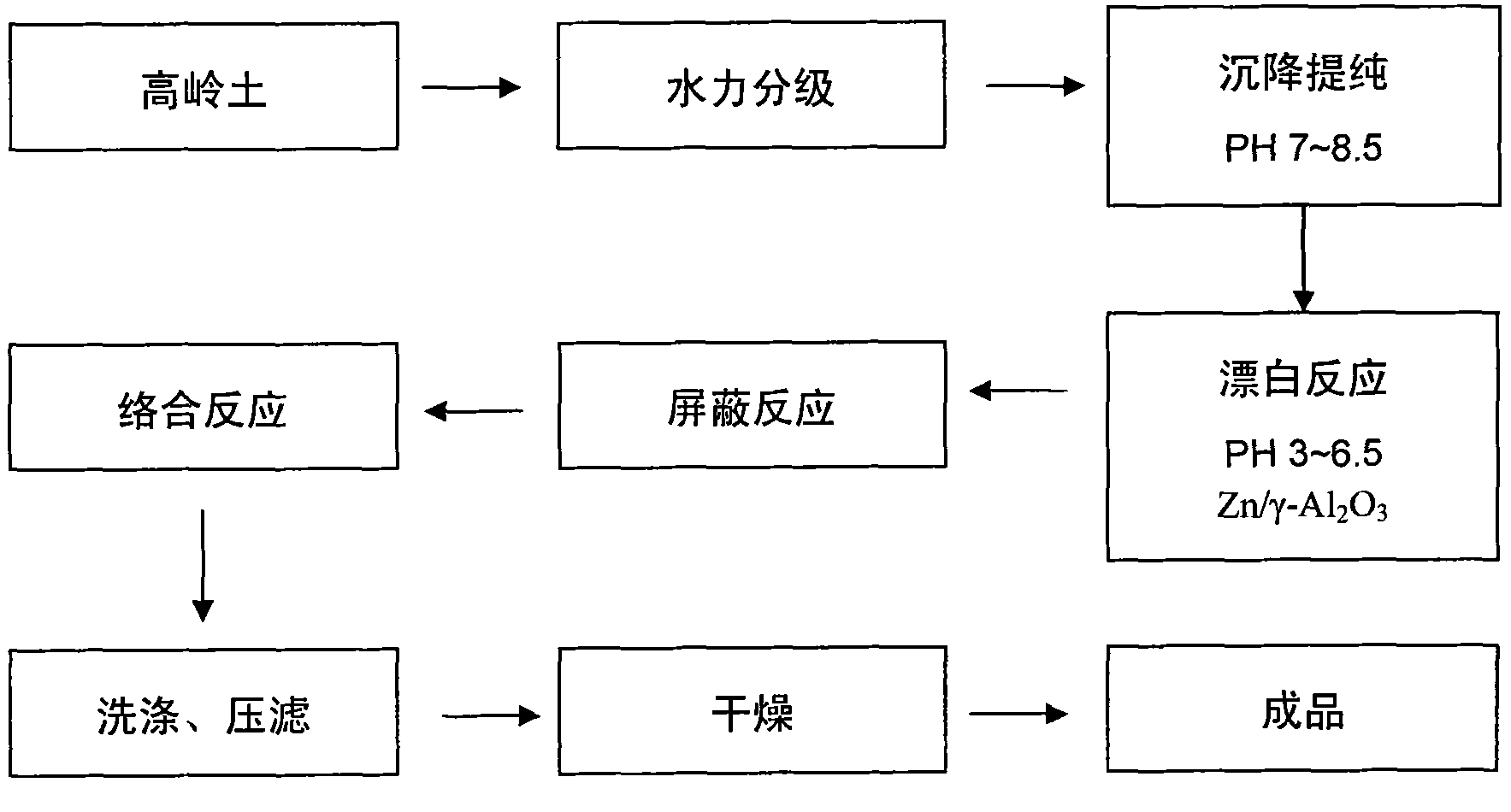

Process for enhanced reduction bleaching of kaolin by using thiocarbamide

The invention relates to a process for enhanced reduction bleaching of kaolin by using thiocarbamide, which uses sodium dithionite as a main reducing agent and the thiocarbamide as an auxiliary reducing agent to perform combined enhanced bleaching on the kaolin under a Zn / gamma-Al2O3 catalyzed condition with the pH value of 3.0 to 6.5 at the normal temperature, and simultaneously perform a shielding reaction and a complex reaction. The process solves the problem that the kaolin is yellowed after bleaching, and has the characteristics of low cost, good bleaching effect and small environmental pollution; besides, a kaolin powder product has the natural whiteness of over 85 percent and the calcination whiteness of over 90 percent, has high brightness, stability and dispersity, and can be widely used in the industries of high-grade fine ceramics, coatings, papermaking and the like.

Owner:广西兖河矿业有限公司 +1

Preparation of conductive gas-phase anti-rust membrane

The invention discloses an electric conduction gas phase rust prevention film which can prevent static and rust. The film is obtained by ingredients such as polyolefin resin, superfine carbon black, a vapor phase inhibitor, chemical inhibitor 1010, light stabilizer 6911, aluminate coupling agent; the polyolefin resin comprises 95% of blending polyolefine (low density polyethylene: linearity low density polyethylene equals to 3:7) and 5% of polyethylene wax; ultrafine grinding and wind force screening are carried out on carbon black powder by a whirlwind mill to obtain the superfine carbon black, the fineness of which reaches 5000 mesh. The vapor phase inhibitor comprises ammonium molybdate 5-30%, sodium benzoate 2-10% , the mixture of hydroxy triazole 5-20%, decanedioic acid sodium 28-45%, oxygen absorbent 5-20%, chrome acid tert-butyl ester 15-35%, and aluminate coupling agent 1-2%; the oxygen absorbent is sodium hydrosulfite or green copperas. The main processing comprises: the solid constituents of the vapor phase inhibitor are ground and coupled; the vapor phase inhibitor and the polyolefin resin are coupled, blended and co-extruded; the superfine carbon black and the polyolefin resin are coupled, blended and co-extruded; a three-layer co-extrusion blown film device is used for putting the polyolefin resin containing the vapor phase inhibitor and the carbon black in a feeding hole for blow molding. The film has the advantages that (1) the film is suitable for the rust prevention of various metals such as various steel, copper, aluminum, chromeplate, does not have undesirable impact on other non-metal materials such as optical equipment, rubber materials, electronic devices and components, and has good compatibility; (2) the film can be suitable for rust prevention packaging of various electronic equipment; the surface resistivity of the packaging film can reach 10 omega; and has excellent static-free and magnetic prevention performances on built-in devices.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

Cotton pulp steam boiling additive

InactiveCN101413227AReduce degradationImprove wettabilityNon-macromolecular organic additionInorganic compound additionSulfite saltCooking process

Owner:CHONGQING YINKE CHEM FERTILIZER

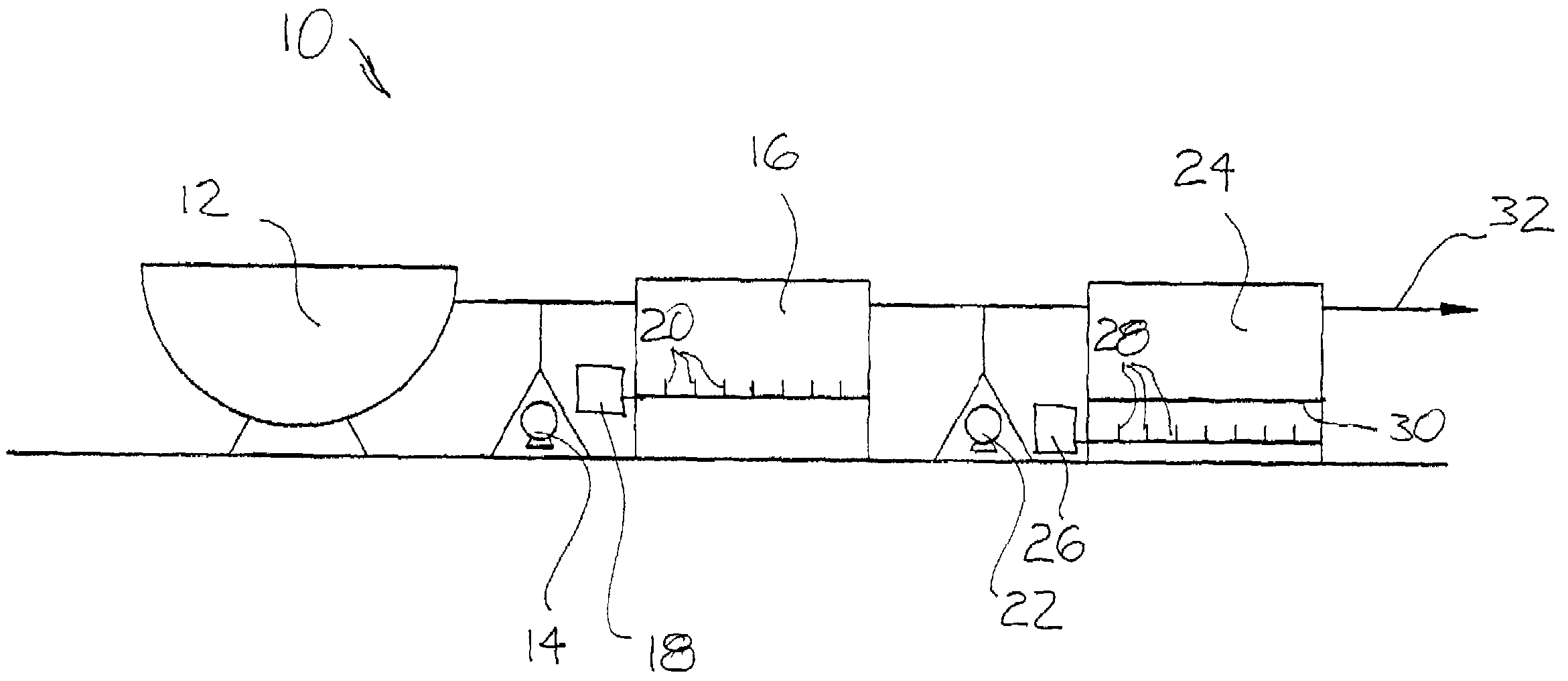

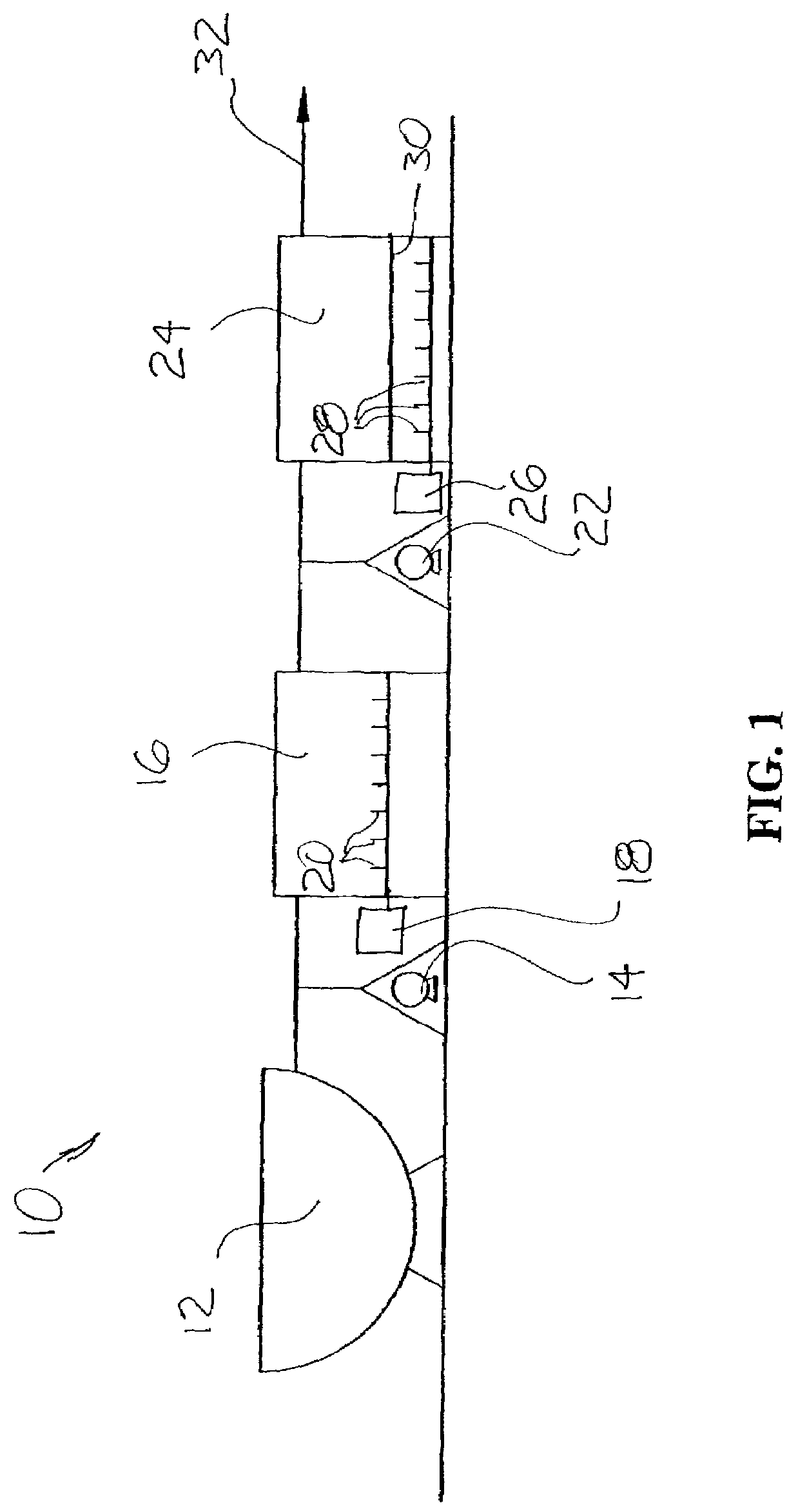

Methods to enhance brightness of pulp and optimize use of bleaching chemicals

InactiveUS7351764B2Low production costAchieve brightnessHydrogen peroxidePulp properties modificationDithionous acidAdditive ingredient

Mechanical or Chemical pulp is treated with about 0.01 weight % to about 5 weight % of a Mixture. The Mixture is water; diethylenetriaminepentakis(methyl)phosphonic acid or its known salts; polyacrylic acid or its known salts; and optionally one or more inert compounds. This Mixture acts to either maintain the brightness level of the pulp at the target level or to increase the brightness level of the pulp. In addition the Mixture allows for maintaining the pulp at the target level of brightness even when the amounts of other ingredients, such as hydrogen peroxide, hydrosulfite, sodium silicate and magnesium, that are typically added to the pulp, are reduced.

Owner:ECOLAB USA INC

Supplementary decoloration process for dye-containing waste water

InactiveCN101058469AFor direct reuseReduce processing costsMultistage water/sewage treatmentWater/sewage treatment by neutralisationDithionous acidSulfite salt

The invention discloses a supplementing decoloring technique of waste water with dye, which comprises the following steps: reserving alkali solution and acid solution of sodium dithionite in the seal container separately; blending the waste water with dye and alkali solution of sodium dithionite under high-speed stirring condition; leading the acid solution to neutrallize the waste water with dye; supplementing the decoloring; bubbling the decolored water through aerating pipe; oxidizing the excessive reduced material; placing the seal container and aerating pipe in the water outlet canal of waste water with dye. The invention reduces cost without changing the present equipment, which is benefit to recycle the waste water directly.

Owner:XIAMEN ZHONGMIN GLOBAL ENVIRONMENTAL

Remediation of sulfur-containing pollutants with hydrocarbon-utilizing bacteria

InactiveUS7329532B2Reducing sulfur-containing compoundEncouraging growthBioreactor/fermenter combinationsBiological substance pretreatmentsAlkaneSulfolane

Methods and apparatus are disclosed for remediating sulfur-containing pollutants with a hydrocarbon that is used to stimulate the growth of hydrocarbon-utilizing bacteria. The hydrocarbon is preferably an alkane such as butane. The sulfur-containing pollutant may comprise sulfate, sulfite, sulfide, disulfides, mercaptans, alkanesulfonates, dialkyl sulfides, thiosulfate, thiofurans, thiocyanates, isothiocyanates, thioureas, thiols, thiophenols, thioethers, thiophene, tetrathionate, dithionite, dialkyl disulfides, sulfones, sulfoxides, sulfolanes, sulfonic acid, dimethylsulfoniopropionate, sulfonic esters, hydrogen sulfide, sulfate esters, sulfur dioxide and any other sour gases, elemental sulfur and any other sulfur-containing material considered to be a contaminant or pollutant.

Owner:GLOBAL BIOSCI

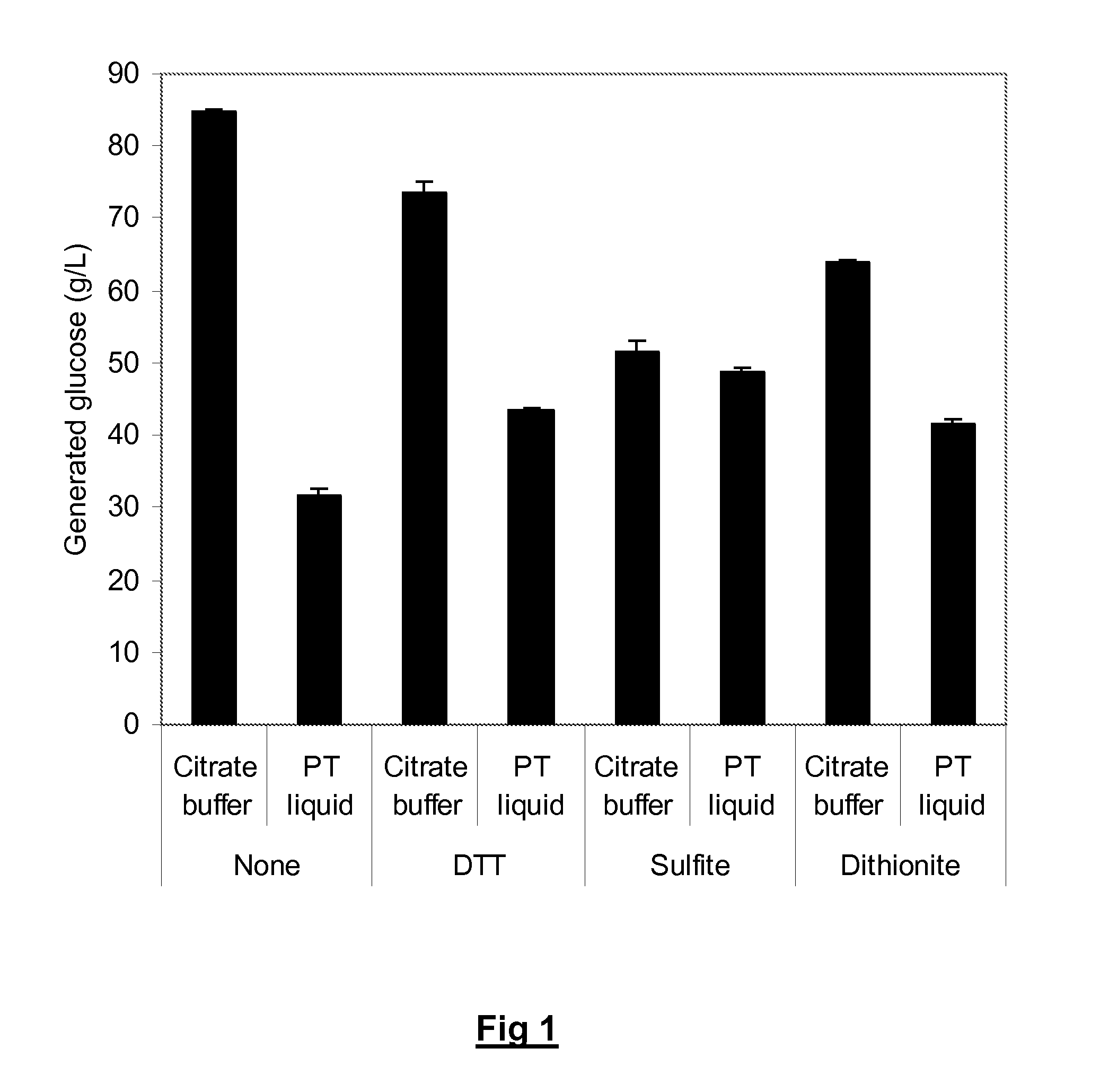

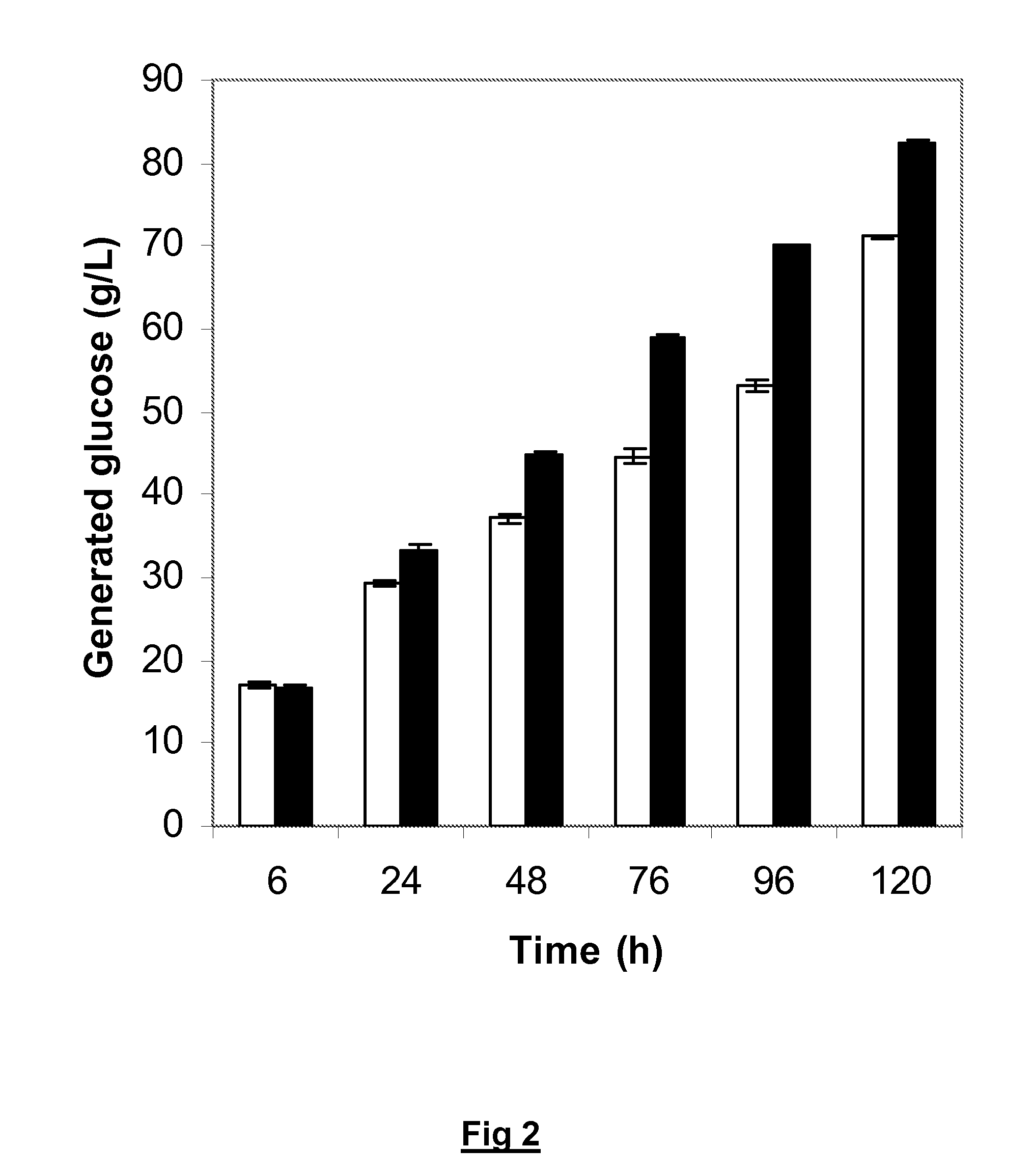

Enzymatic hydrolysis of lignocellulosic material in the presence of sulfite, dithionite and/or dithiothreitol

ActiveUS8871475B2Improve efficiencyImprove enzymatic hydrolysis efficiencyBiofuelsFermentationCelluloseDithionous acid

A method is provided for improving enzymatic hydrolysis in saccharification of a lignocellulosic material. The method is comprising pretreating the lignocellulosic material to obtain a slurry of pretreated lignocellulosic material; adding at least one reducing agent to the slurry of pretreated lignocellulosic material or the liquid fraction thereof to decrease the enzymatic hydrolysis inhibitory properties of slurry of the pretreated lignocellulosic material or the liquid fraction thereof; and subjecting the slurry of pretreated lignocellulosic material or the liquid fraction thereof to enzymatic hydrolysis in the presence of the at least one reducing agent.

Owner:SEKAB E TECH

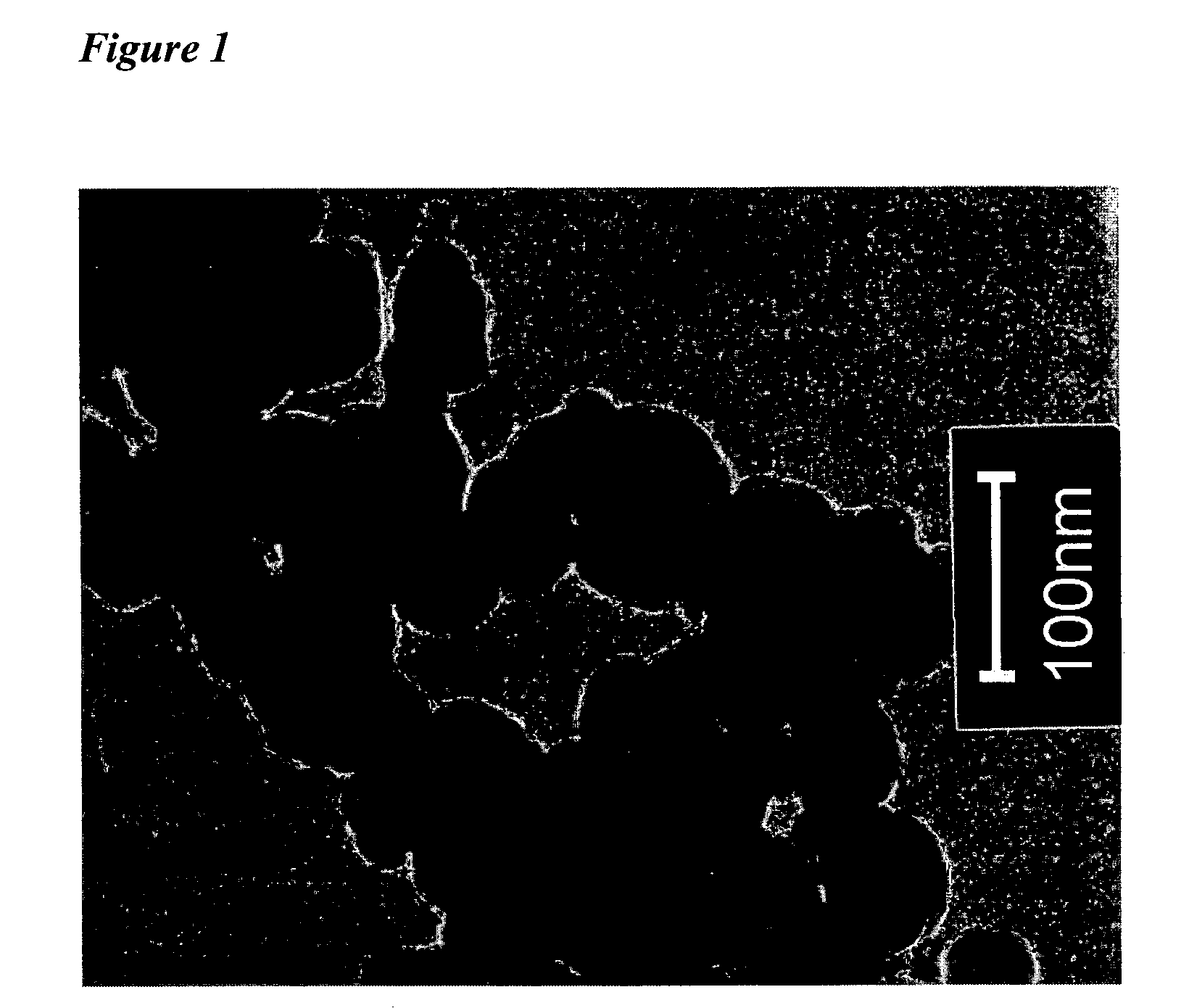

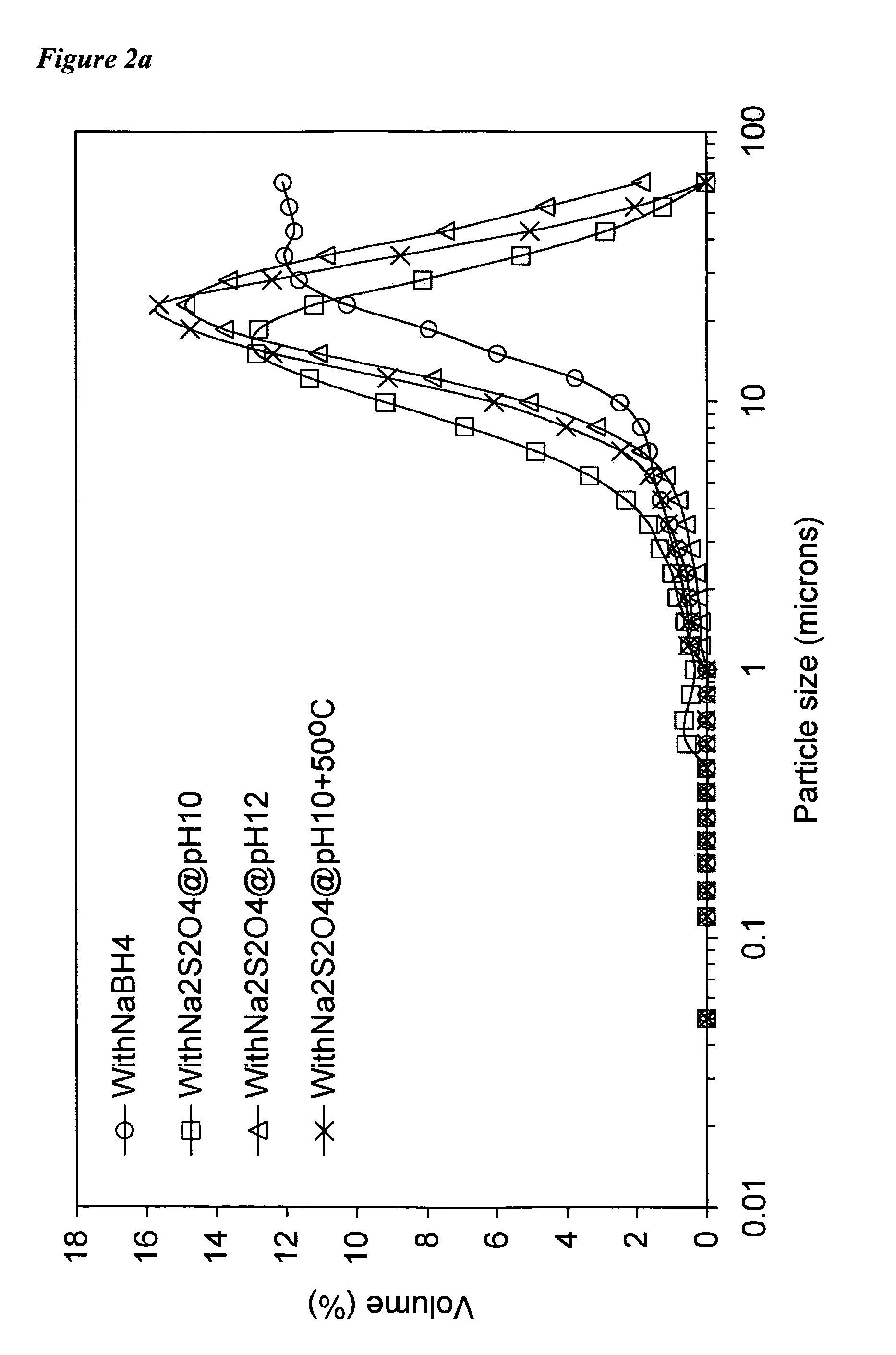

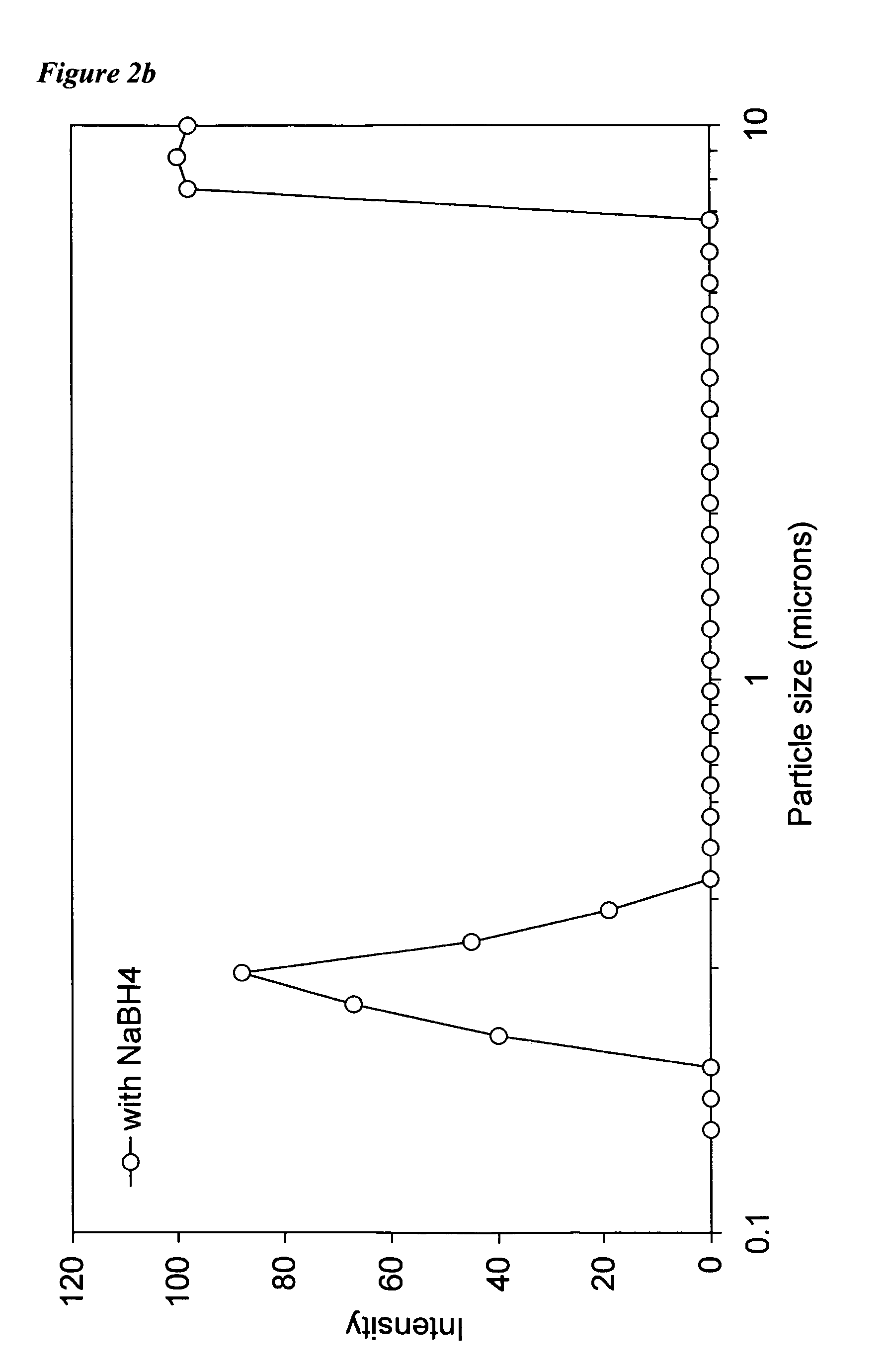

Process for producing a nanoscale zero-valent metal

InactiveUS7674526B2Inhibit productionLiquid surface applicatorsMetal-working apparatusDithionous acidContaminated water

This invention describes a process for producing a nanoscale zero-valent metal, including reduction of a metal ion solution with a dithionite compound, wherein the reduction is carried out under alkaline conditions under substantially an inert atmosphere. A nanoscale zero-valent metal obtainable by this process, and having a new crystalline form, is also described. The nanoscale zero-valent metal produced by the process of the invention is preferably iron, and is advantageously used for the remediation of contaminated water.

Owner:ORICA AUSTRALIA

Process method for preparing ultra-fine high-brightness sericite powder by pyrophyllite

The invention relates to a process method for preparing ultra-fine high-brightness sericite powder by pyrophyllite, which belongs to the chemical field. The process method comprises the following steps: crushing ore with a crusher, adding the crushed ore into a sand making machine to produce sands, feeding the sands into a rotary kiln for calcinations, cooling the calcined ore sands to the room temperature, feeding the cooled ore sands into the crusher, crushing the ore sands into fine powder, feeding the fine powder into a beater, adding sodium hydrosulfite with the weight ratio being 0.1-0.2 percent while beating with the weight ratio of the ore powder and water being 6:4, adding sodium hexametaphosphate while grinding, feeding the ground slurry into a storage tank, adding sulfuric acid according to a weight ratio, feeding the mixture into a high-pressure filter for dehydration, and drying, thereby obtaining the product. The invention has the advantages that: the ultra-fine powder product can be obtained through treatment in the method, and when the particle size is 2mu m, the product can maintain the unique and excellent laminated structure and the excellent radius-thickness ratio, thereby broadening the application scope of the pyrophyllite in high-end products, improving the value of the pyrophyllite, fully developing and utilizing pyrophyllite resources, and increasing the economic and social benefits.

Owner:厦门博大东方新材料有限公司

Method of removal of carbonyl compounds along with acid gases from cracked gas in ethylene process

InactiveUS20050224394A1Reduce concentrationPreventing plugging and foulingThermal non-catalytic crackingCatalytic crackingCaprolactamCaproic Acid

A method for mitigating fouling in a wash unit used in a hydrocarbon cracking process wherein the fouling is due to the presence of polymers and deposits thereof formed by condensation of carbonyl compounds contained within a feed stream of the wash unit. In one embodiment, the invention provides a method of mitigating fouling in a wash unit by introducing into the feed stream an effective amount of an additive including: an inorganic salt of dithionite; and an epsilon caprolactam or a 6-amino caproic acid derivable therefrom. The additive scavenges the carbonyl compounds contained within the feed stream and dissolves deposits of the polymers to thereby mitigate fouling in the wash unit.

Owner:DORF KETAL CHEM

Catalytic pyrolyzing agent for pulping without steaming and boiling

InactiveCN1818205ALow colloidal contentReduce manufacturing costPulp bleachingCellulose material pulpingFiberDithionous acid

A catalyzer used in pulping without steam cooking which consists of at least one enzyme, one anthraquinone compound, one permeate agent, EDTA sodium salt , oxidative bleacher and alkali. Soak fibrous material in solution of this catalyzer for 2 to 6 hours and its OK.The soak separated after reaction shows light yellow color and can be reutilized owing to the low temperature. Other adventages are low energy consumption, high productivity and low cost.

Owner:雷金丰

Use of an aqueous neutral cleaning solution and method for removing rouging from stainless steel surfaces

ActiveUS8192550B2Avoid pollutionNon-surface-active detergent compositionsDetergent mixture composition preparationAcid groupDithionite

The invention relates to a method for removing films and deposits from stainless surfaces, especially from stainless metallic surfaces such as they are used in process stations and production units in the pharmaceutical, food and biotechnological industries, and to an aqueous cleaning solution comprising a reducing agent, in particular dithionite and / or disulfite, and at least two different complexing agents, wherein one of these complexing agents is a compound comprising diacetic acid groups or a salt thereof, for removing rouging on surfaces of stainless steels that come into contact with media selected from the group of chromium / nickel and chromium / nickel / molybdenum steels in the neutral pH range.

Owner:ATECO SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com