Patents

Literature

31results about How to "Recycling resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

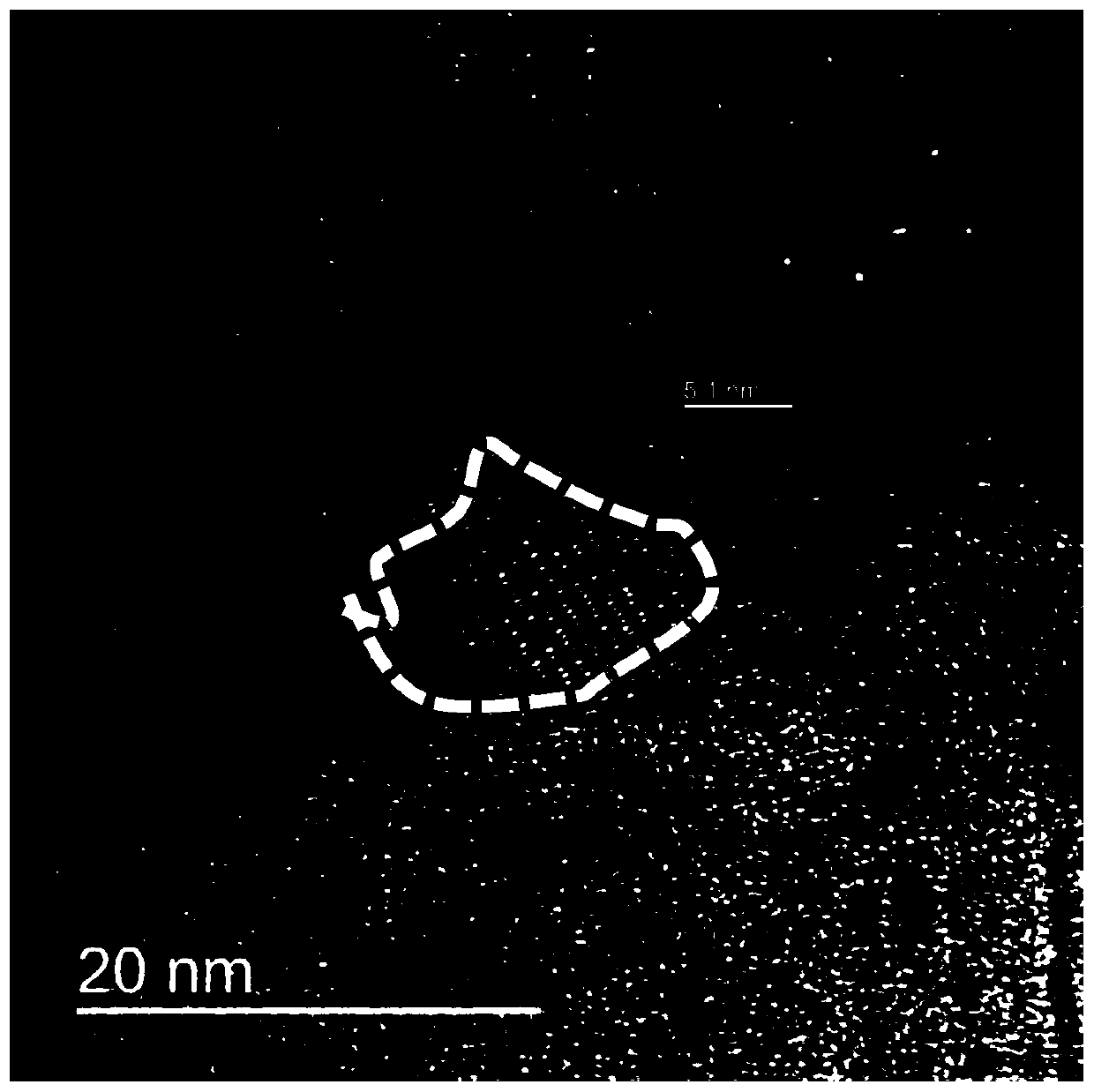

Carbon coated nanosilicon composite material as well as preparation method and application thereof

ActiveCN106784732AEasy to spreadImprove cycle stabilityMaterial nanotechnologySecondary cellsCarbon coatingUltrasound attenuation

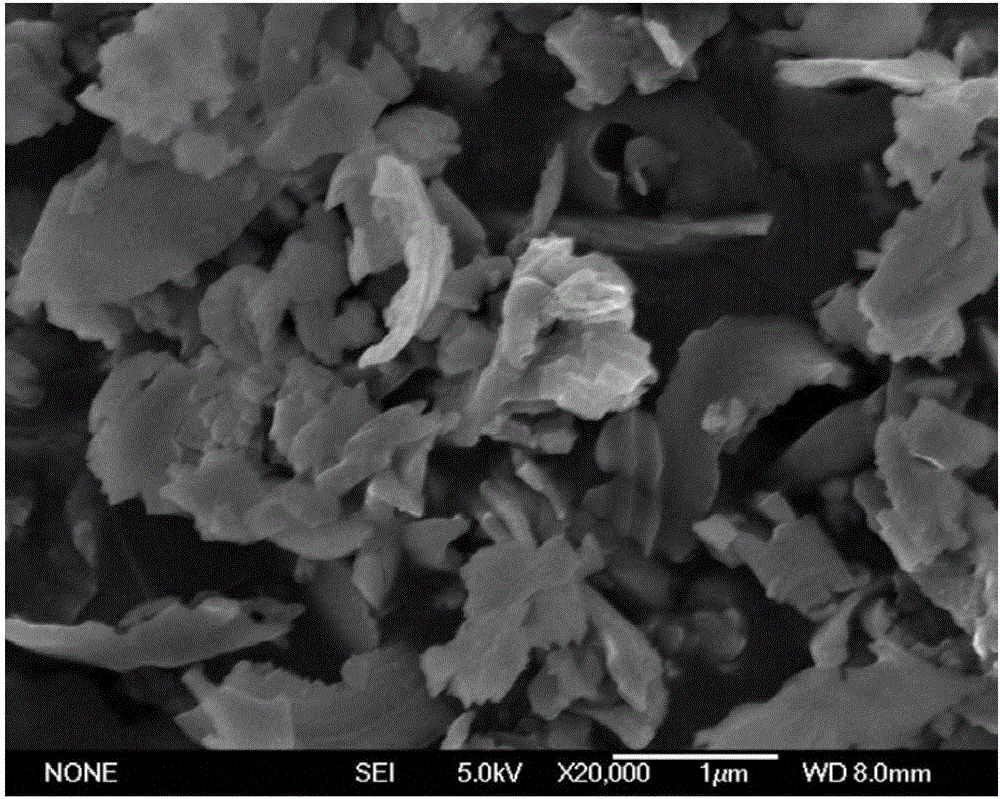

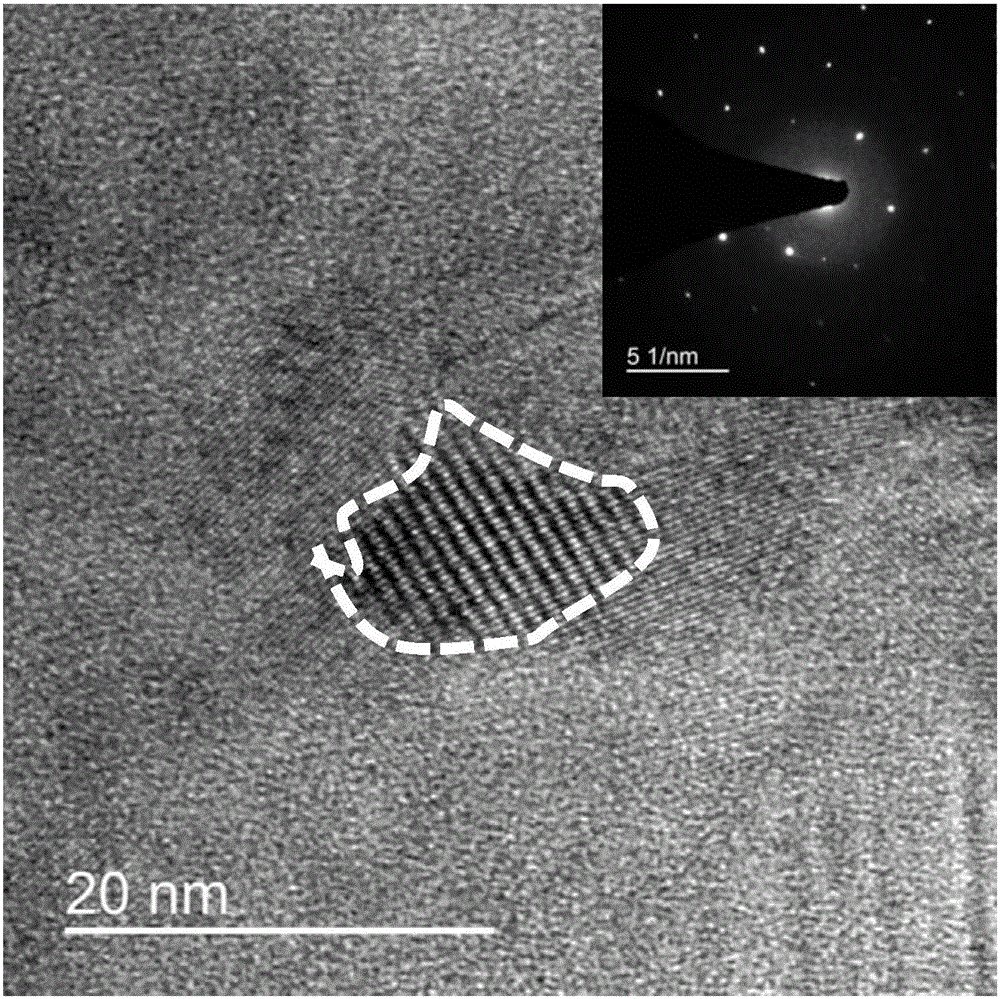

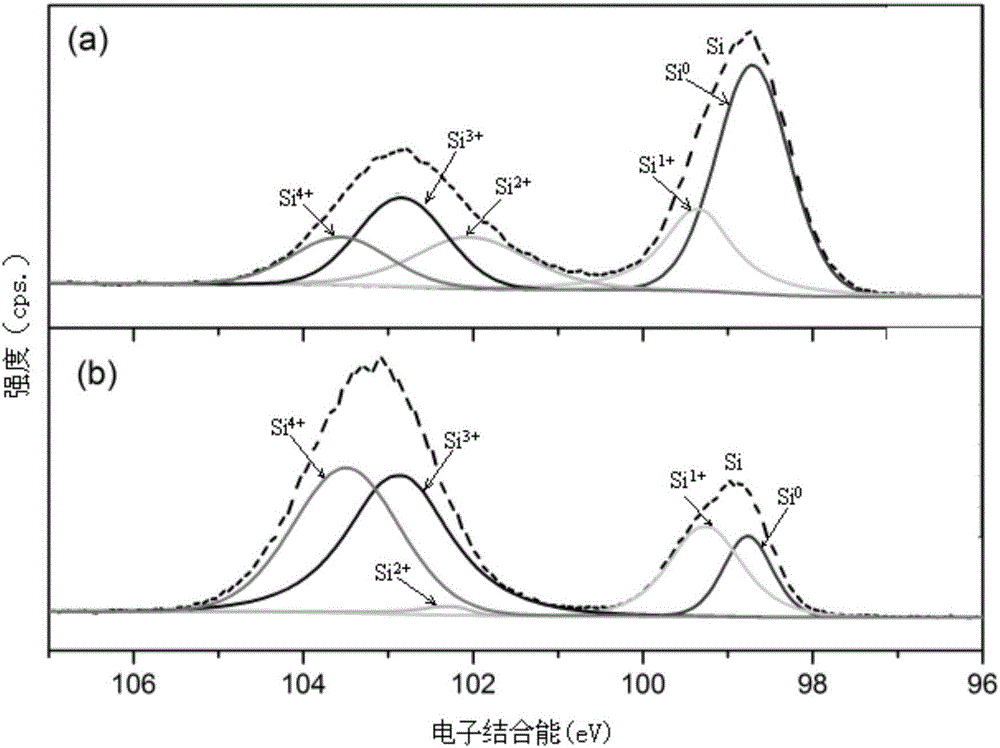

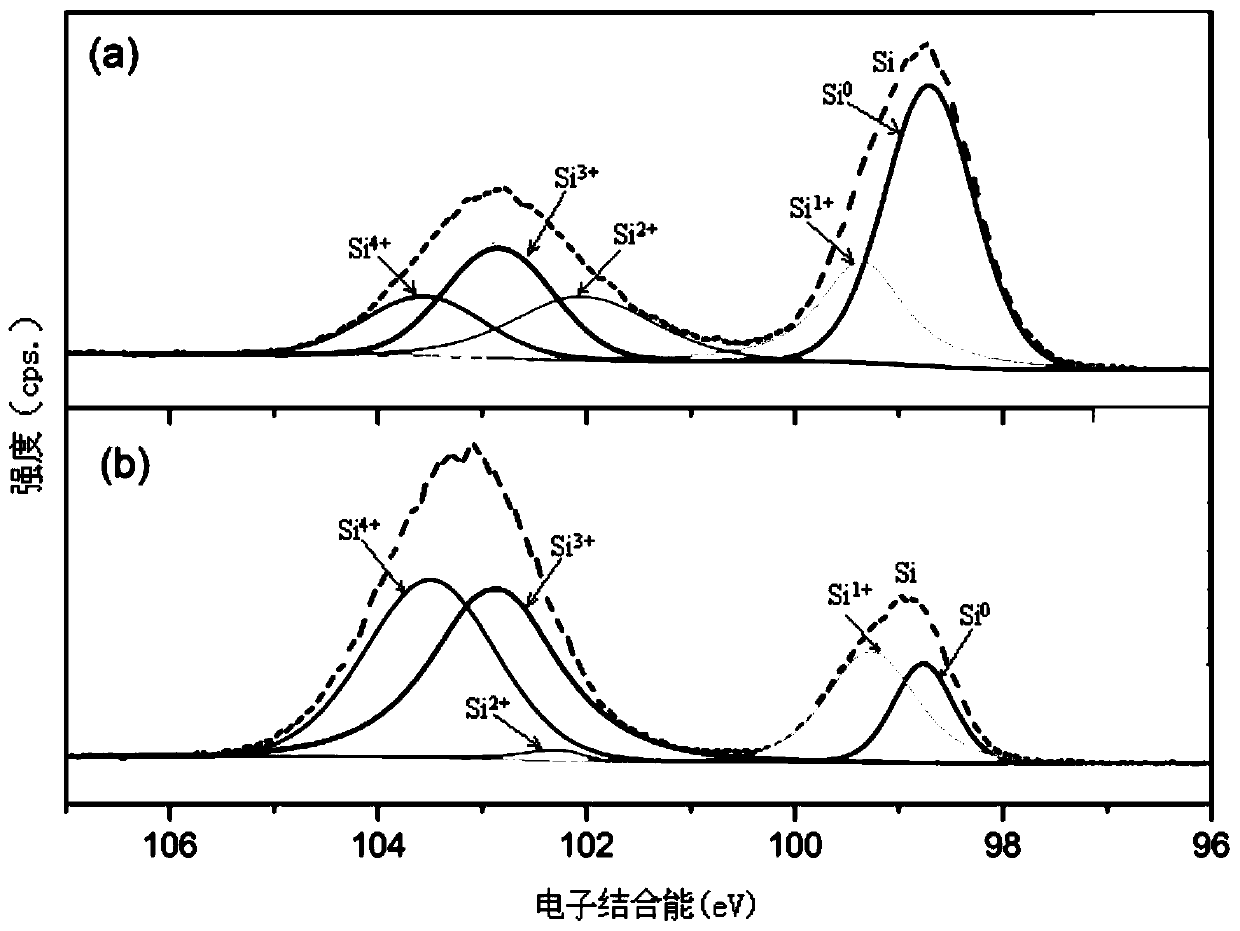

The invention relates to a carbon coated nanosilicon composite material as well as a preparation method and an application thereof. The invention relates to silicon composite powder as well as a preparation method and an application thereof. The invention aims to solve the technical problem that an existing method of reducing the volume effect of a silicon-based cathode material by virtue of nanocrystallization, alloying or porous forming is complex in preparation process and high in cost. The carbon coated nanosilicon composite material provided by the invention is powder of a core-shell structure taking nanosilicon particles as a content and carbon as a shell. The preparation method comprises the following steps: performing oxygen diffusion on nanoscale silicon micropowder with an oxidizing layer on the surface; then performing carbon coating treatment; and then soaking the same with a hydrofluoric acid solution to remove the component of silicon oxide to obtain the carbon coated nanosilicon composite material. The volume of the carbon coated nanosilicon composite material provided by the invention reaches 900mAh / g or above, attenuation after 150 times of cycles is smaller than 4%, and the material can be used as a lithium battery silicon cathode material.

Owner:吕铁铮

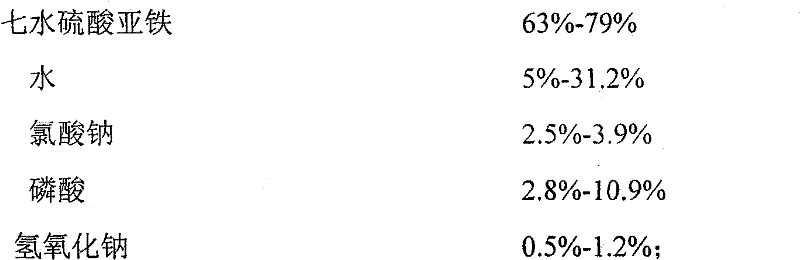

Compound phosphoric polyferric sulfate flocculant and production method thereof

ActiveCN101805051AReduce turbidityReduce CODWater/sewage treatment by flocculation/precipitationPhosphorus compoundsLiquid wasteInorganic compound

The invention provides a novel inorganic compound phosphoric polyferric sulfate flocculant and a production technology thereof. The flocculant can be used in both water treatment and sewage treatment thereby being multifunctional. The phosphoric polyferric sulfate of the invention takes the by-products generated in titanium pigment production, such as ferrous sulfate, phosphoric acid and the like for producing titanium pigment as raw materials thereby having the characteristics of utilization of waste products, simple components, low cost and the like. The production technology of the invention is convenient, has simple operation and can be carried out at normal temperature and normal pressure. In the production process, no liquid waste, waste gas and waste residue can be generated, and the production technology belongs to the cleaner production technology. The invention can be widely applied in water treatment and sewage treatment. Especially in water treatment, the phosphoric polyferric sulfate flocculant of the invention is added to effectively remove soluble phosphorus and phosphorus in other forms in water as well as algae in algae waste water, lower chemical oxygen demand (COD), total phosphorus (TP), suspended solid (SS), chlorophyll (chl-a) and the like.

Owner:善水(南通)工业技术有限公司

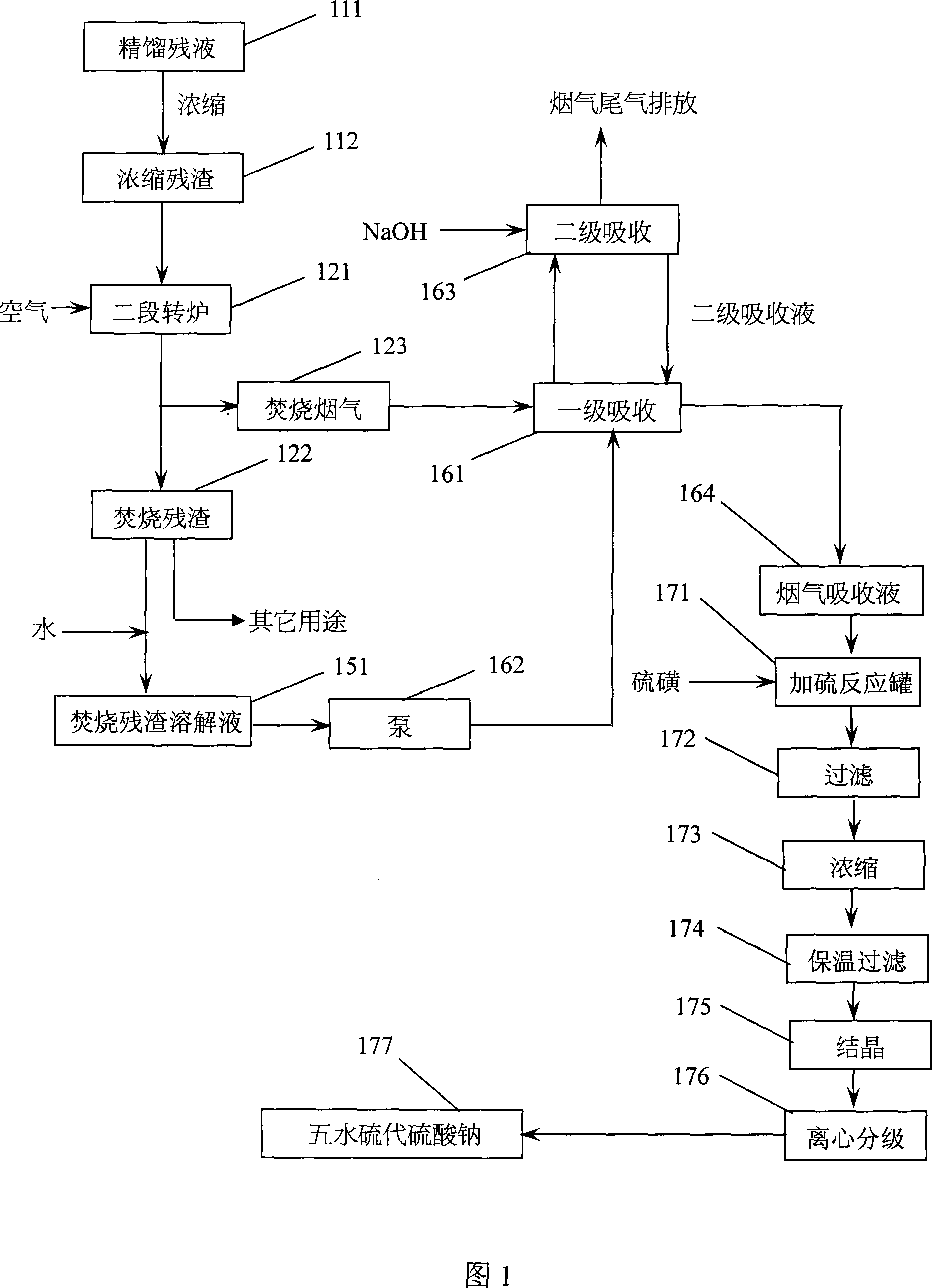

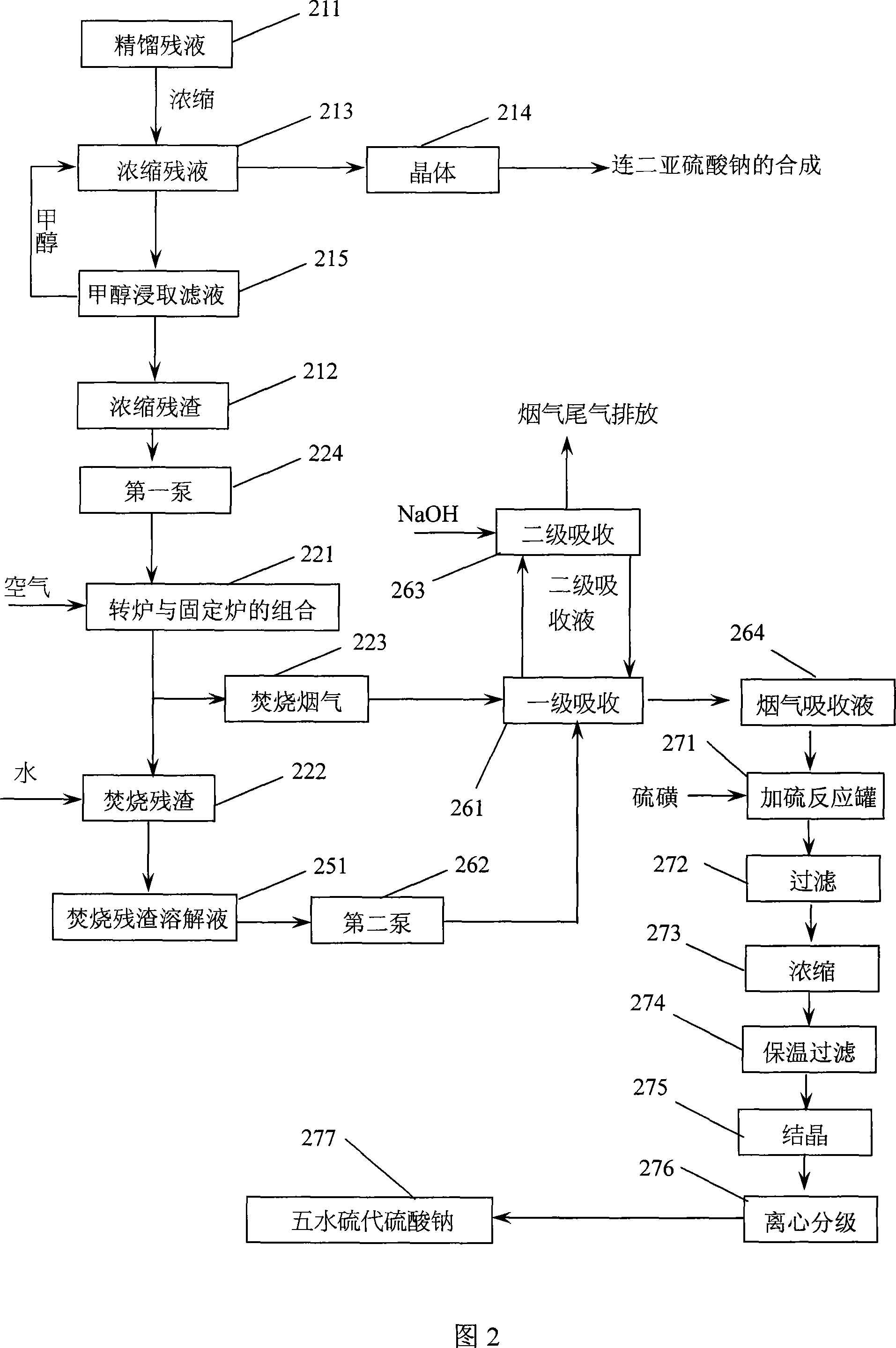

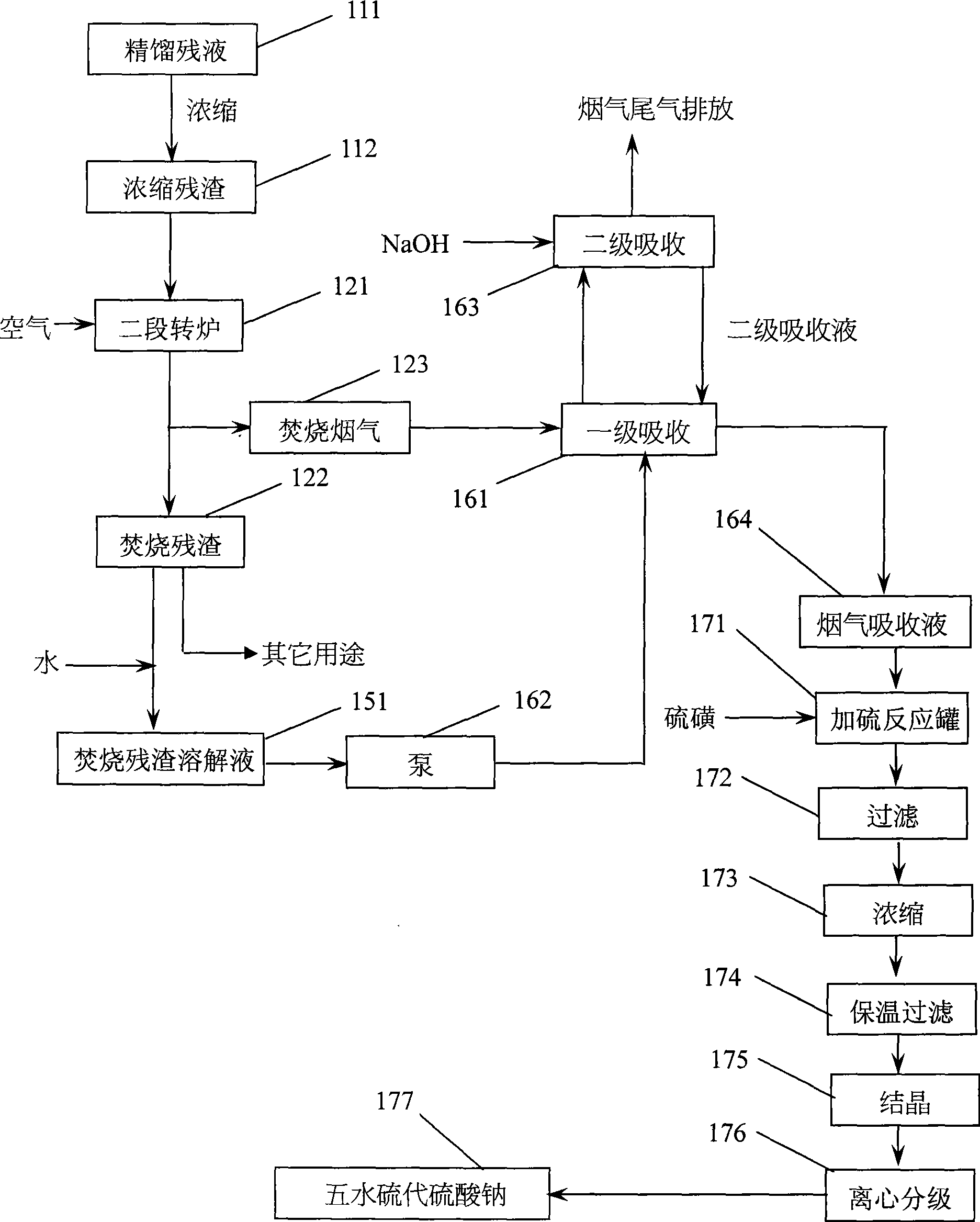

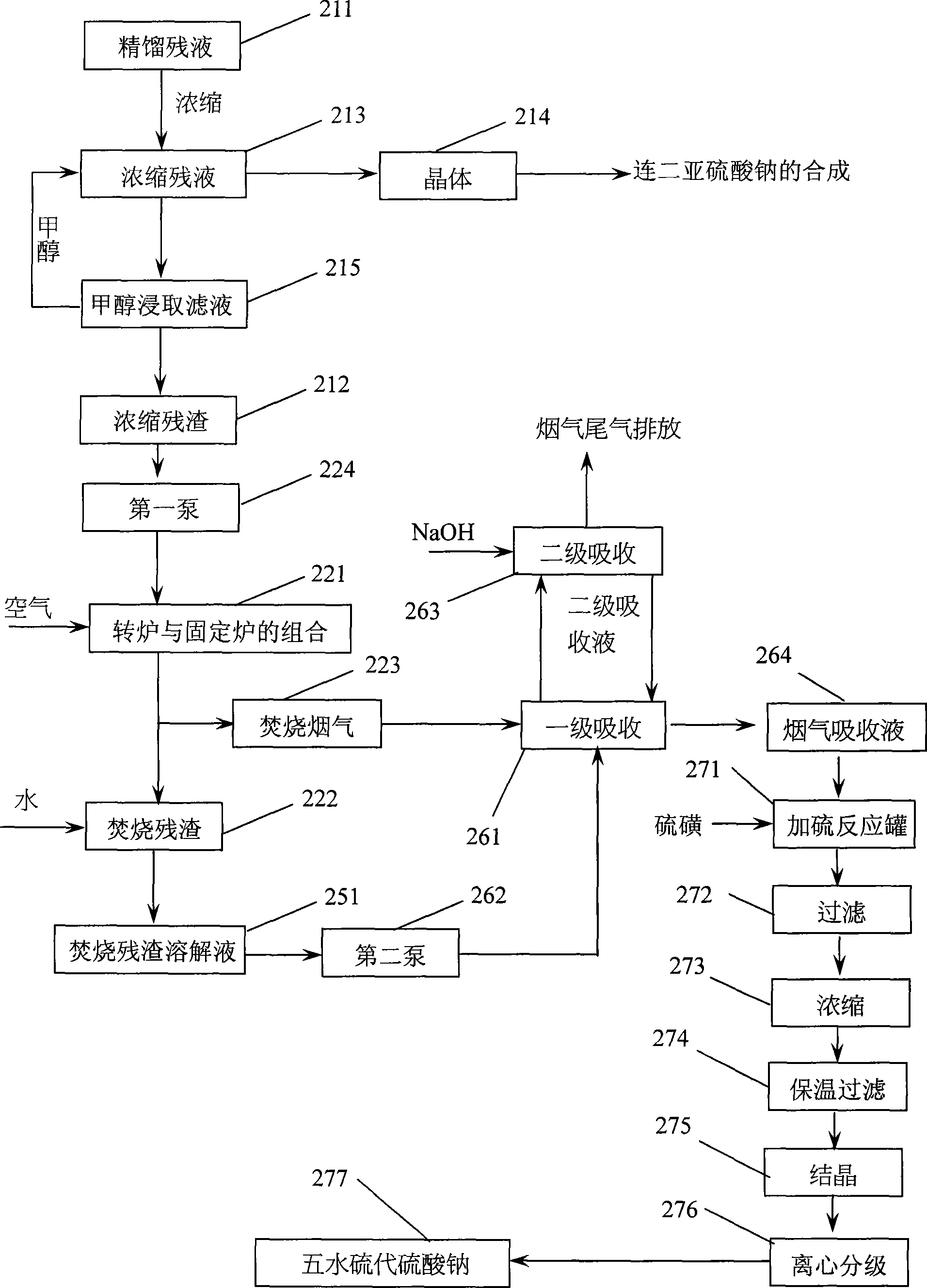

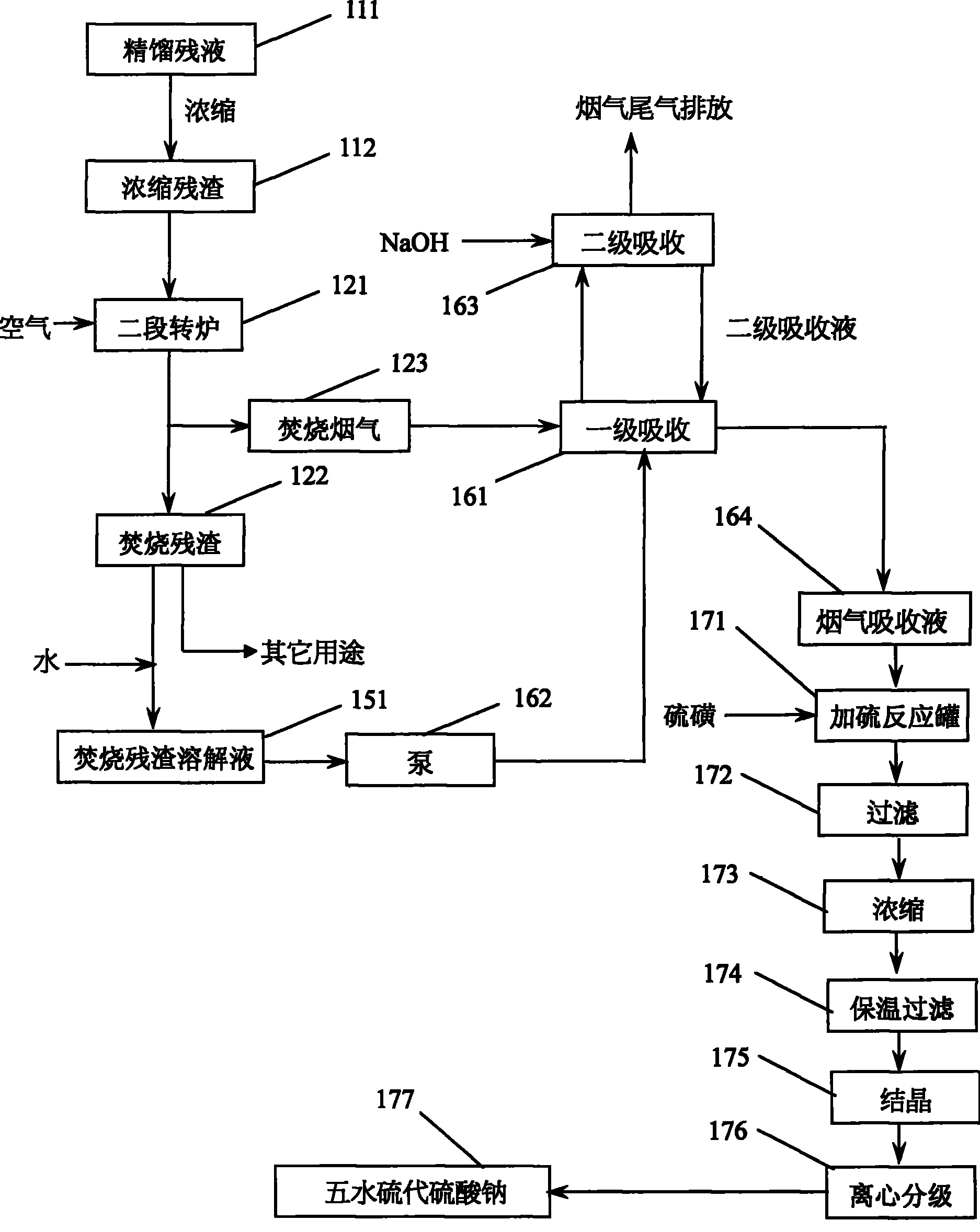

Method for treating residual liquid after mother liquor distillation methanol recovery during production of sodium sulphoxylate by sodium formate process

InactiveCN101081715AEliminate secondary pollutionRecycling resourcesThiosulfates/dithionites/polythionitesDispersed particle separationDithionous acidSulfite salt

The present invention is process of treating mother liquid residue from sodium formate method to produce sodium hyosulfate and after being rectified to recover methanol. The process includes the following steps: 1. concentrating to obtain concentrated residue with or without sodium formate recovery; 2. incinerating the concentrated residue in a converter or one combined furnace to obtain incinerated clinker; 3. discharging high temperature clinker; 4. dissolving the clinker to form water solution; 5. absorbing SO2 from the incinerating fume with the water solution; and 6. adding sulfur to the absorbed solution to prepare sodium thiosulfate. The process can eliminate pollutant while producing sodium thiosulfate as chemical material.

Owner:GUANGDONG ZHONGCHENG CHEM INC LTD

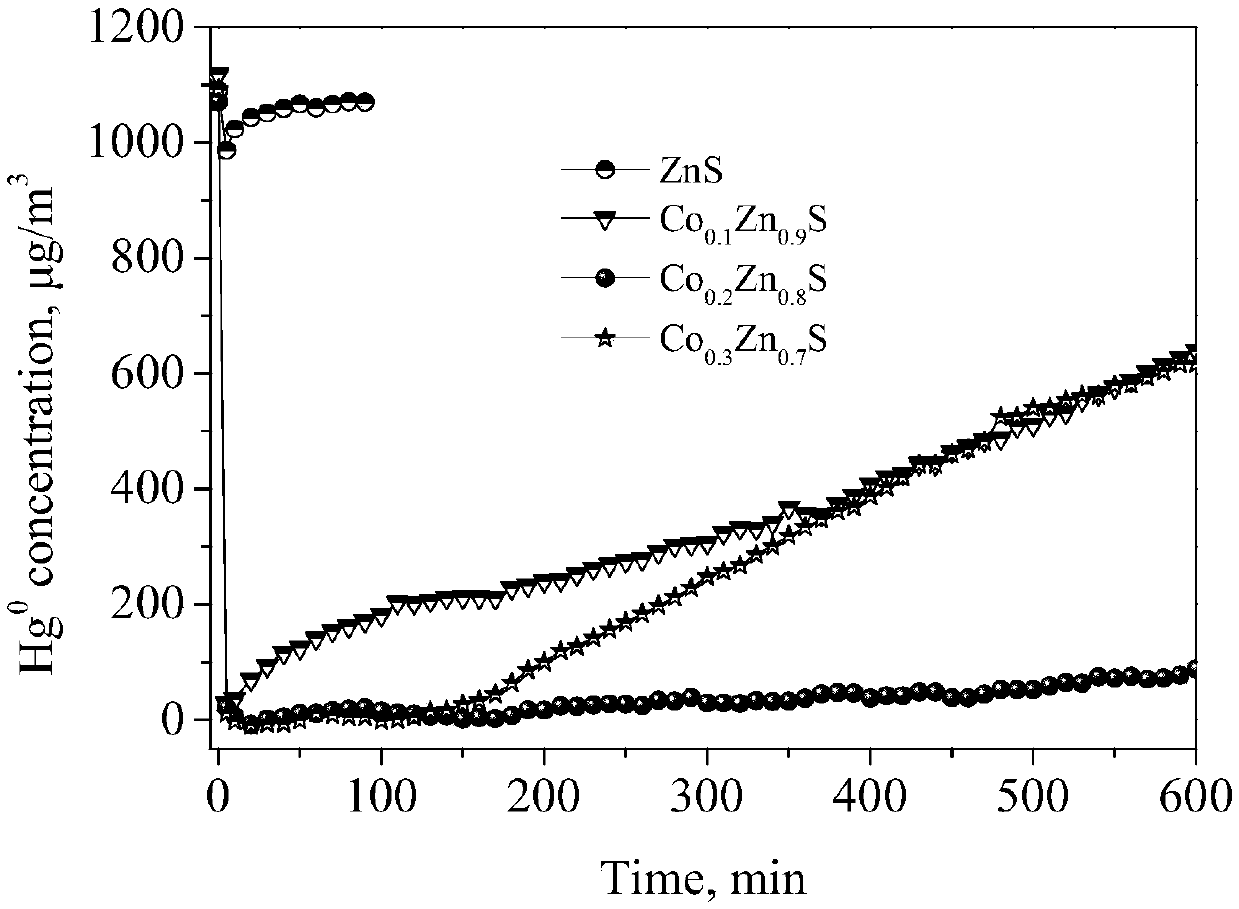

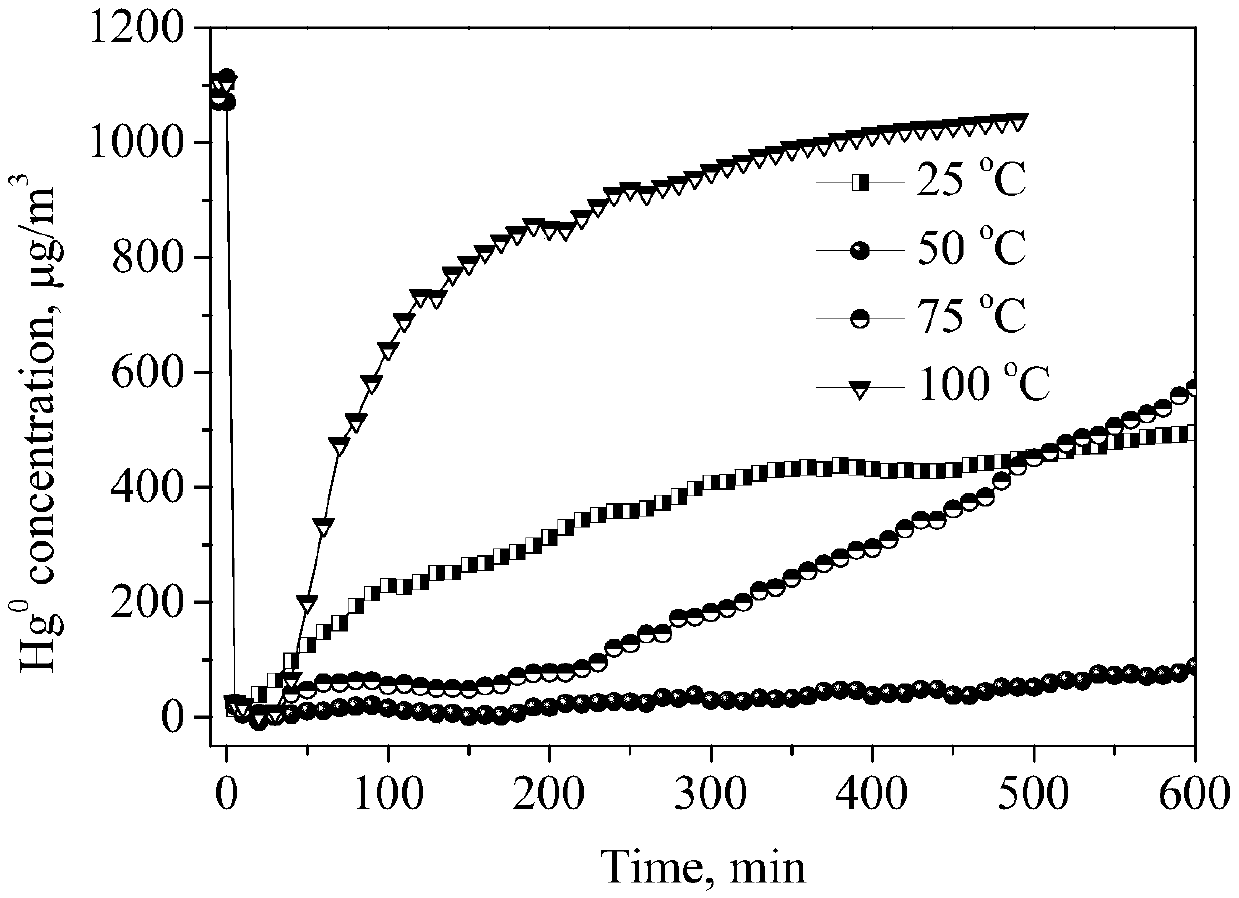

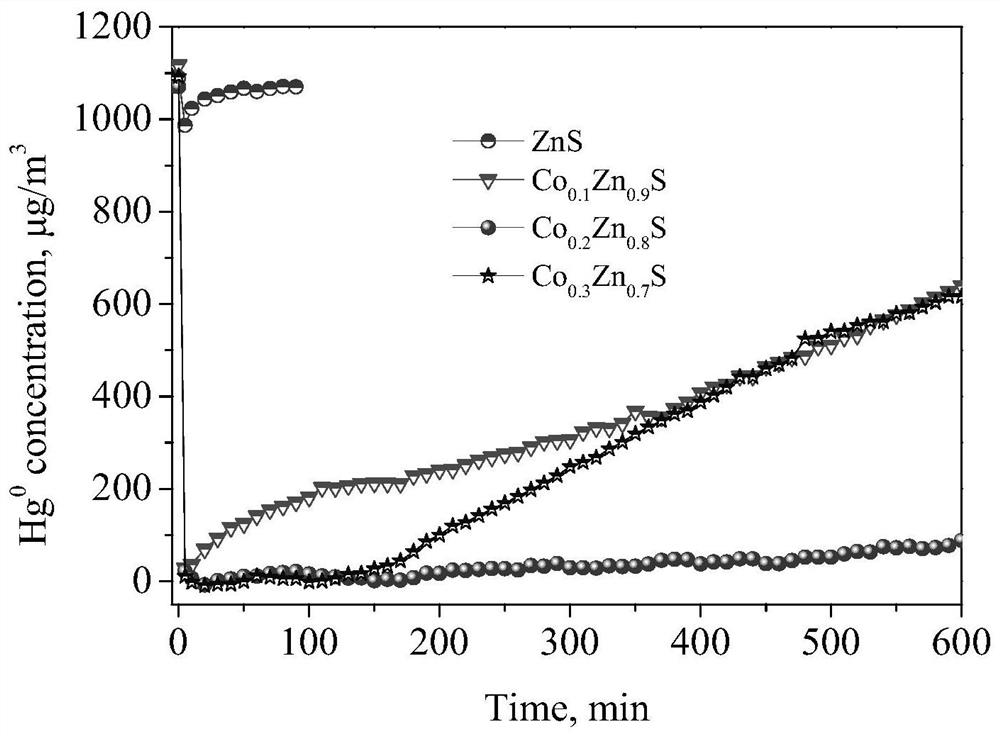

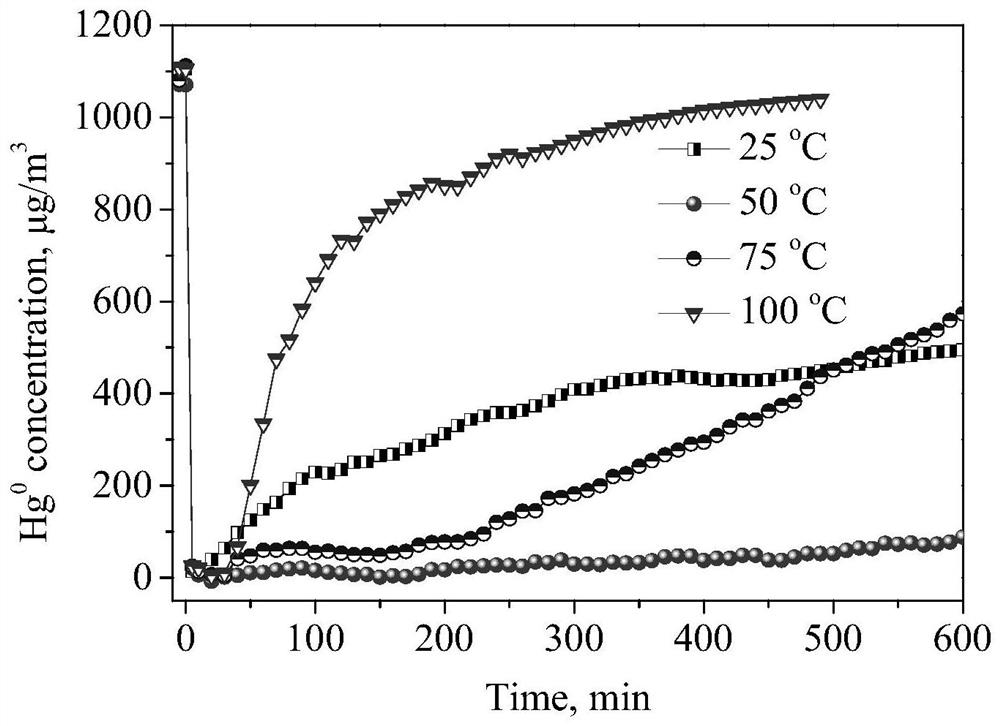

Zinc sulfide based mercury adsorbent for flue gas zero-valent mercury capturing and preparation method of zinc sulfide based mercury adsorbent

ActiveCN109092239ASimple processMild operating conditionsGas treatmentOther chemical processesSorbentFlue gas

The invention relates to a zinc sulfide base mercury adsorbent for flue gas zero-valent mercury capturing and a preparation method of the zinc sulfide based mercury adsorbent. The adsorbent is a cobalt-doped zinc sulfide mercury adsorption material CoxZn1-xS, in the formula, x represents the stoichiometric ratio of cobalt in a solution, and the stoichiometric ratio is 0.1-0.3. The preparation method comprises the following steps: (1) dissolving a cobalt salt and a zinc salt of a certain mole ratio into deionized water so as to obtain a mixed solution; (2) mixing and stirring the mixed solutionwith a precipitant; (3) putting a suspension liquid into a reactor, and carrying out heating treatment on the reactor in a baking oven; (4) repeatedly washing the obtained precipitate with deionizedwater, and drying, thereby obtaining the zinc sulfide based mercury adsorbent. Compared with the prior art, the preparation method is wide in raw material source, simple and controllable in preparation process and gentle in reaction condition, and the prepared adsorbent has a mercury adsorption capability which is improved by dozens of times when being compared with pure zinc sulfide, in additionhas a very good anti-SO2 influence property, is capable of maintaining certain high activity within a long time, and is particularly applicable to adsorption and removal of zero-valent mercury in a metallurgical flue gas.

Owner:SHANGHAI JIAO TONG UNIV

High calcium organic wastewater treatment method

ActiveCN103130353AReduce COD valueRecycling resourcesCalcium/strontium/barium sulfatesMultistage water/sewage treatmentDistillationGas phase

The invention relates to a high calcium organic wastewater treatment method, which comprises: mixing industrial wastewater containing 0.1-20% by mass of organic calcium carboxylate and an inorganic acid according to a molar ratio of 1:1-1:0.2, carrying out an acidification reaction at a temperature of 50-90 DEG C, and separating the resulting mixed material to obtain an inorganic calcium salt crude product; carrying out a liquid-liquid extraction reaction on an aqueous solution containing the organic carboxylic acid and a small amount of the inorganic calcium salt compound to generate an organic carboxylic acid complex having a boiling point of more than a boiling point of the organic carboxylic acid; and carrying out pressure reduction distillation on the upper layer material containing the organic carboxylic acid complex, collecting a distillate with a gas temperature of 60-100 DEG C, and carrying out nature sedimentation separation on the distillate, wherein an organic carboxylic acid aqueous solution with a mass fraction of 20-85% is obtained from the lower layer, and the upper layer material is mixed with the residual liquid on the bottom of a pressure reduction distillation kettle to obtain a recycled extraction agent. The method has characteristics of simple process, less raw material consumption, high yield, high production efficiency, easy reaction process enlargement, and source re-utilization achievement.

Owner:PETROCHINA CO LTD +1

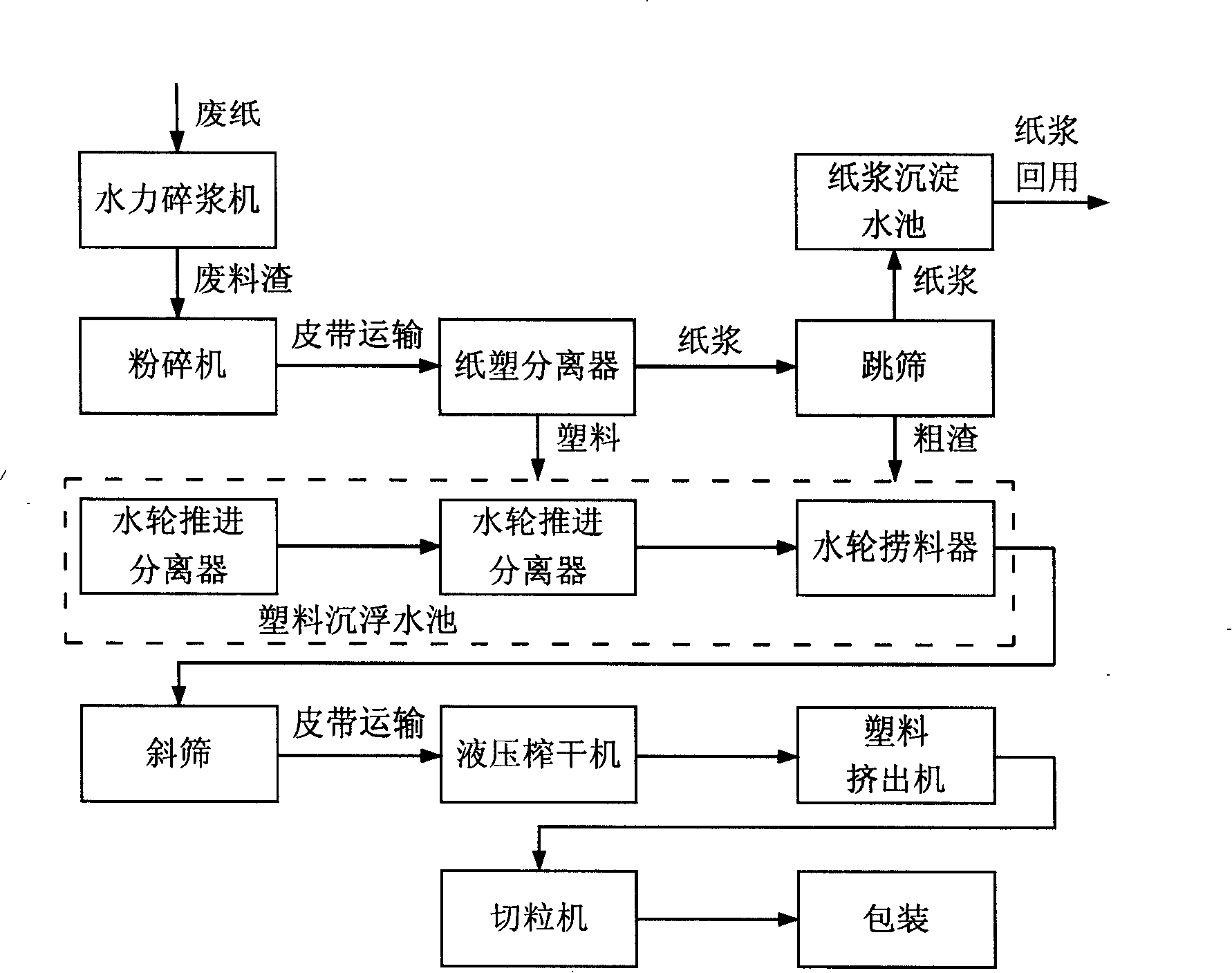

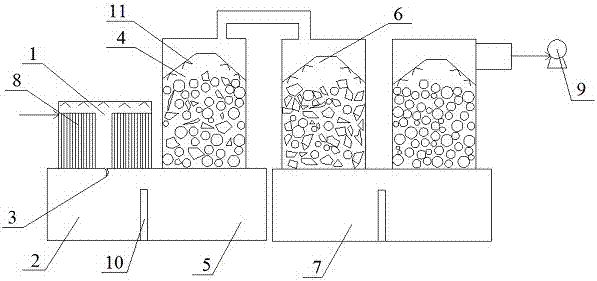

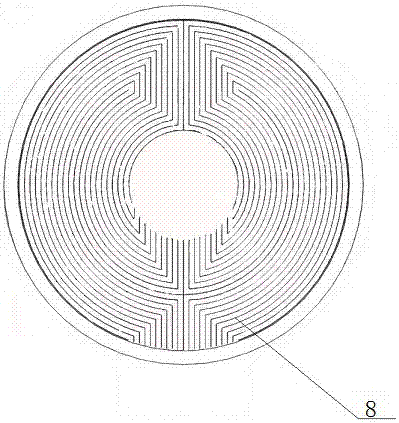

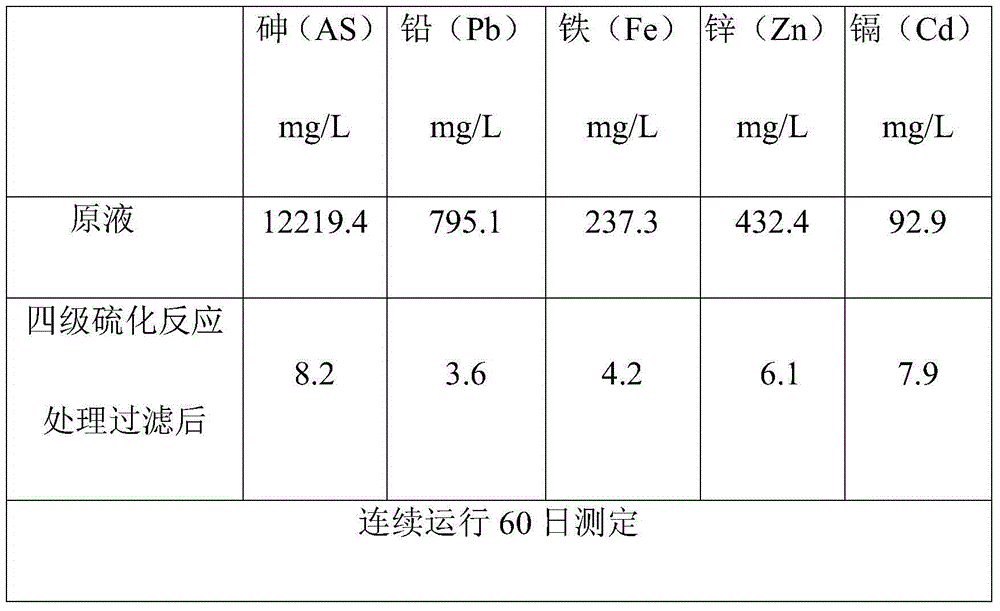

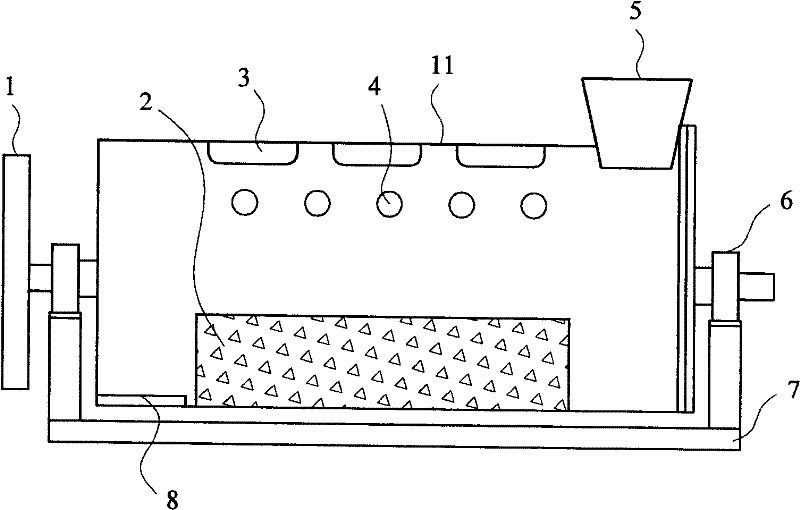

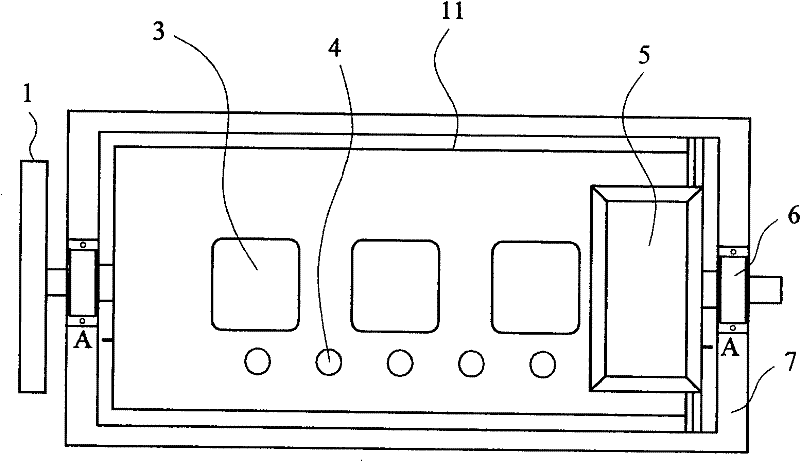

Production processing method and device for regenerating waste material slag in wastepaper papermaking

The invention discloses a production processing method and the device thereof for the waste slag regenerating in paper making through using the paper. The method comprises the following steps: firstly, the paper making waste slag including the waste plastics and paper pulp and discharged from a pulper is sent to a processing field; secondly, the waste slag is cut into pieces, and the ball-shaped waste slag is cut into pieces mainly; thirdly, the water is added into the cut waste slag and drubbed into the paper pulp with the waste plastics; fourthly, the paper pulp and the waste plastic are separated, to get the required paper pulp and plastics. The processing device for the waste slag regenerating comprises a crushing machine, a paper and plastic separator, a water vessel, a water wheel separating pusher, and a water wheel slag gaining apparatus. The invention can automatically separate the waste slag in the paper making industry, the production efficiency of the paper pulp reclamation is improved, and not only the resource is saved, nut also the environmental pollution can not be caused.

Owner:陈维强 +1

Separating, purifying and recycling method of amine substances in sucralose wastewater

InactiveCN108047053ALow toxicityImprove biodegradabilityAmino compound purification/separationWater/sewage treatment by heatingWastewaterEvaporation

The invention provides a separating, purifying and recycling method of amine substances in sucralose wastewater. A resource treating method of the sucralose wastewater comprises the steps of firstly,using an evaporating method to primarily separate the wastewater to obtain evaporation condensate and a concentrated solution, directly using the evaporation condensate as technology water in the sucralose synthesis process, or conducting standard-reaching drainage after biological treatment; adding alkaline into the concentrated solution to be heated to be secondarily separated, so that the aminesubstances in the concentrate solution are volatilized in a gas state and are recycled with acid liquid or water; tertiarily separating volatilization residual liquid according to a cooling and crystalizing method to separate out chlorine salt crystal, after the liquid phase is properly diluted, using a biological method for degrading and harmless treatment and conducting the standard-reaching drainage.

Owner:JIANGNAN UNIV

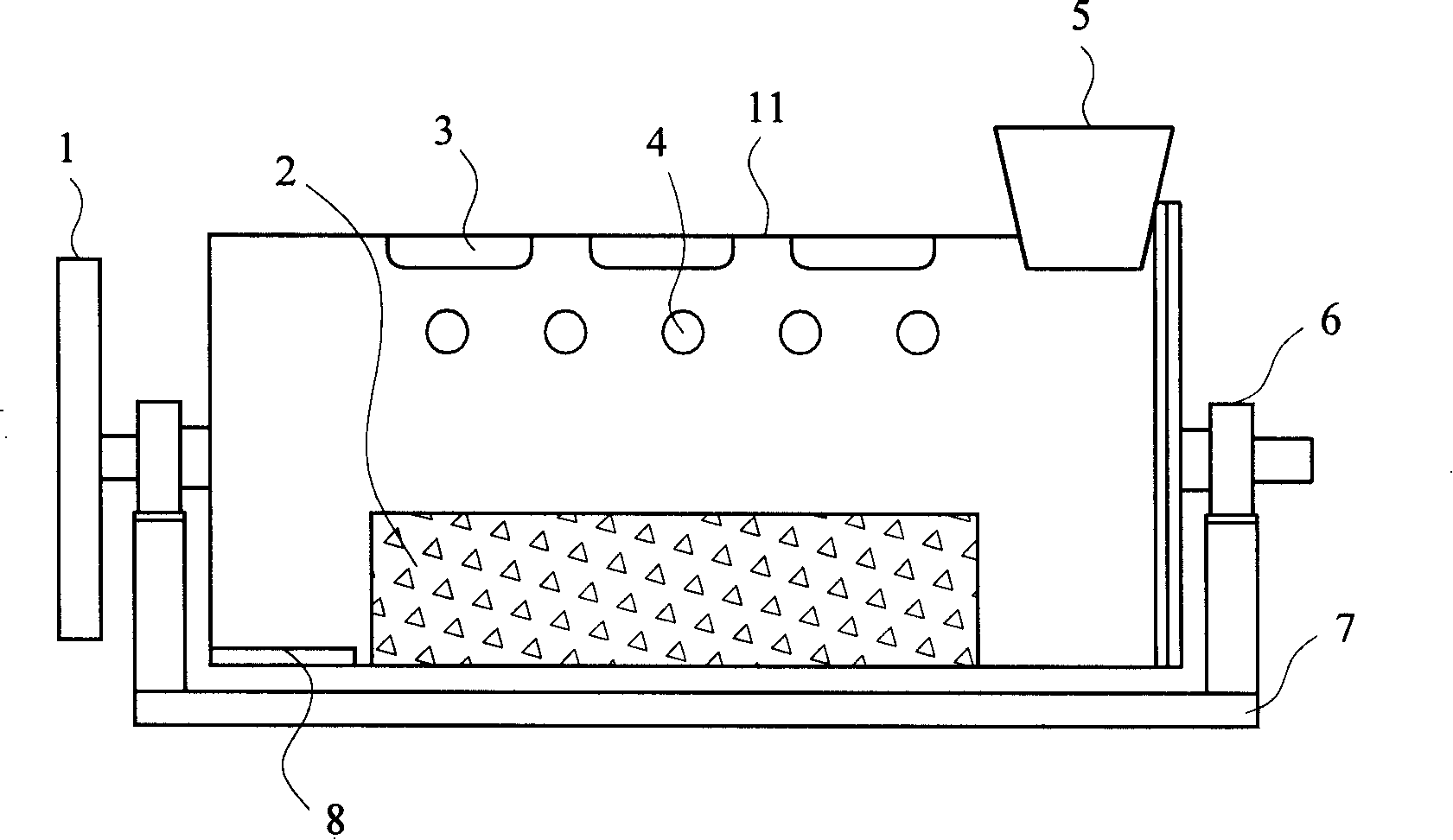

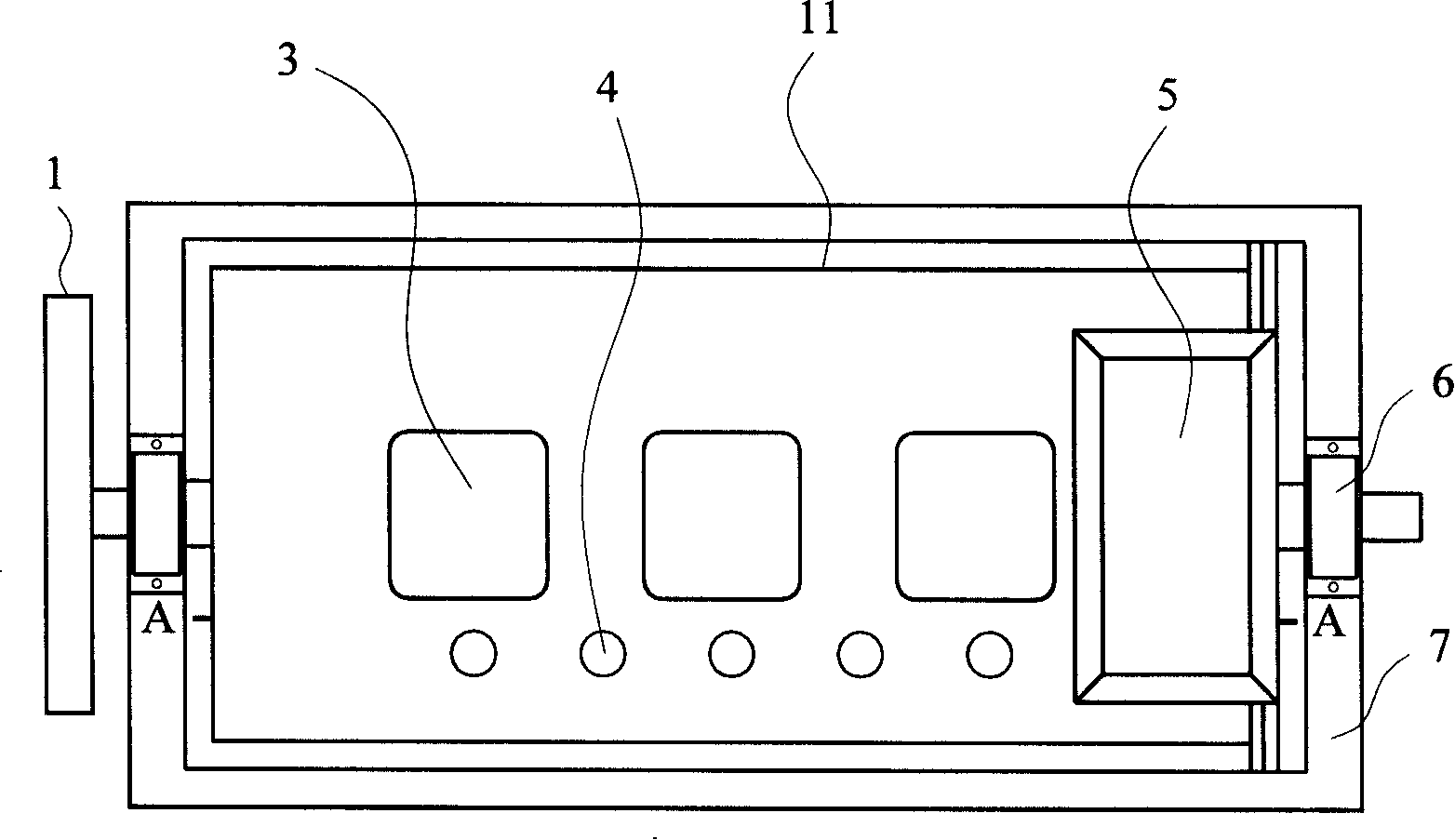

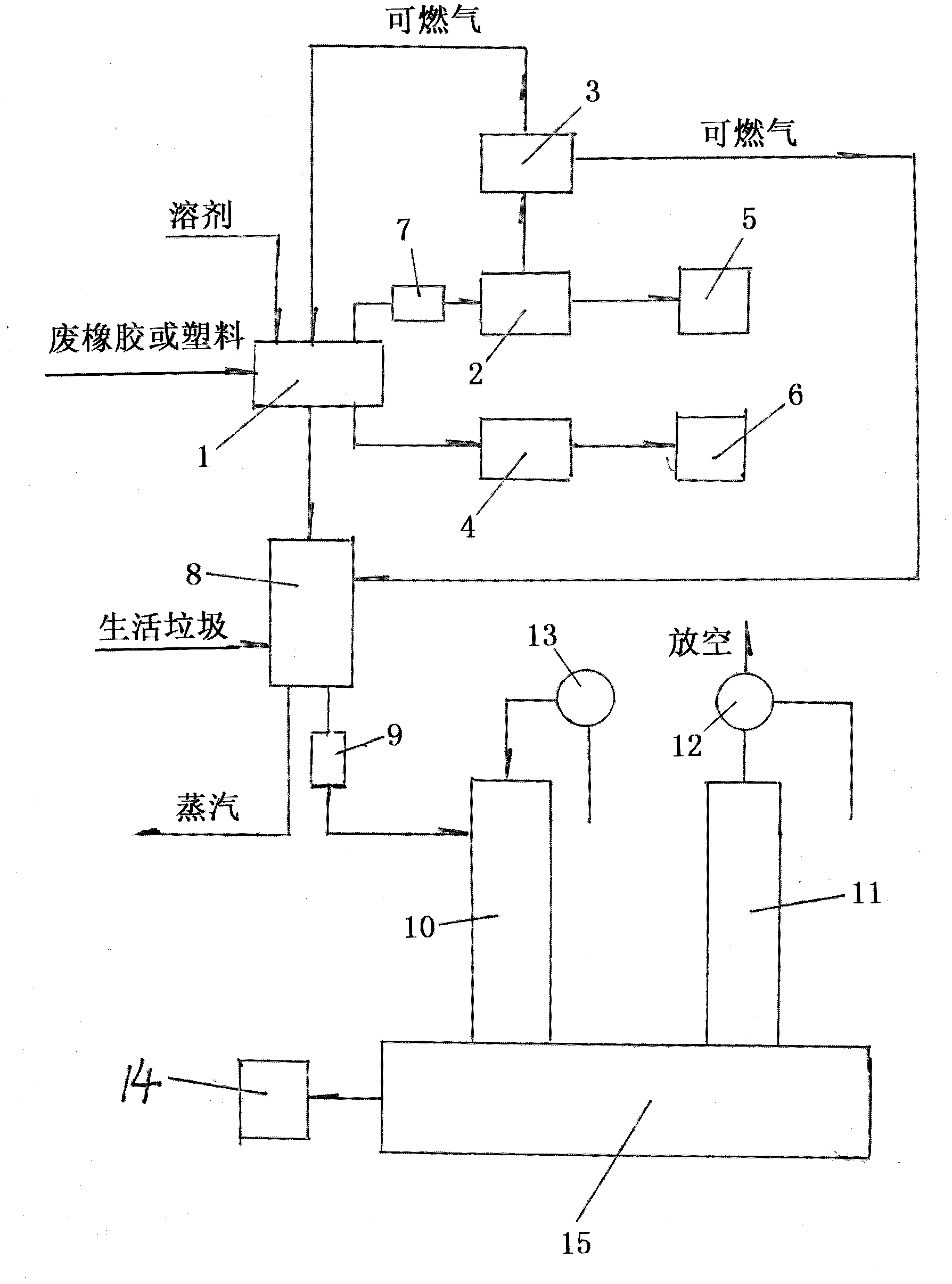

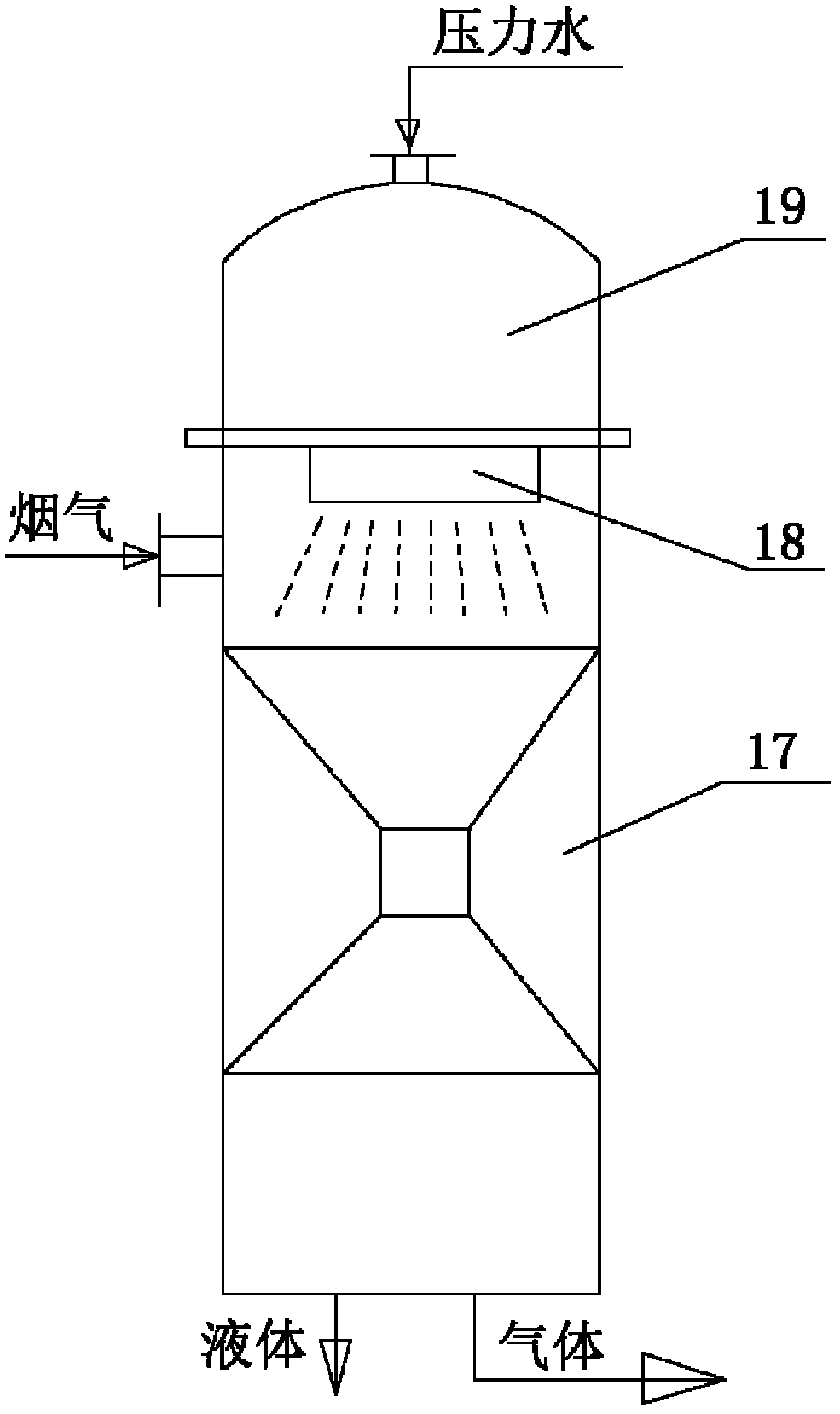

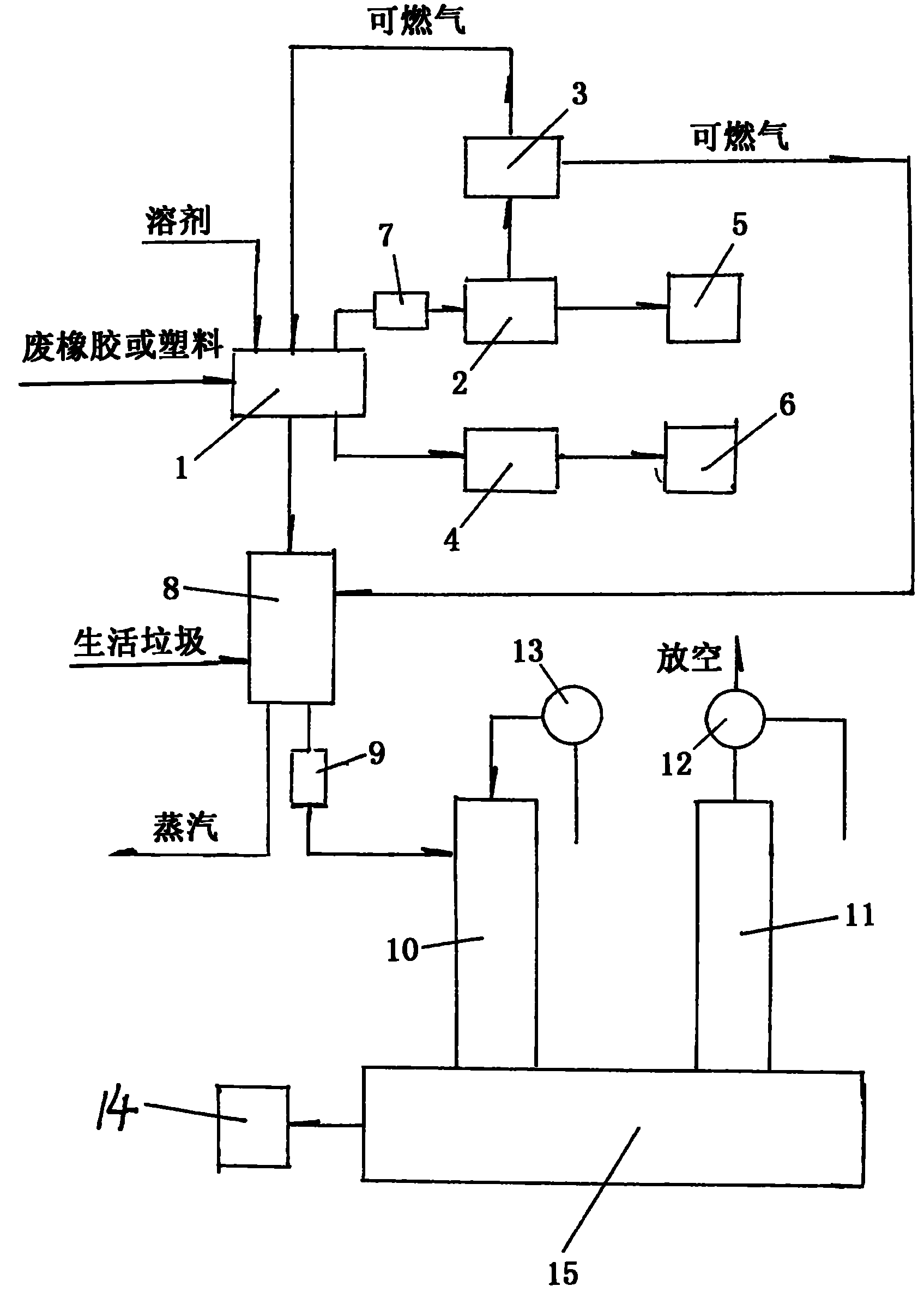

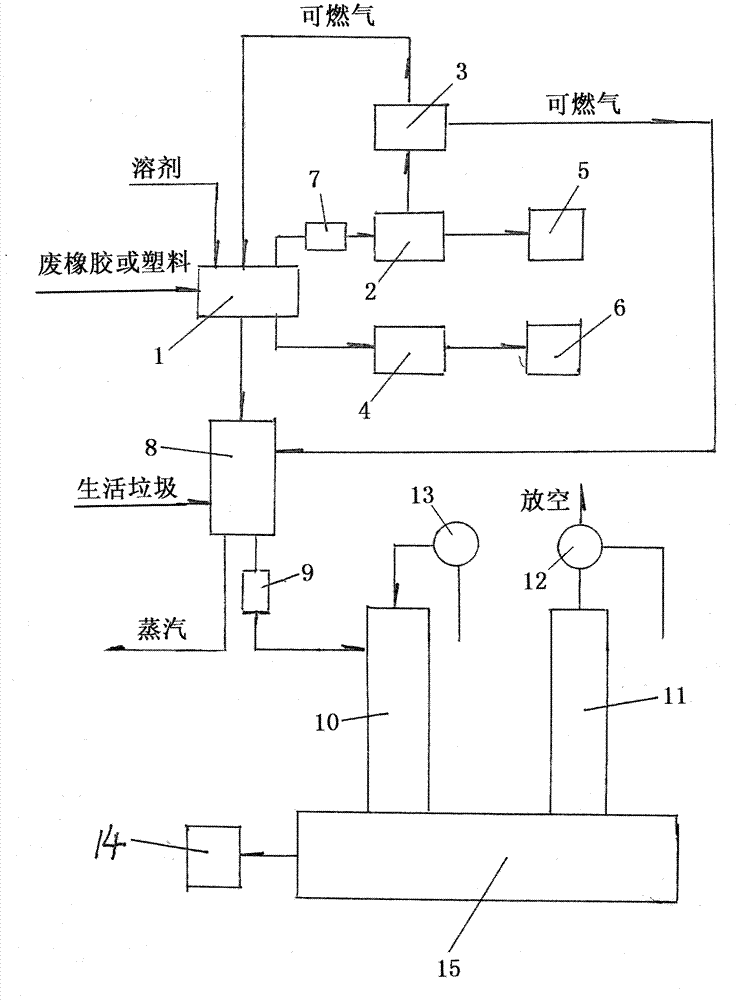

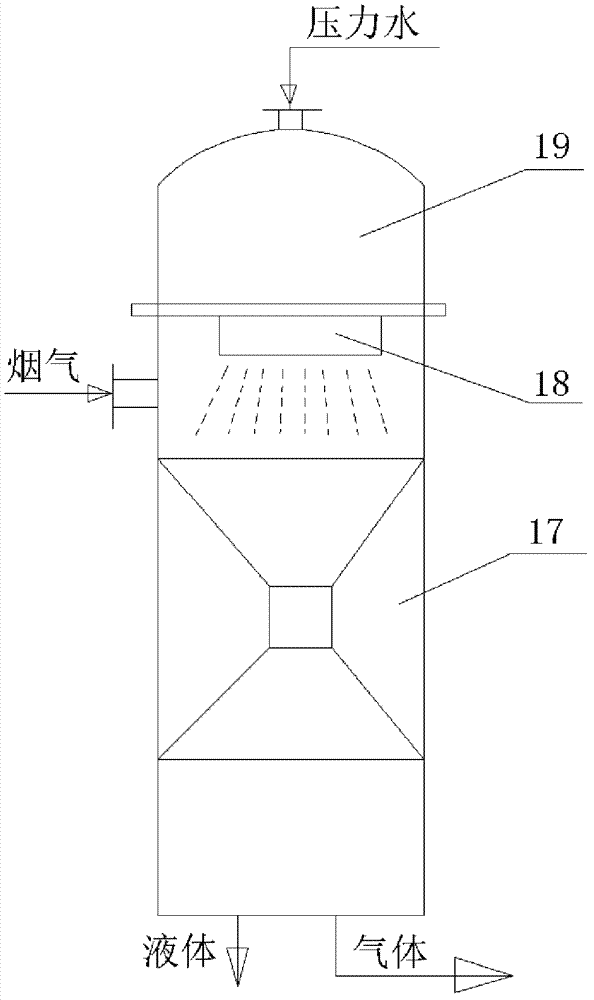

Hazard-free environment-friendly treatment process for reducing and recycling waste rubber, plastic and domestic garbage

InactiveCN102580981ARecycling resourcesAvoid secondary pollutionSolid waste disposalWaste rubberFuel oil

The invention discloses a hazard-free environment-friendly treatment process for reducing and recycling waste rubber, plastic and domestic garbage, which aims to solve the problem of difficulty in treatment of the waste rubber, the plastic and the domestic garbage. The process comprises the following steps of: classifying the waster rubber, the plastic and the domestic garbage, and putting into apyrolysis device and a waste heat boiler; feeding a gaseous product generated by the pyrolysis device into a separation device, and separating to obtain fuel oil and combustible gas; collecting a residual object, namely carbon black in the pyrolysis device; feeding the combustible gas into the pyrolysis device and the waste heat boiler for combustion; feeding flue gas exhausted from the waste heat boiler into a shock cooling device; and purifying by using a purification device, and emptying. The treatment process is easy to operate and control, pyrolysis and combustion are integrated, resources can be effectively recycled, and the problem of secondary pollution of waste gas and waste water is solved synchronously.

Owner:喻万钧

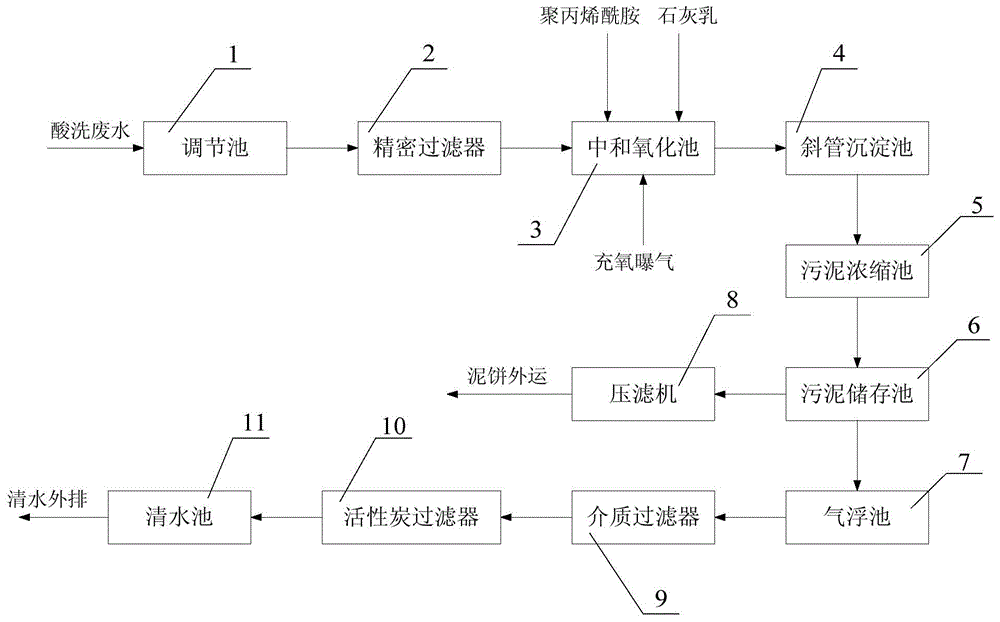

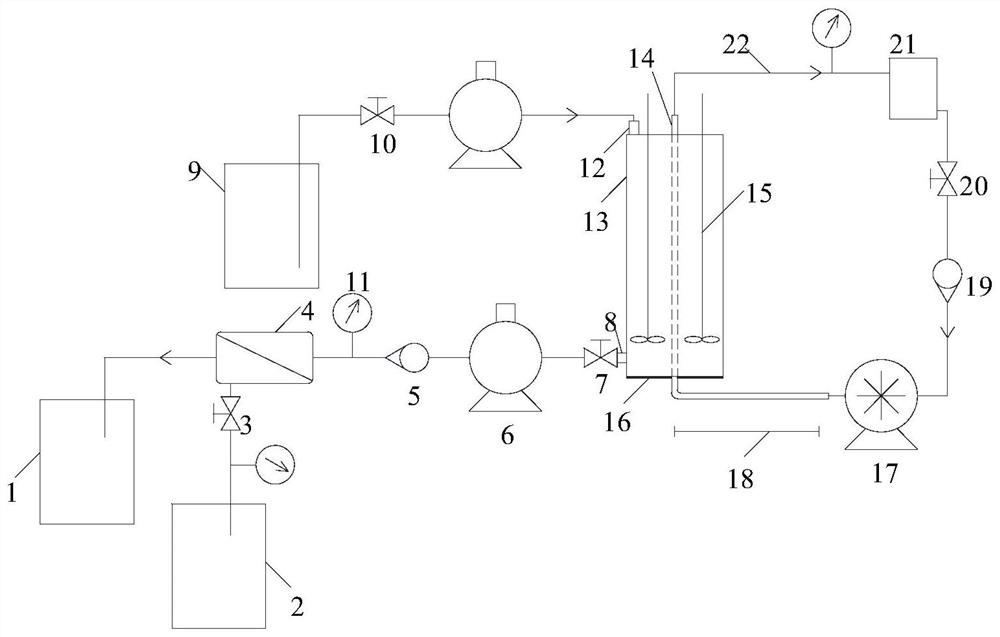

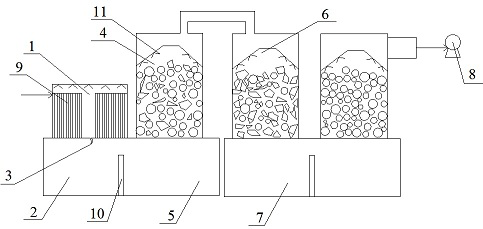

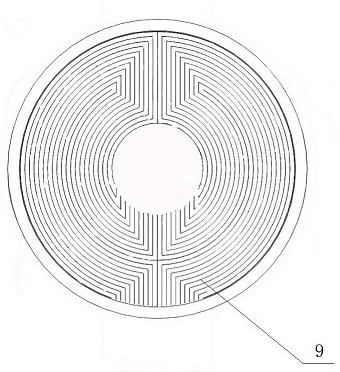

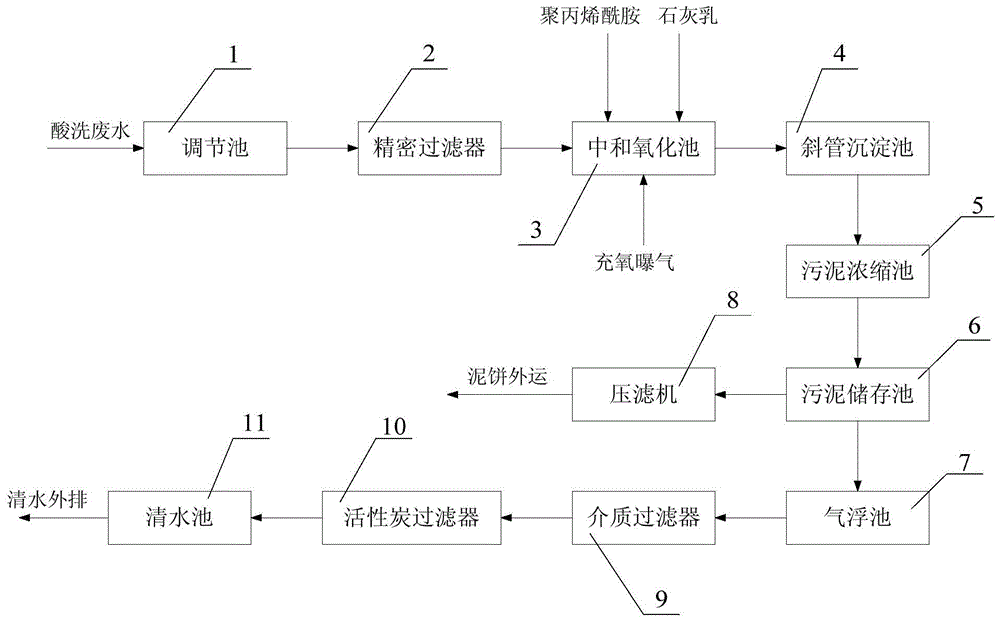

Waste liquid treatment recycling system of stainless steel pickling line

ActiveCN104891709AImprove recycling ratesSimple structureWaste water treatment from metallurgical processMultistage water/sewage treatmentSludgeActivated carbon filtration

The invention discloses a waste liquid treatment recycling system of a stainless steel pickling line. The waste liquid treatment recycling system mainly comprises a regulating reservoir, a precision filter, a neutralizing oxidation pond, an oblique pipe precipitation pond, a sludge concentration pond, a sludge storage pond, an air floatation pond, a press filter, a medium filter, an active carbon filter and a clean water pond, and is characterized in that pickling waste water flows into the regulating reservoir, the regulating reservoir is connected with the precision filter, the precision filter is connected with the neutralizing oxidation pond, the neutralizing oxidation pond is connected with the oblique pipe precipitation pond, the oblique pipe precipitation pond is connected with the sludge concentration pond, the sludge concentration pond is connected with the sludge storage pond, the sludge storage pond extends in two circuits, one circuit is connected to an external mud cake transport device by virtue of the press filter, and the other circuit is connected to a clean water discharge pipe sequentially by virtue of the air floatation pond, the medium filter, the active carbon filter and the clean water pond.

Owner:JIANGSU SERO ANTICORROSION EQUIP

A carbon-coated nano-silicon composite material and its preparation method and application

ActiveCN106784732BEasy to spreadImprove cycle stabilityMaterial nanotechnologySecondary cellsCarbon coatingNano silicon

The invention relates to a carbon coated nanosilicon composite material as well as a preparation method and an application thereof. The invention relates to silicon composite powder as well as a preparation method and an application thereof. The invention aims to solve the technical problem that an existing method of reducing the volume effect of a silicon-based cathode material by virtue of nanocrystallization, alloying or porous forming is complex in preparation process and high in cost. The carbon coated nanosilicon composite material provided by the invention is powder of a core-shell structure taking nanosilicon particles as a content and carbon as a shell. The preparation method comprises the following steps: performing oxygen diffusion on nanoscale silicon micropowder with an oxidizing layer on the surface; then performing carbon coating treatment; and then soaking the same with a hydrofluoric acid solution to remove the component of silicon oxide to obtain the carbon coated nanosilicon composite material. The volume of the carbon coated nanosilicon composite material provided by the invention reaches 900mAh / g or above, attenuation after 150 times of cycles is smaller than 4%, and the material can be used as a lithium battery silicon cathode material.

Owner:吕铁铮

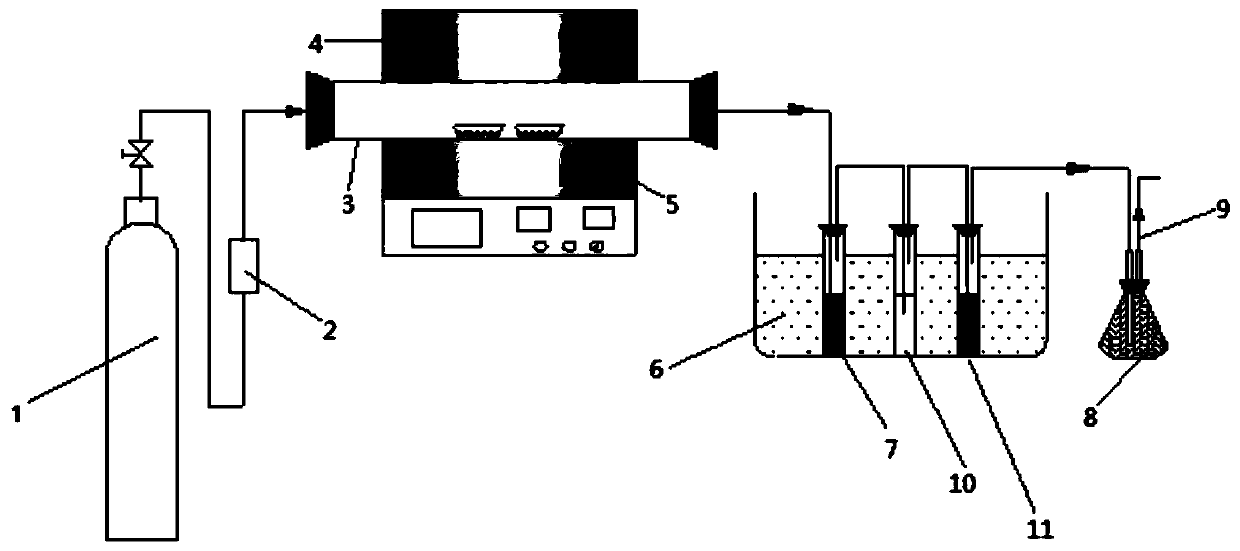

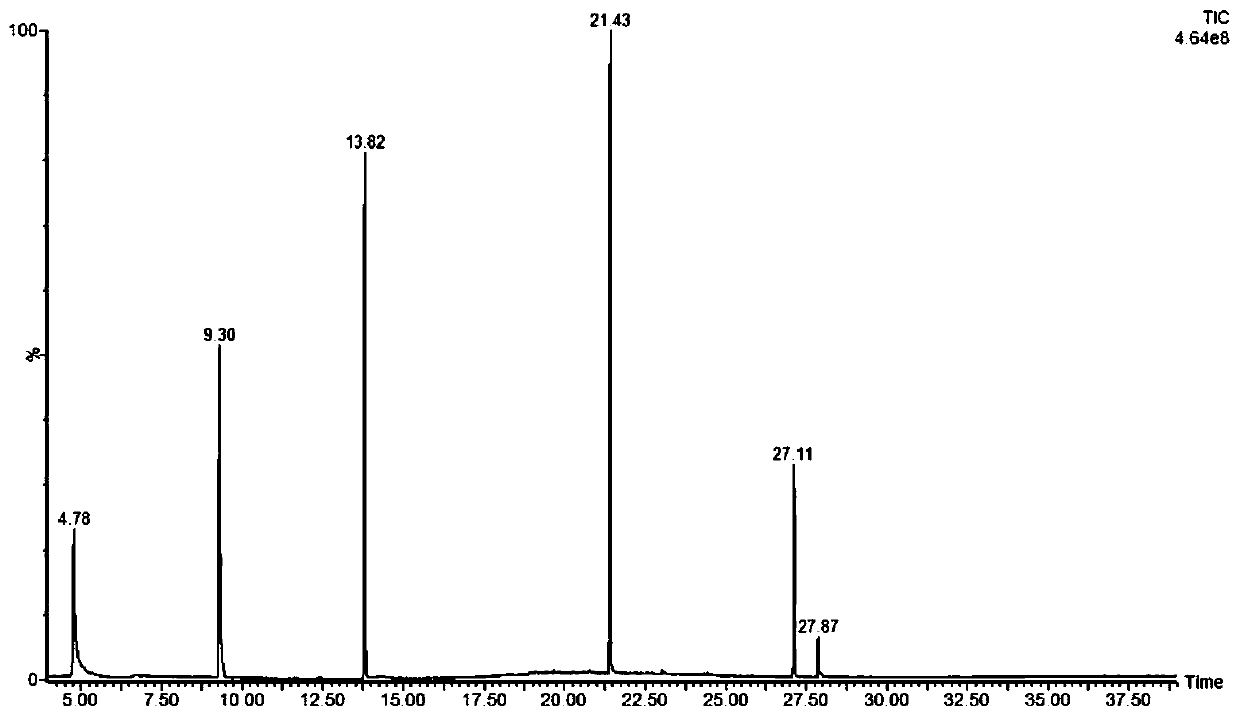

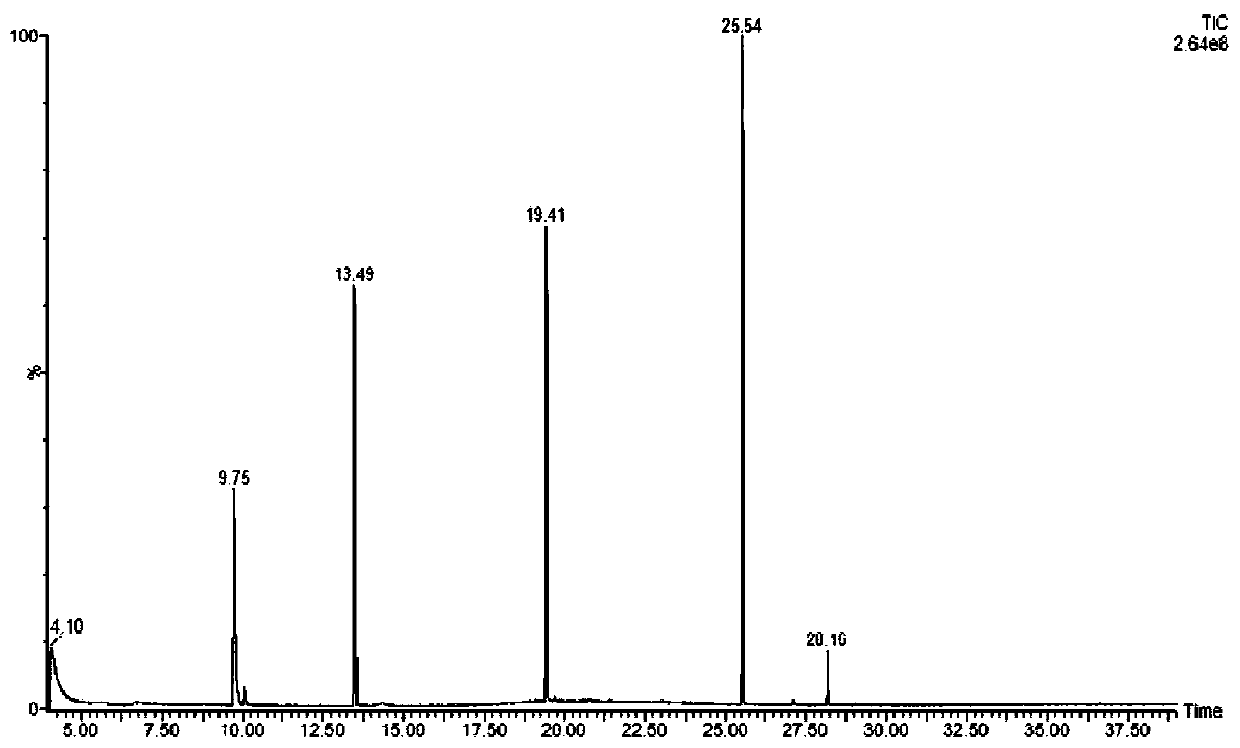

Method and testing device for catalytic pyrolysis treatment of oil-based drilling cuttings produced in shale gas exploitation

PendingCN110982550APromote lysisReduce contentCatalytic crackingDispersed particle separationCatalytic pyrolysisPtru catalyst

The invention relates to the field of petrochemical engineering, in particular to a method and a testing device for catalytic pyrolysis treatment of oil-based drilling cuttings produced in shale gas exploitation. The method for catalytic pyrolysis treatment of oil-based drilling cuttings produced in shale gas exploitation in the invention can overcome the defects of high energy consumption, low recovery rate of valuable products (petroleum hydrocarbons) and the like of conventional pyrolysis methods; and since municipal waste incineration fly ash is adopted as a catalyst, cracking of heavy high-molecular petroleum hydrocarbon can be promoted, and the content of petroleum hydrocarbons in pyrolyzed oil-based drilling cuttings can be further reduced, so pollution is reduced, resources are recycled to the maximum extent, and two kinds of hazardous waste are treated at the same time. The invention further provides the testing device for catalytic pyrolysis treatment of oil-based drilling cuttings produced in shale gas exploitation. By means of the device, the recovery rate of valuable products (petroleum hydrocarbons) can be increased.

Owner:CHONGQING TECH & BUSINESS UNIV

Wood-plastic material prepared from papermaking waste and preparation method thereof

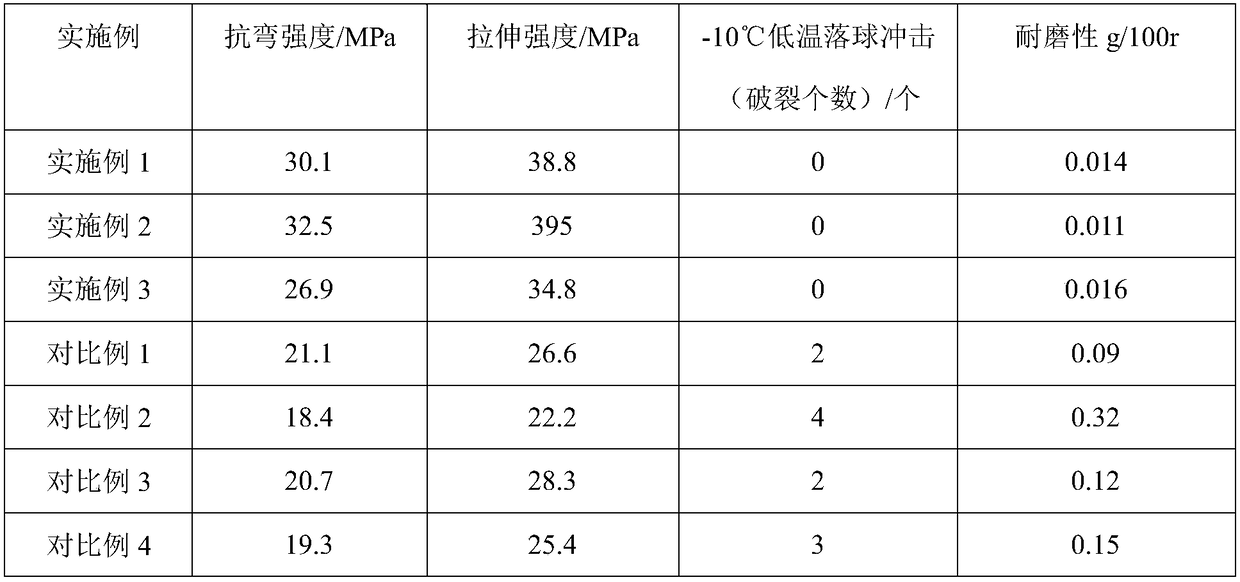

The invention discloses a wood-plastic material prepared from papermaking waste. The wood-plastic material comprises the following components in percentages by mass: 30% to 35% of papermaking waste, 30% to 40% of wood flour, 15% to 20% of ceramic powder, 1% to 5% of sorbitol, 1% to 3% of a silane coupling agent, 3% to 6% of maleic anhydride grafted polyethylene, 1% to 2% of aluminum chloride, 3% to 5% of poly ethylene glycol monomethyl ether and 1% to 2% of blocking isocyanate. Firstly, the silane coupling agent, maleic anhydride grafted polyethylene and aluminum chloride are added and mixed,the aluminum chloride is beneficial for uniform mixing of the raw materials, and in combination with the adding sequence of the raw materials, the modification effect of each accessory ingredient on plastic, wood flour and ceramic powder can be strengthened; the sorbitol is further added as an activation modifier, and is matched with the blocking isocyanate and poly ethylene glycol monomethyl ether, so that modification on the wood four and ceramic powder can be realized sufficiently, the interfacial compatibility among the wood flour, ceramic powder and plastic is improved, and the performance of the wood-plastic material is strengthened.

Owner:HUNAN YINGHONG SCI & TECH

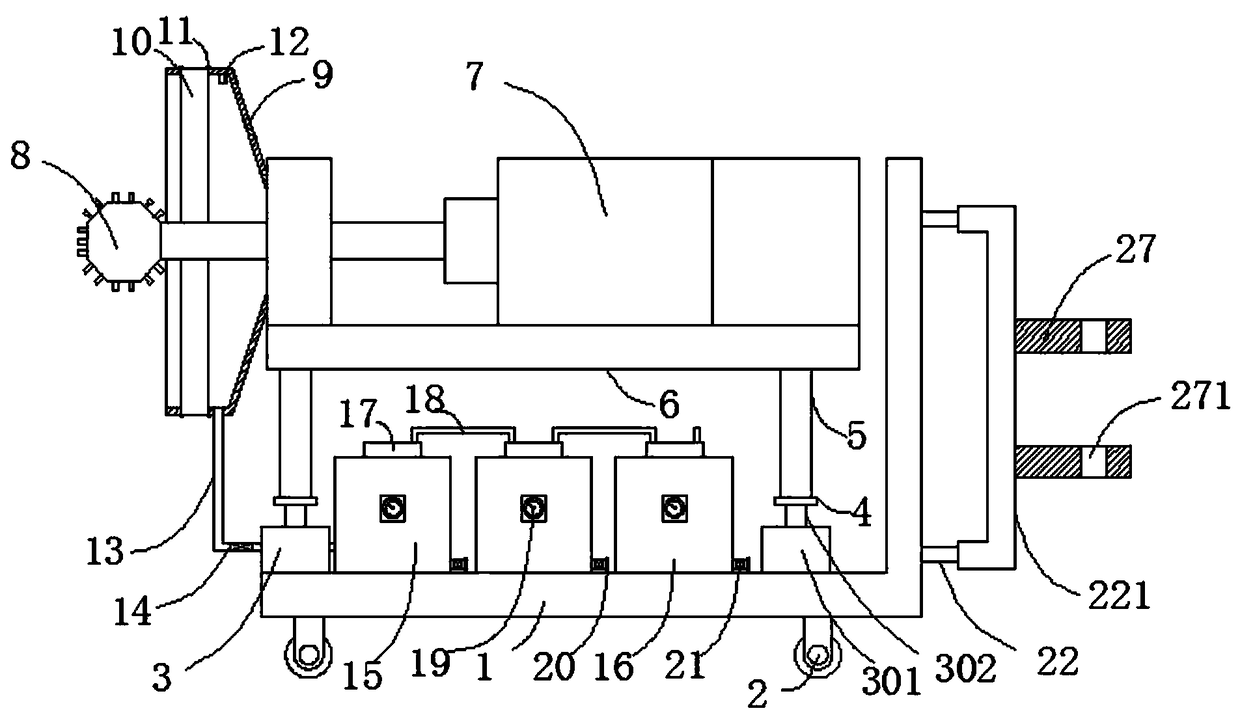

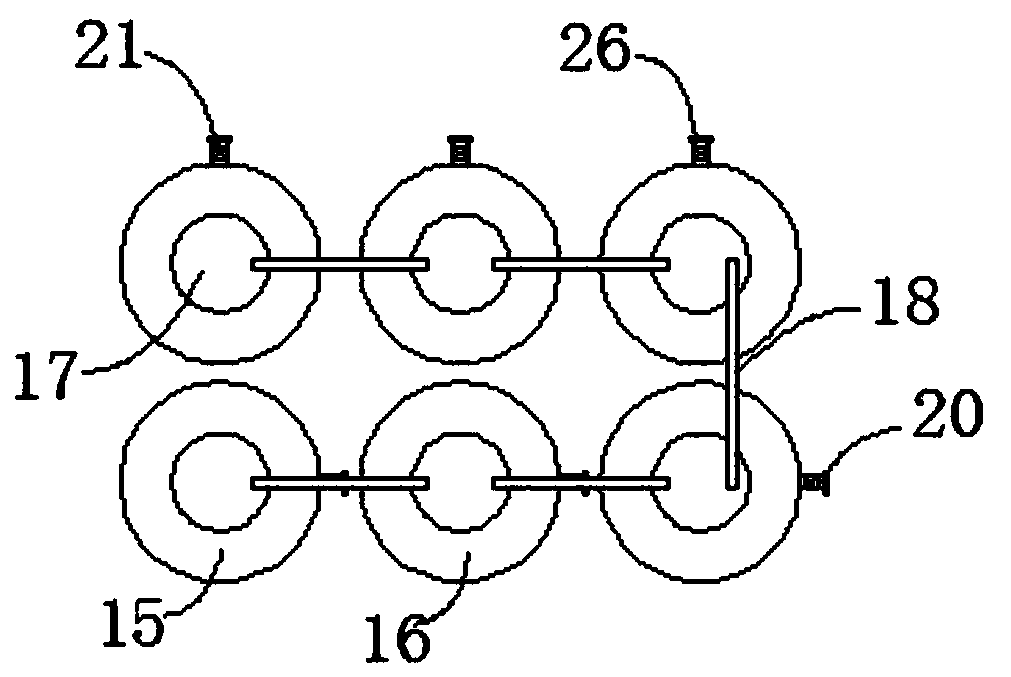

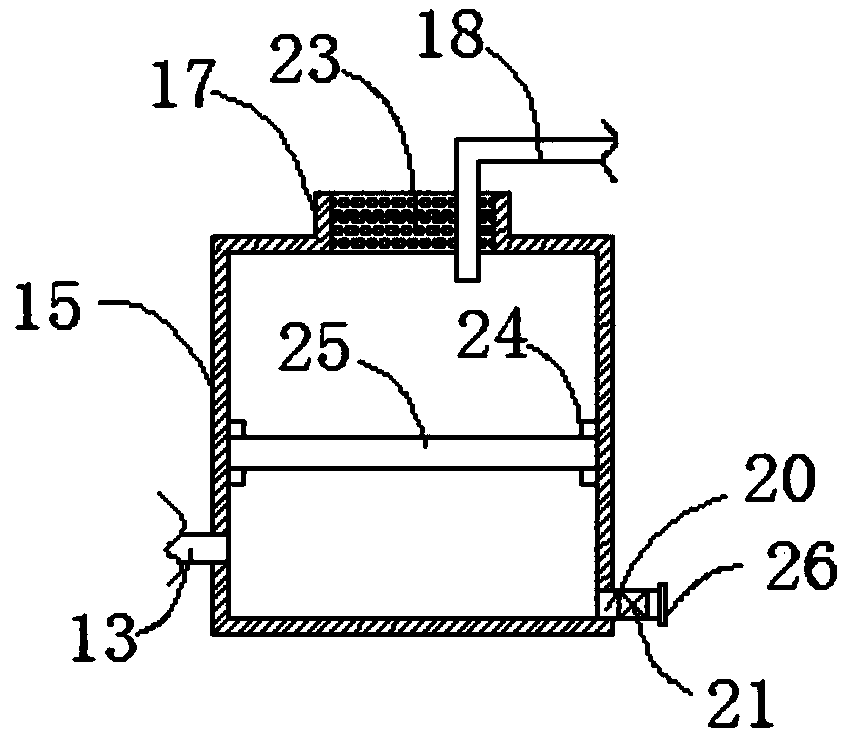

Coal mine heading face boring exploration protection device

The invention discloses a coal mine heading face boring exploration protection device comprising a substrate and self-locking universal wheels arranged on two sides of the substrate bottom; the substrate is provided with a first vacuum tank and second vacuum tanks; a work platform is arranged on top of a vertical rod; a drilling machine body is arranged on top of the work platform; a position, close to a drill bit, on one side of the work platform is provided with a cover plate; a guide tube connected with the first vacuum tank is arranged on the bottom of the cover plate, and provided with asolenoid valve; the first vacuum tank and the second vacuum tank and the second vacuum tanks are respectively connected via breather pipes; a dust filter net is arranged in middle position in the first vacuum tank. The protection device can provide good protection and shield effects, can fast absorb and gather leaking gas and dusts formed in boring into the vacuum tanks, thus reducing gas and dustleakage, recovering gas resources, and reducing dust damages.

Owner:潘旭康

Chroming mist recycling method

ActiveCN107376592AAchieve emission goalsDoes not require manual maintenanceGas treatmentUsing liquid separation agentFilling materialsWastewater

The invention discloses a chroming mist recycling method. A pure physical method is adopted for absorbing chroming mist generated in an electroplating production process into serially connected recycling treating units through a notch fan cover and then performing the processes of diffusing, colliding, coring, agglomerating and settling, so that the chroming mist is stopped and absorbed to the surfaces of a baffle plate and a filling material, and meanwhile, the chroming mist is intermittently and circularly flushed back to the present collecting tank, so that the chroming mist is intercepted, captured and recycled. No wastewater is discharged in the whole process, so that the purpose of environment-friendly emission of the chroming mist is achieved.

Owner:石家庄印钞有限公司

Compound phosphoric polyferric sulfate flocculant and production method thereof

ActiveCN101805051BReduce turbidityReduce CODWater/sewage treatment by flocculation/precipitationPhosphorus compoundsChemical oxygen demandSimple component

The invention provides a novel inorganic compound phosphoric polyferric sulfate flocculant and a production technology thereof. The flocculant can be used in both water treatment and sewage treatment thereby being multifunctional. The phosphoric polyferric sulfate of the invention takes the by-products generated in titanium pigment production, such as ferrous sulfate, phosphoric acid and the likefor producing titanium pigment as raw materials thereby having the characteristics of utilization of waste products, simple components, low cost and the like. The production technology of the invention is convenient, has simple operation and can be carried out at normal temperature and normal pressure. In the production process, no liquid waste, waste gas and waste residue can be generated, and the production technology belongs to the cleaner production technology. The invention can be widely applied in water treatment and sewage treatment. Especially in water treatment, the phosphoric polyferric sulfate flocculant of the invention is added to effectively remove soluble phosphorus and phosphorus in other forms in water as well as algae in algae waste water, lower chemical oxygen demand (COD), total phosphorus (TP), suspended solid (SS), chlorophyll (chl-a) and the like.

Owner:善水(南通)工业技术有限公司

High calcium organic wastewater treatment method

ActiveCN103130353BReduce COD valueRecycling resourcesCalcium/strontium/barium sulfatesMultistage water/sewage treatmentGas phaseDistillation

Owner:PETROCHINA CO LTD +1

Method and device for treating wastewater and producing nutrients

ActiveCN110129398BAchieve removalProtectBioreactor/fermenter combinationsBiological substance pretreatmentsNitrogen sourceSewage

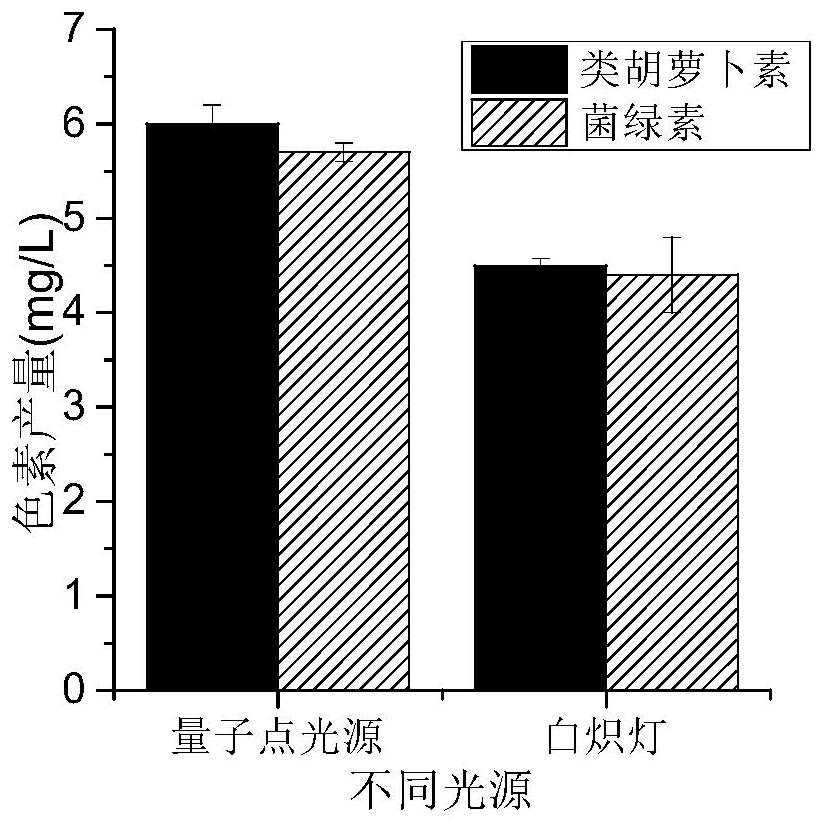

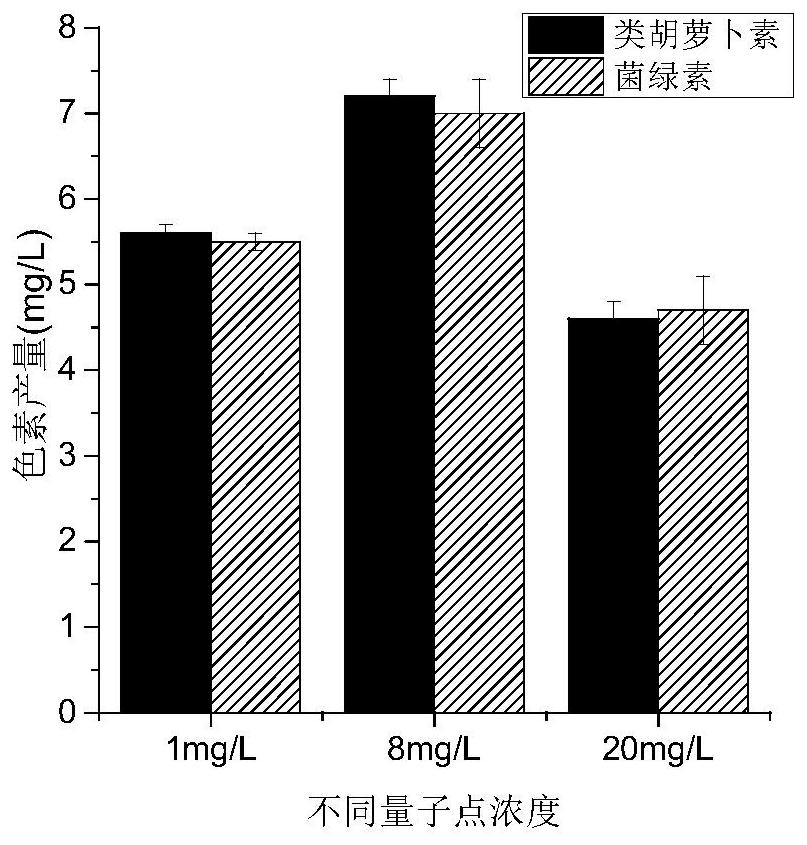

The present invention provides a method and equipment for treating waste water and producing nutrients, said method comprising the steps of: 1) adjusting the concentration of waste water to wherein COD is 6000-8000 mg / L; adding nitrogen source and phosphorus source to adjust carbon in waste water Nitrogen-phosphorus ratio; 2) inoculating photosynthetic bacteria in the logarithmic growth phase in the wastewater; 3) continuously irradiating the graphene quantum dot solution with a wavelength of 365nm ultraviolet rays for the excitation light, and irradiating the wastewater with the flowing graphene quantum dot solution; 4 ) When the growth of photosynthetic bacteria reaches the plateau stage, the filter membrane is used to separate bacteria from water. The present invention proposes a sewage resource utilization method for the production of high-value photosynthetic bacteria, which is a wastewater treatment and resource utilization method that combines the treatment of beer wastewater with the output of high-value nutrients, which can realize the removal of pollutants in wastewater In addition, the generated biomass can extract high-value nutrients, which has multiple functions of environmental protection, cost saving, and resource recovery.

Owner:CHINA AGRI UNIV

A kind of zinc sulfide-based mercury adsorbent for capturing zero-valent mercury in flue gas and preparation method thereof

ActiveCN109092239BImprove mercury removal performanceLow costGas treatmentOther chemical processesSorbentFlue gas

The invention relates to a zinc sulfide-based mercury adsorbent for trapping zero-valent mercury in flue gas and a preparation method thereof. The adsorbent is a cobalt-doped zinc mercury sulfide adsorption material Co x Zn 1‑x S, x represents the stoichiometric ratio of cobalt in the solution, and its ratio is 0.1‑0.3. Its preparation method is as follows: (1) dissolving a certain molar ratio of cobalt salt and zinc salt in deionized water to form a mixed solution; (2) adding a precipitant to the mixed solution for mixing and stirring; (3) putting the suspension into a reactor , and placing the reactor in an oven for heat treatment; (4) repeatedly washing the obtained precipitate with deionized water, and drying to form a zinc sulfide-based mercury-removing adsorption material. Compared with the prior art, the method has wide sources of raw materials, simple and controllable preparation process, mild reaction conditions, and the prepared adsorbent improves mercury absorption performance by dozens of times compared with pure zinc sulfide, and has good anti-SO 2 Affect performance, can maintain a certain high activity stably for a long time, especially suitable for adsorption and removal of zero-valent mercury in smelting flue gas.

Owner:SHANGHAI JIAO TONG UNIV

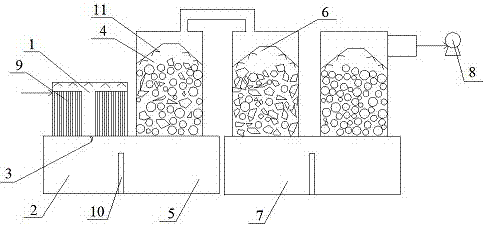

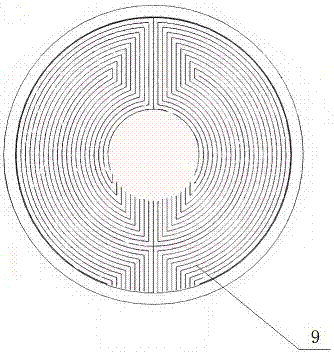

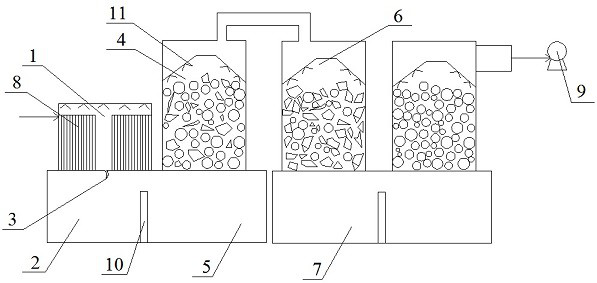

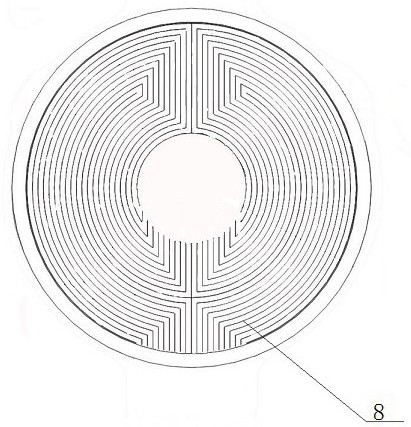

Chromium plating fog recovery and purification device

The invention discloses a chromium plating fog recovery and purification device, and belongs to the technical field of chromium plating waste gas recovery processing technology. The chromium plating fog recovery and purification device includes a chromium fog channel, the chromium fog channel is formed by a plurality of stages of recovery and purification chambers, the plurality of stages of recovery and purification chambers are connected in series in turn, and are communicated with a chromium plating bath and a fan for pumping air. Each recovery and purification chamber comprises a condensing chamber and a recovery water tank, the upper part of the condensing chamber is provided with a spraying device, the recovery water tank is located below the condensing chamber, and the recovery water tank is correspondingly communicated with the condensing chamber, and a next-stage recovery water tank supplies water for the spraying device of a front-stage recovery and purification chamber. The plurality of stages of recovery and purification chambers are used for physical interception of chromium fog in the chromium plating bath, and the whole recovery and purification process is free of wastewater discharge and physical maintenance.

Owner:石家庄印钞有限公司

A kind of chrome-plating mist recovery treatment method

ActiveCN107376592BAchieve emission goalsDoes not require manual maintenanceGas treatmentUsing liquid separation agentWater dischargeWastewater

The invention discloses a method for recovering and treating chromium-plating mist. The chromic acid mist generated in the electroplating production process is sucked step by step into series-connected recovery and treatment units through a notch wind cover through a purely physical method. , sedimentation and other processes, which are intercepted and adsorbed on the surface of the barrier plate and filling material, and recycled to the recovery tank of the same level after intermittent and circular washing, so as to achieve the interception, capture and recycling of chromic acid mist, and realize chrome plating without wastewater discharge in the whole process Exhaust gas meets the purpose of environmental protection emission.

Owner:石家庄印钞有限公司

Method for treating residual liquid after mother liquor distillation methanol recovery during production of sodium sulphoxylate by sodium formate process

InactiveCN101081715BEliminate secondary pollutionRecycling resourcesThiosulfates/dithionites/polythionitesDispersed particle separationDithionous acidDistillation

Owner:GUANGDONG ZHONGCHENG CHEM INC LTD

Pre-spinning process of nitrile-based carbon fiber precursor

Owner:SUZHOU SHARTEL SCI CO LTD

Nitrile group type carbon fiber precursor spinning pretreatment process

The invention discloses a nitrile group type carbon fiber precursor spinning pretreatment process. According to the technical scheme, the process includes the following steps that 1, nitrile group type carbon fiber precursors are subjected to continuous mold pressing curling forming at normal temperature; 2, the nitrile group type carbon fiber precursors obtained in the step 1 are added to a shaping furnace and instantly heated to the shaping temperature in a vacuum state, the vacuumizing time ranges from 5 min to 45 min, achieved negative pressure ranges from 3,000 pa to 5,000 pa, temperature rise time ranges from 5 min to 45 min, and the achieved temperature ranges from 90 DEG C to 150 DEG C; 3, under the condition of the step 2, dry hot gas is instantly injected into the shaping furnace, and the obtained nitrile group type carbon fiber precursors are shaped. The purposes that non-superior products generated in the existing carbon fiber precursor production process are reused, and waste and environmental pollution are reduced are achieved.

Owner:SUZHOU SHARTEL SCI CO LTD

Hazard-free environment-friendly treatment process for reducing and recycling waste rubber, plastic and domestic garbage

InactiveCN102580981BRecycling resourcesAvoid secondary pollutionSolid waste disposalWaste rubberFuel oil

Owner:喻万钧

Chrome-plated mist recovery and purification device

ActiveCN107497246BAchieve emission goalsAvoid pollutionGas treatmentAuxillary pretreatmentProcess engineeringChrome plating

The invention discloses a chrome-plating mist recovery and purification device, which belongs to the technical field of the recovery and treatment process of chrome-plating waste gas. It includes a chromium mist channel formed by several stages of recovery and purification chambers connected in series and connected with the chrome plating tank and the fan for exhausting the chrome plating tank. The recovery and purification room includes a condensation chamber with a spray device on the upper part and a condensation chamber located at the lower part of the condensation chamber. A connected recovery water tank, the lower level recovery water tank supplies water to the spray device of the upper level recovery purification room. The invention adopts a multi-stage recovery and purification chamber to physically intercept the chromium mist in the chrome plating bath, and realizes a chromium plating mist recovery and purification device without waste water discharge in the whole process and without manual maintenance.

Owner:石家庄印钞有限公司

A waste liquid treatment and recovery system for stainless steel pickling line

ActiveCN104891709BImprove recycling ratesSimple structureWaste water treatment from metallurgical processMultistage water/sewage treatmentSludgeActivated carbon filtration

The invention discloses a waste liquid treatment recycling system of a stainless steel pickling line. The waste liquid treatment recycling system mainly comprises a regulating reservoir, a precision filter, a neutralizing oxidation pond, an oblique pipe precipitation pond, a sludge concentration pond, a sludge storage pond, an air floatation pond, a press filter, a medium filter, an active carbon filter and a clean water pond, and is characterized in that pickling waste water flows into the regulating reservoir, the regulating reservoir is connected with the precision filter, the precision filter is connected with the neutralizing oxidation pond, the neutralizing oxidation pond is connected with the oblique pipe precipitation pond, the oblique pipe precipitation pond is connected with the sludge concentration pond, the sludge concentration pond is connected with the sludge storage pond, the sludge storage pond extends in two circuits, one circuit is connected to an external mud cake transport device by virtue of the press filter, and the other circuit is connected to a clean water discharge pipe sequentially by virtue of the air floatation pond, the medium filter, the active carbon filter and the clean water pond.

Owner:JIANGSU SERO ANTICORROSION EQUIP

Industrial waste pervious concrete and preparation method thereof

InactiveCN112624698AImprove impact resistanceImprove frost resistanceSolid waste managementExpanded clay aggregateEnvironmental engineering

The invention discloses industrial waste pervious concrete and a preparation method thereof. The industrial waste pervious concrete is prepared from the following components: cement, siliceous sand grains, barren rock, fly ash, water, a water reducing agent, lightweight aggregate, triethanolamine and polypropylene fibers. The preparation method comprises the following steps: crushing industrial waste; selecting raw materials; preparing fly ash ceramsite; preparing a lightweight aggregate; preparing an additive; stirring and mixing. According to the pervious concrete disclosed by the invention, the fly ash and the barren rock are added into the raw materials for preparing the concrete, so that industrial wastes generated by a thermal power plant can be recycled, and the strength and the adaptability of the pervious concrete can be enhanced; the polypropylene fibers can increase the strength of the concrete and enable the concrete to become wear-resistant and corrosion-resistant, triethanolamine is used as a medium, and the polypropylene fibers can be uniformly mixed with other materials of the concrete, so that the concrete with good water permeability is better in water permeability, higher in strength and longer in service life.

Owner:宿迁市京成建材有限公司

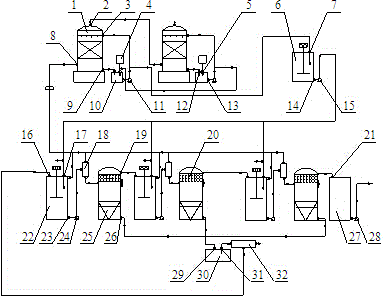

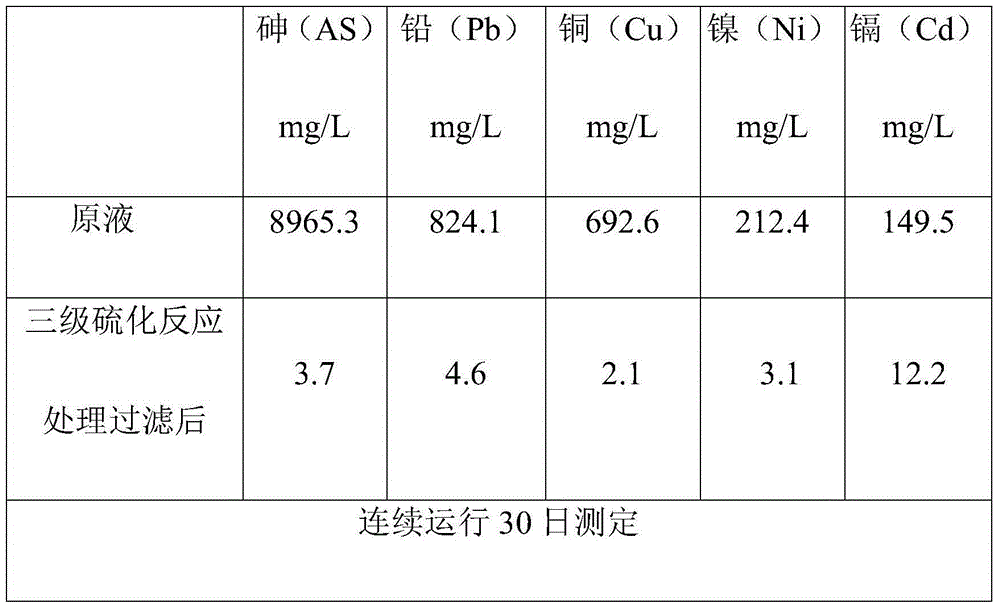

A waste acid purification device and process

ActiveCN104003554BFully recycleReduce wasteSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentChemical industrySludge

The invention discloses waste acid purifying device and process and relates to the technical field of the chemical industry. The device comprises a sulfuration reaction system device, a waste gas recovery system device and a sludge treatment system device, wherein the sulfuration reaction system device comprises a sodium sulfide feeding tank provided with a sodium sulfide inlet and at least one stage of sulfuration device; each sulfuration device is provided with a stirring tank chemicals inlet, a tank gas outlet and an additive inlet; both the tank gas outlet and the gas outlet of a gas-liquid separating device are communicated with the waste gas recovery system device; a filter device is communicated with the sludge treatment system device; the waste gas recovery system device comprises at least one stage of waste gas reaction device; each waste gas reaction device is provided with a lye tank; each lye tank is provided with a lye inlet and a reaction liquid outlet; the reaction liquid outlet of the lye tank is communicated with the sodium sulfide feeding tank; the sodium sulfide feeding tank is communicated with all stages of stirring tanks. The waste acid purifying device disclosed by the invention is high in waste gas recycling rate in waste acid treatment, so that the environmental pollution and the resource waste are reduced.

Owner:WUHAN FEIBOLE ENVIRONMENTAL PROTECTION ENG

A method for comprehensive recovery and utilization of wastewater from alkaline washing process

ActiveCN105036439BReduce inhibitionReduce processing loadOrganic chemistryMultistage water/sewage treatmentBenzoic acidMethyl benzoate

The invention discloses a comprehensive recovery and utilization method for alkali cleaning working procedure waste water. The method comprises the steps that 1, waste alkali water is pumped into a neutralization kettle to be neutralized with hydrochloric acid, the pH value is adjusted to range from 1 to 4, benzoic acid turbid liquid is generated and cooled by cooling water to normal temperature, the turbid liquid is pumped into a plate-and-frame filter press, and a filter cake, namely benzoic acid obtained after filtering and pressing is used for producing methyl benzoate; 2, filter liquor obtained after filtering and pressing in the step 1 is collected into a filter liquor collection groove, caustic soda flakes are added for neutralization, the pH value is adjusted to range from 9 to 10, then the filter liquor is pumped into an evaporator for vacuum concentration, heating is stopped after the volume is concentrated to be 1 / 10-1 / 5 of the original volume, the temperature is cooled to be normal temperature, kettle bottom residual liquor is placed into a filter groove for vacuum concentration, a filter cake, namely sodium chloride is obtained and recycled as industrial salt, and the filter liquor with sodium benzoate is collected into an alkaline water groove for next circulation. According to the comprehensive recovery and utilization method for alkali cleaning working procedure waste water, the salt content and COD content in waste water are effectively reduced, and therefore waste water up-to-standard release is facilitated.

Owner:ANHUI JIAXIAN FUNCTIONAL AUXILIARY

Production processing method and device for regenerating waste material slag in wastepaper papermaking

The invention discloses a production processing method and the device thereof for the waste slag regenerating in paper making through using the paper. The method comprises the following steps: firstly, the paper making waste slag including the waste plastics and paper pulp and discharged from a pulper is sent to a processing field; secondly, the waste slag is cut into pieces, and the ball-shaped waste slag is cut into pieces mainly; thirdly, the water is added into the cut waste slag and drubbed into the paper pulp with the waste plastics; fourthly, the paper pulp and the waste plastic are separated, to get the required paper pulp and plastics. The processing device for the waste slag regenerating comprises a crushing machine, a paper and plastic separator, a water vessel, a water wheel separating pusher, and a water wheel slag gaining apparatus. The invention can automatically separate the waste slag in the paper making industry, the production efficiency of the paper pulp reclamation is improved, and not only the resource is saved, nut also the environmental pollution can not be caused.

Owner:陈维强 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com