A kind of zinc sulfide-based mercury adsorbent for capturing zero-valent mercury in flue gas and preparation method thereof

A zinc sulfide and adsorbent technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of unfavorable fly ash reuse, low mercury adsorption capacity, difficult to popularize and apply, etc., and achieve good mercury removal performance. , simple process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

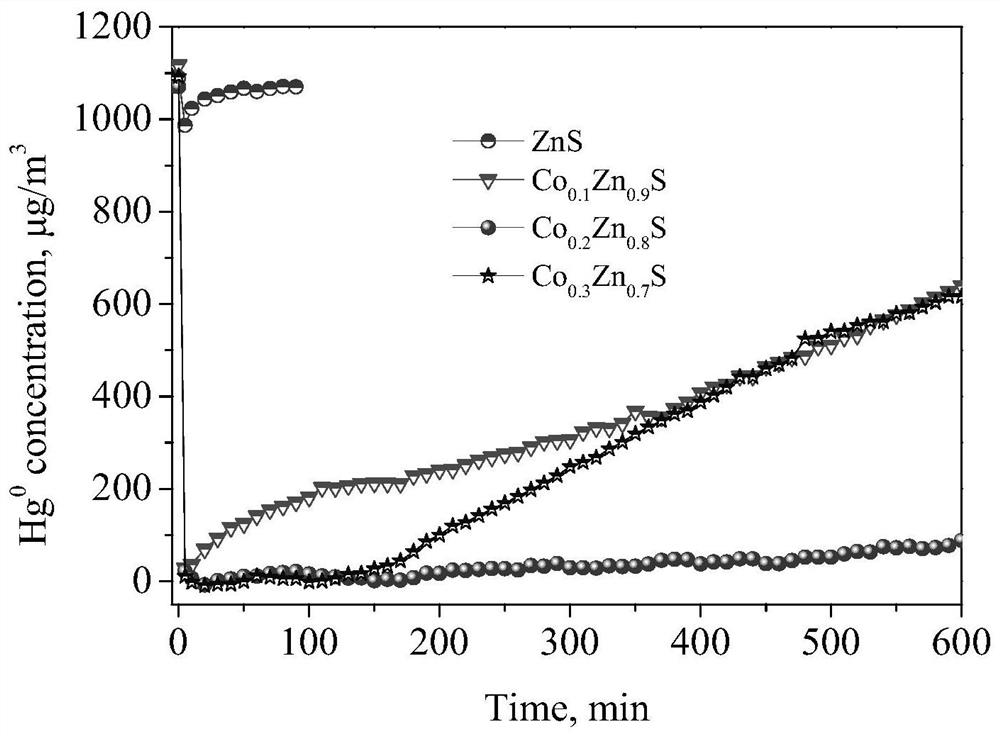

[0029] A kind of cobalt doped zinc mercury sulfide adsorbent, its chemical formula is Co 0.1 Zn 0.9 S, its preparation method comprises the following steps:

[0030] 1) Weigh a certain amount of zinc nitrate, cobalt nitrate and sodium sulfide according to the molar ratio, and dissolve them in deionized water respectively

[0031] 2) Mix and stir the zinc nitrate and cobalt nitrate solutions, then slowly add the sodium sulfide solution dropwise into the mixed solution, and stir rapidly for 20 minutes

[0032] 3) Put the suspension into a stainless steel reaction kettle with a polytetrafluoroethylene liner, put it in an oven, heat it to 140°C, and keep it for 12 hours

[0033] 4) After the reaction kettle is naturally cooled, use deionized water to repeatedly perform centrifugal washing in a high-speed centrifuge

[0034] 5) Vacuum-dry the washed sample at 60° C. for 12 hours, grind and sieve to 100-200 mesh, and put it into a drying dish for use.

Embodiment 2

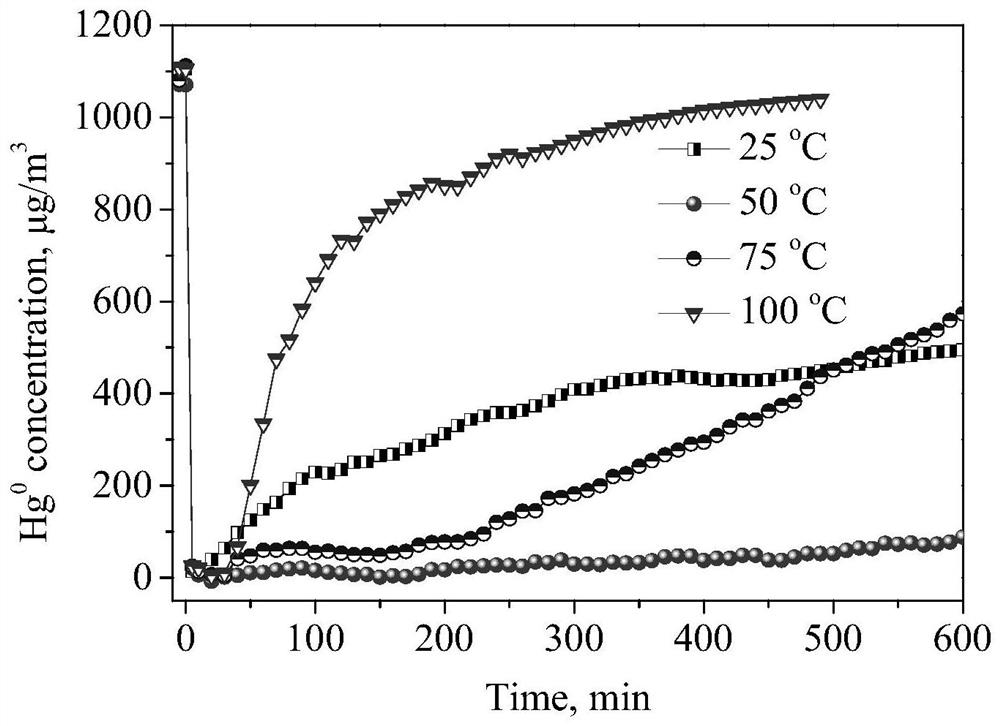

[0036] A kind of cobalt doped zinc mercury sulfide adsorbent, its chemical formula is Co 0.2 Zn 0.8 S, its preparation method comprises the following steps:

[0037] 1) Weigh a certain amount of zinc nitrate, cobalt nitrate and sodium sulfide according to the molar ratio, and dissolve them in deionized water respectively

[0038] 2) Mix and stir the zinc nitrate and cobalt nitrate solutions, then slowly add the sodium sulfide solution dropwise into the mixed solution, and stir rapidly for 20 minutes

[0039] 3) Put the suspension into a stainless steel reaction kettle with a polytetrafluoroethylene liner, put it in an oven, heat it to 140°C, and keep it for 12 hours

[0040] 4) After the reaction kettle is naturally cooled, use deionized water to repeatedly perform centrifugal washing in a high-speed centrifuge

[0041] 5) Vacuum-dry the washed sample at 60° C. for 12 hours, grind and sieve to 100-200 mesh, and put it into a drying dish for use.

Embodiment 3

[0043] A kind of cobalt doped zinc mercury sulfide adsorbent, its chemical formula is Co 0.3 Zn 0.7 S, its preparation method comprises the following steps:

[0044] 1) Weigh a certain amount of zinc nitrate, cobalt nitrate and sodium sulfide according to the molar ratio, and dissolve them in deionized water respectively

[0045] 2) Mix and stir the zinc nitrate and cobalt nitrate solutions, then slowly add the sodium sulfide solution dropwise into the mixed solution, and stir rapidly for 20 minutes

[0046] 3) Put the suspension into a stainless steel reaction kettle with a polytetrafluoroethylene liner, put it in an oven, heat it to 140°C, and keep it for 12 hours

[0047] 4) After the reaction kettle is naturally cooled, use deionized water to repeatedly perform centrifugal washing in a high-speed centrifuge

[0048] 5) Vacuum-dry the washed sample at 60° C. for 12 hours, grind and sieve to 100-200 mesh, and put it into a drying dish for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com