A kind of preparation method of copper sulfide mercury removal agent

A copper sulfide and mercury removal technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of harsh reaction conditions, complicated process steps, and inability to mix sol A and thiourea solution, etc., to increase the load effect, the effect of increasing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Mix 5L, 0.2mol / L copper nitrate solution with 5L, 0.2mol / L ethylenediamine solution, then add 2L, 5mol / L ammonia water and mix to obtain a premixed solution;

[0030] (2) Add 5 L, 0.2 mol / L thiourea solution to the premixed solution and mix evenly to obtain an impregnation solution;

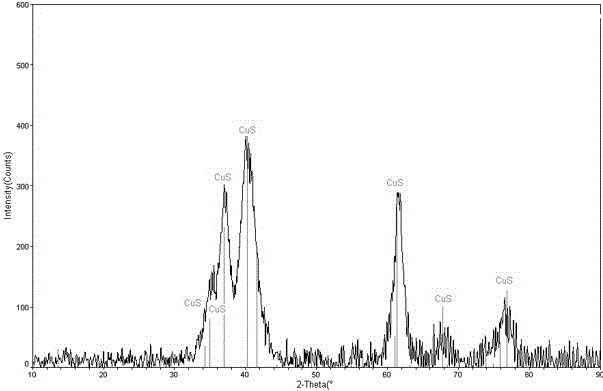

[0031] (3) Immerse 1 kg of alumina carrier in the impregnation solution at 0°C for 3 hours, drain for 30 minutes, activate at 95°C for 1 hour, and then dry at 105°C for 5 hours to obtain mercury removal agent 1, whose XRD spectrum is shown in figure 1 .

Embodiment 2

[0033] (1) Mix 2L, 0.6mol / L copper chloride solution with 2L, 1.5mol / L ethylenediamine solution, then add 2L, 0.6mol / L ammonia water and mix to obtain a premixed solution;

[0034] (2) Add 2 L, 1.2 mol / L thiourea solution to the premixed solution and mix evenly to obtain an impregnation solution;

[0035] (3) Immerse 1 kg of activated carbon carrier in the impregnation solution at 30° C. for 0.5 h, drain for 1 h, activate at 60° C. for 5 h, and then dry at 120° C. for 1 h to obtain mercury removal agent 2.

Embodiment 3

[0037] (1) Mix 2L, 0.5mol / L copper acetate solution with 1L, 1mol / L ethylenediamine solution evenly, then add 2L, 4mol / L ammonia water and mix to obtain a premixed solution;

[0038] (2) Add 1.5L, 1mol / L thiourea solution to the premixed solution and mix evenly to obtain an impregnation solution;

[0039] (3) Immerse 1 kg of 5A molecular sieve in the impregnation solution at 25°C for 2 hours, drain for 1 hour, activate at 80°C for 4 hours, and then dry at 110°C for 3 hours to obtain mercury removal agent 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com