Patents

Literature

51results about How to "Improve mercury removal performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorption tower for desulfurization and denitrification combined with oxidant in forward-flow and back-flow spraying and method

InactiveCN102553428AAchieve removalUnique structureDispersed particle separationAir quality improvementOxidation zoneSlurry

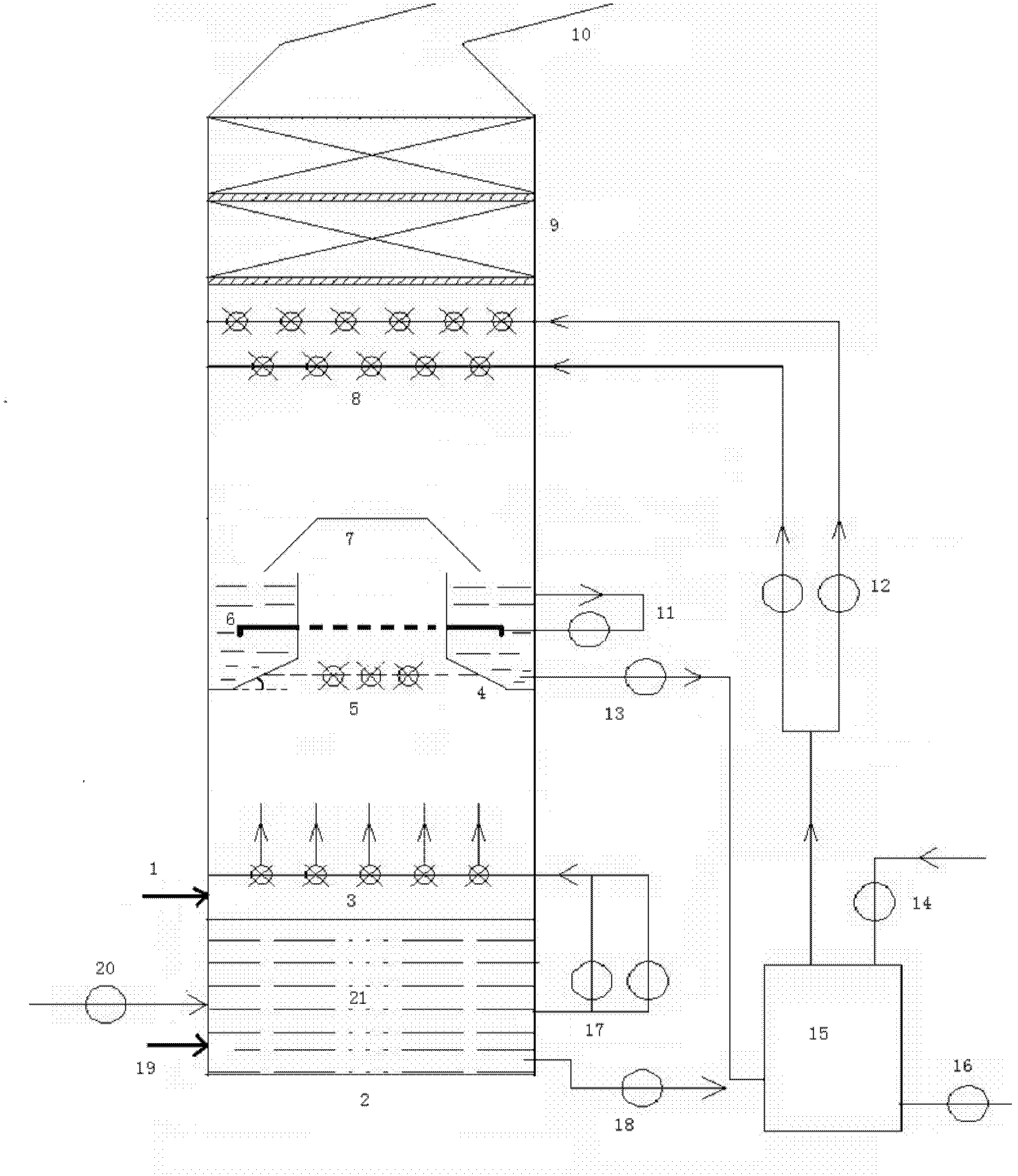

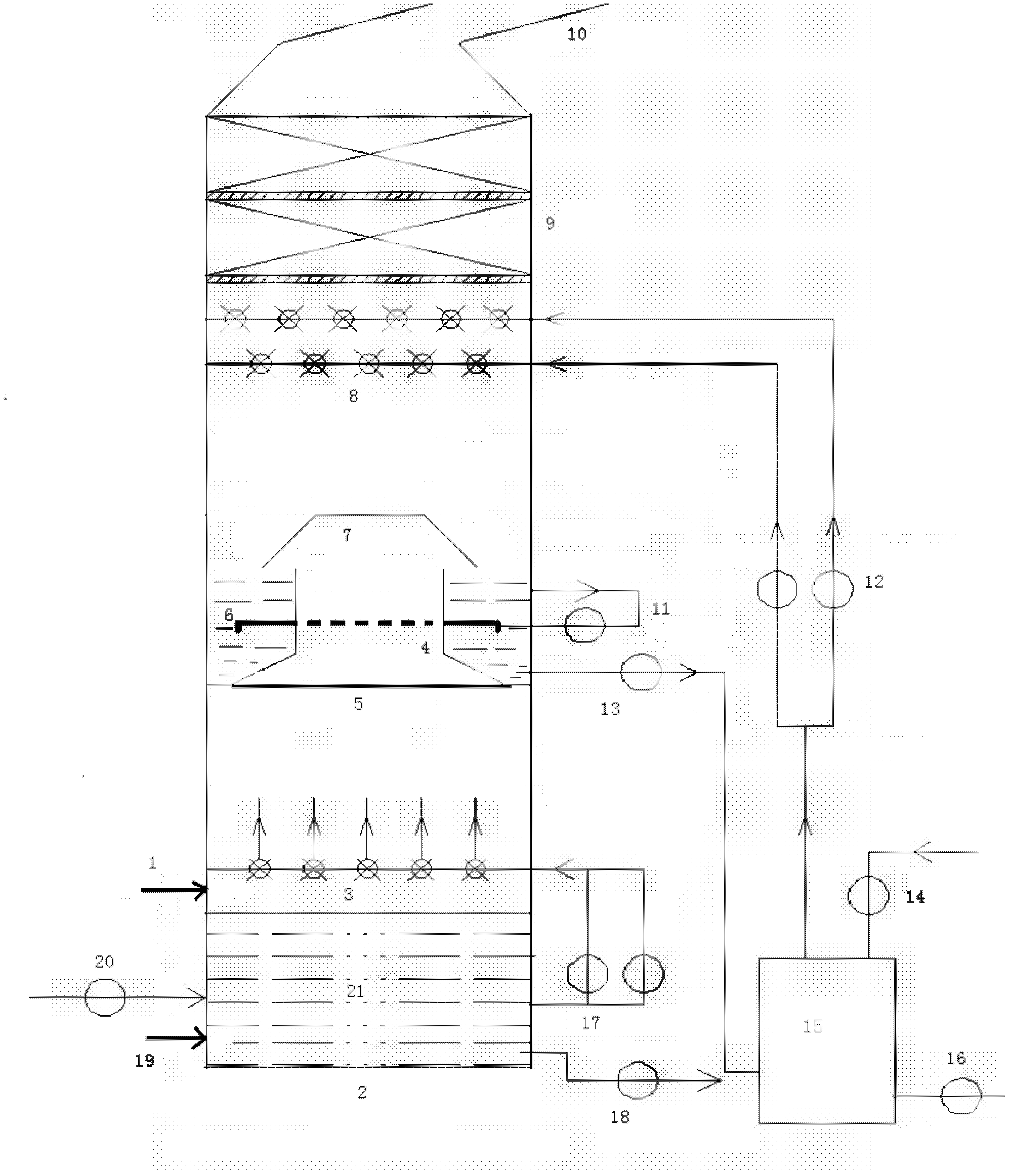

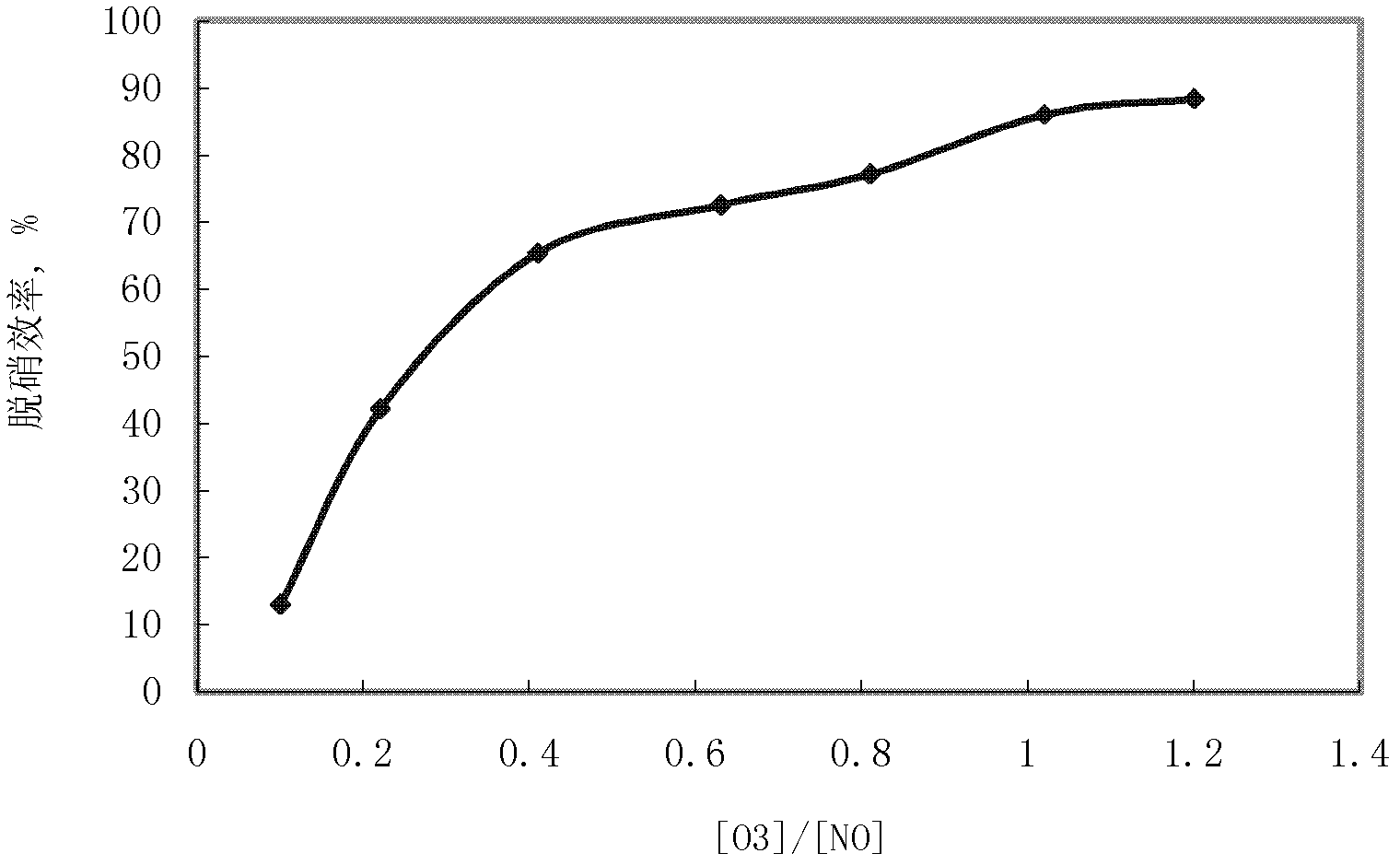

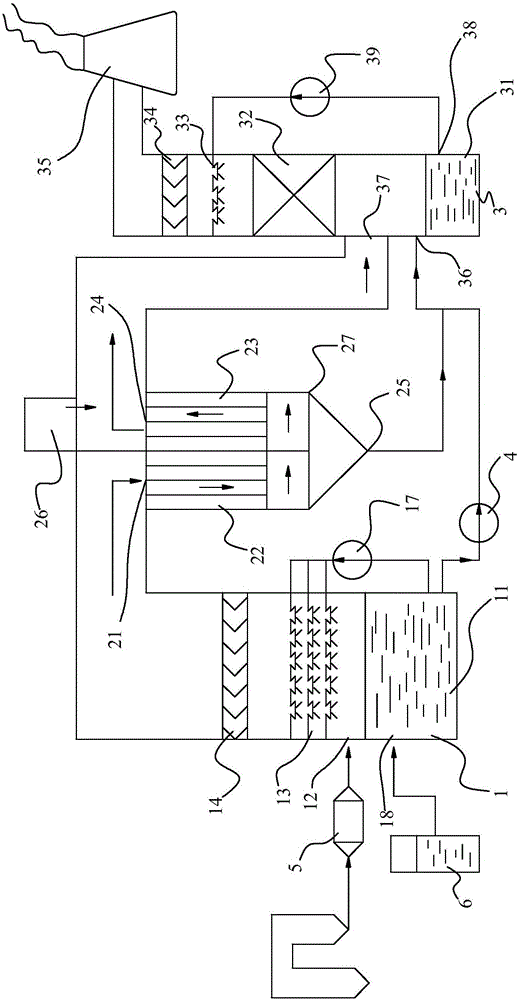

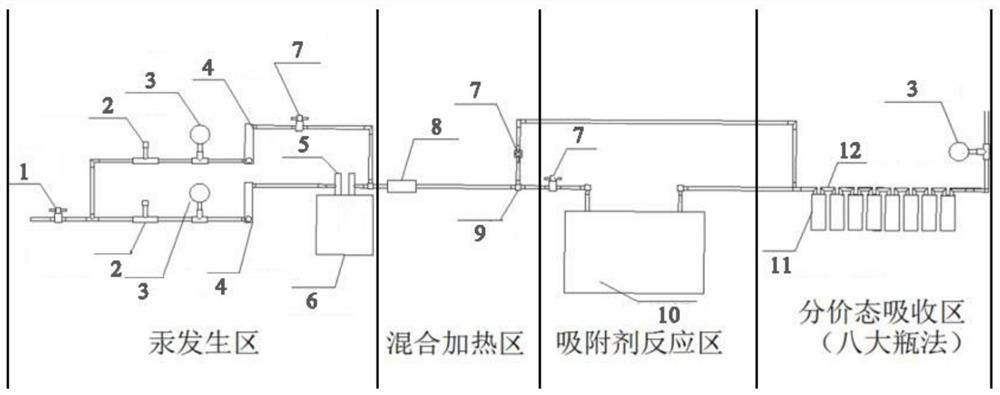

The invention discloses an absorption tower for desulfurization and denitrification combined with an oxidant in forward-flow and back-flow spraying mode and a method. The absorption tower includes two washing sections: a first section is a desulfurization loop and arranged on the lower portion of the absorption tower, and sulfur dioxide and hydrogen chloride are removed through slurry forward-flow and back-flow and smoke contact cleaning; a second section cleans oxidized smoke pollutants in slurry back-flow and smoke contact mode mainly for removing oxynitride and heavy metal mercury. A slurry divider is arranged between the two cleaning sections, the bottom of the slurry divider is an oxidization area, and strong oxidant is sprayed in the area. For reducing consumption of the oxidant, a catalyst is added in second-loop slurry for achieving auxiliary oxidization. Sulfur dioxide, oxynitride, heavy metal mercury and the like can be removed simultaneously in a washing tower by the technology, and the absorption tower has the advantages of being high in efficient and simple and suitable for various combustion devices including fuel coal power stations, refuse incineration plants, organic and inorganic production enterprises and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

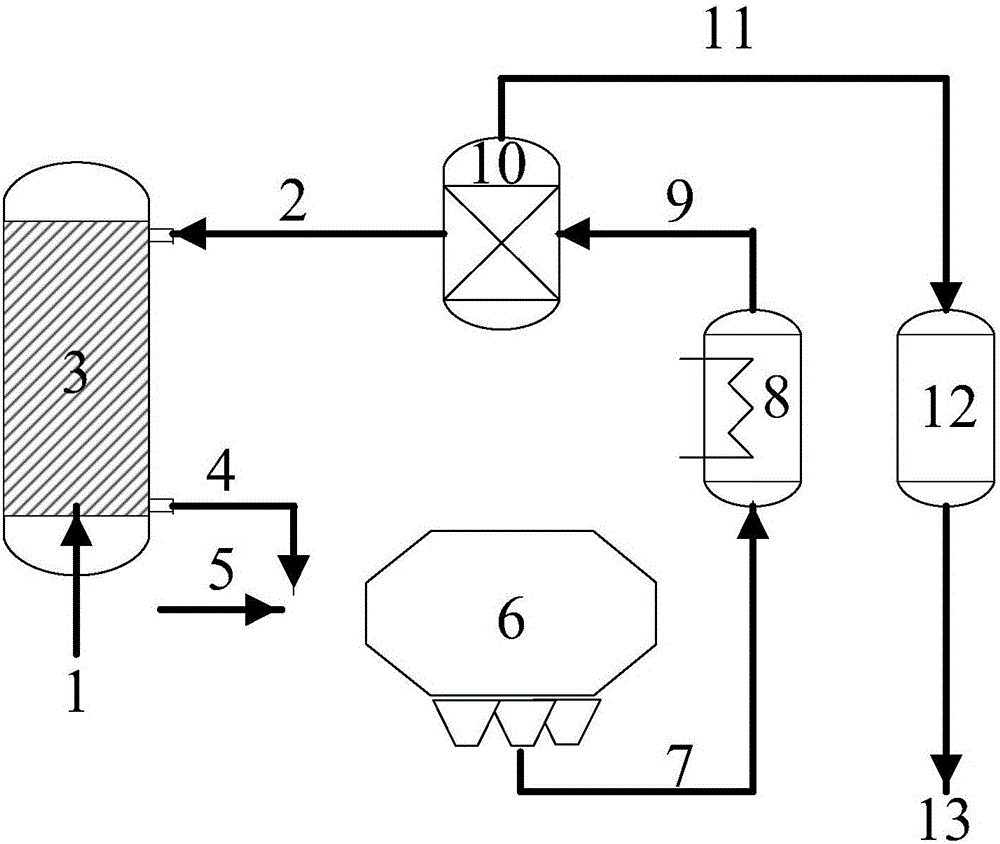

Mercury removal for smoke desulfurizing system by fortified wetting method

InactiveCN1895745AEnhance mercury removal abilityReduce investment and operating costsDispersed particle separationIonCoal

A process for intensifying the Hg removing action of a wet fume desulfurizing system includes such steps as spraying chemical oxidant into the fume generated by burning coal, gas-phase (or catalytic) oxidizing reaction to oxidize Hg, absorbing the mercury oxide along with the 2-valence Hg in the fume by desufurizing liquid, adding the S-contained chemical additive to said desulfurizing liquid, and converting the Hg ions in desulfurizing liquid to stable Hg compound.

Owner:SHANGHAI JIAO TONG UNIV +1

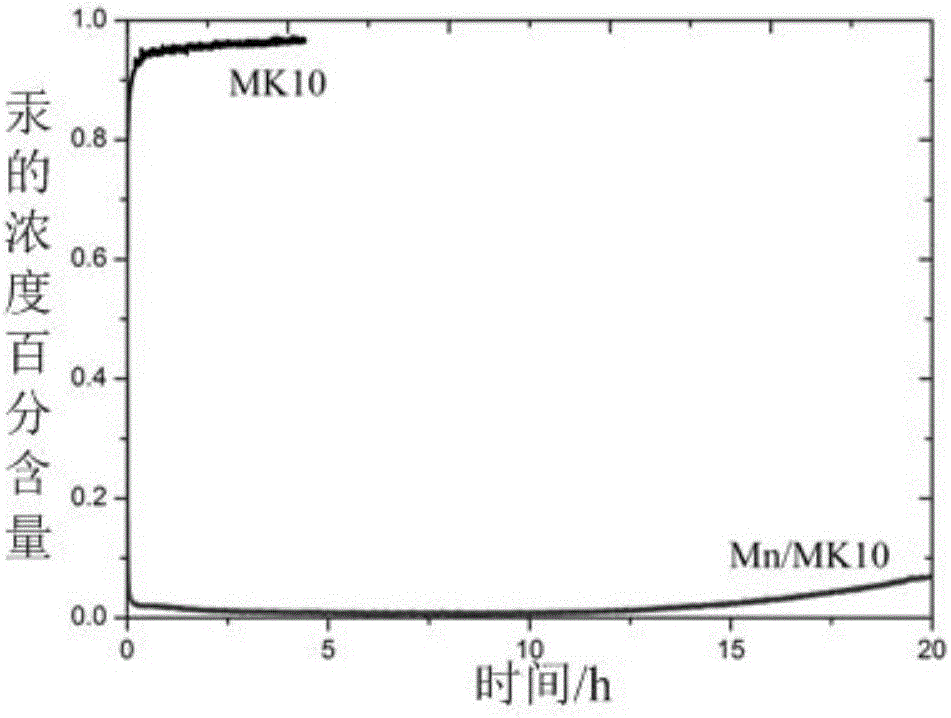

Demercuration adsorbent based on pillared montmorillonite, preparation method and application thereof

InactiveCN105664838AImproving the Ability of Adsorption and Removal of Mercury in Coal-fired Flue GasImprove thermal stabilityGas treatmentOther chemical processesMass ratioSorbent

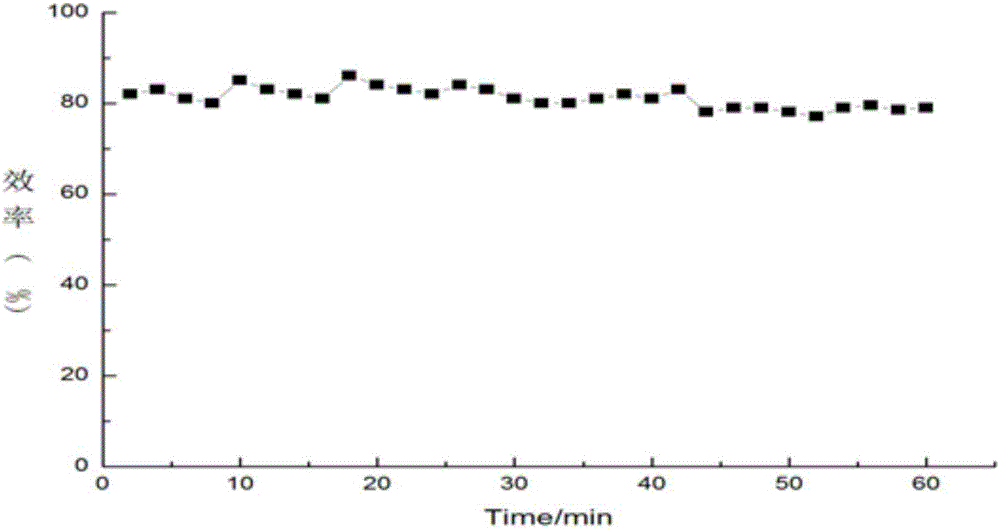

The present invention provides a mercury removal adsorbent based on pillared montmorillonite, its preparation method and application. The adsorbent includes a carrier and an active component loaded on the carrier. The carrier is pillared montmorillonite. The active component is a metal oxide, and the ratio of the mass of the metal element to the mass of the pillared montmorillonite in the metal oxide is ≤10.0wt.%. The adsorbent makes full use of the structural characteristics of montmorillonite and the activity of the active components to adsorb elemental mercury, so that the two can play a synergistic effect; the mercury removal adsorbent not only has high thermal stability: mercury removal within 100-450 °C The efficiency reaches 99%, and it also has a high mercury removal efficiency: the inlet mercury concentration is 120ug / m 3 The mercury removal efficiency is as high as 99% within 10 hours, and over 94% even within 20 hours. It can be used to remove mercury in flue gas produced by power plants, industrial boilers or industrial kilns.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

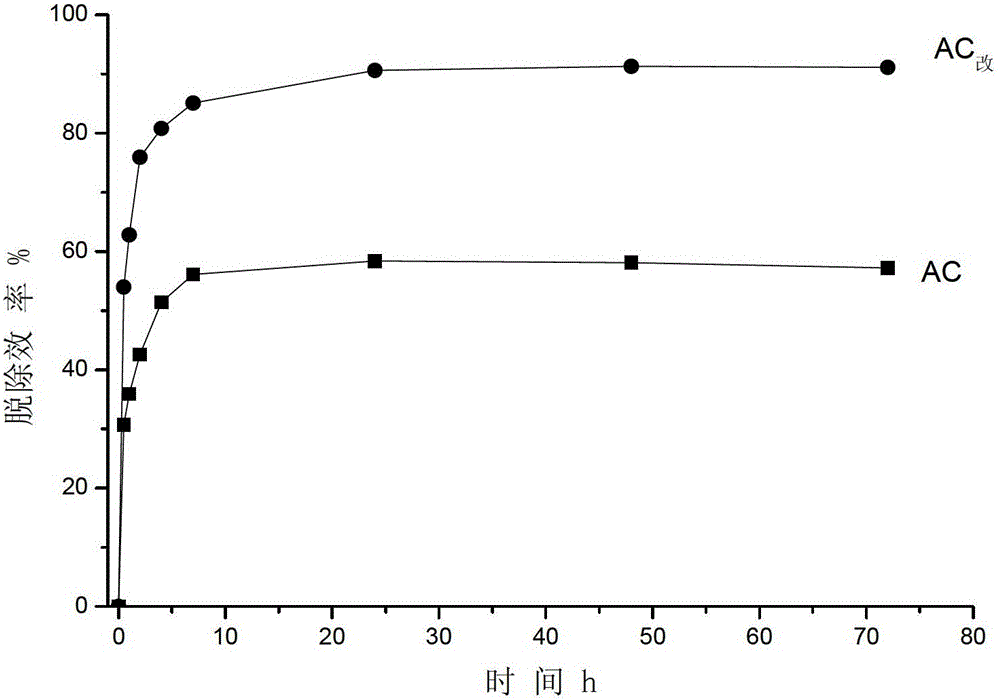

Preparation method of special modified active carbon for removing mercury

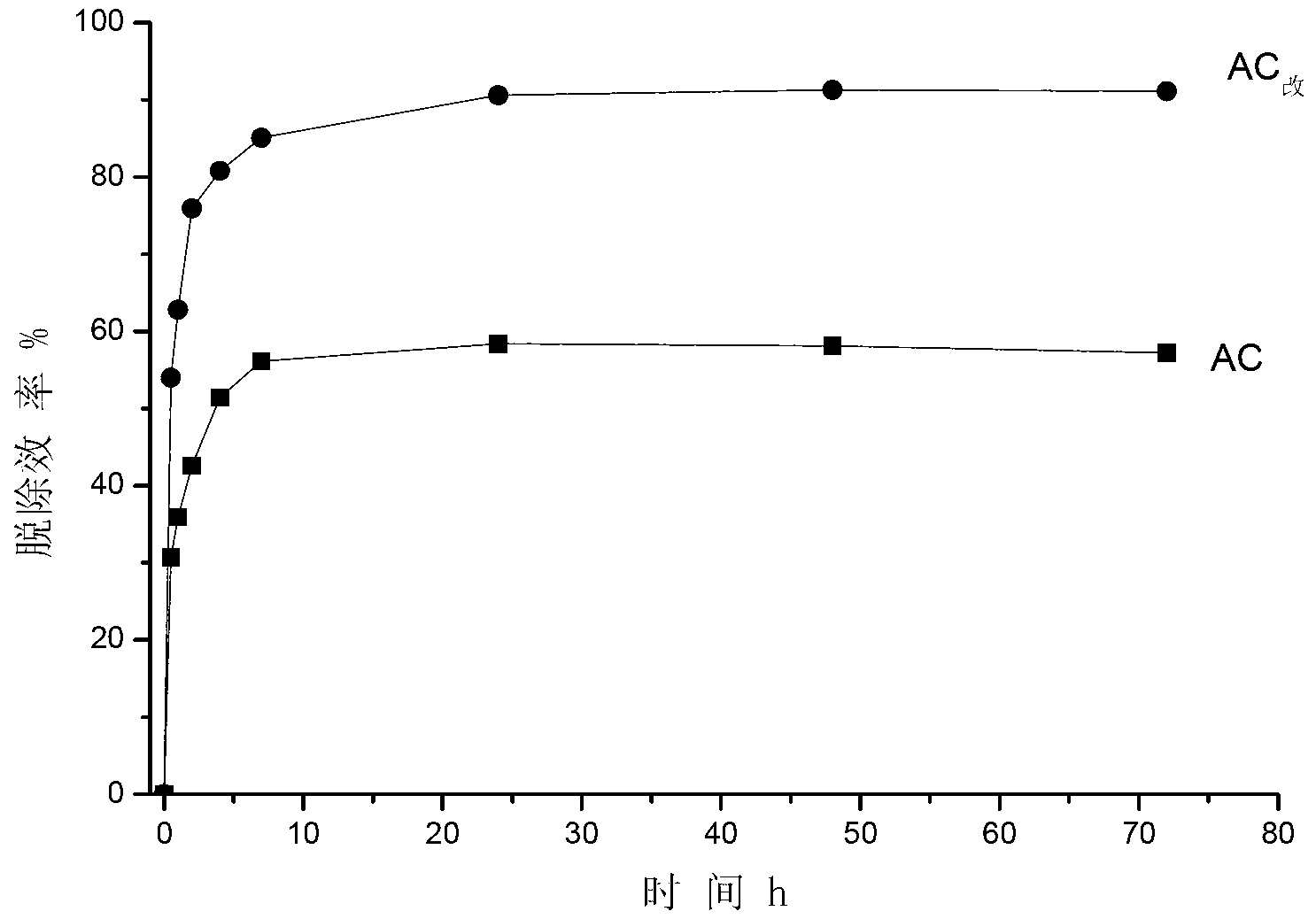

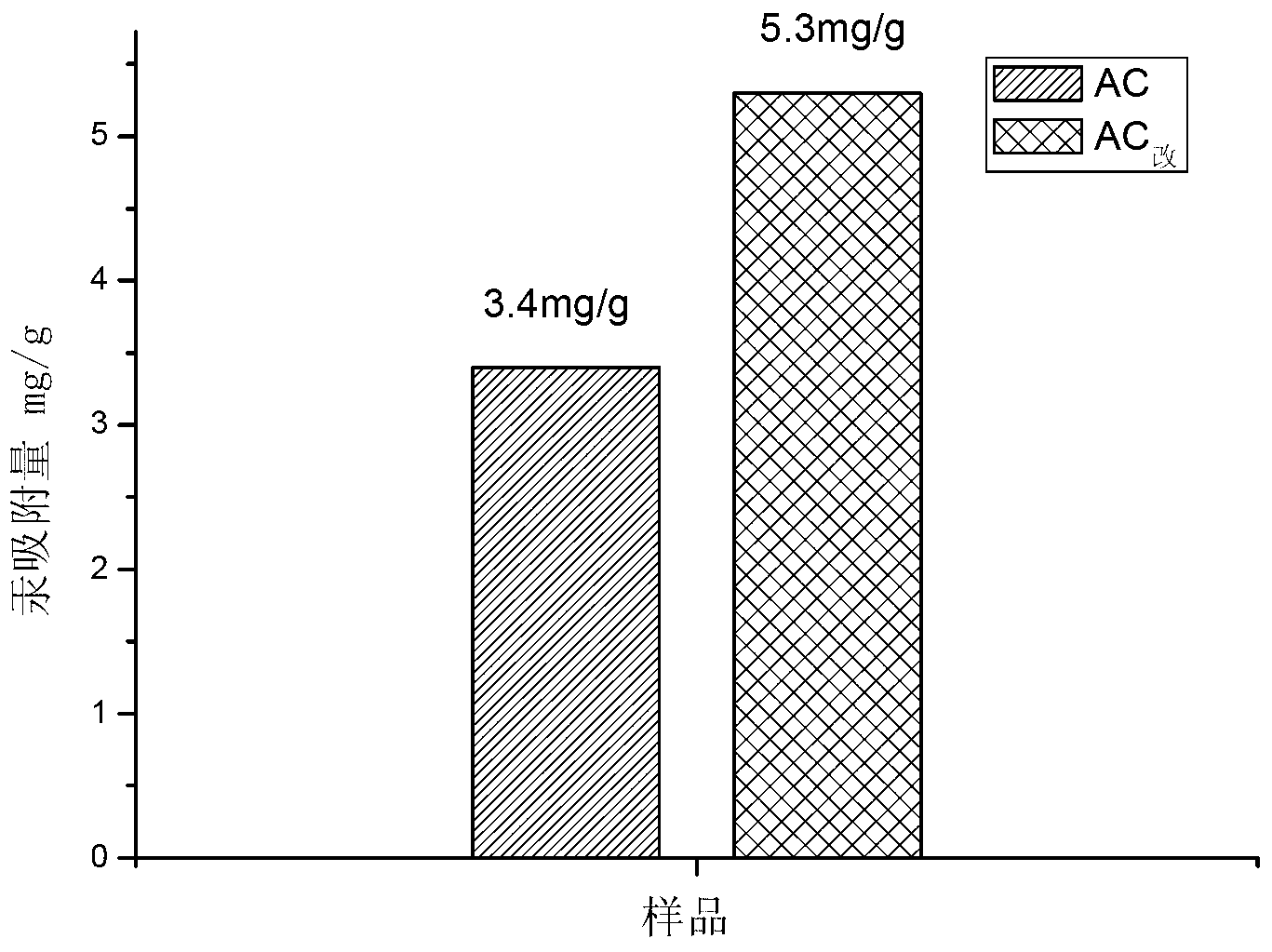

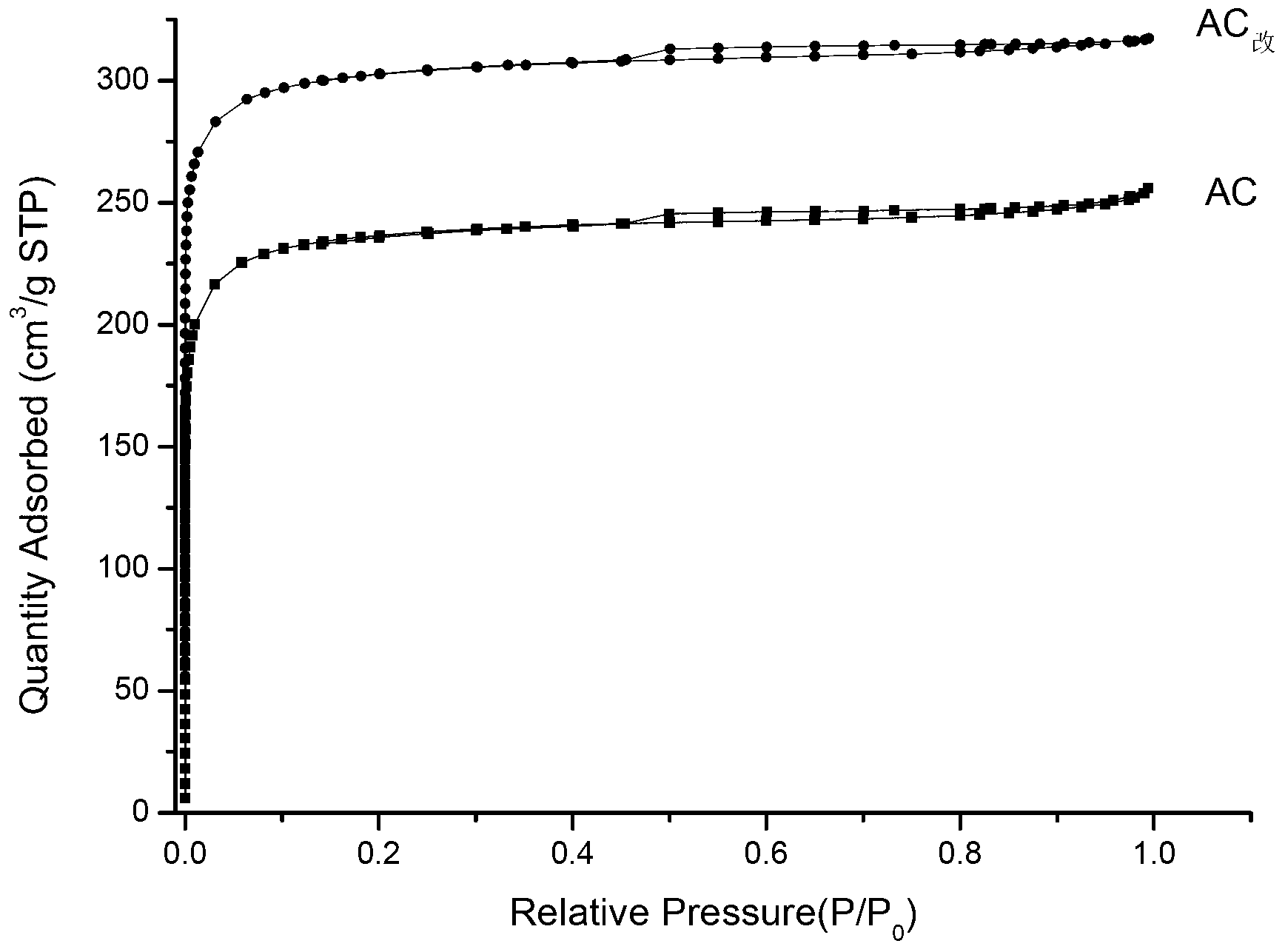

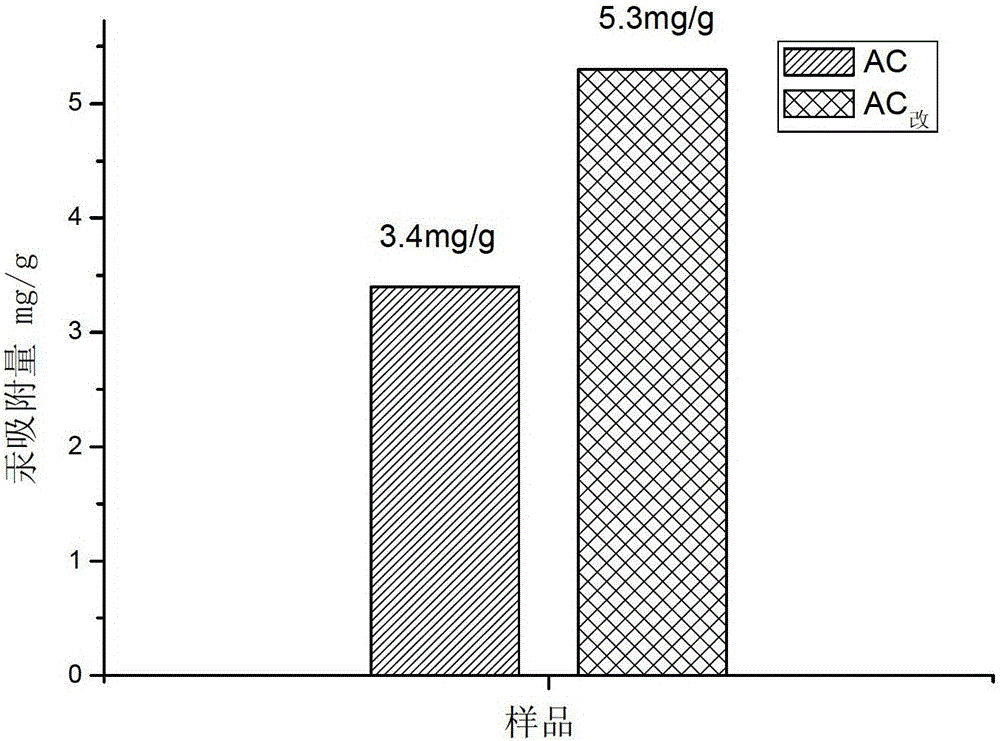

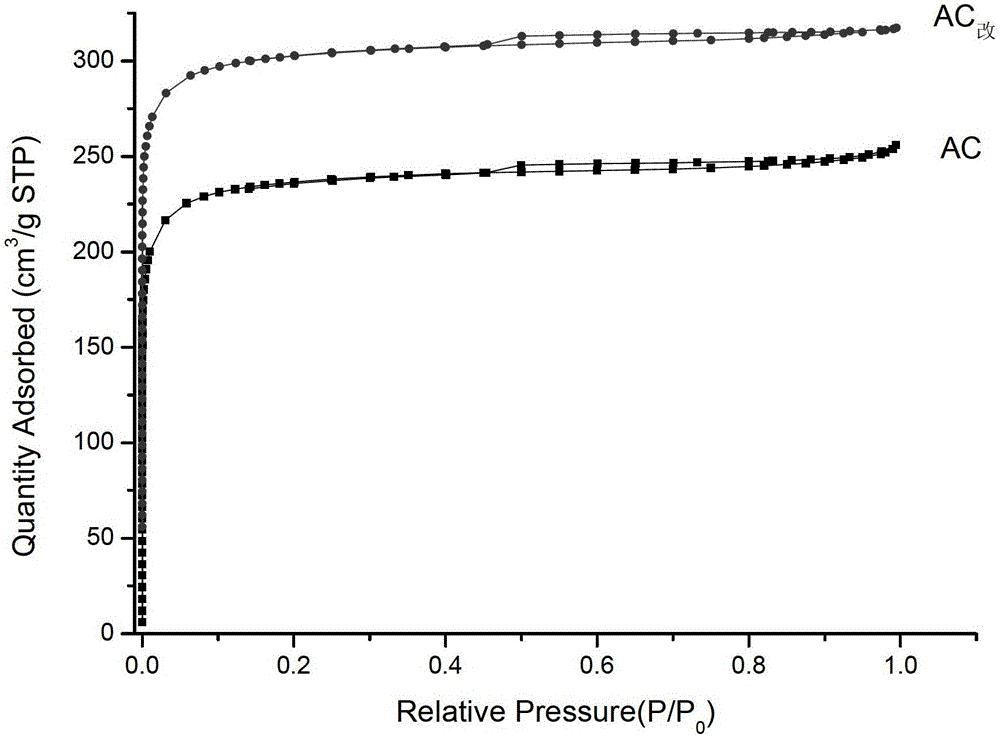

ActiveCN103223330AImprove mercury removal performanceSimple operation processOther chemical processesDispersed particle separationDistilled waterMercury adsorption

The invention discloses a preparation method of special modified active carbon for removing mercury. The method comprises the following steps of: washing wooden particle active carbon through hydrochloric acid and distilled water, and then drying the washed wooden particle active carbon to standby; heating the active carbon and the hydrogen peroxide with the concentration being 25 to 30wt% at the temperature of 50 to 70 DEG C for 2 to 4h according to the mass-to-volume ratio of 6g:(15-10)ml, and then carrying out the ultrasonic treatment on the active carbon for 20 to 40min; and standing, filtering, drying, washing and drying the active carbon to obtain the special modified active carbon for removing the mercury. The special modified active carbon has high mercury removal efficiency, and the maximal mercury adsorption volume can reach 5.3mg / g and is 1.5 times that of unmodified active carbon.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY

Mercury removal process based on lime-gypsum method desulphurization system and mercury removal absorption liquid

ActiveCN101590369APromote absorptionHigh removal rateDispersed particle separationAir quality improvementCALCIUM HYDROXIDE SOLUTIONNitric oxide

The invention discloses mercury removal absorption liquid based on a lime-gypsum method desulphurization system. Main components of the mercury removal absorption liquid comprise desulphurization slurry and oxidant; the desulphurization slurry is at least one of calcium hydroxide solution and calcium sulfite solution, and the mass concentration of the desulphurization slurry is 1 to 30 percent; and the oxidant is soluble salt or mixture of soluble salt of which positive ions contain ammonium radical and negative ions contain peroxosulfuric acid radical or peroxosulfuric acid hydrogen radical. Moreover, a soluble transition metal salt as an oxidation catalyst can be added into the mercury removal absorption liquid to increase the removal efficiency of mercury. The invention also discloses a specific mercury removal process using the mercury removal absorption liquid; and the process has the characteristics of high mercury removal effect, little byproduct and low transformation cost, does not introduce other corrosive ions, does not influence the quality of gypsum, and can promote the system to absorb sulfur dioxide and nitric oxide to a certain extent.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

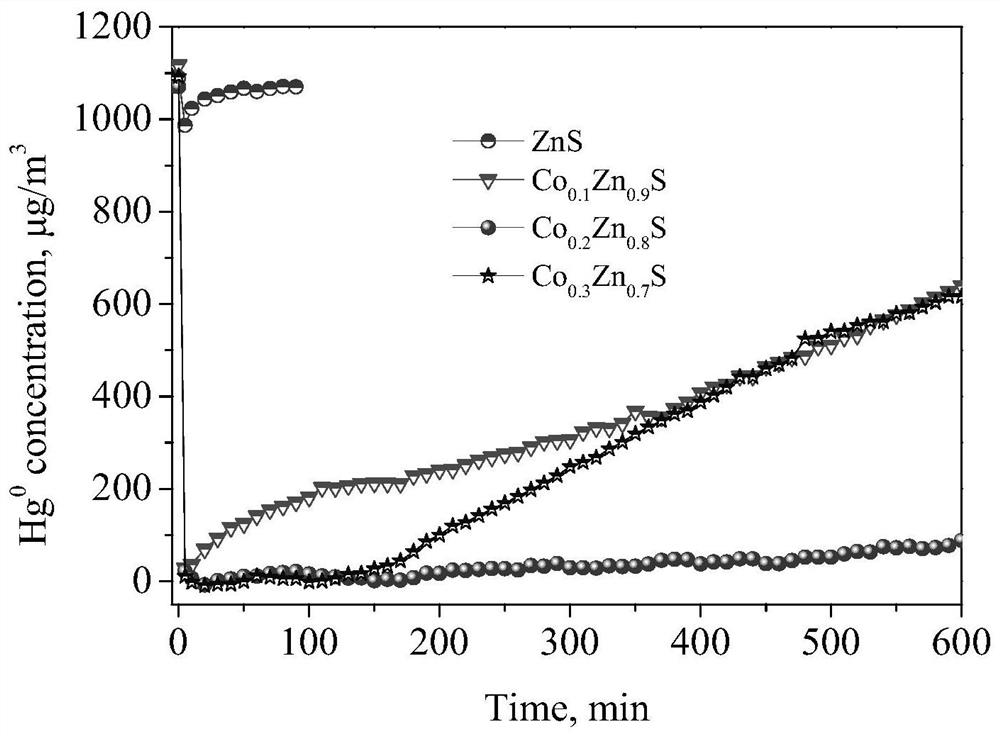

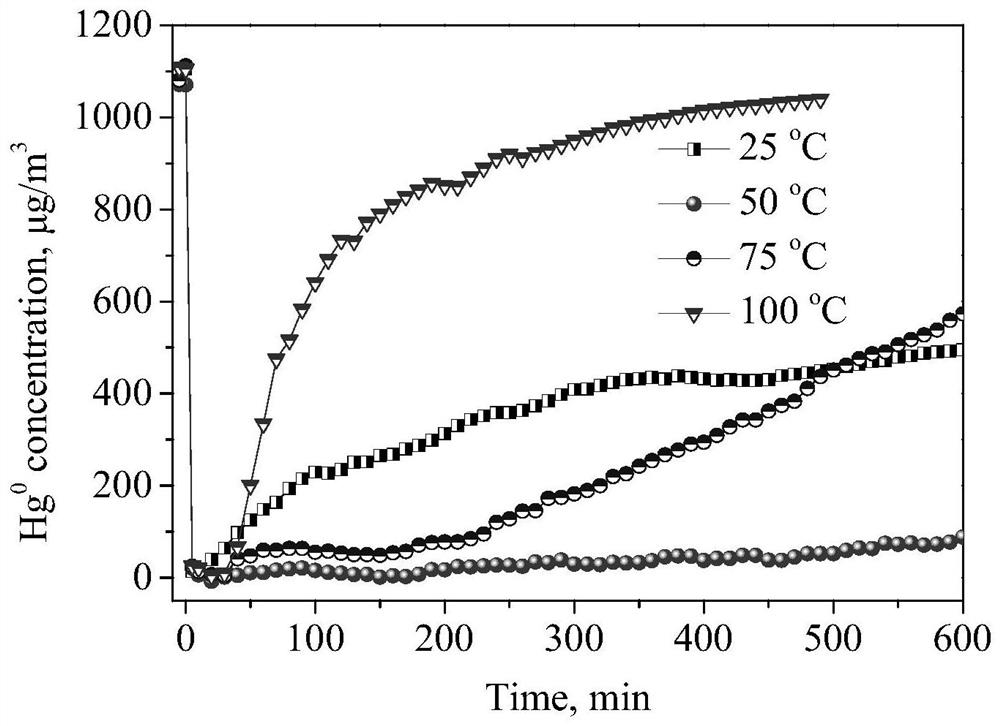

Zinc sulfide based mercury adsorbent for flue gas zero-valent mercury capturing and preparation method of zinc sulfide based mercury adsorbent

ActiveCN109092239ASimple processMild operating conditionsGas treatmentOther chemical processesSorbentFlue gas

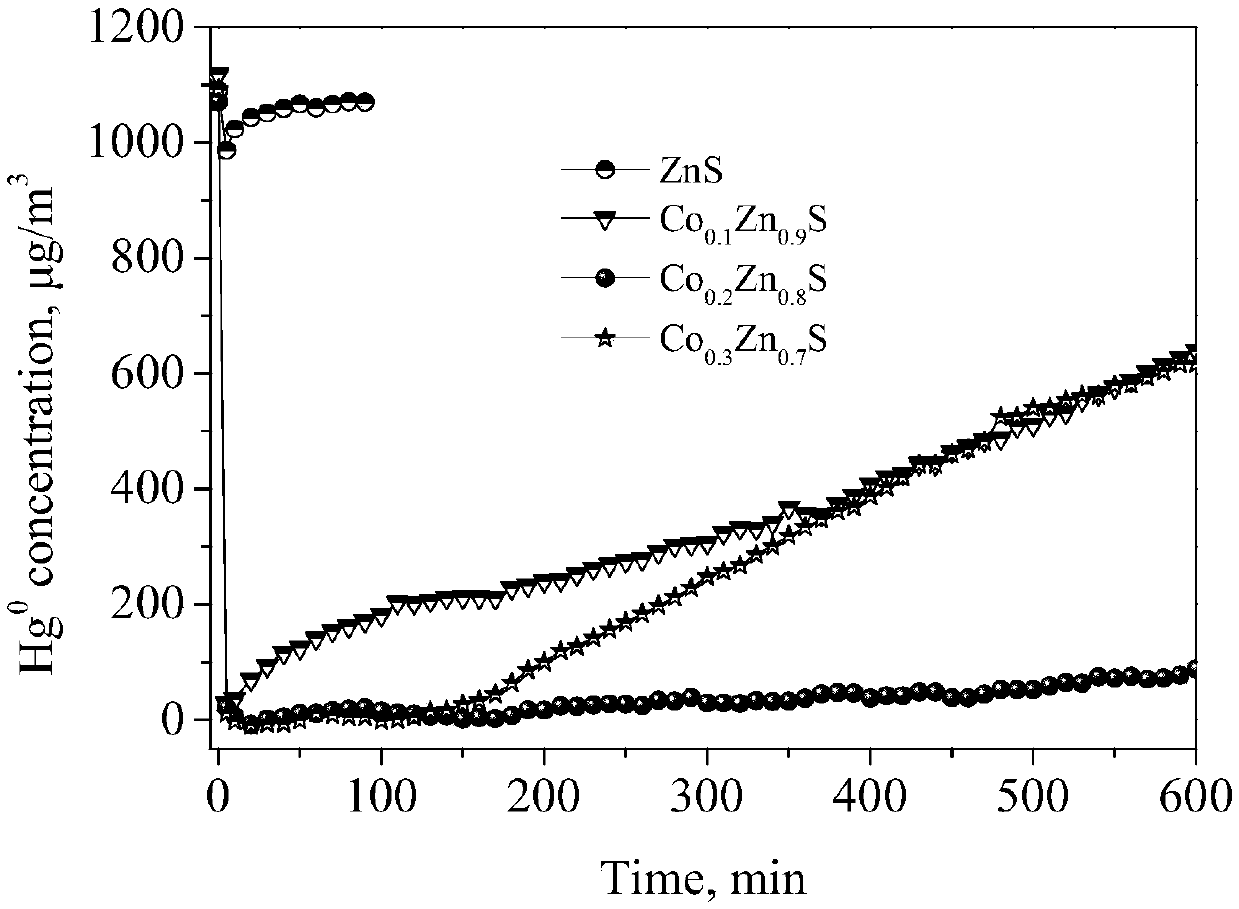

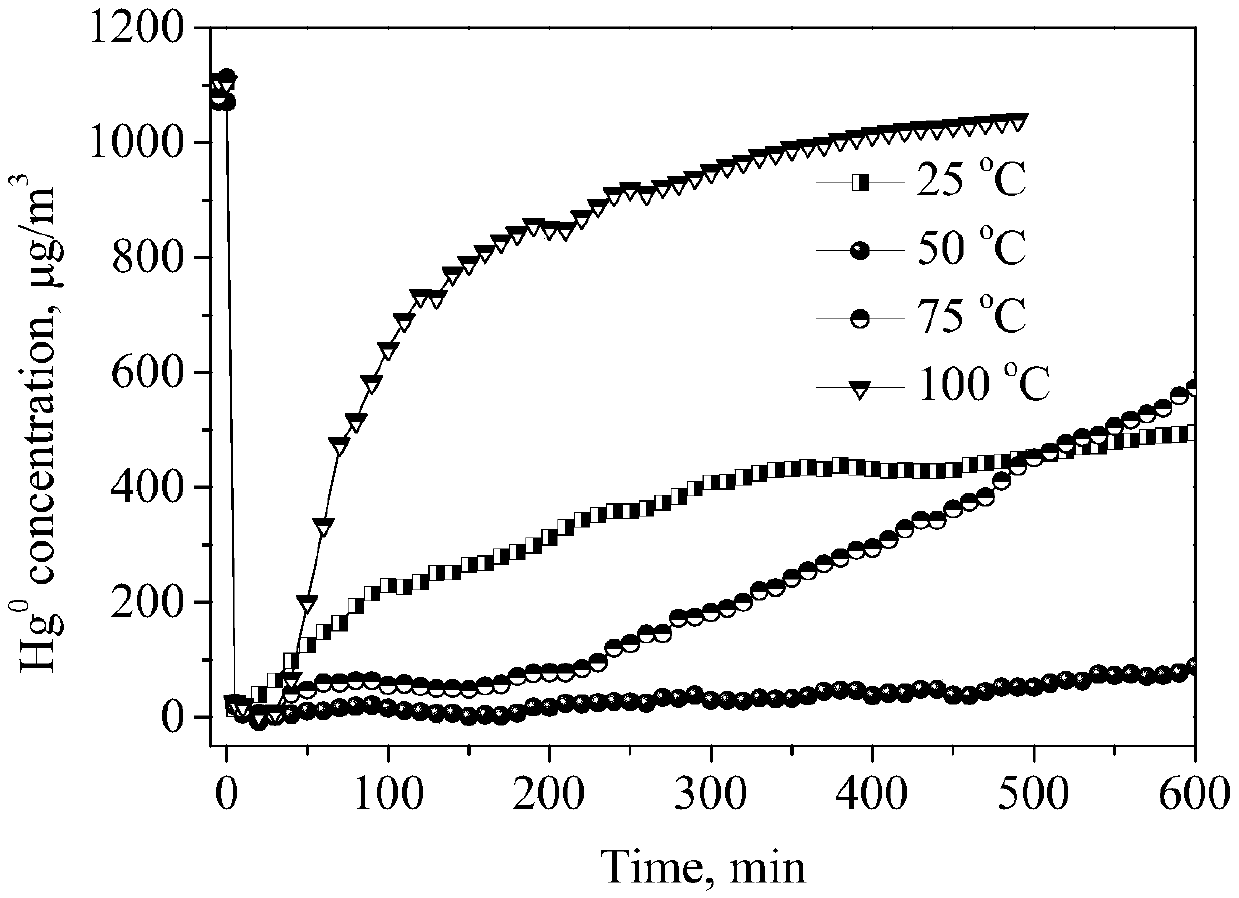

The invention relates to a zinc sulfide base mercury adsorbent for flue gas zero-valent mercury capturing and a preparation method of the zinc sulfide based mercury adsorbent. The adsorbent is a cobalt-doped zinc sulfide mercury adsorption material CoxZn1-xS, in the formula, x represents the stoichiometric ratio of cobalt in a solution, and the stoichiometric ratio is 0.1-0.3. The preparation method comprises the following steps: (1) dissolving a cobalt salt and a zinc salt of a certain mole ratio into deionized water so as to obtain a mixed solution; (2) mixing and stirring the mixed solutionwith a precipitant; (3) putting a suspension liquid into a reactor, and carrying out heating treatment on the reactor in a baking oven; (4) repeatedly washing the obtained precipitate with deionizedwater, and drying, thereby obtaining the zinc sulfide based mercury adsorbent. Compared with the prior art, the preparation method is wide in raw material source, simple and controllable in preparation process and gentle in reaction condition, and the prepared adsorbent has a mercury adsorption capability which is improved by dozens of times when being compared with pure zinc sulfide, in additionhas a very good anti-SO2 influence property, is capable of maintaining certain high activity within a long time, and is particularly applicable to adsorption and removal of zero-valent mercury in a metallurgical flue gas.

Owner:SHANGHAI JIAO TONG UNIV

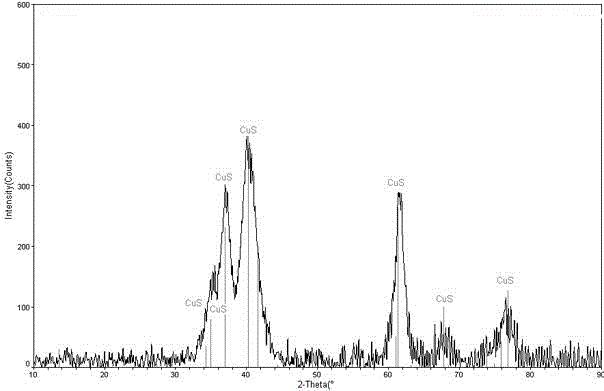

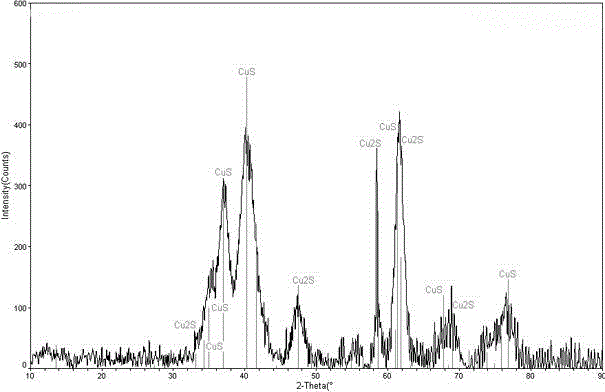

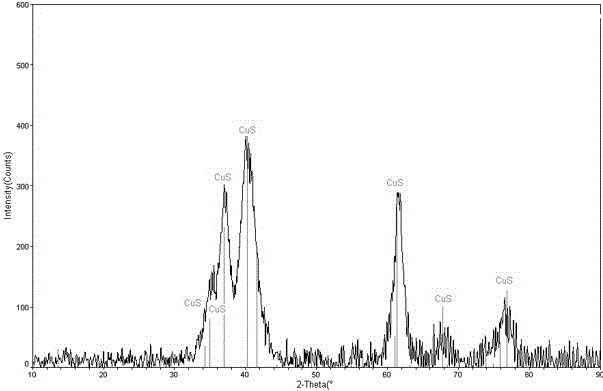

Preparation method of copper sulfide demercuration agent

The invention discloses a preparation method of a copper sulfide demercuration agent. The method comprises the following steps: 1, uniformly mixing a soluble copper salt solution with an ethylene diamine solution, adding ammonia water, and mixing to obtain a premix solution, wherein a molar ratio of the copper salt to the ethylene diamine solution to ammonia water is 1:(1-2.5):(1-10); 2, adding the premix solution to a thiourea solution, and uniformly mixing to obtain an impregnation solution; and 3, immersing a carrier in the impregnation, draining, activating at 60-95DEG C for 1-5h, and drying. The content of copper sulfide in the prepared demercuration agent is 100%, the demercuration agent has no impurities, and the preparation method has the advantages of simplicity and easy realization of reaction conditions.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Twin-tower type flue gas deep purification device through plasma coupling and sodium based absorption and method thereof

ActiveCN105056723AEasy to handleImprove efficiencyLighting and heating apparatusDispersed particle separationEngineeringFlue gas

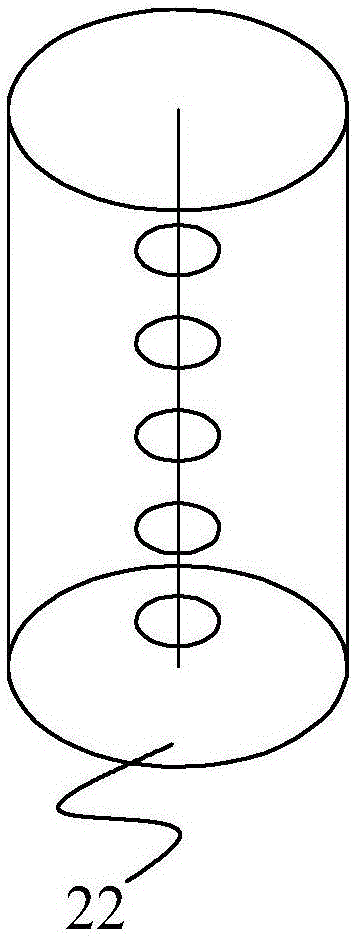

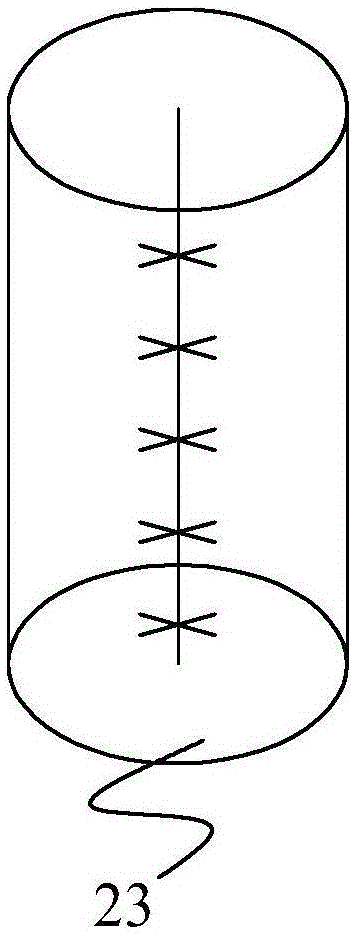

The invention discloses a twin-tower type flue gas deep purification device through plasma coupling and sodium based absorption. The desulfurization tower and denitration tower in the device are separated from each other. The desulfurization tower comprises a desulfurization slurry circulating tank, a desulfurization spraying layer, a desulfurization demister, and a desulfurization flue gas outlet from bottom to top. A plasma demisting and oxidizing device comprises a demisting part and an oxidizing part, and the lower ends of the demisting part and the oxidizing part are both provided with a demisting wastewater outlet. The denitration and demercuration tower comprises a denitration and demercuration slurry circulating tank, a filling material layer, a denitration and demercuration spraying device, a denitration and demercuration demister, and a denitration and demercuration flue gas outlet from bottom to top. A desulfurization flue gas outlet is arranged between the desulfurization slurry circulating tank and the desulfurization spraying layer. The denitration and demercuration slurry circulating tank is connected to the oxidizing part. The demisting part is connected to the desulfurization flue gas outlet. The desulfurization slurry circulating tank is connected to the desulfurization spraying layer. The denitration and demercuration slurry circulating tank is connected to the denitration and demercuration spraying device. The desulfurization slurry circulating tank and the demisting wastewater outlet are both connected to the denitration and demercuration slurry circulating tank.

Owner:ZHEJIANG FUCHUNJIANG ENVIRONMENTAL THERMOELECTRIC CO LTD +1

Carbon-based mercury-removing absorbent and preparation method thereof

ActiveCN106311139AImprove mercury removal performanceHigh specific surface areaGas treatmentOther chemical processesHalogenSorbent

The invention relates to a preparation method of a carbon-based mercury-removing absorbent. The preparation method includes the steps of A), mixing fly ash with alkaline liquid, and etching to obtain etched fly ash; B), mixing the etched fly ash with metal halide and alkali under an inert gas environment, and activating to obtain activated fly ash, wherein activating temperature is 700-800 DEG C and activating time is 90-120 minutes; C), mixing the activated fly ash with a metal halide solution, and modifying to obtain the carbon-based mercury-removing absorbent. The preparation method has the advantages that the fly ash is subjected to alkaline liquid etching first, the alkali is allowed to react with the carbon of the fly ash, and a large amount of pores exist at etched positions; the specific surface area, micropore contents and functional groups of the fly ash are increased to a large extent by the activating; the surface and inside of the fly ash carry halogen elements through the modification by the metal halide solution, and the mercury-removing ability of the fly ash is further increased.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

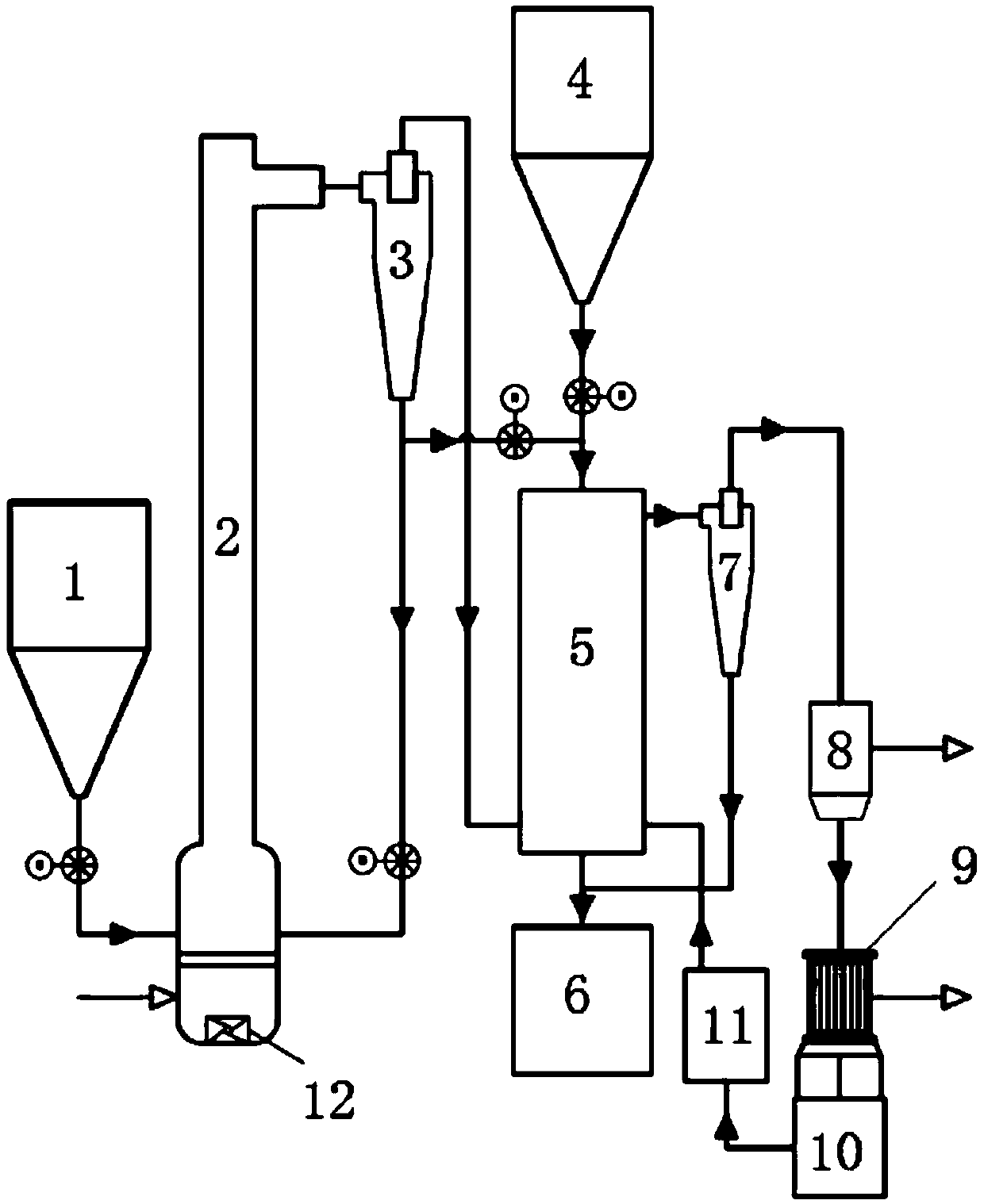

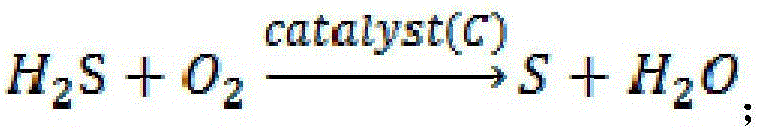

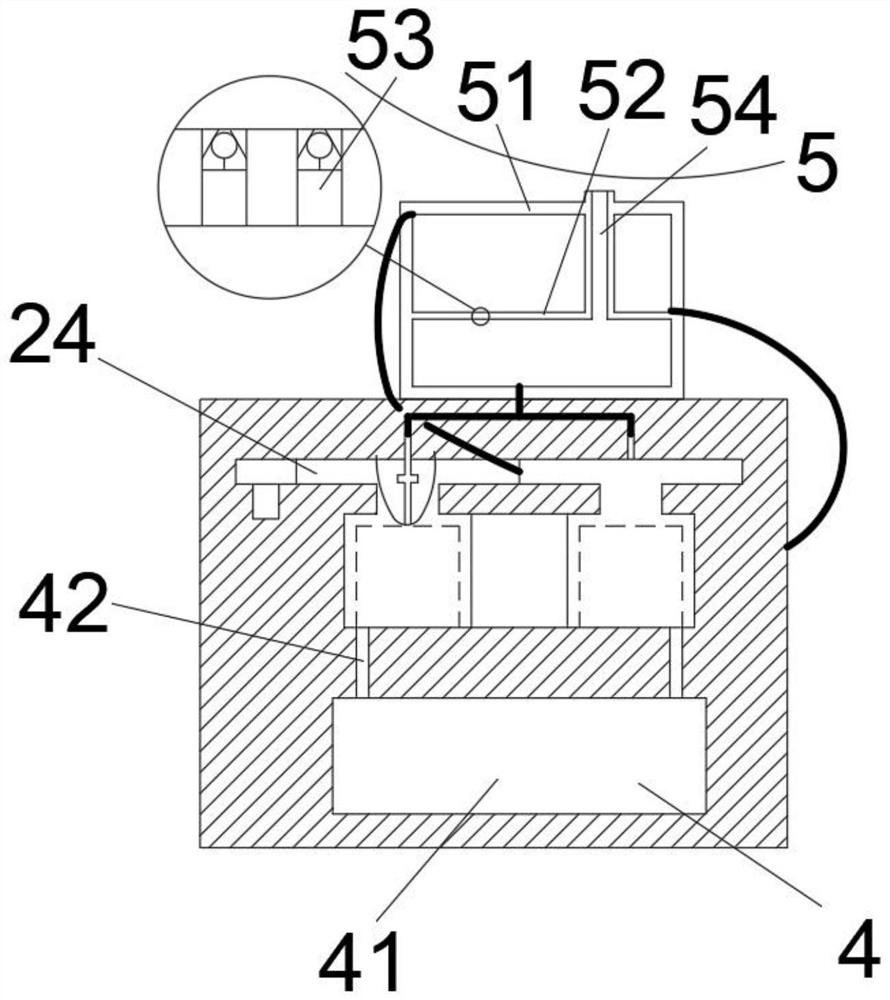

Preparation system and method of mercury-removing sulfur-carrying activated carbon/coke

ActiveCN109621899AImprove mercury removal performanceAchieve removalGas treatmentOther chemical processesActivated carbonGas solid

The invention discloses a preparation system and method of mercury-removing sulfur-carrying activated carbon / coke. The preparation system comprises a thermal carbon reduction tower, a first separatorand an activated carbon sulfur carrier, wherein the thermal carbon reduction tower provides an environment making SO2 in flue gas and a carbon material to achieve thermal carbon reduction and produceselemental sulfur vapor; the gas outlet end of the thermal carbon reduction tower is connected with a first separator, the first separator is used for gas-solid separation; the gas outlet end of the first separator is communicated with the lower end of the activated carbon sulfur carrier, the solid outlet end of the first separator is communicated with the upper end of the activated carbon sulfurcarrier, and the activated carbon sulfur carrier is connected with an activated carbon / coke storage tank. A small amount of calcium sulfate presents in the coke required for thermal carbon reduction,in the process of thermal carbon reduction, calcium sulfate and a carbon material generate calcium sulfide at 400-900 DEG C, the elemental sulfur vapor generated by the thermal reaction of the calciumsulfide and carbon forms calcium sulfide in the range of 750-1000 DEG C, and the calcium persulfate has good mercury removing capability.

Owner:SHANDONG UNIV

Industrial sulfur-containing waste gas modified carbon-based adsorbent and preparation method and application thereof

InactiveCN105921104ARealize desorption and recyclingReduce wasteGas treatmentOther chemical processesNatural resourceDesorption

The invention discloses an industrial sulfur-containing waste gas modified carbon-based adsorbent and a preparation method thereof. A carbon-based adsorbent is put into a flowing industrial sulfur-containing waste gas modifier, heating treatment is carried out, and the industrial sulfur-containing waste gas modified carbon-based adsorbent is obtained. The invention further discloses application of the industrial sulfur-containing waste gas modified carbon-based adsorbent in flue gas demercuration and an application method of the industrial sulfur-containing waste gas modified carbon-based adsorbent. Compared with the prior art, by modifying the carbon-based adsorbent with the industrial sulfur-containing waste gas, the demercuration performance of the adsorbent is improved, the effect of treating waste with waste is achieved, desorption and recycling of mercury are achieved at the same time, the content of total mercury entering the atmosphere is reduced, and meanwhile waste of the valuable natural resource mercury is reduced.

Owner:南京正森环保科技有限公司

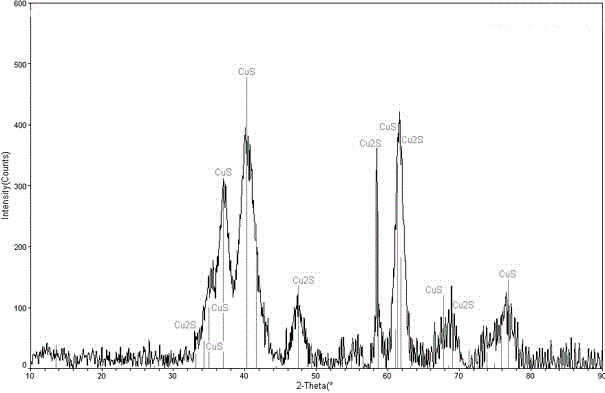

Mercury removal agent for moisture mercury removal and preparation method of mercury removal agent

InactiveCN108456574AImprove mercury removal performanceGood mercury removal effectOther chemical processesGaseous fuelsActivated carbonVulcanization

The invention provides a mercury removal agent for moisture mercury removal. The mercury removal agent comprises an active substance, carrier particles and an auxiliary component, wherein the active substance is metal sulfide, wherein copper sulfide accounts for 80% or more by mass; the carrier particles include active aluminum oxide, coconut shell activated carbon and an adhesion promoter; the auxiliary component is silver sulfide; the active substance and the auxiliary component are loaded on the carrier particles. The invention also provides a preparation method of the mercury removal agent. The preparation method comprises the following steps: mixing the active aluminum oxide, the coconut shell activated carbon and the adhesion promoter, performing extrusion forming, and drying to obtain the carrier particles; impregnating the carrier particles in a solution containing Cu<2+> and Ag<+>; after complete impregnation, calcining at 500-800 DEG C to obtain a mercury removal agent precursor; impregnating the mercury removal agent precursor in a sulfide solution for 2-4h; after vulcanization, calcining at 500-800 DEG C to obtain the mercury removal agent, wherein the mercury removal agent has better mercury removal performance when the loading quantity of copper sulfide is the same.

Owner:SOUTHWEST PETROLEUM UNIV +1

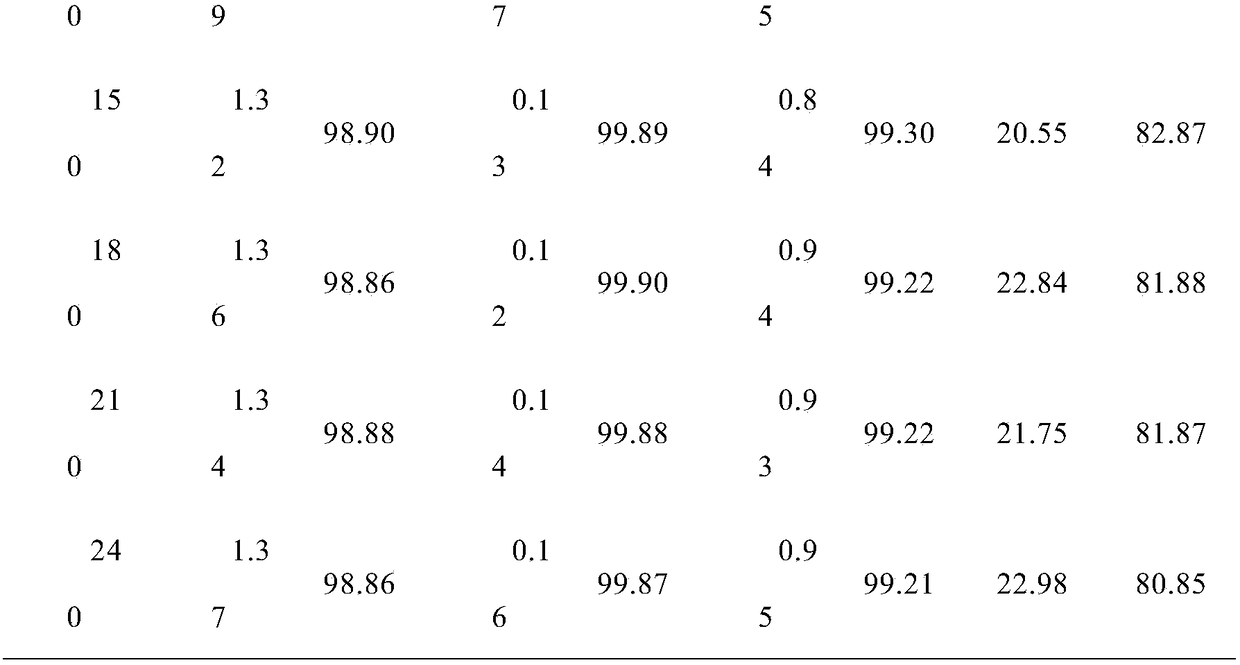

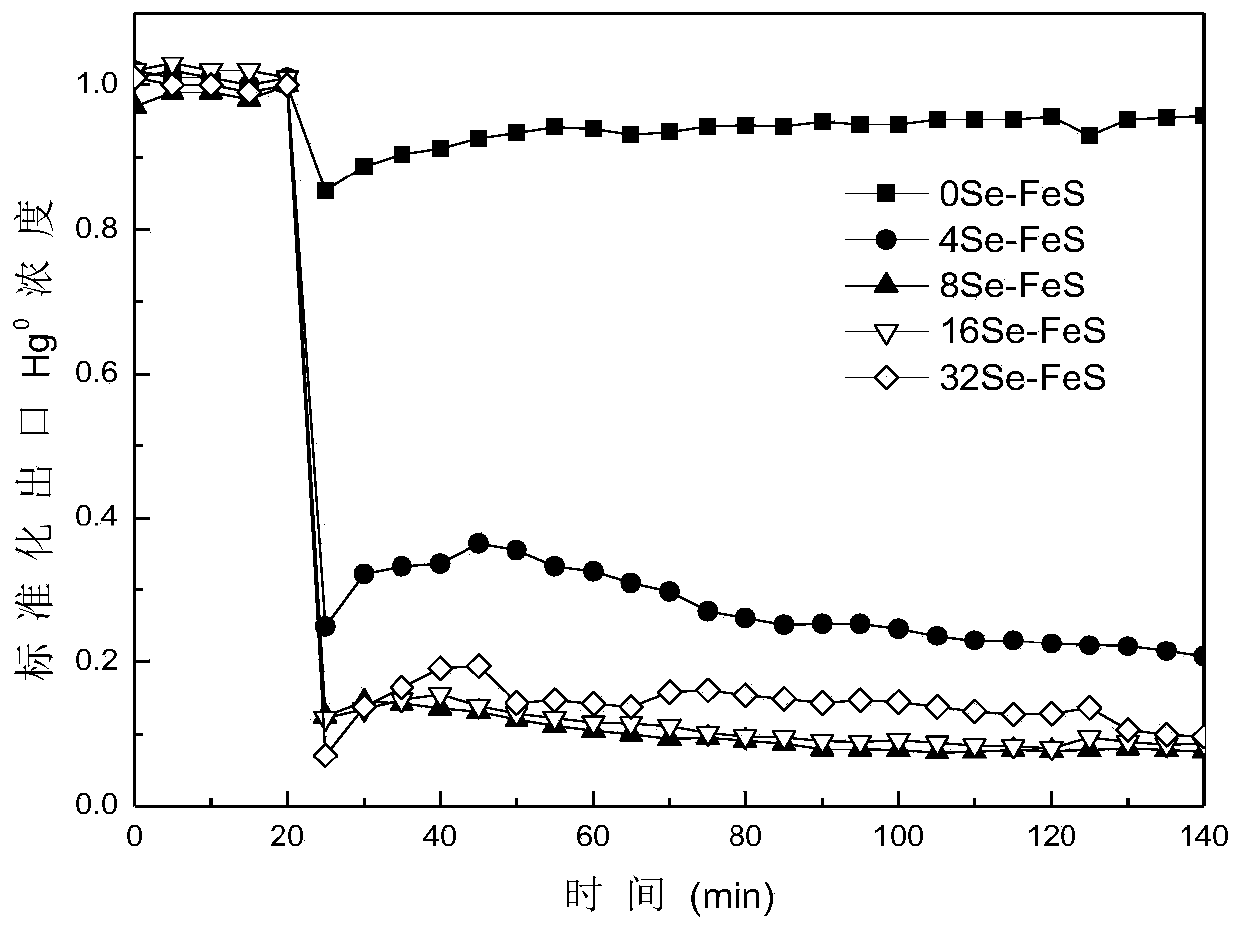

Additive capable of simultaneous desulphurization and demercuration and preparation method thereof

ActiveCN103143252AImprove desulfurization and mercury removal efficiencyReduce pollutionDispersed particle separationIron sulfatePhthalaldehyde

The invention discloses an additive capable of simultaneous desulphurization and demercuration. The additive comprises sodium benzoate, ferric sulfate, adipic acid and ortho-phthalaldehyde. The invention further discloses a preparation method for the additive capable of simultaneous desulphurization and demercuration. The additive can realize simultaneous desulphurization and demercuration, has high desulphurization and demercuration efficiency and has the advantages of improvement of activity of limestone, capacity of preventing fouling and blocking of a WFGD system and reduction of system energy loss.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

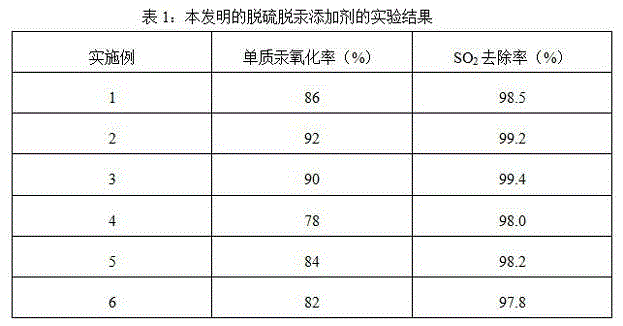

Natural sulfide mineral-based material as well as preparation method and application thereof

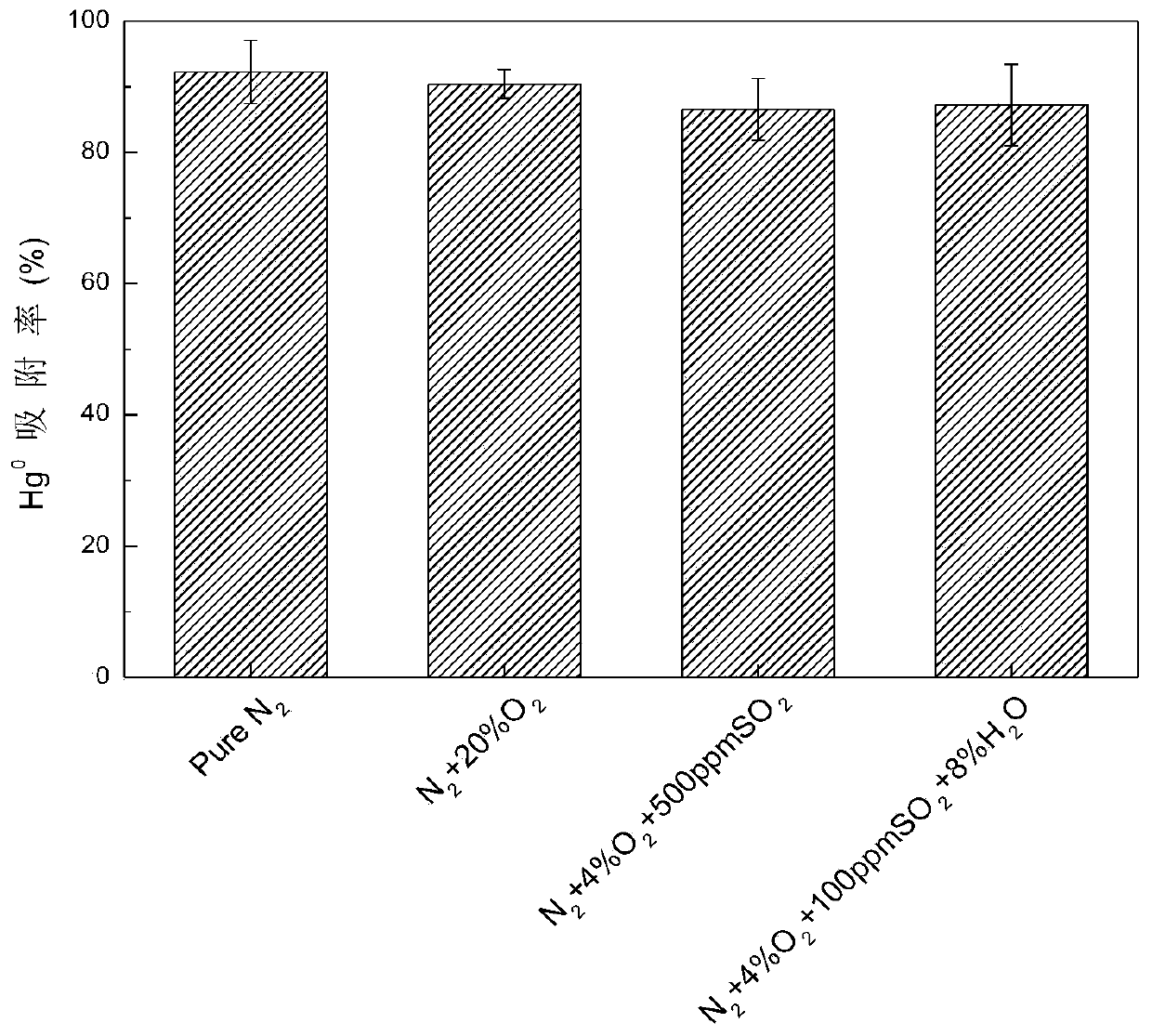

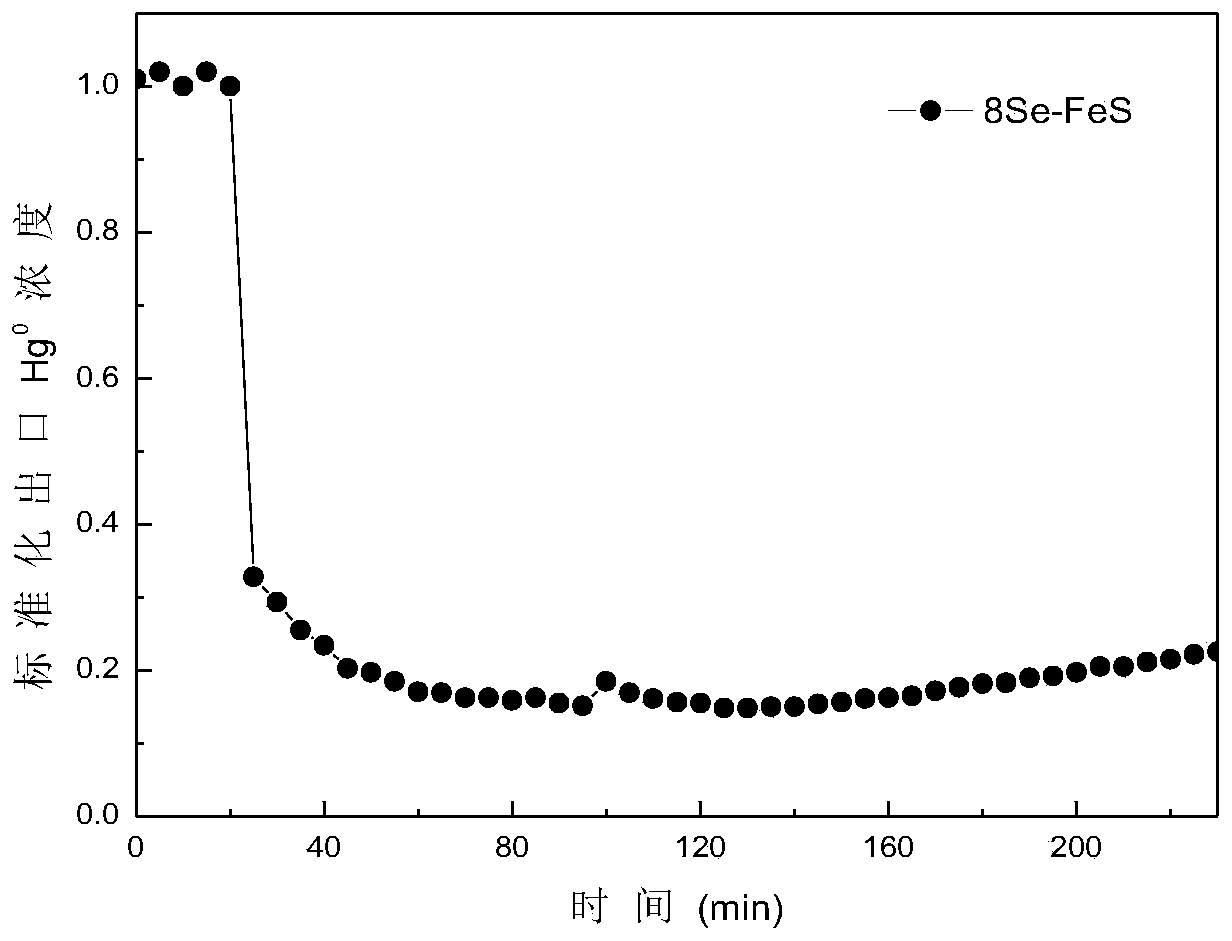

The invention discloses a natural sulfide mineral-based material as well as a preparation method and an application thereof. According to the method, a simple one-step anion exchange reaction is employed, and natural metal sulfide minerals are soaked in a Se2-precursor solution to synthesize selenium ion-coated natural sulfide minerals serving as a novel mercury adsorbent; the natural metal sulfide mineral comprises pyrrhotite, pyrite, sphalerite, alabandite, tungstenite and a mixture of the pyrrhotite, pyrite, sphalerite, alabandite and tungstenite. The mercury adsorbent obtained by the invention is used as a mercury removal medium to be in contact with gas-phase elemental mercury in a fixed bed, a fluidized bed or an injection tower, so that the gas-phase elemental mercury is converted into stable mercury sulfide. The preparation method of the natural sulfide mineral-based material is rich in raw material reserve, simple in process and wide in application range; the natural sulfide mineral-based material has extremely high mercury adsorption capacity and adsorption rate, is applied to removal of elemental mercury in a gas phase, and has the advantages of simplicity in operation,high efficiency, environmental friendliness of mercury removal products and the like.

Owner:CENT SOUTH UNIV

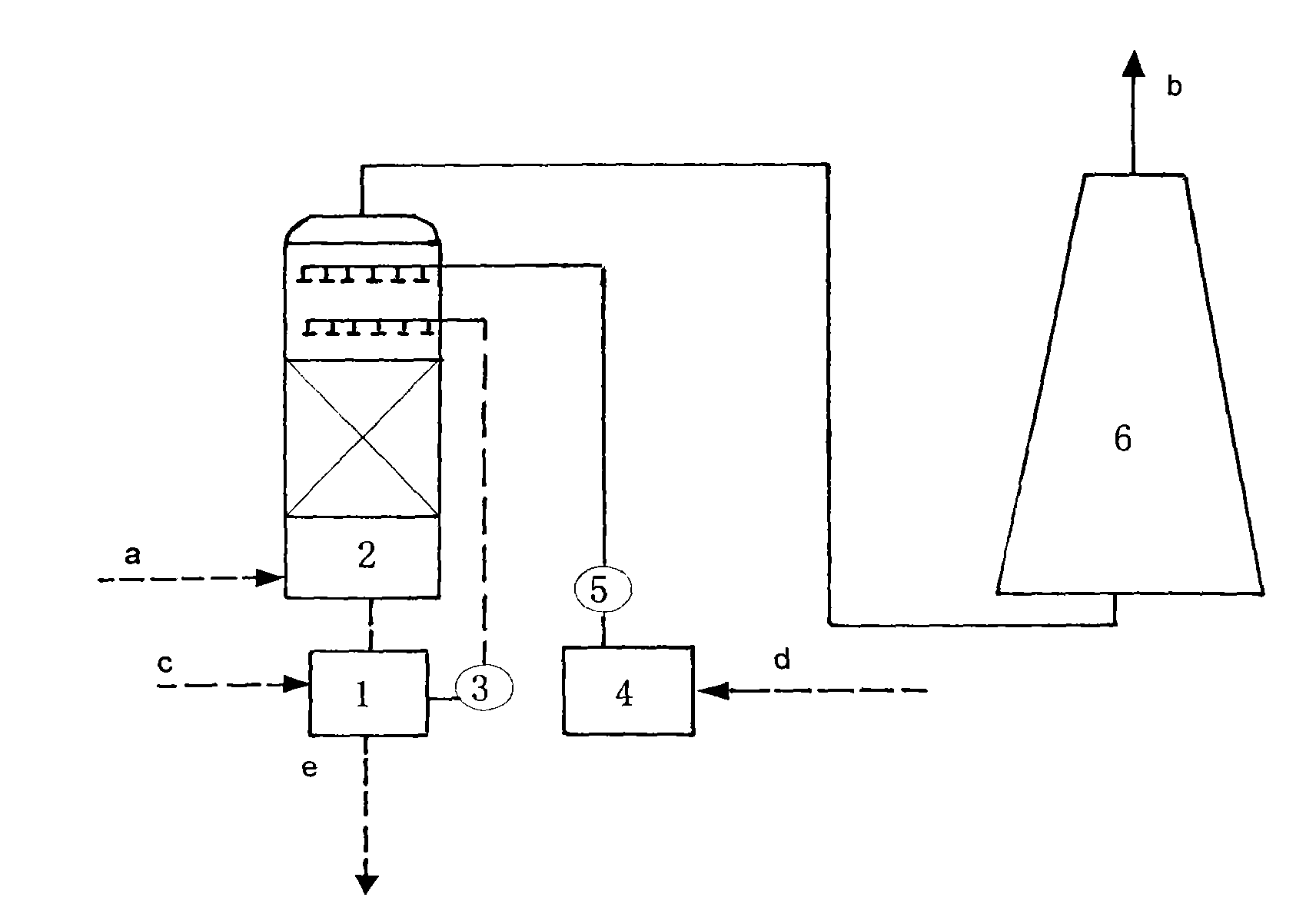

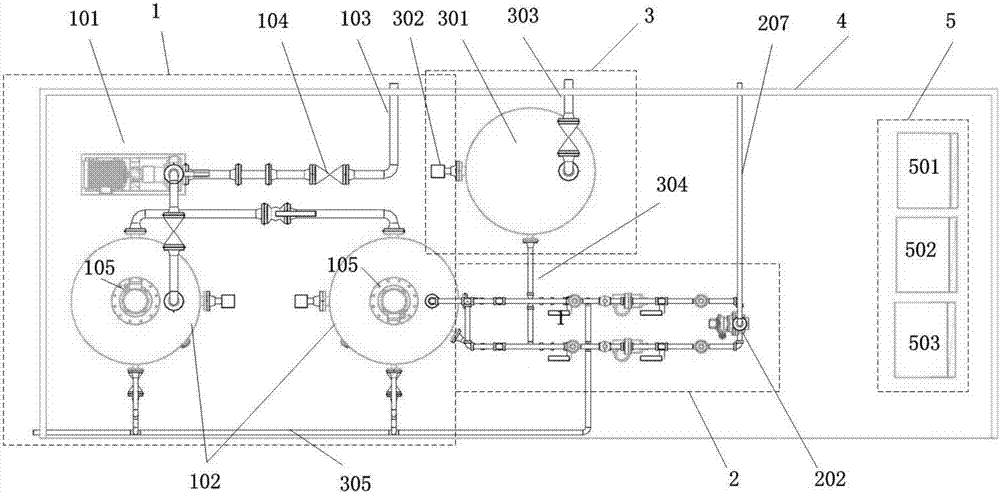

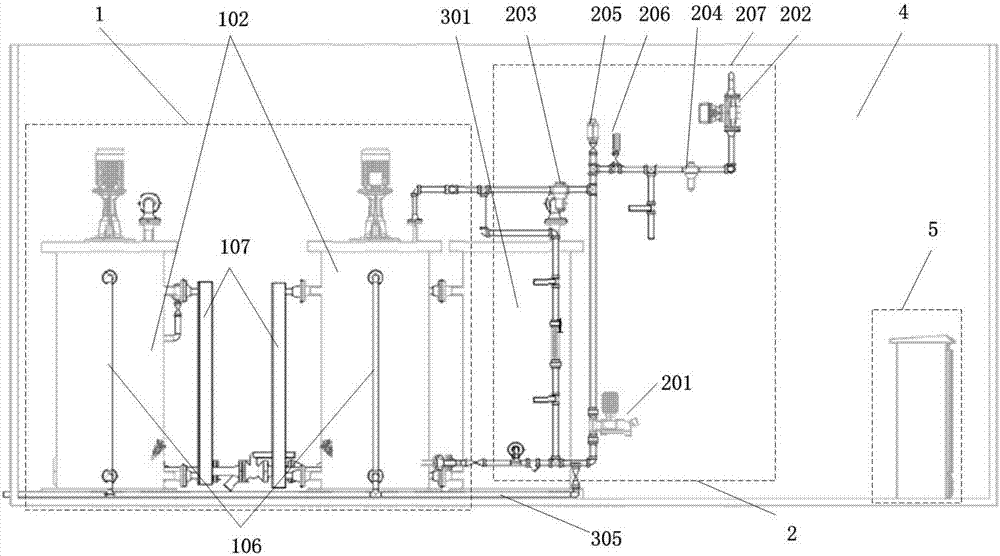

Container type additive solution feeding system for removing mercury from flue gas

PendingCN107029530AImprove mercury removal performanceHigh degree of automationGas treatmentDispersed particle separationFlue gasProcess engineering

The invention discloses a container type additive solution feeding system for removing mercury from flue gas. The container type additive solution feeding system comprises an additive solution storage system, a feeding system, a washing system, an electric control device and related pipelines, and is characterized in that the additive solution storage system comprises at least one additive delivery pump, additive storage tanks and delivery pipes, an inlet of the additive solution storage system is connected with external additive solution, and an outlet of the additive solution storage system is connected with the feeding system; the feeding system is communicated with an additive input point by a metering pump via a feeding pipeline; system washing water can be supplied by the washing system, the mentioned devices are controlled by the electric control device, and the mentioned devices and the related pipelines are arranged in a container in a communicated manner. The container type additive solution feeding system has the advantages that the container type additive solution feeding system can flexibly move and can be quickly deployed to different flue gas treatment sites; the container type additive solution feeding system is low in investment, small in occupied area, high in reaction speed and automation degree and convenient to move and is environmentally friendly, and energy can be saved.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

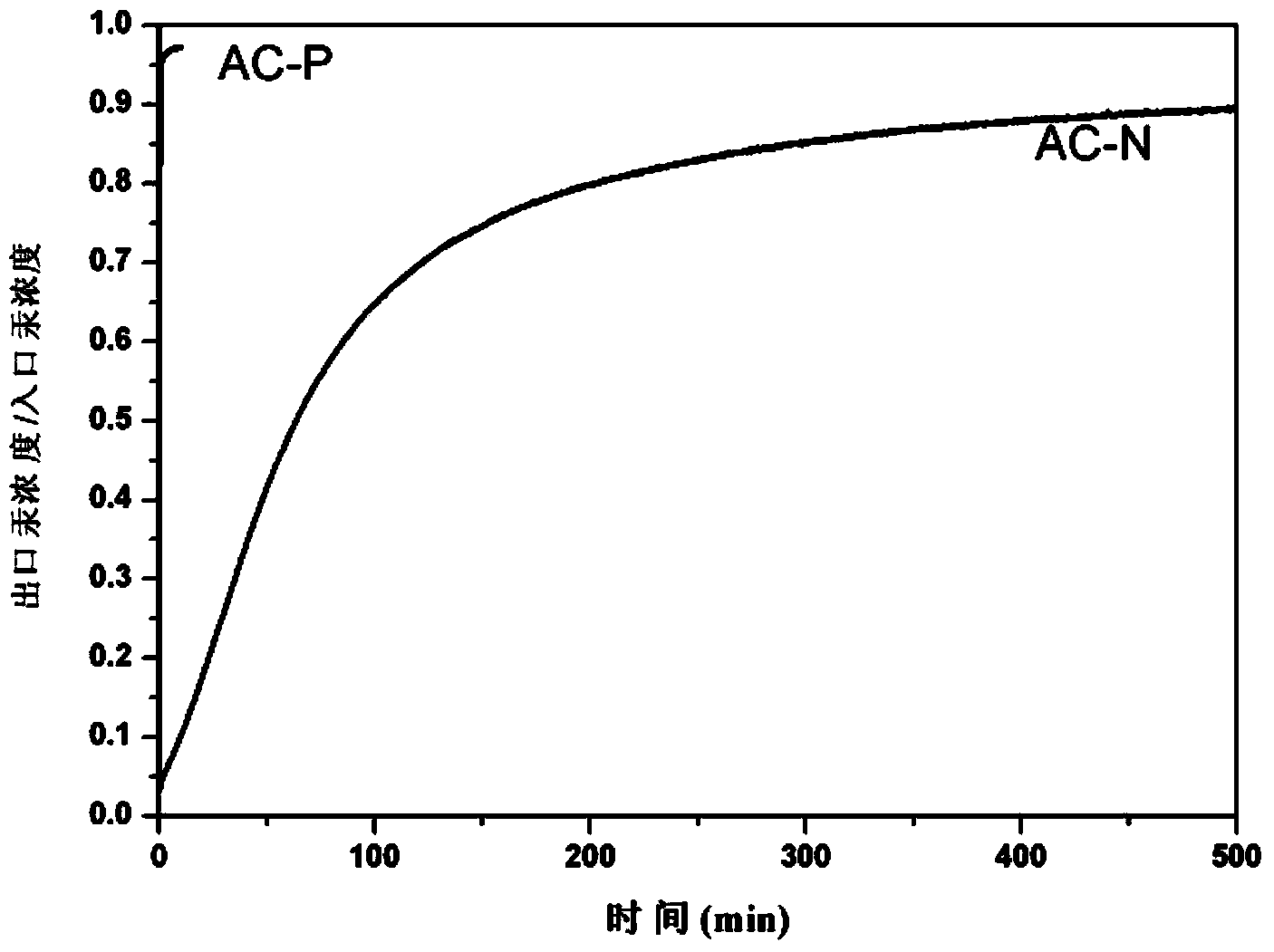

Nitric acid modified activated carbon adsorbent for demercuration of flue gas, and preparation method and application thereof

InactiveCN104014304AImproving the Ability of Adsorption and Removal of Mercury in Coal-fired Flue GasEasy to prepareOther chemical processesDispersed particle separationFlue gasSorbent

The invention relates to a nitric acid modified activated carbon adsorbent for demercuration of a flue gas, and a preparation method and application thereof. The preparation method comprises the steps of washing activated carbon in a certain size range clean with distilled water, drying for use; preparing a certain concentration of a nitric acid modified solution; then impregnating the activated carbon by using the solution; and finally washing a filtrate and drying to obtain the nitric acid modified activated carbon adsorbent used for the demercuration. The nitric acid modified activated carbon adsorbent takes use of the characteristic that nitric acid can increase surface functional groups of the activated carbon, so that mercury is captured when a mercury-containing flue gas component enters a porous structure of the activated carbon. The nitric acid modified activated carbon is an efficient demercuration adsorbent specialized forflue gas injection demercuration of power plants, industrial boilers and industrial furnaces; operation and the preparation processes have the advantages of low energy consumption, simple operations and low cost; and mercury adsorption capacity of the modified activated carbon is greatly improved, thereby effectively controlling mercury in the coal-fired flue gas.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Multifunctional desulfurization, denitrification, demercuration adsorbent and preparation and application thereof

InactiveCN105289492AOvercome high pricesOvercome strengthOther chemical processesDispersed particle separationFlue gasDenitrification

The invention provides a multifunctional desulfurization, denitrification, demercuration adsorbent and preparation and application thereof. The multifunctional desulfurization, denitrification, demercuration adsorbent is characterized by comprising active coke, a vanadium SCR catalyst and magnetic silver-carrying zeolite, wherein mass ratio of active coke to magnetic silver-carrying zeolite is 1:0.25-4; and the vanadium SCR catalyst is loaded on the surface of active coke to magnetic silver-carrying zeolite. The adsorbent of the invention has an obvious purification effect when used in simultaneous desulfurization, denitrification and demercuration of flue gas.

Owner:DONGHUA UNIV

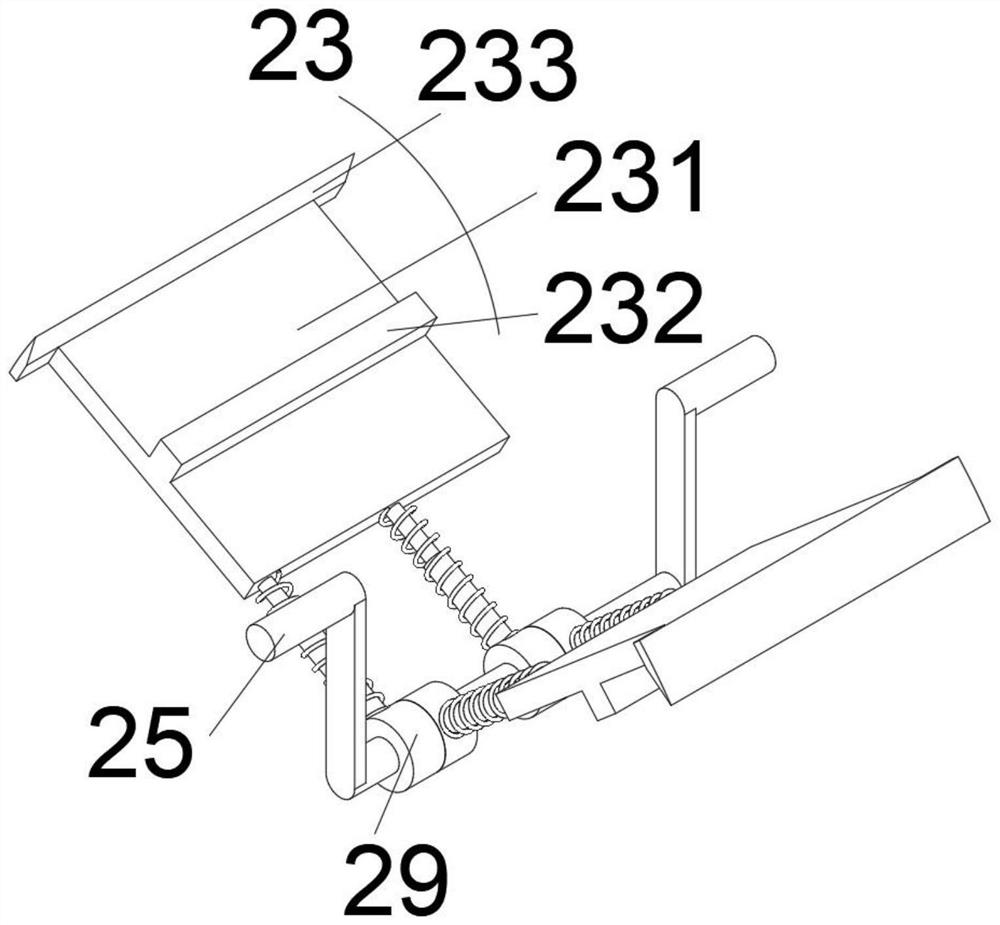

Adsorbent injection device based on adsorbent injection mercury removal

ActiveCN112426850AAvoid cloggingPrevent volatilizationGas treatmentDispersed particle separationExhaust fumesSorbent

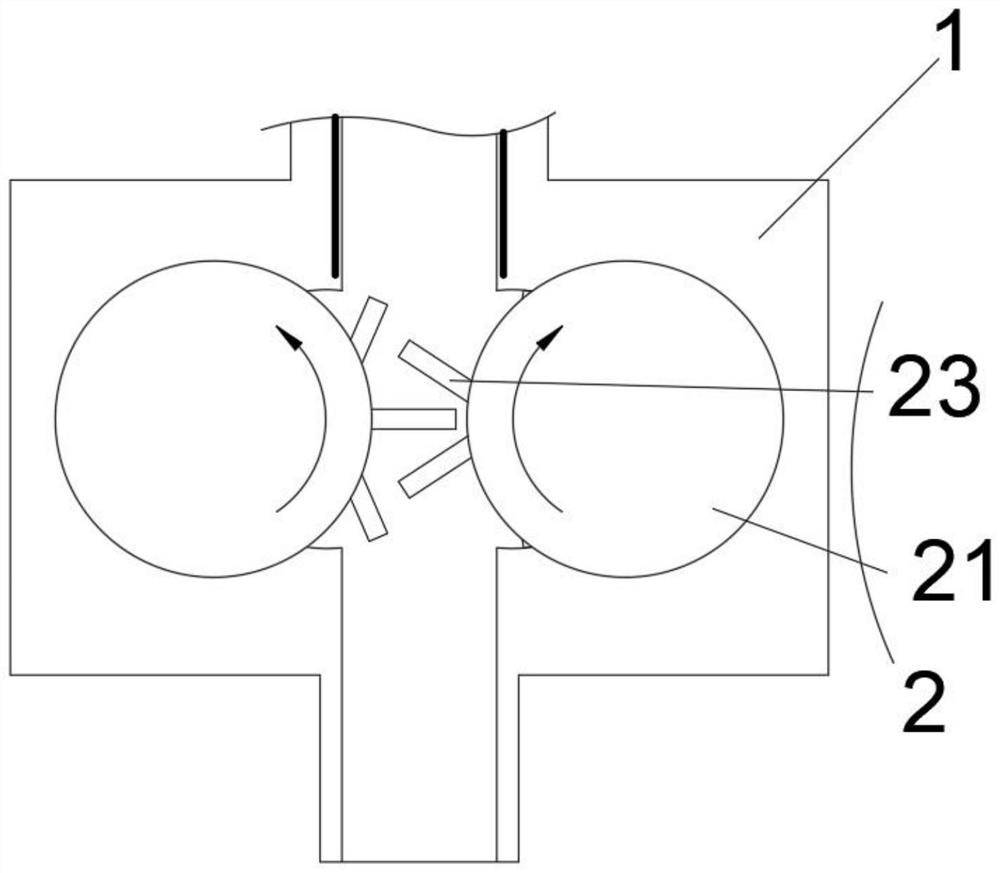

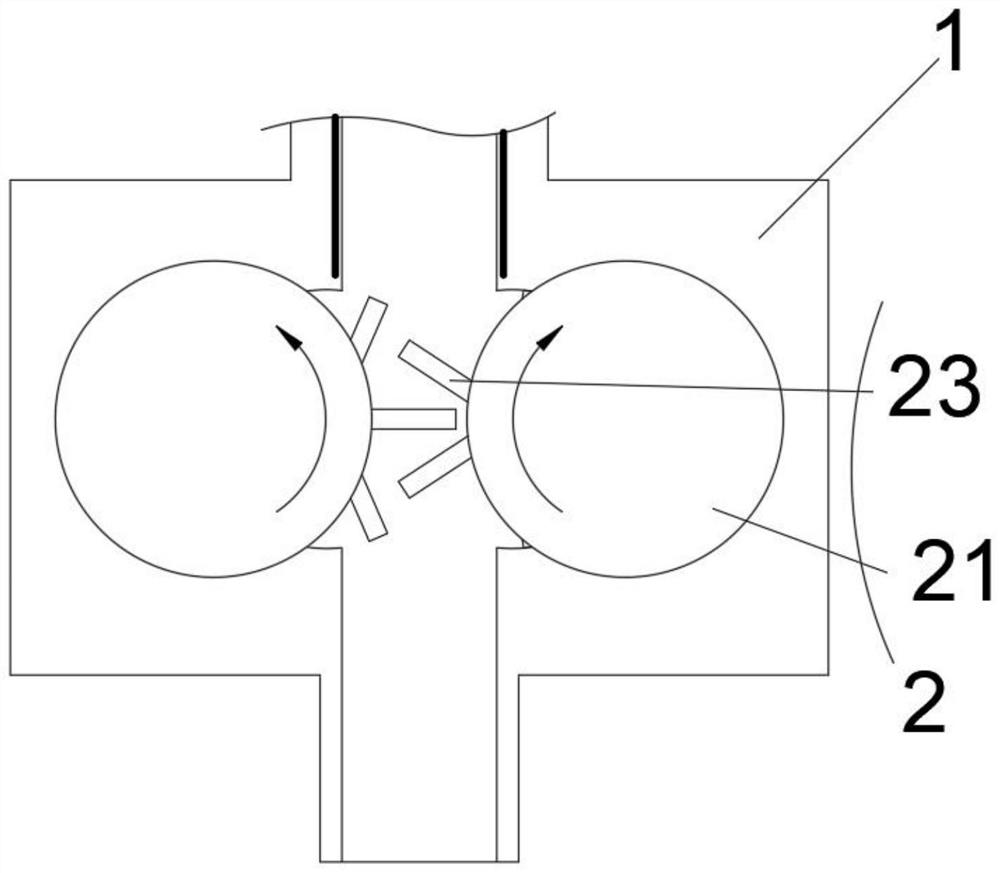

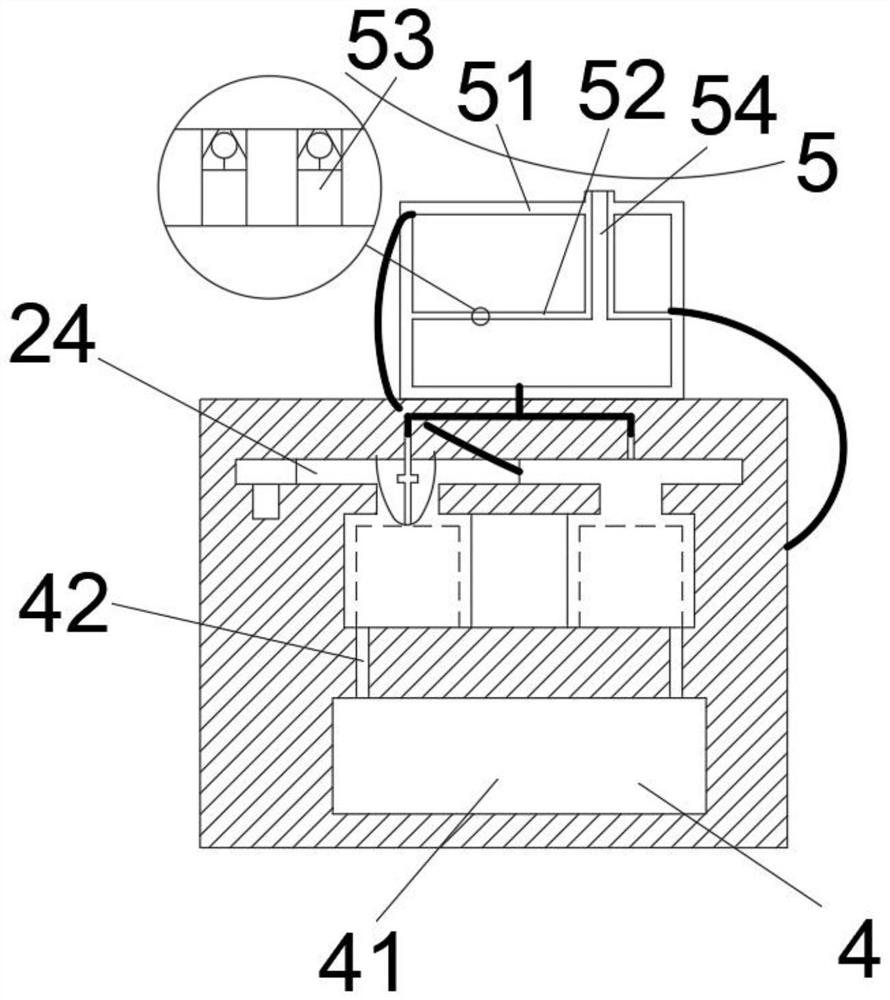

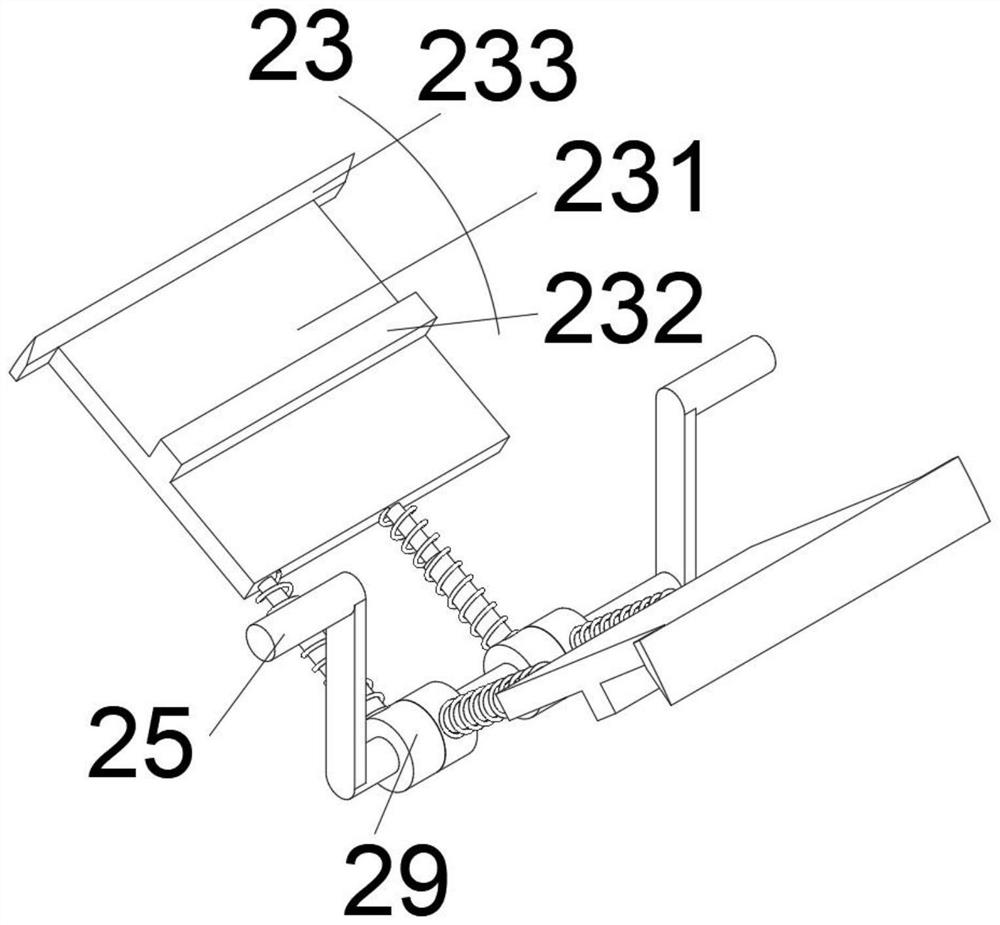

The invention discloses an adsorbent injection device based on adsorbent injection mercury removal. The device comprises an air suction pipe, an air pipe behind the air suction pipe is obliquely upward, an air suction assembly comprises two eccentric cylinders, blade sleeves are arranged in the two eccentric cylinders respectively, blades are arranged in the blade sleeves respectively in a sleevedmode, gears are arranged at the upper ends of the two eccentric cylinders respectively, neutralizing assemblies are arranged in the blades and the blade sleeves, recycling assemblies are arranged onthe side faces of the blades, cooling assemblies are arranged above the gears, and coal-fired waste gas can be sucked into the air suction pipe through the air suction assembly to be subjected to mercury removal, the cooling assemblies reduce the temperature of waste gas and liquefy most mercury vapor, the neutralizing assemblies neutralize the remaining mercury vapor and mercury oxide into substances difficult to volatilize, then the recycling assemblies recycle neutralized by-products and adsorption materials, and the by-products are prevented from being accumulated in the air suction pipe.The device provided by the invention has the characteristics of simultaneous desulfurization, mercury removal and mercury oxide removal and high adsorption efficiency.

Owner:苏州麟琪程科技有限公司

Mesoporous carbon carrier and preparation method thereof

ActiveCN111135849AImprove surface reactivityLow surface reactivityCatalyst carriersCarbon compoundsSurface reactionPtru catalyst

The invention belongs to the technical field of petrochemical engineering, and particularly relates to a mesoporous carbon carrier and a preparation method thereof. The method comprises the followingsteps: adding a carbon source into a saturated solution of a nitrogen source, and uniformly mixing to obtain a first mixed solution; dipping a template into the first mixed solution to obtain a secondmixed solution; adding an activating agent into the second mixed solution for activation to obtain a first activated intermediate, and then dipping the first activated intermediate into the first mixed solution again for mixing to obtain a third mixed solution; and sequentially crystallizing, filtering, drying and thermally treating the third mixed solution to obtain the mesoporous carbon carrier. According to the method, the mesoporous carbon carrier with good chemical stability and low surface reaction activity can be prepared without adding strong oxidizing acid in the preparation process,the mesoporous carbon carrier has good acid and alkali resistance and high temperature resistance, and the mercury removal catalyst prepared from the mesoporous carbon carrier has a good mercury removal effect.

Owner:SHENYANG SANJUKAITE CATALYST

A kind of method that utilizes waste methanol catalyst to prepare mercury removing agent

ActiveCN104475009BGood three-dimensional structureHigh pore volumeGas treatmentOther chemical processesActive componentSulfur containing

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

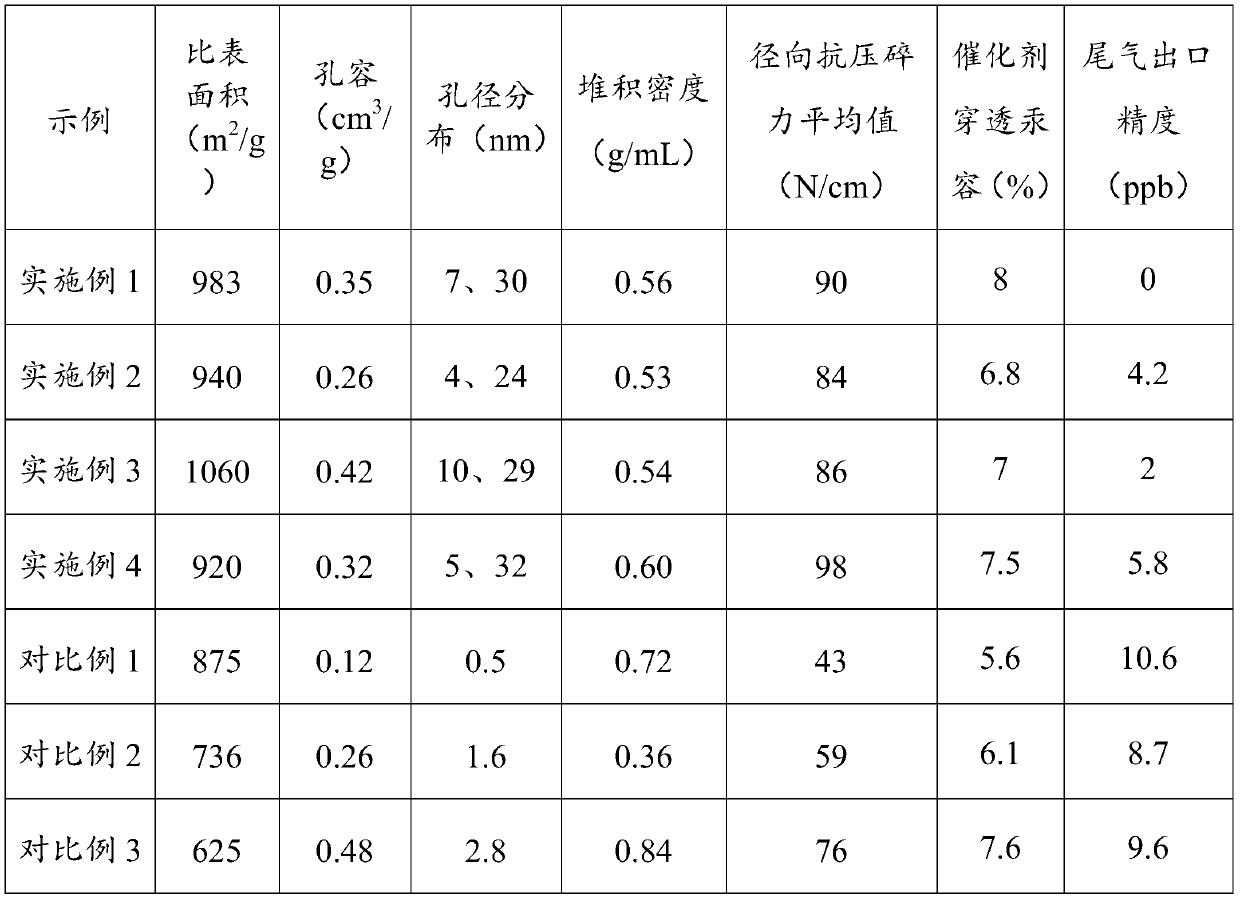

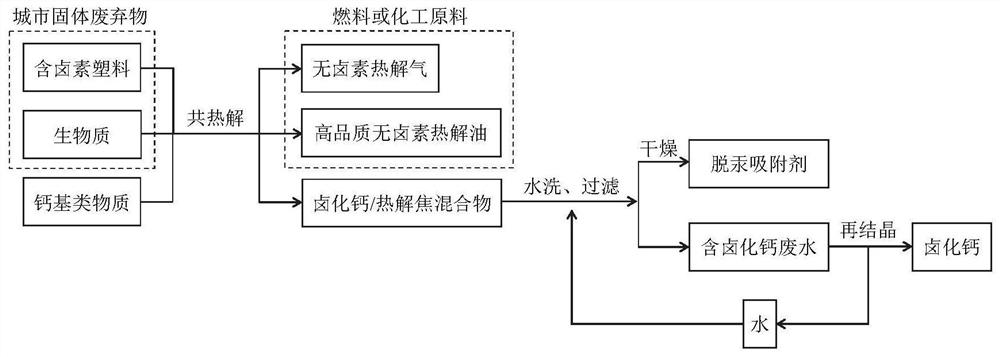

Method for simultaneously preparing high-quality bio-oil and high-performance mercury removal adsorbent from city solid wastes

The invention discloses a method for simultaneously preparing high-quality bio-oil and a high-performance mercury removal adsorbent from city solid waste. The preparation method comprises the following steps: mixing biomass / biomass waste, halogen-containing plastic and a calcium-based substance, carrying out pyrolysis; washing a solid product obtained by pyrolysis with water, filtering, and dryingto obtain the mercury removal adsorbent. The generation of CaCl2 / CaBr2 in the co-pyrolysis process can reduce the activation energy required by an original pyrolysis reaction; precipitation and release of more volatile components are promoted; a pyrolysis reaction path is changed; the pore structure of the generated adsorbent becomes more developed, and the mercury removal active sites on the surface of the adsorbent becomes richer, such that the mercury removal reaction can be easily performed, the quality and the yield of the bio-oil can be substantially improved through the interaction, and the bio-oil and the pyrolysis gas do not contain halogen so as to easily achieve the commercial use of the pyrolysis product.

Owner:SHANDONG UNIV

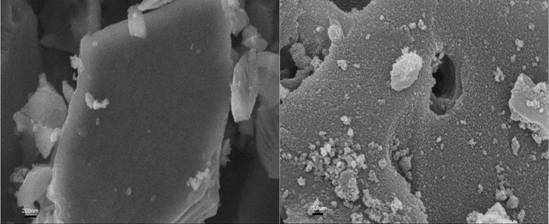

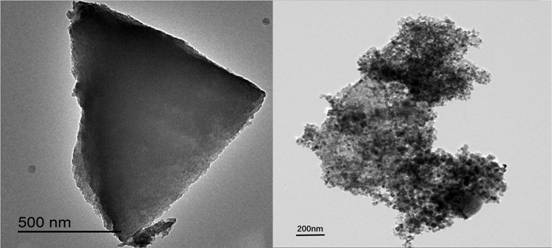

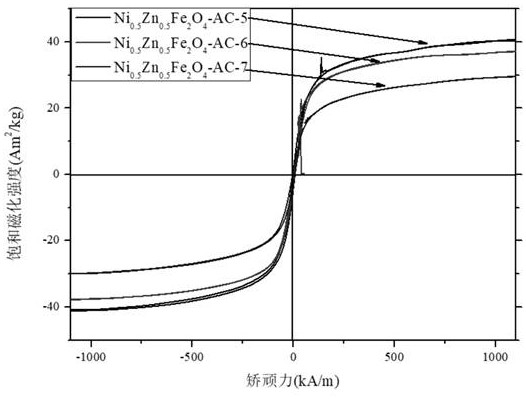

Preparation method of magnetic activated carbon and application of magnetic activated carbon in flue gas demercuration

PendingCN114345297AHelp adsorptionHelp oxidationOther chemical processesDispersed particle separationActivated carbonAlcohol

The invention discloses a preparation method of magnetic activated carbon and application of the magnetic activated carbon in flue gas demercuration, and relates to the technical field of composite material preparation, and the preparation method comprises the following steps: (1) proportionally weighing activated carbon, soluble salt of iron, soluble salt of nickel and soluble salt of zinc, dissolving in absolute ethyl alcohol or deionized water, and uniformly stirring to obtain a mixed solution, and (2) roasting the mixed solution obtained in the step (1) in a nitrogen atmosphere at 300-500 DEG C for 1-4 hours, stopping heating, and cooling to room temperature in the nitrogen atmosphere to obtain the magnetic activated carbon. The magnetic medium in the magnetic activated carbon material is the Ni0. 5Zn0. 5Fe2O4 nano material, the magnetic property is higher, the dispersity is good, the adsorption performance is more durable and stable, and due to the existence of Ni, Zn and Fe elements, the mercury removal performance of the magnetic activated carbon is enhanced, and magnetic separation and recycling are easier.

Owner:YANGZHOU UNIV

A kind of preparation method of special modified activated carbon for mercury removal

ActiveCN103223330BImprove mercury removal performanceSimple operation processOther chemical processesDispersed particle separationDistilled waterMercury adsorption

The invention discloses a preparation method of special modified active carbon for removing mercury. The method comprises the following steps of: washing wooden particle active carbon through hydrochloric acid and distilled water, and then drying the washed wooden particle active carbon to standby; heating the active carbon and the hydrogen peroxide with the concentration being 25 to 30wt% at the temperature of 50 to 70 DEG C for 2 to 4h according to the mass-to-volume ratio of 6g:(15-10)ml, and then carrying out the ultrasonic treatment on the active carbon for 20 to 40min; and standing, filtering, drying, washing and drying the active carbon to obtain the special modified active carbon for removing the mercury. The special modified active carbon has high mercury removal efficiency, and the maximal mercury adsorption volume can reach 5.3mg / g and is 1.5 times that of unmodified active carbon.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY

A catalytic oxidation additive for wet flue gas mercury removal and preparation method thereof

ActiveCN103381337BImprove removal efficiencySolve control problemsDispersed particle separationCatalytic oxidationEnvironmental engineering

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

A kind of zinc sulfide-based mercury adsorbent for capturing zero-valent mercury in flue gas and preparation method thereof

ActiveCN109092239BImprove mercury removal performanceLow costGas treatmentOther chemical processesSorbentFlue gas

The invention relates to a zinc sulfide-based mercury adsorbent for trapping zero-valent mercury in flue gas and a preparation method thereof. The adsorbent is a cobalt-doped zinc mercury sulfide adsorption material Co x Zn 1‑x S, x represents the stoichiometric ratio of cobalt in the solution, and its ratio is 0.1‑0.3. Its preparation method is as follows: (1) dissolving a certain molar ratio of cobalt salt and zinc salt in deionized water to form a mixed solution; (2) adding a precipitant to the mixed solution for mixing and stirring; (3) putting the suspension into a reactor , and placing the reactor in an oven for heat treatment; (4) repeatedly washing the obtained precipitate with deionized water, and drying to form a zinc sulfide-based mercury-removing adsorption material. Compared with the prior art, the method has wide sources of raw materials, simple and controllable preparation process, mild reaction conditions, and the prepared adsorbent improves mercury absorption performance by dozens of times compared with pure zinc sulfide, and has good anti-SO 2 Affect performance, can maintain a certain high activity stably for a long time, especially suitable for adsorption and removal of zero-valent mercury in smelting flue gas.

Owner:SHANGHAI JIAO TONG UNIV

Preparation and regeneration methods of high-effective carbon-based mercury removal adsorbent

InactiveCN110479208AThe process is simple and controllableMild operating conditionsGas treatmentOther chemical processesIonActivated carbon

The invention provides preparation and regeneration methods of a high-effective carbon-based mercury removal adsorbent. The preparation method comprises the following specific steps: mixing fly ash with alkali liquor, and performing etching; uniformly mixing resin balls and dichloroethane at the temperature of 80 DEG C; adding sulfuric acid, heating the mixture, and cooling and filtering the mixture; acid-washing the resin balls in dilute sulfuric acid, and washing the resin balls with deionized water to be neutral; mixing the pretreated resin balls with etched fly ash, metal halide and alkali, carbonizing the resin balls at a constant temperature, and activating the carbon material at a constant temperature; mixing and modifying the activated carbon material and a metal halide solution; and carrying out heat treatment to prepare the high-effective carbon-based mercury removal adsorbent. The preparation method disclosed by the invention is simple and controllable in process and mild inoperation condition, so that the preparation cost of the mercury removal adsorbent is reduced; the carrier is prepared from two raw materials including the fly ash and the resin balls and is activated and modified, so that the effective temperature range of the carrier and active ingredients of the prepared mercury removal adsorbent is widened, the average mercury removal rate of the mercury removal adsorbent at different temperatures reaches 75 percent, and the mercury removal effect is improved.

Owner:天津浩创节能环保设备有限公司

An adsorbent injection device based on adsorbent injection for mercury removal

ActiveCN112426850BEasy to recycleImprove mercury removal performanceGas treatmentDispersed particle separationSorbentGear wheel

The invention discloses an adsorbent injection device based on adsorbent injection for mercury removal, comprising a suction pipe, the air pipe behind the suction pipe is inclined upward, and the suction component comprises two eccentric cylinders, two The eccentric cylinders are respectively provided with blade sleeves, the blade sleeves are respectively sleeved with blades, the upper ends of the two eccentric cylinders are respectively provided with gears, the blades and the blade sleeves are provided with neutralization components, and the side surfaces of the blades are provided with neutralization components. A recovery component is provided, a cooling component is arranged above the gear, the suction component can suck the coal-fired waste gas into the suction pipe for mercury removal, the cooling component reduces the temperature of the exhaust gas and liquefies most of the mercury vapor, and the neutralization component removes the remaining mercury vapor. Mercury vapor and oxidized mercury are neutralized into non-volatile substances, and then the neutralized by-products and adsorbents are recovered by the recovery component to prevent by-products from accumulating in the suction pipe. and high adsorption efficiency.

Owner:苏州麟琪程科技有限公司

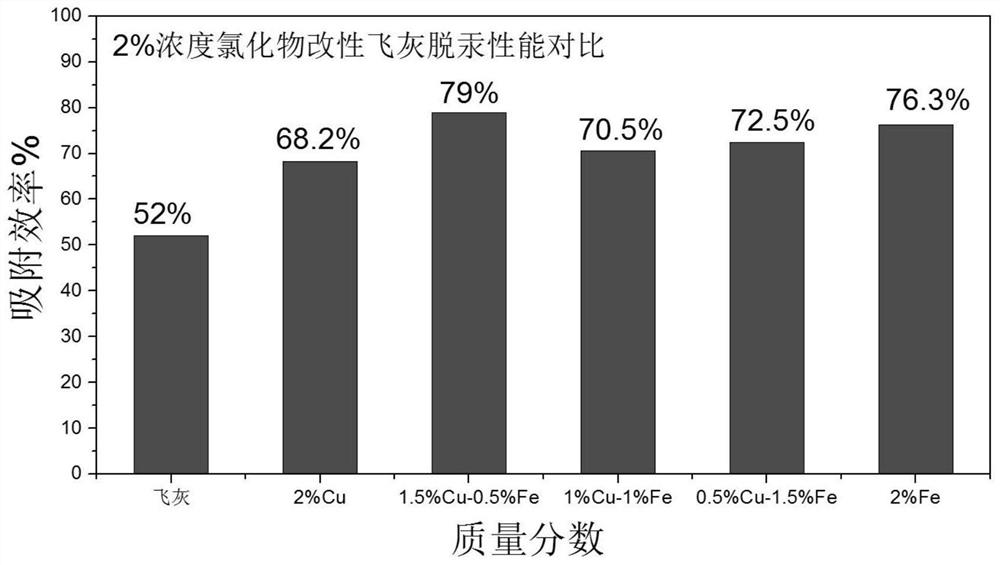

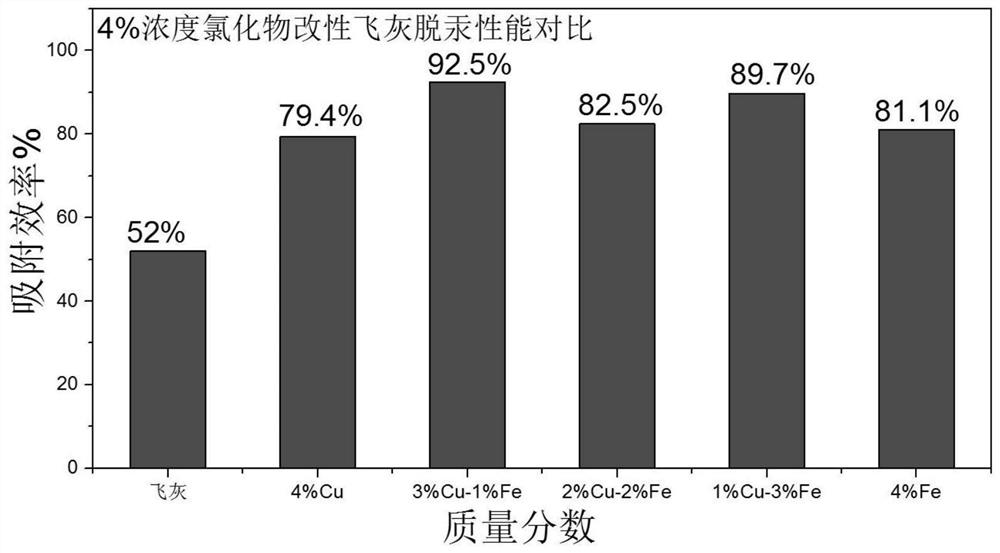

Modified fly ash adsorbent for mercury removal from flue gas and preparation method thereof

ActiveCN111686681BImprove mercury removal performanceLow costGas treatmentOther chemical processesFlue gasEnvironmental engineering

The invention provides a modified fly ash adsorbent for flue gas mercury removal, the modified fly ash adsorbent includes copper chloride, ferric chloride and fly ash, the copper chloride: ferric chloride : The mass ratio of fly ash is 1‑6:1‑6:5. The copper-iron-chloride modified fly ash adsorbent of the invention has low cost, simple and convenient preparation method and high mercury removal efficiency. Using the copper-iron-chlorine modified fly ash adsorbent to remove mercury in flue gas can significantly improve the utilization efficiency of fly ash and reduce injection costs.

Owner:CHONGQING UNIV +1

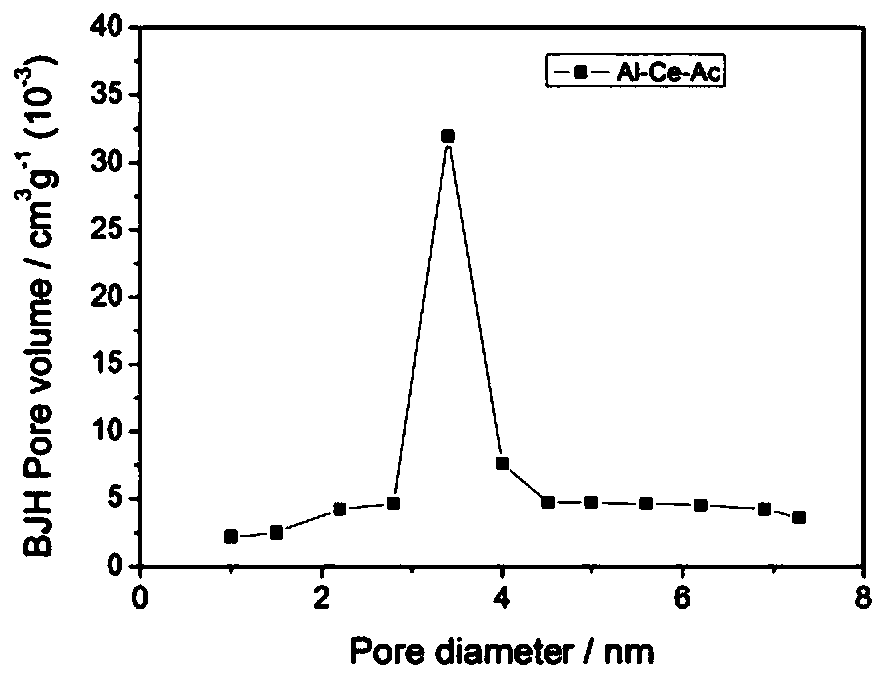

Production method of novel modified activated carbon material used for smoke mercury removal

ActiveCN110013828ALarge specific surface areaImprove mercury removal performanceGas treatmentOther chemical processesActivated carbonProduct gas

The invention discloses a production method of a novel modified activated carbon material used for smoke mercury removal. The production method of the novel modified activated carbon material used forsmoke mercury removal comprises the steps of adopting cation exchange resin as an activated carbon precursor, adopting Al(NO3)3 and Ce(NO3)3 as modifiers, and conducting treatment in different gas atmospheres. The modification method adopts in-situ growth, the characteristics of the modifying substances and activated carbon can be fully utilized through the produced activated carbon, the defect that the activity is reduced and lost due to the fact that an original site of activated carbon is occupied by a modifying substance is overcome, and the novel modified activated carbon material used for smoke mercury removal has high mercury removal performance.

Owner:HANGZHOU DIANZI UNIV

A kind of preparation method of copper sulfide mercury removal agent

ActiveCN105126557BAvoid prone toPromote generationDispersed particle separationEthylene diamineThiourea

The invention discloses a preparation method of a copper sulfide demercuration agent. The method comprises the following steps: 1, uniformly mixing a soluble copper salt solution with an ethylene diamine solution, adding ammonia water, and mixing to obtain a premix solution, wherein a molar ratio of the copper salt to the ethylene diamine solution to ammonia water is 1:(1-2.5):(1-10); 2, adding the premix solution to a thiourea solution, and uniformly mixing to obtain an impregnation solution; and 3, immersing a carrier in the impregnation, draining, activating at 60-95DEG C for 1-5h, and drying. The content of copper sulfide in the prepared demercuration agent is 100%, the demercuration agent has no impurities, and the preparation method has the advantages of simplicity and easy realization of reaction conditions.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com