Production method of novel modified activated carbon material used for smoke mercury removal

A new type of activated carbon technology, applied in the field of preparation of new modified activated carbon materials, can solve the problems of catalyst service life to be questioned, unsuitable for mercury removal, low yield of final products, etc., to achieve easy production of raw materials and high mercury removal performance , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

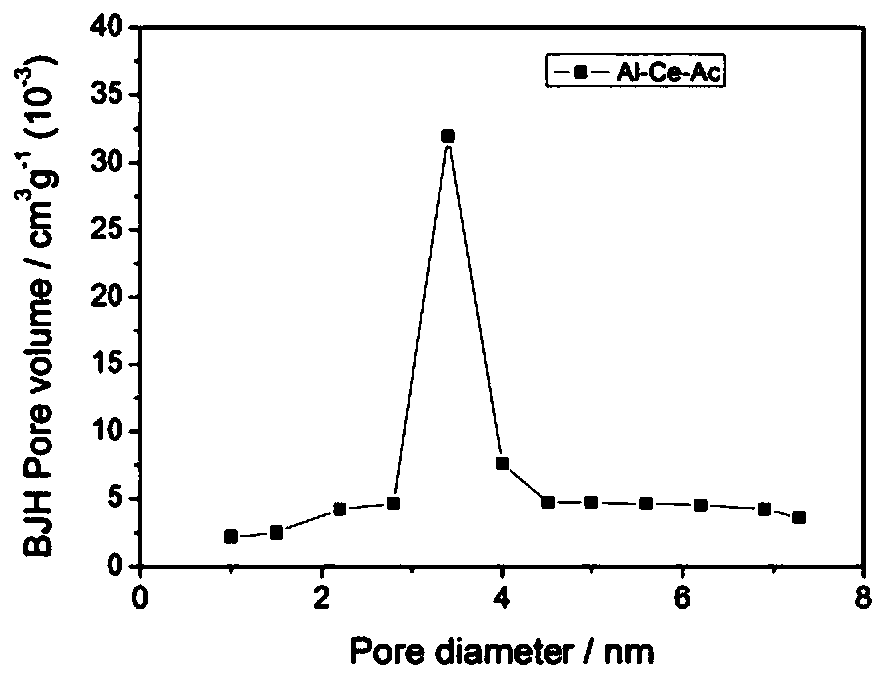

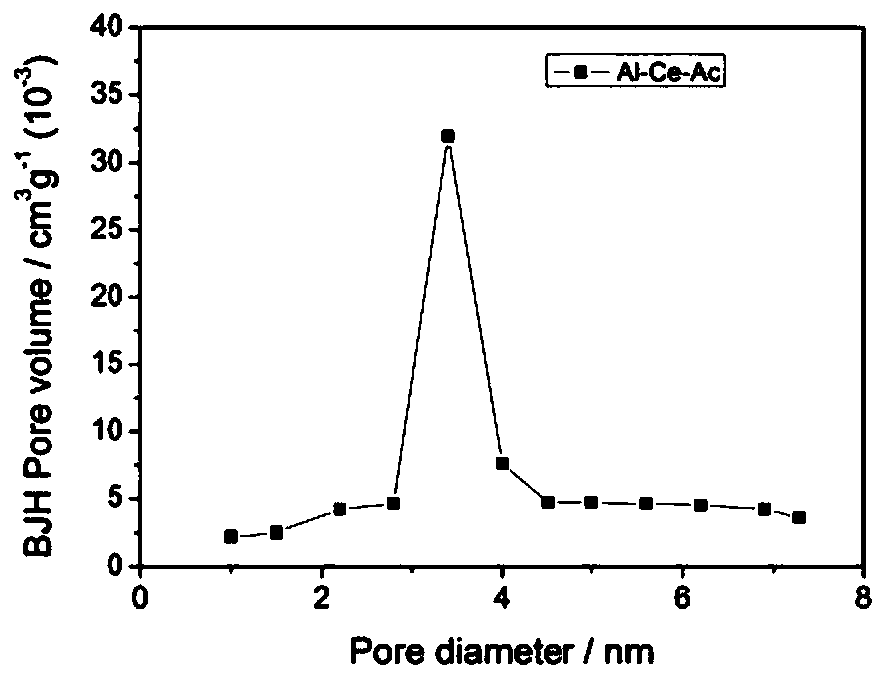

Image

Examples

Embodiment 1

[0023] Get cation exchange resin (Mitsubishi Chemical CR11, polystyrene polymer resin with high porosity) 10g, add to Al(NO 3 ) 3 and Ce(NO 3 ) 3 In the mixed solution, the solution concentration is 1mol / L, Al(NO 3 ) 3 with Ce(NO 3 ) 3 to a certain molar ratio, and stirred at a constant speed. After ion exchange for 2 hours, the resin was filtered out and dried at 20°C. Then, the resin was pretreated at 120°C in the air atmosphere for 2 hours, and then the product was placed in a nitrogen atmosphere at 800°C. ℃ for 2 h, and then the product was 2 The activated carbon was activated at 550°C for 2 hours in the atmosphere, and finally the modified activated carbon was used in the flue gas mercury removal experiment. Al(NO 3 ) 3 with Ce(NO 3 ) 3 The effect on the mercury removal effect is shown in Table 1.

[0024] Table 1. Al(NO 3 ) 3 and Ce(NO 3 ) 3 Influence on mercury removal effect

[0025] Al(NO 3 ) 3 : Ce(NO 3 ) 3

Embodiment 2

[0027] Get cation exchange resin (Mitsubishi Chemical CR11, polystyrene polymer resin with high porosity) 10g, add to Al(NO 3 ) 3 and Ce(NO 3 ) 3 In the mixed solution, the solution concentration is 1mol / L, Al(NO 3 ) 3 with Ce(NO 3 ) 3 The molar ratio was 1:10, and stirred at a constant speed for ion exchange. After a certain period of time, the resin was filtered out and dried at 20°C, and then the resin was pretreated at 120°C for 2 hours in the air atmosphere, and then the product was placed in Carbonization treatment was carried out at 800 °C for 2 h in a nitrogen atmosphere, and then the product was 2 The activated carbon was activated at 550°C for 2 hours in the atmosphere, and finally the modified activated carbon was used in the flue gas mercury removal experiment. The effect of different ion exchange time on the mercury removal effect is shown in Table 2.

[0028] Table 2. Effect of different ion exchange time on mercury removal effect

[0029] ion ...

Embodiment 3

[0031] Get cation exchange resin (Mitsubishi Chemical CR11, polystyrene polymer resin with high porosity) 10g, add to Al(NO 3 ) 3 and Ce(NO 3 ) 3 In the mixed solution, the solution concentration is 1mol / L, Al(NO 3 ) 3 with Ce(NO 3 ) 3 The molar ratio was 1:10, and stirred at a constant speed. After ion exchange for 2 hours, the resin was filtered out and dried at a certain ambient temperature. Then, the resin was pretreated at 120°C for 2 hours in the air atmosphere, and then the product was placed in a nitrogen atmosphere. Carbonization treatment was carried out at 800 °C for 2 h, and then the product was 2 The activated carbon was activated at 550°C for 2 hours in the atmosphere, and finally the modified activated carbon was used in the flue gas mercury removal experiment. The effect of different ion exchange time on the mercury removal effect is shown in Table 3.

[0032] Table 3. Effect of different drying temperatures on mercury removal

[0033] Drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com