Patents

Literature

88results about How to "Improve surface reactivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene oxide/cellulose compound material as well as preparation method and application of same

ActiveCN102489259AImprove toughnessGood film formingOther chemical processesWater/sewage treatment by sorptionFiberCellulose compounds

The invention belongs to the field of material science and particularly relates to a graphene oxide / cellulose compound material as well as a preparation method and application of the material. The compound material is prepared by mixing graphene oxide suspension and alkaline solution of cellulose, and forming a compound structure of the graphene oxide and the cellulose under the action of mechanical stirring, shearing, ultrasonic or the like. In the preparation method, raw materials are cheap and easy to obtain, a water system is simple and free of pollution, equipment is simple and low in cost, and the industrial preparation is easy to realize; and the prepared compound material has the properties of fiber and the graphene oxide and is widely applied.

Owner:HENAN UNIVERSITY

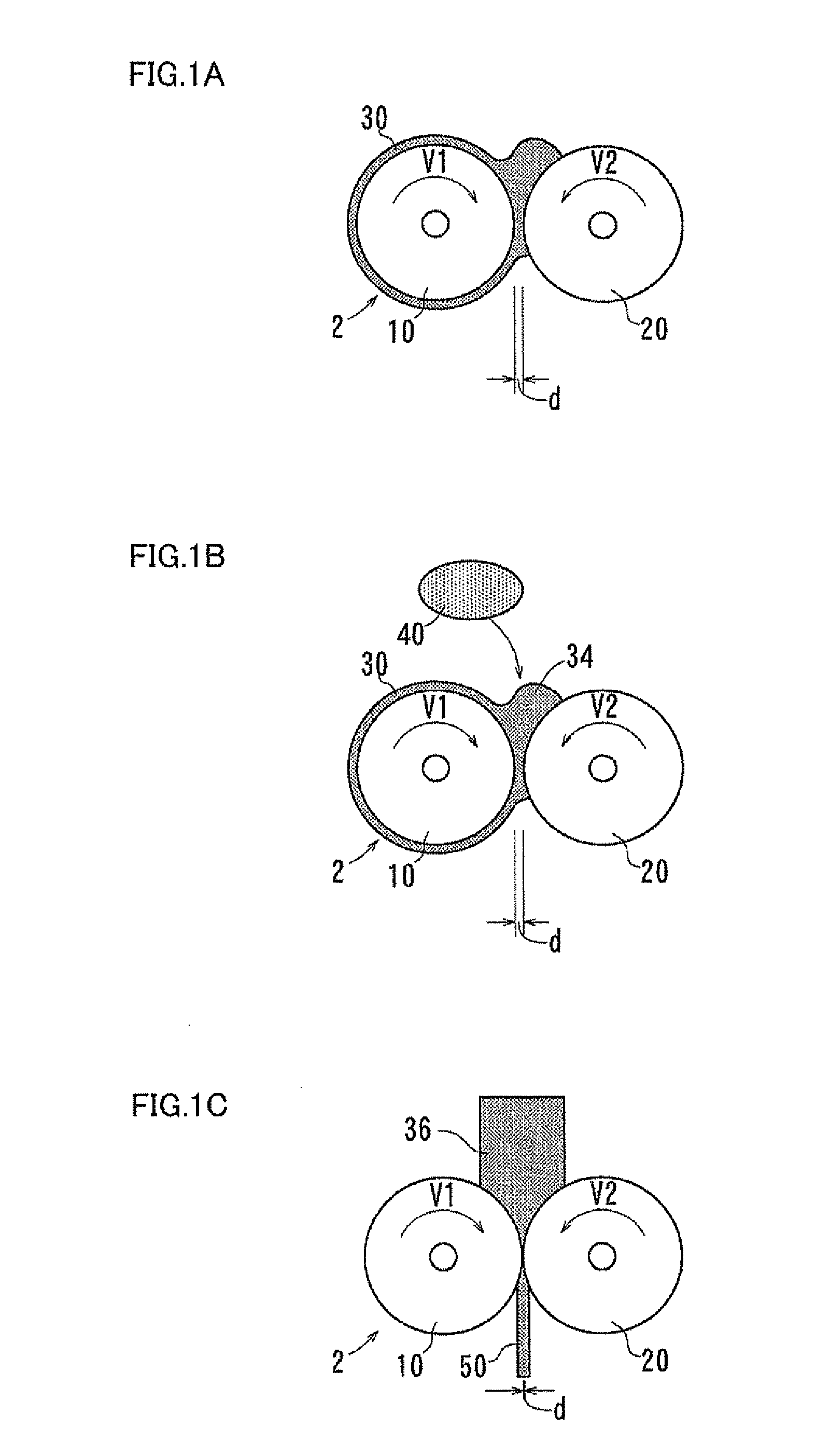

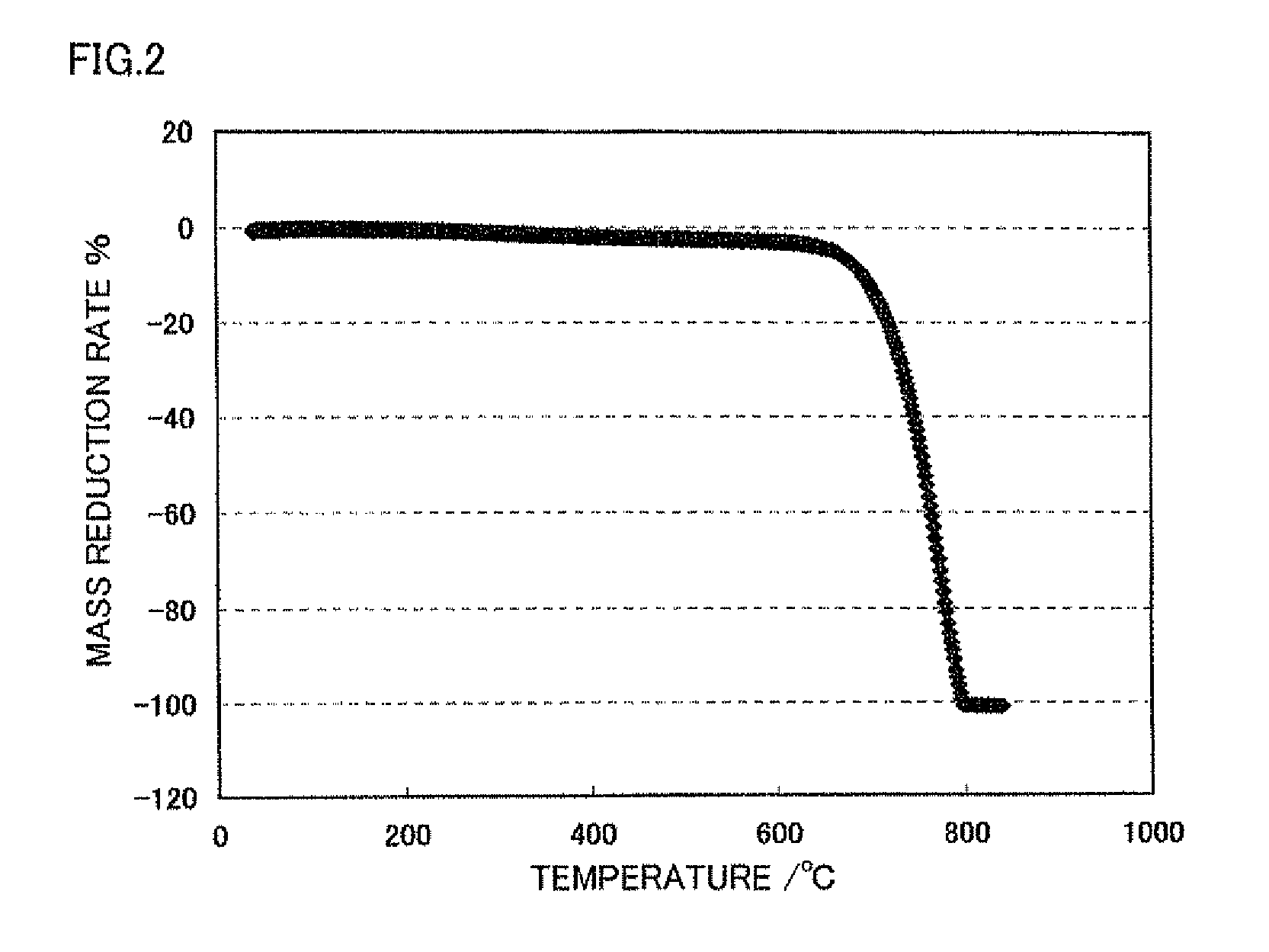

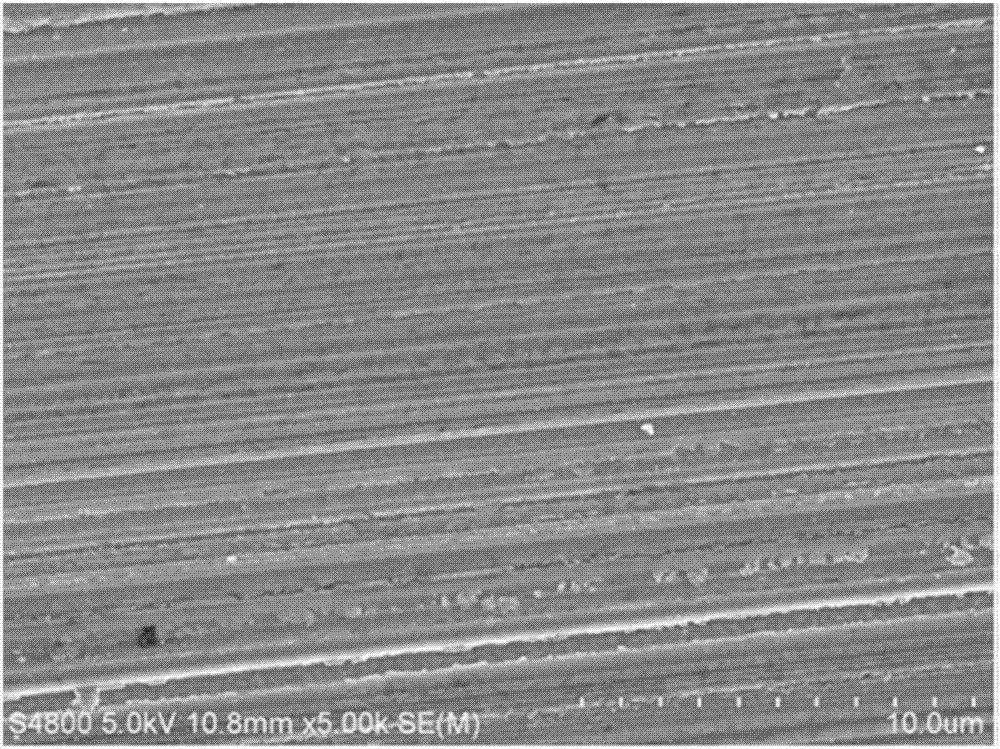

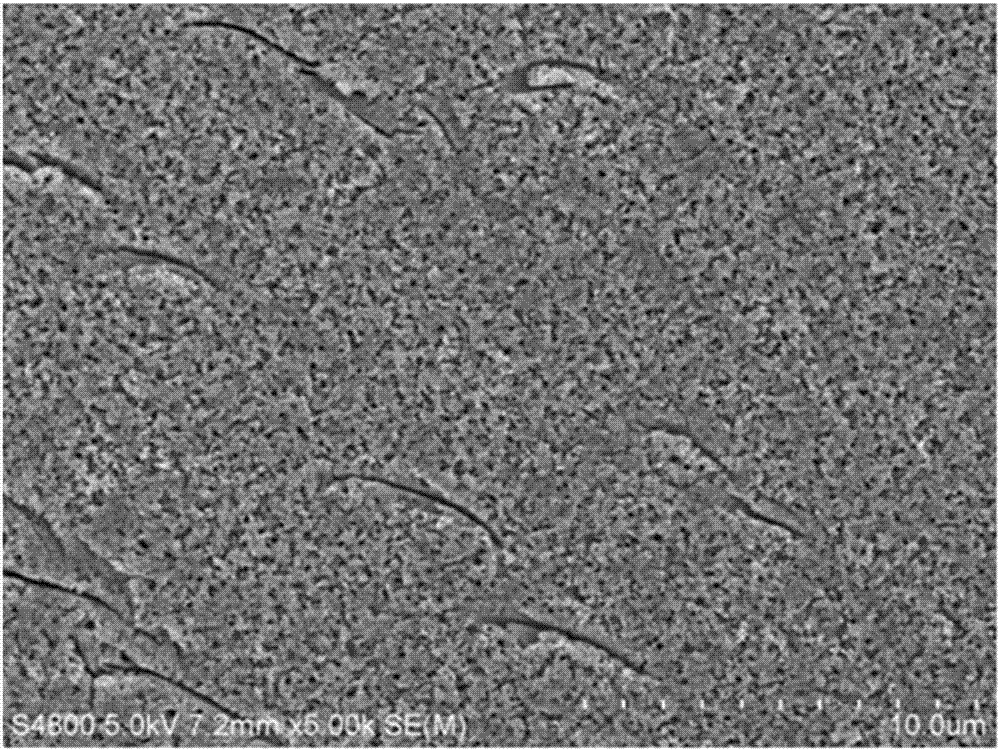

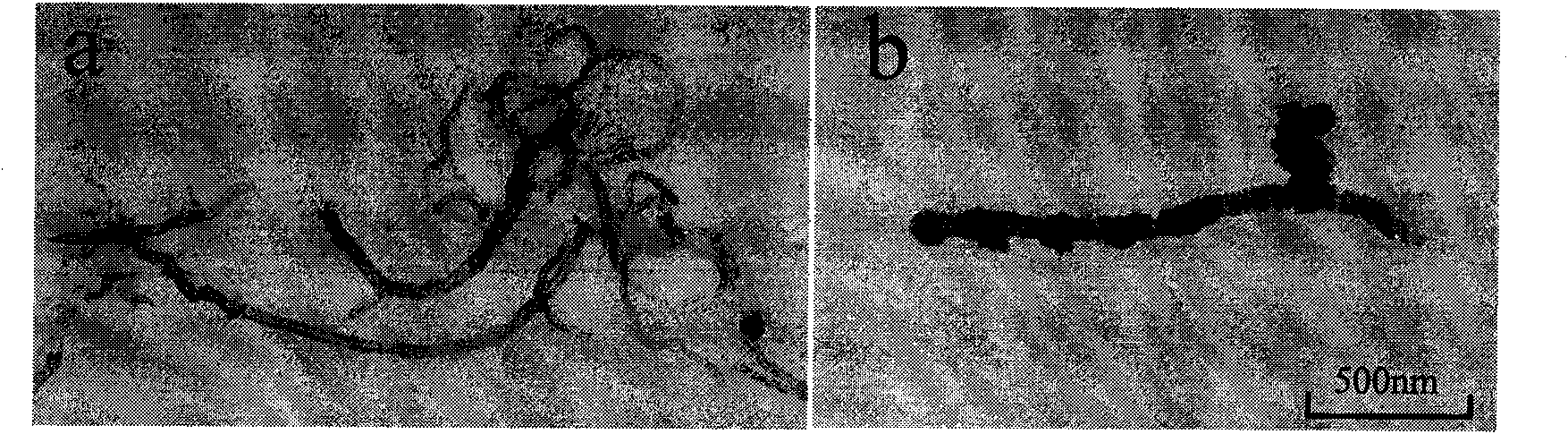

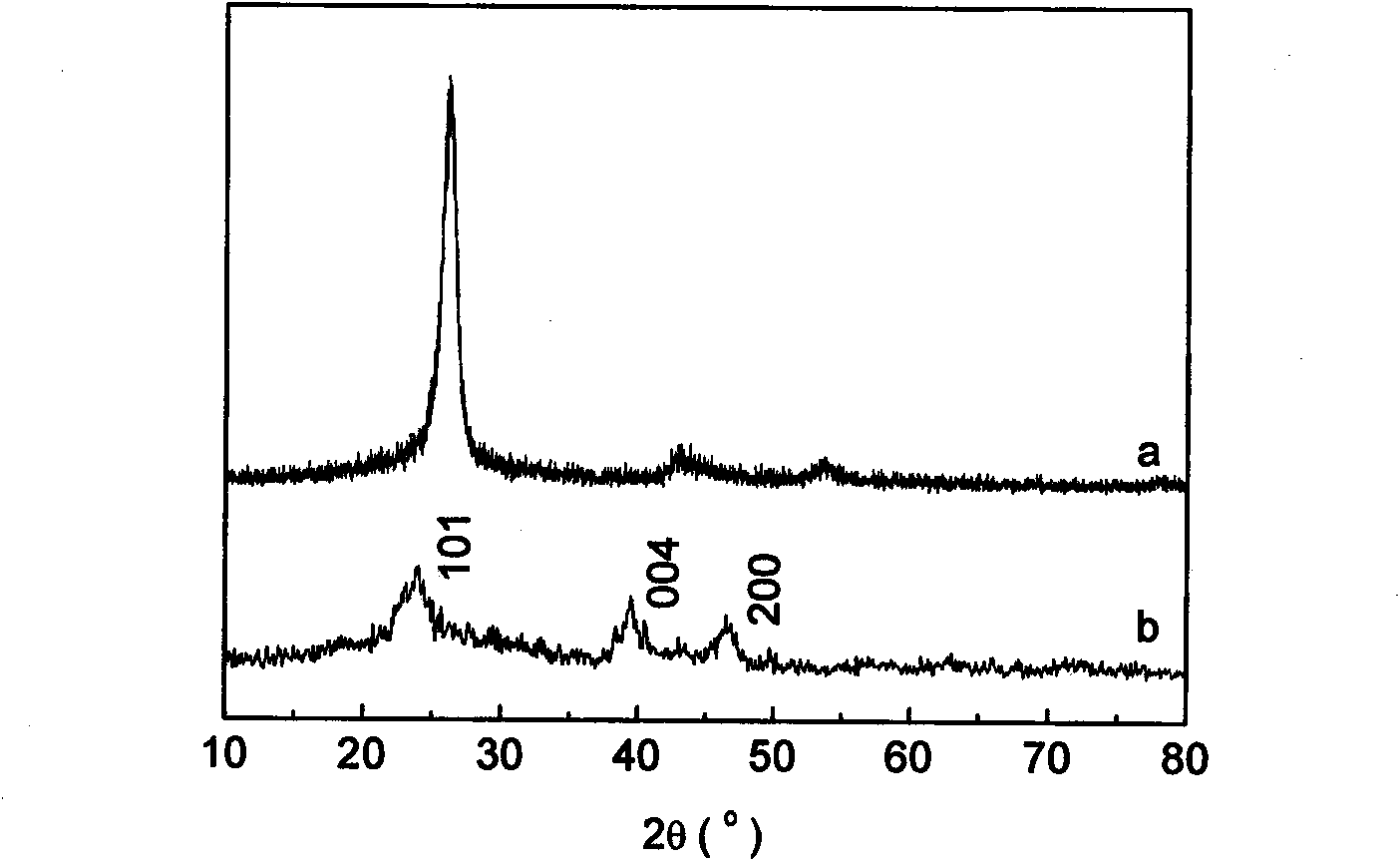

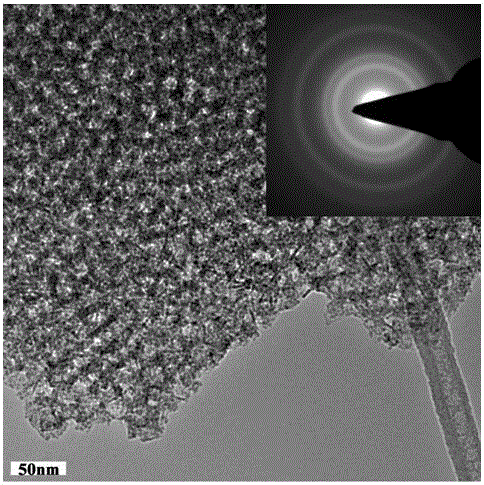

Carbon nanofiber, method for production thereof, method for production of carbon fiber composite material using carbon nanofiber, and carbon fiber composite material

ActiveUS20110060087A1Improve surface reactivityImprove wettabilityMaterial nanotechnologySpecial tyresElastomerFiber

A method of producing a carbon fiber composite material includes a first step and a second step. The first step includes oxidizing first carbon nanofibers produced by a vapor growth method to obtain second carbon nanofibers having an oxidized surface. The second step includes mixing the second carbon nanofibers into an elastomer, and uniformly dispersing the carbon nanofibers in the elastomer by applying a shear force to obtain the carbon fiber composite material. The second carbon nanofibers obtained by the first step have a surface oxygen concentration measured by X-ray photoelectron spectroscopy (XPS) of 2.6 to 4.6 atm %.

Owner:HITACHI ASTEMO LTD +1

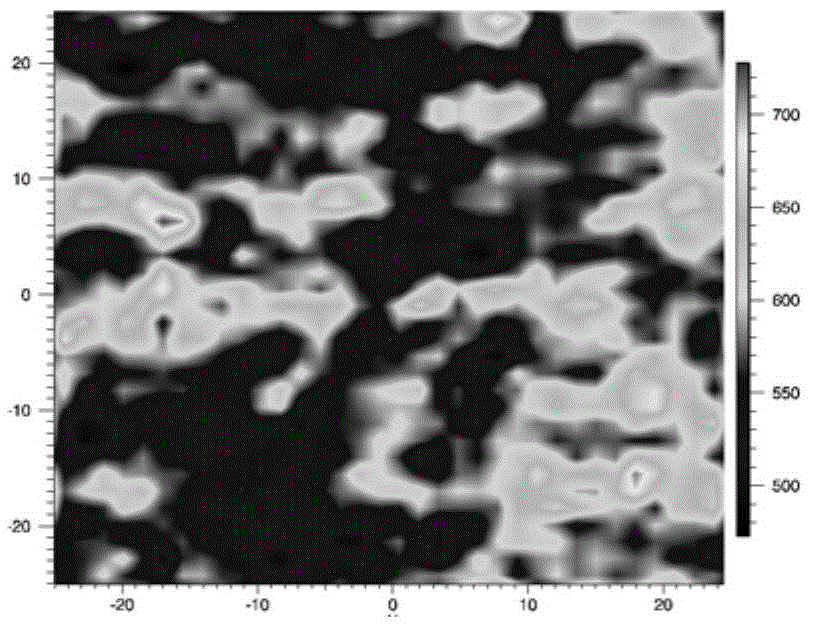

Metal catalytic texturing method for decreasing reflectance of polycrystalline silicon wafer cut with diamond wire

InactiveCN107268087AImprove surface reactivitySimple processAfter-treatment detailsEtchingNanoporous silicon

The invention relates to a metal catalytic etching method for decreasing a reflection rate of a polycrystalline silicon wafer cut with a diamond wire. The method comprises the following steps: soaking a polycrystalline silicon wafer cut with a diamond wire in an alkaline solution, and removing a mechanically damaged layer on the surface of the silicon wafer in an etching manner; and integrally treating the treated polycrystalline silicon wafer by virtue of metal catalysis, chemical etching and silver plating and hole digging, and forming a nano porous silicon structure on the surface of the polycrystalline silicon wafer; soaking the polycrystalline silicon wafer treated in the step II in a second mixed solution, performing the etching treatment, so that a honeycomb-shaped suede-like structure is formed on the surface of the silicon wafer; alkaline washing and desilverizing the polycrystalline silicon wafer treated by the last step in an alkaline mixed solution; and cleaning the treated polycrystalline silicon wafer successively with an acid mixed solution and deionized water, and finally drying. By adopting the method, cut marks of the diamond wire can be eliminated, the reflection rate of the polycrystalline silicon etched surface can be effectively decreased to 15 percent, the compatibility with a conventional etching process is good, and the conversion efficiency of a solar cell can be increased.

Owner:NANJING NAXIN NEW MATERIAL

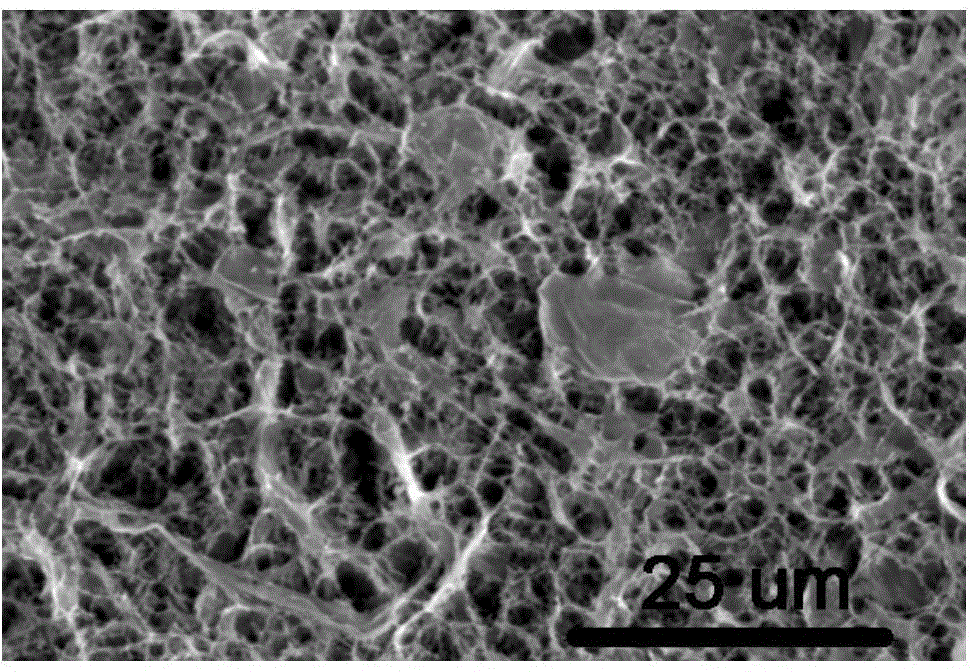

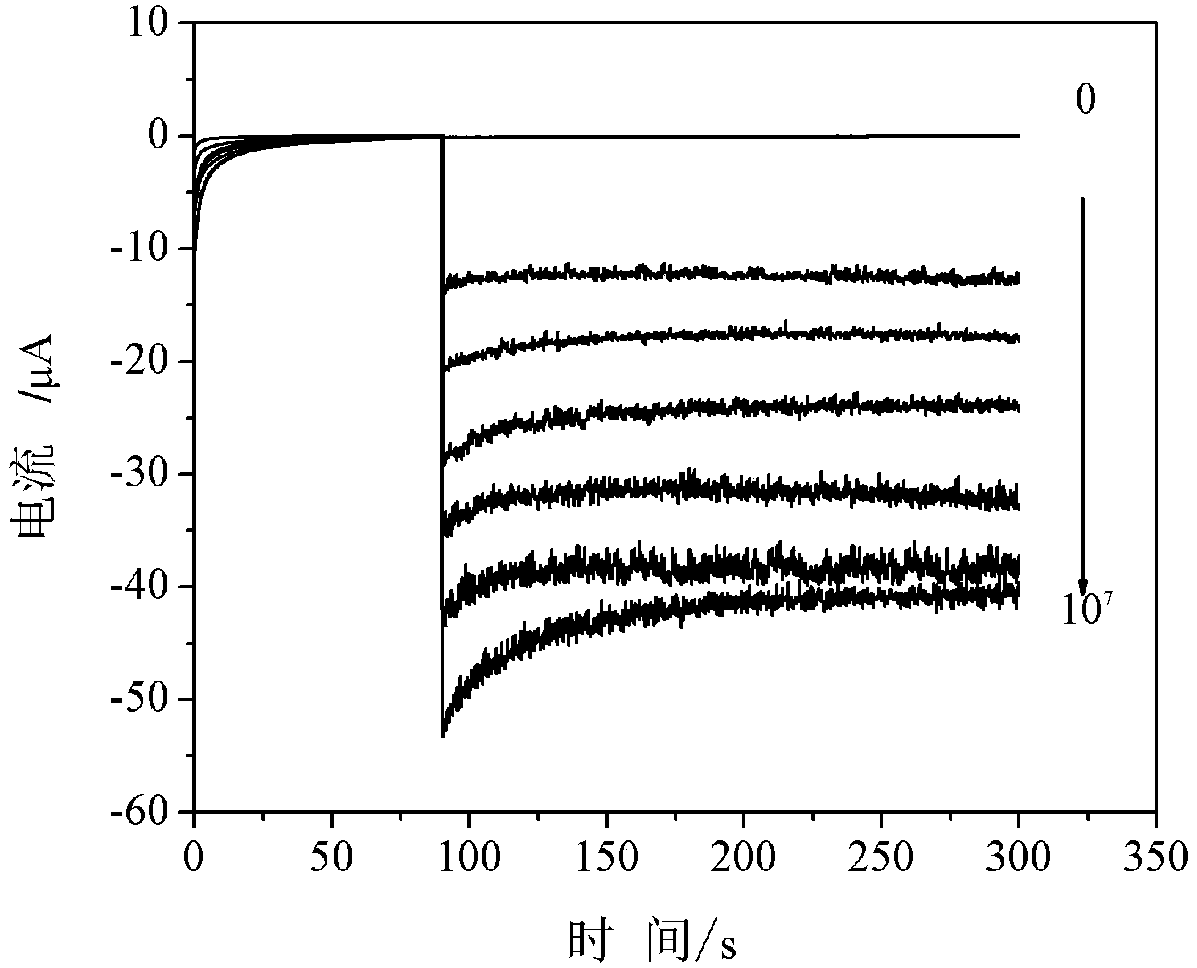

Method for preparing enzyme electrode with MWCNTs-TiO2/Nafion composite medium

InactiveCN101603940AExplanation of validityImprove catalytic abilityMaterial electrochemical variablesBiocompatibility TestingCore shell nanocomposites

The invention discloses a method for preparing an enzyme electrode with an MWCNTs-TiO2 / Nafion composite medium. In the method, MWCNTs-TiO2 core-shell nanocomposite materials are scattered into Nafion to prepare an organic-inorganic composite membrane as a fixed matrix for biological molecules for structuring a hemoglobin electrode, and a hemoglobin biosensor with fast response, high sensitivity and strong catalytic capacity is prepared by using the properties of large specific surface area, high surface reactivity, strong adsorption capacity, large electrical conductivity and the like of the MWCNTs-TiO2 core-shell nanocomposite materials and the properties of membrane forming, high chemical stability, high anti-interference capacity and the like of the Nafion. The biosensor has good biocompatibility, stability and repeatability, and has potential application in structuring biosensors. The sensor can be used for detecting the substances of hydrogen peroxide, trichloroacetic acid and the like, and has the advantages of low sensitivity, low detection limit and the like.

Owner:NANJING UNIV OF TECH

High-nitrogen vanadium-nitrogen alloy VN18 and production method thereof

The invention discloses a high-nitrogen vanadium-nitrogen alloy VN18 and a production method thereof, which aim at solving the problems of poor quality, low nitrogen content, higher production cost and instable product quality in the prior art. The high-nitrogen vanadium-nitrogen alloy VN18 comprises the following components: vanadium oxide, carbon powder, a catalyst, a guiding agent, a nitrogen fixating agent, a densifying agent and a binding agent according to the weight ratio of (70-80):(15-25):(4-6):(0.5-2):(0.2-1):(0.6-0.8):(2-6). The invention further provides a production method of the high-nitrogen vanadium-nitrogen alloy VN18. The high-nitrogen vanadium-nitrogen alloy VN18 is high in nitrogen content, large in density, high in vanadium yield, and low in production cost.

Owner:高波

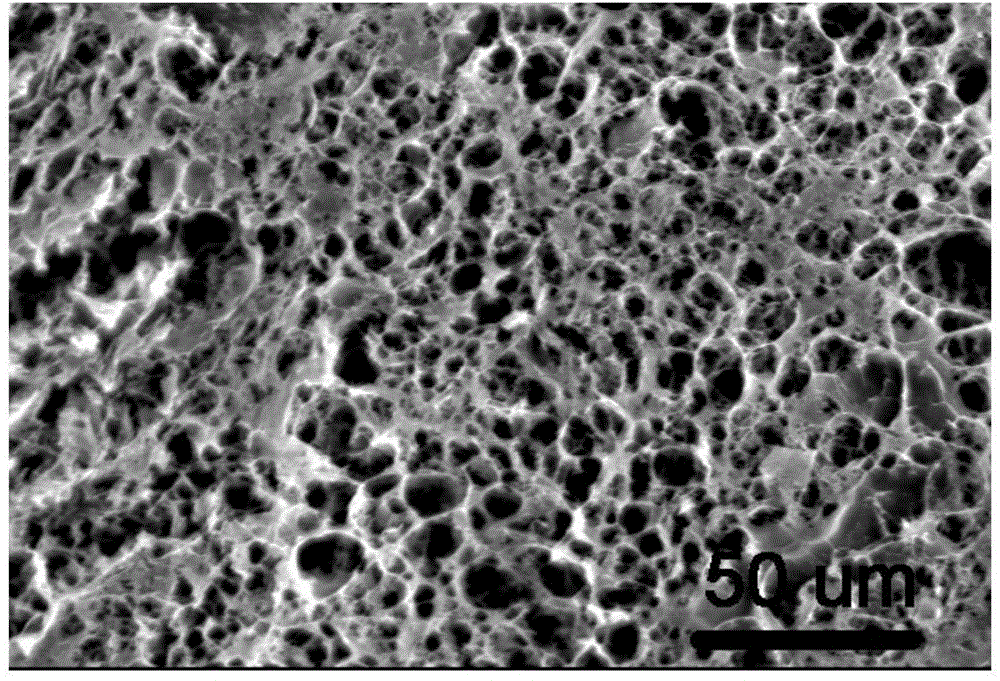

Cellulose-based composite material with three-dimensional porous structure and preparation method of cellulose-based composite material

The invention relates to a cellulose-based composite material with a three-dimensional porous structure. The cellulose-based composite material comprises the following components in percentage by mass: 0.01-99.99% of graphene oxide and 0.01-99.99% of cellulose, wherein an oxygen-containing group in the graphene oxide and hydroxyl in cellulose form a hydrogen bond, and the cellulose is natural or regenerated cellulose with molecular weight smaller than or equal to 4*10<5>. The invention further relates to a preparation method of the cellulose-based composite material with the three-dimensional porous structure. The cellulose-based composite material with the three-dimensional porous structure disclosed by the invention has the advantages of graphene oxide and cellulose, is adjustable in structural performance and wide in application. The preparation method of the cellulose-based composite material has the advantages of cheap and rich raw materials, a simple process and easy industrialization.

Owner:BOZHOU TEACHERS COLLEGE

Detection method of staphylococcus aureus in milk through double signal amplification effect

ActiveCN108020587AHigh sensitivityDoubly magnifiedBiological material analysisMaterial electrochemical variablesColony countingStaphylococcus aureus

The invention discloses a detection method of staphylococcus aureus in milk through a double signal amplification effect and belongs to the technical field of biosensing. According to the technology,a gold-platinum nano composite material and DNA mimic enzyme are used for synthesizing nano probes which have the good double catalytic effect on H2O2, a modified electrode made of a graphene / gold nanoparticle nano composite material is used so that the electron transfer capacity of the modified electrode can be improved, and accordingly quick high-sensitivity detection for staphylococcus aureus is achieved. Under the optimized experimental conditions, an electrochemical immunosensor has a wide linear detection range for staphylococcus aureus. In addition, the sensor is successfully applied toquantitative detection of staphylococcus aureus in pure milk and yogurt samples. Compared with traditional methods such as a slab colony counting method, the detection method is convenient and fast,easy to operate and high in sensitivity, and quick high-sensitivity detection for staphylococcus aureus is achieved.

Owner:JIANGSU UNIV

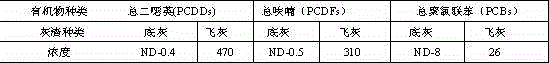

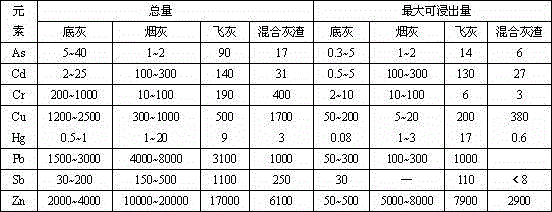

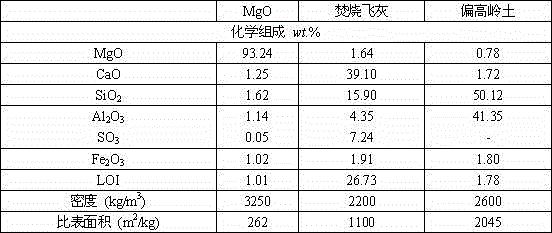

Method for producing cement-based composite material for injection reinforcement from waste incineration fly ash

InactiveCN104803655AScientific treatmentEfficient disposalSolid waste managementMagnesium phosphateMagnesium orthophosphate

The invention relates to a method for producing a cement-based composite material for injection reinforcement from waste incineration fly ash. The method specifically comprises steps as follows: MgCO3 is decomposed at the high temperature of 1000-1300 DEG C, and MgO with the specific surface area ranging from 1800 cm<2> / g to 3010 cm<2> / g is prepared; the surface of the MgO is pretreated, the pretreated MgO is mixed with phosphate, the waste incineration fly ash, metakaolin and a retarder in proportion, and the magnesium phosphate cement-based composite material is prepared; the composite material comprises, in percentage by mass, 10-30% of the pretreated MgO, 15-40% of the phosphate, 10-40% of the waste incineration fly ash, 15-40% of the metakaolin and 2-8% of the retarder; the total mass is 100%. With the adoption of the method, the excellent product performance is obtained, meanwhile, the temperature required for calcination of the MgO is decreased, toxic and harmful solid waste such as the waste incineration fly ash and the like can be disposed and utilized scientifically and efficiently, the waste has high added value, and the method has positive significance in developing low-carbon economy and building resource-saving and environment-friendly society.

Owner:TONGJI UNIV

Oil-proof food packaging paper and preparation method thereof

InactiveCN107574723AAntibacterialImprove firmnessNon-fibrous pulp additionFlexible coversAcetic acidCellulose

The invention discloses an oil-proof food packaging paper and a preparation method thereof. The packaging paper consists of a raw paper and an oil-proof layer; the raw paper is prepared from the following components in parts by weight: 10 to 20 parts of microfibrillated cellulose or modified microfibrillated cellulose, 40 to 50 parts of bleached wood pulp and 20 to 30 parts of bamboo pulp; and theoil-proof layer is prepared from the following materials in parts by weight: 1 to 10 parts of chitosan, 1 to 10 parts of acetic acid, 1 to 5 parts of silk fibroin solution, 0.01 to 0.1 parts of graphene oxide, 0.1 to 2 parts of crosslinking agent and 80 to 150 parts of water.

Owner:安徽蓝韵包装有限公司

Preparation of polyacrylonitrile modified membrane and method using polyacrylonitrile modified membrane for immobilizing enzyme

The invention provides a preparation of a polyacrylonitrile modified membrane and a method using the polyacrylonitrile modified membrane for immobilizing an enzyme; a hollow membrane carrier is prepared from polyacrylonitrile as a raw material in the presence of polyethylene glycol as a pore-foaming agent and N,N-dimethylformamide as a solvent by a L-S phase transformation method; polyamine substance polyethyleneimine is cross-linked on the surface of the polyacrylonitrile hollow membrane carrier by a chemical method, and the enzyme is immobilized by electrostatic adsorption after acidification; in the process of the immobilizing of the enzyme, sodium alginate with biocompatibility is added to increase the immobilized amount of the enzyme and the stability of the immobilized enzyme; finally, different chemical reagents are used to increase the rigidity between the immobilized enzyme and the immobilizing carrier. The immobilizing carrier is obtained by surface modification of a polyacrylonitrile hollow membrane prepared by the phase transformation method, and an electrostatic adsorption immobilization method and an embedding / crosslinking method are combined in the process of the immobilizing of the enzyme to obtain the immobilized enzyme excellent in recyclability. The method is simple in operation, material performance is stable, and the polyacrylonitrile modified membrane hasgood research and industrial application prospects.

Owner:JIANGNAN UNIV

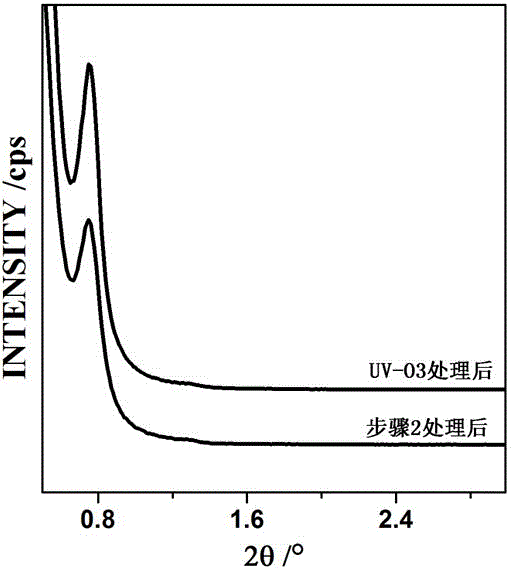

Ordered Cu-doped nano-porous tin oxide sensing device

InactiveCN105067670AExcellent sensing performanceShort response timeMaterial nanotechnologyMaterial analysis by electric/magnetic meansCu dopingTin

The invention discloses an ordered Cu-doped nano-porous tin oxide sensing device. The sensing device is produced through the following steps: 1, producing an interdigital electrode-based graphene oxide film through adopting a spin coating method; 2, producing a device coated with a composite sensing film through a spin coating method, drying, and carrying out hot steam treatment; 3, removing a template from the device obtained in step 2; and 4, carrying out a reduction reaction on the device obtained in step 3 under an ultraviolet radiation condition to obtain the nano-porous tin oxide sensing device. The ordered Cu-doped nano-porous tin oxide sensing device has an excellent sensing performance, and the response time and the recovery time to low concentration H2S gas are shorter than 20s respectively.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

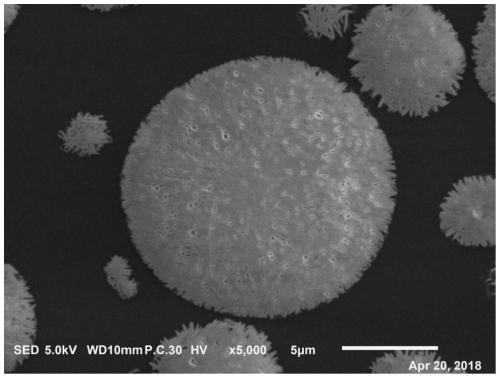

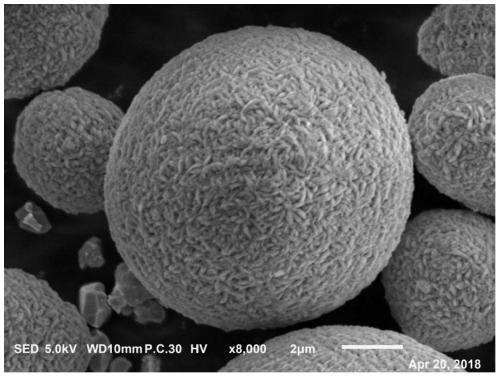

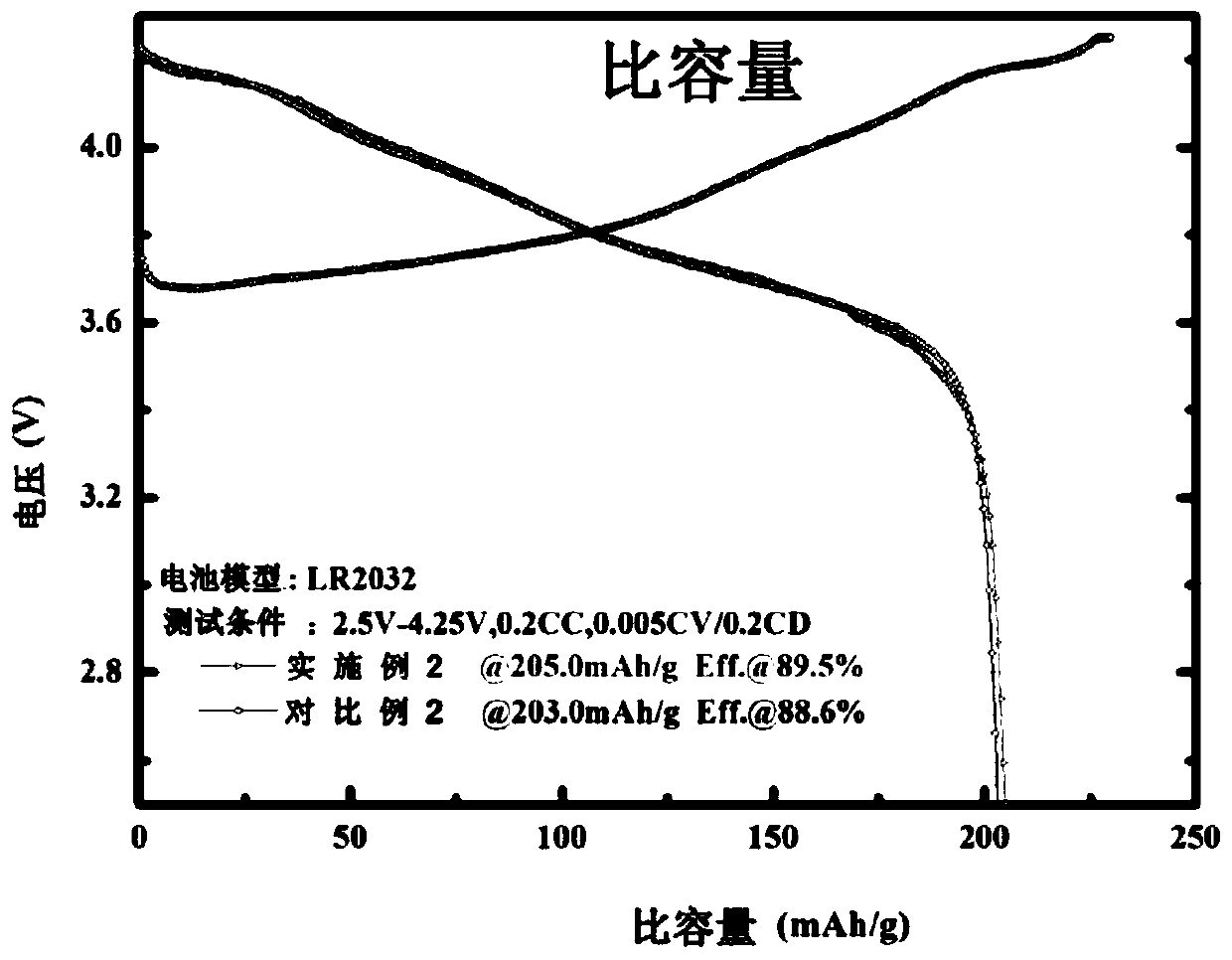

High-performance lithium nickel cobalt aluminum oxide positive material and preparation method thereof

The invention discloses a high-performance lithium nickel cobalt aluminum oxide positive material and a preparation method thereof. Polystyrene microspheres can be adopted as a self-sacrificing template; and the high-performance lithium nickel cobalt aluminum oxide positive material can be prepared through high temperature oxygen calcination after uniform precipitation by combining a co-precipitation method. The prepared material is good in volume stability, and can effectively inhibit the generation and deteriorating evolution of a microfracture between primary particles even under high voltage and a high temperature of 60 DEG C; and as multiple gaps exist in secondary particles of the material, volume changes generated during the deintercalation of lithium of the primary particles can beeffectively dealt with, and the high temperature cycling performance of the material can be enhanced.

Owner:TIANJIN B&M SCI & TECH

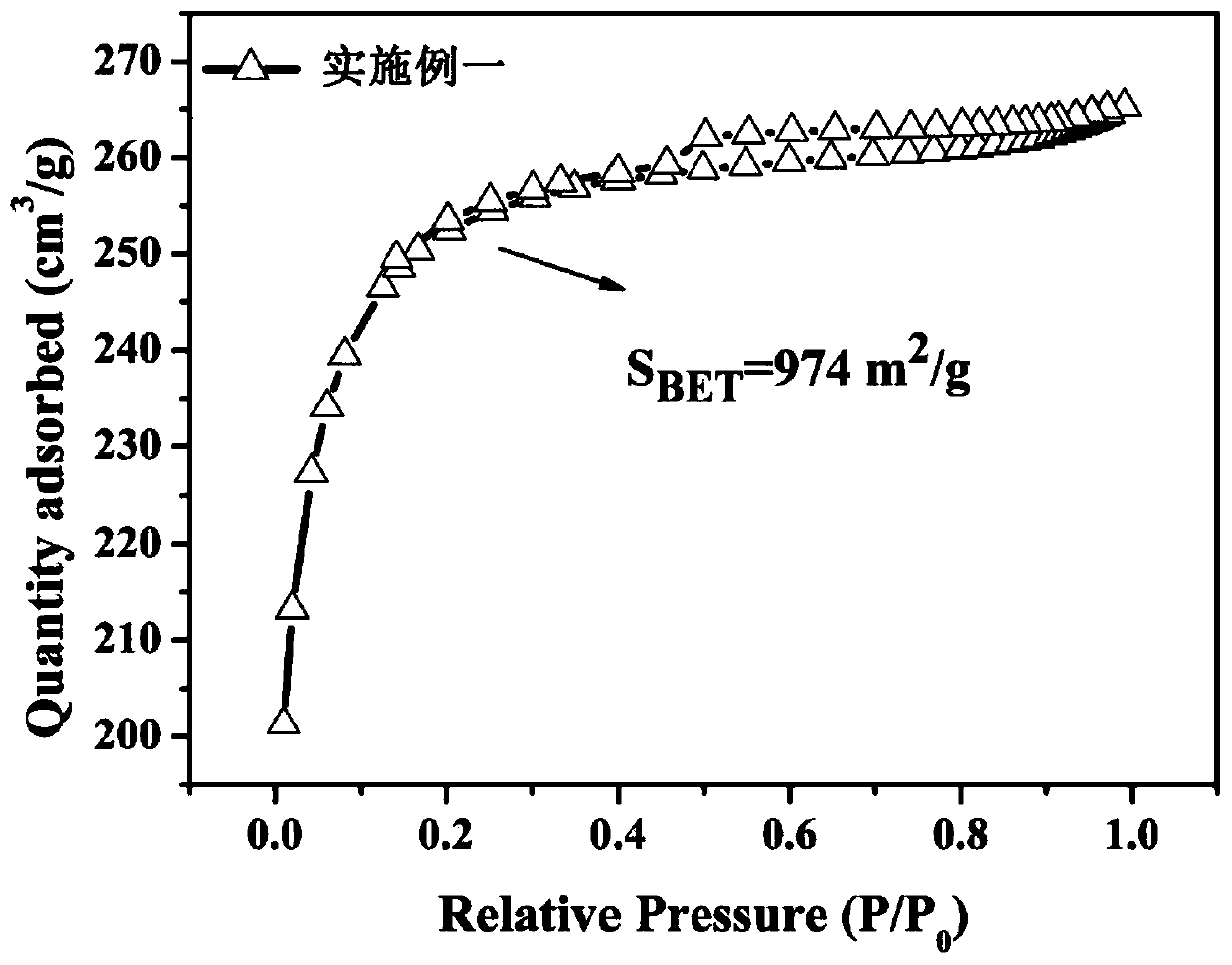

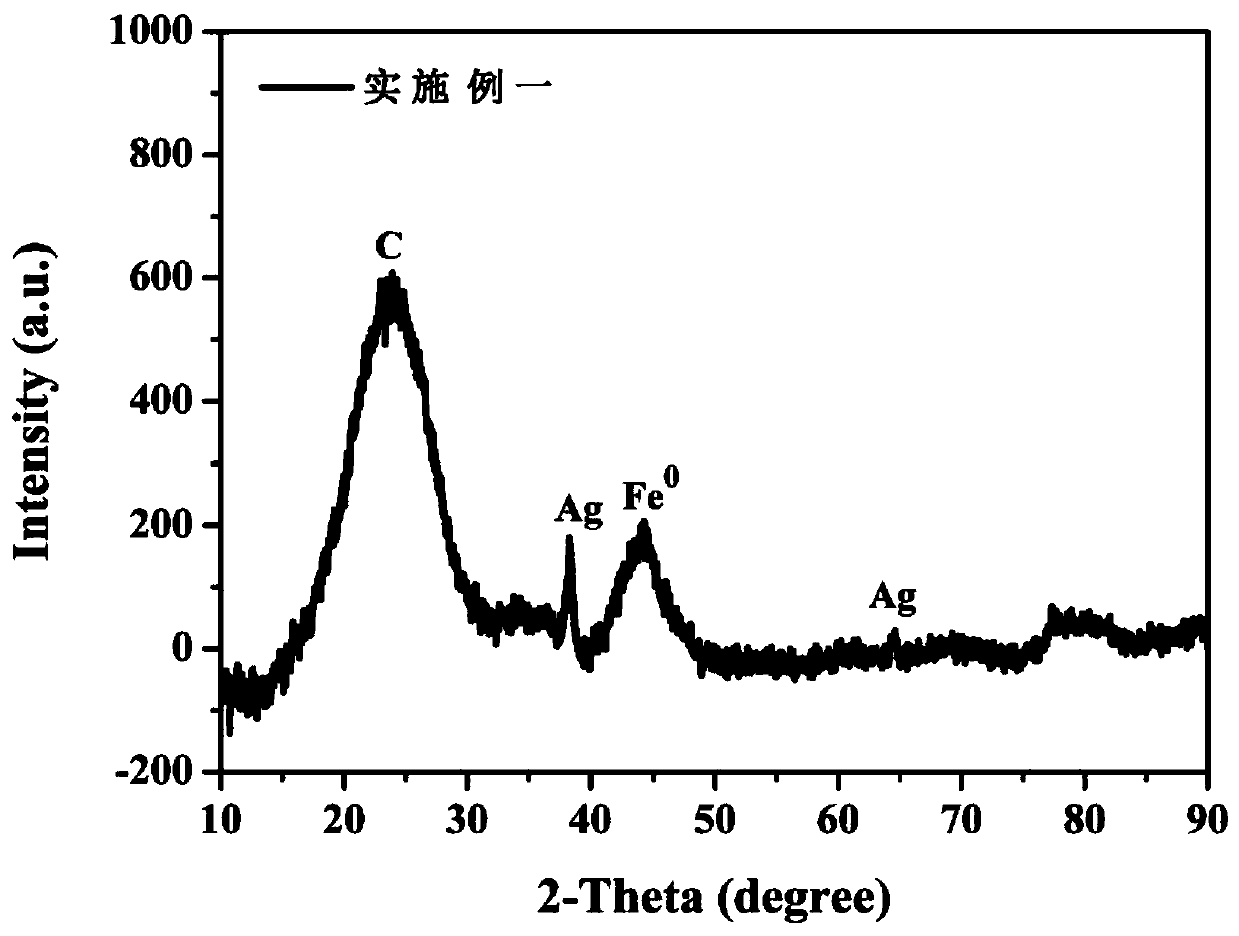

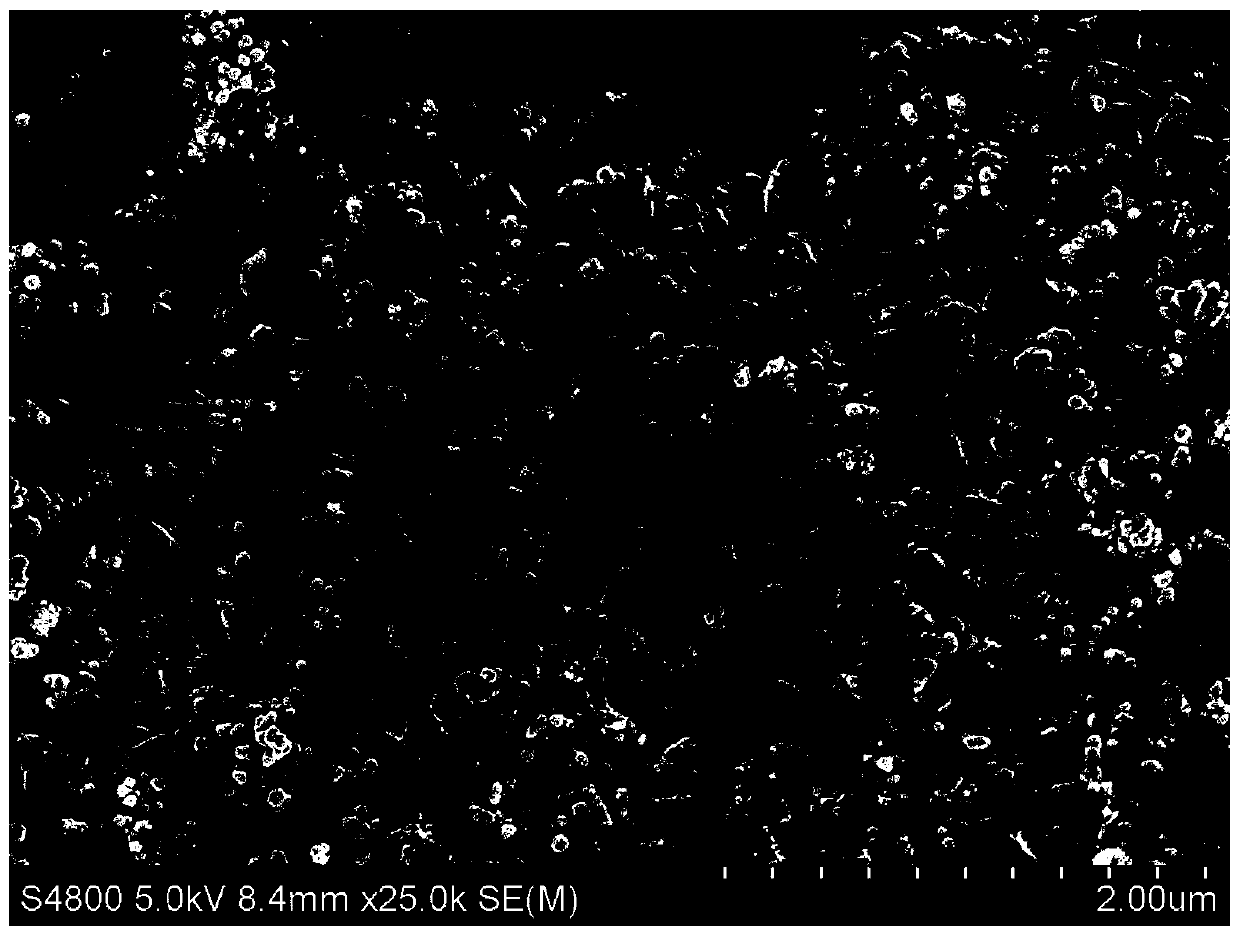

Preparation method of water purification carbon composite material with low nano zero-valent iron and nano-silver loading capacities

PendingCN110559990ALarge specific surface areaSmall specific surface areaOther chemical processesWater contaminantsCarbon compositesMulti pollutant

The invention relates to a preparation method of a water purification carbon composite material with low nano zero-valent iron and nano-silver loading capacities. The water purification carbon composite material with the low nano zero-valent iron and nano-silver loading capacities, which is prepared by the preparation method, has a high specific surface area; the loading capacity of iron and the loading capacity of silver in the composite material are low; the particle size of nano zero-valent iron and the particle size of nano silver are both smaller than 20nm; the water purification carbon composite material can adsorb, convert or degrade various pollutants in drinking water at the same time; the release amount of iron and silver is extremely low; and the water purification carbon composite material is a water purification material with extremely high application values.

Owner:KETAN XIAMEN NEW CARBON MATERIAL CO LTD +1

Large interlamellar spacing and high activity modified calcium-base montmorillonite and preparation method thereof

ActiveCN101058678AIncrease layer spacingImprove surface reactivityInorganic pigment treatmentMontmorilloniteHigh activity

The invention discloses a large-layer distance and high-property modified calcium-based montmorillonite and making method, wherein the maximum layer distance of the modified montmorillonite is 1. 4nm-7. 42nm. The manufacturing method of the modified montmorillonite is characterized by the following: adopting acid solution as disperser; making the layer of montmorillonite striped through solventing action of water under certain temperature; activating Si-O-Si bond on the surface of montmorillonite to generate Si-OH; obtaining the product. The specific making method comprises the following steps: (1) allocating the modifying solution through acid and water with weight rate at 1:0. 5-2; stirring and blending to form the acid dispersing liquid; (2) adding montmorillonite; allocating the acid dispersing liquid and powder-shaped montmorillonite with weight rate at 1:1-3; adding the composition into the dispersing liquid batch by batch; heating to 30-90 deg. c; stirring 0. 5-3h; cooling; filtering; washing to neutral through water; obtaining the product.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH +1

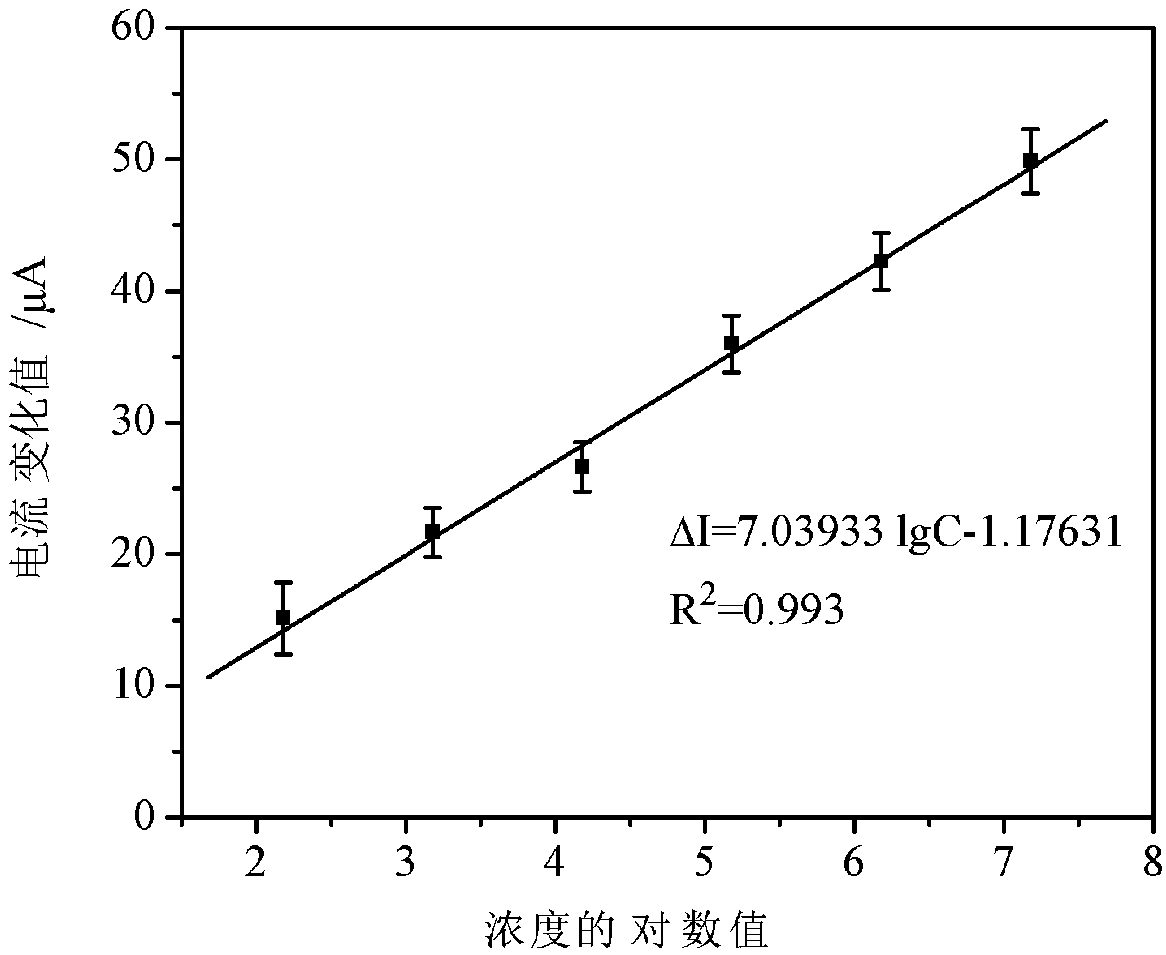

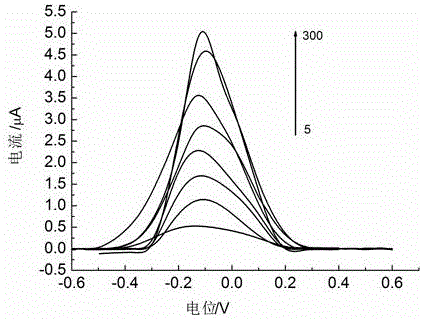

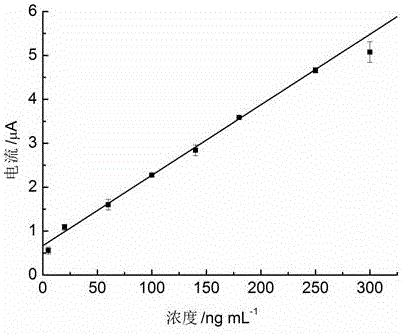

Electrochemical method for rapidly detecting fenitrothion pesticide residue

InactiveCN106248770ALarge specific surface areaImprove surface reactivityMaterial electrochemical variablesPesticide residueOrganophosphorus pesticides

The invention discloses an electrochemical method for rapidly detecting fenitrothion pesticide residue, and belongs to the technical field of biological sensing. According to the present invention, fenitrothion has the good oxidation reduction characteristic on the electrode surface and a gold nano-rod nanometer composite material has advantages of strong adsorption ability, good conductivity and the like, such that the rapid enrichment and the high sensitivity detection of the fenitrothion pesticide can be achieved; the prepared gold nano-rod / chitosan / glassy carbon electrode is used to perform the electrochemical detection on the fenitrothion pesticide; the results show that the linear detection range of the electrochemical sensor on the fenitrothion pesticide is 5-300 ng mL<-1>, the detection limit is 1.74 ng mL<-1>, and the electrochemical sensor is successfully used for the quantitative determination of the fenitrothion in the vegetable sample; and compared with the traditional organophosphorus pesticide residue detection method, the method of the present invention has advantages of convenience, rapidness, simple operation, high sensitivity, good reproducibility, and direct and rapid detection of the fenitrothion pesticide residue.

Owner:JIANGSU UNIV

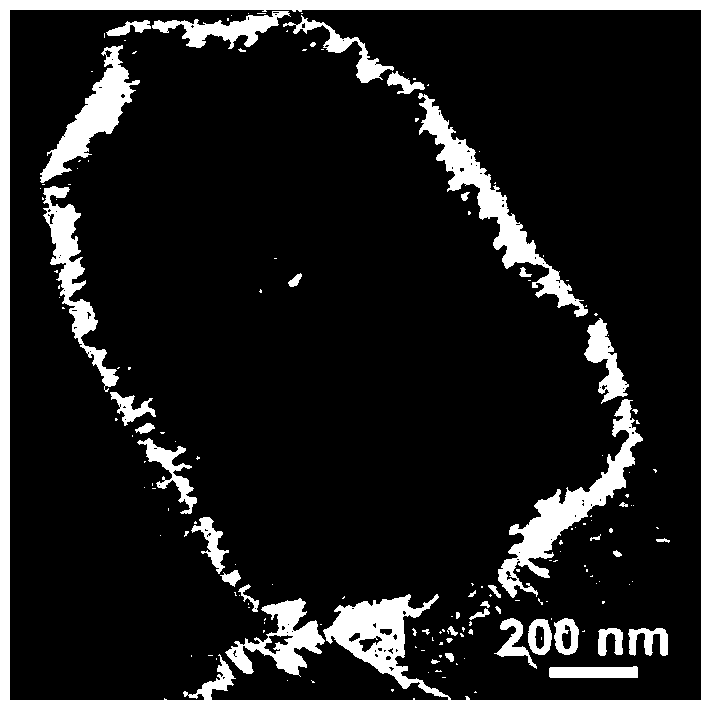

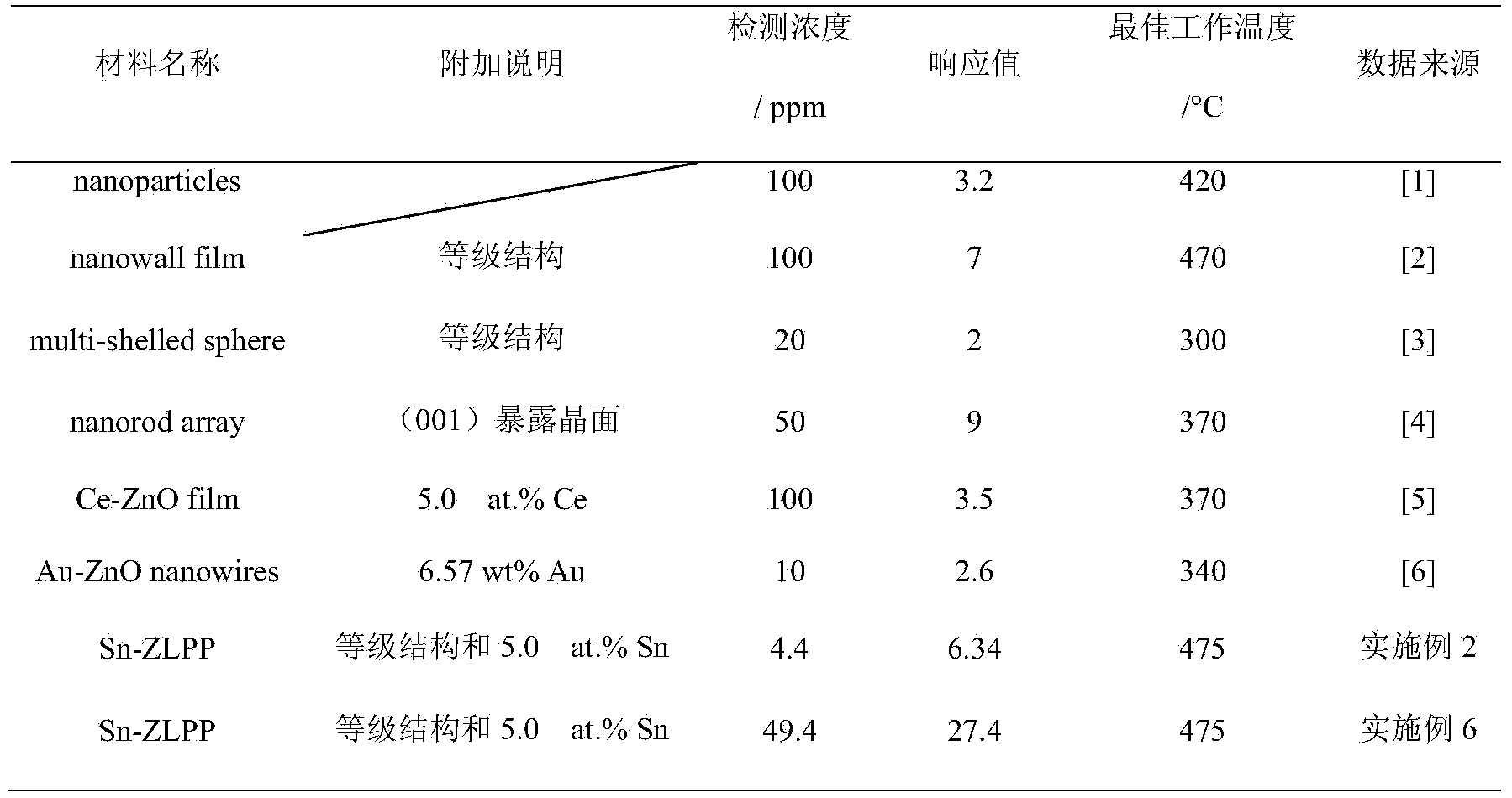

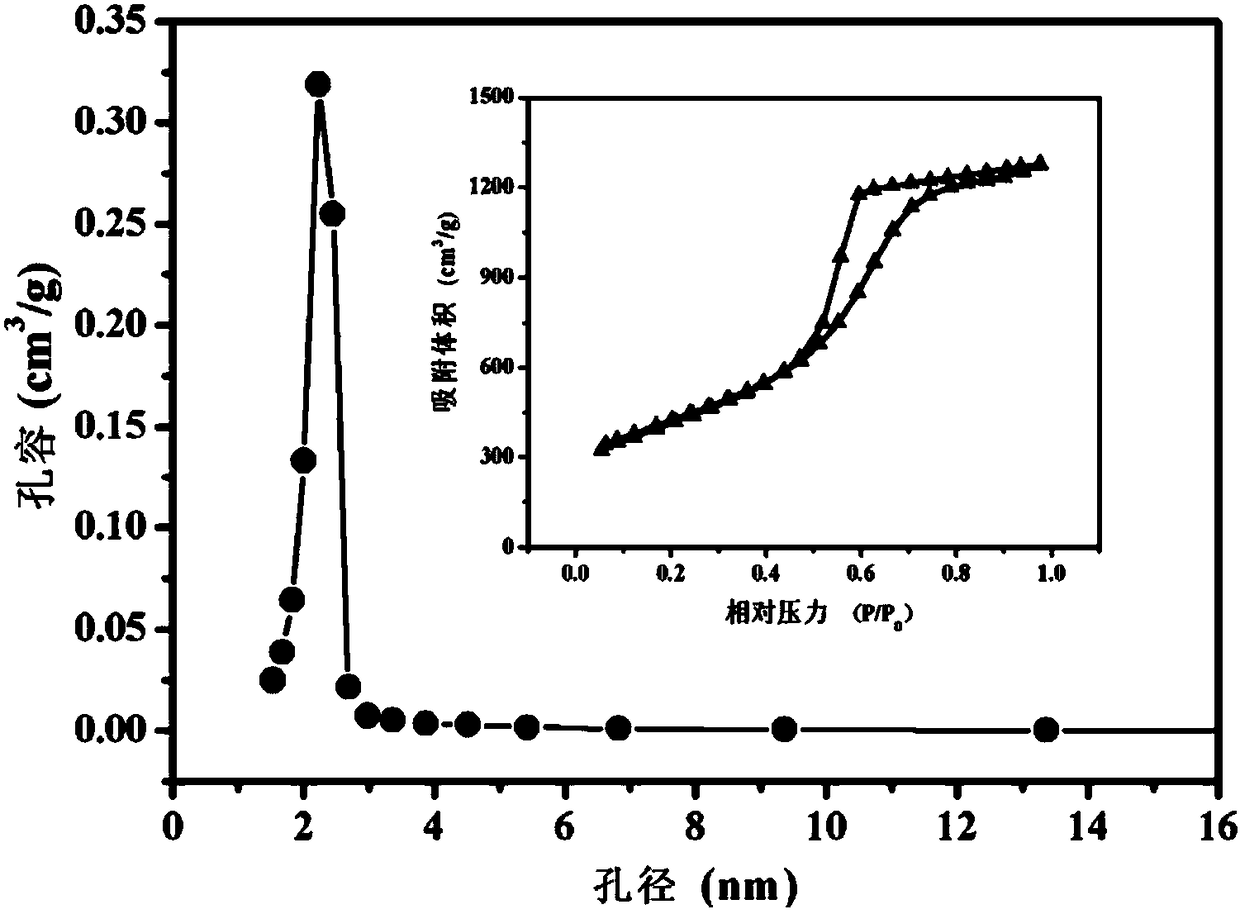

Tin-doped layered porous nanometer zinc oxide as well as preparation method and application thereof

ActiveCN103663542AFacilitated DiffusionImprove adsorption capacityMaterial nanotechnologyZinc oxides/hydroxidesGlycerolZno nanoparticles

The invention provides tin-doped layered porous nanometer zinc oxide. The tin-doped layered porous nanometer zinc oxide is characterized in that the tin-doped layered porous nanometer zinc oxide is of a three-dimensional porous layered structure formed by crystal particles and nanopores on the whole, the thickness of each layer of tin-doped layered porous nanometer zinc oxide is about 10-20nm, the length of each layer of tin-doped layered porous nanometer zinc oxide is about 0.8-1.2 micrometers, the width of each layer of tin-doped layered porous nanometer zinc oxide is about 300-700nm, and the tin doping content is 0.1-22.0at.%. A typical preparation method of the tin-doped layered porous nanometer zinc oxide comprises the steps of weighing zinc salt, dissolving the zinc salt by adding water, adding stannous chloride according to proportions, stirring so as to form white emulsion, slowly adding polyhydric alcohols (such as ethylene glycol, glycerol, 1,2-propylene glycol, 1,4-butanediol) till forming semitransparent light white mixed liquid, transferring the mixed liquid to a reaction kettle, sealing the reaction kettle, carrying out thermal reaction by adding hot water, then carrying out solid-liquid separation on a reaction product after the reaction, and washing and drying the solid product. The tin-doped layered porous nanometer zinc oxide provided by the invention has excellent gas-sensitive property for volatile organic compounds, and has the advantages of simple method and low cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Composite filter material prepared by blending melt-blown polypropylene with modified organic bentonite and used for sewage treatment and preparation method thereof

ActiveCN104759154AImprove purification efficiencyImprove pollution interception effectArtificial thread manufacturing machinesMelt spinning methodsAluminium hydroxideZinc alloys

The invention relates to a filter material used in sewage treatment and particularly relates to a composite filter material prepared by blending melt-blown polypropylene with modified organic bentonite and used for sewage treatment and a preparation method thereof. The filter material is prepared from following raw materials, by weight: 2-3 parts of calcium alginate, 30-34 parts of polypropylene, 1-2 parts of a titanate coupling agent, 0.2-0.4 parts of polyacrylamide, 20-24 parts of the organic bentonite in 200-300 meshes, 2-3 parts of polyether modified silicone, 2-3 parts of nano aluminum hydroxide, 0.1-0.2 parts of nano copper-zinc alloy powder, 0.8-1 part of lauryl sodium sulfate, and 35-45 parts of water. In the invention, the modified organic bentonite-based filter material micro powder is supported onto the modified polypropylene master batch melt-blown filaments to form a stereoscopic network structure. The filter material is excellent in mechanical performance, is not liable to break in use, is higher in purification efficiency, is stable in performance and is flexible in shape.

Owner:南京瑜铨环保技术有限公司

Preparation process of vanadium-nitrogen alloy

The invention discloses a preparation process of a vanadium-nitrogen alloy. The preparation process comprises the steps that a vanadium-containing compound is subjected to mechanical activation treatment at first, a reaction promoter, graphene and a binder are added to obtain qualified mixed materials, the mixed materials are subjected to aging treatment and fed into a calcining kiln to be calcined, a drying stage, a carbonization stage, a nitridation stage and a cooling stage are sequentially carried out, a product is discharged from the kiln, and the vanadium-nitrogen alloy finished productwith the vanadium content larger than or equal to 77.0% is obtained. According to the preparation process, quality is good, product quality is stable, the production process is stable, and the production cost is low.

Owner:涂绪洋

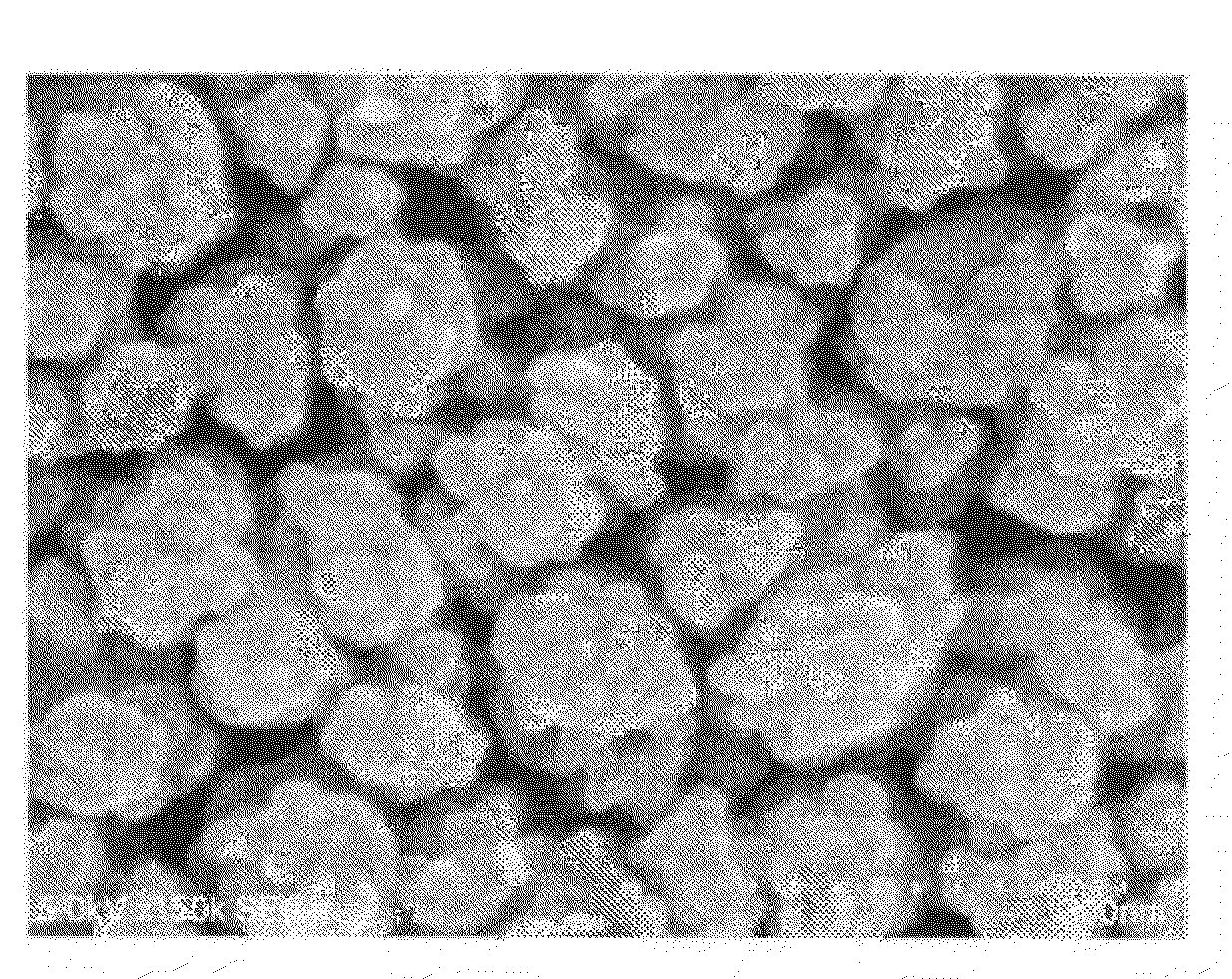

Porous metal thin film, method for manufacturing the same, and capacitor

ActiveUS20090174987A1Increase surface areaIncreasing capacitance of capacitorLiquid electrolytic capacitorsLayered productsCapacitorFilm structure

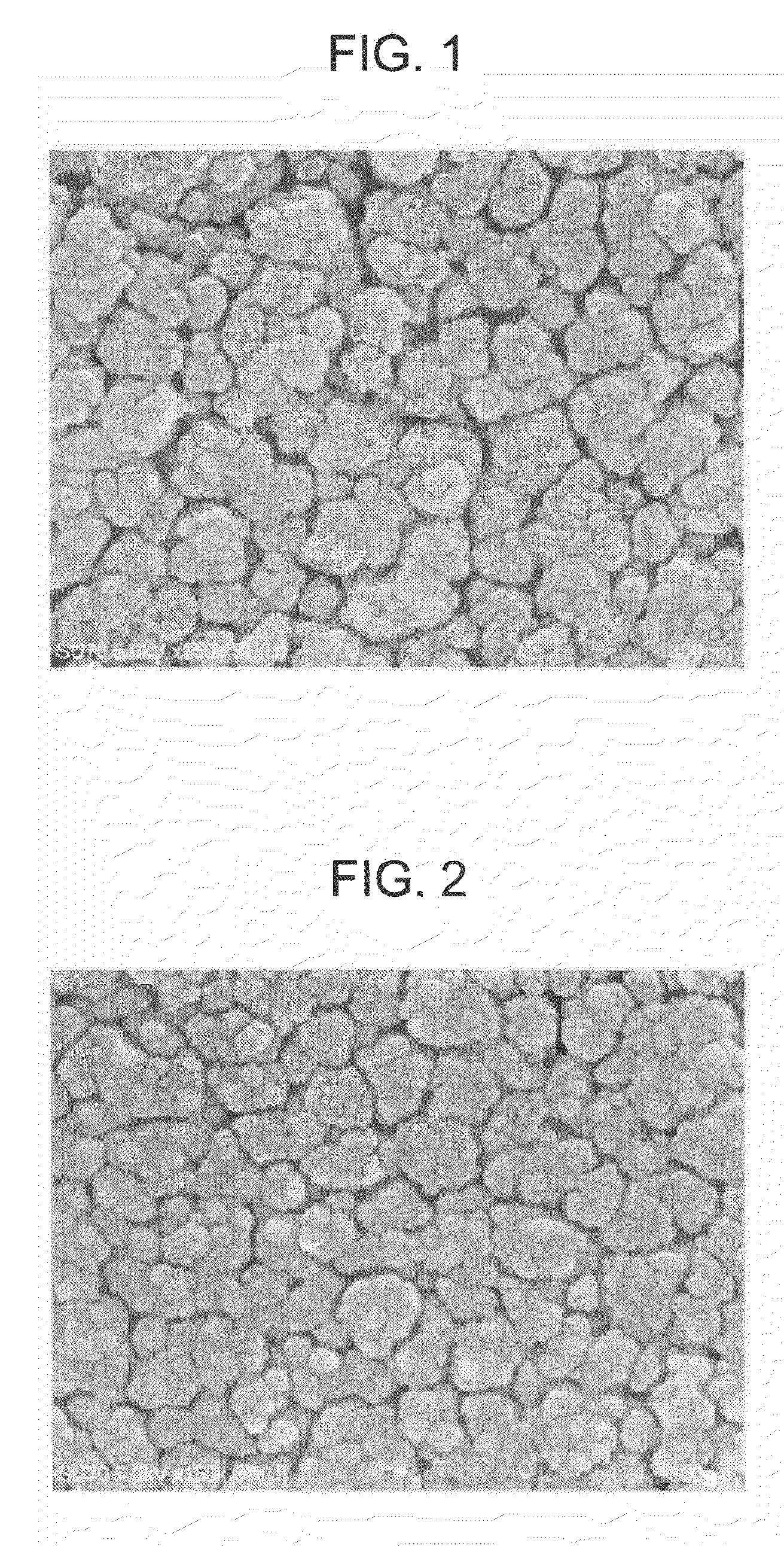

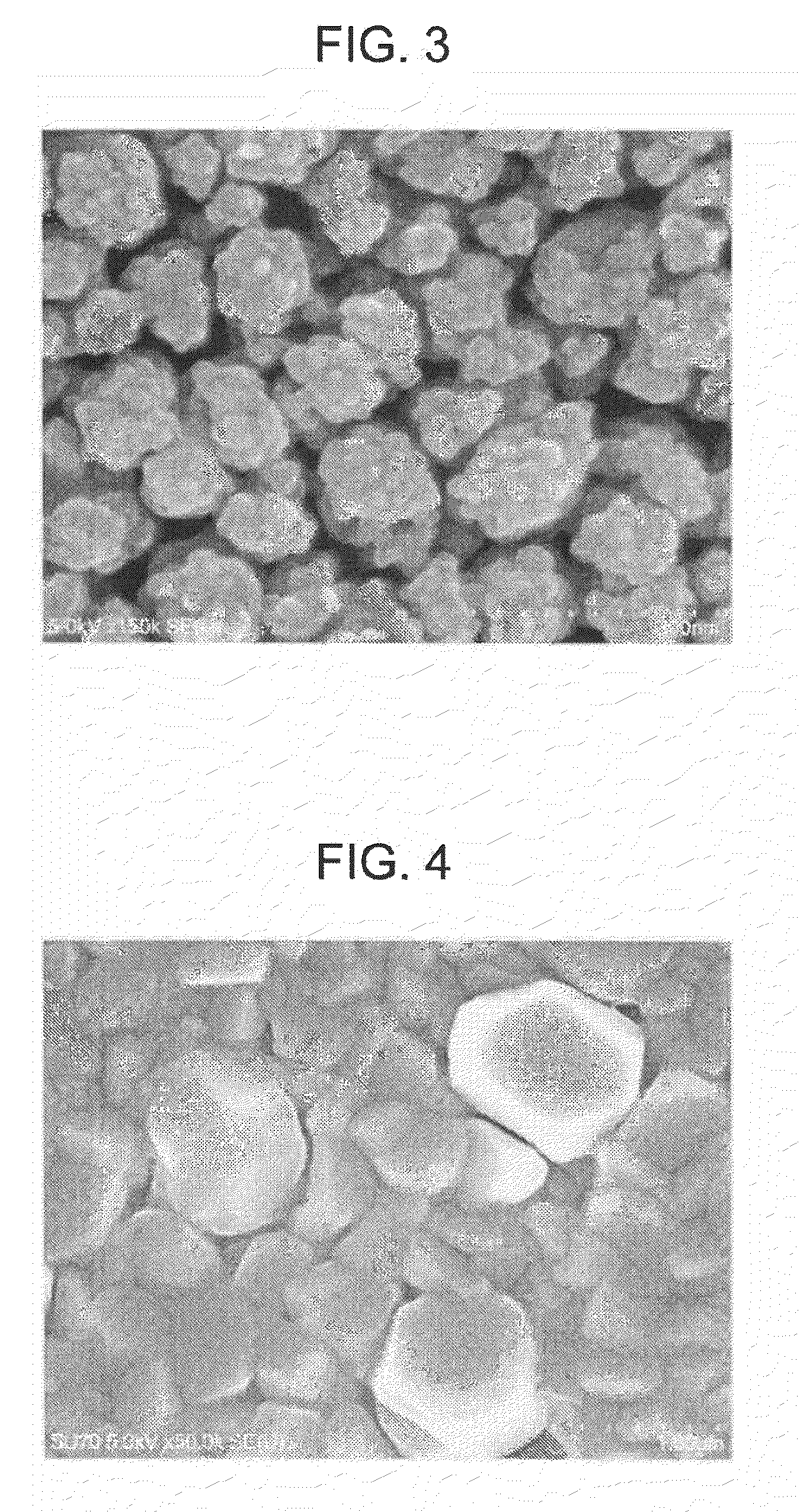

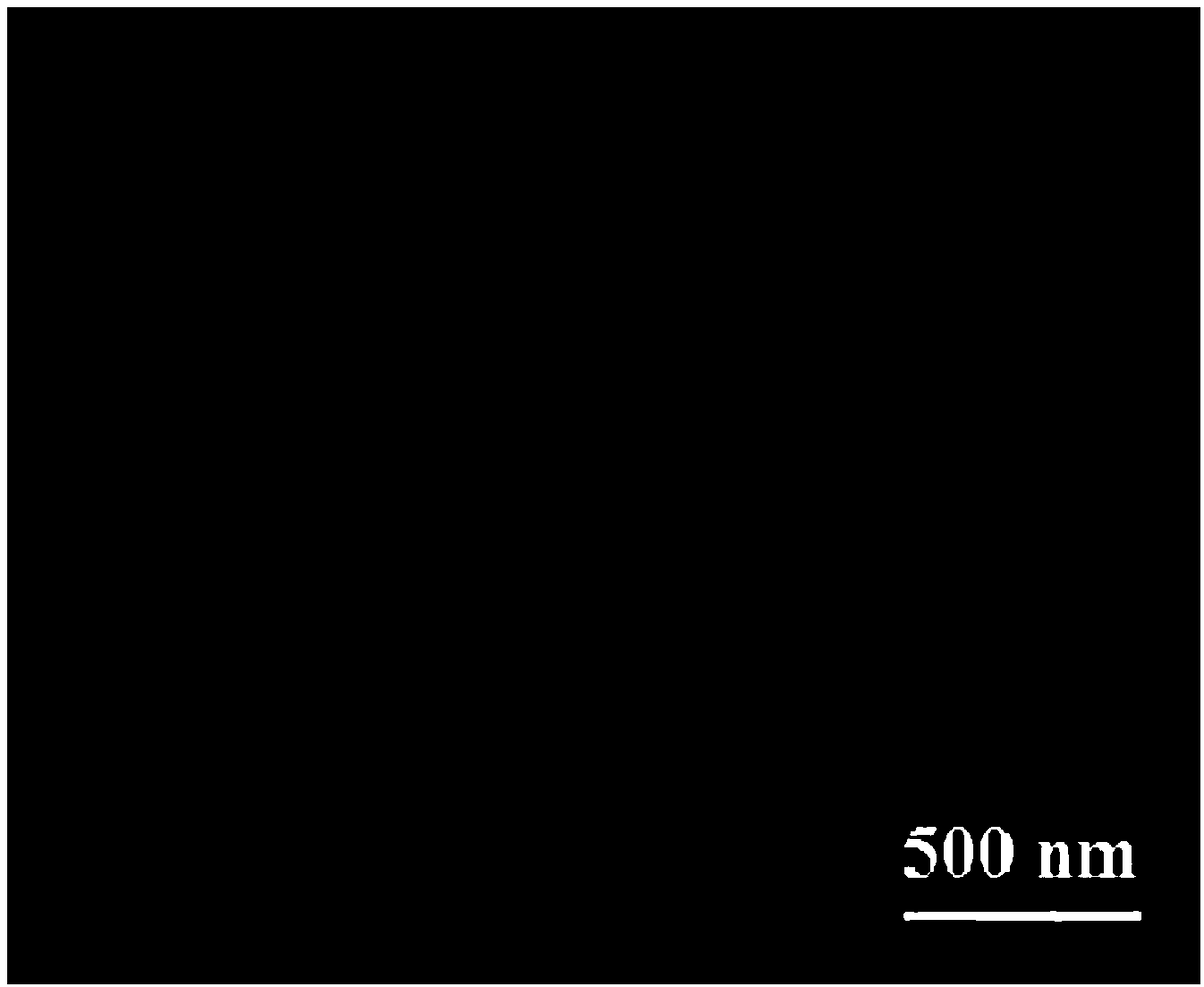

A porous metal thin film formed from aluminum has a film structure in which domains having an average diameter of 200 nm or more, and 500 nm or less and being formed through aggregation of a plurality of grains having an average grain diameter of 50 nm or more, and 160 nm or less are distributed discretely at an average distance of 5 nm or more, and 40 nm or less, wherein the area occupied by the above-described domains is 60% or more, and 90% or less in a cross-section in any direction of the porous metal thin film.

Owner:KOBE STEEL LTD

Electrochemical sensor for detecting lead ion and/or cadmium ion, and preparation method and application thereof

ActiveCN108226244AHigh detection sensitivityLarge specific surface areaMaterial electrochemical variablesElectrochemistryBismuth

The invention discloses an electrochemical sensor for detecting lead ions and / or cadmium ions, and a preparation method and an application thereof. The electrochemical sensor includes a glassy carbonelectrode, of which the surface of a reaction terminal is modified by ordered mesoporous carbon supporting hollow spherical bismuth oxide, which is formed with the ordered mesoporous carbon as a carrier, of which the surface supports the hollow spherical bismuth oxide. The preparation method includes a step of modifying the ordered mesoporous carbon supporting hollow spherical bismuth oxide onto the surface of the reaction terminal of the glassy carbon electrode. The electrochemical sensor has advantages of good stability, long service life, wide detection range, low detection limit, good selectivity and strong anti-interference capability. The preparation method has simple processes, low cost and convenient operations, is pollution-free and has extensive application range. The electrochemical sensor is used for detecting lead ions and / or cadmium ions, has simple operation, low cost, short responsive time and high sensitivity, and has great application prospect.

Owner:HUNAN UNIV

Method for degradation of organochloride

InactiveCN101367562AEasy to operateImprove efficiencyWater contaminantsWater/sewage treatment by sorptionMicrowaveOrganochloride

The invention relates to a method for degrading the chloride, which comprises the following steps: firstly the surface of the hollow glass micro balloon is loaded with the iron and nickel dual-metal particles so as to modify the surface of the hollow glass micro balloon in liquid-phaseelectroless plating way; secondly, the modified hollow glass micro balloon is adopted as the absorption agent, the restoration agent and the catalyst to degrade the organic chloride. On the one hand, the problem of the load of the catalyst (Fe-Ni) is resolved; on the other hand, the surface area of the catalyst is enlarged, so that the active center of the reaction is increased; moreover, after heating and promoting with the micro wave in the reaction, a plurality of heat points can be generated on the surface of the hollow glass micro balloon, thereby greatly improving the absorption efficiency of the micro-wave energy. Under the cooperative effect of the absorption of the modified hollow glass micro balloon and the inducement of the micro wave, the degradation of the organic chloride is more efficient and more thorough. The method is simple to be operated, and is free from generating the toxic intermediate bodies, and has good effect to degrade the organic chloride, and is a good method for processing the organic chloride waste water.

Owner:CHONGQING UNIV

Graphene conducting material and preparation method thereof

The invention discloses a graphene conducting material. The graphene conducting material is prepared from the following raw materials in parts by weight: 30 to 41 parts of graphene oxide, 20 to 30 parts of a conducting dispersion solution, 35 to 40 parts of aniline, 1 to 2 parts of ammonium persulfate, 0.4 to 1 part of melamine, 0.1 to 0.2 part of tert-butyl p-diphenol, 4 to 5 parts of diphenyl silanediol and 2 to 3 parts of calcium propionate. According to the graphene conducting material disclosed by the invention, various conducting substances, such as polyaniline, acetylene carbon black and graphene, are added; all the raw materials are blended and the graphene conducting material has very strong cooperatively enhanced conductivity; after the raw materials are treated by a method disclosed by the invention, the effects of stable finished products and efficient electric conduction are realized.

Owner:温州市赢创新材料技术有限公司

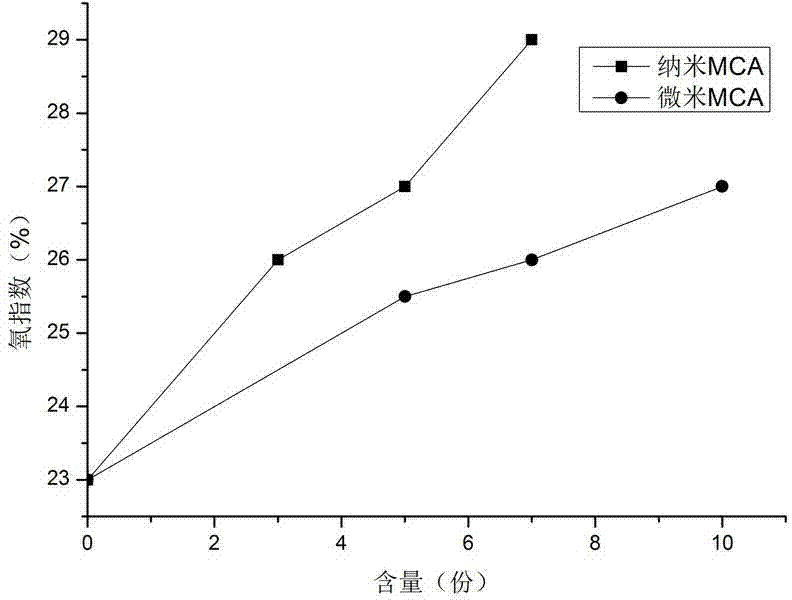

Method of nano halogen-free flame retardant polyamide-6

The invention relates to a preparation method of nano halogen-free flame retardant polyamide-6. The preparation method comprises the steps: firstly weighing polyamide-6, nano MCA halogen-free flame retardant agent and an antioxidant, and mixing uniformly the raw materials; and then preheating a double-screw extruder to the temperature of 185-280 DEG C, adding the uniformly-mixed raw materials into the double-screw extruder, and then carrying out granulation on the product, to obtain the nano halogen-free flame retardant polyamide-6. The prepared nano halogen-free flame retardant PA 6 has the advantages of good flame retardant effect, less adding amount of the flame retardant agent, small combustion smoke formation quantity, and no production of toxic and corrosive gases, and has mechanical properties higher than those of a common halogen-free flame retardant PA6 in markets.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Fe3O4-loaded chiral catalyst and preparation method and application thereof

InactiveCN105195228AThe preparation method is simple and environmentally friendlyLarge specific surface areaOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEnantioselective synthesisCycloaddition

The invention discloses a Fe3O4-loaded chiral catalyst and a preparation method and application thereof and belongs to the technical field of chiral catalysis and asymmetric synthesis. According to a technical scheme, the Fe3O4-loaded chiral catalyst is formed by copolymerizing Fe3O4 nanospheres each having a double-bonded surface and a chiral monomer having a chemical formula shown below; this catalyst has a structure shown below. The invention further discloses the preparation method of the Fe3O4-loaded chiral catalyst and application of the Fe3O4-loaded chiral catalyst in Diels-Alder cycloaddition reaction. The Fe3O4-loaded chiral catalyst may be separated by magnetic attraction as one end of a polymer chain is fixed to one magnetic Fe3O4 nanosphere insoluble in a reaction medium, via a covalent bond; this catalyst has the advantage that the catalyst a heterogeneous catalyst is easy to recover and reusable.

Owner:HENAN NORMAL UNIV

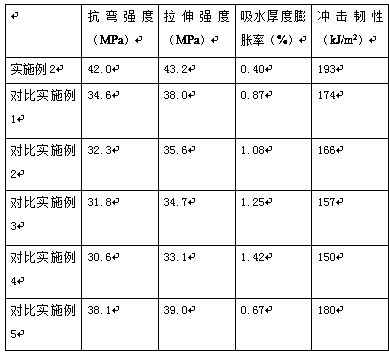

Preparation method of water-resistant and high-strength PVC wood-plastic composite

InactiveCN109135109AEasy to prepareImprove the quality of useWater resistantUltimate tensile strength

The invention discloses a preparation method of a water-resistant and high-strength PVC wood-plastic composite. The method includes the following steps of 1, preparation of a functional additive, 2, weighing of raw materials for use, 3, mixing treatment, 4, extrusion molding and 5, grinding treatment. According to the preparation method of the water-resistant and high-strength PVC wood-plastic composite, all steps are reasonably matched, the process is simple, the method is easy to apply and popularize, and the prepared PVC wood-plastic composite has high mechanical strength, good water resistance, strong corrosion resistance, long service life, great market competitiveness and application value.

Owner:宣城市聚源精细化工有限公司

Graphene-grafted modified calcium carbonate powder and preparation method thereof

InactiveCN106590043AImprove filling modification effectImprove performancePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSurface reactionDispersity

The invention discloses graphene-grafted modified calcium carbonate powder. According to the graphene-grafted modified calcium carbonate powder, calcium carbonate is subjected to wet ball milling pretreatment through a titanate coupling agent / ethanol solution at first, the dispersity of the calcium carbonate is improved, and the surface reaction activity is improved; then, a graphene-polyethyleneimine thin film is grafted on the surface of the calcium carbonate, and the advantages of graphene are introduced; and meanwhile, the powder has amphipathy and has a good suspension dispersion effect in a water system and an oil system, so that the filling modification effect of the calcium carbonate powder is effectively improved, and a product with better performance is obtained.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

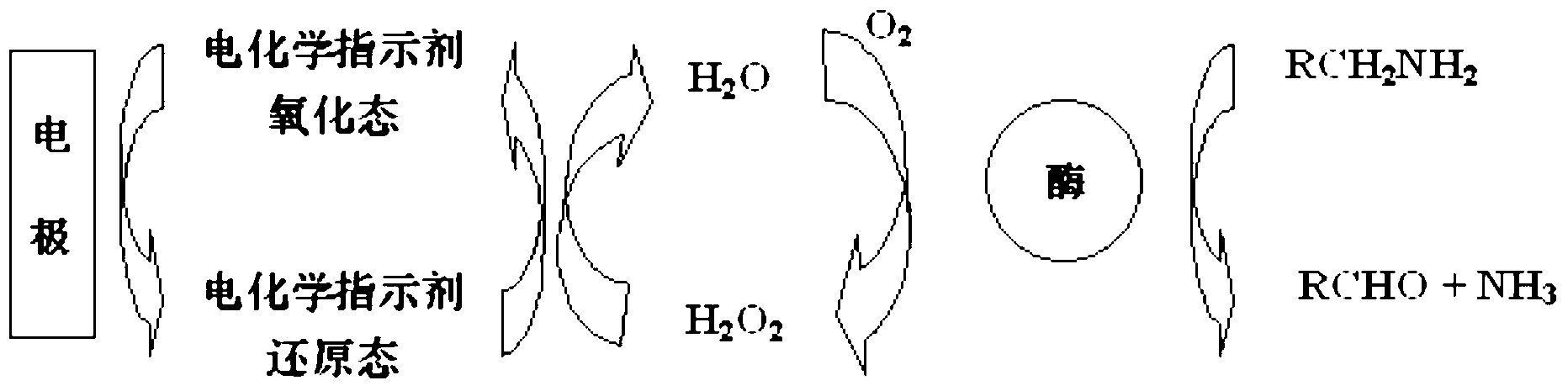

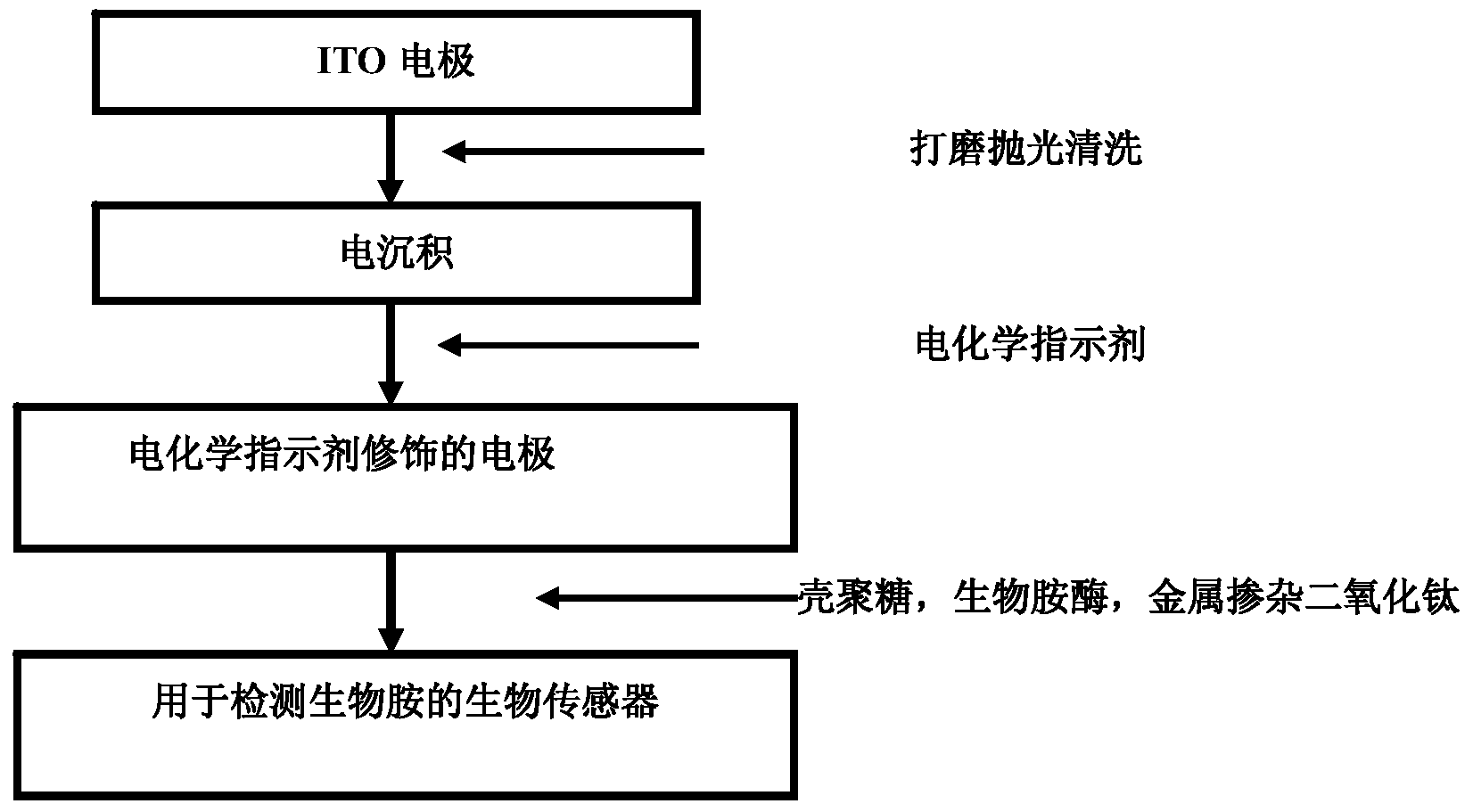

Biosensor for detecting biogenic amine and preparation method thereof

InactiveCN103926296AImprove surface reactivityHigh catalytic efficiencyMaterial analysis by electric/magnetic meansBiogenic amineOxide

The invention discloses a biosensor for detecting biogenic amine and a preparation method thereof, belonging to the technical field of sensor detection. The biosensor comprises an electrode with the surface provided with a composite film, the composite film consists of an electrochemical indicator, biogenic amine enzyme, and metallic oxide nanoparticles doped with conductive metals; the metallic oxide has semiconductor property; the mole percent of the conductive metals and the metallic oxide is 0.5-10mol%. According to the biosensor, the surface of the electrode is coated with the metallic oxide nanoparticles doped with conductive metals, the electrochemical indicator and biogenic amine enzyme; the nanoparticles are introduced to the construction of the biological sensitive interface by utilizing the surface effect, quantum size effect and dielectric confinement effect and the like of the nanoparticles; the conductive metals are doped in the metallic oxide nanoparticles; the electron transfer efficiency of the composite film is improved, redox electrochemical signals are enhanced, the sensitivity of the sensor is improved and the detection limit is lowered.

Owner:GUANGDONG TESTING INST OF PROD QUALITY SUPERVISION +1

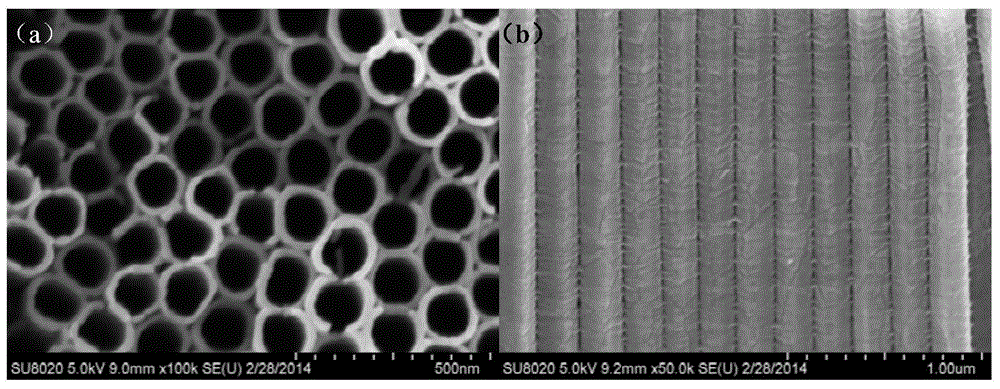

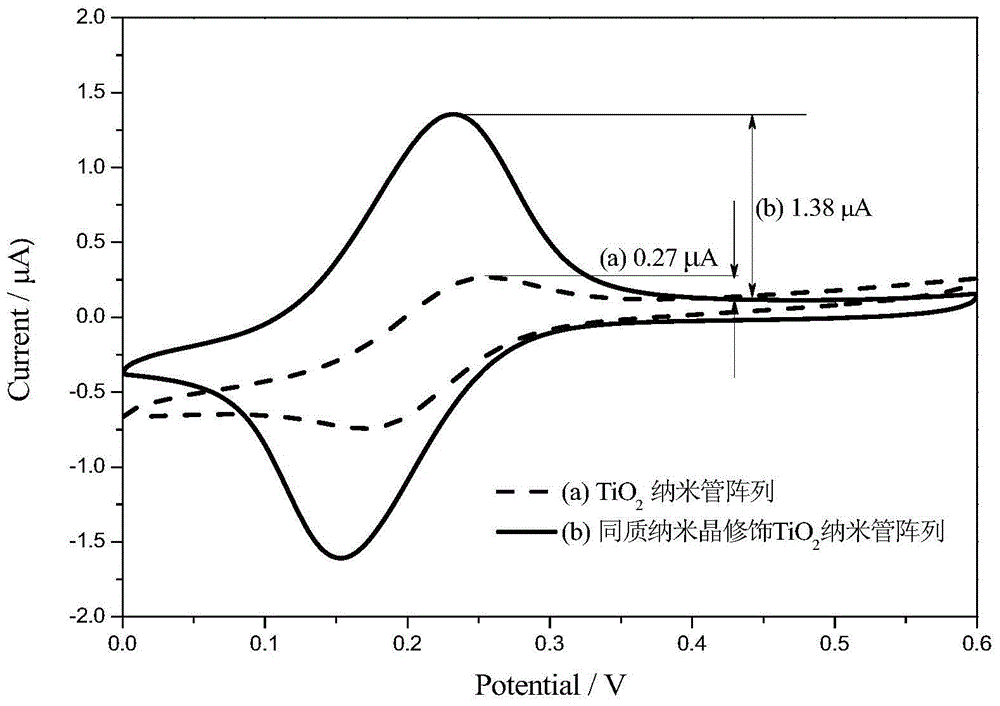

Homogeneous nanocrystal modified TiO2 nanotube array and preparation method thereof

ActiveCN105063719AImprove surface reactivityReduce chance of recombinationFrom gel statePolycrystalline material growthSurface reactionTio2 nanotube

The invention discloses a homogeneous nanocrystal modified TiO2 nanotube array and a preparation method thereof. The homogeneous nanocrystal modified TiO2 nanotube array and the preparation method thereof is characterized in that TiO2 nanocrystals of a single-crystal structure grow in a depositing mode on the inner walls of all TiO2 nanotubes forming a TiO2 nanotube array. When the preparation is conducted, firstly, TiO2 colloid particles are deposited on the surface of the TiO2 nanotube array by adopting a sol-dipping method; then the colloid particles in the TiO2 nanotube array are converted into the nanocrystals through a solvent thermal treatment process, accordingly, the homogeneous nanocrystal modified TiO2 nanotube array is obtained. According to the homogeneous nanocrystal modified TiO2 nanotube array and the preparation method thereof, the homogeneous nanocrystals of the single-crystal structure grow on the inner walls of the nanotubes of the TiO2 nanotube array, so that the TiO2 nanotube array has a larger specific surface area and higher surface reaction activity compared with an original TiO2 nanotube array. Therefore, higher photoelectric conversion efficiency and higher photocatalysis and photoelectrochemistry activity are shown.

Owner:黄山市开发投资集团有限公司

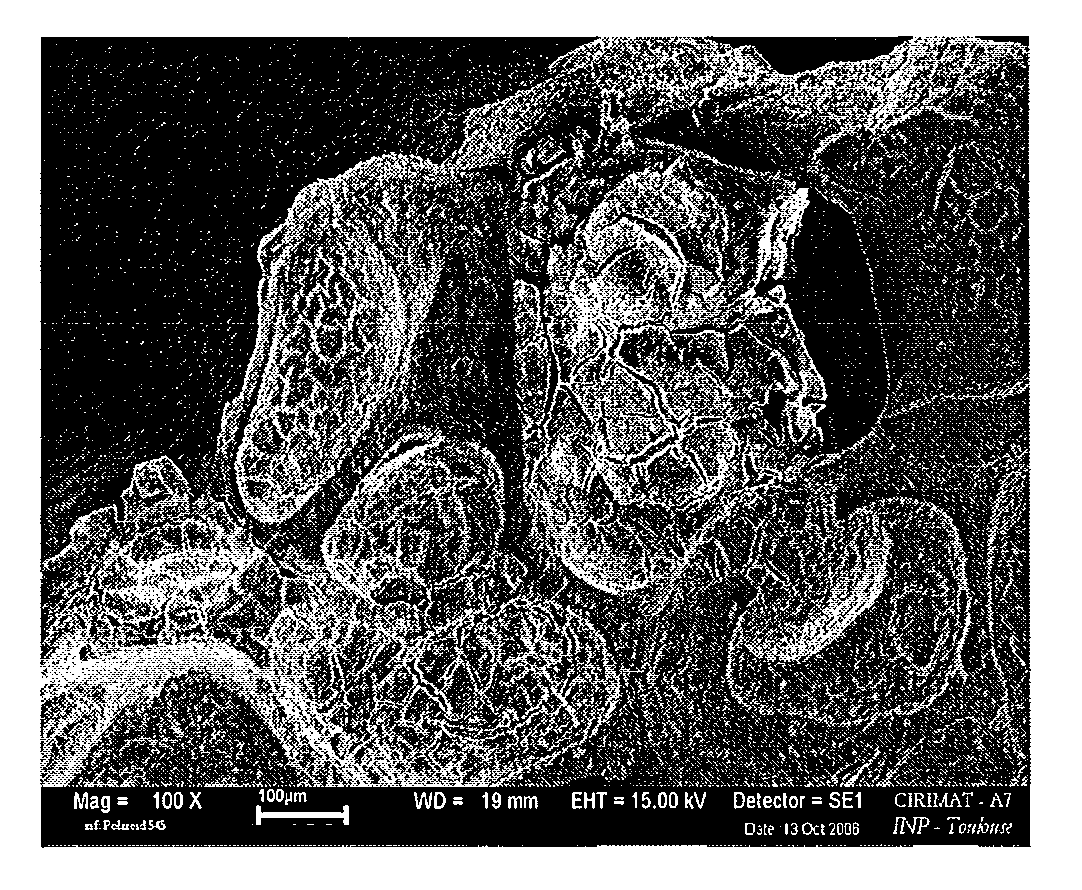

Porous biomaterials surface activation method

InactiveUS8216630B2Improve surface reactivityImprove adsorption capacityBiocideImpression capsActivation methodPhosphate

The present invention relates to a porous biomaterials surface activation method by coating with a layer of apatitic nanocrystals in order to increase their surface reactivity. The method according to the invention is characterized by the following steps: a) preparing a nanocrystalline apatitic calcium phosphate analogous to bone mineral by mixing a calcium salt solution with a phosphate salt solution in a Ca / P ratio ranging between 1.3 and 2 at a temperature ranging between 0 and 60 ° C., b) slurrying the mixture obtained in step a) in an aqueous solution so as to obtain a fluid, homogeneous paste containing 80 to 98% of water, c) bringing a porous biomaterial into contact with the suspension obtained in step b), d) drying the porous biomaterial at a temperature below 100 ° C.

Owner:INST NAT POLYTECHNIQUE DE TOU LOUSE +1

Cross-linked polyethyleneimine-modified calcium carbonate powder for waterborne paint and preparation method thereof

InactiveCN106566308AStable amphipathicGood dispersionCoatingsPigment treatment with macromolecular organic compoundsCross-linkCross-linked polyethylene

The invention discloses a cross-linked polyethyleneimine-modified calcium carbonate powder for waterborne paint. A preparation method for the modified calcium carbonate powder comprises the following steps: subjecting calcium carbonate to pretreatment via titanate coupling agent / ethanol solution wet-process ball milling so as to improve the dispersibility and surface reactivity of calcium carbonate; and allowing a polyethyleneimine film to grow on the surface of calcium carbonate in situ. The eventually prepared modified calcium carbonate powder has stable amphipathy, shows affinity to resin molecules in the system of the waterborne paint, can be dispersed in and coexist with solvents in the system of the waterborne paint, and is not prone to settlement, so excellent filling effect is obtained.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com