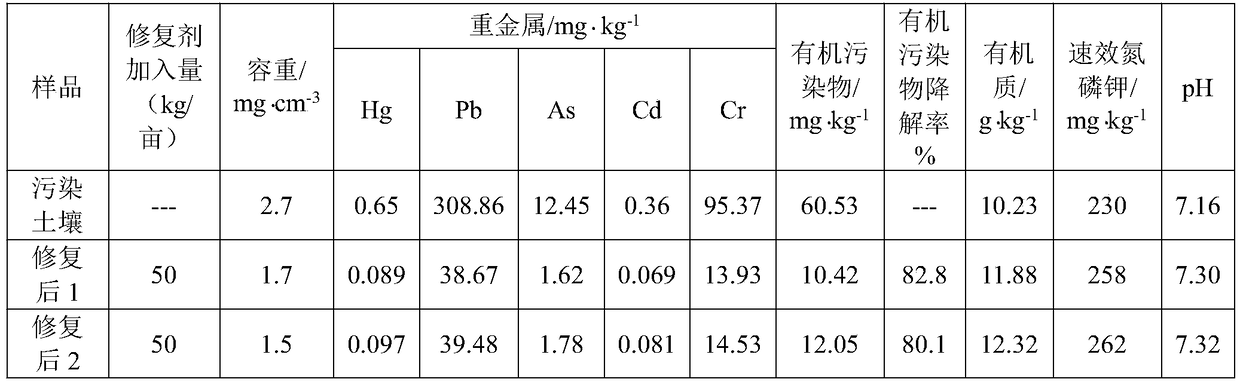

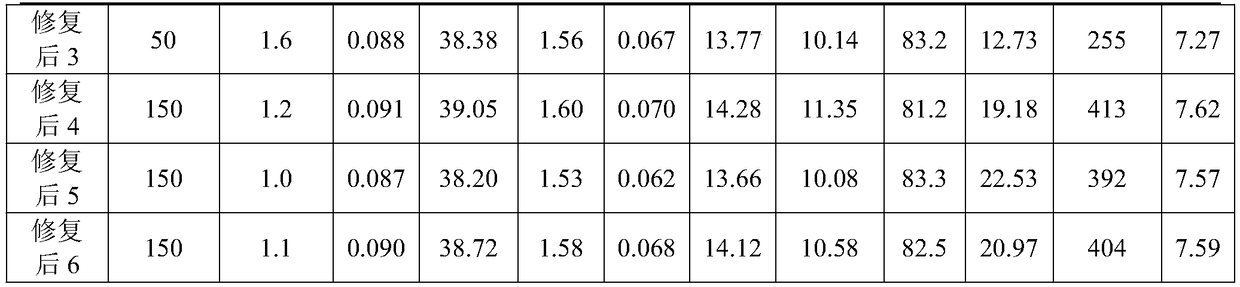

Patents

Literature

157 results about "Tin doping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

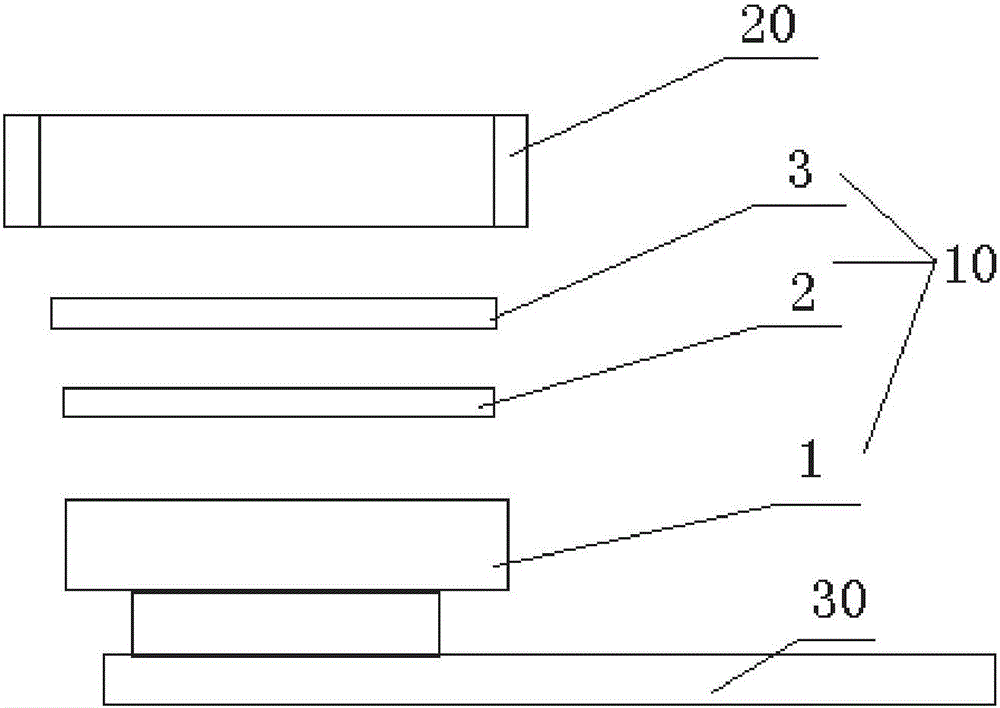

Transparent conductive film

ActiveCN102034565AInhibit coloringImprove transmittanceConductive layers on insulating-supportsInput/output processes for data processingPolyesterIndium

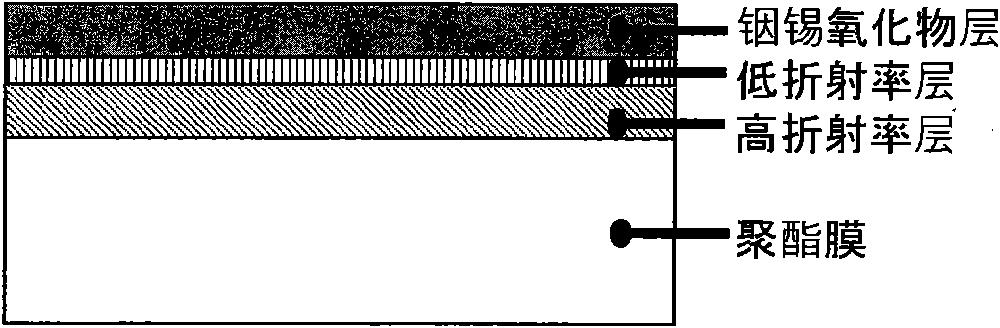

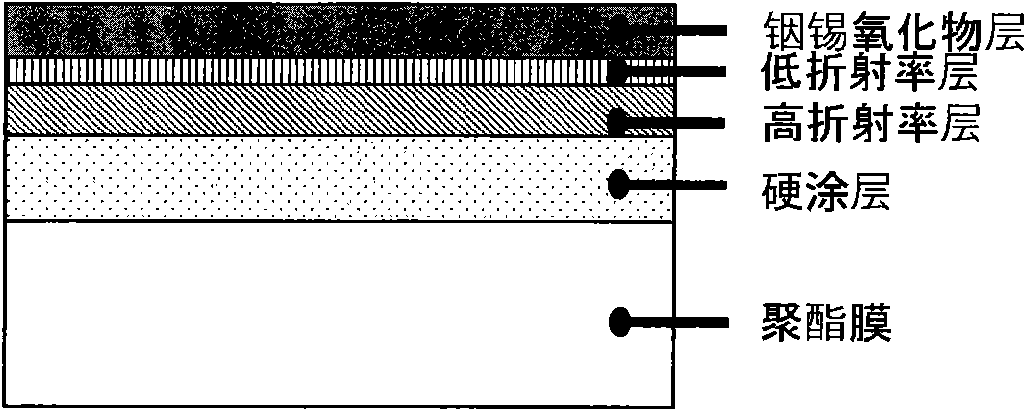

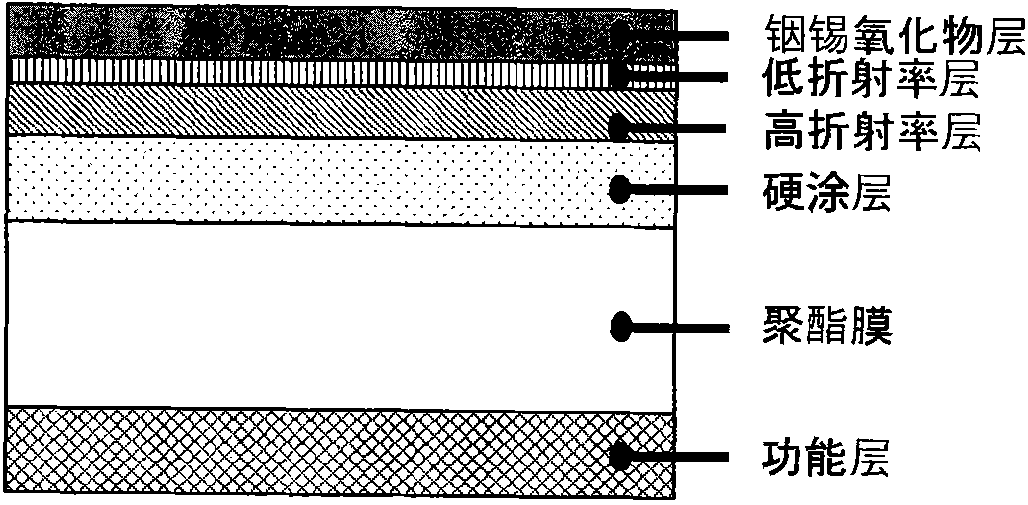

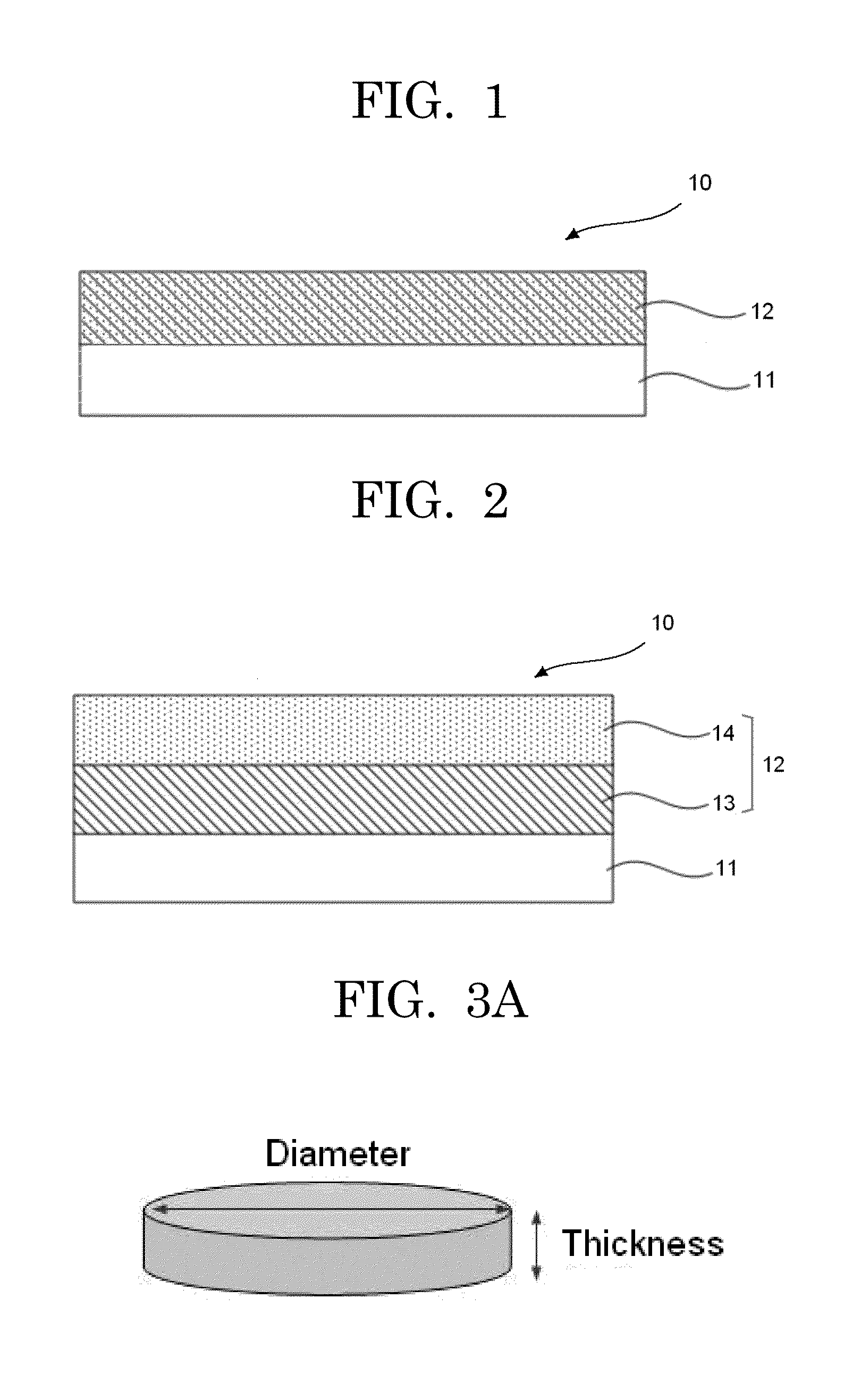

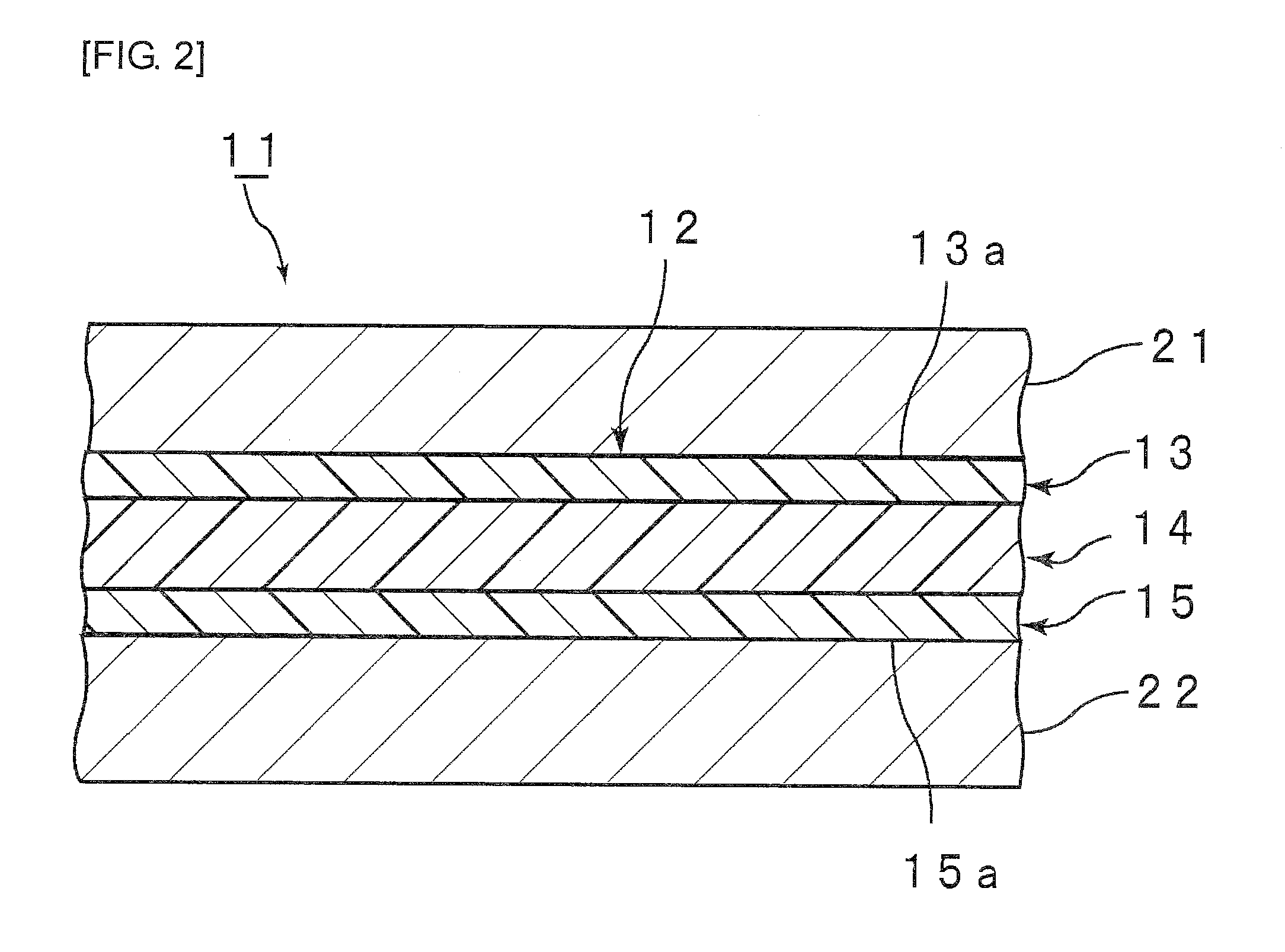

A transparent conductive film has a high-refractive index layer, a low-refractive index layer and a tin-doped indium oxide layer (ITO layer) which are laminated in order on a first main surface of a polyester film. The high-refractive index layer is composed of metal oxide particles and ultraviolet curing adhesives. When the wavelength is 400nm, the refractive index of the high-refractive index layer is 1.63-1.86, and the thickness of the high-refractive index layer is 40-90nm. When the wavelength is 400nm, the refractive index of the low-refractive index layer is 1.33-1.53, and the thickness of the low-refractive index layer is 10-50nm. When the wavelength is 400nm, the refractive index of the ITO layer is 1.85-2.35, and the thickness of the ITO layer is 5-50nm.

Owner:NOF CORP

Heat-ray shielding material

InactiveUS20130260139A1High shielding ratioSuperior lightfastnessLayered productsCoatingsIndiumSilver particles

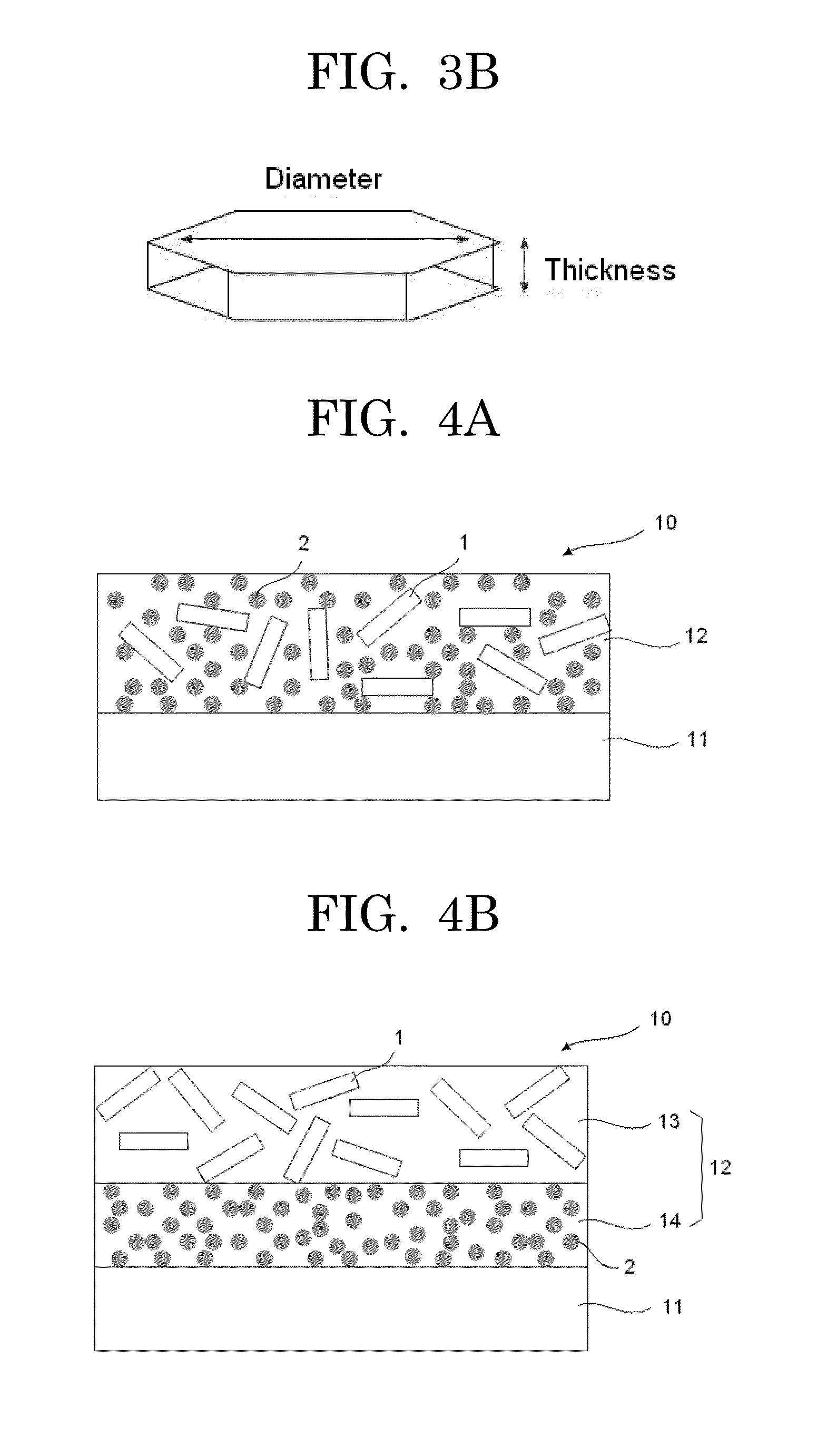

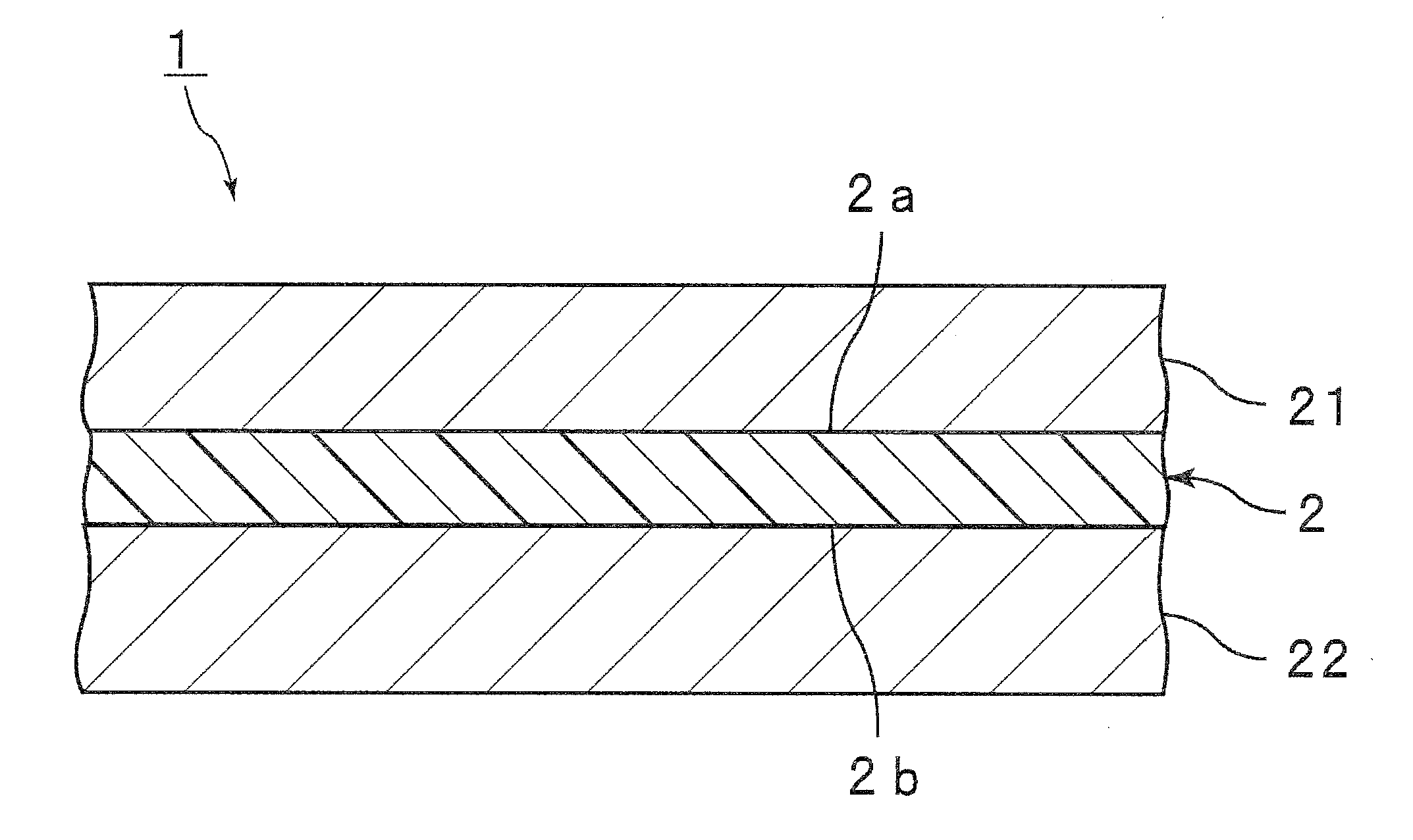

A heat ray-shielding material including a heat ray-shielding layer which includes flat silver particles and metal oxide particles is provided. Preferable aspects include: an aspect of the metal oxide particles including tin-doped indium oxide particles; an aspect of the heat ray-shielding layer including flat silver particles and metal oxide particles mixed and dispersed in a binder; and an aspect of the heat ray-shielding layer including a flat silver particle-containing layer including the flat silver particles and a metal oxide particle-containing layer including the metal oxide particles laminated therein.

Owner:FUJIFILM CORP

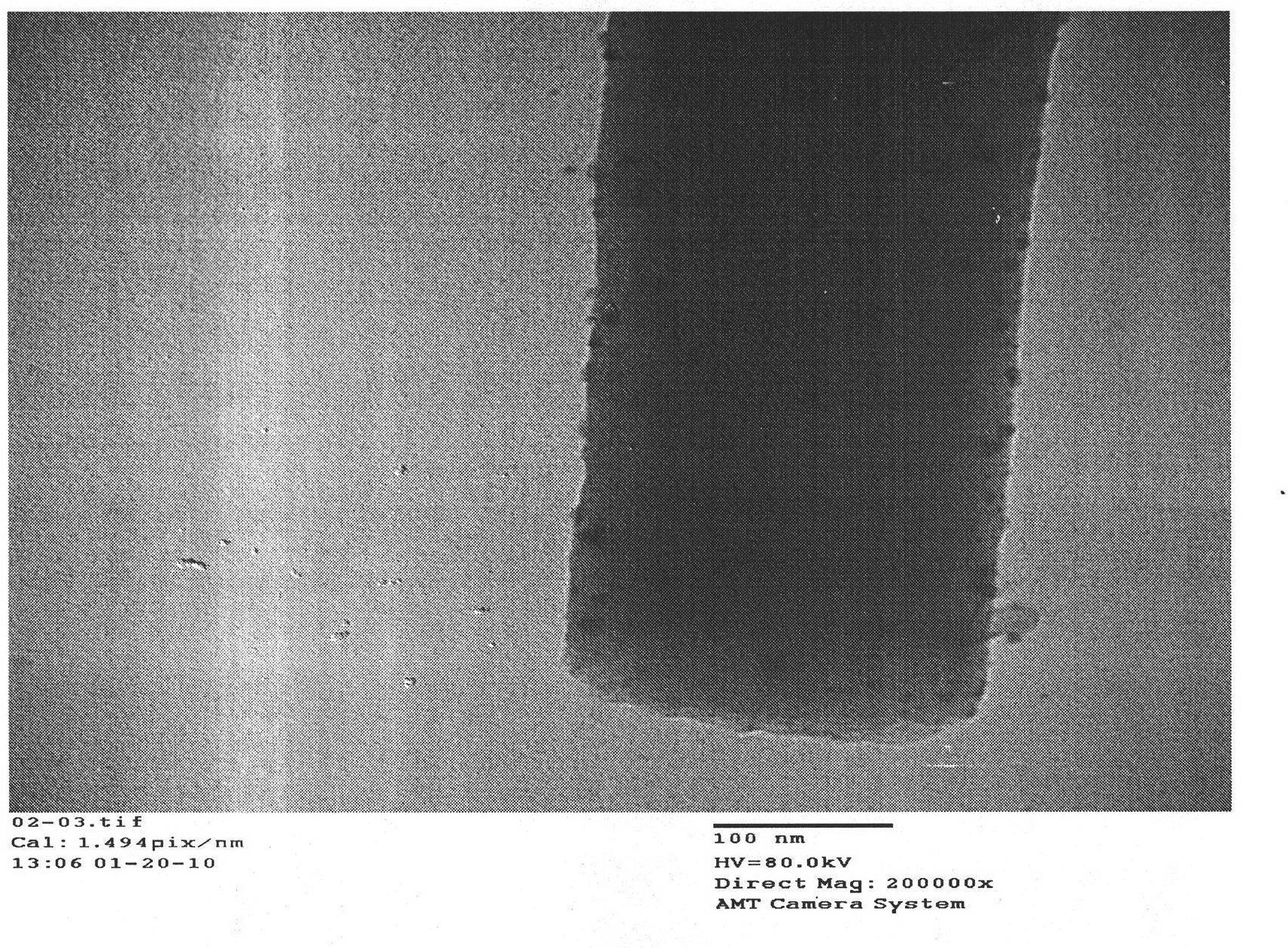

Interlayer film for laminated glass and laminated glass

InactiveUS20050181220A1Improve insulation effectImprove transmittanceCeramic layered productsGlass/slag layered productsIndiumGlass sheet

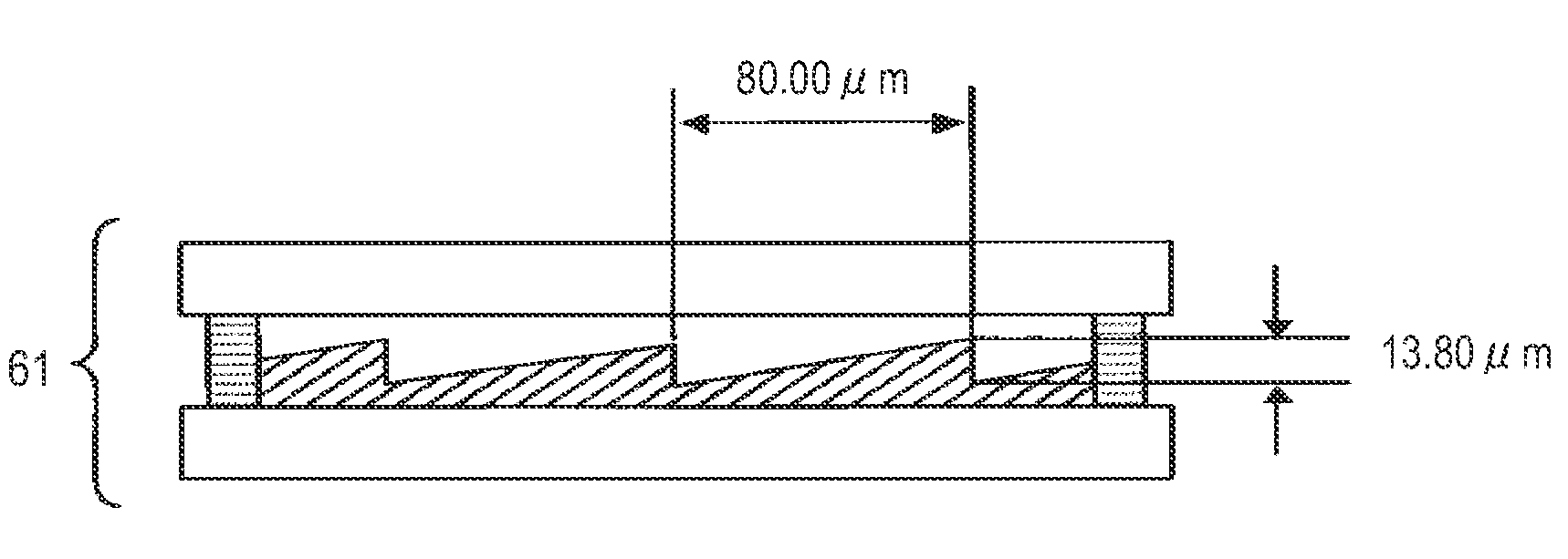

The object of the present invention is to provide an interlayer film for laminated glass which exerts excellent heat insulation or electromagnetic wave transmittance and which is suitable for producing a laminated glass having excellent fundamental performance characteristics required for the laminated glass, such as transparency, especially good haze, appropriate bond strength between an interlayer film and glass, penetration resistance, impact absorption, weather resistance, and so on. Also, the object of the present invention is to provide a laminated glass produced by using the above-mentioned interlayer film. These objects are realized by the interlayer film for laminated glass comprising an adhesive resin, wherein the average particle diameter of tin-doped indium oxide and / or antimony-doped tin oxide is ranging from 0 to 80 nm, and the number of the tin-doped indium oxide or antimony-doped tin oxide particles with a particle diameter of not less than 100 nm are dispersed not more than 1 per 1 μm2, and also, by a laminated glass produced by interposing said interlayer film for laminated glass between at least a pair of glass sheets having a visible light transmittance rate (Tv) of not less than 65% in the light rays of 380 to 780 nm, a solar radiation transmittance rate (Ts) in the light rays of 300 to 2500 nm of not more than 80% of the mentioned visible light transmittance rate (Tv), the haze value (H) of up to 1.0% and electromagnetic wave shield (ΔdB) of not more than 10 dB in the wavelength of 10 to 2000 MHz.

Owner:SEKISUI CHEM CO LTD

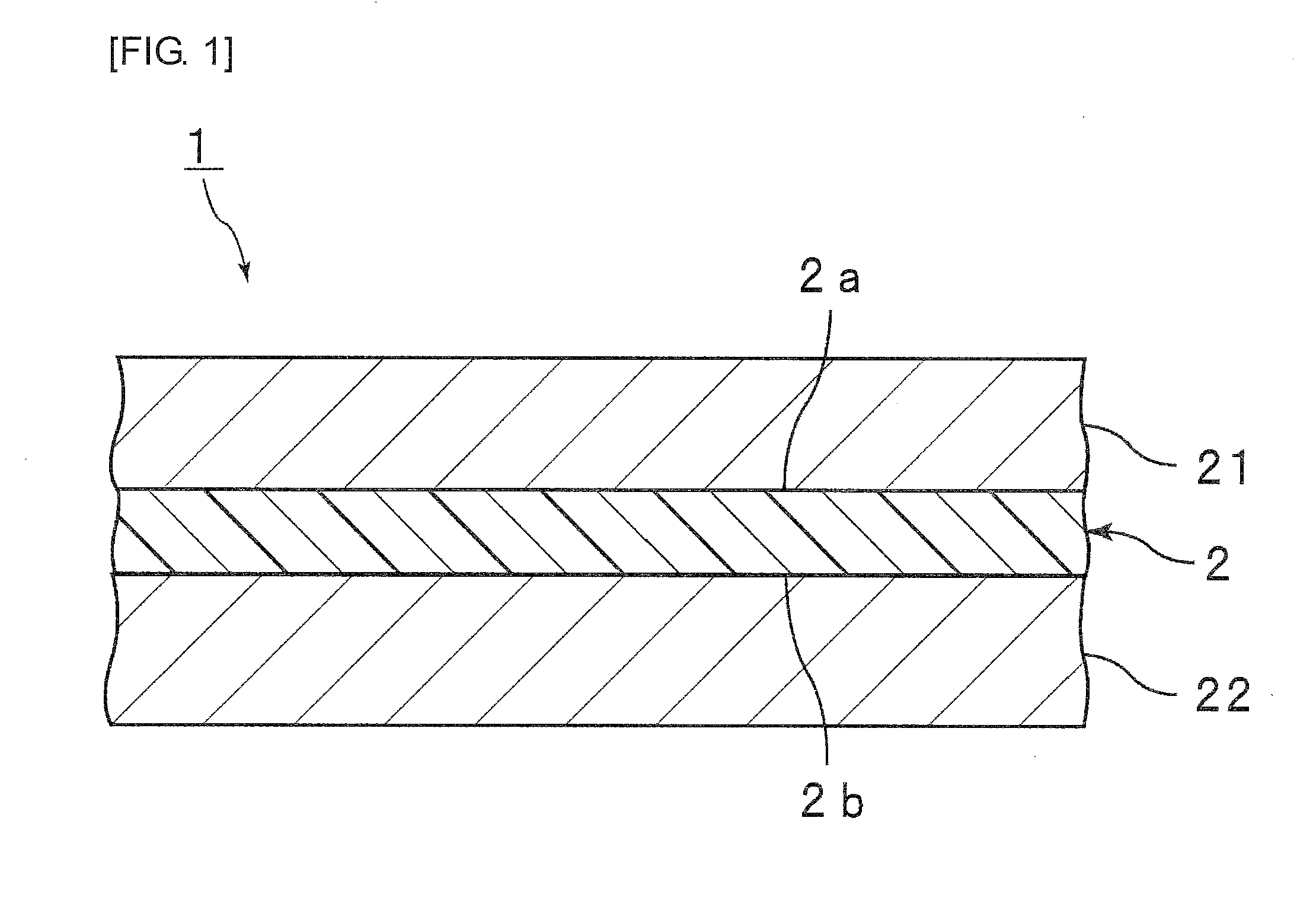

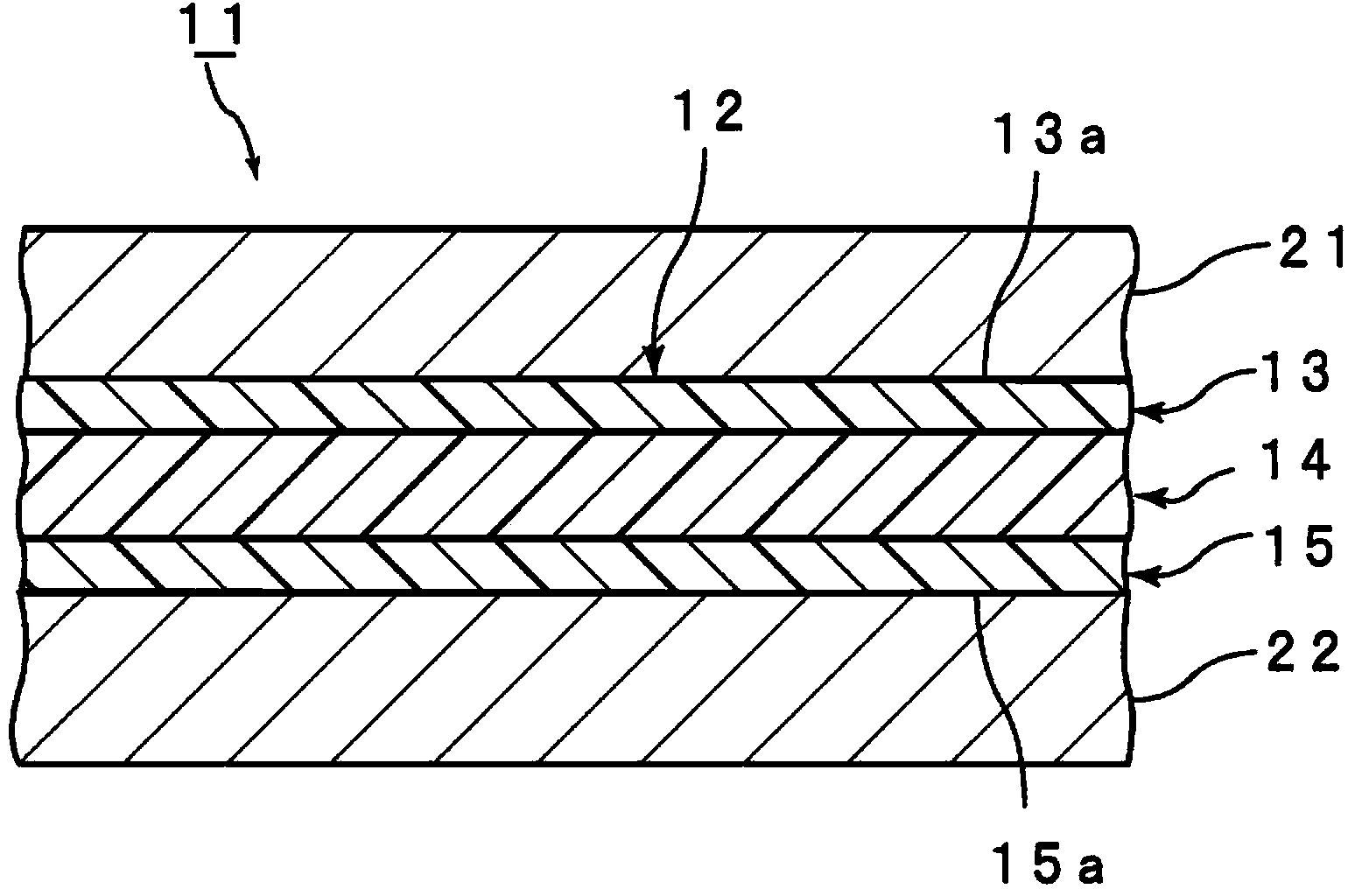

Intermediate film for laminated glass, and laminated glass

InactiveUS20140377567A1Improve insulation performanceHigh visible light transmittanceThermal insulationBuilding constructionsIndiumTransmittance

There is provided an interlayer film for laminated glass which is capable of effectively enhancing heat shielding properties and enhancing visible light transmittance. The interlayer film for laminated glass according to the present invention comprises a thermoplastic resin, tin-doped indium oxide particles, tungsten oxide particles and at least one kind of compound among a phthalocyanine compound, a naphthalocyanine compound and an anthracyanine compound.

Owner:SEKISUI CHEM CO LTD

Pulsed laser deposition of transparent conducting thin films on flexible substrates

InactiveUS20020098668A1Flat surfaceGood light transmissionSolid-state devicesSemiconductor/solid-state device manufacturingIndiumAluminum doped zinc oxide

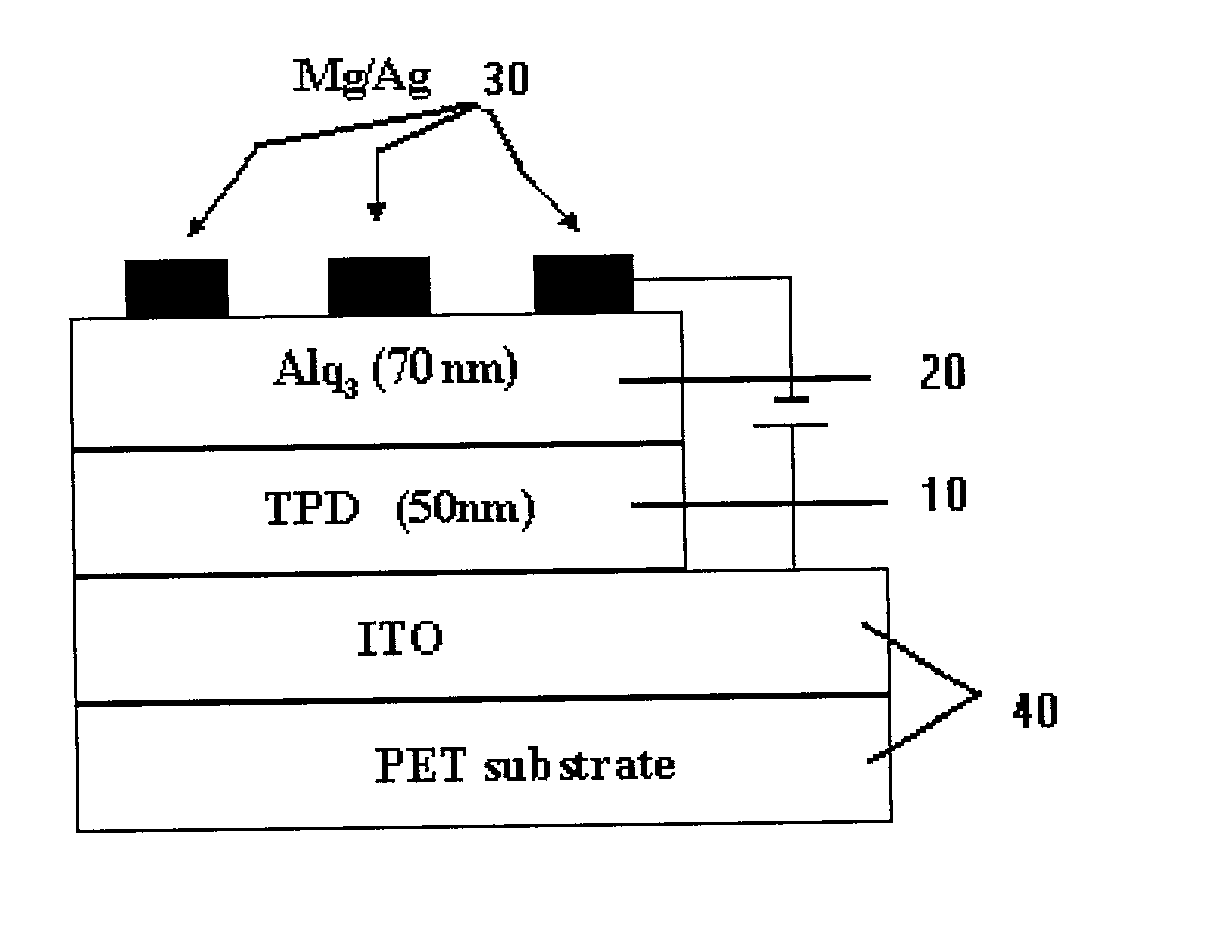

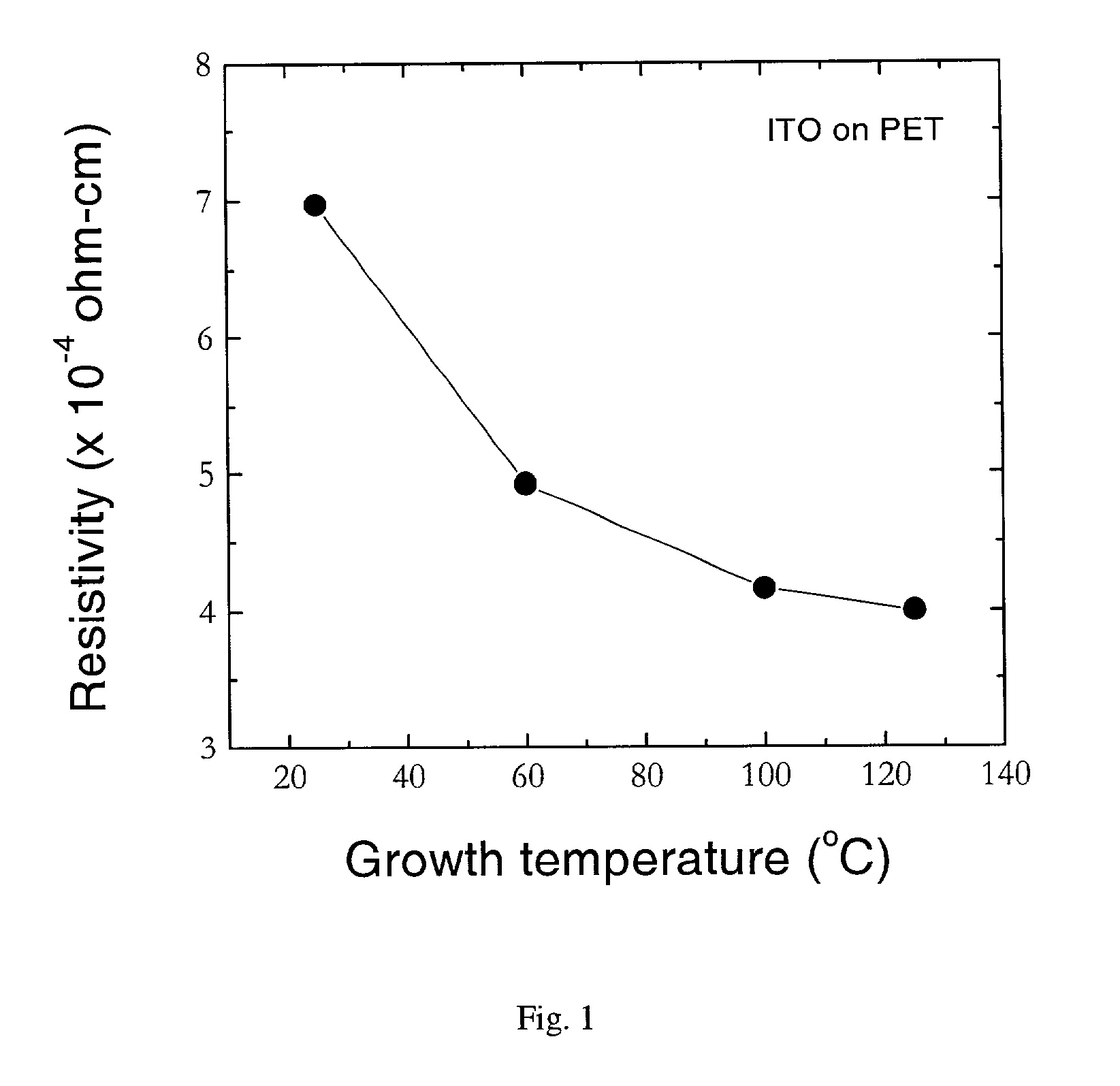

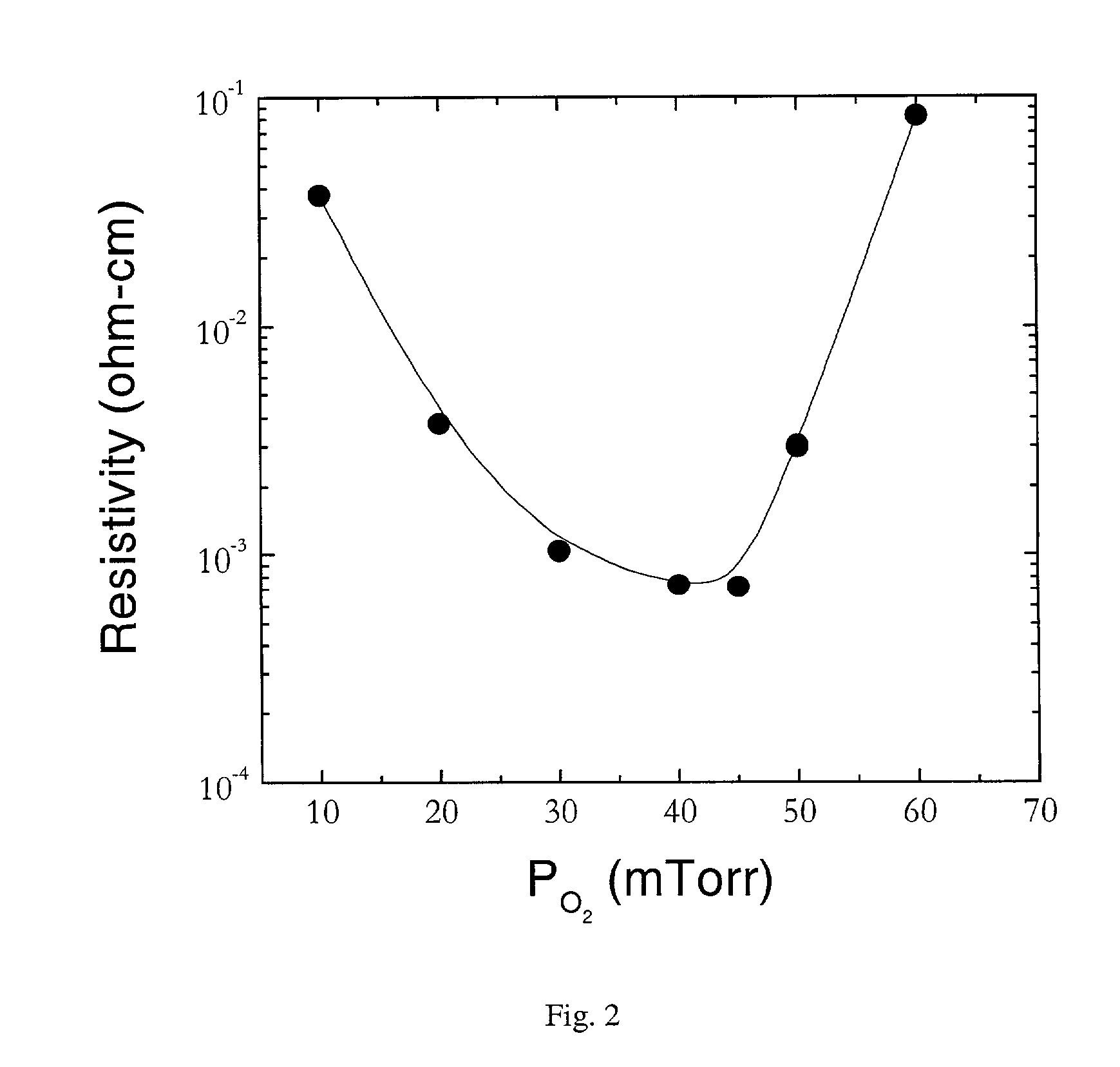

The invention relates to the deposition of transparent conducting thin films, such as transparent conducting oxides (TCO) such as tin doped indium oxide (ITO) and aluminum doped zinc oxide (AZO) on flexible substrates by pulsed laser deposition. The coated substrates are used to construct low cost, lightweight, flexible displays based on organic light emitting diodes (OLEDs).

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

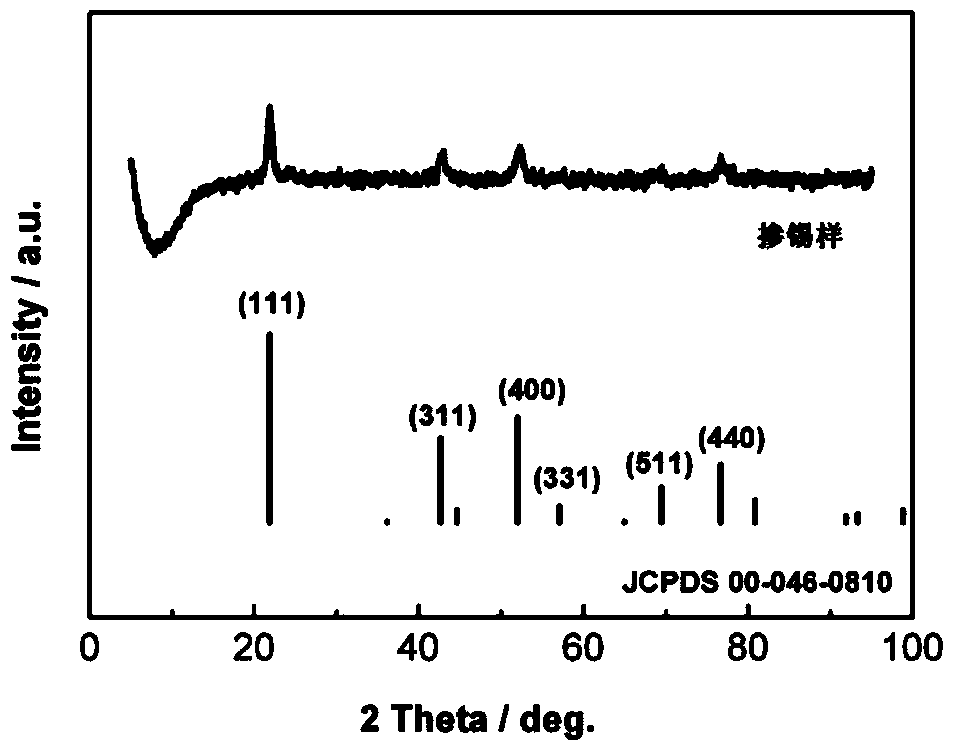

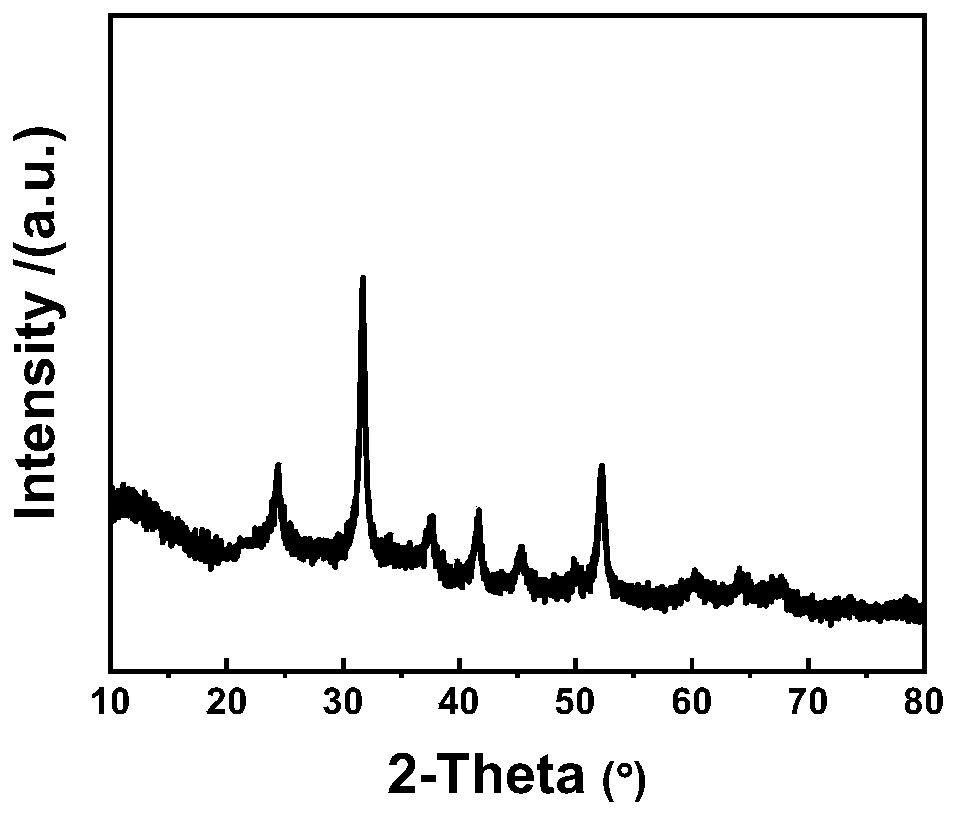

Method for preparing tin-doped spinel lithium-rich lithium manganate cathode material by using two-stage sintering process

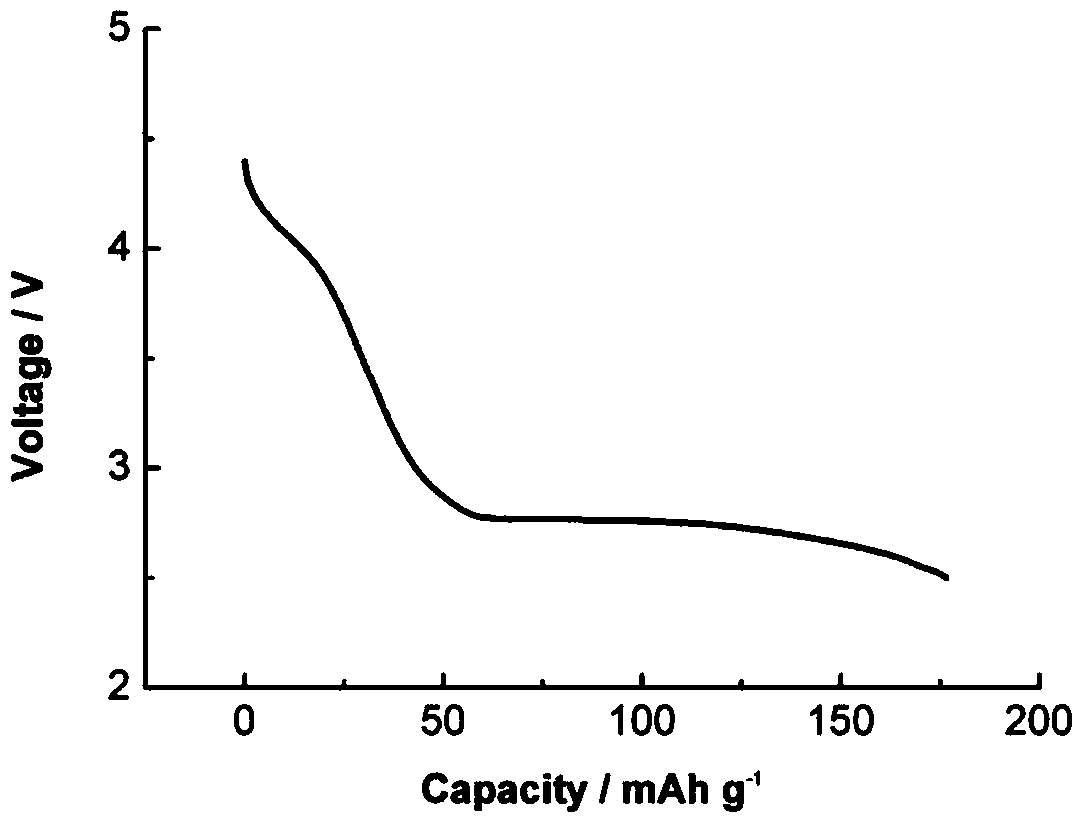

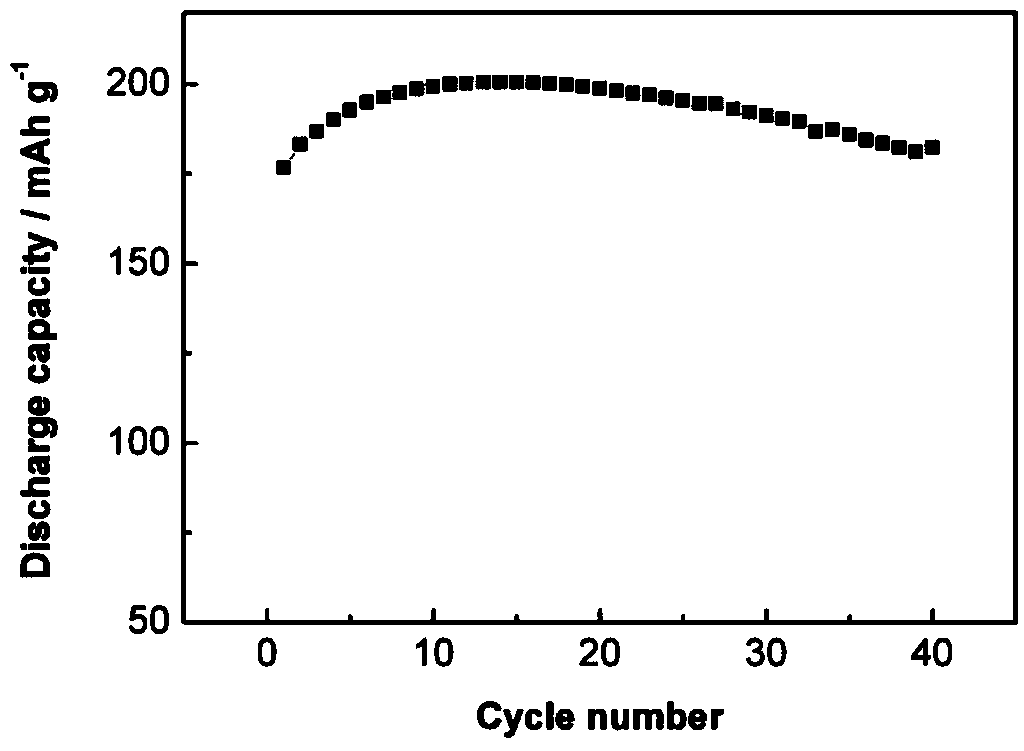

ActiveCN103594702ALow costWide variety of sourcesCell electrodesManganates/permanganatesManganateSpinel

The invention relates to a method for preparing tin-doped spinel lithium-rich lithium manganate cathode material by using two-stage sintering process, which is characterized in that the compounds of lithium, manganese and tin are respectively weighted according to mol ratio of lithium ion to manganese ion to tin ion with (0.95<=x<=1.06): (1.05<=y<=1.25): (0.05<=z<=0.21), the weighted compound can be mixed, a wet grinding medium is added, a predecessor 2 is prepared through the steps of wet grinding and drying, and the predecessor 2 is prepared to a tin-doped spinel lithium-rich lithium manganate cathode material by using a two-stage sintering process. The cost of raw materials in the present invention is low, the stability of sample structure can be improved by doping tin, discharge capacity is increased, so that good base can be established for industrialization.

Owner:DYNABAT NEW ENERGY SCI & TECH CO CLD FUJIAN

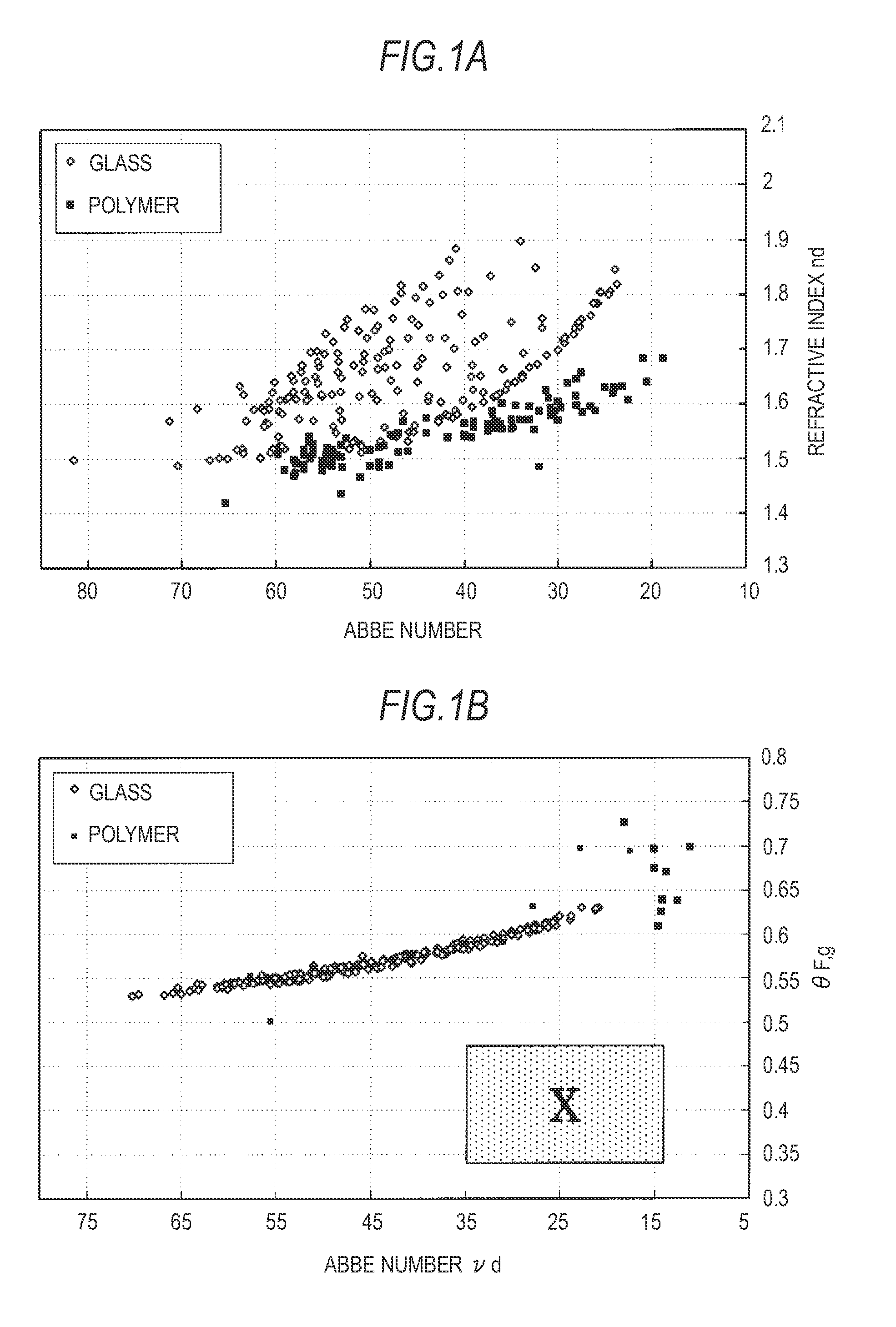

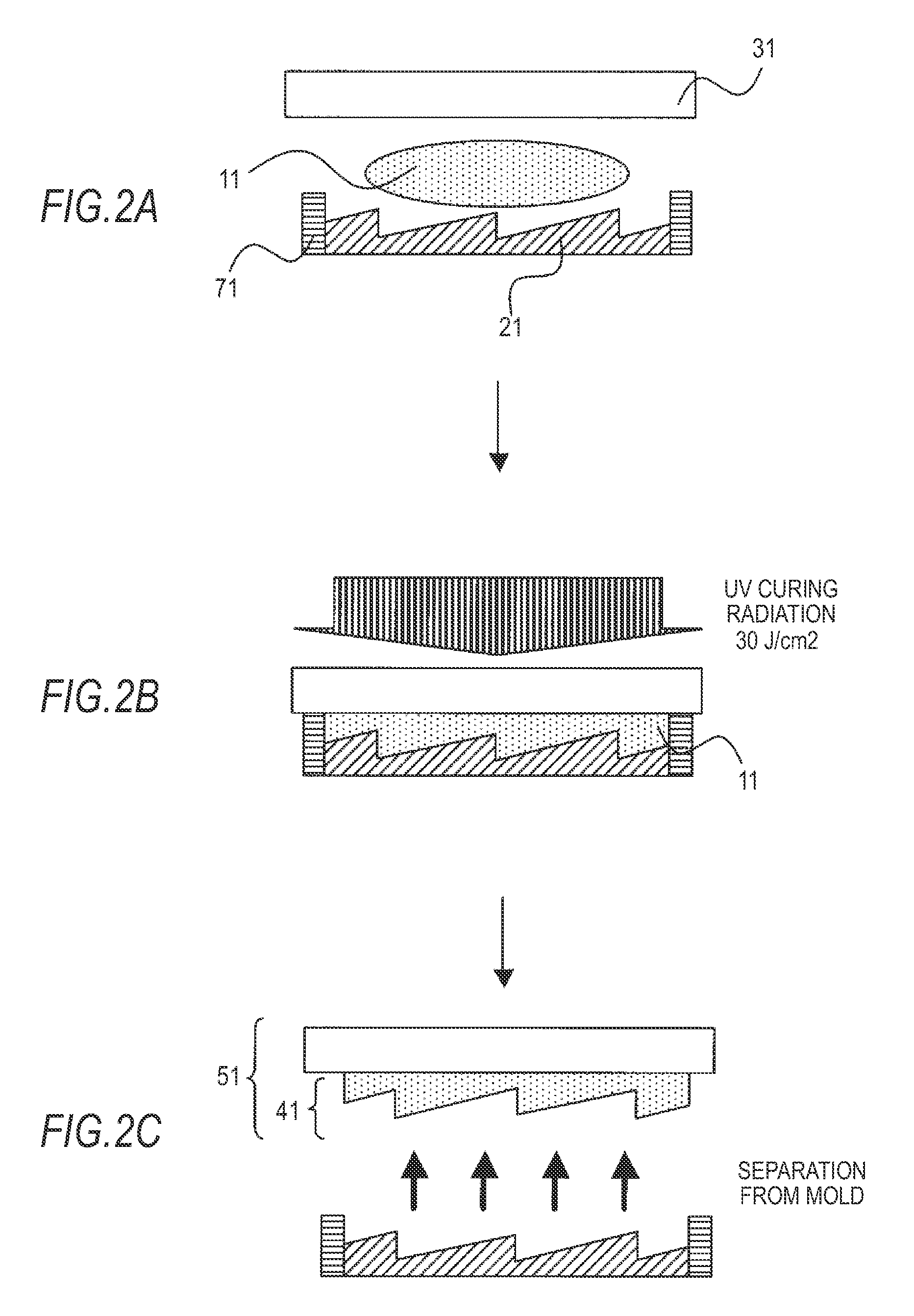

Laminated diffractive optical element and resin composition therefor

InactiveUS20090190224A1Eliminate the effects ofReliable environmentPhotomechanical apparatusOptical articlesTin dioxideAluminum doped zinc oxide

A resin composition includes a binder component having at least one of a monomer and an oligomer of one or more of a fluorine system and a silicone system having a polymerizable functional group in a molecule. The resin composition also includes fine metal oxide particles, and a polymerization initiator. The fine metal oxide particles include particles selected from the group of zinc oxide, indium oxide, tin oxide, antimony oxide, tin-doped indium oxide (ITO), antimony-doped tin oxide (ATO), zinc-doped indium oxide (IZO), aluminum-doped zinc oxide (AZO), and fluorine-doped tin oxide (FTO).

Owner:CANON KK

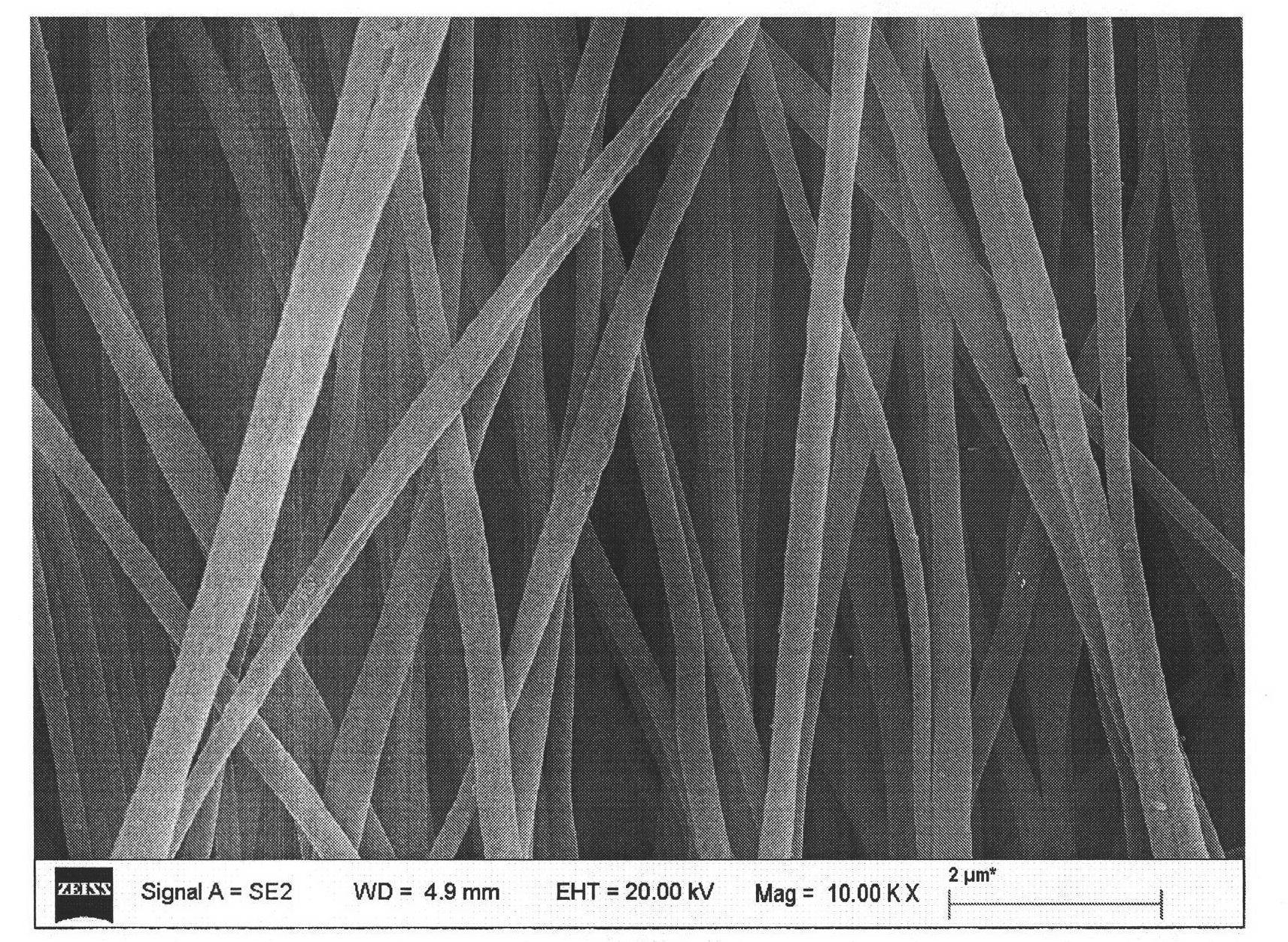

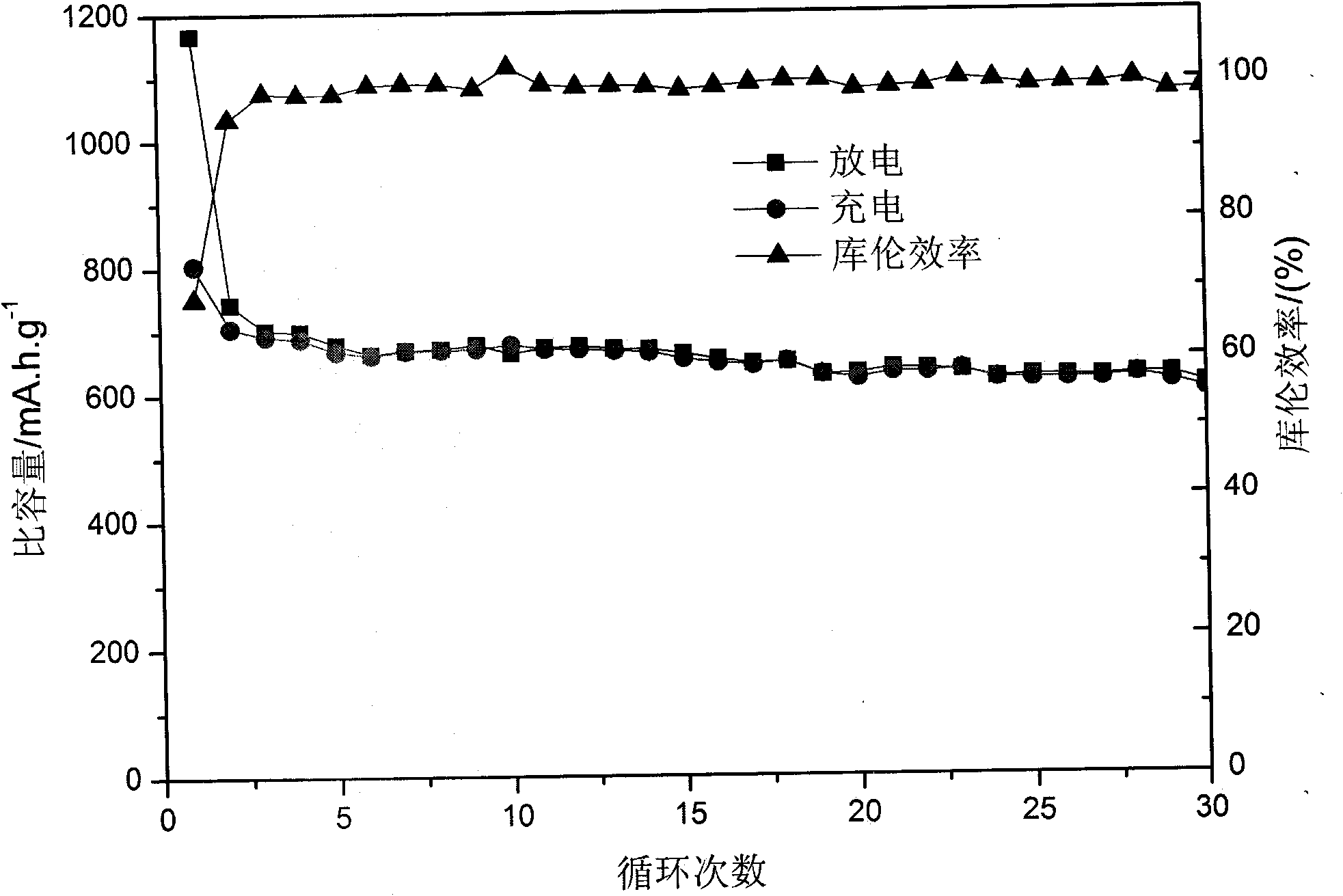

Preparation method of tin/carbon composite nano fiber film cathode material

The invention discloses a preparation method of a tin / carbon composite nano fiber film cathode material. In the method, a tin-doped carbon-based nano fiber film obtained by an electrostatic spinning method is thermally drawn in a certain temperature range at a drawing rate of 5-60%, and is sequentially preoxidated and carburized to ultimately obtain the required cathode material. After the thermal drawing, the electrochemical performance of the tin / carbon composite film material is obviously improved, the specific capacity and the cycle performance of a battery are effectively enhanced, and the coulomb efficiency is more than 90% after 30 cycles. Besides, the method also has the advantages of simple and feasible operation, easy process control, moderate condition and the like.

Owner:BEIJING UNIV OF CHEM TECH

Optical fiber with tin doped core-cladding interface

ActiveUS7493009B2Glass making apparatusOptical fibre with graded refractive index core/claddingFiberTin dioxide

Owner:BAKER HUGHES HLDG LLC

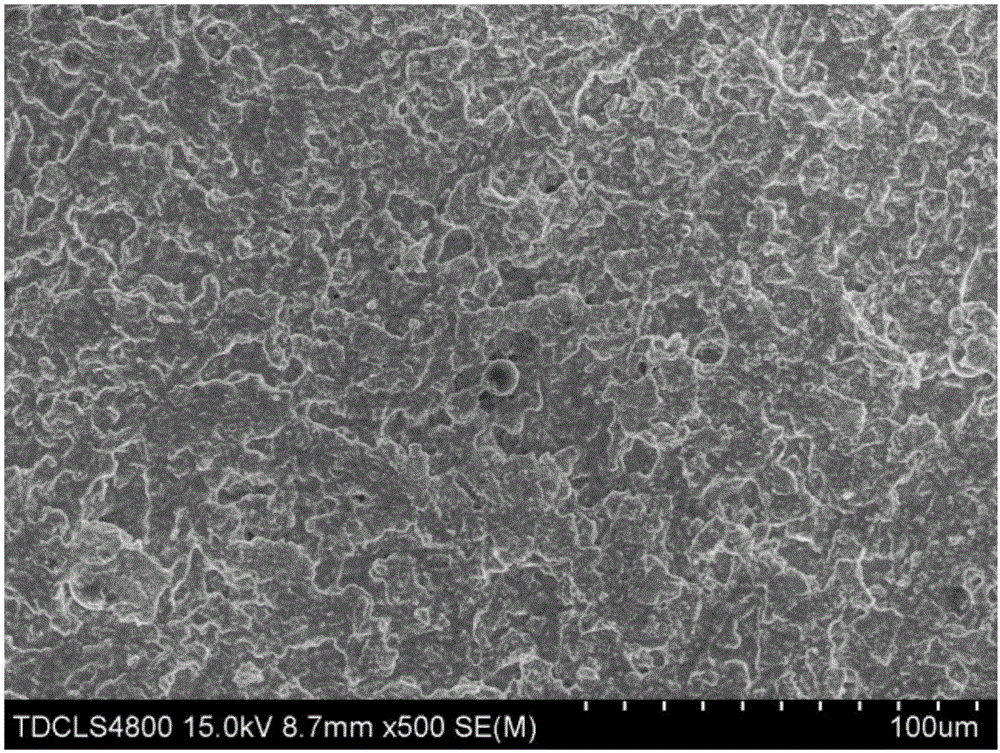

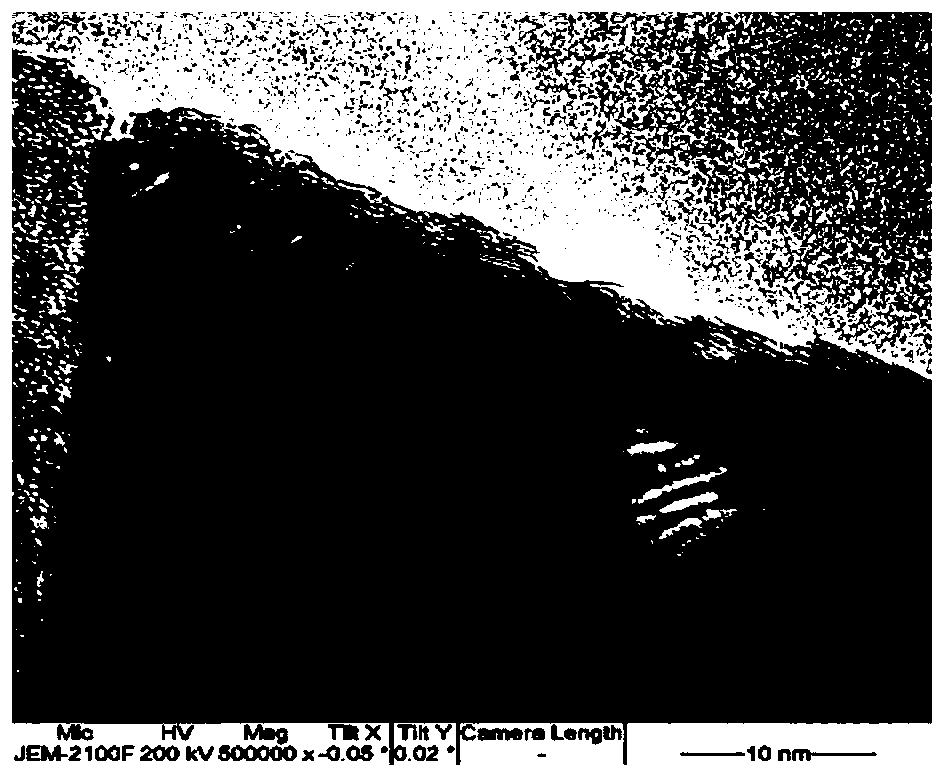

Method for preparing tin-doped indium oxide nano powder

InactiveCN1775693AEasy to getEase of industrial productionTin compoundsGallium/indium/thallium compoundsIndiumCoprecipitation

The invention relates to a method for preparing Sn-doped indium trioxide (ITO) nano powder by coprecipitation method, coprecipitating Sn / In water solution without chlorine ions with ammonia water to prepare the ITO nano powder whose size is 8-3 nanometers and whose specific surface area is 20-60 sq m g-1. The ITO nano powder has the characters of small size, large specific surface area, good dispersivity, not corroding the service parts. Besides, the invention has the advantages of short preparing cycle, high efficiency, low cost, ability to produce in large scale, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

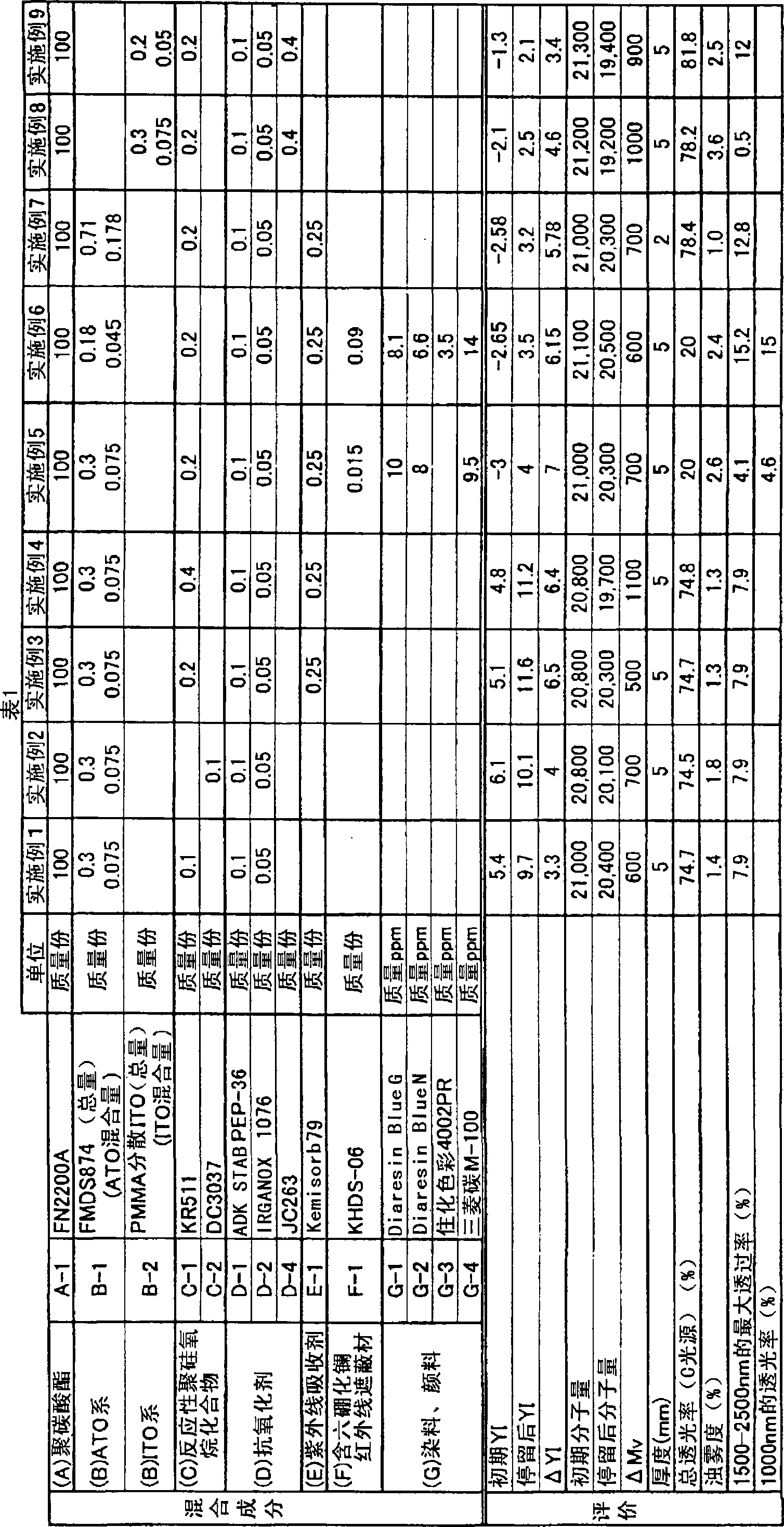

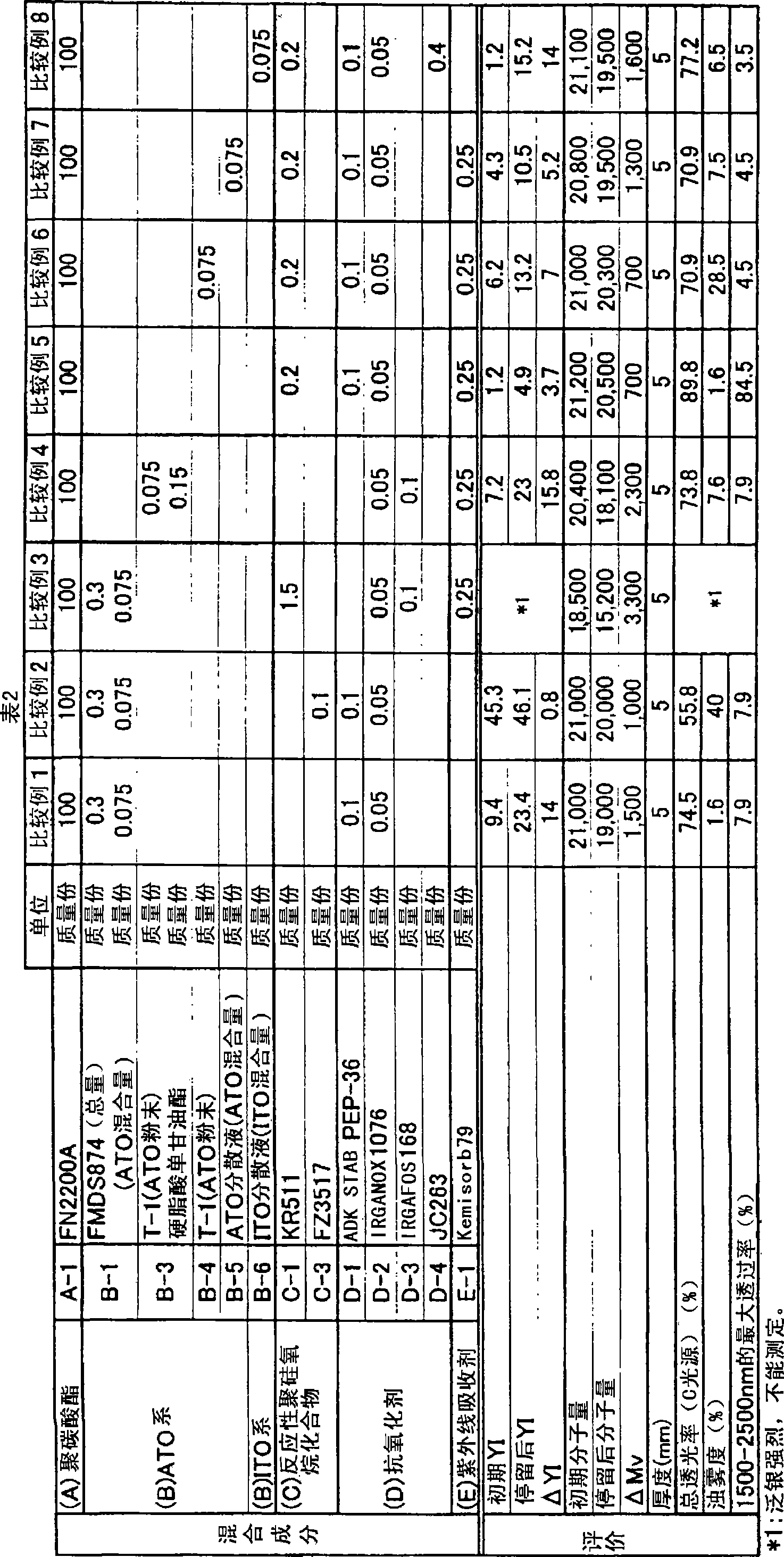

Polycarbonate resin composition and molded plate obtained therefrom

Provided are a polycarbonate resin composition including the following substances in a specific proportion: a polycarbonate, a fine particle of antimony-doped tin oxide (ATO) treated with a polymeric dispersant and / or a fine particle of tin-doped indium oxide (ITO) treated with a polymeric dispersant, and a reactive silicone compound having one or more alkoxy groups and a phenyl group in a molecule thereof, and a molded plate formed by subjecting the polycarbonate resin composition to an injection molding or an extrusion molding. That is, the polycarbonate resin composition which shields a mid-infrared region and is excellent in transparency and thermal stability and the molded plate obtained therefrom are provided.

Owner:IDEMITSU KOSAN CO LTD

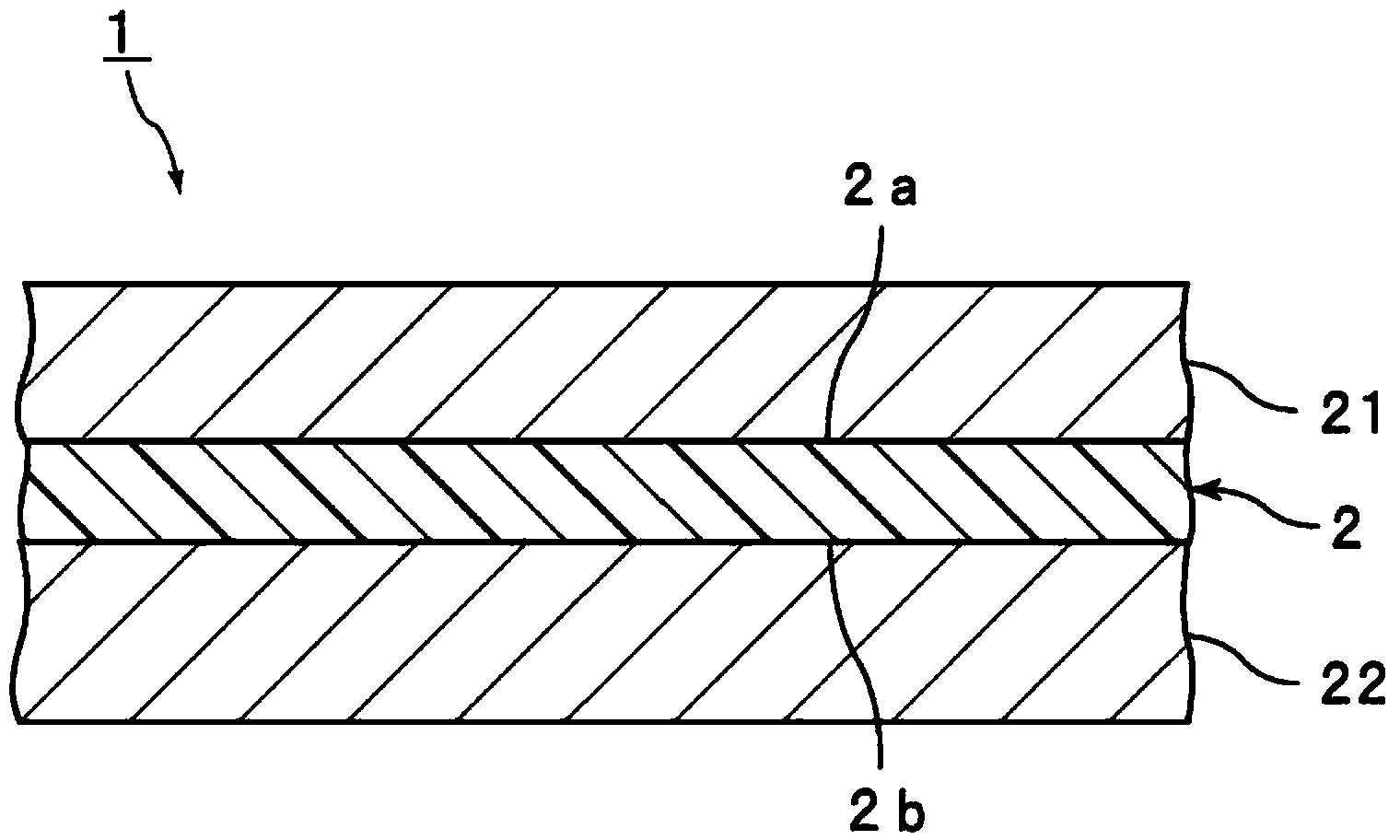

Intermediate film for laminated glass, and laminated glass

InactiveCN103889917AImprove transmittanceImprove insulation performanceGlass/slag layered productsIndiumTransmittance

Provided is an intermediate film for laminated glass, which is capable of effectively improving heat shielding properties, while increasing visible light transmittance. An intermediate film (2) for laminated glass of the present invention contains a thermoplastic resin, tin-doped indium oxide particles, tungsten oxide particles and at least one compound selected from among a phthalocyanine compound, a naphthalocyanine compound and an anthracyanine compound.

Owner:SEKISUI CHEM CO LTD

Nb-doped nano indium tin oxide powder and method for preparing high density sputtering coating target thereof

InactiveCN101580379AHigh puritySmall granularityVacuum evaporation coatingSputtering coatingIndiumNiobium

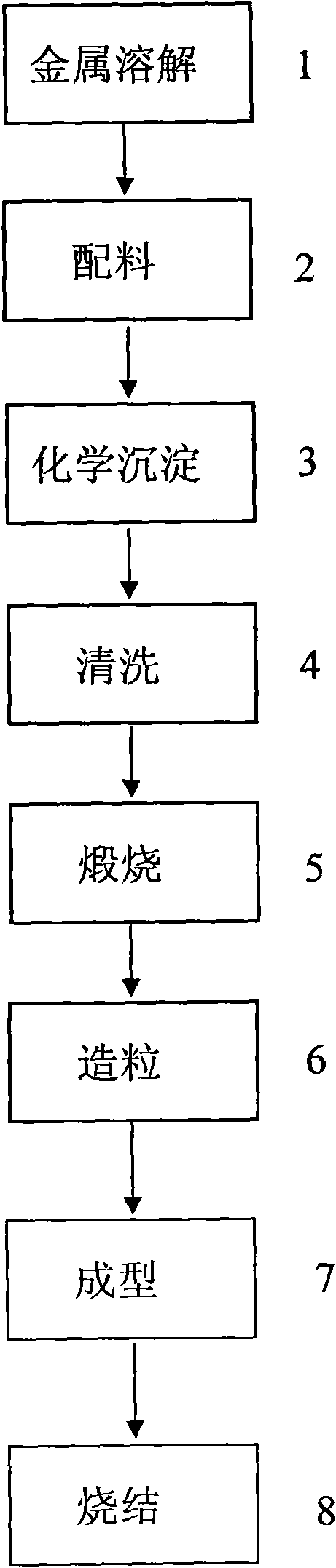

The invention relates to an Nb-doped nano indium tin oxide powder and a method for preparing high density sputtering coating target thereof. The method comprising the following steps: (1) dissolving high pure metals: high pure metal niobium, high pure metal indium and high pure metal tin are respectively dissolved into transparent solutions by inorganic acid; (2) mixing: the obtained transparent solutions are respectively filled into containers according to the proportion; (3) chemical precipitation: the three transparent solutions are made into Nb-doped and heavily tin-doped indium hydroxide nano-powder; (4) washing: the Nb-doped and heavily tin-doped tin indium hydroxide nano-powder is washed by de-ionized water and then precipitated; (5) calcinating: the nano-powder is calcined, and the Nb-doped nano indium tin oxide powder is prepared; (6) granulation: the Nb-doped nano indium tin oxide powder is added with a bonding agent and then dried, so that Nb-doped nano indium tin oxide powder before molding can be prepared; (7) molding: the Nb-doped nano indium tin oxide powder before molding is pressed into early embryo; (8) sintering: the early embryo is sintered under the normal pressure, and the high density sputtering coating target of the Nb-doped indium tin oxide can be prepared; in addition, pressure sintering can be adopted to further improve the density of the target.

Owner:BEIHANG UNIV +1

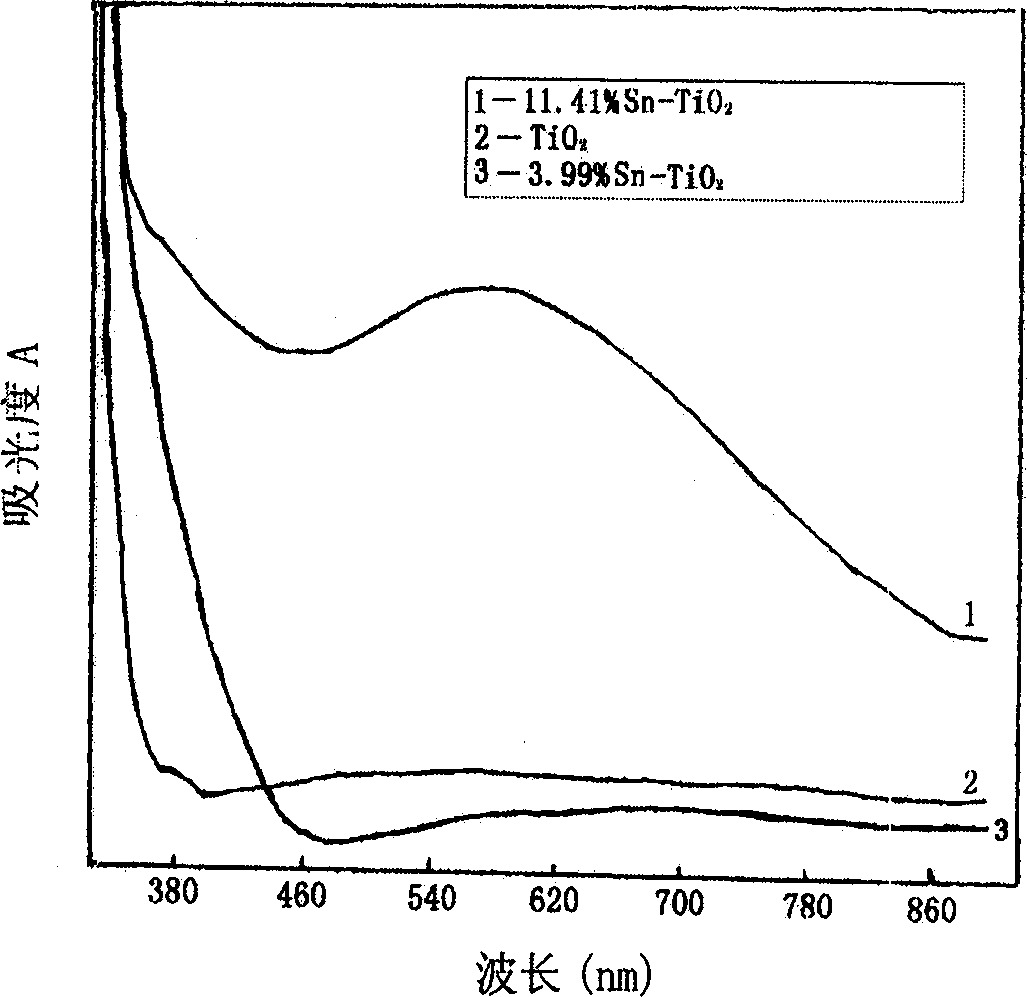

Method for preparing visible light-inducing stannum-doped highly catalytic nano photocatalyst of titanium dioxide

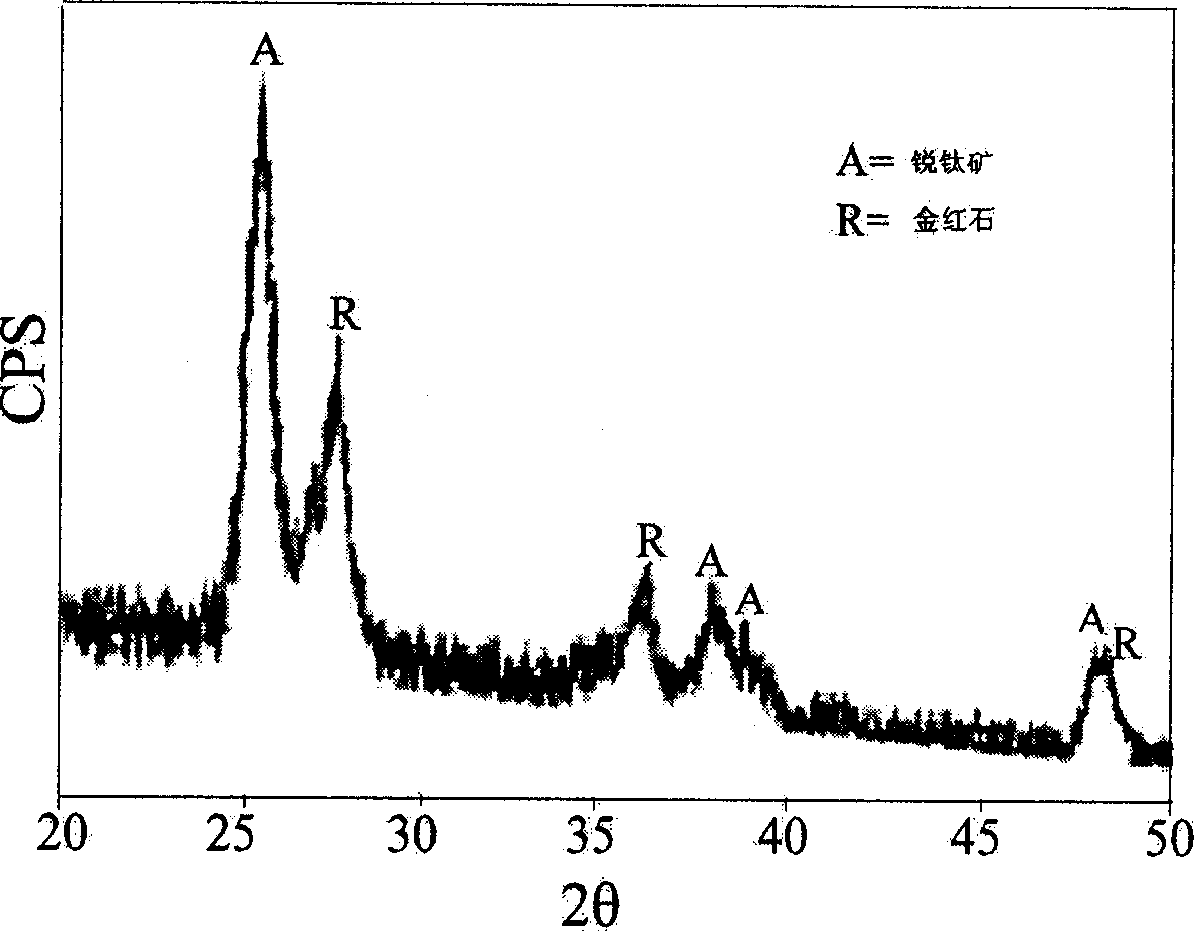

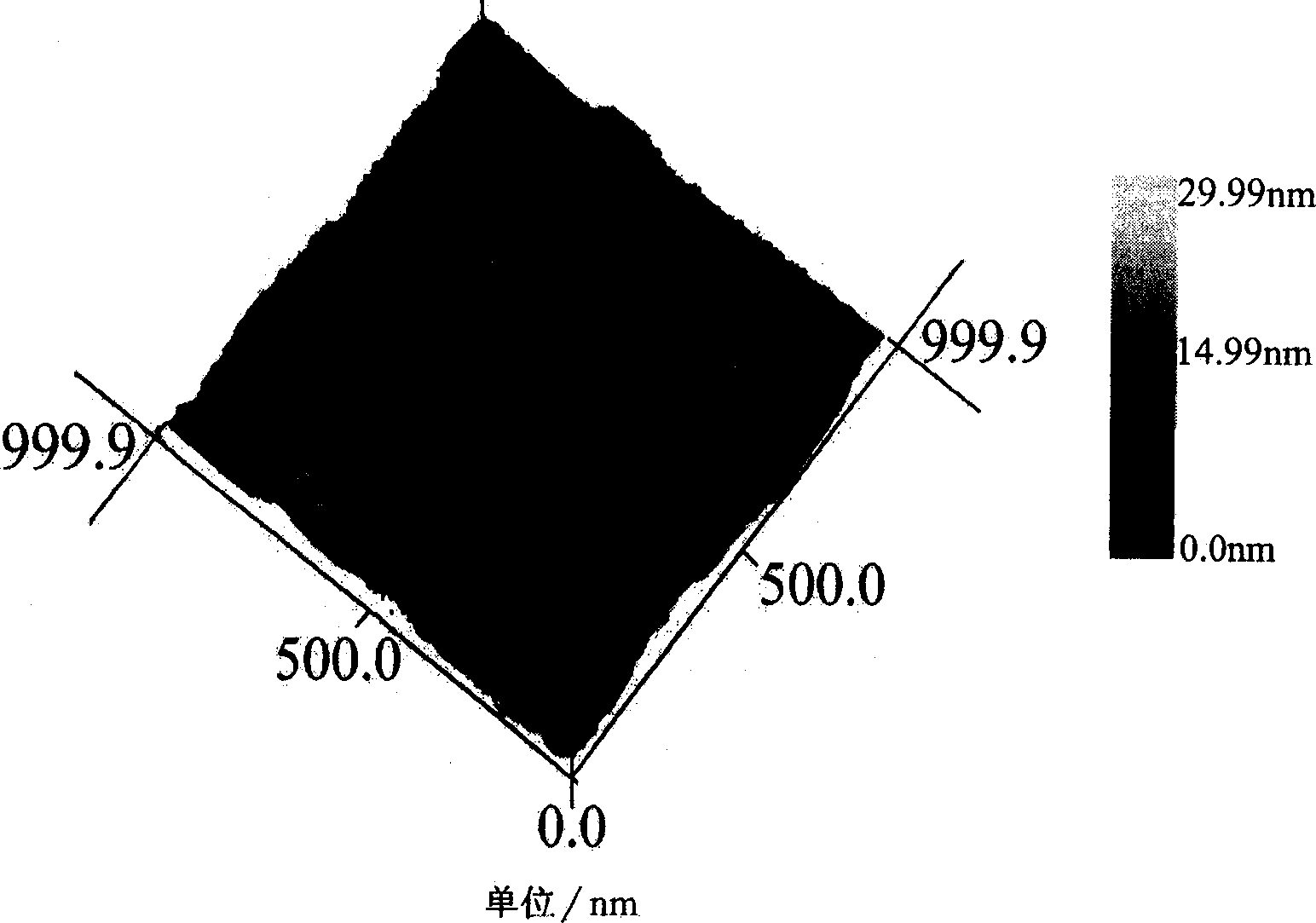

InactiveCN1799692AImprove photocatalytic activityHigh photocatalytic degradation rateCatalyst activation/preparationGrain structurePhotocatalytic degradation

The invention provides a method for preparing visible light-induced high catalysis activity tin-doping nanometer titanium oxide photo-catalyst, belonging to the photo-catalyst material technique. It comprises following steps: first preparing tin-doping TiO2 sol; then, preparing tin-doping TiO2 film. The invention comprises the advantages that the prepared nanometer TiO2 film doping with Sn4+ has the duplex grain structure between anatase and red schorl; the average size of crystal grain ranges between 25-30nm, while the red schorl is formed by solid solving the Sn4+ into TiO2 crystal lattice; the surface of transparent film is smooth with a certain coarseness; the absorption band to incident light of TiO2 photo-catalyst film is removed to visible light band by doping Sn4+ to improve the visible light-induced photo-catalyst. The photo-catalyst activity is presented as the photo-catalyst degradation rate of helianthin and doping Sn4+ in right amount can effectively improve the photo-catalyst activity of TiO2 film, while compared with absolute nanometer TiO2 film, its photo-catalyst degradation rate of helianthin is improved more than 34%.

Owner:UNIV OF SCI & TECH BEIJING

Substratum with conductive film and process for producing the same

InactiveUS20070228369A1Small surface irregularityImprove flatnessSolid-state devicesVacuum evaporation coatingIndiumOxygen plasma

A process for producing a substratum with conductive film excellent in surface smoothness, is provided which does not require complicated steps after film-forming such as heating treatment, polishing of film surface or oxygen plasma treatment after film-forming. The present invention provides a substratum with conductive film comprising a substratum and a conductive film containing tin-doped indium oxide as the main component, wherein a foundation film containing zirconium oxide doped with yttrium oxide as the main component is formed on the substratum side of the conductive film, and wherein the content of yttrium oxide in the foundation film is preferably from 0.1 to 50 mol % based on the total amount of Y2O3 and ZrO2.

Owner:ASAHI GLASS CO LTD

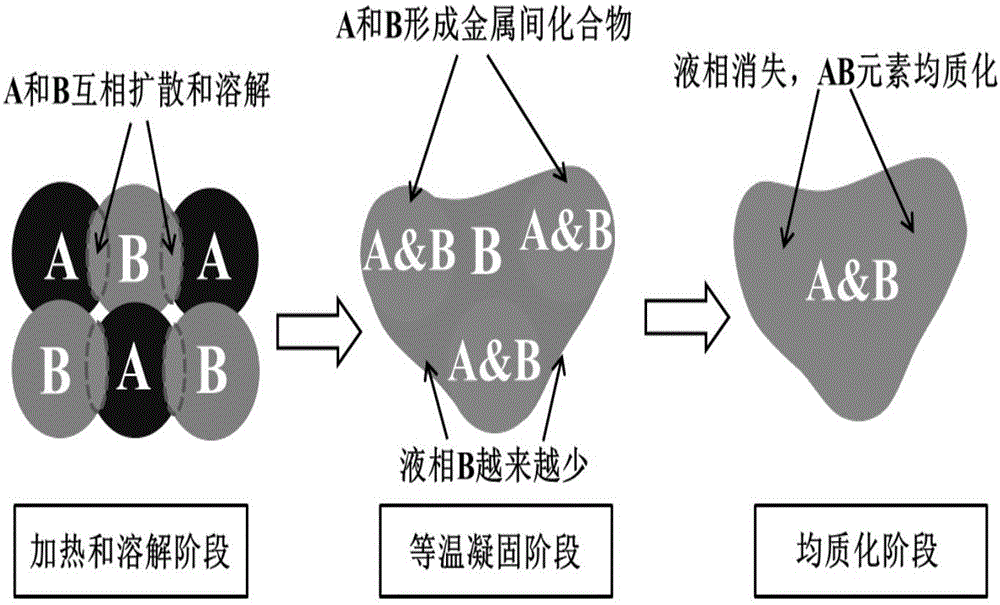

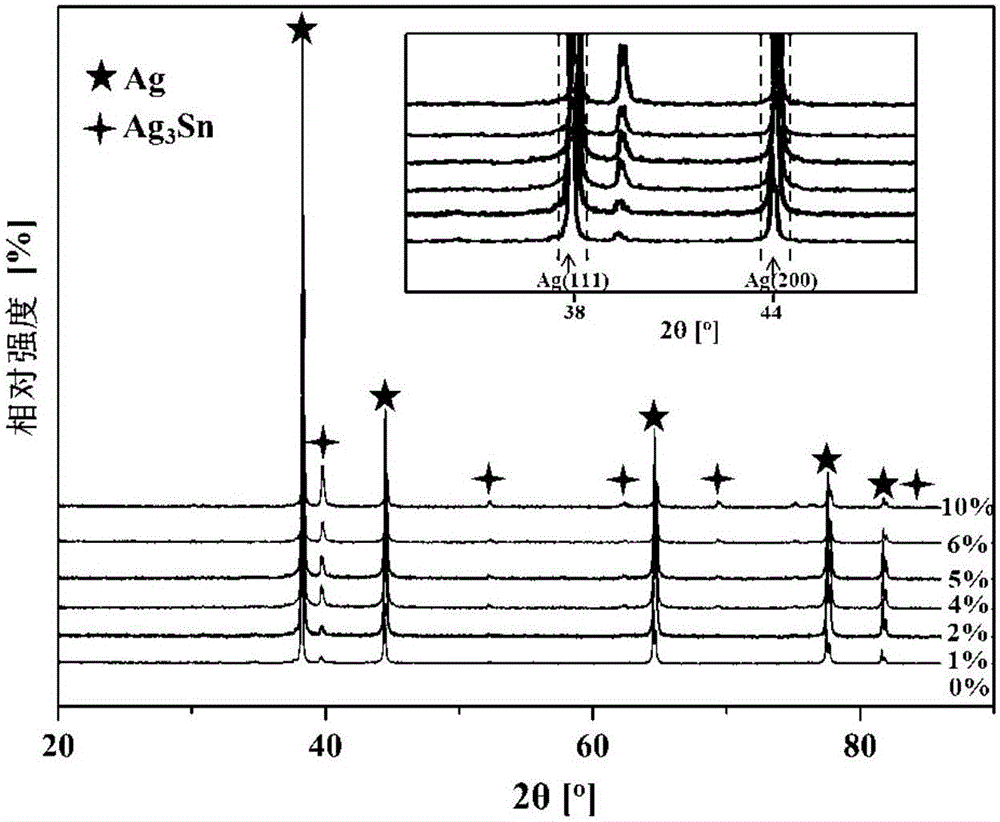

Preparation method for low-temperature sintered tin-doped nano-silver soldering paste

InactiveCN107175433ARigorous processRigorous implementationWelding/cutting media/materialsSoldering mediaRosinUltimate tensile strength

The invention relates to a preparation method for low-temperature sintered tin-doped nano-silver soldering paste. According to the mass ratio of tin powder to a soldering flux, 90% of powder and 10% of the rosin soldering flux are prepared, wherein raw material of the powder is Sn element. A micron solder paste is prepared through stirring, the silver mass fraction is 90-99%, and the tin mass fraction is 1-10%; a nano-silver soldering paste and the micron solder paste are weighed and added with terpilenol to be dissolved, firstly mechanical oscillation is conducted by using a spiral oscillator, then ultrasonic oscillation is conducted by using an ultrasonic cleaner, and a mixture is obtained; and constant temperature bath and volatilization are conducted on the mixture at the temperature of 70 DEG C till the mixture is in a paste shape. Pressure is not added in the sintering process of the tin-doped nano-silver soldering paste, protection of inert gases is not needed, and the maximum sintering temperature is 235 DEG C. According to the preparation method for the low-temperature sintered tin-doped nano-silver soldering paste, the process procedure is well-conceived, and implementation is strict; and the sintering temperature of the low-temperature sintered tin-doped nano-silver soldering paste is lower than the sintering temperature of a traditional silver soldering paste, and compared with a pure nano-silver soldering paste, under the same sintering process, the connection strength of the low-temperature sintered tin-doped nano-silver soldering paste after being sintered is double of the connection strength of the pure nano-silver soldering paste.

Owner:TIANJIN UNIV

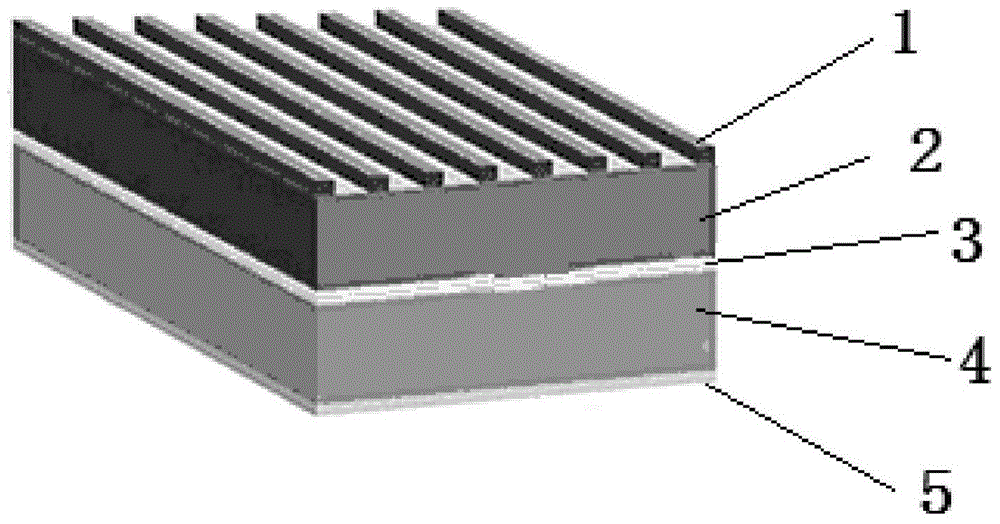

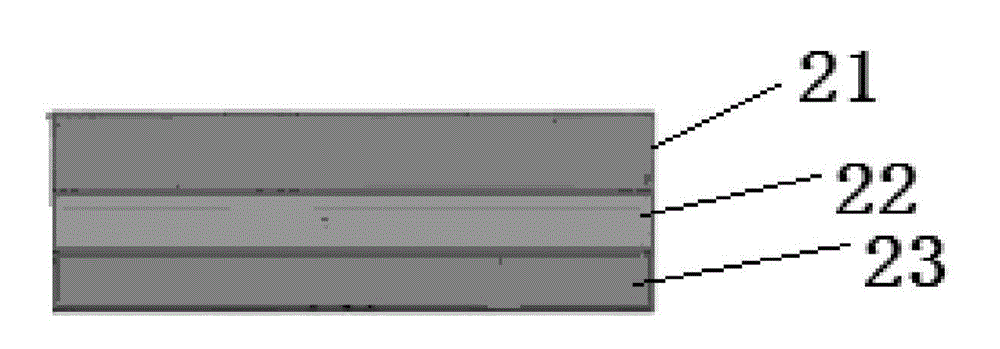

Solar battery with structure of oxide-metal multilayer film/silicon substrate

ActiveCN104916709ASimple structureReduce production processFinal product manufacturePhotovoltaic energy generationSolar batteryIon implantation

The invention discloses a solar battery with a structure of an oxide-metal multilayer film / a silicon substrate. The solar battery structure, from the top to the bottom, successively comprises: a silver electrode, an oxide-metal multilayer film, a passivation layer, a silicon substrate and a full aluminum back electrode. The oxide-metal multilayer film is obtained through compositing a first oxide film, a metal film and a second oxide film. The first oxide film or the second oxide film is a MoO3 film, a tin-doped In2O3 film, a fluorine-doped SnO2 film or an aluminum-doped ZnO film. The metal film is an Ag film, an Au film or an Al film. The solar battery can prevent the tradition thermal diffusion or can prevent the auger recombination and the dead layer phenomenon which are caused by the preparation emission electrode of the ion injection method. Furthermore, the invention also discloses a method for the solar battery with a structure of an oxide-metal multilayer film / a silicon base, which is less in the preparation procedures, applicable to the batch production and high temperature free during the whole preparation process.

Owner:江苏润阳悦达光伏科技有限公司

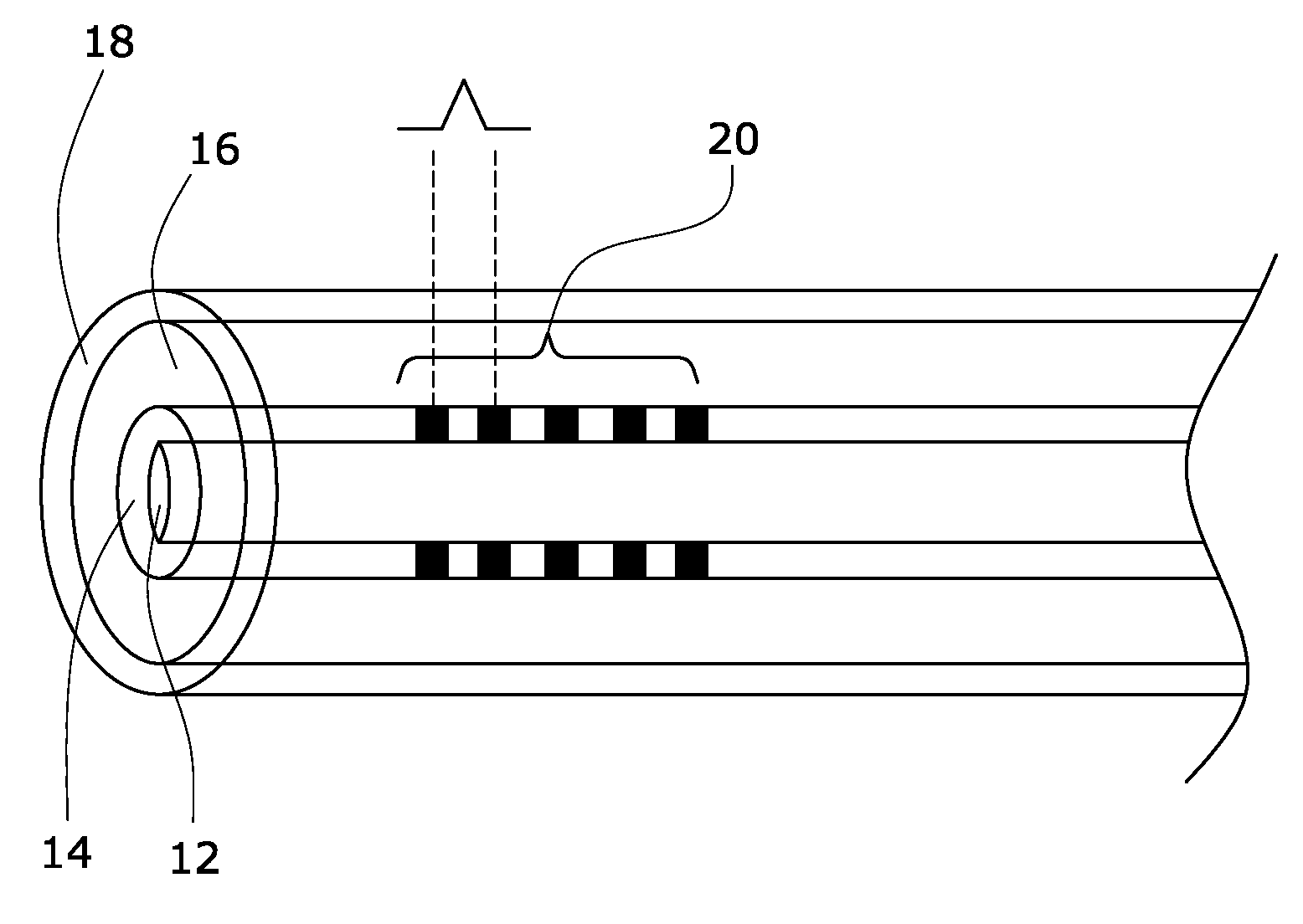

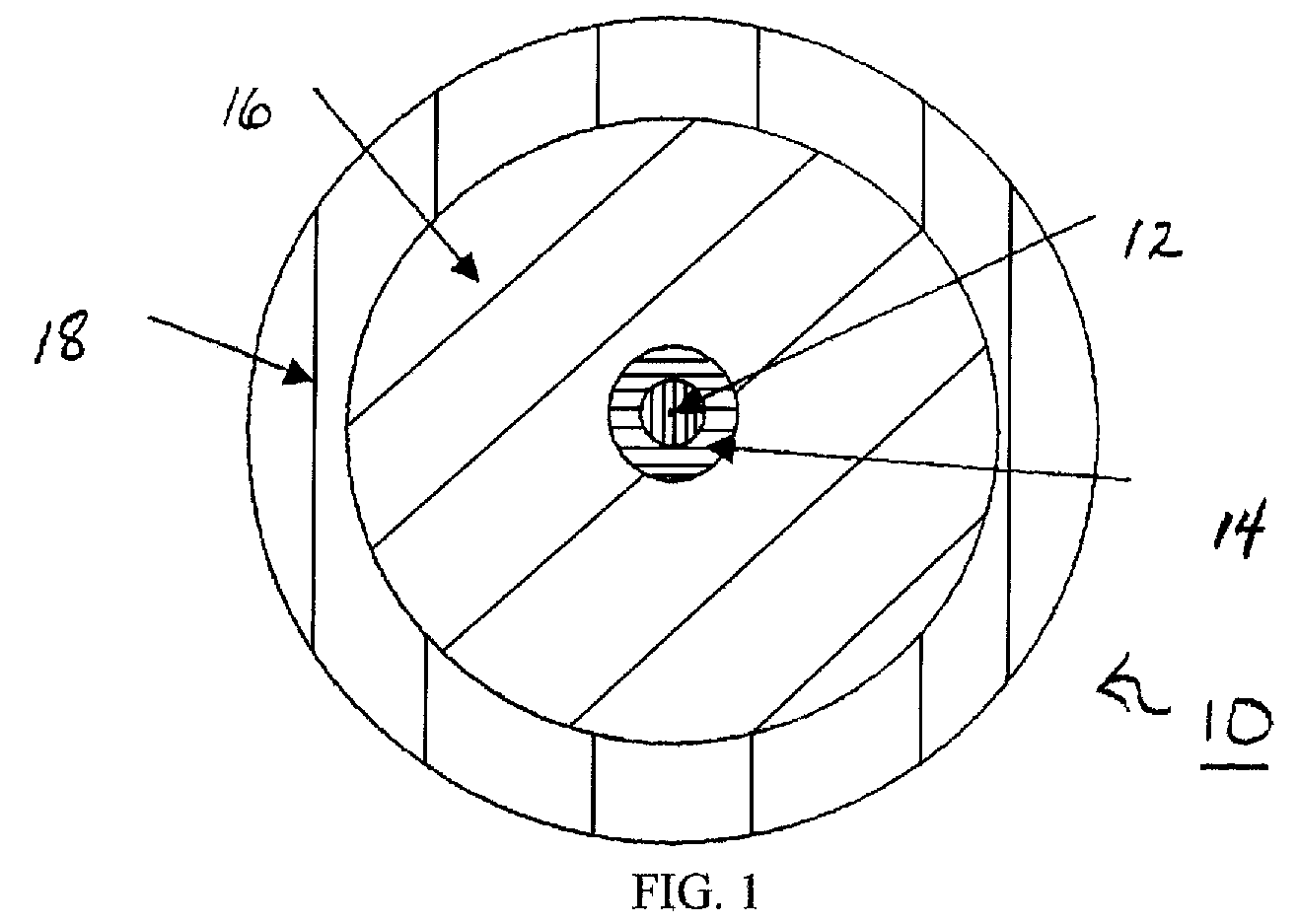

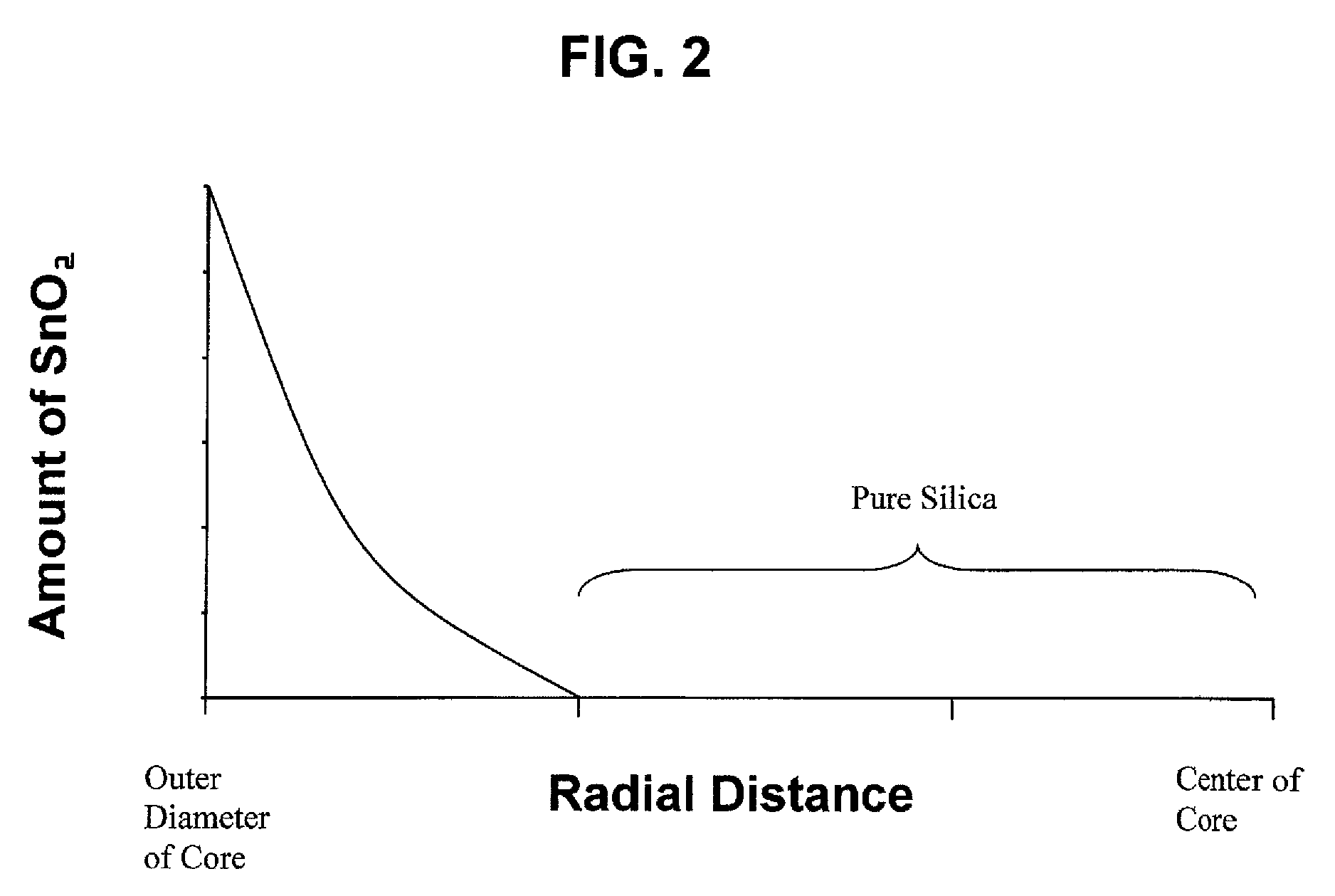

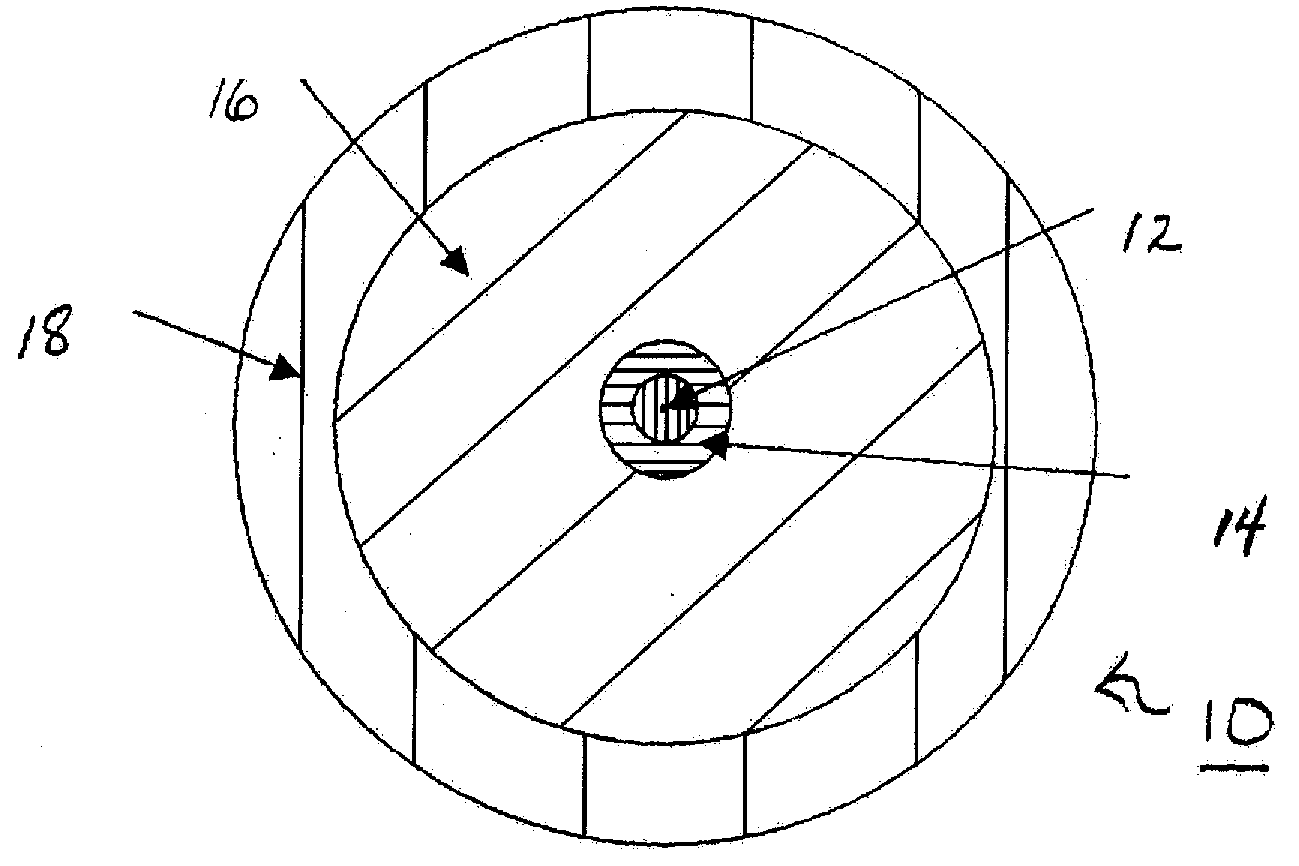

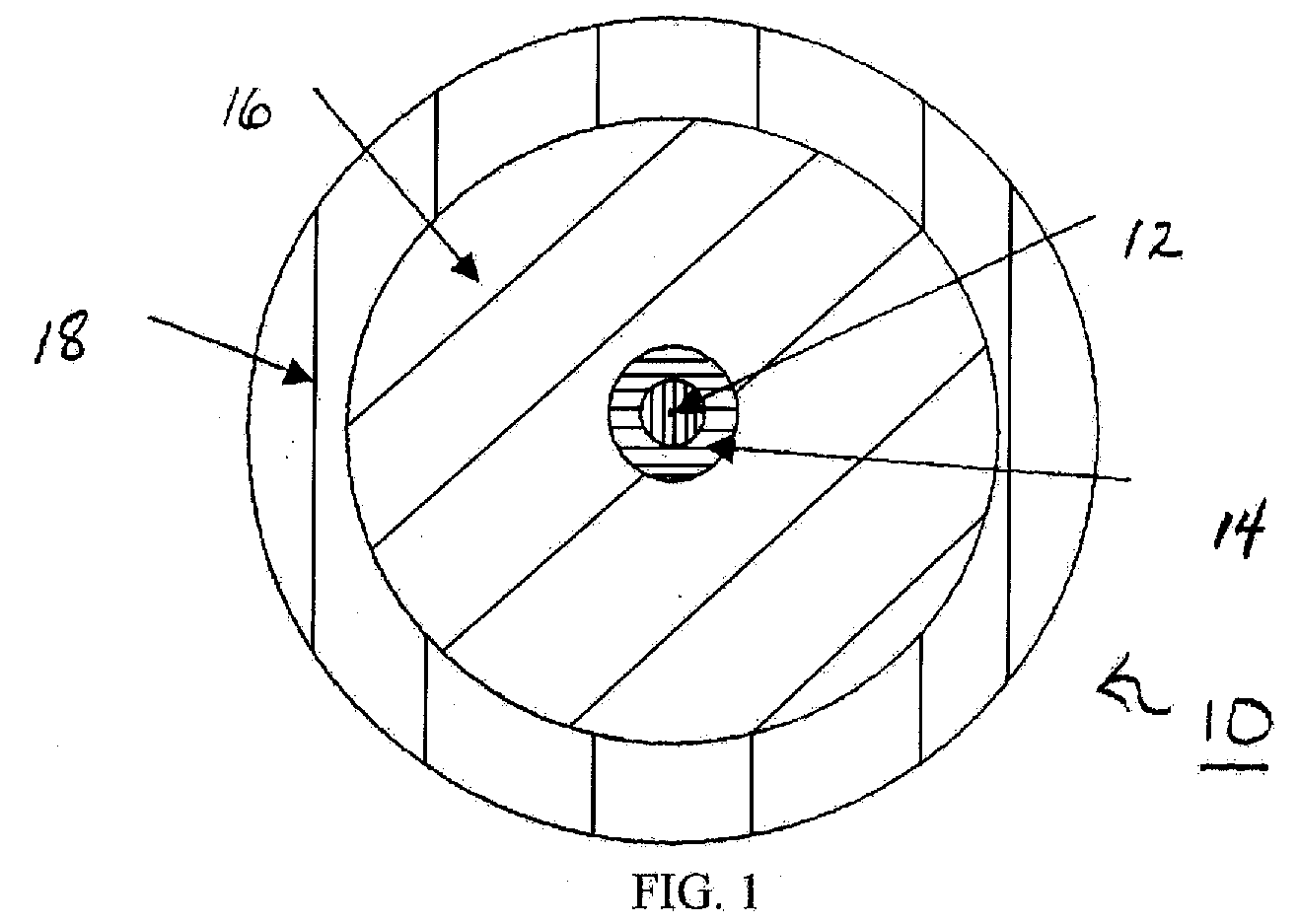

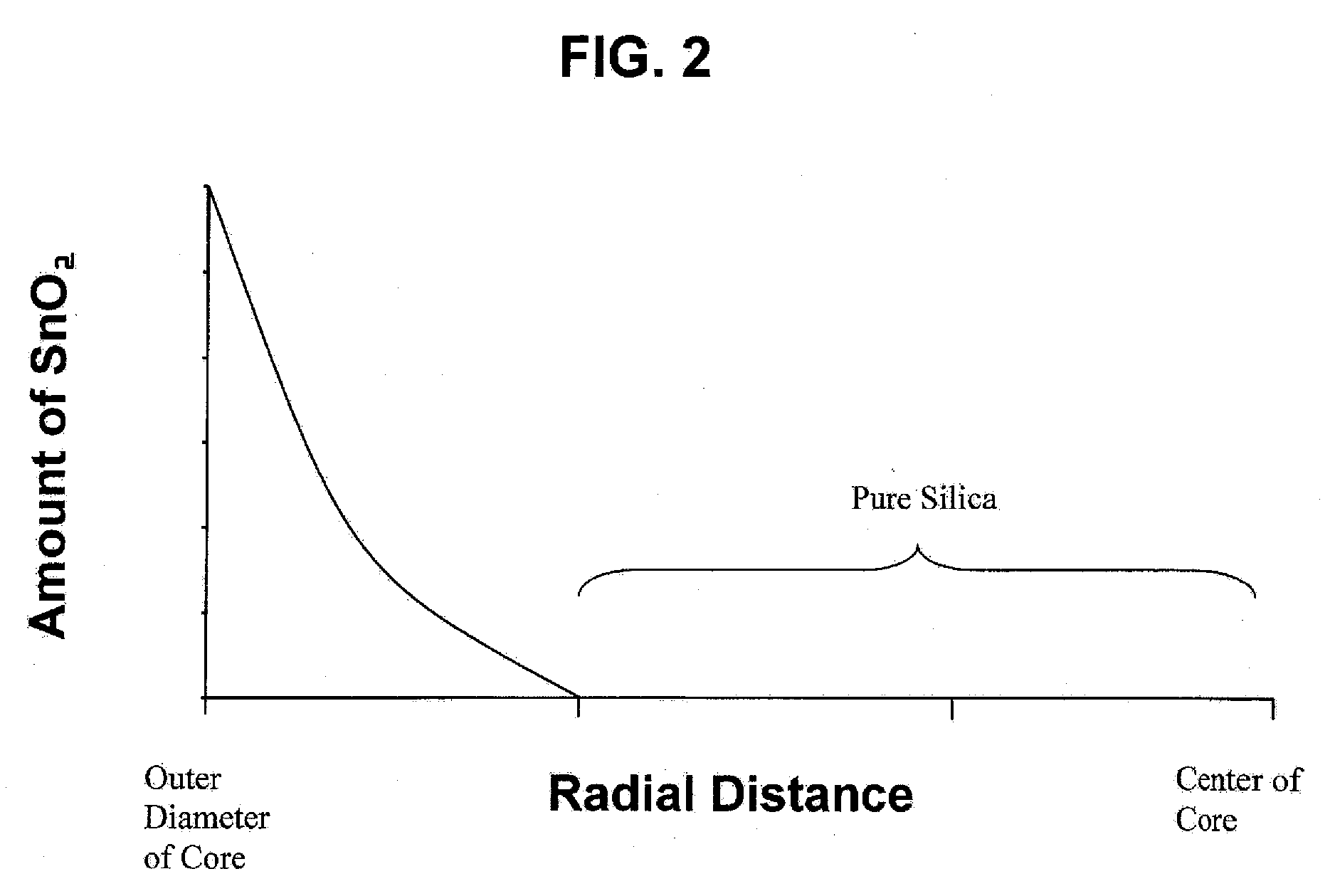

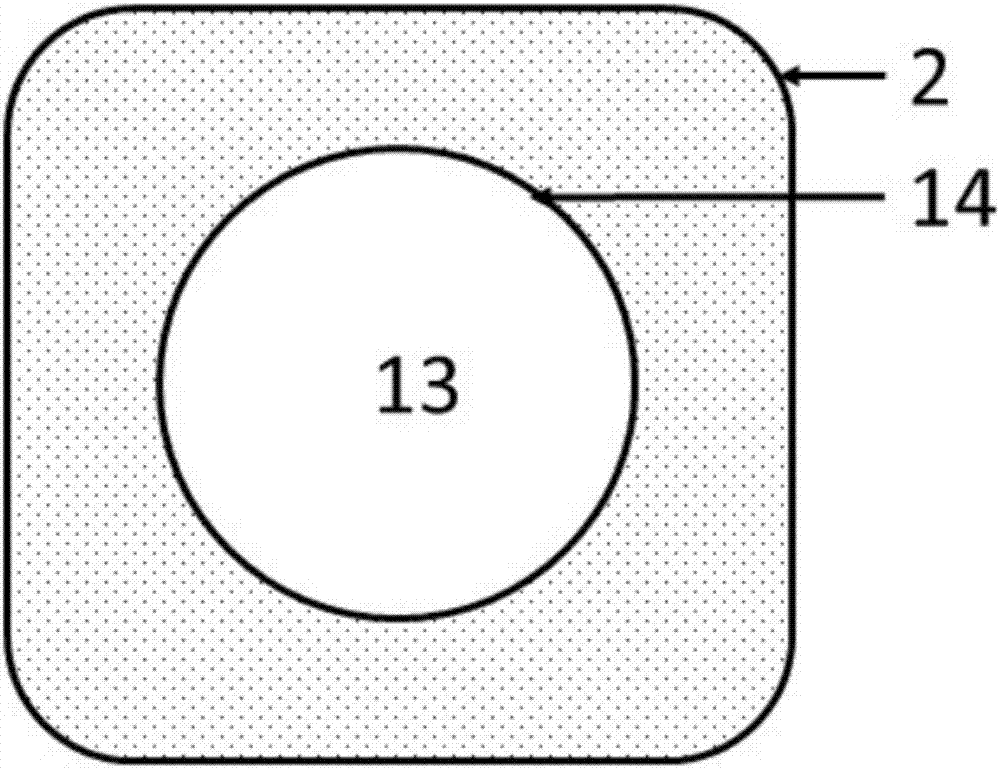

Optical Fiber with Tin Doped Core-Cladding Interface

ActiveUS20080292256A1Glass making apparatusOptical fibre with graded refractive index core/claddingFiberTin dioxide

The present invention concerns an optical fiber 10 comprising a substantially pure silica glass core 12, a concentric tin-doped core / cladding interface region 14, and a concentric fluorine-doped depressed cladding layer 16. The tin-doped core / cladding interface region 14 comprises a low concentration gradient of tin dioxide, which advantageously results in a de minimis refractive index change, resistance to hydrogen incursion, and thermal stability of any fiber Bragg gratings written into the interface region 14.

Owner:BAKER HUGHES INC

Lens and camera equipped with lens

InactiveCN106125464ANot easy to ageReduce energy consumptionCamera body detailsCamera lensElectrical resistance and conductance

The invention discloses a lens and a camera equipped with the lens. The lens comprises an eyeglass set, a lens cover which is arranged outside the eyeglass set and is used for fixing the eyeglass set, and an assembled printed circuit board which is arranged at one side of the eyeglass set and is connected with the eyeglass set, wherein the eyeglass set comprises eyeglasses, waterproof glass arranged at outer sides of the eyeglasses and electrical heating sheets arranged between the eyeglasses and the waterproof glass, the electrical heating sheets are used for conducting heat to the waterproof glass to realize anti-mist anti-frost functions, and the electrical heating sheets comprise one type of graphene film heating sheets and tin-doped indium oxide film heating sheets. Resistance of the electrical heating sheets employed by the lens is 300-350 ohm, when the external temperature is 10-25 DEG C, the arrival heating temperature of the electrical heating sheets is 35-45 DEG C, the heating temperature can be realized through 3-second heating; when the external temperature is 0-5 DEG C, the arrival heating temperature of the electrical heating sheets is 25-30 DEG C, the heating temperature can be realized through 5-second heating. According to the lens, the heating temperature is relatively mild, a heating speed is relatively fast, not only can aging of the eyeglasses be not easy, but also energy loss is low, and the heat conduction effect is relatively good.

Owner:苏州国创电子科技有限公司

Tin-doped indium oxide microparticle dispersion, process for producing the same, interlayer for laminated glass having heat-ray blocking property produced with the dispersion and laminated glass

ActiveUS20060225614A1Easy to controlGood effectPigmenting treatmentOptical filtersIndiumMicroparticle

A dispersion of tin-doped indium oxide fine particles has tin-doped indium oxide fine particles, a plasticizer for an interlayer film, an organic solvent containing alcohols as a main component, and a dispersion stabilizer, wherein under measuring conditions of a concentration of tin-doped indium oxide fine particles of 0.7% by weight and an optical path length of a glass cell of 1 mm, a visible light transmittance is 80% or more, a solar radiation transmittance at a wavelength within a range from 300 nm to 2100 nm is ¾ or less of the visible light transmittance, a haze value is 1.0% or less, and a reflection yellow index is −20 or more.

Owner:MITSUBISHI MATERIALS CORP +2

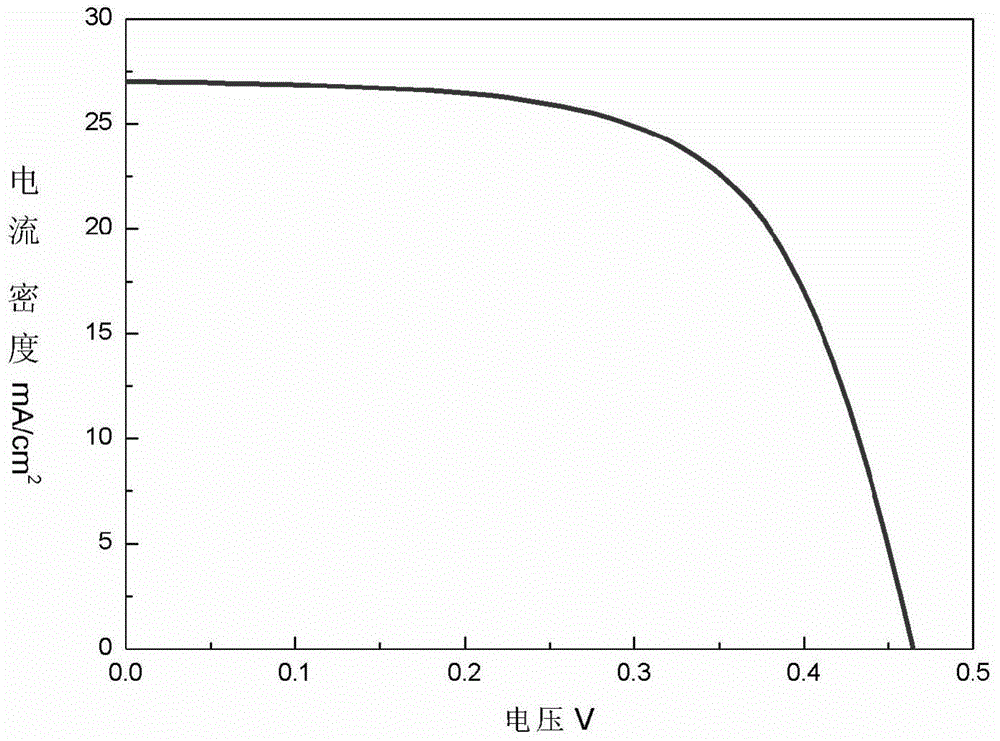

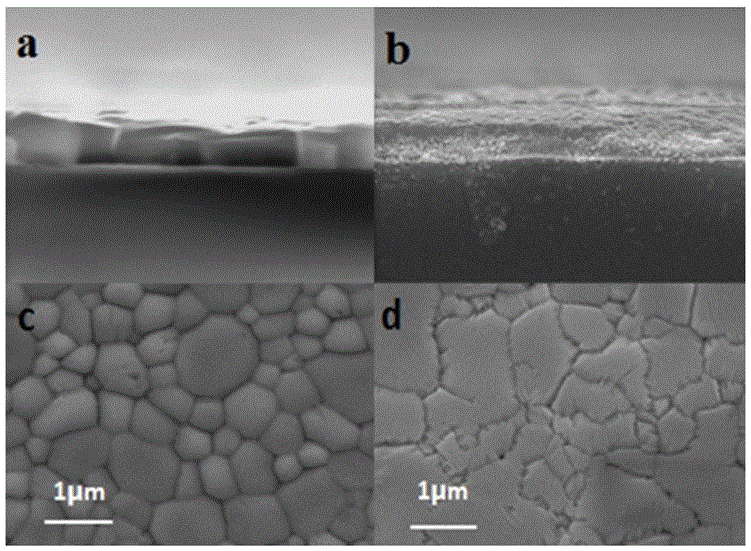

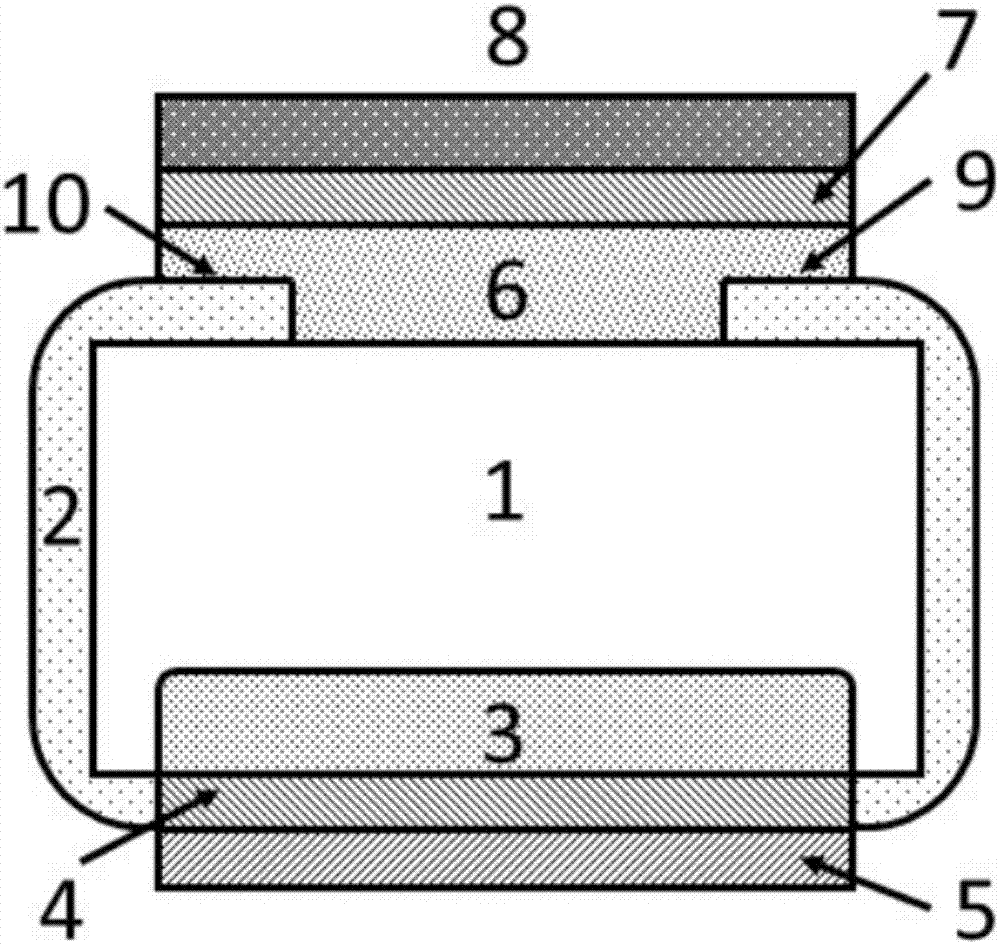

Tin-doped CH3NH3SnxPb1-xI3 perovskite solar cell

ActiveCN106384785ALow toxicityEasy to changeSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionPerovskite solar cell

Owner:TAIYUAN UNIV OF TECH

Tin-doped indium oxide film and making process of fine pattern

InactiveCN1599024ATranslucentConductiveSemiconductor/solid-state device detailsSolid-state devicesUltraviolet lightsHigh pressure

The invention discloses the indium oxide film adulterating with tin and the preparation technique of minute figures. The indium nitrate and the tin tetrachloride are put into the acetylacetone solrent, add the deionized water to it and get the solution A; add the chelating agent of benzoyl acetone into the ethylene glycol monomethyl ether solvent and get the solution B; mix the solution A with the solution B, whisk it, aggradate it and get the indium oxide sol adulterated with light sensitive tin. The high pressure mercury lamp or ultraviolet laser pass through the masking with minute figures, irradiate the indium oxide sol adulterated with light sensitive tin, irradiate it with ultraviolet light in the air environment, get rid of its masking, put it in the absolute ethyl alcohol, dissolve the part that is not irradiated by the ultraviolet light, keep the part irradiated, heat it to get rid of the organic material and get the minute figure of the indium oxide film adulterated with tin. The invention does not need special vacuum, reaction chamber, photoresist and corrosive medium, can produce great areal minute figure and can get the high class minute figures of the ITO film.

Owner:XIAN UNIV OF TECH

Process for Producing Base Material for Forming Heat Shielding Film

InactiveUS20090087573A1Sufficient heat-ray shielding capabilityLow costBuilding constructionsGlue/gelatin preparationOrganic solventIndium

There is provided a production process of a heat-ray shielding film-formed base member comprising the steps of mixing a sol solution, formed by using a starting raw material of trialkoxysilane or trialkoxysilane and tetraalkoxysilane, with a solution in which tin-doped indium oxide ultra-fine particles are dispersed, to make a treatment agent; and applying the treatment agent to a base member. In this production process, the treatment agent has an organic solvent having a boiling point of 100-200° C. as a dispersion medium, and the application is conducted by a means by bringing a member retaining the treatment agent into contact with the base member or by a means by spraying the treatment agent, thereby adjusting haze value of the film to be formed to 0.5% or less.

Owner:CENT GLASS CO LTD

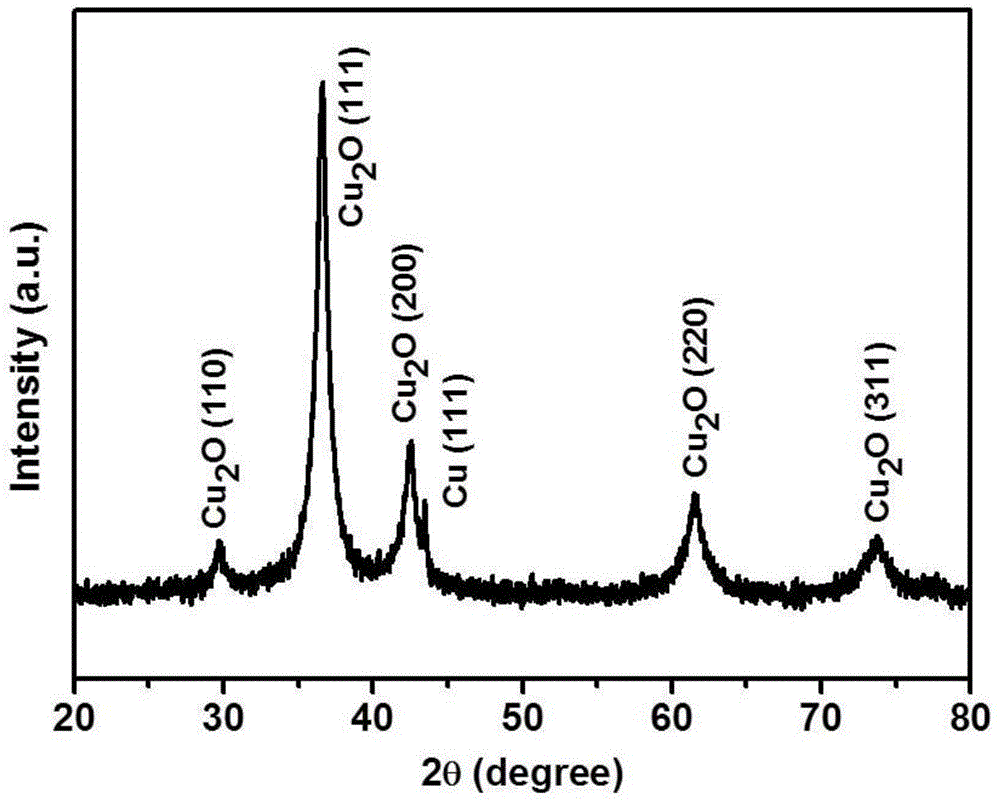

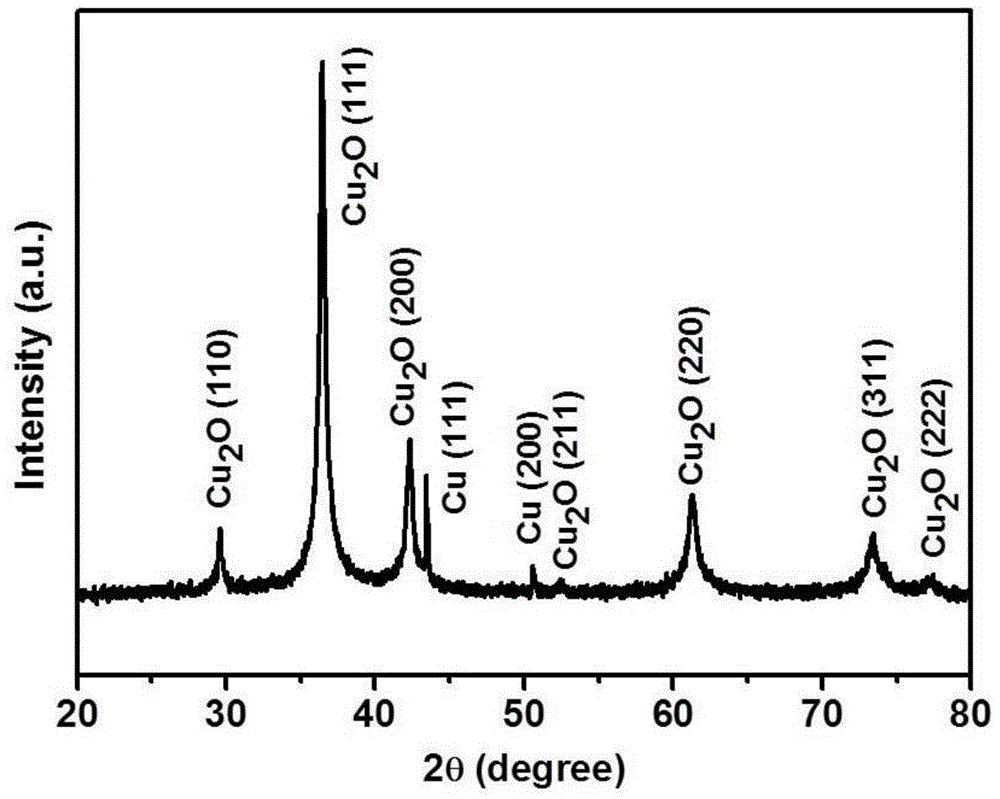

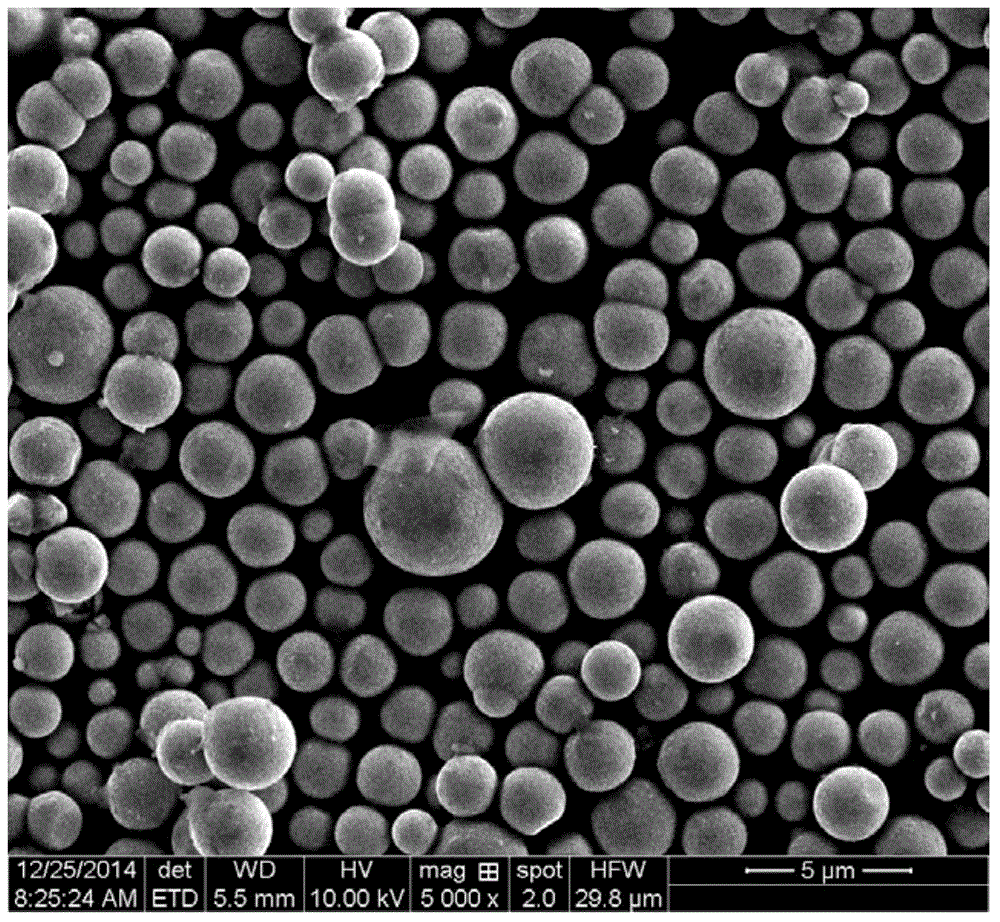

Preparation method of tin-doped cuprous oxide

InactiveCN104874400AAbundant raw materialsLow costMetal/metal-oxides/metal-hydroxide catalystsHigh pressureSolvent

The invention belongs to the technical field of photocatalysts, in particular to a preparation method of tin-doped cuprous oxide. The preparation method provided by the technical scheme of the invention comprises the following steps: adding ethanediol to cupric nitrate and stannous chloride to be prepared into a solution; stirring the solution fiercely and transferring into a high-pressure autoclave, reacting for 10 hours at 140 DEG C to obtain the precipitate; cleaning the precipitate and placing the cleaned precipitate into a vacuum drying oven for drying for 12 hours at 60 DEG C to obtain the end product. The preparation method of tin-doped cuprous oxide, provided by the invention, is simple in process, simple in equipment, and a solvothermal method is adopted, so that the solution is directly mixed to be placed in the high-pressure autoclave for reaction at 140 DEG C to obtain the end product, the yield is high, and the raw materials adopted by the method are abundant and non-toxic.

Owner:UNIV OF JINAN

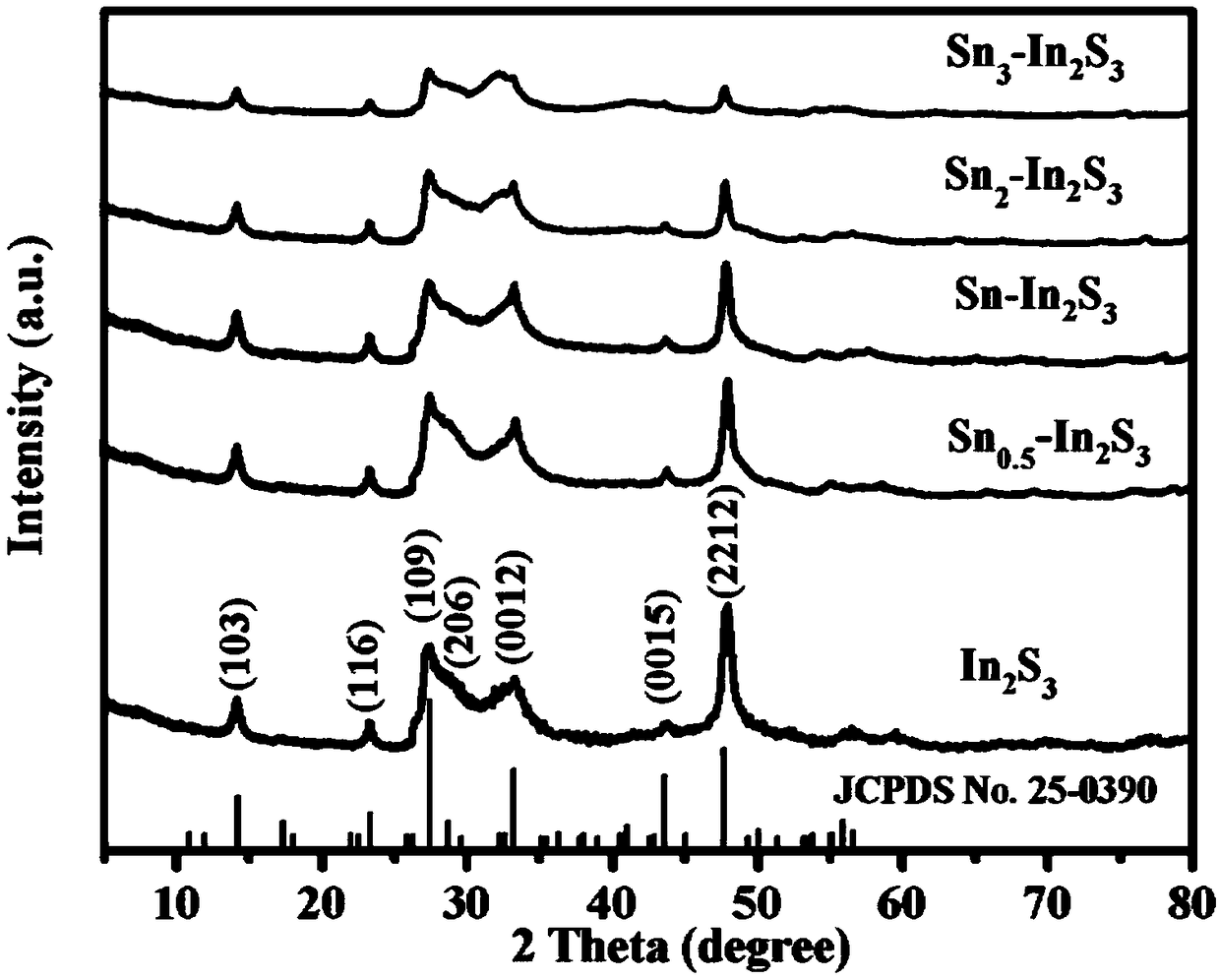

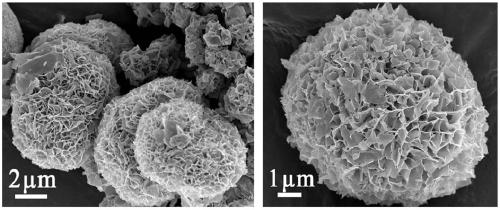

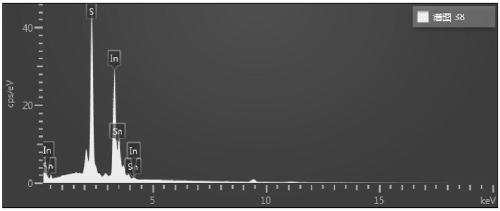

Preparation method for tin-doped indium sulfide flower-like nano material and application of nano material in photocatalytic reduction

InactiveCN109261166AReduce recombination rateLarge specific surface areaMaterial nanotechnologyPhysical/chemical process catalystsAbsorption capacityHigh pressure

The invention relates to a preparation method for a tin-doped indium sulfide flower-like nano material and application of the nano material in photocatalytic reduction. The method comprises the following steps that absolute ethyl alcohol serves as a solvent, indium(III) chloride tetrahydrate, tin(IV) chloride pentahydrate and thioacetamide are sequentially added, uniform stirring is carried out, then the mixture is put into a polytetrafluoroethylene high-pressure reaction kettle, reaction is carried out for 8-20 hours at the temperature of 120-180 DEG C, and natural cooling is carried out to reach room temperature; and a product is treated so as to obtain a Sn-In2S3 photocatalytic material. According to the preparation method for the tin-doped indium sulfide flower-like nano material and the application of the nano material in photocatalytic reduction, the photocatalytic material has relatively large specific surface area and a proper pore structure, so that surface active sites are increased, the absorption capacity of visible light can be enhanced after tin is doped, so that compounding of photo-induced electrons and holes can be effectively inhibited, and more excellent photocatalytic performance can be achieved; and the Sn-In2S3 photocatalytic material can reduce uranium-containing wastewater, 95% or more of target pollutants can be reduced within 40 min, and excellent photocatalytic activity is achieved.

Owner:SOUTH CHINA UNIV OF TECH

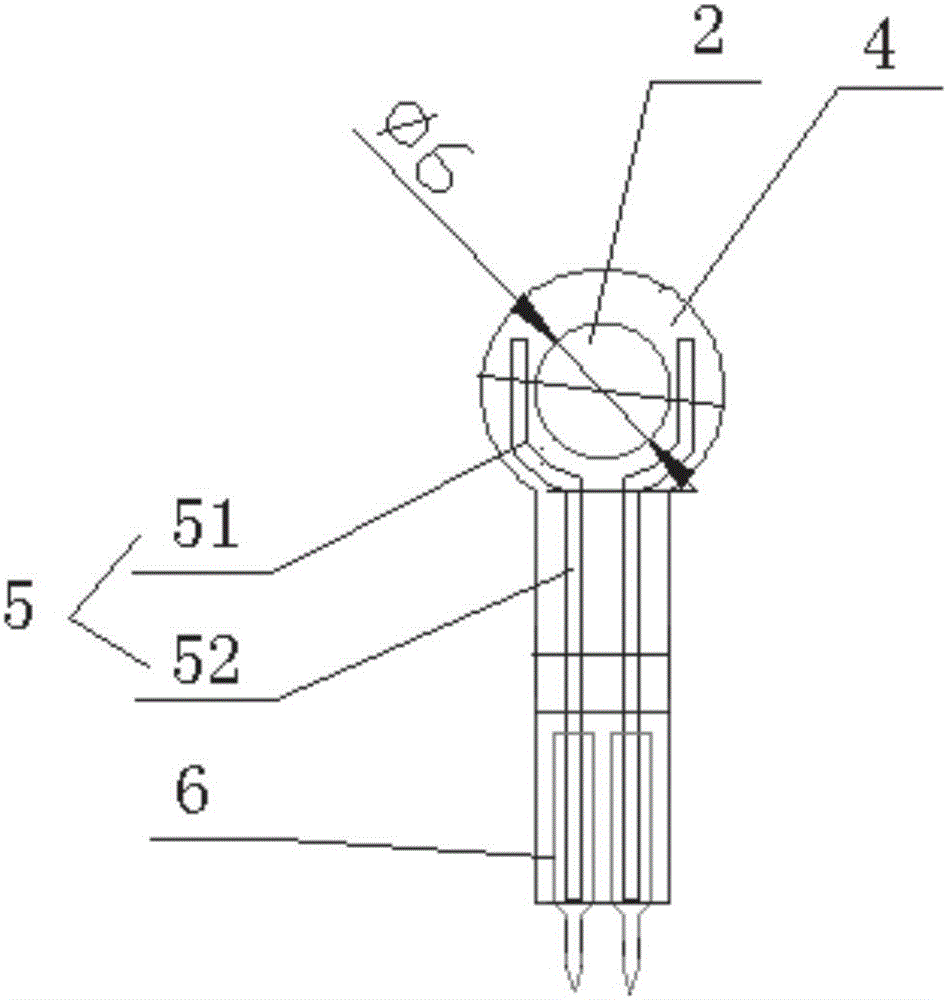

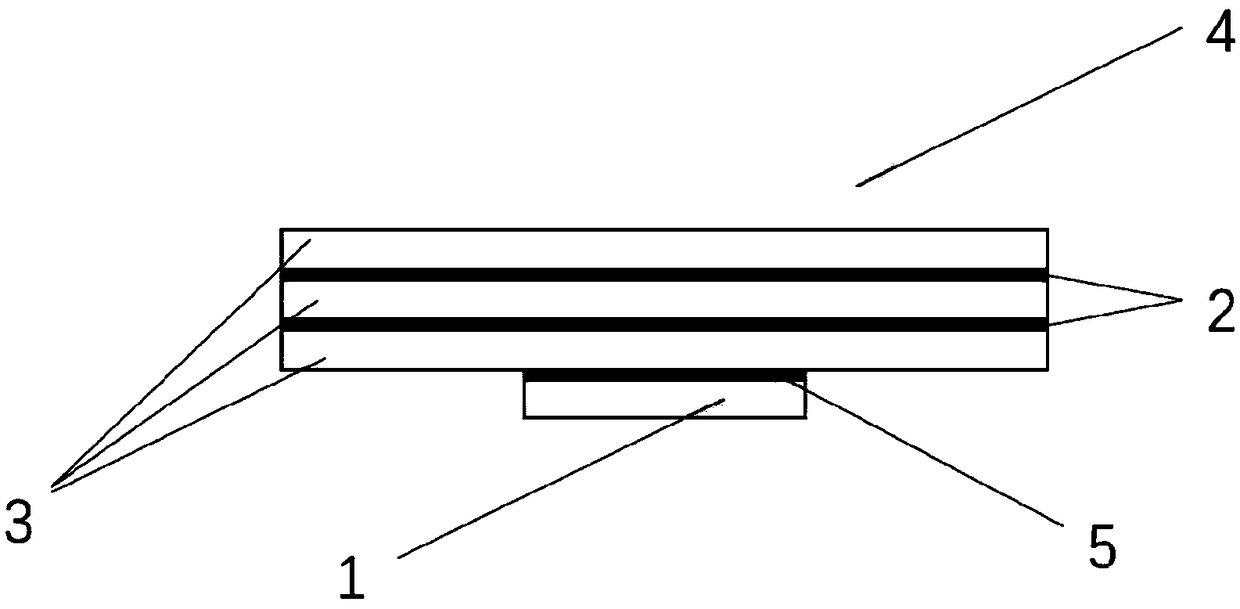

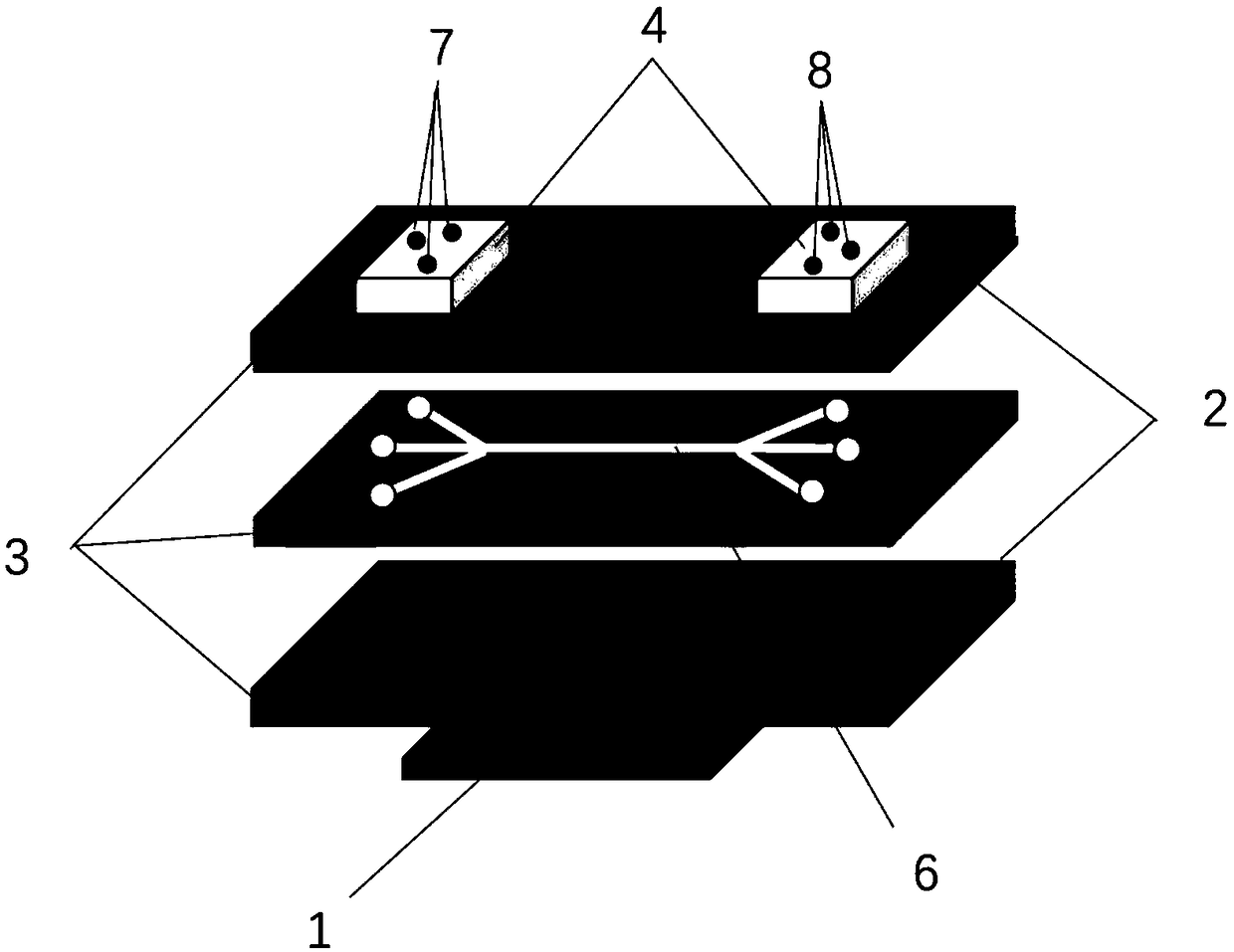

Completely transparent microfluidic acoustic body wave chip and preparation method thereof

The invention discloses a completely transparent microfluidic acoustic body wave chip and a preparation method thereof. The product consists of three glass sheets and one piece of piezoelectric material. The three glass sheets are stacked from top to bottom to form a standing wave reaction chamber, the upper glass sheet is equipped with holes for fluid to come in and out by laser, and thick piecesof polydimethylsiloxane (PDMS) with corresponding holes are bonded to the surface holes. A micron-scale channel is prepared on the middle glass sheet by laser cutting and penetration of the glass. The lower glass is complete glass, and is used for chamber encapsulation. The piezoelectric material is made of lithium niobate single crystal, the upper surface and lower surface of the piezoelectric material are both plated with a layer of transparent tin-doped indium oxide (ITO) conductive film, and the piezoelectric material is sticked at the lower surface of a resonant cavity, both sides of thelithium niobate wafer undergo silver slurry curing, and two leads are led out. The chip prepared by the method provided by the invention is completely transparent and highly visible, and can be usedfor gathering, separation and manipulation of cells / particles and other samples. The preparation process adopted by the invention is simple, and the cost is low.

Owner:WUHAN UNIV

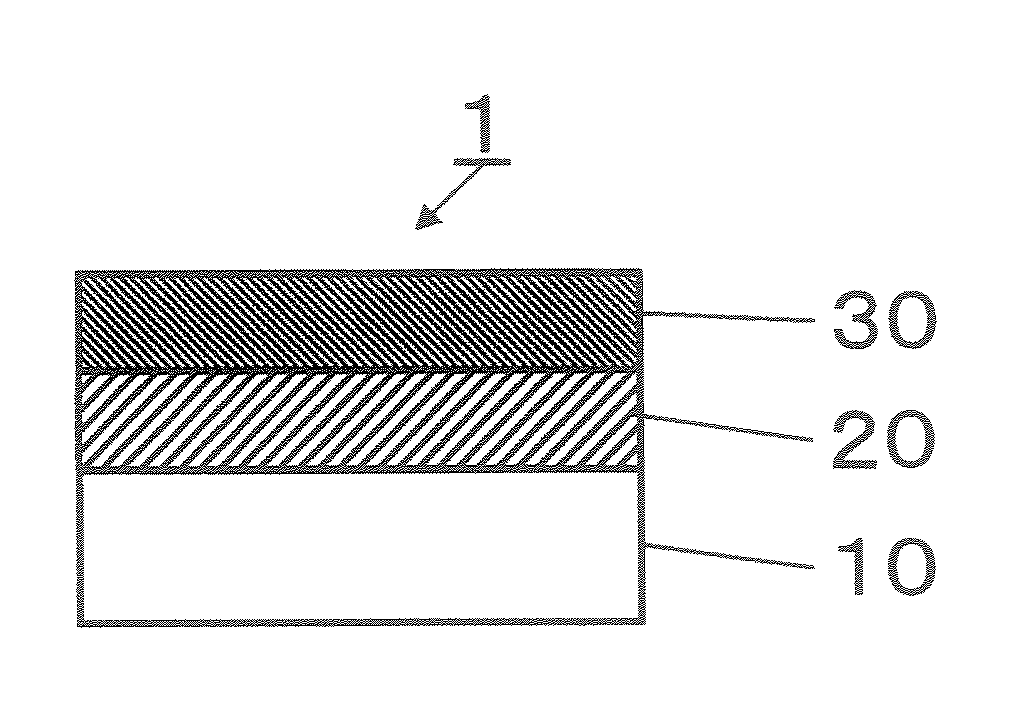

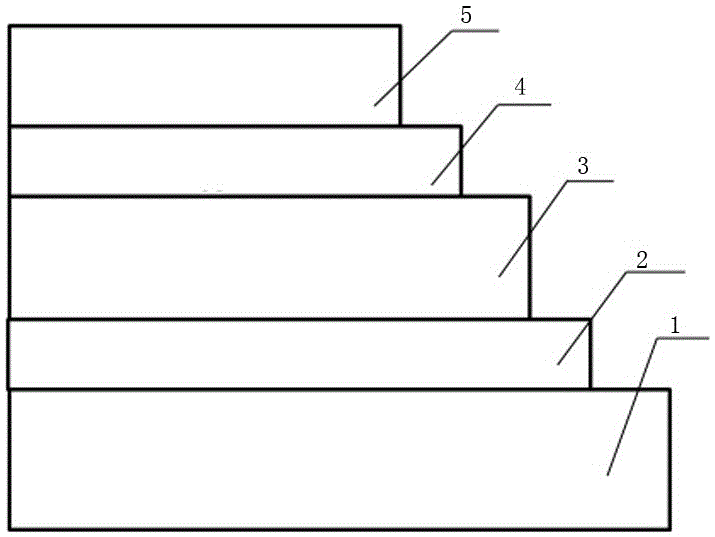

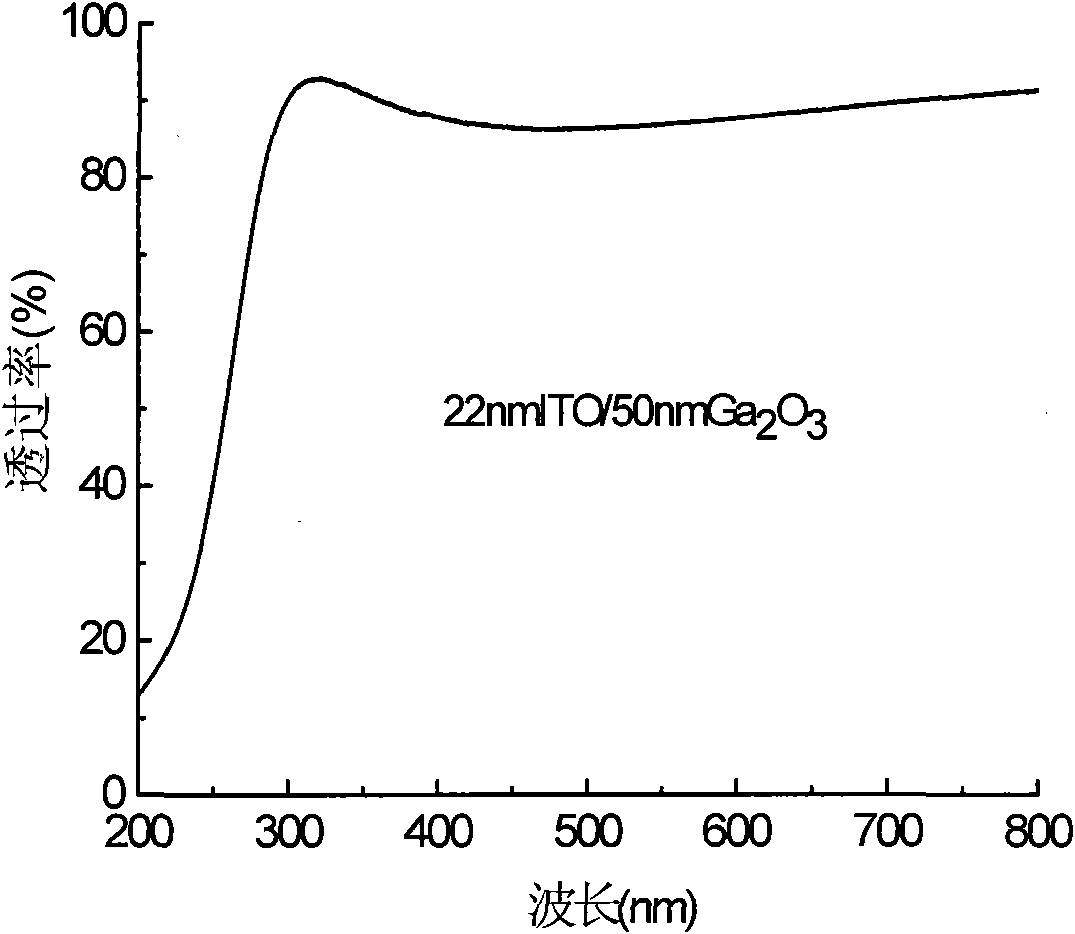

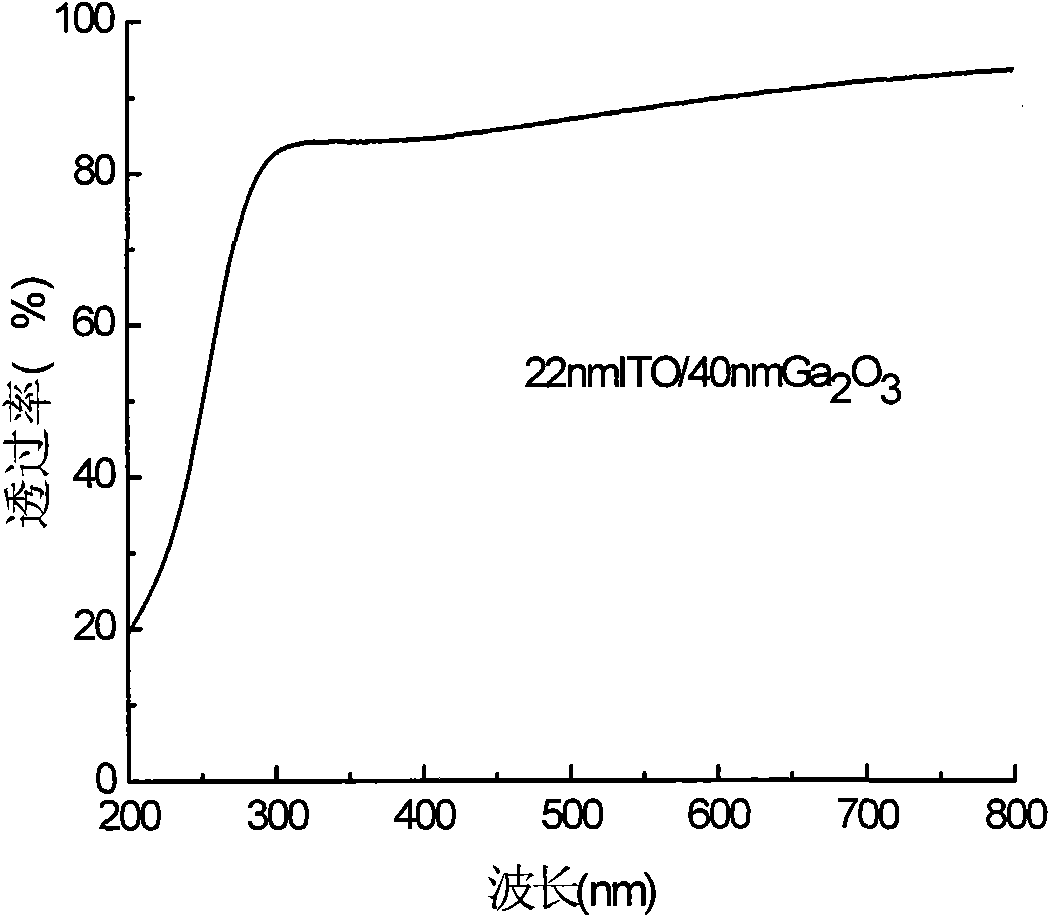

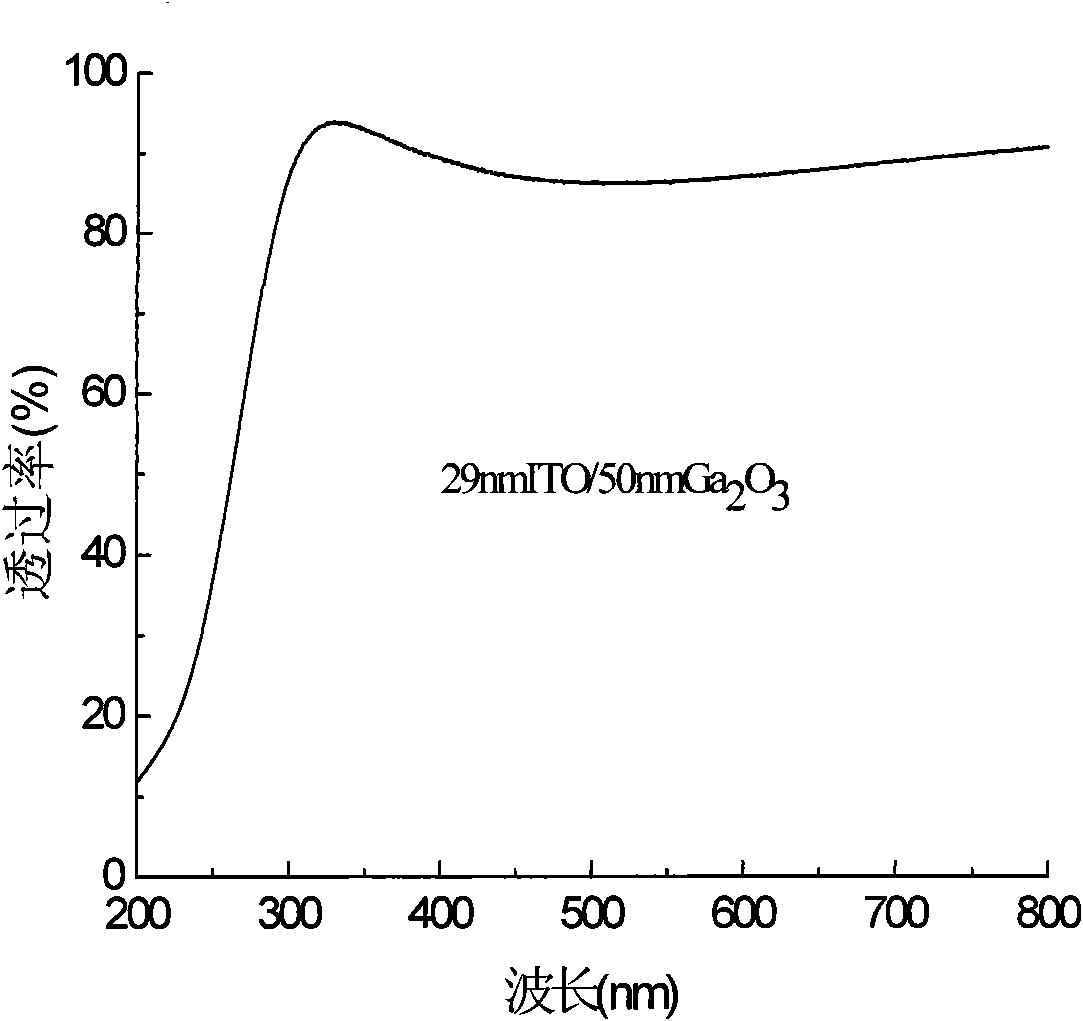

Double-layer structure deep-ultraviolet transparent conductive film and preparation method thereof

InactiveCN101841003AWith deep ultraviolet transparent optical propertiesImprove conductivitySolid-state devicesVacuum evaporation coatingIndiumRadio frequency magnetron sputtering

The invention relates to a tin-doped indium oxide (ITO) / gallium oxide (Ga2O3) double-layer structure deep-ultraviolet transparent conductive film and a preparation method thereof, and belongs to the technical field of electronic materials. The preparation method comprises the following steps: ultraviolet optical quartz glass is used as the substrate, and radio-frequency magnetron sputtering is carried out on the Ga2O3 ceramic target to prepare a Ga2O3 layer the thickness of which is 30-60 nm; and direct-current magnetron sputtering is carried out on an ITO target to prepare an ITO layer the thickness of which is 15-29 nm. The pressure intensity of argon gas for sputtering is 0.2-2 Pa, the power for radio-frequency sputtering is 50-100 W, the substrate temperature is 200-300 DEG C, the current for direct-current sputtering is 80-150 mA, and the voltage for direct-current sputtering is 200-400 V. The prepared film has the advantages of low resistivity, high transmittivity within the range of visible light, ultraviolet light and deep-ultraviolet light, and other favorable photoelectric properties. The film otained by the method of the invention has wide application prospects in the fields of ultraviolet photoelectric devices and the like.

Owner:LUDONG UNIVERSITY

Soil restoration agent containing loaded nano titanium dioxide

InactiveCN109134146AReduce utilizationImprove utilization efficiencySuperphosphatesAlkali orthophosphate fertiliserFumed silicaCoal

The invention discloses a soil restoration agent containing loaded nano titanium dioxide. The soil restoration agent can be used for restoring soil polluted by heavy metal and organic pollutants. Thesoil restoration agent comprises loaded nano titanium dioxide and straw powder, and the loaded nano titanium dioxide is prepared by loading anatase nano titanium dioxide and tin doped modified anatasenano titanium dioxide onto fumed silica and coal ash. The soil restoration agent can effectively reduce heavy metal ions in soil to lower heavy metal content in planted crops, effectively degrade organic pollutants in the soil, remarkably improve pollution degree of polluted soil and improve cultivation performance of the soil. Inorganic fertilizer and / or organic fertilizer can be added selectively into the soil restoration agent to increase nutritional fertility of the soil and promote crop growth, and effects of improving crop yield and quality are realized.

Owner:HEBEI MILSON TITANIUM DIOXIDE

Tin-doped lithium-rich manganese-based positive electrode material and preparation method thereof

ActiveCN110492095AImprove electrochemical performanceUniform size distributionCell electrodesSecondary cellsNickel saltManganese

The invention belongs to a lithium ion battery positive electrode material, and particularly relates to a tin-doped lithium-rich manganese-based positive electrode material and a preparation method thereof. The materials are metered according to stoichiometry; manganese salt, nickel salt, cobalt salt and tin salt are mixed to prepare a mixed salt aqueous solution, and performing coprecipitation toform a precursor precipitate; and mixing the precursor precipitate with a lithium source compound, and carrying out sectional heat treatment to obtain the tin-doped lithium-rich manganese-based positive electrode material of which the chemical formula is Li[LiaMnbCocNidSnx]O2, wherein a + b + c + d + x = 1, a, b, c, d and x is more than 0. The coprecipitation method for preparing the tin-doped lithium-rich manganese-based positive electrode material is simple in technological process, convenient to operate and suitable for industrial large-scale production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

Gallium oxide single crystal based radiation detector and preparation method thereof

ActiveCN107068800ASolving Manufacturing ChallengesRealize developmentSemiconductor devicesHigh resistanceManufacturing technology

The invention belongs to the technical field of semiconductor device preparation, and relates to a gallium oxide single crystal based radiation detector and a preparation method thereof. The radiation detector takes a high-resistance gallium oxide single crystal as a substrate, the upper and lower surfaces and the side surfaces of the gallium oxide single crystal are provided with an SiO2 protection layer, a tin-doped gallium oxide layer, a titanium layer and a gold layer which are formed by tin atom diffusion are sequentially arranged in a mask pattern formed at the lower surface of the SiO2 layer of the gallium oxide single crystal; and a nickel layer, a titanium layer and a gold layer are sequentially arranged in a mask pattern formed at the upper surface of the SiO2 protection layer of the gallium oxide single crystal, and each layer has an overlapping region with the SiO2 protection layer retained at the upper surface. The invention provides an effective, simple and convenient processing and manufacturing technology, a problem of preparation for a high-performance gallium oxide radiation detector is solved, and the development of a novel gallium oxide based radiation detector is realized.

Owner:DALIAN UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com