Tin-doped CH3NH3SnxPb1-xI3 perovskite solar cell

A technology of solar cells and methyl ammonium, applied in the field of solar cells, can solve the problems of cumbersome production process, high production cost, and resource consumption, and achieve the effects of promoting flatness, low cost, and increasing current intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

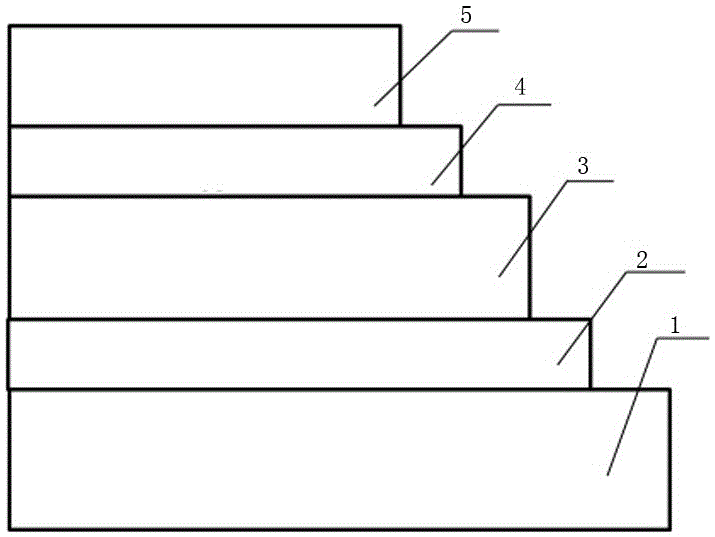

[0017] Such as figure 1 As shown, the tin-doped methylammonium lead iodide perovskite solar cell has a planar heterojunction structure: the structure of the solar cell in this embodiment is: ITO / PEDOT:PSS / CH 3 NH 3 sn x Pb 1-x I 3 / PC 60 BM / Al.

[0018] In the battery structure, the thickness of the ITO anode is 100 nm, and the sheet resistance is 10Ω.

[0019] In the battery structure, the thickness of the hole transport layer PEDOT:PSS is 30 nm, which is formed by solution spin coating and then annealed in air. The spin coating rate is 3000 rpm, the spin coating time is 30 s, the annealing temperature is 120 °C, and the annealing time is 10 minutes,

[0020] In the battery structure, the active layer is CH 3 NH 3 sn 0.25 Pb 0.75 I 3 Perovskite thin films prepared from methylamine iodide (CH 3 NH 3 I), lead iodide (PbI 2 ) and tin iodide (SnI 2 ) was dissolved in a mixed solvent of N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) according to the mola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com