Patents

Literature

130results about How to "Increase the current intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

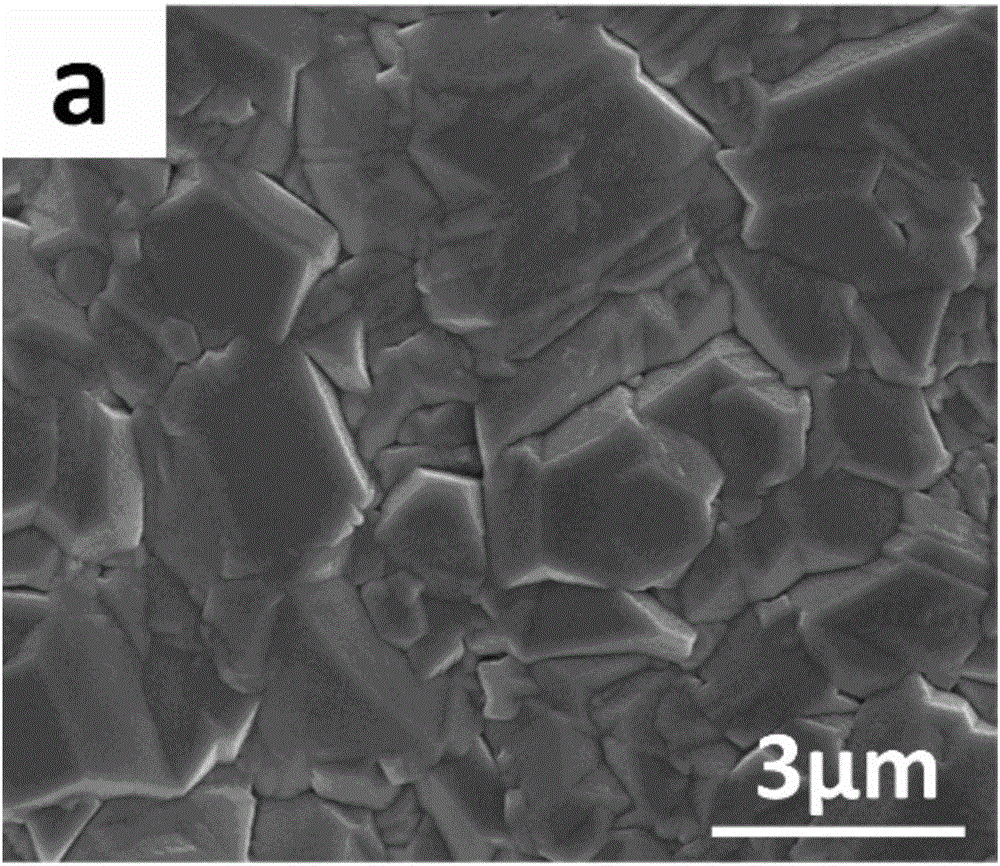

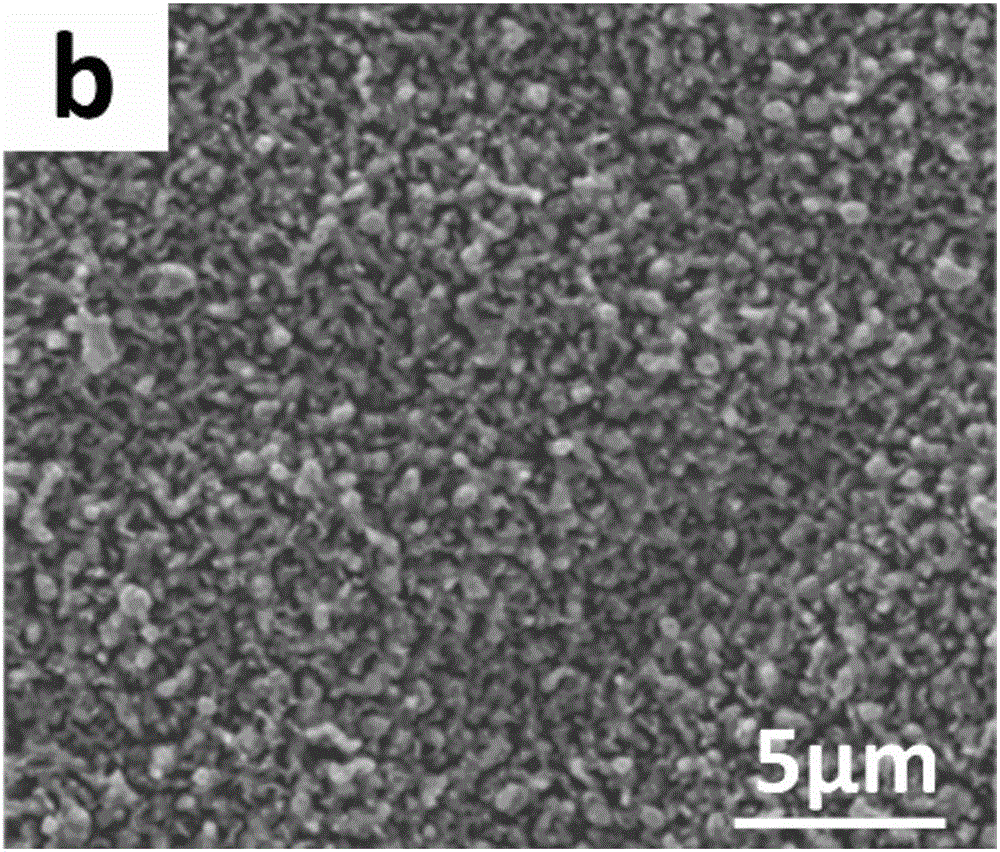

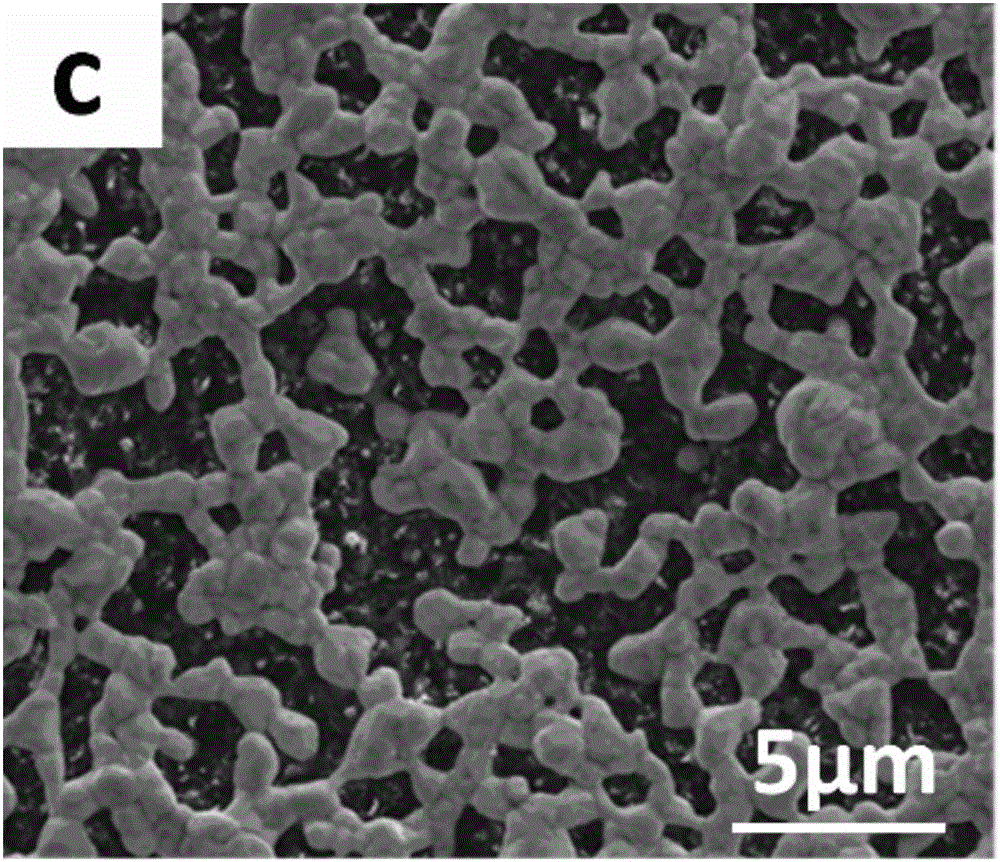

High-specific-surface-area boron-doped diamond electrode and preparation method and application thereof

ActiveCN106435518AHigh activityLarge electrochemical reaction interfaceWater contaminantsWater/sewage treatmentElectrochemical biosensorDiamond electrodes

The invention discloses a high-specific-surface-area boron-doped diamond (BDD) electrode which comprises an electrode substrate. A boron-doped diamond layer is arranged on the surface of the electrode substrate. Or, a transition layer is arranged on the surface of the substrate, and then a boron-doped diamond layer is arranged on the surface of the transition layer. Metal particles are distributed in the diamond layer, and tiny holes and / or pointed cones are distributed on the surface of the diamond layer. Compared with a traditional plate electrode, the boron-doped diamond electrode contains a large number of tiny holes and pointed cones and has the extremely high specific surface area, and the large current intensity is provided through the low current intensity; and meanwhile, due to the different electrode configurations of the substrate and modification of surface graphene and / or carbon nano tubs (CNT), the mass transfer process can be greatly improved, the current efficiency and the electrochemical property are greatly improved, and the BDD electrode with high electrocatalytic activity and high using efficiency is prepared. The electrode can be widely applied in the fields of electrochemical wastewater purification treatment, electrochemical biosensors, strong oxidant electrochemical synthesis, electrochemical detection and the like.

Owner:NANJING DAIMONTE TECH CO LTD

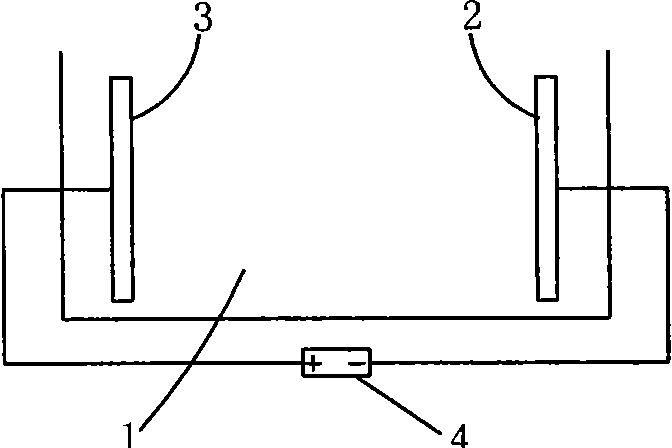

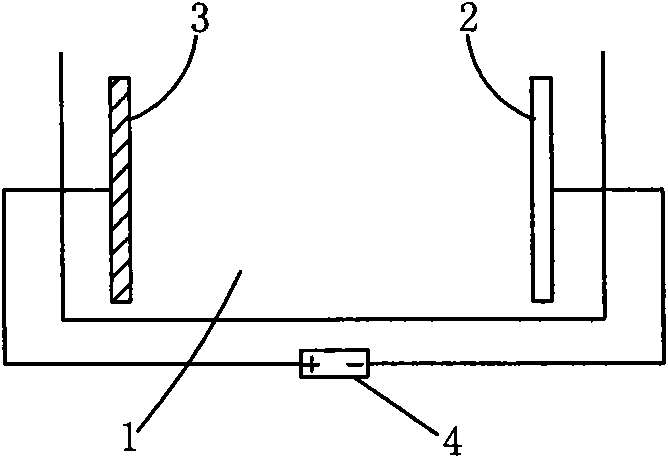

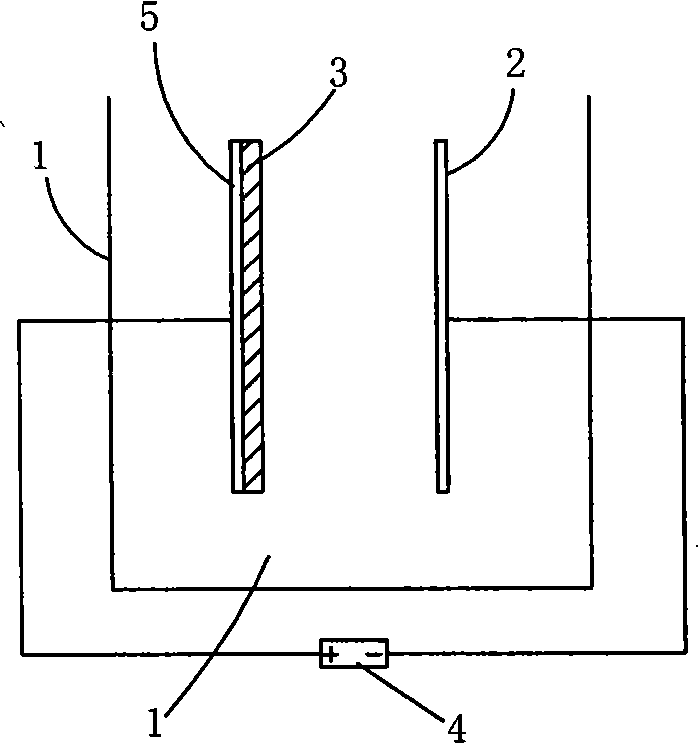

Alkali reductive water diaphragm-free electrolysis device

ActiveCN101805046AImprove electrode conductivityReduce power consumptionWater/sewage treatmentAlkalinityElectrolysis

The invention relates to an alkali reductive water diaphragm-free electrolysis device, which belongs to the technical field of functional water electrolysis devices. The device comprises a water container, a pair of negative and positive electrodes placed in the water container, and a direct-current power supply electrically connected with the negative and positive electrodes; the positive electrode mainly comprises an active carbon electrode made of active carbon; and the negative electrode mainly comprises a metal electrode made of metal. The device can effectively obtain alkali reductive water of wide-range alkalinity (PH value from 7 to 13) and negative oxidation-reduction potential by adopting the negative and positive electrode group mainly comprising the active carbon electrode and the metal electrode, and can reduce the consumption of electrolysis power.

Owner:珠海市旖辰科技有限公司

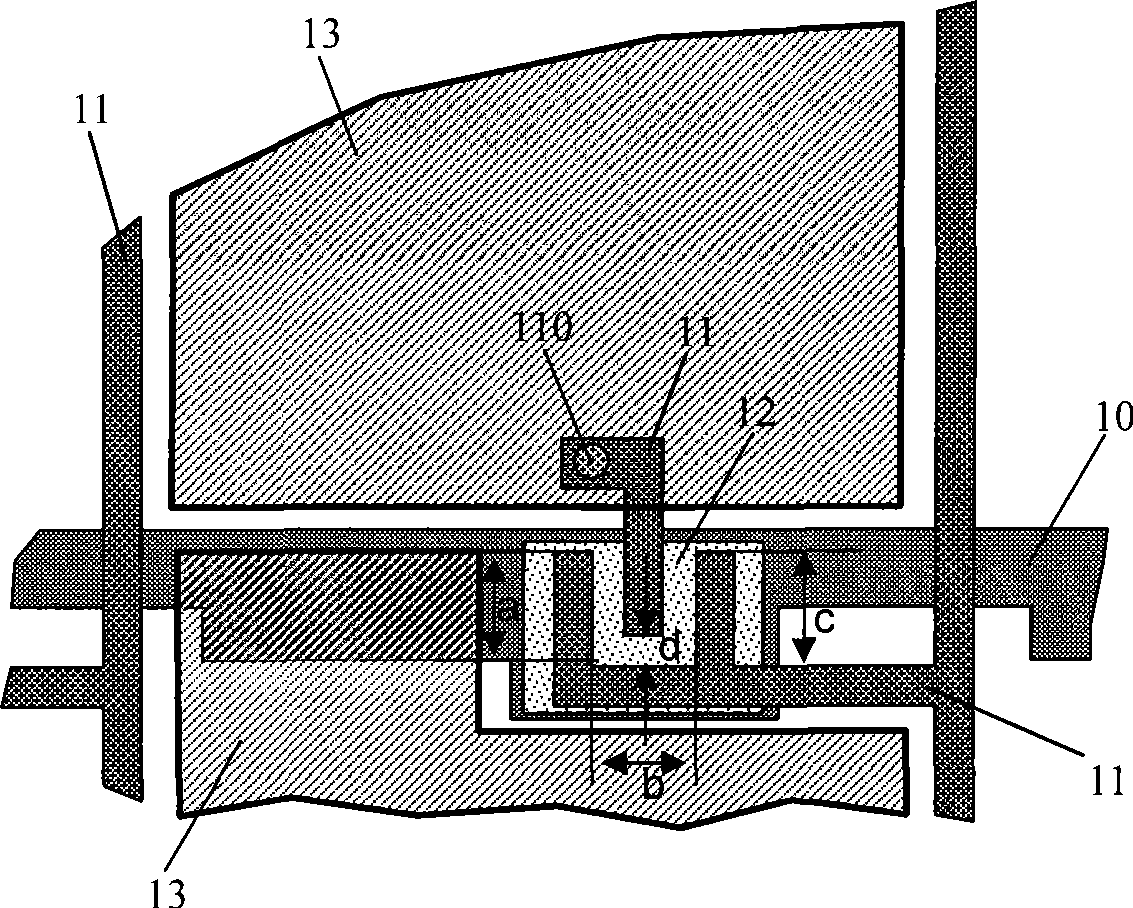

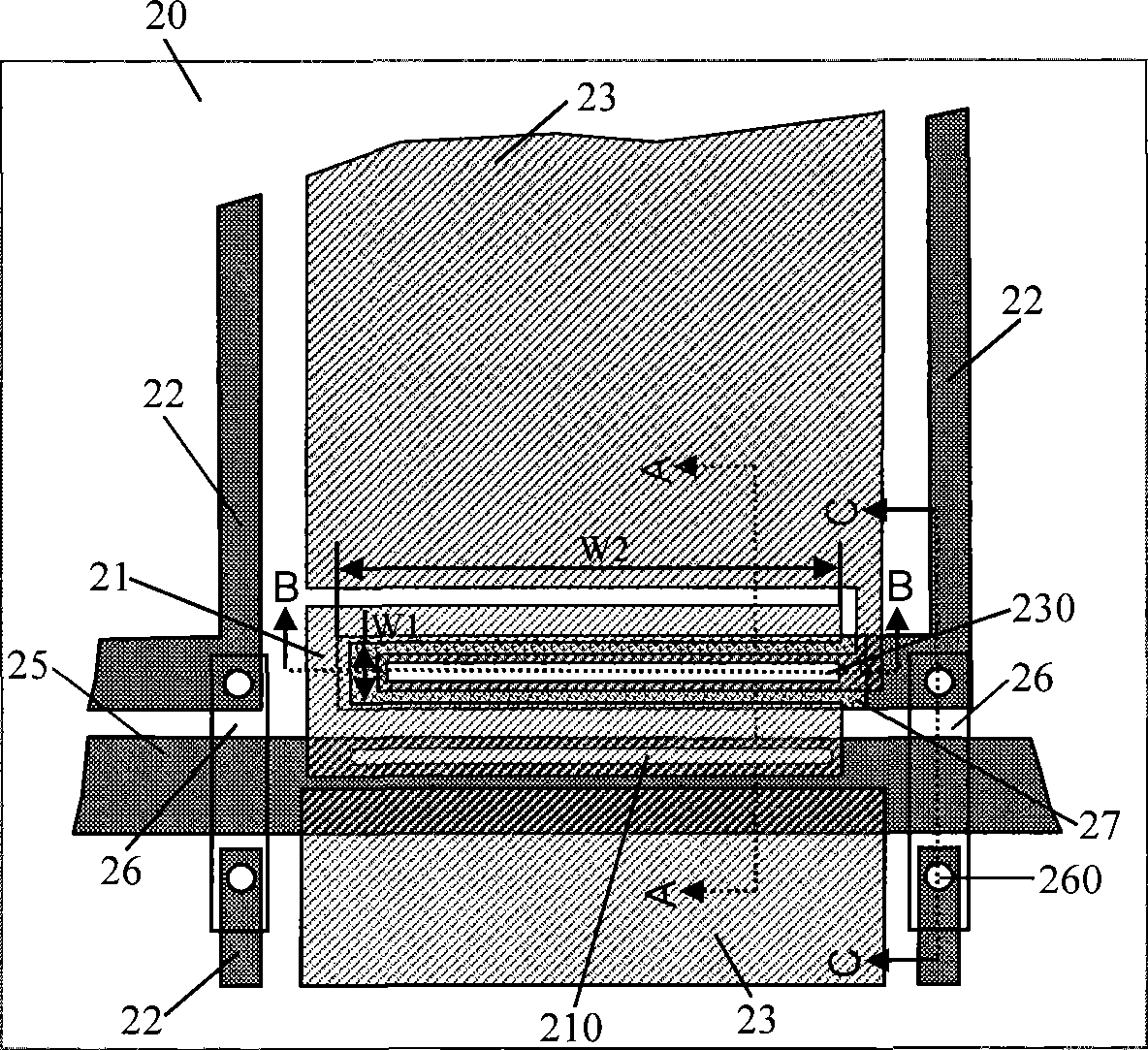

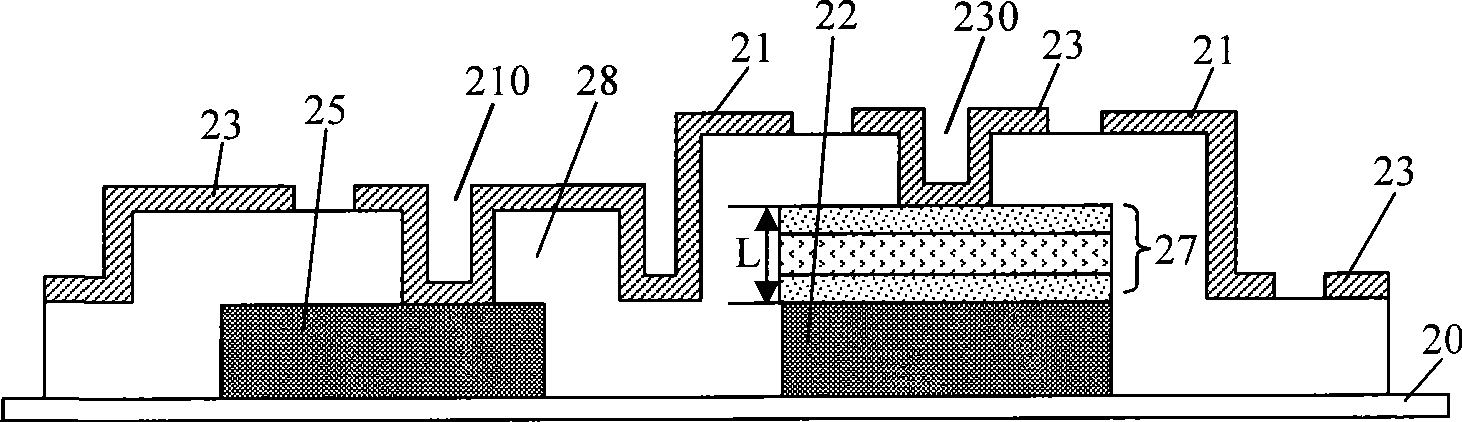

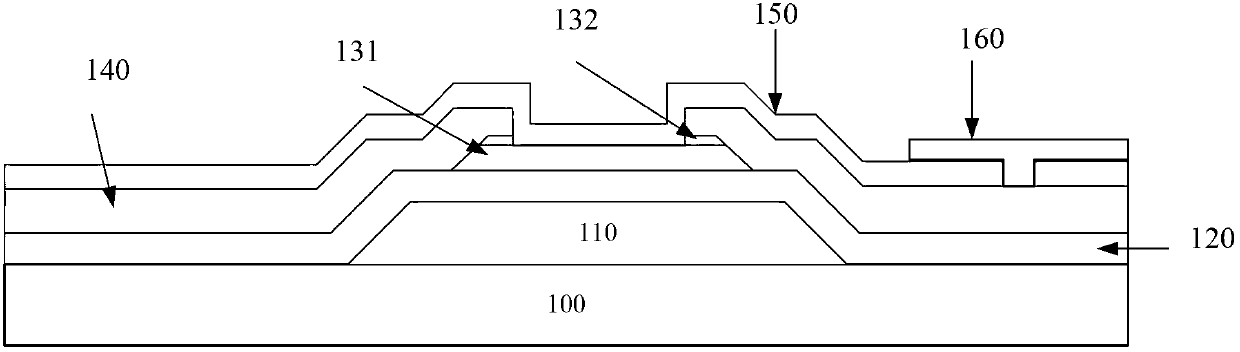

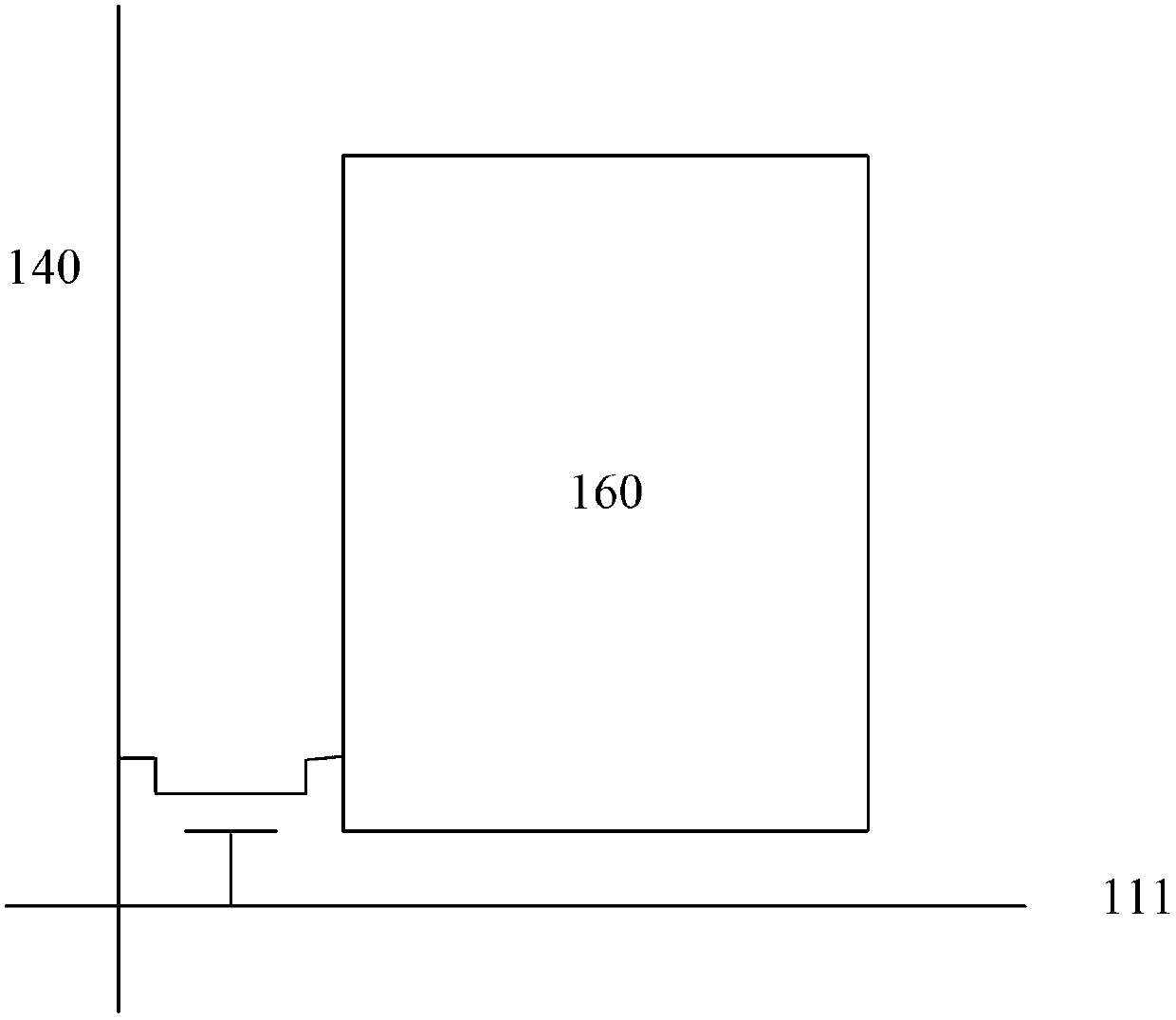

Pixel structure of thin film transistor-liquid crystal display and manufacturing method thereof

ActiveCN101546077AIncrease the current intensityReduce manufacturing stepsTransistorSolid-state devicesLiquid-crystal displayCurrent channel

The invention discloses a pixel structure of a thin film transistor-liquid crystal display and relates to a TFT-LCD technology, which is provided aiming to solve the problems of poor display effect and complex process of the current TFT-LCD. The invention adopts the technical scheme that the pixel structure comprises a grid line and a data line, wherein the grid line and the data line are intercrossed to form a pixel area, the pixel area comprises at least one thin film transistor and a pixel electrode, the source electrode of the thin film transistor is formed at the bottom layer, an active layer and a drain electrode are arranged on the source electrode in sequence, the source electrode is connected with the data line and the drain electrode is connected with the pixel electrode; the grid is formed on the side surface of the active layer and is connected with the grid line; and the side surface of the active layer and the grid part opposite to the side surface of the active layer form a vertical current channel, i.e., a side grid channel is formed. The invention also discloses a manufacturing method of the pixel structure. The invention obviously enhances the current intensity of the TFT channel, improves the display effect of the TFT-LCD and improves the manufacturing efficiency of the pixel structure of the TFT-LCD.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

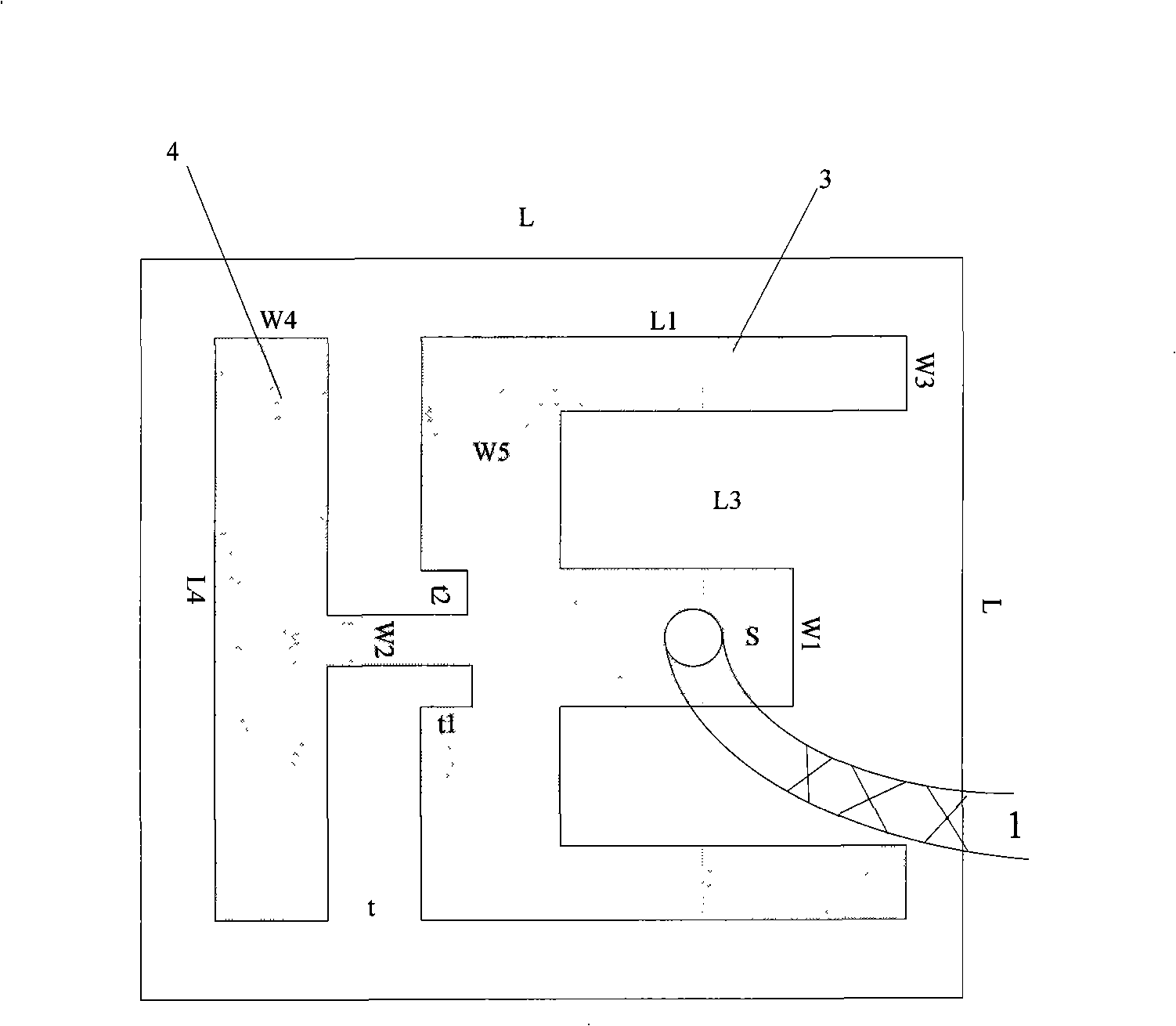

Double-frequency broadband E-shaped microstrip antenna

InactiveCN101527392AChange working frequencyChange jobSimultaneous aerial operationsSlot antennasCommunication qualityCurrent distribution

The invention provides a double-frequency broadband E-shaped microstrip antenna, comprising an E-shaped patch 3. A main feeder line 1 is directly connected to an SMA joint 2 of coaxial feeding point of the E-shaped patch 3, the SMA joint passes through the ground and medium and then is directly in contact with the intermediate arm of the E-shaped patch 3, another two arms of the E-shaped patch 3 are symmetrically distributed at the two sides of the feeding point and have a distance of L3 from the edge of the intermediate arm, the E-shaped patch 3 is connected with a T-shaped patch (bent T-shaped patch) 4 by loading to form a main radiating unit of the antenna, a width t is arranged between the E-shaped patch 3 and T-shaped patch (bent T-shaped patch), and a slot with width t2 and depth t1 is respectively arranged at the two sides of the joint between the T-shaped patch (bent T-shaped patch) and the E-shaped patch. The invention has relatively high gain, wide working frequency band, uniform current distribution, light weight and small volume, can effectively improve communication quality, is easily integrated with a circuit, and can be widely used for a portable device and in indoor coverage and wireless local area network.

Owner:HARBIN ENG UNIV

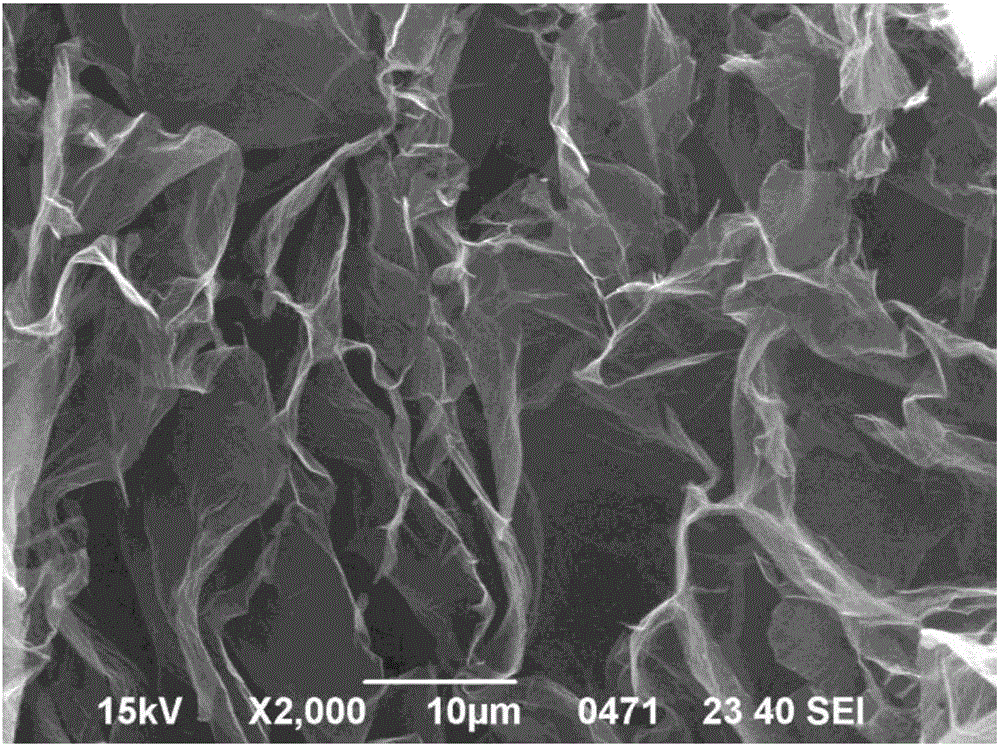

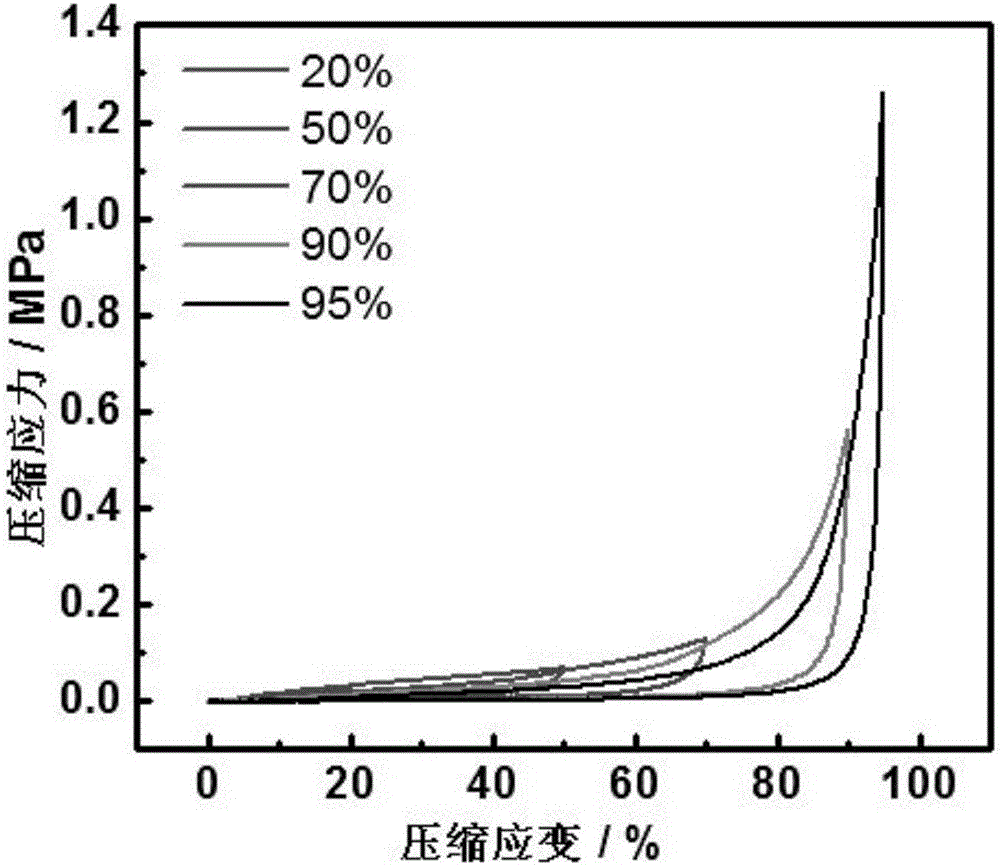

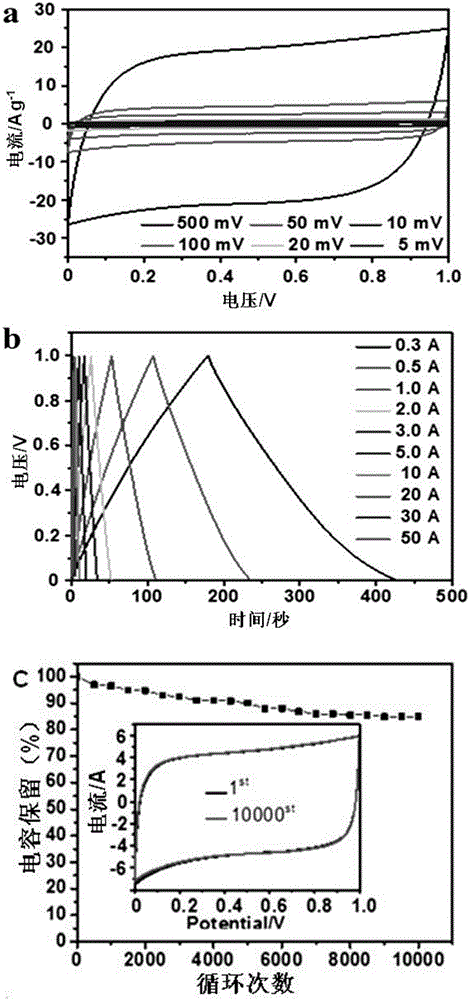

Preparation method of super-elasticity graphene aerogel

ActiveCN106809822AImprove electrochemical performanceReduce manufacturing costGrapheneFreeze-dryingElectrochemistry

The invention belongs to the technical field of aerogel preparation and relates to a preparation method of super-elasticity graphene aerogel. The preparation method includes: adding a proper amount of reducing agent into oxidized graphene dispersion, using a polymer foam block to adsorb the oxidized graphene dispersion, and performing oil path heating on the foam block to reduce oxidized graphene; drying a sample through freeze-drying; removing polymer foam through high-temperature thermal treatment to obtain graphene aerogel. Shape of final graphene aerogel is regulated by designing shape of the polymer foam, but the shape of the graphene aerogel is regulated by changing shape of containers in other preparation processes of graphene aerogel, so that preparation cost of the graphene aerogel is lowered greatly, and the graphene aerogel in complex shape can be prepared. The preparation method is simple in preparation process, ingenious in design concept, easy-to-get in raw material for preparation and high inpreparation efficiency, and the graphene aerogel prepared by the method is excellent in electrochemical performance, friendly to application environment and wide in market prospect.

Owner:戴天元

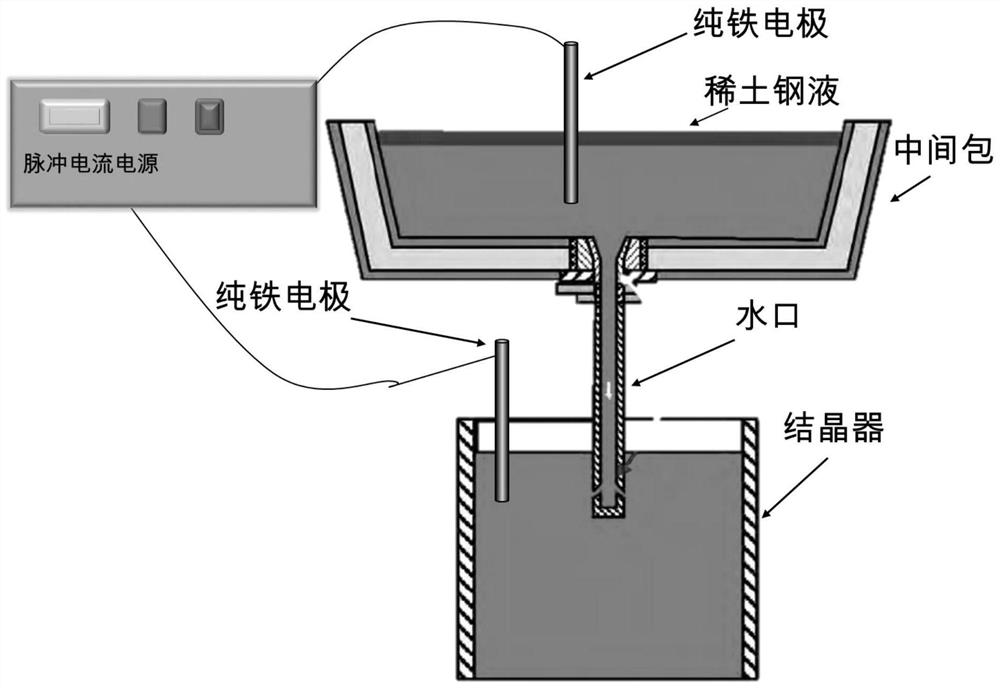

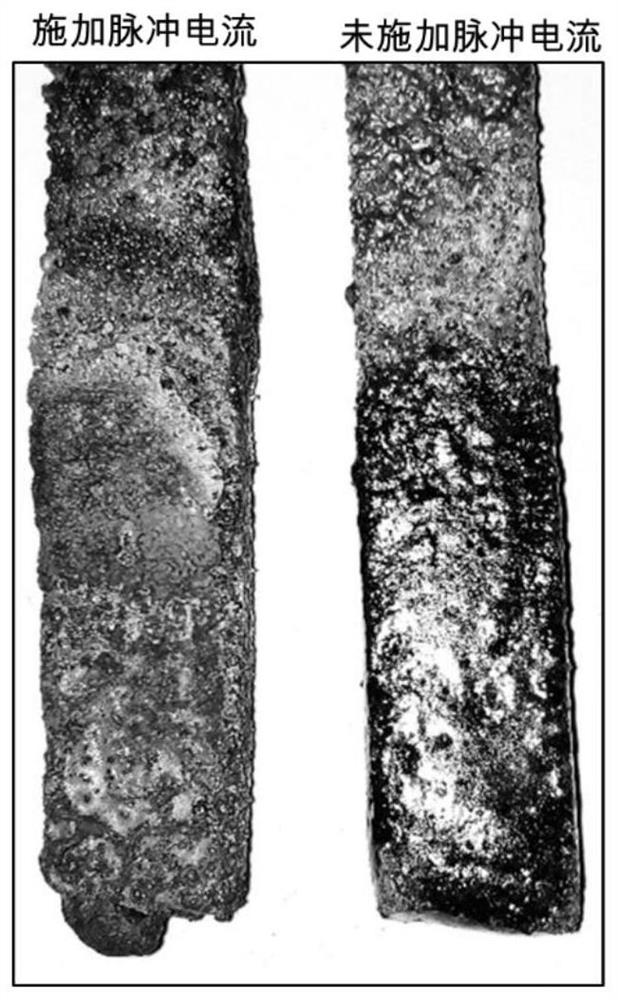

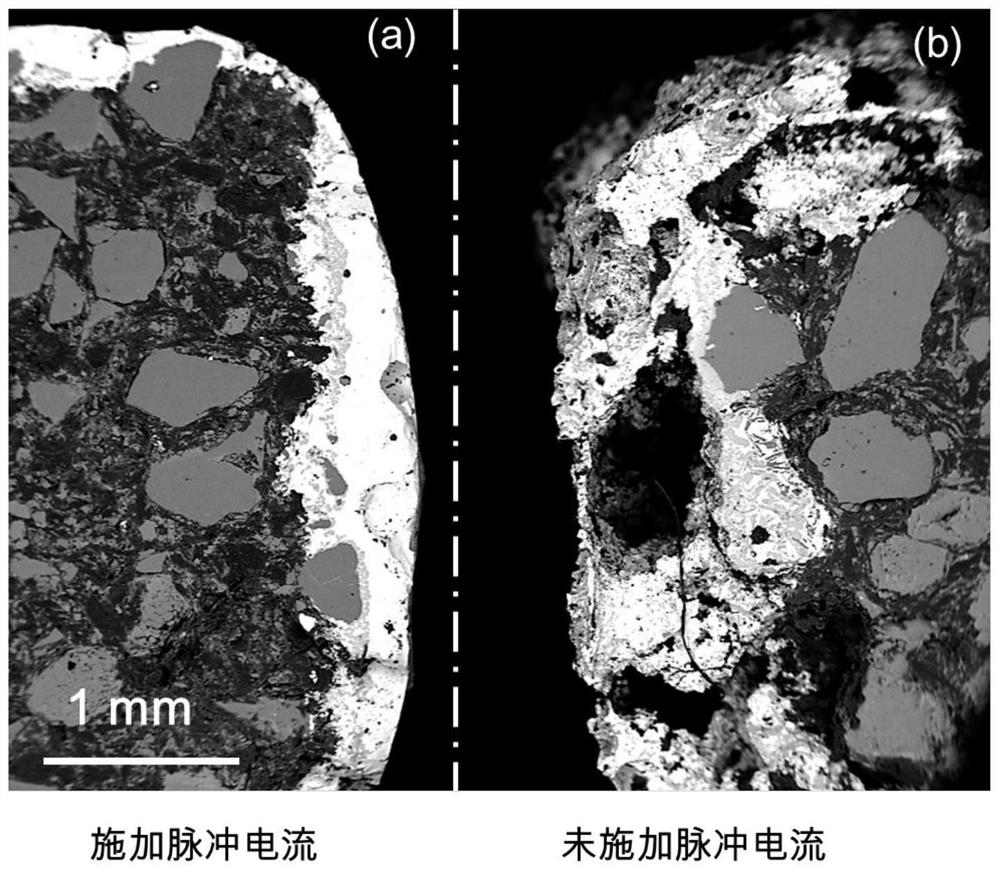

Method for inhibiting blockage of rare earth molten steel pouring nozzle through pulse currents

ActiveCN111906266AChemically activeAccelerated decarbonizationMelt-holding vesselsMischmetalEngineering

The method includes the steps that an electrode is inserted into rare earth molten steel, the pulse currents are applied to the electrode through a power supply device, the erosion reaction between the inner wall of the nozzle and an interface of the rare earth molten steel is intervened through the pulse currents, the rare earth molten steel corrosion resistance of the inner wall of the nozzle isimproved, and inclusions in the molten steel are further prevented from adhering to the inner wall of the nozzle. The method for inhibiting blockage of the rare earth molten steel pouring nozzle through the pulse currents is provided in order to solve the problems that rare earth metal elements in the molten steel erode the nozzle and rare earth inclusions adhere to the nozzle to cause nodulationand blockage of the nozzle in rare earth steel smelting and pouring, so that a rare earth steel smelting and continuous casting process is stabilized, and the quality of continuous casting billets isimproved. The invention discloses a method for inhibiting blockage of a rare earth molten steel pouring nozzle through pulse currents, and relates to the field of rare earth steel smelting and casting.

Owner:UNIV OF SCI & TECH BEIJING

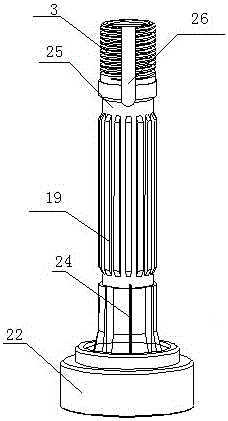

Efficient water-cooling argon arc welding gun

The invention provides an efficient water-cooling argon arc welding gun. The efficient water-cooling argon arc welding gun is composed of a handle, a gun head body, a gun head body protecting sleeve, a rear cap, a tungsten electrode rod, a tungsten electrode clamp, an inner heat insulation sleeve, an outer heat insulation sleeve, an outer connection sleeve, a spray nozzle connection ring and a ceramic spray nozzle, wherein the middle of the handle is provided with a gas inlet pipe, a water inlet pipe and a water outlet pipe; the right end of the handle is connected with a machine head body outer sleeve covering the exterior of the gun head body; the lower end of the gas inlet pipe is connected with a gas inlet hole in the side face of the upper end of the gun head body; the gas inlet hole communicates with a vertical through hole in the center of the gun head body; the tungsten electrode clamp is arranged in the middle of the vertical through hole; the tungsten electrode rod penetrates a middle hole of the tungsten electrode clamp; an annular groove is machined in the middle of the outer circle of the gun head body; the exterior of the annular groove is closely sleeved with the inner circle of the inner heat insulation sleeve, and the annular groove is closed into a water-cooling sleeve; the water inlet pipe and the water outlet pipe communicate with the water-cooling sleeve; the outer heat insulation sleeve is arranged outside the inner heat insulation sleeve; the exterior of the outer heat insulation sleeve and the inner circle at the upper end of the ceramic spray nozzle are connected together in a sleeving manner; the outer connection sleeve is arranged at the lower end of the gun head body protecting sleeve; the spray nozzle connection ring is connected to the lower end of the outer connection sleeve and connected with the outer circle at the upper end of the ceramic spray nozzle in a thread screwing manner; and the rear cap is arranged at the top end of the gun head body.

Owner:济南尼克焊接技术有限公司

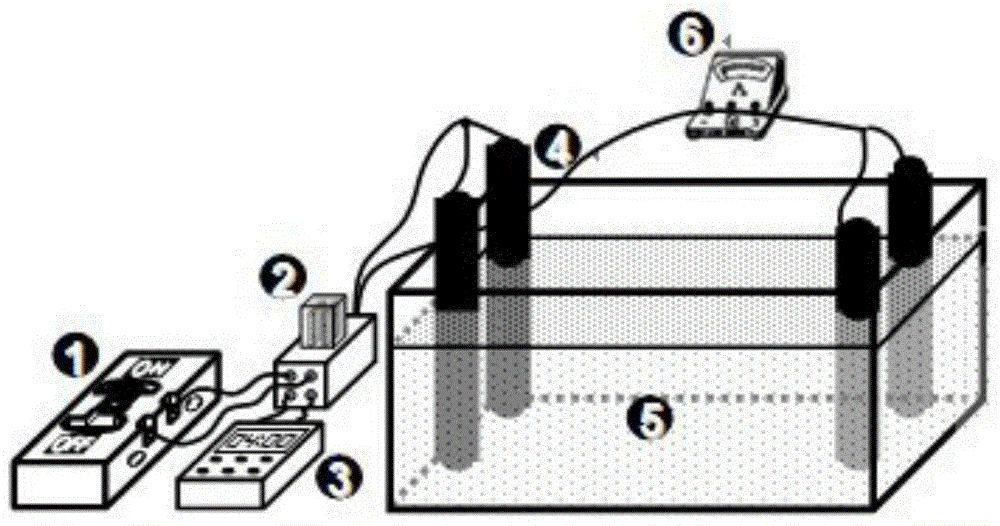

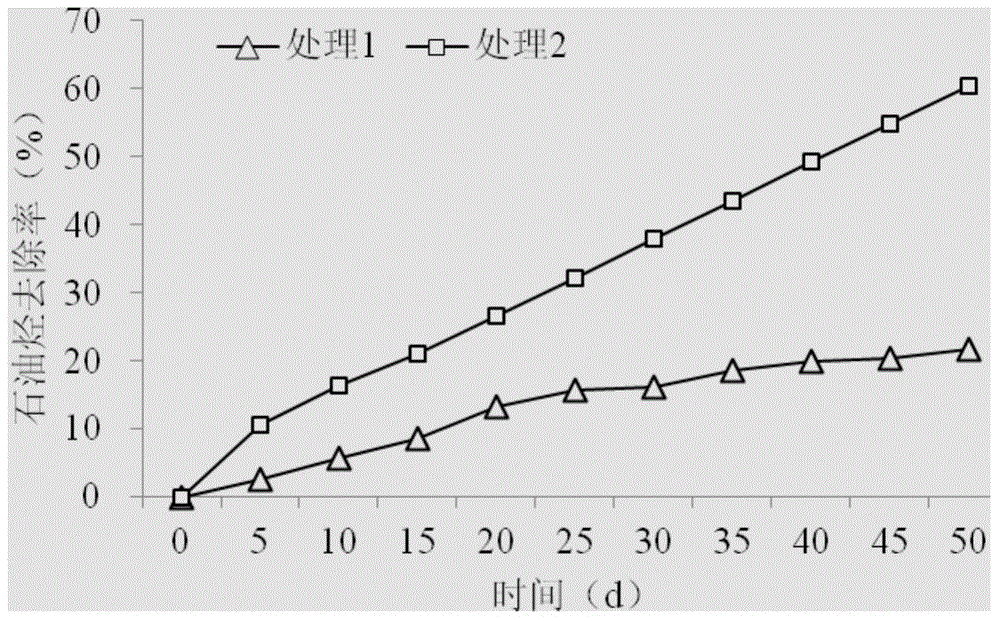

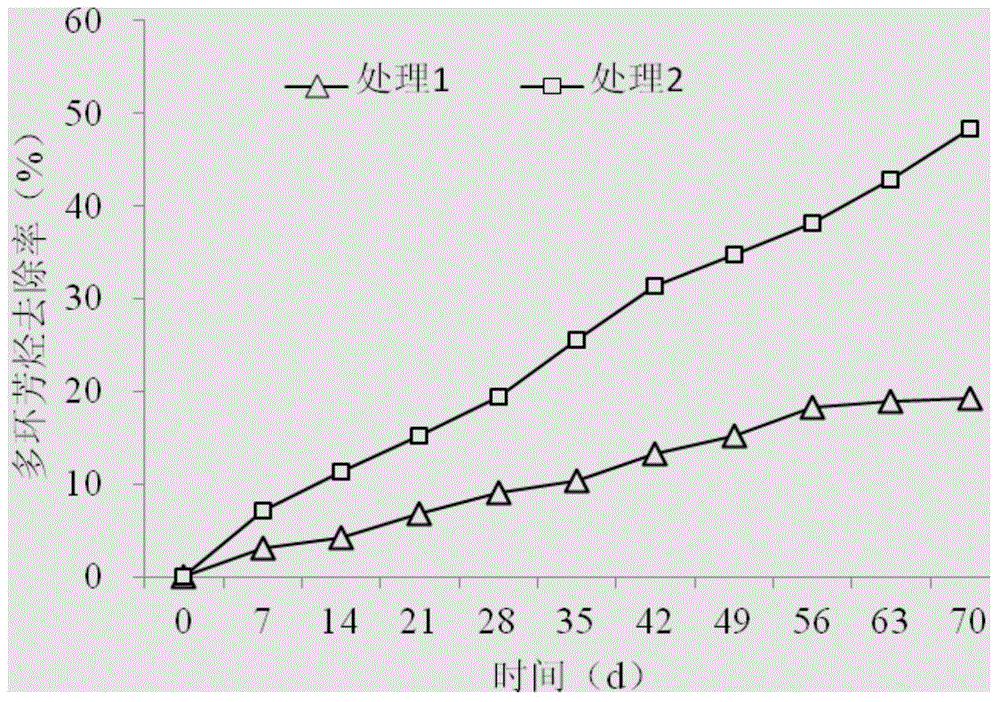

Renovating preparation for improving electric-microbial remediation of organic substance contaminated soil and using method for renovating preparation

InactiveCN104624622AHelp desorptionIncrease chance of contactAgriculture tools and machinesContaminated soil reclamationMicroorganismElectrokinetic remediation

The invention belongs to the technical field of environmental renovation, and particularly relates to a renovating preparation for improving electric-microbial remediation of organic substance contaminated soil and a using method for the renovating preparation. The preparation is prepared from the following components in percentage by weight: 10-20% of a solubilizer, 40-60% of electrolyte and the balance of water, wherein the solubilizer is one or more of Triton X-100, beta-cyclodextrin and Brij35. The renovating preparation disclosed by the invention can improve the contact efficiency of pollutants and microorganisms, and also can keep the pH of the soil unchanged, can improve the soil current intensity and can provide sufficient nutrient salts to the microorganisms, so that the electric renovating efficiency is improved by over 30%.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

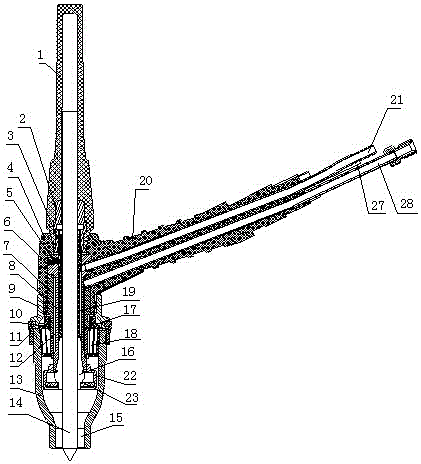

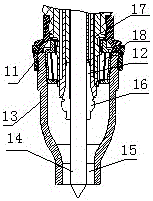

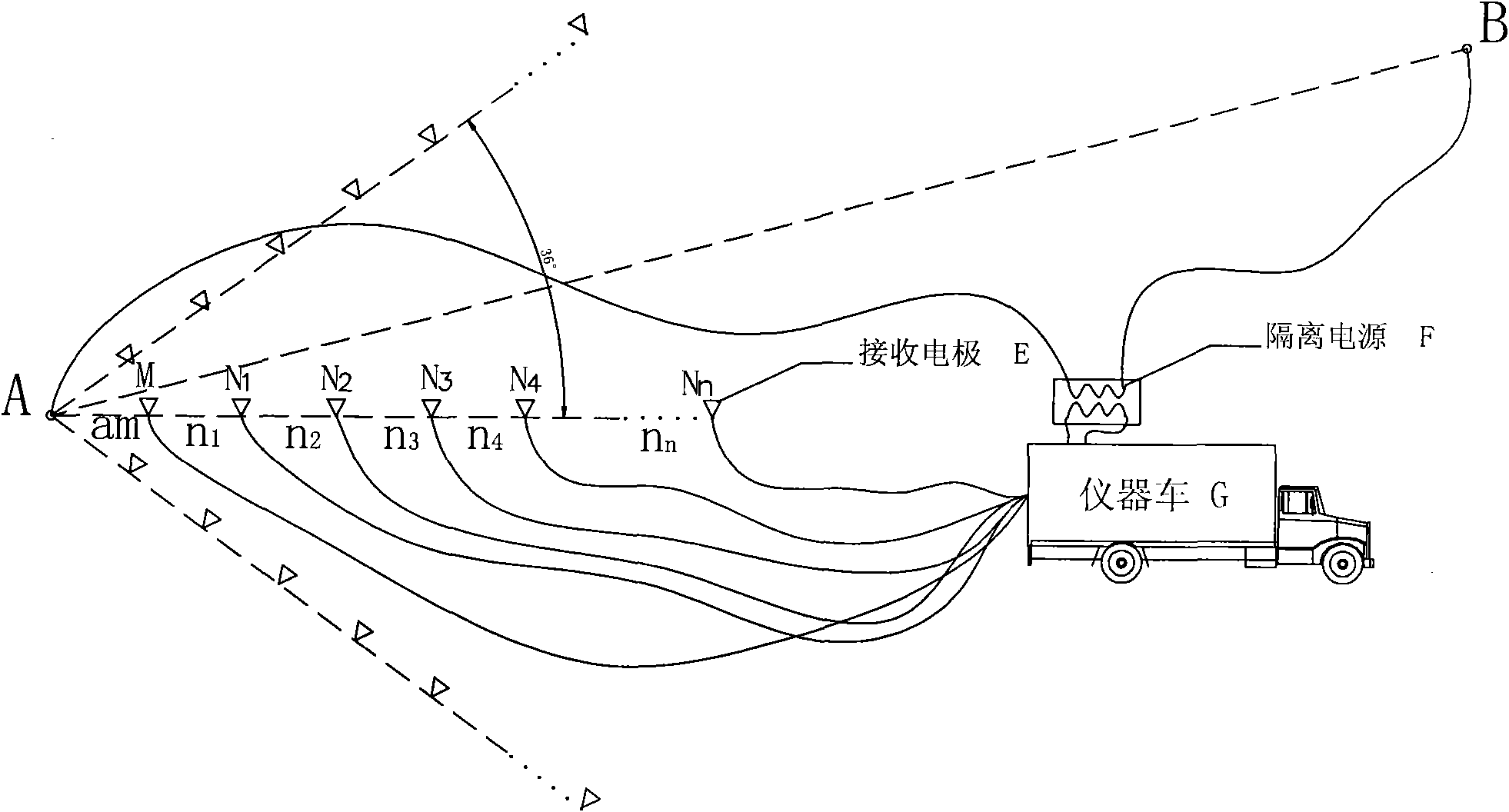

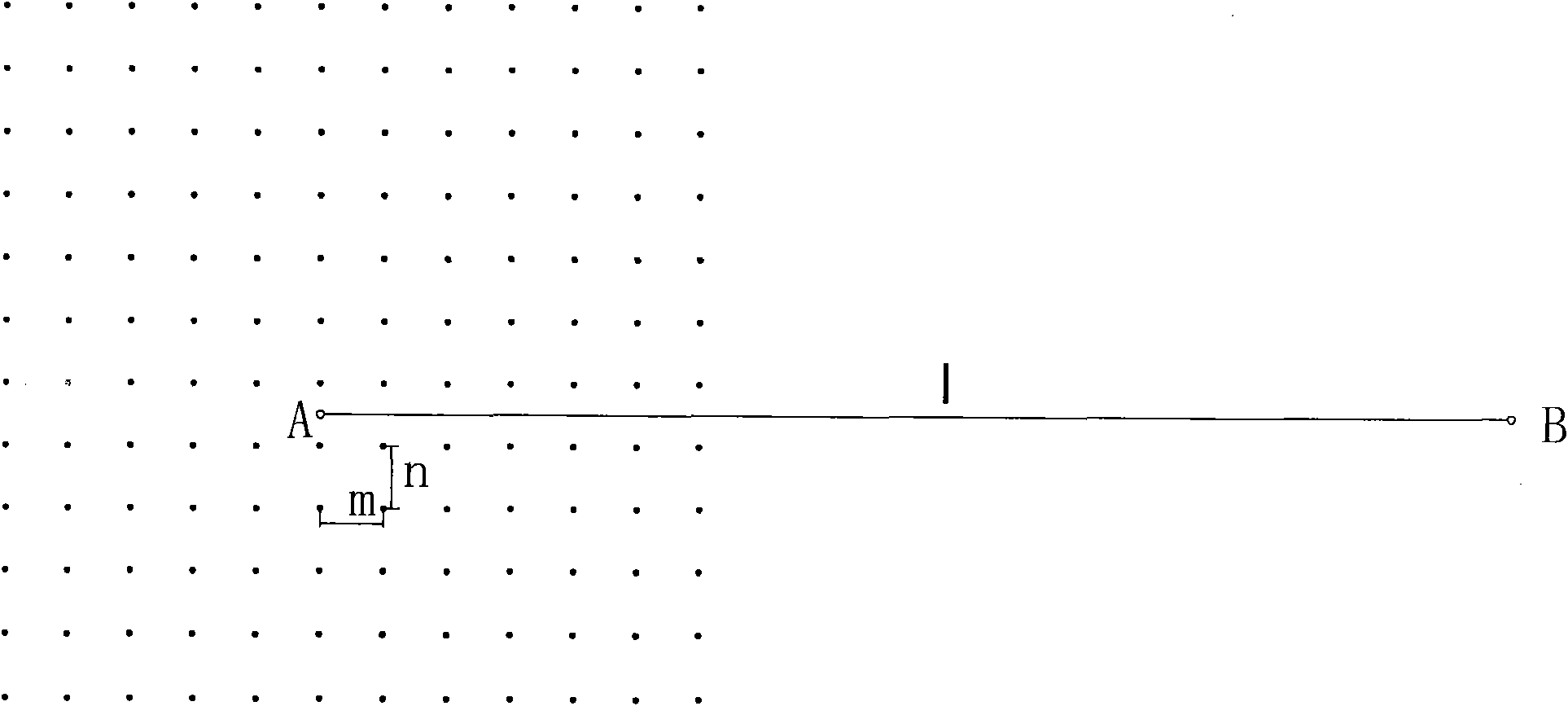

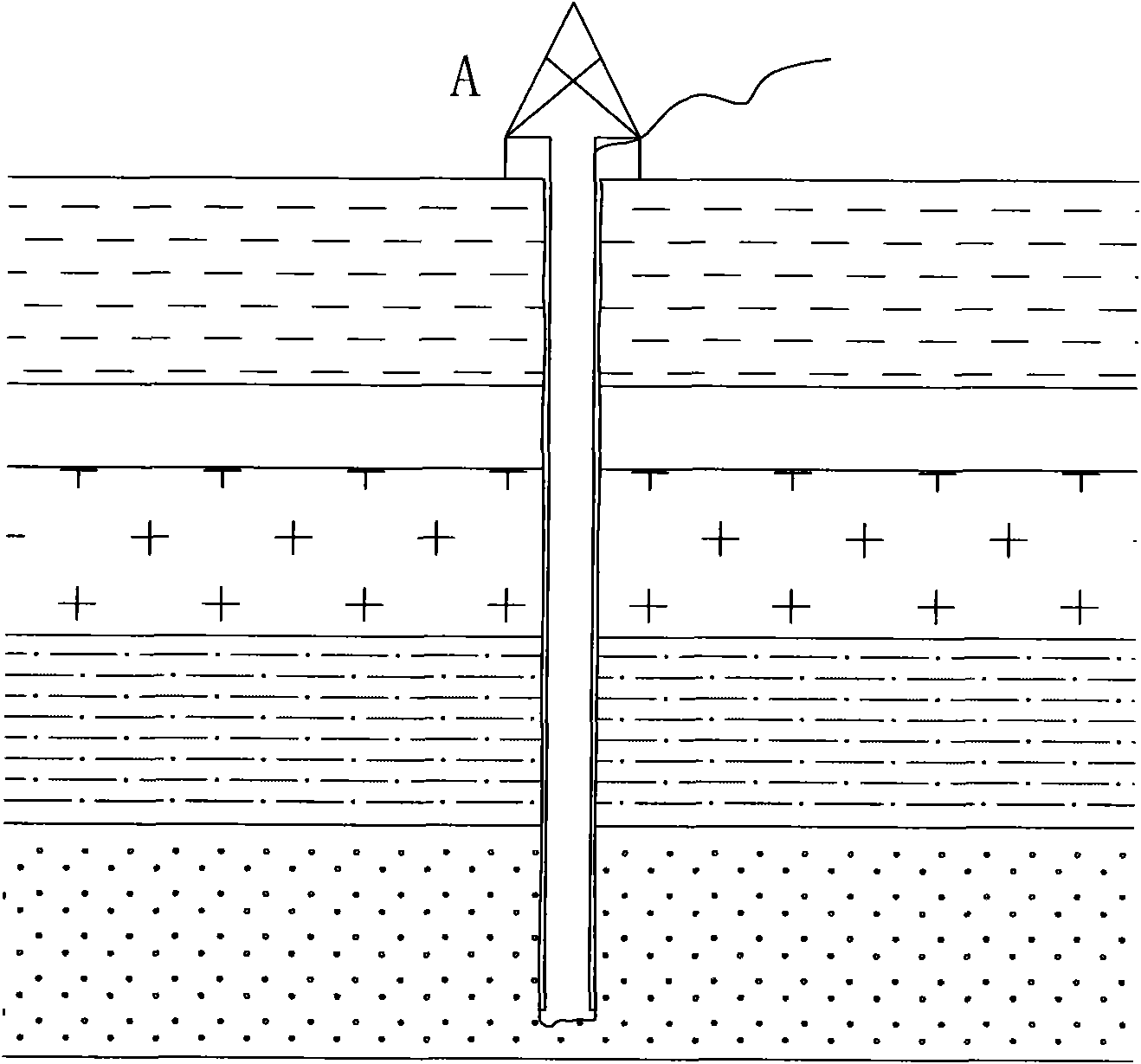

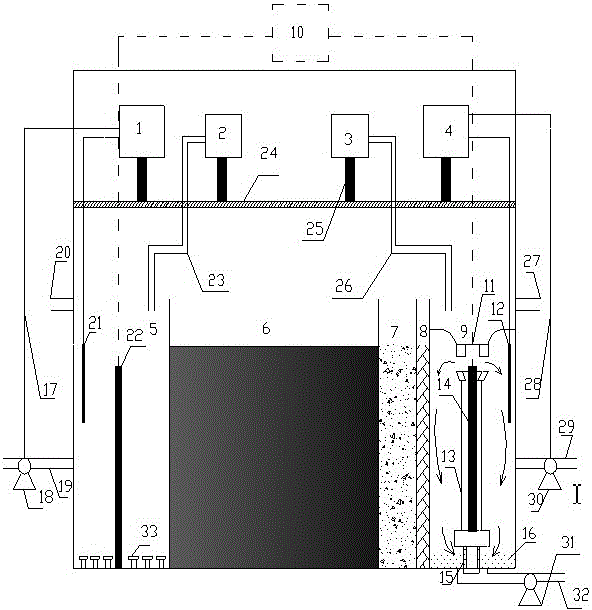

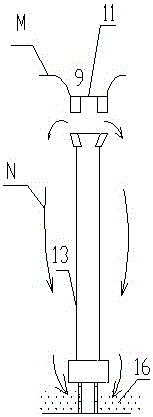

While-drilling electric method

InactiveCN101793973AReduce the impact of power supplyIncrease the current intensityElectric/magnetic detection for well-loggingAcoustic wave reradiationImage resolutionEngineering

The invention discloses a while-drilling electric method, which involves a power supply electrode A, a power supply electrode B, and a ground surface detection system, wherein the power supply electrode A is an electrode, of which the depth gradually changes from the ground surface to the underground or from the underground to the ground surface and which supplies power at a preset time interval, and is a constantly drilling drill stem of a drill or a drill stem, of which the depth constantly varies in hoisting and drilling processes of the drill, of the drill; the power supply electrode B is an electrode fixed underground and is an electrode inserted underground or a sleeve pipe placed in an in-completion well or a cable arranged in the well in which the sleeve pipe is not placed; and the ground surface detection system is arranged on the ground surface, and when an observation target well is a straight well, adopts a radial arrangement structure using the observation target well as a center, and the included angle between each two radioactive lines and the number and distance between the measurement points in each radioactive line are determined according to the requirements of observation precision and the sensitivity of the instruments. The method can improve the intensity of the current supplied to a target layer and also improve the accuracy and resolution of the detection of the target layer.

Owner:TIANJIN YINGCHI EXPLORATION TECH +1

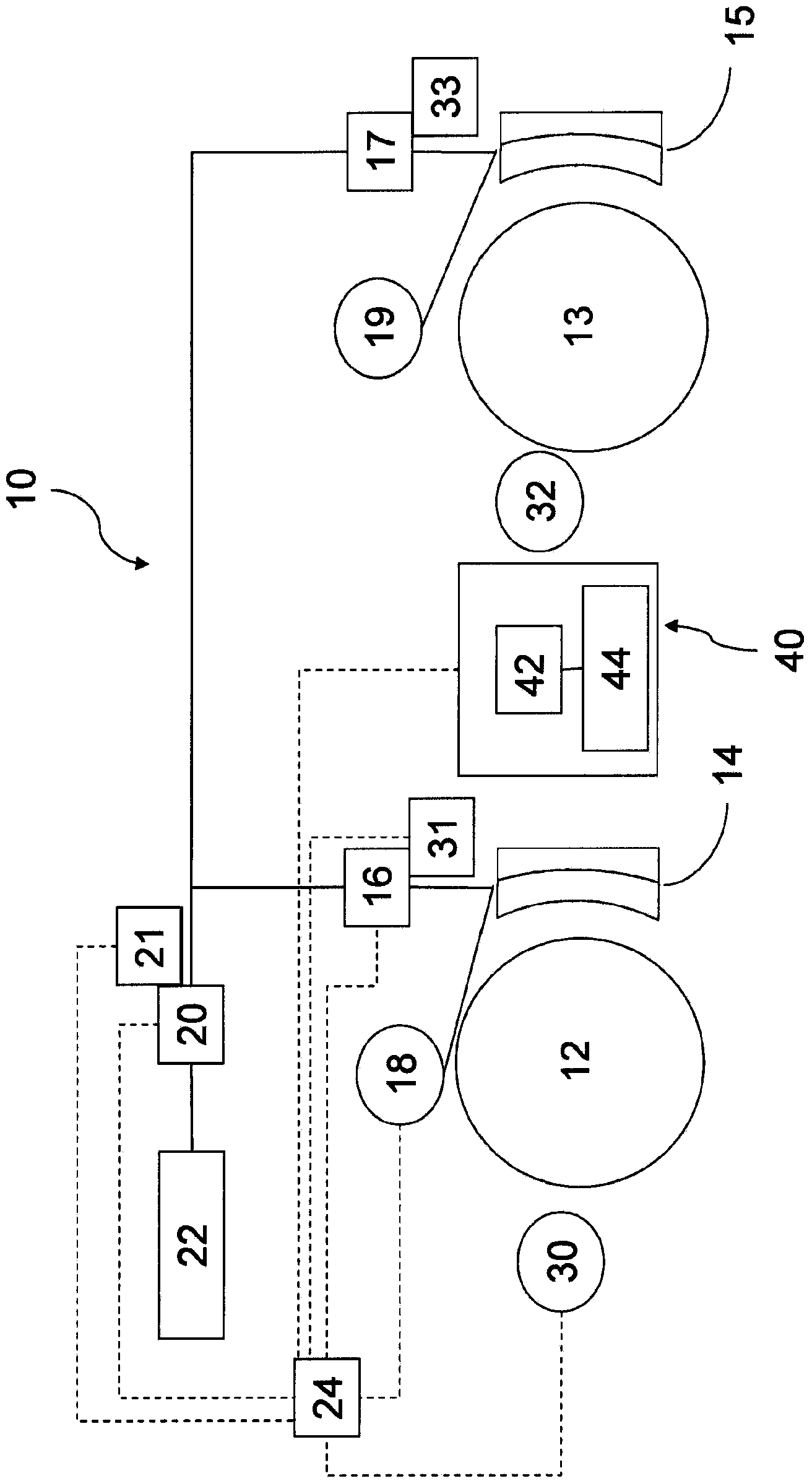

Brake system having an electromagnetic track brake device

ActiveCN103747997AChange the cleaning current strengthWill not loadBraking element arrangementsRail brake actuationPower flowEngineering

The invention relates to a brake control device (24) for a brake system (10), wherein the brake system (10) has at least one electromagnetic track brake device (40), which can be supplied with current at variable amperage according to the brake control device (24) in order to create a braking force, and wherein the brake control device (24) is designed to actuate the at least one electromagnetic track brake device (40) at a cleaning amperage during travel in order to clean a rail. The invention further relates to a brake system having such a brake control device, a rail vehicle, and a method for cleaning a rail by means of an electromagnetic track brake device.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

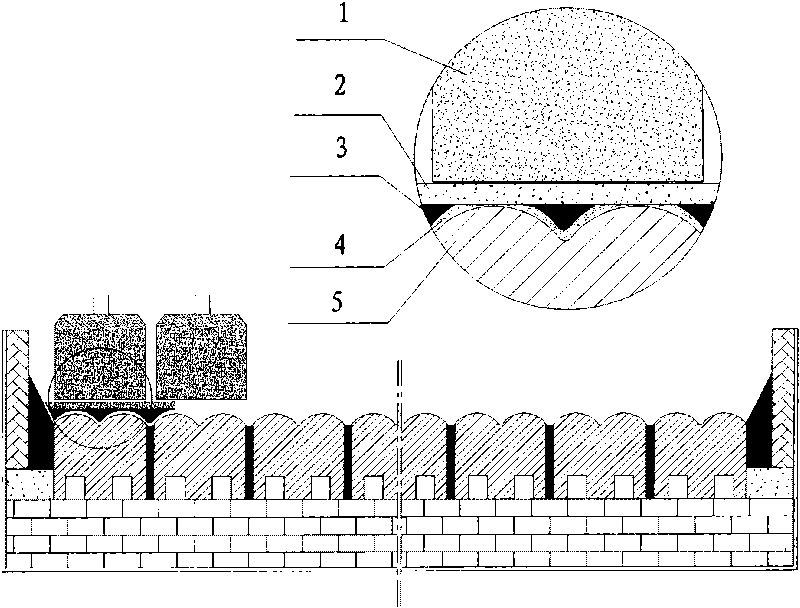

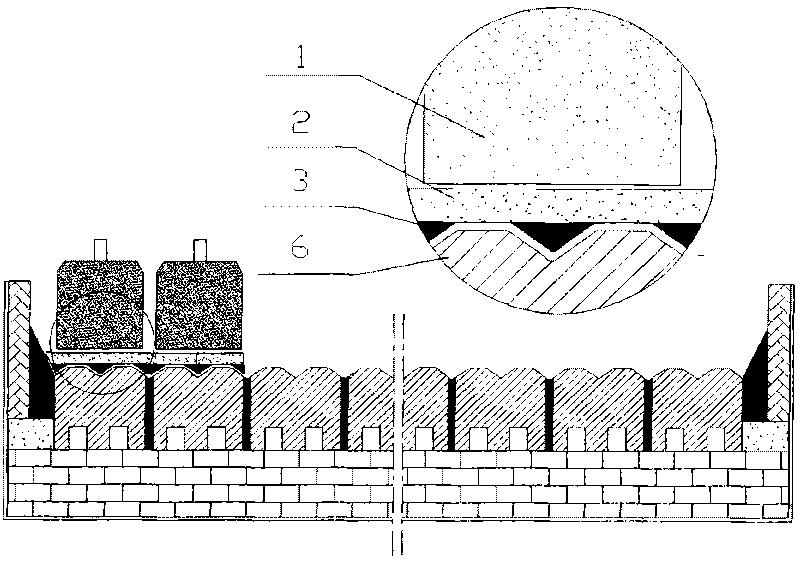

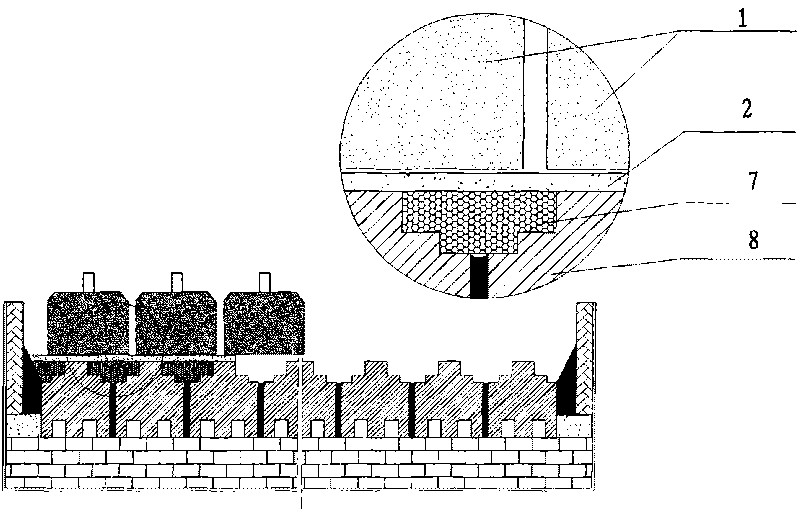

Method for roasting aluminum electrolytic bath with polymorphic structure cathode

InactiveCN101724859AAvoid thermal shockSolve the problem of uneven distribution of cathode currentThermal shockElectrolyte

The invention discloses a method for roasting an aluminum electrolytic bath with a polymorphic structure cathode, which comprises the following steps of: filling a concave part on the surface of the polymorphic structure cathode with aluminum powder or aluminum blocks with shapes corresponding to that of the concave part to ensure that the filled surface and a convex surface of the polymorphic cathode are in the same horizontal plane; paving a layer of coke particles on a plane of the cathode; hanging an anode on the layer of the coke particles, and electrifying and roasting the aluminum electrolytic bath until 60 to 70 percent of the area of the surface of the cathode reaches or exceeds 900 DEG C; and when over 60 percent of the area in the electrolytic bath has a fused electrolyte with the thickness of 10 centimeters, infusing the electrolyte into the electrolytic bath to perform a wet method or adopt a dry method to start the roasting. The aluminum block / powder-coke particle composite roasting technique is favorable for the even distribution of the current and the temperature on the surface of the cathode and the reduction of heat vibration, thereby not only preventing an aluminum liquid roasting method from performing thermal shock on an inner lining of the cathode, but also solving the problems of uneven distribution of the current of the cathode and the like caused by large differences of the coke particle thickness when the aluminum electrolytic bath with the polymorphic structure cathode singly adopts coke particle roasting, and improving the roasting quality of the inner lining of the cathode.

Owner:CENT SOUTH UNIV

Intelligently-manufactured moisture-proof and dust-removing electrical cabinet

InactiveCN112366533ALower the resistance valueIncrease the current intensityElectrostatic cleaningSubstation/switching arrangement casingsDust controlEnvironmental engineering

The invention relates to the technical field of electrical cabinets, and discloses an intelligently-manufactured moisture-proof and dust-removing electrical cabinet. The electrical cabinet comprises acabinet body, water absorption blocks are fixedly installed at the upper end and the lower end of the cabinet body, water guide pipes are fixedly connected to the ends, close to the interior of the cabinet body, of the water absorption blocks, and water swelling water stop strips are fixedly installed at the ends, away from the water absorption blocks, of the water guide pipes. A spring is fixedly installed at the end, away from the middle of the cabinet body, of each water-swelling water stop strip, and push rods are fixedly installed at the ends, away from the water-swelling water stop strips, of the springs. According to the intelligently-manufactured moisture-proof and dust-removing electrical cabinet, an air bag is automatically compressed after excessive dew is condensed, the air bag sprays out a drying agent through a spray head to dry the interior of the electrical cabinet, dew is prevented from corroding internal elements, the service life is prolonged, a dust collection discdrives a wool rod and a rubber rod to rub to generate an electrostatic field to adsorb dust in air, and dust is collected to facilitate centralized cleaning, so that the service life of equipment isprolonged.

Owner:王敏

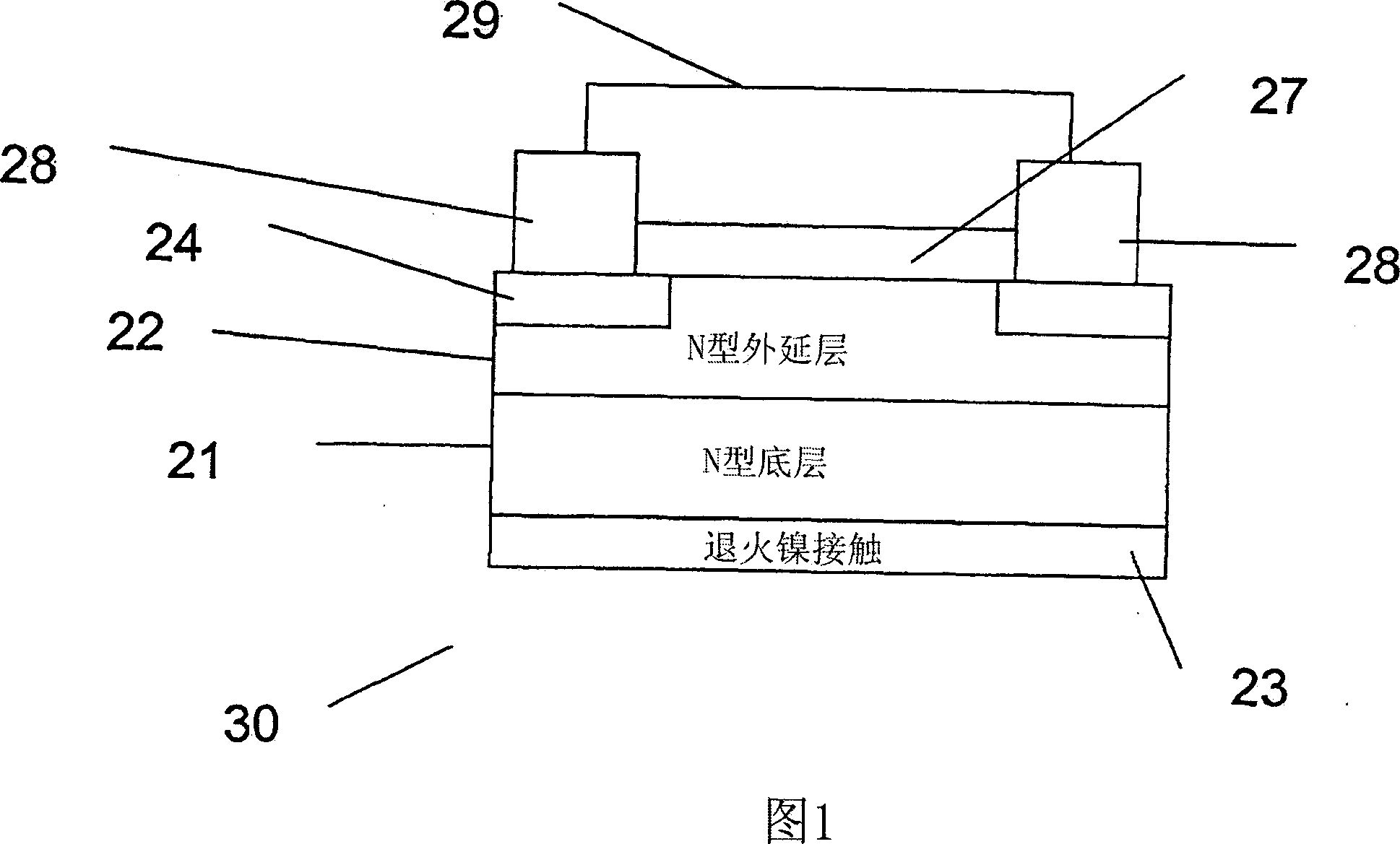

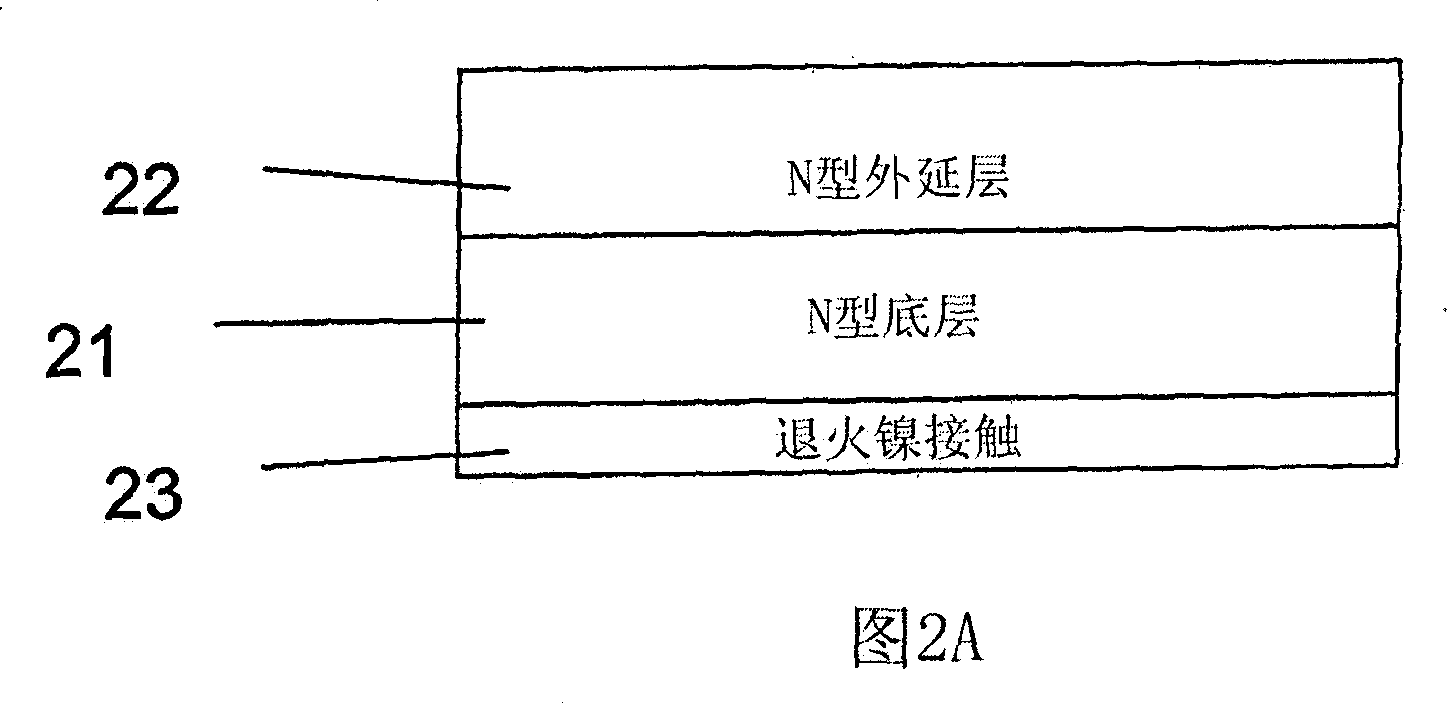

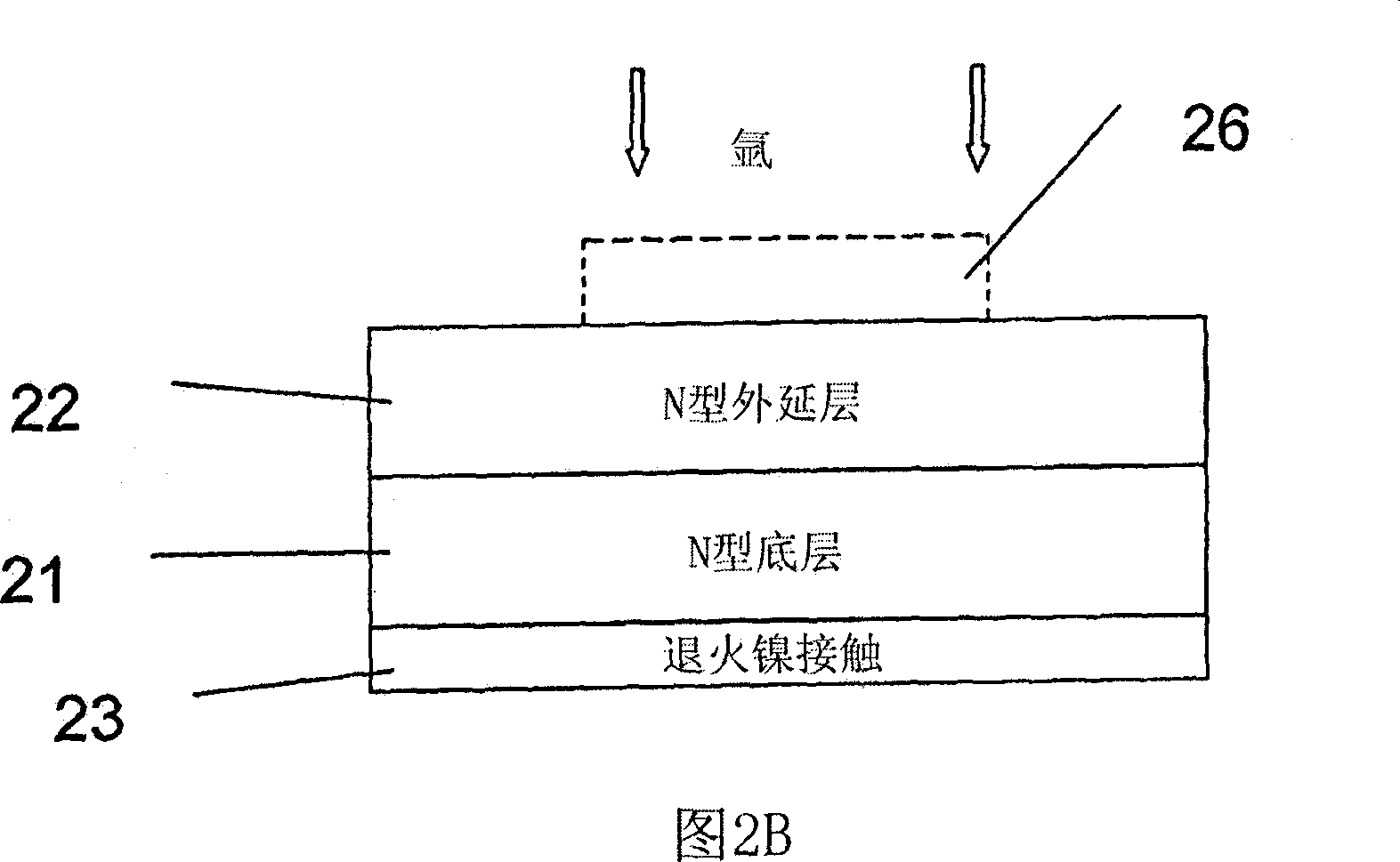

Method and device with durable contact on silicon carbide

ActiveCN1961427AGuaranteed contactSolve the problem of easy degradationTransistorSemiconductor/solid-state device manufacturingSchottky barrierMetal

Owner:FAIRCHILD SEMICON CORP

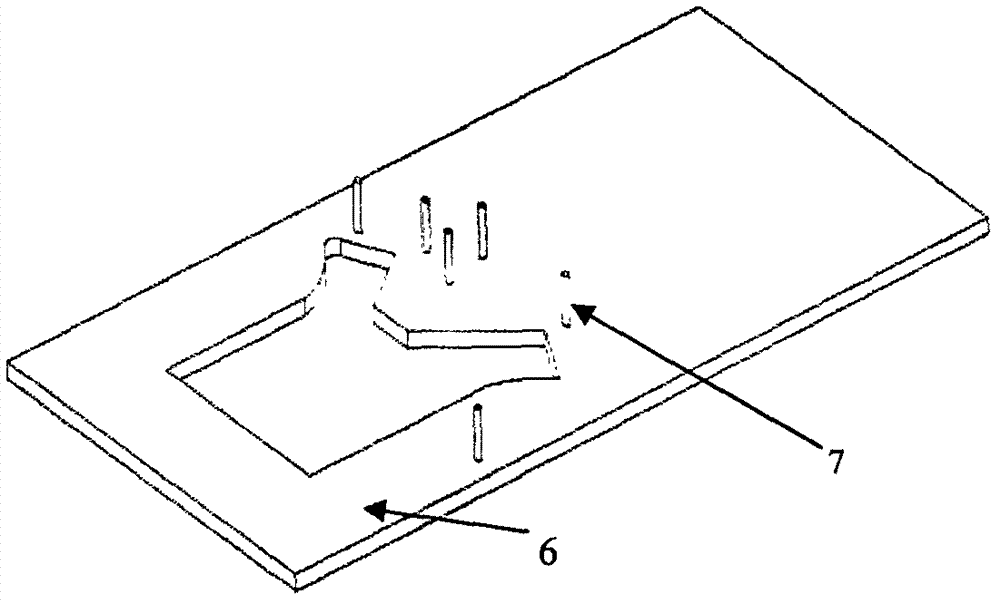

Automatic fill light suspended sash window for breeding factory

InactiveCN109267893AReduce concentrationReduce morbidityPower-operated mechanismWing arrangementsCapacitanceSash window

The invention discloses an automatic fill light suspended sash window for a breeding factory. The window comprises a window frame and a window body, wherein two side walls of the window frame are symmetrically provided with rotating grooves, two side walls of the window body are symmetrically provided with rotating shafts, and the rotating shaft are inserted into the rotating grooves and in rotating connection with the rotating grooves. The upper end side wall of the window frame is provided with a mounting cavity, and the mounting cavity is provided with a first magnetic strip. The outer sidewall of the first magnetic strip is sleeved with an excitation coil, and the magnetic field directions of the first magnetic strip and the excitation coil are the same. The side wall on one side of the window body is provided with a second magnetic strip, and the opposite sides of the second magnetic strip and the first magnetic strip are same in polarity. A liquid storage chamber is arranged inthe window body and filled with electrorheological fluid. The upper and lower side walls of the window body are provided with a placement chamber provided with a capacitance board. The automatic filllight suspended sash window can automatically compensate the light in a shed. At the same time, the window body can be opened automatically for ventilation.

Owner:张冉

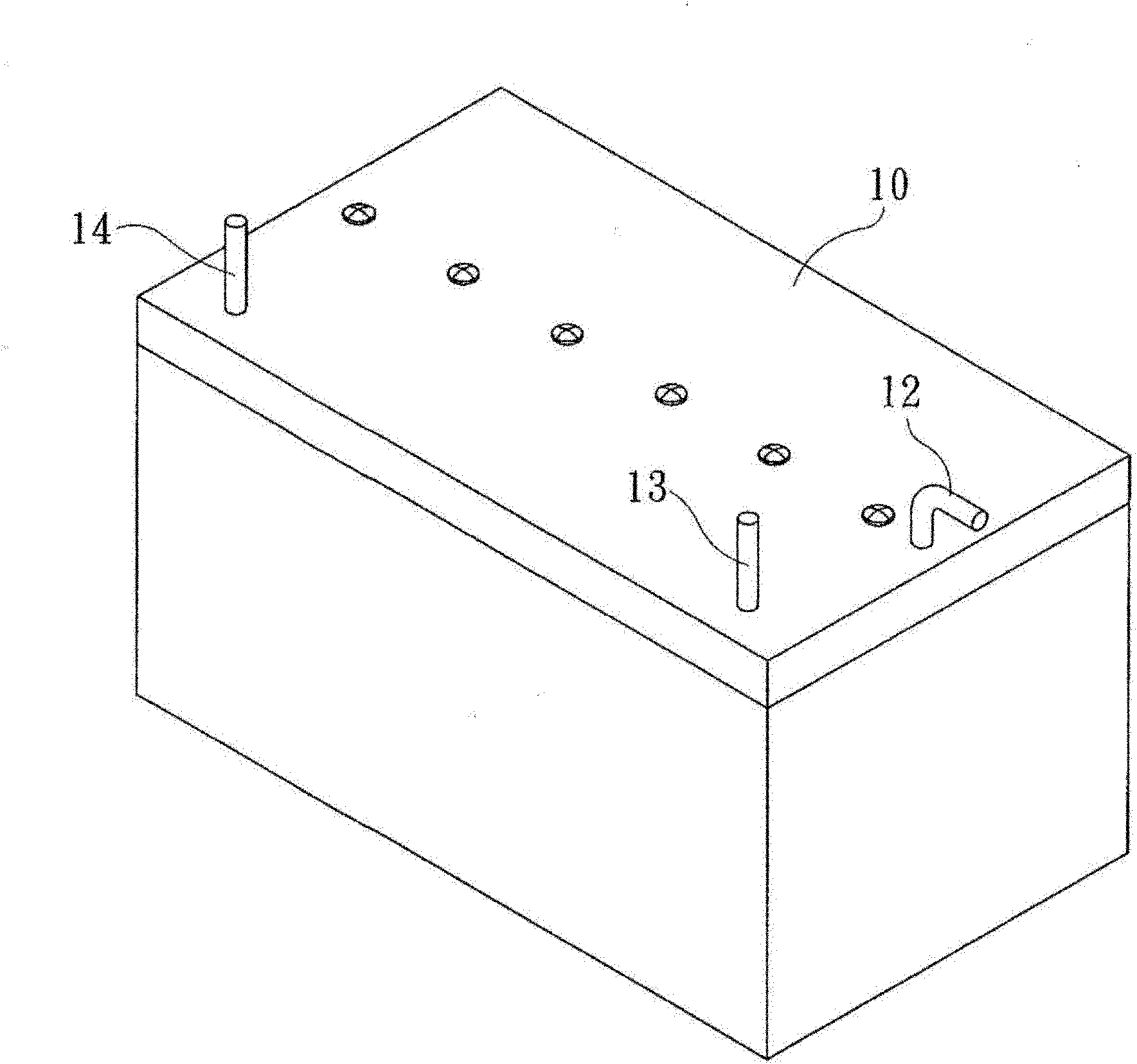

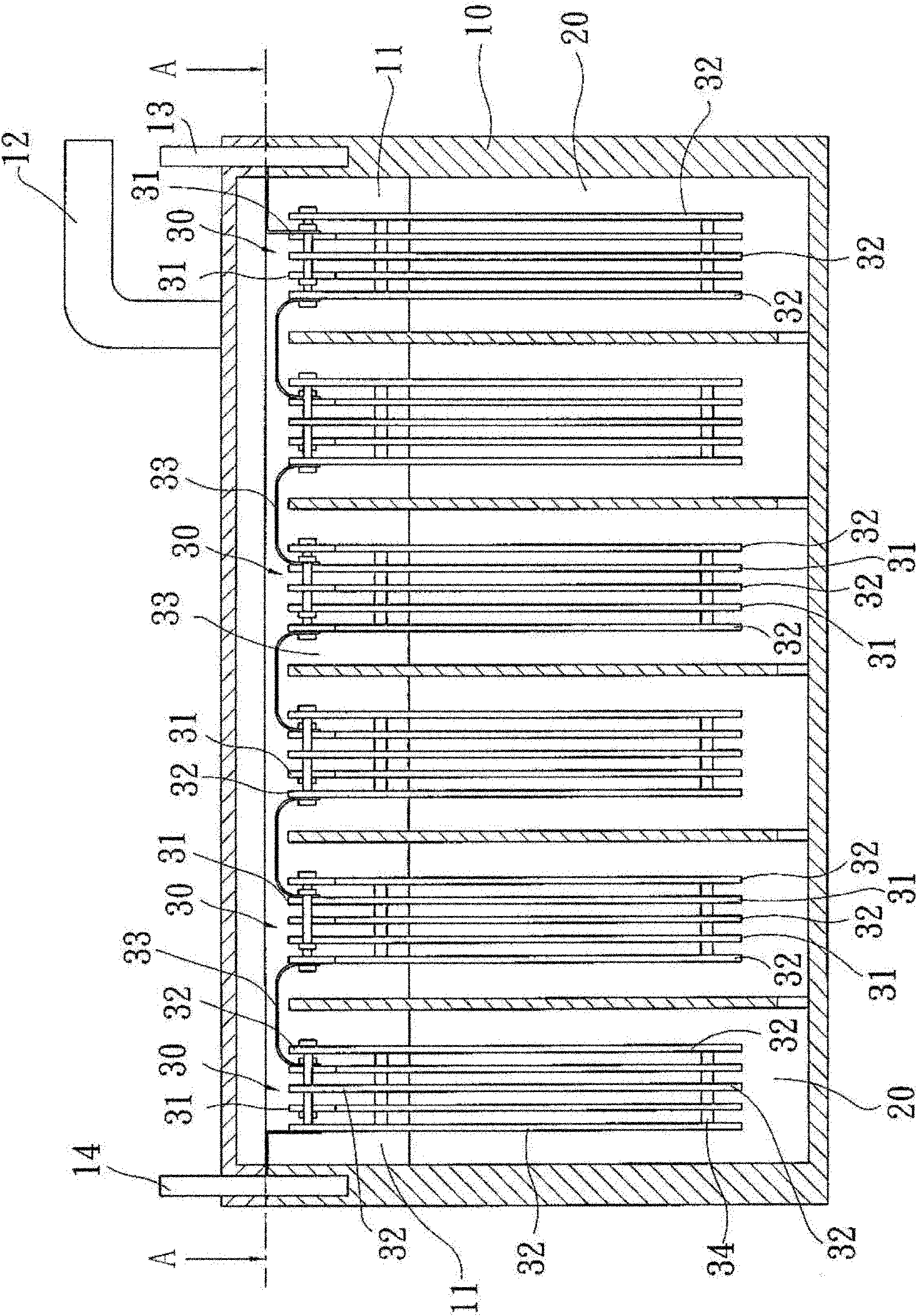

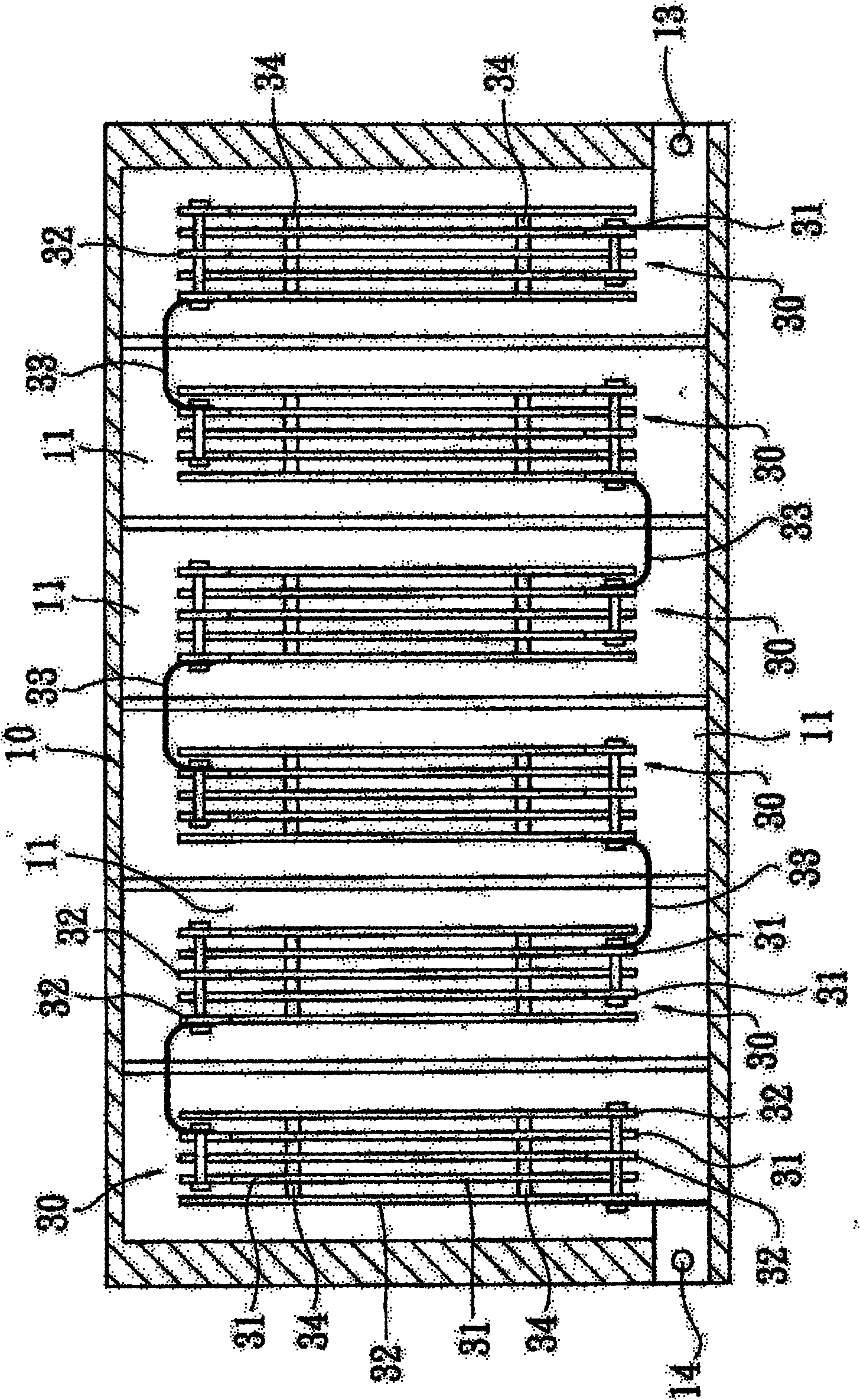

Zinc-air battery pack employing vertical circulation of electrolyte

ActiveCN105914430AImprove current intensity deficiencyEasy to remove and replaceFuel and primary cellsZincEngineering

The invention discloses a zinc-air battery pack employing vertical circulation of an electrolyte. The zinc-air battery pack comprises a box body, a top plate, zinc electrode support frames, zinc anode plates, zinc electrode conducting plates, an anode terminal, air cathode plates, an air electrode conducting plate and a cathode terminal. The zinc anode plates and the air cathode plates are arranged at an included angle which is greater than 0 and smaller than 180 degrees from the horizontal plane, so that the defect of insufficient current intensity caused by an electrode putting way is improved. Meanwhile, a detachable form is adopted by the zinc anode plates and the air cathode plates, so that late maintenance, replacement and disassembly are relatively simple and convenient. Certain gaps exist between the zinc anode plates and the air cathode plates; after the height of the horizontal liquid level of the electrolyte exceeds the heights of the zinc anode plates, the electrolyte drops down along the gaps in a form similar to a waterfall due to the action of gravity; the electrolyte contacts the zinc anode plates and the air cathode plates in the dropping process; and batteries are discharged immediately. Therefore, the space utilization rate of the battery pack is improved; and relatively high current density is generated.

Owner:HEBEI UNIV OF TECH

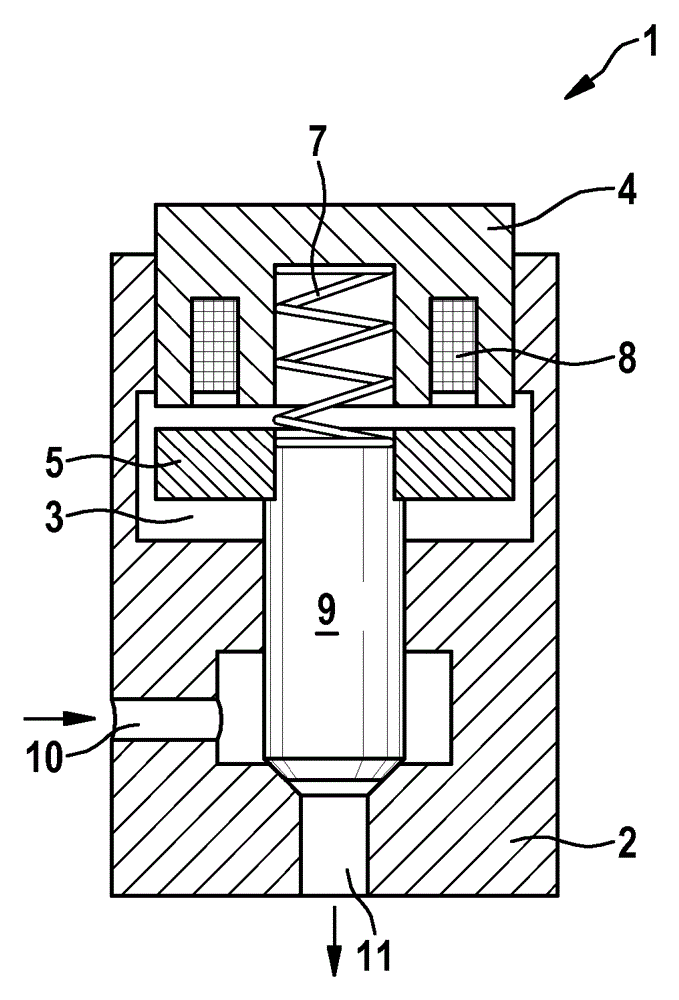

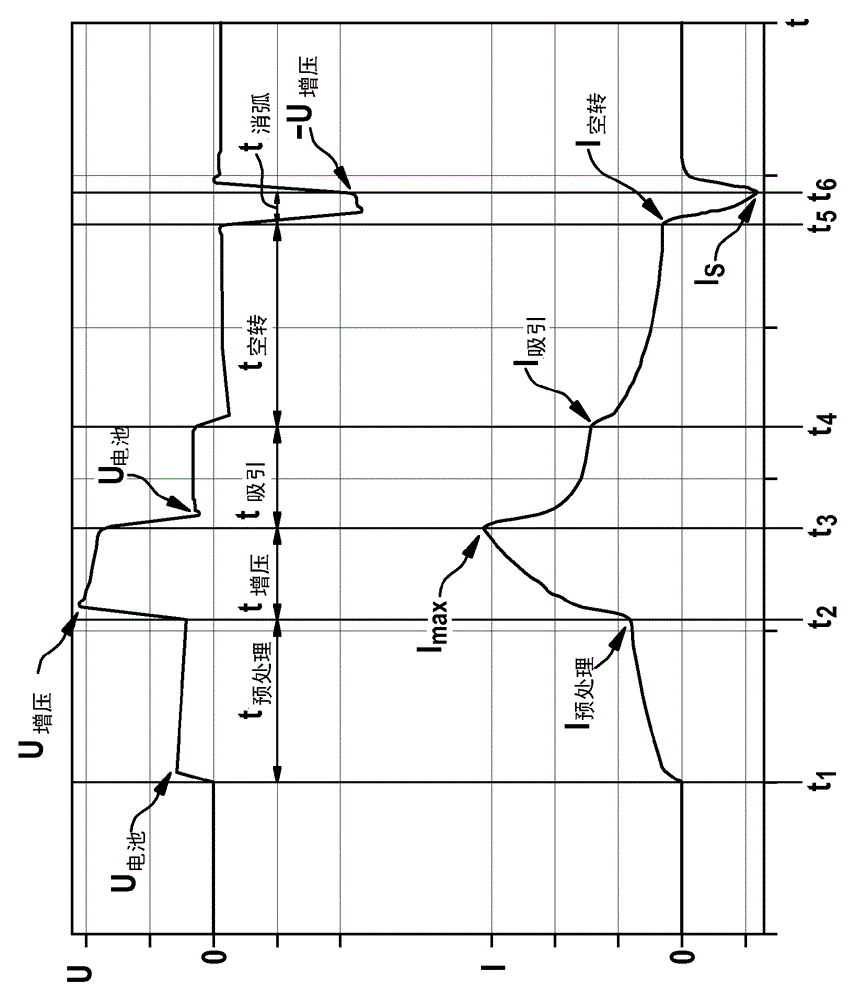

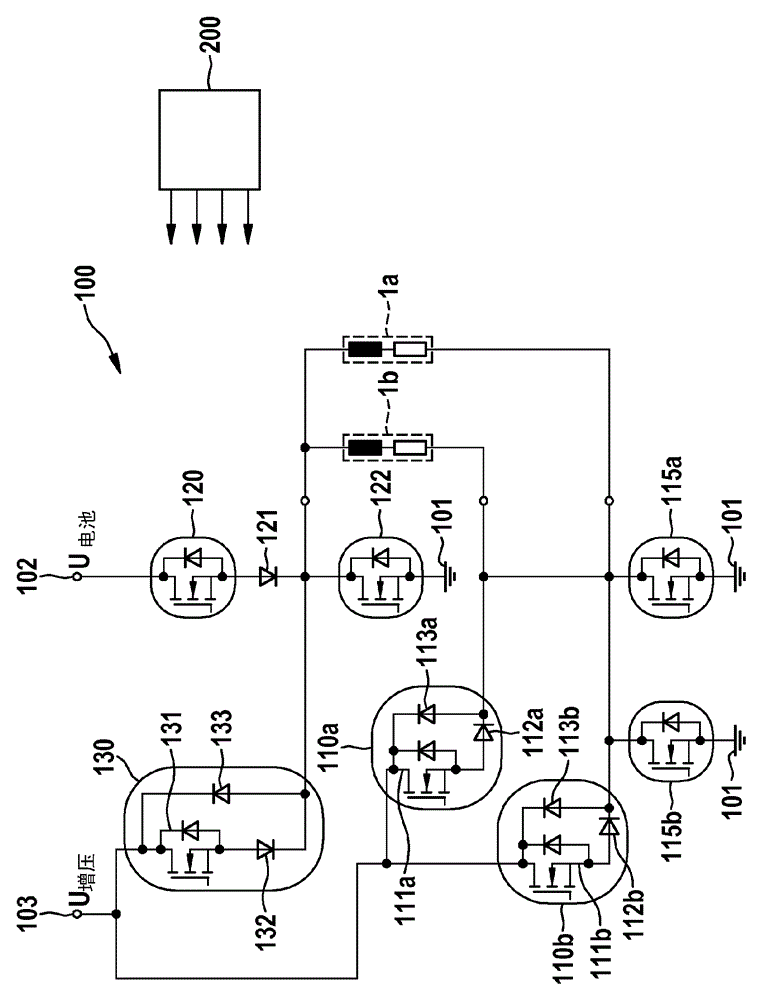

Method for controlling an injection process of a magnetic injector

ActiveCN105009232AEliminate magnetic field energyDuration determinedElectrical controlFuel injection apparatusEngineeringInternal combustion engine

The invention relates to a method for controlling an injection process of a magnetic injector of an internal combustion engine, wherein the magnetic injector has a coil. In order to open the magnetic injector, the coil is charged with a first current (IVK, Imax, Ipull). In order to keep the magnetic injector open, the coil is short-circuited, and in order to close the magnetic injector, the coil is charged with a second current (1s), wherein the second current (1s) is directed in the opposite direction of the first current (IVK, Imax, IAnzug).

Owner:ROBERT BOSCH GMBH

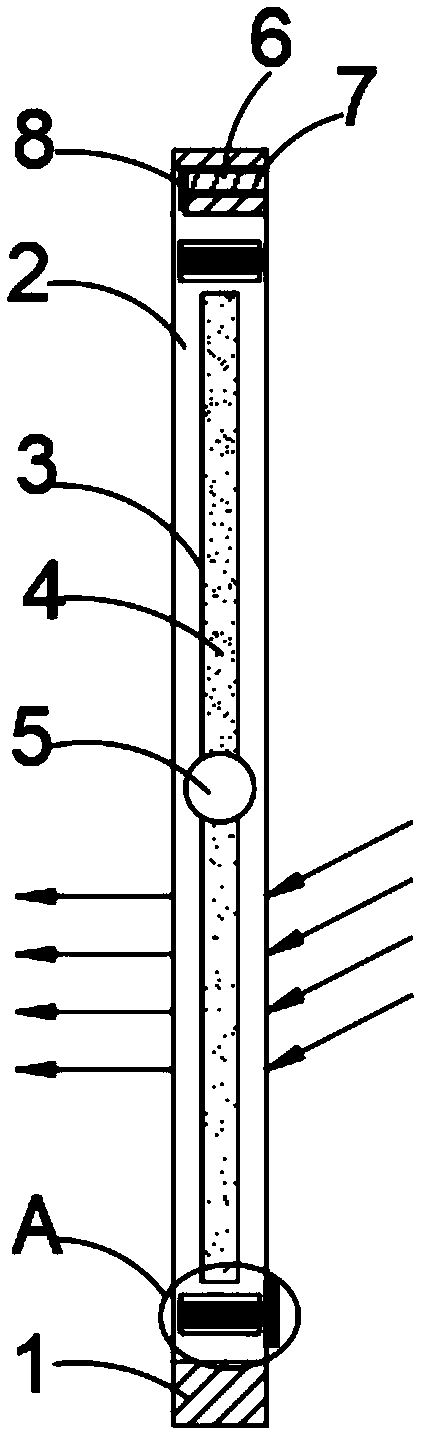

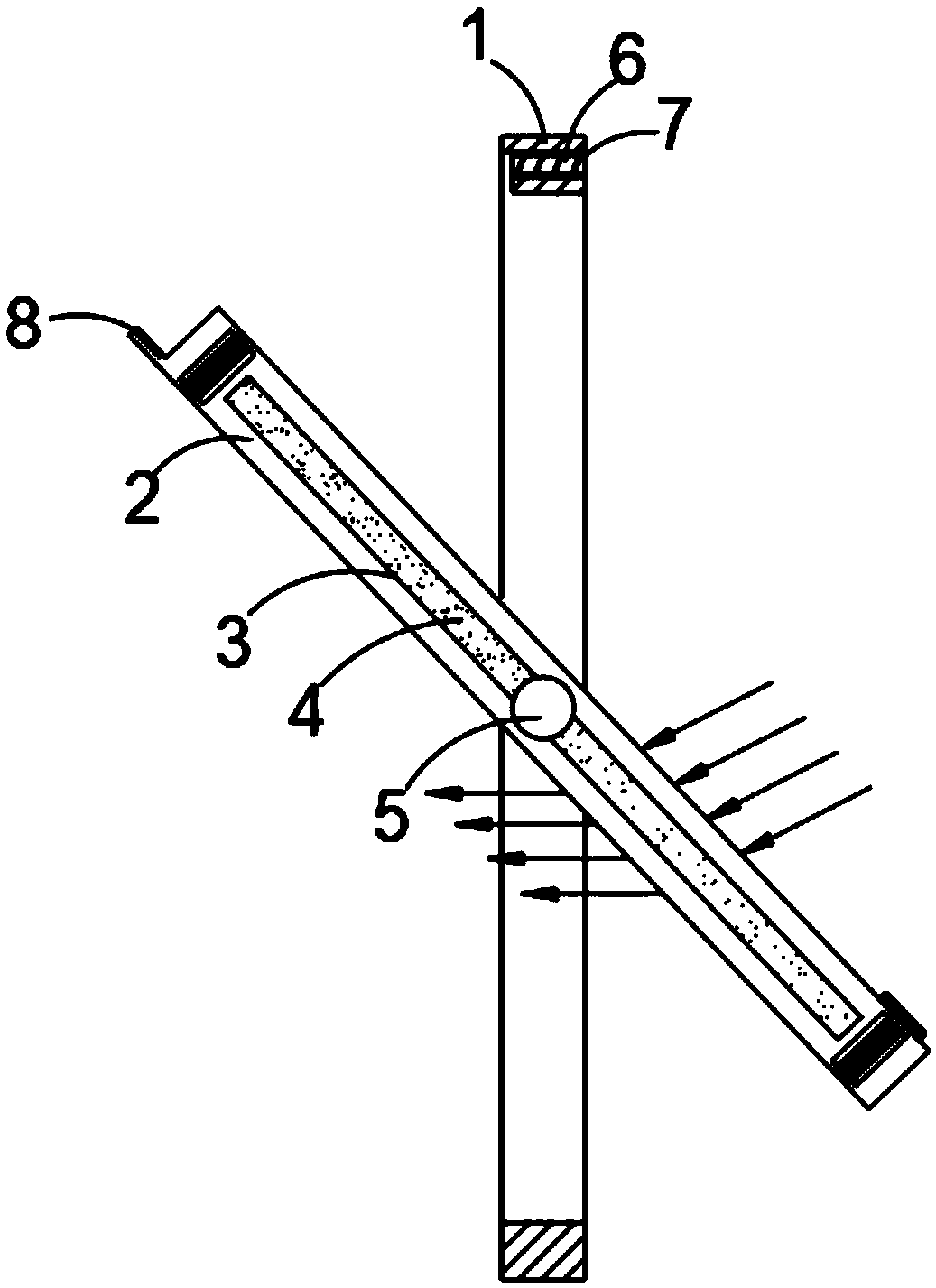

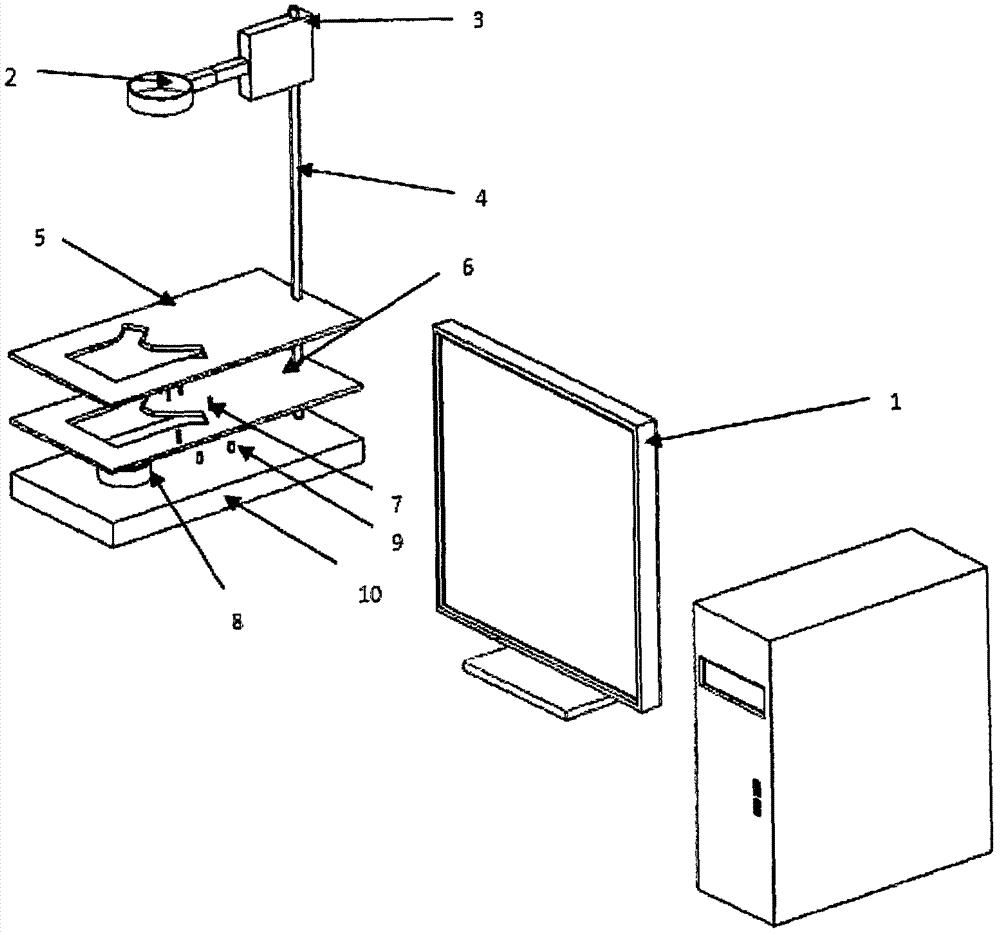

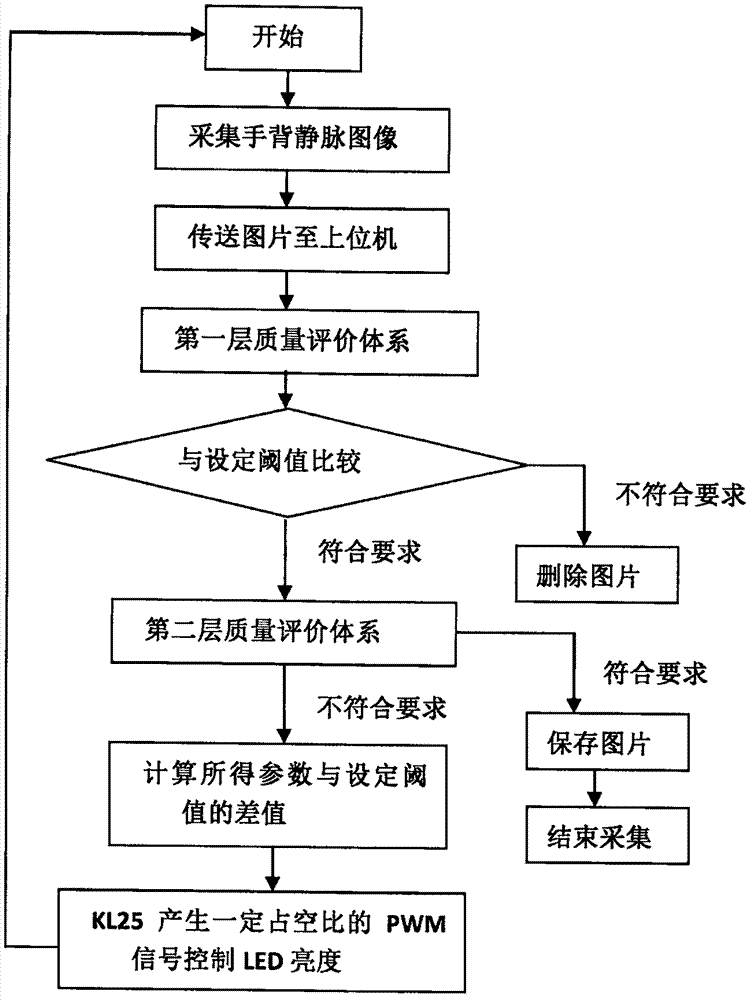

High-quality vein image development system

InactiveCN107169428AAmperage adjustmentIncrease the current intensityCharacter and pattern recognitionWavelength filterDisease patient

The invention discloses a high-quality hand back vein image development system and relates to the research fields of bio-feature identification, high-precision medical vein assisted injection and the like. By improving vein image collection quality, the problems of difficult vein image information-based identity authentication, difficult vein injection of partial disease patients due to fuzzy hand back veins, and the like are solved. The system mainly consists of a computer, a single-chip microcomputer, upper computer software, a near-infrared light source, an LED driving module, a near-infrared CCD camera, a specific-wavelength light filter, a camera fixing slot, a fixing ring, a support rod, a vein image shooting template, a palm placement template, a near-infrared light source placement box and a base. According to the system, the LED driving module is controlled to adjust the magnitude of a current through the single-chip microcomputer according to a corresponding relationship between a difference value of a parameter value of a hand back vein image and an empirical threshold preset according to statistics, and current intensity, so that the radiation intensity of a near-infrared LED is adjusted and the high-quality hand back vein image meeting the requirements is obtained.

Owner:杨明远

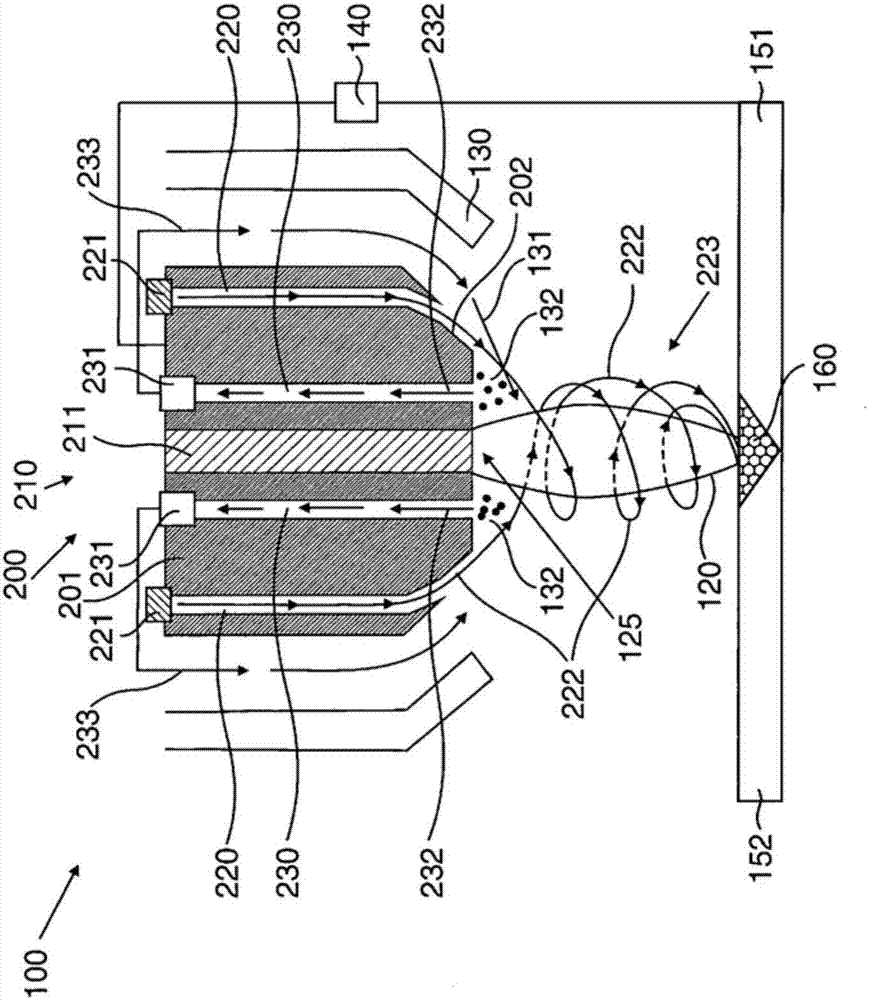

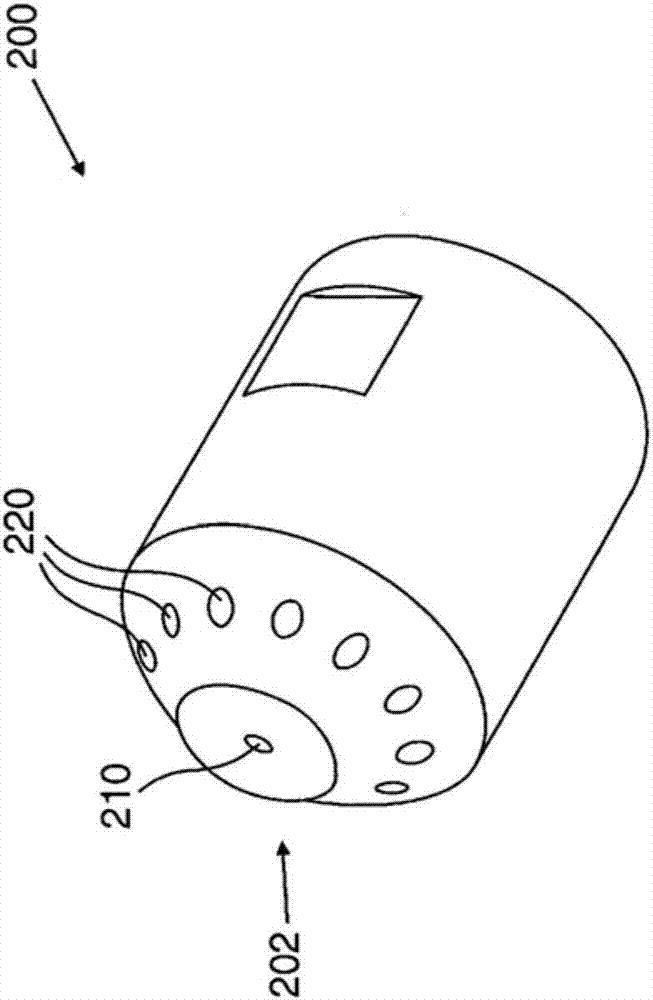

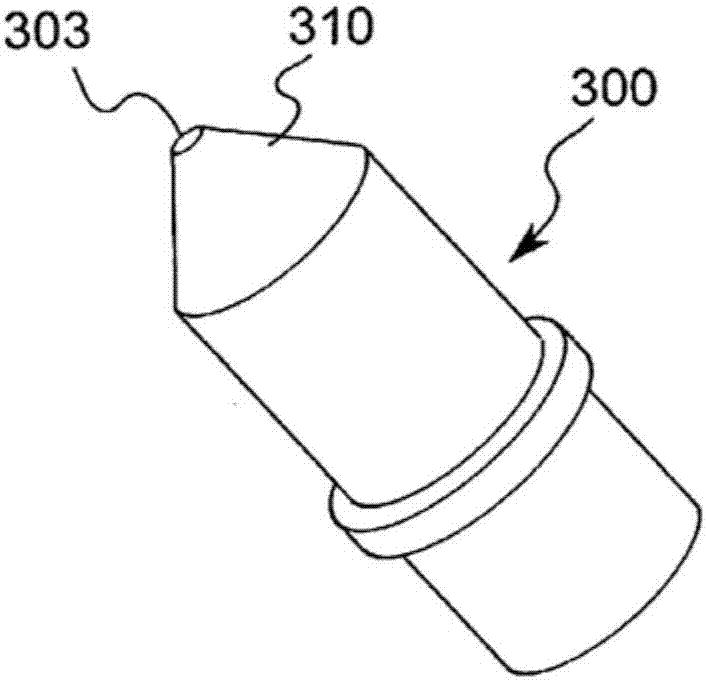

Electrode for a welding torch for tungsten gas-shielded welding and welding torch having such an electrode

ActiveCN107000103AReduce energy densityLarge capacityWelding/cutting media/materialsWelding electrode featuresWelding torchElectrode material

The present invention relates to an electrode (200) for a welding torch (100) for tungsten gas-shielded welding, in particular for tungsten inert gas welding or for plasma welding, wherein the electrode (200) comprises at least one insert (210) composed of a material (211) different from the electrode material (201), wherein the insert (210) at least partially forms an arc-side surface (202) of the electrode, the electrode (200) has, on the arc-side surface thereof, a plurality of focusing-gas bores (220) for supplying a focusing gas (222) for focusing an arc (120), and the electrode (200) has at least one axially extending gas removal bore (230) for removing a gas (132) from the arc-side surface (202) of the electrode (200) through the axially extending gas removal bore (230).

Owner:LINDE AG

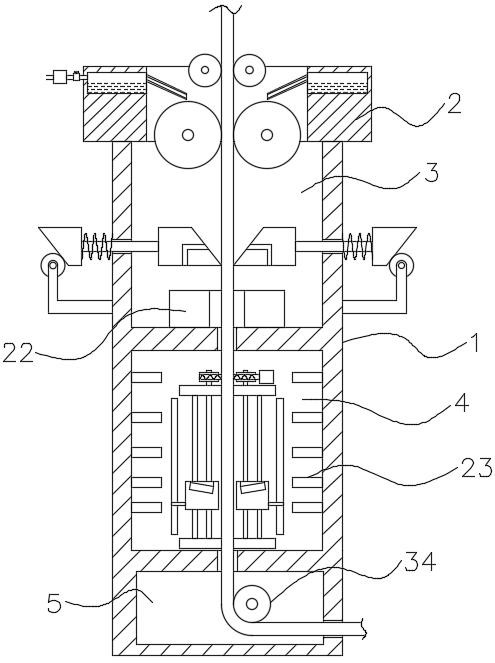

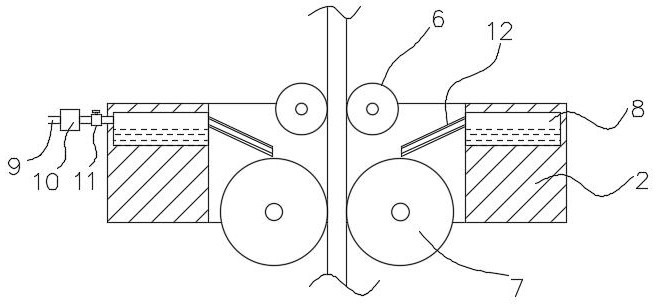

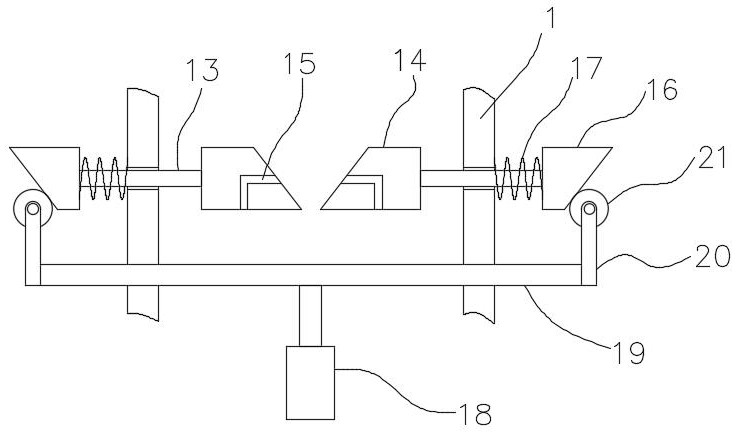

Coating device and coating method for graphene lithium battery pole piece

ActiveCN112076943ALower resistanceIncrease the current intensityLiquid surface applicatorsCoatingsElectric machineEngineering

The invention discloses a coating device and a coating method for a graphene lithium battery pole piece. The coating device comprises a coating device body, wherein a coating chamber, a drying chamberand a transfer cavity are formed in the coating device body from top to bottom; the upper side of the coating chamber is open, and a top plate is fixedly connected to the opening; a coating opening is formed in the top plate; a pair of guide rollers and a pair of coating rollers are rotationally mounted on the inner walls of the two sides of the coating opening in sequence from top to bottom; thetwo coating rollers are connected with first motors; telescopic cylinders are mounted on the sides, far away from each other, of the two first motors; a coating cavity is formed in the top plate; a coating outlet pipe is arranged on the inner walls of the other two sides of the coating opening, is positioned above the coating rollers and is communicated with the coating cavity; and the end, far away from the coating cavity, of the coating outlet pipe is a lower end. The coating device and the coating method have the advantages that the coating thickness can be freely controlled, the coating quality is improved, and the wind power is changed according to the height during subsequent drying, so that the coating is more uniform.

Owner:海南唯时新能源科技有限公司

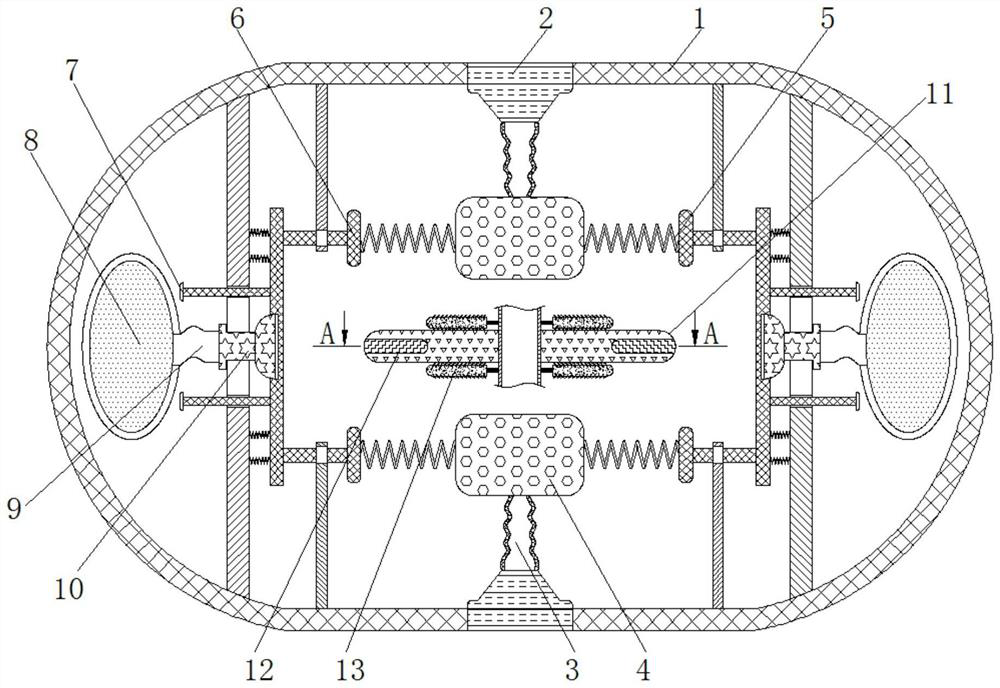

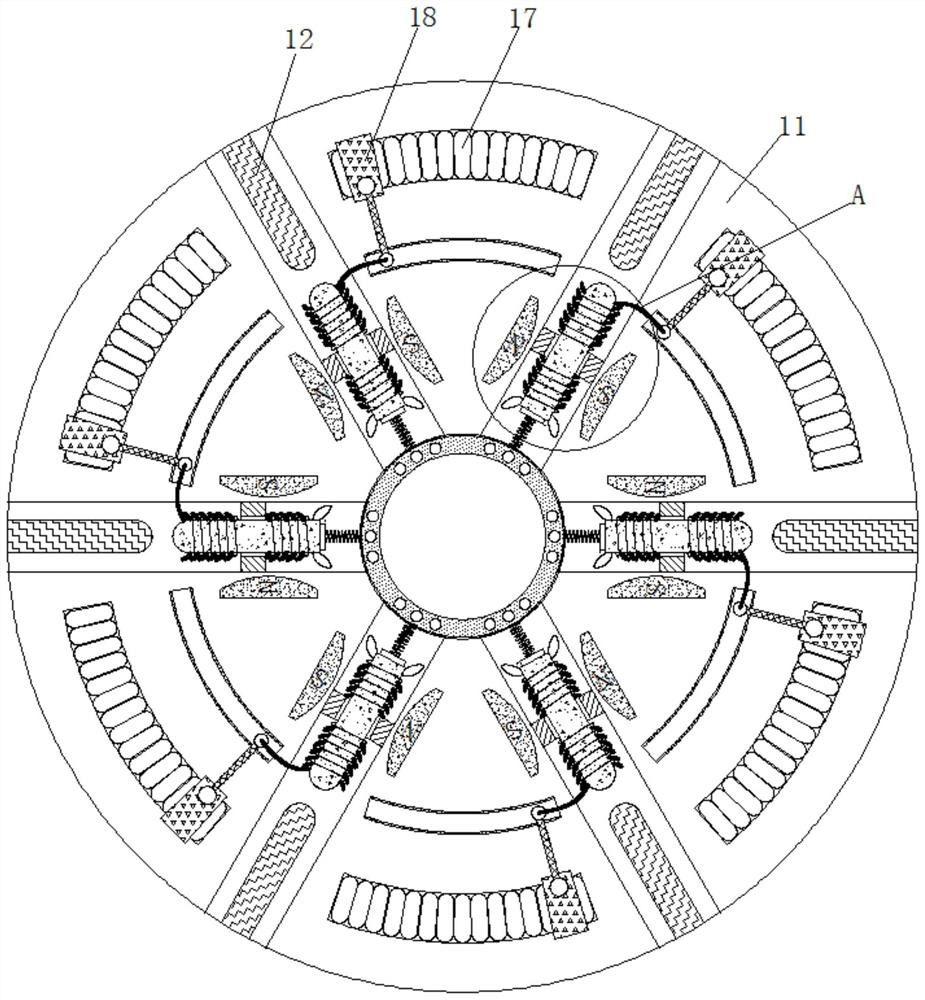

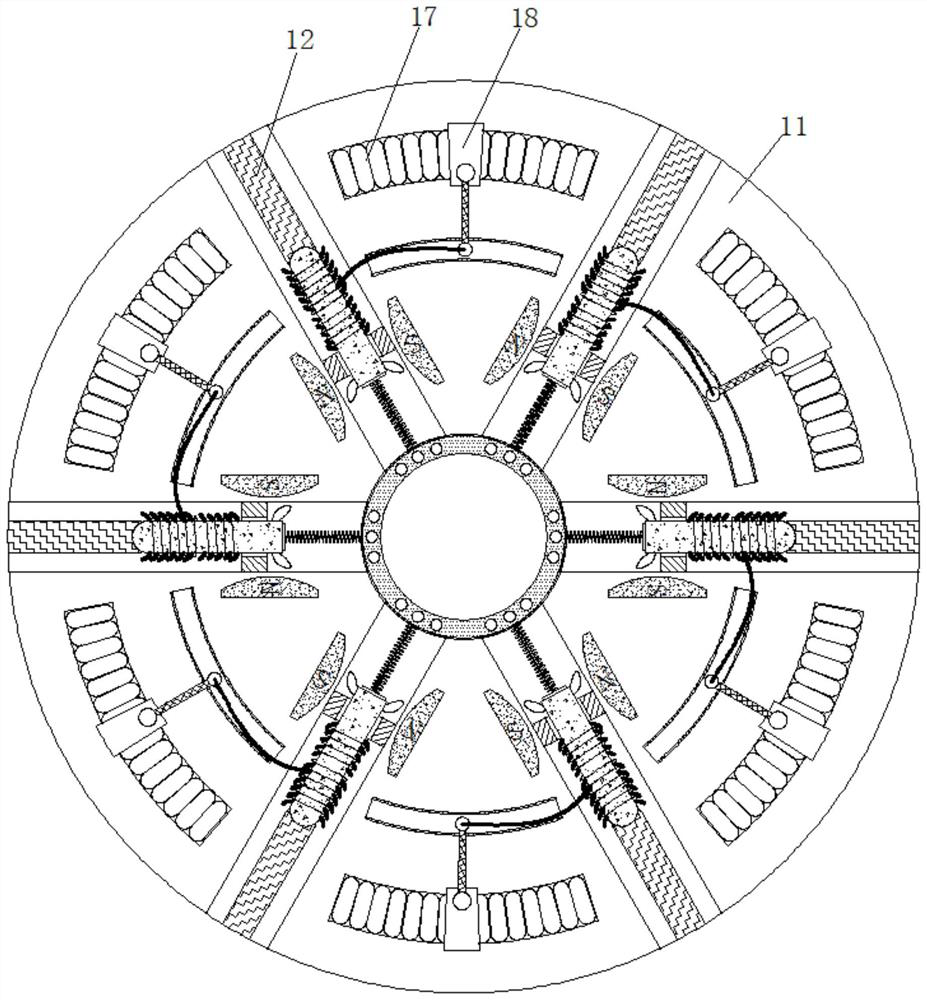

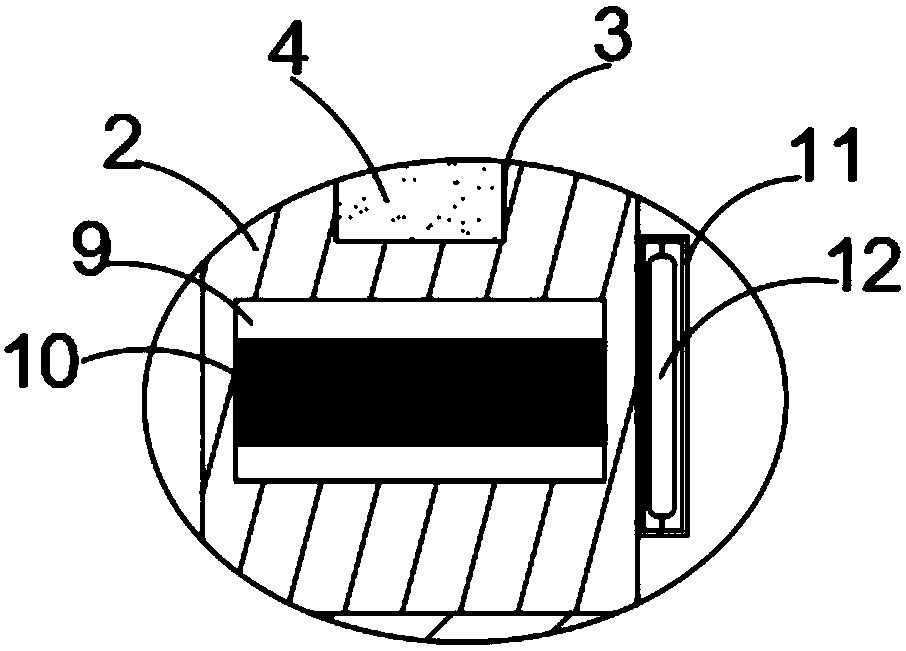

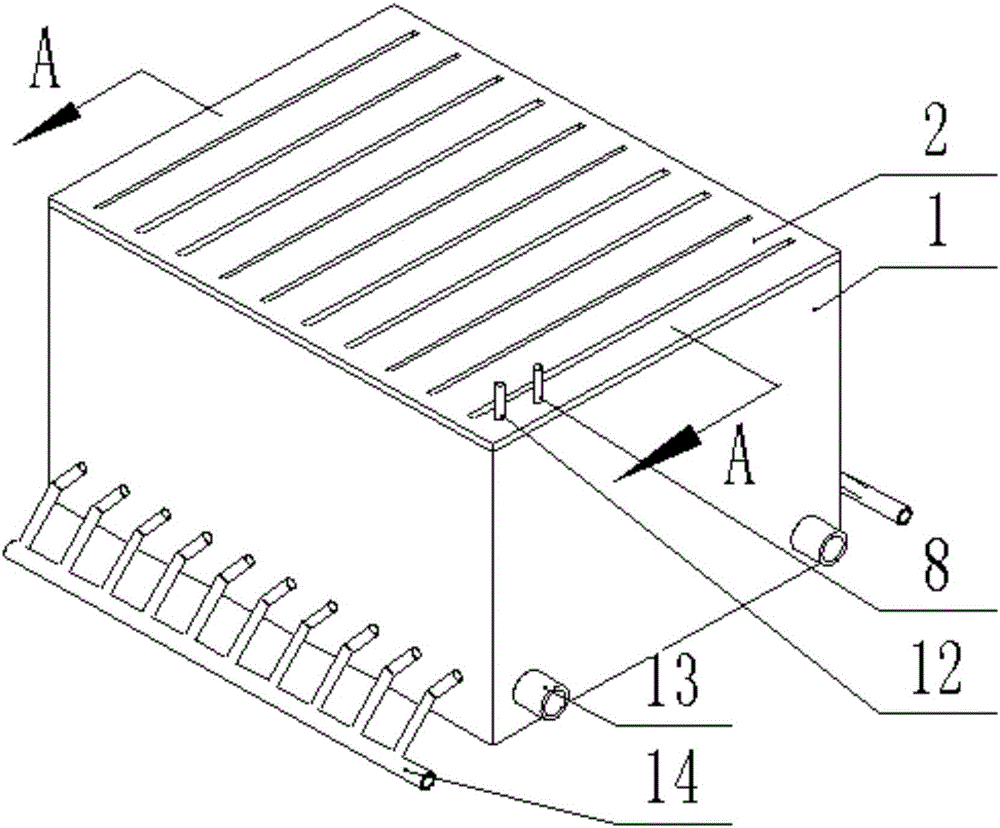

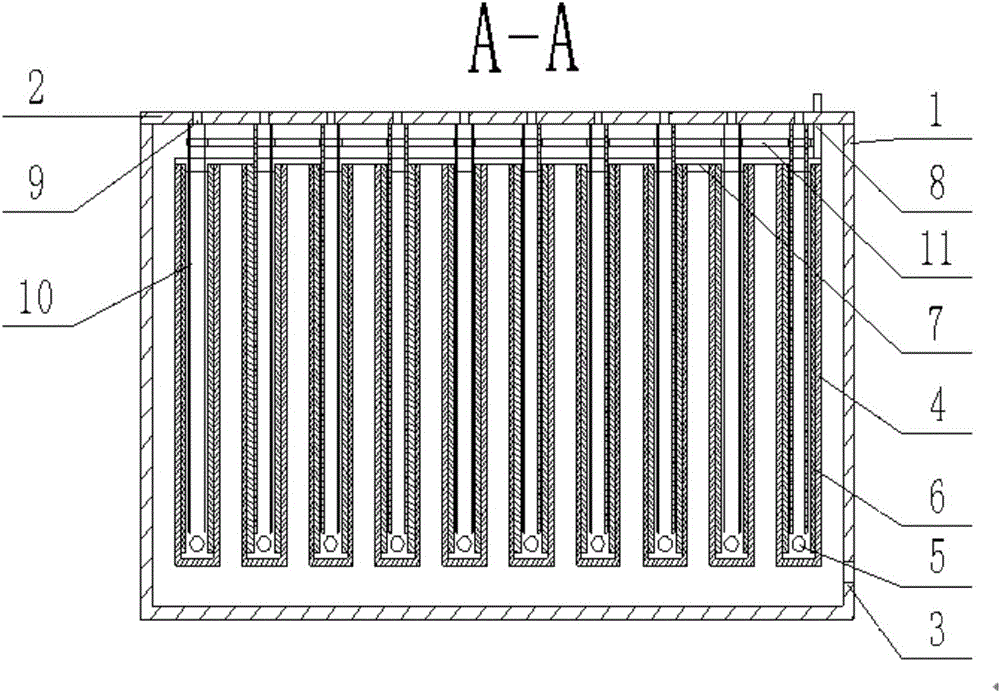

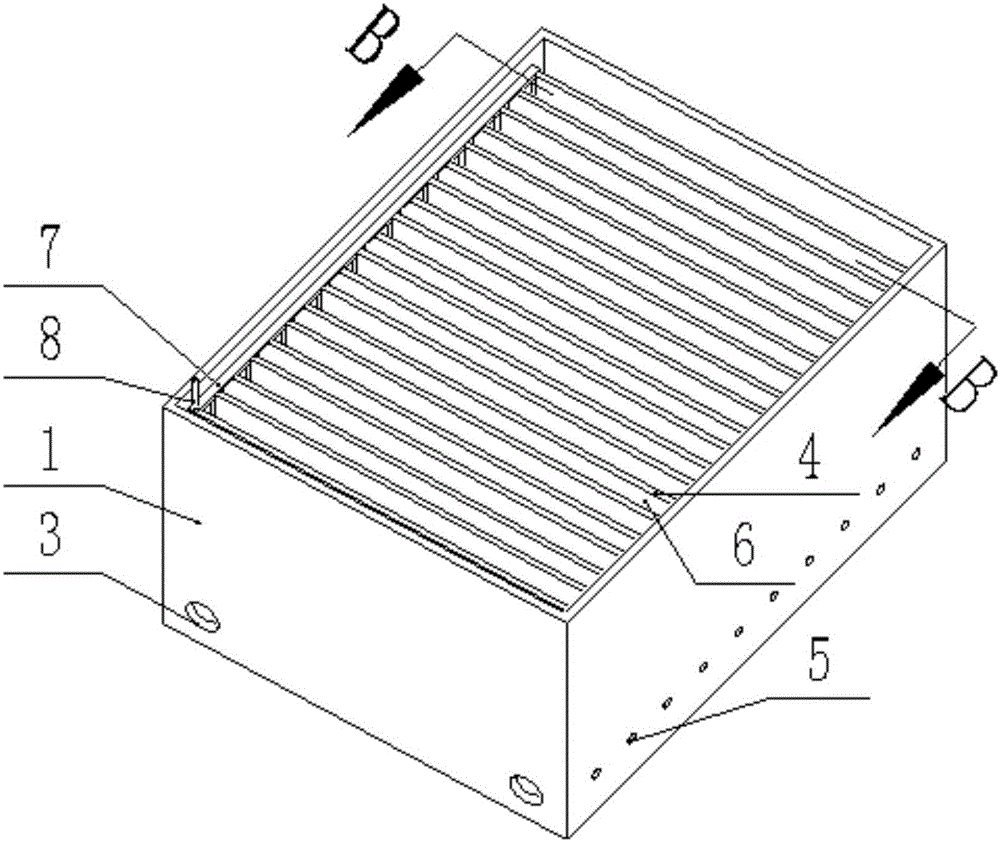

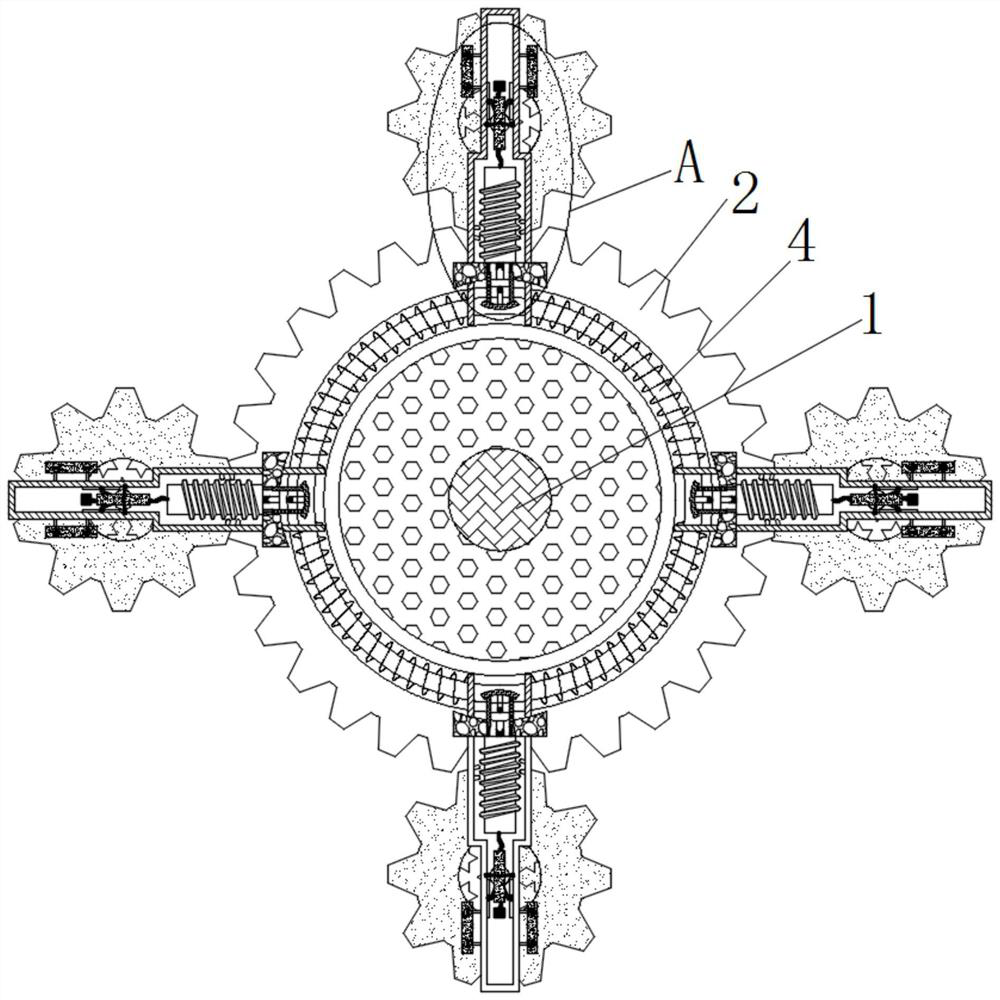

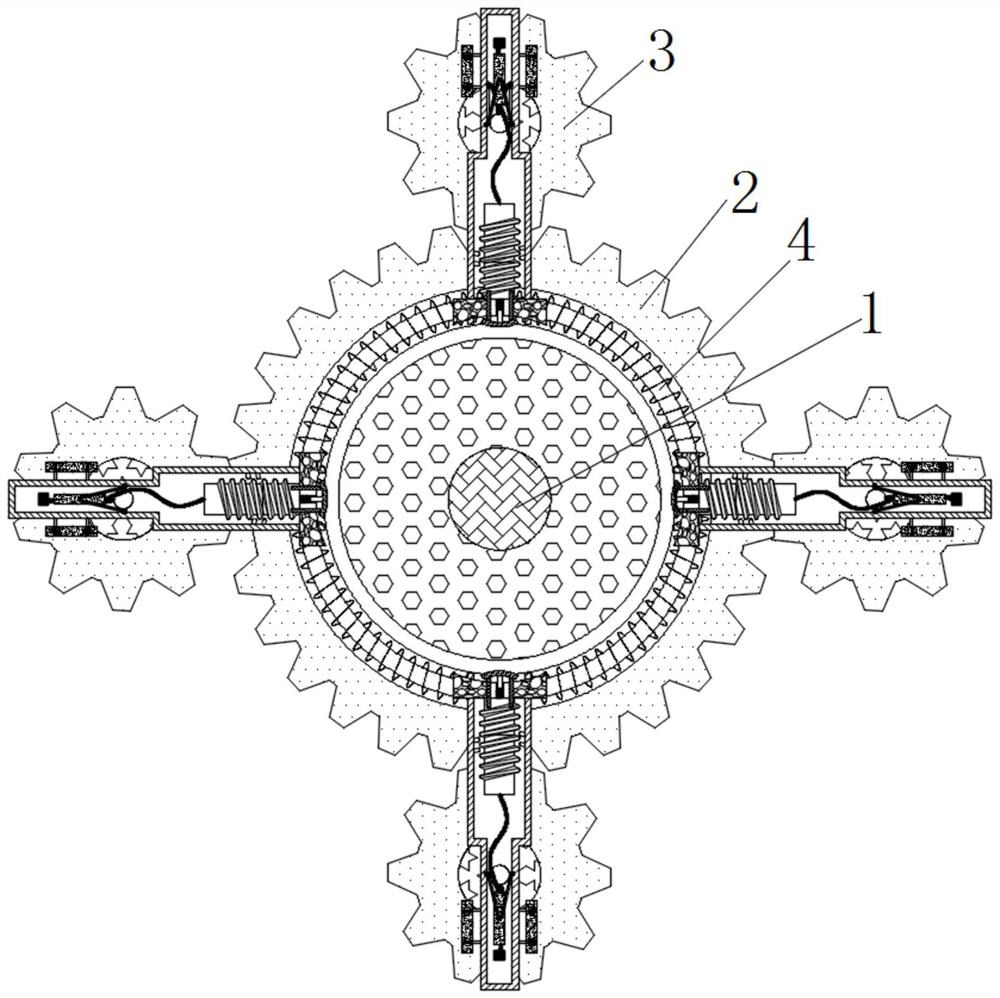

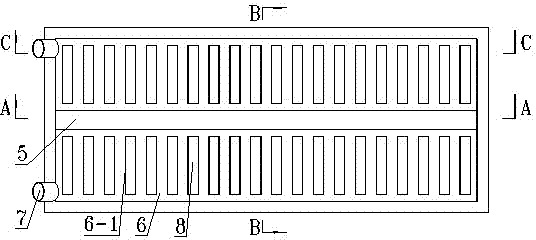

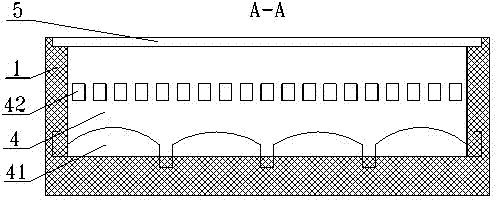

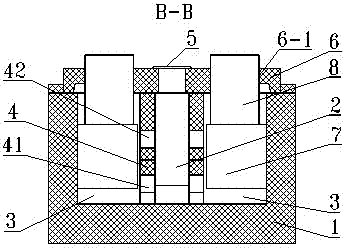

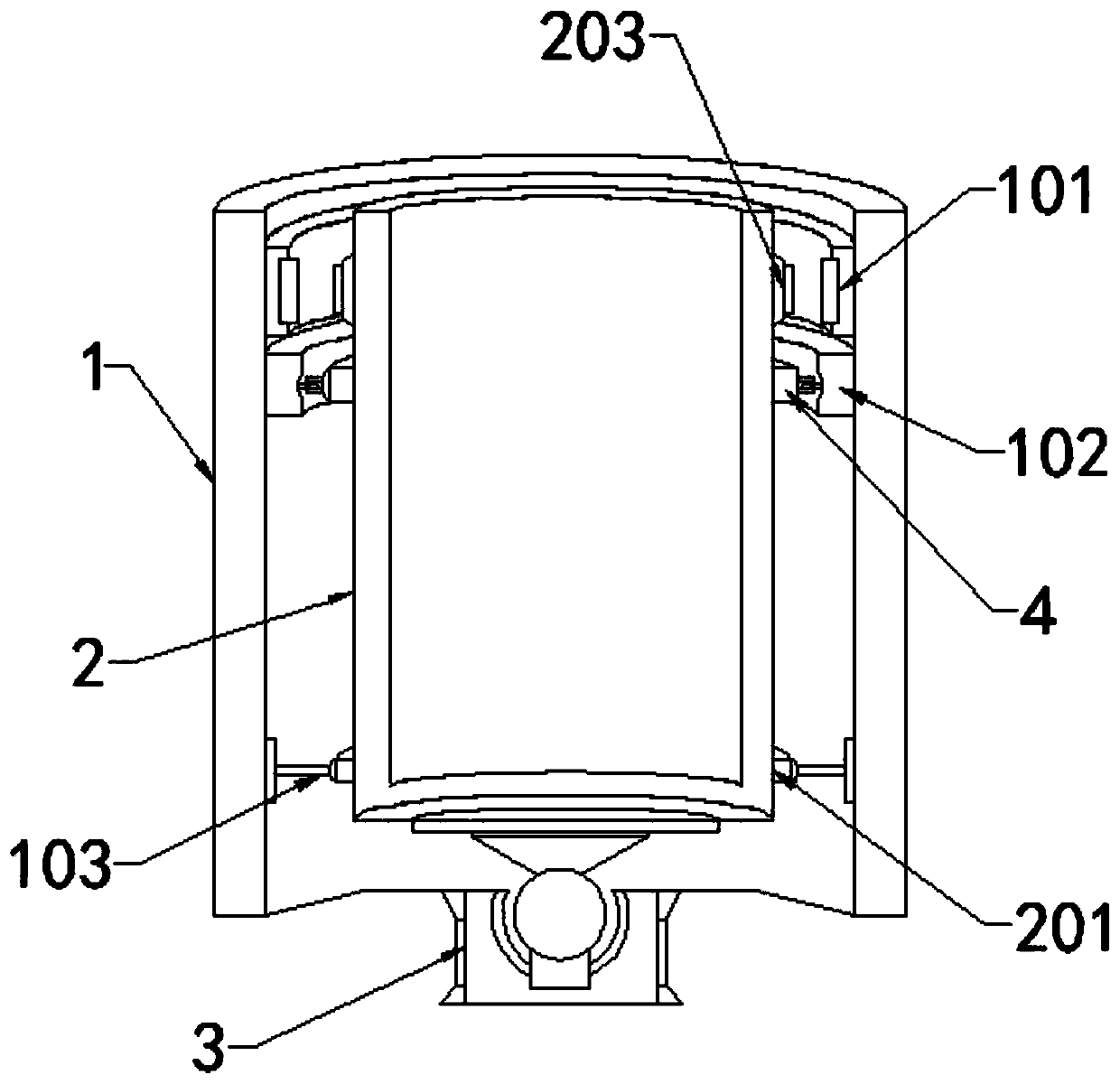

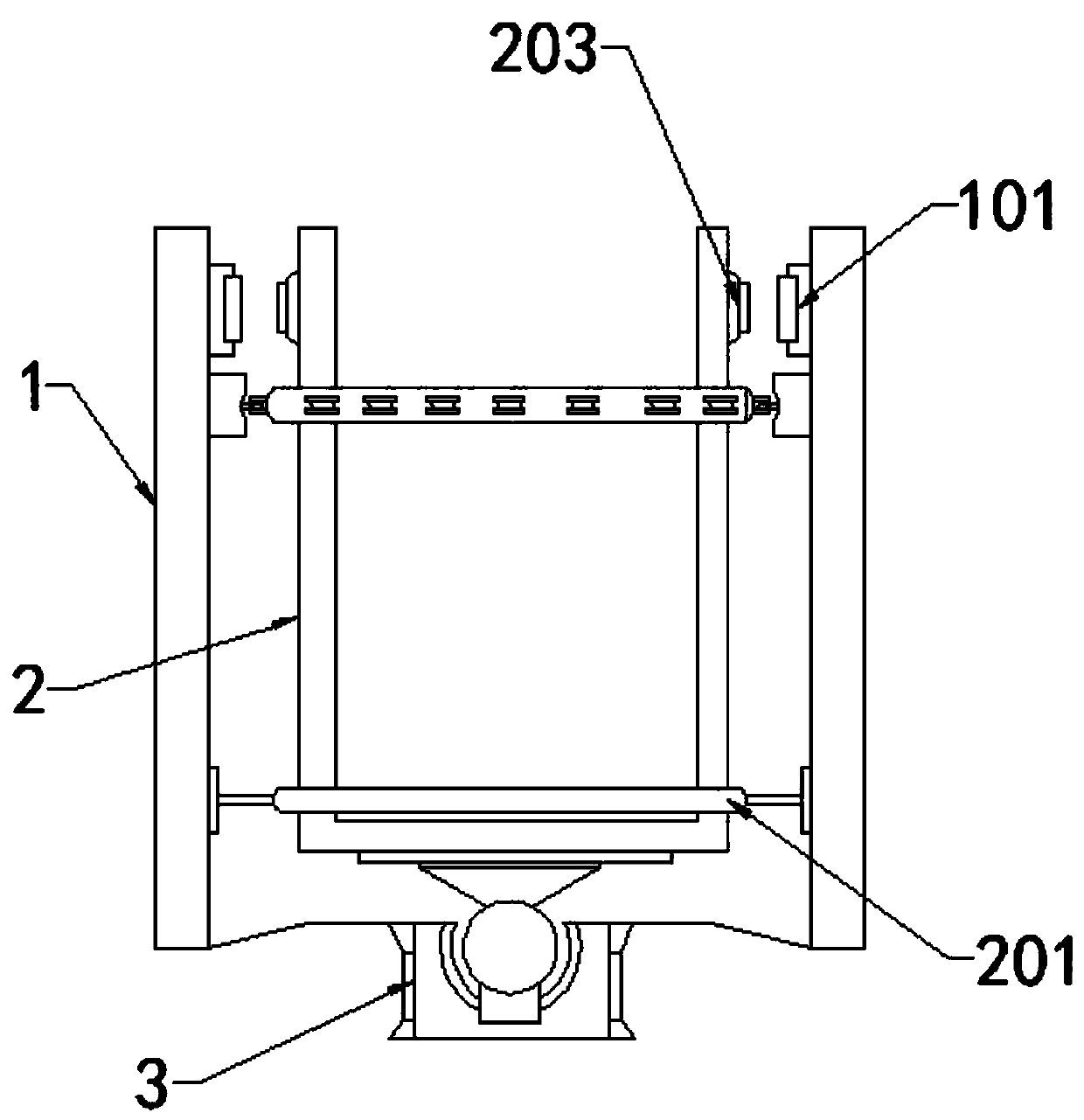

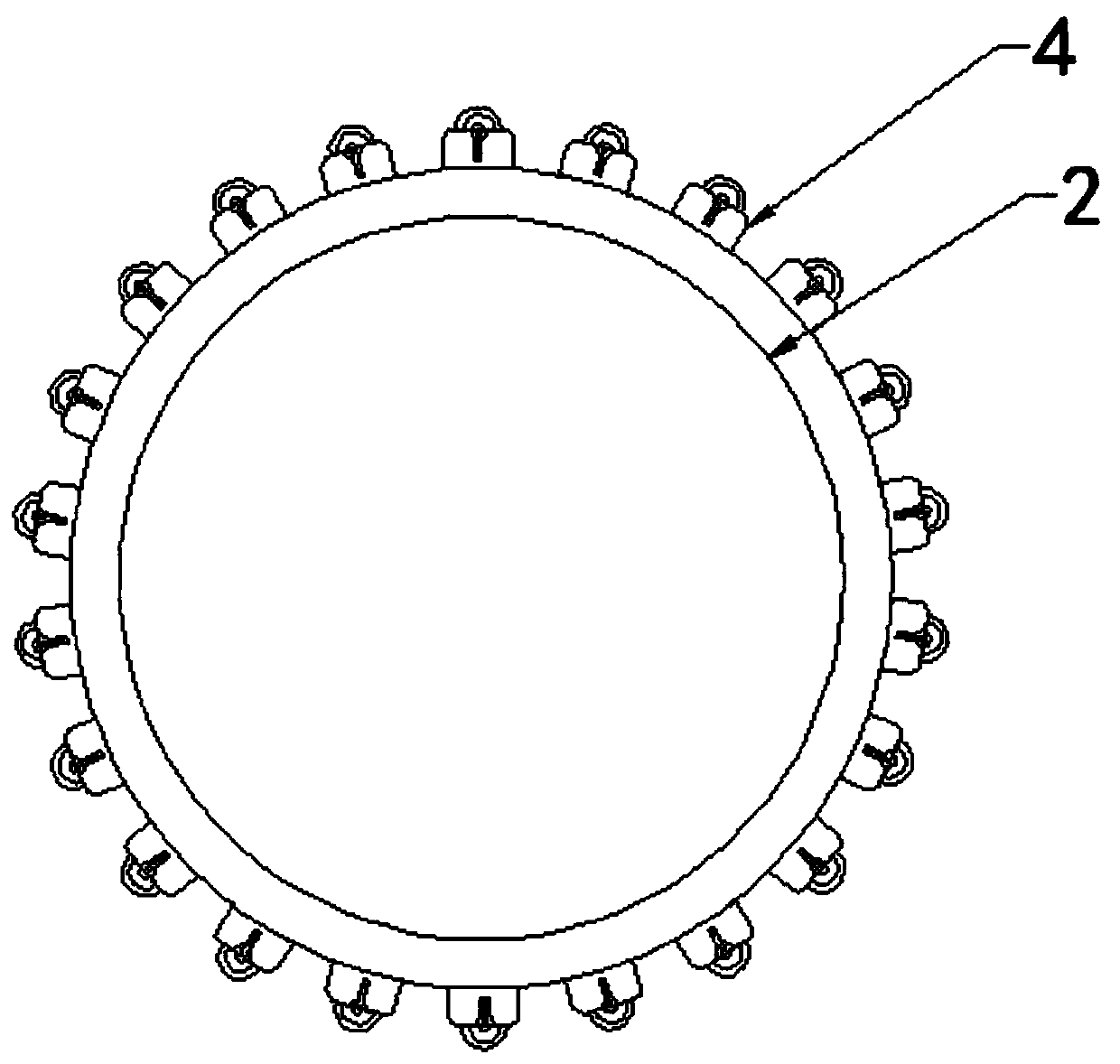

Electrolysis apparatus for preparing oxyhydrogen

The invention discloses an electrolysis apparatus for preparing oxyhydrogen. The apparatus comprises an electrolytic tank, in which at least two individually working electrolytic chambers and an oxyhydrogen outlet are provided, wherein, the electrolytic chambers are filled with a proper amount of electrolyte, each electrolytic chamber is provided with an electrolytic pole plate group, each electrolytic pole plate group of the electrolytic chambers is arranged in the form of a serial circuit, the electrolytic pole plate group comprises at least one positive plate and at least two negative plates, and each positive plate and each negative plate in the electrolytic pole plate group are arranged in the form of a parallel circuit; one positive plate is inserted in a gap between two arbitrary adjacent negative plates, and the number of gaps generated due to arrangement of the negative plates is equal to that of the positive plate. The electrolysis apparatus provided in the invention enables electrolysis to be carried out under the conditions of low voltage and low current, has high security, and can improve the generation amount of oxyhydrogen and increase economic benefits.

Owner:HUOCHUAN LINENG TECH

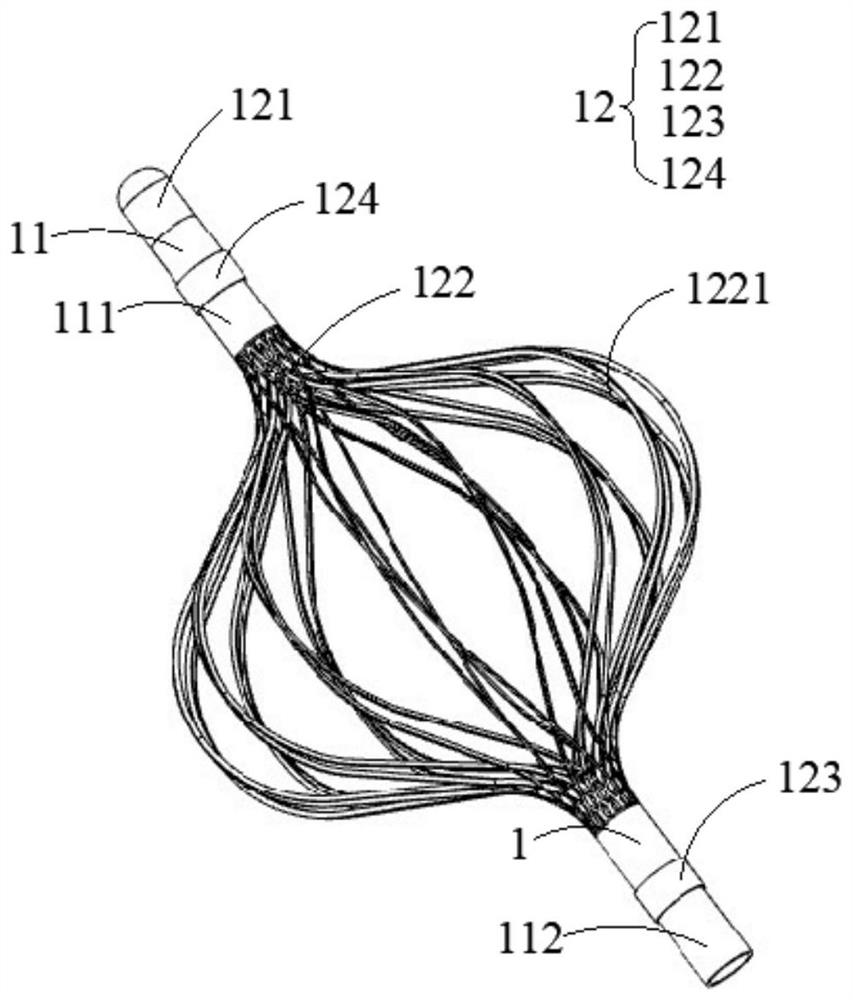

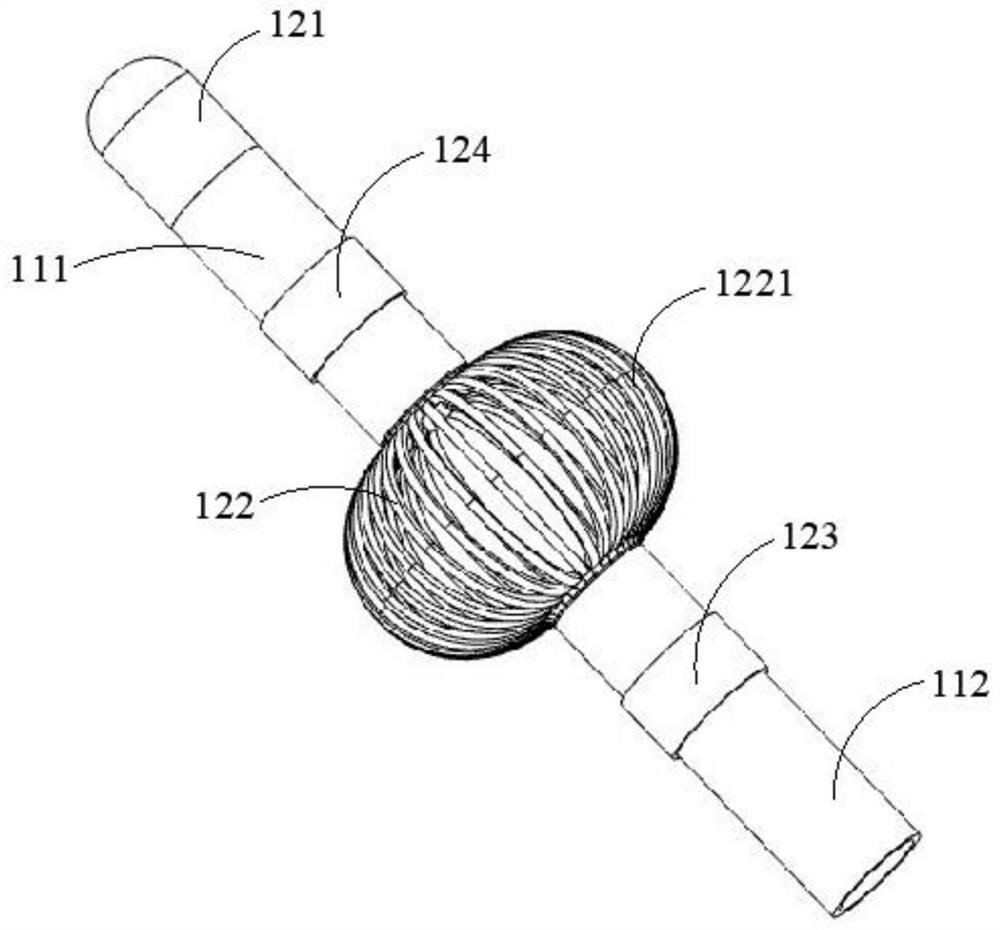

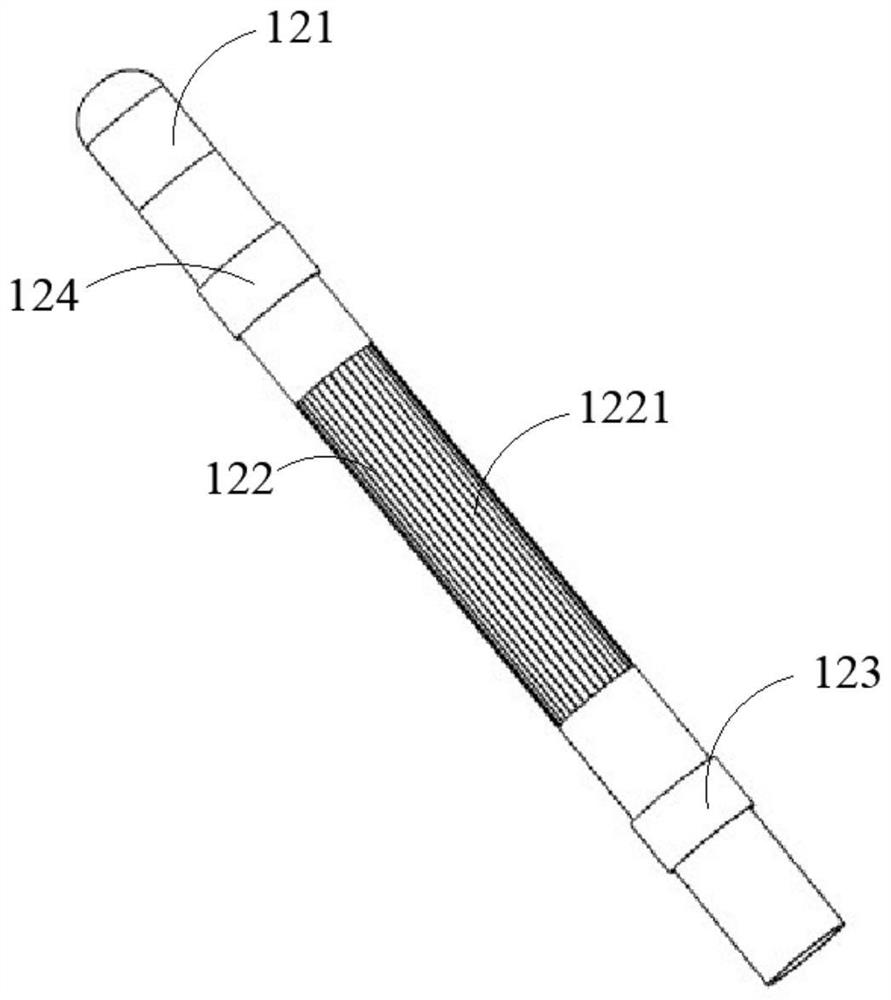

Electrode assembly, ablation catheter and ablation system

PendingCN113616317AIncrease surface areaNo arc exothermic phenomenonSurgical instruments for heatingCatheterElectric current flow

The invention provides an electrode assembly, an ablation catheter and an ablation system. The electrode assembly at least comprises a first electrode and a second electrode, wherein the second electrode is arranged farther away from target tissue relative to the first electrode and can be used for current shunting. The working state of the second electrode can be switched between a contraction state and an expansion state. The ablation system comprises a pulse ablation module, an ablation catheter and a control device. Part of the second electrode in the ablation catheter expands outwards, so that the second electrode can perform current shunting without generating a current electric field concentration effect, and the ablation catheter can be used in a pulsed electric field with higher voltage. In addition, due to the fact that the first electrode and the second electrode cooperate for ablation, the ablation depth of the ablation catheter at the target tissue can be increased. Meanwhile, according to the ablation system, the attaching degree of the ablation catheter and the target tissue is preferably obtained through the control device.

Owner:SHANGHAI ARTECHMED MEDICAL TECH CO LTD

Device for electro-kinetic remediation of heavy metal contaminated soil by utilizing copper salt reinforced cathode

ActiveCN106424117AReduce experimental errorReal-time monitoring of pH changesContaminated soil reclamationFiberElectrolysis

The invention provides a device for electro-kinetic remediation of heavy metal contaminated soil by utilizing a copper salt reinforced cathode. According to the device provided by the invention, a soil chamber is arranged between a cathode chamber and an anode chamber; the volume ratio of the cathode chamber to the anode chamber to the soil chamber to an active carbon fiber chamber is 3 to 3 to (5-50) to 1; copper salt is used as a cathode electrolyte; a citric acid-sodium citrate buffer solution is used as an anode electrolyte; automatic remediation of the heavy metal contaminated soil is performed for 36 to 500 hours under a voltage of 5V to 50V. According to the device provided by the invention, the copper salt is used as the cathode electrolyte to promote an electro-kinetic reaction in an electrolysis process, and an electro-kinetic technology and a cation exchange membrane technology are combined to maintain the pH value of a soil sample within a certain acidity range during electrolysis; by virtue of a pH control and regulation system and a cathode electrolyte reflux system, the remediation efficiency is improved.

Owner:TAIYUAN UNIV OF TECH

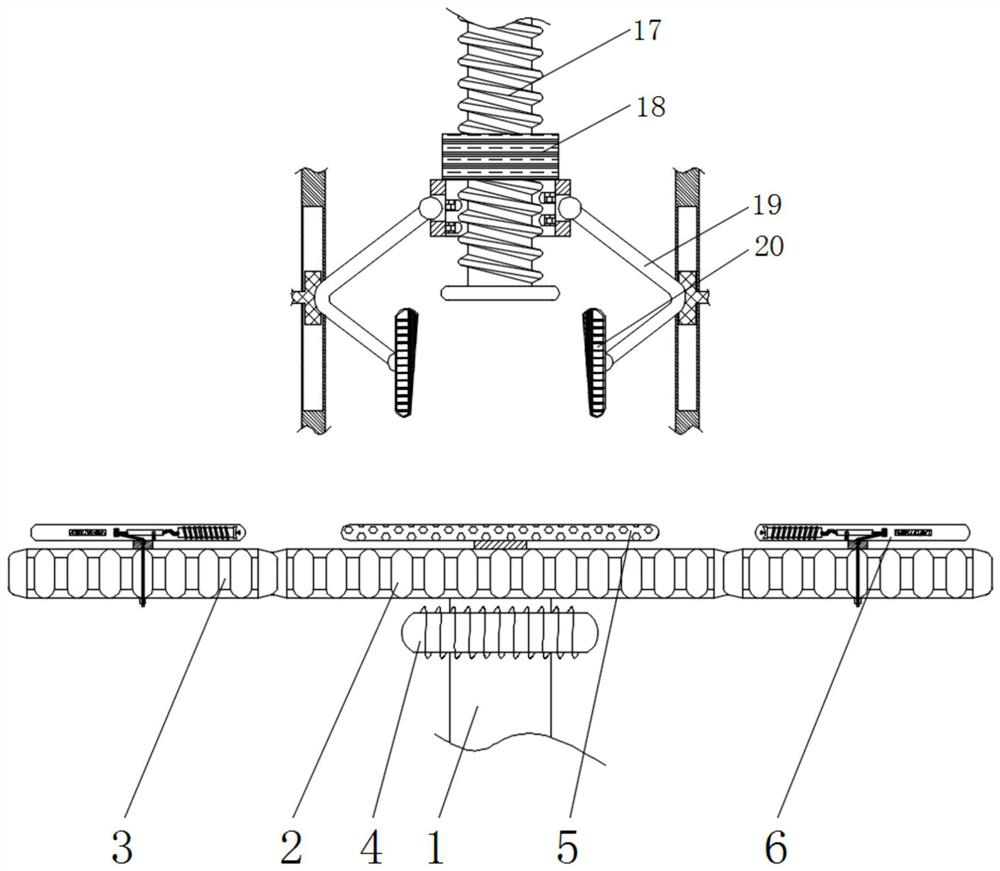

Intelligent manufacturing rust-proof equipment for fixing hardware machines of different sizes

InactiveCN112589637ALarge capacityIncrease the current intensityGrinding drivesGrinding machinesDrive shaftMachining

The invention relates to the technical field of hardware machining, and discloses intelligent manufacturing rust-proof equipment for fixing hardware machines of different sizes. The intelligent manufacturing rust-proof equipment comprises a driving shaft, the surface of the driving shaft is fixedly connected with a sun wheel, and the edge of the sun wheel is in engaged connection with planet wheels. A coil bundle is fixedly mounted on the surface of the part, below the sun wheel,of the driving shaft, a mounting table is fixedly mounted at the top end of the sun wheel, a fixing table is fixedlymounted at the top of each planet wheel, a fixing groove is fixedly formed in the surface of each fixing table, and a screw rod is rotatably connected into each fixing groove. According to the intelligent manufacturing rust-proof equipment for fixing the hardware machines of different sizes, iron products of different shapes and sizes can be clamped, clamping damage to a to-be-machined workpieceis prevented under the condition that clamping is stable, the friction strength of rust removal is gradually improved in the rust removal process of the to-be-machined workpiece, and processing of aniron product is more thorough.

Owner:杭州锐霓机械科技有限公司

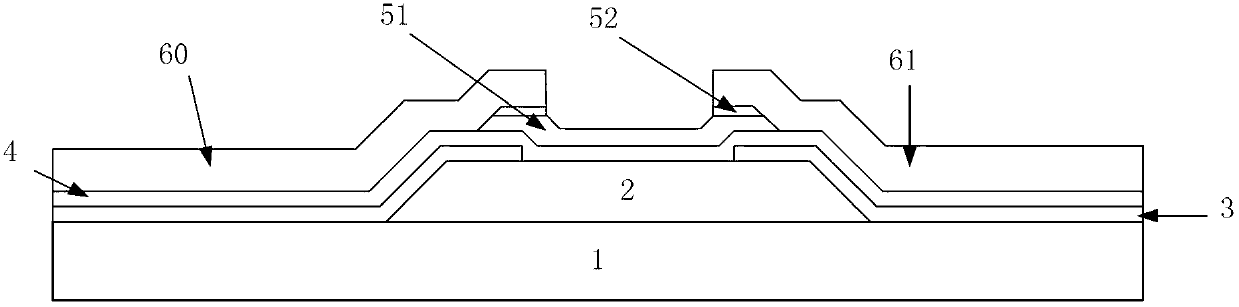

Method for manufacturing thin film transistor and thin film transistor

ActiveCN103295906AReduce thicknessIncreasing the thicknessTransistorSemiconductor/solid-state device manufacturingTime delaysSemiconductor

The invention discloses a method for manufacturing a thin film transistor. The method comprises the steps of providing a substrate, forming the grid electrode of the thin film transistor on the surface of the substrate, depositing a first grid electrode insulating layer on the grid electrode and the surface of the substrate, forming a first grid electrode insulating layer opening in an area above the grid electrode, depositing a second grid electrode insulating layer on the grid electrode and the first grid electrode insulating layer, depositing a semiconductor layer on the surface of the second grid electrode insulating layer to form a silicon island arranged on an area above the grid electrode, and depositing a second metal layer on the silicon island and the surface of the second grid electrode insulating layer to form the source electrode and the drain electrode of the thin film transistor. The thickness of the grid electrode insulating layers is the thickness of the second grid electrode insulating layer in an area with the thickness of a grid electrode insulating film needing to be reduced. The thickness of the grid electrode insulating layers is the superposition of the thickness of the first grid electrode insulating layer and the thickness of the second grid insulating layer in an area with the thickness of the insulating film needing to be increased. The problems of the waveform deformation of signals output by an integrated circuit driving the thin film transistor and time delay can be avoided.

Owner:SHANGHAI AVIC OPTOELECTRONICS

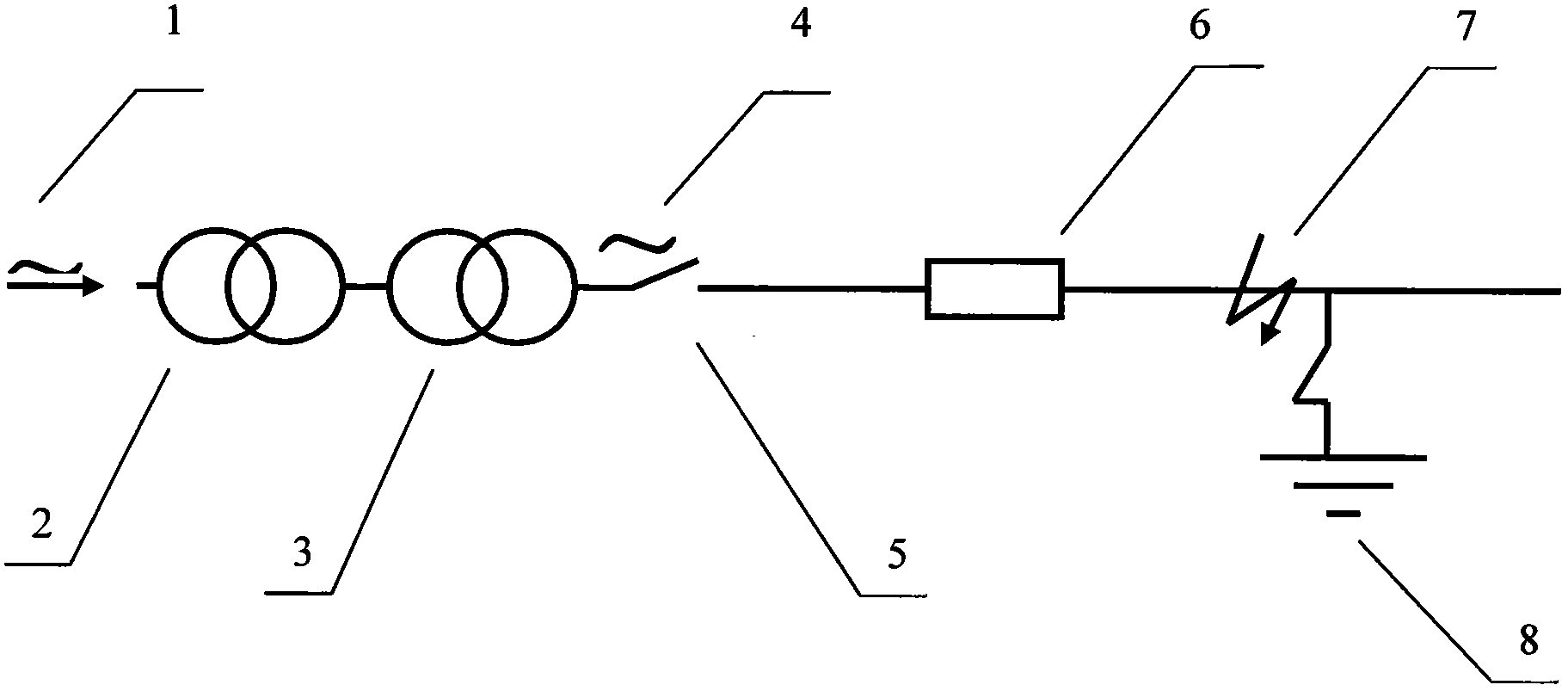

Ice-melting method with voltage reduction, current increase and short circuit by using series connection of two transformers

InactiveCN103236668AReduce voltageIncrease the current intensityOverhead installationLow voltageEngineering

The invention relates to an ice-melting method with voltage reduction, current increase and short circuit by using series connection of two transformers. In the ice-melting method, a high-voltage transformer (2) is electrically connected in series with a high-voltage transformer (3) according to voltage reduction functions of high-voltage transformers, an initial power source (1) is connected to a high-voltage side of the high-voltage transformer (2), and a low-voltage side of the high-voltage transformer (3) is electrically connected with an ice-coated wire (6) through an electric switch (5). According to conditions of the ice-coated wire and parameters of ice-melting equipment, a three-phase short-circuit connection point (7) of the ice-coated wire (6) is selected and an earthing knife-switch (8) is mounted; after the voltage of the initial power source (1) is reduced by the high-voltage transformer (2), the voltage of the initial power source (1) is further reduced by the high-voltage transformer (3) to acquire an ice-melting power source (4) with low voltage and high current intensity; and then the electric switch (5) is switched on, and the ice-melting power source (4) can melt the ice on the ice-coated wire (6).

Owner:KAILI POWER SUPPLY BUREAU

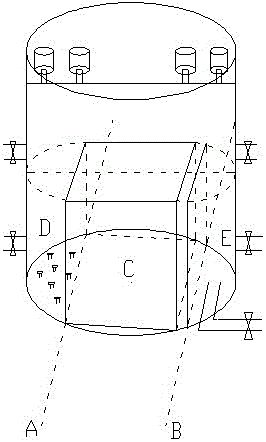

Baffleless magnesium electrolytic cell and use method thereof

The invention discloses a baffleless magnesium electrolytic cell, and is used for solving the problems that a conventional baffleless magnesium electrolytic cell has relatively small capacity, is not applicable to production of larger metal magnesium plants, the current efficiency is not high and the electrolytic magnesium generation energy consumption is larger. A magnesium collecting chamber and electrolytic chambers are arranged in the electrolytic cell, a gas collecting cover is arranged on the upper part of the magnesium collecting chamber, and a cell lid is arranged on the upper ends of the electrolytic chambers. The magnesium collecting chamber is arranged at the middle of the electrolytic cell, two sides of the magnesium collecting chamber are each provided with the electrolytic chamber, separating walls are arranged between the magnesium collecting chamber and the electrolytic chambers, each separating wall is provided with melt communication passages, and the cell lid at the upper parts of the electrolytic chambers is also provided with chlorine gas discharge outlets communicated with the electrolytic chambers. The baffleless magnesium electrolytic cell is used for electrolytic production of magnesium.

Owner:GUIYANG AL-MG DESIGN & RES INST

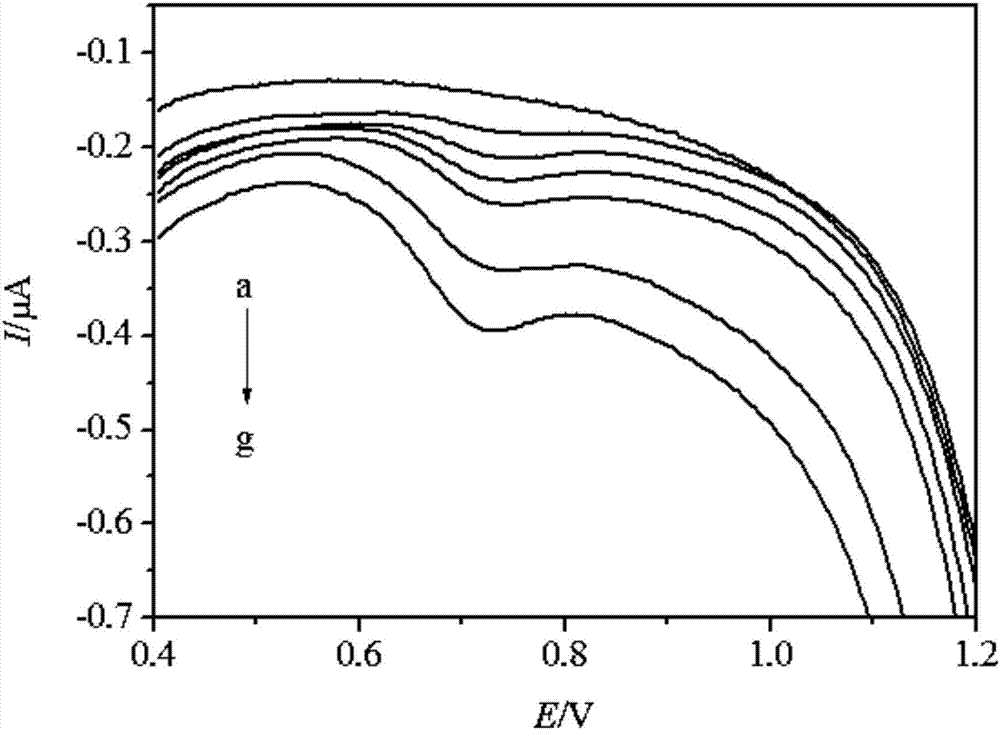

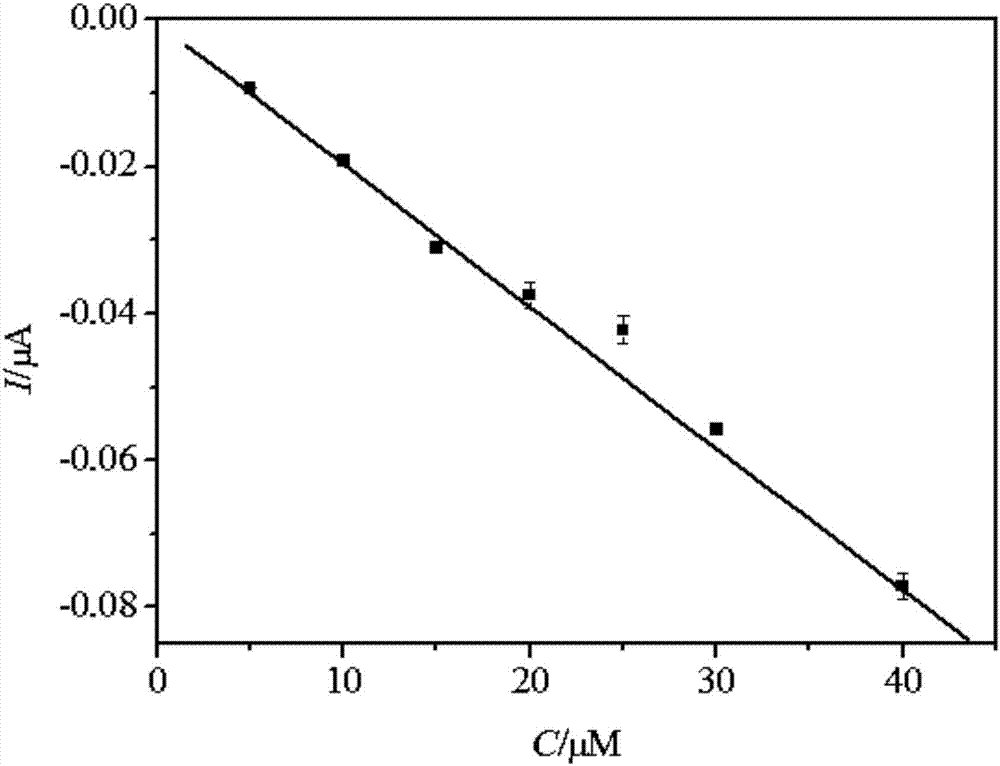

Method for detecting tyrosine by using chitosan-functionalized gold nano-modified glassy carbon electrode

ActiveCN107271506AEasy to makeFast electron transfer rateMaterial electrochemical variablesTyrosinePhysical chemistry

The invention discloses a method for detecting tyrosine by using a chitosan-functionalized gold nano-modified glassy carbon electrode. The method comprises the following steps of (1) preparing a mixed liquid A, mixing the mixed liquid and a chitosan solution with the mass fraction of 0.5wt% at the volume ratio of 1:1, carrying out ultrasonic treatment, carrying out centrifugal treatment, taking sediments, dispersing the sediments into water at the mass-volume ratio of (5-8mg):1ml, carrying out ultrasonic treatment to obtain a micro-solution, titrating the micro-solution on the surface of the glassy carbon electrode and airing to obtain the chitosan-functionalized gold nano-modified glassy carbon electrode; and (2) adopting the chitosan-functionalized gold nano-modified glassy carbon electrode prepared from the step (1) as a working electrode, and detecting the concentration of tyrosine in a to-be-detected solution by using a differential pulse voltammetry of a three-electrode system according to a differential pulse voltammetry curve of the tyrosine. The method has the advantages of being simple in operation, fast in detection and high in sensitivity, and high-sensitivity recognition of the tyrosine in the mixed sample solution can be carried out.

Owner:美也环境科技(江苏)有限公司

Colloid mixing barrel with electromagnetic balance and assistance functions

InactiveCN110368852AReduce frictionExpand the scope of useRotating receptacle mixersTransportation and packagingOhmEngineering

The invention provides a colloid mixing barrel with electromagnetic balance and assistance functions. A mixing barrel body is rotatably connected into an outer barrel through a rotating shaft, a balance structure and an assisting structure are arranged between the mixing barrel body and the outer barrel in a closed mode, the bottom of the mixing barrel body is fixedly connected with a damping transmission piece, and the damping transmission piece extends out of the outer barrel all the way. An embedded groove is formed in a middle opening of a positioning plate, a resistance rod is just located in the embedded groove, a brush is arranged in the embedded groove and makes contact with the resistance rod, thus when one side is particularly stressed, the depth of the resistance rod in the embedded groove is changed, according to the ohm law, the strength of a current and resistance are inversely proportional, then the current conduction strength of the resistance rod is changed, then the current strength borne by a second electromagnet is larger, then an emitted magnetic pole is stronger, and finally the mixing barrel body and the outer barrel are reset.

Owner:张智会

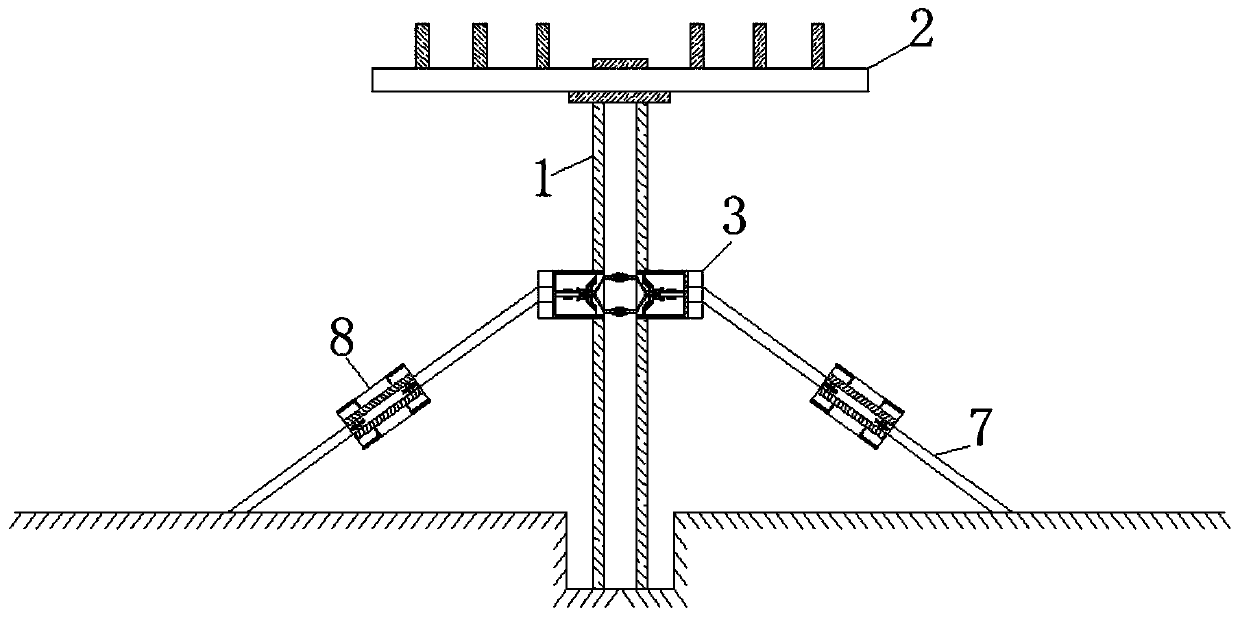

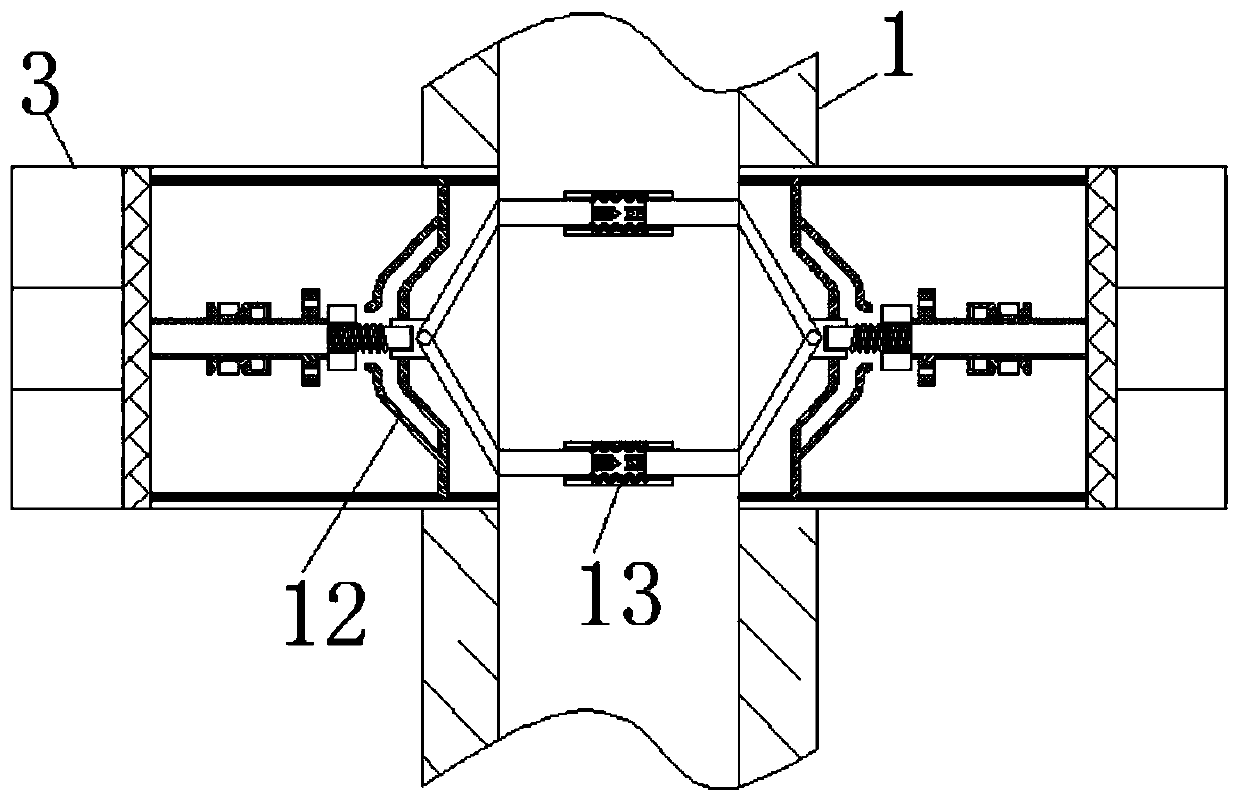

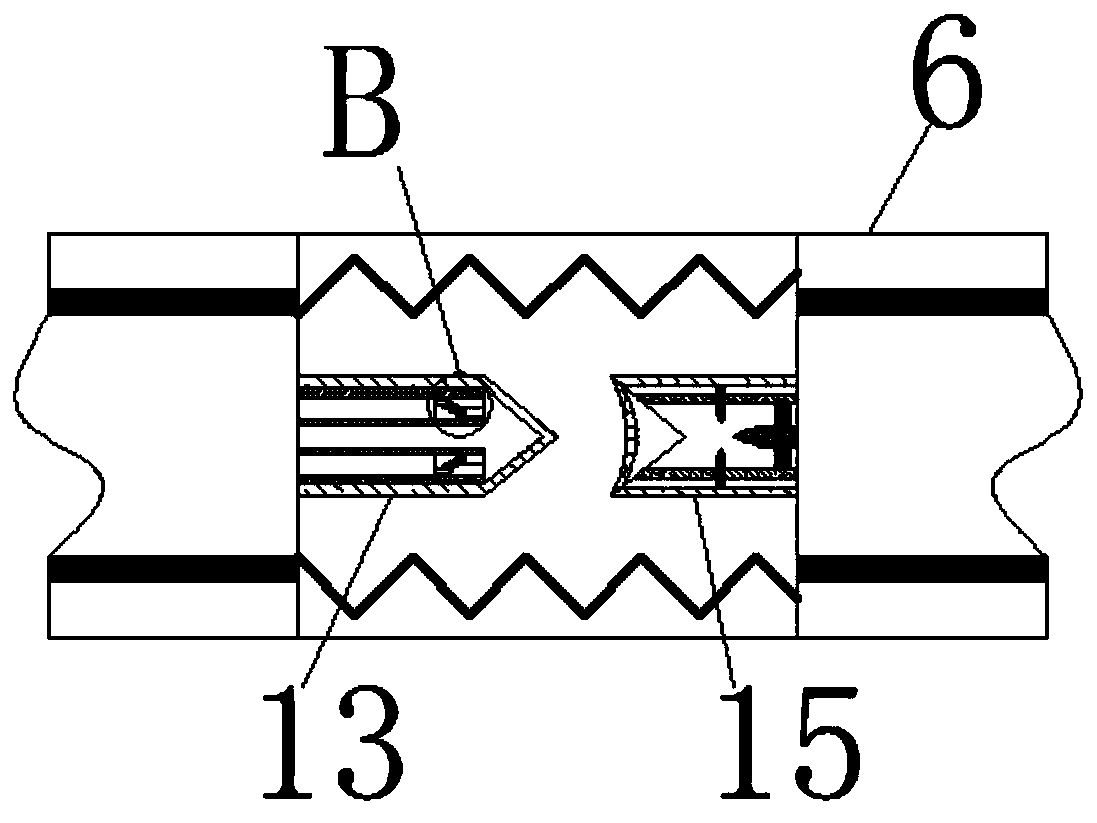

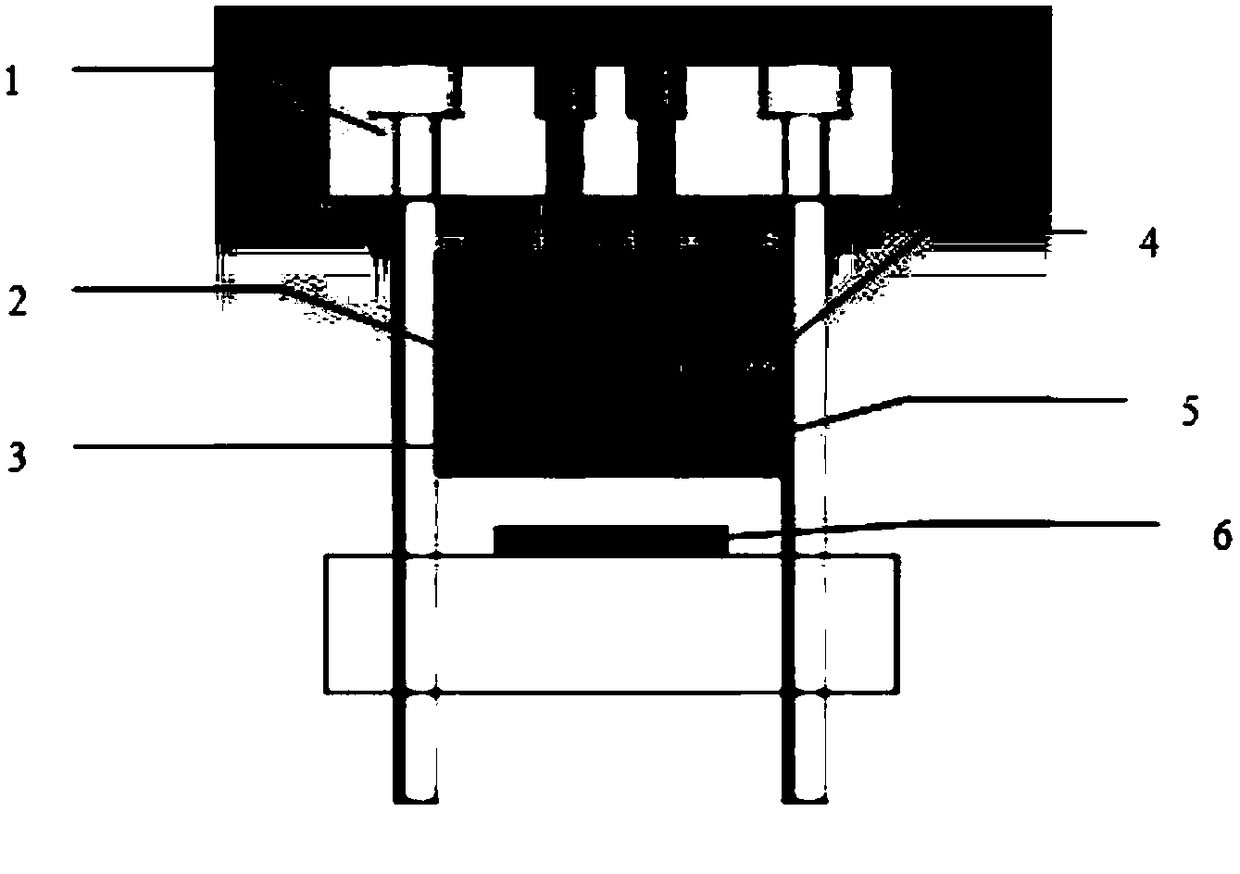

Appliance special for overhead line structure device anti-theft device

The invention relates to the technical field of anti-theft technologies of pole tower devices, and discloses an appliance special for an overhead line structure device anti-theft device. The applianceincludes a vertical pole, the top of the vertical pole is fixedly connected with a support plate, the surface of the vertical pole is sleeved with an anti-theft box in a connected manner, a push plate is movably connected to the inside of the anti-theft box, a screw is movably connected to the surface of the push plate, and a conductive member is movably connected to the end, away from the push plate, of the screw; and pull wires are movably connected to the surface of the anti-theft box, the surfaces of the pull wires are sleeved with adjusting boxes, and the interiors of the adjusting boxesare movably connected with a gear. When a thief conducts twisting, the pull wires can be tightened rather than being released, and the effect that the connecting manner is only known by professionaland the stealing difficulties are increased is achieved; when the thief conducts twisting to rotate the gear, the pull wire on the lower portion is contracted, the pull wire on the upper portion stretches out, and the effect of adjusting the supporting force of the vertical pole is achieved; and when the thief conducts twisting on the adjusting boxes on the two sides, the effect of adjusting the verticality of the vertical pole is achieved.

Owner:郑程育

Micro-electrolytic tank for detecting formaldehyde and preparation method thereof

ActiveCN108152351AGood acid and alkali resistanceExtend your lifeMaterial electrochemical variablesWorking electrodeEngineering

The invention relates to a micro-electrolytic tank for detecting formaldehyde and a preparation method thereof. The micro-electrolytic tank is of a four-layer structure, the upper layer and the lowerlayer of the micro-electrolytic tank are acrylic plates, the two middle layers are a PDMA tank body and ITO glass respectively, a counter electrode inserting hole is formed in one side of the PDMA tank body, a reference electrode inserting hole is formed in the other side of the PDMA tank body, a storage hole channel for liquid to be measured is formed in the bottom of the PDMA tank body, and workelectrode ITO glass is fixed to the acrylic plate at the lower layer. According to the micro-electrolytic tank disclosed by the invention, the PDMS is utilized as an electrolyte solution carrier, theITO glass work electrode can effectively improve formaldehyde detection flexibility, effects of oxygen in air to electrochemical detection are reduced, and experiment accuracy is improved; by means of utilizing the acrylic plates as an external structure of the electrolytic tank, light transmission and impact resistance are effectively improved; meanwhile, cost of the electrolytic tank is reduced.

Owner:DALIAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com