Baffleless magnesium electrolytic cell and use method thereof

A magnesium electrolytic cell without separator technology, applied in the field of electrolytic cell, can solve the problems of small capacity of magnesium electrolytic cell without separator, difficulty in increasing electrolytic cell capacity, high energy consumption of electrolytic magnesium production, etc., and achieve reduction of chlorine gas outlet , Enhanced sealing performance and compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

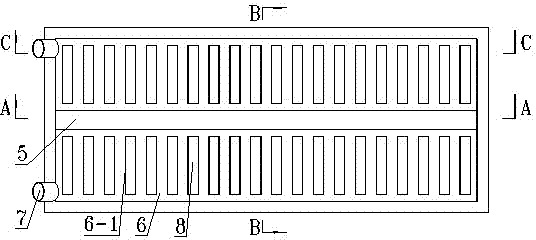

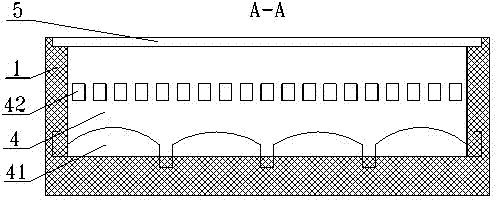

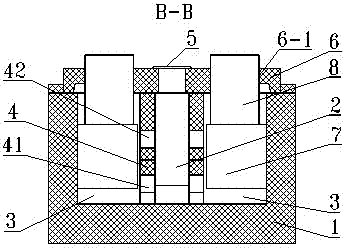

[0018] refer to figure 1 , figure 2 , image 3 and Figure 4 , the magnesium electrolytic cell without a partition, a magnesium collecting chamber 2 and an electrolytic chamber 3 are arranged in the electrolytic cell 1, a gas collecting hood 5 is arranged above the magnesium collecting chamber 2, and a tank cover 6 is arranged above the electrolytic chamber 3 , the magnesium collection chamber 2 is provided in the middle of the electrolytic cell 1 along the length direction of the electrolytic cell 1, and an electrolytic chamber 3 is arranged on both sides of the magnesium collection chamber 2, and the two electrolytic chambers 3 are also arranged along the length direction of the electrolytic cell 1 A partition wall 4 is arranged between the magnesium collection chamber 2 and the electrolysis chamber 3, and a plurality of melt communication channels 41 and a plurality of melt circulation holes 42 are opened on the partition wall 4, and the melt communication channel 41 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com