Colloid mixing barrel with electromagnetic balance and assistance functions

A mixing tank and electromagnet technology, which is applied to mixers with rotating containers, mixers, dissolving, etc., can solve problems such as not easy to melt, different quality, and damage to the mixing tank, so as to improve the scope of use and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

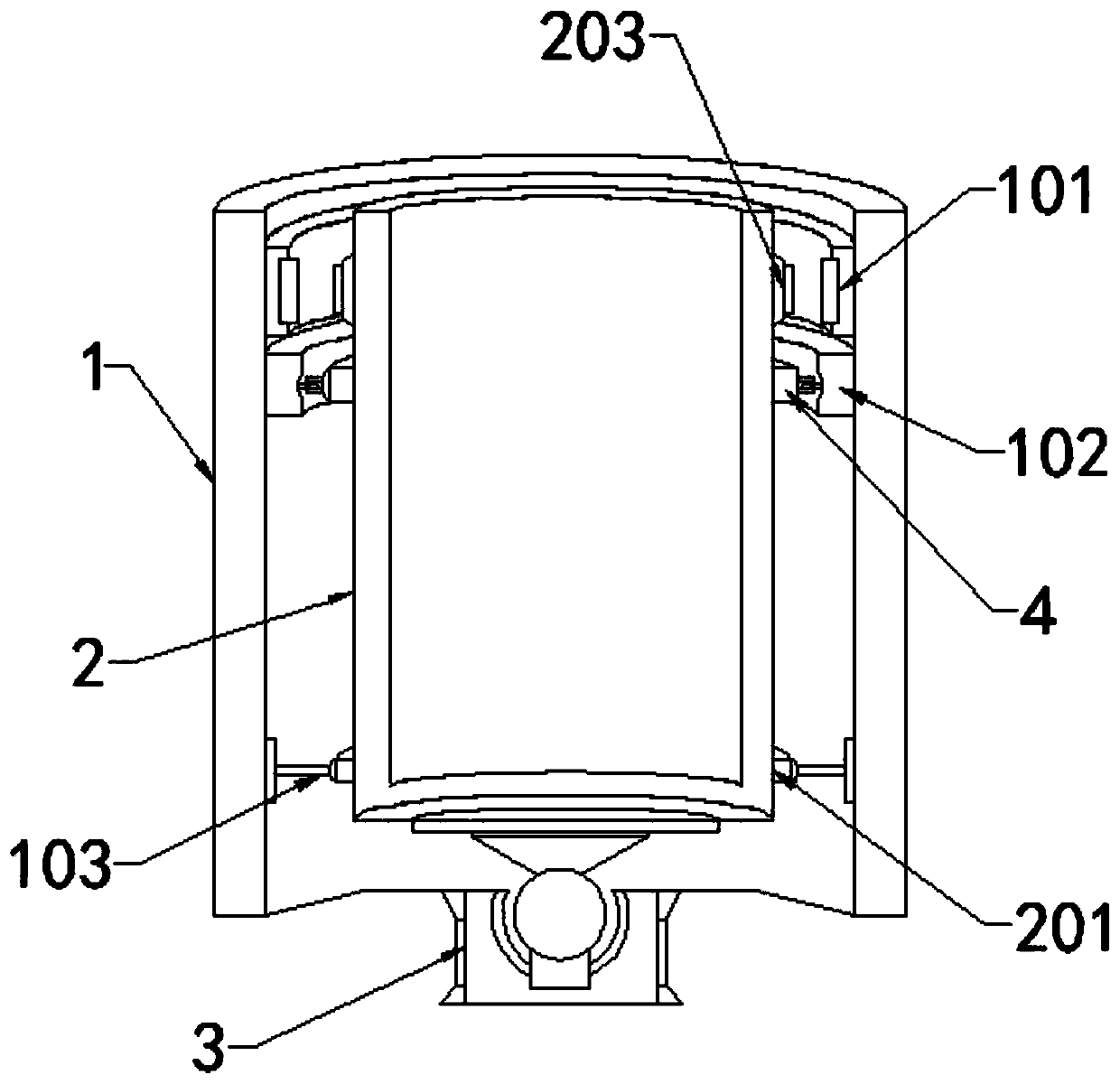

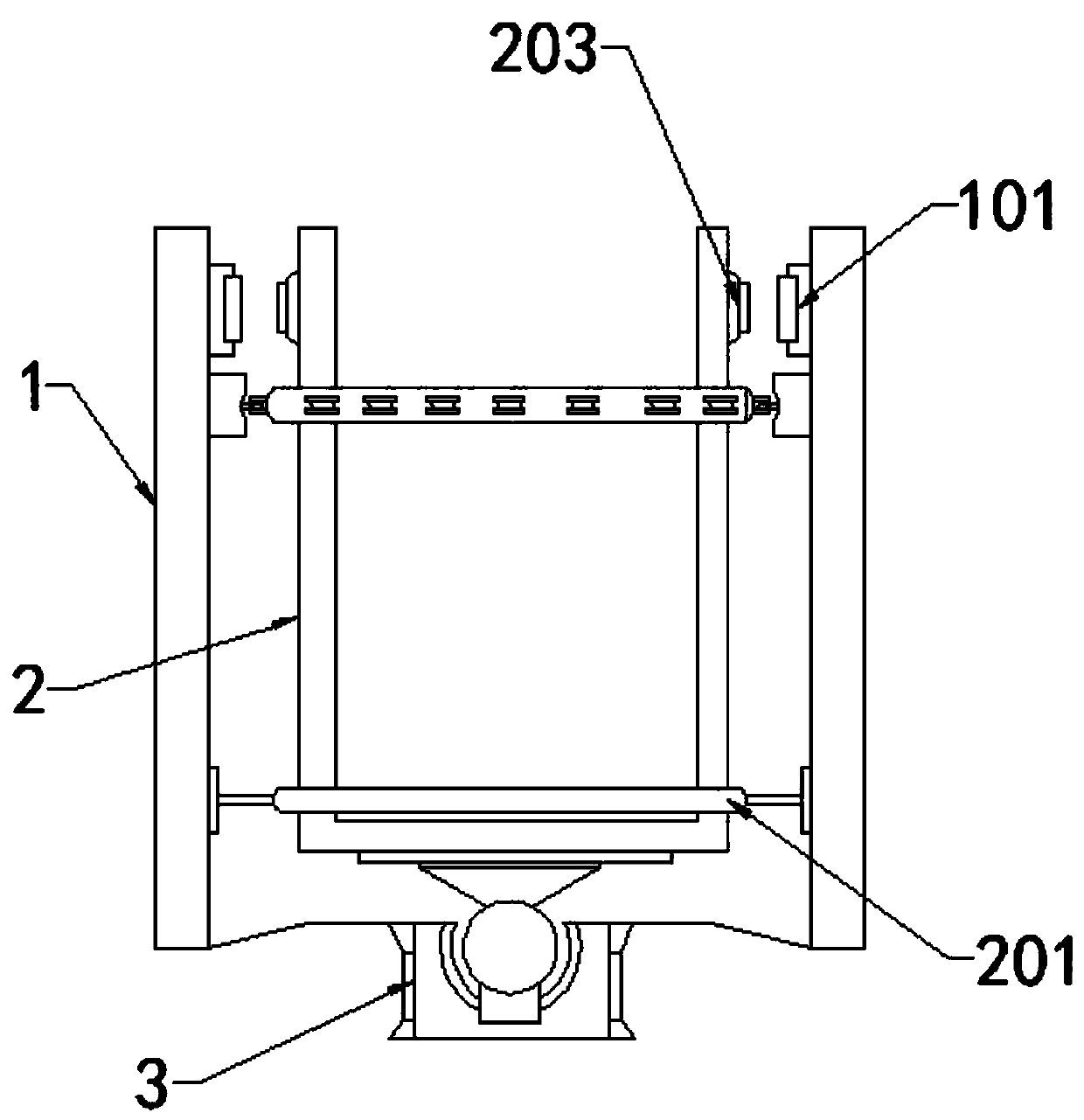

[0030] as attached figure 1 To attach Figure 5 Shown:

[0031] The present invention provides a colloid mixing barrel with electromagnetic balance assistance. The colloid mixing barrel with electromagnetic balance assistance includes a mixing barrel 2 connected to the inside of an outer cylinder 1 through a rotating shaft. The mixing barrel 2 and the outer cylinder 1 are sealed with a balance Structure and auxiliary structure, the bottom of the mixing barrel 2 is fixedly connected with a shock-absorbing transmission part 3, and the shock-absorbing transmission part 3 extends out of the outer cylinder 1 all the time.

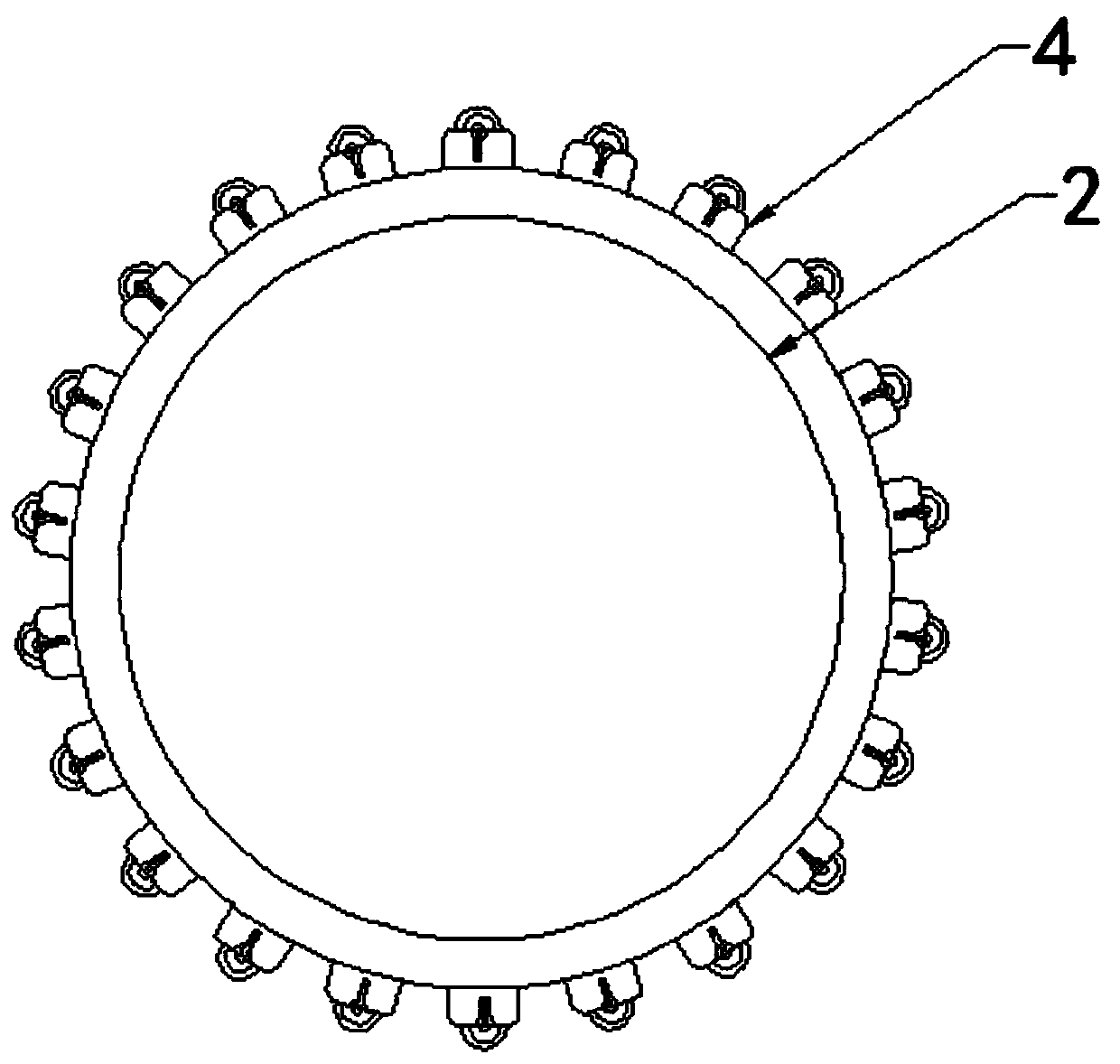

[0032] as attached figure 1 , 2 , 5: wherein, the balance structure includes conductive brushes 103 fixedly connected under the inner surface of the outer cylinder 1, and the number of conductive brushes 103 is four, which are evenly distributed on the inner surface of the outer cylinder 1, and the outer surface of the mixing barrel 2 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com