Ice-melting method with voltage reduction, current increase and short circuit by using series connection of two transformers

A series step-down, double transformer technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of high harmonic content, large reactive power loss, complex structure of the controllable rectifier device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

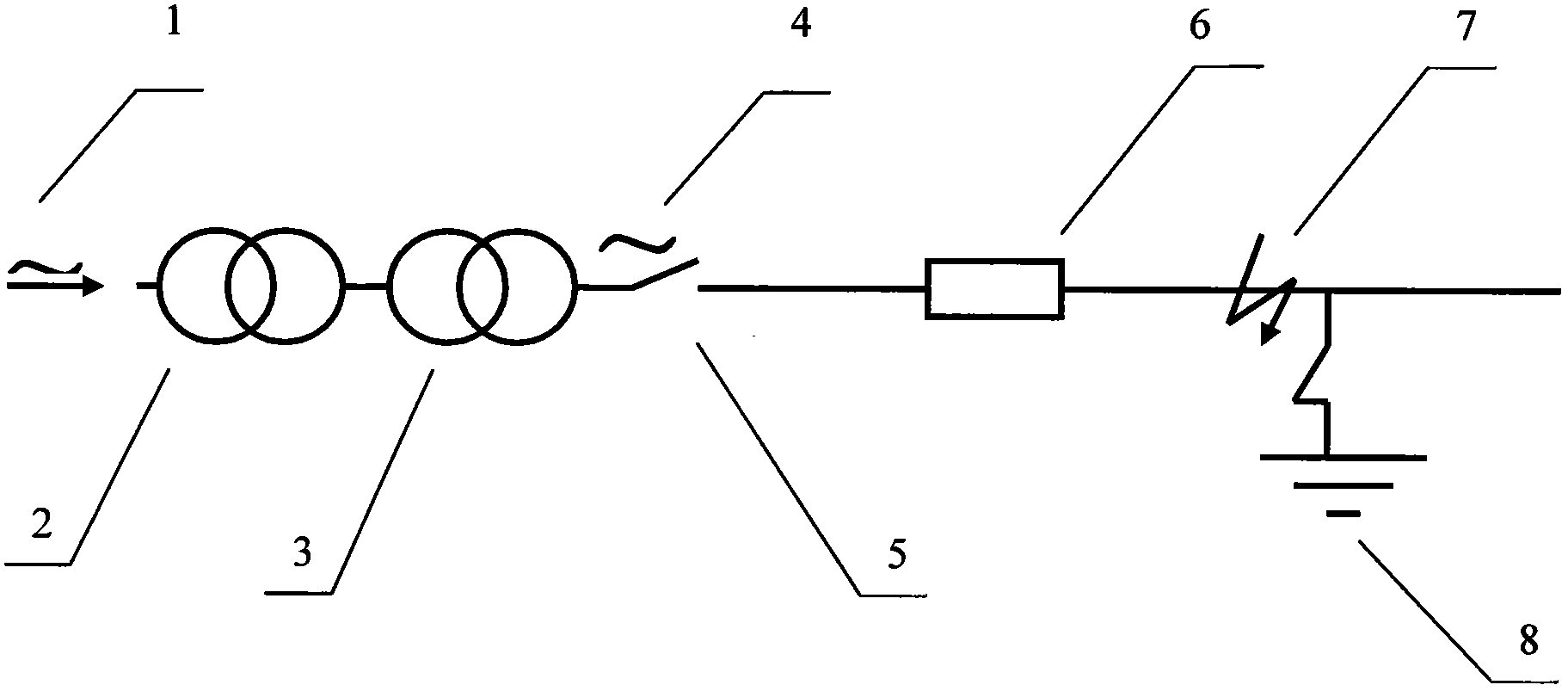

[0022] Such as figure 1 As shown, the high-voltage transformer (2) and the high-voltage transformer (3) are electrically connected in series, the initial power supply (1) is connected to the high-voltage side of the high-voltage transformer (2), and the low-voltage side of the high-voltage transformer (3) is passed through the electrical switch (5) Make an electrical connection to the iced wire (6). According to the icing condition of the wire and the parameters of the ice-melting equipment, the length of the short-circuit line of the ice-coated wire (6) is selected, that is, the three-phase short-circuit point (7) from the electrical switch (5) to the ice-coated wire (6), And a grounding knife switch (8) is installed to prevent the ice-melting current from affecting the safety of electrical equipment at the end line.

[0023] Its working principle is as follows: after the initial power supply (1) is stepped down by the high-voltage transformer (2), the voltage is further ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com