Micro-electrolytic tank for detecting formaldehyde and preparation method thereof

A micro-electrolytic cell and formaldehyde technology, applied in the direction of material electrochemical variables, etc., can solve the problems of unsuitable microfluidic electrochemistry, insufficient linear range, and difficult to achieve detection limit, etc., to achieve good chemical inertness and light transmittance The effect of good and excellent acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

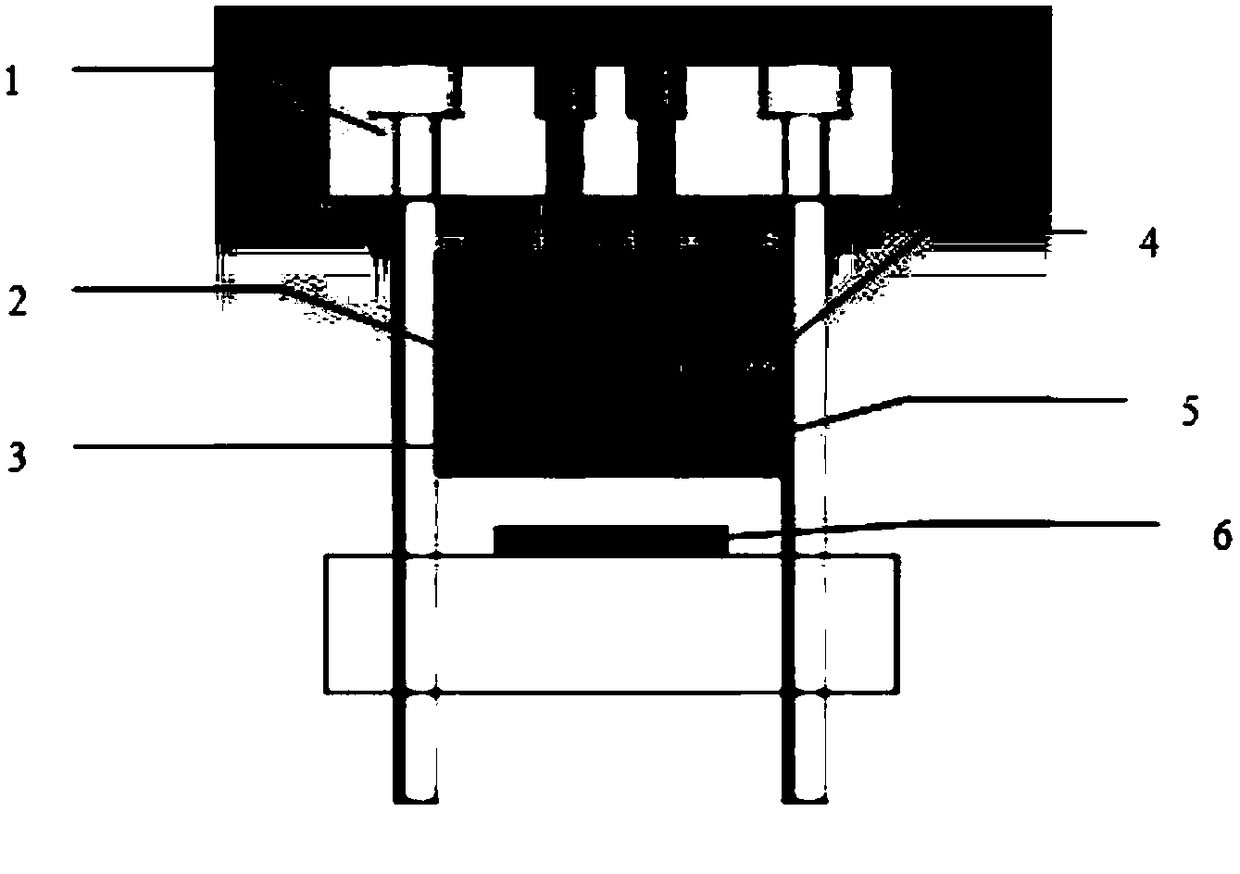

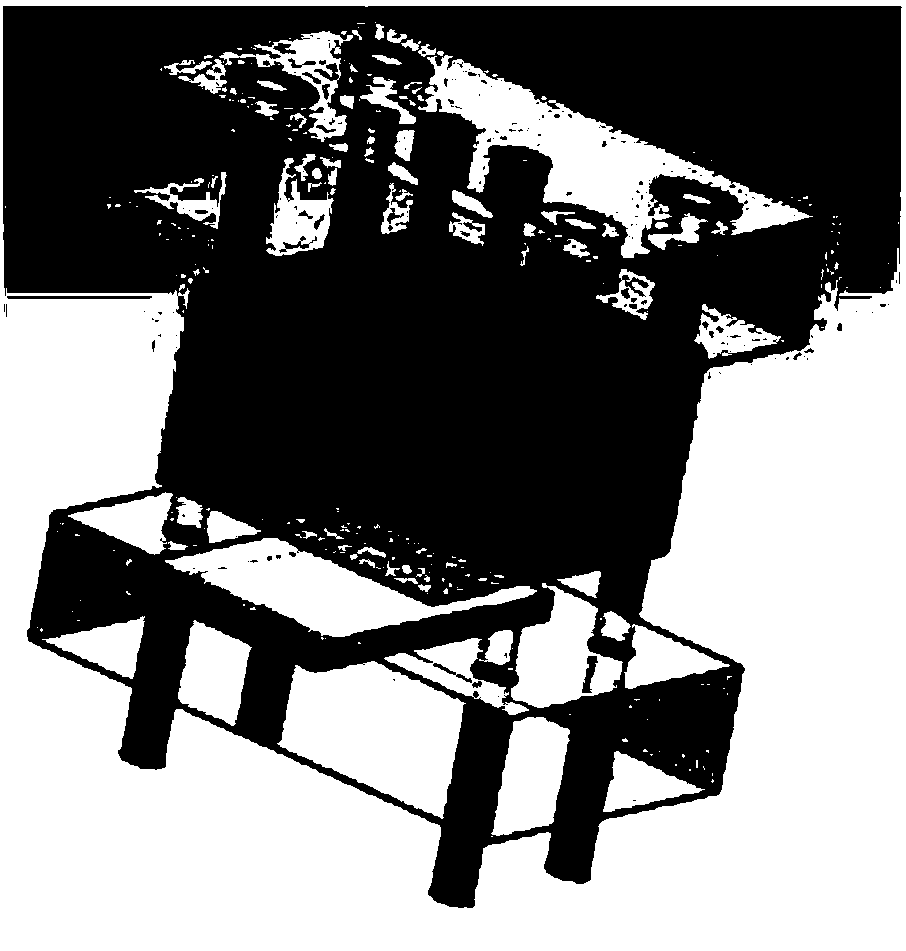

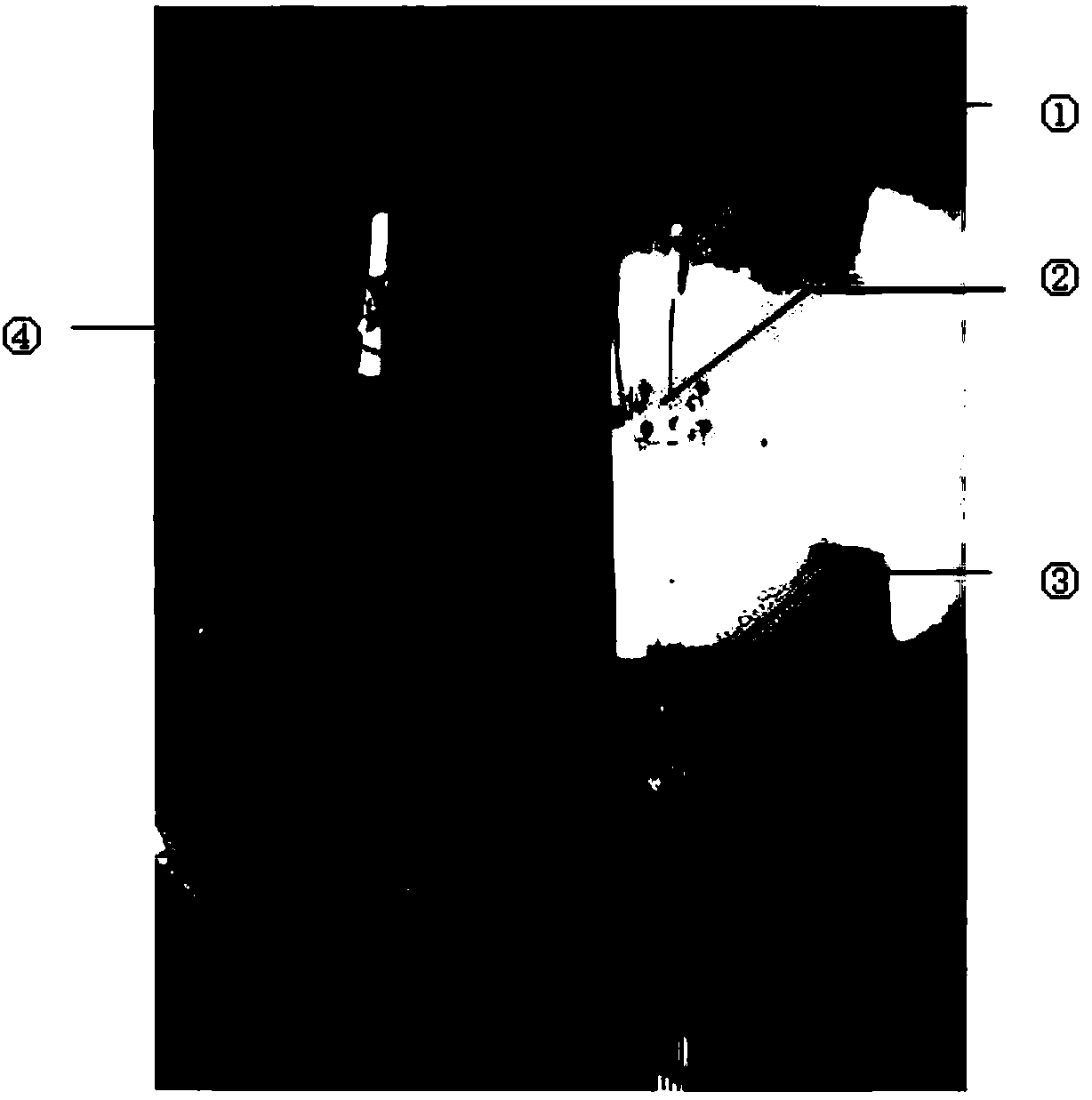

Image

Examples

Embodiment 1

[0036] 1. Preparation of formaldehyde solution

[0037] Weigh 25mg of formaldehyde, place it in a 25mL volumetric flask, and dilute it to the standard mark of the volumetric flask with PBS solution of pH=6. Configured as a 1mg / mL formaldehyde solution.

[0038] 2. Preparation of PDMS mold

[0039](1) Heat the silicon wafer directly in a rubber drying table at 200°C for 15 minutes, then take out the silicon wafer and place it in a petri dish to cool to room temperature.

[0040] (2) Prepare the channel mold by using industrial-grade 3D printing technology. Spin-coating technique was used to bond the channel mold to the silicon wafer to prepare the PDMS template.

[0041] 3. Fabrication of PDMS cell body

[0042] Pour PDMS liquid A (monomer) and liquid B (initiator) into a beaker at a mass ratio of 10:1, stir with a glass rod for 5 minutes, and then pour into the above-mentioned Petri dish equipped with a silicon chip. The culture dish was placed in a concentrated desiccato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com