Patents

Literature

114results about How to "Good self-cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

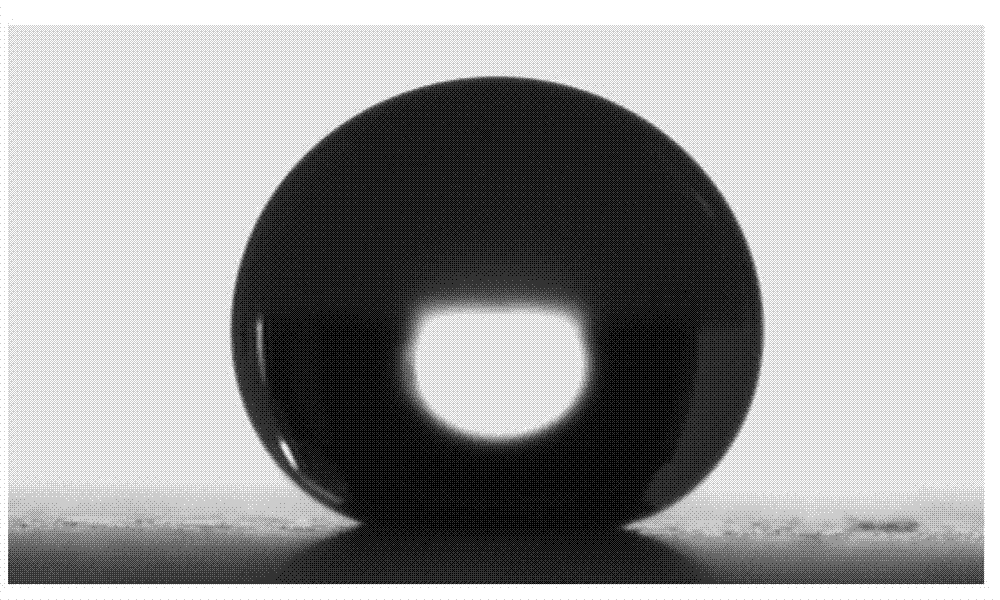

Method for preparation of superhydrophobic timber on the basis of sol-gel method

InactiveCN105599077AHas a superhydrophobic surfaceEasy to operateWood treatment detailsPretreated surfacesSilica nanoparticlesSilanes

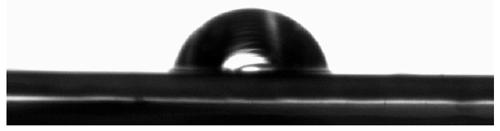

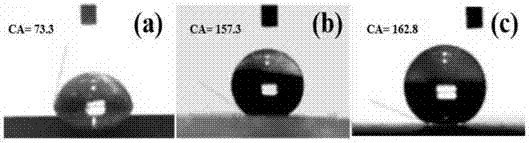

The present invention pertains to a method for preparation of superhydrophobic timber on the basis of a sol-gel method, and the method is as follows: (1), silica sol synthesis, to be more specific, materials are prepared in the volume ratio of ammonia to anhydrous ethanol to ethyl orthosilicate of 1:15 to 17:1; (2), hydrophobic modification of monodispersed nano silica sol, to be more specific, hexadecyl trimethoxysilane, or triethoxysilane-1H, 1H, 2H, 2H-heptadecafluorodecyl silane is used for hydrophobic modification of the synthesized monodispersed nano silica sol, and the hydrophobic agent promotes mutual aggregation of nanoparticles to promote the formation of aggregates of silica nanoparticles; and (3) timber coating processing, to be more specific, the timber surface is coated with the hydrophobically modified silica sol solution by dipping or spraying process. Contact angles of the processed timber surface and water droplets are greater than 150 degrees, roll angles are less than 10 degrees, and a superhydrophobic film has good resistance to acid and alkali erosion and stability in high-humidity environment. The method is simple in operation, less demanding on equipment, and capable of scale production, and has wide market prospects.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

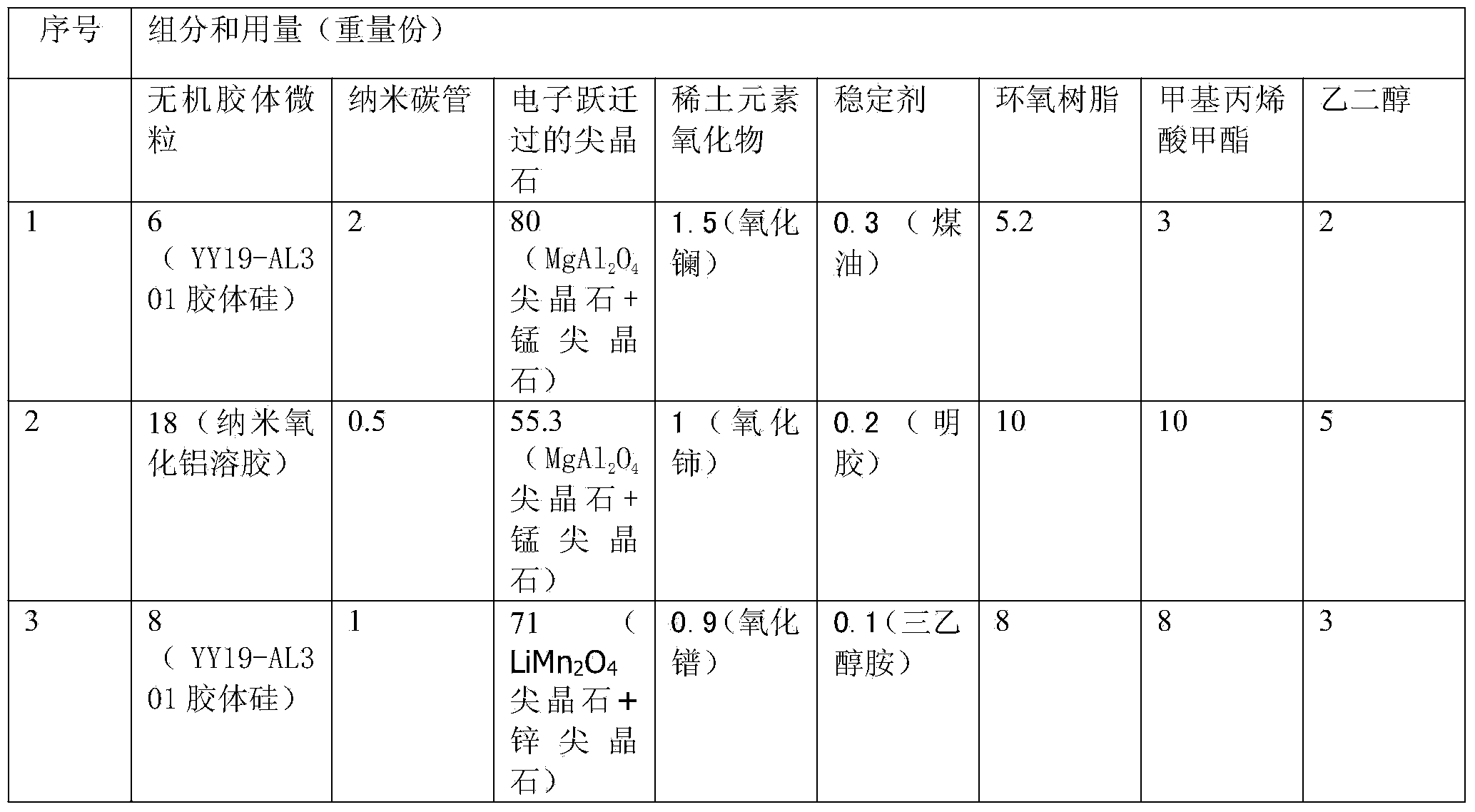

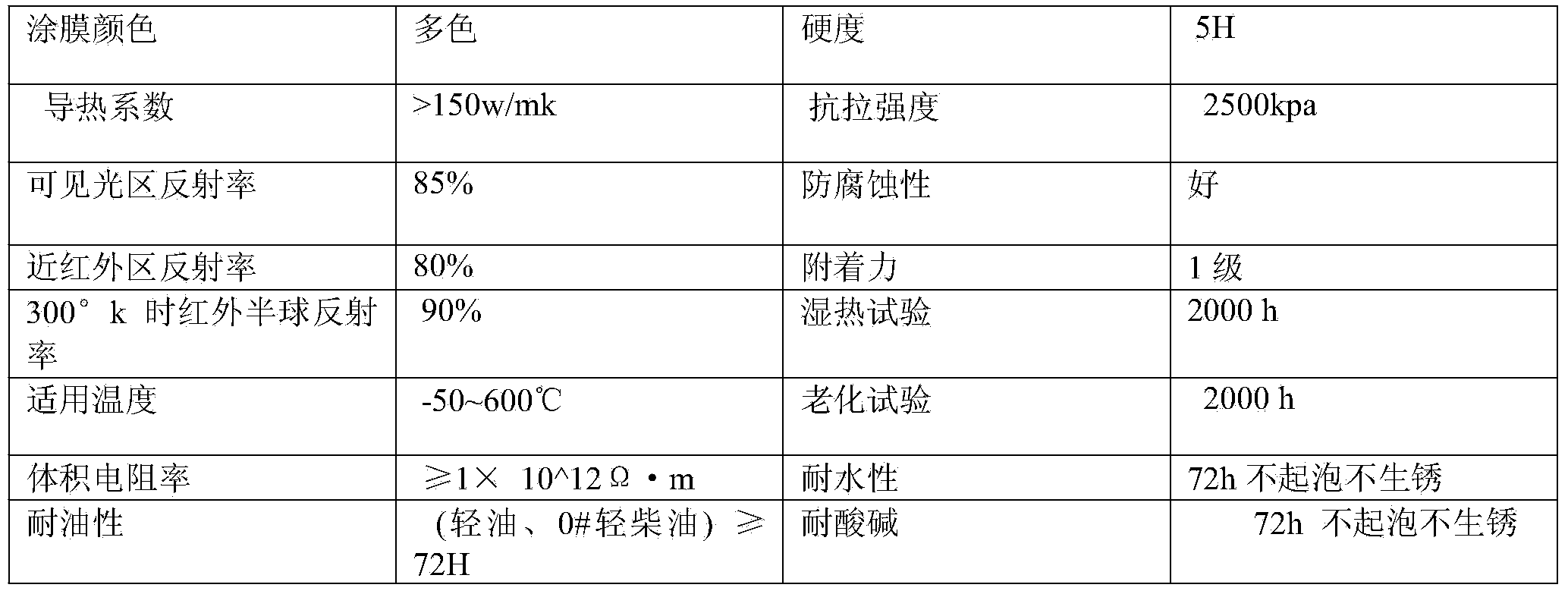

Coating for cooling surface of light-emitting diode (LED) radiator

ActiveCN103965671AGood self-cleaningEasy constructionReflecting/signal paintsRare-earth elementCorrosion

The invention discloses a coating for cooling the surface of a light-emitting diode (LED) radiator. The coating is characterized by being prepared from the following components in parts by weight: 6-20 parts of inorganic colloidal particle, 0.5-2 parts of carbon nano-tube, 15-80 parts of electron transition spinel, 0.05-2 parts of rare-earth element oxide, 0.1-0.3 parts of stabilizer, 3-10 parts of epoxy resin, 3-10 parts of methyl methacrylate and 2-5 parts of ethylene glycol. The coating has obvious heat dissipating and cooling effects, is not affected by surrounding medium when taking the cooling effect, can be used in a vacuum environment, also has the advantages of good self-cleaning property, corrosion resistance, waterproofness, fire retardancy, insulativity, and acid and alkali resistance, and convenient construction when taking a radiation cooling effect.

Owner:NINGBO AISHI ELECTRIC EQUIP

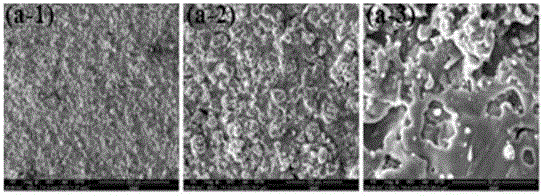

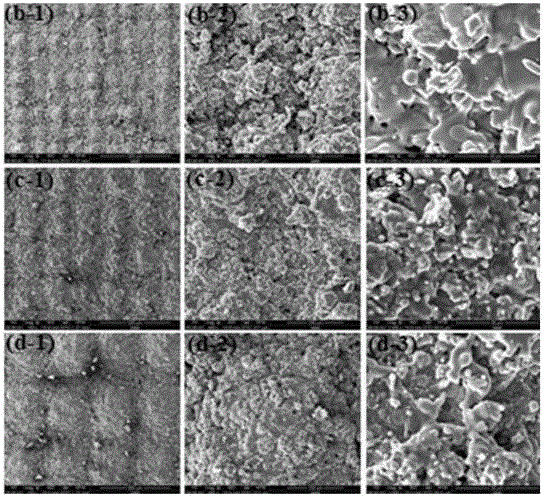

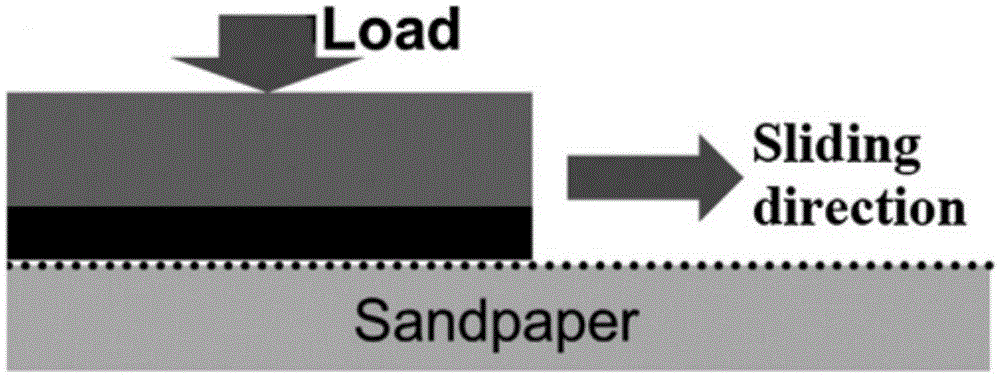

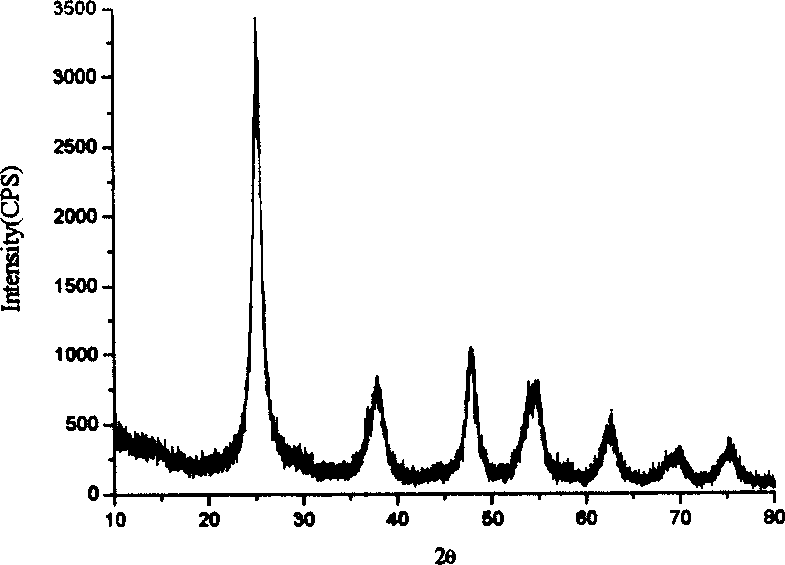

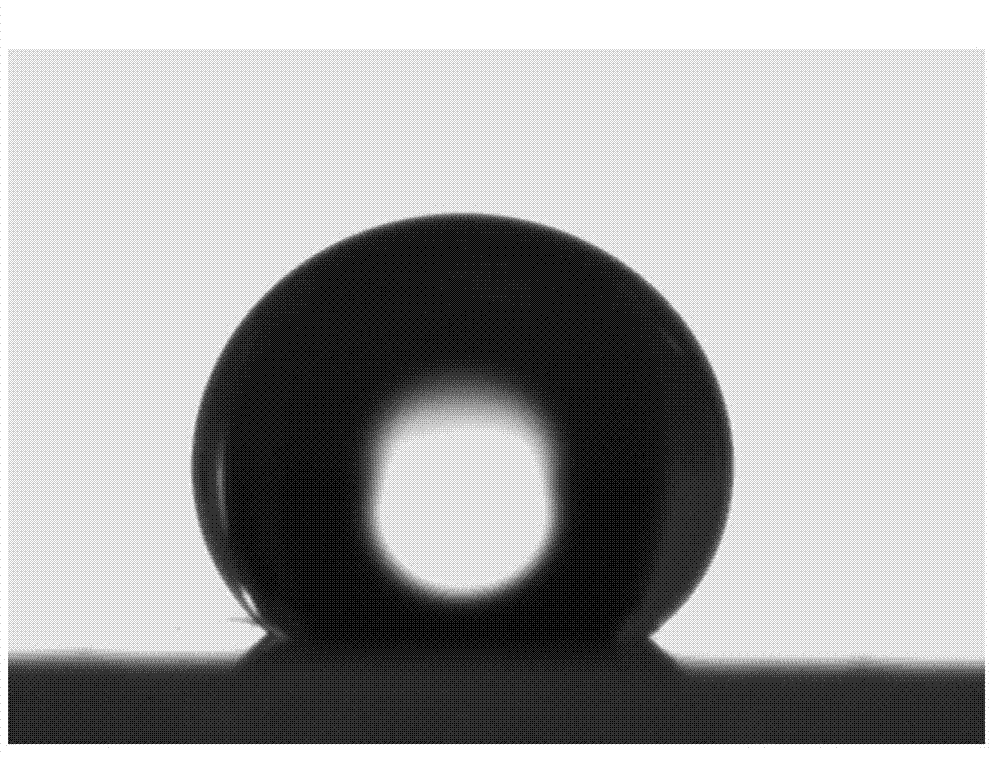

Method for preparing abrasion-resistant super-hydrophobic ceramic coating through thermal spraying technology and product

ActiveCN105316619AExtended service lifeGood self-cleaningMolten spray coatingSurface energyRolling angle

The invention discloses a method for preparing an abrasion-resistant super-hydrophobic ceramic coating through a thermal spraying technology and a product. The method includes the following steps that (1) a substrate is subjected to surface roughening treatment; (2) a micro-patterned ceramic coating is prepared on the surface of the substrate through a plasma spraying technology; and (3) a low surface energy substance layer is sprayed to the obtained ceramic coating through a liquid material flame spraying technology, and the super-hydrophobic abrasion-resistant coating can be obtained. The material obtained through the preparing method has both the advantages of abrasion resistance and super-hydrophobic property, the tribological property of the super-hydrophobic coating is greatly improved, the static contact angle of the obtained coating can reach 150-180 degrees, and the rolling angle of the coating is smaller than 5 degrees. The method can prepare the abrasion-resistant super-hydrophobic coating on the basis of the surfaces of different substrates and is wide in the application range.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Nanometer silicon wall paint for external wall

ActiveCN102702907AAchieve hydrophobic self-cleaning effectImprove breathabilityAntifouling/underwater paintsPaints with biocidesFoaming agentEmulsion

The invention relates to a nanometer silicon wall paint for an external wall, which is prepared by using the following raw materials by weight part: 20-40 parts of de-ionized water, 0.5-0.8 parts of dispersing agents, 0.1-0.3 parts of wetting agents, 0.1-0.3 parts of bactericides, 1-3 parts of anti-freezing agents, 0.1-0.2 parts of pH regulators, 0.2-0.4 parts of de-foaming agents, 15-25 parts of pigments, 15-25 parts of fillers, 5-8 parts of nanometer calcium carbonate, 0.2-0.4 parts of mildew preventives, 0.3-1.0 parts of thickening agents, 15-35 parts of silicone acrylic emulsions, 3-5 parts of organic silicon modified acrylic ester polymerized emulsions and 0.5-1.0 parts of film-forming auxiliaries. The nanometer silicon wall paint for the external wall has a hydrophobic self-cleaning effect and has super climate resistance.

Owner:山东乐化漆业股份有限公司

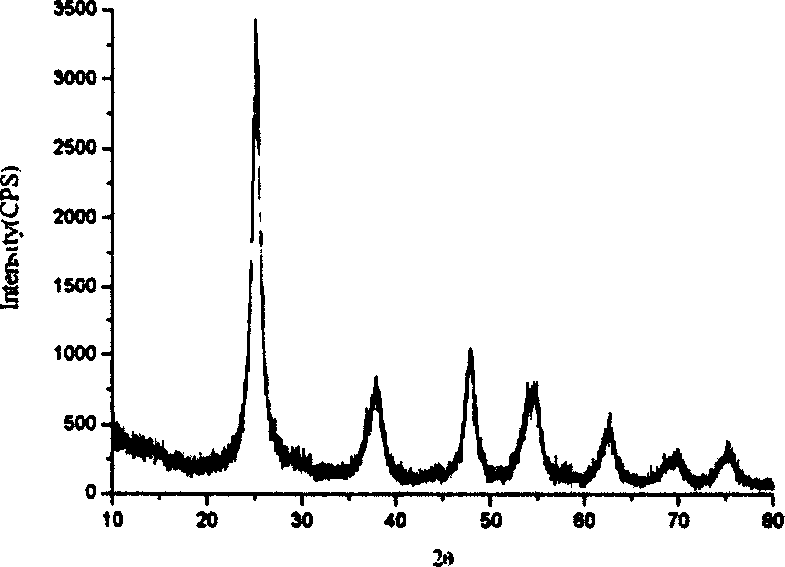

Normal temperature solidified titania sol

InactiveCN1530326ALow costNo operating temperatureTitanium dioxideColloidal chemistry detailsPhysical chemistryPeptization

A TiO2 sol able to be solidified at ordinary temp to become anatase crystal type TiO2 is prepared through hydrolyzing the compound of inorganic titanium to obtain spontaneous crystal seed, ordinary-pressure hydrolyzing inorganic titanium compound under the action of said crystal seed to obtain white deposit, and dissolving in inorganic acid. Its advantages are low cost, low operation temp, and no pollution.

Owner:INST OF CHEM CHINESE ACAD OF SCI

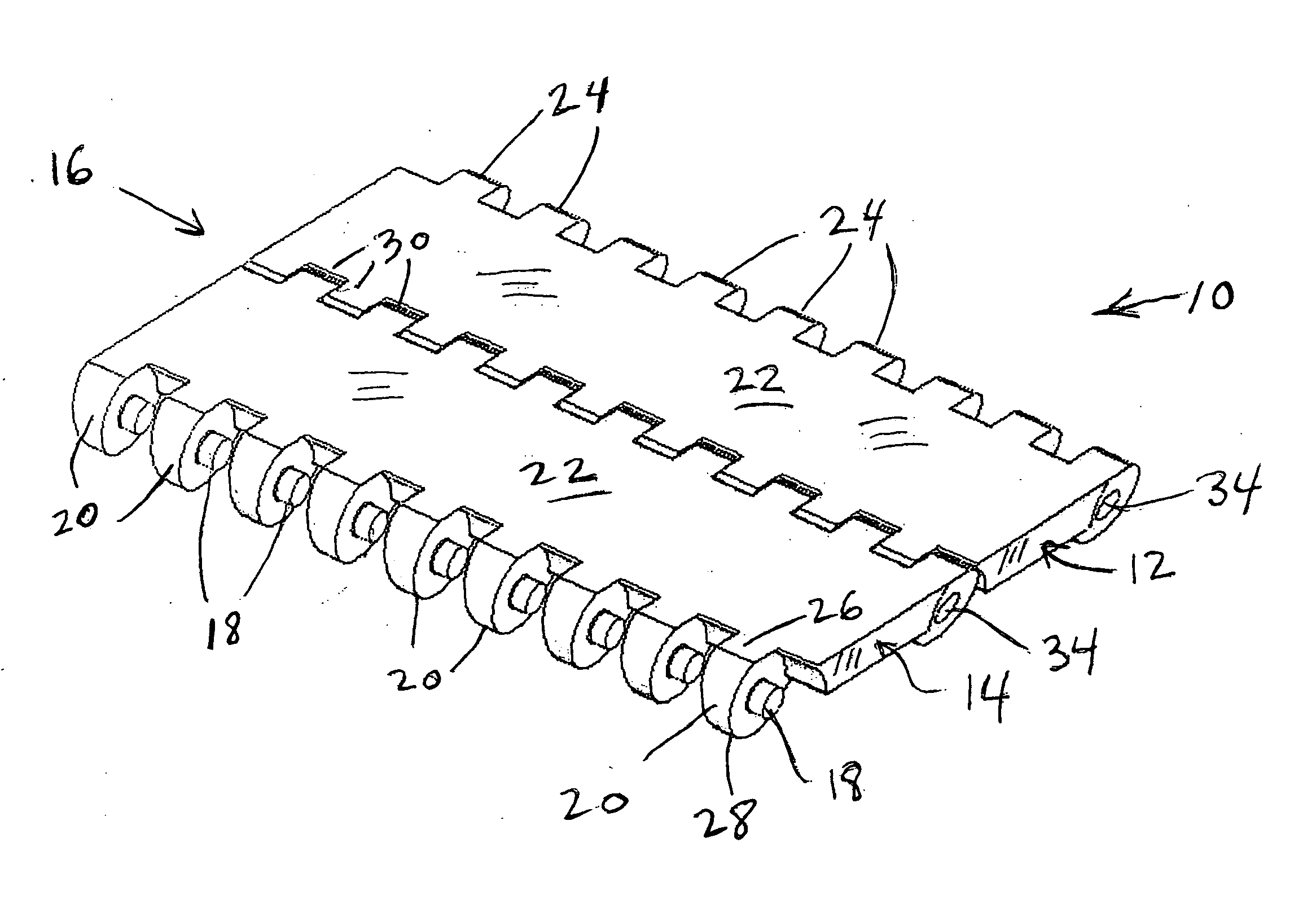

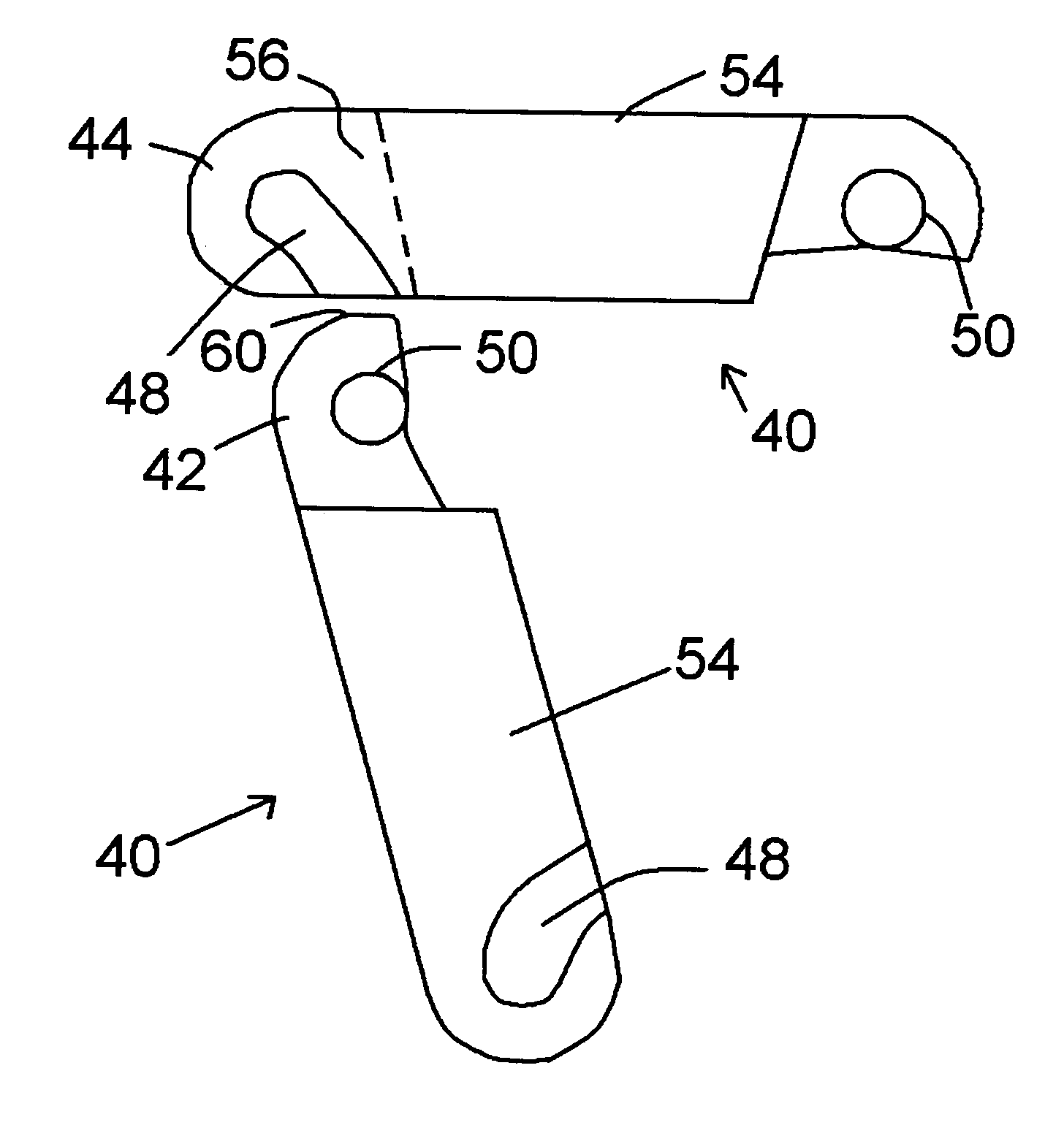

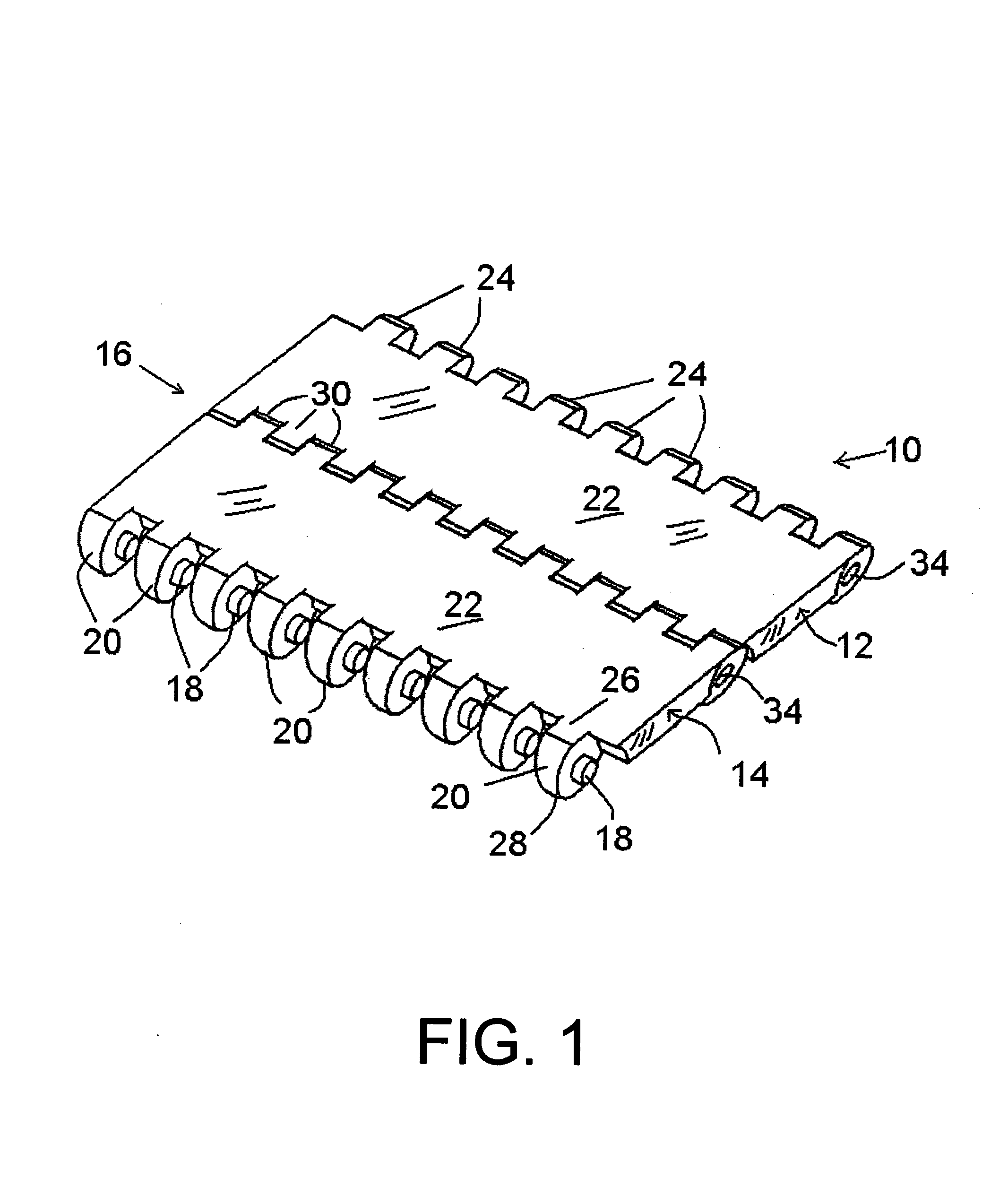

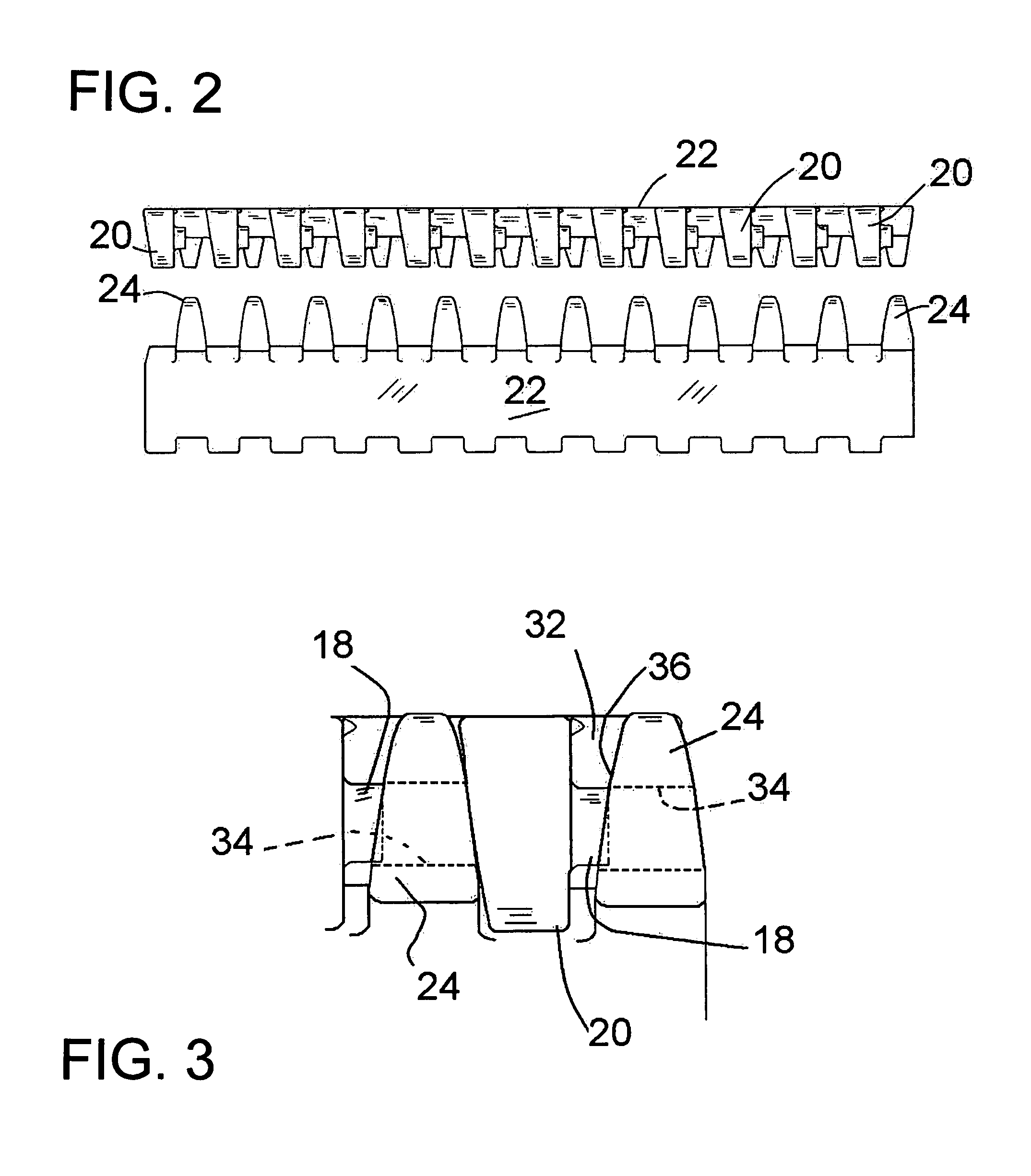

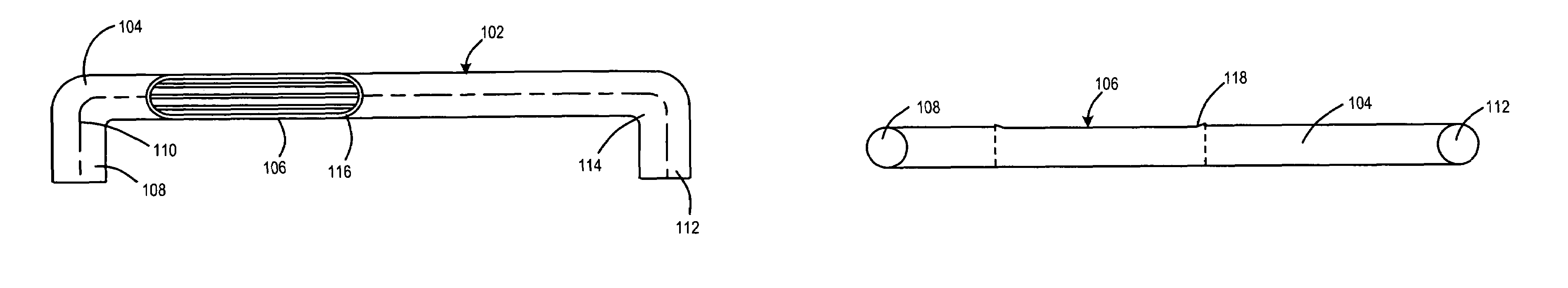

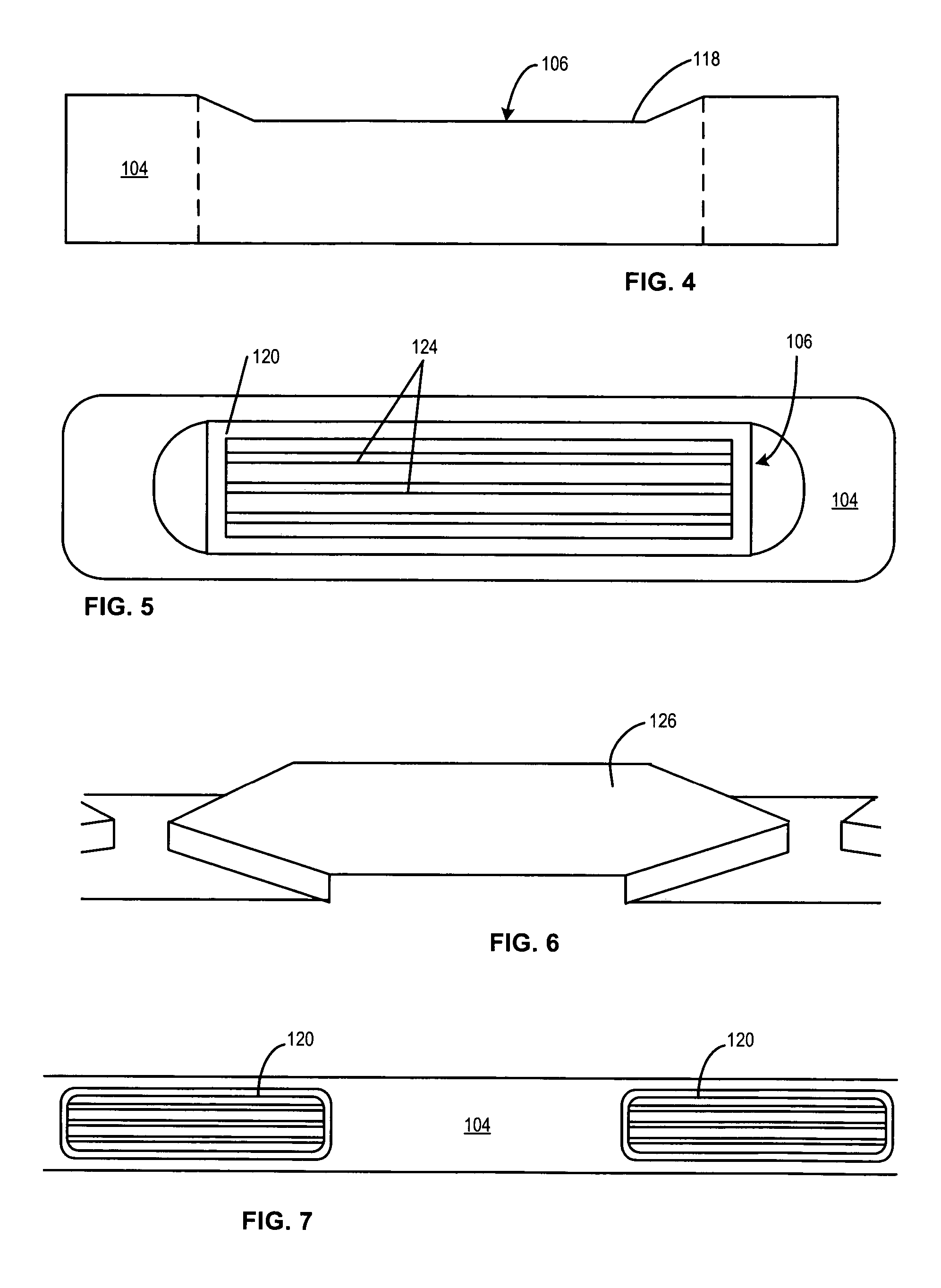

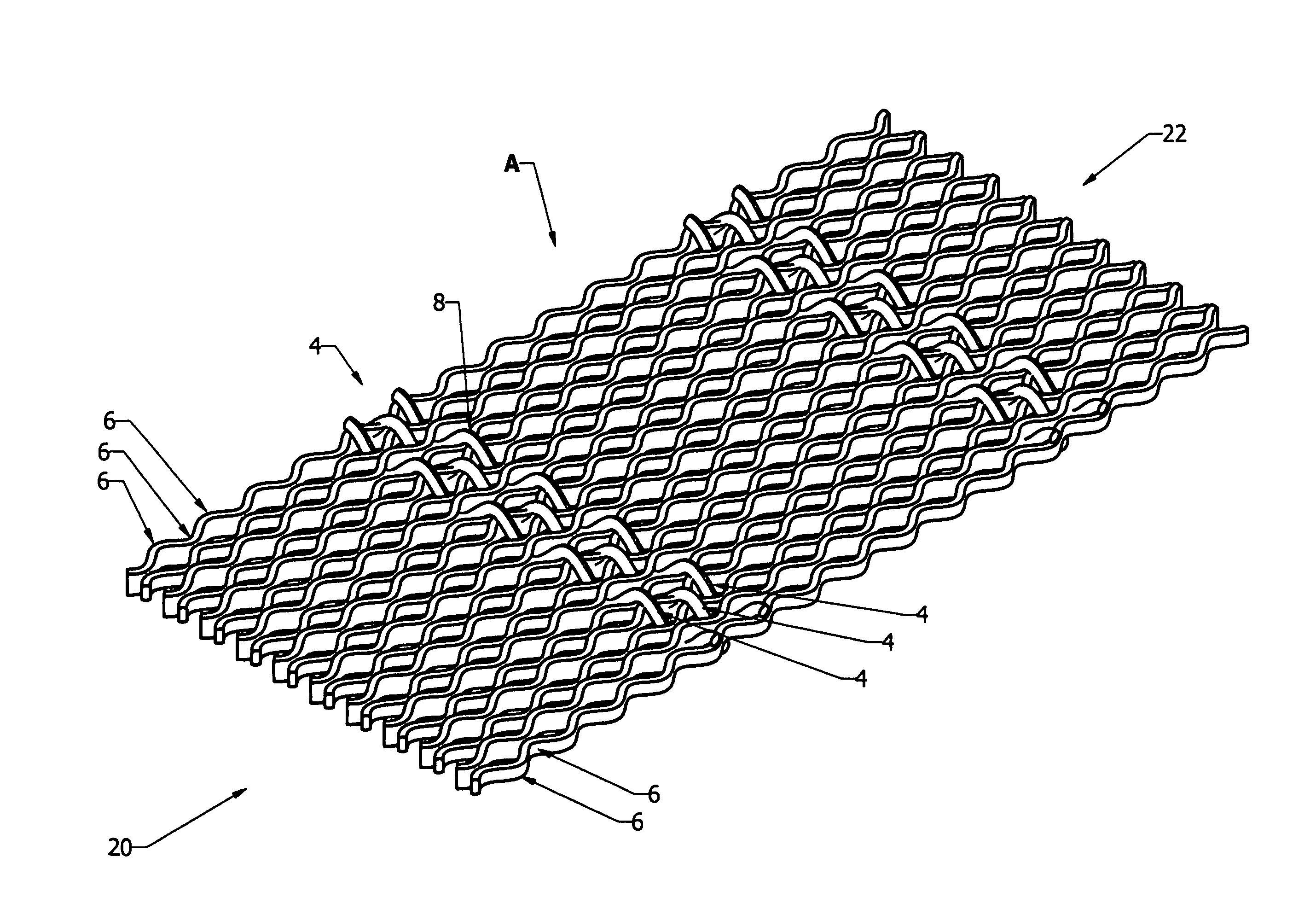

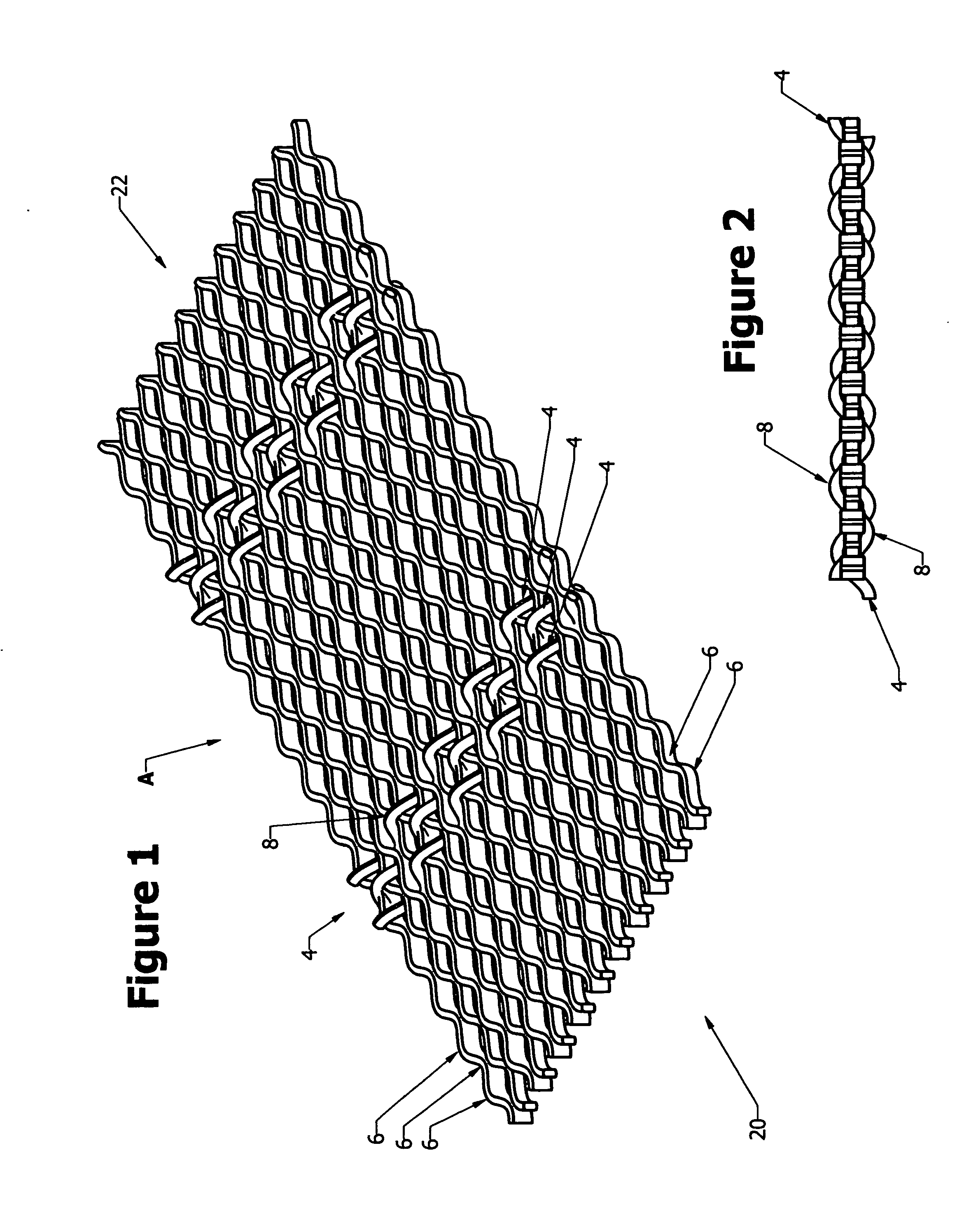

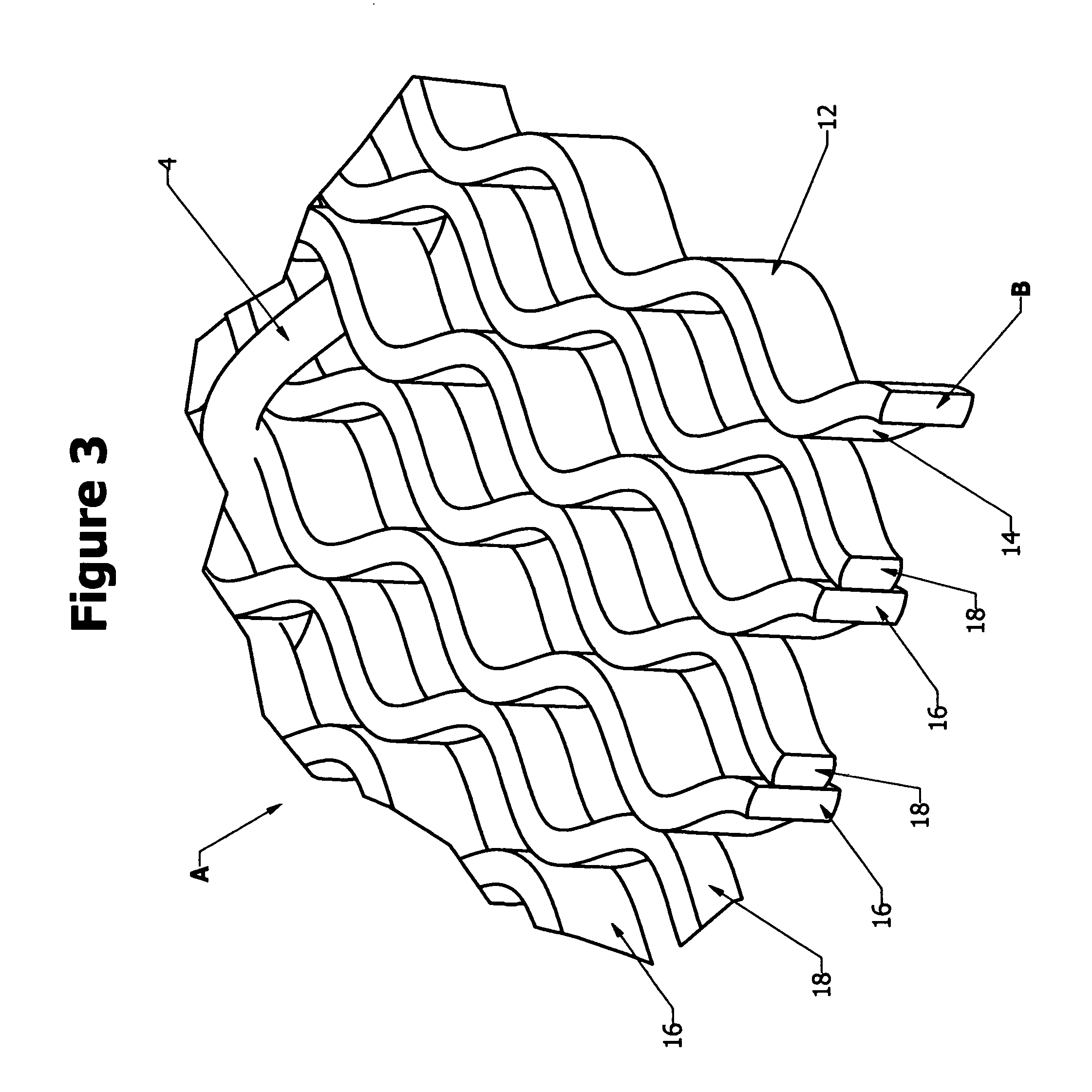

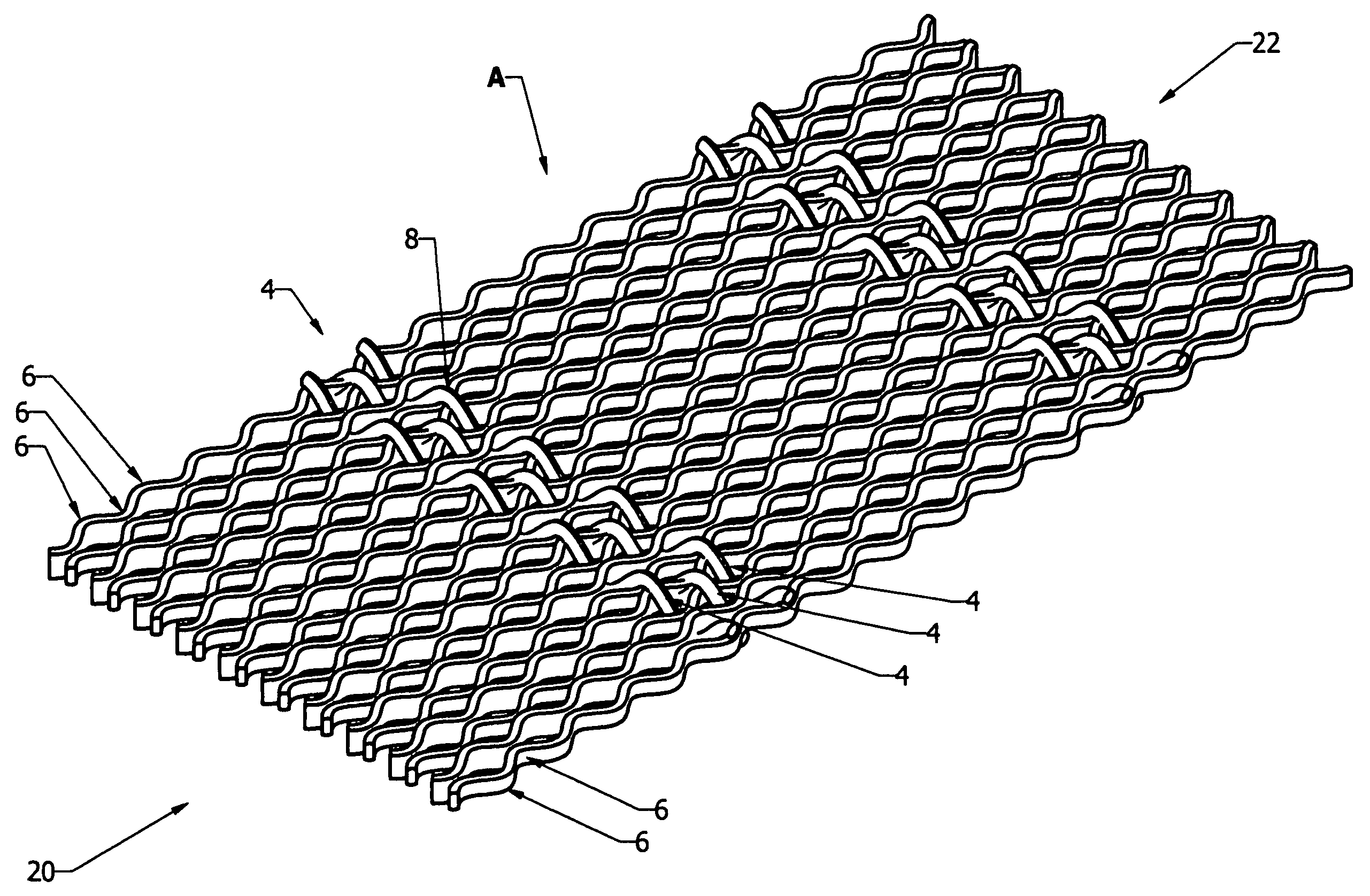

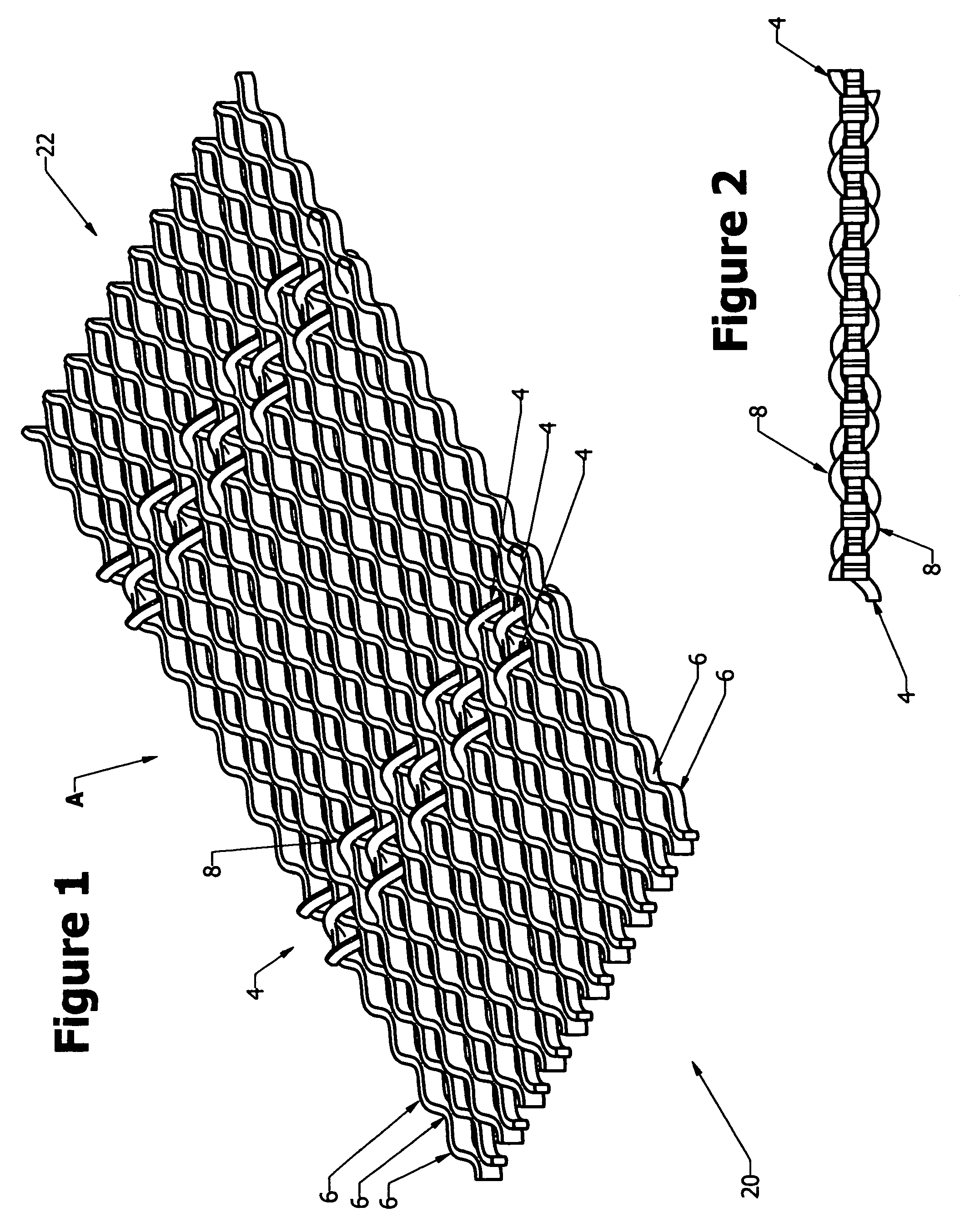

Rodless modular conveyor belt

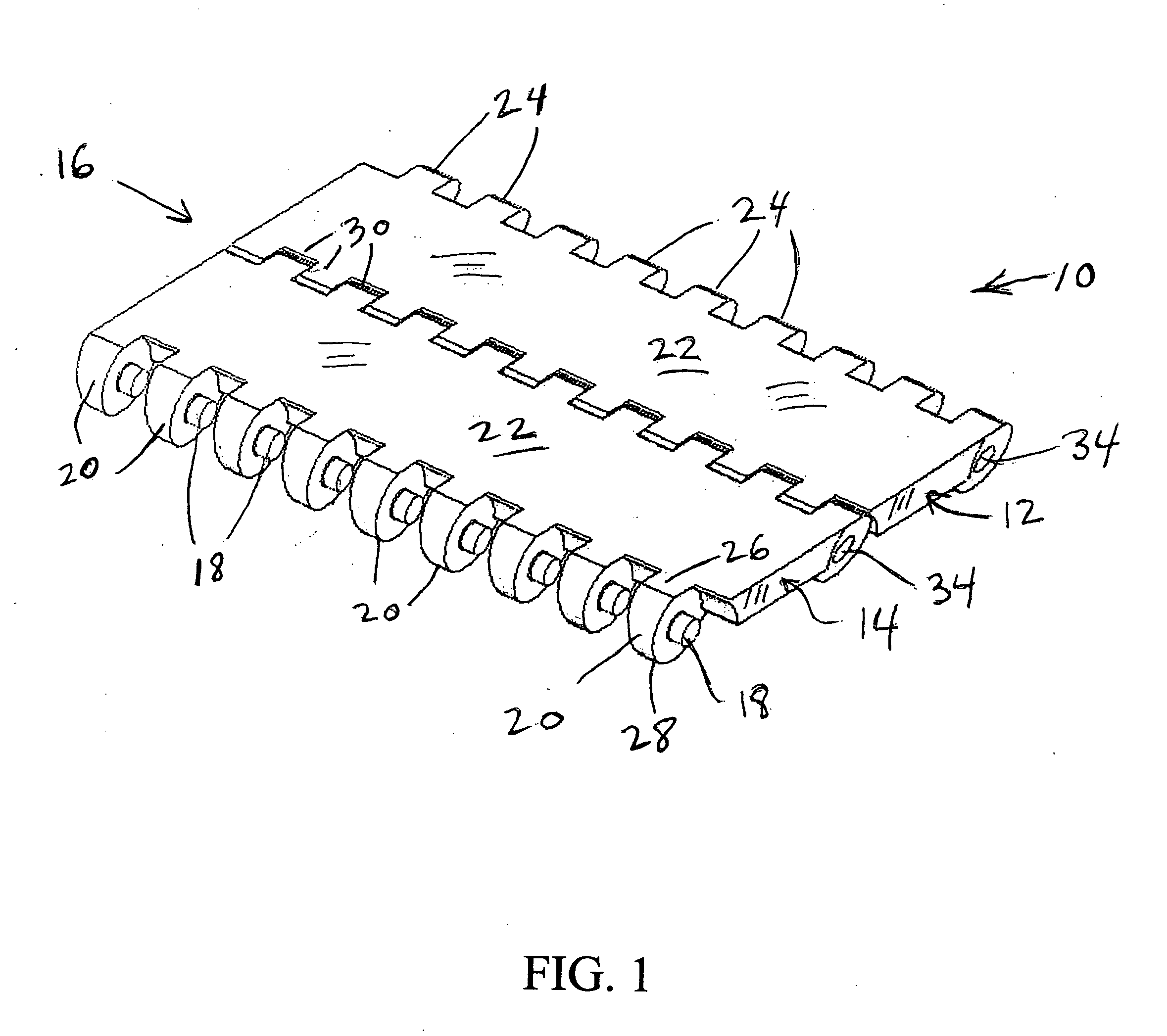

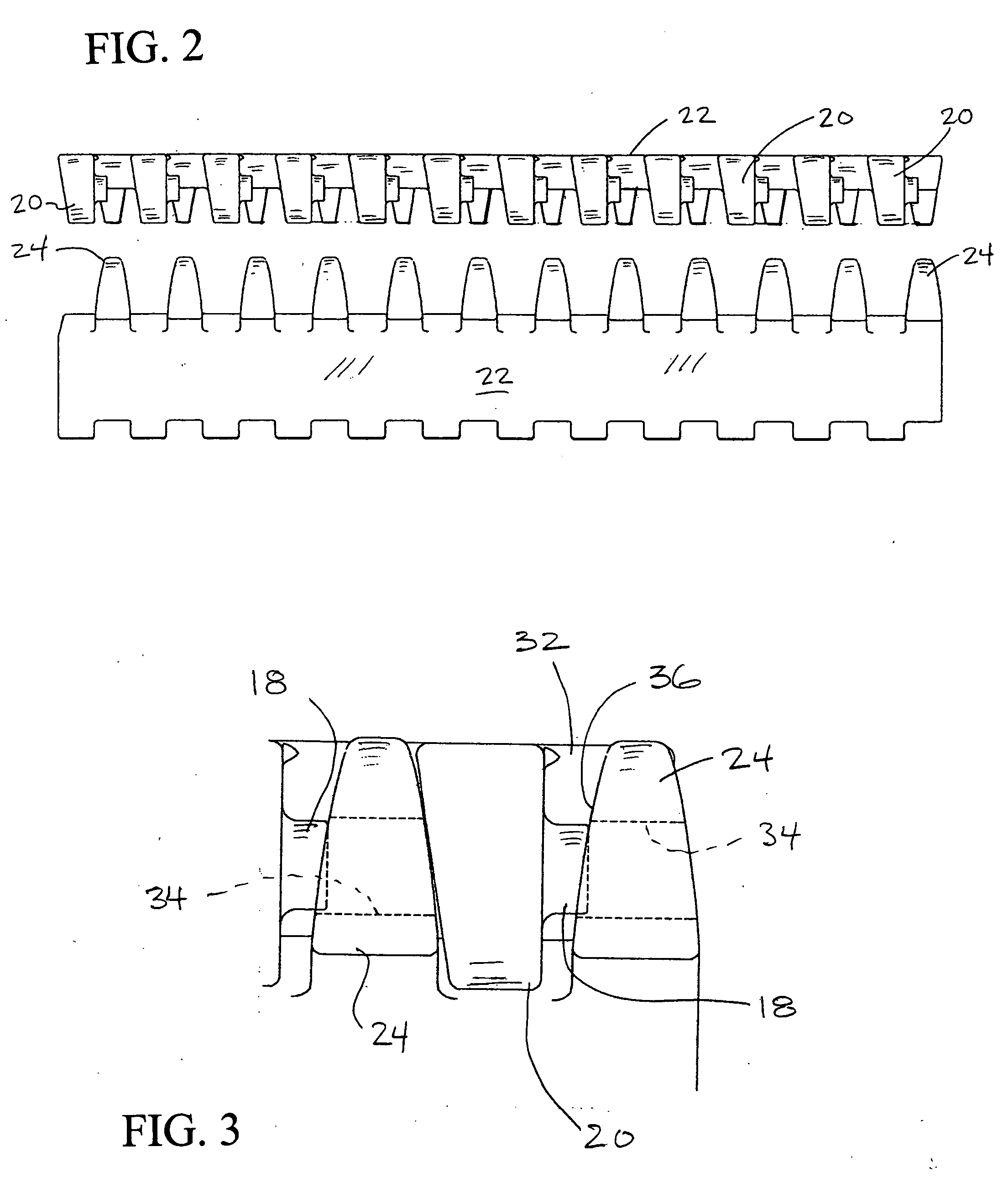

A conveyor belt assembled of modular plastic components is retained together without the usual connecting rods or pins. In one embodiment the modules, each of which has series of finger-like projections or knuckles both at forward and rear ends of the module, the projections are tapered to narrows in width from top to bottom. The projections at either the forward or rear side have laterally extending posts or dowels at one side of each projection, each with a length that extends through only part of the width of the gap between adjacent projections. In the opposite set of projections are holes, similar to the aligned holes that are present when module rows are connected by rods. With the projections being tapered, modules of adjacent rows can be put together by interdigiting the projections with the modules of adjacent rows held at an angle, preferably an acute angle beyond 90°. When the modules are brought back toward alignment to a common plane, the pivot posts of one module become locked in the holes of the module of the adjacent row.

Owner:HABASIT AG

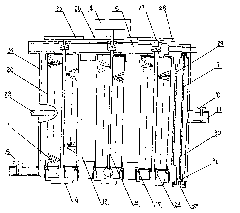

Multipath sewage filtering apparatus

InactiveCN101822918AReduce volumeEasy to useStationary filtering element filtersWater savingCoupling

The invention belongs to a multipath sewage filtering apparatus which mainly comprises a housing and a tubular filter screen. The multipath sewage filtering apparatus is at least provided with a double-screen filter unit. The double-screen filter unit has a structure that the housing is a seal housing; a filtered water chamber is arranged at the middle part of the housing, a unfiltered water chamber is arranged at the upper side of the filtered water chamber; the lower side of the filtered water chamber is divided by a top cover support to form a self-cleaning chamber; the tubular filter screen is a cylindrical filter screen with openings at both ends, and the upper end and the lower end of the filtered water chamber are communicated through the tubular filter screen; and a secondary filter screen is a cylindrical filter screen with openings at both ends. A self-cleaning device comprises a motor, a motor shaft, a shaft seal, a coupling, a brush rod shaft, and brush hair positioned on the brush rod shaft. Because of adopting the double-screen filter unit, the multipath sewage filtering apparatus has the advantages of small volume, simple installation and use, convenient, automatic and mechanical clean of the filter screens, good filtering effect, no occurrence of the phenomenon that pump blockage affects the cyclic utilization of water and obvious water saving effect.

Owner:李立功

Super-hydrophobic surface coating and preparation method thereof

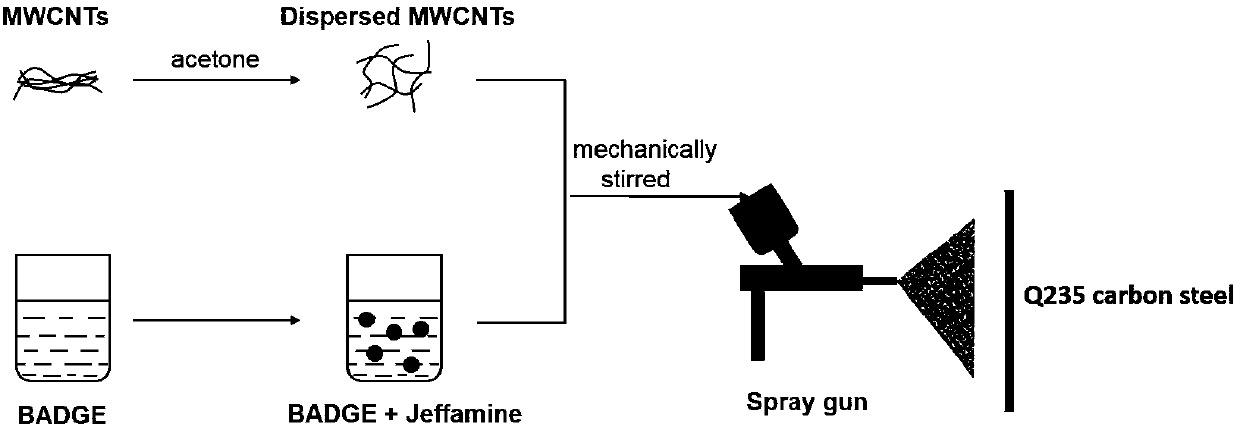

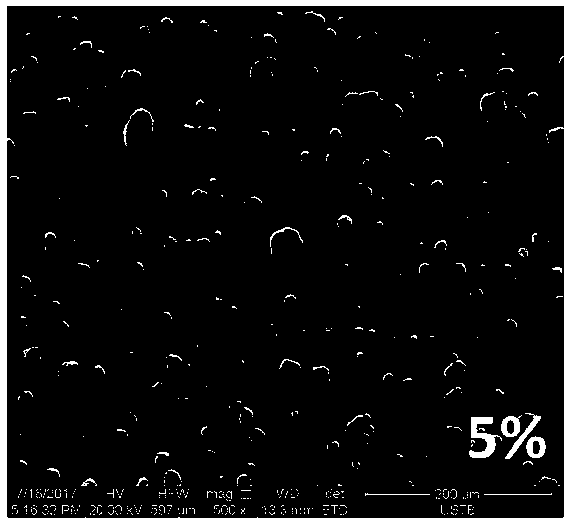

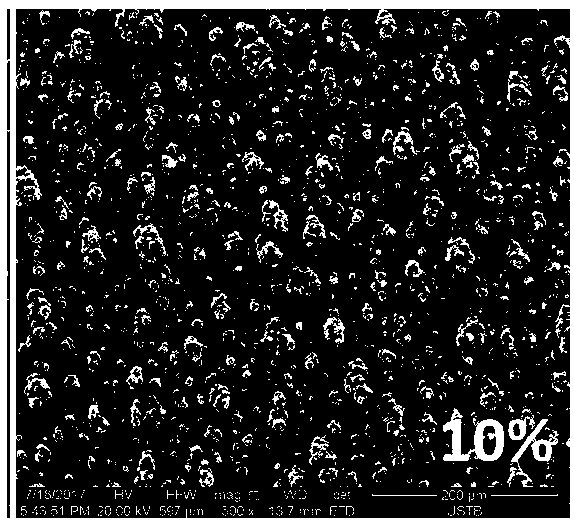

InactiveCN108047884AImprove production efficiencyGood self-cleaningEpoxy resin coatingsElectrically-conductive paintsEpoxyCarbon nanotube

The invention relates to a super-hydrophobic surface coating and a preparation method thereof, and belongs to the field of polymer coating materials. The super-hydrophobic surface coating is obtainedby spraying a super-hydrophobic solution containing epoxy resin, an epoxy curing agent, an epoxy solvent and carbon nanotubes on a substrate material. The super-hydrophobic surface coating has the advantages that materials are easy to obtain, self-cleaning is achieved, and icing is prevented, the preparation technology is simple, and large scale production and application are facilitated.

Owner:UNIV OF SCI & TECH BEIJING

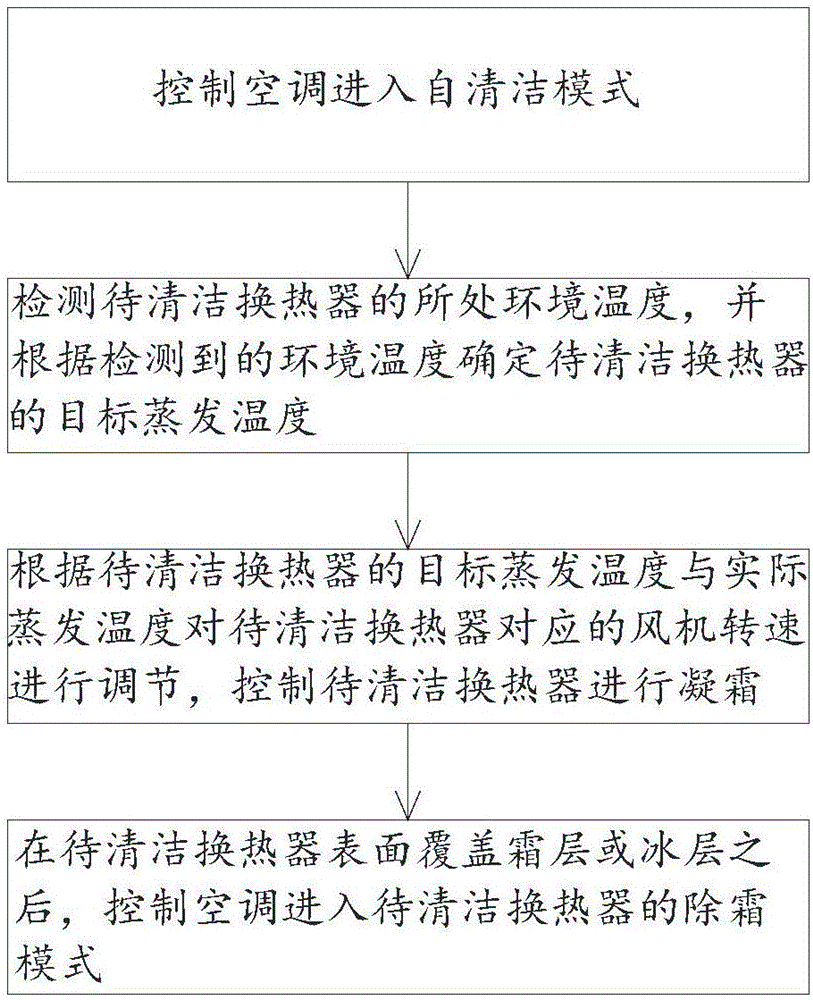

Self-cleaning method of air conditioner heat exchanger

InactiveCN106765866AGood self-cleaningImprove self-cleaning effectMechanical apparatusSpace heating and ventilation safety systemsFrostCleaning methods

The invention discloses a self-cleaning method of an air conditioner heat exchanger. The self-cleaning method of the air conditioner heat exchanger includes the steps of controlling an air conditioner to go into a self-cleaning mode; detecting the environment temperature of the heat exchanger to be cleaned and determining the target evaporation temperature of the heat exchanger to be cleaned according to the detected environment temperature; adjusting the rotary speed of a fan corresponding to the heat exchanger to be cleaned according to the target evaporation temperature of the heat exchanger to be cleaned and the actual evaporation temperature and controlling the heat exchanger to be cleaned to conduct frosting; and controlling the air conditioner to go into a defrosting mode of the heat exchanger to be cleaned after the surface of the heat exchanger to be cleaned is covered with a frost layer or ice layer. According to the self-cleaning method of the air conditioner heat exchanger, the air conditioner heat exchanger can be self-cleaned conveniently, the self-cleaning effect is good, and the cleaning efficiency is high.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Self-cleaning antifouling organic-inorganic super-amphiphobic polymer coating

InactiveCN106590385AGood gloss and color retentionThe advantage is: polyurethane resin has good heat resistanceAntifouling/underwater paintsPaints with biocidesDibenzoyl PeroxideOrganic inorganic

The invention discloses a self-cleaning antifouling organic-inorganic super-amphiphobic polymer coating which is prepared from the following raw materials: perfluoroalkyl ethanol, methyl isobutyl ketone, HDI trimer, methyl methacrylate, styrene, hydroxyethyl methacrylate, perfluorooctyl methacrylate, benzoyl peroxide, 25-28 parts of methanol silica sol, propylene glycol methyl ether acetate, titanium dioxide, sodium hexametaphosphate, ethyl orthosilicate, vinyl triethoxysilane, an appropriate amount of ammonia water, an appropriate amount of silane coupling agent KH570, an appropriate amount of methyl hydroxyl silicone oil, an appropriate amount of 10% dibutyltin dilaurate, a dispersant, a leveling agent, a defoamer, an appropriate amount of butyl acetate, an appropriate amount of anhydrous ethanol, and an appropriate amount of deionized water. The super-amphiphobic polymer coating provided by the invention is simple and feasible in preparation method, can be firmly combined with a variety of substrates, and has universality, good self-cleaning performance, dirt resistance, scrub resistance, corrosion resistance and other performance, and good application prospects.

Owner:TIANCHANG YINHU PAINT

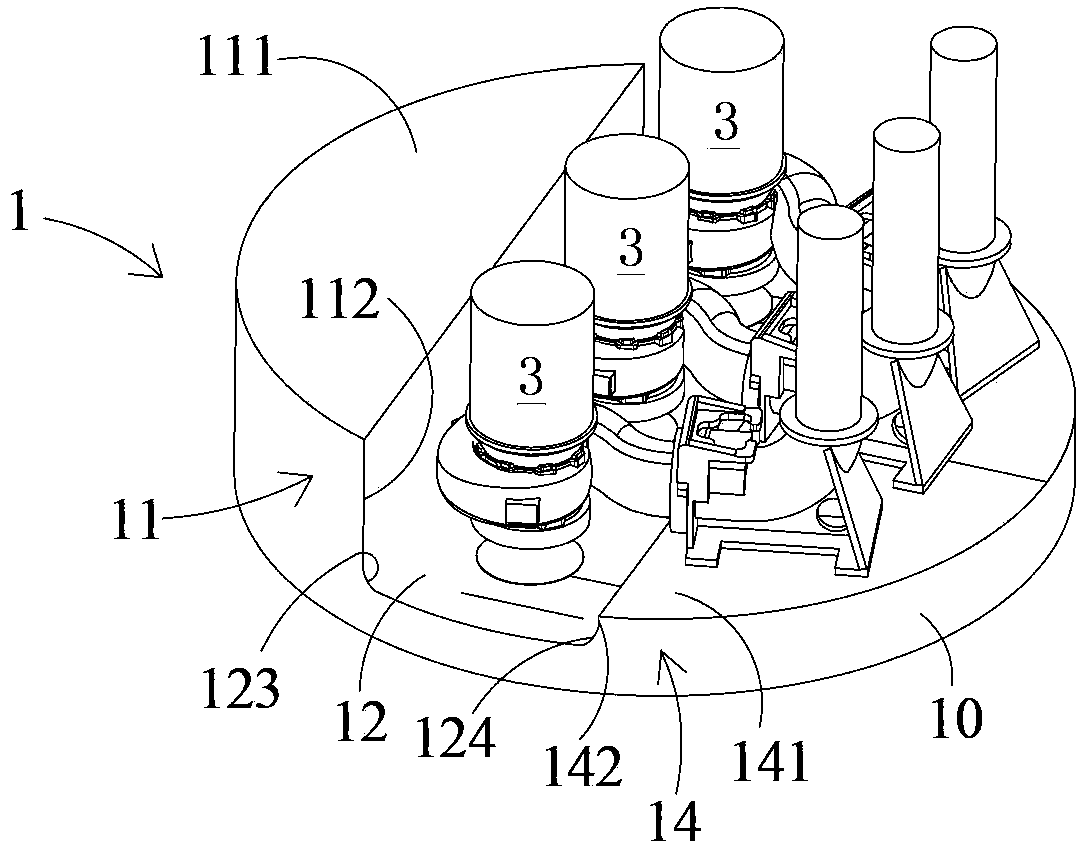

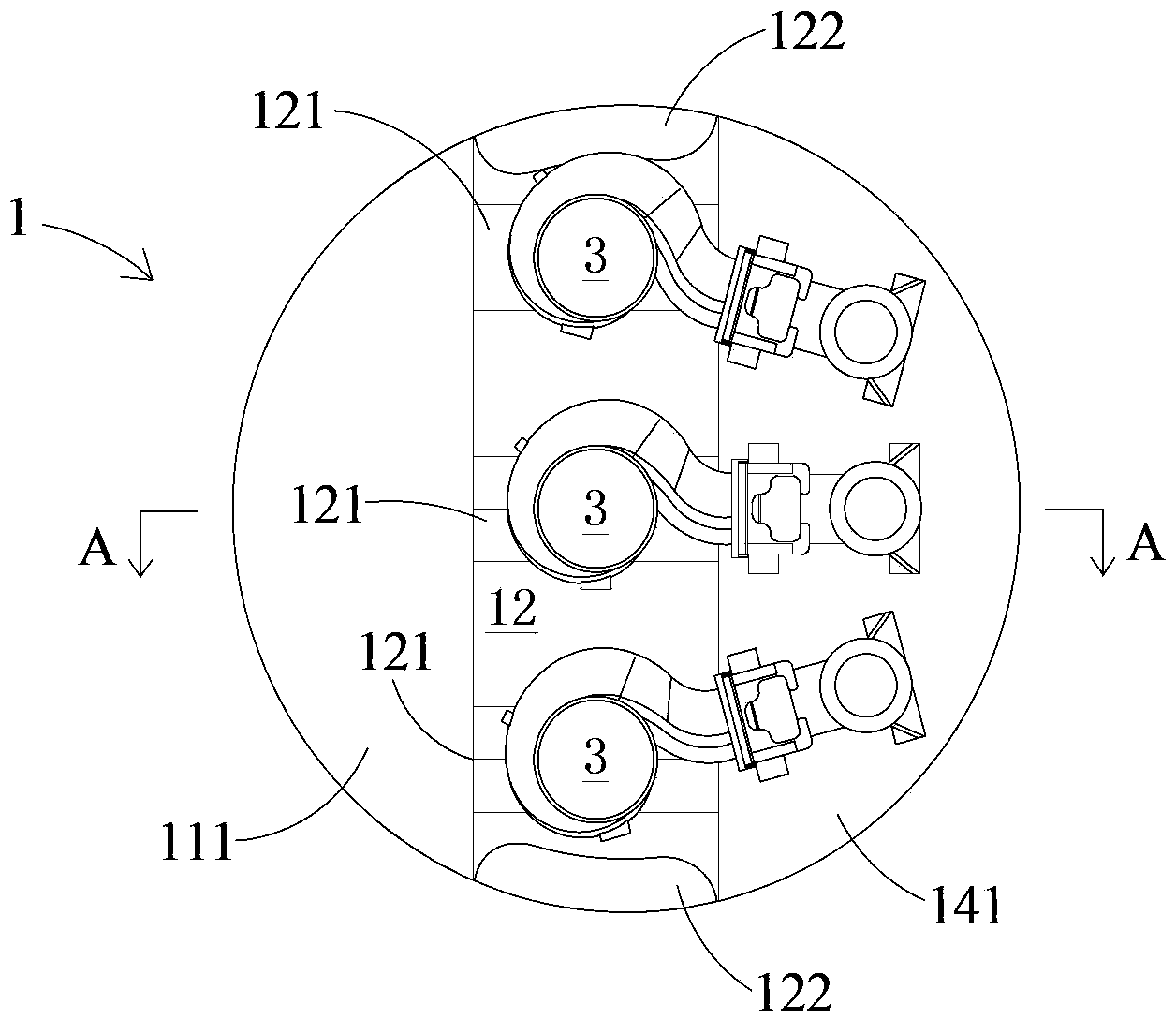

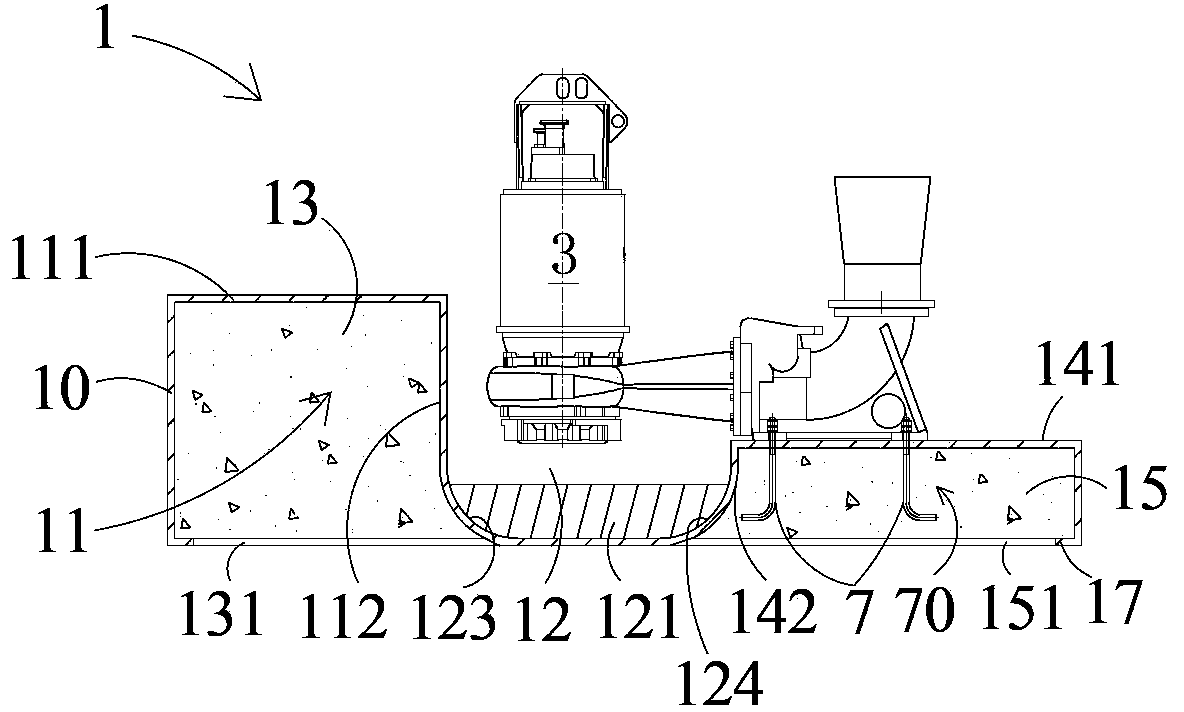

Pump station base, pump station and mounting method for pump station

The invention discloses a pump station base, a pump station and a mounting method for the pump station. The pump station base comprises at least one hollow portion, each hollow portion is provided with at least one pouring portion, and filler can be poured into the hollow portions through the pouring portions. In the site mounting process, concrete is poured into the first hollow portion, the weight of the pump station base is increased, the bearing capacity of the pump station base is enhanced, the pump station can be mounted reliably, the running stability of the pump station is improved, and a large amount of raw material cost is saved. The pump station comprises the pump station base.

Owner:GRUNDFOS HLDG

Rodless modular conveyor belt

A conveyor belt assembled of modular plastic components is retained together without the usual connecting rods or pins. In one embodiment the modules, each of which has series of finger-like projections or knuckles both at forward and rear ends of the module, the projections are tapered to narrows in width from top to bottom. The projections at either the forward or rear side have laterally extending posts or dowels at one side of each projection, each with a length that extends through only part of the width of the gap between adjacent projections. In the opposite set of projections are holes, similar to the aligned holes that are present when module rows are connected by rods. With the projections being tapered, modules of adjacent rows can be put together by interdigiting the projections with the modules of adjacent rows held at an angle, preferably an acute angle beyond 90°. When the modules are brought back toward alignment to a common plane, the pivot posts of one module become locked in the holes of the module of the adjacent row.

Owner:HABASIT AG

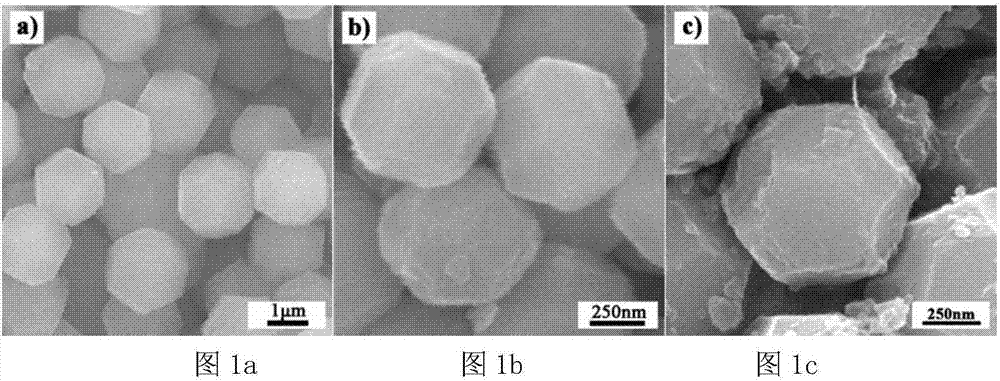

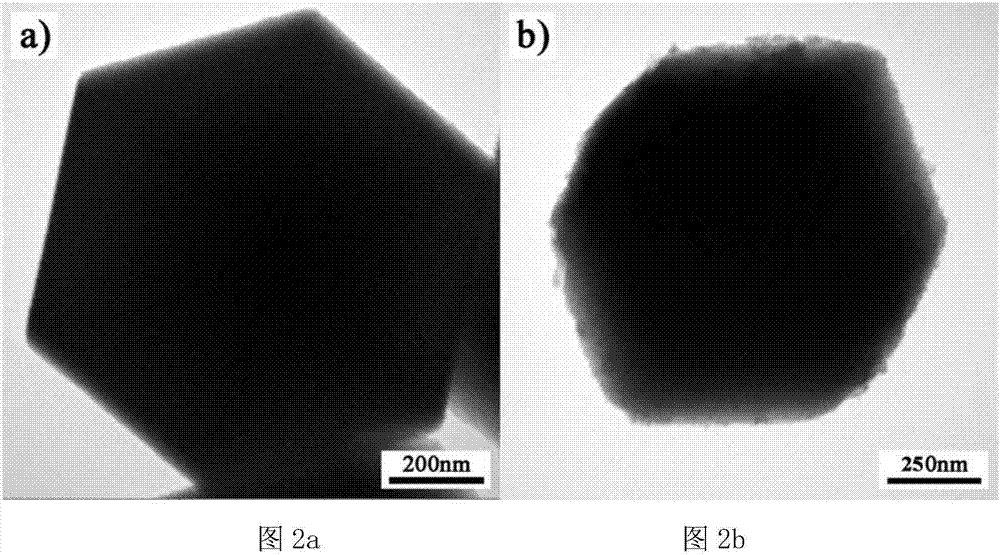

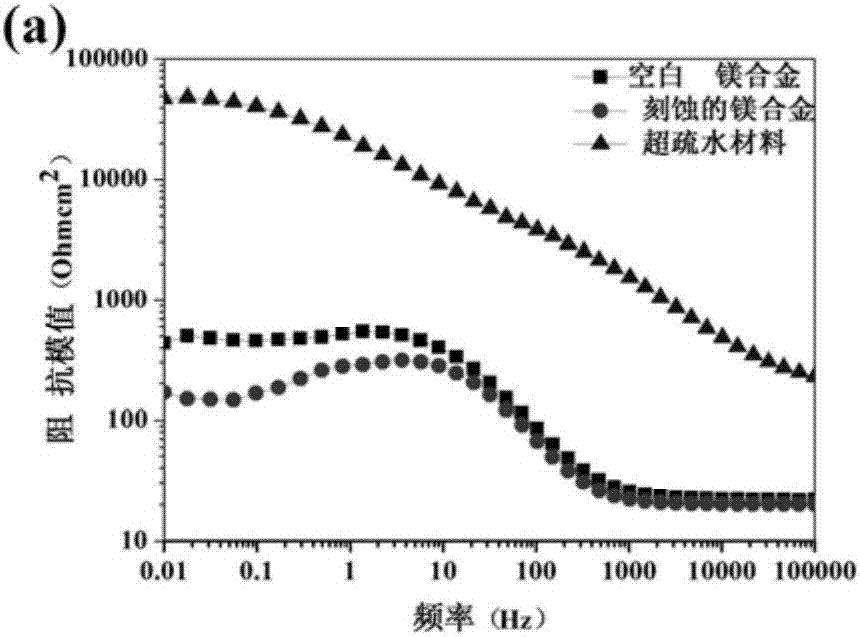

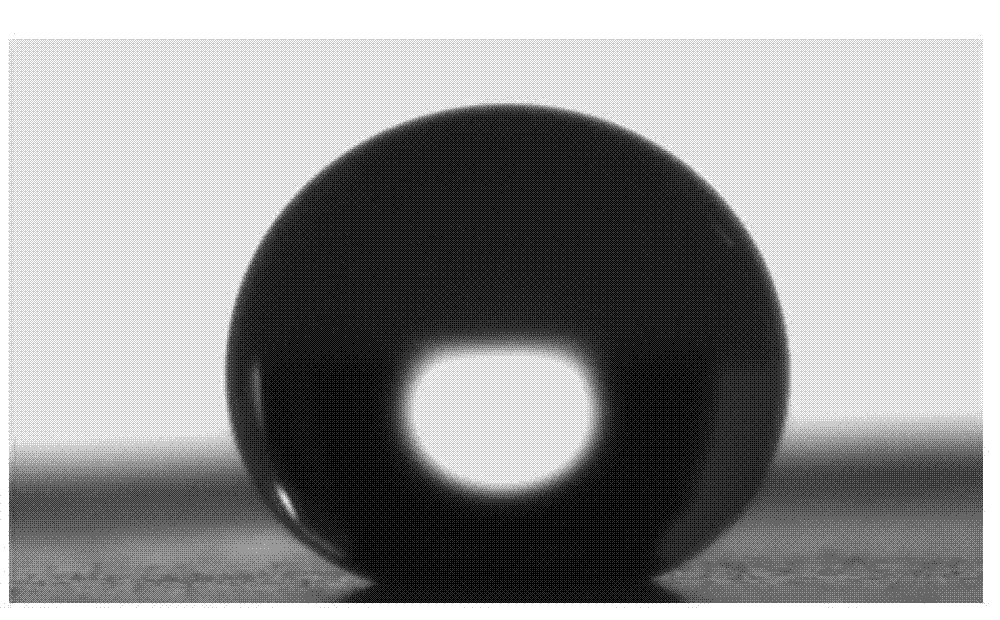

Super-hydrophobic material and preparation method thereof

ActiveCN106975588AGood self-cleaningImprove self-cleaning effectPretreated surfacesSpecial surfacesAlloy substrateCorrosion

The invention provides a super-hydrophobic material and a preparation method thereof. The construction of the super-hydrophobic material with a special structure on an alloy substrate is realized through controlling the stirring time and the adding quantities of TEOS and ammonia water; a nuclear structure is a regular dodecahedron structure; and the structure is not changed after coating of silicon dioxide. Meanwhile, a micron structure etched with an alloy structure is combined for mutual embedding, so that the surface roughness of the hydrophobic material is increased, the drop and solid surface contact area is reduced, meanwhile, the compactness of the hydrophobic material and a film layer is increased, and a substrate is effectively protected. The super-hydrophobic material constructed on an alloy by the method achieves long-time stability, self-cleanness, corrosion resistance and wear resistance.

Owner:青岛鑫鼎万兴新材料有限公司

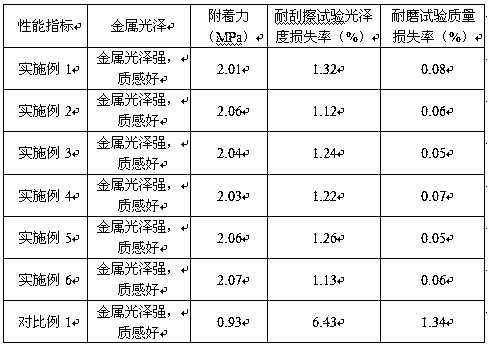

Scratch-resistant UV metal gloss coating for electrical appliances and usage method thereof

InactiveCN109401602AViscosity controllableGood solubilityPolyurea/polyurethane coatingsSpecial surfacesChemistryPhosphate

The invention belongs to the technical field of electrical appliance coatings, and provides a scratch-resistant UV metal gloss coating for electrical appliances and a usage method thereof. The coatingis prepared from the following raw materials: urethane acrylate, carboxylic acrylic ester, epoxy acrylate, phosphate resin, sericite, barium sulfate, metal powder, acetylene black, graphene, perhydropolysilazane, a leveling agent and a photo-initiator. The usage method comprises the following steps: firstly, fully and uniformly stirring the scratch-resistant UV metal luster coating; then, spraying the coating on the surfaces of the electrical appliances; meanwhile, performing UV light irradiation and maintaining in the atmosphere of ammonia to obtain a dense bright-black metal luster coating. Compared with the conventional method, the prepared UV metal gloss coating has the advantages that a dense silicon dioxide membrane is formed during the formation of the membrane through photo-curing, so that the prepared coating has high metal gloss, the texture of the electrical appliances is improved greatly, and the adhesive force of the coating is improved remarkably. The scratch-resistantUV metal gloss coating has superior wear resistance and scratch resistance, and can be widely applied in the fields of electrical appliance coatings.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

High-temperature-resisting breathable graphene/ultra-high molecular weight polyethylene fiber and preparation method

InactiveCN109234830AImprove breathabilityComfortable to wearMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberWater baths

The invention belongs to the technical field of preparation of polyethylene fibers and particularly relates to a high-temperature-resisting breathable graphene / ultra-high molecular weight polyethylenefiber and a preparation method. The preparation method comprises the following steps: preparing a graphene oxide solution, adding titanium dioxide rutile and adjusting a pH value; adding a reducing agent, carrying out hydrothermal reaction, cooling, filtering, washing, freezing and drying to obtain three-dimensional porous graphene / titanium dioxide; adding the three-dimensional porous graphene / titanium dioxide into polyethylene resin, adding white oil and a proper amount of functional additives, and swelling in a twin-screw extruder to form a spinning solution; extruding and carrying out water bath solidification to form gel silks; carrying out drying, multistage heat drawing, winding and the like through a guide roller to obtain the porous graphene / ultra-high molecular weight polyethylene fiber. Three-dimensional porous graphene / titanium dioxide powder is added when the spinning solution is prepared by adopting ultra-high molecular weight polyethylene, so that high temperature resistance and breathability of the fiber are improved. The graphene / ultra-high molecular weight polyethylene fiber prepared by adopting the method has excellent high temperature resistance, corrosion resistance and breathability.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Titanium dioxide/baffeta with super-hydrophobic and self-cleaning functions

InactiveCN107653673AEasy to operateReaction temperatureStain/soil resistant fibresBiochemical fibre treatmentAnti wrinkleIon

The invention discloses titanium dioxide / baffeta with super-hydrophobic and self-cleaning functions. The titanium dioxide / baffeta is prepared by the steps of in-situ generating nanometer TiO2 particles in the baffeta, and cladding the TiO2 particles in the middle of BSA to obtain BSA / TiO2 / BSA modified baffeta; then soaking the BSA / TiO2 / BSA modified baffeta into a fluoroalkyl silane ethanol solution with the volume fraction being 1 to 10 percent for 1 to 24h, and after finishing reaction, repeatedly cleaning through deionized water, and vacuum drying to obtain the titanium dioxide / baffeta withthe super-hydrophobic and self-cleaning functions. A preparation method provided by the invention has the advantages of simplicity in operation, moderate reaction conditions and the like; the baffetahas an excellent super-hydrophobic performance, an excellent self-cleaning performance, an excellent anti-microbial performance, an excellent uvioresistant performance, an excellent photocatalysis performance, an excellent anti-wrinkle performance and excellent washing resistance.

Owner:钱景

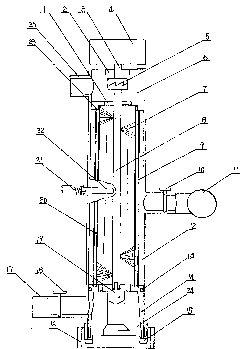

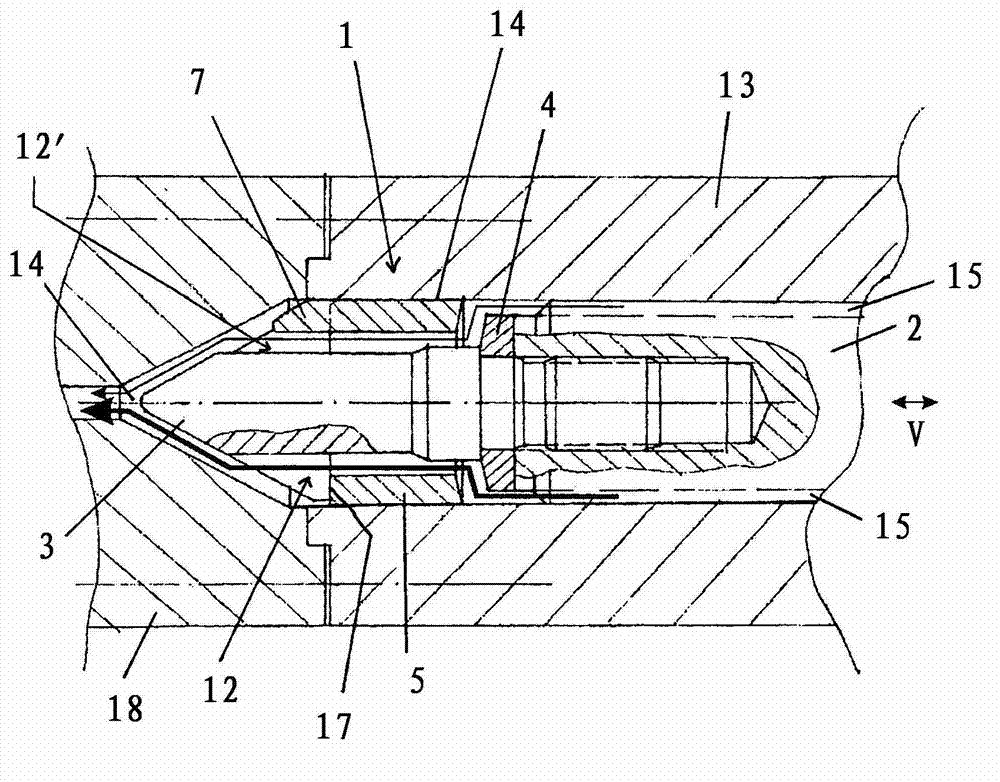

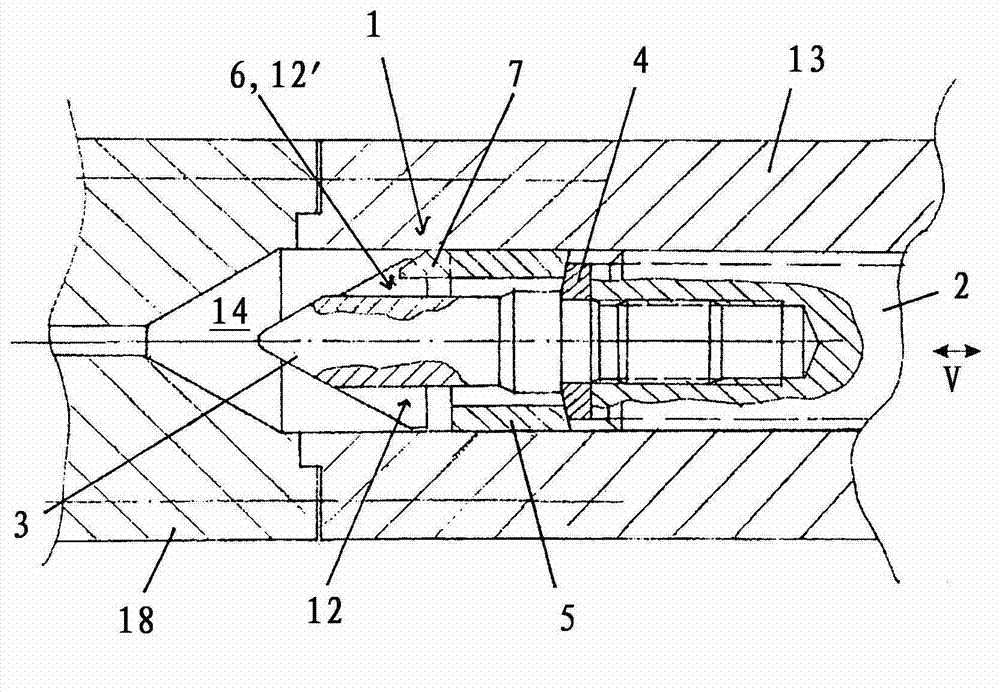

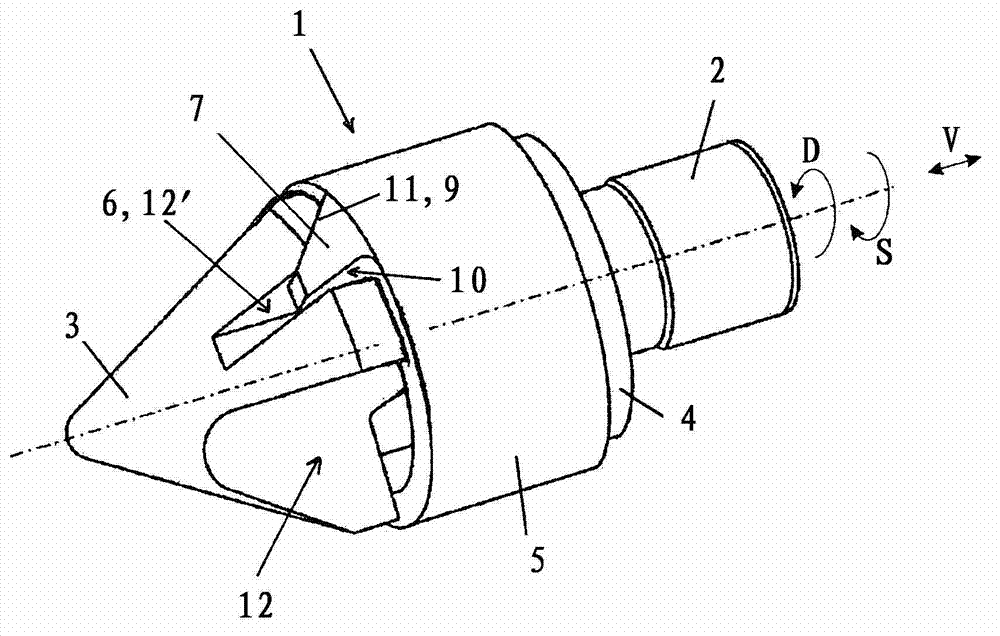

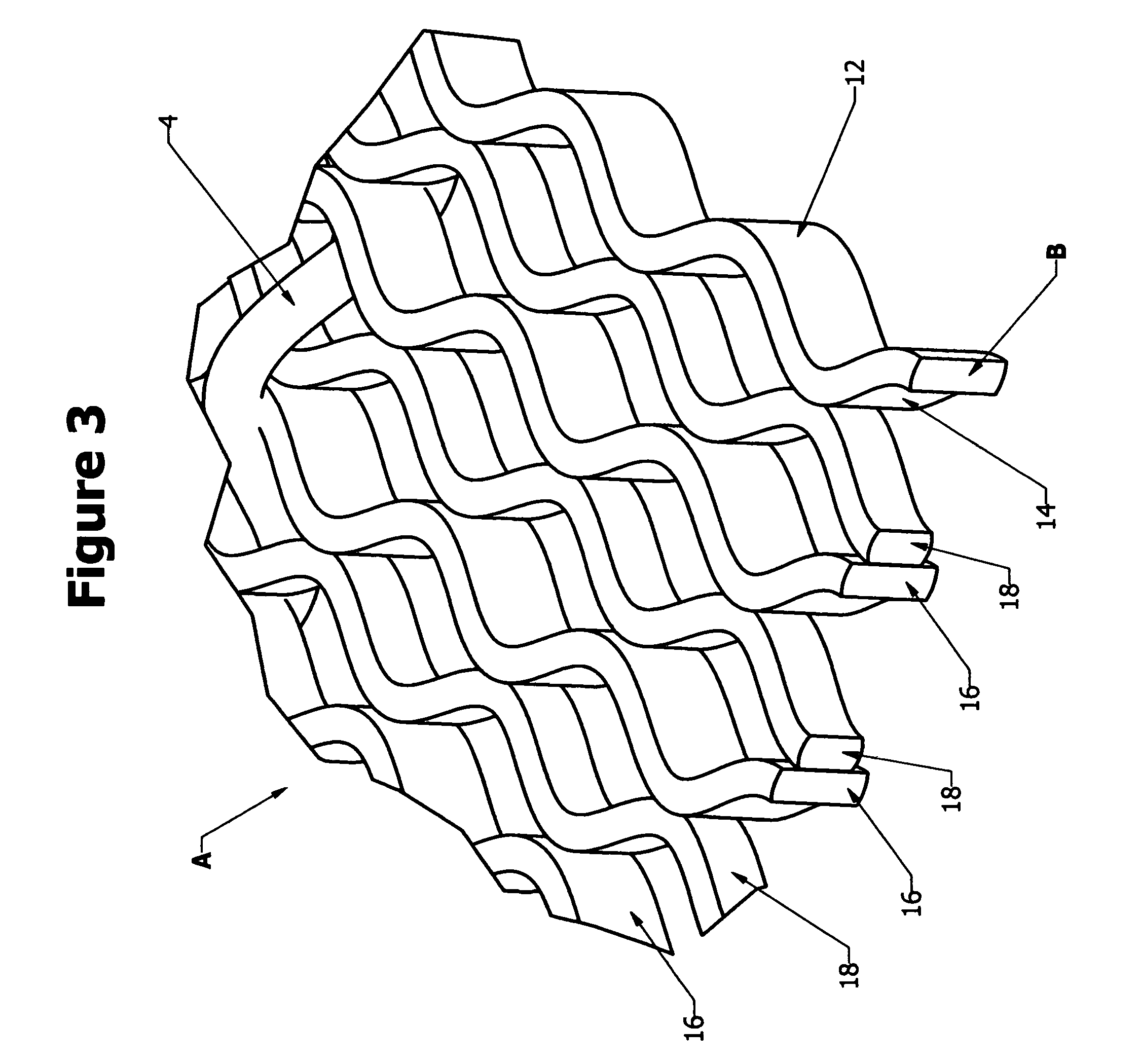

Non-return valve for plasticizing screw of injection molding machine

The invention relates to a non-return valve (1) for plasticizing the screw (2) of an injection molding machine, which comprises a tip (3), a pressure ring (4) and a locking ring (5) displaceably arranged relative to the tip (3) and the pressure ring (4). At least one guide rail (6) of at least one carrier (7) is arranged on the tip (3) or on the locking ring (5). The at least one guide rail (6) is provided with a wall (8) parallel to the displacement direction (V) of the locking ring (5) and a wall (9) obliquely arranged relative to the displacement direction (V) of the locking ring (5). the at least one carrier (7)is provided with parallelly extended sections (10, 11). The tip (3) is provided with at least one flow passage (12, 12') for plastic melt, besides the existing guide rail (6).

Owner:ENGEL AUSTRIA

Hydrophobization and moth proofing processing method for surface of wickerwork

InactiveCN106217527AStrengthen anti-corrosion and insect-proof abilityStress reliefWood treatment detailsReed/straw treatmentMechanical stabilityUltimate tensile strength

The invention discloses a hydrophobization and moth proofing processing method for the surface of wickerwork. Firstly, a painting solution is prepared; then, the wickerwork is processed under the environment with the temperature being 65 DEG C and the air relative humidity being 60%; then, pressurization cold leaching and pressure reduction cold leaching are conducted on the wickerwork in a combined manner; and finally, the painting solution is painted on the surface of the wickerwork, and then drying is conducted. The hydrophobization and moth proofing processing method for the surface of the wickerwork is easy to operate and achieve, stress formed inside the wickerwork can be eliminated, the occurrence rate of cracks, deformation and other defects is decreased, and the mechanical strength, waterproof performance and flame resistance of the wickerwork can be effectively improved. The method solves the problems that super-hydrophobic wickerwork prepared through an existing method is poor in film layer mechanical stability and short in service life. The wickerwork processed through the method has good hydrophobicity, self-cleaning performance and anti-fouling performance, the corrosion prevention and moth proofing performance is remarkable, the service life of the wickerwork can reach 8 years or longer, and the wickerwork is durable in use.

Owner:ANHUI CHANGFA IND

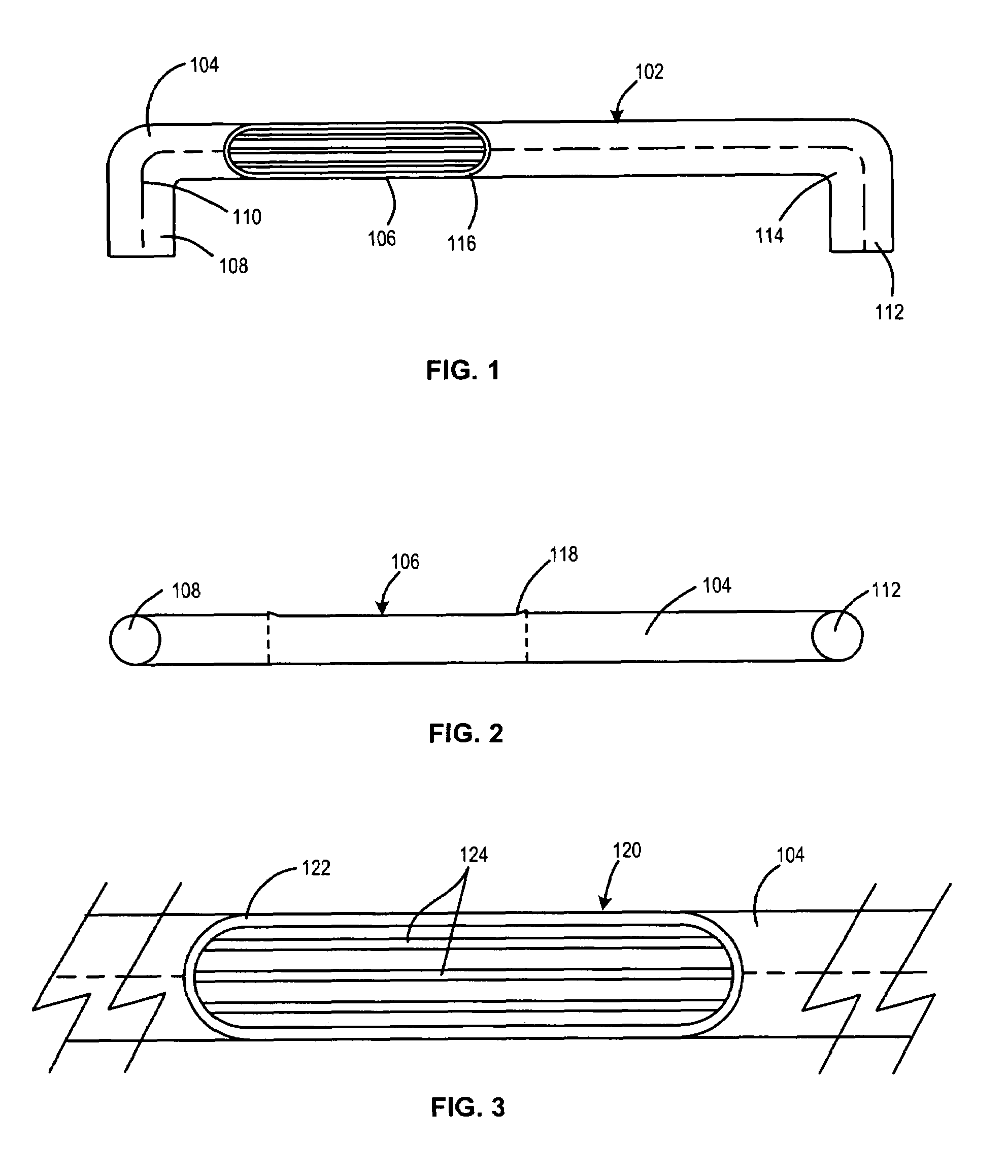

Vehicle running step

ActiveUS7722067B2Facilitates disbursement and eradicationGood self-cleaningSteps arrangementTreadSnow

A vehicle running step formed of an elongate tube, the tube having an opening therethrough with a plurality of spaced apart tread plates mounted within the opening. The spaced apart tread plates form a non-slip self-cleaning step area along the tube. Dirt, debris, snow and ice can pass between the spaced apart tread plates to increase overall safety of the device. Furthermore, the spaced apart tread plates are aesthetically pleasing and relatively simple to manufacture.

Owner:GRATE STEP LLC

Transparent noise-barrier wall

InactiveUS7021421B2High light transmittanceGood self-cleaningCeilingsPhysical/chemical process catalystsBrookiteNoise barrier

An object of the present invention is to provide a transparent noise-barrier wall which is slow to foul, easy to clean even when fouled, and capable of maintaining these effects over a long period of time. The transparent noise-barrier wall has brookite titanium dioxide substantially existing on the surface. The titanium dioxide particles preferably contain about 20% by mass or more of brookite titanium dioxide.

Owner:SHOWA DENKO KK

LED street lamp with adjustable light path and angle

InactiveCN101886776AReduce the temperatureExtended service lifePoint-like light sourceLighting heating/cooling arrangementsEngineeringRoad surface

The invention provides an LED street lamp with adjustable light path and angle. The LED street lamp comprises an LED light source and a heat dissipation system thereof; an LED light source module is fixed on a heat dissipation pedestal through a high heat-conducting material; serrated heat dissipation passages formed on the heat dissipation pedestal and the surface of the lamp can improve the heat dissipation property of the LED light source module and prolong the service life of an LED; and the heat dissipation pedestal is fixed in the lamp through a bracket. The included angle of the plane of the heat dissipation pedestal and the pavement can be adjusted by adjusting the bracket so as to fulfill the purposes of adjusting the luminous light path and angle and adjusting the illumination area of the pavement.

Owner:BEIJING UNIV OF TECH

Environment-friendly diatom ooze decorative wall material

InactiveCN106007559AImprove adsorption capacityWith sound and heat insulationHazardous substanceAntibacterial activity

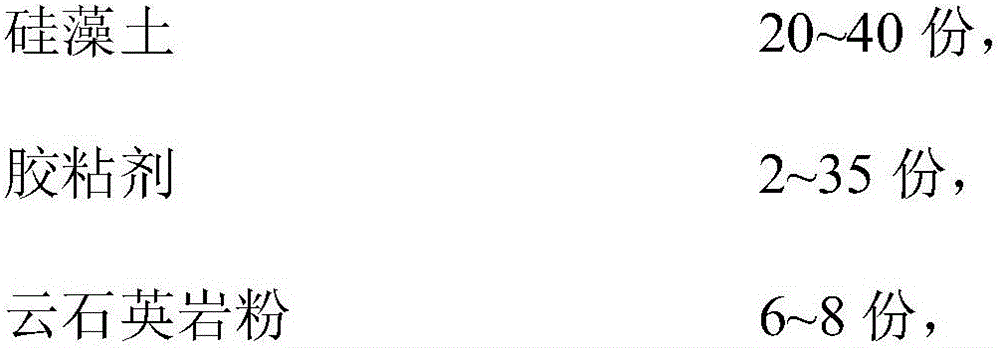

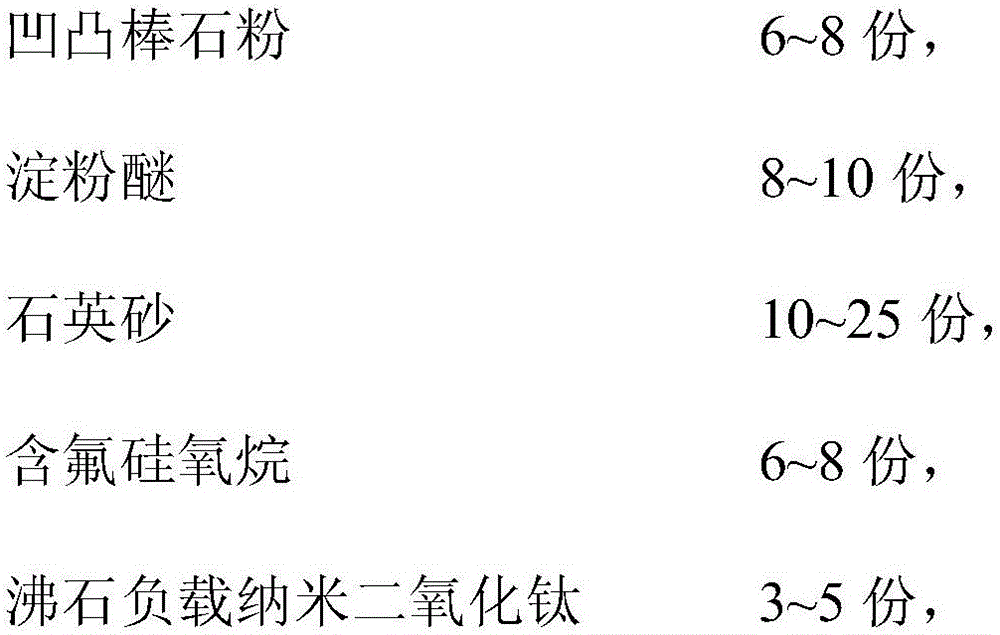

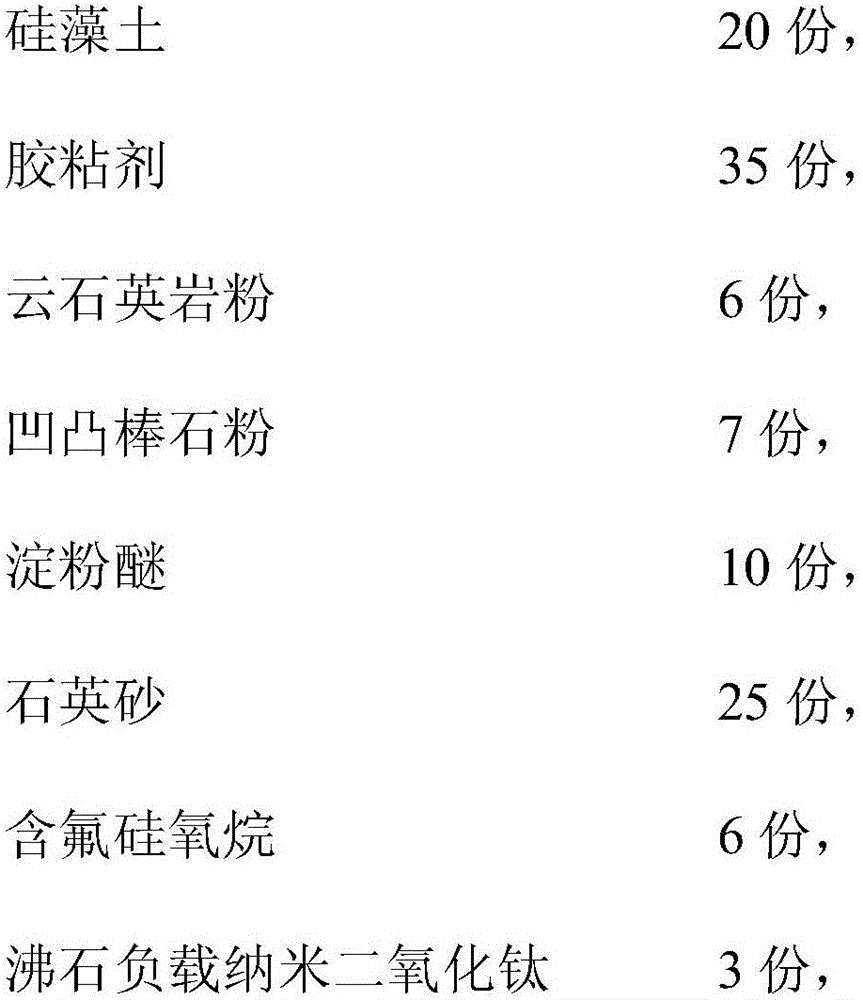

The invention relates to the field of coatings, and discloses an environment-friendly diatom ooze decorative wall material. The environment-friendly diatom ooze decorative wall material is prepared from components in parts by weight as follows: 20-40 parts of diatomite, 2-35 parts of an adhesive, 6-8 parts of marble quartzite powder, 6-8 parts of attapulgite powder, 8-10 parts of starch ether, 10-25 parts of quartz sand, 6-8 parts of fluorine-containing siloxane and 3-5 parts of zeolite-loaded nanometer titania. The energy-saving and environment-friendly diatom ooze decorative wall material contains no harmful substances and has the advantages of good cohesiveness, high formaldehyde removal efficiency, high antibacterial activity and deodorization performance and excellent self-cleaning and purification durability, and the performance index meets requirements specified in the JC / T2177-2013 standard.

Owner:HANGZHOU MAKEDOLLAR ENVIRONMENTAL PROTECTION NEW MATERIAL

Coating for building external wall

InactiveCN106700755AReduce rain stain pollutionUniform particle distributionAntifouling/underwater paintsPaints with biocidesEmulsionWeather resistance

The invention relates to a coating for a building external wall. The coating is prepared from the following raw materials in percentage by weight: 15 to 20 percent of fluorocarbon emulsion, 6 to 10 percent of organic silicon modified crylic acid emulsion, 6 to 10 percent of organic fluorine modified crylic acid emulsion, 6 to 12 percent of cellular quartz powder, 25 to 36 percent of anatase nano TiO2, 5 to 10 percent of nano zinc oxide. 1 to 3 percent of a compatilizer, 1 to 3 percent of a defoaming agent, 1 to 4 percent of a dispersing agent, 2 to 6 percent of hydroxyethyl cellulose, 1 to 3 percent of a thickener, 1 to 3 percent of a PH regulator, 1 to 2 percent of an antifreezing agent and 3 to 9 percent of water. The coating is plump and fine in paint film, has a bright color, is high in leveling property, high in adhesive force, nontoxic, long-acting, antibacterial, environmentally friendly, and high in weather resistance, stain resistance and chemical stability, and can achieve long-term effective cleaning.

Owner:ANHUI CHAOYANG DECORATION ENG

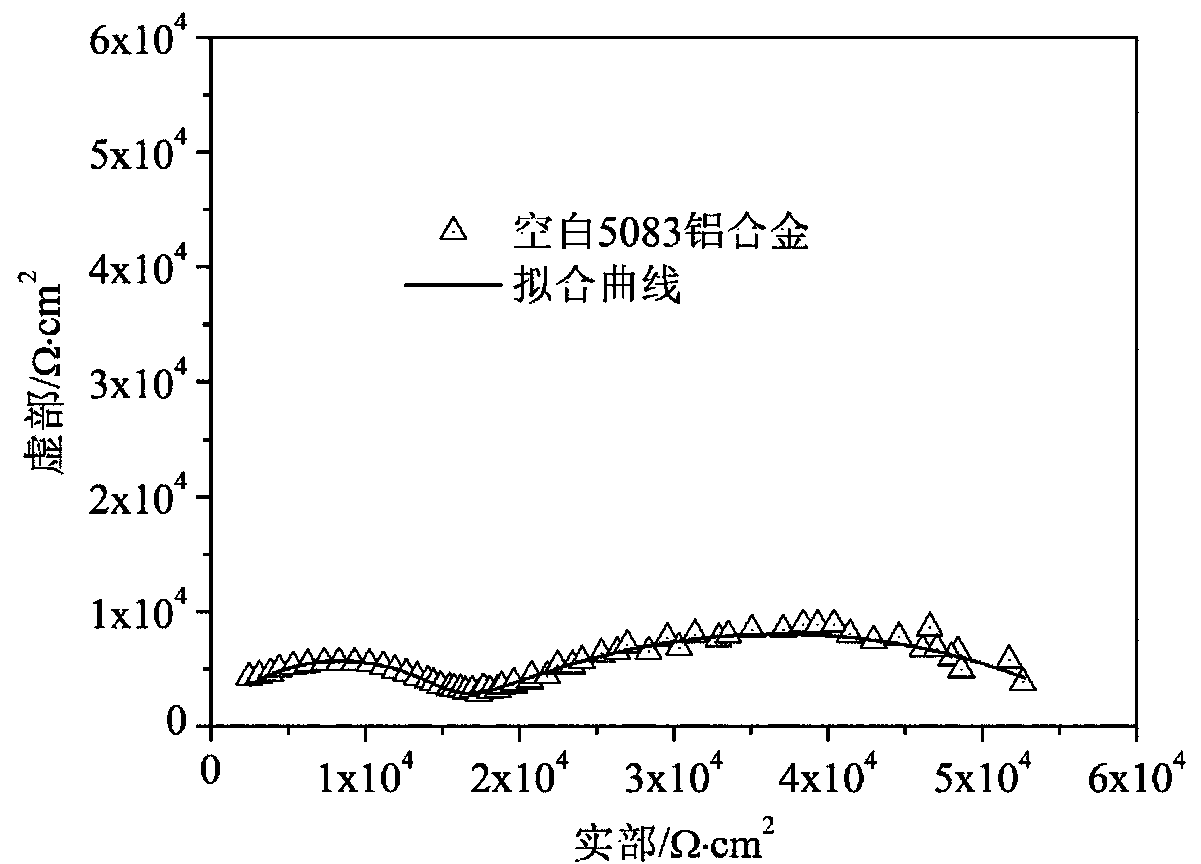

Preparation method of aluminum based fluoride-free superhydrophobic membrane

InactiveCN109939906AEasy to interceptReduce contact areaPretreated surfacesCoatingsSilanesAqueous sodium hydroxide

The invention belongs to the technical field of metal surface processing, in particular to a preparation method of an aluminum based fluoride-free superhydrophobic membrane. The method comprises the steps that a processed aluminum material is placed in a sodium hydroxide solution with the concentration of 10-25 g / L to conduct surface etching to form a multi-stage texture structure, the aluminum material is placed in an ethanol solution with the silane concentration of 1-5% to perform lower-surface energy molecule self assembling, and the superhydrophobic membrane is obtained on the surface ofthe aluminum material after drying. The method has the advantages that the operation is simple and convenient, the method is environmental-friendly, the scale preparation of the superhydrophobic membrane is convenient, and excellent surface self-cleaning and corrosion-resistance characteristics are achieved.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Wood surface hydrophobic insect-resistant treatment method

InactiveCN106142249AEasy to operateEasy to implementWood treatment detailsPretreatment apparatusRolling angleSurface finishing

The invention discloses a wood surface hydrophobic insect-resistant treatment method. A painting solution is firstly prepared, wood is treated under the environment at the temperature being 65 DEG C and the air relative humidity being 60%, the wood is put into soaking liquid to be soaked, the wood surface is painted with the painting solution, and then drying is carried out. The wood surface hydrophobic insect-resistant treatment method is easy to operate and easy to implement, the method solves the problems that a super-hydrophobic wood film layer prepared through an existing method is poor in mechanical stability and short in service life, and the good mechanical stability and the good durability are achieved. After wood surface treatment, the contact angle ranges from 156 degrees to 158 degrees, the rolling angle is smaller than 5 degrees, the super-hydrophobic performance is achieved, and the method is green and environment-friendly. The wood prepared through the method can be applied to occasions of decoration in a bathroom, landscape architecture buildings, wooden palisades, balcony floors and the like due to the good hydrophobic property, the good self-cleaning property, the good anti-fouling property and the like, and the market prospect is wide.

Owner:ANHUI CHANGFA IND

Epoxy resin with super-hydrophobic surface and preparation method for epoxy resin

The invention relates to an epoxy resin with a super-hydrophobic surface and a preparation method for the epoxy resin. Due to many excellent characteristics, epoxy resin has wide applications in national economy and industrial and agricultural production. A contact angle of the super-hydrophobic surface with water ranges from 150 degrees to 170 degrees, a rolling angle of water drops on the super-hydrophobic surface is smaller than 5 degrees, and the super-hydrophobic surface has excellent performances such as self cleaning, waterproofness and corrosion resistance. The invention further provides a preparation method for the epoxy resin with the super-hydrophobic surface. The preparation method is simple in process, good in repeatability and free of any expensive equipment and complex chemical processing and has quite good industrial application prospects.

Owner:上海长歌包装材料有限公司

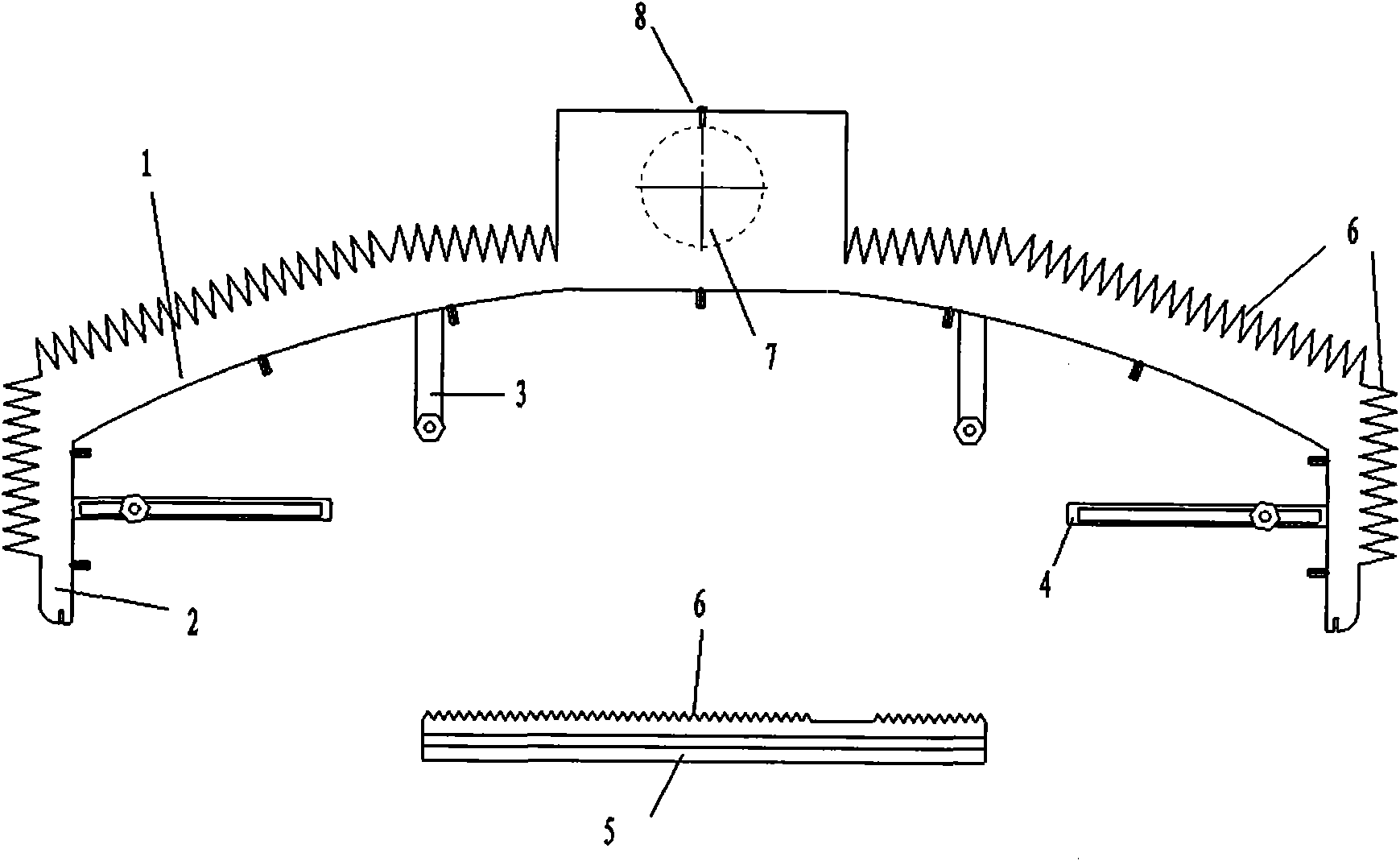

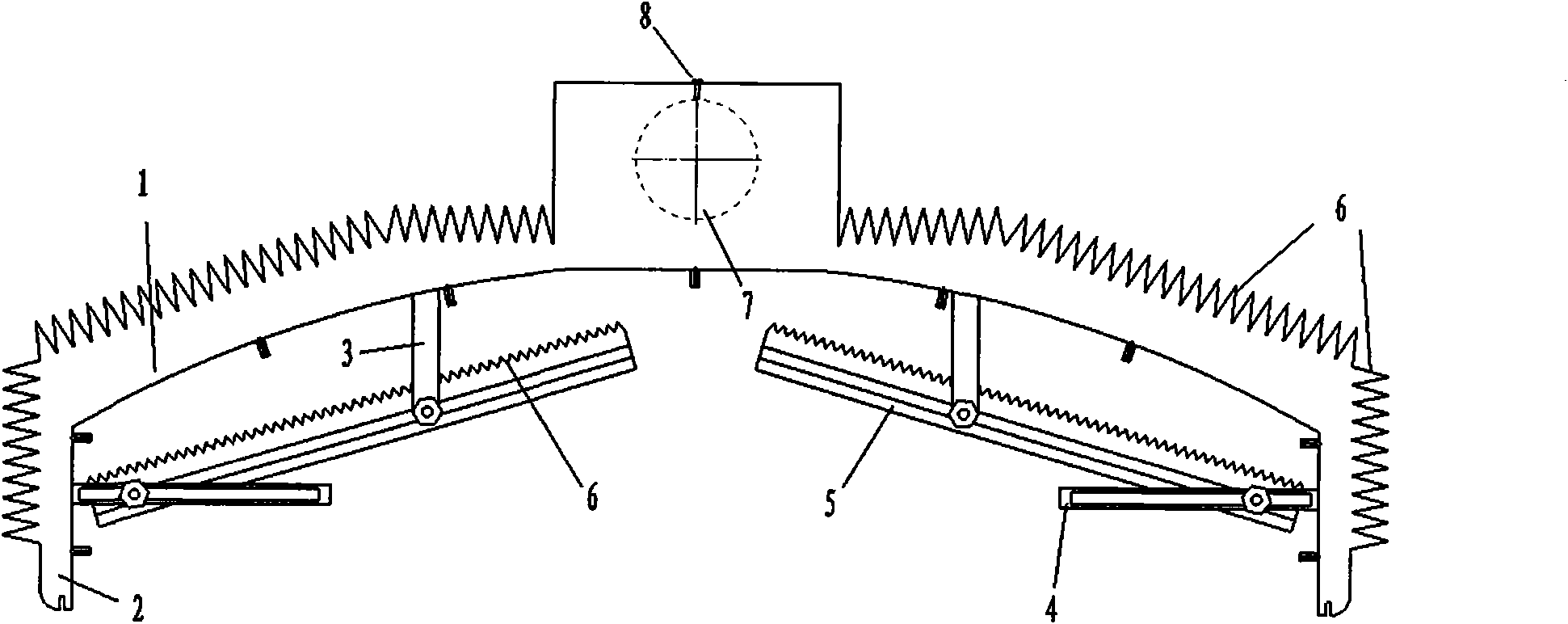

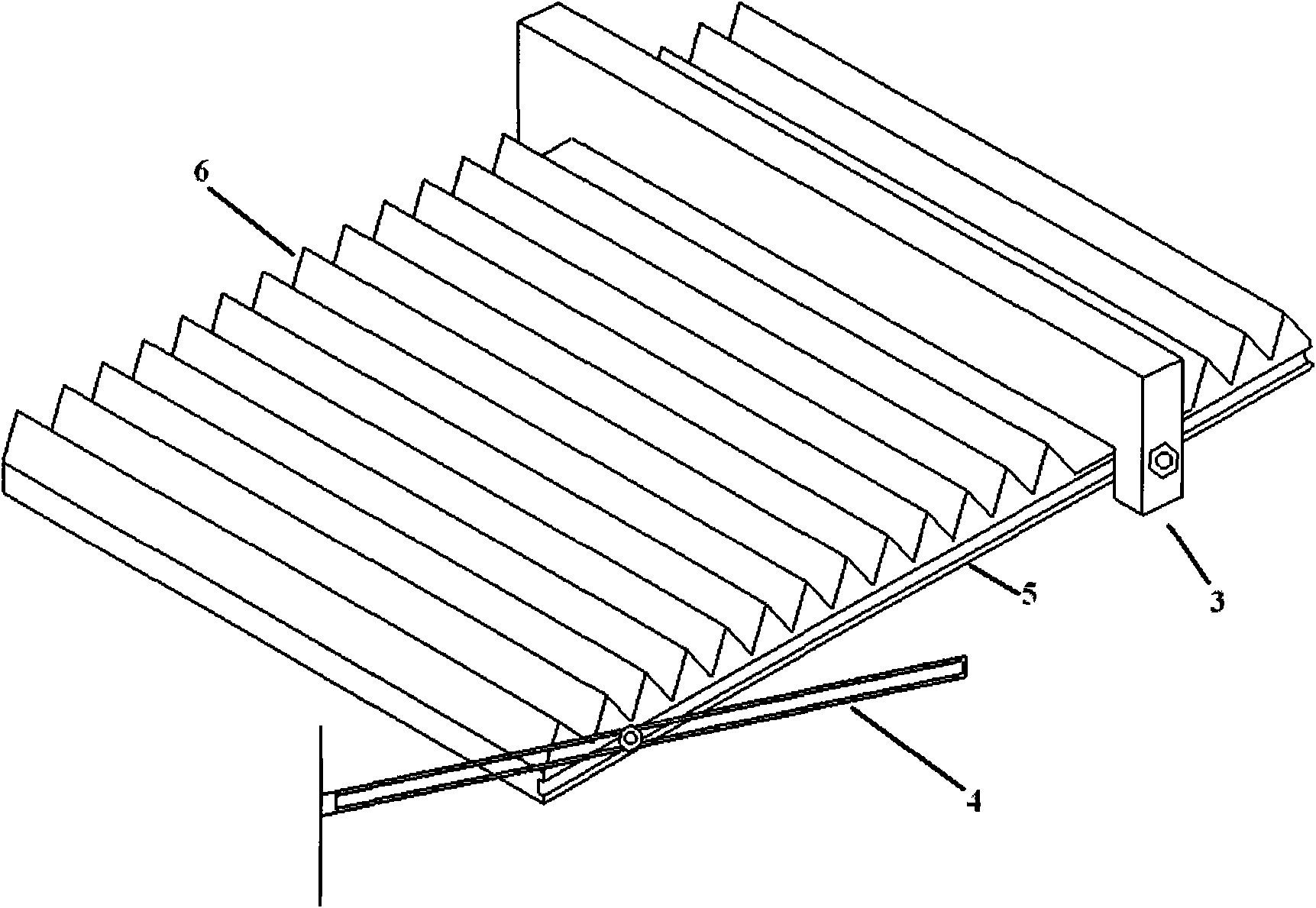

Screening for classifying a material

ActiveUS20130068668A1Avoid blindingEnhance tumblingSievingScreeningEngineeringMechanical engineering

Owner:LUMSDEN CORP

Screening for classifying a material

ActiveUS8919568B2Avoid blindingEnhance tumblingSievingScreeningMechanical engineeringNetwork segment

Owner:LUMSDEN CORP

Normal temperature solidified titania sol

InactiveCN1218878CLow costNo operating temperatureTitanium dioxideColloidal chemistry detailsPhysical chemistryPeptization

Owner:INST OF CHEM CHINESE ACAD OF SCI

Super-hydrophobic epoxy solid buoyancy material, and preparation method thereof

The invention discloses a super-hydrophobic epoxy solid buoyancy material, and a preparation method thereof. The super-hydrophobic epoxy solid buoyancy material comprises, by mass, 100 parts of epoxy resin, 5 to 20 parts of a diluents, 2 to 20 parts of a flexibilizer, 60 to 80 parts of a curing agent, 0.5 to 5 parts of a catalyst, 10 to 80 parts of hollow microsphere, and 2 to 15 parts of a fluorated acrylic acid prepolymer. The fluorated acrylic prepolymer is a novel fluorine-modified acrylic acid prepolymer; comprises one or a plurality of compounds selected from a fluorine-modified acrylic acid prepolymer A, a fluorine-modified acrylic acid prepolymer B, and a fluorine-modified acrylic acid prepolymer C; and is prepared via successive synthesis of the fluorine-modified acrylic acid prepolymer A, the fluorine-modified acrylic acid prepolymer B, and the fluorine-modified acrylic acid prepolymer C, and hot-press curing molding with other formula ingredients. The super-hydrophobic epoxy solid buoyancy material possesses excellent selt-cleaning performance, water resistance, and corrosion resistance; the preparation method is simple; repeatability is high; cost is low; complex chemical processing processes are not needed; and industrialized application prospect is promising.

Owner:平凉幄肯中晶新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com