Preparation method of aluminum based fluoride-free superhydrophobic membrane

A super-hydrophobic, aluminum-based technology, applied to the surface coating liquid device, special surface, pre-treated surface, etc., can solve the problems of reducing surface free energy, threatening the ecological environment and human safety, etc., to achieve good water repellency, The effect of reducing the solid-liquid contact area and facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The 5083 aluminum alloy was polished smooth with 200-mesh, 400-mesh, 800-mesh, 1200-mesh and 2000-mesh sandpaper in sequence. After grinding, it was placed in excess absolute ethanol and deionized water for 10 minutes, and then the sample was taken out and placed in a Etched in 15g / L sodium hydroxide aqueous solution at room temperature for 30min, then dried and soaked in ethanol solution containing 2% hexadecyltrimethoxysilane for 2 hours, and then placed in a 120°C Heating and drying in an oven for 10 minutes can form a non-fluorinated superhydrophobic film on the surface of the sample.

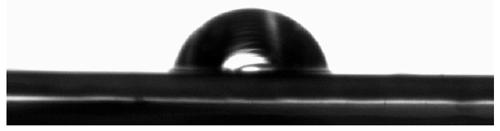

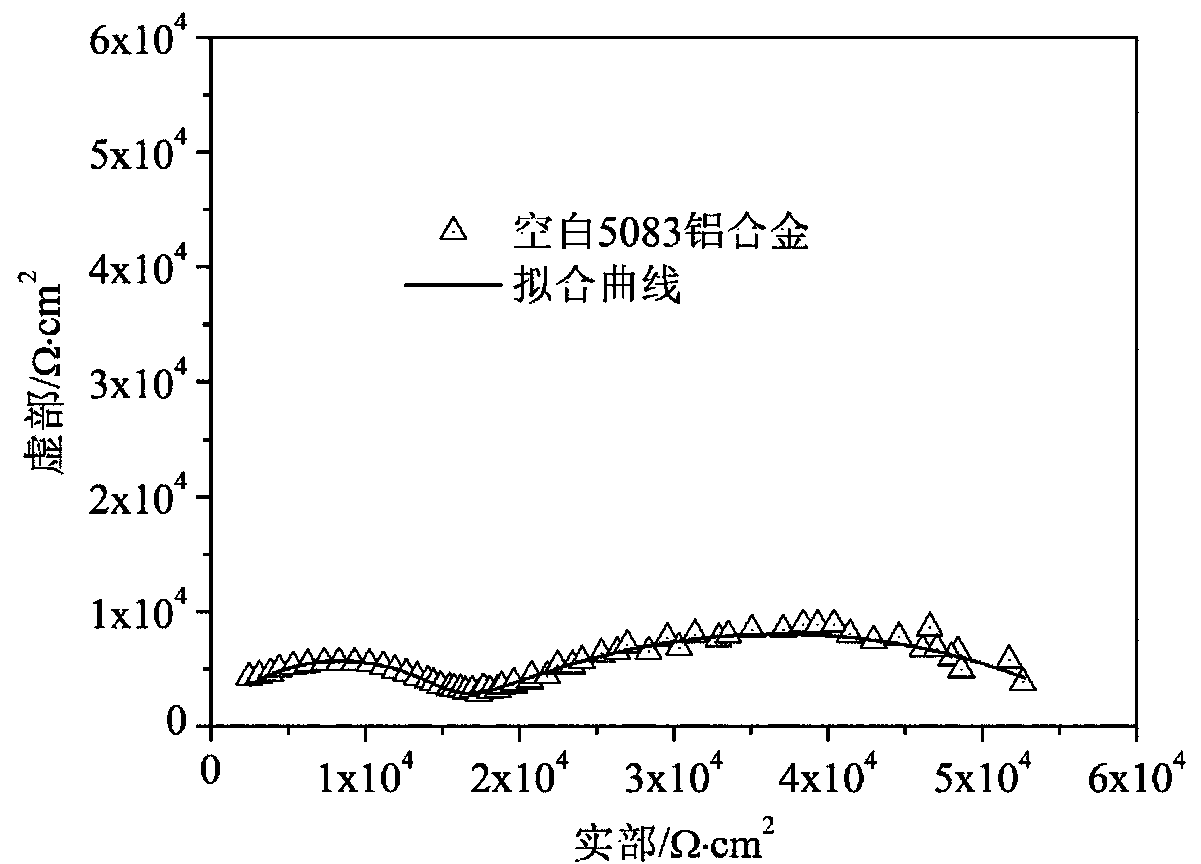

[0029] Then the static contact angle of the blank 5083 aluminum alloy substrate and the above-mentioned super-hydrophobic 5083 surface is tested by a contact angle measuring instrument, wherein, the 5083 aluminum alloy without super-hydrophobic treatment is used as a blank, by figure 1 and figure 2 The static contact angle shown is seen by figure 1 It can be seen that the static c...

Embodiment 2

[0033] The 6061 aluminum alloy was polished smooth with 200-mesh, 400-mesh, 800-mesh, 1200-mesh and 2000-mesh sandpaper in sequence. After grinding, it was placed in excess absolute ethanol and deionized water for 5 minutes, respectively, and then the sample was taken out and placed in a Etch in 10g / L sodium hydroxide aqueous solution at room temperature for 60min, then dry it and place it in an ethanol solution containing 3% octadecyltriethoxysilane for 1 hour, then place it at 100°C Heating and drying in a special oven for 30 minutes can form a non-fluorinated superhydrophobic film on the surface of the sample. The static contact angle of the resulting superhydrophobic film is 154.2°, as Figure 5 shown.

Embodiment 3

[0035] The 2024 aluminum alloy was polished smooth with 200-mesh, 400-mesh, 800-mesh, 1200-mesh and 2000-mesh sandpaper in sequence. After grinding, it was placed in excess absolute ethanol and deionized water for 5 minutes, and then the sample was taken out and placed in a Etched in 20g / L sodium hydroxide aqueous solution at room temperature for 20min, then dried and soaked in an ethanol solution containing 1% octadecyltrimethoxysilane for 12 hours, and then placed in a 150°C Heating and drying in an oven for 10 minutes can form a non-fluorinated superhydrophobic film on the surface of the sample. The resulting superhydrophobic film has a static contact angle of 155.5°, as Figure 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com