Patents

Literature

154results about How to "Good water repellency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unsaturated fatty acid microcapsule preparing technology and application

InactiveCN101125133AGood water repellencyGuaranteed qualityCosmetic preparationsOrganic active ingredientsCooling temperatureChemistry

The present invention relates to a preparation technique and an application of unsaturated fatty acid microcapsules. The preparation technique of the unsaturated fatty acid microcapsules is characterized in that the present invention includes the following steps: 1) the selection of the raw materials: the inner layer coating materials and the outer layer wall materials are selected for standby according to that the weight ratio of the inner layer coating materials and the outer layer wall materials is 0.7 to 1.5: 3 to 5; the inner layer coating materials are unsaturated fatty acid; the outer layer wall materials are the mixture of any two or more of the natural rubbers, carbohydrates and soluble proteins; 2) the outer layer wall materials are mixed evenly, the weight ratio of the outer layer wall materials and the water is 3 to 4: 6 to 7, the evenly mixed outer layer wall materials are added after the water temperature is increased to 50 DEG C, so as to get the pre-emulsion; 3) the inner layer coating materials are added into the pre-emulsion and is homogenized at the high pressure of 30 to 35MPa, so as to get the emulsion; 4) the emulsion is treated by the spray drying, the materials after the spray drying is cooled by a fluidized bed, the cooling temperature is 30 to 50 DEG C, then the materials pass through a 20 to 60 mesh vibrating screen, so as to get the unsaturated fatty acid microcapsules. The present invention is characterized by water repellency.

Owner:武汉麦可得生物技术有限公司

Emulsion type fluorine-containing textile finishing agent and preparation method thereof

This invention relates to an emulsion-type fabric finishing agent containing fluorine and its method for making. It is a high molecular polymer emulsion of acrylic esters containing full-fluorine alkyl on the lateral chain. The finishing agent includes: fluorine monomer(10.00-30.00%), non-fluorine monomer (1.00-15.00%), functional monomer(0.10-5.00%), monomer of enhancing adhesive force(0.10-5.00%), initiating agent(0deionized water.10-2.00%), emulsifier(1.00-3.50%), chain-transferring agent(0.01-0.20%) and deionized water(60.00-80.00%), beforehand emulsifying them and polymerizing the emulsion to get it. It can be used in water and oil repellent finish of polyurethane, polyester, chandar, chandar / polyester, chandar / natural hemp, spun rayon fabric. Compared with the present technique, the finishing agent produced with the invention comprises the following merits: big adhesive force, no volatile solvent, good water and oil repellency, fine durability.

Owner:辽宁氟材料研究院有限公司 +1

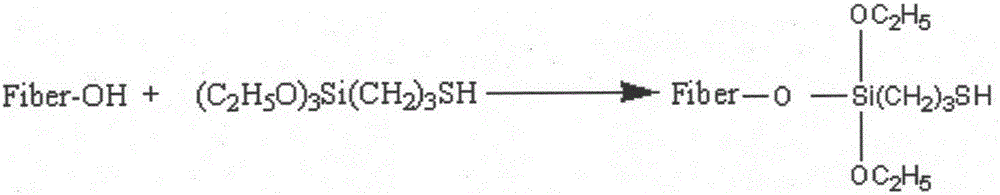

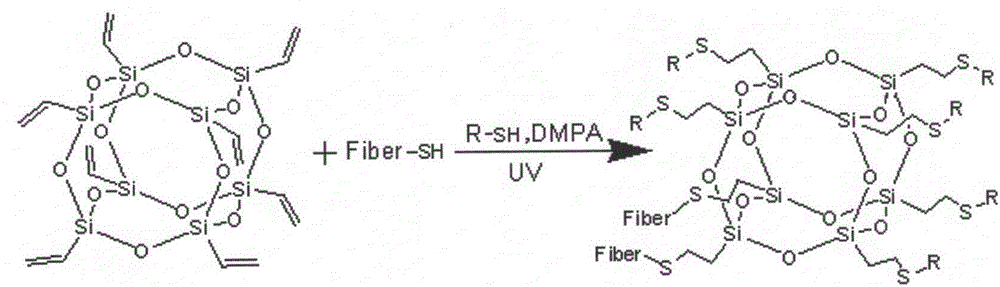

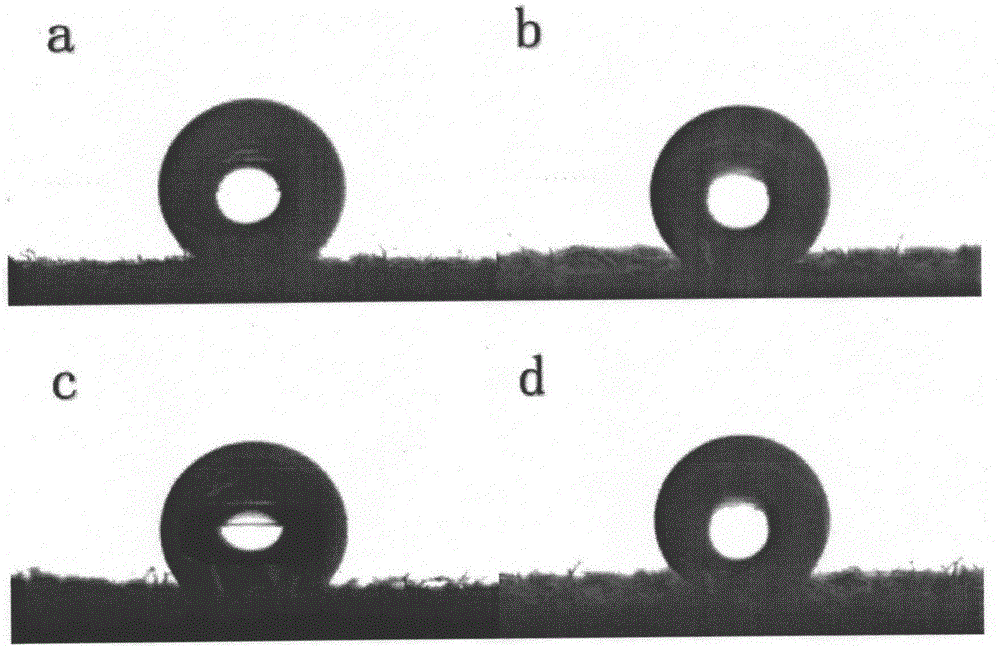

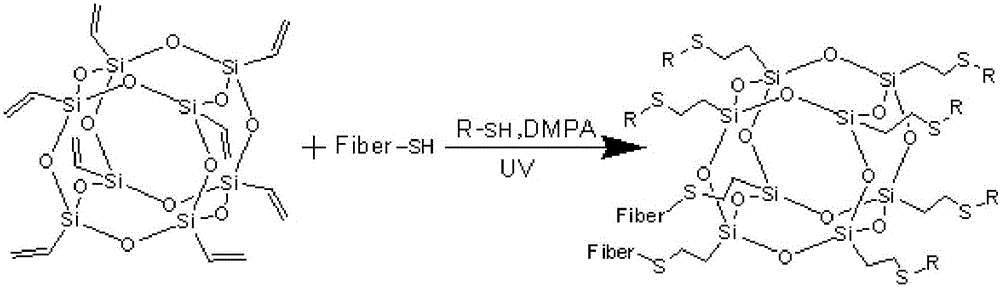

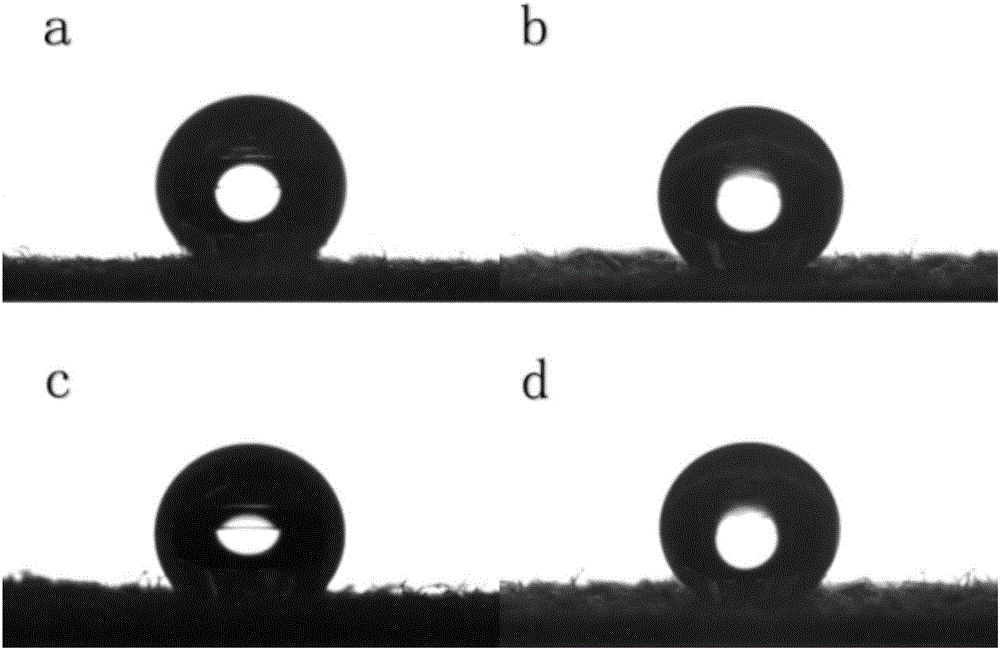

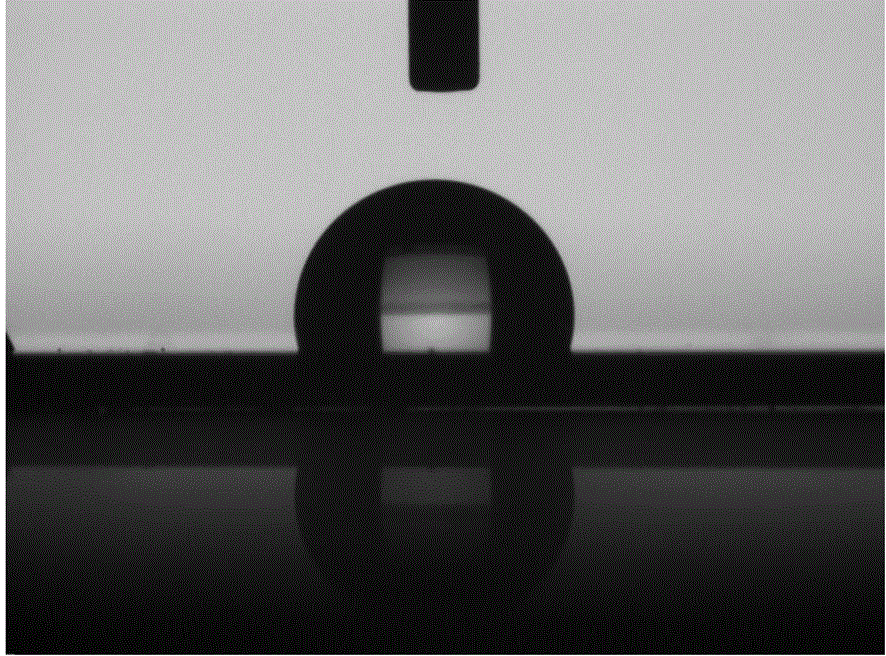

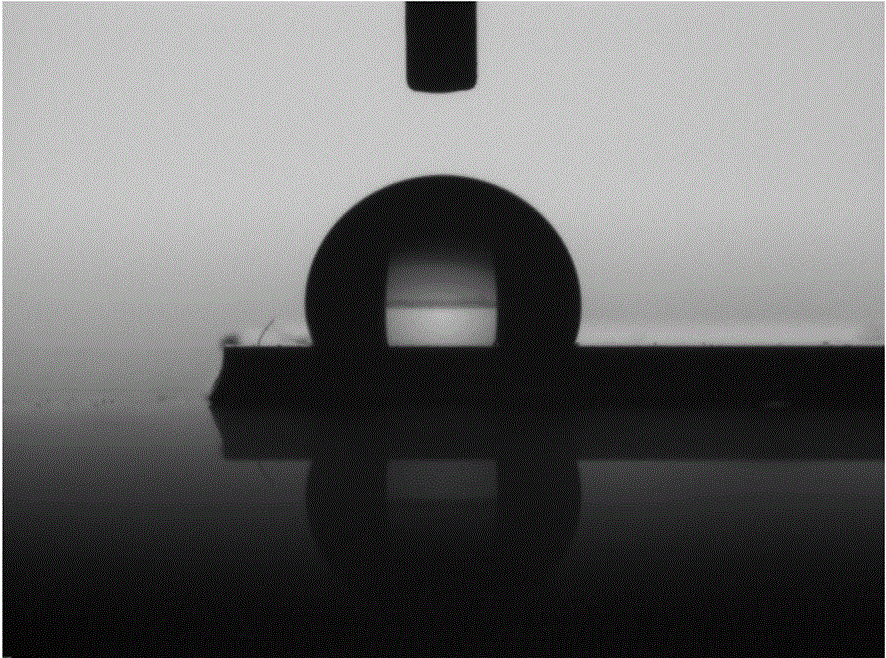

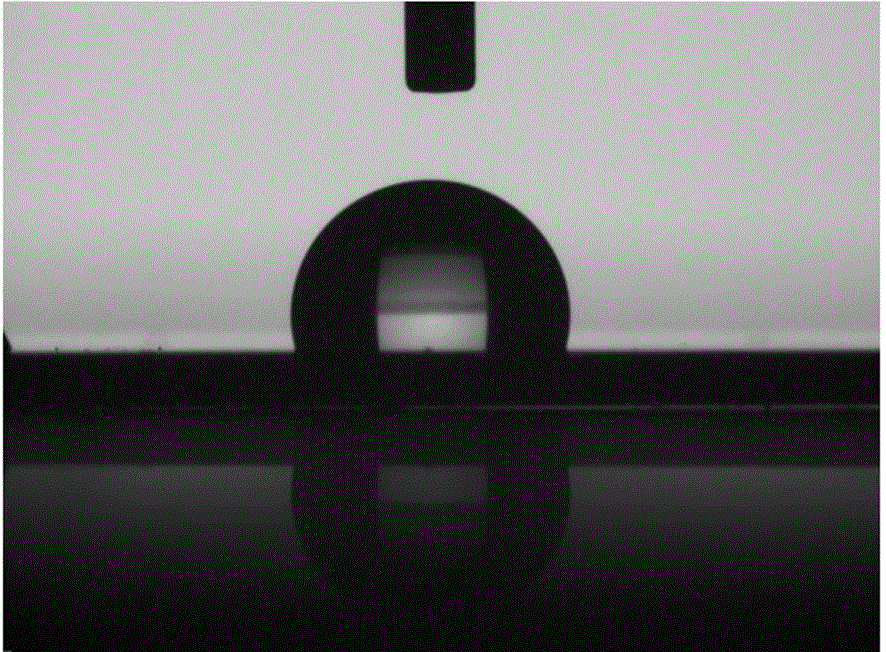

Ultraviolet curing reaction-based fluoride-free and water-repellent finishing method of cotton fabric

InactiveCN106637959AImprove water repellency durabilityHigh activityPhysical treatmentLiquid repellent fibresAcetic acidTriethoxysilane

The invention discloses an ultraviolet curing reaction-based fluoride-free and water-repellent finishing method of cotton fabric. The method comprises the steps of putting the cotton fabric into 3-mercaptopropyl triethoxysilane ethyl acetate solution and carrying out mercapto modification to obtain pretreated cotton fabric; dipping the cotton fabric subjected to mercapto modification into vinyl polyhedral oligomeric silsesquioxane solution, and obtaining the fluoride-free and water-repellent cotton fabric, which has a surface with an approximate super-hydrophobic effect, under the ultraviolet curing condition. The reaction is based on the principle of click chemistry, so that a static contact angle is basically remained unchanged after soaping treatment is carried out. Furthermore, according to a test method of AATCC 22-2005 waterproof spray test, the waterproof spray test score of the cotton fabric subjected to water-repellent finishing reaches 95. The ultraviolet curing reaction-based fluoride-free and water-repellent finishing method of the cotton fabric is simple in operation and high in efficiency, obvious in water-repellent effect under the condition that a finishing agent is fluoride-free, and high in finishing washing fastness.

Owner:DONGHUA UNIV

Fluoride-free water-repellent textile fabric finishing method based on ultraviolet light curing reaction

InactiveCN106592222AImprove water repellency durabilityEasy to operateLiquid repellent fibresVegetal fibresOrganic solventSilanes

The invention relates to a fluoride-free water-repellent textile fabric finishing method based on an ultraviolet light curing reaction. The method comprises the steps that a textile fabric is cleaned and then subjected to sulfydryl modification; vinyl cage-type silsesquioxane and sulfydryl silane or vinyl cage-type silsesquioxane and alkyl sulfhydryl are dissolved into an organic solvent, and ultrasonic oscillation is conducted to obtain a mixed solution; a photoinitiator is added, and ultrasonic oscillation is conducted to obtain a finishing solution; the textile fabric obtained after sulfydryl modification is steeped in the finishing solution, ultraviolet curing, cleanign and drying are conducted, and then the finished textile fabric is obtained. According to the method, operation is easy, the efficiency is high, and under the fluoride-free condition of a finishing agent, the water-repellent effect is obvious, and the treated washable fastness is high.

Owner:DONGHUA UNIV

Water-base metal antirusting agent and preparation method thereof

InactiveCN101660148AThe mechanism of action is simple and scientificImprove rust resistanceMetallic material coating processesTriethanolamineBenzotriazole

The invention relates to a water-base metal antirusting agent and a preparation method thereof. The antirusting agent comprises the components by weight percentage of 1-3% of dicarboxylic acid, 3-4% of triethanolamine, 0.5-1% of monoethanolamine, 5-10% of synthesized borate, 3-10% of polyethylene glycol, 1-3% of antiseptic, 0.1-1% of benzotriazole and the balance of water. The preparation method mainly comprises the following steps of: firstly preparing an antirusting agent body and subsequently adding and mixing the antiseptic, the polyethylene glycol, benzotriazole and the like, thus preparing the antirusting agent. In the invention, the action mechanism is simple and scientific, the cleaning and antirusting effect achieves the best by the cooperative function of all components; the antirusting agent contains the antiseptic that can effectively prevent the antirusting agent from cankering during the memory and working process, the polyethylene glycol can help forming film so that theantirusting agent has good water-repellent function and the antirusting capability can be effectively improved.

Owner:华阳新兴科技(天津)集团有限公司

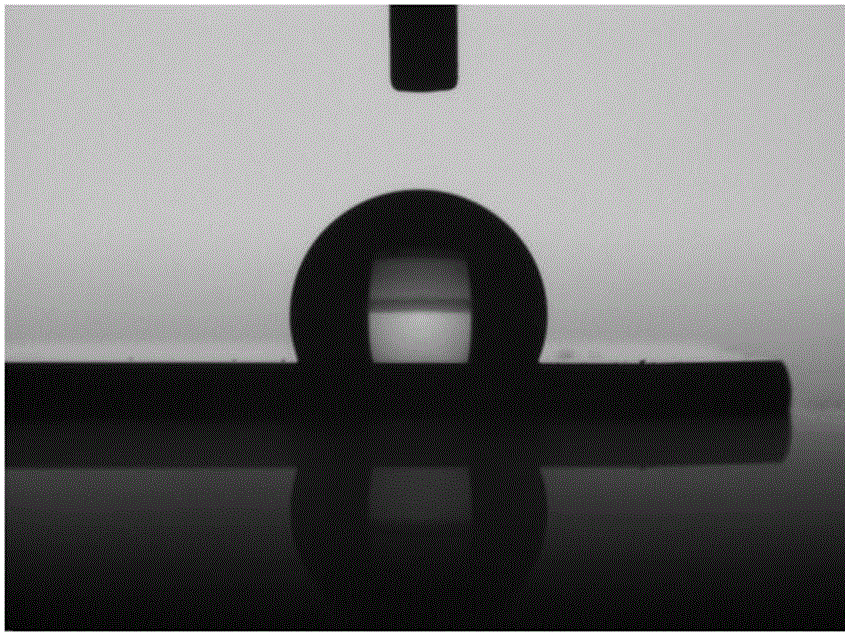

Fluorinated polyurethane and preparation method thereof

ActiveCN106674473AEasy to storeEasy to migrateAntifouling/underwater paintsPaints with biocidesDiolFluorine containing

The invention discloses fluorinated polyurethane and a preparation method thereof. The fluorinated polyurethane is prepared through the steps: fluoroalkyl-containing polyether glycol and diisocyanate perform addition polymerization reaction, a tin catalyst is utilized to catalyze, a chain extender is utilized to extend a chain, and an amino silane coupling agent is added to seal ends. A product contains a fluorine-containing polyether block, the fluorine content is high, fluoroalkyl on a polyether lateral group is prone to generating microphase separation and surface migration, polyurethane surface energy is low, and the fluorinated polyurethane is easy to store and cure as the silane coupling agent is utilized to seal the ends. A water contact angle of a coating prepared from the fluorinated polyurethane is higher than 110 degrees, and the coating has excellent water repellency.

Owner:UPCHEM CHINA

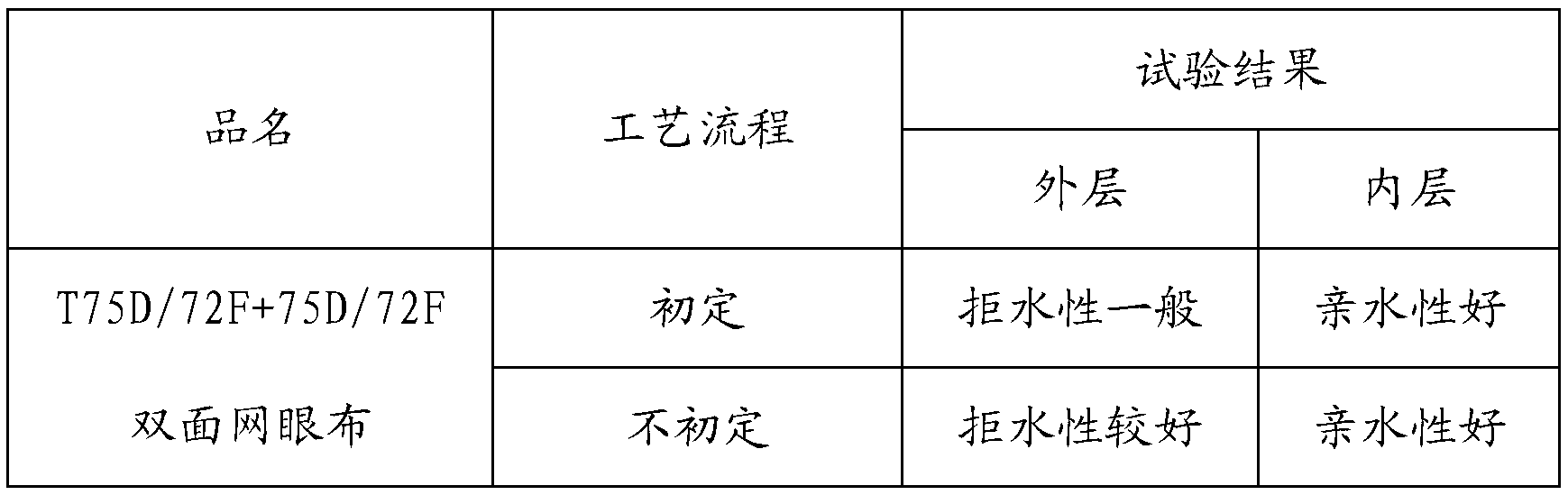

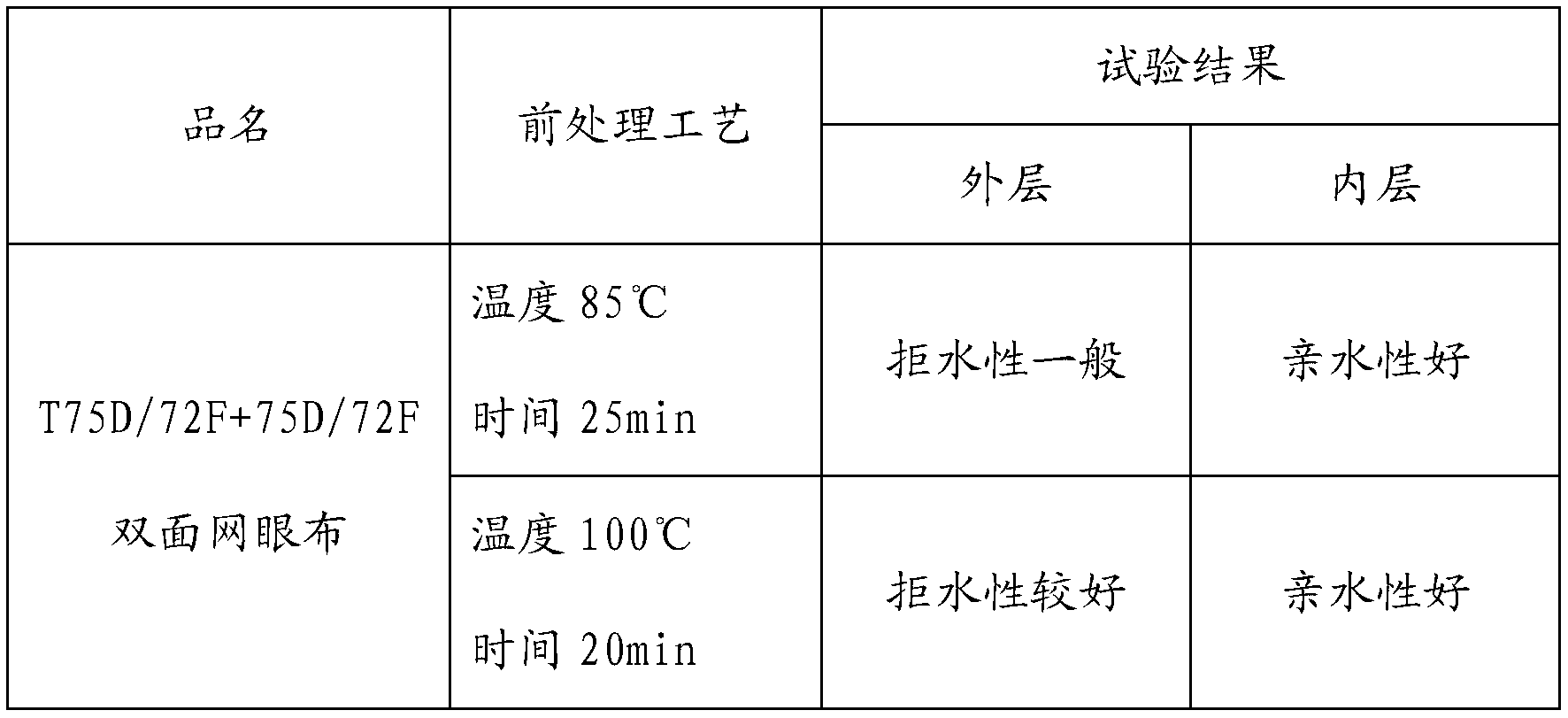

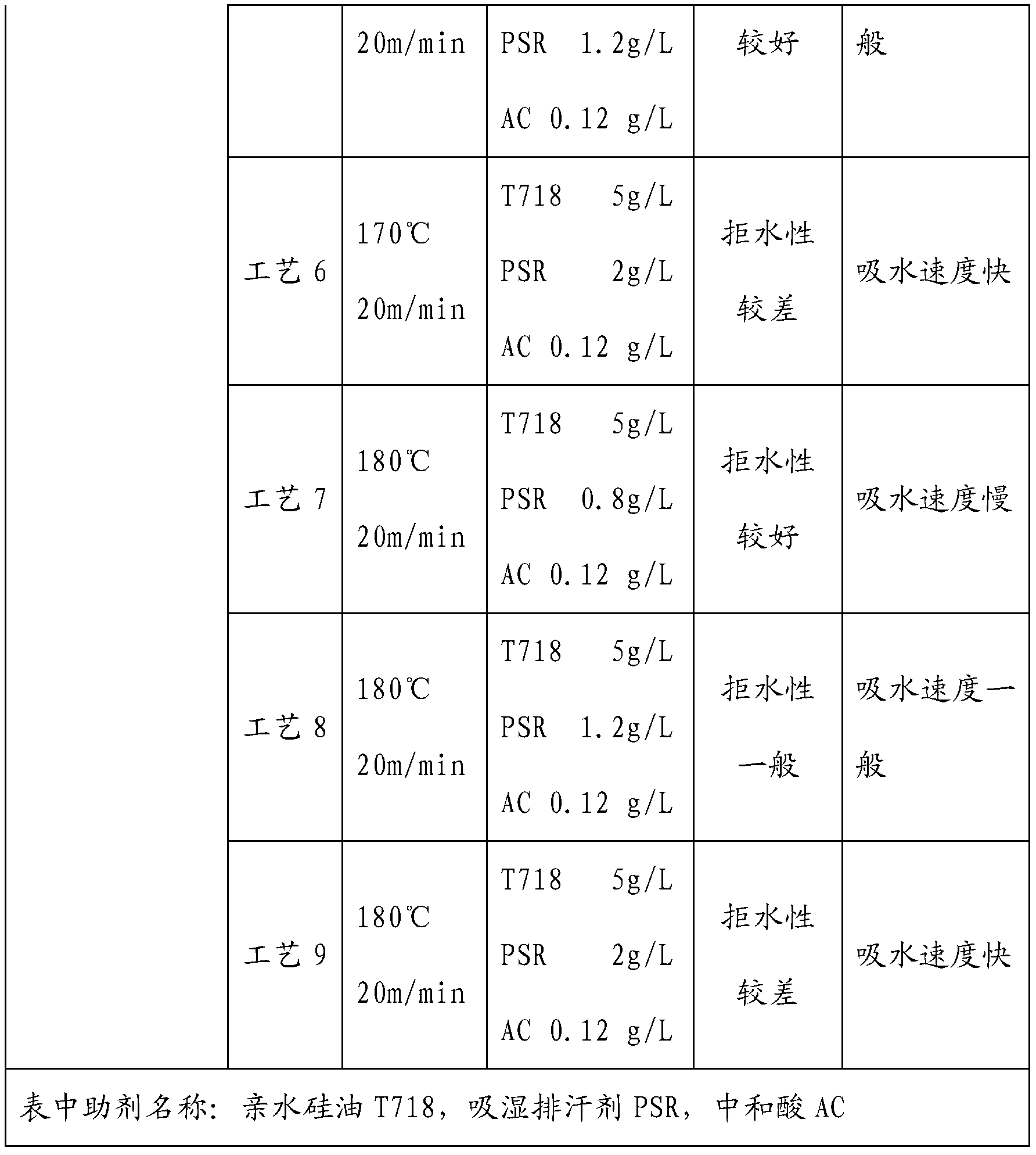

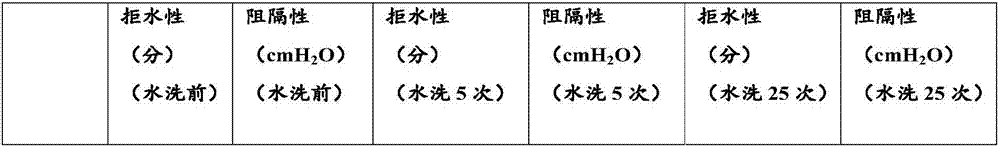

Anti-permeability and moisture absorption different-function knitted fabric and production process thereof

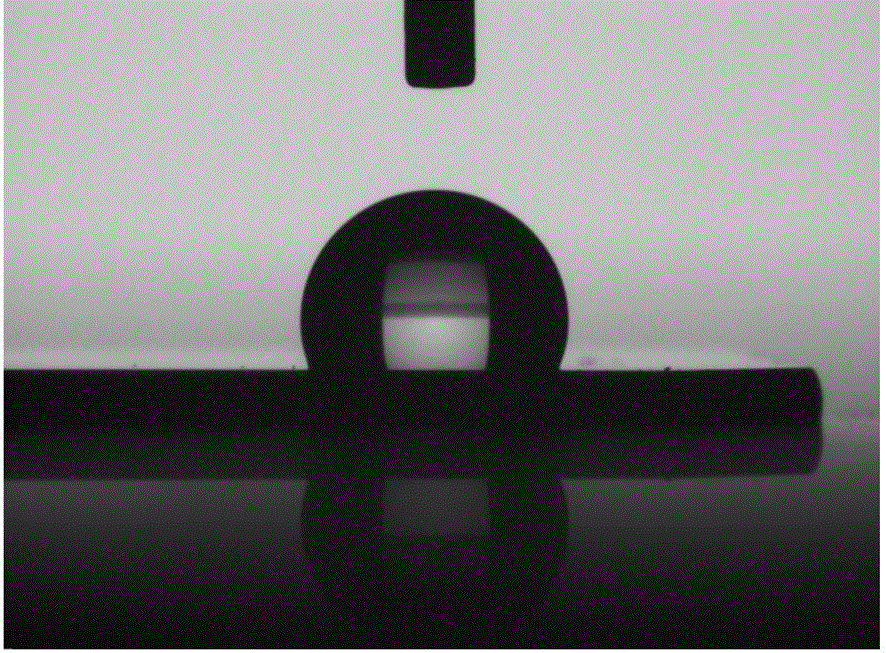

InactiveCN103233317AGood water repellencyWater repellency is not affectedSucessive textile treatmentsWeft knittingTextile designMoisture absorption

The invention discloses an anti-permeability and moisture absorption different-function knitted fabric and a production process thereof. The anti-permeability and moisture absorption different-function knitted fabric is of a double-layer structure, a middle connection tuck is connected between the outer layer and the inner layer, the outer layer and the middle connection tuck are made of water-repellency terylene subjected to surface modification processing, and the inner layer is made of terylene with irregular sections and having moisture absorption and sweat releasing functions. The production process of the anti-permeability and moisture absorption different-function knitted fabric includes steps of performing weaving to obtain grey fabric according to the double-layer textile design; performing preprocessing, dyeing, softening, dewatering and wet cutting for the grey fabric; and performing after finishing through a setting machine. According to the anti-permeability and moisture absorption different-function knitted fabric and the production process thereof, two different functions are combined in the inner layer and the outer layer of the fabric, and requirements of sports knitwear for combining inner layer moisture absorption and sweat releasing functions with outer layer sweat stain prevention function are met.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Paint for preventing covering ice for insulator and its preparation method

InactiveCN1995251AGood water repellencyStrong hydrophobic migration propertiesCoatingsChemistryOxide

The invention discloses an anti-insulator ice-coating paint and making method, which comprises the following parts: 100g polydimethyl siloxane, 100-150g organic solvent, 12-15g conductive fill, 10g carbon fiber powder, 15-30g aluminium hydroxide, 3g silica, 3g zinc oxide and 7g silane coupler, wherein the paint is coated on the insulator surface to prevent ice from covering, which improves stability of electric system operation.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

High solid share fluorine-containing polyurethane preparation method

The invention discloses a making method of high-solid fluorine polyurethane, which comprises the following steps: adding polyol, polyisocyanates, fluorine monomer, vinyl monomer, initiator, catalyst, solvent with weight rate at 5-20 2-80.5-5. 51-60.015-0.100.001-0.060-2 in the reactor; stirring to react at 20-100 deg. c for 10-300 min; obtaining the product A; using product A and hardener B with weight rate at 0.5- 50-5 to form fluoropolyurethane resin; solidifying the resin for 4-72h at 0-120 deg. c to obtain the product.

Owner:JIAXING HEXIN CHEM IND

Chlorine collecting agent and its prepn and application

ActiveCN1973965AImprove hydrophobicityGood water repellencyDispersed particle separationCalcium hydroxideTextile mill

The present invention discloses one kind of chlorine collecting agent and its preparation process. The chlorine collecting agent is prepared with calcium hydroxide, surfactant, filming drier, diluent and sodium silicate. It has high chlorine eliminating efficiency, waterproof and moistureproof property, no caking, high air permeability and other advantages. It is used in absorbing and eliminating chlorine in various kinds of production fields, such as chloralkali plant, papermaking mill, textile mill, sewage treating yard, etc.

Owner:夏元超 +1

Naturally degradative cotton linter plastic film and manufacture process thereof

InactiveCN101629398AEfficient use ofUnable to penetrateWater-repelling agents additionPaper/cardboardFiberParaffin wax

The invention relates to a naturally degradative short linter plastic film and a manufacture process thereof, belonging to the field of plastic films. The manufacture process comprises the following steps: dedusting short linters, ramie short fibers and silk leftover bits; uniformly mixing according to a proportion; cutting short; placing in a cooking boiler; adding NaOH, anthraquinone and water; increasing temperature; keeping pressure; boiling; preparing pulp by a sulphate pulping method; filtering pulp liquid; cleanly flushing filtered substances; adding water to prepare the pulp liquid; beating the pulp liquid at a beating degree of 50 DEG SR; adding daiamid epoxy chloropropane resin and cellulose to uniformly scatter in a pulp scattering machine; diluting with water; forming handsheets in a water circulating handsheet former; airing the handsheets at a room temperature; steeping the handsheets in a whiteruss steeping tank; immediately fishing out and smoothening the handsheets with a brush; enabling the prepared handsheets, i.e. paper-based semi-finished products of non-weaving cloth, to keep still at the room temperature; steeping the semi-finished products in a sizing liquid steeping tank; immediately fishing out and smoothening the semi-finished products; placing the semi-finished products in an oven to prebake so that sizing liquid is fully permeated and stuck to the semi-finished products; and raising the temperature and baking for molding treatment to obtain the naturally degradative short linter plastic film.

Owner:JIANGNAN UNIV +1

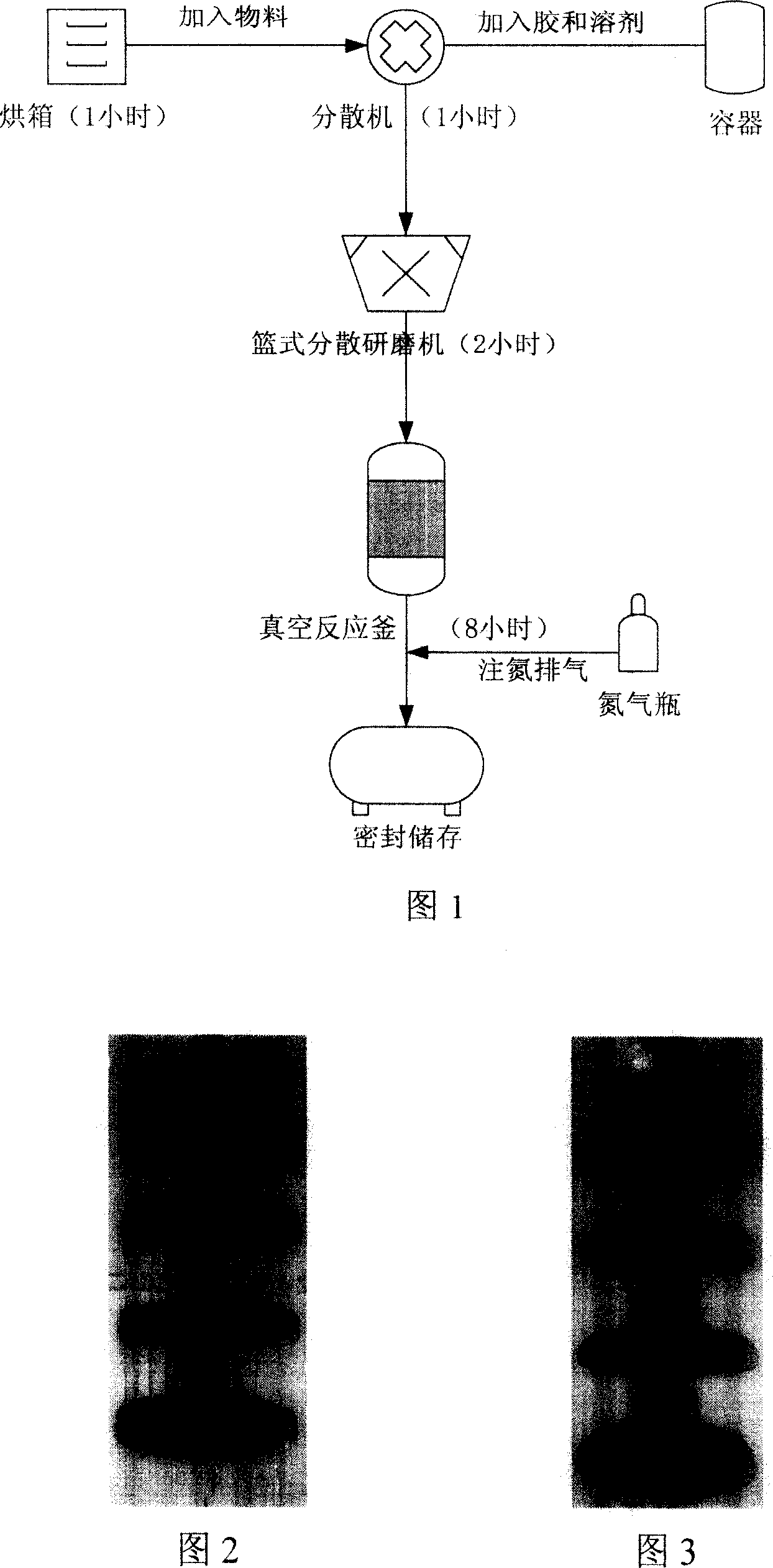

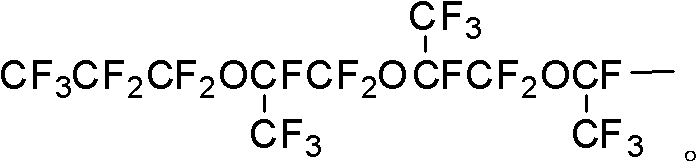

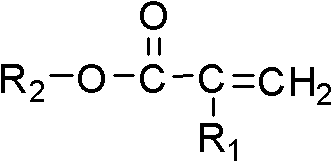

Fluorine-containing polyether acrylate polymer and preparation method thereof

InactiveCN102504136AGood water repellencyGood weather resistanceVegetal fibresFunctional monomerEmulsion

The invention relates to a fluorine-containing polyether acrylate polymer and a preparation method thereof. The structural formula of the polymer is shown in the specifications. The preparation method comprises the following steps of: (1) dissolving an emulsifier into a solvent, and stirring at the temperature of 20-200 DEG C for 2-24 hours to obtain an emulsion; (2) dropwise adding a functional monomer and fluorine-containing polyether acrylate into the emulsion respectively, stirring at the temperature of 20-200 DEG C for 2-24 hours, and performing ultrasonic treatment for 2-24 hours to obtain a pre-emulsion; and (3) under the protection of N2, heating to 20-200 DEG C, dropwise adding an initiator into the pre-emulsion, and reflowing for 2-24 hours. The fluorine-containing polyether acrylate polymer has the advantages of easiness for biodegrading, low environmental pollution and simple preparation method; and perfluoropolyether is adopted instead of long chain perfluoralkane, so that the defects of non-biodegradability of long chain perfluoralkane and harm of perfluoroctane sulphonated substance serving as a raw material of long chain perfluoralkane to human beings are overcome.

Owner:DONGHUA UNIV

Water-based lotus-leaf-structured hydrophobic over-printing varnish for wallpaper and preparation method of over-printing varnish

The invention specifically relates to water-based lotus-leaf-structured hydrophobic over-printing varnish for wallpaper and a preparation method of the over-printing varnish, and belongs to the technical field of ink. The technical problem to be solved is to provide an over-printing varnish by using which the surface of a wallpaper product can be smooth, bright and wear-proof and the lotus leaf type waterproof and moisture-roof effects can be realized, and a preparation method of the over-printing varnish. In order to solving the technical problem, the technical scheme adopted is as follows: the water-based lotus-leaf-structured hydrophobic over-printing varnish for the wallpaper is prepared from raw materials including a modified organic silicon polymer emulsion, a non-film-forming acrylate emulsion, an styrene-acrylic emulsion, neutralizing amine, propylene glycol, a water-based coalescing agent, a water-based leveling wetting agent, a mineral defoamer, a water-based nanoscale organosilicon waterproofing agent, a waterborne polyurethane thickening agent, deionized water and an organic silicon defoamer; the raw materials are stirred and mixed in a specific order to form the over-printing varnish.

Owner:山西金博雅油墨科技有限责任公司

Elastic non-woven cloth with high water absorption and air permeability for medical magnetic therapy

InactiveCN108978042AAppropriate intensityAppropriate softnessMonocomponent polyurethanes artificial filamentElectrotherapyFiberBiocompatibility Testing

The invention discloses elastic non-woven cloth with high water absorption and air permeability for medical magnetic therapy. The elastic non-woven cloth is made from, by weight, 20-27 parts of modified polylactic acid fiber, 20-33 parts of modified bamboo fiber, 10-20 parts of hydroxymethyl cellulose, 2-5 parts of casein, 20-30 parts of soybean fiber, 5-10 parts of sodium alginate, 20-35 parts ofstarch, 20-23 parts of magnetic starch, 40-45 parts of modified polyacrylamide fiber and 3-5 parts of a plant extract. The non-woven cloth has bacteriostatic activity, can effectively prevent wound infection, and is suitable for extensive symptoms, remarkable in health effect, safe and reliable in magnetic therapy function and economical and practical; raw materials adopted are biodegradable natural polymer materials and have good biocompatibility, and simpleness in the method is achieved.

Owner:HEFEI SHENGDA GARMENT ACCESSORIES CO LTD

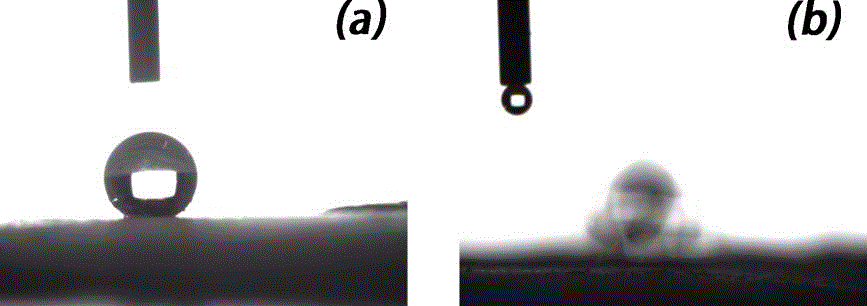

Hydrophobic membrane based on fluorine-containing polyurethane and preparation method of hydrophobic membrane

ActiveCN106750432AEasy to storeEasy to migrateAntifouling/underwater paintsPaints with biocidesPolymer scienceDiol

The invention discloses a hydrophobic membrane based on fluorine-containing polyurethane and a preparation method of the hydrophobic membrane. The preparation method comprises the following steps: spin-coating the fluorine-containing polyurethane into a film; curing to obtain the hydrophobic membrane based on the fluorine-containing polyurethane; taking fluorine-containing alkyl polyether glycol and diisocyanate to be subjected to addition polymerization reaction; and catalyzing through a tin catalyst and extending a chain through a chain extender; and adding an amino silane coupling agent and capping an end to prepare the fluorine-containing polyurethane. The product has a fluorine-containing polyether block and high fluorine content; perfluoroalkyl located at a polyether side easily has micro-phase separation and surface migration; the surface energy of the polyurethane is low; and the fluorine-containing polyurethane is subjected to end capping by the silane coupling agent and is easy to store and easy to cure. The hydrophobic membrane based on the fluorine-containing polyurethane, disclosed by the invention, has a water contact angle higher than 110 degrees and good water repellency.

Owner:SUZHOU UNIV

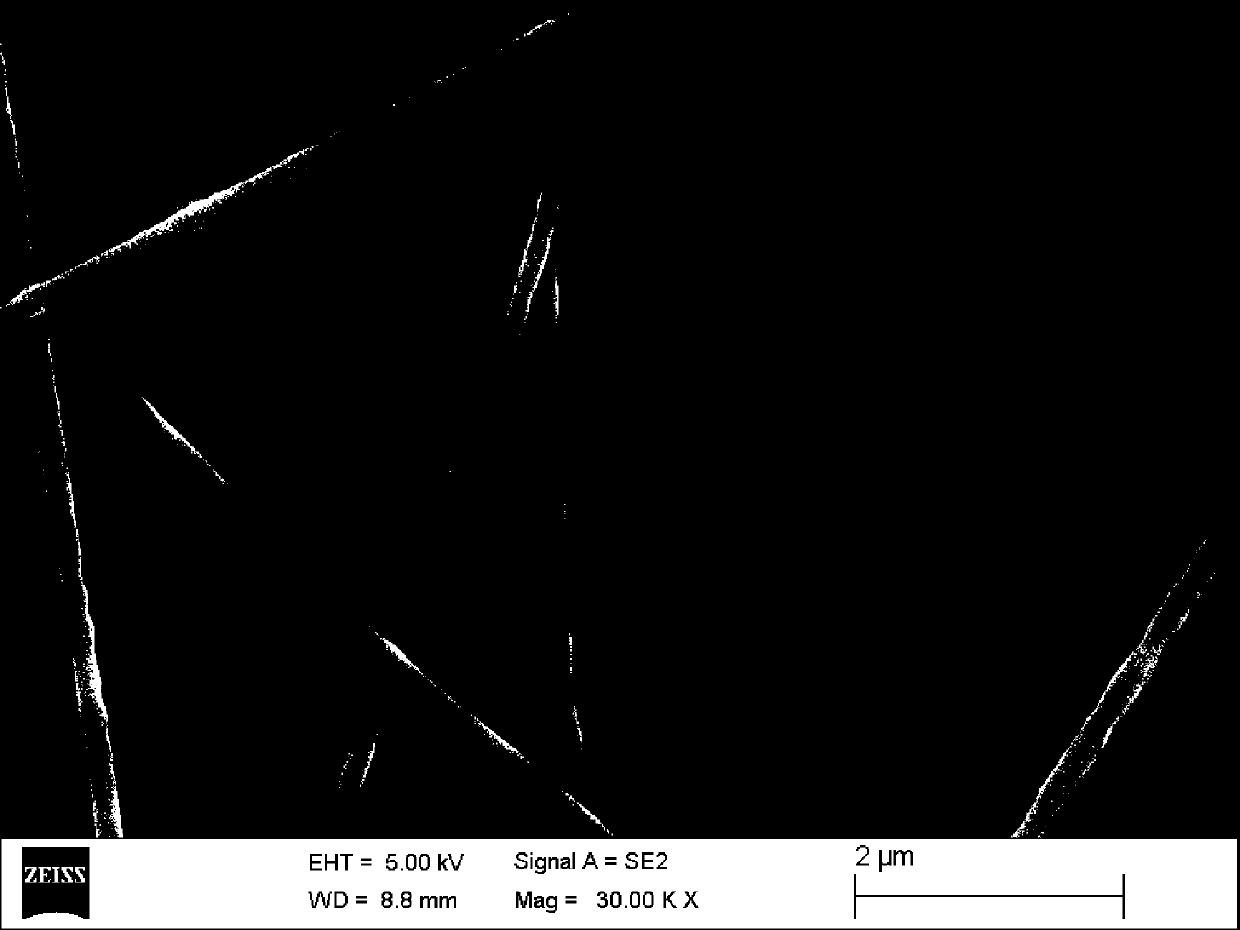

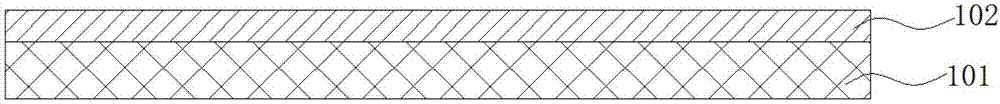

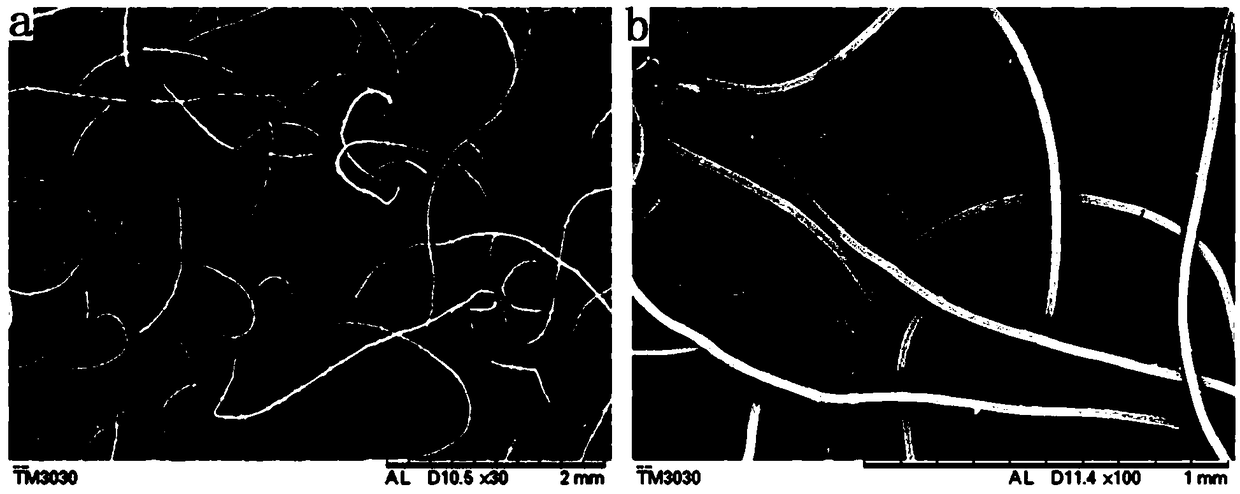

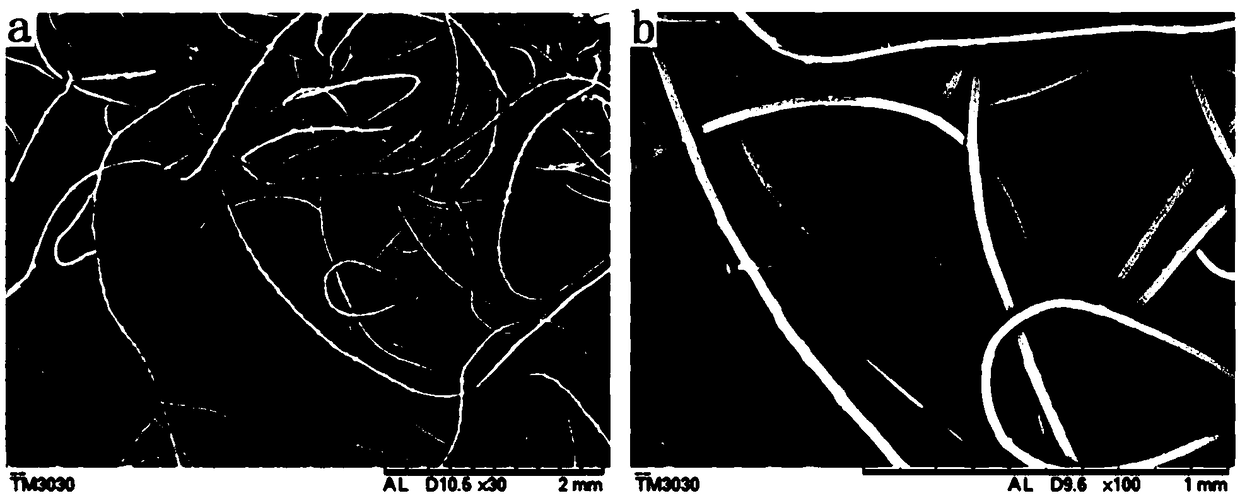

Fluorinated graphene-containing waterproof and moisture-permeable composite fabric and preparation method thereof

ActiveCN110973743AReduce weightGood water repellencySynthetic resin layered productsLaminationFiberHuman body

The invention belongs to the field of electrostatic spinning functional materials, and relates to a preparation method of a material capable of being applied to the waterproof and moisture permeable field, in particular to a fluorinated graphene-containing waterproof and moisture-permeable composite fabric and a preparation method thereof. The composite fabric has the advantages of super-hydrophobicity, high efficiency, better air and moisture permeability, energy conservation and the like. The average diameter of the fiber is 130 to 150 nm, the nanofiber waterproof and moisture permeable composite film is of a three-dimensional network structure, the hole diameter is small, a curved communication hole structure is formed, breathability is good, external severe weather infringement can beeffectively avoided, rain and snow penetration is prevented, sweat and moisture generated by movement of a human body can be discharged in time, so that the microenvironment of the human body is regulated and controlled, good comfort is provided for the human body, the protection function and the heat and moisture comfort of the garment fabric are unified, and the composite fabric is innovativelyapplied to the fields of medical treatment and public health, building outer walls, aerospace, aquatic product industry and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Cationic fluorine-containing paper oil-proofing agent

InactiveCN103396510AGood water repellencyGood oil repellencyNon-fibrous pulp additionFiberFunctional monomer

The invention relates to a cationic fluorine-containing paper oil-proofing agent which is an acrylate high molecular polymer solution containing perfluorohexylethyl on a side chain, wherein the high molecular polymer solution is prepared from 55.0-85.0% of fluorine-containing monomer, 5.0-35.0% of methyl / acrylate monomer, 3.0-10.0% of cationic monomer, 3.0-10.0% of functional monomer and 2.0-10.0% of adhesion reinforcement monomer through copolymerization reaction. The oil-proofing agent provided by the invention has the characteristics of high adhesion, low consumption, favorable oil / water resistance and the like; and by adding the adhesion reinforcement monomer, the fluorine-containing activating agent can be adsorbed on fiber of paper, so that the surface property of the paper fiber is reduced, thereby improving the oil-proofing property of the paper and simultaneously increasing the strength and stiffness of the paper.

Owner:XIAMEN AISIKANG NEW MATERIAL

Cationic waterborne organic fluorine acrylate polymer as well as preparation method and application of cationic waterborne organic fluorine acrylate polymer

ActiveCN103980418AImprove performanceSimple production equipmentFibre treatmentEmulsionWater soluble

The invention discloses a cationic waterborne organic fluorine acrylate polymer as well as a preparation method and application of the cationic waterborne organic fluorine acrylate polymer. The cationic waterborne organic fluorine acrylate polymer is prepared by using a semicontinuous dripping method and taking perfluoroalkyl acrylates and acrylate as main monomers, a reactive unsaturated monomer as a modified monomer, a cationic Gemini surfactant and a nonionic emulsifying agent as an emulsion system and water-soluble azobis(isobutylamidine hydrochloride) as an initiator. The polymer system disclosed by the invention is high in stability, and the emulsion storage stability is not shorter than 12 months. A textile treated by using the emulsion prepared by the invention has better water and oil repellent effects.

Owner:深圳天鼎新材料有限公司

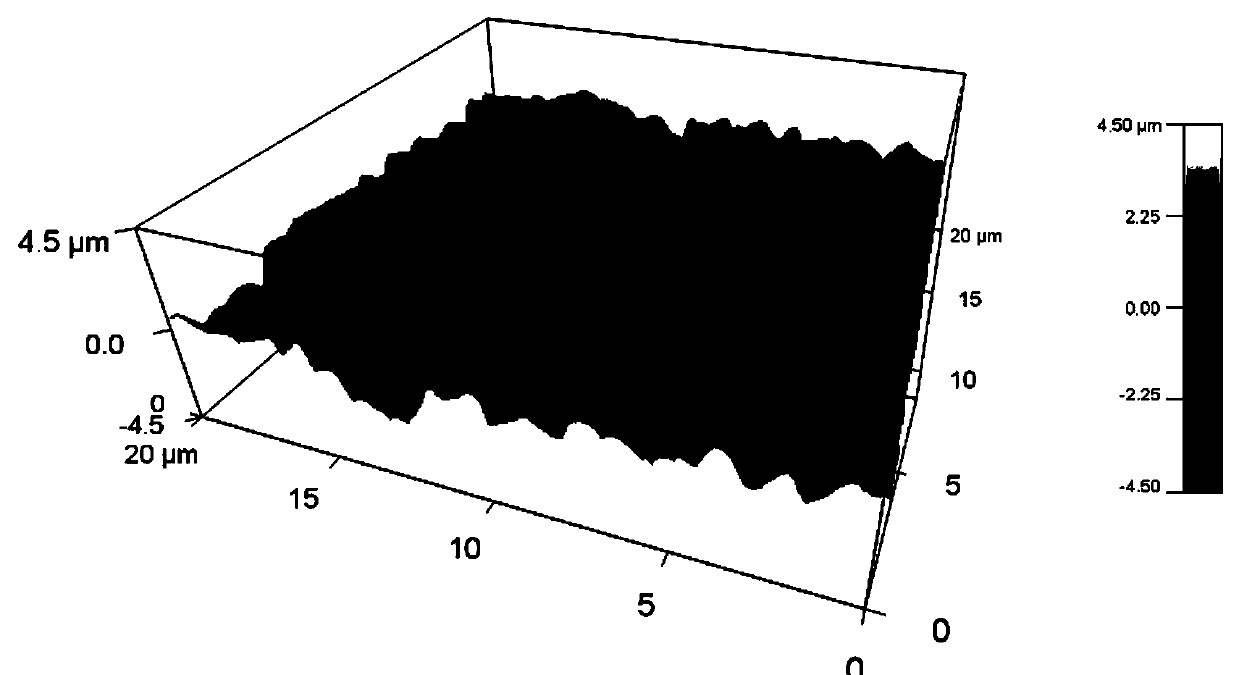

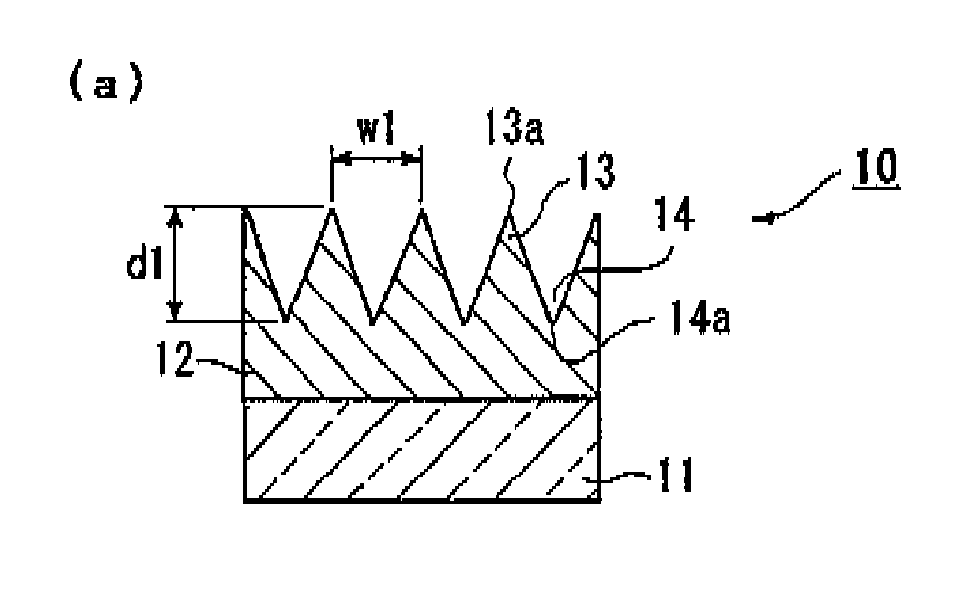

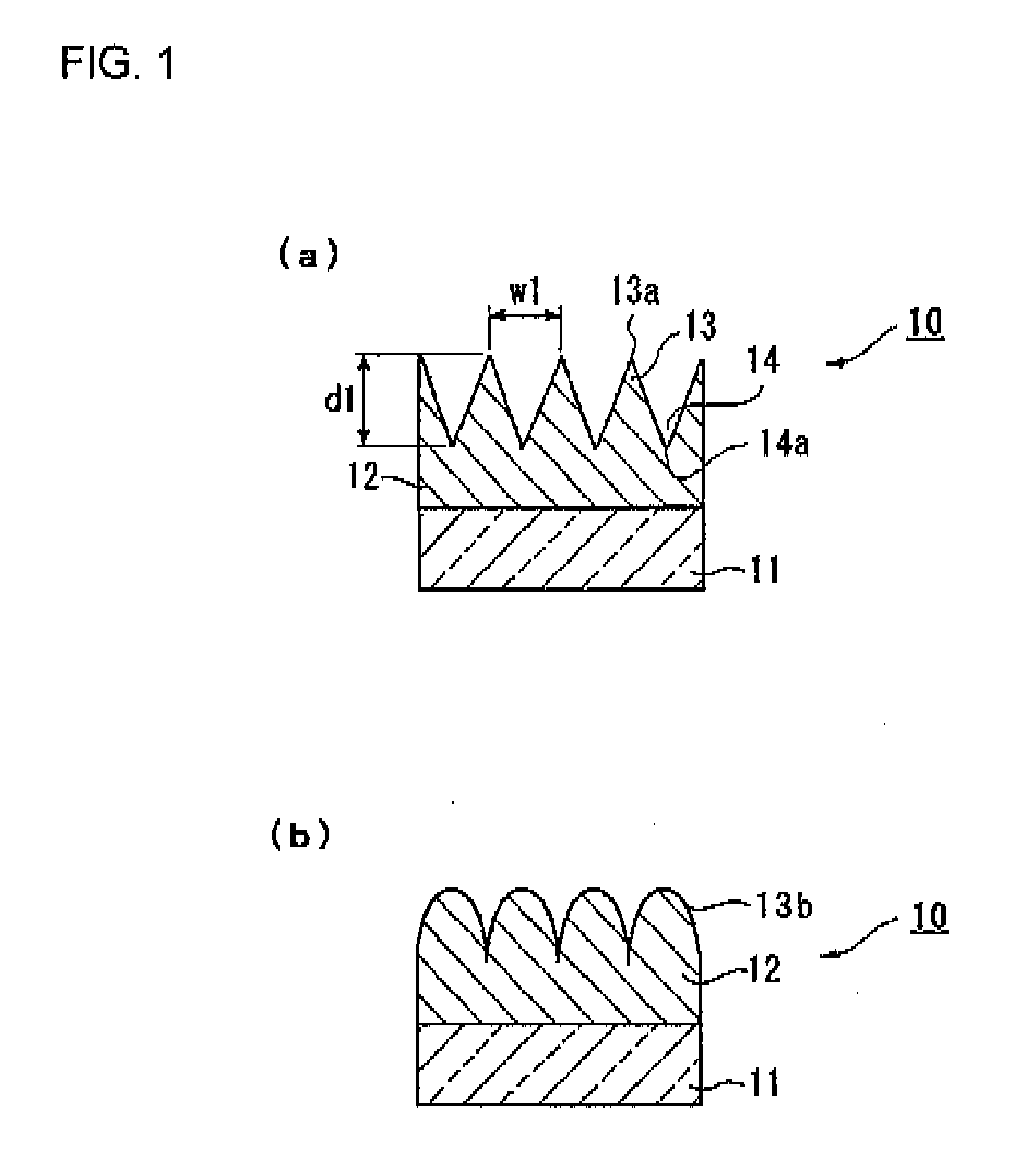

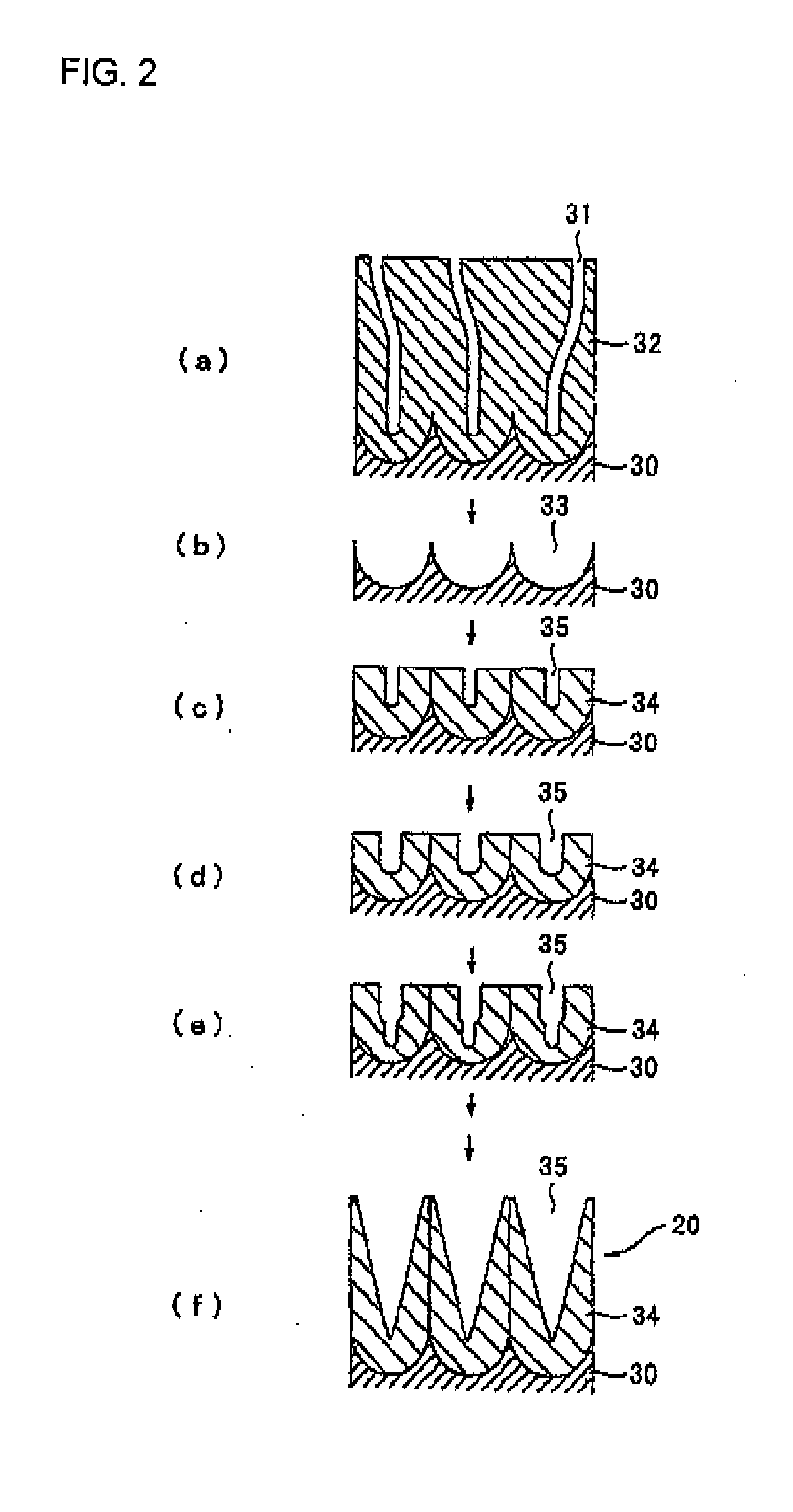

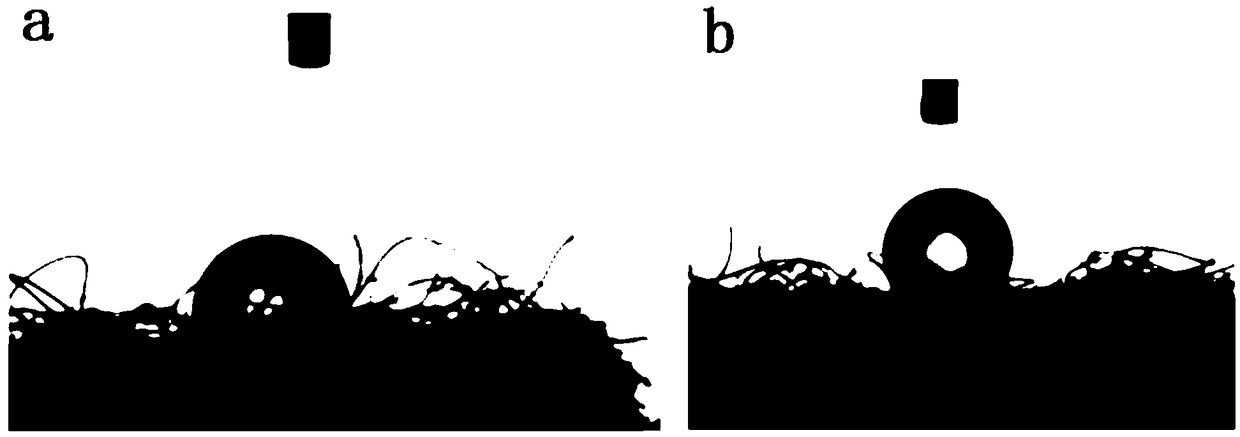

Active-Energy-Curable Resin Composition, Molding, Microrelief Structure, Water-Repellent Article, Mold, and Method for Producing Microrelief Structure

InactiveUS20140037900A1Excellent mechanical propertyGood water-repellencyConfectioneryRecord information storageMeth-Estimation methods

Disclosed is an active energy ray-curable resin composition comprising 3 to 18 parts by mass of an alkyl (meth)acrylate (A) having an alkyl group of 12 or more carbon atoms, and 82 to 97 parts by mass of a multifunctional monomer (B) having 3 or more radical polymerizable functional groups in the molecule wherein the sp value as expressed by the Fedor's estimation method is 20 to 23, per 100 parts by mass of the total content of all monomers, and which gives a cured material having excellent water repellency and scratch resistance; and a molded article, a fine uneven structure body and a water-repellent article prepared by using the active energy ray-curable resin composition; and a method for producing a fine uneven structure body.

Owner:MITSUBISHI CHEM CORP

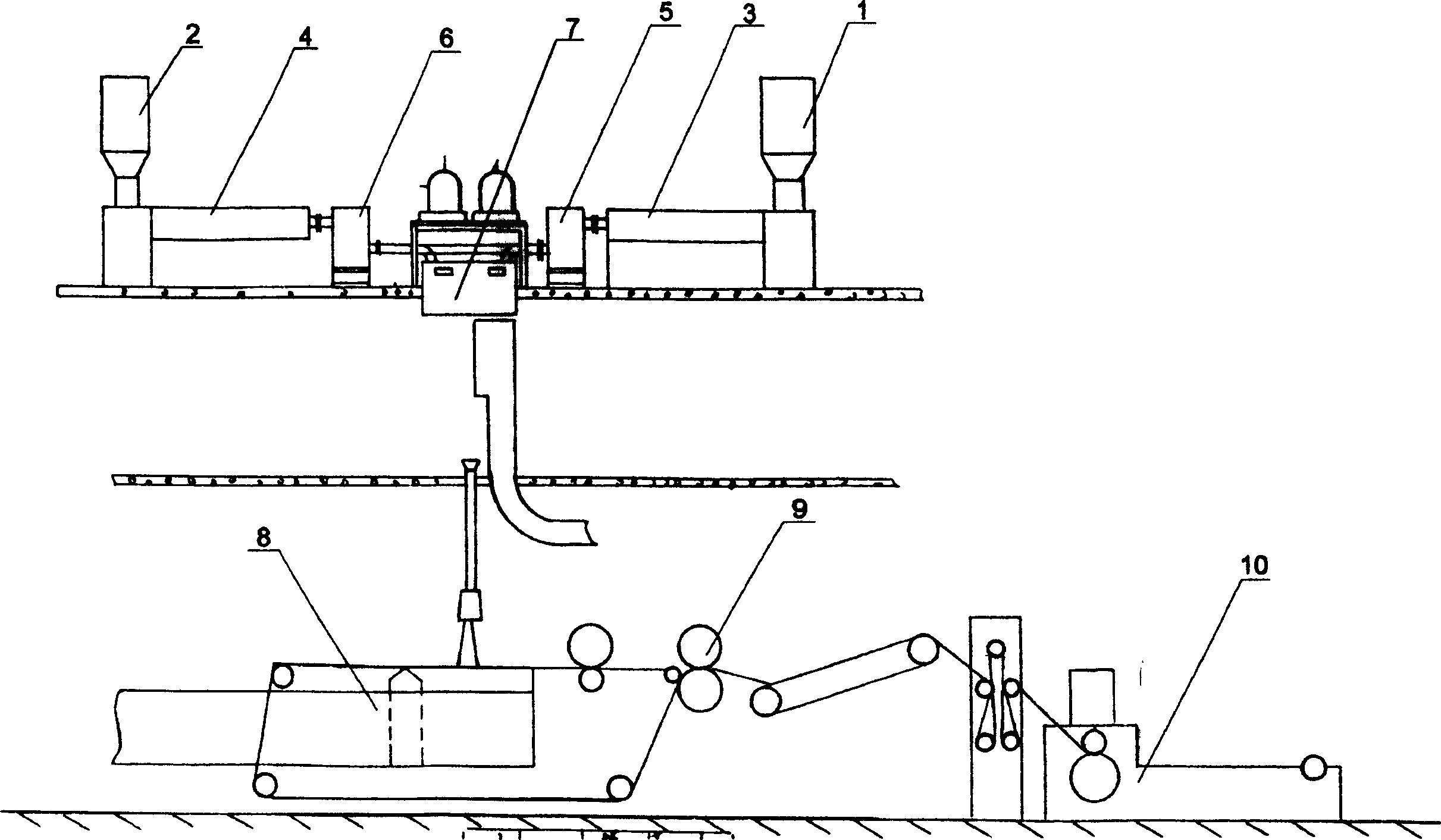

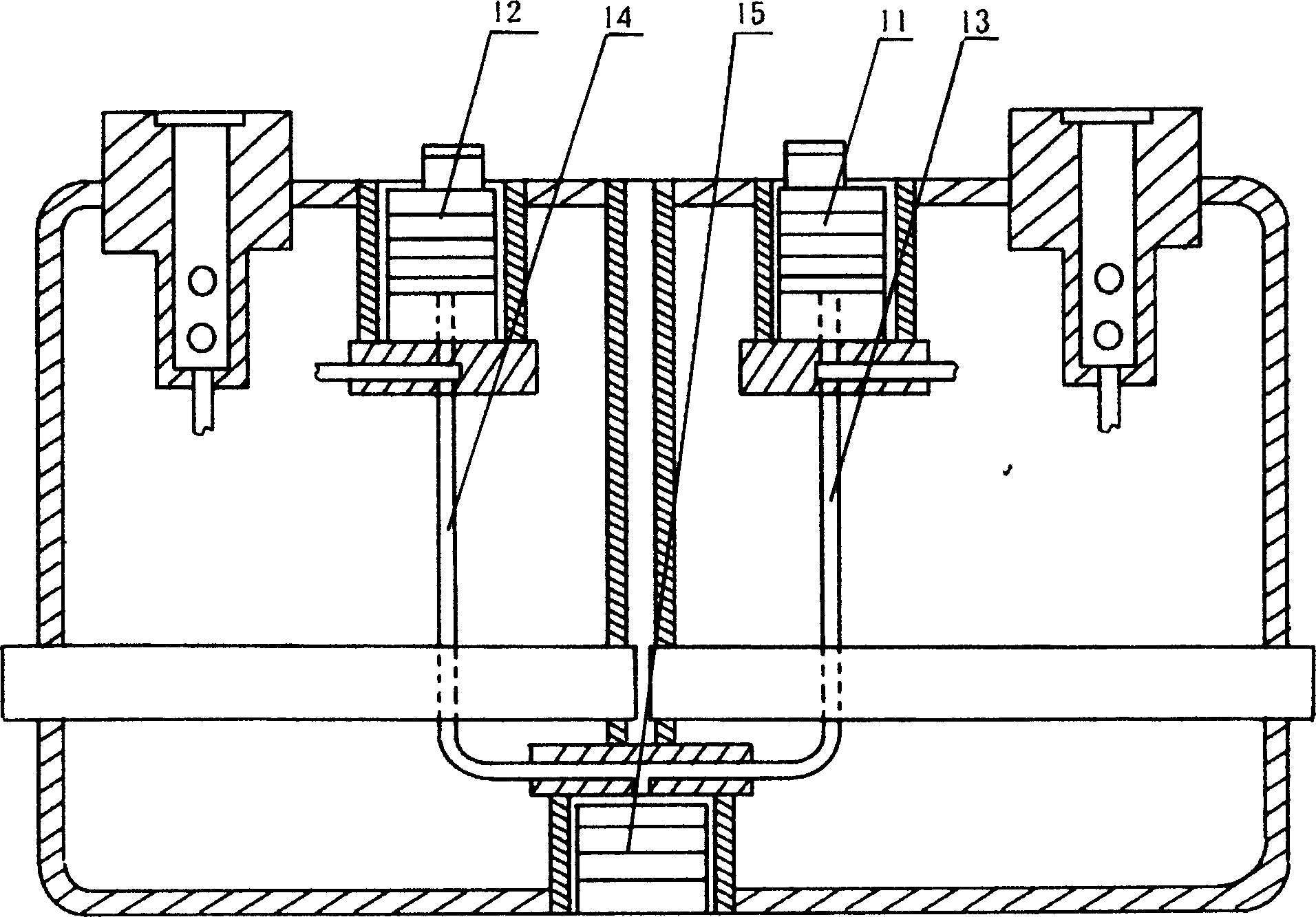

Process for preparing double component spunbonded nonwoven fabrics

InactiveCN1629368AGood flexibilityHigh tear strengthFilament/thread formingNon-woven fabricsEngineeringNonwoven fabric

The invention provides a process for preparing double component spun-bonded nonfabrics, wherein a compound spinning device is employed to prepare composite fabrics, wherein the device comprises two screw-spindle extrusion press, two melt filter, a composite spinning casing, the number of measuring pumps and filament spray board is increased by one times.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

Environmentally-friendly durable water repellent fabric and processing method thereof

InactiveCN101922118AGood water repellencyNon-bioaccumulativeSynthetic resin layered productsTextiles and paperParaffin oilsPerfluorooctanoic acid

The invention discloses an environmentally-friendly durable water repellent fabric and a processing method thereof. A water repellent layer contains at least one of a polyurethane treelike macromolecular structure unit and an aliphatic paraffin structure. The fabric has the advantages of high water repellency, air permeability, washability, abrasion resistance, no use of fluoride-containing waterrepellent, no edge substances such as perfluorooctanoic acid (PFOA) and perfluorooctane sulfonates (PFOS) and precursor substances thereof, no biological accumulation and no production of fluoride-containing gas and belongs to a high-performance environmentally-friendly water repellent fabric.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Medical protective clothing fabric and preparation method thereof

InactiveCN107419544ADense tissueImprove good performanceMedical preparationsTextiles and paperEngineeringTreatment costs

The invention provides a medical protective clothing fabric and a preparation method thereof and relates to the technical field of textile fabrics. The medical protective clothing fabric comprises a base fabric, wherein a hydrophobic layer is arranged on the outer surface of the base fabric; the base fabric is formed by weaving warp yarns and weft yarns; the warp density of the base fabric is 65 to 75 pieces / cm and the weft density of the base fabric is 30 to 35 pieces / cm; the warp yarns are 70-80D / 34-38F polyester filament yarns and the weft yarns are 70-80D / 34-38F polyester filament yarns; the technical problems that existing medical protective clothing is disposable medical protective clothing which needs to be discarded after being used, so that great environmental pollution is caused as well as the treatment cost of patients is increased are solved; the technical effects that the medical protective clothing fabric can effectively protect personal safety of medical workers and can be repeatedly used, so that environmental pollution is reduced and the consumption cost of a hospital is reduced are realized.

Owner:杭州康升纺织有限公司

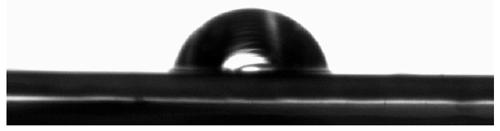

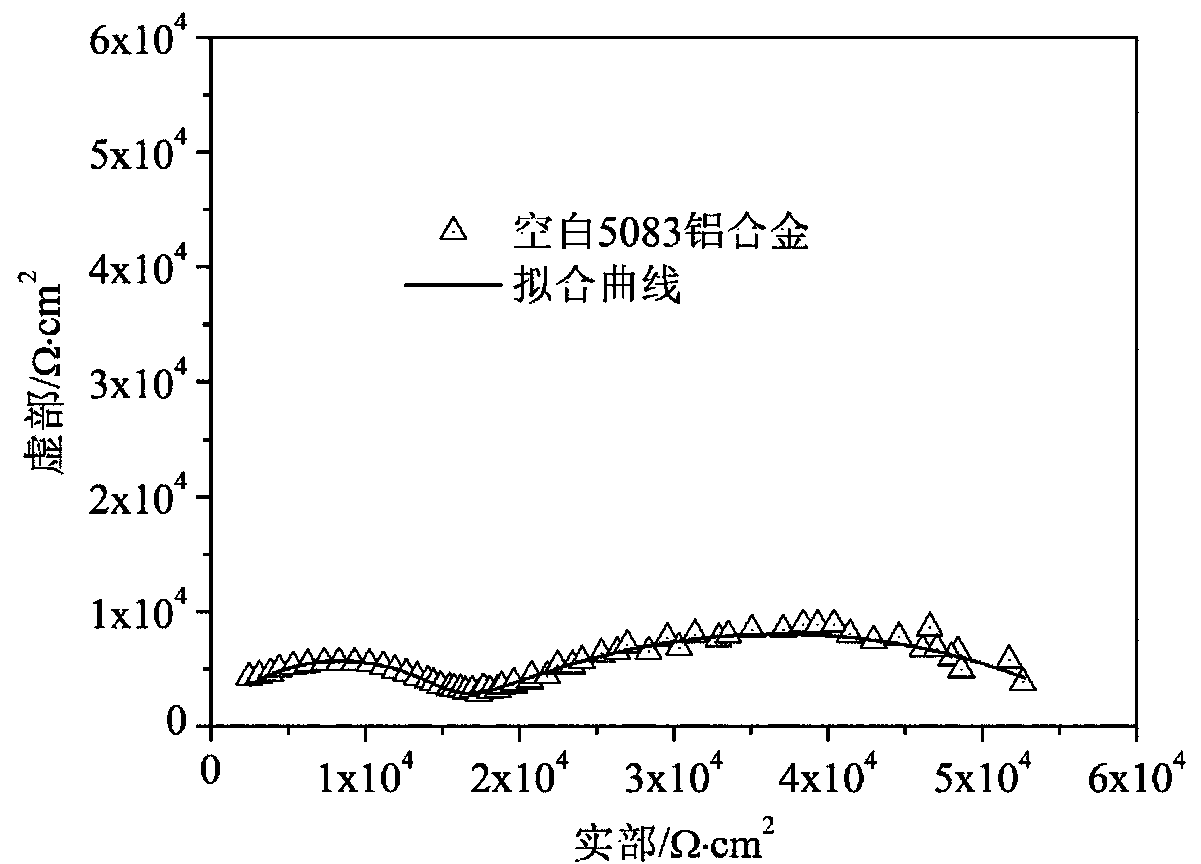

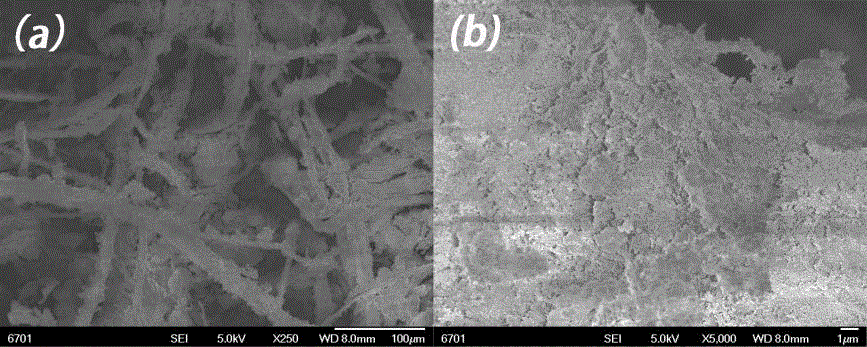

Preparation method of aluminum based fluoride-free superhydrophobic membrane

InactiveCN109939906AEasy to interceptReduce contact areaPretreated surfacesCoatingsSilanesAqueous sodium hydroxide

The invention belongs to the technical field of metal surface processing, in particular to a preparation method of an aluminum based fluoride-free superhydrophobic membrane. The method comprises the steps that a processed aluminum material is placed in a sodium hydroxide solution with the concentration of 10-25 g / L to conduct surface etching to form a multi-stage texture structure, the aluminum material is placed in an ethanol solution with the silane concentration of 1-5% to perform lower-surface energy molecule self assembling, and the superhydrophobic membrane is obtained on the surface ofthe aluminum material after drying. The method has the advantages that the operation is simple and convenient, the method is environmental-friendly, the scale preparation of the superhydrophobic membrane is convenient, and excellent surface self-cleaning and corrosion-resistance characteristics are achieved.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Preparation and use method of waterproof coating agent of outdoor exercise rope

InactiveCN106957387AMeet the requirements of waterproof performanceLow costFibre treatmentRope making machinesPerformance indexAqueous solution

The invention discloses a preparation and use method of a waterproof coating agent of an outdoor exercise rope and relates to the field of a rope net. The waterproof coating agent is formed by pre-polymerizing and polymerizing acrylate and fluorine-containing acrylic monomer in an initiator and emulsifier aqueous solution system. The preparation technology and the use method are relatively simple; the cost of the raw materials is low; the raw materials are simple and are easily acquired; the water absorption not more than 5% is required on the basis of the requirement for waterproof property according to a performance index of the outdoor exercise rope; after the invention is applied, the test is performed according to a waterproof test method for Power Rope on the basis of international mountain climbing union standard UIAA101; the water absorption of the rope after being settled is 0-4%, meets the standard requirement and meets the requirement for the waterproof property of the rope in outdoor exercise.

Owner:SHANDONG ROPE TECH CO LTD

Waterborne metal rust inhibitor

InactiveCN105949975AGood water repellencyImprove rust resistanceAnti-corrosive paintsPolyether coatingsChemistryTriethanolamine

The invention provides a waterborne metal rust inhibitor. The waterborne metal rust inhibitor comprises the following components in parts by weight: 8 to 14 parts of tribasic acid, 10 to 20 parts of triethanolamine, 8 to 16 parts of cyclohexane, 4 to 8 parts of diethanolamine, 20 to 30 parts of maleic-methyl acrylate copolymer, 40 to 60 parts of triethanolamine borate, 40 to 60 parts of polyethylene glycol, 0.5 to 1.5 parts of a silicone defoamer, and 500 to 700 parts of water. According to the invention, the rust-proof effect is the best due to the synergistic effect of the components of the waterborne metal rust inhibitor. The polyethylene glycol contained in the waterborne metal rust inhibitor can assist film forming, so that the rust inhibitor has a better water repellent effect, and the rust-proof capability is effectively improved, furthermore, the rust-proof time can be prolonged, so that the rust-proof effects of parts can be obviously improved.

Owner:陆倩

Water repellent and oleophylic composite needling non-woven fabric and preparation method thereof

ActiveCN109234910APrevent water absorptionEffective tangleGeneral water supply conservationLiquid repellent fibresPolymer sciencePolyolefin

The invention relates to a water-repellent and oleophylic composite needling non-woven fabric and a preparation method thereof. The method comprises the following steps of: blending PET fiber and polyolefin fiber with to a mass ratio of 3:1-1:3, and carrying out needling to obtain the composite needling non-woven fabric; carrying out hot-drying treatment on the composite needling non-woven fabricat 110-160 DEG C, wherein the treatment time is 40-90 minutes; carrying out padding and water-repellent finishing on the hot-dried fabric by using a modified resin-like fluorine-free waterproof agentaqueous solution with the concentration of 50-70mL / L, wherein the air pressure of the padding and water-repellent finishing is 1.8 kPa, the liquid rate is 160-230%, and drying to obtain the water-repellent and oleophylic composite needling non-woven fabric. The preparation method is simple, the water repellency, lipophilicity and tensile strength of the prepared composite needling non-woven fabricare obviously improved compared with the fabric before treatment.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Butyl sealant

InactiveCN103992763AGood water repellencyIncrease sealing and anti-seepage performanceMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesSolventChemistry

The invention discloses a butyl sealant comprising the following raw materials by weight: 55-65 parts of butyl rubber, 20-30 parts of natural rubber, 40-50 parts of petroleum resin, 3-8 parts of titanium dioxide, 4-9 parts of antioxidant D, 140-160 parts of xylene, 15-25 parts of fumed silica, 95-105 parts of talcum powder, 9-15 parts of a thickening agent and 10-20 parts of a moisturizing agent; the butyl rubber, the natural rubber, the antioxidant D and the titanium dioxide are mixed for 25-35min in an open mill for plastics to obtain a glue film sheet, the glue film sheet is placed in xylene solvent for soaking for 20-30h to obtain a glue liquid, the glue liquid is poured into a kneading machine for kneading until the glue liquid is even and free of particles, then the petroleum resin, the moisturizing agent, the thickening agent, the talcum powder and the fumed silica are added for continuing kneading for 8-15min to obtain the butyl sealant. The butyl sealant has excellent air tightness and is used for doors and windows and other places with high air tightness requirements.

Owner:TIANCHANG YONG TAI SEALING MATERIAL

Production process of ice oxygen bar cool-feel bacteriostatic water-repellent fabric

InactiveCN111118718AGood moisture absorption and perspirationGood water repellencyShrinkingWeft knittingYarnPolymer science

The present invention discloses a production process of an ice oxygen bar cool-feel bacteriostatic water-repellent fabric. The fabric is woven by blended yarns with the fineness of 32-40S and 20-30D spandex yarns on a knitted single-side circular knitting machine according to a weft plain stitch weaving mode, wherein the blended yarns are woven by viscose fibers, cotton and ice oxygen bar fibers in a blending mode, and the production process comprises the steps of weaving, pretreating, dyeing, dewatering, slitting, drying, shaping, preshrinking and finished product obtaining. According to theproduction process, the blended yarns woven by viscose fibers, cotton and ice oxygen bar fibers in a blending mode and the spandex yarns are selected to weave the fabric, so that the fabric not only has the hygroscopicity of viscose and cotton, but also has the low-temperature cool sense characteristics of the ice oxygen bar fiber, the fabric has excellent moisture absorption and sweat dischargingperformance, even in a humid environment, also can keep the skin dry and comfortable, thereby effectively inhibiting the growth of bacteria, and the fabric has good bacteriostasis and health care performance; and the outer layer of the fabric is subjected to water repellent finishing, so that the fabric water repellent effect is relatively high.

Owner:JIANGSU DONGYUAN TEXTILE SCI & TECH IND

Preparation method of super-hydrophobic flame-retardant recycled paper

InactiveCN105803849ASecondary useSimple processWater-repelling agents additionPaper/cardboardPapermakingOil water

The invention belongs to the technical field of preparation of super-hydrophobic natural flame-retardant materials and particularly relates to a preparation method of super-hydrophobic flame-retardant recycled paper.The method includes the steps of preparation of an inorganic-organic compound super-hydrophobic filling material, preparation of a hydrophobic flame retardant, preparation of super-hydrophobic flame-retardant recycled paper and other steps.A contact angle of the super-hydrophobic flame-retardant recycled paper is 150 degrees, and a rolling angle of the paper is 10 degrees.The super-hydrophobic flame-retardant recycled paper has a good flame-retardant effect, the original writing performance, bendability and other properties of the paper are retained, and no influence is produced on daily usage.In addition, the super-hydrophobic flame-retardant recycled paper has very good self-cleaning performance and antifouling performance, meanwhile has super-lipophilicity and can be used for separation of oil-water mixtures.Furthermore, the material can be extracted from water by using waste oil, and secondary utilization can be achieved.The preparation method is simple, the raw materials are easy to obtain, the recycled paper is non-toxic, environmentally friendly, low in cost, good in stability and suitable for large-scale preparation, the application range of the paper is widened, and the energy source crisis and ecological crisis brought by the papermaking industry are also eased.

Owner:HUBEI UNIV

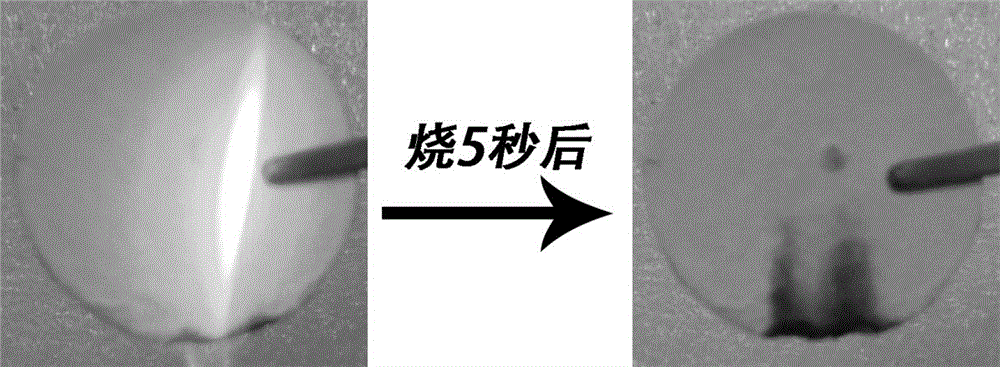

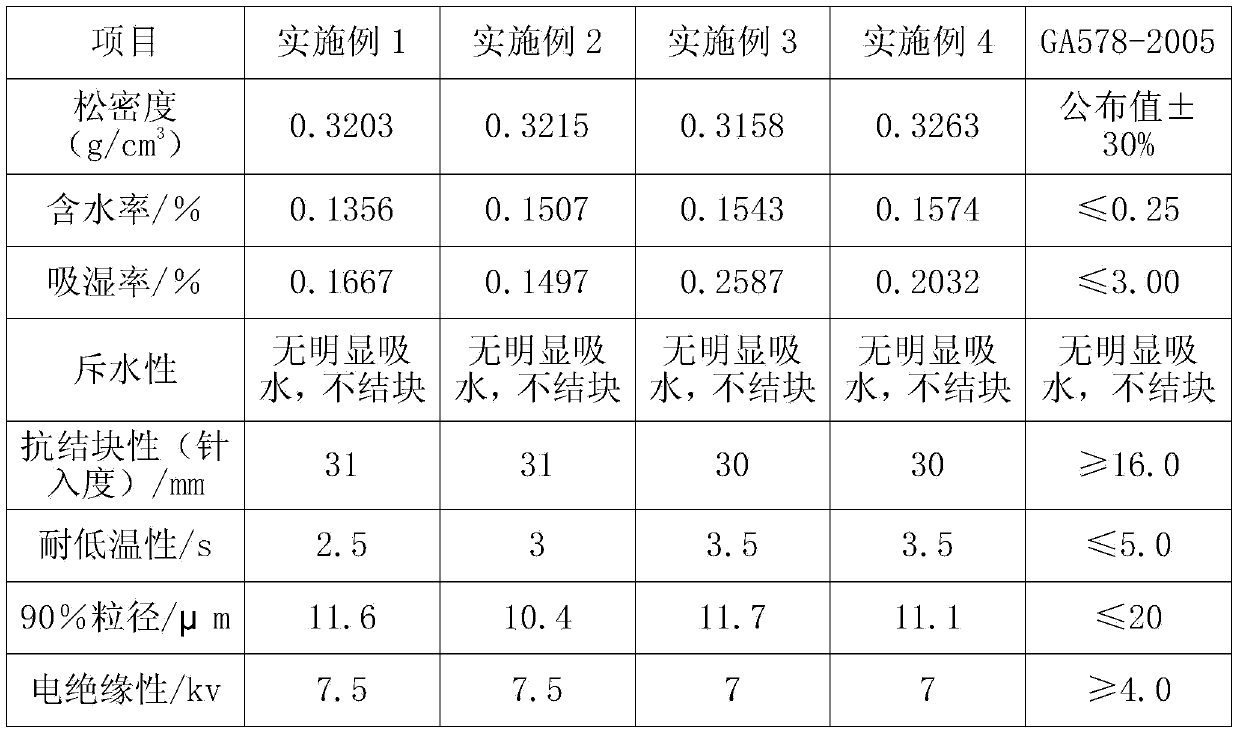

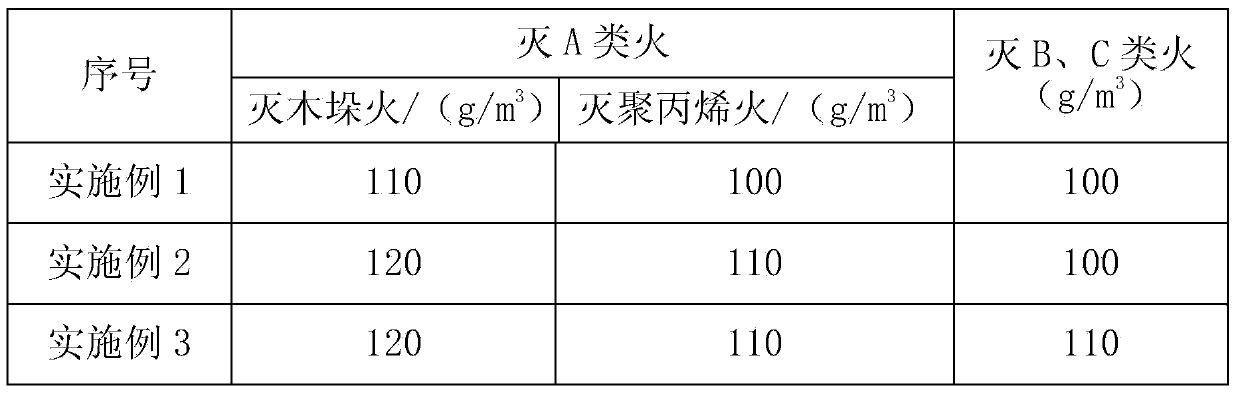

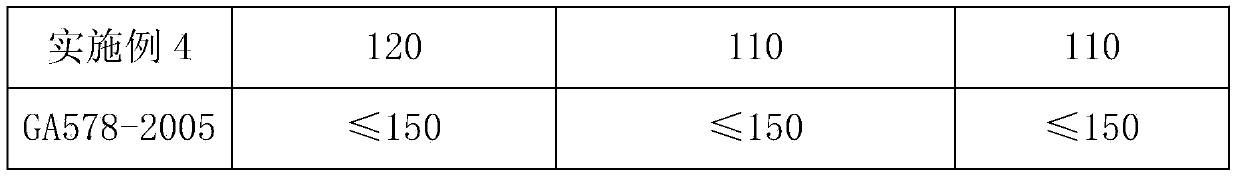

ABC superfine dry powder extinguishing agent and preparation method thereof

ActiveCN104190040AEasy to achieve batch ultra-fine crushingGood lookingFire extinguisherWater basedGasoline

The invention relates to the field of fire fighting and extinguishing and discloses an ABC superfine dry powder extinguishing agent and a preparation method thereof. The extinguishing agent comprises the following components by mass percent: 3-5% of mica powder, 3-6% of hydrophobic fumed silica, 0.9-1.5% of high-boiling silicone oil, 0.8-1.5% of water, 1-1.5% of gasoline and the balance of ethylenediamine phosphate. The prepared ABC superfine dry powder extinguishing agent has the beneficial effects that as 90% of particle sizes are less than or equal to 12mu m, the properties of the ABC superfine dry powder extinguishing agent meet relevant requirements of GA578-2005 superfine dry powder extinguishing agents, and the ABC superfine dry powder extinguishing agent can achieve the total flooding extinguishing and flooding extinguishing effects; moreover, the dry powder extinguishing agent has excellent water repellency and long storage period and is especially suitable to serve as the extinguishing agent of water-based and dry powder composite jet extinguishing equipment.

Owner:国兴一实安防科技实业(浙江)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com