Patents

Literature

303results about How to "Big profit margin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

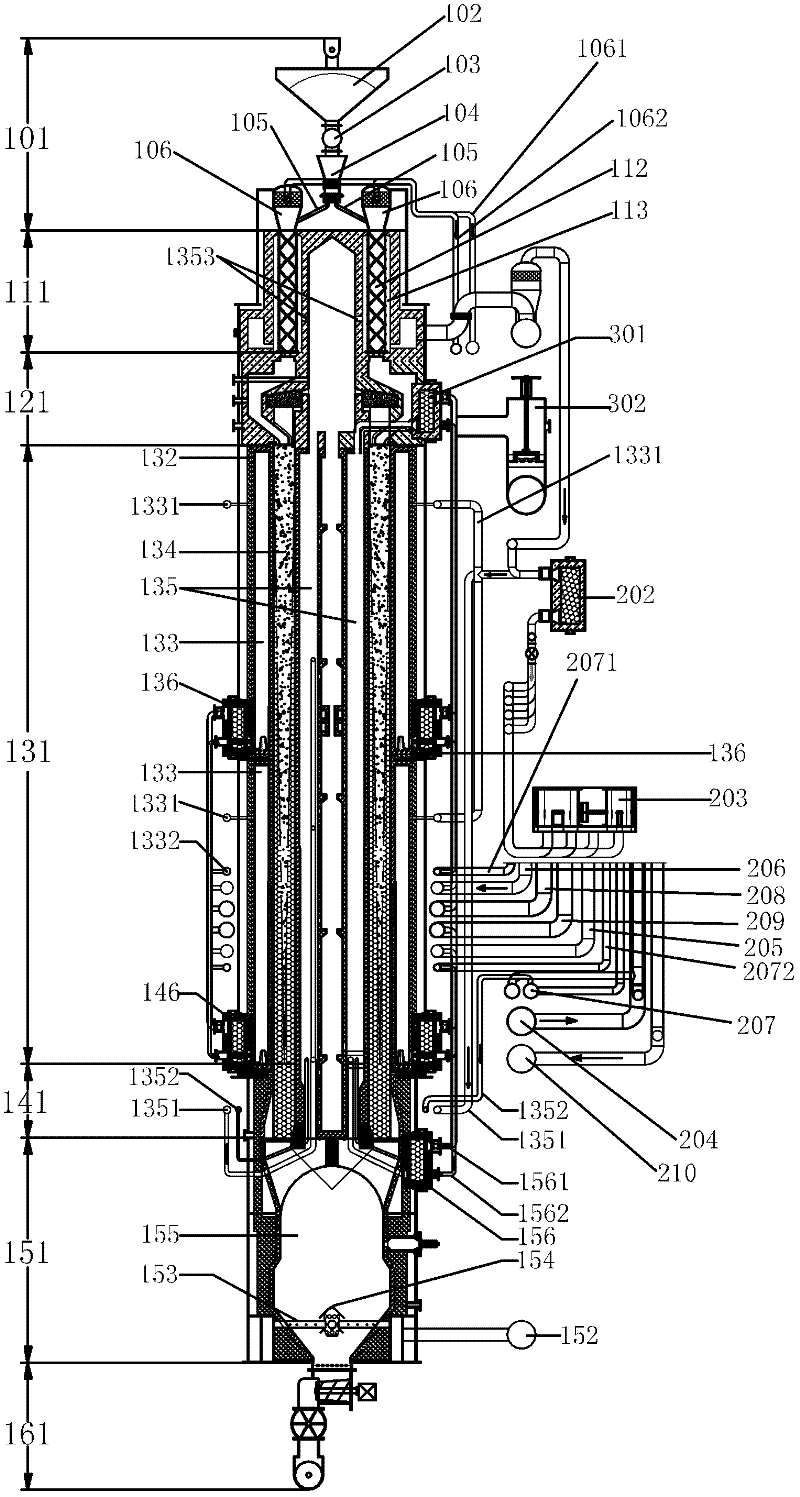

Coking furnace capable of recycling heat energy and coking method

InactiveCN102250629AExtend the industrial chainReduce pollutionCoke quenchingGas purification with selectively adsorptive solidsThermal energyCombustion

The invention discloses a coking furnace capable of recycling heat energy, and the coking furnace comprises a furnace body, an exhaust gas recycling system and a raw coal gas treatment system, wherein the furnace body sequentially comprises a coal feeding segment, a rapid coal heating segment, a raw coal gas leading-out segment, a coal carbonization coking segment, a coke quenching and tempering segment, a dry coke quenching segment and a coke discharging segment from top to bottom; the exhaust gas recycling system comprises an exhaust gas leading-out unit, an exhaust gas heat exchanger, a commutator and the like; and the raw coal gas treatment system comprises a raw coal gas leading-out unit. By using the coking furnace disclosed by the invention, continuous coal carbonization coking canbe achieved and the exhaust gas after combustion is used for dry coke quenching in the furnace; pre-dried coal can be quickly heated to 300 DEG C during entering the furnace, the coal is carbonized and coked in the furnace body, and the exhaust gas generated by self-combustion is used for dry coke quenching at the furnace bottom after the exhaust gas is cooled by heat exchange with air, thus continuously producing coke; the pollution is less in the production process; the coal industrial chain is extended, the coking cost is lowered, the coking coal types are broadened, and the product quality is improved; the profit margins are expanded in a large extent; and the maintenance cost is low.

Owner:山西华天新能源发展有限公司

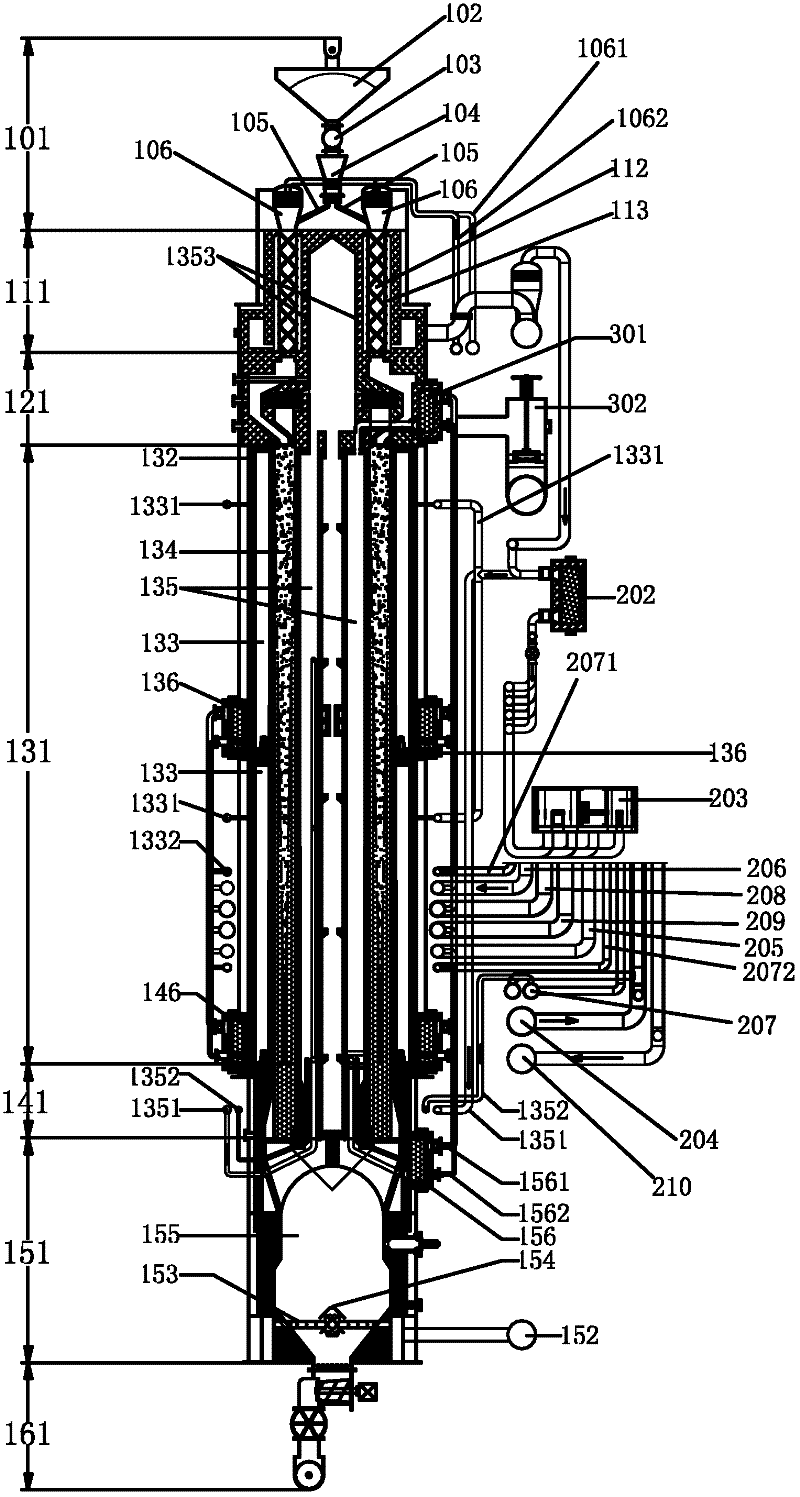

Oxyether triazole compound, and preparation method and application thereof

InactiveCN103772305AHigh reaction yieldHigh purityOrganic chemistryLuminescent compositionsSimple Organic CompoundsDiphenyl ether

The invention discloses a preparation method of 1-(4-(4-(1H-1,2,4-triazolyl-1-yl)phenoxy)phenyl)-1H-1,2,4-triazole. The organic compound is prepared by heating 4,4'-dibromodiphenyl ether, triazole, potassium carbonate and copper oxide by a one-pot process. The preparation method has the characteristics of simple technological operation, low production cost and low environmental pollution, and is suitable for large-scale industrial production. The invention also discloses application of the 1-(4-(4-(1H-1,2,4-triazolyl-1-yl)phenoxy)phenyl)-1H-1,2,4-triazole in photoelectric materials.

Owner:TIANJIN NORMAL UNIVERSITY

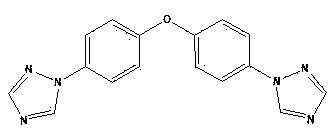

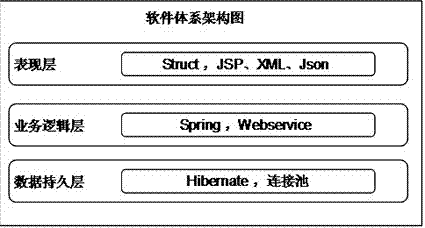

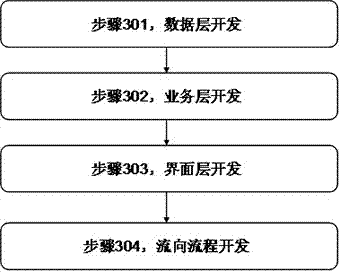

Component-oriented multi-language collaborative development device, method and system

ActiveCN107193545AImprove adaptabilityReduce manpower requirementsSoftware designOffice automationMulti languageSoftware system architecture

The invention discloses a component-oriented multi-language collaborative development device, method and system. According to the method, multiple engines are concentrated under an MVC software system architecture to be constructed; rapid construction of business logic, establishment of a database table and an access system and visual composition of an interface UI are realized through a business logic engine, a database engine, a form engine, etc.; the development process is based on a data layer process, a business layer process and an interface layer process; and multi-person online collaborative programming can be realized through an architecture of a client server. On the basis of component orientation, software fine-grained reuse can be done, a product can be developed through a business custom system, the software development cycle is greatly shortened, working efficiency is improved, and human cost is reduced.

Owner:GUANGDONG SCI & TECH INFRASTRUCTURE CENT

Centralized and remote control monitoring, and fault diagnosis system of wind turbine

InactiveCN101825893AImprove running qualityReduce maintenance costsTotal factory controlProgramme total factory controlElectricityRemote control

The invention relates to a centralized and remote control monitoring, and fault diagnosis system of wind turbine. Various sensors sample an original signal from a wind turbine; the signal obtained by the various sensors is converted into a digital signal by a data conversion module and conveyed to a site controller, the data processed is conveyed to a host computer; and two manners including centralizing and remote controlling are included. Accident alerting program software in the computer analytically analyzes and judges testing data, and draws a conclusion to alert an accident; and fault diagnosis specialist program software in the computer analyzes the testing data, draws a diagnosis conclusion and displays the conclusion in text on the display. Online monitoring on comprehensiveness of key parameters of all important parts of the whole wind turbine is realized; the accident alerting program software is used to analyze and judge the testing data to draw a conclusion and alert an accident; and the fault diagnosis specialist program software is used to diagnose operation condition, thereby improving operation safety reliability and service life of a large-sized wind turbine and enhancing the operation quality of a wind turbine.

Owner:HUZHOU TEACHERS COLLEGE

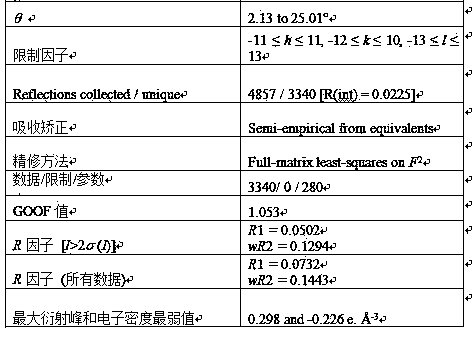

Phenyl bistriazole compound, and preparation method and application thereof

InactiveCN103086988AThe reaction is easy to operateHigh reaction yieldPolycrystalline material growthOrganic chemistrySimple Organic CompoundsBis triazole

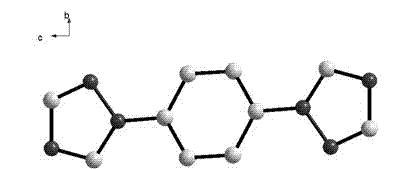

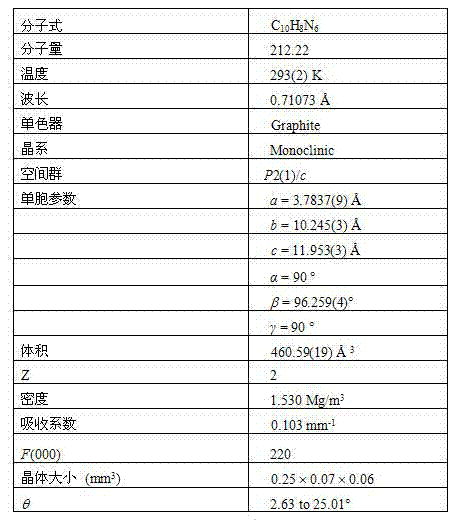

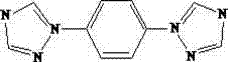

The invention discloses a phenyl bistriazole compound, and a preparation method and application thereof, and particularly relates to a 1-[4-(1H-1,2,4-triazole-1-yl)phenyl]-1H-1,2,4-triazole single crystal and a preparation method of 1-[4-(1H-1,2,4-triazole-1-yl)phenyl]-1H-1,2,4-triazole. The organic compound is prepared by heating ethylenediamine, 1H-1,2,4-triazole, potassium carbonate, 1,4-diiodobenzene and cuprous iodide through a one-pot method. The preparation method disclosed by the invention has the characteristics simple process operation, low production cost and less environmental pollution, and is suitable for large-scale industrial production. The 1-[4-(1H-1,2,4-triazole-1-yl)phenyl]-1H-1,2,4-triazole single crystal prepared by the invention can be used in the aspect of photoelectric materials, especially dye and luminescent agents.

Owner:TIANJIN NORMAL UNIVERSITY

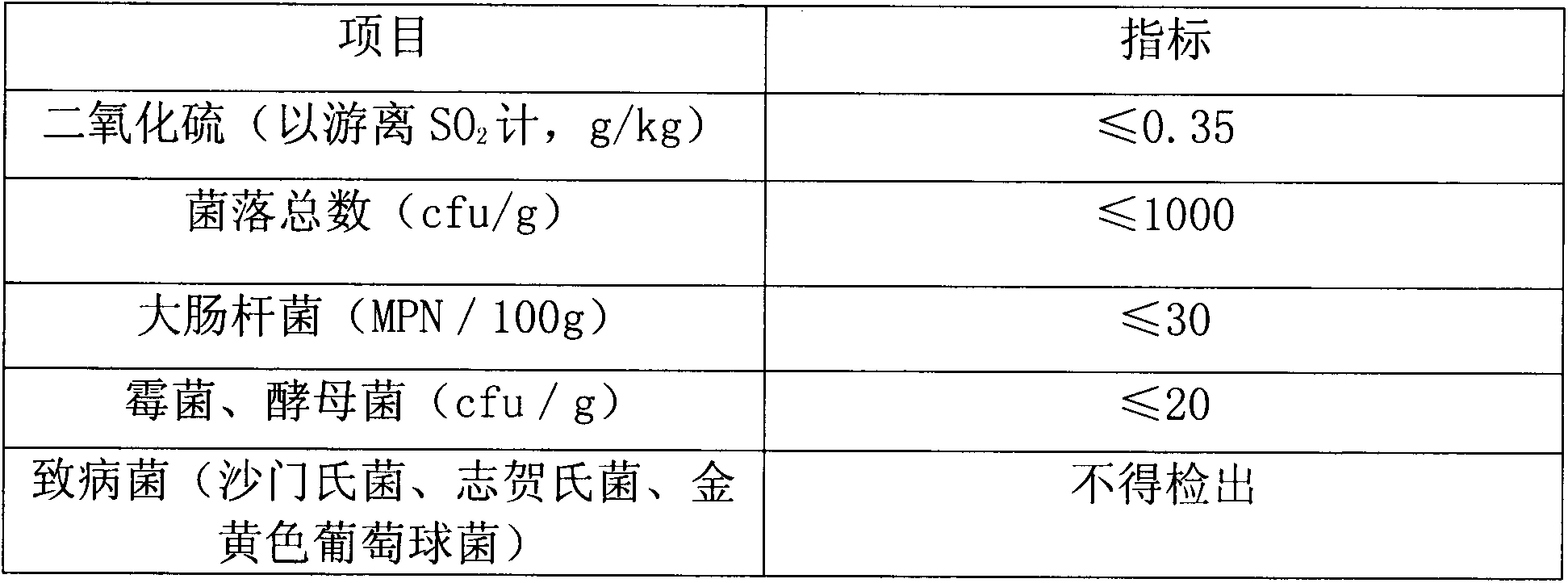

Preserved passion fruits and processing method thereof

The invention discloses preserved passion fruits and a processing method thereof. The method comprises the concrete steps of firstly, cleaning and cutting fresh passion fruits as raw materials, and separating peels from pulp by removing the pulp; secondly, boiling the peels, removing cuticula, enzymatically hydrolyzing, protecting the color and sugaring; thirdly, mixing the pulp with white granulated sugar and citric acid or citric acid to prepare mixed pulp, and burying the mixed pulp into the peels; finally performing processes of drying, cooling and the like to prepare finished products of preserved passion fruits. According to the method, the selectivity on fruit raw materials is good; the processed preserved passion fruits keep the original aroma and taste of passion fruits, are bright as ever and soft in mouth feel, and have remarkable market competition advantages; a new way is opened up for deep processing of the passion fruits, a very good method is provided for improving the value of the passion fruits, and relatively large profit space is created for enterprises.

Owner:广西田阳嘉佳食品有限公司

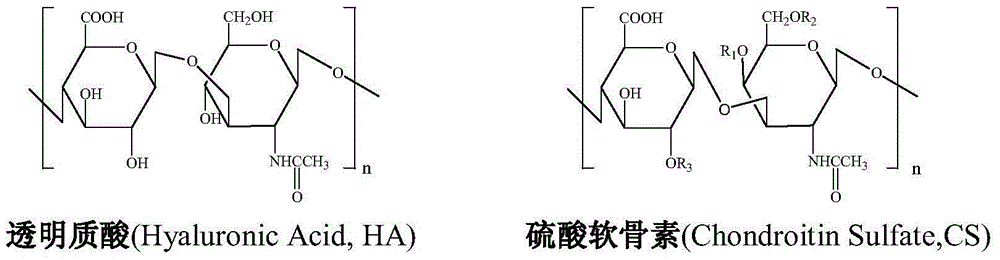

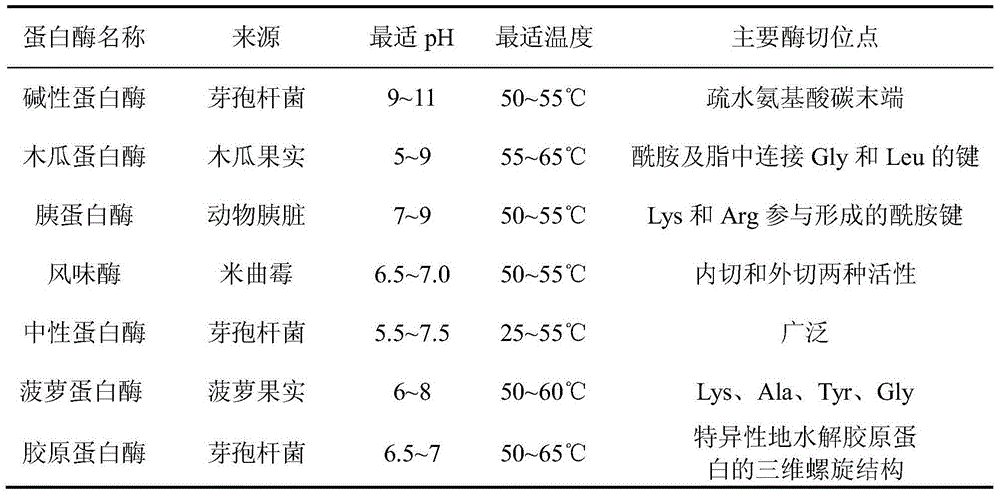

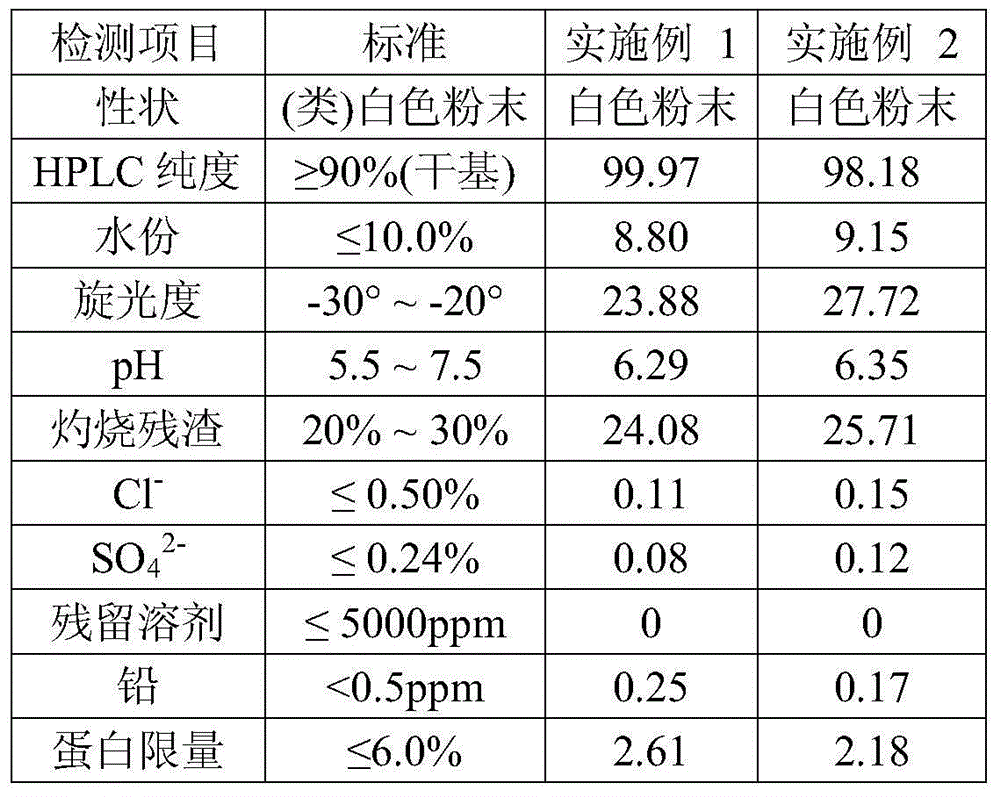

Combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap

ActiveCN104531817ARealize simultaneous hydrolysisEmission reductionConnective tissue peptidesCutting soapResource utilizationHydrolysate

The invention discloses a combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap. The method mainly comprises the process steps that animal cartilage is soaked with water and smashed to obtain cartilage powder, the cartilage powder undergoes protease enzymolysis and then is adsorbed by resin, adsorbed enzymatic hydrolysate is collected, the resin undergoes gradient elution through a NaCl aqueous solution, and eluants undergo desalination, concentration, sterilization and drying to obtain finished products of the hyaluronic acid and chondroitin sulfate; the adsorbed enzymatic hydrolysate undergoes decoloration, anion and cation exchange resin mixed column treatment, nanofiltration purification, concentration, sterilization and drying to manufacture finished products of the collagen peptide; grease undergoes extraction saponification to manufacture the soap; denatured protein-bone dreg compounds and other materials are mixed to manufacture the fodder. According to the combined production method, by utilizing the process of resin adsorption-spray drying, highly-intensified resource utilization of cartilage is achieved, energy saving and emission reduction are achieved, and the economic benefit and the social benefit are remarkable.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

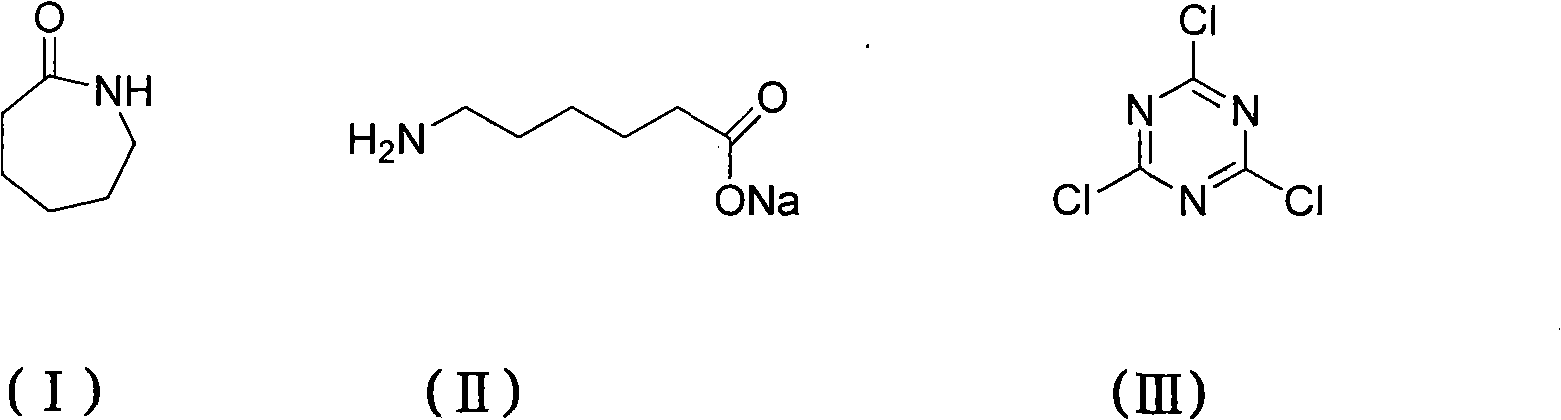

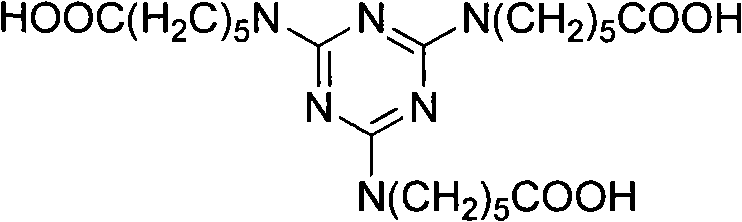

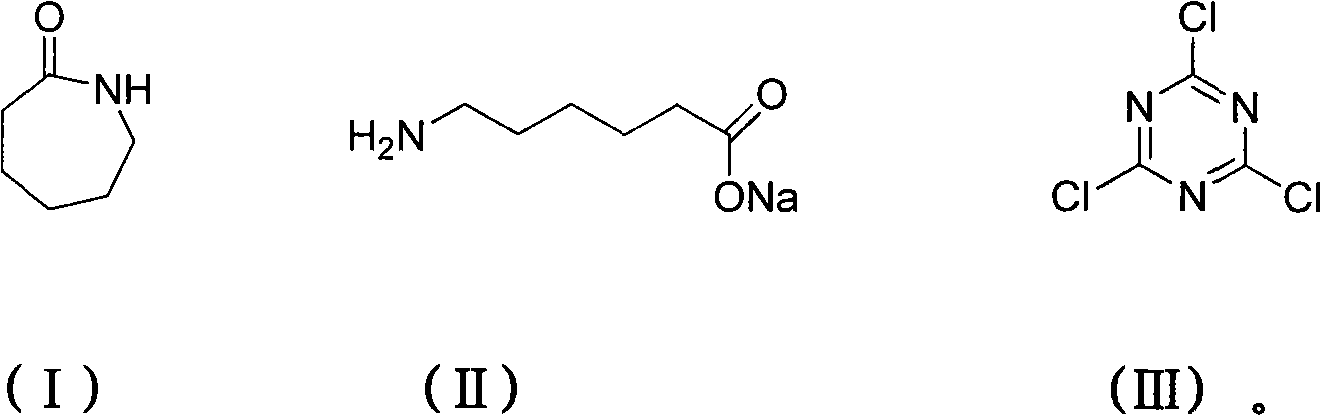

Method for preparing 2,4,6-tri(amino caproyl)-1,3,5-triazine

InactiveCN101973949AThe reaction is easy to operateMild reaction conditionsOrganic chemistryCarboxylic acidSolvent

The invention discloses a method for preparing an organic ternary polycarboxylic acid dustless antirust additive 2,4,6-tri(amino caproyl)-1,3,5-triazine by adopting a one-pot method, which comprises the following steps of: ring-opening caprolactam with alkali to generate carboxylate of aminocaproic acid first; then performing a substitution reaction by the carboxylate of aminocaproic acid and cyanuric chloride; and finally, acidizing with hydrochloric acid to prepare derivatives of organic ternary polycarboxylic acid. The preparation method is free from a toxic organic solvent and employs common water as a solvent for reaction. The preparation method ha the advantages of simple process operation, low production cost and low environmental pollution and is more suitable for large scale industrial production.

Owner:TIANJIN NORMAL UNIVERSITY

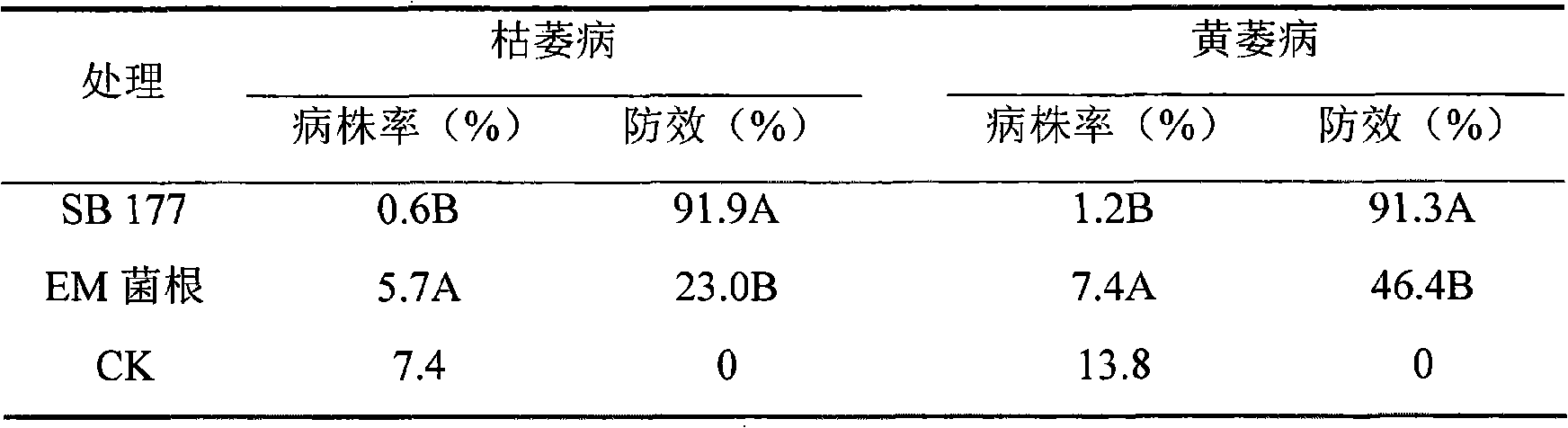

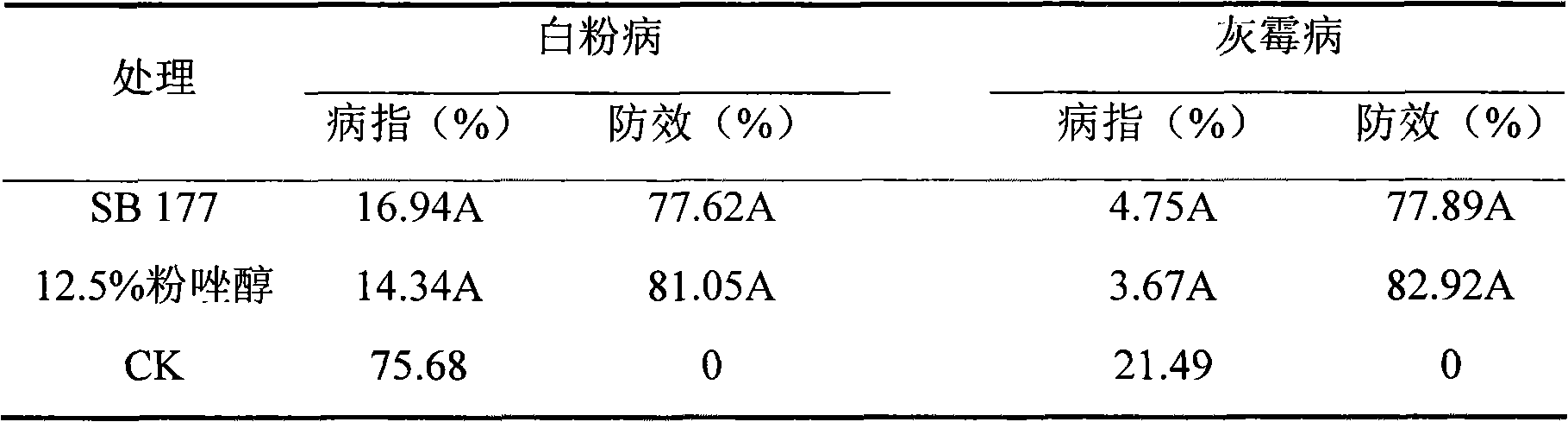

Strain SB177 for controlling strawberry replant diseases and preparation thereof

InactiveCN101555459AGood prevention effectReduce the amount of applicationBiocideBacteriaFragariaPlant disease

The invention discloses a strain SB177 for controlling strawberry replant diseases and a preparation thereof, belonging to the technical field of preventing and curing diseases of fruit trees. The strain SB177 and the preparation thereof are specially used for biological control of the fruit trees. The microbial inoculum also can be used for controlling strawberry overground part diseases such as powdery mildew of strawberry, gray mold, etc. The preparation prepared from the strain has the performances of long shelf life, high control effect, wide control spectrum as well as promoting and increasing production. The invention is realized by the following technical proposal: the strain SB177 for controlling strawberry replant disease is bacillus amyloliquefaciens which is the Latin literature name and is preserved in China Center for Type Culture Collection (CCTCC) in March 19th, 2009 with the preservation number of CCTCC NO: M209037.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

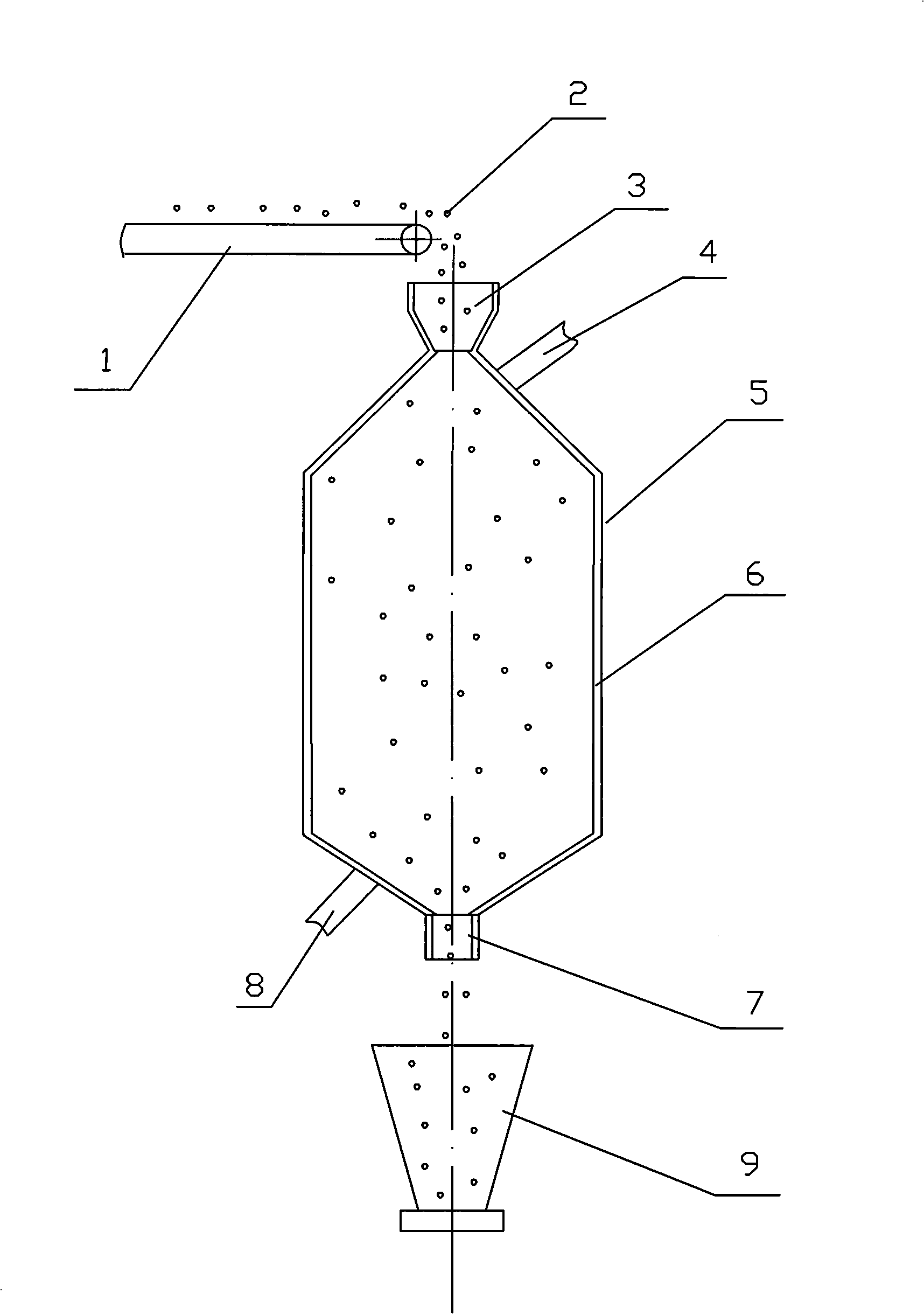

Preheating method and apparatus for glass batch

InactiveCN101328005AWill not polluteReduce manufacturing costGlass productionThermal insulationFlue gas

The invention relates to a pre-heating method and a device especially for glass batch oxy fuel combustion comprising a vessel with an interlayer composed of an inner shell(6) and an outer shell(5), wherein the batch(2) is transported into the inner shell(6) through a belt conveyer(1), while the flue gas from the melting furnace enters into the interlayer of the pre-heating device through an inferior flue gas inlet(8) and is discharged from a flue gas outlet(4) by the draught of the chimney hot air flow. The high temperature flue gas heats the batch to 300-600 DEG C in the interlayer through radiation conduction heat exchange, the pre-heated batch enters into a high temperature heat-resistant sealing pushing batch feeder through a thermal insulation bucket(9) and finally enters into the melting furnace. The advantages of the invention are as follows: pre-heating the batch by flue gas can reach the saving energy purpose and reduce the production cost of the glass production enterprises. The batch can not be polluted by the flue gas because of the radiation conduction heat exchange between the batch and the flue gas.

Owner:CHINA TRIUMPH INT ENG +1

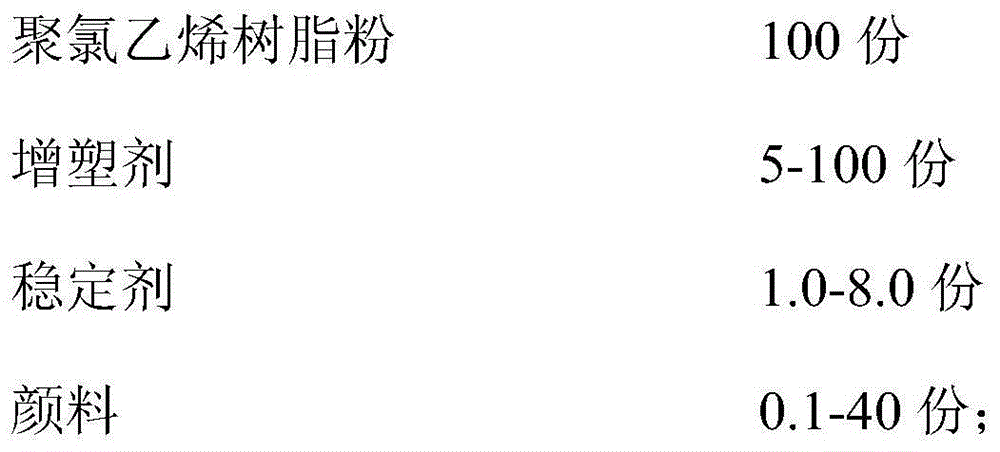

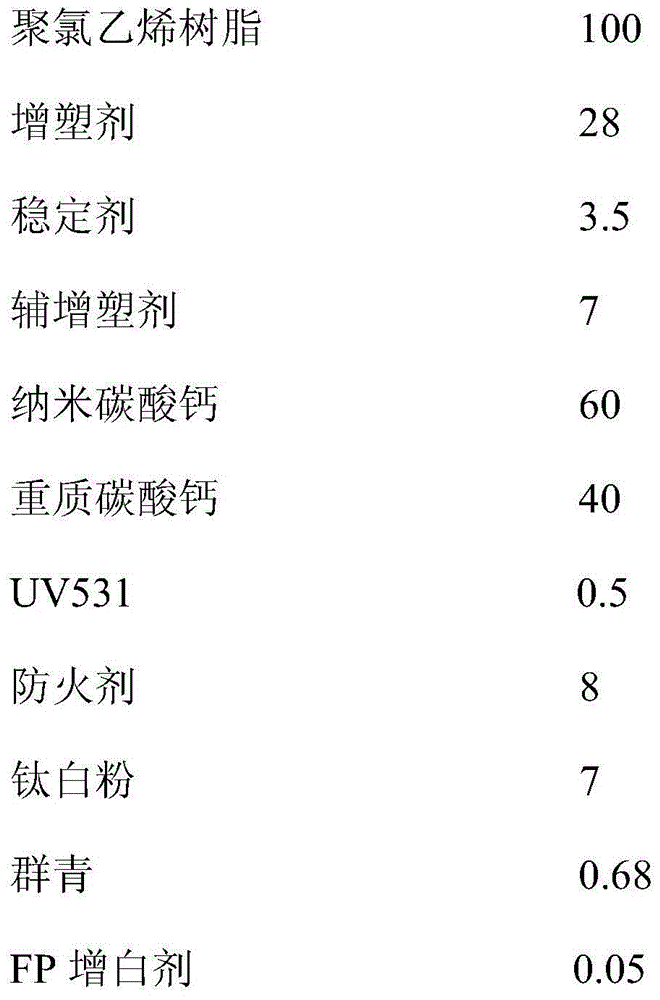

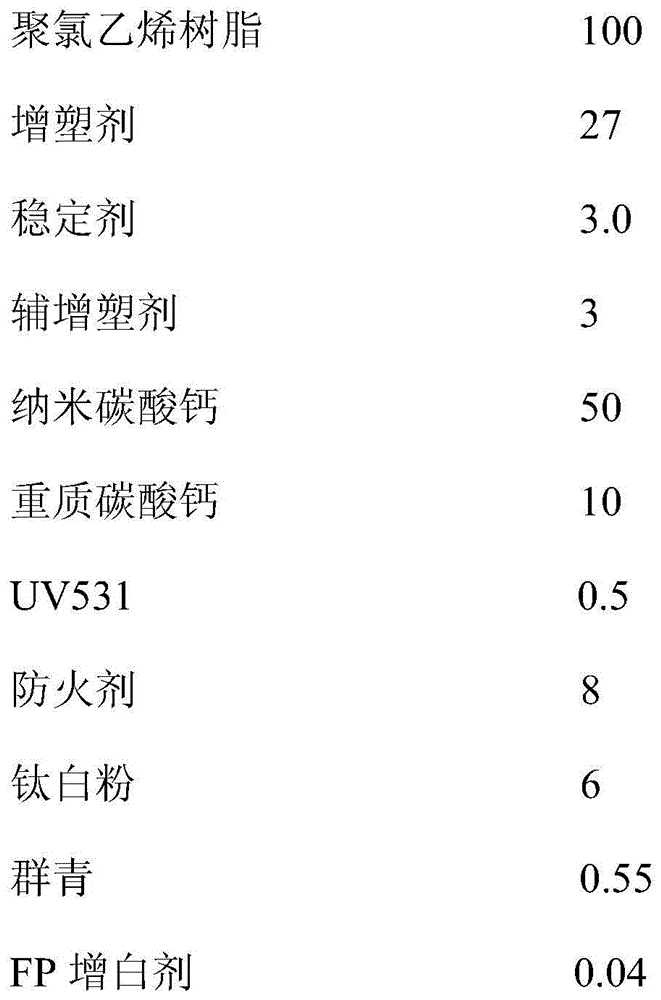

PVC laminated composite cloth comprising films formed through extrusion method and preparation method thereof

InactiveCN104149448ALow costImprove performanceLamination ancillary operationsSynthetic resin layered productsAging resistanceEngineering

The invention relates to a laminated composite material synthesized of warp-knitted and textile materials and PVC and discloses PVC laminated composite cloth comprising films formed through extrusion method. The PVC laminated composite cloth comprises base cloth, a bottom film and a surface film, wherein the bottom film and the surface film are arranged at the two sides of the base cloth and are both PVC thin films The PVC laminated composite cloth has the advantages that the cost is low, the applicability is strong, the performances are good, specifically, the peeling strength, the elasticity, the tensile strength and the tearing strength are obviously improved and the waterproof performance, the flame-retardant performance and the ageing resistance are excellent. The invention also discloses a preparation method of the PVC laminated composite cloth comprising films formed through extrusion method. The preparation method comprises the following steps of: firstly compositing the specific bottom film prepared by extrusion and the base cloth, then compositing with the specific surface films prepared by extrusion. The preparation method disclosed by the invention has the advantages that since no boiler is used and carbon dioxide is not exhausted, air pollution is hardly caused; only cooling circulation water is used, so water pollution cannot be caused; and the process is simple, the energy consumption is low, the popularity rate is high, the cost is low, the profit margin is large and the application prospect is wide.

Owner:胡新佳

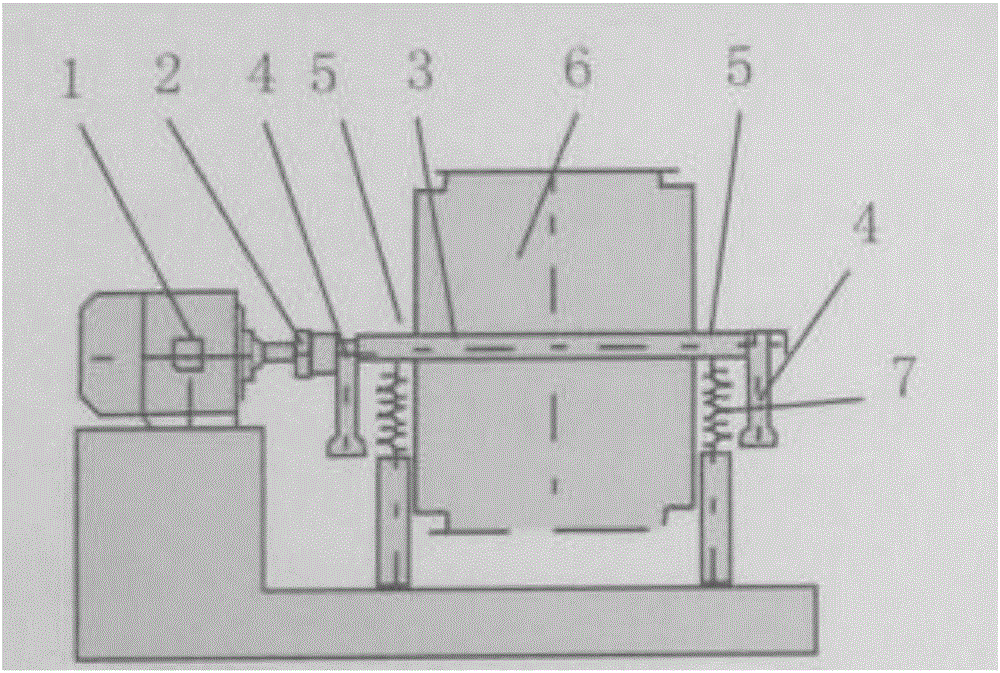

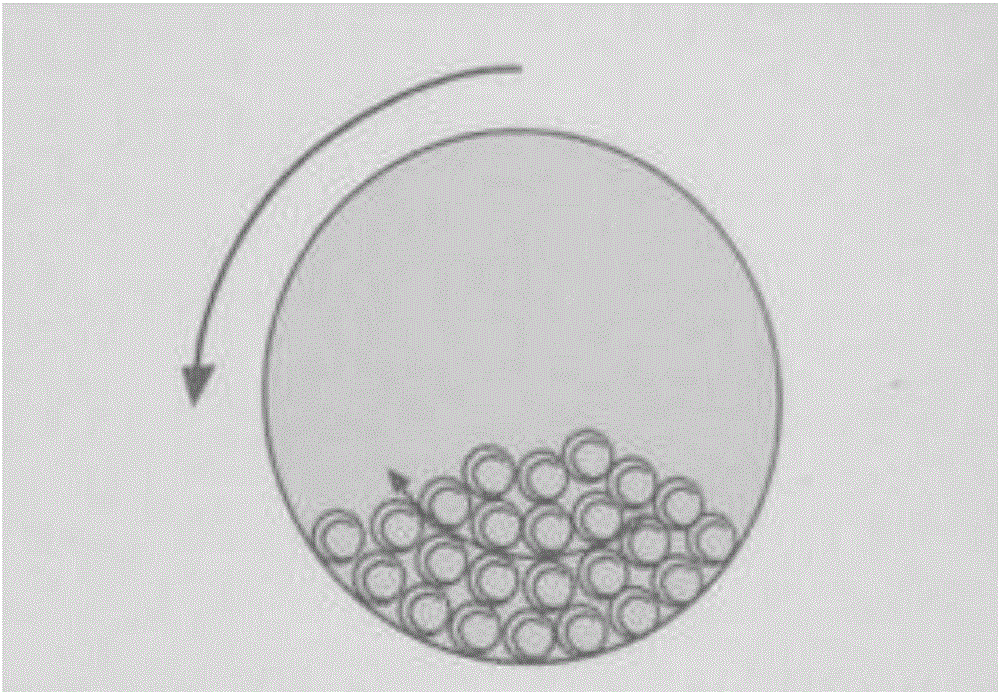

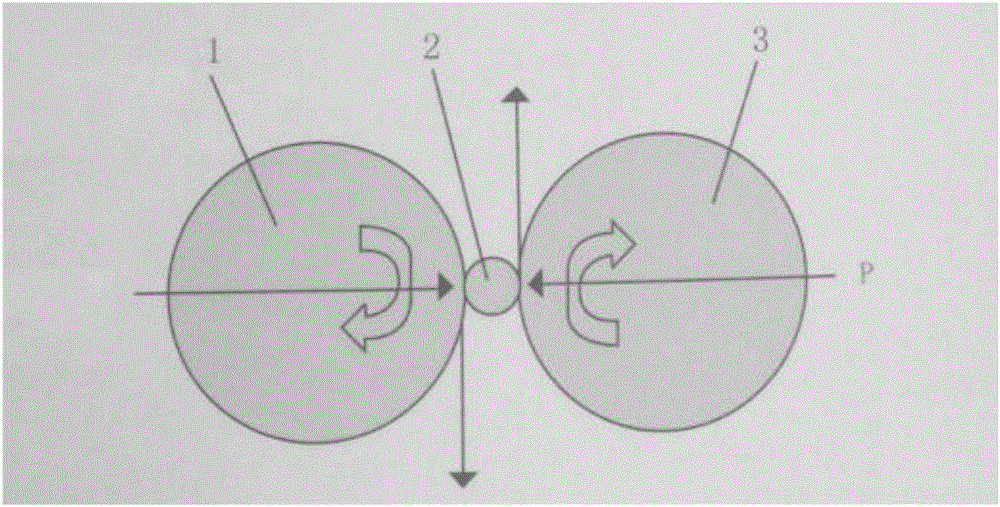

Wall-breaking and superfine grinding process and device for better ground traditional Chinese medicine decoction piece

ActiveCN105344428AImprove qualityStable and controllable qualityGrain treatmentsLiquid-crystal displayMedicine

The invention belongs to the field of medicinal material grinding and smashing equipment and method, and particularly relates to a wall-breaking and superfine vibration grinder for a better ground traditional Chinese medicine decoction piece, a traditional Chinese medicine decoction piece preparation method adopting the grinder, and the better ground traditional Chinese medicine decoction piece. The grinder comprises a motor (1), a coupler (2), a rotating spindle (3), a bearing pedestal (4), a drum holder (5), a drum (6), a supporting spring (7), a base, an excitation vibration absorber, a controller, a timer, a liquid crystal display operating panel, a central processing unit and a silencing case. By means of the specific rotating speed and the specific motion trace of the motor of the grinder, the grinder achieves the advantages of energy conservation, high efficiency and smaller sizes of smashed grains.

Owner:SHAANXI NIANQINGBAO PHARMA CO LTD

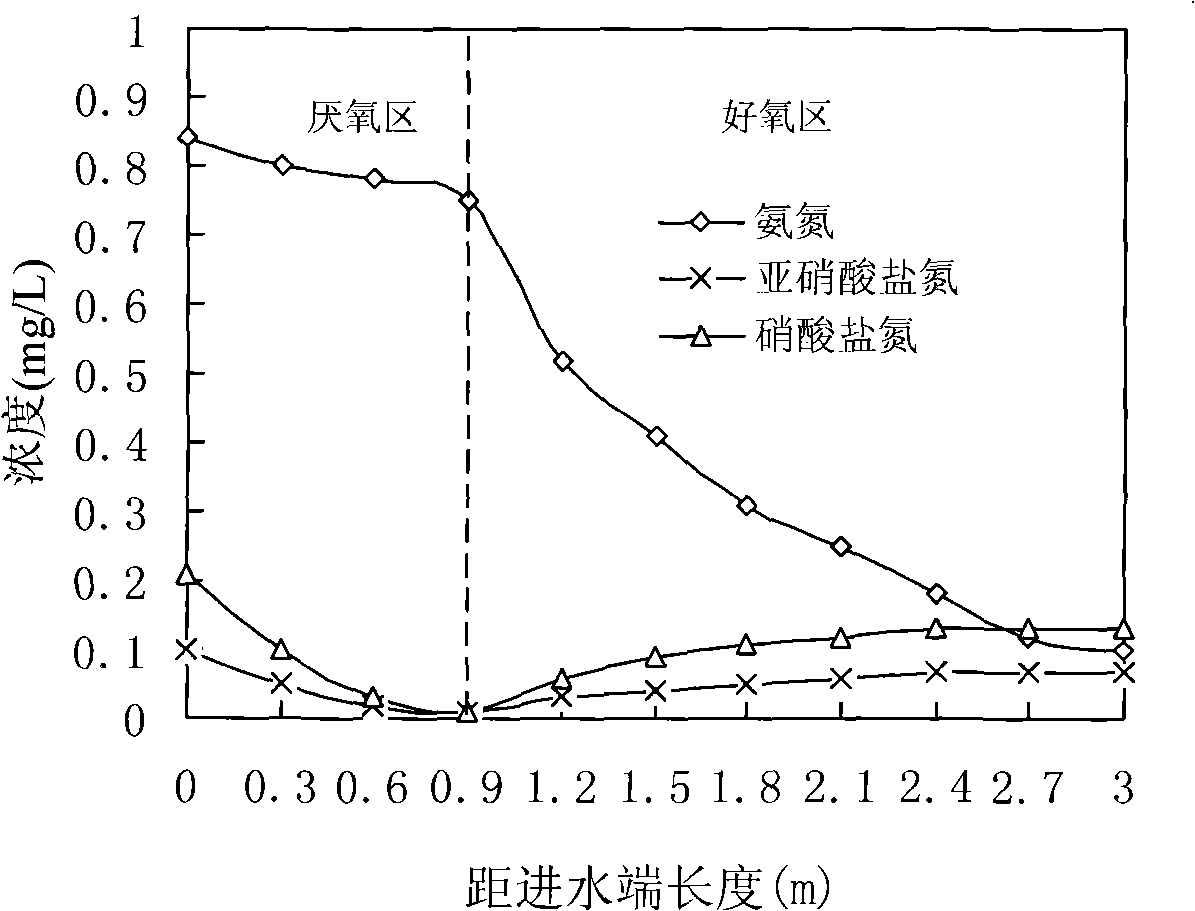

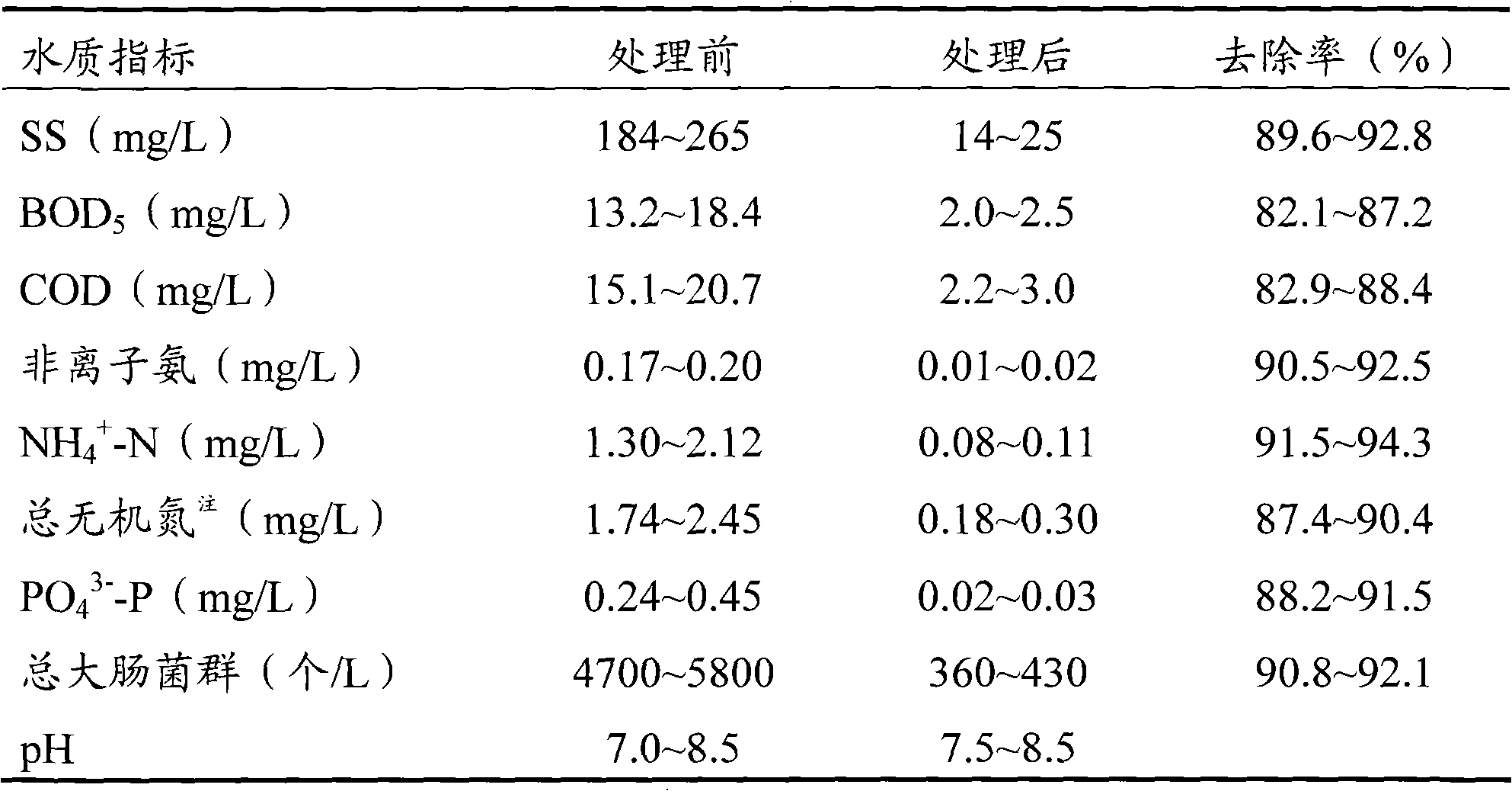

Method for processing waste water of circulating marine culture by using artificial wet land

InactiveCN101407360AOpen up new ways to deal withGood removal effectTreatment with aerobic and anaerobic processesSustainable biological treatmentConstructed wetlandWater quality

The invention provides a method for using artificial wetlands for processing the waste water in circular seaculture, which comprises the following steps: the waste water is first filtered by a microstrainer and then led to an artificial wetland for treatment; the artificial wetland is in the form of a horizontal undercurrent packed bed and is divided into a front anaerobic zone and a back aerobic zone, the surface area ratio of which is 1-2:4-3, no plants are in the filler of the anaerobic zone while salt tolerant plants are planted in the filler of the aerobic zone; the effluent from the microstrainer sequentially flows through the anaerobic zone and the aerobic zone to be discharged, and the water flowing to the anaerobic zone contains the water flowing out of the aerobic zone. The artificial wetland provided by the invention is capable of seawater processing, denitrification, denitrogenation and dephosphorization, and can effectively process the suspended matters, organic matters, nitrogen, phosphorus and the like in the sewage flowing through the artificial wetland in multiple ways and cause the effluent quality to reach the water quality standard requirements of fishery industry of China, thus realizing the aim of recycling the effluent. Compared with the prior art, the invention has the advantages of good treatment effect, low cost and environment protection but no pollution.

Owner:ZHEJIANG OCEAN UNIV

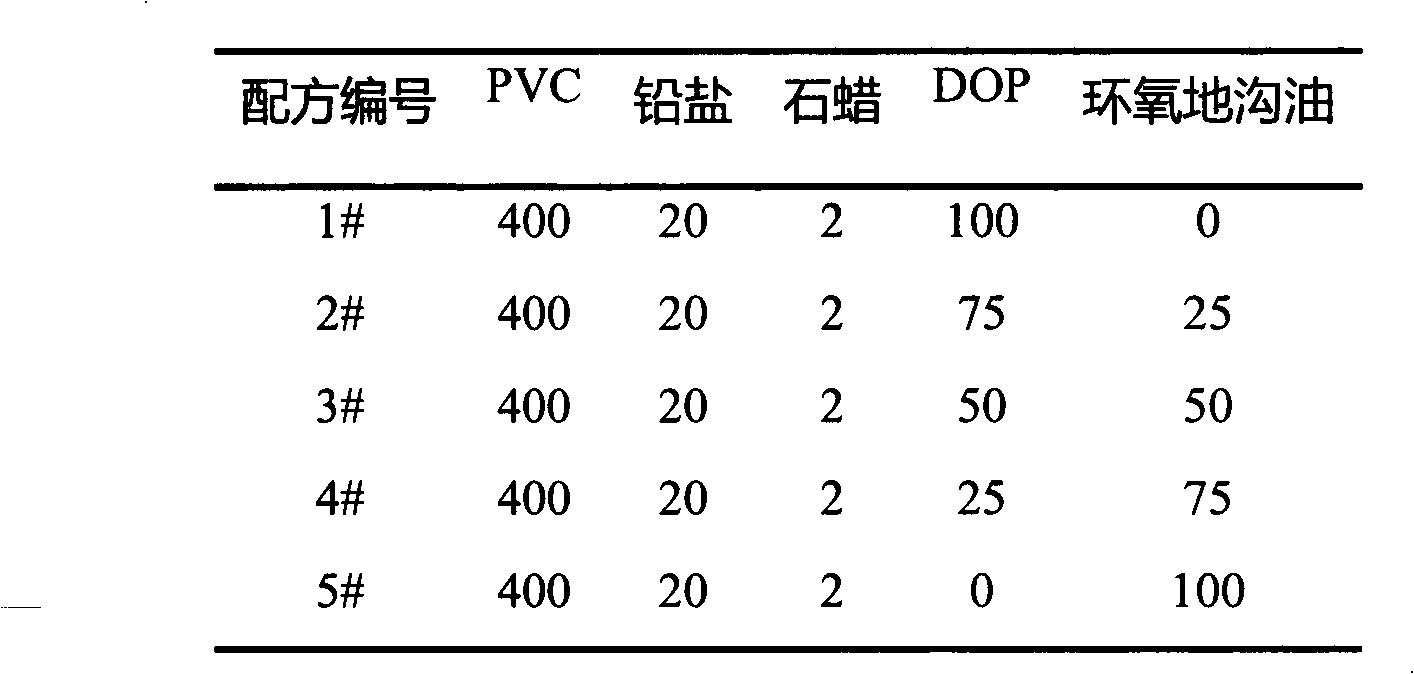

Formula of epoxy gutter oil plasticized PVC (Poly Vinyl Chloride)

InactiveCN103013675ASimple processLow costFatty oils/acids recovery from wasteFatty acid chemical modificationEpoxyGutter oil

The invention relates to a formula of epoxy gutter oil plasticized PVC (Poly Vinyl Chloride). In a test, sulfuric acid is taken as a catalyst, hydrogen peroxide is taken as an oxygen supply agent, formic acid is taken as an oxygen receiving agent, and the epoxidation reaction conditions of gutter oil are researched in one step by adopting performic acid. The method is suitable for industrial popularization and application. Therefore, the optimal processing formula of the epoxy gutter oil plasticized PVC is designed by taking the epoxy gutter oil as a plasticizer in the PVC production process instead of the conventional dioctyl phthalate.

Owner:SHIHEZI UNIVERSITY

Method for producing flour yeast by using corn flour as raw material

InactiveCN101570735AIncrease added valueImprove fermentation effectFungiPre-baking dough treatmentLiquid glucoseAdditive ingredient

The invention relates to a method for producing flour yeast by using corn flour as a raw material. The method adopts the corn flour to prepare liquid glucose by a double enzymolysis method to culture the yeast, carries out feeding culture of the yeast through controlling pH value, fermentation temperature, inoculation quantity, fermentation time, oxygen dissolving amount and other parameters, and prepares a yeast product applicable to flour fermentation through adding yeast protecting agent, granulating, drying and other processes. The culture medium is rich in carbon source, nitrogen source, inorganic salt, trace elements, vitamin and other growth factors; the method can ensure completeness of nutrient components of the flour yeast; the finally obtained yeast has higher fermentation capability, and can be used for fermentation of flour; the filtered side product corn pulp can be used as feed; new technology of wastewater circulating utilization is adopted, so that the process production realizes non discharge of wastewater or dreg, does not pollute environment. The method is applicable to large-scale industrial production.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for preparing feedstuff yeast from maize peel hydrolysis solution

InactiveCN101054559AReduce generationHigh yieldFungiAnimal feeding stuffEvaporationSimulated moving bed

The present invention relates to method for preparing feedstuff yeast using corn husk hydrolyzed liquor as material. Acid is separated and recovered from the hydrolyzed liquor adopting simulated moving bed chromatogram separation system. The normal neutralization is substituted. The method is : mixing corn-soaking water, corn husk hydrolyzed liquor for preparing culture medium, carrying out three-stage culture at bevel medium, and ferment culture, concentration and evaporation, spray drying for preparing feedstuff yeast. The inventive medium is enriched with nitrogen source, carbon, inorganic salt, microelement and vitamin, growth factor etc. The inventive method can ensure the feedstuff yeast nutrient integrity, and substitute for the fish powder in fowl and stock breeding and effectively reduce the cost. The present invention promote the additive value of product, reduce the environmental pollution.

Owner:SHANDONG LUZHOU FOOD GROUP

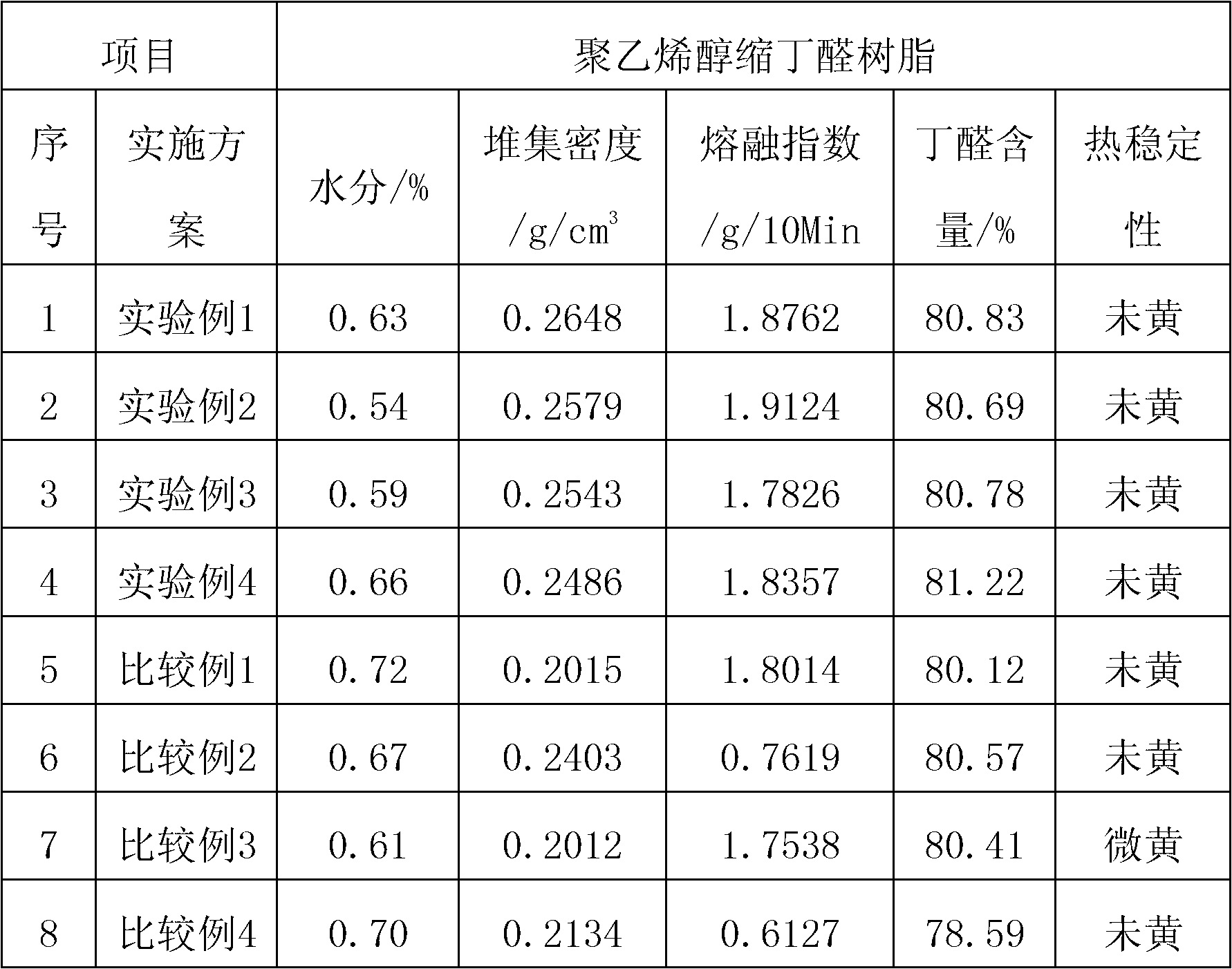

High-hydroformylation-degree polyvinyl butyral resin and preparation method thereof

ActiveCN102649825AIncrease the degree of hydroformylationBig profit marginCoatingsAdhesivesAdhesivePVA - Polyvinyl alcohol

The invention discloses high-hydroformylation-degree polyvinyl butyral resin and a preparation method thereof. The polyvinyl butyral resin with the hydroformylation degree of more than 78 percent is prepared by using polyvinyl alcohol and n-butanal as raw materials and hydrochloric acid as a catalyst through low-temperature continuous condensation and recondensation, wherein the reaction temperature during the low-temperature continuous condensation is 0 to 35 DEG C; and the reaction temperature during the recondensation is 5 to 75 DEG C. According to the invention, the hydroformylation degree of the polyvinyl butyral resin is increased and the application field of the polyvinyl butyral resin is expanded. According to the polyvinyl butyral resin prepared by the existing production technology in China, the hydroformylation degree is far less than the level, and the using fields are narrow and mainly comprise the fields of coating and adhesive. The product prepared by the method of the invention is mainly applied to the industries, such as automobile industry, building industry and photovoltaic industry, with high requirements on the polyvinyl butyral resin, and has large profit space.

Owner:安徽皖维膜材料有限责任公司

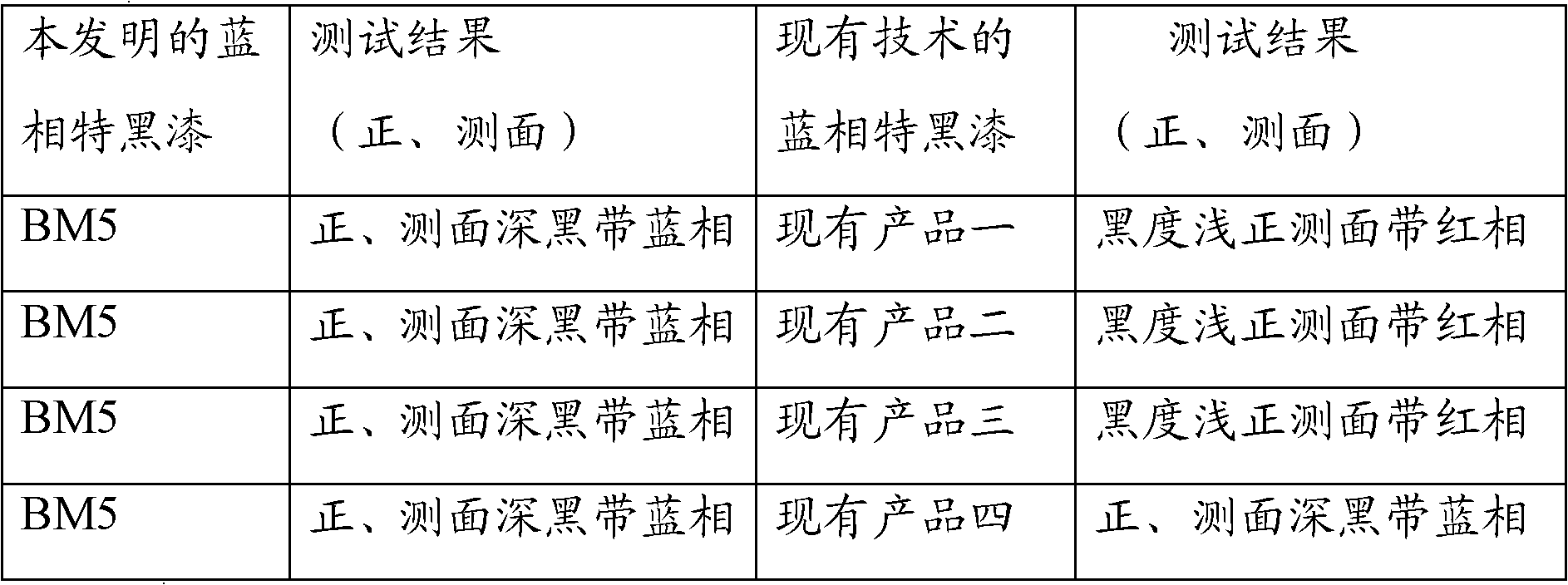

Lanxiang ultra black automobile refinishing coating and preparation method thereof

InactiveCN102146245ADarkness deepMeet the requirements of the high-end product marketCoatingsTO-18Acrylic resin

The invention discloses Lanxiang ultra black automobile refinishing coating, which is prepared from the following raw materials in part by weight: 74.29 to 78.29 parts of acrylic resin, 2.40 to 2.60 parts of high-pigment carbon black powder, 1.90 to 2.10 parts of super dispersant, 0.95 to 1.05 percent of synergist, 0.07 to 0.09 part of high-pigment dye, 0.45 to 0.55 part of nano titanium dioxide and 16.63 to 18.63 parts of mixed solvent. Through formula design, the blackness of the Lanxiang ultra black automobile refinishing coating disclosed by the invention is deep enough, the performance and hue effect of the Lanxiang ultra black automobile refinishing coating completely meet the requirements of high-quality product markets. Through formula design, the Lanxiang ultra black automobile refinishing coating disclosed by the invention is manufactured by using a material with a high performance to price ratio as a raw material, so Lanxiang ultra black automobile refinishing coating has an absolute advantage in manufacturing cost compared with imported products; therefore, the Lanxiang ultra black automobile refinishing coating can bring a greater benefit space for users and improves market competitive power of the users. The invention also discloses a preparation method of the Lanxiang ultra black automobile refinishing coating.

Owner:广东同步化工股份有限公司

Machine vision based cloth inspection device and method

ActiveCN108921819ATake advantage of generalizationThe result is obviousImage enhancementImage analysisGrey levelHistogram equalization

The invention discloses a machine vision based cloth inspection method. The machine vision based cloth inspection method includes: adopting an industrial camera to focus on and shoot a finished fabricto be inspected after heat-setting, and acquiring a real-time image; and then using the first and second methods to calculate the longitudinal density and the transverse density of the fabric; and obtaining the actual density of the fabric according to the longitudinal density and the transverse density obtained by the first and second methods. The invention also discloses a machine vision basedcloth inspection device. An output end of an image acquisition unit is connected with an input end of an image processing unit; an output end of the image processing unit is connected with an input end of a density detection unit; the image acquisition unit acquires a reflective image of a fabric surface; the image processing unit is used for performing image Fourier transformation, grey level transformation, histogram equalization and image binarization; and the density detection unit uses the edge detection algorithm, Hough transform, and the kernel density estimation algorithm to analyze the inclination of the fabric, the number of ridge lines, and the number of circular columns according to the processed image, and calculates out the density of the fabric.

Owner:LIMING VOCATIONAL UNIV

Preparation method for high-strength wear-resistant alloy Cu-15Ni-8Sn

The invention discloses a preparation method for a high-strength wear-resistant alloy Cu-15Ni-8Sn. The process comprises the following steps: adding electrolytic copper and nickel; pouring the electrolytic copper and nickel in an intermediate-frequency coreless induction furnace; adding charcoal; charging nitrogen gas with one barometric pressure; melting; melting for 30-65 minutes at 1300-1350 DEG C; adding tin and melting at 1250-1300 DEG C; adding a refiner and a deoxidizer; stirring; adding a grain refiner; adding a modifier; slagging off; carrying out inspection before melting; carrying out electromagnetic casting after ingredients are qualified; cutting a head and a tail; scalping; carrying out ingredient inspection after melting; carrying out organization structure analysis; and carrying out performance detection. A Cu-15Ni-8SnC72900 alloy melt and cast by virtue of the intermediate-frequency coreless induction furnace, which is obtained by the preparation method disclosed by the invention, is low in production cost; and the developed products are high in quality. The developed products can be applied to national defense and military industry, ocean engineering and high-end preparation manufacturing industry; and the increasingly urgent needs of the national defense and military industry, ocean engineering and high-end preparation manufacturing industry on high-performance copper alloy materials are met.

Owner:JINCHUAN GROUP LIMITED

Method for preparing potash fertilizer and building material products from white alkali-making mud

ActiveCN101880179ASolve processingSolve technical problems of utilizationPotassium fertilisersPotashMaterials science

The invention provides a method for preparing a potash fertilizer and building material products from white alkali-making mud. The method comprises the following steps of: blending 20 to 70 mass percent of the white alkali-making mud, 20 to 70 mass percent of potassium ore and 0.3 to 15 mass percent of additive; performing ball-milling on the mixture to prepare block bodies and drying the block bodies; allowing the block bodies to enter a high-temperature furnace to calcine at the temperature of between 950 and 1,100 DEG C; dissolving the obtained calcined substances in water after the complete reaction; concentrating and crystallizing soluble substances to prepare the potash fertilizer; after filtering, adding activated clay into insoluble substances and mixing uniformly; and compressing, molding and performing steam curing to produce the building material products. The method solves the problems of bulk deposition of the white alkali-making mud and environmental pollution, so the method has the advantages of simple process, less investment of equipment, low cost and wide application prospect, wherein the equipment is the conventional and standard equipment.

Owner:中盈华富(贵州)科技产业集团有限公司

Method for making polar fleece fabrics with polypropylene as raw materials and products thereof

The invention disclosed a in a method for preparation and its products of Polar Fleece textile commodity using polypropylene as raw material. It includes testing grey fabric, degreasing, acid dipping, adding fuzzy agent in tanks, dehydration, drying, cutting amplitude vertically, carding, shearing, grain and shaping the products. The said processing of degreasing is: adding degreasing adjuvant into dyeing still at 25 DEG C, operating for 5-15 minutes, warming-up to 115-125 DEG C in the rate of 1.0-1.5 DEG C per minute, heat preservation for 15-25 minutes, then cooling-down to 75-85 DEG C in the rate of 1.0-1.5 DEG C per minute, shearing sample, acid dipping for 5 minutes and warm water scrubbing for 10 minutes. The Polar Fleece products prepared according the invention can make up for the defects of prior regular Polar Fleece and have some advantages of soft, high resilient, portable, warming and so on.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Waterfroof agent for cement mortar and its preparation method

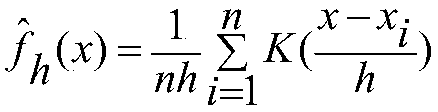

The invention relates to a waterfroof agent used in cement mortar and a preparation method thereof. The waterfroof agent comprises the following raw materials of: by weight, 5.0-15.0 parts of paraffin, 3.0-5.0 parts of silicone oil, 0.5-3.0 parts of aliphatic acid, 1.0-3.0 parts of triethanolamine, 0.4-2.5 parts of sodium hydroxide and 60.0-100.0 parts of deionized water. The preparation method comprises the following steps of: firstly respectively weighing the above raw materials, mixing, melting, heating, saponifying, cooling, homogenizing, examining, and packaging to obtain a milky thick liquid waterfroof agent. The waterproof agent is aqueous and environmentally friendly, is nontoxic and tasteless, causes no pollution, is convenient to use, and has good compatibility with cement mortar. With the addition of the waterproof agent, cured and dried cement mortar has a strong waterproof function and can effectively avoid entry of rainwater, thus guaranteeing construction quality and service life.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD +1

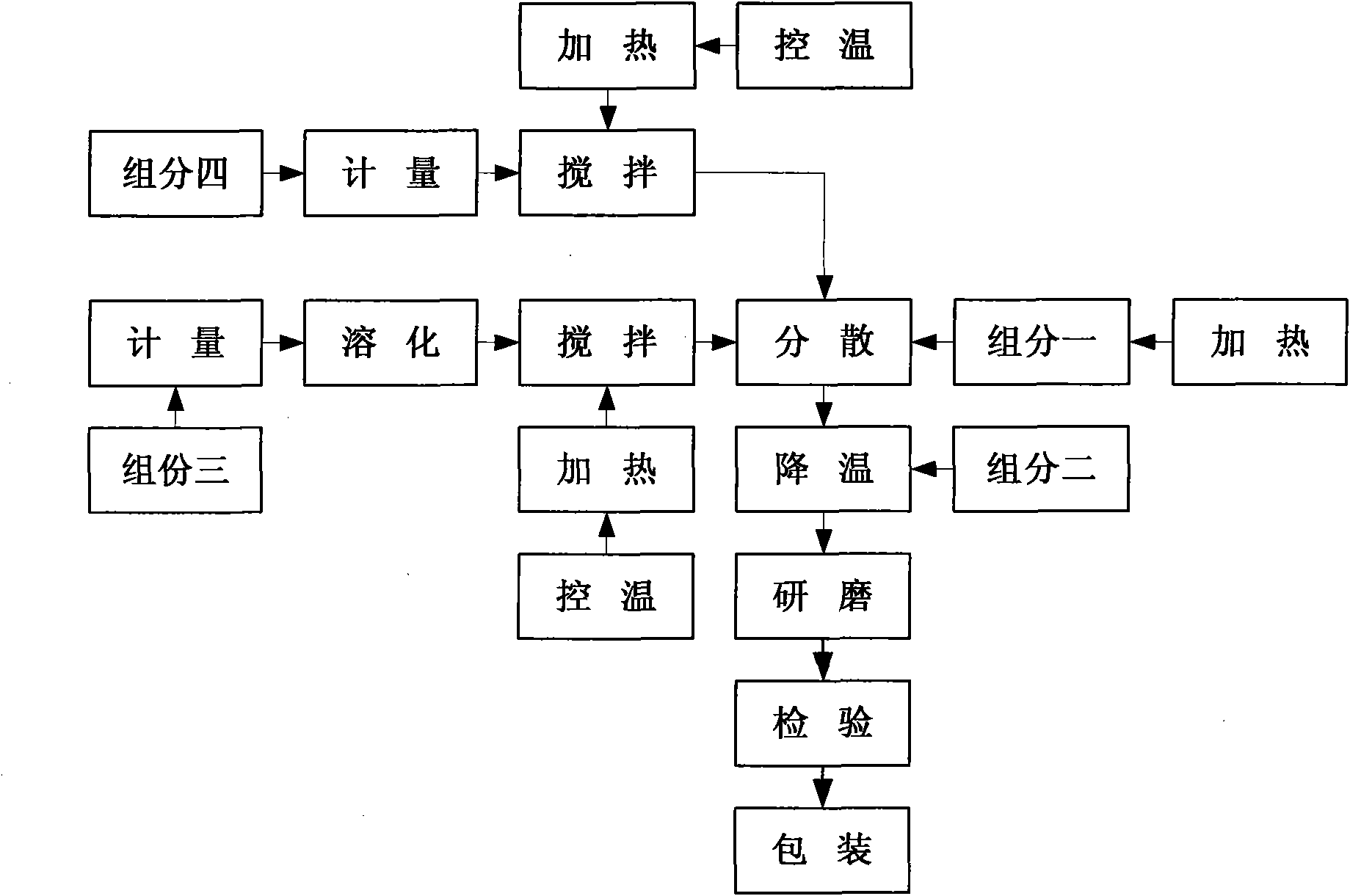

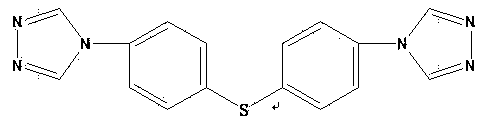

Thioether bitriazole compound as well as preparation method and application of thioether bitriazole compound

InactiveCN104370837AReduce manufacturing costBig profit marginOrganic chemistryAzo dyesThioetherPhenyl group

The invention discloses a thioether bitriazole compound as well as a preparation method and application of the thioether bitriazole compound, and particularly discloses a bi(4-(4H-1, 2, 4-triazole-4-yl)phenyl)thioether compound and a preparation method of the bi(4-(4H-1, 2, 4-triazole-4-yl)phenyl)thioether compound. The organic compound is prepared by using a one-pot method, namely heating 4, 4'-biamino diphenyl sulfide and diformylhydrazine. The preparation method disclosed by the invention has the characteristics of simple technological operation, low production cost and little environmental pollution and is suitable for large-scale industrial production. The bi(4-(4H-1, 2, 4-triazole-4-yl)phenyl)thioether compound prepared by using the preparation method can be applied to the aspects of photoelectric materials and luminescent agents.

Owner:TIANJIN NORMAL UNIVERSITY

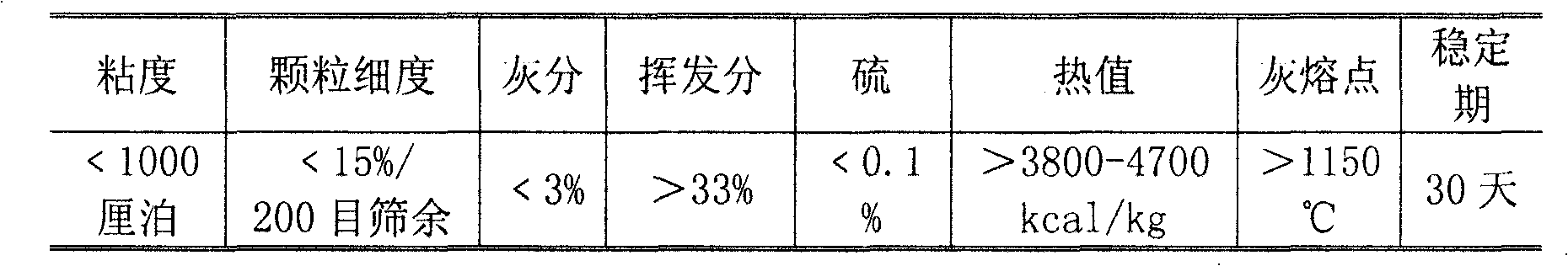

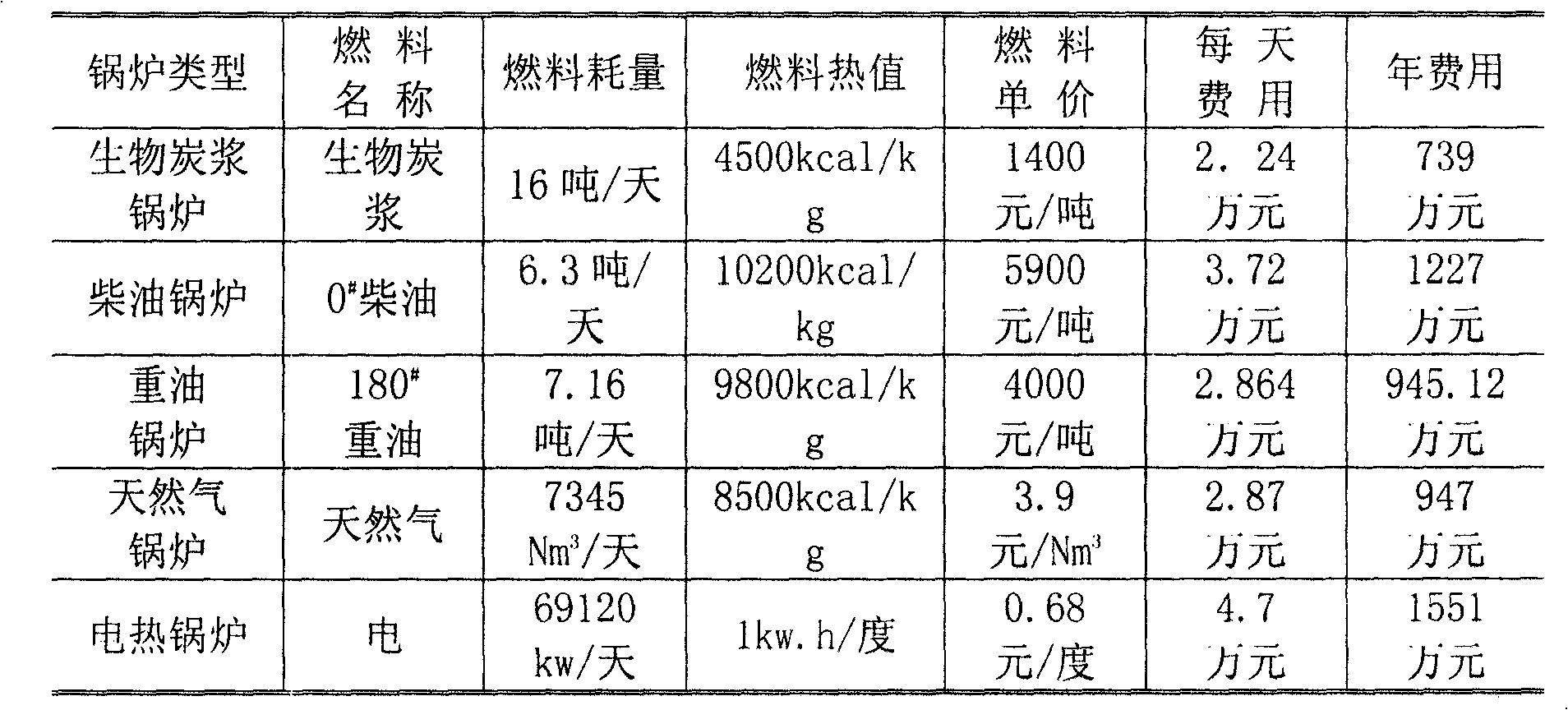

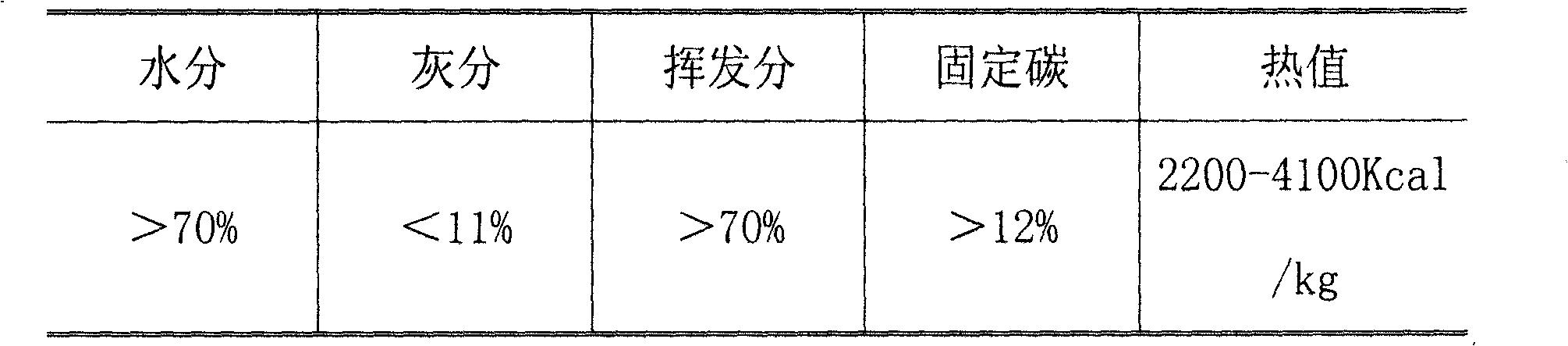

Biochar pulp prepared from garbage leachate serving as raw material and preparation process thereof

ActiveCN101787312AEmission reductionLow in sulfur and nitrogenLiquid carbonaceous fuelsPower stationEnvironmental engineering

The invention discloses a biochar pulp prepared from garbage leachate serving as a raw material and a preparation process thereof, and aims to provide the biochar pulp prepared from the garbage leachate serving as the raw material and the preparation process thereof, which have the advantages of the combination of energy saving and emission reduction and environmental management and low cost. Thepreparation process comprises the following steps of: mixing biochar, the garbage leachate, methanol, high-temperature sand and additives serving as raw materials; and crushing, homogenizing and filtering the mixed raw materials to prepare the biochar pulp. The biochar pulp is used for replacing fuel oil so as to effectively save energy and reduce fuel cost, plays a good part in managing urban environment, and fulfills the aims of promoting economic and environmental health and sustainable development. The biochar can be widely applied in the fields of substitute oil firing such as industrialboilers, power station boilers, industrial furnaces and the fields of urban environment management and the like.

Owner:珠海中水环保科技有限公司

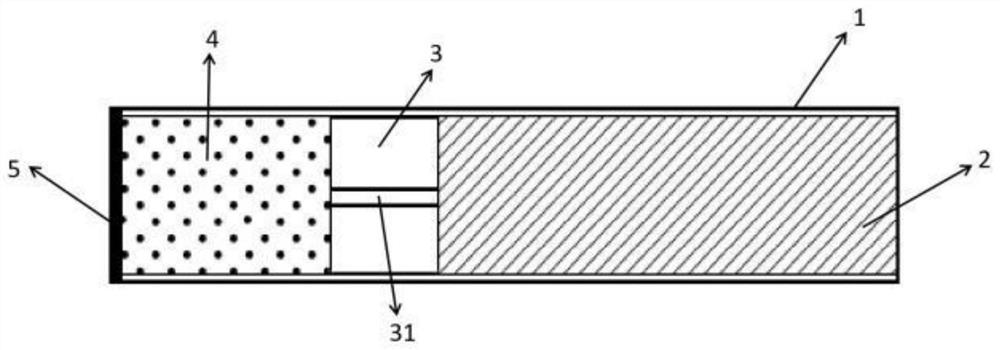

Method for filling aerosol generating product and aerosol generating product prepared thereby

PendingCN111802698AAvoid pollutionBig profit marginCigar manufactureCigarette manufactureEngineeringMechanical engineering

The invention discloses a method for filling an aerosol generating product. The method comprises the following steps of (1) preparing a tube body (1) of the aerosol generating product, (2) filling a filtering part (2) in the tube body (1), wherein the filtering part (2) is close to the near lip end of the tube body (1), (3) installing the blocking flow guide part (3) from the far lip end of the tube body (1), (4) installing a fuming unit (4) from the far lip end of the tube body (1), wherein the smoke generating unit (4) is positioned at the far lip end of the tube body (1), and (5) sealing the far lip end of the tube body (1), and forming a sealing piece (5) on the end surface of the far lip end of the tube body (1). Each part is sequentially filled from the near lip end to the far lip end of the aerosol generating product for the first time, so that the pollution to the tube body (1) caused by the fuming unit (4) when the fuming unit (4) is filled is effectively avoided, the appearance qualification rate of the product can reach 100%, the manual quality inspection strength is reduced, the efficiency is improved, the loss is reduced, and the profit margin is increased for enterprises.

Owner:YUNNAN XIKE TECH CO LTD

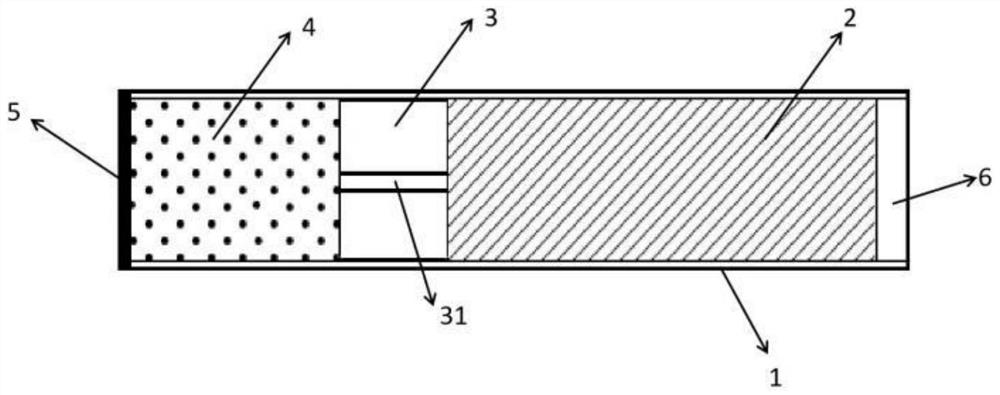

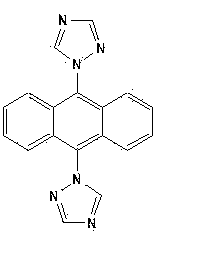

Anthracene ring triazole compound, and preparation method and application thereof

InactiveCN103772303AReduce manufacturing costBig profit marginOrganic chemistryLuminescent compositionsAnthraceneSimple Organic Compounds

The invention discloses a preparation method of 1-[9-(1H-1,2,4-triazolyl-1-yl)anthryl-10-yl]-1H-1,2,4-triazole monocrystal and 1-[9-(1H-1,2,4-triazolyl-1-yl)anthryl-10-yl]-1H-1,2,4-triazole thereof. The organic compound is prepared by heating 9,10-dibromoanthracene, triazole, potassium carbonate and copper oxide by a one-pot process. The preparation method has the characteristics of simple technological operation, low production cost and low environmental pollution, and is suitable for large-scale industrial production.

Owner:TIANJIN NORMAL UNIVERSITY

Preparation method of high-acetalization-degree high-flowability polyvinyl butyral resin

The invention provides a preparation method of a high-acetalization-degree high-flowability polyvinyl butyral resin, which comprises the following steps: a. condensation reaction: heating polyvinyl alcohol to 95 DEG C, dissolving in water to prepare a 10% solution, cooling the solution to 40-60 DEG C, adding n-butyl aldehyde to carry out reaction, cooling to 20-25 DEG C, adding a catalyst hydrochloric acid to react for 1 hour, sending the mixed reaction solution to a condensation kettle, gradually heating to 35-40 DEG C within 1 hour, keeping the temperature to react for 1 hour, gradually heating to 50-55 DEG C within 1 hour, keeping the temperature to react for 1 hour, and cooling; b. neutralizing treatment: sending the cooled reaction solution to a water washing kettle to carry out water washing 5-6 times, heating to 40-50 DEG C, adding a right amount of caustic soda solution to regulate the pH value to 8-10, and keeping the temperature for 2-3 hours for sufficient neutralization and acid removal; and c. dehydration and drying: washing the reaction solution subjected to neutralization and acid removal with water 6-8 times, and dehydrating and drying with a centrifugal machine to obtain the polyvinyl butyral resin finished product. The polyvinyl butyral resin prepared by the method provided by the invention has the advantages of high acetalization degree and favorable flowability.

Owner:ZHEJIANG DECENT PLASTIC

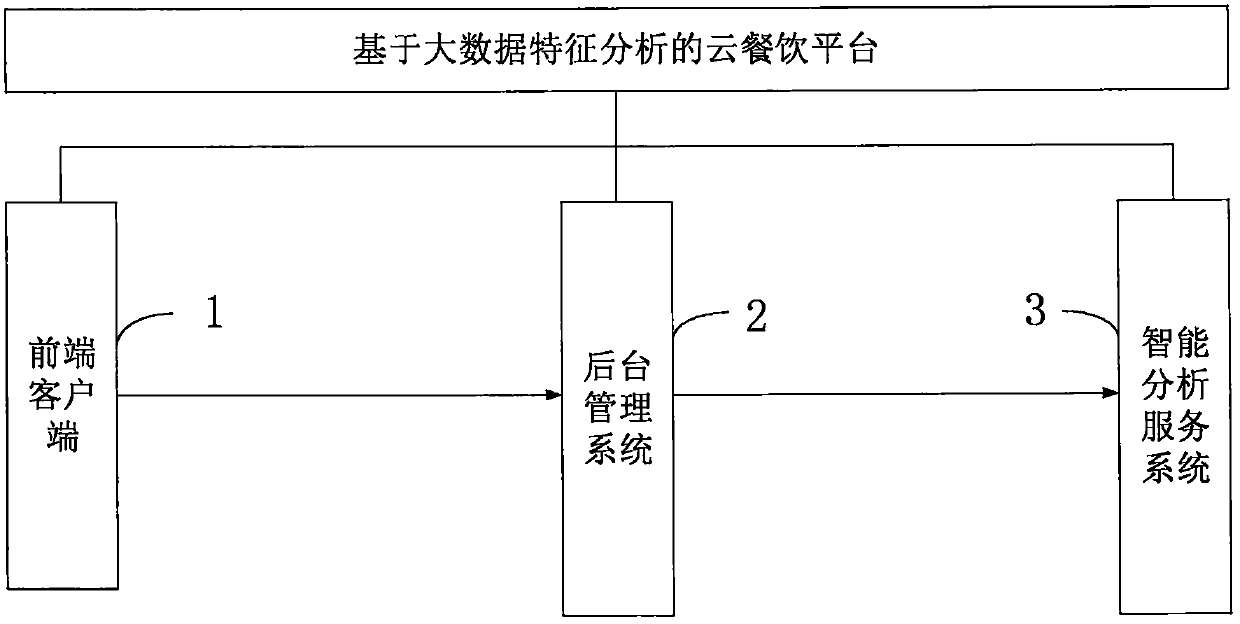

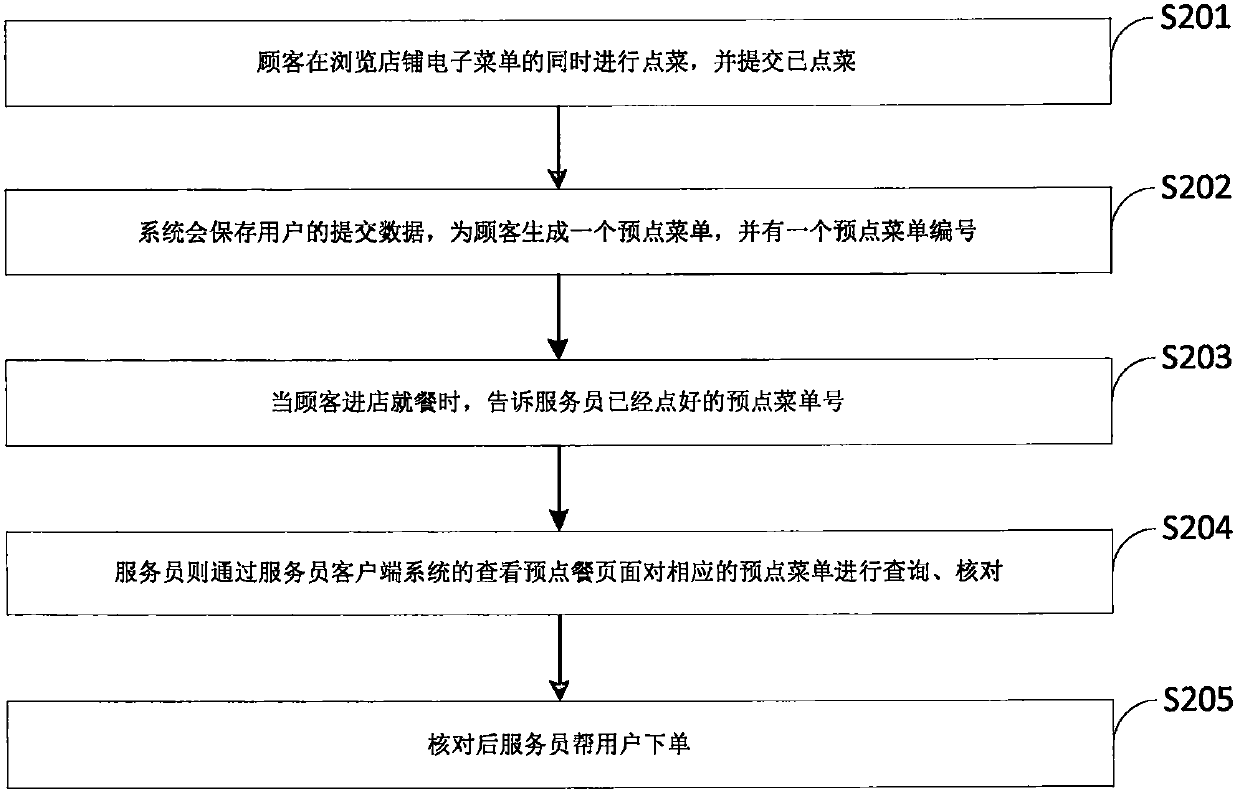

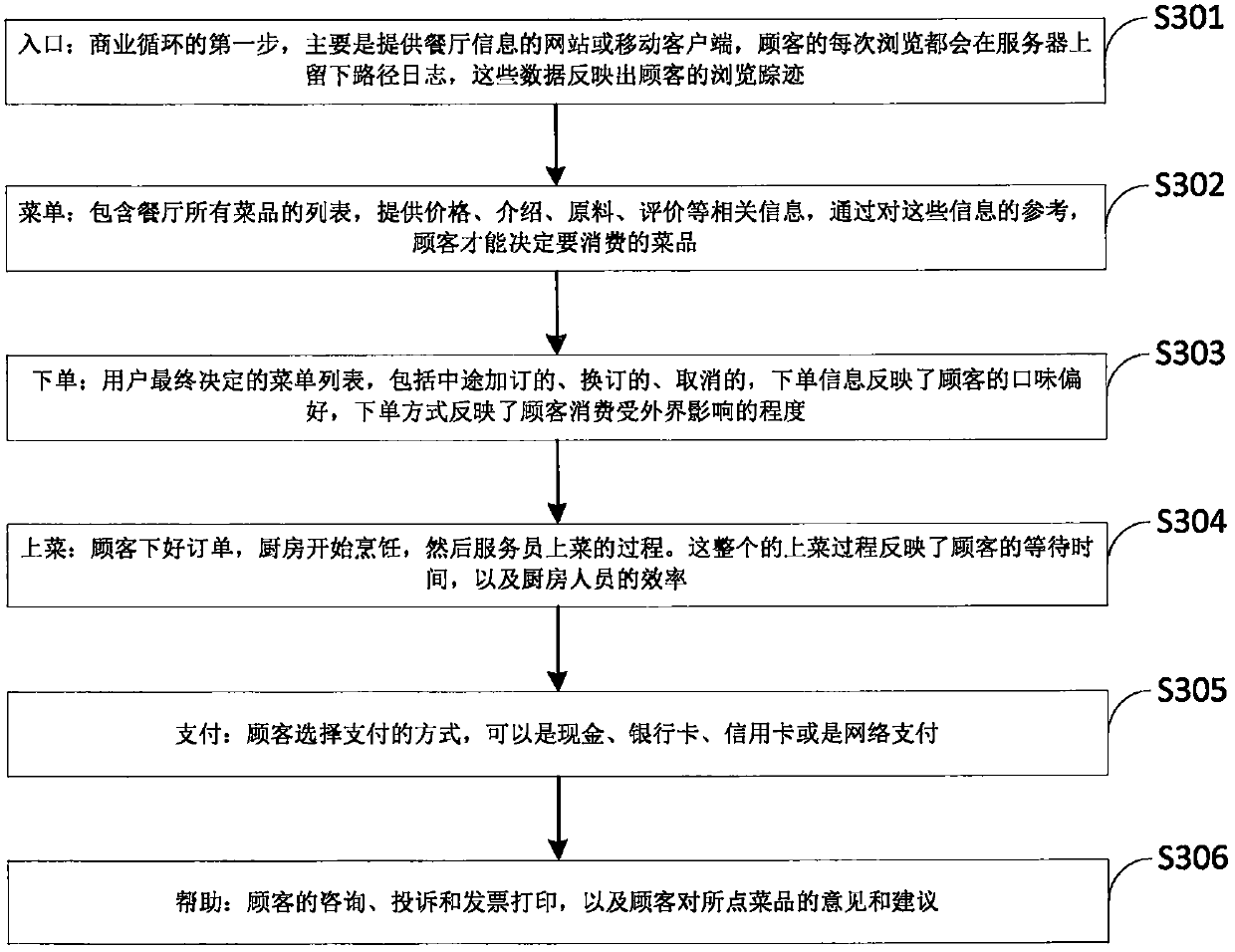

A cloud food and beverage platform and analysis method based on big data feature analysis

InactiveCN109102326AImprove service efficiencyReduce investmentAdvertisementsBuying/selling/leasing transactionsHabitOperation mode

The invention belongs to the technical field of food and beverage, and discloses a cloud food and beverage platform and an analysis method based on big data characteristic analysis. The cloud food andbeverage platform comprises a front-end client, a background management system and an intelligent analysis service system. The analysis method includes selecting different models and algorithms, configuring different parameter settings, carrying out multiple tests and evaluations according to business data and specific business objectives, and carrying out in-depth analysis on the intelligent analysis results of potential consumer dishes and members' consumption habits. The invention breaks through the original operation mode of the restaurant, comprehensive coverage of queuing, ordering, payment, cash register, reporting and marketing functions, increases the efficiency of our staff, improves work efficiency, and lets online catering, offline businesses quickly complete the constructionand interoperability of a variety of business models, to achieve resource and service sharing, effectively saves the cost of production input, creates a greater profit margin.

Owner:SHANDONG VOCATIONAL COLLEGE OF IND

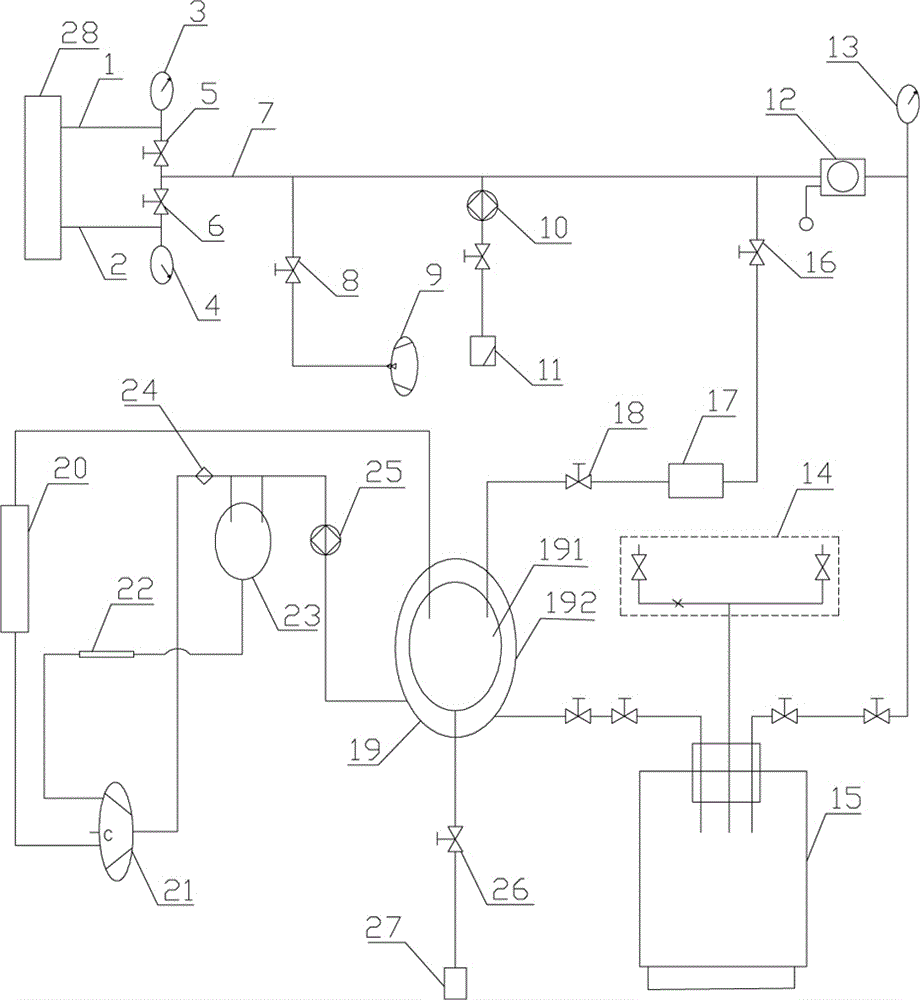

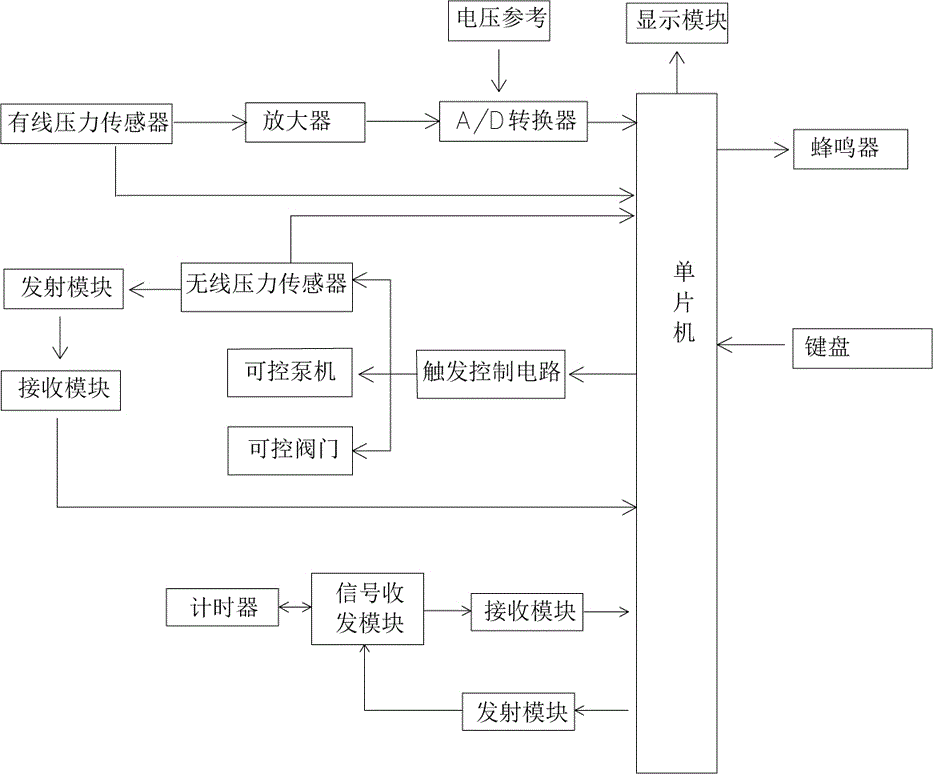

Intelligent refrigerant charging and recovering device

InactiveCN106338166AReduce operational complexityLow maintenanceRefrigerantsElectricitySolenoid valve

The invention discloses an intelligent refrigerant charging and recovering device which comprises a control circuit, a high-pressure manifold, a low-pressure manifold, a first pipeline valve, a second pipeline valve, a first pipeline, a vacuum valve, a vacuum pump, a first check valve, an oil filling cup, a refrigerant recovery unit, an electromagnetic valve and a liquid storage tank; the first end of the first pipeline valve is connected with a high-pressure pipeline of a vehicle air conditioning system; the second end of the first pipeline valve is connected with the first end of the electromagnetic valve, the second end of the second pipeline valve, the first end of the vacuum valve, the inlet of the refrigerant recovery unit and the first end of the first check valve; the second end of the electromagnetic valve is connected to the liquid storage tank; the first end of the second pipeline valve is connected to a low-pressure pipeline of the vehicle air conditioning system; the second end of the vacuum valve is connected with the vacuum pump; the second end of the first check valve is connected with the oil filling cup; the outlet of the refrigerant recovery unit is connected with the liquid storage tank; and the refrigerant recovery unit and the valves are all electrically connected with the control circuit. According to the technical scheme of the invention, an old refrigerant can be separated and reused and is suitable for maintaining an air conditioning of a vehicle or a house.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com