Preparation method of high-acetalization-degree high-flowability polyvinyl butyral resin

A polyvinyl butyral resin, high fluidity technology, applied in the field of heat-shrinkable polymer materials, can solve the problem of increasing the amount of plasticizer used in processing temperature, affecting the strength and stability of products, and breaking the macromolecular chain of products, etc. problems, to achieve good fluidity, reduce the breakage of product macromolecular chains, and achieve the effect of good resin bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

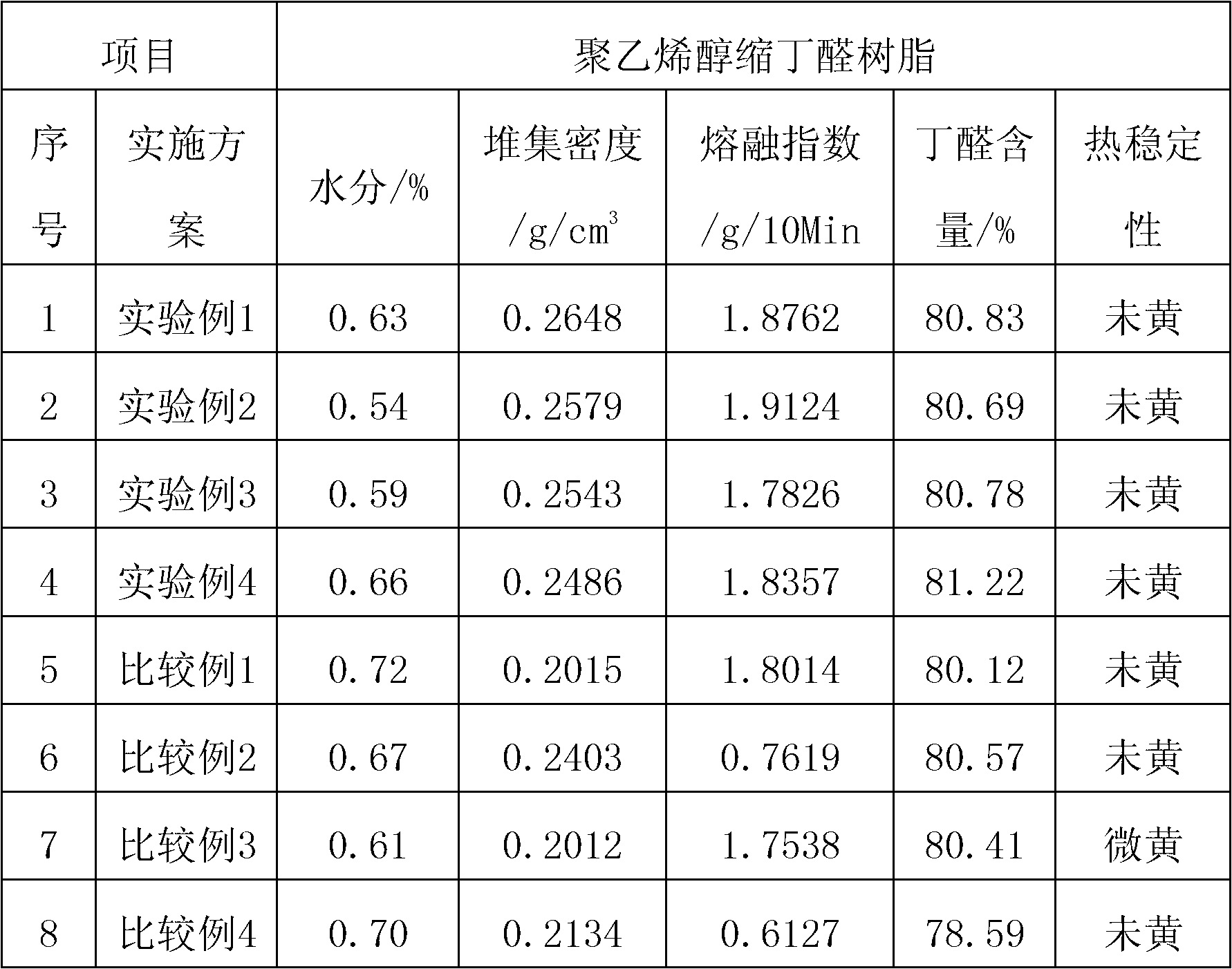

Examples

Embodiment 1

[0021] Heat 100g of polyvinyl alcohol to 95°C and dissolve it in 900g of water, then cool down to 45°C and add all proportion of n-butyraldehyde. Continue to cool down the liquid to the reaction temperature of 20°C, add all proportion of hydrochloric acid, the mass ratio of the reaction material is polyvinyl alcohol: hydrochloric acid = 100:50, the mass concentration of hydrochloric acid is 32%, keep the reaction for 1 hour, and then use the reaction solution for 1 hour Gradually raise the temperature to 35°C, keep it warm for 1 hour, then gradually raise the temperature to 50°C for 1 hour again, keep it warm for 1 hour, then cool down and wash the reaction product 6 times with water, then raise the temperature to 45°C, add an appropriate amount of caustic soda solution to adjust the pH To 9, keep warm for 2 hours, fully neutralize and remove acid, and finally wash 8 times again, and the polyvinyl butyral resin after washing is centrifugally dehydrated and dried to obtain a fin...

Embodiment 2

[0023] Heat 100g of polyvinyl alcohol to 95°C and dissolve it in 900g of water, then cool down to 45°C and add all proportion of n-butyraldehyde. Continue to cool down the liquid to the reaction temperature of 25°C, add all proportion of hydrochloric acid, the mass ratio of the reaction material is polyvinyl alcohol: hydrochloric acid = 100:50, the mass concentration of hydrochloric acid is 32%, keep the reaction for 1 hour, and then use the reaction solution for 1 hour Gradually raise the temperature to 40°C, keep it warm for 1 hour, then gradually raise the temperature to 55°C for 1 hour again, keep it warm for 1 hour, then cool down and wash the reaction product 6 times with water, then raise the temperature to 45°C, add an appropriate amount of caustic soda solution to adjust the pH To 9, keep warm for 2 hours, fully neutralize and remove acid, and finally wash 8 times again, and the polyvinyl butyral resin after washing is centrifugally dehydrated and dried to obtain a fin...

Embodiment 3

[0025] Heat 100g of polyvinyl alcohol to 95°C and dissolve it in 900g of water, then cool down to 45°C and add all proportion of n-butyraldehyde. Continue to cool down the liquid to the reaction temperature of 20°C, add all proportion of hydrochloric acid, the mass ratio of the reaction material is polyvinyl alcohol: hydrochloric acid = 100:50, the mass concentration of hydrochloric acid is 32%, keep the reaction for 1 hour, and then use the reaction solution for 1 hour Gradually raise the temperature to 35°C, keep it warm for 1 hour, then gradually raise the temperature to 50°C for 1 hour again, keep it warm for 1 hour, then cool down and wash the reaction product 6 times with water, then raise the temperature to 45°C, add a small amount of caustic soda solution to adjust the pH To 9, keep warm for 2 hours, fully neutralize and remove acid, and finally wash 8 times again, and the polyvinyl butyral resin after washing is centrifugally dehydrated and dried to obtain a finished p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com