Patents

Literature

47results about "Cutting soap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

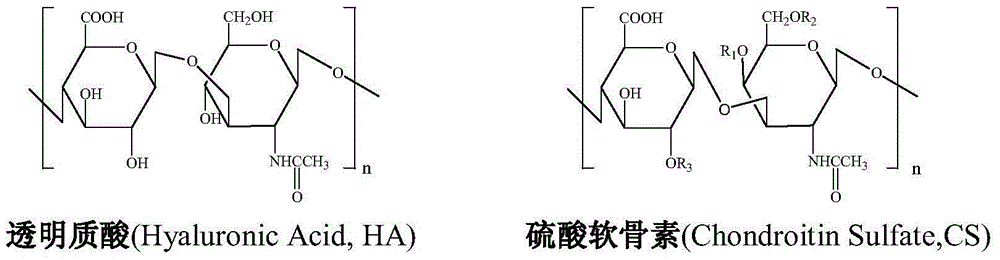

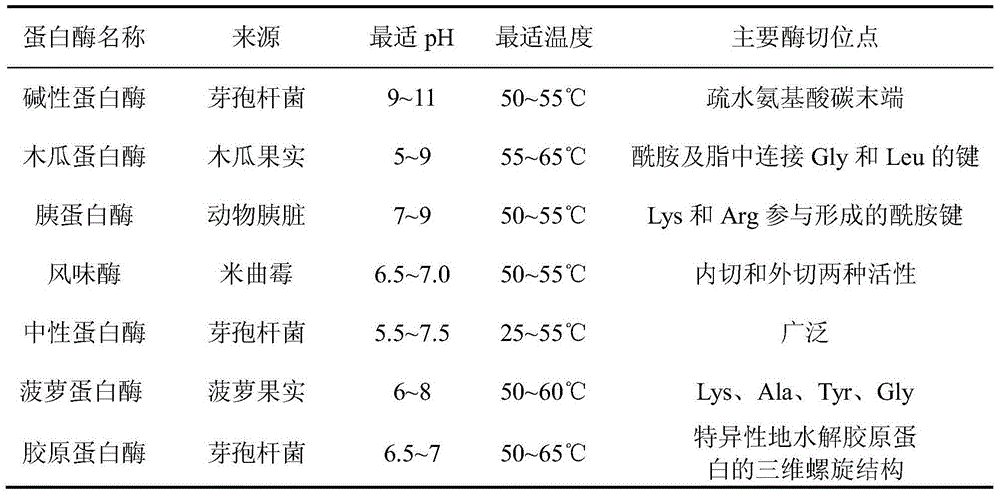

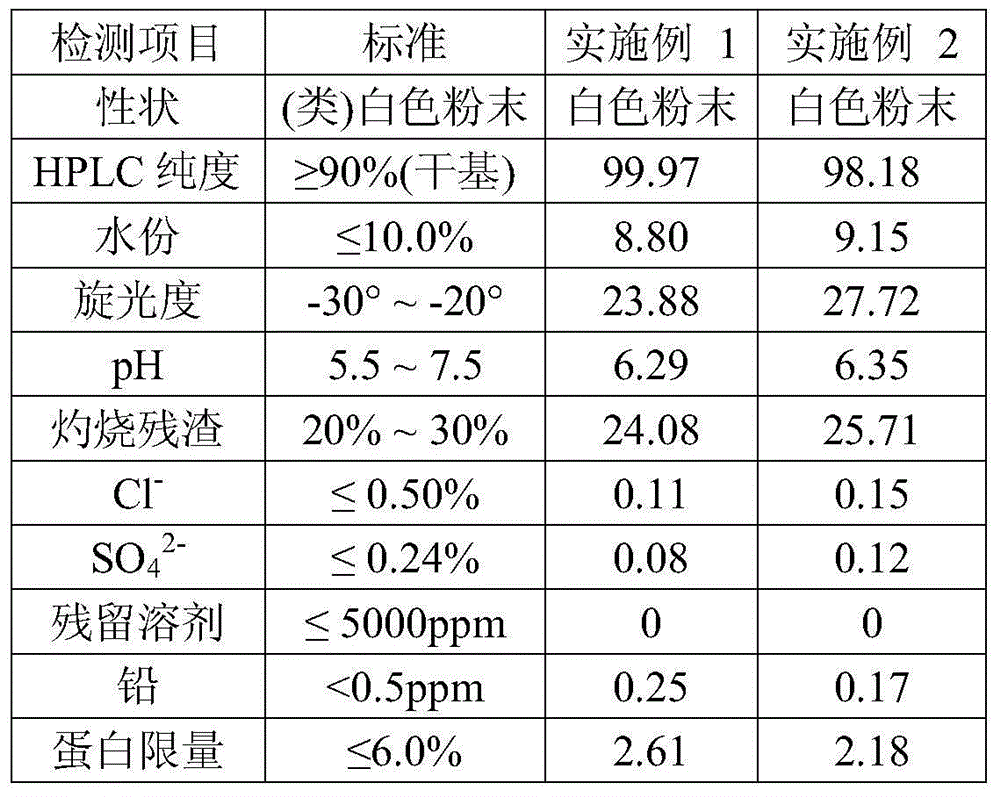

Combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap

ActiveCN104531817ARealize simultaneous hydrolysisEmission reductionConnective tissue peptidesCutting soapResource utilizationHydrolysate

The invention discloses a combined production method of hyaluronic acid, chondroitin sulfate, collagen peptide, bone meal fodder and soap. The method mainly comprises the process steps that animal cartilage is soaked with water and smashed to obtain cartilage powder, the cartilage powder undergoes protease enzymolysis and then is adsorbed by resin, adsorbed enzymatic hydrolysate is collected, the resin undergoes gradient elution through a NaCl aqueous solution, and eluants undergo desalination, concentration, sterilization and drying to obtain finished products of the hyaluronic acid and chondroitin sulfate; the adsorbed enzymatic hydrolysate undergoes decoloration, anion and cation exchange resin mixed column treatment, nanofiltration purification, concentration, sterilization and drying to manufacture finished products of the collagen peptide; grease undergoes extraction saponification to manufacture the soap; denatured protein-bone dreg compounds and other materials are mixed to manufacture the fodder. According to the combined production method, by utilizing the process of resin adsorption-spray drying, highly-intensified resource utilization of cartilage is achieved, energy saving and emission reduction are achieved, and the economic benefit and the social benefit are remarkable.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Microcapsules

ActiveUS7435715B2Physical stabilityIncrease pressureInorganic/elemental detergent compounding agentsCosmetic preparationsPolyelectrolyteSemipermeable membrane

Microcapsules for use in liquid detergents having a core and a polyelectrolyte complex shell in the form of a semipermeable membrane capable of withstanding a force before bursting of from about 20 mN to about 20,00 N and having a density of from about 900 Kg / m3 to about 1,300 Kg / m3 at 25° C. The invention also relates to a process for making the microcapsules and liquid detergents comprising said microcapsules.

Owner:PROCTER & GAMBLE CO

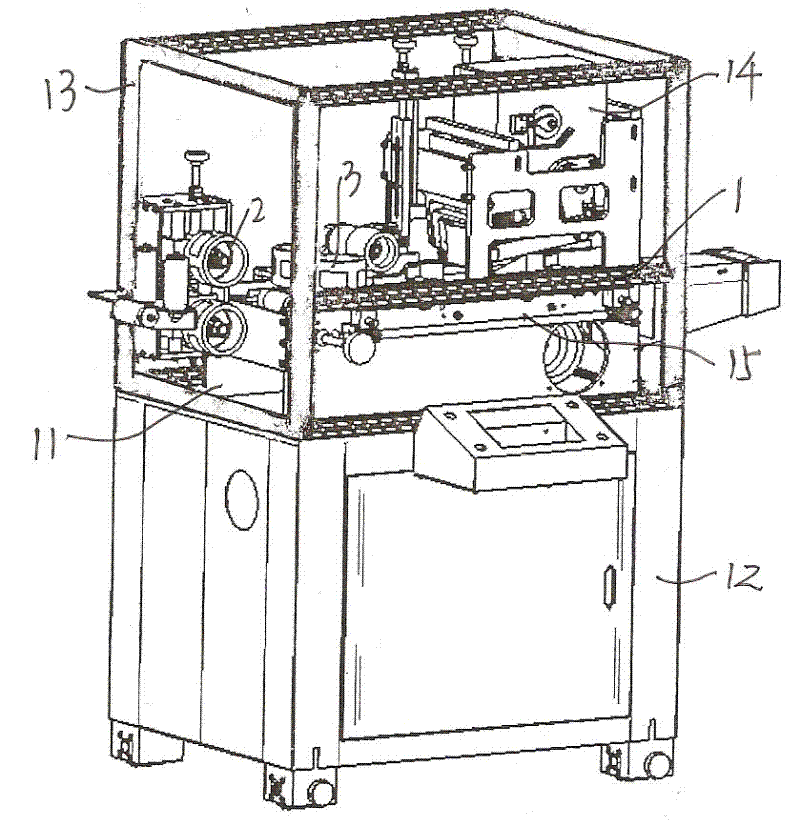

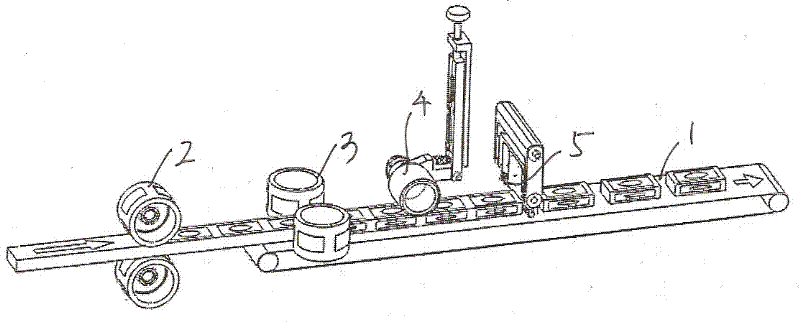

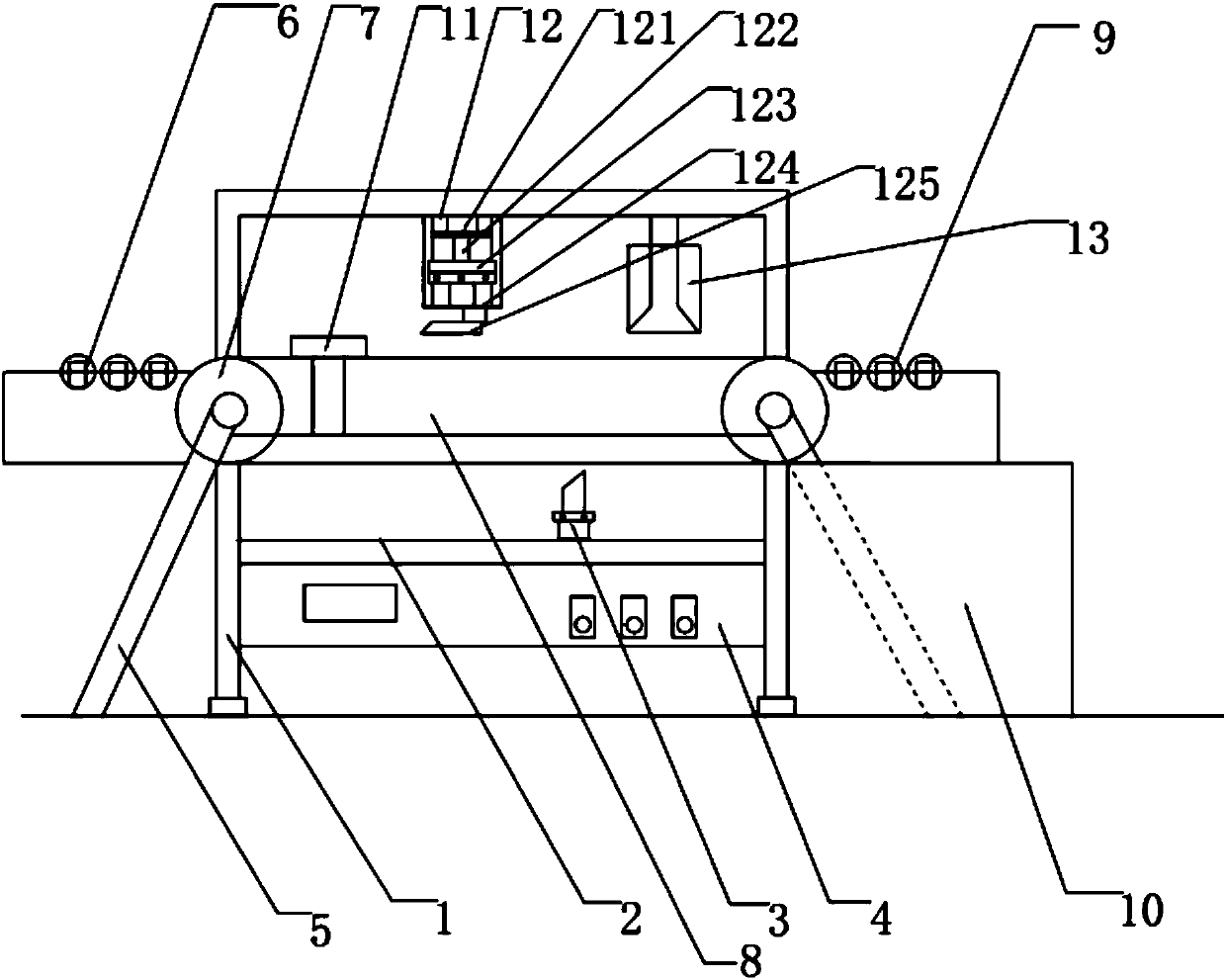

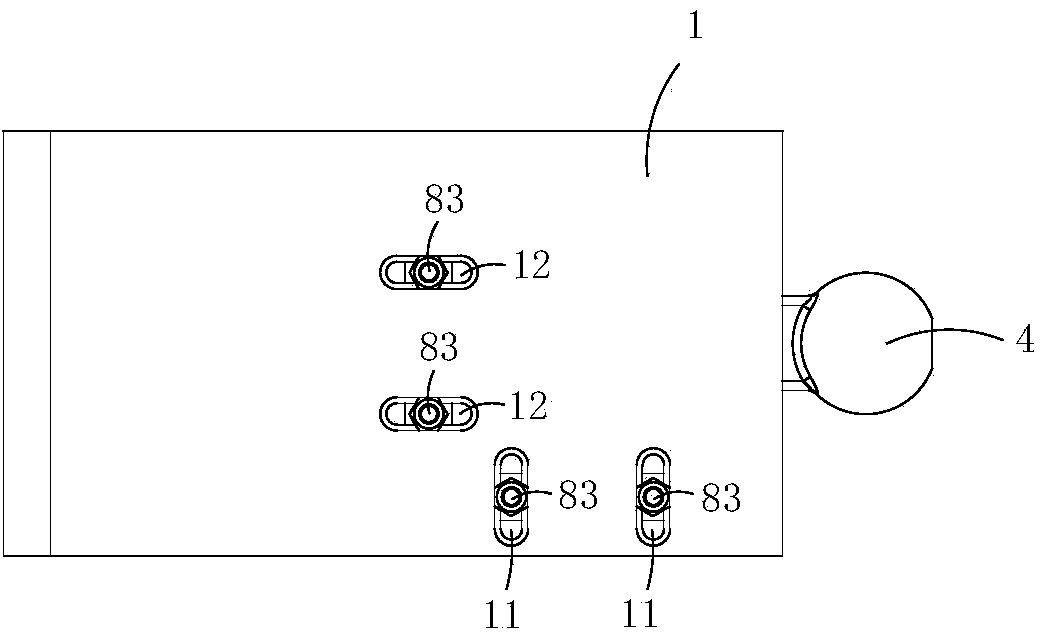

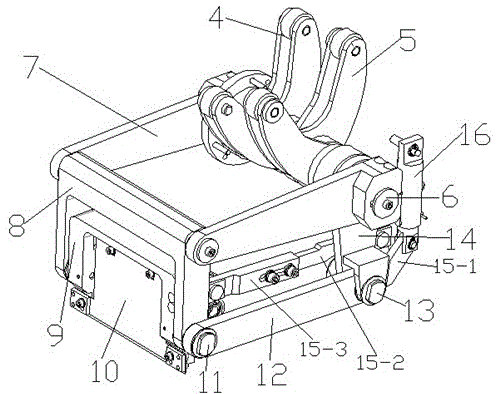

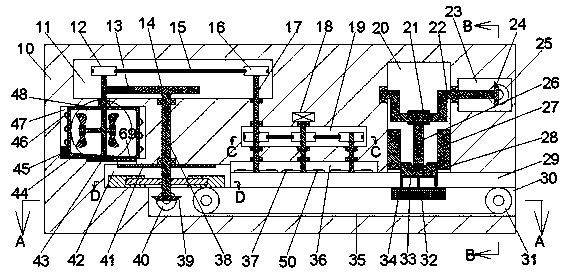

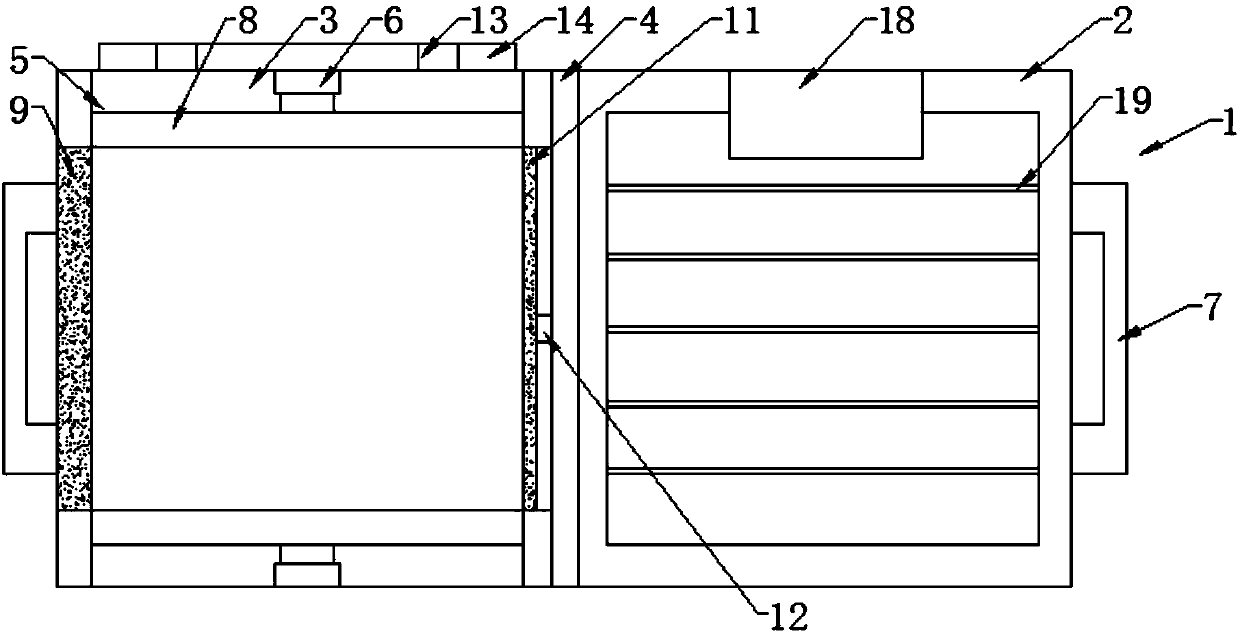

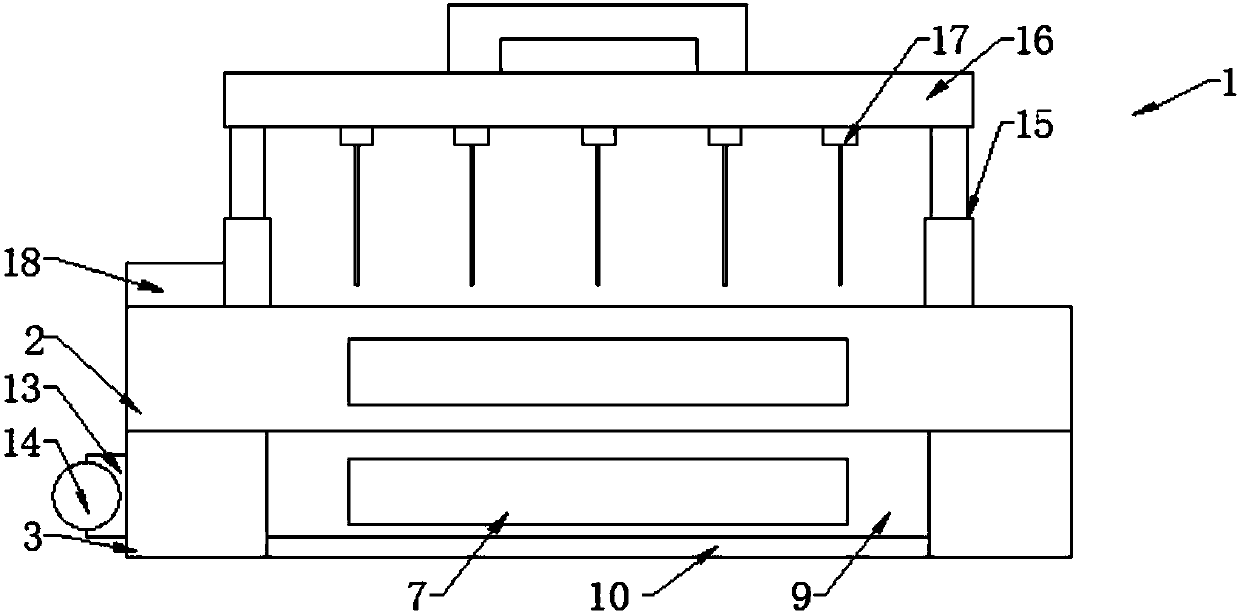

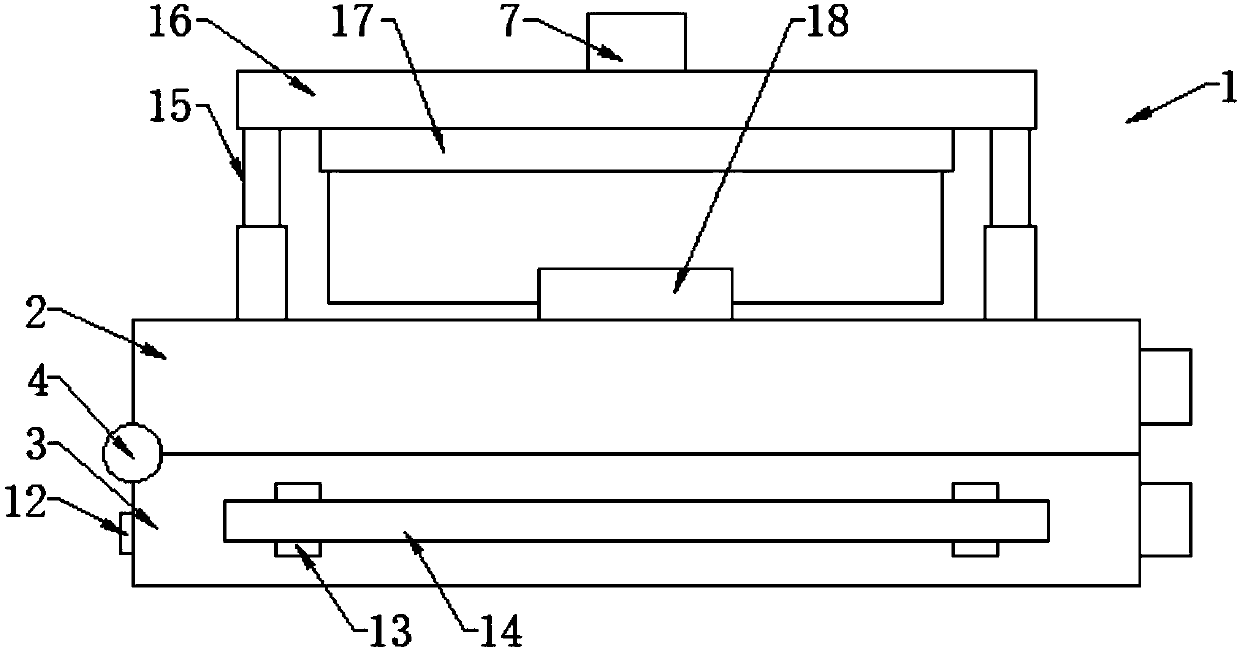

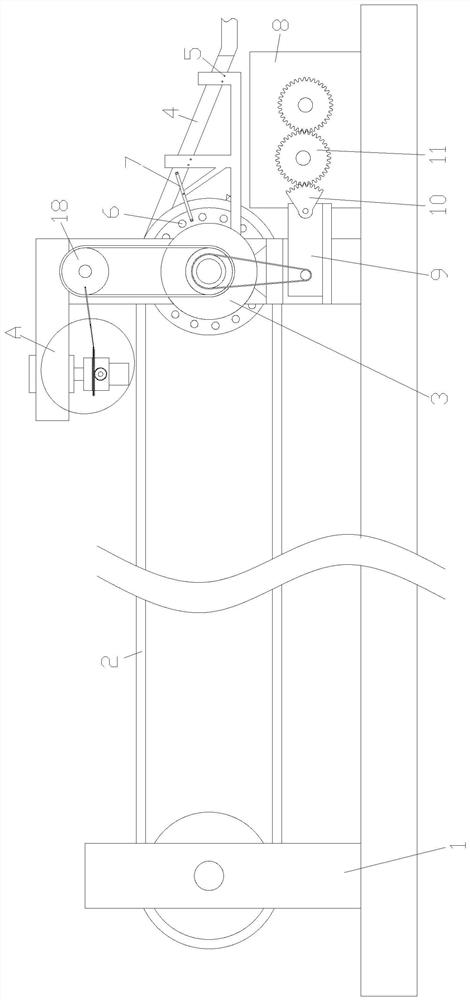

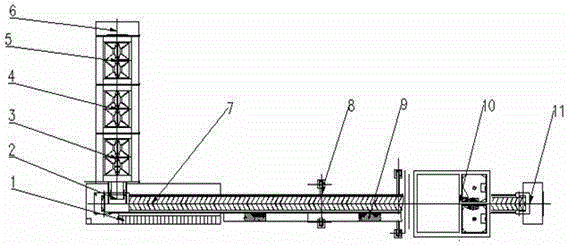

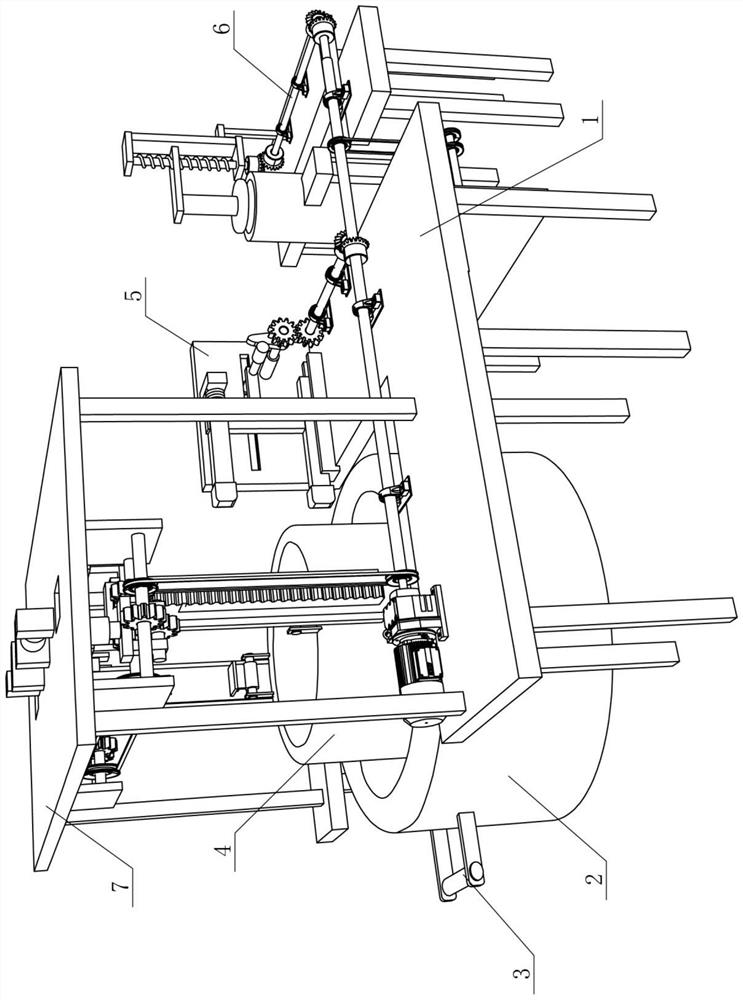

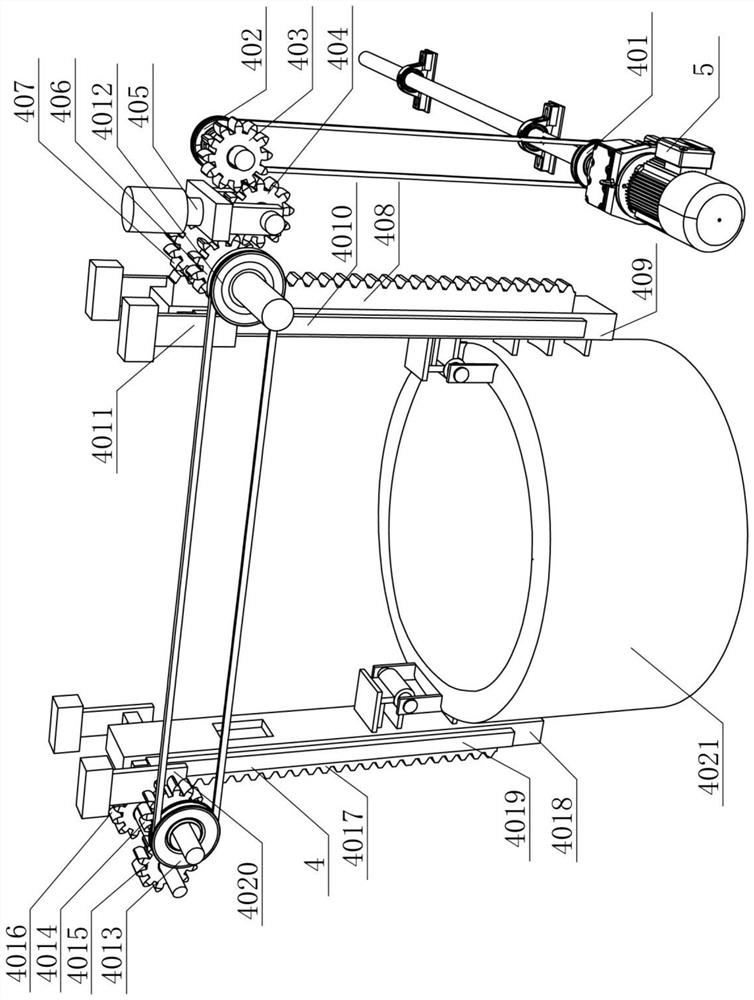

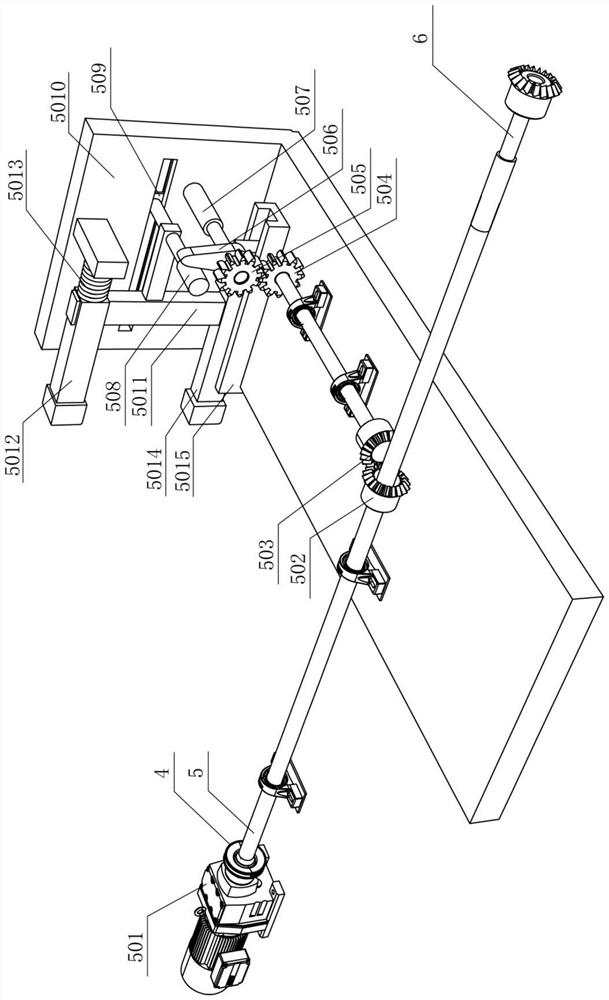

Four-side roll printing block cutting machine

InactiveCN102504987AReasonable designReasonable structureCutting soapEmbossing/polishing soapProduction lineEngineering

The invention discloses a four-side roll printing block cutting machine. The near side of a soap block conveying line is sequentially provided with an upper and lower roll printing mold device and a left and right roll printing mold device, an encoder capable of outputting pulse signals to a programmable controller during operation is arranged on the upper and lower roll printing mold device and the left and right roll printing mold device, a speed measuring wheel for measuring the speed of the conveying line is arranged behind the left and right roll printing mold device, a speed measuring encoder capable of outputting pulse signals to the programmable controller during the operation is arranged on the speed measuring wheel, a cutting knife for cutting soap strips is arranged behind the speed measuring wheel, and the programmable controller controls the cutting speed of the cutting knife through a transmission system. The four-side roll printing block cutting machine has the advantages that the structure is reasonable and compact, the operation is reliable, and the precision is high; and the double-encoder sampling and speed measuring technology meets the high-precision control requirements of on-line detection, continuous tracking and fixed length cutting. The programmable controller is adopted for control, and in addition, the linkage control with other equipment on a production line can be realized.

Owner:NANTONG UNIVERSAL MACHINERY

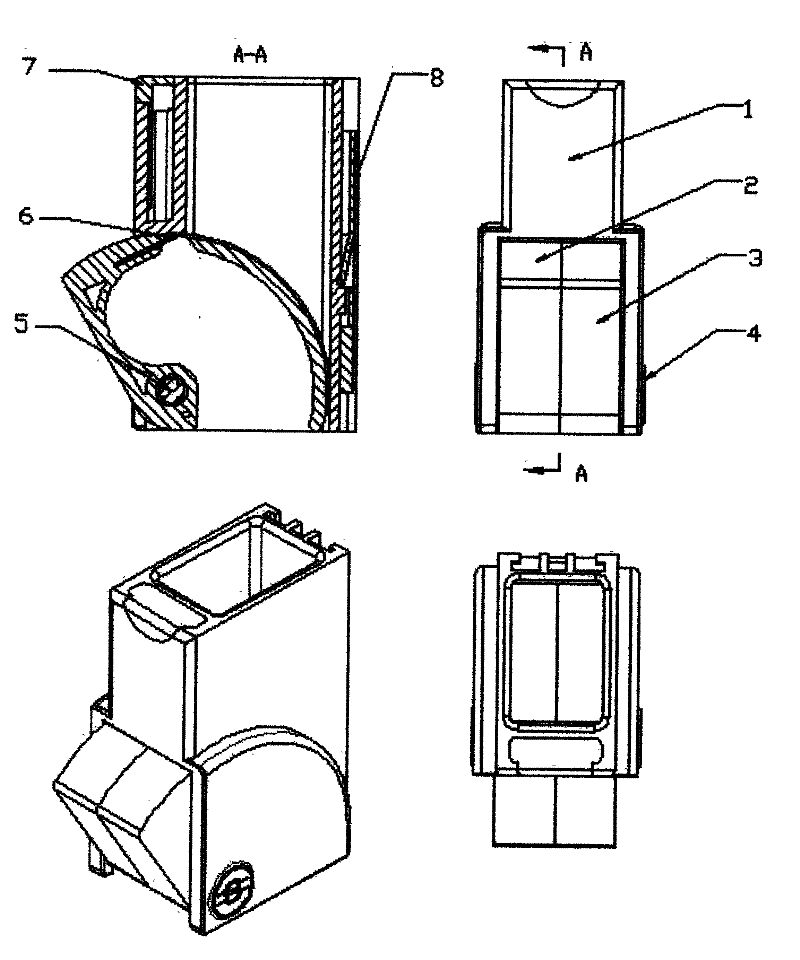

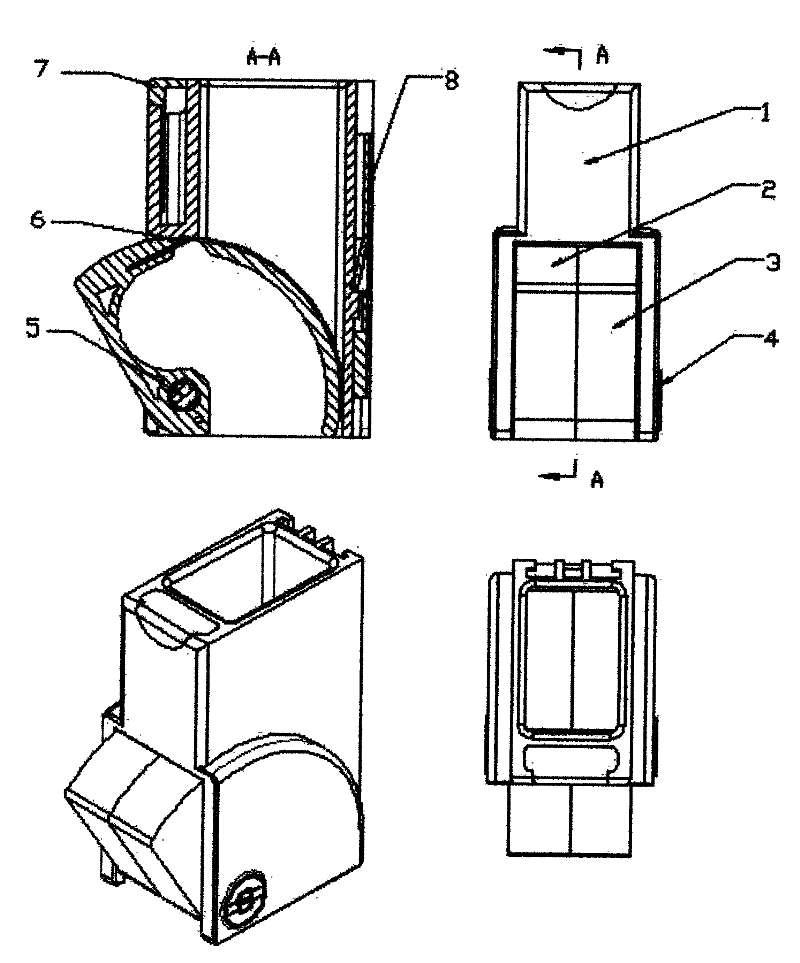

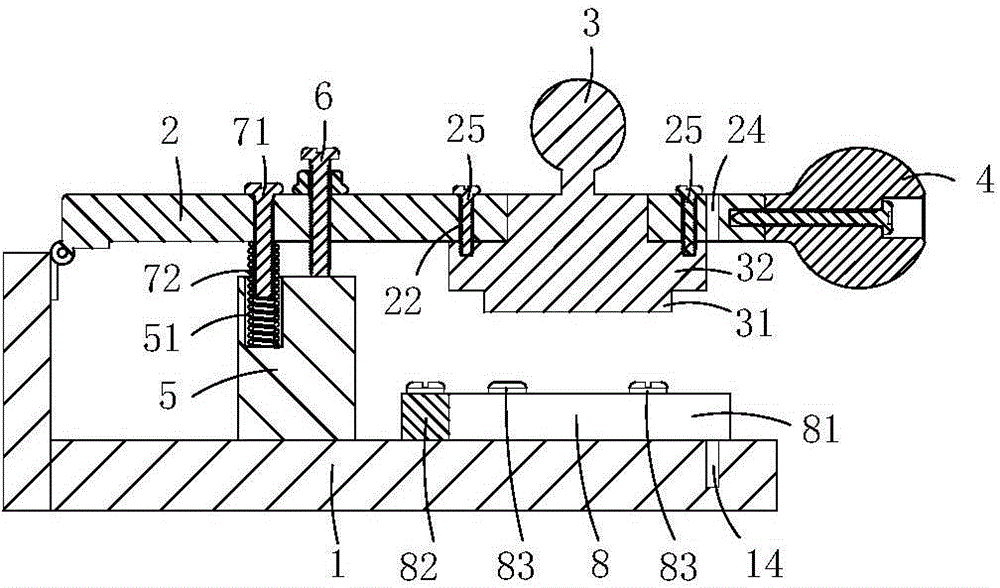

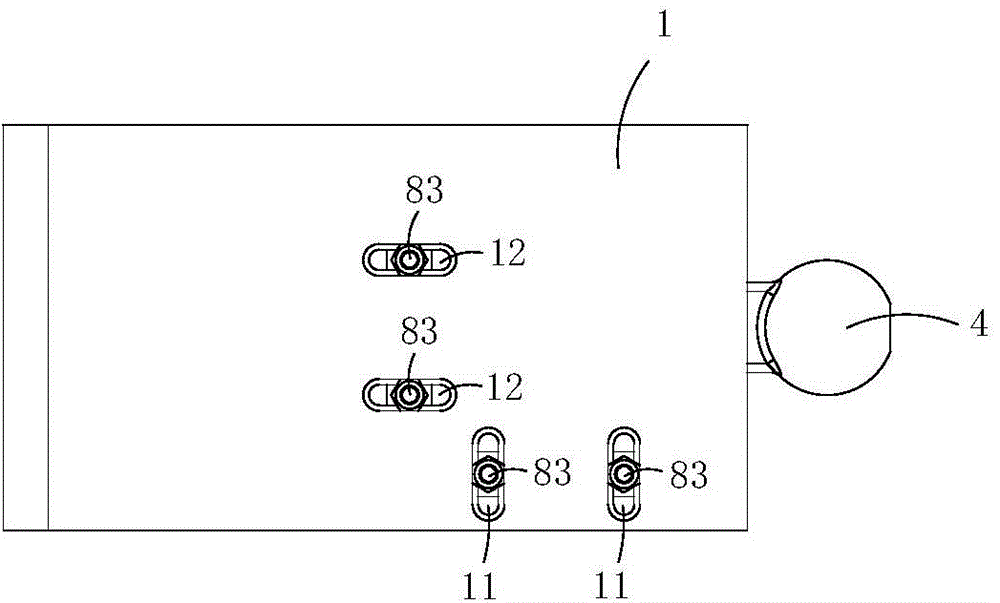

Toilet soap slicing device

The invention relates to a toilet soap slicing device which belongs to a washroom appliance from the personal or household article subsection of the human life necessity section according to the partition of the International Patent Classification. The toilet soap slicing device is used for slicing solid toilet soap for one-time use. The device comprises a shell (1), a left knife rest (2), a right knife rest (3), a retainer ring (4), a shaft (5), a slicing knife (6), a sealing cover (7) and a hanging piece (8). The toilet soap slicing device is characterized in that the slicing knife located at the bottom of the soap makes a reciprocating circular motion to slice the soap by using the self weight of the soap, and a space and an opening are reserved inside the circular slicing knife rest so that soap slices can be taken out. When the slicing knife makes circular motion to cut the soap, the slicing knife cuts the soap downwards from the highest point, and the soap is subject to horizontal and downward component forces so that the soap can not move upwards. The height of the slicing knife edge above the circular surface of the knife rests is cutting thickness.

Owner:张利民 +1

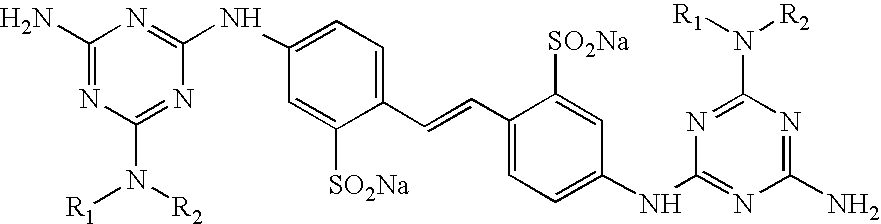

Method for manufacturing a shaped article

ActiveUS20090023621A1Efficient and reliableGood colorInorganic/elemental detergent compounding agentsCutting soapPolymer scienceMechanical engineering

A method for manufacturing a shaped article comprising the step of cutting a shaped article from a first article; wherein as the shaped article is cut from the first article the shaped article's cross-section is deformed and wherein the first article's cross-section is shaped such that it compensates for the deformation during the cutting step so as to achieve a shaped article with a desired cross-section. Shaped articles and compositions comprising shaped articles are also described.

Owner:THE PROCTER & GAMBLE COMPANY

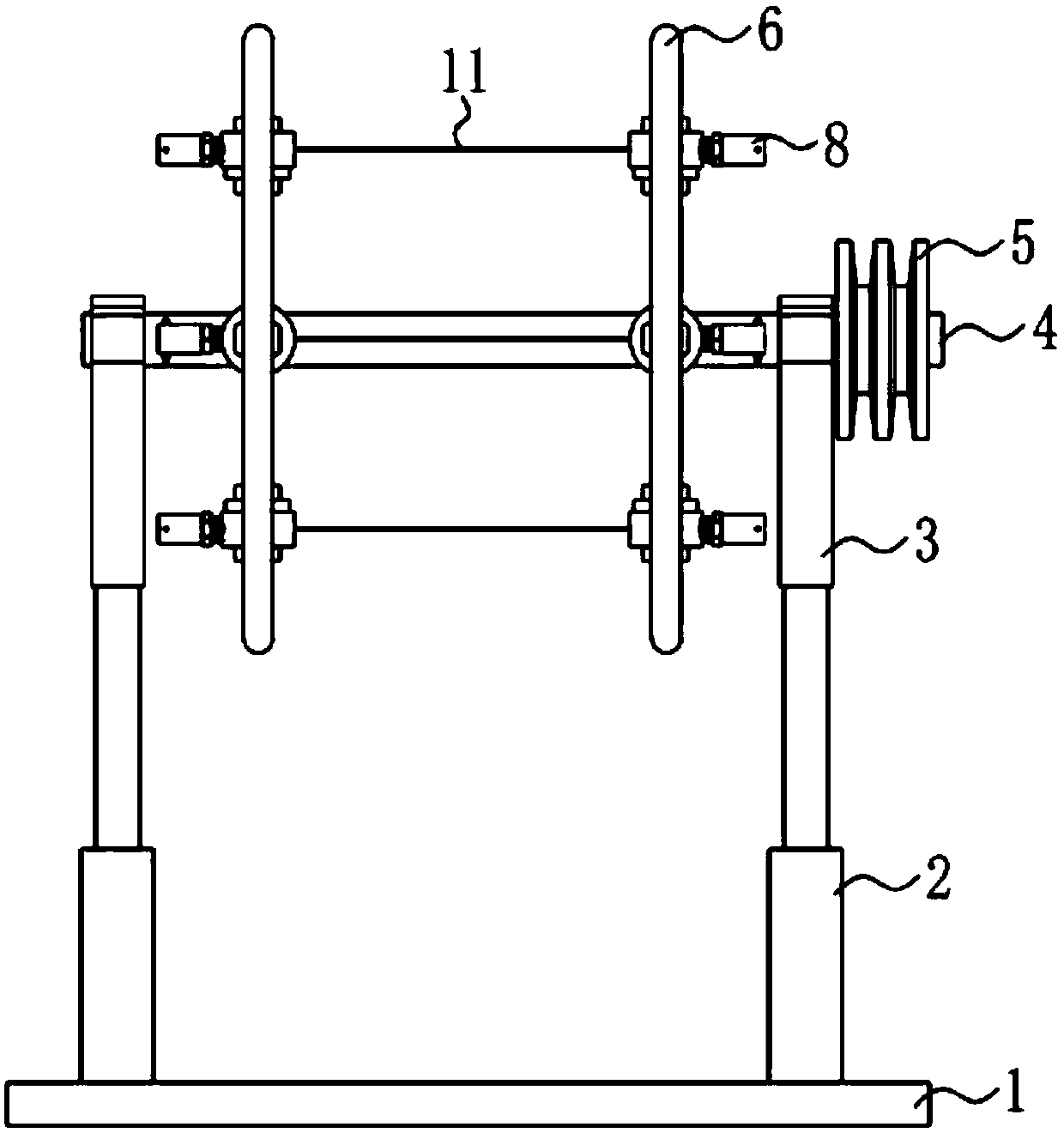

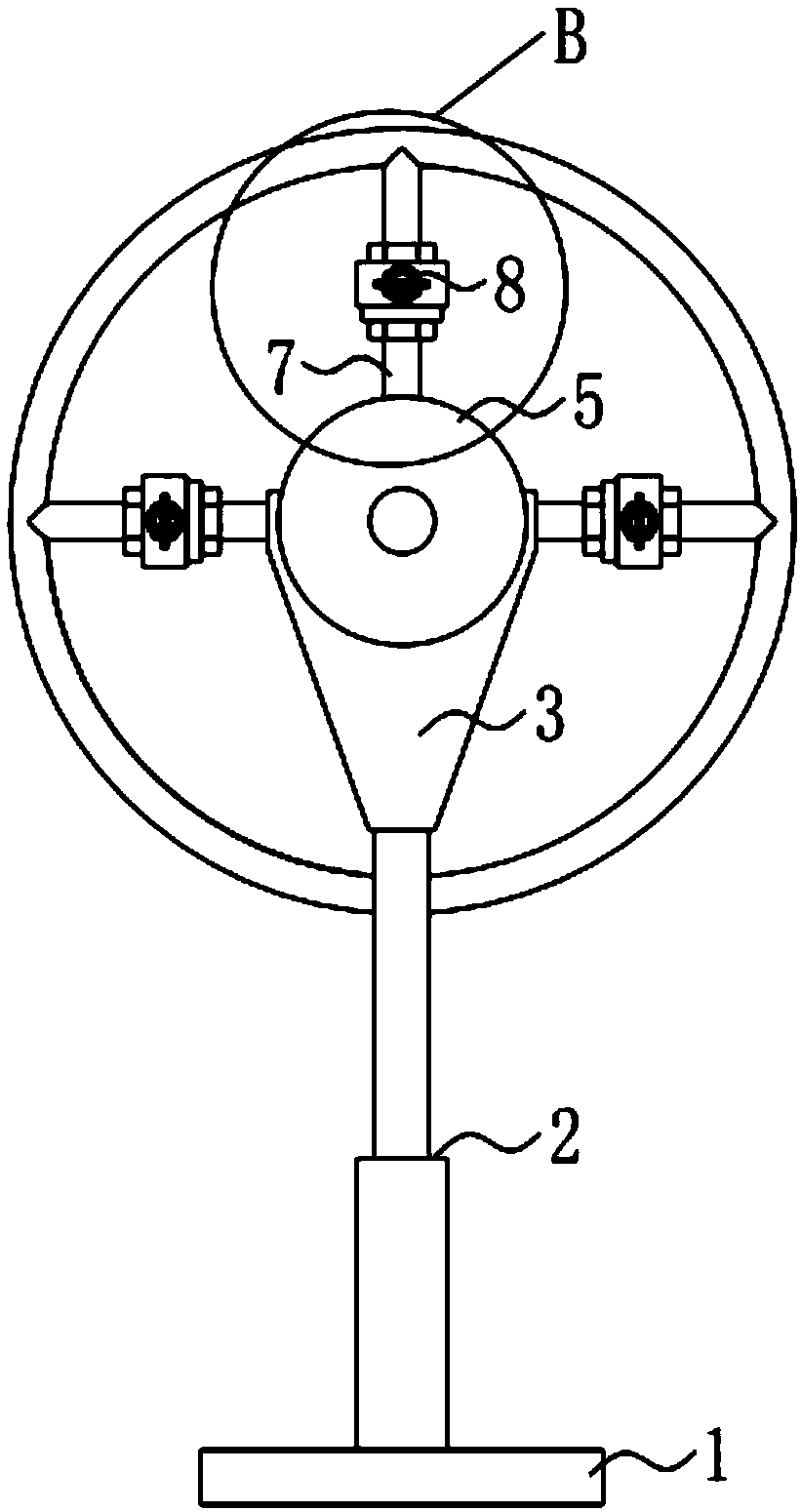

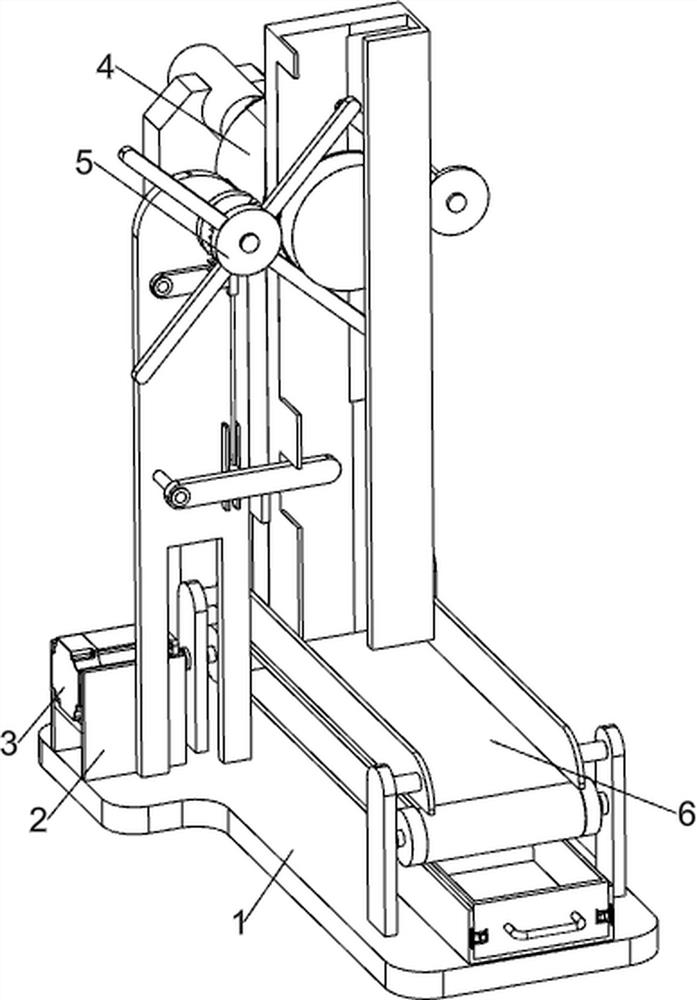

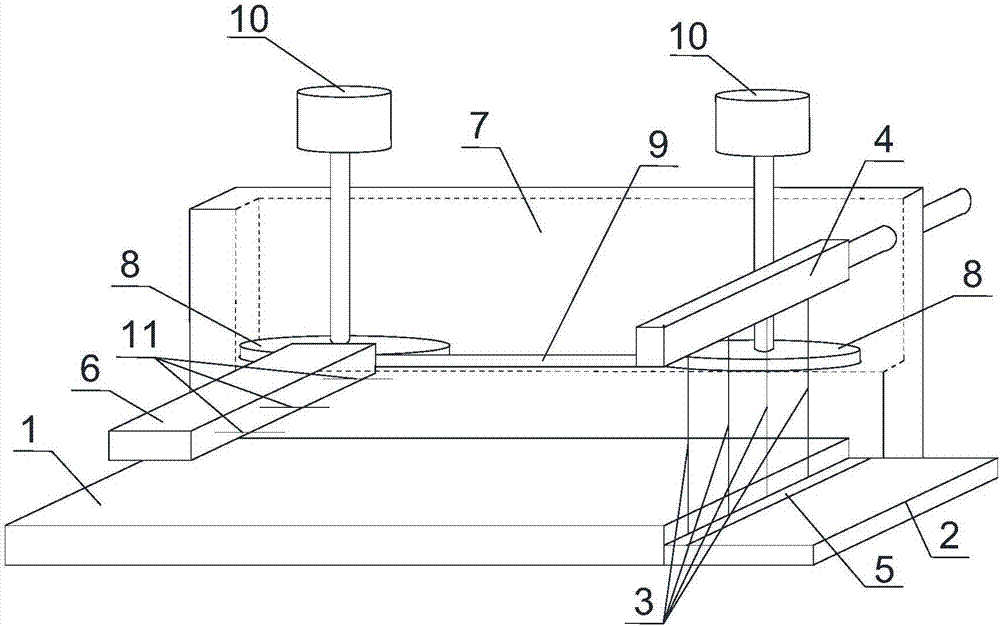

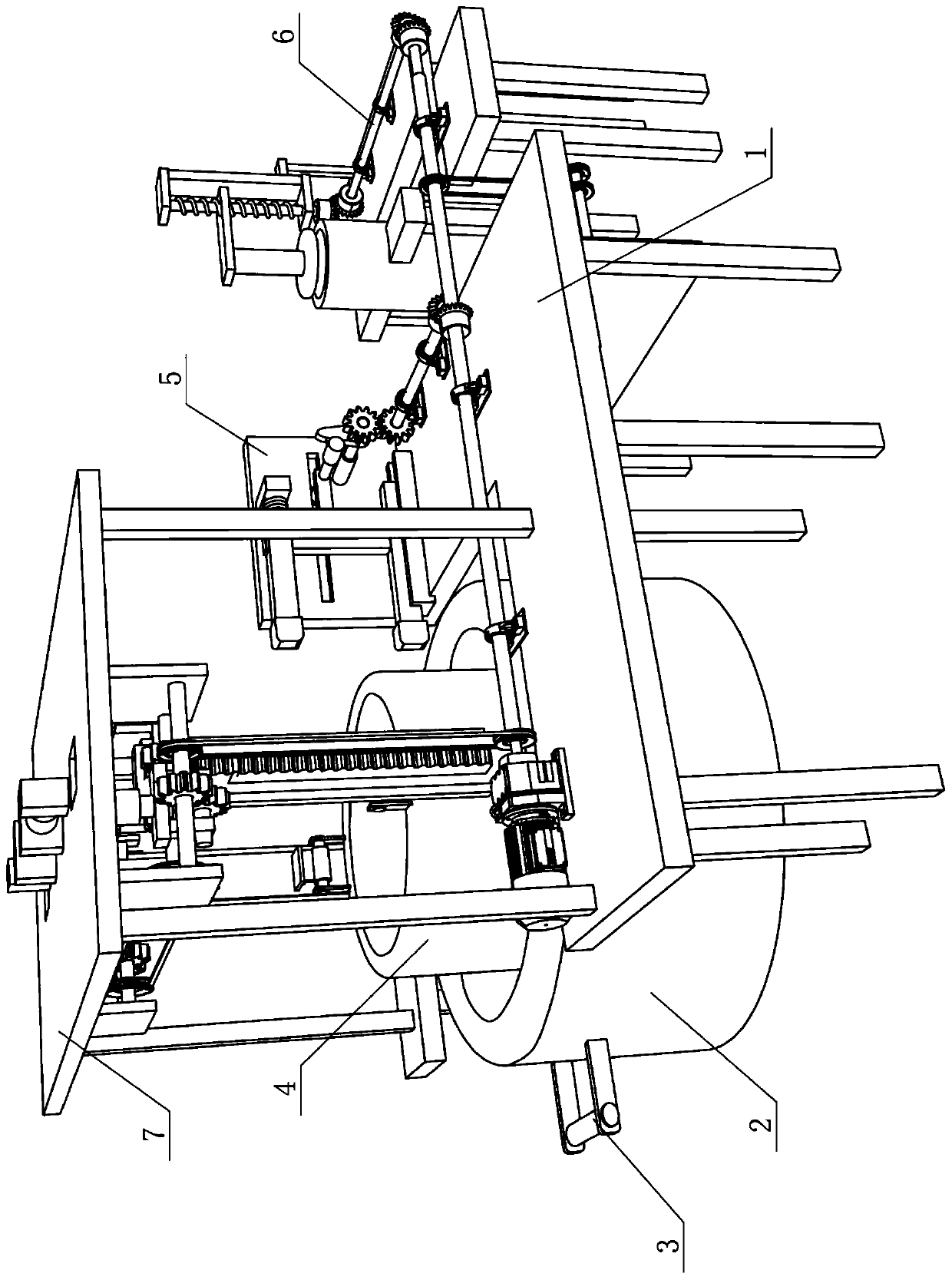

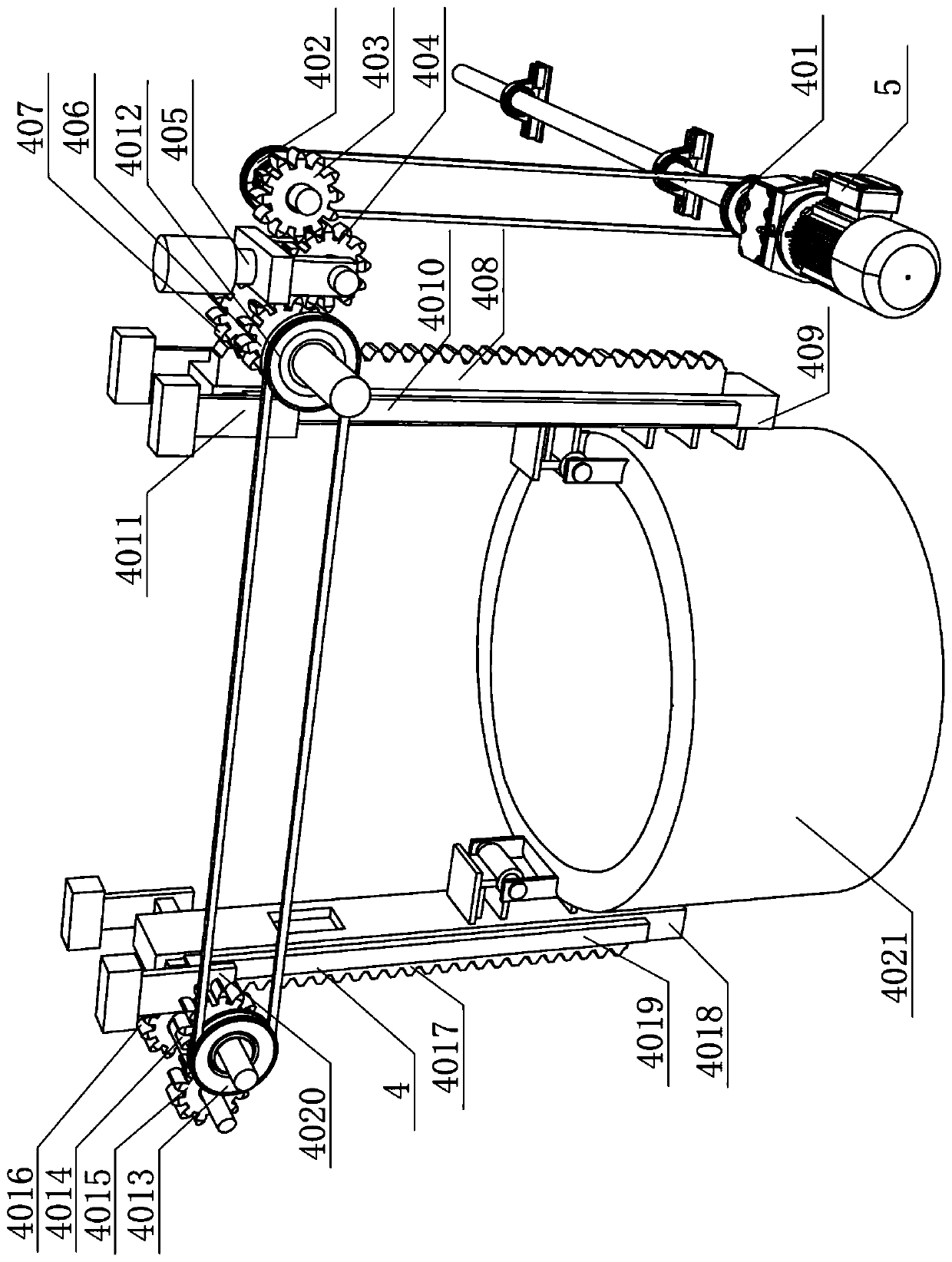

Soap slab cutting apparatus

A soap slab cutting apparatus is used for cutting soap slabs according to a certain length. The apparatus comprises: a base, wherein height adjusting rods for adjusting the height of the entire apparatus are fixedly mounted on the base, the upper end of every height adjusting rod is fixedly connected with a connecting support, a rotating shaft is movably arranged between the supports, and a transmission shaft power input device for connecting a conveyor belt is fixedly mounted at one end of the rotating shaft; discs symmetrically arranged at two ends of the rotating shaft and fixedly connectedwith the rotating shaft through adjusting rods; and cutting wires fixedly connected between adjusting devices on the discs and used for cutting the soap slabs. The arrangement of the discs and cutting wires avoids the pausing of the conveyor belt during cutting of the soap slabs on the conveyor belt, so the production efficiency is improved; and the arrangement of the adjusting rods and the adjusting devices realizes the cutting of the soap slabs to different lengths, so the versatility of the apparatus is improved.

Owner:安徽省玉兔日用化学品有限公司

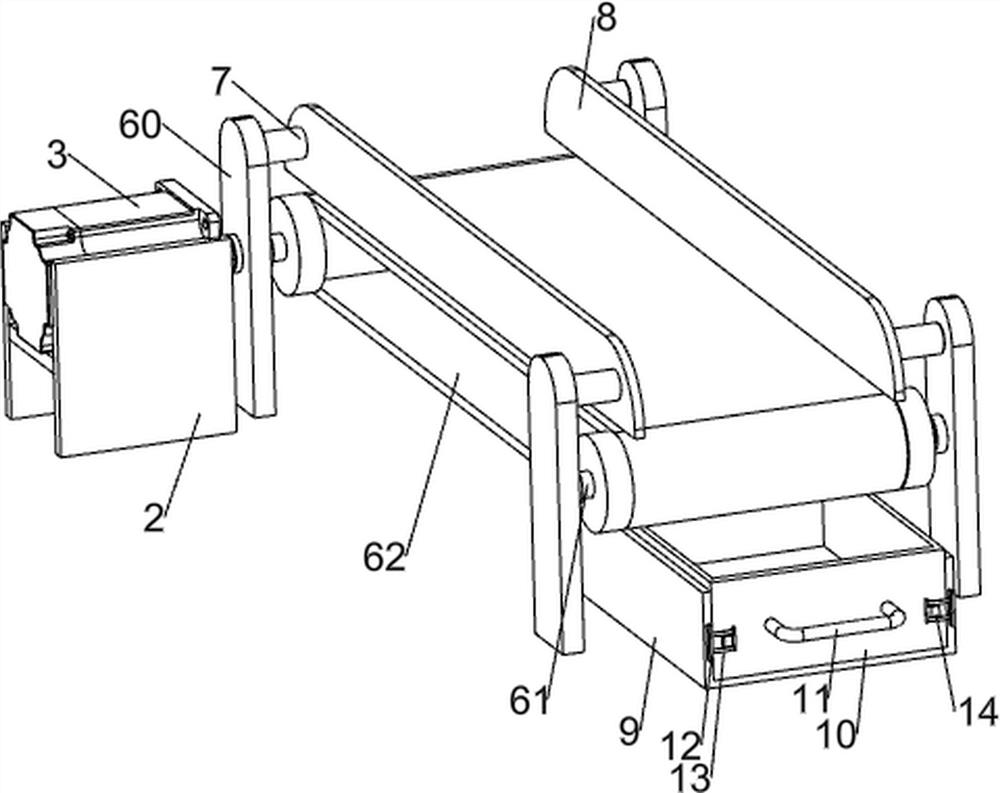

Stripping and slicing device for soap production

PendingCN108015836AGuaranteed transmission performanceSimple structureCutting soapCleaning using toolsEngineeringConveyor belt

The invention provides a stripping and slicing device for soap production. The device comprises a support, a conveying structure, a stripping and slicing mechanism, a material scraping mechanism and acold air device, wherein the conveying mechanism mainly comprises a soap strip rolling shaft, a conveyor belt, a finished soap rolling shaft and a soap collecting box; the soap strip rolling shaft and the finished soap rolling shaft are correspondingly arranged at two ends of a belt wheel; lateral cutting blades are symmetrically arranged on two side surfaces of the conveyor belt; the stripping and slicing mechanism is arranged above the running surface of the conveyor belt; the material scraping mechanism is positioned below a returning route of the surface of the conveyor belt; the stripping and slicing mechanism is fixed to the support through a pushing cylinder; stripping and slicing steel wires are fixed below a pushing plate through a cutter rack; a pneumatic pressing block is arranged at the bottom part of a connecting rack. The device is high in automation degree, fast to cut, and low in energy consumption; and meanwhile, the problem that the residues of stripped and sliced soap are adhered to the surface of the conveyor belt during conveying through an existing stripping and slicing machine can be avoided, thus the conveying capacity of the conveyor belt is ensured, the working accuracy is high, and the finished product quality is improved.

Owner:TIANJIN RUIHAI PENGXIANG TRADING

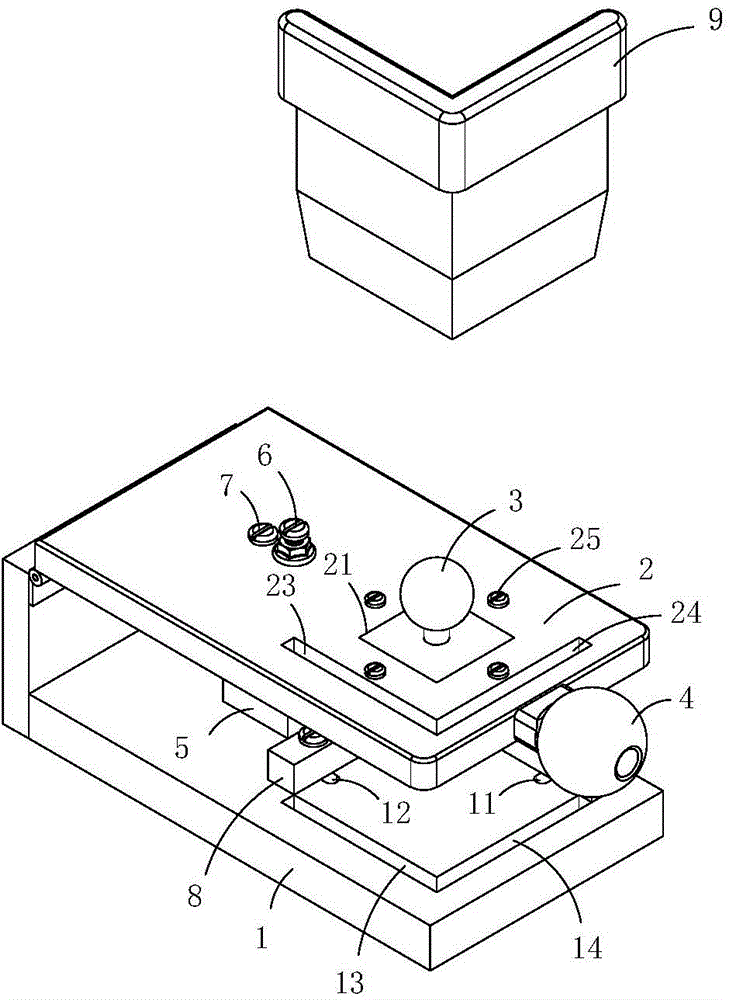

Manually-operated soap imprinting device

The invention discloses a manually-operated soap imprinting device. The manually-operated soap imprinting device comprises a base, a pressing plate, a soap stamp and a handle, wherein the pressing plate is rotationally arranged on the base, the soap stamp is fixed to the pressing plate, and the handle drives the pressing plate to rotate; the pressing plate is provided with a longitudinal-cutting limiting hole and a transverse-cutting limiting hole, the base is provided with a longitudinal-cutting limiting groove and a transverse-cutting limiting groove, the position of the longitudinal-cutting limiting hole is matched with that of the longitudinal-cutting limiting groove, and the position of the transverse-cutting limiting hole is matched with that of the transverse-cutting limiting groove. The manually-operated soap imprinting device is easy and convenient to operate, and can guarantee imprinting quality.

Owner:启东市恒力纺织有限公司

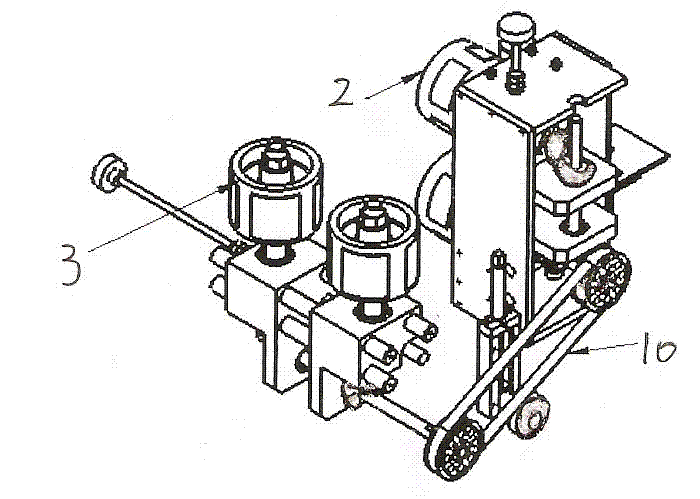

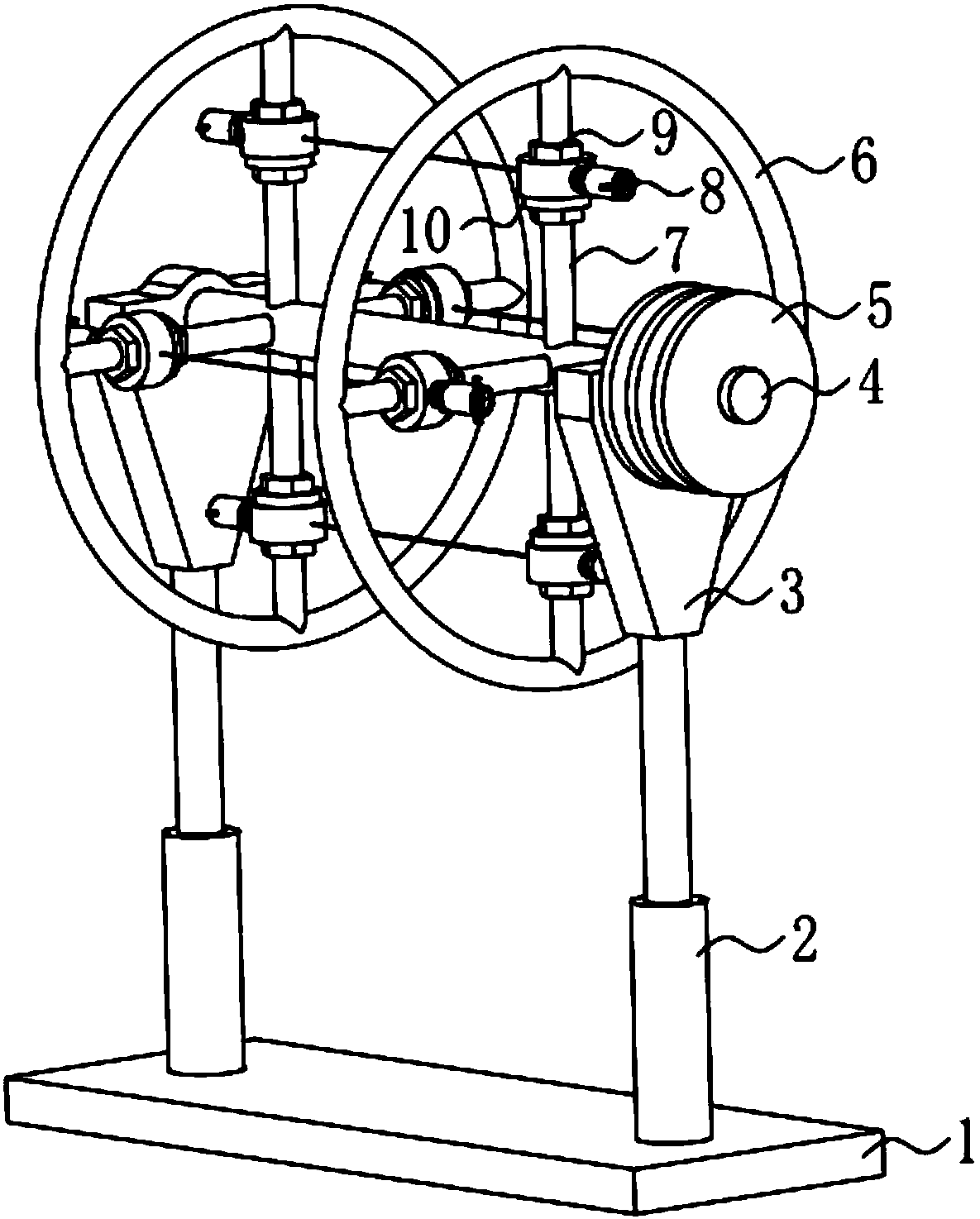

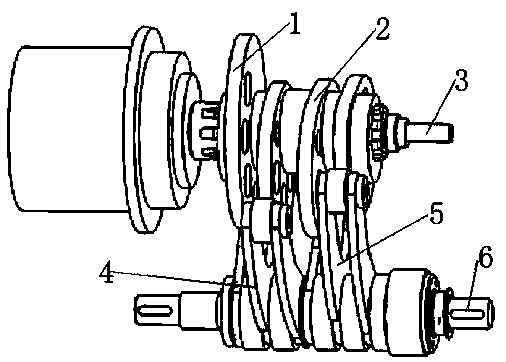

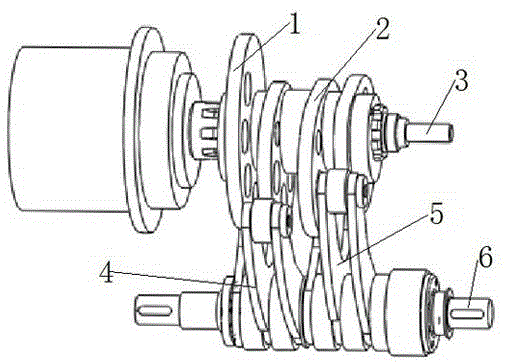

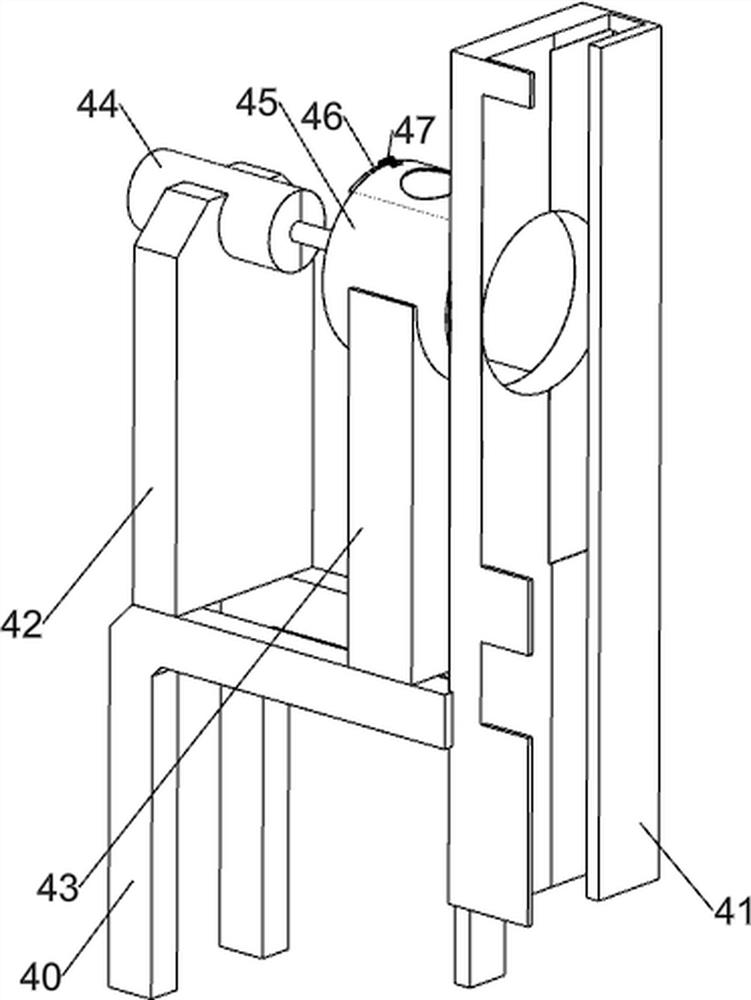

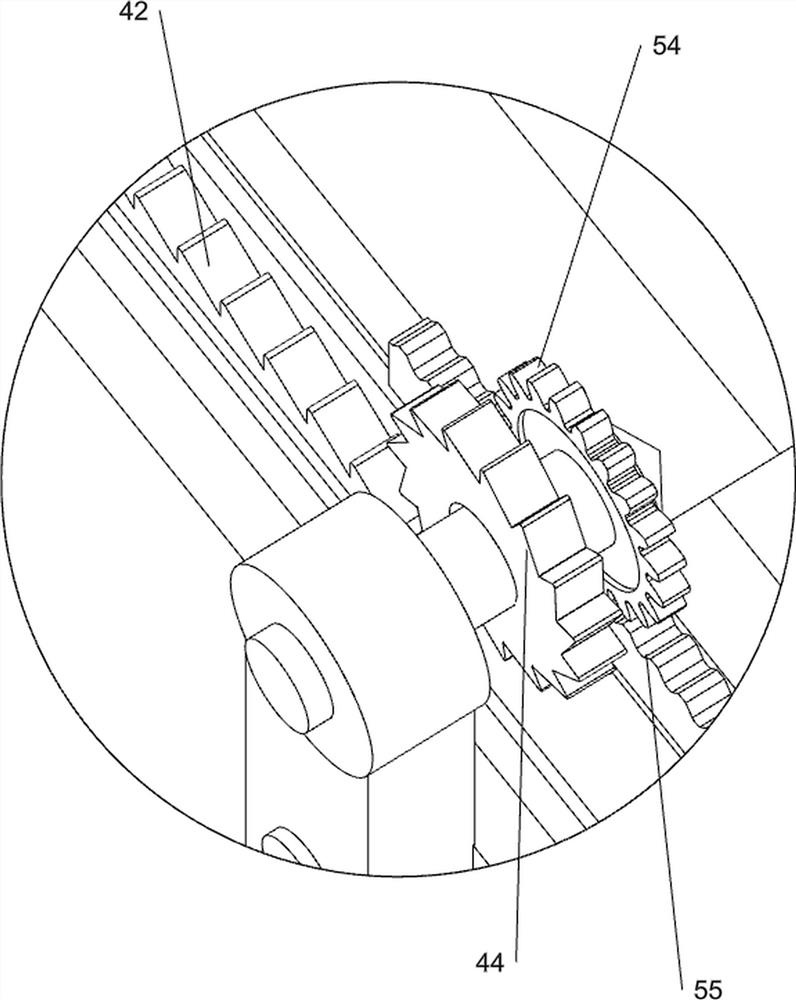

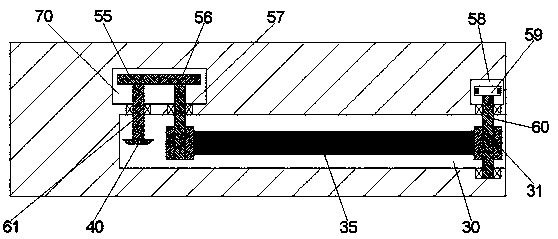

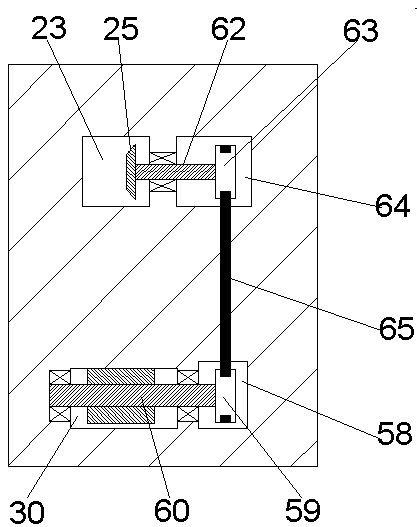

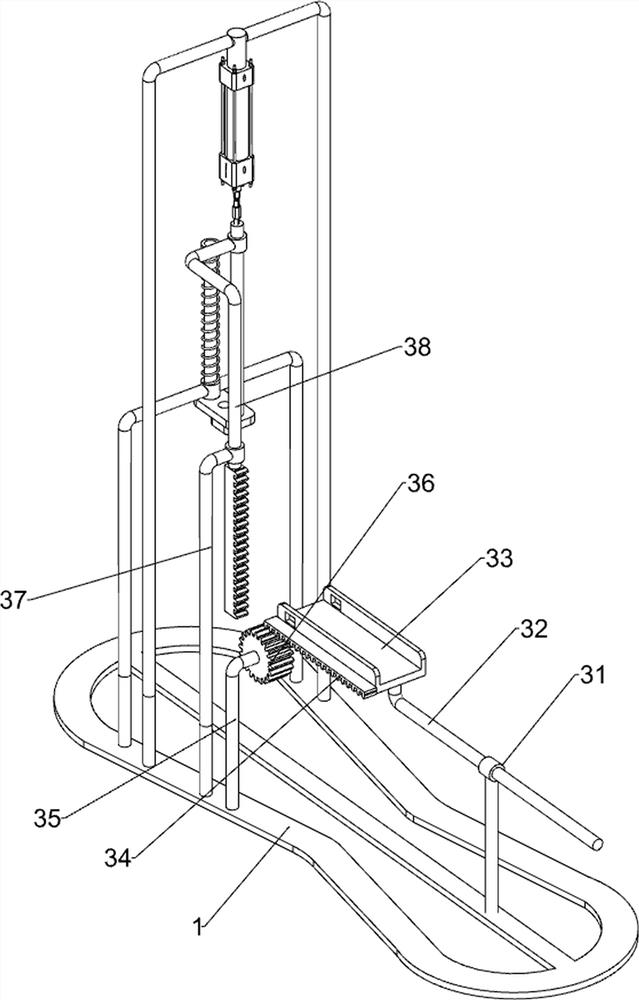

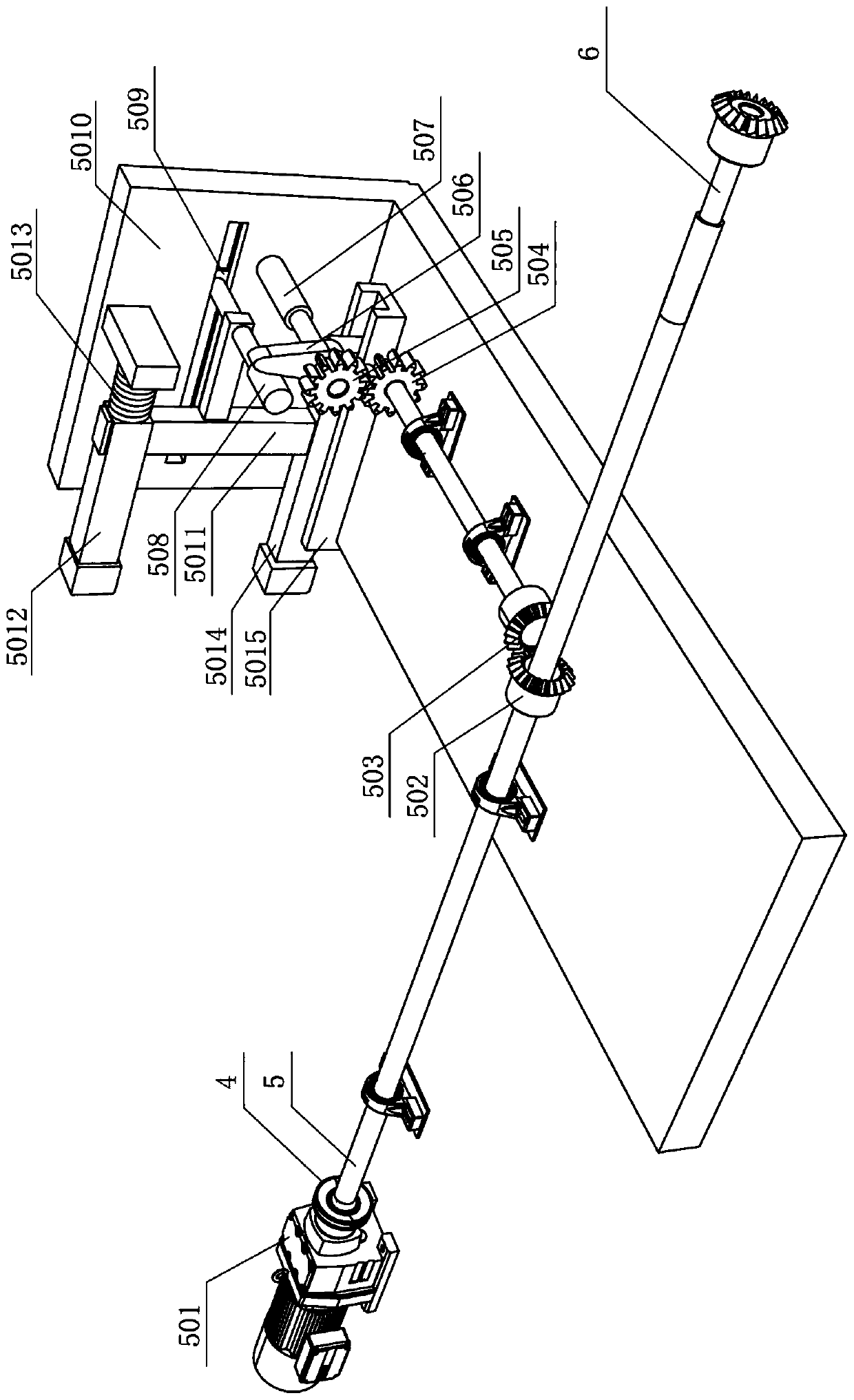

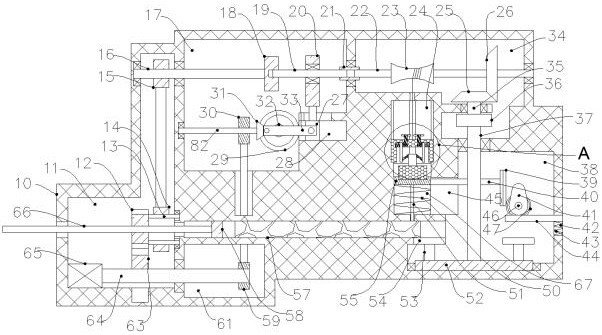

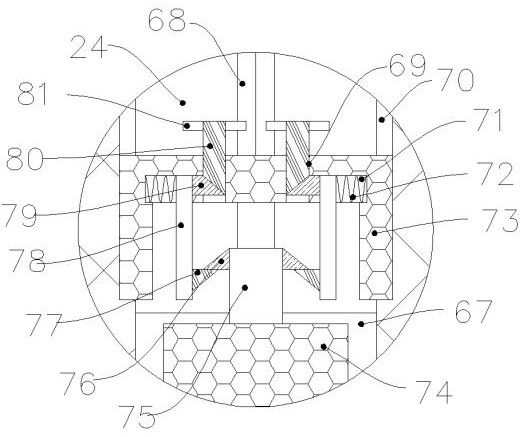

Cam connecting rod mechanism of soap dicer

The invention discloses a cam connecting rod mechanism of a soap dicer. The cam connecting rod mechanism comprises a cam mechanism and a connecting rod mechanism, wherein the cam mechanism drives the connecting rod mechanism. The main components are as follows: the cam mechanism is composed of two groups of conjugated cams, a cam shaft, an oscillating bar and an oscillating bar shaft; the cams are fixed on the cam shaft, the oscillating bar is fixed on the oscillating bar shaft, and the oscillating bar is driven by the cams; the connecting rod mechanism is composed of a connecting rod, a driving oscillating arm, a driven oscillating arm, a rotating frame, an auxiliary connecting rod and a cushion collar; the driving oscillating arm, the driven oscillating arm, the rotating frame and the auxiliary connecting rod form a parallelogram; the connecting rod, the auxiliary connecting rod and the driven oscillating arm form a pin shaft hinge; one end of the cushion collar is hinged with a dicer shell, and the other end of the cushion collar is hinged with the connecting rod. In the movement process, the mechanism can accurately ensure such requirements of the produced soap as gram weight, appearance and the like so as to meet the market demands.

Owner:NANTONG UNIVERSAL MACHINERY

A cam linkage mechanism of a soap cutting machine

The invention discloses a cam connecting rod mechanism of a soap dicer. The cam connecting rod mechanism comprises a cam mechanism and a connecting rod mechanism, wherein the cam mechanism drives the connecting rod mechanism. The main components are as follows: the cam mechanism is composed of two groups of conjugated cams, a cam shaft, an oscillating bar and an oscillating bar shaft; the cams are fixed on the cam shaft, the oscillating bar is fixed on the oscillating bar shaft, and the oscillating bar is driven by the cams; the connecting rod mechanism is composed of a connecting rod, a driving oscillating arm, a driven oscillating arm, a rotating frame, an auxiliary connecting rod and a cushion collar; the driving oscillating arm, the driven oscillating arm, the rotating frame and the auxiliary connecting rod form a parallelogram; the connecting rod, the auxiliary connecting rod and the driven oscillating arm form a pin shaft hinge; one end of the cushion collar is hinged with a dicer shell, and the other end of the cushion collar is hinged with the connecting rod. In the movement process, the mechanism can accurately ensure such requirements of the produced soap as gram weight, appearance and the like so as to meet the market demands.

Owner:NANTONG UNIVERSAL MACHINERY

Soap containing yak milk components and preparation method thereof

InactiveCN106281801ASignificant cleanlinessSignificant skin care effectCutting soapDrying soapFlavorPreservative

The invention discloses a soap containing yak milk components and a preparation method thereof. The preparation method comprises the following steps: mixing Tibetan yak butter, sea-buckthorn seed oil, coconut oil, palm oil and olive oil, heating the mixture in water, keeping the temperature of the oil mixture in the range of 30-45 DEG C; mixing sodium hydroxide with water, stirring the mixture until the sodium hydroxide is completely dissolved, maintaining the alkali liquor temperature between 30 DEG C and 45 DEG C; slowly pouring the oil mixture into the alkali liquor, mixing and stirring the mixture until the soap liquid is in a thick paste state, and when the saponification reaction is complete, adding a perfume and a preservative into the mixture, then slowly adding yak milk, continuously stirring, and finally pouring the soap liquid into a mould to be formed. The preparation method disclosed by the invention has the beneficial effects that (1) the preparation method is simple and practical, and the production cost is low; the physiological activity of the yak milk is greatly protected, and the preparation method is suitable for popularization and application; (2) the content of the yak milk in the soap is 5%-45% and the physiological activity is strong, the soap has the effects of cleaning, whitening, freckle-removing, skin nourishing, anti-aging and the like.

Owner:西宁琉璃王生物科技有限公司

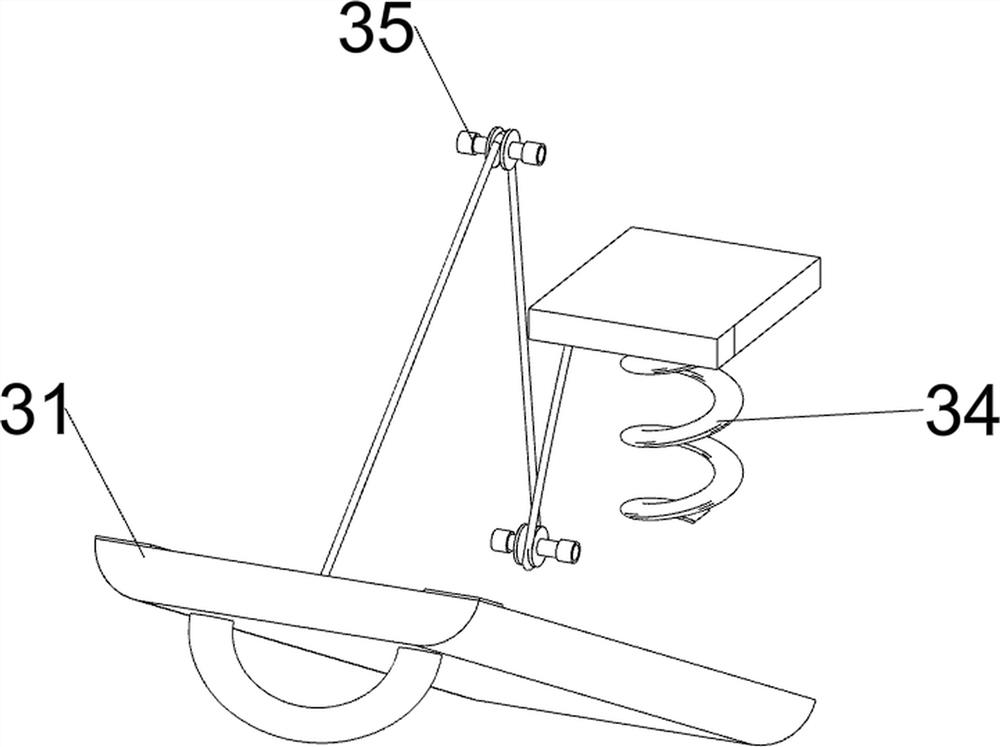

Small soap production equipment

InactiveCN112812907AControl one by one outputCutting soapMechanical engineeringIndustrial engineering

The invention relates to production equipment, in particular to small soap production equipment. The small soap production equipment is free of manual cutting, high in production efficiency and regular in appearance. The small soap production equipment comprises a bottom plate, a first supporting frame, a first servo motor, an extrusion mechanism and a scraping mechanism, the first supporting frame is arranged on the left rear side of the top of the bottom plate, the first servo motor is connected to the top of the first supporting frame, the extrusion mechanism is arranged on the rear side of the top of the bottom plate, and the scraping mechanism is arranged on the rear portion of the top of the bottom plate. Through cooperation of a first rotating plate, a second rotating plate, a connecting rope and a spring, the first rotating plate is pressed downwards by manpower or falling soap, so that a wedge-shaped block of the second rotating plate does not abut against a wedge-shaped disc any more, a scraping plate is driven to rotate under the gravity action of the soap, and under the action of the spring, the wedge-shaped block of the second rotating plate abuts against the wedge-shaped disc again, so that the soap is controlled to be intermittently discharged one by one.

Owner:郭小光

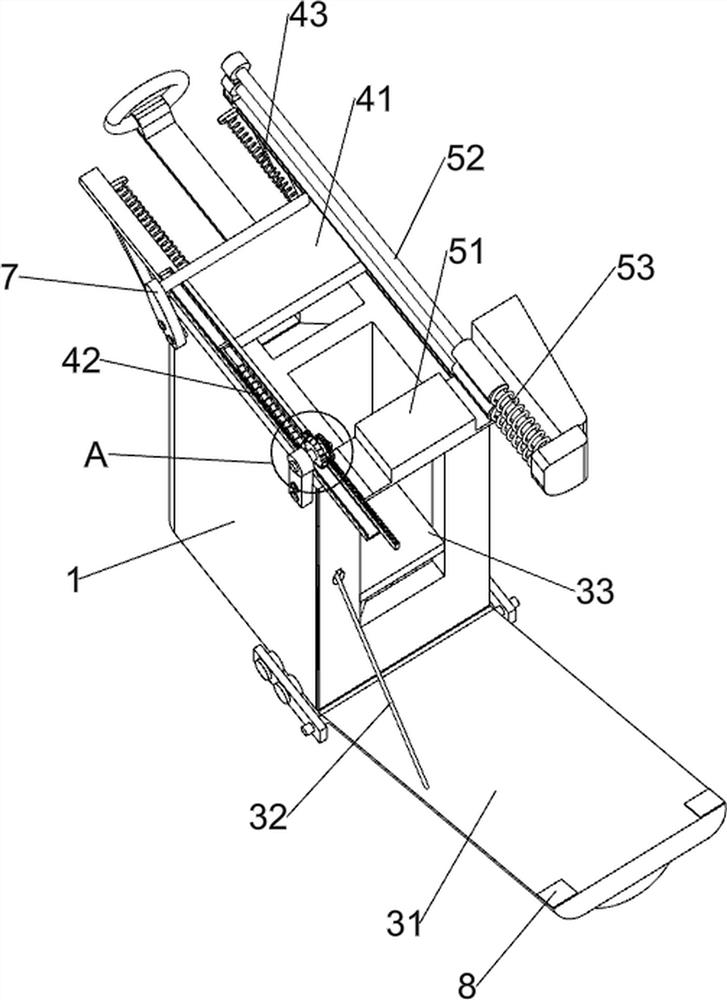

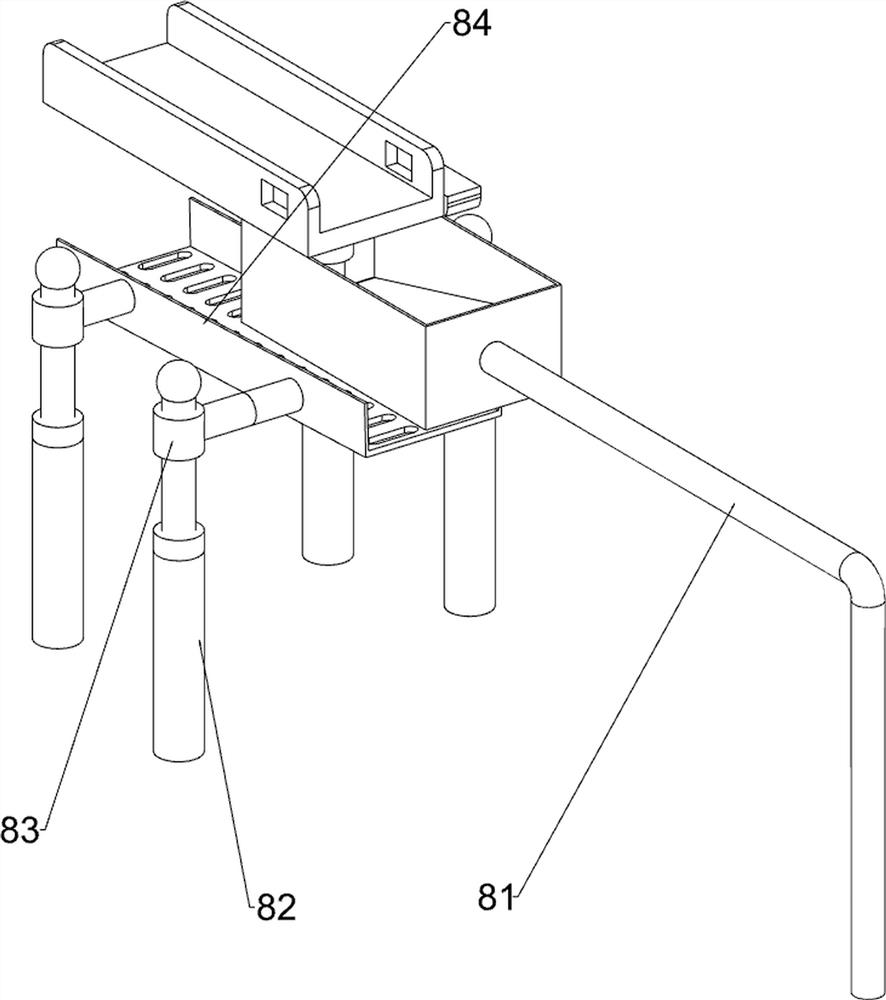

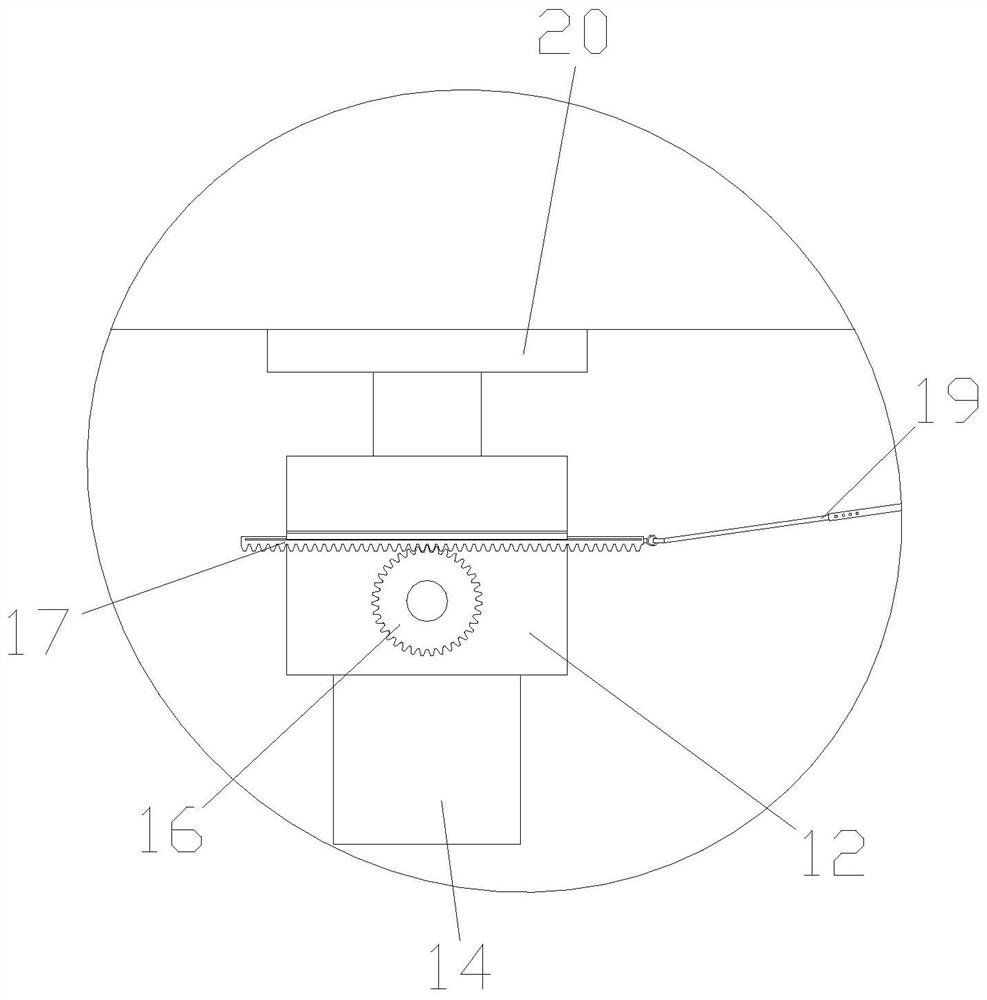

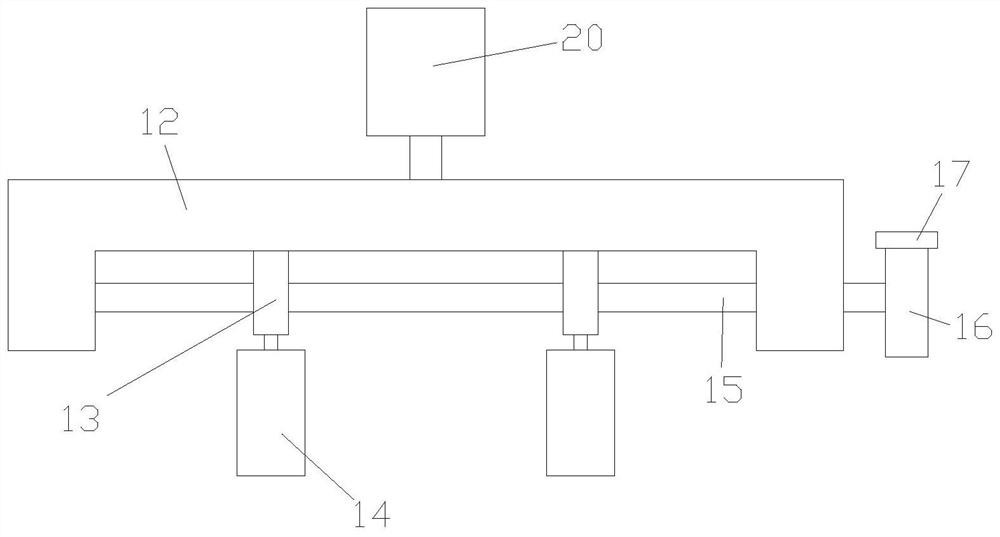

Strip soap processing and cutting device

PendingCN112720587ARealize transmissionImprove work efficiencyCutting soapMetal working apparatusMechanical engineeringIndustrial engineering

The invention relates to a cutting device, in particular to a strip soap processing and cutting device. The invention aims to provide the strip soap processing and cutting device capable of improving work efficiency and being uniform in specification of sap. The strip soap processing and cutting device comprises a worktable and a pressing block, a conveying mechanism, a cutting mechanism and a pushing mechanism, wherein the pressing block is connected to the top wall in the worktable; the conveying mechanism is connected in the worktable; the cutting mechanism is connected to the upper portion of the worktable; and the pushing mechanism is connected between the cutting mechanism and the worktable. By matching the conveying mechanism, the cutting mechanism and the pushing mechanism, soap can be conveyed, and meanwhile, a cutting knife is moved to cut the soap. The cut soap is pushed leftwards, and thus, the work efficiency can be improved.

Owner:廖立勇

Soap shaping and dicing device

InactiveCN111117818AMix well and evenlySimple structureCutting soapDrying soapEngineeringWater circulation

The invention discloses a soap shaping and dicing device. A stirring mechanism is arranged in a machine body; the stirring mechanism comprises a cooling cavity positioned at the left end in the machine body; fixing blocks are fixed to the upper end wall and the lower end wall in the cooling cavity; a water cooling pipe is wound outside the fixed blocks; a water circulation cooling device which isfixed on the lower end wall of the cooling cavity and is communicated with the water cooling pipe is arranged at the left ends of the fixed blocks; a stirring cavity of which the lower end wall is aninclined surface is formed in the fixed blocks; the rear end of the stirring cavity is provided with a channel, and the channel is communicated with the outside of the machine body and allows materials to enter; air drying is divided into three small parts, the middle part is responsible for absorbing heat, the parts at the two ends are responsible for air drying, and thus the solidification speedis increased; finally, a mold is cut through a cutter, marks are embossed while cutting is conducted, a soap is shaped and transported away, time is saved, and production efficiency is improved.

Owner:FUZHOU GULOU DISTRICT XIARONG TRADING CO LTD

Water soluble pellet and method for manufacturing said water soluble pellet

ActiveUS11499123B2Soap detergents with organic compounding agentsCutting soapEnvironmental engineeringWater soluble

A water soluble pellet for releasing one or more actives including a vegetable soap carrier in an amount of 10-95 wt %; a perfume oil in an amount of 2-12 wt %; and a dye in an amount of 0.001 to 0.5 wt %. The method for manufacturing the water soluble pellet includes the following steps: mixing the composition; extruding the composition; and cutting the extruded composition to form water soluble pellets.

Owner:ZOBELE HLDG SPA

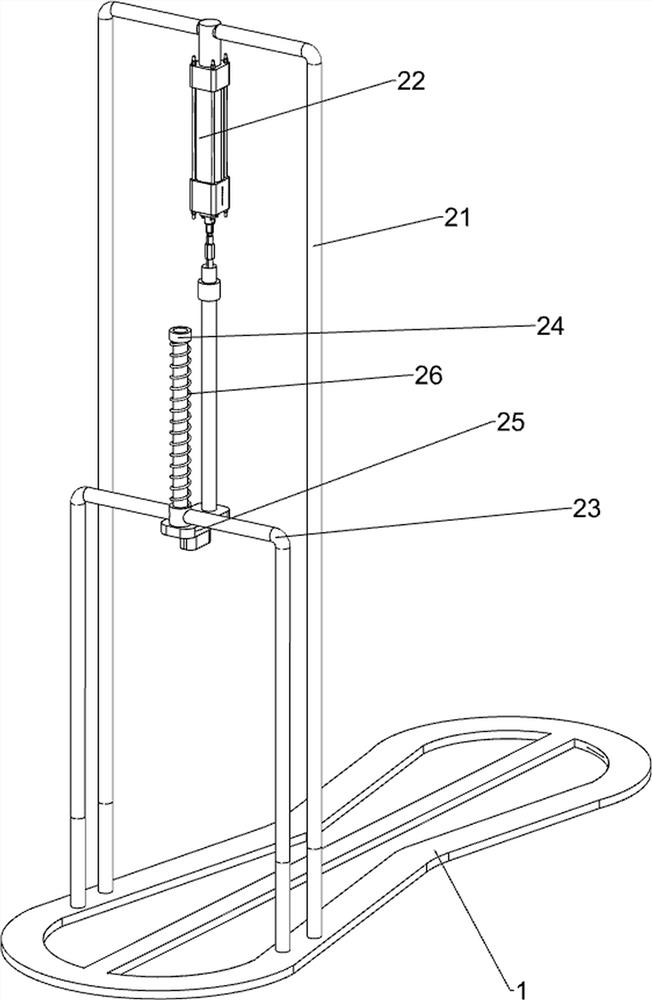

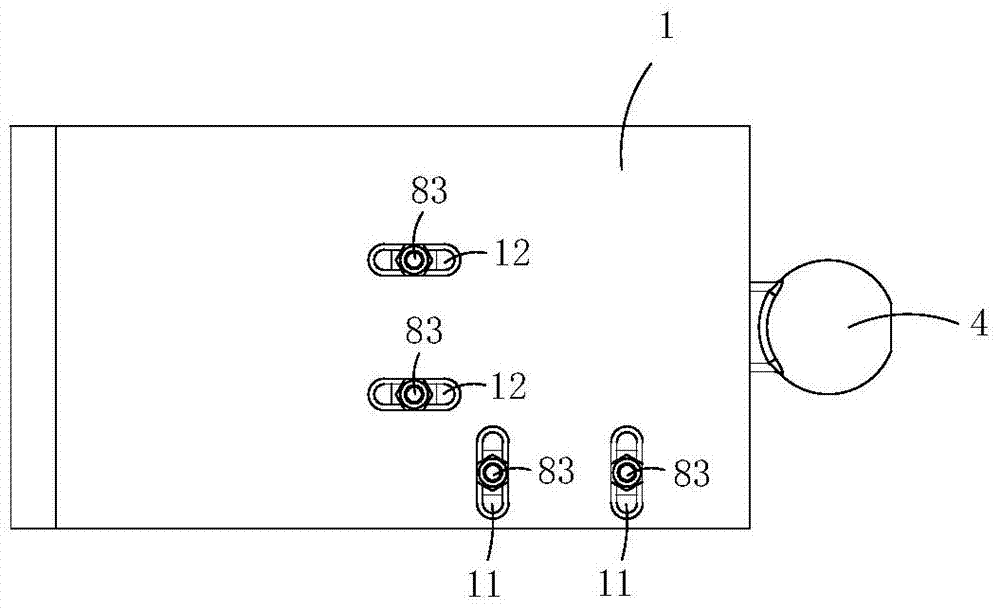

Cutting device for post processing of handmade soap

The invention discloses a cutting device for post processing of handmade soap. The cutting device comprises a cuboid workbench placed horizontally, wherein the workbench is connected with a supporting plate parallel to a side face using width and height as sides; the upper part of the supporting plate are connected with at least three cutting wires; the cutting wires are distributed in parallel at equal intervals along the width direction of the workbench; all the cutting wires are perpendicular to the supporting plate respectively; the upper ends of the cutting wires are respectively connected onto a fixed block; the lower ends of the cutting wires are respectively connected onto a sliding plate sliding along the width direction of the width direction; the sliding plate is connected with the supporting plate in a sliding manner; a pushing plate is arranged above the workbench; the pushing plate is positioned on the other side of the workbench and is opposite to the cutting wires; and a fixed device for fixing the handmade soap is arranged on the side face, facing the cutting wires, of the pushing plate. The handmade soap is pushed along the long side of the workbench, so that the handmade soap with long side is prevented from being collided or broken by manual operation, the cutting quality of the handmade soap is improved, and then the cutting efficiency of the handmade soap is improved.

Owner:橄享成都科技有限责任公司

Soap custom surface engraving machine

PendingCN112406388ARealize the engraving workAchieve clampingCutting soapDetergent materialsComputer printingEngineering

The invention relates to an engraving device, in particular to a soap custom surface engraving machine. Through the soap custom surface engraving machine, soaps can be engraved, automatically replacedat intervals, clamped and fixed and screened, and soapsuds can be shaken off the soaps. The soap custom surface engraving machine comprises a base and a printing mechanism, and the printing mechanismis welded to the top of the base. According to the soap custom surface engraving machine, the printing mechanism is arranged and is matched with a receiving mechanism, so that soap engraving work canbe realized; a clamping mechanism is matched with the printing mechanism, so that the soaps can be clamped, and the engraving efficiency is effectively improved; and a discharging mechanism is matched with a storage mechanism, so that the soaps can be conveyed to a receiving working plate at intervals, and the labor intensity of workers is effectively lowered.

Owner:张驰

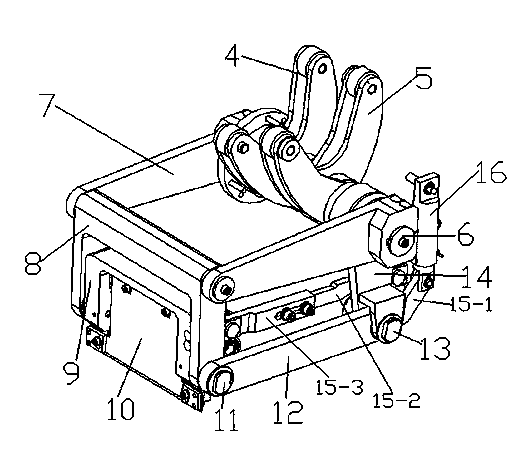

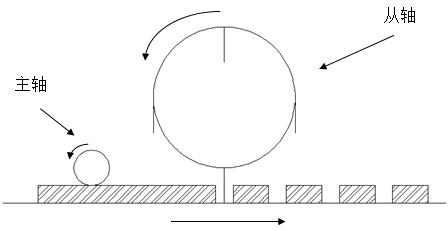

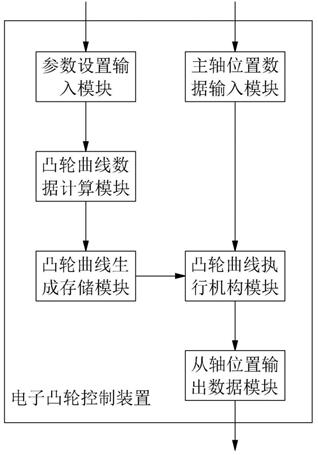

Electrical control device and method of four-knife roll printing dicer

ActiveCN112305991AReduce shockFlat cutting surfaceCutting soapTotal factory controlControl engineeringElectrical control

The invention provides an electrical control device and method for a four-knife roll printing dicer. The control device structurally comprises a main shaft position data input module, a parameter setting input module, a cam curve calculation module, a cam curve generation and storage module, a cam curve execution mechanism module and a slave shaft position data output module. The control method specifically comprises the following steps: 1) specifying a main shaft and a slave shaft; 2) determining the period of a cam; 3) planning a cam curve; 4) drawing a cam curve; 5) carrying out PLC curve data processing; and 6) executing the cam curve by a PLC. Aiming at the structural characteristic design of the four-knife roll printing dicer, the continuous operation of equipment can be ensured, obvious rapid acceleration, deceleration and stop are avoided, and the impact on mechanical equipment is small; and a knife edge and a soap bar are relatively static through synchronous application, so that the cutting surface of a product is smoother, long-time continuous operation of equipment can be ensured, and the working efficiency is improved.

Owner:NANTONG UNIVERSAL MACHINERY

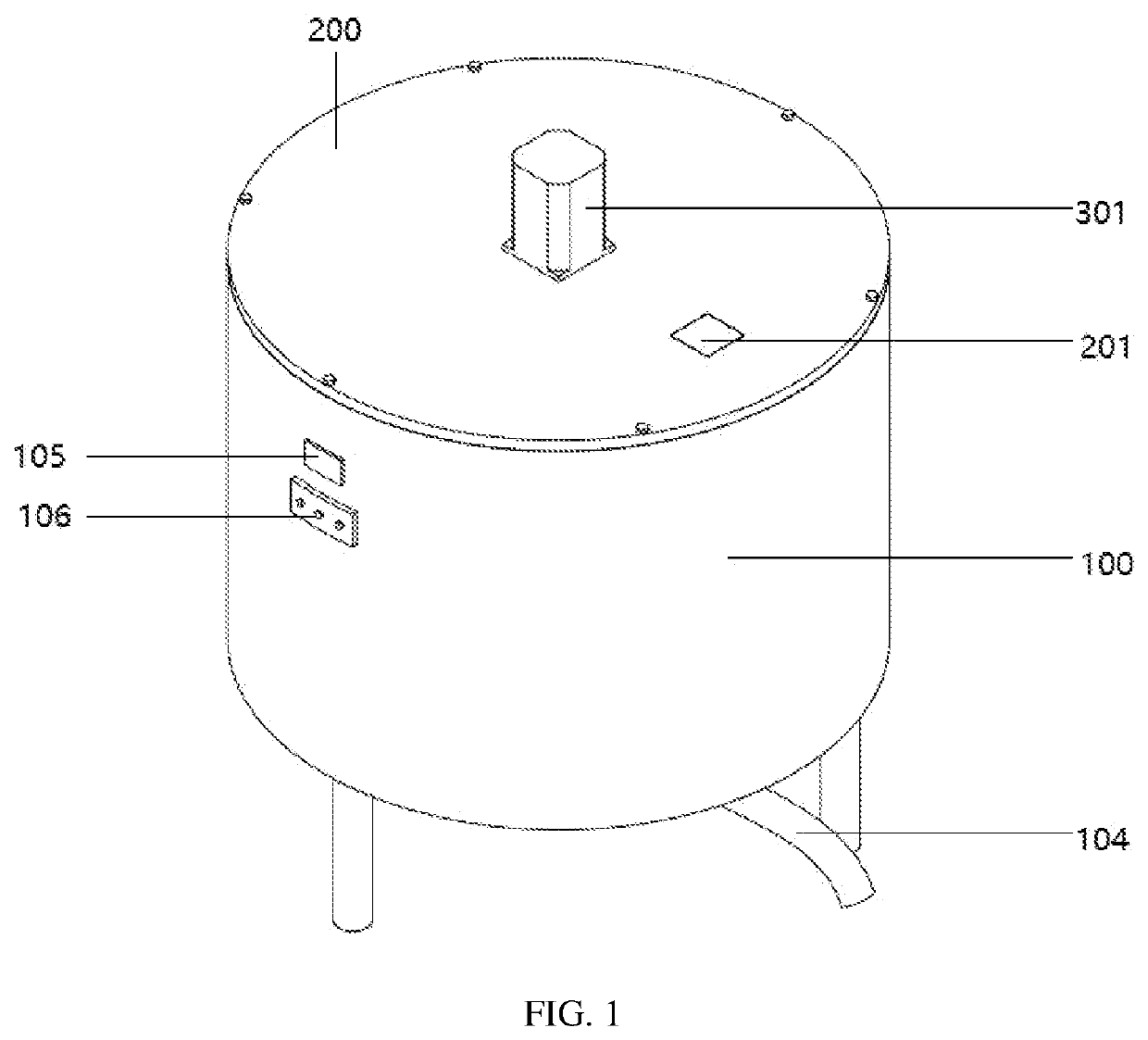

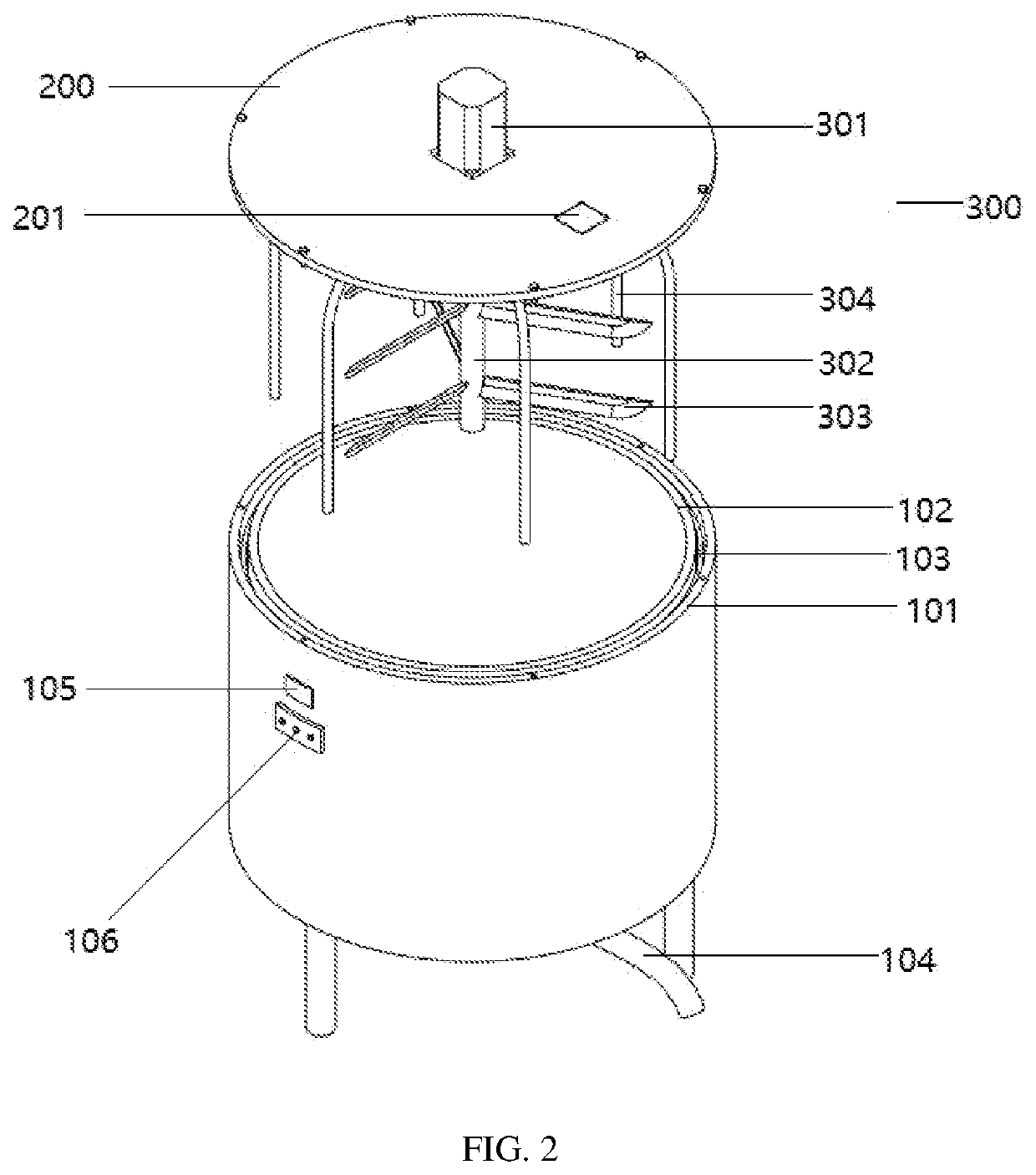

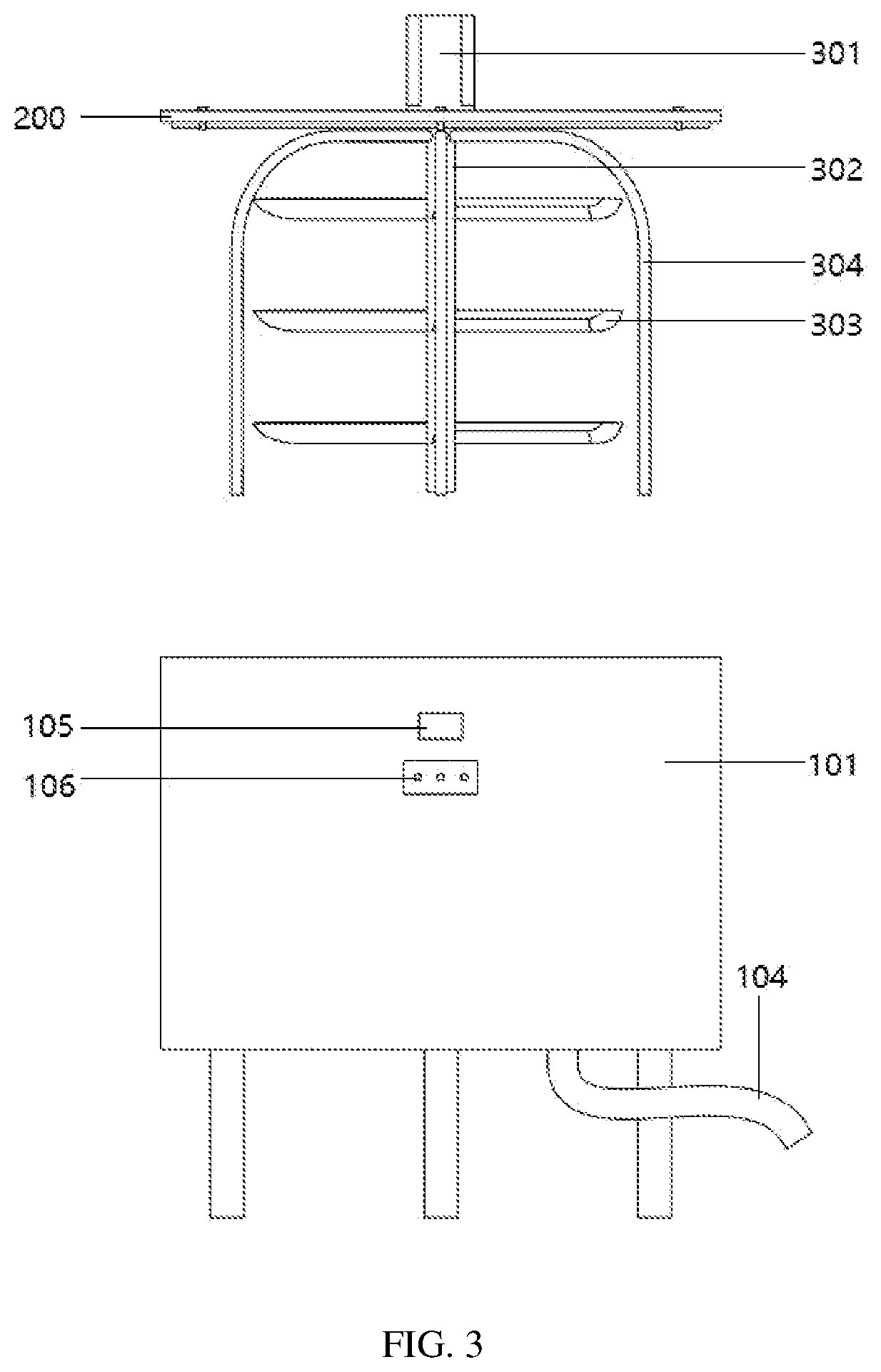

Perfumed latex soap and preparation method thereof

ActiveUS11236292B1Improve skin conditionEasy to adjustSoap detergents with organic compounding agentsCosmetic preparationsHuman skinGlycerol

Perfumed latex soap is prepared from the following components in parts by weight: 2-5 parts of natural latex, 5-12 parts of glycerin, 8-10 parts of sodium dodecyl sulfate, 5-10 parts of coconut oil, 6-8 parts of palm oil, 1-3 parts of titanium dioxide, 0.8-1.2 parts of ethylenediamine tetraacetic acid, 0.6-0.8 part of sulfur, and 0.8-1.0 part of radix asparagine essential oil. The perfumed latex soap is mild, safe, and non-irritating and has aroma of the natural latex. In addition, the added radix asparagine essential oil can effectively improve the skin condition of a human body without causing the human body to generate dependence. The temperature of the mixing tank in which the perfumed latex soup is prepared is convenient to adjust and materials in a mixing cylinder can be agitated and sheared during agitating, so that the materials are fully mixed and the quality of a product is improved.

Owner:WENZHOU JIABO LATEX PROD CO LTD

Easy-to-use soap mould

The invention discloses an easy-to-use soap mould. The easy-to-use soap mould comprises a mould body, wherein the mould body comprises a first template and a second template, the first template is movably connected with the second template through a movable shaft, telescopic rods are fixedly connected to the four corners of the outer upper end of the first template, the upper ends of the telescopic rods are all fixed at the lower end of a fixing plate, a plurality of blades are fixedly connected to the lower end of the fixing plate, a plurality of inserting slots are formed in the first template, a cavity is formed in the second template, hydraulic cylinders are fixedly connected to both the upper end and the lower end in the cavity and moving blocks are fixedly connected to all the hydraulic cylinders. The easy-to-use soap mould disclosed by the invention has the beneficial effects of having more convenient use for being formed by combining the two templates and being capable of beingdirectly cut after the soap is formed without dividing, thereby being more convenient because the fixing plate with a plurality of the blades is connected to the first template through the telescopicrods and the inserting slots which correspond to the blades one by one are formed in the first template rightly below the blades.

Owner:重庆贵腾模具有限公司

Manually-operated soap imprinting device

Owner:启东市恒力纺织有限公司

Handmade soap manufacturing device

ActiveCN111286427AAutomatic anti-scorch meltingAvoid heating upCutting soapShaping soapProcess engineeringMechanical engineering

The invention relates to the field of soap, and in particular, relates to a handmade soap manufacturing device. The technical problem to be solved by the invention is to provide the handmade soap manufacturing device. The handmade soap manufacturing device comprises a table frame, a heating mechanism, an anti-scorching self-heating device, an anti-foaming fusion device, a sheet separation device and a top plate; the rear part of the top end of the table frame is connected with the anti-foaming fusion device; the left top of the outer surface of the heating mechanism is connected with a handle;the anti-coking self-heating device is arranged in the middle in the heating mechanism. When a soap base is about to reach the scorching temperature, a melting container is automatically separated from a heat source, the temperature of the container is prevented from rising, and soap base scorching prevention melting is automatically carried out; the container is vibrated to accelerate additive fusion on the basis of no foaming, so that the manufacturing efficiency is improved; the soap base is automatically slit, so that a soap maker who cannot skillfully use a cutter is prevented from forcibly using the cutter to injure the soap maker, and the safety effect of handmade soap making is improved.

Owner:山东智汇新谷科技企业孵化器有限公司

Simple soap cutting device

InactiveCN104371868AEasy to produceEasy to operateCutting soapStructural engineeringMechanical engineering

The invention discloses a simple soap cutting device which comprises an upper box cover and a bottom plate, wherein the upper box cover is movably connected with the bottom plate, a cavity which is moderate in depth is formed on the upper box cover, and a small groove a is formed on the inner face of the upper box cover on the upper part of the cavity. The simple soap cutting device disclosed by the invention is simple in structure, convenient to operate and very suitable for simple manufacturing.

Owner:绵阳原香农业科技有限公司

Soap uniform sectioning equipment for production and processing

PendingCN114770612AMove fastEasy to replaceCutting soapMetal working apparatusElectric machineryEngineering

The invention relates to section cutting equipment, in particular to uniform section cutting equipment for soap for production and processing. According to the soap uniform cutting equipment for production and processing, the cutter can be automatically lifted to cut soap into sections, and the working efficiency is improved. Soap uniform sectioning equipment for production and processing comprises a shell, a clamping seat, a cutting mechanism and the like, the clamping seat is arranged on the lower right side of the shell, the cutting mechanism is arranged on the shell and comprises a first fixing block, an electric push rod and a push frame, the first fixing block is arranged on the upper right side of the shell, and the electric push rod is arranged in the middle of the first fixing block; pushing frames are arranged at the bottoms of telescopic rods of the electric push rods. A telescopic rod of the electric push rod continuously stretches out and draws back, the tool rest and the cutter can be driven to continuously move up and down, and the cutter can cut off soap at intervals; and meanwhile, when the output shaft of the gear motor rotates, the conveying belt can rotate, so that the soap can be conveyed rightwards.

Owner:李彪

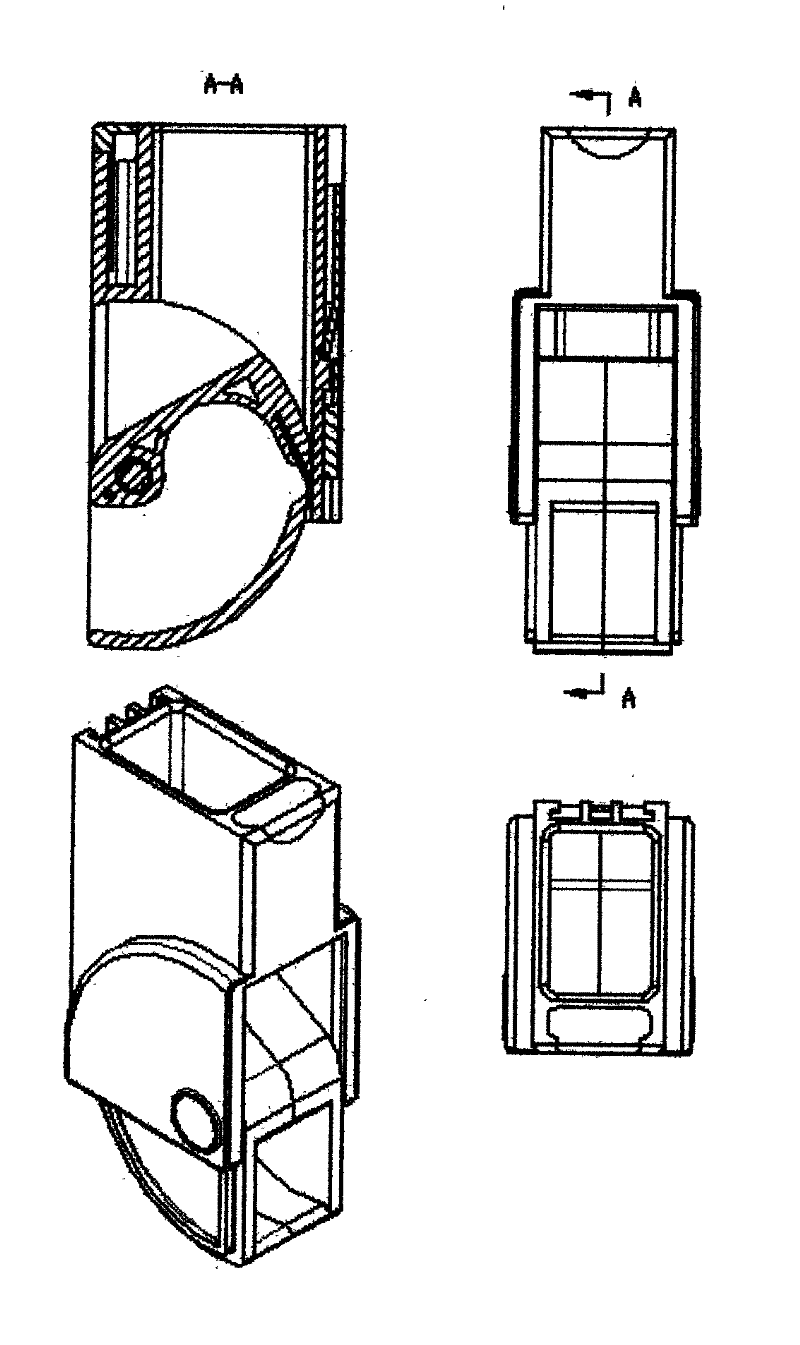

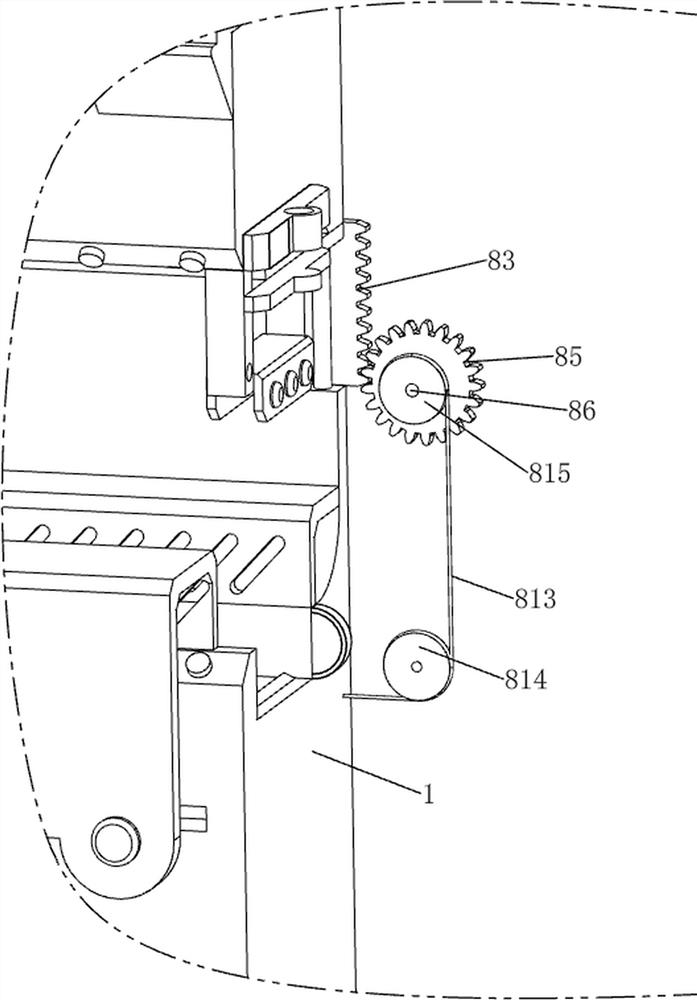

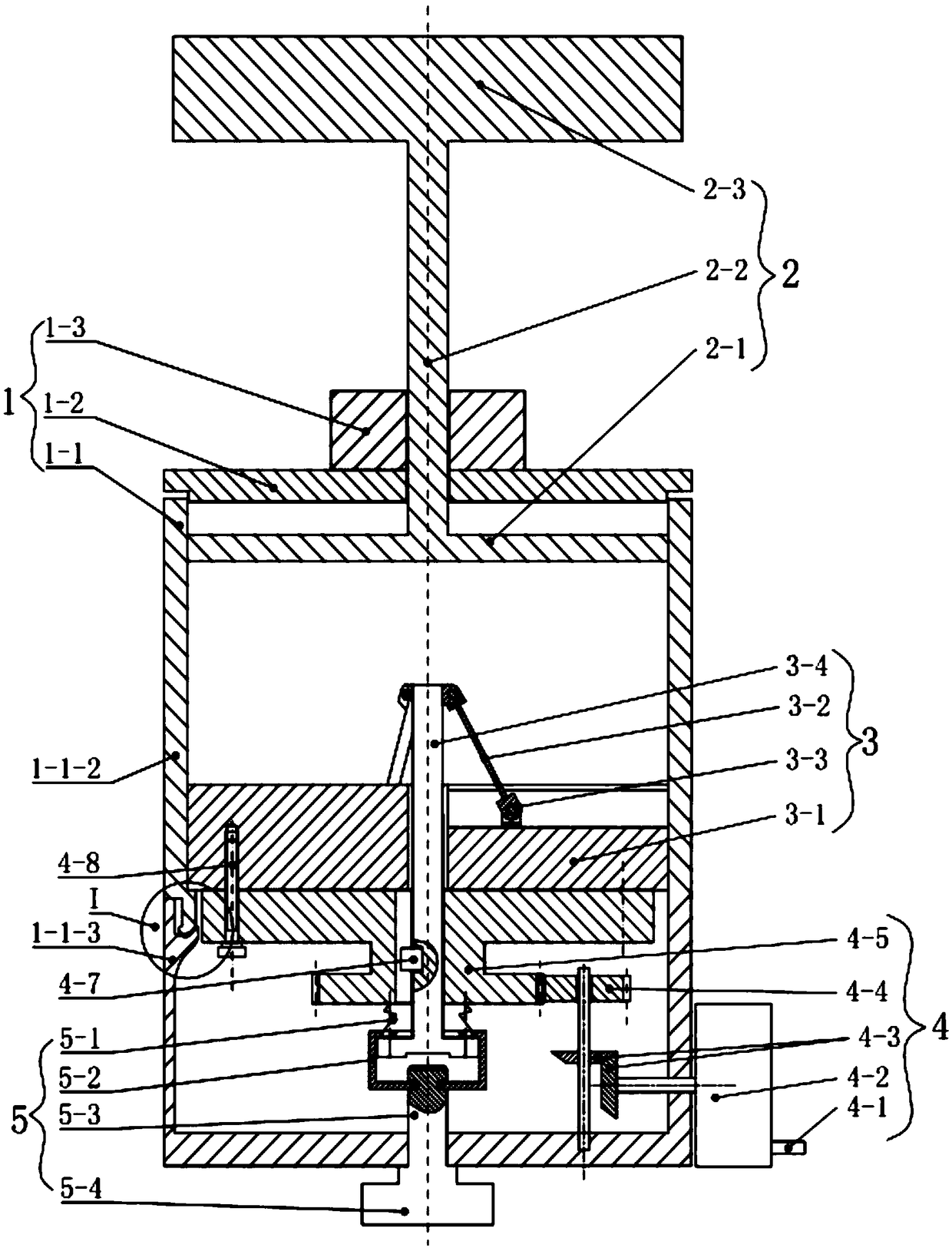

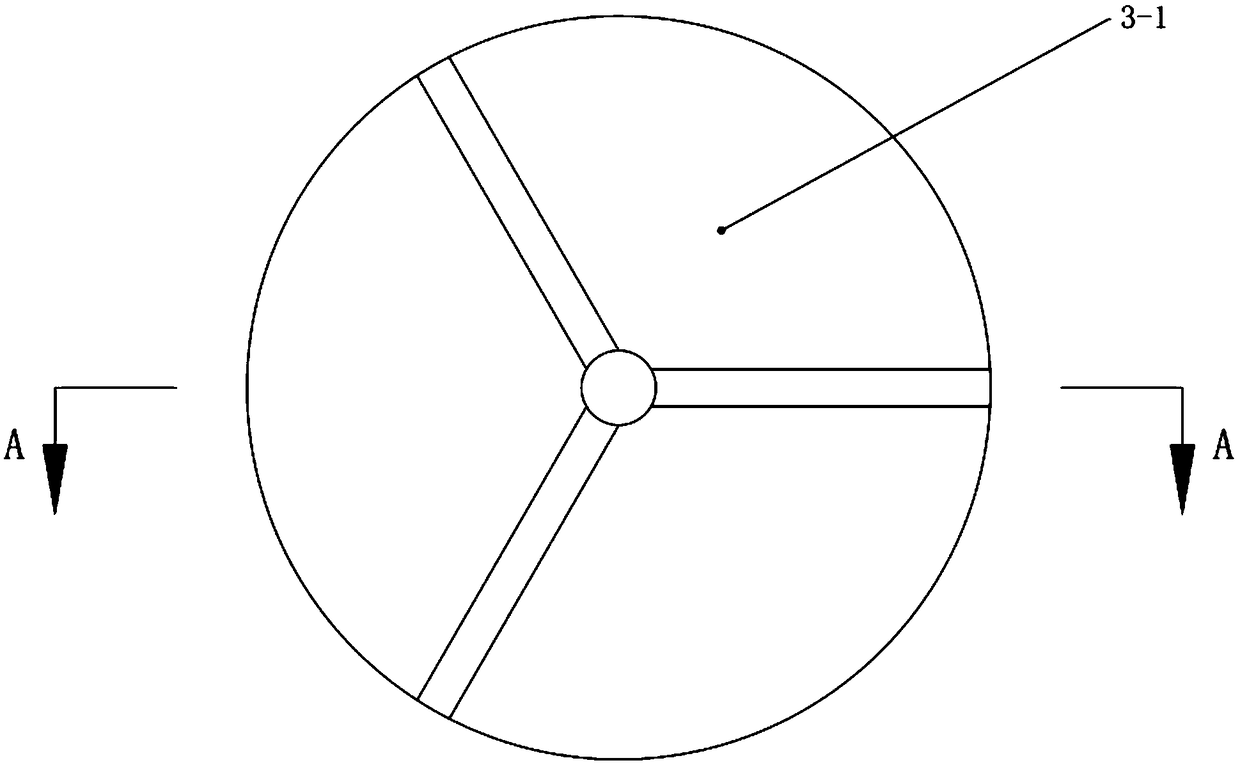

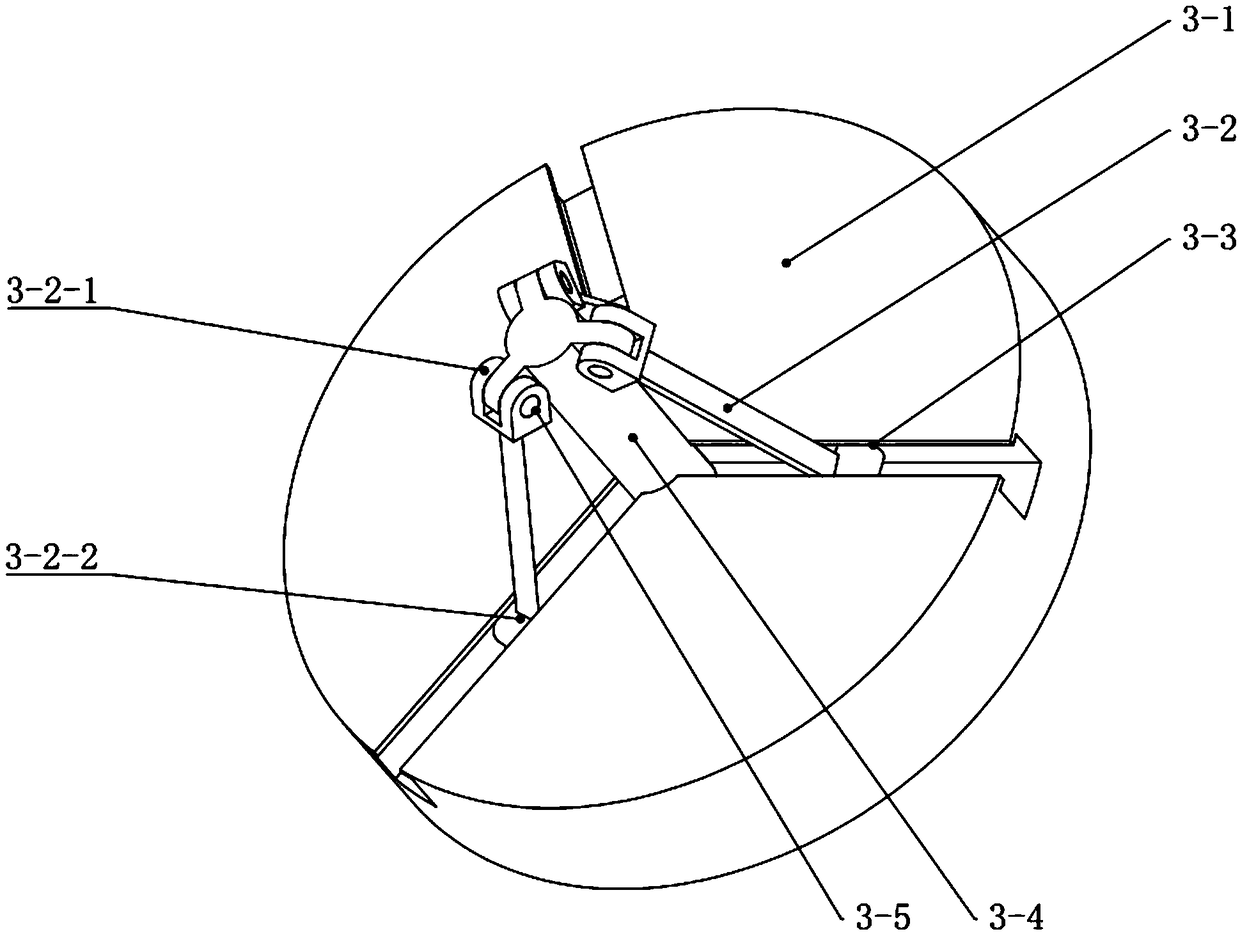

Broken soap recycling device

A broken soap recycling device comprises a cartridge body, a press forming mechanism, a cutting mechanism, a power mechanism, and an ejector rod resetting mechanism; the cartridge body comprises a housing cylinder and a cylinder end cap, and the cylinder end cap is assembled above the housing cylinder; the press forming mechanism comprises a pressing plate, a pressing rod and a handle, and one endof the pressing rod movably penetrates through the cylinder end cap; the cutting mechanism comprises a cutter head, a cutter, a slider, an ejector rod and a spring, and is arranged in the housing cylinder; the power mechanism comprises a driving wheel, a connecting wheel and a transmission mechanism, and the connecting wheel is coaxially arranged directly below the cutter head; and the ejector rod resetting mechanism comprises a buffer spring, a movable connecting lantern ring, and a resetting push rod. The device is simple and compact in structure, convenient to operate, low in cost, clean and hygienic, environmentally friendly and energy-saving, and integrates the functions of crushing and press-forming broken soap.

Owner:XIANGTAN UNIV

A pepper soap cutting device

ActiveCN110744617BEasy to separateCompact designSievingCutting soapStructural engineeringConveyor belt

The invention discloses a prickly ash soap slitting device, which comprises a conveyor belt and a slitting mechanism. A material guiding and screening net is obliquely arranged at the end of the conveyor belt. The material screening net is connected with the frame through a plurality of support rods. The reciprocating swing mechanism includes a return spring and a push rod assembly. The return spring and the ejector rod assembly are located on the opposite side of the guide screen net; There are multiple offset grooves evenly distributed in its circumferential direction. The ejector rod assembly includes a swing rod whose middle part is hinged on the frame. One end of the swing rod is hinged with an active rod that is offset against the offset groove. The ejector bar with the sieve mesh offsetting; compared with the prior art, the present invention can quickly separate the leftovers and soap pieces after cutting, and avoid the leftovers from adhering to the soap pieces and affecting the appearance and quality of the soap pieces after packaging.

Owner:CHONGQING UNIV OF EDUCATION +1

Novel processing device for manufacturing of fragrant soap

InactiveCN106554868AIncrease productivityReduce blemishesCutting soapShaping soapEngineeringConveyor belt

The invention discloses a novel processing device for manufacturing of fragrant soap. The device includes a support bench, a shaping chamber, a conveyor belt, and a packaging chamber. A soap outlet pipe is arranged on the upper end of the support bench. The shaping chamber is communicated to the upper part of the soap outlet pipe. A solidifying chamber is communicated to the upper part of the shaping chamber. A material blending box is connected to the upper part of the solidifying chamber. A material inlet pipe is arranged on the upper end of the material blending box. The conveyor belt is supported above the support bench. A polishing machine is installed above the middle of the conveyor belt. An observation bench is arranged at the lower-right side of the polishing machine. The packaging chamber is arranged at the right side of the observation bench. The novel processing device achieves full-automatic fragrant soap processing from material blending, shaping, packaging and box packaging, so that the device not only saves manpower resource but also increases production efficiency of the fragrant soap. With the polishing machine and the observation bench, defects on the fragrant soap are reduced. The device is high in quality and efficiency and can satisfy demand on high quality fragrant soap of users.

Owner:CHONGQING YUWEI KNITWEAR BUSINESS DEPT

An automatic mold forming method

An automatic mold molding method, wherein the molding equipment includes a molding box and a cutting device arranged in the molding box, the cutting device includes a power storage mechanism and a cutting mechanism, and the power storage mechanism uses a wire wheel to wind the inertia The block is lifted upwards to store power, and after the power storage is completed, release and press down the cutting mechanism to cut the bar soap. A power chamber is provided in the forming box, and a power device is provided in the power chamber. There is a switching cavity in the forming box, and a power switching device is set in the switching cavity; the device is simple in structure and easy to use, and the prepared bar soap can be placed in the device, and the cutting and pattern pressing can be completed automatically , greatly improving efficiency, saving labor, reducing costs, and at the same time avoiding irregular cutting edges caused by manual cutting, or chaotic knife marks caused by uneven strength, which reduces the quality of handmade soap.

Owner:青岛恒泰机械配件有限公司

A device for making handmade soap

ActiveCN111286427BAutomatic anti-scorch meltingAvoid heating upCutting soapShaping soapPolymer scienceEngineering

The invention relates to the field of soap, in particular to a handmade soap making device. The technical problem to be solved by the present invention is to provide a handmade soap making device. A handmade soap making device, including a table frame, a heating mechanism, an anti-scorch self-heating device, an anti-foam fusion device, a sheet separation device and a top plate; the rear part of the top of the table frame is connected to the anti-foam fusion device; the left top of the outer surface of the heating mechanism It is connected with the handle; the middle part of the heating mechanism is equipped with an anti-coking self-heating device. The present invention achieves the automatic separation of the melting container from the heat source when the soap base is about to reach the scorching temperature, prevents the container from heating up, and automatically melts the soap base against scorching; vibrates the container, accelerates the fusion of additives on the basis of no foaming, and improves the manufacturing process. Efficiency; automatic cutting of soap base, preventing soap makers who are not proficient in using knives from forcibly using them to harm themselves, and improving the safety of hand-made soap.

Owner:山东智汇新谷科技企业孵化器有限公司

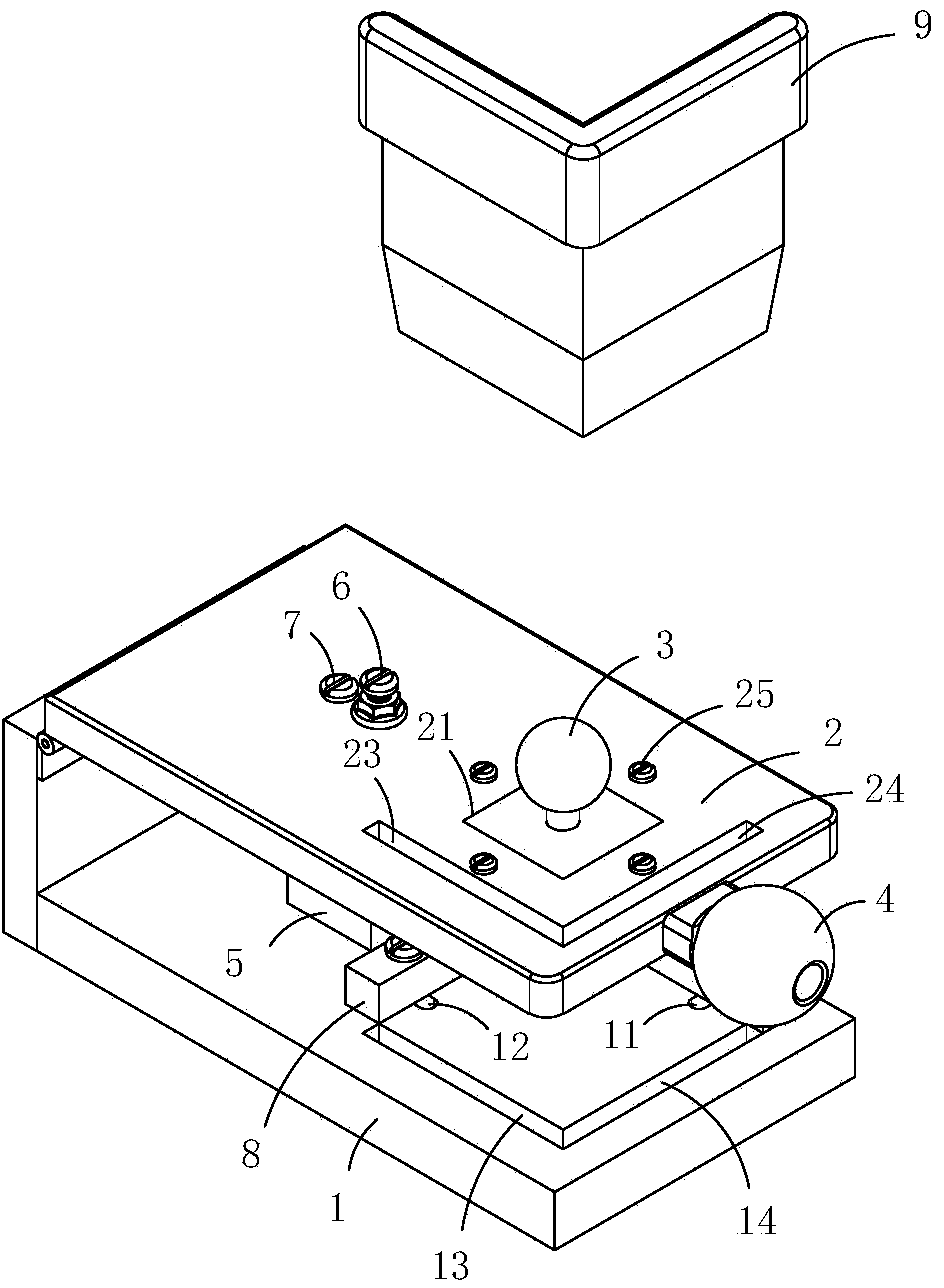

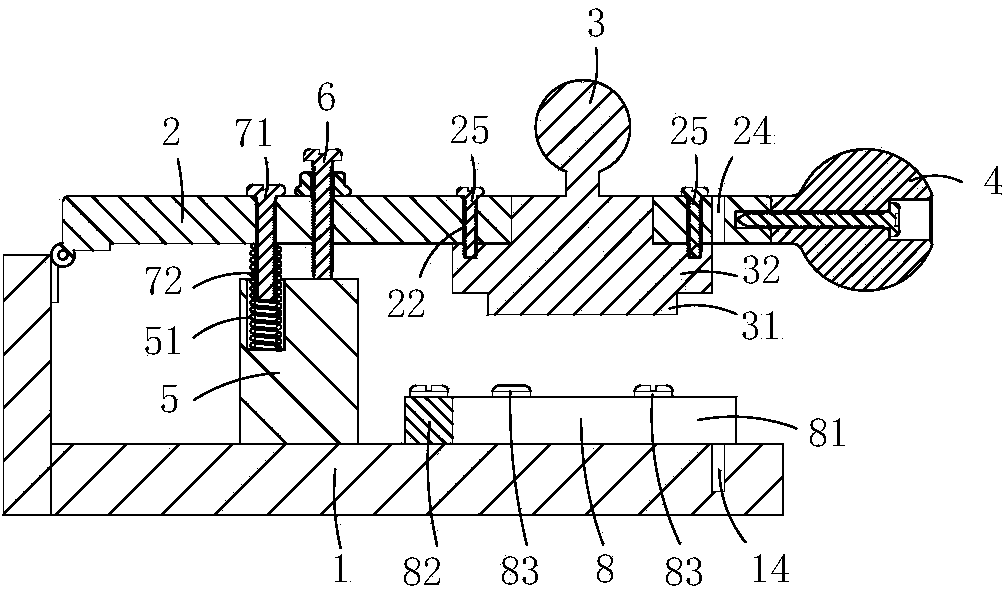

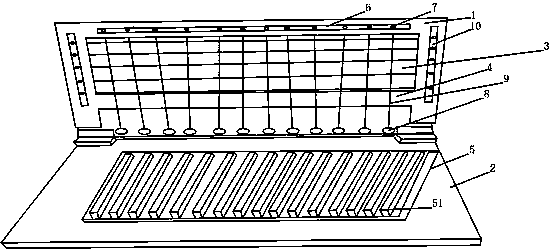

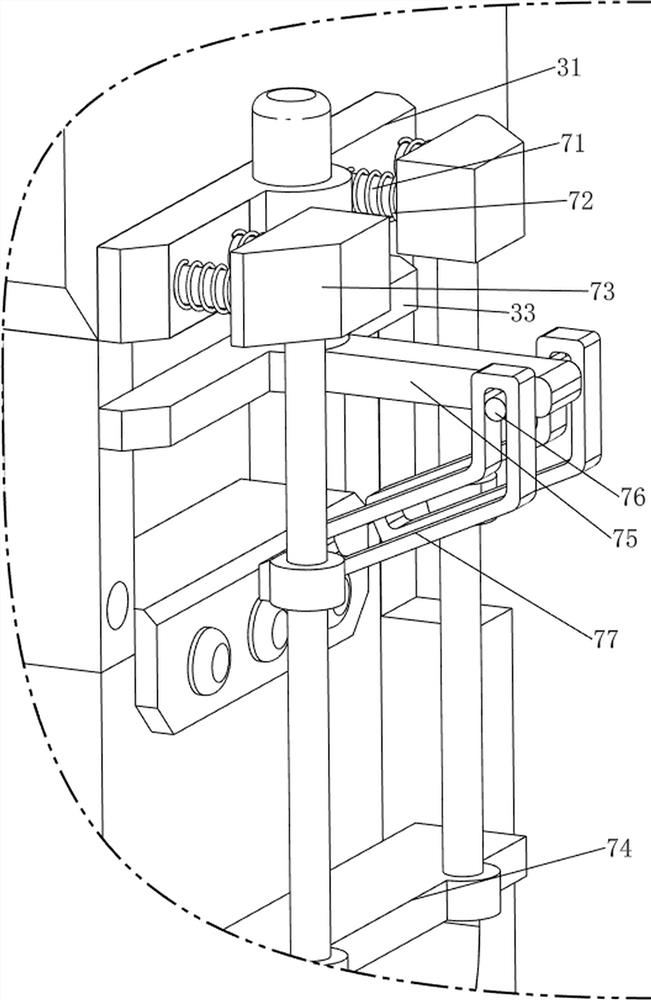

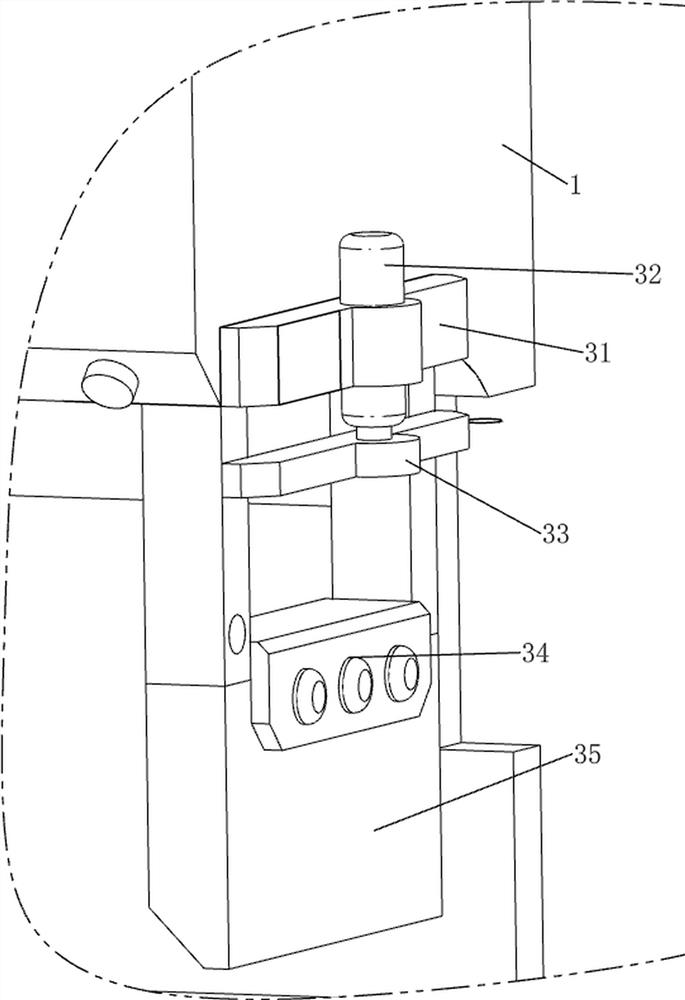

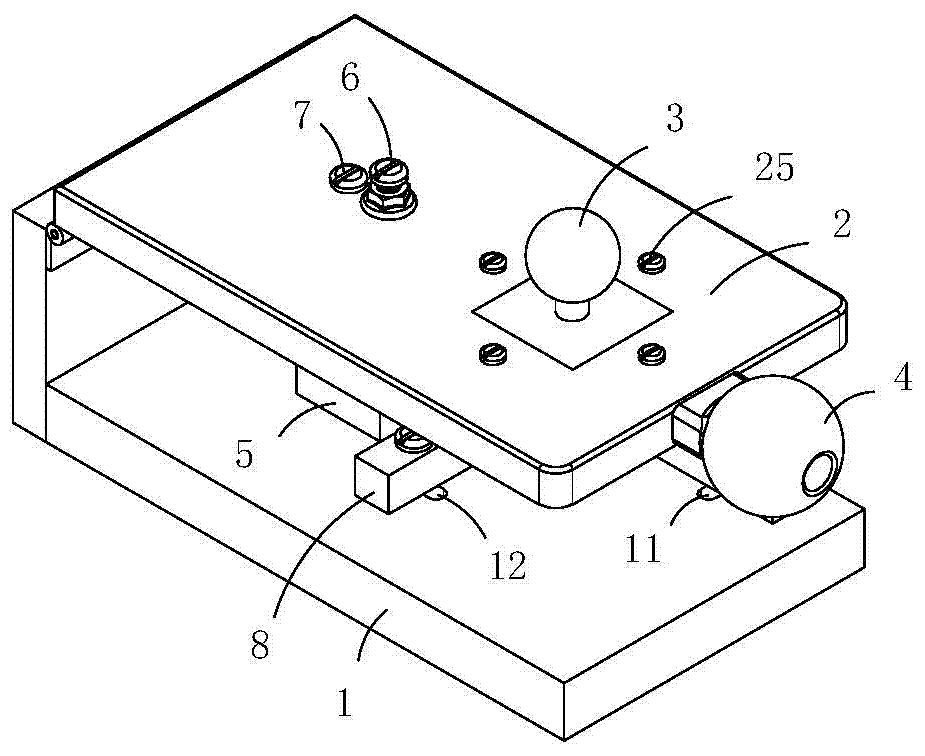

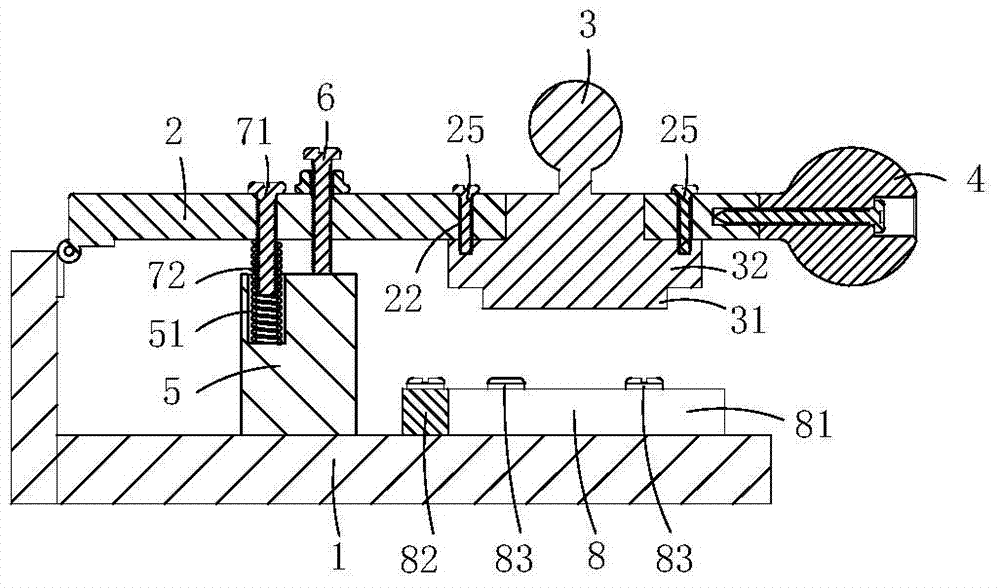

Soap printing device for improving imprinting quality

InactiveCN104726243AEasy to operateImprove quality and efficiencyCutting soapEmbossing/polishing soapMechanical engineeringSOAP

The invention discloses a soap printing device for improving imprinting quality. The soap printing device comprises a base, a pressure plate, a soap print, a handle, a limiting lug boss, an adjusting bolt, a resetting mechanism and a positioning mechanism, wherein the resetting mechanism comprises a resetting limiting column and a resetting spring; the pressure plate extends down out of the bottom end of the resetting limiting column; the resetting spring sleeves on a partial column body, which extends down out of the pressure plate downwards, of the resetting limiting column; a slide hole is formed in the limiting lug boss; the bottom end of the resetting limiting column can be inserted into the slide hole when the resetting limiting column rotates along with the pressure plate; the positioning mechanism comprises longitudinal adjusting baffle tables, transverse adjusting baffle plates and adjusting bolt assemblies; a longitudinal mounting hole group and a transverse assembly mounting hole group are formed in the base and are both waist holes; the longitudinal adjusting baffle tables penetrate through the adjusting bolt assemblies of the longitudinal assembly mounting holes and are fixedly arranged on the base; and the transverse adjusting baffle plates penetrate through the adjusting bolt assemblies of the transverse assembly mounting holes and are fixedly arranged on the base. According to the soap printing device, the imprinting quality and the production efficiency are effectively improved.

Owner:申清章

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com