Manually-operated soap imprinting device

A soap printing, installation and adjustment technology, applied in the direction of cutting soap, embossing/polishing soap, etc., can solve the problems of large deformation of handmade soap, unsightly, and different depths of word and picture marks, and achieve a good consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

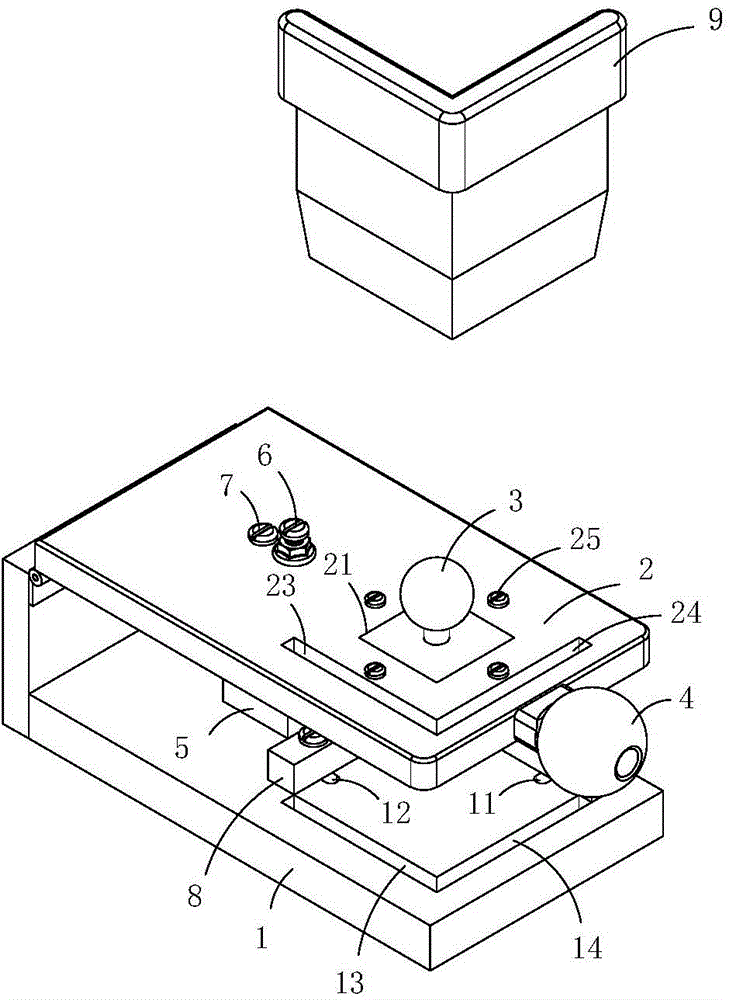

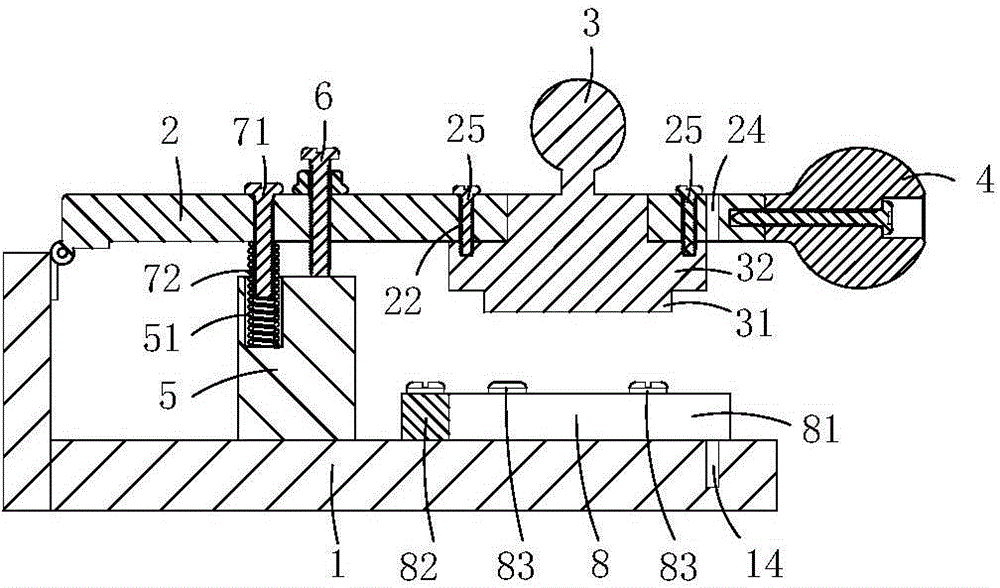

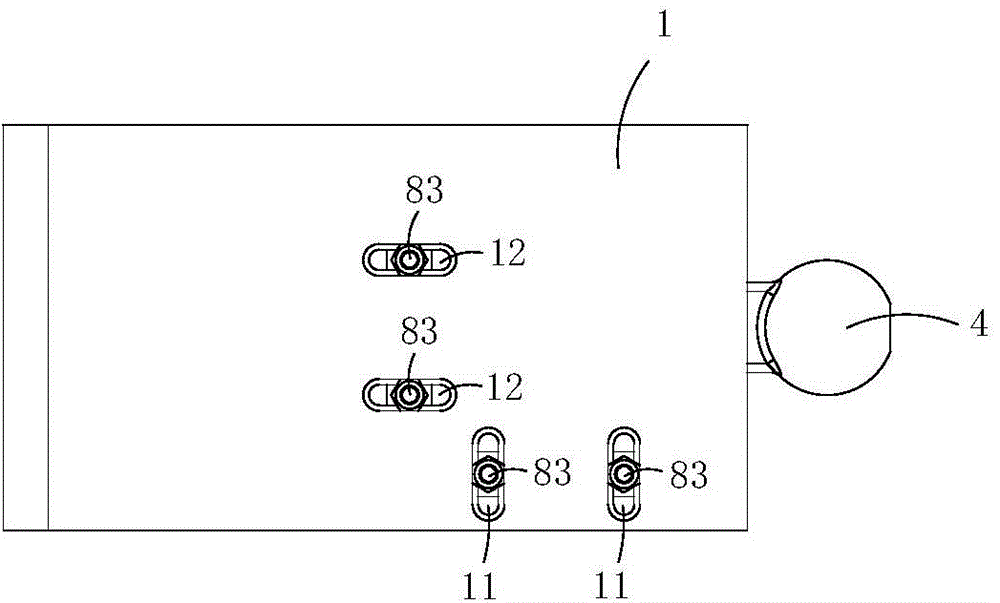

[0012] Present embodiment is a kind of manual soap printing device, see Figure 1 to Figure 5 As shown, it includes the base 1, the rotating pressing plate 2 set on the base, the soap stamp 3 fixed on the pressing plate, the handle 4 driving the pressing plate to rotate, the limiting boss 5 set on the base, and the adjusting bolt set on the pressing plate 6. The reset mechanism 7, the position adjustment mechanism 8, and the cutter 9;, the bottom end of the adjustment bolt stretches out of the pressure plate downwards, and when the pressure plate rotates to the lowest position, it abuts on the limit boss.

[0013] The reset mechanism includes a reset limit post 71 arranged on the pressing plate and a reset spring 72 sleeved on the reset limit post. Stretch out from the part of the cylinder of the pressure plate; the limit boss is provided with a slide hole 51, and when the reset limit post rotates with the pressure plate, its bottom end can be inserted in the slide hole.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com